Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

2386 results about "Pressure increase" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

There are three ways to increase the pressure: Add more gas. Decrease the volume. Increase the temperature.

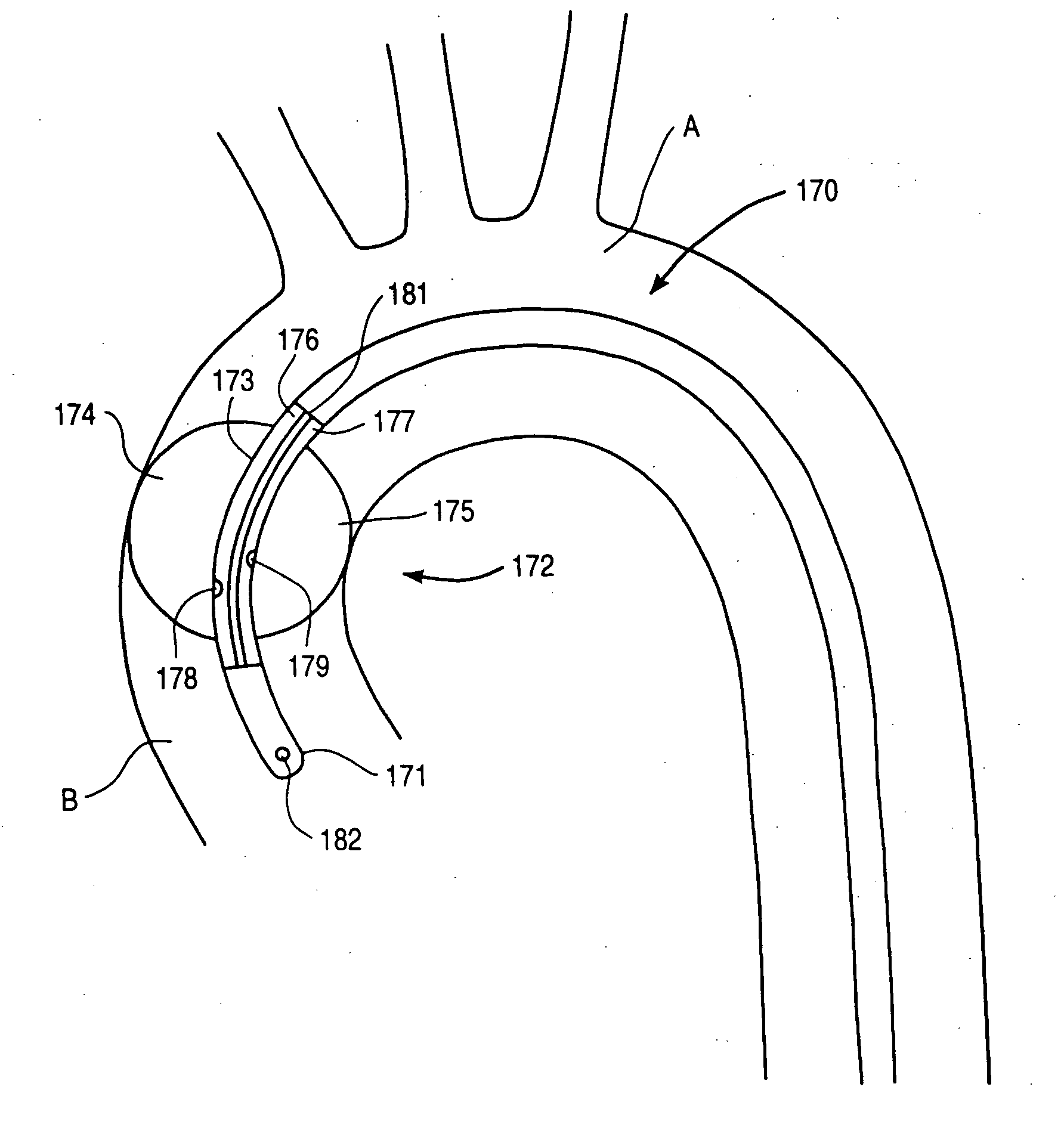

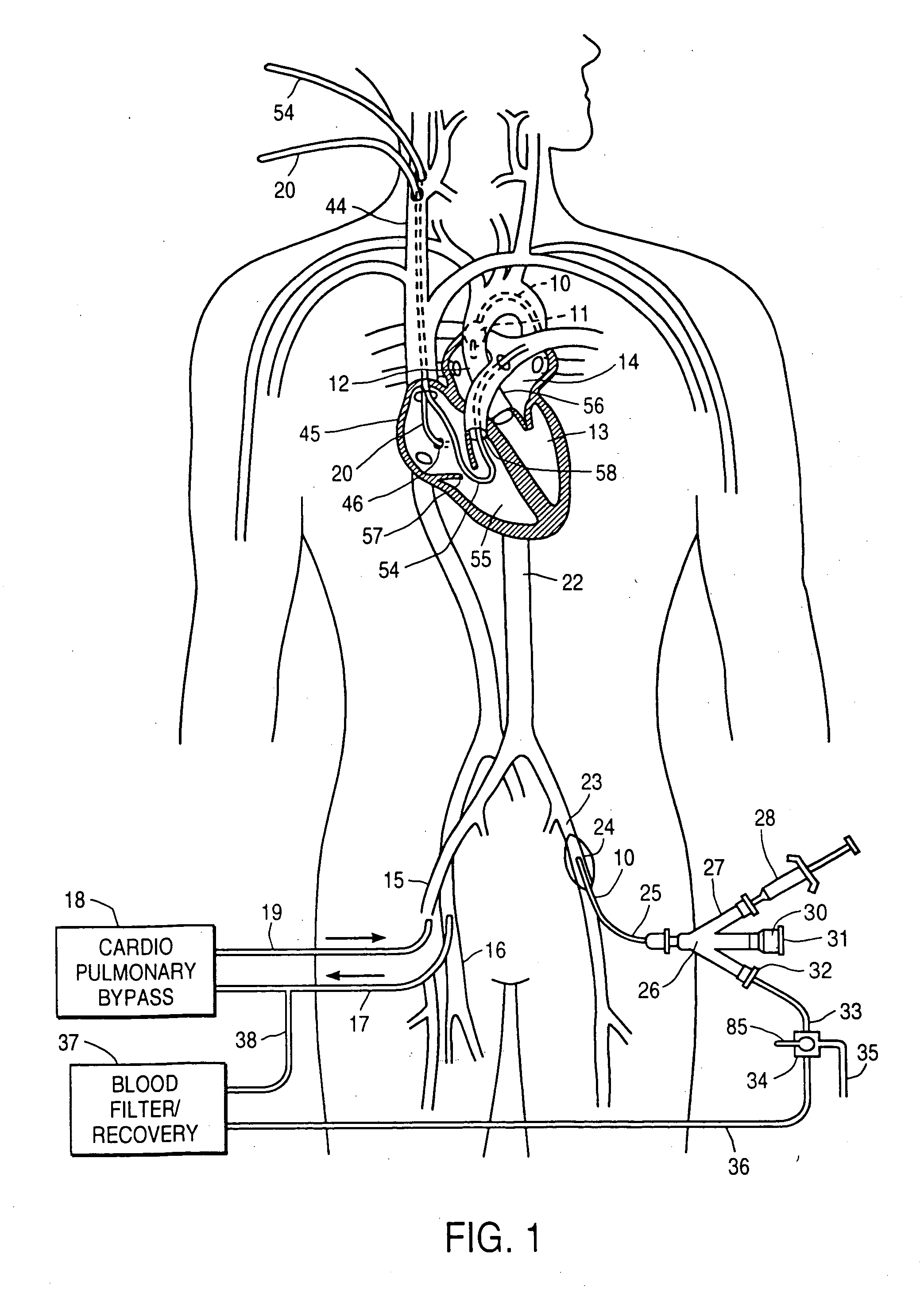

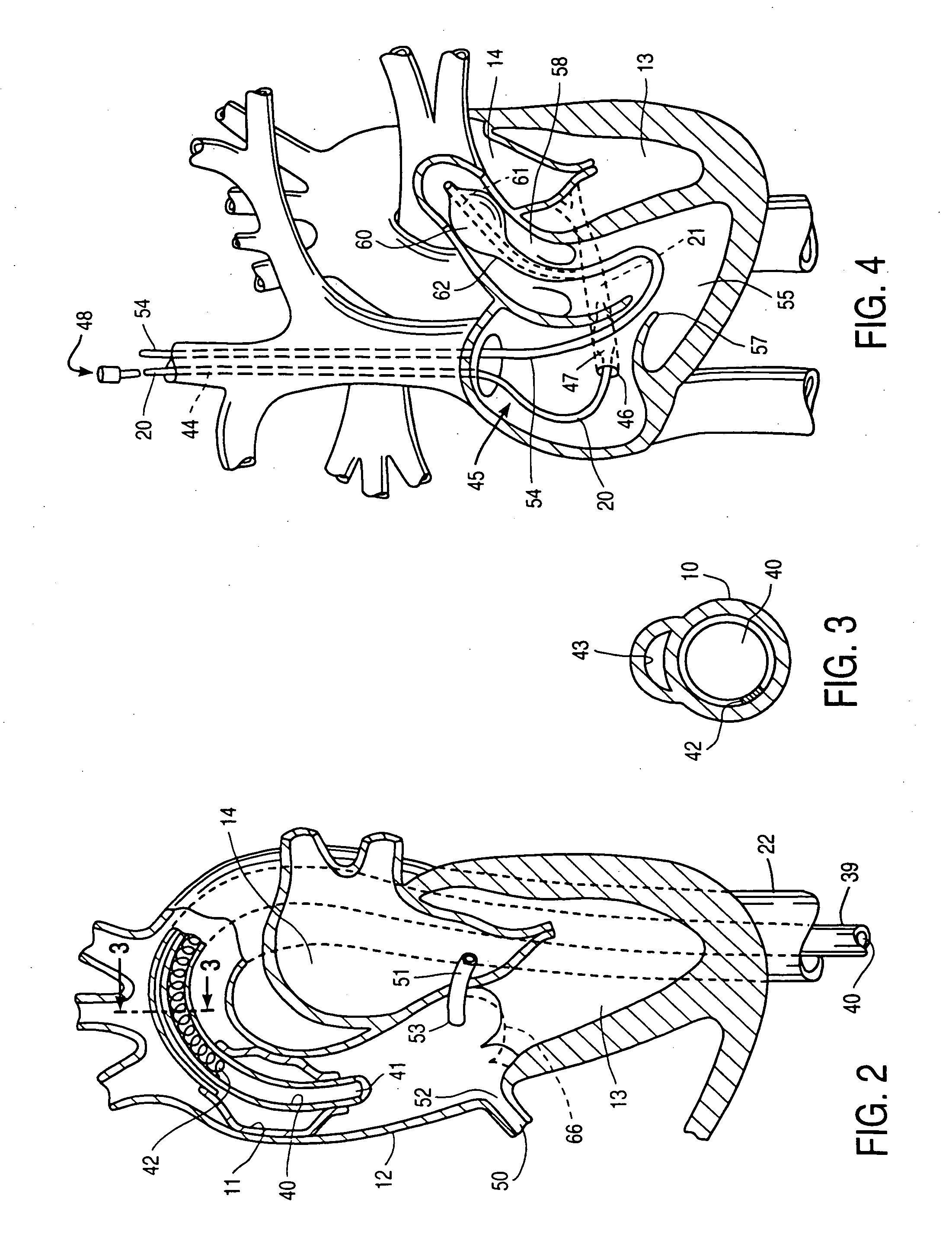

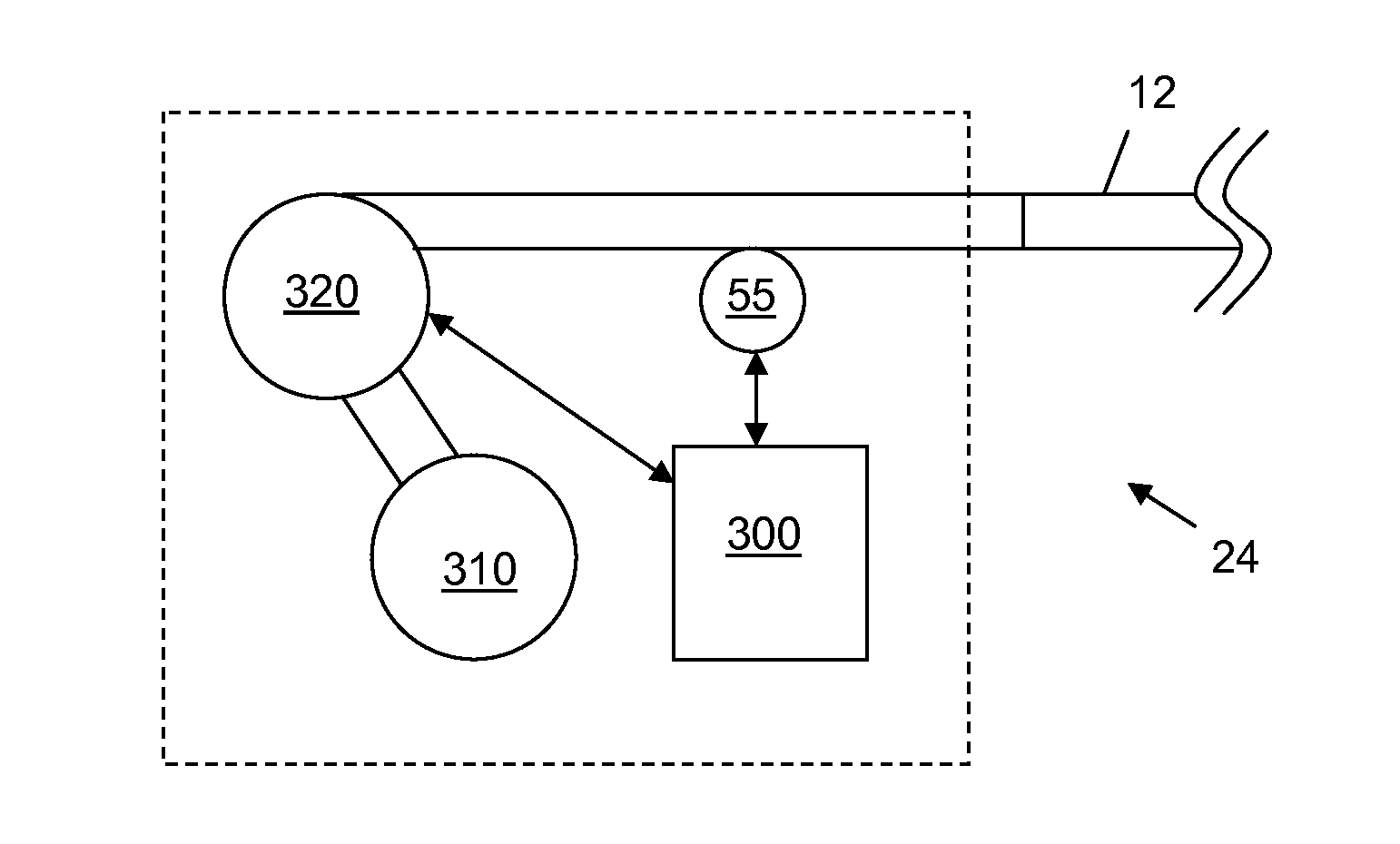

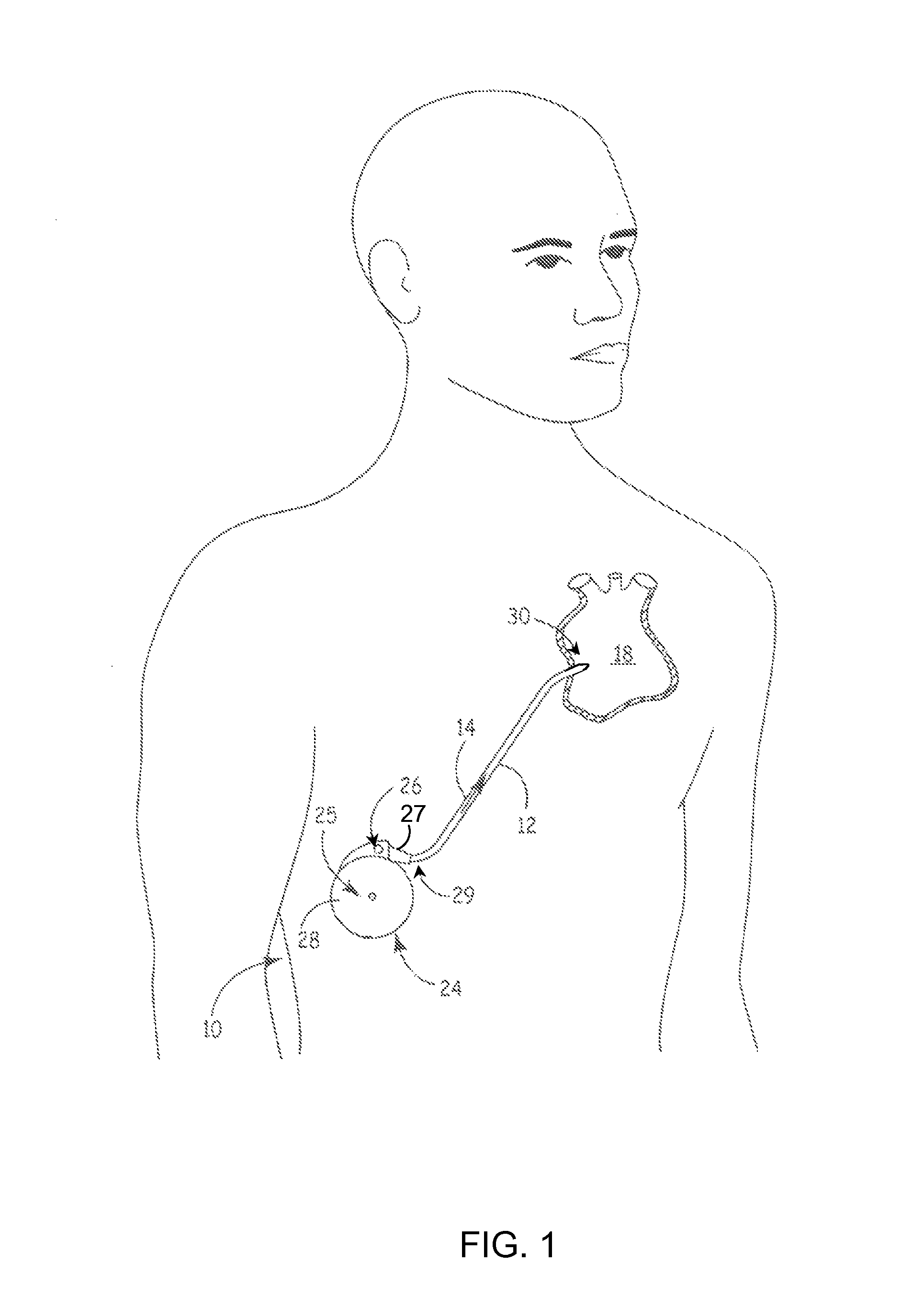

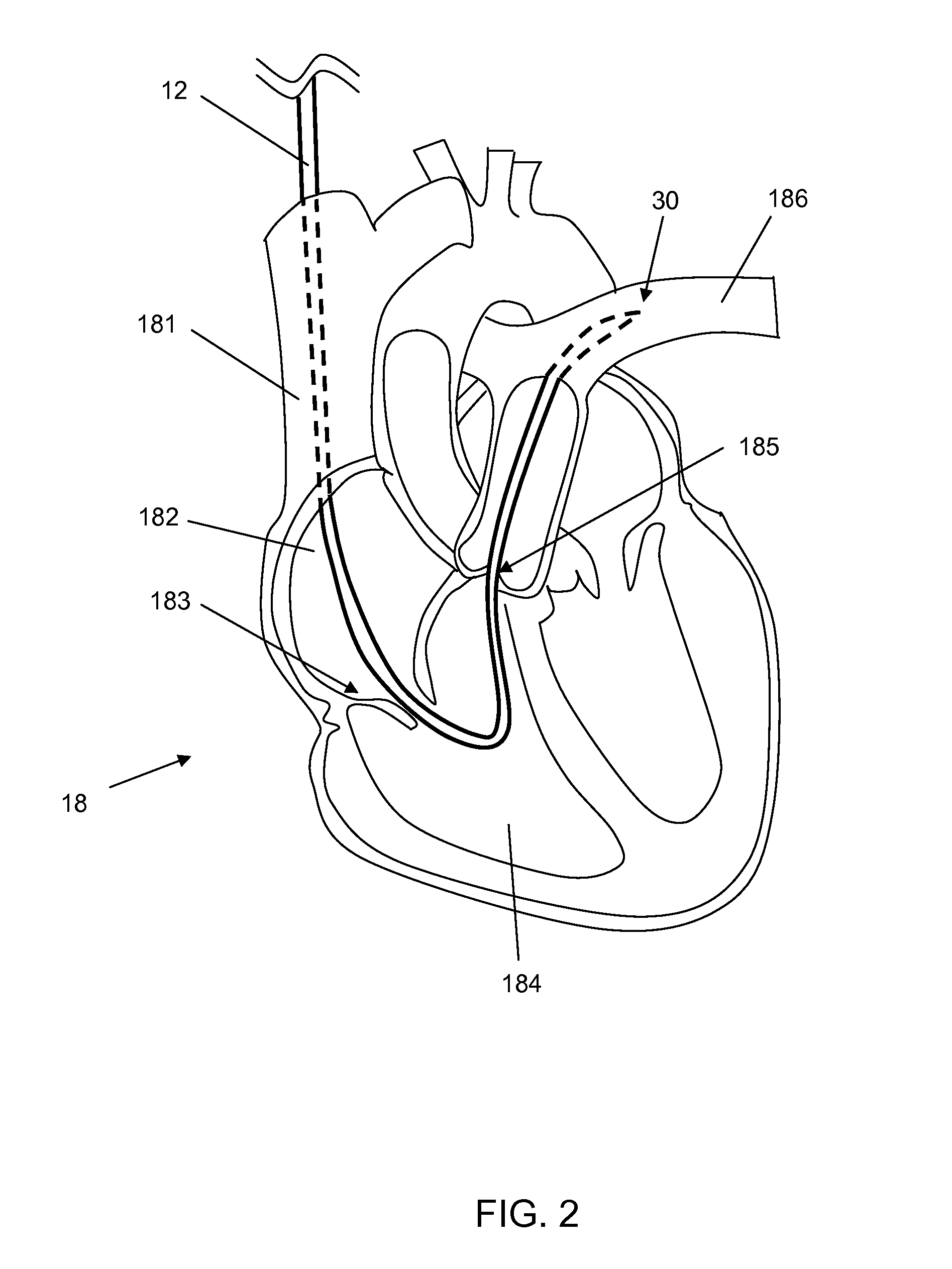

Methods and apparatus for anchoring an occluding member

Pressure is measured on both sides of an occluding member for determining when pressure forces on the occluding member may cause migration of the occluding member. An alarm indicates when the pressure force on the balloon exceed a predetermined threshold. In another aspect of the invention, a pressure monitor determines when a rate of pressure increase with respect to the fluid volume in the balloon reaches a predetermined threshold when inflating the occluding member. A predetermined amount of fluid is then added to the balloon so that the balloon is not under inflated or over inflated.

Owner:VALLEY KIRSTEN L +3

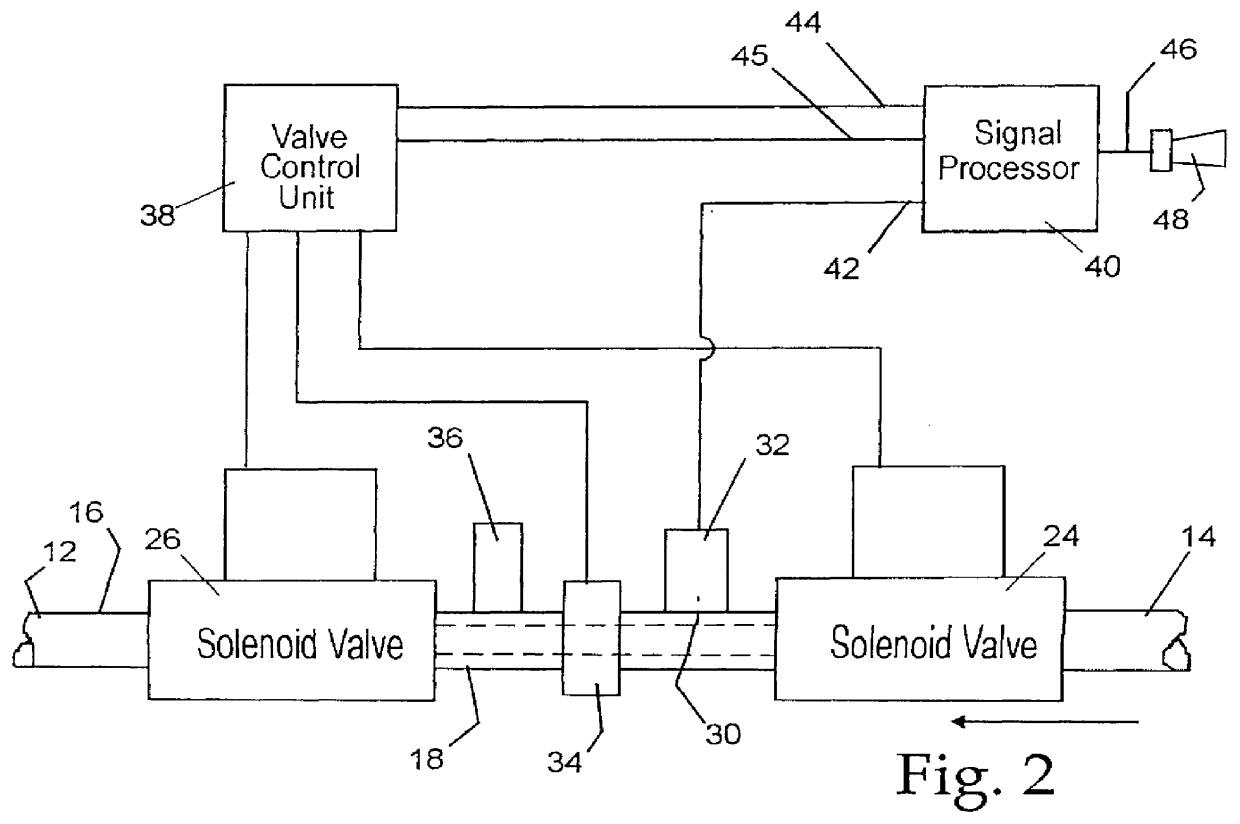

Fluid delivery apparatus

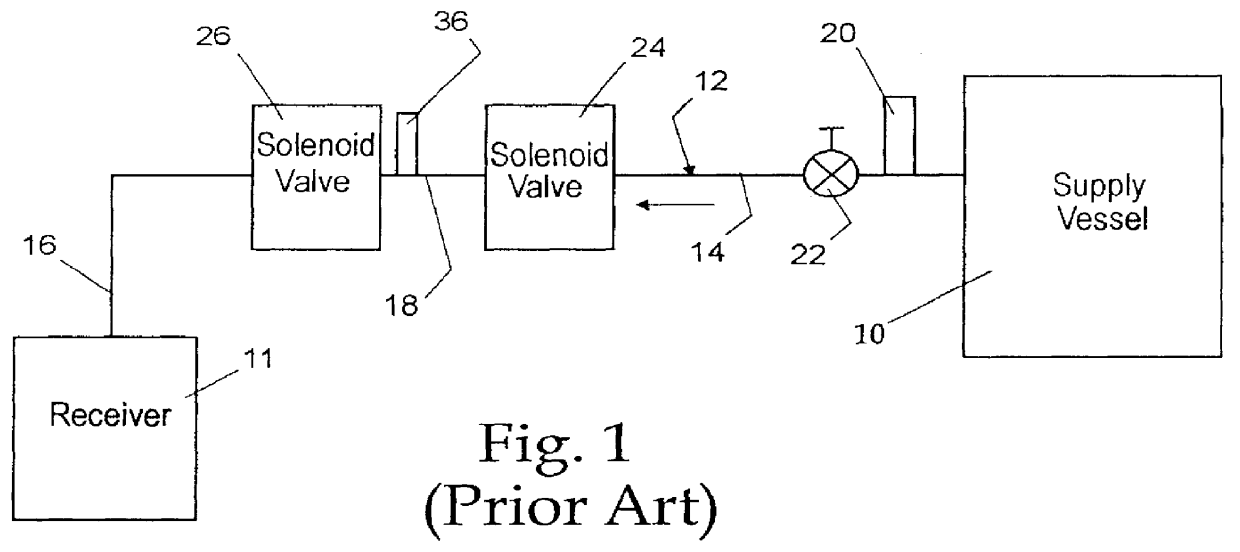

A line, especially for delivery of liquefied gas at ambient temperature, has two solenoid valves connected in series with an intermediate section of the line between them. In normal operation when both valves are closed, the isolated intermediate section contains liquid which absorbs heat from the atmosphere and / or from a heater, and the resulting increase in pressure is detected by a pressure sensor. If either valve fails to close fully to shut off flow, the intermediate section is not then isolated, so the absence of a signal from the sensor (the valves being set to close fully) indicates that at least one of them has not properly closed, and an alarm is given.

