Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

471results about How to "Accurate pressure" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

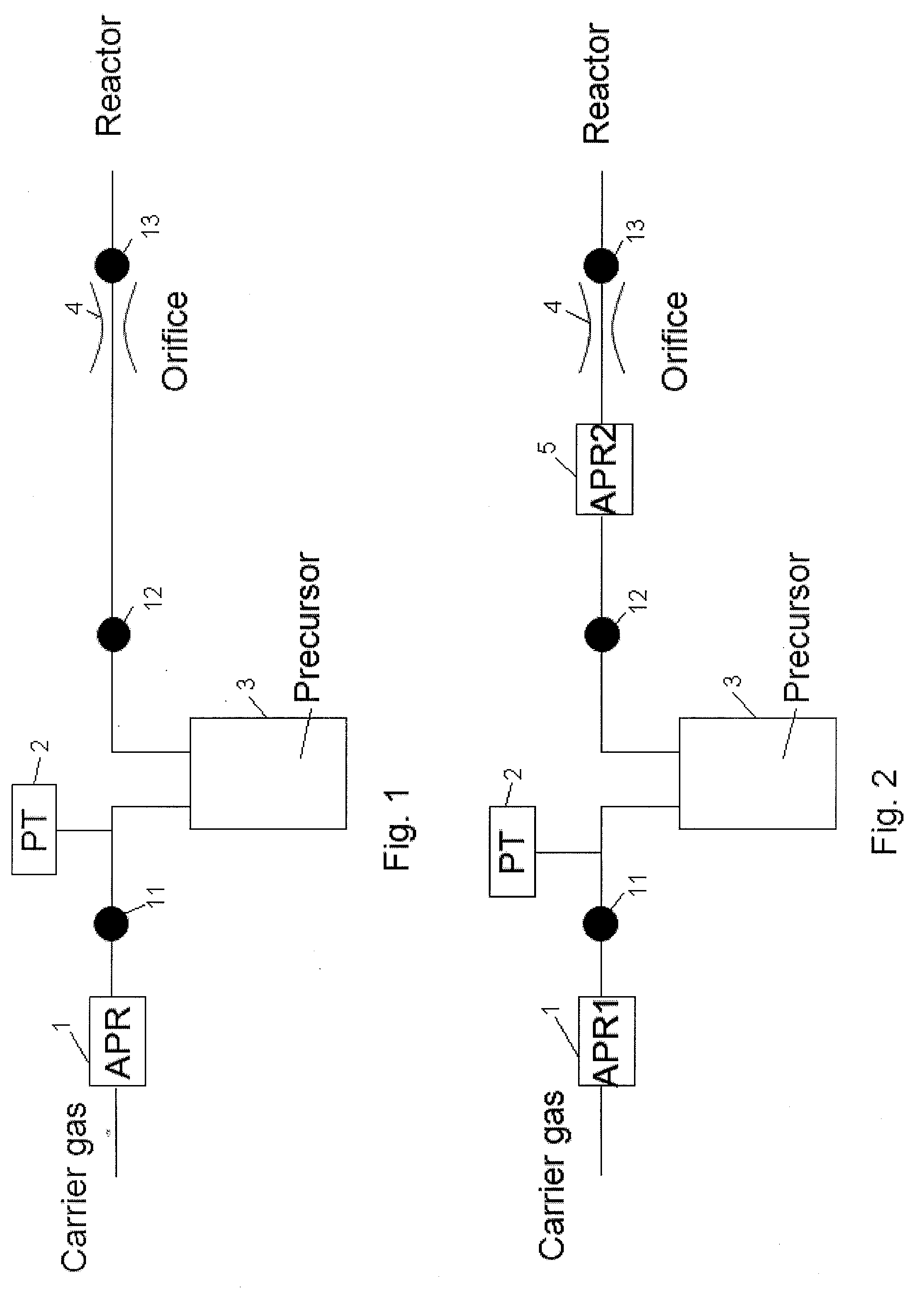

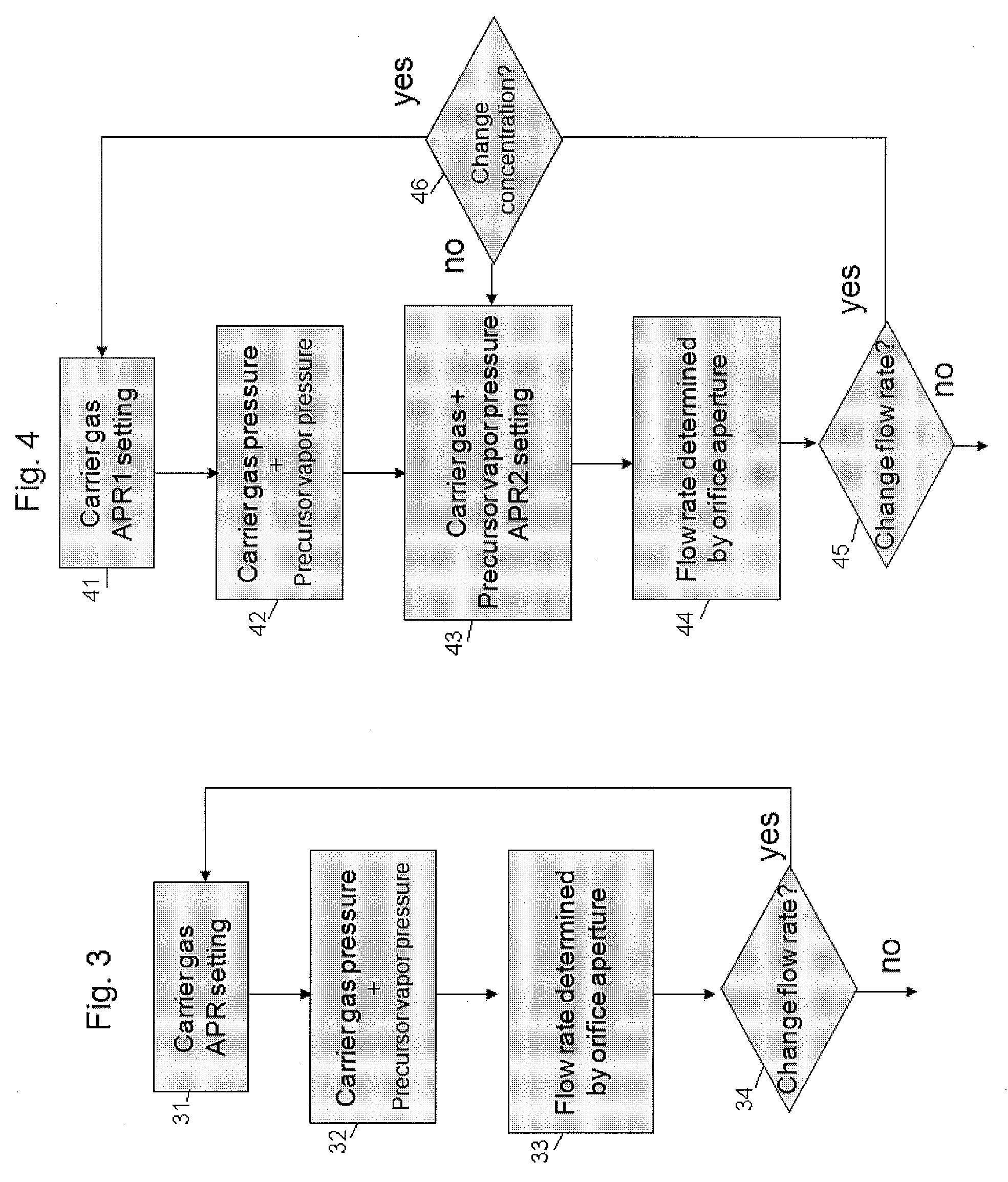

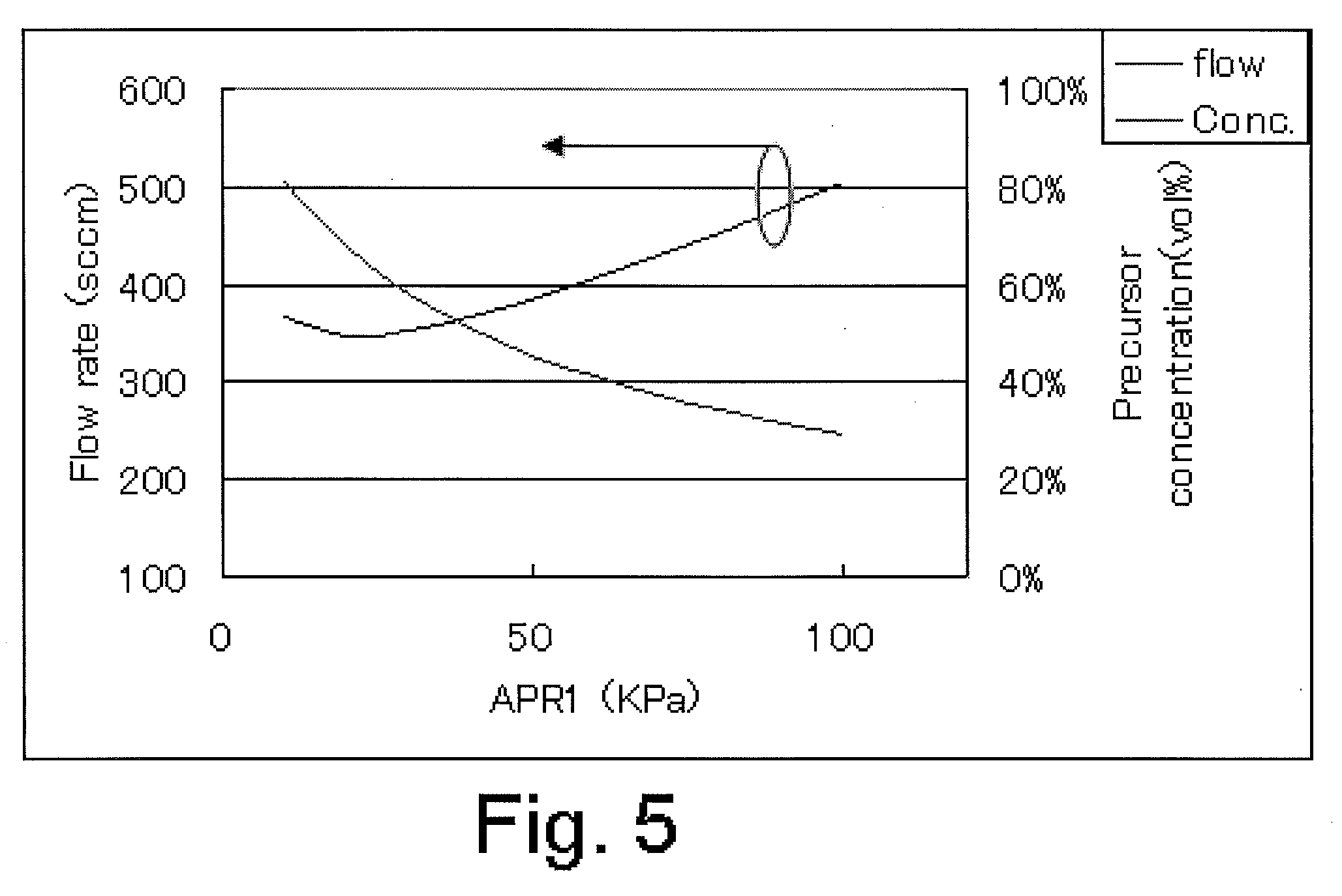

Method for controlling flow and concentration of liquid precursor

ActiveUS20100178423A1Material concentration can be controlledLine pressure can be accuratelyLiquid surface applicatorsVacuum evaporation coatingControl flowPressure regulator

A method for controlling flow and concentration of a liquid precursor includes: supplying a carrier gas to a first auto-pressure regulator and outputting therefrom the carrier gas at a first pressure to a precursor reservoir; outputting the mixture of the vaporized precursor and the carrier gas from the precursor reservoir; and supplying the mixture to a second auto-pressure regulator and outputting therefrom the mixture at a second pressure to a reactor via an orifice.

Owner:ASM JAPAN

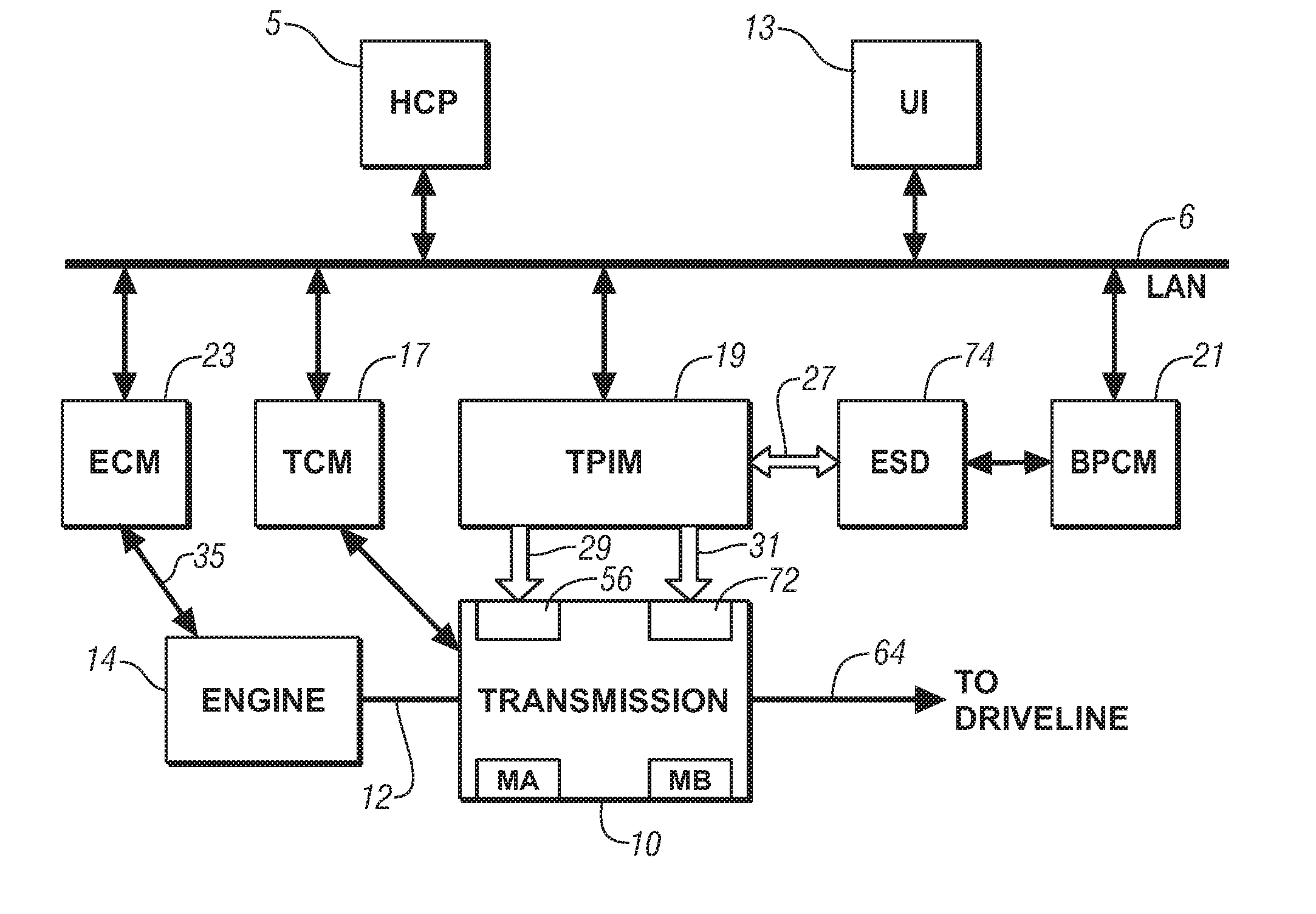

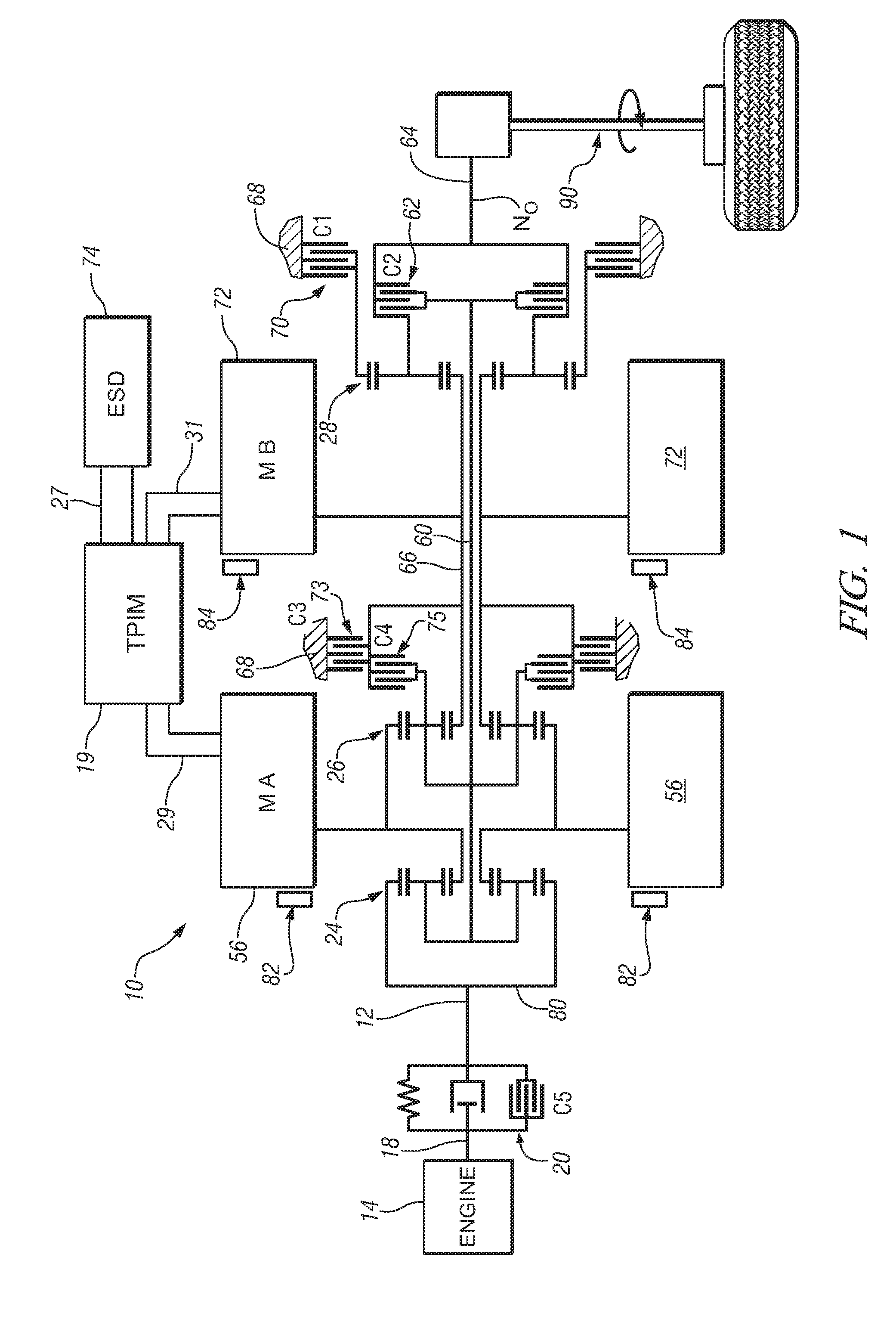

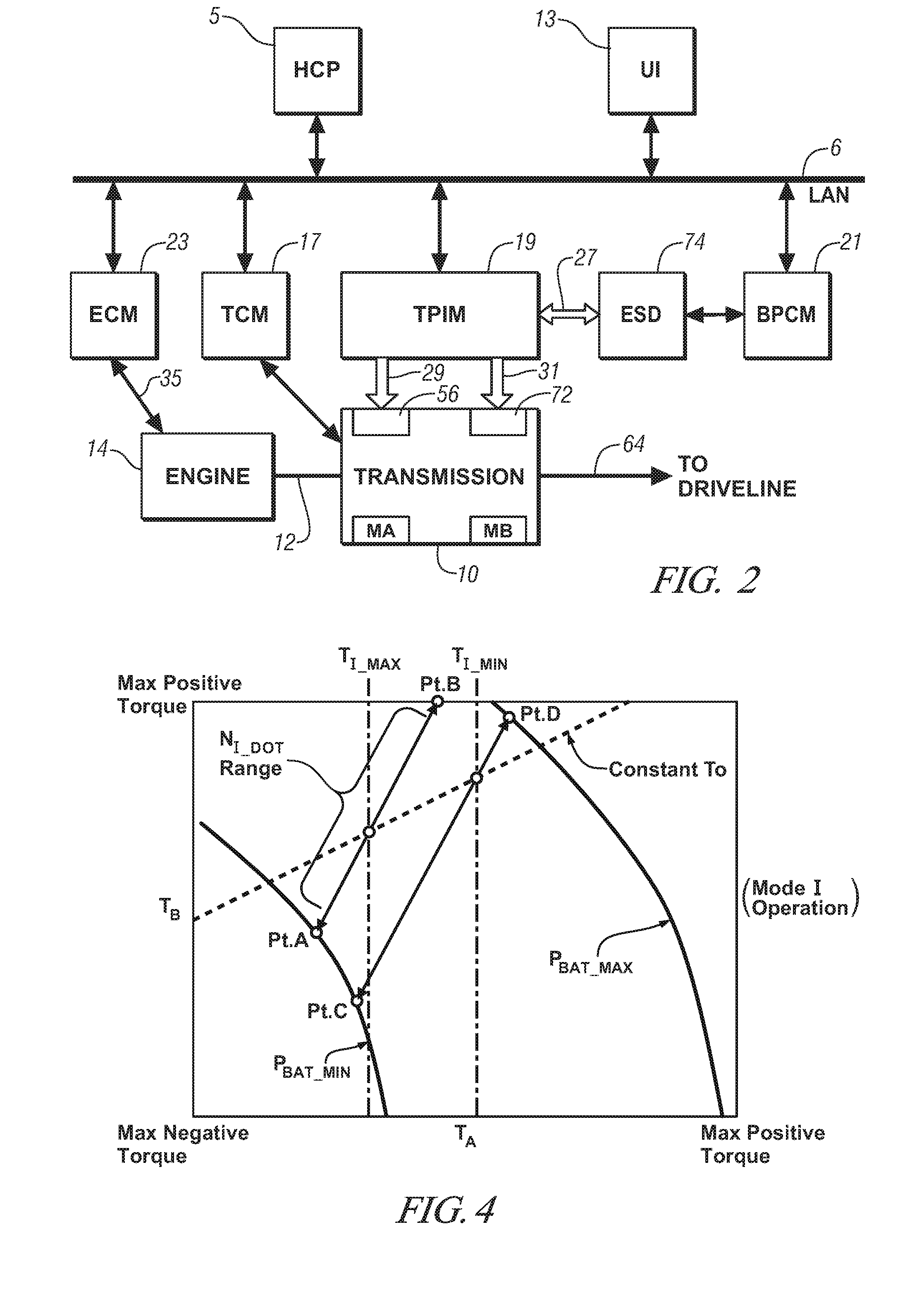

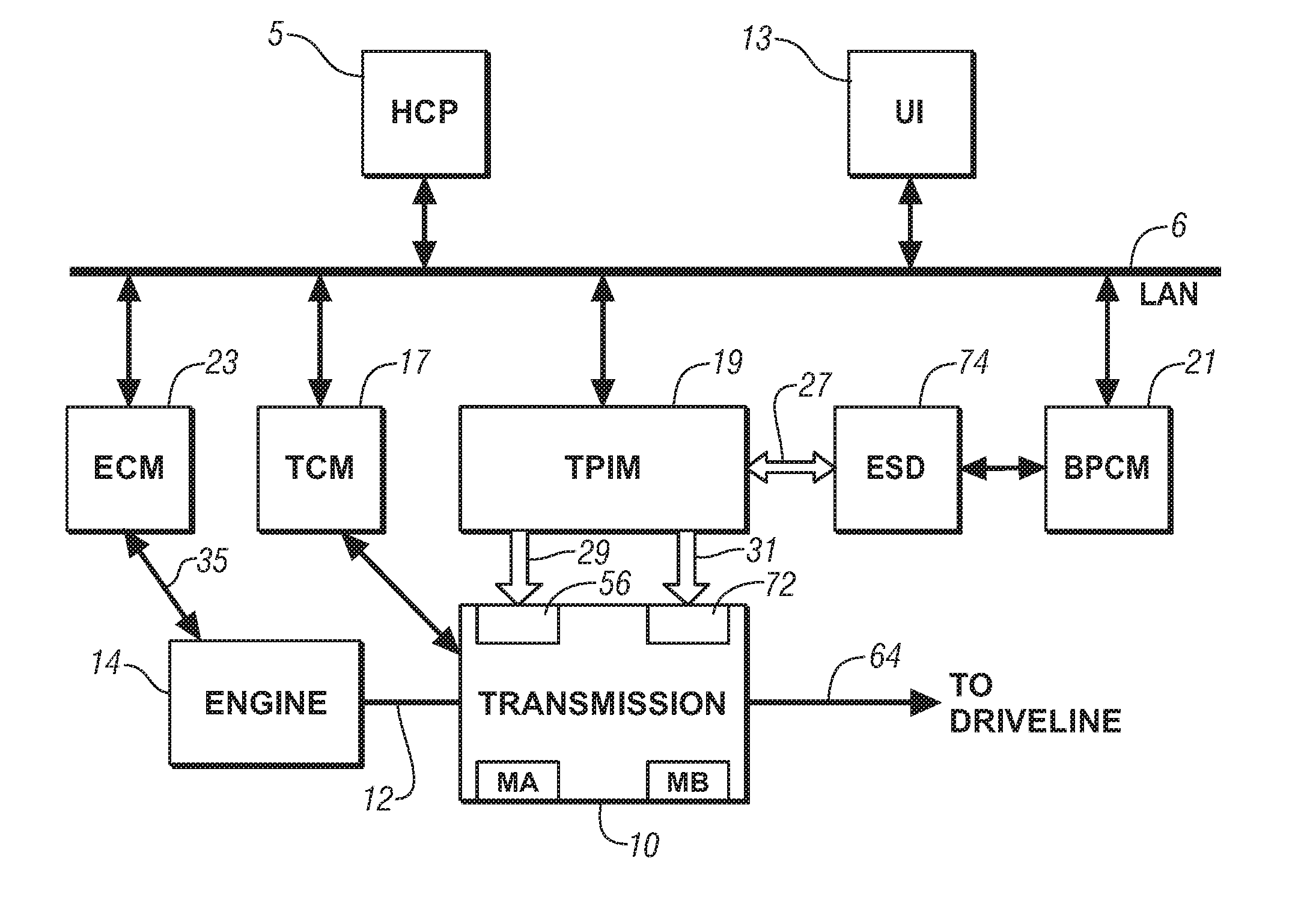

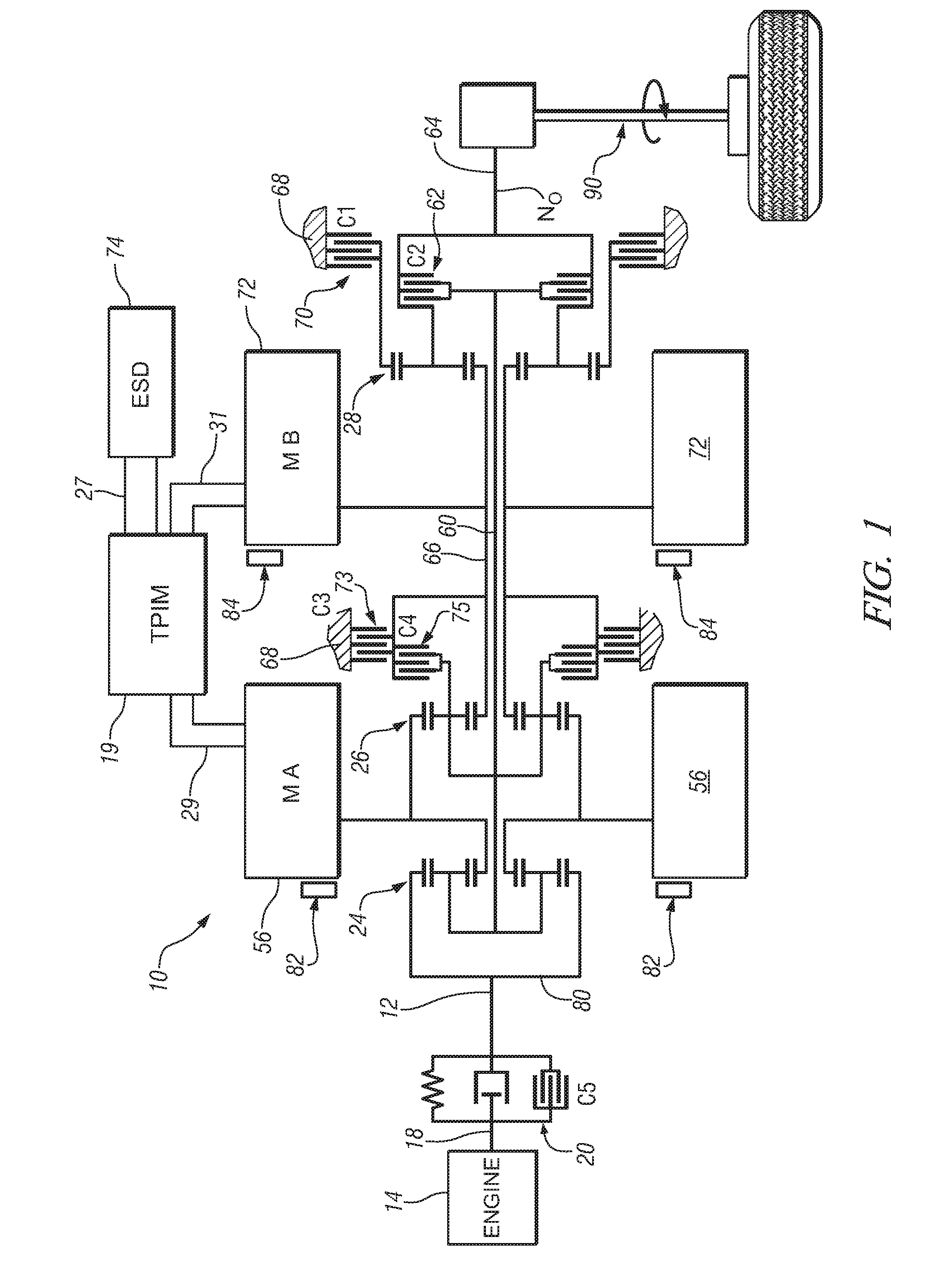

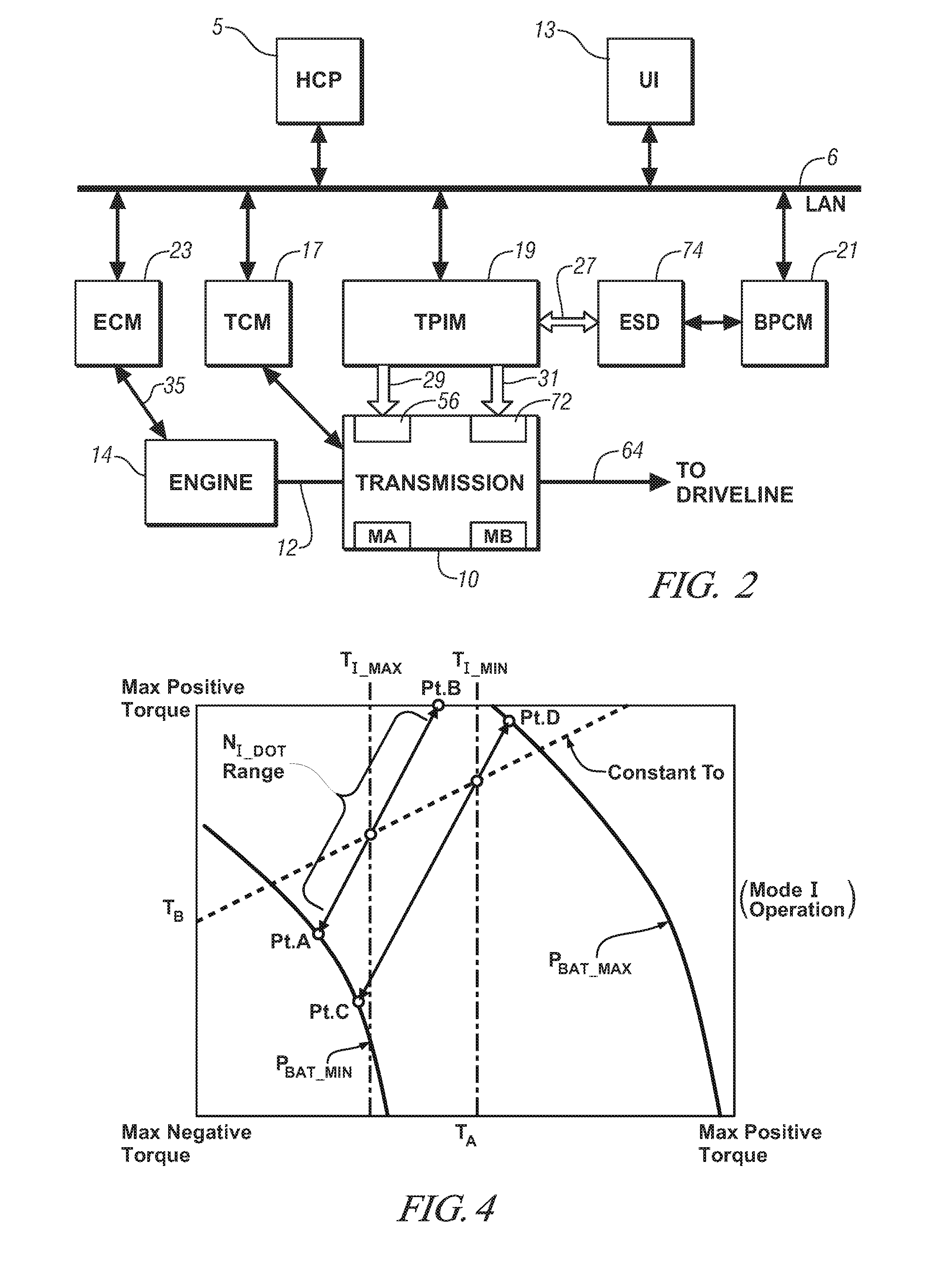

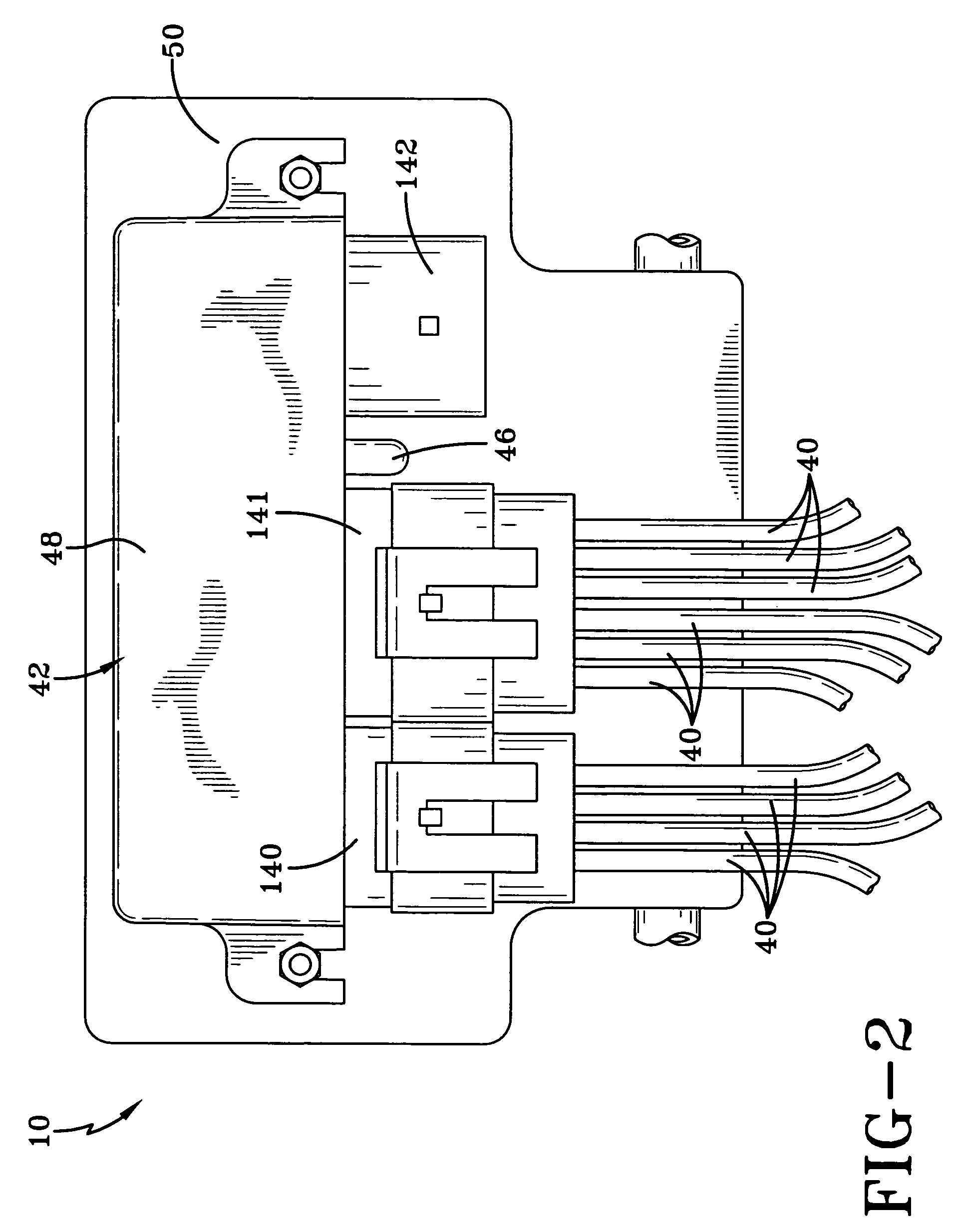

Method and apparatus to control engine restart for a hybrid powertrain system

ActiveUS20080275624A1Accurately determineAccurate pressureInternal combustion piston enginesDigital data processing detailsRotary engineInternal combustion engine

There is provided a control scheme for restarting an internal combustion engine of a hybrid powertrain during ongoing vehicle operation. The method comprises generating a torque output from an electrical machine to rotate the engine, and determining an engine crank torque. The torque output from the electrical machine is selectively controlled based upon the engine crank torque. The engine is fired when rotational speed of the engine exceeds a threshold. An engine torque simulation model accurately determines engine compression pressures in real-time to accommodate changes in engine operating conditions, based upon present engine operating conditions.

