Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

5711results about "Bulk conveyors" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

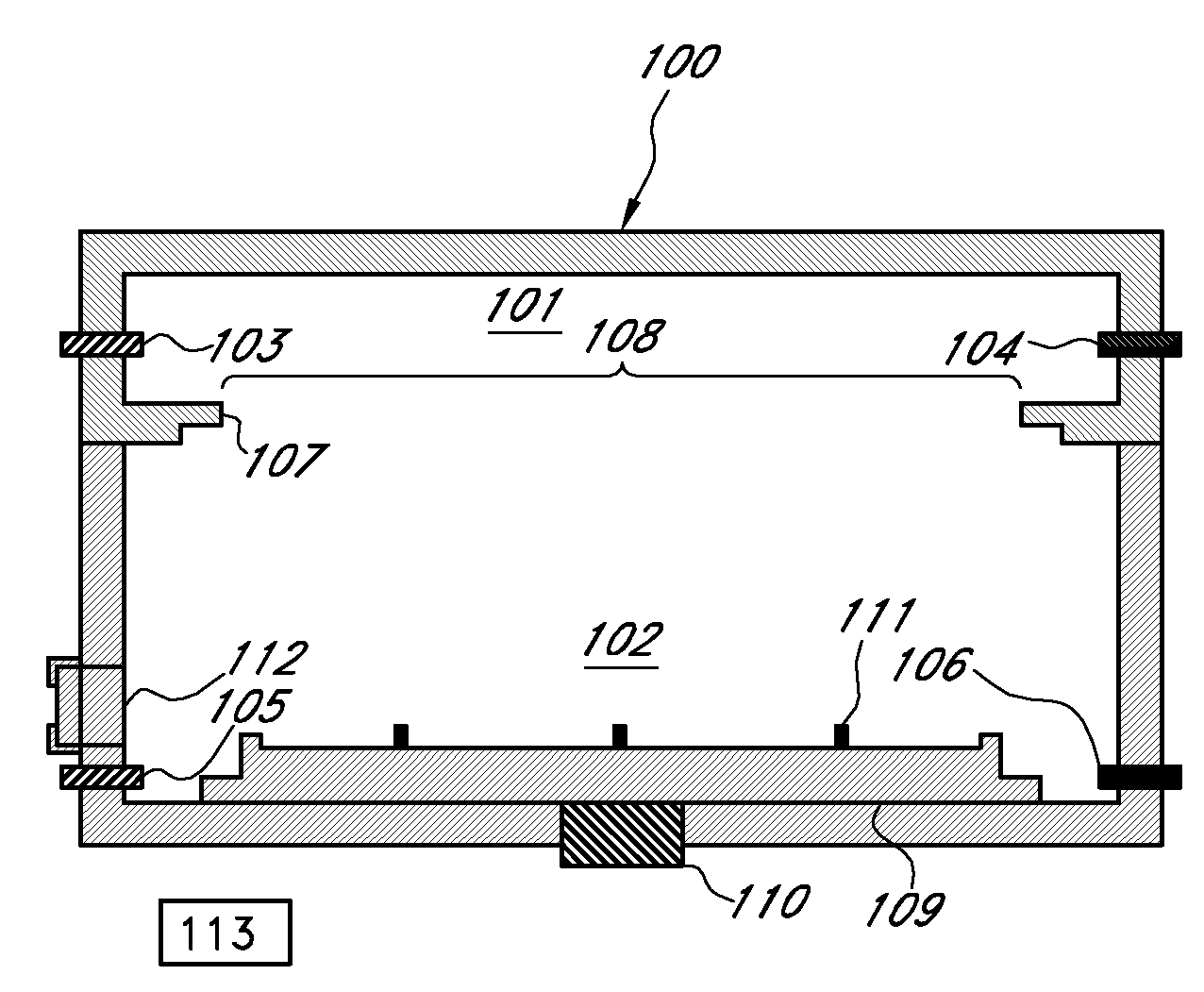

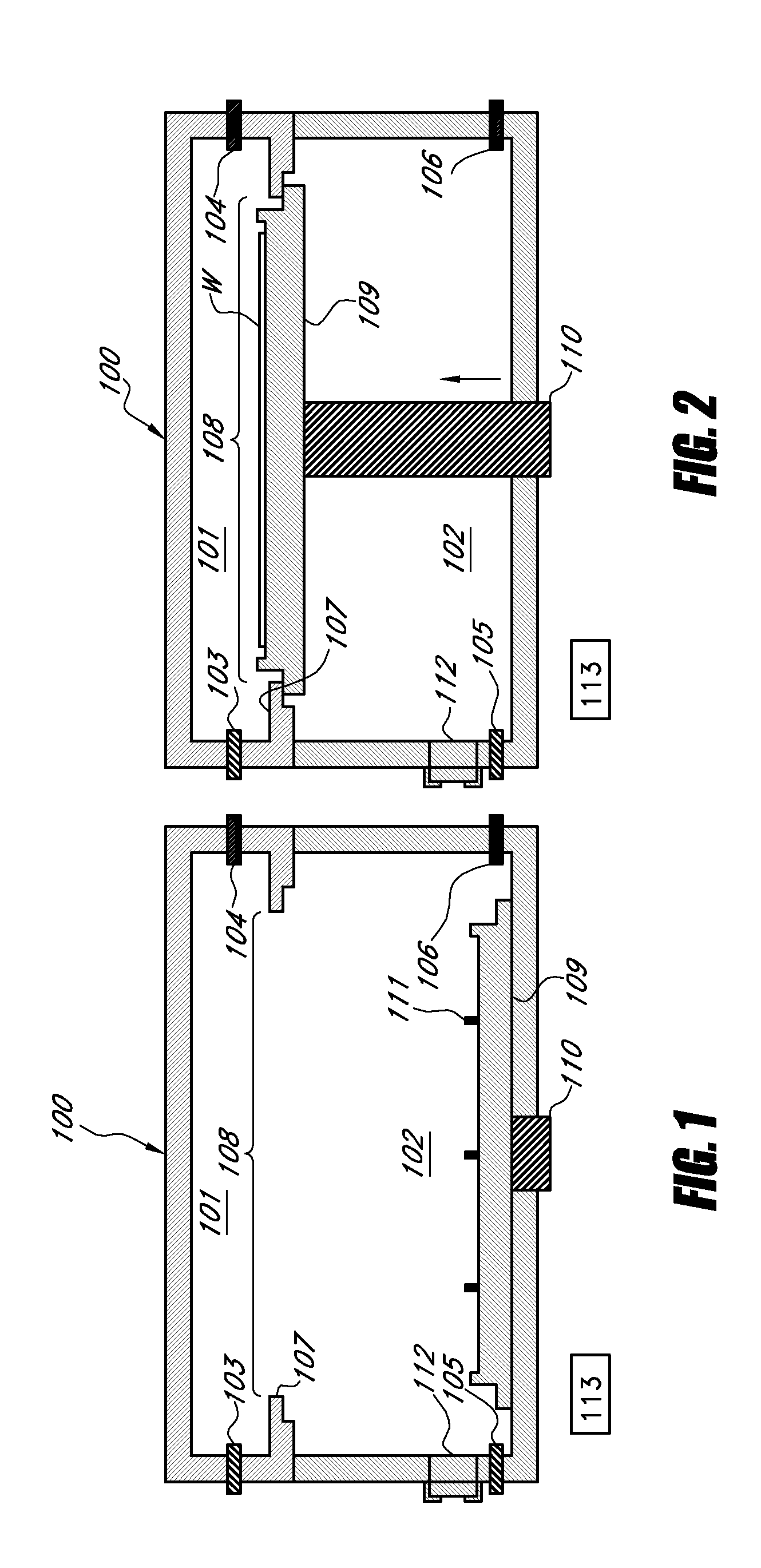

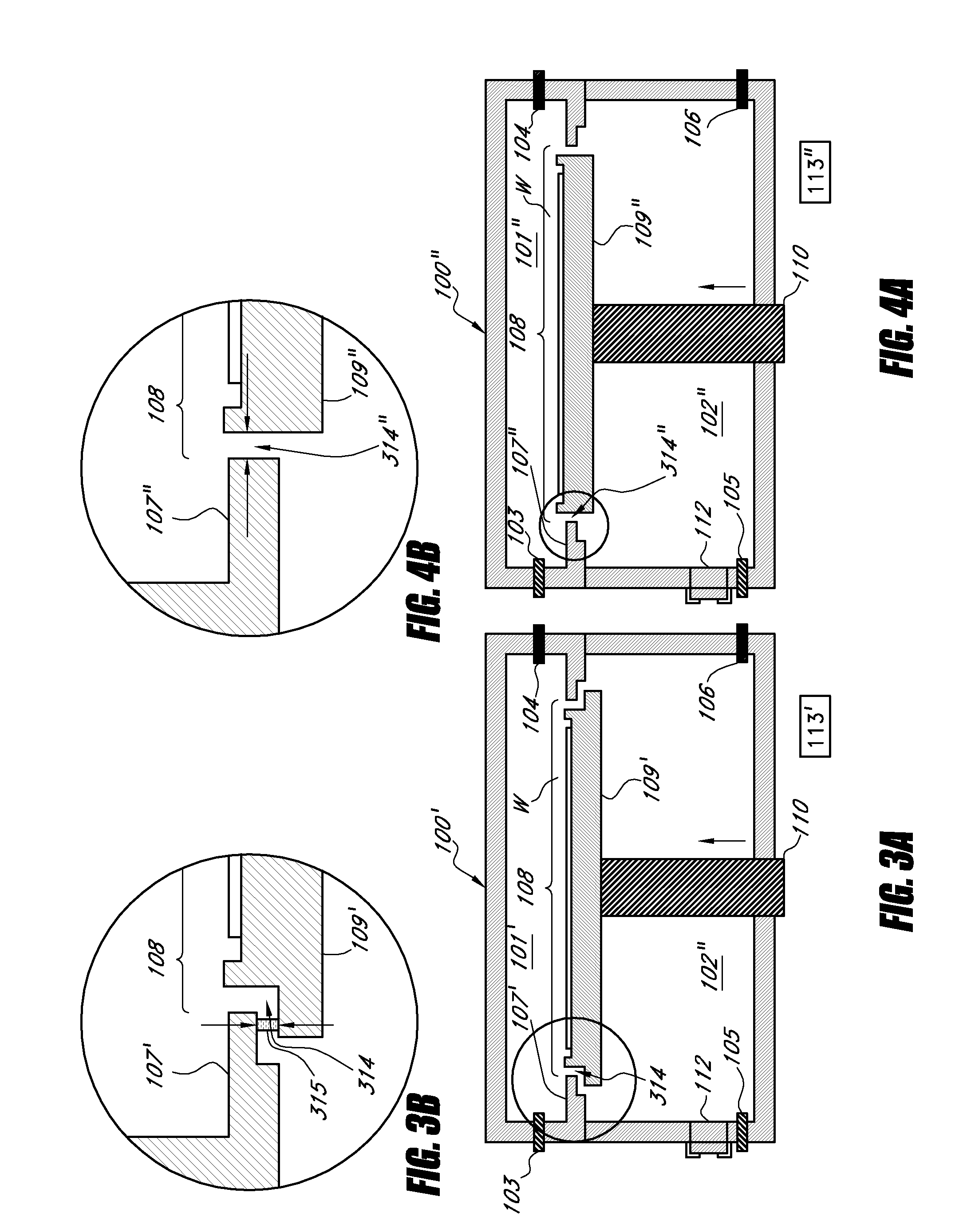

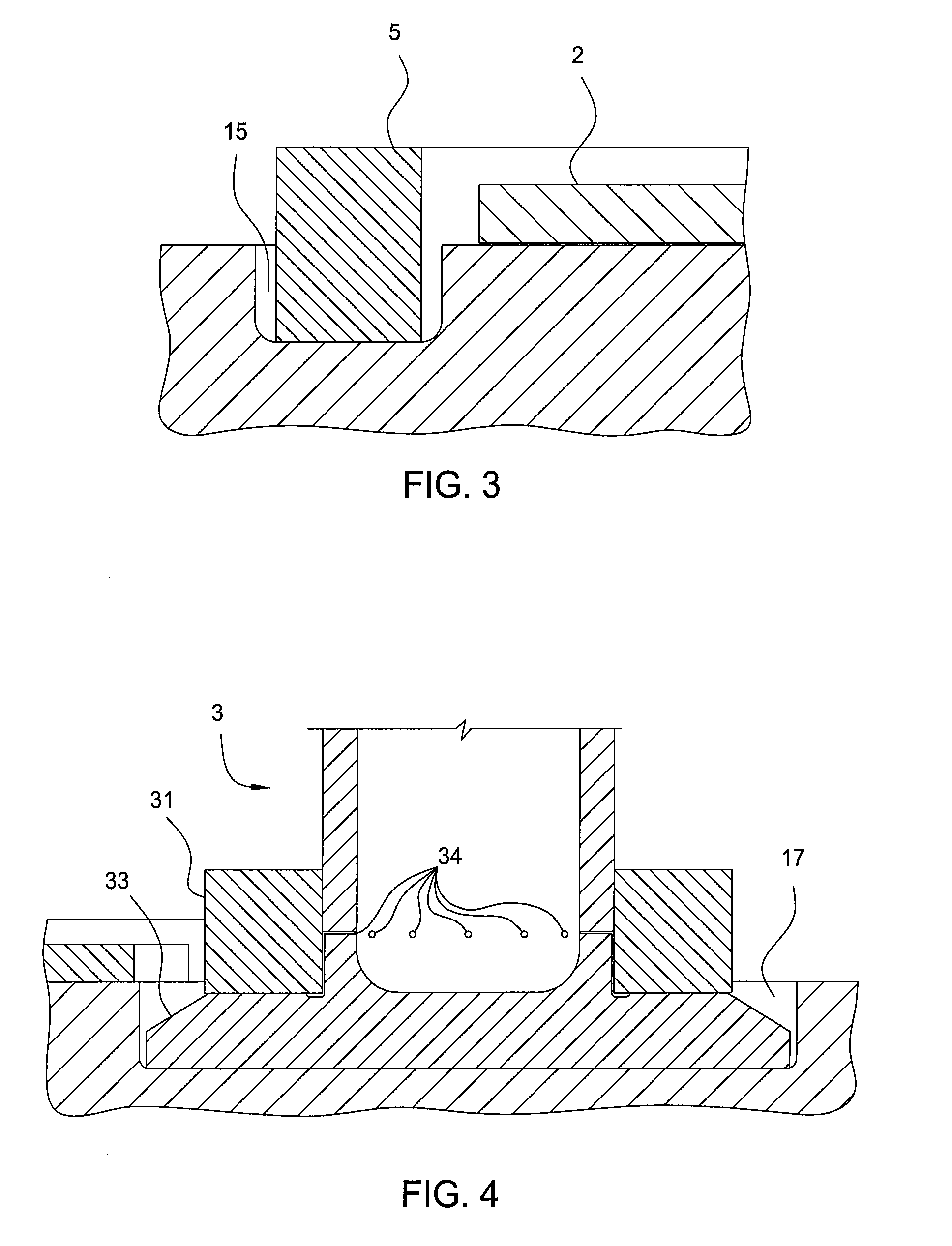

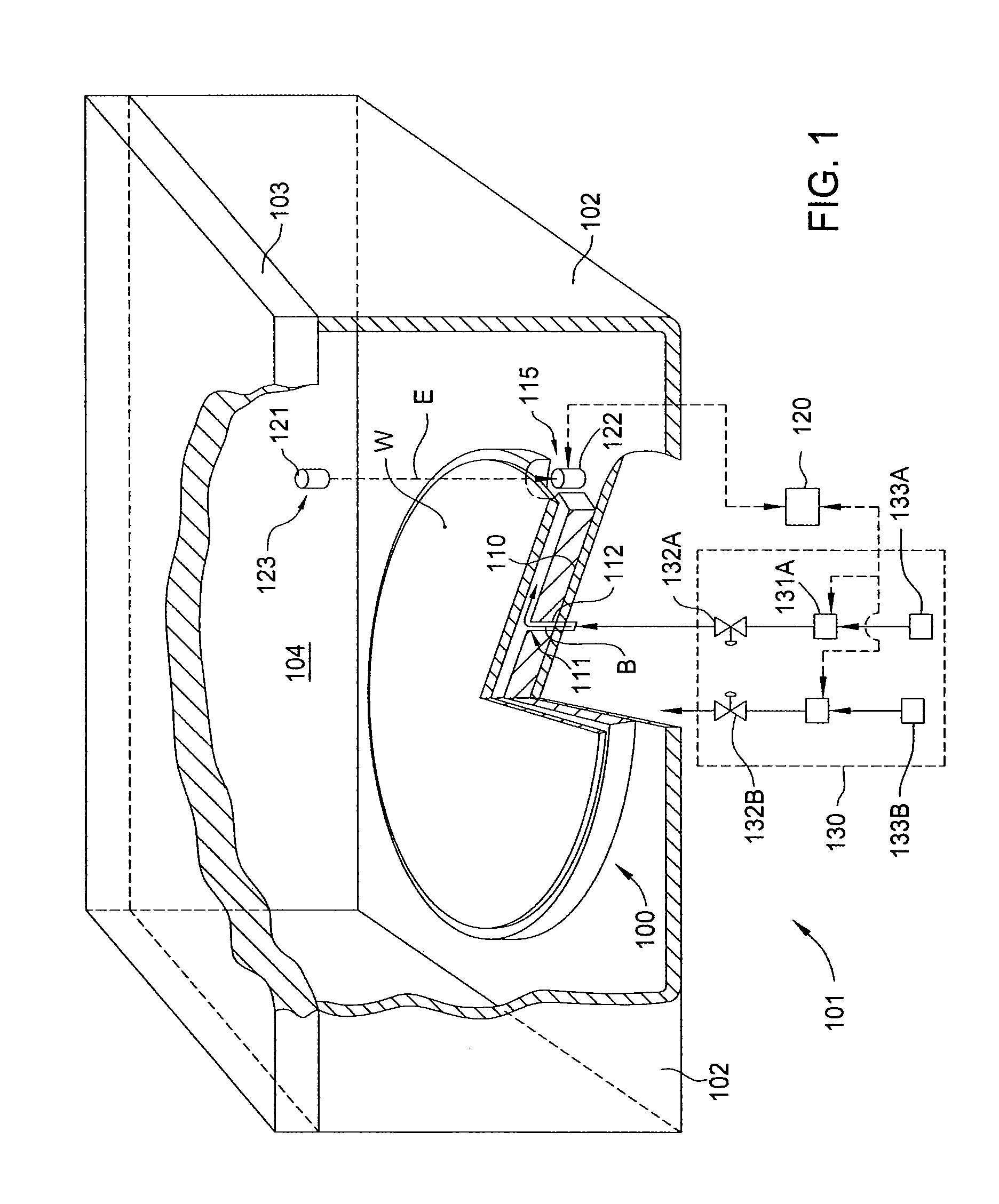

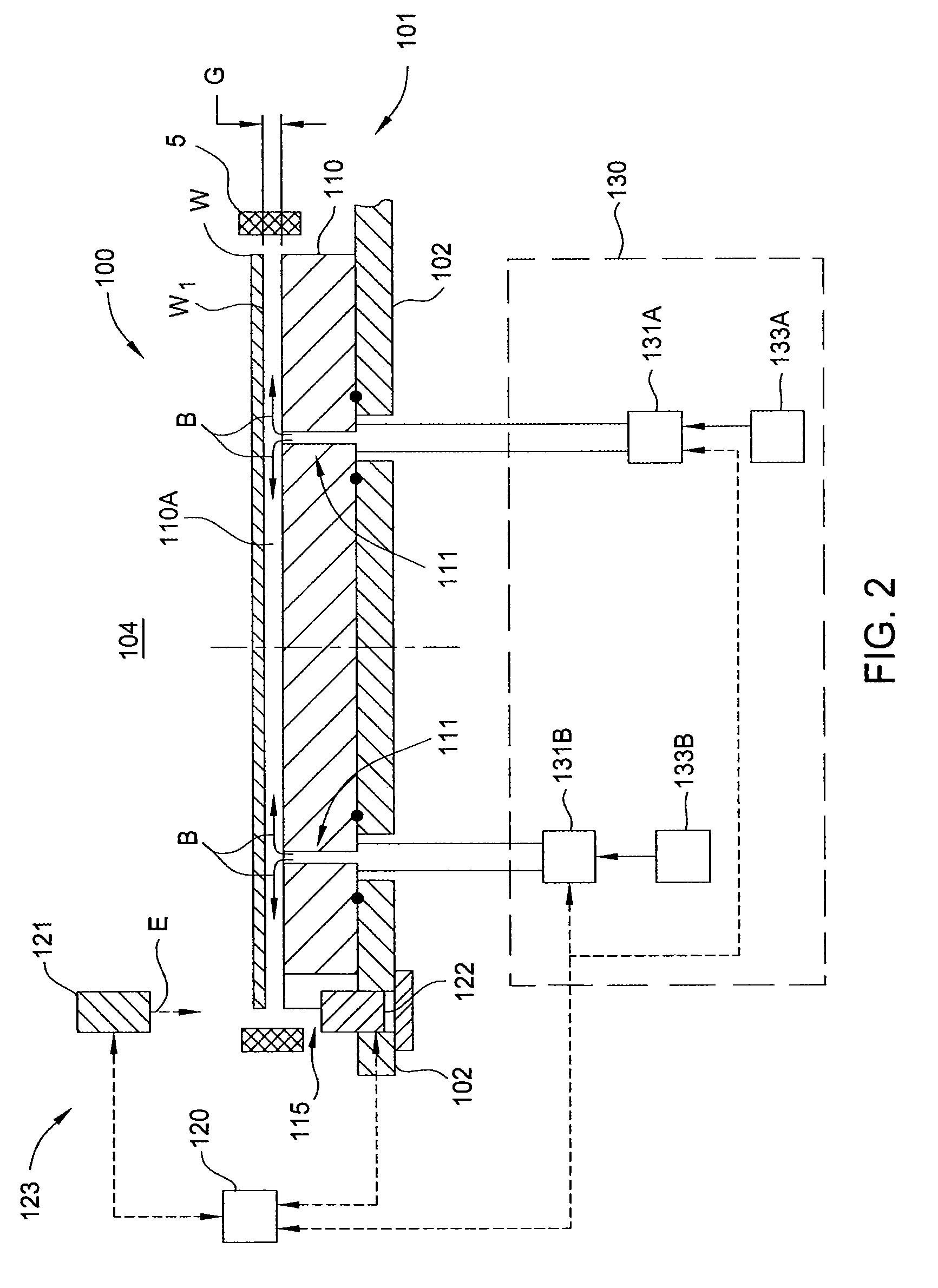

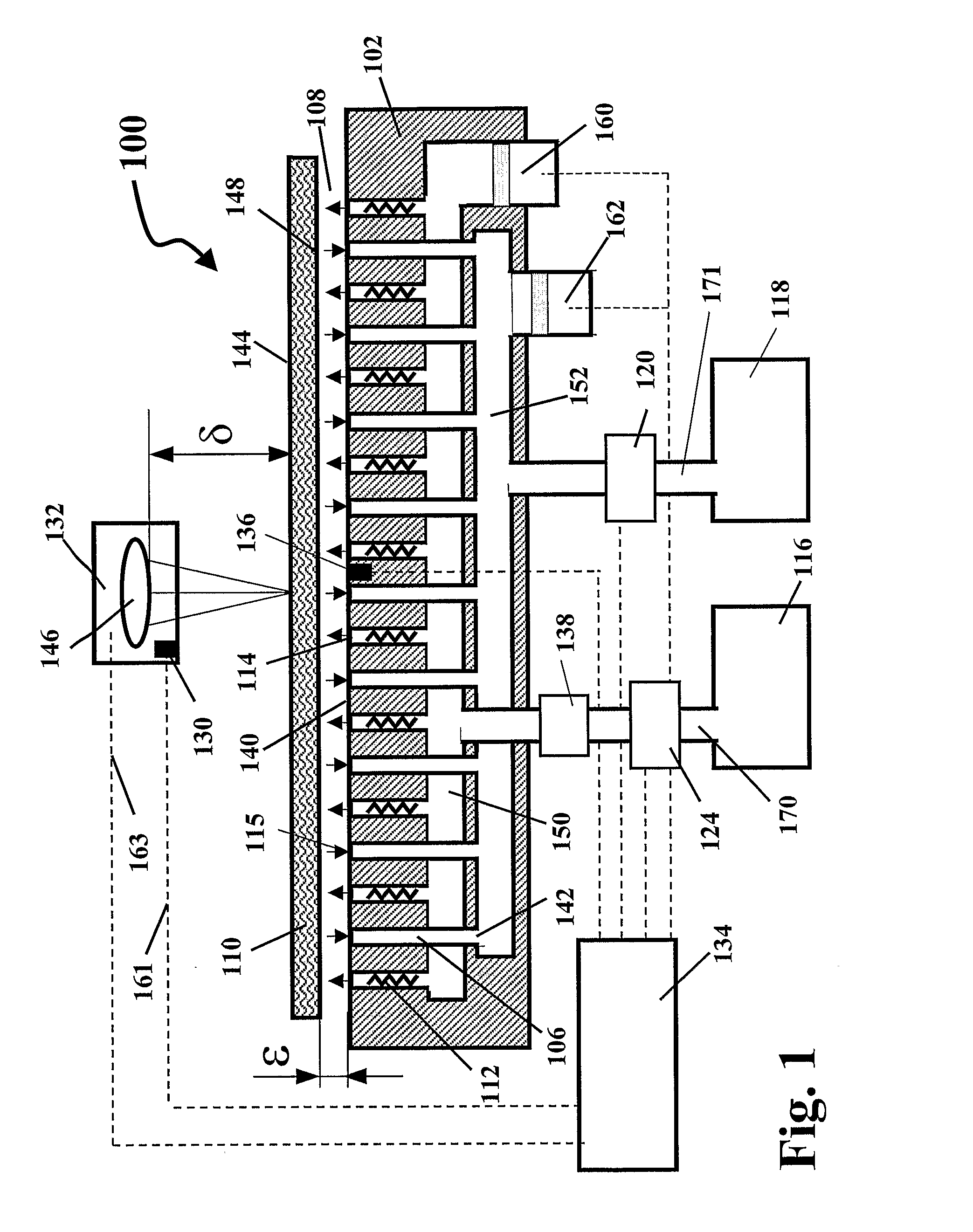

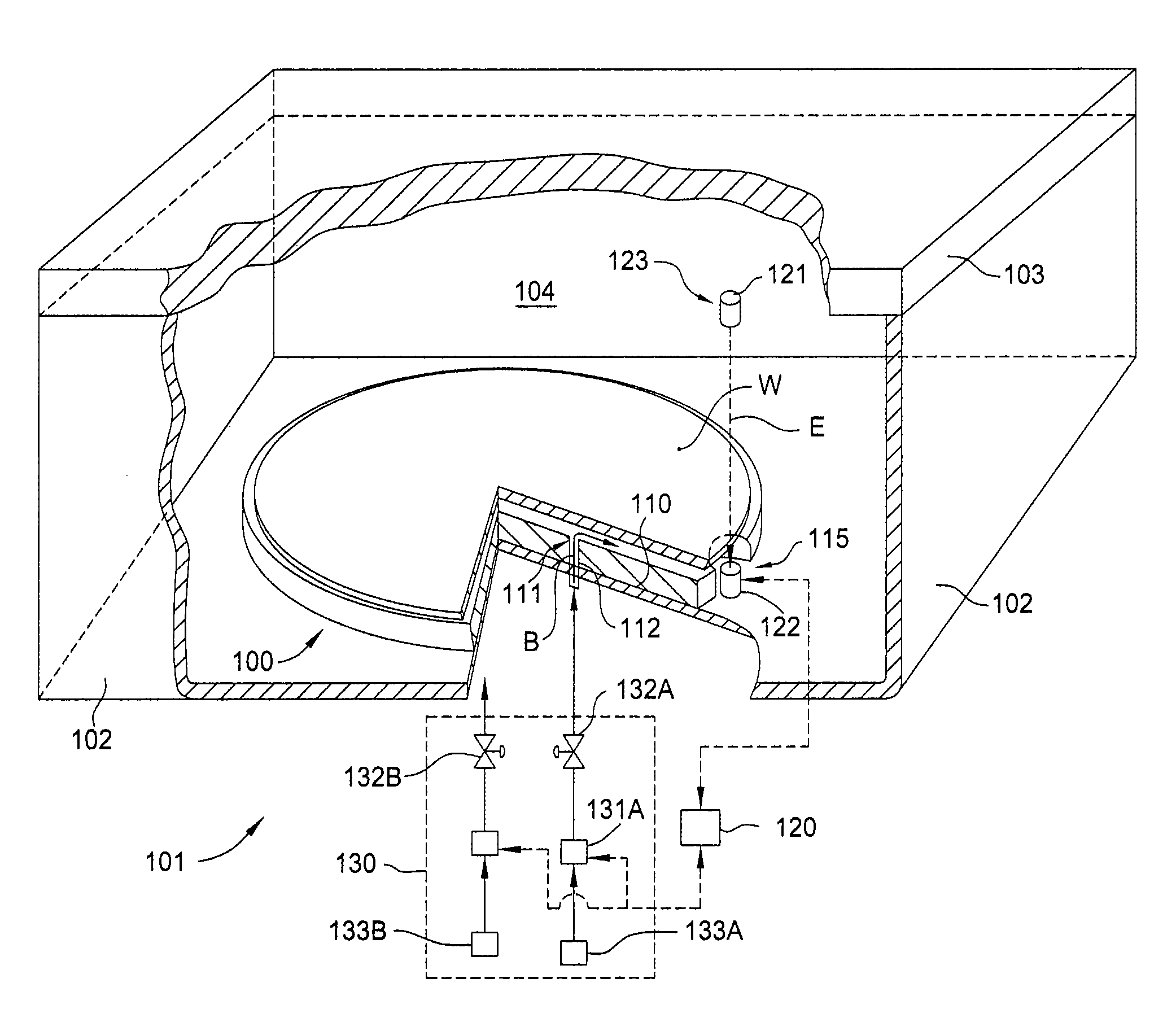

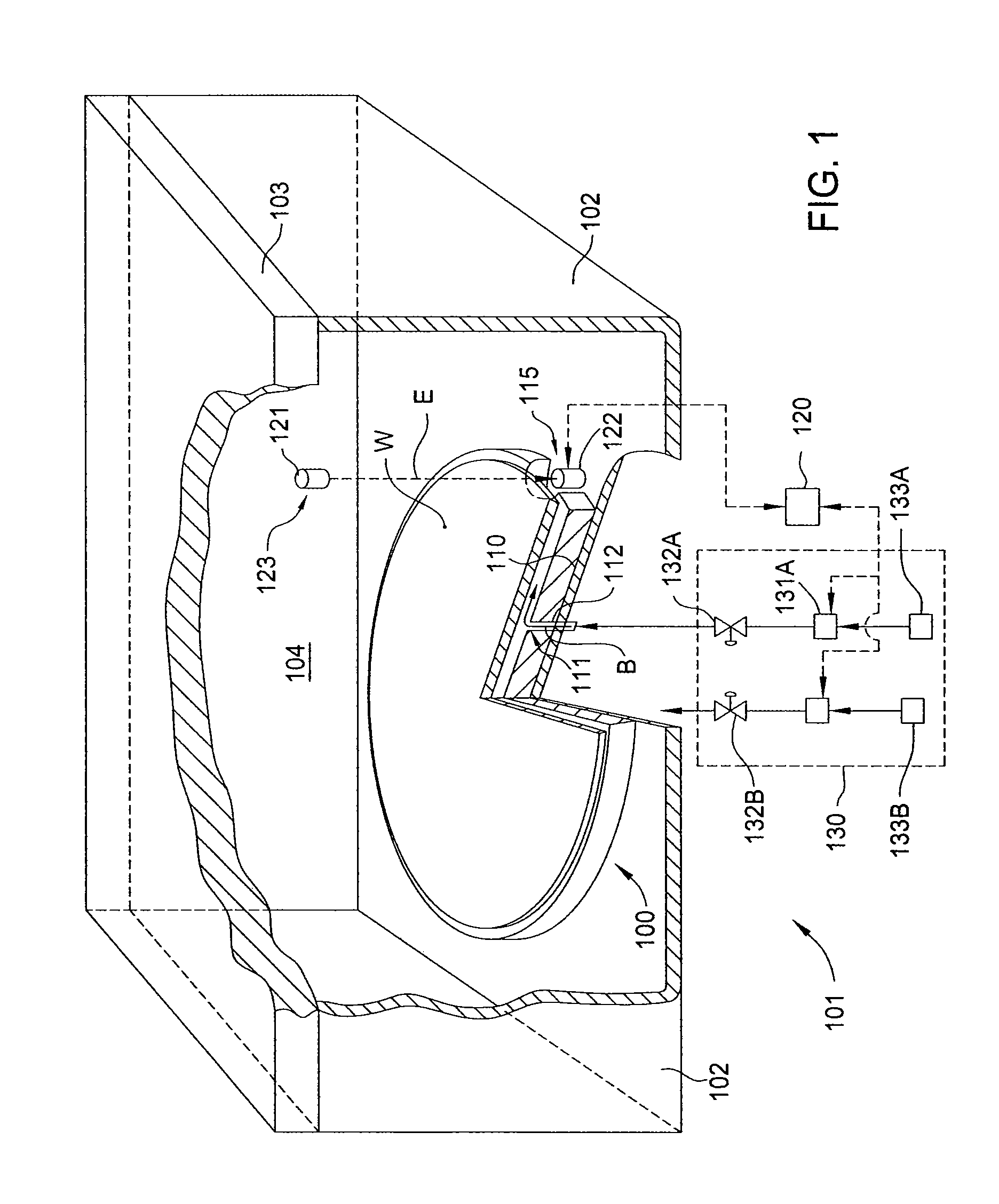

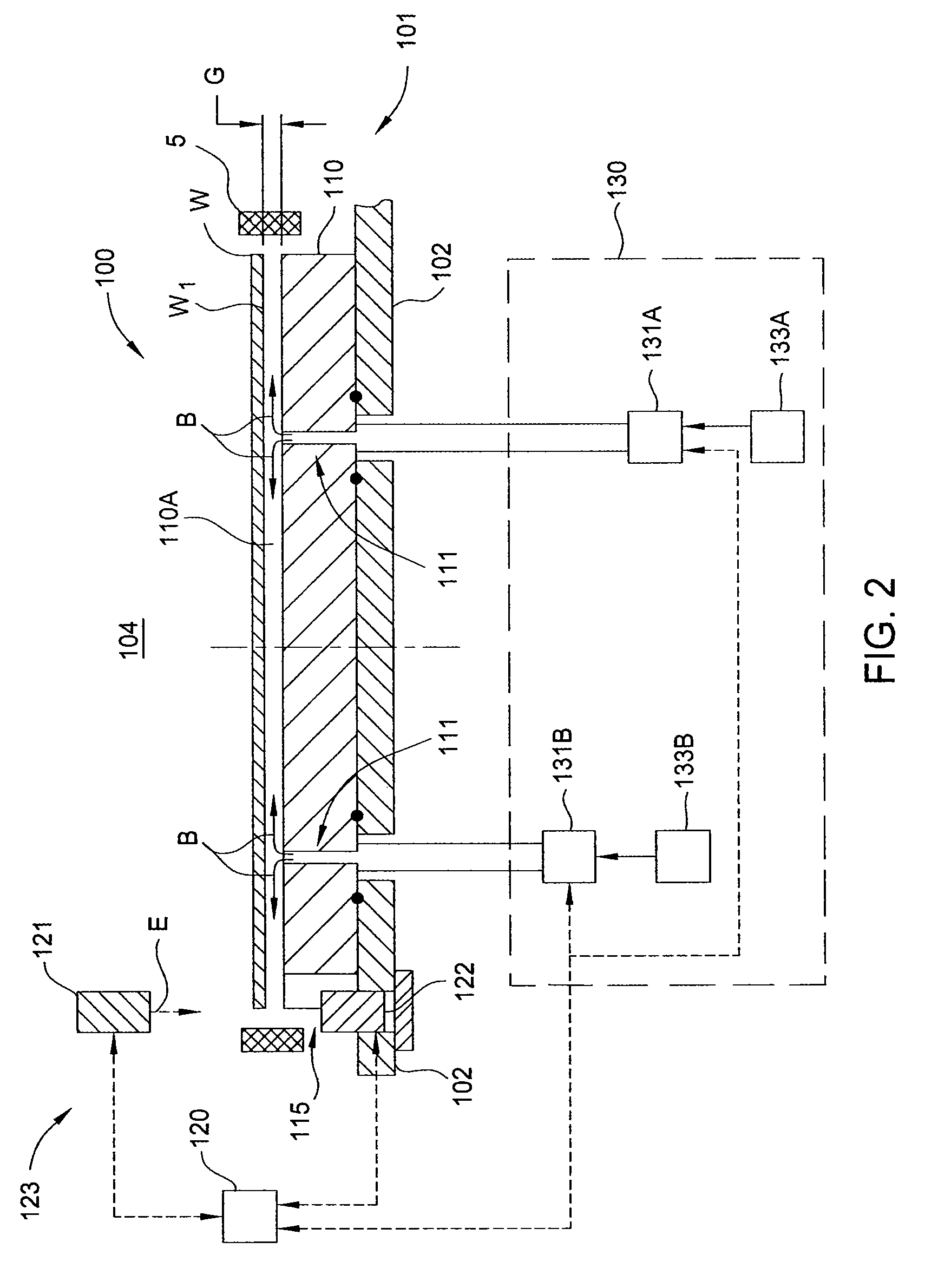

Method and apparatus for minimizing contamination in semiconductor processing chamber

ActiveUS20100202860A1Maintain gapCreate sealLiquid surface applicatorsSemiconductor/solid-state device manufacturingPositive pressureControl system

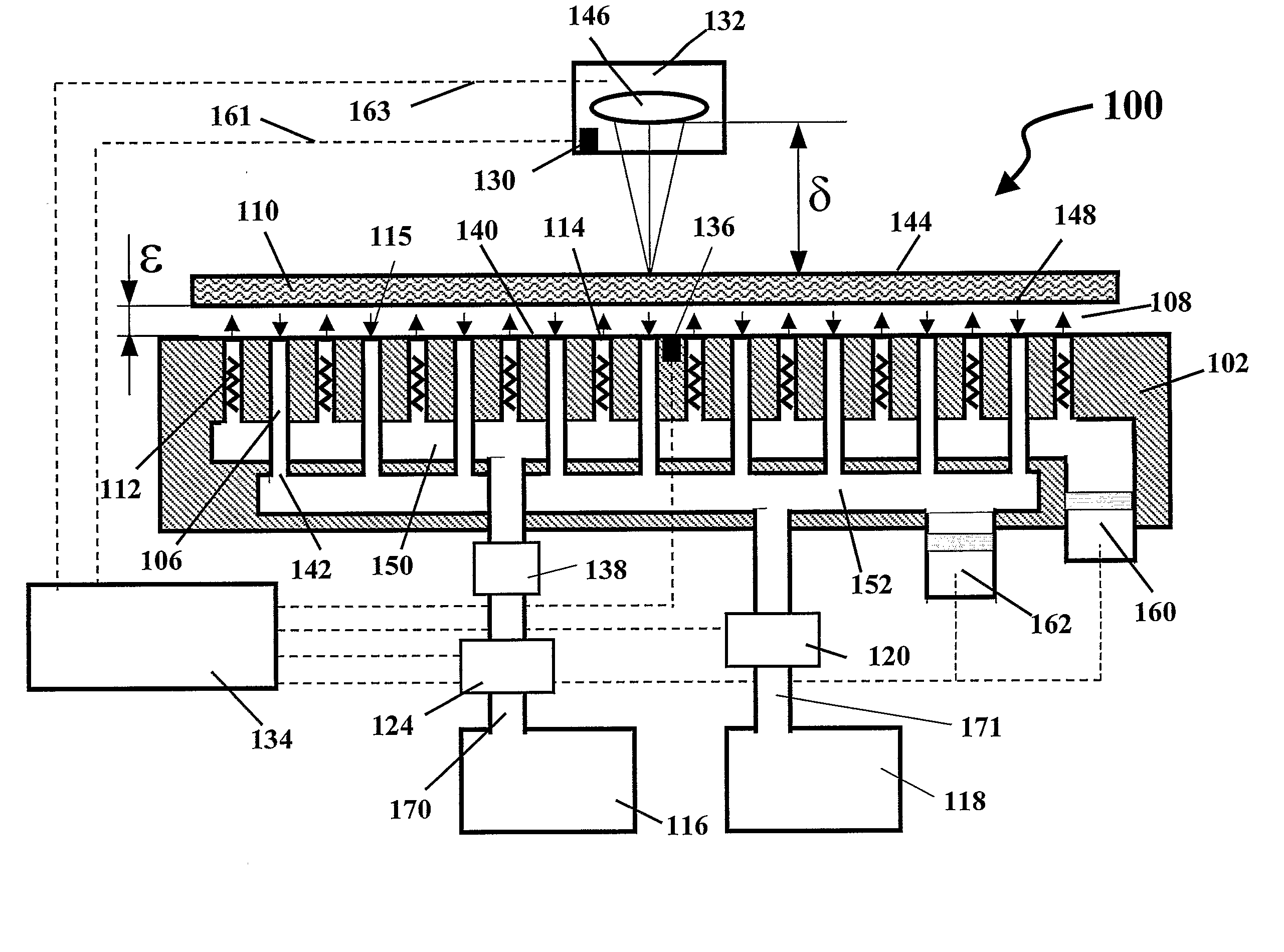

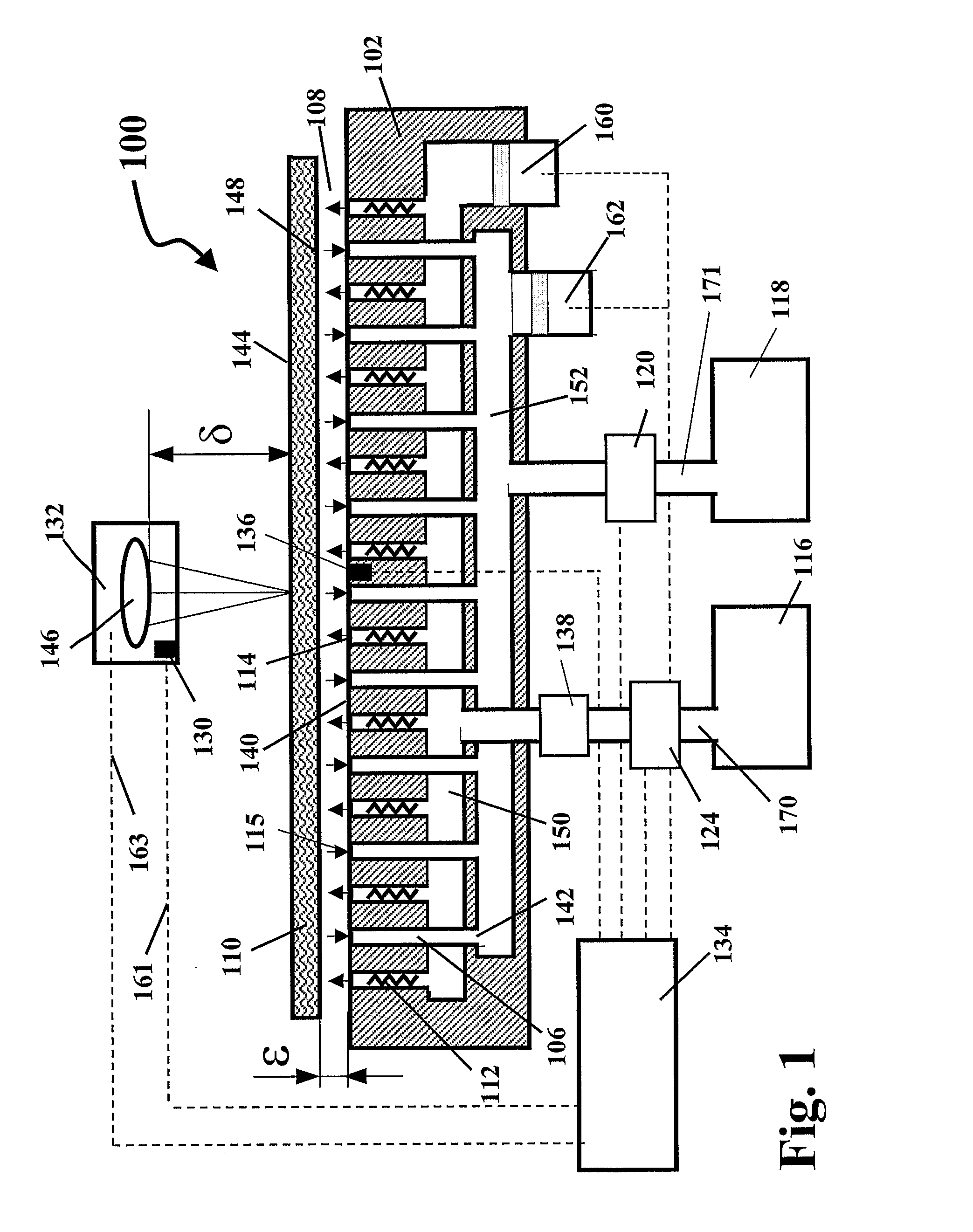

A semiconductor processing apparatus includes a reaction chamber, a loading chamber, a movable support, a drive mechanism, and a control system. The reaction chamber includes a baseplate. The baseplate includes an opening. The movable support is configured to hold a workpiece. The drive mechanism is configured to move a workpiece held on the support towards the opening of the baseplate into a processing position. The control system is configured to create a positive pressure gradient between the reaction chamber and the loading chamber while the workpiece support is in motion. Purge gases flow from the reaction chamber into the loading chamber while the workpiece support is in motion. The control system is configured to create a negative pressure gradient between the reaction chamber and the loading chamber while the workpiece is being processed. Purge gases can flow from the loading chamber into the reaction chamber while the workpiece support is in the processing position, unless the reaction chamber is sealed from the loading chamber in the processing position.

