Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

158 results about "Hyperbaric oxygen" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

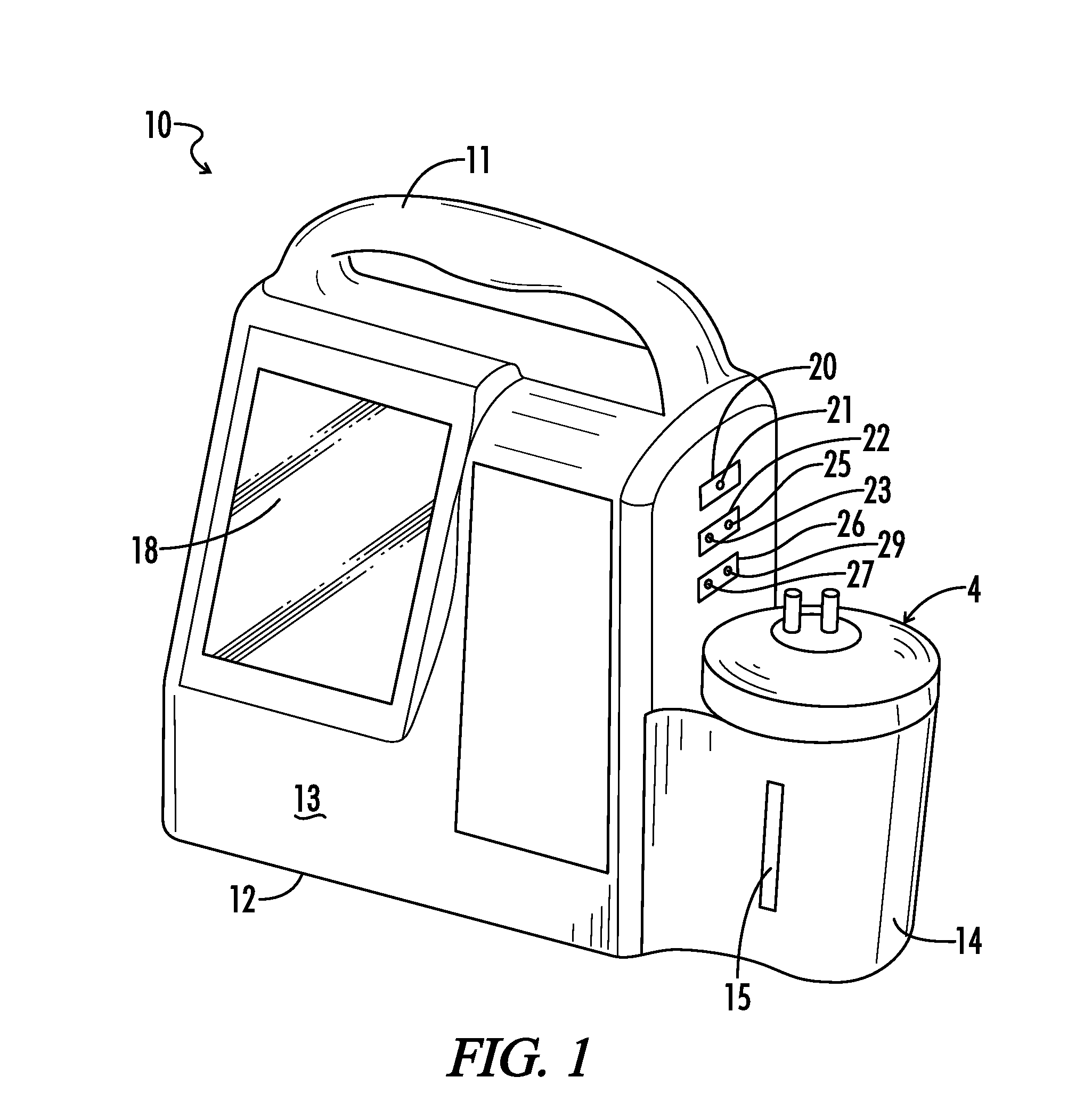

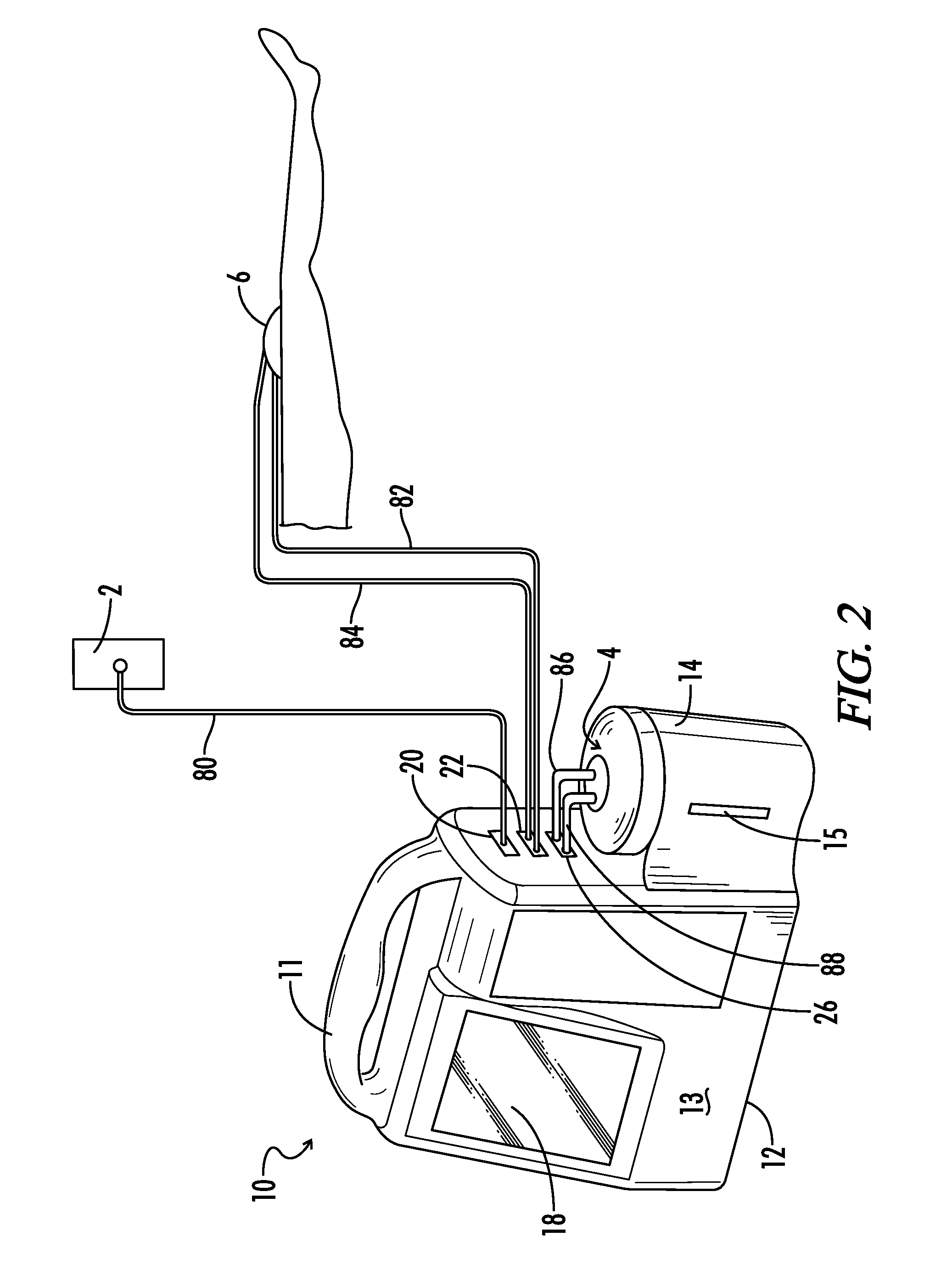

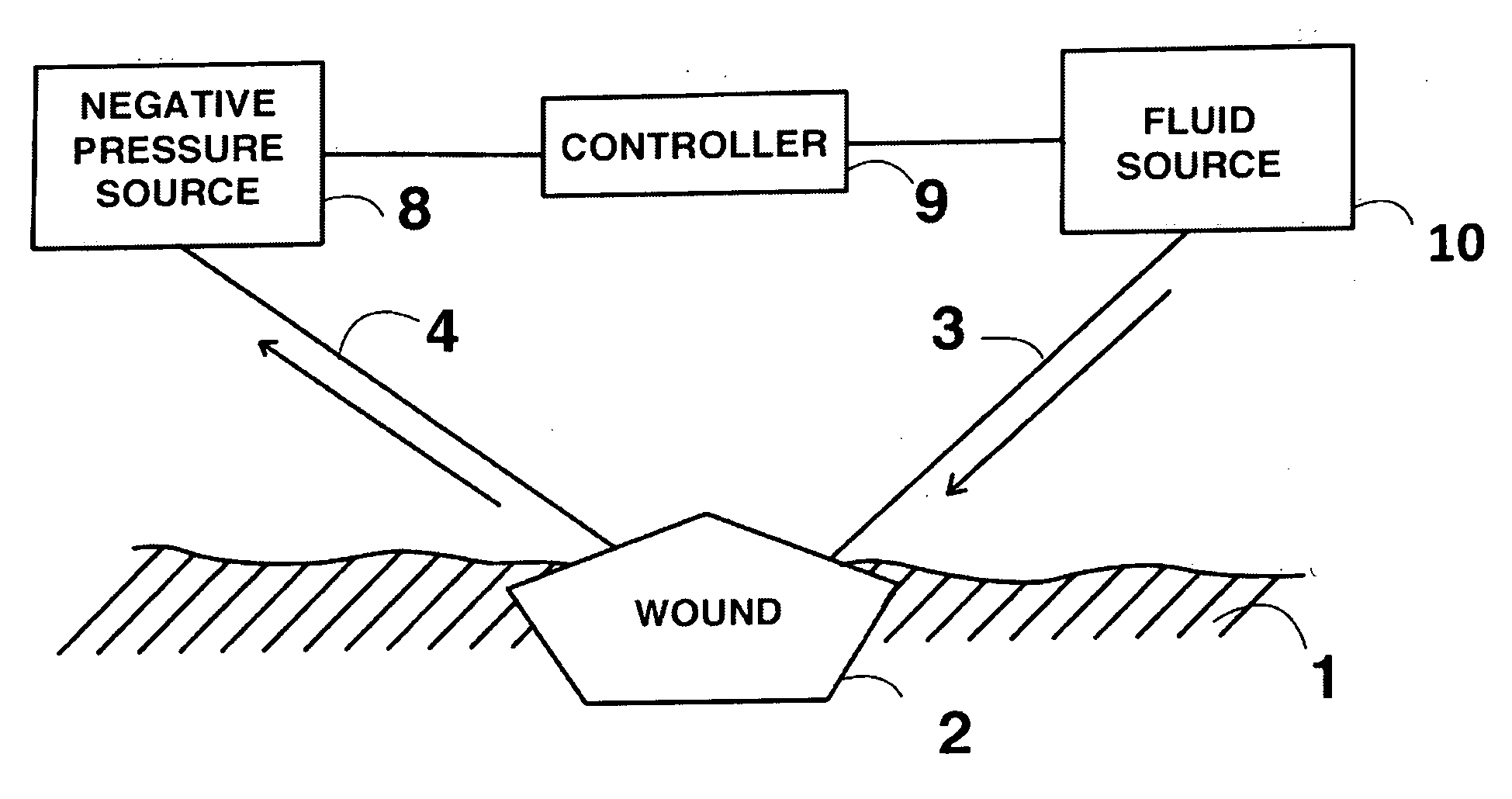

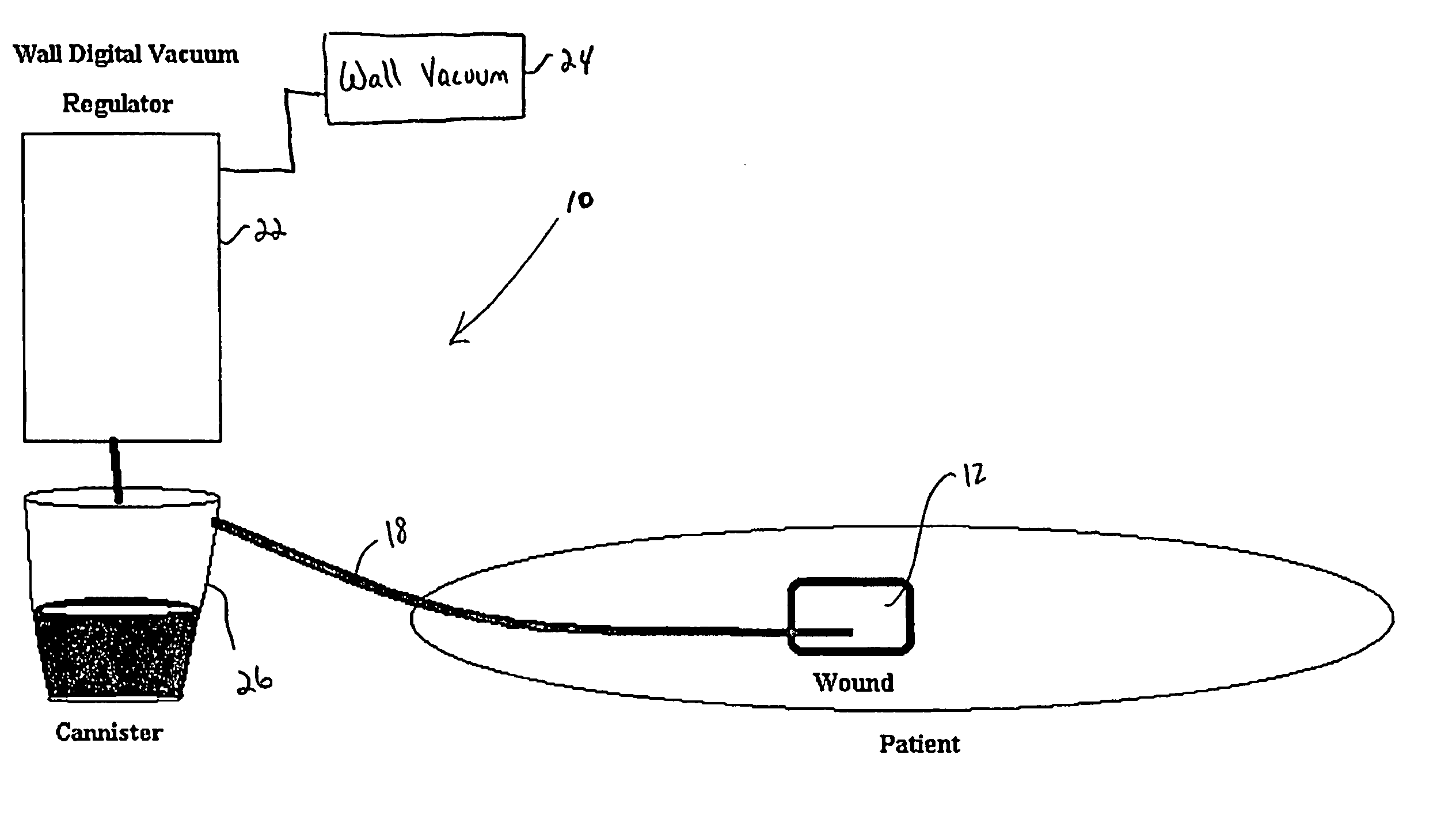

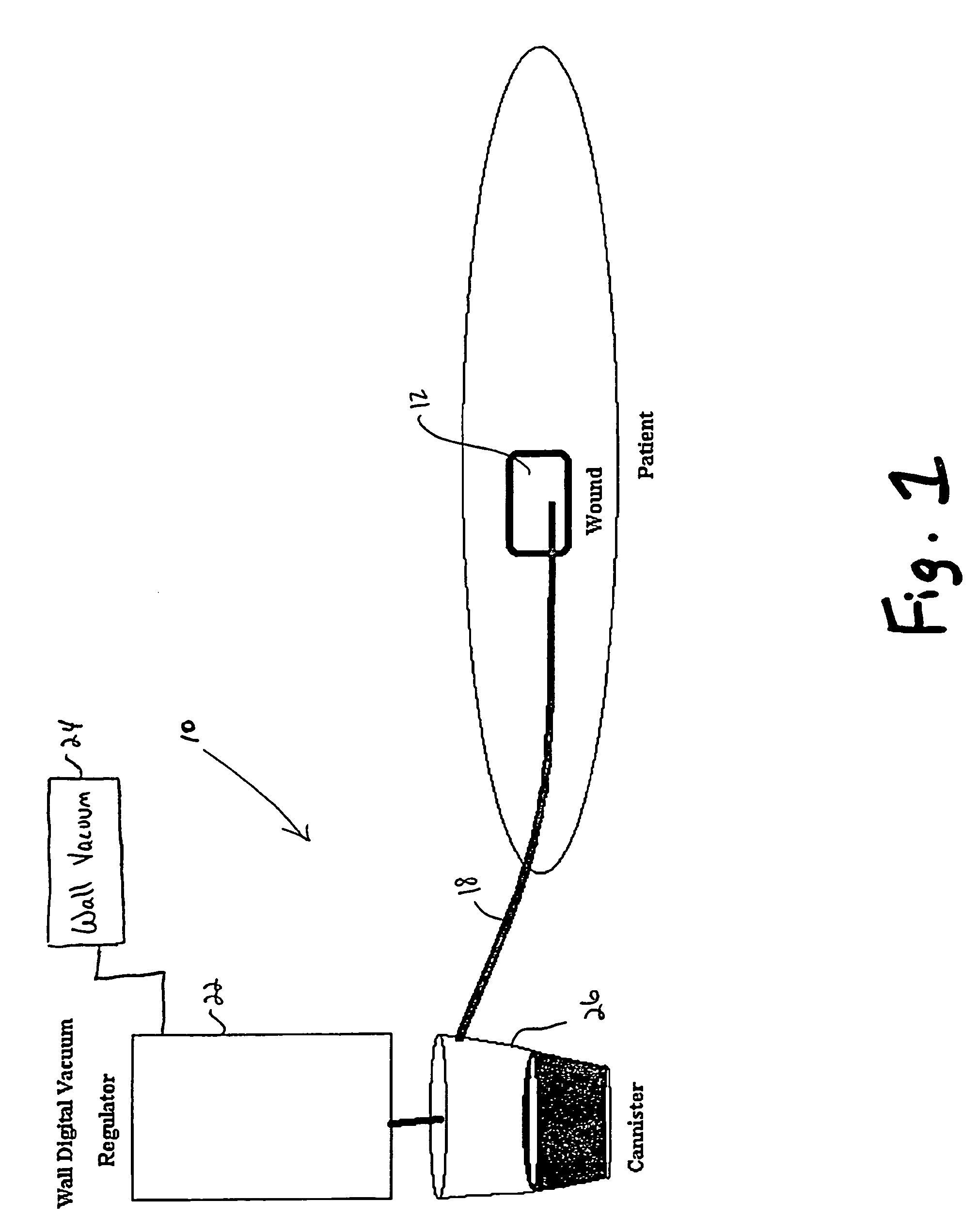

Wound care apparatus

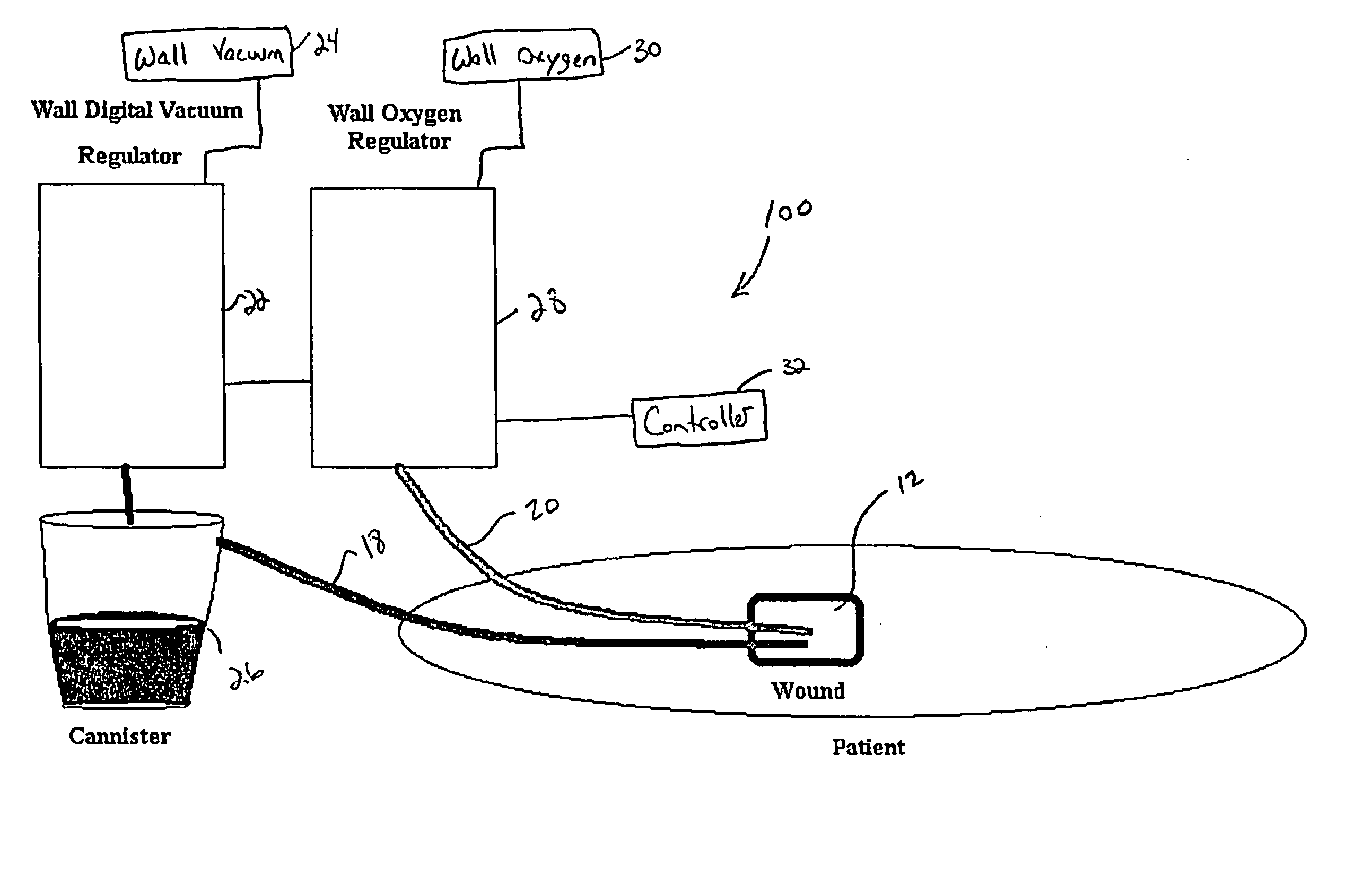

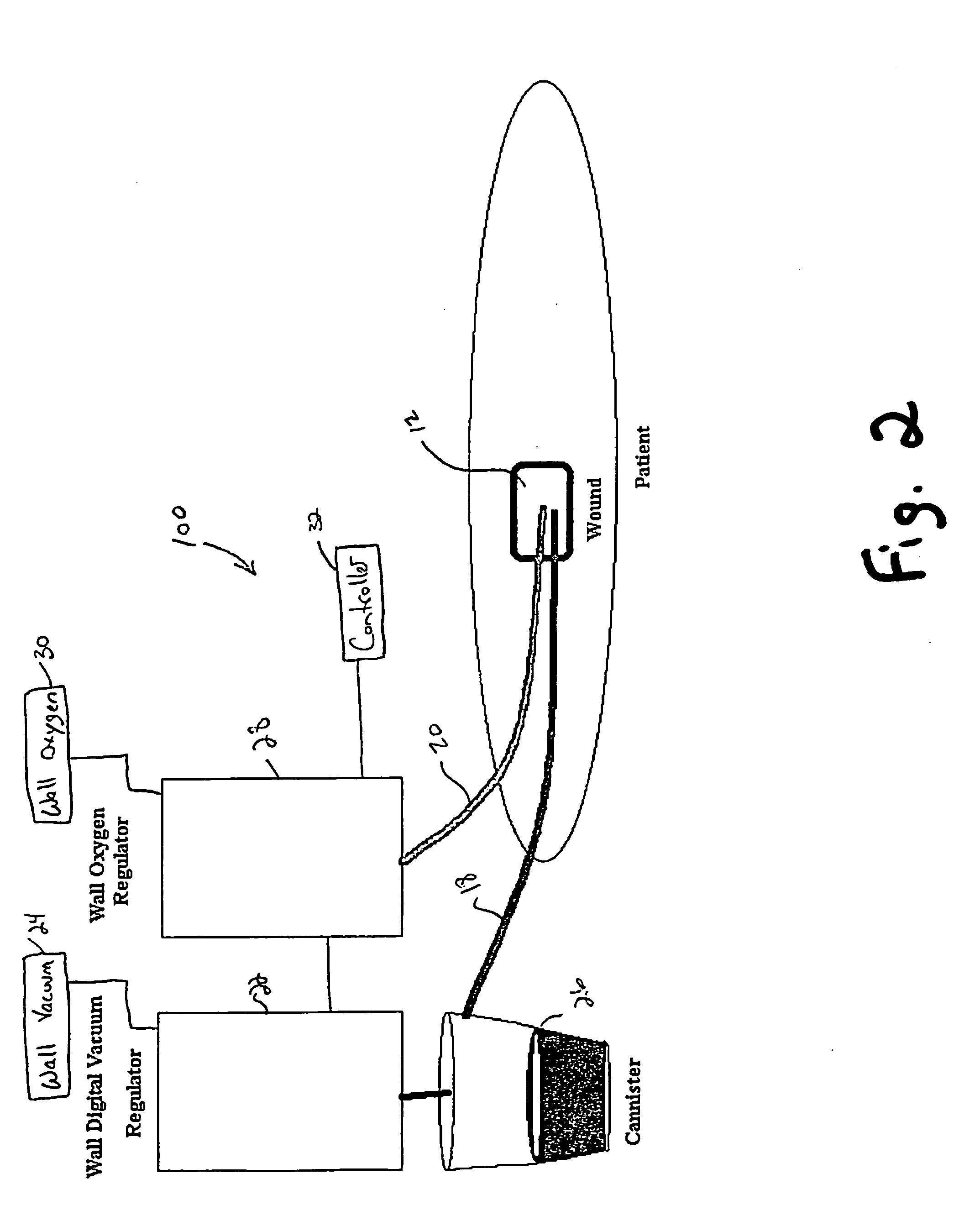

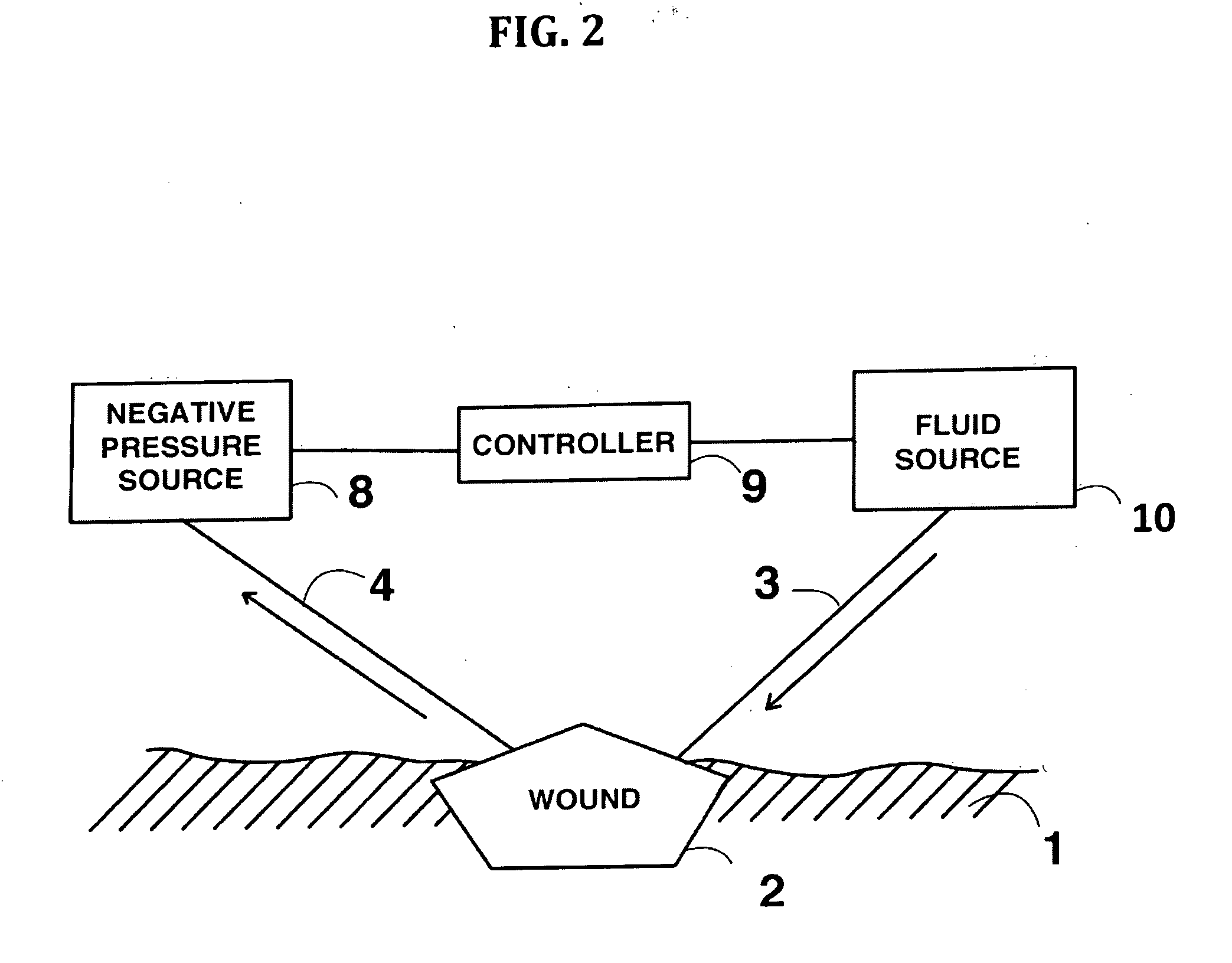

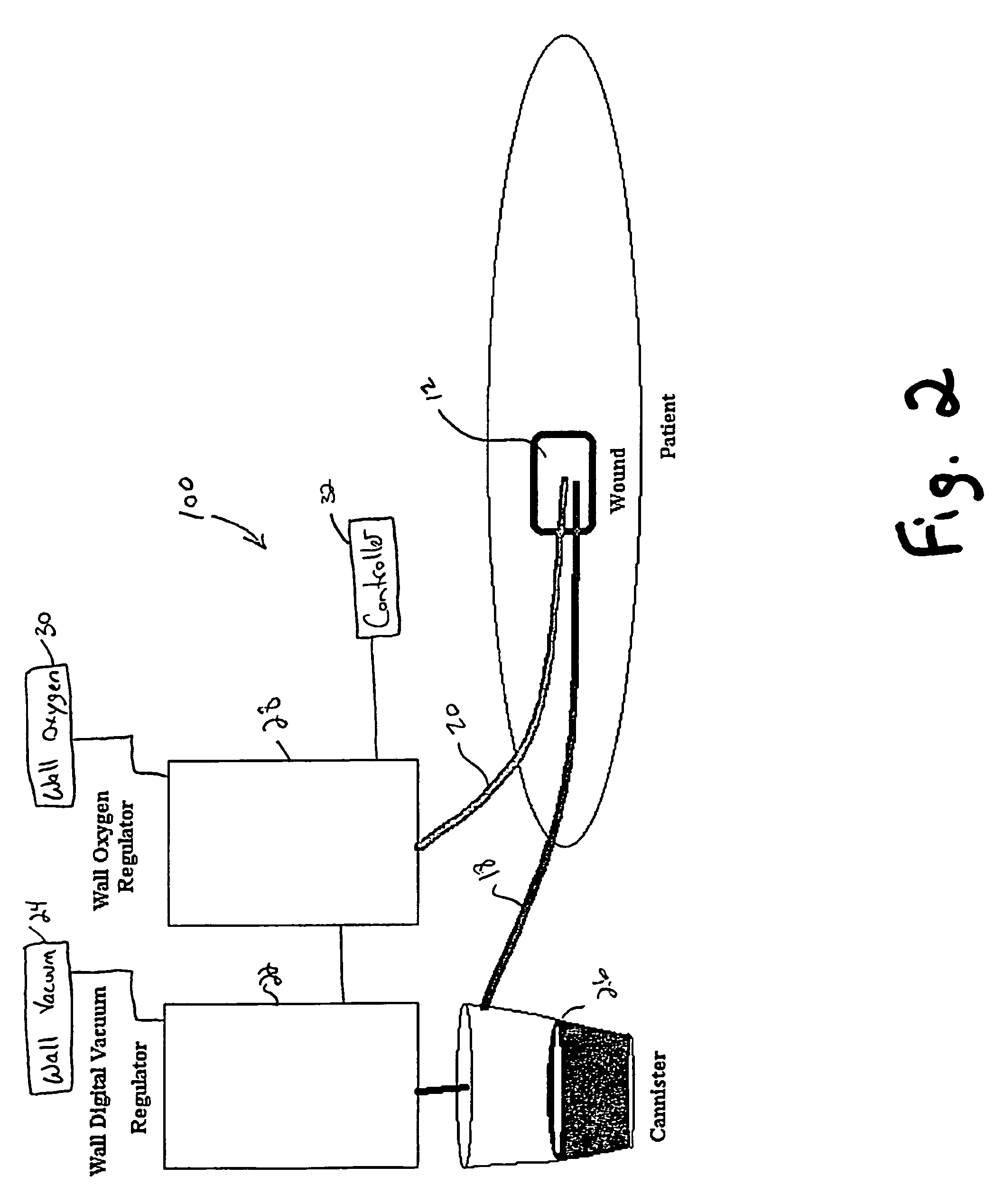

Disclosed is an apparatus for the treatment of a wound on a patient. The apparatus is capable of administering localized negative pressure therapy to the wound using a hospital wall vacuum source and a drain line for removing exudate from the wound. The apparatus may also be capable of administering localized hyperbaric oxygen therapy to the wound using a hospital wall oxygen source and a supply