Owner:GM GLOBAL TECH OPERATIONS LLC

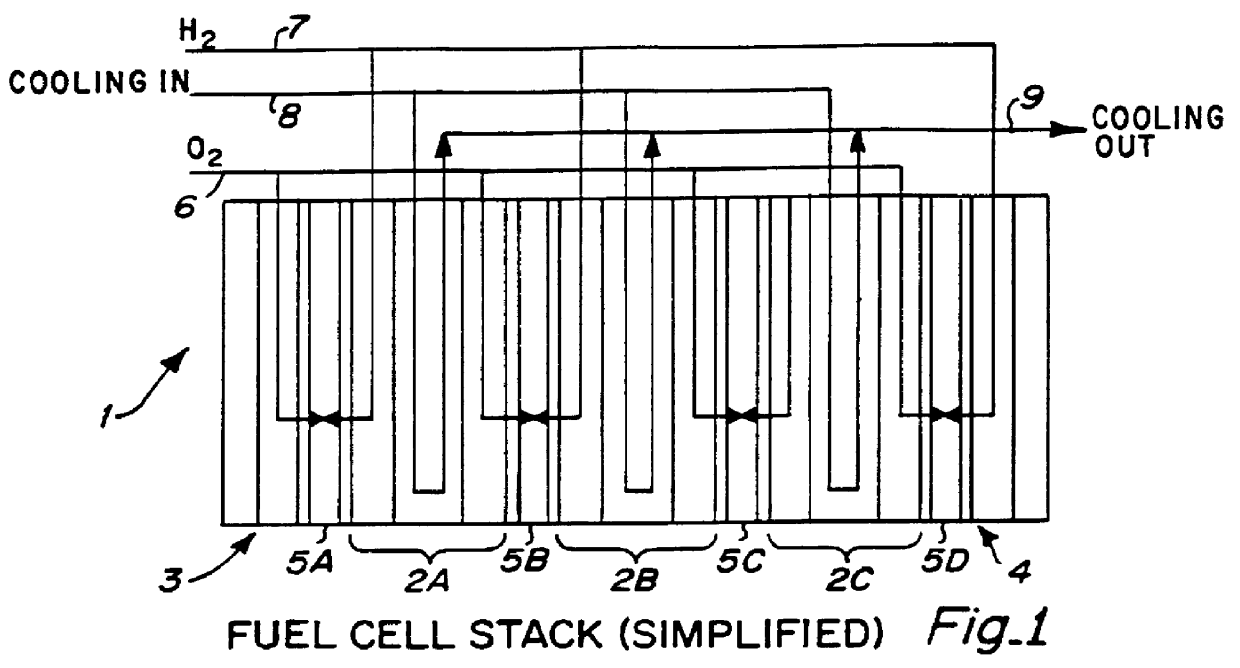

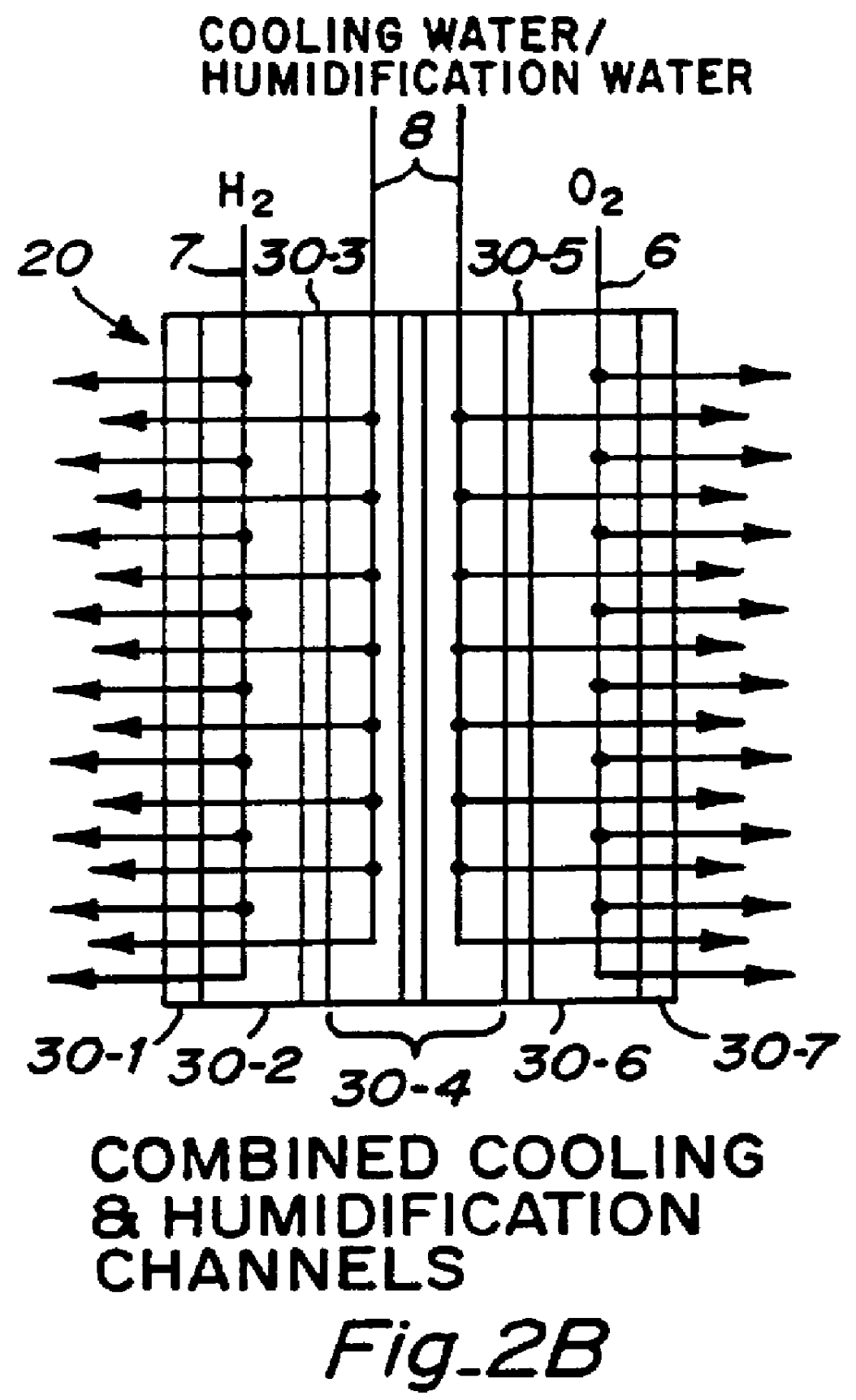

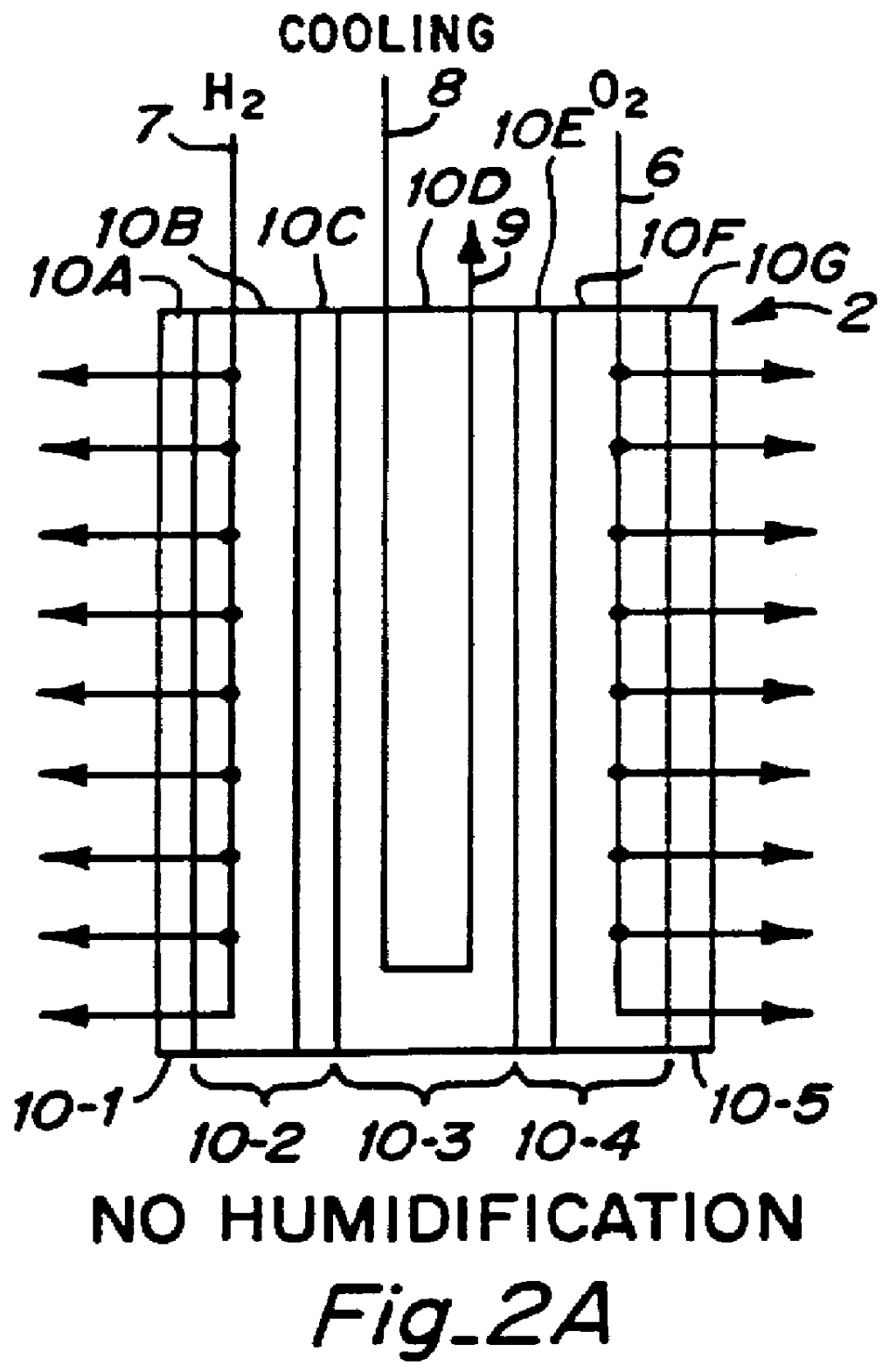

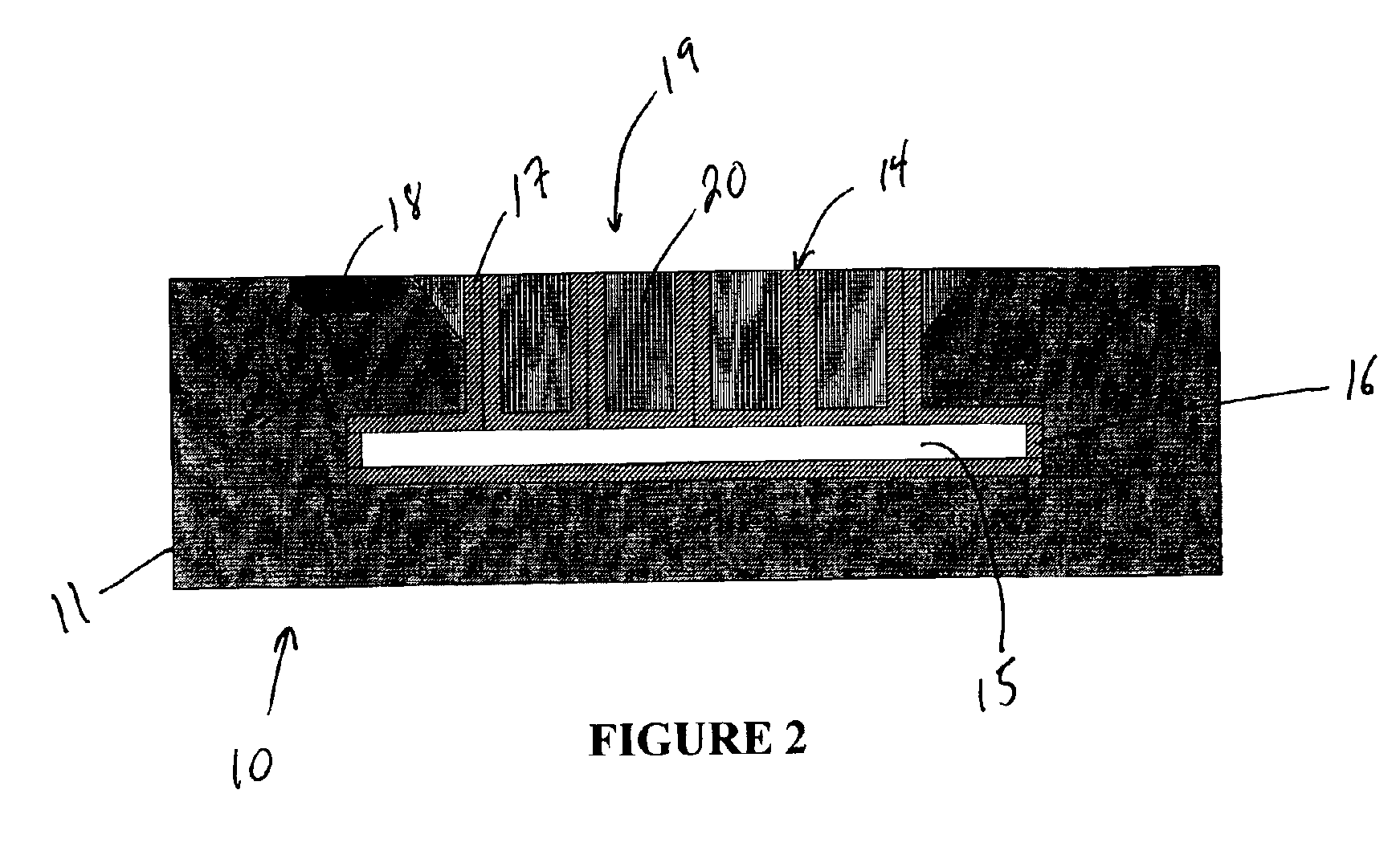

Fuel cell platelet separators having coordinate features

InactiveUS6051331ASimple designEvenly distributedSolid electrolytesFuel cells groupingLaser etchingFuel cells

PCT No. PCT / US95 / 13325 Sec. 371 Date Sep. 28, 1997 Sec. 102(e) Date Sep. 28, 1997 PCT Filed Oct. 10, 1995 PCT Pub. No. WO96 / 12316 PCT Pub. Date Apr. 25, 1996Fuel cell stacks comprising stacked separator / membrane electrode assembly fuel cells in which the separators comprise a series of thin sheet platelets, having individually configured serpentine micro-channel reactant gas humidification active areas and cooling fields therein. The individual platelets are stacked with coordinate features aligned in contact with adjacent platelets and bonded to form a monolithic separator. Post-bonding processing includes passivation, such as nitriding. Preferred platelet material is 4-25 mil Ti, in which the features, serpentine channels, tabs, lands, vias, manifolds and holes, are formed by chemical and laser etching, cutting, pressing or embossing, with combinations of depth and through etching preferred. The platelet manufacturing process is continuous and fast. By employing CAD based platelet design and photolithography, rapid change in feature design can accommodate a wide range of thermal management and humidification techniques. One hundred H2-O2 / PEM fuel cell stacks of this IFMT platelet design will exhibit outputs on the order of 0.75 kW / kg, some 3-6 times greater than the current graphite plate PEM stacks.

Owner:H POWER

Method and apparatus to control engine stop for a hybrid powertrain system

ActiveUS20080275625A1Accurately determineAccurate pressureHybrid vehiclesAnalogue computers for vehiclesElectric machineSnubber

A control scheme is provided for stopping an internal combustion engine of a hybrid powertrain during ongoing vehicle operation. The method, executed as program code in an article of manufacture comprises the following steps in the sequence set forth. First, engine operation is controlled to stop firing the engine. A damper clutch is controlled to lock rotation of the engine and the electro-mechanical transmission. Torque outputs from the first and second electrical machines are then selectively controlled to reduce engine speed. Torque outputs from the first and second electrical machines are then selectively controlled to stop rotation of the engine substantially near a predetermined crank position.

Owner:GM GLOBAL TECH OPERATIONS LLC

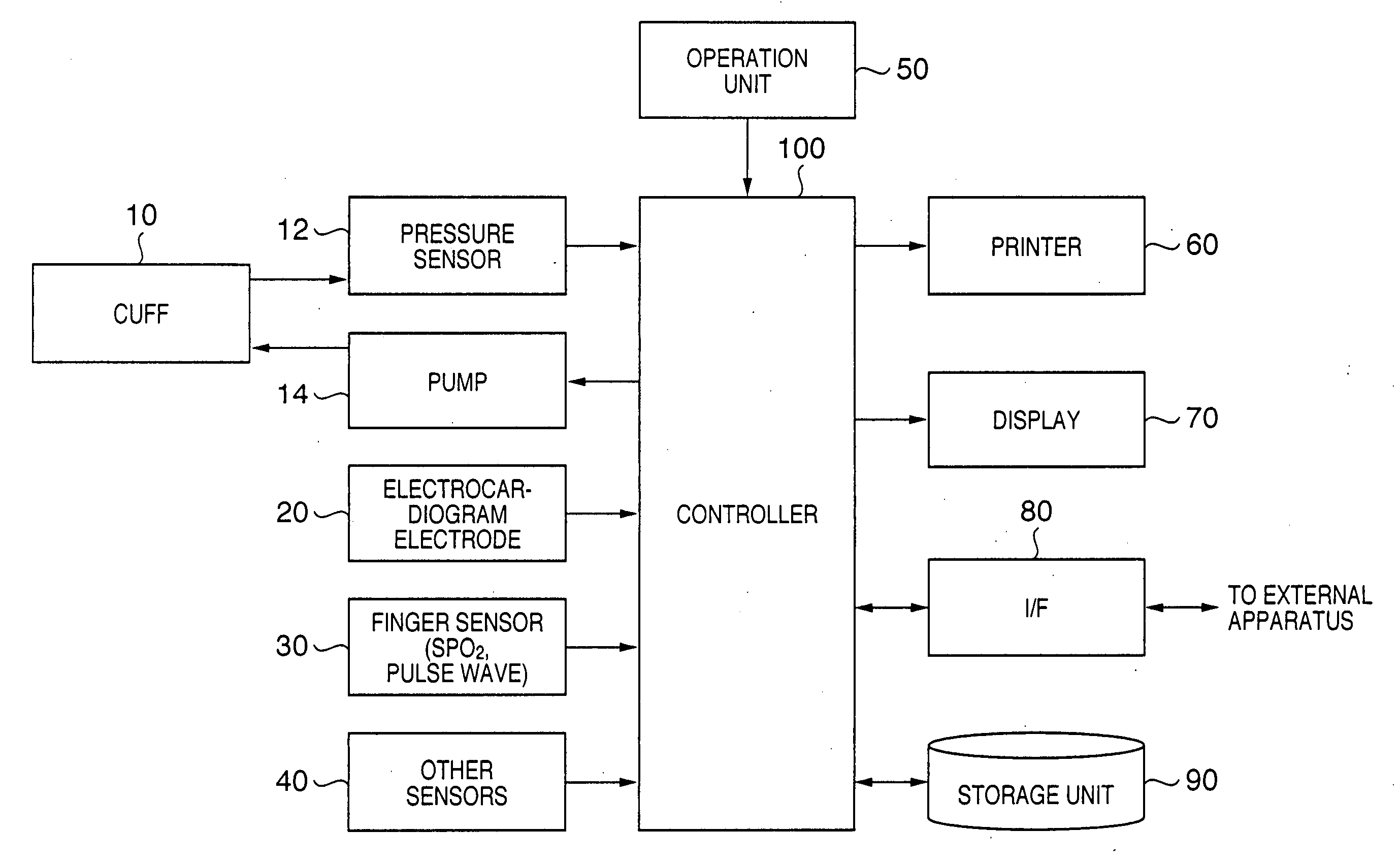

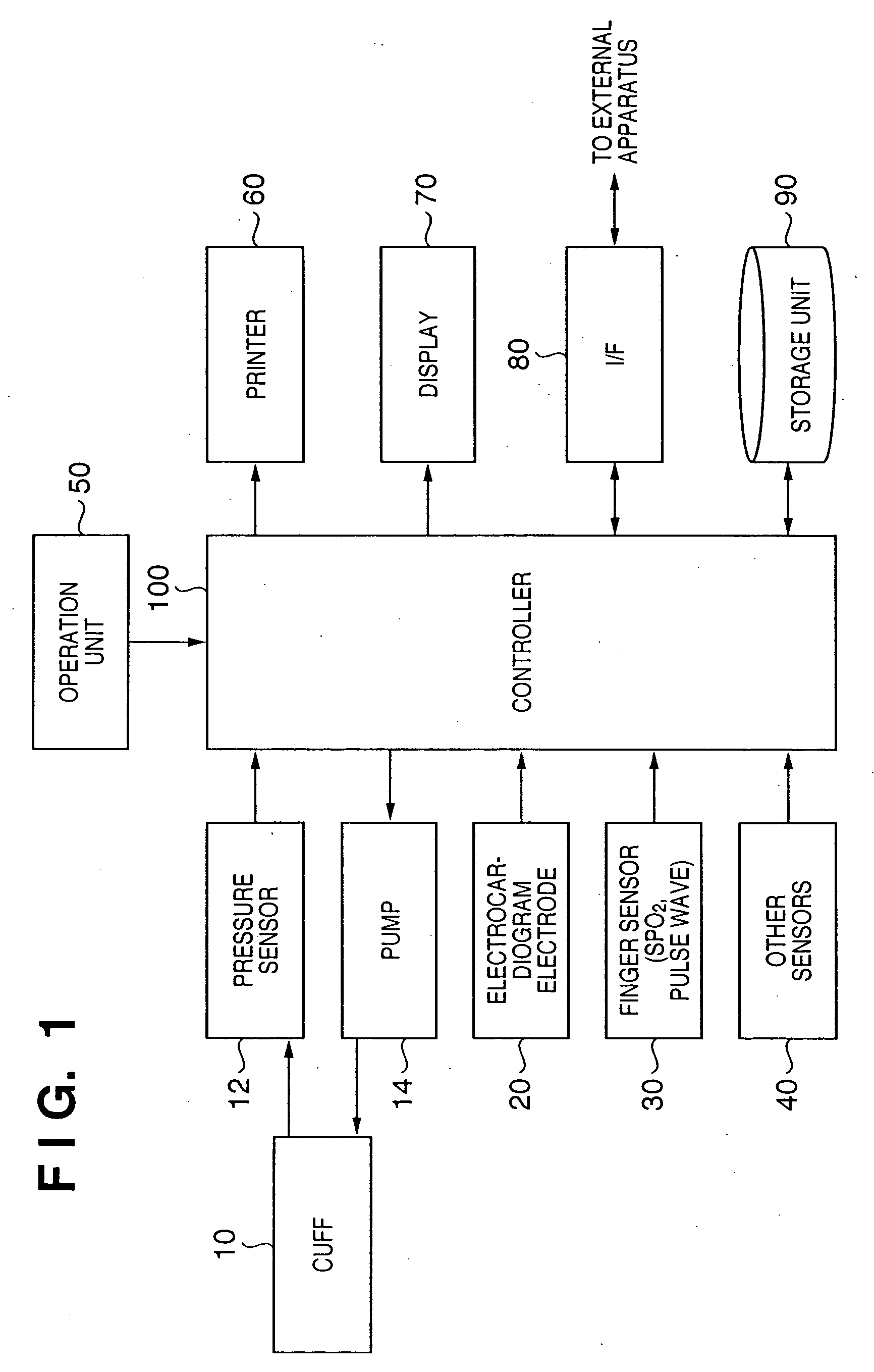

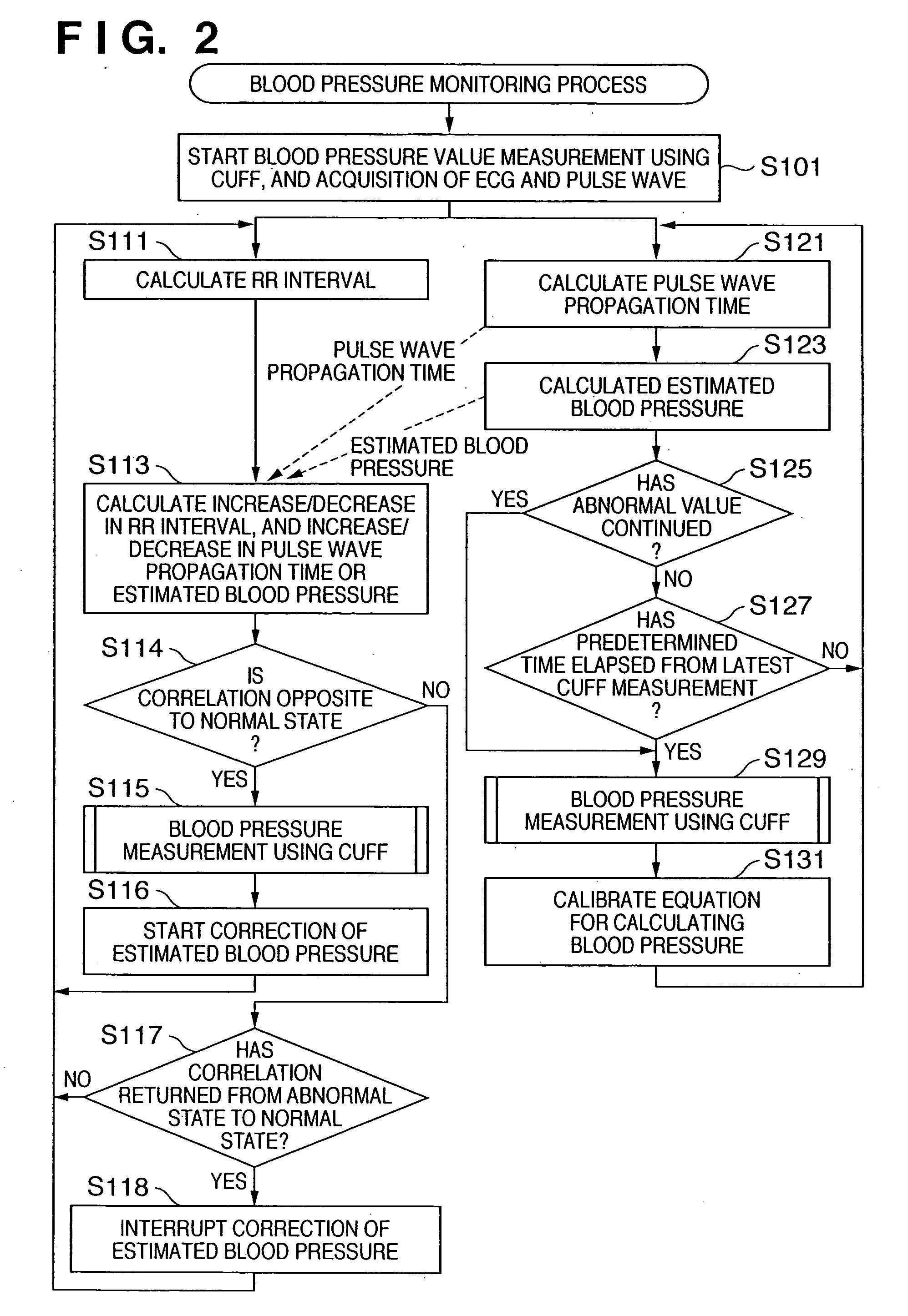

Blood pressure monitoring apparatus

ActiveUS20070066910A1Accurately measure blood pressureAccurate pressureCatheterDiagnostic recording/measuringEmergency medicineMeasured blood pressure

A blood pressure monitoring apparatus which continuously estimates and monitors the blood pressure by using the pulse wave propagation time can accurately estimate the blood pressure. While an estimated blood pressure is continuously calculated by using the pulse wave propagation time, the correlation between the pulse wave propagation time and the interval between feature points contained in two consecutive heart beat waveforms of an electrocardiogram is monitored. If the correlation is reversed, the blood pressure is actually measured, and the estimated blood pressure is corrected on the basis of the difference between the estimated blood pressure and actually measured blood pressure.

Owner:FUKUDA DENSHI CO LTD

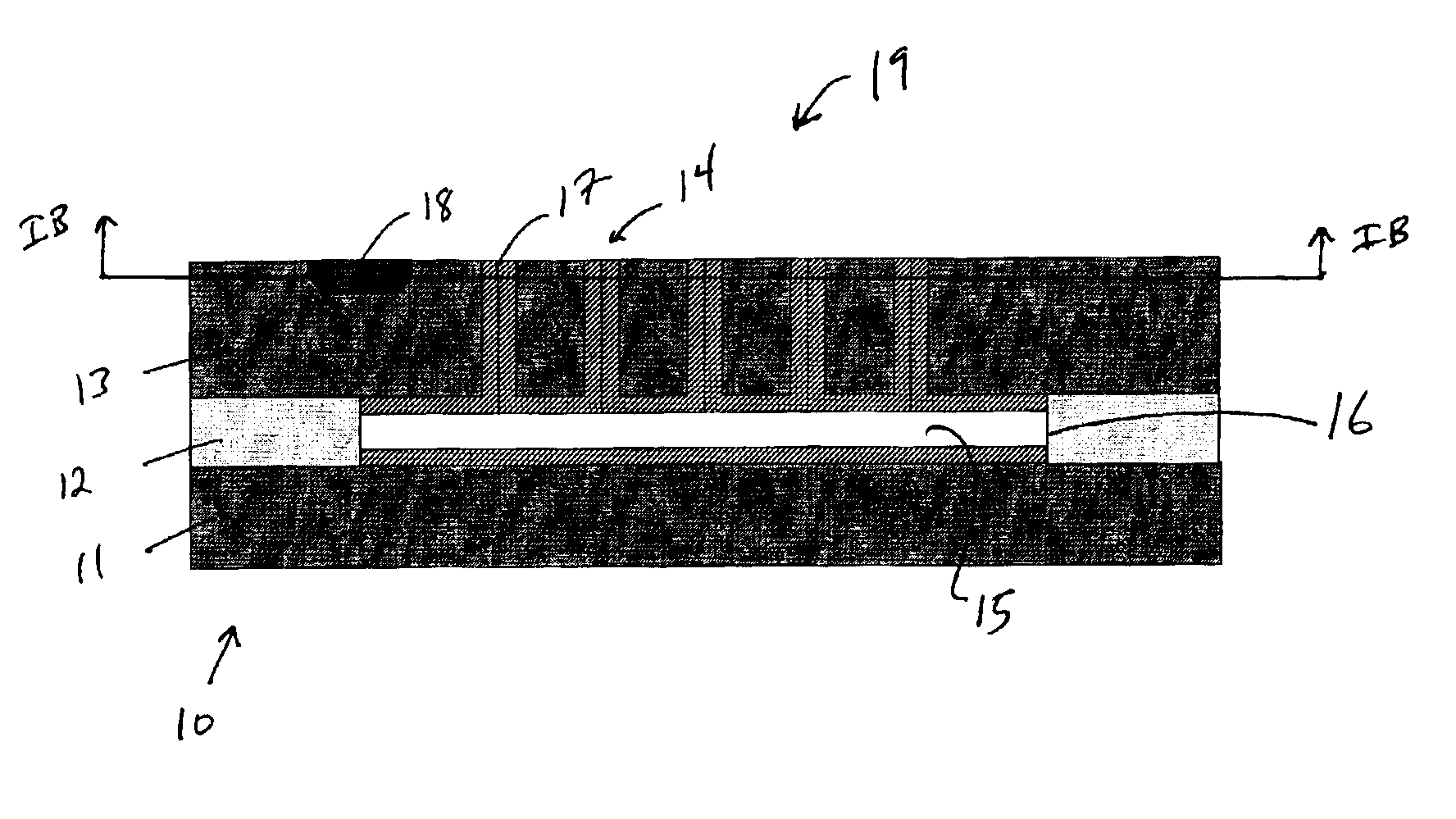

Episeal pressure sensor and method for making an episeal pressure sensor

InactiveUS6928879B2Avoid problemsQuality improvementFluid pressure measurement by electric/magnetic elementsFluid pressure measurement by mechanical elementsCapacitanceStrain gauge

A method for making a pressure sensor by providing a wafer including a base silicon layer, a buried sacrificial layer, and a top silicon layer. The top silicon layer is arranged over the buried sacrificial layer and the buried sacrificial layer is arranged over the base silicon layer. Etching vents through the top silicon layer to the buried sacrificial layer and removing a portion of the buried sacrificial layer. Depositing silicon to seal the vents and arranging a strain gauge or a capacitance contact on the wafer. A method for making a pressure sensor including providing a bulk wafer and depositing a sacrificial layer on the bulk wafer. Depositing silicon on the sacrificial layer and the bulk wafer to form an encapsulation layer. Etching vents through the encapsulation layer to the sacrificial layer and removing the sacrificial layer. Closing the vents with a silicon deposition and arranging a strain gauge or a capacitance contact on the encapsulation layer. A pressure sensing device including a substrate, an encapsulation layer with vents, and voids between the substrate and the encapsulation layer. A portion of the encapsulation layer above the voids forms a membrane and deposited silicon plugs fill the vents. A strain gauge or a top capacitive contact arranged on the membrane.

