Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

1216results about "Tyre-inflating valves" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

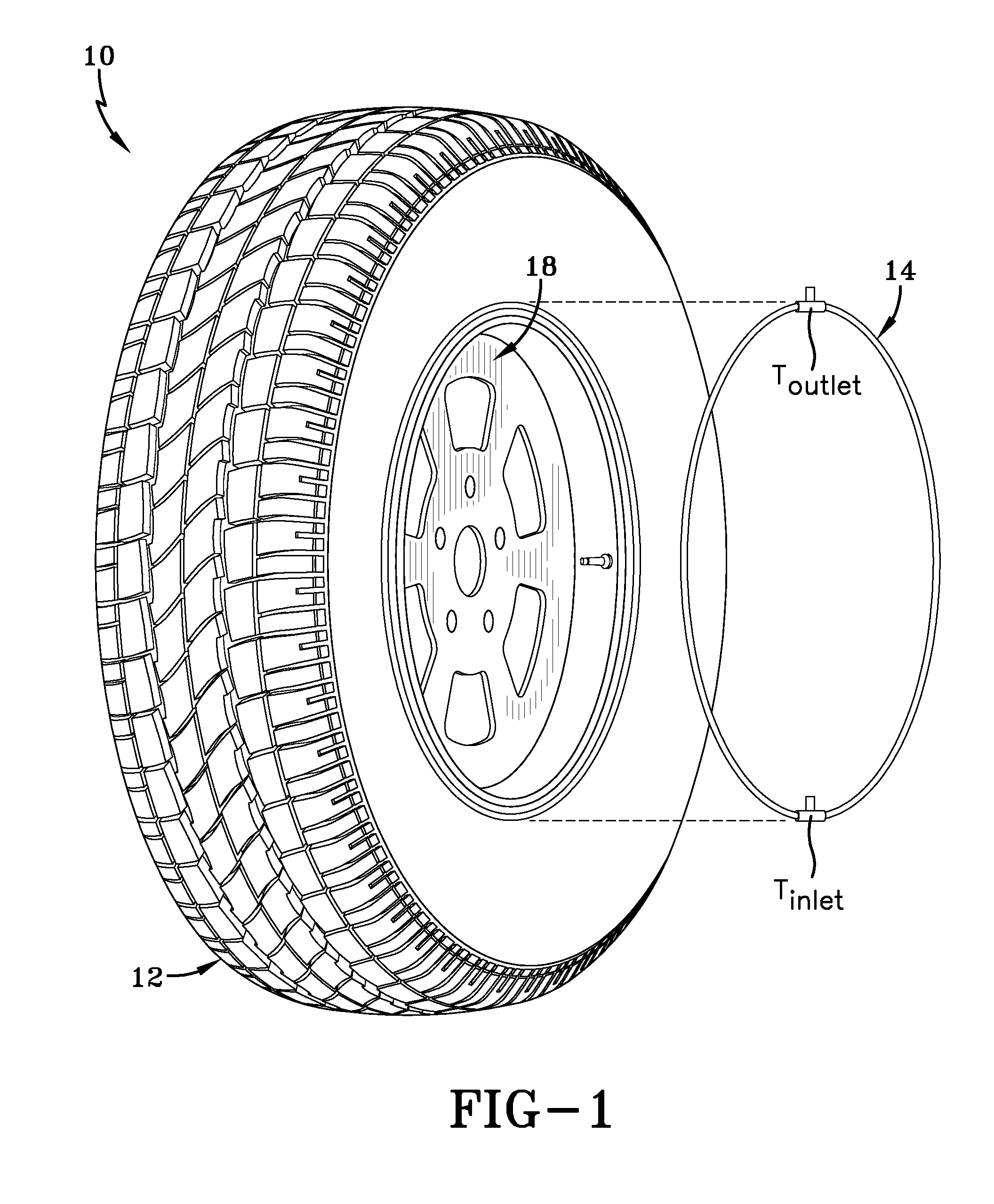

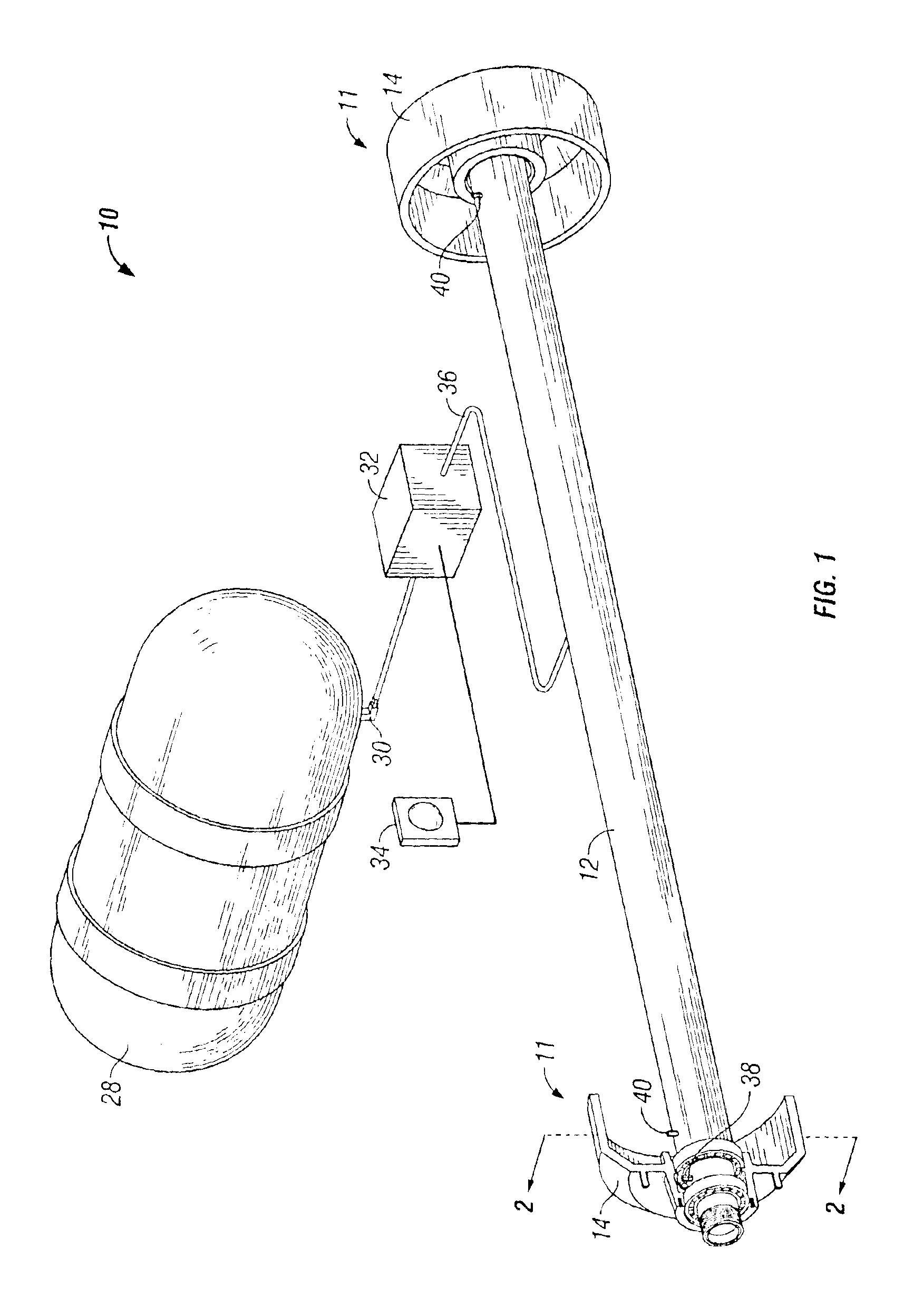

Self-inflating tire

ActiveUS8113254B2Great tractionTyre measurementsTyre-inflating valvesEngineeringMechanical engineering