Owner:ASM IP HLDG BV

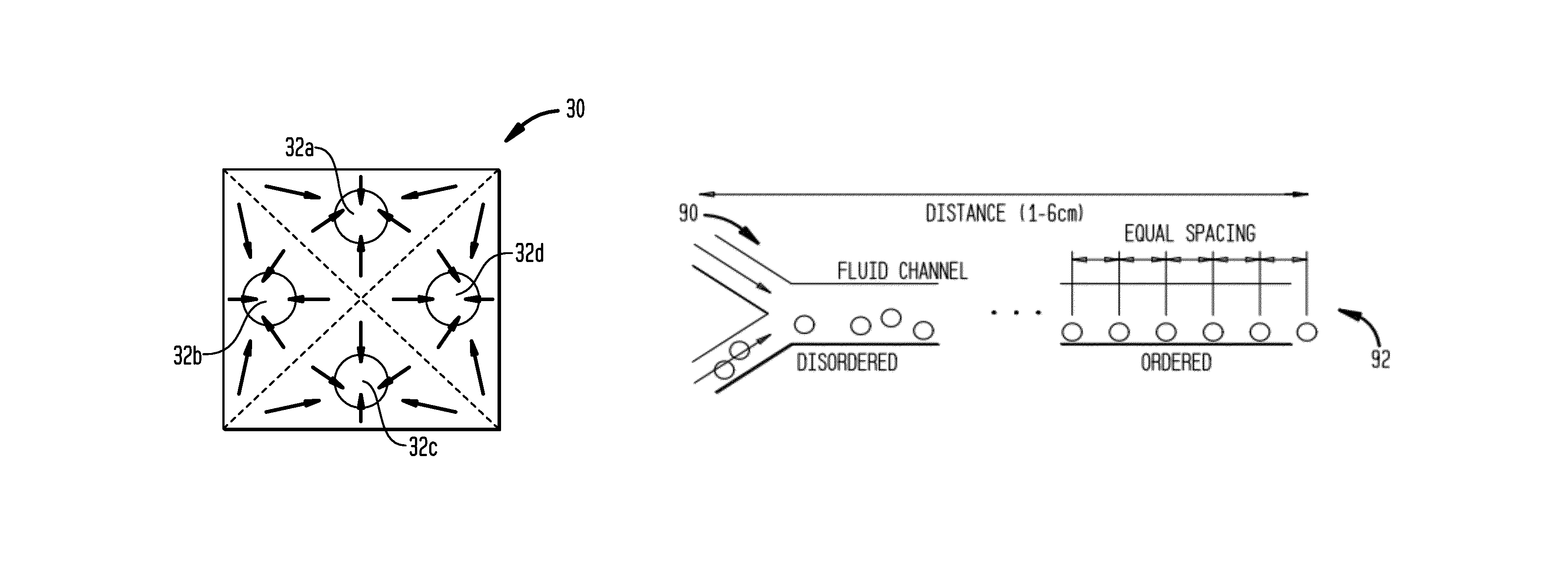

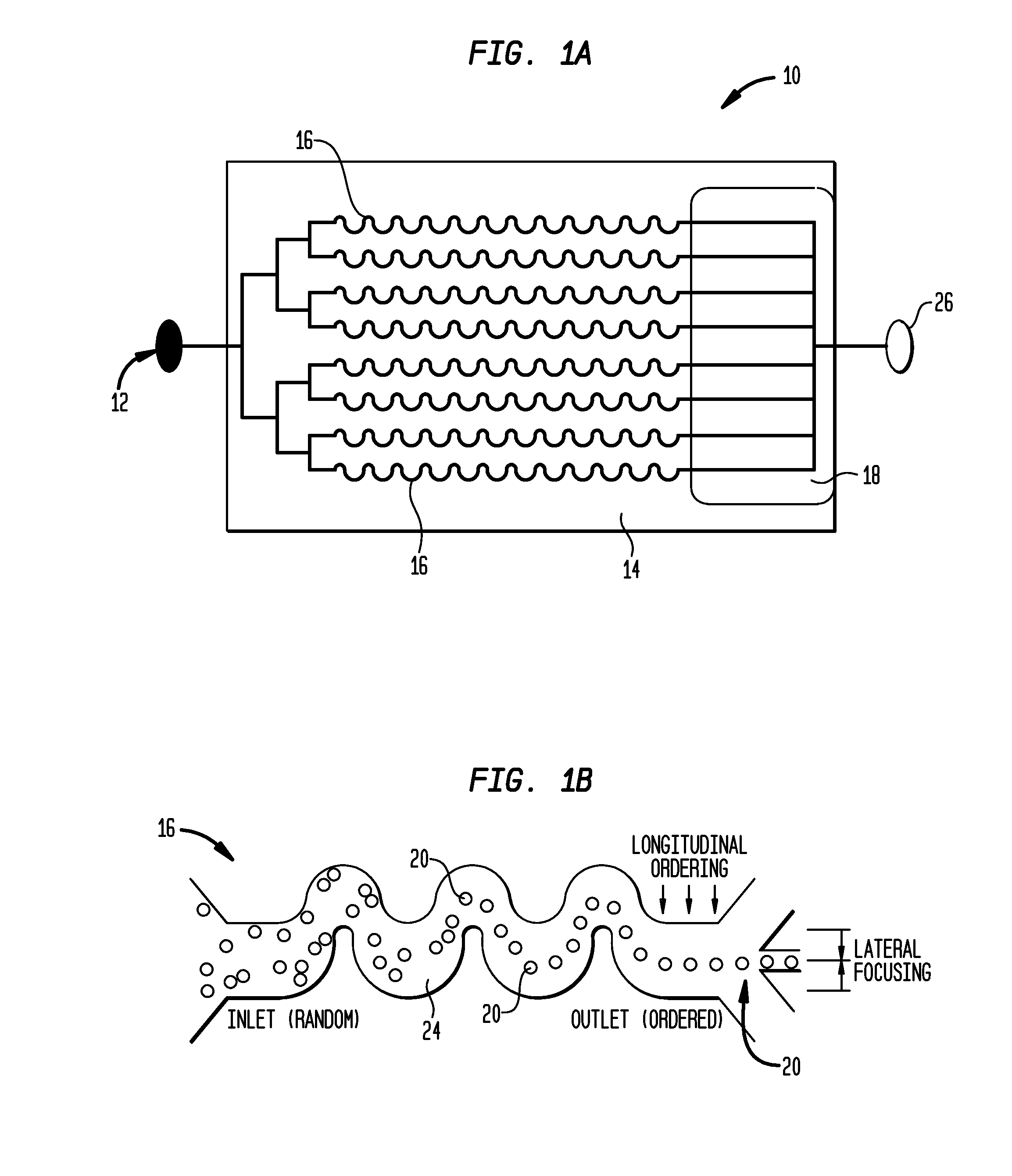

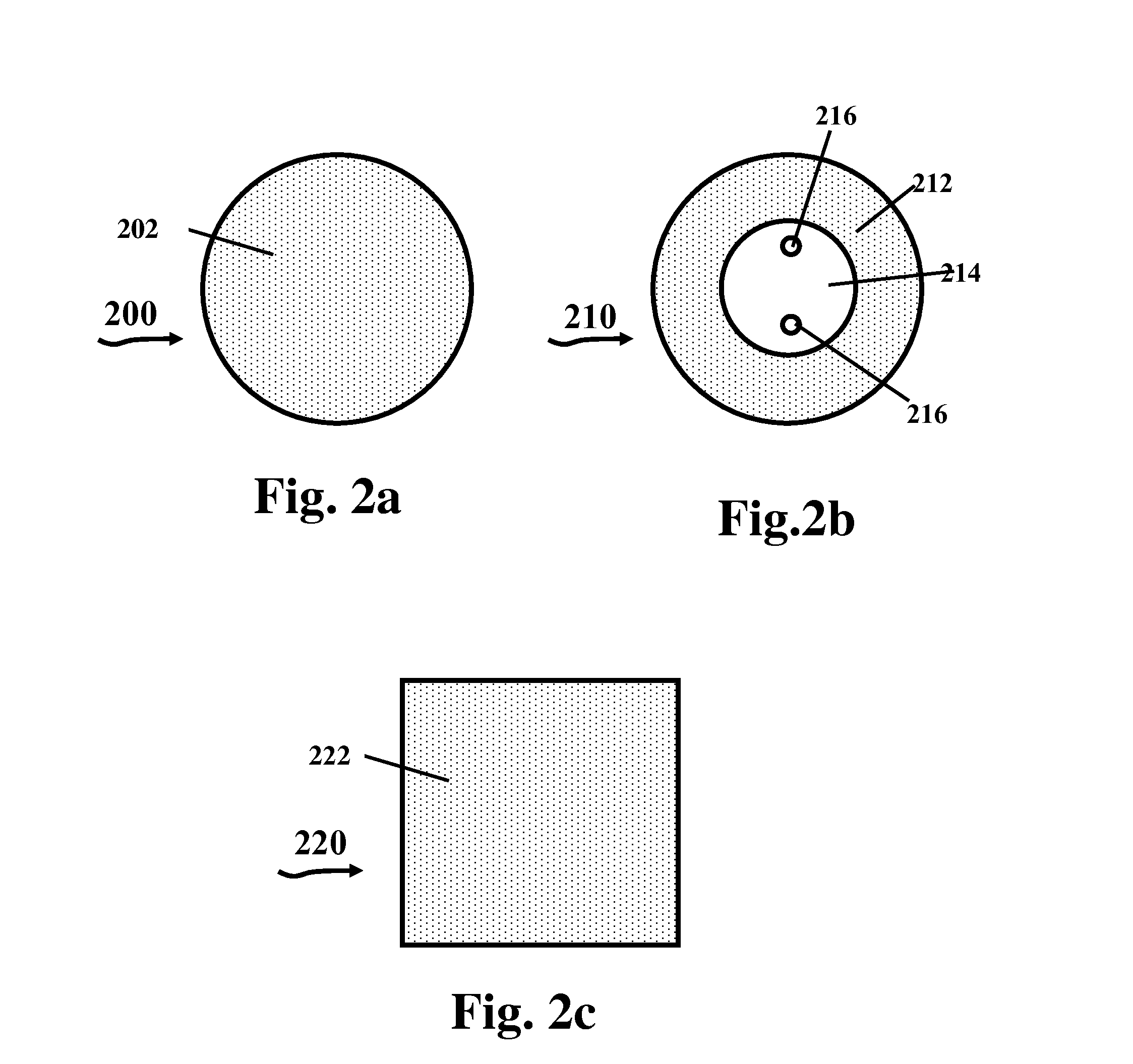

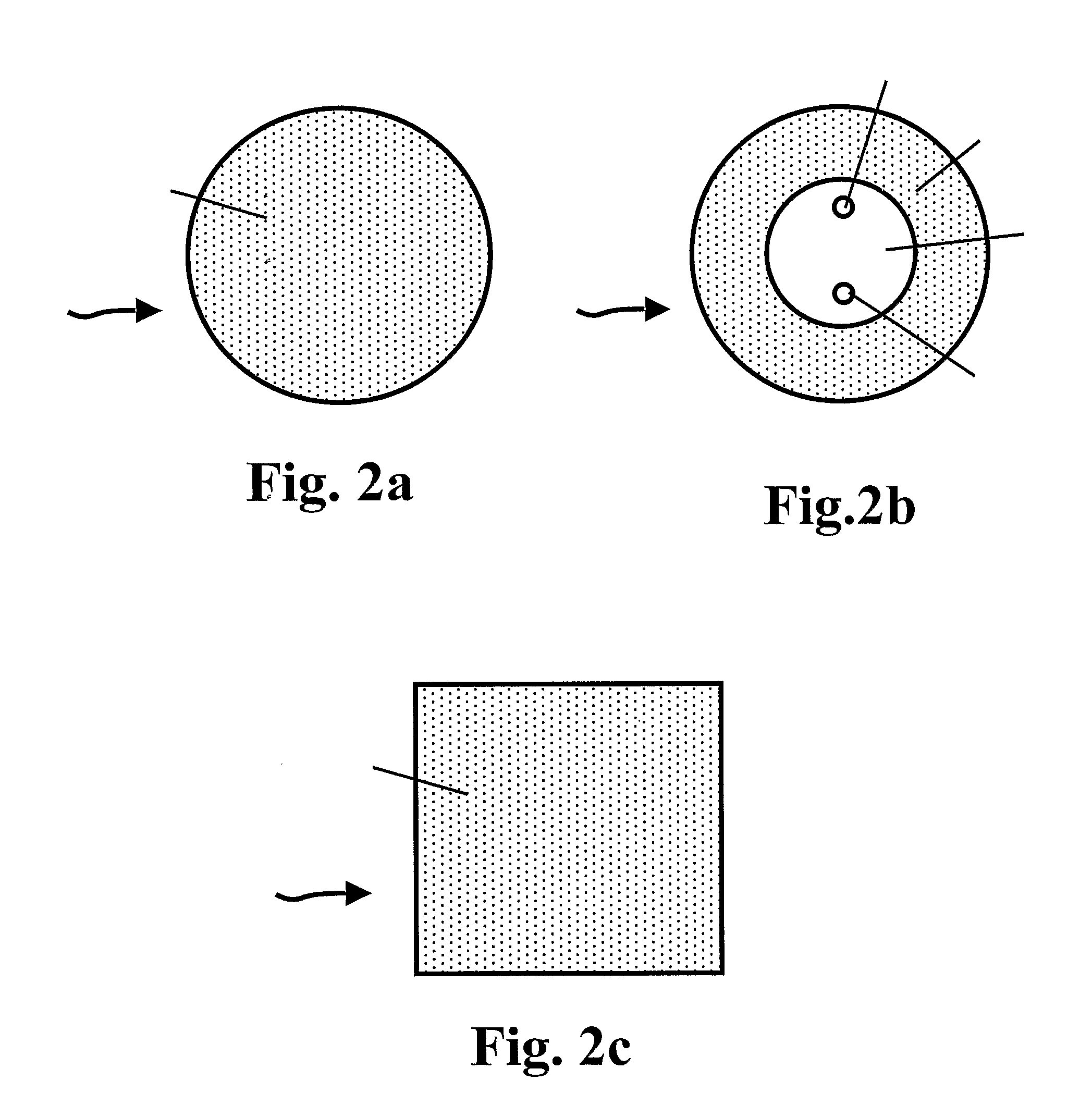

Systems and methods for particle focusing in microchannels

ActiveUS8186913B2Improve concentrationEvenly distributedImmobilised enzymesSolvent extractionSuspended particlesEngineering

Various systems, methods, and devices are provided for focusing particles suspended within a moving fluid into one or more localized stream lines. The system can include a substrate and at least one channel provided on the substrate having an inlet and an outlet. The system can further include a fluid moving along the channel in a laminar flow having suspended particles and a pumping element driving the laminar flow of the fluid. The fluid, the channel, and the pumping element can be configured to cause inertial forces to act on the particles and to focus the particles into one or more stream lines.

Owner:THE GENERAL HOSPITAL CORP

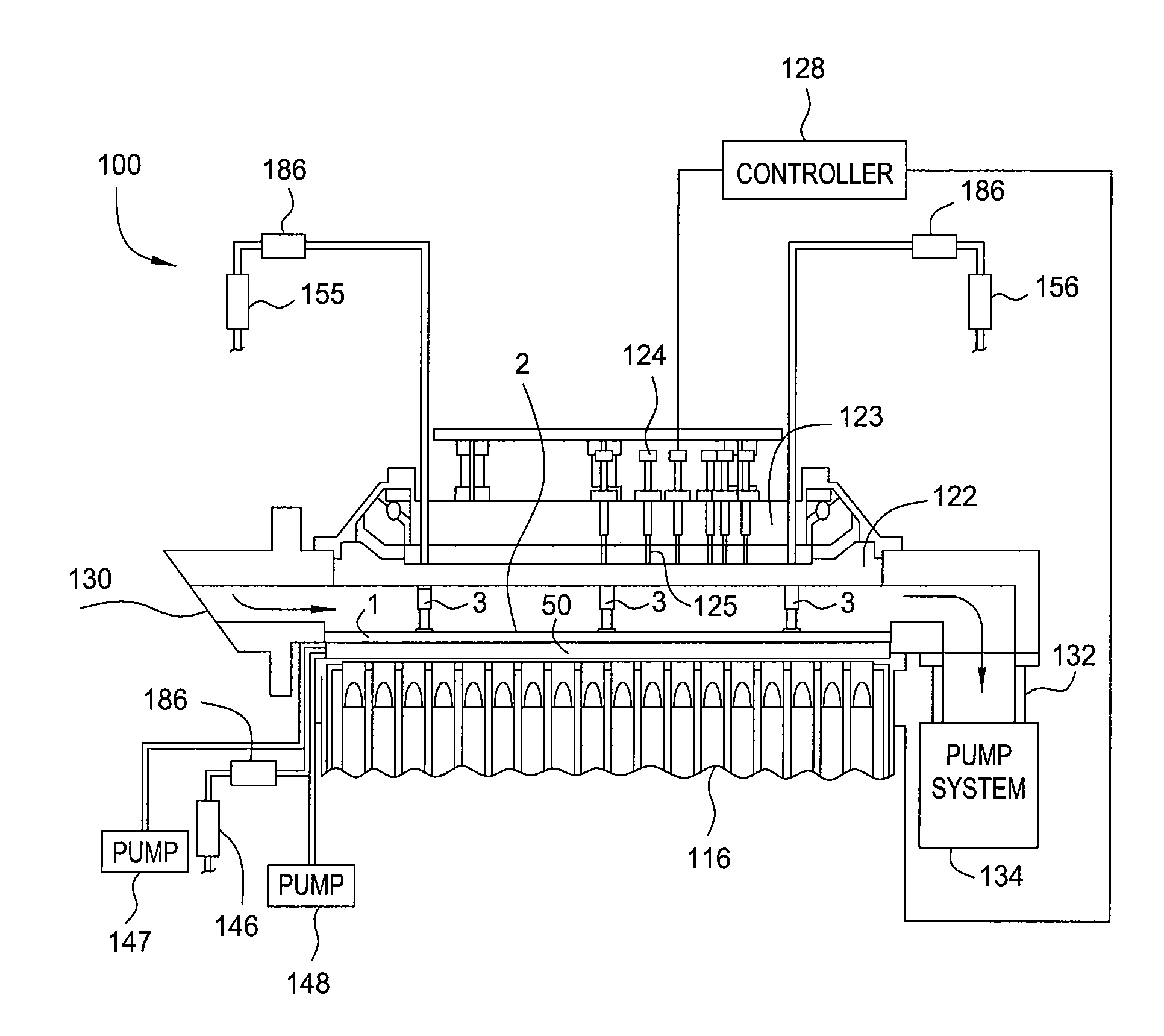

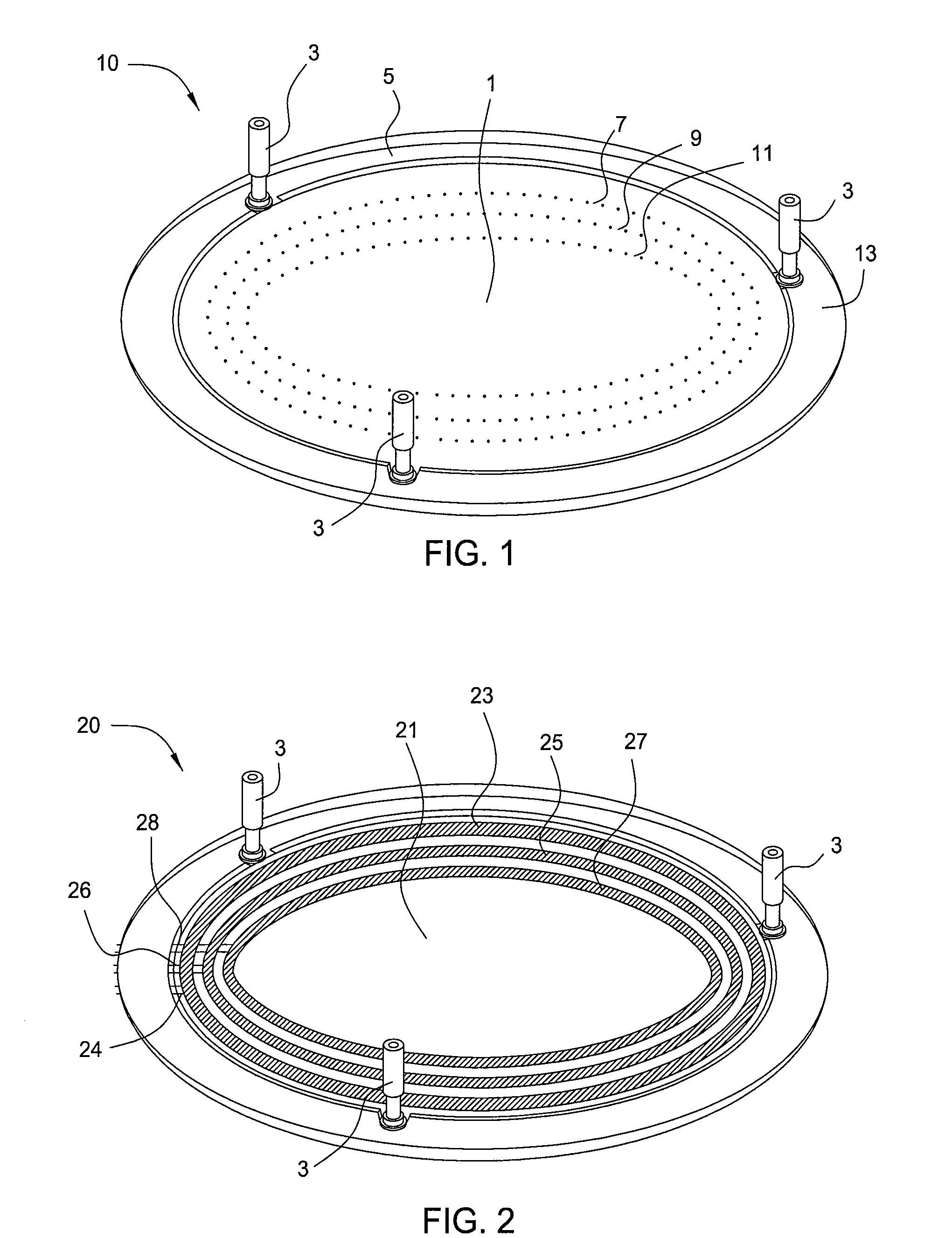

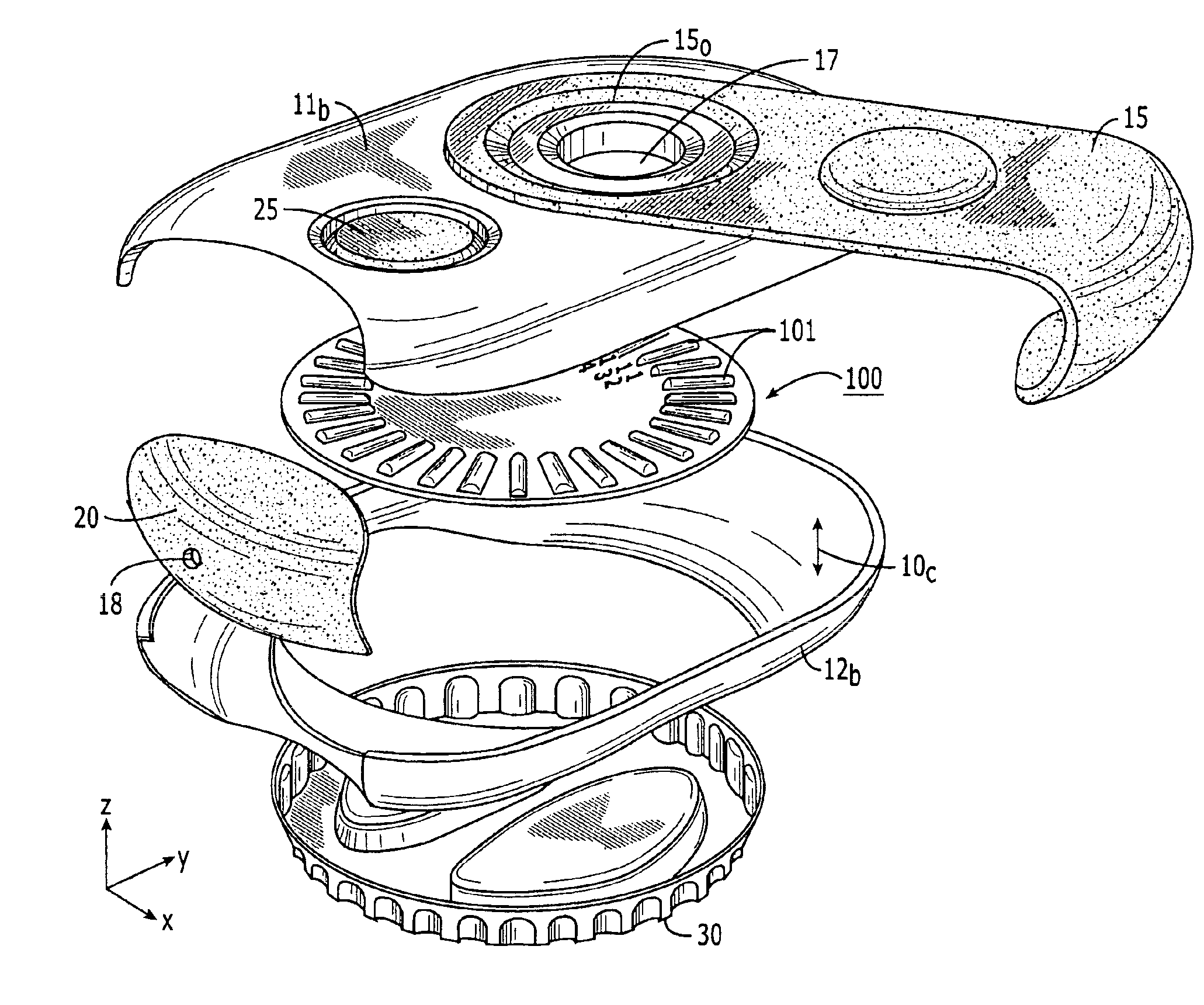

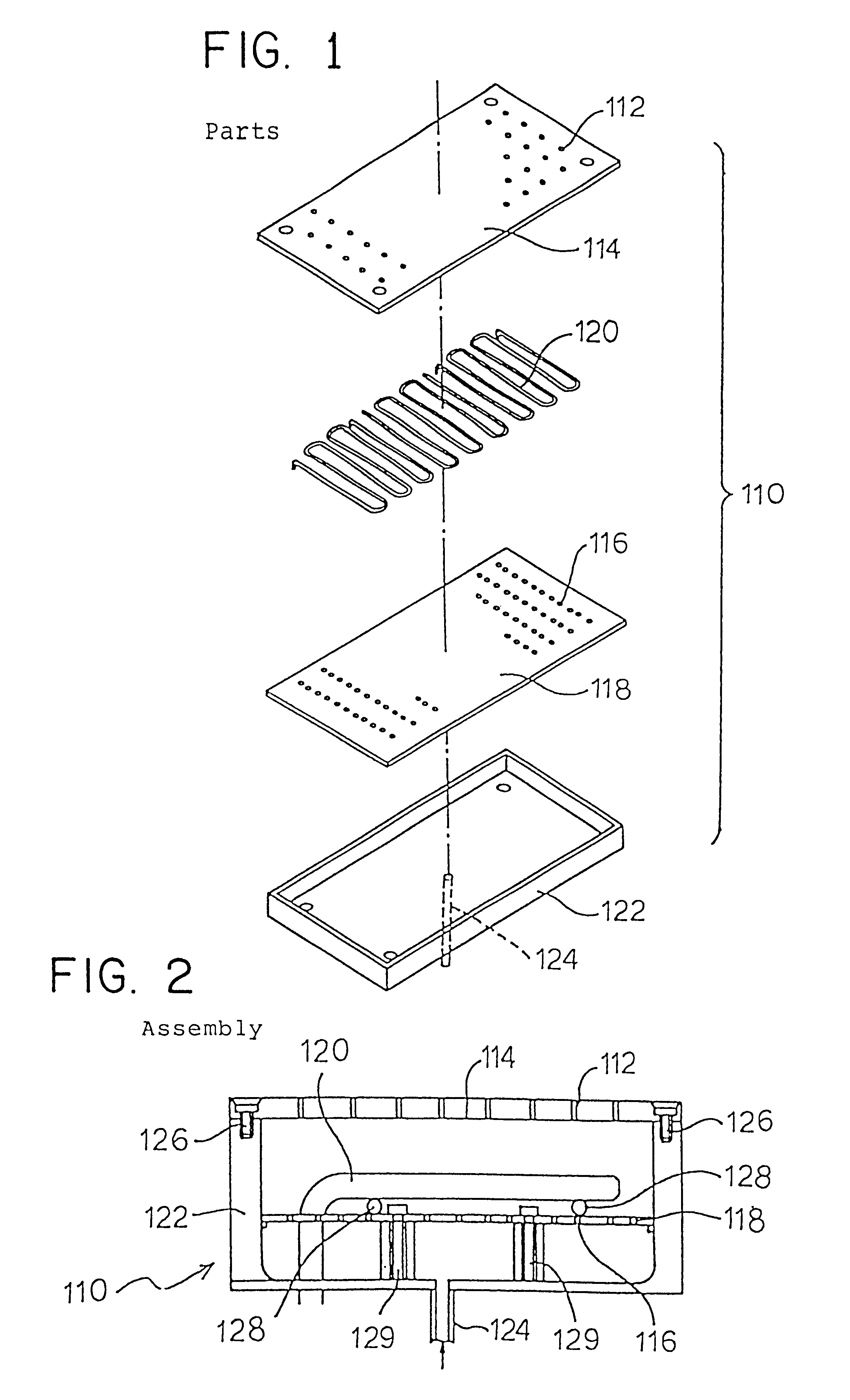

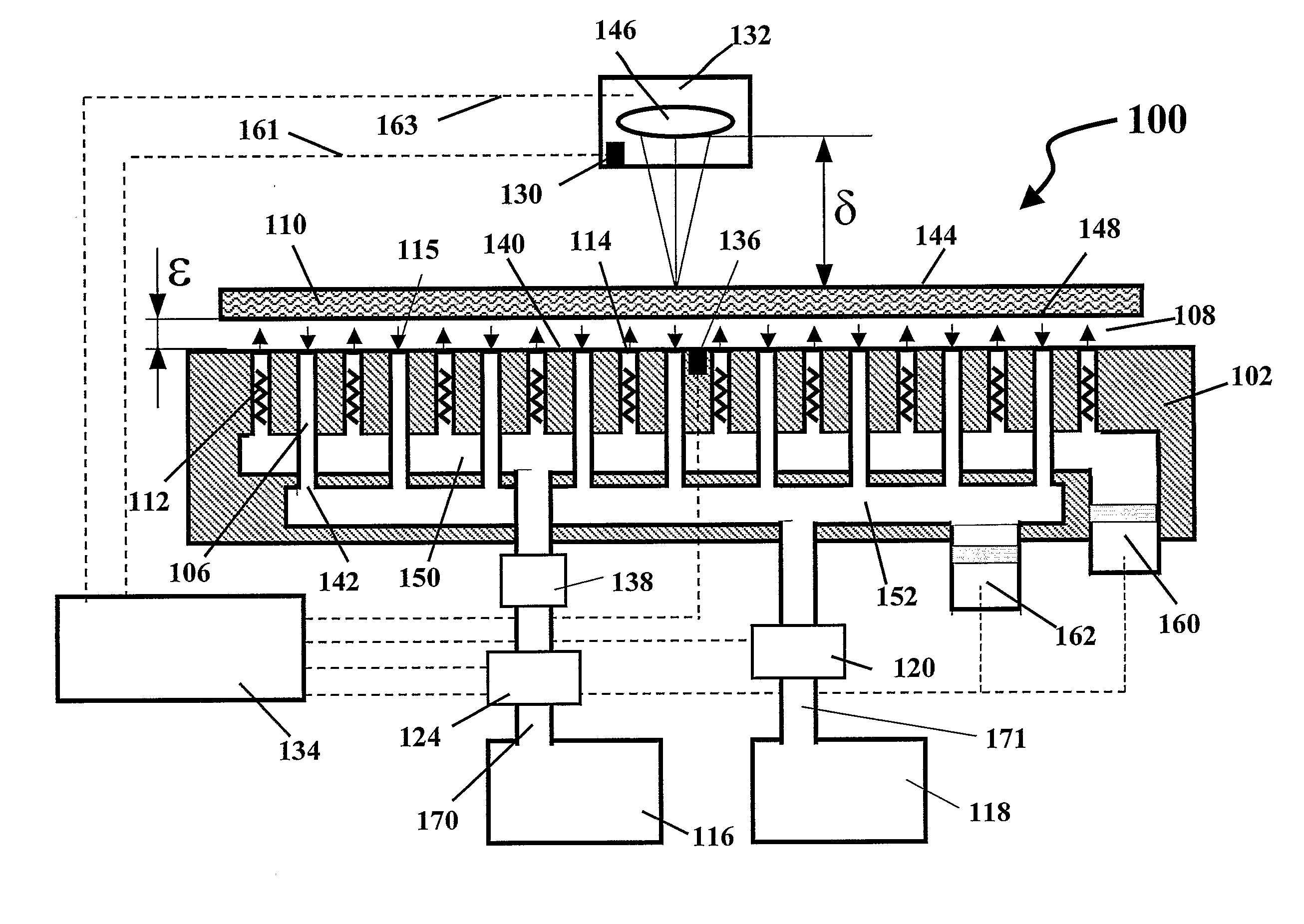

Apparatus and method for supporting, positioning and rotating a substrate in a processing chamber

ActiveUS20080276864A1Increase pressureReduce stressLiquid surface applicatorsSemiconductor/solid-state device manufacturingAir bearingThin layer

An apparatus and method for supporting, positioning and rotating a substrate are provided. In one embodiment, a support assembly for supporting a substrate includes an upper base plate and a lower base plate. The substrate is floated on a thin layer of air over the upper base plate. A positioning assembly includes a plurality of air bearing edge rollers or air flow pockets used to position the substrate in a desired orientation inside above the upper base plate. A plurality of slanted apertures or air flow pockets are configured in the upper base plate for flowing gas therethrough to rotate the substrate to ensure uniform heating during processing.