line for supplying oxygen to the wound. The apparatus includes at least one regulator to control the application of negative pressure therapy and hyperbaric oxygen therapy.

Owner:INTEGRATED HEALING TECH

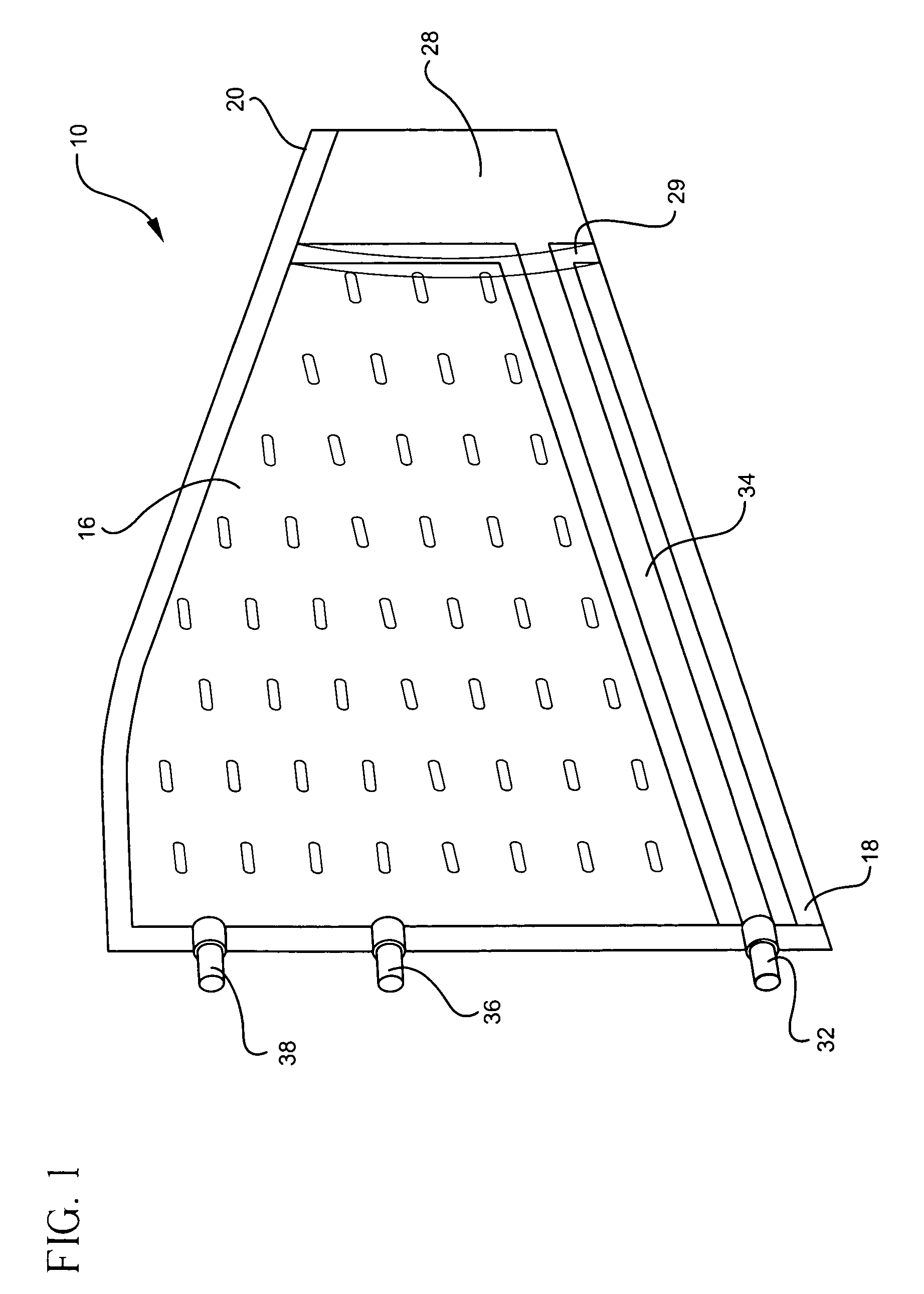

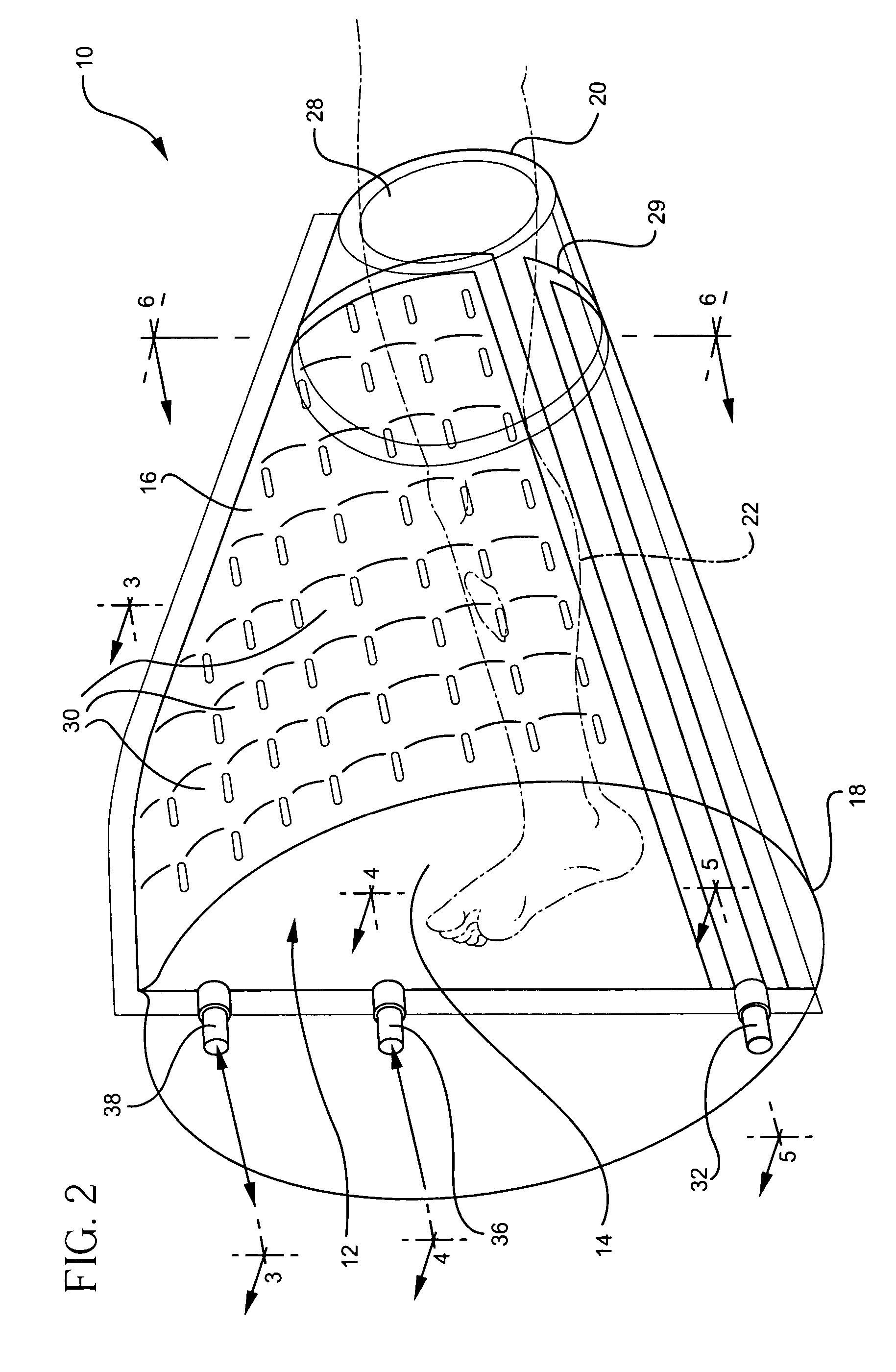

Hyperbaric oxygen devices and delivery methods

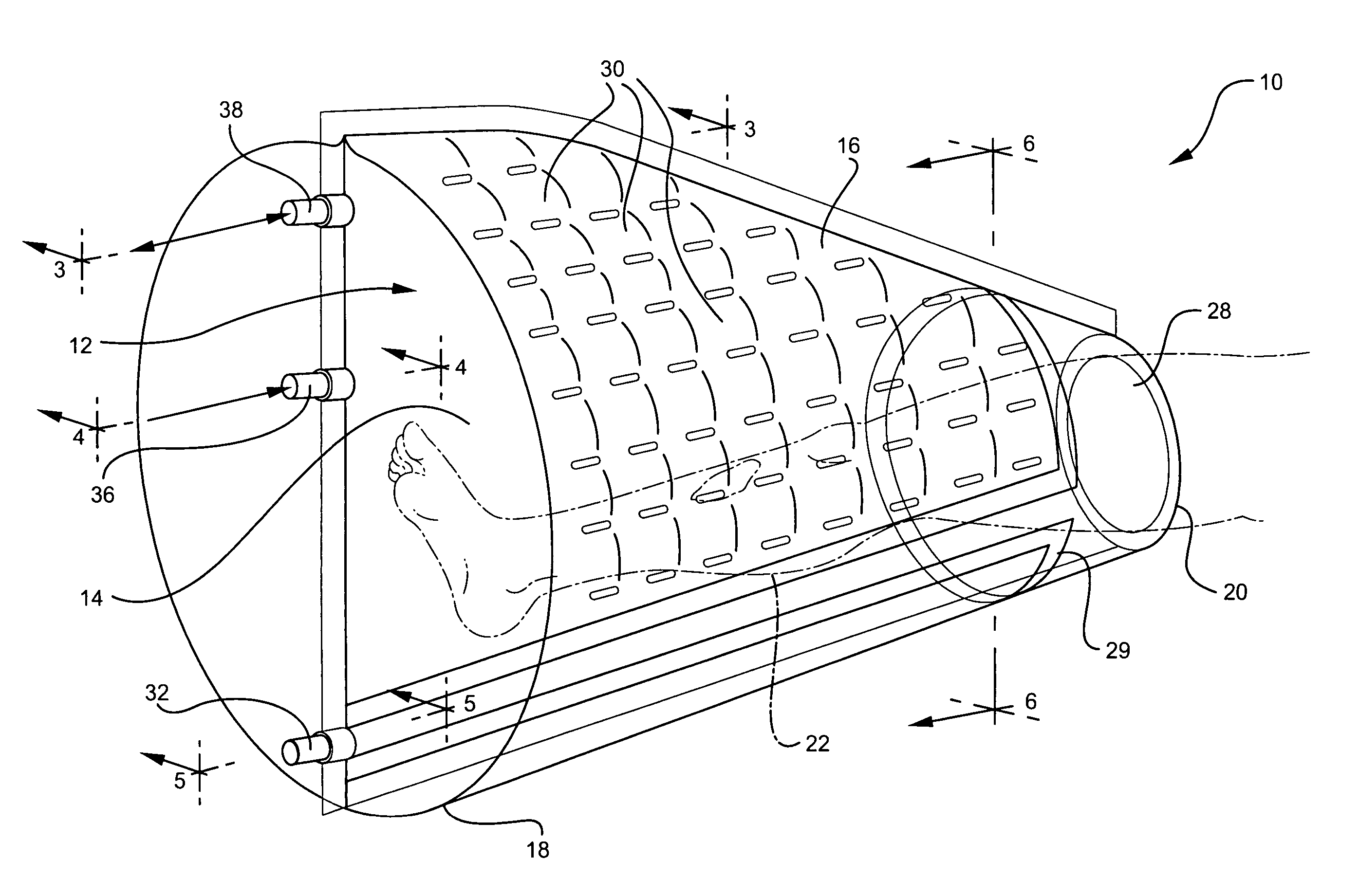

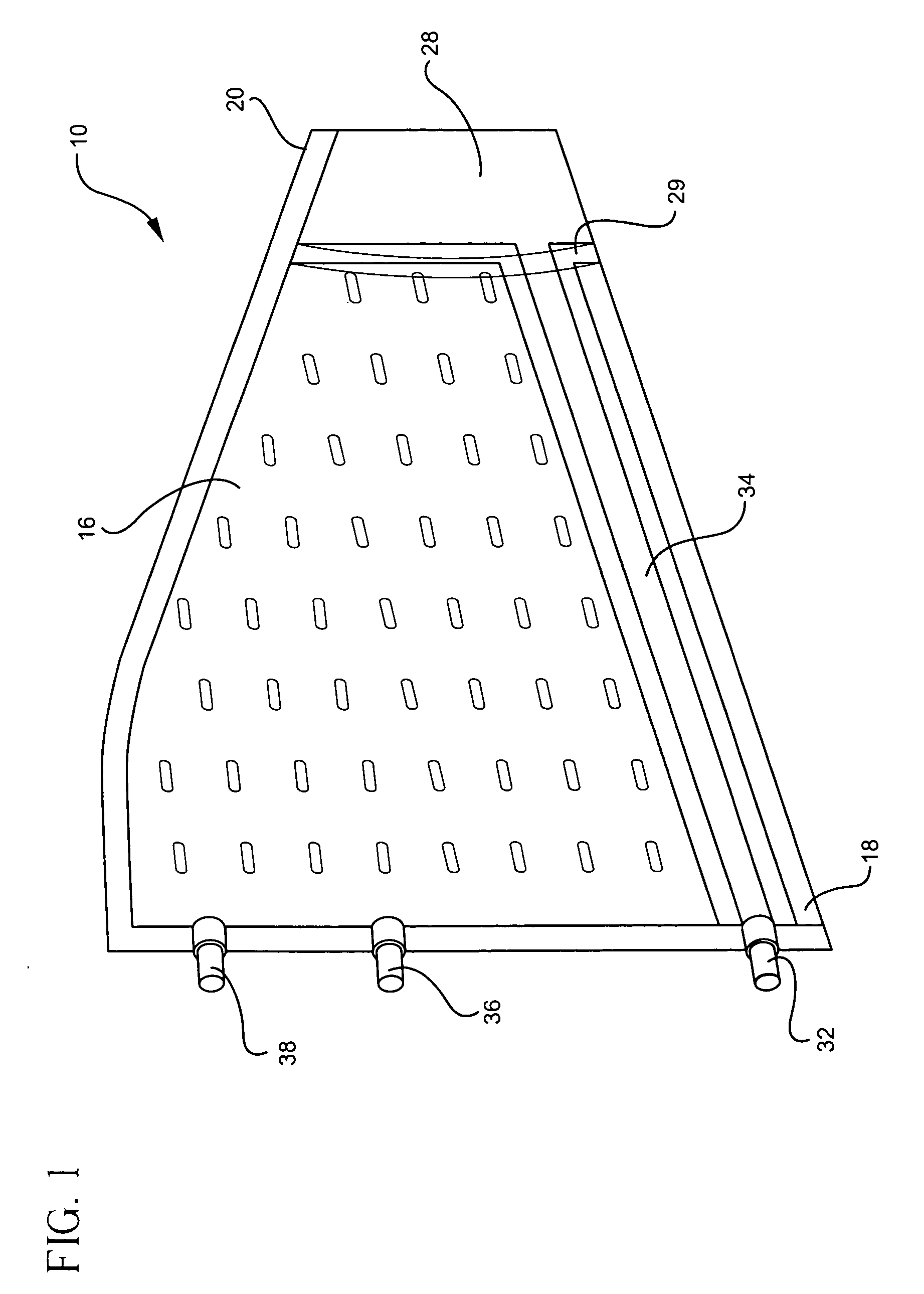

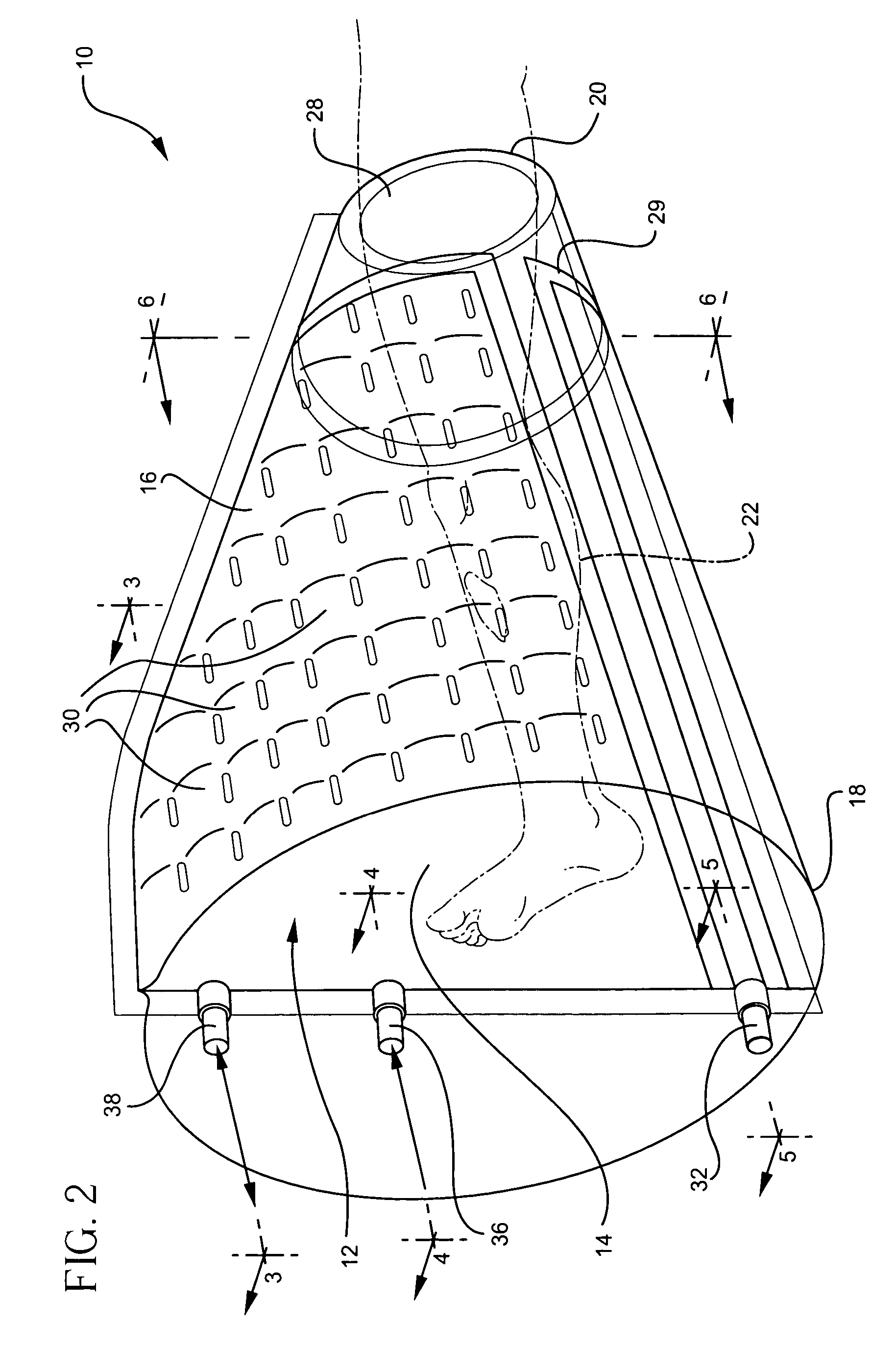

A hyperbaric oxygen device and methods of applying hyperbaric oxygen are disclosed. The device comprises an enclosure including a collapsible bag defined by two sheets of fluid impervious material sealed together at both ends such that gas can be delivered between the sheets to inflate the enclosure to a rigid state and maintain the enclosure in the rigid state when oxygen pressure in the interior of the enclosure is cycled between ambient pressure and above ambient pressure.