Owner:PLANER PROD LTD

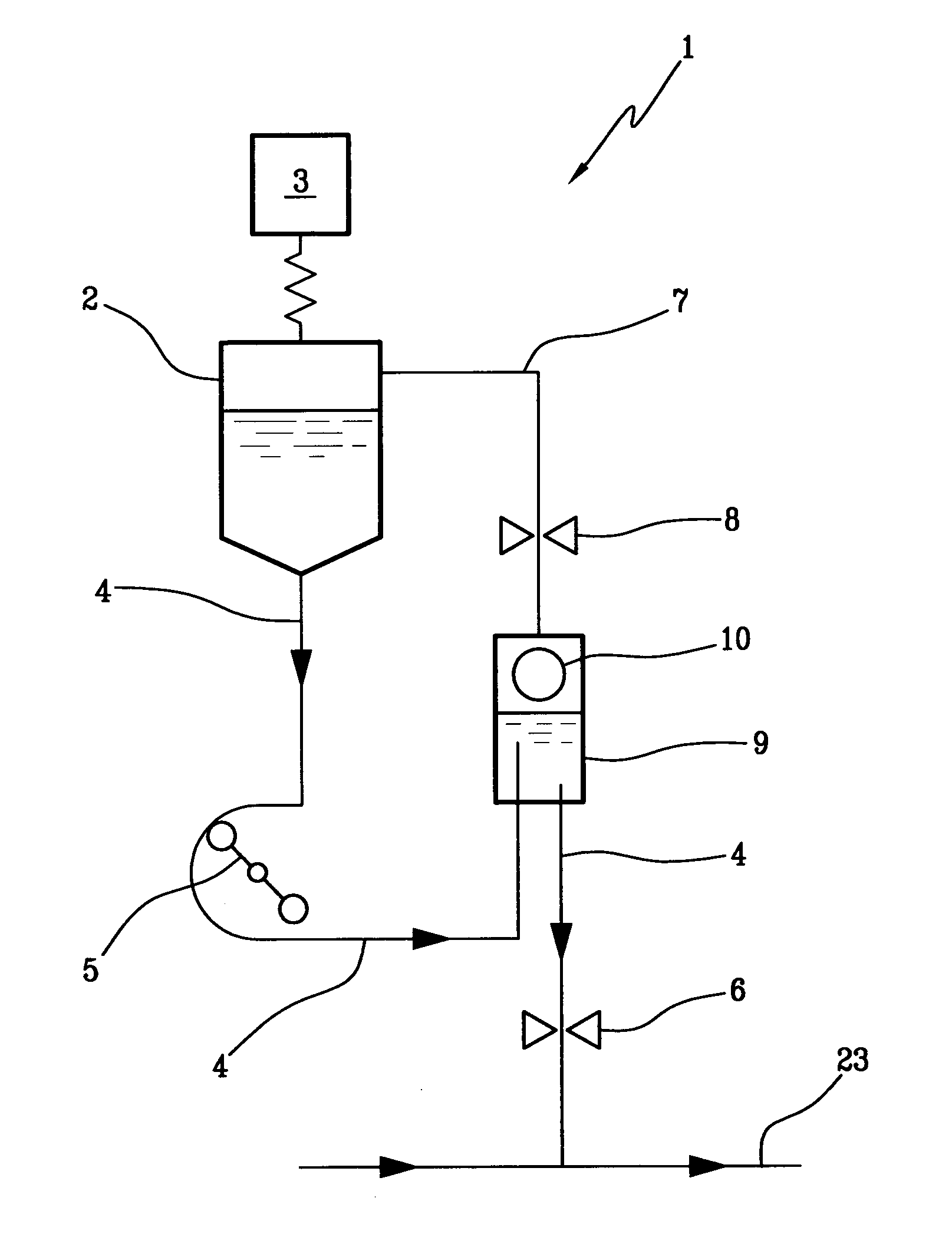

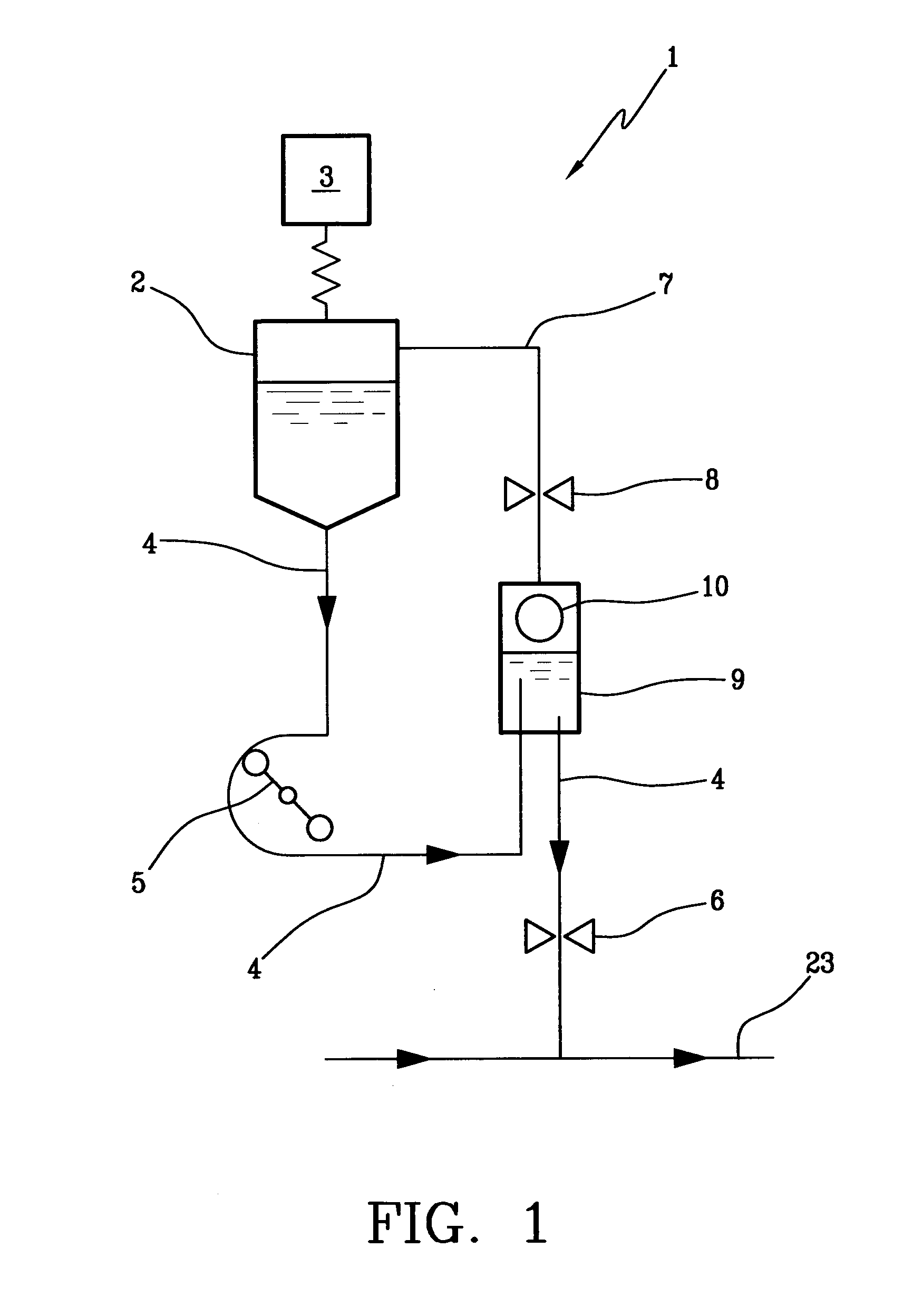

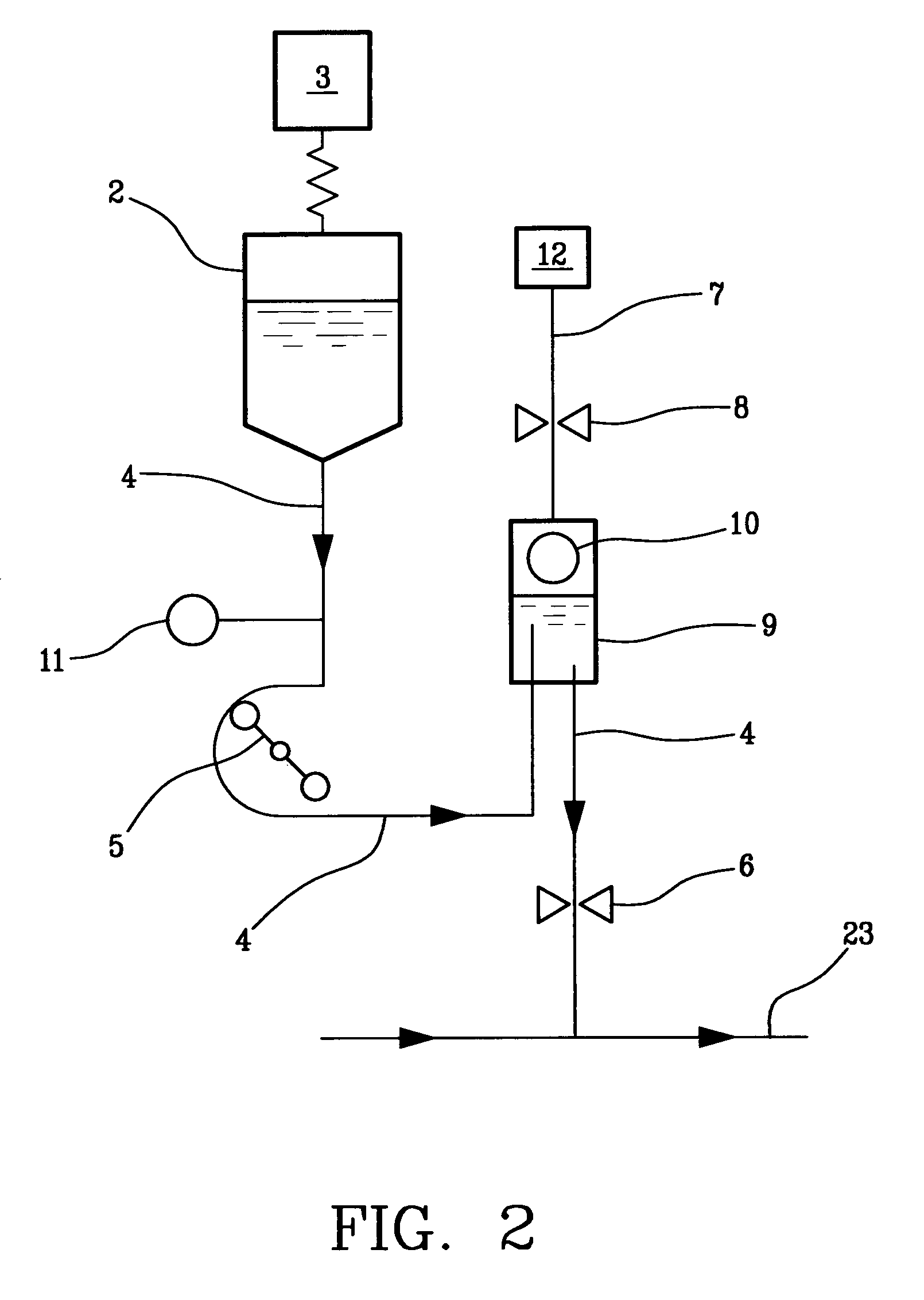

Infusion apparatus

ActiveUS20100280430A1Reduce need for interventionReduce riskMedical devicesPressure infusionEngineeringExpansion chamber

In an infusion apparatus, an infusion line (4) connects a container (2) of an infusion fluid to an extracorporeal blood circuit (23). A first valve (6) closes the infusion line downstream of an infusion pump (5). An expansion chamber (9), provided with a pressure sensor (10), is arranged between the infusion pump and the first valve. A second valve (8) closes a vent line (7) of the expansion chamber. The processor closes the first valve when the container is emptied. After replacement with a new and full container, the processor restarts the pump and selectively opens the first valve or the second valve according to the increase in pressure measured in the expansion chamber.

Owner:GAMBRO LUNDIA AB

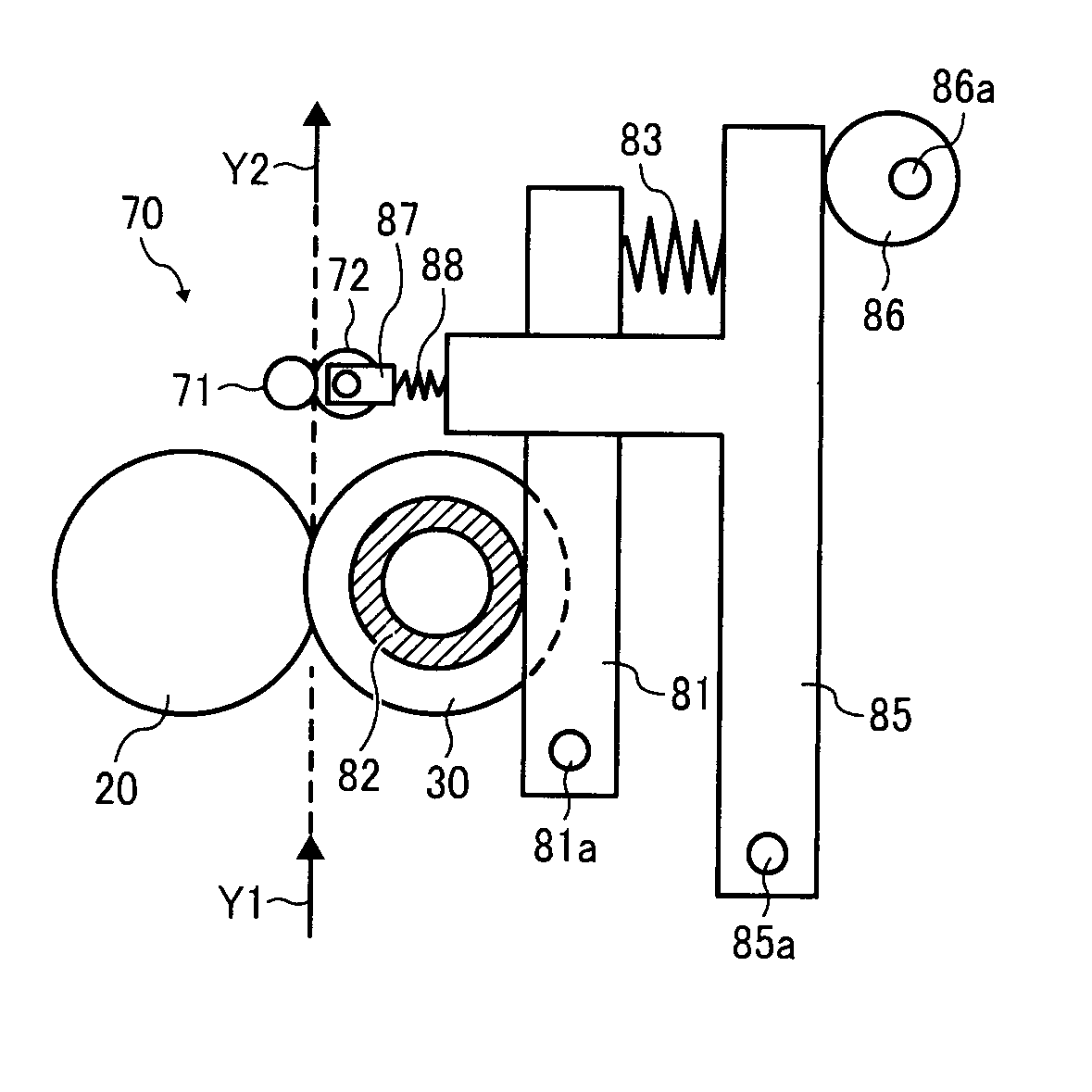

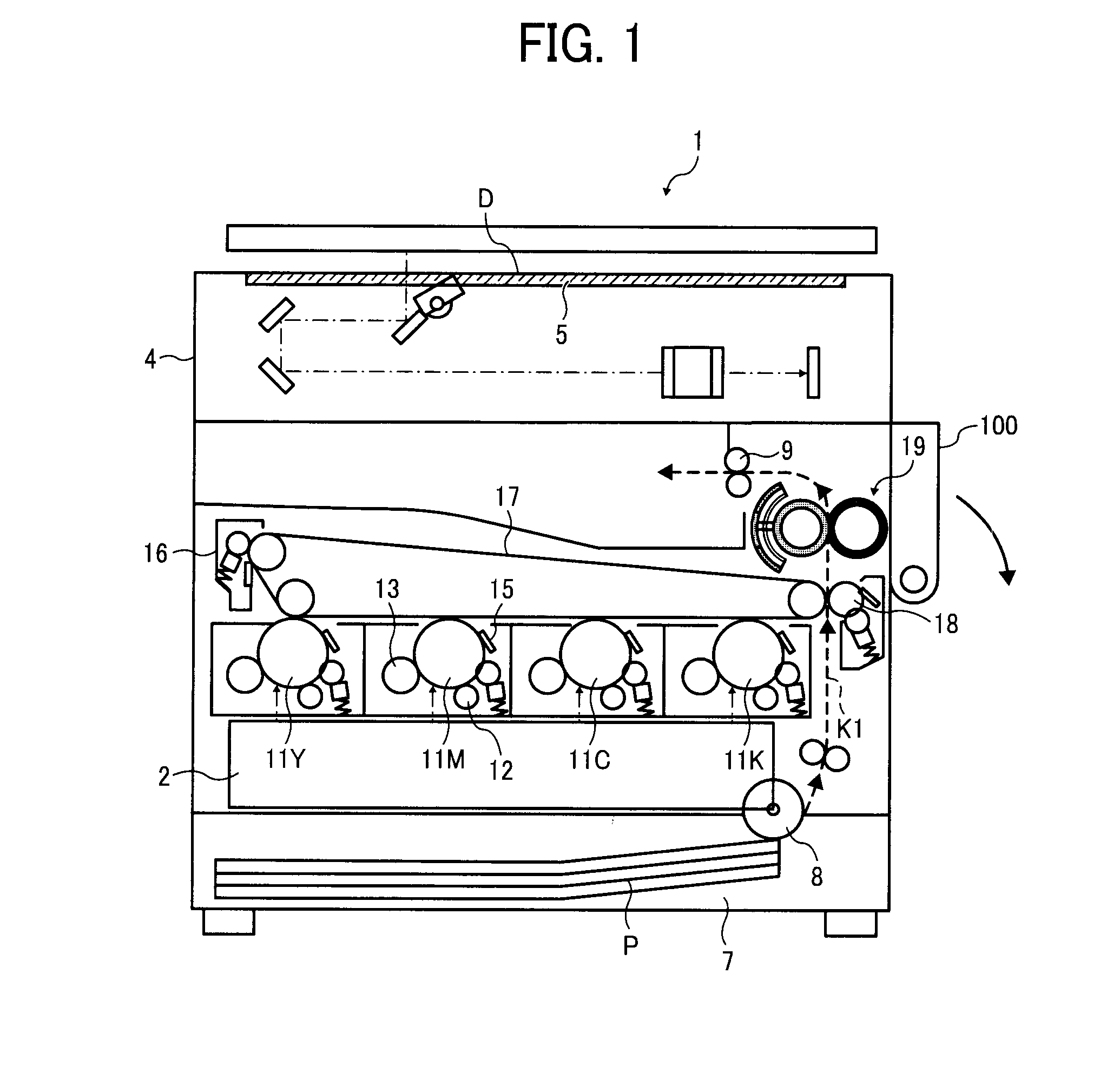

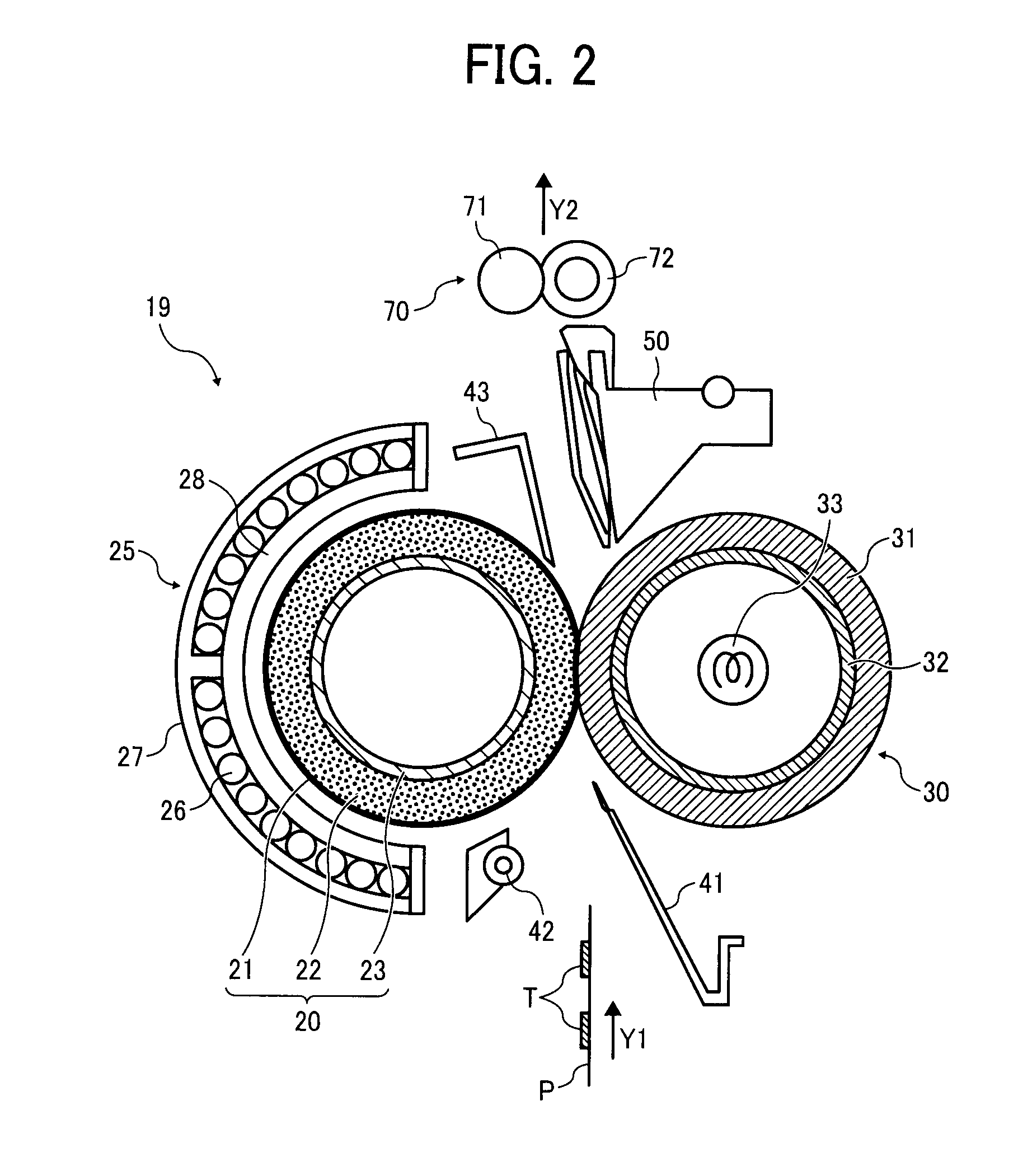

Fixing unit and image forming apparatus

A fixing unit includes a fixing member to fuse a toner image on a recording medium on the recording medium; a pressure member to press against the fixing member to define a first nip between the fixing member and the pressure member through which the recording medium is transported; a shifting unit to move the pressure member relative to the fixing member to increase or decrease a pressure of the first nip; a curling correction unit disposed downstream from the first nip in a transport direction of the recording medium that imparts a second curling direction to the recording medium; and a variable setting unit operatively connected to the curling correction unit to variably set an amount of the second curling direction to the recording medium by the curling correction unit depending on the first nip pressure increased or decreased by the shifting unit.

Owner:RICOH KK

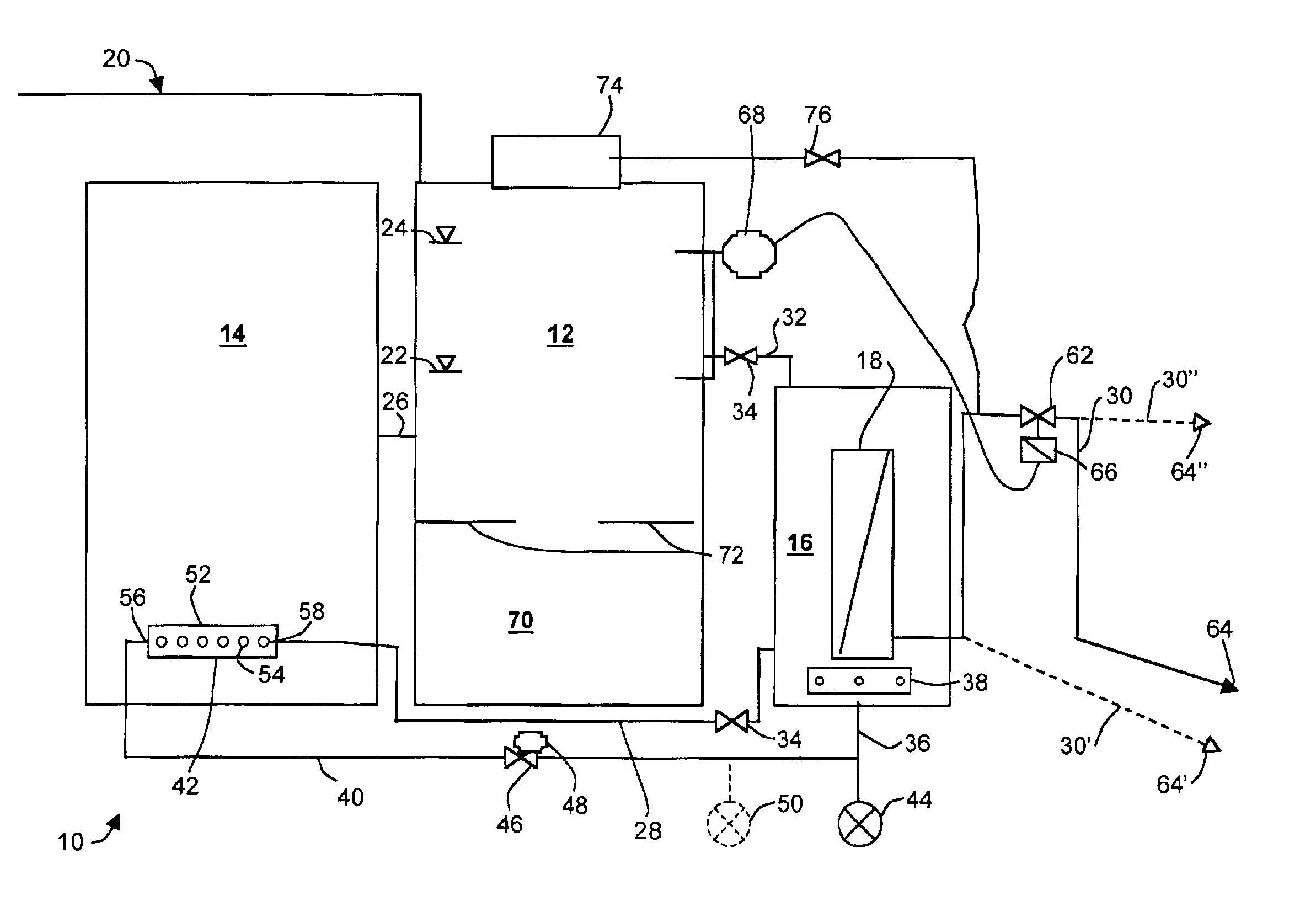

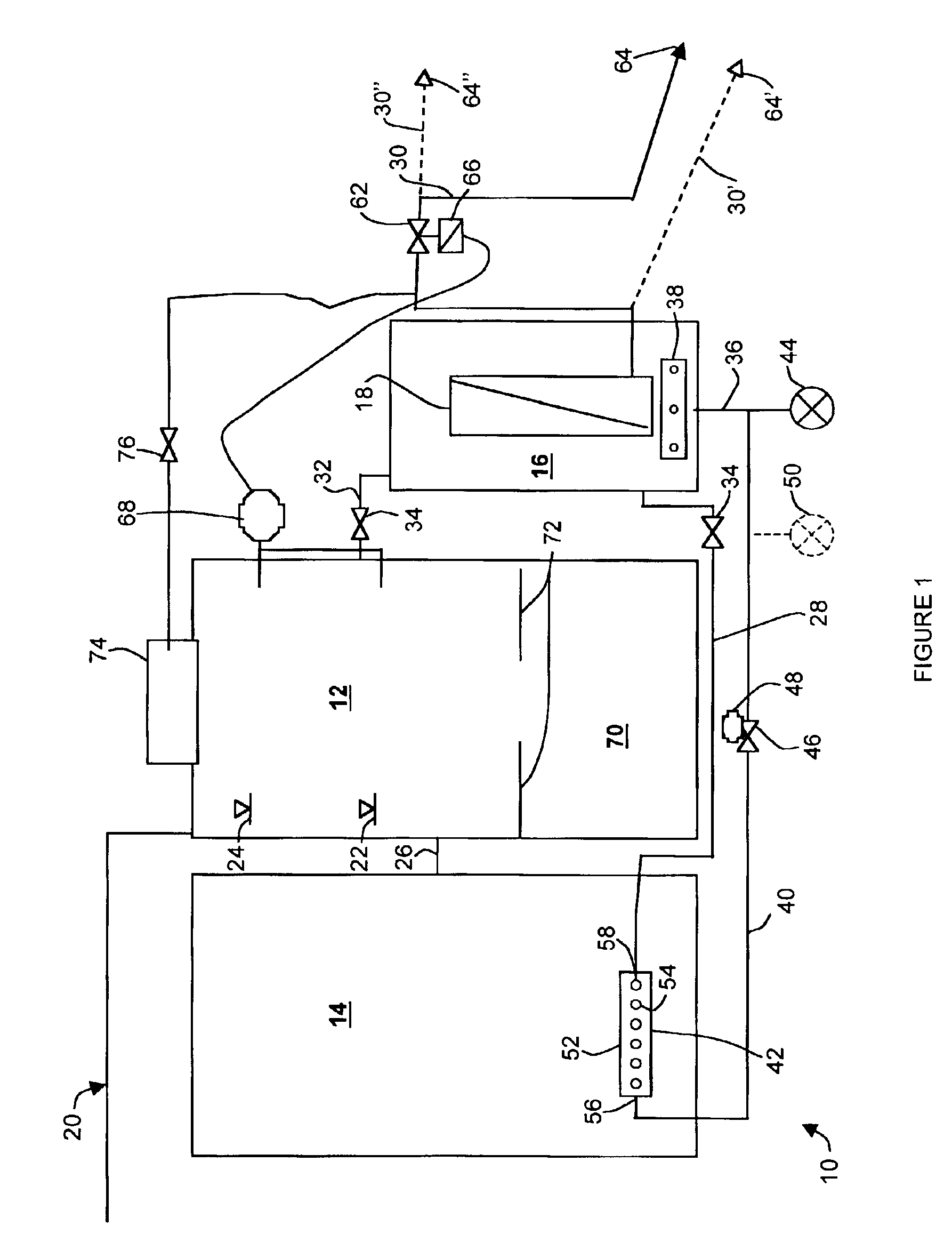

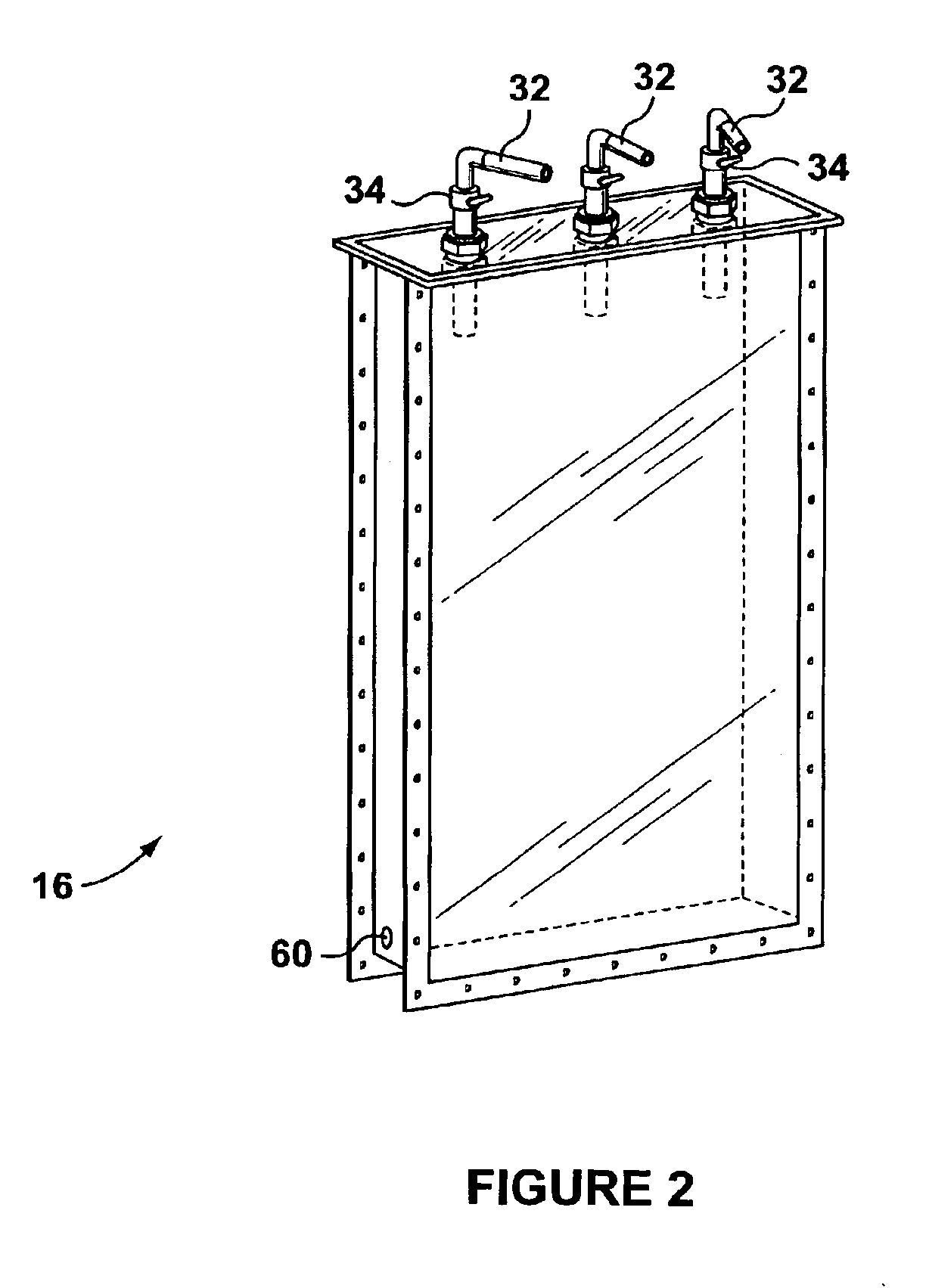

Membrane bioreactor, process and aerator

InactiveUS6863817B2Increase pressureEasy to moveTreatment using aerobic processesUsing liquid separation agentSiphonGravity flow

A reactor has an aerobic tank, an anoxic tank and a sealed membrane tank with conduits for circulating mixed liquor between them. Permeation starts when the mixed liquor reaches a high level and stops when the mixed liquor reaches a low level. A sensor, for detecting the mixed liquor level, may stop and start permeation. Pressure builds in the membrane tank when membrane air is on. Transmembrane pressure is also provided by gravity flow or siphon. Membrane air generates an air lift which drives the mixed liquor circulation. The total amount of air provided by an air source is divided and varied in time between the membrane aerator and the process aerator. The process aerator acts as a screening inlet to the conduit to the membrane tank. Chemical maintenance cleaning is provided by gravity flow.