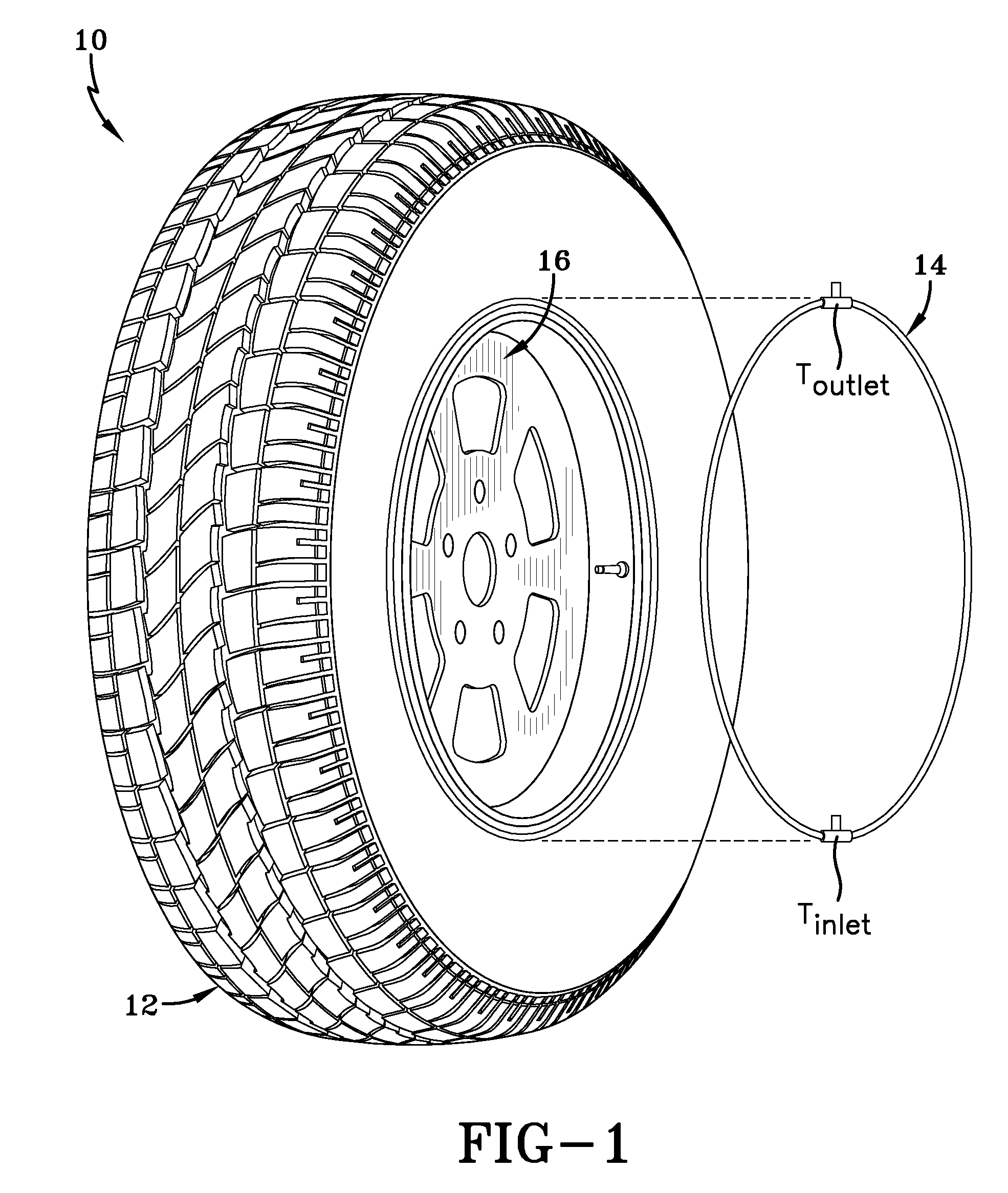

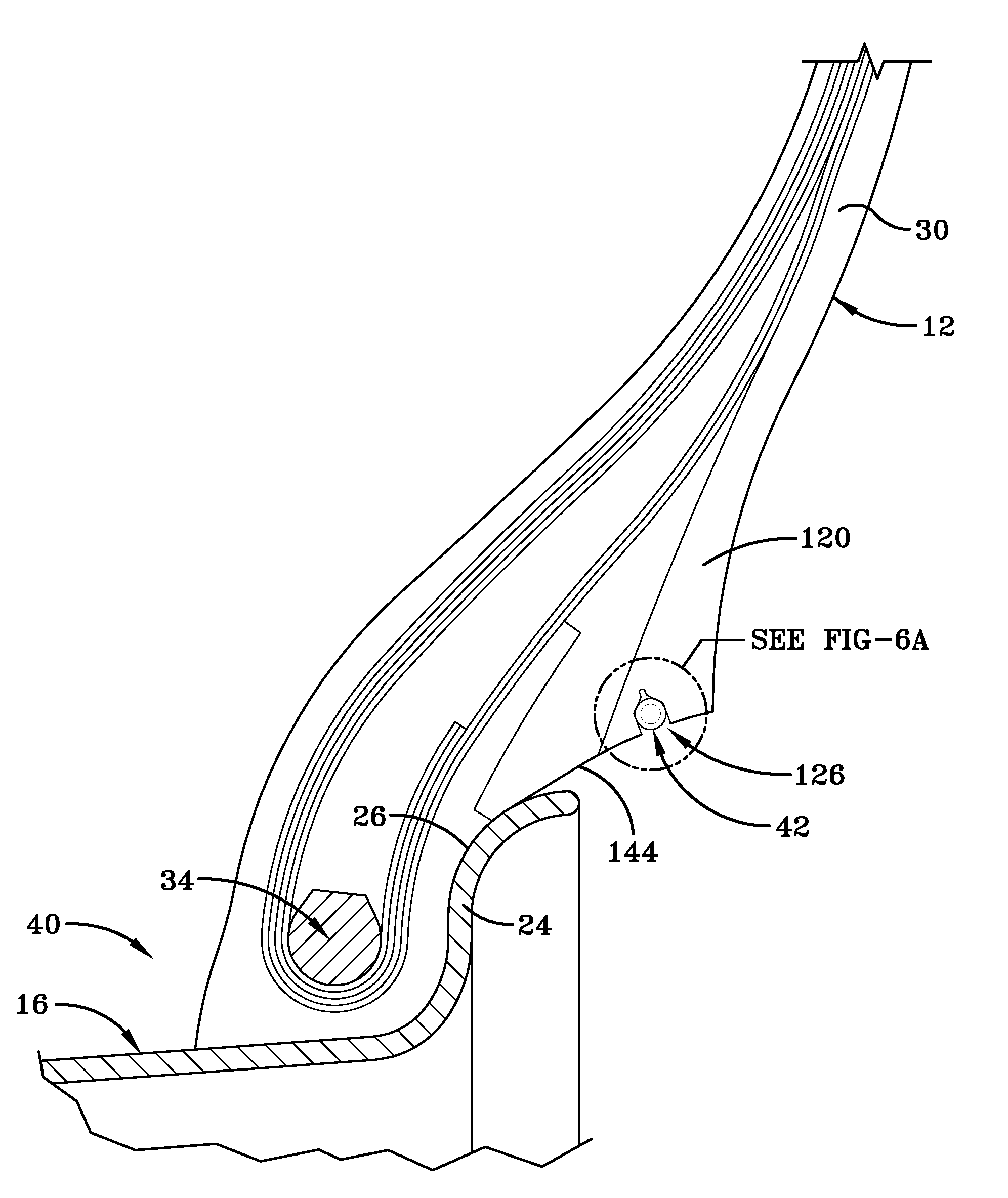

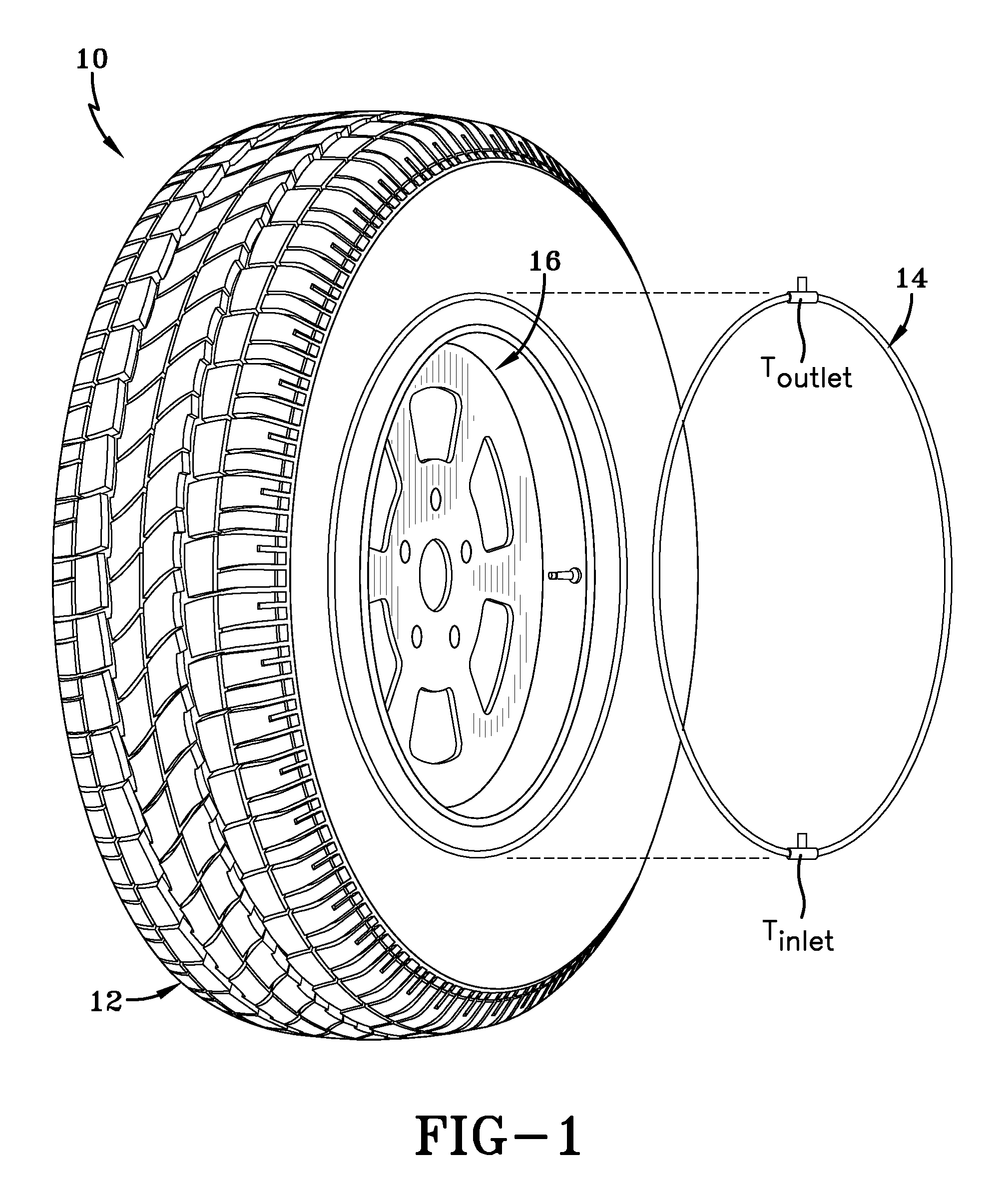

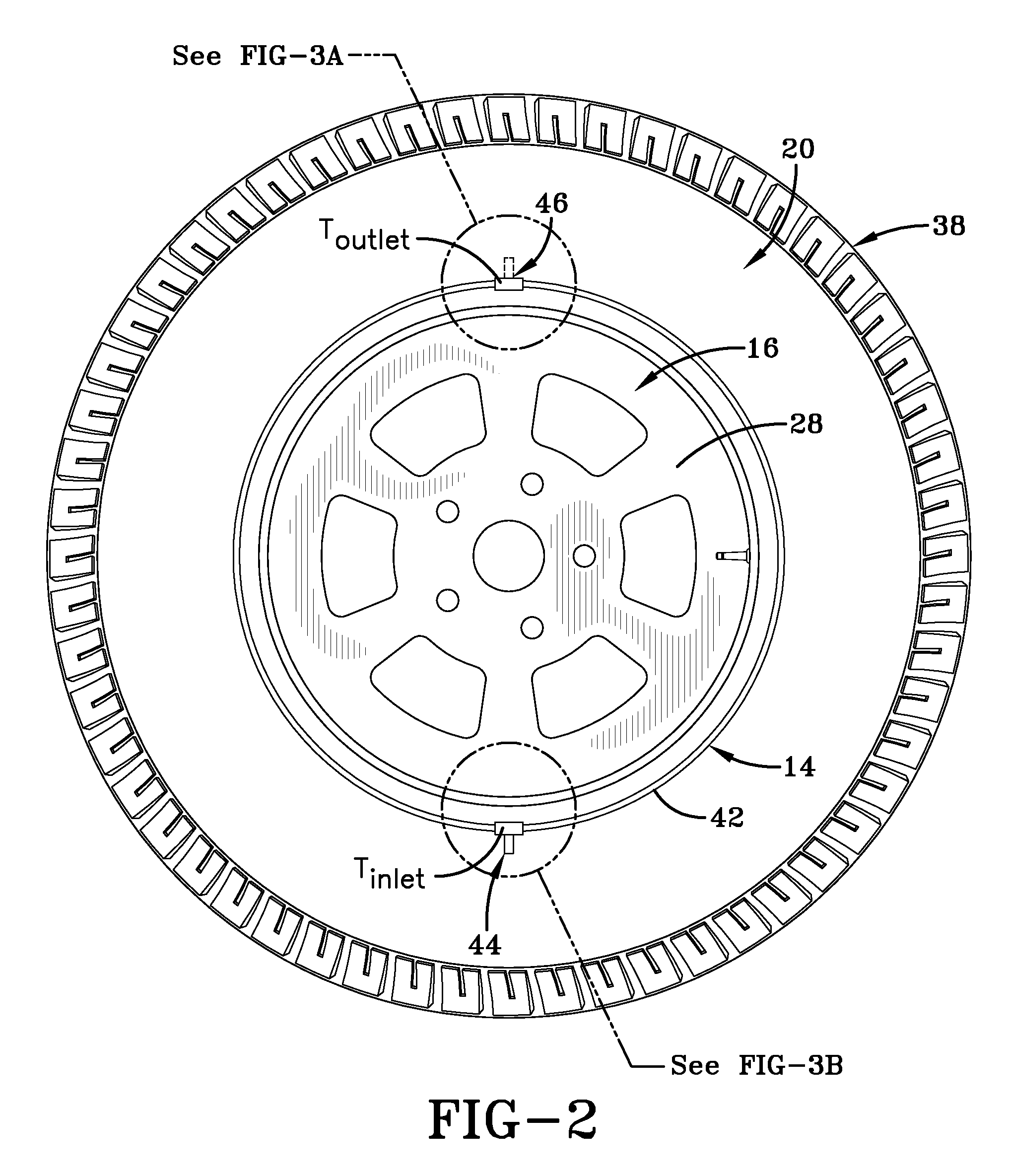

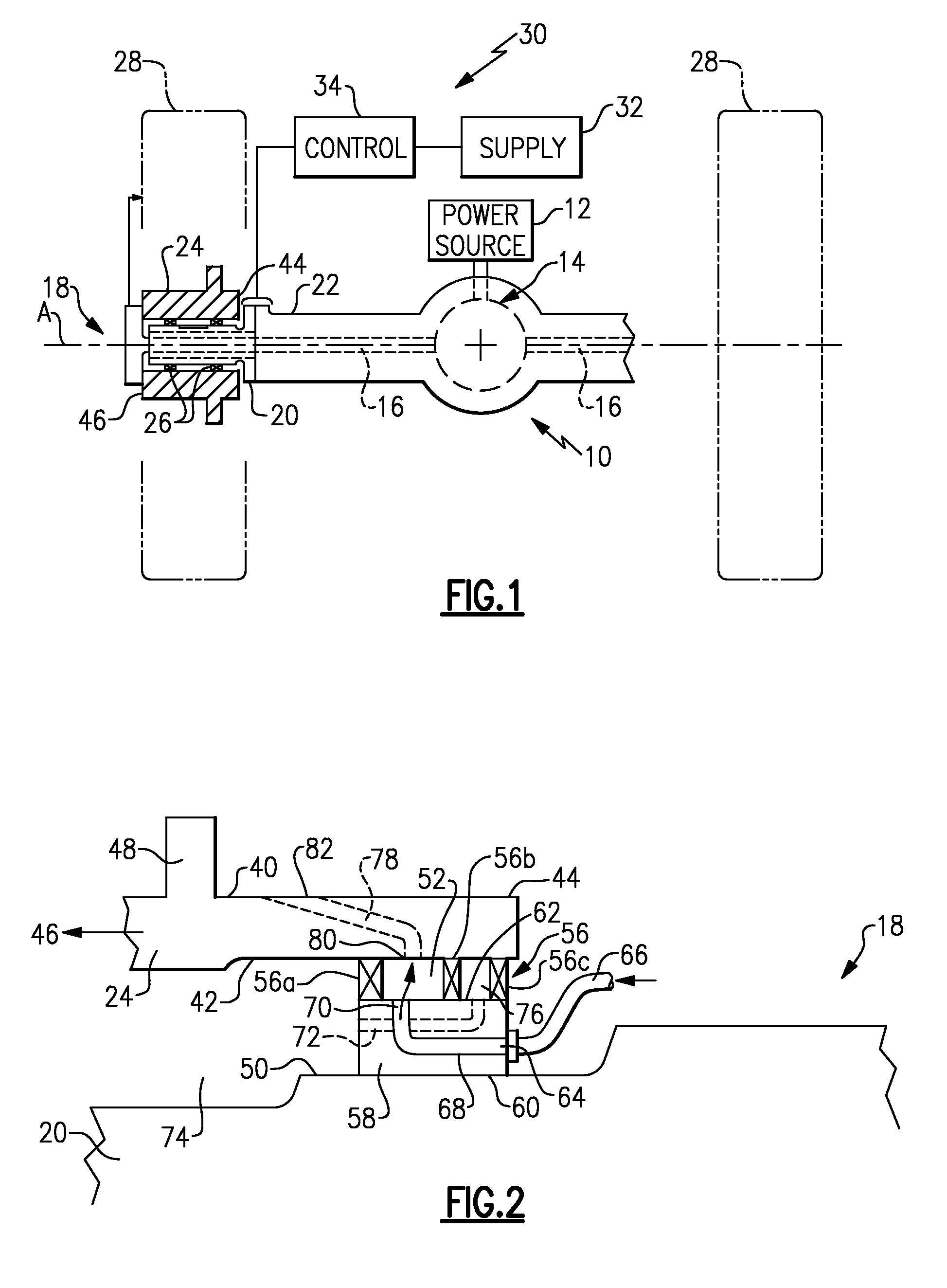

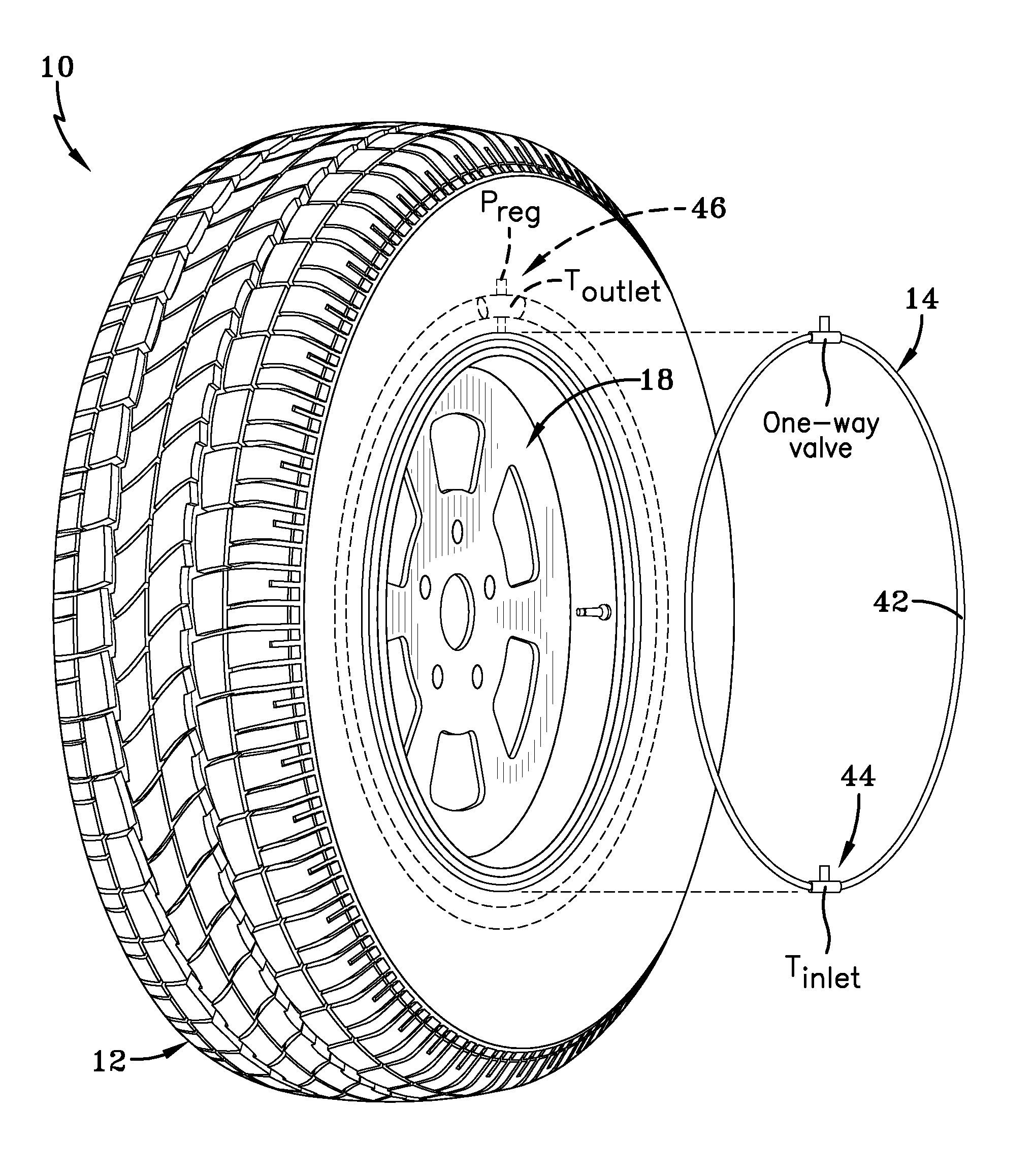

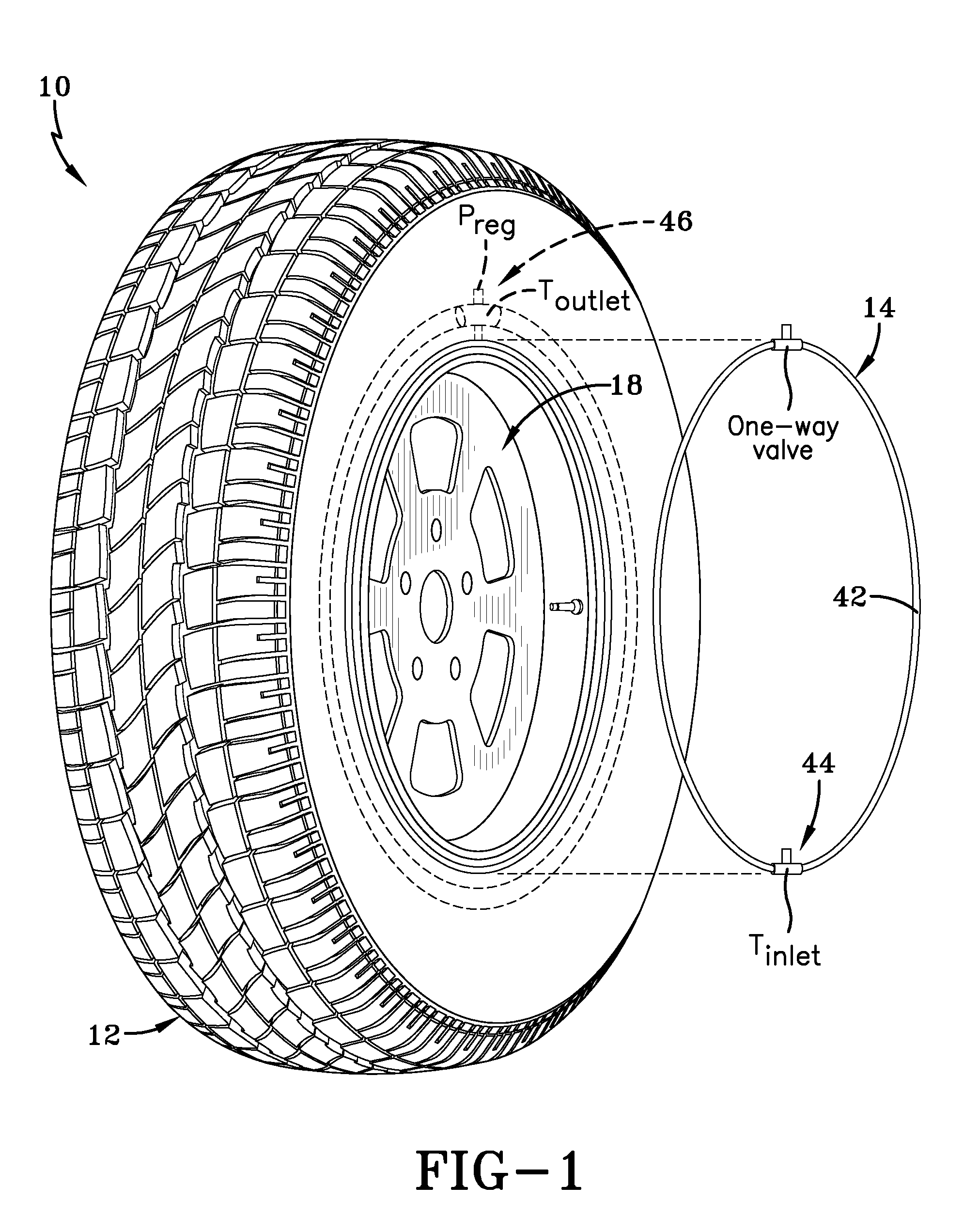

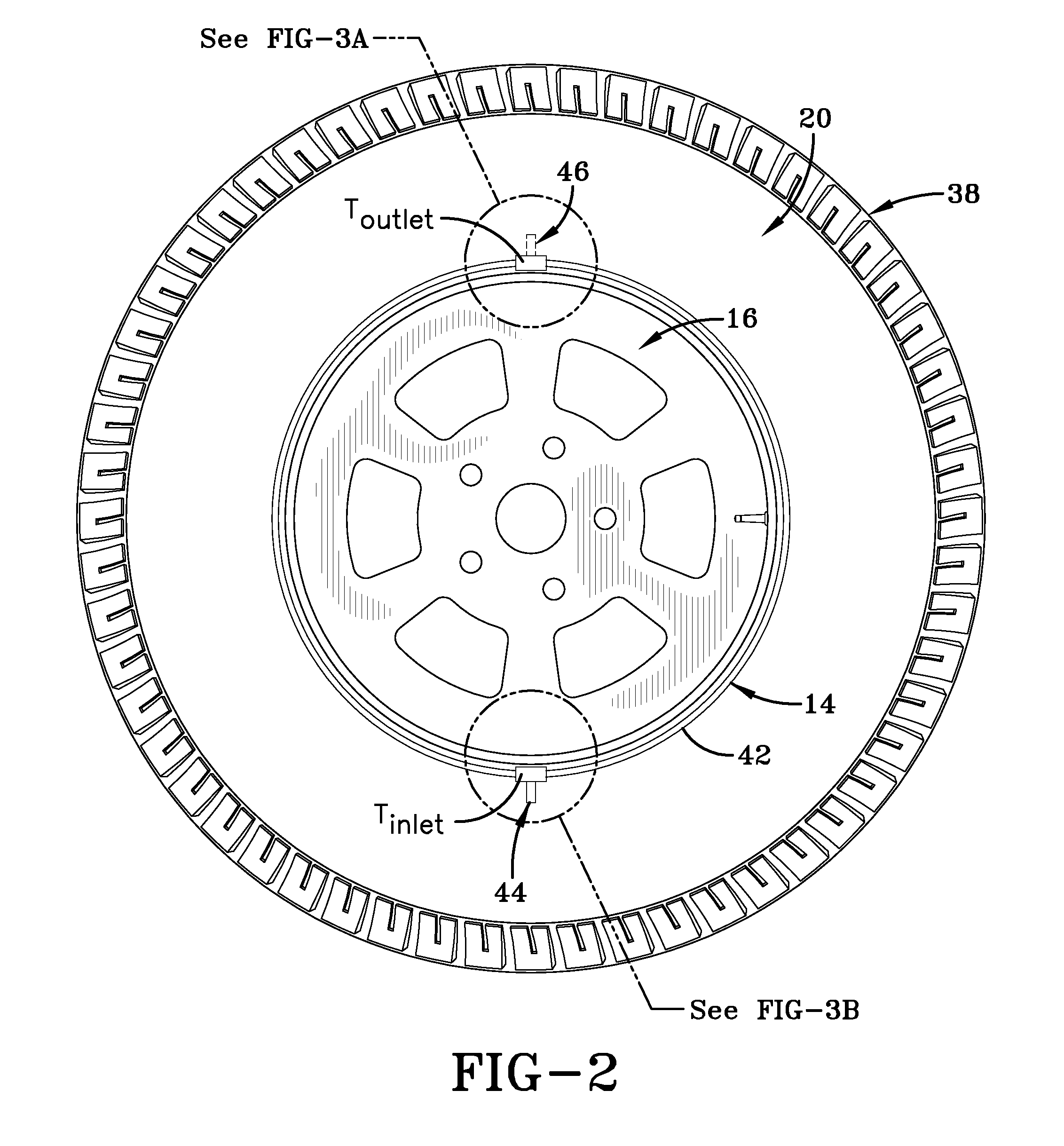

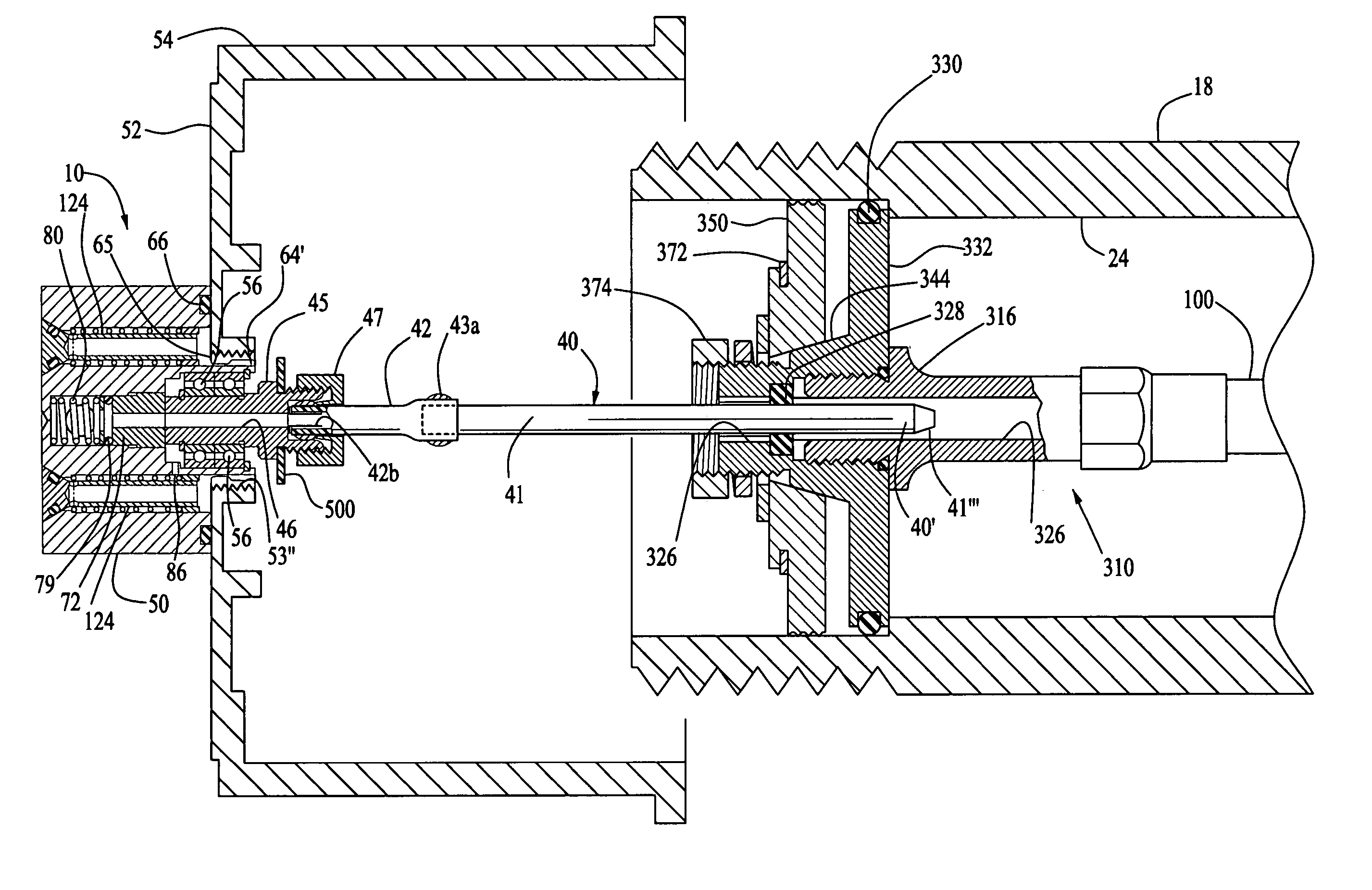

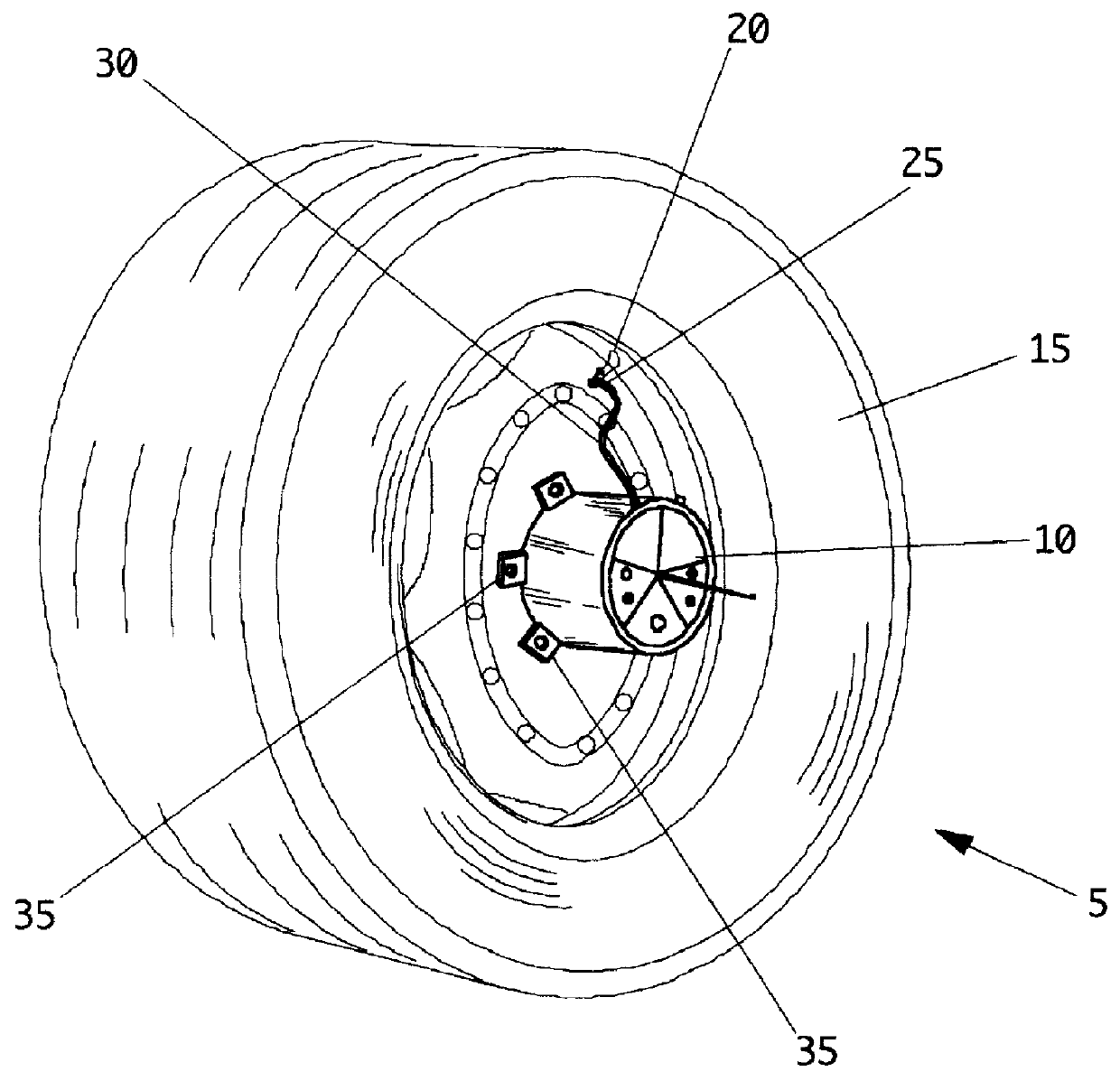

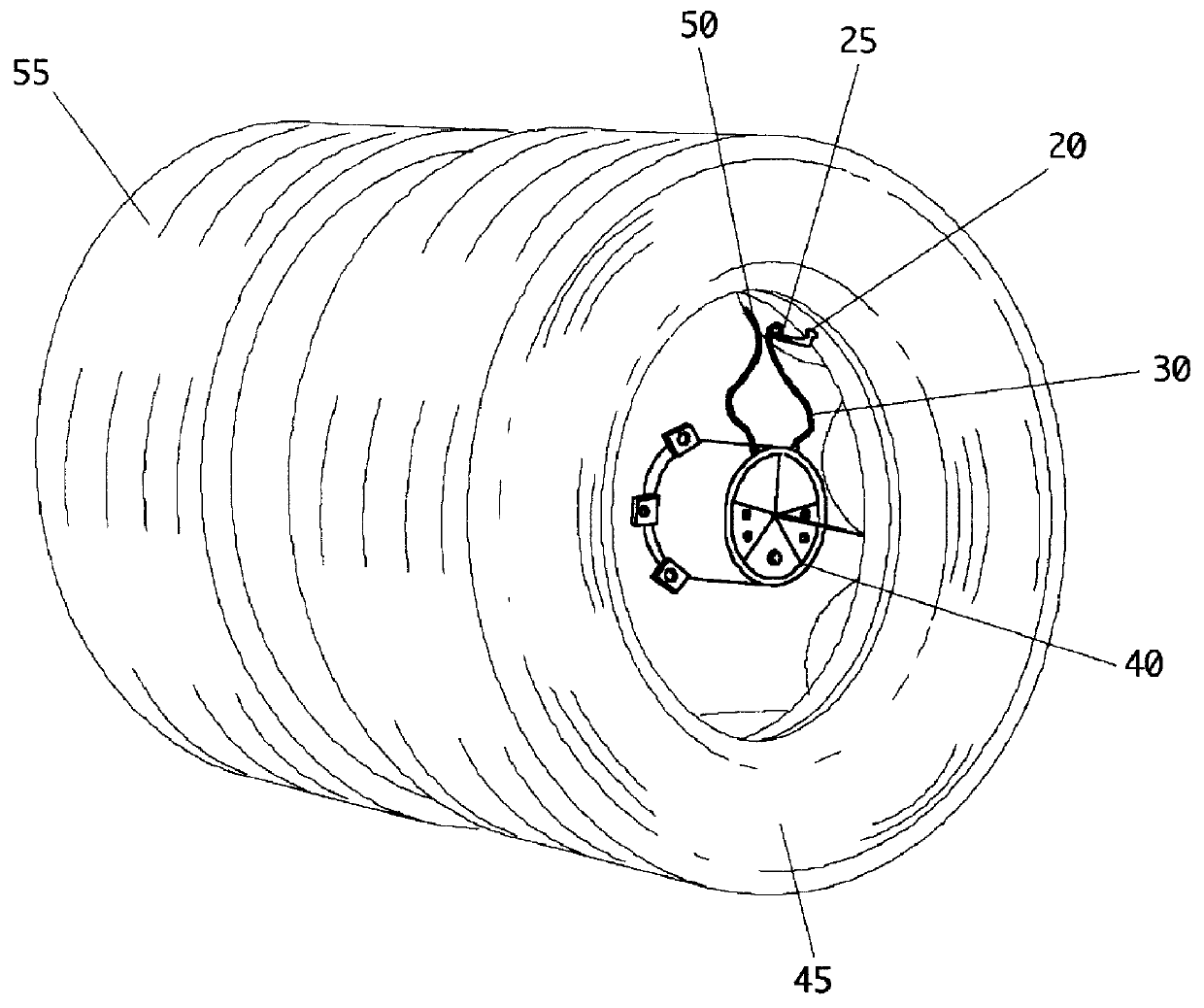

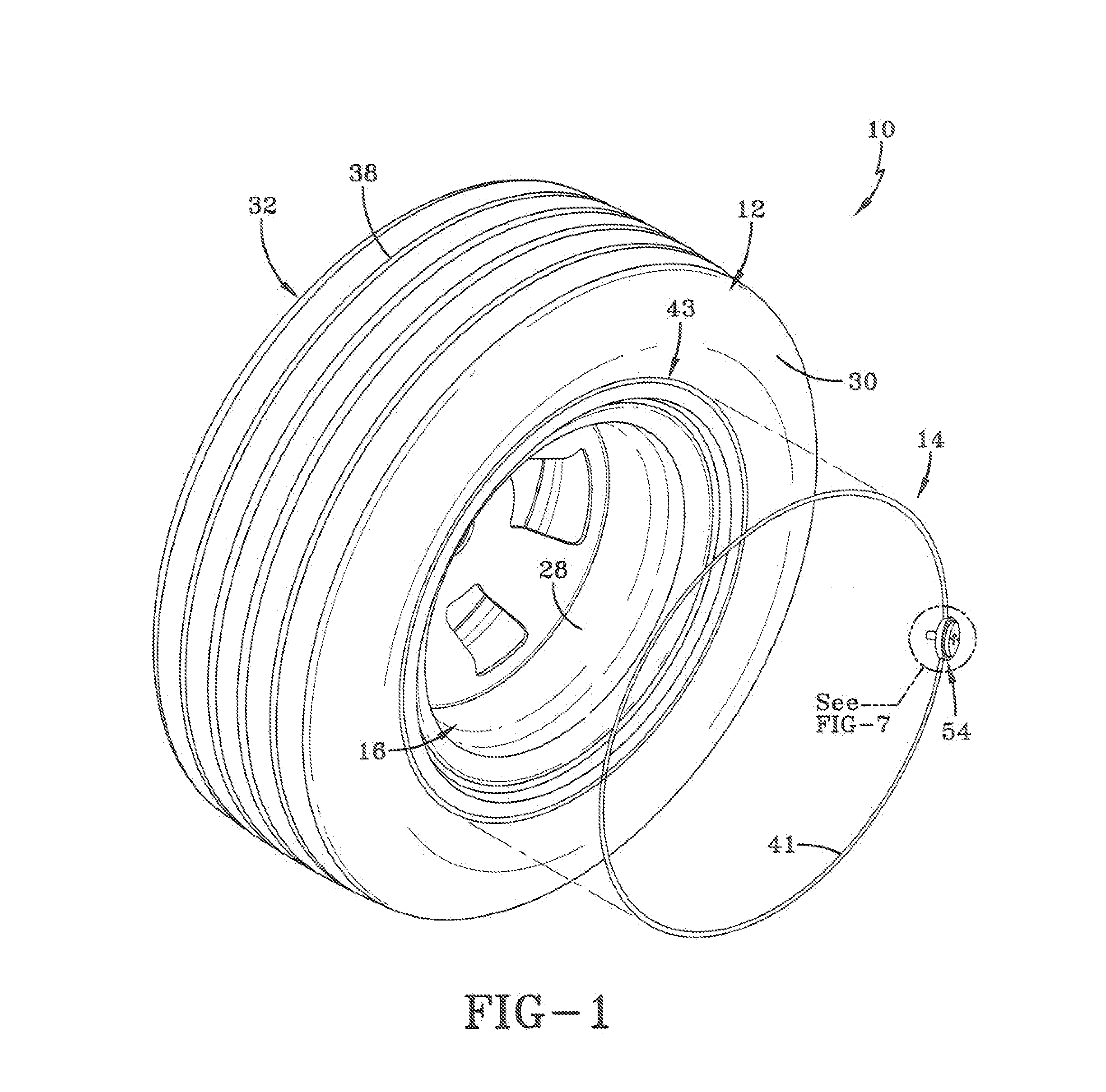

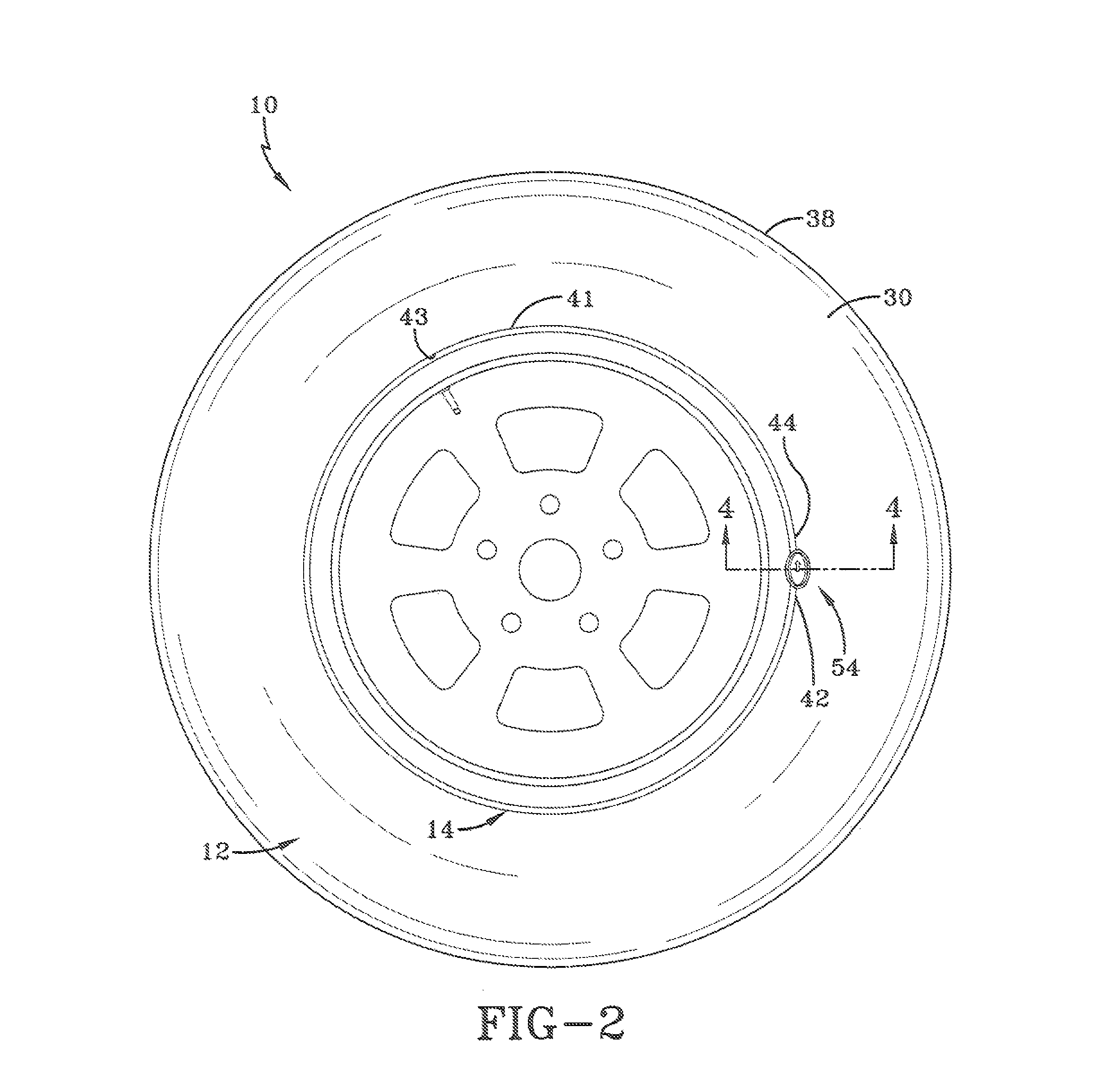

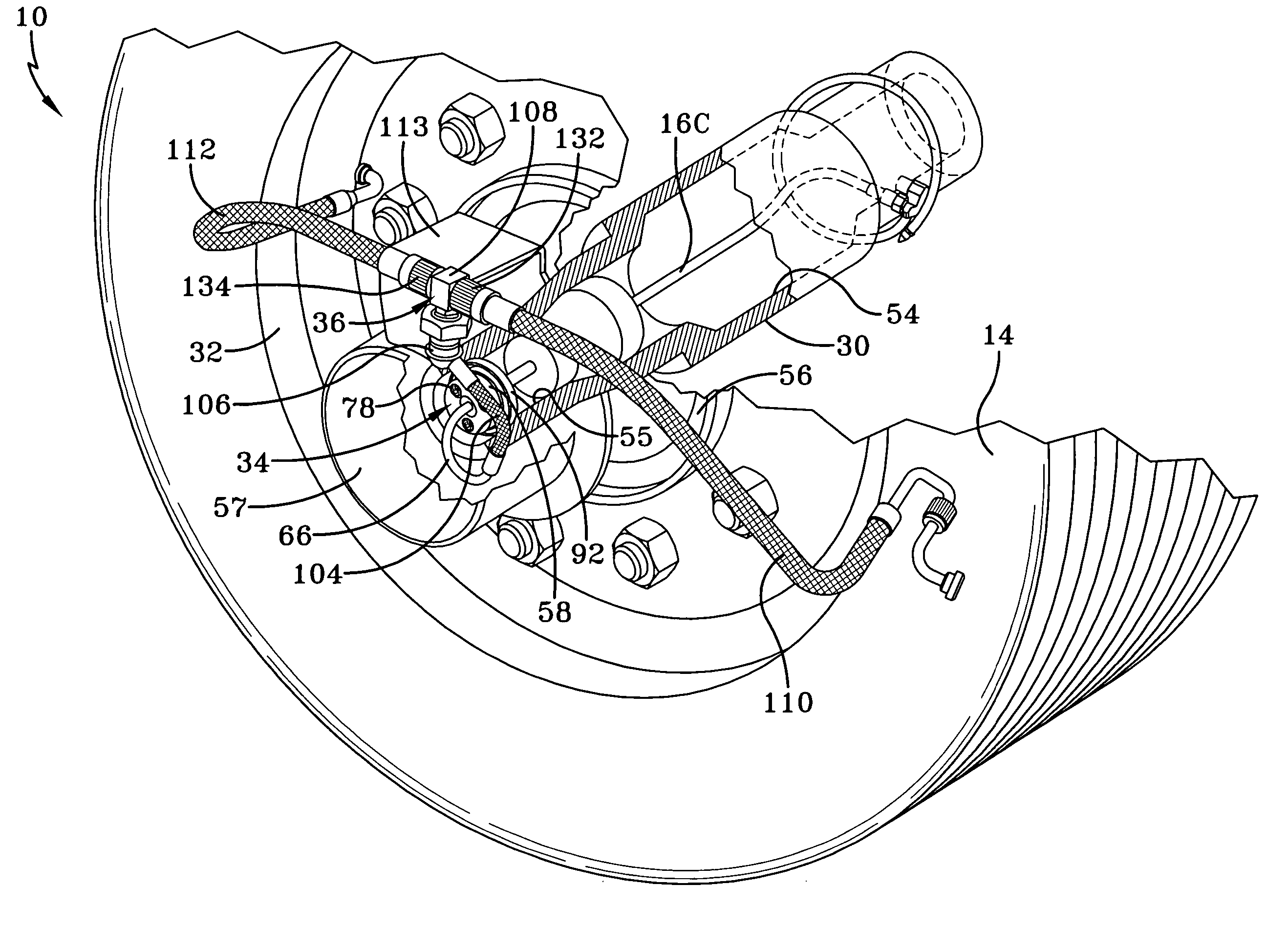

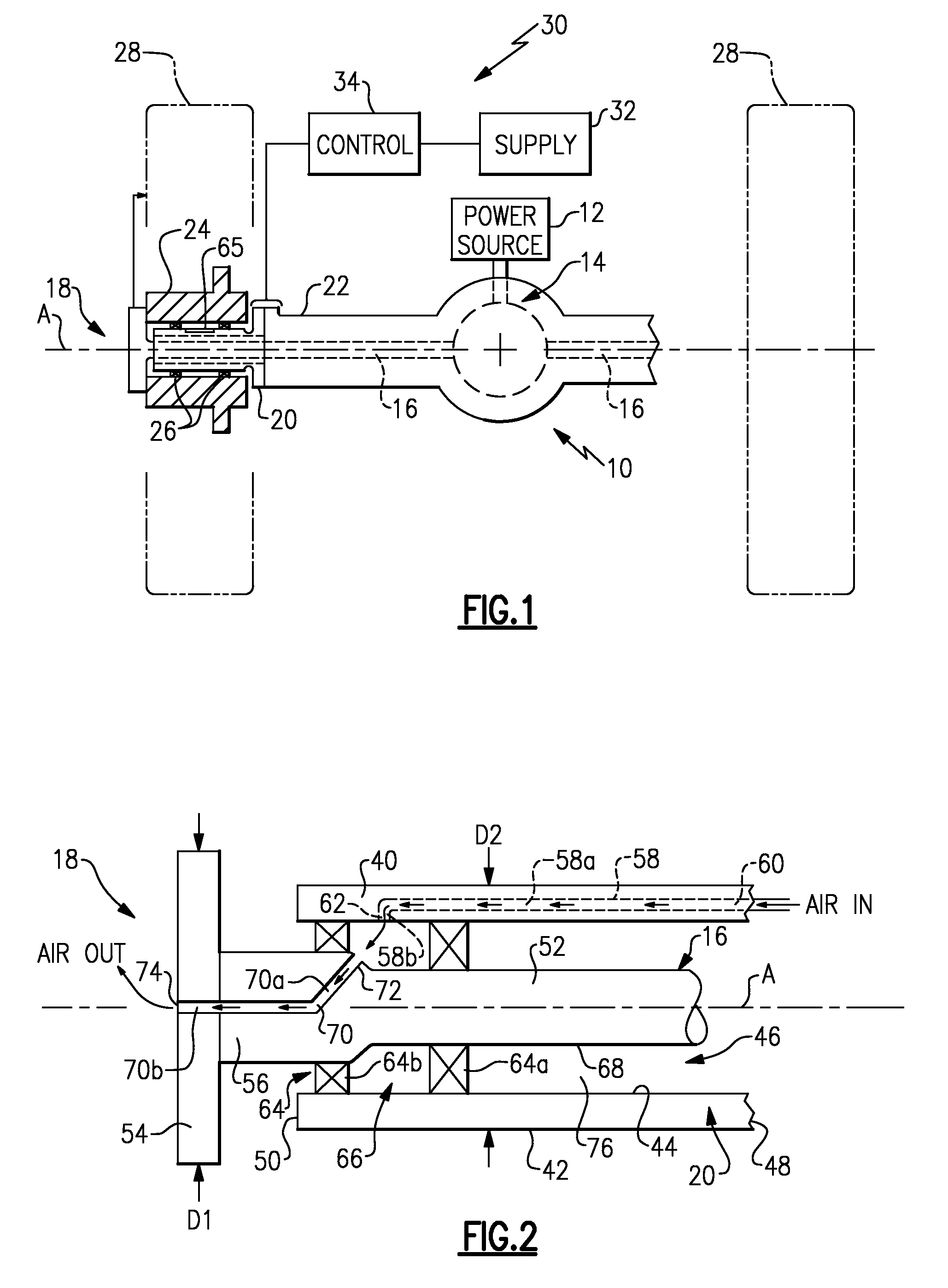

A self-inflating tire assembly includes an annular air tube connected to a tire and defining an annular air passageway, the air tube being composed of a flexible material operative to allow an air tube segment opposite a tire footprint to flatten, closing the passageway, and resiliently unflatten into an original configuration. The air tube is sequentially flattened by the tire footprint in a direction opposite to a tire direction of rotation to pump air along the passageway to an inlet device for exhaust from the passageway or to an outlet device for direction into the tire cavity. The inlet device is positioned within the annular passageway 180 degrees opposite the outlet device such that sequential flattening of the air tube by the tire footprint effects pumping of air along the air passageway with the tire rotating in either a forward or reverse direction of rotation.

Owner:THE GOODYEAR TIRE & RUBBER CO

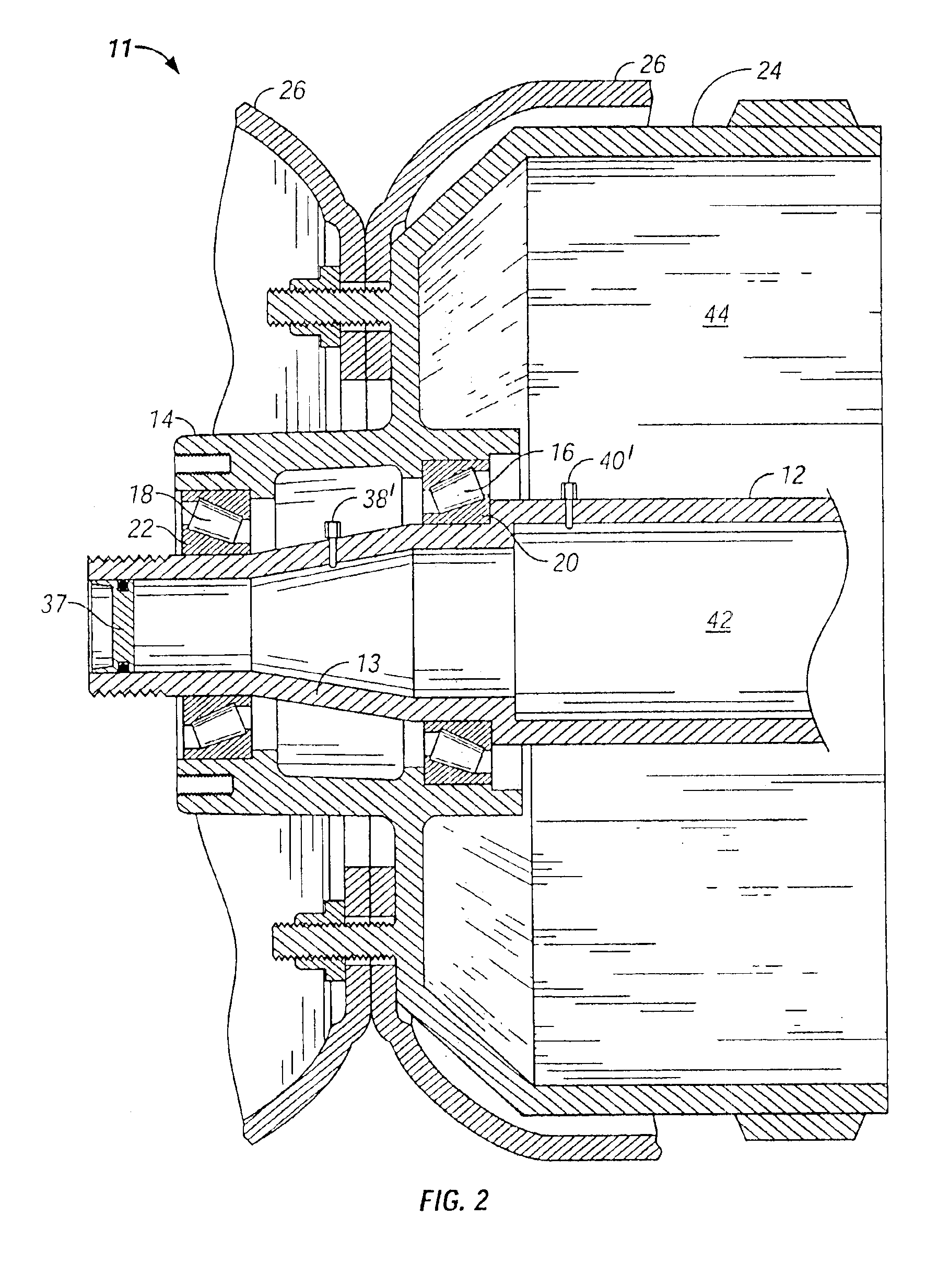

Self-inflating tire assembly

A self-inflating tire assembly includes an air tube mounted within a tire sidewall groove. The air tube is in contacting engagement with opposite angled groove surfaces surrounding the air tube. A segment of the air tube is flattened from an expanded diameter to a flat diameter by bending and compression of the groove in a rolling tire footprint to force air evacuated from the flattened segment along a tube air passageway. The sidewall groove extends into an annular, axially extending, sidewall surface such as an axially oriented surface of a tire chafer protrusion located in non-contacting relationship with the rim.

Owner:THE GOODYEAR TIRE & RUBBER CO

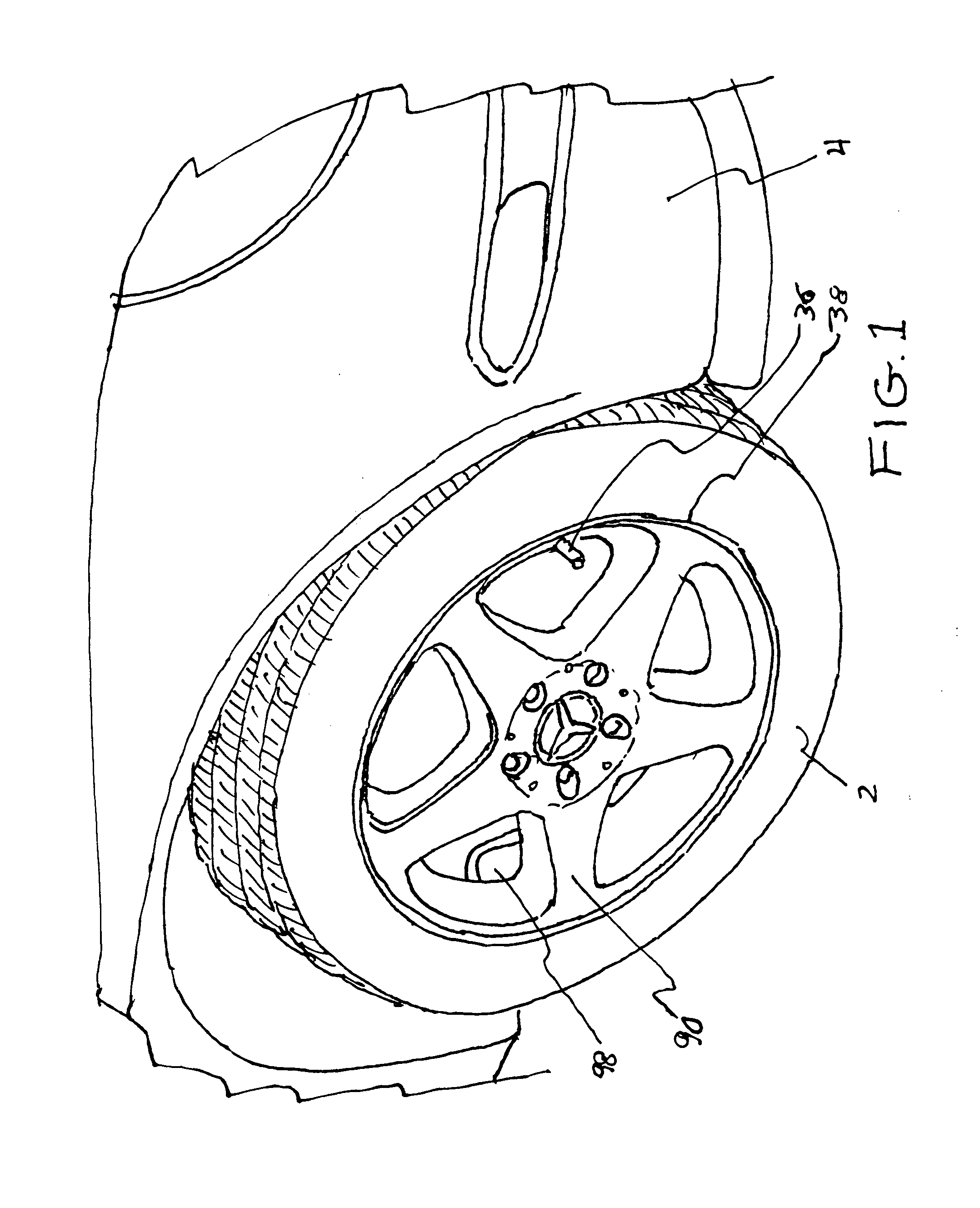

Arrangement for filling air into a rotating pneumatic tire

InactiveUS7225845B2Reduced strengthLose their sealing capabilityTyre measurementsTyre-inflating valvesFlangeTire pressure

A hose-type structure is arranged essentially between the tire and the rim, which structure is connected at the end side with the environment and, by way of a valve, with the interior of the tire. The hose-type structure fills the tire during its rotating movement, and is locally squeezed from the environment side toward the tire interior, in which case the hose-type structure is provided in the area between the tire and the rim flange. A duct is provided in the rim flange or in the tire in the area of its bead chamfer, and at least partially receives the hose-type structure in the form of a hose. The geometry of the duct and of the hose-type structure is selected such that this air-conveying squeezing essentially takes place only as long as the internal tire pressure is below a desired value.

Owner:BAYERISCHE MOTOREN WERKE AG

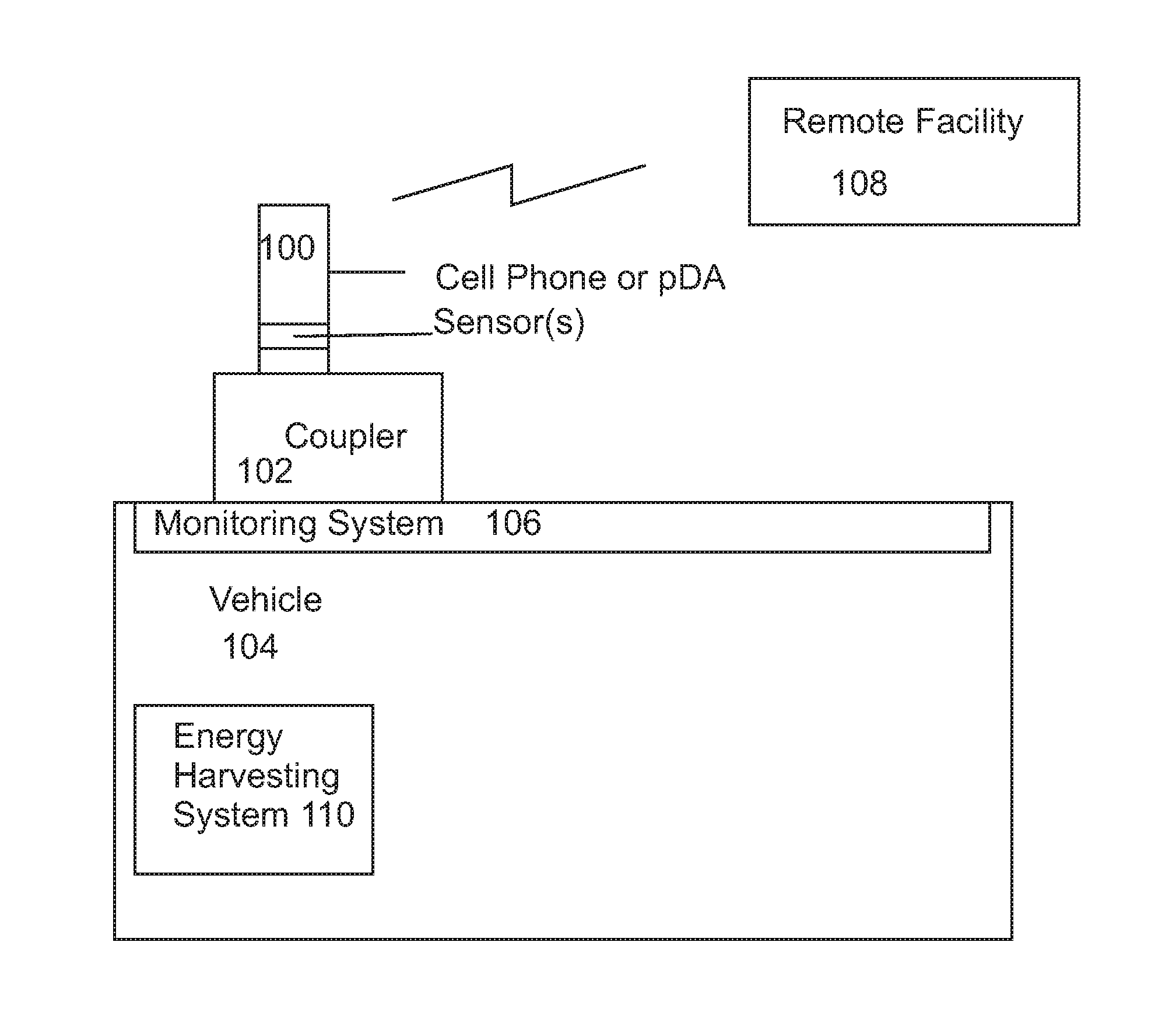

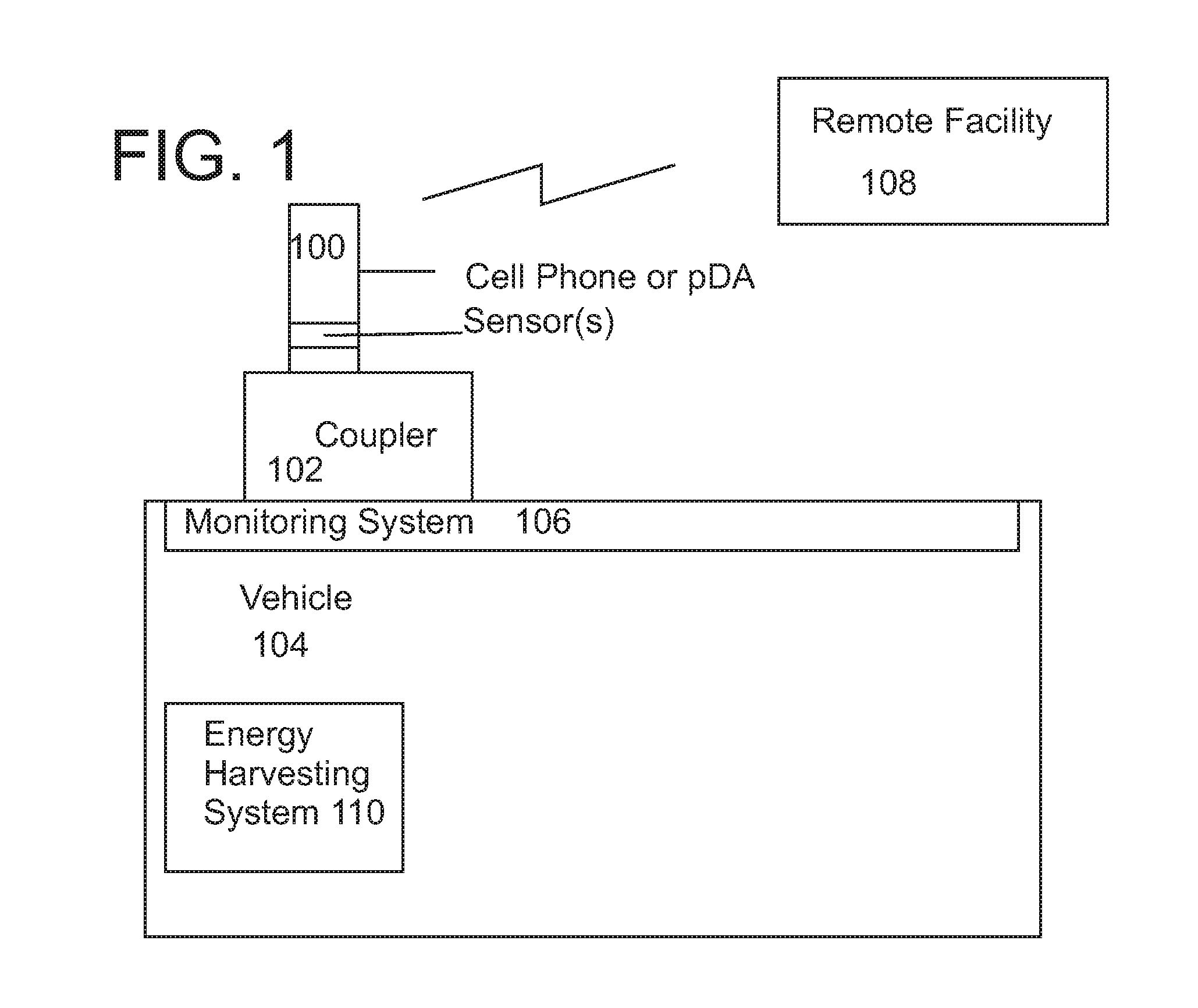

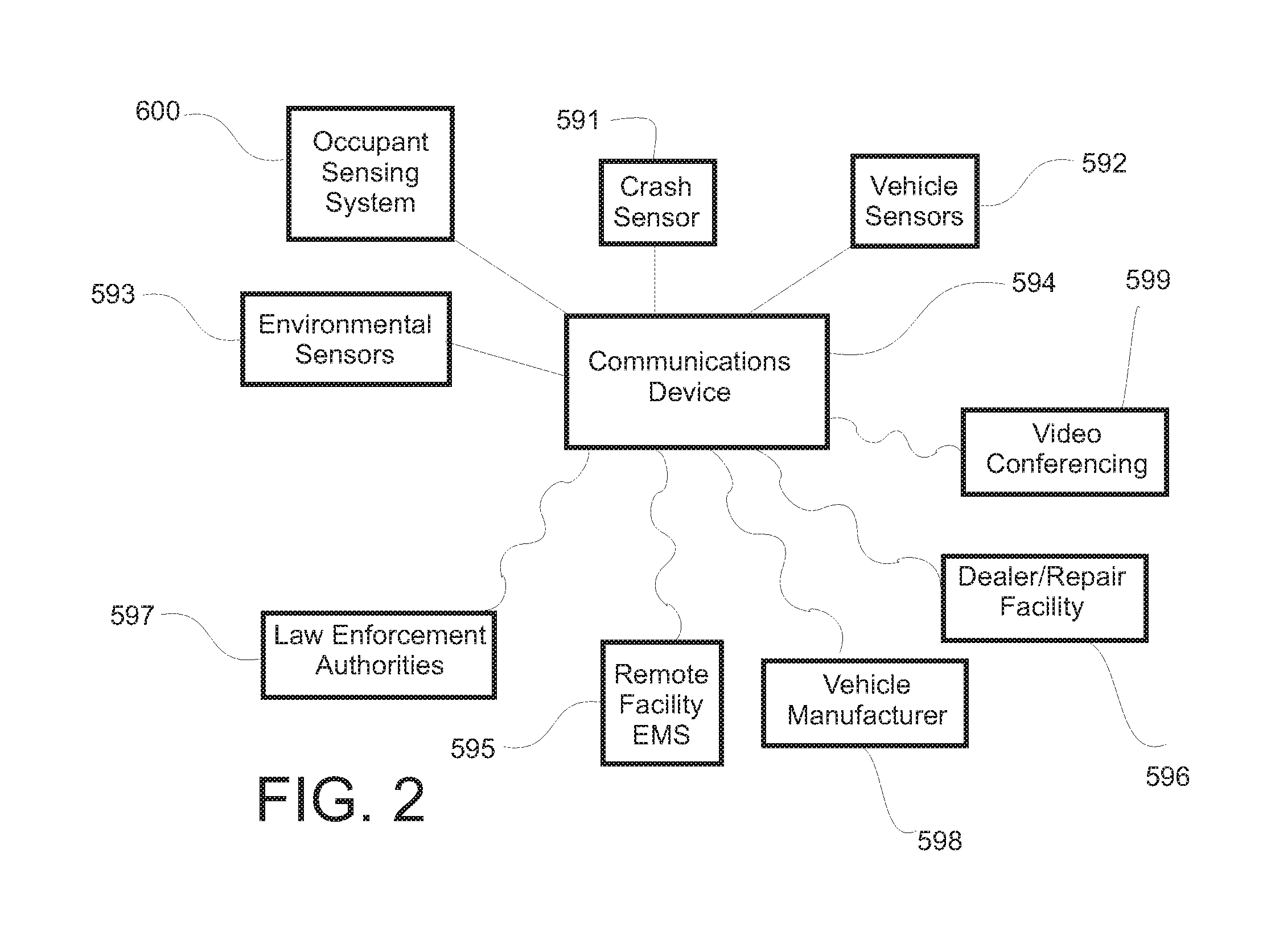

Smartphone-Based Vehicle Control Methods

InactiveUS20160090055A1Vehicle seatsRegistering/indicating working of vehiclesTemperature controlControl system

Method for controlling a vehicle including a smartphone-engaging coupling element. Data about operational status of the vehicle is transferred from one or more vehicle-resident systems to a smartphone when the smartphone is engaged with the coupling element. Commands are received by the vehicle from the smartphone when the smartphone is engaged with the coupling element, which commands being based in part on data previously transferred from the vehicle-resident system(s) to the smartphone when the smartphone is engaged with the coupling element. A vehicular system, e.g., seat positioning system, mirror positioning system, passenger compartment temperature control system, route guidance or navigation system, changes its operation in accordance with the commands received by the vehicle from the smartphone when the smartphone is engaged with the coupling element.