Owner:AOTI

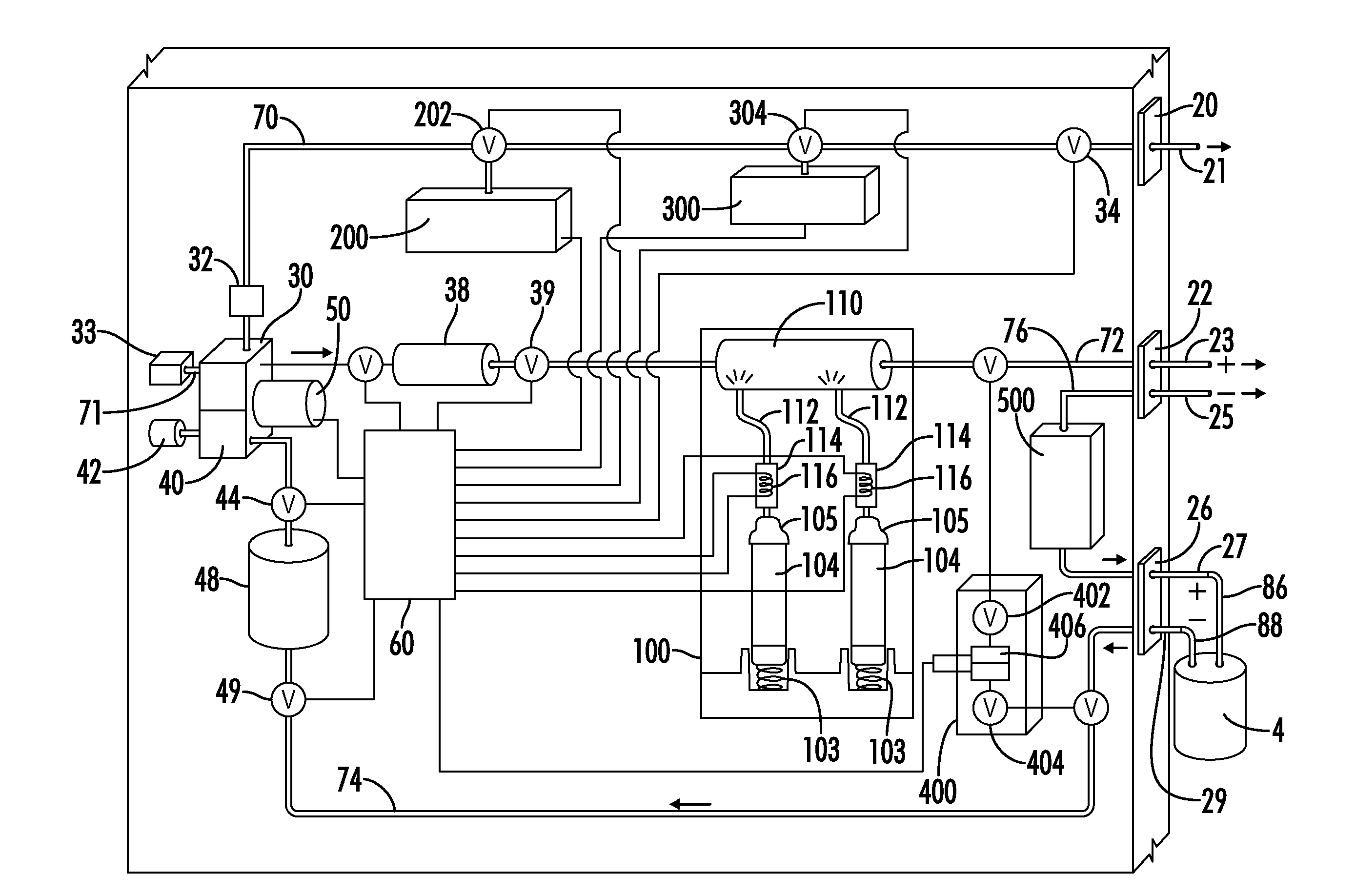

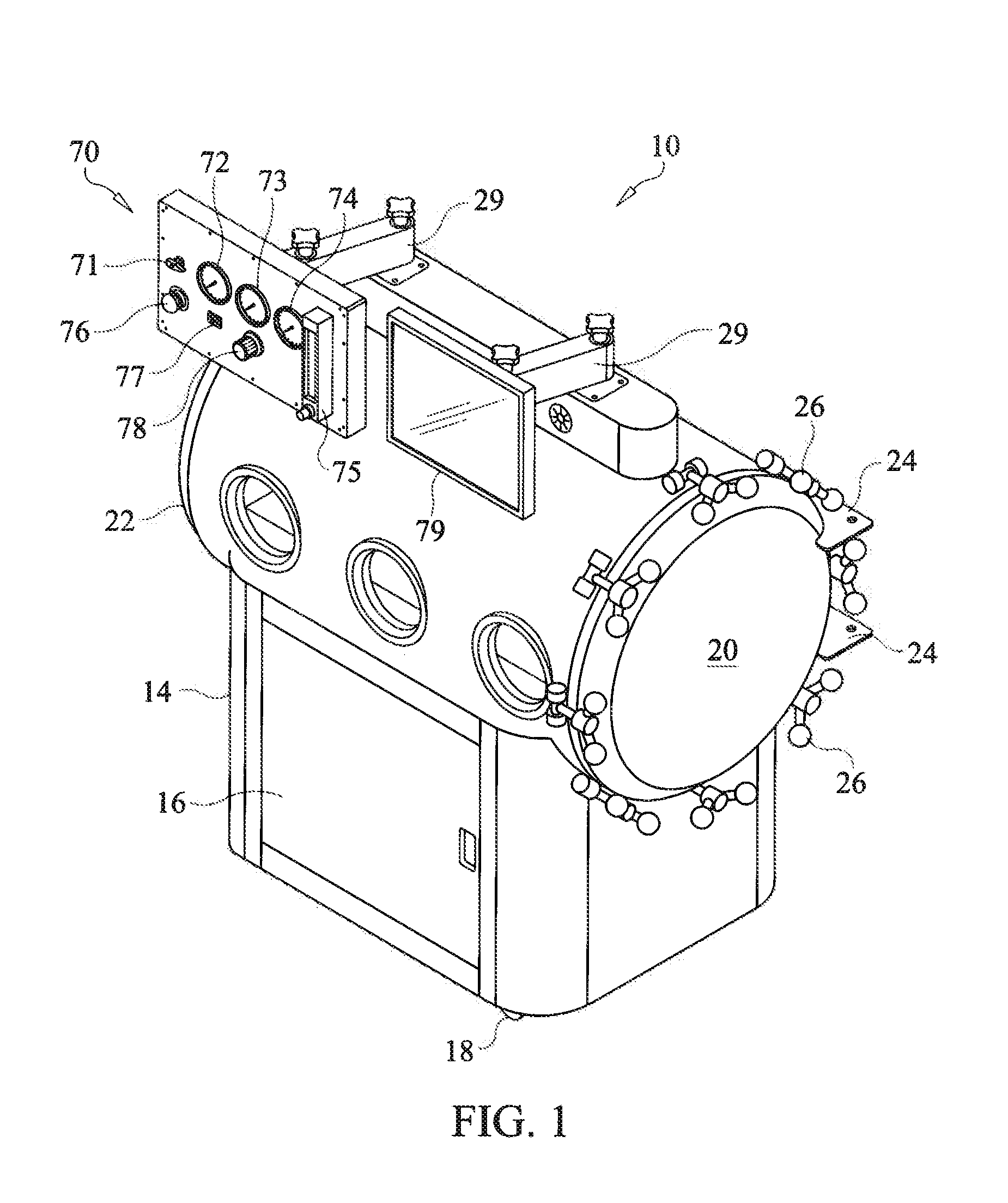

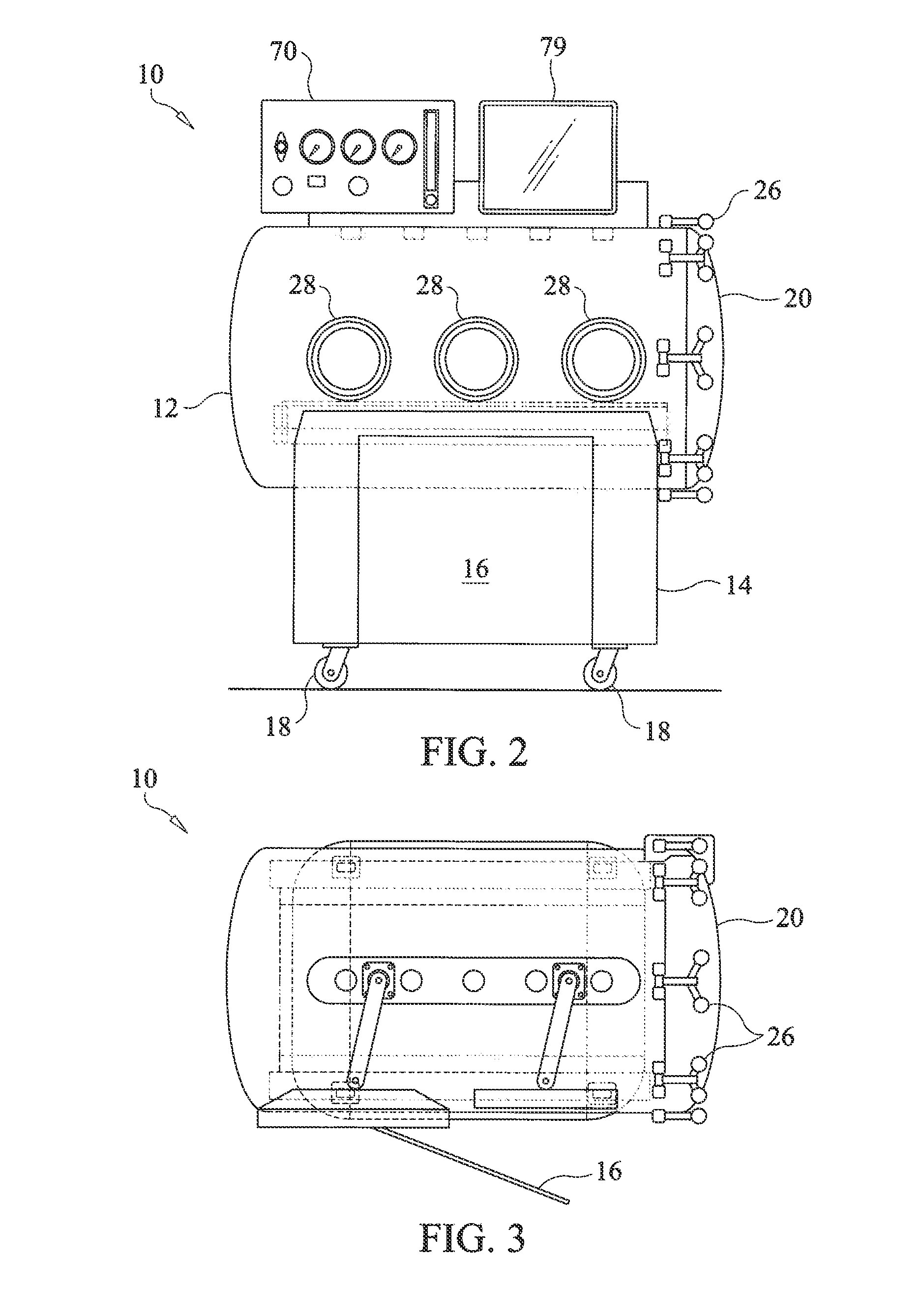

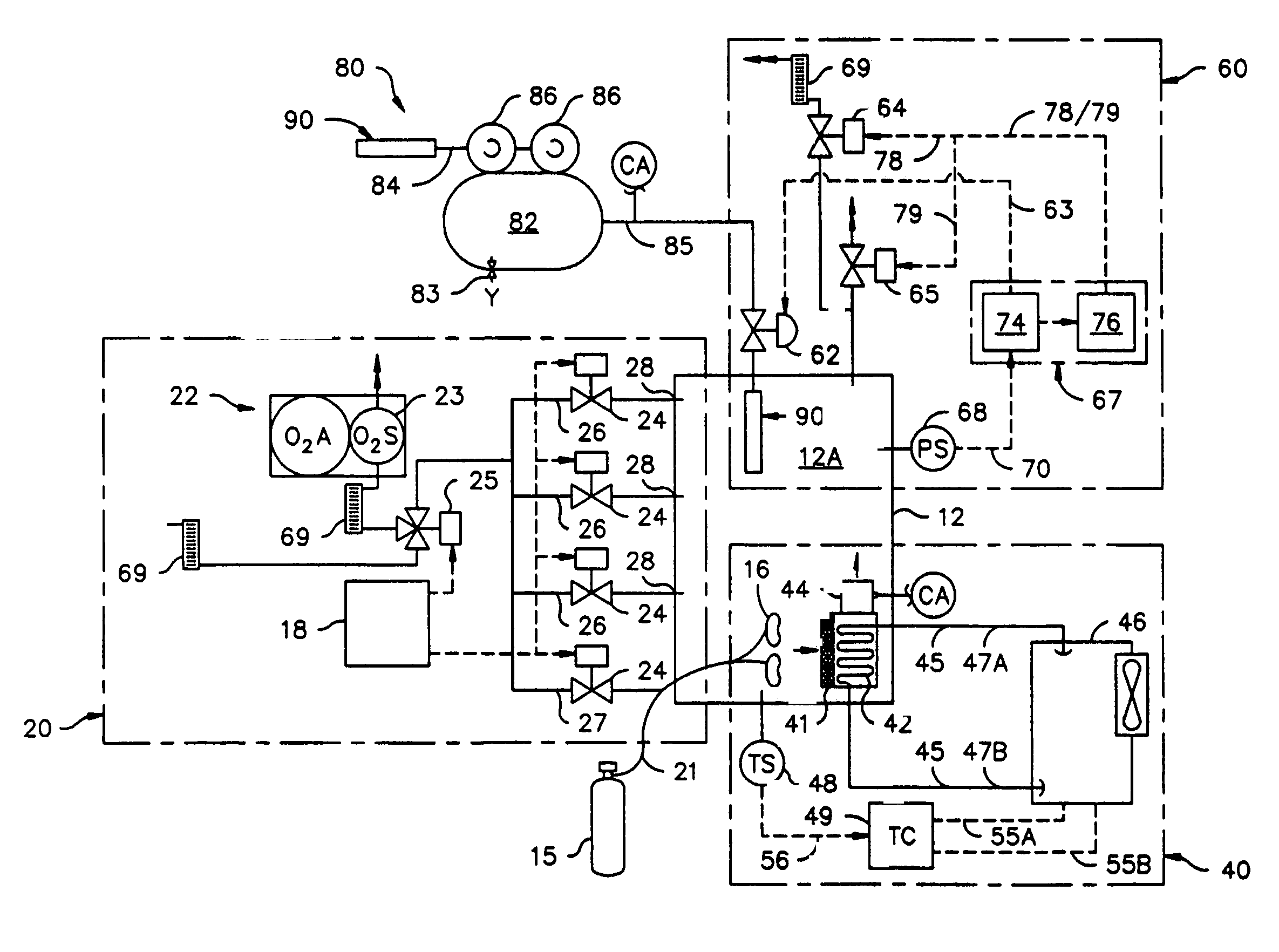

Multi-modal wound treatment apparatus

ActiveUS20150290364A1Broaden applicationMedical devicesMedical applicatorsElectronic controllerPositive pressure

The wound treatment apparatus combines an internal negative pressure (vacuum) pump and an internal positive pressure (compressor) pump connectable to an external oxygen supply for providing both negative pressure wound therapy and hyperbaric oxygen wound therapy to a wound site. The apparatus also includes a user interface operatively connected to an electronic controller that monitors and actuates the vacuum and compressor pumps. The user interface and controller enables the apparatus to provide multiple modes of operation and the ability to selectively change between negative pressure therapy operational modes and hyperbaric oxygen operational modes.

Owner:INTEGRATED HEALING TECH

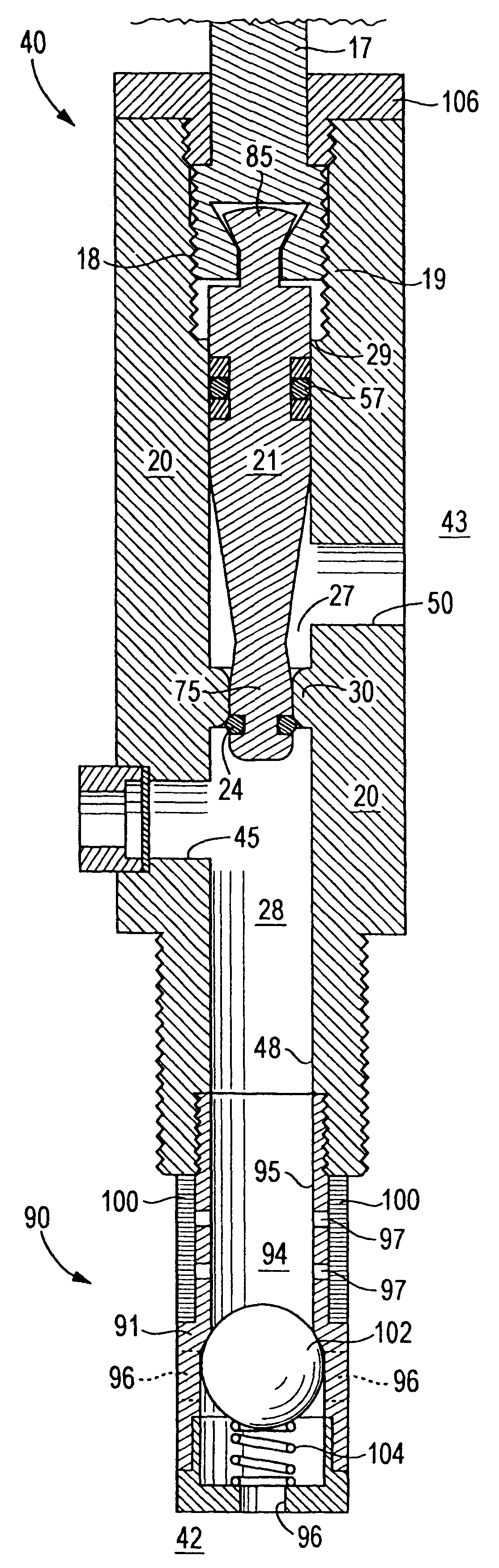

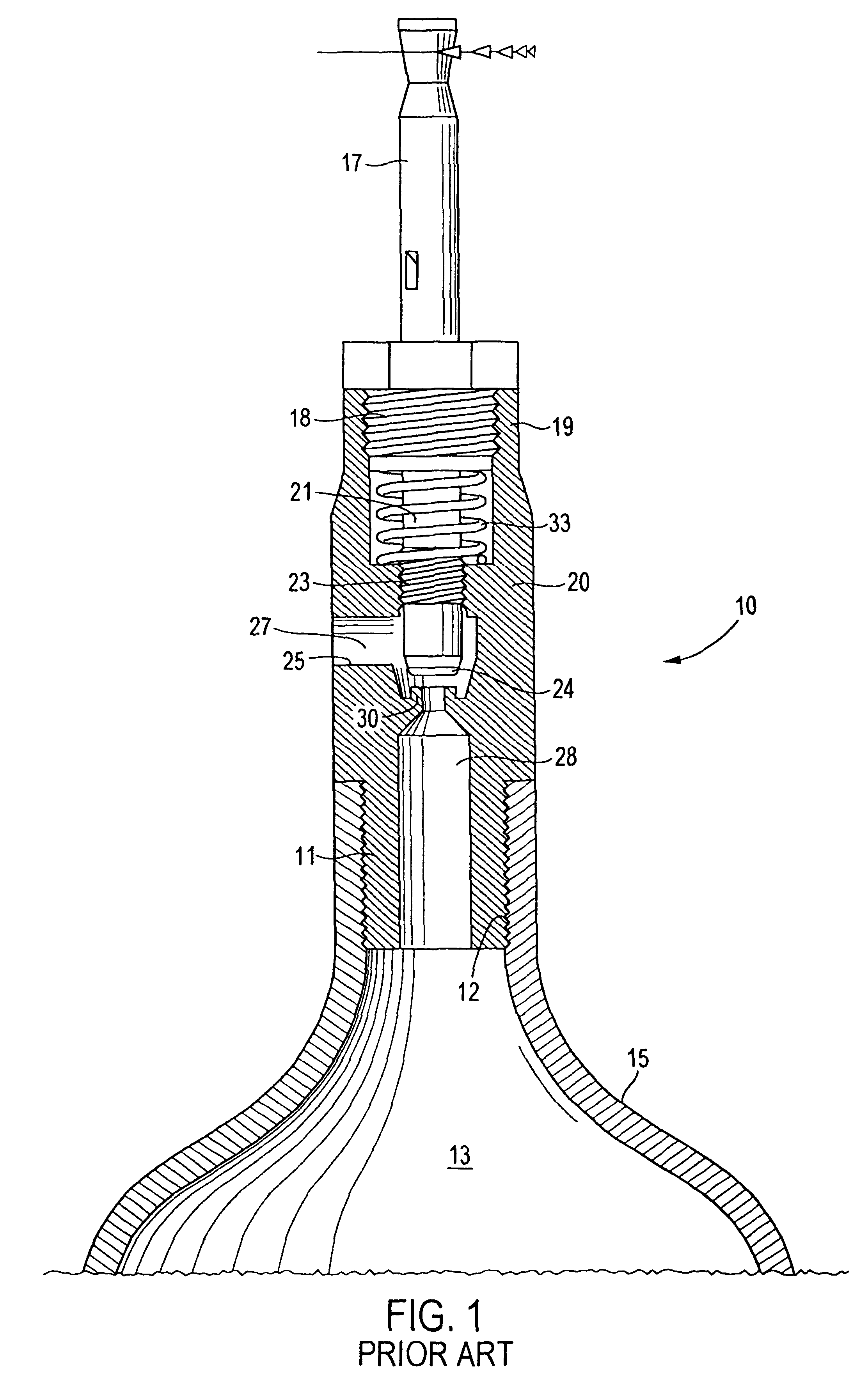

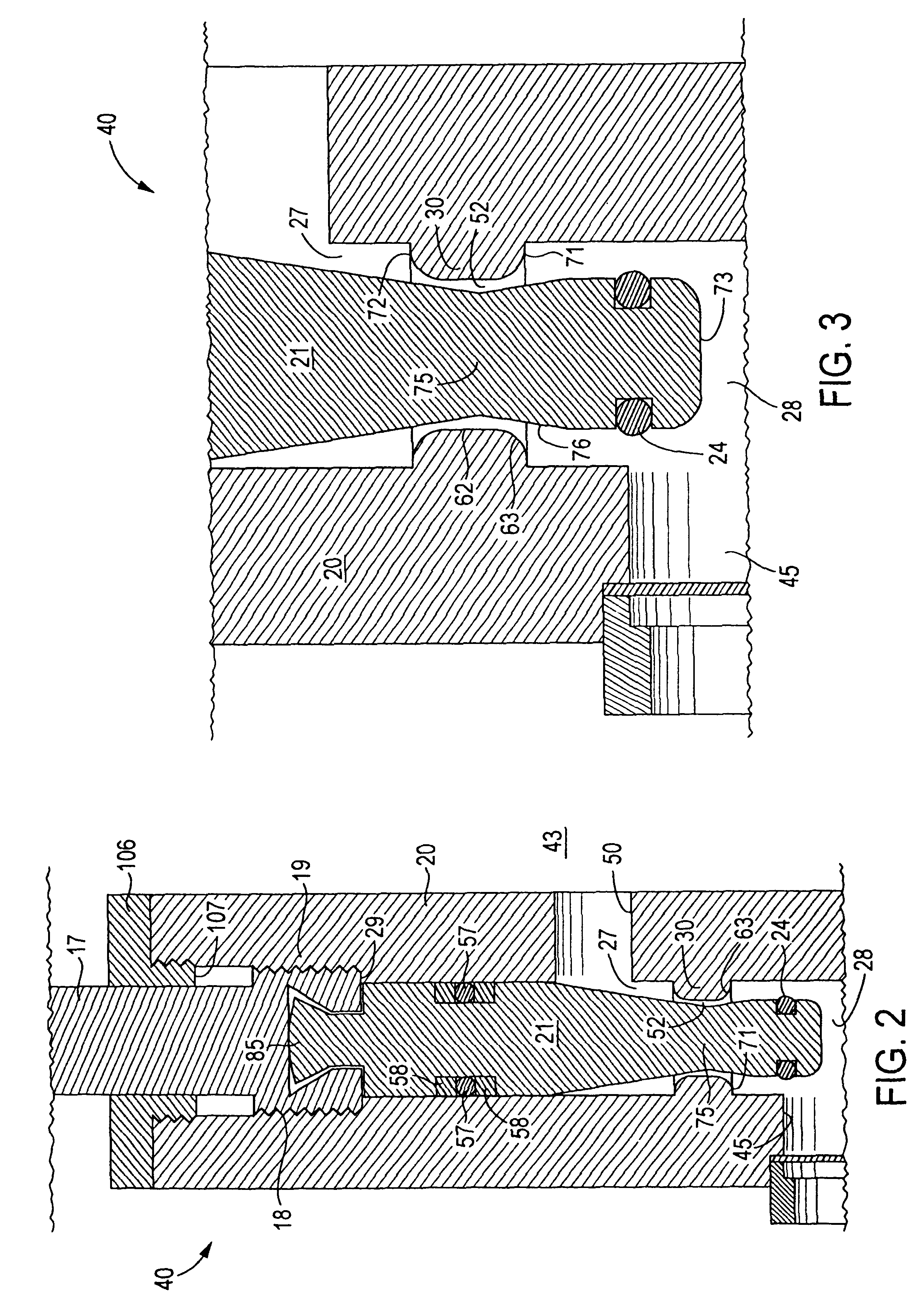

Cylinder valve and bayonet check-filter with excess-flow protection feature

InactiveUS6607007B1Reduce the risk of fireLower potentialFunctional valve typesContainer filling methodsOxygen systemHigh pressure oxygen

A valve apparatus especially well-suited for use in gaseous oxygen delivery systems. A valve apparatus is provided that substantially reduces the risk of fire in high-pressure oxygen systems. The apparatus is particularly well-suited for use as a plug valve on ordinary cylinder containers, but may be beneficially used in any pressurized gas system, particularly oxygen systems such as those encountered in many industrial facilities. The wetted portion of the valve is isolated from threaded portions to prevent particulate contamination of the gas stream. The valve seat is located to protect it from direct impact of high-velocity gas streams. The inventive valve, and its associated inventive check-filter and excess-flow prevention features, reduces the potential for hazardous combustion at valve points within oxygen delivery systems.

Owner:LUXFER INC

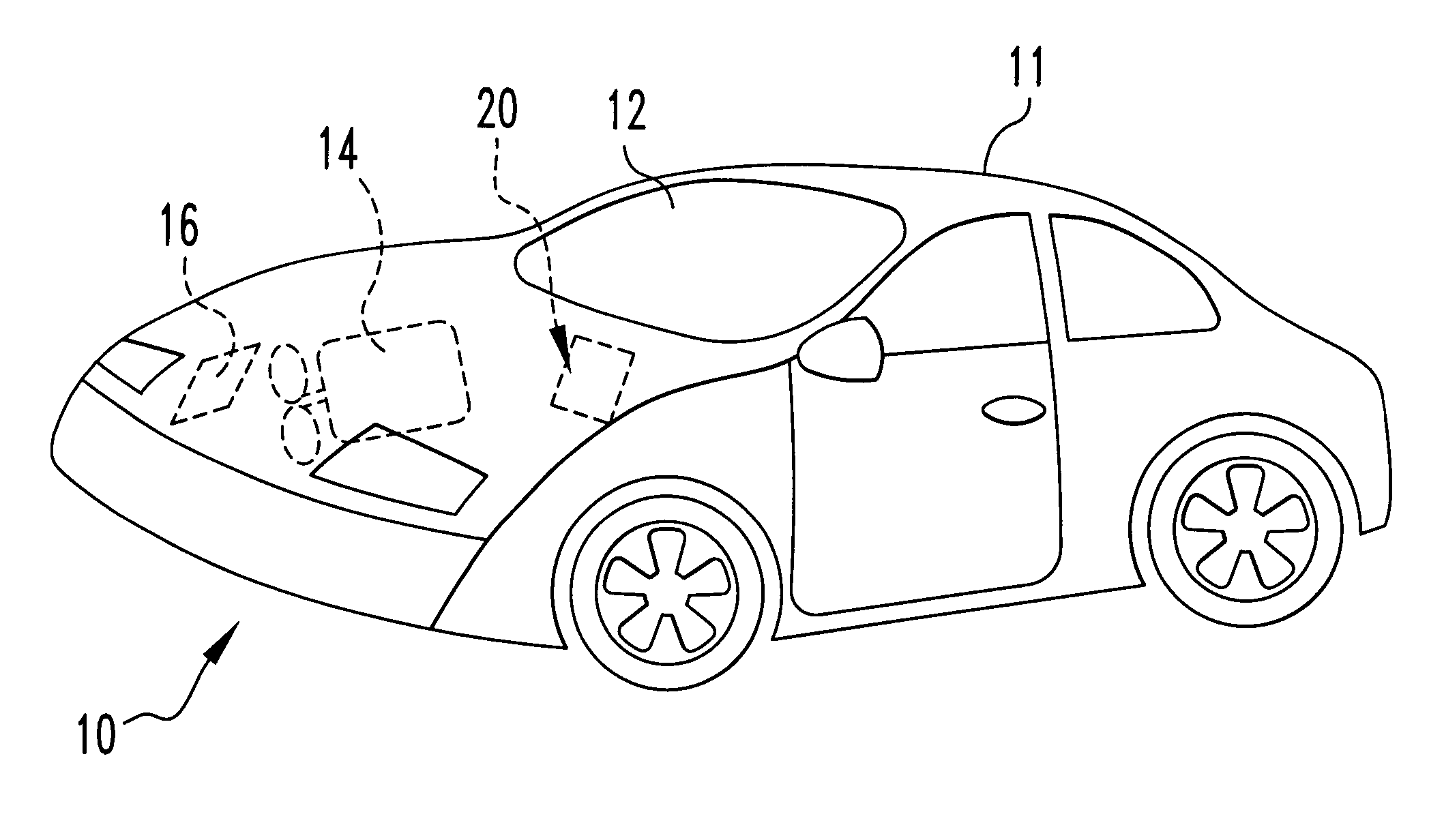

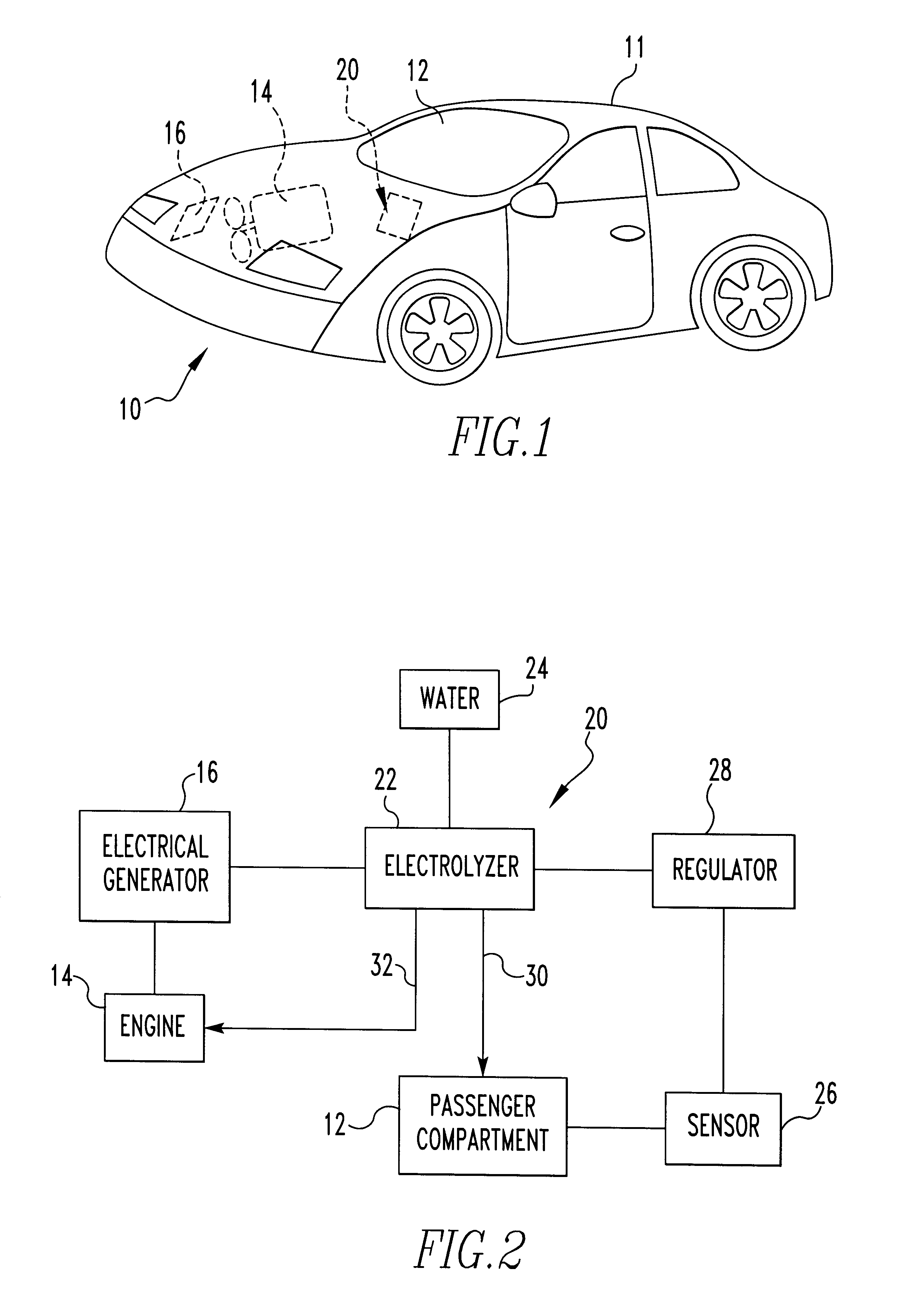

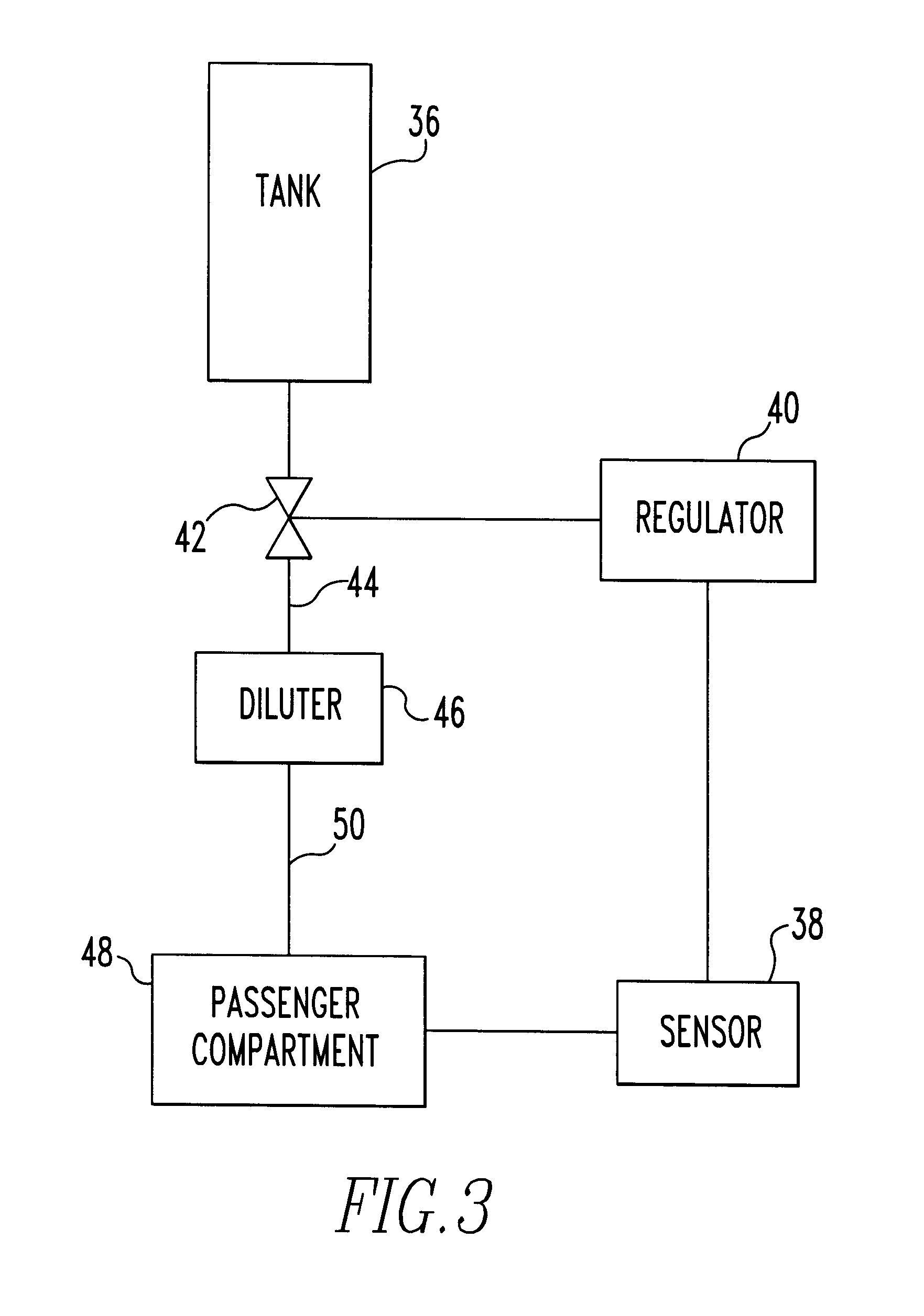

Hyperbaric oxygen enrichment system for vehicles

This invention provides oxygen-enriched air to the passenger compartment of wheeled vehicles under hyperbaric conditions to reduce drowsiness of drivers of wheeled vehicles so as to reduce the number of accidents caused by drowsy drivers. The invention also makes drivers and passengers in wheeled vehicles more alert and feel better by increasing the percentage of oxygen in the passenger compartments of wheeled vehicles to a beneficial and safe level.

