Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

1405 results about "Labyrinth seal" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

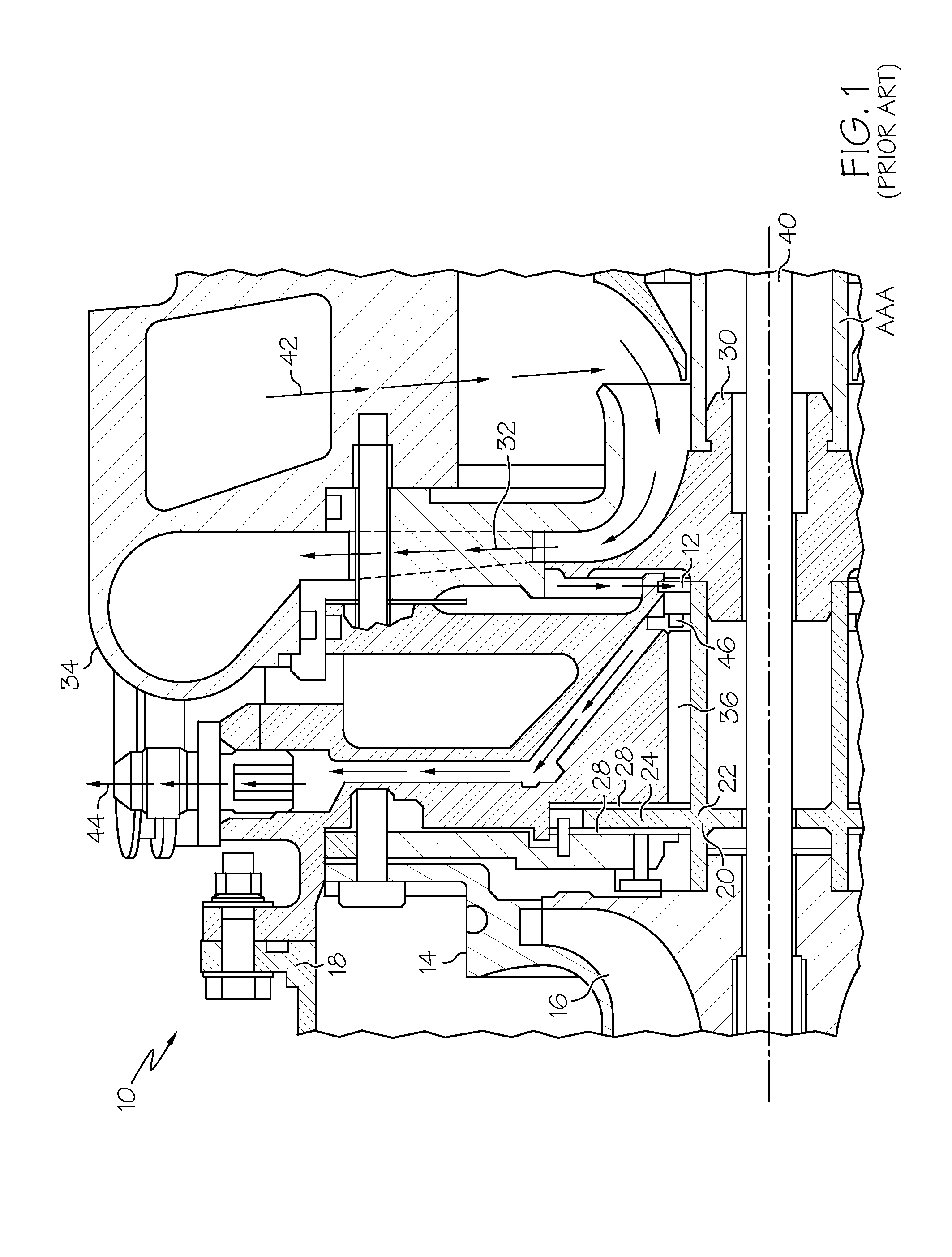

A labyrinth seal is a type of mechanical seal that provides a tortuous path to help prevent leakage. An example of such a seal is sometimes found within an axle's bearing to help prevent the leakage of the oil lubricating the bearing.