Owner:ZENON TECH PARTNESHIP

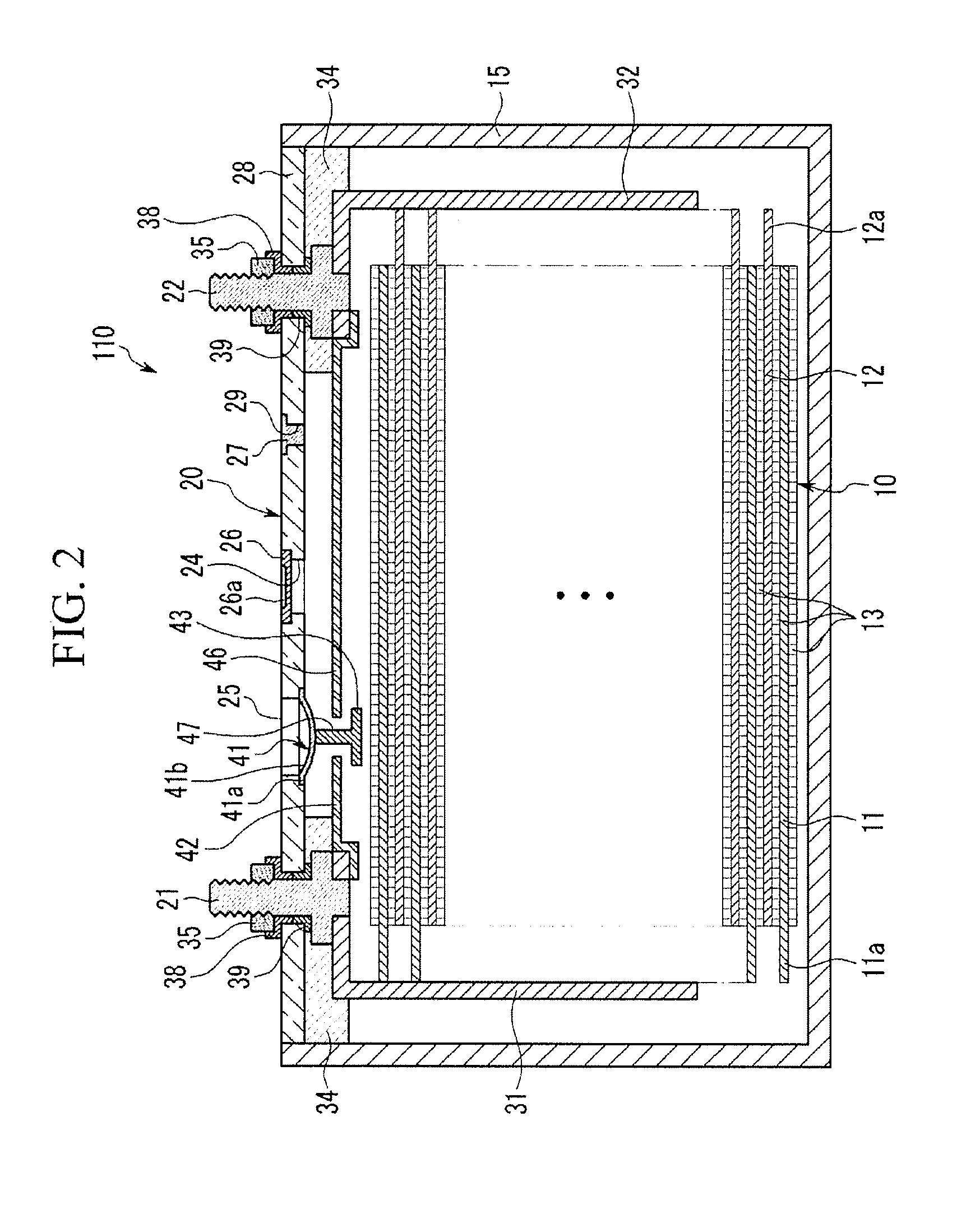

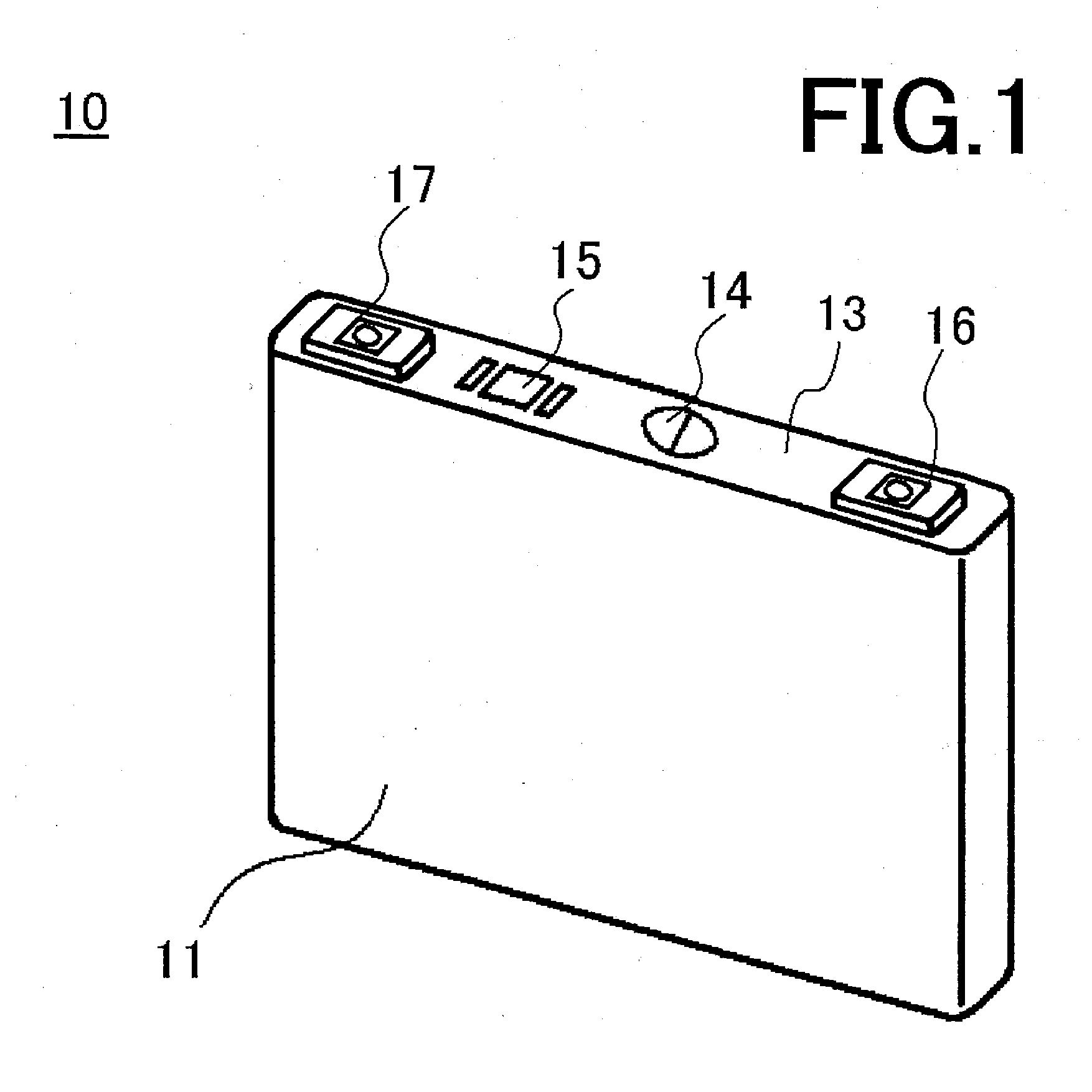

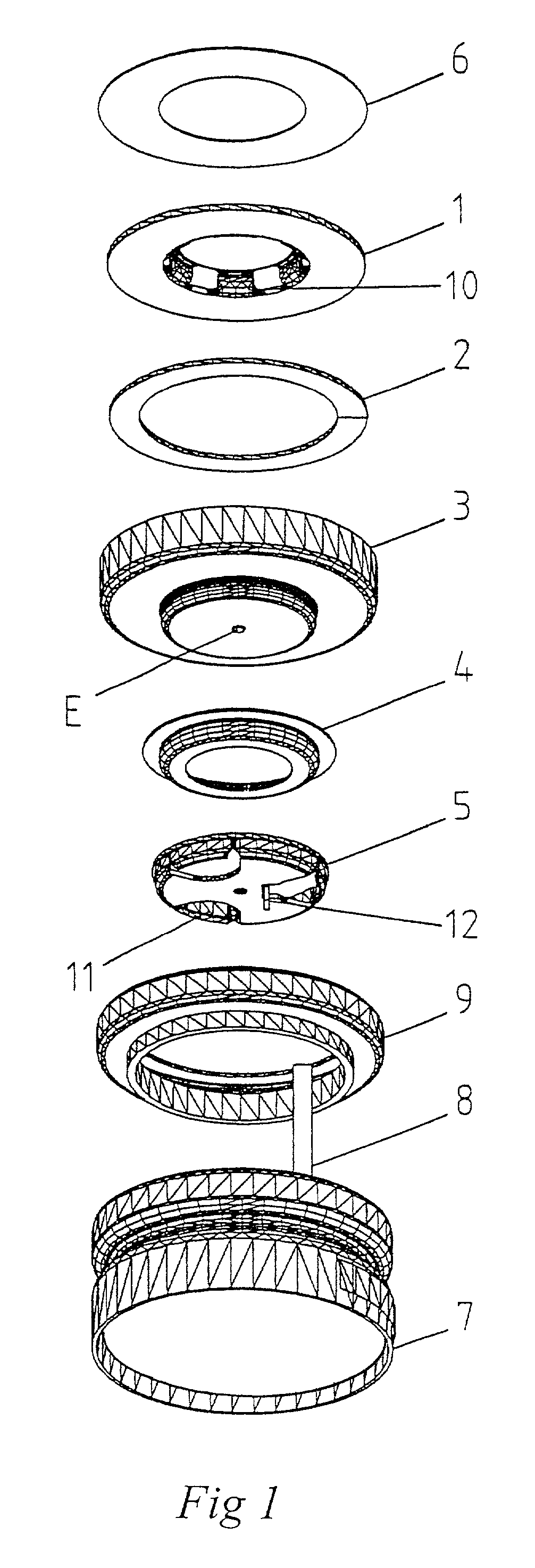

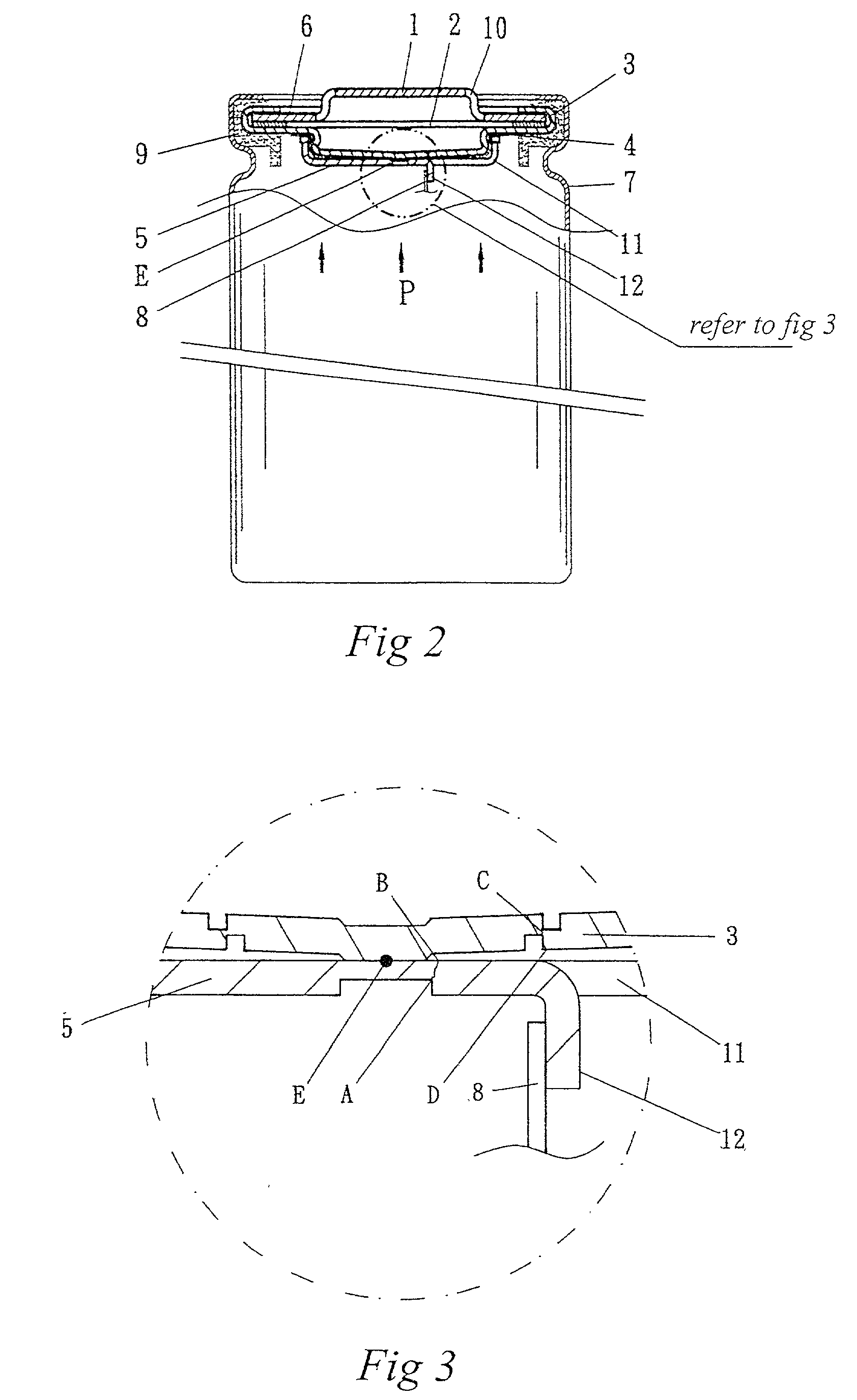

Rechargeable battery

A rechargeable battery includes an electrode assembly including a first electrode, a second electrode, and a separator between the first and second electrodes; a case housing the electrode assembly; and a cap assembly connected to the case. The cap assembly includes a first tab electrically connected to the first electrode, a second tab electrically connected to the second electrode, an deformable plate capable of electrically connecting the first tab and the second tab by being deformed due to a pressure increase, and an intermediate member formed between the first tab and the deformable plate.

Owner:ROBERT BOSCH GMBH +1

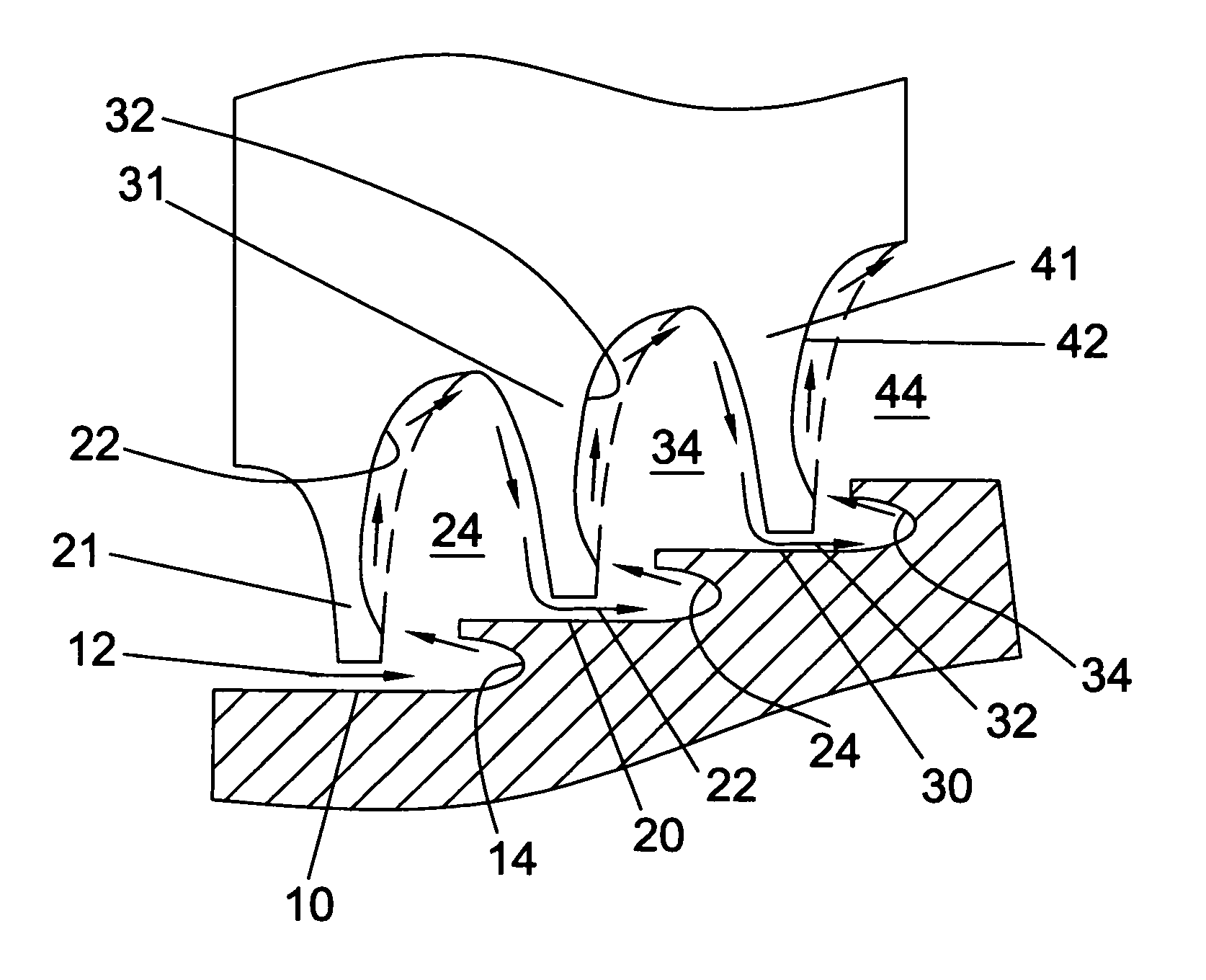

Stepped labyrinth seal

InactiveUS7445213B1Without slowing leakage flowReduce the impactEngine sealsEngine manufactureEngineeringLeakage flow

A stepped labyrinth seal for a turbomachine, the seal having a stepped portion with a redirecting groove formed thereon to redirect a leakage flow through the gap in substantially a reverse direction and onto a surface of the finger such that the dynamic pressure of the leakage flow is not substantially reduced and the static pressure increased. The cavity formed between adjacent fingers has a flow guiding surface that maintains the dynamic pressure of the flow, thereby keeping the flow at high velocity and low static pressure.

Owner:FLORIDA TURBINE TECH

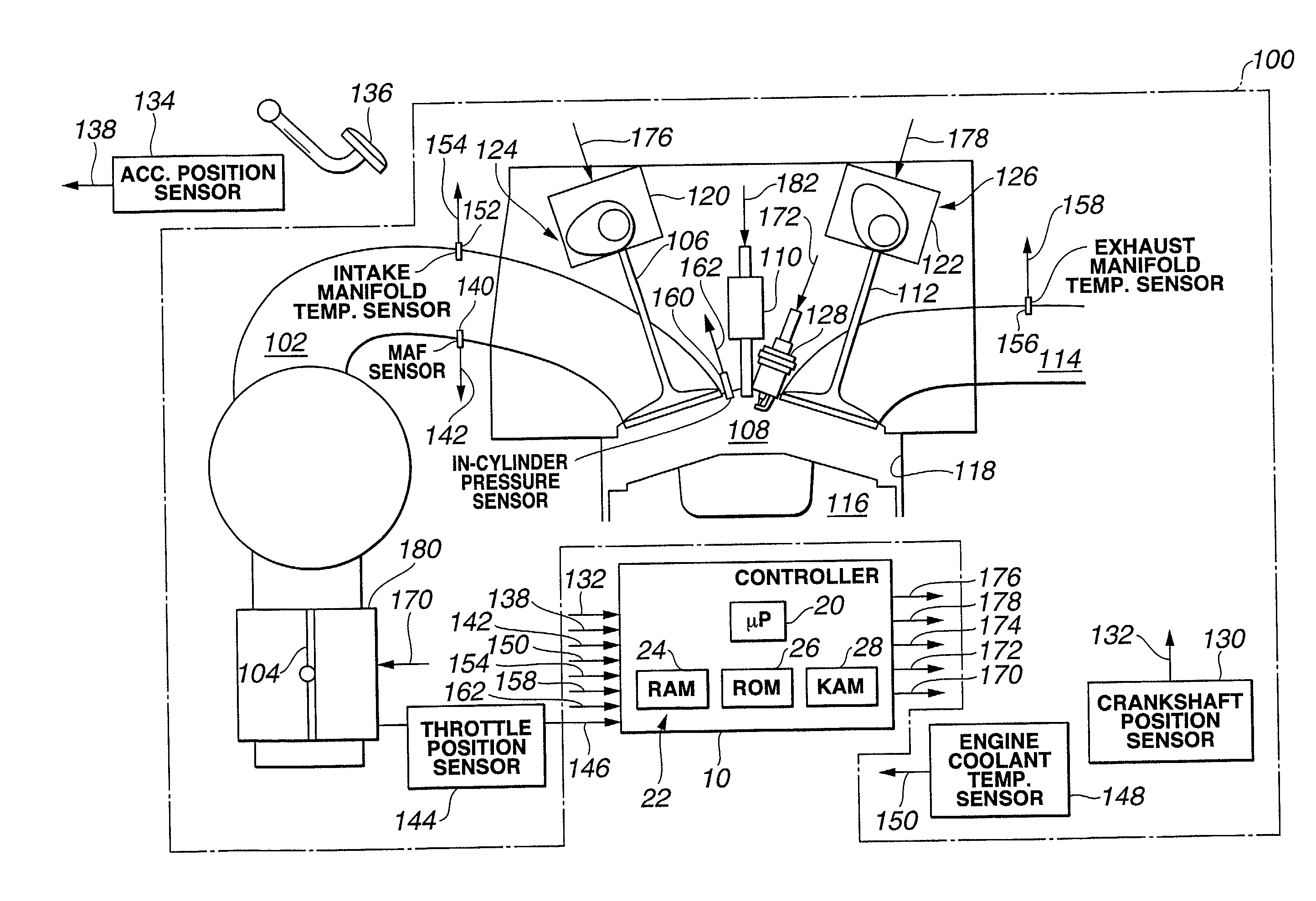

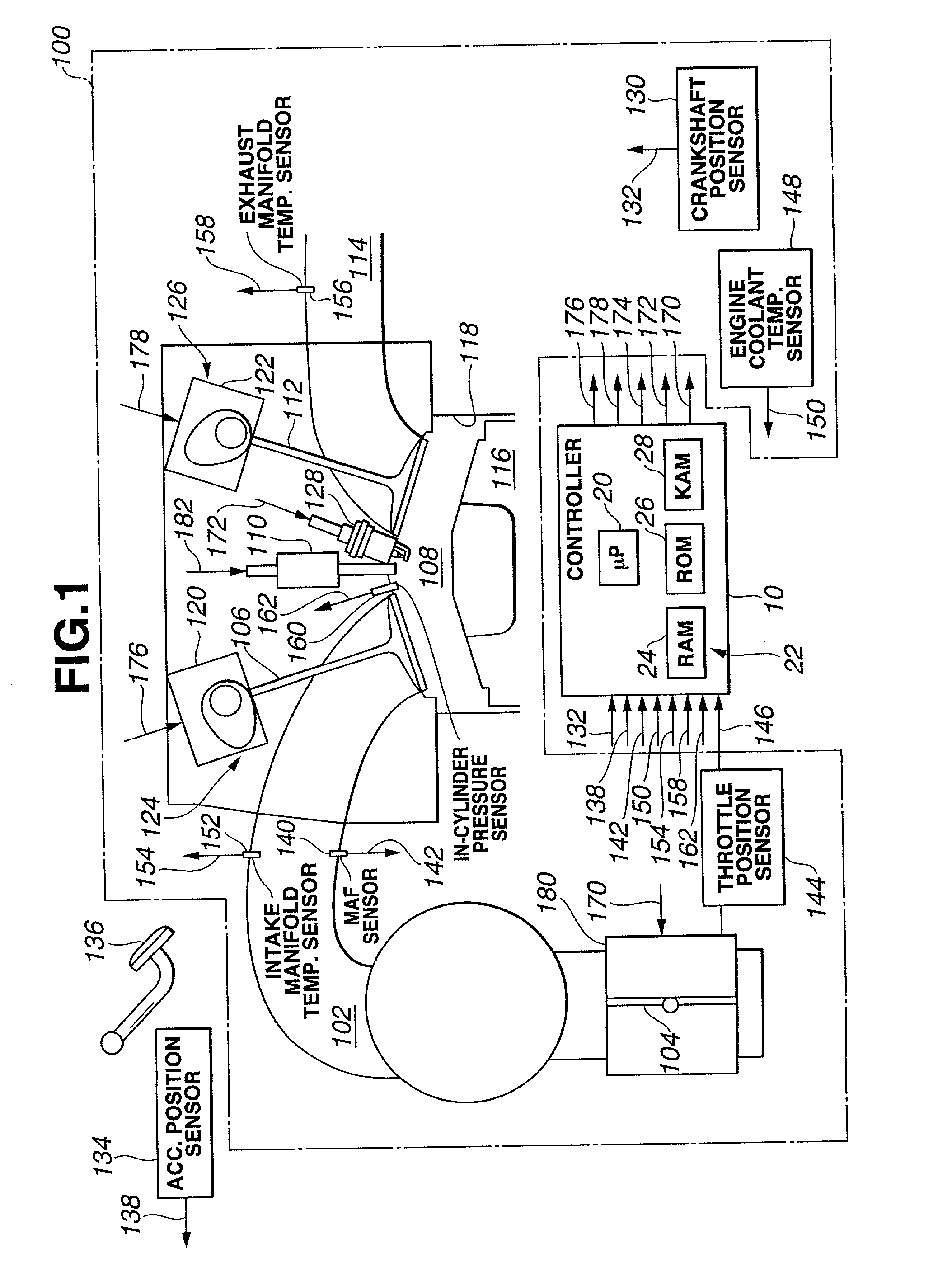

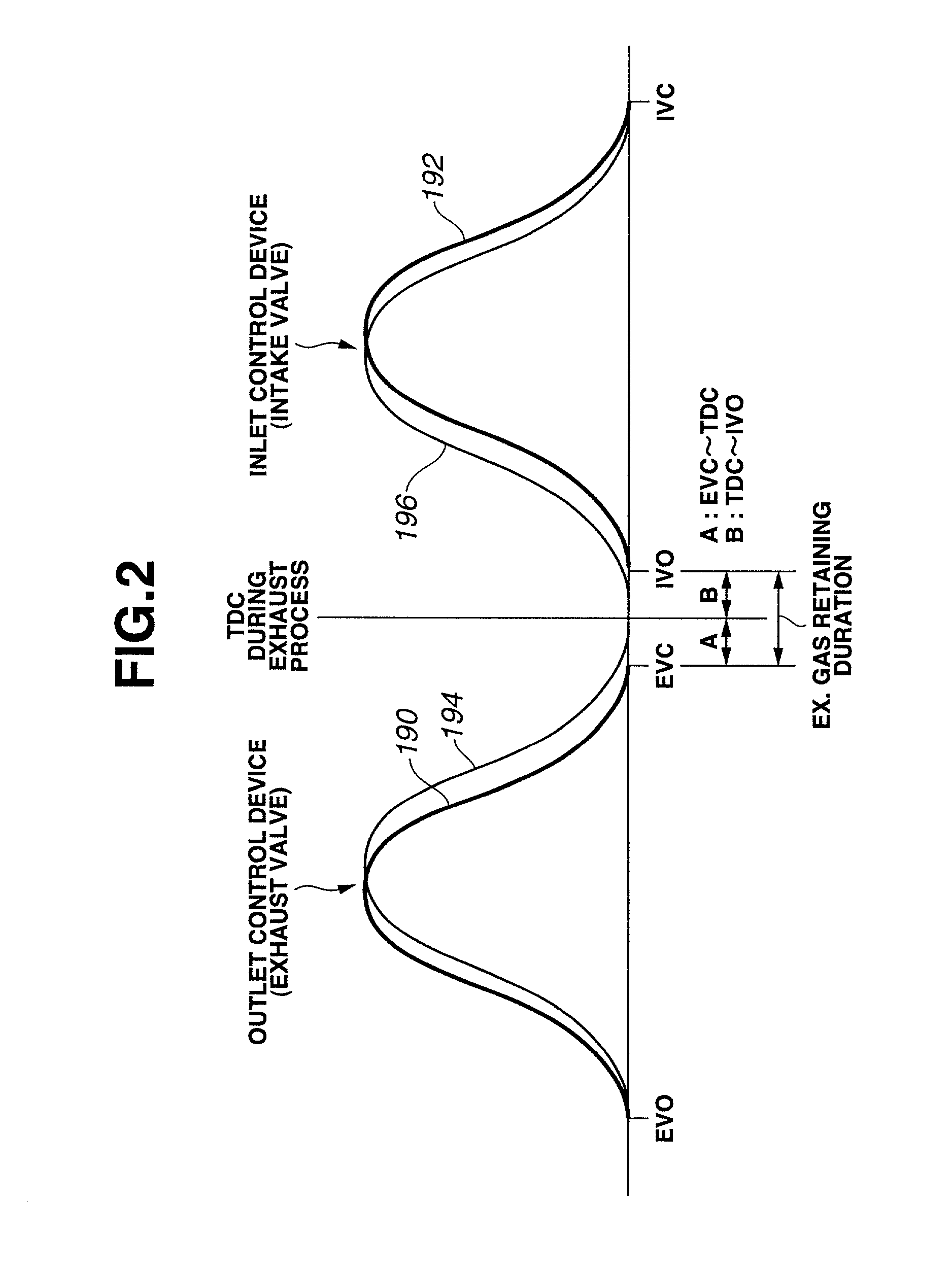

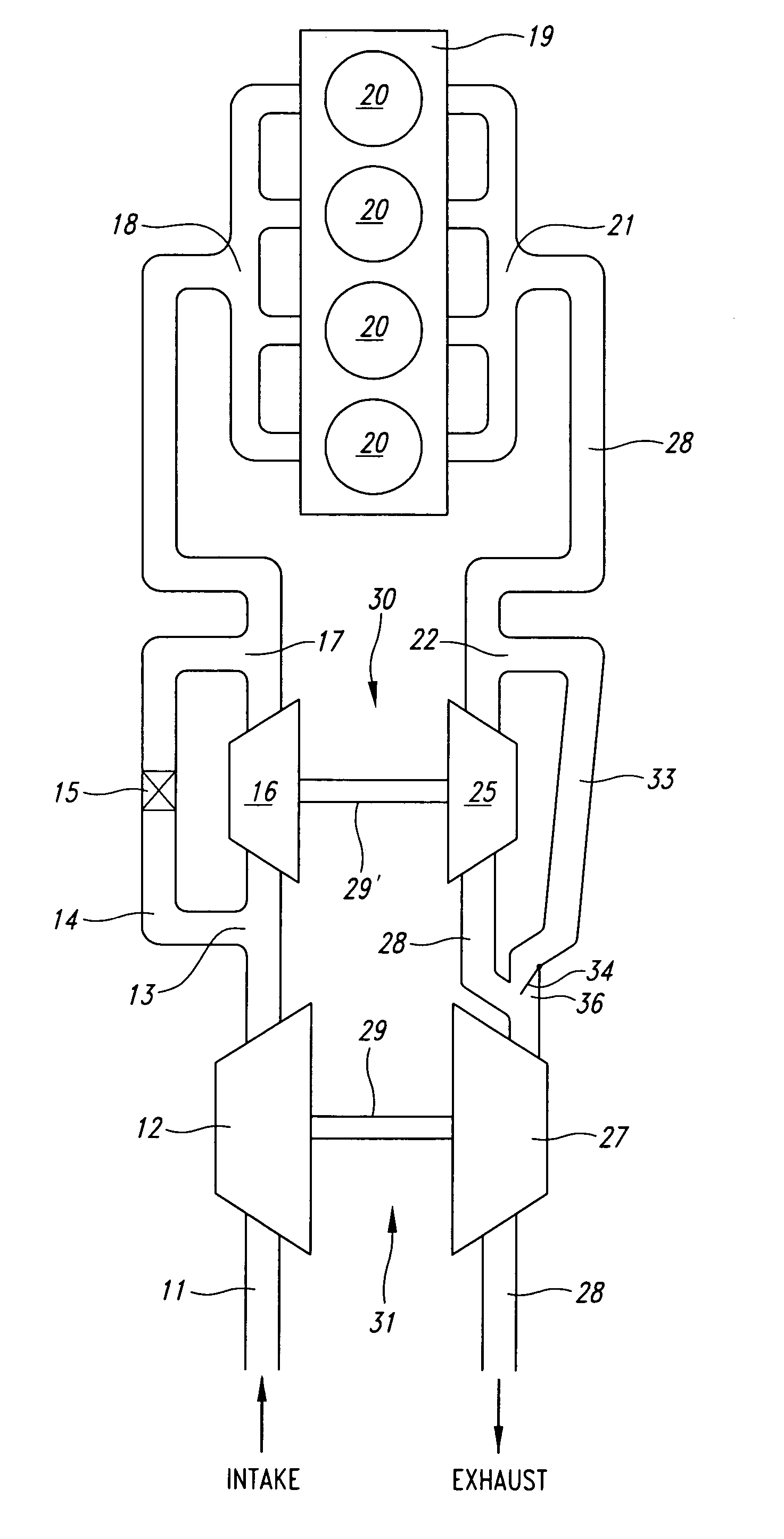

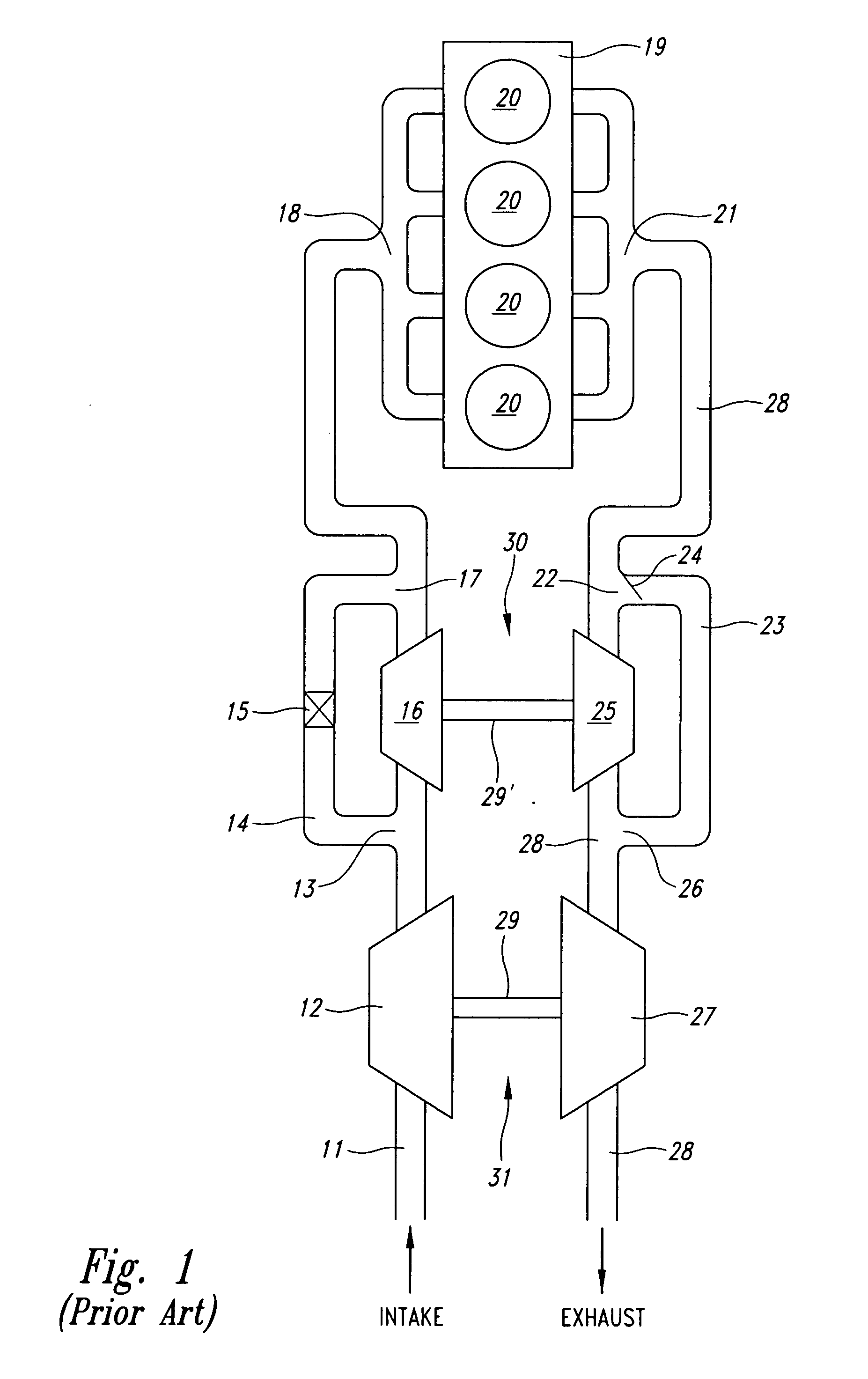

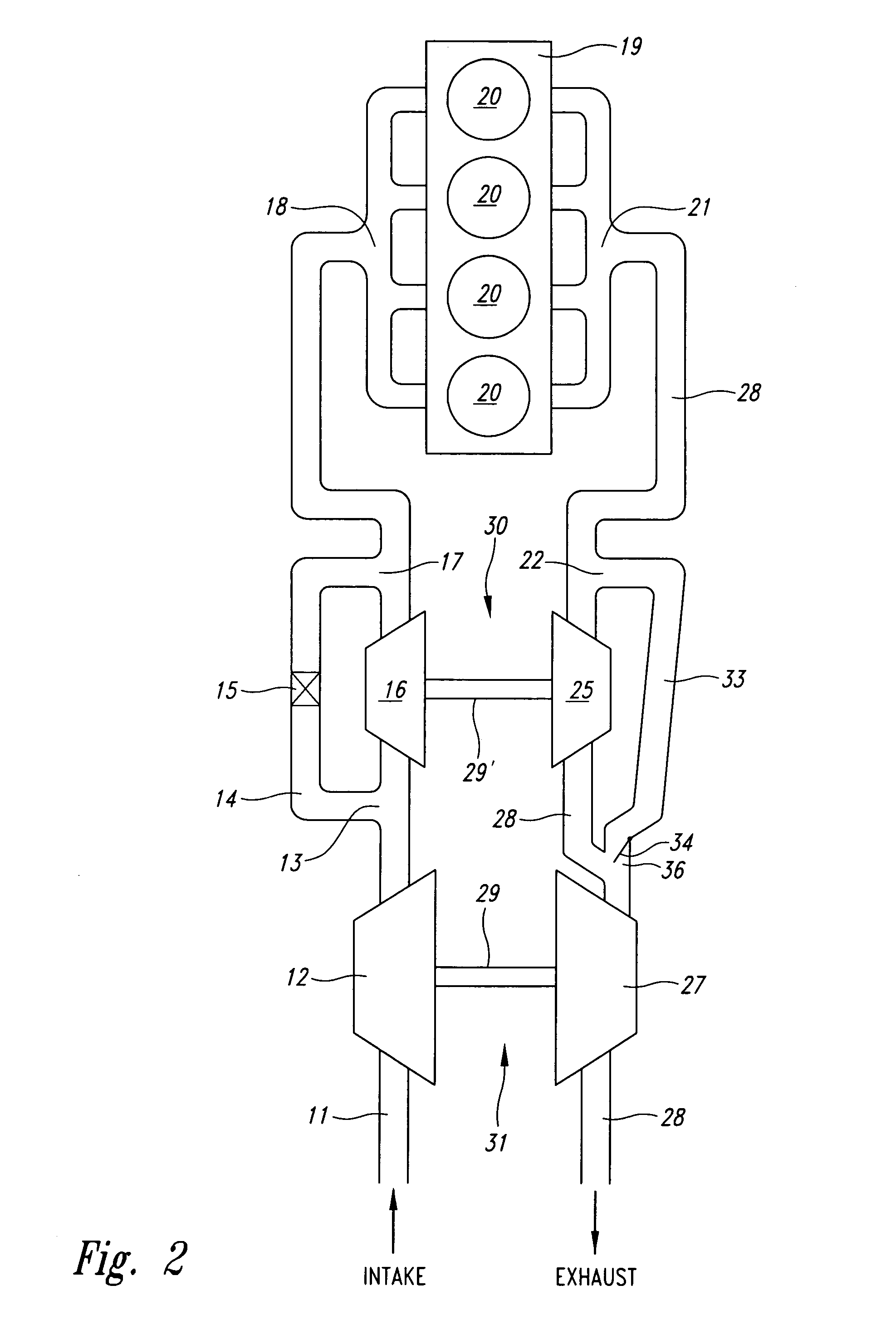

Intelligent control to stabilize auto-ignition combustion without rapid pressure increase

InactiveUS20020046741A1Combustion of suppressedIgnition of suppressedValve arrangementsElectrical controlEngineeringIntelligent control

The present invention concerns a method and a system for operating an internal combustion engine capable of performing auto-ignition combustion as well as spark-ignition combustion. In auto-ignition combustion mode, inlet and outlet control devices are adjusted to retain a portion of exhaust gas for subjecting the retained exhaust gas to compression. In one preferred embodiment, a parameter indicative of engine-surrounding environment is monitored. Closing timing of the outlet control device is adjusted in response to the monitored parameter, thereby to vary an exhaust gas retaining duration when there is a change in the monitored parameter.