Owner:APPLIED MATERIALS INC

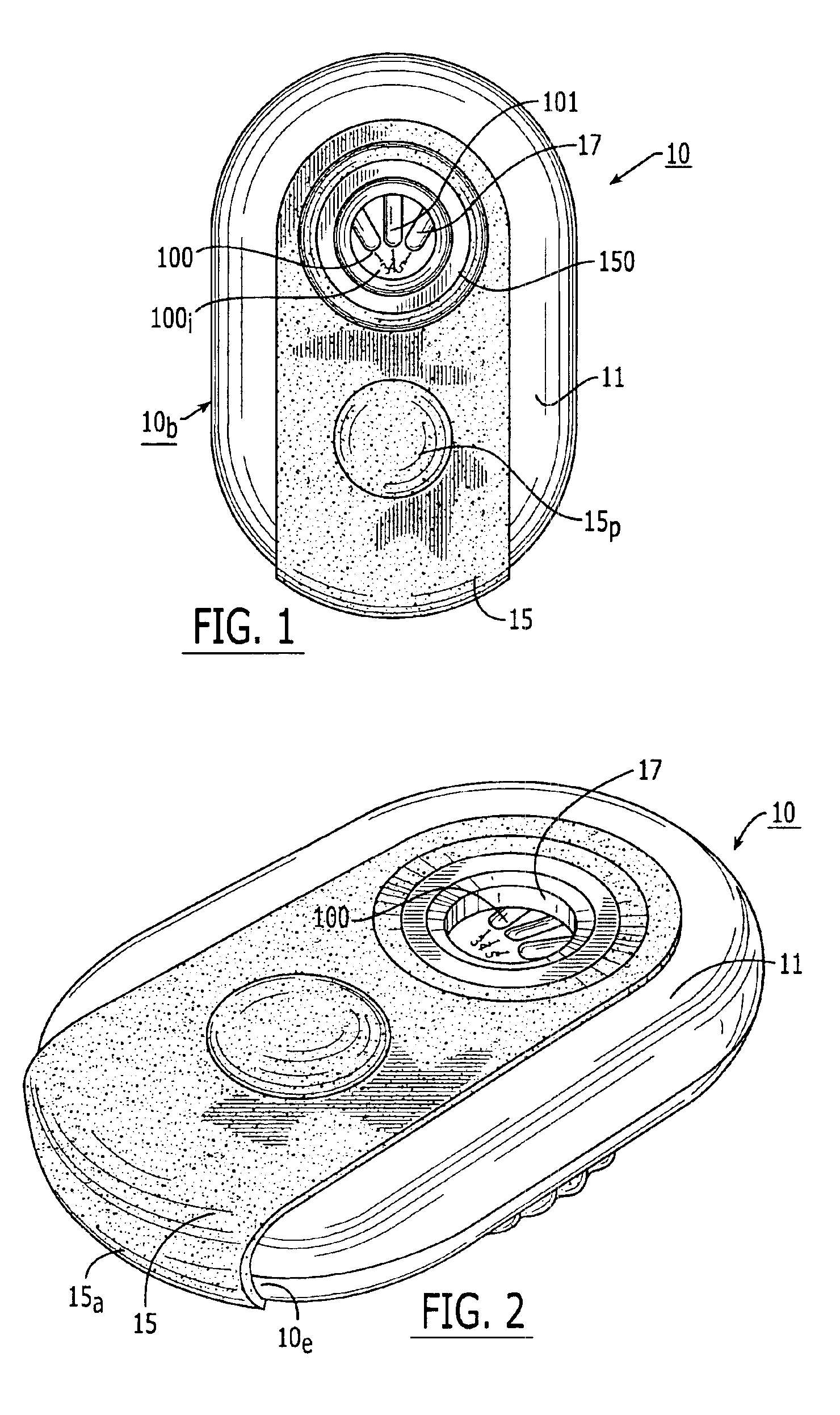

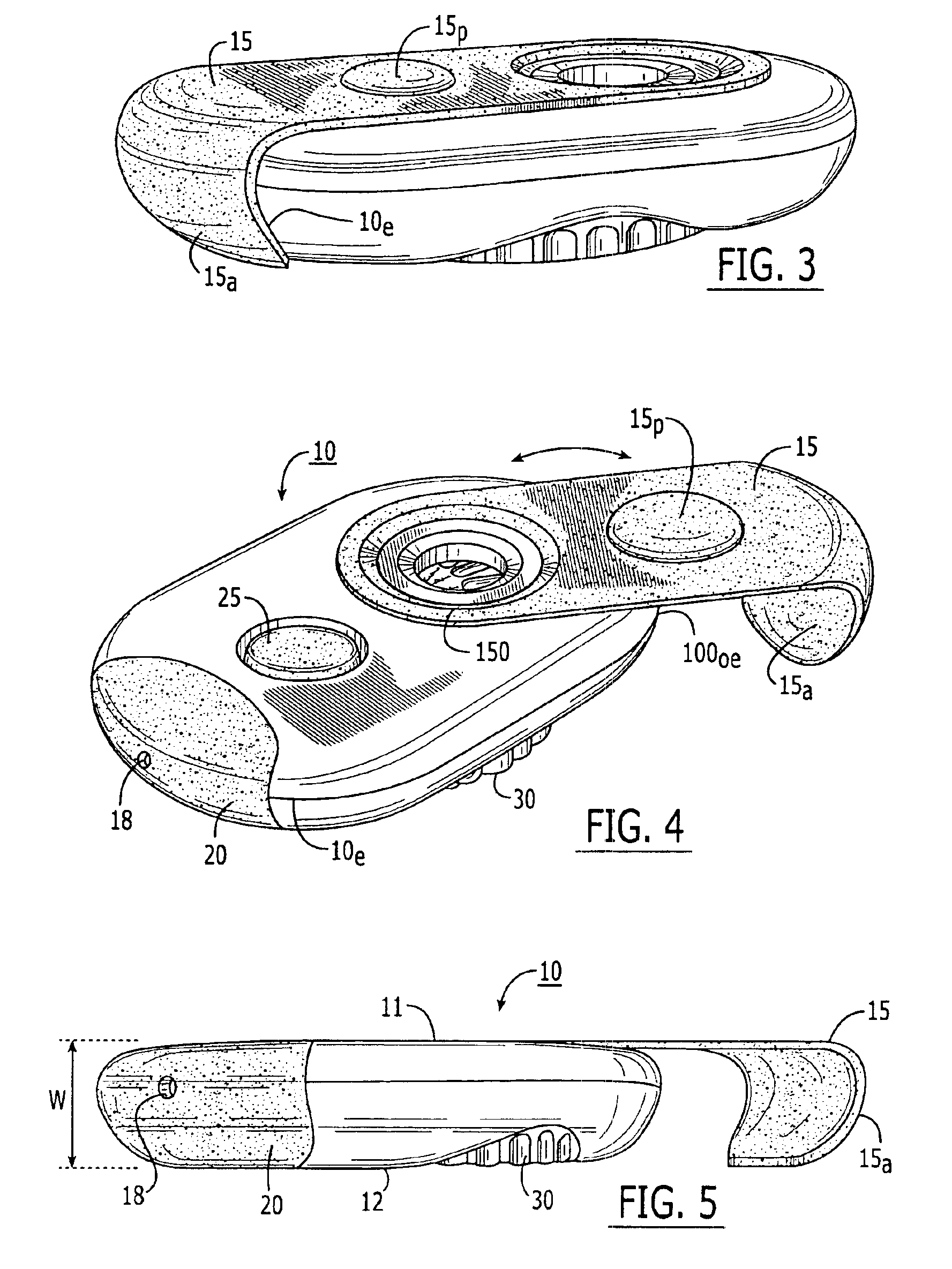

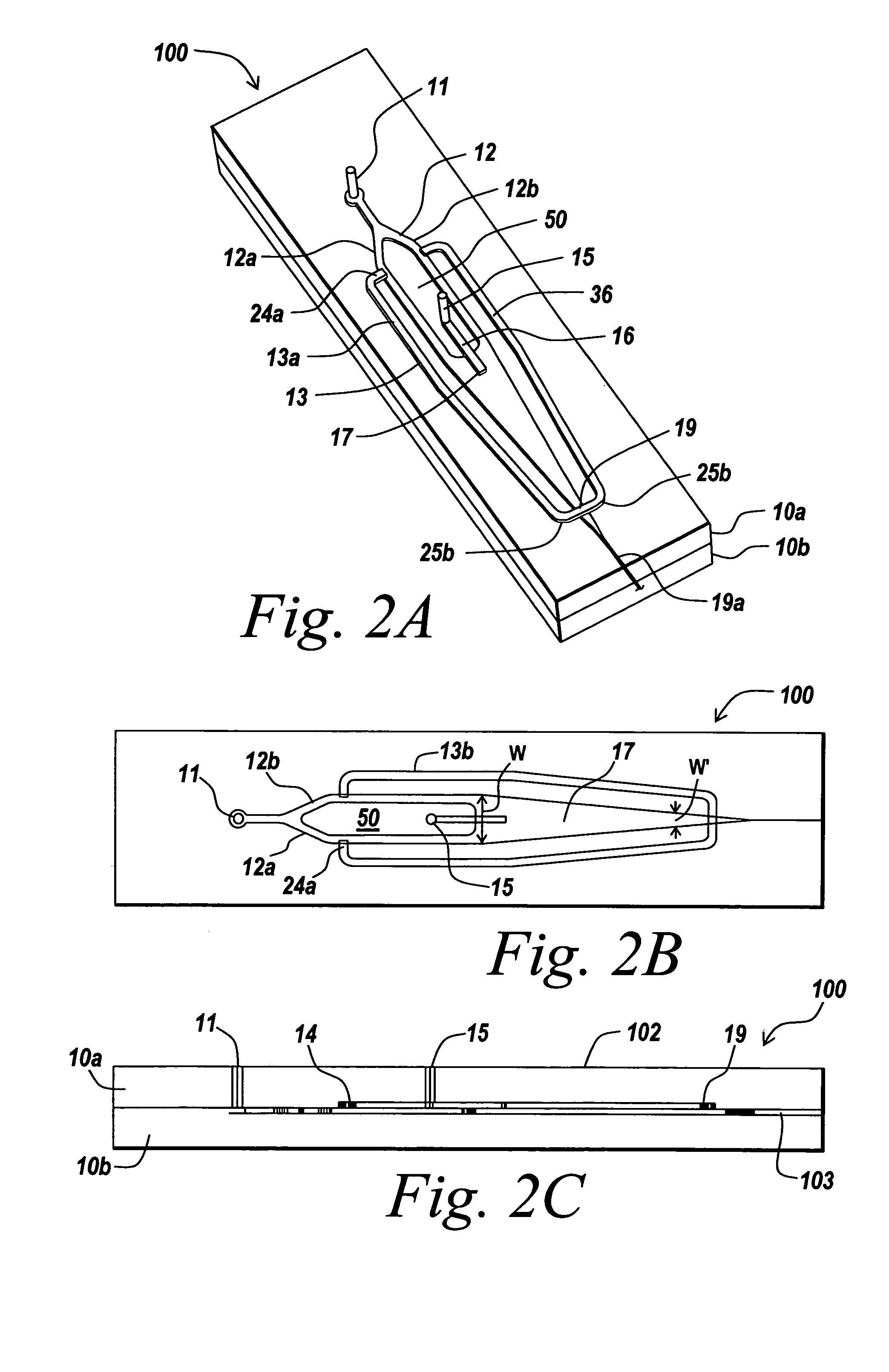

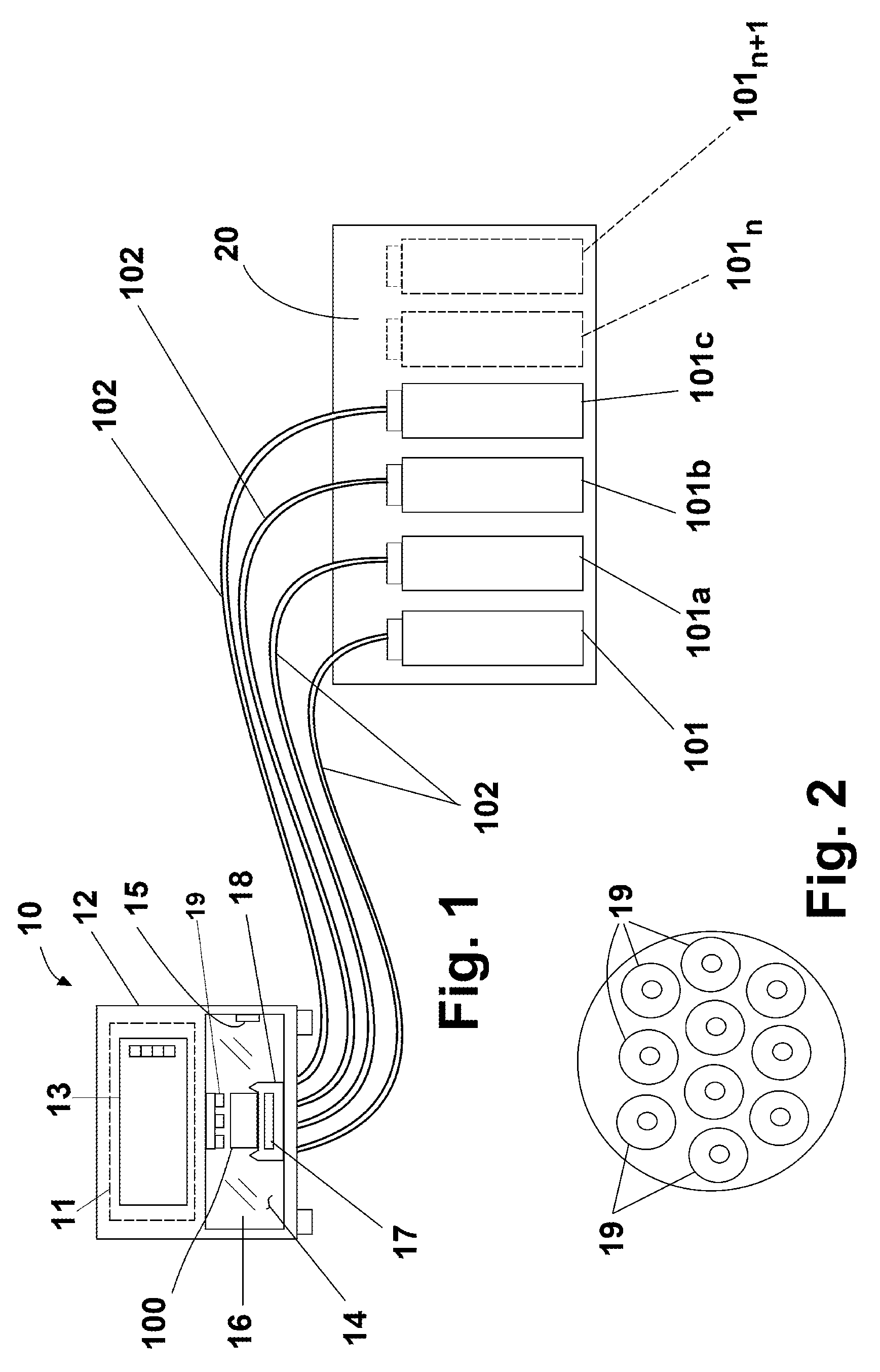

Dry powder inhalers, related blister devices, and associated methods of dispensing dry powder substances and fabricating blister packages

InactiveUS6889690B2Easy to optimizeLimit amount of resistanceSmall article dispensingLiquid surface applicatorsPowder InhalerInhalation

The present invention includes dry powder inhalers and associated multi-dose dry powder packages for holding inhalant formulated dry powder substances and associated fabrication and dispensing methods. The multi-dose package can include a platform body comprising at least one thin piezoelectric polymer material layer defining at least a portion of a plurality of spatially separated discrete elongate dry powder channels having an associated length, width and height; and a metallic material attached to selected portions of the piezoelectric polymer material including each of the regions corresponding to the elongate dry powder channels to, in operation, define active energy releasing vibratory channels. In operation, the elongate channels can be selectively individually activated to vibrate upon exposure to an electrical input.The dry powder inhaler includes an elongate body having opposing first and second outer primary surfaces with a cavity therebetween and having opposing top and bottom end portions and a multi-dose sealed blister package holding a plurality of discrete meted doses of a dry powder inhalable product located in the cavity of the elongate body. The inhaler also includes an inhalation port formed in the bottom end portion of the elongate body, the inhalation port configured to be in fluid communication with at least one of the discrete meted doses during use and a cover member that is pivotably attached to the elongate body so that it remains attached to the body during normal operational periods of use and moves to a first closed position to overlie the inhalation port at the bottom end portion of the body during periods of non-use and moves to a second open position away from the inhalation port during periods of use to allow a user to access the inhalation port.

Owner:ORIEL THERAPEUTICS INC

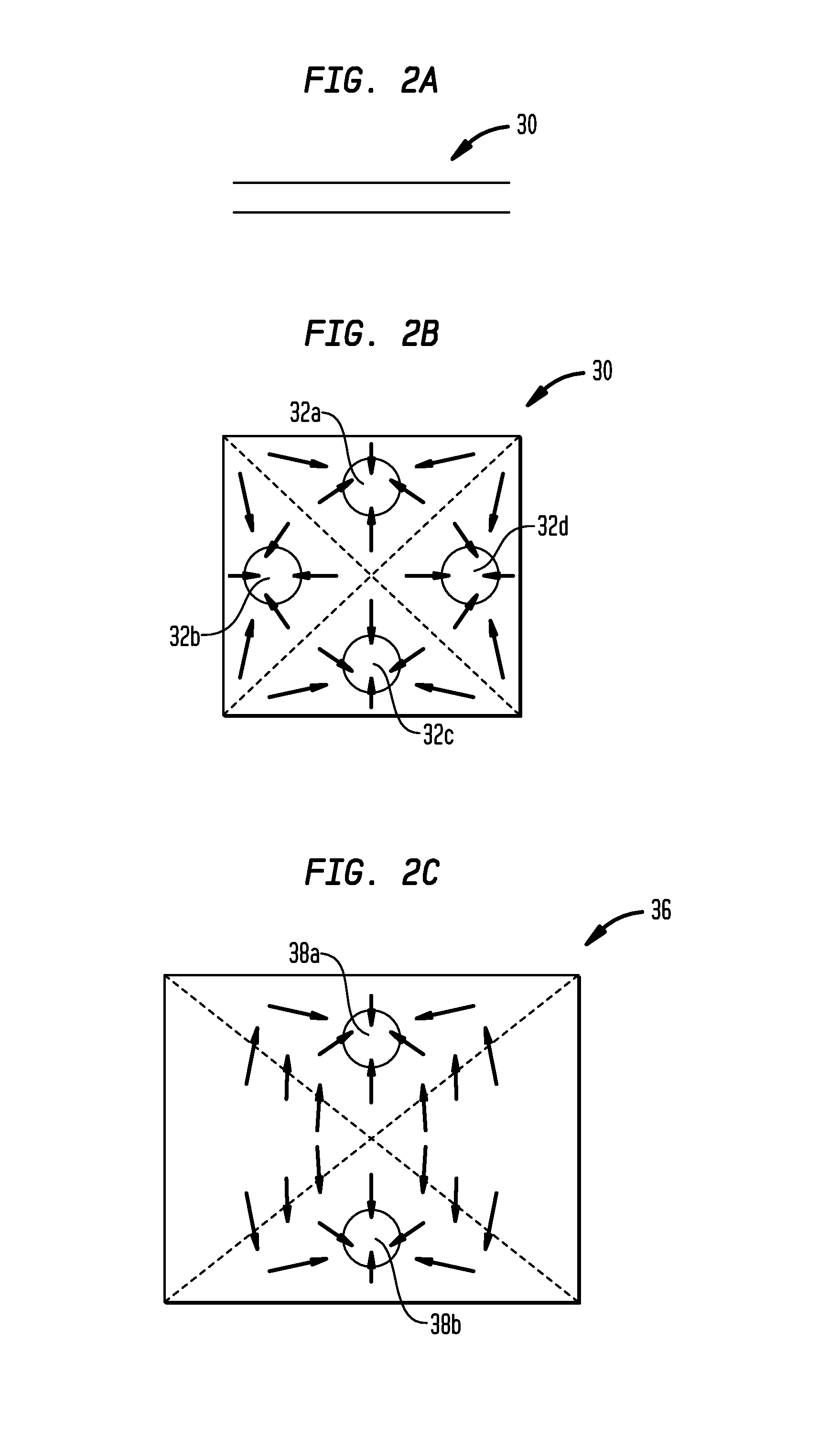

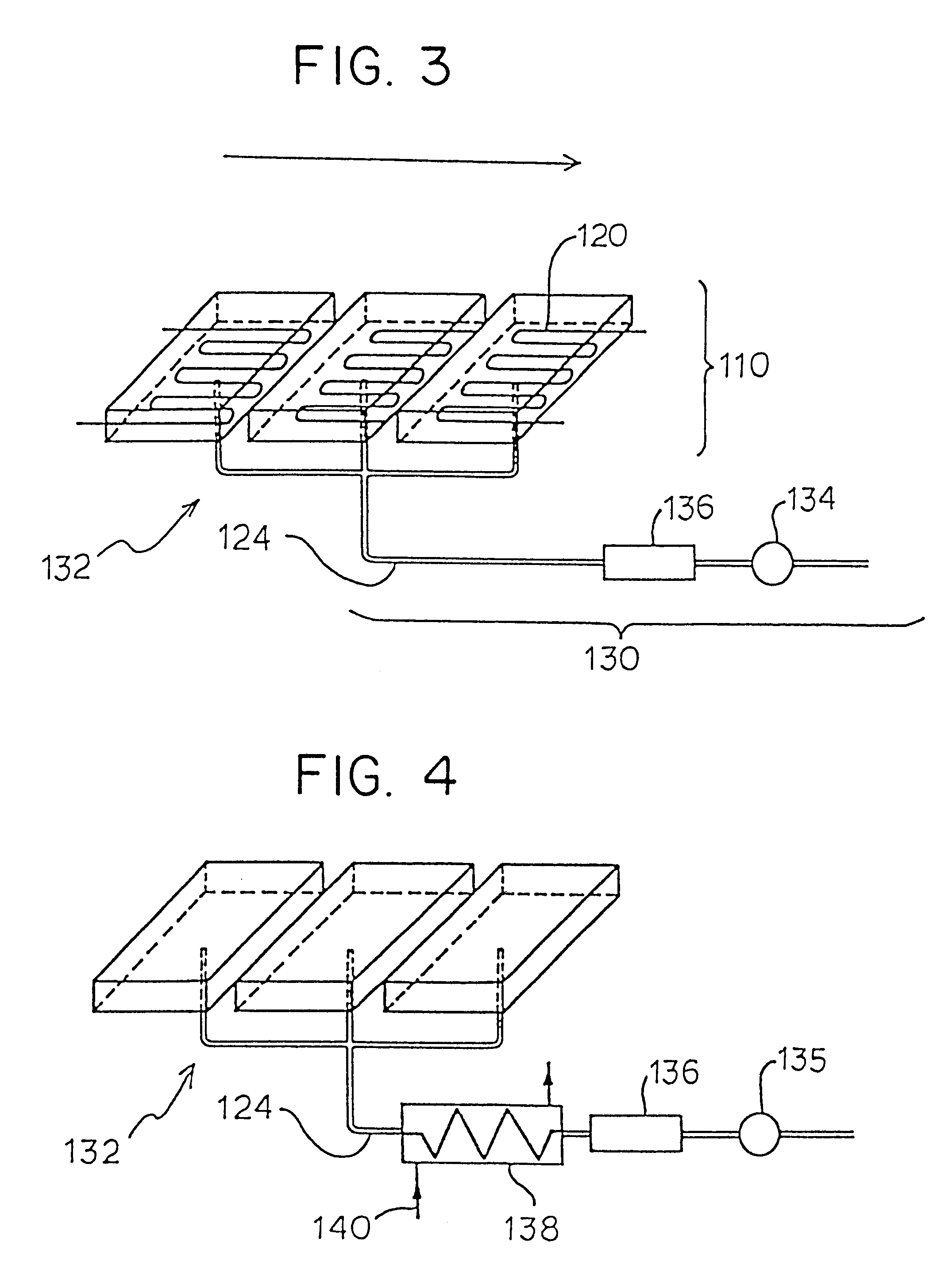

Non-contact support platforms for distance adjustment

An apparatus for supporting a stationary or moving substantially flat object without physical contact on an fluid-cushion. The object floats on a fluid cushion gap, the apparatus aimed for globally or locally adjusting the gap. The apparatus comprising: a first platform for supporting the object without contact, the platform having a substantially flat active surface comprised of one or more sectors, each sector comprising at least one of a plurality of basic cells, each basic cell having at least one of a plurality of pressure outlets fluidically connected through a pressure flow restrictors to a higher-pressure manifold associated with the sector in which the basic cell lies, the higher-pressure manifold is fluidically connected through main supply pipeline to pressurized fluid supply and at least one of a plurality of fluid-evacuation channels fluidically connected to a lower-pressure manifold associated with the sector in which the basic cell lies having main evacuation pipeline; wherein the flow restrictor characteristically exhibiting fluidic return spring behavior; and wherein at least one pressure control valve is interposed with at least one of the two main pipelines of at least one sector for controlling pressure levels of at least one of the two manifolds of that sector.

Owner:COREFLOW SCI SOLUTIONS

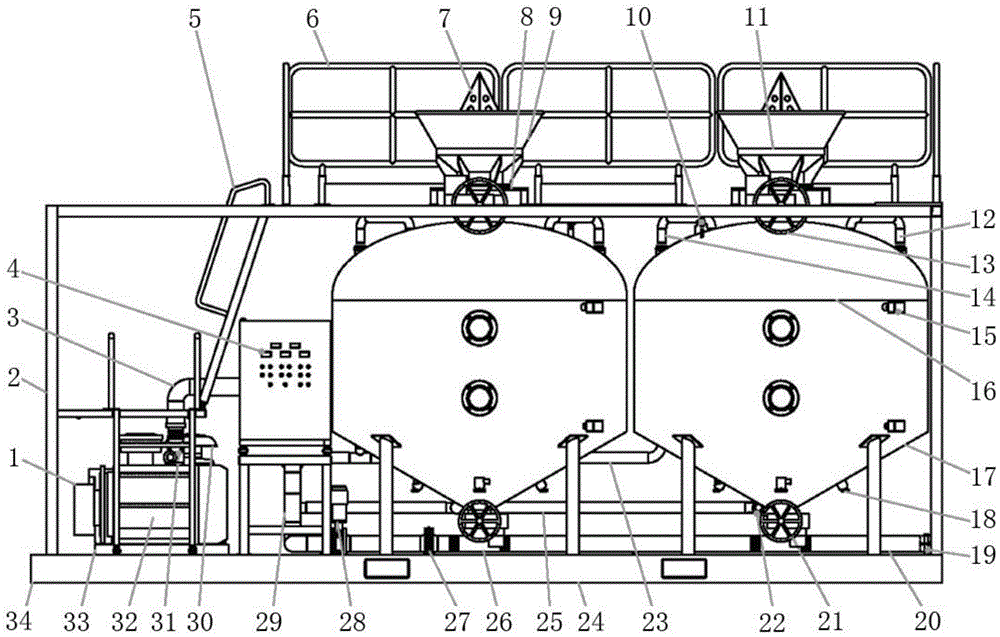

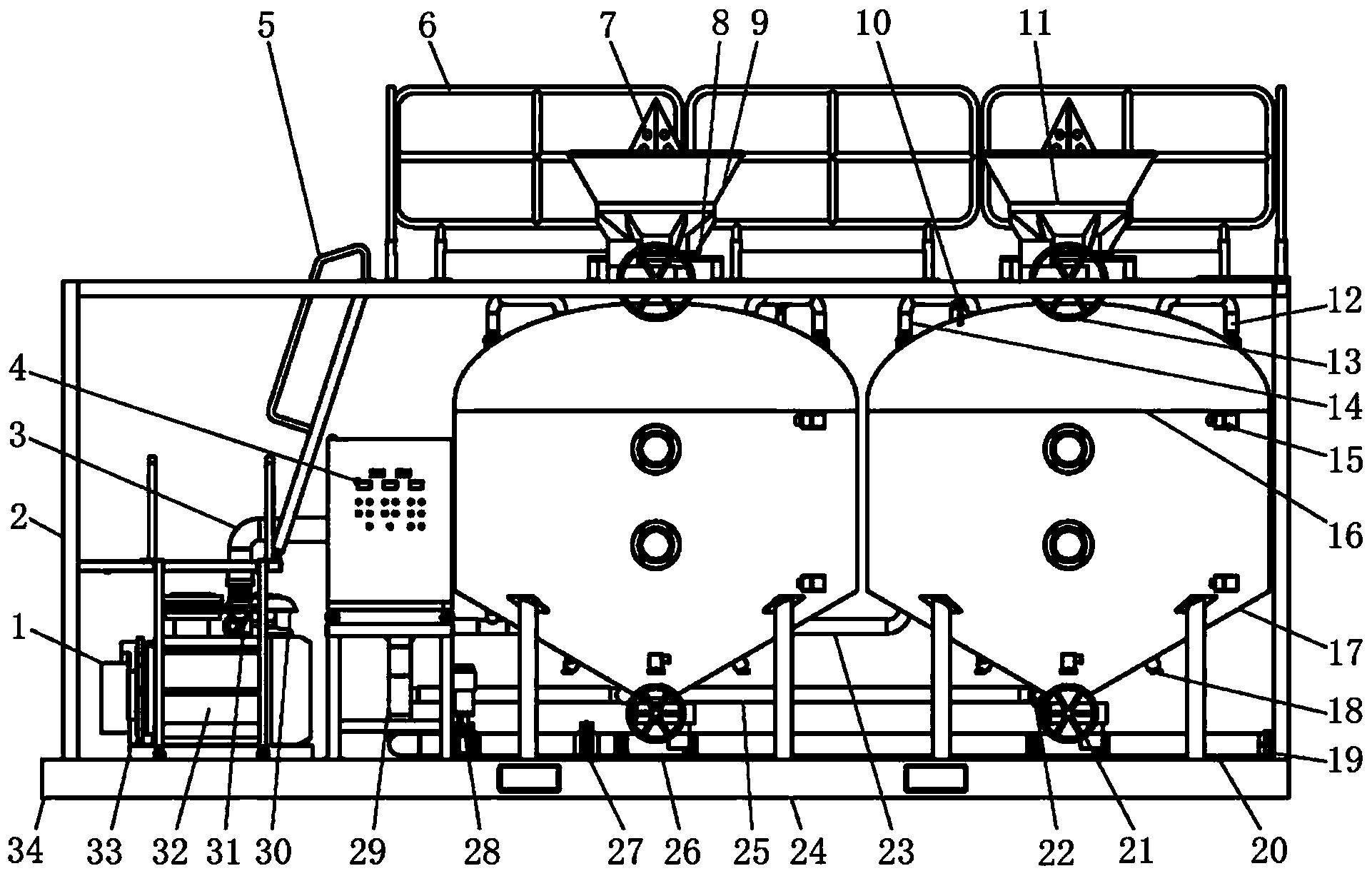

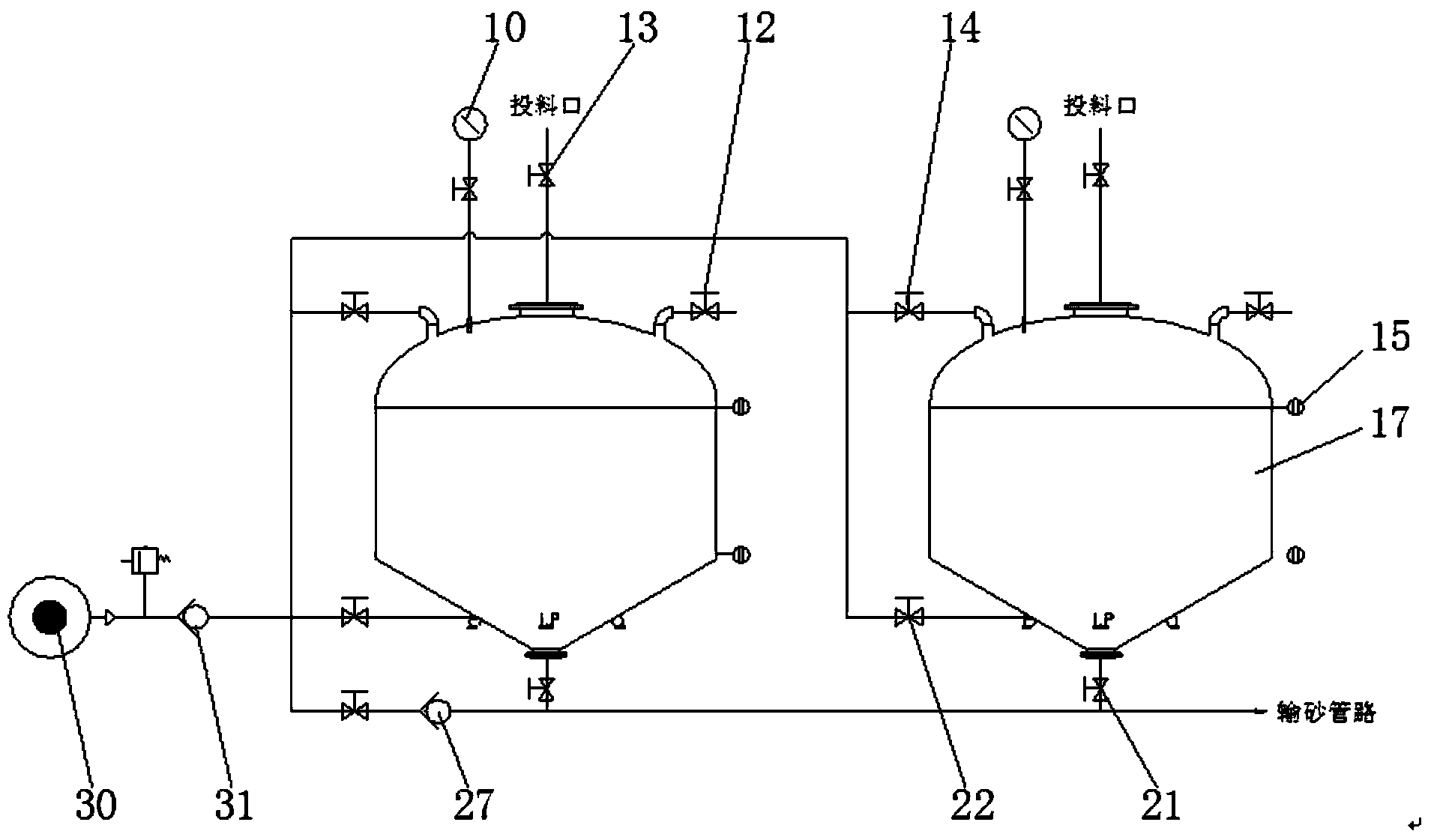

A positive pressure pneumatic conveying skid for oil field fracturing proppant

ActiveCN104340682BImprove securityReduce the difficulty of homeworkBulk conveyorsPositive pressureControl system

Owner:YANTAI JEREH PETROLEUM EQUIP & TECH CO LTD

Gas floating apparatus, gas floating-transporting apparatus, and thermal treatment apparatus

InactiveUS6336775B1Large heat capacityWaste of energyGlass transportation apparatusSemiconductor/solid-state device manufacturingEngineeringThermal treatment

A gas floating-transporting apparatus transports a material to be treated along a predetermined direction in a thermal space so as to thermally treat the material to be treated. The apparatus includes a gas floating mechanism and a transporting mechanism. The gas floating mechanism includes a gas ejection device which expels the gas toward a portion of the material to be treated on which a floating force is acted so as to float the material to be treated, and a gas supply device which supplies the gas to the gas ejection means. The transporting mechanism includes an abutting member which abuts a trailing end of the floated material to be treated and moves along the predetermined direction, and which pushes the material to be treated by the movement thereof, whereby the floated material to be treated is moved along the predetermined direction.

Owner:PANASONIC CORP

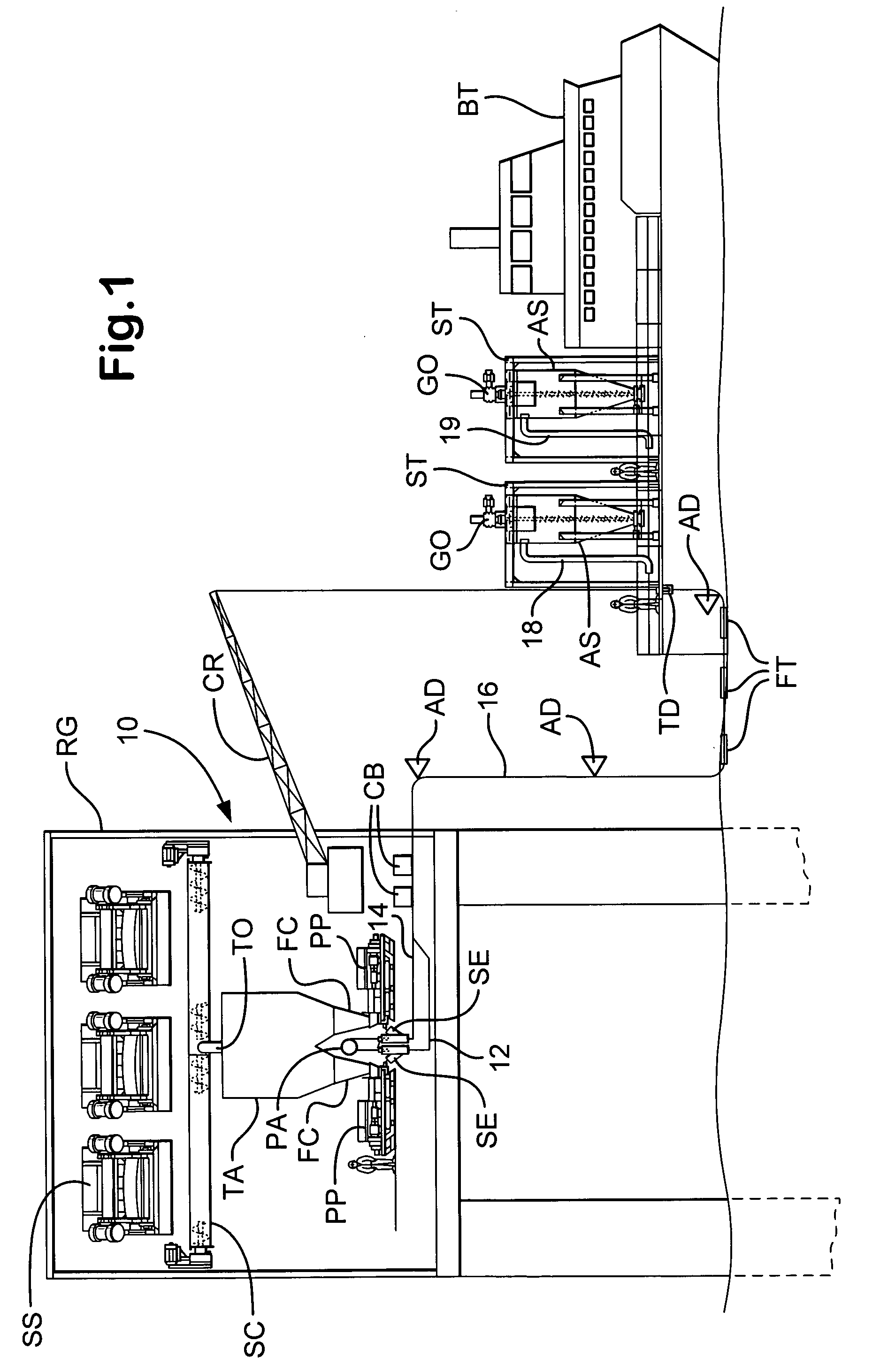

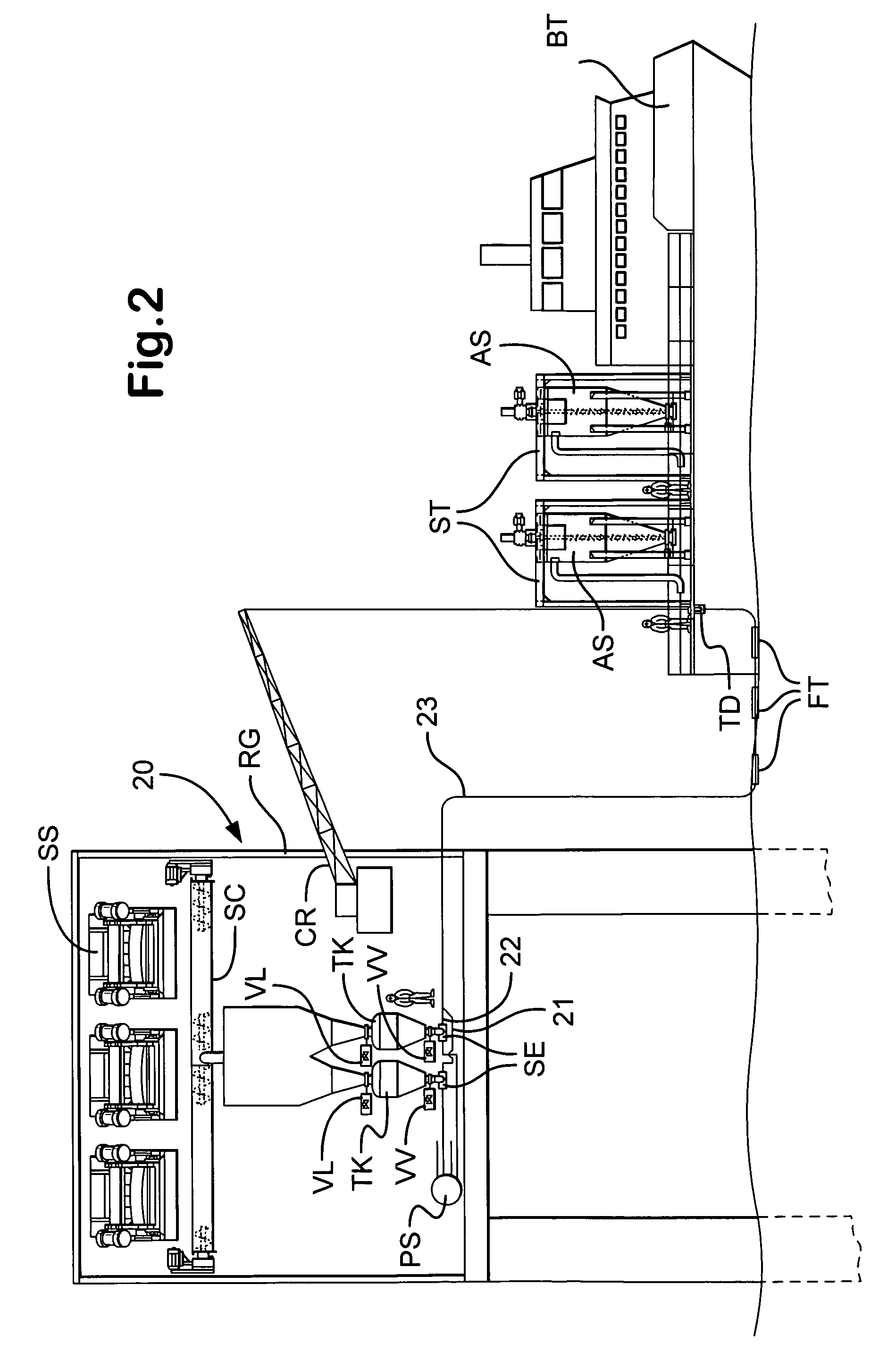

Positive-pressure pneumatic conveying skid for oilfield fracturing propping agent

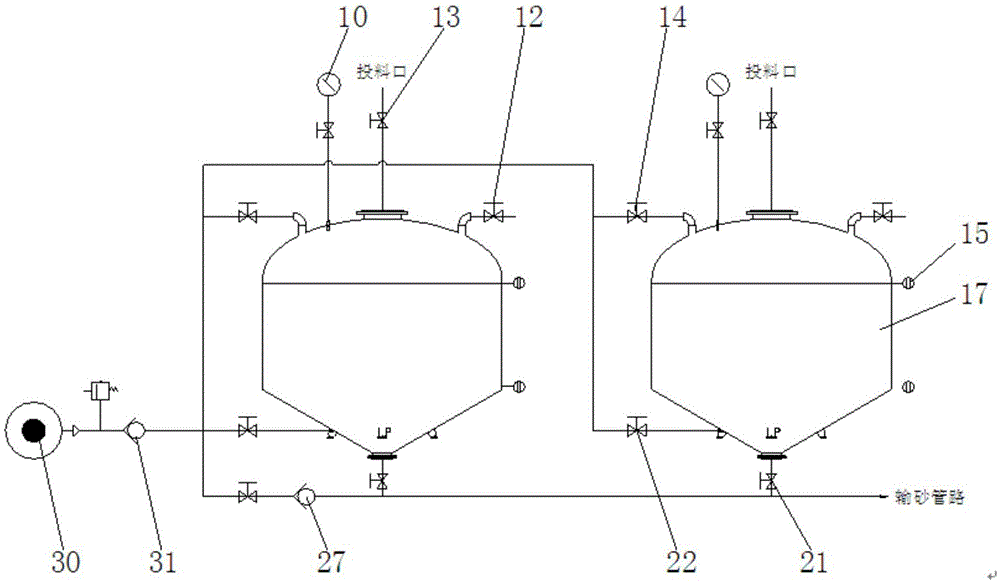

ActiveCN104340682AImprove securityReduce the difficulty of homeworkBulk conveyorsPositive pressureControl system

The invention relates to a positive-pressure pneumatic conveying skid for an oilfield fracturing propping agent. The positive-pressure pneumatic conveying skid for the oilfield fracturing propping agent comprises a skid frame and is characterized in that a fan power-driven system, a gas channel and sand conveying system, a delivery tank assembly, movable feeding devices and an electric control system are arranged on the skid frame. The positive-pressure pneumatic conveying skid for the oilfield fracturing propping agent has the benefits as follows: the occupied area is small, the transportation is convenient, the operation environment and the operation safety are improved, and the efficiency of operation for conveying a material to a high storage tank is improved.