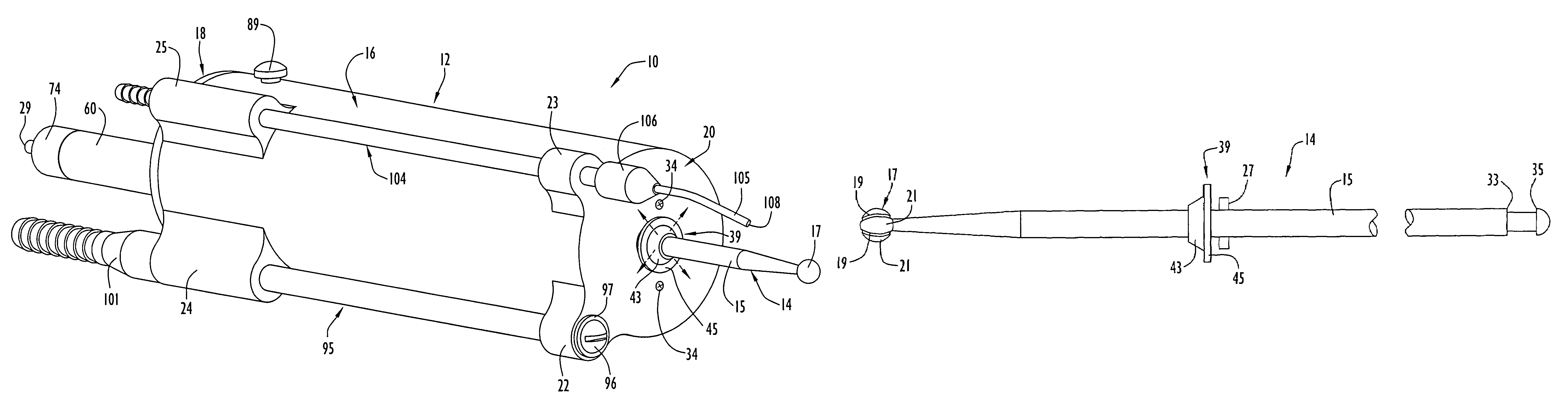

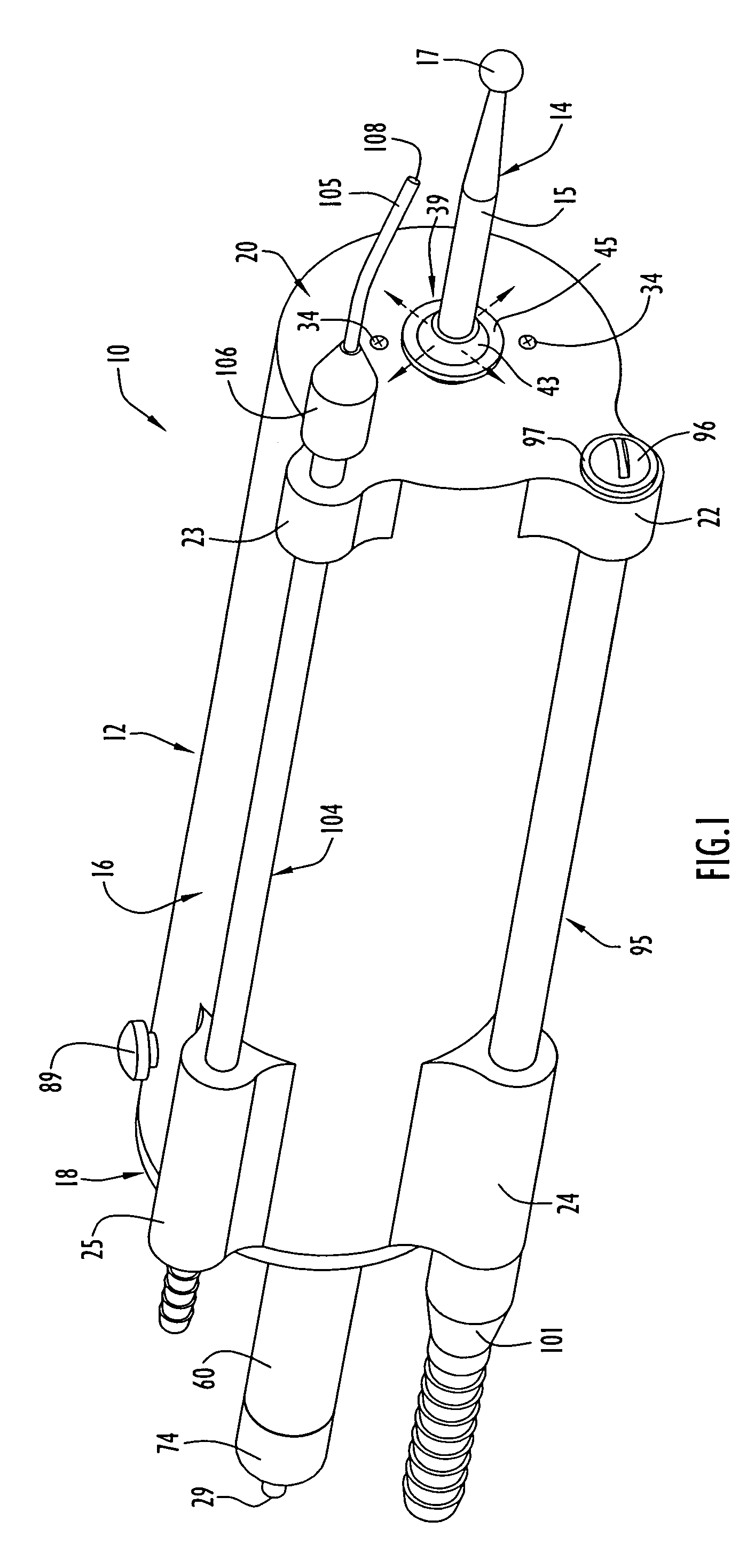

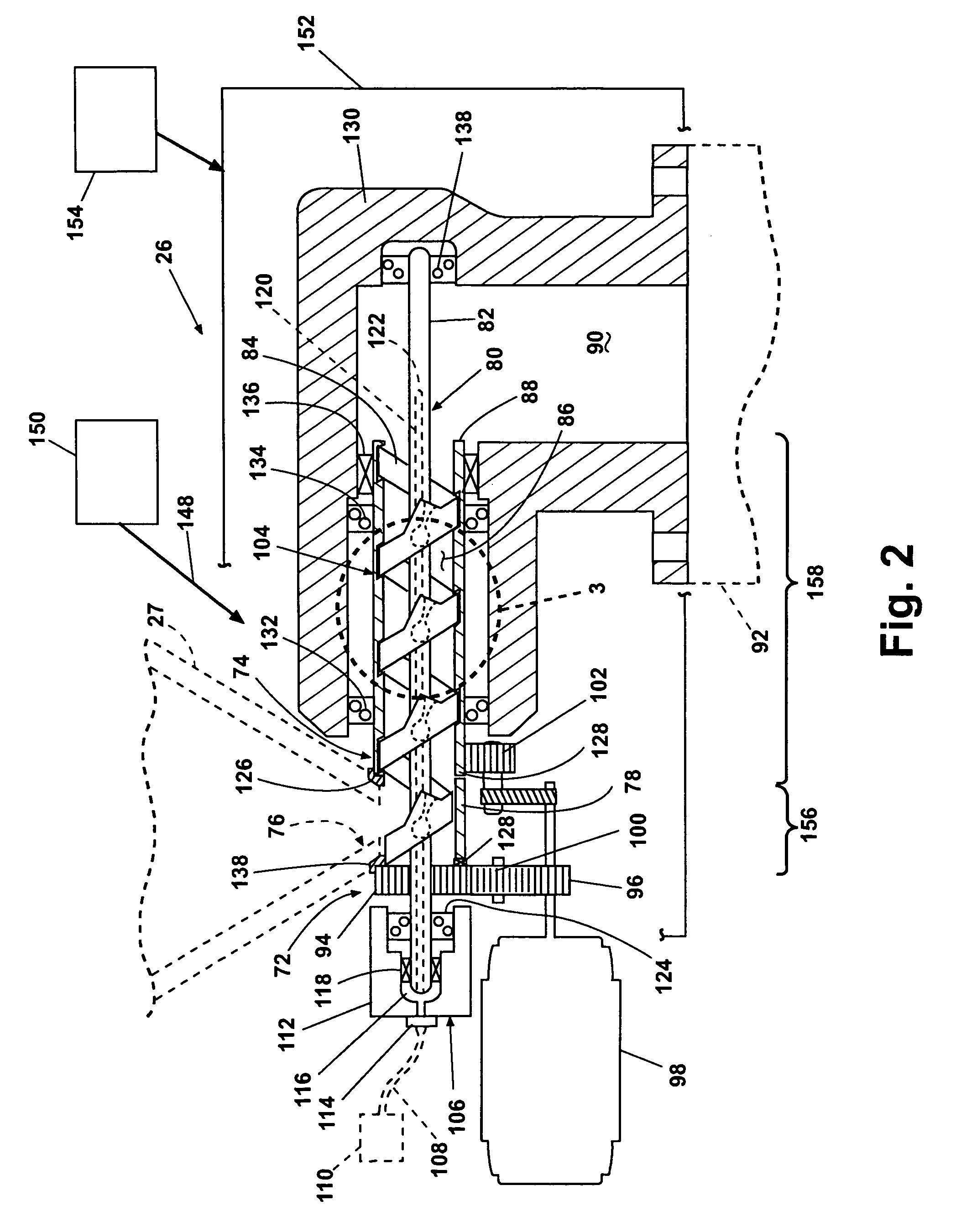

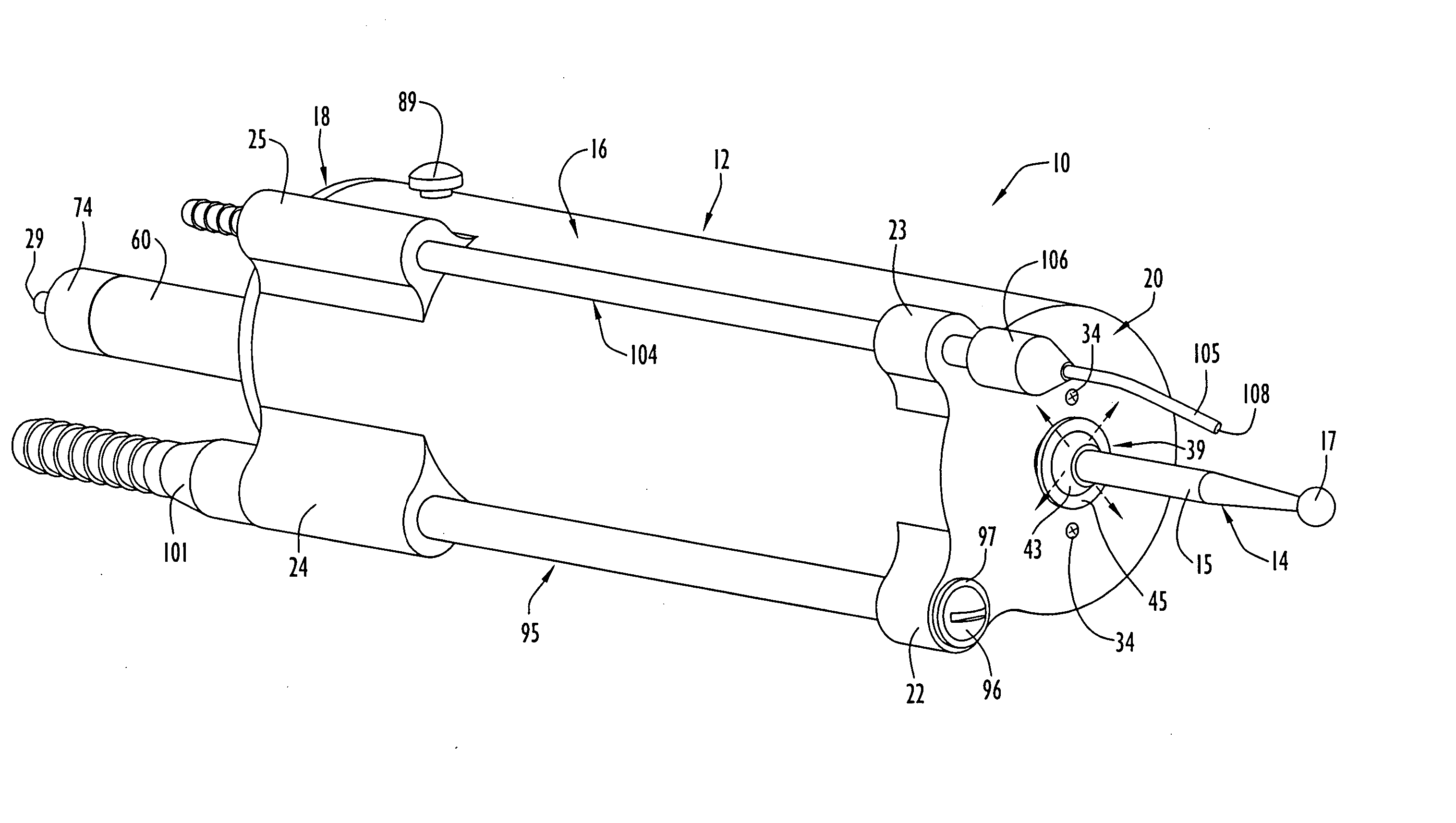

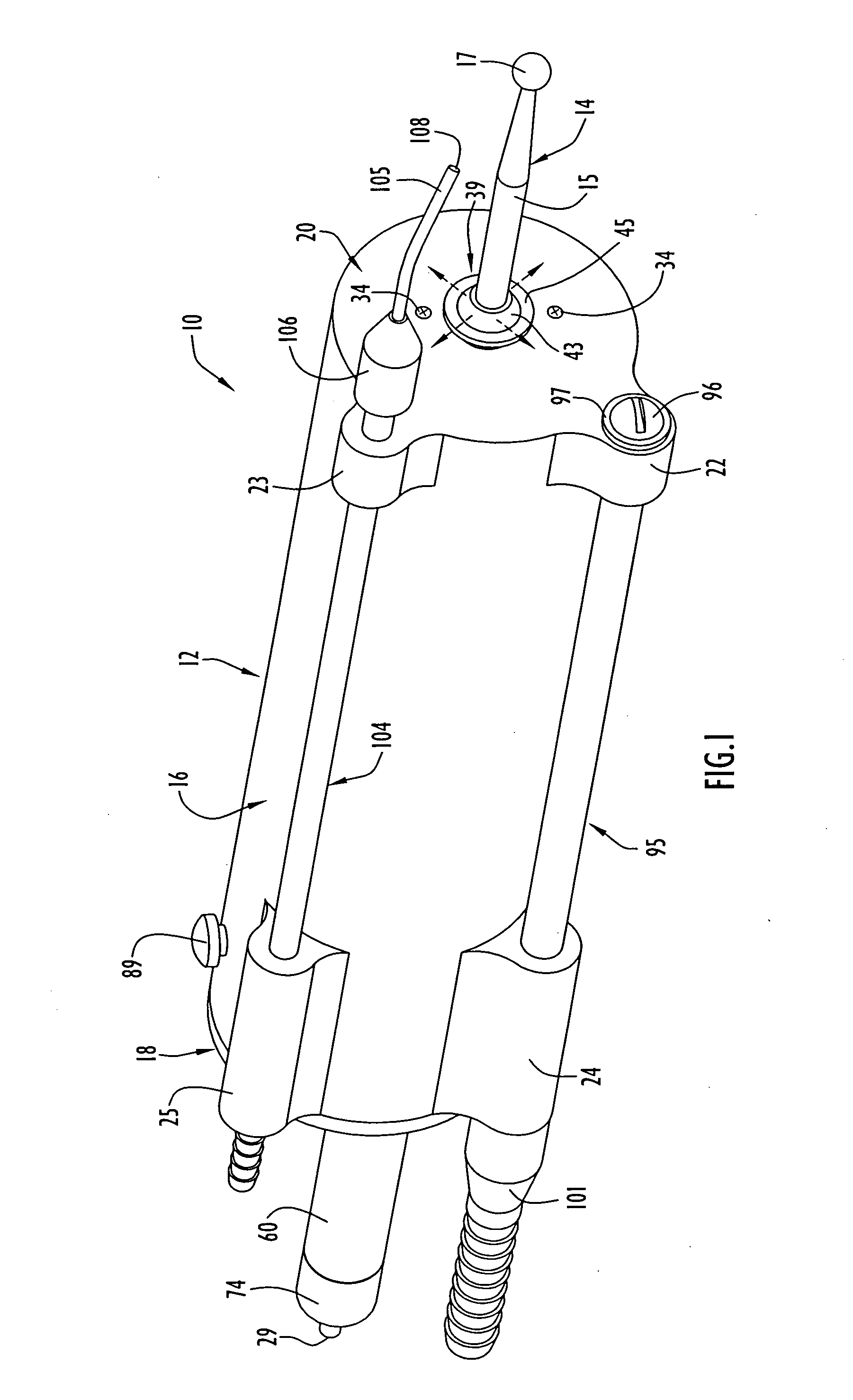

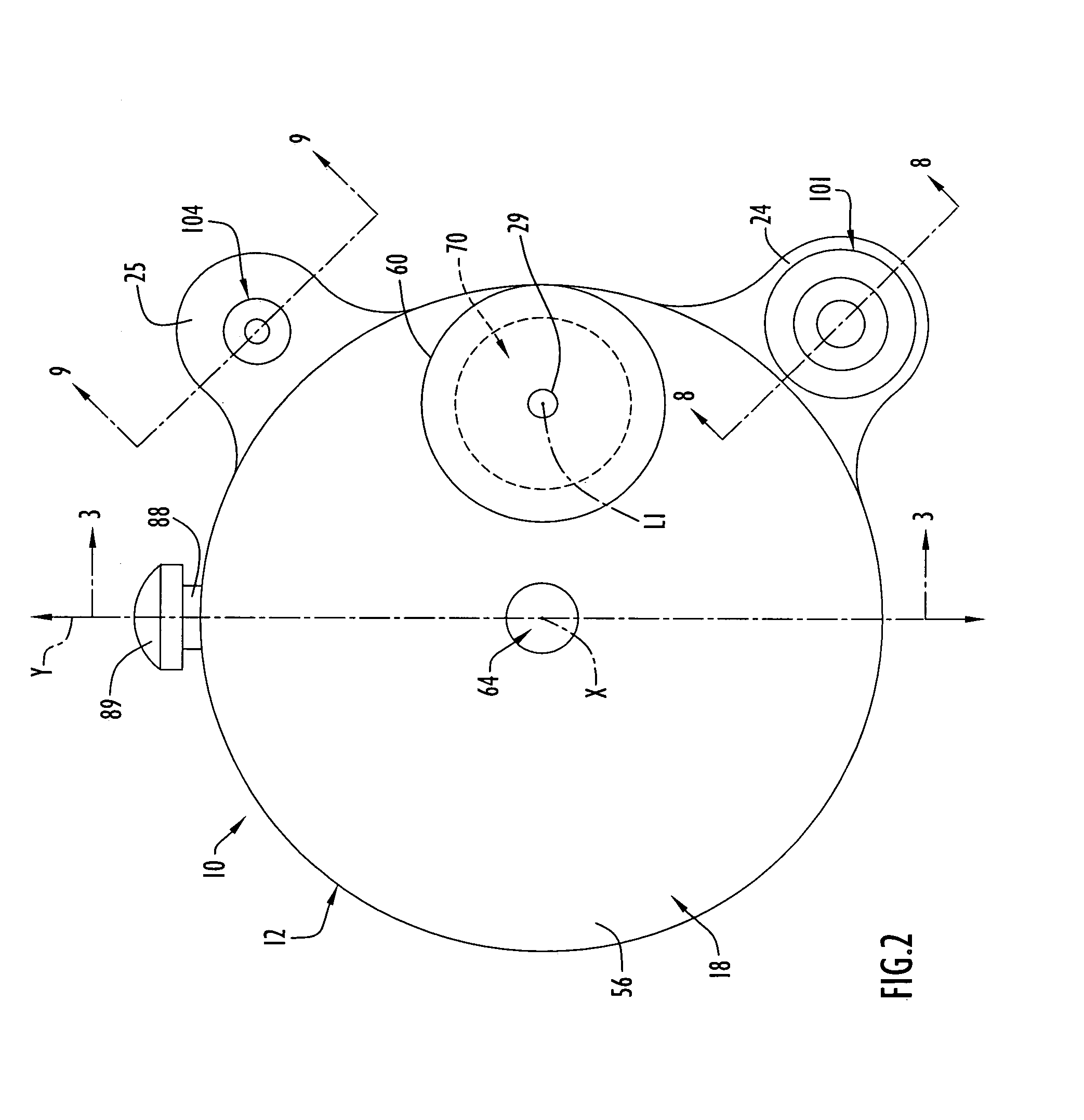

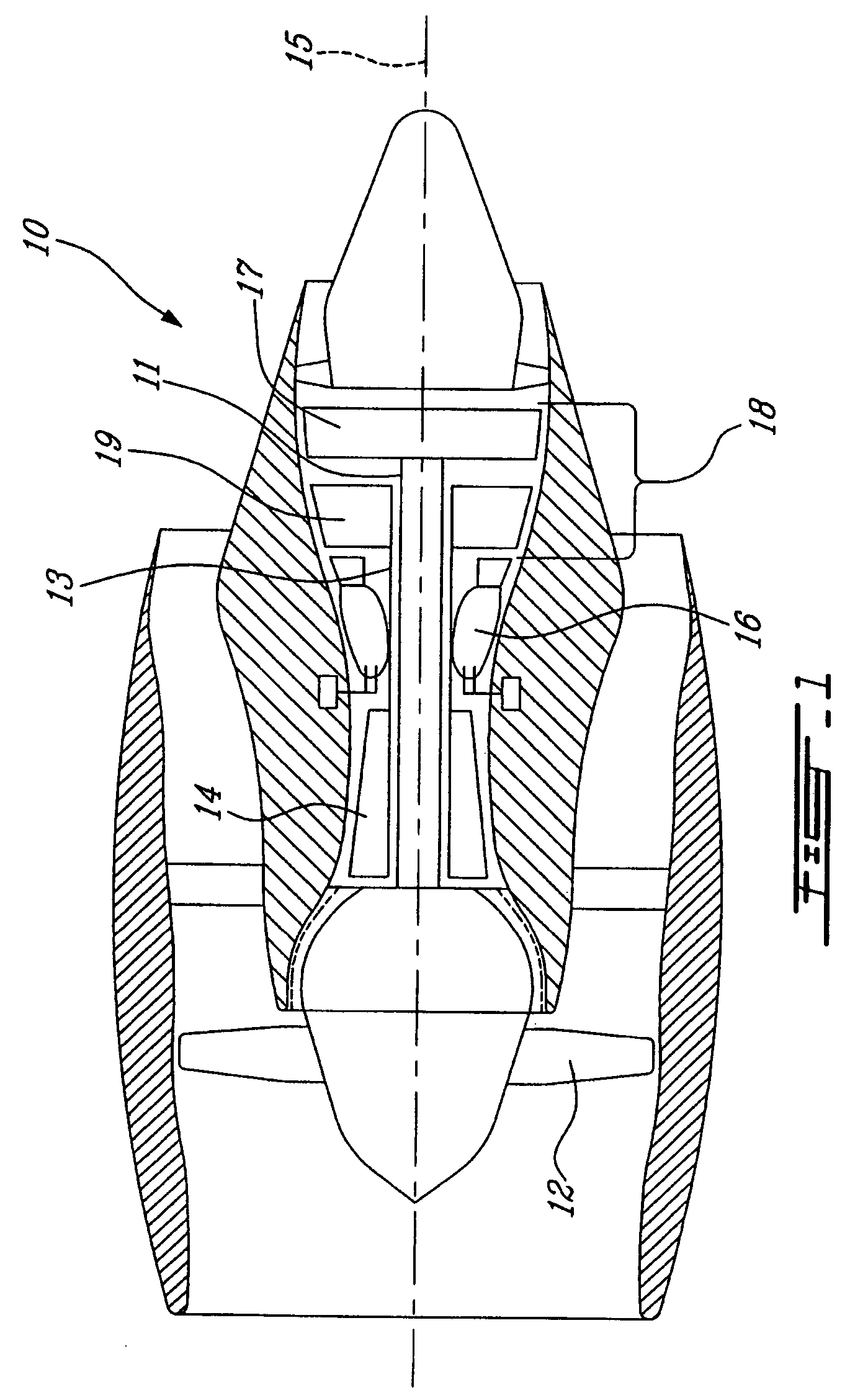

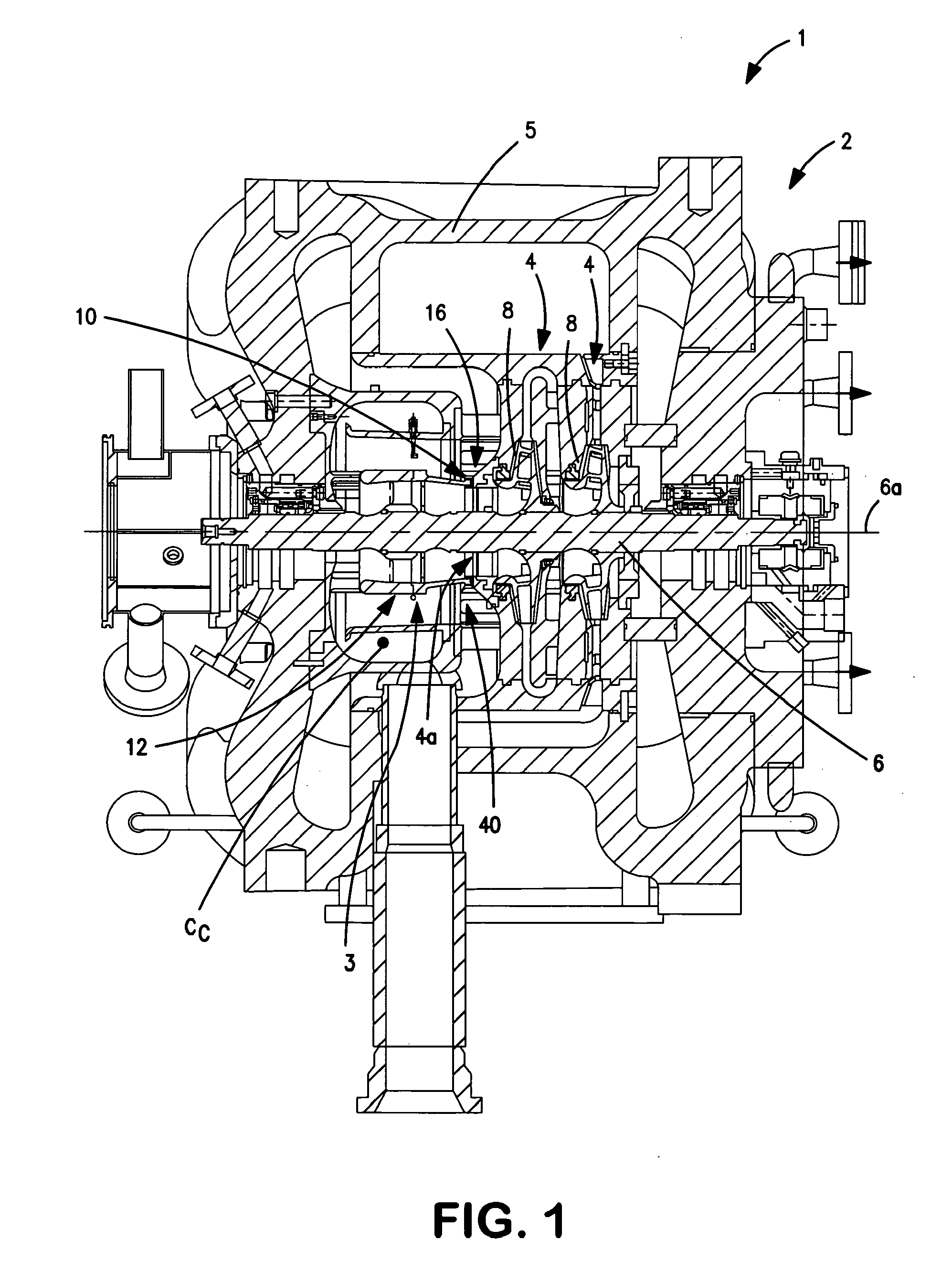

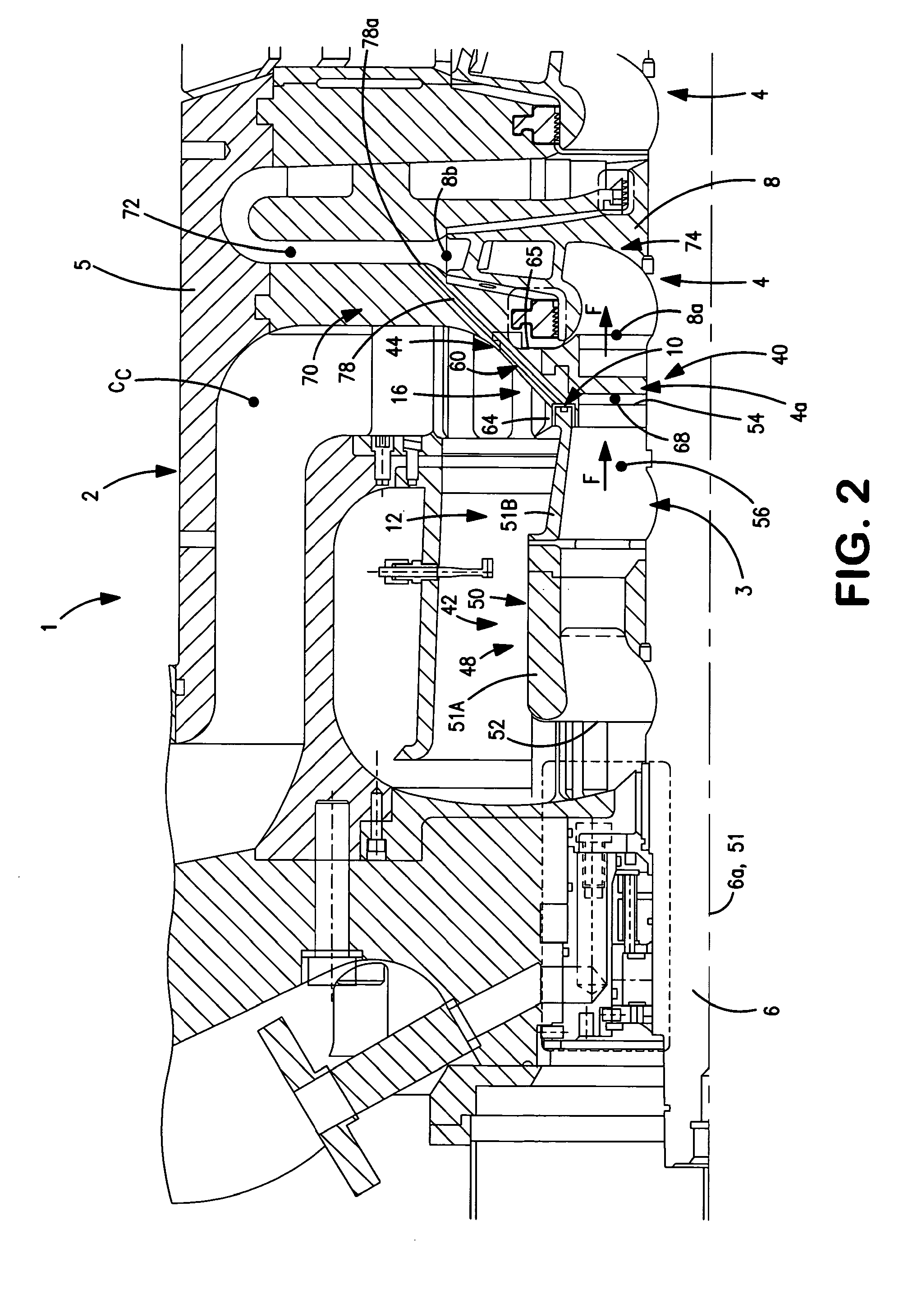

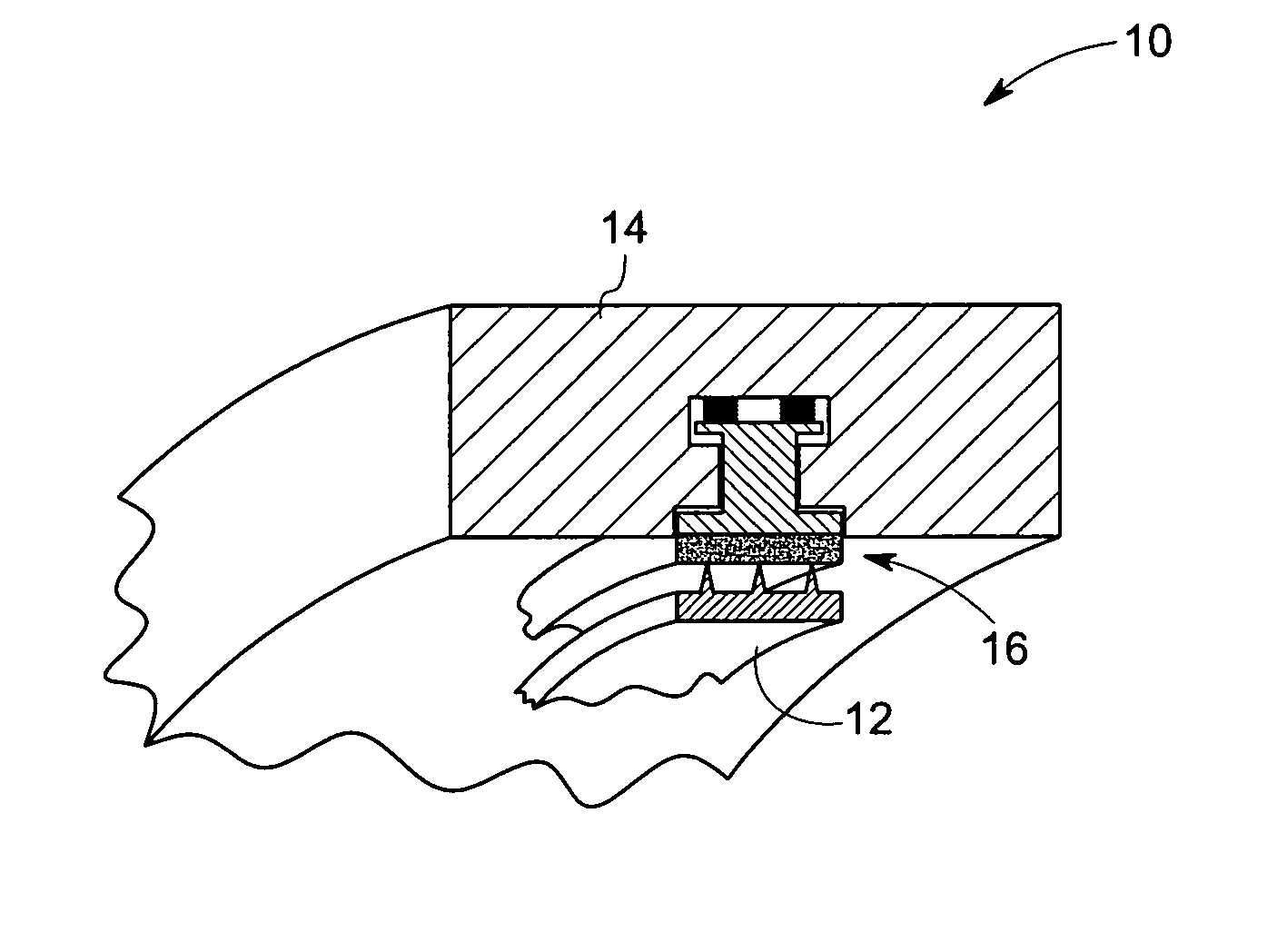

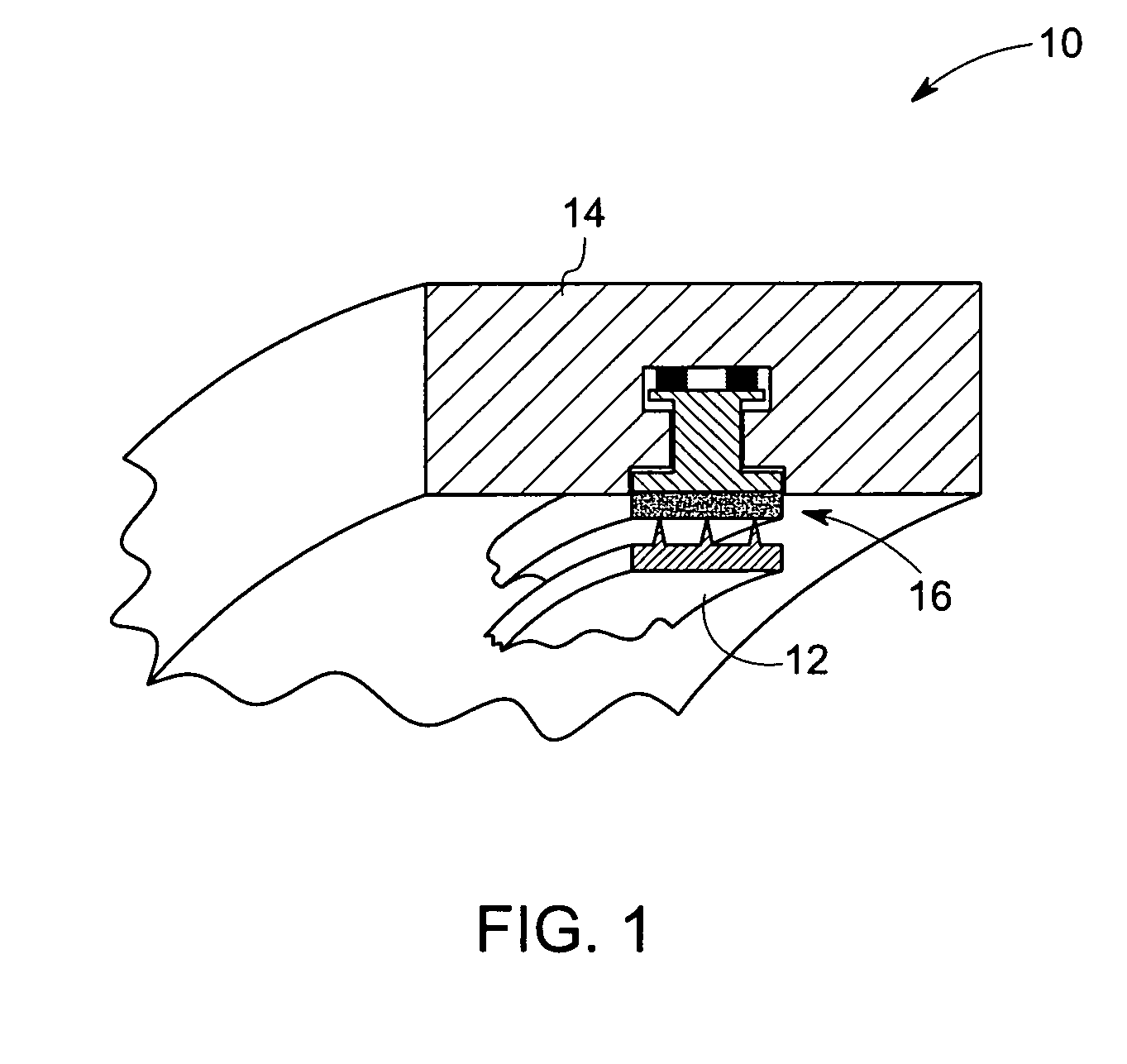

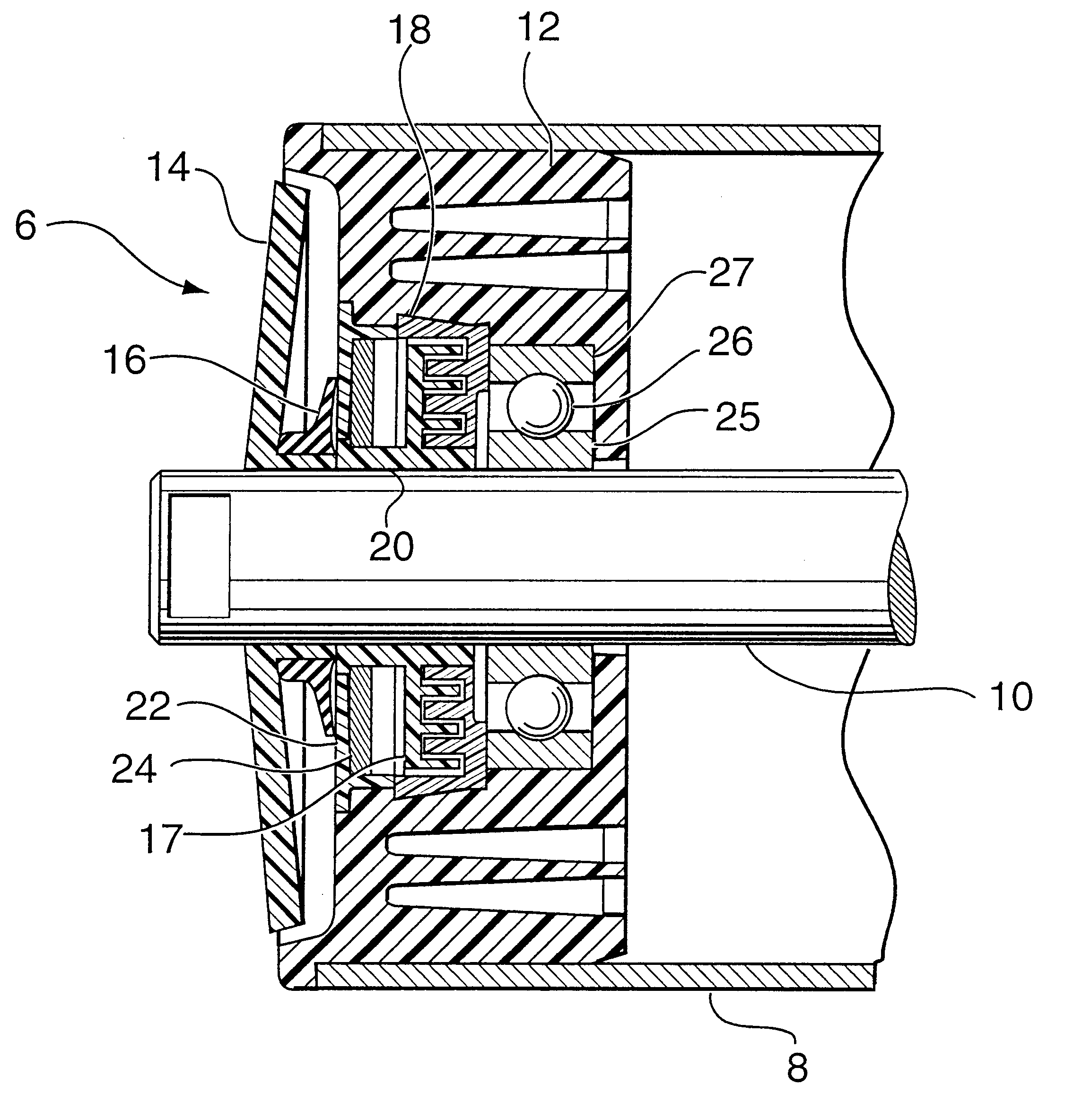

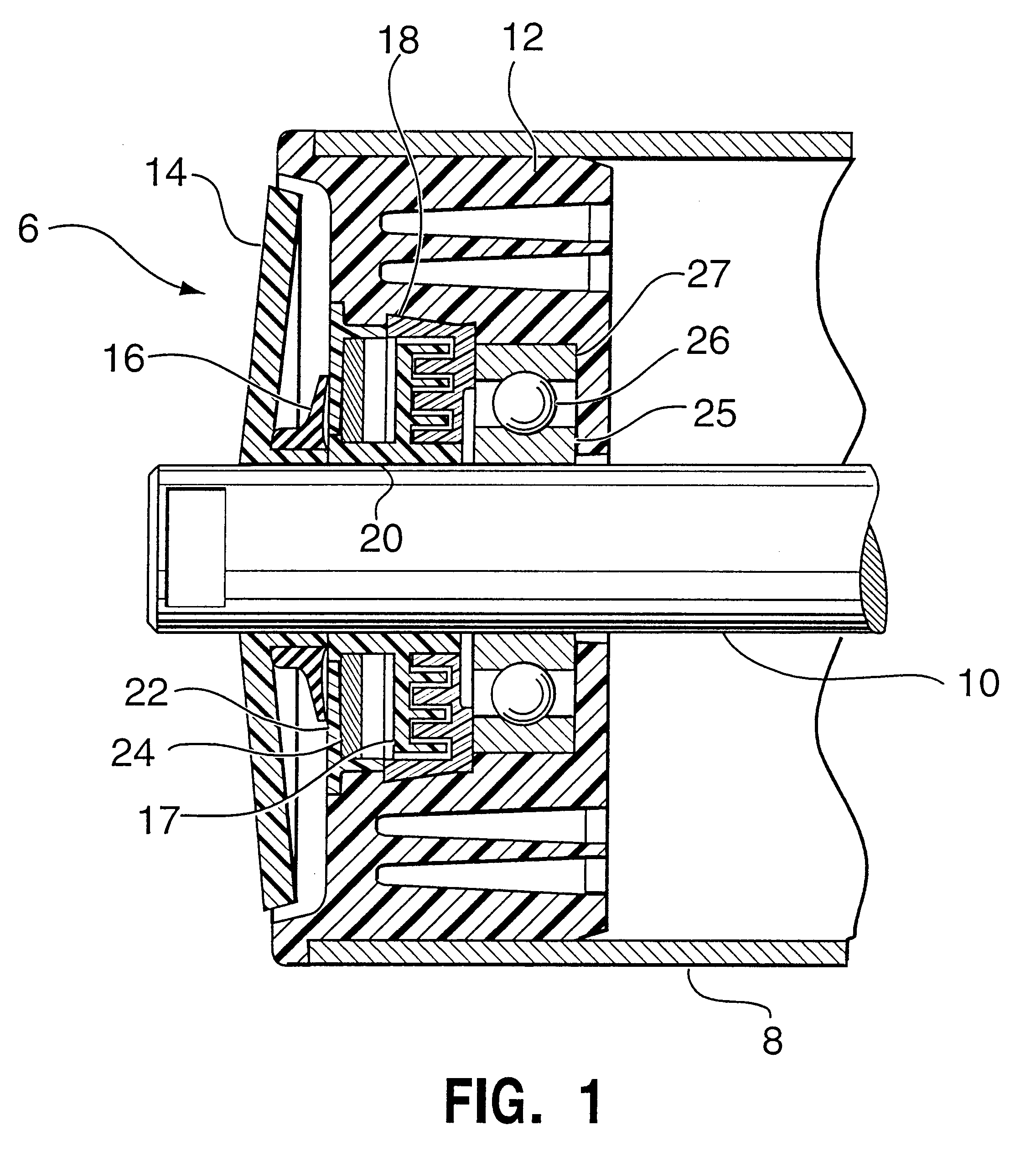

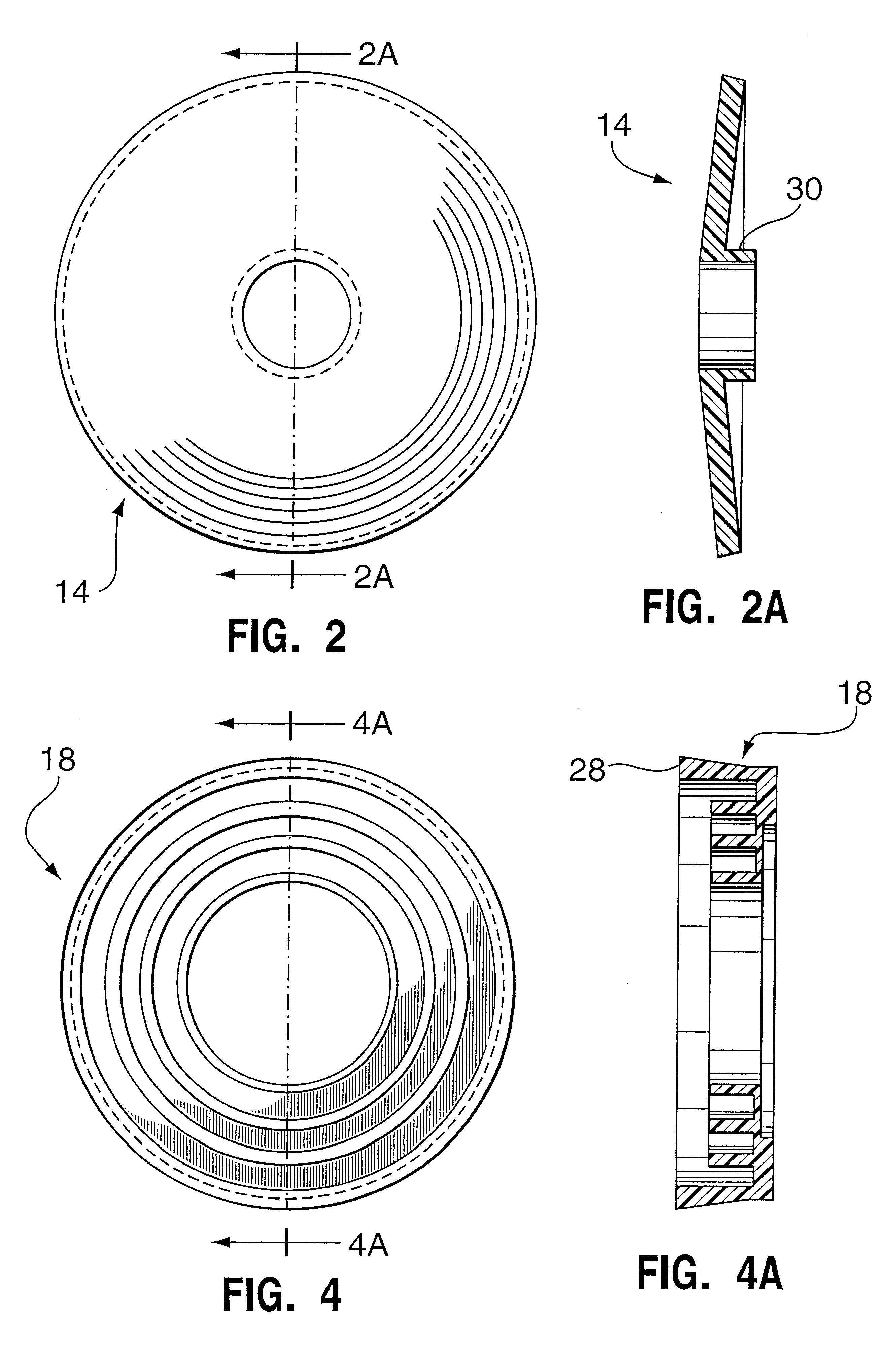

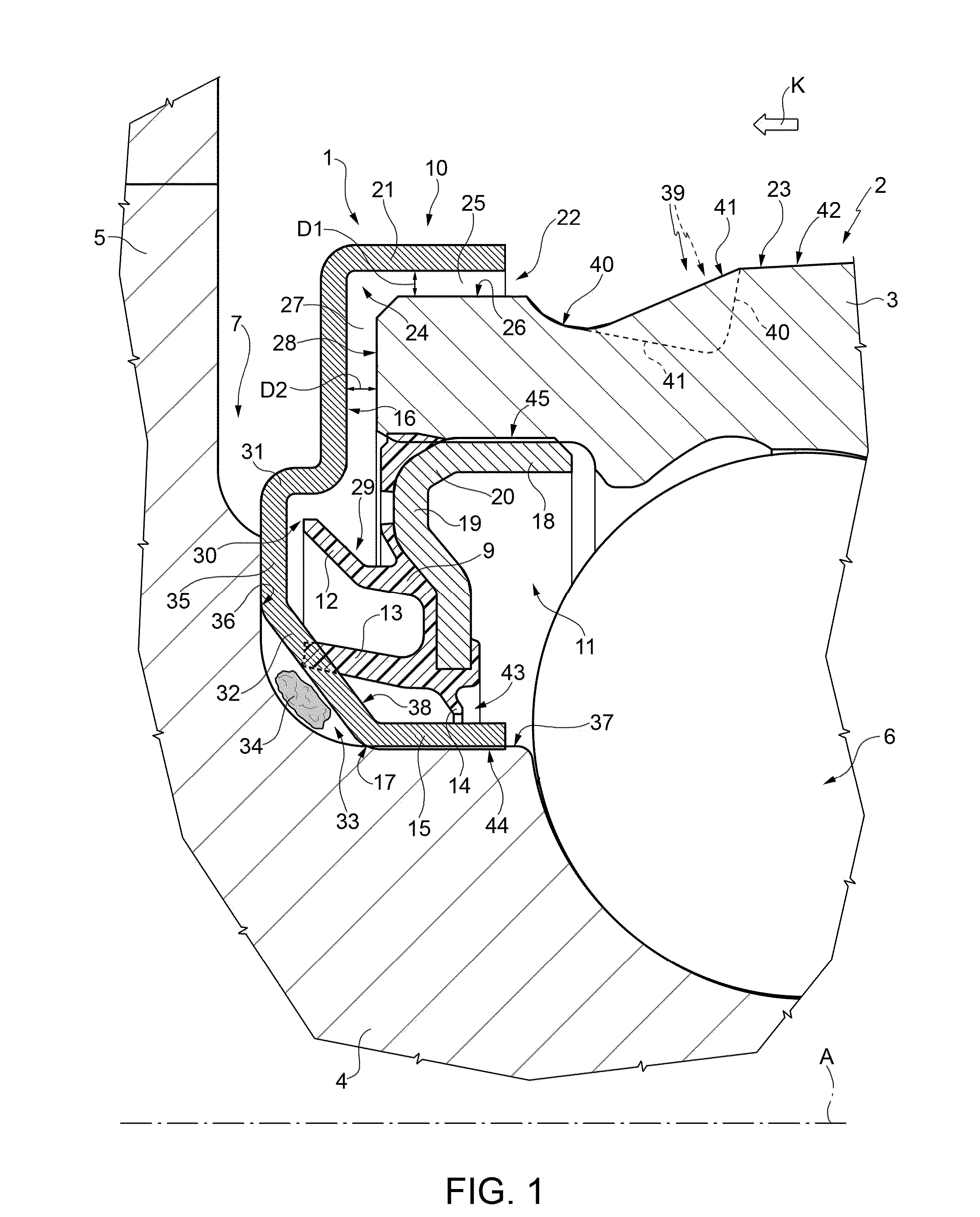

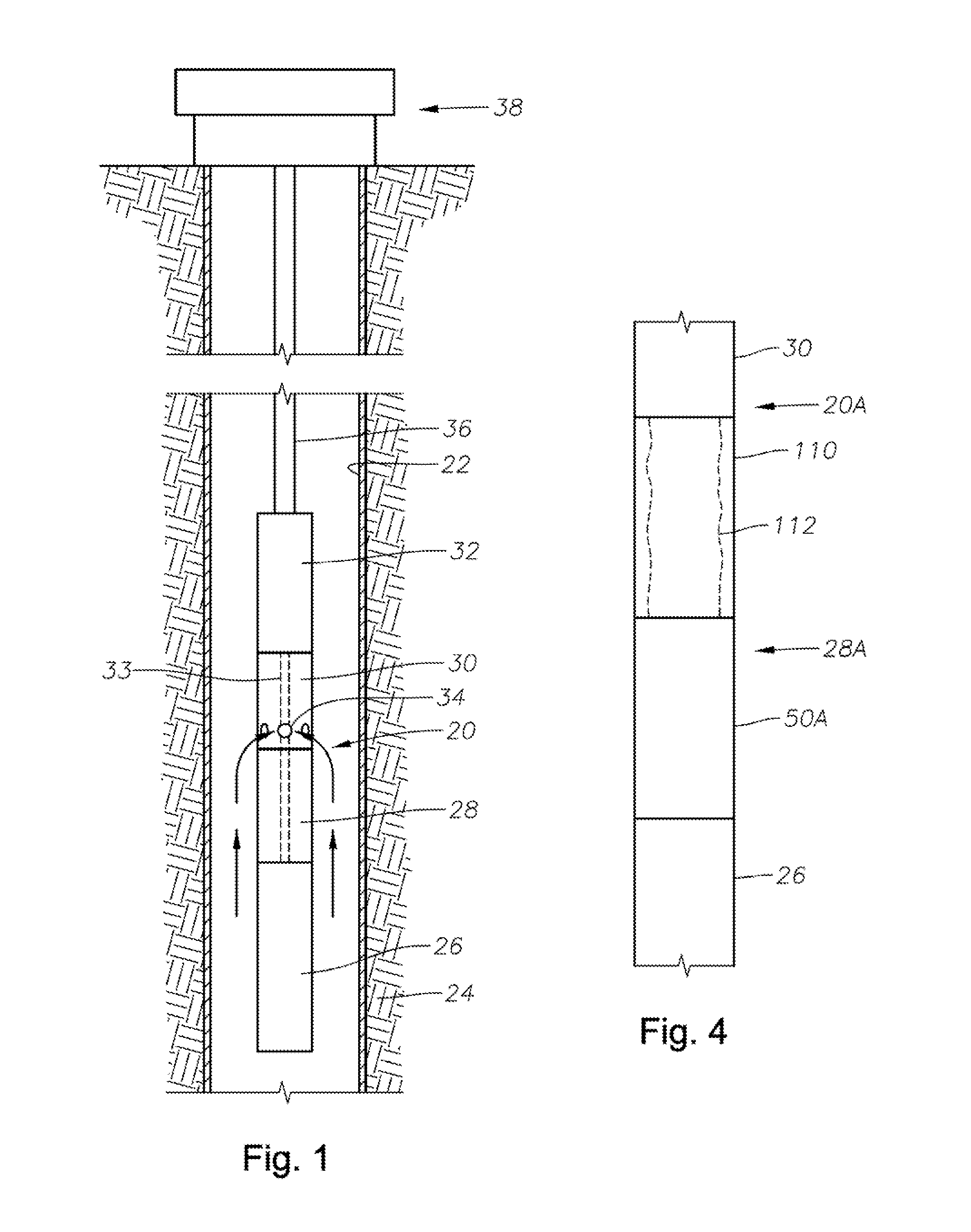

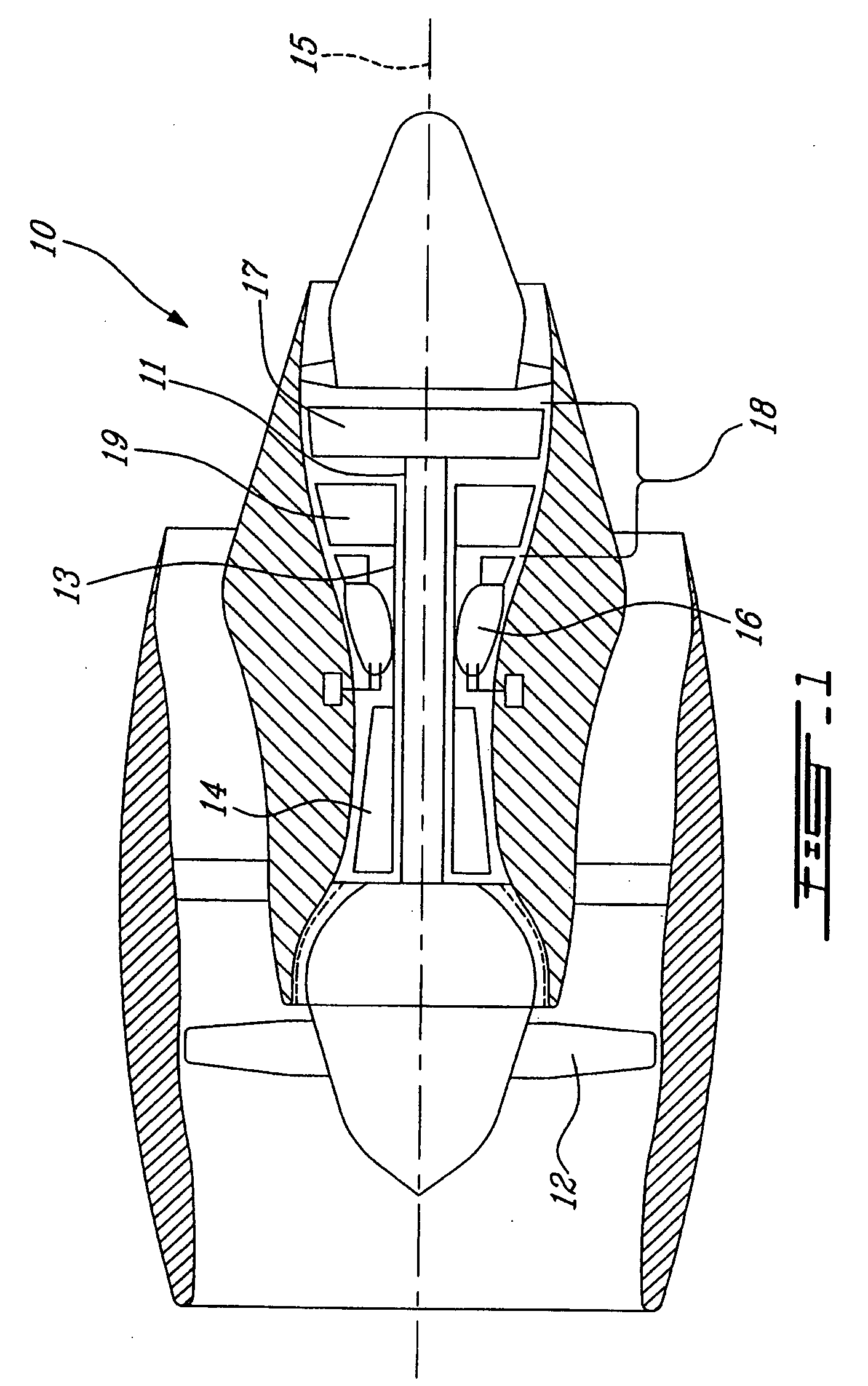

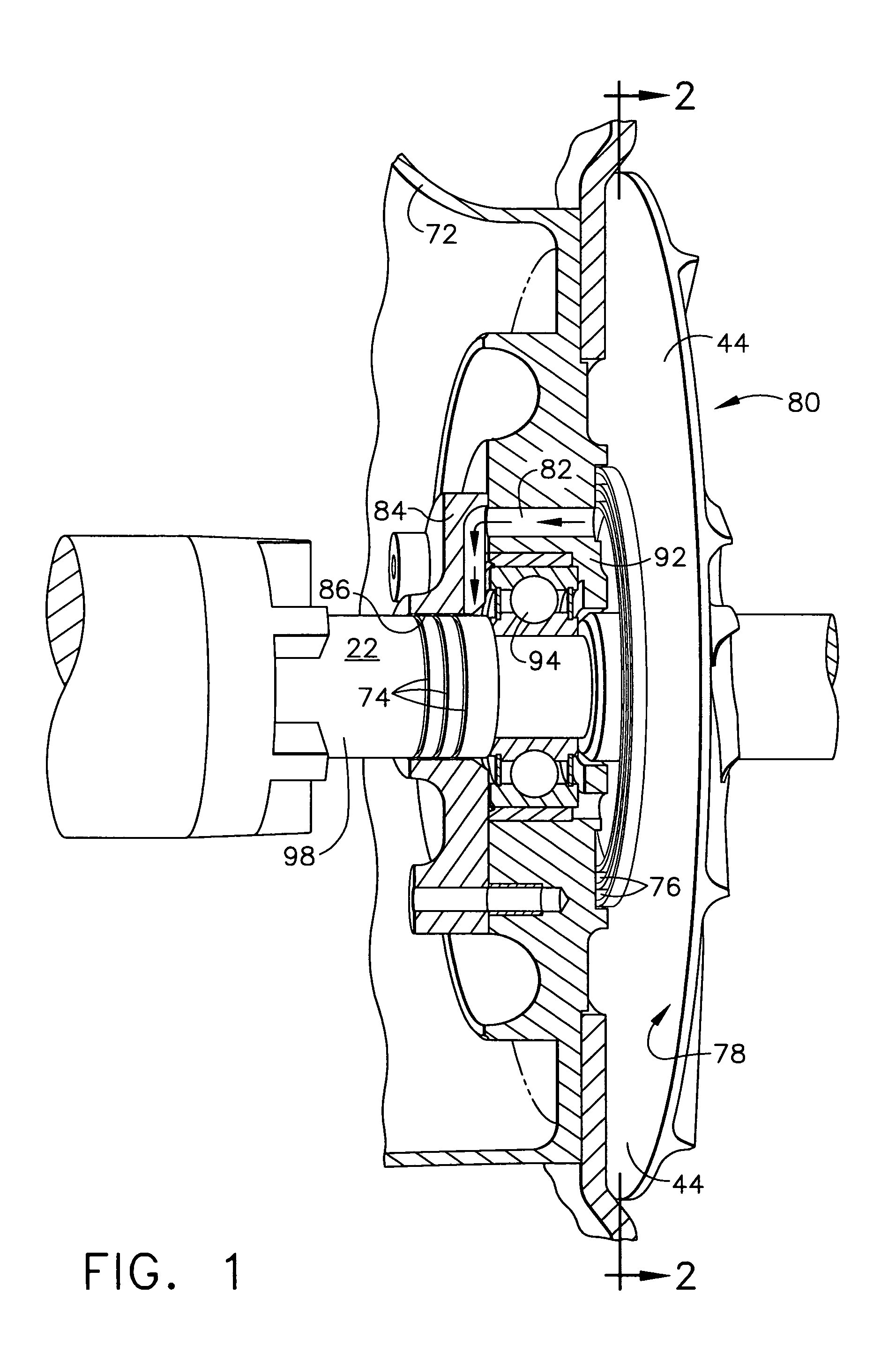

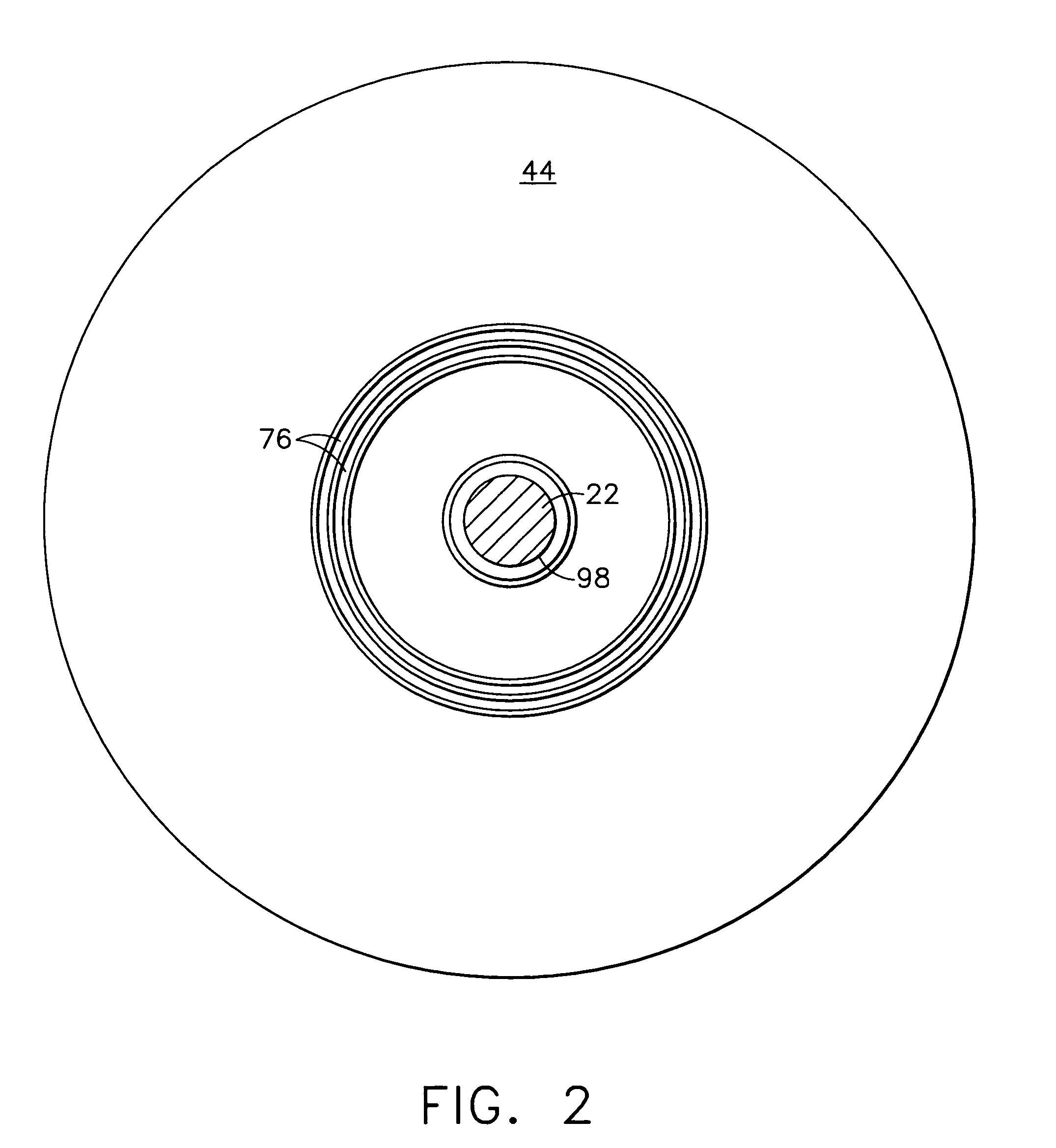

Motorized surgical handpiece

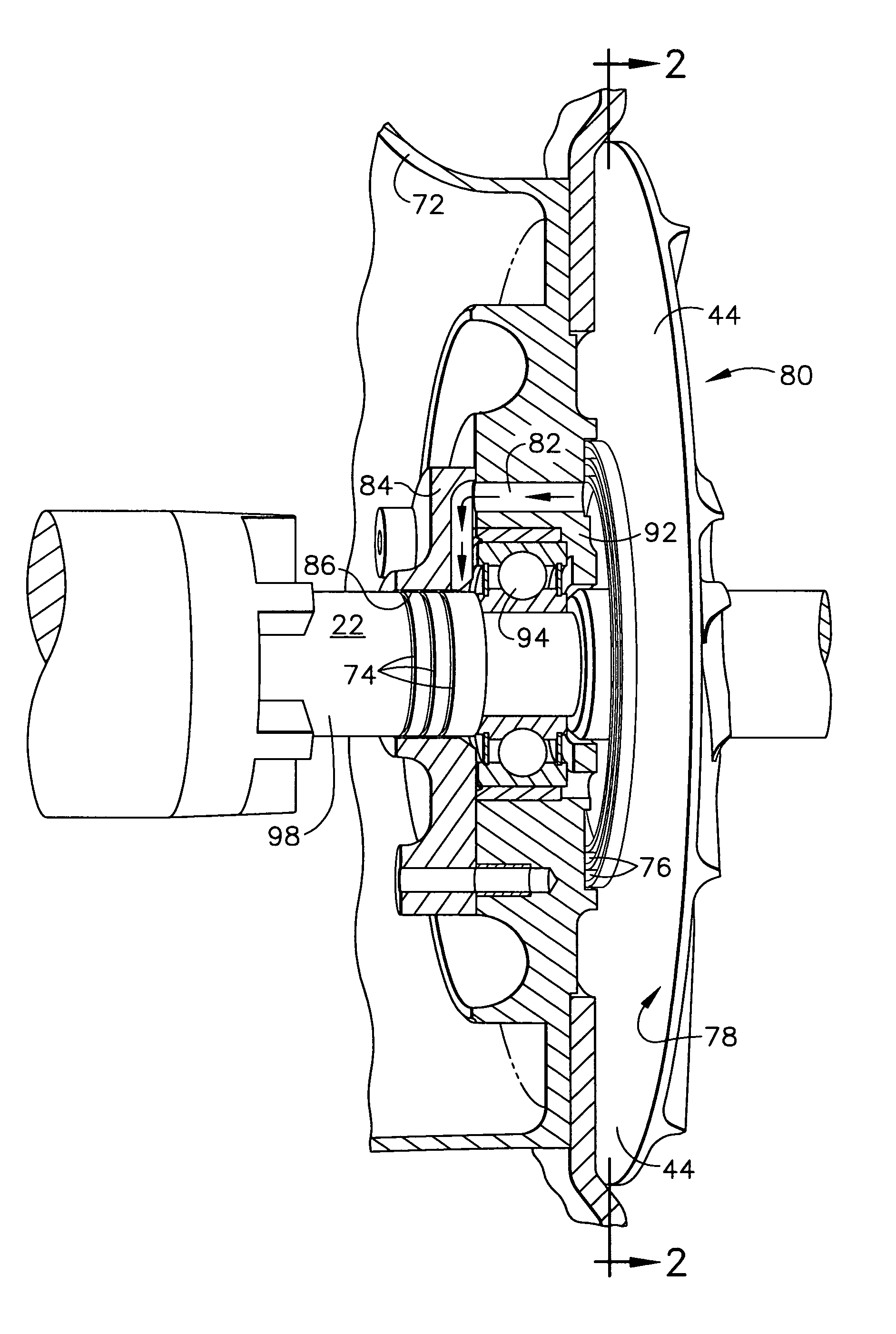

A motorized surgical handpiece comprises a housing enclosing an interior containing a motor and an output shaft for being driven in rotation by the motor. The output shaft has a central longitudinal axis, a bore extending therethrough for receiving a shank of a surgical tool to be rotatably driven by the output shaft, a forward end portion extending forwardly beyond the motor and a rearward end portion extending rearwardly beyond the motor. The housing has a continuous lumen extending entirely therethrough formed in part by the output shaft bore for insertion of a bore brush through the lumen for cleaning when the surgical tool is removed from the handpiece. The handpiece has forward and rearward labyrinth seals comprising rotor components respectively attached to the forward and rearward end portions of the output shaft for rotation in corresponding stator components with there being a labyrinthine clearance between each rotor component and its stator component to receive pressurized air during use and during cleaning of the handpiece to avoid the entry of contaminants.