Owner:ROBERT BOSCH GMBH

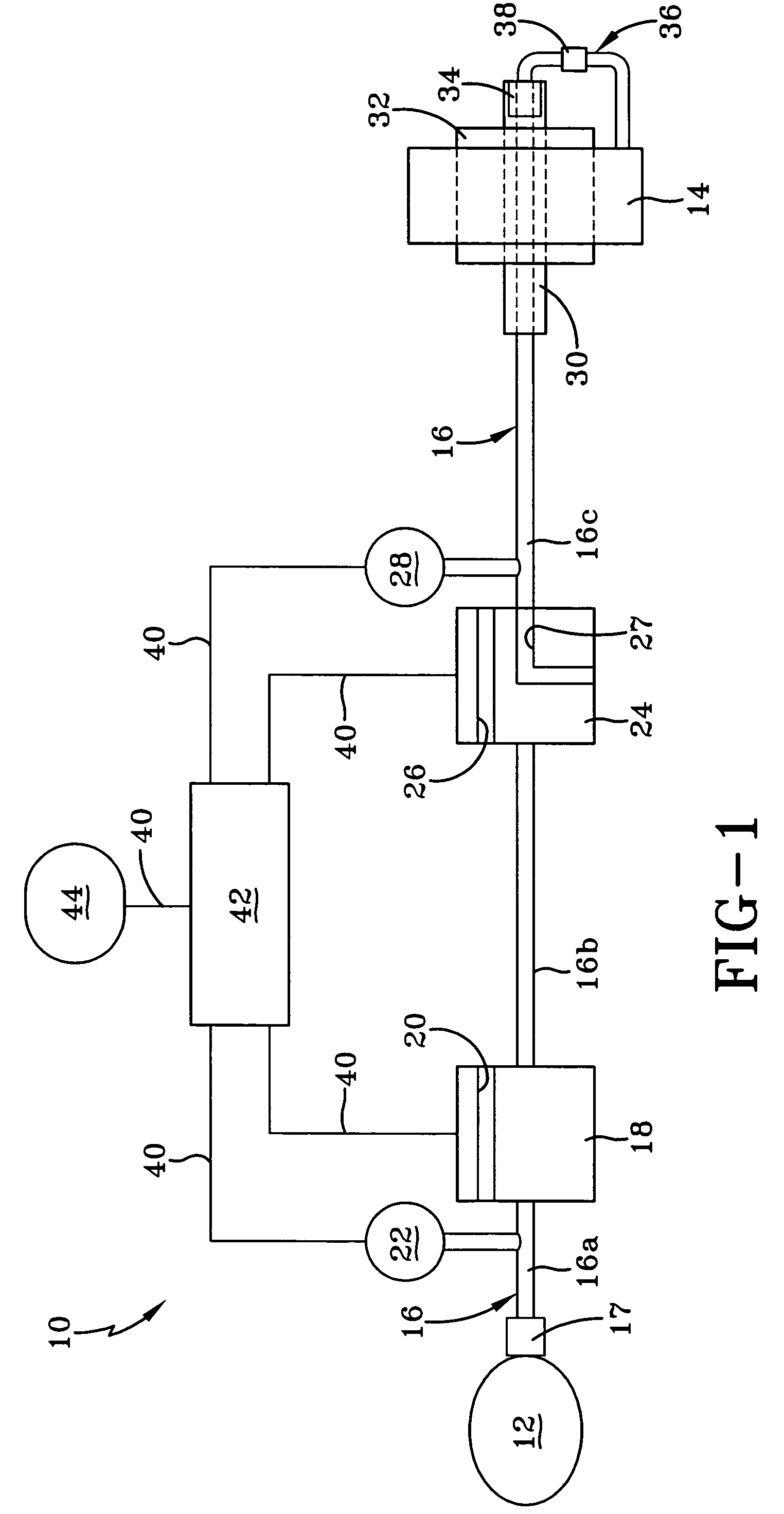

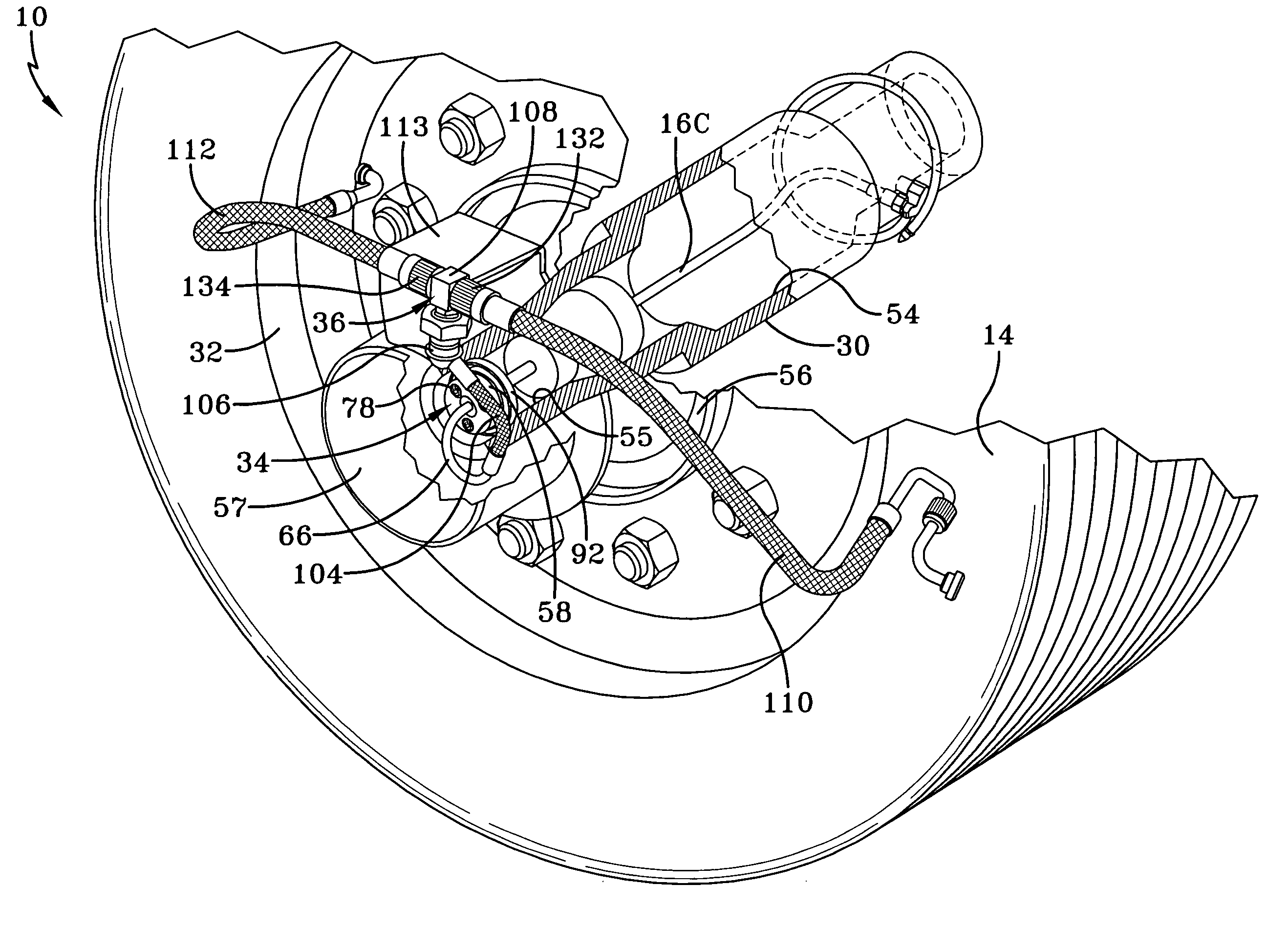

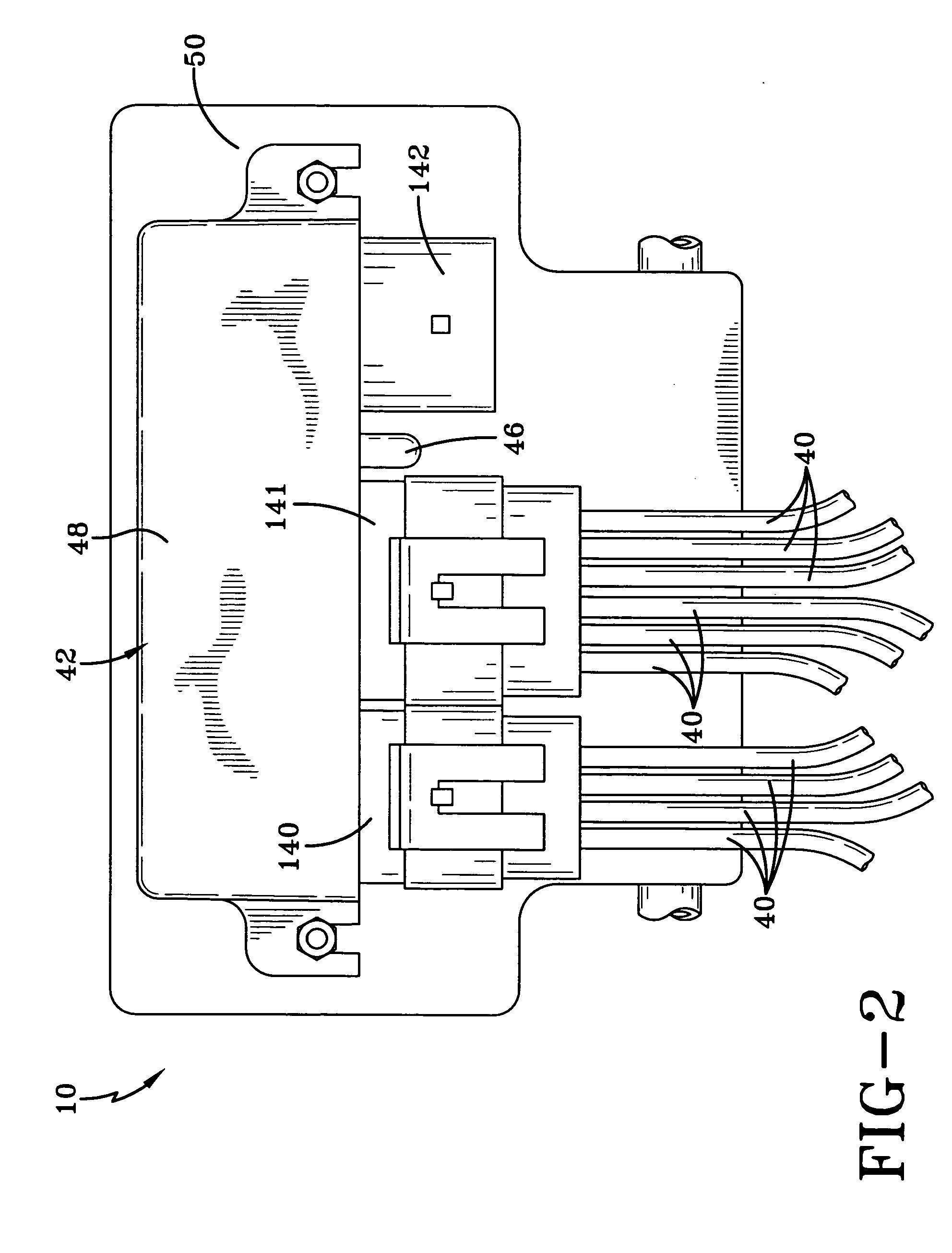

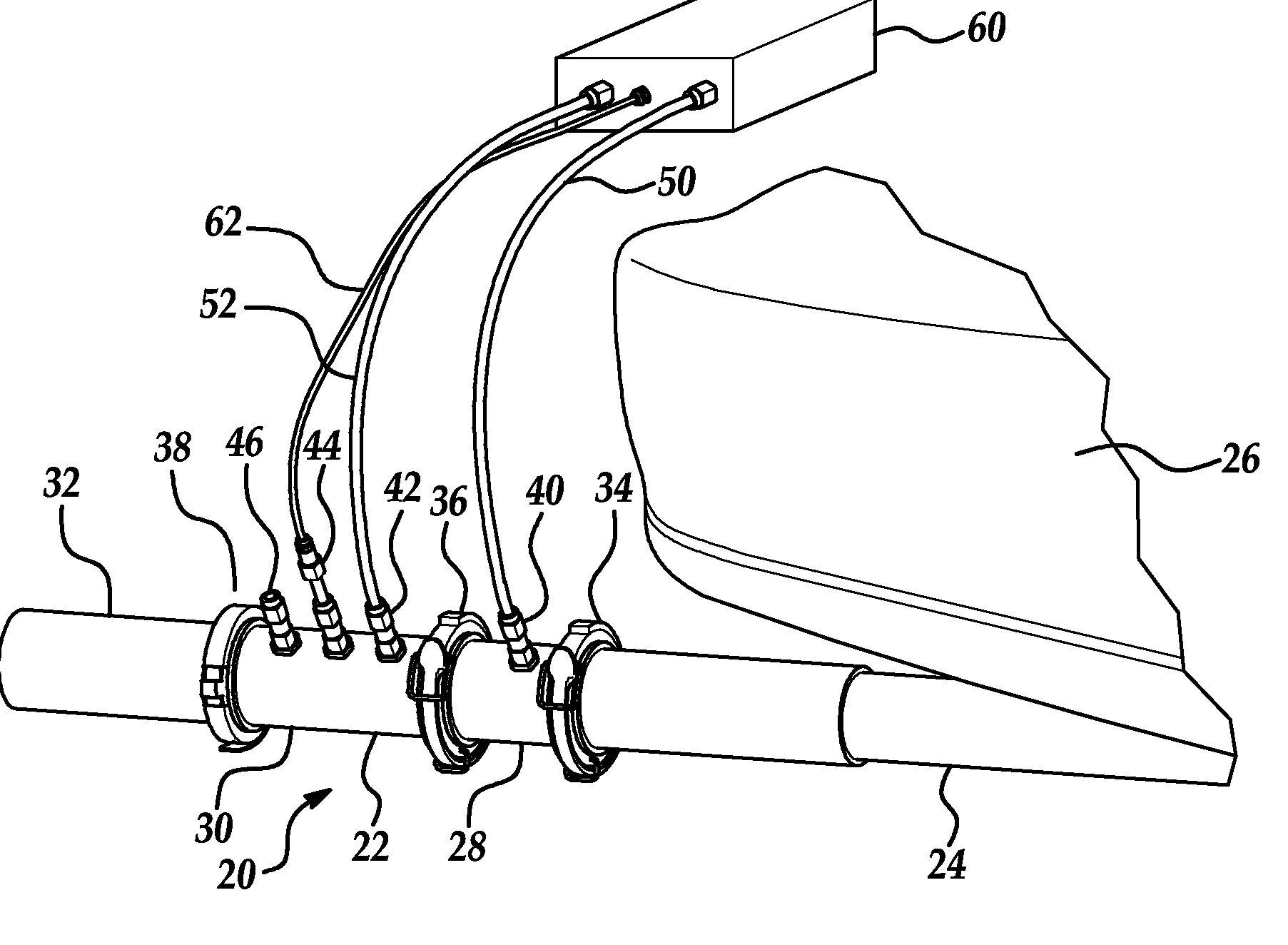

Tire inflation system apparatus and method

ActiveUS7273082B2Accurate checkAccurate pressureTyre measurementsTyre-inflating valvesEngineeringTire pressure

A tire inflation system includes an air supply source in selective fluid communication with a tire via a pneumatic conduit. A method of inflating the system includes providing a tire pressure retention valve in the pneumatic conduit adjacent to the tire. An inflation pressure of the tire is determined with a step-up procedure, in which air bursts are communicated from the air supply source to a portion of the pneumatic conduit between the air supply source and the tire pressure retention valve. The volume of at least one selected communicated air burst is related to a volume of a section of the conduit. The tire is inflated with an extended-pulse procedure, in which extended bursts of air are communicated from the air supply source to the tire. A shut-down sequence is performed once a predetermined target inflation pressure in the tire is reached.

Owner:HENDRICKSON USA L L C

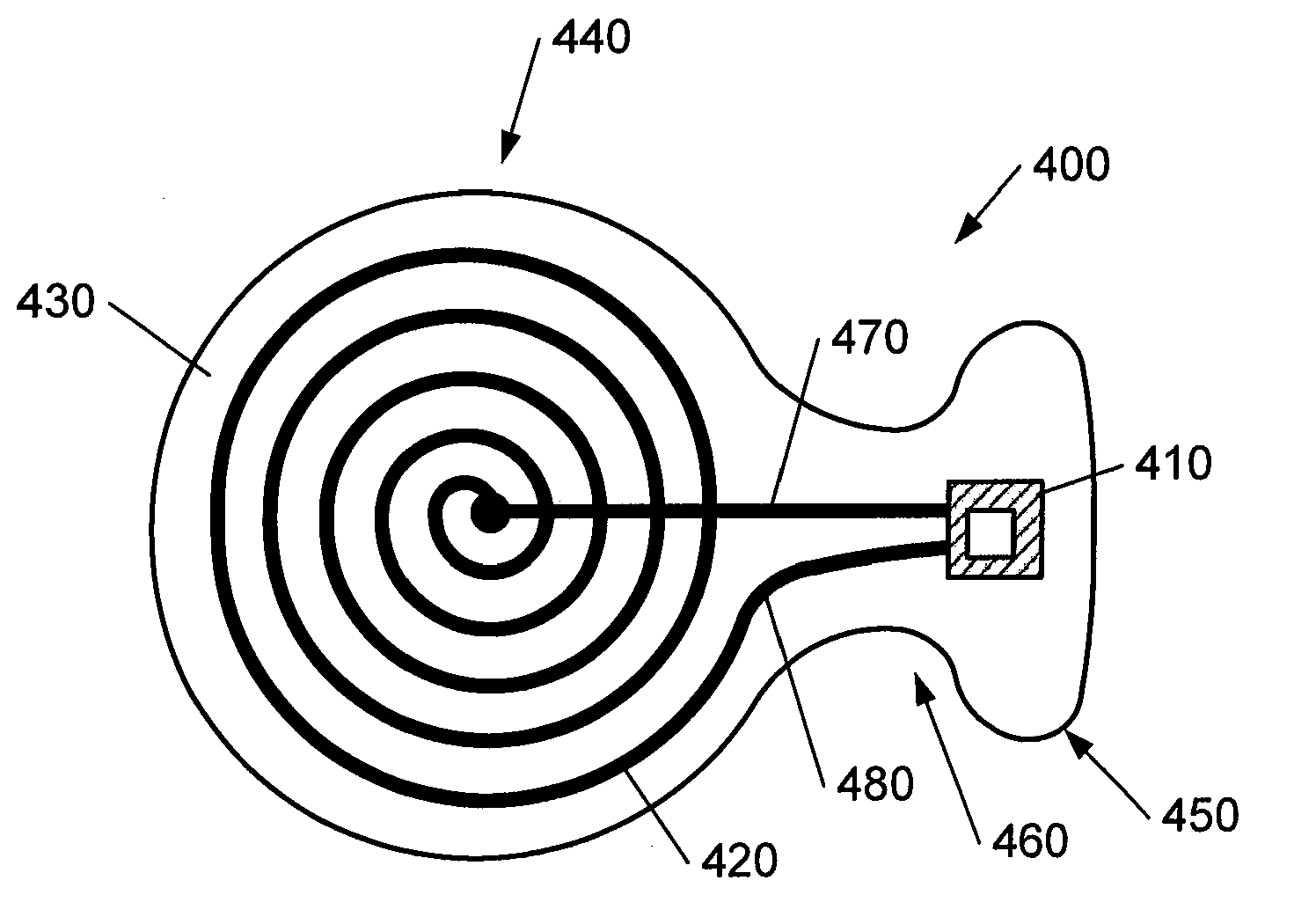

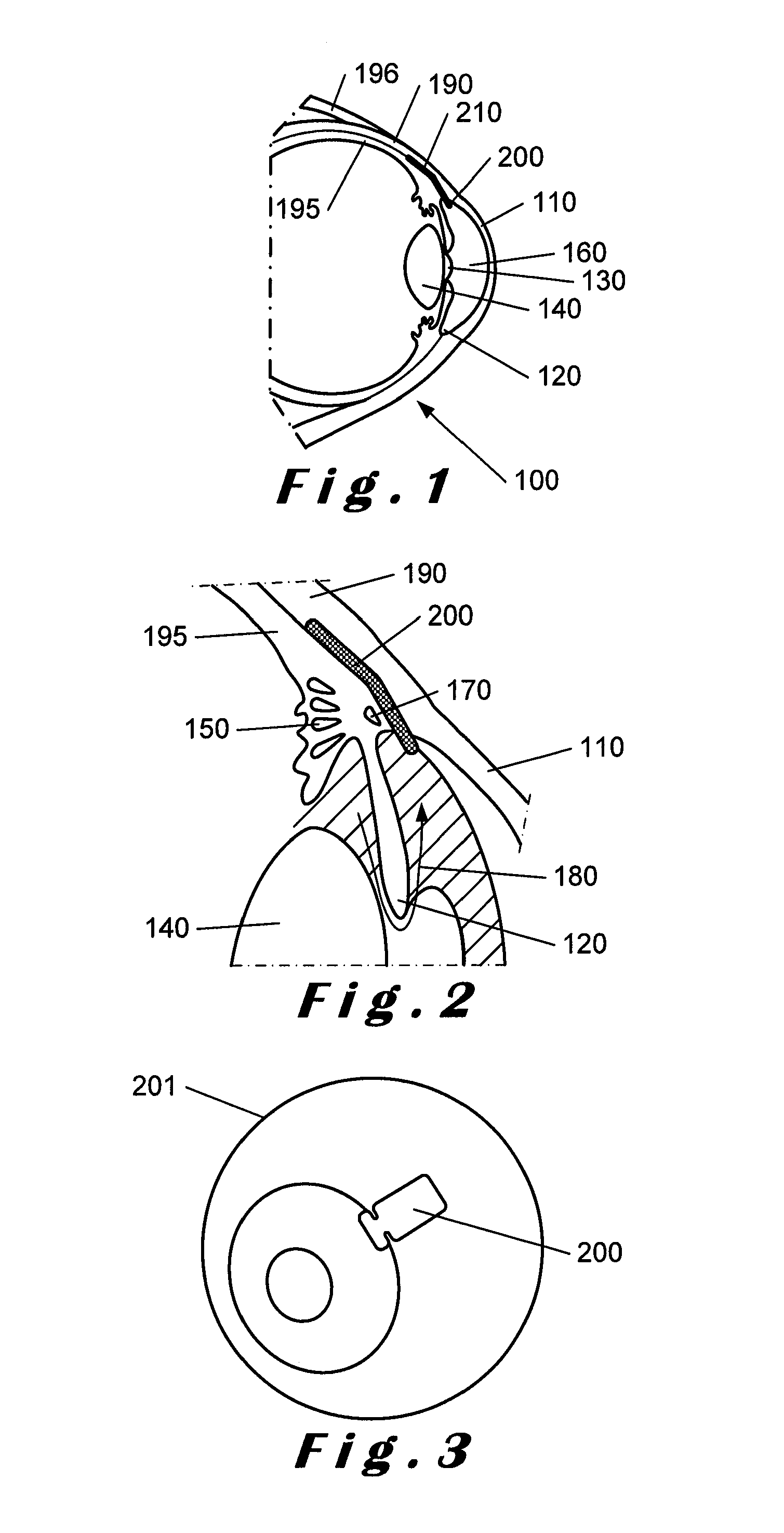

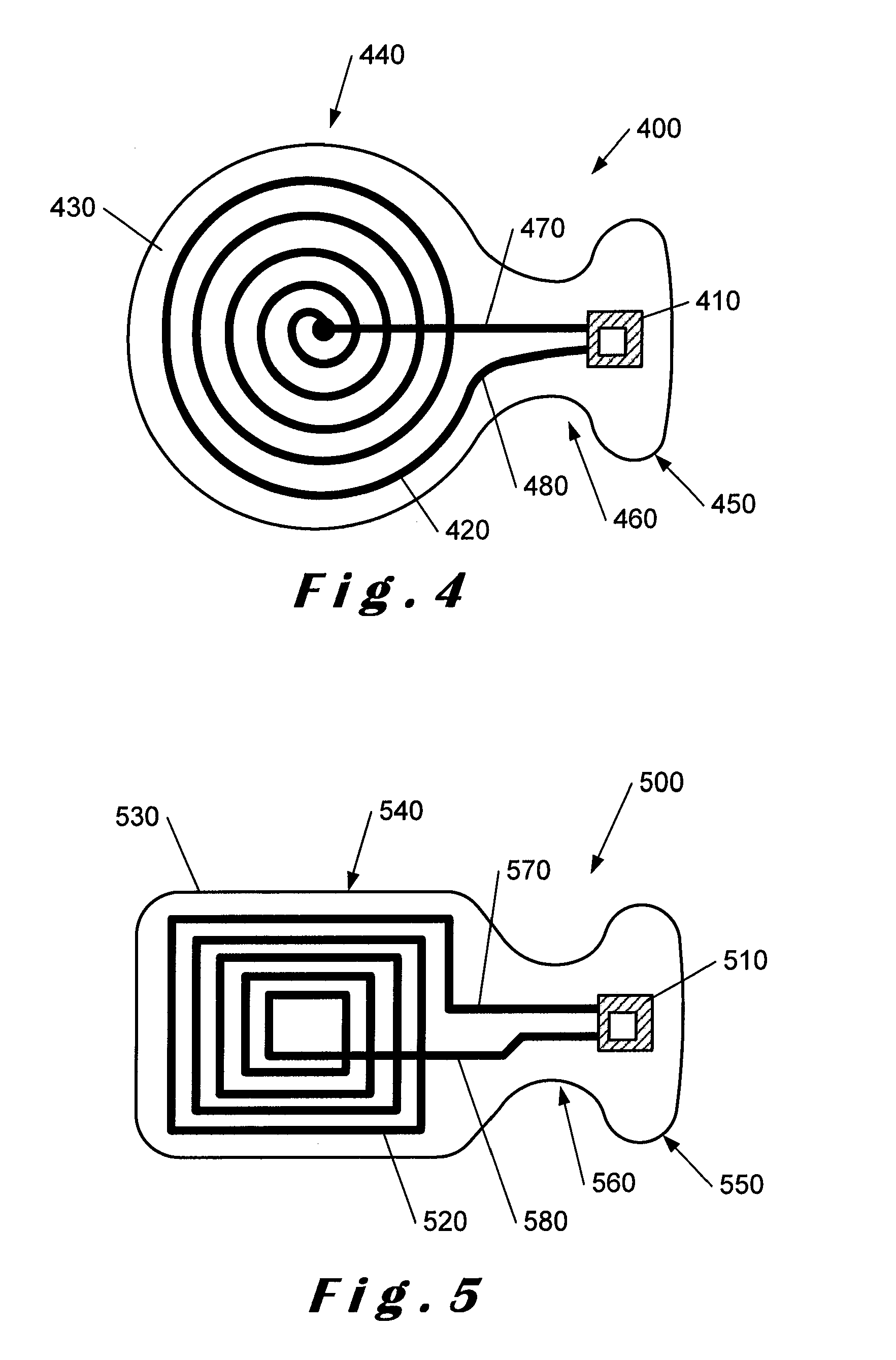

Device and method for glaucoma management and treatment

ActiveUS20120302861A1Readily conform to eye contourMinimize traumaEye surgeryDiagnostic recording/measuringAqueous humourIOPS

Described herein is a device for glaucoma treatment and monitoring that comprises a combination of an intraocular pressure (IOP) sensor and a glaucoma drainage device. The device comprises an IOP sensor and an inductive antenna mounted within a porous biocompatible material that forms the drainage path. The IOP sensor is mounted in a footplate portion of the device and is mountable in the anterior chamber of an eye. The footplate portion is connected to a body portion that houses the spiral antenna by a neck portion which retains the footplate portion in a suitable position within the anterior chamber. Due to its size, the footplate portion housing the IOP sensor can readily be inserted into the anterior chamber with the body portion housing the spiral antenna located outside of the anterior chamber in a sub-scleral space to disperse the aqueous humour.

Owner:ISTAR MEDICAL

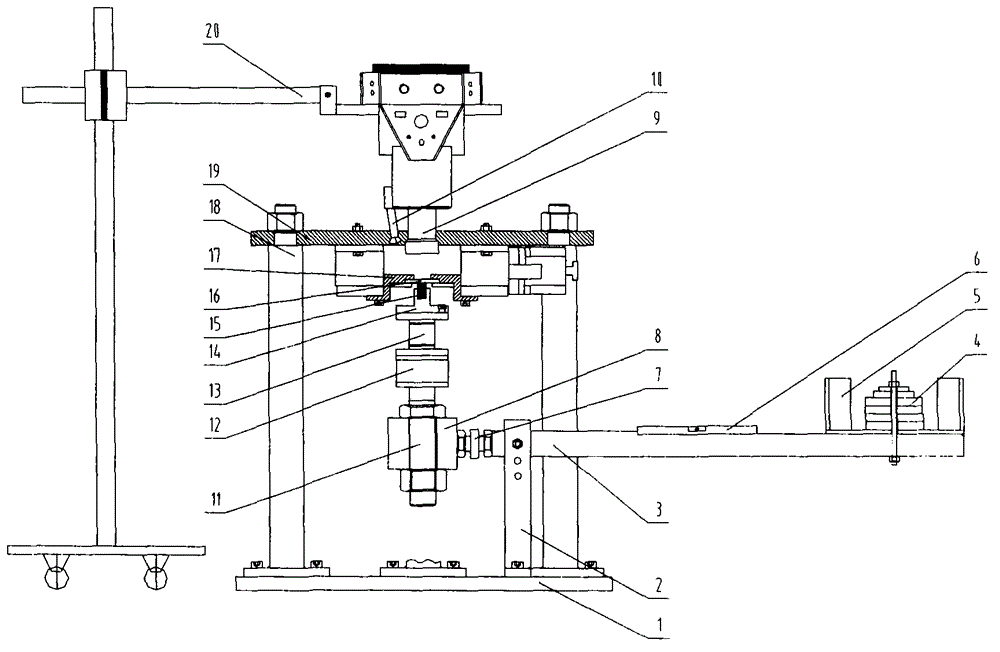

Test machine and test method for real-time and dynamic observation of end surface torsion friction and abrasion of friction interface

ActiveCN102944512AHigh rotation accuracyRun smoothlyUsing mechanical meansMaterial analysisElectric machineryGear transmission

The invention discloses a test machine and a test method for real-time and dynamic observation of end surface torsion friction and abrasion of a friction interface. The test machine comprises a pressure applying device, a rotary platform, a friction interface observing device and an adjusting device, wherein the pressure applying device comprises a lever, a lever bracket and weights, the rotary platform comprises a motor, a shaft encoder and a worm and gear transmission mechanism, the friction interface observing device comprises a high-speed camera, a torque sensor and a pressure sensor, and the adjusting device comprises a level and a vertical adjustable rod element. The axial loading is applied to a lower specimen by the lever and the weights, the rotary platform drives an upper specimen to do reciprocating torsion, the high-speed microscopic camera is used for observing the friction interface, the torsion friction and abrasion tests under different external loads are simulated by the adding and reducing of the weights, the change of the torsion frequency and the like, then the friction coefficient, the abrasion shape and the abrasion chip real-time movement in the friction process are obtained, and the friction and abrasion performances of transparent material in the whole process are evaluated. The test machine has the advantages that the structure is simple, the operation is convenient, and the repetitiveness is high.