Owner:NISSAN MOTOR CO LTD

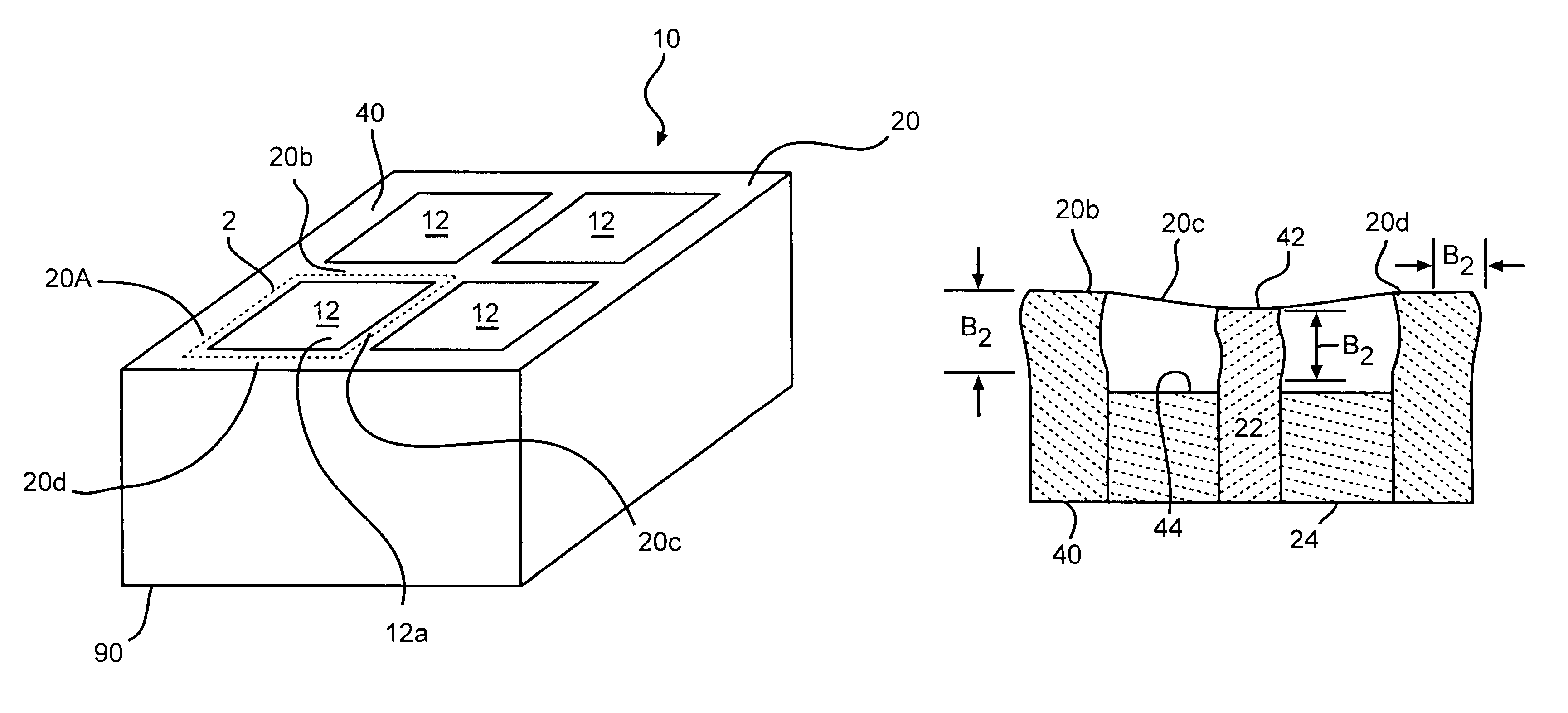

Multi-walled gelastic material

The present invention is directed to a gelastic cushion. The gelastic cushion is made from a conventional gelastic composition. The gelastic cushion has a structure having a first wall that defines an opening area and buckles when a force is applied to the first wall. When the first wall buckles a predetermined amount, a second wall, interconnected to the first wall, also buckles. The second wall decreases the chance that the first wall bottoms out. Bottoming out increases the pressure on the patient (a.k.a., the force) overlying the gelastic cushion. That increased pressure is undesirable.

Owner:STRYKER CORP

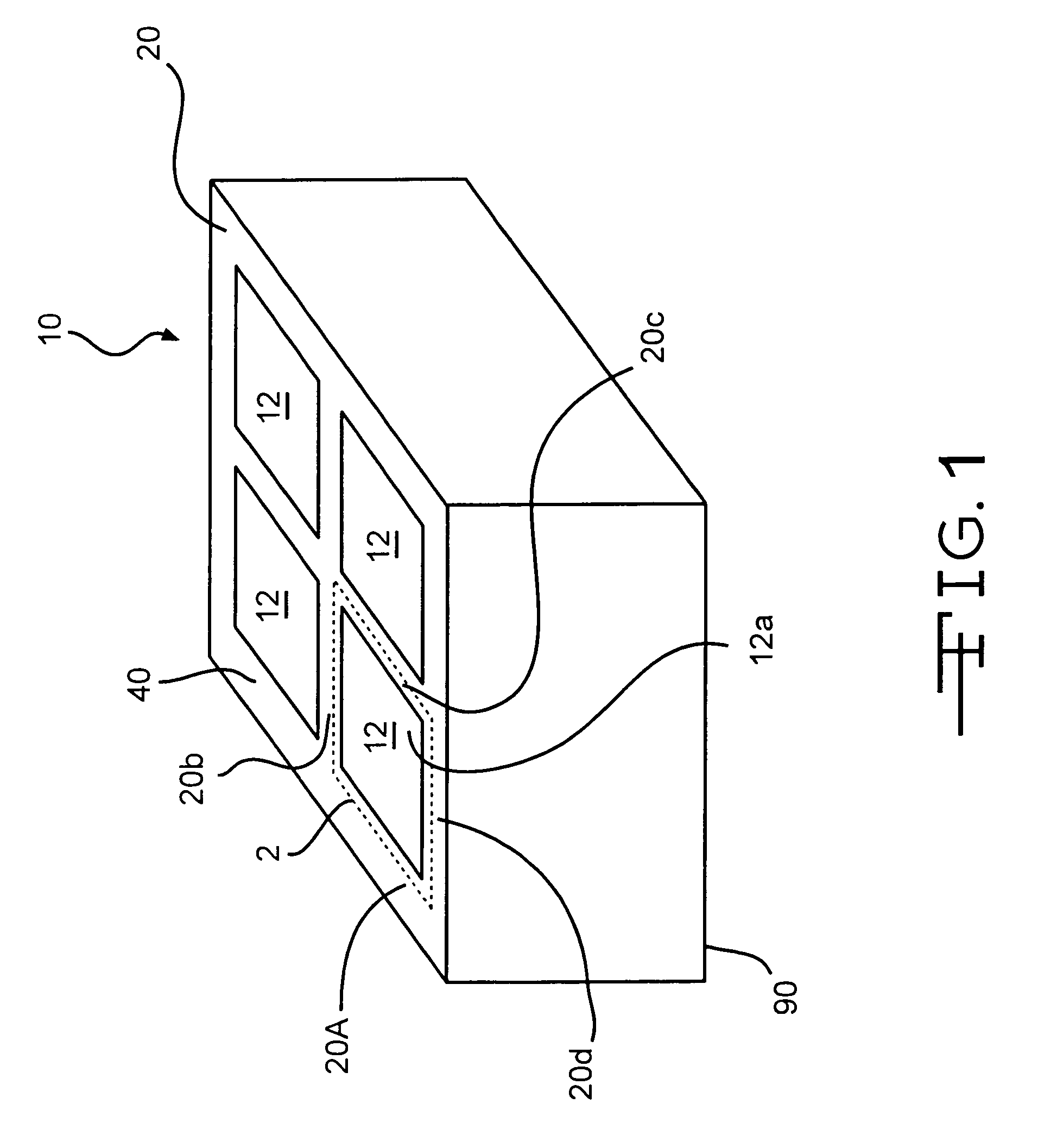

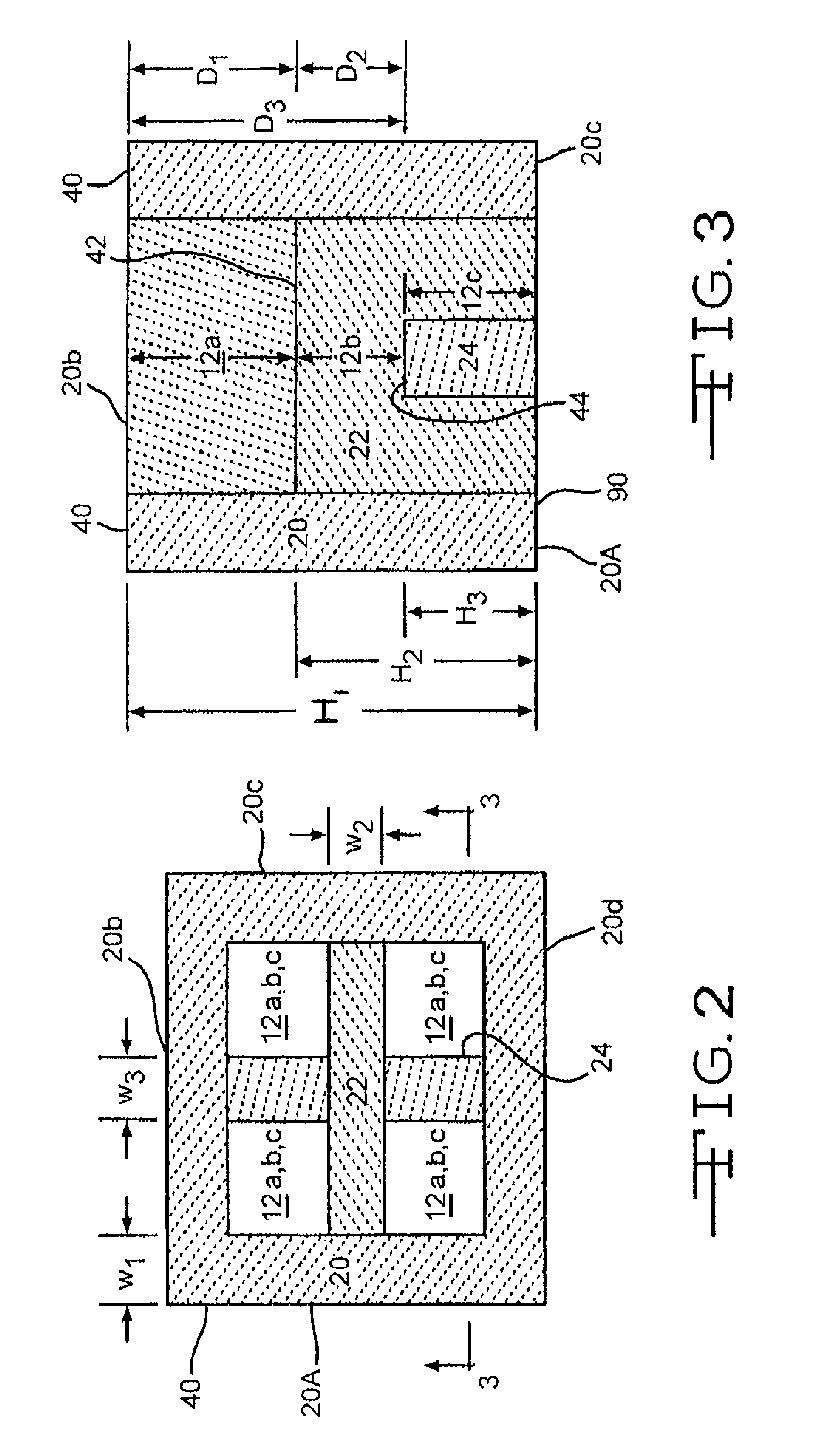

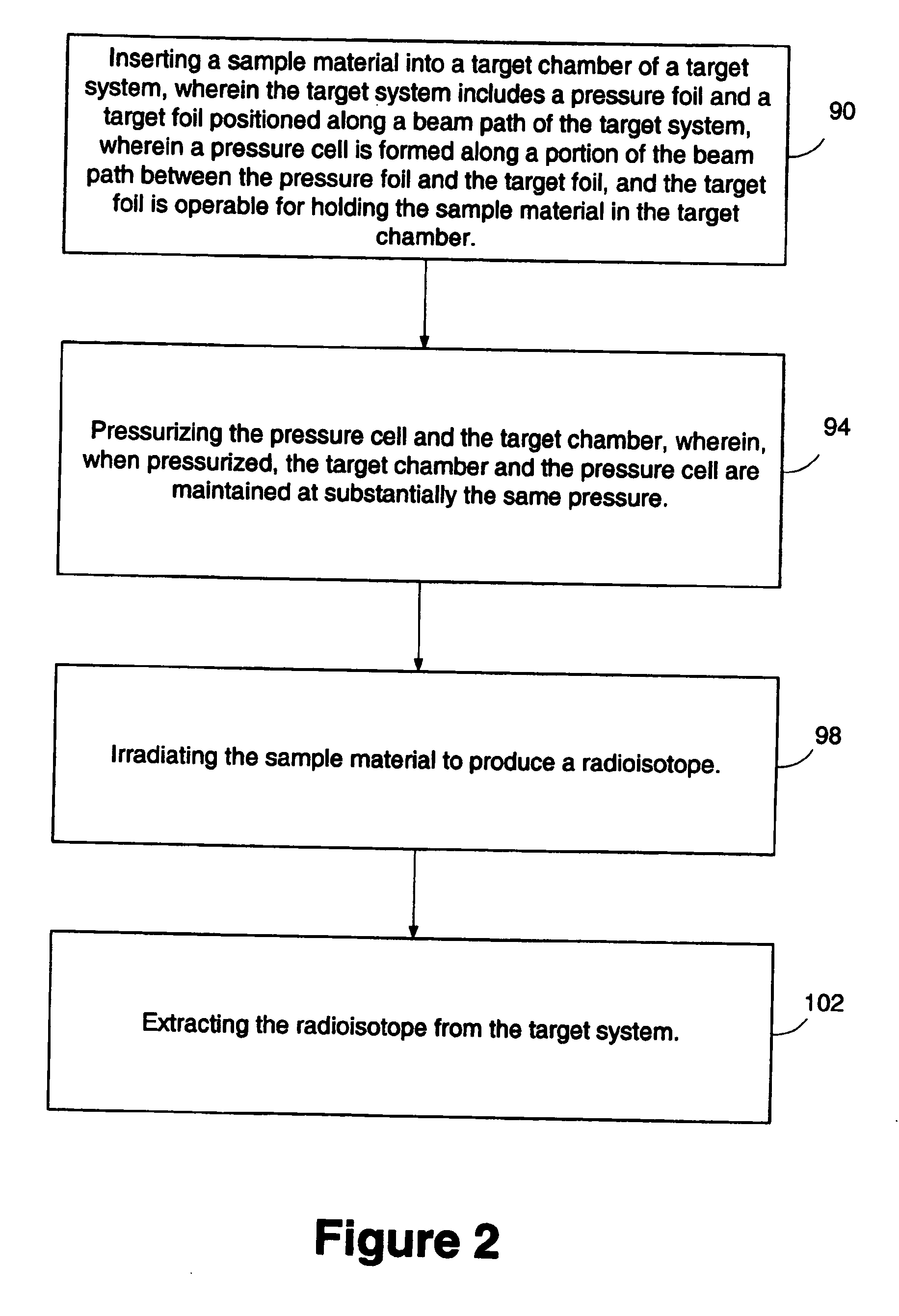

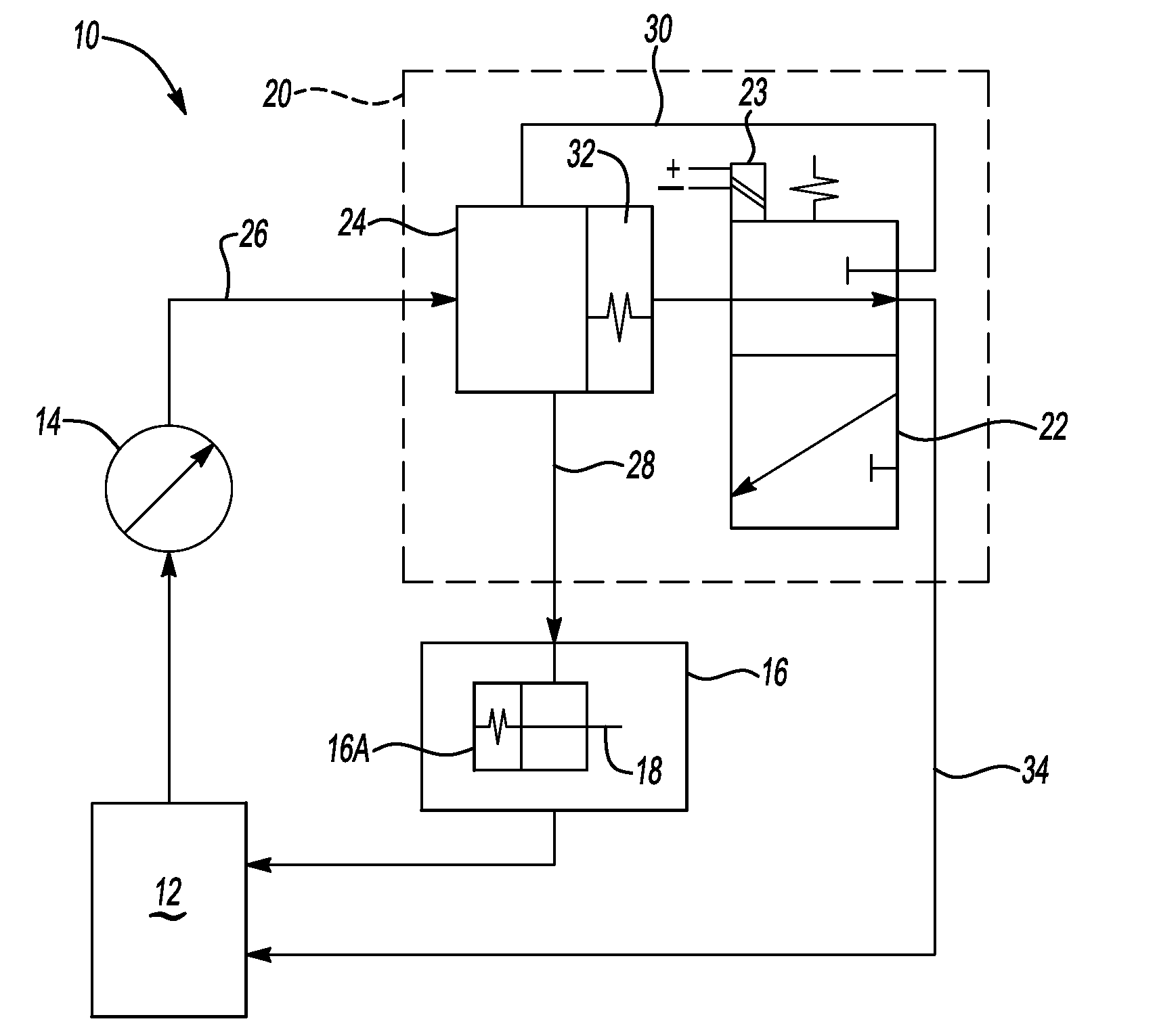

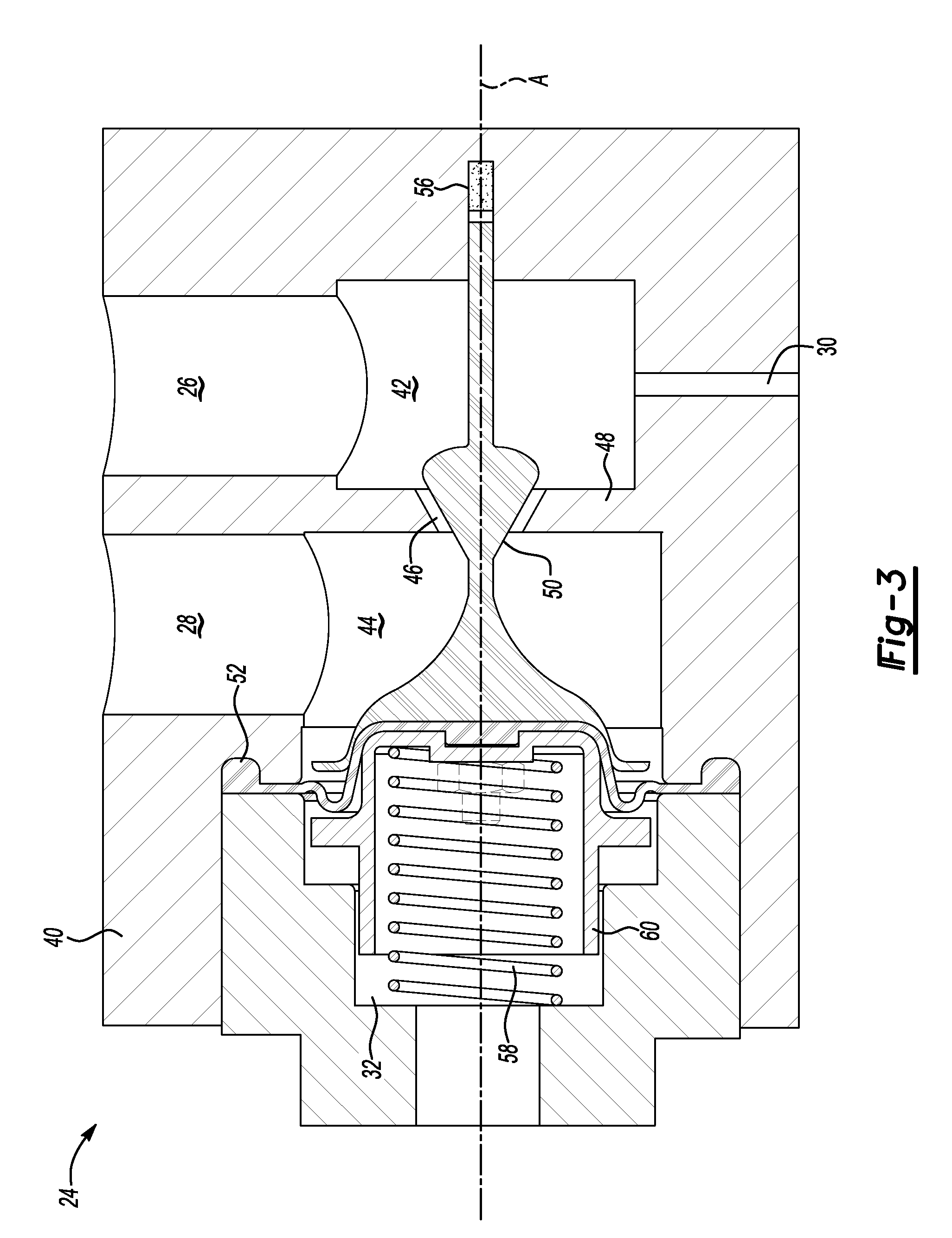

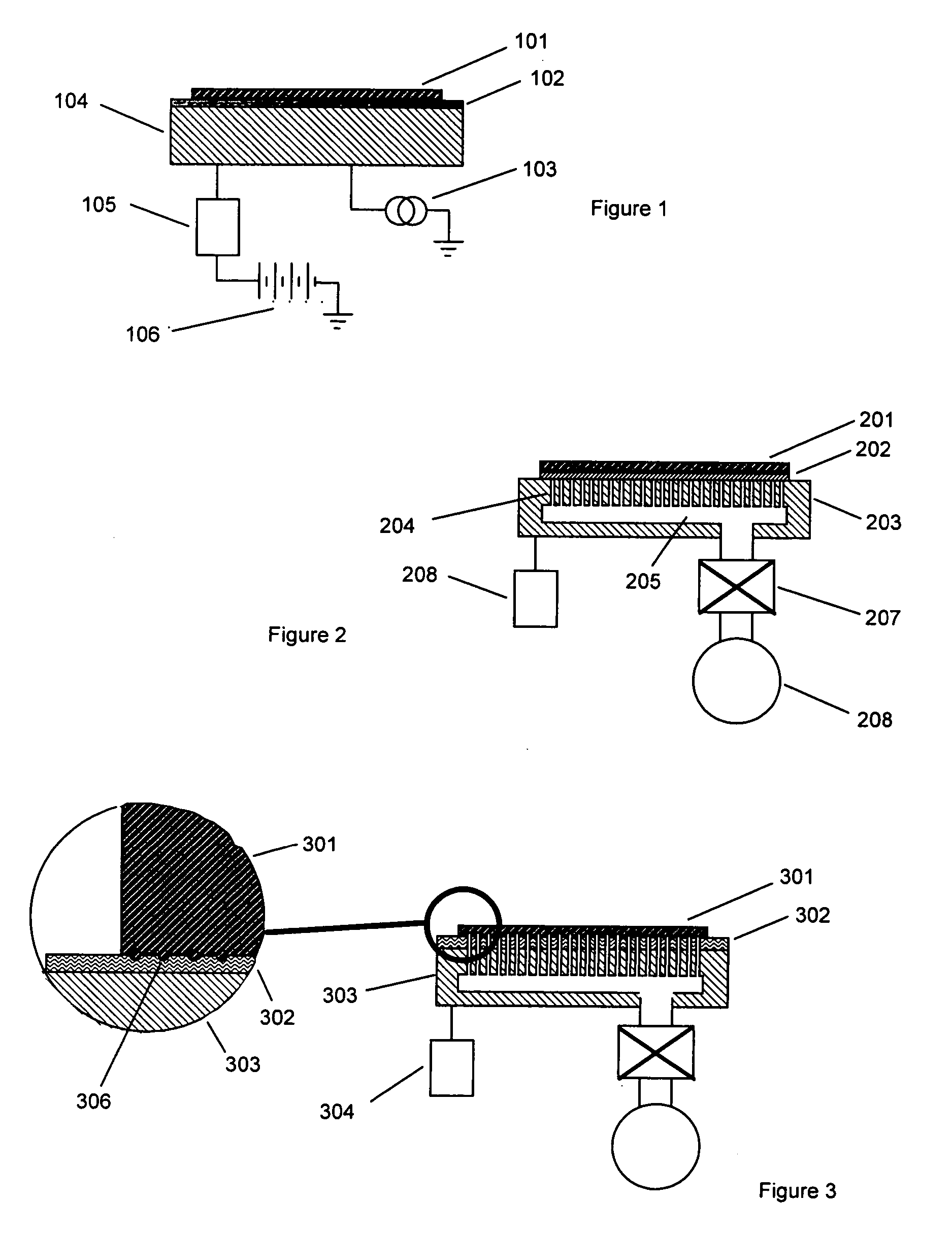

Method and apparatus for the production of radioisotopes

InactiveUS20060062342A1Conversion outside reactor/acceleratorsNuclear targetsParticle beamPressure cell

A target system includes a beam path for receiving a particle beam and a target chamber for housing a sample material. A target foil is operable for holding the sample material in the target chamber. A pressure cell is formed along a portion of the beam path between the target foil and a pressure foil. When irradiating the sample material with the particle beam, the pressure inside the target chamber and the pressure cell is increased and maintained at substantially the same pressure. A method includes inserting a sample material into a target chamber of a target system. The target system includes a pressure cell formed along a portion of a beam path between a pressure foil and a target foil, adjacent the target chamber. The pressure cell and the target chamber are pressurized and maintained at substantially the same pressure. The sample material is irradiated to produce a radioisotope.