Owner:ROGERS WILLIAM G

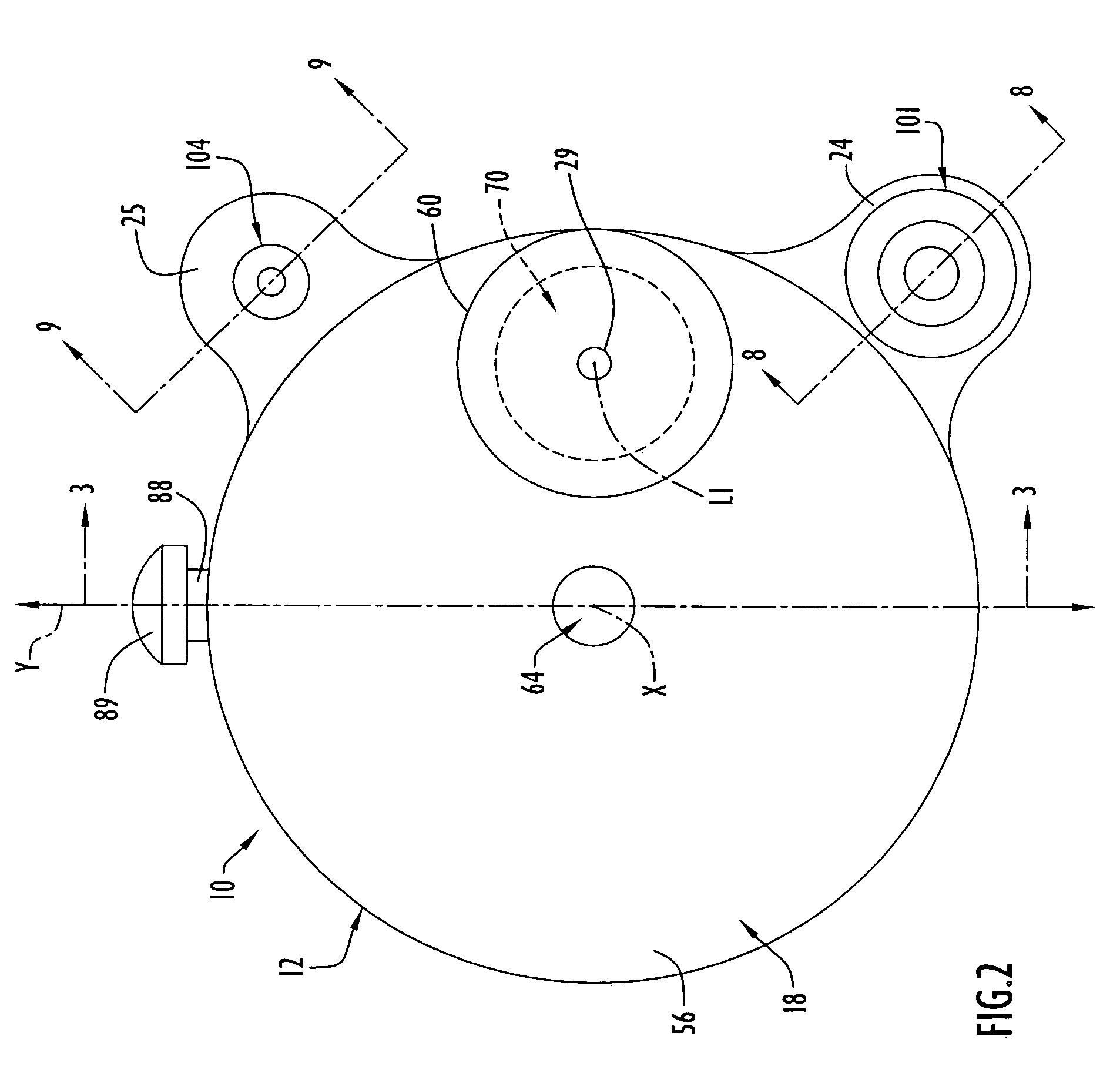

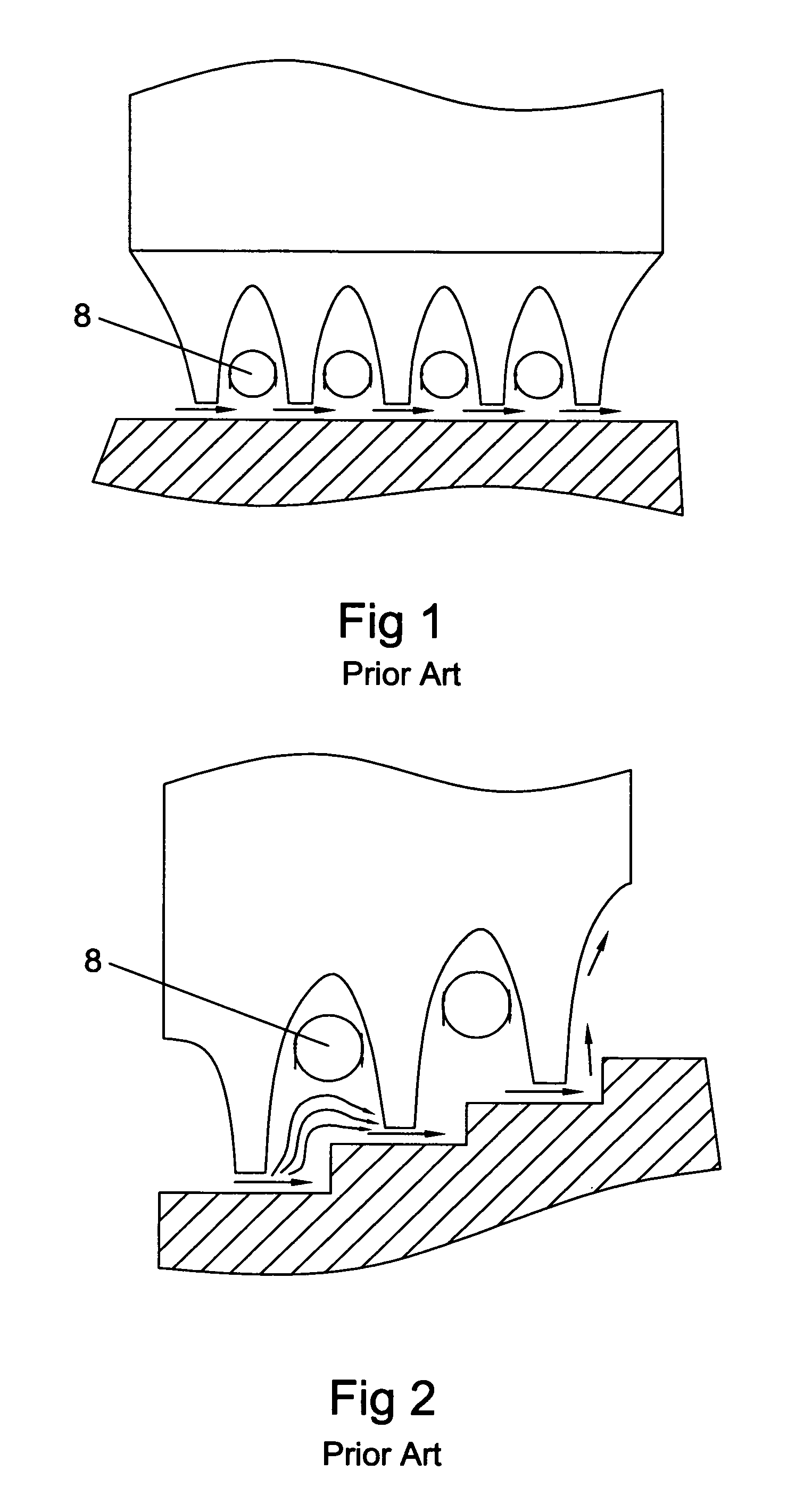

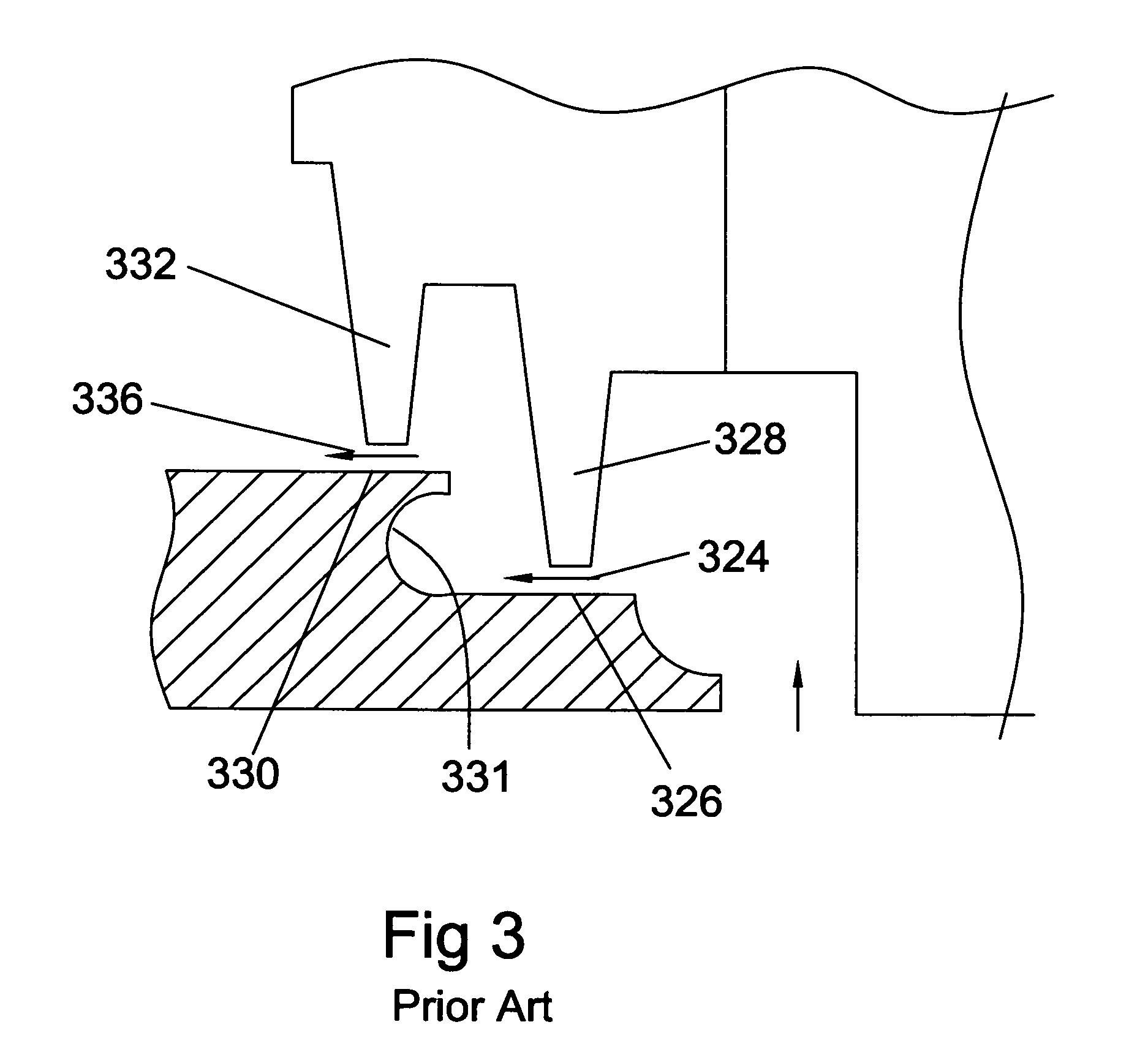

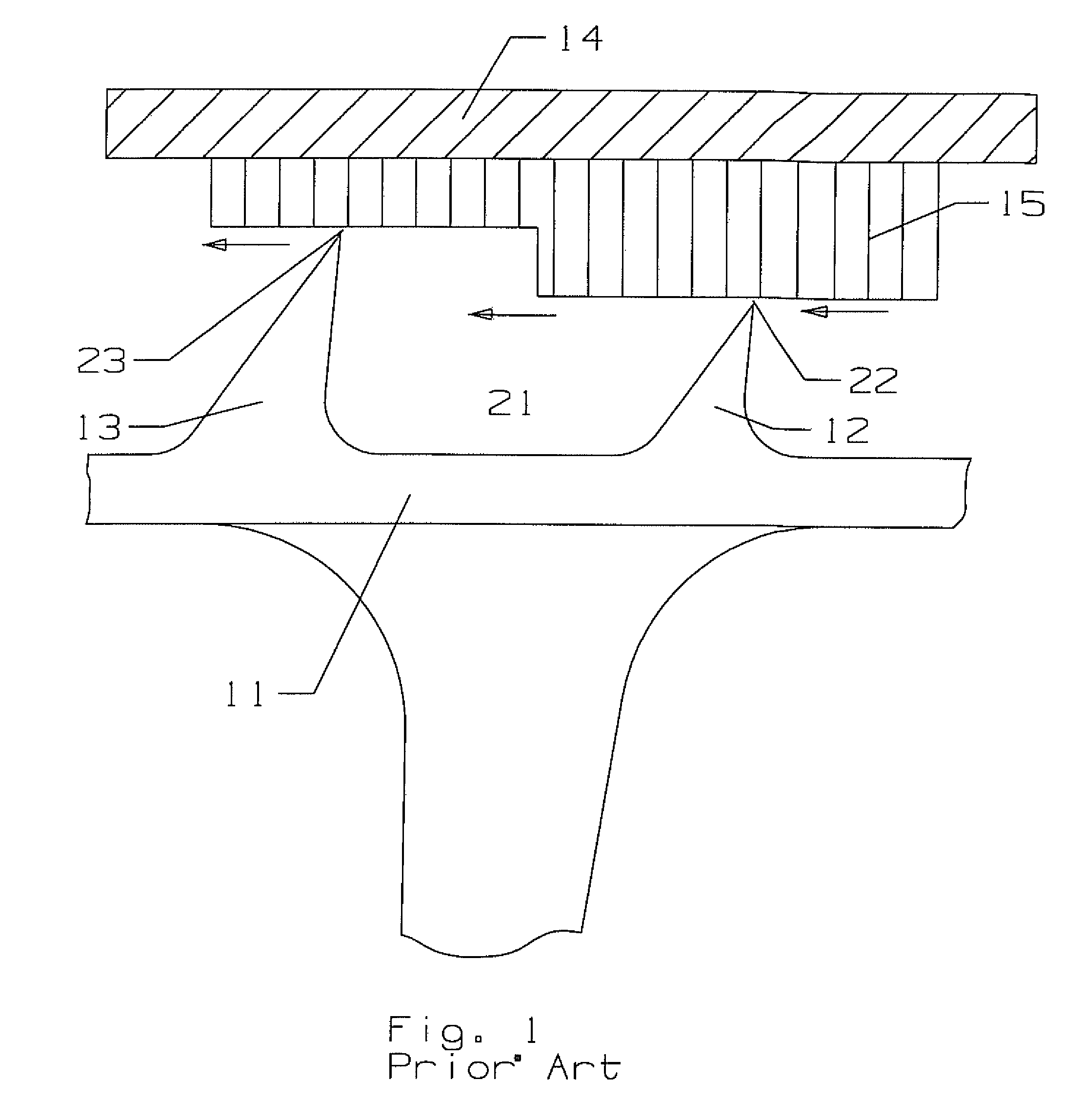

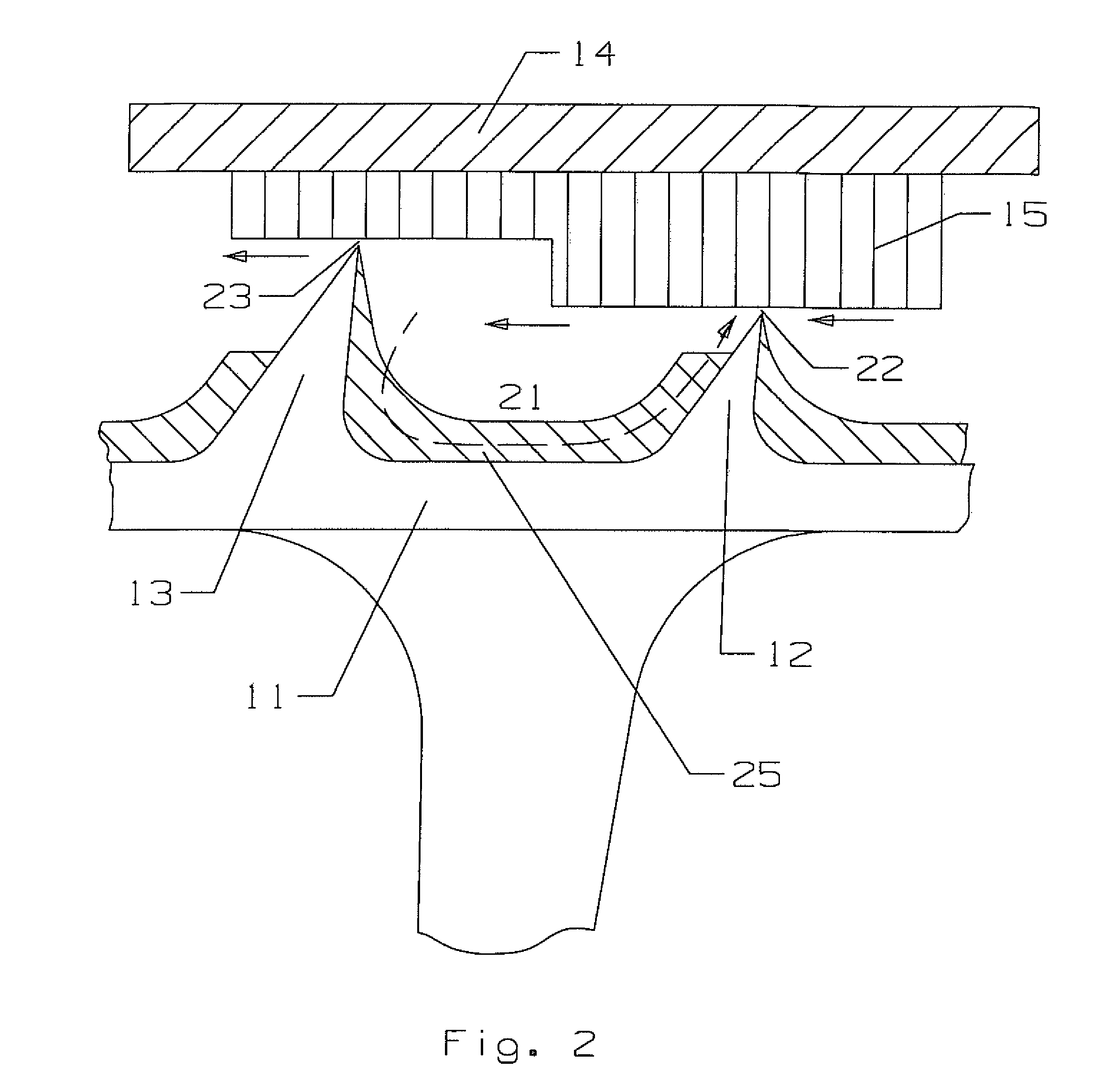

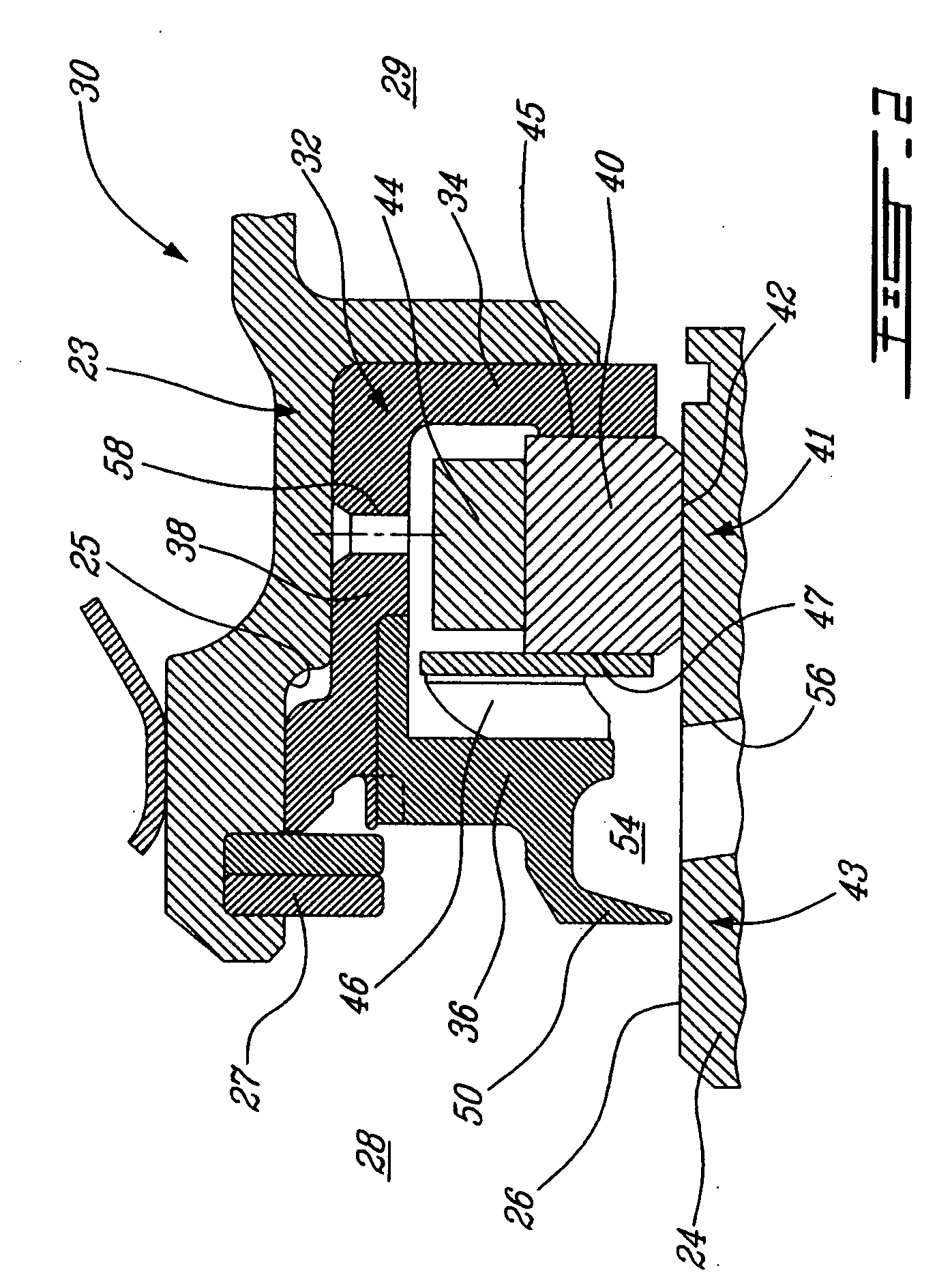

Stepped labyrinth seal

InactiveUS7445213B1Without slowing leakage flowReduce the impactEngine sealsEngine manufactureEngineeringLeakage flow

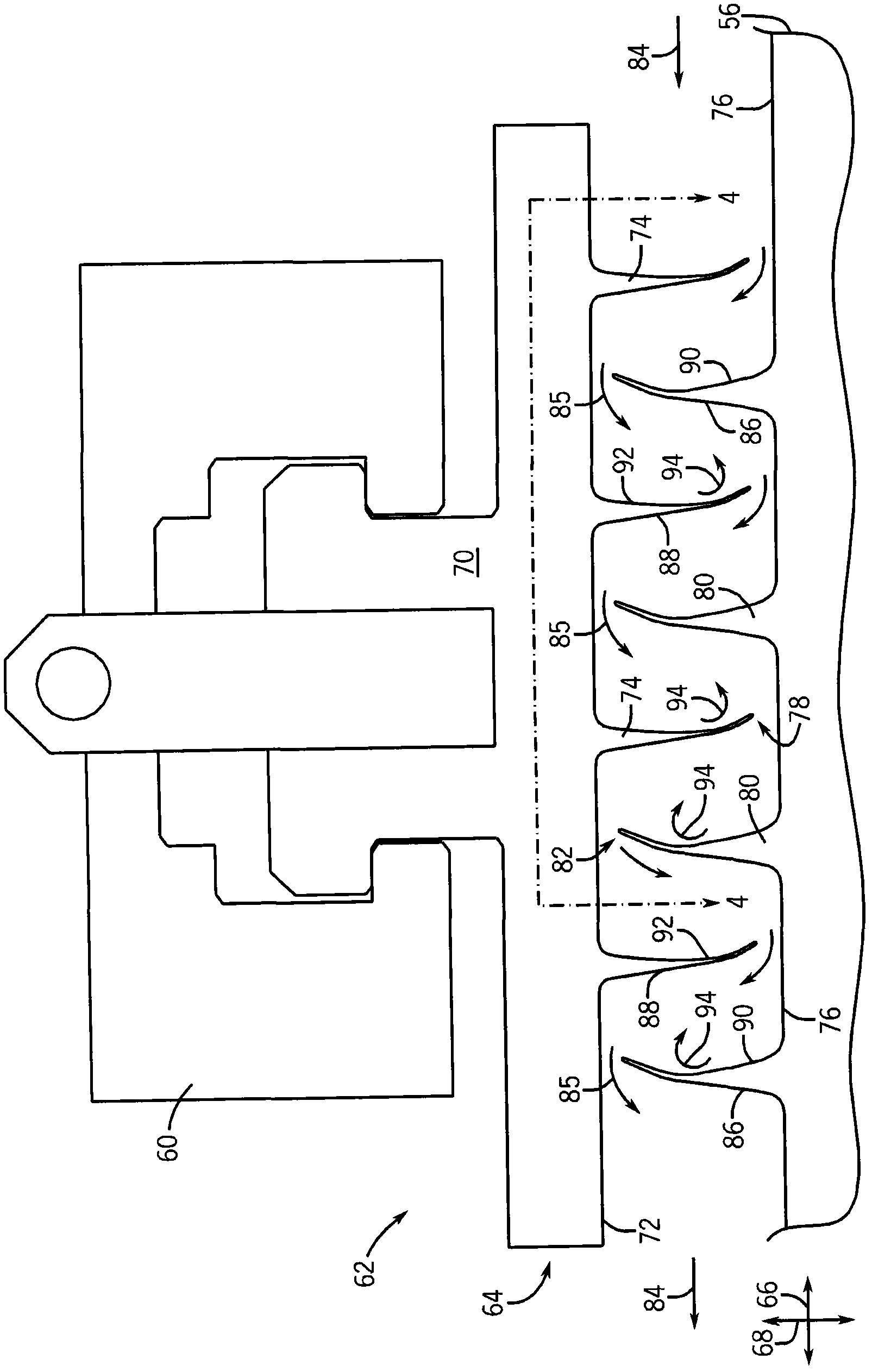

A stepped labyrinth seal for a turbomachine, the seal having a stepped portion with a redirecting groove formed thereon to redirect a leakage flow through the gap in substantially a reverse direction and onto a surface of the finger such that the dynamic pressure of the leakage flow is not substantially reduced and the static pressure increased. The cavity formed between adjacent fingers has a flow guiding surface that maintains the dynamic pressure of the flow, thereby keeping the flow at high velocity and low static pressure.

Owner:FLORIDA TURBINE TECH

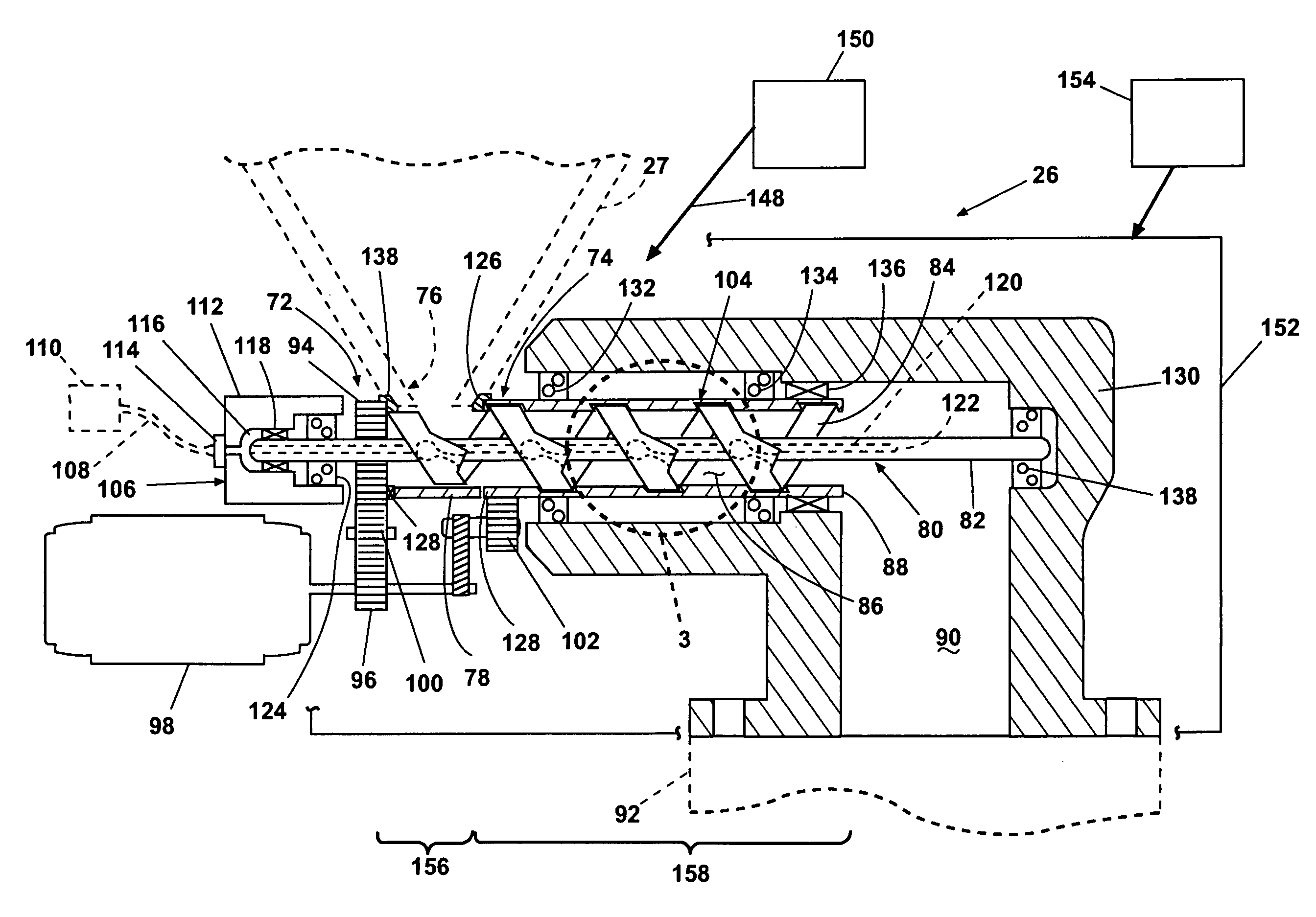

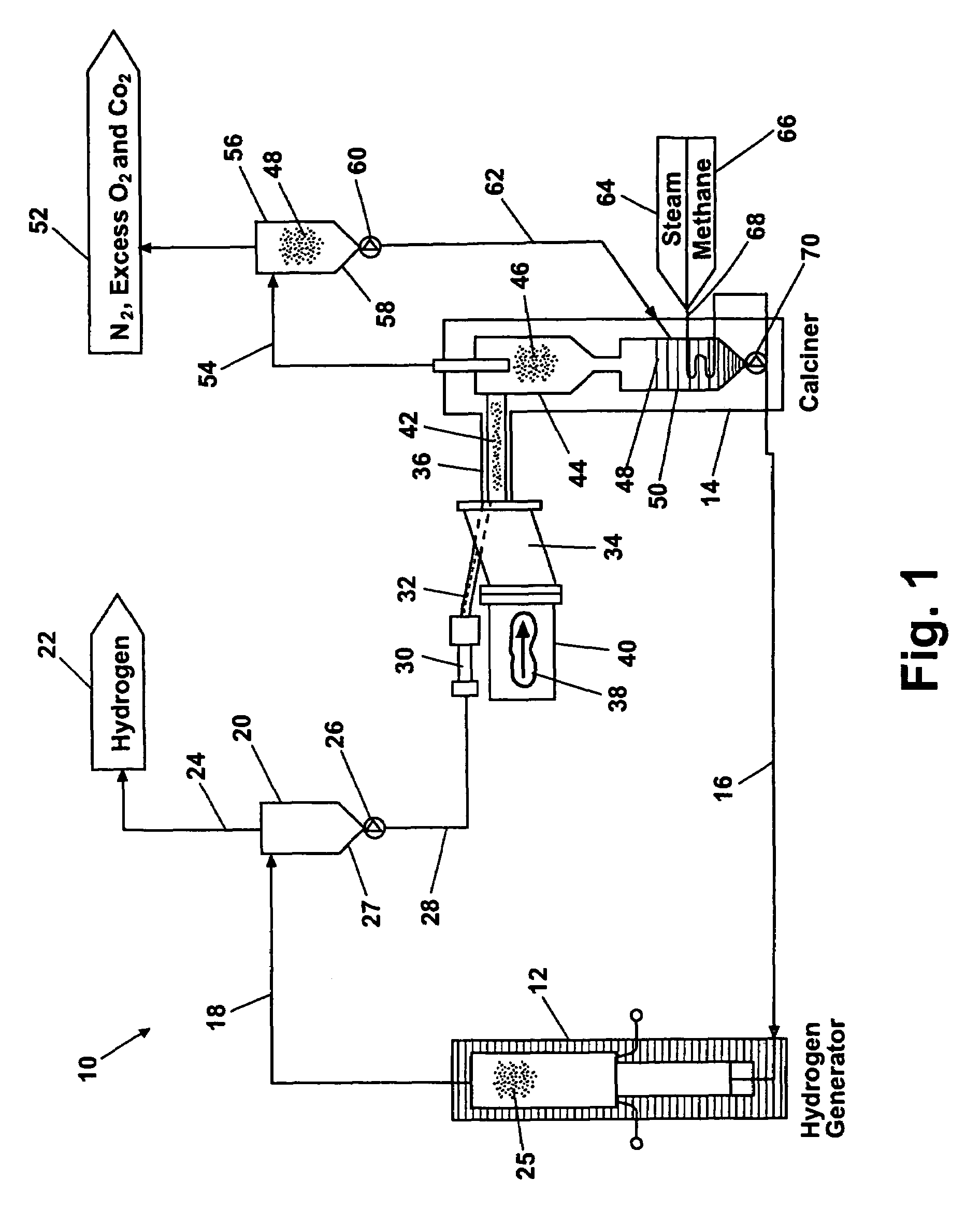

Hot rotary screw pump

ActiveUS7360639B2Eliminate movementReduce cloggingHydrogen separation using solid contactBulk conveyorsEngineeringPressure difference

A screw feeder can be used to transport a high temperature particulate material. A housing contains the material within the screw feeder which includes an inlet and an outlet port. A screw is rotatably positioned within the housing to advance the material from the inlet port to the outlet port, which rotates axially. A labyrinth seal can be formed around and in communication with the screw to eliminate reverse movement of the material. A cooling medium can be directed into contact with at least the housing. A fluid can be injected through the screw to prevent blockage of the particulate material. A pressure differential is created from the inlet to the outlet port of at least 0.069 MPad.