Owner:CHINA UNIV OF MINING & TECH

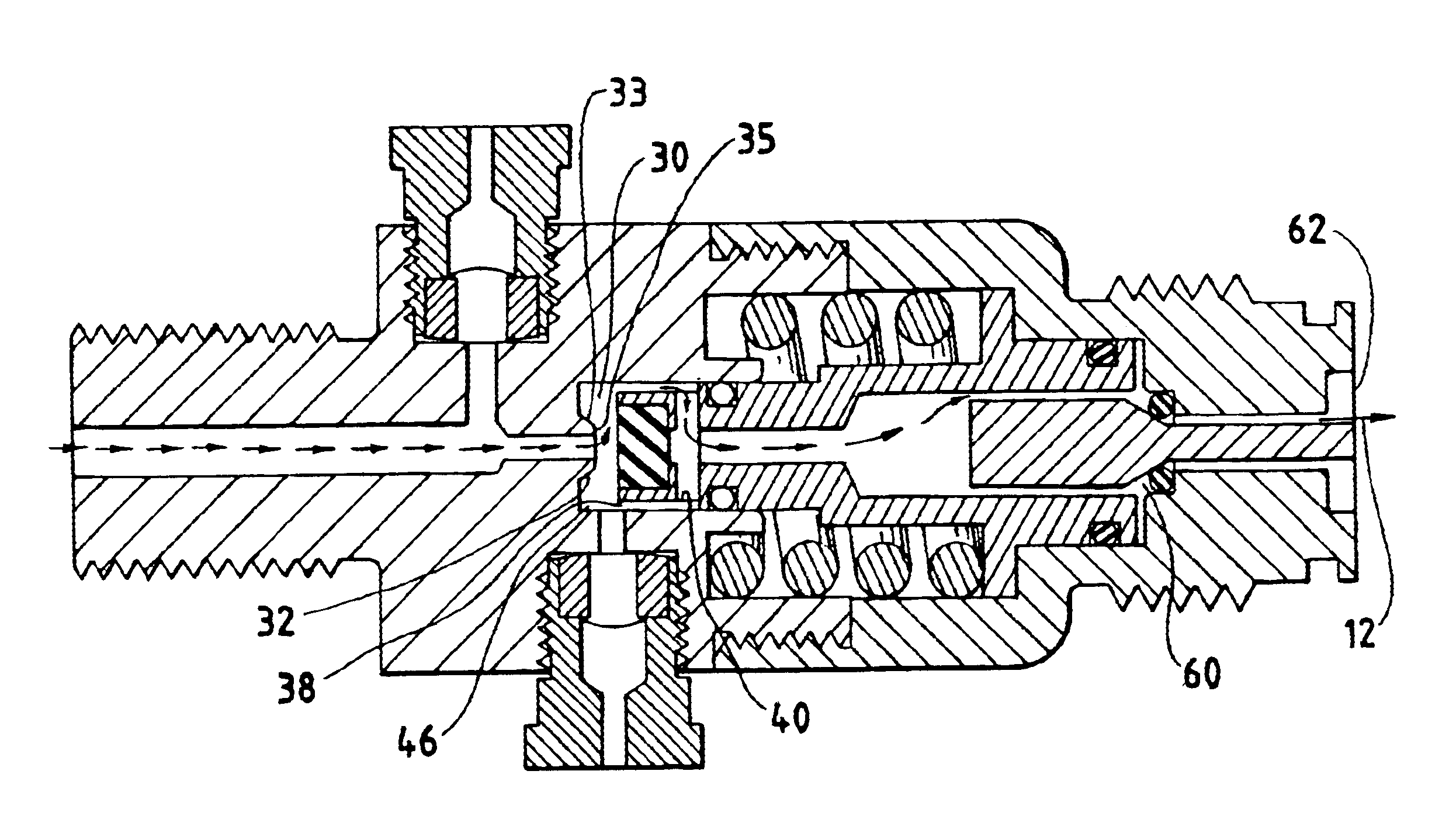

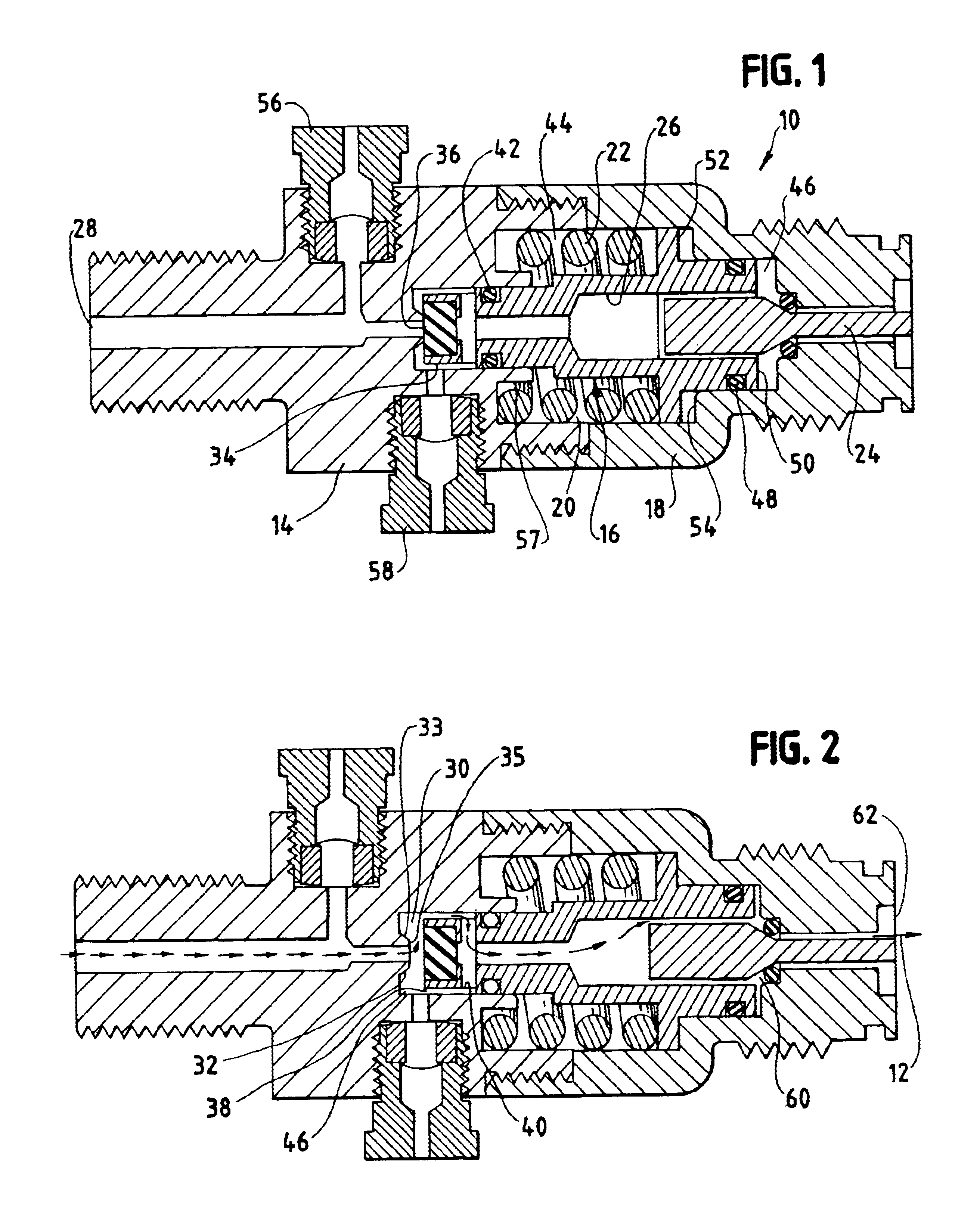

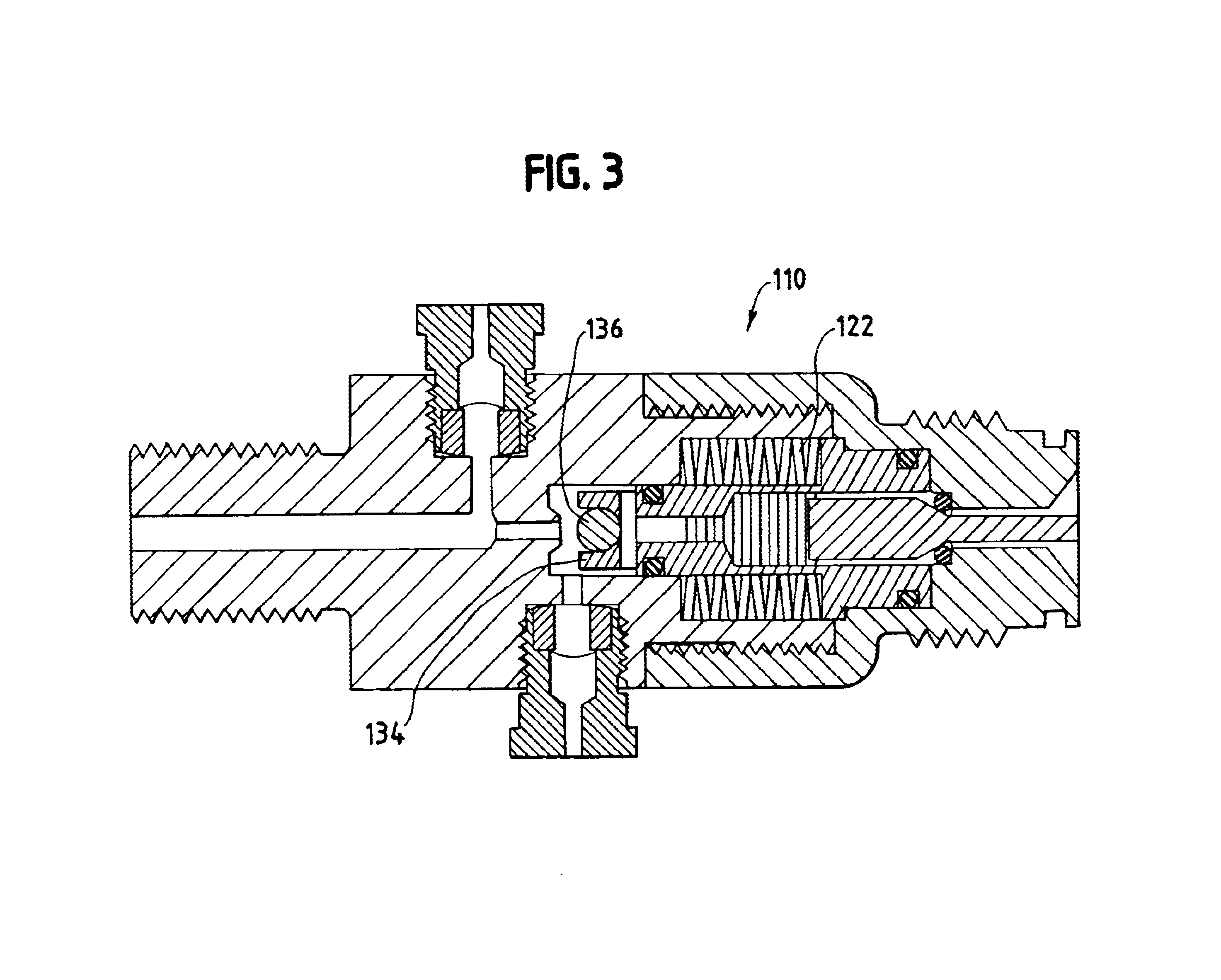

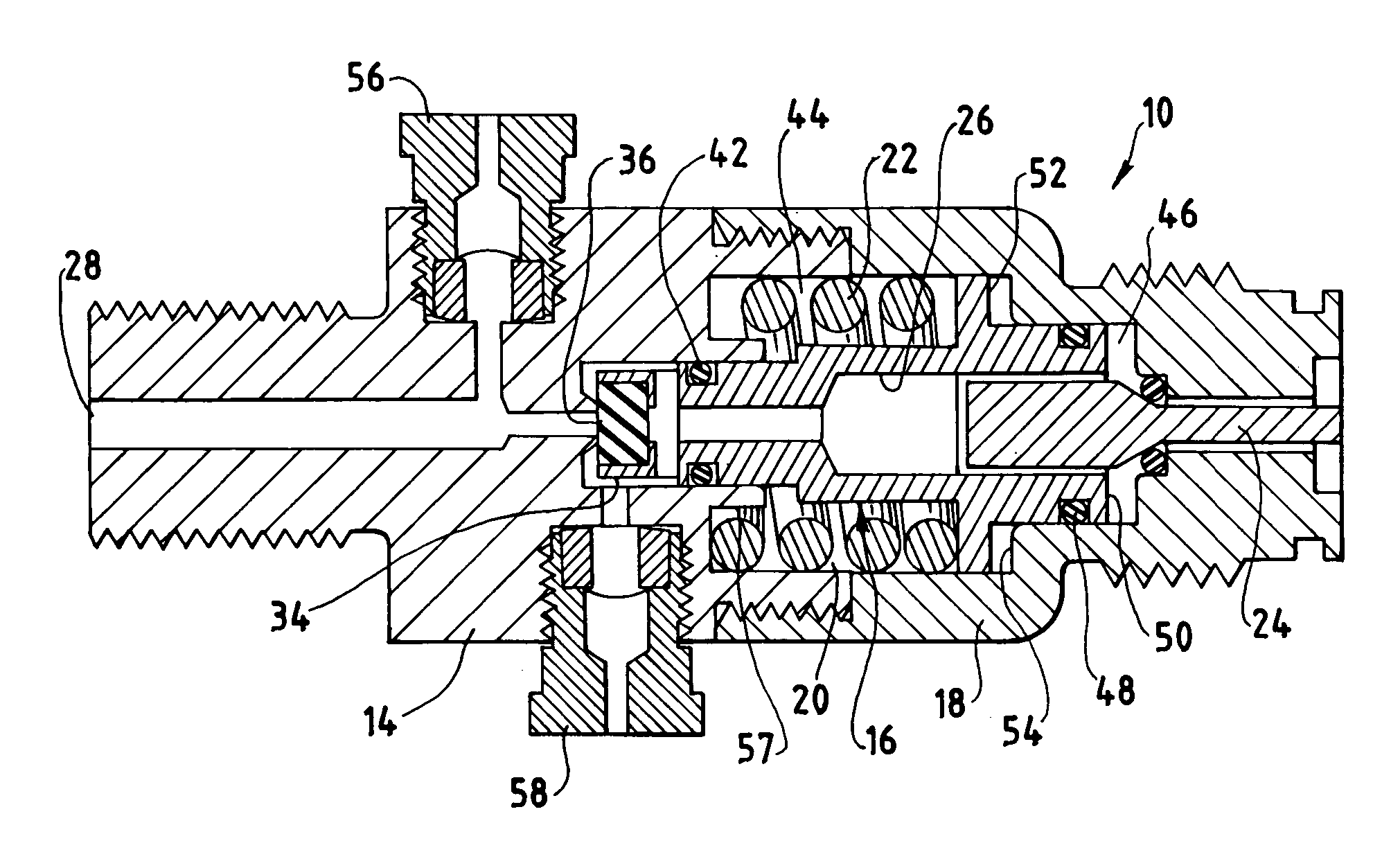

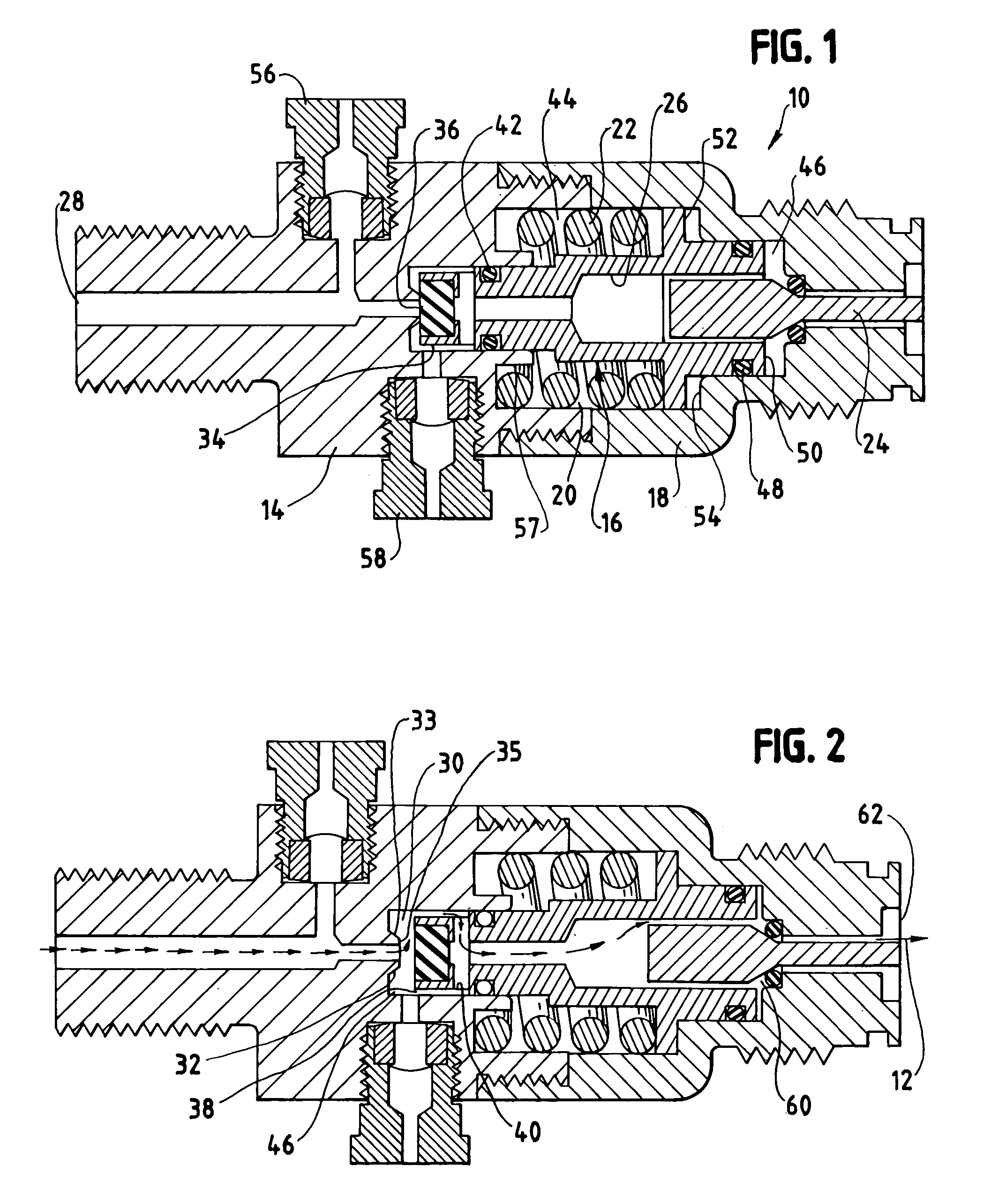

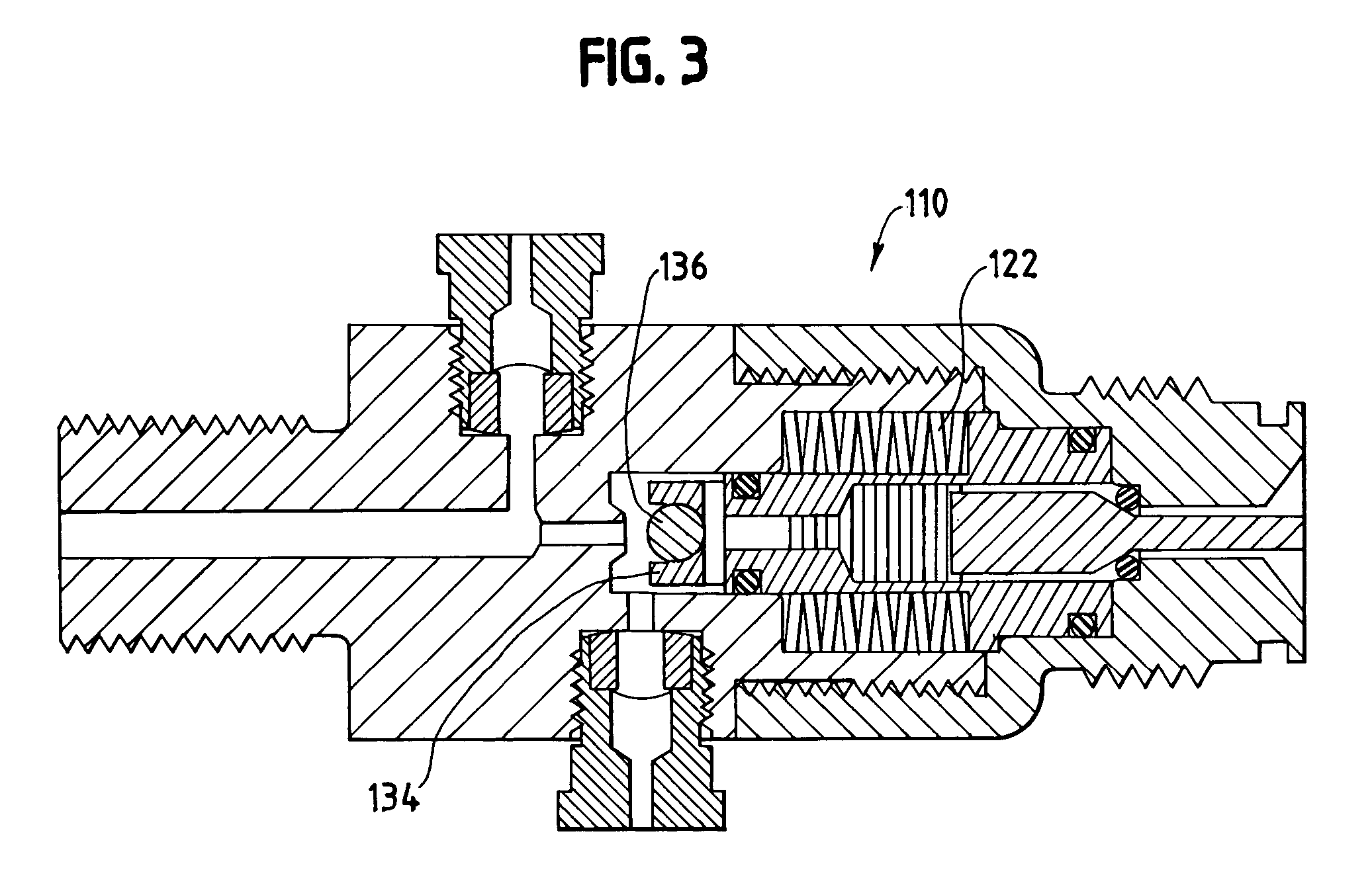

Direct acting gas regulator

InactiveUS6851447B1Improve accuracyLow costOperating means/releasing devices for valvesFluid pressure control without auxillary powerEngineeringHigh pressure

A direct acting pressure regulator controls the flow of a gas from a high pressure source to a low pressure device. Gas is delivered from the regulator at a predetermined outlet pressure. The regulator includes a body having a high pressure inlet and defining a seat. A bonnet is engageable with the body to define a piston chamber within the body and the bonnet. The bonnet has a regulated gas outlet. A piston is disposed within the piston chamber and defines a gap between the piston and a wall defining the chamber. The piston is movable between an open regulator condition and a closed regulator condition. The piston includes a plug having a sealing surface engageable with the seat and movable toward the seat to the closed regulator condition and away from the seat to the open regulator condition. The plug includes axially disposed openings therein for communicating gas from around the plug to a central longitudinal bore in the piston. The piston has an impingement surface in flow communication with the central bore such that gas pressure on the impingement surface exerts a force on the piston to move the piston to the closed regulator condition. A spring urges the piston to the open regulator condition.

Owner:PRESSURE SPECIALIST

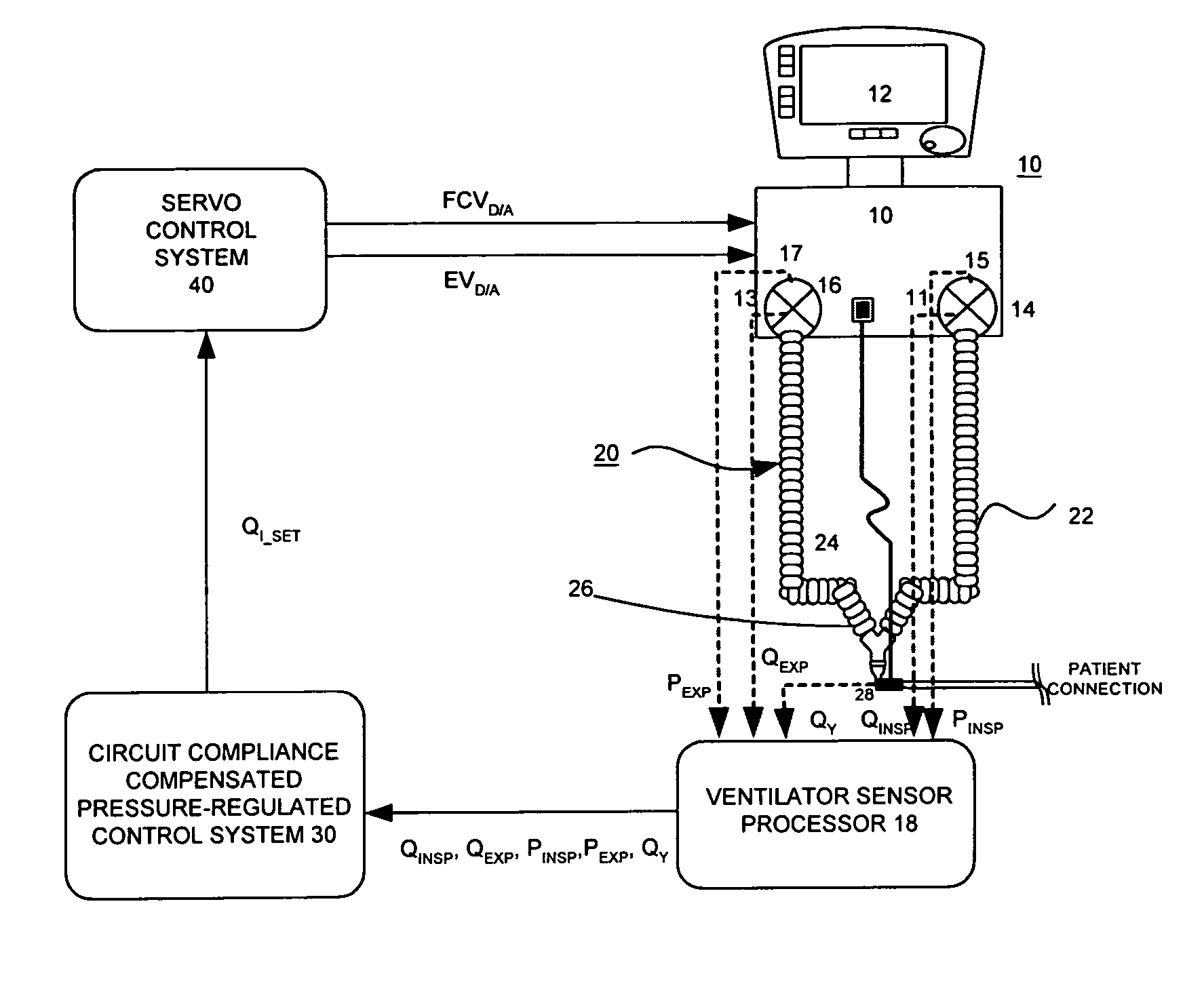

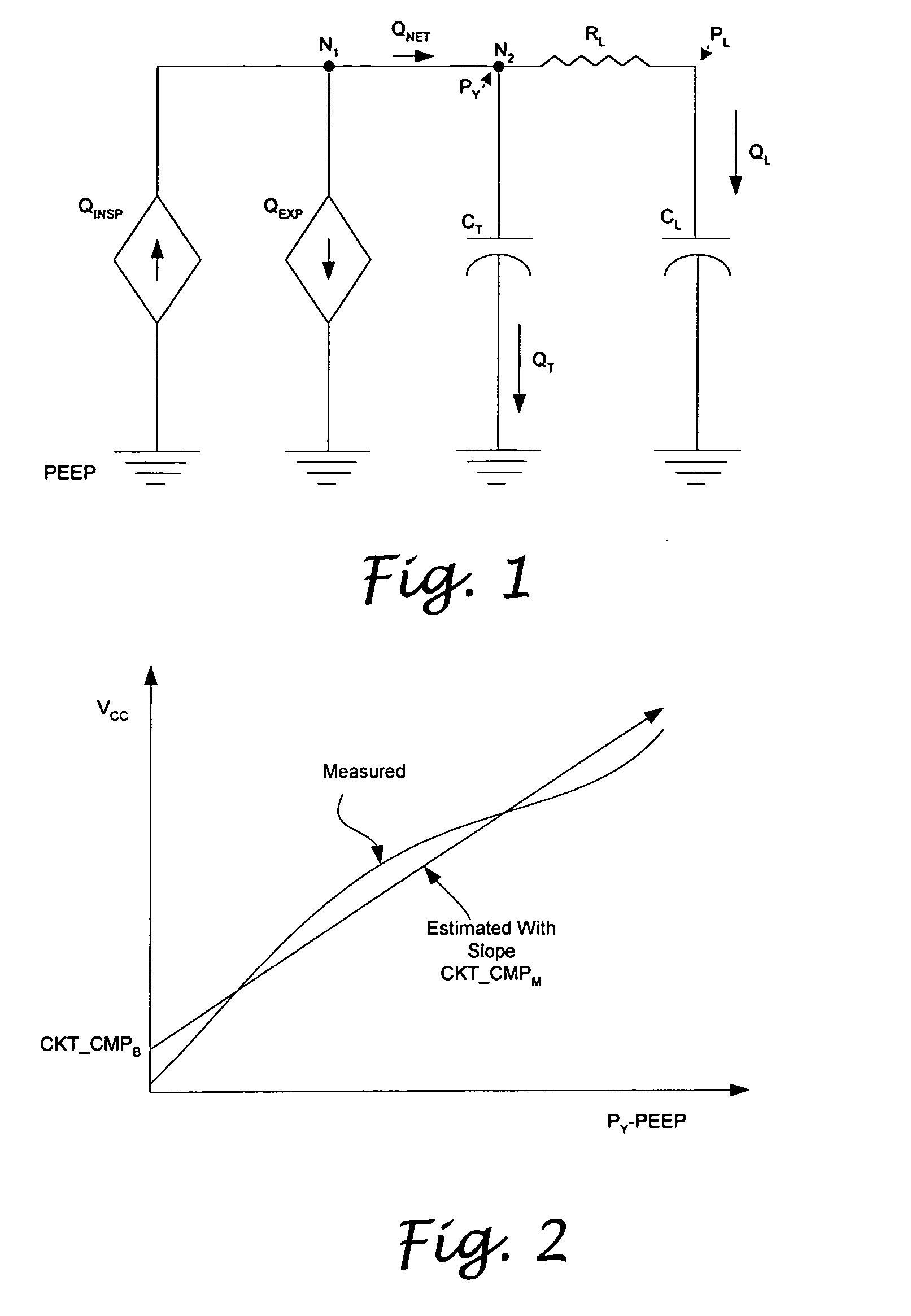

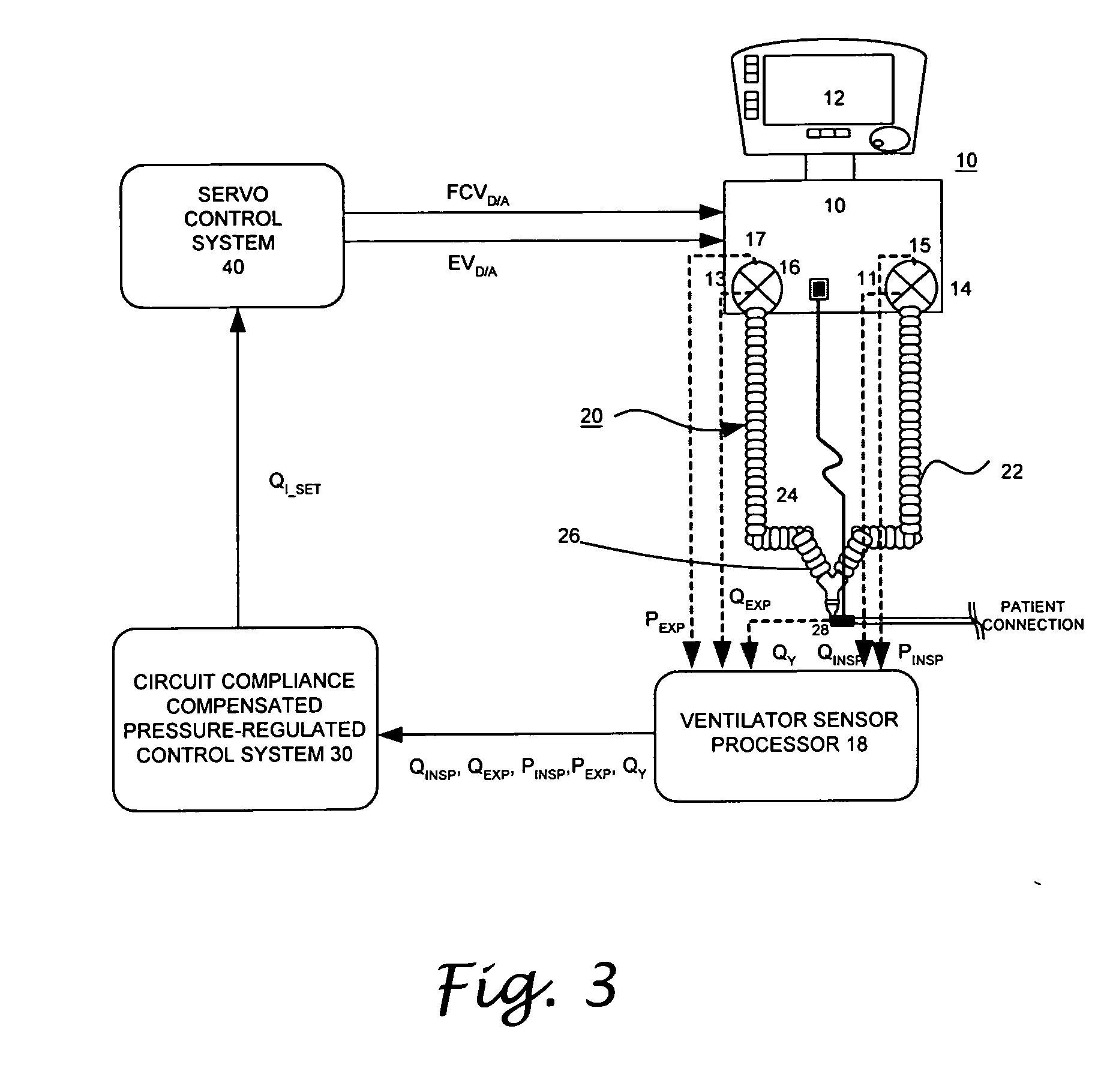

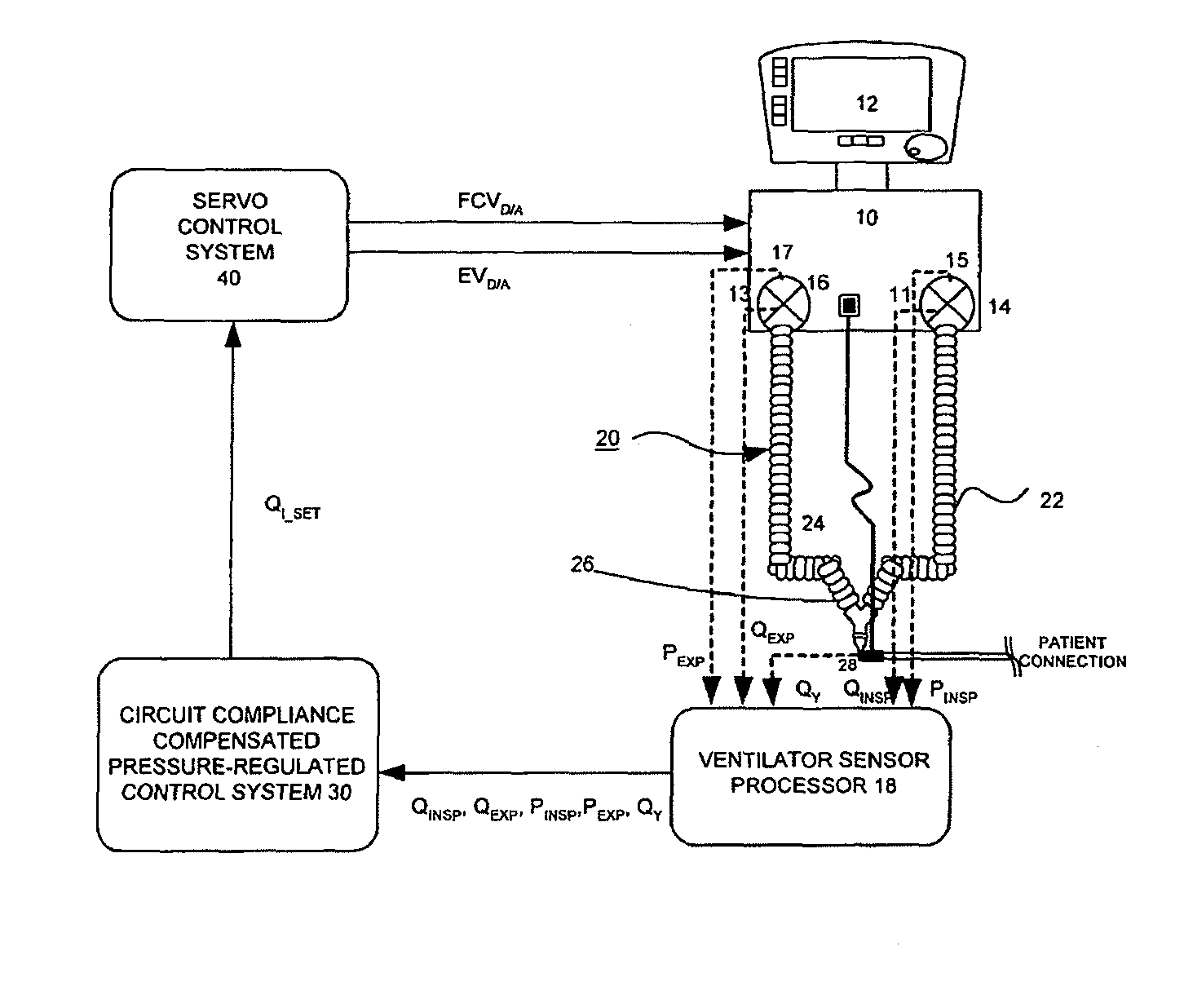

System and method for circuit compliance compensated pressure-regulated volume control in a patient respiratory ventilator

ActiveUS20070101992A1Prolonging inspiratory timeAccurate pressureRespiratorsOperating means/releasing devices for valvesPeak valueAirway pressures

A system and a method for circuit compliance compensated pressure control in a patient respiratory ventilation system, having a pressure regulated feedback servo control loop, a pressure-regulated volume controller, and a patient volume observer. The patient volume observer is operative to estimate a patient volume, that is, the volume actually delivered to the patient by accounting for volume deviation or loss caused by patient circuit leakage and valve dynamics. Based on the difference between the estimated patient volume and a set tidal volume, the pressure-regulated volume controller is operative to generate and update a circuit compliance pressure compensation factor. The pressure regulated feedback servo control loop is operative to modulate the peak airway pressure based on the circuit compliance pressure compensation factor, so as to achieve the set tidal volume while maintaining a constant inspiratory time and a constant I:E ratio.

Owner:VYAIRE MEDICAL 211 INC

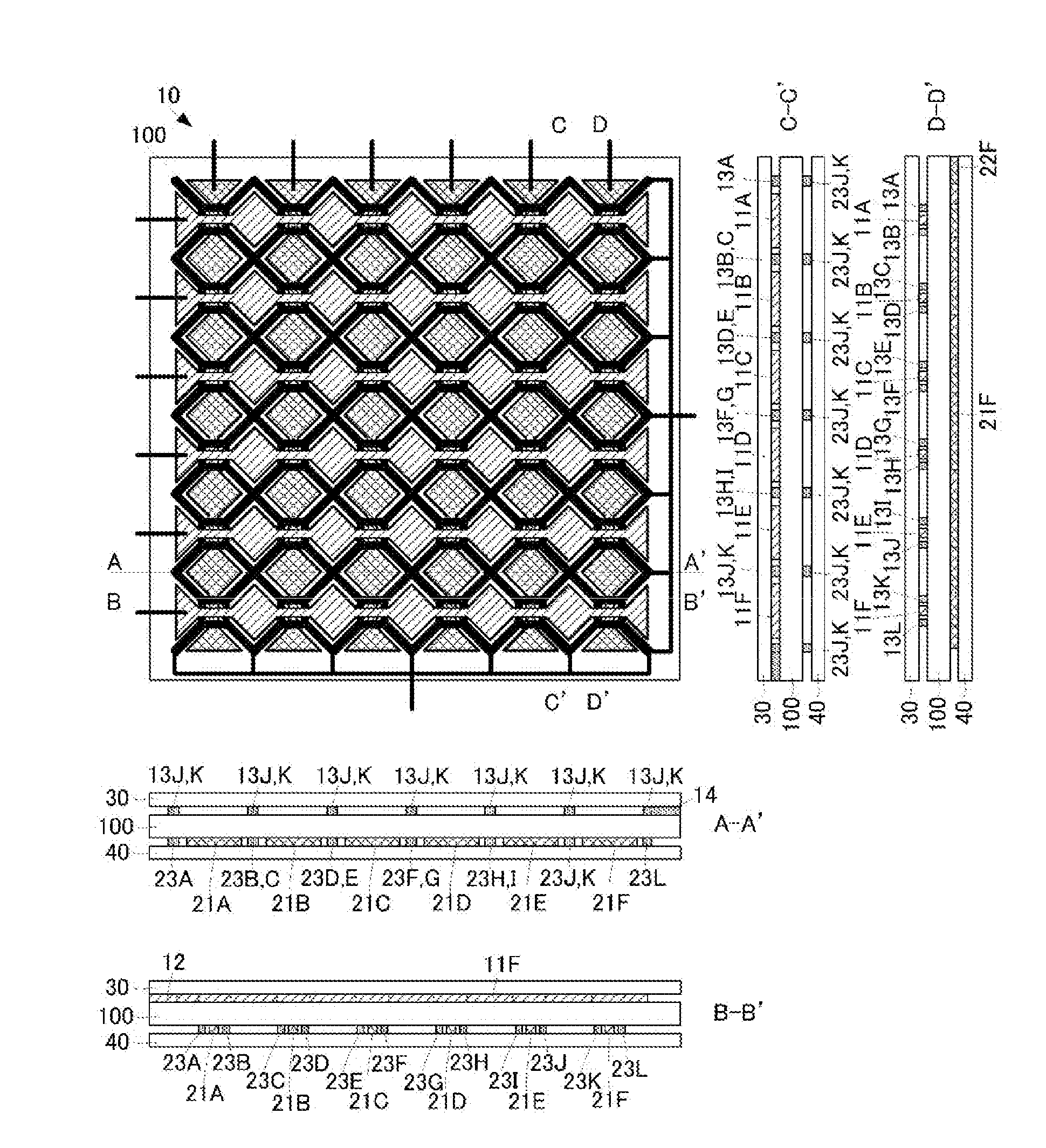

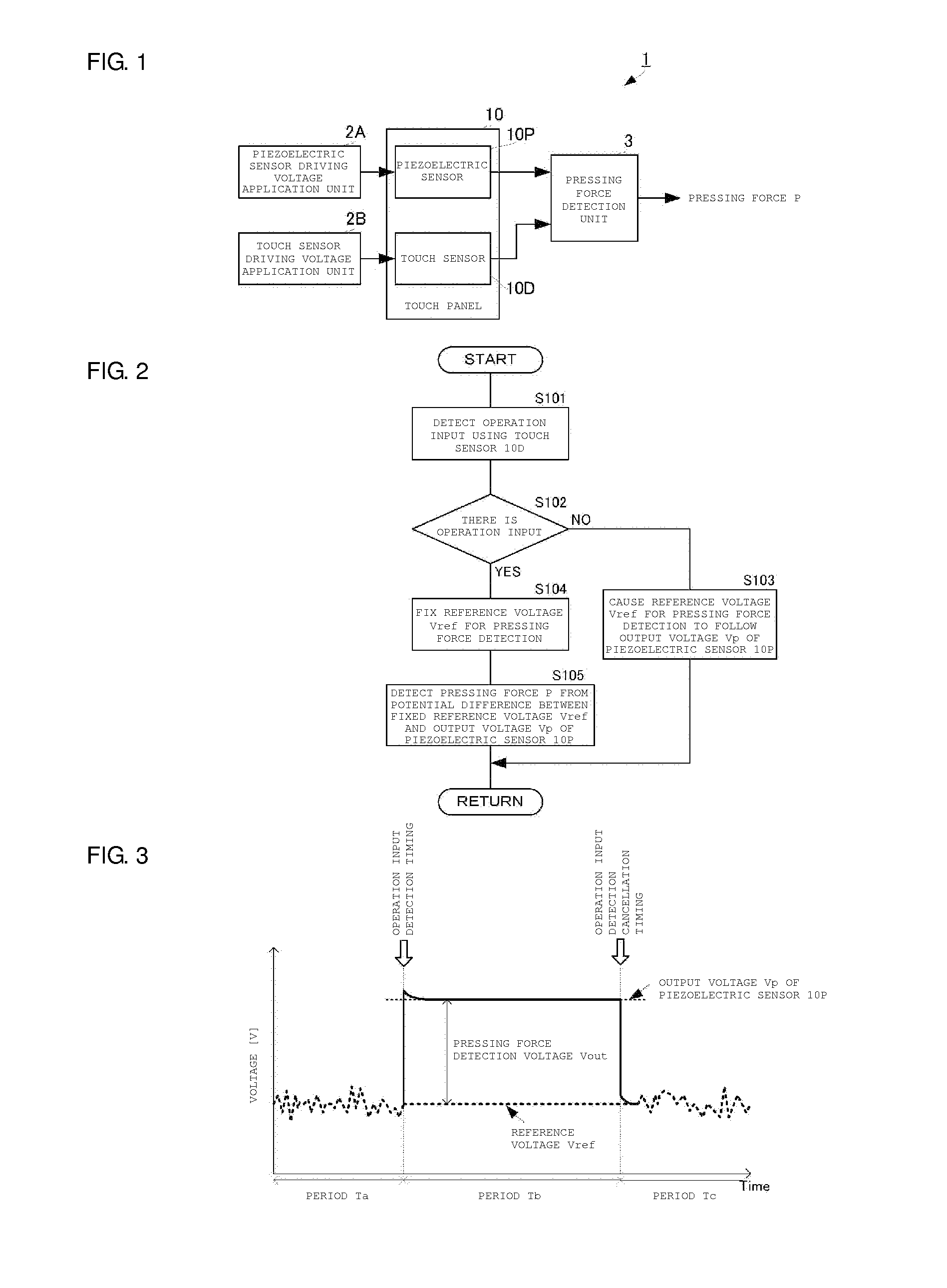

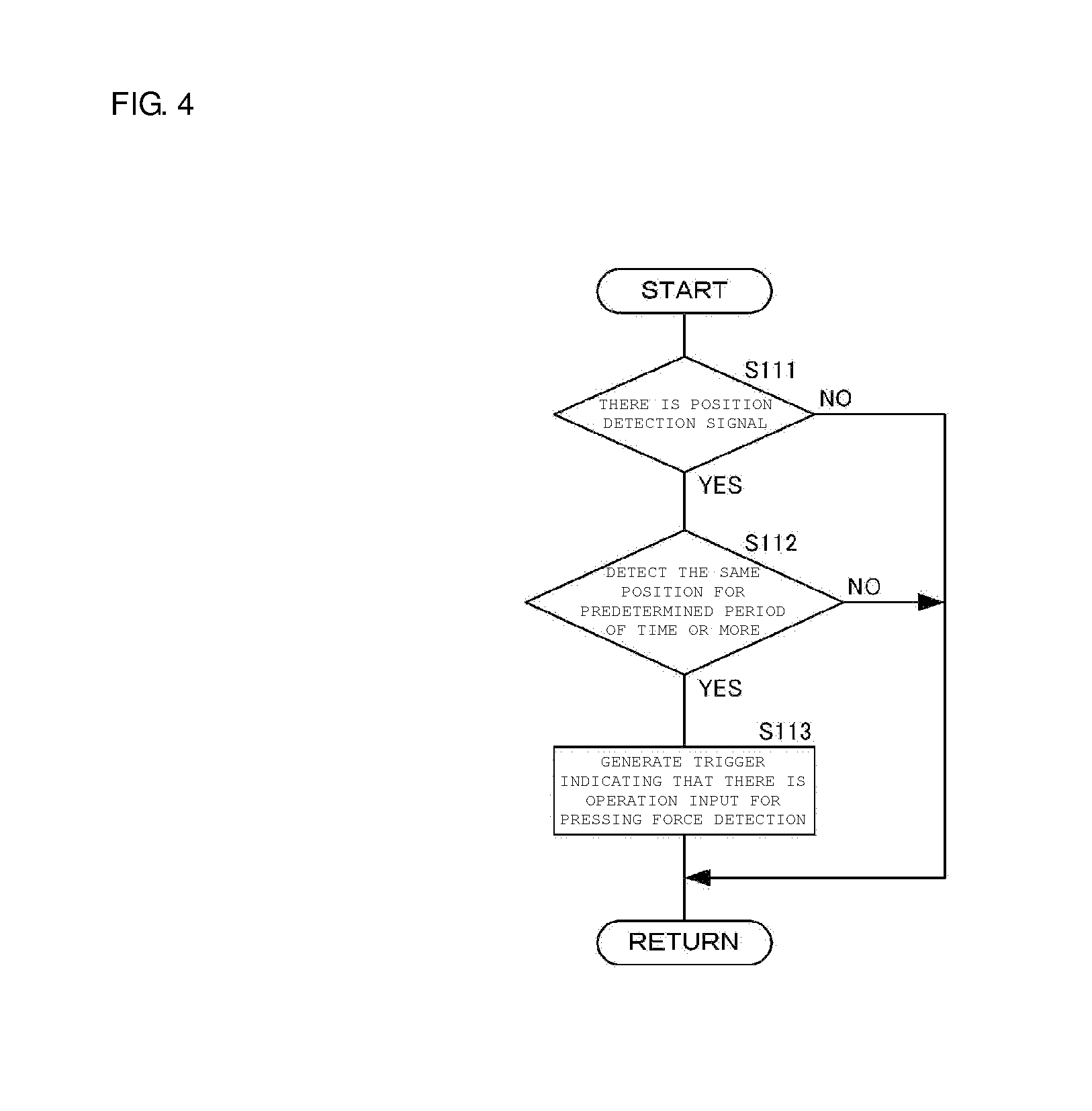

Touch Type Operation Input Device

ActiveUS20140292699A1High detection sensitivityHigh constantElectronic switchingInput/output processes for data processingLocation detectionVoltage reference

A touch type operation input device capable of accurately detecting pressing force with which an operator presses is provided. The touch type operation input device includes a touch panel including a piezoelectric sensor and a touch sensor, and a pressing force detection unit. Until the pressing force detection unit detects a position detection signal given by the touch sensor, the pressing force detection unit causes a reference voltage of the pressing force detection to follow an output voltage of the piezoelectric sensor to be the same as the output voltage of the piezoelectric sensor. When the pressing force detection unit obtains the position detection signal given by the touch sensor, the pressing force detection unit fixes the reference voltage. The pressing force detection unit calculates a pressing force detection voltage from the difference between the output voltage and the fixed reference voltage, and detects the pressing force.

