Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

1659results about "Glass transportation apparatus" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

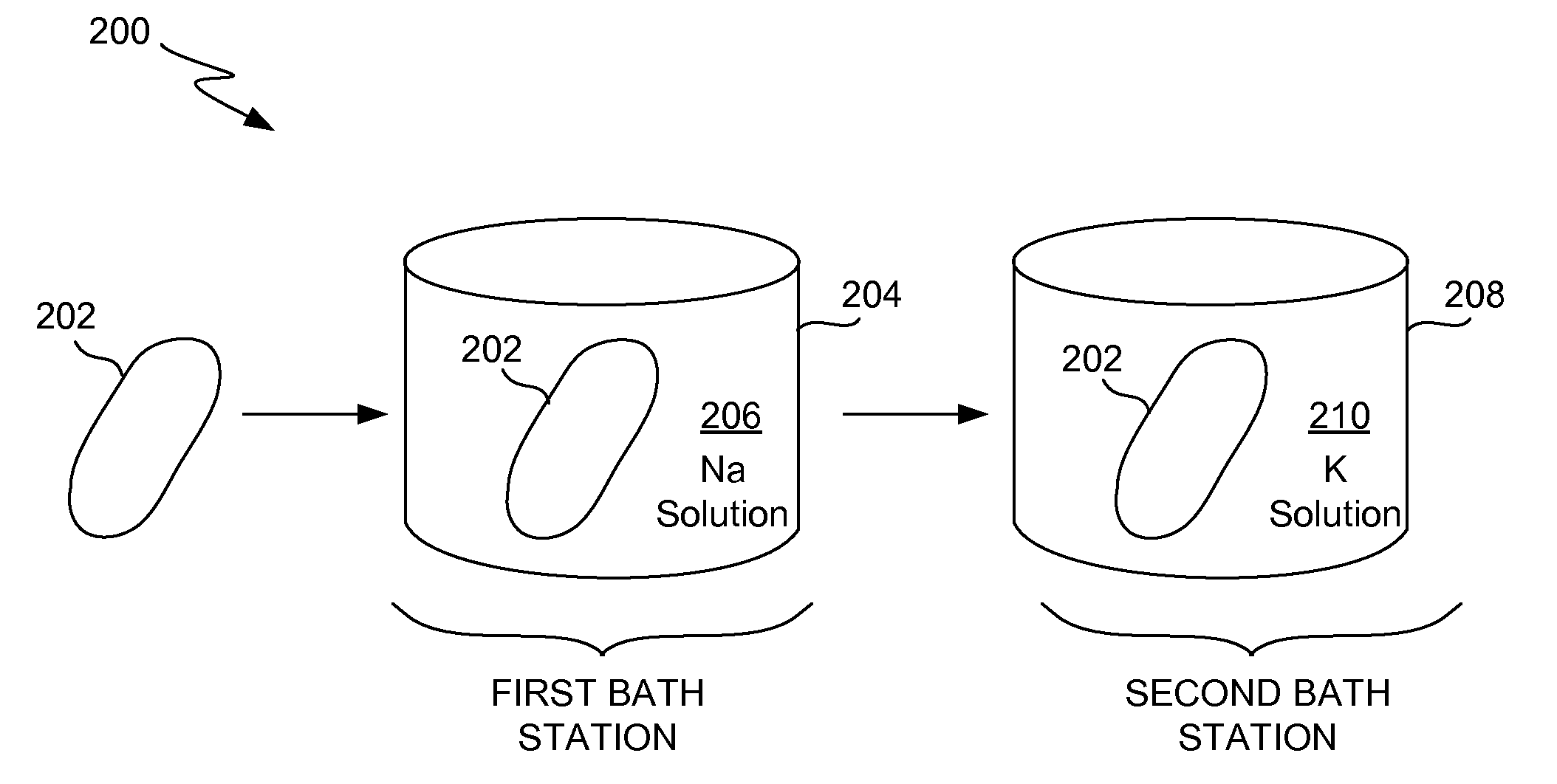

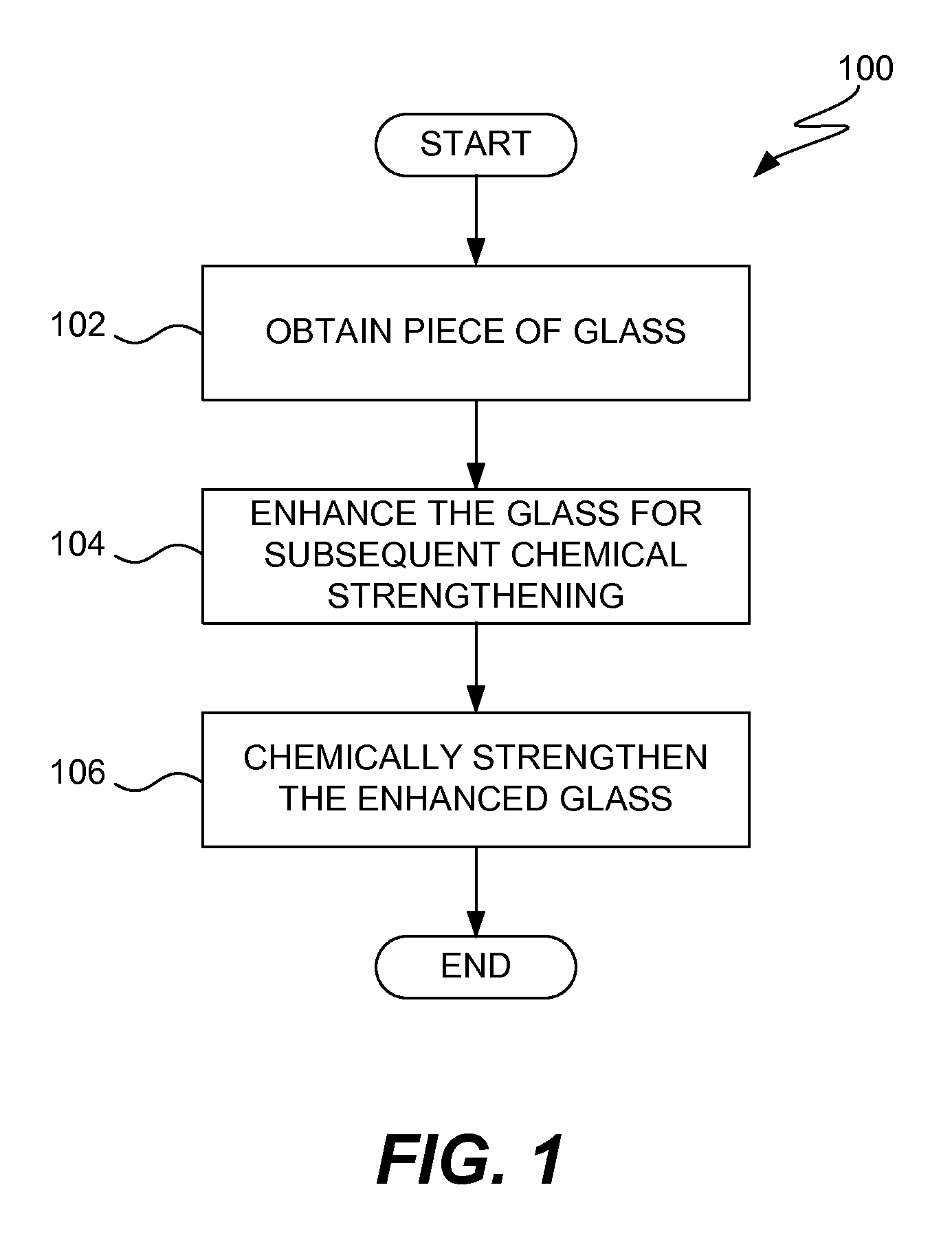

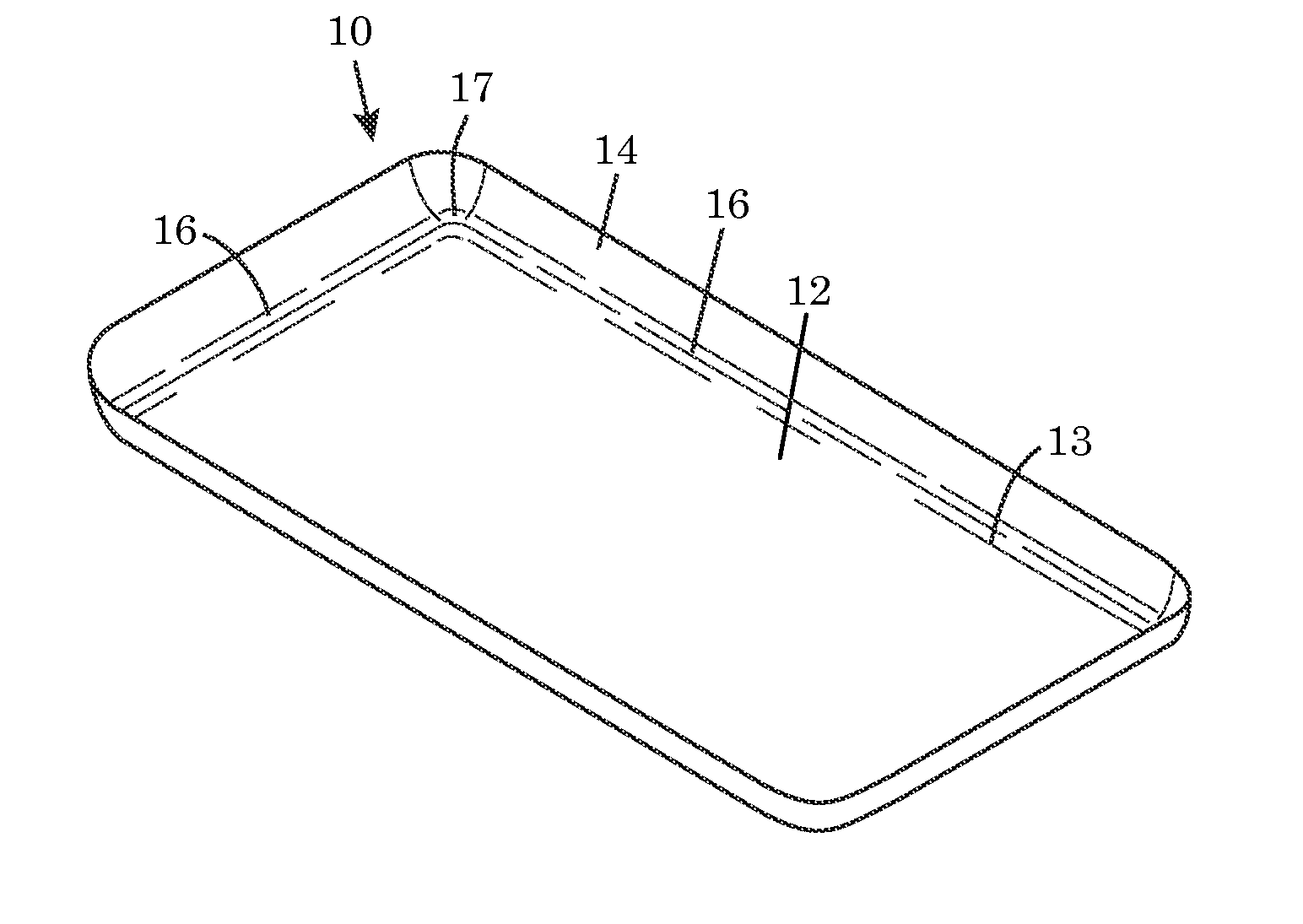

Enhanced Strengthening of Glass

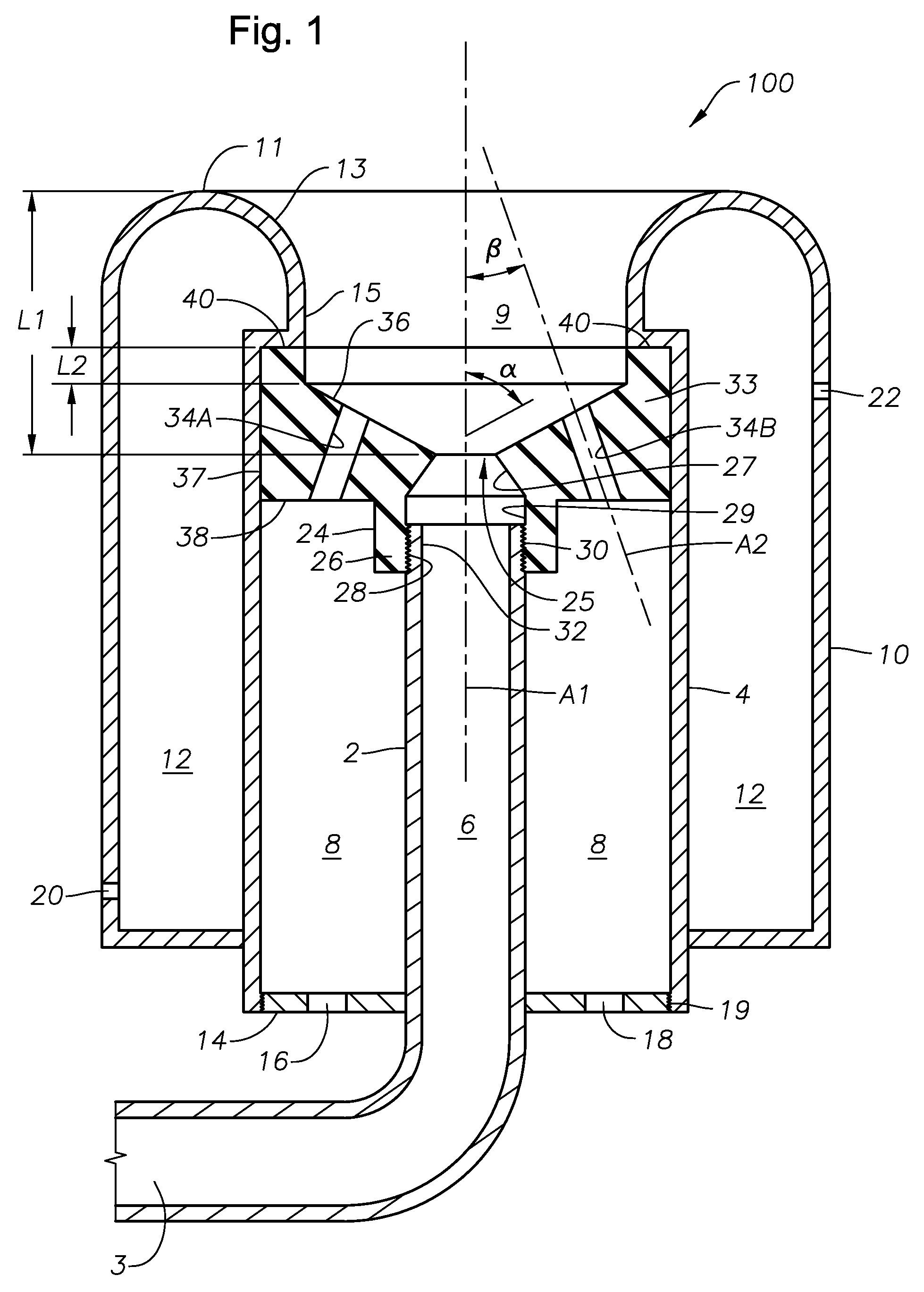

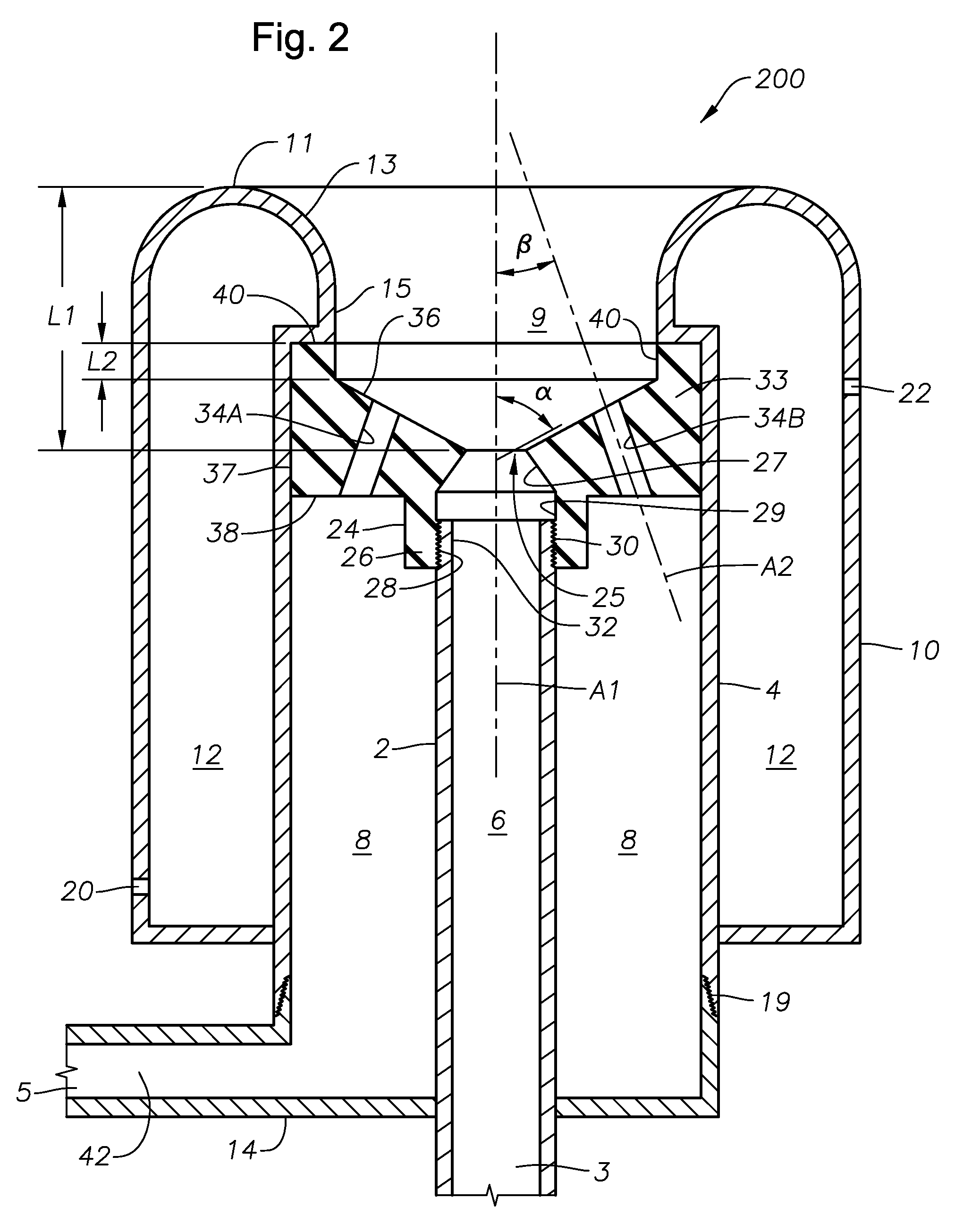

ActiveUS20110067447A1Improve glass strengthImprove the level ofGlass drawing apparatusGlass transportation apparatusChemical treatmentGlass cover

Apparatus, systems and methods for improving strength of a thin glass member for an electronic device are disclosed. In one embodiment, the glass member can have improved strength by using multi-bath chemical processing. The multi-bath chemical processing allows greater levels of strengthening to be achieved for glass member. In one embodiment, the glass member can pertain to a glass cover for a housing of an electronic device.

Owner:APPLE INC

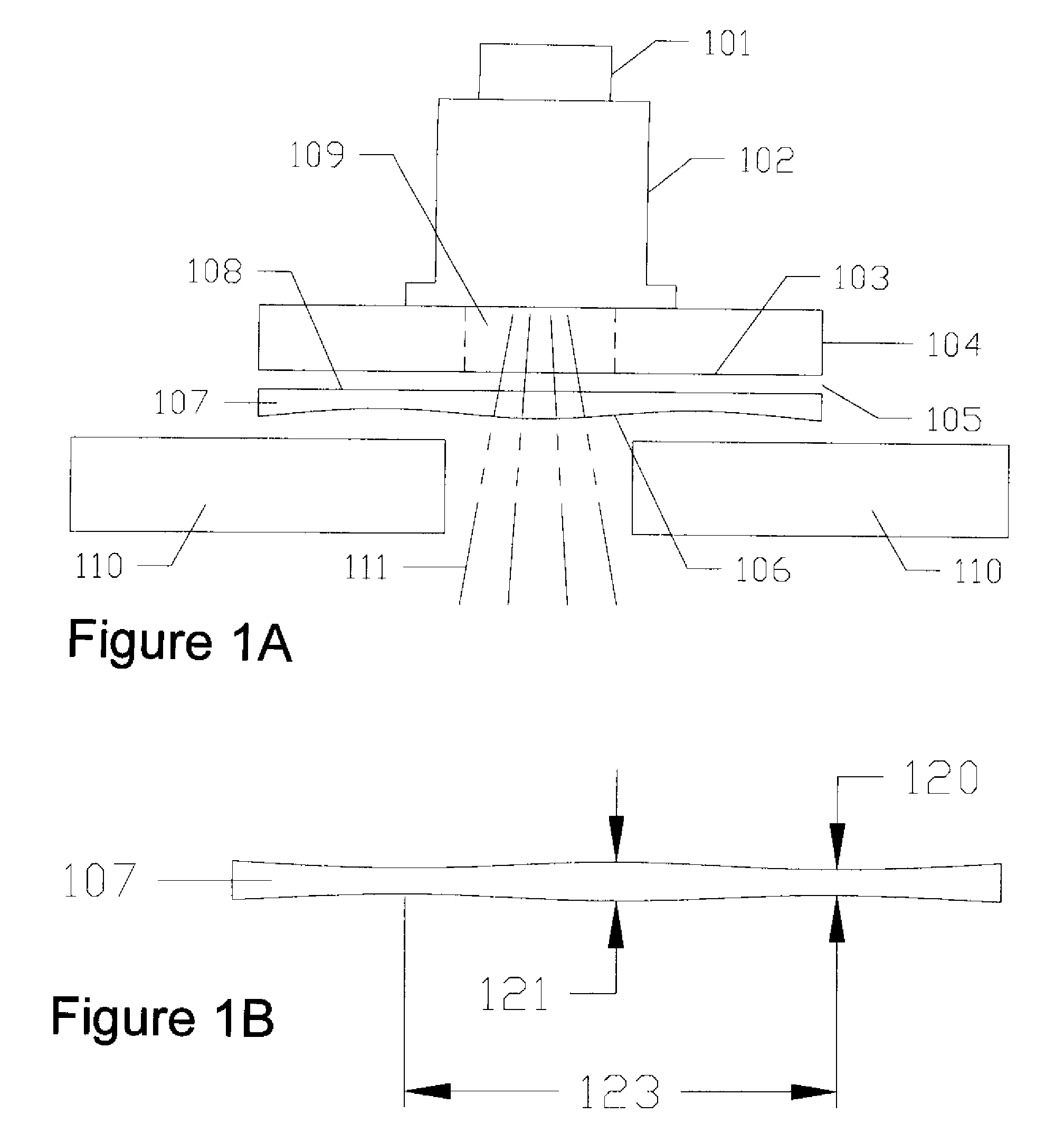

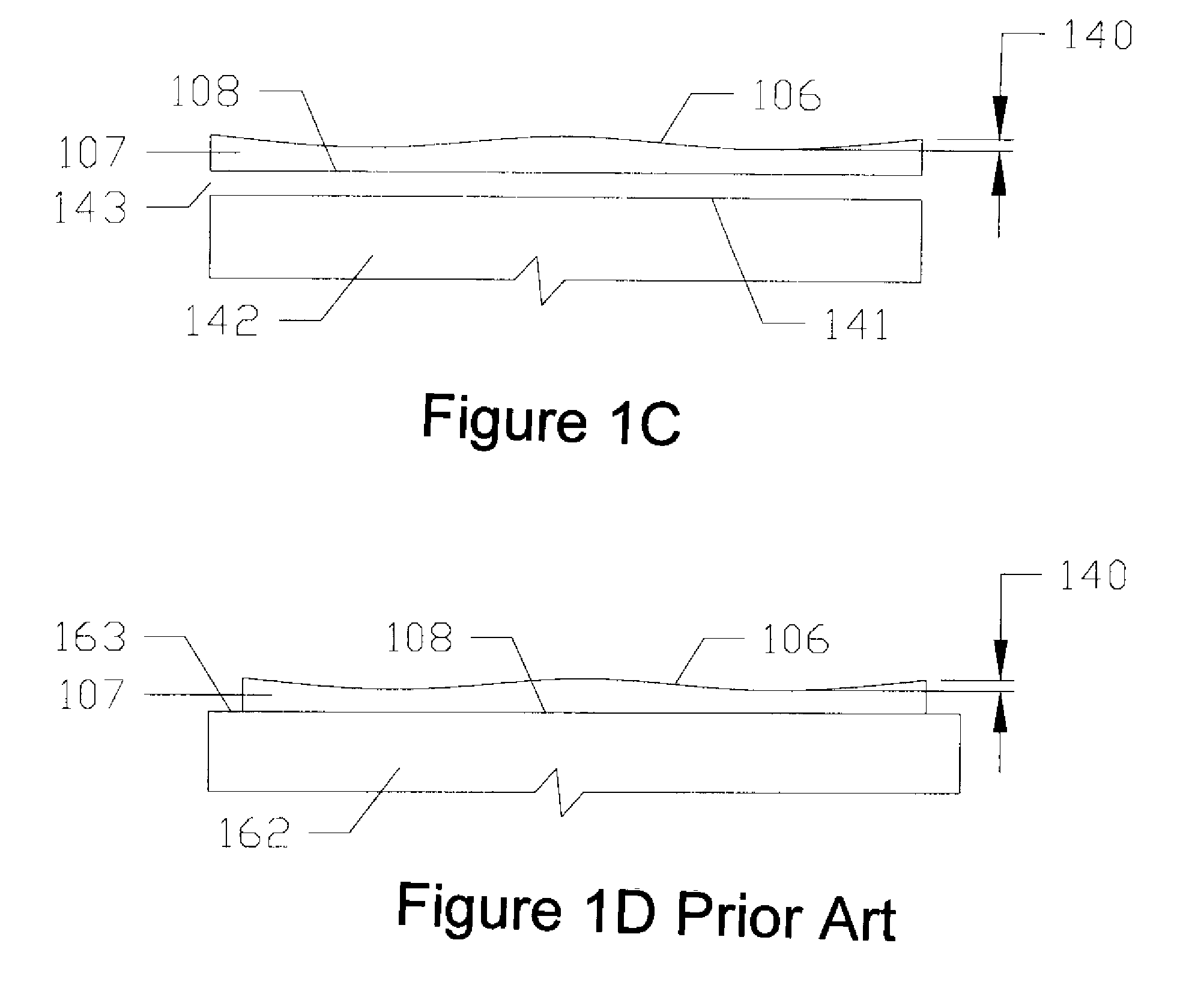

Pulling rolls for use in manufacturing sheet glass

InactiveUS6896646B2Easy to useImprove the level ofShaft and bearingsMetal-working apparatusFlat glassRoom temperature