Owner:BROWNLEE DAVID W

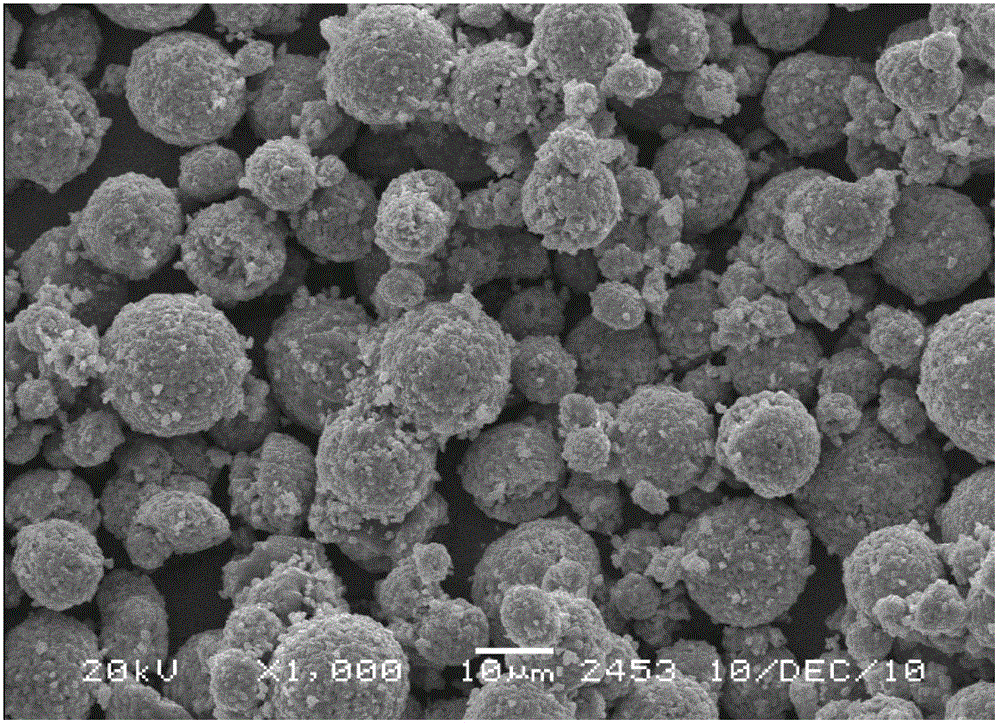

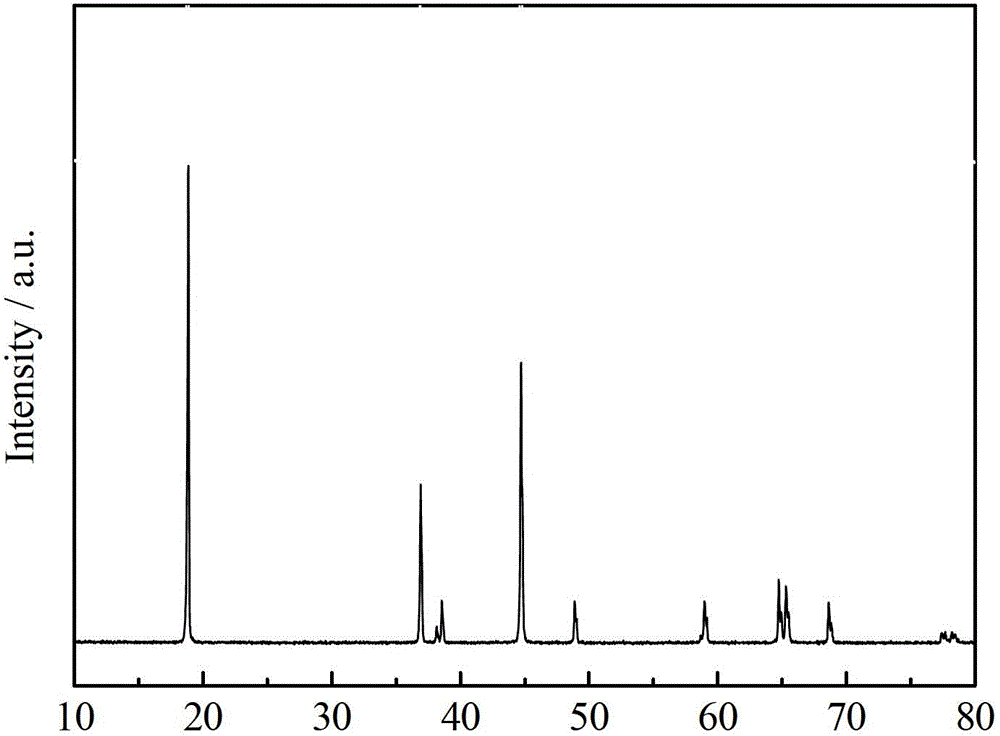

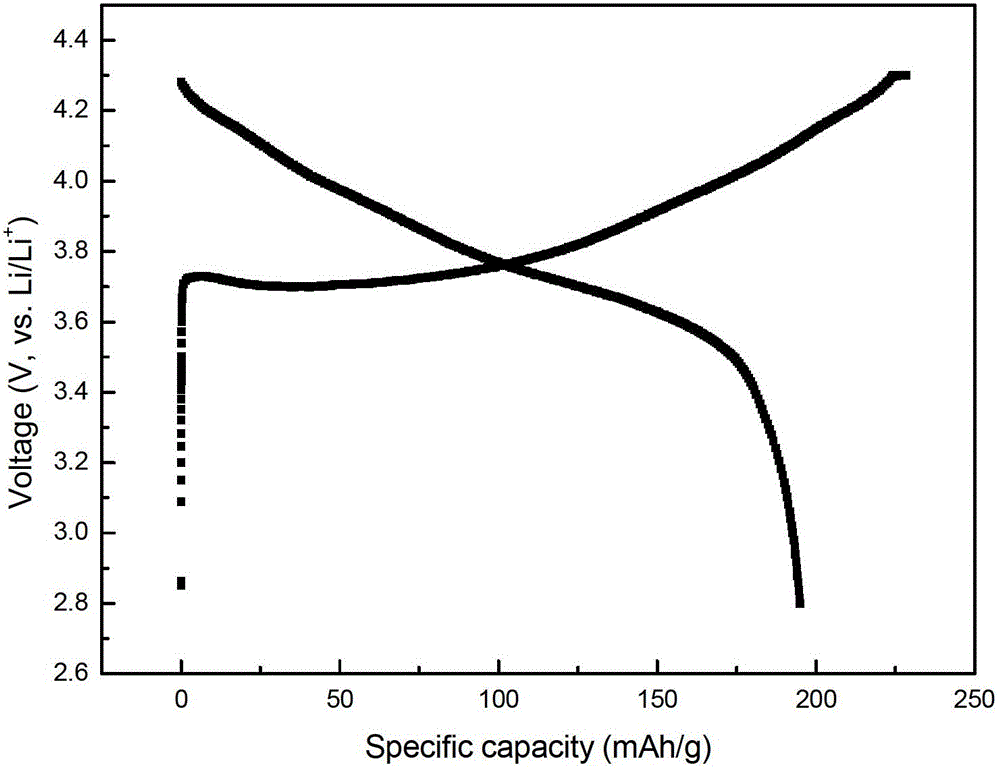

Preparation method of lithium-nickel-cobalt-aluminum oxide for anode materials of lithium ion batteries

ActiveCN103066257ASolve the problem of complete oxidationPrevent "cation mixing" phenomenonCell electrodesLithium hydroxideOxygen

The invention provides a preparation method of lithium-nickel-cobalt-aluminum oxide for anode materials of lithium ion batteries. The method comprises: step 1, using a nickel-cobalt-aluminum precursor prepared through a coprecipitation method and doped with mixed ions as raw materials, putting the raw materials into a sealed hearth of a pressure furnace, continuously introducing oxygen until a fixed pressure value is formed, then heating to a pre-burning temperature and keeping warm for a period of time, and cooling to obtain an oxidized precursor; and step 2, adding measured lithium salt or lithium hydroxide into the oxidized precursor, ball milling and uniformly mixing; heating the uniformly mixed raw materials to a certain temperature and keeping warm for a period of time, and meanwhile continuously introducing oxygen to complete a sintering process, thereby obtaining the finish product. According to the invention, through a hyperbaric oxygen atmosphere, the oxygen are enabled to fully infiltrate into particles of the raw materials which has a certain accumulation thickness, thereby preventing situations that only surface materials are oxidized under a normal pressure, and ensuring a full conversion of Ni<2+> to Ni<3+> by a full pre-oxidation.

Owner:GUANGZHOU LIBODE NEW MATERIAL

Hyperbaric oxygen devices and delivery methods

A hyperbaric oxygen device and methods of applying hyperbaric oxygen are disclosed. The device comprises an enclosure including a collapsible bag defined by two sheets of fluid impervious material sealed together at both ends such that gas can be delivered between the sheets to inflate the enclosure to a rigid state and maintain the enclosure in the rigid state when oxygen pressure in the interior of the enclosure is cycled between ambient pressure and above ambient pressure.

Owner:AOTI

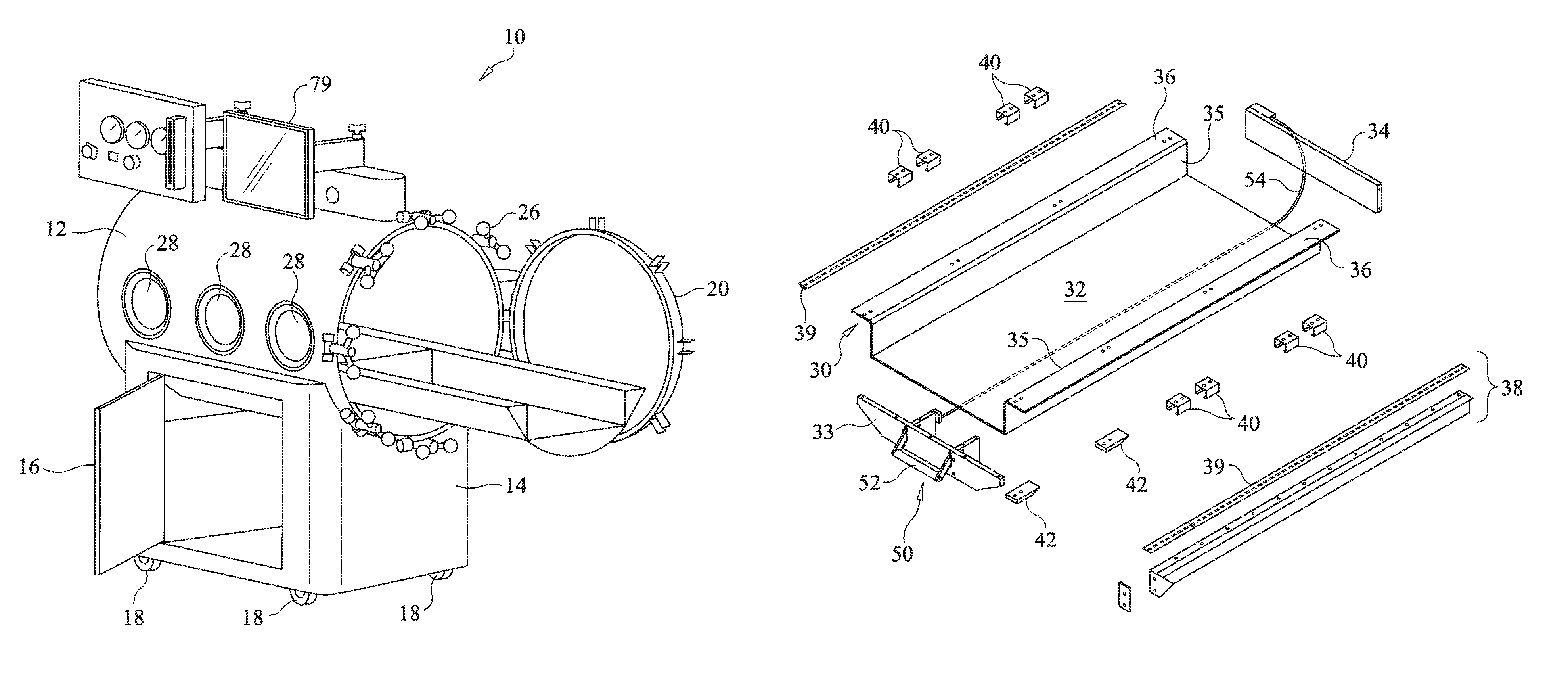

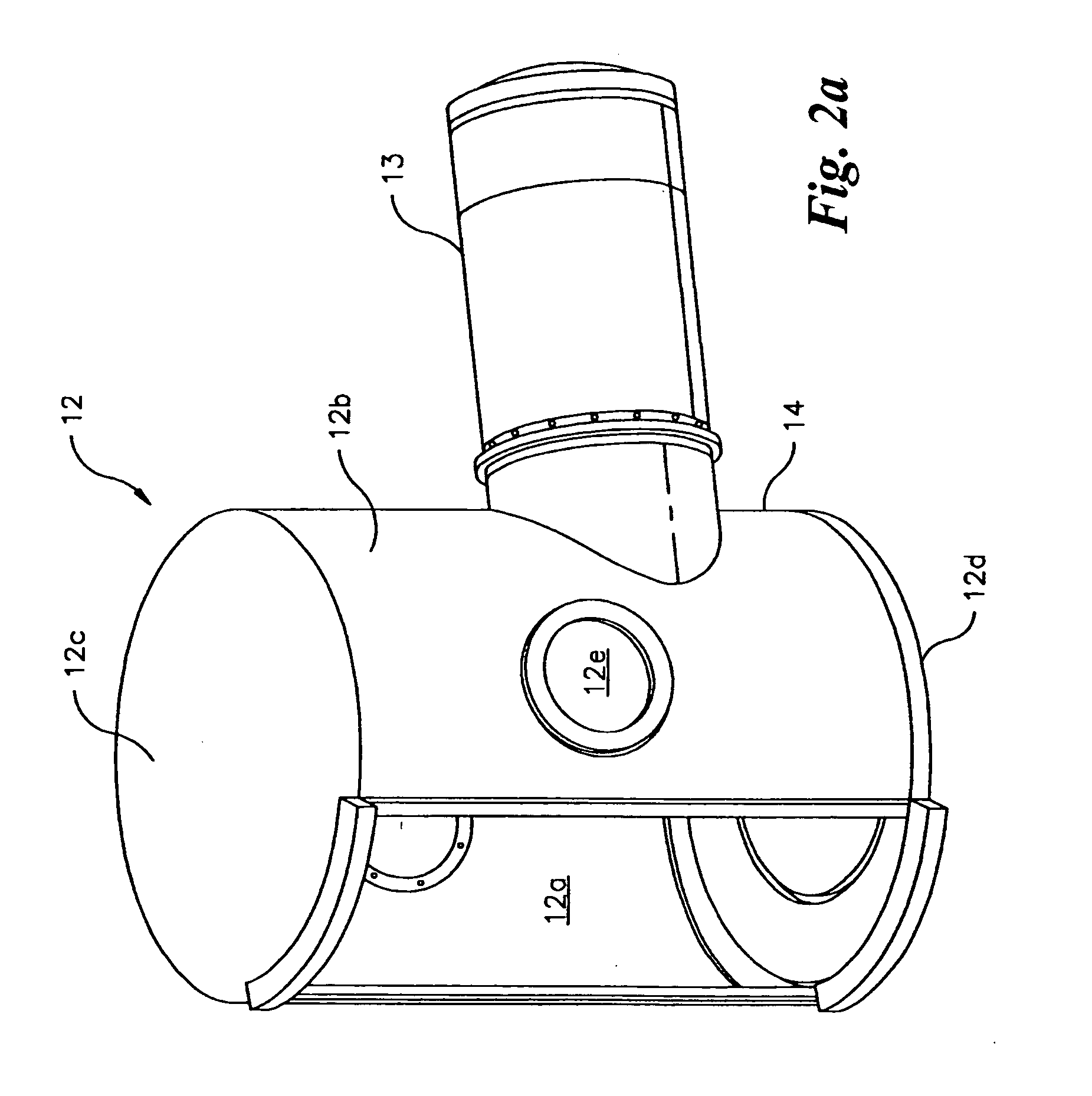

Hyperbaric oxygen therapy chamber and system for use in veterinary medicine

ActiveUS9186232B1Overcomes limitation and disadvantageEasy to insertRespiratorsBreathing protectionRegimenVeterinary Patient

Systems and methods for use in providing hyperbaric oxygen therapy (“HBOT”) sessions to veterinary patients includes providing HBOT chambers specifically adapted for use with veterinary patients. HBOT chambers are adapted with a rail mounted platform upon which one or more animals may be supported and confined within an enclosure during the application of HBOT. Viewing ports are provided at the appropriate level to allow the pets being treated to see out from their position within the chamber. The system is provided with a closed circuit video system including a plurality of chamber mounted cameras configured allow for remote monitoring of the animals within the chamber, and a room mounted camera configured to allow for remote monitoring of the chamber and surrounding environment. Remote central station monitoring allows for widespread deployment of hyperbaric chambers in accordance with a business method wherein revenue is generated on per-use and / or per-patient basis.

Owner:OTTO EDGAR

Composition for Injectable Cement Useful as Bone Replacement

InactiveUS20080027455A1High compressive strengthImprove absorption rateBiocideCosmetic preparationsPowder mixtureMicroparticle

The invention relates to a composition for injectable cement, comprising a mineral sold phase, a separate liquid phase and, optionally, microparticles of a biocompatible and biodegradable polymer. The mineral solid phase comprises a mixture of powders with the molar composition: (CP)6 (CaO)y (SrCO3)z, [CP being CaHPO42H2O, CaHPO4, Ca1-xSrxHPO4, an equimolar mixture of bis(Ca(H2PO4)2, H2O and CaO, or a mixture of two or three of said compounds] and y+z=4?1. The liquid phase comprises pure apyrogeneic water or a saline aqueous solution with pH 4 to 9. The ratio L / P [volume of liquid phase / mass of solid mineral phase] is at least 0.4 ml / g. The above is of application as bone replacement.