Owner:MURATA MFG CO LTD

Tire inflation system apparatus and method

ActiveUS20050194080A1Accurate checkAccurate pressureTyre measurementsTyre-inflating valvesVALVE PORTTire pressure

A tire inflation system includes an air supply source in selective fluid communication with a tire via a pneumatic conduit. A method of inflating the system includes providing a tire pressure retention valve in the pneumatic conduit adjacent to the tire. An inflation pressure of the tire is determined with a step-up procedure, in which air bursts are communicated from the air supply source to a portion of the pneumatic conduit between the air supply source and the tire pressure retention valve. The volume of at least one selected communicated air burst is related to a volume of a section of the conduit. The tire is inflated with an extended-pulse procedure, in which extended bursts of air are communicated from the air supply source to the tire. A shut-down sequence is performed once a predetermined target inflation pressure in the tire is reached.

Owner:HENDRICKSON USA L L C

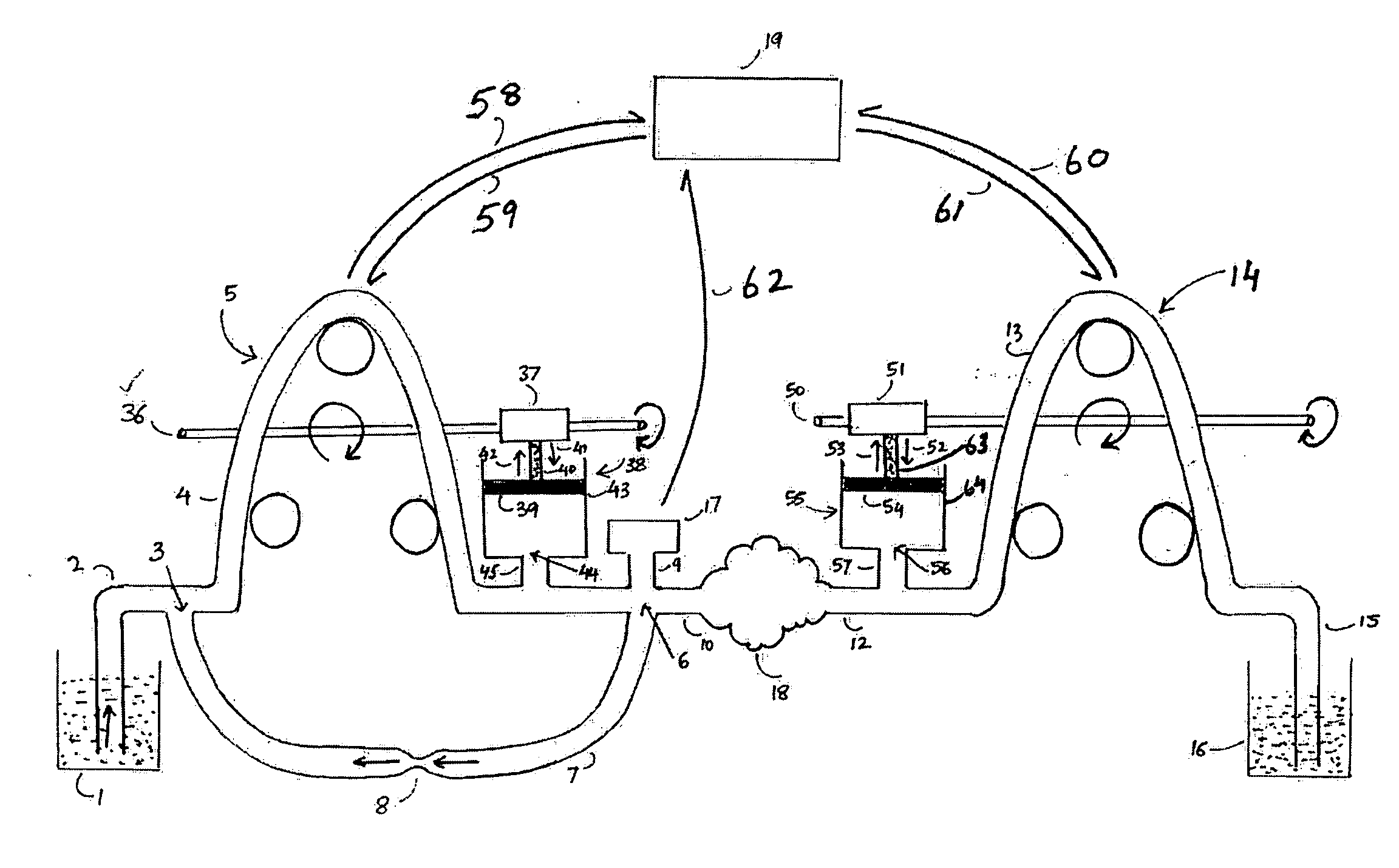

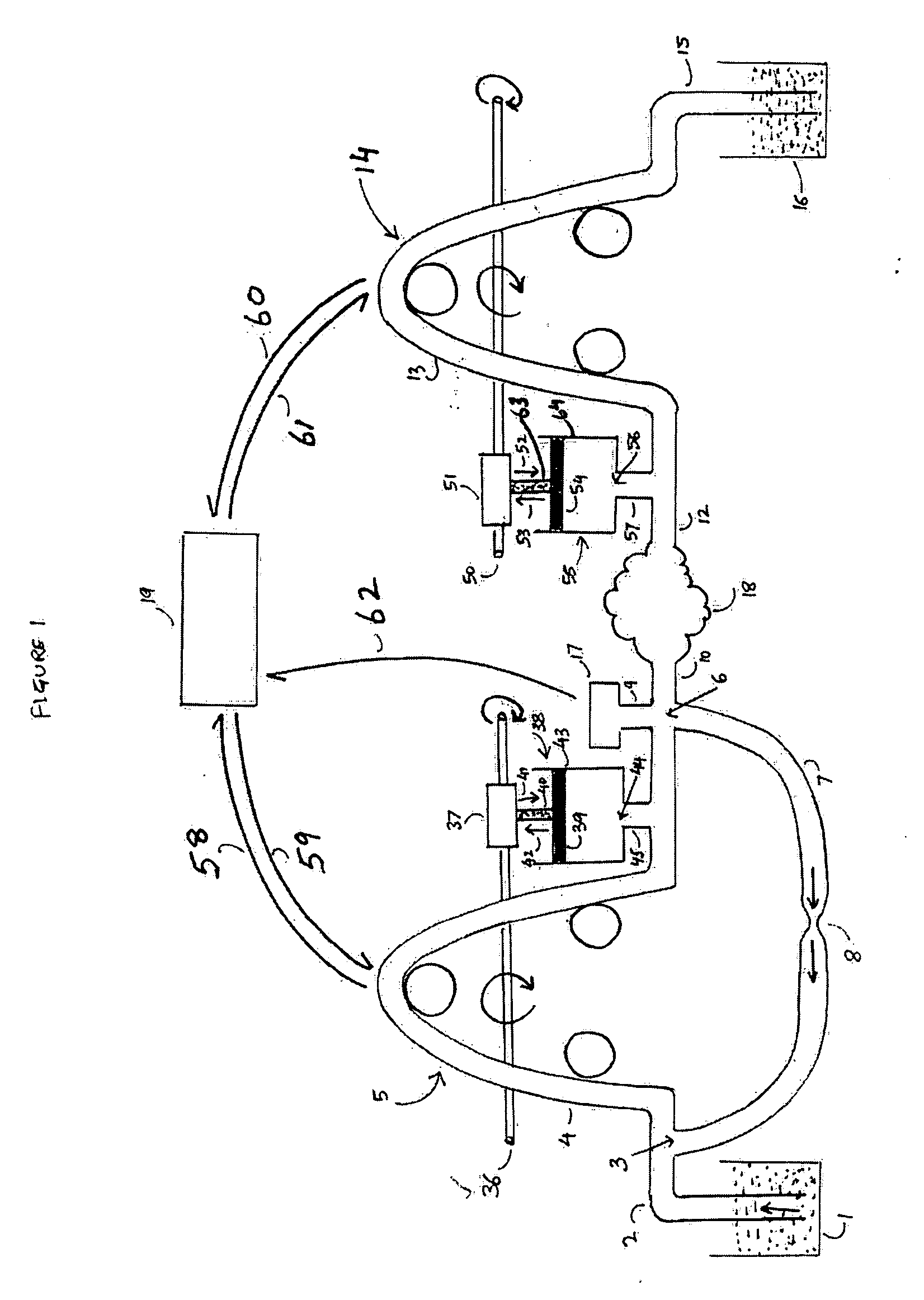

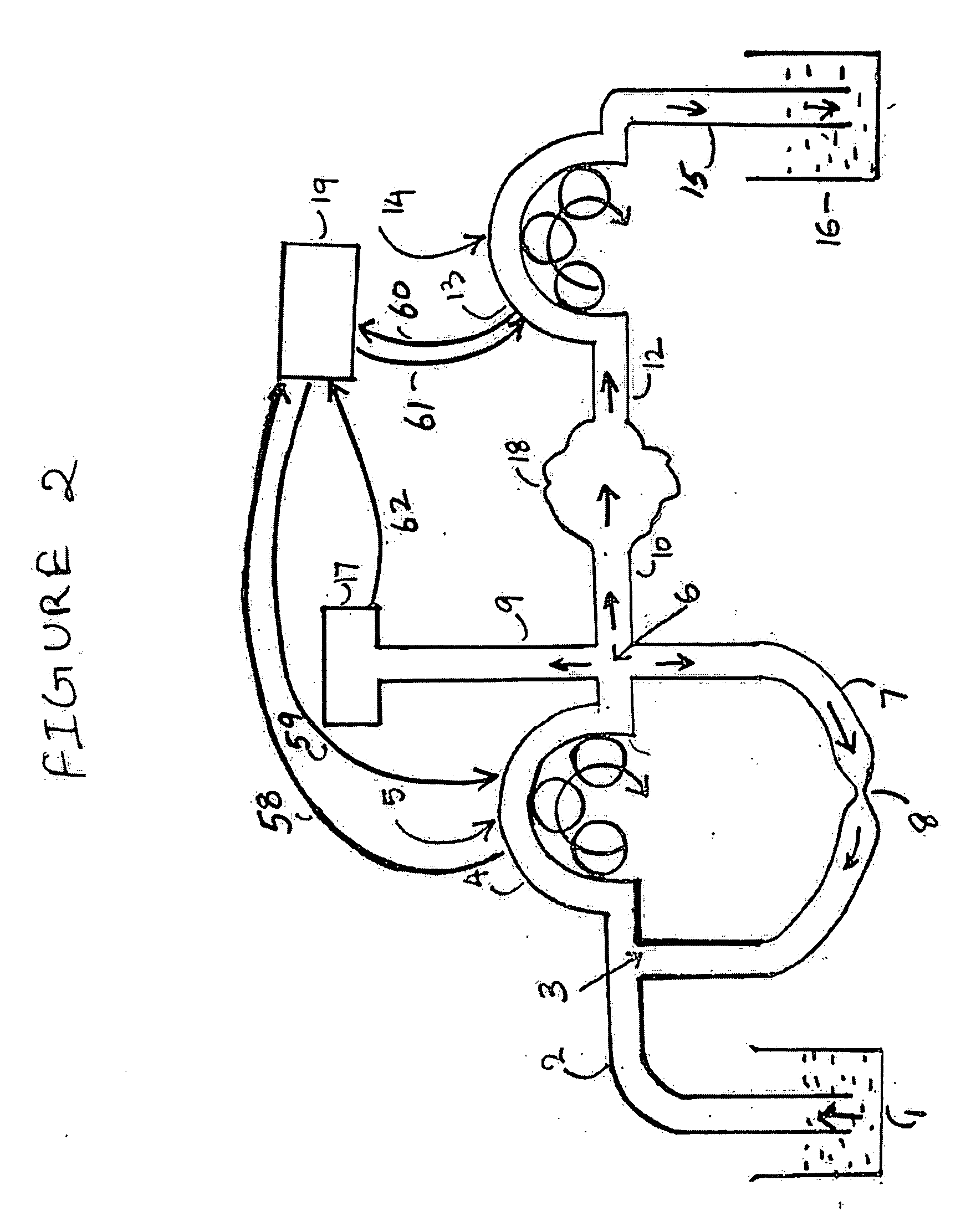

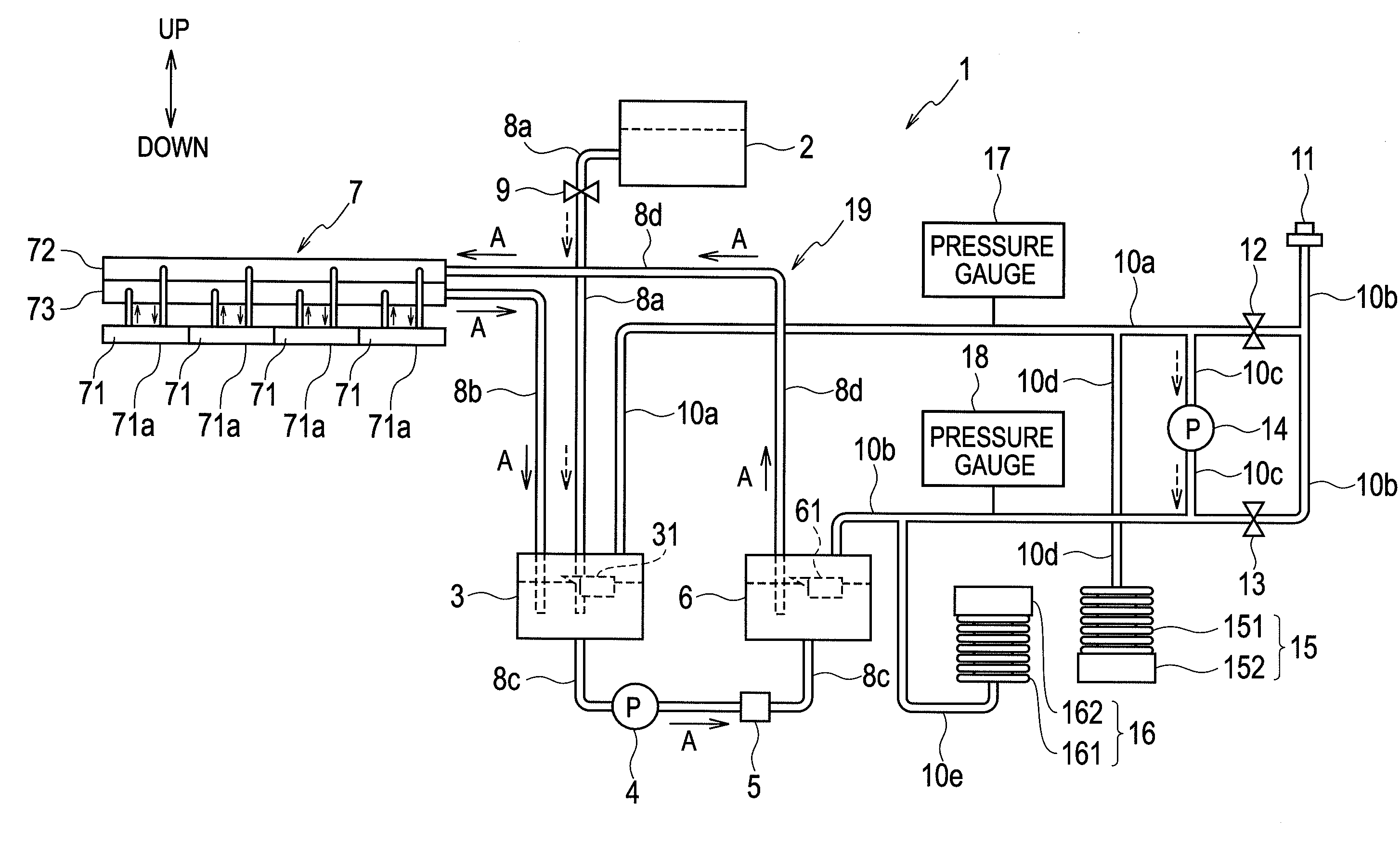

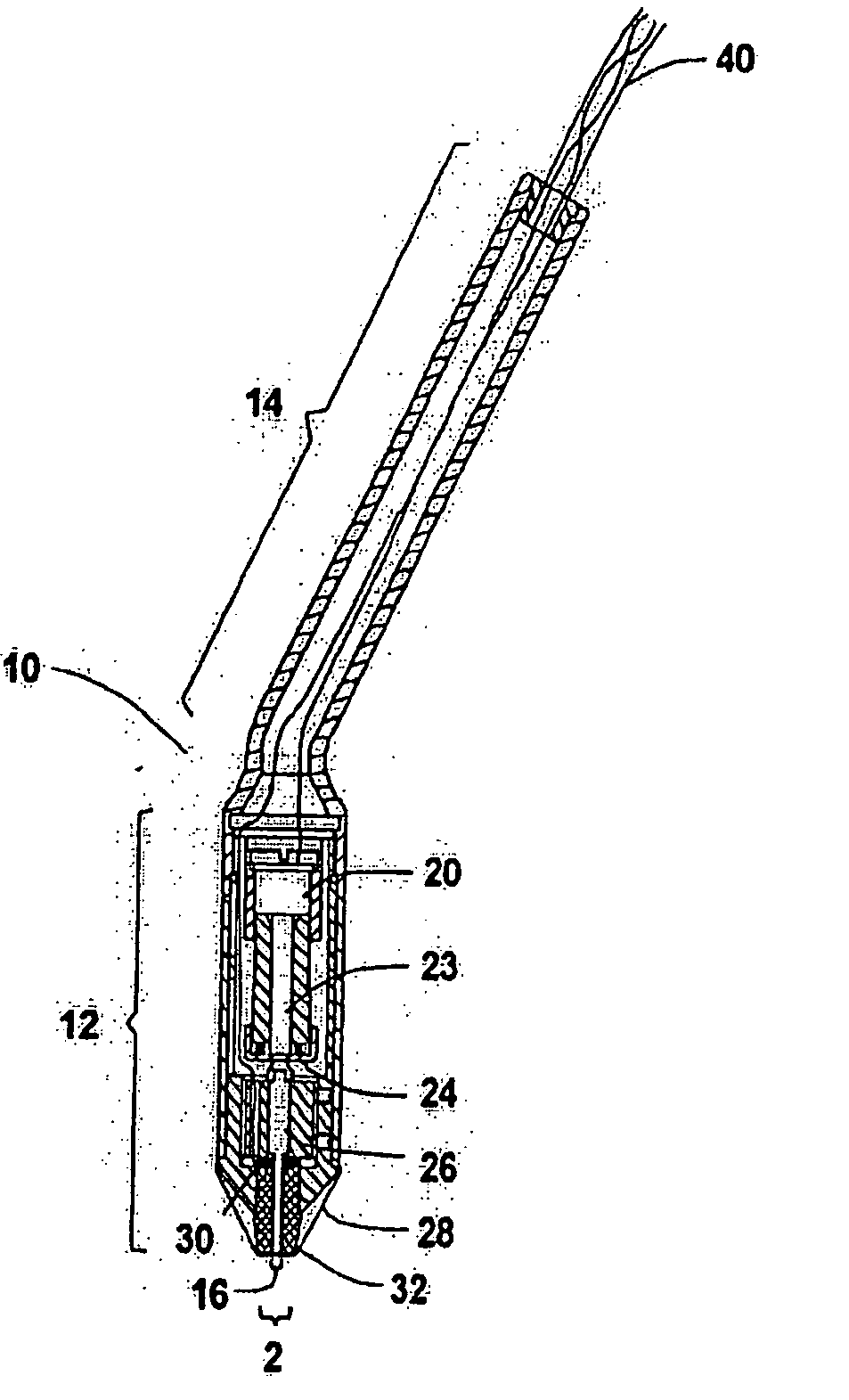

Low turbulence fluid management system for endoscopic procedures

ActiveUS20060122556A1Reduce cavity filling timeMinimize such riseEndoscopesMedical devicesPeristaltic pumpEndoscopic Procedure

The present invention provides a system and a method for distending a body tissue cavity of a subject by continuous flow irrigation by using two positive displacement pumps, such as peristaltic pumps, one pump on the inflow side and another pump on the outflow side, such that the amplitude of the pressure pulsations created by a the said positive displacement pumps inside the tissue cavity is substantially dampened to almost negligible levels. The present invention also provides a method of reducing the frequency of the said pressure pulsations. The present invention also provides a method for accurately determining the rate of fluid loss, into the subject's body system, during any endoscopic procedure without utilizing any deficit weight or fluid volume calculation, the same being accomplished by using two fluid flow rate sensors. The present invention also provides a system of creating and maintaining any desired pressure in a body tissue cavity for any desired cavity outflow rate. The system and the methods of the present invention described above can be used in any endoscopic procedure requiring continuous flow irrigation few examples of such endoscopic procedures being hysteroscopic surgery, arthroscopic surgery, trans uretheral surgery, endoscopic surgery of the brain and endoscopic surgery of the spine.

Owner:KUMAR BV

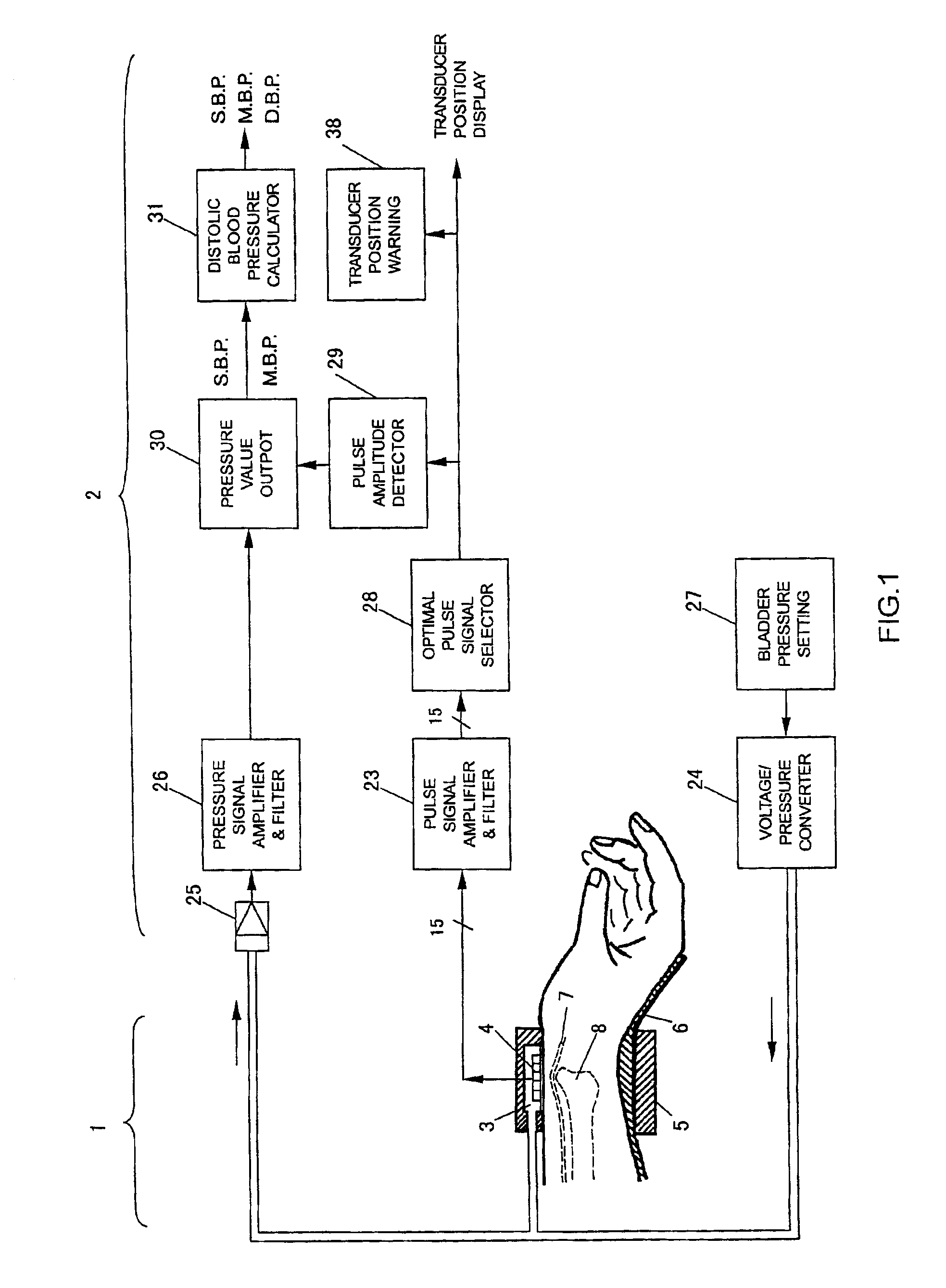

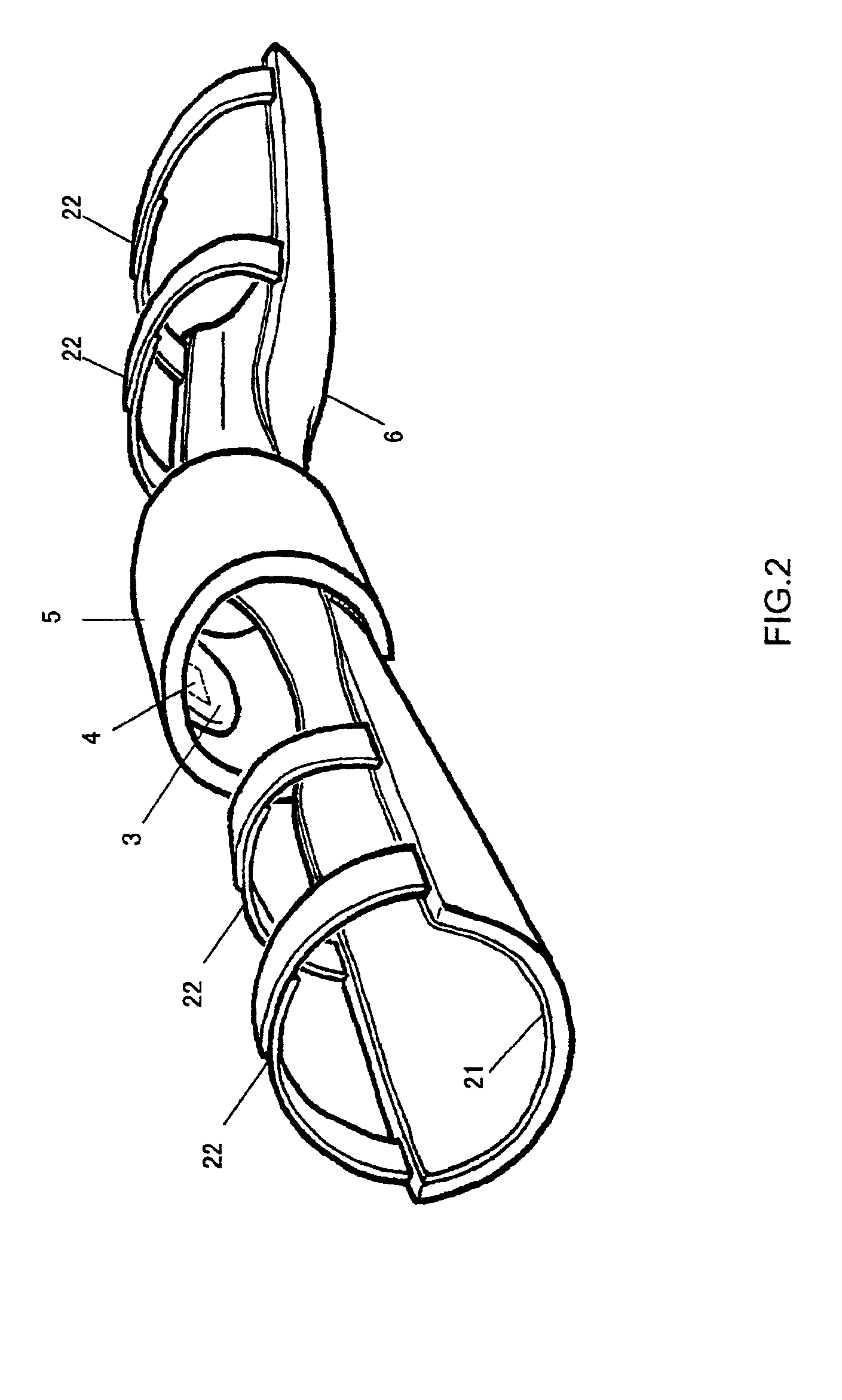

Noninvasive blood pressure measuring method and apparatus

InactiveUS6932772B2Exclusion from blood circulationEliminate circulationEvaluation of blood vesselsCatheterTurn angleUlnar artery

A method and a device for non-invasive blood pressure measurement wherein the angle between the hand and the wrist, and the turning angle of the wrist relative to the middle part of the forearm, are kept to the most suitable degree for measuring the blood pressure of the radial artery. At least one pressure bladder and one arterial pulse transducer array are placed on the skin over the radial artery of the wrist to apply the external pressure to the artery and to detect the change of the arterial pulse signals. This method and device can correctly measure the intermittent or continuous blood pressure of the radial artery or the ulnar artery based on the principles of oscillation method and volume compensation method, and effectively eliminate the influence on the measurement due to body movement and the influence on blood circulation and neural function of the hand caused by long-term blood pressure measurement.