Owner:HOUSTON CYCLOTRON PARTNERS

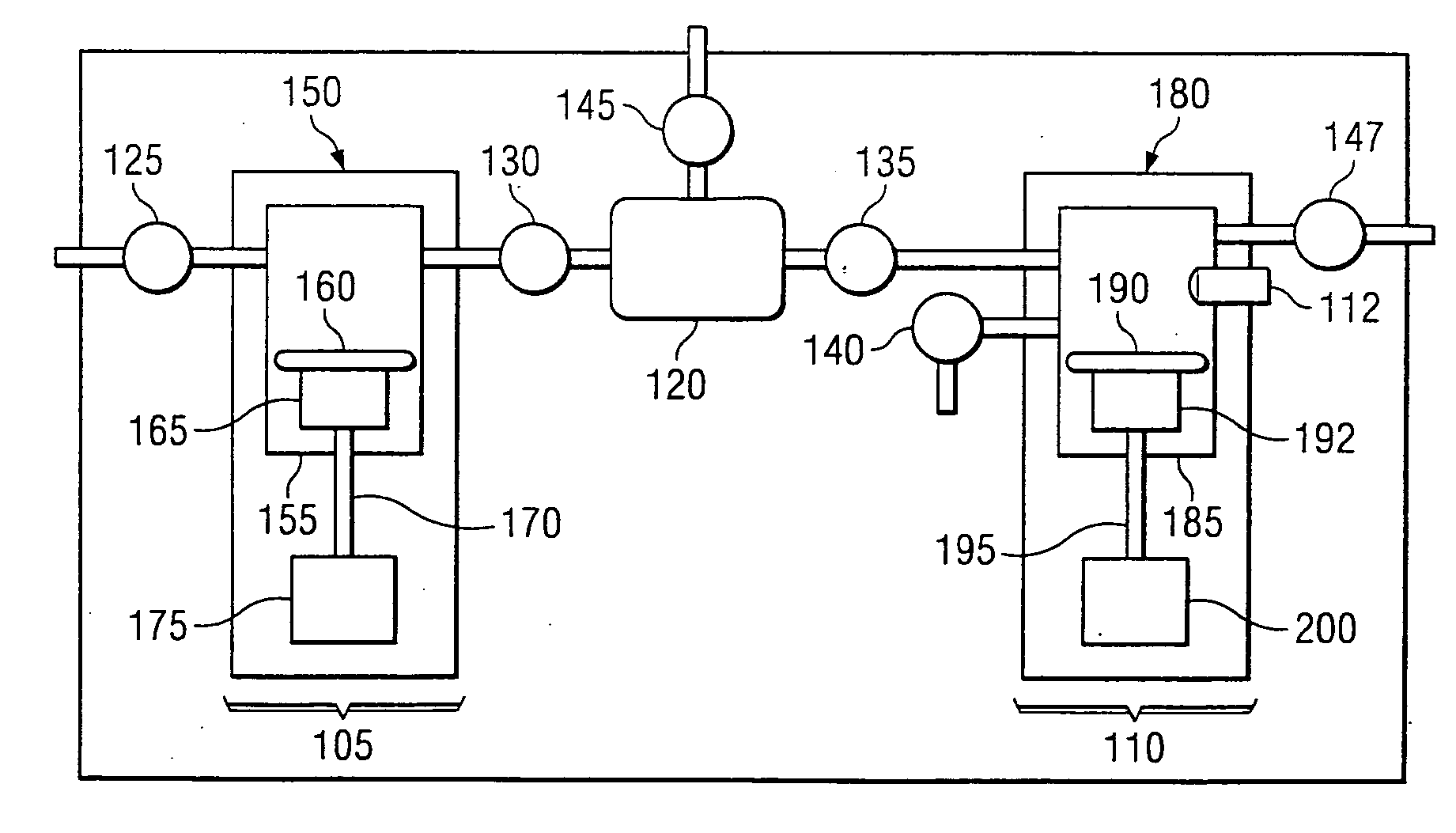

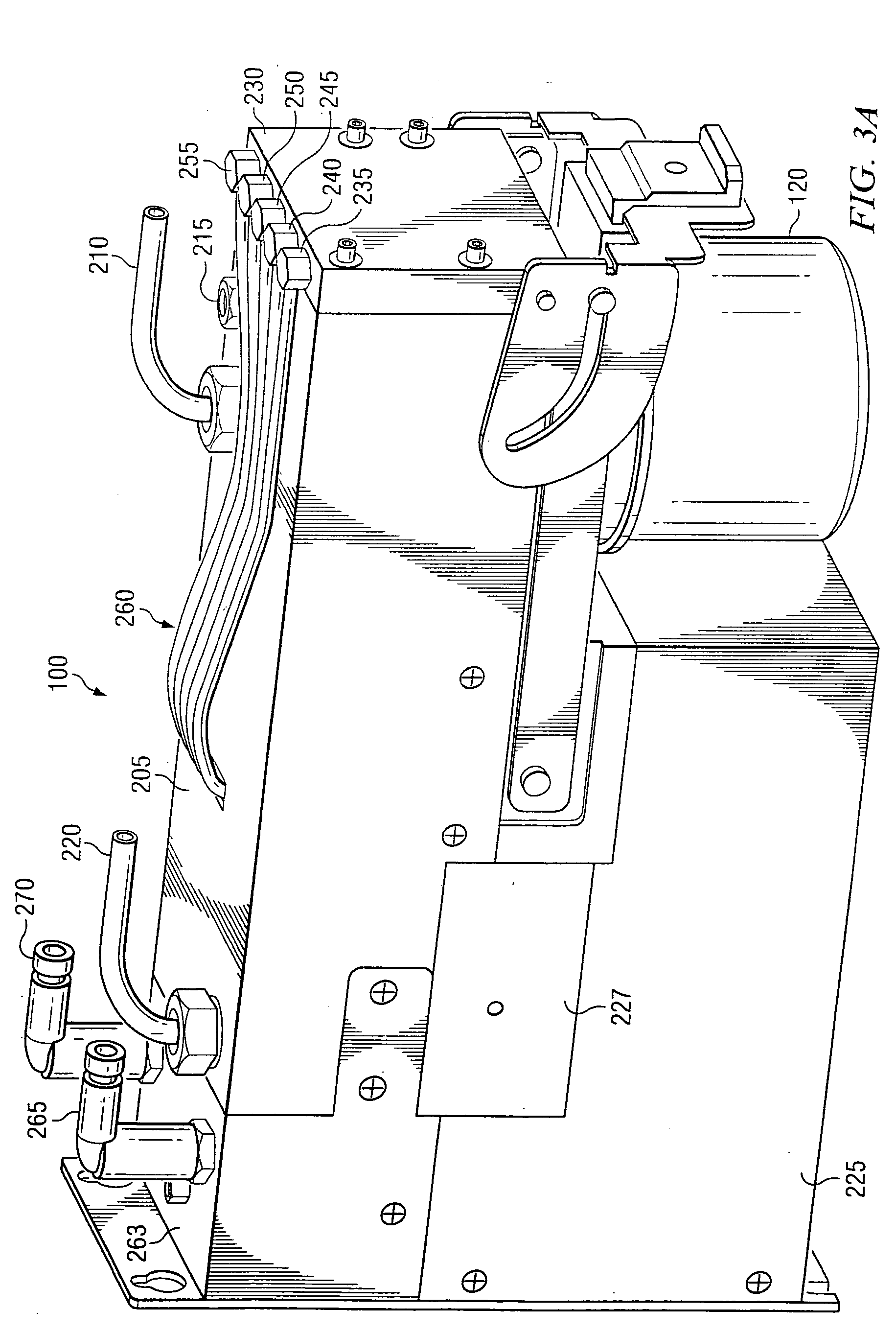

Valvetrain oil control system and oil control valve

InactiveUS20100018482A1Reduce fuel consumptionOperating means/releasing devices for valvesPipeline systemsControl systemEngineering

A hydraulic control system includes an oil control valve to control oil flow within a valvetrain. The control valve varies the flow rate to actuate an engine component from a first position to a second position based upon fluid pressure from the control valve. Varying the flow rate through the control valve includes increasing the flow rate through the control valve to increase the pressure to a first level to actuate the engine component to the first position. After the engine component is actuated, the flow rate through the control valve is maintained at a level sufficient to maintain the engine component in the first position. To actuate the engine component to the second position the flow rate through the control valve is then decreased. The fluid flow rate through the control valve is then maintained at a level sufficient to maintain the engine component in the second position.

Owner:EATON CORP

System and method for correcting for pressure variations using a motor

Owner:ENTEGRIS INC

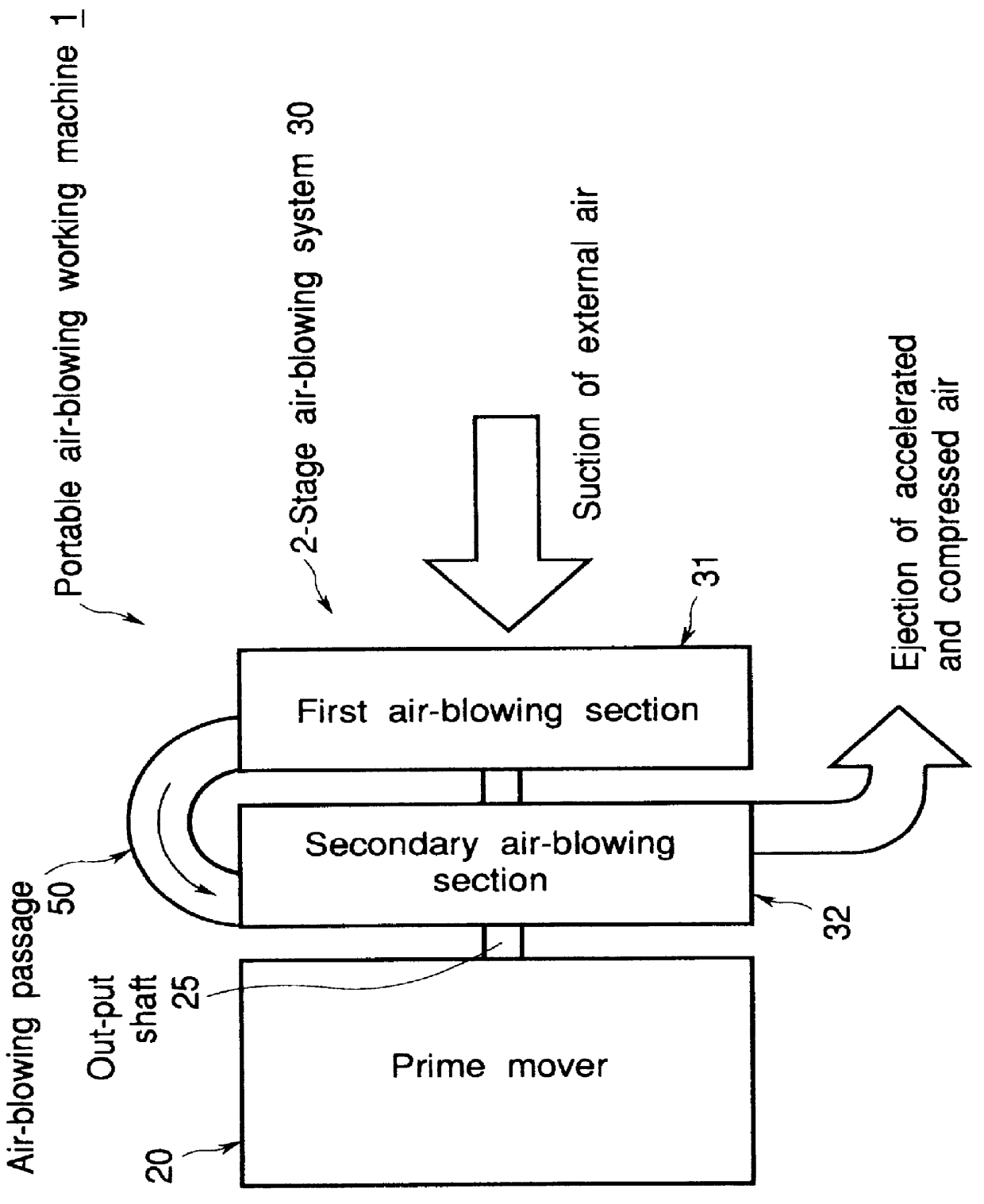

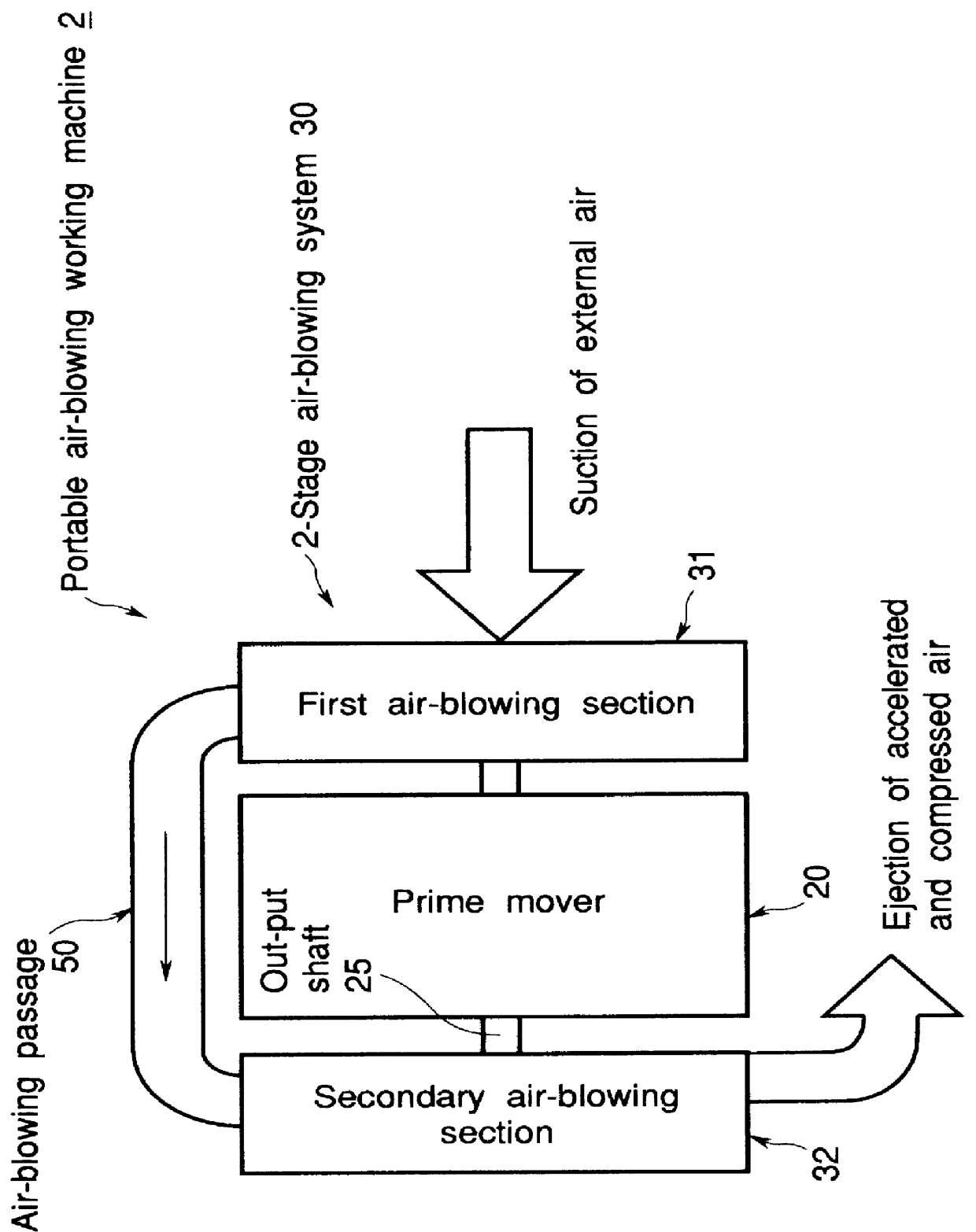

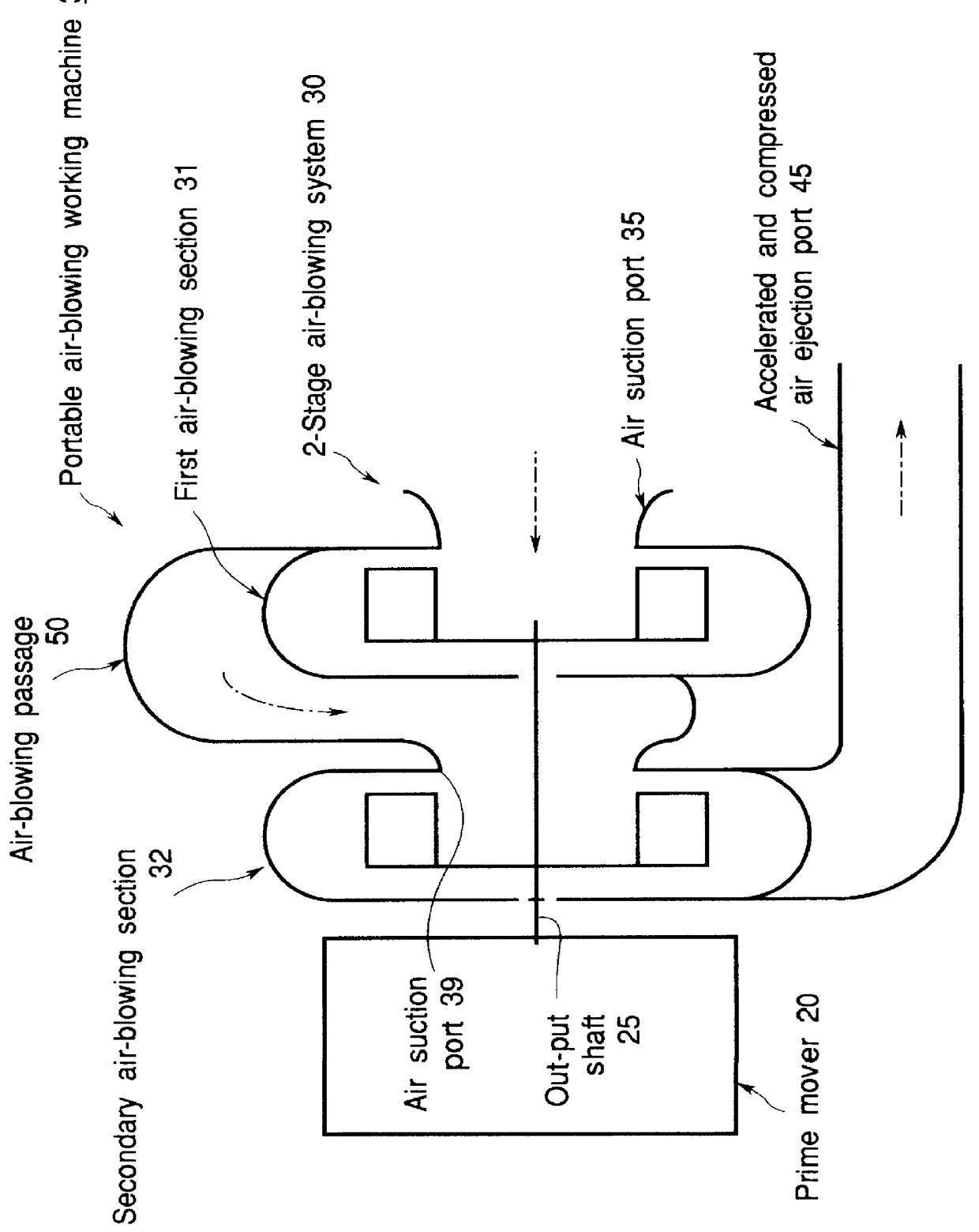

Portable air-blowing working machine

InactiveUS6109865ARevolution can be reducedReduce noiseHops/wine cultivationTurf growingAtmospheric airAtmosphere

A portable air-blowing working machine includes a prime mover and an air-blowing system. The air-blowing system incorporates first-stage and second-stage centrifugal air-blowing sections, which are rotatably driven by an output shaft of the prime mover and are interconnected by an air-blowing passage for delivering air discharged from the first-stage air-blowing section to the intake of the second-stage. In operation, external air is drawn into the first-stage air-blowing section, increased therein in velocity and pressure, and then continuously discharged via the air-blowing passage to the second-stage air-blowing section, where the air is further accelerated and compressed before being finally discharged to the atmosphere.

Owner:KIORITZ

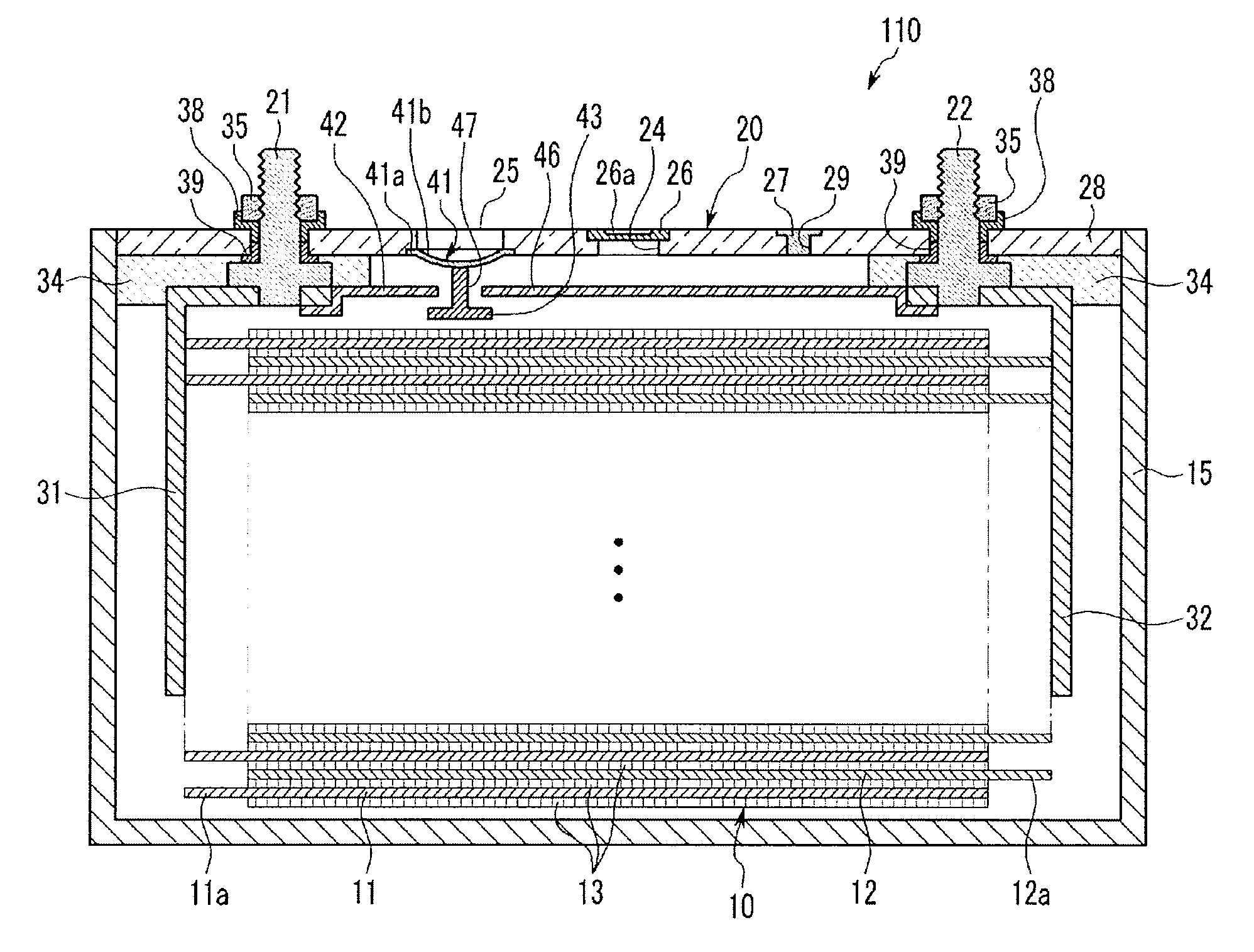

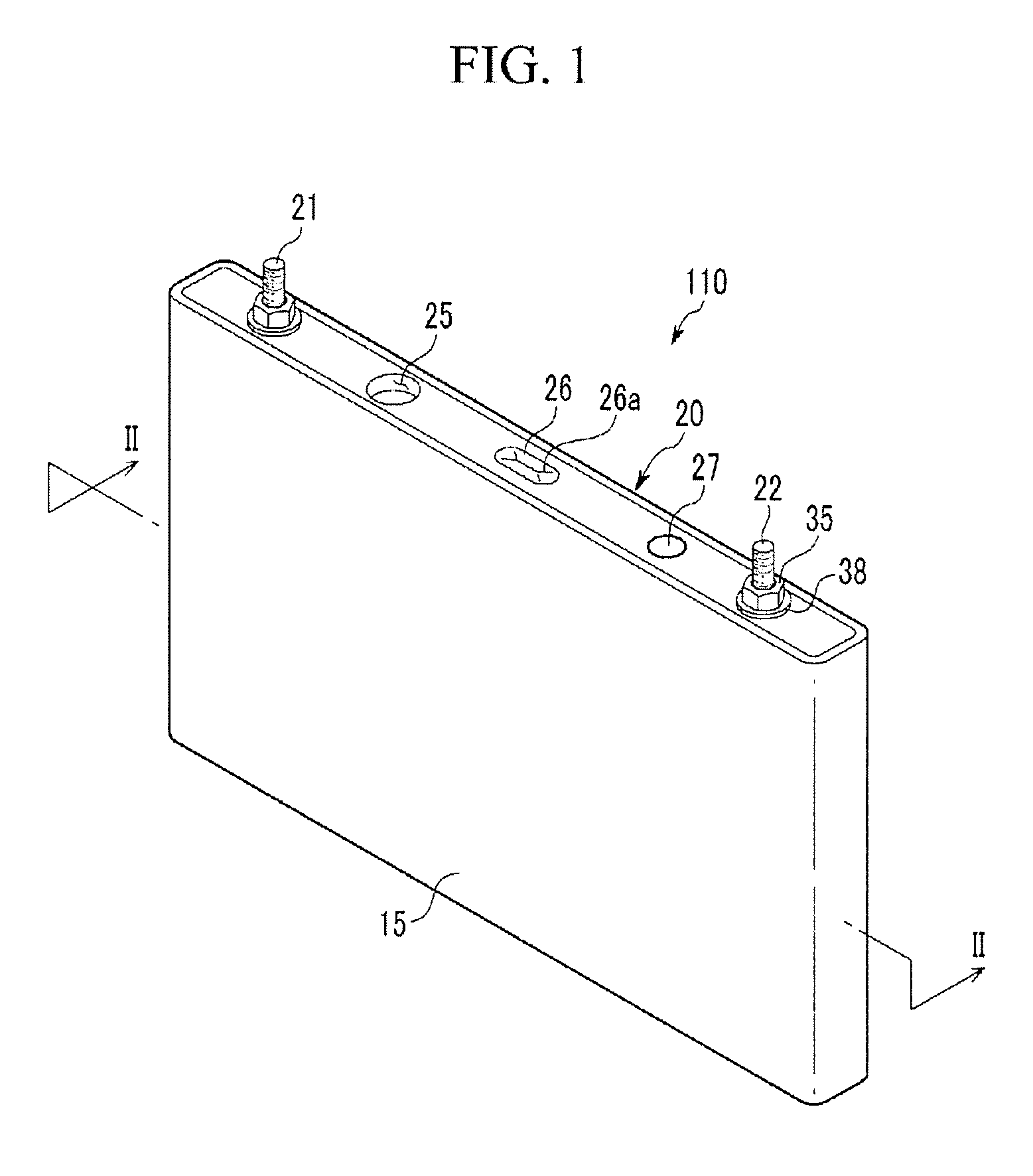

Sealed battery and method for manufacturing the same

ActiveUS20100233529A1Improve reliabilityImprove sealingFinal product manufactureSmall-sized cells cases/jacketsEngineeringElectrolyte

The sealed battery includes a sealing plate 13 sealing a mouth of an outer can, an external terminal 16 attached to the sealing plate 13 and having a connecting terminal 23, and a current interruption mechanism 18 interrupting current in response to pressure increase in the outer can that is installed in a conductive pathway electrically connecting the connecting terminal 23 and an electrode assembly. In the connecting terminal 23, a through-hole 23b continuing to the space on the current interruption mechanism 18 at the side corresponding to the outside of the battery is formed. The through-hole 23b is sealed with a terminal stopper 30 made of an elastic member so as to form a closed space between the terminal stopper 30 and current interruption mechanism 18. An electrolyte or washing solution hardly enters the current interruption mechanism during the manufacture can be provided.

Owner:SANYO ELECTRIC CO LTD

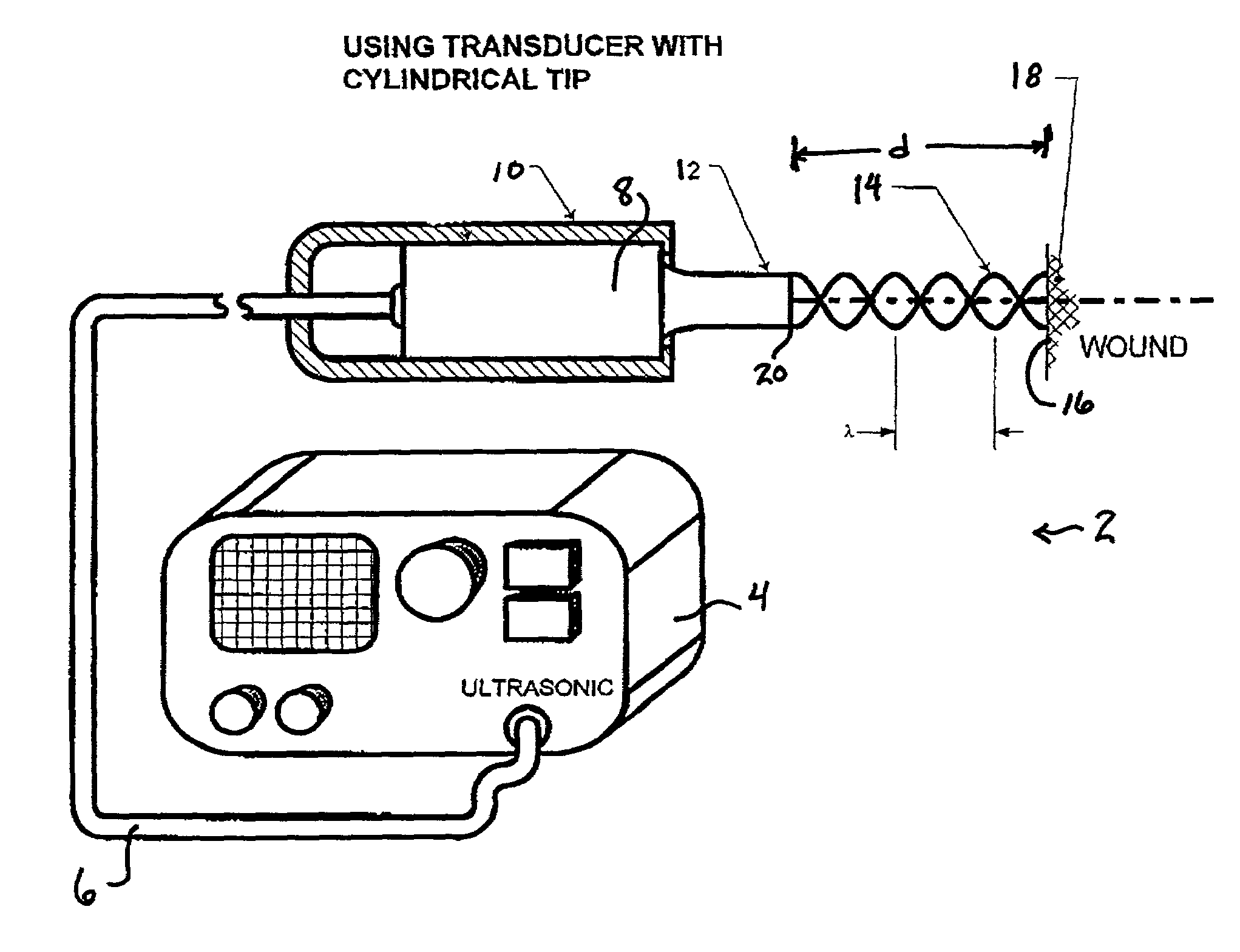

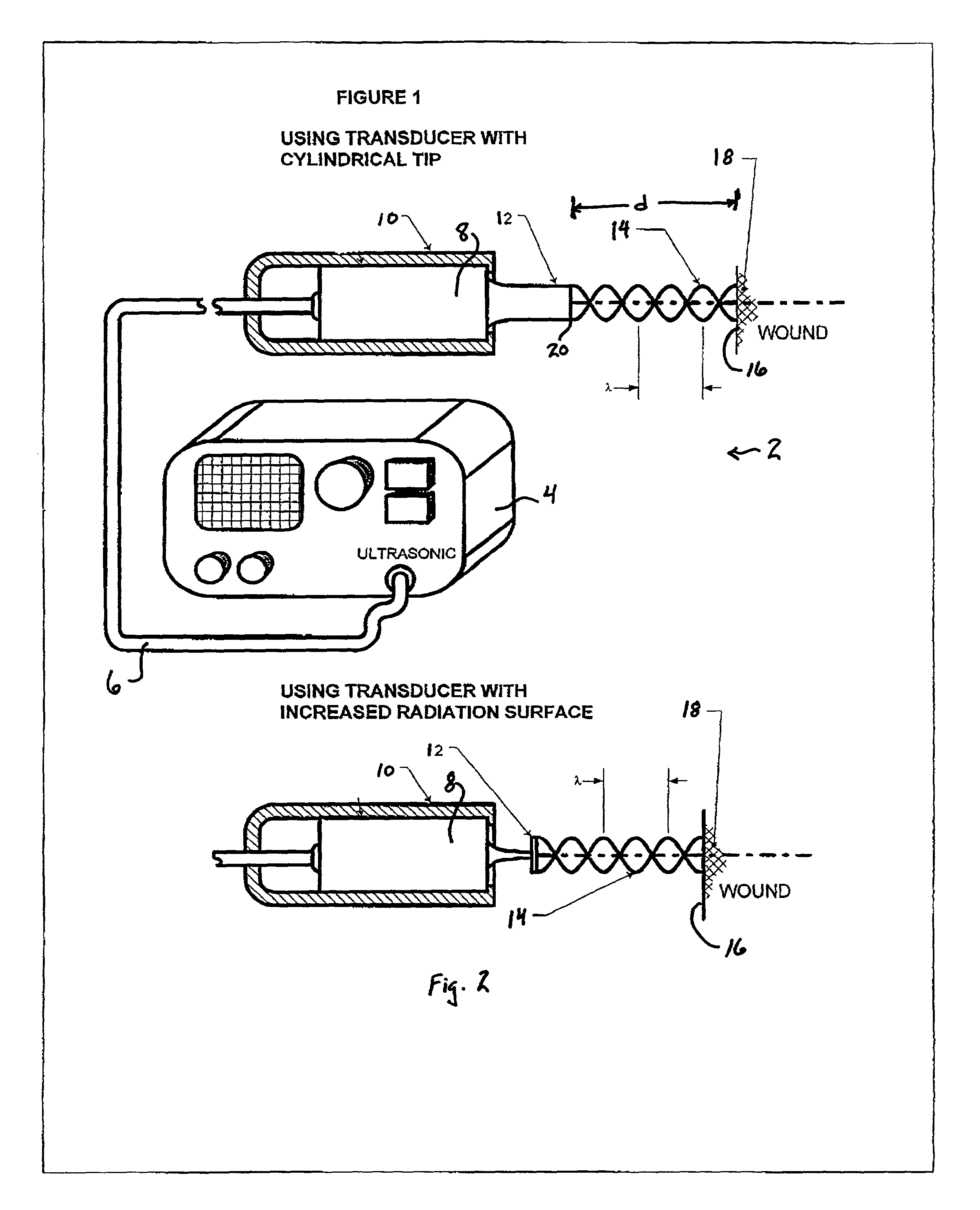

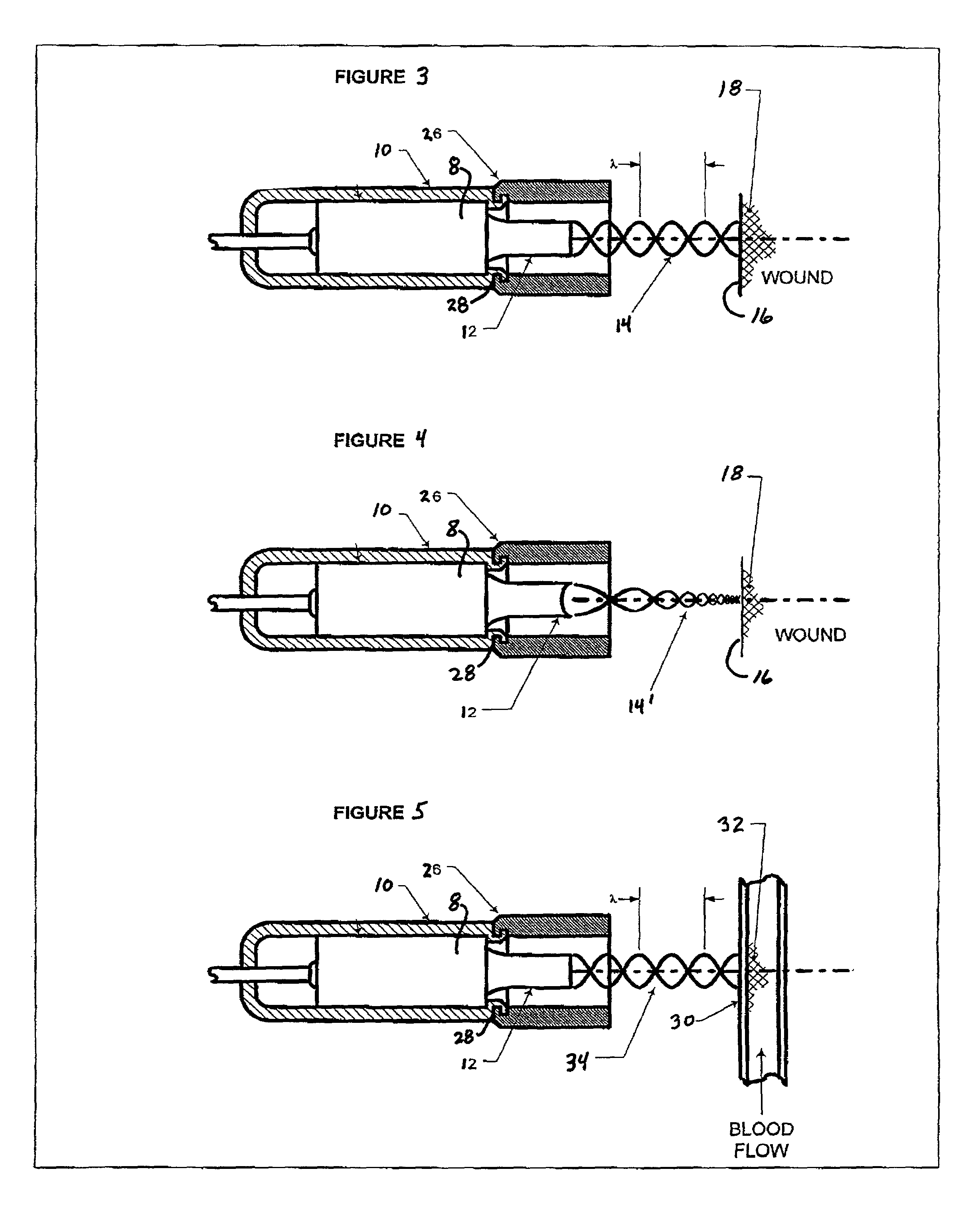

Ultrasound wound treatment method and device using standing waves

InactiveUS6960173B2Increase blood flowImprove disinfection effectUltrasound therapyChiropractic devicesUltrasonic radiationReflected waves

The method and device of the present invention for wound treatment with ultrasound standing waves includes a transducer probe to produce ultrasonic waves. The ultrasonic transducer has a tip with a distal radiation surface that radiates ultrasound energy toward the surface of a wound. Ultrasound standing waves occurring as a result of incident and reflected waves from the wound surface create ultrasonic radiation pressure. Ultrasound radiation pressure increases the blood flow in wound area, and ultrasound waves kill bacteria, stimulate healthy tissue cell and treat wounds.