Owner:CENT NAT DE LA RECHERCHE SCI +1

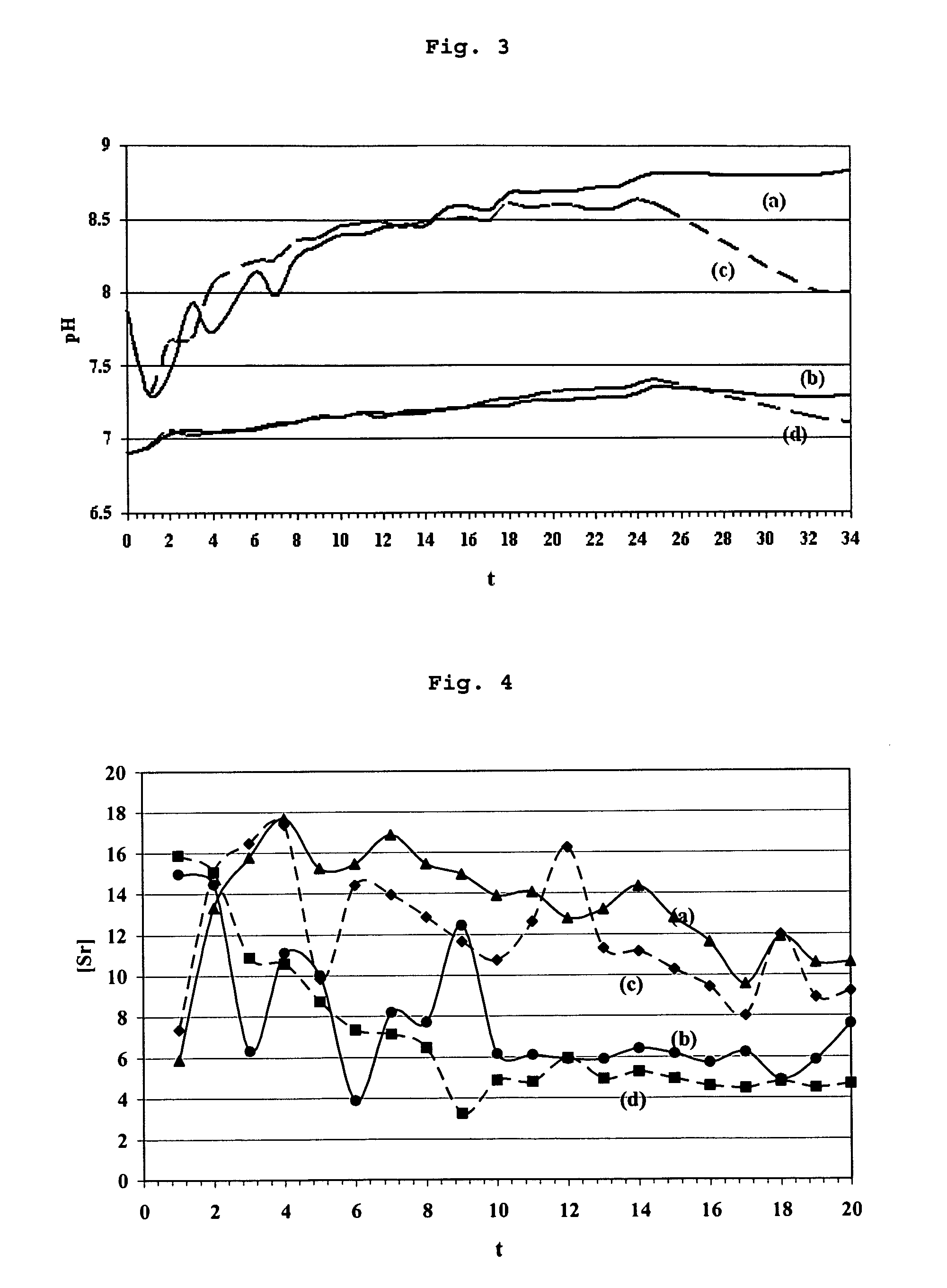

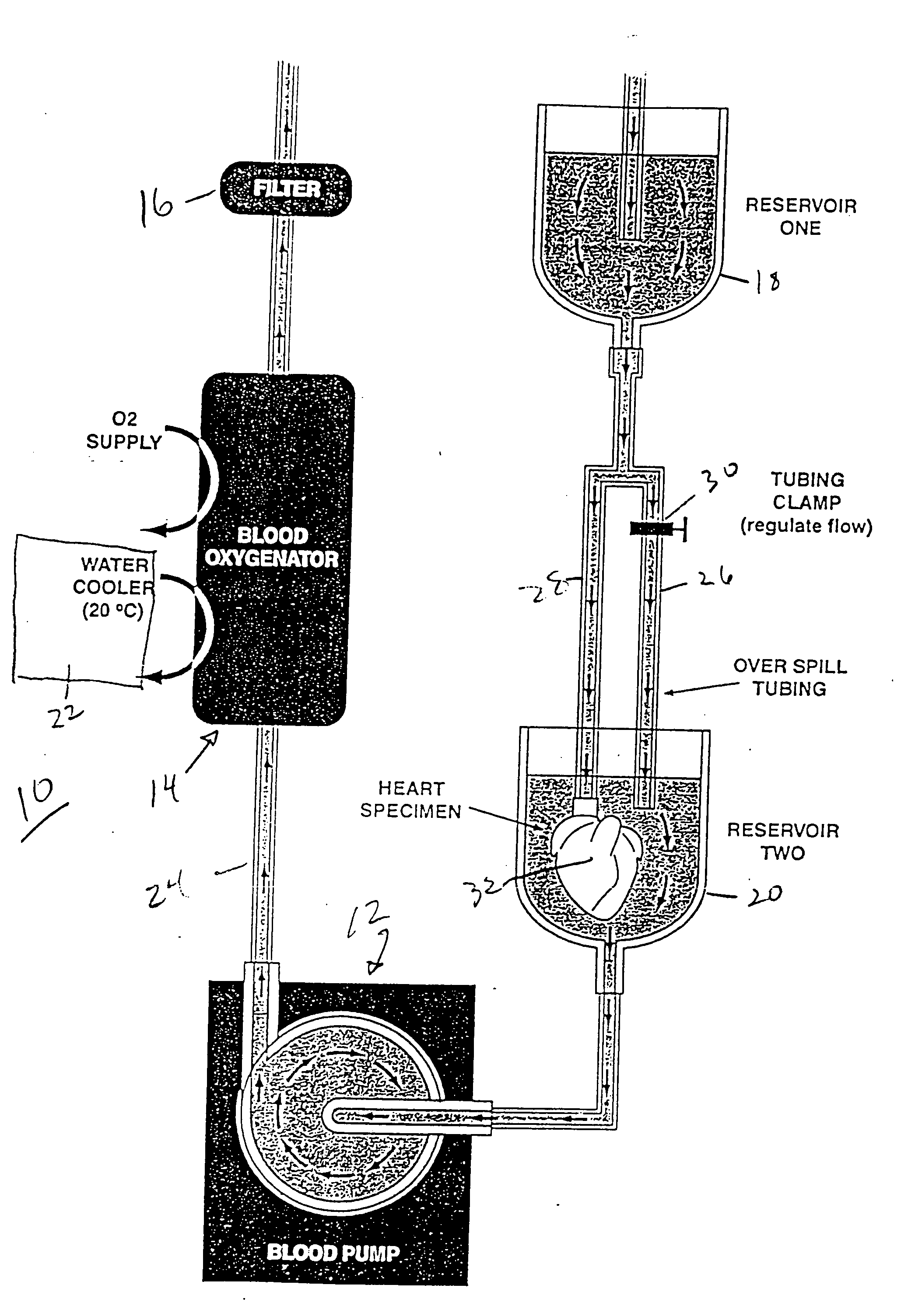

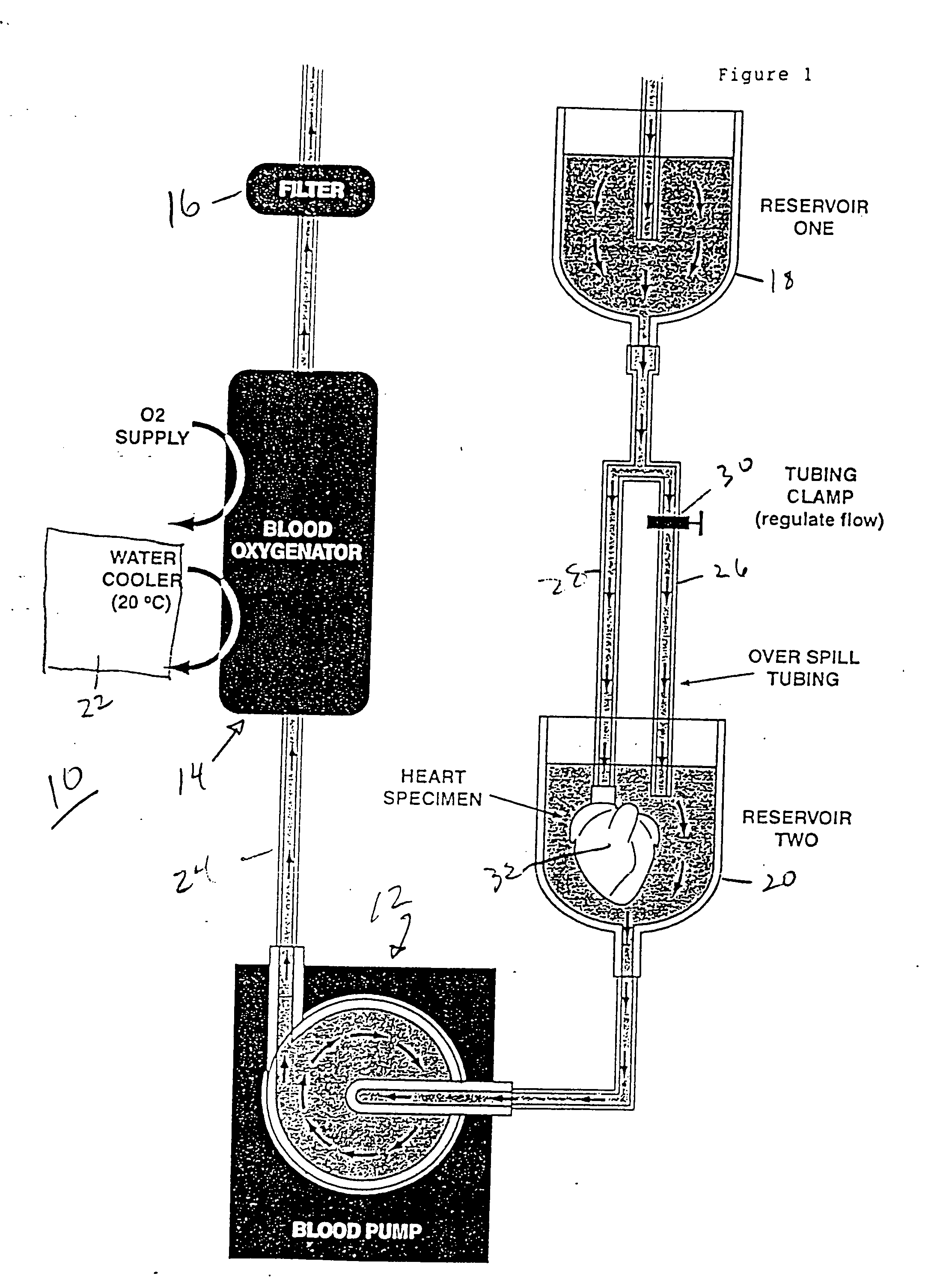

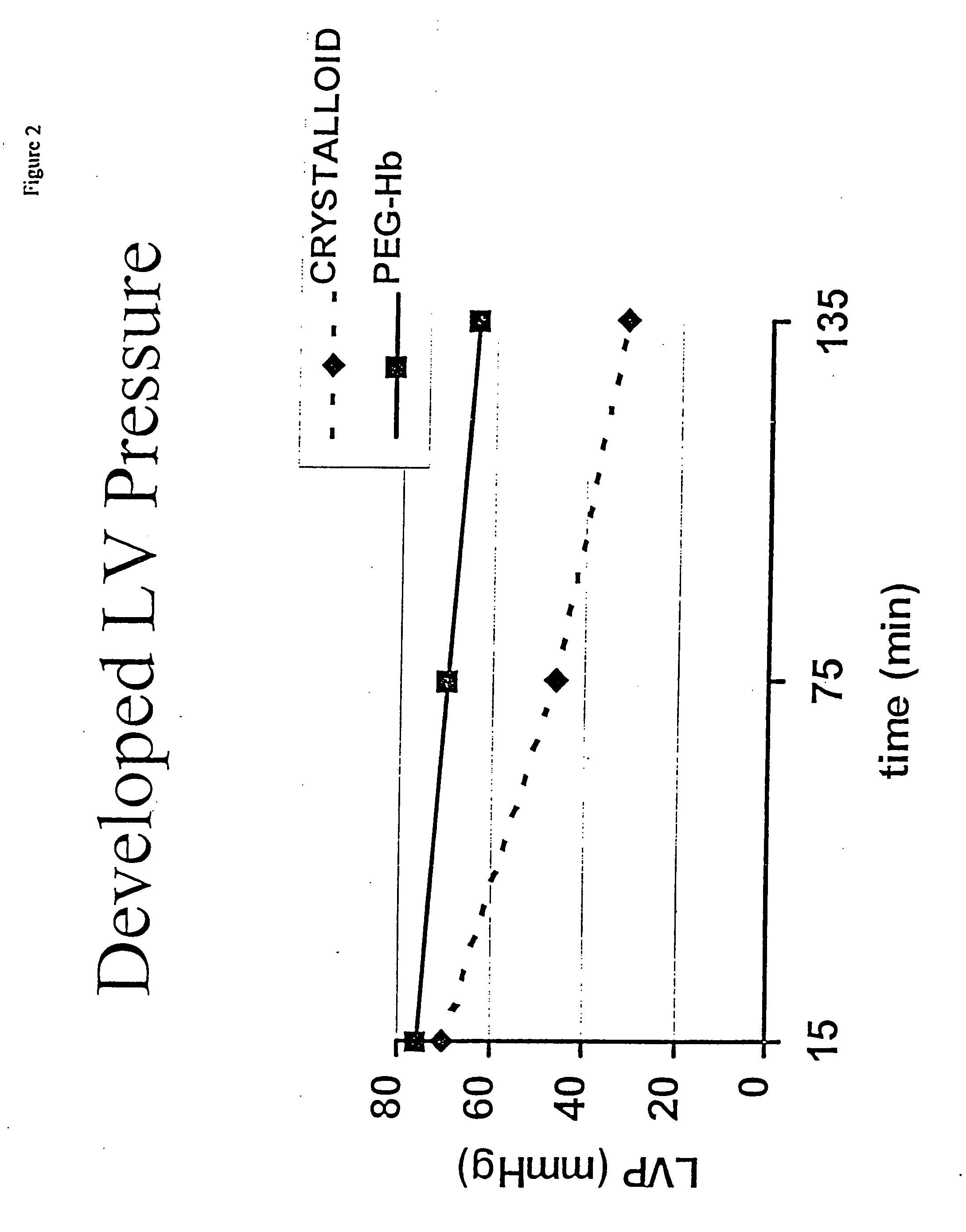

Continuous cardiac perfusion preservation with PEG-HB for improved hypothermic storage

InactiveUS20070243518A1Extended storage timeEasy to storeDead animal preservationHuman albuminPotassium

Efforts to extend myocardial preservation for transplantation by perfusion with prior crystalloid based solutions have been limited by edema and compromised function. Hypothermic perfusion preservation with a polyethylene glycol (PEG) conjugated hemoglobin solution extends preservation times. The polyethylene glycol (PEG) conjugated hemoglobin solution comprises PEG-Hb, and at least one of the constituents selected from the group of human albumin, dextrose, heparin sodium, lidocaine HCl, MgSO4, KCl, CaCl2, Tromethamine (THAM) solution, NaCl, NaHCO3, and Na2HPO4 / NaH2PO4. Comparison of cardiac function after continuous perfusion using a hypocalcemic normokalemic crystalloid perfusate is made with and without the addition of PEG-Hemoglobin (Hb).

Owner:RGT UNIV OF CALIFORNIA

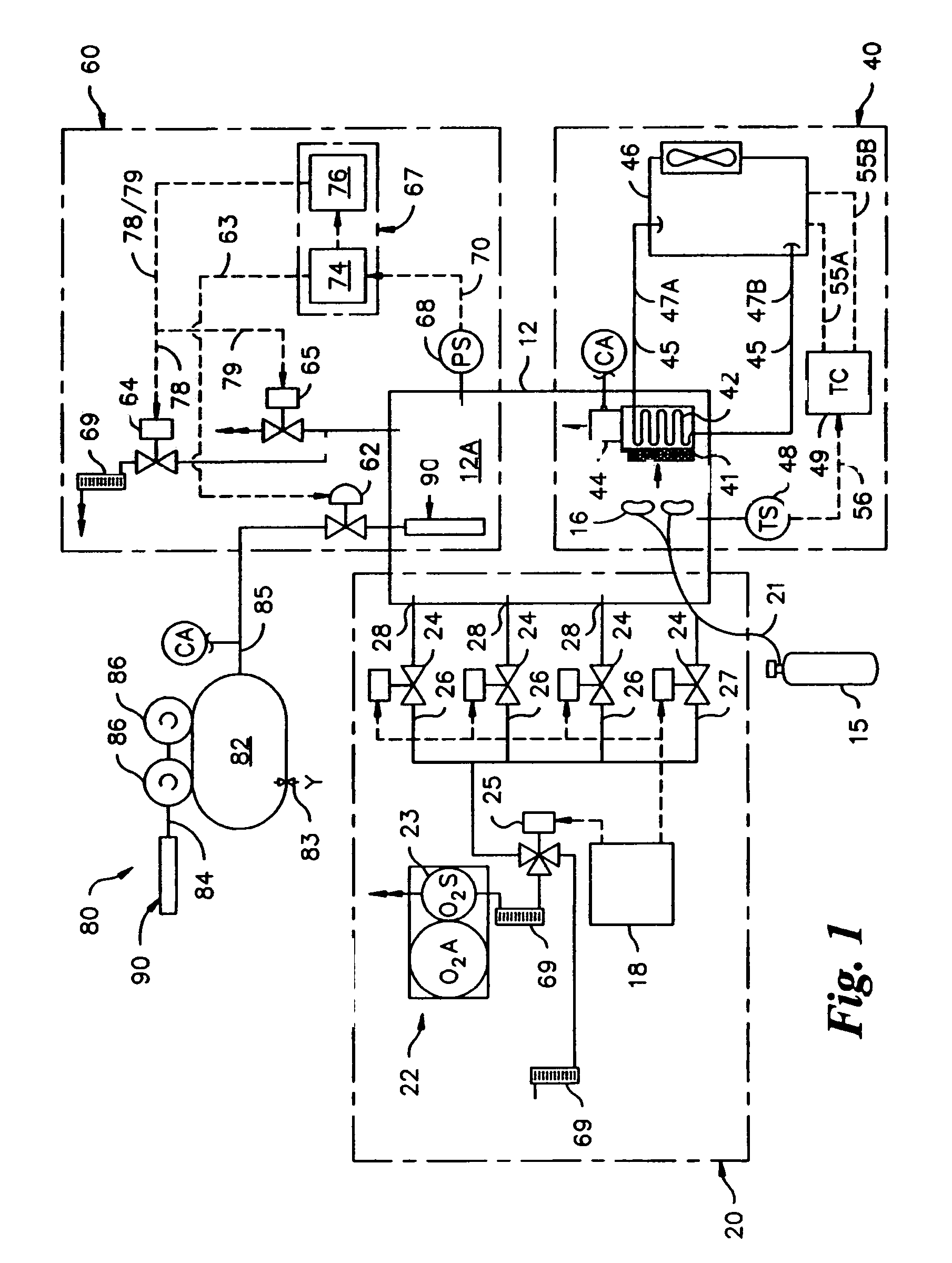

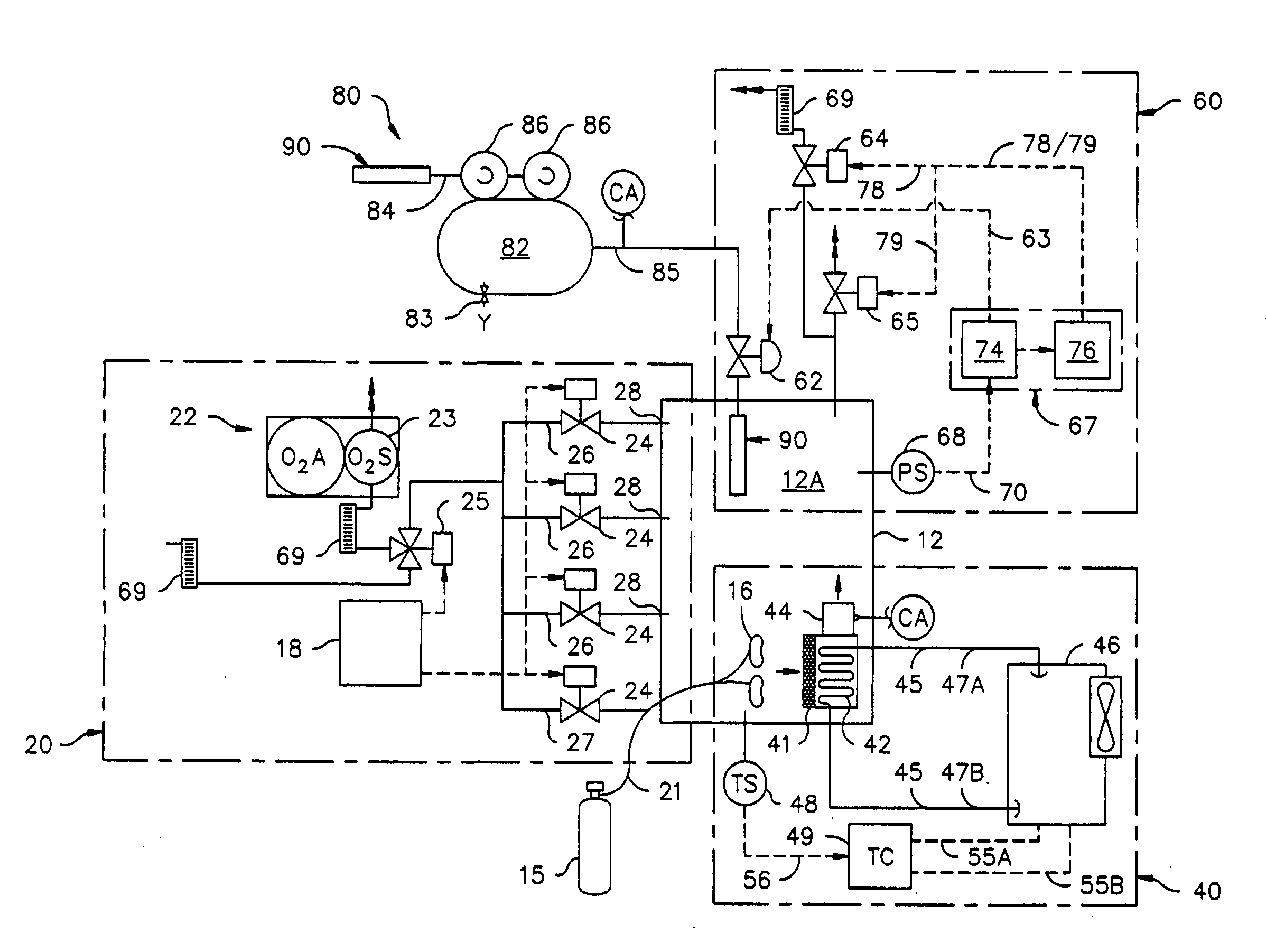

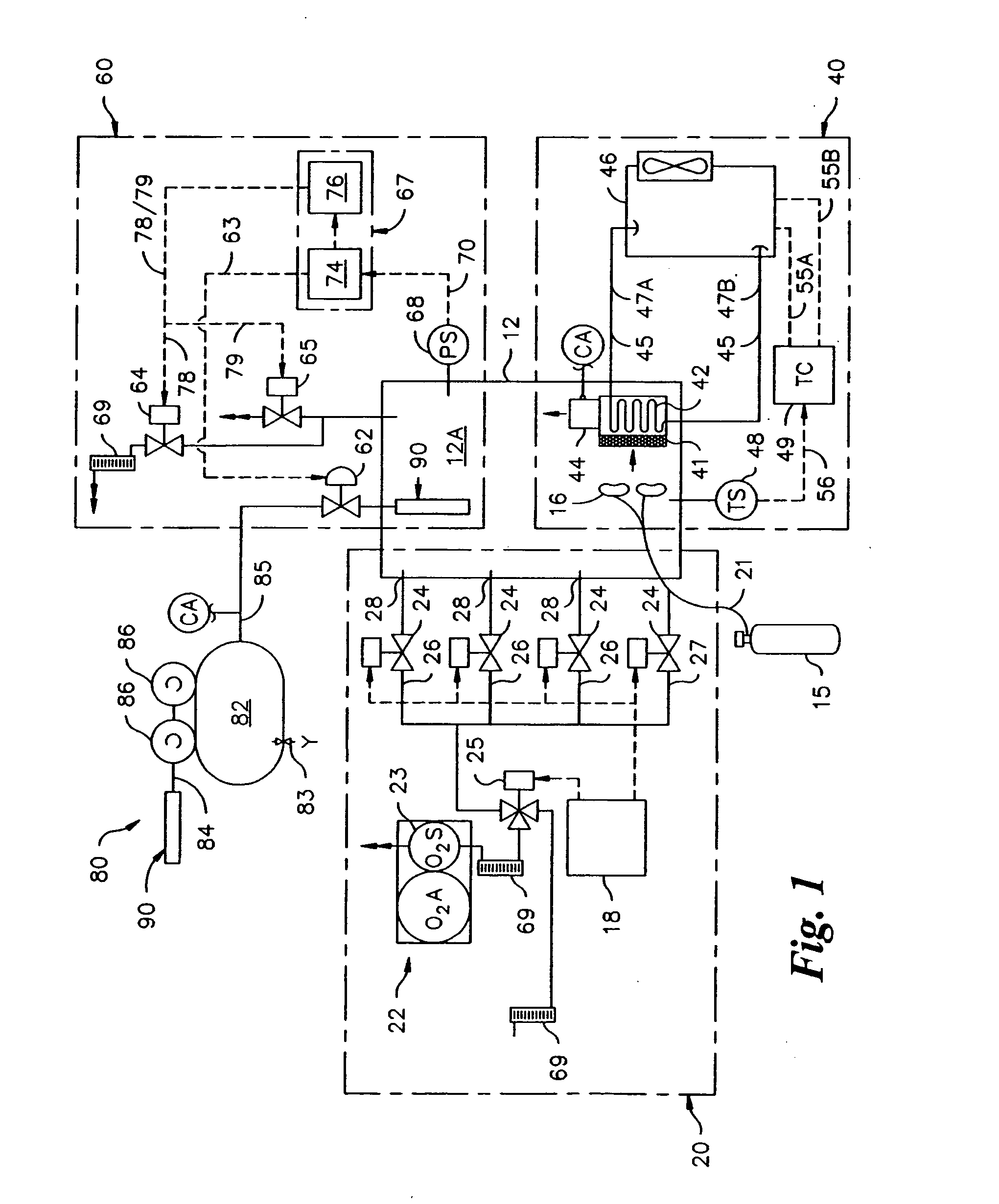

Hyperbaric oxygen therapy system controls

A hyperbaric oxygen therapy system includes a pressure vessel containing a gas, an oxygen concentration measurement apparatus for monitoring the concentration of oxygen in the gas, an environmental control apparatus for controlling the temperature of the gas in the vessel, and a pressure / ventilation control apparatus for controlling the pressure of the gas in the vessel. The pressure vessel is capable of accommodating a patient. The oxygen concentration measurement apparatus includes an oxygen concentration analyzer and a plurality of gas lines connecting the oxygen analyzer to the pressure vessel. The pressure / ventilation control apparatus includes a pressure controlling valve, a pressure sensor, a ventilation valve, and a controller having a programmable pressure profile. The environmental control apparatus includes a scrubber, a heat exchanger and a blower located within the pressure vessel. A compressor for the system includes a compressor silencer. An airlock providing access to the pressure vessel includes a safety mechanism.

Owner:OXYHEAL MEDICAL SYST INC

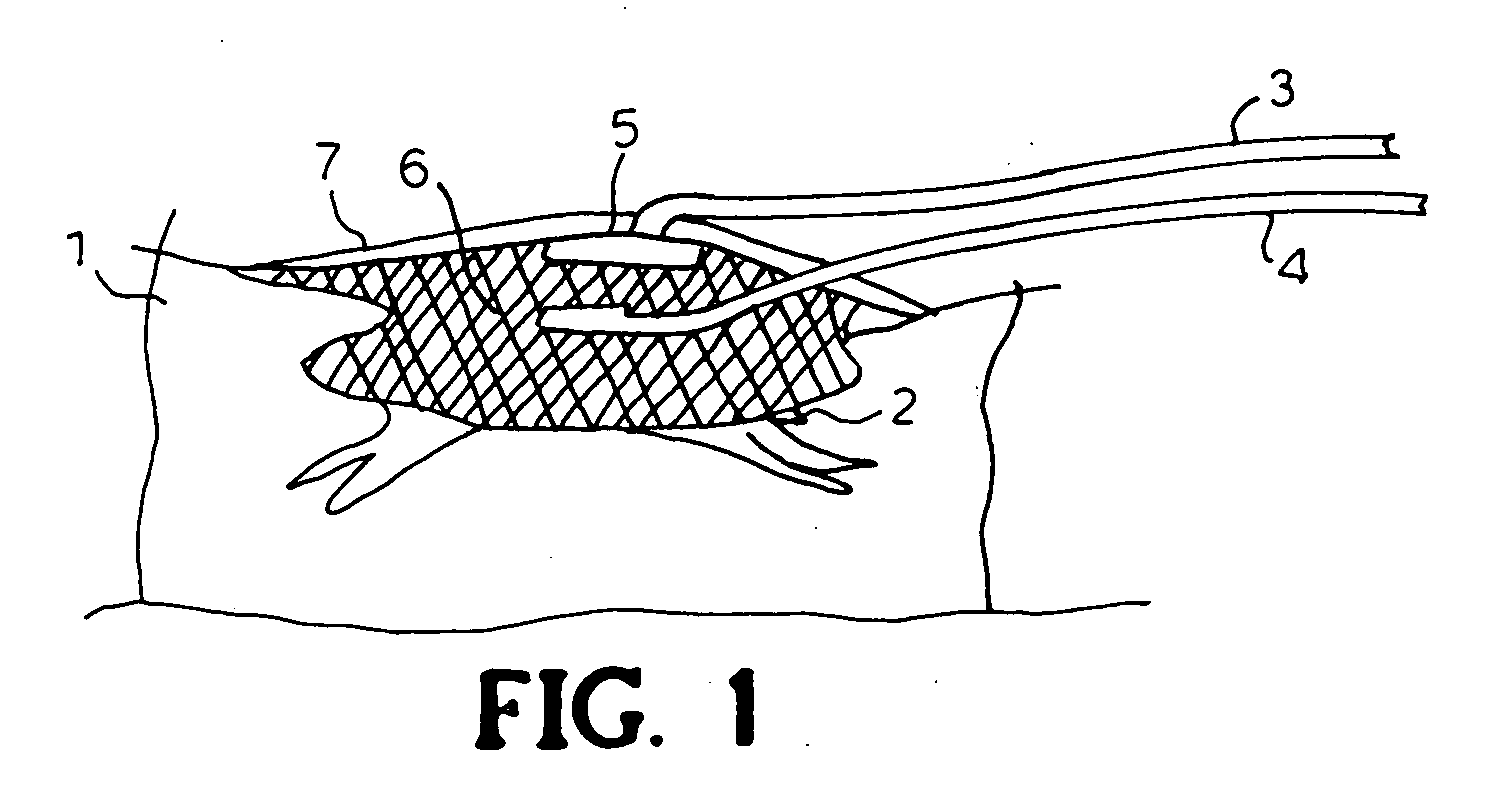

Method for dressing a wound

ActiveUS20100160853A1Reduce in quantityPromote wound healingPlastersMedical devicesWound dressingWound surface

A method for dressing a wound is provided including providing a wound dressing pad of hydrophobic fabric that is treated to bind microorganisms; placing the hydrophobic fabric so that it faces the wound; and applying negative pressure therapy to the wound dressing so that microorganisms in the wound surface adhere to the dressing through hydrophobic interaction. The negative pressure therapy may be alternated with hyperbaric oxygen treatments of the wound dressing.