Owner:CORNING INC

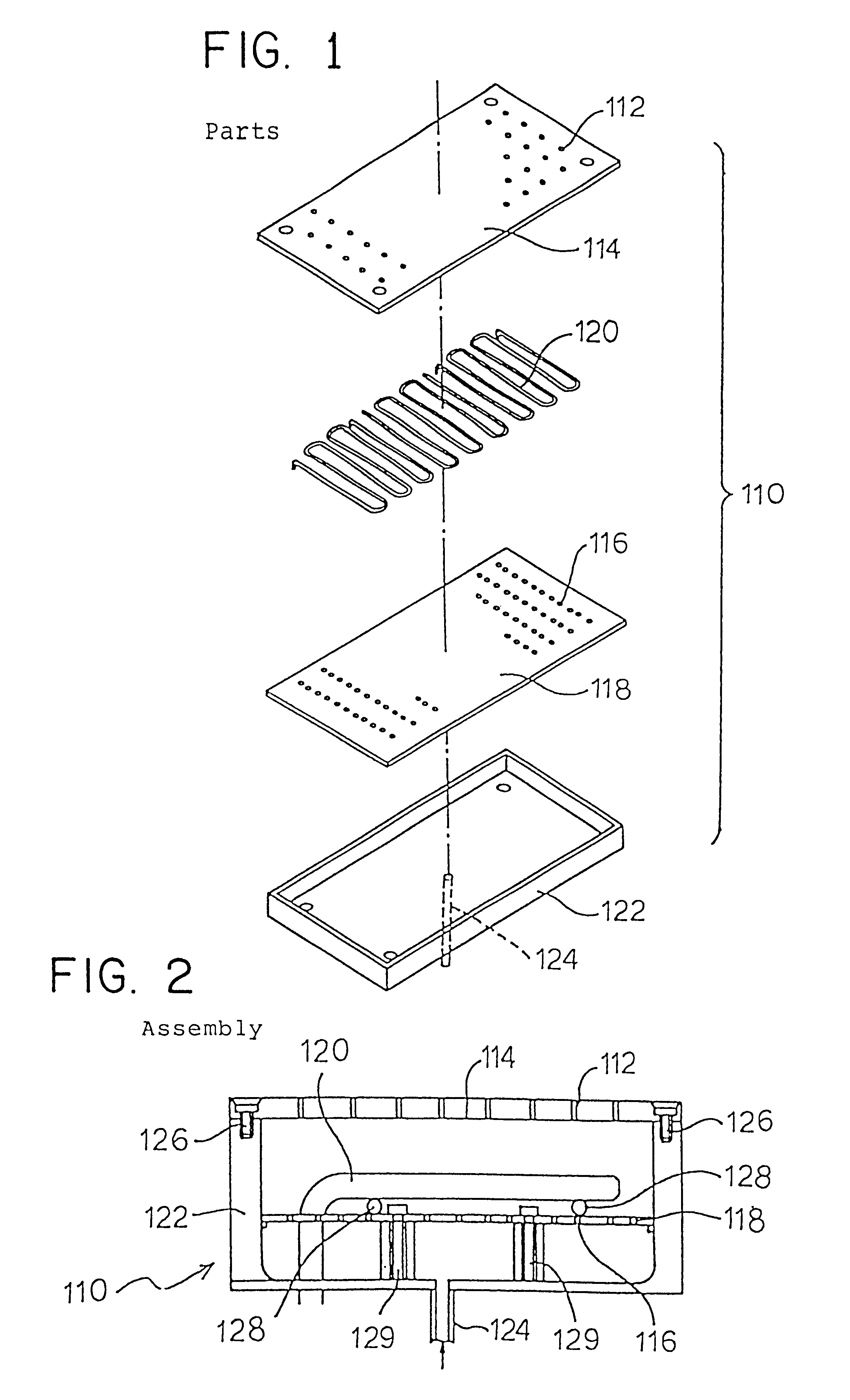

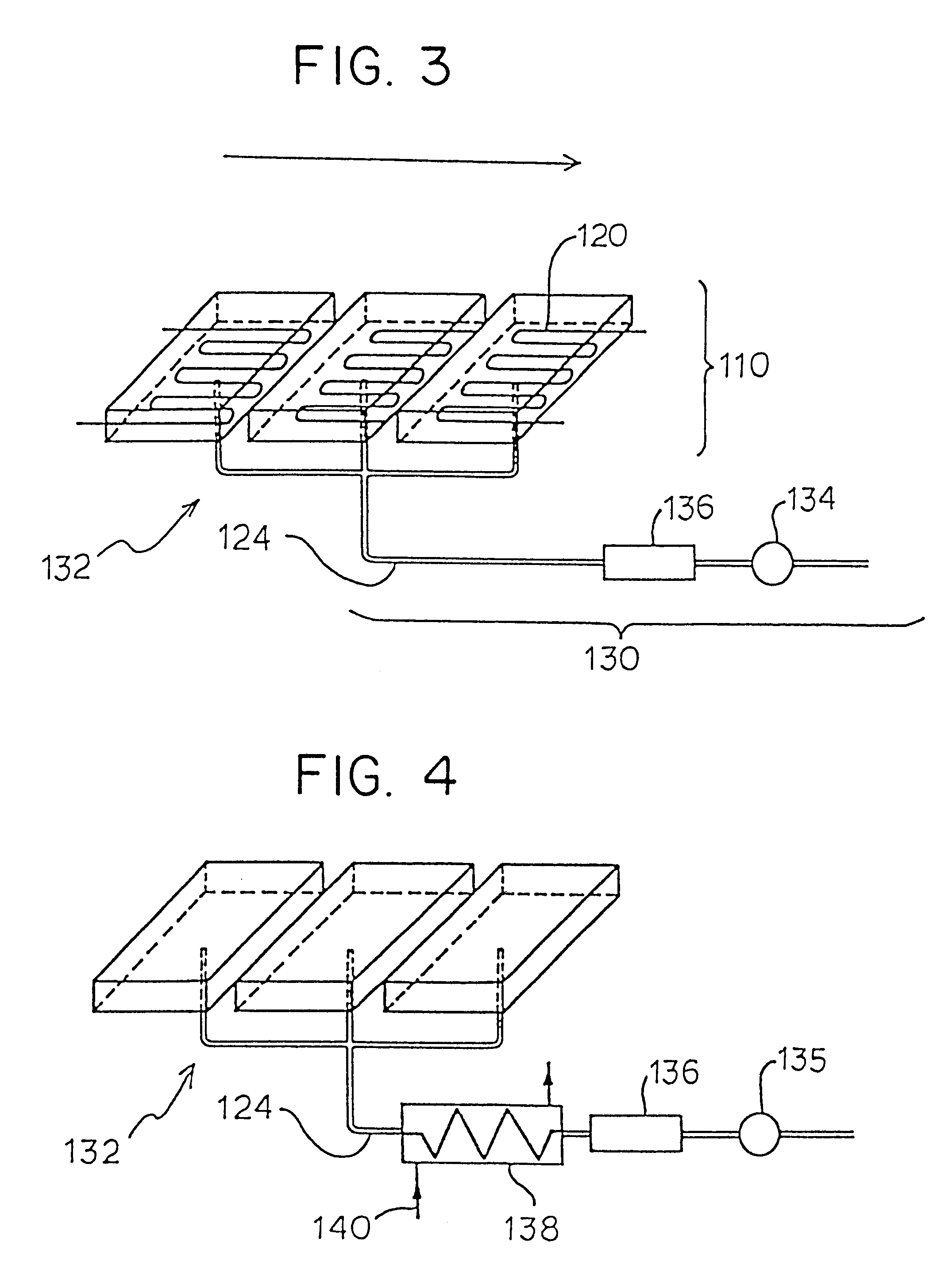

Gas floating apparatus, gas floating-transporting apparatus, and thermal treatment apparatus

InactiveUS6336775B1Large heat capacityWaste of energyGlass transportation apparatusSemiconductor/solid-state device manufacturingEngineeringThermal treatment

A gas floating-transporting apparatus transports a material to be treated along a predetermined direction in a thermal space so as to thermally treat the material to be treated. The apparatus includes a gas floating mechanism and a transporting mechanism. The gas floating mechanism includes a gas ejection device which expels the gas toward a portion of the material to be treated on which a floating force is acted so as to float the material to be treated, and a gas supply device which supplies the gas to the gas ejection means. The transporting mechanism includes an abutting member which abuts a trailing end of the floated material to be treated and moves along the predetermined direction, and which pushes the material to be treated by the movement thereof, whereby the floated material to be treated is moved along the predetermined direction.

Owner:PANASONIC CORP

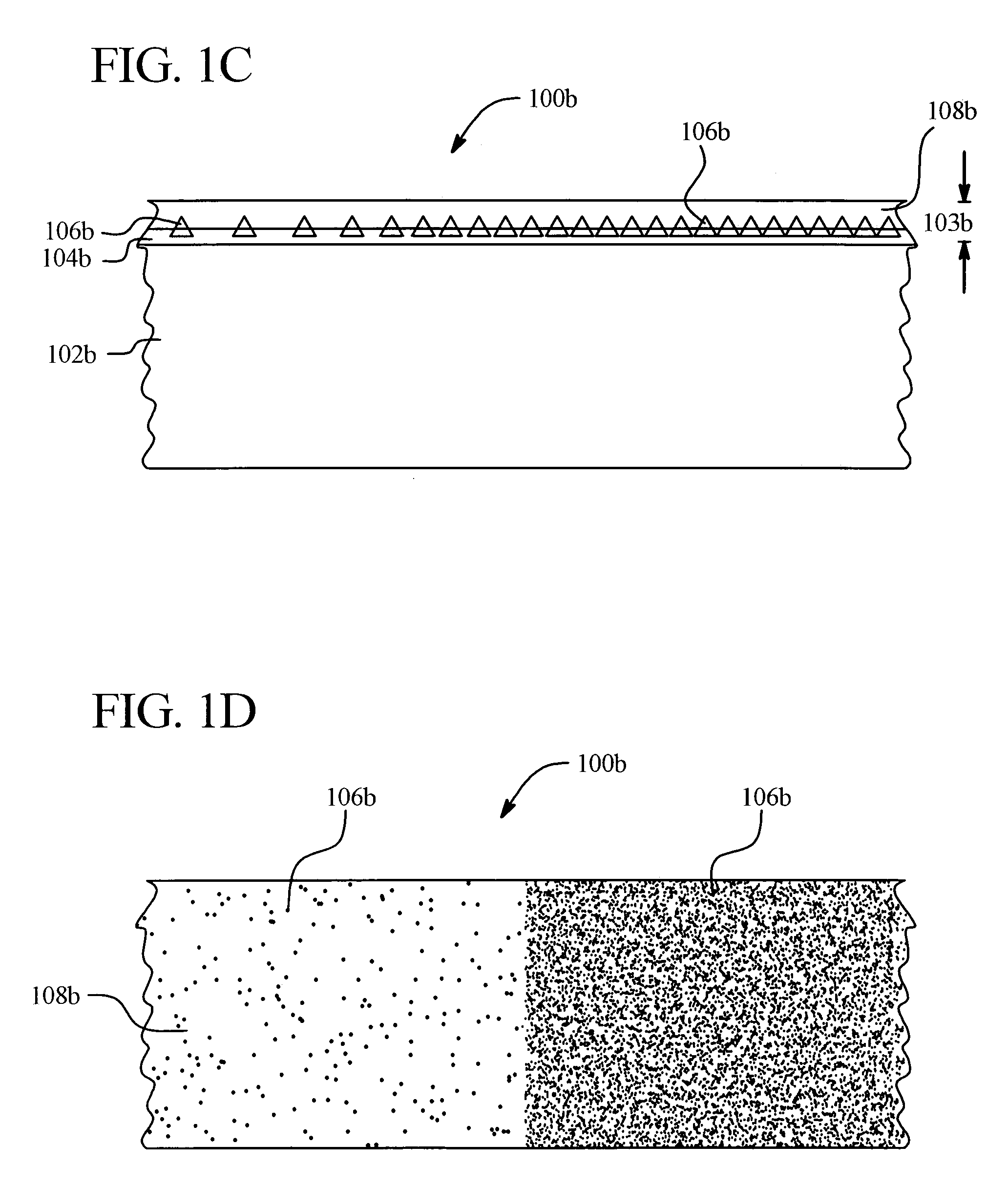

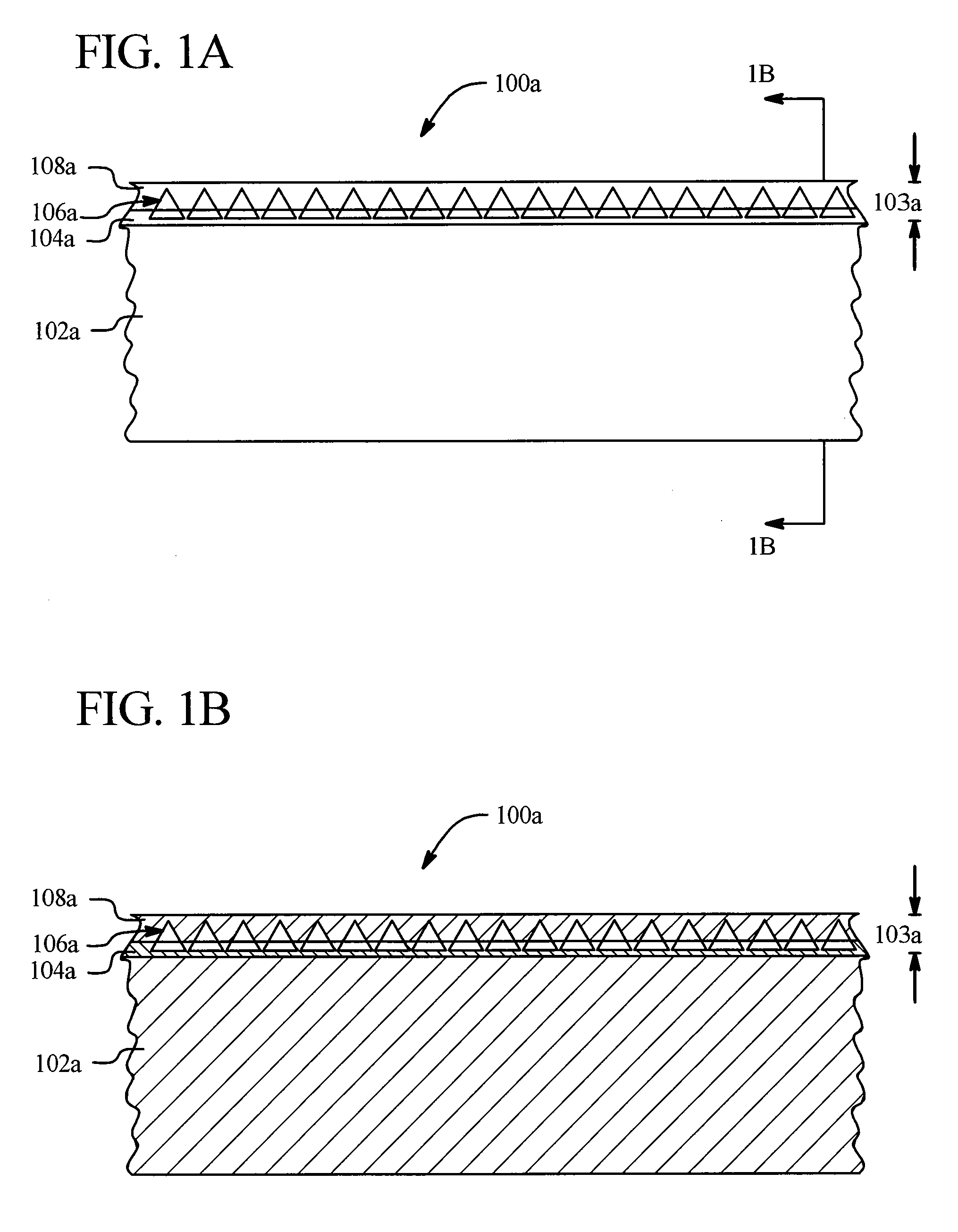

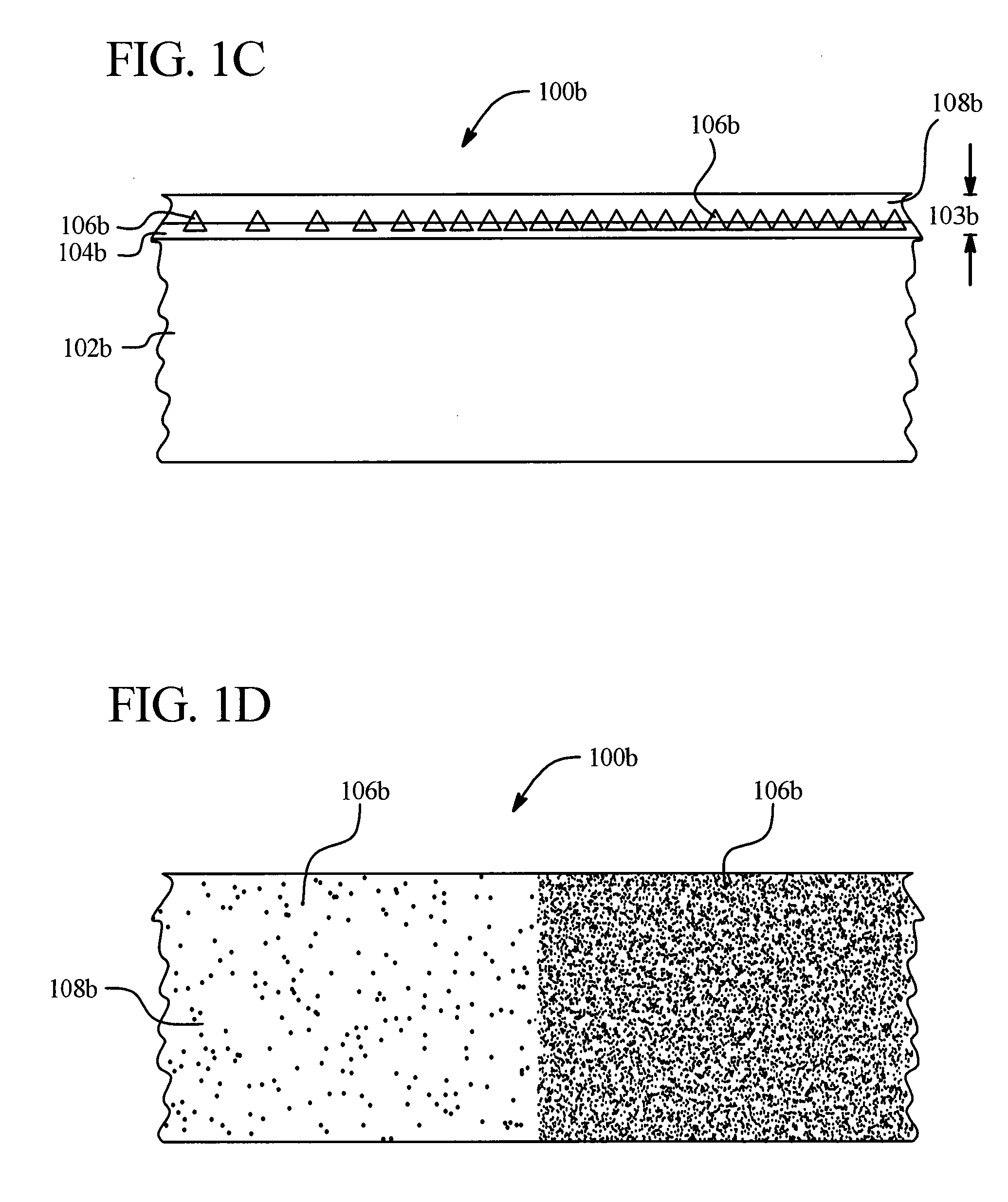

Heat resistant separation fabric

InactiveUS20160083285A1Improve optical qualityImproved heat resistant separation fabricLiquid surface applicatorsGlass transportation apparatusAlloyStainless steel fiber

A heat resistant separation fabric including stainless steel fibers. The stainless steel fibers are made out of an alloy comprising more than 12% by weight of chromium. The stainless steel fibers include an oxide skin. The atomic percentage of Cr at 5 nm depth of the oxide skin divided by the sum of the atomic percentages of Cr and Fe at 5 nm depth of the oxide skin, and multiplied with 100 to express as a percentage, is higher than 30%.