Owner:GAS TECH INST +1

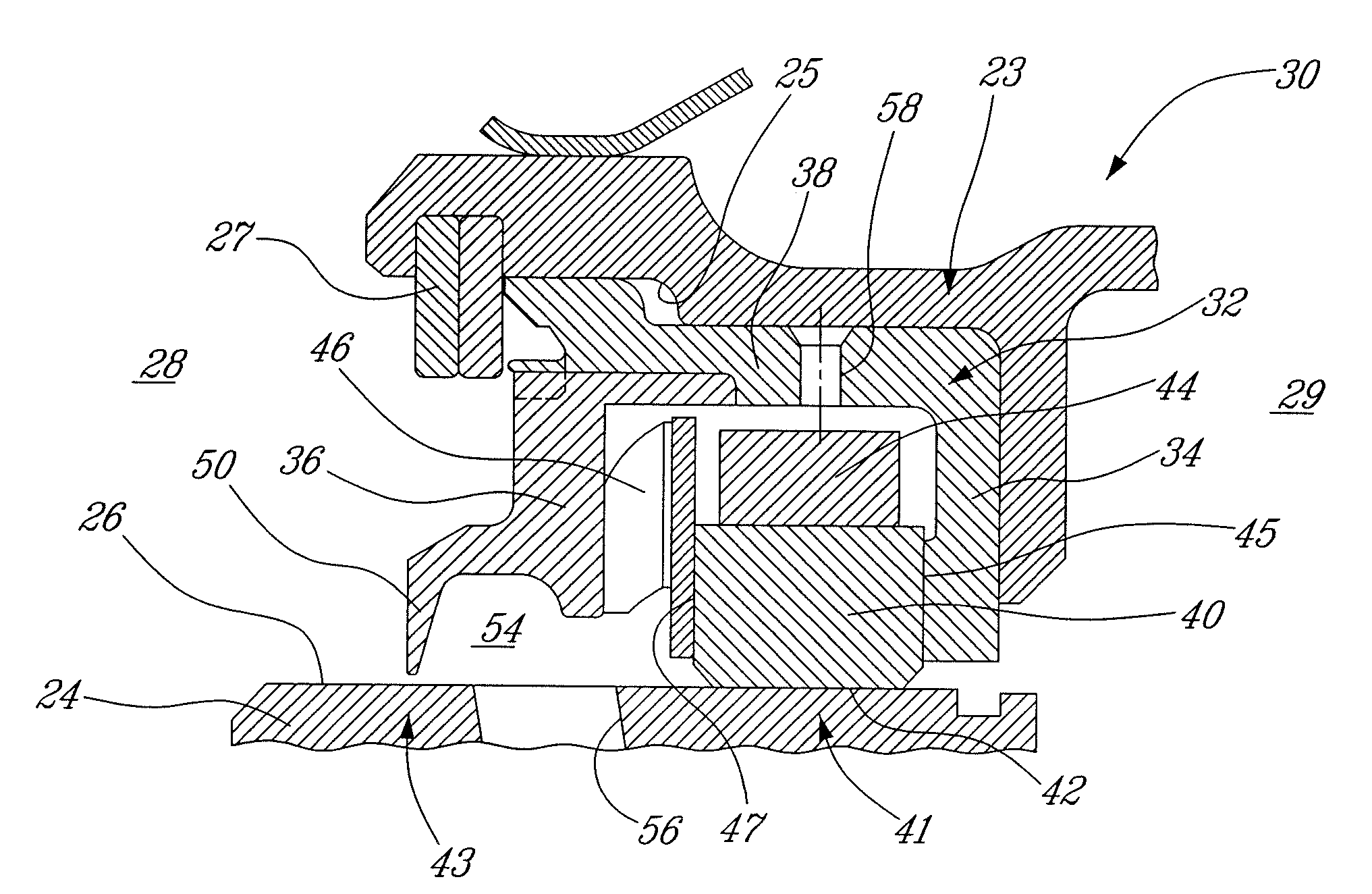

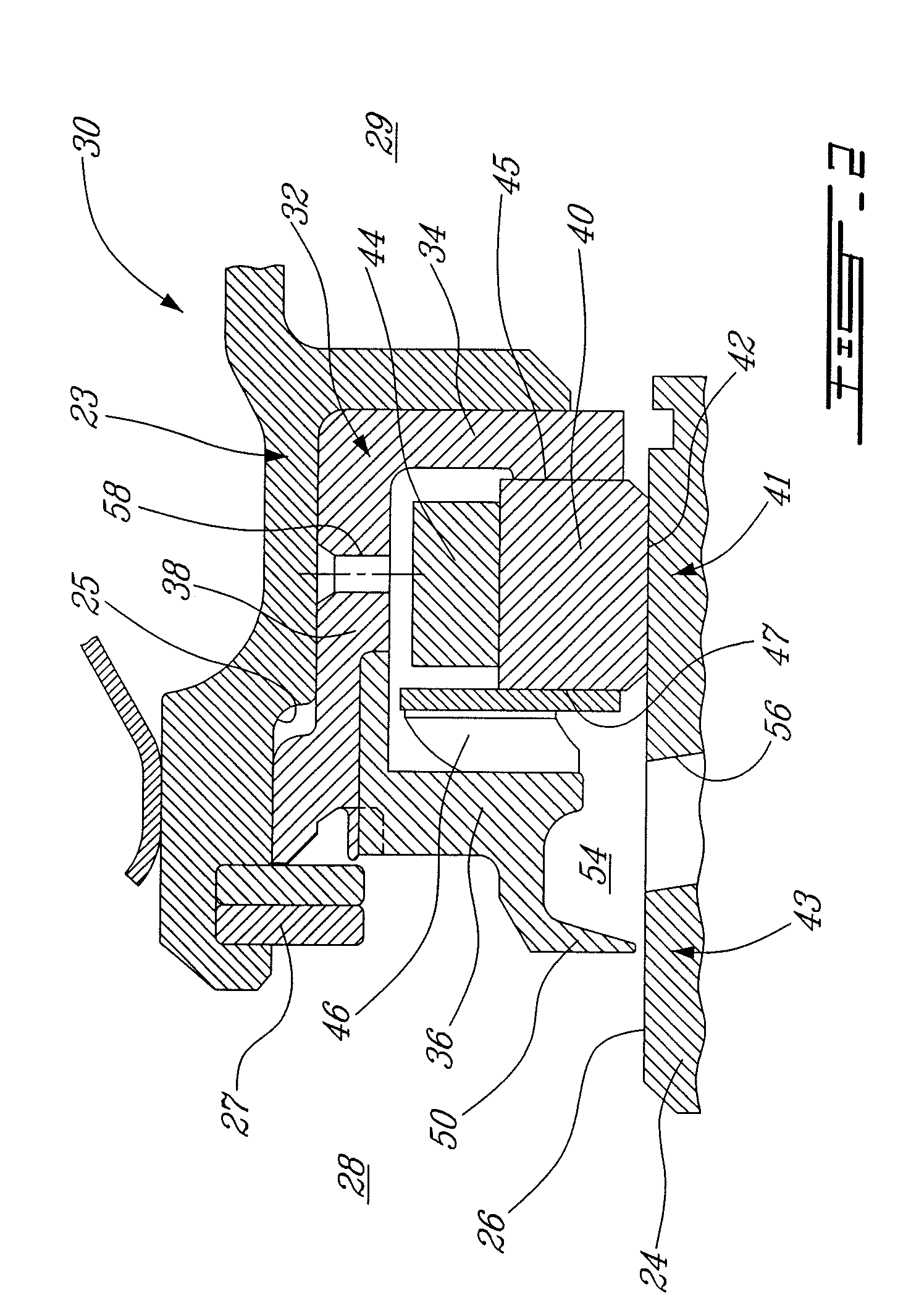

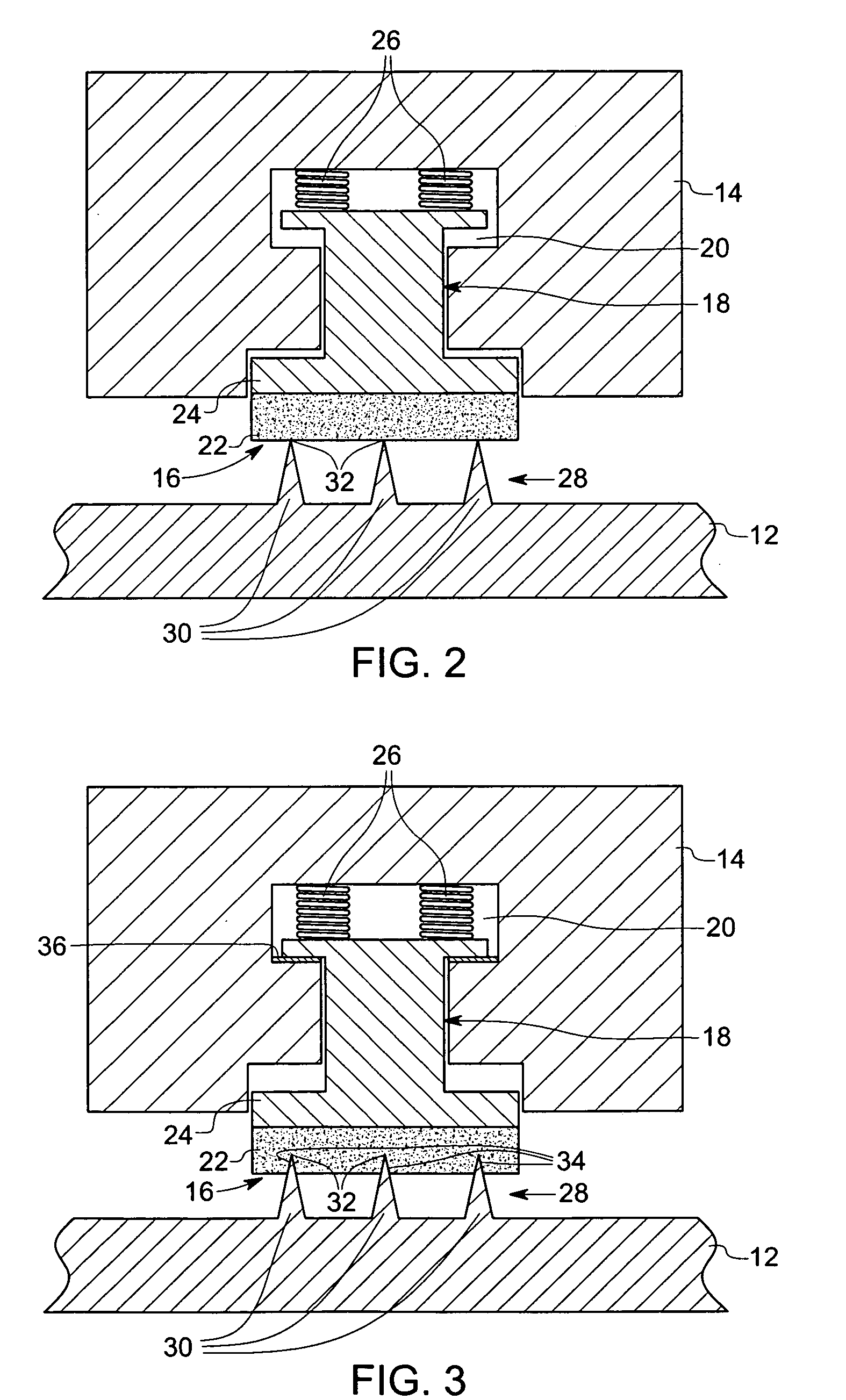

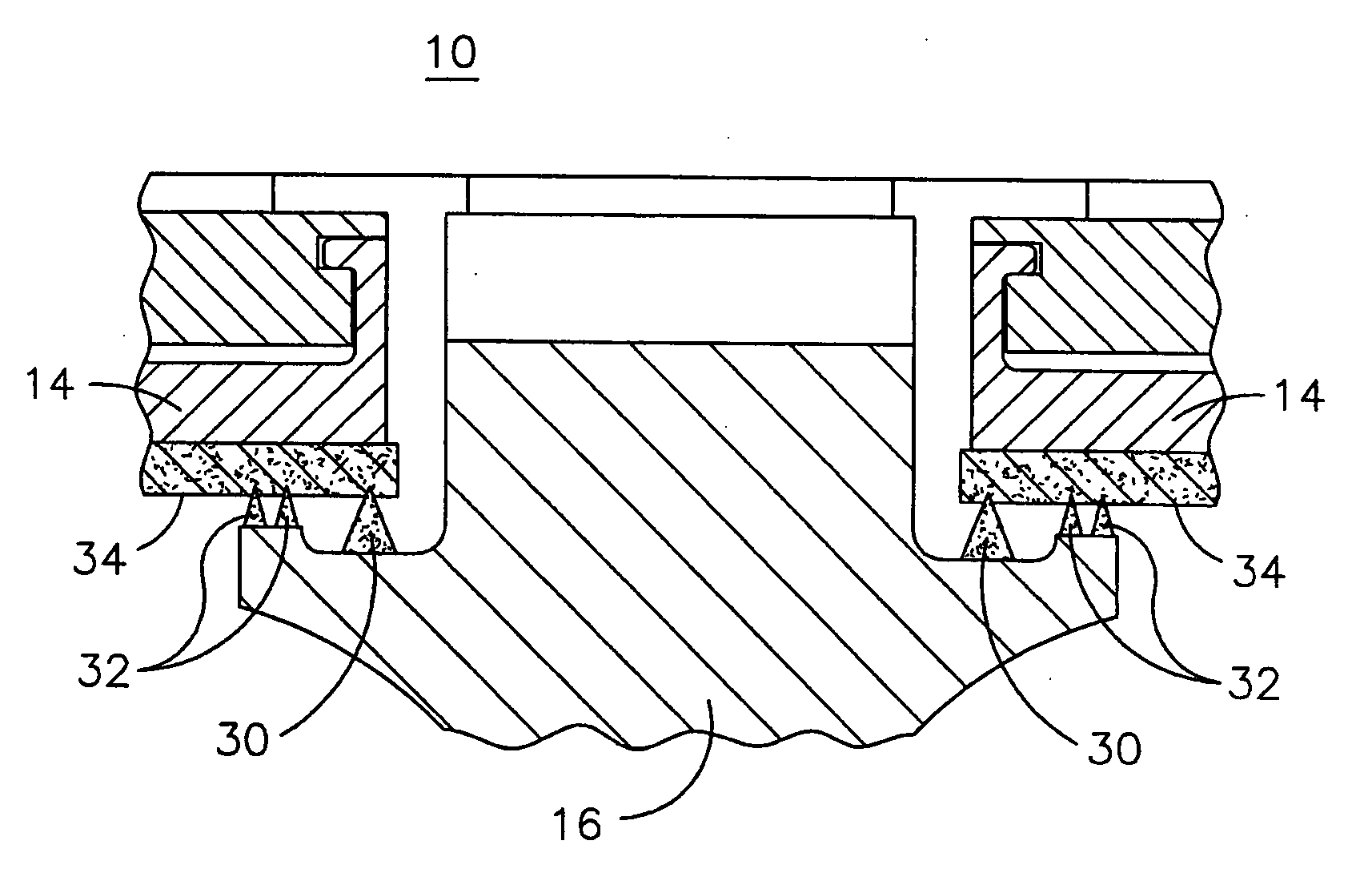

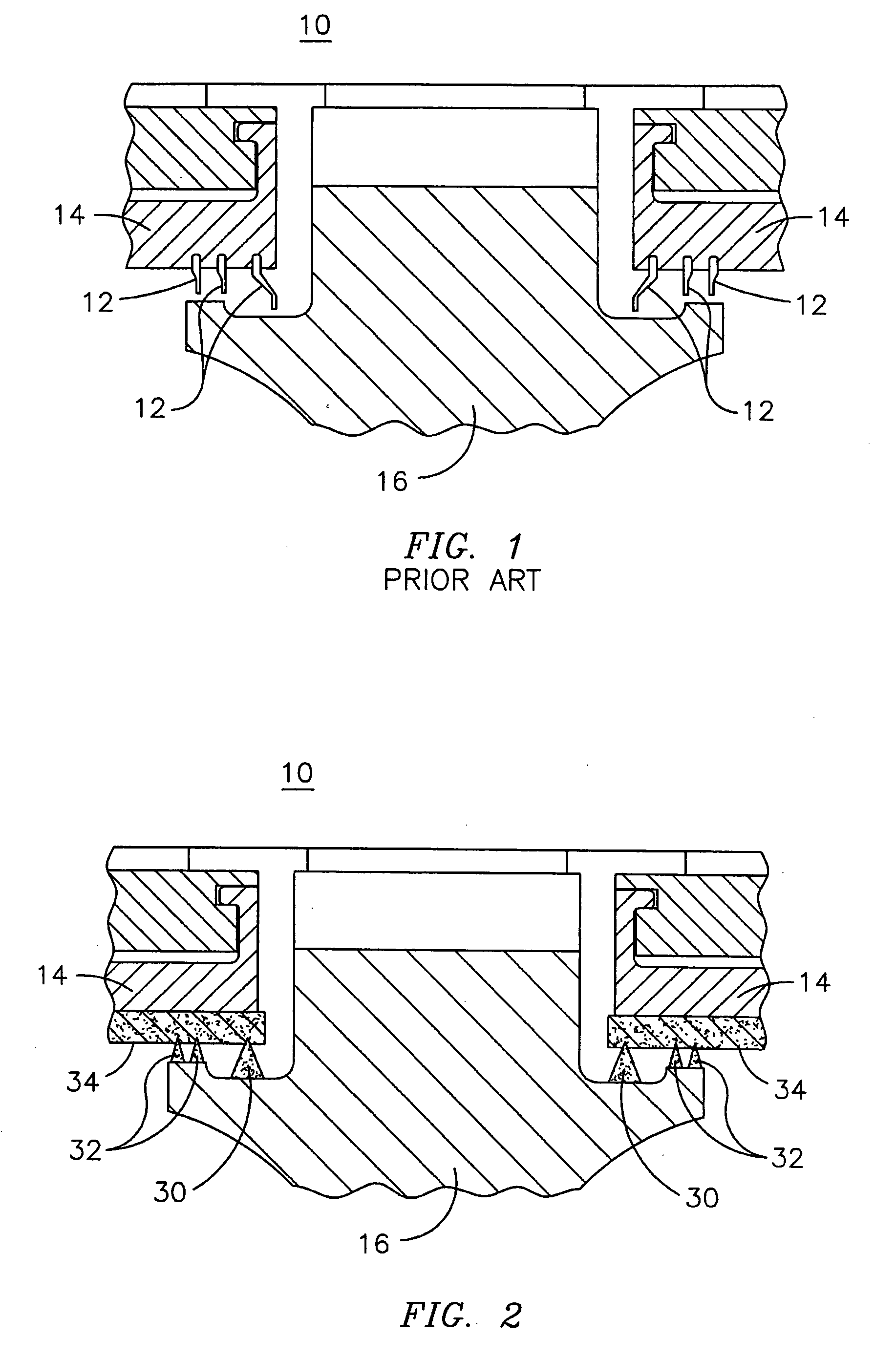

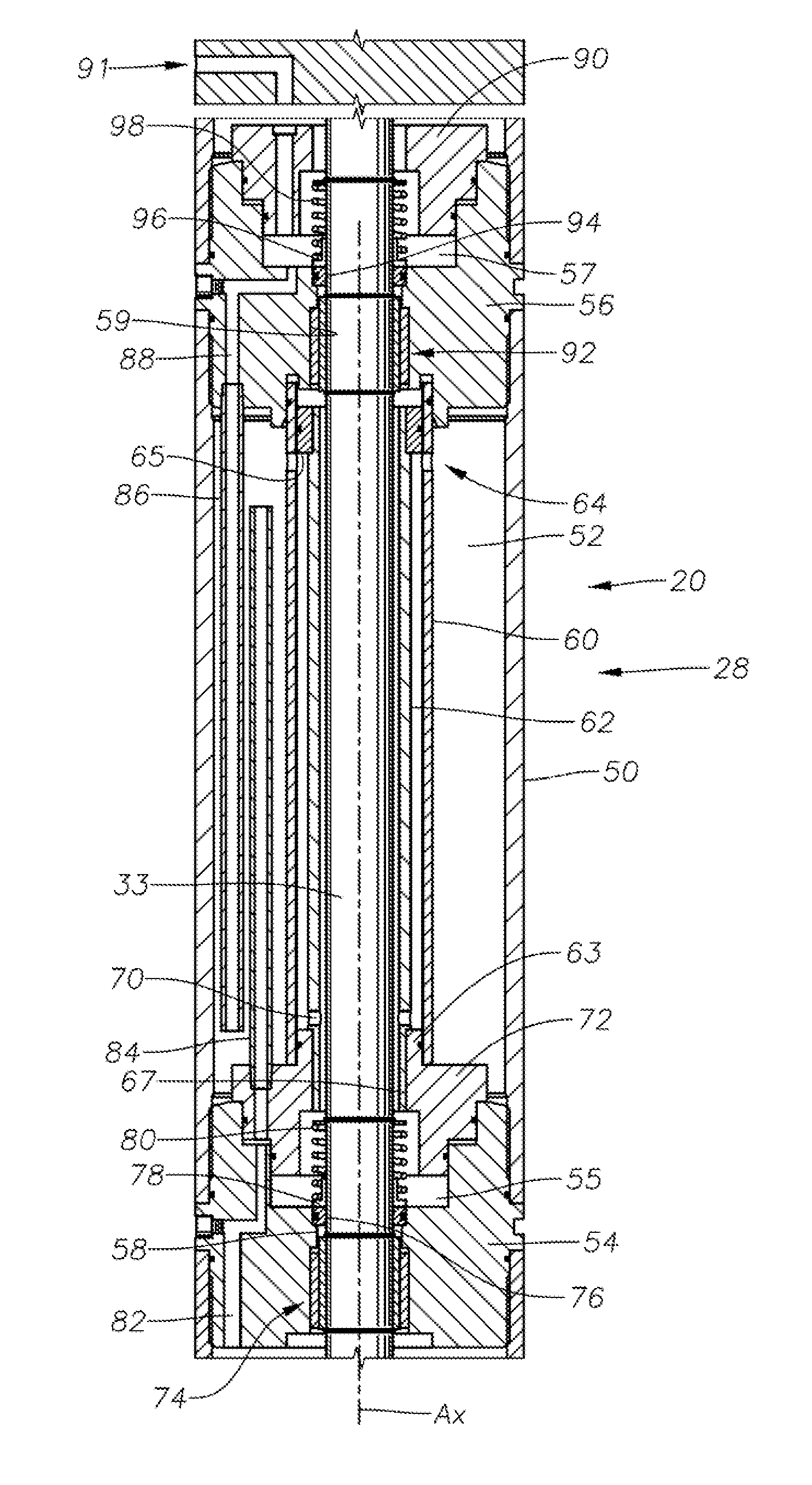

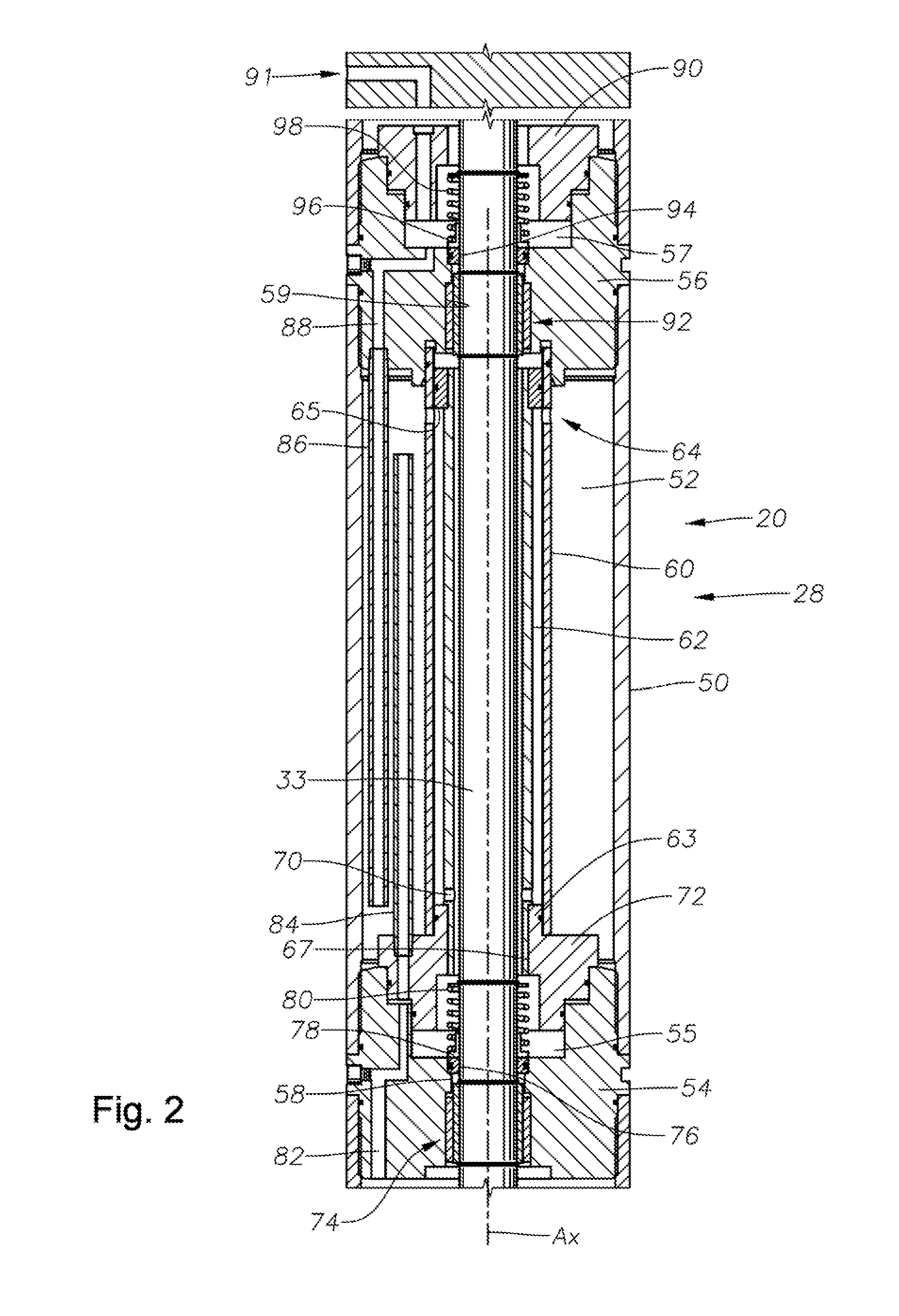

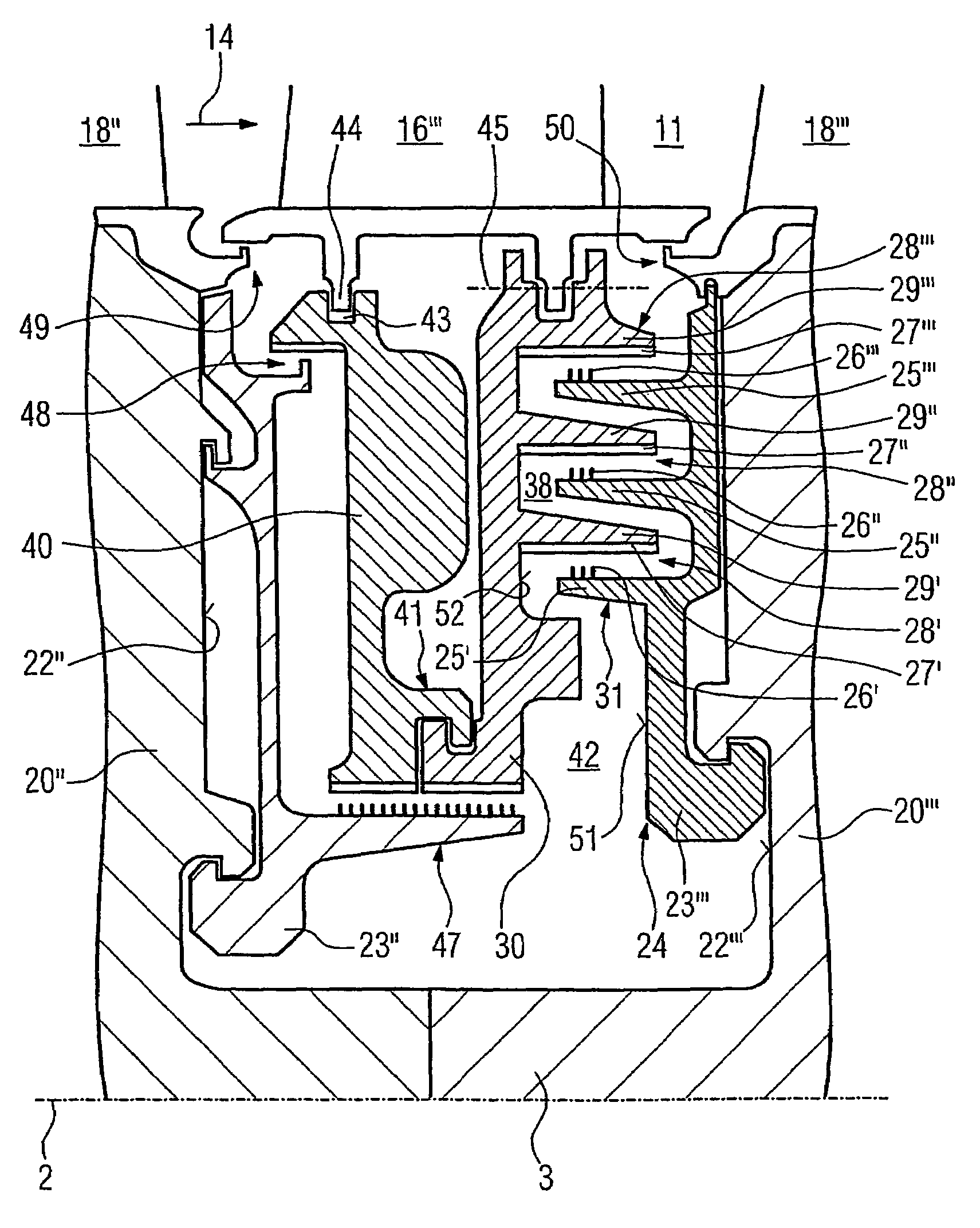

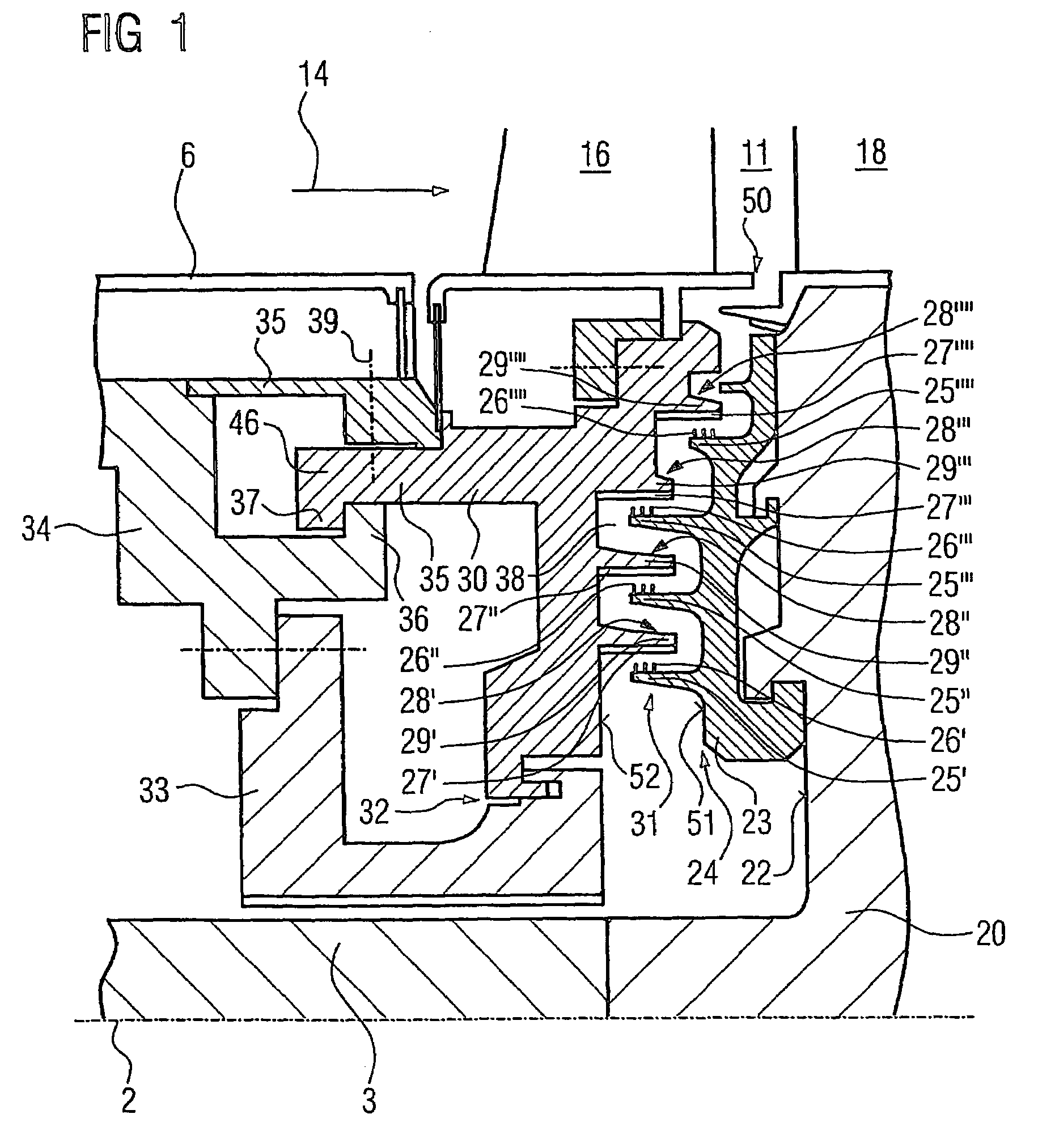

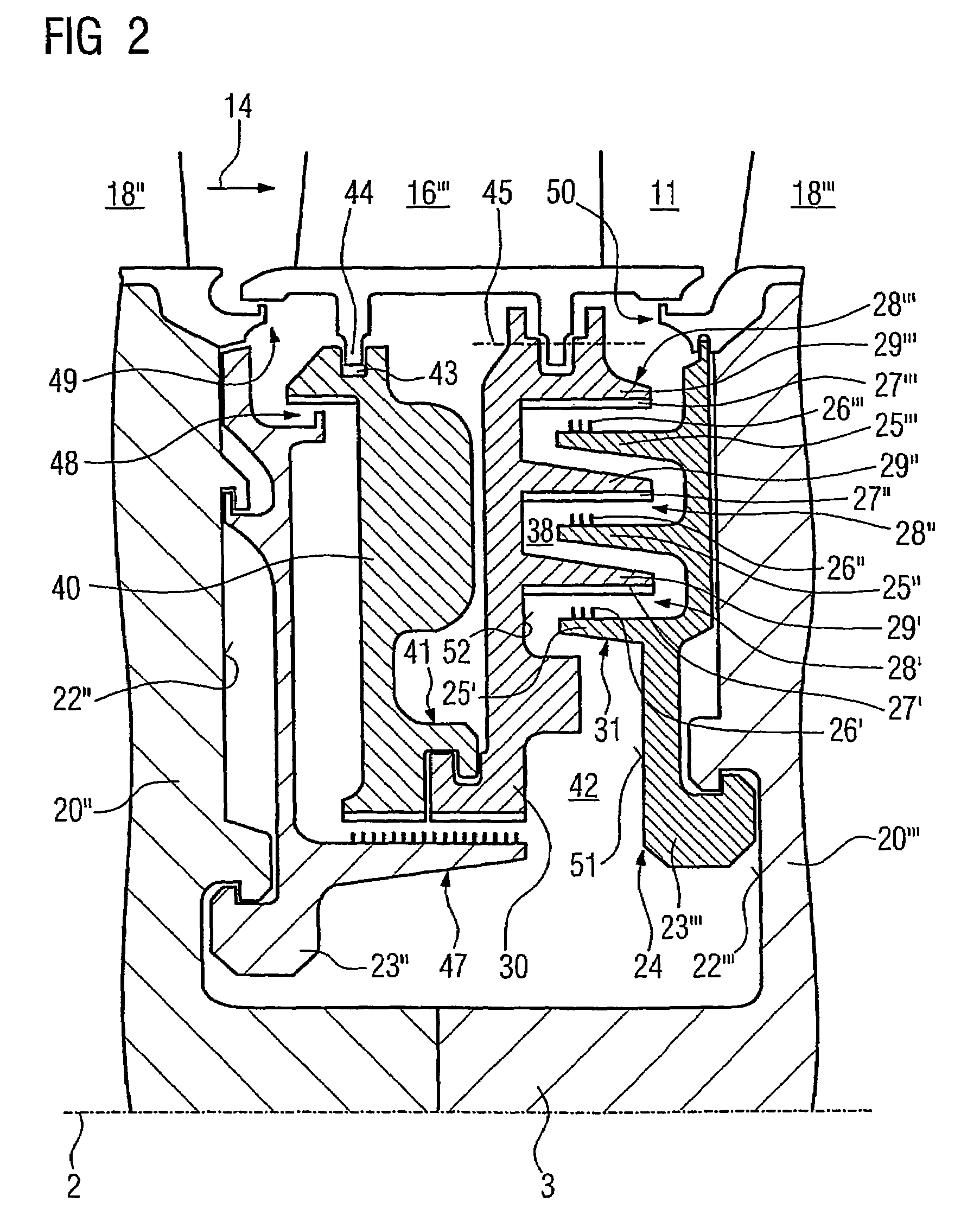

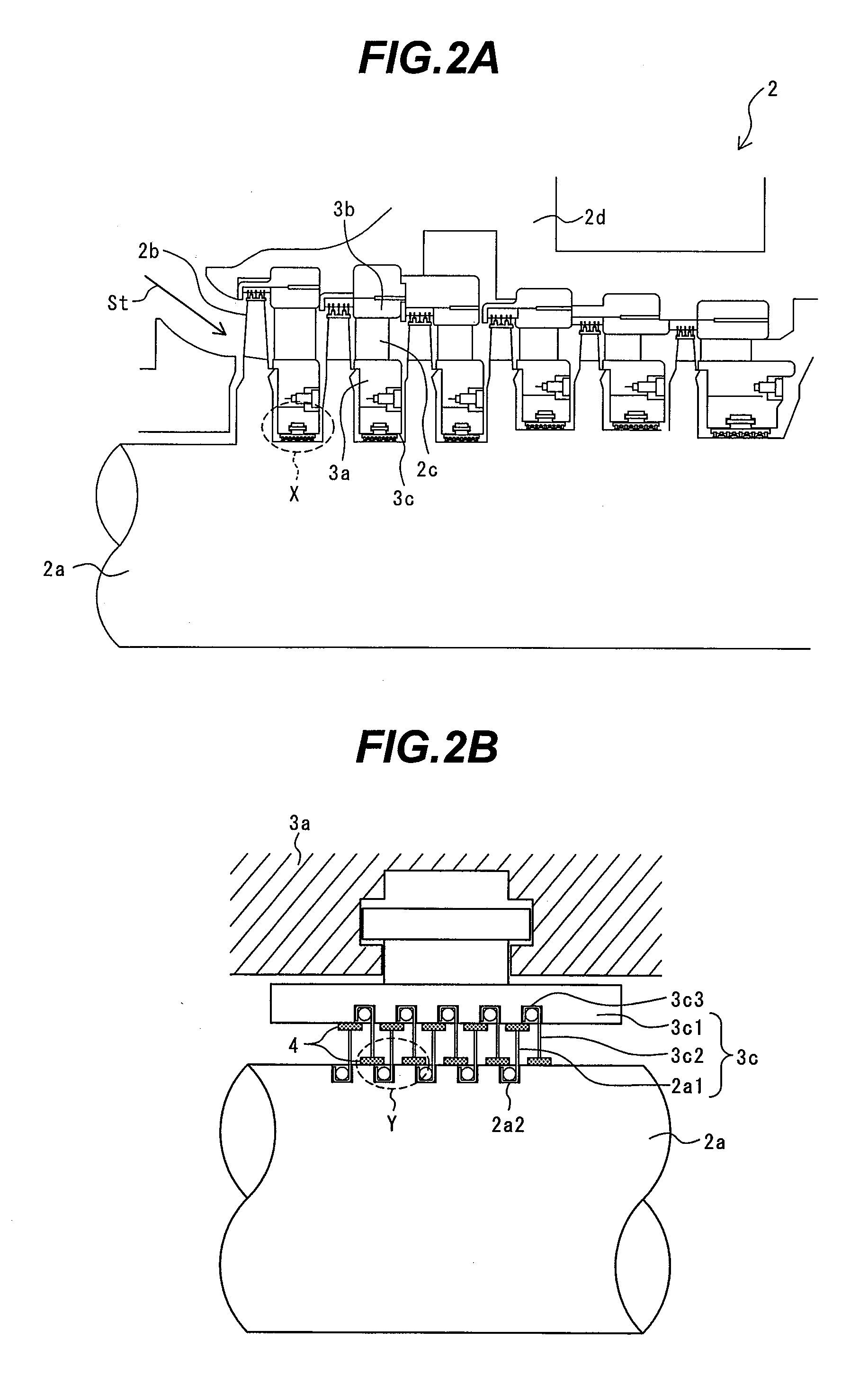

Motorized surgical handpiece

InactiveUS20070021752A1Avoid contactAvoid enteringEngine sealsDrilling rodsEngineeringFront and back ends

A motorized surgical handpiece comprises a housing enclosing an interior containing a motor and an output shaft for being driven in rotation by the motor. The output shaft has a central longitudinal axis, a bore extending therethrough for receiving a shank of a surgical tool to be rotatably driven by the output shaft, a forward end portion extending forwardly beyond the motor and a rearward end portion extending rearwardly beyond the motor. The housing has a continuous lumen extending entirely therethrough formed in part by the output shaft bore for insertion of a bore brush through the lumen for cleaning when the surgical tool is removed from the handpiece. The handpiece has forward and rearward labyrinth seals comprising rotor components respectively attached to the forward and rearward end portions of the output shaft for rotation in corresponding stator components with there being a labyrinthine clearance between each rotor component and its stator component to receive pressurized air during use and during cleaning of the handpiece to avoid the entry of contaminants.