Owner:INTELLIGENT TECH INT

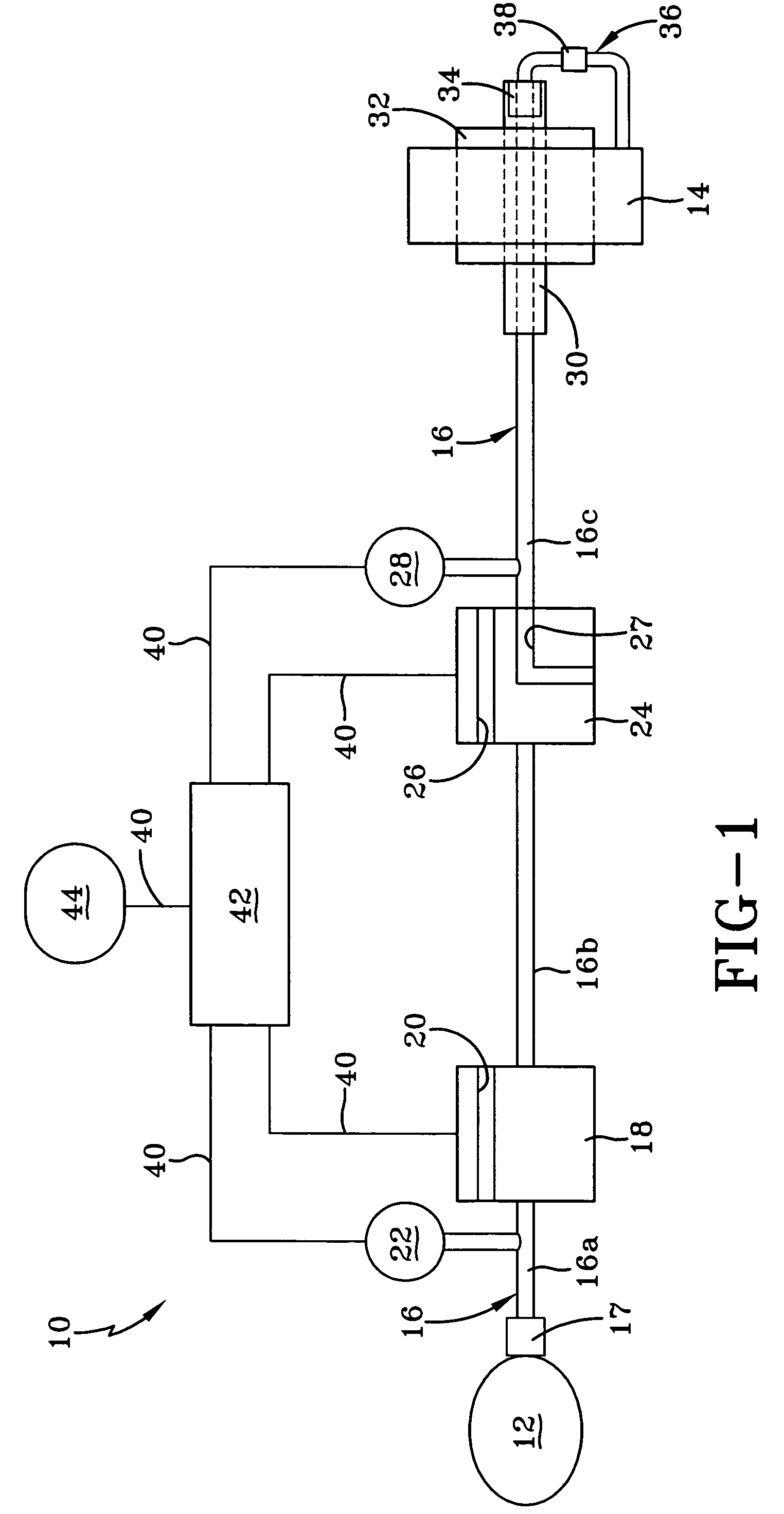

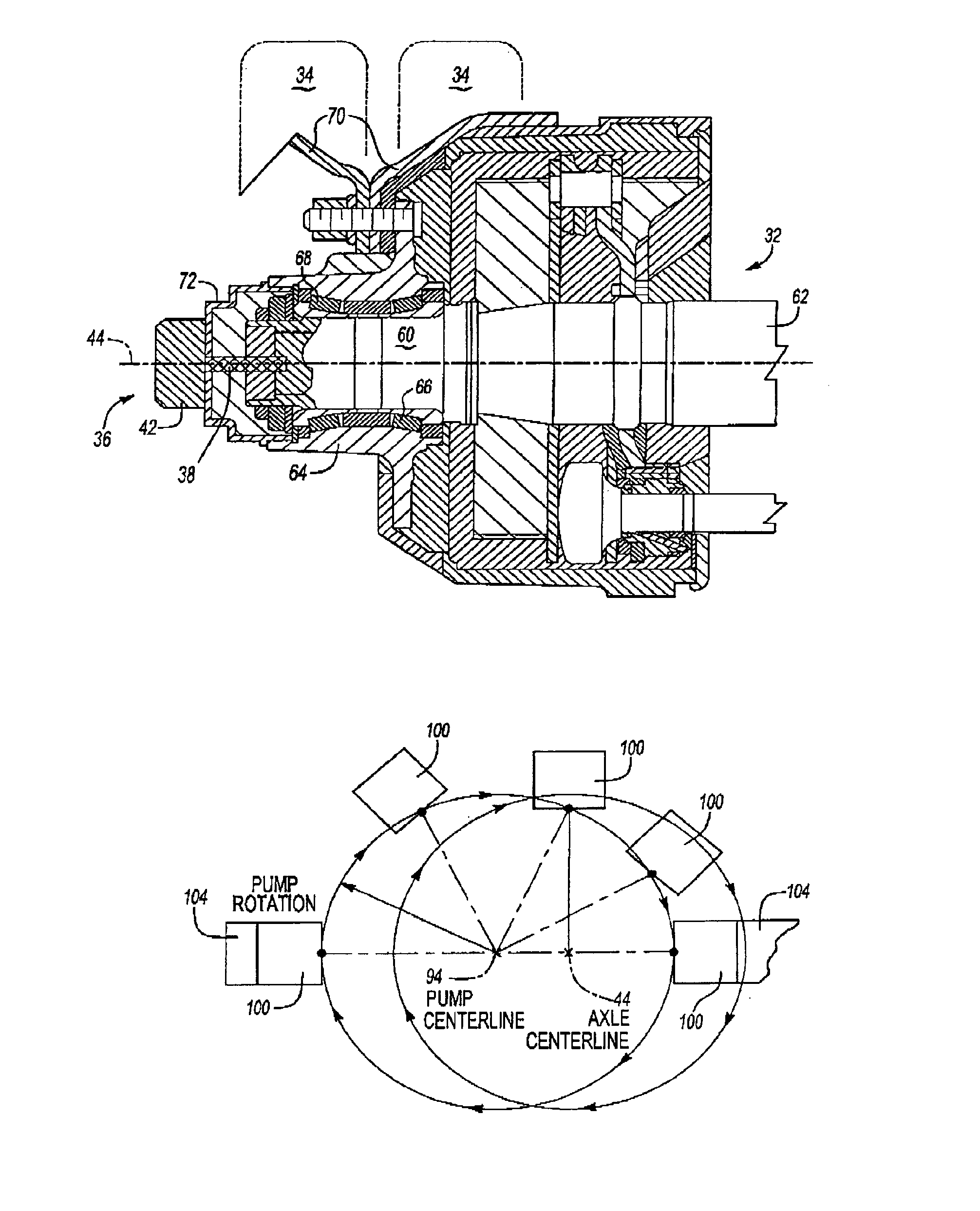

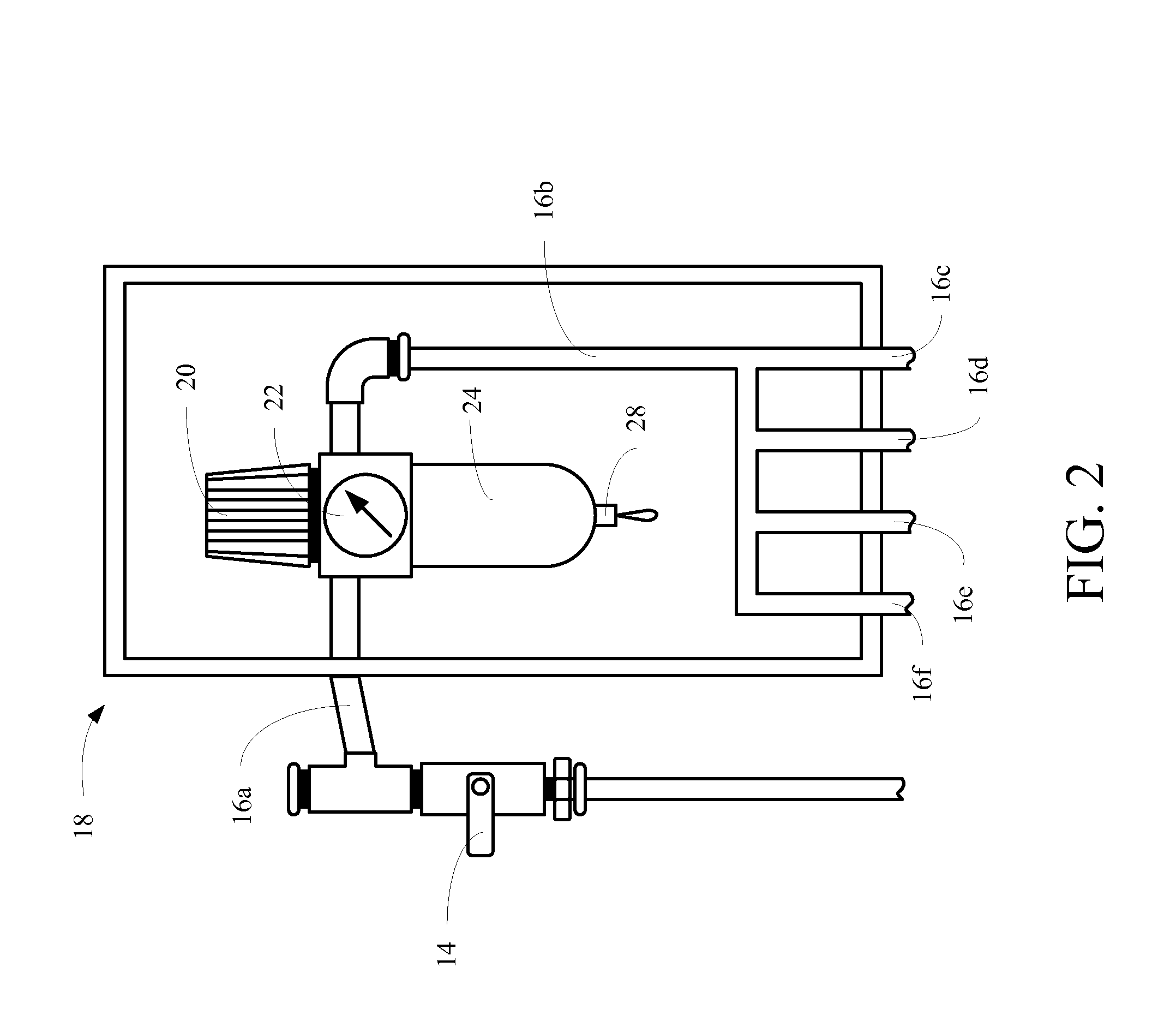

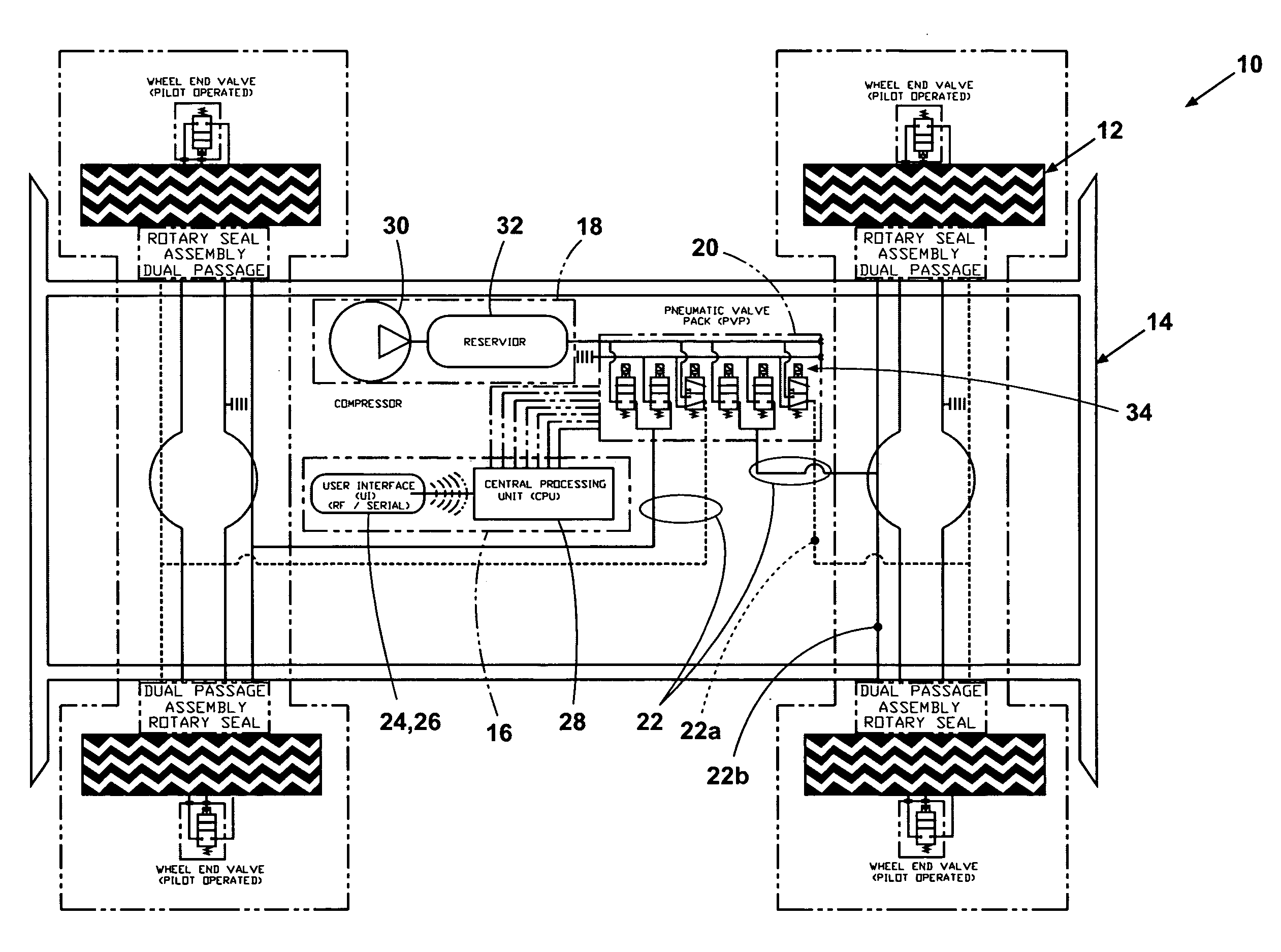

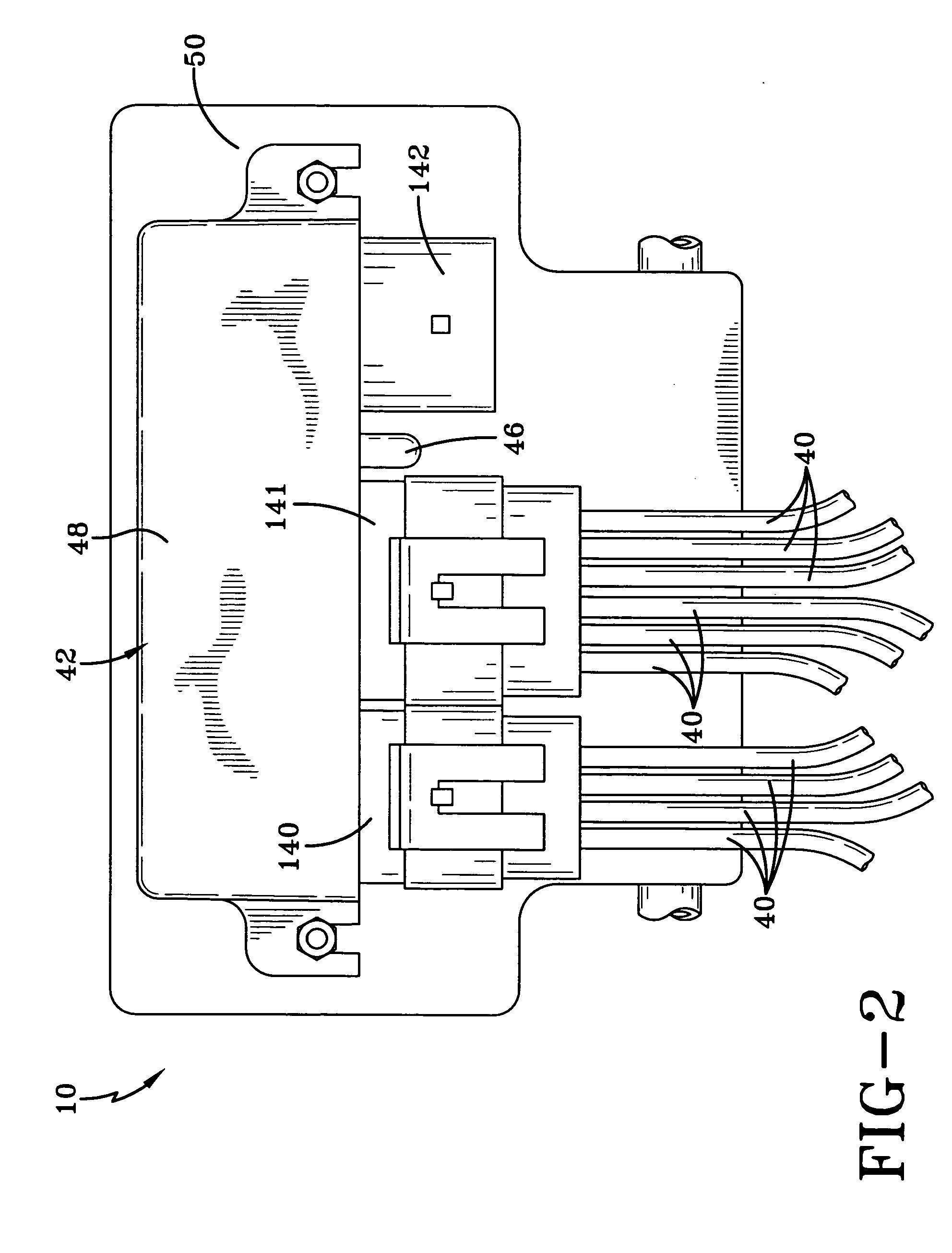

Tire inflation system apparatus and method

ActiveUS7273082B2Accurate checkAccurate pressureTyre measurementsTyre-inflating valvesEngineeringTire pressure

A tire inflation system includes an air supply source in selective fluid communication with a tire via a pneumatic conduit. A method of inflating the system includes providing a tire pressure retention valve in the pneumatic conduit adjacent to the tire. An inflation pressure of the tire is determined with a step-up procedure, in which air bursts are communicated from the air supply source to a portion of the pneumatic conduit between the air supply source and the tire pressure retention valve. The volume of at least one selected communicated air burst is related to a volume of a section of the conduit. The tire is inflated with an extended-pulse procedure, in which extended bursts of air are communicated from the air supply source to the tire. A shut-down sequence is performed once a predetermined target inflation pressure in the tire is reached.

Owner:HENDRICKSON USA L L C

Tire inflation system with integrated wheel seal

An axle assembly includes a non-rotating component and a wheel hub supported for rotation relative to the non-rotating component about an axis. The wheel hub includes a hub air passage that has a hub inlet and a hub outlet to be fluidly connected to at least one tire. An air chamber is formed at least in part between the non-rotating component and the wheel hub. The air chamber receives air flow from an air source and directs air flow into the hub inlet. A seal assembly engages the wheel hub to seal the air chamber.

Owner:ARVINMERITOR TECH

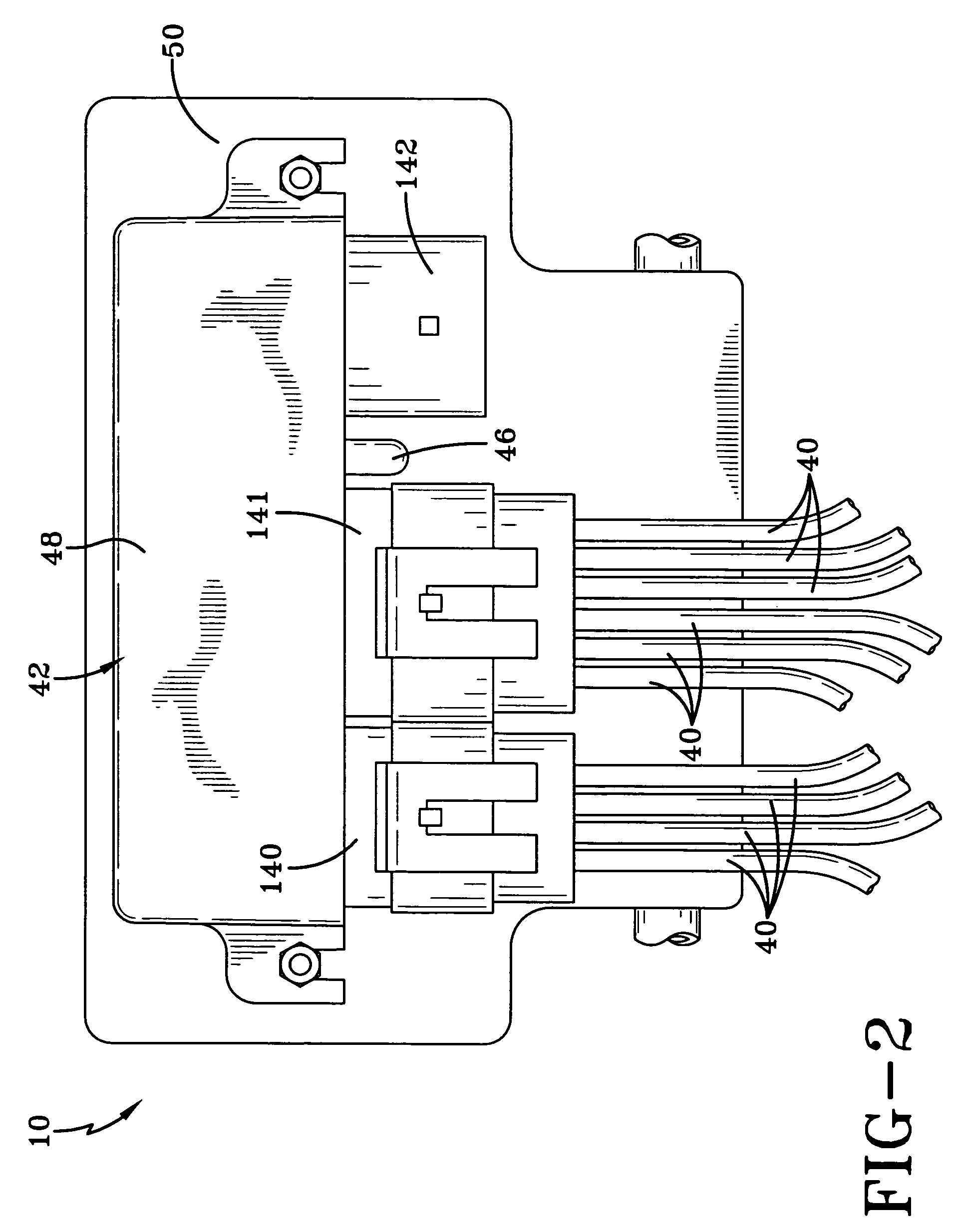

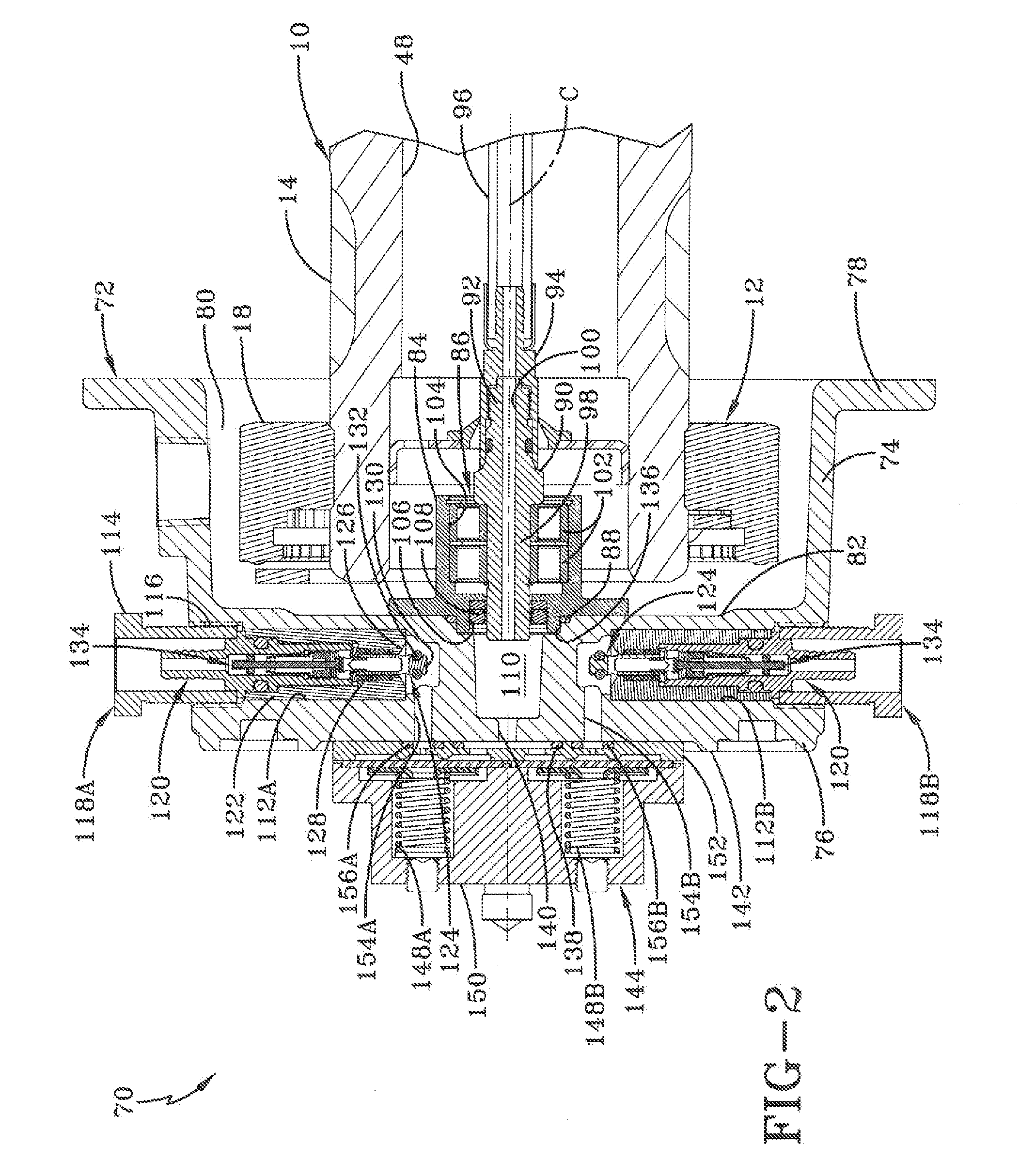

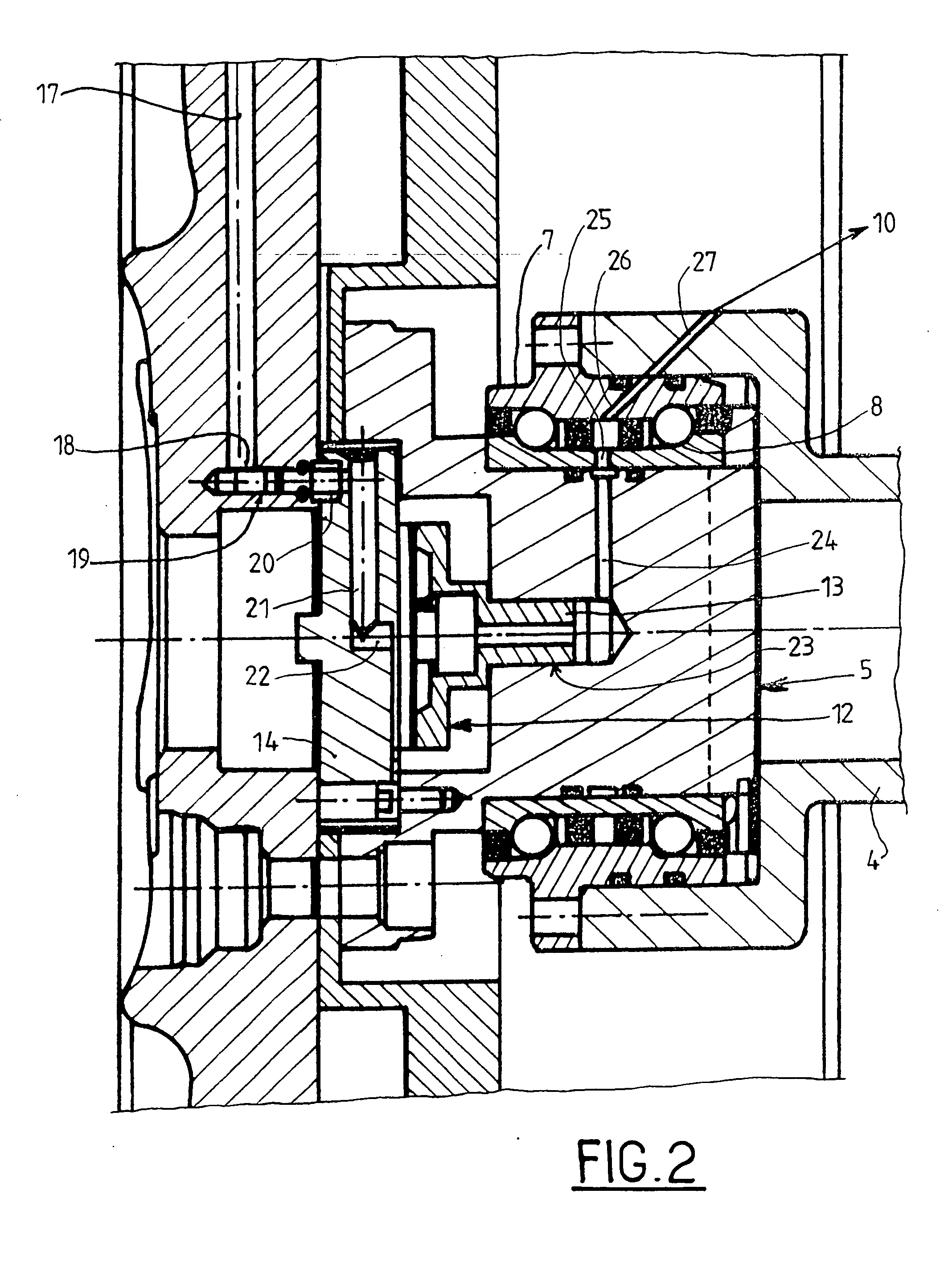

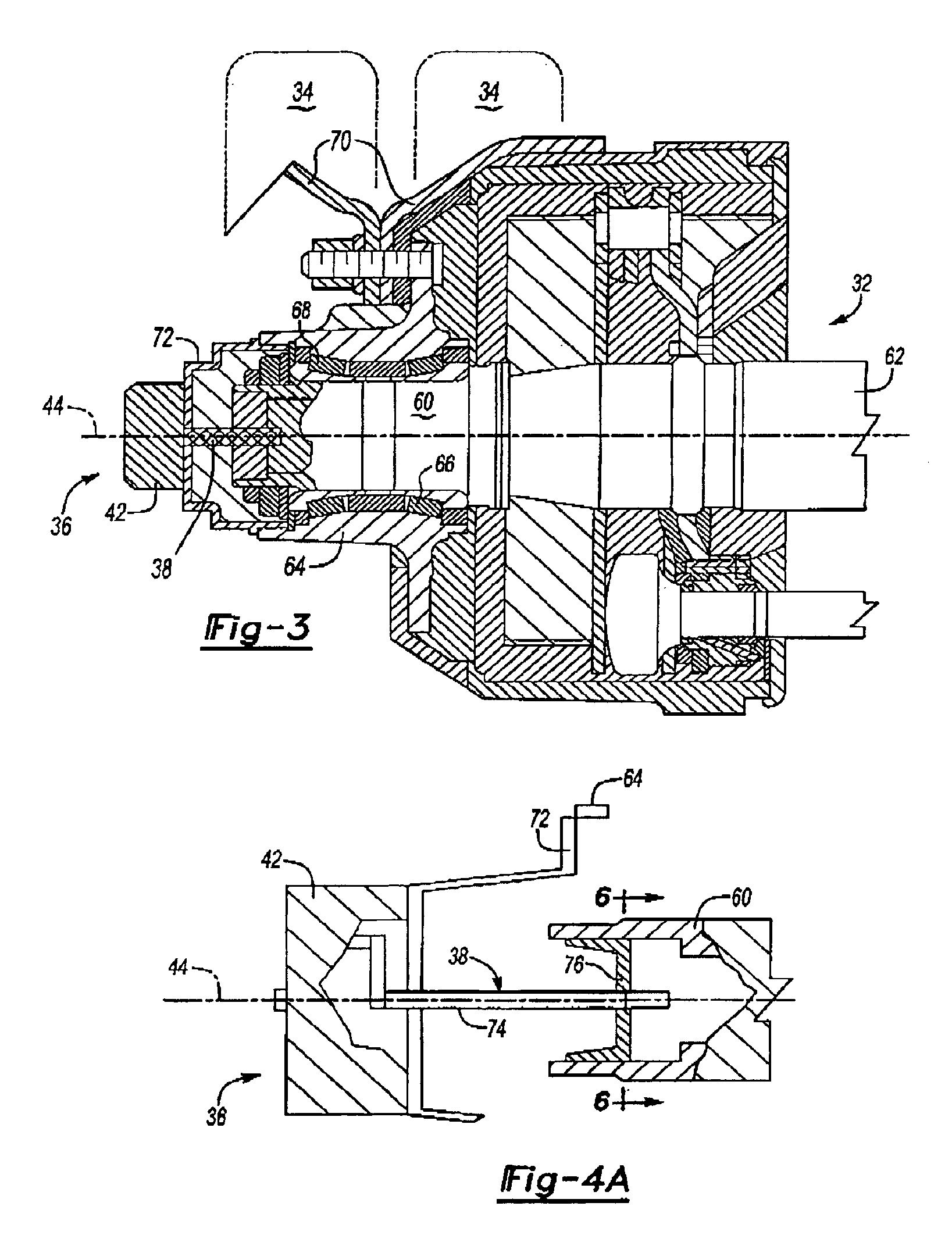

Integrated rotary union and hub cap

ActiveUS20090283190A1Easy to installReduce misalignmentTyre measurementsTyre-inflating valvesEngineeringHeavy duty

A rotary union is integrated into the interior of a heavy-duty vehicle hub cap. The hub cap includes a cylindrical sidewall, and an outboard wall that is integrally formed with an outboard end of the sidewall, and which extends generally perpendicular to the sidewall. The hub cap also includes a radially-extending flange that is formed on an inboard end of the sidewall, which receives fasteners to mount the hub cap on a wheel hub. The sidewall and the outboard wall form an interior compartment in the hub cap, and a rotary union is mounted to the hub cap in the interior compartment. The rotary union is mounted on the inboard surface of the outboard wall of the hub cap and is in general axial alignment with an axial centerline of a wheel end assembly, providing fluid communication from a tire inflation system to the tires of the vehicle.