Owner:NV BEKAERT SA

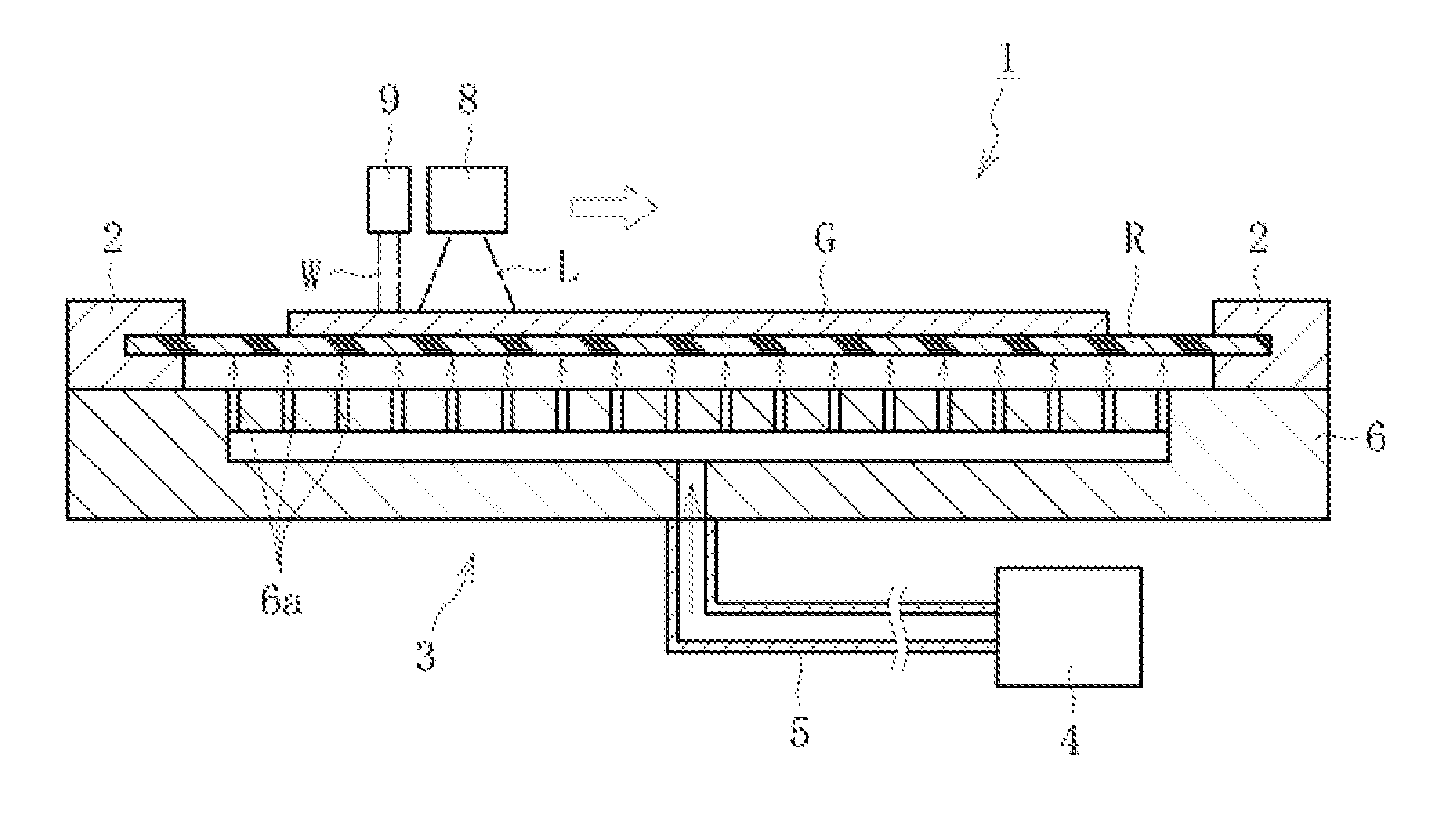

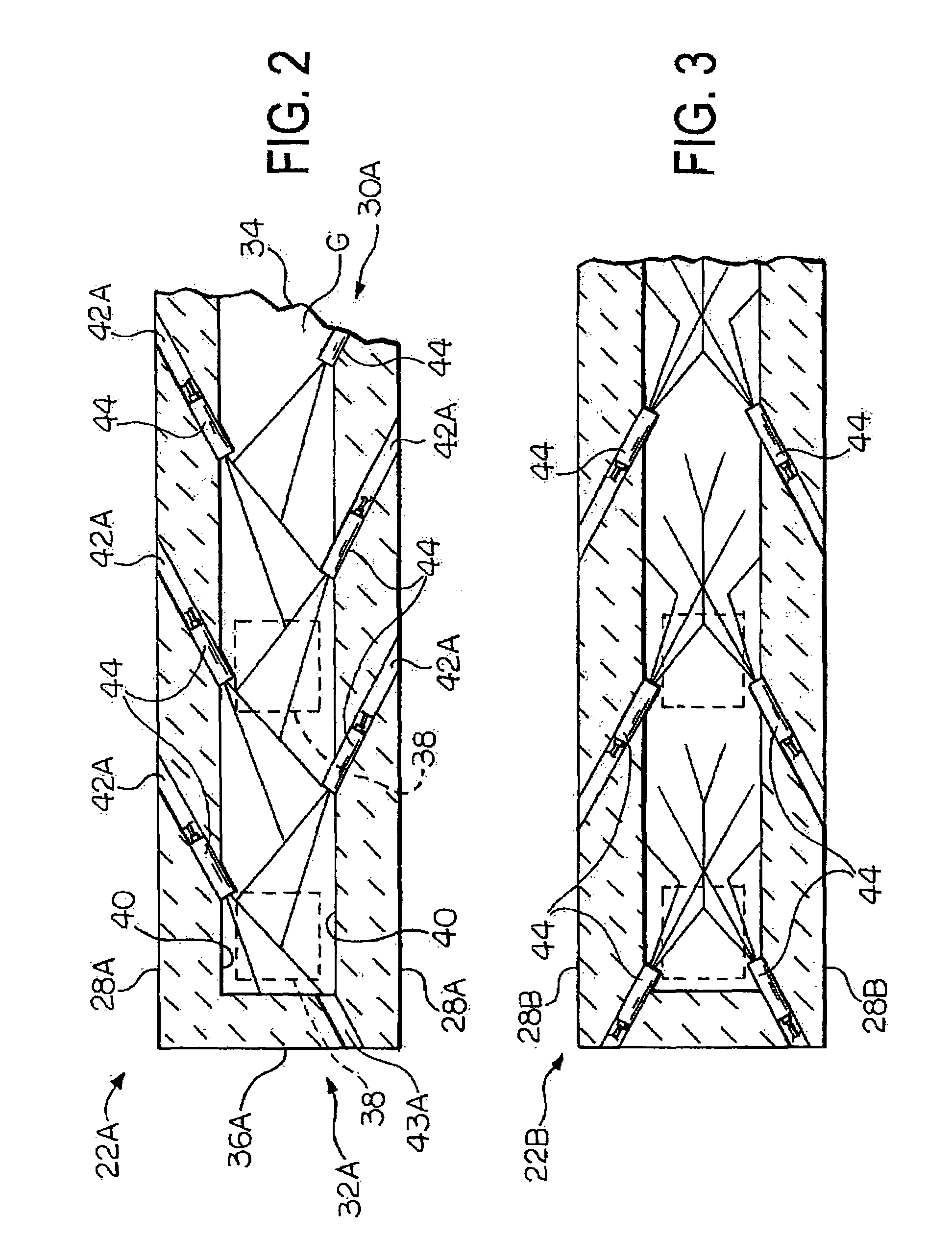

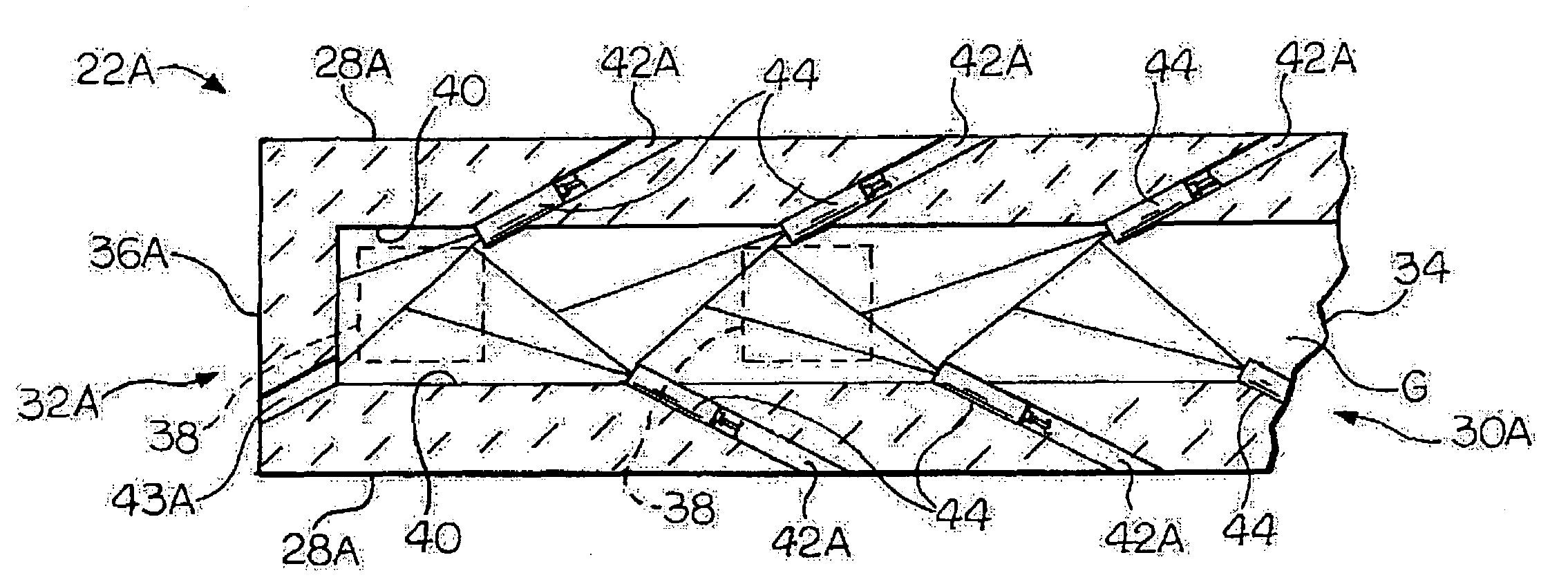

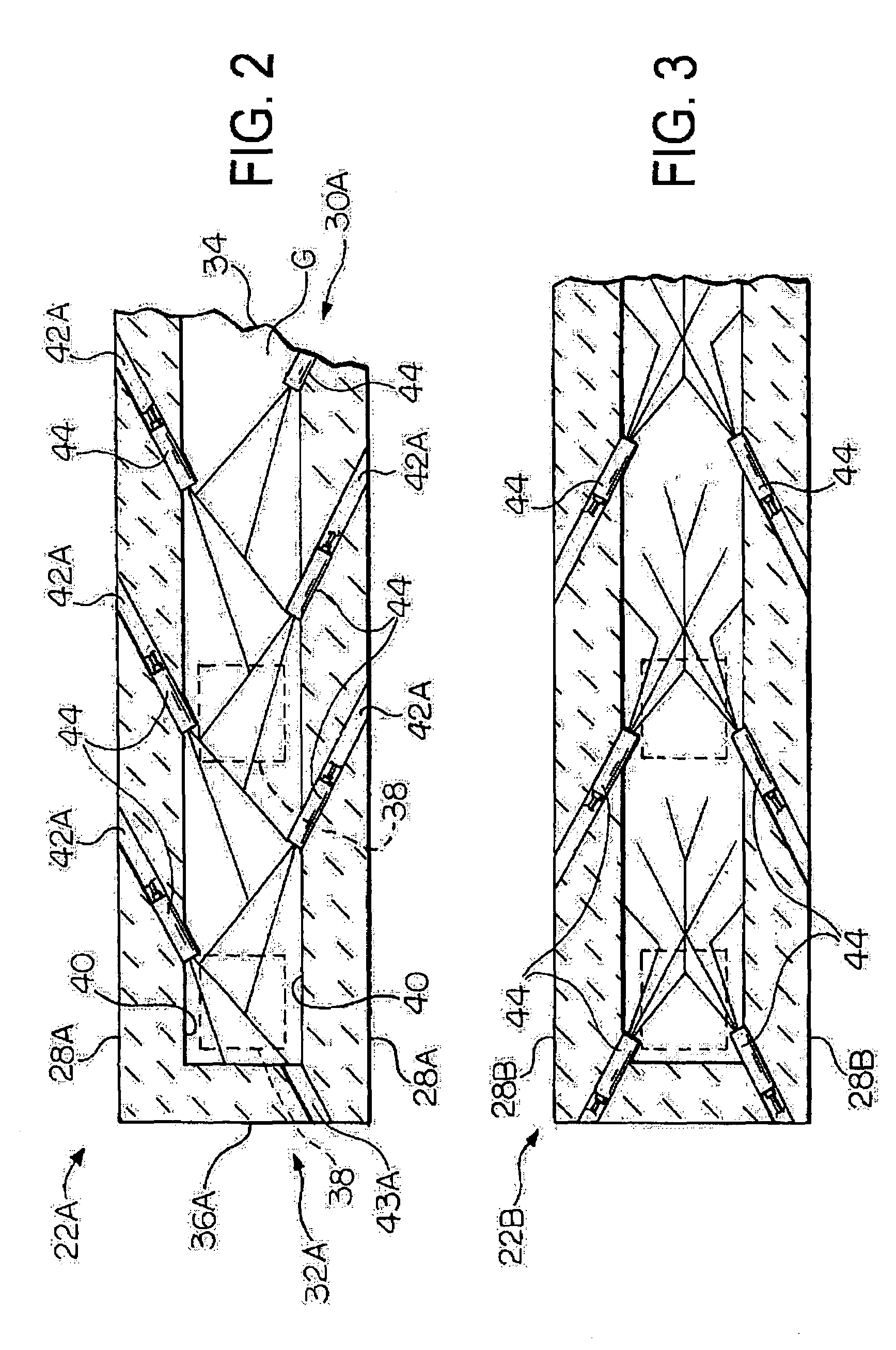

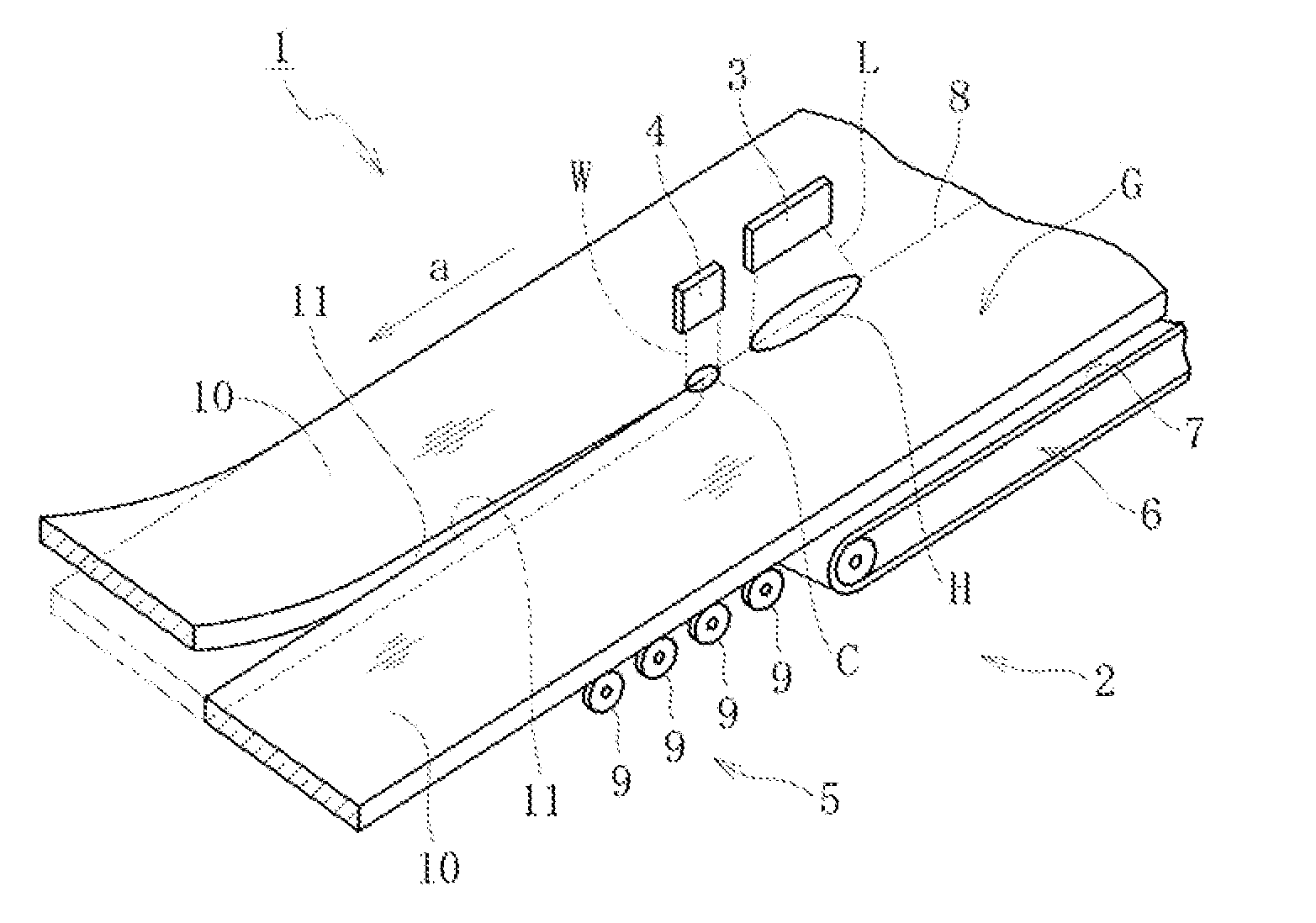

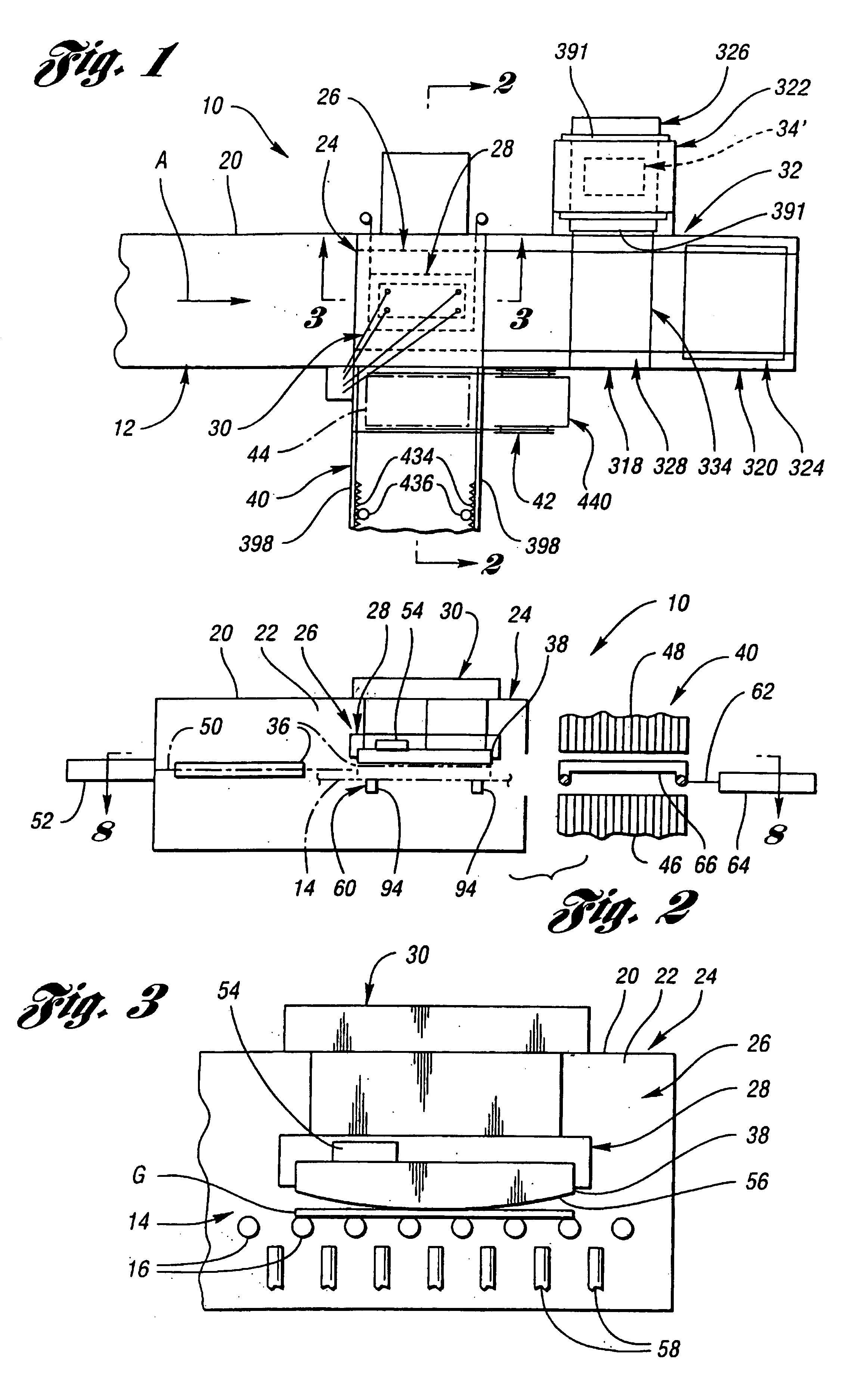

Cleaving method for a glass film, manufacturing method for a glass roll, and cleaving apparatus for a glass film

ActiveUS20120017642A1Efficient cuttingGlass drawing apparatusGlass transportation apparatusMaterials scienceGlass film

In a cleaving apparatus (1) for a glass film, an initial crack (10), which is formed at a leading end portion of a preset cleaving line (7) of a glass film (G), is propagated along the preset cleaving line (7) by a thermal stress generated in the glass film (G) through localized heating performed along the preset cleaving line (7) and cooling of a heated region resulting from the localized heating. At this time, a resin sheet (R) having higher flexibility than the glass film (G) is arranged in a cleaving region, and the resin sheet (R) is floated by blowing a gas on a lower surface of the resin sheet (R) by a floating unit (3). Then, a preset cleaving portion of the glass film (G) including the preset cleaving line (7) is lifted and supported while being covered with the floated resin sheet (R) from below, and in this state, the glass film (G) is cleaved.

Owner:NIPPON ELECTRIC GLASS CO LTD

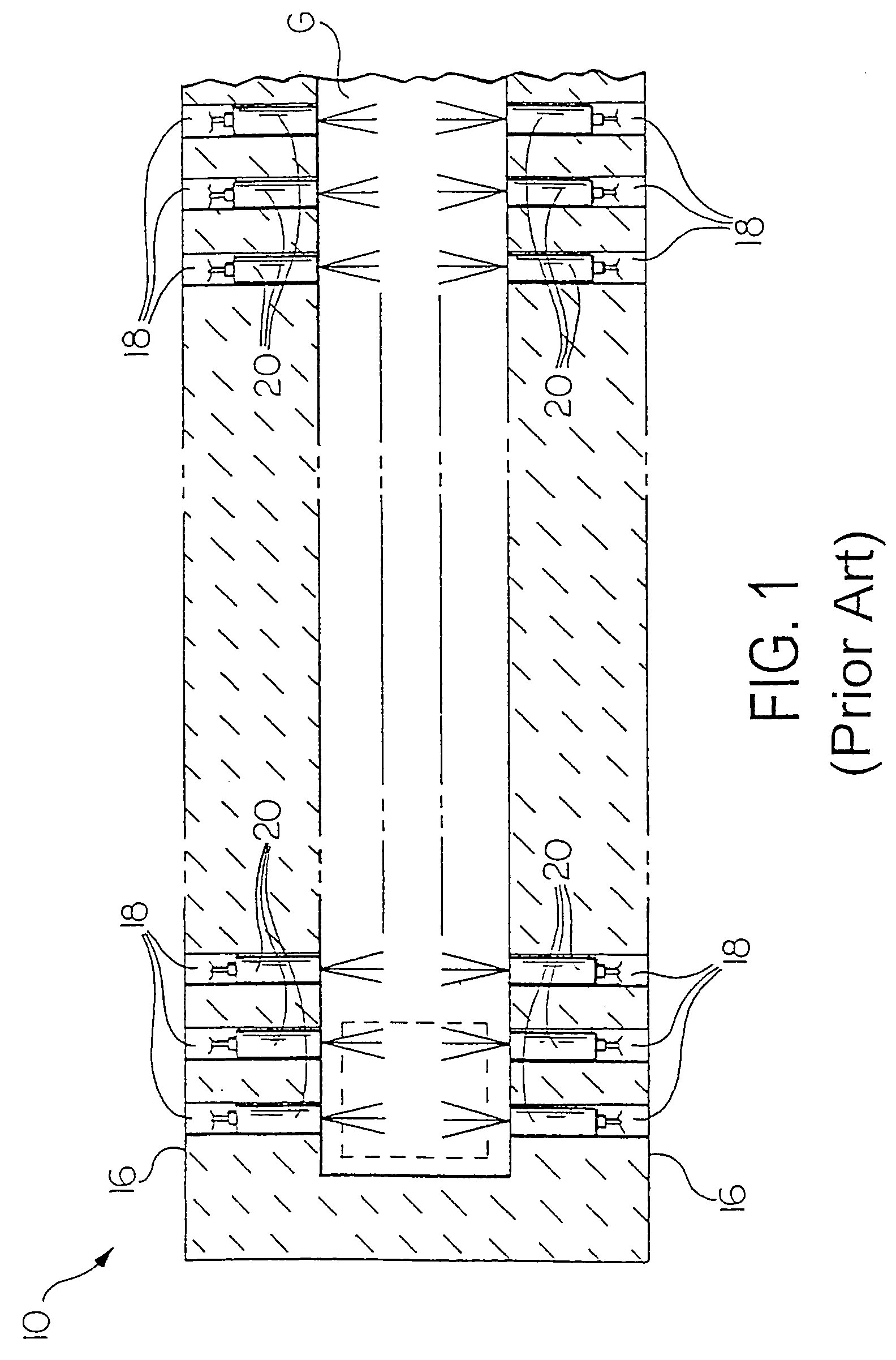

Oxygen-fired front end for glass forming operation

A front end for a glass forming operation comprises an open channel and at least one burner. The channel has at least one surface. The surface has at least one hole therein. The burner is oriented in the hole at an acute angle relative to the surface. In another embodiment of the invention, the channel has a top and a pair of sidewalls each having a surface. At least one hole is in at least one of the surfaces. The hole is at an acute angle relative to at least one surface. The burner is an oxygen-fired burner. In yet another embodiment of the invention, the top and sidewalls each have a super structure surface constructed of refractory material. The channel has an upstream end and a downstream end. At least one of the surfaces has a plurality of holes therein. The burners extend at an acute angle relative to at least one surface and in a plane extending between the upstream end and the downstream end and perpendicular to at least one surface. Oxygen-fired burners extend axially through corresponding holes.

Owner:OCV INTELLECTUAL CAPITAL LLC

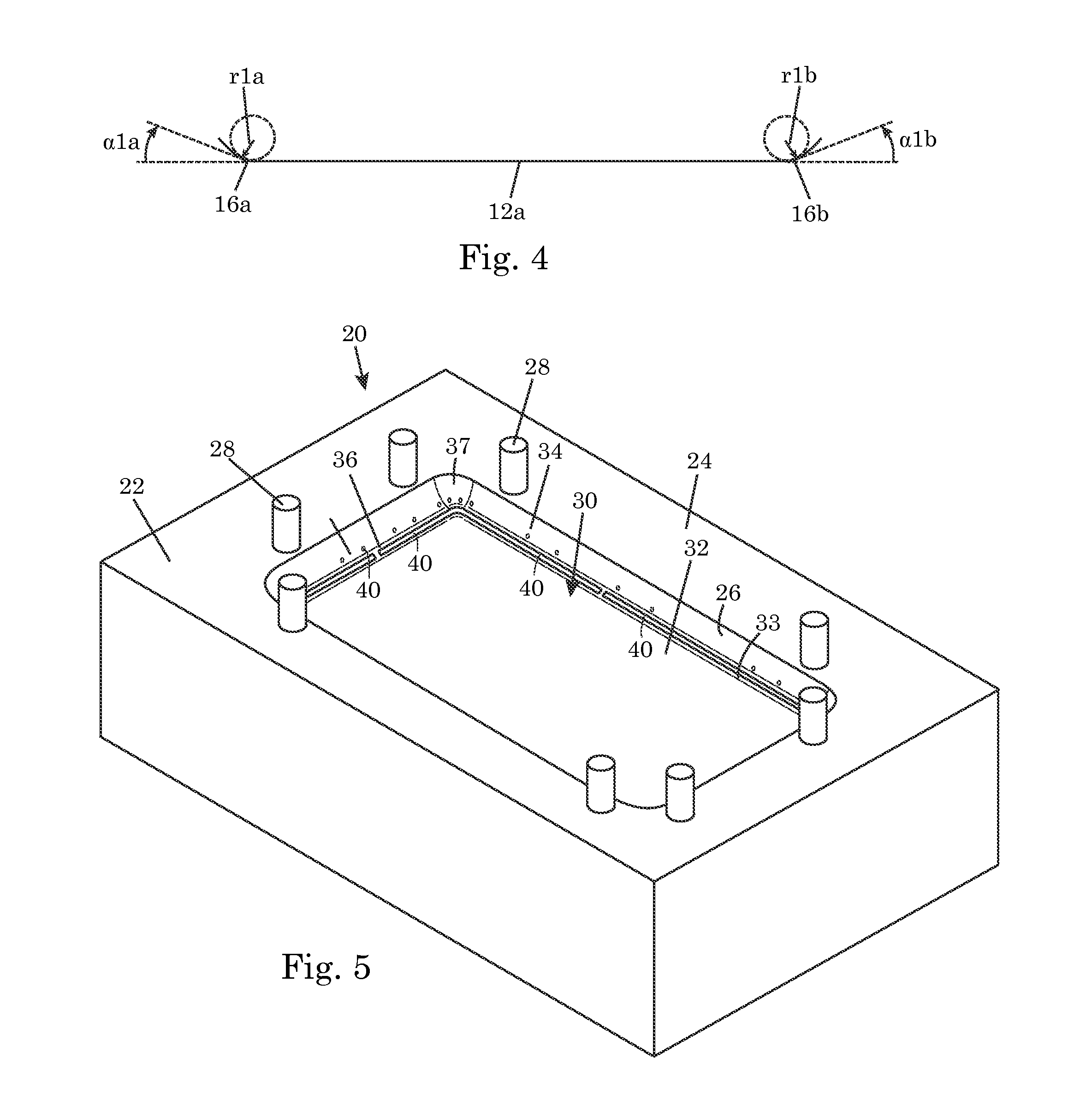

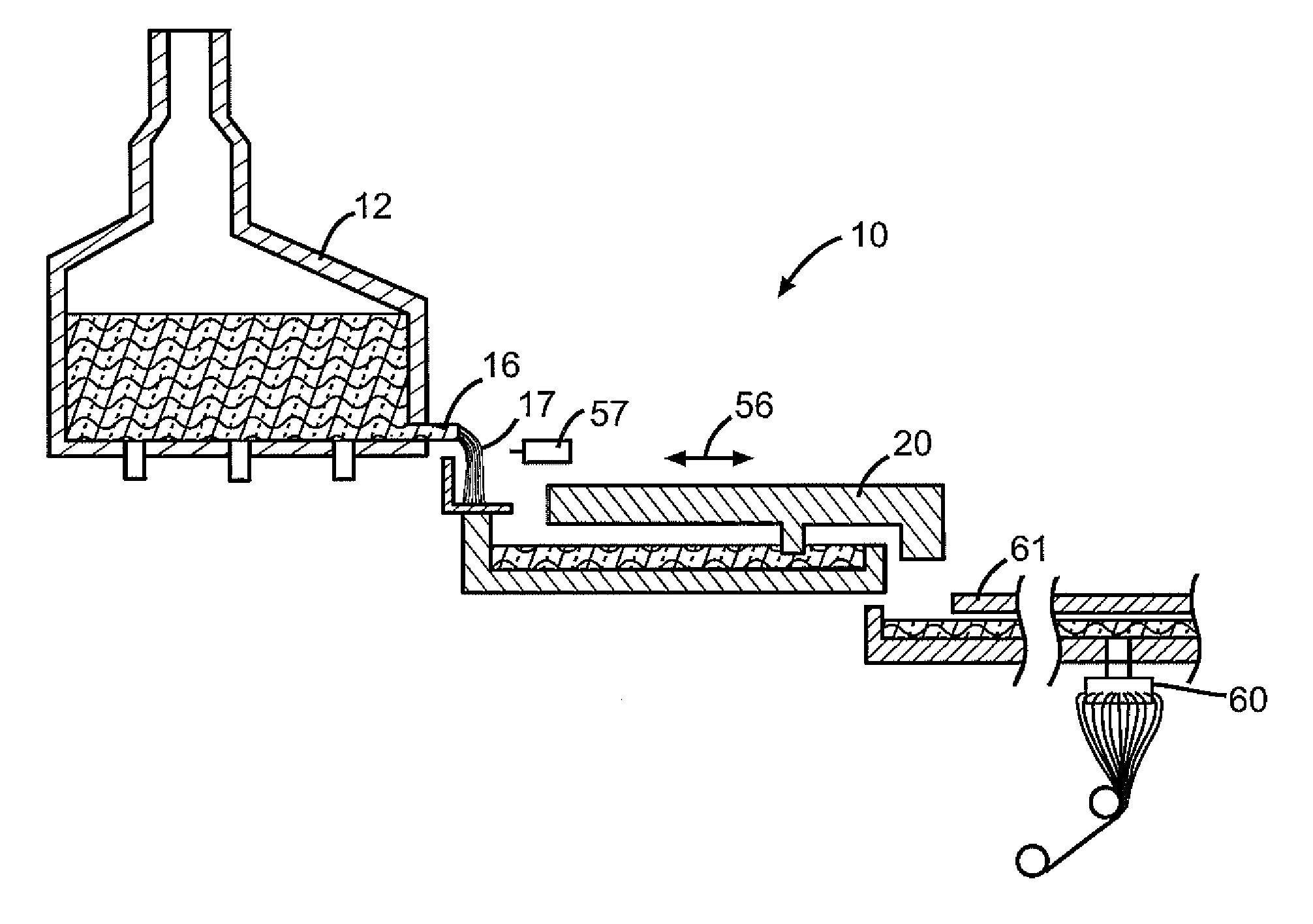

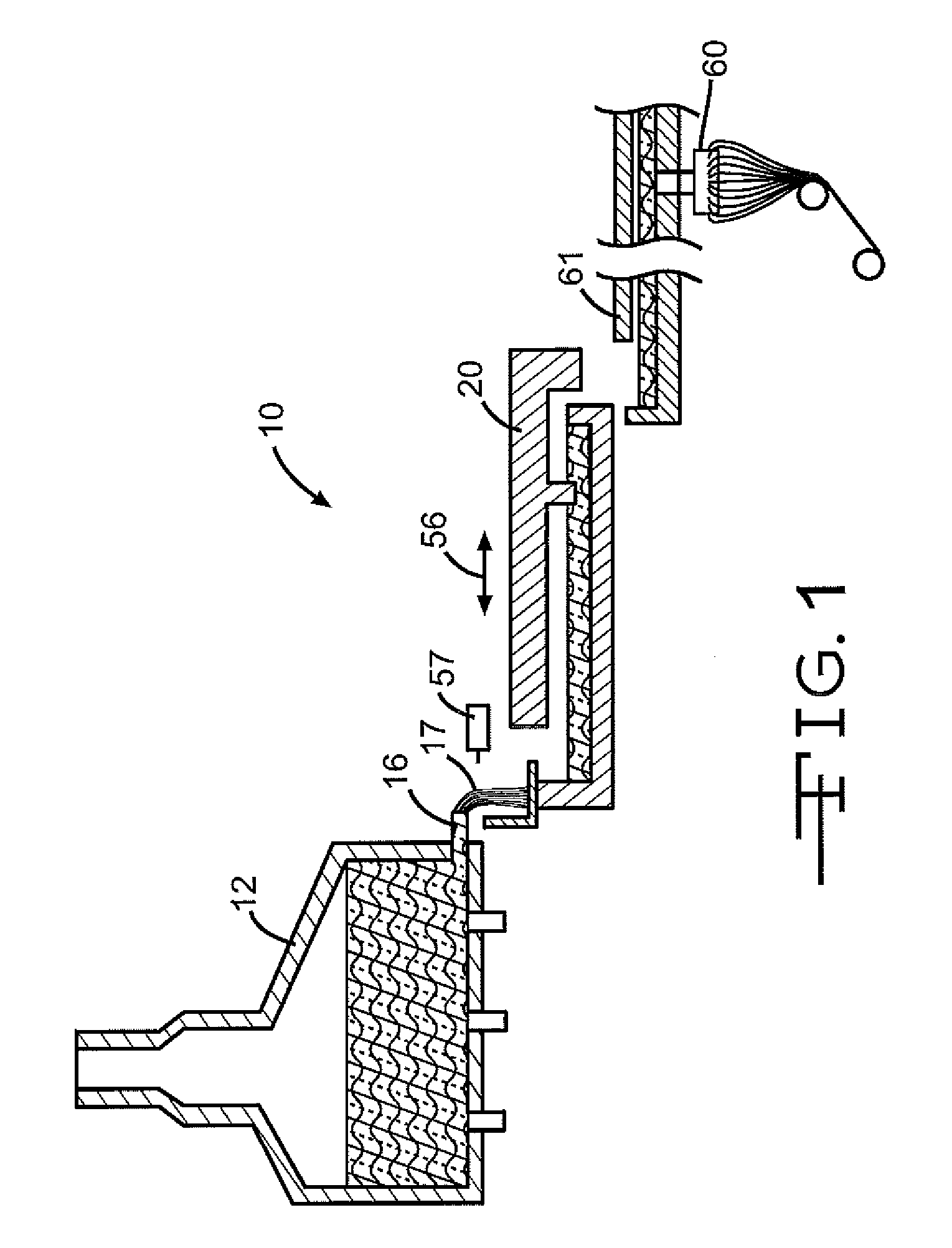

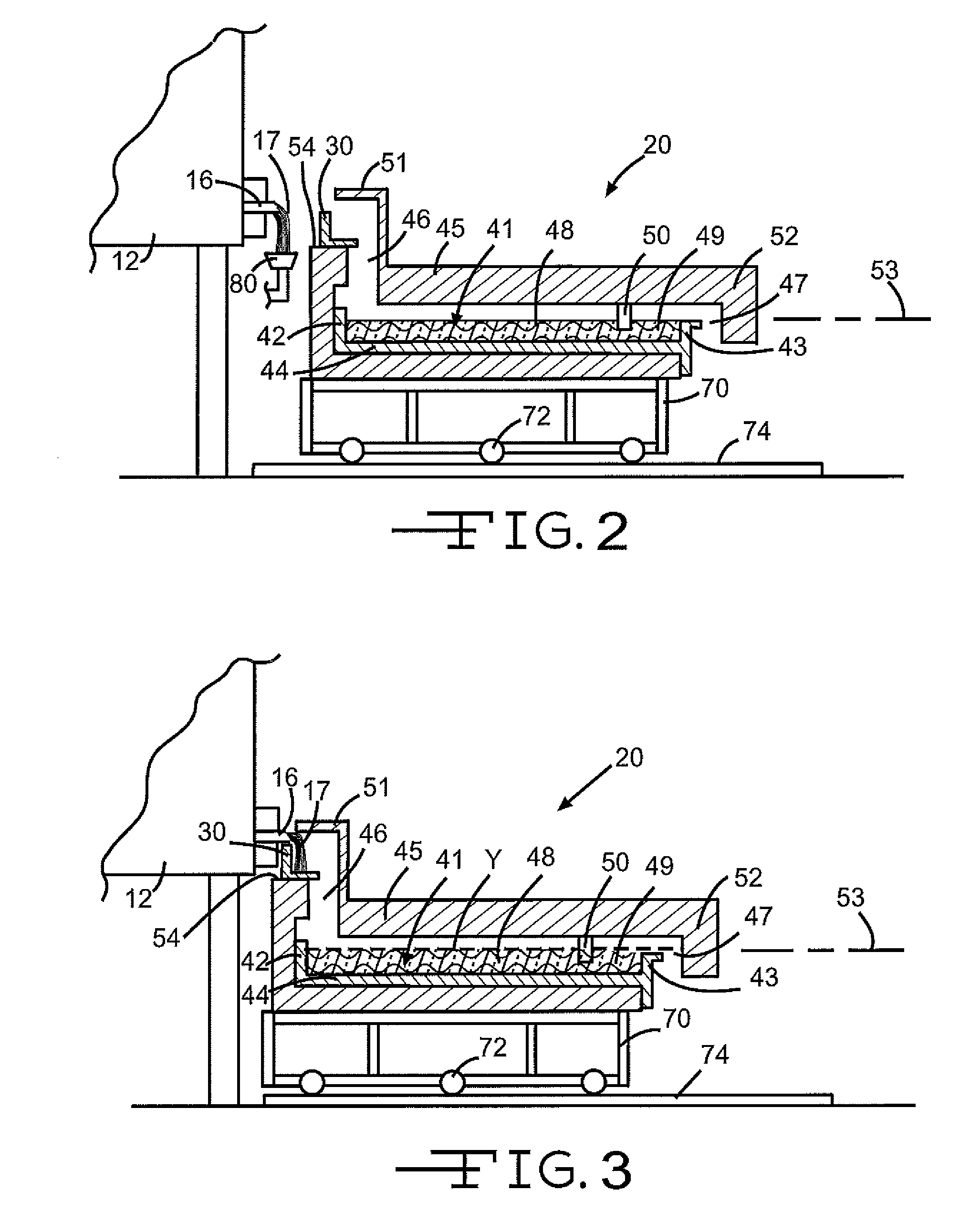

Method and system for forming shaped glass articles

ActiveUS20140234581A1Forming accuratelyLayered productsDigital data processing detailsPoiseGlass sheet

A method of forming a shaped glass article includes placing a glass sheet on a mold such that a first glass area of the glass sheet corresponds to a first mold surface area of the mold and a second glass area of the glass sheet corresponds to a second mold surface area of the mold. The first glass area and the second glass area are heated such that the viscosity of the second glass area is 8 poise or more lower than the viscosity of the first glass area. A force is applied to the glass sheet to conform the glass sheet to the mold surface. During the heating of the second glass area, the first mold surface area is locally cooled to induce a thermal gradient on the mold.