Owner:ROGERS WILLIAM G

Integrated labyrinth and carbon seal

An integrated double seal assembly includes a carbon seal ring and at least one annular labyrinth seal fin. The seal provides a compact solution for sealing a rotating shaft.

Owner:PRATT & WHITNEY CANADA CORP

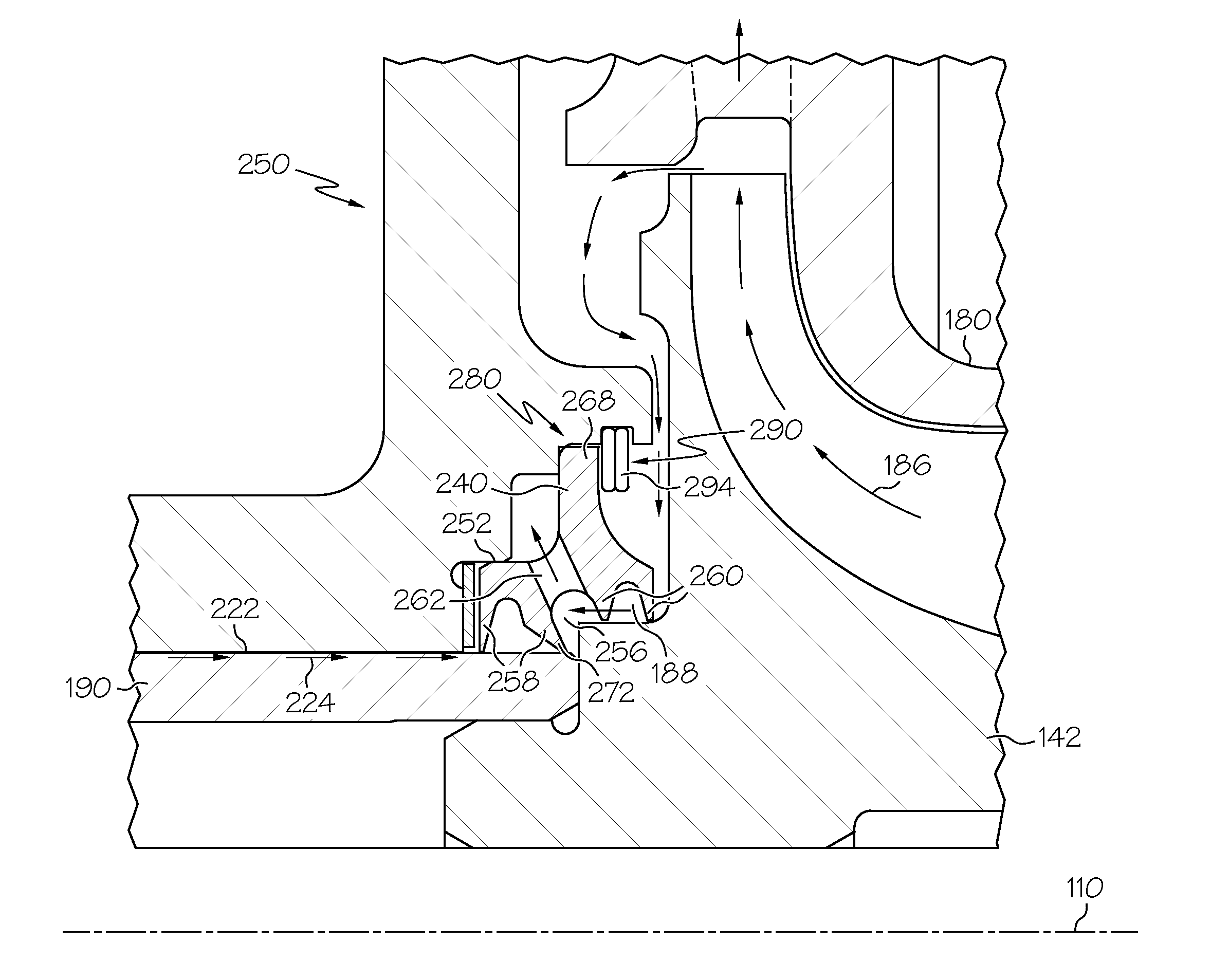

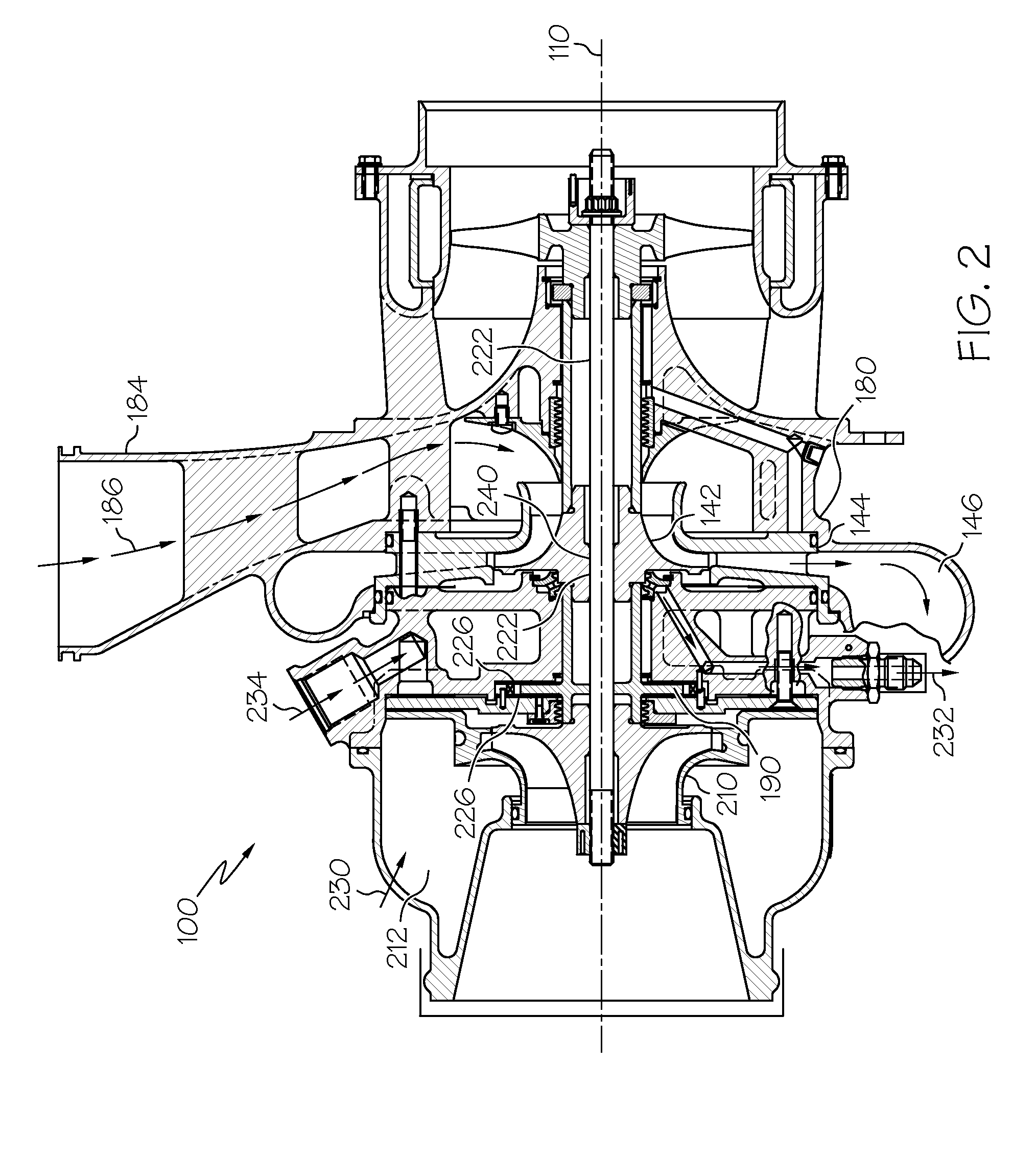

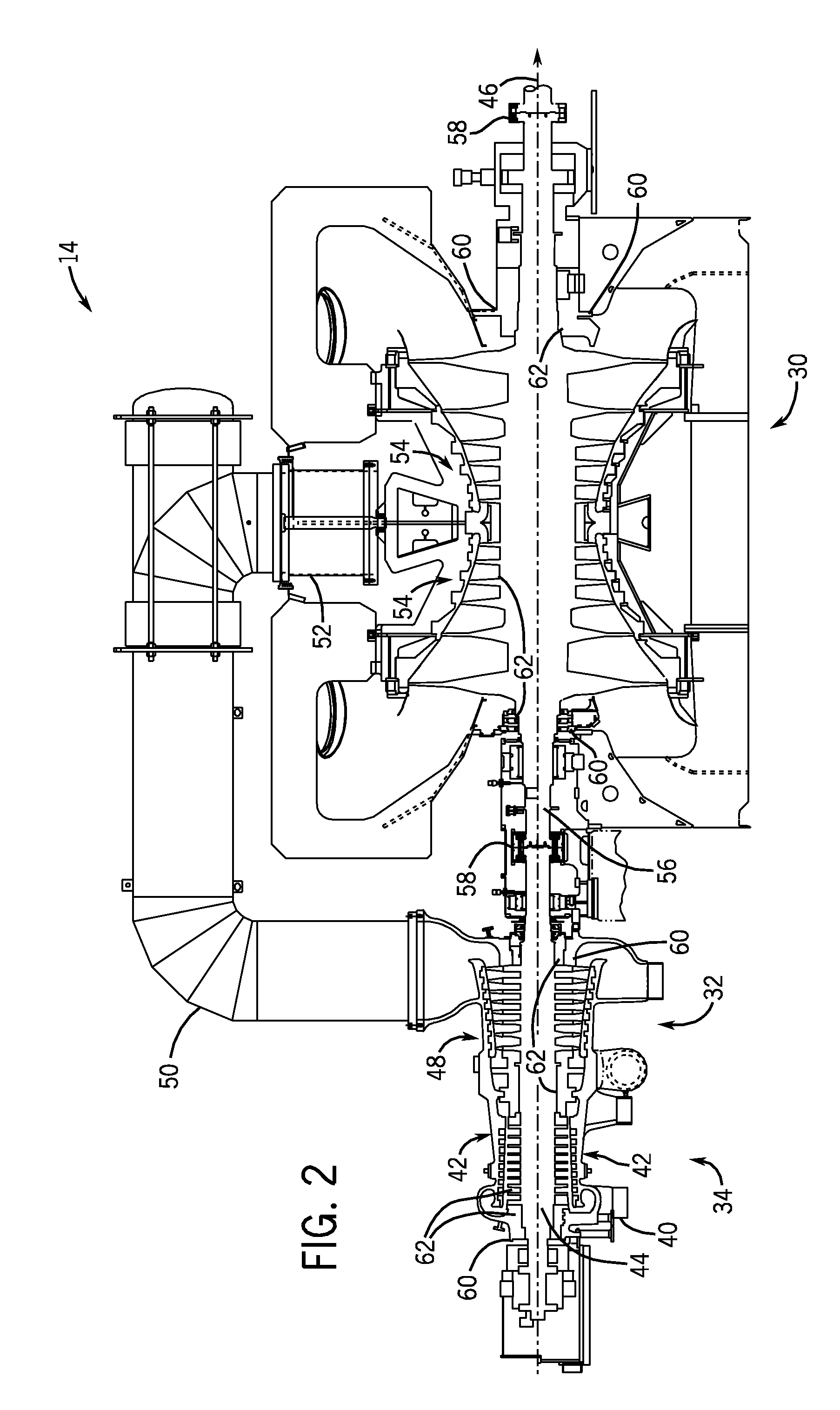

Rotary separator drum seal

A seal assembly for a compressor includes a static member fixedly disposed within a compressor casing and having an end surface and a rotatable separator coupled with a compressor shaft and spaced from the static member. The separator has an axial end with a radial end surface located adjacent to the static member end surface such that a clearance space is defined therebetween. The separator has a plurality of openings extending inwardly from the end surface and spaced about the shaft axis such that land surface sections are defined on the end surface. The land surface sections or / and the openings are configured to prevent fluid flow radially inwardly through the clearance space. The static member has two annular walls receiving an end portion of the separator, with annular ridges providing labyrinth seals disposed against inner and outer surfaces of the separator, and an annular deflector with an angled deflector surface.

Owner:DRESSER RAND CO

Non-contact labyrinth seal assembly and method of construction thereof

A non-contact labyrinth seal assembly, bearing assembly therewith, and method of construction thereof, has an outer rigid carrier and an inner sleeve. The carrier has an outer cylindrical flange and a radially inwardly extending leg and the sleeve has a cylindrical wall and a radially outwardly extending flange. A body is attached to at least one of the leg and the flange, wherein the body provides, at least in part, a purely non-contact labyrinth passage extending between the carrier and the sleeve.

Owner:THE TIMKEN CO +1

Method and appartus for labyrinth seal packing rings

A seal assembly for a turbomachine may include at least one arcuate plate coupled to an interior surface of a stationary housing; a circumferentially-segmented packing ring disposed intermediate to a rotor and the plate; a plurality of arcuate teeth disposed intermediate to the ring and the rotor, wherein a clearance of each tooth decreases progressively going from an upstream side of the turbomachinery to a downstream side; wherein the progressive decrease in the clearances of the teeth creates a passive feedback, such that as a tip clearance decreases, outward radial forces cause the packing ring to move away from the rotor and as the tip clearance increases, inward radial forces cause the packing ring to move toward the rotor; and a biasing member disposed intermediate to the arcuate plate and the ring and coupled to both.

Owner:GENERAL ELECTRIC CO

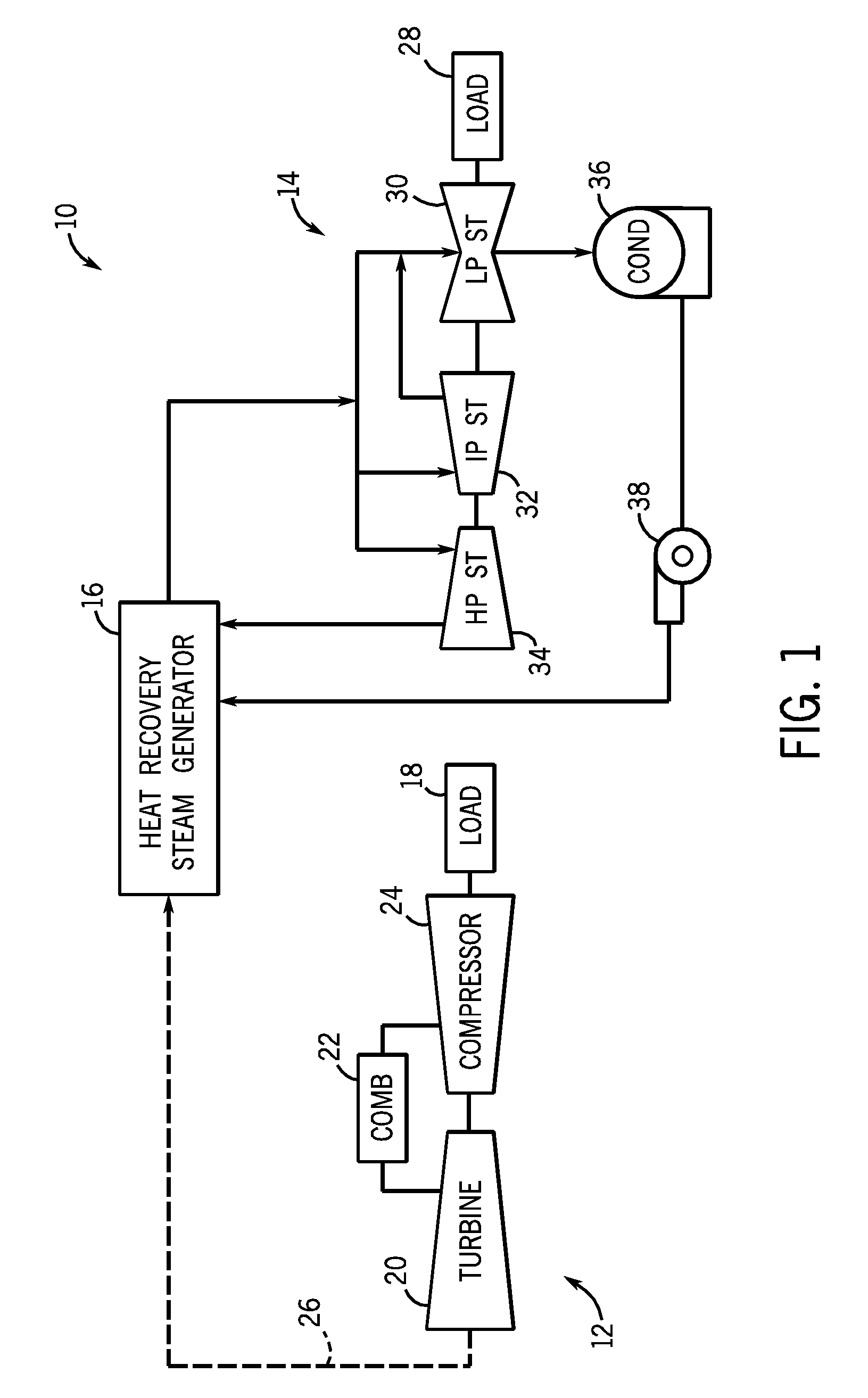

Compliant abradable sealing system and method for rotary machines

A method for operating a compliant abradable sealing system includes biasing a radially movable sealing element to contact a mating radially fixed sealing element. The radially fixed sealing element is rotated relative to the radially movable sealing element. The radially fixed sealing element is provided on a rotor. The radially movable sealing element is provided in a stator housing. The radial movement of the movable sealing element is limited by a stopping device provided between the movable sealing element and the stator housing. A plurality of permanent sealing grooves are formed in the radially movable sealing element to form a zero-clearance labyrinth seal.

Owner:GENERAL ELECTRIC CO

Contaminant-deflector labyrinth seal and method of operation

ActiveUS20090274548A1Avoid problemsAvoid componentsEngine sealsPump componentsAir bearingBearing wear

A seal assembly for deflecting contaminated fluid flowing through the seal assembly from an upstream space to a downstream space includes an annular housing, at least one vent hole peripherally disposed on the annular housing, a first set of seals disposed within the annular housing adjacent to the downstream space, the first set of seals having an inclined surface to deflect the flow of contaminated fluid through the at least one vent hole, and a second set of seals mounted on the shaft, disposed within the annular housing, adjacent to the first set of seals and adjacent to the upstream space. The second set of seals may have larger inside diameter than the first set of seals. The seal assembly may prevent contaminated fluid from entering an air bearing cooling circuit, thereby preventing bearing wear, erosion and failure.

Owner:HONEYWELL INT INC

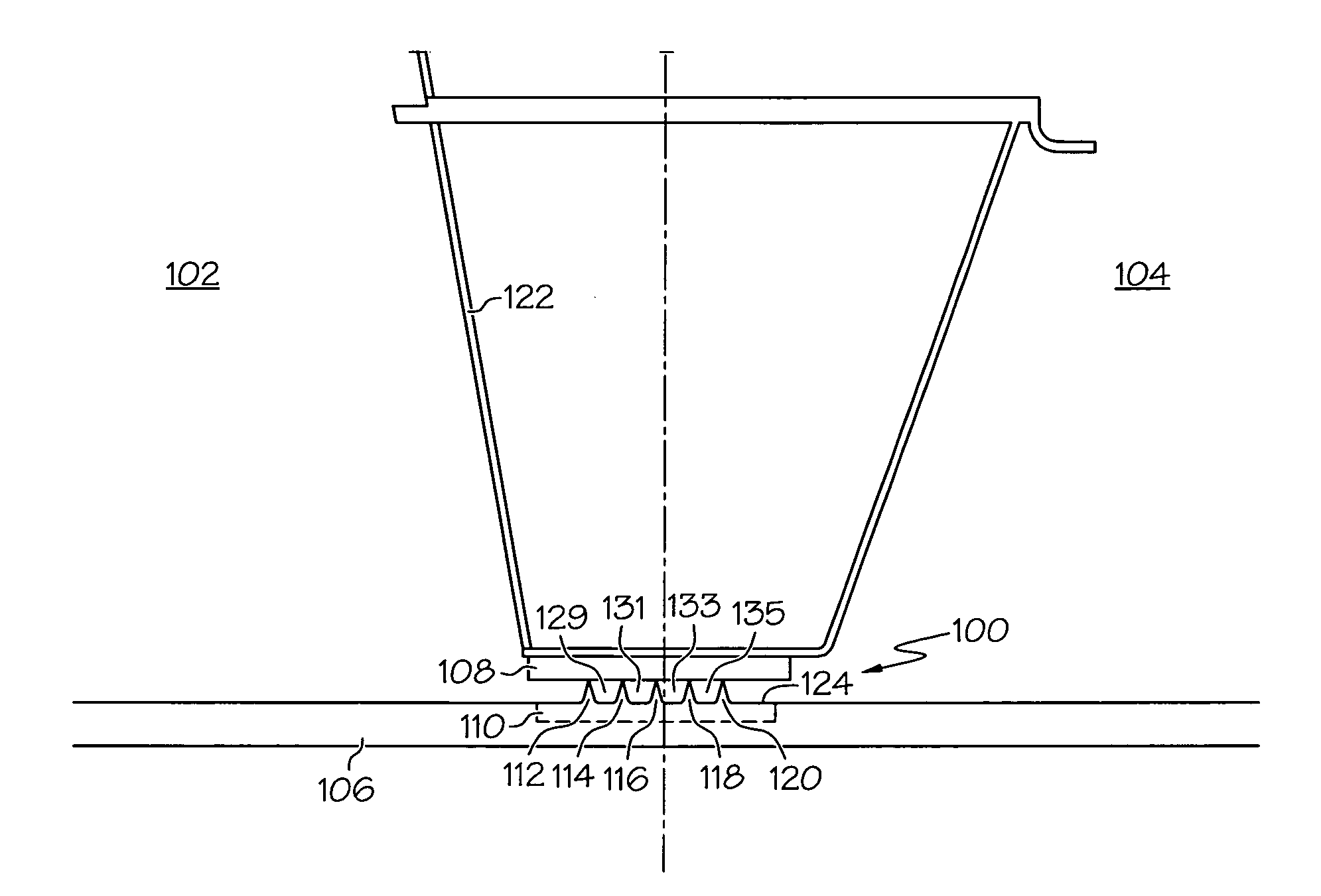

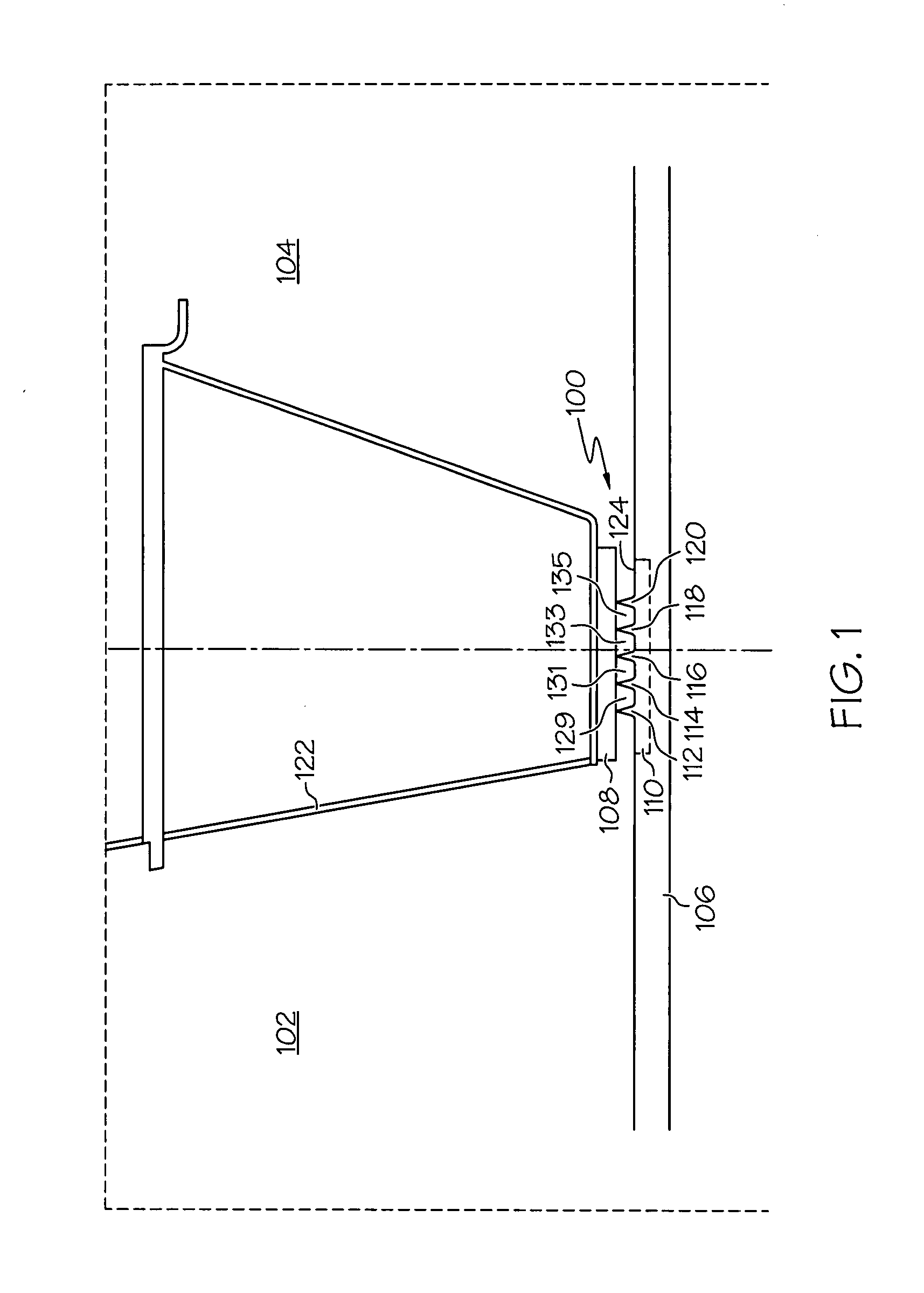

Conveyor-belt roller assembly

InactiveUS6234293B1Increased roller support strengthQuick and safe installationBall bearingsBearing componentsEngineeringHigh intensity

A conveyor-belt roller assembly secured inside a conveyor-belt roller and onto an inner shaft, preferably used in conveyor-belts used for carrying high loads of material in hazardous environments. The conveyor-belt roller assembly has a stationary anti-lock shield which protects the rotating exterior surface from coming into contact with the outside elements for example debris and machinery. A dust shield is also position aft of the anti-lock shield to prevent the penetration of small particles and dust into the inner workings of the conveyor-belt roller assembly. The conveyor-belt roller assembly also has deep rings in the load-bearing portion for thermal expansion and contraction as well as heat dissipation. Bridging ribs are positioned across the deep rings to greatly increase the strength and therefore load-baring capacity of the conveyor-belt roller assembly. A tapered labyrinth seal is used so that it can be press locked into position making installation quicker and easier. The main load-baring component and tapered labyrinth seal component are preferably fabricated from a high strength, heat resistant 30% glass filled polypropylene.

Owner:LUFF INDS

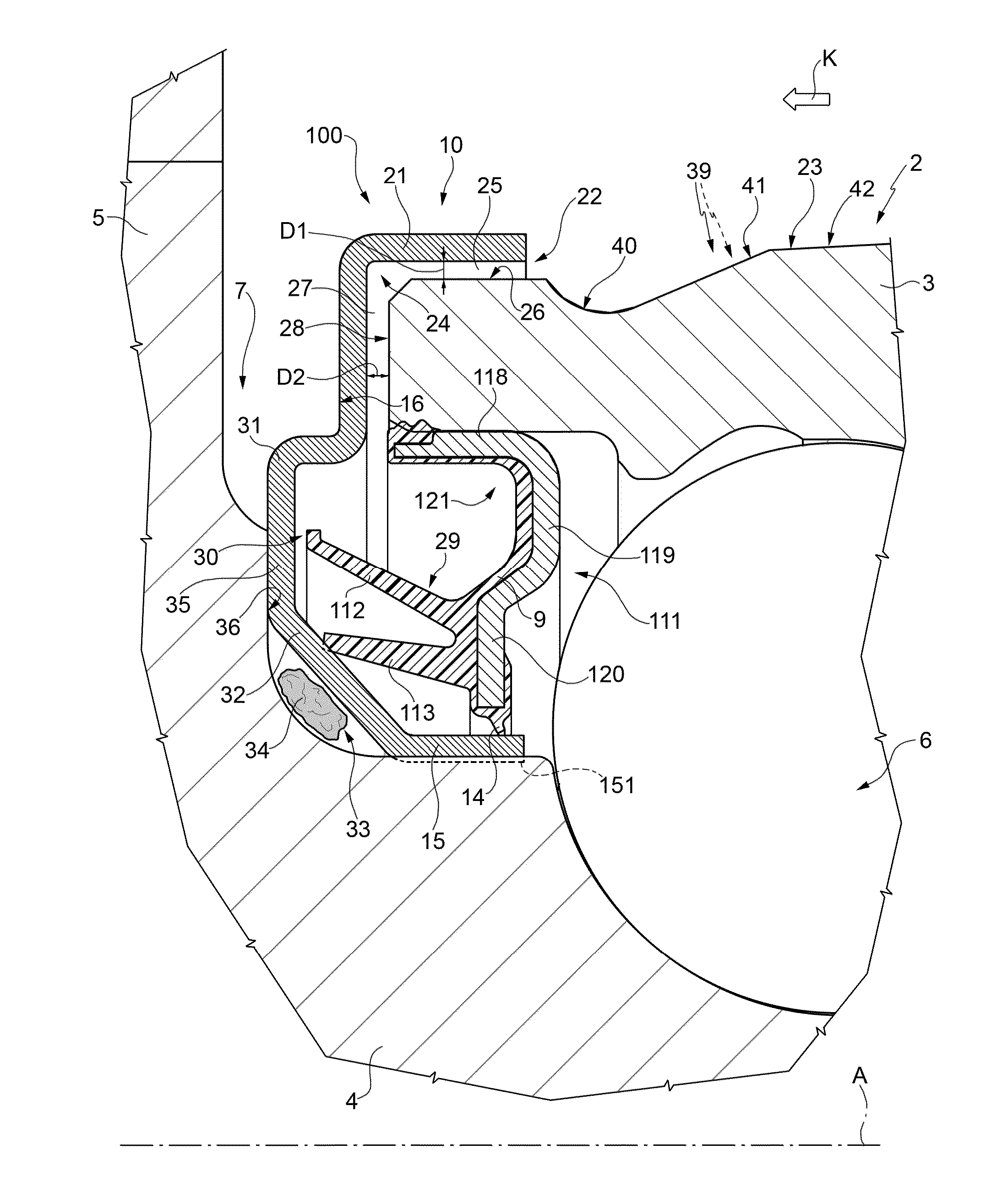

Hub bearing unit equipped with a low friction sealing assembly

ActiveUS20150003766A1Improve protection efficiencyEasy and affordable to embodyHubsBall bearingsFlangeLow friction

An assembly providing a first annular shield including a sleeve portion integral with a rotating member and with a flange portion, which radially extends to protrude from the first sleeve portion; a second annular shield having a sleeve portion integral with a stationary member and with a flange portion that radially extends to protrude on the opposite side of the sleeve portion of the first shield and facing the flange portion; and an annular seal, which the flange portion of the first shield ends with an L-shaped annular portion that protrudingly radially and axially extends out of an annular gap delimited between the rotating and stationary members to define an L-shaped channel in radial section having constant width and forming a first labyrinth seal; the channel leads into an annular recess, delimited between the second shield and a first lip of the annular seal without contacting the first shield.

Owner:AB SKF

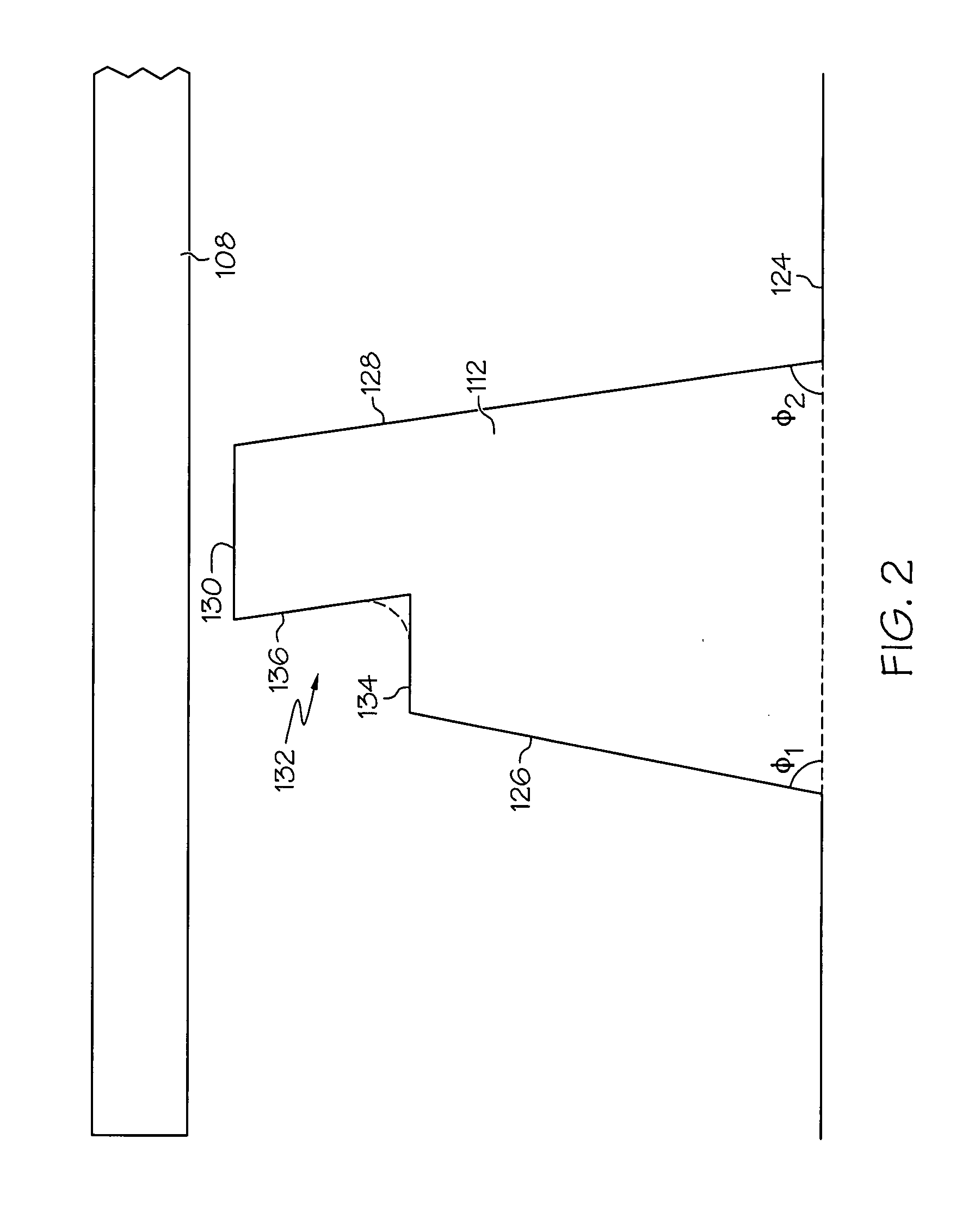

Notched tooth labyrinth seals and methods of manufacture

Labyrinth seals and methods of manufacturing the seals are provided. In an embodiment, the seal includes a seal base and a first annular tooth. The seal base has an outer peripheral surface. The first annular tooth extends radially from the seal base outer peripheral surface. The first annular tooth includes a forward wall, an aft wall, and a tip wall, and the forward wall and the aft wall each include bottom sections that contact the seal base and angle upwardly toward or substantially parallel to each other. The forward wall has a notch formed therein defined by a shelf wall and a side wall, the shelf wall and side wall join the forward wall to the tip wall, and the aft wall is formed without a notch. The side wall and the aft wall extend substantially parallel to each other.