Owner:HENDRICKSON USA L L C

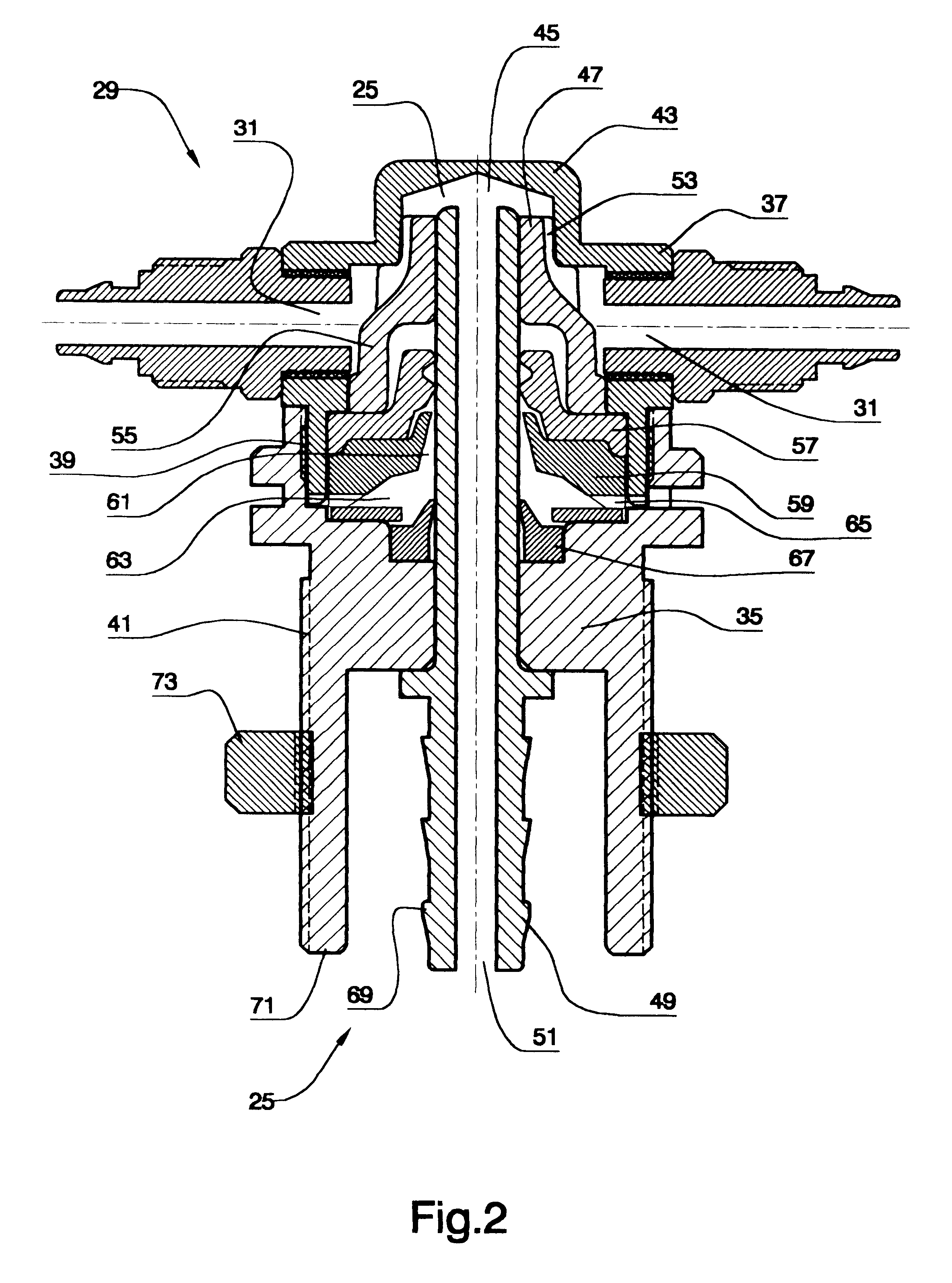

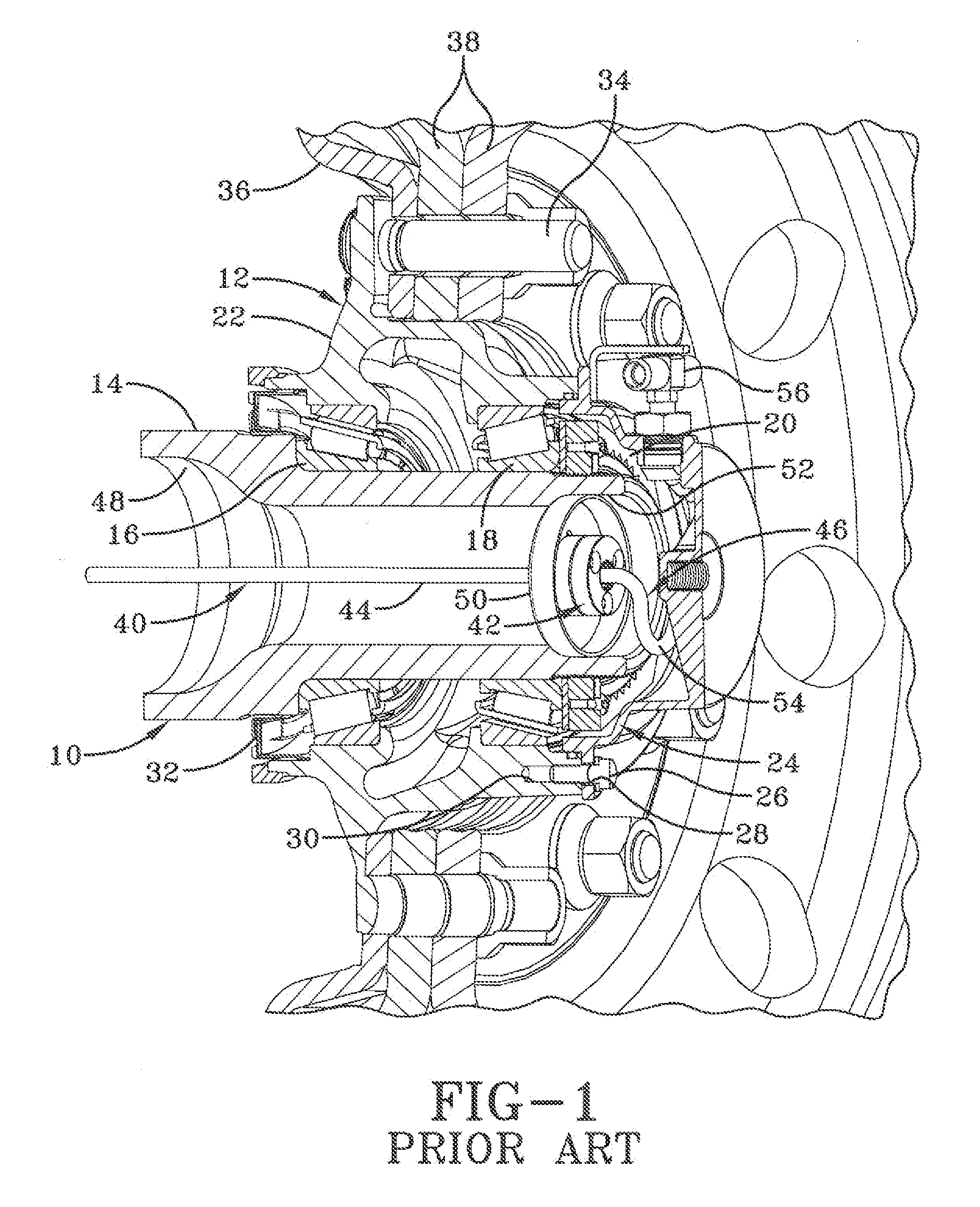

Pneumatic rotary wheel coupling

InactiveUS6325124B1Avoid exposing the wheel's bearingsTyre measurementsTyre-inflating valvesControl theoryWheel and axle

A pneumatic rotary coupling (25) for an air pressure installation for one or more wheels of a vehicle, in which the wheel's axle (11) is used as the section of the pipe of the static installation, in accordance to the system of the coupling used. The coupling's stem (49) has one end formed in the shape of a nozzle which extends in the plane of the wheel, disposed as an axial extension of the wheel's axle end. The stem is located rotatable and slidable inside block (35) which is fixed to the wheel's hub cover. A cover (37) fixed to the block presents a cavity (45) with an edge that defines a seat for a plastic bushing (47) that supports the coupling's stem. The external surface of this bushing is conformed by grooves (53) that communicate the cavity towards the orifices linking with the tires. One method allows for the detection of bearing faults using the same coupling when the axial sliding of the stem is sufficient to vent the pressurized air.

Owner:COL VEN

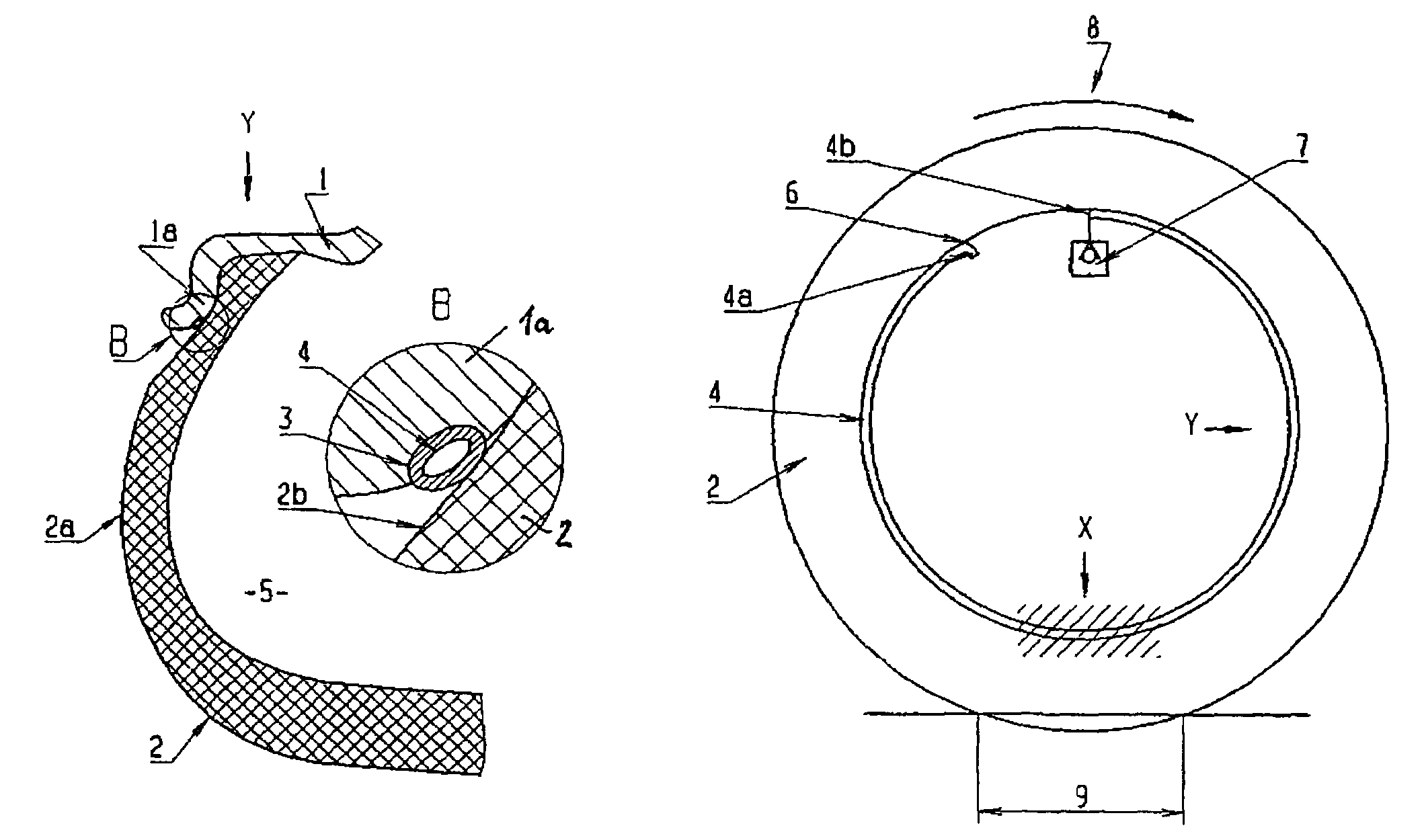

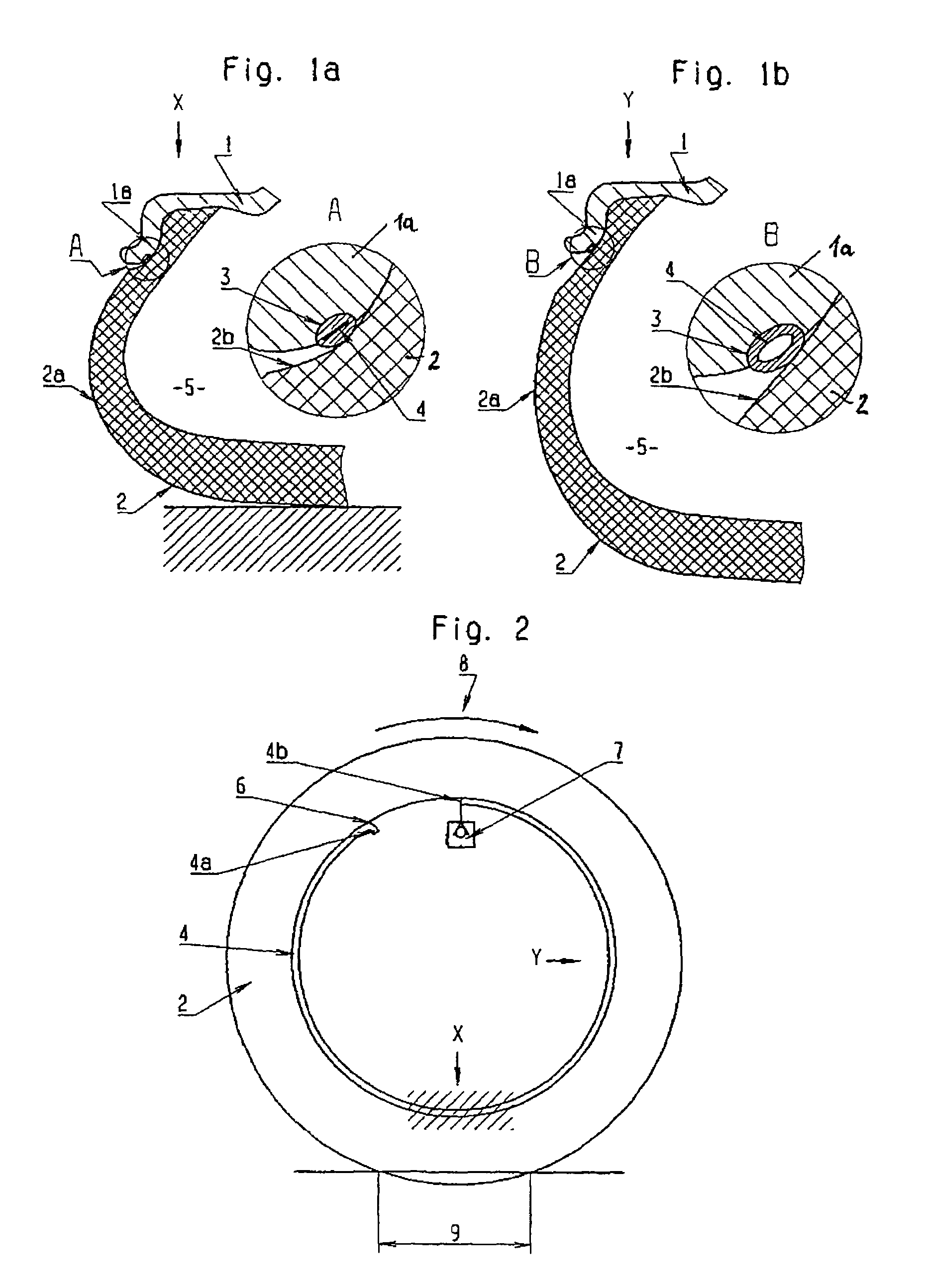

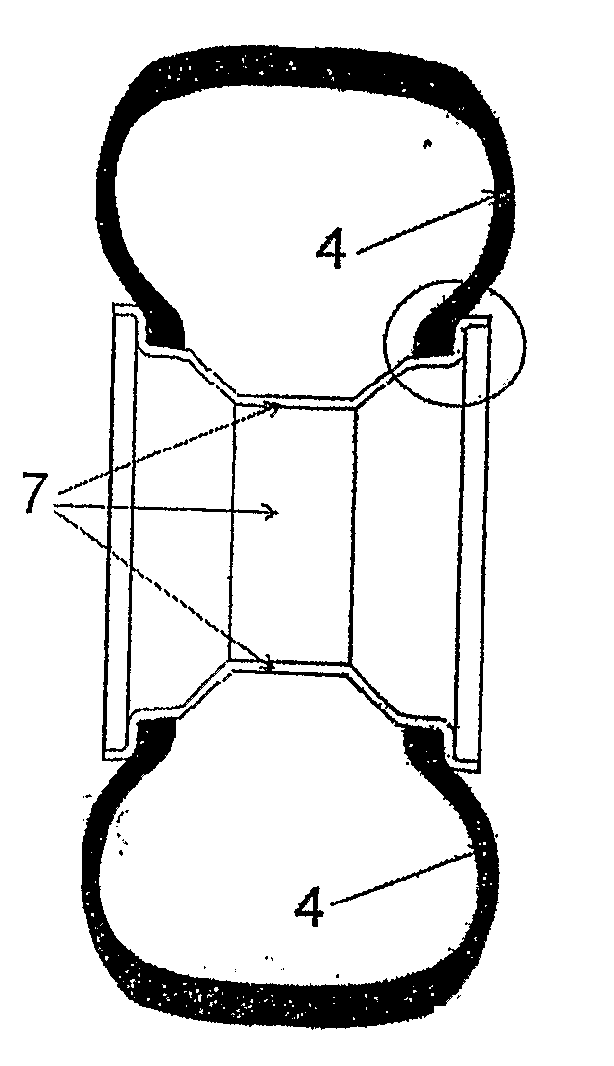

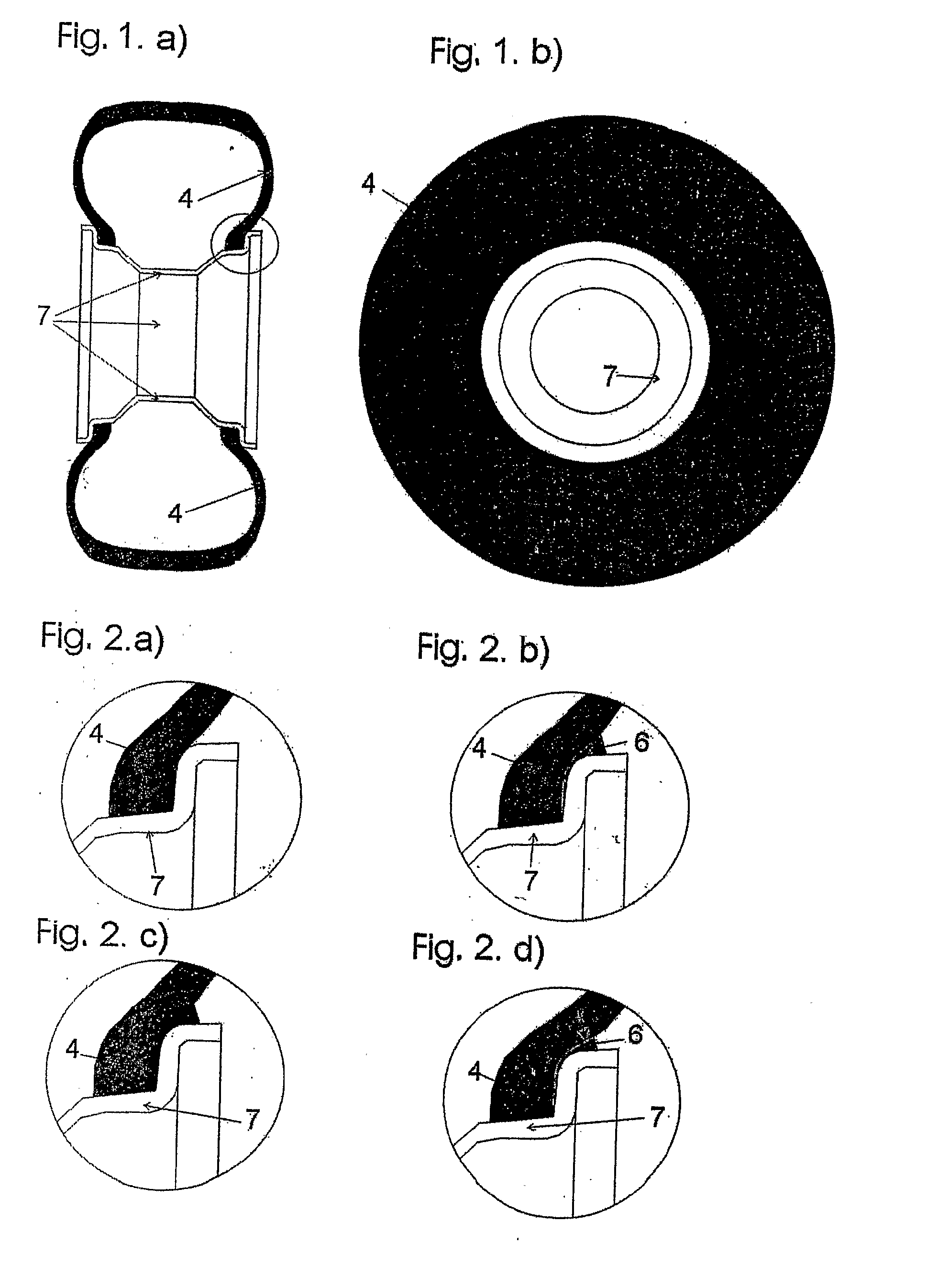

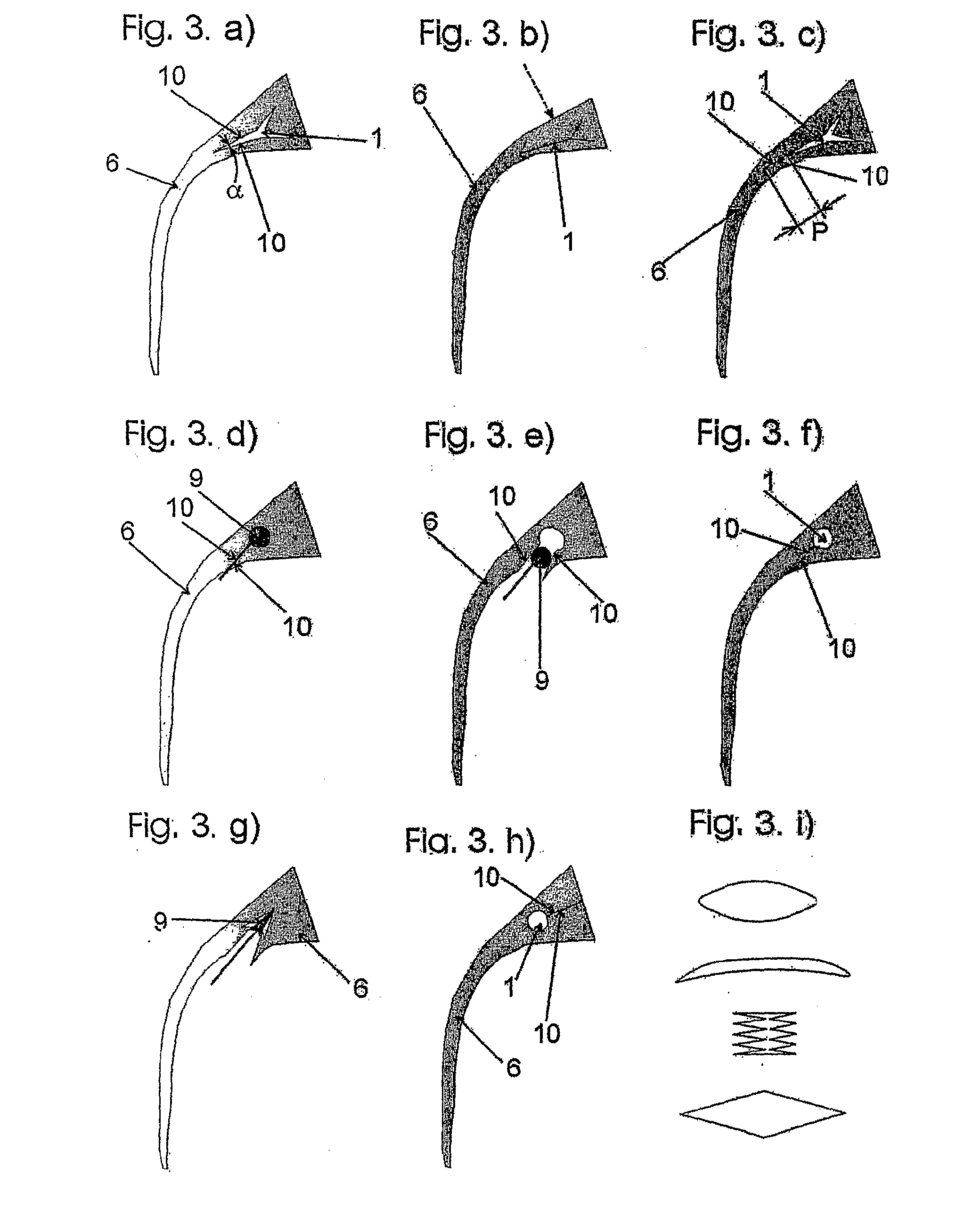

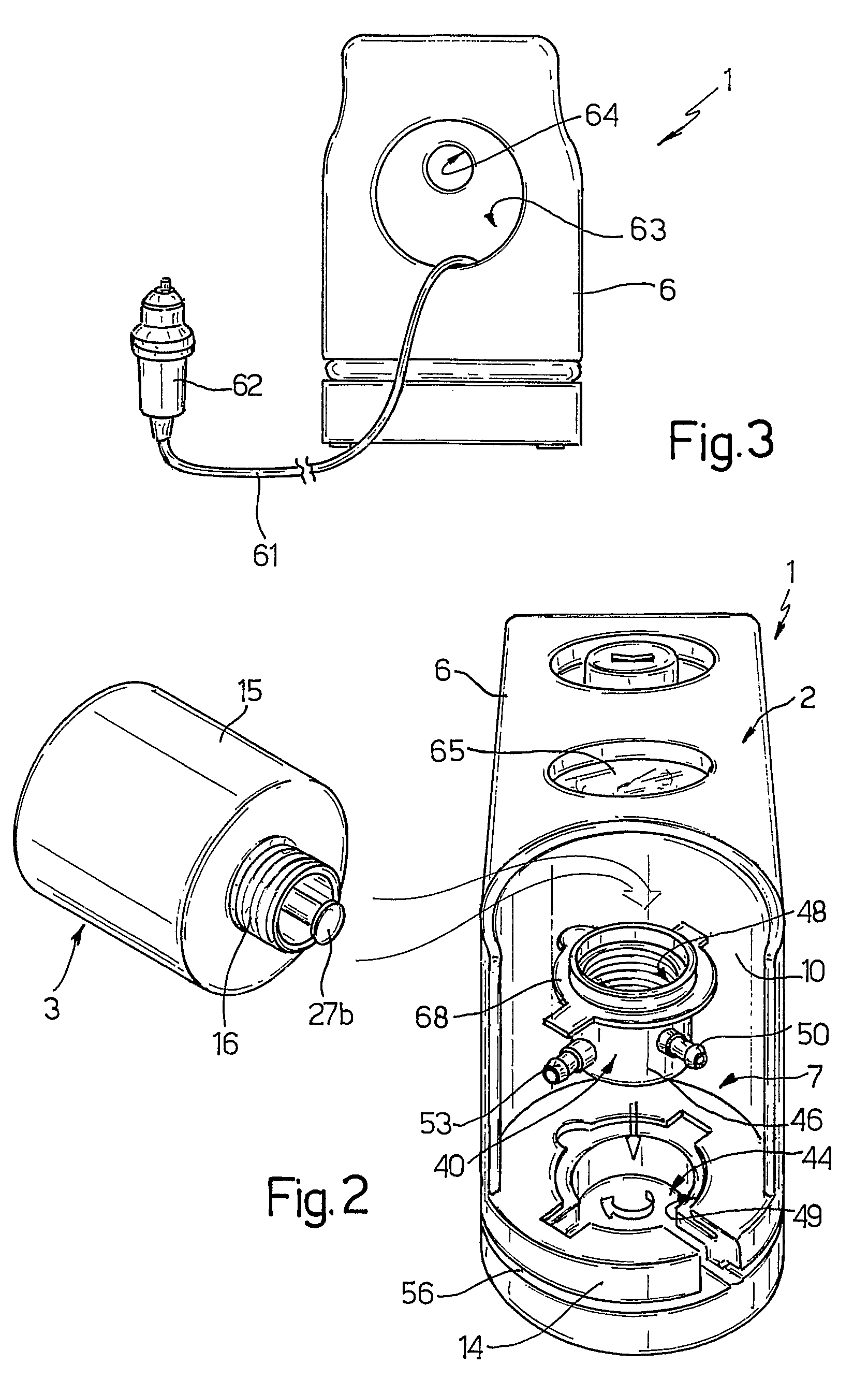

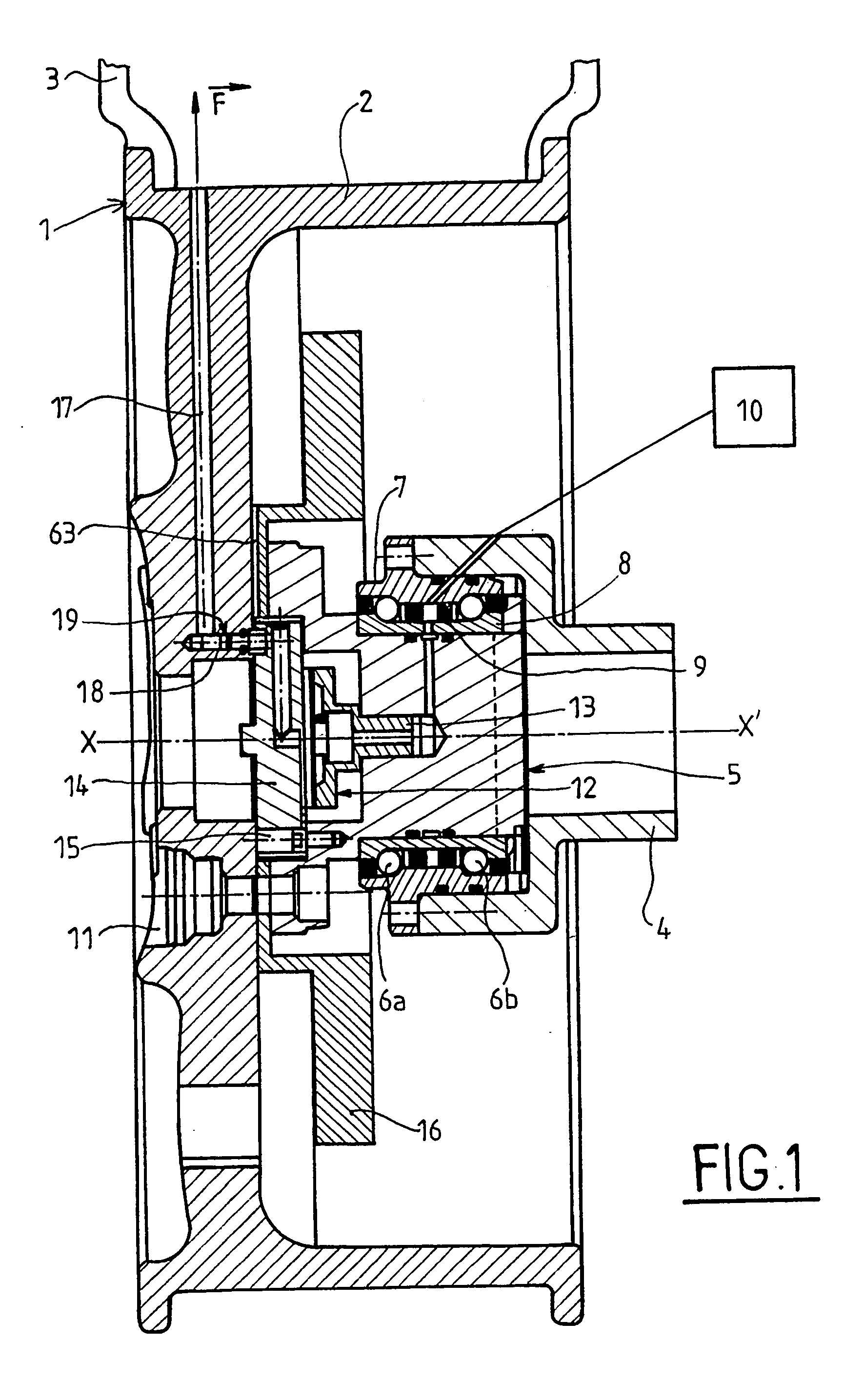

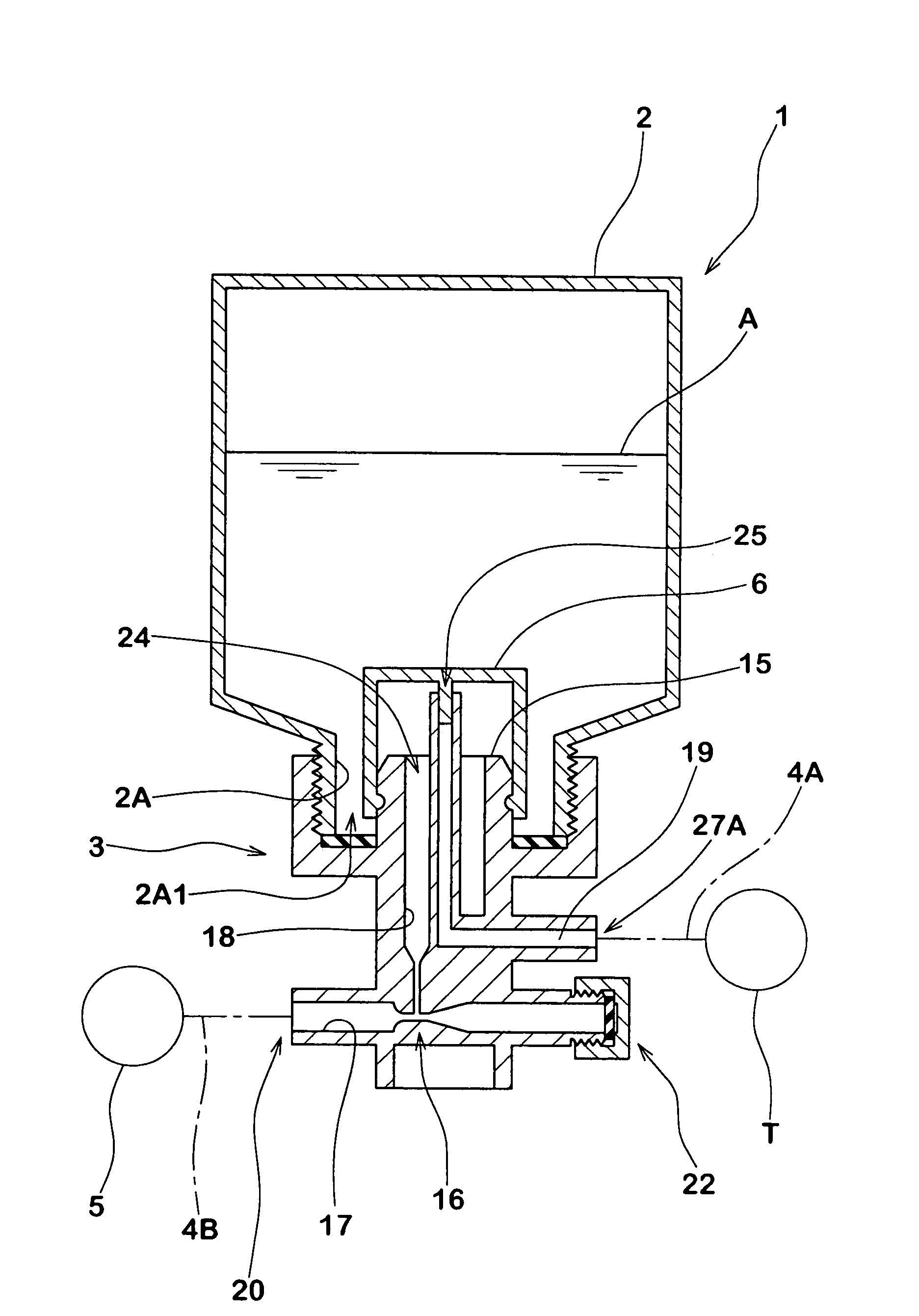

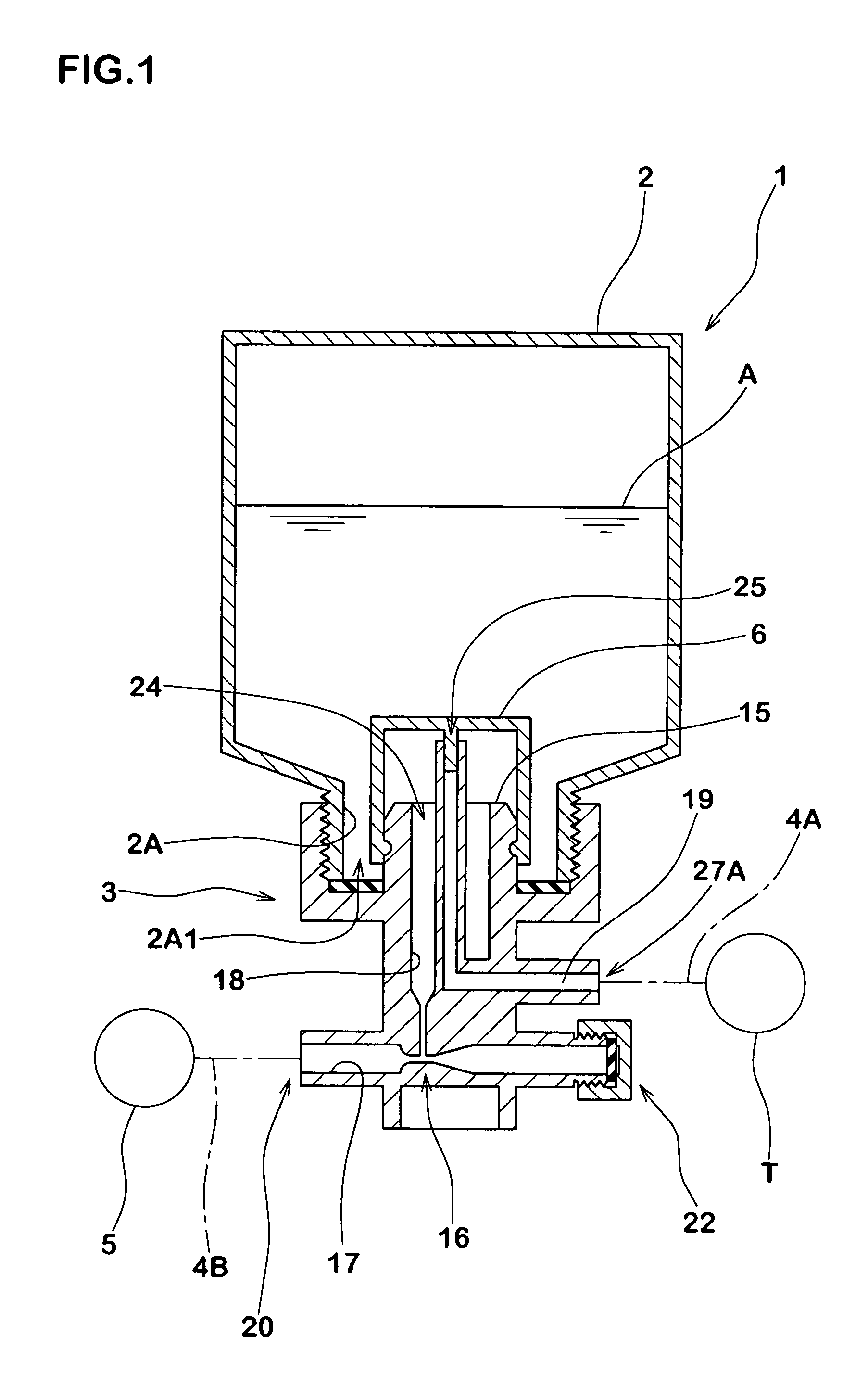

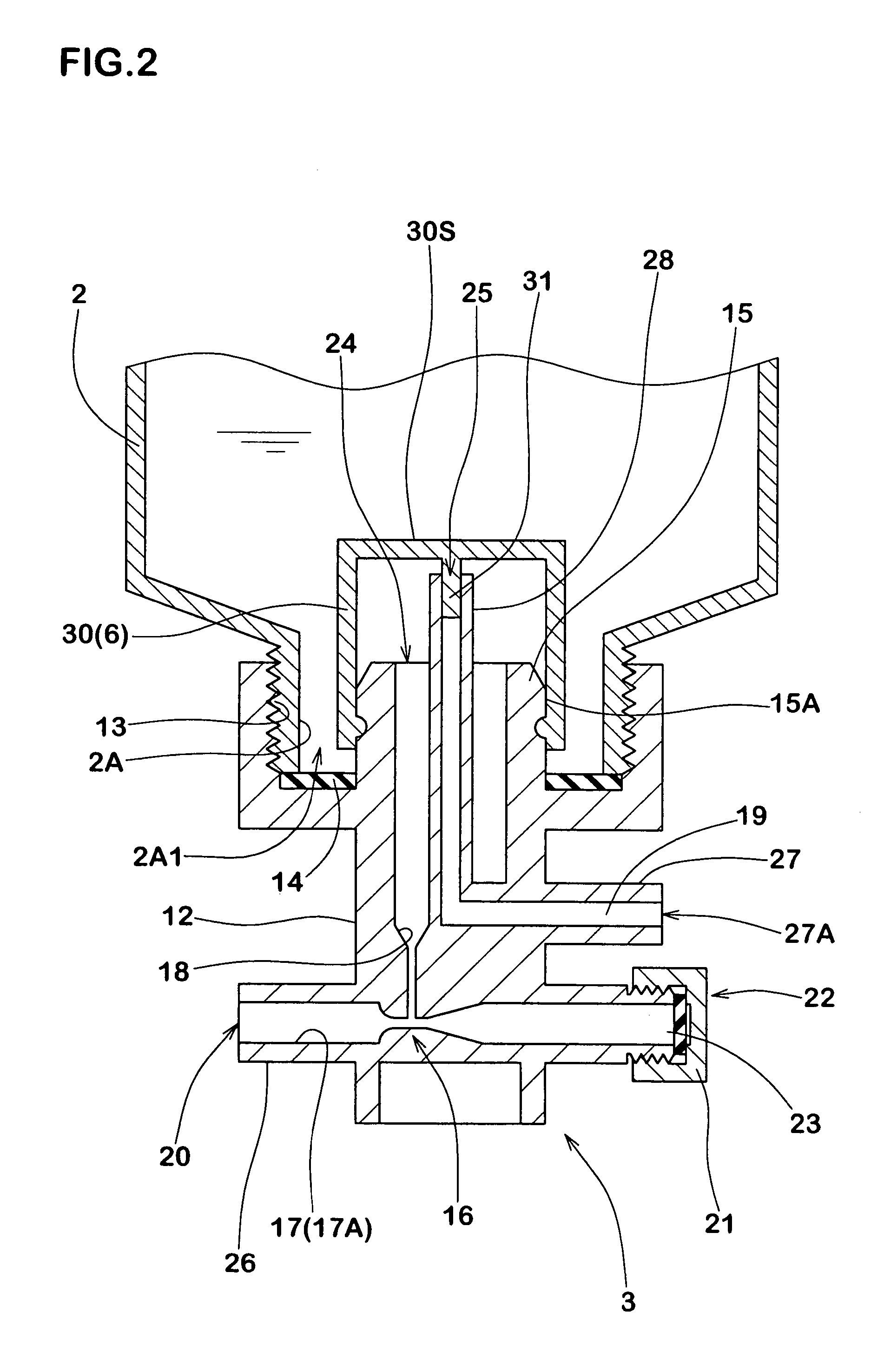

Chamber of a peristaltic pump for tire pressure adjustment

InactiveUS20090294006A1Effective shapingReduced service lifeTyresTyre beadsTire beadPeristaltic pump

A chamber (1) that works as a peristaltic pump for the pressure correction in the tire (4), which is a part of the tire (4) or of an ancillary structure (6) placed between the rim (7) and the tire bead (4) and is connected with the tire (4) internal space at one end and with the external environment at the other end. The chamber (1) is in the shape of a curved hollow channel, where at least one enclosing wall is at least partially formed by at least a pair of surfaces (10) coplanar with the longitudinal direction of the chamber (1). When the tire is mounted on the rim, the pair of surfaces (10) are pressed together thus hermetically closing the chamber (1). When the chamber (1) is closed during rotation of the wheel, the surfaces (10) can slightly slide on one another taking internal wall tensions onto themselves thus decreasing the possibility of wall damage through ripping. A method of producing the chamber (1) is also disclosed.