Owner:CORNING INC

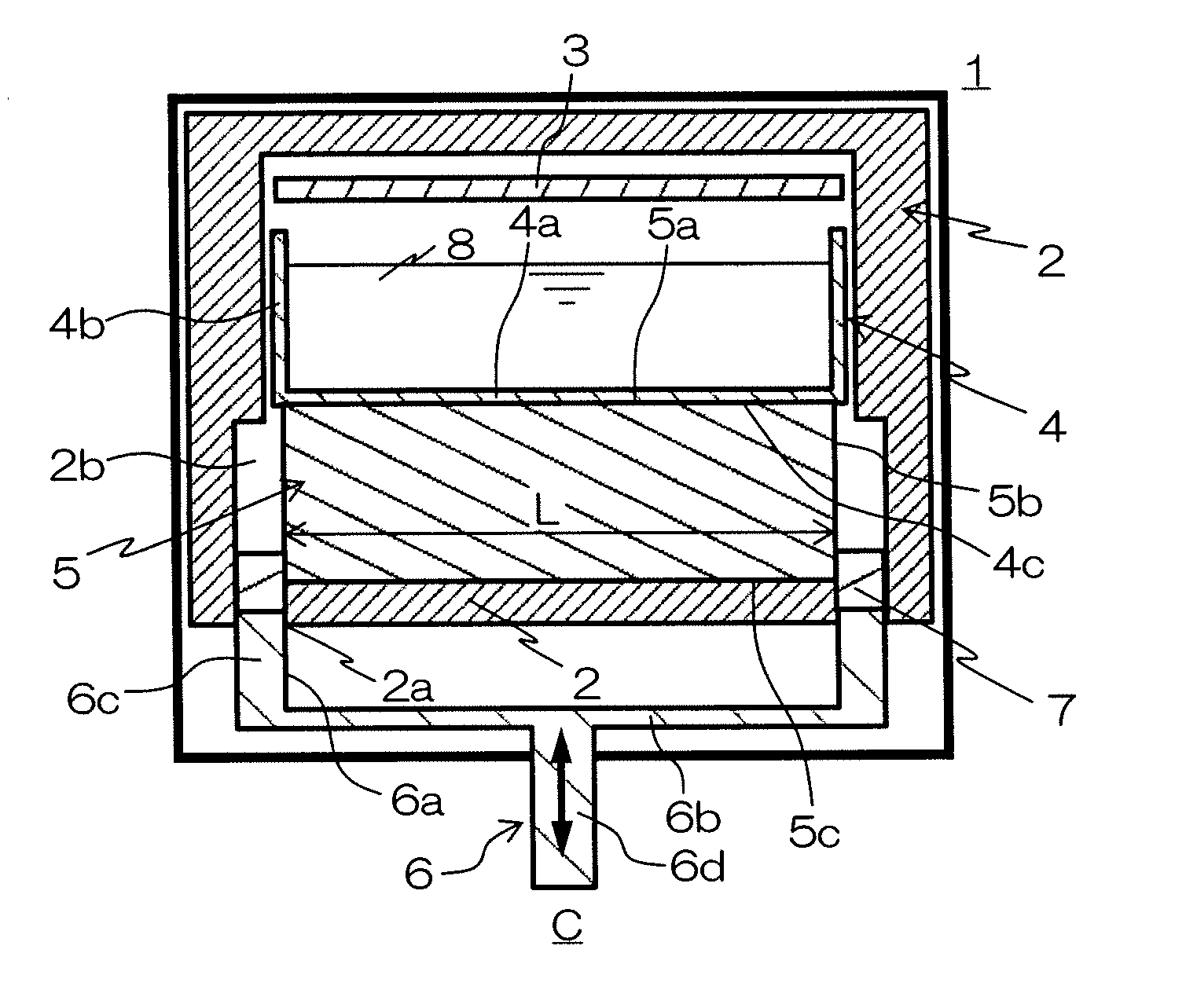

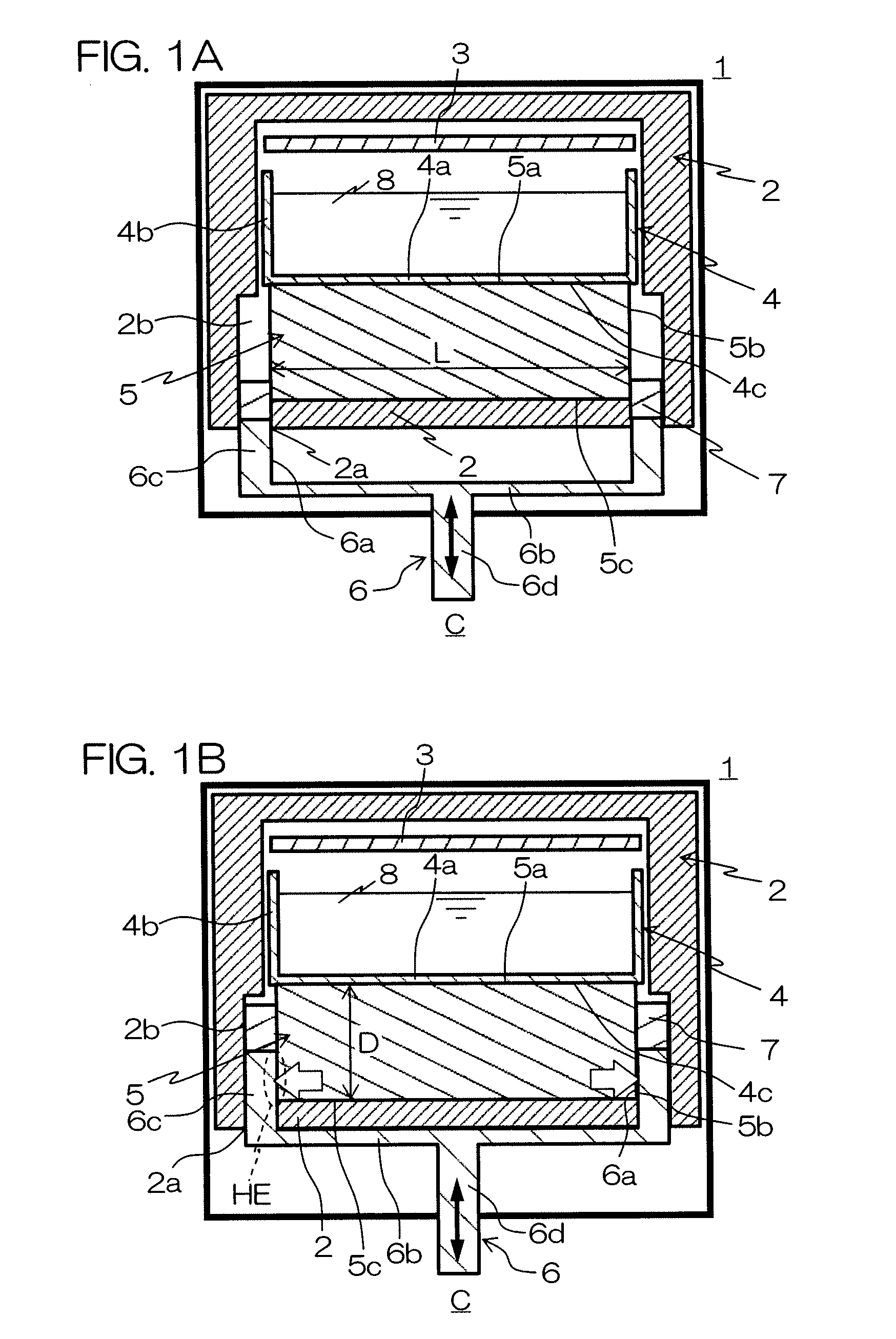

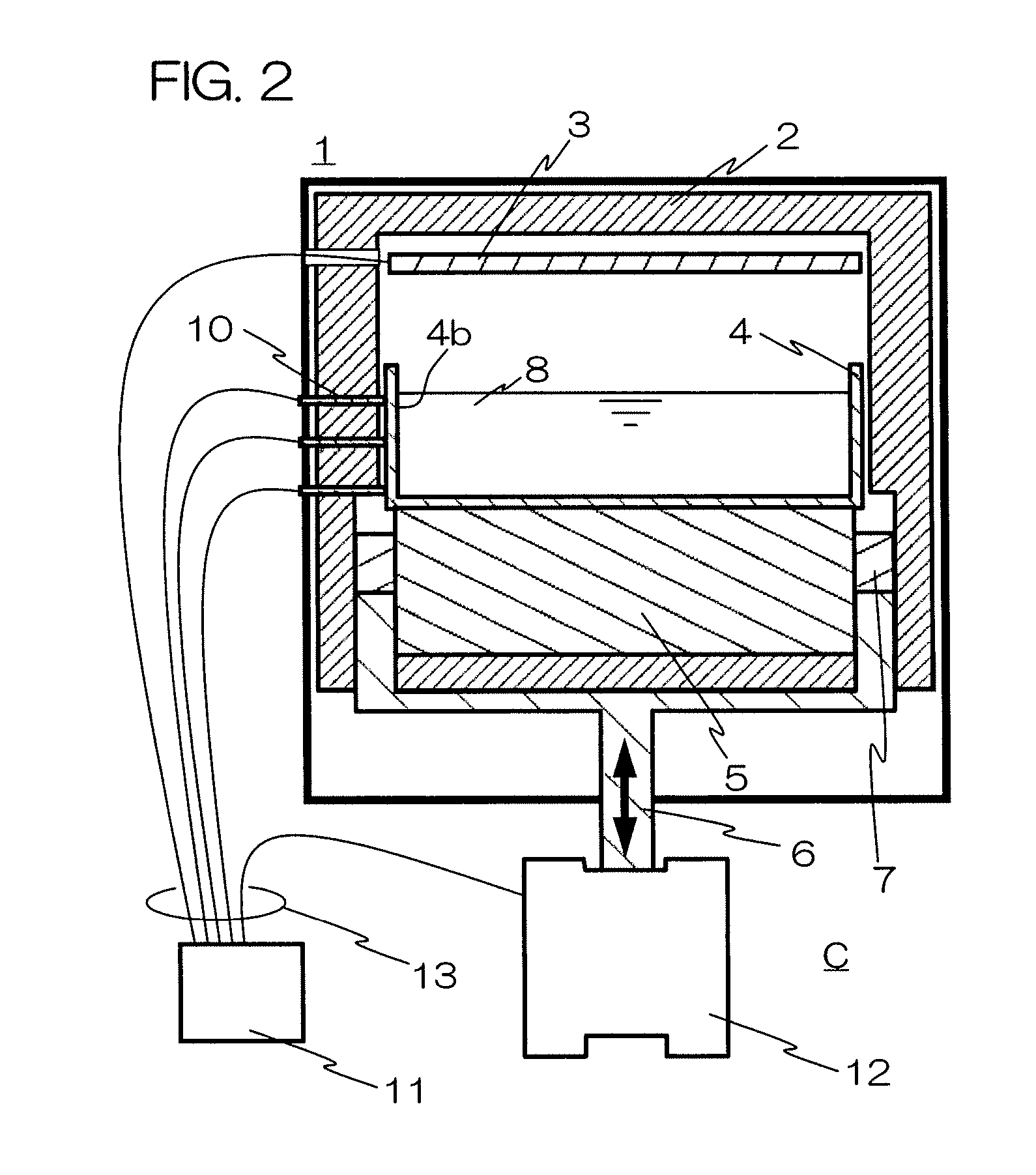

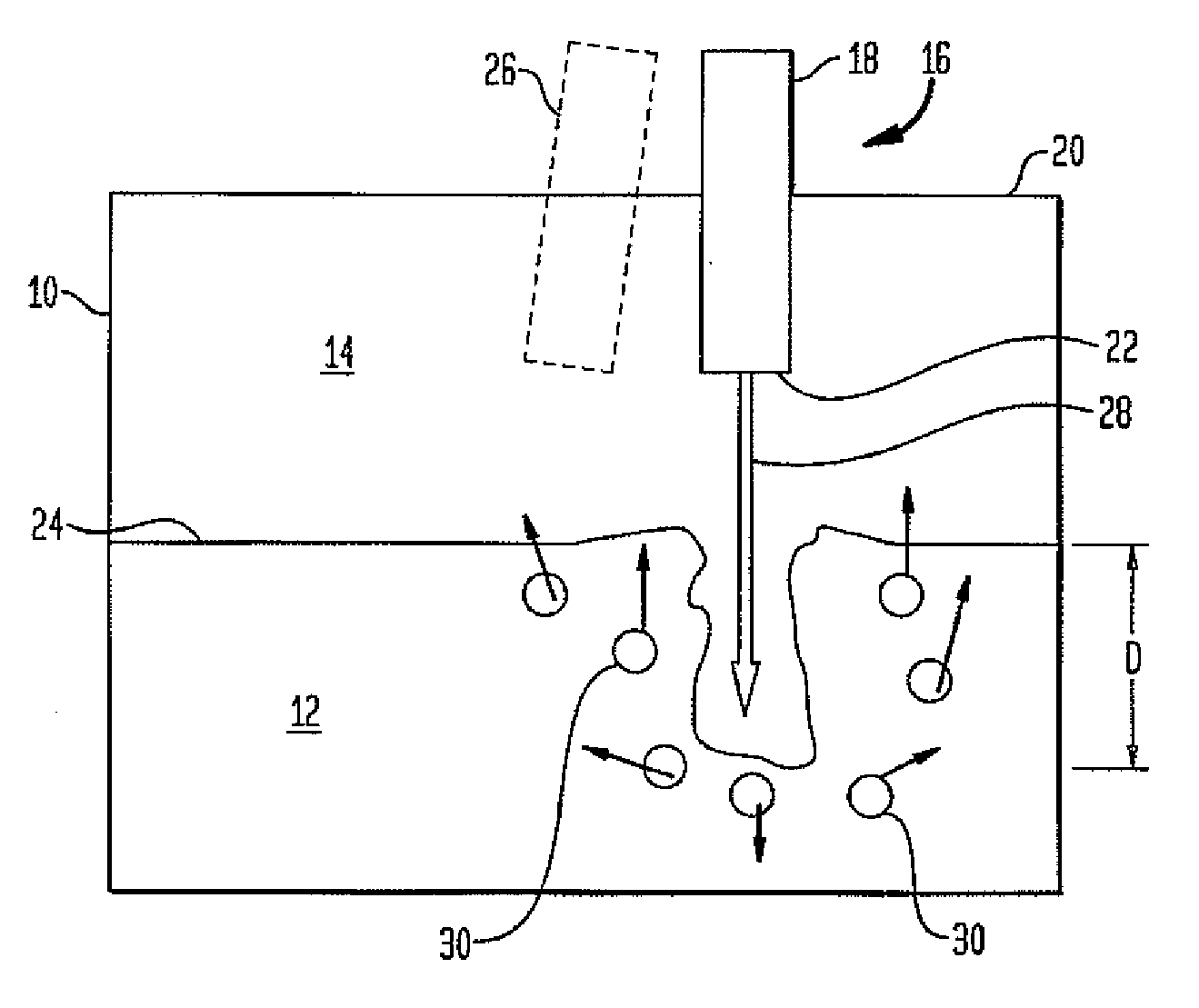

Silicon Casting Apparatus and Method of Producing Silicon Ingot

InactiveUS20070227189A1Good reproducibilityLow costFinal product manufactureGlass drawing apparatusIngotTemperature gradient

A silicon casting apparatus for producing polycrystal silicon ingot by heating a silicon melt (8) held in a mold (4) from above by a heater (3) and cooling it from below while changing the heat exchange area of a heat exchange region (HE), defined between a pedestal (5) having the mold (4) placed thereon and a bottom cooling member (6), in such a manner as to keep pace with the rise of the solid-liquid interface of the silicon melt (8), thereby causing unidirectional solidification upward along the mold (4); and a method of producing polycrystal silicon ingot using such apparatus. According to this production method, the temperature gradient given to the silicon melt (8) can be maintained at constant by adjusting the heat exchange area, so that polycrystal silicon ingot having good characteristics can be produced with good reproducibility.

Owner:KYOCERA CORP

Molten glass delivery and refining system

Methods and apparatus for refining and delivering a supply of molten glass include melting a supply of glass in a melter and discharging a stream of molten glass. A refining section is provided to refine the molten glass discharged by the melter and to deliver the molten glass downstream to a glass forming apparatus. The refining section is mounted for movement into and out of contact with the stream of molten glass to connect and disconnect the glass forming apparatus with the stream of molten glass.