Owner:HONEYWELL INT INC

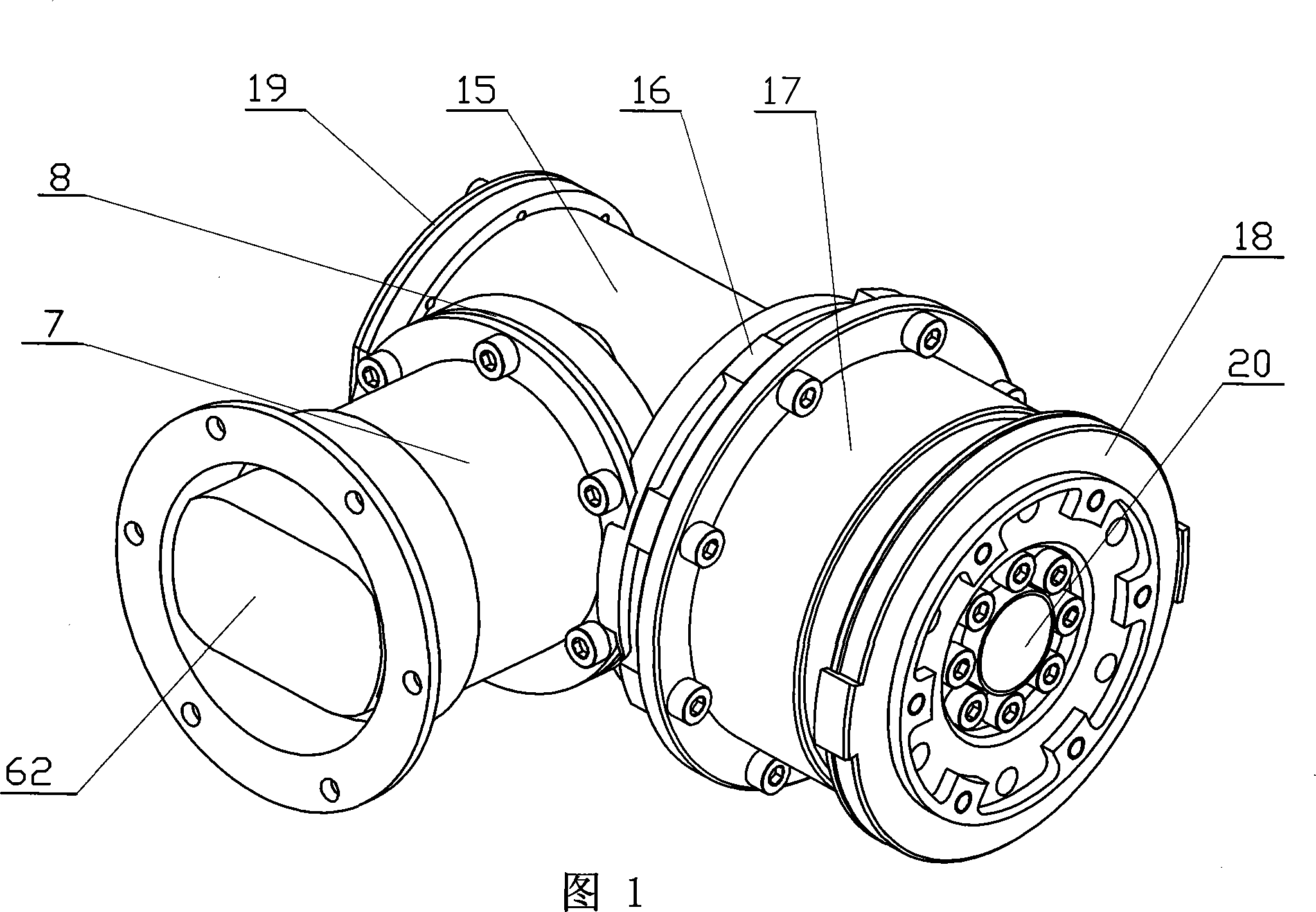

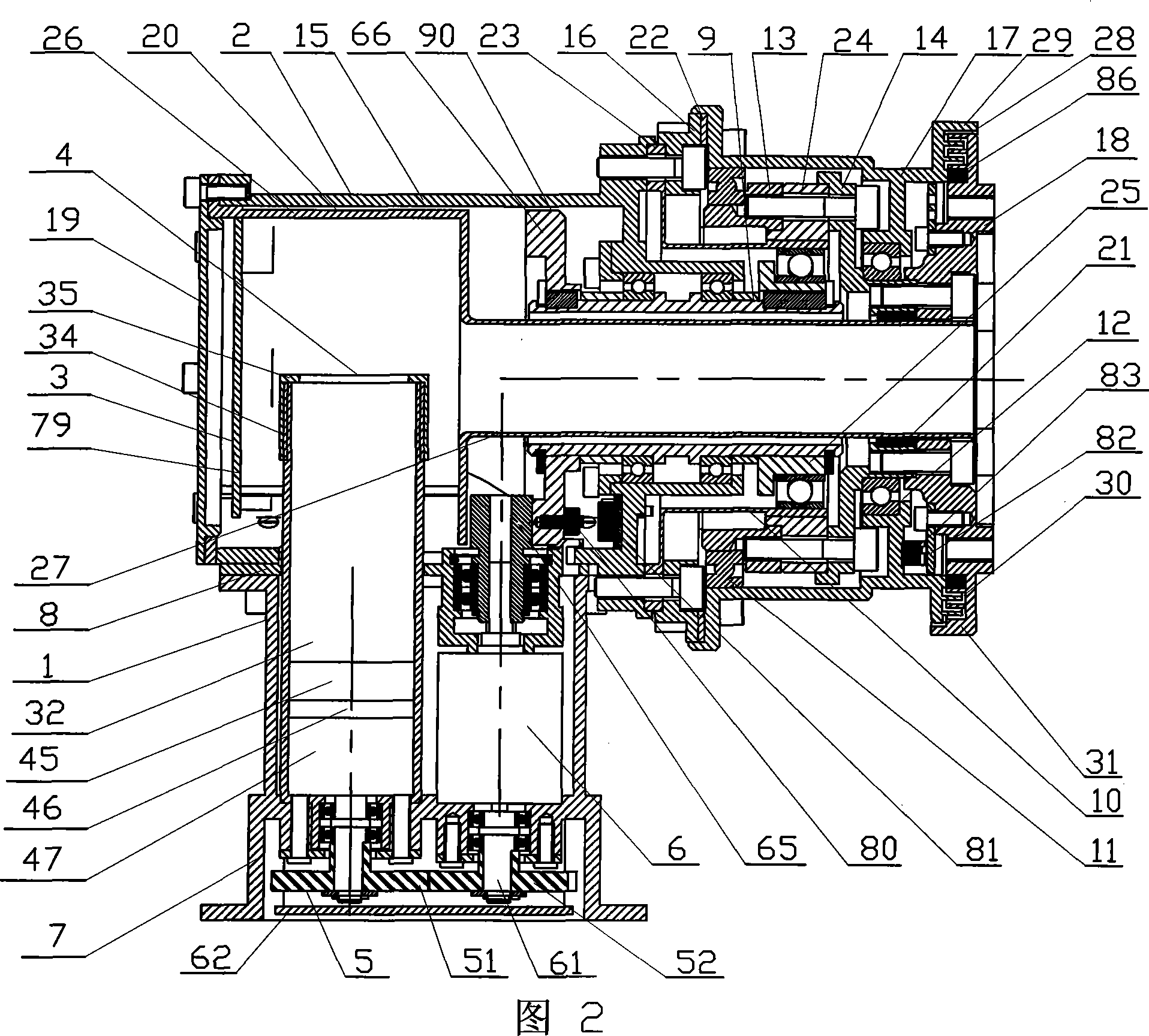

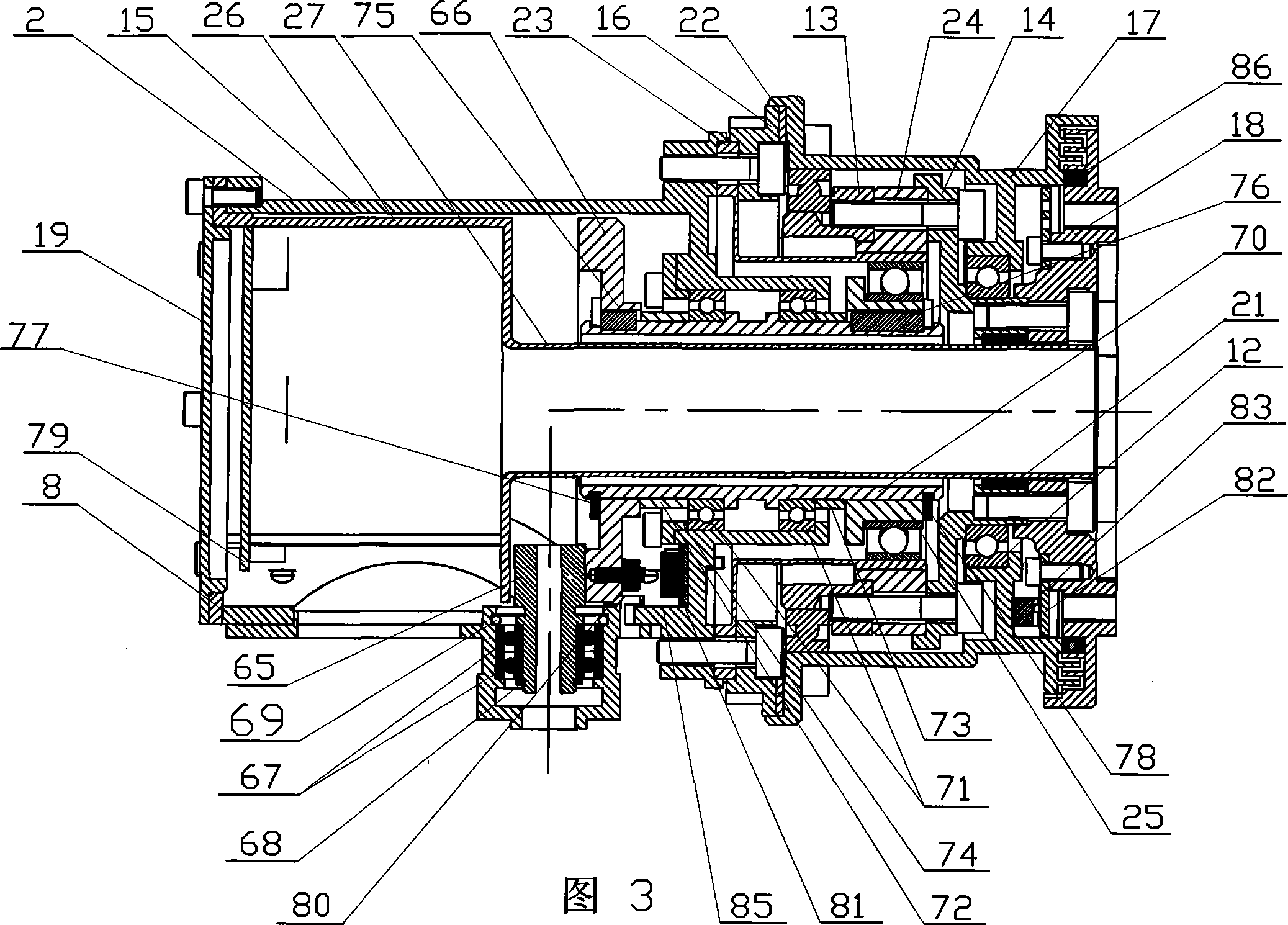

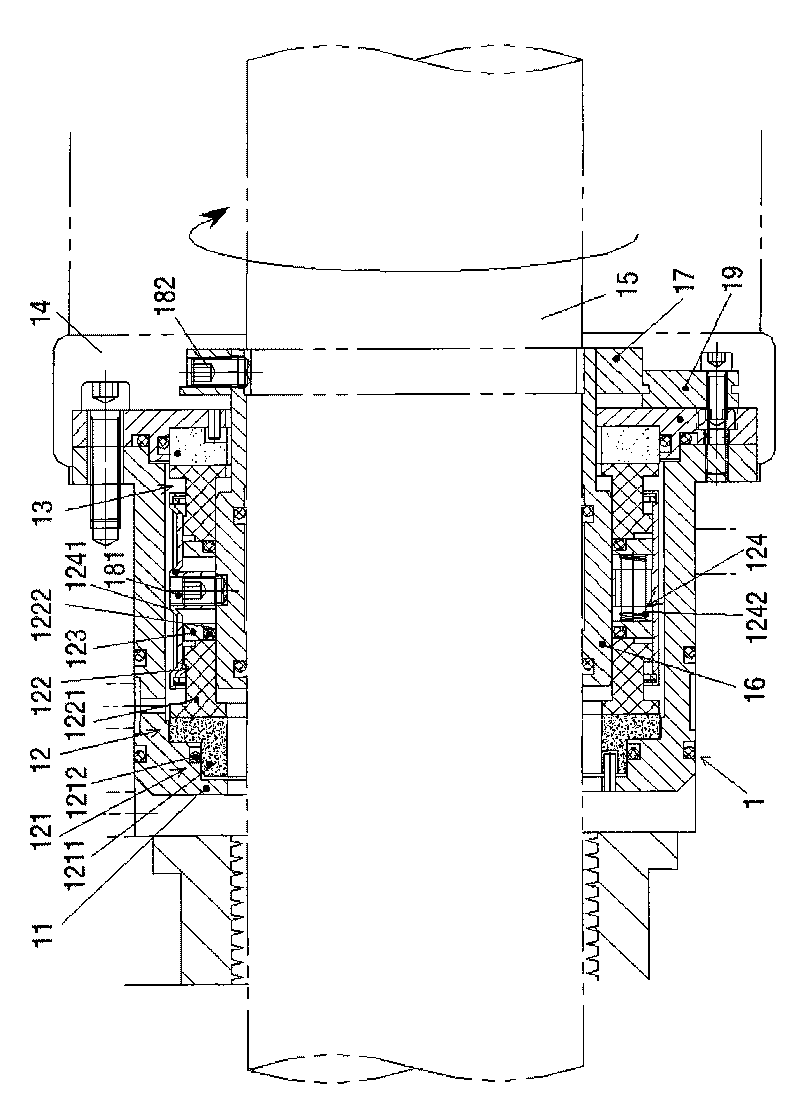

Spacing mechanical arm modularization joint

A space manipulator modularization arthrosis relates to a space manipulator arthrosis. The invention aims at the problems of the prior space manipulator modularization arthrosis of large volumes, large masses and large powers. A drive device (4) is connected with a planetary reducer (6) by a gear device (5); the planetary reducer (6) is connected with a crown gear device (90) which as well as a wave generator (25) is connected with a hollow transmission shaft device (9); a first external shell (15) is fixedly connected with a flexible wheel (23), a middle connecting flange (16) and a second external shell (17); the flexible wheel (23) is arranged on the hollow transmission shaft device (9) which is sleeved on a small-end sleeve (27); large and small thin-wall bearings are arranged between large and small thin-wall bearing internal ring supporting seat and the second external shell (17); a labyrinth-typed sealing structure and a mechanical position limit structure are arranged between the second external shell (17) and an output flange disc (18). An electric device (3) is fixedly arranged in the output device (2). The invention has the advantages of small volume, light mass, low powder consumption, and meeting the performance requirement of the space manipulator modularization arthrosis of low power consumption, large output moment and high reliability.

Owner:HARBIN INST OF TECH

Cold spray process for seal applications

A method of forming an interstage seal including removing a diaphragm seal box (14) from a gas turbine compressor assembly (10) and removing a labyrinth sealing member (12) from the diaphragm seal box (14). An abradable material layer (34) may be deposited on the diaphragm seal box (14). A spray gun may be mounted in relation to an engine disk (16) of the gas turbine compressor assembly (10) for cold-spraying a quantity of particles toward the engine disk (16). The particles may be sprayed at a velocity sufficiently high to cause at least a portion of the quantity of particles to adhere to the engine disk (16). The spray gun may be controlled to deposit a quantity of particles on the compressor disk (16) to form a geometry (32) that will abrade the abradable material layer (34) during operation of the gas turbine compressor assembly (10). The geometry (32) abrading the abradable material layer (34) forms an interstage seal. Rotation of the engine disk (16) within the gas turbine compressor assembly (10) may be controlled during the step of controlling the spray gun. The diaphragm seal box (14) may be reinstalled within the gas turbine compressor assembly (10) so that the geometry (32) aligns with the abradable material layer (34).

Owner:SIEMENS ENERGY INC

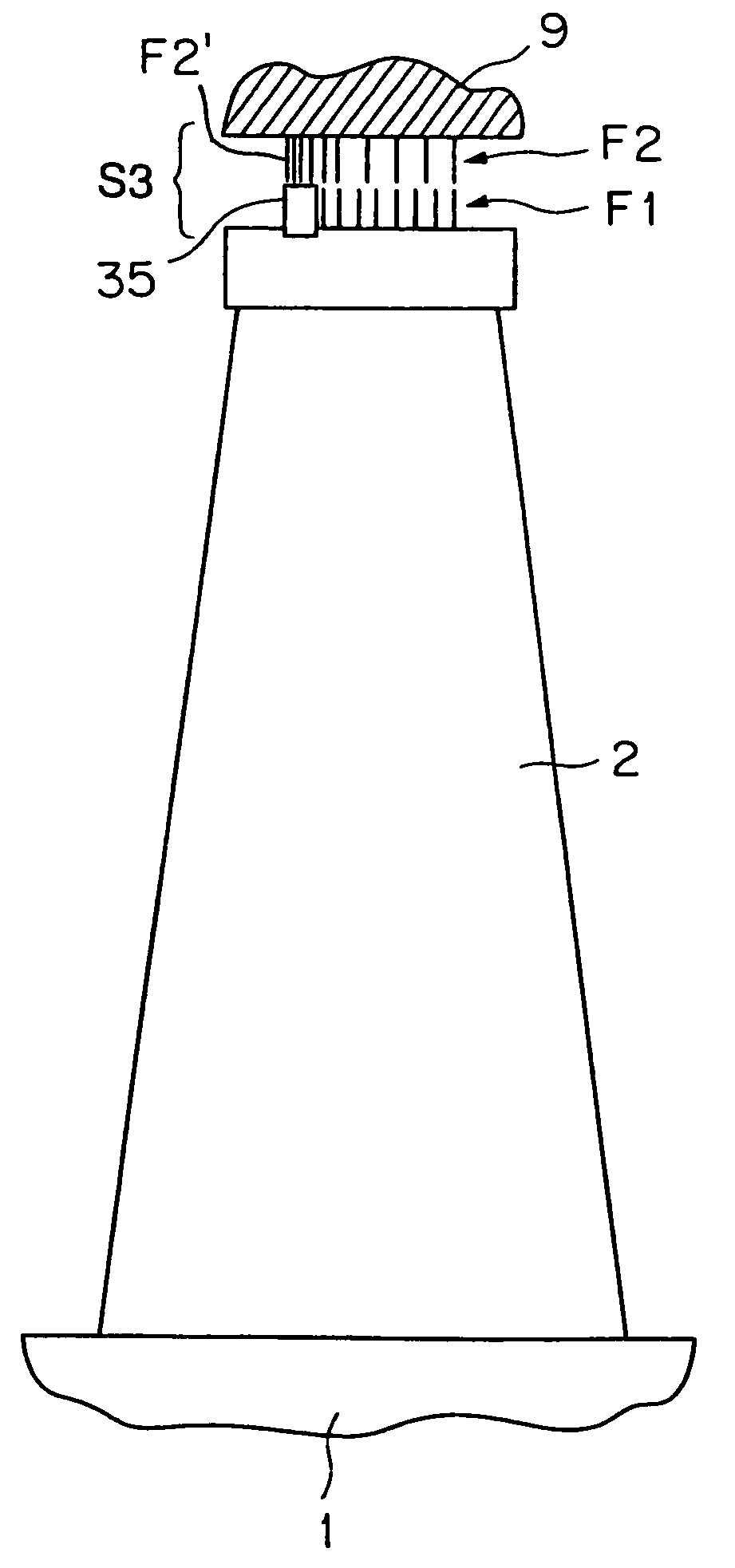

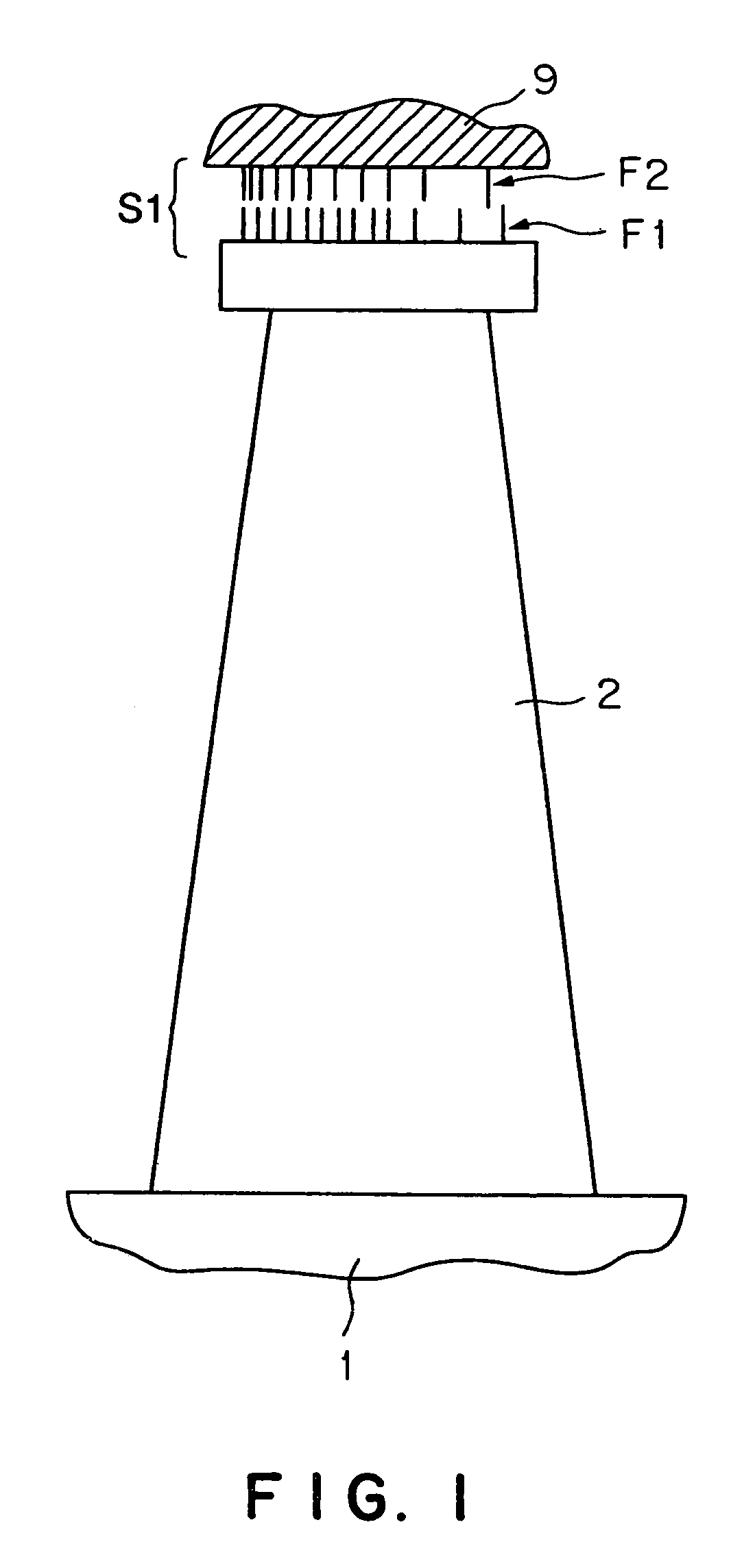

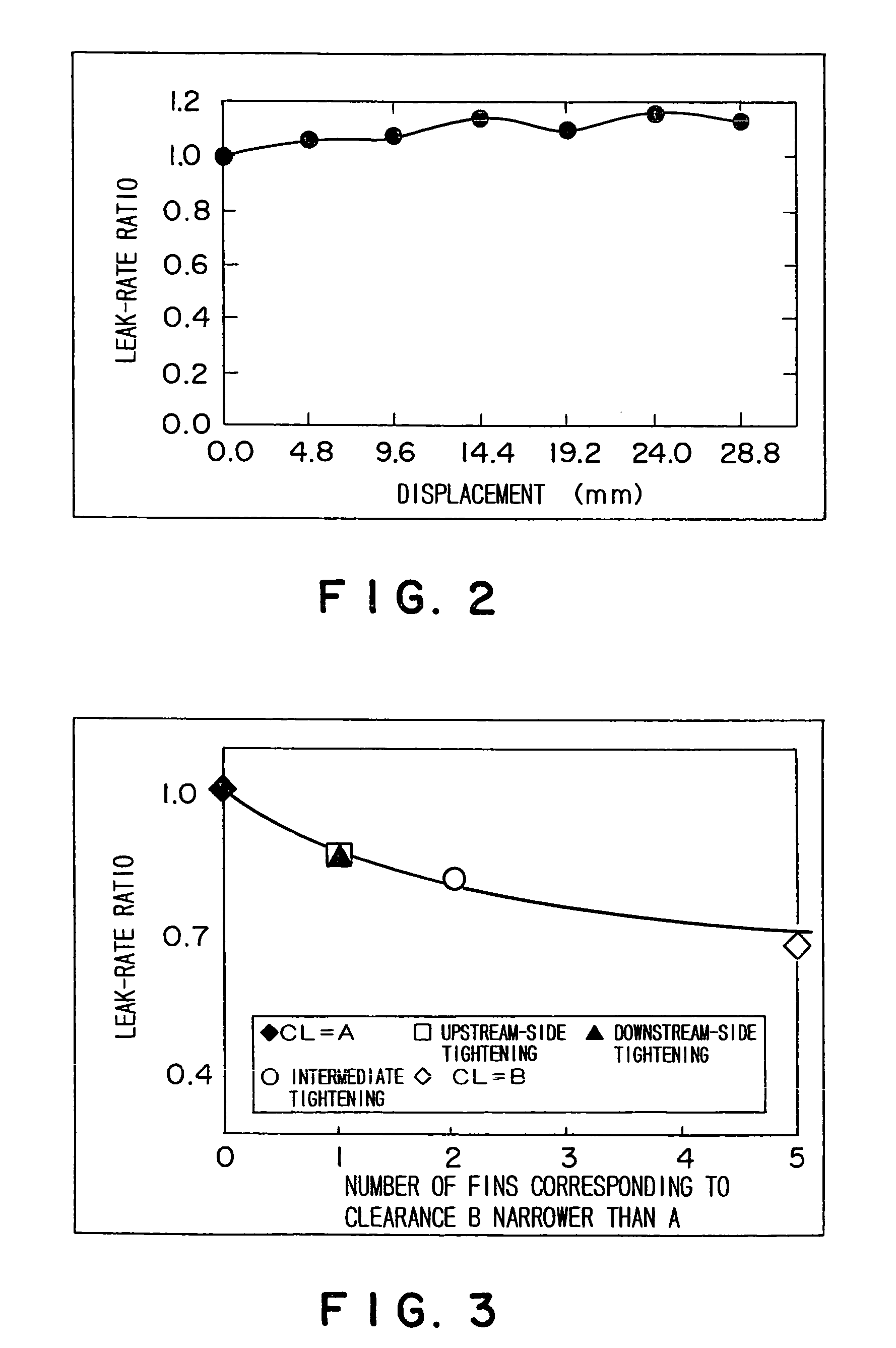

Rotary machine with seal

InactiveUS7052017B2Reduced sealing performanceImprove sealingEngine sealsPump componentsThermal expansionEngineering

The so-called comb-type labyrinth sealing device (S1) is disposed in a gap between a rotor blade (2), i.e. a rotating member, and a labyrinth packing (9), i.e. a stationary member. The sealing device (S1) has a plurality of sealing fins (F1, F2) arranged on the opposite sides of the gap opposite to each other. The sealing fins are axially spaced apart at unequal pitches, and hence a possibility that some of the clearances between the opposite sealing fins (F1, F2) decrease when a casing holding the labyrinth packing (9) and a rotor (1) are axially displaced relative to each other due to the difference in thermal expansion between the rotator and the casing increases.