Owner:CODA INNOVATIONS SRO

Constant pressure pneumatic balancing tire inflation system

A constant pressure vehicle tire inflation system includes an air supply source. A first wheel valve is in fluid communication with a first tire of the vehicle, and a second wheel valve is in fluid communication with a second tire of the vehicle. A pneumatic conduit extends between and is in fluid communication with the air supply source and the wheel valves. At least a portion of the pneumatic conduit remains charged with air from at least one of the supply source and the tires. The system includes means for distributing air flow between the pneumatic conduit and the first and second wheel valves, in which the wheel valves and the means selectively maintain fluid communication between the first and second tires and the pneumatic conduit to provide pneumatic balancing between the tires, and the wheel valves provide emergency protection when a tire experiences significant pressure loss.

Owner:HENDRICKSON USA L L C

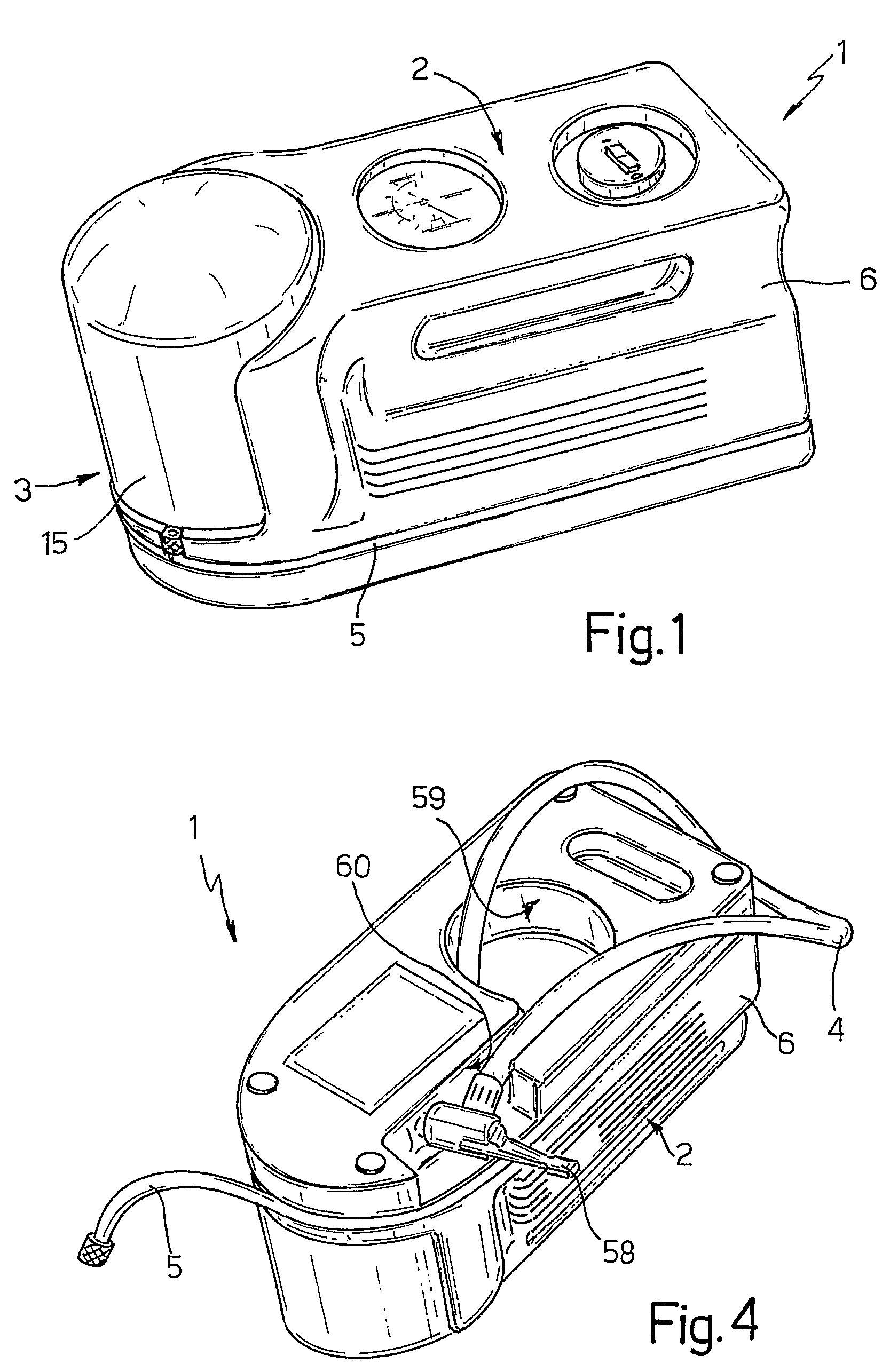

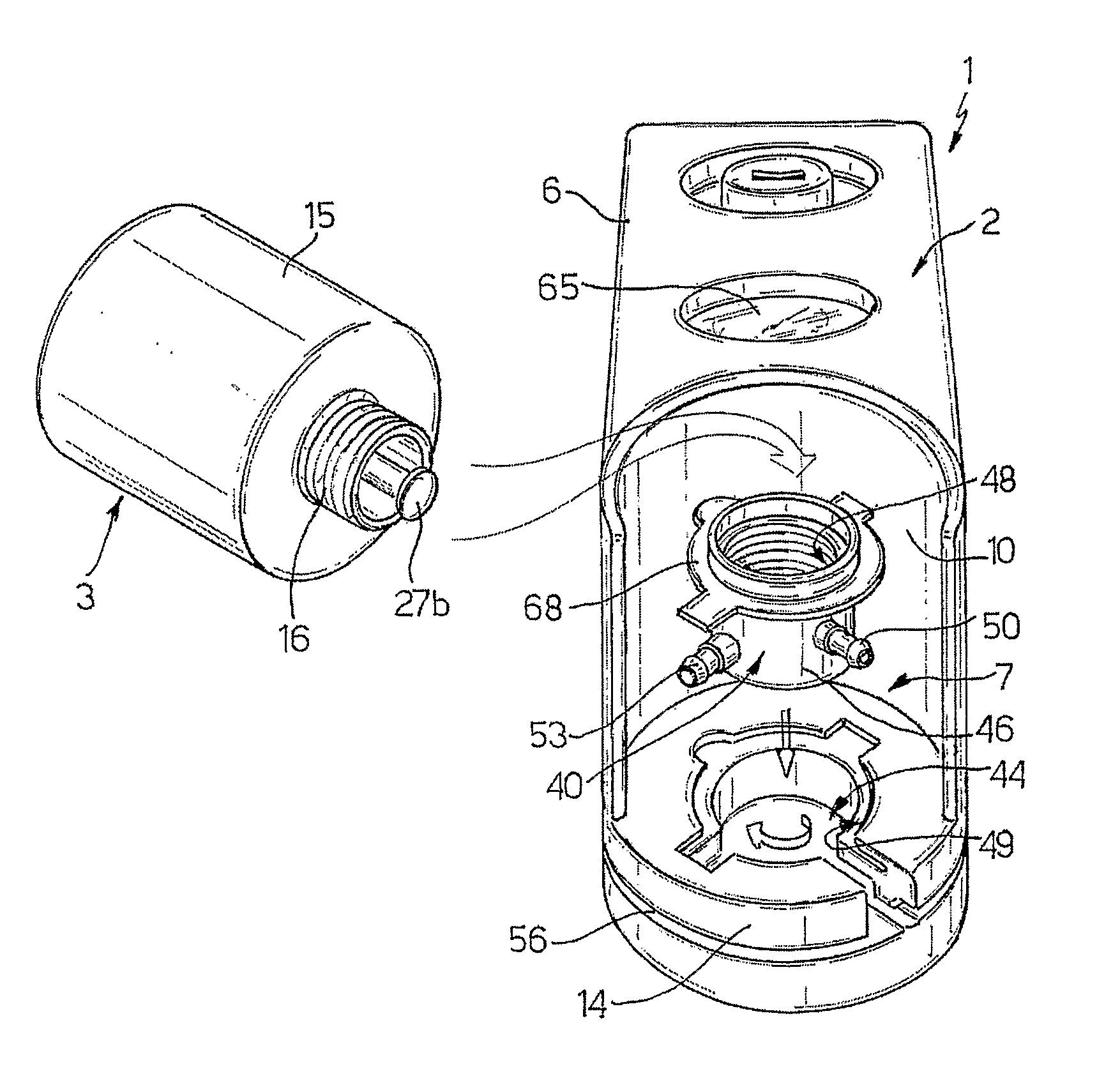

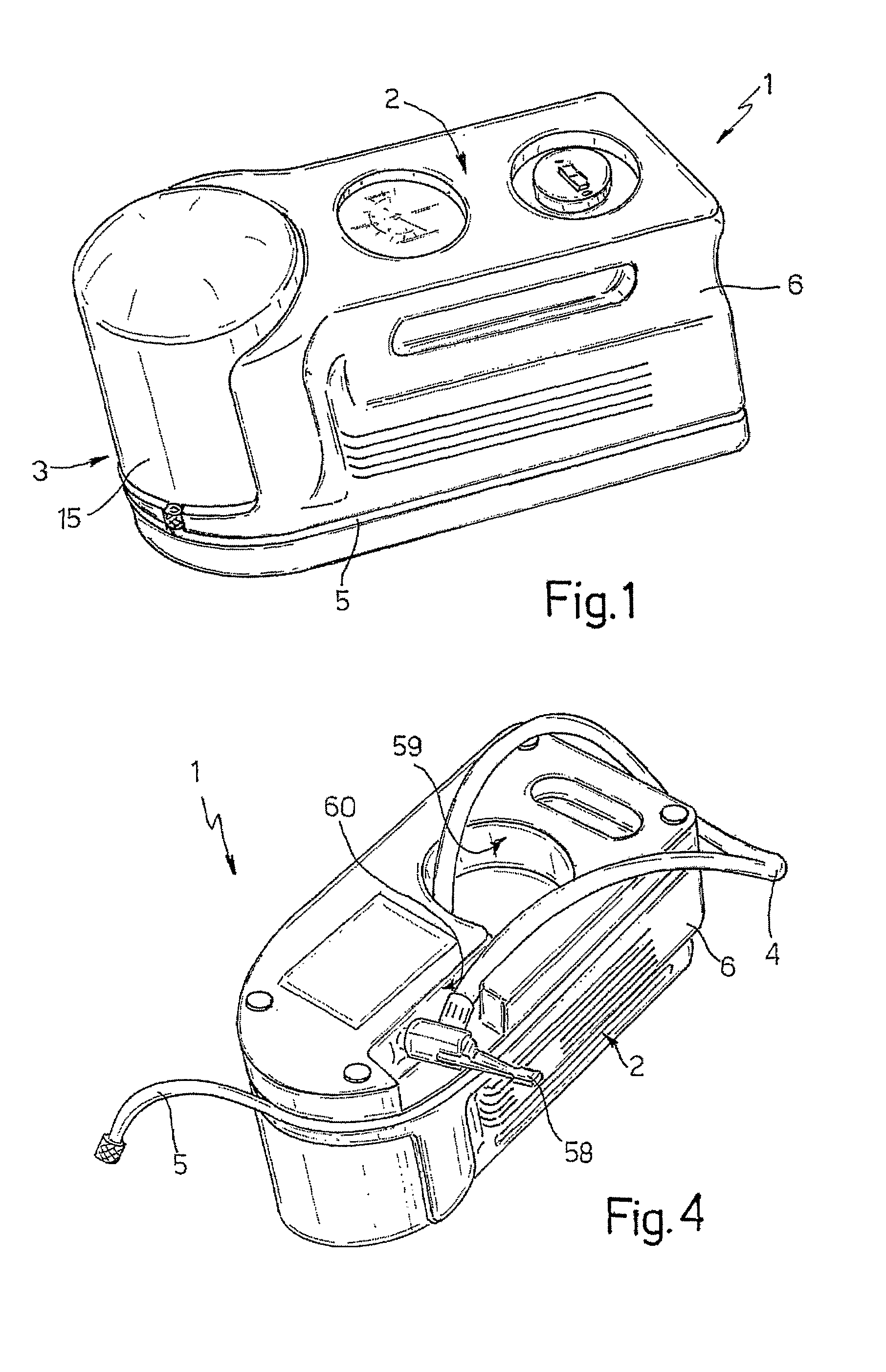

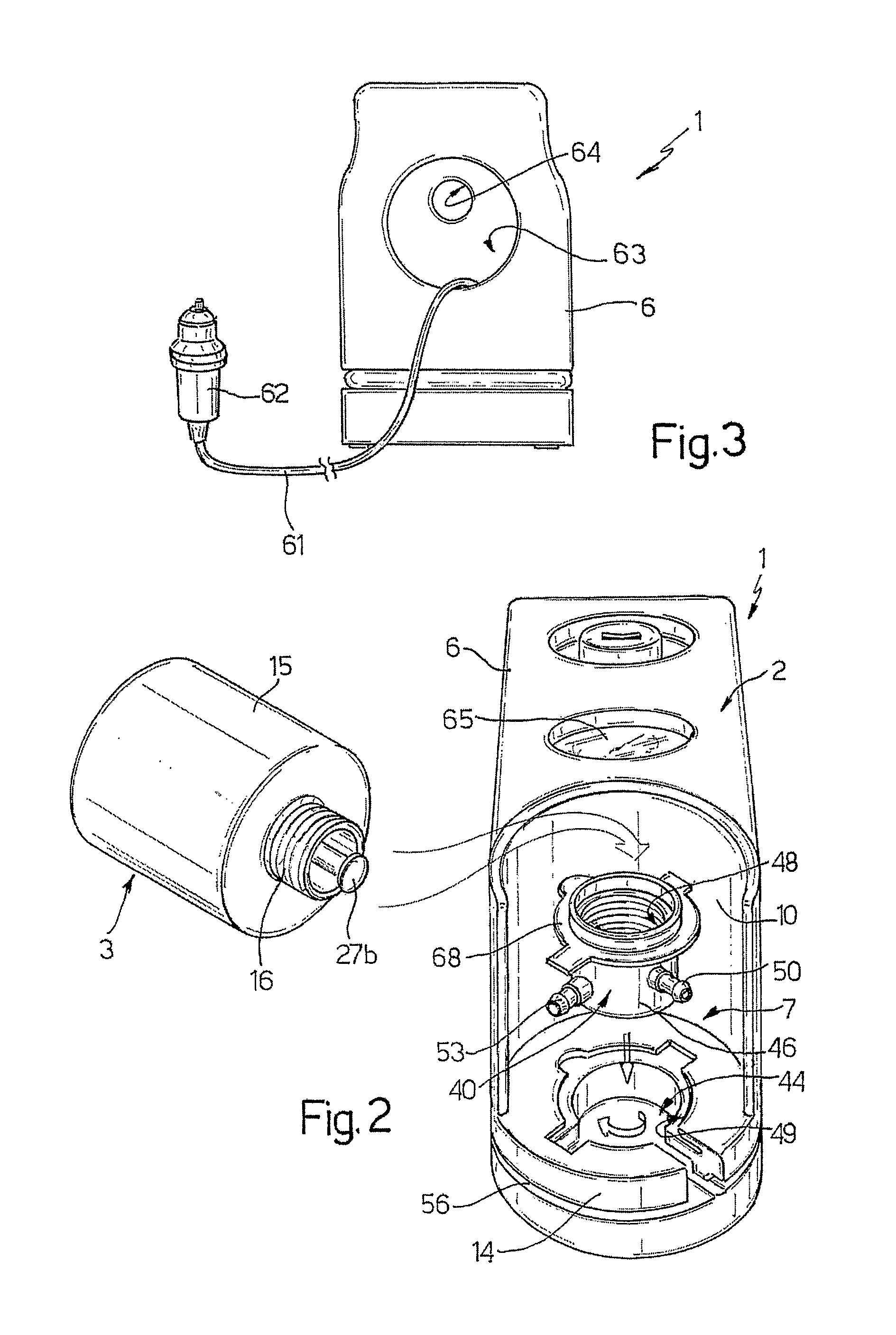

Kit for inflating and repairing inflatable articles, in particular tyres

A kit for inflating and repairing inflatable articles, in particular tires, the kit having a compressor assembly, a container of sealing liquid and connectors for connecting the container to the compressor assembly and to an inflatable article for repair or inflation; the compressor assembly being housed in an outer casing defining a seat for the container of sealing liquid. The container is housed removably in the seat and functionally connected to the compressor assembly so as to form a compact unit ready for use.

Owner:TEK GLOBAL SRL

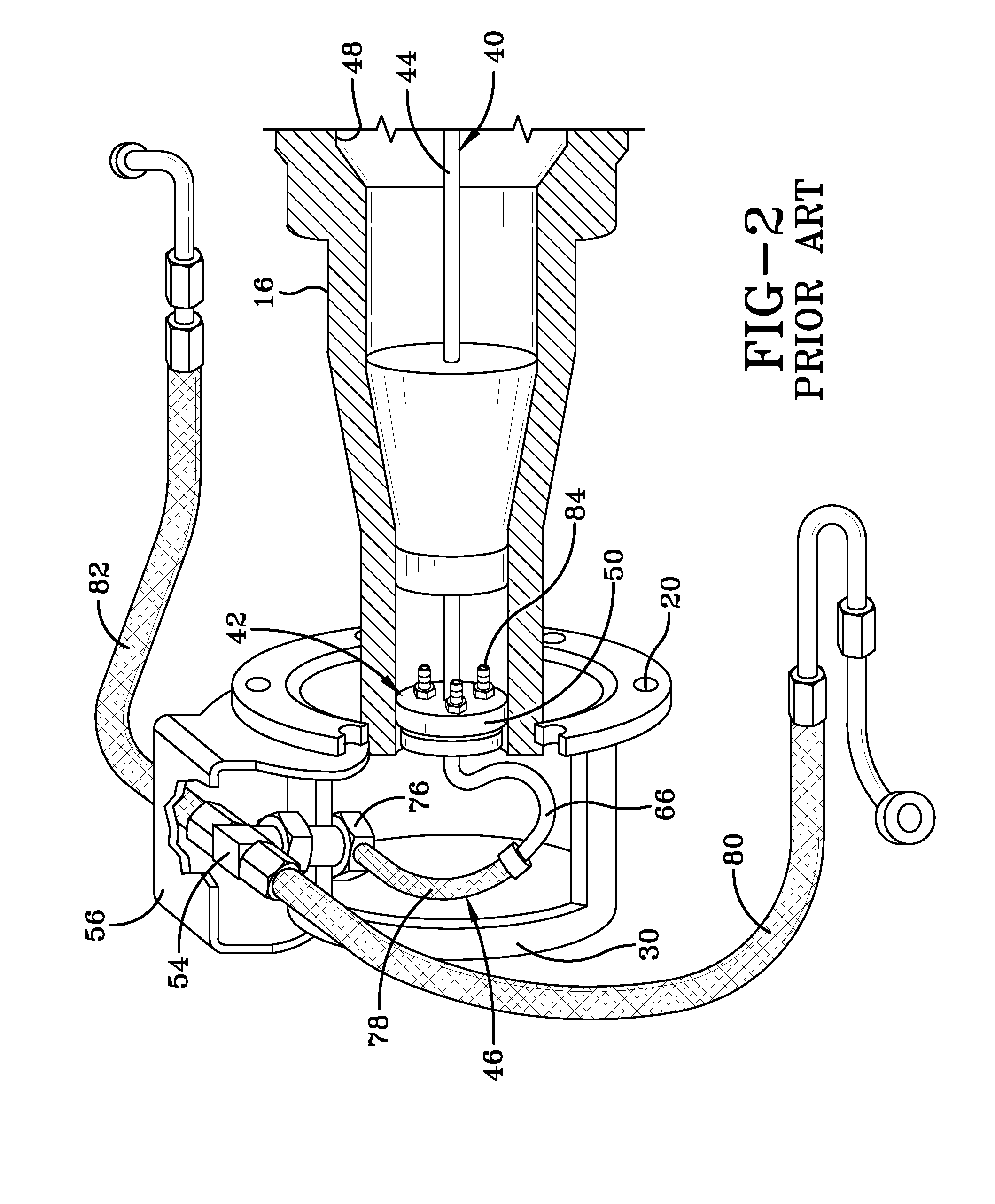

Integrated compressor-tire sealant injection device with large mouth sealant container

ActiveUS7798183B2More dispensing orientationsWide mouthLiquid fillingLiquid flow controllersLarge mouthComposite material

An integrated compressor-tire sealant injection device with a sealant container and a compressor is provided. The integrated compressor-tire sealant injection device has a compressor unit that has a compressor and a connector to a bottle of sealant integrated into the compressor unit so that a bottle of sealant is connectable to the device to inflate a tire wherein the connector has first and second ball valves.

Owner:ACCESSORIES MARKETING INC

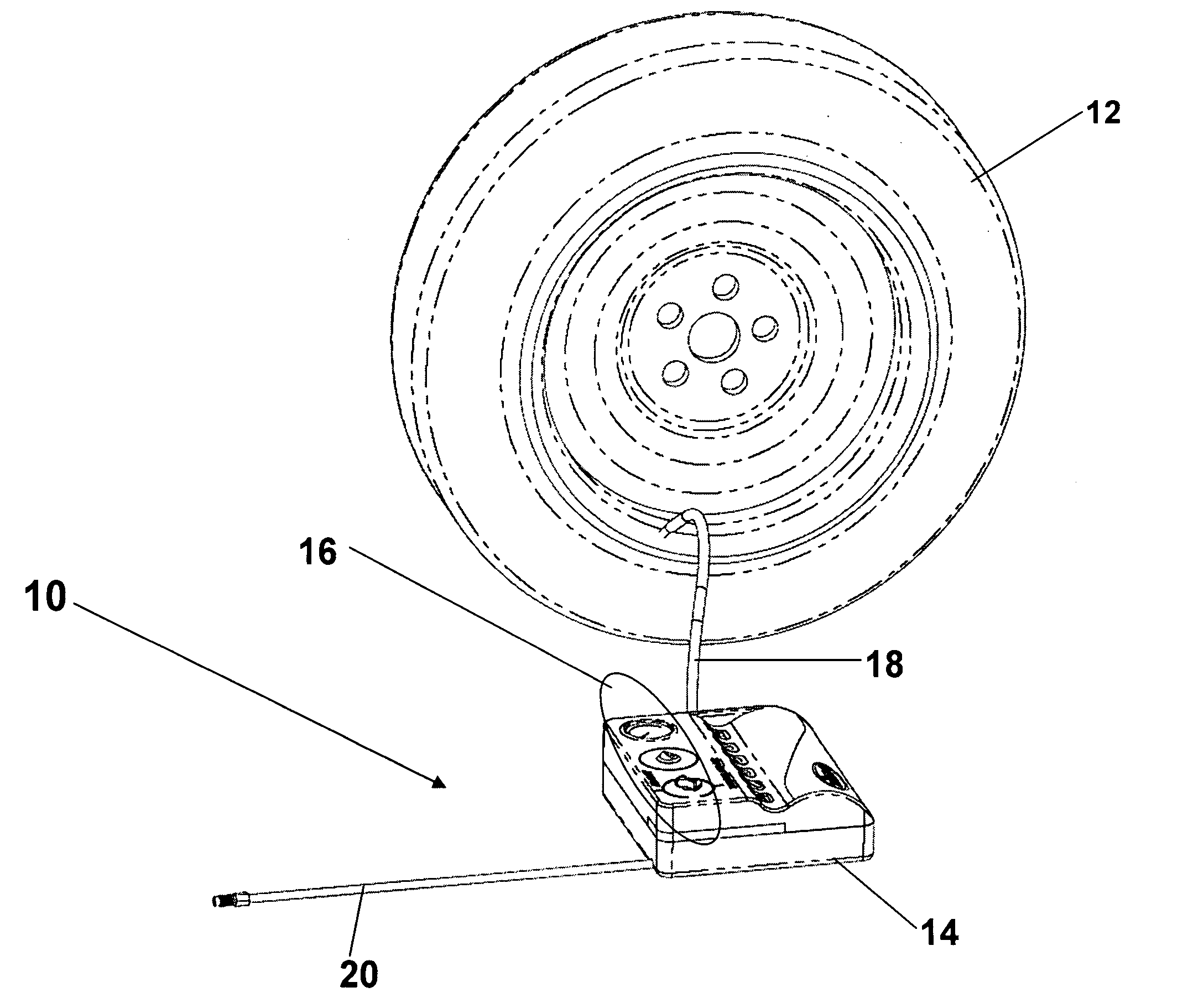

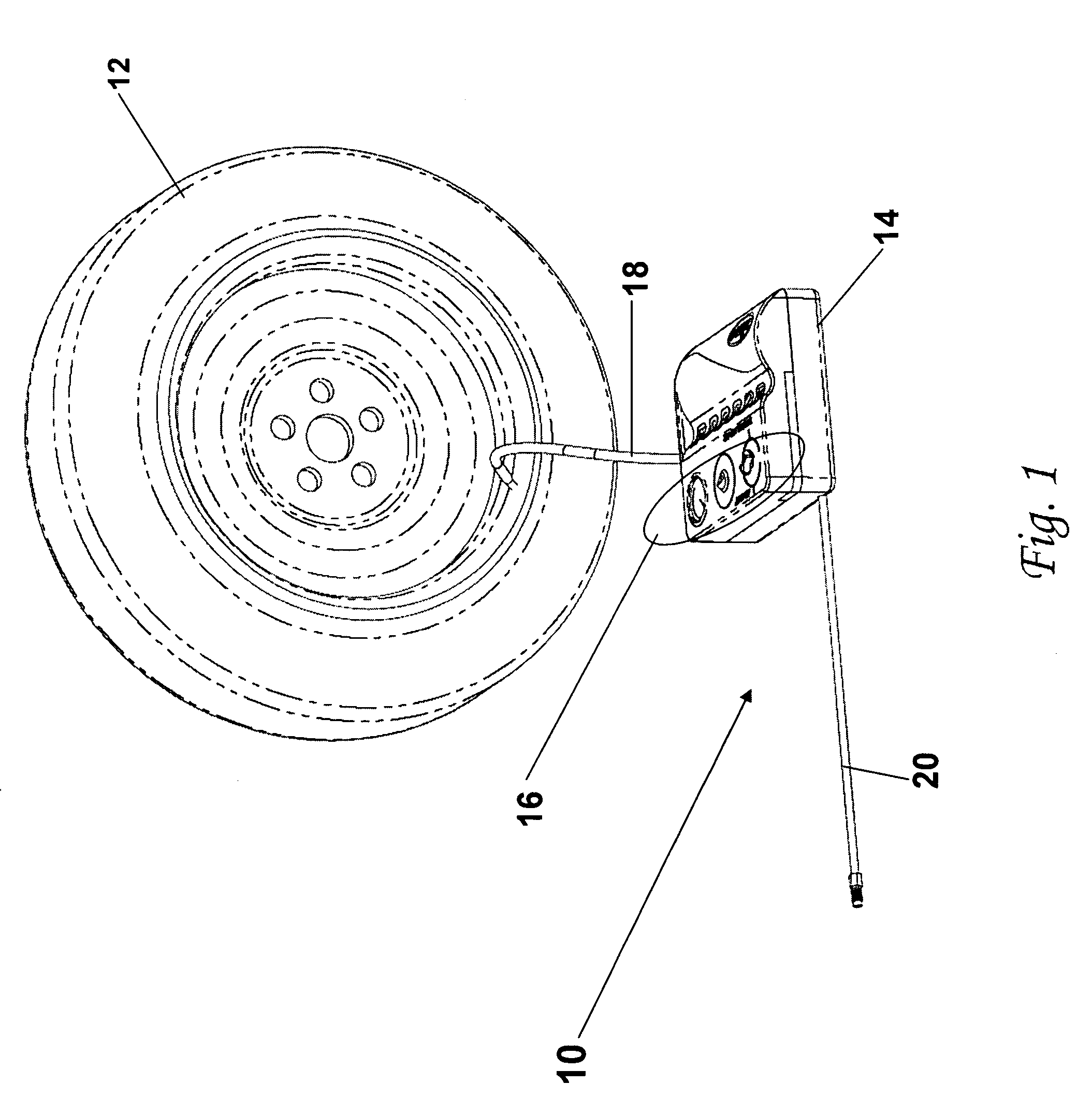

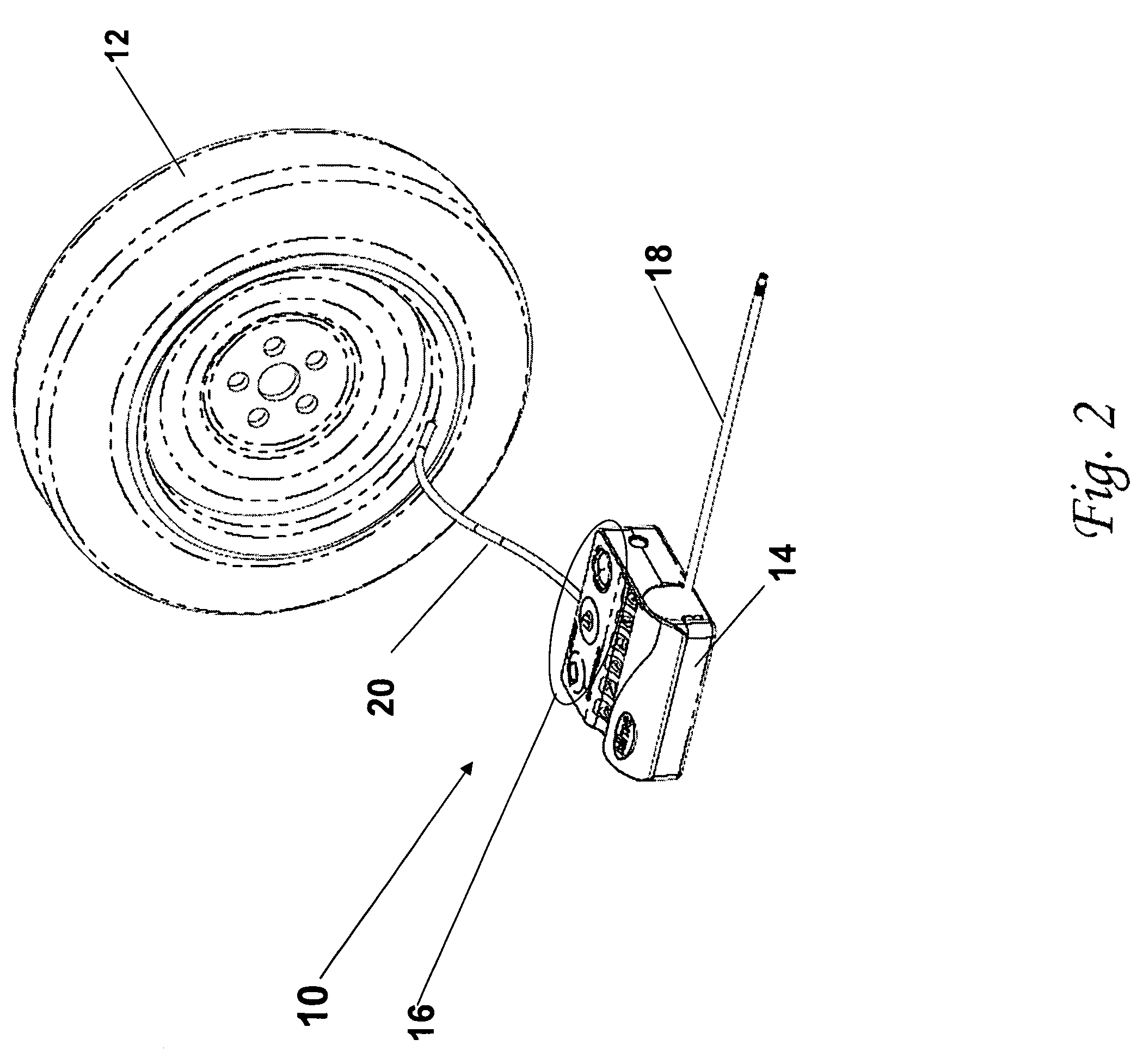

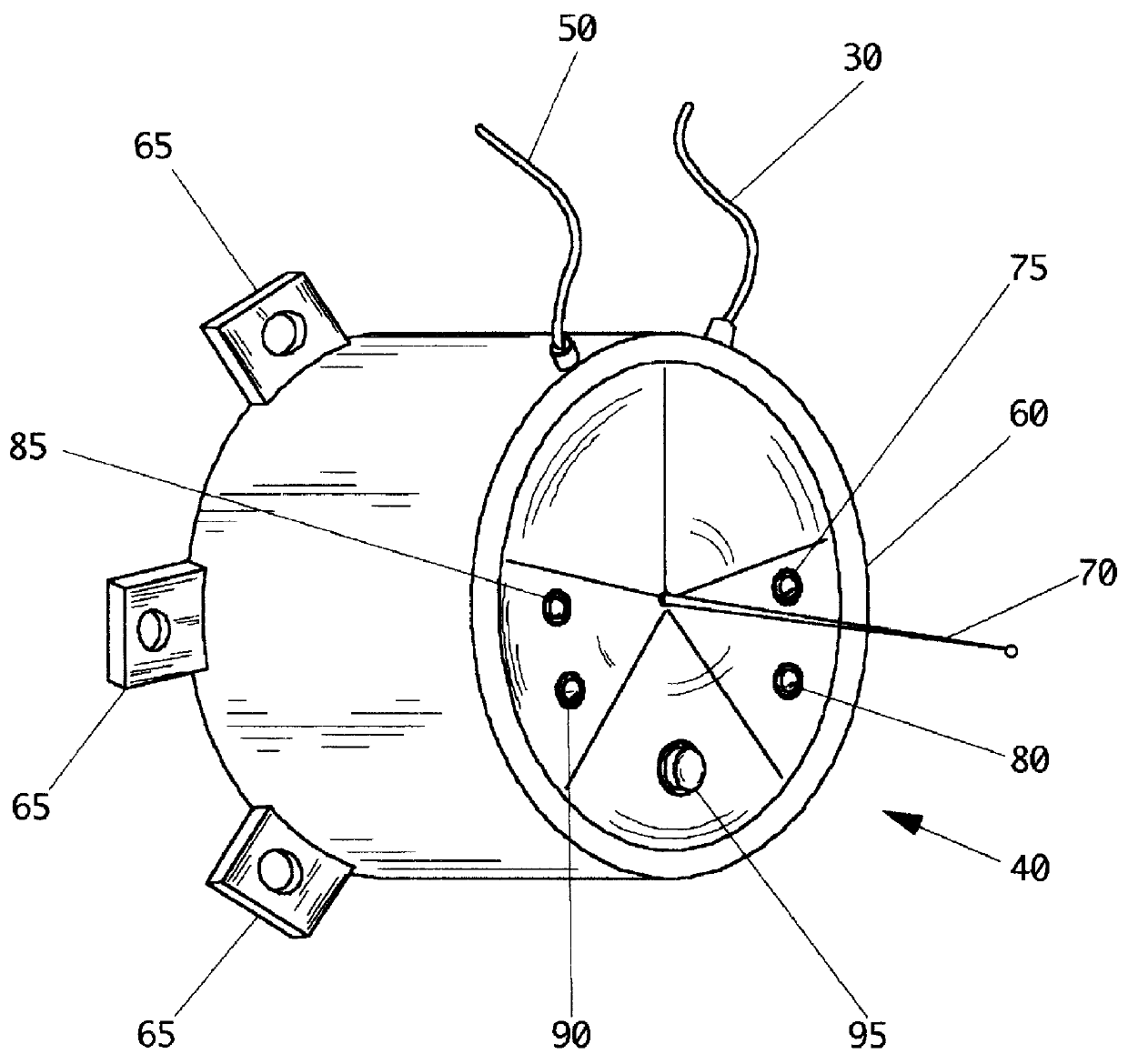

Automatic tire inflation system

An automatic tire inflation system including an air pump, a pressure sensor, a microprocessor and a rechargeable battery power supply all housed in a water resistant housing. The housing conforms to the diameter of the rim of a standard vehicle tire and is held to the tire by rim retaining fingers. A recharging jack is mounted inside the housing and is accessed through an aperture on the housing which is sealed by a removable waterproof cover. The microprocessor monitors air tire pressure being sent from the pressure sensor and activates the air pump when the pressure is determined to be too low by the microprocessor. The air pump turns off when the air tire pressure reaches a predetermined set point. The rechargeable battery is recharged by a standard charging device attached by a plug to the recharging jack. Similar automatic tire inflation systems can be mounted to each tire of the vehicle.