Owner:OWENS CORNING INTELLECTUAL CAPITAL LLC

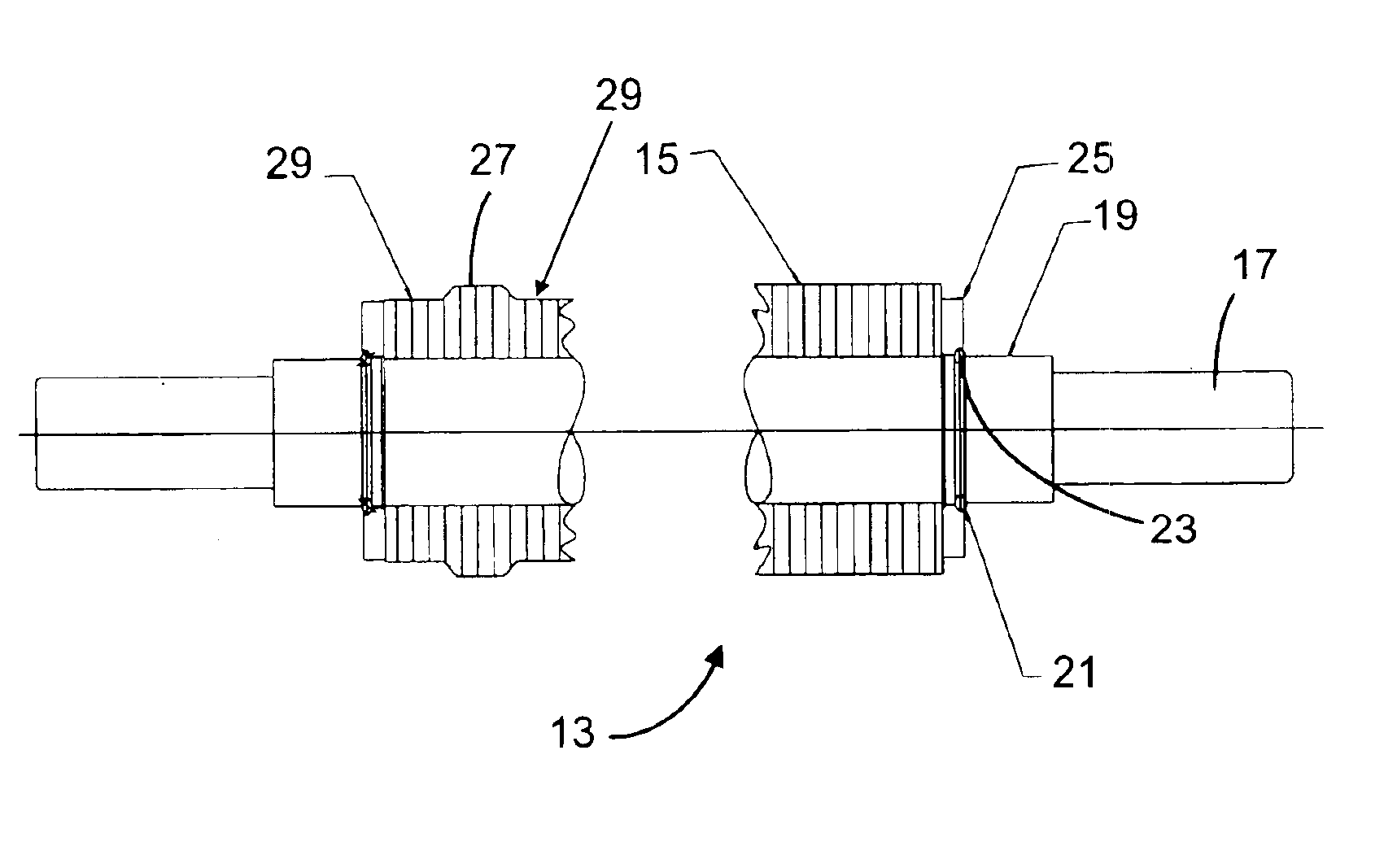

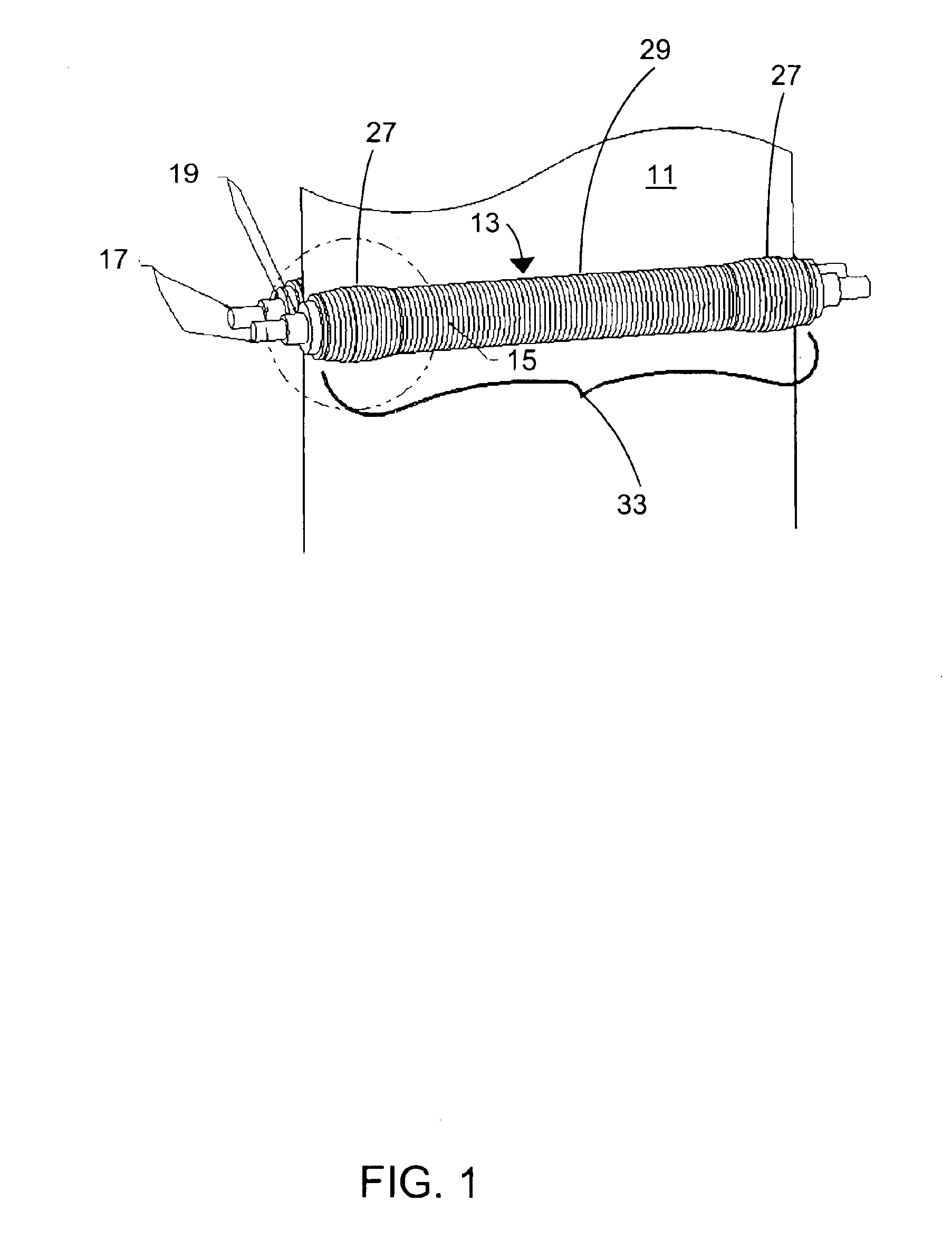

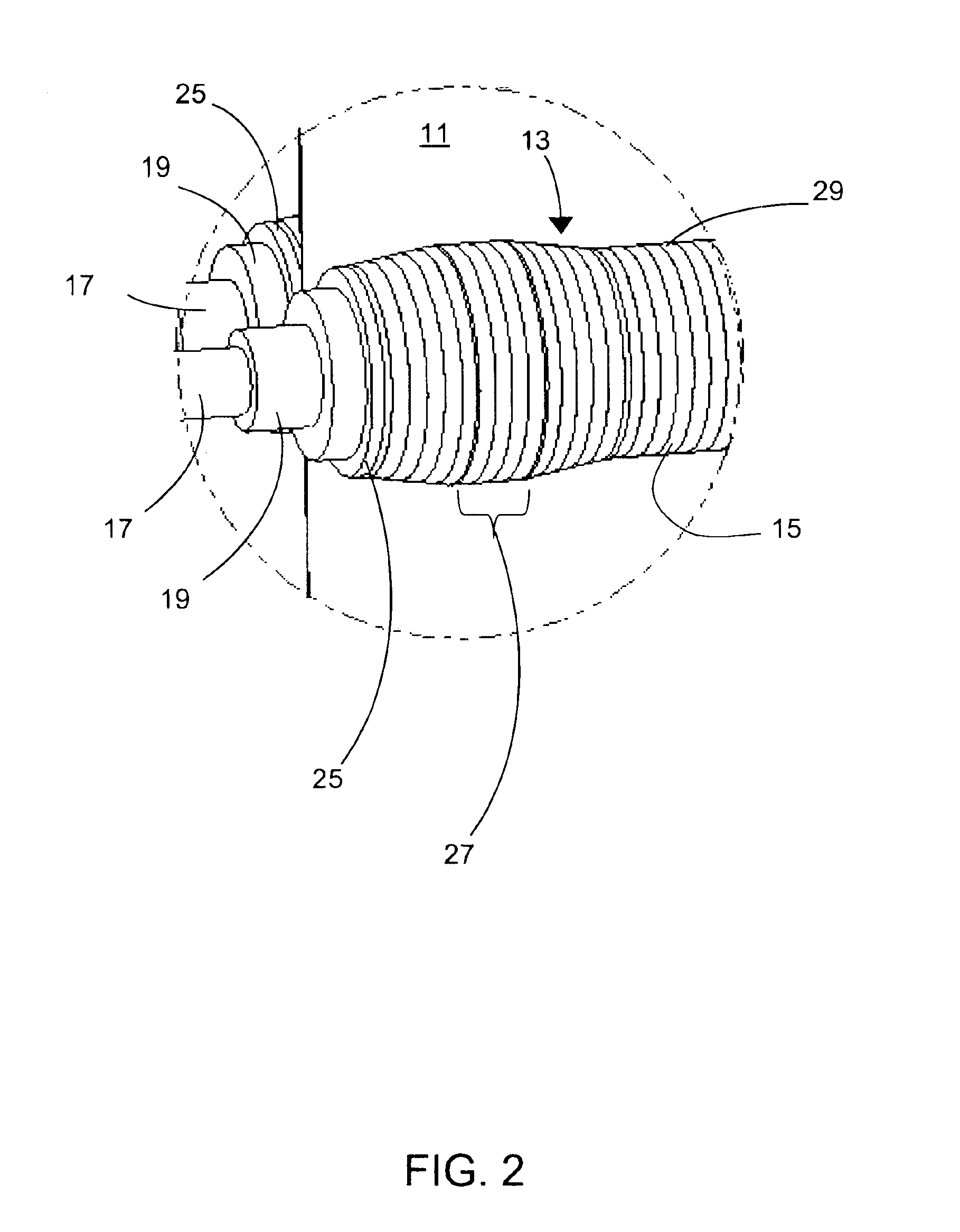

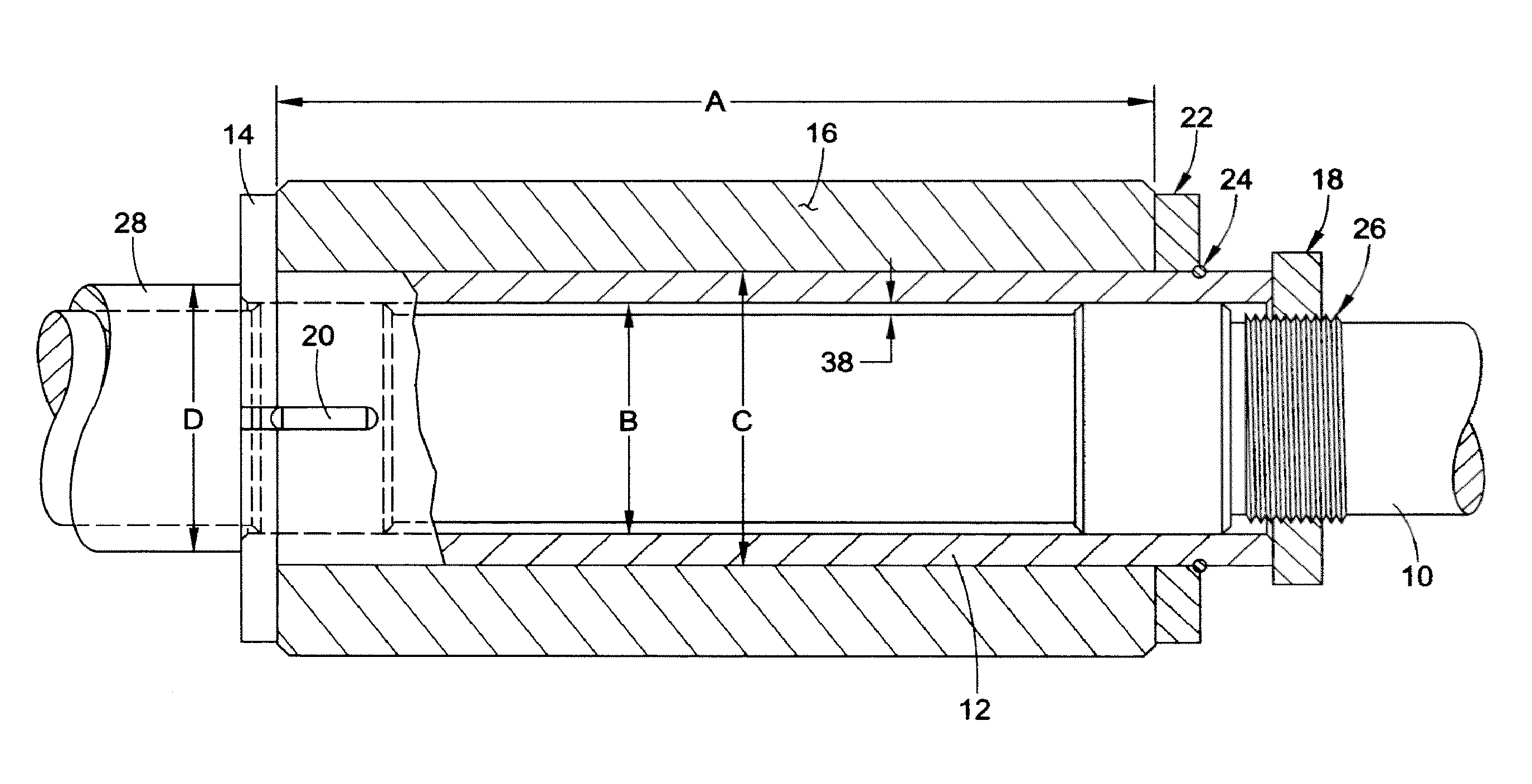

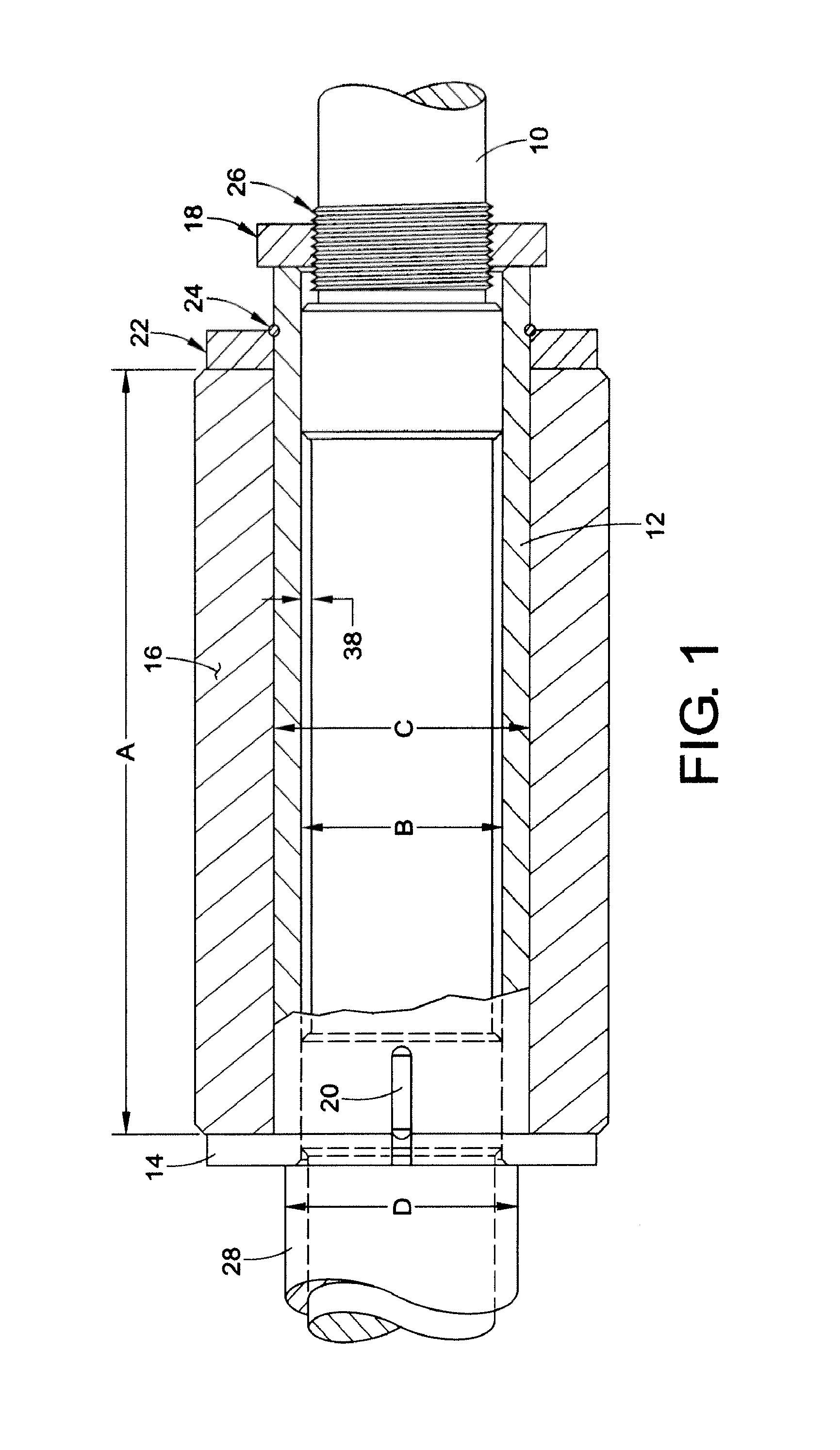

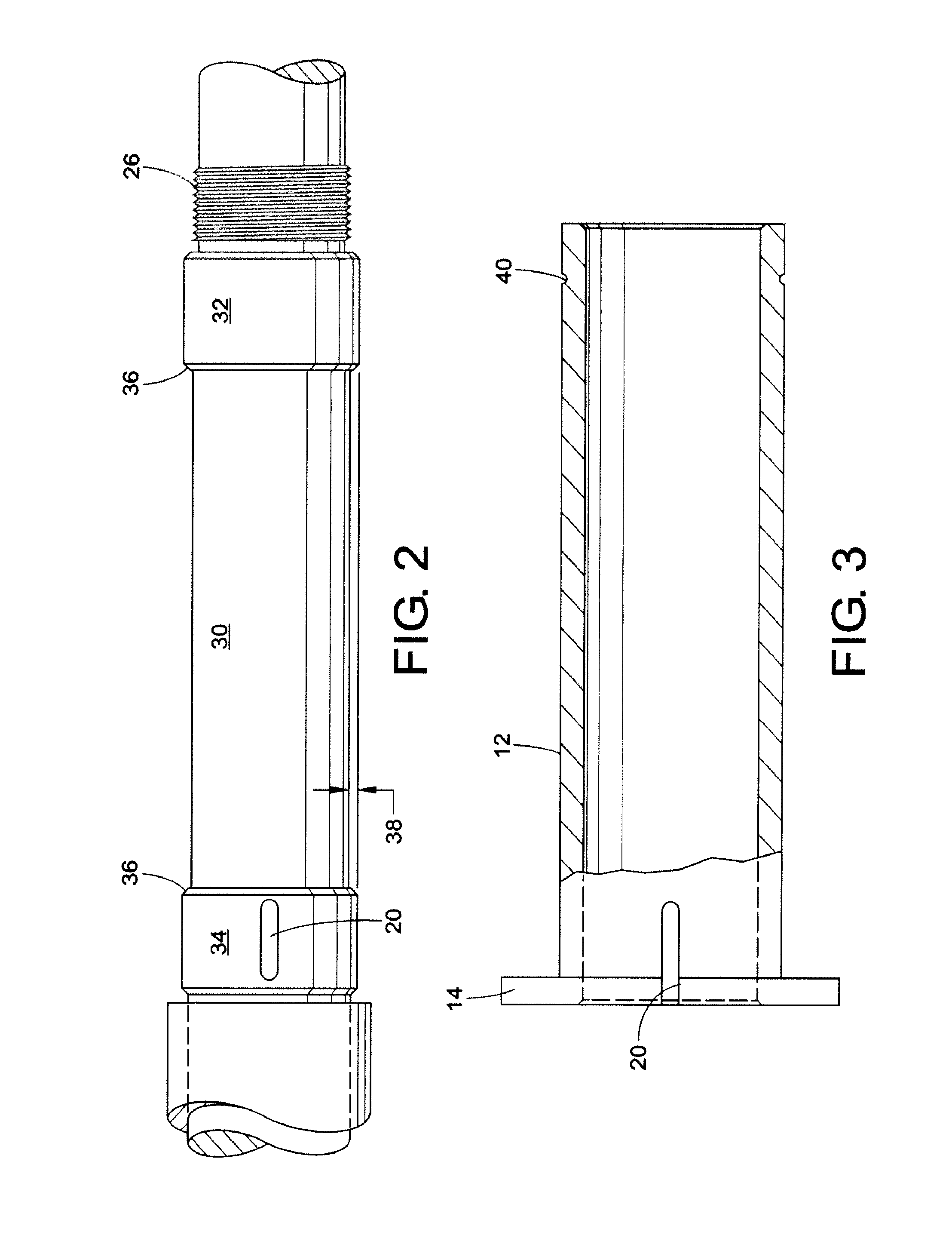

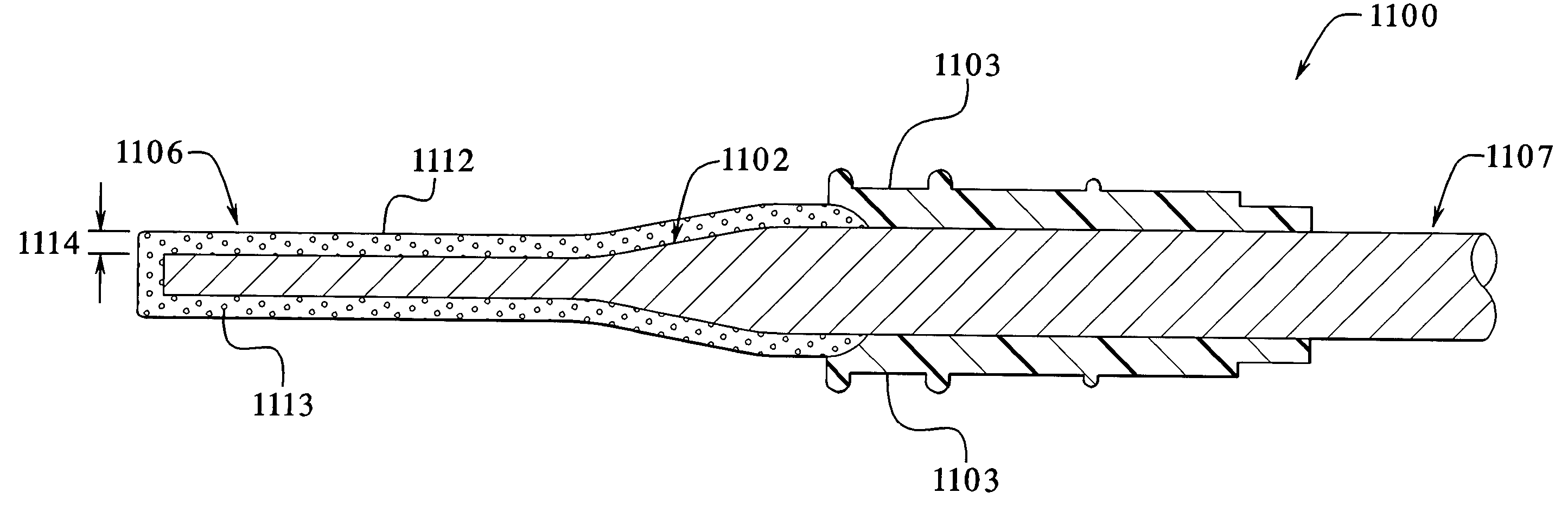

Quick change conveyor roll sleeve assembly and method

InactiveUS8915830B2Hot-dipping/immersion processesElectrolysis componentsEngineeringMechanical engineering

A quick change conveyor roll assembly for metal or glass processing comprising an inner roll shaft having a rigid and elongated cylindrical surface supported and rotationally driven by an associate rotor mean. At least one removable spool having a cylindrical body with a first diameter, a hollow interior therethrough and a collar rigidly adapted at a first end, the collar having a second diameter whereby the second diameter is greater than the first diameter. At least one removable and replaceable insulated roll sleeve being slidably mounted over at least a portion of said removable spool and abutting said collar, the insulated roll sleeve including at least one layer of an insulation material and a securing means operably adjustable to hold said roll sleeve about said removable spool at a second end in a predetermined location on said inner roll shaft.

Owner:PYROTECK INC

Low heat capacity gas oxy fired burner

A front end for a glass forming operation including an open channel and at least one burner. The channel surface has at least one burner port and a burner oriented in the burner port at an acute angle relative to the channel surface. The surface may be a top, side or end wall and the burner port is at an acute angle relative to the surface of the wall.

Owner:OCV INTELLECTUAL CAPITAL LLC

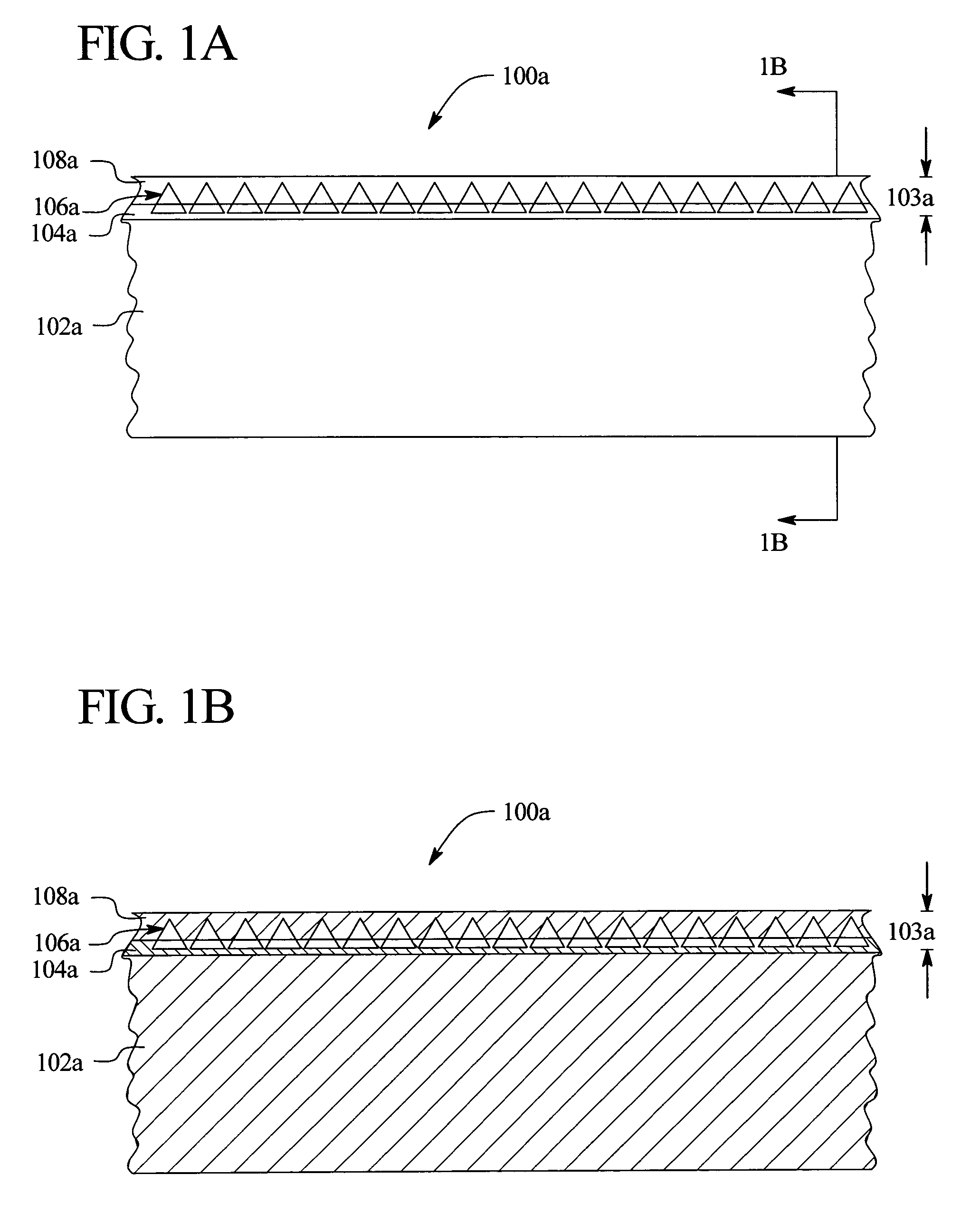

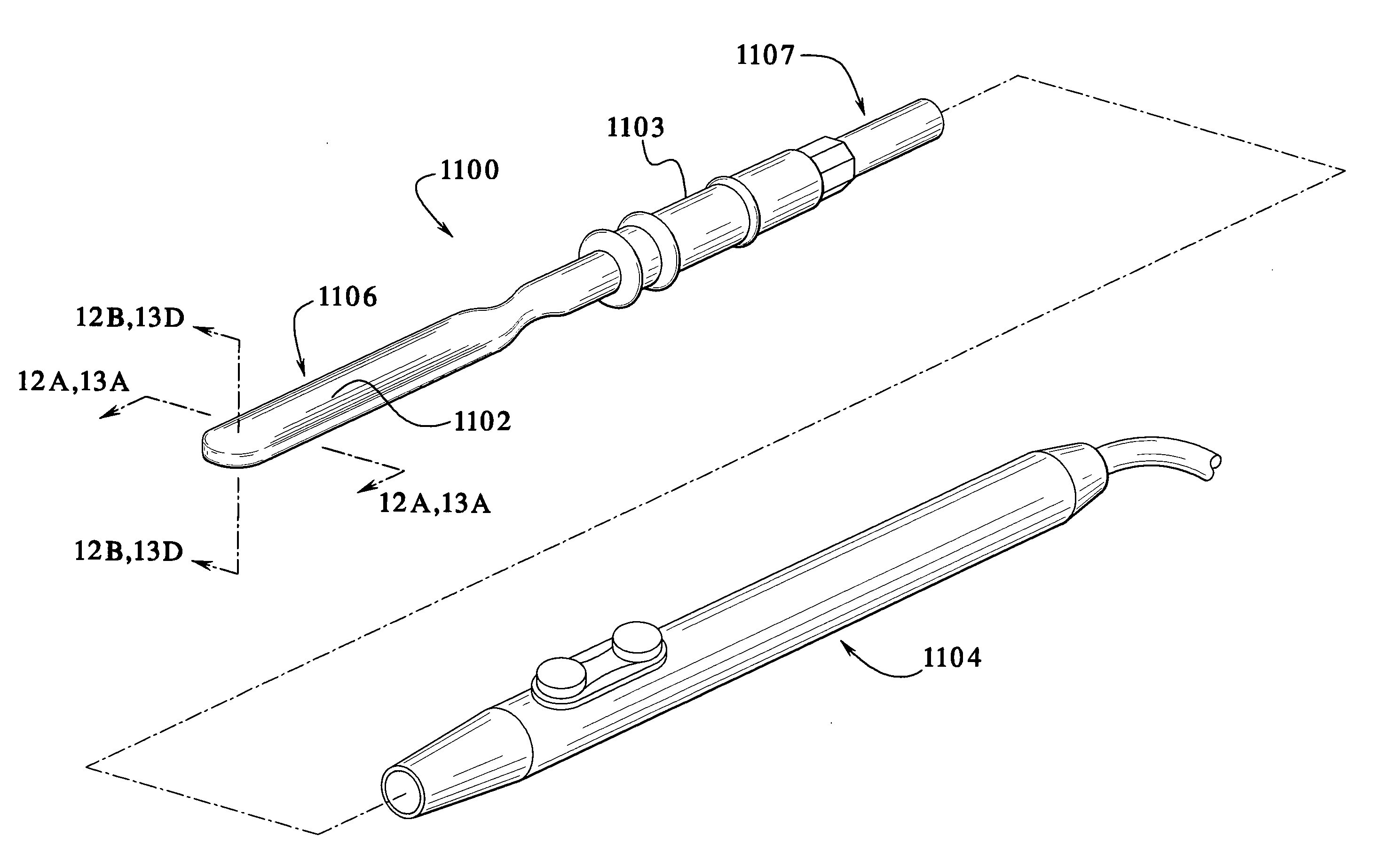

Anti-microbial electrosurgical electrode and method of manufacturing the same

InactiveUS7160297B2Improve featuresExcellent characteristicsConveyorsLayered productsELECTROSURGICAL DEVICEMaterials science

An electrosurgical device including a reinforcing underlayment having a non-stick, anti-microbial coating. In one embodiment, the coating includes a non-stick material having anti-microbial particles interspersed in the non-stick material. This coating is applied to the surfaces of the electrode to minimize the build-up of charred tissue on the surfaces of the electrode. Also, the coating tends to kill harmful organisms residing on the surfaces of the electrode. In another embodiment, a primer coating is initially applied to the surfaces of the electrode. A plurality of anti-microbial particles are then applied to the primer coating layer and engage and are embedded in the primer coating layer. A top coat including a non-stick material is applied to the anti-microbial particle layer. In either embodiment, the coating layers applied to the surfaces of the electrode are cured to harden and adhere the layers to the electrode.

Owner:INNOVATECH

Non-contact porous air bearing and glass flattening device

Owner:NEW WAY MACHINE COMPONENTS

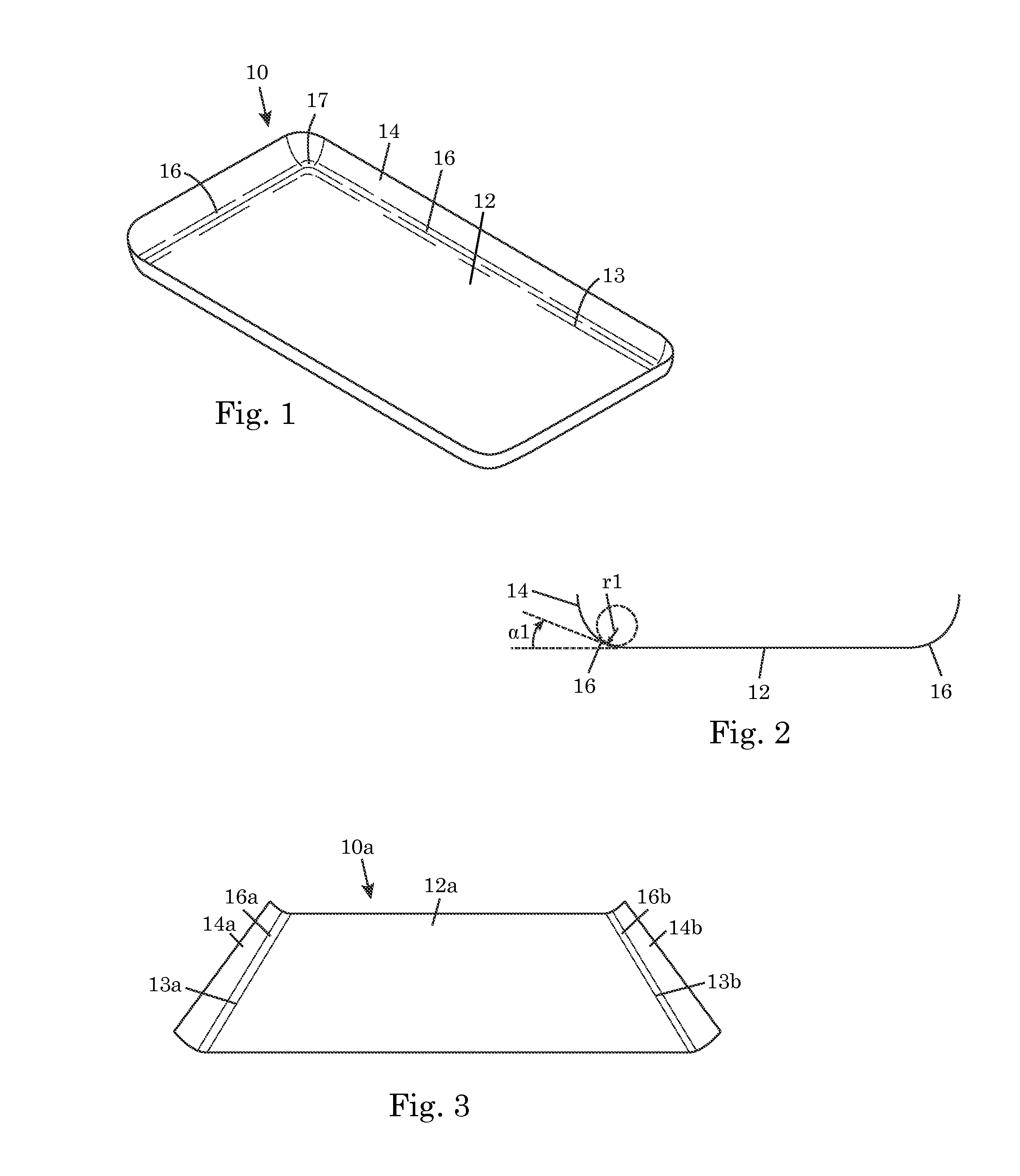

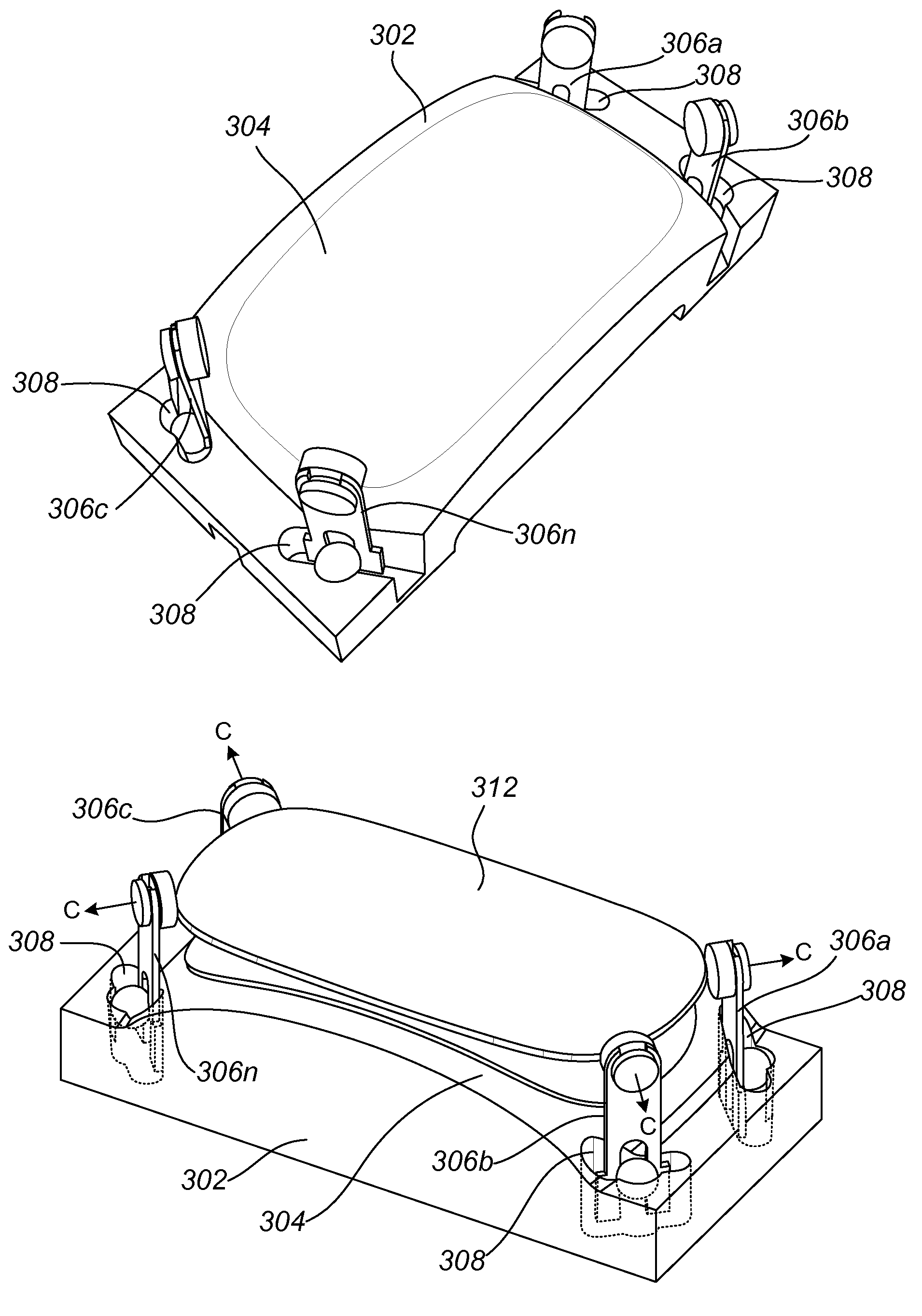

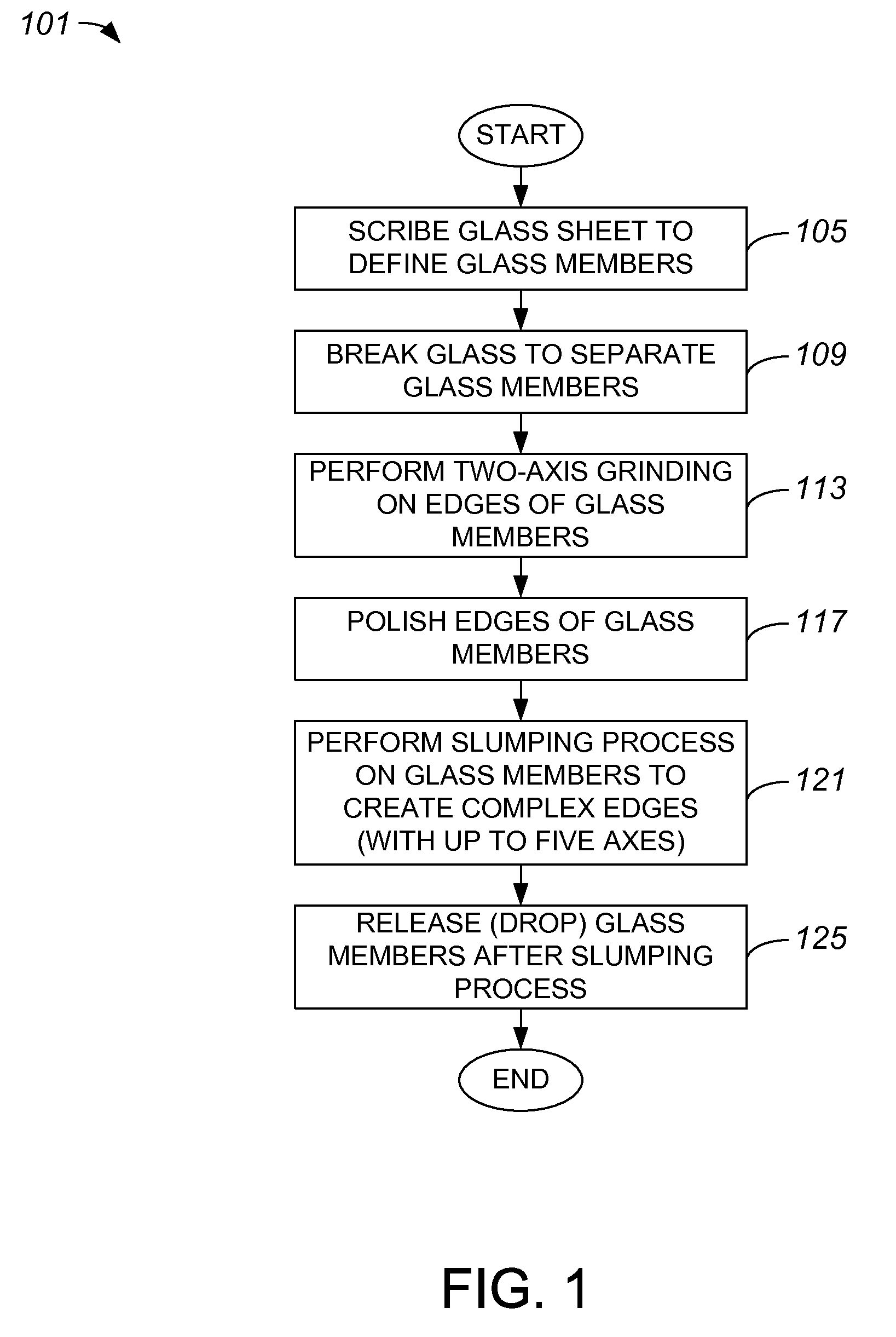

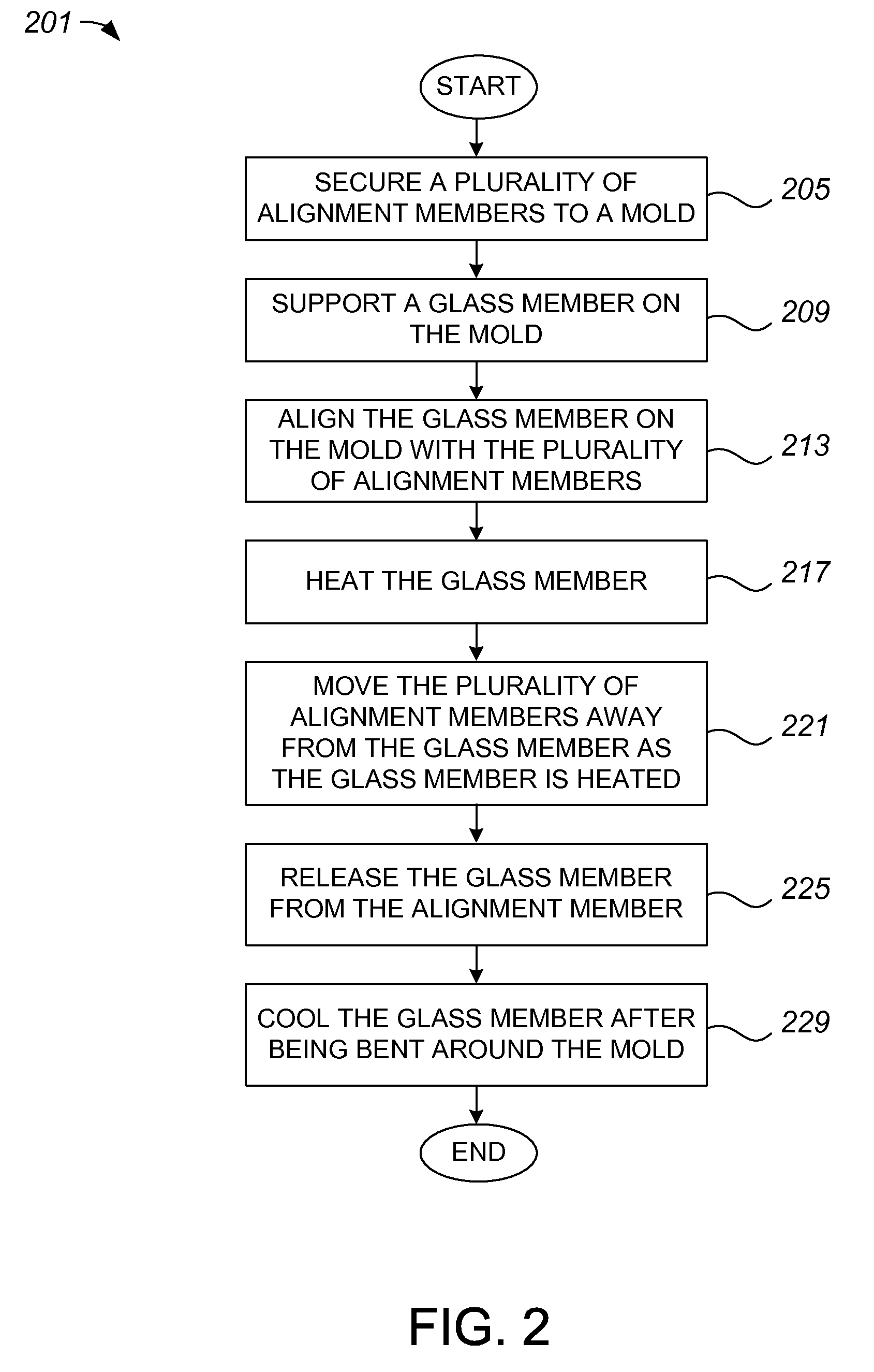

Pre-Processing Techniques to Produce Complex Edges Using a Glass Slumping Process

ActiveUS20110072856A1Effectively be molded into a complex geometryEdge grinding machinesGlass transportation apparatusPre treatmentGlass forming

Apparatus, systems and methods for forming complex edges on a glass member through the use of a glass slumping process are disclosed. According to one aspect of the invention, a method of forming a complex edge in a glass forming process includes grinding an edge of a glass member and polishing the edge of the glass member. Grinding the edge of the glass member causes the edge of the glass member to have a first level of complexity. The method also includes performing a slumping process on the glass member. Performing the slumping process causes the edge of the glass member to have a second level of complexity that is more complex than the first level of complexity.