Owner:KK TOSHIBA

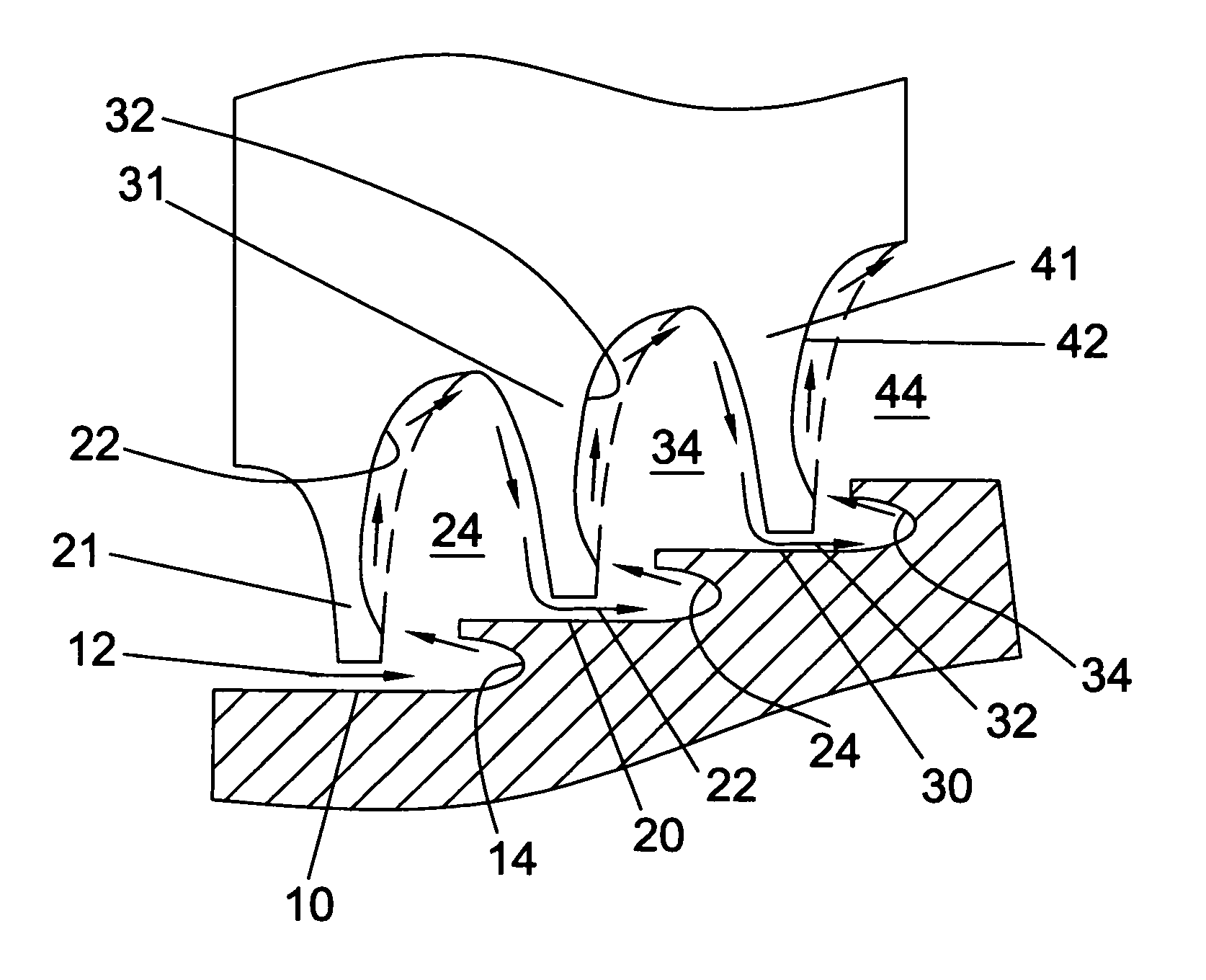

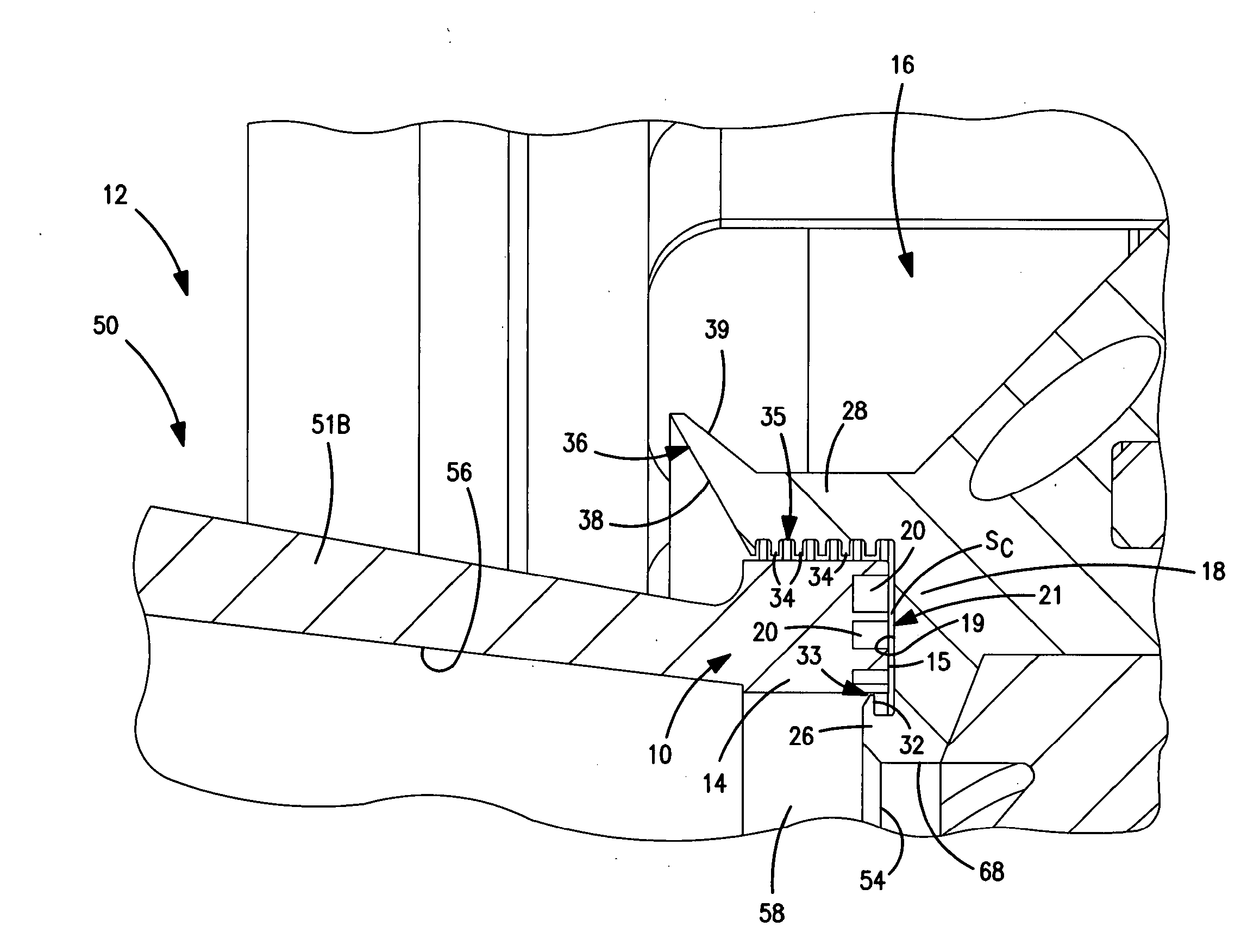

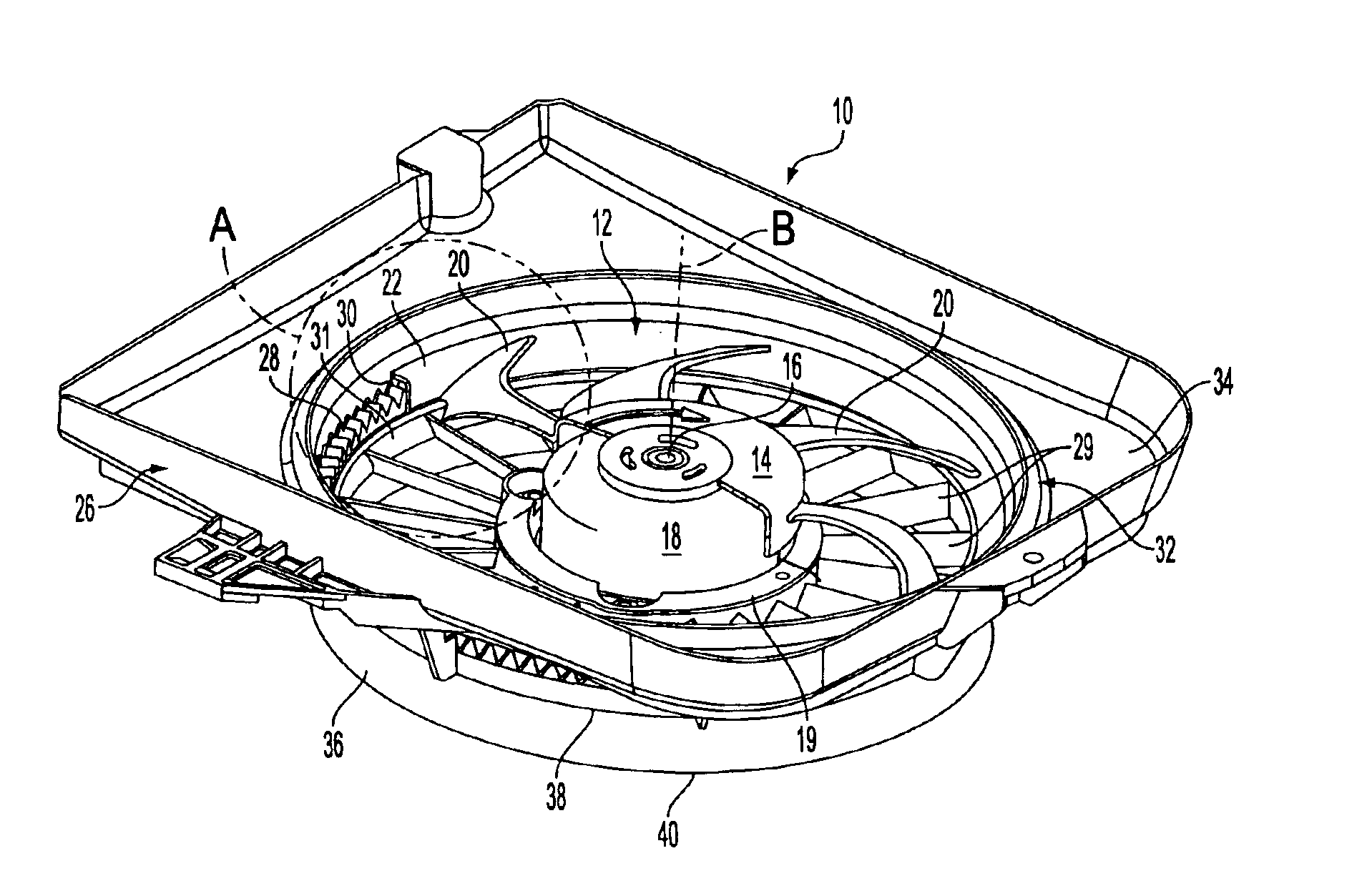

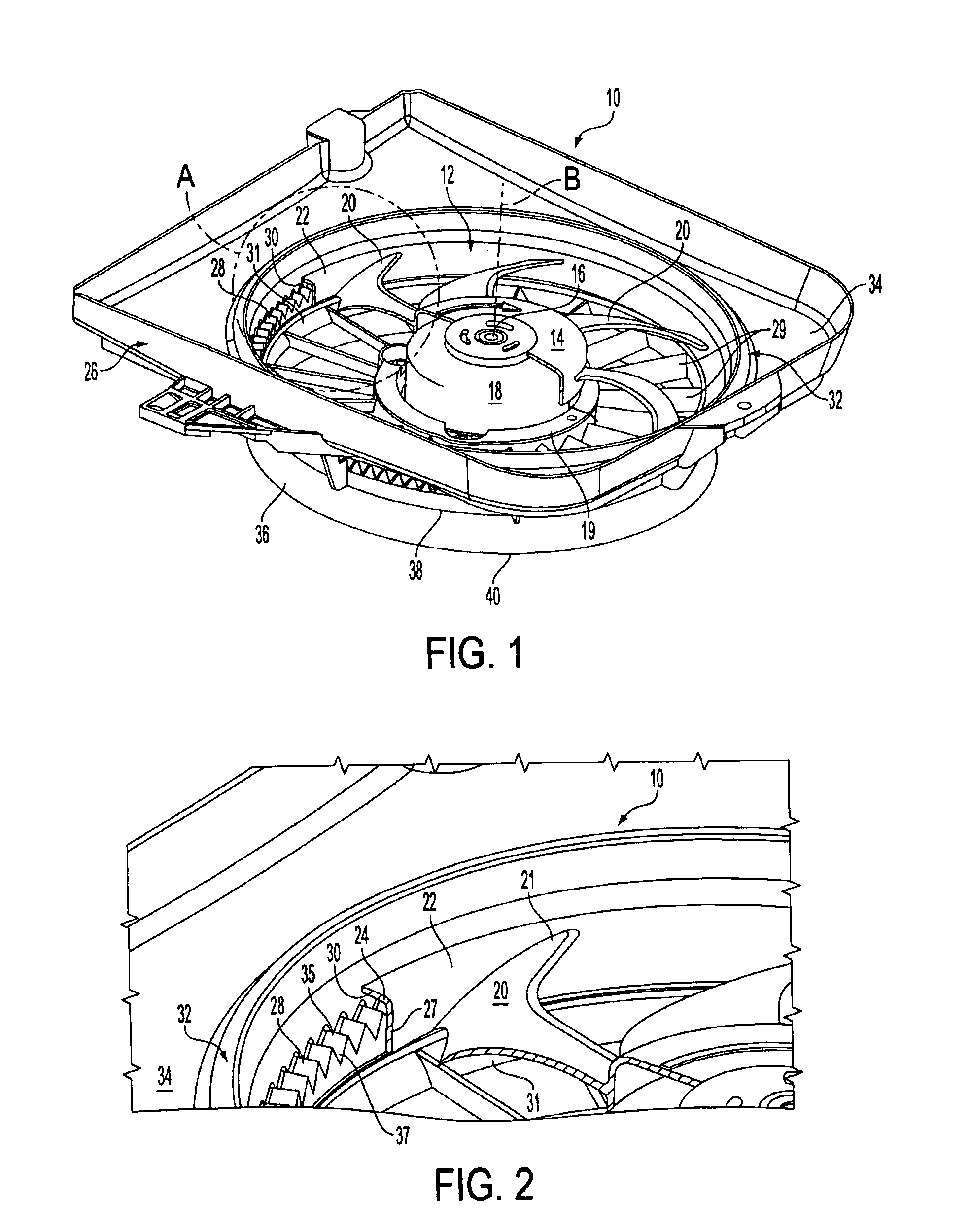

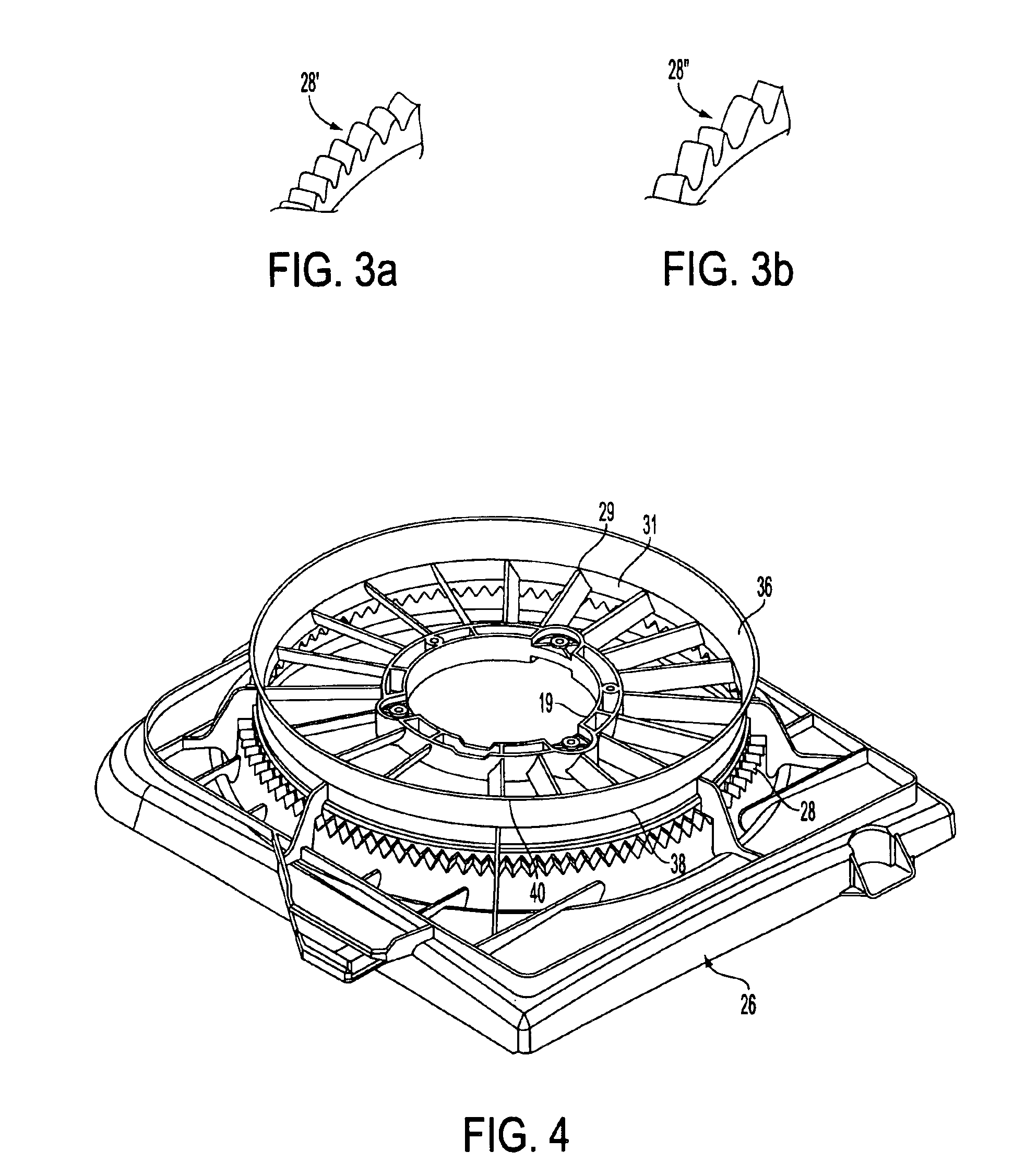

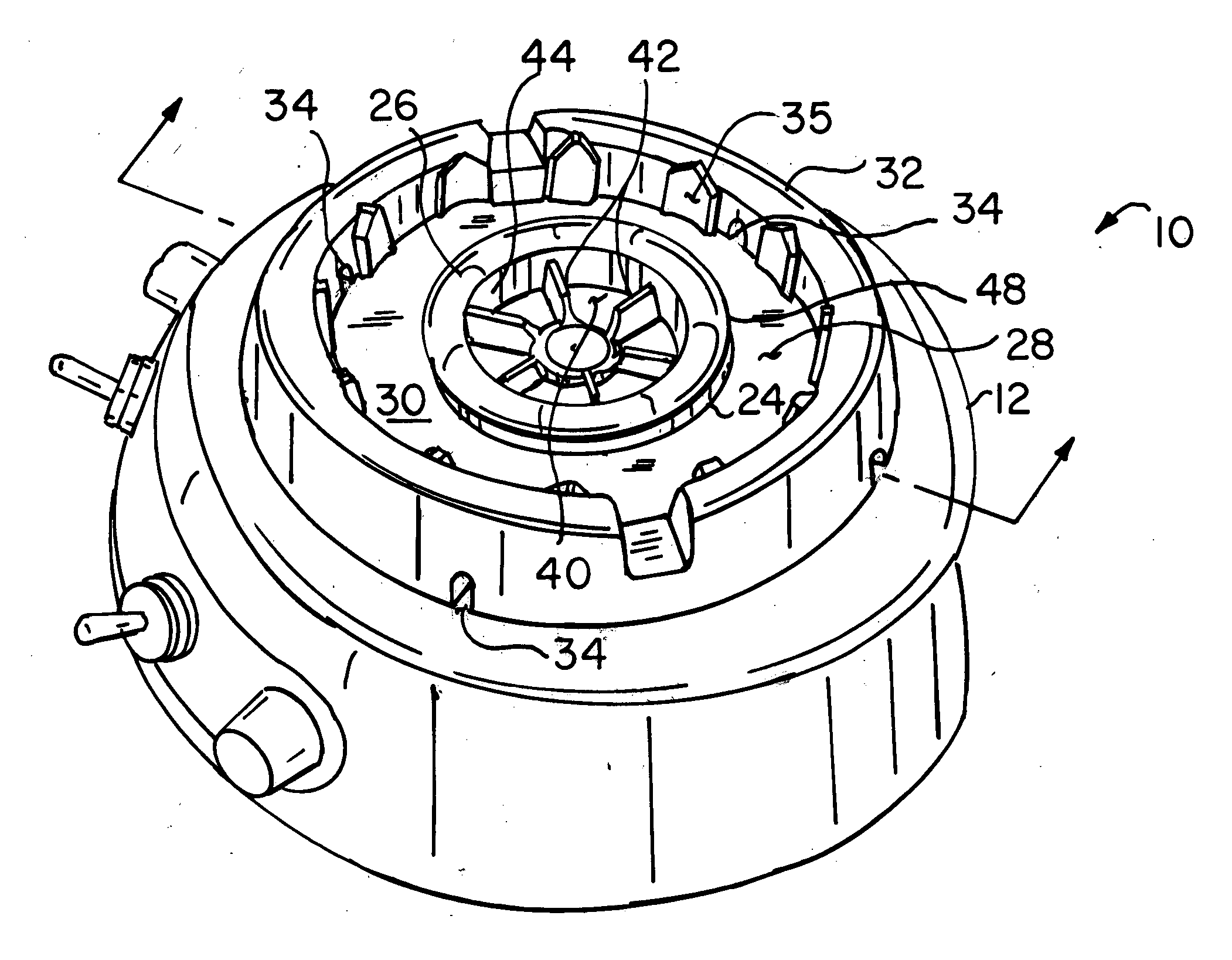

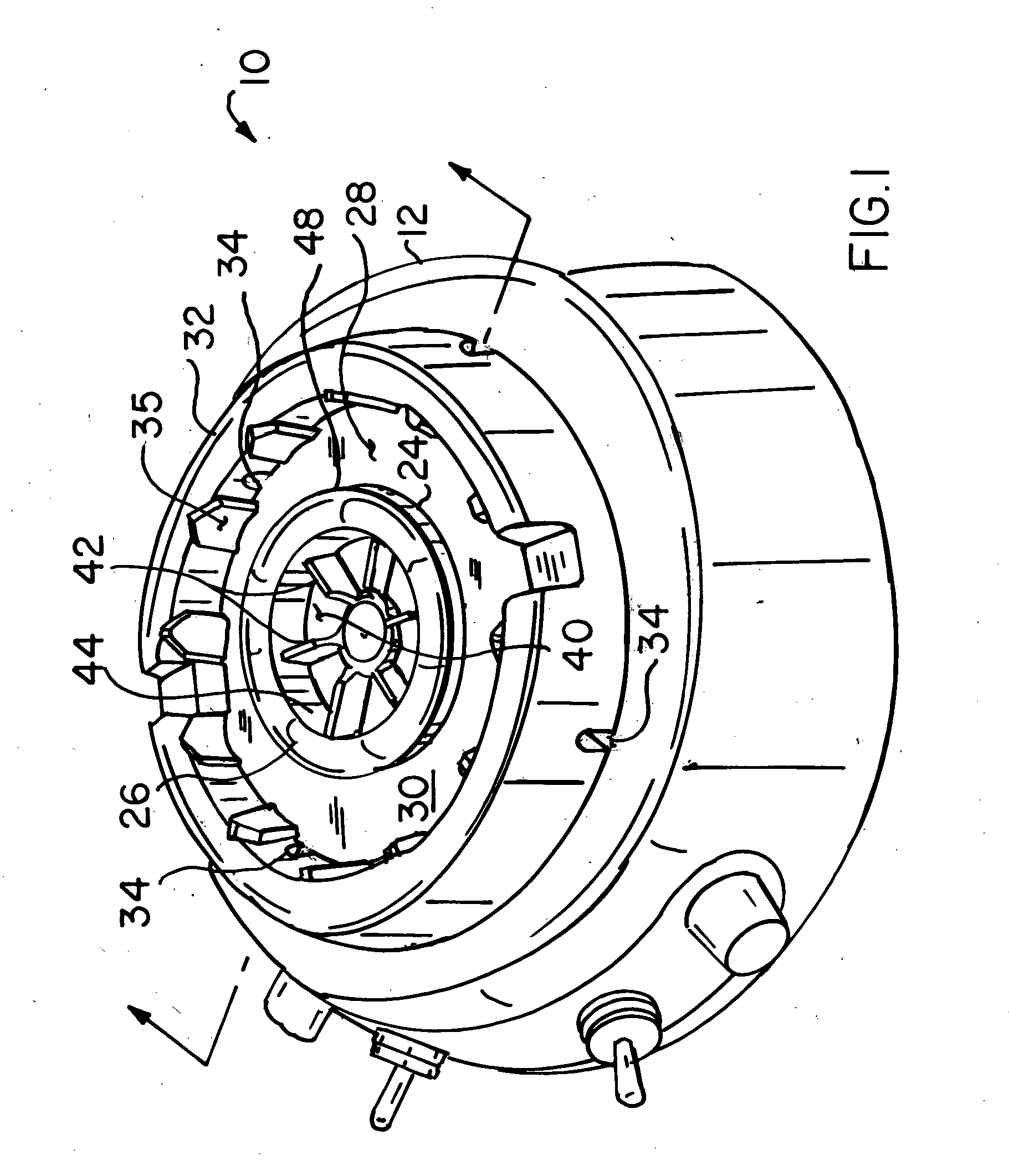

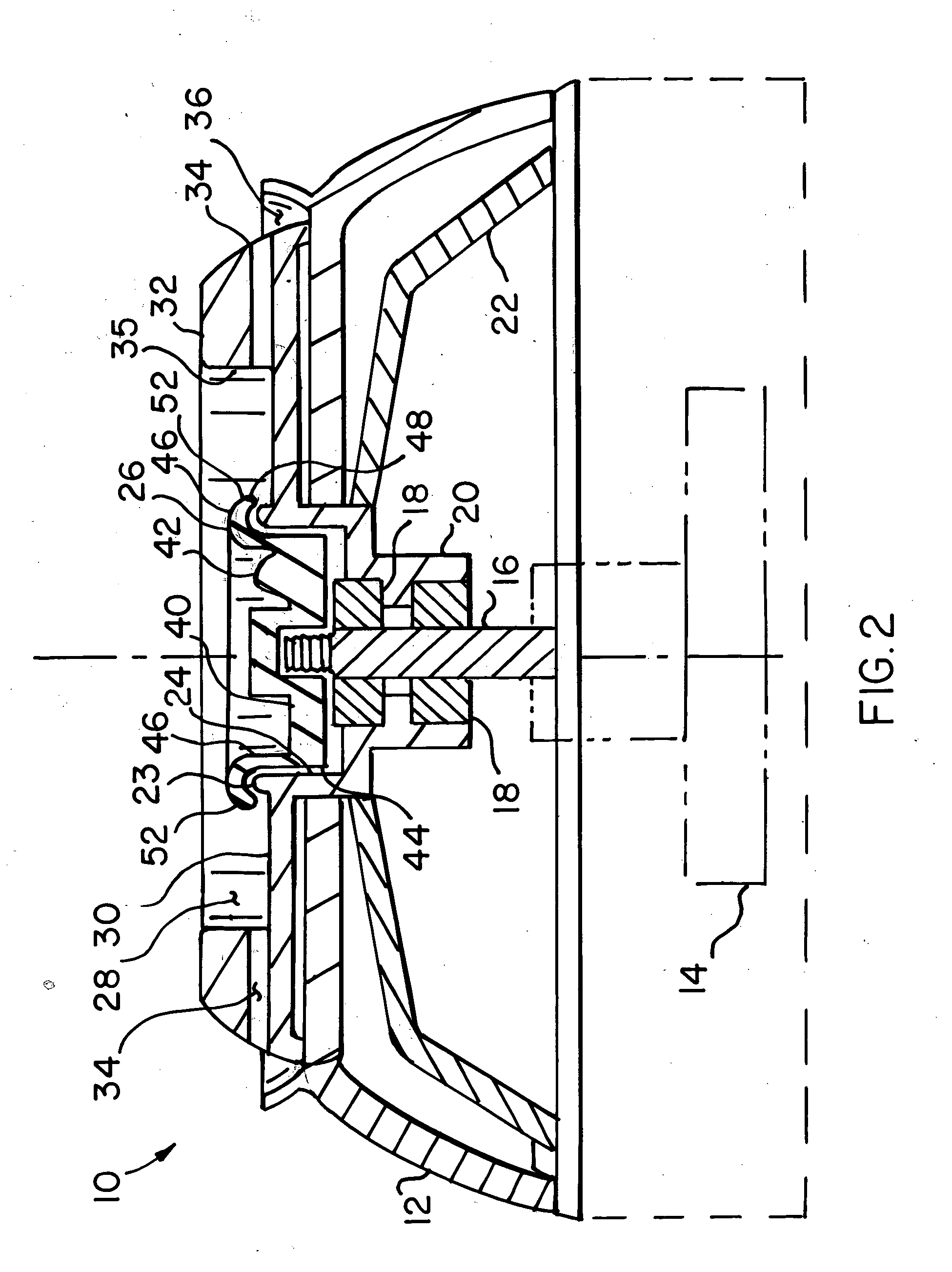

Integral tip seal in a fan-shroud structure

InactiveUS6874990B2Reduce noiseImprove fan efficiencyPropellersPump componentsEngineeringMechanical engineering

A fan-shroud structure 10 includes a fan 12 mounted for rotation about an axis B. The fan has a plurality of blades 20 with tips of the blades being coupled to an annular band 22. A shroud 26, including an annular labyrinth seal 28, is disposed generally adjacent to the annular band thereby defining a gap 30 between the annular band and the seal. The seal has a corrugated profile and is constructed and arranged to provide resistance to air flow as air swirls and flows back into the gap and to minimize air leakage across the gap.

Owner:BROSE FAHRZEUGTEILE GMBH & CO KG HALLSTADT (DE)

Hub and spindle assembly having asymmetrical seals for a disc drive memory system

A rotating hub and fixed spindle assembly with first and second fluid dynamic journal bearings and first and second fluid dynamic thrust bearings for a disc drive memory system has a pump seal and a radial ring seal at a first axial terminus for lubricant containment, and a capillary seal and a labyrinth seal at a second axial terminus for lubricant containment and storage. Lubricant fluid pressure differences between first and second seals are minimized through one or more lubricant fluid communicating channels in the hub assembly, in order to minimize lubricant fluid loss through a seal. Lubricant fluid can also be purged of any air bubbles by lubricant fluid circulation through the channel.

Owner:SEAGATE TECH LLC

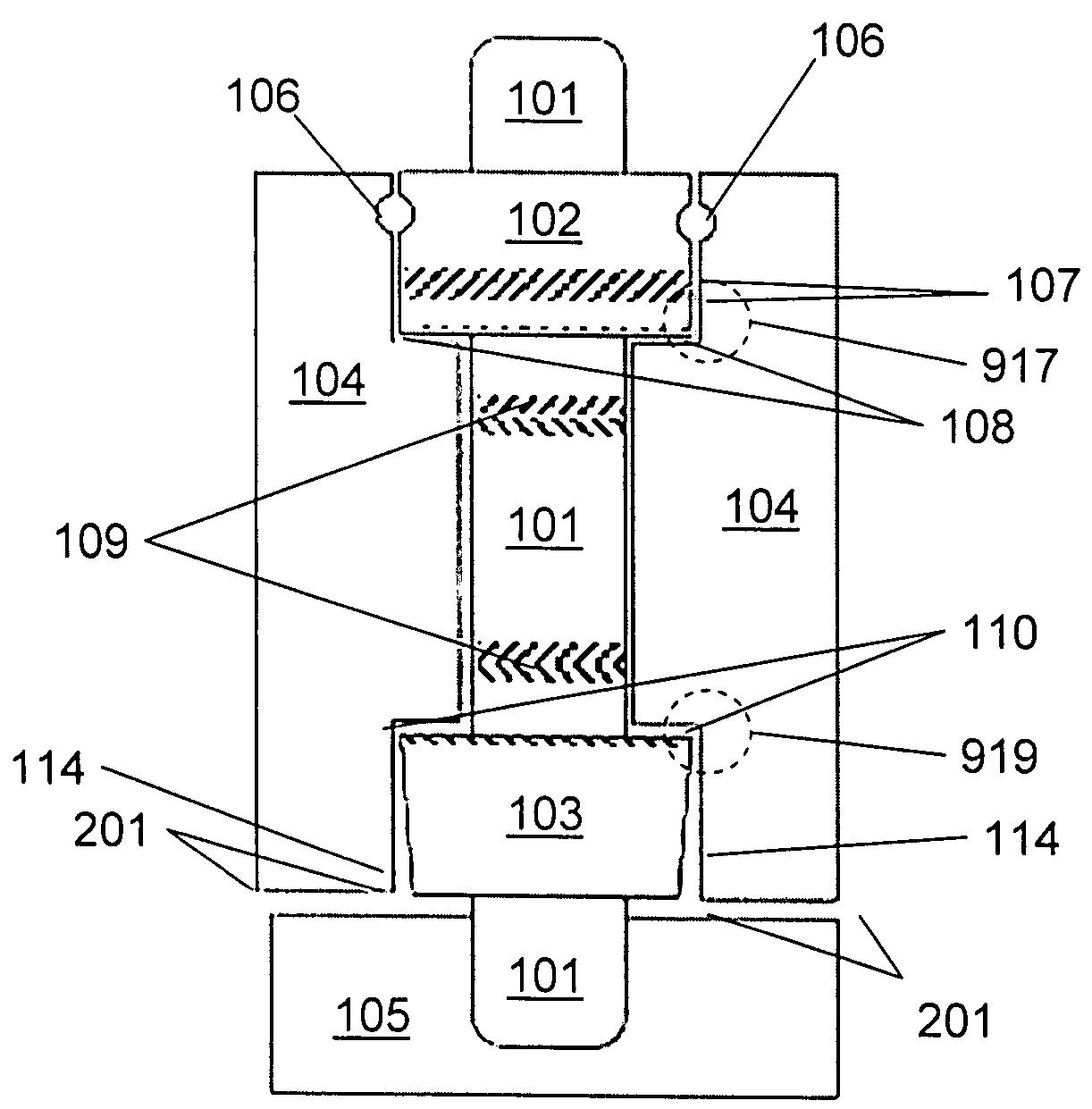

Double Sealing Labyrinth Chamber for Use With a Downhole Electrical Submersible Pump

InactiveUS20110236233A1Prevent leakagePiston pumpsPositive-displacement liquid enginesEngineeringGuide tube

A labyrinth seal assembly for an electrical submersible pumping system that communicates downhole pressure to a pump motor while sealing wellbore fluids from the motor. The labyrinth seal assembly includes a chamber circumscribing a pump shaft, labyrinth tubes, upper and lower shaft seals, and inner and outer guide tubes coaxially circumscribing the shaft. One labyrinth tube has an end in fluid communication with the wellbore fluid and another has an end in fluid communication with the pump motor. The labyrinth tubes extend into the chamber from opposite directions and each have an opening distal from where they enter the chamber. A port is provided in the inner guide tube distal from the upper shaft seal, and a port in the outer guide tube is provided proximate the upper shaft seal. Thus a labyrinth path is provided between the upper shaft seal and the chamber.

Owner:BAKER HUGHES INC

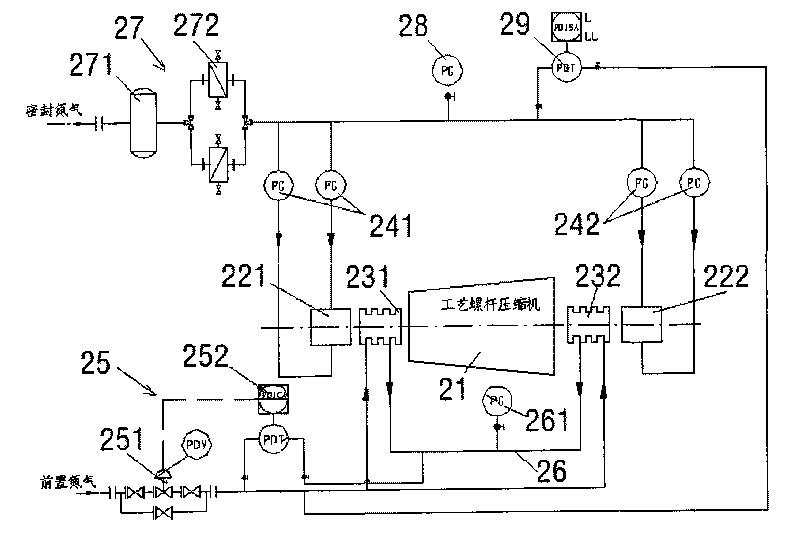

Dry gas sealing device for technical screw compressor and application system thereof

InactiveCN101713461AImprove performanceGuaranteed uptimeEngine sealsRotary piston pumpsNitrogenDry gas seal

The invention discloses a dry gas sealing device for a technical screw compressor and an application system thereof. The dry gas sealing device is characterized by comprising two sets of single sealing mechanisms with the same structure, wherein each set of single sealing mechanism comprises a static ring component, a moving ring component, a push ring and a spring component, wherein the static ring component is fixedly connected with a gland, and the moving ring component, the push ring and the spring component are fixedly connected with a shaft sleeve. The application system comprises a technical screw compressor, two dry gas sealing devices, two labyrinth sealing devices, two groups of gas flowmeters of sealed gas, a front-end gas input device and a sealed gas input device, wherein the two dry gas sealing devices and the two labyrinth sealing devices are symmetrically arranged at two ends of the shaft of the technical screw compressor. The invention also discloses an application method of the application system.The dry gas sealing device for the technical screw compressor of the invention has self adaptation and non-contact characteristics, can ensure reliable operation of dry gas sealing by matching the combined application system which has balancing cavity pressure relief, labyrinth seal obstruction, front-end nitrogen protection and dry gas sealing, and is especially suitable for high-pressure technical screw compressors with high rotary speed.

Owner:NO 711 RES INST CHINA SHIPPING HEAVY IND GRP

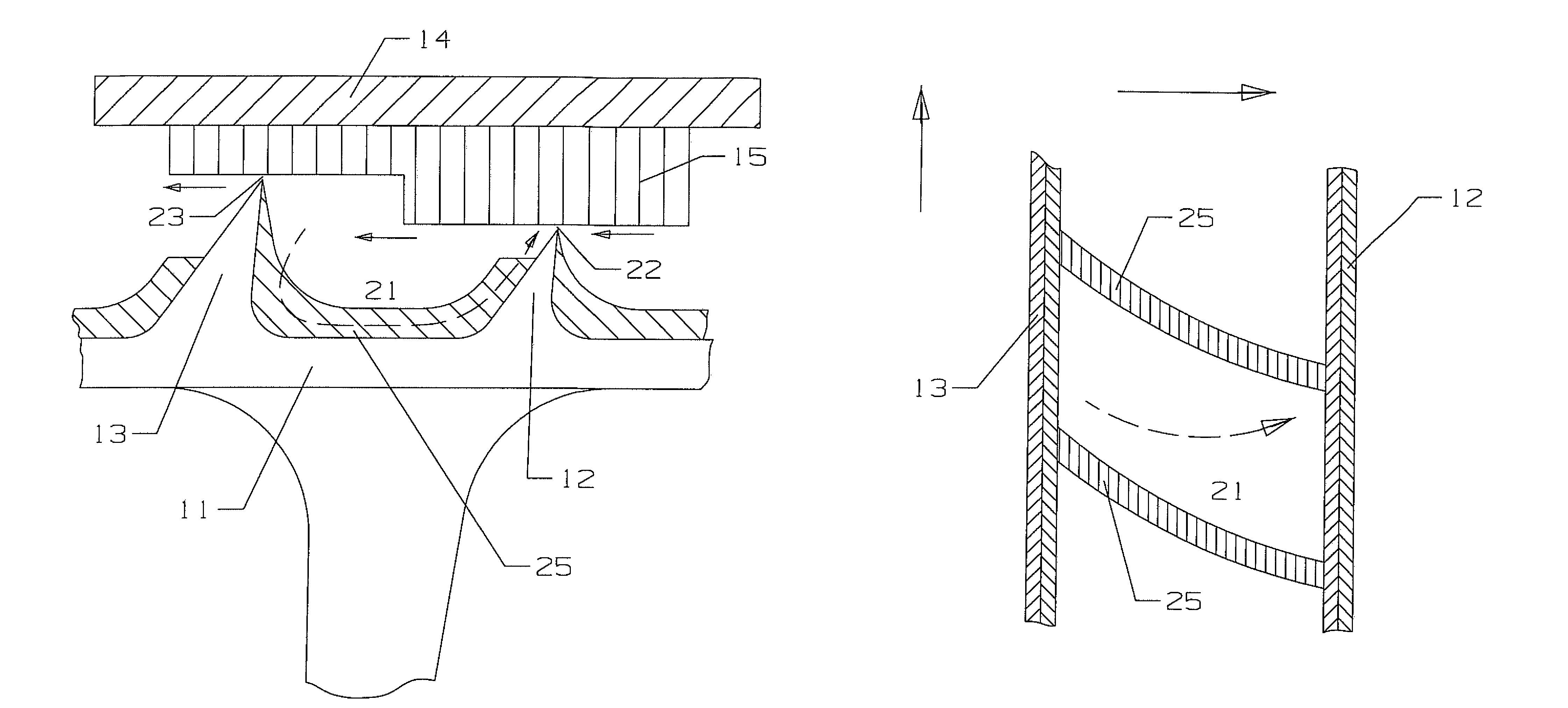

Curved labyrinth seals

InactiveUS20110280715A1Avoid large gapsEngine sealsEngine manufactureEngineeringMechanical engineering

In one embodiment, a system includes a rotary machine and a packing seal that is disposed between rotary and stationary components of the rotary machine. The packing seal includes a pair of seal lands spaced axially along the rotary component and a seal tooth disposed at an axial position between the pair of seal lands. At least one seal land of the pair of seal lands or the seal tooth includes a curved flow-facing side and is slanted toward the curved flow-facing side.

Owner:GENERAL ELECTRIC CO

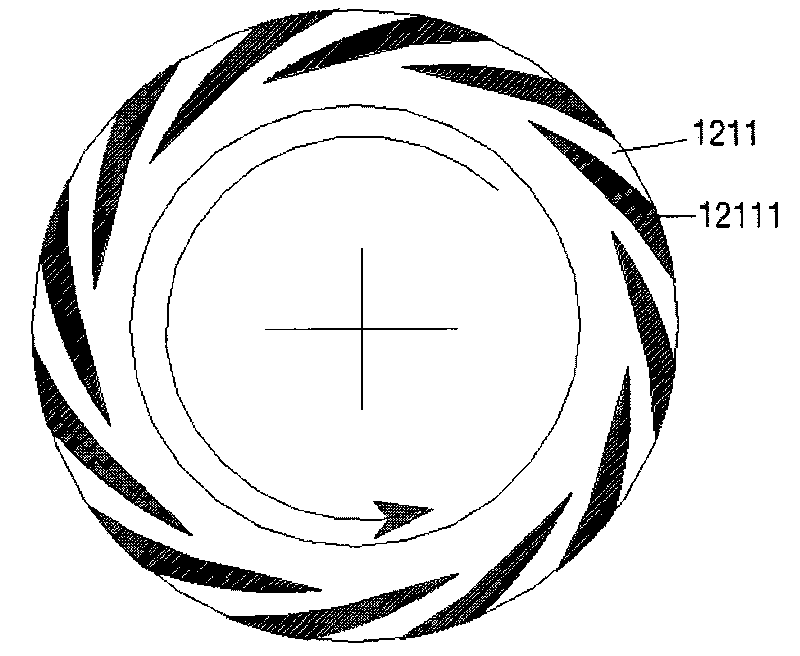

Labyrinth seal

A stepped labyrinth seal having a plurality of teeth forming gaps between a stationary honeycomb member, where the cavities formed between adjacent teeth include a plurality of vortex flow generating strips on the wall of the cavity that redirect the leakage flow from a gap back toward the gap and in a direction toward the gap in order to limit the leakage flow through the gap. The vortex generating strips extend along the cavity floor and up the sides of the teeth forming the cavity. The strips slope downward from the downstream tooth toward the upstream tooth in the direction of rotation, and with a curvature in the direction of rotation. The stepped labyrinth seal is intended for use in a gas turbine engine having a plurality of stages in the turbine, with the labyrinth seal being used to seal the gap between rotating blades and the honeycomb surface on the stationary casing.