Owner:NARLOCH ANDREW JOSEPH +1

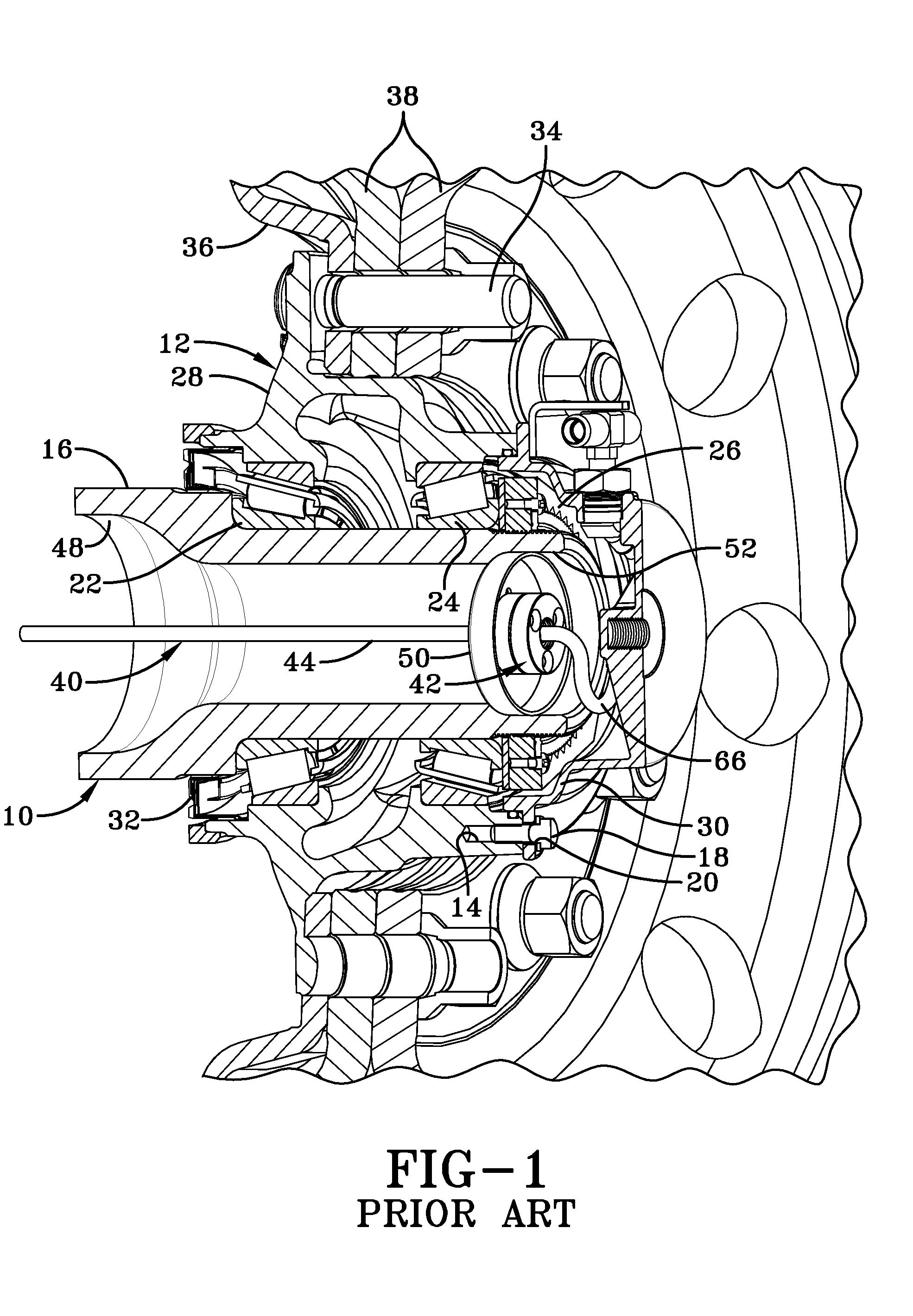

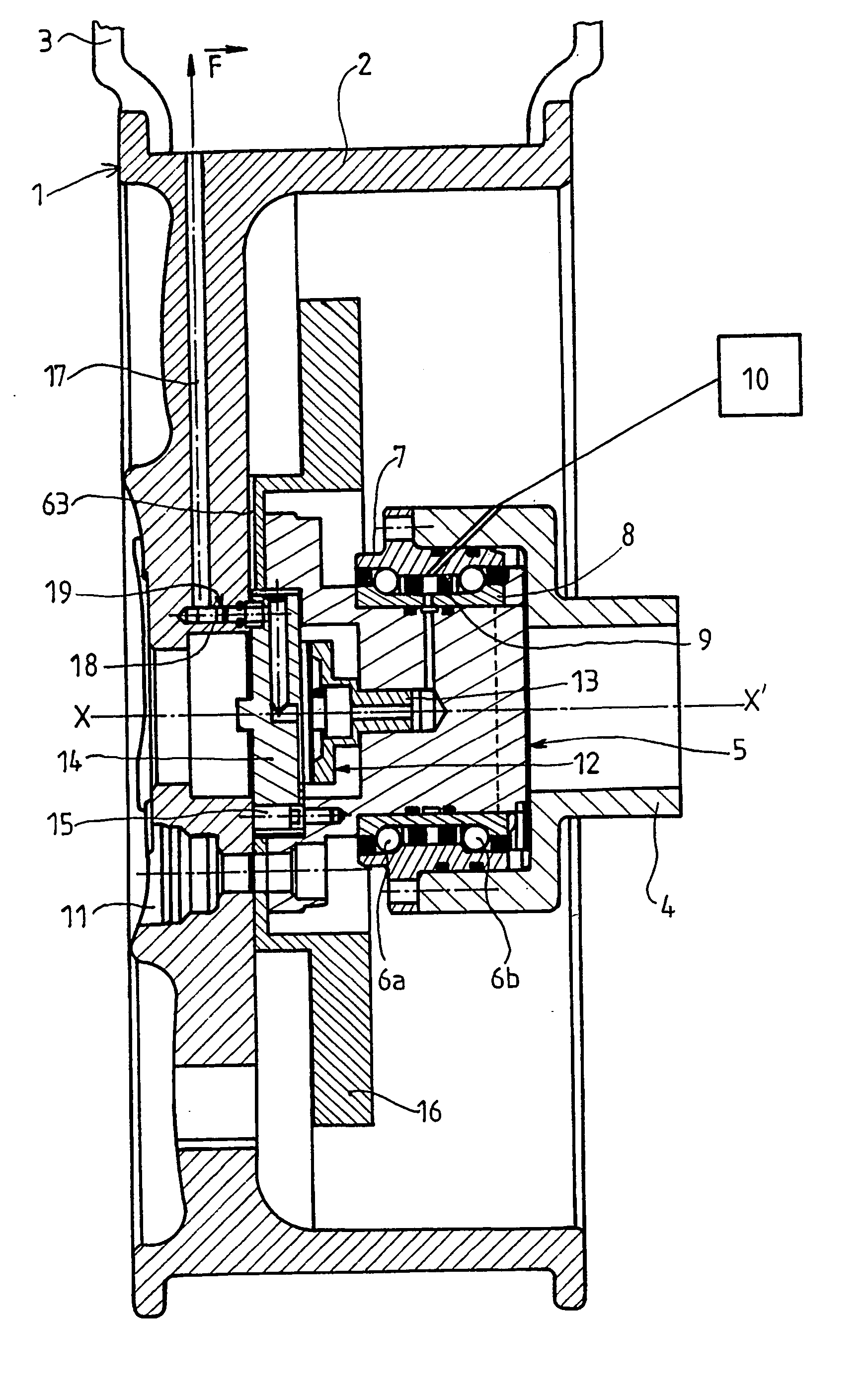

Tyre self-sealing device for the wheel of a vehicle

InactiveUS20050205182A1Quick and easy dismountingImprove reliabilityBearing assemblyTyre measurementsEngineeringVALVE PORT

A self-sealing device for a tire on a vehicle wheel, including a wheel, a wheel hub supporting the wheel, a wheel supply circuit, an inflating and deflating valve for supplying compressed air from a pressurized circuit, wherein the valve is positioned between the wheel and the wheel hub and includes sealing means integrated into the wheel supply circuit, wherein the sealing means is activatable to an open position in the presence of the valve and to a closed position in the absence of the valve.

Owner:SYEGON

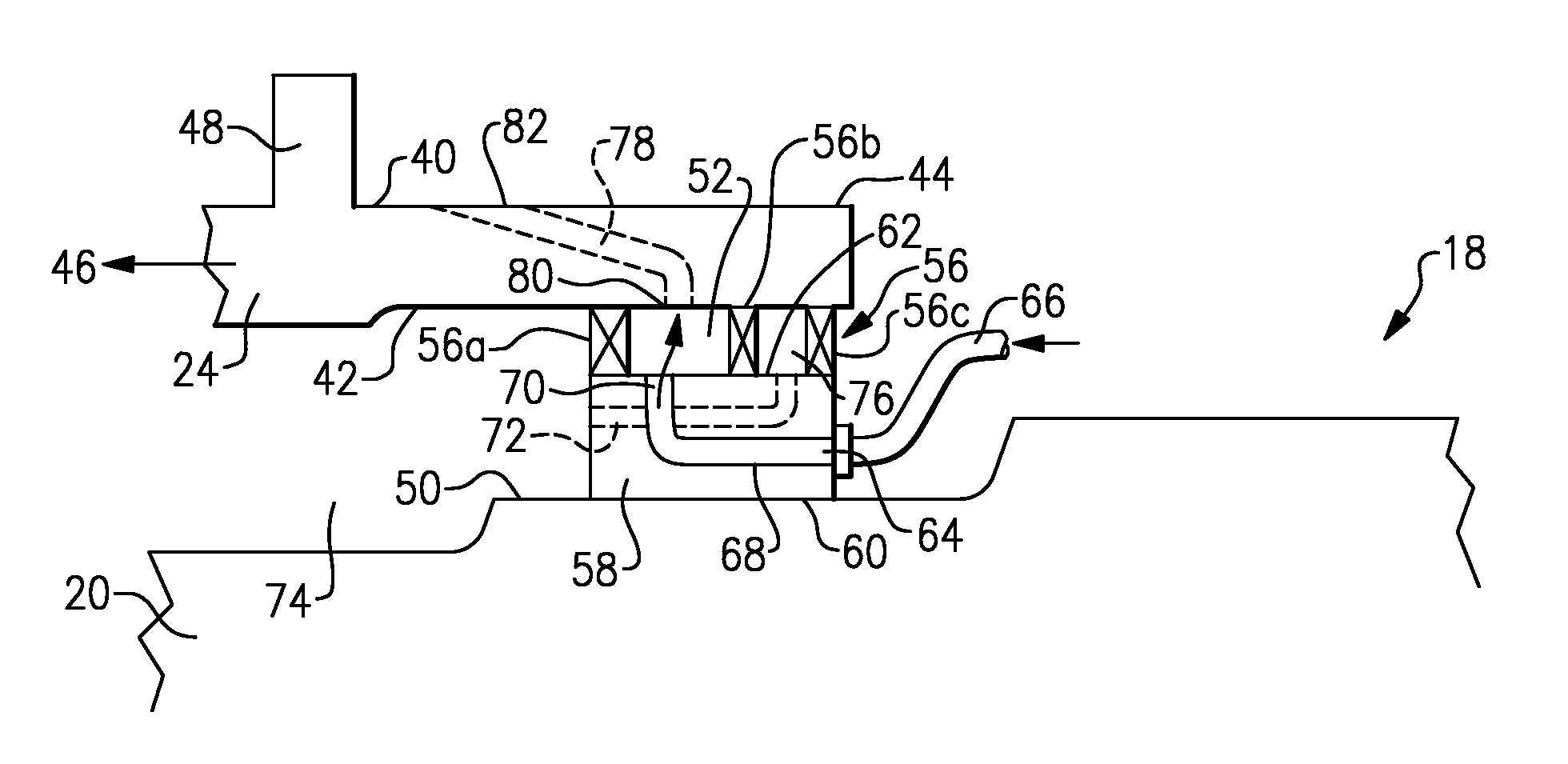

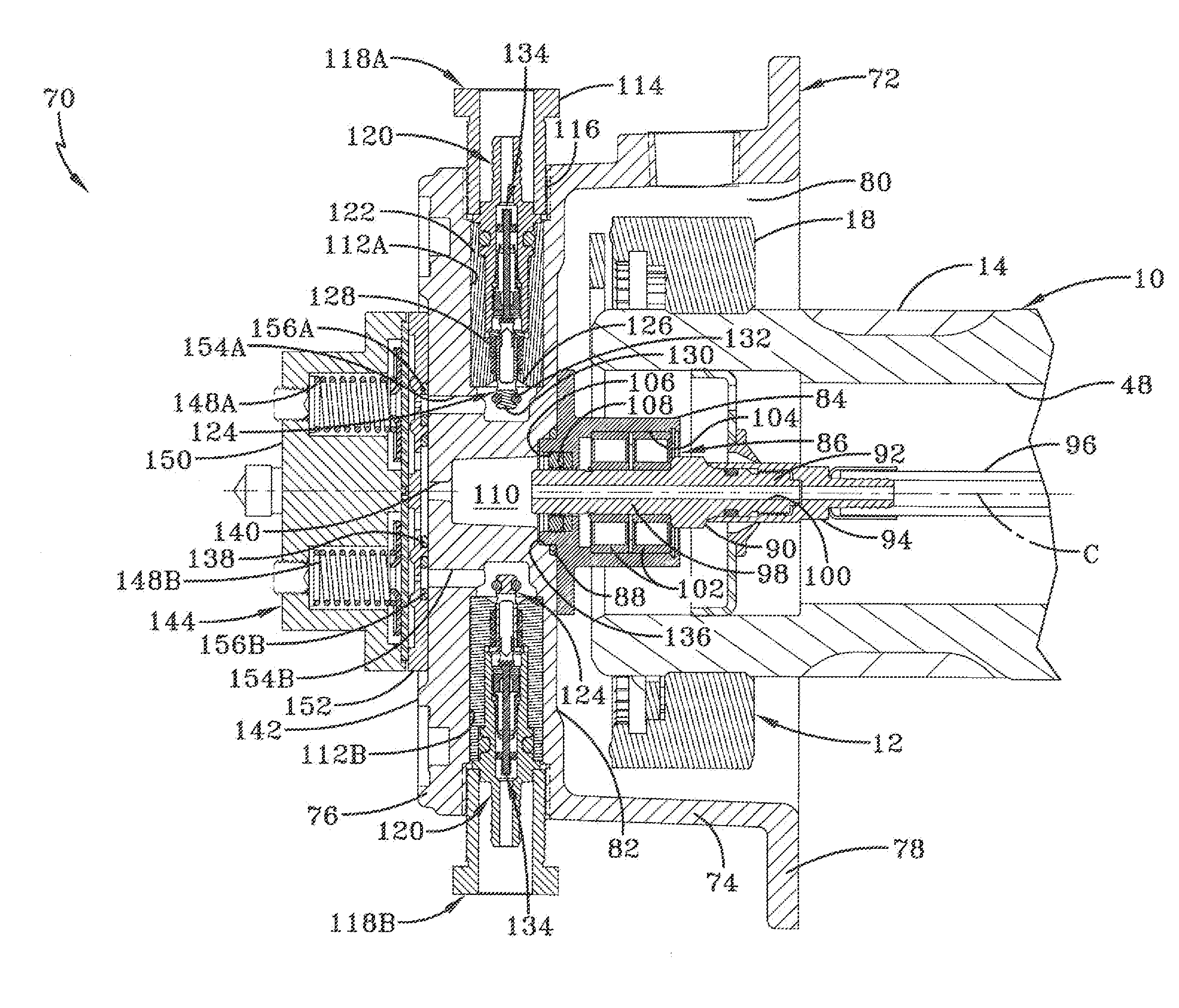

Wheel end tire air pump

A wheel end assembly includes a self-contained air pump mechanism that maintains tire pressure at a desired level. The pump mechanism includes a piston and cylinder assembly that rotate with the tire. A linkage assembly drives the piston within the cylinder as the wheel end assembly rotates to pump air into the tire via a valve. The linkage assembly includes a first link fixed to a non-rotating wheel end component and a second link that rotates relative to the first link and which is coupled to drive the piston within the cylinder. The tire valve is in fluid communication with the cylinder and automatically opens when air pressure in the tire falls below a predetermined level and automatically closes when the air pressure achieves the predetermined level. An atmospheric valve is in fluid communication with the cylinder, and automatically opens to recharge the cylinder once the initial pressure charge has been delivered to the tire.

Owner:ARVINMERITOR TECH

Container for sealing liquid for repairing inflatable articles, in particular tyres, and repair kit featuring such a container