Owner:XIAN LIBANG MEDICAL ELECTRONICS

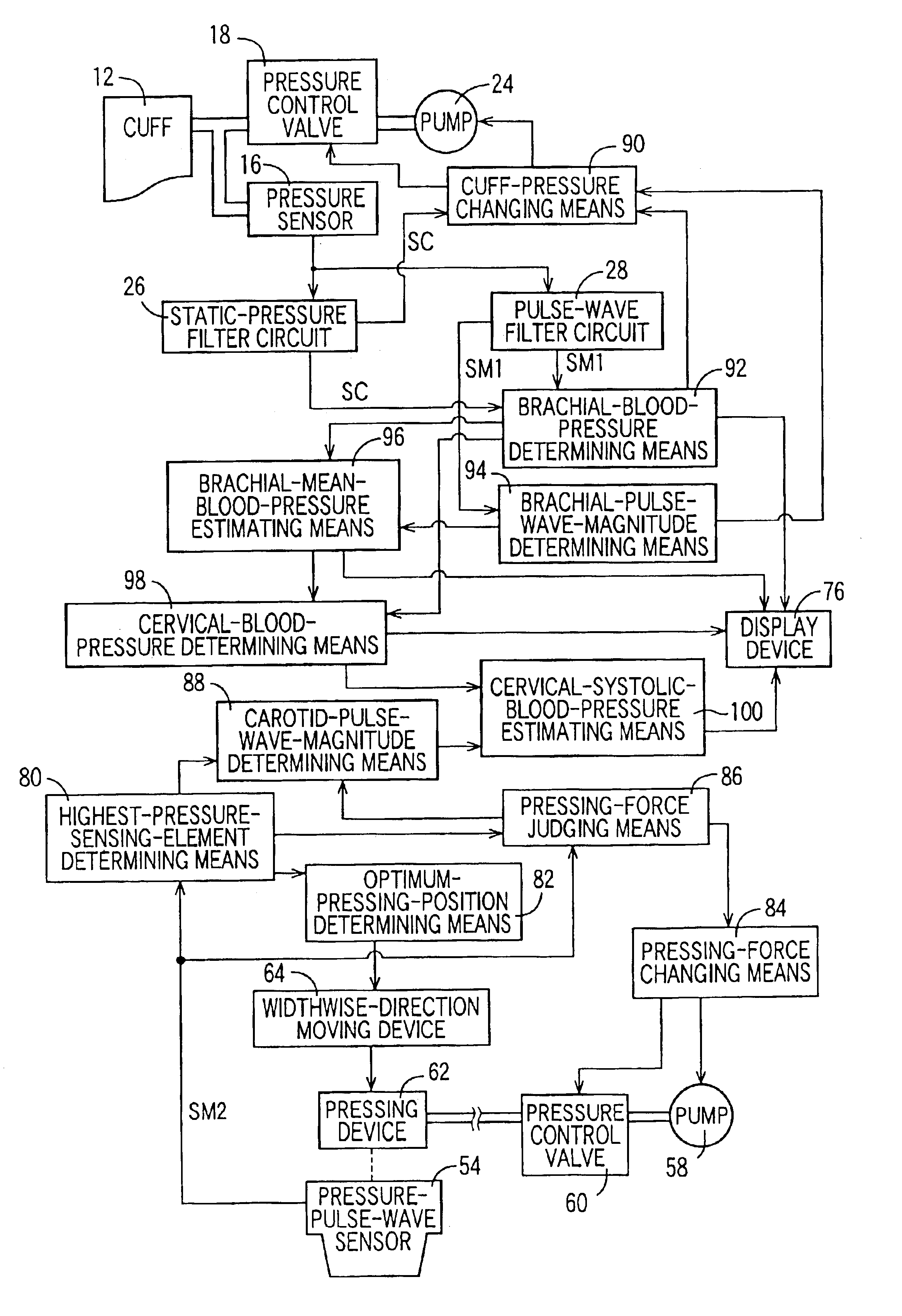

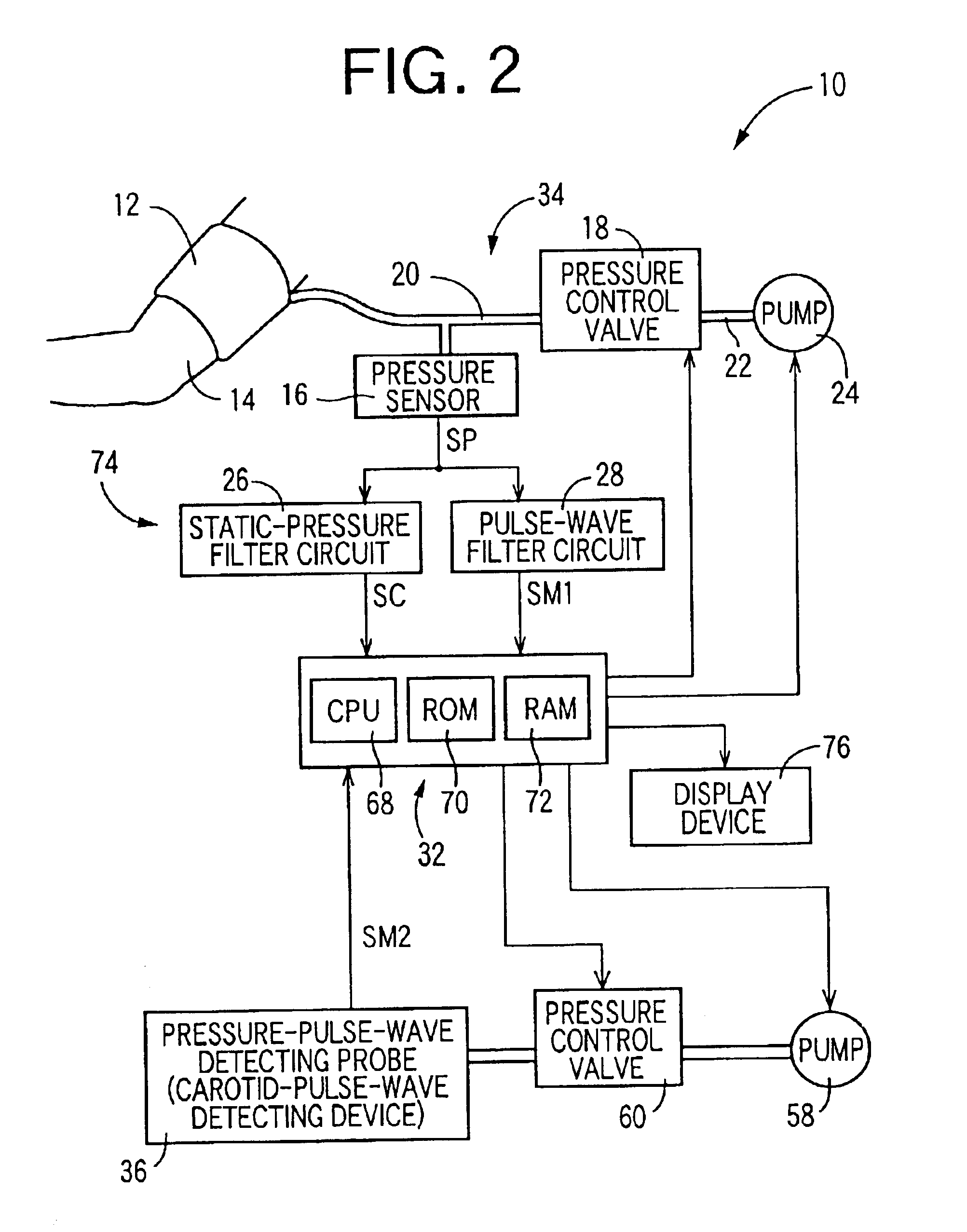

Blood-pressure determining apparatus

InactiveUS6869403B2High accuracyAccurate pressureEvaluation of blood vesselsCatheterMean blood pressureBiological body

A blood-pressure estimating apparatus, including a pulse-wave detecting device which detects a pulse wave from a portion of a living subject, a blood-pressure measuring device which includes an inflatable cuff adapted to be worn on the portion of the subject and measures, with the cuff, a diastolic blood pressure and a systolic blood pressure of the portion of the subject, and a mean-blood-pressure estimating device which converts, based on a minimum magnitude and a maximum magnitude of the pulse wave detected by the pulse-wave detecting device and the diastolic and systolic blood pressure measured by the blood-pressure measuring device, a magnitude of a gravity center of an area defined by the pulse wave into an estimated mean blood pressure of the portion of the subject.

Owner:OMRON HEALTHCARE CO LTD

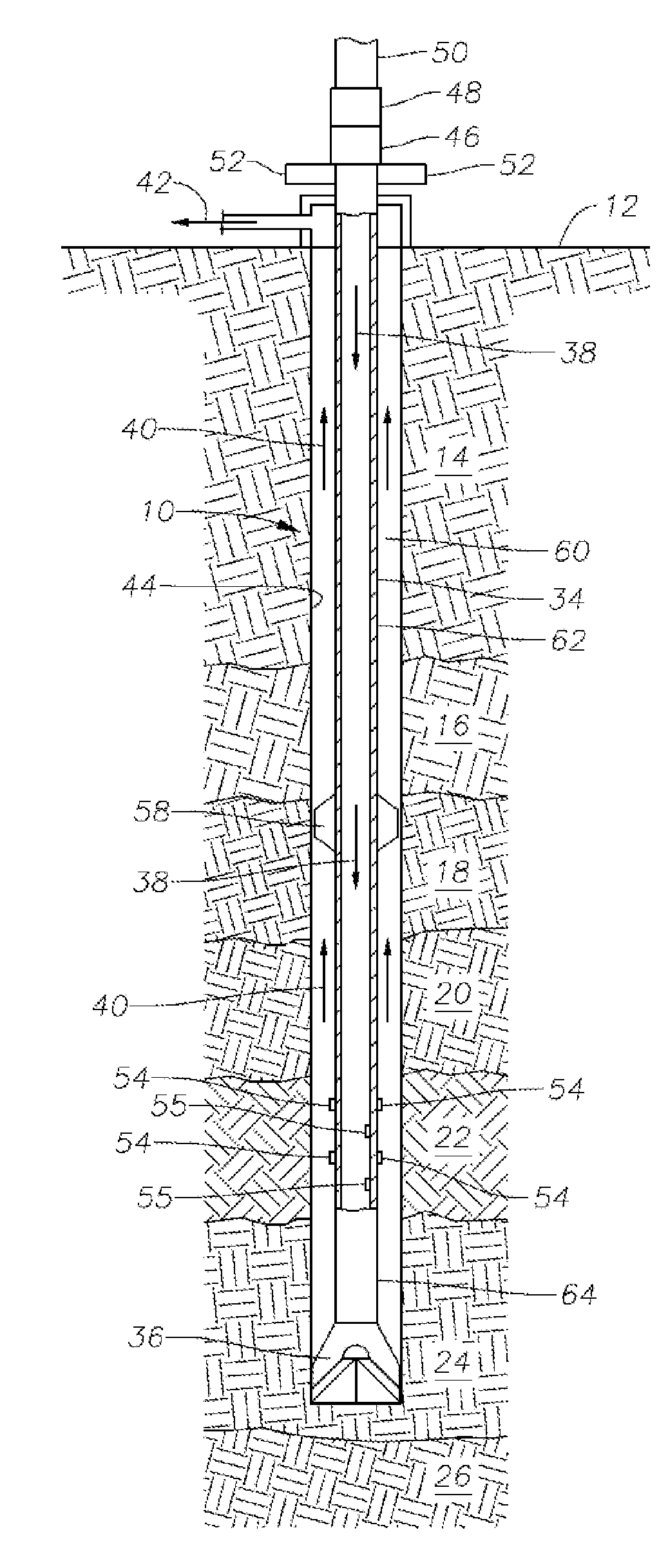

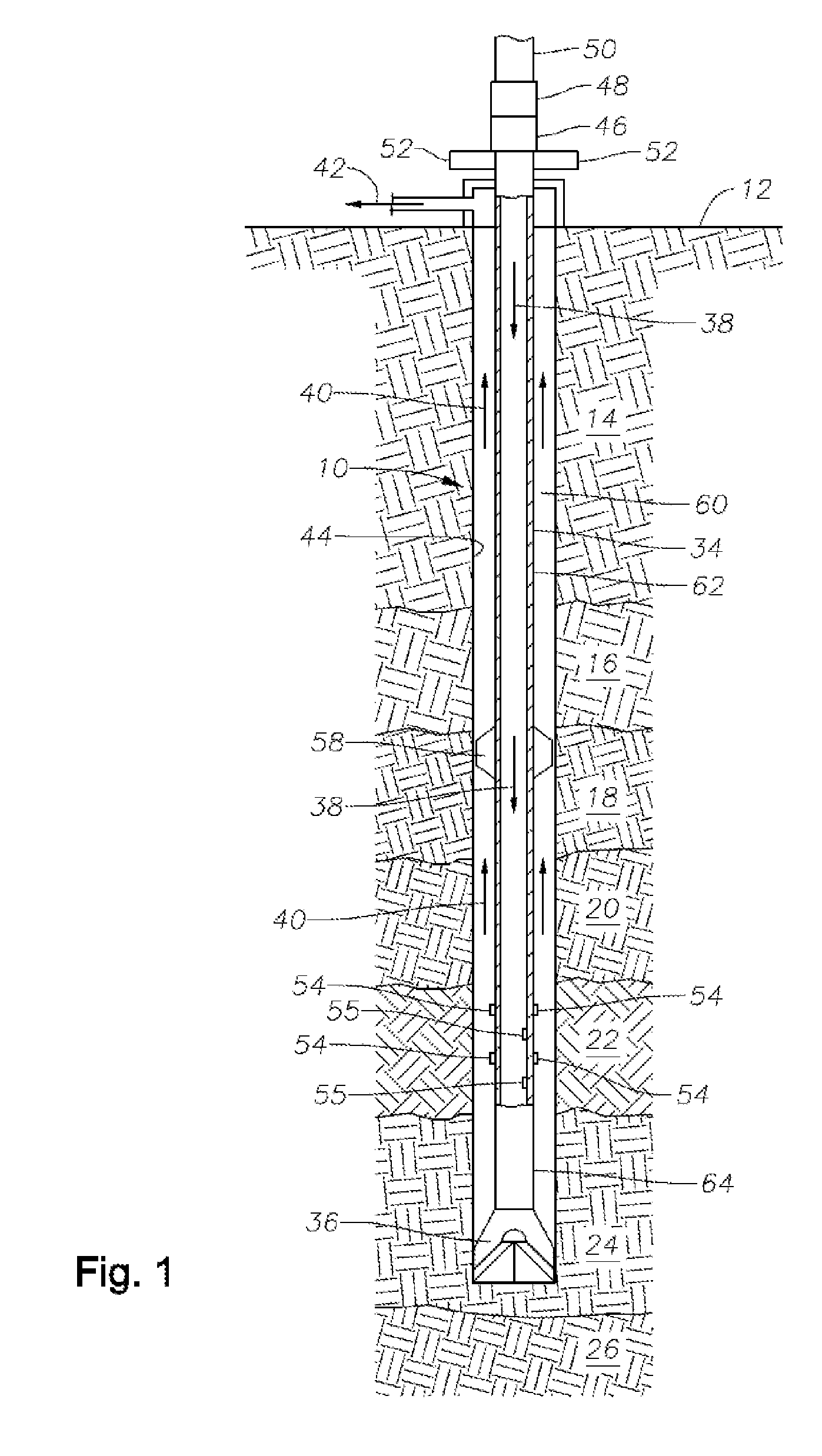

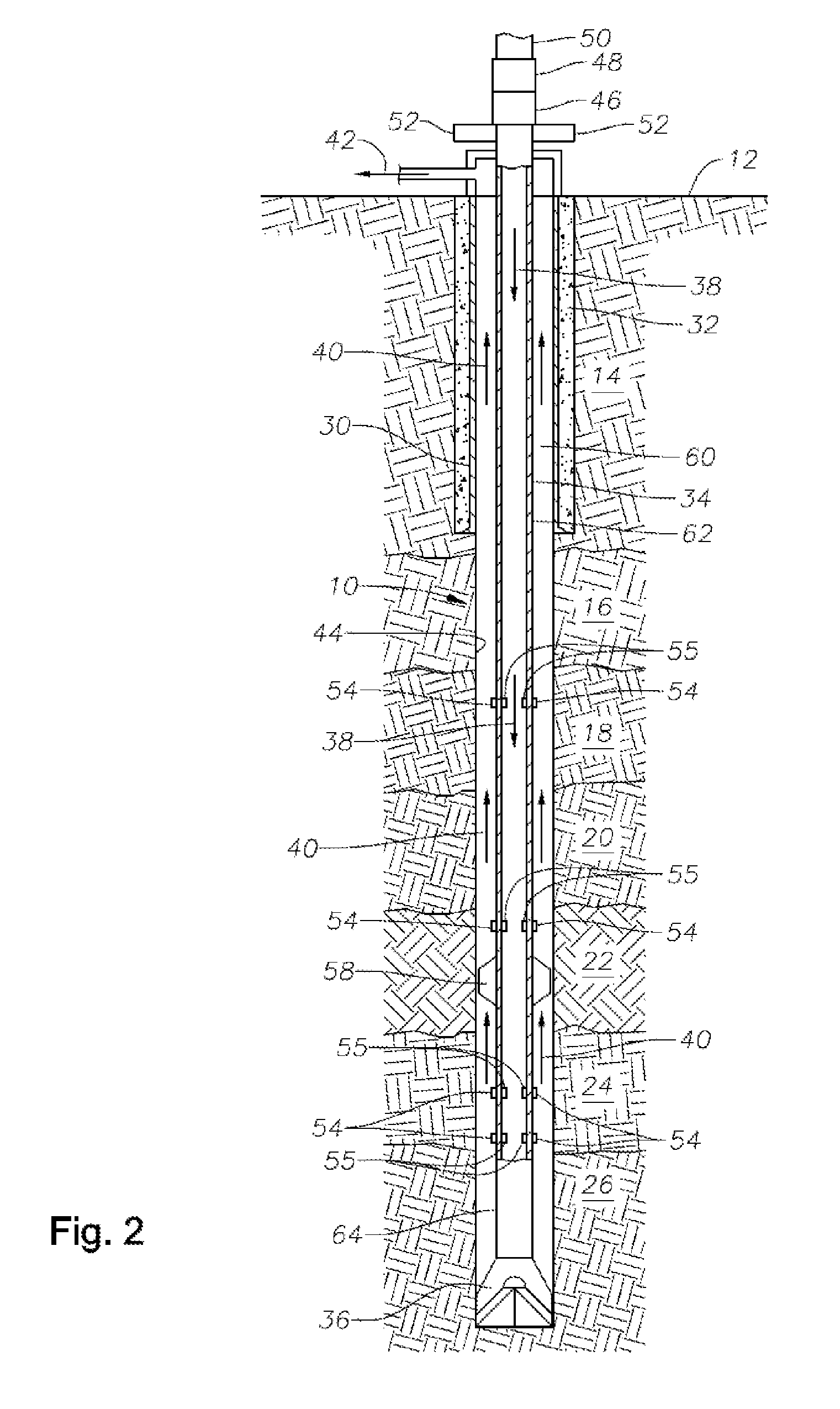

Method for detecting formation pore pressure by detecting pumps-off gas downhole

Methods and systems are described for drilling a well while distinguishing circulated gas or air from pumps-off gas in a drilling fluid at downhole pressure and temperature. A well is drilled with a drilling fluid, drill string, and drill bit. Drilling fluid is pumped through the drill string, drill bit, and into an annulus between the drill string and a wellbore. The drill string comprises one or more sensors sensing a parameter indicative of circulated gas or air in the drilling fluid flowing through the drill string, one or more sensors being behind and near the drill bit. The sensors measuring gas in the drill string may be at the same level as gas detectors in the annulus. The measurements are communicated to a human-readable interface at the surface, allowing an operator to determine if pressure of the wellbore fluid is greater than formation fluid pressure.

Owner:BP CORP NORTH AMERICA INC

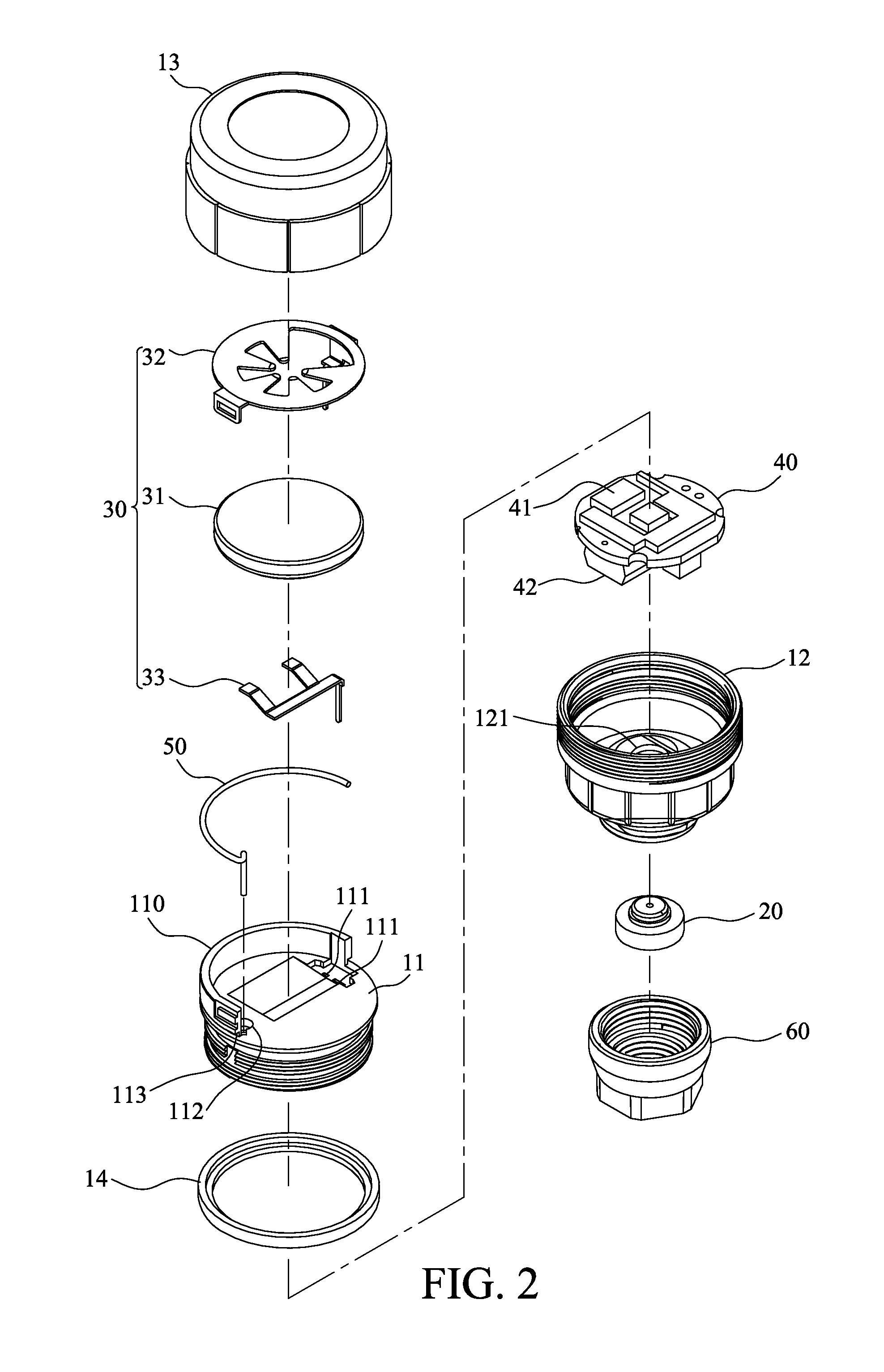

Tire temperature and tire pressure wireless sensing device

ActiveUS20140010265A1Instant and accurate temperature and pressureAccurate pressureThermometer detailsInflated body pressure measurementElectrical and Electronics engineeringTire pressure

A tire temperature and tire pressure wireless sensing device is provided, which includes a housing, a valve body, a power supply module, a circuit board and a transmission antenna. The power supply module is disposed on the fixed seat of the housing, and the circuit board includes a wireless transmission module and a sensing module thereon. The sensing module is disposed corresponding to an air-intake through hole of the bottom seat of the housing. The valve body is engaged with the air-intake through hole and one end of the transmission antenna is disposed in an antenna slot.

Owner:JINGRUI TECH

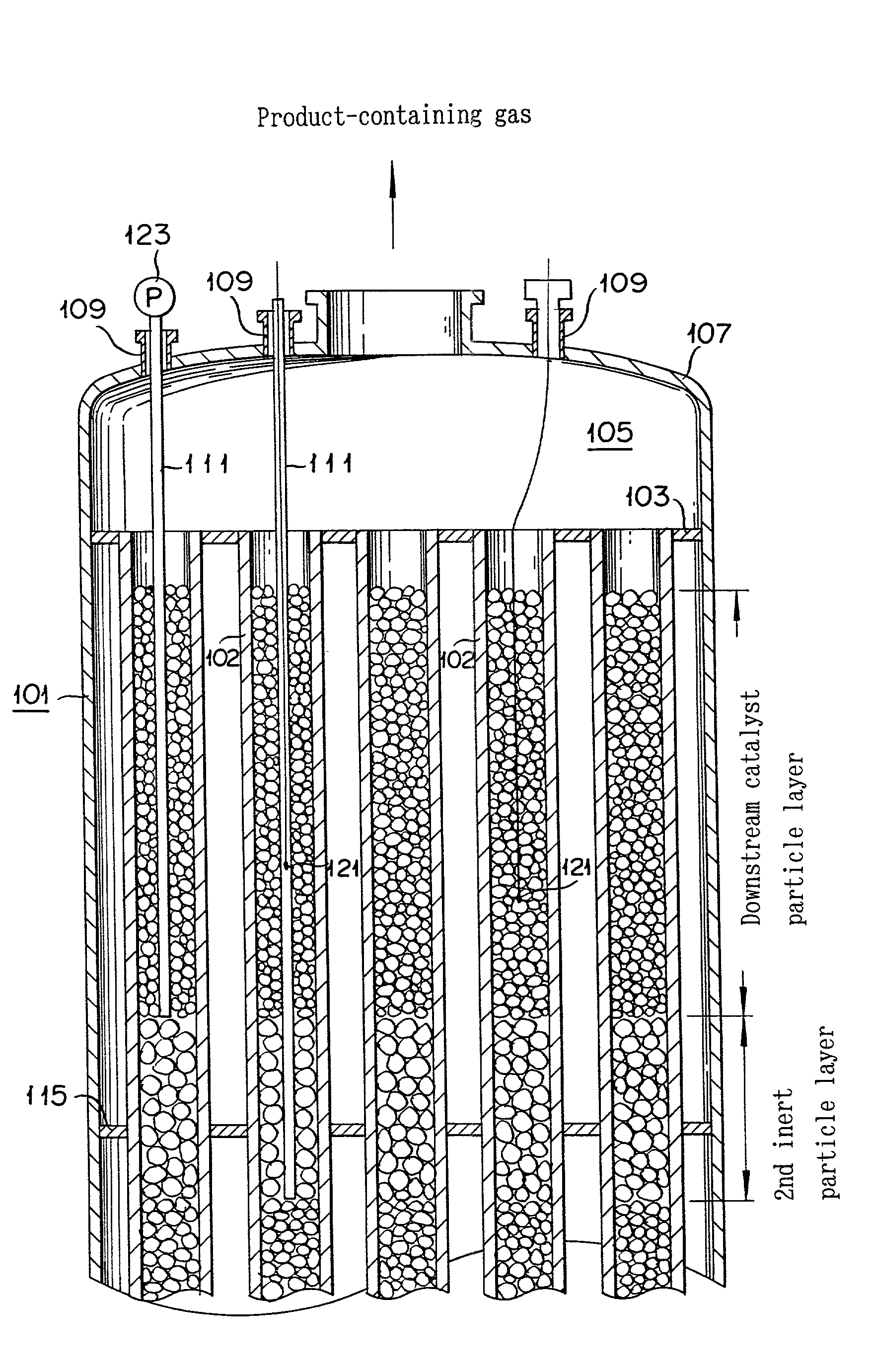

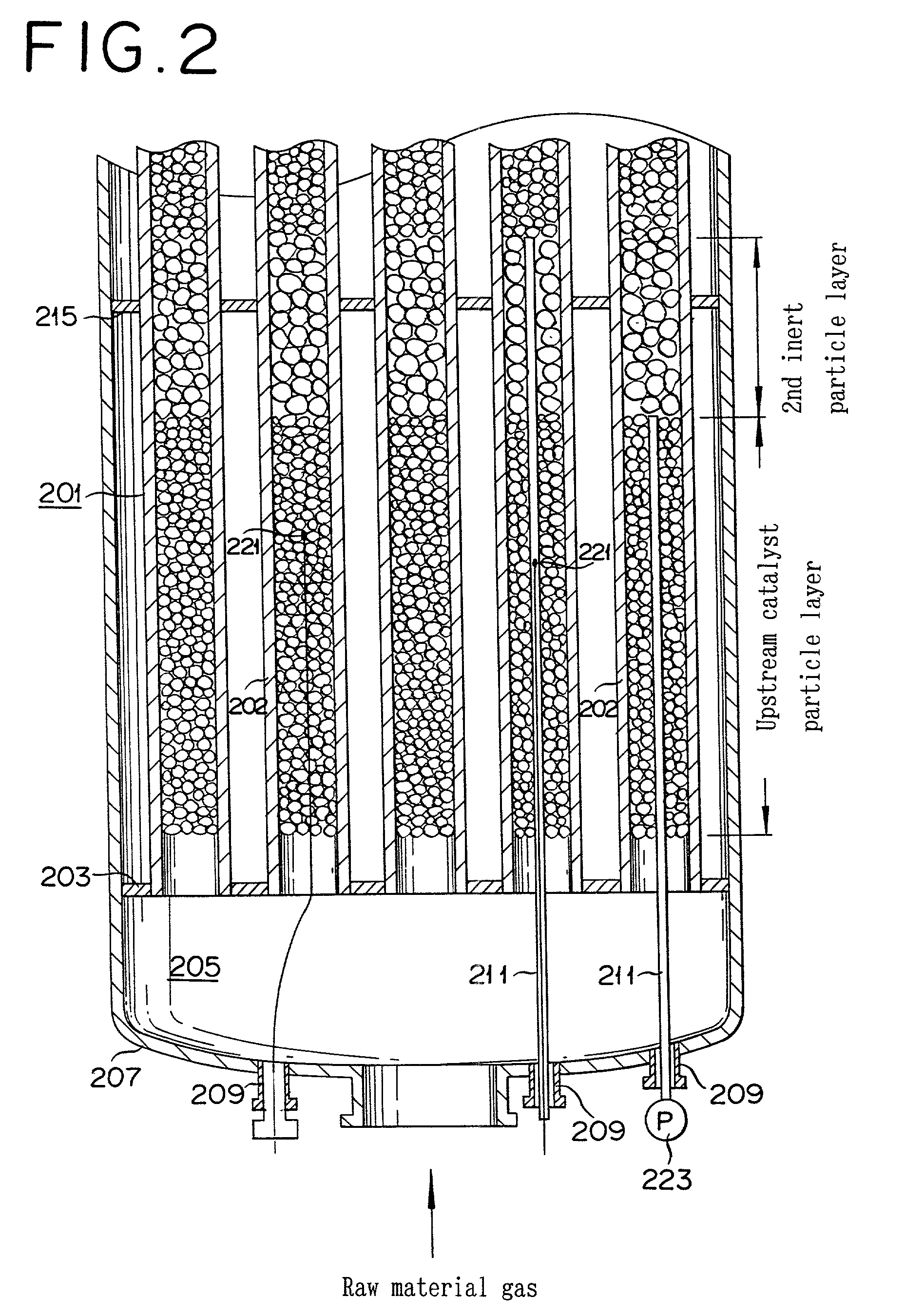

Reactor filled with solid particle and gas-phase catalytic oxidation with the reactor

InactiveUS20030006026A1Accurate pressureAccurate temperatureOrganic compound preparationOrganic chemistry methodsGas phaseCatalytic oxidation

A shell-and tube reactor including at least one reaction tube with a measuring means, substantially same solid particles being filled in the reaction tubes with or without the measuring means, a length of the filled solid particle layer, and a pressure drop thereof while passing a gas through the reaction tube, per each reaction tube, being substantially the same, respectively. By measuring the temperature of the catalyst particle layer, such a temperature as a representative can be gasped.