Owner:APPLE INC

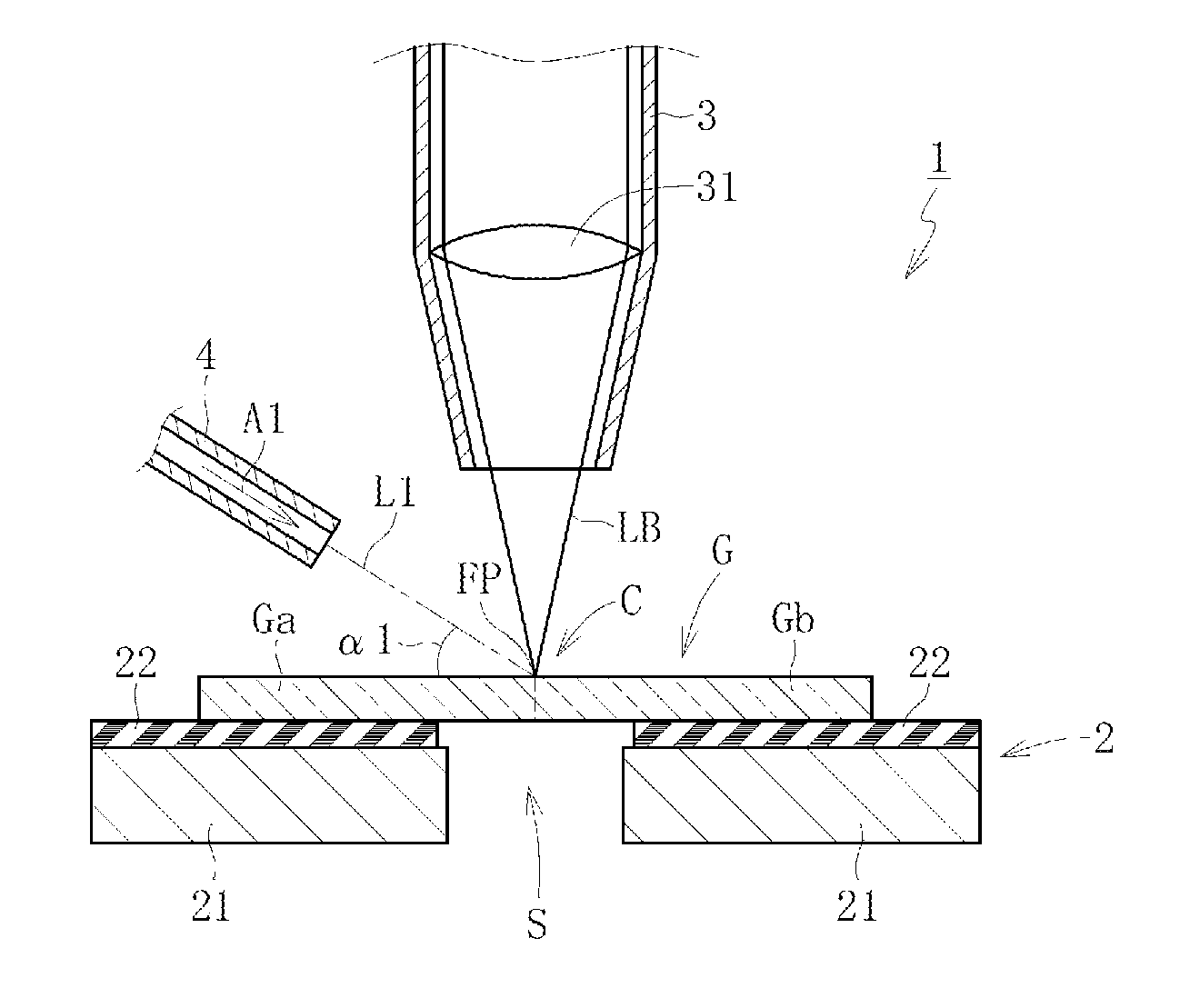

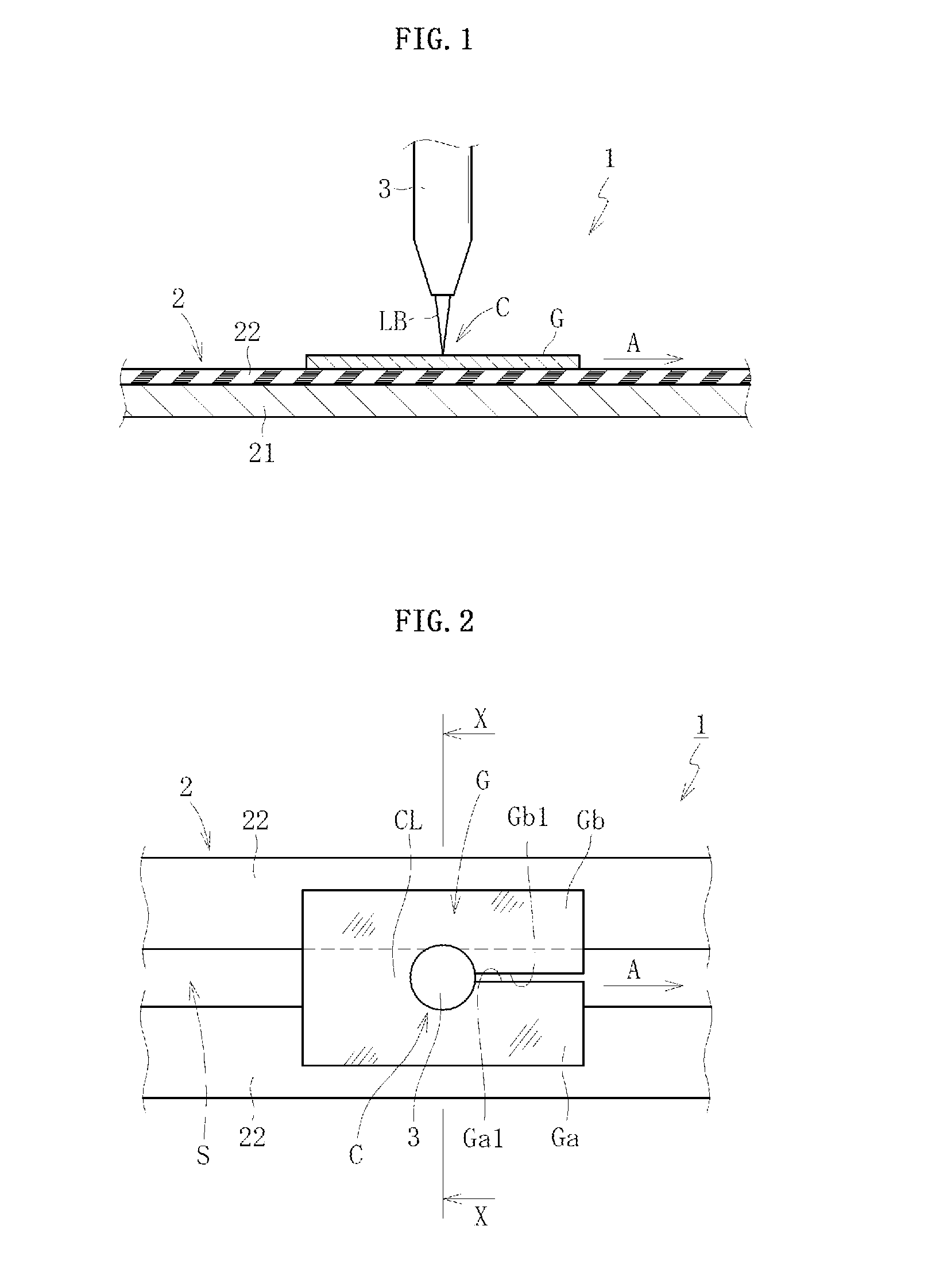

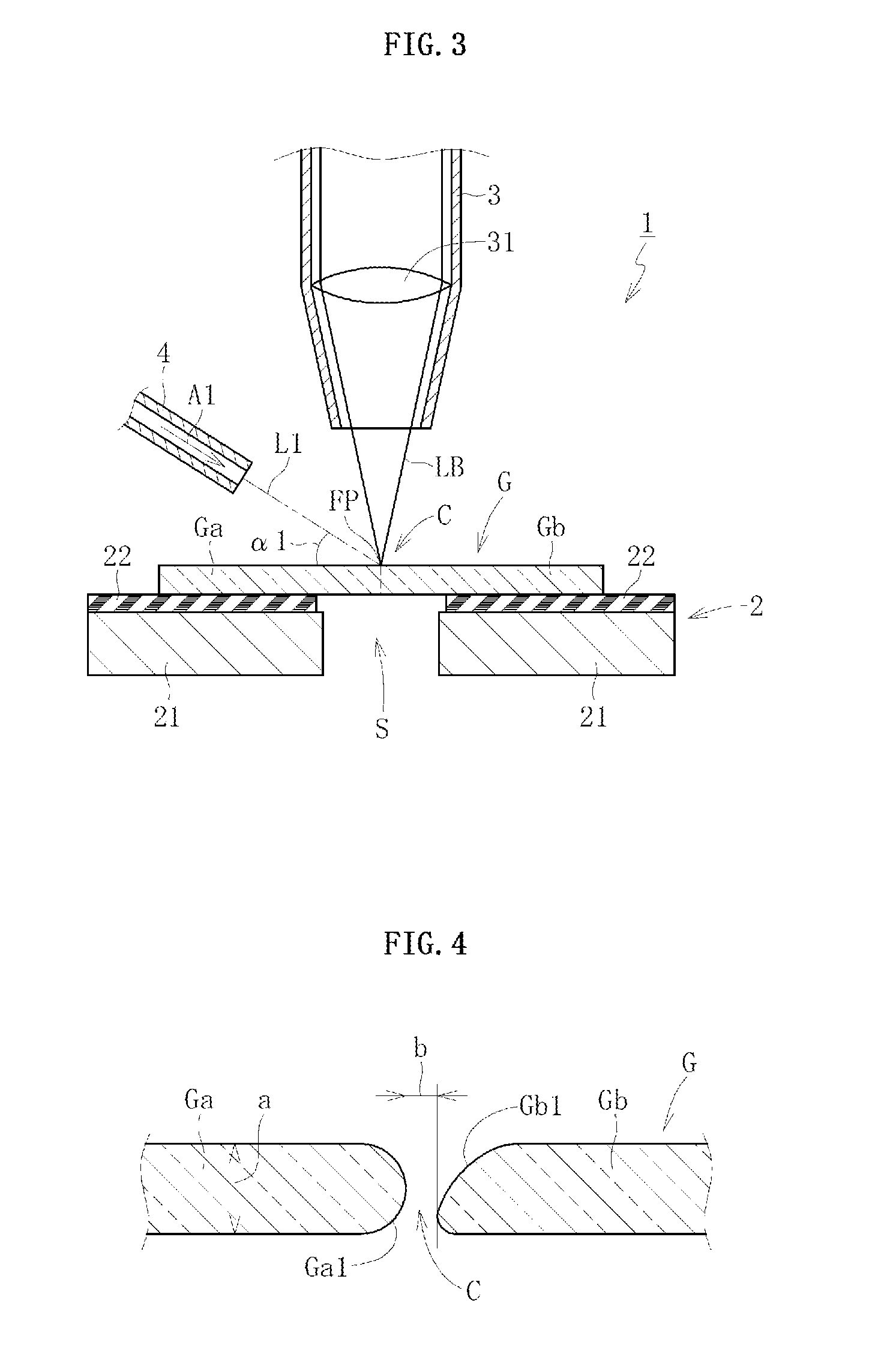

Cutting method for glass sheet and glass sheet cutting apparatus

ActiveUS20130122264A1Safe separationStrict managementGlass furnace apparatusCellulosic plastic layered productsLaser beamsGlass sheet

Provided is a cutting method for a glass sheet, comprising radiating a laser beam to a cutting portion (C) of a glass sheet (G) having a thickness of 500 μm or less to fuse the glass sheet (G), wherein a narrowest gap between fused end surfaces (Ga1 and Gb1) of the glass sheet (G), which face each other in the cutting portion (C), is managed to satisfy a relationship of 0.1≦b / a≦2, where “a” is a thickness of the glass sheet (G) and “b” is the narrowest gap.

Owner:NIPPON ELECTRIC GLASS CO LTD

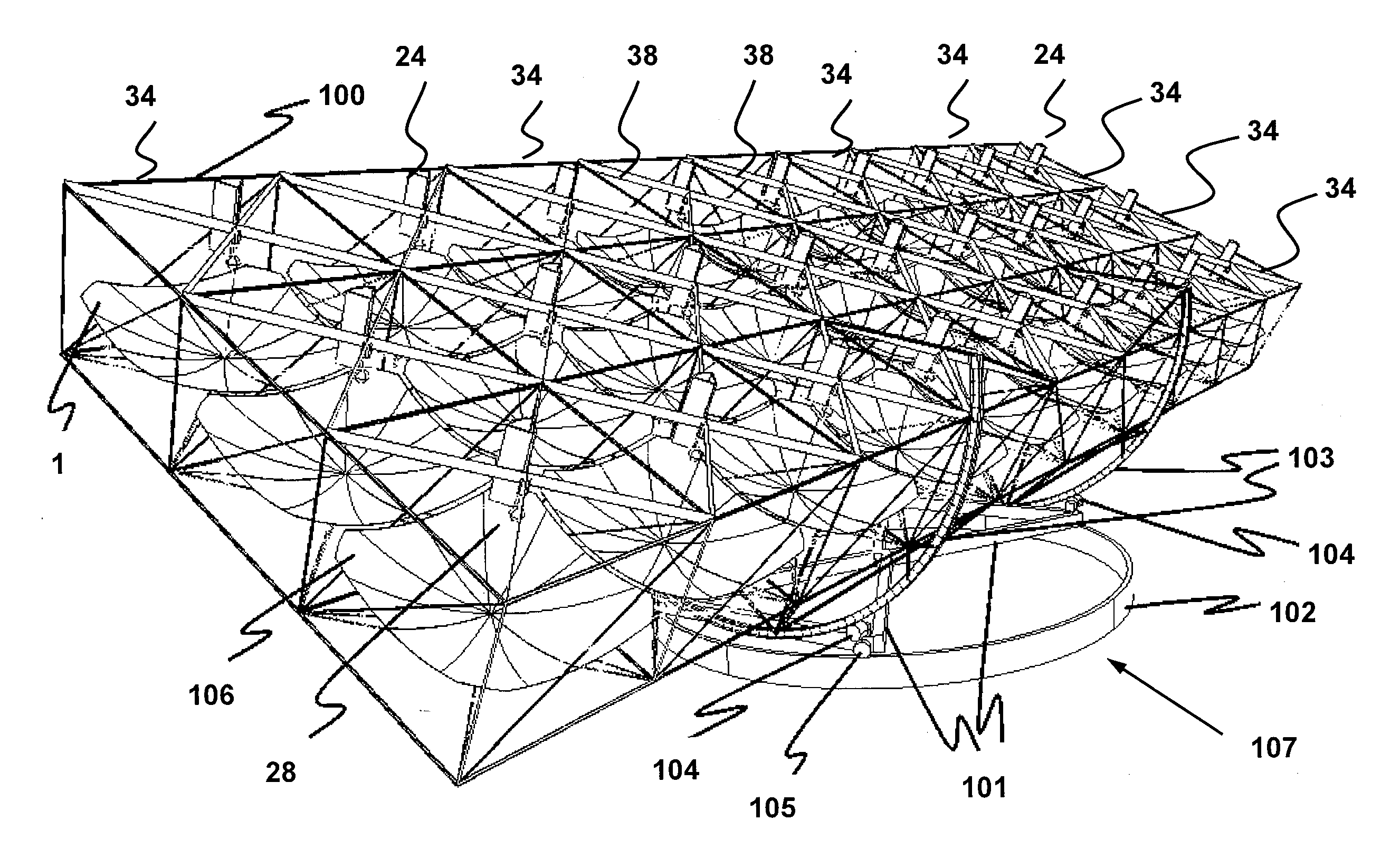

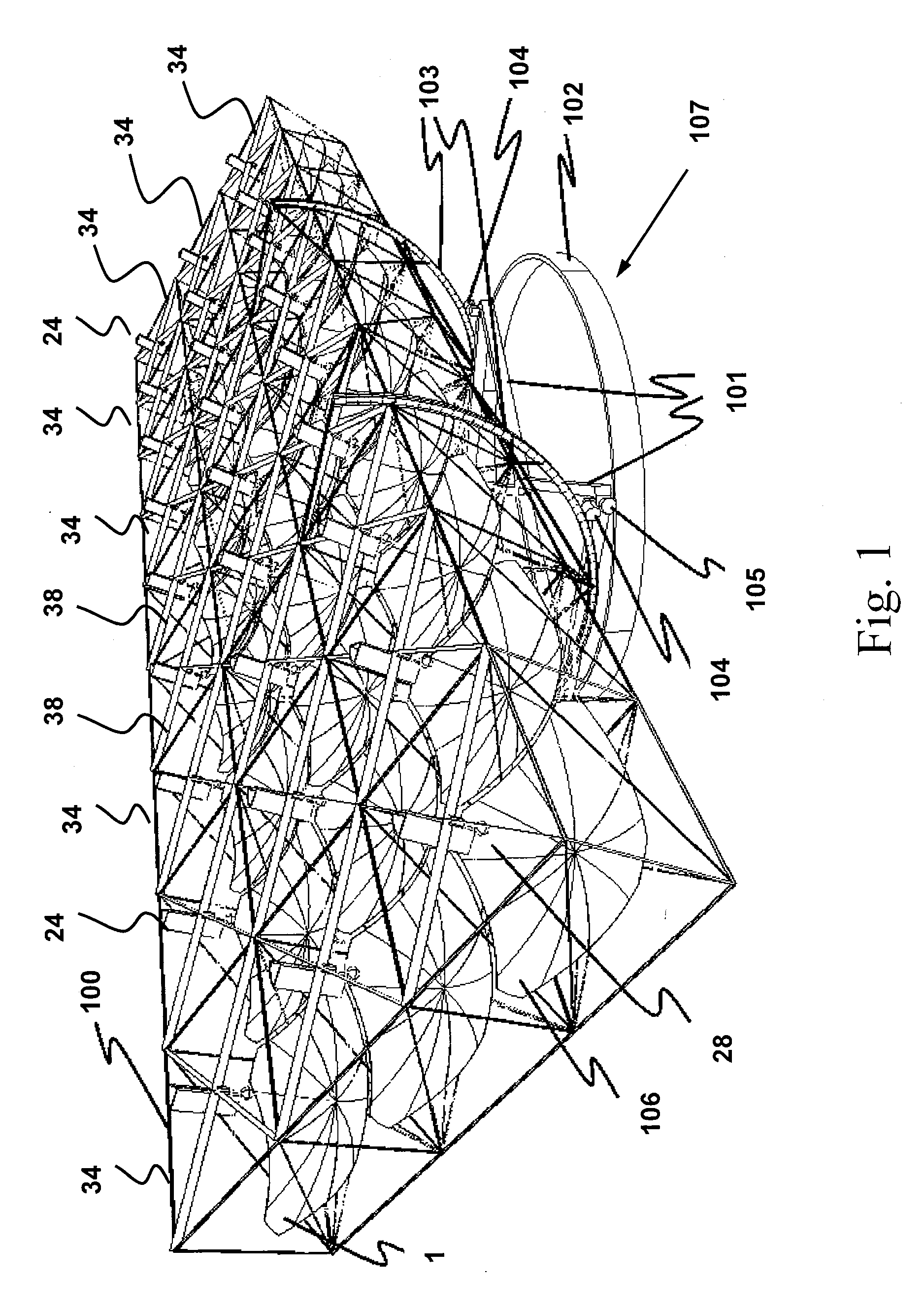

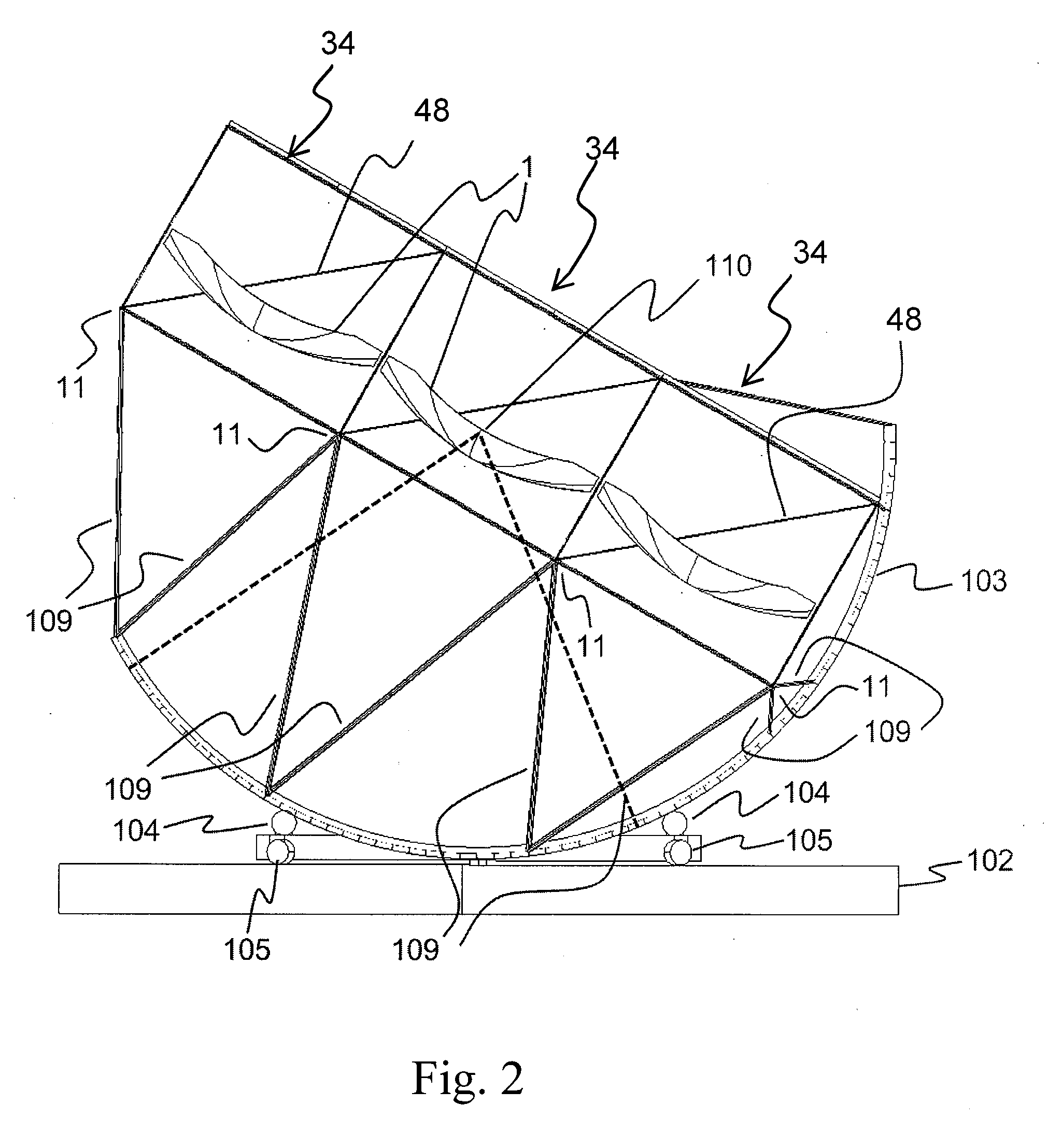

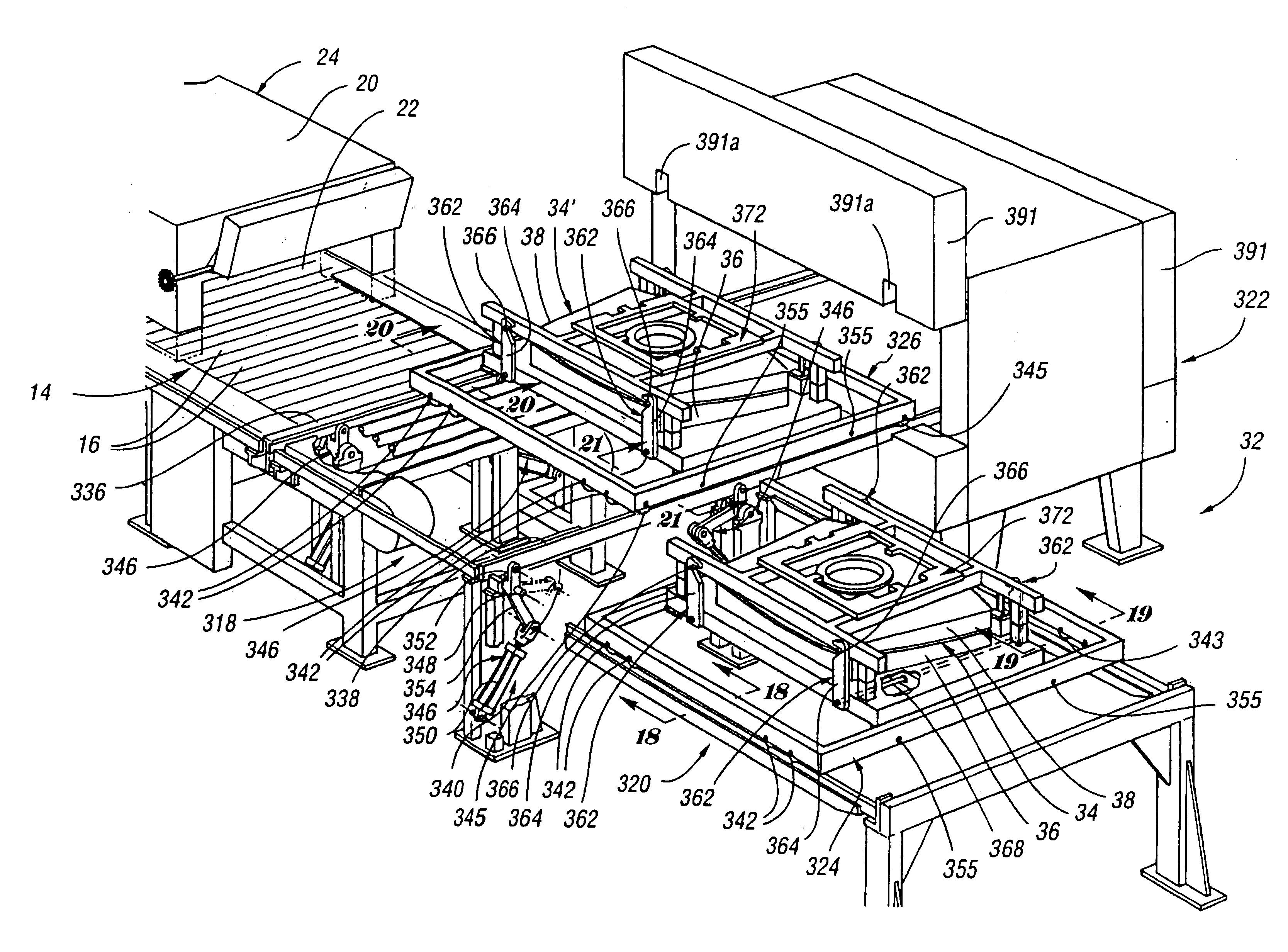

Method of manufacturing large dish reflectors for a solar concentrator apparatus

ActiveUS20090277224A1Reduce supporting costsMaximizes stiffnessSolar heating energySolar heat devicesProduction rateProduction line

A method of manufacturing monolithic glass reflectors for concentrating sunlight in a solar energy system is disclosed. The method of manufacturing allows large monolithic glass reflectors to be made from float glass in order to realize significant cost savings on the total system cost for a solar energy system. The method of manufacture includes steps of heating a sheet of float glass positioned over a concave mold until the sheet of glass sags and stretches to conform to the shape of the mold. The edges of the dish-shaped glass are rolled for structural stiffening around the periphery. The dish-shaped glass is then silvered to create a dish-shaped mirror that reflects solar radiation to a focus. The surface of the mold that contacts the float glass preferably has a grooved surface profile comprising a plurality of cusps and concave valleys. This grooved profile minimizes the contact area and marring of the specular glass surface, reduces parasitic heat transfer into the mold and increases mold lifetime. The disclosed method of manufacture is capable of high production rates sufficiently fast to accommodate the output of a conventional float glass production line so that monolithic glass reflectors can be produced as quickly as a float glass production can make sheets of float glass to be used in the process.