Owner:ABIGO MEDICAL AB

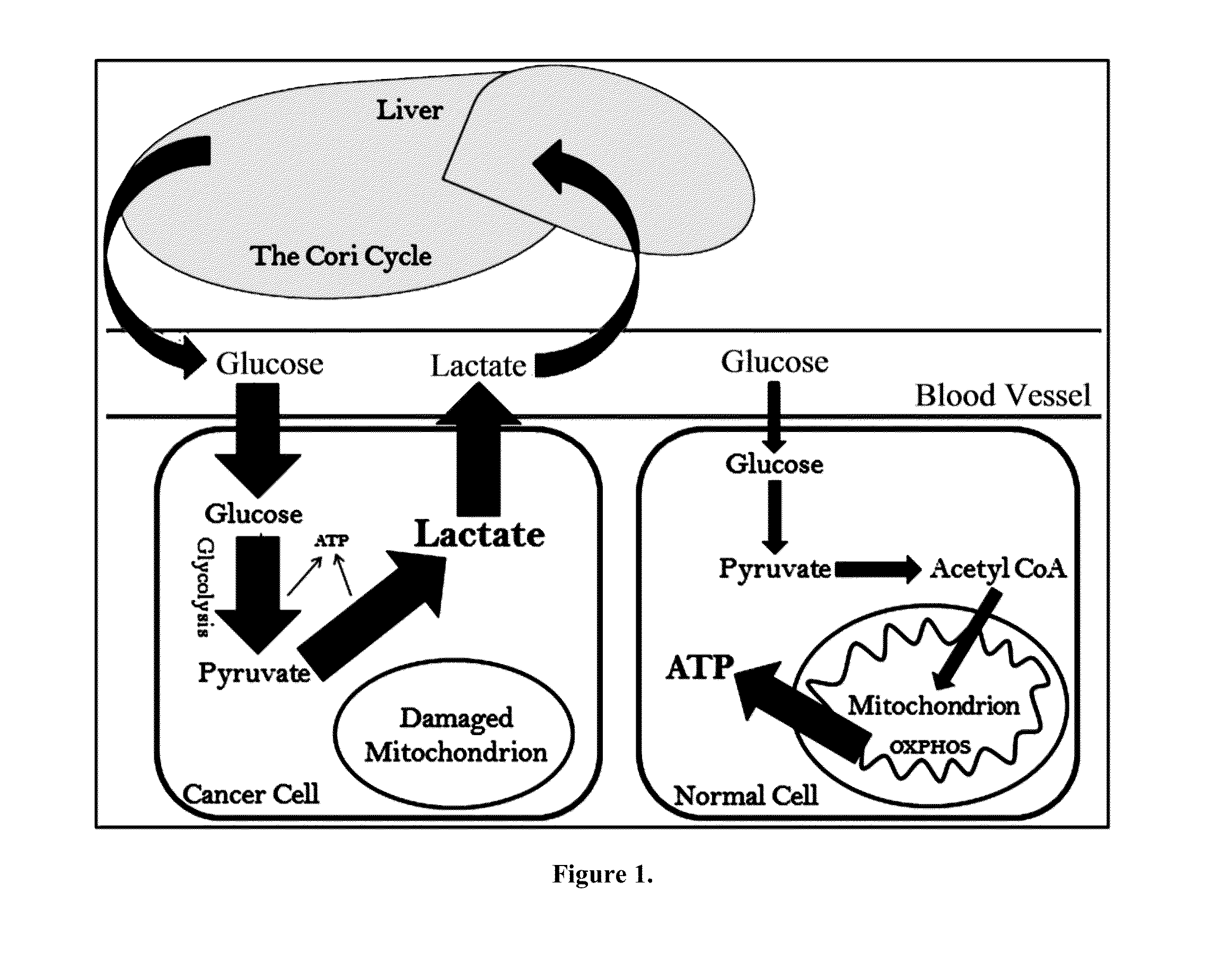

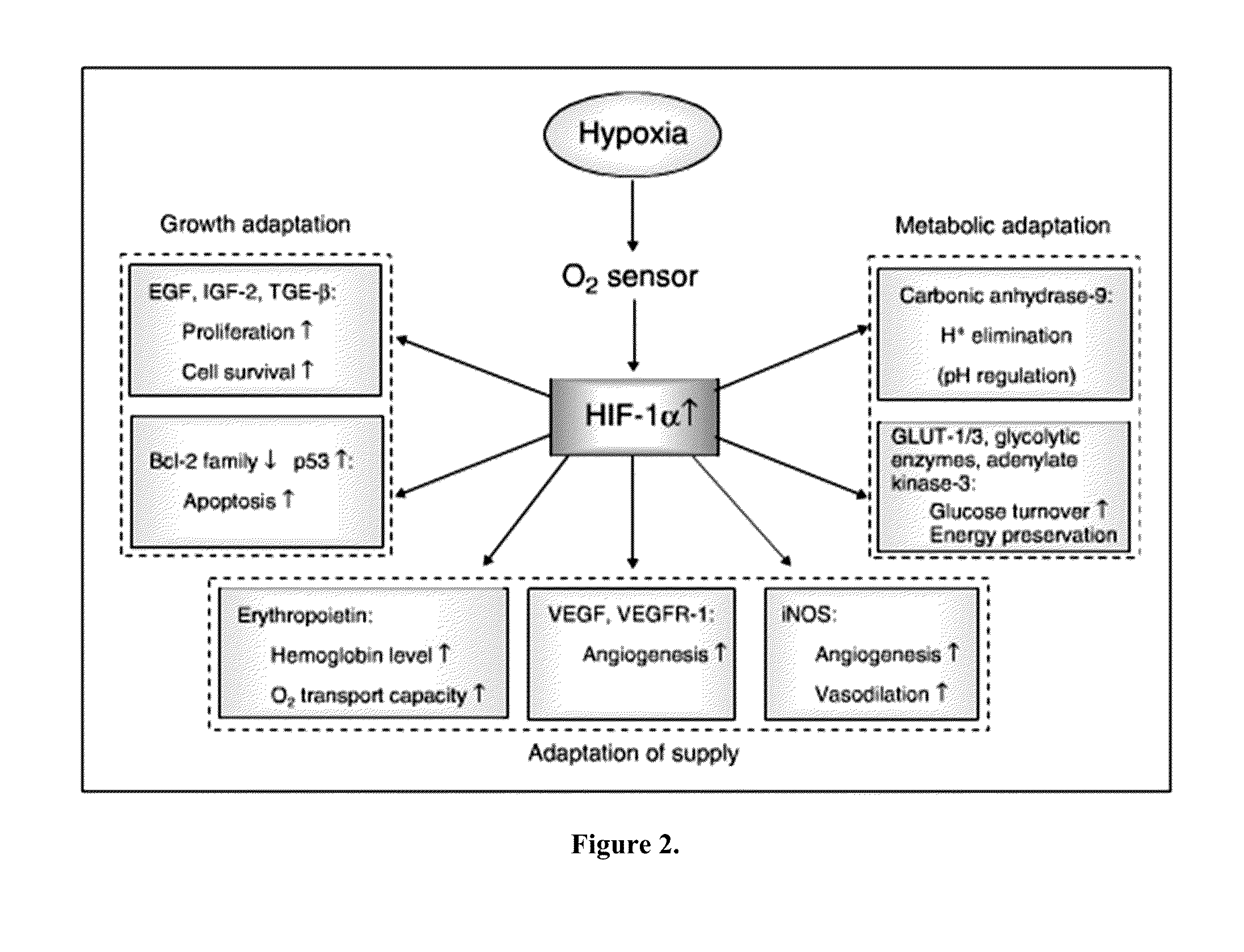

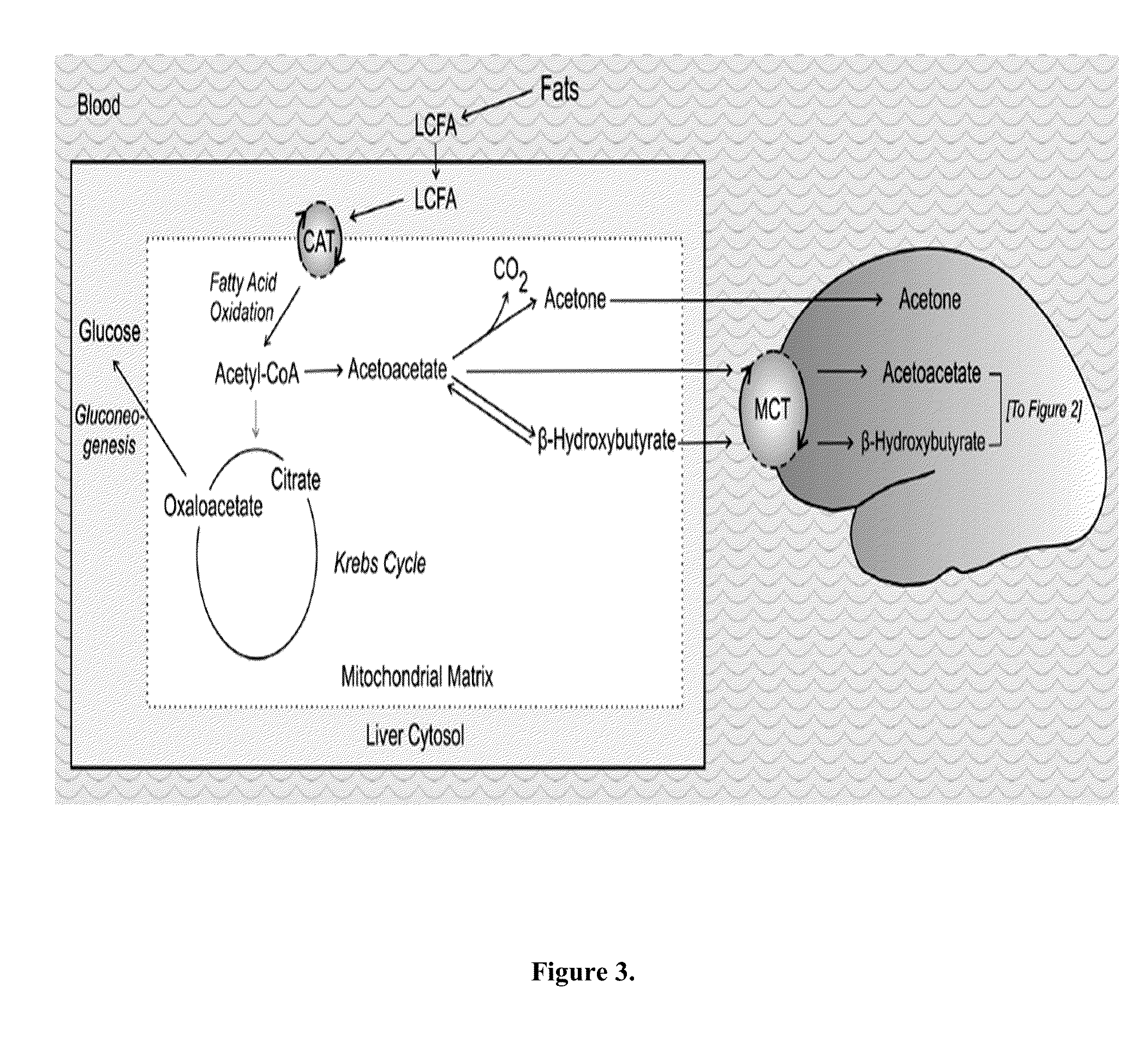

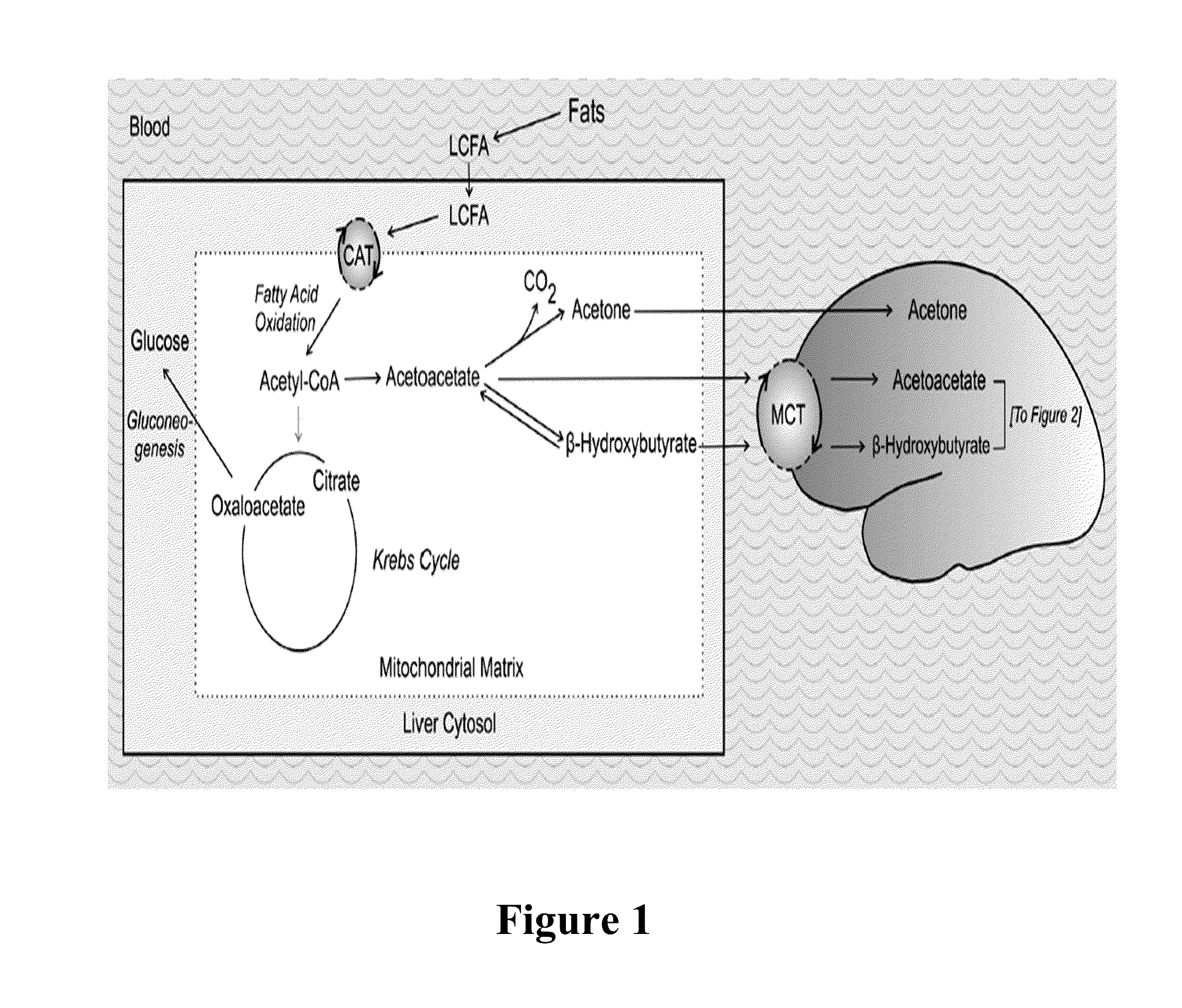

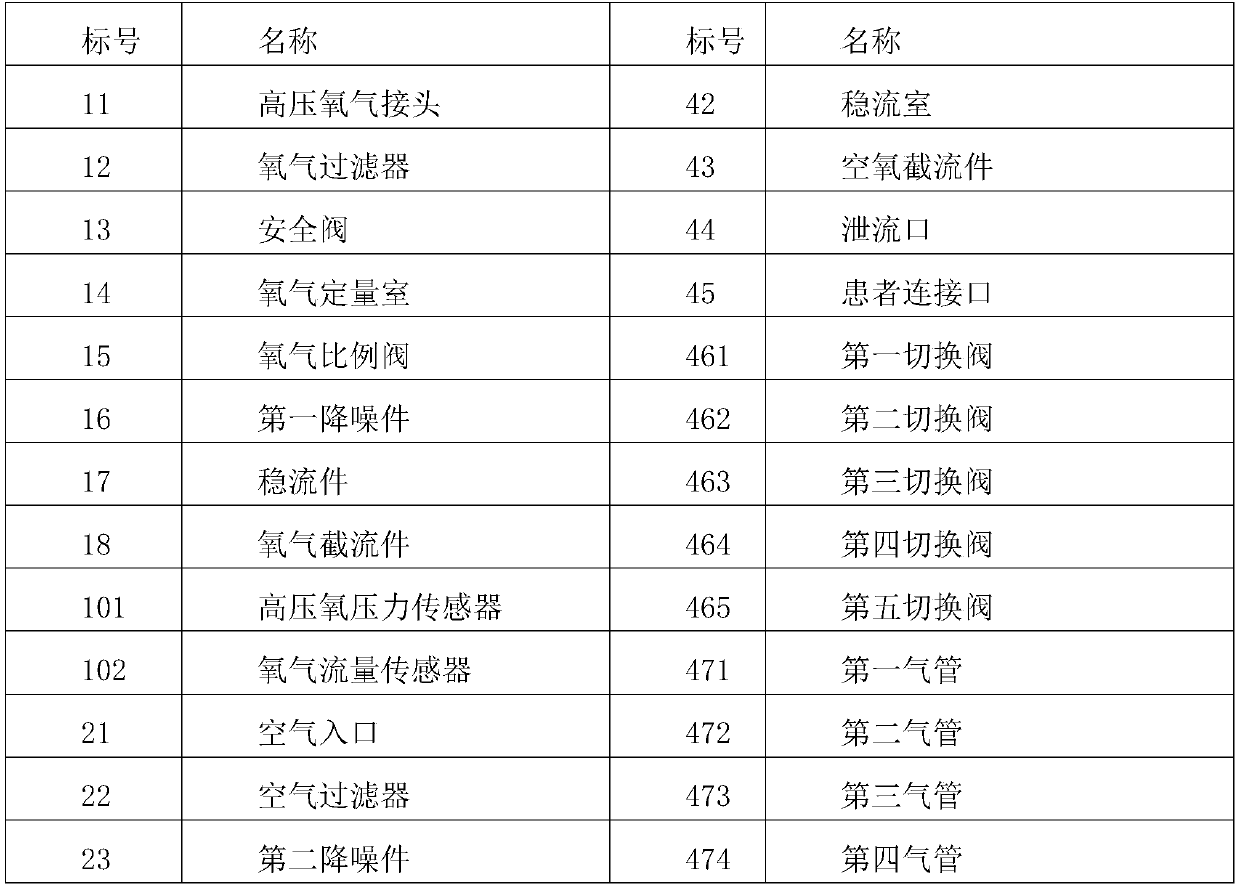

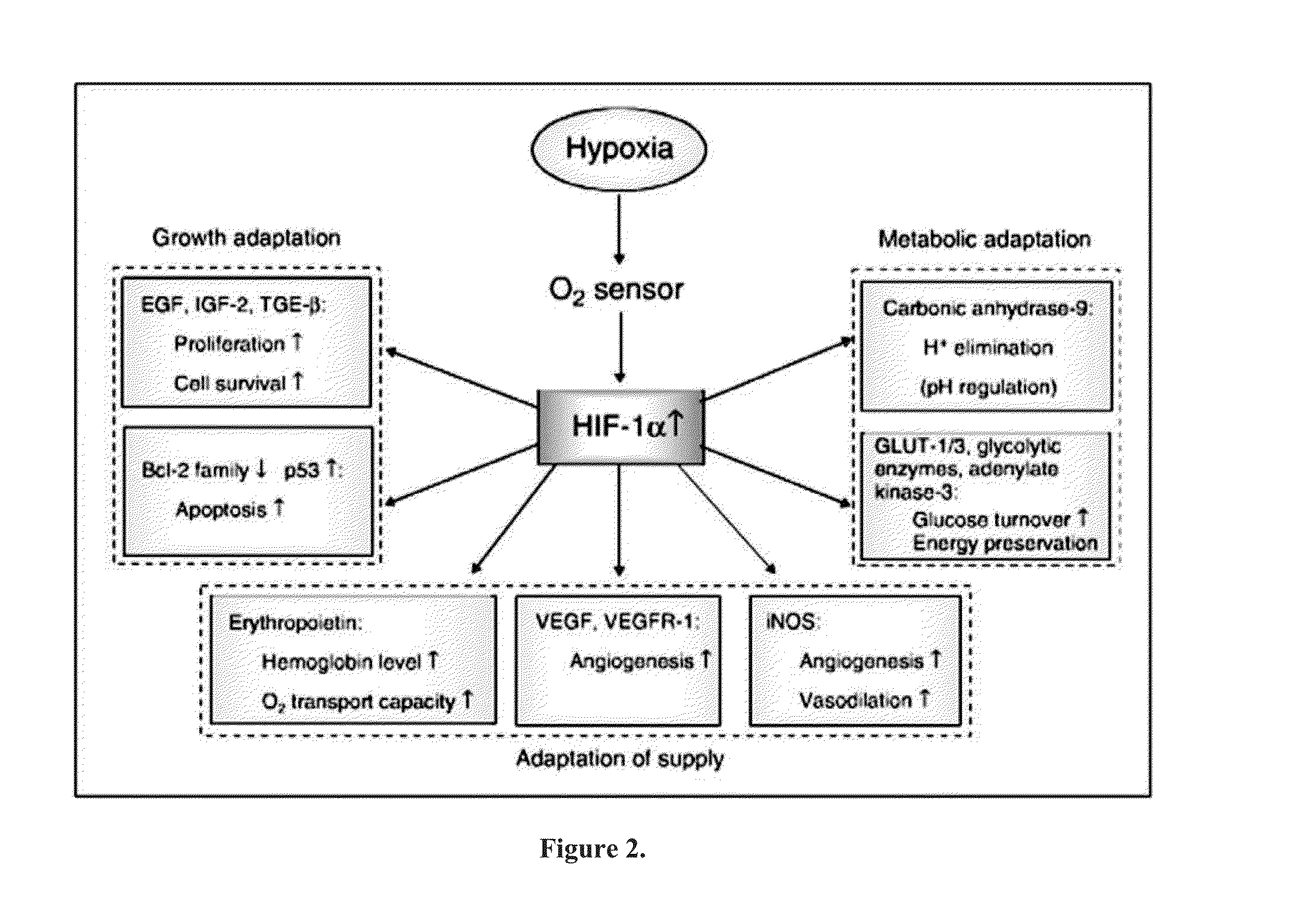

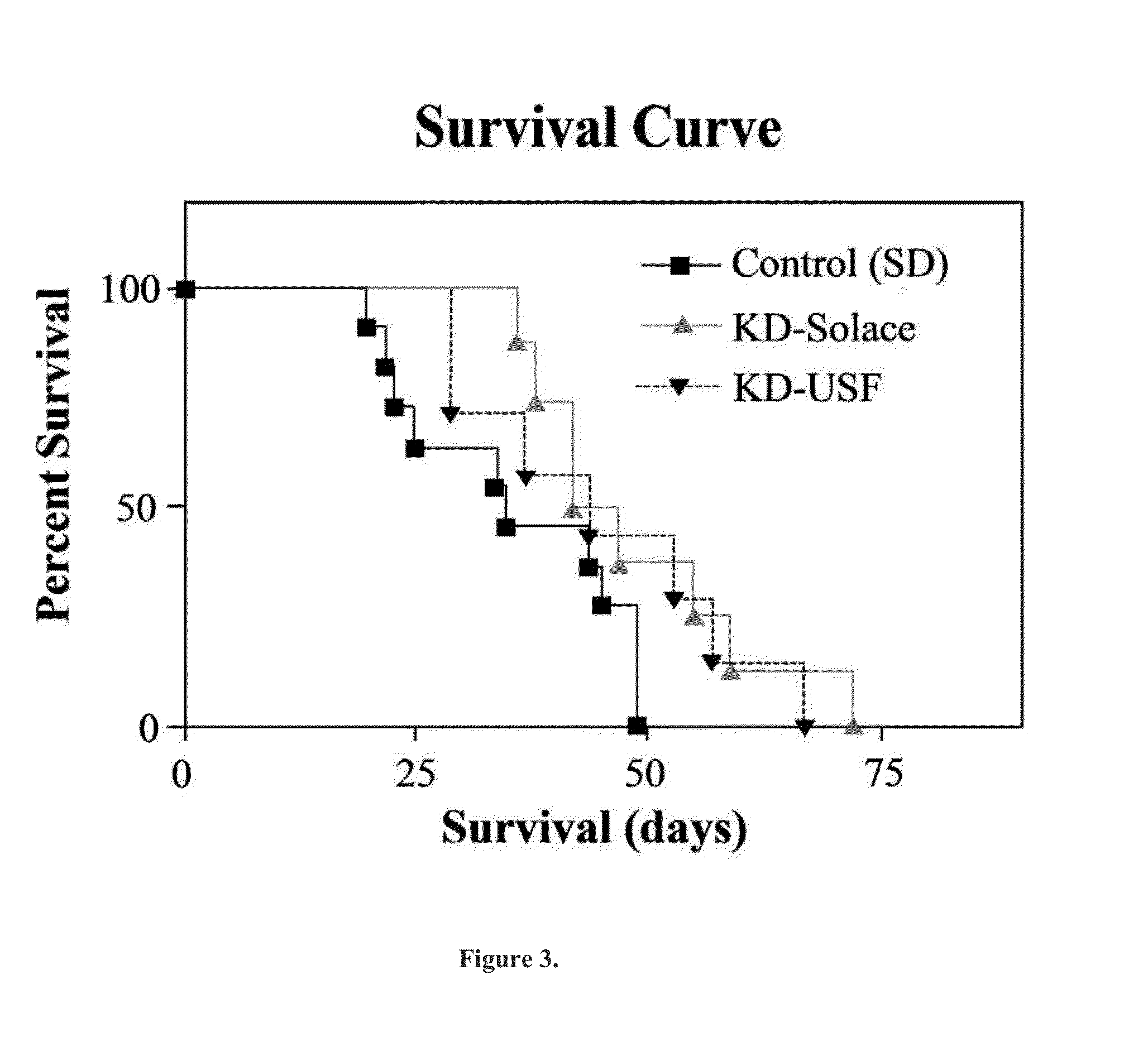

Cancer with metabolic therapy and hyperbaric oxygen

InactiveUS20140072654A1Raise the possibilityIncrease productionBiocidePeroxide active ingredientsDiseaseAcetoacetates

The present invention demonstrates the therapeutic use of ketone esters for seizure disorders, Alzheimer's disease malignant brain cancer, and other cancers, which are associated with metabolic dysregulation. The administration of a ketogenic diet, such as ketone esters, while concurrently subjecting the patient to a hyperbaric, oxygen-enriched environment resulted in therapeutic ketosis. Optionally, the hyperbaric, oxygen-enriched environment is 100% oxygen at 2.5 ATA absolute. The ketone esters may be derived from acetoacetate and can include R,S-1,3-butanediol acetoacetate monoester, R,S-1,3-butanediol acetoacetate diester, or a combination of the two. The treatment may further include administering at least 10% ketone supplementation, such as acetoacetate, adenosine monophosphate kinase, 1,3-butanediol, or ketone ester, to the patient.