Owner:NIPPON SHOKUBAI CO LTD

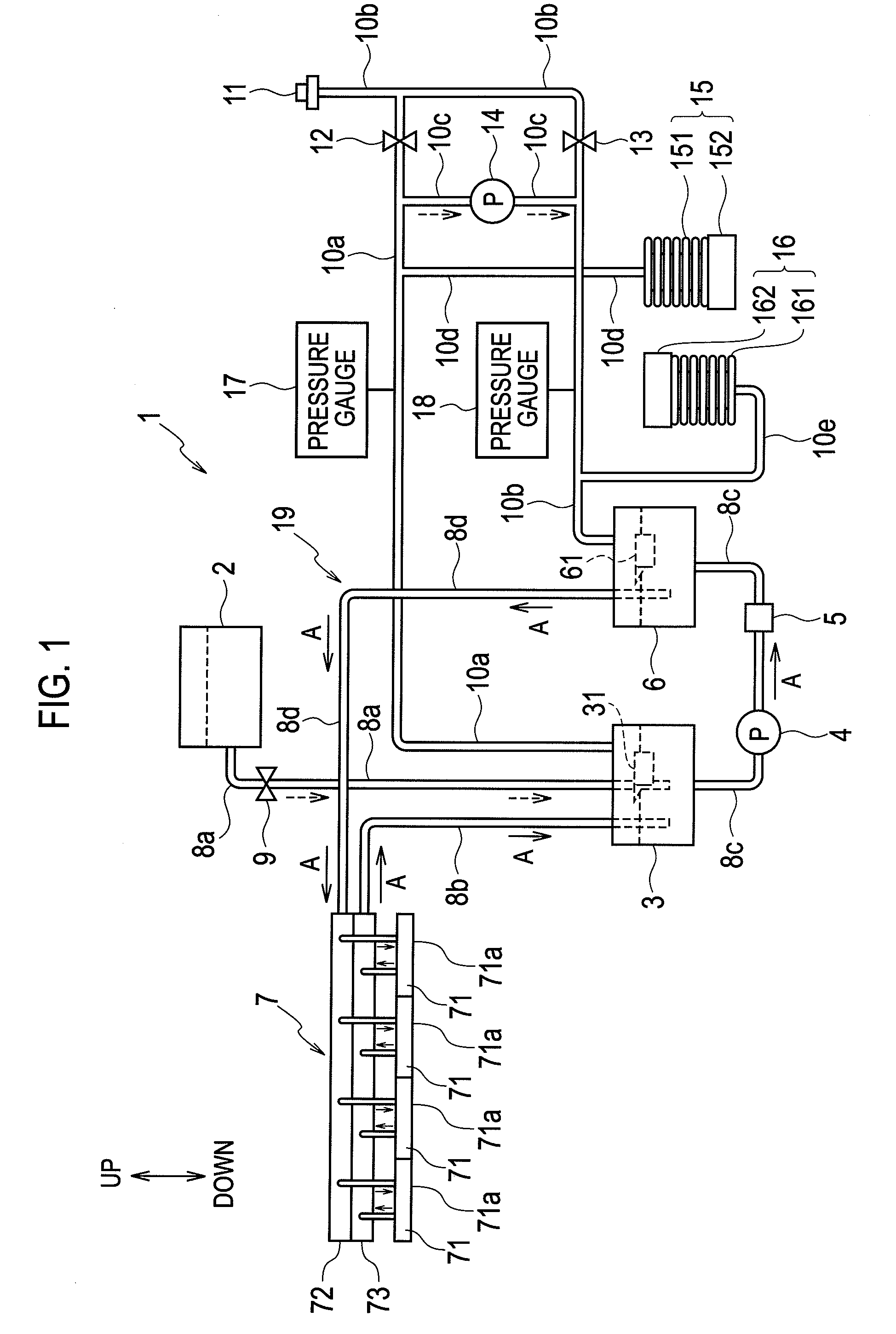

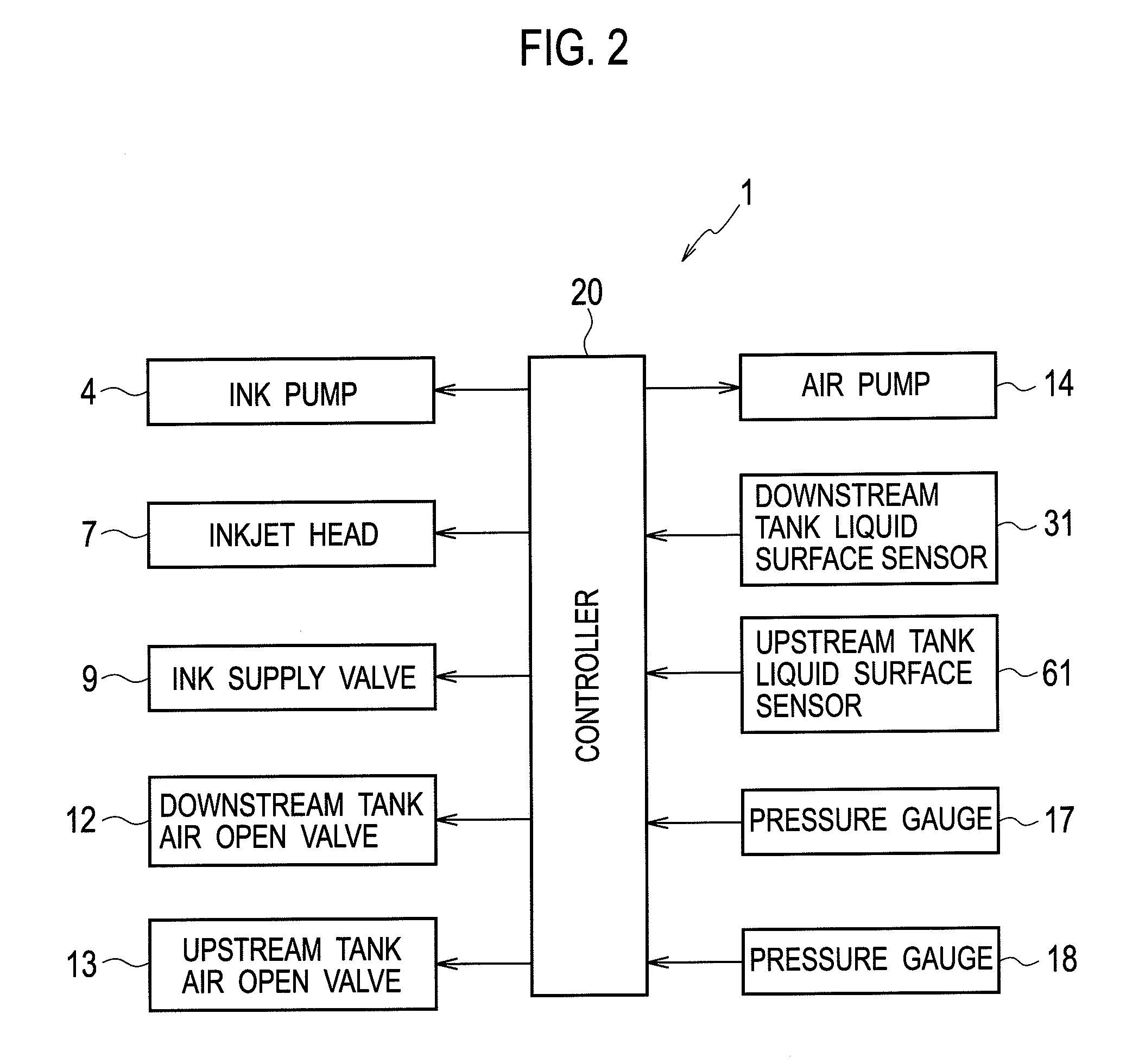

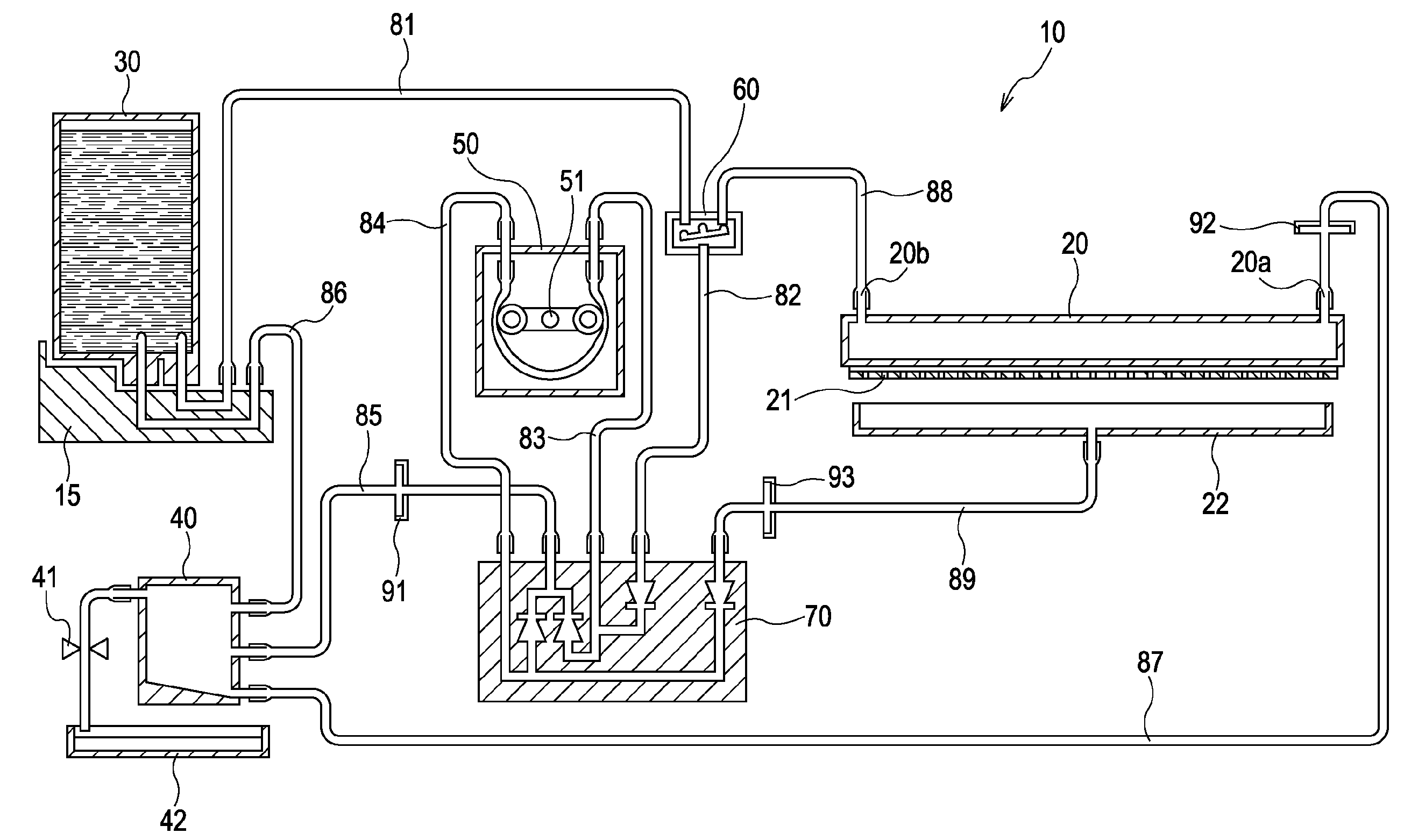

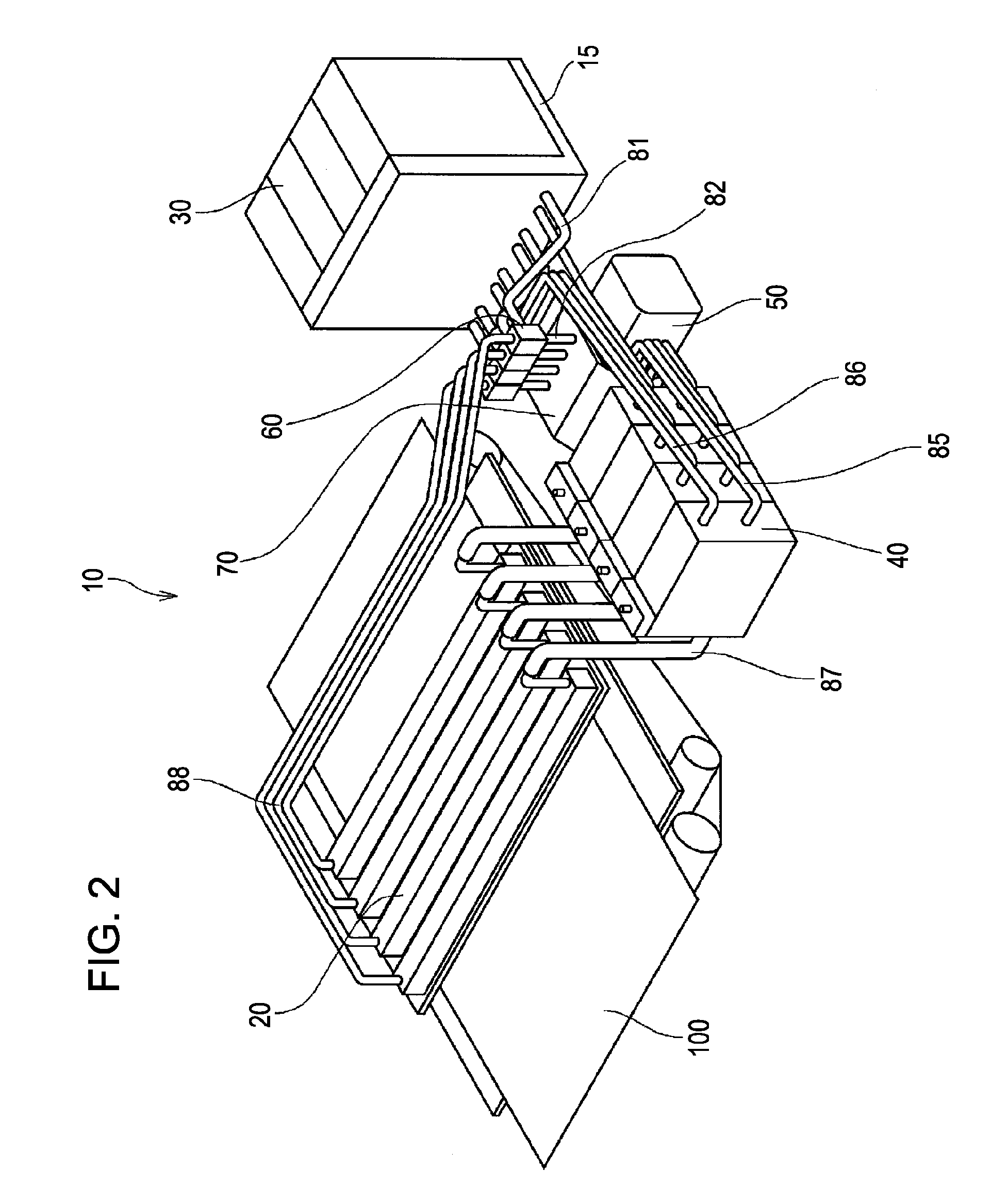

Inkjet printing apparatus

InactiveUS20120188314A1Flow passage resistance is thereby highIncrease in sizeOther printing apparatusEngineeringPressurizer

An inkjet printing apparatus includes: an inkjet head configured to discharge ink; a first tank configured to store ink to be supplied to the inkjet head; a second tank configured to store ink not consumed by the inkjet head; an ink circulation path for circulation of ink among the first tank, the inkjet head, and the second tank; a pressurizer configured to provide the first and second tanks with a pressure for the circulation of ink through the ink circulation path; a first pressure adjuster configured to adjust a pressure inside the first tank during the circulation of ink; and a second pressure adjuster configured to adjust a pressure inside the second tank during the circulation of ink.

Owner:RISO KAGAKU CORP

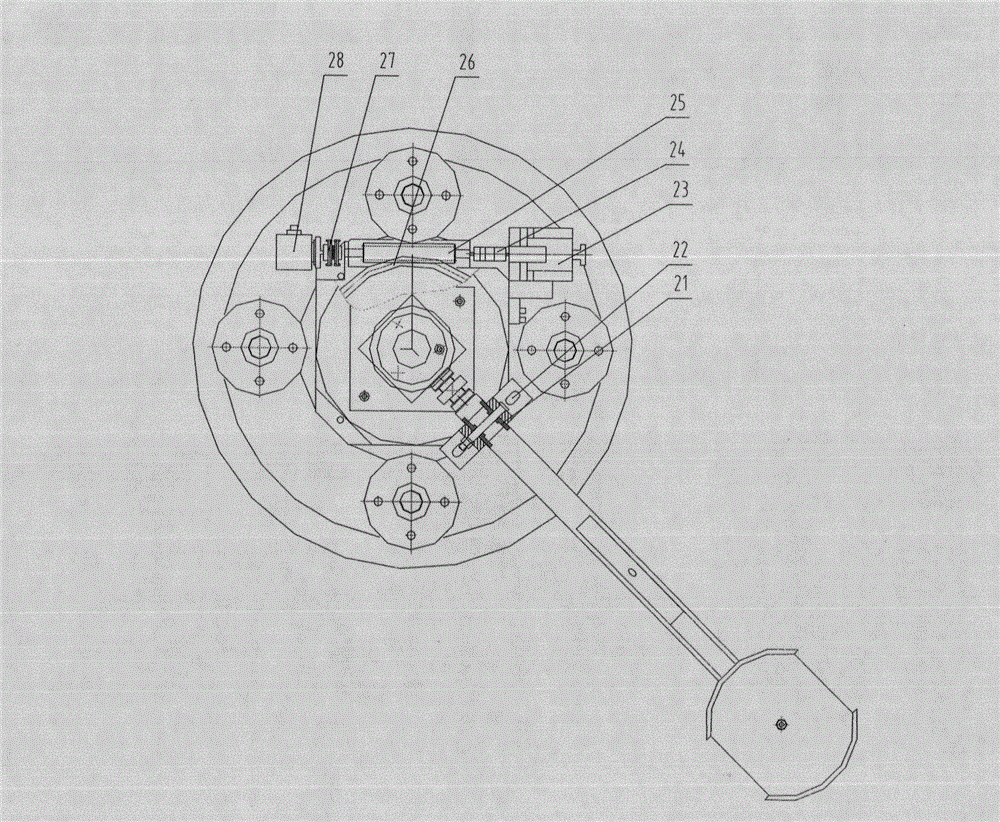

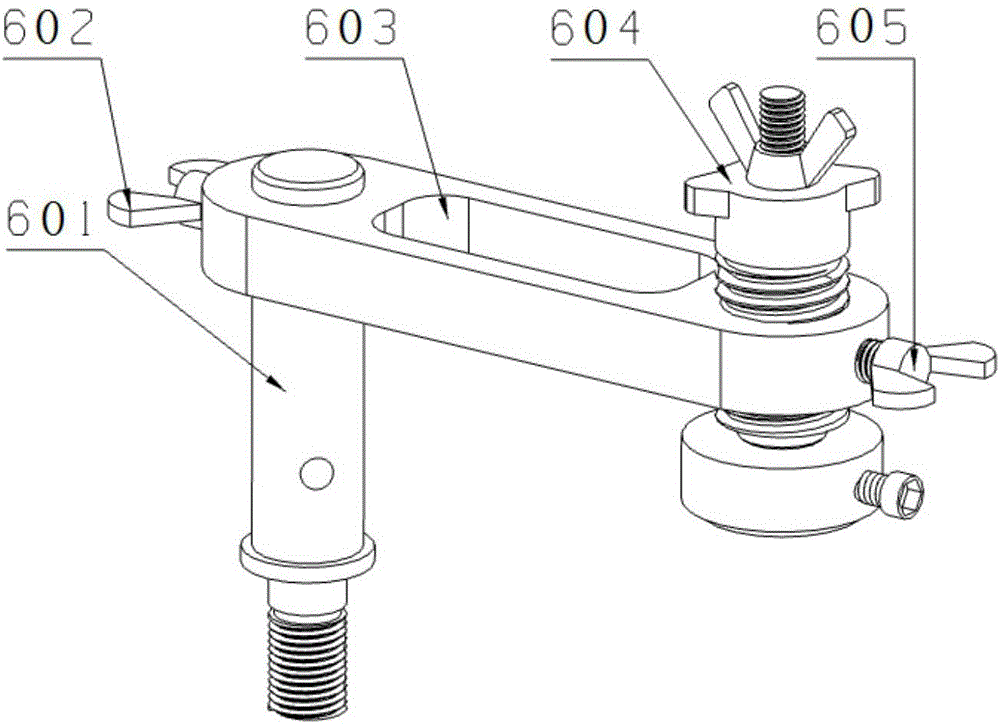

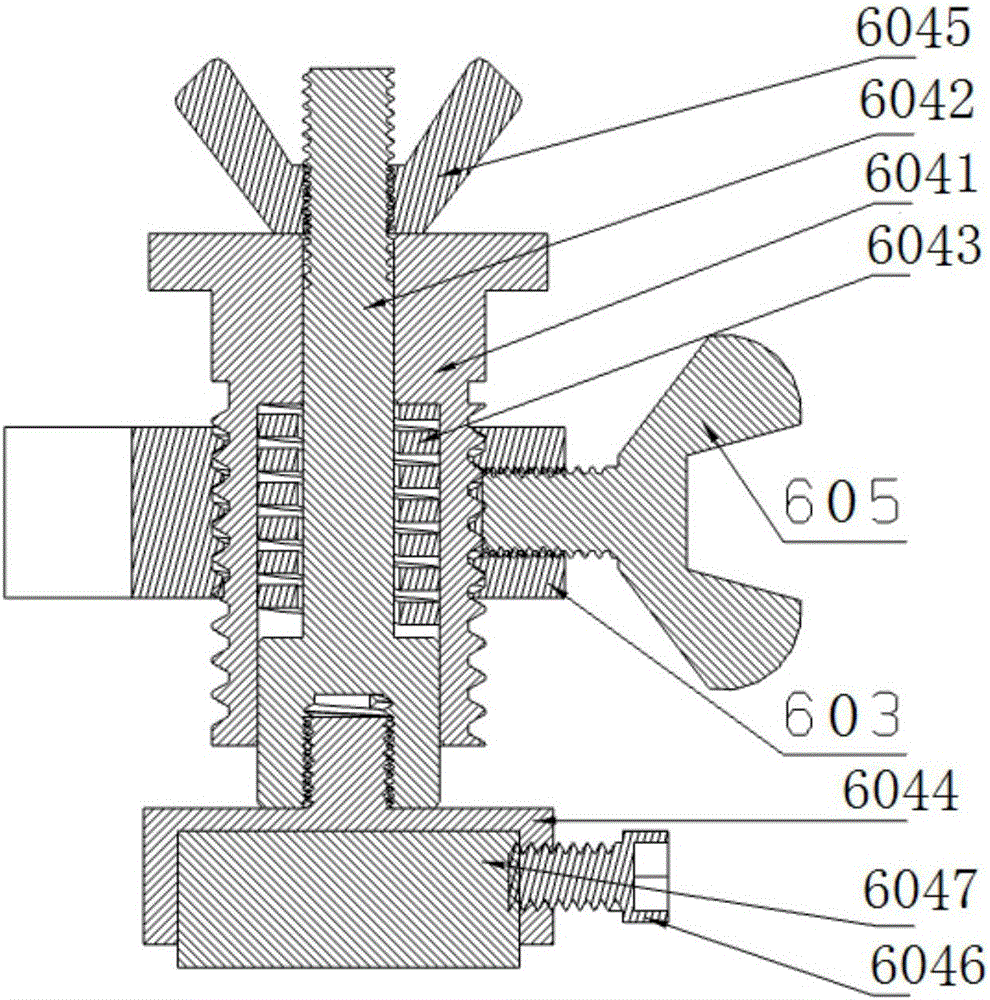

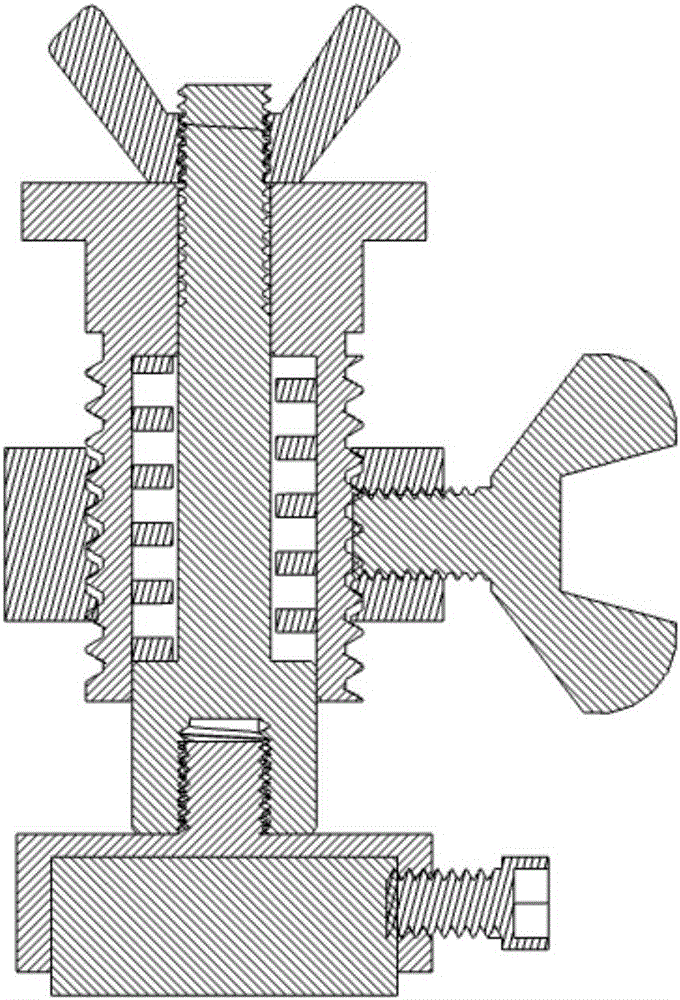

Metallographic phase grinding sample pressure adjusting device and metallographic phase grinding and polishing device and method

ActiveCN105904336AAchieve polishAdjustable speedLapping machinesWork carriersPulp and paper industryFastener

The invention relates to the technical field of metallographic phase grinding, in particular to a metallographic phase grinding sample pressure adjusting device and a metallographic phase grinding and polishing device and method. The metallographic phase grinding sample pressure adjusting device comprises a fixed rod, a rotary connection rod and a sample clamping mechanism which are all sequentially connected; the sample clamping mechanism comprises an adjusting sleeve, a pin shaft arranged in the adjusting sleeve, a fastener installed at the upper end of the pin shaft, a spring arranged on the pin shaft in a sleeving manner and pressed in the adjusting sleeve through the pin shaft, and a sample clamping sleeve detachably installed at the lower end of the pin shaft and used for clamping a metallographic phase sample. The metallographic phase grinding and polishing device comprises the metallographic phase grinding sample pressure adjusting device, a cushion plate, a grinding and polishing disk and a motor. During grinding and polishing, firstly, pressure is preset, and then by adjusting the fastener of the pin shaft to be connected with the adjusting sleeve, the pressure is loaded onto the metallographic phase sample. According to the metallographic phase grinding sample pressure adjusting device and the metallographic phase grinding and polishing device and method, one or more metallographic phase samples can be pre-ground and polished on the same equipment, and pressure acting on the samples is adjustable and can be automatically released.

Owner:NORTHEASTERN UNIV

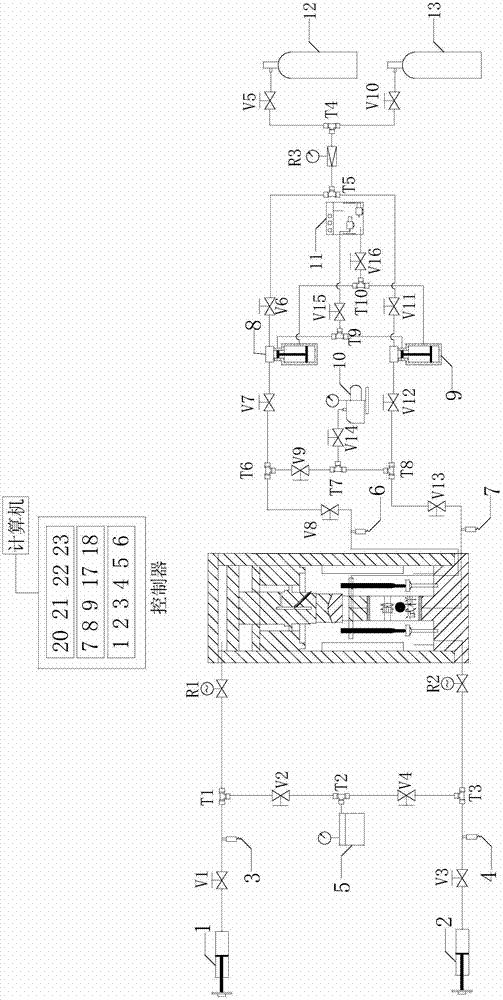

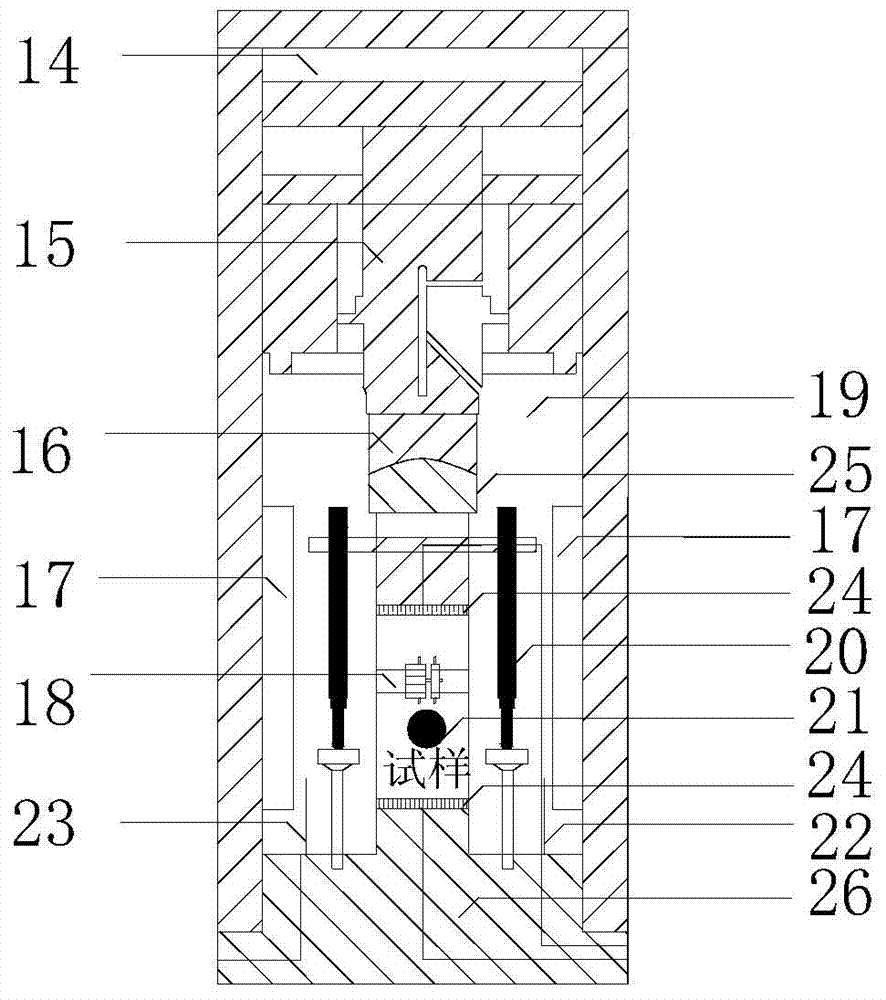

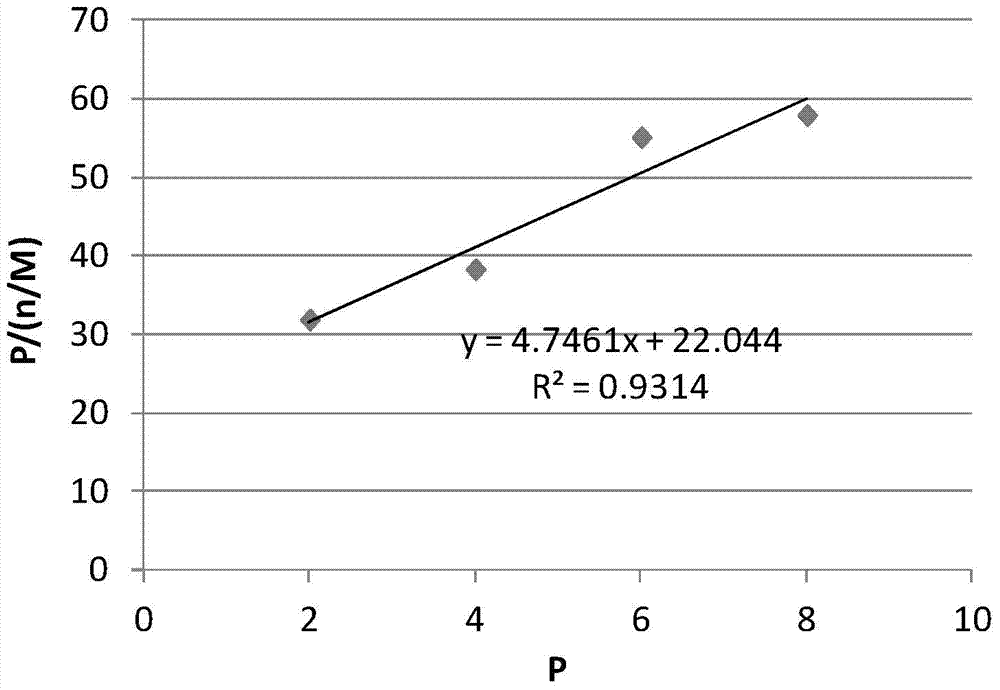

Device and method for testing porosity and adsorption parameters of gas-bearing shale

ActiveCN103940722ATrue AdsorptionAccurate pressurePermeability/surface area analysisAxial pressureNatural gas

The invention discloses a device and a method for testing porosity and adsorption parameters of gas-bearing shale, belonging to the fields of shale engineering and unconventional gas engineering. The device for testing the porosity and adsorption parameters of the gas-bearing shale comprises a constant-temperature triaxial cell, an axial pressure loading system, a confining pressure loading system, an upper end adsorbing system, a lower end adsorbing system, a vacuuming system, a constant temperature system and a data acquisition control system. The method for testing the porosity and adsorption parameters of the gas-bearing shale is used for simultaneously testing the porosity and adsorption parameters of the shale at different temperatures and under different bias environments and calculating the real adsorption quantity and is applicable to the environment with deep high ground stress and high temperature, the axial pressure is as high as 300MPa, the confining pressure is as high as 100MPa, the pressure of filled gas is as high as 70MPa, the highest temperature is up to 100 DEG C, a sample is a virgin rock core of which the size is as large as Phi 50mm*100mm, the test time is saved by nearly 75%, and the test efficiency is improved greatly.

Owner:NORTHEASTERN UNIV

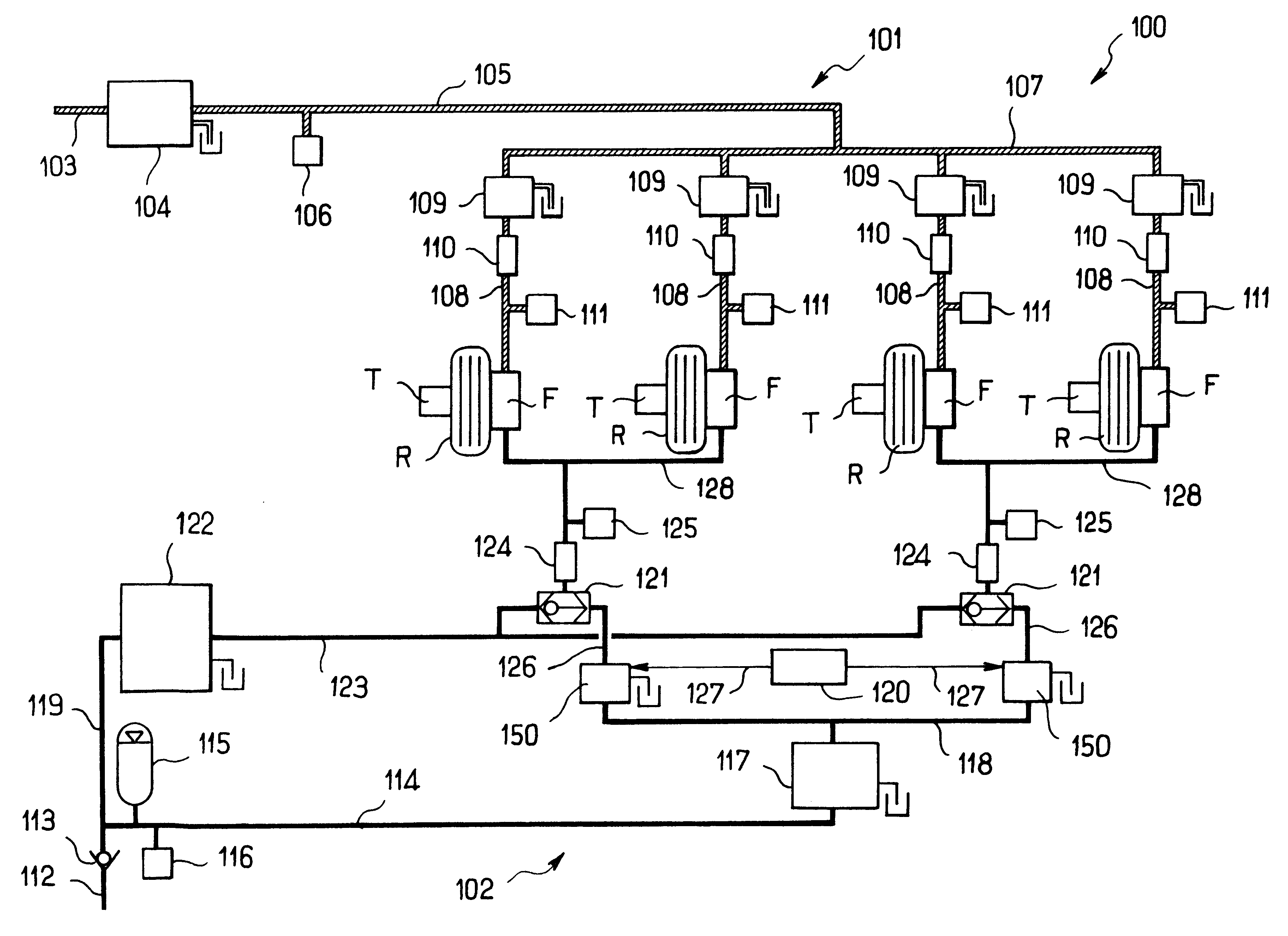

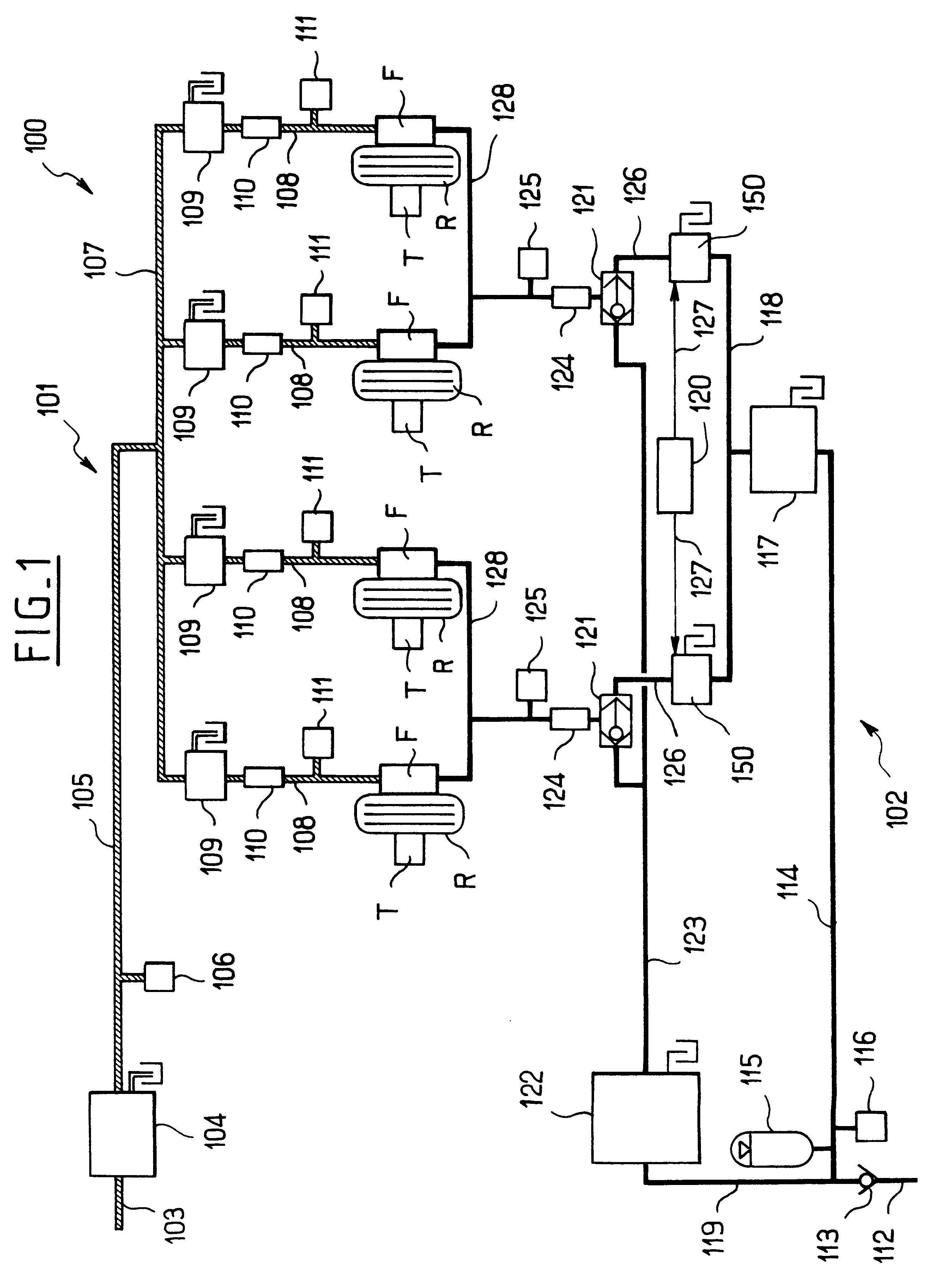

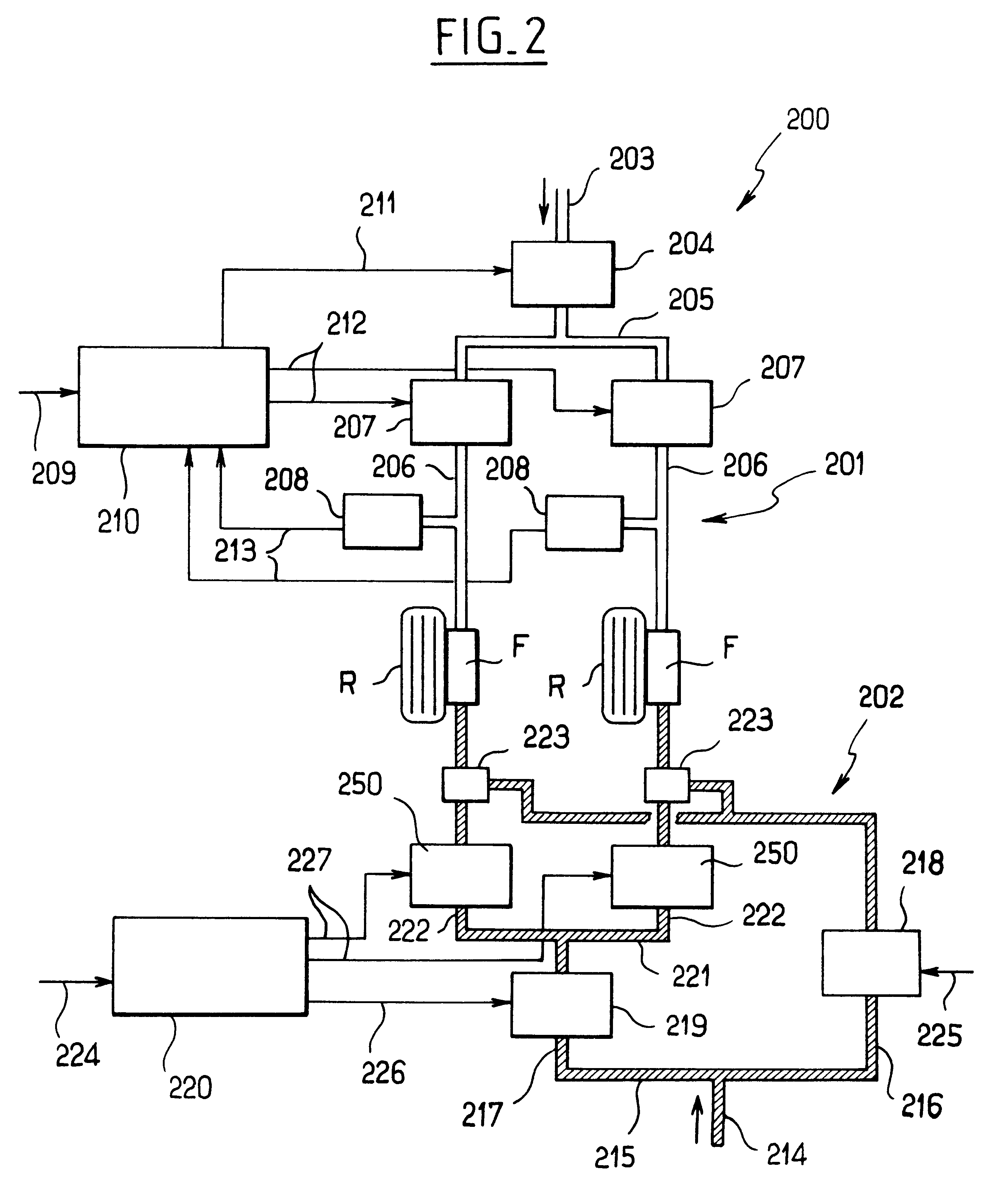

Apparatus for braking a set of aircraft wheels

InactiveUS6193326B1Improve performanceAccurate operating pressureAircraft brake actuating mechanismsFluid braking transmissionHydraulic circuitEngineering

The invention relates to apparatus for braking a set of aircraft wheels, the apparatus comprising a normal hydraulic circuit and an emergency hydraulic circuit, both circuits leading to each of the various brakes via associated brake valves. According to the invention, the brake valves of the normal circuit and / or of the emergency circuit are constituted by direct drive valves that are electrically controlled by an associated electronic control unit.