Owner:YANTAI JEREH PETROLEUM EQUIP & TECH CO LTD

Apparatus and method for supporting, positioning and rotating a substrate in a processing chamber

ActiveUS20080280453A1Liquid surface applicatorsSemiconductor/solid-state device manufacturingGas phaseEngineering

Embodiments of the invention contemplate a method, apparatus and system that are used to support, position, and rotate a substrate during processing. Embodiments of the invention may also include a method of controlling the transfer of heat between a substrate and substrate support positioned in a processing chamber. The apparatus and methods described herein remove the need for complex, costly and often unreliable components that would be required to accurately position and rotate a substrate during one or more processing steps, such as an rapid thermal processing (RTP) process, a chemical vapor deposition (CVD) process, a physical vapor deposition (PVD) process, atomic layer deposition (ALD) process, dry etching process, wet clean, and / or laser annealing process.

Owner:APPLIED MATERIALS INC

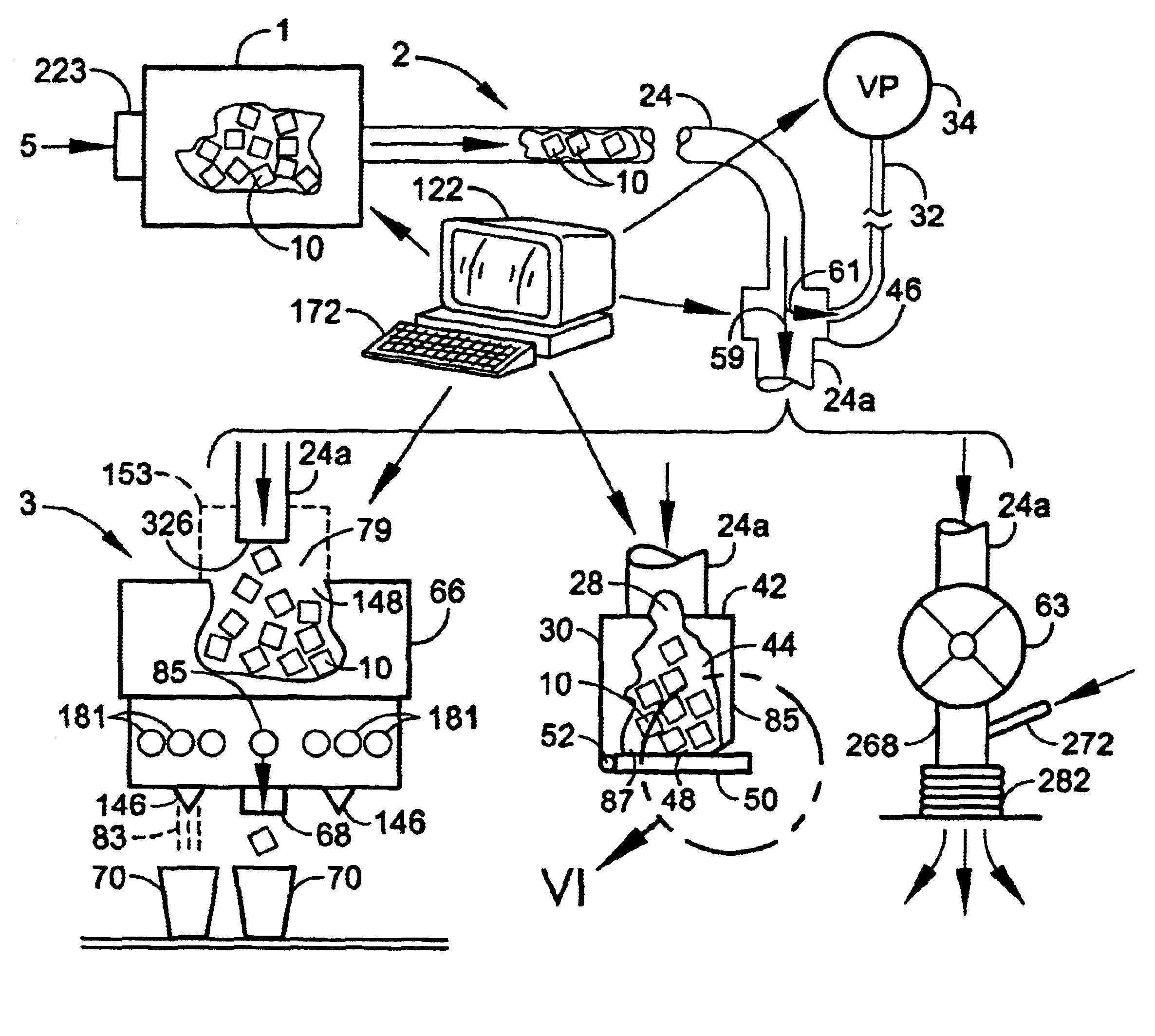

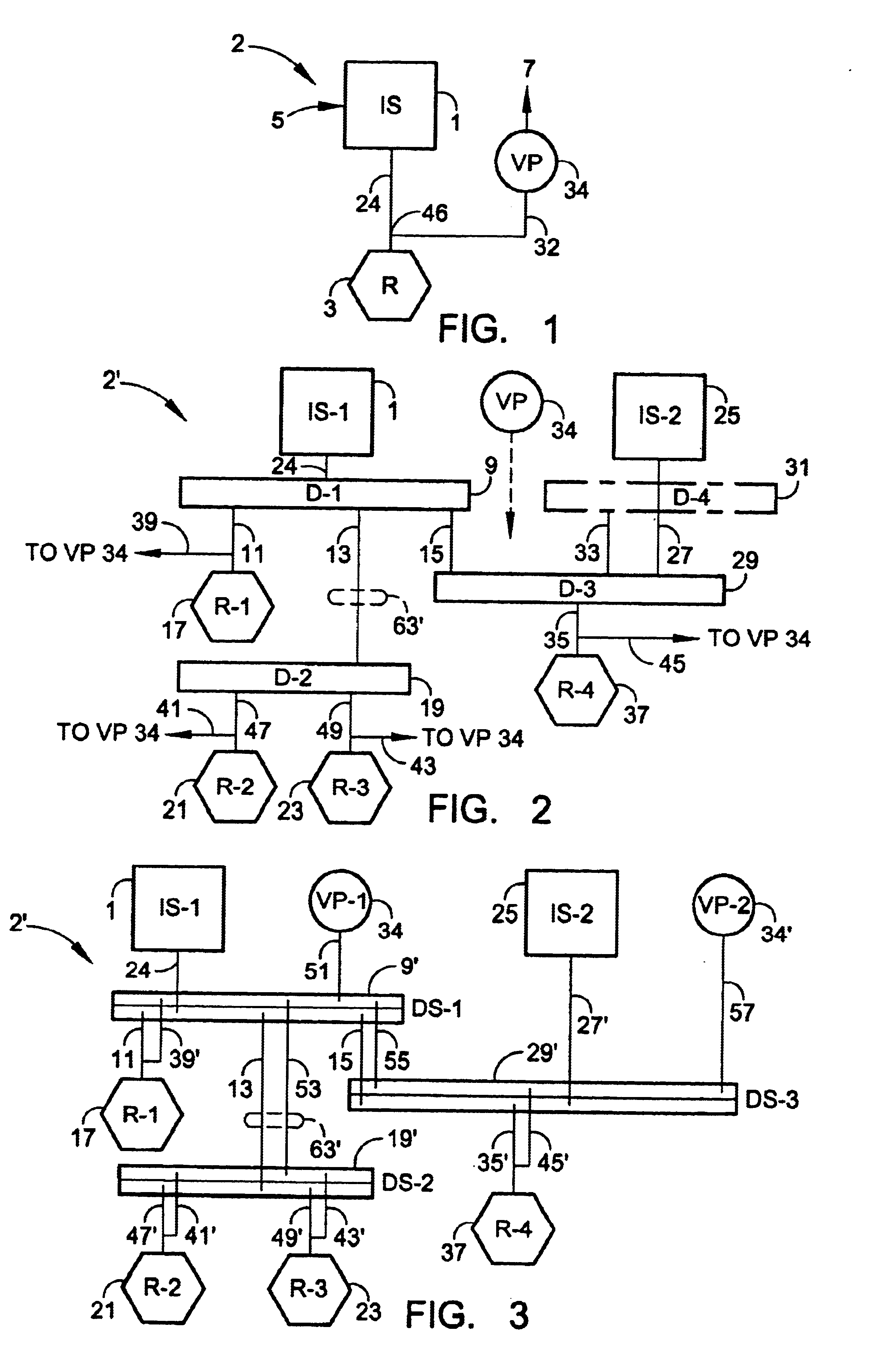

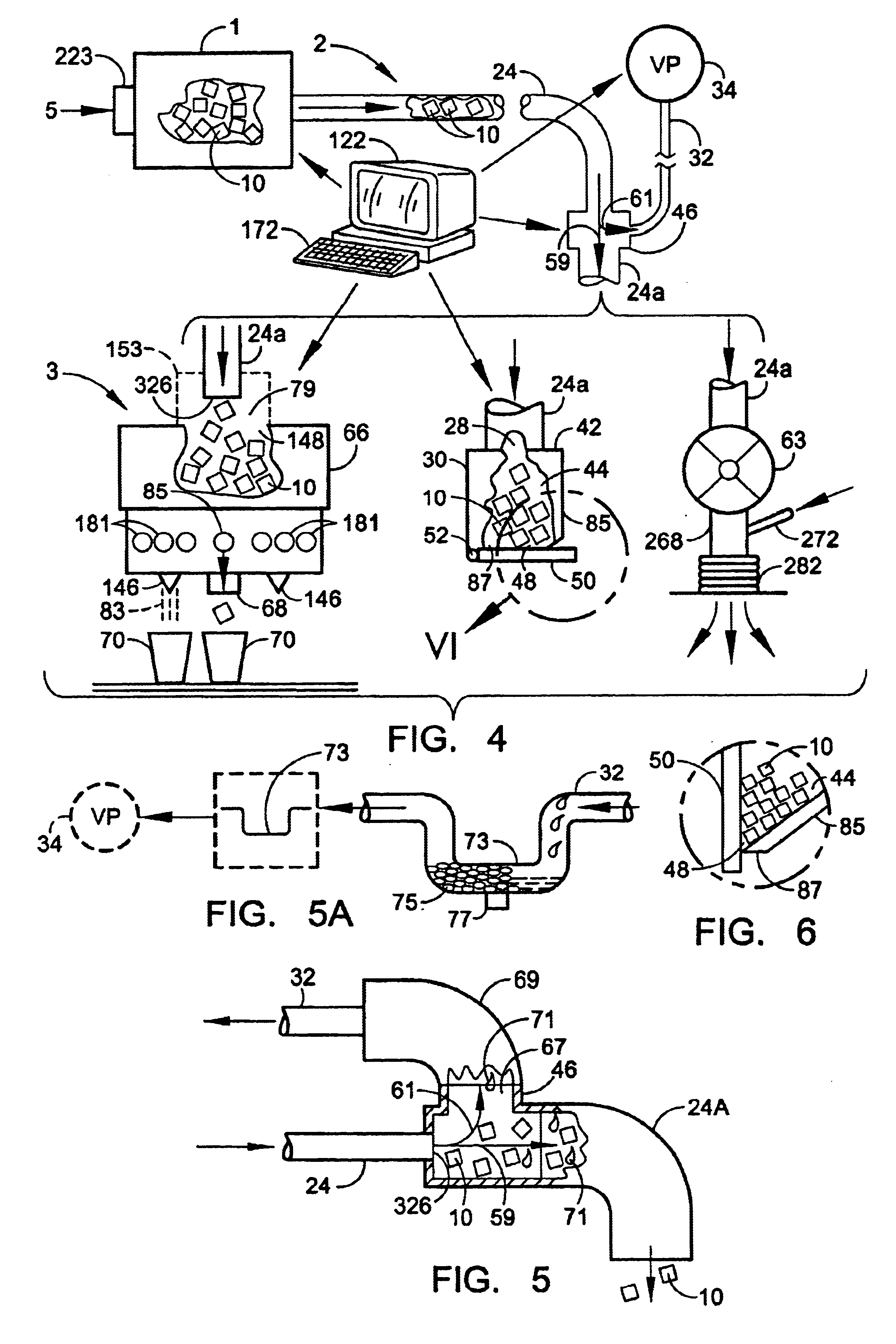

Vacuum pneumatic system for conveyance of ice

InactiveUS6827529B1Readily vacuum conveyedLess costlyLighting and heating apparatusIce productionSystem configurationEngineering

Vacuum pneumatic conveying apparatus and method are described to provide for a simple, economical, convenient (and preferably automatic) system for conveying ice on an as-required basis from a source such as an ice maker to one or more receptors at locations remote from that source. The system can be configured such that dispensing locations can be added or eliminated from the system or temporarily taken "off line" from the system without the need to change the basic system configuration or the central ice providing apparatus. The apparatus in various embodiments includes an ice source, a conveying conduit from the source to the receptor, a vacuum pump for moving the ice through the conduit by vacuum, and the receptor to collect the conveyed ice. The receptor may be an ice / beverage dispenser, an accumulator for retention and discharge to further devices, an intermediate storage dispenser, or an air lock device from where the ice can be projected over significant distances. Ice and vacuum may simultaneously be routed into different branched routes, utilizing a unique diverter / air shifter with the capability of providing routing to up to four different routes. Appropriate sensors and controllers, which may be microprocessor-based, may be used to automate the system. The entire system is easily cleanable. The system is advantageously used by restaurants, groceries, hotels and motels, hospitals, laboratories, and many other establishments where the providing of ice at various locations is desirable or required.

Owner:TEK SOLUTIONS

Non-contact support platforms for distance adjustment

ActiveUS20070195653A1Effectively rigidCombination recordingLinear bearingsHigh pressurePressure control

An apparatus for supporting a stationary or moving substantially flat object without physical contact on an fluid-cushion. The object floats on a fluid cushion gap, the apparatus aimed for globally or locally adjusting the gap. The apparatus comprising: a first platform for supporting the object without contact, the platform having a substantially flat active surface comprised of one or more sectors, each sector comprising at least one of a plurality of basic cells, each basic cell having at least one of a plurality of pressure outlets fluidically connected through a pressure flow restrictors to a higher-pressure manifold associated with the sector in which the basic cell lies, the higher-pressure manifold is fluidically connected through main supply pipeline to pressurized fluid supply and at least one of a plurality of fluid-evacuation channels fluidically connected to a lower-pressure manifold associated with the sector in which the basic cell lies having main evacuation pipeline; wherein the flow restrictor characteristically exhibiting fluidic return spring behavior; and wherein at least one pressure control valve is interposed with at least one of the two main pipelines of at least one sector for controlling pressure levels of at least one of the two manifolds of that sector.

Owner:COREFLOW SCI SOLUTIONS

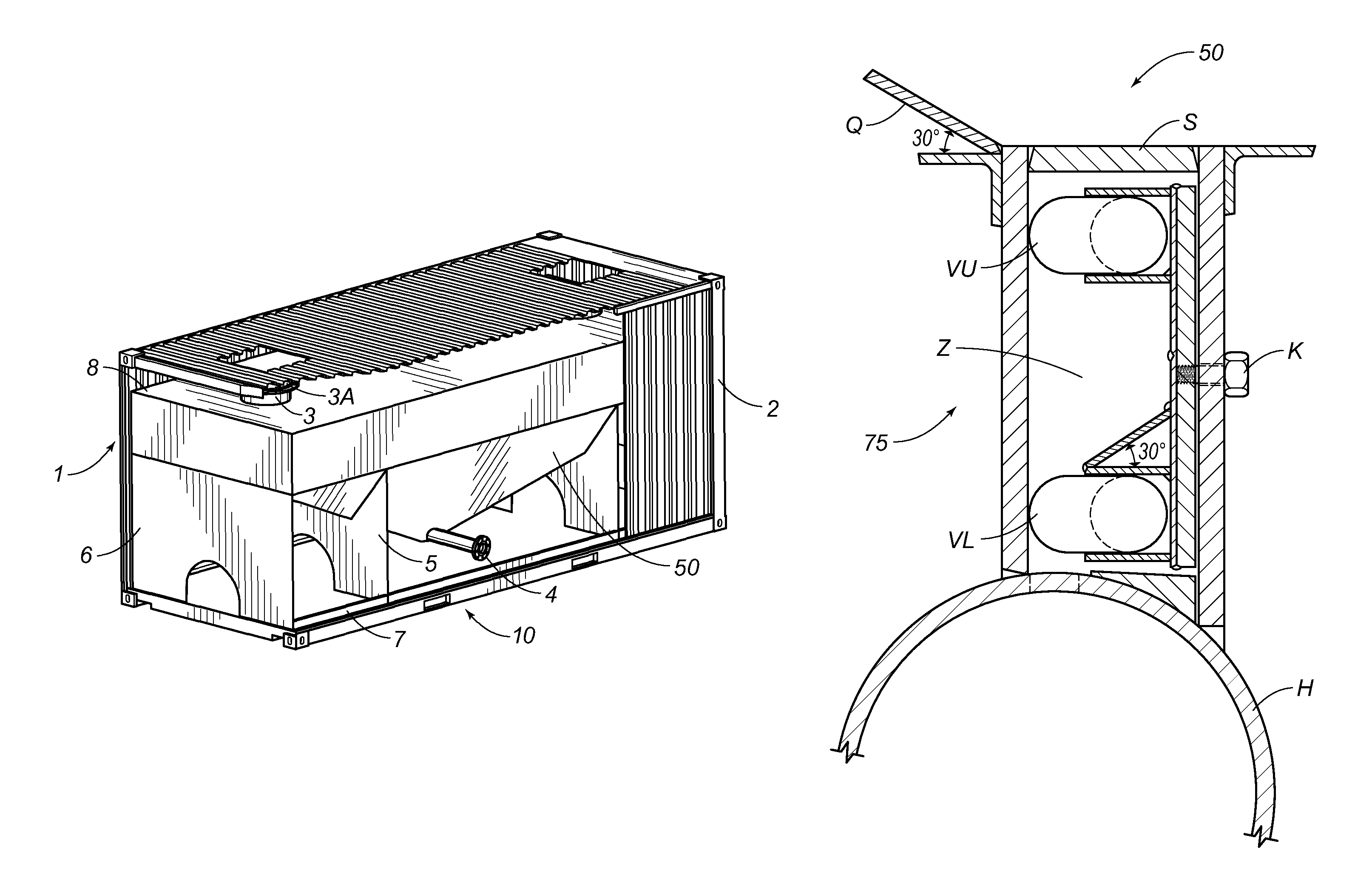

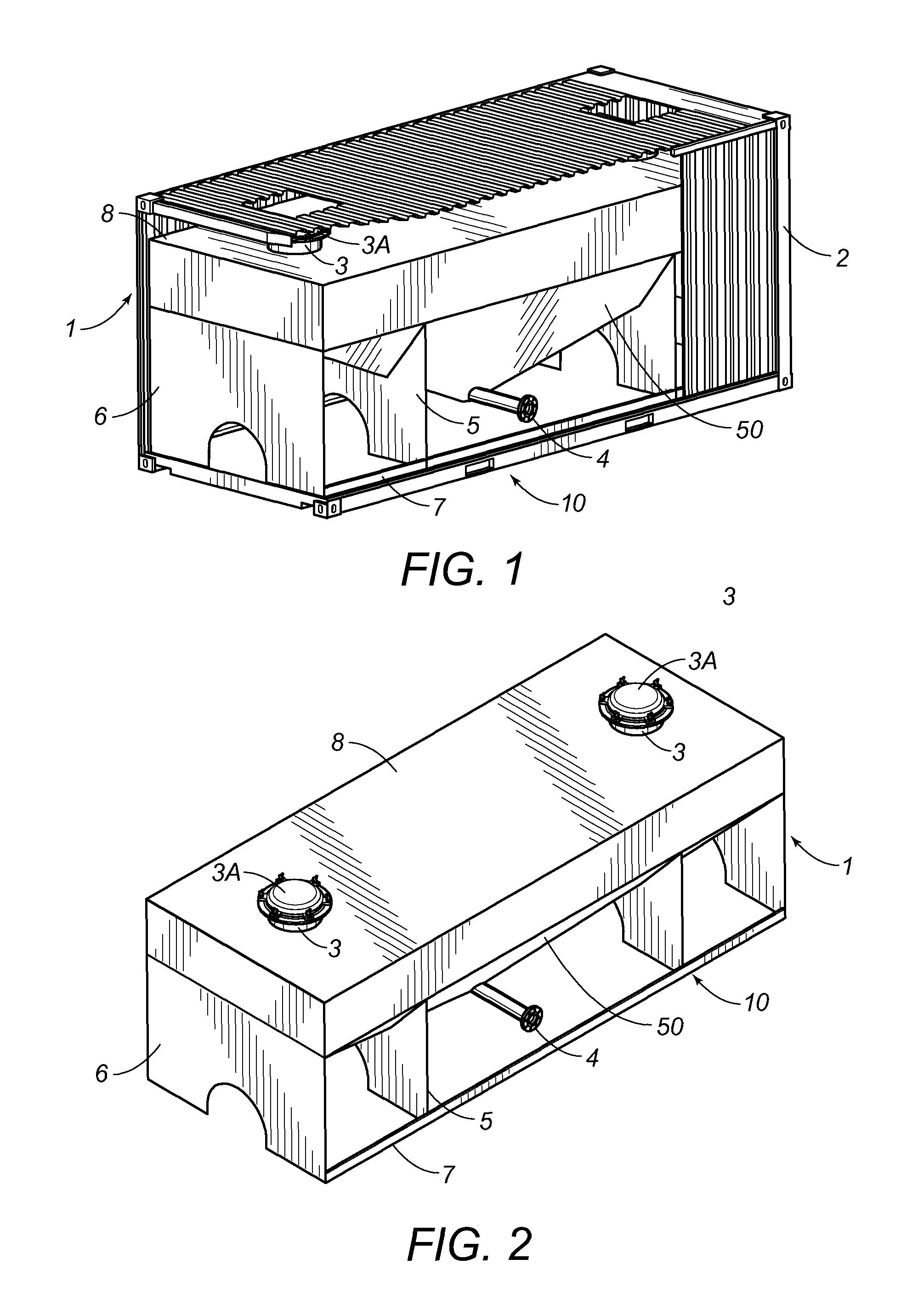

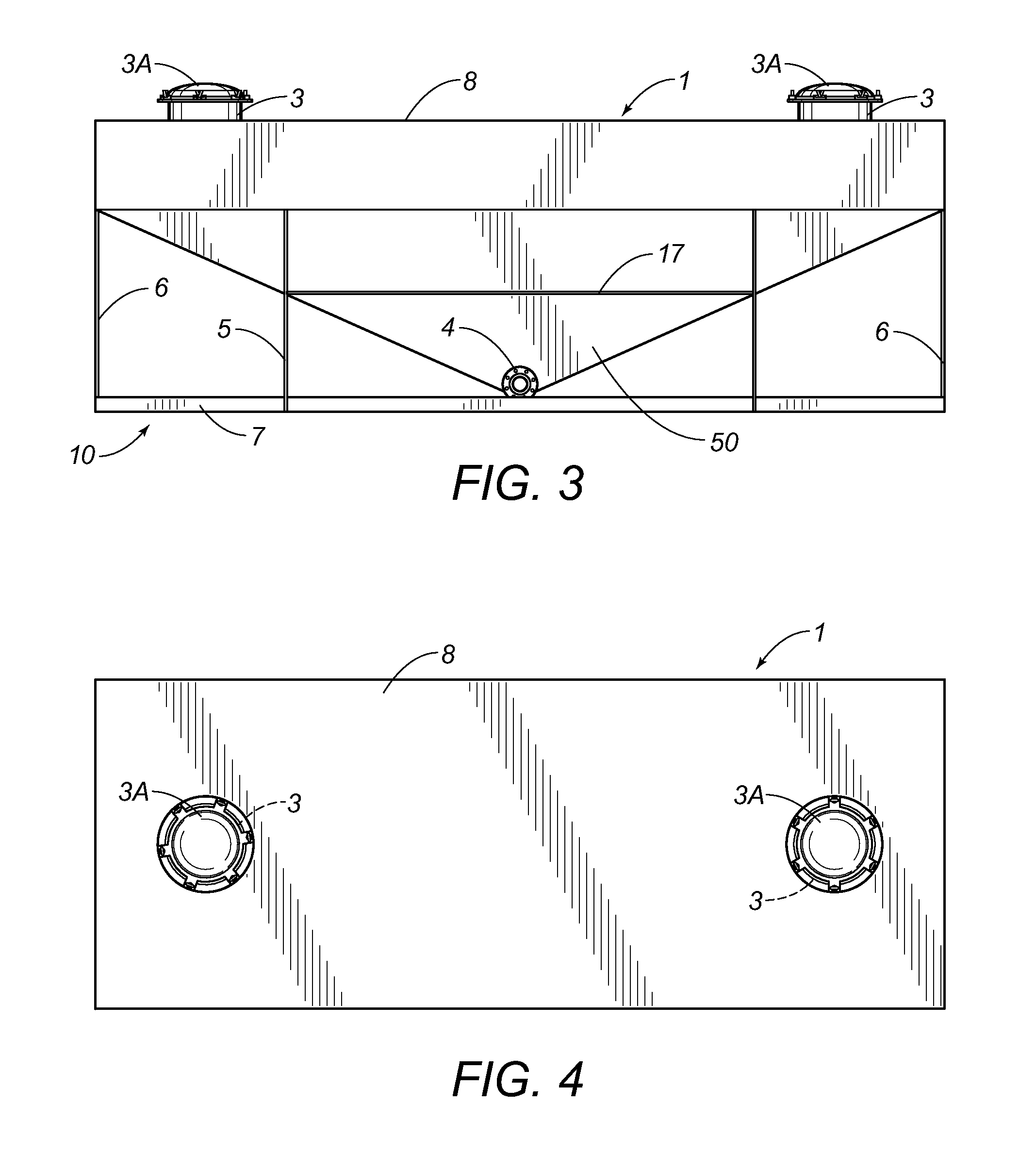

Apparatus for transporting frac sand in intermodal container

Apparatus for transporting frac sand and / or proppant for use in standard ISO intermodal containers and for delivering frac sand and / or proppant to well sites. Configured for being inserted into a container and adapted for transporting frac sand and proppant from a quarry or other frac sand supply source to a well site. A plurality of inlet ports disposed atop the roof, with the inlet ports receiving the frac sand from a frac sand supply source into a funnel-hopper, and a plurality of outlet ports for receiving the frac sand and proppant within the funnel-hopper and delivering the frac sand and proppant proximal to the well site. An in situ valve apparatus disposed within the hopper assembly for effectuating industry standard continuous pressurized discharge of stored frac sand material into a discharge pipe for delivery downhole.

Owner:MINTZ MICHAEL

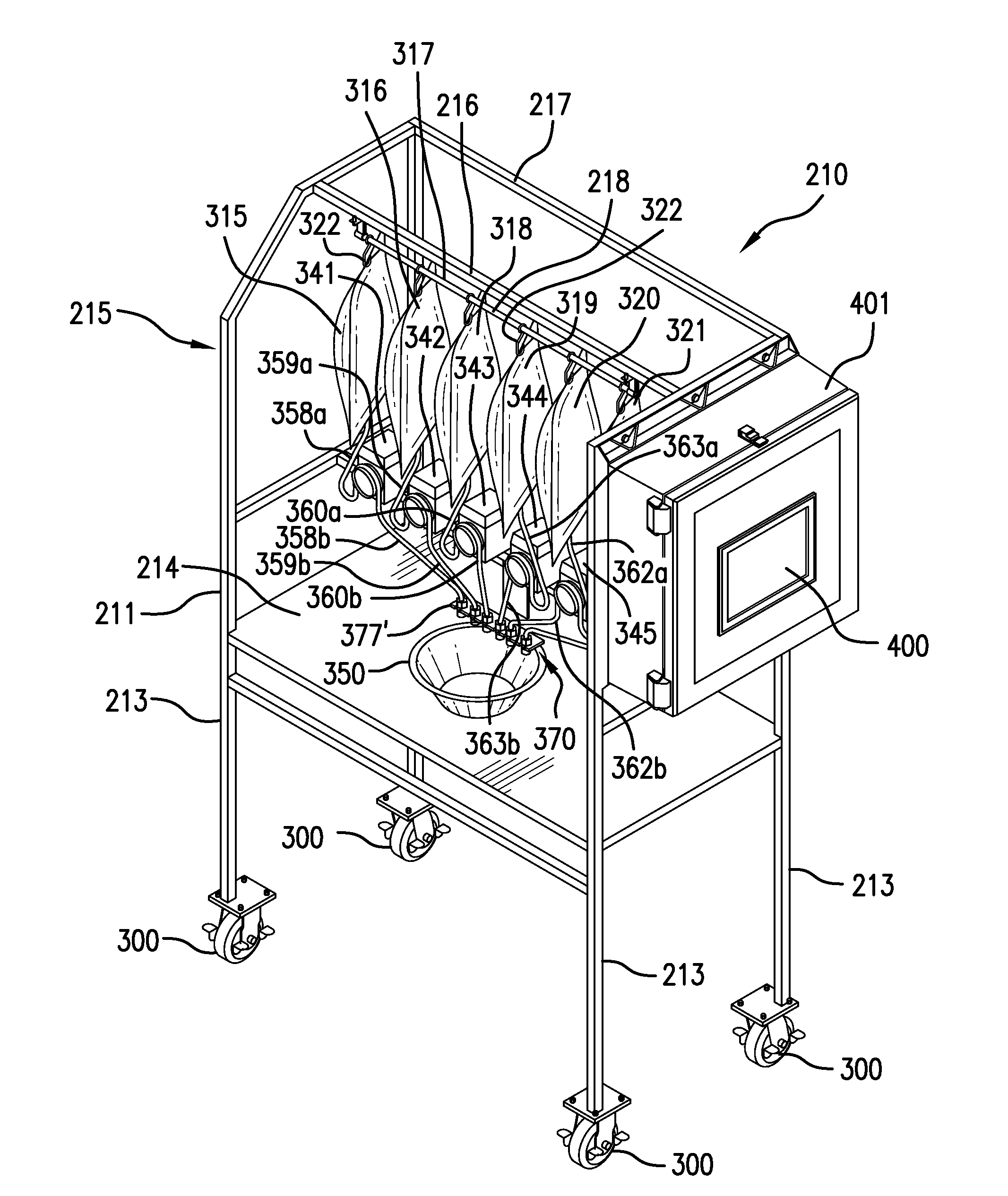

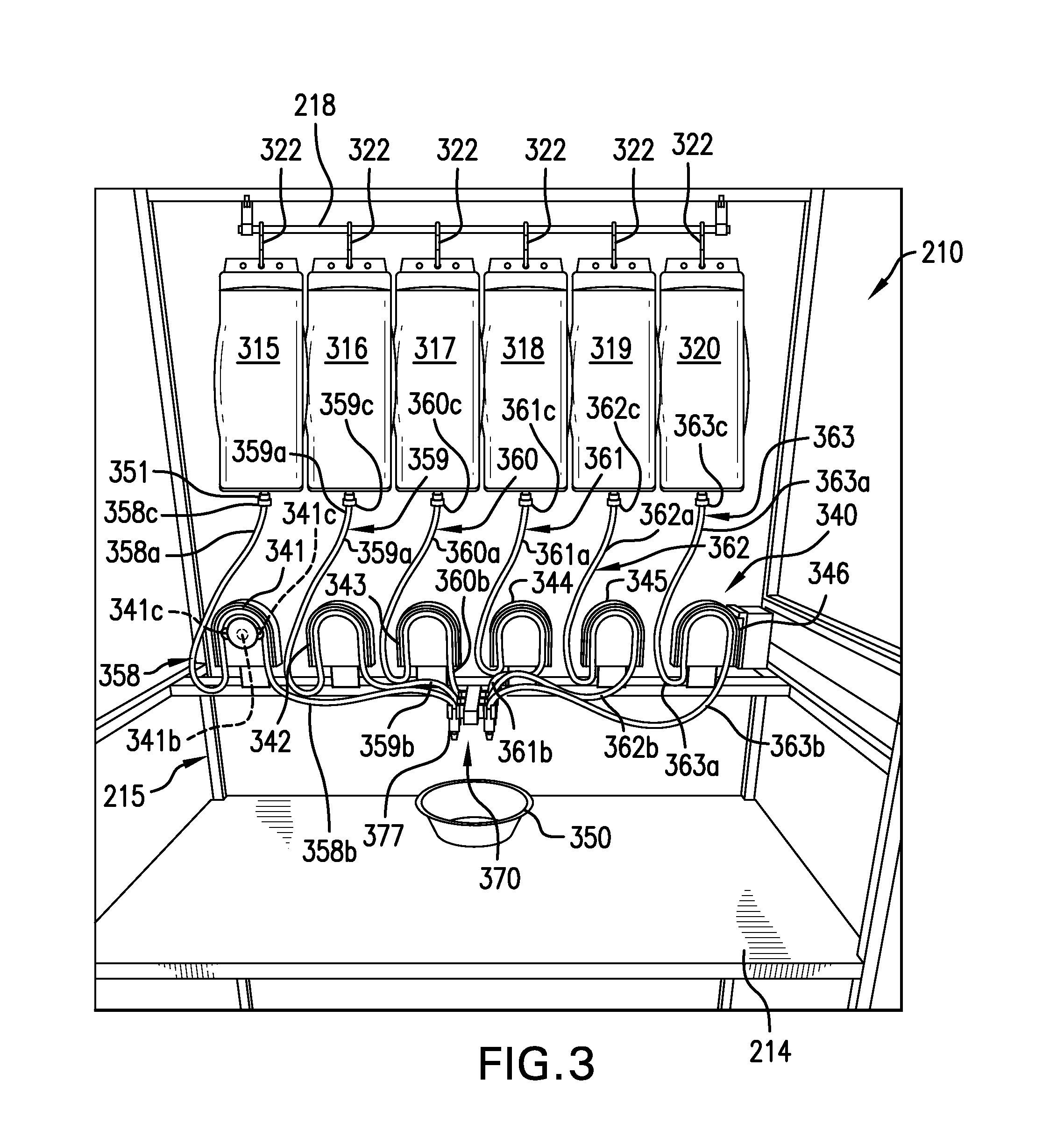

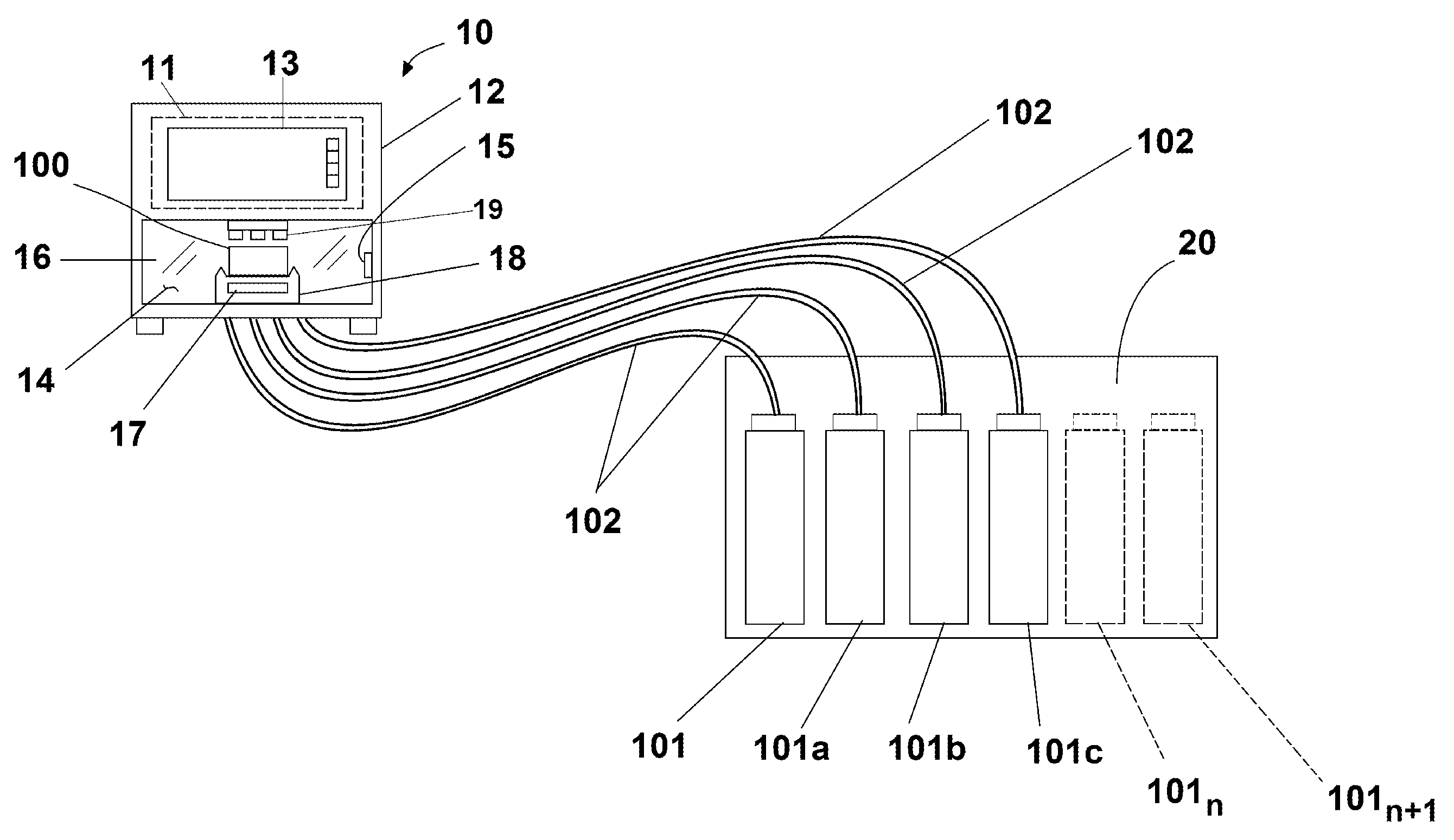

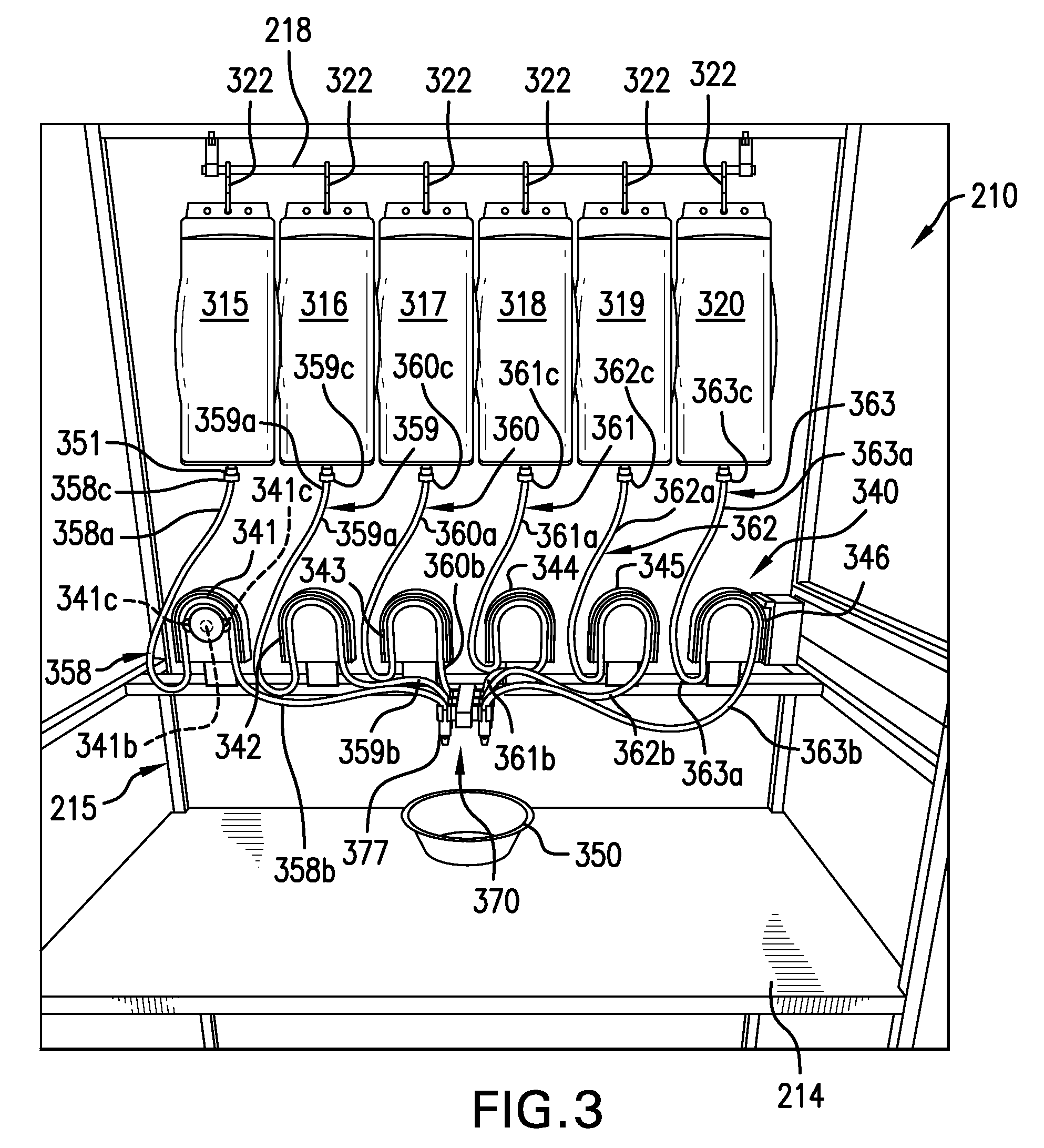

Method, system and apparatus for dispensing products for a personal care service, instructing on providing a personal care treatment service, and selecting a personal care service

A method, system and apparatus for delivery of custom blended dispensing custom blended personal care beauty products for a beauty service, wherein one or more components of a beauty product are stored where they may be supplied as needed to a dispenser, and where a control mechanism regulates the dosage of beauty components to provide a desired selected personal care beauty product with the characteristics selected. A selection screen display provides an image of a person and the person's hair that may be manipulated to simulate modifications that may include cut or styling and color or other effects. The selections are processed and stored and a formula is generated and communicating to a dispensing device to deliver the product components to produce the formula.