Owner:UNIV OF SOUTH FLORIDA

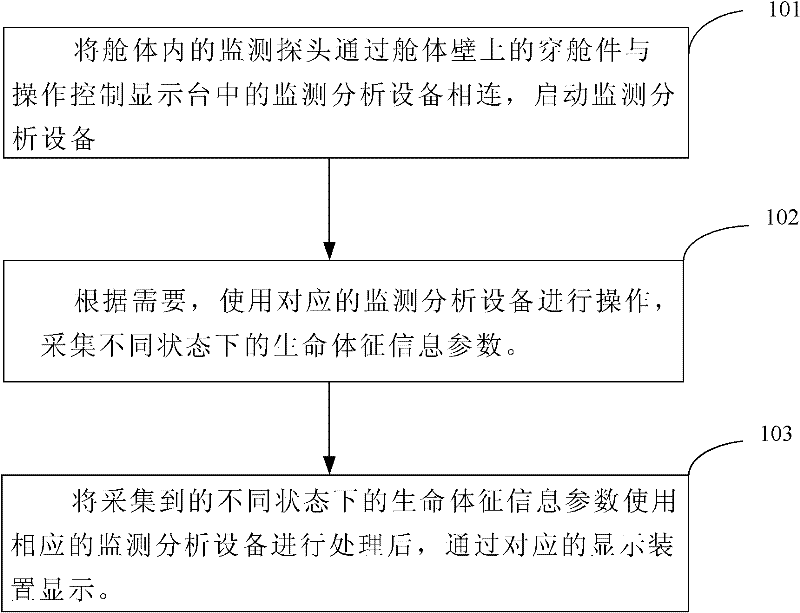

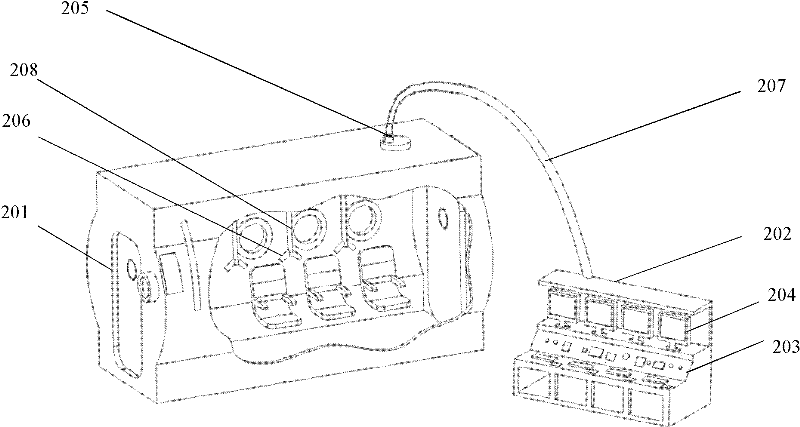

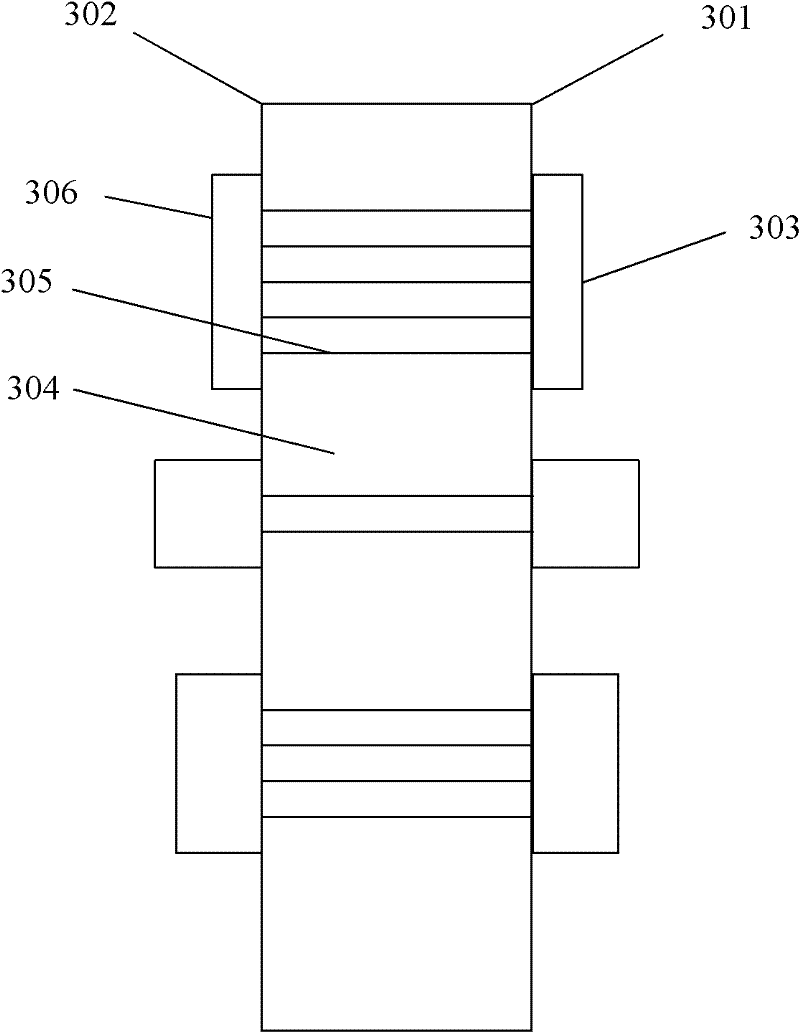

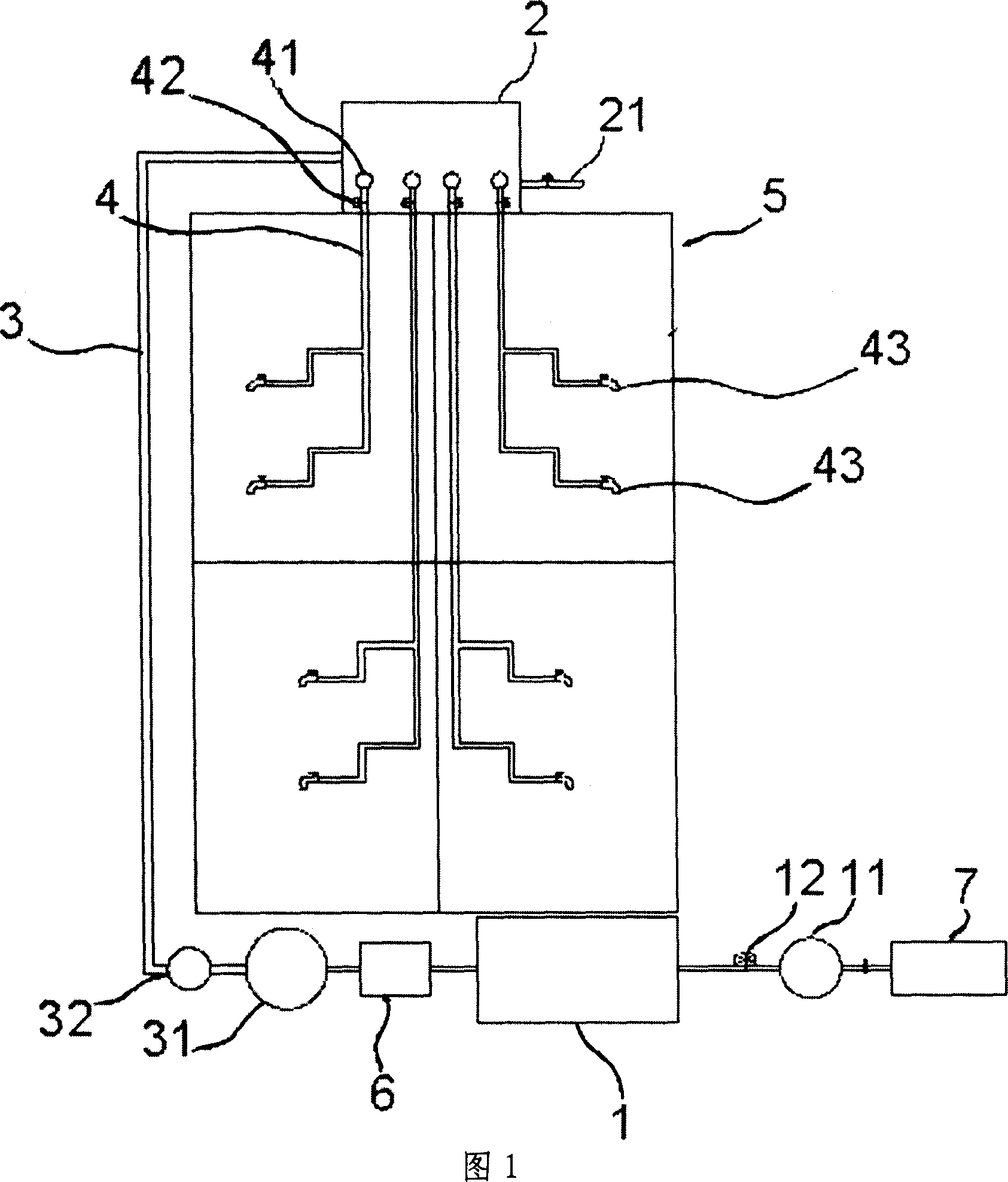

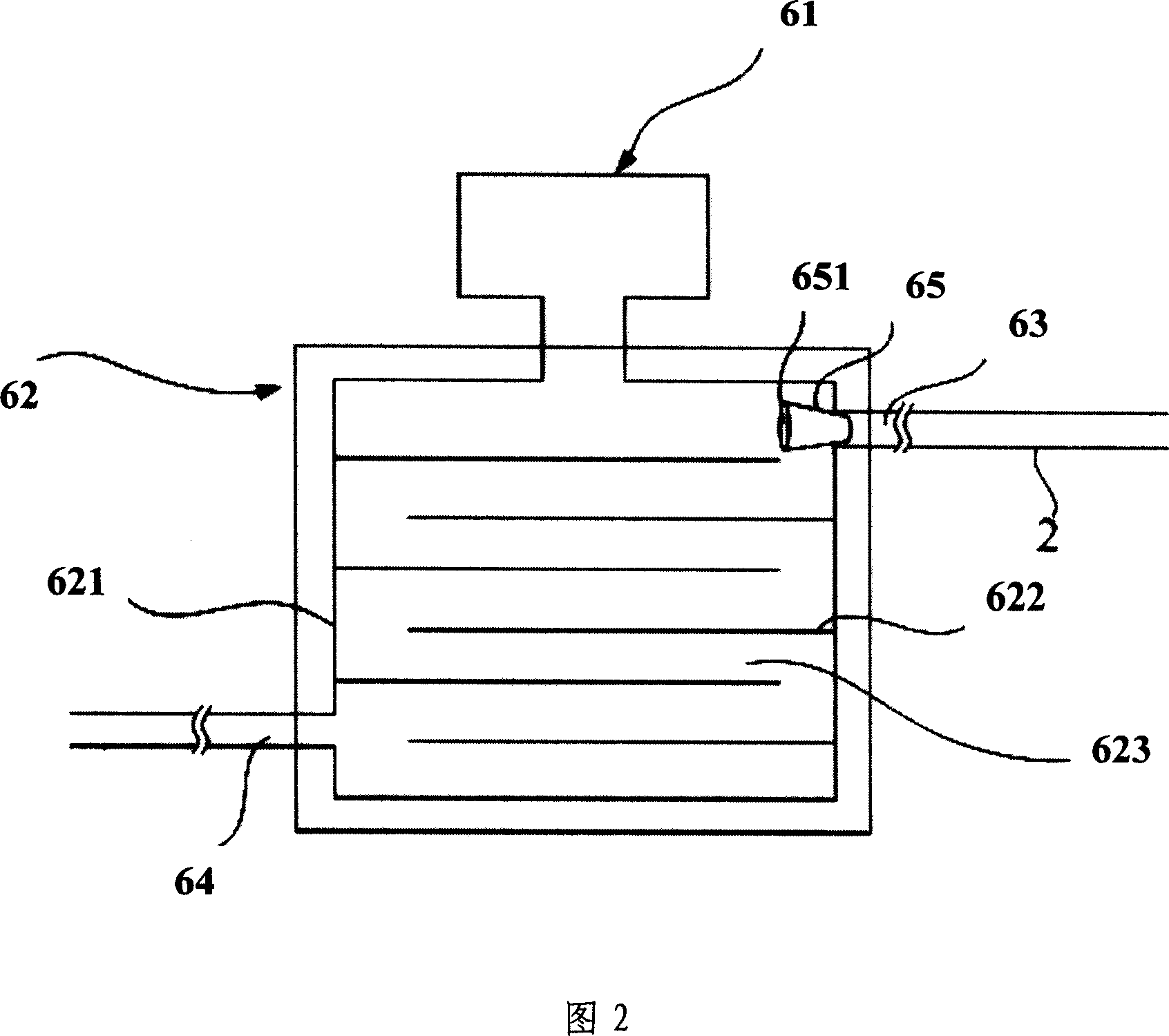

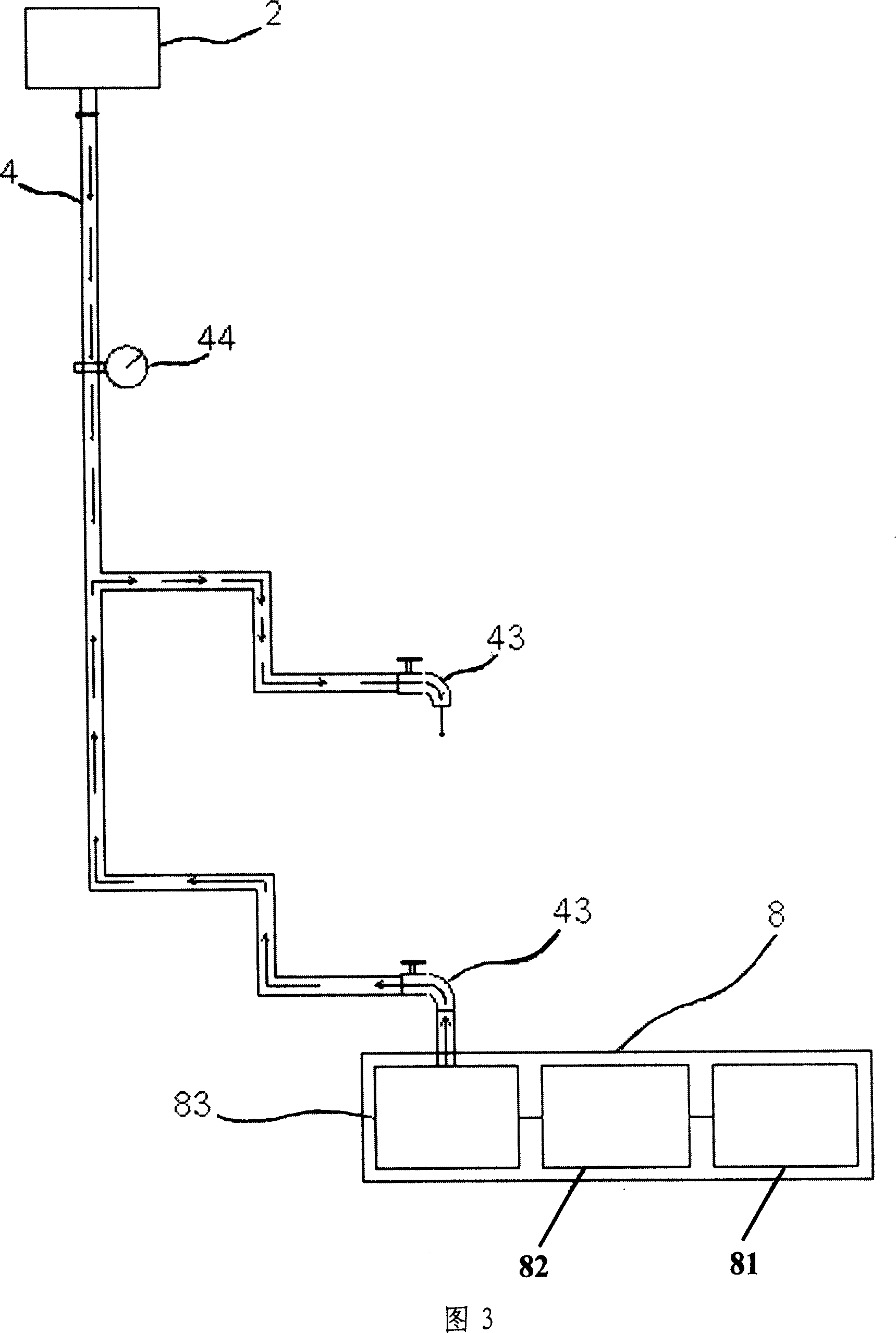

Vital sign monitoring method and system of high pressure oxygen cabin

ActiveCN102335079APrevent atmospheric leakageEnsure rated atmospheric pressureBreathing protectionTreatment roomsDisplay deviceHigh pressure oxygen

The invention discloses a vital sign monitoring method and system of a high pressure oxygen cabin. The vital sign monitoring method comprises the steps of: connecting a monitoring probe in a cabin body with a monitoring and analyzing device in an operation control display platform through a cabin penetrating member on the wall of the cabin body, starting the monitoring and analyzing device; acquiring various vital sign information parameters of a human body under different states by using the corresponding monitoring and analyzing device according to the demands; and displaying the acquired vital sign information parameters of the human body under different states through a corresponding display device. The technical scheme provided by the invention can be used for acquiring the vital sign information parameters of the human body under different states in the high pressure oxygen cabin.

Owner:常骅

Hyperbaric oxygen therapy system controls

A hyperbaric oxygen therapy system includes a pressure vessel containing a gas, an oxygen concentration measurement apparatus for monitoring the concentration of oxygen in the gas, an environmental control apparatus for controlling the temperature of the gas in the vessel, and a pressure / ventilation control apparatus for controlling the pressure of the gas in the vessel. The pressure vessel is capable of accommodating a patient. The oxygen concentration measurement apparatus includes an oxygen concentration analyzer and a plurality of gas lines connecting the oxygen analyzer to the pressure vessel. The pressure / ventilation control apparatus includes a pressure controlling valve, a pressure sensor, a ventilation valve, and a controller having a programmable pressure profile. The environmental control apparatus includes a scrubber, a heat exchanger and a blower located within the pressure vessel. A compressor for the system includes a compressor silencer. An airlock providing access to the pressure vessel includes a safety mechanism.

Owner:OXYHEAL MEDICAL SYST INC

Smelting furnace soot treatment method

InactiveCN105039724AAchieve recyclingHigh purityProcess efficiency improvementSocial benefitsEconomic benefits

The invention relates to a smelting furnace soot treatment method, and belongs to the field of waste resourceful treatment. The smelting furnace soot treatment method comprises the steps of: (1) reductive roasting; (2) high-pressure oxygen leaching; (3) lead recovery; (4) copper recovery; and (5) zinc recovery. The smelting furnace soot treatment method, provided by the invention, can realize total recovery of lead, copper and zinc, so that obtained products are high in purity; meanwhile, the high-pressure oxygen leaching process is adopted to improve the recovery rate of lead, copper and zinc; a wet method is adopted to treat lead to prevent the pollution caused by lead steam; and the social benefit and the economic benefit are higher.

Owner:谭建新

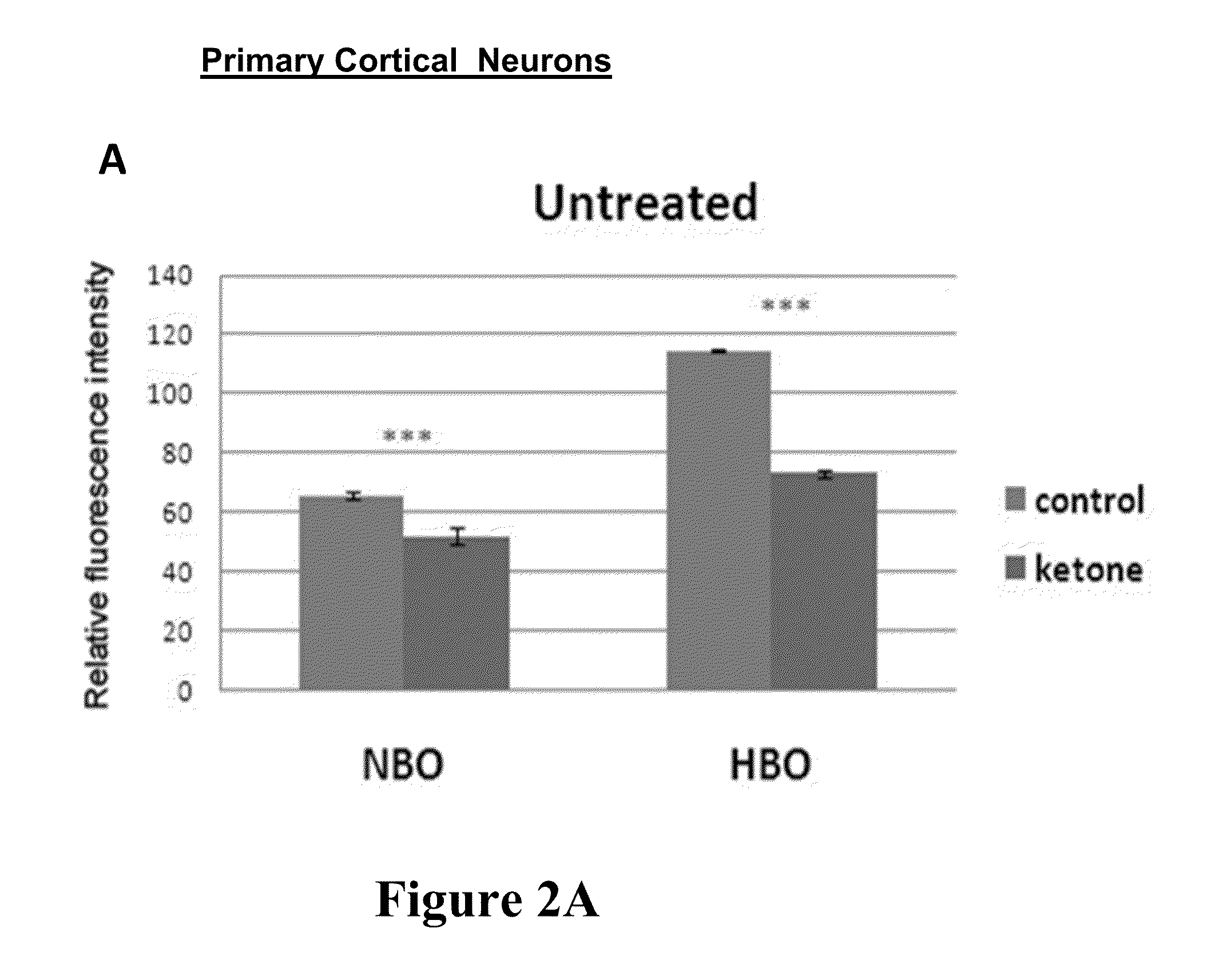

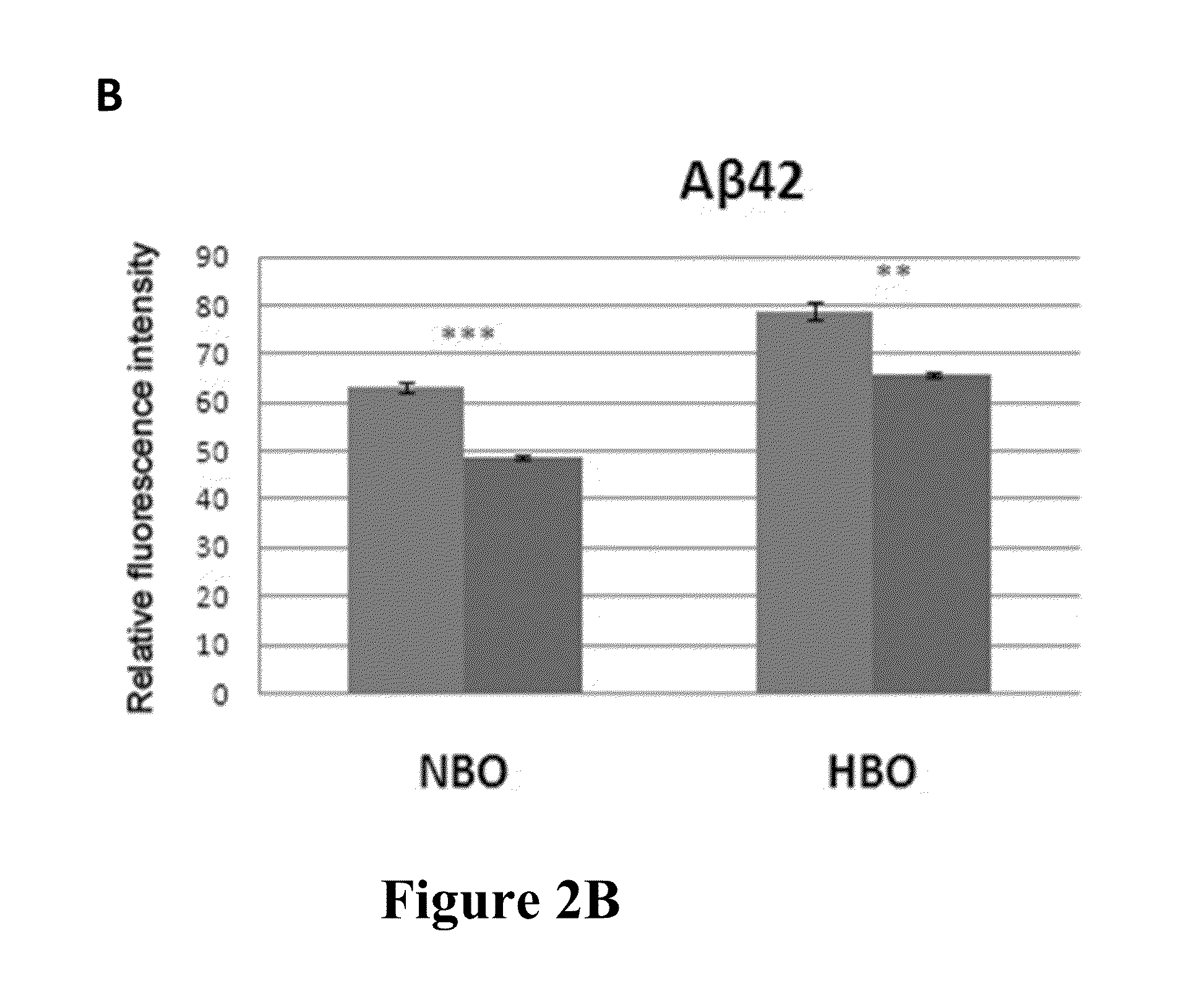

Use of ketone esters for prevention of CNS oxygen toxicity

The present invention demonstrates the therapeutic use of ketone esters for seizure disorders, Alzheimer's disease and malignant brain cancer, which are associated with metabolic dysregulation. The administration of ketone esters resulted therapeutic ketosis and neuroprotection against seizures resulting from CNS oxygen toxicity. Supplemental ketones were also found to reduce superoxide production in cultured cortex neurons exposed to hyperbaric oxygen and Aβ-42, and to decrease proliferation and viability in U87 glioma cells. These observations support the therapeutic effect of ketones for seizure disorders, Alzheimer's disease and malignant brain cancer. The ketone esters may be derived from acetoacetate and can include R,S-1,3-butanediol acetoacetate monoester, R,S-1,3-butanediol acetoacetate diester, or a combination of the two.

Owner:UNIV OF SOUTH FLORIDA

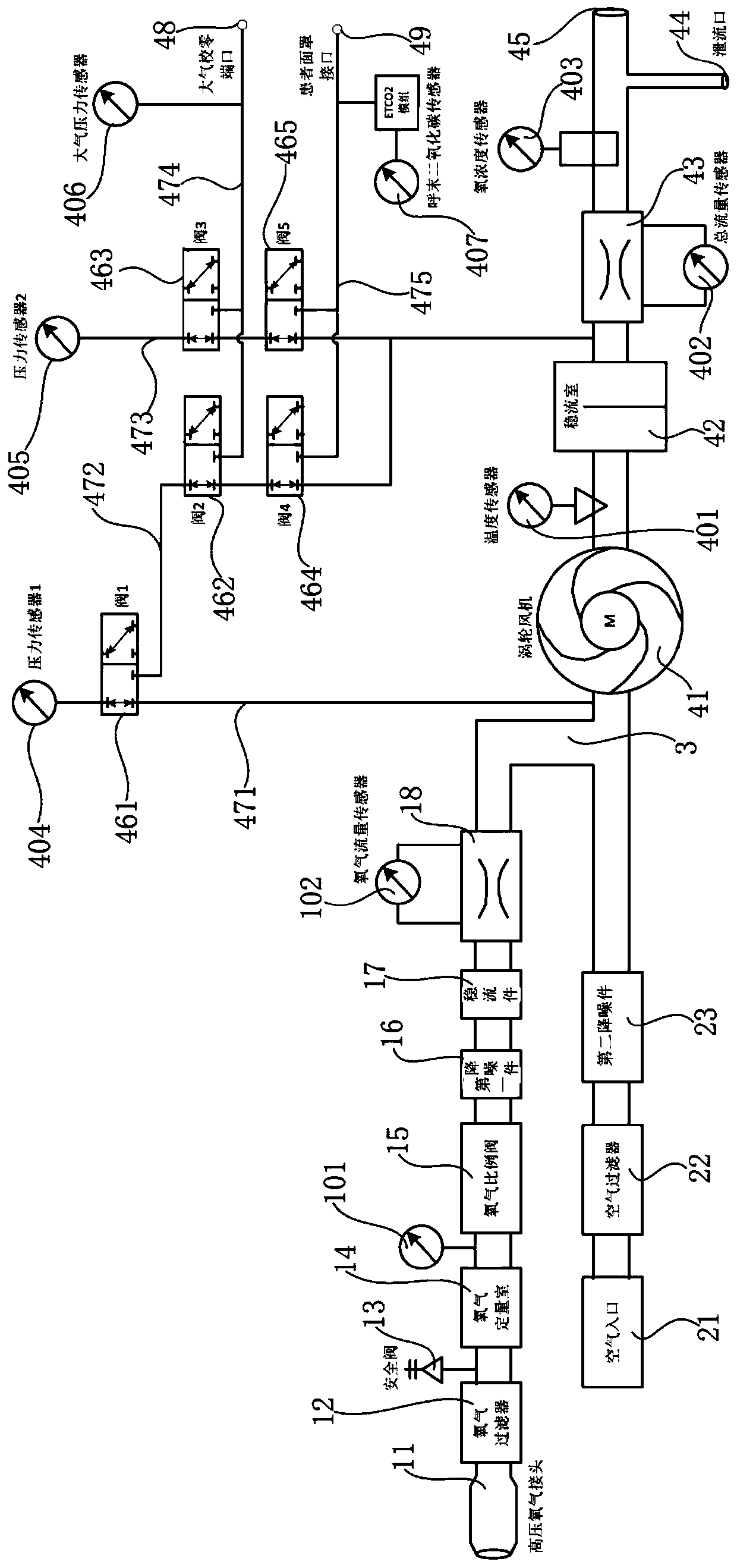

Breathing support device

The invention discloses a breathing support device. The device comprises an oxygen gas circuit, an air gas circuit and an air-oxygen mixing chamber, the air inlet end of the oxygen gas circuit is connected to a hyperbaric oxygen source, the air inlet end of the air gas circuit is connected to an air source, the air inlet end of the air-oxygen mixing chamber is connected to the air outlet ends of the oxygen gas circuit and the air gas circuit, and the air outlet end of the air-oxygen mixing chamber is connected to a patient connecting port; and an air-oxygen mixing gas channel is arranged between the air-oxygen mixing chamber and the patient connecting port, the air-oxygen mixing gas channel comprises a turbofan, a steady flow chamber and an air-oxygen closure member which are sequentiallyconnected, the air outlet of the steady flow chamber is connected to a first pressure sensor for detecting the air flow pressure of an air outlet of the steady flow chamber, total flow sensors are arranged at the front end and the rear end of the air-oxygen closure member, and an oxygen concentration sensor is arranged at the rear end of the air-oxygen closure member. The device is provided with the total flow sensors for detecting the total flow of the air-oxygen mixed airflow behind the turbofan, and is provided with the oxygen concentration sensor for detecting the oxygen concentration of the air-oxygen mixed airflow, wherein the measured value is more direct and more accurate.

Owner:HUNAN MICOME ZHONGJIN MEDICAL SCI & TECH DEV CO LTD

Targeting cancer with metabolic therapy and hyperbaric oxygen

ActiveUS20150231172A1Good curative effectReversal of the cancer-promoting effectsBiocideHydroxy compound active ingredientsAcetoacetatesKetone

A method of treating cancer using ketogenic diet, while concurrently subjecting the patient to a hyperbaric, oxygen-enriched environment. Optionally, the hyperbaric, oxygen-enriched environment is 100% oxygen at 2.5 ATA absolute. The treatment may further include administering at least 10% ketone supplementation, such as acetoacetate, adenosine monophosphate kinase, 1,3-butanediol, or ketone ester, to the patient.

Owner:UNIV OF SOUTH FLORIDA

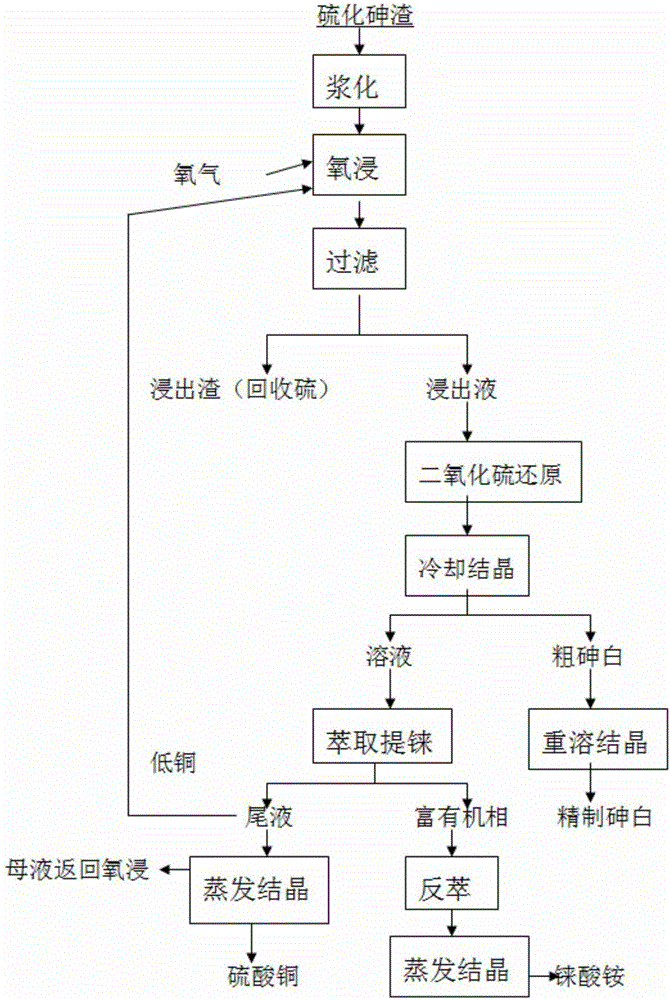

Resource utilization process for high pressure oxygen continuous leaching of arsenic sulfide slag

ActiveCN106086426AHigh recovery rateNo pollution in the processProcess efficiency improvementSlagResource utilization

The invention discloses a resource utilization process for high pressure oxygen continuous leaching of arsenic sulfide slag. The arsenic sulfide slag is treated through high pressure oxygen and then is reduced and extracted so that refined arsenic trioxide, copper sulfate and ammonium rhenate can be obtained; meanwhile, obtained waste acid liquid can be recycled for slurrying of the arsenic sulfide slag; and the whole process is high in recycling rate and free of pollution and is a novel and environment-friendly arsenic sulfide slag recycling process.