Owner:THE ARIZONA BOARD OF REGENTS ON BEHALF OF THE UNIV OF ARIZONA

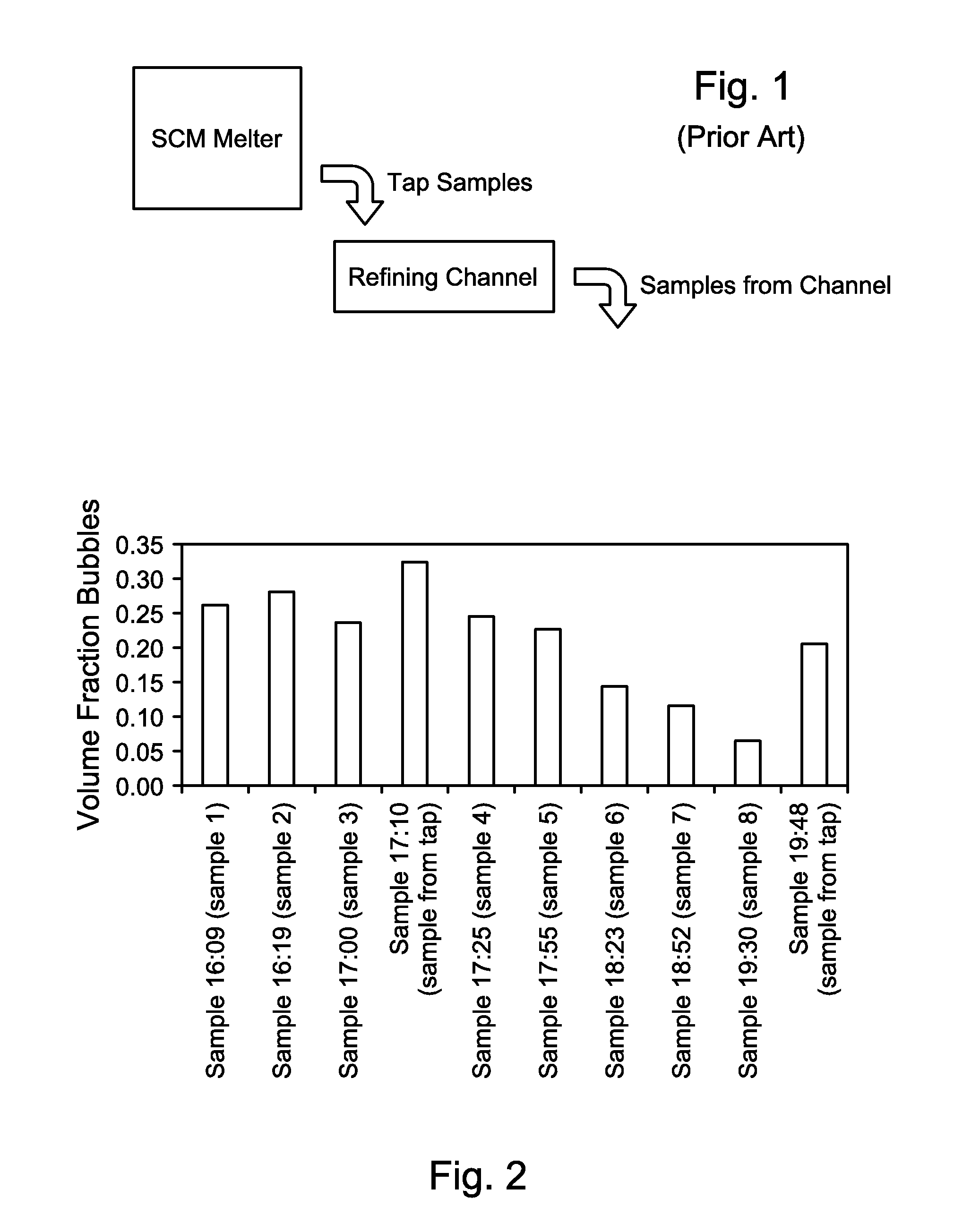

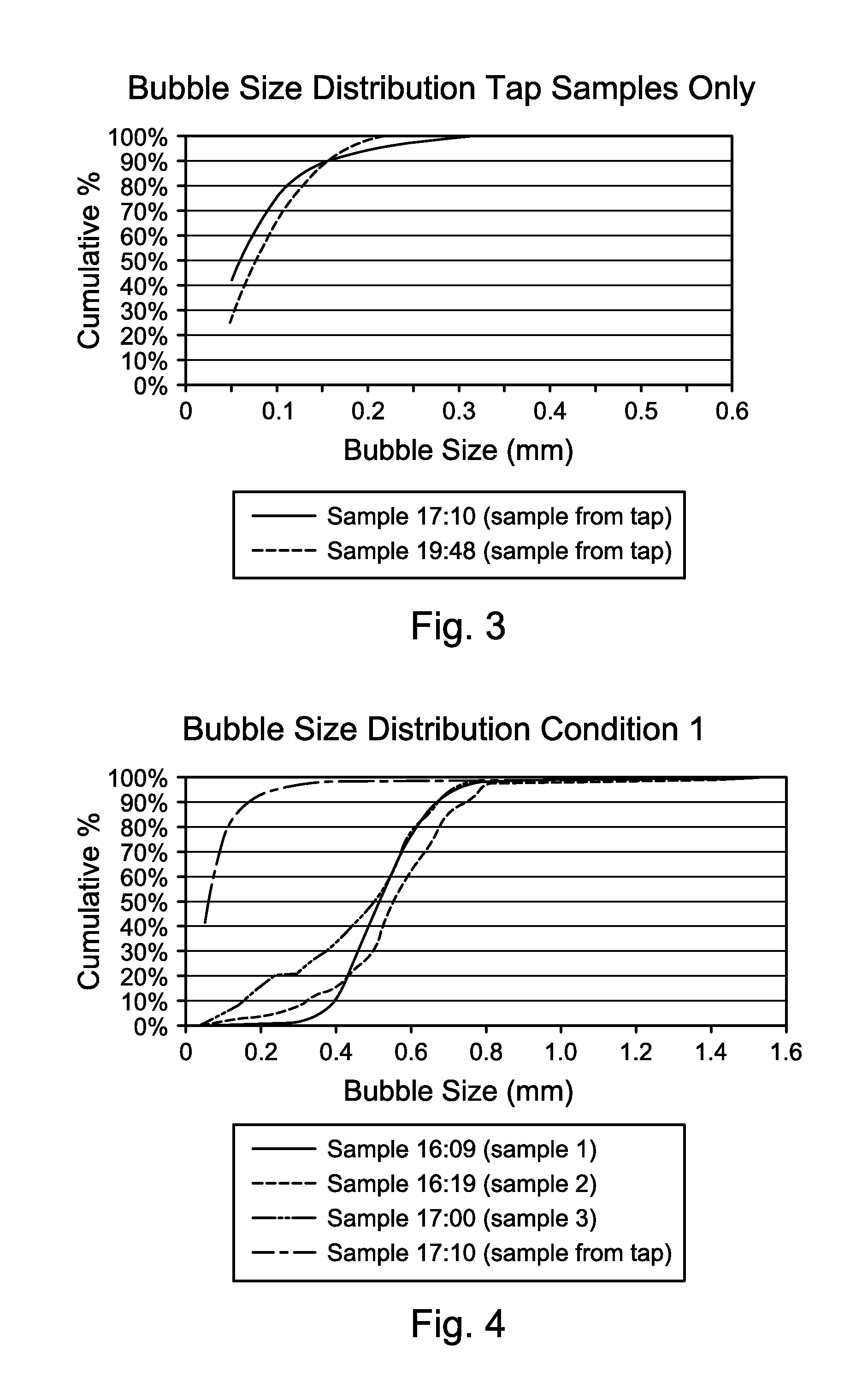

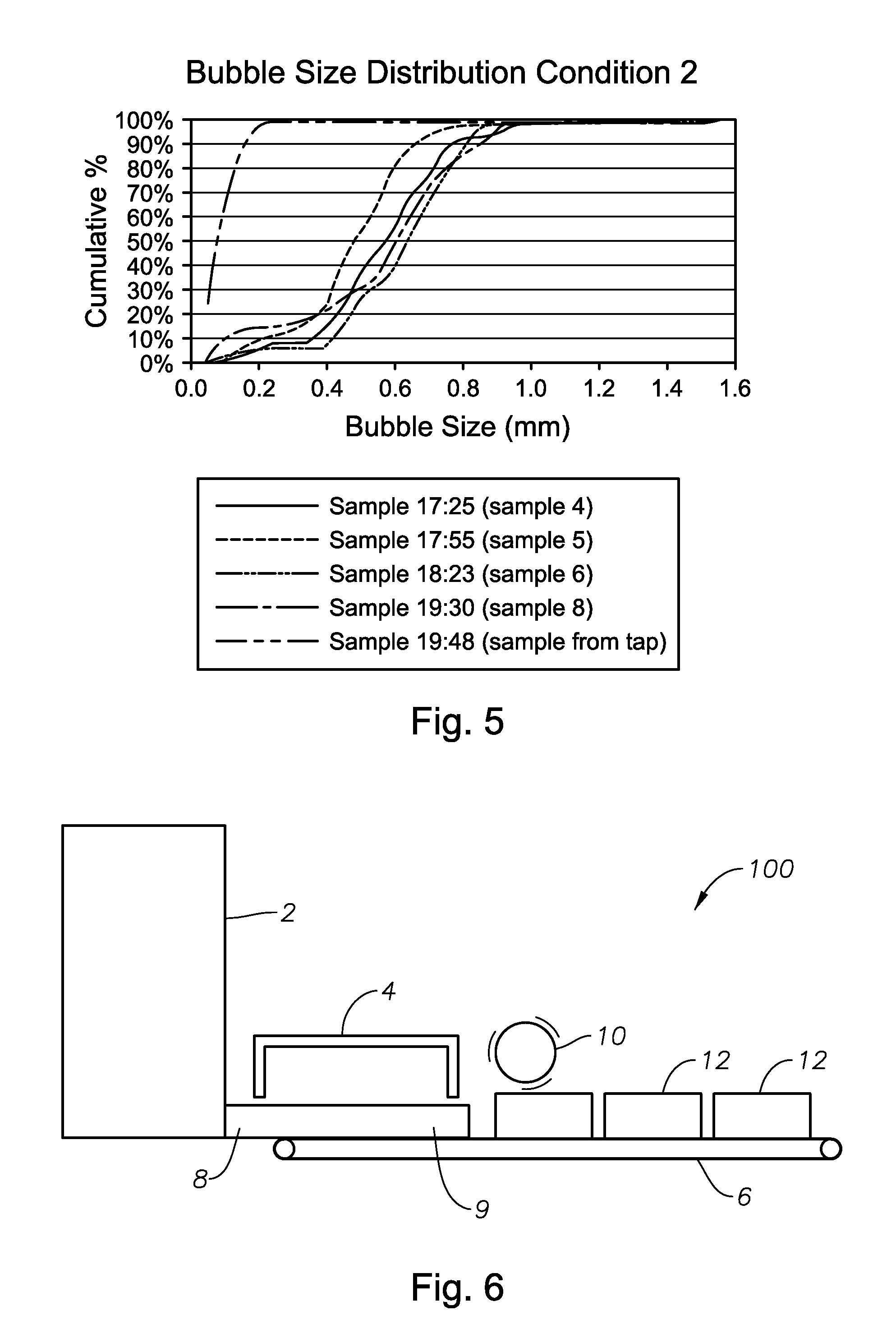

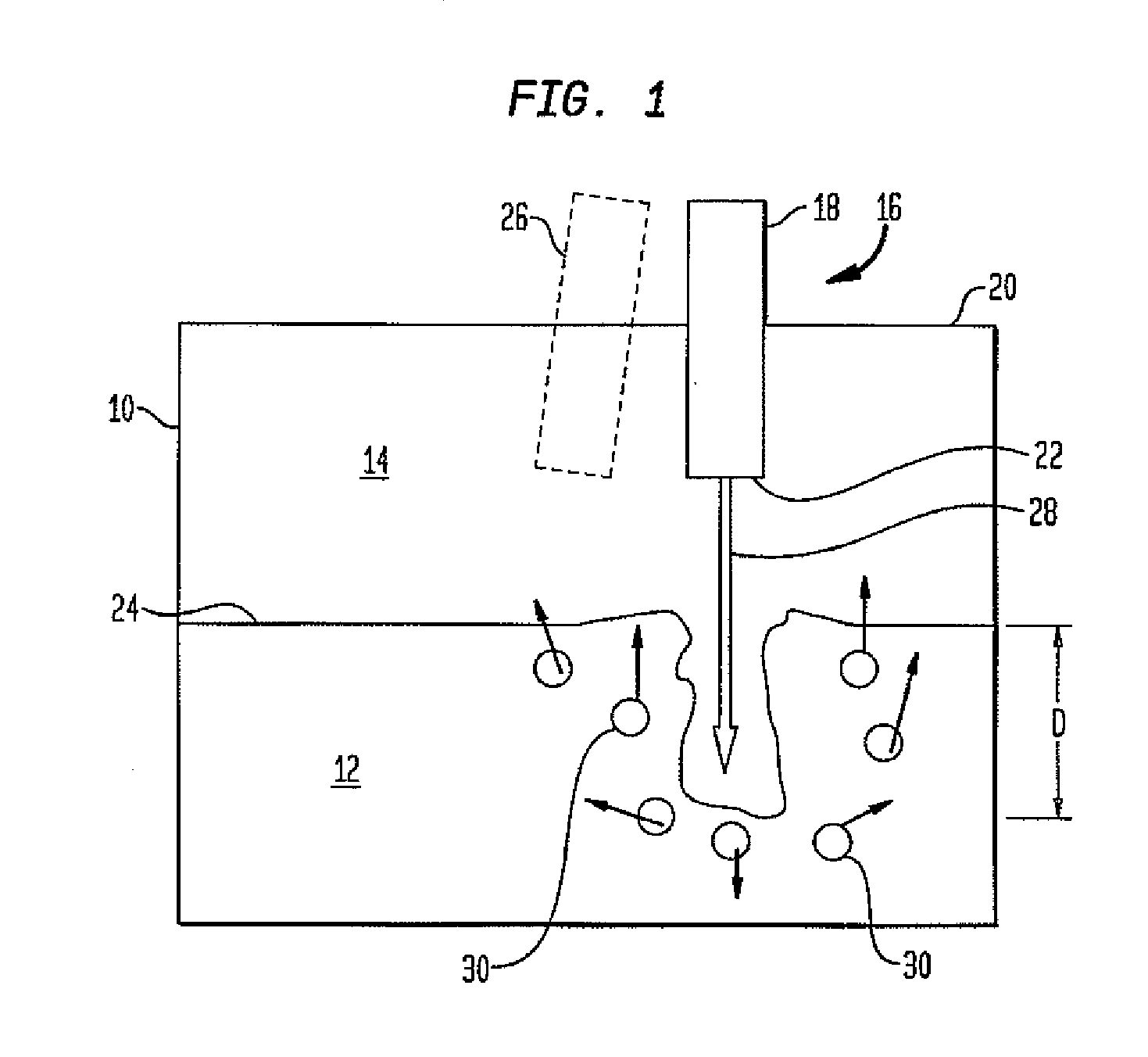

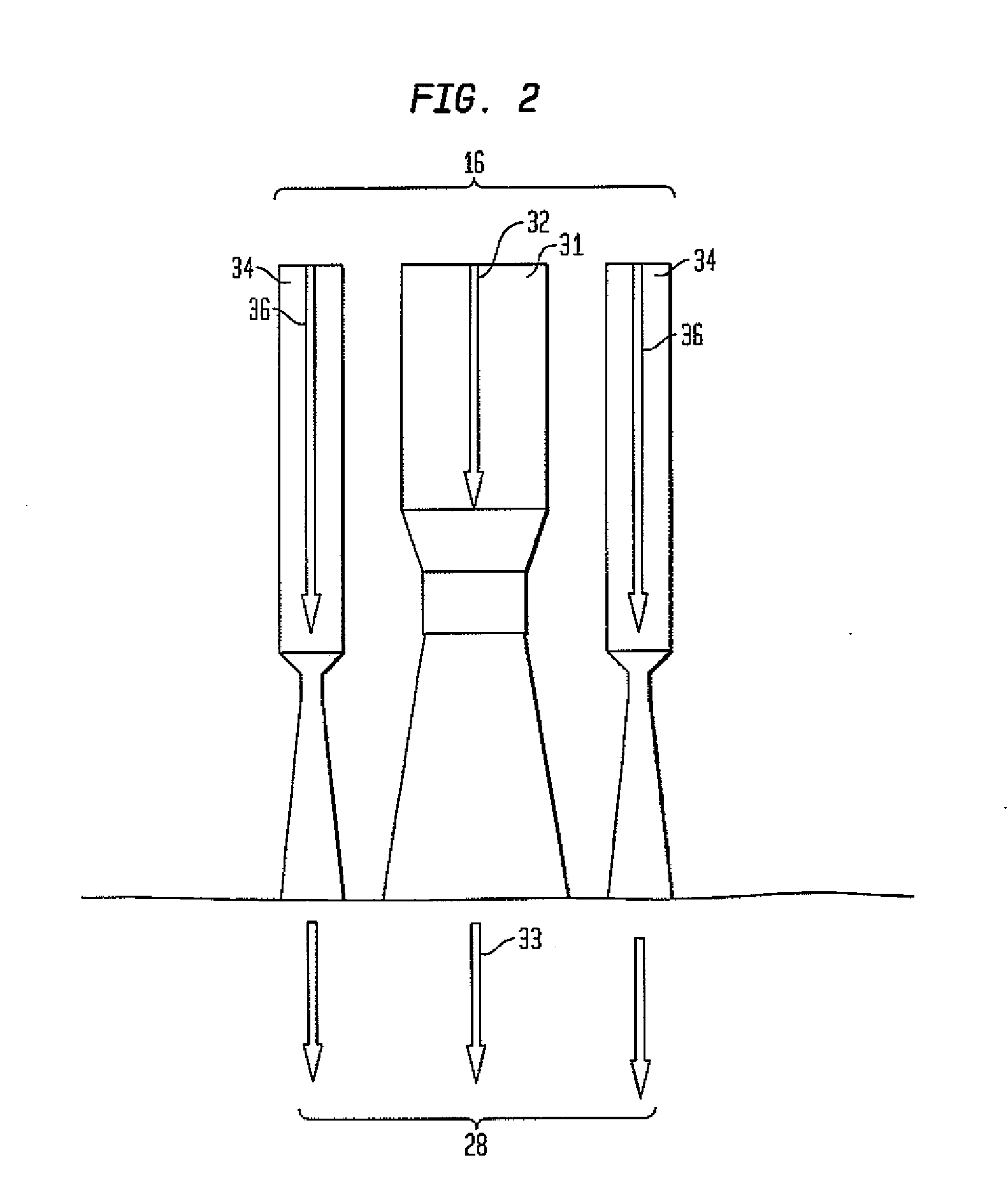

Systems and methods for making foamed glass using submerged combustion

ActiveUS20130086944A1High densityLow densityRibbon machinesGlass furnace apparatusCombustion systemDownstream processing

Submerged combustion systems and methods of use to produce foamed glass. One system includes a submerged combustion melter having an outlet, the melter configured to produce an initial foamy molten glass having a density and comprising bubbles filled primarily with combustion product gases. The initial foamy molten glass is deposited directly onto or into a transport apparatus that transports the initial foamy molten glass to a downstream processing apparatus. An intermediate stage may be included between the melter and the transport apparatus. One intermediate stage is a channel that includes gas injectors. Another intermediate stage is a channel that produces an upper flow of a less dense glass and a relatively more dense glass lower flow. The upper flow may be processed into foamed glass products, while the more dense flow may be processed into dense glass products.

Owner:JOHNS MANVILLE CORP

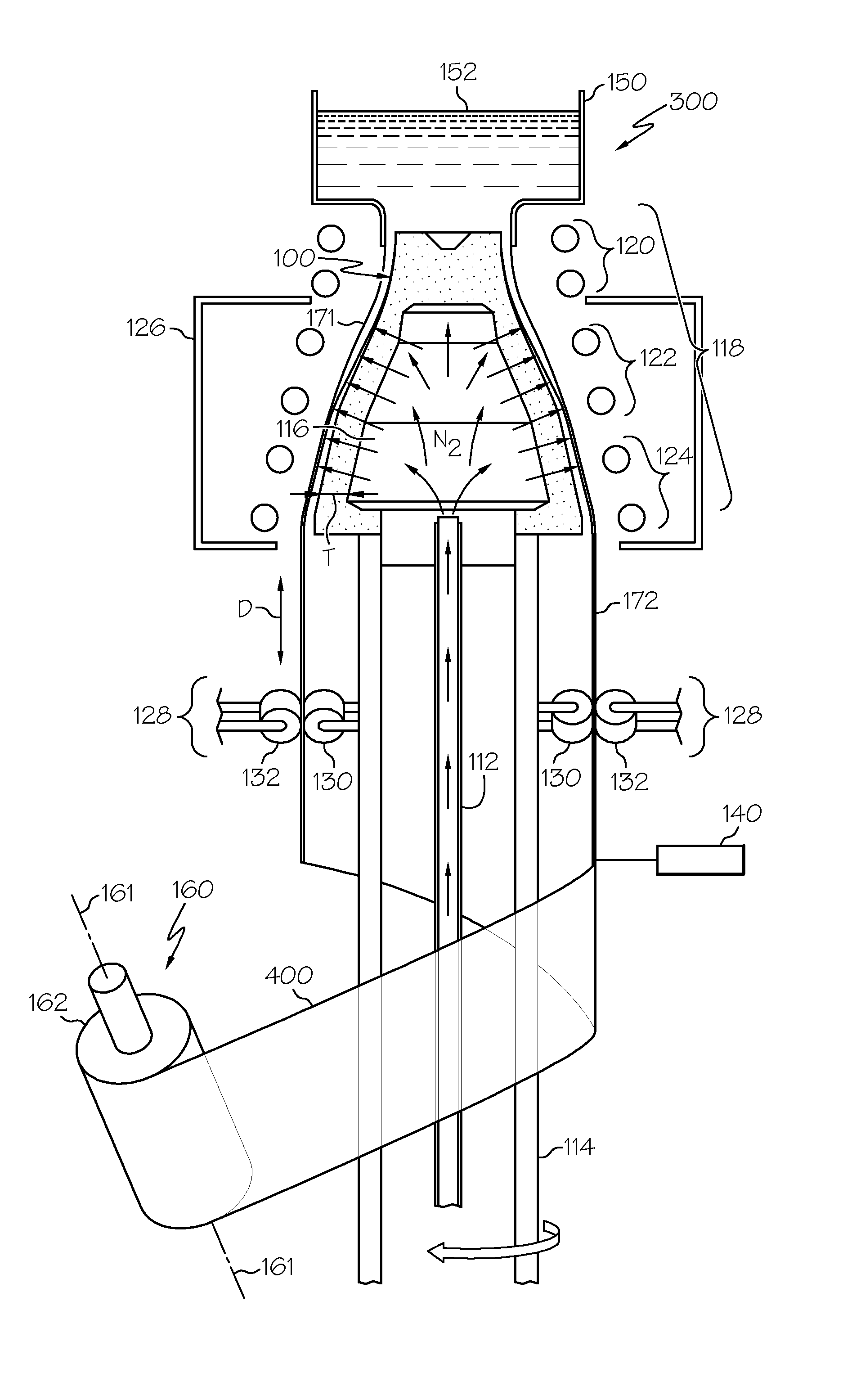

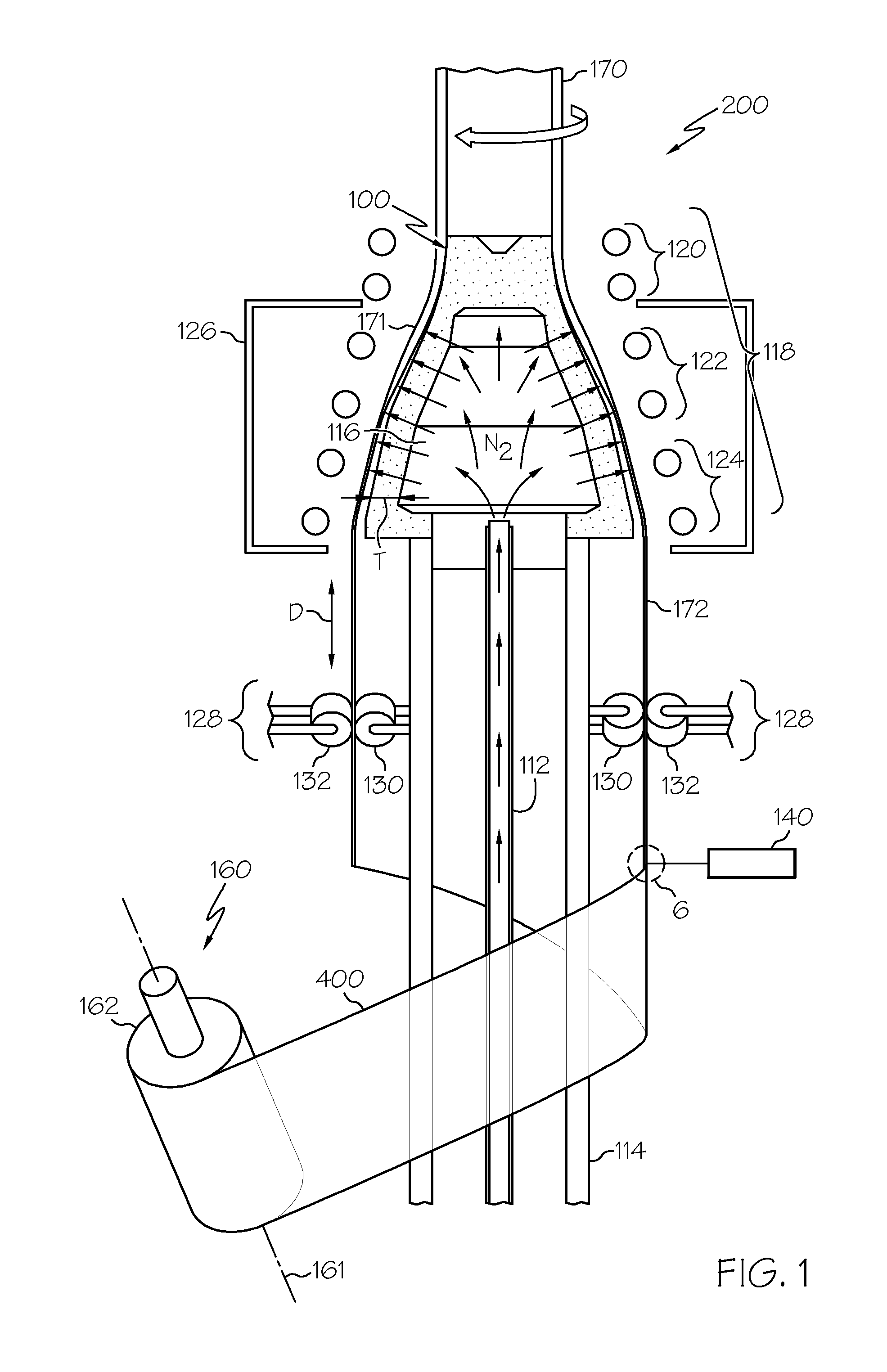

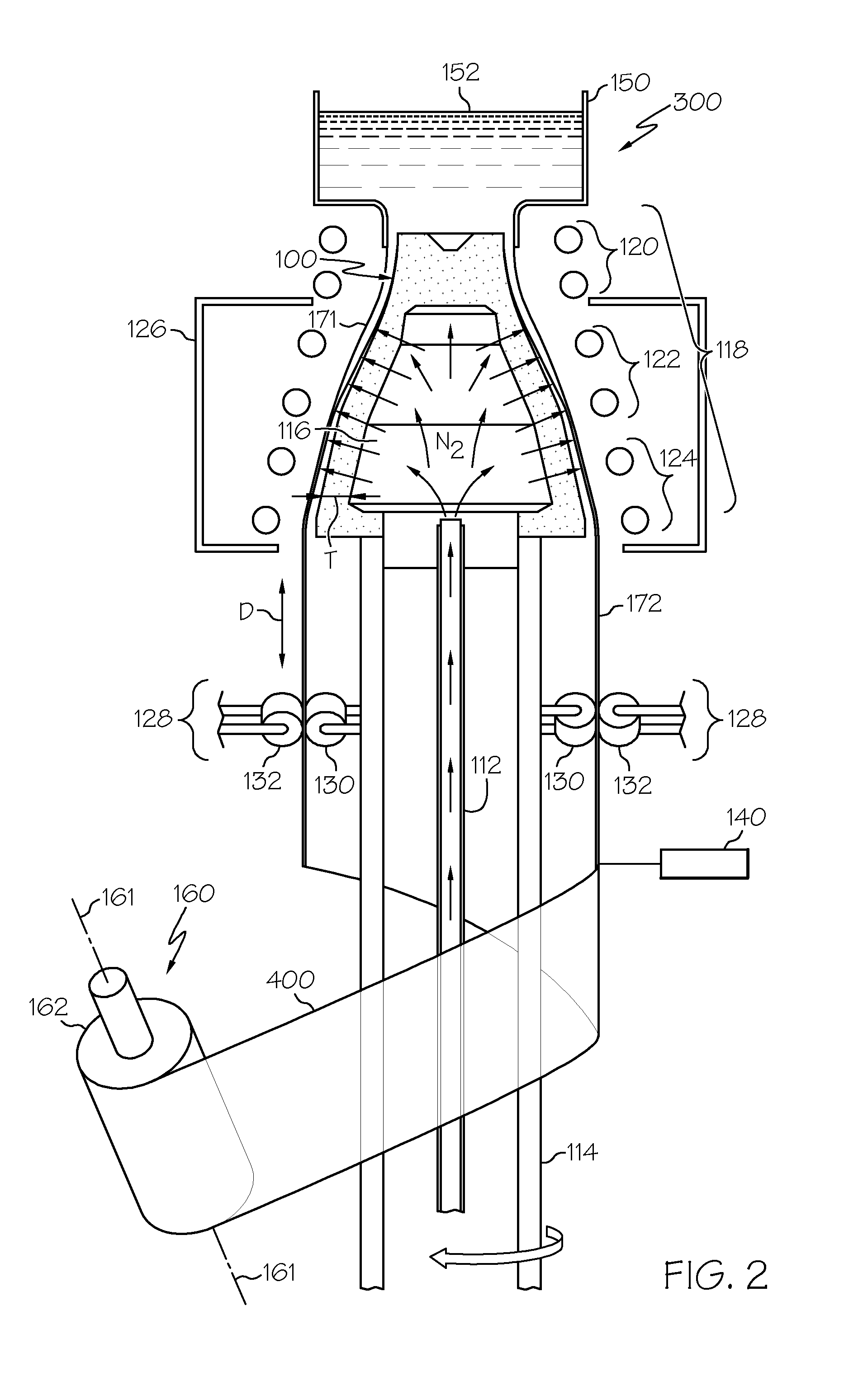

Methods and systems for forming continuous glass sheets

ActiveUS20120047951A1Increase the diameterGlass transportation apparatusGlass forming apparatusSusceptorEngineering

Owner:CORNING INC

Burner injection system for glass melting

A burner for melting glass forming batch material includes a burner assembly constructed and arranged with a first passage for providing a fuel stream and a second passage for providing an oxidant stream, the first and second streams coacting to produce a supersonic combustion jet flame penetrable into glass melt. A method for melting glass forming batch material is also provided and includes providing a fuel stream; providing an oxidant stream; mixing the fuel and oxidant streams with sufficient force for providing a supersonic combustion jet flame; directing the supersonic combustion jet flame to contact the glass forming batch material; and penetrating the glass forming batch material to a select depth with the supersonic combustion jet flame.