Owner:COLORCULTURE NETWORK

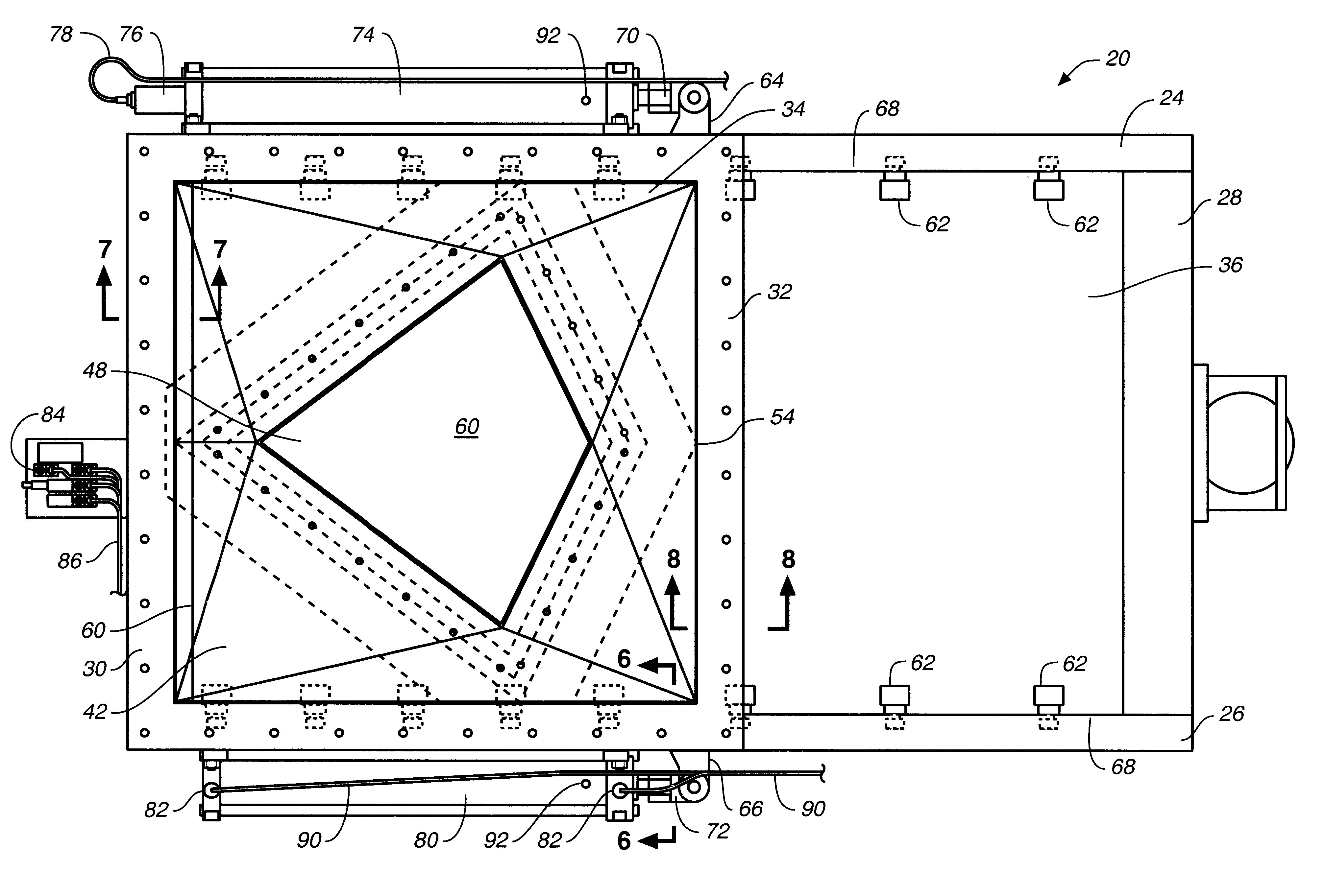

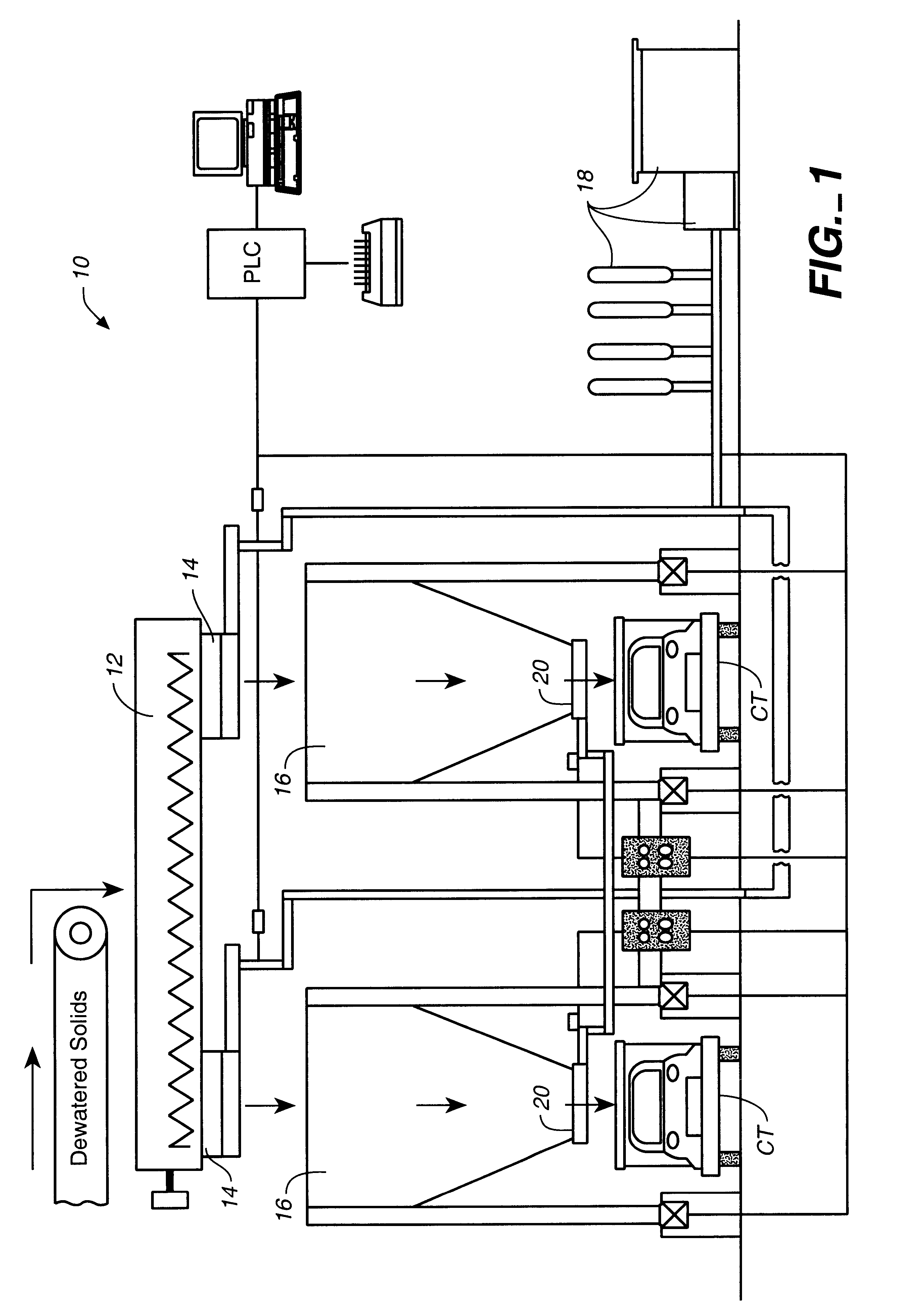

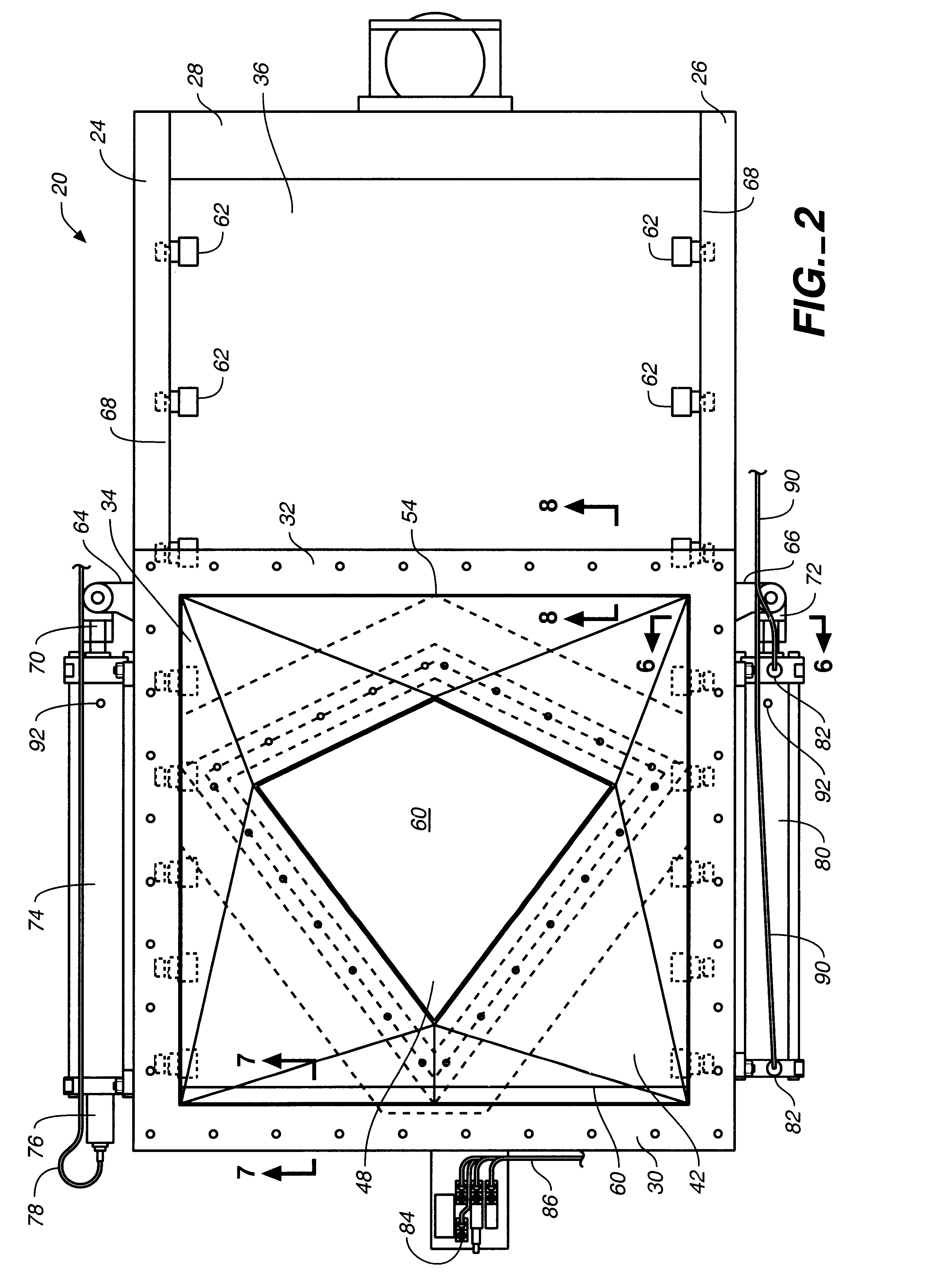

Gravity flow sludge load-out metering gate

InactiveUS6508387B1Easy to controlReduction in splashing and splatteringClosuresLiquid flow controllersSludgeEngineering

A gravity flow sludge load-out metering gate comprising a frame having longitudinal and horizontal frame rails and a transverse rail member which defines a gate front portion and a smaller gate rear portion. A sludge inlet funnel is positioned above the front portion for insertion into the interior of a hopper discharge outlet. In the preferred embodiment, the sludge inlet funnel is substantially square and has four triangular, tapering interior sides, which, when viewed from above define an asymmetrical four-pointed star, the interior configuration of which further defines an asymmetrical diamond-shaped sludge discharge orifice. Interior to the metering gate frame is a metering gate blade, slidingly positioned between a plurality of support rollers and a bulb seal, the gate operatively connected to electric, hydraulic, or pneumatic power.

Owner:RDP TECH

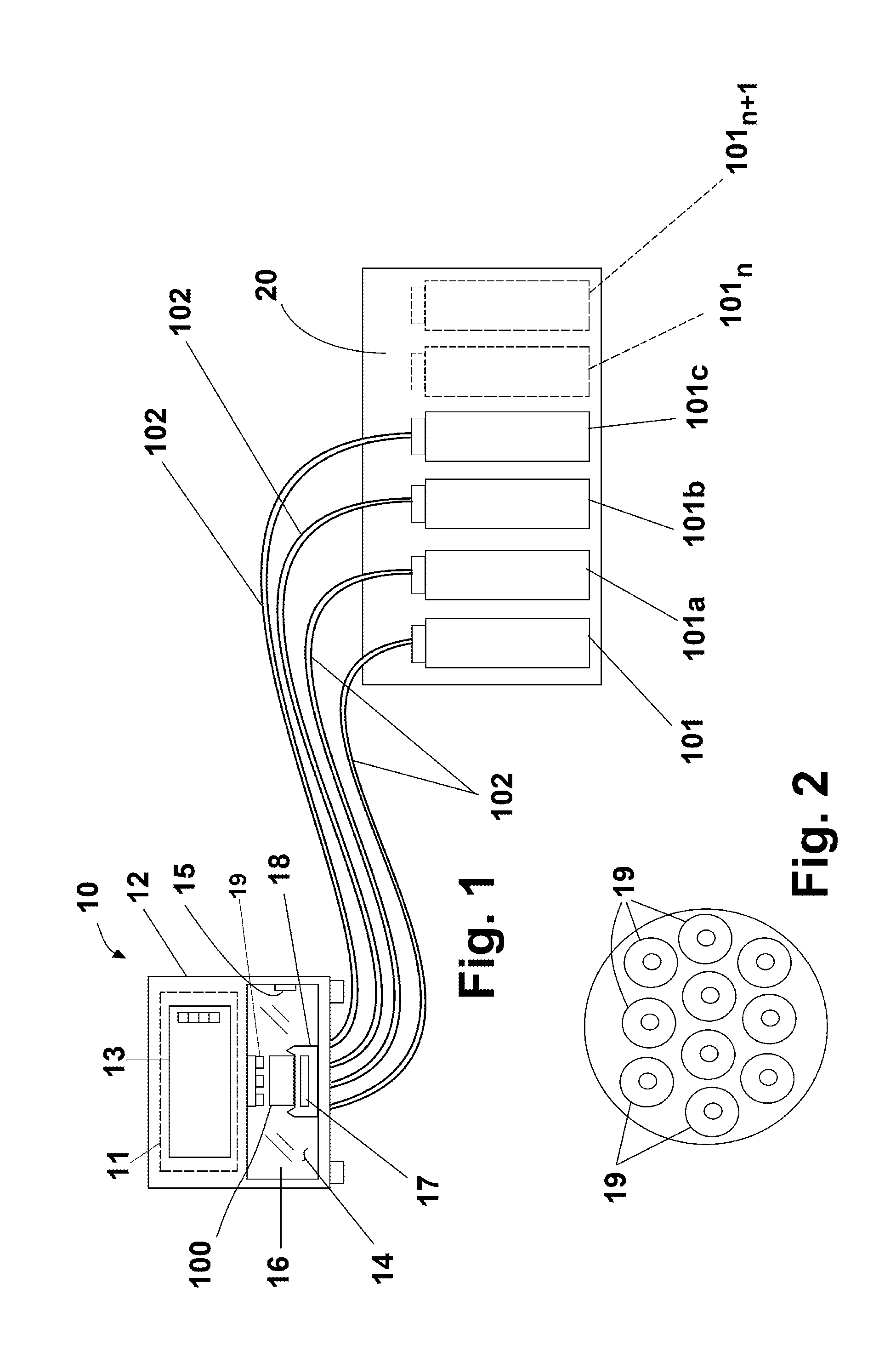

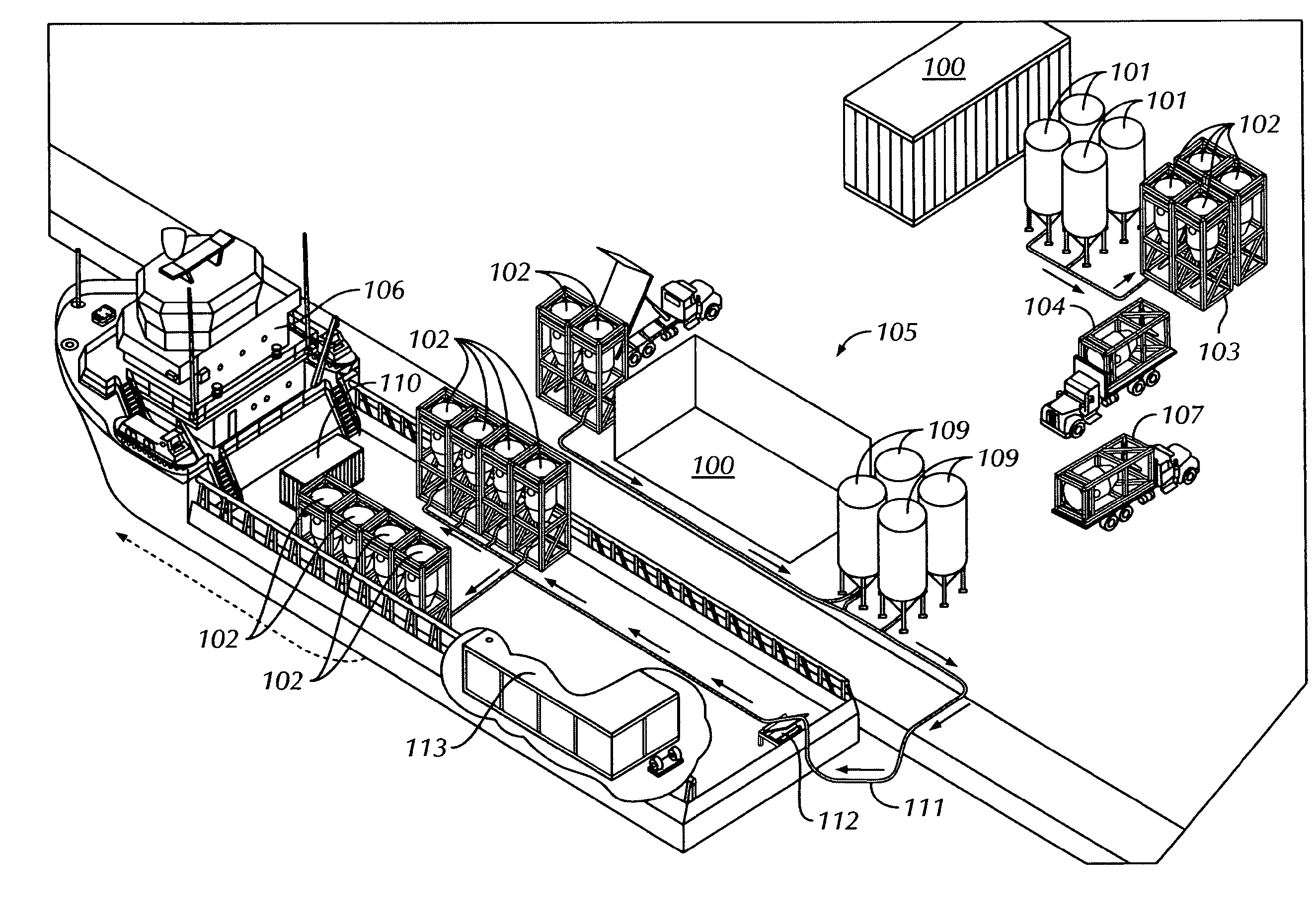

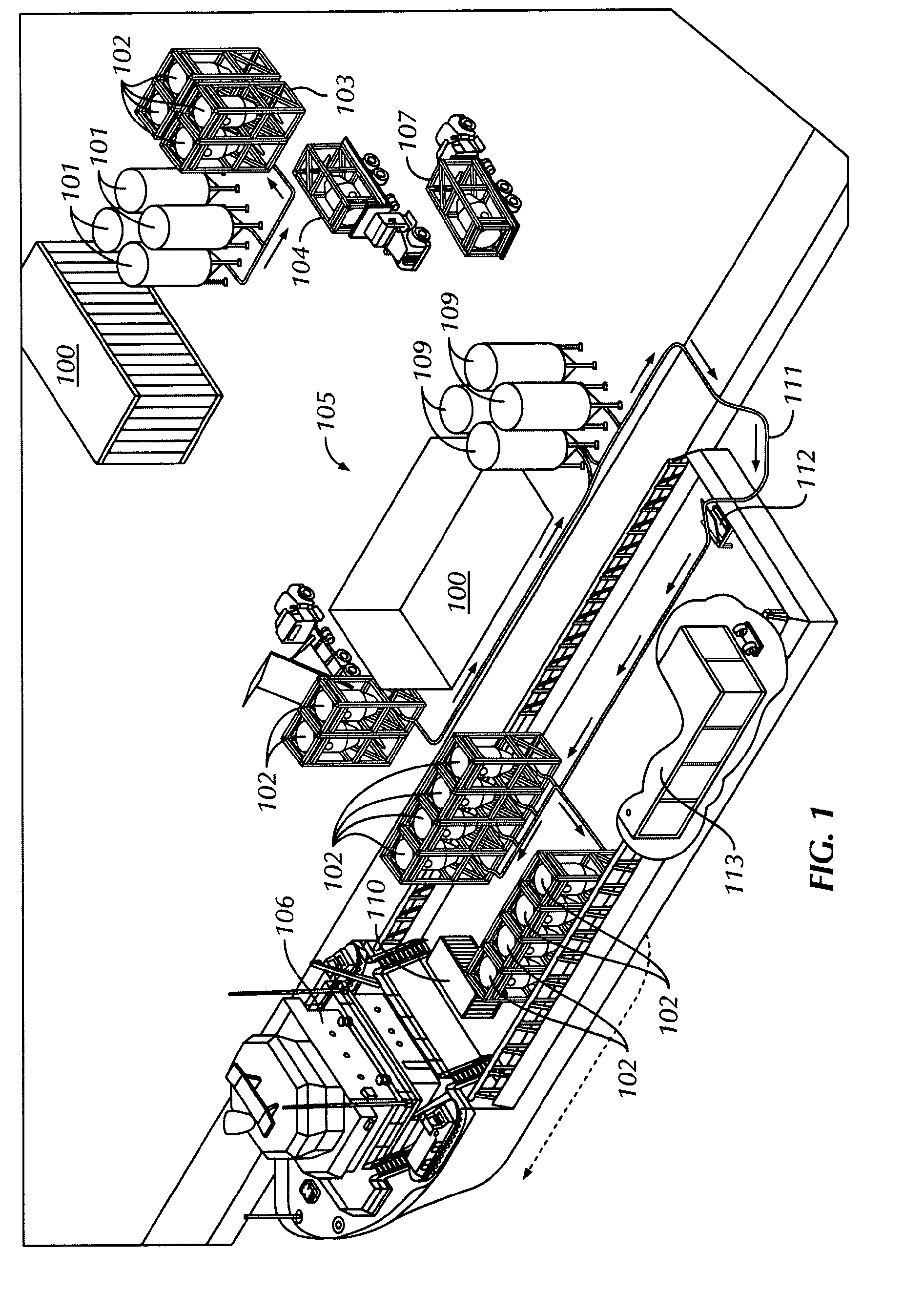

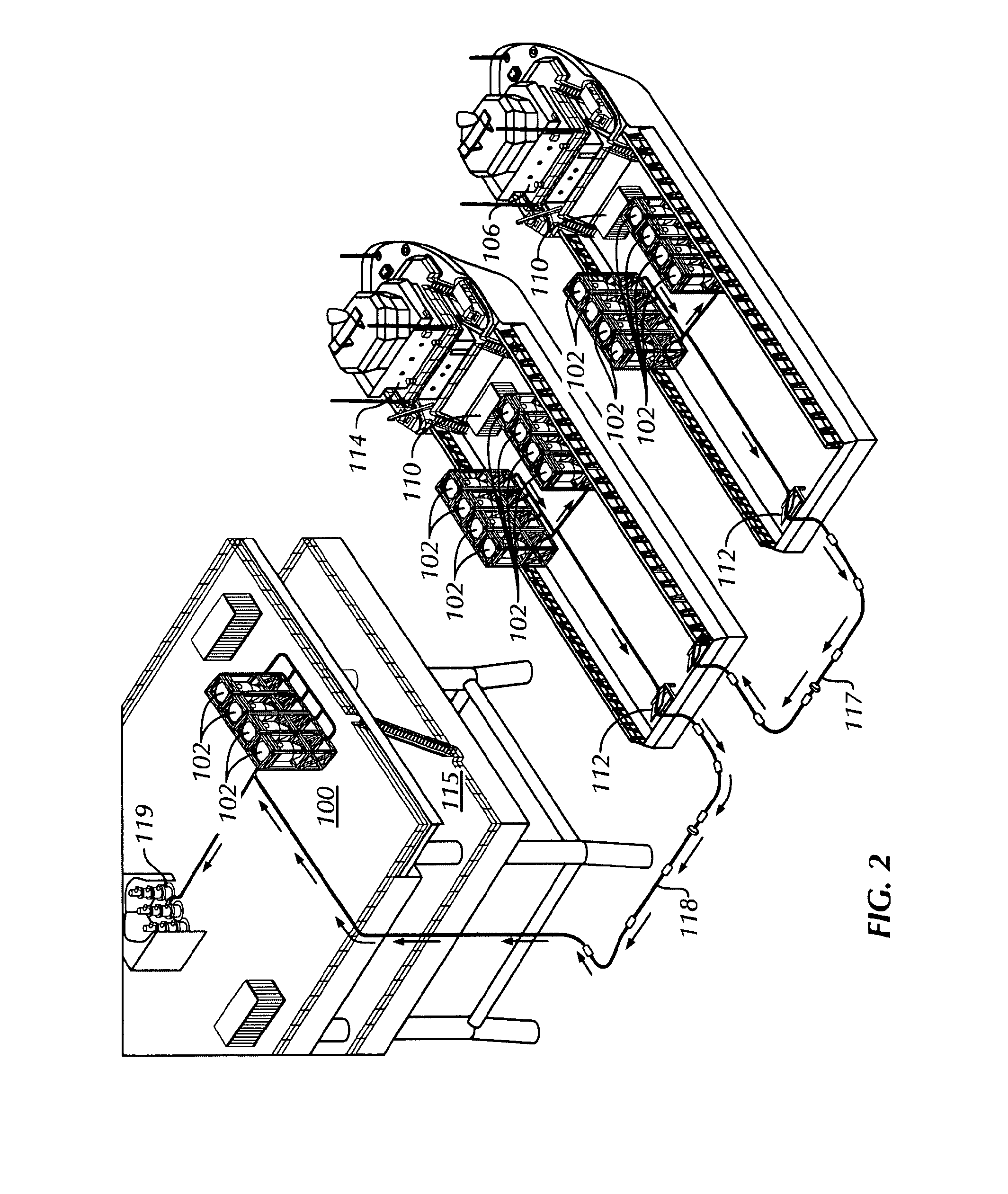

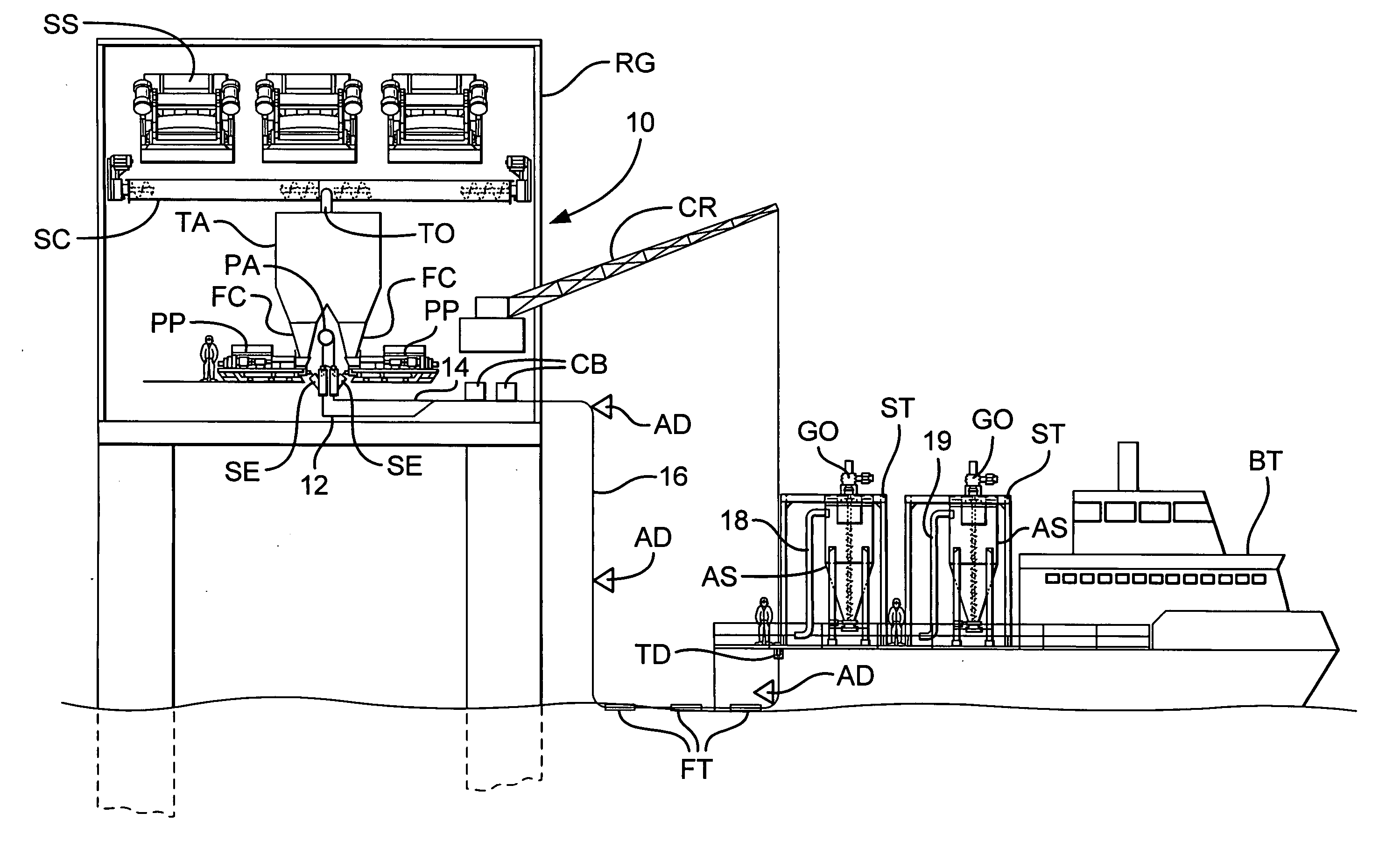

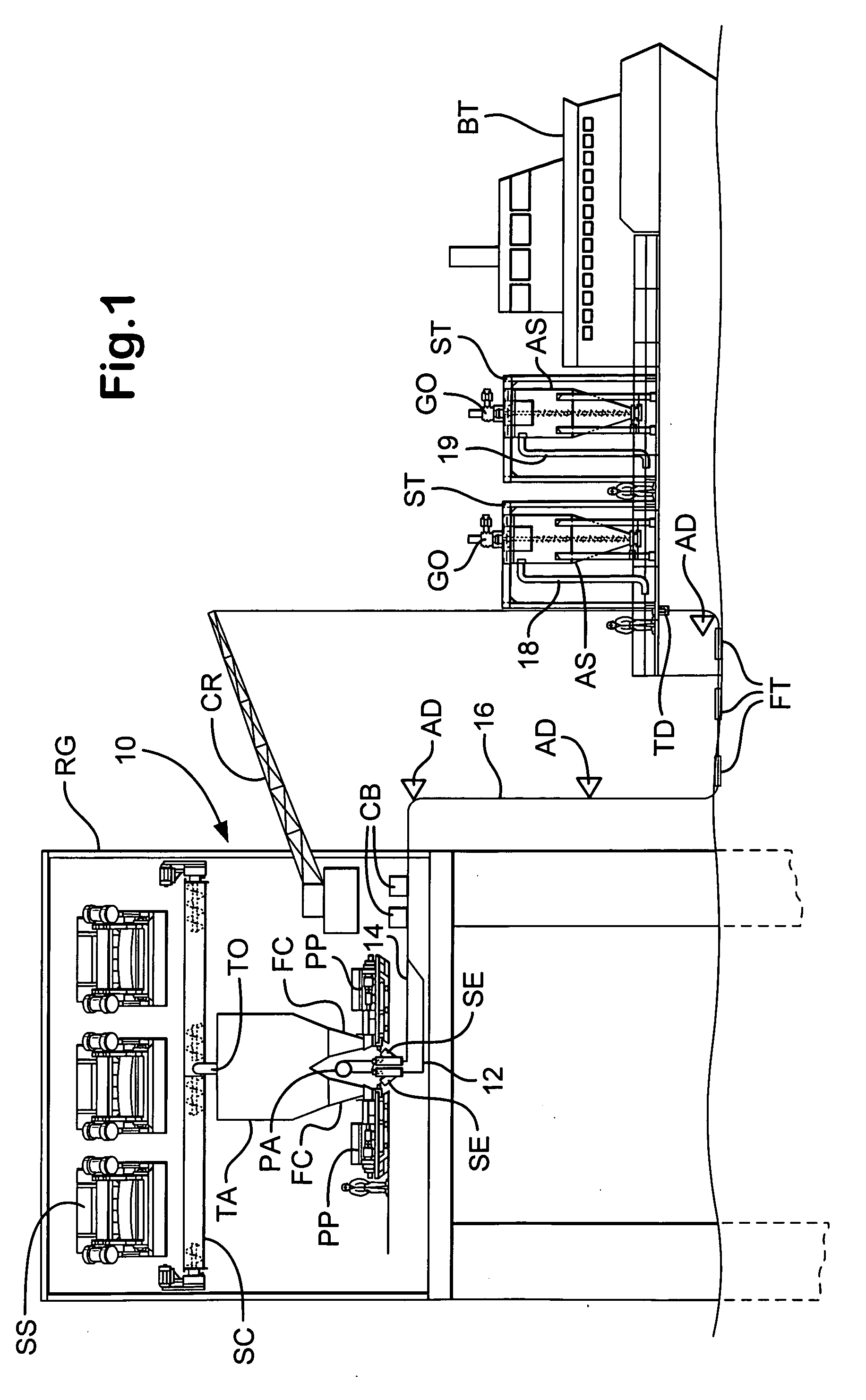

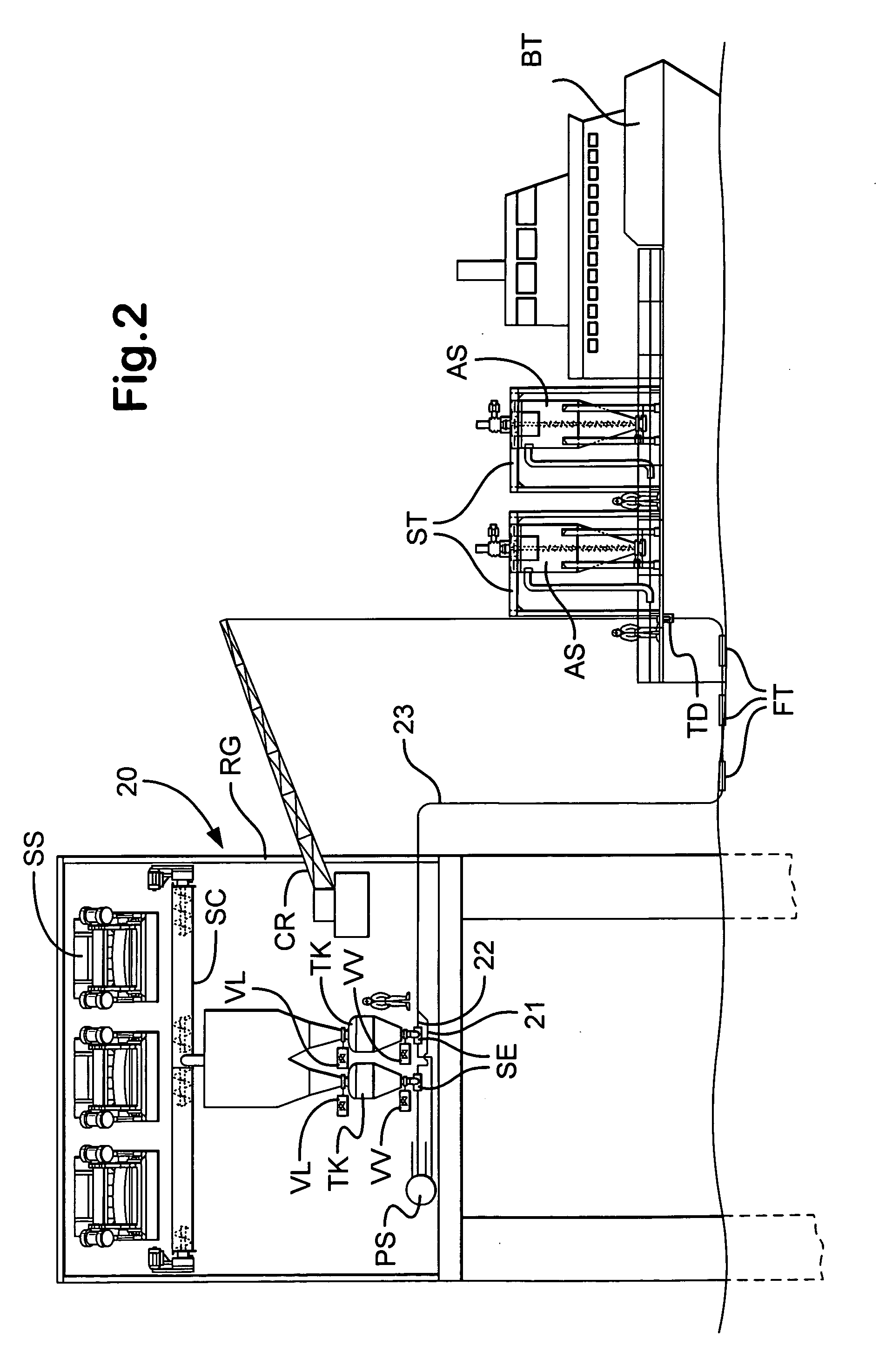

System and method for proppant transfer

A method of transferring proppant materials, wherein the method includes providing a first pressurized container (102) containing proppant materials on a first vessel (106). The method also includes connecting the first pressurized container (102) on the first vessel (106) to a second container (102) on a second vessel (114) and transferring pneumatically, proppant materials from the first pressurized container (102) on the first vessel (106) to the second container (102) on the second vessel (114). Also, a method of transferring proppant materials, the method including removing a wellbore fluid comprising excess proppant materials from a well, and screening the excess proppant materials from the wellbore fluid. The method also includes transferring the excess proppant materials to a first pressurized container (102) and transferring pneumatically, the excess proppant materials from the first pressurized container to a second pressurized container.