Owner:TEK GLOBAL SRL

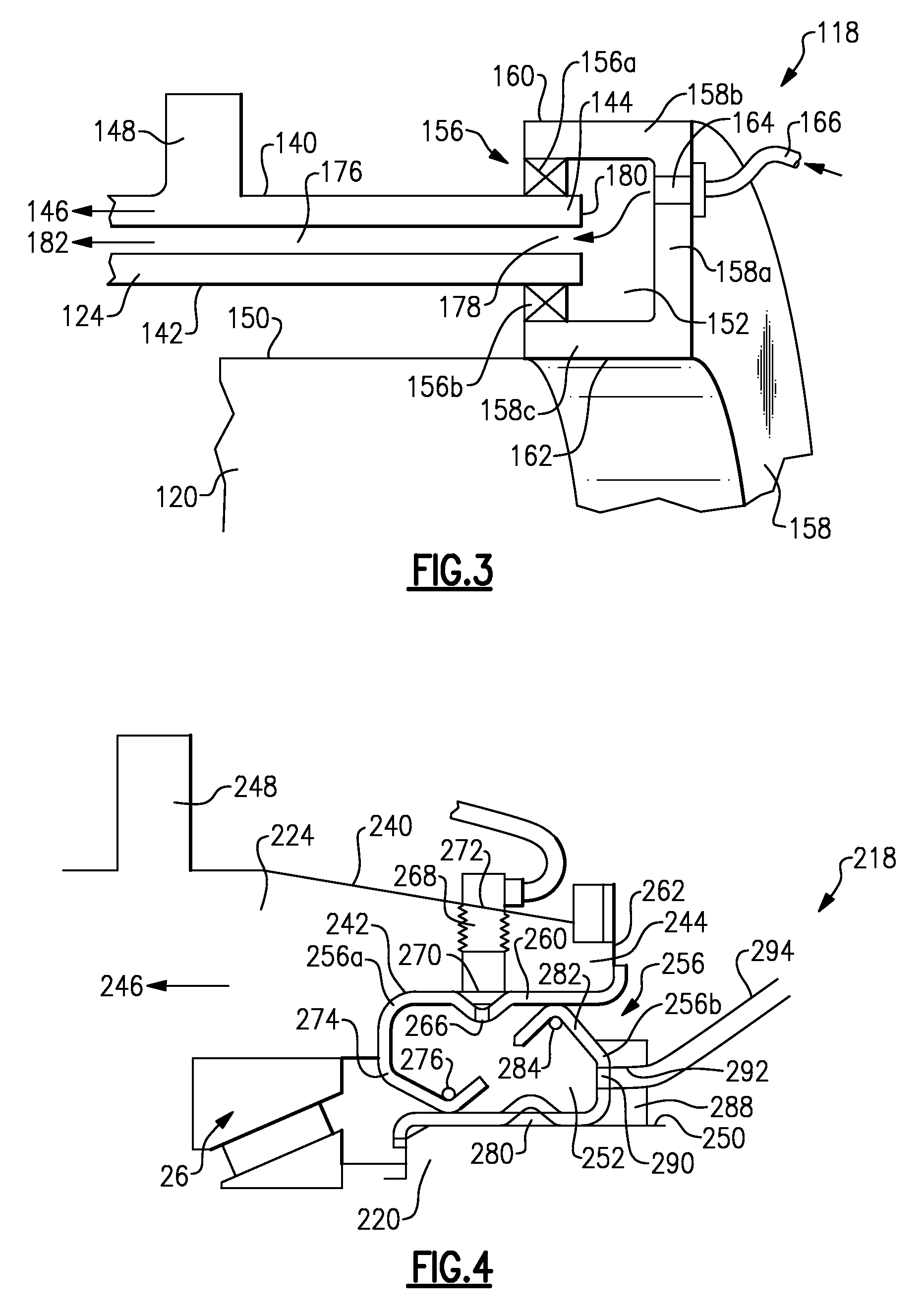

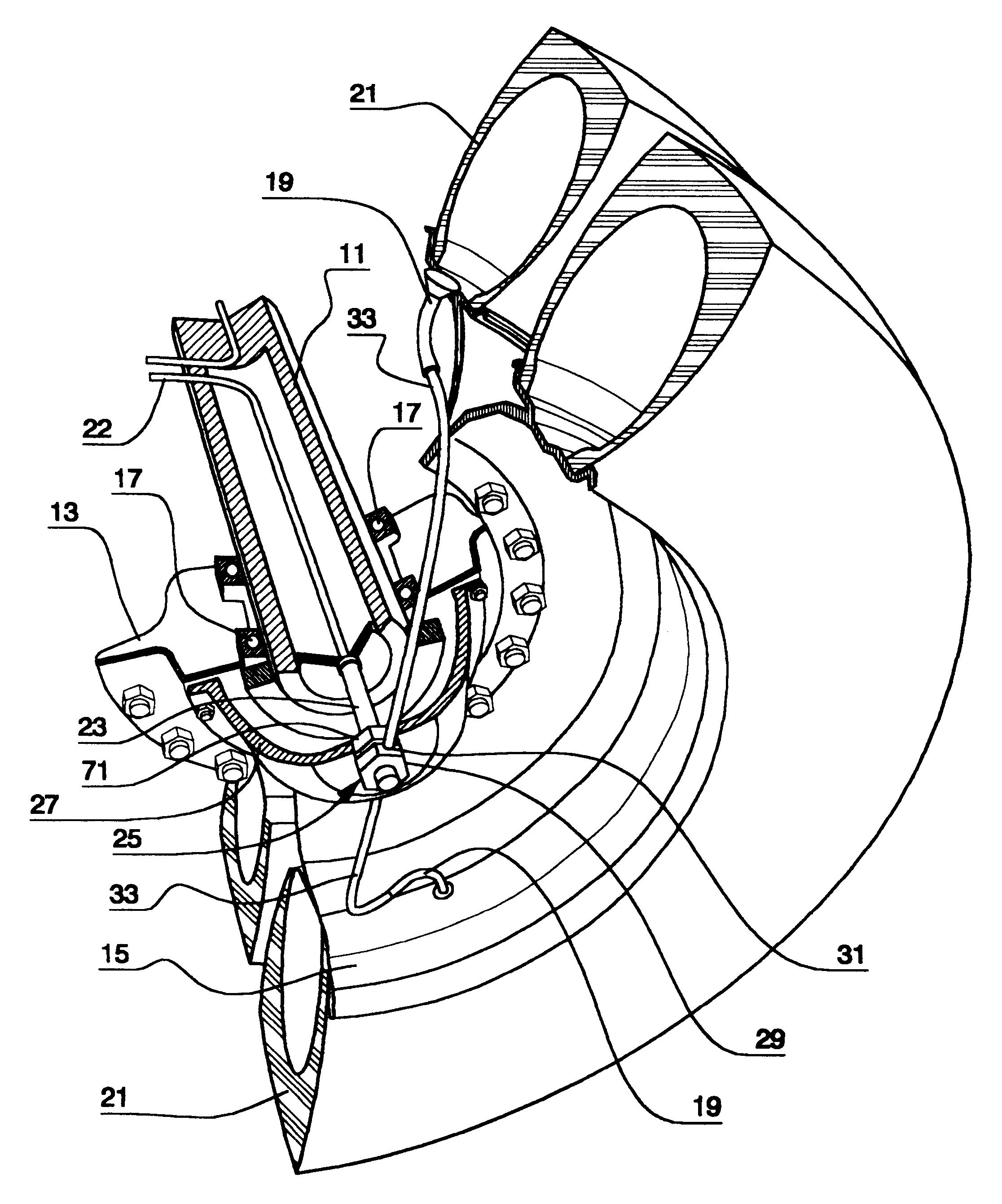

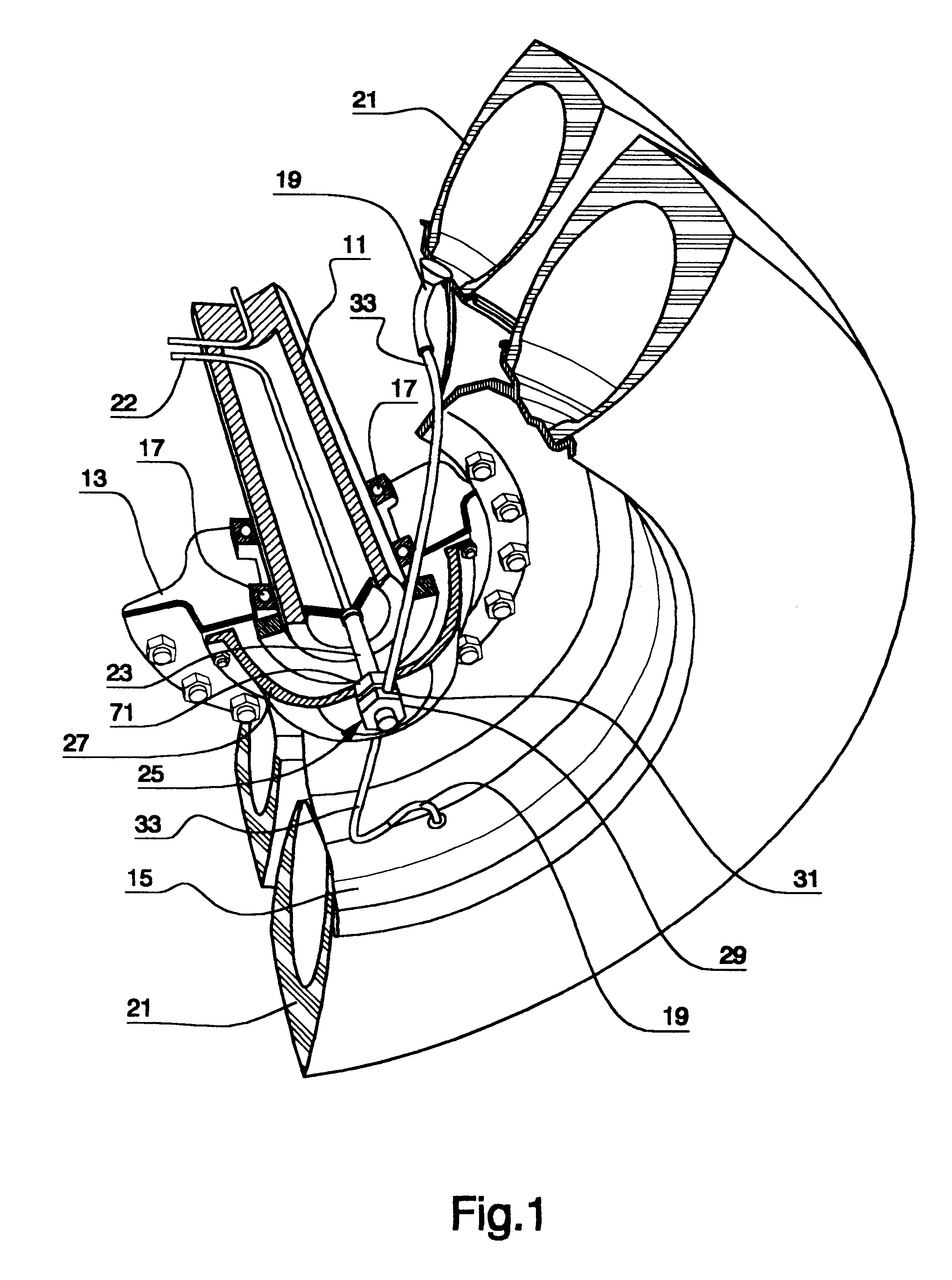

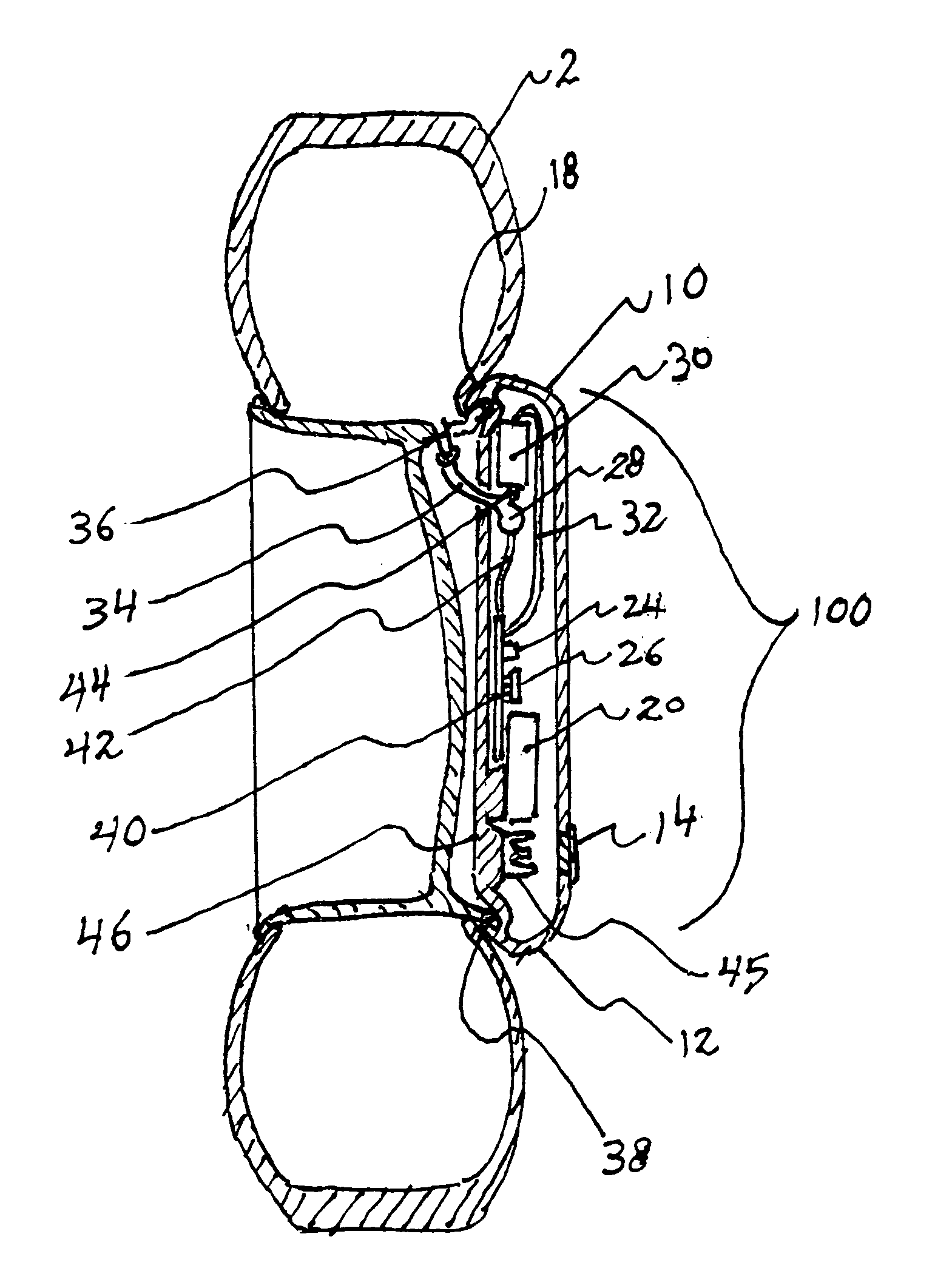

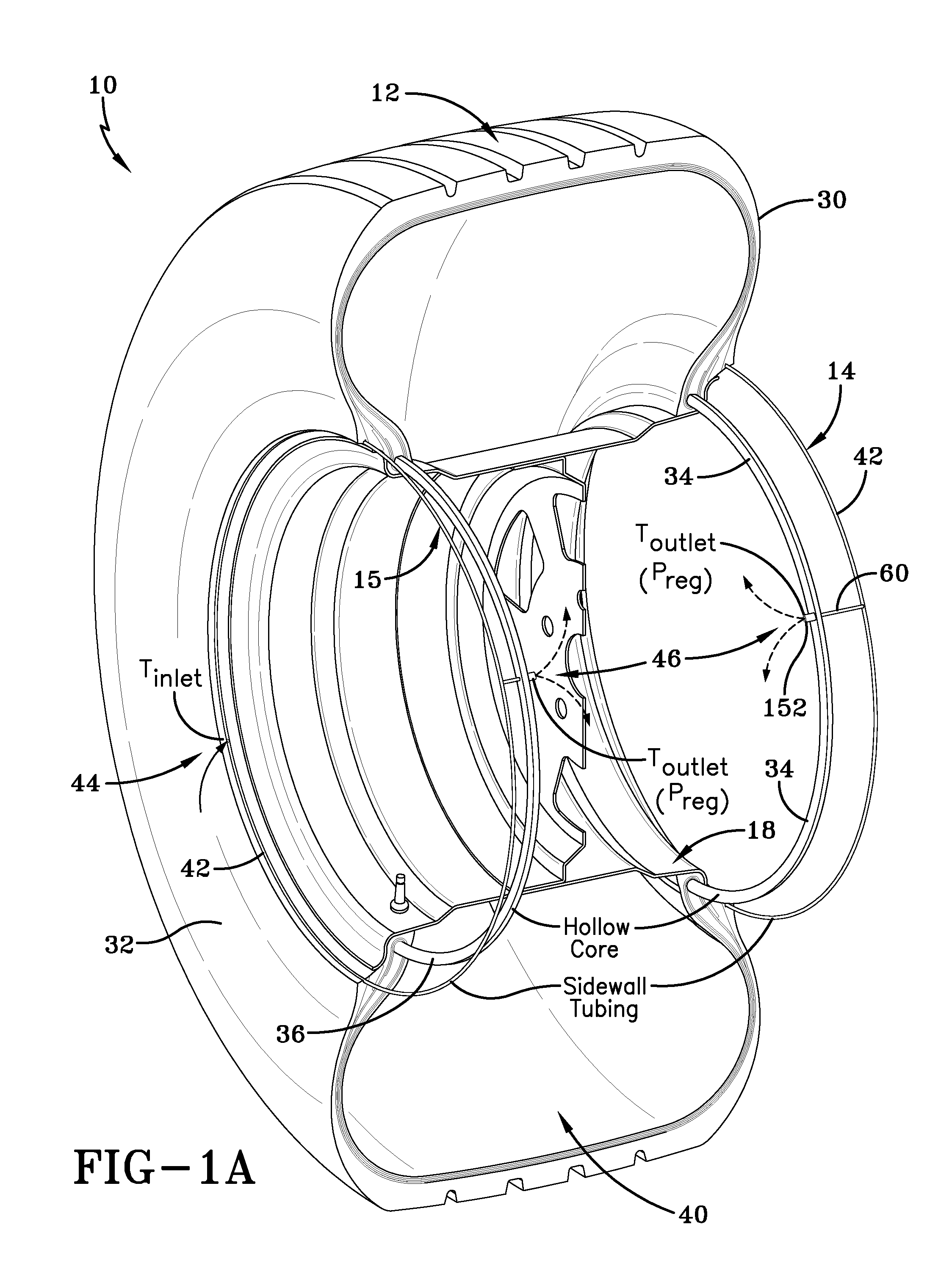

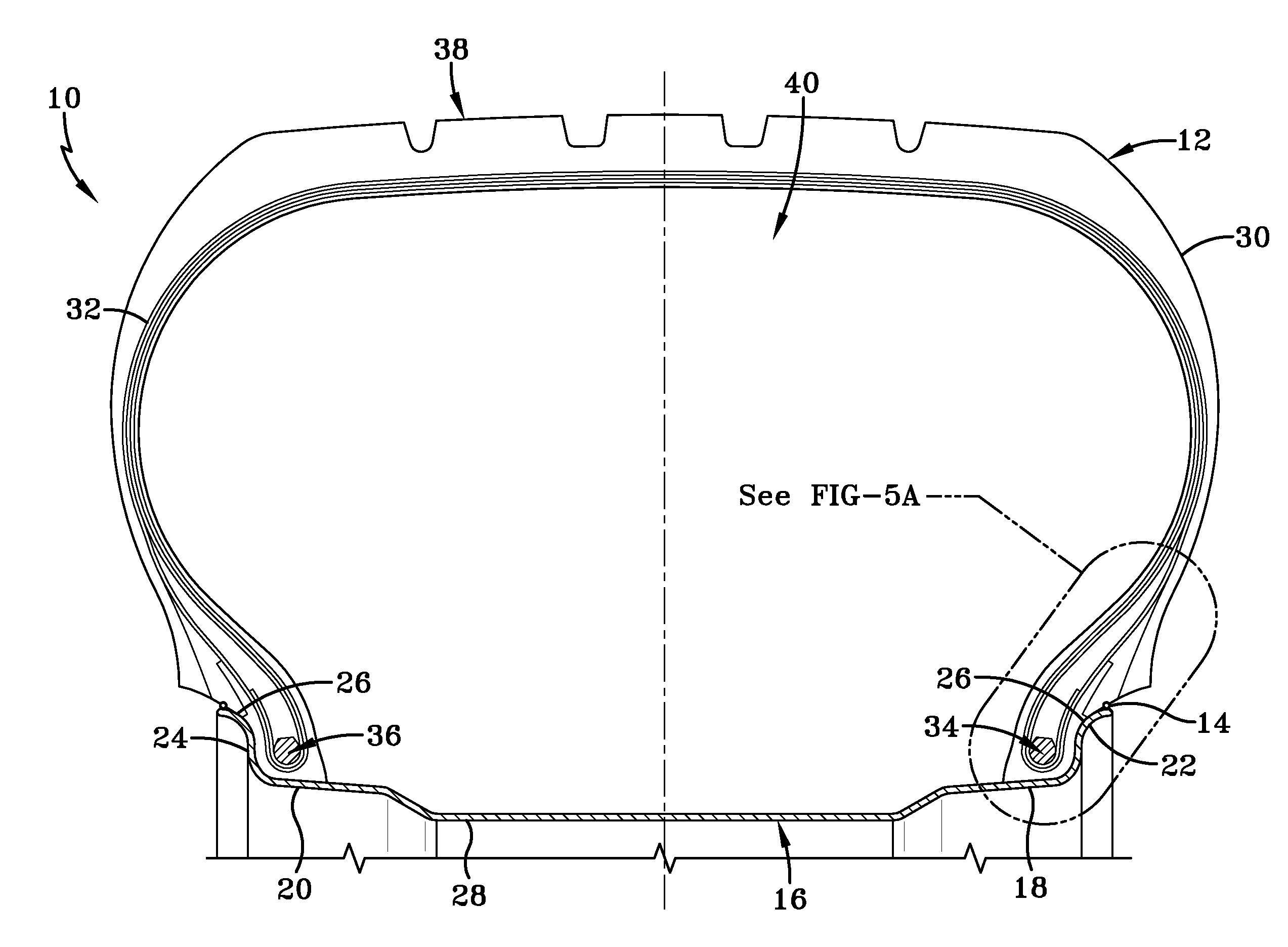

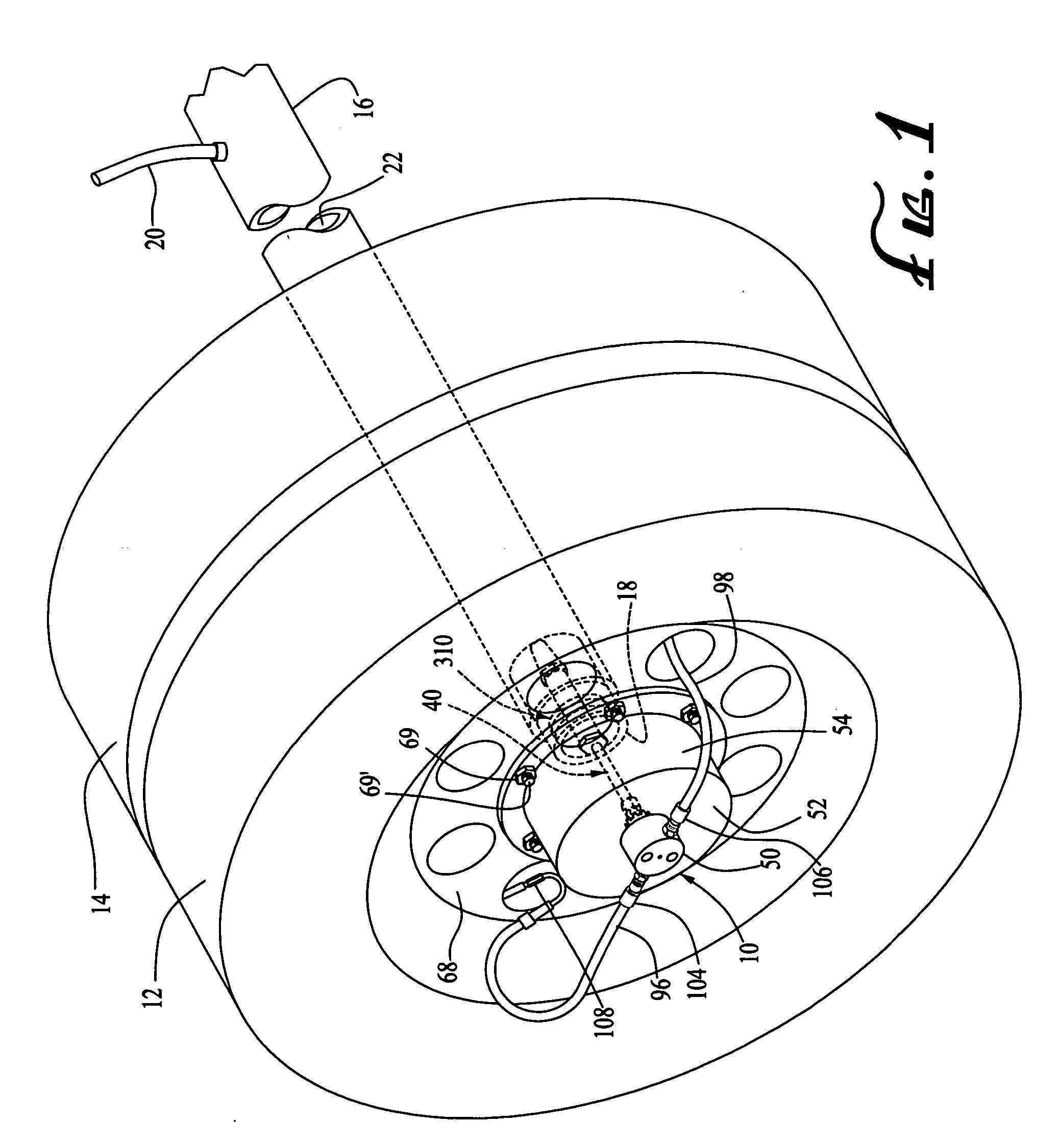

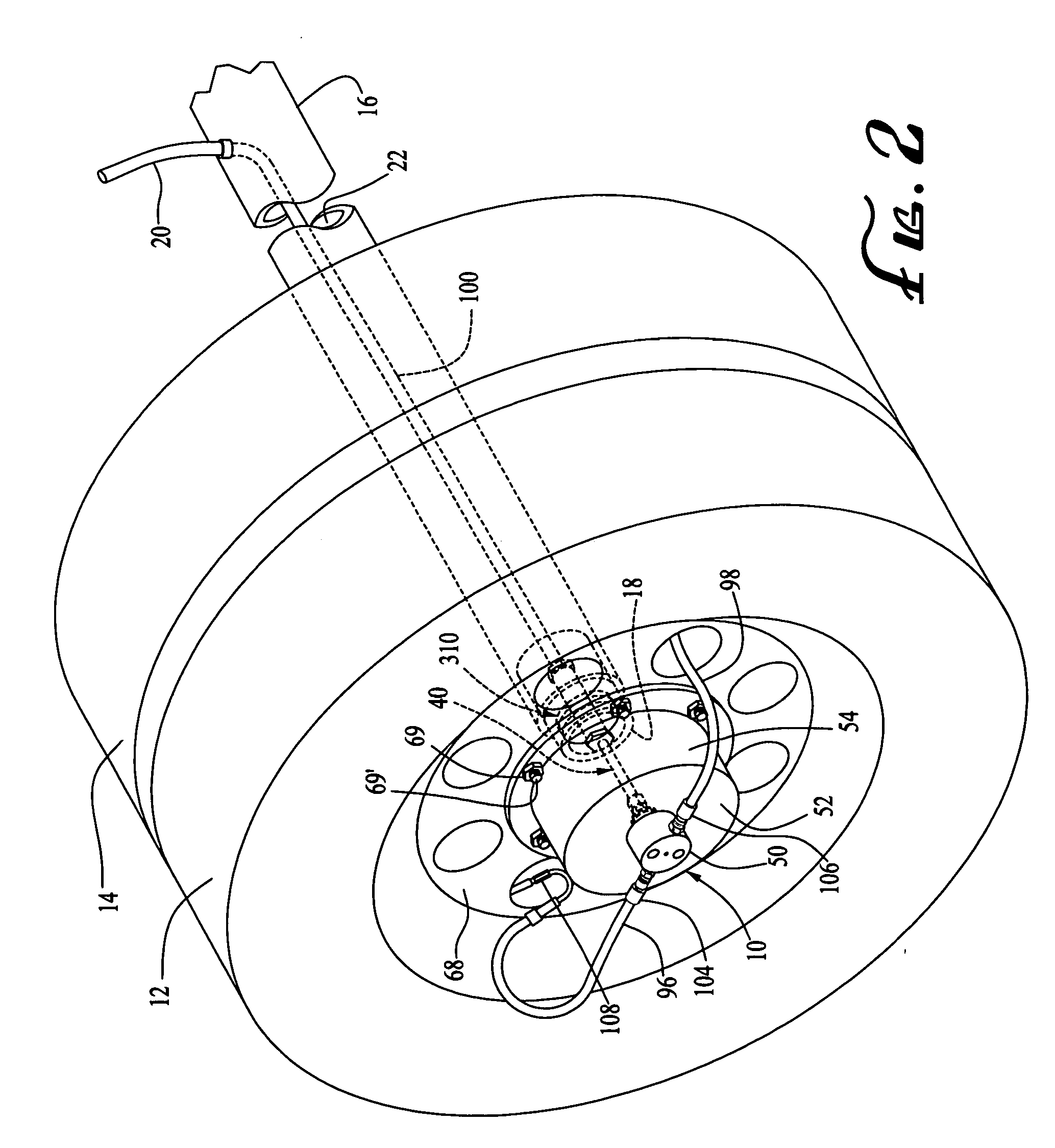

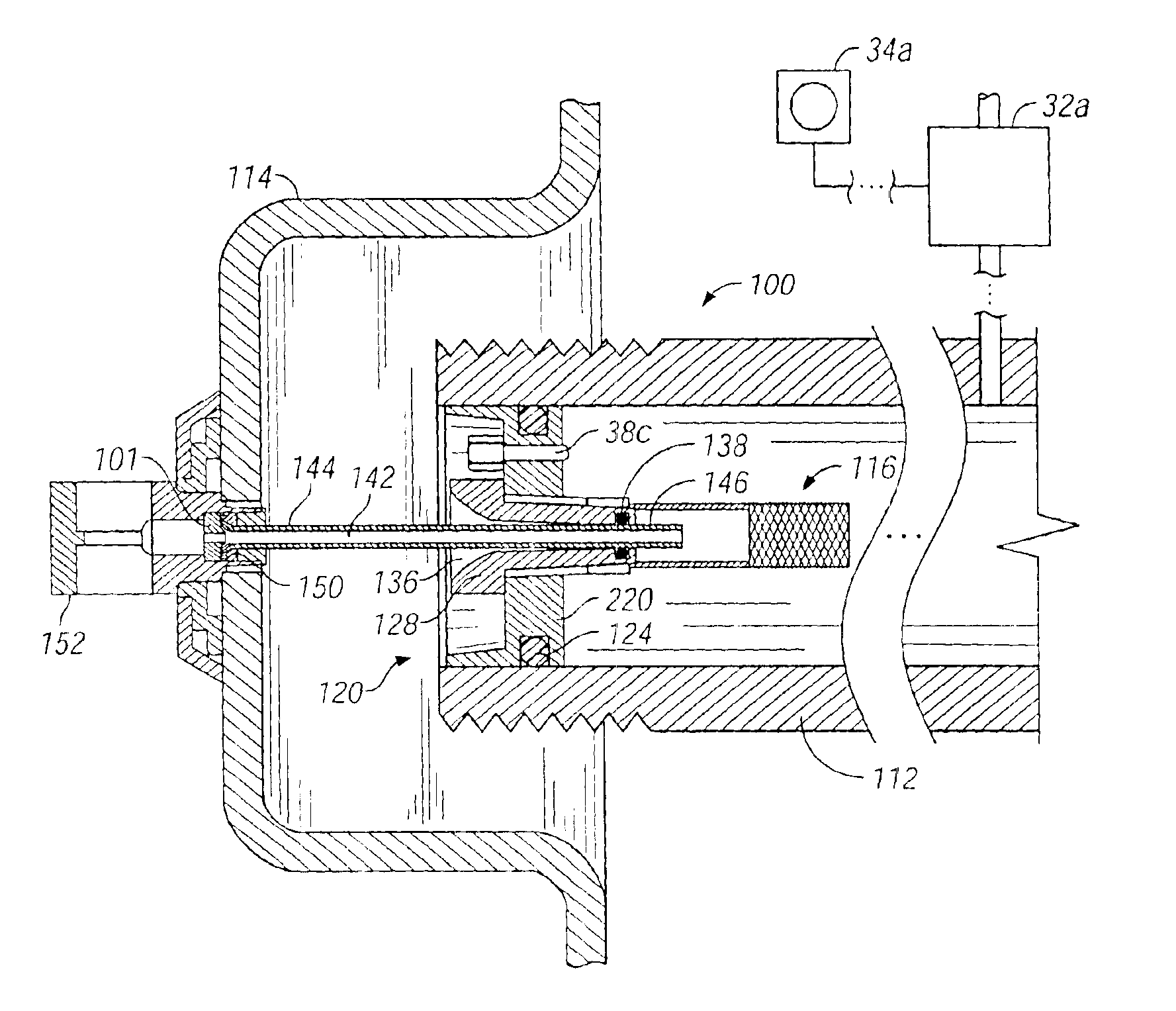

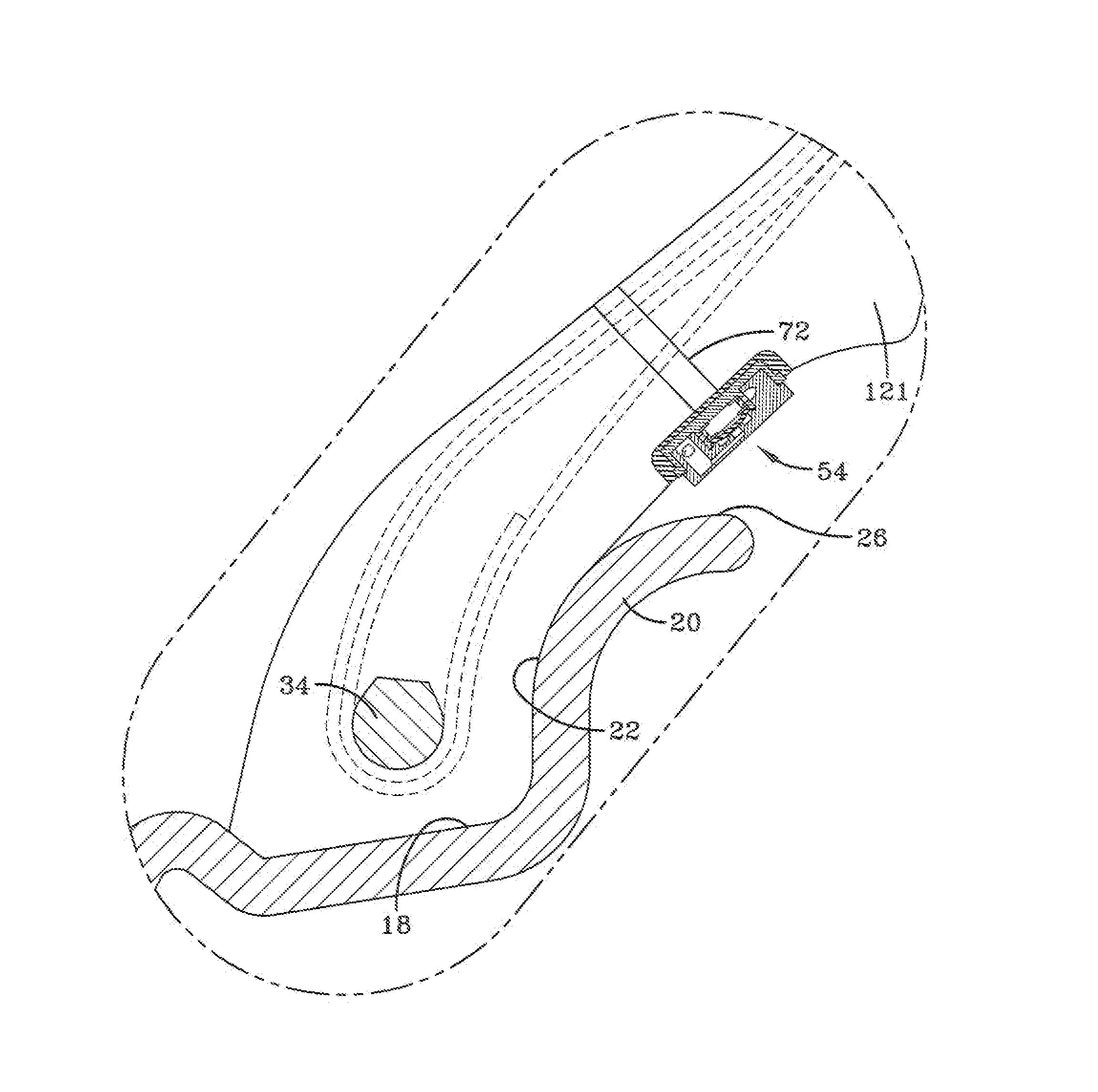

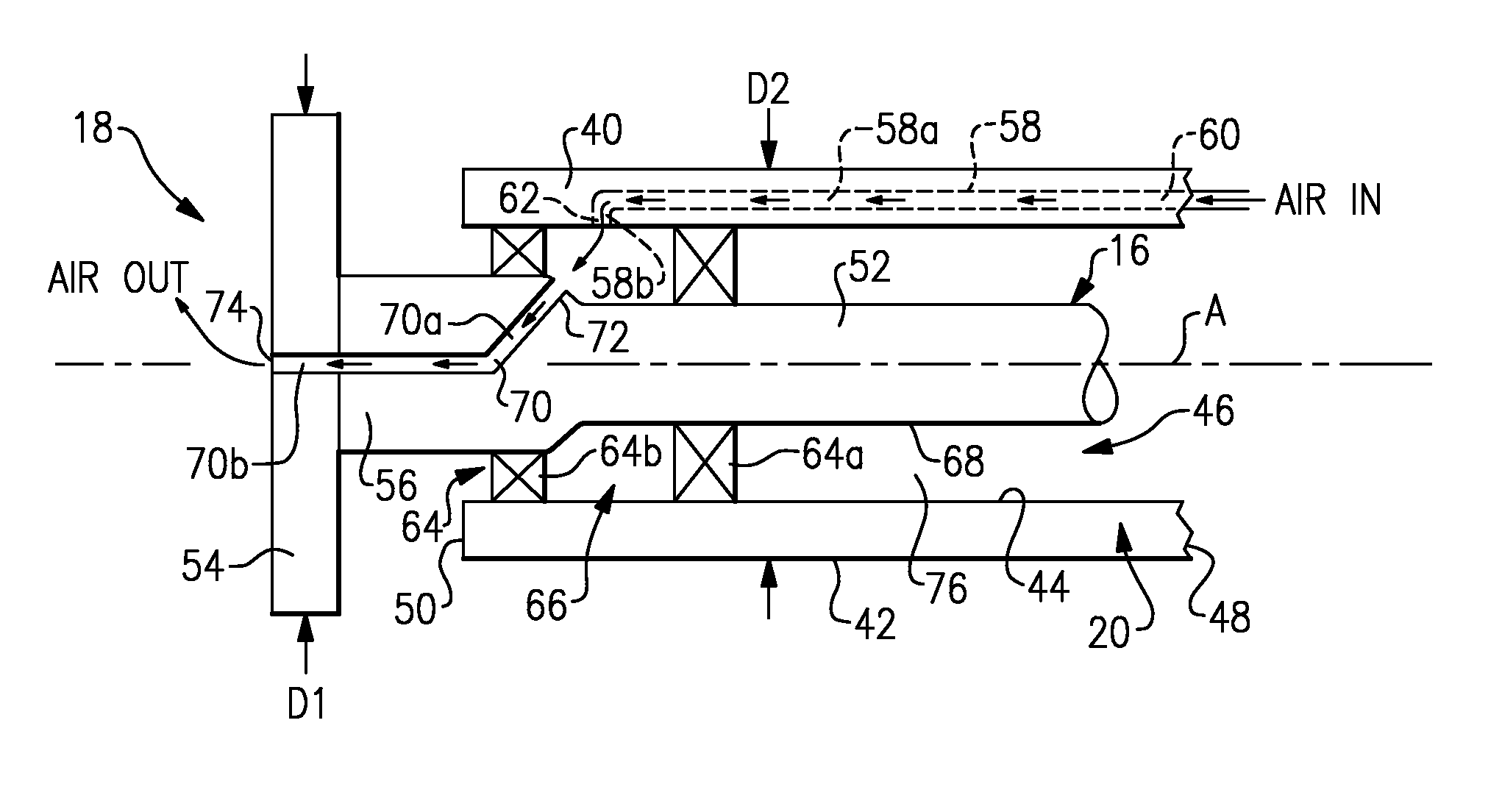

Self-inflating tire assembly

ActiveUS20110272073A1Great tractionWith multiple inflatable chambersTyre measurementsPeristaltic pumpEngineering

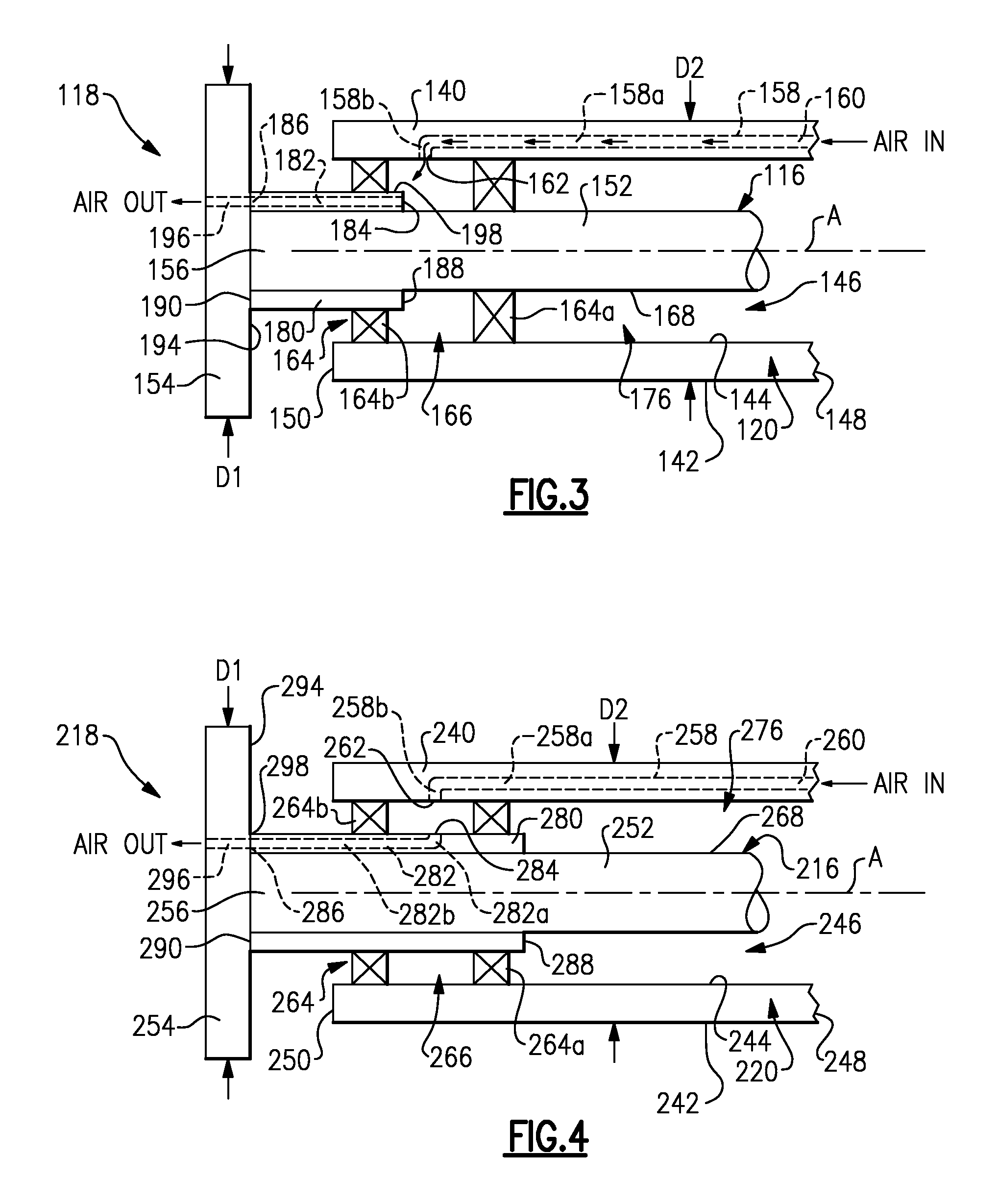

A self-inflating tire assembly includes a tire having a tire cavity between first and second sidewalls that extend respectively from first and second tire core beads to a tire tread region. At least one of the sidewalls is provided with an air tube peristaltic pump assembly. An air tube has an internal tube air passageway and is positioned within a sidewall groove in contacting engagement with opposite groove surfaces surrounding the air tube. The sidewall groove operatively bends within a rolling tire footprint to compress the air tube from an expanded diameter to a flat diameter adjacent the rolling tire footprint. A core bead passageway extends within a core bead adjacent the one tire sidewall for operatively storing air evacuated from the air tube passageway. Conduits are provided to route air from the air tube to the core bead passageway and valve mechanisms are positioned within the core bead passageway to control the flow of air from the core bead passageway into the tire cavity.

Owner:THE GOODYEAR TIRE & RUBBER CO

Tire inflation system

InactiveUS7530379B1Increase in tire pressureIncrease pressureTyre measurementsTyre-inflating valvesTerrainTire maintenance

Land transportation vehicles using pneumatic tires loose air over time, including tractor trailers, private vehicles, race cars and other vehicle classifications. Tire pressure is important, but only a small number of attendants are concerned. Our invention is an automatic device which supplies air to tractor trailer tires using an onboard air supply. This air, supplied to the rotary air chamber system can be adjusted to a desired tire air pressure by the individual driver to suitable levels of load weights, climates, travel speed and terrain. Rotating tires at high speeds build up friction raising tire pressure to dangerous levels. This will be corrected by built in relief valves. To maintain and verify tire pressures each tire is protected by check valves and visible pressure gauges. The rotary air chamber automates, corrects continuously the neglect of proper tire maintenance, adds road safety for users and public alike.

Owner:TRANS TECH CO

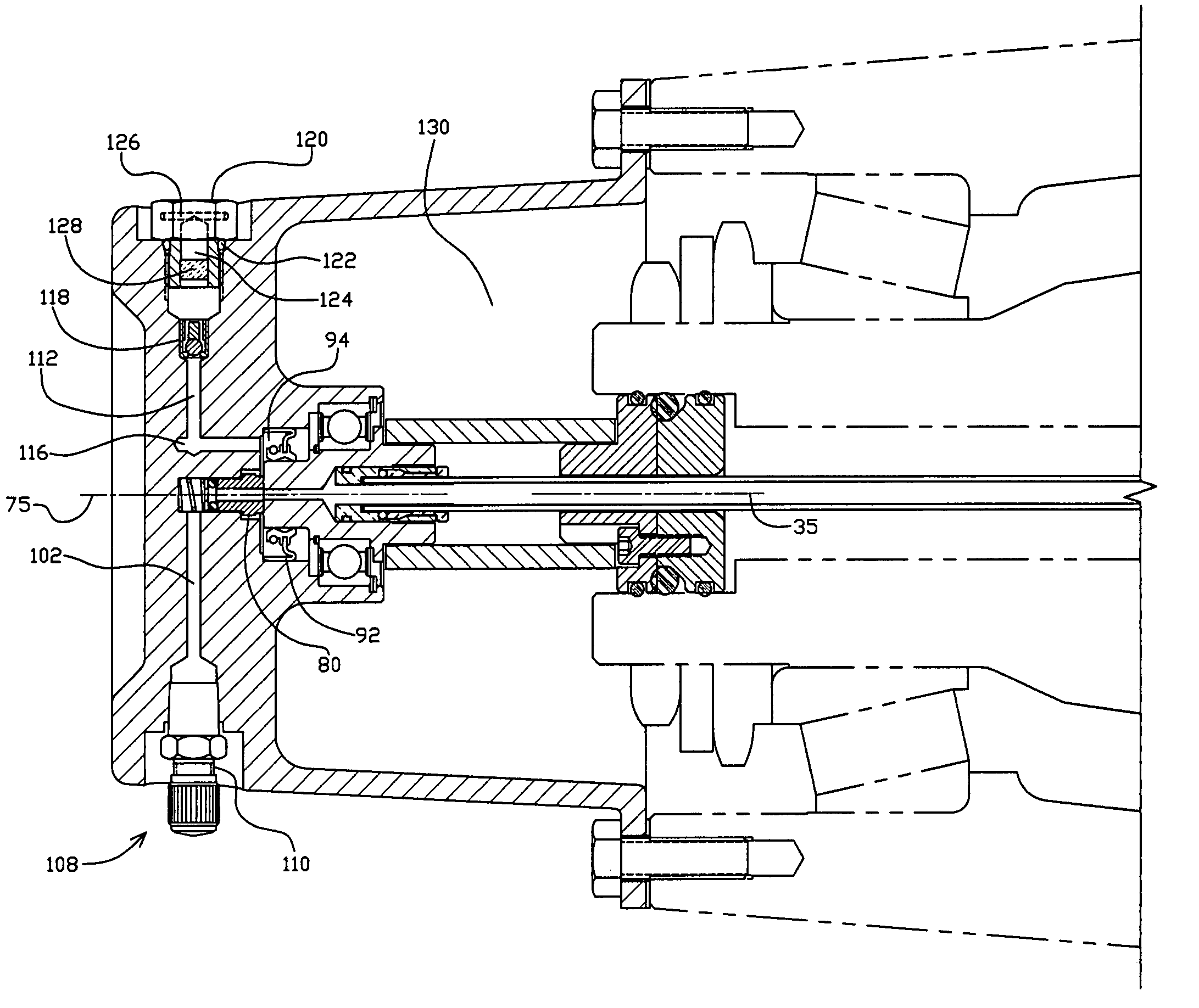

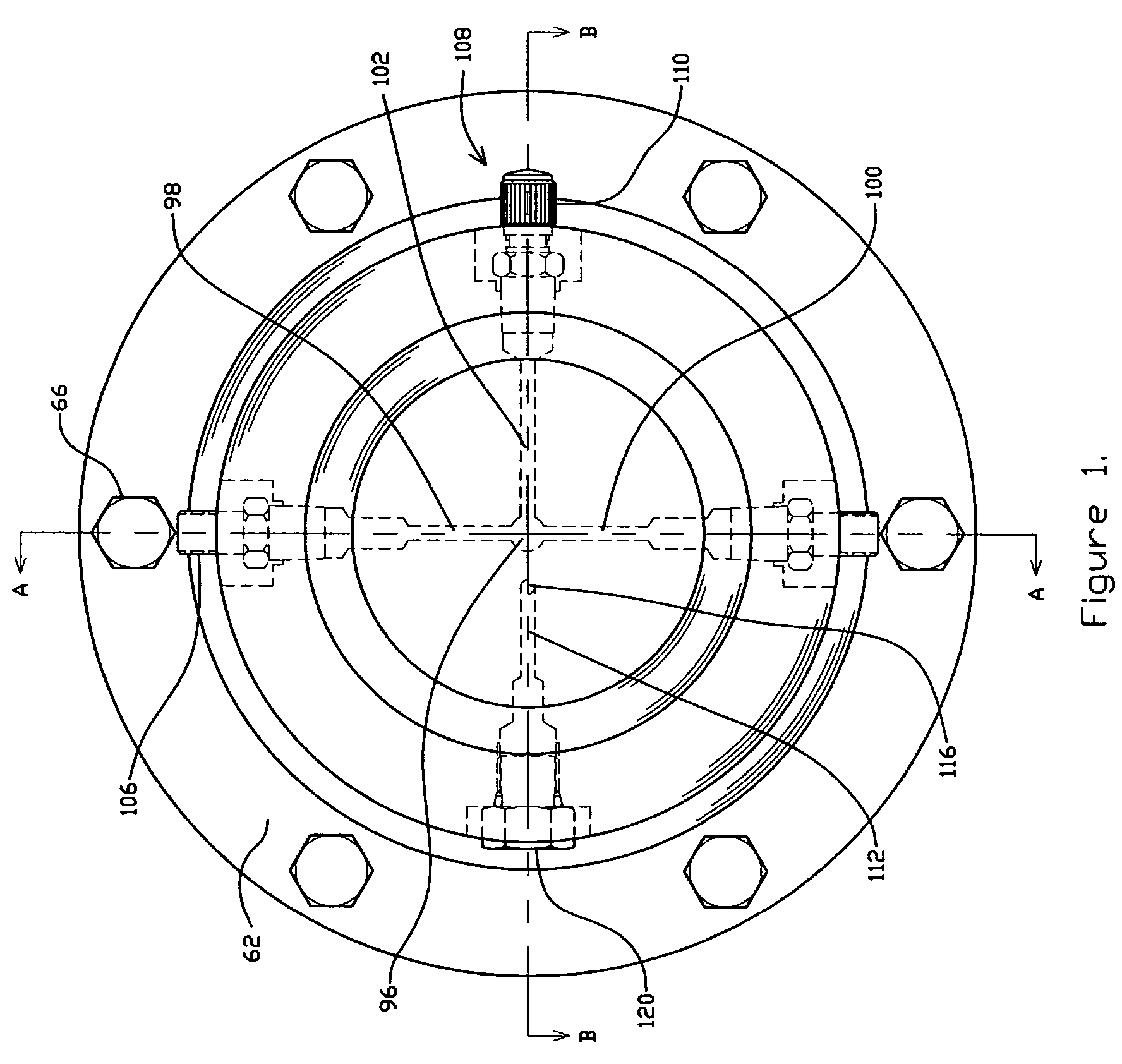

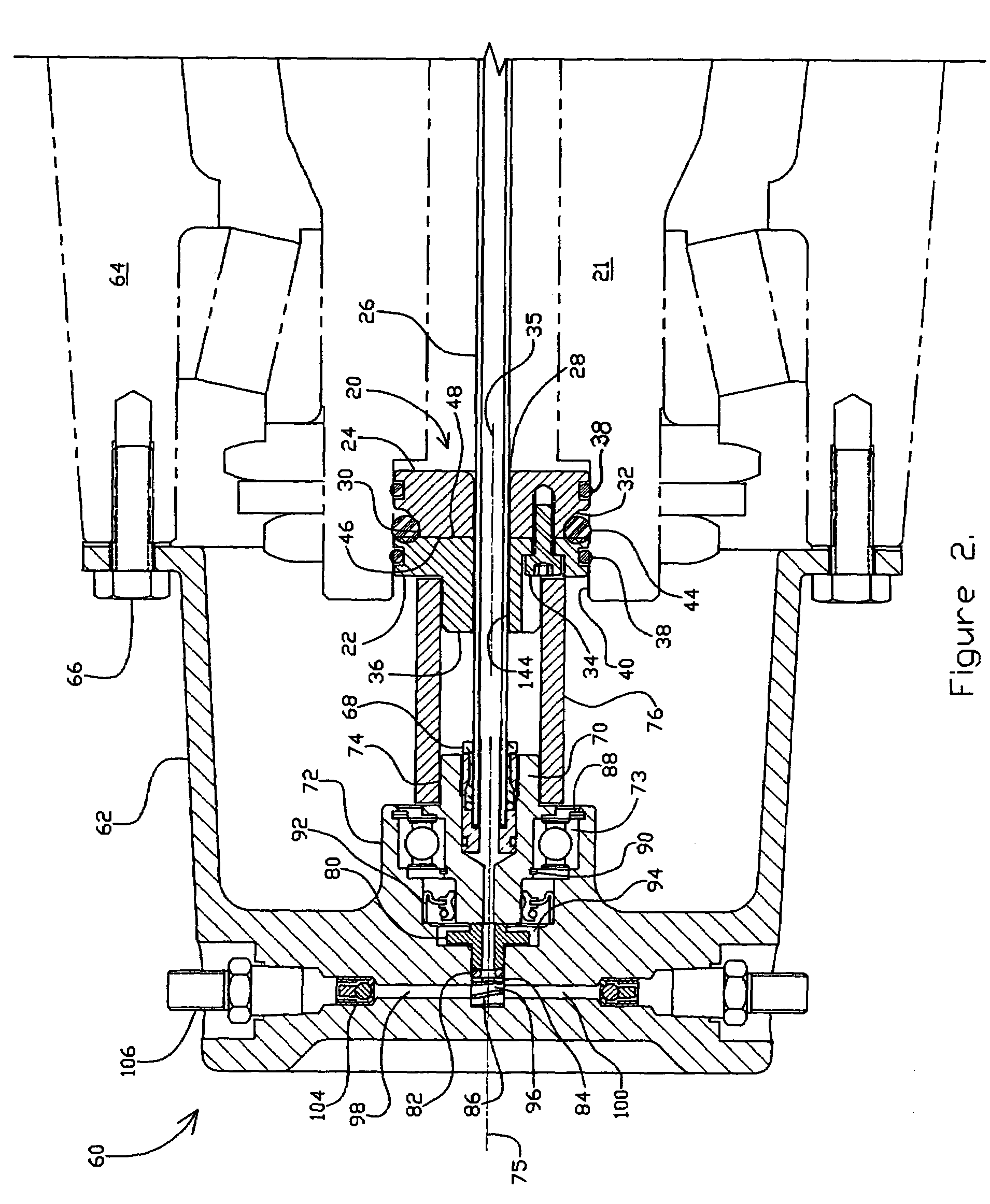

Central tire inflation system rotary air union

ActiveUS7207365B2Tyre measurementsTyre-inflating valvesCentral tire inflation systemAtmospheric pressure

A central tire inflation system for maintaining tire inflation on a vehicle having a torque transfer sleeve connected between an axle plug assembly and a stationary shaft on the rotary union assembly. A flexible conduit extends through the axle plug to the rotary union assembly and is used to provide air pressure to tires connected to the rotary union assembly. The torque transfer sleeve limits rotational torque on the flexible conduit. Primary and secondary seals are provided on the rotary union assembly as well. A vent chamber between the primary and secondary seals allows the release of air which exits the primary seal, which prevents pressure from entering the lubrication area of the rotary union assembly.

Owner:PRESSURE SYST INT LLC

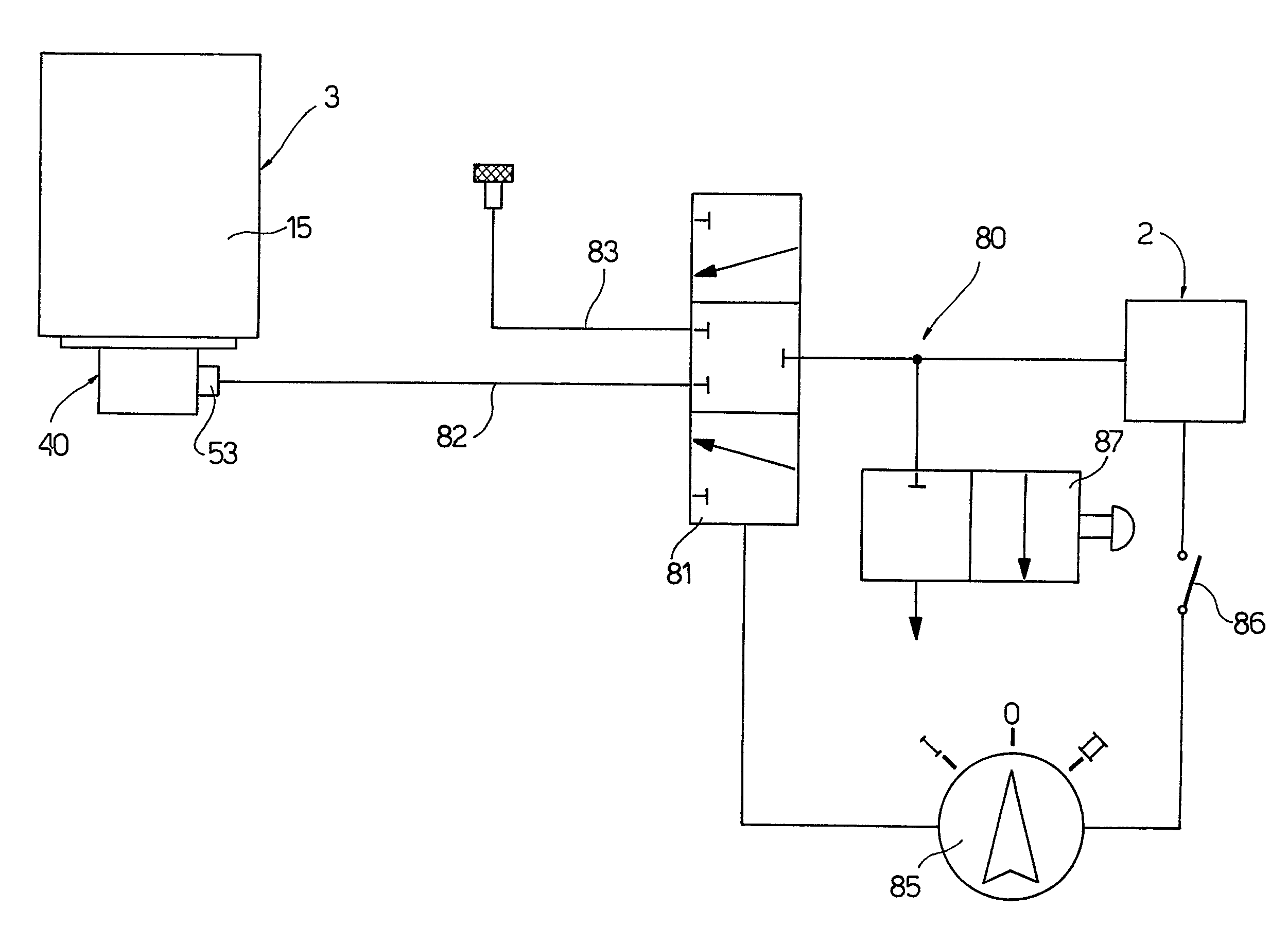

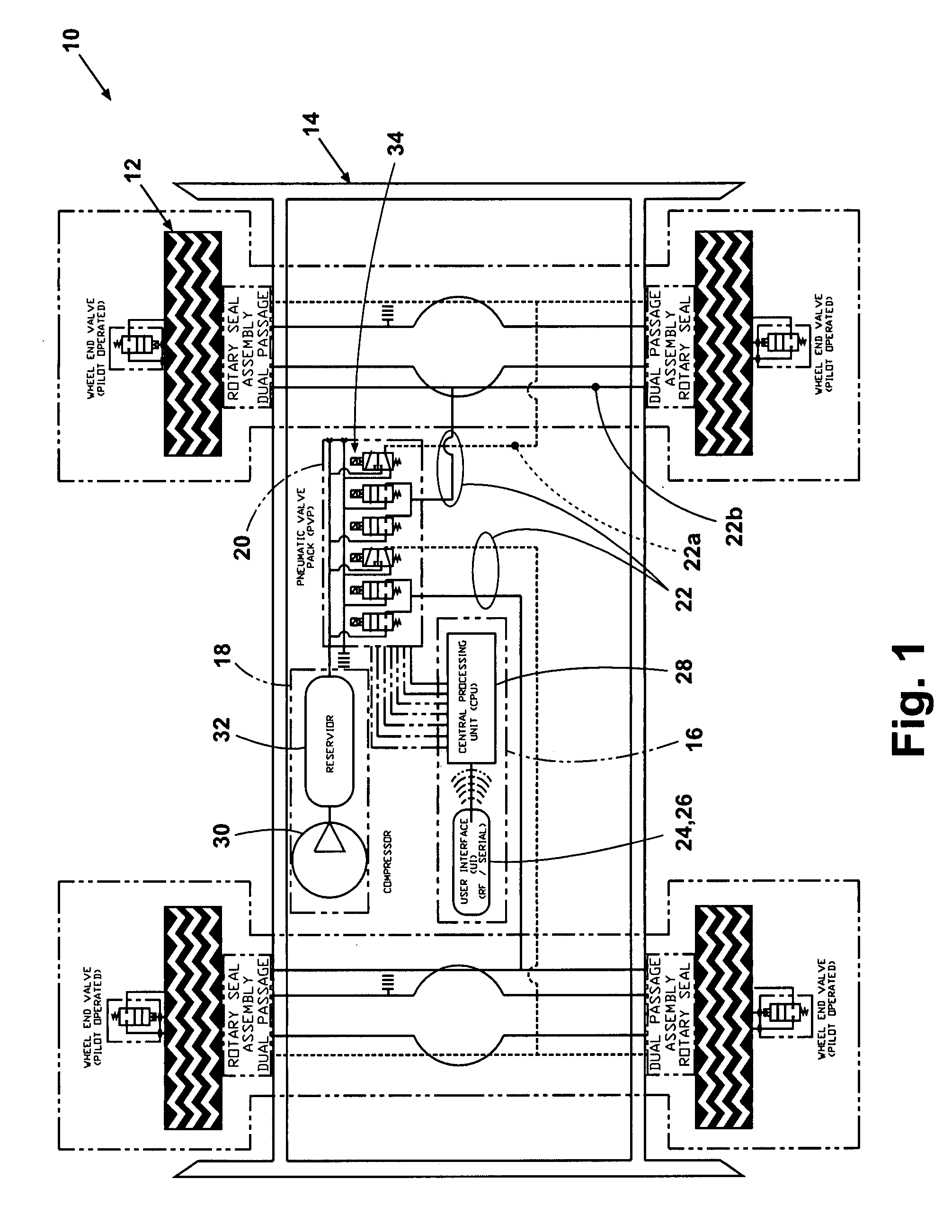

Tire inflation control method and apparatus

An apparatus and method are provided for controlling the air pressure within one or more tires on a vehicle. Means are provided for controlling air pressure dynamically or manually in response to road conditions. Instrumental in the invention is the ability to control the air pressure at each wheel from a remote location using positive control that substantially reduces the chance leaks anywhere else in the system would result in inadvertent flat tires.