Owner:SANUWAVE HEALTH INC

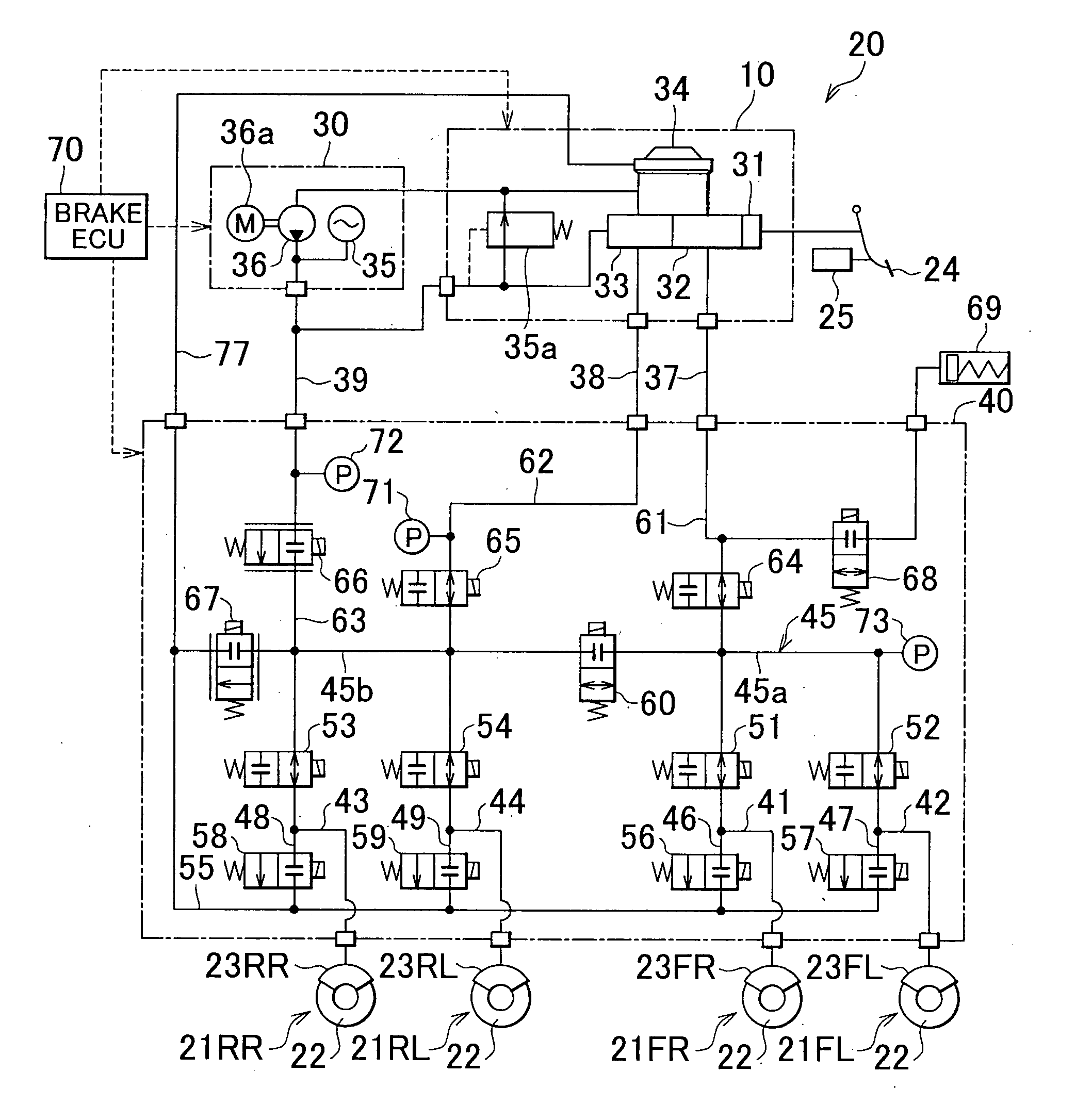

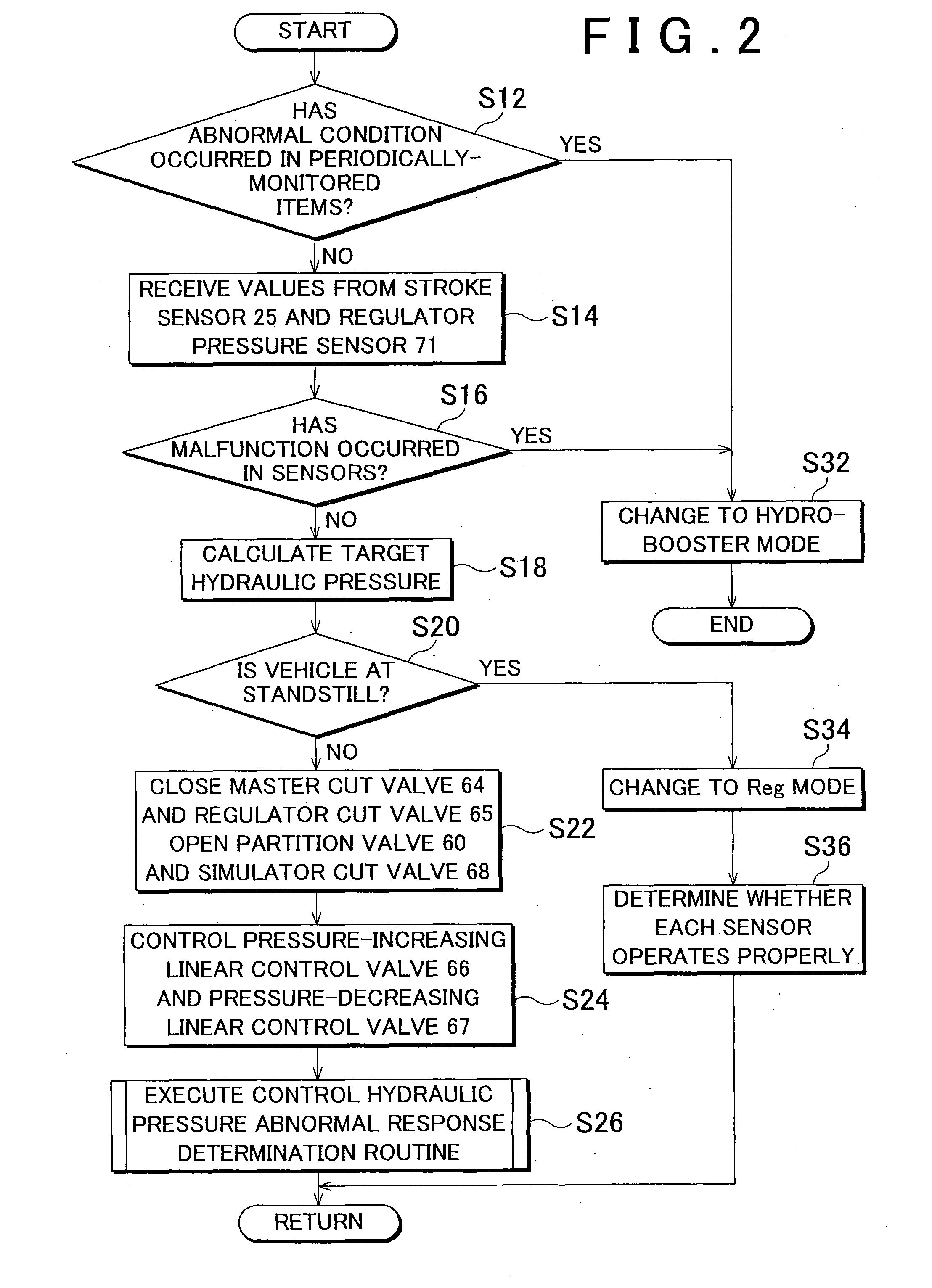

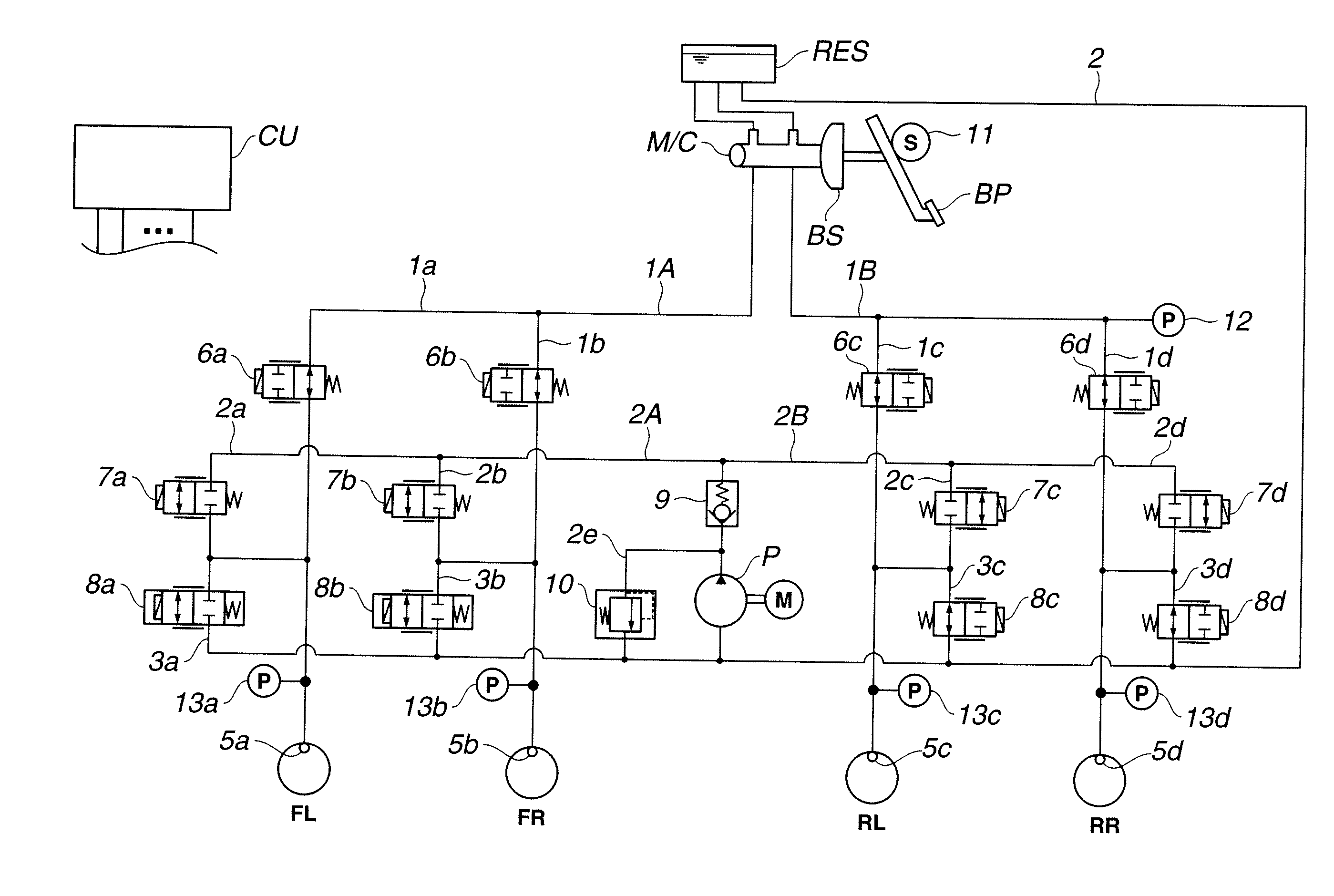

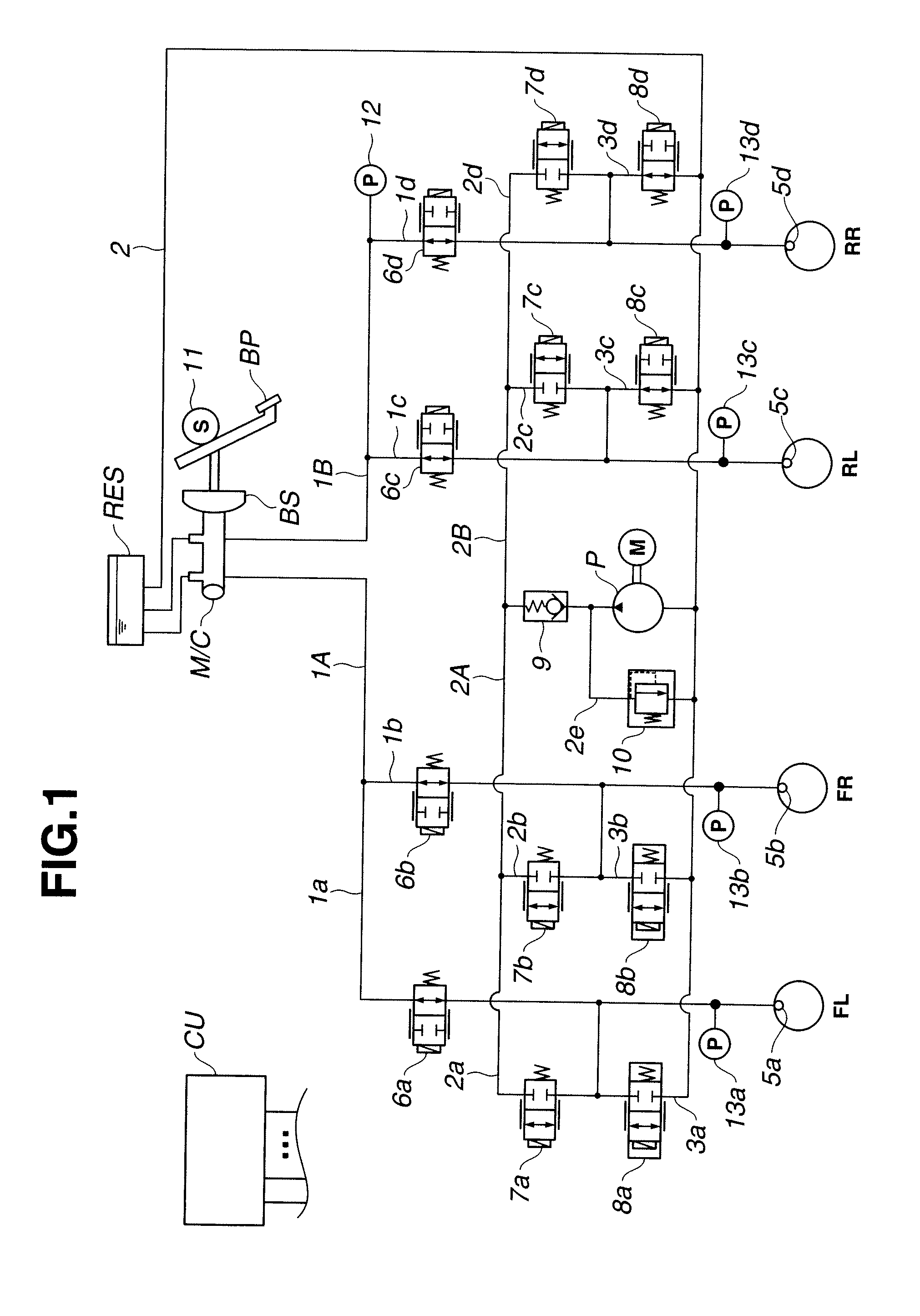

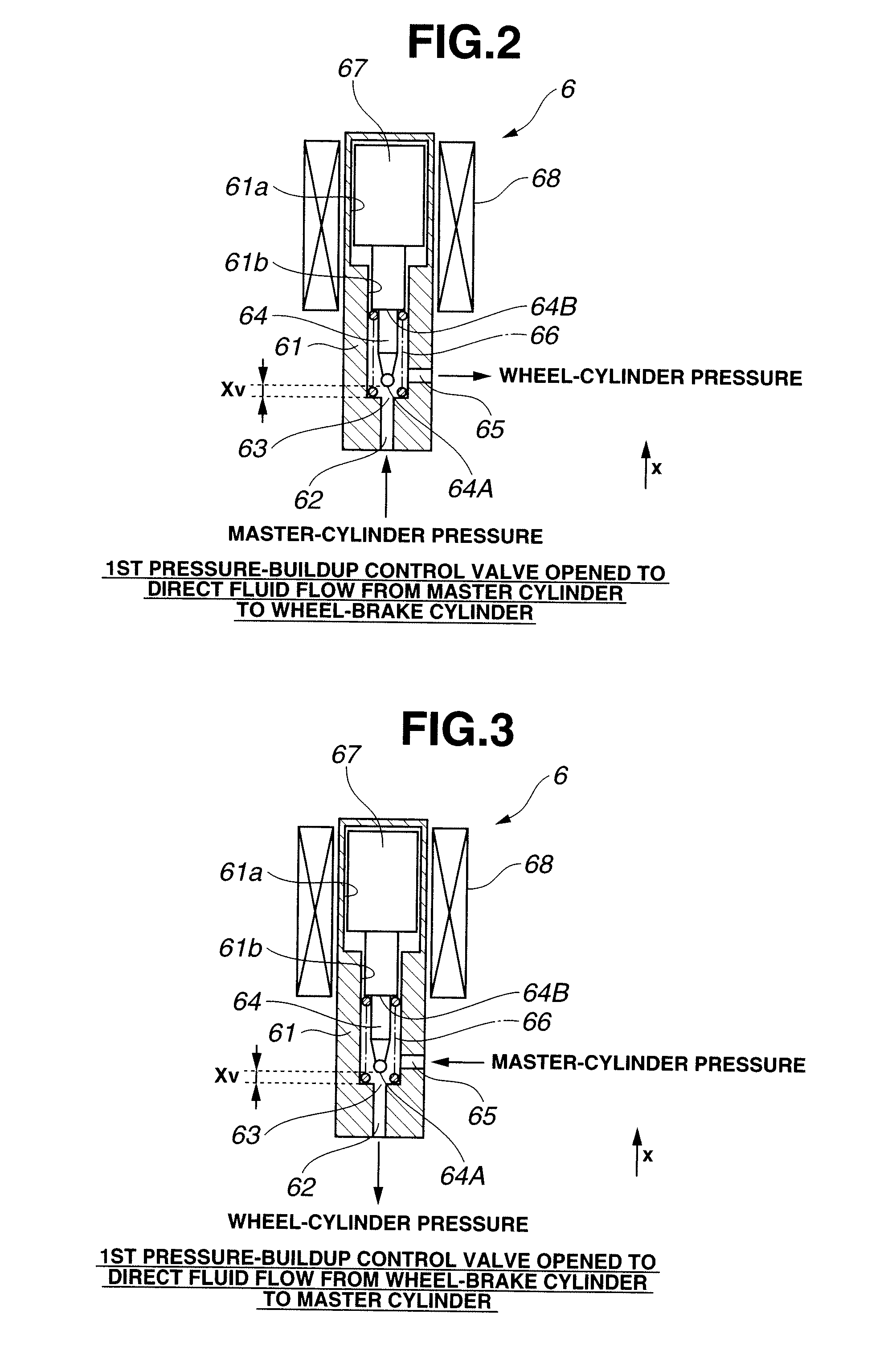

Brake control apparatus and control method for the brake control apparatus

ActiveUS20100211282A1Suppress occurrence of a malfunction in the pressure sensorAnalogue computers for trafficBraking action transmissionPressure decreaseHydraulic circuit

In a brake control apparatus that controls braking forces which are applied to wheels based on the pressure of the hydraulic fluid, when the pressure detected by a control pressure sensor (73) is equal to or higher than a predetermined value while a partition valve (60) is closed, a master cut valve (64) is closed to suppress an increase in the pressure in a first passage (45) in a first hydraulic circuit (37), to which the control pressure sensor (73) is connected. Alternatively, the control pressure sensor (73) is protected against overpressure by opening the outlet valve (56,57) or the pressure-decreasing valve (67).

Owner:TOYOTA JIDOSHA KK

Visual wear indicator for footwear

InactiveUS7353770B2Quick and easy read on how worn the shoe isStress on region will increaseAnalysis using chemical indicatorsMeasured value indication by color changeEngineeringViscosity

A visual wear indicator is disclosed capable of giving a visual indication of the degree of wear on an athletic or other type of shoe. In general, the visual wear indicator may operate by having two different colored regions, each having a viscosity which varies a function of pressure. Before pressure is applied, the boundary between the two regions is clear. However, over time, as the midsole and / or outer sole of the shoe wear away, the pressure exerted on the visual wear indicator increases during activity. As the pressure increases, the viscosity of the regions eventually decreases. When the viscosity decreases, the regions bleed together, and the boundary between the regions becomes less clear. The degree of mixture between the regions may be calibrated to give a clear visual indication of when the shoe has worn down to the point where the shoe is unable to provide a desired level of support and stress absorption.

Owner:SANGUINETTI CHERI

Efficient bypass valve for multi-stage turbocharging system

InactiveUS20060042246A1High speedOperating means/releasing devices for valvesInternal combustion piston enginesTurbochargerDischarge pressure

A turbocharger system includes first and second turbines arranged such that exhaust gas passes through the first turbine then the second turbine. A bypass channel is configured such that exhaust gas entering the channel passes only through the second turbine. A valve positioned in the bypass channel regulates the flow of gas therethrough. The valve accelerates a stream of gas and focuses the stream toward the second turbine such that a large part of the added velocity of the stream is preserved as it enters the second turbine. Operation of the valve may be controlled so as to maintain the valve in a closed position while exhaust gas pressure above the first turbine pressure is below a first threshold, to progressively open the valve as the pressure increases above the first threshold, and to maintain the valve in a full-open position while the pressure is above a second threshold.

Owner:UNITED STATES OF AMERICA

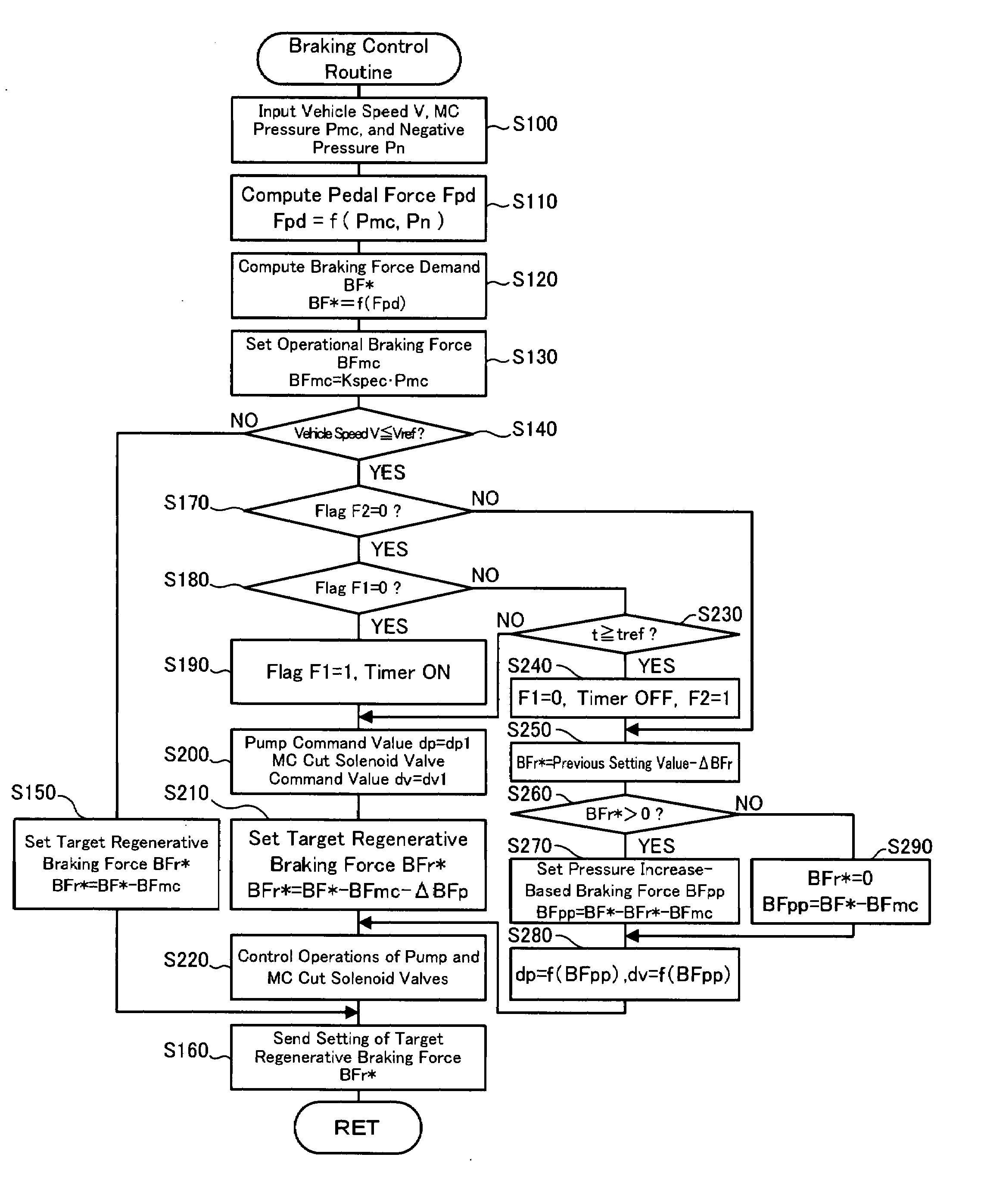

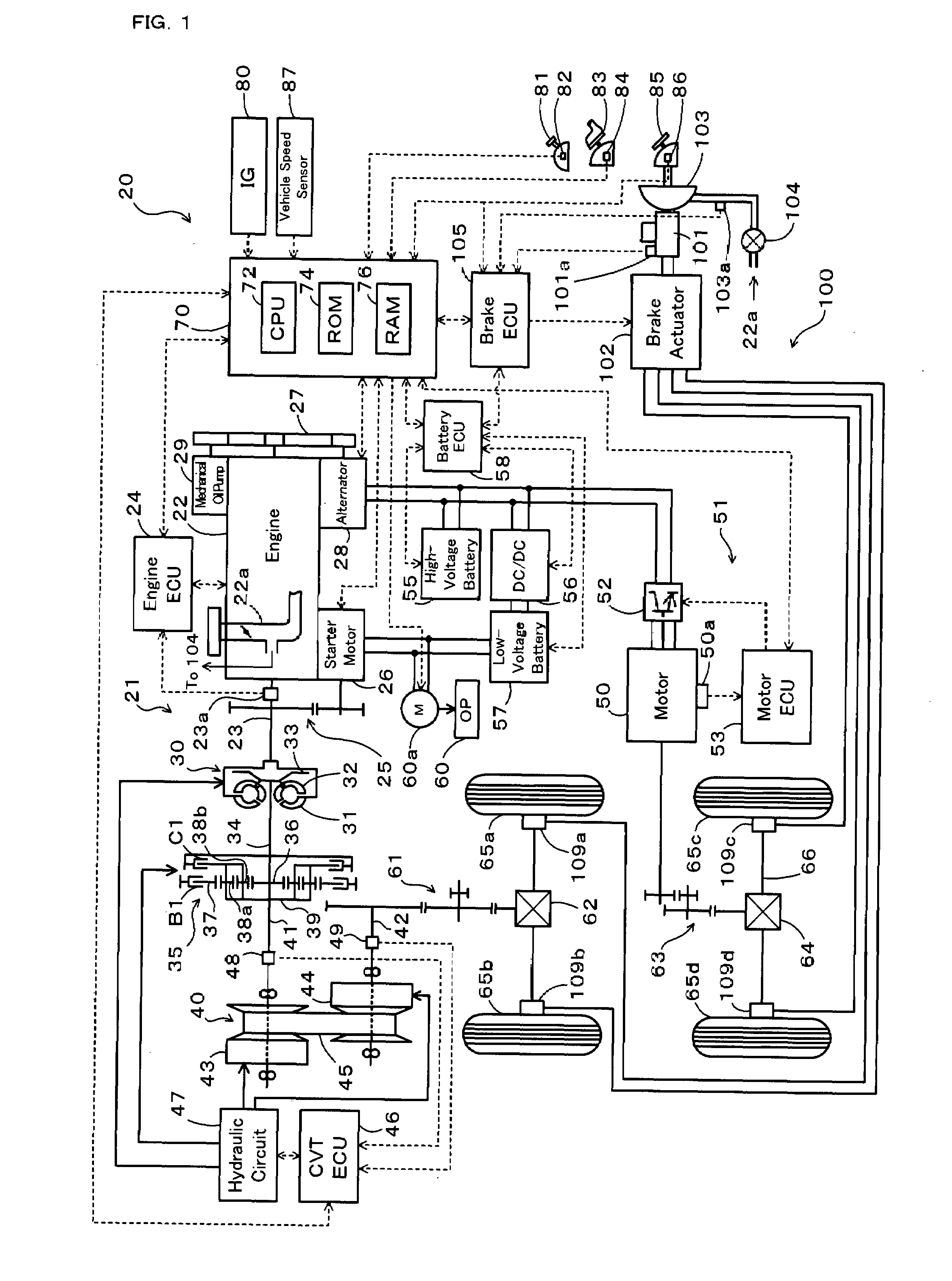

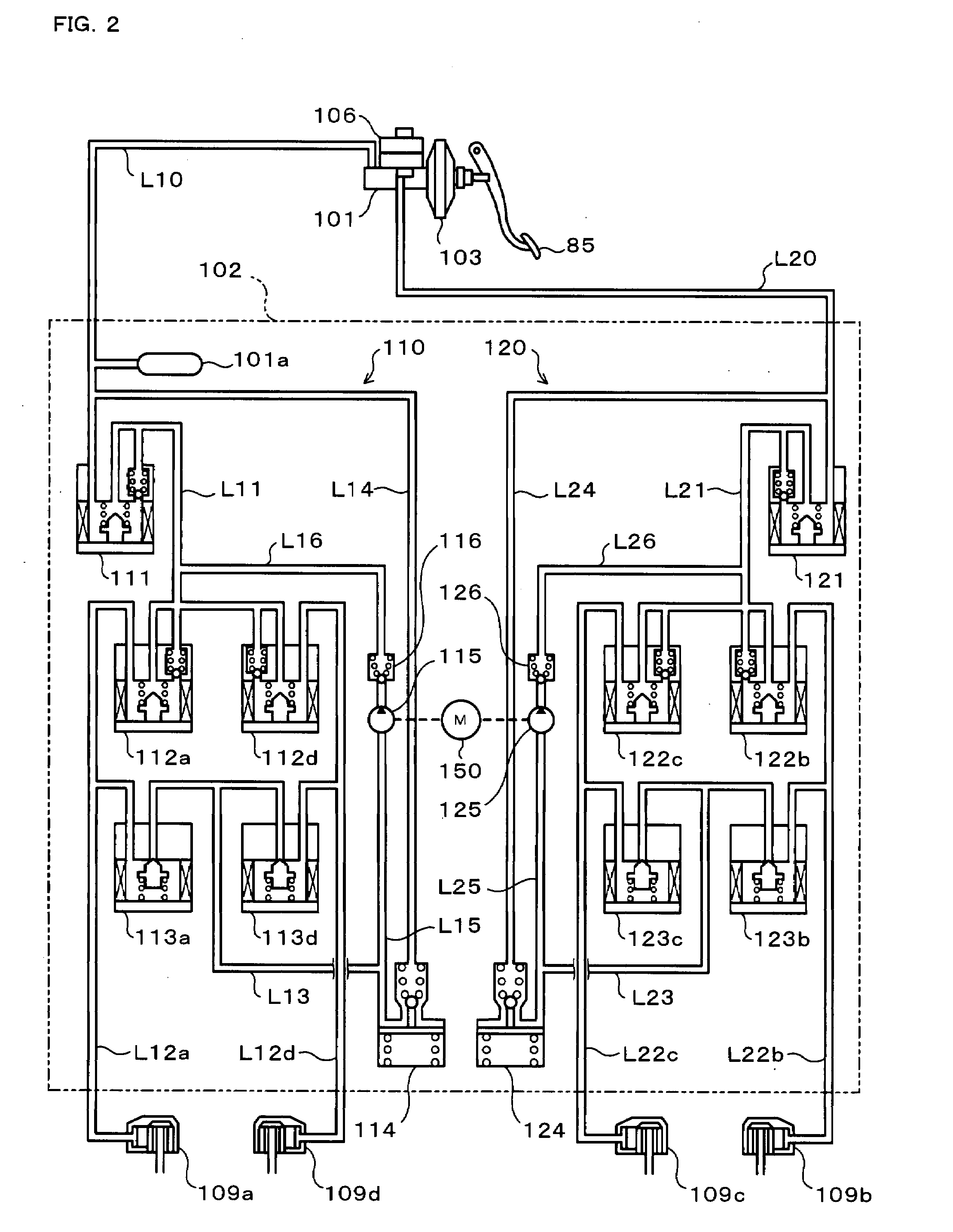

Vehicle and control method of vehicle

ActiveUS20070241611A1Ensure correct executionGuaranteed outputBraking element arrangementsPlural diverse prime-mover propulsion mountingRegenerative brakeDriver/operator

When vehicle speed V decreases to or below a preset reference vehicle speed Vref during output of regenerative braking force from a motor in response to the driver's depression of a brake pedal, the vehicle of the invention performs a replacement pre-operation (steps S190 to S220 and S160) and a replacement operation (steps S240 to S280 and S160) and controls the motor and an electronically controlled hydraulic braking system to satisfy a braking force demand BF*. The replacement pre-operation actuates and controls pumps included in a brake actuator of the electronically controlled hydraulic braking system to exert their proper pressurization performance. The replacement operation decreases the regenerative braking force output from the motor and enhances a pressure increase by the pumps to replace the regenerative braking force with a pressure increase-based braking force BFpp.