Owner:SHCLUMBERGER NORGE AS

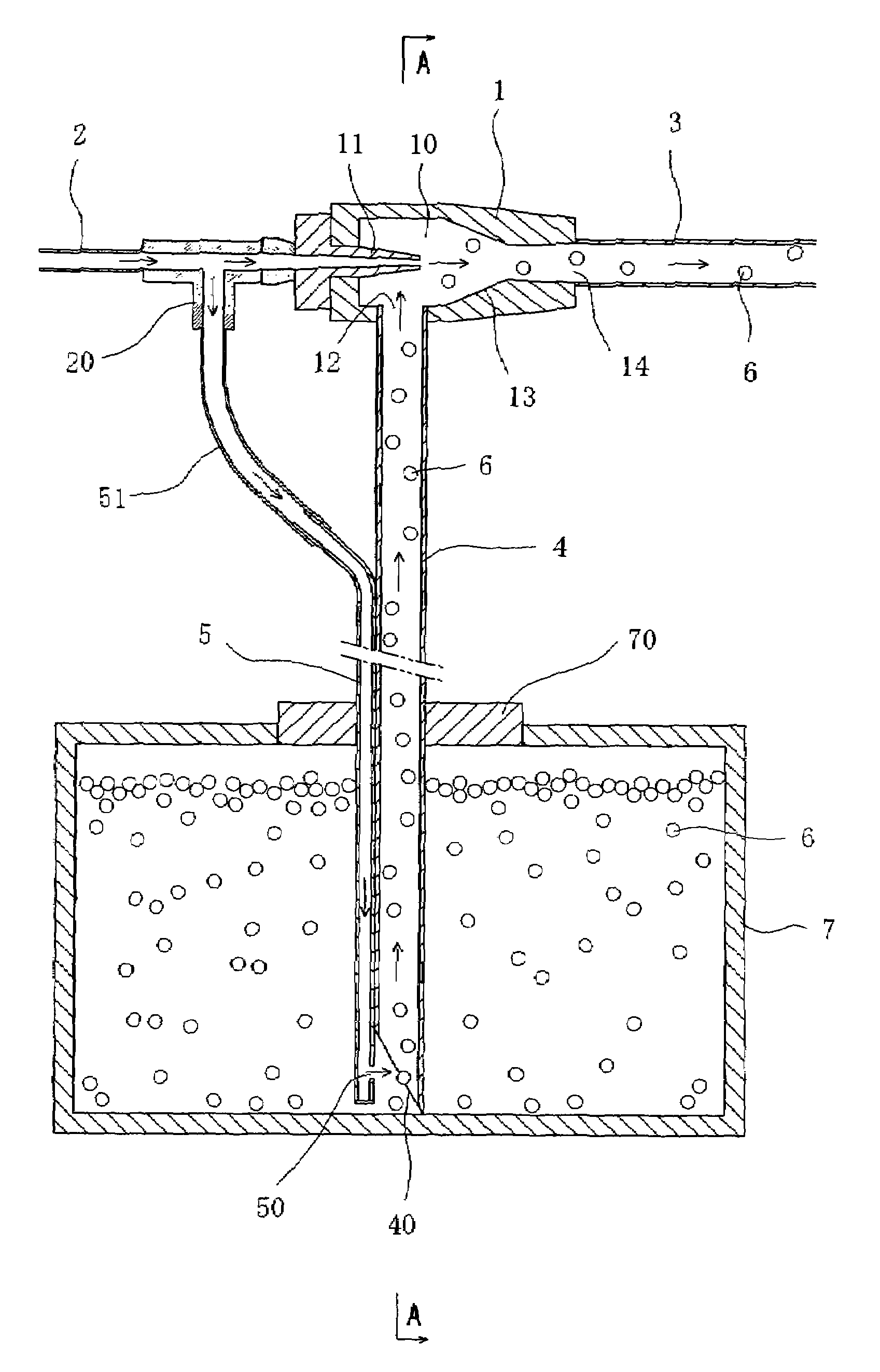

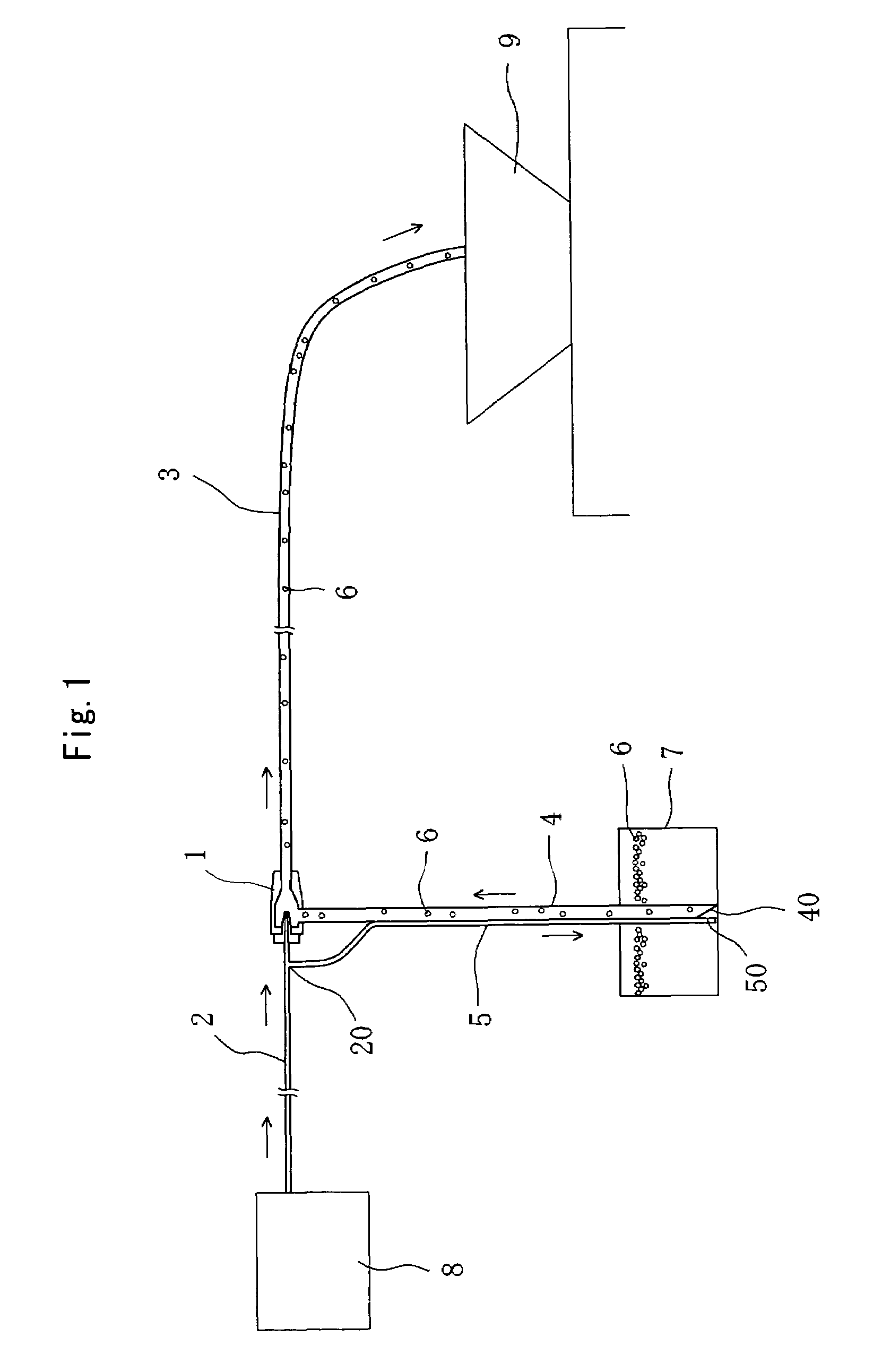

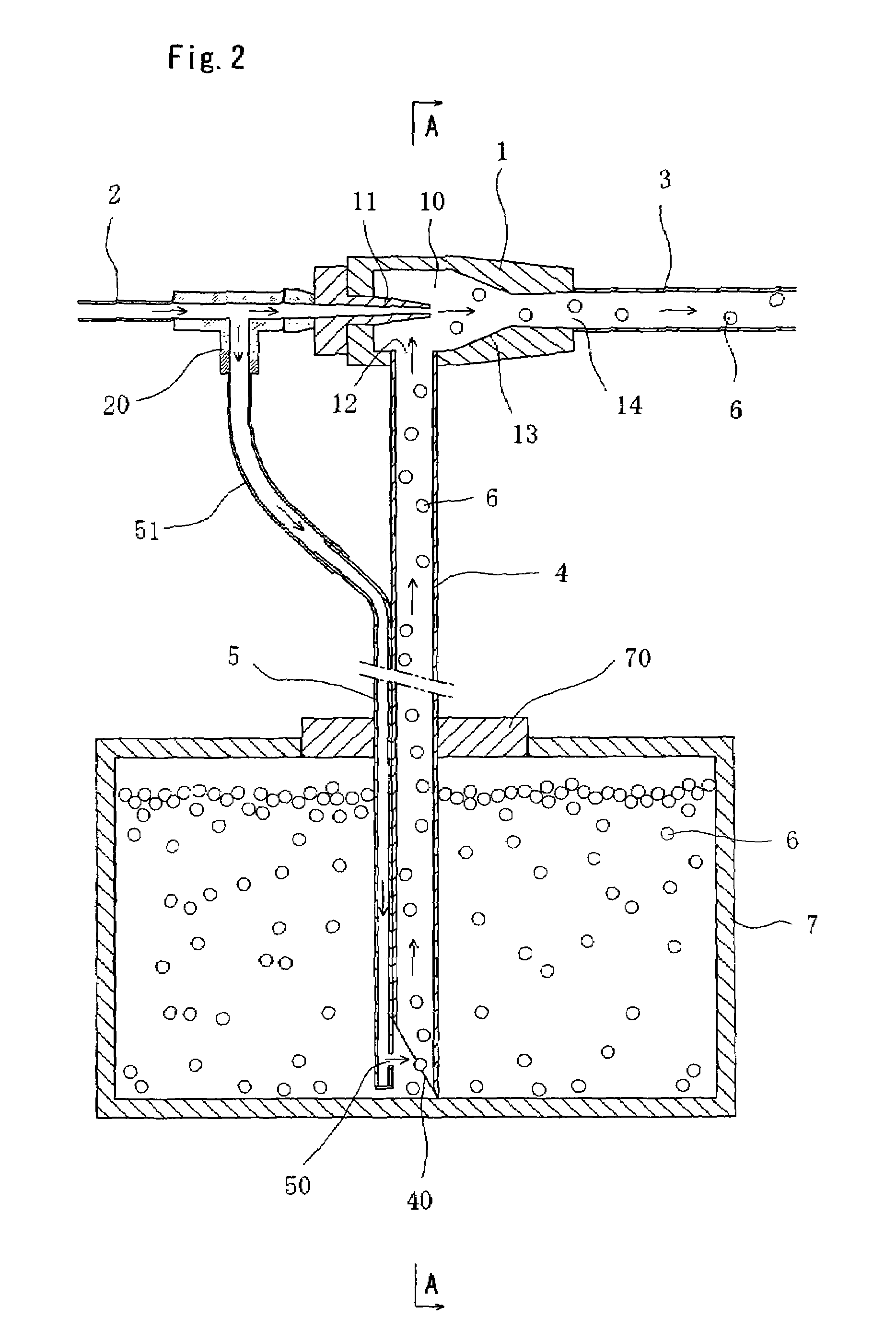

Pellet loader

A pellet loader according to the present invention is provided with an ejector portion 1. A gas supply pipe 2 is connected to an injection nozzle 11 of the ejector portion 1 for supplying compressed gas from a compressed gas source 8. An insert pipe 4 is connected to a suction inlet 12 of the ejector portion 1. Pellets are sucked from the suction inlet 40 of the insert pipe 4 into the ejector portion 1. A gas pipe 5 is arranged along the insert pipe 4 and one end of the gas pipe 5 has an opening 50 positioned at the vicinity of the suction inlet 40 of the insert pipe 4 and faced to the suction inlet 40 of the insert pipe 4 for injecting the compressed gas into the insert pipe 4. A transport pipe 3 is connected to an outlet portion 14 of the ejector portion 1.

Owner:ITSWA

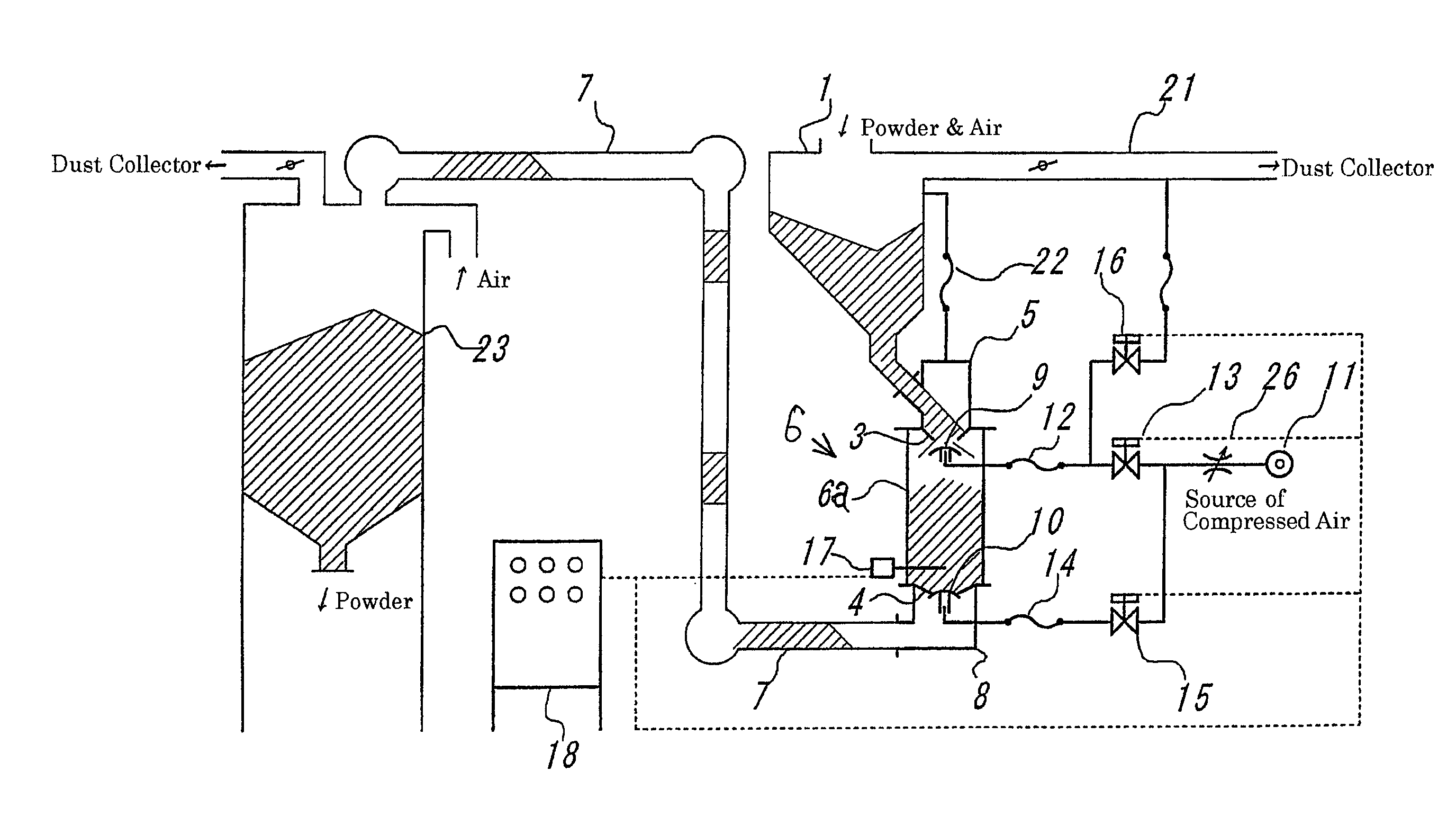

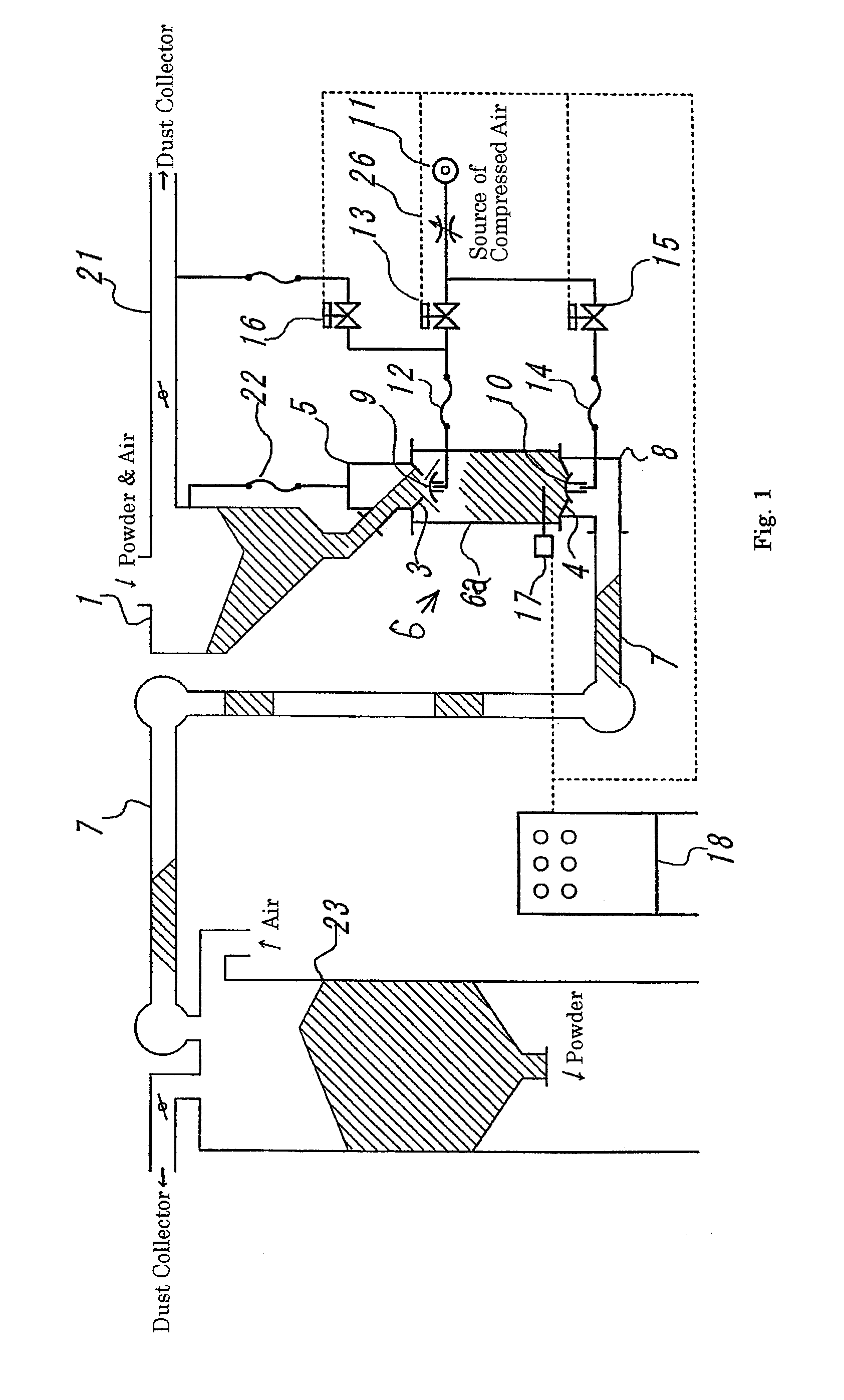

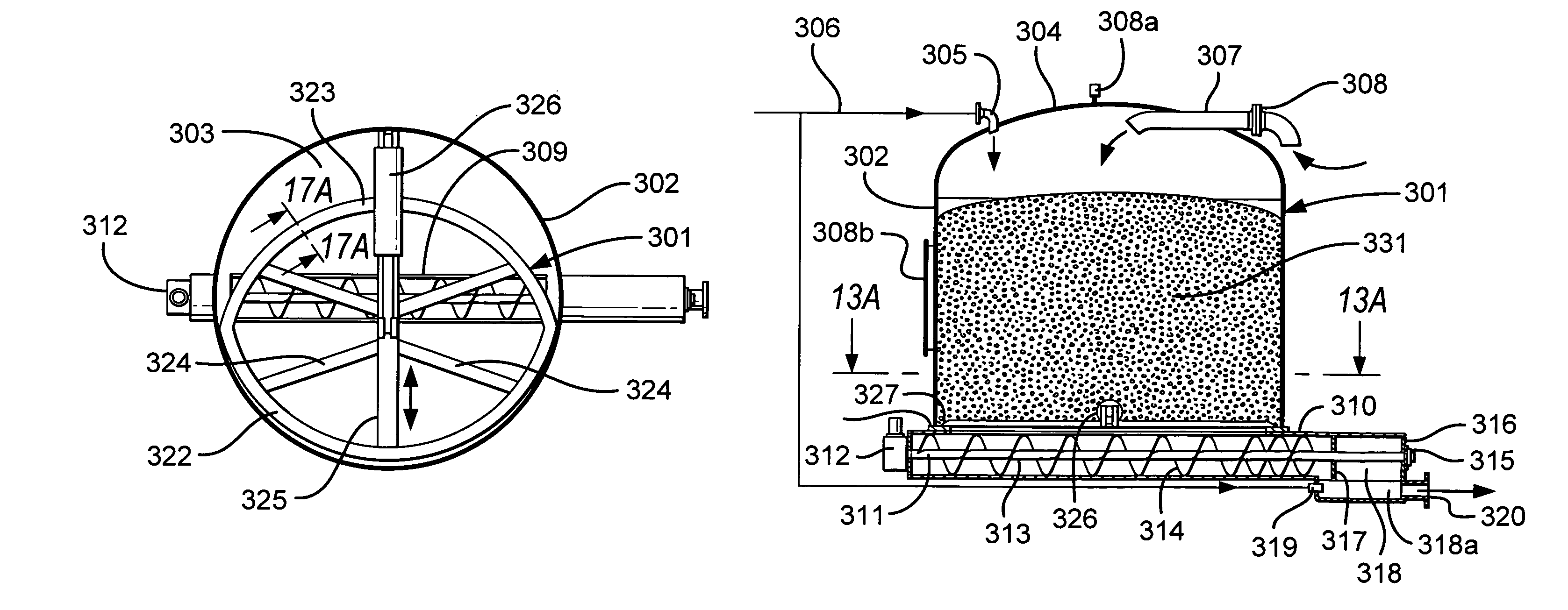

Pressure tank, an device for feeding powder to a conveying pipe, and its feeding method, and method for determining feeding intervals of powder to the conveying pipe

A pressure tank having a simple structure to intermittently feed powder to a conveying pipe, and a method for determining the intervals for feeding the powder to the conveying pipe. The pressure tank includes a tank body used as a structure of a pressure vessel having a receiving port at its upper portion and a discharging port at its lower portion, a first check valve disposed just under the receiving port so that it can freely move up and down, and so that it can close the receiving port by its upward movement that is caused by means of compressed air, and a second check valve disposed just under the discharging port so that it can freely move up and down, and so that it can close the discharging port by its upward movement that is caused by means of compressed air. To determine the intervals for feeding the powder to the conveying pipe, the apparatus is controlled based on measurements of the pressure loss or of the time that is required for feeding the powder to the conveying pipe, so that the pressure loss of the compressed air in the conveying pipe corresponds to the pressure of the compressed air supplied to the conveying pipe.

Owner:SINTOKOGIO LTD

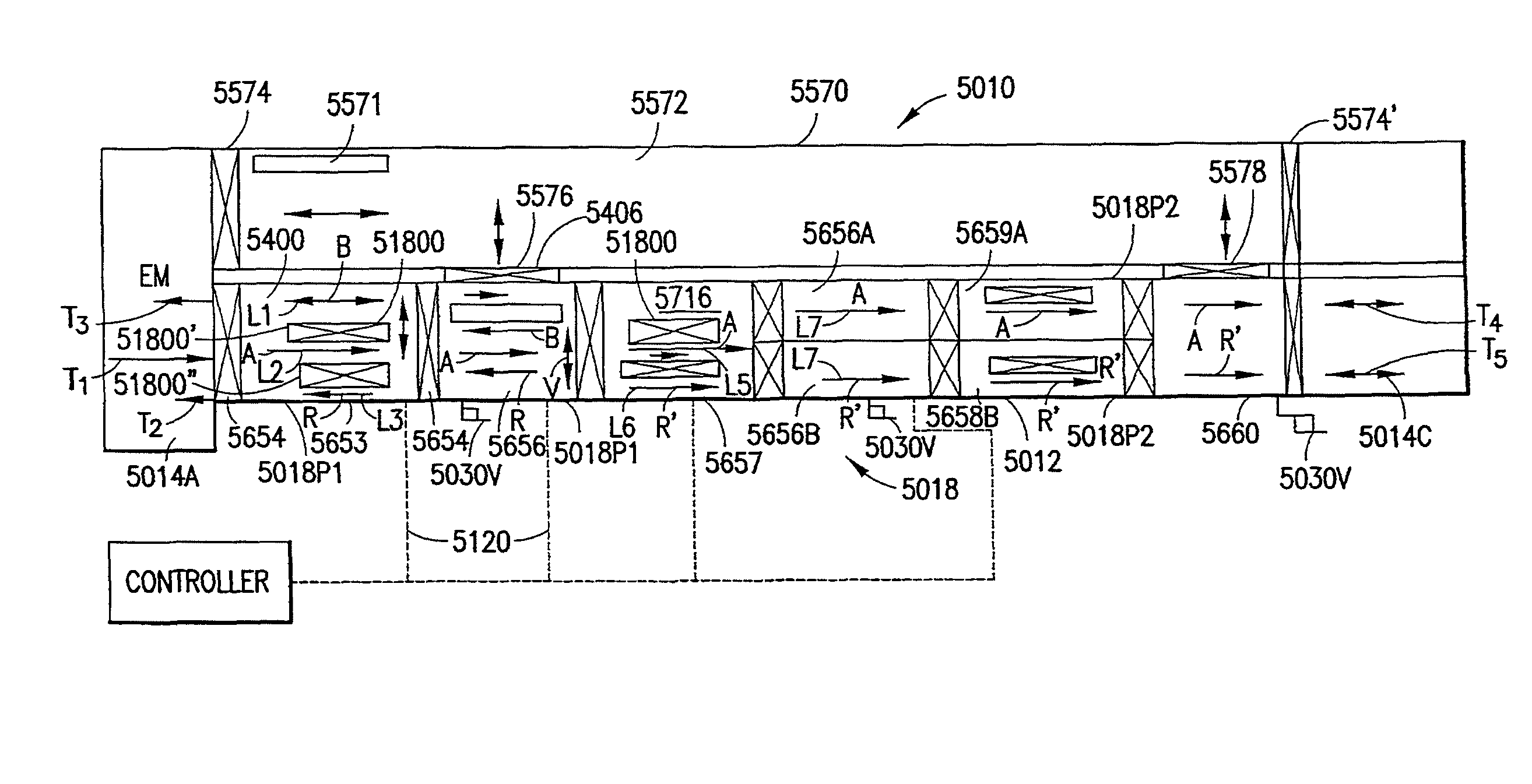

Substrate processing apparatus

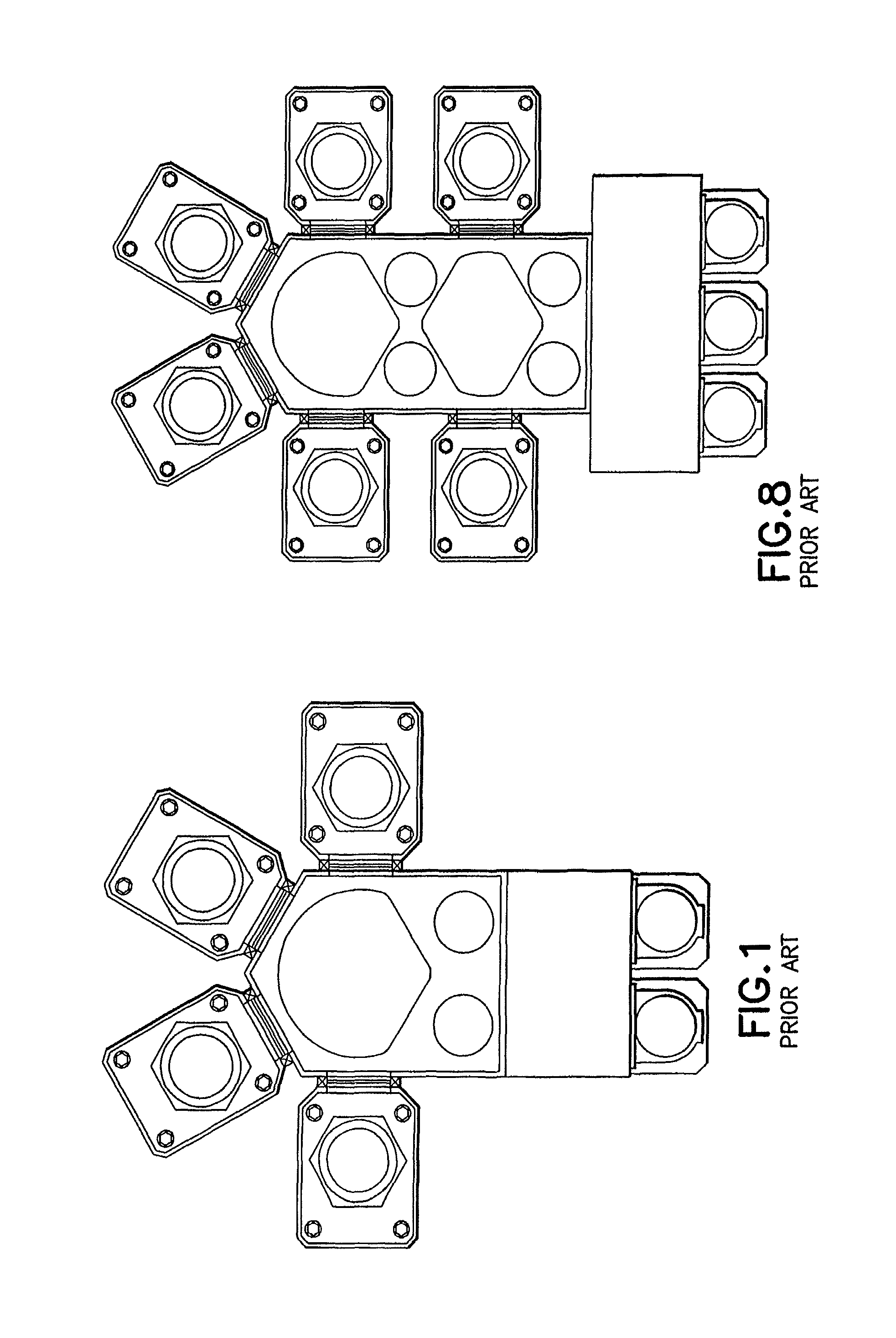

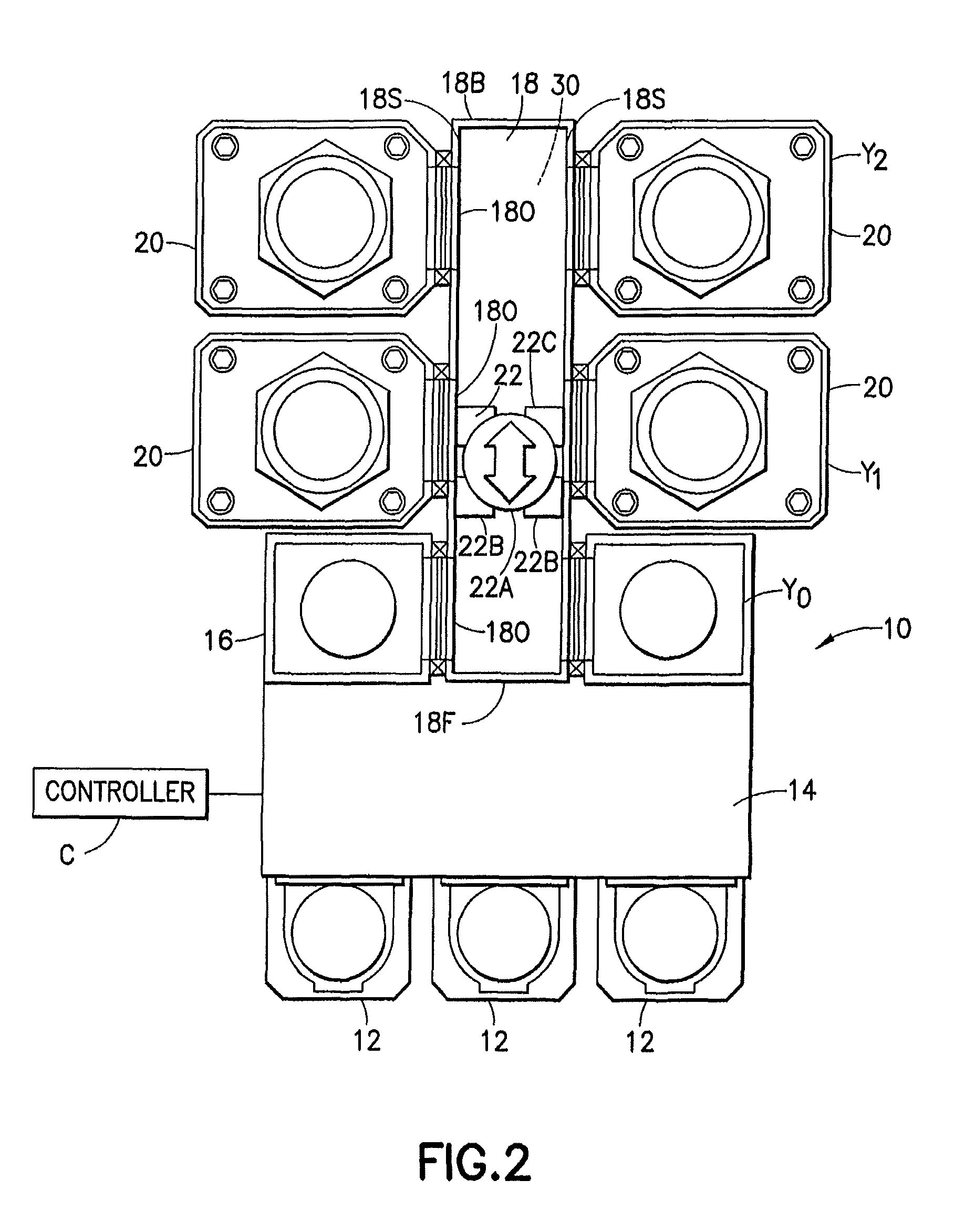

InactiveUS7959395B2Semiconductor/solid-state device manufacturingBulk conveyorsTransport engineeringLinear array

Substrate processing apparatus having a transport chamber, a linear array of substrate holding modules alongside the transport chamber, and a substrate transport located in the chamber. The chamber can hold an isolated atmosphere, and defines more than one substantially linear transport paths extending longitudinally along the transport chamber. The transport in the chamber is capable of transporting the substrate along the linear transport paths. The transport has a transporter capable of holding and moving the substrate. The transporter interfaces a wall of the transport chamber for moving along at least one of linear paths. The transport chamber has interfaces for mating with other substrate holding modules at opposite ends of the transport chamber. Each interface has an opening through which at least one of the more than one linear transport paths extends, and the transport chamber has a selectably variable longitudinal length between the interfaces.

Owner:BOOKS AUTOMATION US LLC

Multilayer hydrodynamic sheath flow structure

A microfabricated sheath flow structure for producing a sheath flow includes a primary sheath flow channel for conveying a sheath fluid, a sample inlet for injecting a sample into the sheath fluid in the primary sheath flow channel, a primary focusing region for focusing the sample within the sheath fluid and a secondary focusing region for providing additional focusing of the sample within the sheath fluid. The secondary focusing region may be formed by a flow channel intersecting the primary sheath flow channel to inject additional sheath fluid into the primary sheath flow channel from a selected direction. A sheath flow system may comprise a plurality of sheath flow structures operating in parallel on a microfluidic chip.