Owner:KALAVITZ MICHAEL V

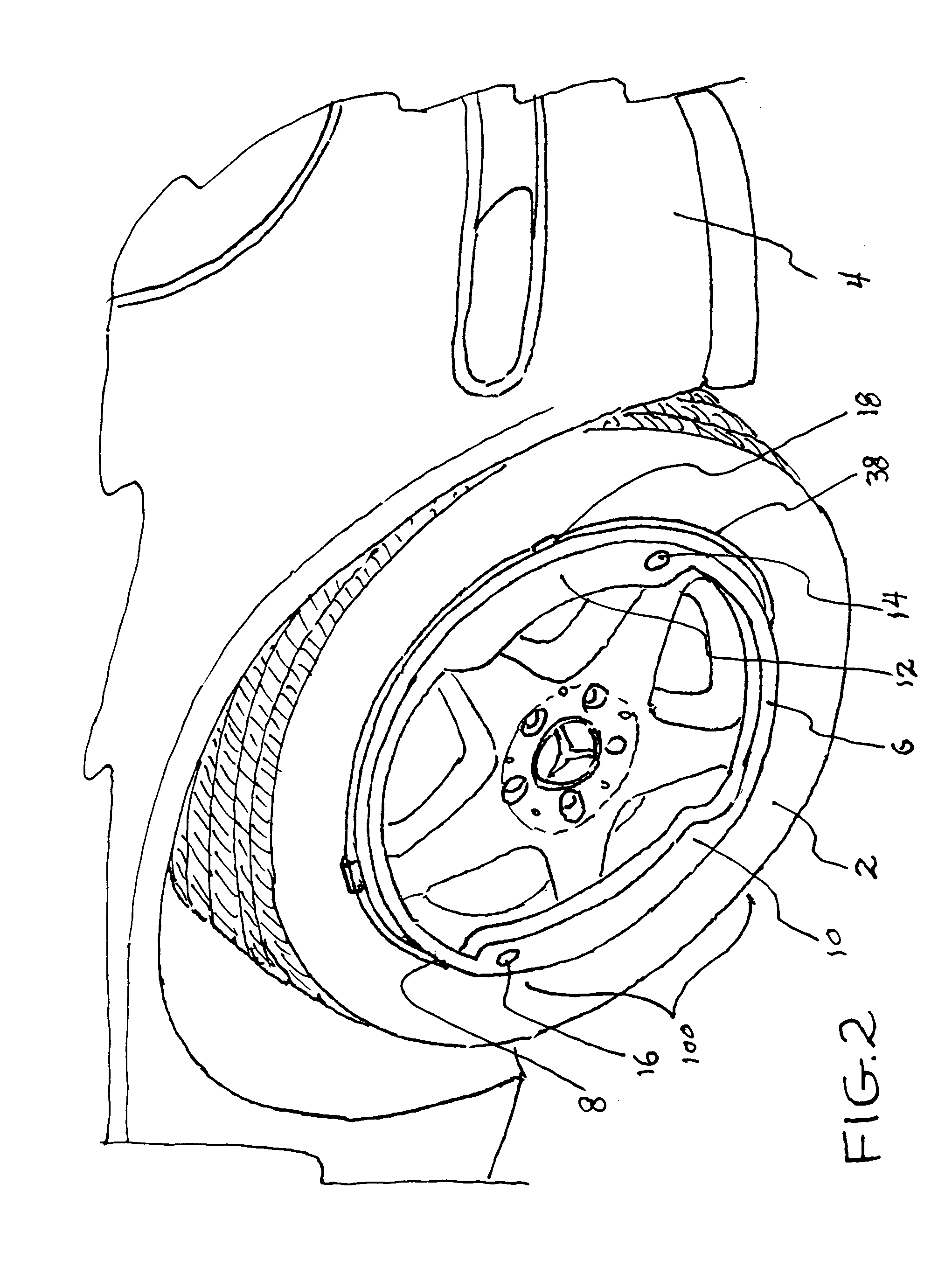

Self-inflating tire

ActiveUS20110146867A1Great tractionTyre measurementsTyre-inflating valvesEngineeringMechanical engineering

A self-inflating tire assembly includes an annular air tube connected to a tire and defining an annular air passageway, the air tube being composed of a flexible material operative to allow an air tube segment opposite a tire footprint to flatten, closing the passageway, and resiliently unflatten into an original configuration. The air tube is sequentially flattened by the tire footprint in a direction opposite to a tire direction of rotation to pump air along the passageway to an inlet device for exhaust from the passageway or to an outlet device for direction into the tire cavity. The inlet device is positioned within the annular passageway 180 degrees opposite the outlet device such that sequential flattening of the air tube by the tire footprint effects pumping of air along the air passageway with the tire rotating in either a forward or reverse direction of rotation.

Owner:THE GOODYEAR TIRE & RUBBER CO

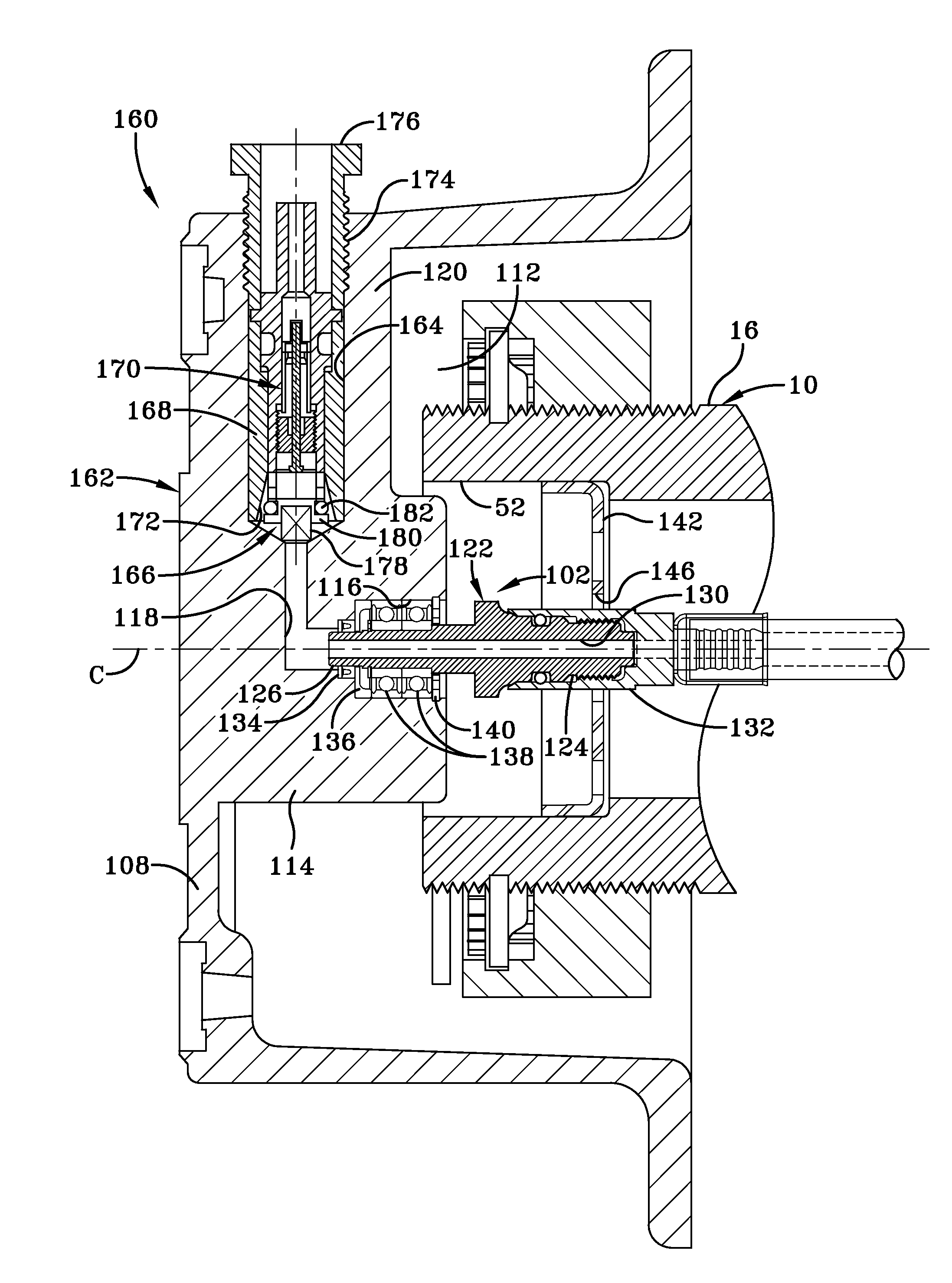

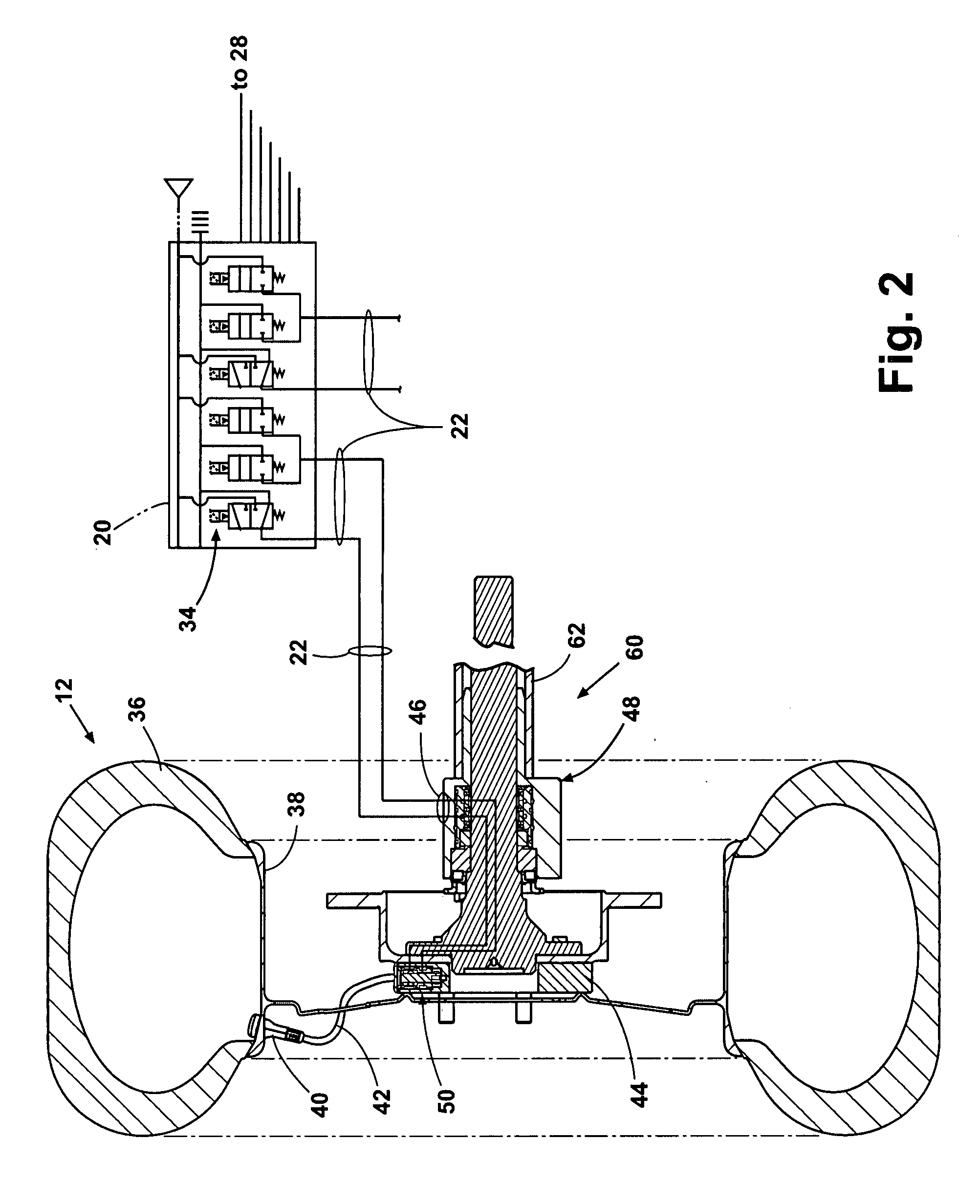

Rotary union assembly for use in air pressure inflation systems for tractor trailer tires

InactiveUS20050133134A1Prevent pressure buildupAvoid distortionTyre measurementsTyre-inflating valvesAtmospheric pressureGuide tube

A rotary union assembly for an automatic tire inflation system for maintaining the pressure in the tires on a tractor trailer or other vehicle having a source of pressurized air for communication with the tires. The assembly communicates the tires with the air source through the axle interior using a conduit having a rigid portion and a flexible portion that extends between a support in the axle spindle and a rotary union housing secured against the outside end surface of the hub cap so as to be outside the wheel lubrication compartment and rotatable with the hub cap. The two-component conduit allows for a durable seal with the support in the axle spindle and accommodates misalignment of the rotary union housing with the conduit support. Relief valves in the housing prevent excessive pressure buildups in the housing and in the hub cap in the event of an air leak.

Owner:AIRGO IP

Universal, remote, continuous vehicle tire air pressure monitoring and reporting system

InactiveUS6011463AReduce inventory costsReduce manufacturing costTyre measurementsTyre-inflating valvesLow voltageRadio reception

This invention is a method and system for reporting the under or over pressure conditions on motor vehicle tires. The device is comprised of air hoses, pressure sensors, radio transmitters with antennas, a radio receiver, a display unit with lights, batteries, lights, and associated electrical components. An assembly mounted on the front of each wheel, over or in place of the hubcap, consists of an air pressure monitor utilizing air pressure inflation valves, a radio transmitter with battery cell, a radio transmitter antenna, and high / low indicator lights. Air hoses attached to each tire's valve stem are connected to the air pressure inflation valves of the air pressure monitors. The wheel mounted transmitters are powered by a low voltage battery that is normally powered off until activated by the changes of the pre-set air pressure of the tire air pressure monitoring sensor.

Owner:CORMIER SR LEVITE

Supplying/removing apparatus of puncture sealant of tire

A puncture sealant supplying / removing apparatus includes a pressure-resistant bottle, an apparatus body on which the pressure-resistant bottle can be mounted, supply hose means which supplies or returns a puncture sealant accommodated in the pressure-resistant bottle to or from a tire, and a high pressure air source.The apparatus body comprises a venturi flow-path having a venturi portion, a first flow-path extending from the venturi portion into the pressure-resistant bottle, and a second flow-path extending from an inside of the pressure-resistant bottle and connected to one end of the supply hose means. The venturi flow-path is provided at its one end with an air intake which is connected to the high pressure air source, the venturi flow-path is provided at its other end with an opening / closing tool capable of opening and closing the other end.

Owner:SUMITOMO RUBBER IND LTD

Tire pressure management system valve integrity verification method

A method of verifying the integrity of a valve in service in a tire pressure management system is disclosed. The method of verifying valve integrity of a valve interposed between a tire and conduit assemblies for conducting fluid to and / or from the tire in a tire maintenance system includes closing the valve for prohibiting fluid flow into the conduit assemblies in fluid communication with the valve and monitoring the pressure of fluid in the conduit assemblies in fluid communication with the valve for ascertaining a pressure increase therein.

Owner:DANA HEAVY VEHICLE SYSTEMS GROUP LLC

Wheel end assembly high-temperature warning system

Owner:PRESSURE SYST INT LLC

Self-inflating tire and pressure regulator

A self-inflating tire assembly includes an air tube connected to a tire and defining an air passageway, the air tube being composed of a flexible material operative to allow an air tube segment opposite a tire footprint to flatten, closing the passageway, and resiliently unflatten into an original configuration. The air tube is sequentially flattened by the tire footprint in a direction opposite to a tire direction of rotation to pump air along the passageway to a regulator device. The regulator device regulates the inlet air flow to the air tube and the outlet air flow to the tire cavity.

Owner:THE GOODYEAR TIRE & RUBBER CO

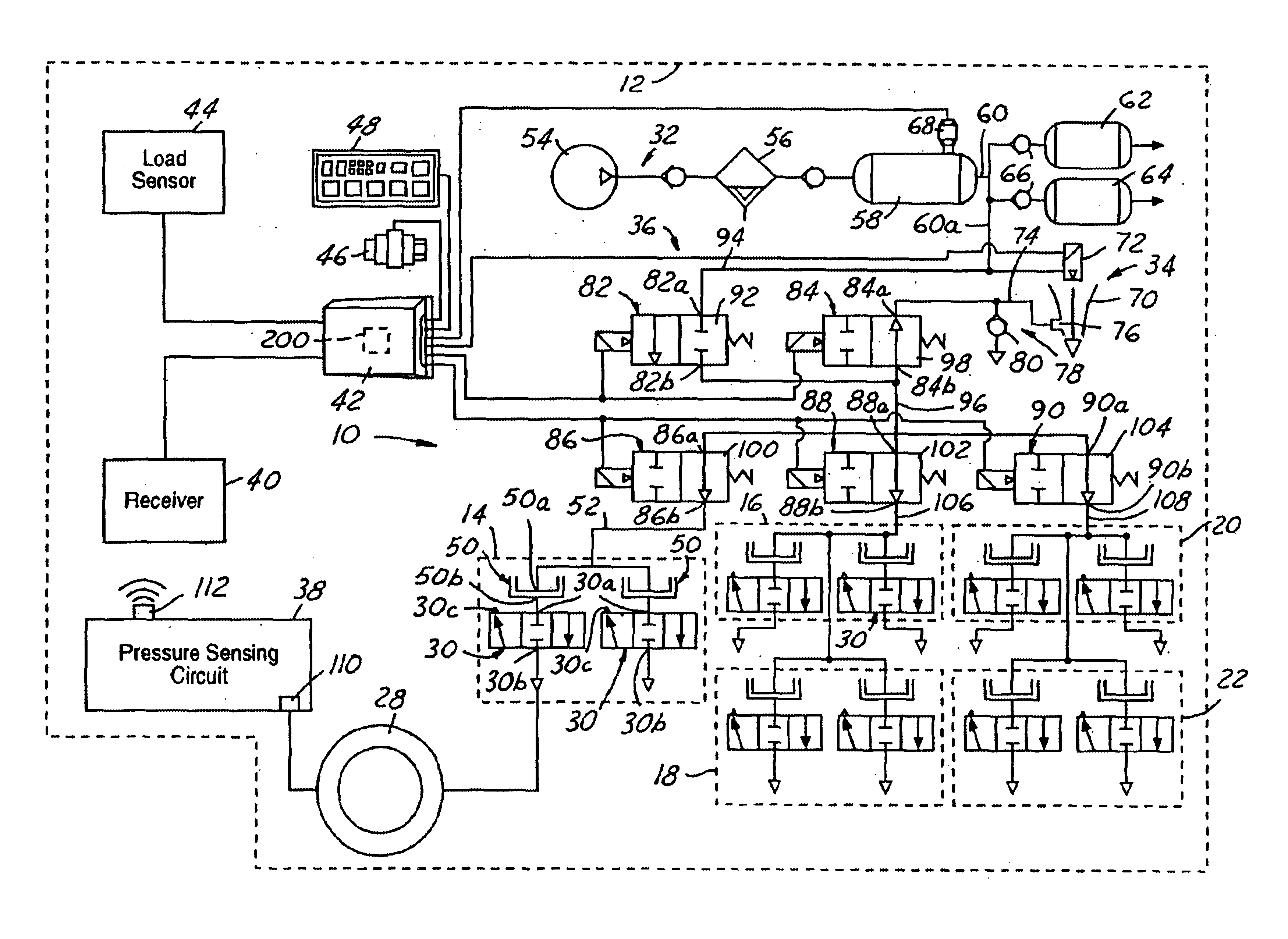

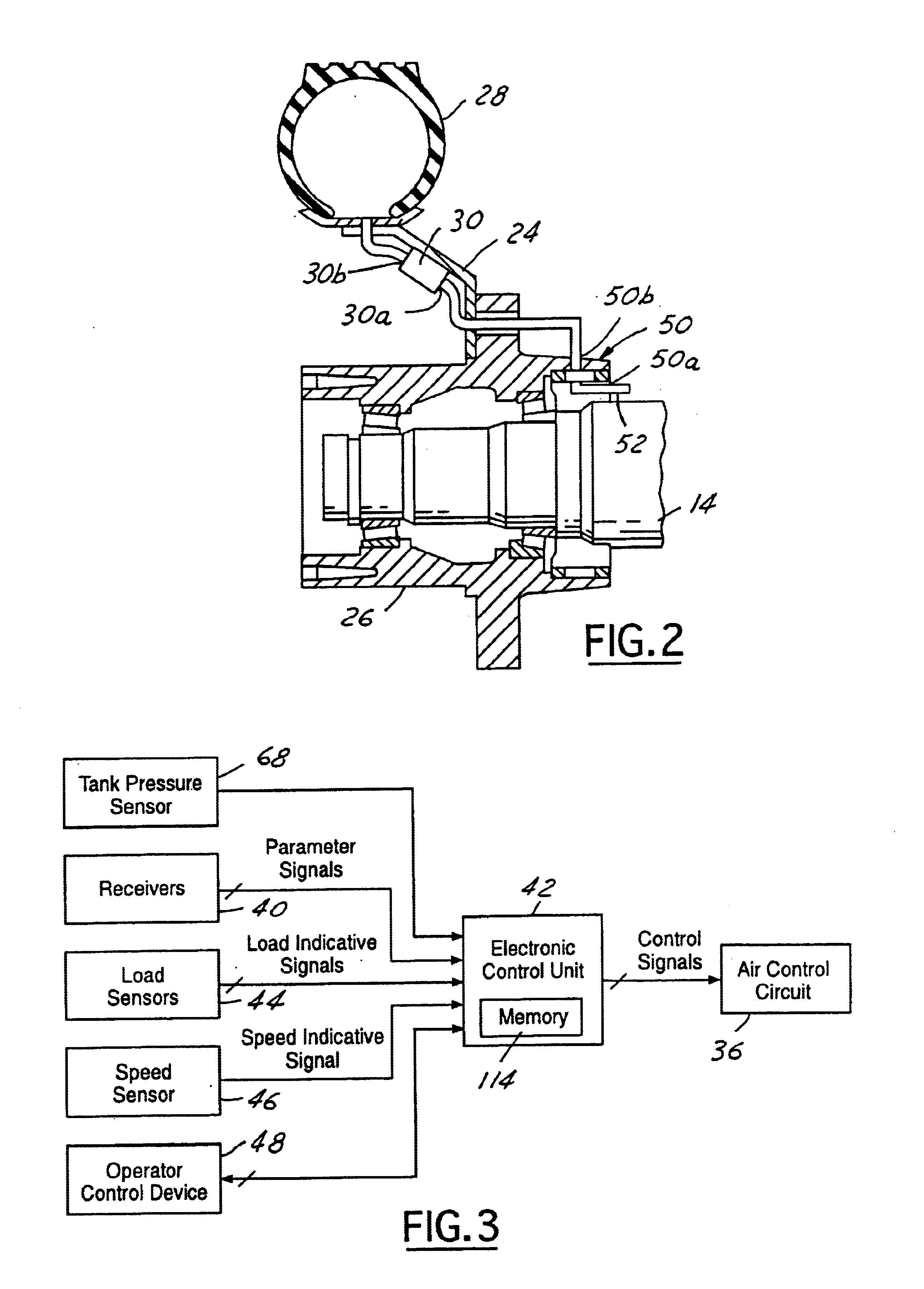

Tire inflation system apparatus and method

ActiveUS20050194080A1Accurate checkAccurate pressureTyre measurementsTyre-inflating valvesVALVE PORTTire pressure

A tire inflation system includes an air supply source in selective fluid communication with a tire via a pneumatic conduit. A method of inflating the system includes providing a tire pressure retention valve in the pneumatic conduit adjacent to the tire. An inflation pressure of the tire is determined with a step-up procedure, in which air bursts are communicated from the air supply source to a portion of the pneumatic conduit between the air supply source and the tire pressure retention valve. The volume of at least one selected communicated air burst is related to a volume of a section of the conduit. The tire is inflated with an extended-pulse procedure, in which extended bursts of air are communicated from the air supply source to the tire. A shut-down sequence is performed once a predetermined target inflation pressure in the tire is reached.

Owner:HENDRICKSON USA L L C

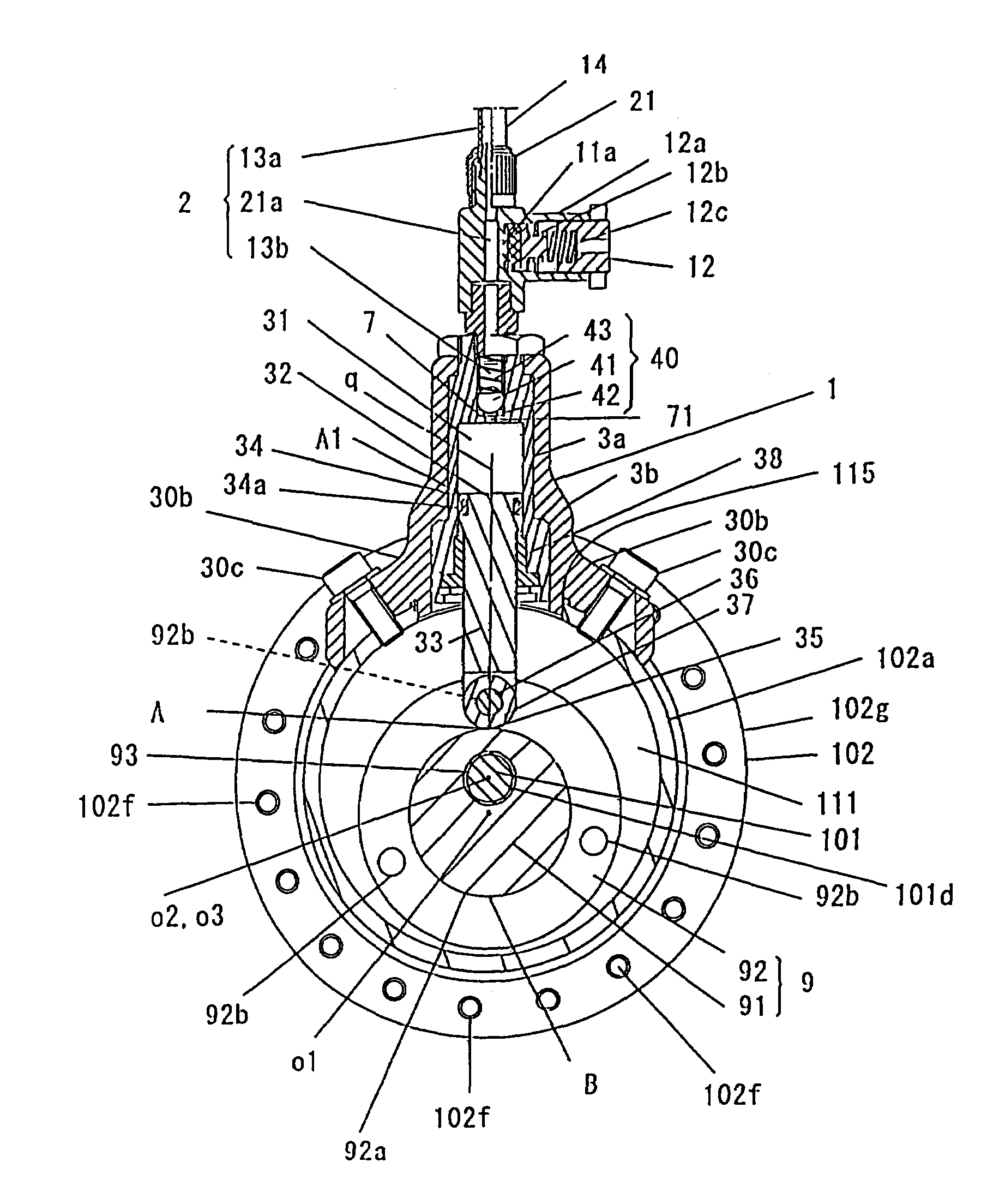

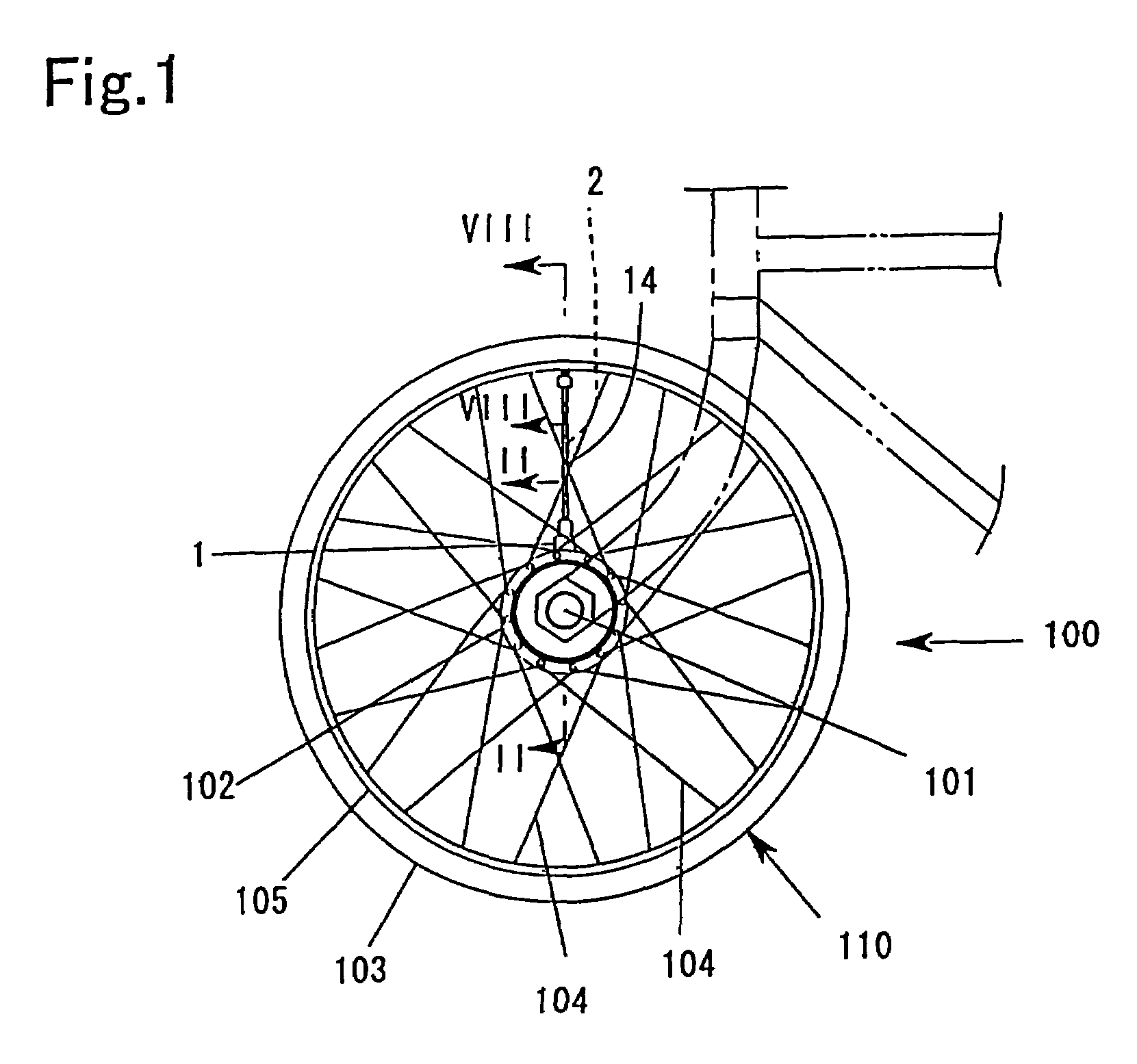

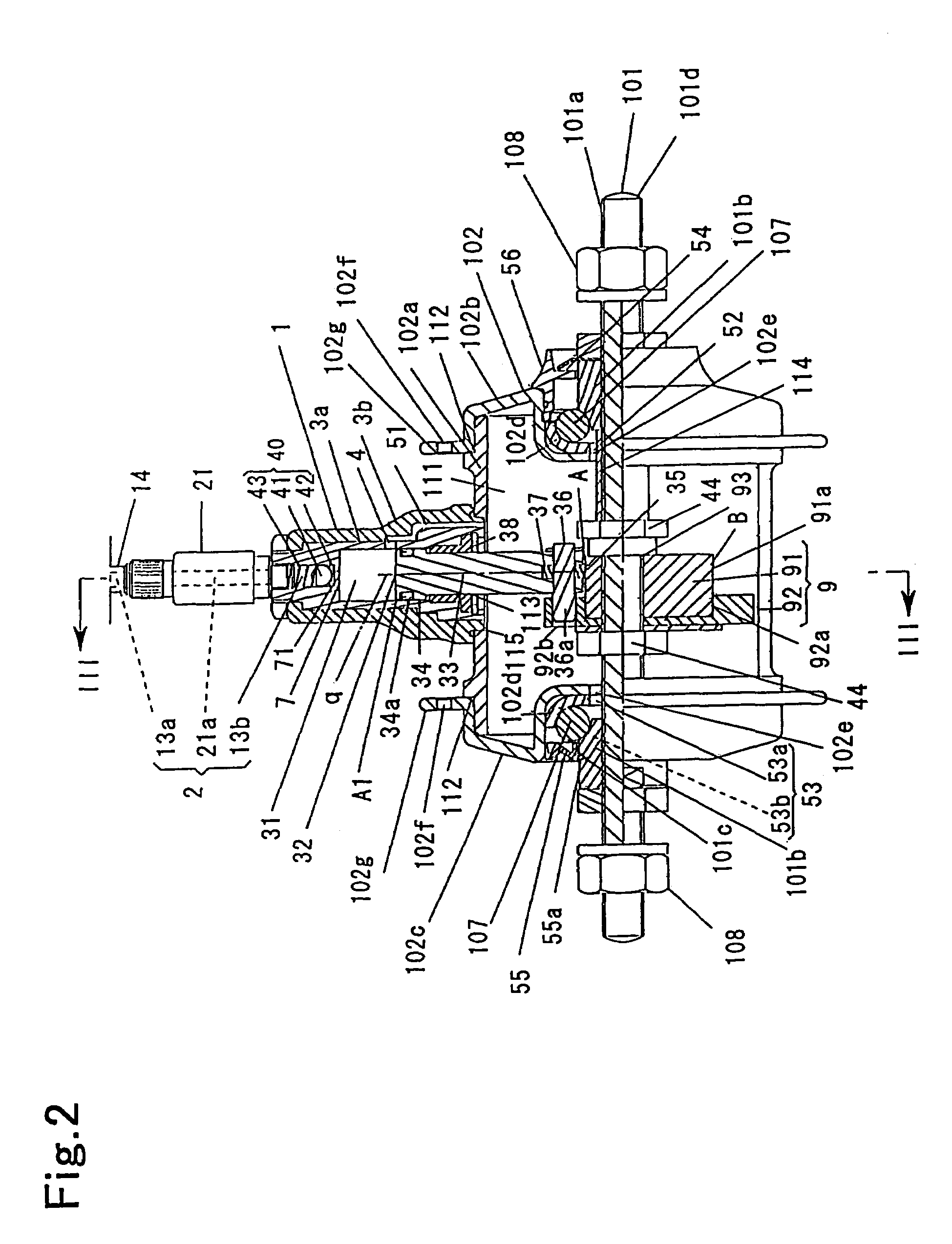

Automatic air-feeding mechanism for pneumatic tire

InactiveUS7581576B2Force is smallA large amountPiston pumpsTyre measurementsEngineeringCompressed air

To provide an automatic air-feeding mechanisms which can produce a large amount of compressed air with a small number of rotations of a wheel body and with a small force. The automatic air-feeding mechanisms has first and second compressed air producing sections 1a and 1b, and pneumatic tire compressed air supply passages 2a and 2b for introducing the compressed air produced in the compression air producing sections to a pneumatic tire. The first and second compressed air producing sections 1a and 1b are attached to a hub drum 102a of the hub 102 at positions 180° apart from each other. When the wheel body is rotated, the first and second compressed air producing sections 1a and 1b alternately produce compressed air.

Owner:NAKANO TAKAJI

Drive axle with air passage for tire inflation system

A drive axle assembly includes a non-rotating spindle having a cylindrical body defining an internal cavity and an axle shaft assembly mounted within the internal cavity for rotation about an axis. A seal assembly is positioned within the internal cavity to provide a sealed chamber between the axle shaft assembly and the non-rotating spindle. A first air passage is formed within the cylindrical body and includes an air inlet to be in fluid communication with an air supply and an air outlet in fluid communication with the sealed chamber. A second air passage is formed within the axle shaft assembly and receives air input from the sealed chamber and includes an air output to be associated with at least one tire.

Owner:ARVINMERITOR TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com