Owner:TOYOTA JIDOSHA KK +1

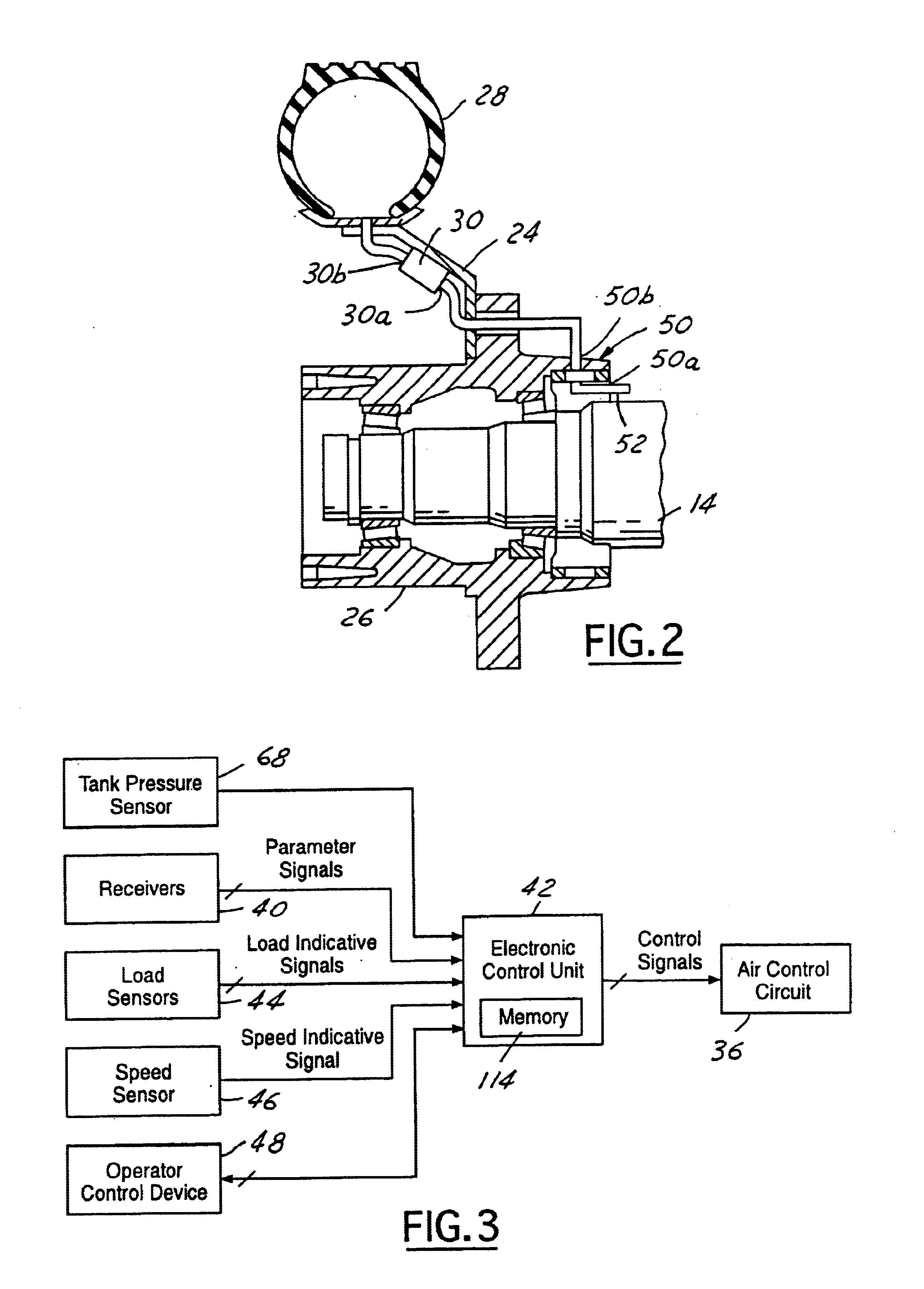

Tire pressure management system valve integrity verification method

A method of verifying the integrity of a valve in service in a tire pressure management system is disclosed. The method of verifying valve integrity of a valve interposed between a tire and conduit assemblies for conducting fluid to and / or from the tire in a tire maintenance system includes closing the valve for prohibiting fluid flow into the conduit assemblies in fluid communication with the valve and monitoring the pressure of fluid in the conduit assemblies in fluid communication with the valve for ascertaining a pressure increase therein.

Owner:DANA HEAVY VEHICLE SYSTEMS GROUP LLC

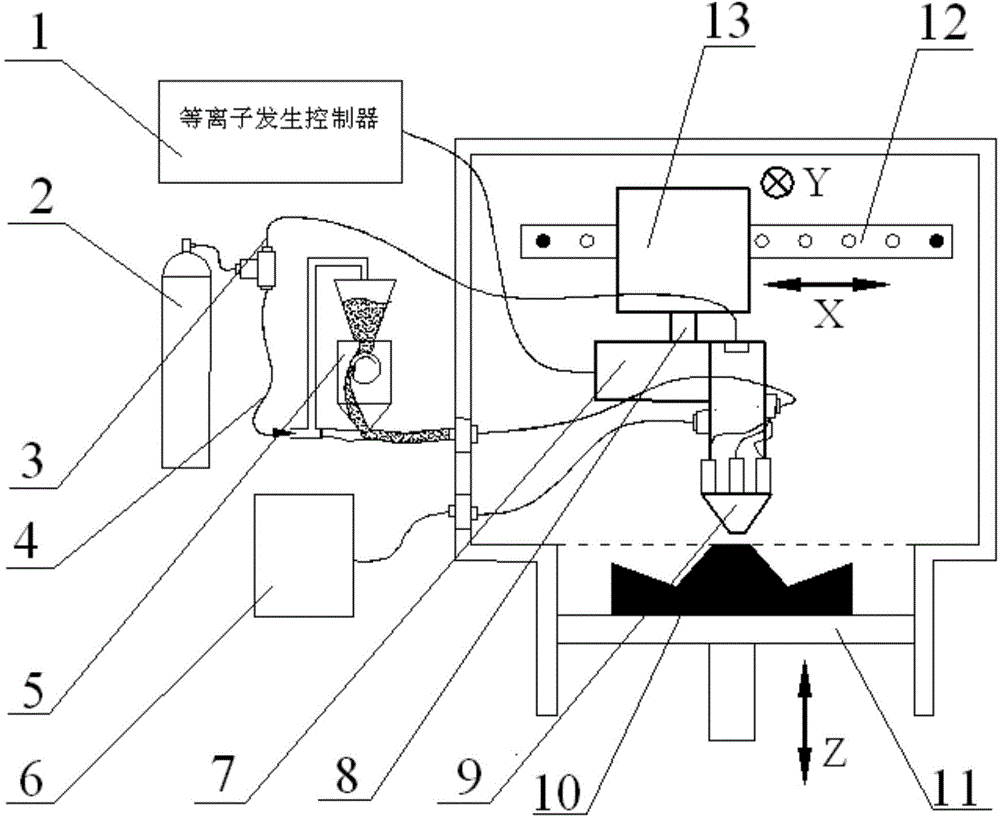

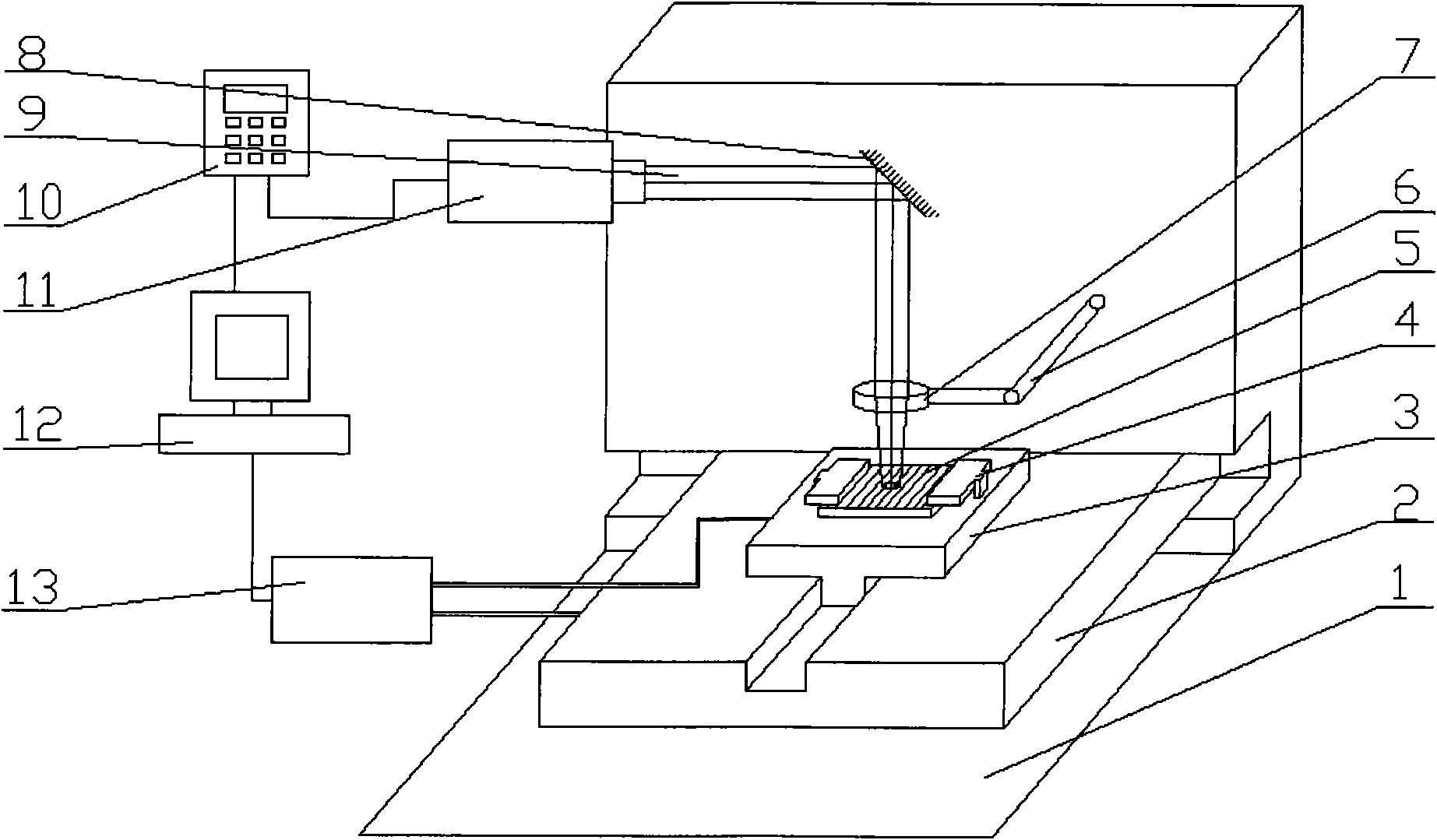

Micro beam plasma 3D (three dimensional) printing device and method

The invention discloses a micro beam plasma 3D (three dimensional) printing device and a micro beam plasma 3D printing method. The micro beam plasma 3D printing device comprises a plasma processing device, a central control system, a shaping chamber, a work platform, a numerical control main shaft, a drive device and a powder feeding device. The plasma processing device comprises a plasma power source, a plasma generator, a plasma arc pressure increasing device, a plasma gun, a work gas circuit and a cooling water circuit. The plasma generator, the plasma arc pressure increasing device, the plasma gun, the work gas circuit and the cooling water circuit form a plasma processing integration unit. When the micro beam plasma 3D printing device is used in processing, the numerical control main shaft clamps the plasma processing integration unit, and is driven by the drive device to move in the XYZ direction, and the work platform moves up and down, and achieves feeding in the X direction. According to the micro beam plasma 3D printing device and the micro beam plasma 3D printing method, micro beam plasma is used as a hot source of melting metal material in metal 3D printing, and the industrial grade metal part 3D printing device high in efficiency and low in cost can be obtained on the premise that shaping accuracy similar to that in a laser 3D printing technology is guaranteed.

Owner:SOUTH CHINA UNIV OF TECH

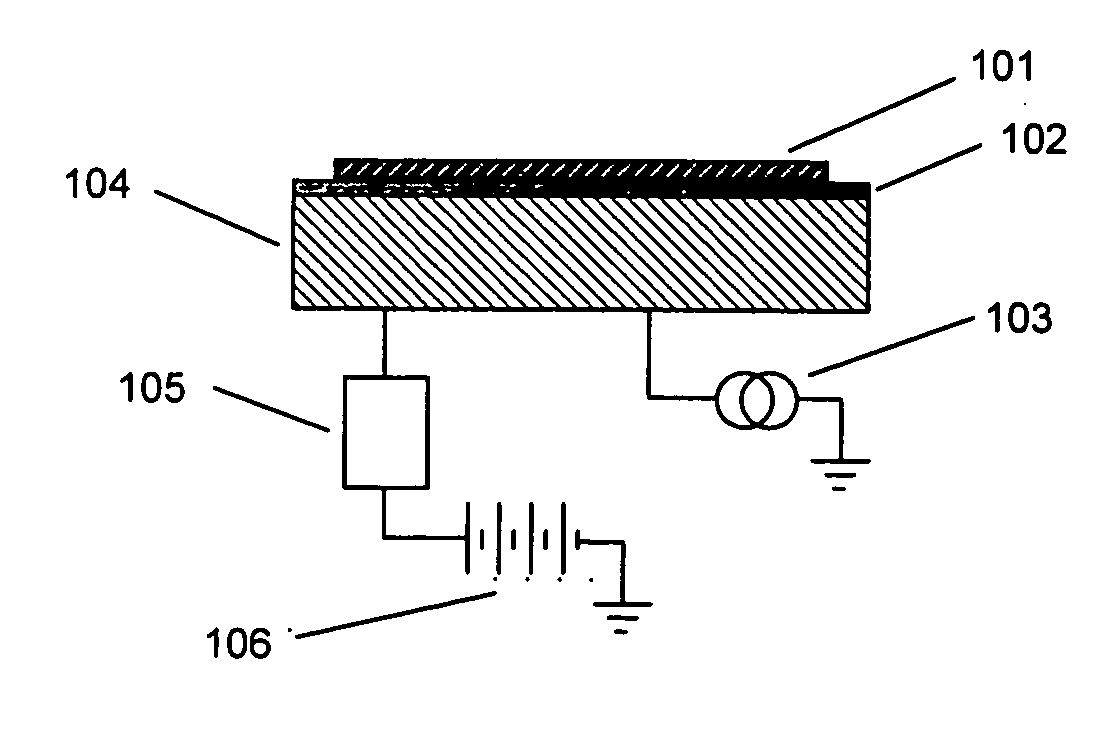

Clamp for holding and efficiently removing heat from workpieces

InactiveUS20050036267A1Effectively safely clampIncrease resistanceSemiconductor/solid-state device manufacturingEmergency protective arrangement detailsEtchingCelsius Degree

The invention described in this disclosure is an apparatus and method for clamping semiconductor wafers or other substrates or workpieces during etching, CVD, or surface modification processes. The purpose of the invention is to achieve improved heat transfer during processing between the wafer / substrate and a temperature controlled pedestal used for supporting it in the process chamber. The typical level of process heat put into the wafer during plasma-based etching or deposition processes will be up to about 10 Watts per centimeter squared while the maximum acceptable temperature differential between wafer / substrate and pedestal is less than about 100 Celsius. In such low gas pressure environments typical for plasma-based processes, the heat removal from the wafer / substrate by gaseous conduction may be inadequate to meet requirements. This invention achieves excellent heat transfer to the pedestal from the wafer / substrate when there is a thin, resilient, electrically insulating layer (tape) bonded to the wafer / substrate or the pedestal. Wafer / substrate clamping for improved process heat removal is achieved by a combination of vacuum clamping of the wafer / substrate beginning prior to evacuation of the processing chamber, along with or followed by electrostatic clamping of the wafer / substrate which continues during processing. The invention also permits the wafer / substrate to be rapidly and safely released from the electrostatic clamping when the chamber is returned to atmospheric pressure by a providing a slight pressure increase, above atmospheric pressure, between wafer and pedestal. The pedestal may have some roughening or narrow grooves on the wafer clamping surface, and some small holes from its surface leading to an evacuated plenum or channel within the pedestal. Alternatively, the pedestal may have a layer of a porous metal extending from its surface down to the evacuated channel or plenum which permits gas to be evacuated. These structures allow vacuum pumping of gas that might otherwise be trapped between the insulating layer and the pedestal. When a wafer / substrate is placed on the pedestal by loading at atmospheric pressure, vacuum pumping through the pedestal is commenced. This causes the workpiece to be pressed to the pedestal clamping surface with approximately atmospheric pressure compressing the soft layer against its clamping surface. This provides sufficient contact of the soft layer with the pedestal to greatly improve heat transfer from the wafer / substrate to the pedestal. A voltage is applied to the pedestal, beginning any time after the wafer is on the pedestal, to further clamp the wafer electrostatically. As the processing chamber is then pumped down to operating pressure for processing the electrostatic clamping voltage maintains sufficient pressure of the wafer / substrate against the pedestal to maintain the heat conductive contact between the soft layer and the pedestal. This permits good heat conduction to be maintained during the low pressure plasma-based etching or CVD processing. Following processing when the wafer / substrate is to be removed it may be rapidly de-clamped from the electrostatic clamping by application of a slight over-atmospheric pressure in the reservoir or pumping channels within the pedestal.

Owner:SAVAS STEPHEN EDWARD +1

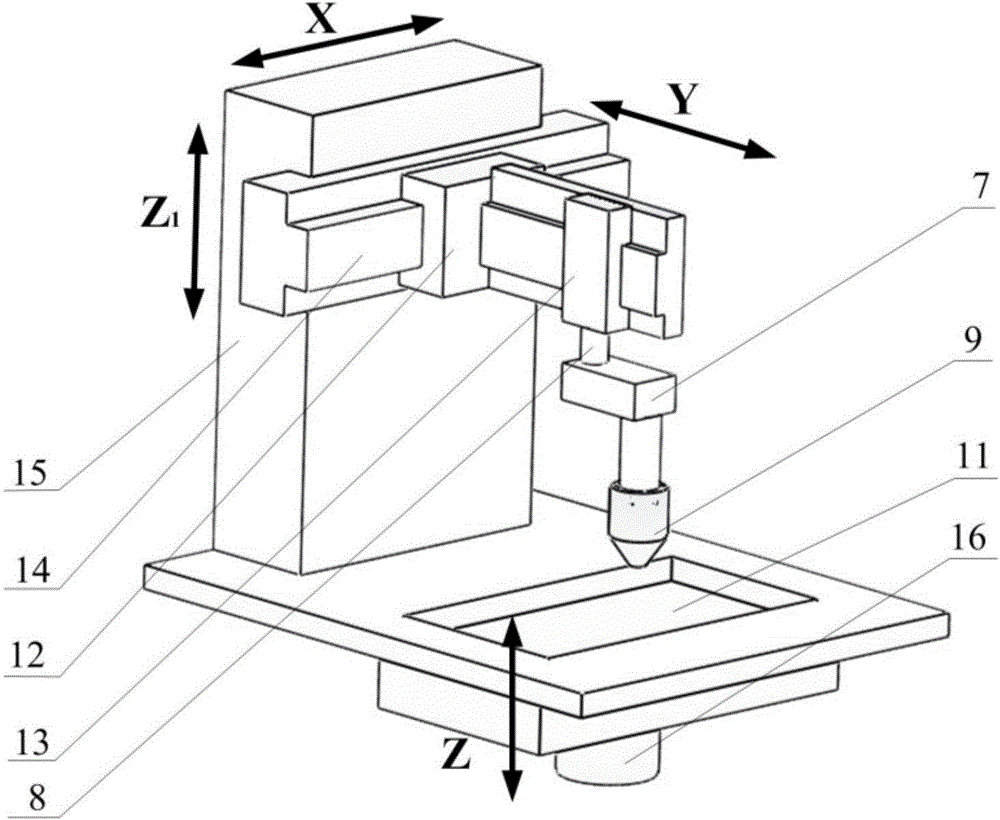

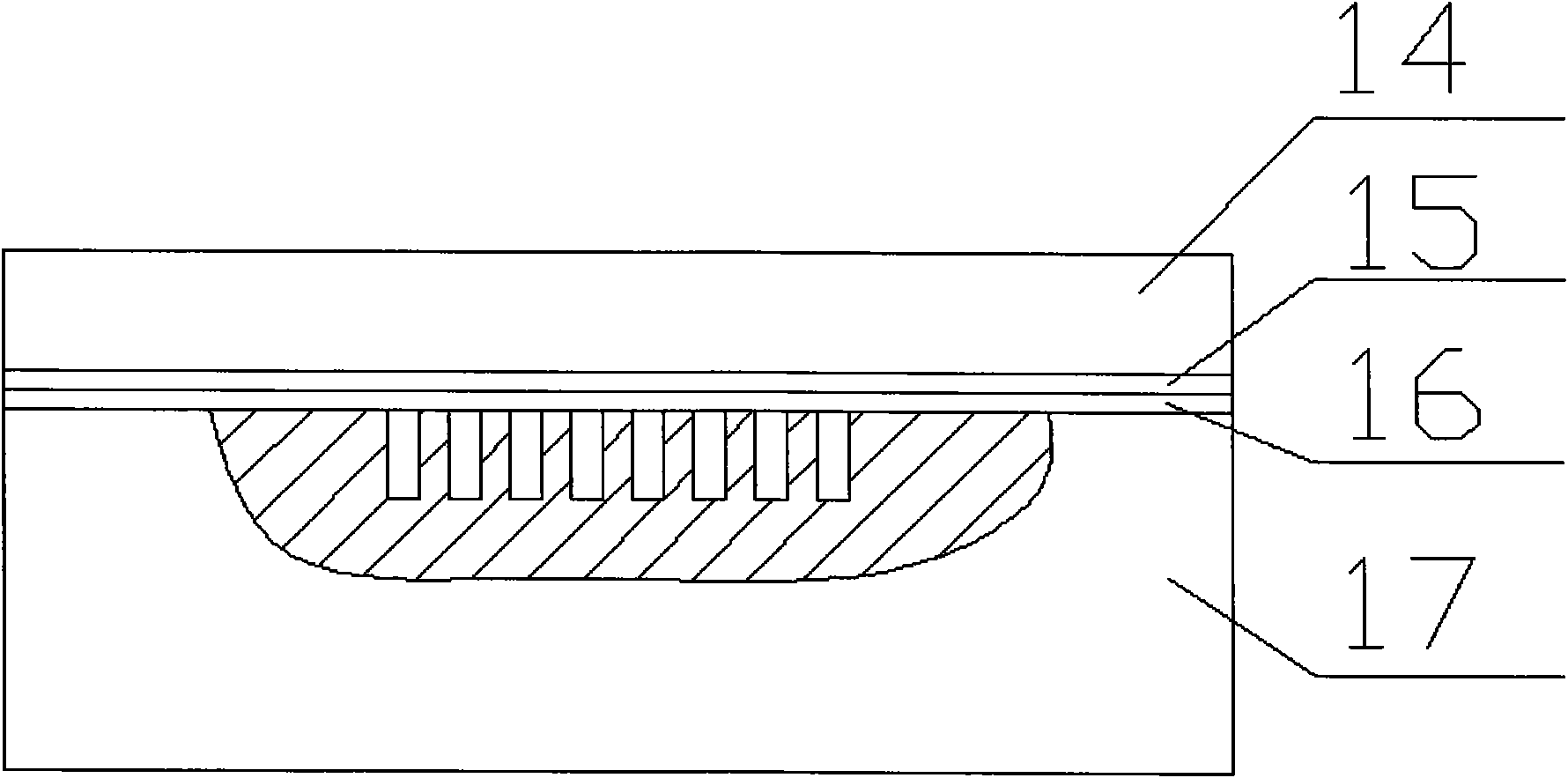

Laser direct-compounding micro-plastic forming device and method

InactiveCN102029317APrecise and controllable parametersGood repeatabilityLaser beam welding apparatusLaser processingPunching

The invention discloses a laser direct-compounding micro-plastic forming device and method, belonging to the technical field of parts of a laser processing micro-electromechanical system (MEMS). The device comprises a laser loading system, a forming system and a control system. The method comprises the following steps: laser penetrates through a restraint layer after being focused by lens and acts on an energy-absorbing layer; the energy-absorbing layer absorbs the laser energy; a high pressure and high temperature plasmasphere is formed in a very short period of time and sprayed outward quickly; the expanded plasmas are limited by the restraint layer, so that the plasma pressure increases quickly and causes impact loading on a workpiece; the workpiece is extruded between the restraint layer and a compound micro-mould, so that the workpiece generates plastic deformation and copies the appearance of the compound micro-mould; and a compound process of stretching, punching and trimming a target workpiece is realized in one impact forming process by a stretching female mould, a trimming female mould and a punching male mould which are arrayed on the compound micro-mould, and simultaneously workpieces can be formed in batch.

Owner:JIANGSU UNIV

Pressure monitoring to control delivery of therapeutic agent

A method for adjusting delivery of a therapeutic fluid to a patient suffering from or at risk of pulmonary arterial hypertension includes introducing the therapeutic fluid to a patient via a catheter at a predetermined rate. The catheter is positioned to deliver the fluid to the right ventricle or the pulmonary artery. The catheter a one-way valve configured to allow the fluid to flow from the catheter to the target location. The method further includes monitoring pressure of the target location by monitoring internal catheter pressure, and adjusting the rate at which the therapeutic fluid is introduced to the catheter based on the monitored pressure. The rate at which the fluid is introduced to the catheter is increased if internal catheter pressure increases, and the rate at which the fluid is introduced to the catheter is decreased if the internal catheter pressure decreases.

Owner:MEDTRONIC INC

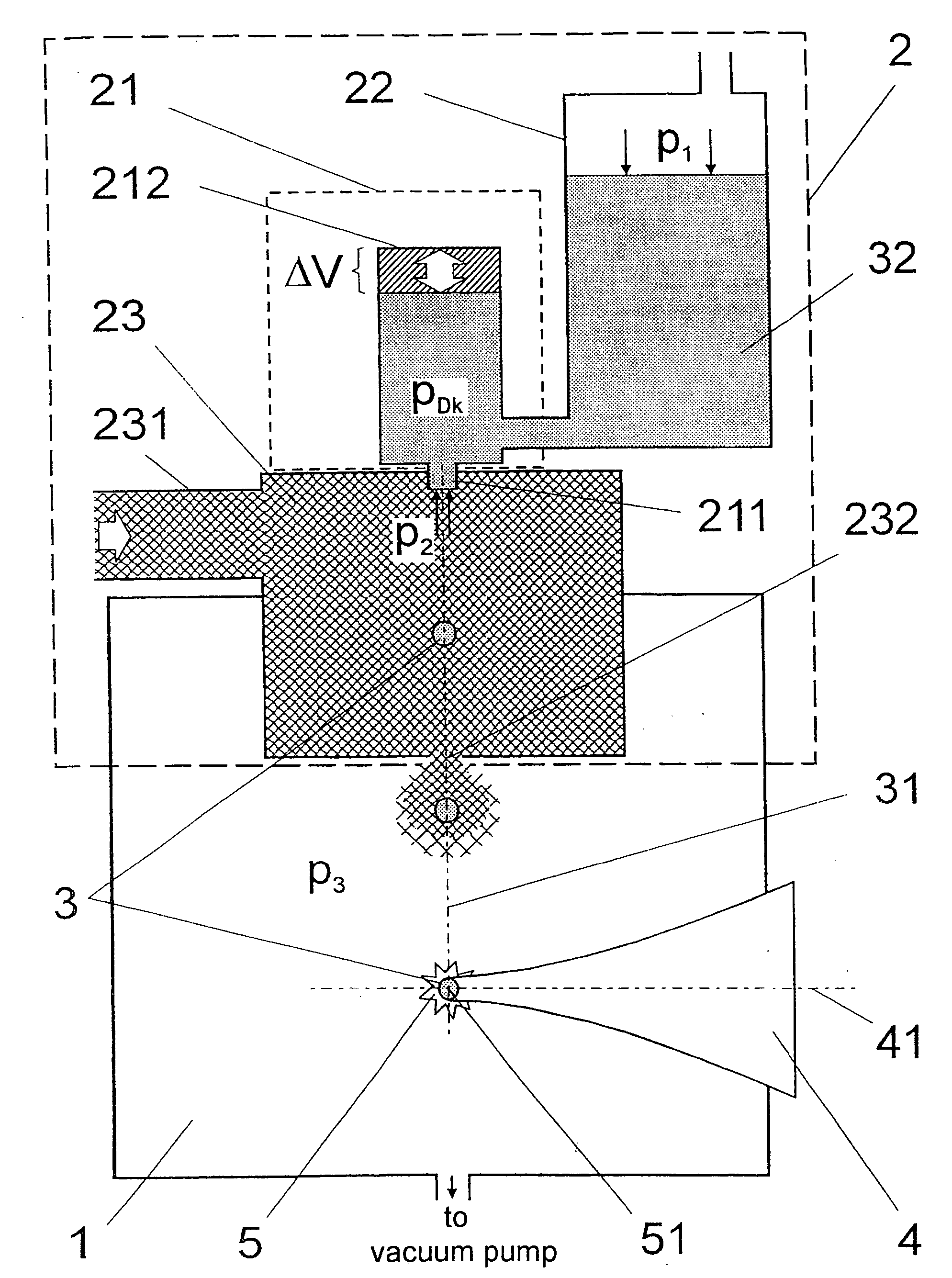

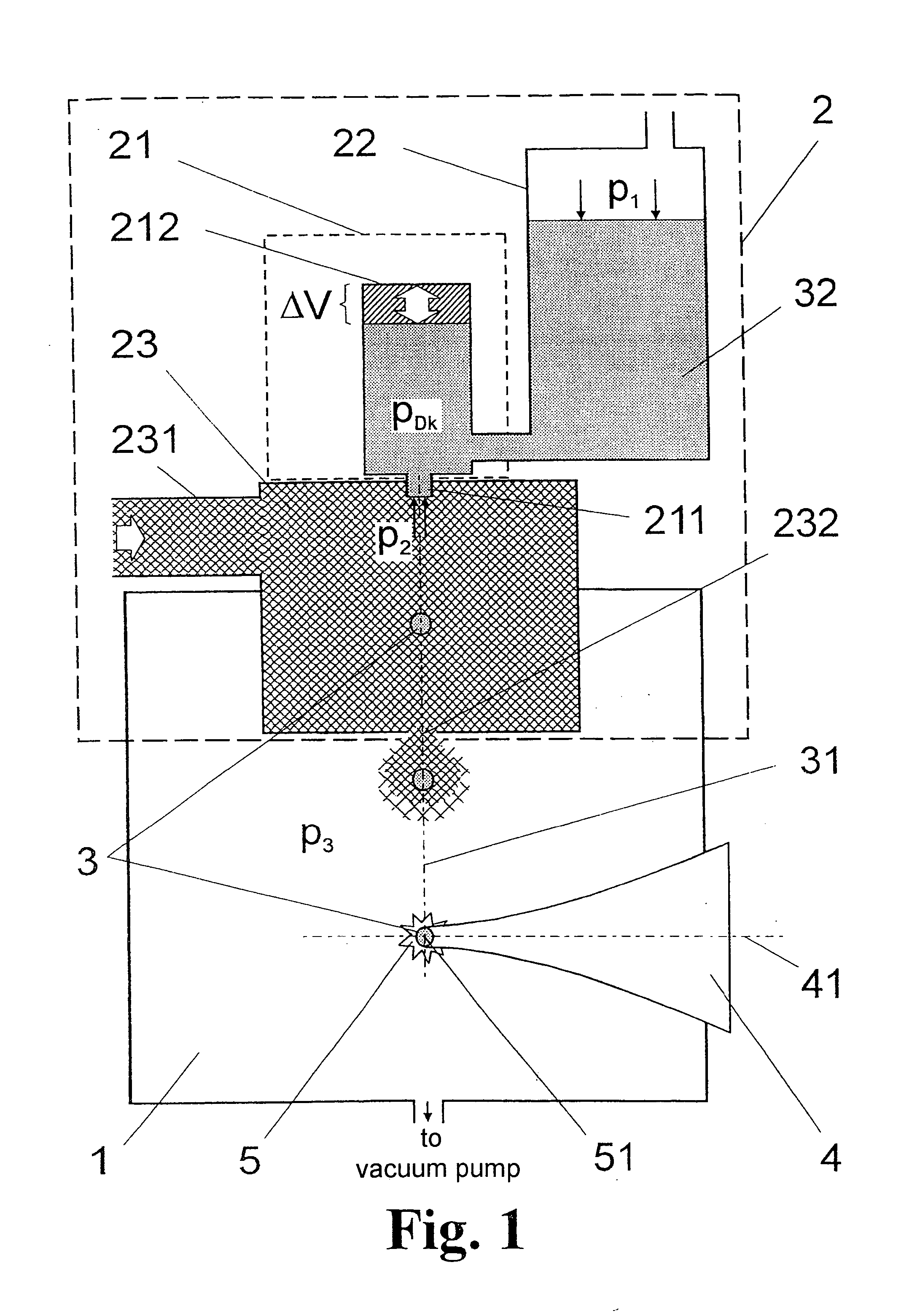

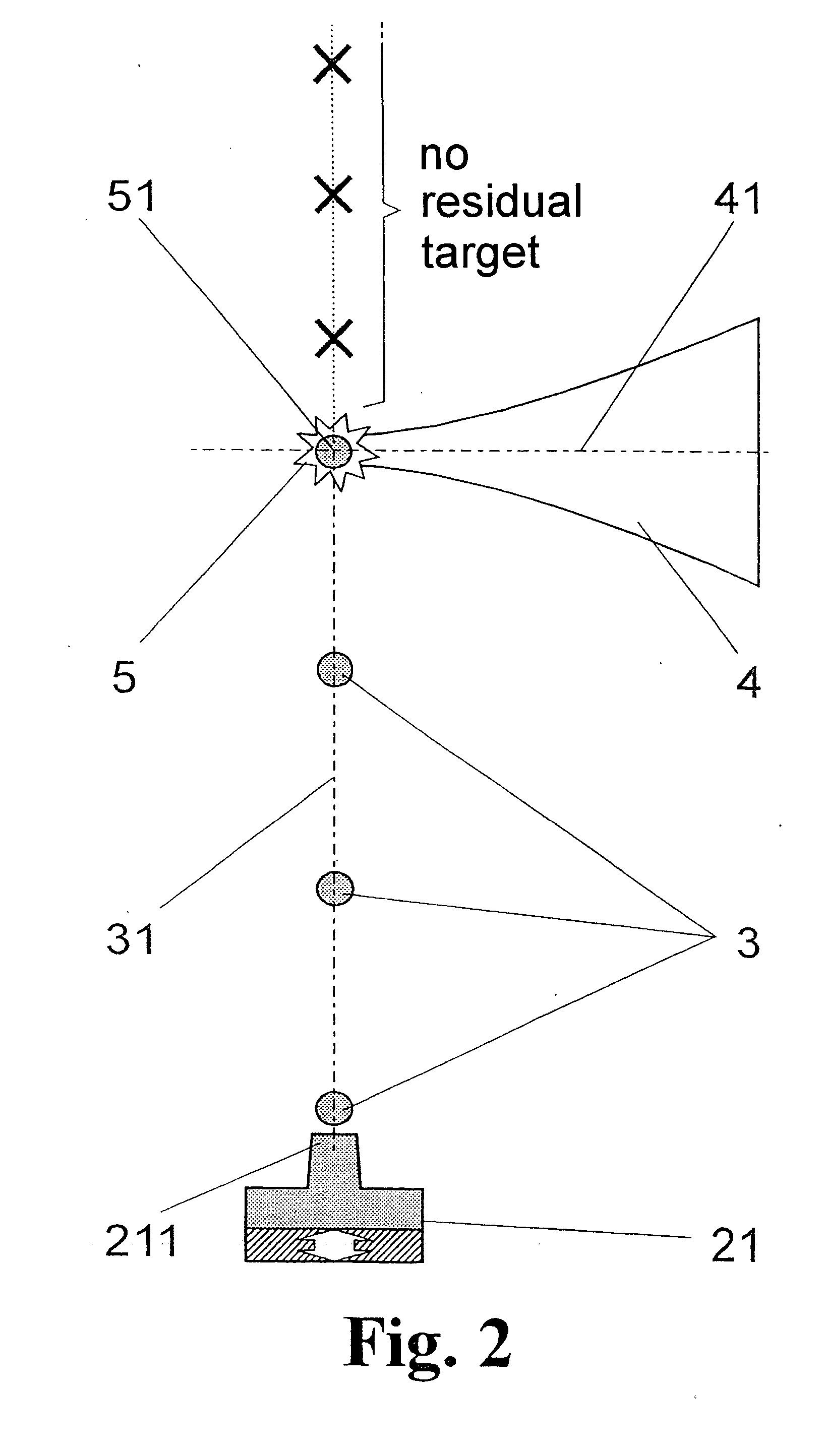

Arrangement and method for metering target material for the generation of short-wavelength electromagnetic radiation

InactiveUS20060017026A1Generate debrisReduce the burden onRadiation pyrometryX-ray tube electrodesAntechamberElectromagnetic radiation

The invention is directed to an arrangement for metering target material for the generation of short-wavelength electromagnetic radiation from an energy beam induced plasma, in particular X radiation and EUV radiation. The object of the invention is to find a novel possibility for metering target material for the generation of short-wavelength electromagnetic radiation from an energy beam induced plasma which makes it possible to provide reproducibly supplied mass-limited targets in such a way that only the amount of target material for plasma generation that can be effectively converted to radiating plasma in the desired wavelength region arrives in the interaction chamber and, therefore, debris generation and the gas burden in the interaction chamber are minimized. This object is met, according to the invention, in that an injection device is provided for target generation, wherein means are arranged upstream of the nozzle in a nozzle chamber for a defined, temporary pressure increase in order to introduce an individual target into the interaction chamber exclusively when required, and an antechamber is arranged around the nozzle for generating a quasistatic pressure upstream of the interaction chamber, wherein an equilibrium pressure in the antechamber prevents the escape of target material as long as there is no pressure increase in the nozzle chamber.