Owner:FLORIDA TURBINE TECH

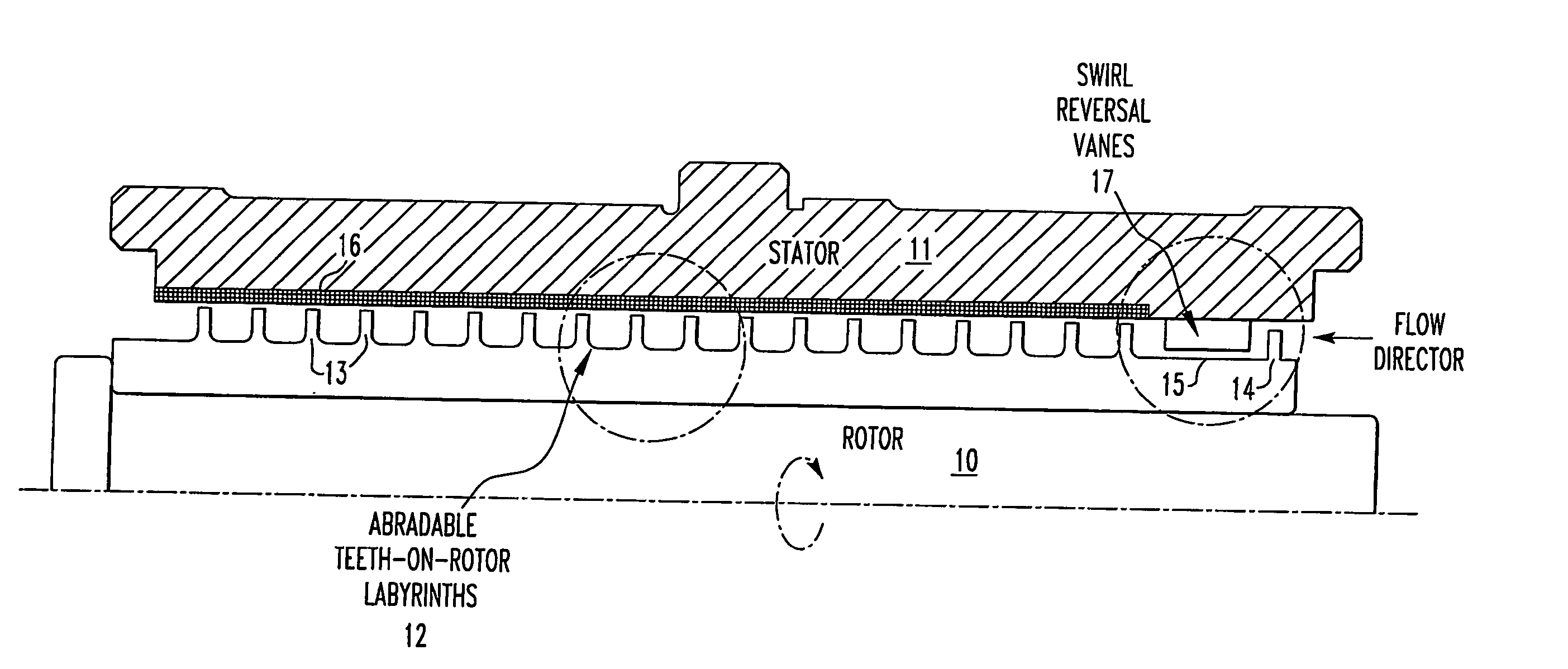

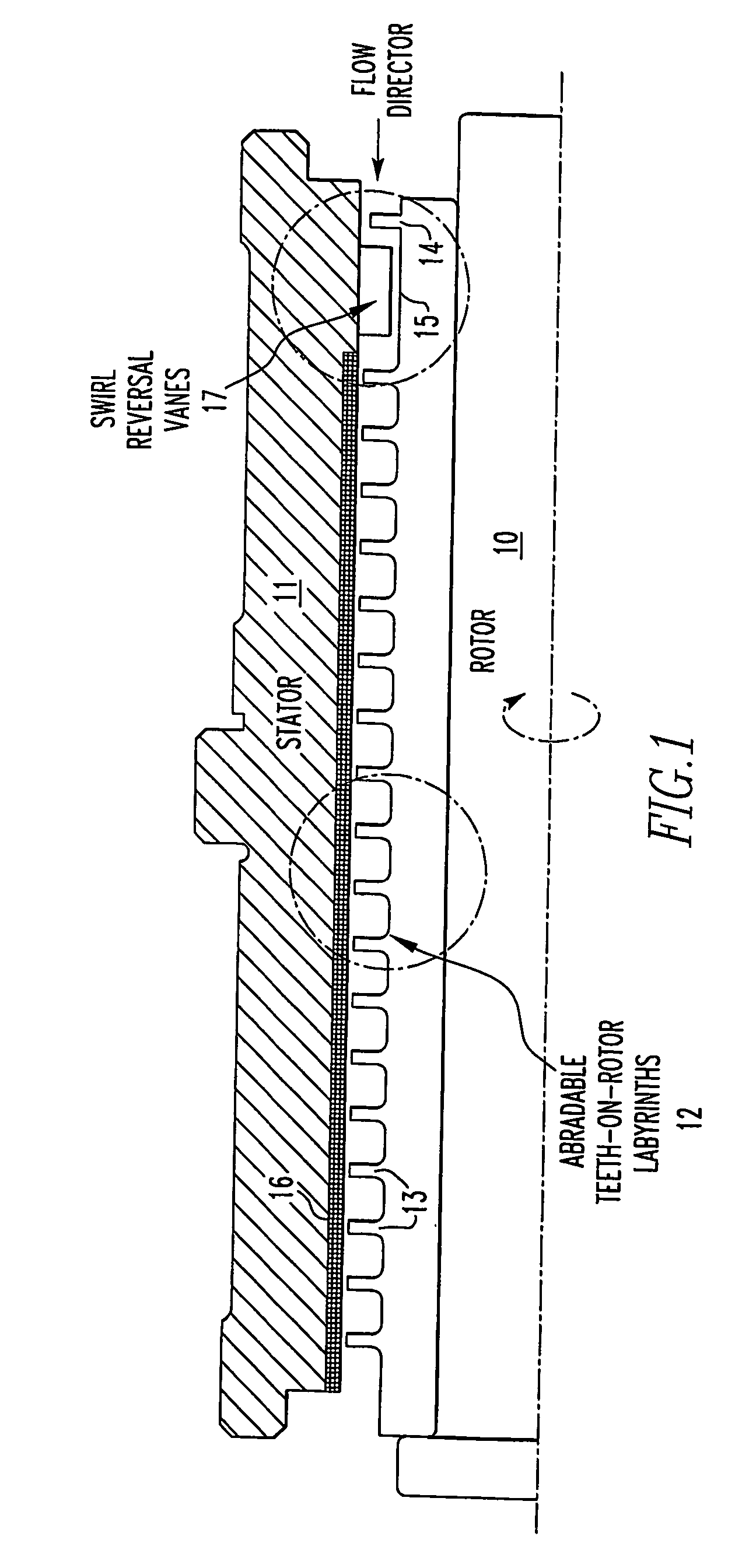

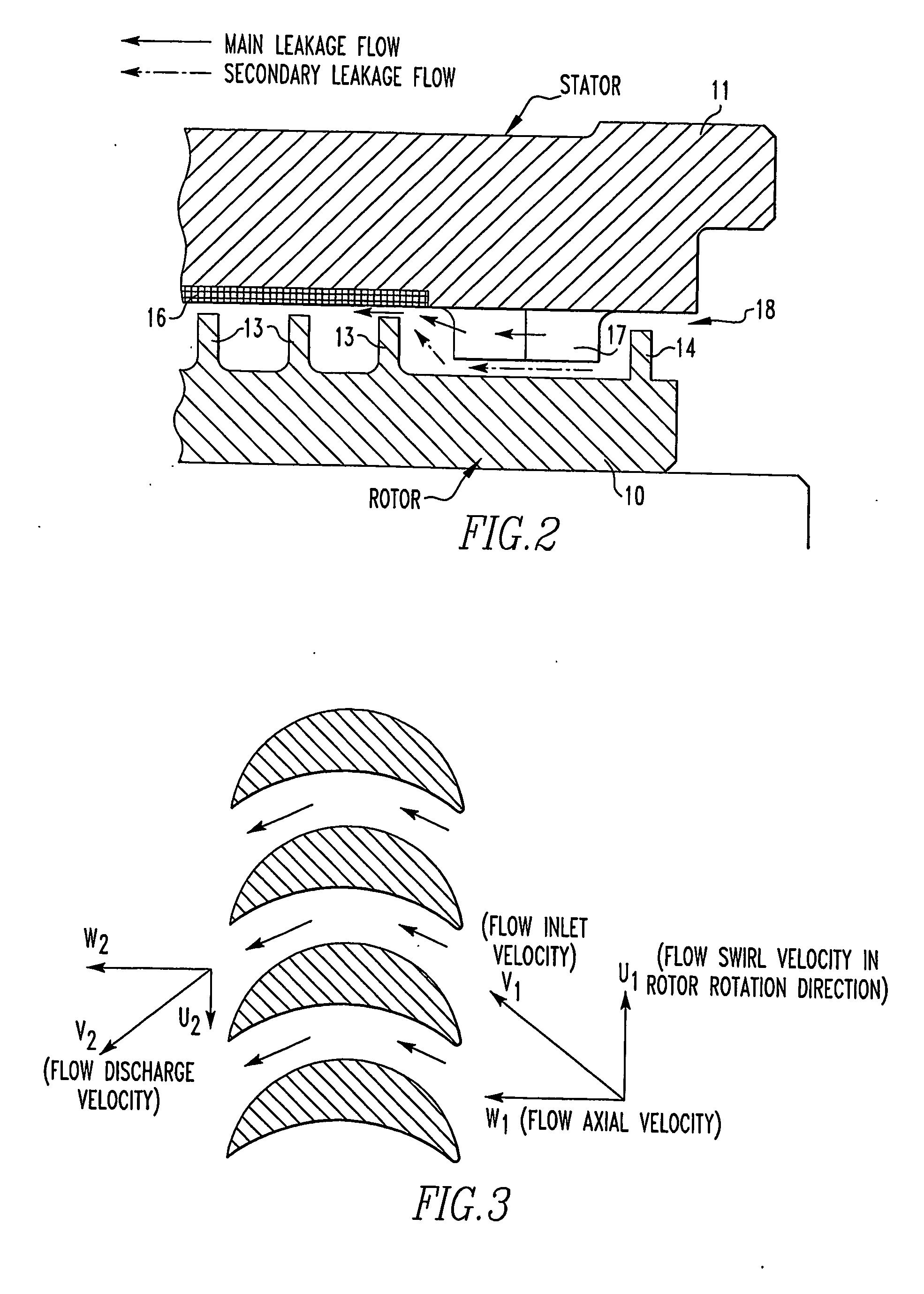

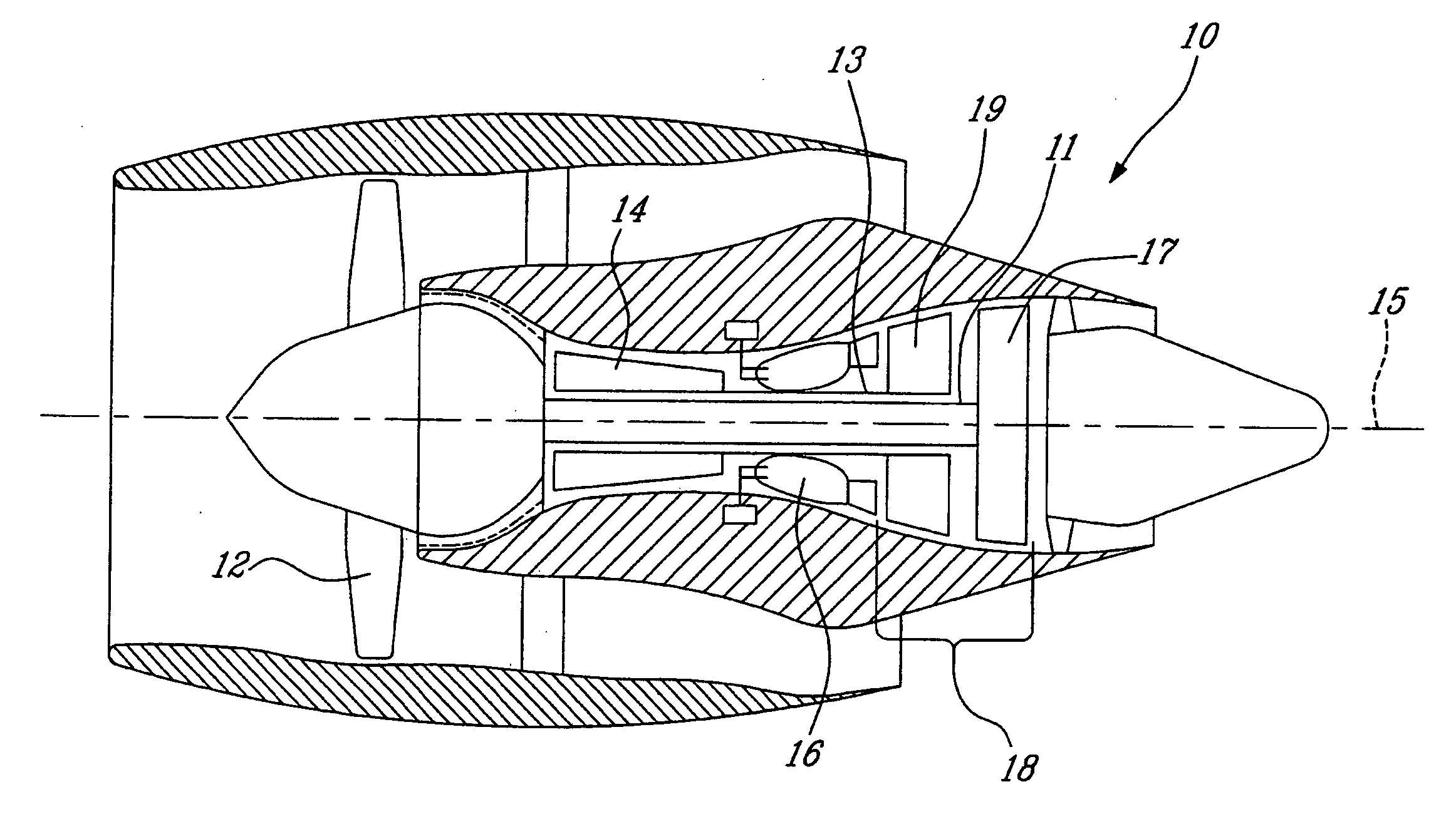

Swirl-reversal abradable labyrinth seal

InactiveUS20060237914A1Effective dampingImproved rotor stabilityEngine sealsPump componentsEngineeringMechanical engineering

An apparatus for restricting axial flow through the clearance between a rotating shaft and a seal stator comprises an abradable labyrinth seal and swirl-reversal vanes upstream of the labyrinth seal. The shaft comprises a first toothed axial section having a plurality of annular teeth, a second upstream toothed axial section having a few annular teeth from one to three, and a section therebetween having a cylindrical surface of diameter less than the outer edge of the teeth of the toothed sections, the swirl-reversing vanes being fastened to the stator seal between the toothed sections.

Owner:ELLIOTT CO

Integrated labyrinth and carbon seal

An integrated double seal assembly includes a carbon seal ring and at least one annular labyrinth seal fin. The seal provides a compact solution for sealing a rotating shaft.

Owner:PRATT & WHITNEY CANADA CORP

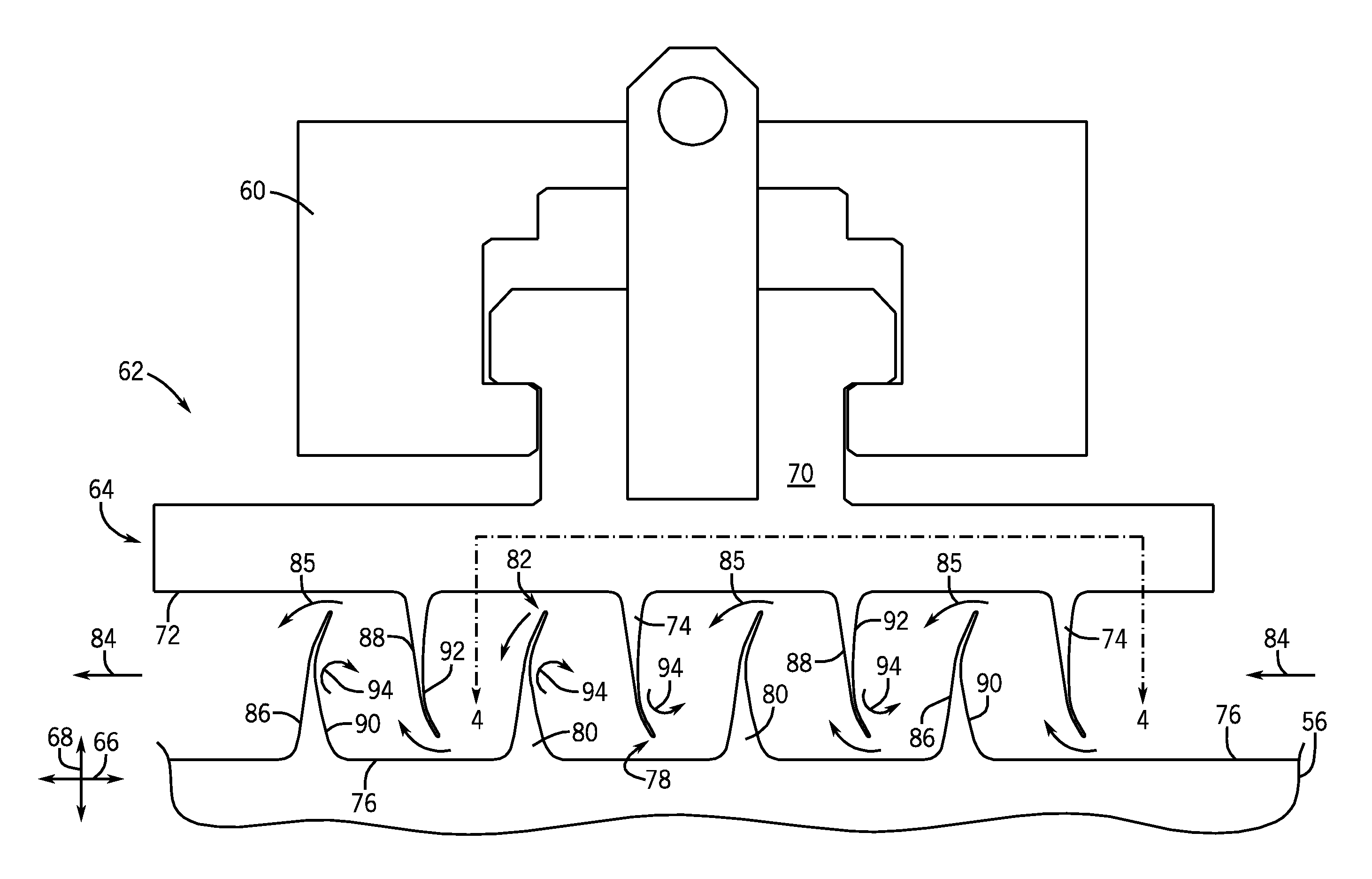

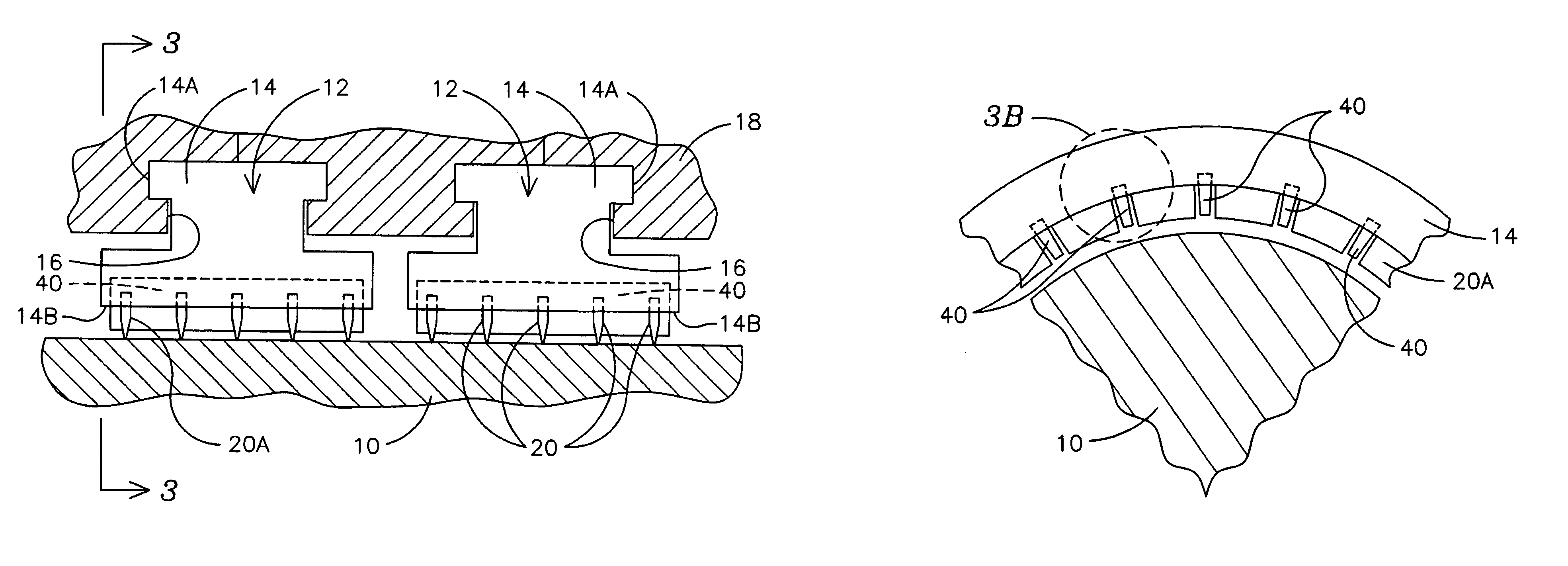

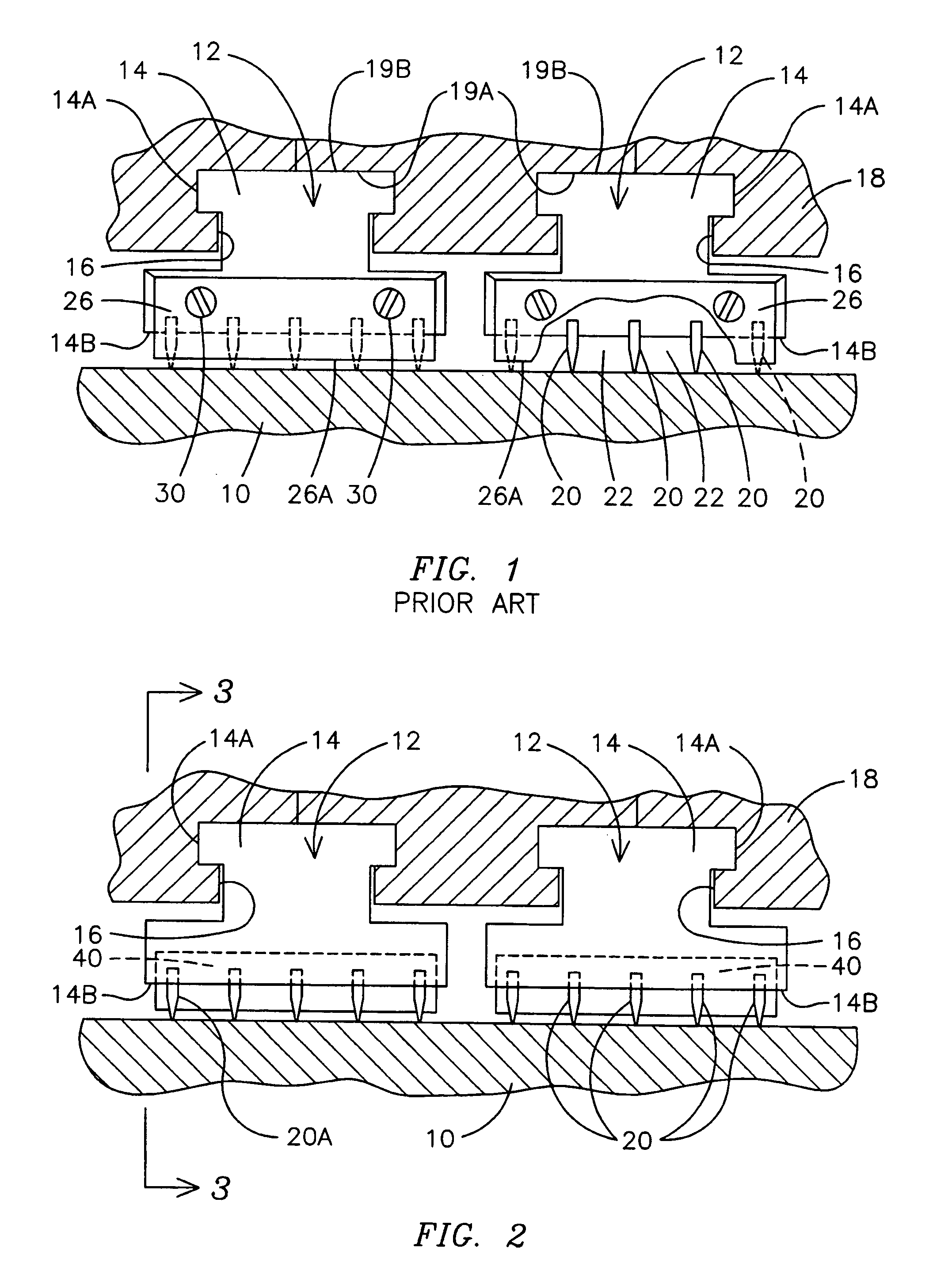

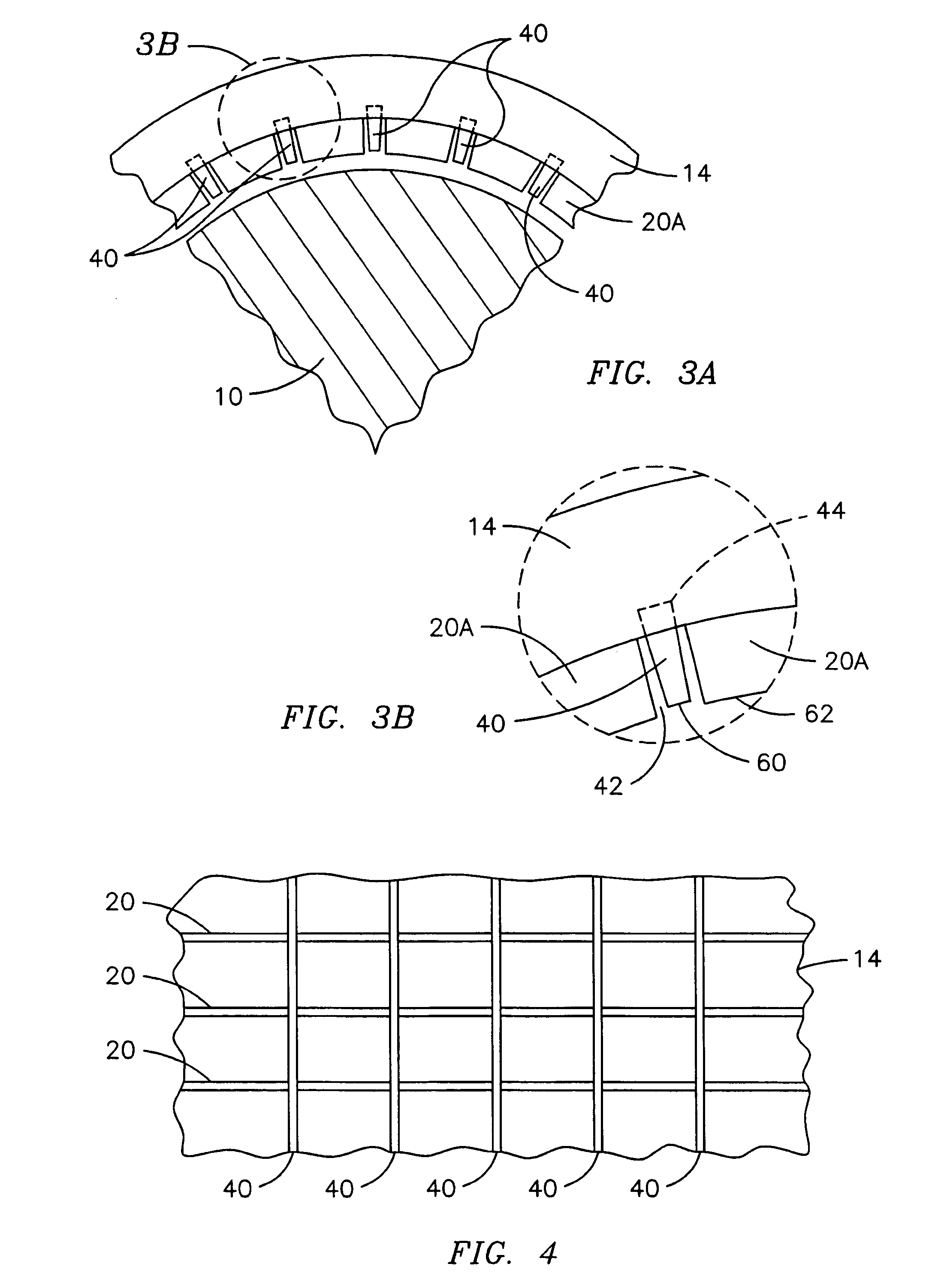

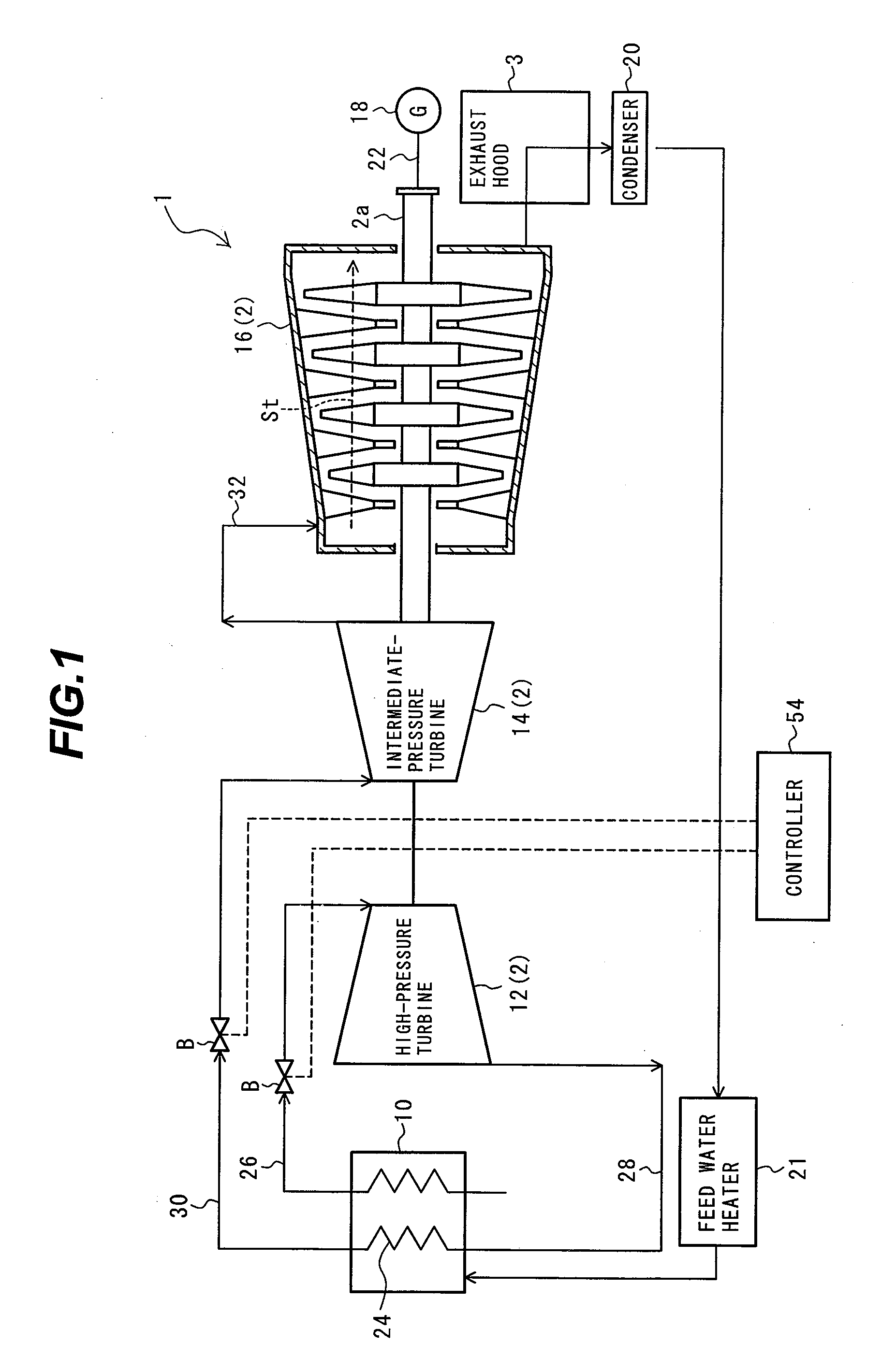

Flow dam design for labyrinth seals to promote rotor stability

A method and apparatus for reducing steam swirl in a steam turbine. A plurality of seal segments (14) are circumferentially juxtaposed to form a seal ring (12) encircling the turbine shaft (10), each seal segment (14) supporting a plurality of circumferentially disposed annular seal fins (20) to limit axial steam flow along the shaft (10). A plurality of flow dams (40) are disposed within grooves (42) defined in the plurality of seal fins (20) and seal segments (14) for limiting circumferential steam flow and thereby reducing rotor instability.

Owner:SIEMENS ENERGY INC

Labyrinth seal in a stationary gas turbine

InactiveUS7430802B2Low efficiencyReduced space requirementsEngine sealsPump componentsTurbineGas turbines

The invention relates to a segmented inner ring for holding guide blades. According to the invention, a lateral wall opposing the front side of the inner ring and pertaining to a shaft shoulder formed on the rotor shaft extends radially, and respectively one half of a labyrinth seal is formed on the front side of the inner ring and on the shaft shoulder. The aim of the invention is to apply an arrangement of stacked labyrinth seals, known from airplane turbines, to a stationary gas turbine having a separation plane. To this end, a method is used to mount an inner ring of a gas turbine. The invention also relates to a stationary gas turbine comprising a segmented inner ring.

Owner:SIEMENS AG

Curved labyrinth seal

Owner:GENERAL ELECTRIC CO

Bearing pressure balance apparatus

The present invention provides a method and apparatus for balancing the pressure across a front bearing in a compressor housing. The present invention may protect the bearing from lubricant migration by eliminating pressure differentials across the bearing. When a blower or fan is running, the bearing experiences the same pressure differential that is across the blower. Unless this pressure is balanced, lubricant may migrate from the bearing very quickly. The present invention may provide a pressure balance and sealing across the front bearing of a blower or fan. A plurality of grooves on the face of a compressor impeller and a plurality of grooves on a compressor shaft surface restrict the gas flow to balance pressure across a bearing. Alternatively, a labyrinth seal may cooperate with a plurality of grooves on the face of a compressor impeller to balance pressure across the bearing.

Owner:HONEYWELL INT INC

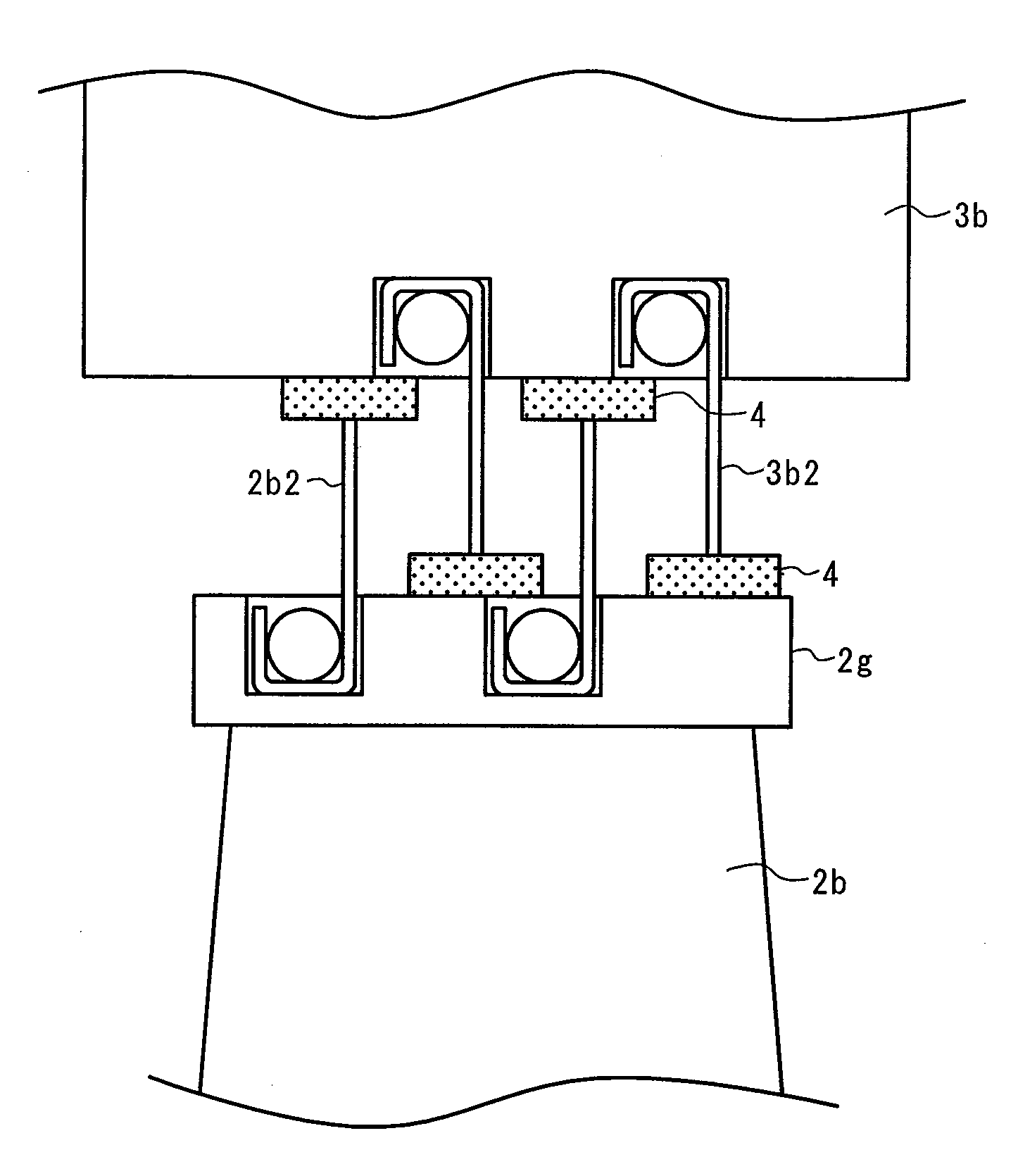

Seals in steam turbine

A seal structure for a steam turbine is provided, which is capable of suppressing transfer of heat generated by a friction between a rotating portion and a fixed portion to the rotating portion and of suppressing an increase in the temperature of the rotating portion. A labyrinth seal device serves to suppress the amount of steam leaking from a clearance present between each stator blade (fixed portion) of the steam turbine and a rotor (rotating portion). The seal structure for the steam turbine is formed to ensure that permeable spacers made of a permeable metal are provided on the rotor and a seal stationary body and face respective seal fins provided in the labyrinth seal device.

Owner:MITSUBISHI HITACHIPOWER SYST LTD

Seal and drain for blenders

InactiveUS20070140048A1Reduce frictionInhibit wearRotary stirring mixersKitchen equipmentCouplingEngineering

A dynamic and static seal is formed by a close clearance fit between a rotary coupling and a static upstanding wall on a motor housing such as a base for an electric blender. The seal centrifugally ejects spilt liquid during operation towards a network of drainage holes which direct the liquid away to prevent it from leaking into the blender's base. A down-turned U-shaped lip rotates around both sides and the top edge of the upstanding wall so as to form a rotary labyrinth seal. The wall forms a static barrier to liquid when the blender is not rotating.

Owner:SUNBEAN PROD INC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com