Owner:SAFRAN LANDING SYSTEMS

System and method for circuit compliance compensated pressure-regulated volume control in a patient respiratory ventilator

ActiveUS7918223B2Accurate pressureProlonging inspiratory timeRespiratorsOperating means/releasing devices for valvesPeak valueAirway pressures

A system and a method for circuit compliance compensated pressure control in a patient respiratory ventilation system, having a pressure regulated feedback servo control loop, a pressure-regulated volume controller, and a patient volume observer. The patient volume observer is operative to estimate a patient volume, that is, the volume actually delivered to the patient by accounting for volume deviation or loss caused by patient circuit leakage and valve dynamics. Based on the difference between the estimated patient volume and a set tidal volume, the pressure-regulated volume controller is operative to generate and update a circuit compliance pressure compensation factor. The pressure regulated feedback servo control loop is operative to modulate the peak airway pressure based on the circuit compliance pressure compensation factor, so as to achieve the set tidal volume while maintaining a constant inspiratory time and a constant I:E ratio.

Owner:VYAIRE MEDICAL 211 INC

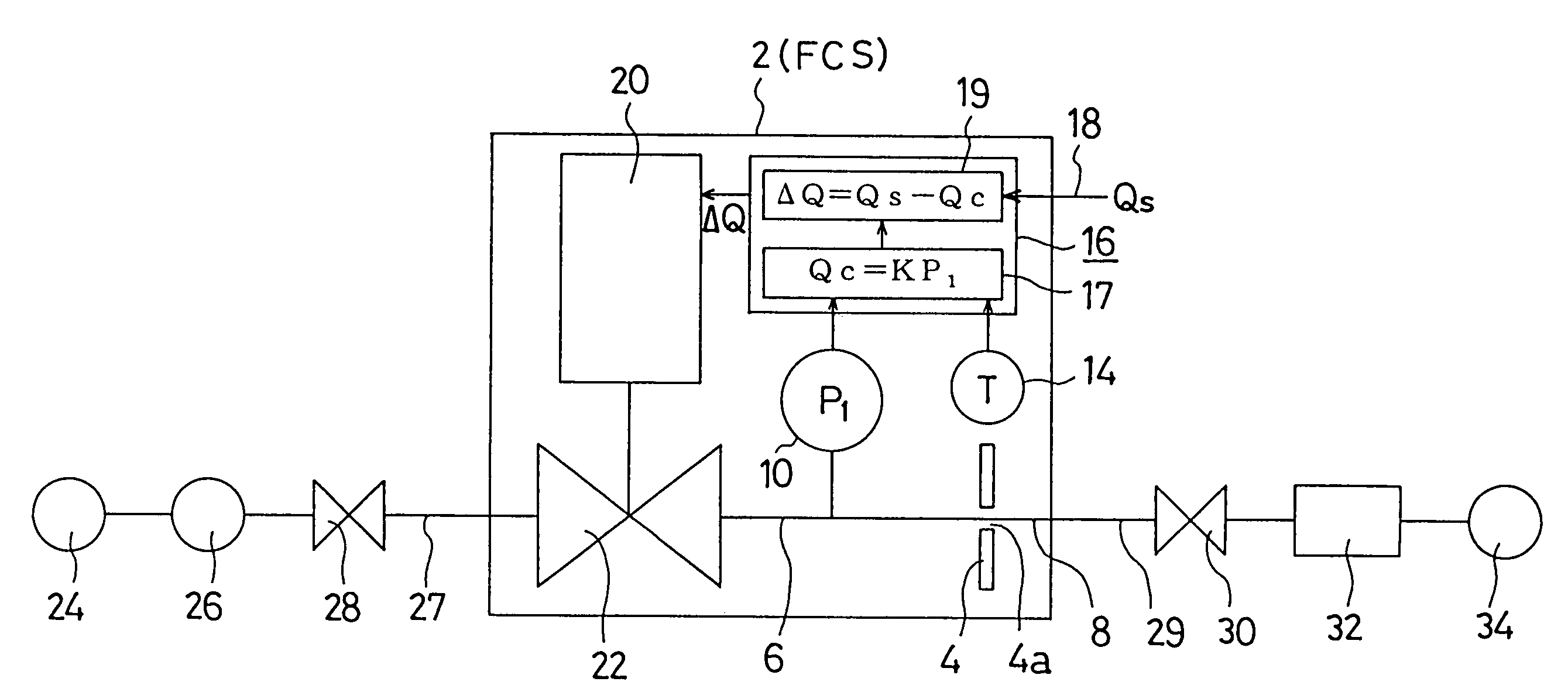

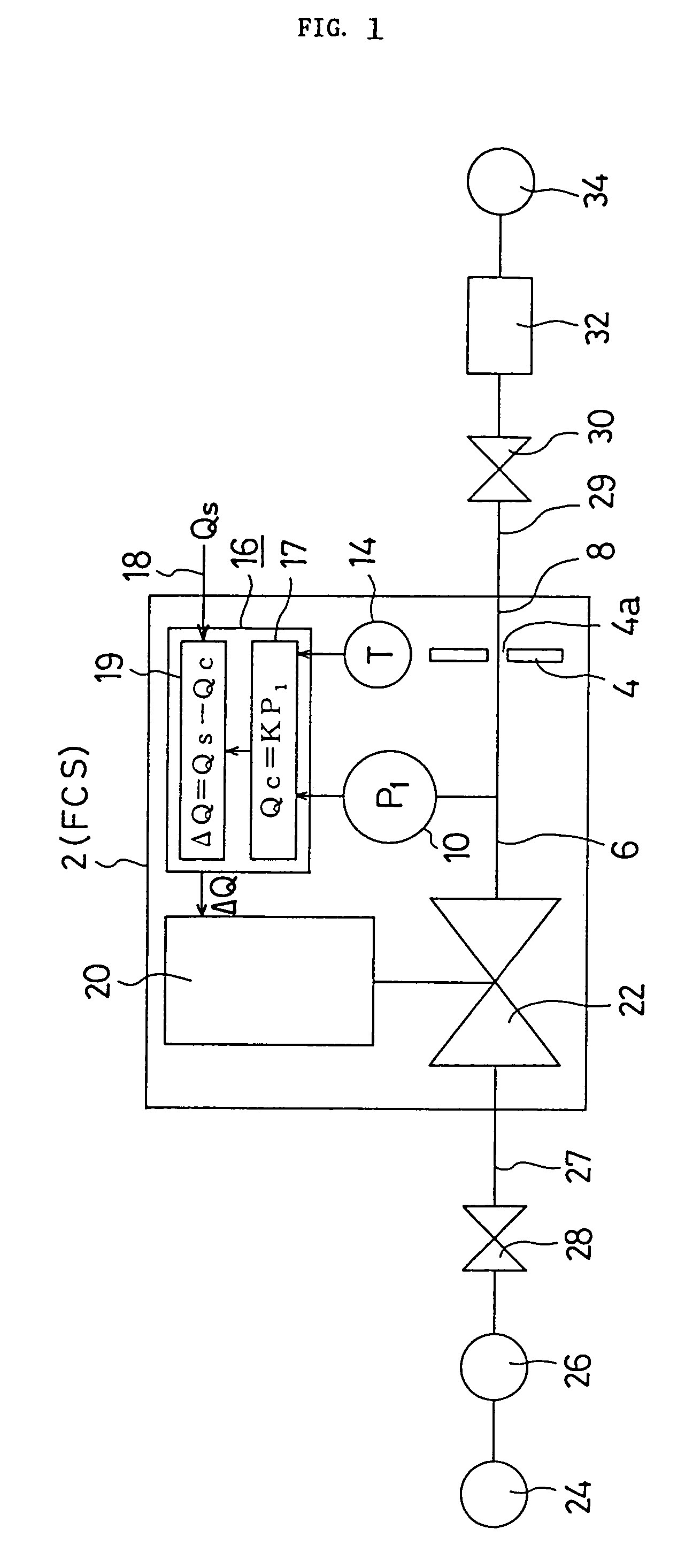

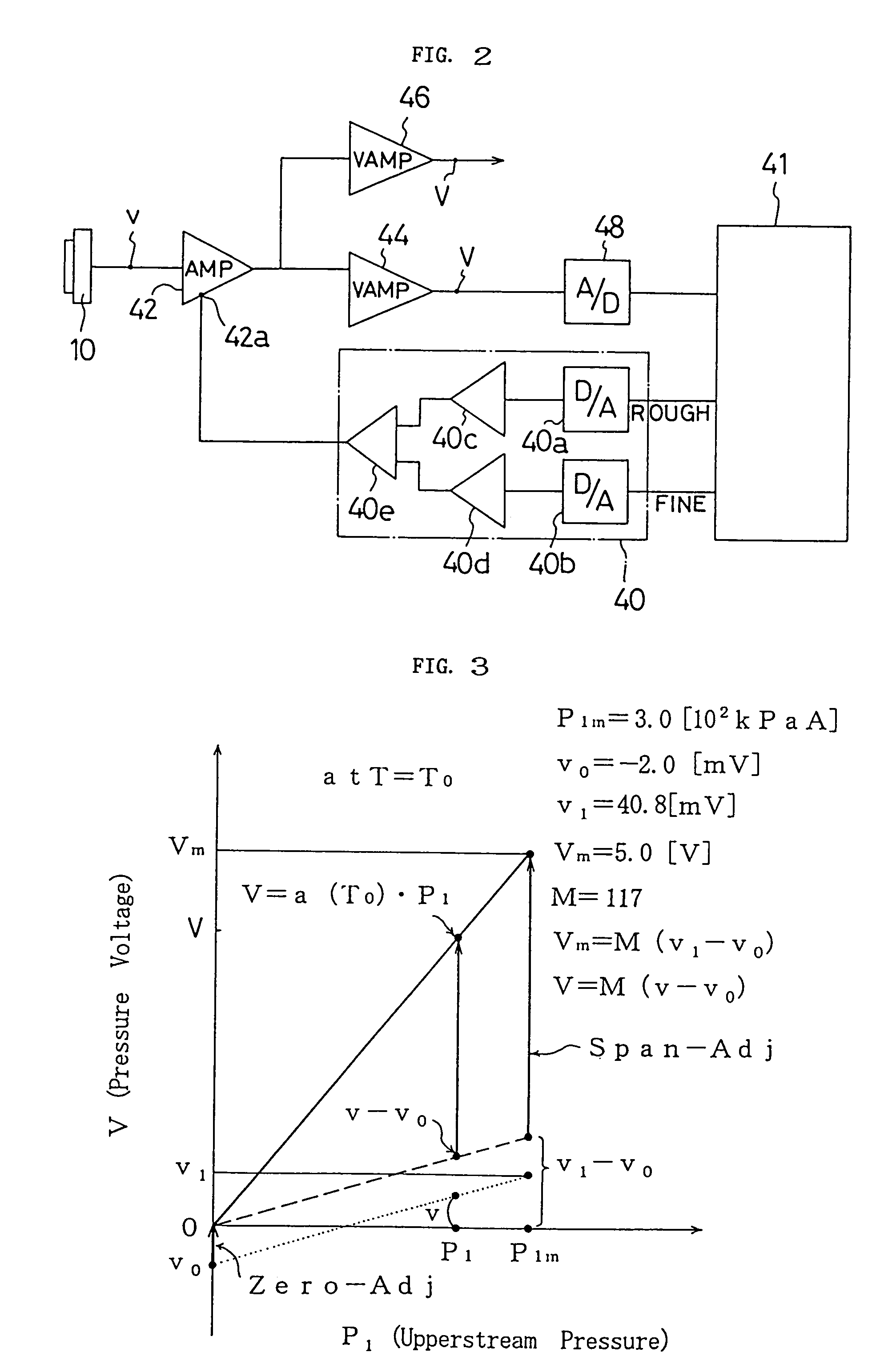

Apparatus for the correction of temperature drift for pressure sensor, pressure control apparatus and pressure-type flow rate control apparatus

ActiveUS7085628B2Accurately controlAccurately measureSampled-variable control systemsComputer controlEngineeringPressure sensor

A pressure sensor, a pressure control apparatus, and a flow rate control apparatus are provided to automatically correct temperature drift of the pressure sensor and accurately detect pressure despite changes in temperature. An embodiment includes an upstream side pressure sensor between an orifice and a control valve, to control flow rate through the orifice by a regulating control valve, while calculating the flow from the upstream side pressure. With a temperature sensor, a memory means, and a temperature drift correcting means which calculates drift of the upstream side pressure sensor from data in the memory means when the temperature of the fluid changes and offsets the output drift of the upstream side pressure sensor with the calculated amount of the output drift, temperature drift of the pressure sensor is automatically corrected, enabling accurate control of flow rate.

Owner:FUJIKIN INC +2

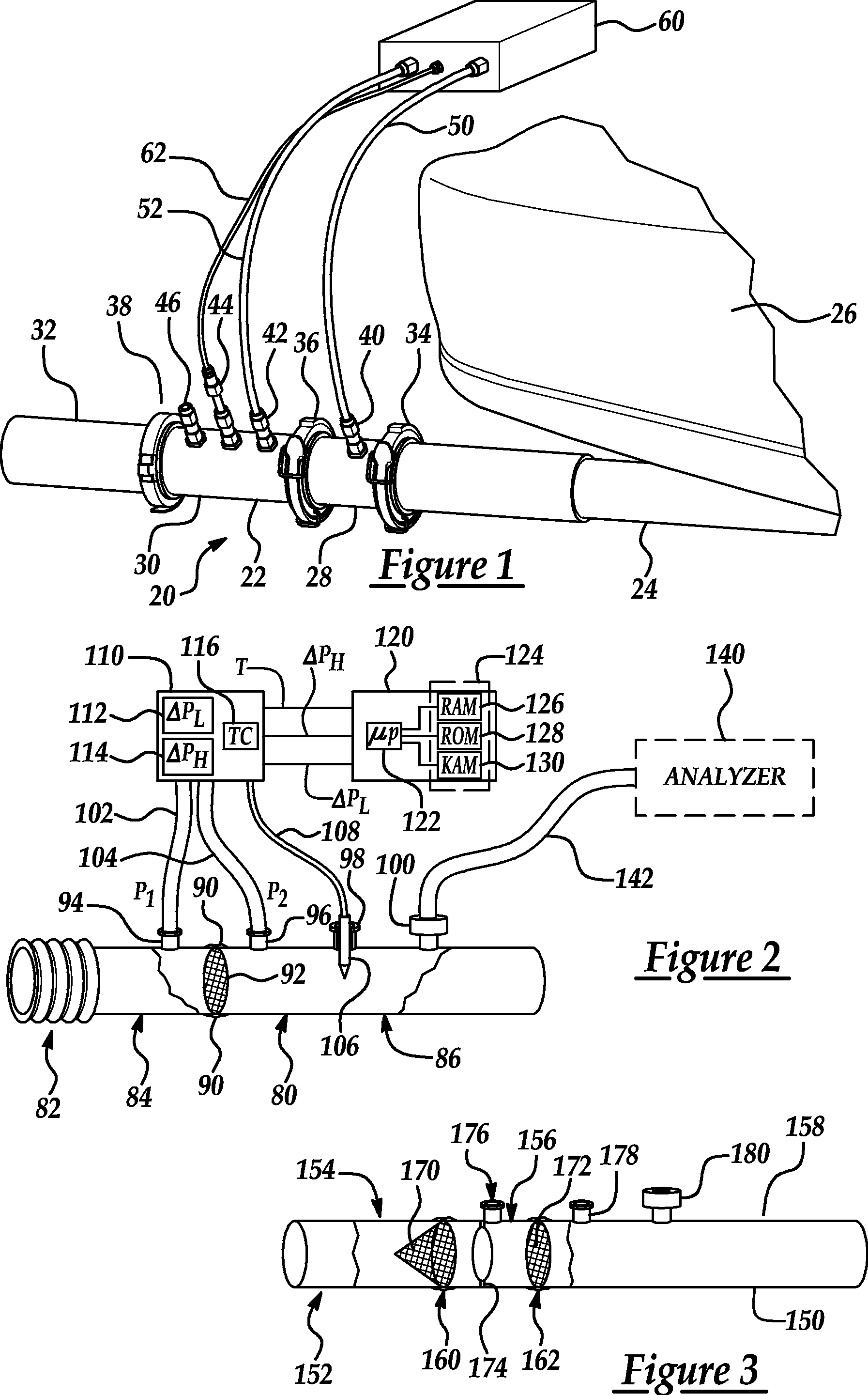

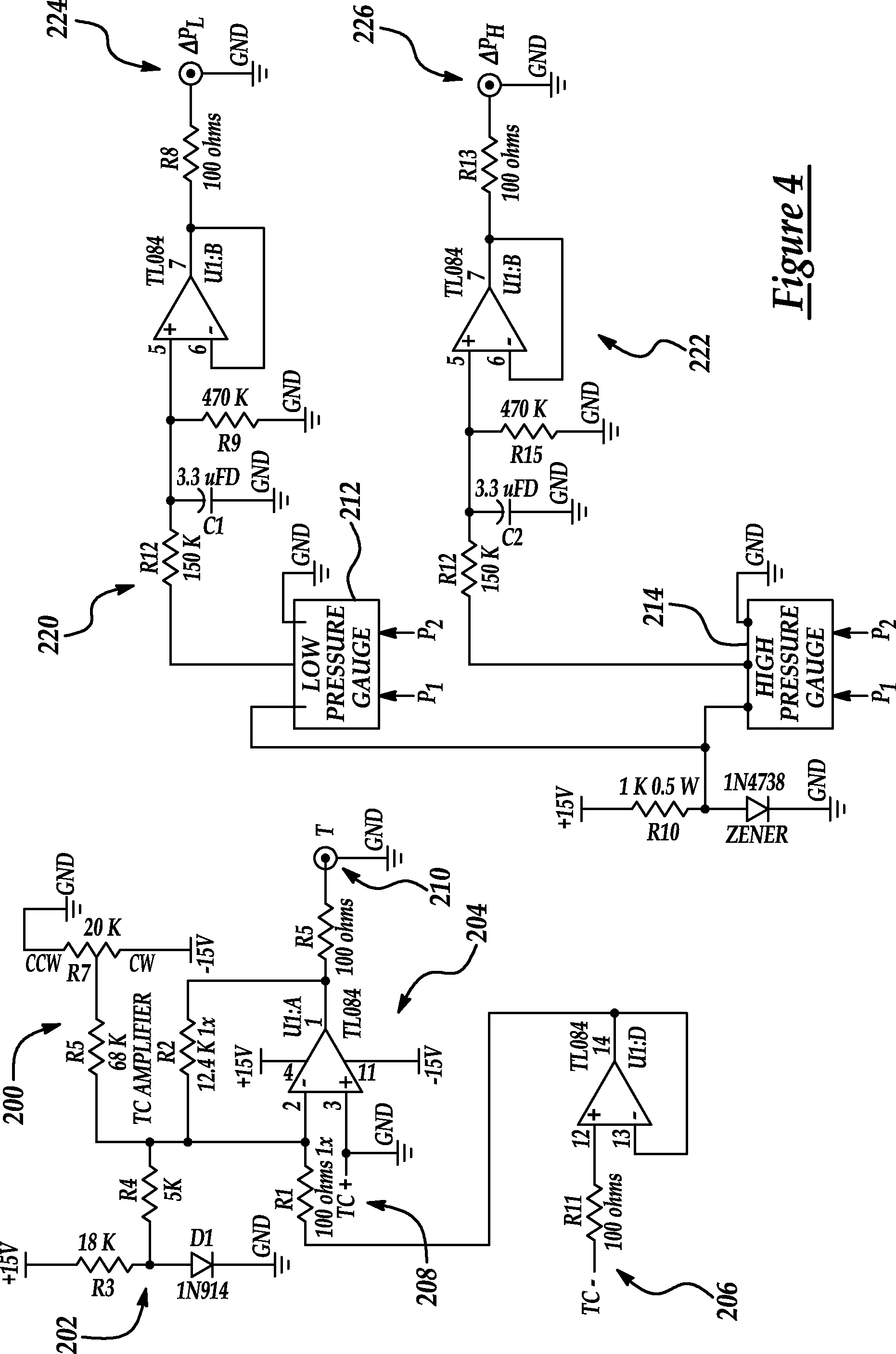

Portable vehicle exhaust flow sensor

InactiveUS20050257605A1Accurately determineAdditional back pressureExhaust apparatusEngine testingExhaust gasEngineering

A portable exhaust gas flow sensor includes a tube for coupling to an exhaust pipe of a vehicle. The tube includes a circular flow restricting element to induce a pressure drop based on the exhaust gas flow with an upstream port and a downstream port relative to the flow restricting element connected to a differential pressure transducer. A thermocouple extends through a temperature port to measure exhaust gas temperature flowing through the tube. A processor in communication with the thermocouple and the differential pressure transducer determines the exhaust gas flow based on the differential pressure and the temperature. The circular flow restricting element includes sufficient spaces to resist formation of condensation and minimize added back pressure while providing an accurately measurable pressure drop for flows ranging from idle to full throttle.

Owner:FORD GLOBAL TECH LLC

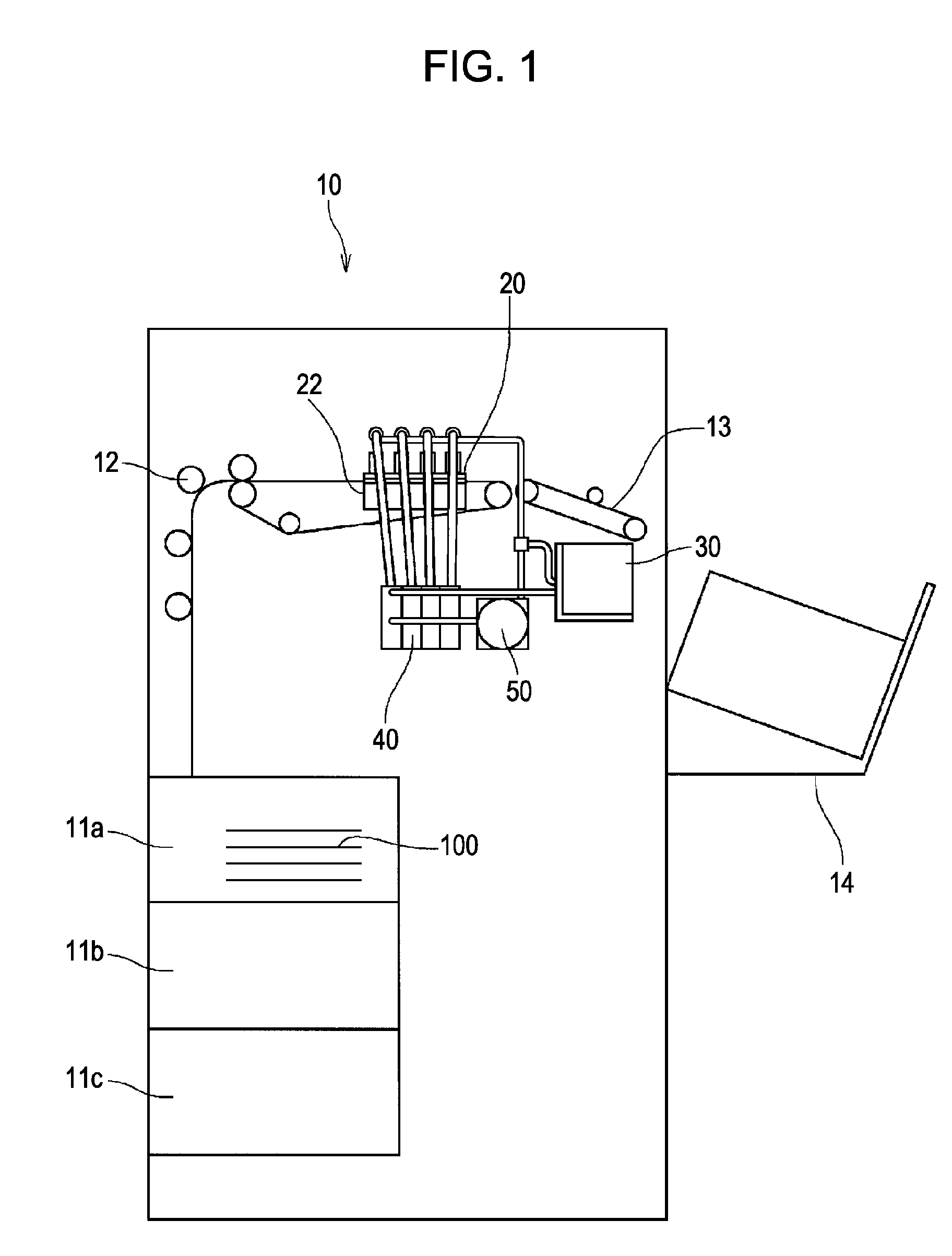

Liquid supplying device, liquid discharging device, and method of controlling liquid discharging device

InactiveUS20100026739A1Convenient and stableAccurate pressureOther printing apparatusLiquid tankEngineering

A liquid supplying device includes a liquid tank storing liquid that is supplied to a consumption object that consumes the liquid, a transfer pump for transferring the liquid stored in the liquid tank, an auxiliary tank temporarily storing the liquid transferred by the transfer pump before supplying the liquid to the consumption object, and a return pipe disposed so as to return the liquid to the liquid tank from the auxiliary tank when an amount of the liquid stored in the auxiliary tank becomes greater than or equal to a certain amount.

Owner:SONY CORP

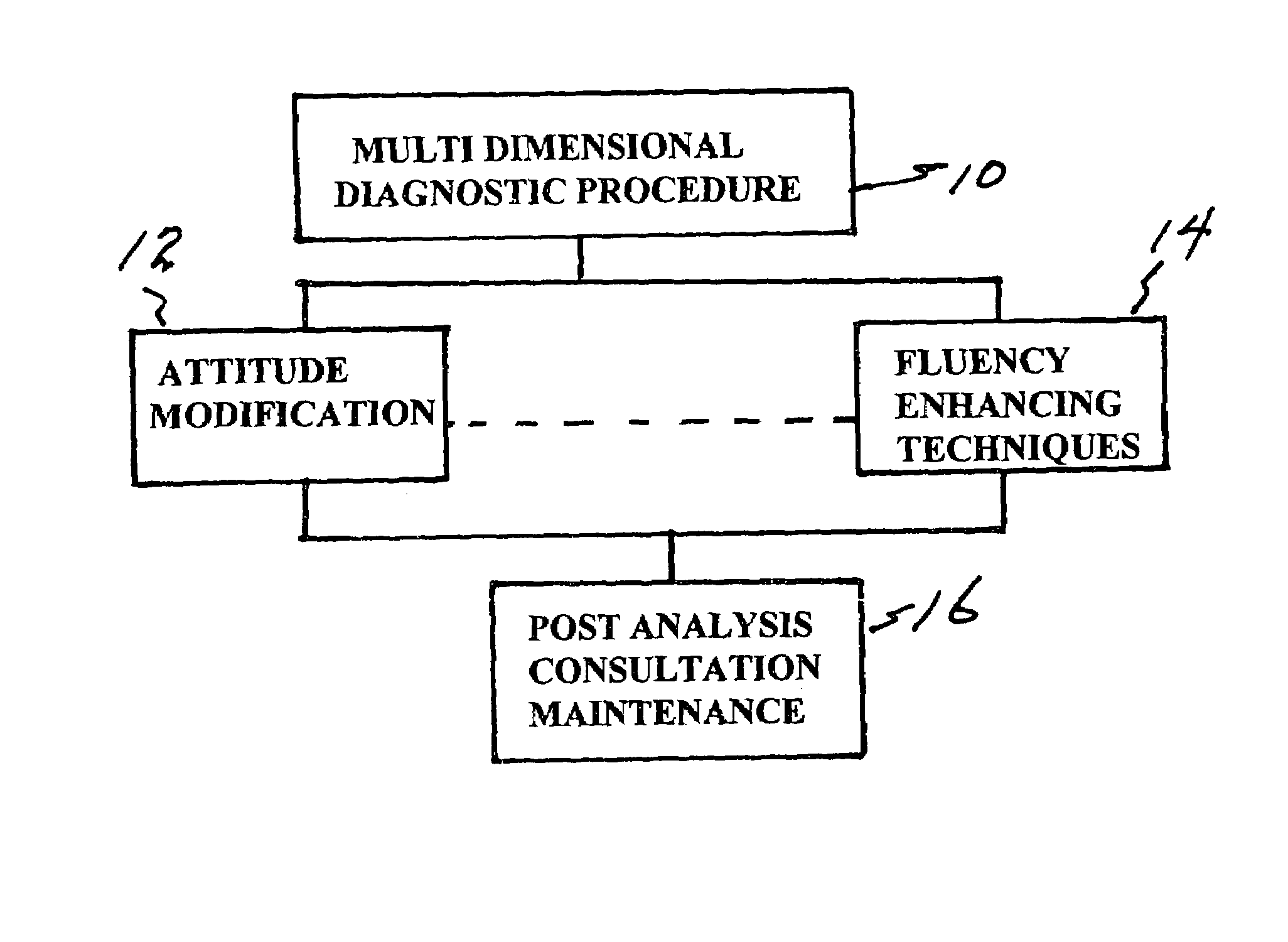

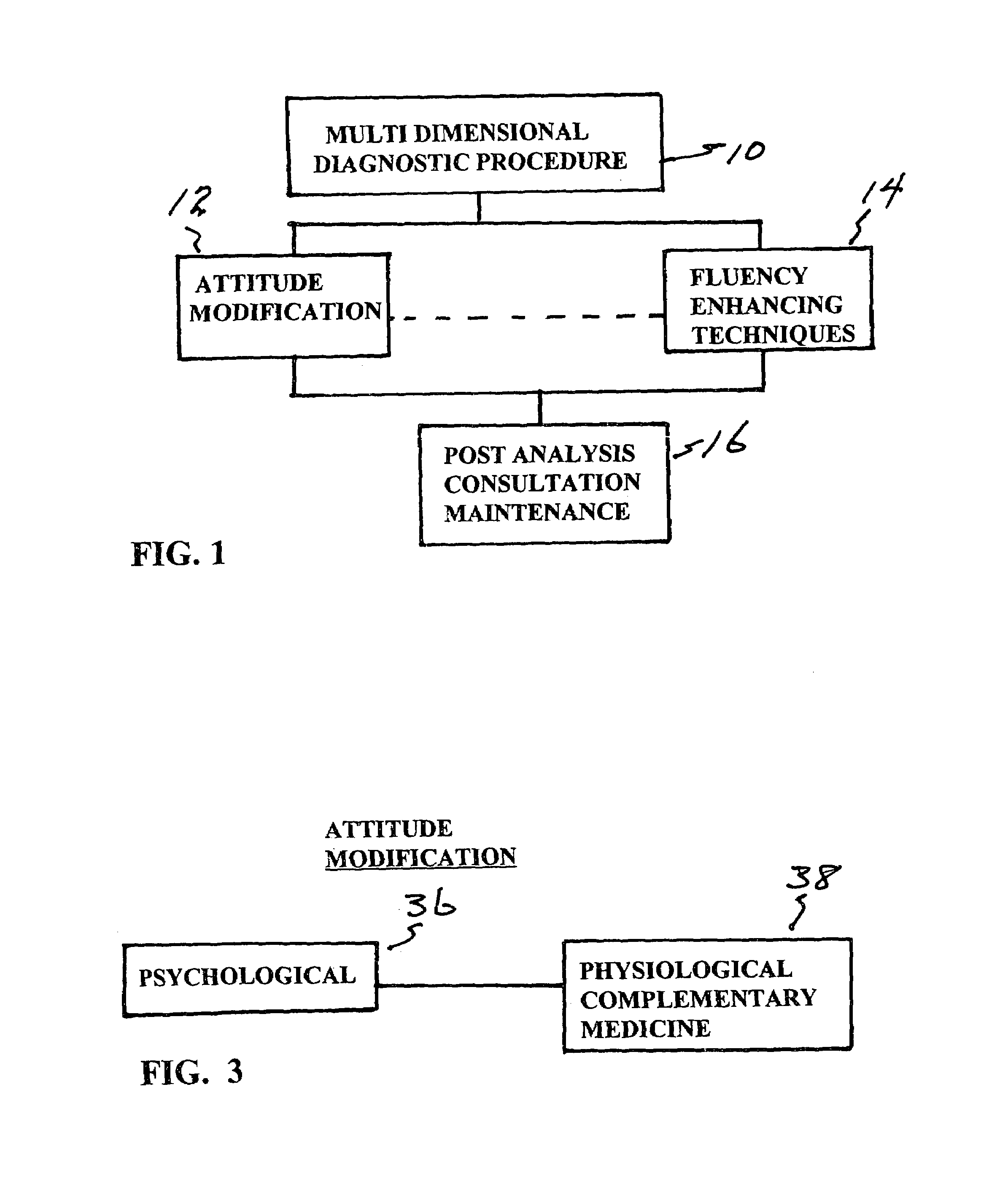

Speech therapy method

InactiveUS7258660B1Difficult to correctDifficult to overcomeStammering correctionSurgerySpeech-Language PathologyMulti dimensional

An improved stuttering treatment program provides for a multi dimensional diagnostic procedure for identifying the problems associated with stuttering. A simultaneous attitude modification phase and a speech fluency enhancing techniques phase define a supervised, hands-on exercise portion of the program which is intended to advance the level of speech of a stutter afflicted person to speech fluency. Upon completion of attitude modification and speech fluency enhancing exercises, which raises the patient to speech fluency, a self-discipline phase of the program is provided where the patient supervises himself during speech exercising, monitors and analyzes exercise effect and reports his analysis to speech professionals. The self-supervised exercise is up-dated and communicated to the patient, for preventive maintenance of speech fluency.

Owner:SARFATI ROY J

Direct acting gas regulator

InactiveUS7059343B2Low costAccurate pressureOperating means/releasing devices for valvesOffice automationHigh pressurePressure regulator

A direct acting pressure regulator controls the flow of a gas from a high pressure source to a low pressure device. Gas is delivered from the regulator at a predetermined outlet pressure. The regulator includes a body having a high pressure inlet and defining a seat. A bonnet is engageable with the body to define a piston chamber within the body and the bonnet. The bonnet has a regulated gas outlet. A piston is disposed within the piston chamber and defines a gap between the piston and a wall defining the chamber. The piston is movable between an open regulator condition and a closed regulator condition. The piston includes a plug having a sealing surface engageable with the seat and movable toward the seat to the closed regulator condition and away from the seat to the open regulator condition. The plug includes axially disposed openings therein for communicating gas from around the plug to a central longitudinal bore in the piston. The piston has an impingement surface in flow communication with the central bore such that gas pressure on the impingement surface exerts a force on the piston to move the piston to the closed regulator condition. A spring urges the piston to the open regulator condition.

Owner:PRESSURE SPECIALIST

Tonometer-pachymeter apparatus for measurement of intraocular pressure

ActiveUS20070123769A1Easy to useAccurate pressureInfrasonic diagnosticsSonic diagnosticsApplanation tonometerMembrane stretch

An apparatus for determining intraocular pressure includes a transducer assembly containing an applanation tonometer for the determination of a cornea applanation pressure and an ultrasonic pachymeter to determine the thickness of the cornea at the site of applanation. The assembly has a tip end which includes an applanation surface and an ultrasonic coupler surface, and an end cap membrane holder is adapted to fit over the tip end of the transducer assembly and hold a thin film membrane stretched over the applanation and ultrasonic coupler surfaces. The transducer assembly also has a detector for detecting the presence or absence of the end cap membrane holder, the detector may generate a signal to disable movement of the transducer assembly if the end cap is not detected.

Owner:EMOTION PACIFICA

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com