Owner:XTREME TECH

Valvetrain oil control system and oil control valve

InactiveUS8327750B2Reduce fuel consumptionOperating means/releasing devices for valvesServomotor componentsControl systemEngineering

A hydraulic control system includes an oil control valve to control oil flow within a valvetrain. The control valve varies the flow rate to actuate an engine component from a first position to a second position based upon fluid pressure from the control valve. Varying the flow rate through the control valve includes increasing the flow rate through the control valve to increase the pressure to a first level to actuate the engine component to the first position. After the engine component is actuated, the flow rate through the control valve is maintained at a level sufficient to maintain the engine component in the first position. To actuate the engine component to the second position the flow rate through the control valve is then decreased. The fluid flow rate through the control valve is then maintained at a level sufficient to maintain the engine component in the second position.

Owner:EATON CORP

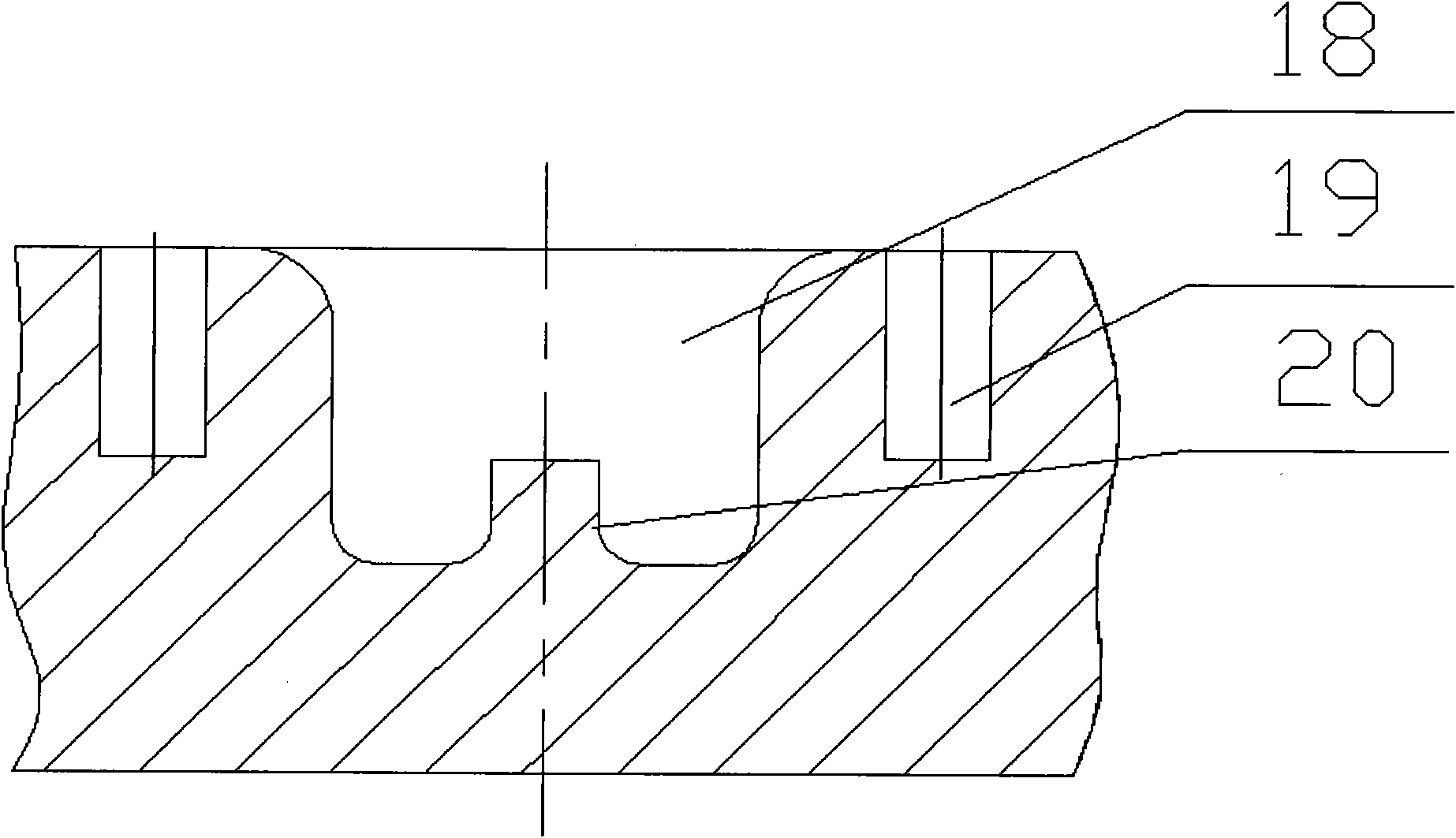

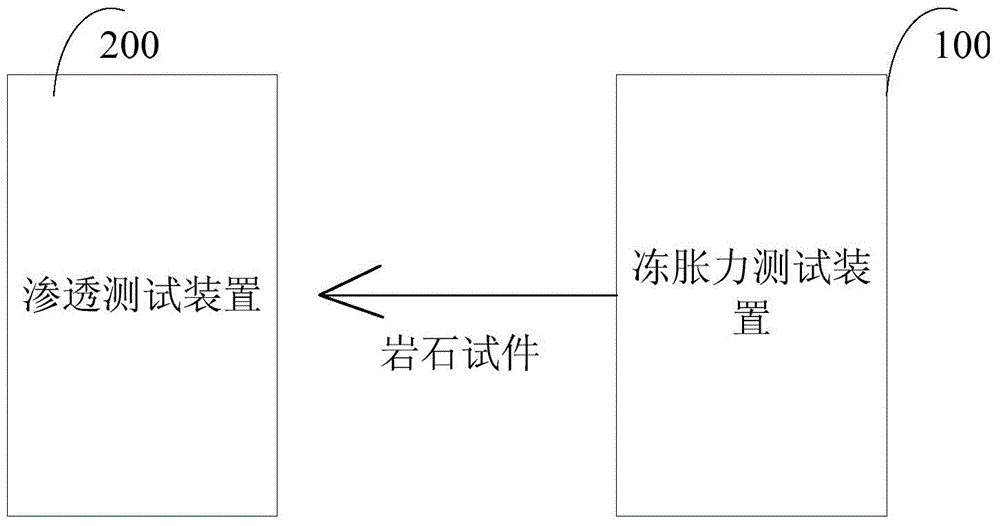

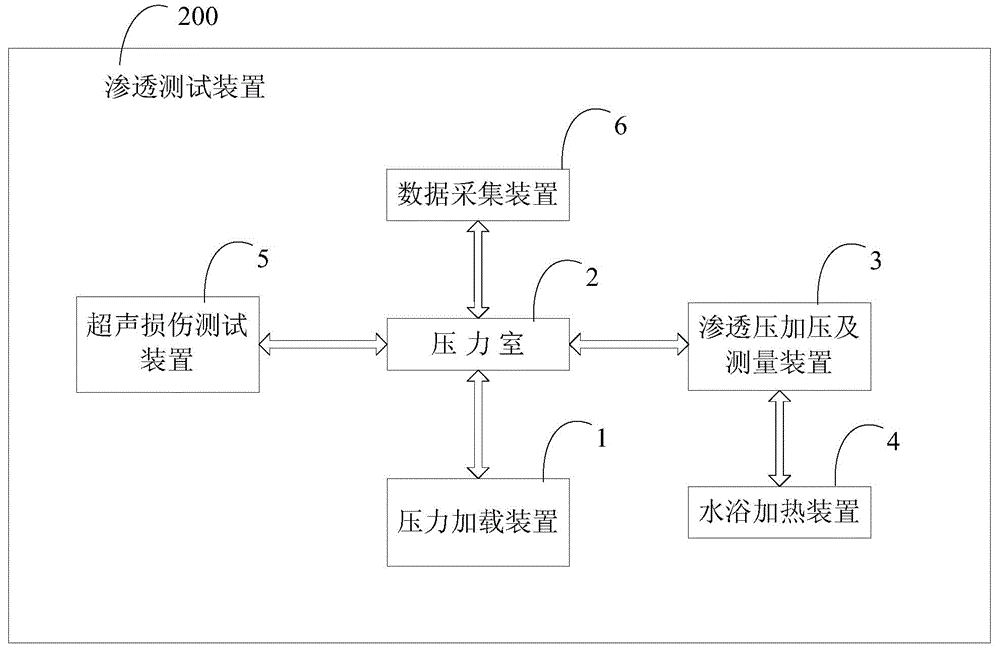

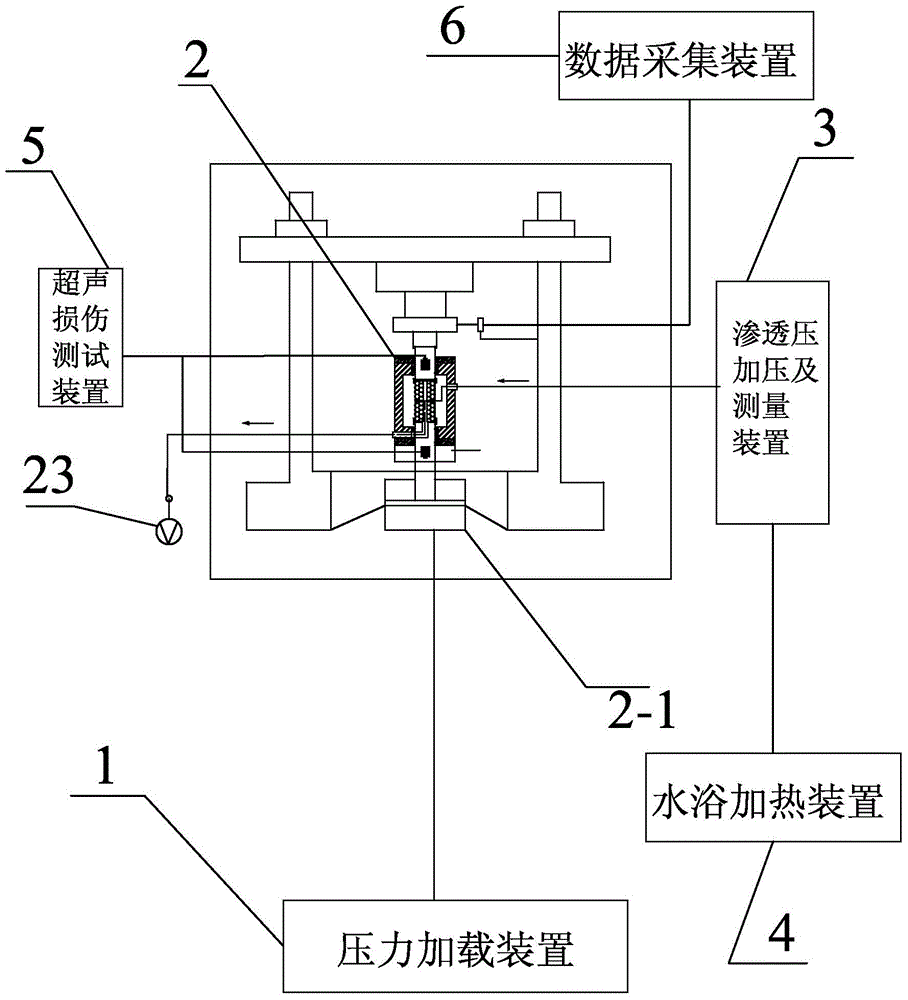

System and method for testing rock damage and permeability under coupling effect of temperature stress and circumferential seepage

InactiveCN103558136AMaterial strength using tensile/compressive forcesPermeability/surface area analysisWater bathsFreezing thawing

The invention discloses a system for testing rock damage and permeability under the coupling effect of temperature stress and circumferential seepage. The system comprises a frozen-heave force test device and a permeation test device, wherein the permeation test device comprises a pressure chamber for loading a rock test piece to be tested, a pressure loading device, a permeation pressure increasing and measuring device, a water bath heating device, an ultrasonic damage test device and a data acquisition device. The invention further discloses a method for testing rock damage and permeability under the coupling effect of temperature stress and circumferential seepage. The method comprises the following steps: carrying out repeated freezing-thawing tests on a rock by the frozen-heave force test device, measuring the frozen-heave force change of the rock test piece, putting the rock into the pressure chamber, applying a pressure to the rock test piece by the pressure loading device, and testing a rock permeation coefficient k and ultrasonic wave speed transmission time t under the action of flowing liquid with different temperatures and pressures so as to make a research on rock damage and permeability.

Owner:DALIAN MARITIME UNIVERSITY

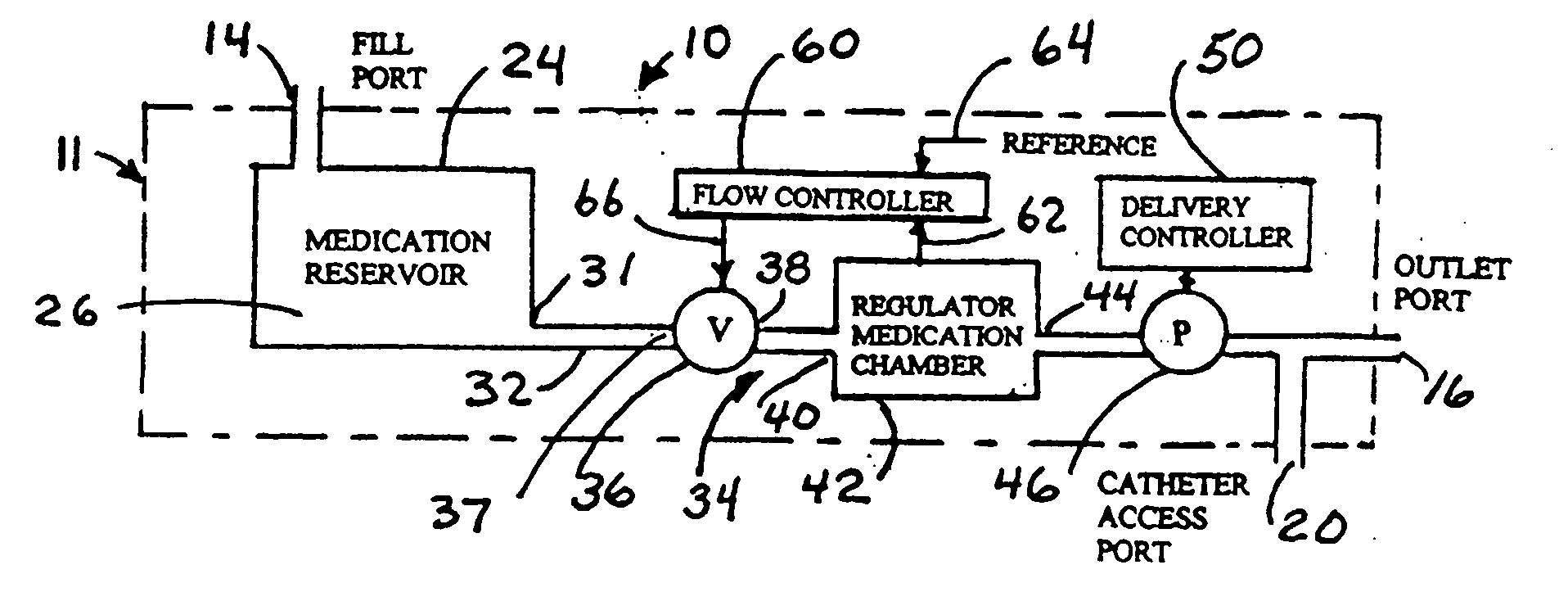

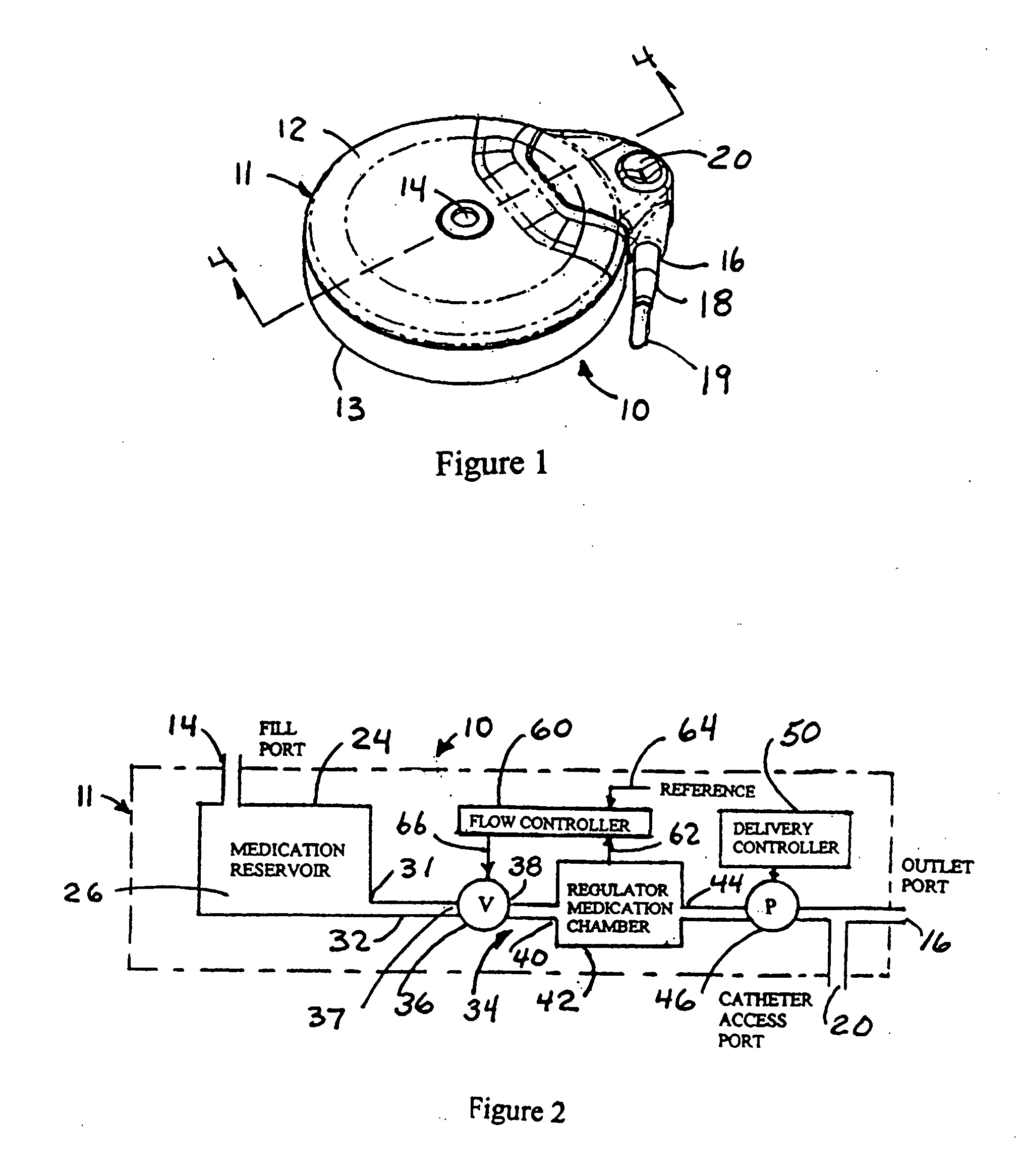

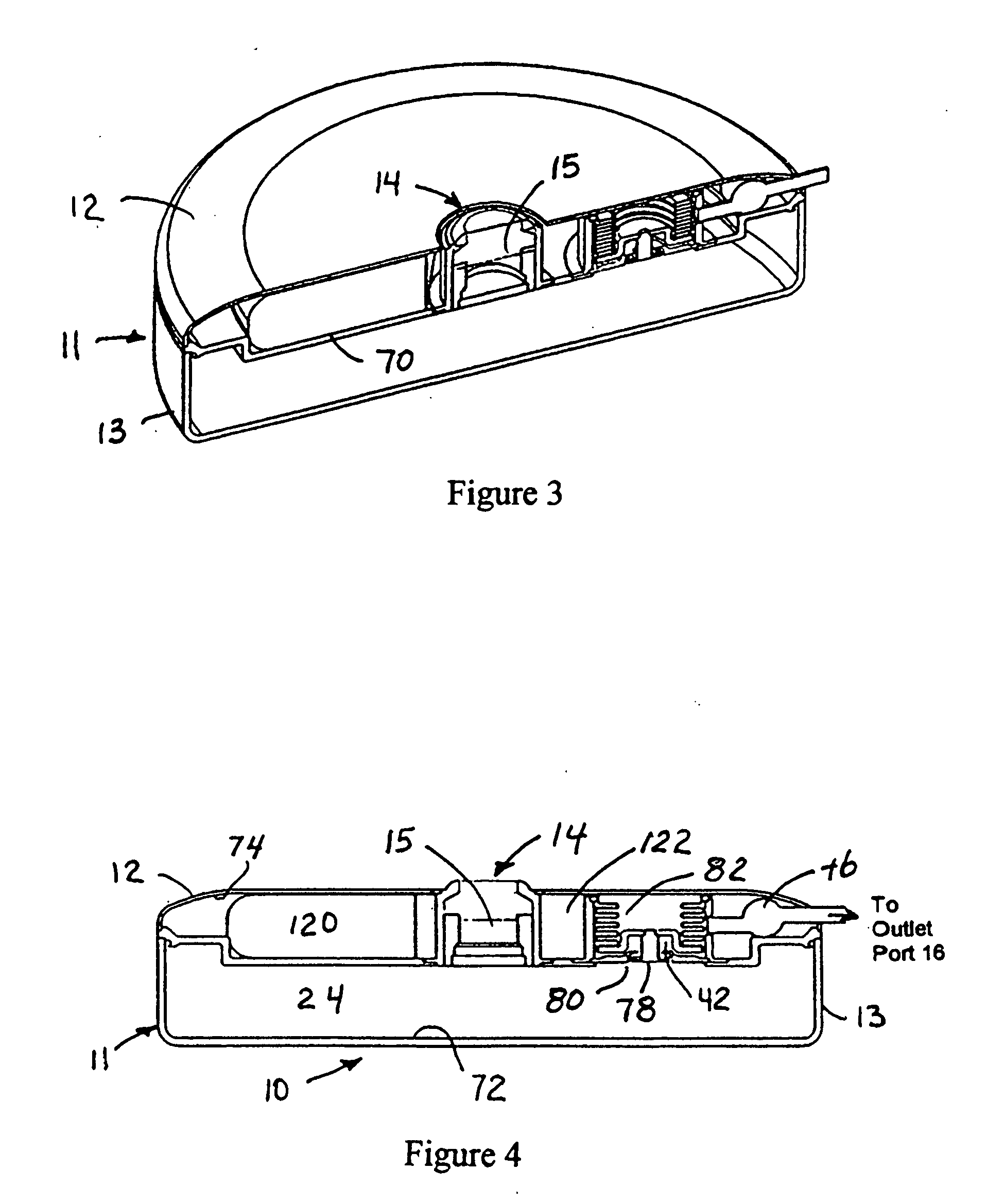

Implantable medication delivery device using pressure regulator

ActiveUS20050273083A1Limiting the magnitude of pressure transfer prevents overpressurization of the reservoirLimit magnitudeMedical devicesPharmaceutical delivery mechanismDrug StorageReservoir pressure

An implantable medication delivery apparatus including a flow path coupling a medication reservoir to a device outlet port where the flow path includes a regulator means for limiting the magnitude of pressure transferred downstream from the medication reservoir. The regulator means is configured to respond to the reservoir pressure exceeding a certain threshold for closing a valve located downstream from the reservoir. The valve closure functions to isolate the device outlet port from further reservoir pressure increases which otherwise could induce unintended medication flow from the device outlet port.

Owner:MEDTRONIC MIMIMED INC

Explosion-proof safety structure for column shape lithium battery

InactiveUS20030013005A1Avoid structureSafer and cheap and smallPrimary cell maintainance/servicingSmall-sized cells cases/jacketsInternal pressureInternal resistance

The present invention relates to an explosion-proof safety structure for column shape lithium battery, particularly relates to a safe and explosion-preventing structure which prevents the battery from ignition or explosion caused by the condition of overcharging described as follows: while the lithium battery is under overcharging condition, a sudden rise of the battery internal temperature takes place and the pressure increases; at the beginning of the sudden rise of temperature, the internal resistance value of the positive temperature coefficient of resistivity board redoubles to slow down the input of current; when the temperature keeps on rising, the electrolyte starts to gasify so as to increase the internal pressure of the battery up to a level which exceeds what the breaker sheet thin portion can take, the thin portion of the breaker sheet breaks to cause an open charging circuit and the charging activity stops; however, the battery internal pressure can not be released, which once exceeds the break pressure of the safety valve, the safety valve explodes to release the pressure.

Owner:NANYA PLASTICS CORP

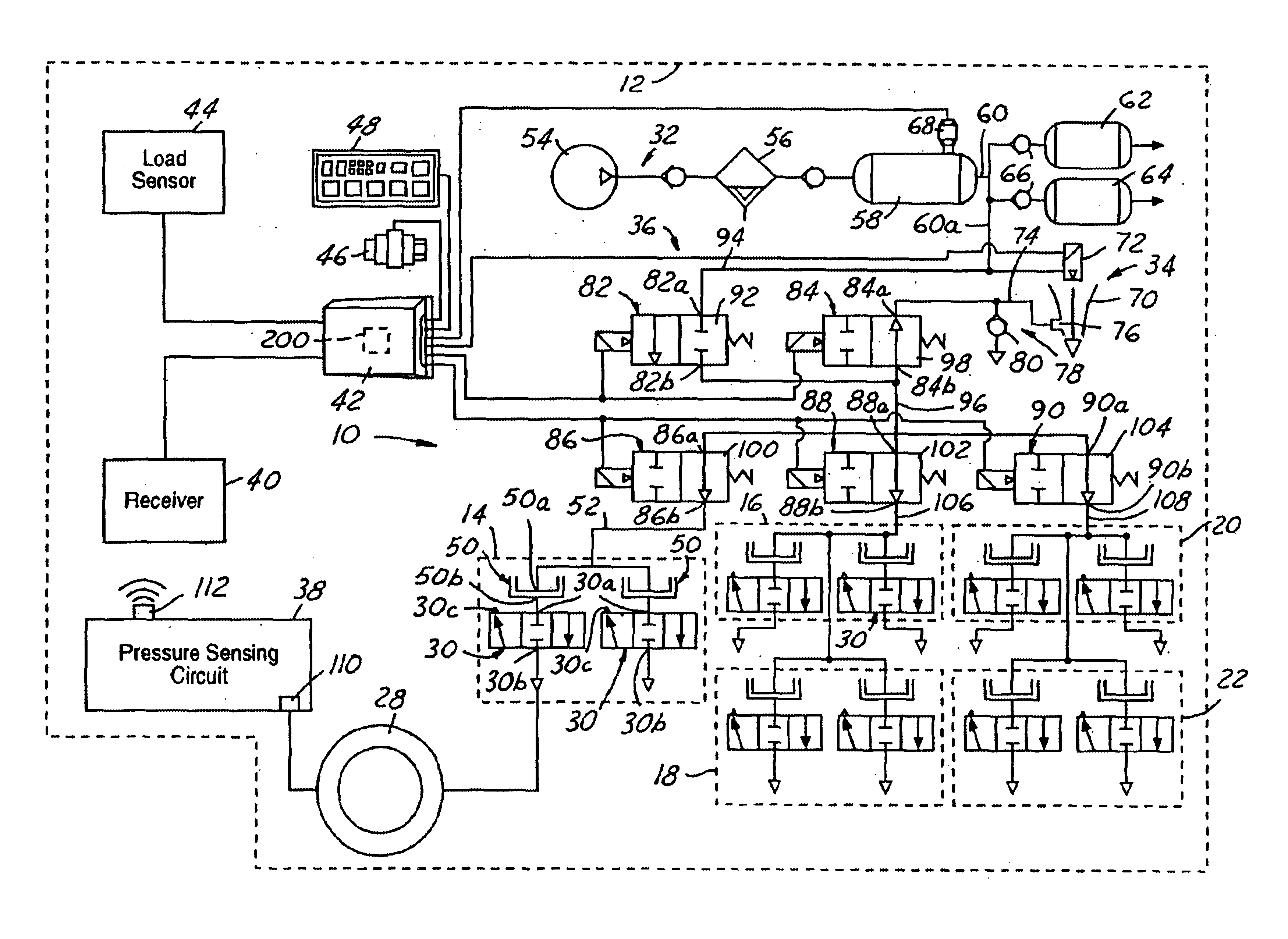

Apparatus for and method of controlling brakes

InactiveUS20090072615A1Improve controllabilityDigital data processing detailsAutomatic initiationsEngineeringWheel cylinder

An apparatus for controlling brakes, includes a first brake circuit for supplying brake fluid, pressure-increased by a booster, to a wheel-brake cylinder, a first control valve disposed in the first brake circuit for establishing and blocking fluid communication between a master cylinder and the wheel-brake cylinder, a second brake circuit arranged in parallel with the first brake circuit for supplying brake fluid, pressure-increased by a fluid-pressure source, to the wheel-brake cylinder, and a second control valve disposed in the second brake circuit for establishing and blocking fluid communication between the fluid-pressure source and the wheel-brake cylinder. Also provided is a control unit, which is configured to selectively control the first and second control valves when building-up wheel-cylinder pressure, and further configured to build-up the wheel-cylinder pressure by operating the fluid-pressure source when at least the second control valve is controlled to a valve-open position.

Owner:HITACHI LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com