Owner:郴州金铖环保科技有限公司

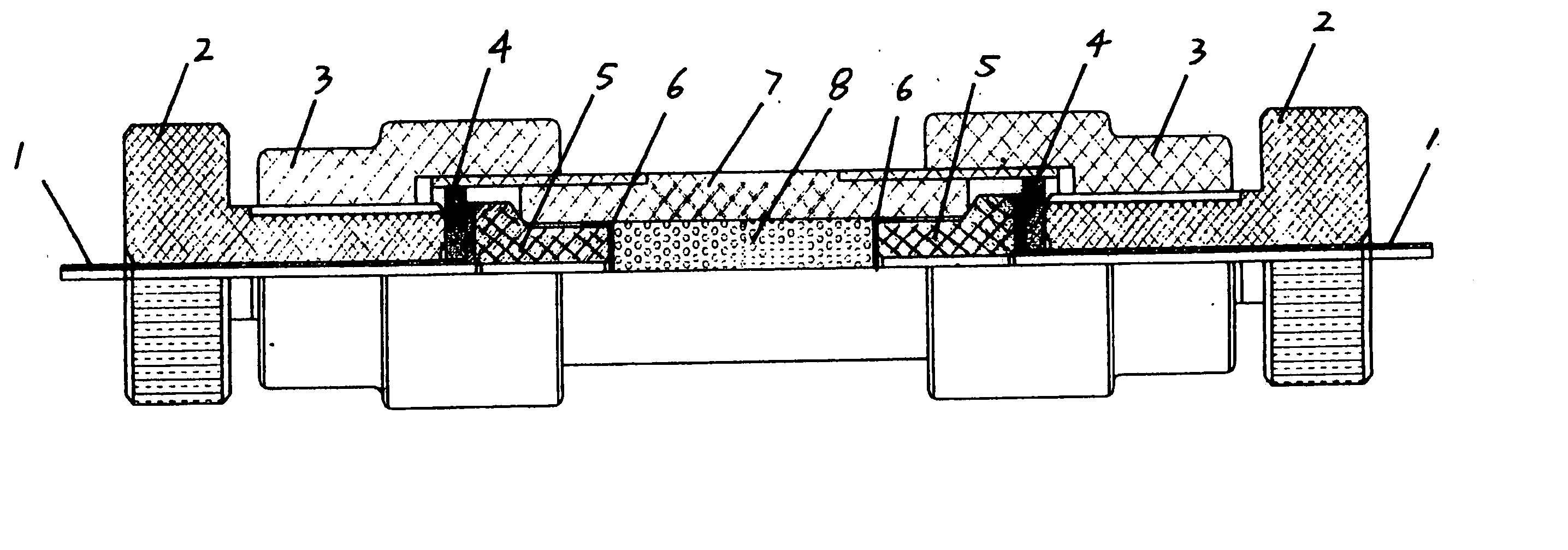

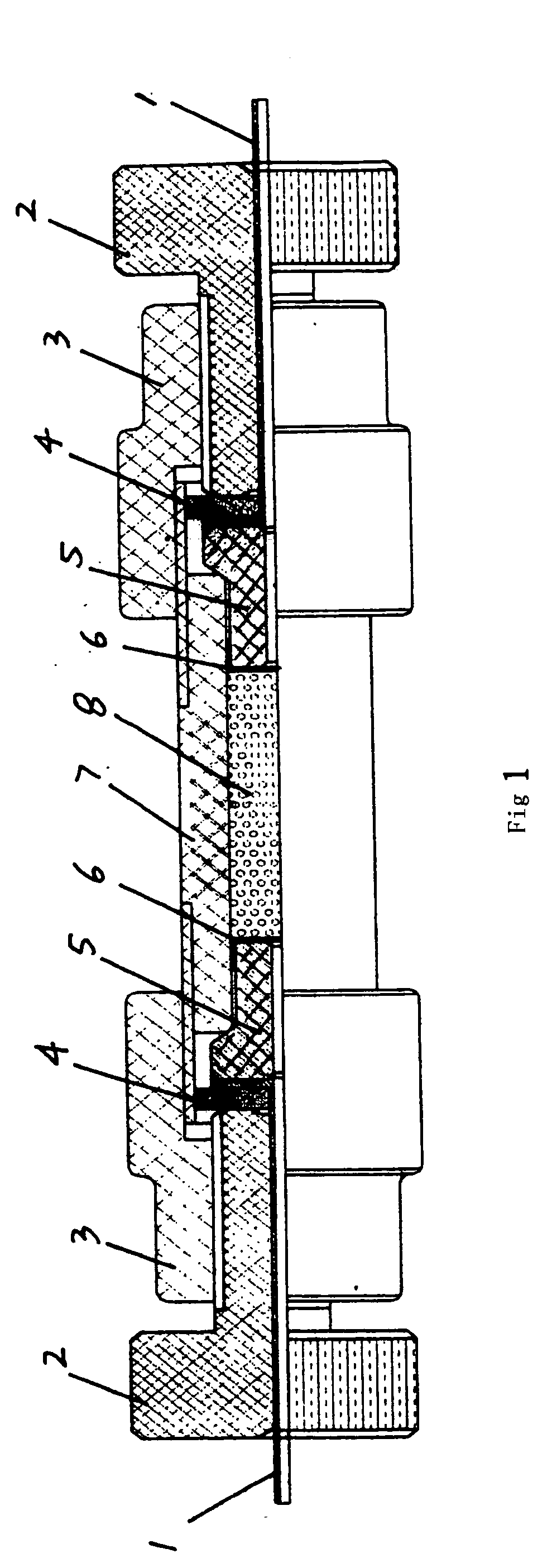

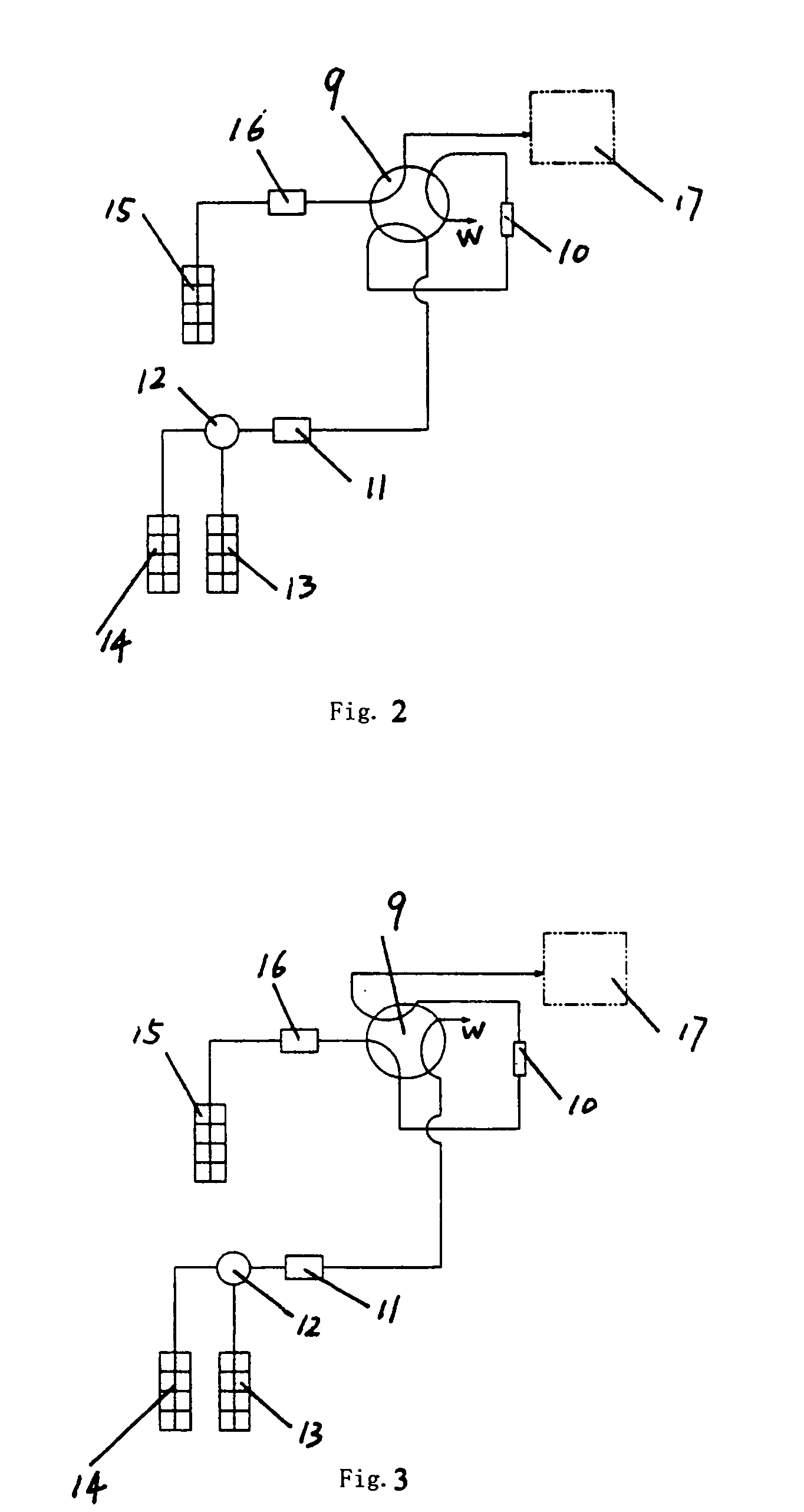

Concentrating column and sample processing device useful for elemental analysis of trace metals

InactiveUS20060039827A1Improve adsorption capacityEasy to prepareComponent separationDispersed particle separationOn columnFiltration membrane

A concentrating column useful for elemental analysis of trace metals consists mainly of column body, filtration membranes 6 fixed at the fluid inlet end and the outlet end of the column body, and column packing 8 packed inside the column body, wherein column packing 8 is prepared from the swollen and cleaned macroporous adsorbent resin of high, medium or non-polarity treated with a mixture of 3 mol / L NH4OH-1 mol / L HAC-3.0˜6.0×10−4 mol / L pyridin-(2-azo-4-)resorcin or a mixture of 0.5 mol / L Na2HPO4-1.0˜2.0×10−4 mol / L pyridin-(2-azo-4-)resorcin by dynamic on-column treatment or static immersion treatment. Two types of sample processing devices useful for elemental analysis of trace metals are provided with concentrating column employing the above-mentioned column packing. The concentrating column of the present invention simplifies the sample processing flow and the structure of sample processing device, saves chemical reagent, increases sample processing rate, and particularly prevents the toxic methanol from doing harm to the operator's health.

Owner:SICHUAN UNIV

Wound care apparatus

Disclosed is an apparatus for the treatment of a wound on a patient. The apparatus is capable of administering localized negative pressure therapy to the wound using a hospital wall vacuum source and a drain line for removing exudate from the wound. The apparatus may also be capable of administering localized hyperbaric oxygen therapy to the wound using a hospital wall oxygen source and a supply line for supplying oxygen to the wound. The apparatus includes at least one regulator to control the application of negative pressure therapy and hyperbaric oxygen therapy.

Owner:INTEGRATED HEALING TECH

Compositions and methods for treating crohn's disease and related conditions and infections

In alternative embodiments, the invention provides a “triple combination” therapy for treating, ameliorating and preventing Crohn's Disease (or Crohn syndrome, terminal or distal ileitis or regional enteritis) or related disorders and conditions in mammals, such as paratuberculosis in mammals, or Johne's disease, including genetically-predisposed and chronic disorders, where the microbial or bacterial flora of the bowel is at least one causative or symptom-producing factor; and compositions for practicing same. In alternative embodiments, methods and compositions of the invention comprise or comprise use of therapies, medications, formulations and pharmaceuticals comprising active agents that can suppress or eradicate the microbiota super-infection that causes Crohn's Disease or paratuberculosis infection in mammals. In alternative embodiments, the methods and uses of the invention for treating, ameliorating and preventing Crohn's Disease and complications of Crohn's Disease, or related disorders and conditions in mammals, such as paratuberculosis in mammals, or Johne's disease, comprises administration to an individual (human or mammal) in need thereof: (1) an anti-TNFα composition, or a composition capable of down-modulating TNFα activity; (2) a Hyperbaric Oxygen Treatment, or HBOT; and (3) an anti-Mycobacterium avium sub species paratuberculosis (MAP) (an anti-MAP) agent, composition or therapy.

Owner:高拉夫·阿格拉沃尔

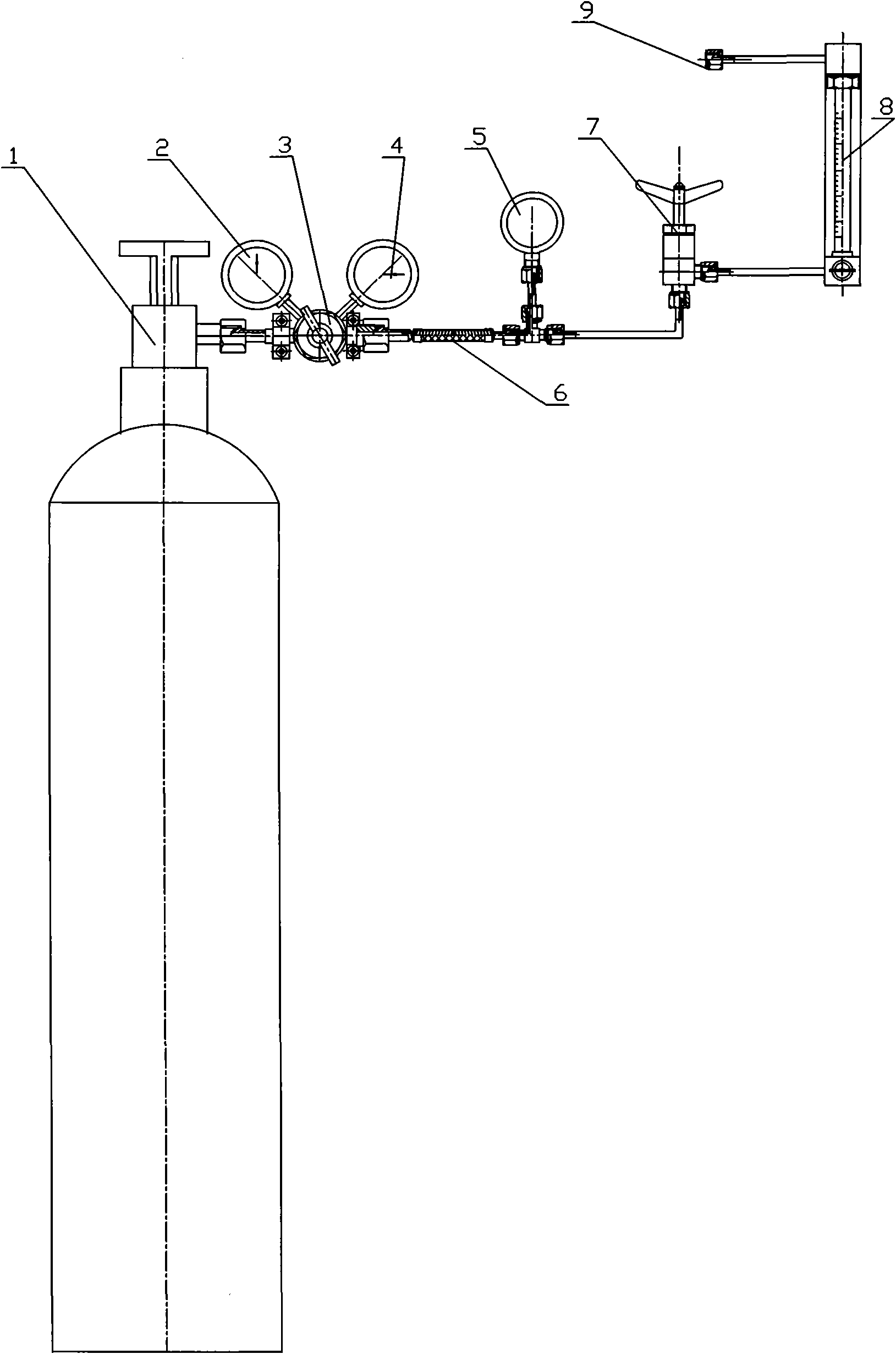

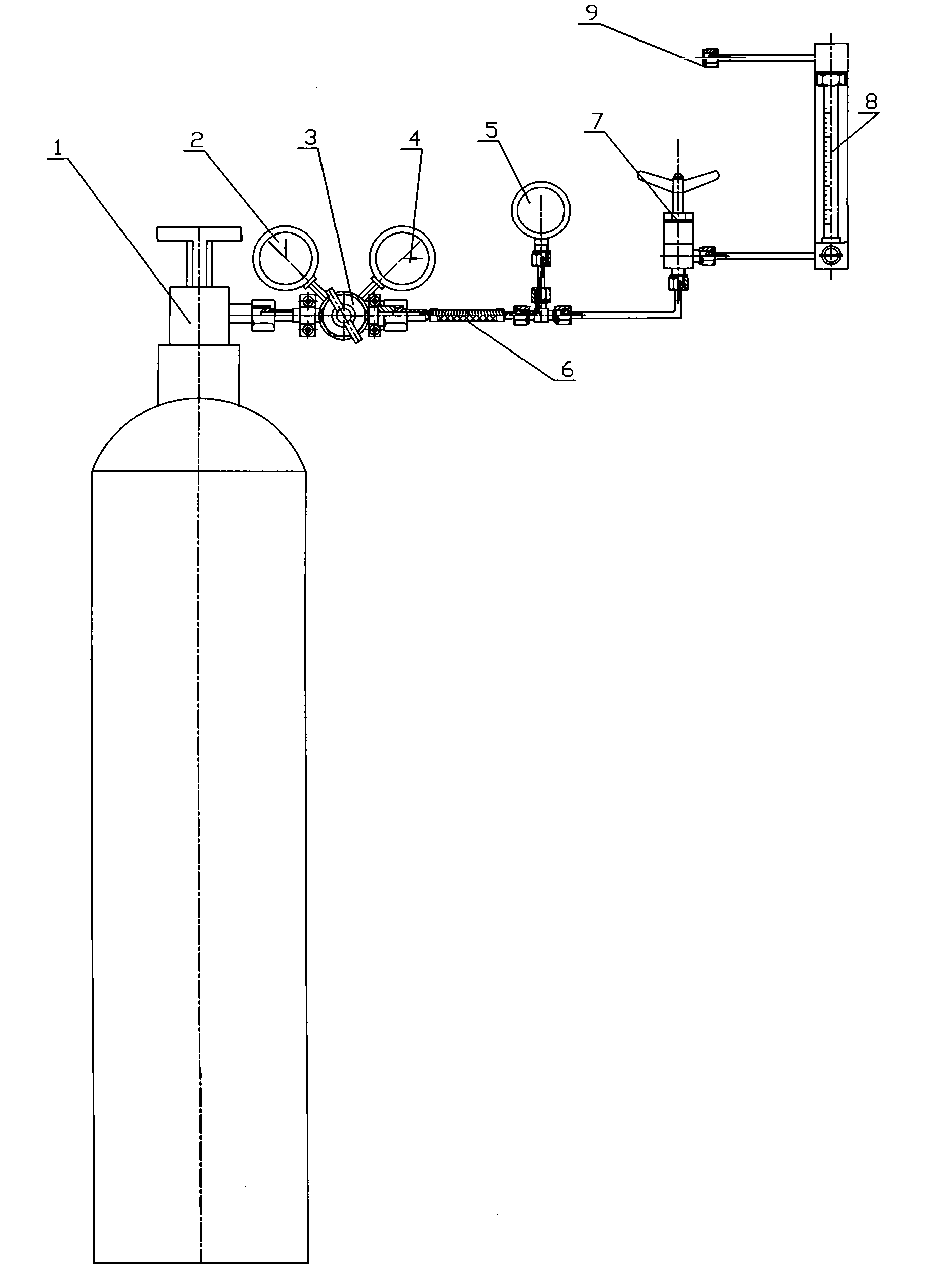

An oxygen supply apparatus for underground shelter

InactiveCN102019050AAvoid irritabilityEasy to operateFire rescueRespiratory apparatusBottleOxygen pressure

The invention relates to an oxygen supply apparatus for underground shelter. Currently, there are no factories producing such oxygen supply apparatuses for underground shelter. The oxygen supply apparatus comprises: an oxygen bottle(1), of which an oxygen outlet is connected with a pressure-reducing valve(3); a hyperbaric oxygen pressure gauge(2) and a low-pressured oxygen pressure gauge one(4) both of which are connected with the pressure-reducing valve; a noise-reducing pipeline(6) which is also connected with the pressure-reducing valve(3); a low-pressured oxygen pressure gauge two(5) which is connected with the noise-reducing pipeline; a stop valve(7)which is connected with the low-pressured oxygen pressure gauge two; a flow meter(8) which is connected with the said stop valve; and an oxygen outlet(9) which is connected with the said flow meter. The present product can be applied in the underground shelter.

Owner:黑龙江龙煤卓异救援装备科技有限公司

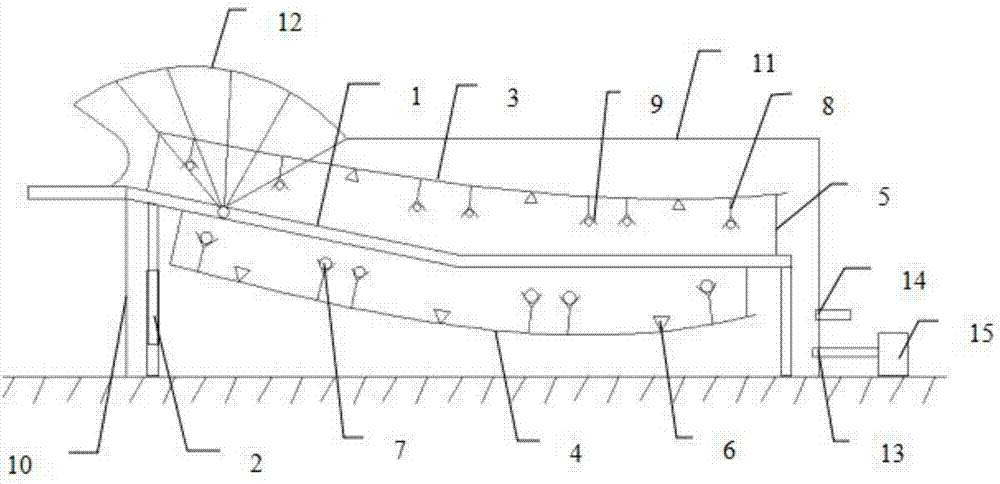

High-pressure oxygen cabin door

ActiveCN102988143AEasy accessSmooth in and outBreathing protectionTreatment roomsHigh pressure oxygenHeight difference

The invention relates to a high-pressure oxygen cabin door belonging to the technical field of high-pressure oxygen cabin structures. The high-pressure oxygen cabin door is characterized by comprising a cabin door body, wherein cabin door sealing rubber skin is arranged on the cabin door body; a door frame is arranged inside the cabin door body; a pull locking device and a pull locking cylinder are arranged above the cabin door body; a main moving cylinder is arranged on one side of the cabin door body; push moving devices are arranged below the cabin door body; a main moving device is arranged below the push moving devices and is arranged on a base; a push locking device is arranged between the push moving devices; a push locking cylinder is arranged inside each push locking device; a left mechanical limiting device is arranged on the left side of the left push moving device; and a right mechanical limiting device is arranged on the right side of the right push moving device. The high-pressure oxygen cabin door is easy to operate and is not required to be locked manually; base plates inside and outside the cabin are positioned on the same level, and a height difference is avoided; people can safely get into and get out of the cabin; a stretcher can steadily enter and exit the cabin; and the cabin door sealing rubber skin is arranged on the cabin door body, so that the air tightness is well guaranteed.

Owner:烟台豪特氧业设备有限公司

Fumigation healthcare instrument for treating arthralgia

ActiveCN106859952APromote softeningSignificant effectAntipyreticAnalgesicsJoint arthralgiaIrritation

The invention discloses a fumigation healthcare instrument for treating arthralgia. The fumigation healthcare instrument comprises a bed, a support, a spray mechanism, a far infrared irritation device and a shell, wherein a bed board of the bed is provided with fumigation holes and can be bent by a certain angle; the support comprises an upper support body and a lower support body, and can be bent along with the bed board with a net on the support kept parallel to the bed board all the time; the spray mechanism comprises a spray opening, an atomizer and a medicine box used for containing liquid medicine, the atomizer is communicated with the medicine box, and the spray opening is formed in the side, corresponding to the bed board, of the support and is communicated with the atomizer; the shell covers the bed and the support to form an airtight space, the end, corresponding to the bedside, of the shell is provided with an opening, and the opening is provided with a flexible tightening device. The fumigation healthcare instrument can combine far infrared irradiation, traditional Chinese medicine fumigation and hyperbaric oxygen therapy, perform the functions of warming the channel for expelling cold, dredging the channel and regulating qi and blood, and effectively treat arthralgia.

Owner:北京承道易医药研究院

Mobile hyperbaric oxygen workstation system based on Internet of Things

ActiveCN105574559ARealize the whole process trackingGood serviceCo-operative working arrangementsResourcesHand heldThe Internet

The invention discloses a mobile hyperbaric oxygen workstation system based on the Internet of Things. The system mainly comprises following modules and systems: a two-dimension code read / write module, a patient preview module, an identity information collection module, a vital sign real time collection module, a treatment form module, a propaganda and education security check module, a device patrol early warning module, a quality control module and a remote control module. The mobile hyperbaric oxygen workstation system based on the Internet of Things depends on the existing hospital information system (HIS) and hyperbaric oxygen information management system; a palm mobile workstation hand-held terminal executing system for real time and qualified management of hyperbaric oxygen treatment and nursing work is realized; the full process tracking to the hyperbaric oxygen treatment is actually realized; the patient information is input timely; the working error rate is reduced; more time and better service can be provided to the patient; the integral nursing quality is improved; meanwhile, the device maintenance and patrol can be recorded in real time; and paper free and wireless network free work can be realized.

Owner:秦军 +1

Non ethyne metal cutting method

InactiveCN101190473AReduce production processReduce transportationGas flame welding apparatusEngineeringHigh pressure oxygen

The invention discloses a no-ethine metal cutting method. The invention is characterized in that the initial point of the metal cutting line is instantly heated to ignition point, a pure-oxygen switch of a welding gun is rapidly turned on, air pressure is adjusted to be optimum and the cutting is normally carried out till the metal is sliced off. The invention can instantly heat the initial point of the metal cutting line to the ignition point by using a solder rod or a plurality of oxyacetylene flame. The invention replaces the oxyacetylene flame with the solder rod, instantly heats the metal to the ignition point and cut with pure oxygen. The metal is preheated by the high temperature generated when the metal combusts in cutting process. The high-pressure pure oxygen leads the metal to continuously burn, generated liquid oxide is continuously blown away by high pressure oxygen and the workpiece is then sliced off. Less ethine is adopted for oxyacetylene flame. The invention has the advantages of simpleness, feasibility, safety and reliability, using a plurality of ethine or no ethines, thus reducing environmental pollution.

Owner:胡保银

Method for normal-pressure distillation of zinc direct-dipping residue to extract sulfur

InactiveCN105197896ANo accumulationMeet balance needsSolid waste disposalSulfur preparation/purificationIndiumDistillation

The invention discloses a method for normal-pressure distillation of zinc direct-dipping residue to extract sulfur. The method includes six processes such as blending, neutralizing and drying of sulfur residue, melting of sulfur, normal-pressure distillation of sulfur, cooling and humidifying of residue and condensing of sulfur steam, and specifically includes: enabling lime and wet sulfur residue after being blended through a belt to fall into a rotary kiln for neutralizing and drying of the sulfur residue to form neutral dry sulfur residue; enabling the dry sulfur residue to fall into a sulfur melting furnace of 130-160 DEG C to form sulfur residue slurry; feeding the sulfur residue slurry into a normal-pressure distillation tank with temperature higher than 500 DEG C; allowing the surface of the sulfur residue slurry to be fully spread in the normal-pressure distillation tank, separating sulfur out, and enabling residue to fall into a residue collection tank; allowing indirect cooling and mist humidifying of the residue in the residue collection tank, discharging the residue, and allowing a condensing tank to continuously spray to condense and cool sulfur steam to room temperature; feeding water steam below 130 DEG C into the rotary kiln, and laying a heat insulating layer in high-temperature equipment pipelines and connectors without air seeping. The method can be used for extracting sulfur from zinc high-pressure oxygen direct-dipping hot filter residue and normal-pressure oxygen direct-dipping sulfur residue. By the method, recovery rate of lead, zinc, silver and indium is 99.5%, and sulfur extraction rate is 95%; the method is supportive of high-yield continuous running and free of oxygen seepage explosion potential.

Owner:ZHUZHOU FLASHLIGHT IND FURNACE

Pulse type ozone descaling method and device used for buildings water supply system

InactiveCN101054227AAvoid wastingAvoid residueScale removal and water softeningWater/sewage treatment by oxidationWater storageWater source

An impulse ozone descale method for building water supply system, comprising a water storage cleaning process and a user pipe cleaning process, in the water storage cleaning process, first turning off a water tower and connecting with the user pipe, then mixing tap water and ozone gas and supplying in the water tower, holding ozone water in the water tower, a ascending pipe and a reservoir at least ten minutes, finally discharging ozone water, in the user pipe cleaning process, first storing tap water mixed with ozone in the water tower, then sending tap water mixed with ozone off water faucets through the user pipe, and feeding hyperbaric oxygen into the user pipe by means of impulse form through one of water faucets, in action of high pressure, tap water mixed with ozone impact tube wall intermittently in the user pipe to improve descale efficiency in pipes. The invention also provides an impulse ozone descale device, which not only get sterilisation and cleaning function, but also avoid water waste during cleaning, technical problems of agent residual and inconvenient operation.

Owner:茅良

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com