Owner:CYTONOMEST

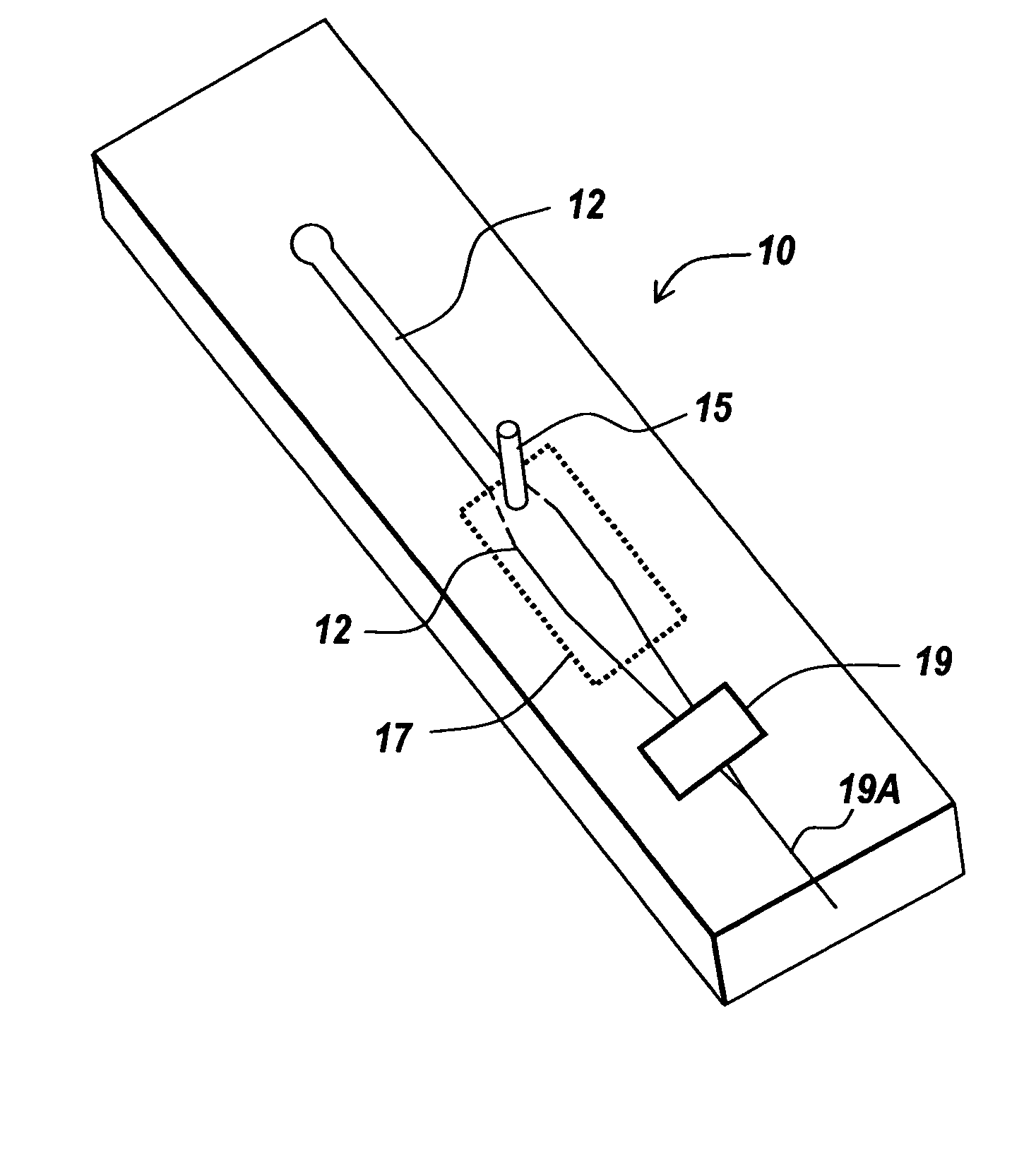

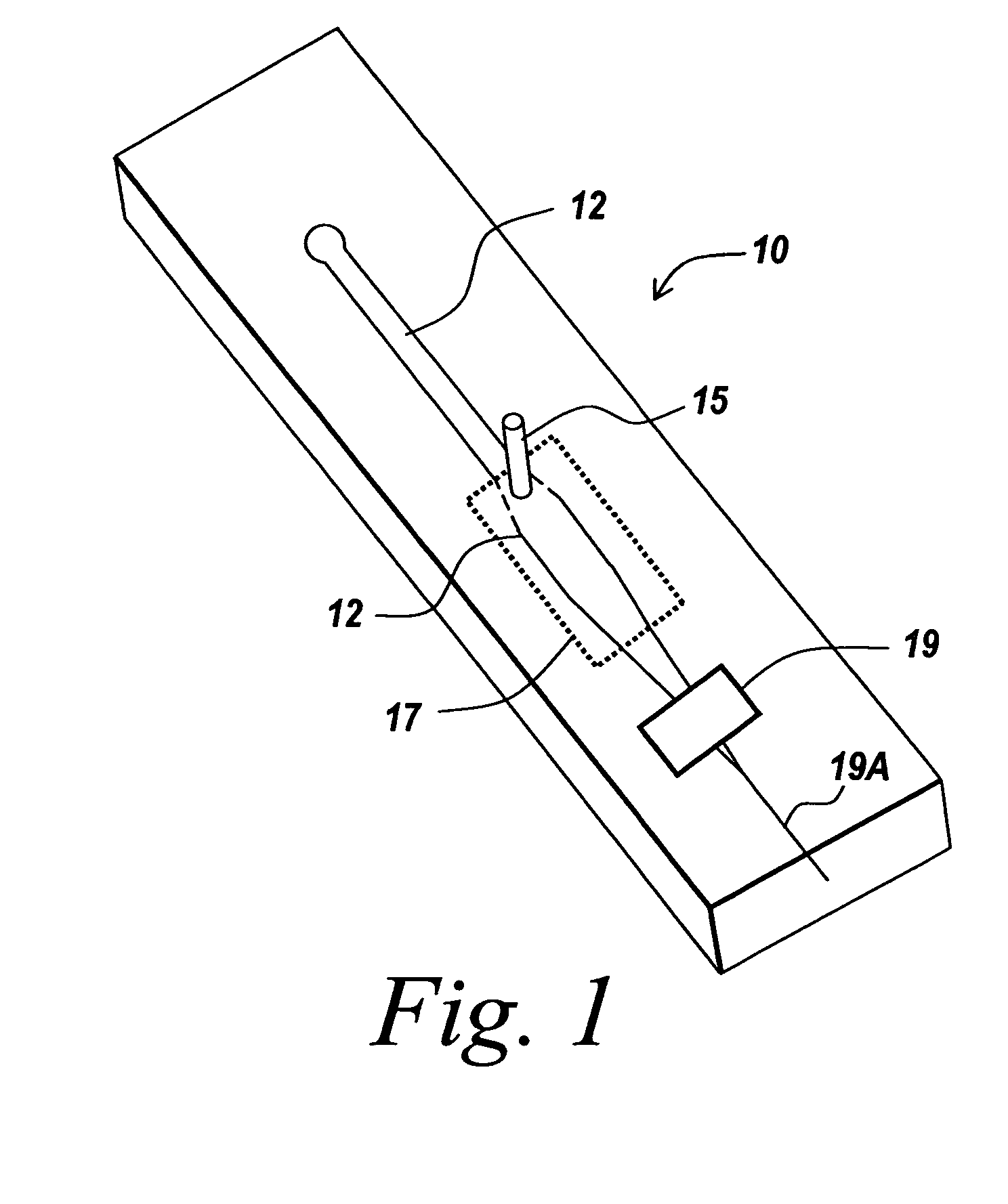

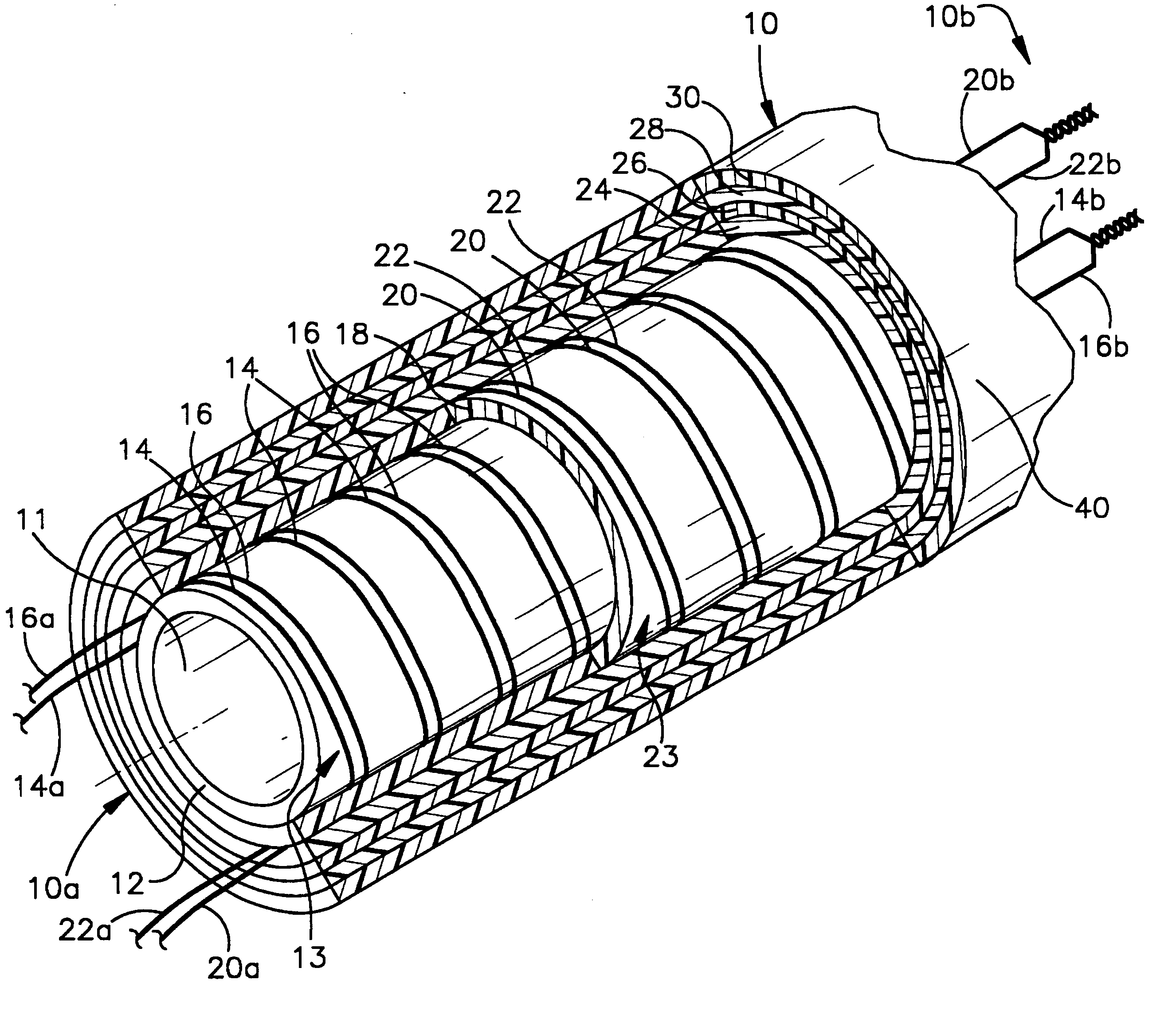

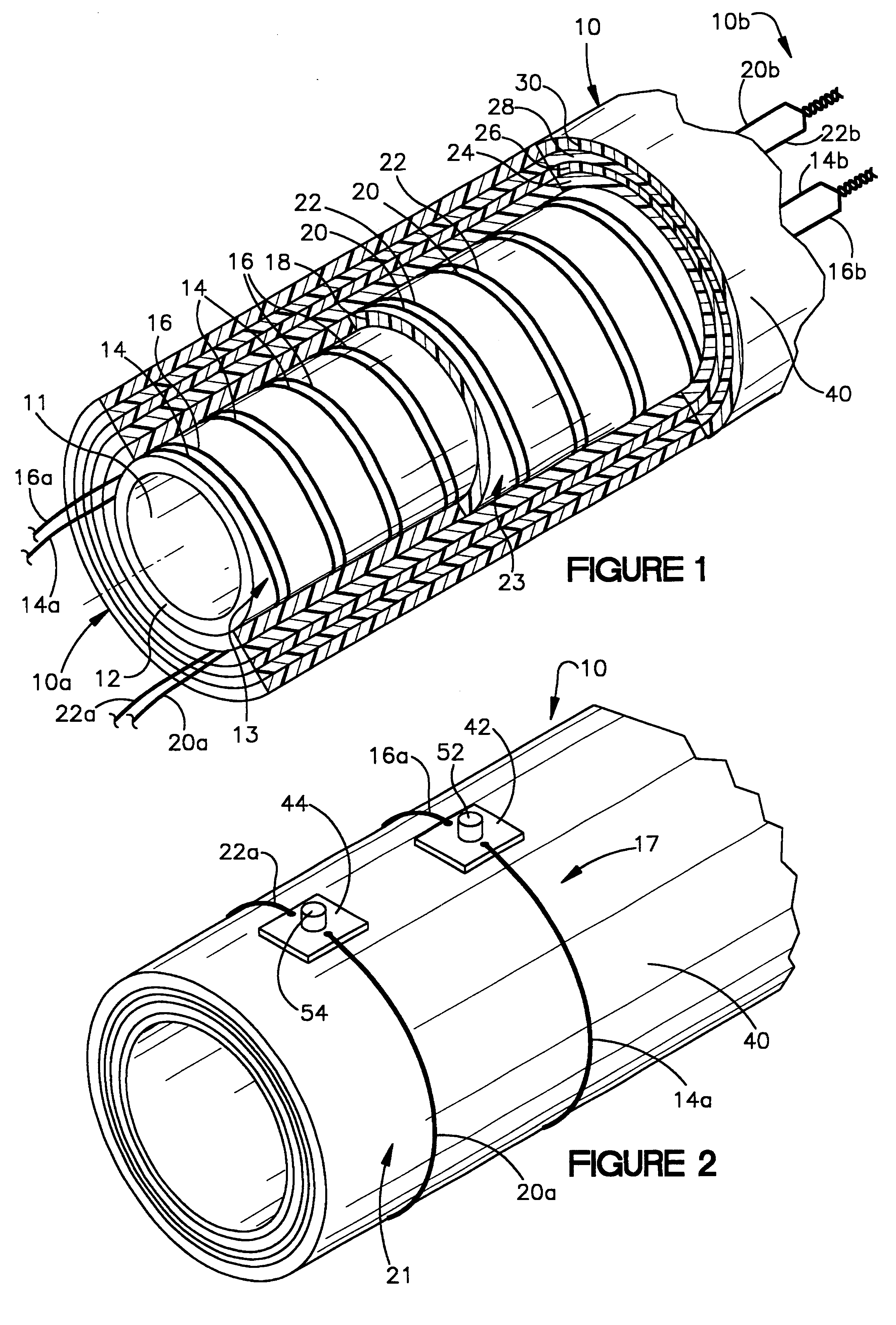

Abrasive material transport hose with wear detecting sensors

InactiveUS6386237B1Easy to replaceMaximum service lifePipe elementsFluid-tightness measurementEngineeringMaterial transport

The useful life of an abrasive material transport hose (10) can be maximized if the hose is repositioned at the first signs of internal wear. This is accomplished by disposing at least two wear sensing elements (17, 21), each at a specified distance from the inwardmost surface of the inner tube (12), and each monitoring a condition indicative of wear of the hose (10) at its specified distance from the inwardmost surface of the inner tube. When the innermost wear sensing element (17) implies wear, the hose can be repositioned to extend the useful life until the outermost wear sensing element (21) indicates wear requiring replacement of the hose.

Owner:CONTITECH USA INC

Systems and methods for storing and handling drill cuttings

Vessels for selectively holding drilling cuttings material and methods employing such vessels; the vessels, in at least certain aspects, having a body with a hollow container with an interior space for receiving drilling cuttings material and from which the material may exit from the body; a first opening through which the material enters into the container; a second opening through which the material passes out from the container; and movement apparatus with a movement member within the container movable adjacent the second opening to facilitate passage of the material into the second opening; and in certain aspects, the vessels having moisture-content sensor apparatus on the body for sensing moisture content of material within a vessel; conduit apparatus for conducting drilling cuttings from the exit opening; valve apparatus for selectively controlling flow of material in the conduit apparatus; and a controller in communication with the moisture-content sensor apparatus and the valve apparatus for selectively controlling flow in the conduit apparatus.

Owner:VARCO I P INC

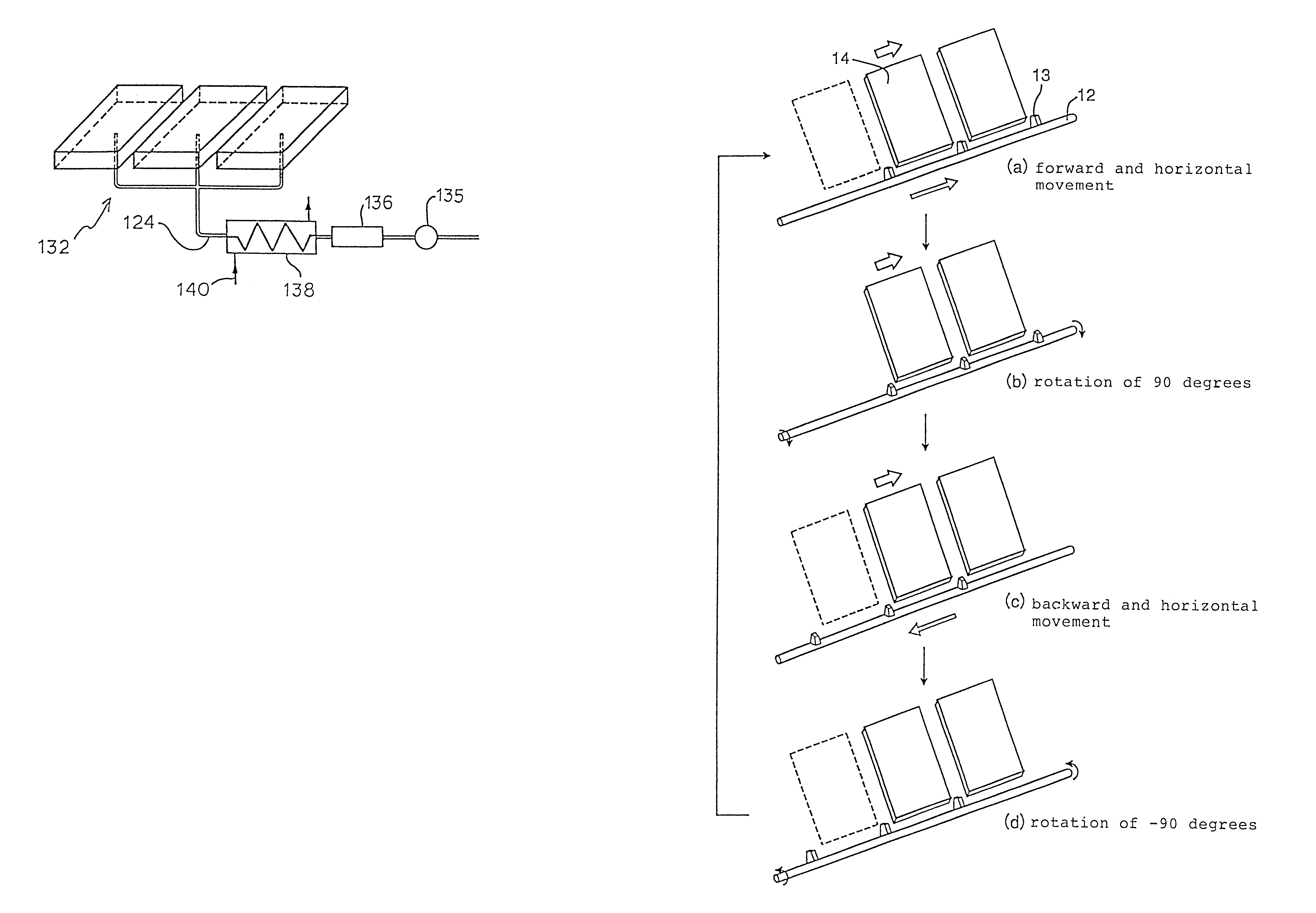

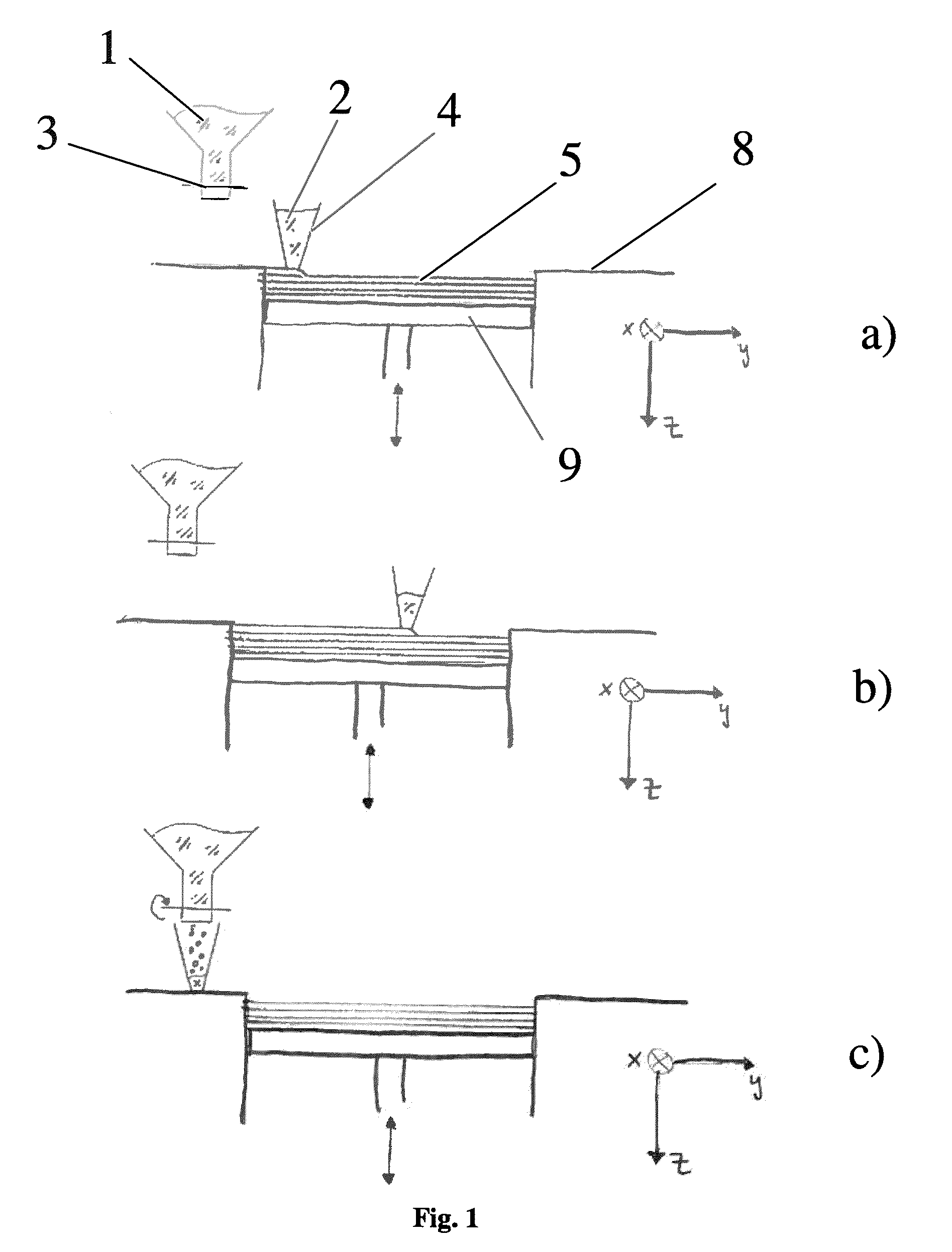

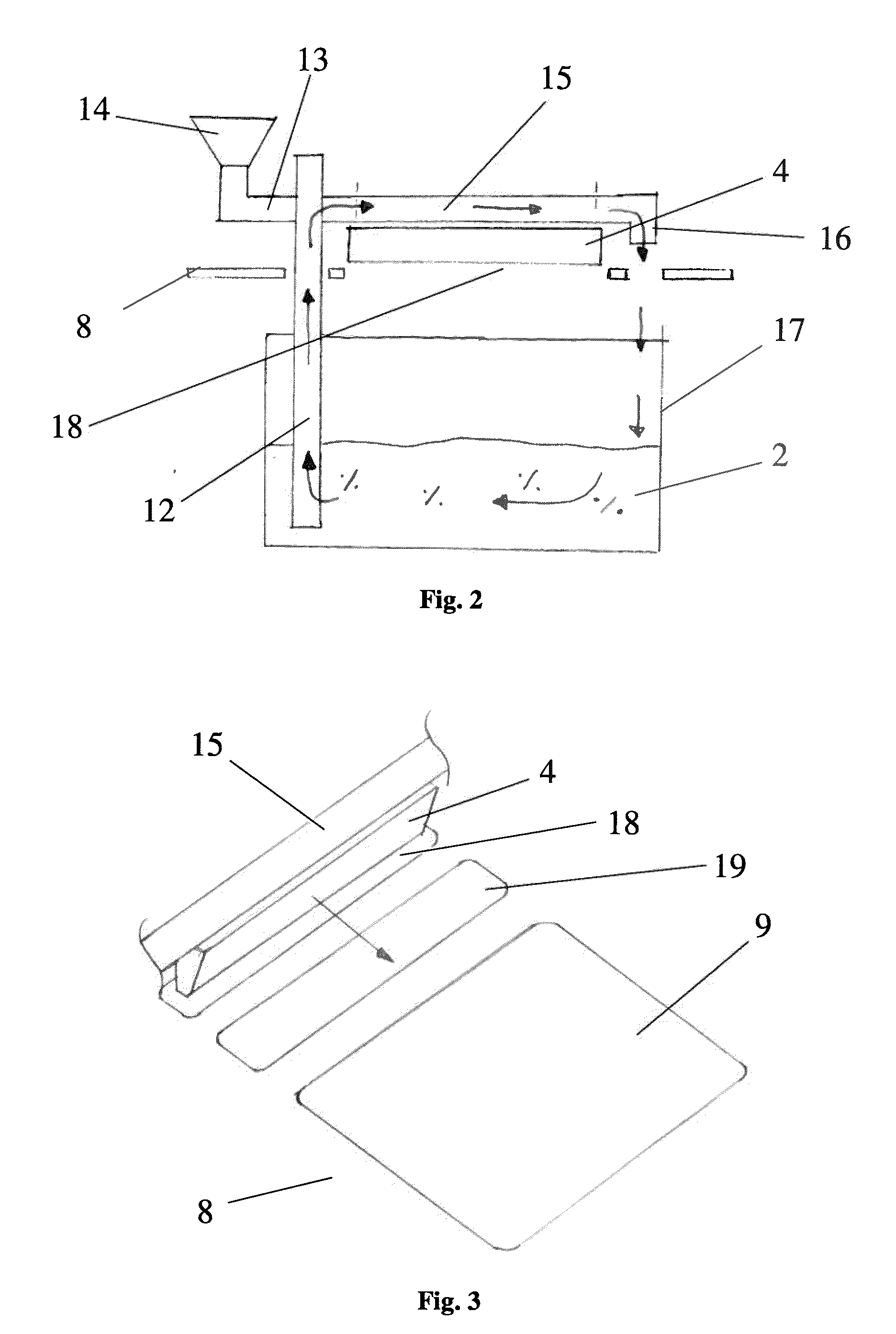

Method and device for conveying particulate material during the layer-wise production of patterns

ActiveUS20100272519A1Evenly filledAdditive manufacturing apparatusLiquid surface applicatorsEngineeringMechanical engineering

The present invention relates to a method for conveying particulate material during the manufacture of patterns in layers, wherein powder is conveyed out of a reservoir into a spreader unit and, if applicable, excess powder fed to the spreader unit is again conveyed back into the reservoir and wherein this conveying takes place in a closed conveying circuit.

Owner:VOXELJET AG

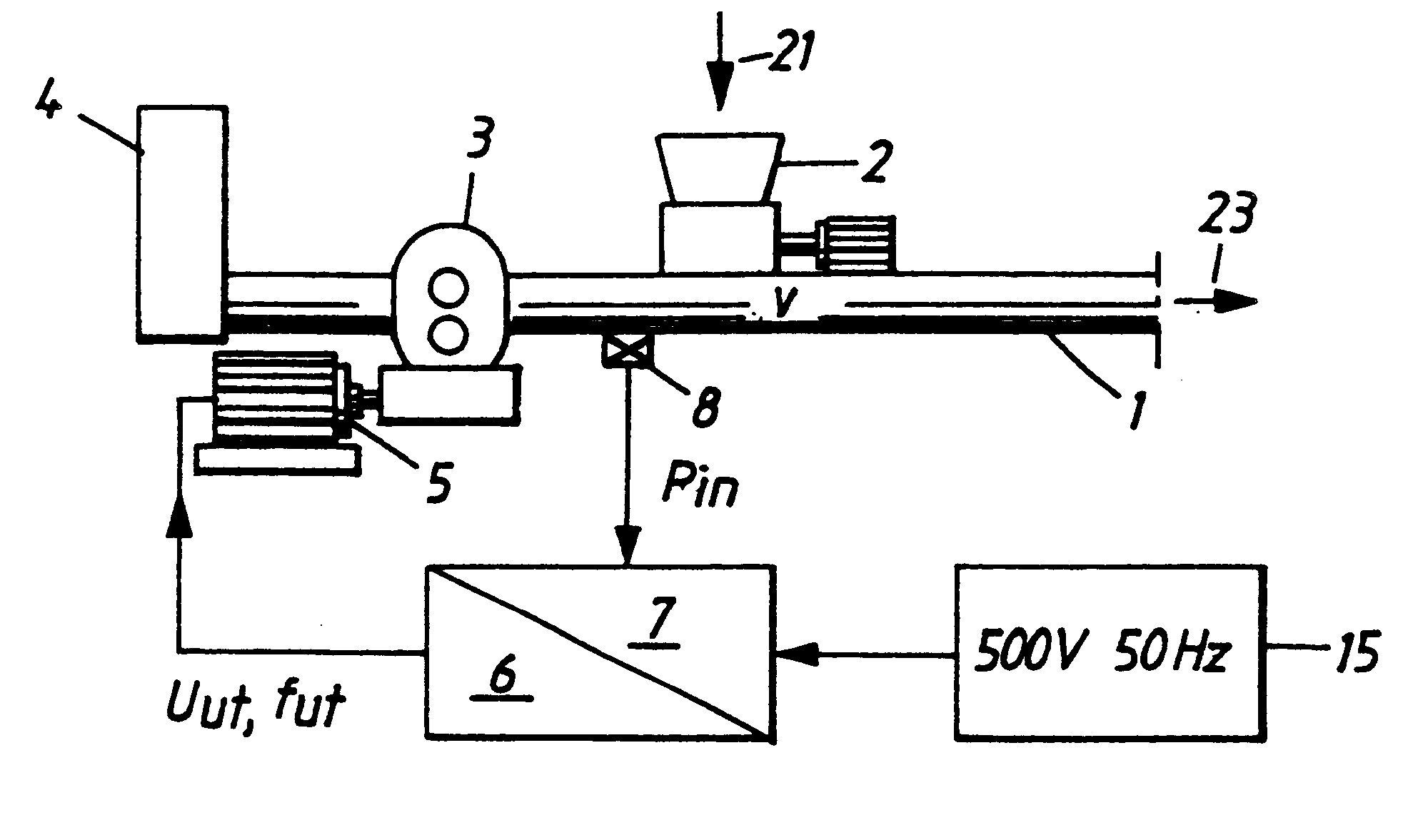

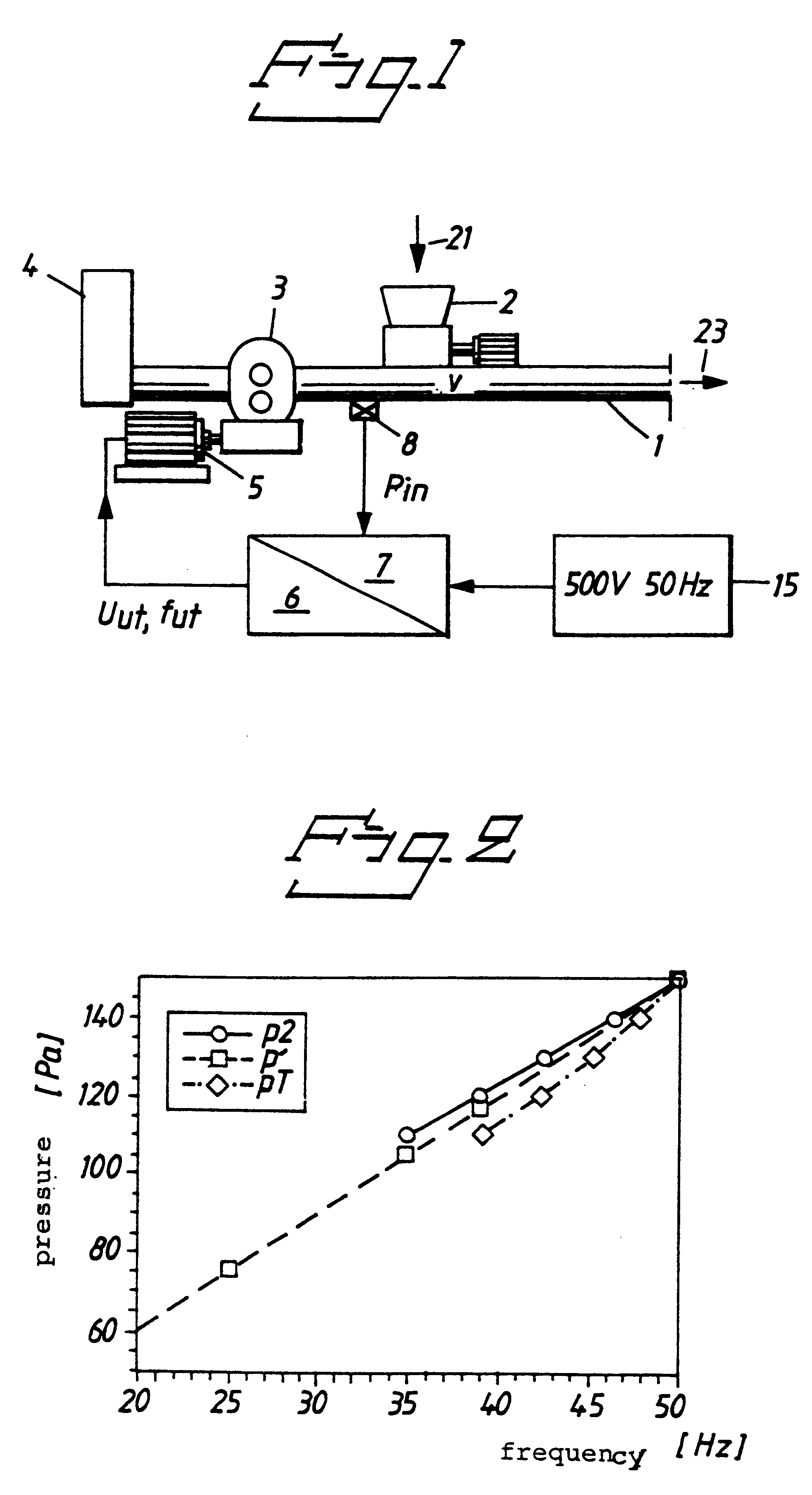

Method and plant for pneumatic transport of solid particles

The present invention provides a method and plant for the pneumatic transportation of solid particles in the form of a diluted phase through a conduit (1), with which the transport air in said conduit is given a velocity which is at most equal to the air velocity chosen for a maximum particle load level. The free flow from the pressurized air source (3) is regulated on the basis of measured air velocity or on the basis of a state corresponding thereto, such as air pressure in the conduit, and an established relationship between the free flow and the said measured velocity of the air or a state (pressure) corresponding thereto, essentially independently of the particle load. There is thus maintained in the conduit a preferably constant transport air velocity with all different occurring levels of particle load.

Owner:FASTIGHETABBOLAGET AXELN 5

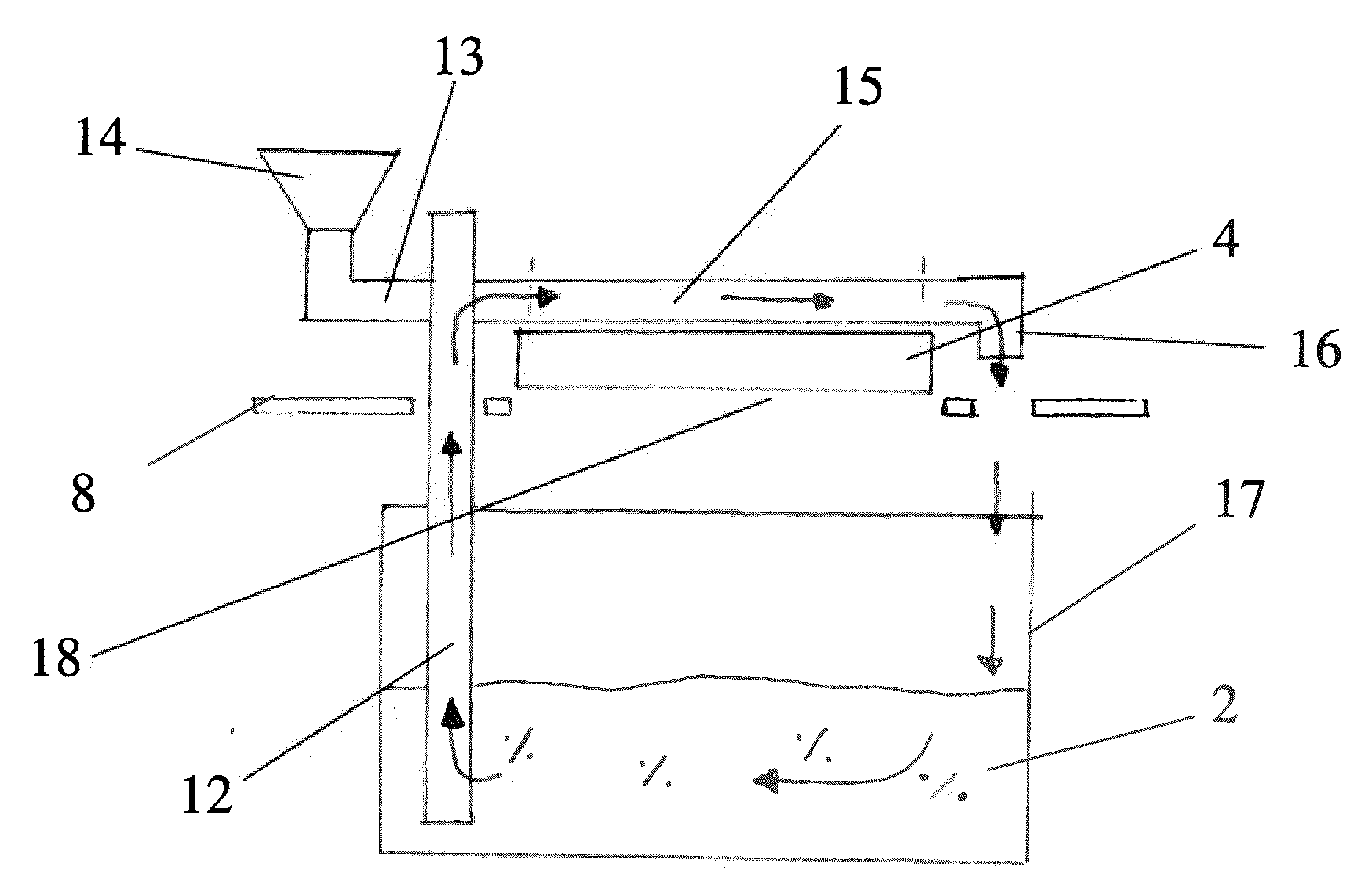

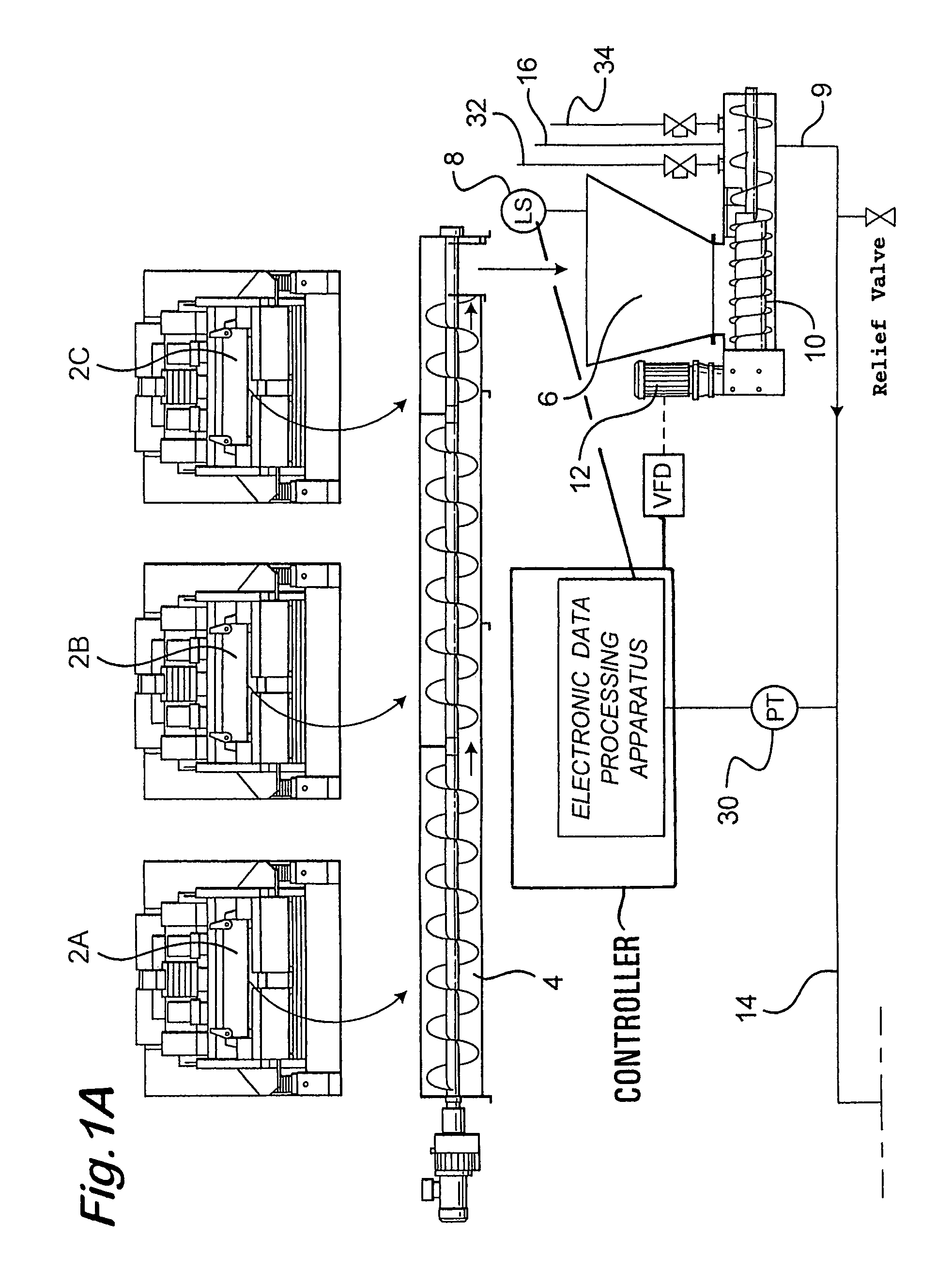

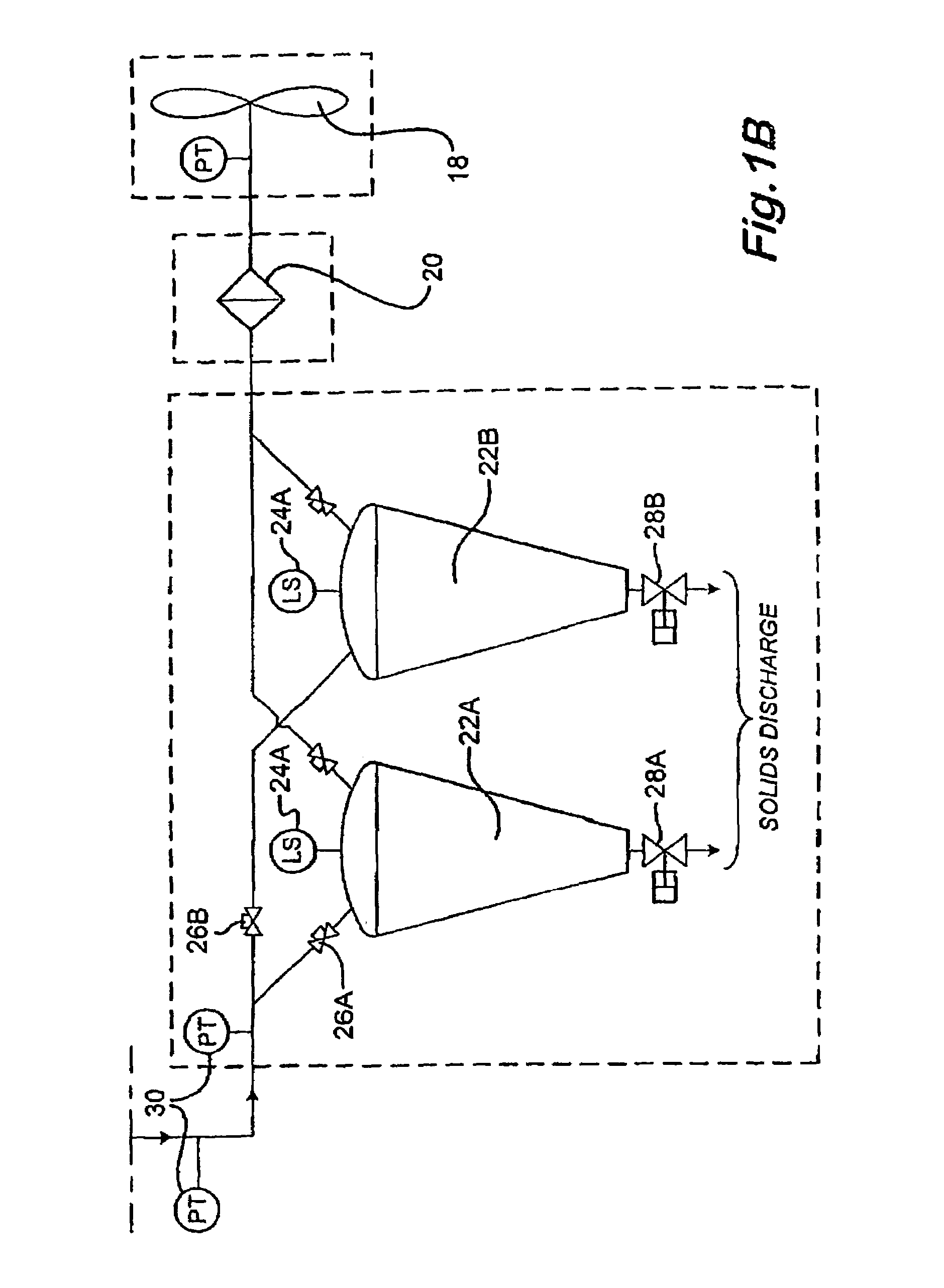

Drill cuttings conveyance systems and methods

ActiveUS20060102390A1Low densityEasy accessCargo handling apparatusDispersed particle separationPressure senseDrill cuttings

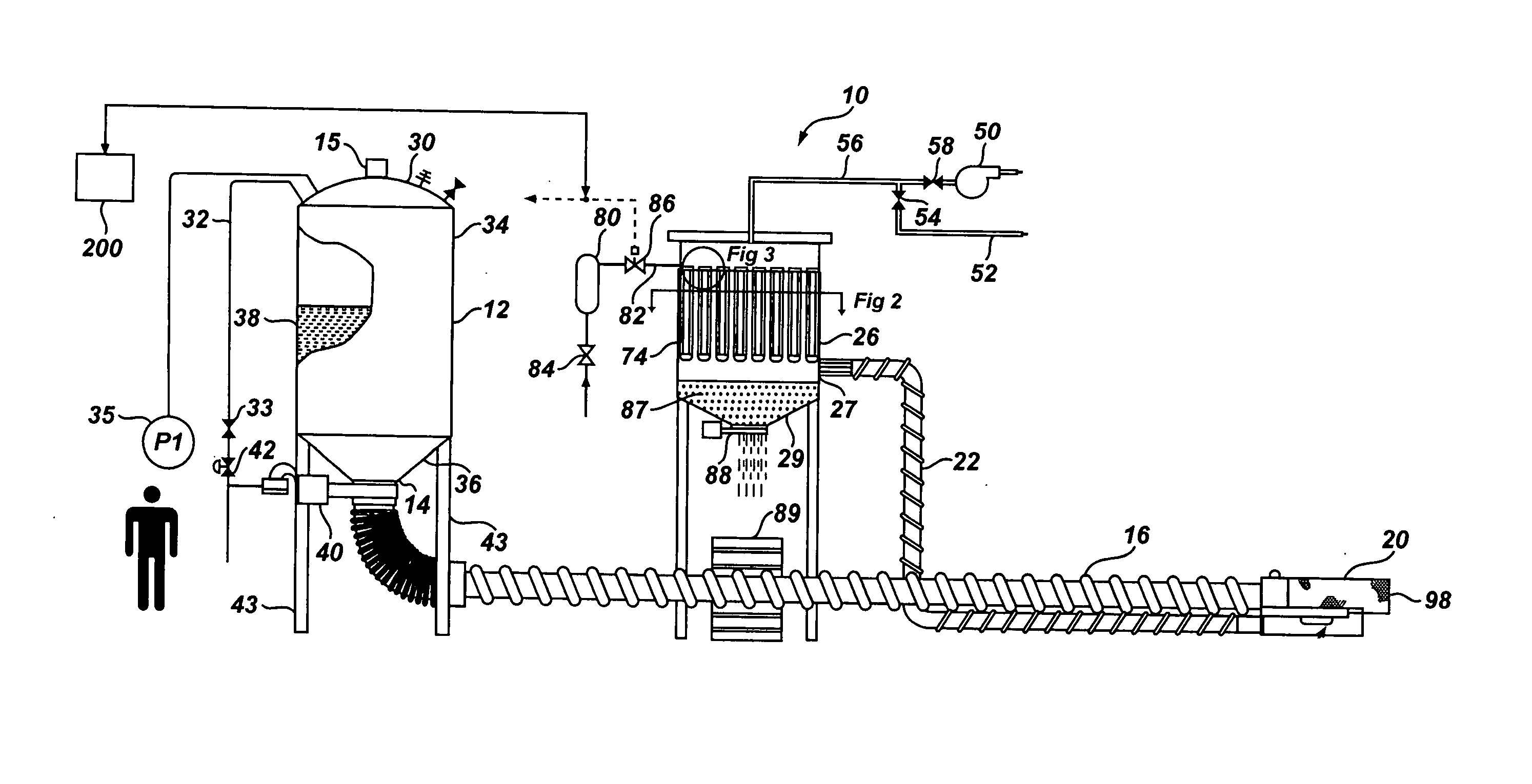

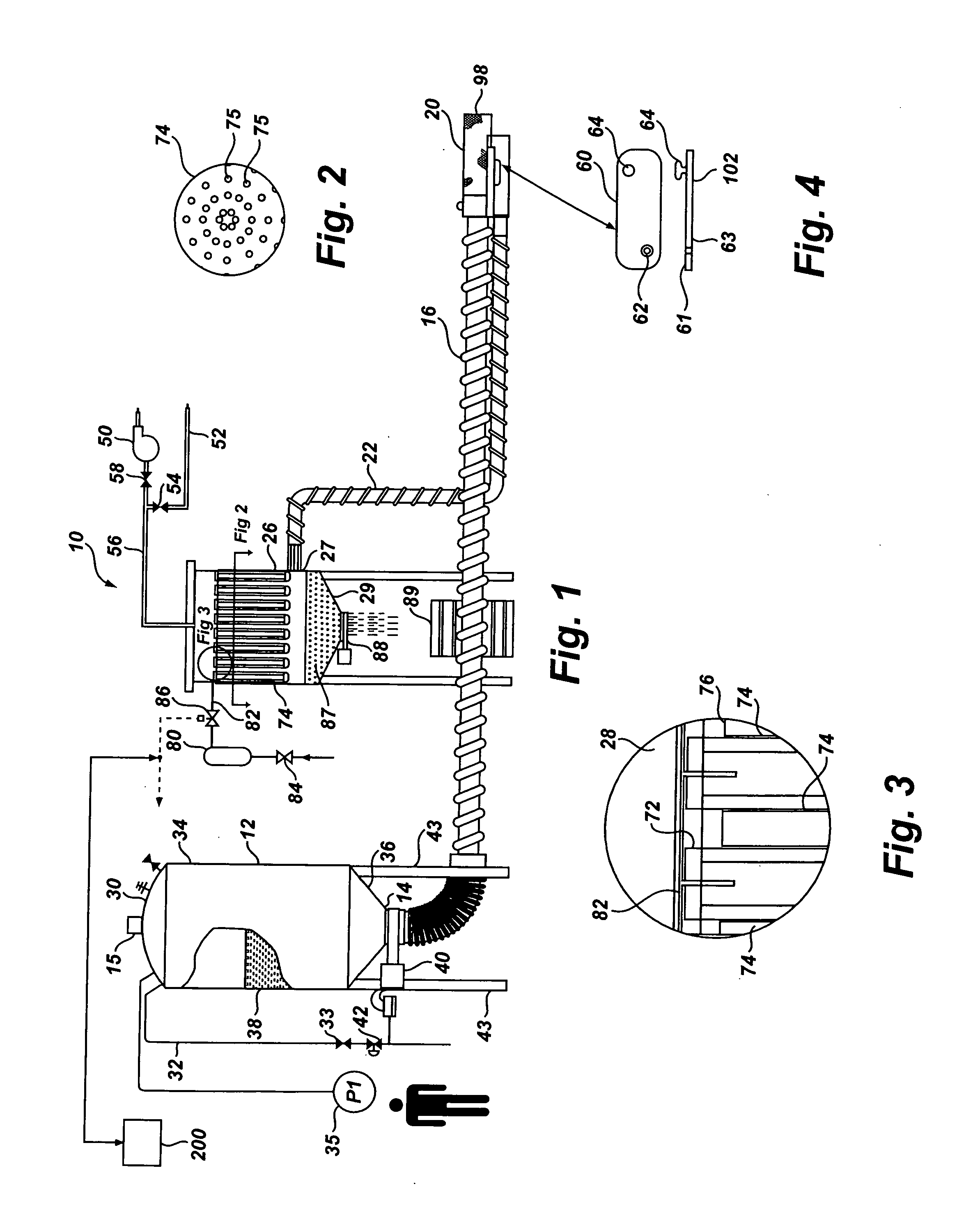

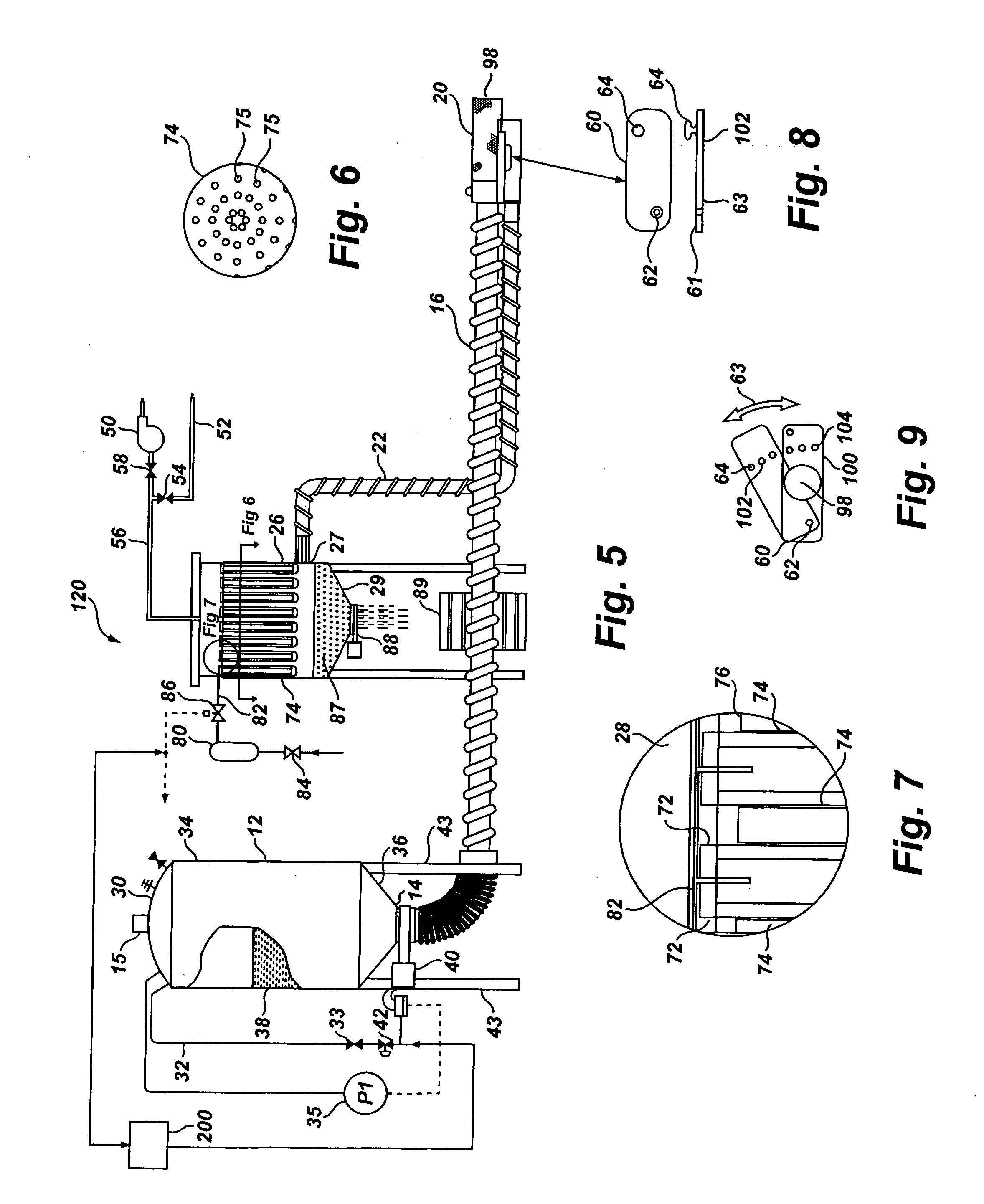

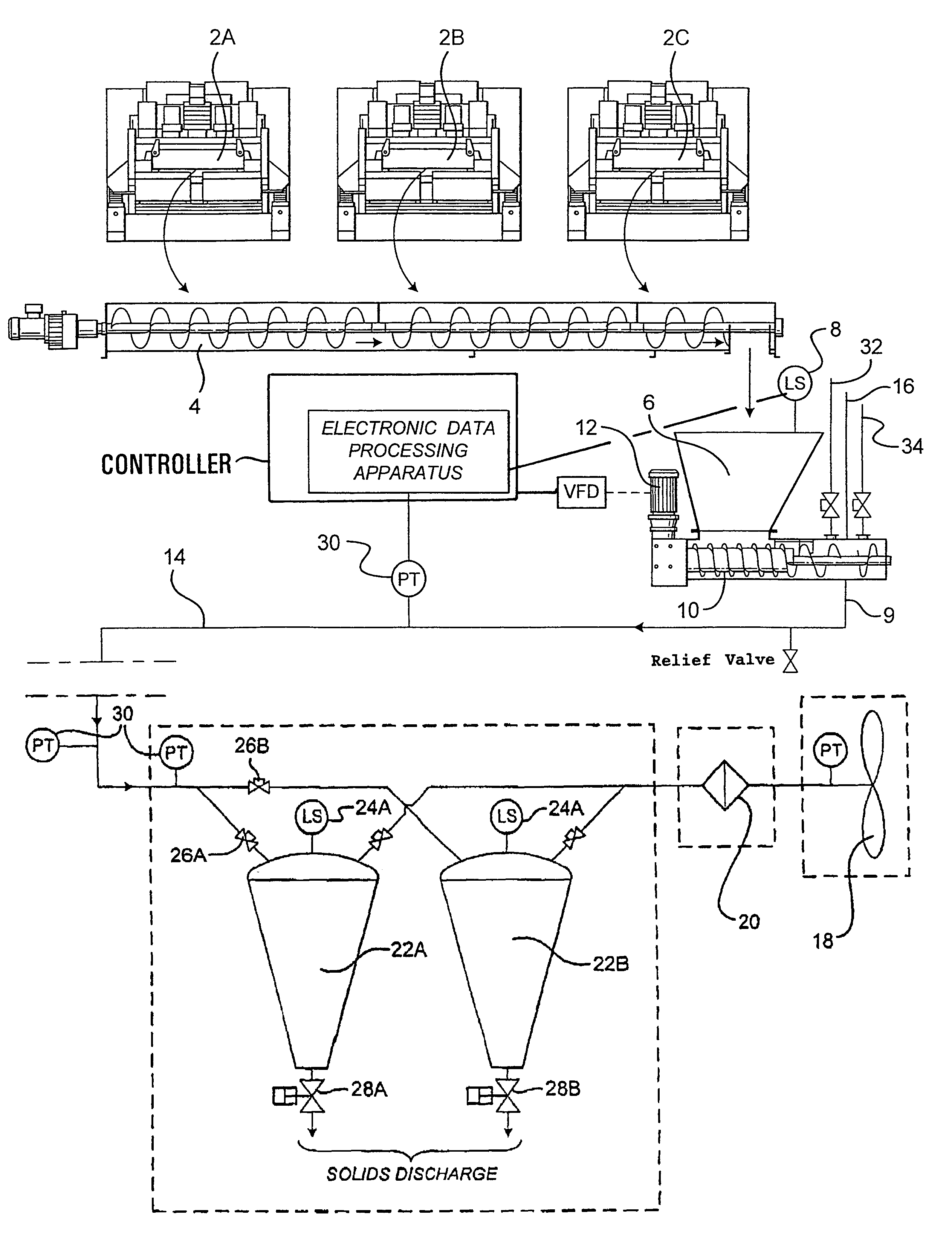

Vessels, system and methods for conveying drilling cuttings material, which, in certain aspects, include a system for conveying material from a vessel, the system having a vessel for receiving material to be conveyed, a first conduit for conveying air, a second conduit for receiving air from the first conduit and for conveying air into the vessel, a metering screw for receiving material from the vessel and for moving the material from the vessel, a discharge line for receiving the material from the metering screw, the discharge line having an exit end, pressure sensor apparatus for sensing pressure in the discharge line, and control apparatus for automatically controlling the metering screw in response to a pressure sensed by the pressure sensor apparatus.

Owner:VARCO I P INC

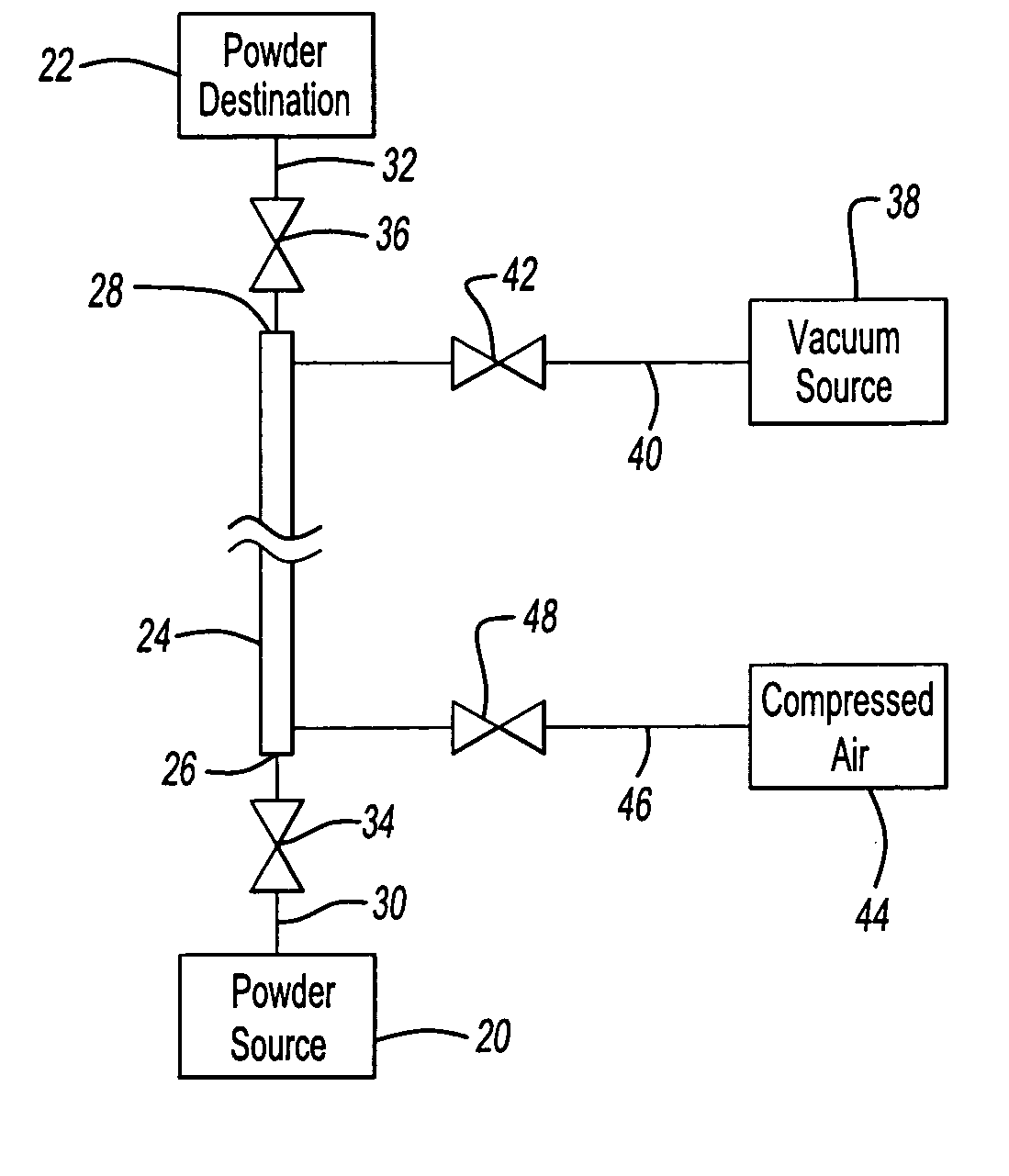

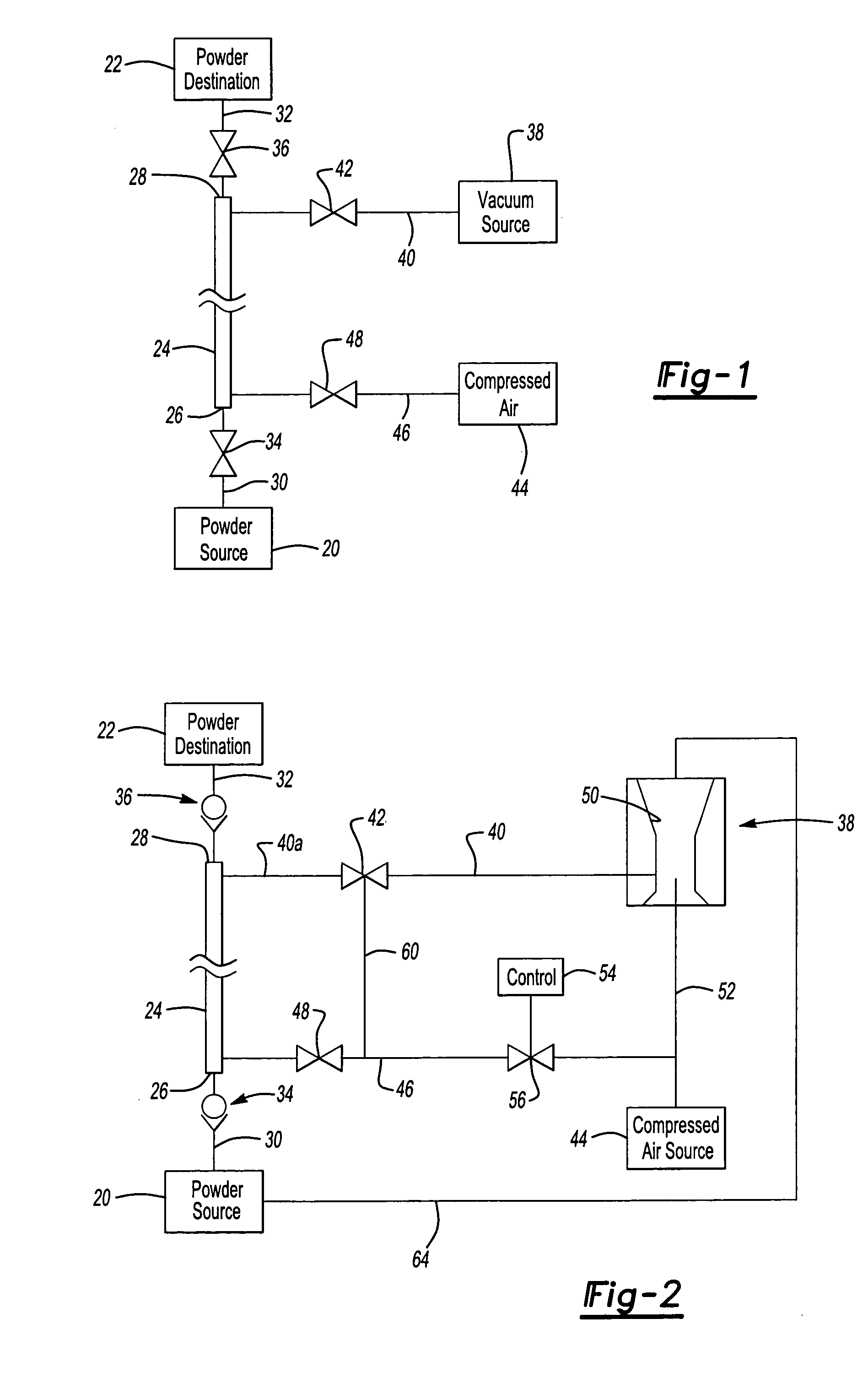

Pump for transferring particulate material

A pump for transferring particulate material from a source to a remote location, including a particulate chamber having open ends, check valves at the open ends, a vacuum source connected to the chamber adjacent one end, a gas source at the opposed end of the chamber and a control which alternatively connects the vacuum to the chamber to draw particulate material from the source to the chamber and connecting the gas under pressure to drive the particulate material to the remote location. In a preferred embodiment, the chamber has a cylindrical inner diameter and the source of vacuum is a venturi pump connected to a pinch valve permitting overflow of particulate material through the pinch valve and venturi pump, which is returned to the source. In one embodiment, the pinch valve surrounds an open end of the chamber permitting overflow while avoiding agglomeration of the particulate material.

Owner:DURR SYST INC

Method, system and apparatus for dispensing products for a personal care service, instructing on providing a personal care treatment service, and selecting a personal care service

A method, system and apparatus for delivery of custom blended dispensing custom blended personal care beauty products for a beauty service, wherein one or more components of a beauty product are stored where they may be supplied as needed to a dispenser, and where a control mechanism regulates the dosage of beauty components to provide a desired selected personal care beauty product with the characteristics selected. A selection screen display provides an image of a person and the person's hair that may be manipulated to simulate modifications that may include cut or styling and color or other effects. The selections are processed and stored and a formula is generated and communicating to a dispensing device to deliver the product components to produce the formula.

Owner:COLORCULTURE NETWORK

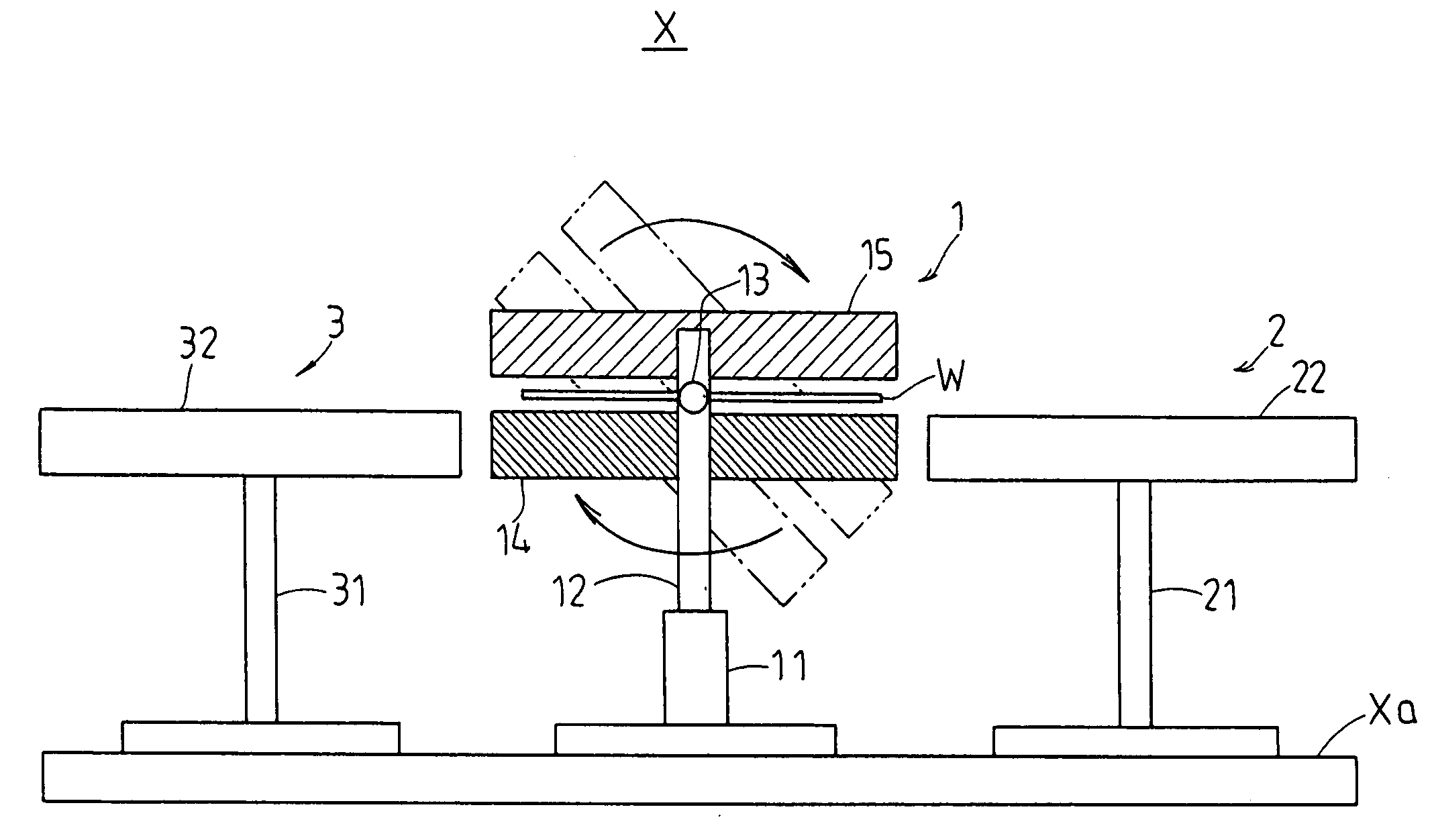

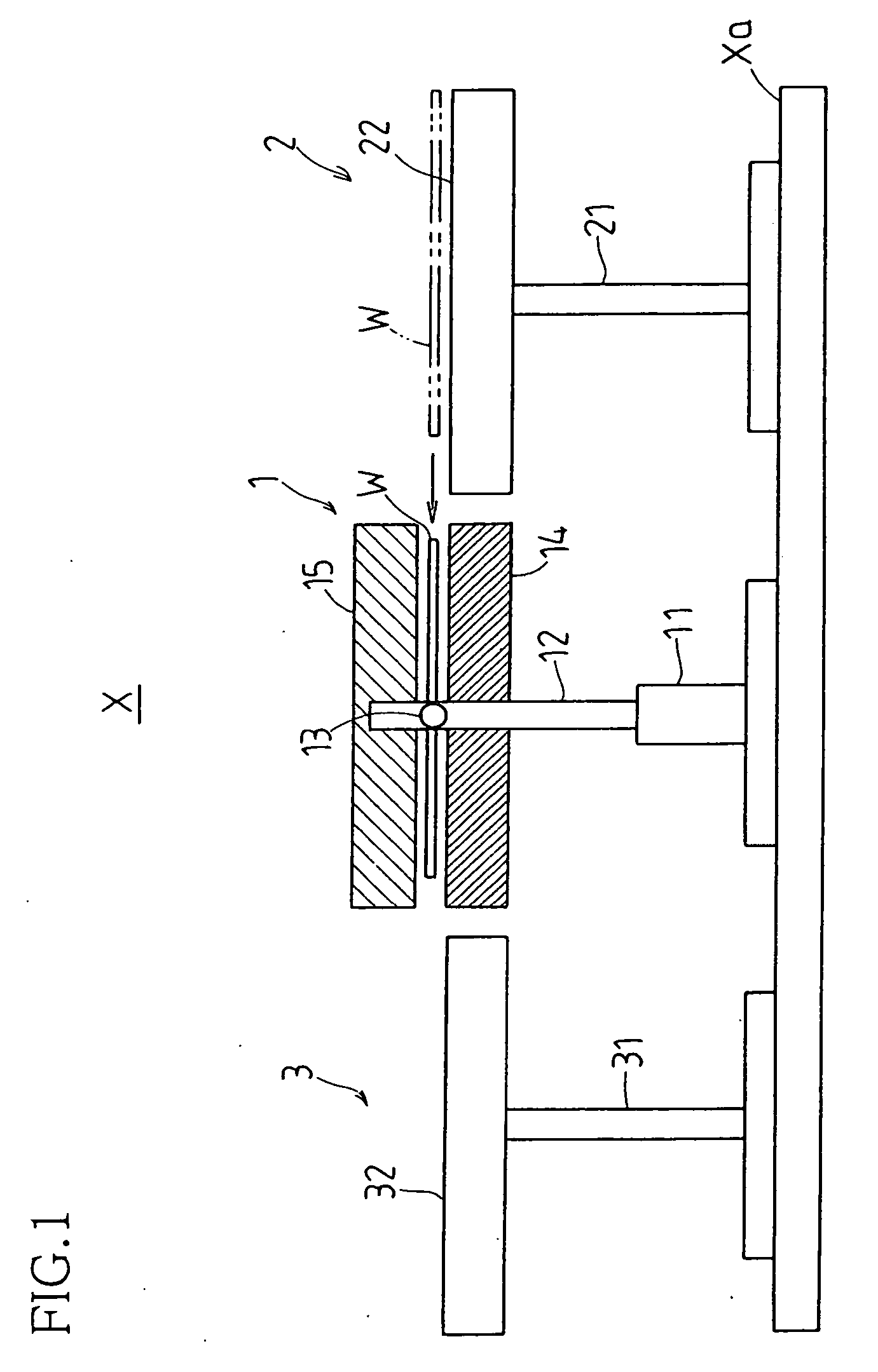

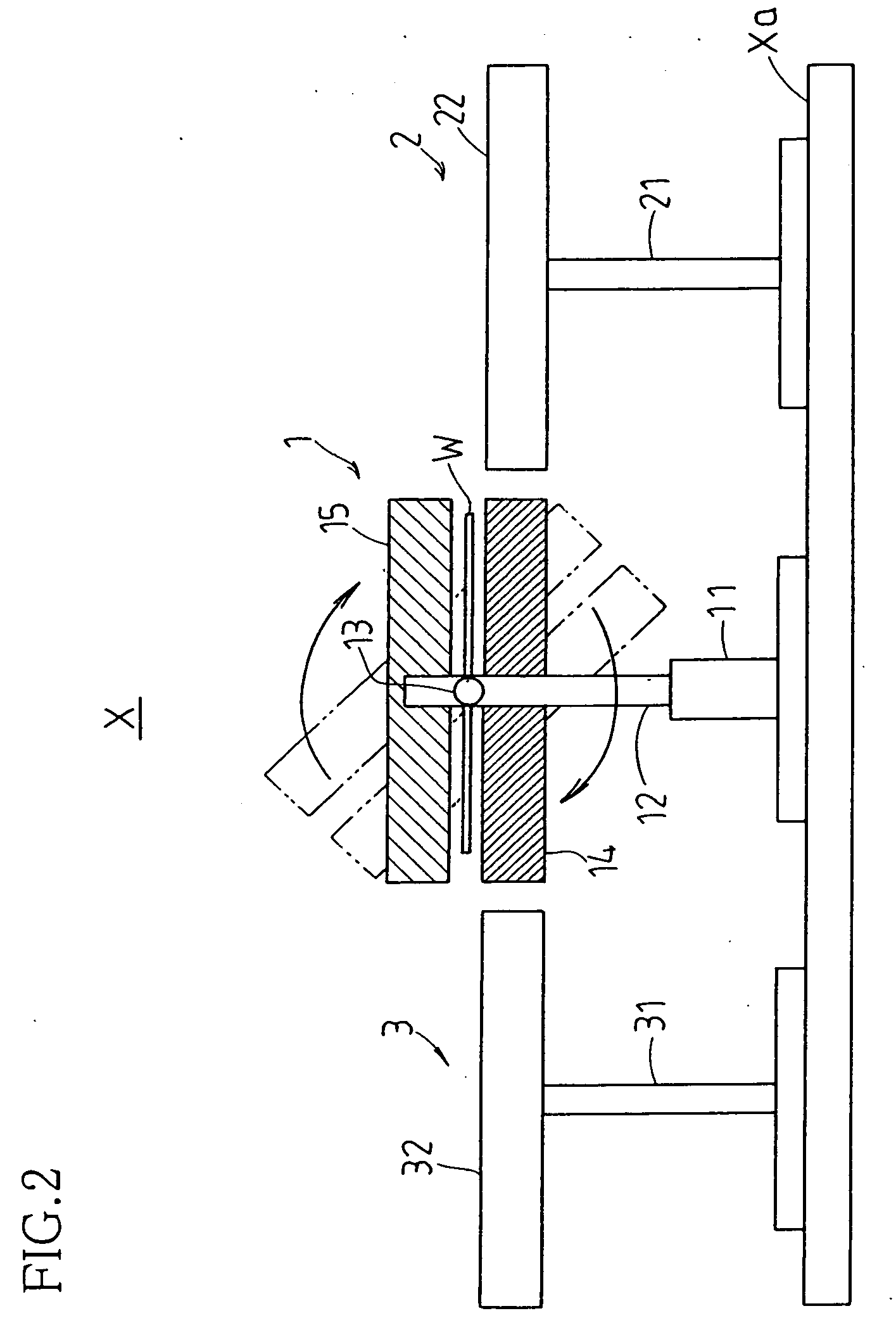

Workpiece transport apparatus

InactiveUS20040197184A1Reduce Particle GenerationEliminate mechanical partForging hammersSemiconductor/solid-state device manufacturingTransport engineering

While periphery or peripheries of workpiece(s) W lifted in floating fashion by simultaneous suction and expulsion of gas(es) between pair(s) of first and second, or upper and lower, transport stages 14, 15 is / are retained by plurality of elevator pins 16, respective transport stage(s) is / are inverted vertically and workpiece(s) is / are transferred from upper first transport stage(s) to lower second transport stage(s) such that workpiece(s) W is / are lifted in floating fashion thereabove by simultaneous suction and expulsion of gas(es) in accompaniment to lowering of respective elevator pin(s) at said first transport stage(s).

Owner:SHARP KK

Apparatus and method for supporting, positioning and rotating a substrate in a processing chamber

InactiveUS8057602B2Semiconductor/solid-state device manufacturingPackaging by pressurising/gasifyingEngineeringChemical vapor deposition

Embodiments of the invention contemplate a method, apparatus and system that are used to support, position, and rotate a substrate during processing. Embodiments of the invention may also include a method of controlling the transfer of heat between a substrate and substrate support positioned in a processing chamber. The apparatus and methods described herein remove the need for complex, costly and often unreliable components that would be required to accurately position and rotate a substrate during one or more processing steps, such as an rapid thermal processing (RTP) process, a chemical vapor deposition (CVD) process, a physical vapor deposition (PVD) process, atomic layer deposition (ALD) process, dry etching process, wet clean, and / or laser annealing process.

Owner:APPLIED MATERIALS INC

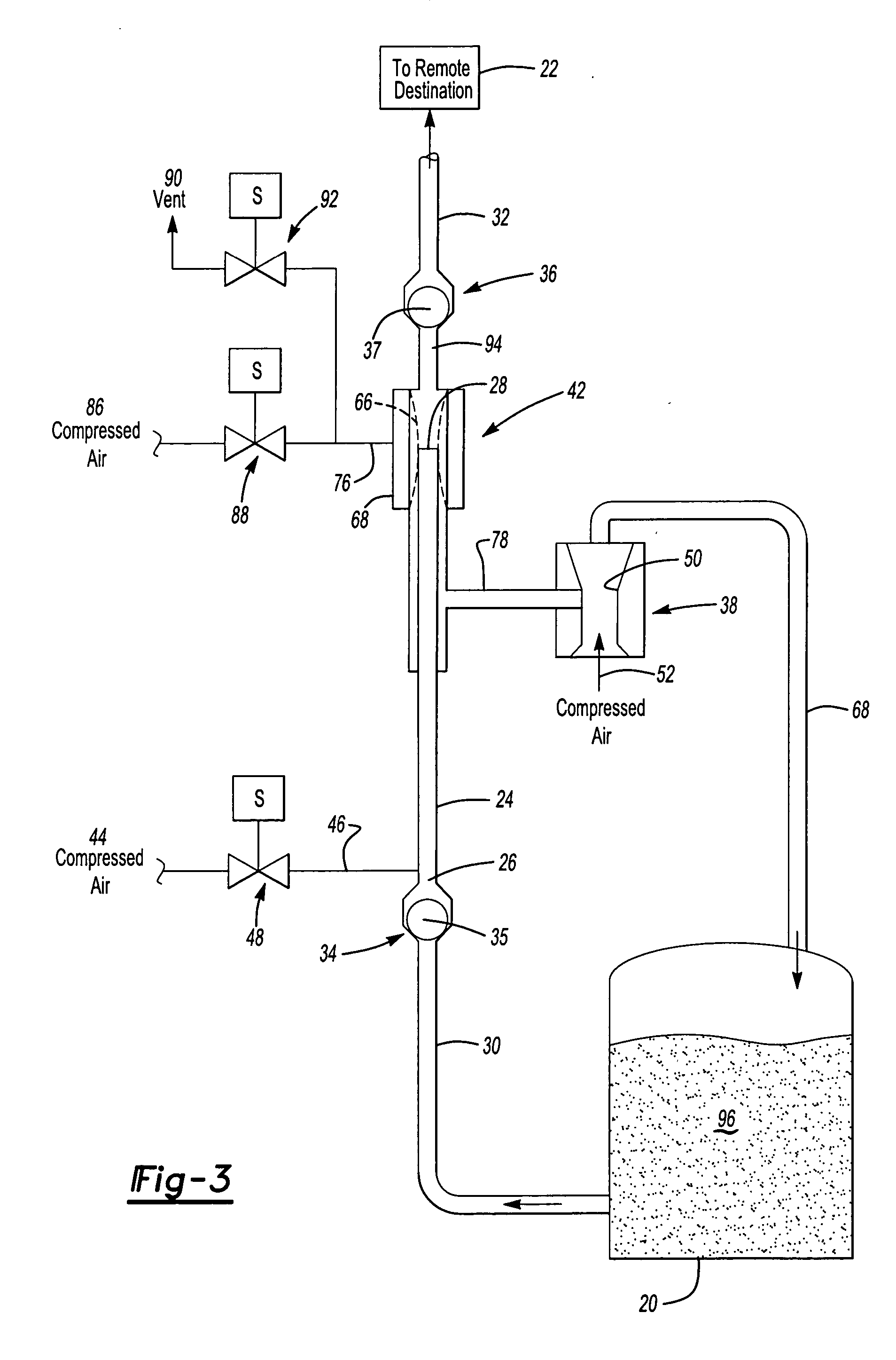

System for delivering solid particulate matter for loading

ActiveUS20150110565A1Avoid spreadingEasy loadingBulk conveyorsLoading/unloadingParticulatesSolid particle

An assembly for transferring solid particulate matter has a pressurized vessel for retaining a pre-determined quantity of the solid material. A transfer conduit connected to the vessel carries the solid material to a loading vessel, be it a processing tank, a storage vessel, or any other similar container. A discharge nozzle carried by a distant end of the transfer conduit is connected to a vacuum source, whereby a slight vacuum is created at the discharge opening. A separate dust removal conduit is secured immediately adjacent to the discharge nozzle for removal of the dust particles away from the discharge nozzle. The dust particles are collected in a separate vessel, which is mounted in a flow of air from the dust collection conduit and an exhaust fan. Mesh sleeves suspended in the vessel, capturing the dust particles on exterior surface thereof. Periodically, the dust particles are dislodged from the sleeves by blowing air through the sleeves. The dislodged dust particles are collected for disposal or recycling.

Owner:HARRIS JACK

Apparatus and method for transporting waste materials

InactiveUS7080960B2Reduce feed rateHigh speedControl devices for conveyorsFlushingDrill cuttingsWaste material

Owner:VARCO I P INC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com