Owner:LINDE AG

Anti-microbial electrosurgical electrode and method of manufacturing same

InactiveUS20070106294A1Improve featuresExcellent characteristicsConveyorsGlass transportation apparatusMaterials scienceELECTROSURGICAL DEVICE

An electrosurgical device including a reinforcing underlayment having a non-stick, anti-microbial coating. In one embodiment, the coating includes a non-stick material having anti-microbial particles interspersed in the non-stick material. This coating is applied to the surfaces of the electrode to minimize the build-up of charred tissue on the surfaces of the electrode. Also, the coating tends to kill harmful organisms residing on the surfaces of the electrode. In another embodiment, a primer coating is initially applied to the surfaces of the electrode. A plurality of anti-microbial particles are then applied to the primer coating layer and engage and are embedded in the primer coating layer. A top coat including a non-stick material is applied to the anti-microbial particle layer. In either embodiment, the coating layers applied to the surfaces of the electrode are cured to harden and adhere the layers to the electrode.

Owner:INNOVATECH

Optical glass, press-molding glass gob and optical element

InactiveUS6912093B2Reduce colorHigh refractive indexGlass transportation apparatusMountingsRefractive indexOptical glass

An optical glass whose refractive index is high and whose coloring is decreased comprising, by weight %, 2 to 45% of B2O3, 0 to 30% of SiO2 provided that the content of B2O3>the content of SiO2, 10 to 50% of La2O3, 0 to 30% of TiO2, 0 to 15% of ZnO, 0 to 15% of ZrO2, 0 to 35% of Nb2O5, 0 to 35% of BaO, 0 to 5% of SrO, 0% or more but less than 8% of CaO, 0% or more but less than 13% of MgO, provided that the total content of BaO, SrO, CaO and MgO is 0 to 40%, 0 to 20% of Gd2O3, 0 to 15% of Y2O3, 0 to 18% of Ta2O5, 0% or more but less than 0.5% of WO3, 0% or more but less than 1.5% of a total of Na2O, K2O and Li2O, 0 to 10% of GeO2, 0 to 20% of Bi2O3, 0 to 10% of Yb2O3, 0 to 10% of Al2O3, 0% or more but less than 2% of Sb2O3 and 0 to 1% of SnO2.

Owner:HOYA CORP

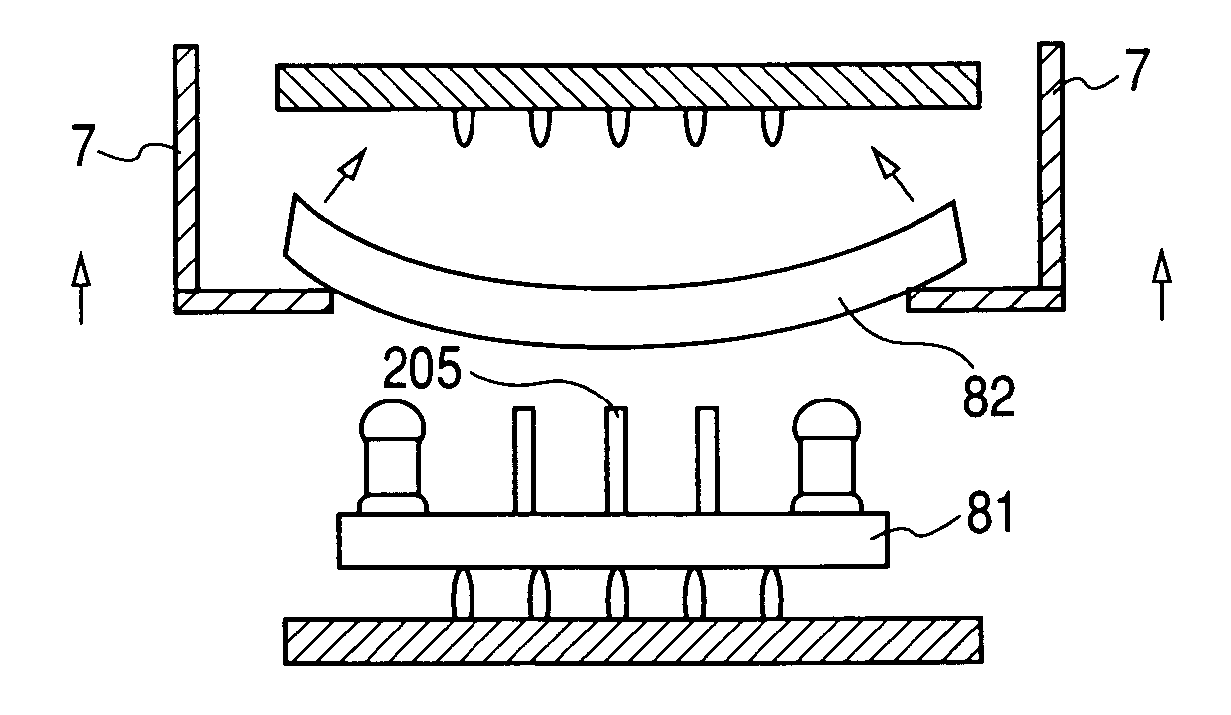

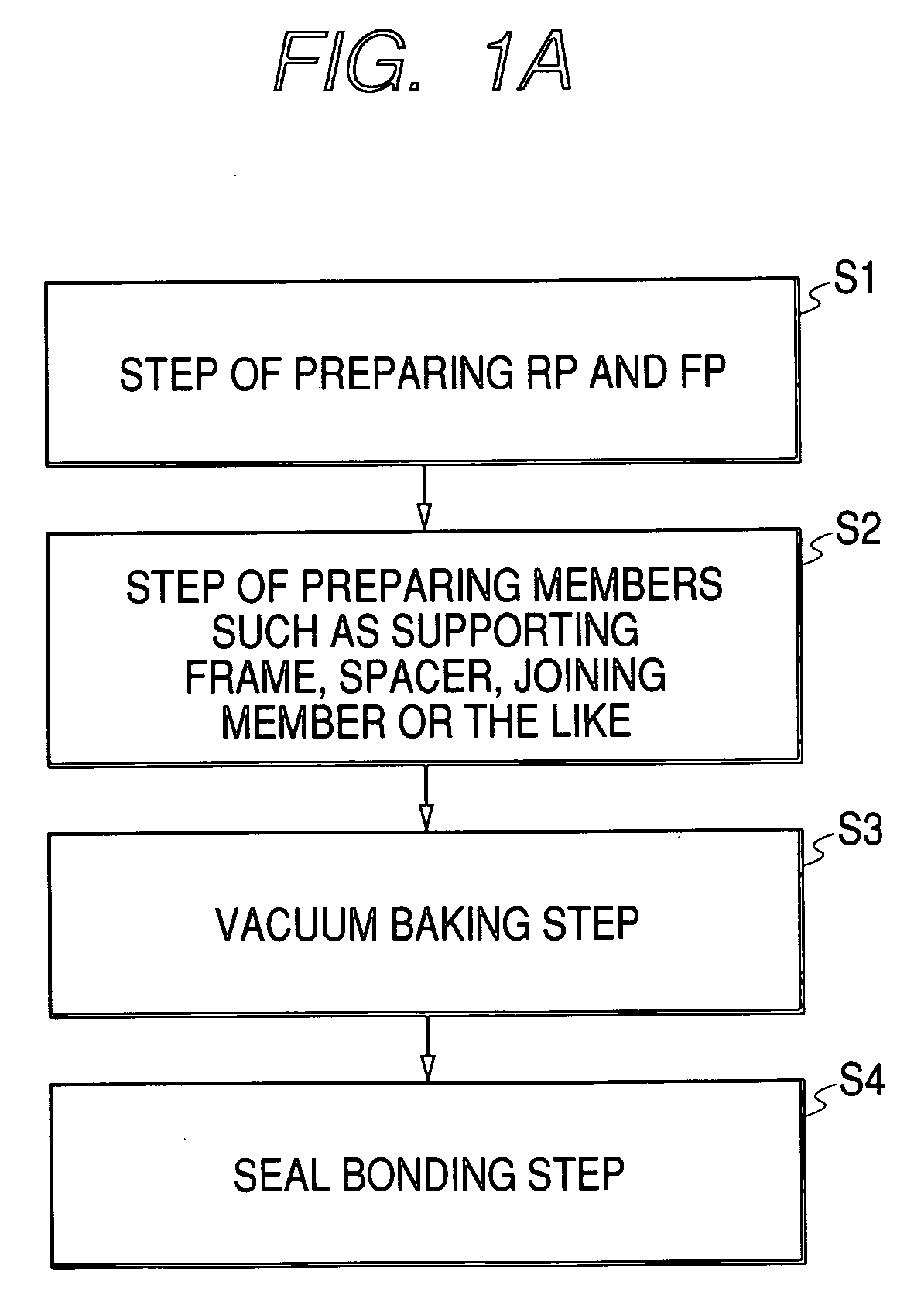

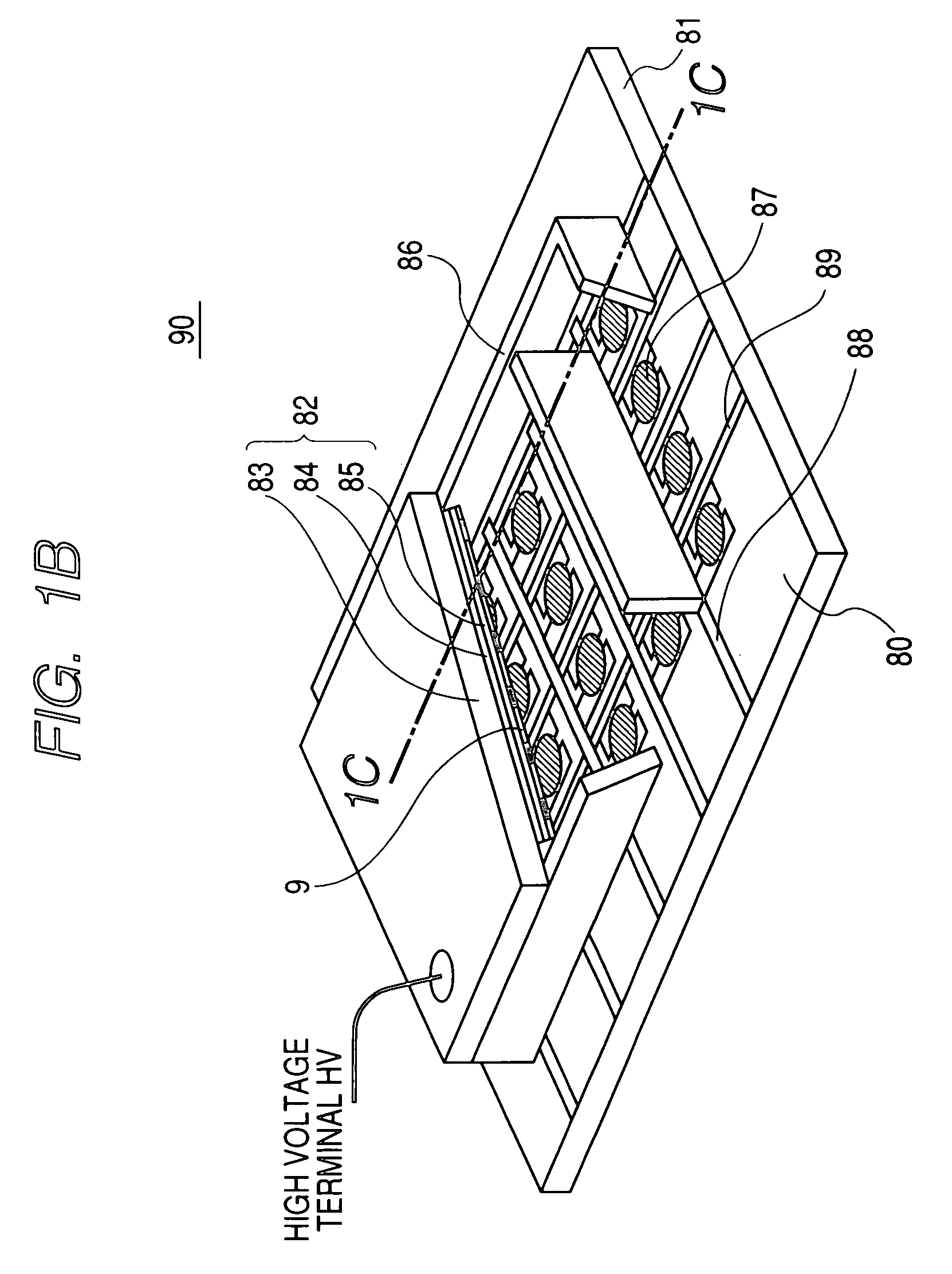

Manufacturing method and manufacturing apparatus of envelope

In a manufacturing method of forming a hermetically sealed container by bringing a pair of substrates into intimate contact via a supporting frame between them, one of the substrates is warped in a depressurized atmosphere before getting into intimate contact and is thereby separated from the other substrate so as to evacuate inside of the hermetically sealed container by releasing the depressurized atmosphere therein. Relative positions of the substrates are restored by having the warp undone thereafter. Therefore, it is possible to achieve evacuation inside the hermetically sealed container without causing the relative positions of the substrates to deviate.

Owner:CANON KK

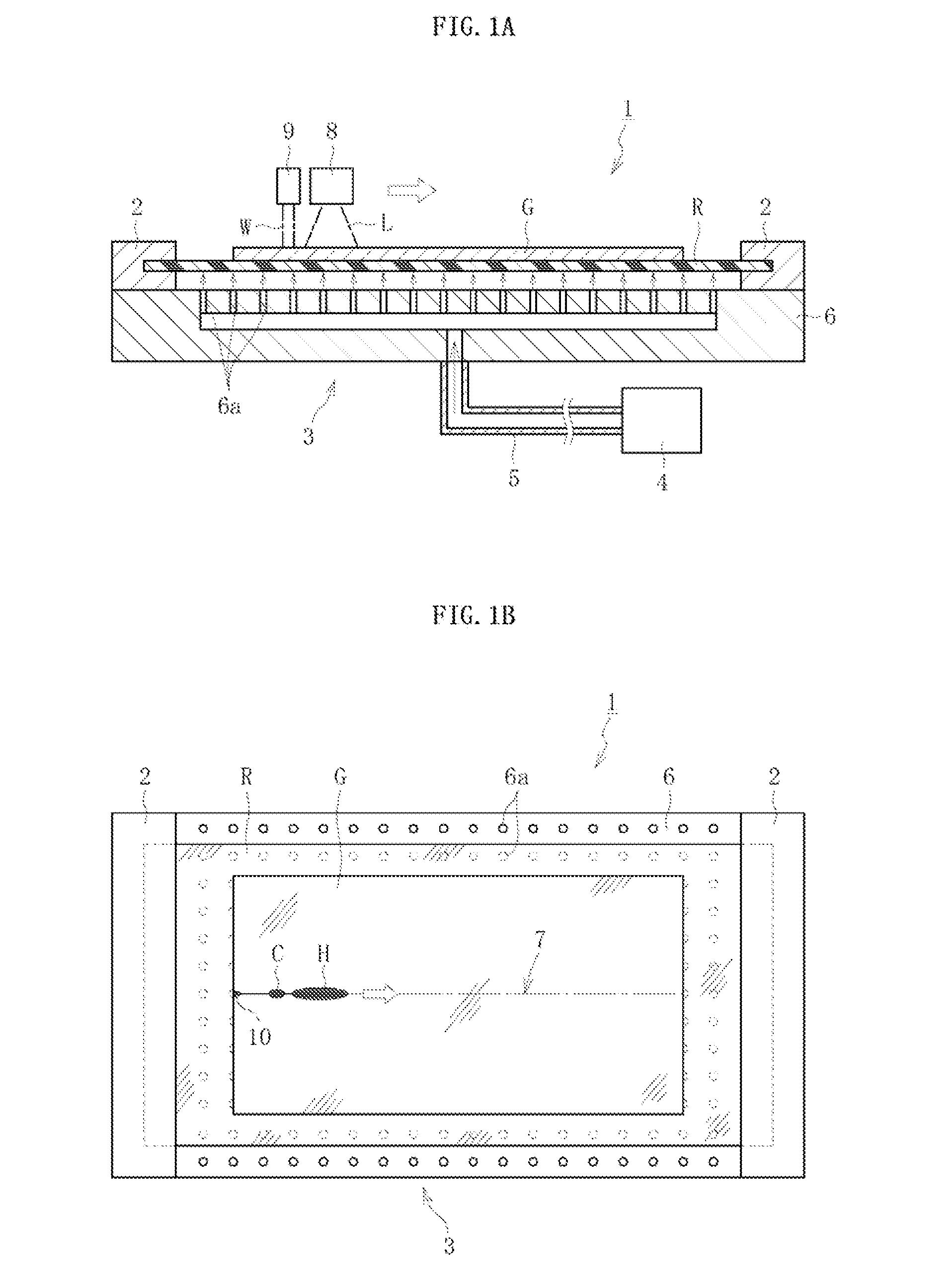

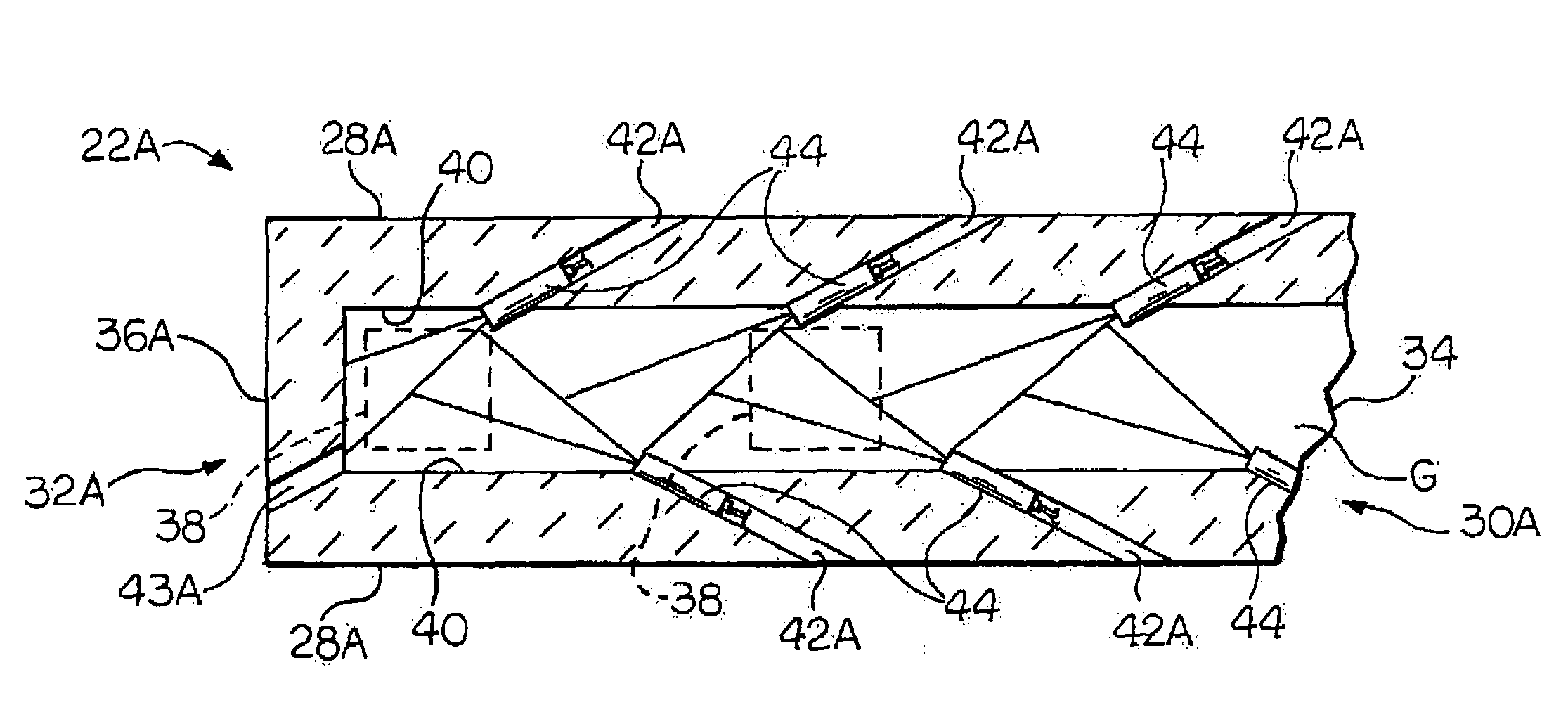

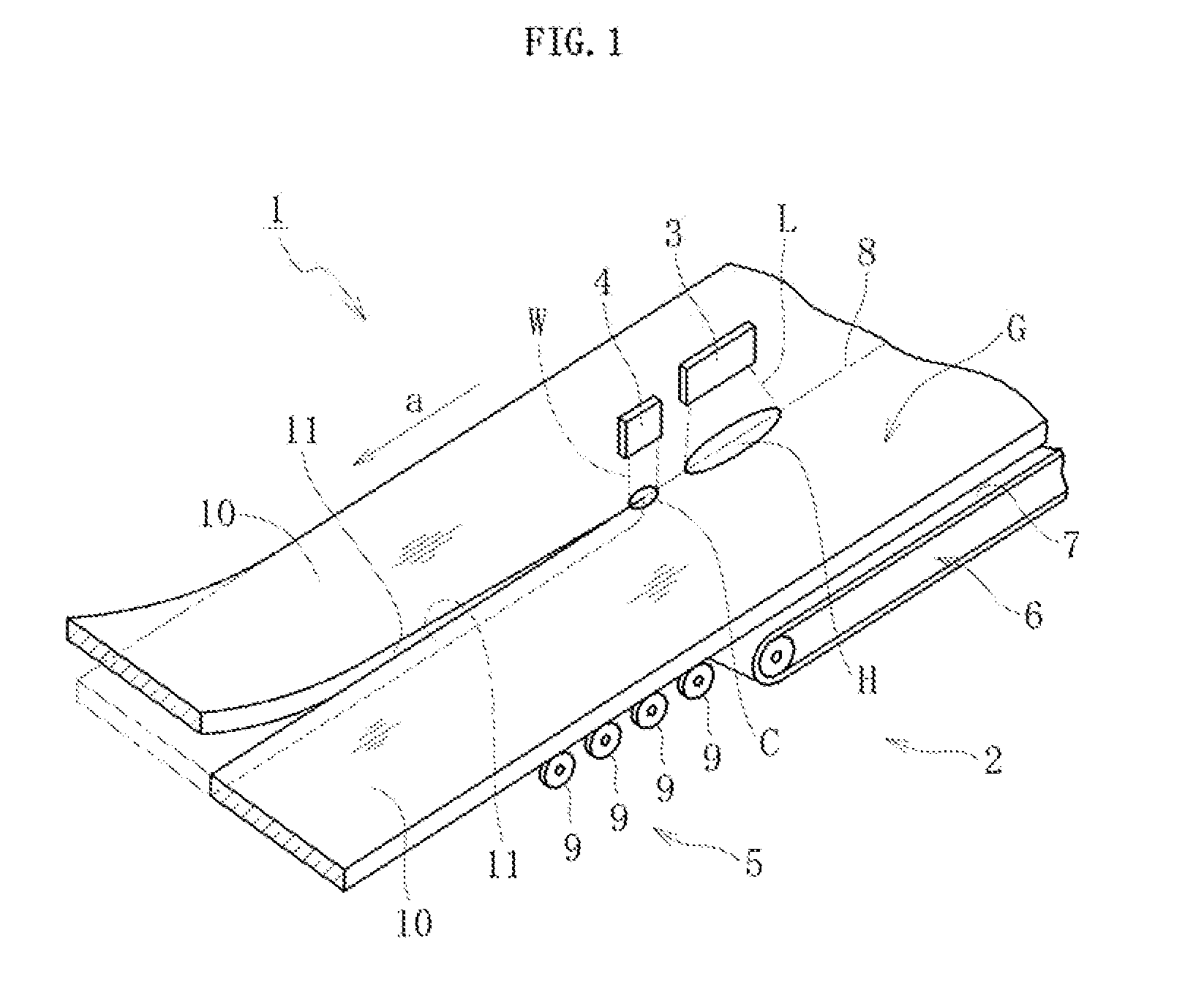

Cleaving method for a glass film

ActiveUS20120024928A1Stable jobInterferenceGlass transportation apparatusGlass severing apparatusGlass filmElectrical and Electronics engineering

Provided is a cleaving method for a glass film (G) including: cleaving, during conveyance of the glass film (G) in a predetermined direction, the glass film (G) continuously along a preset cleaving line (8) extending in a predetermined conveying direction (a) by a thermal stress generated through localized heating performed along the preset cleaving line (8) and through cooling of a locally heated region (H); dividing the glass film (G) in a width direction of the glass film (G) ; diverting, after the dividing, adjacent divided glass films (10) , which are obtained by the dividing, so that the adjacent divided glass films (10) are separated in a front and rear direction of the adjacent divided glass films; and forming a predetermined widthwise clearance between the adj acent divided glass films after the dividing of the glass film (G) and before the diverting of the adjacent divided glass films (10).

Owner:NIPPON ELECTRIC GLASS CO LTD

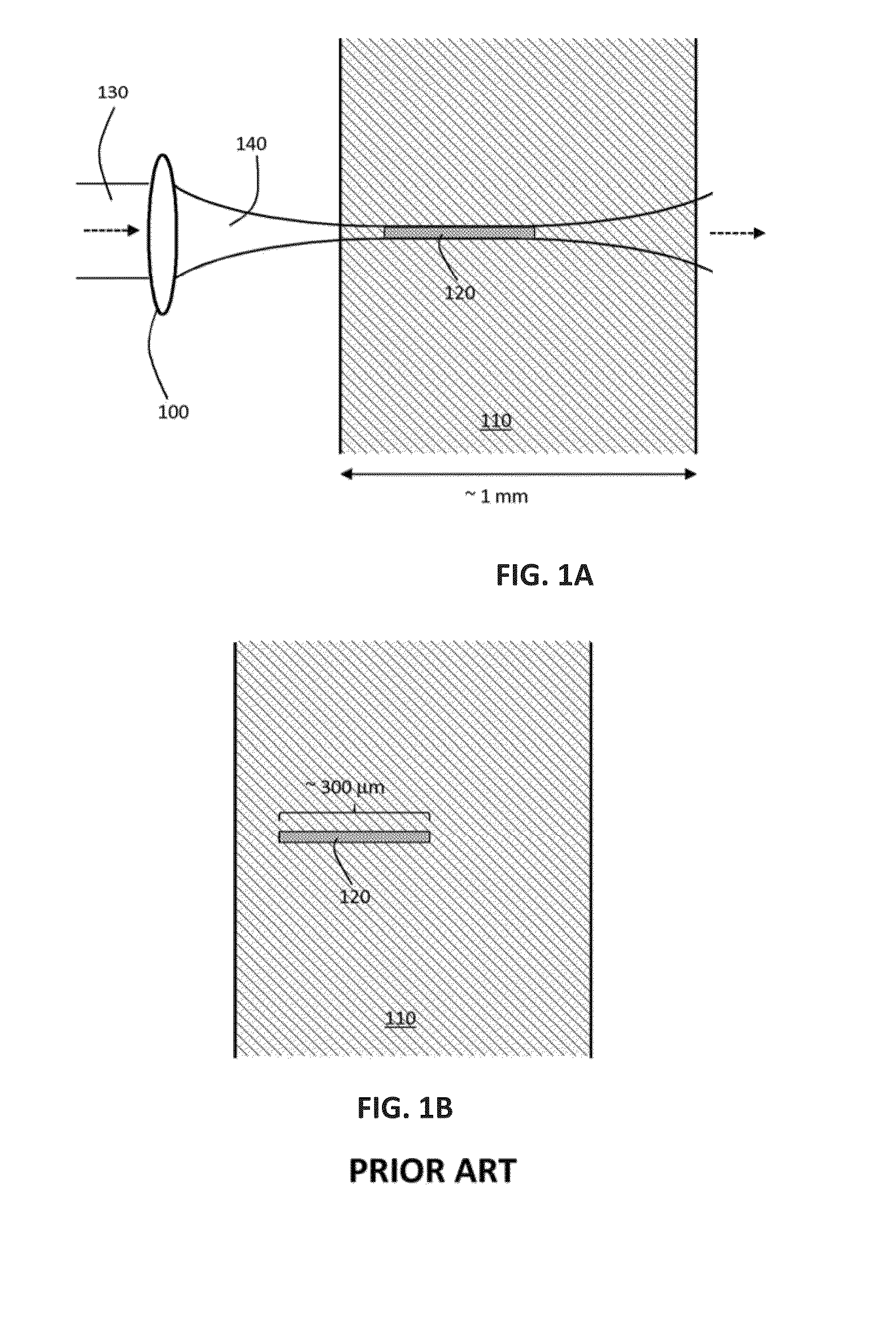

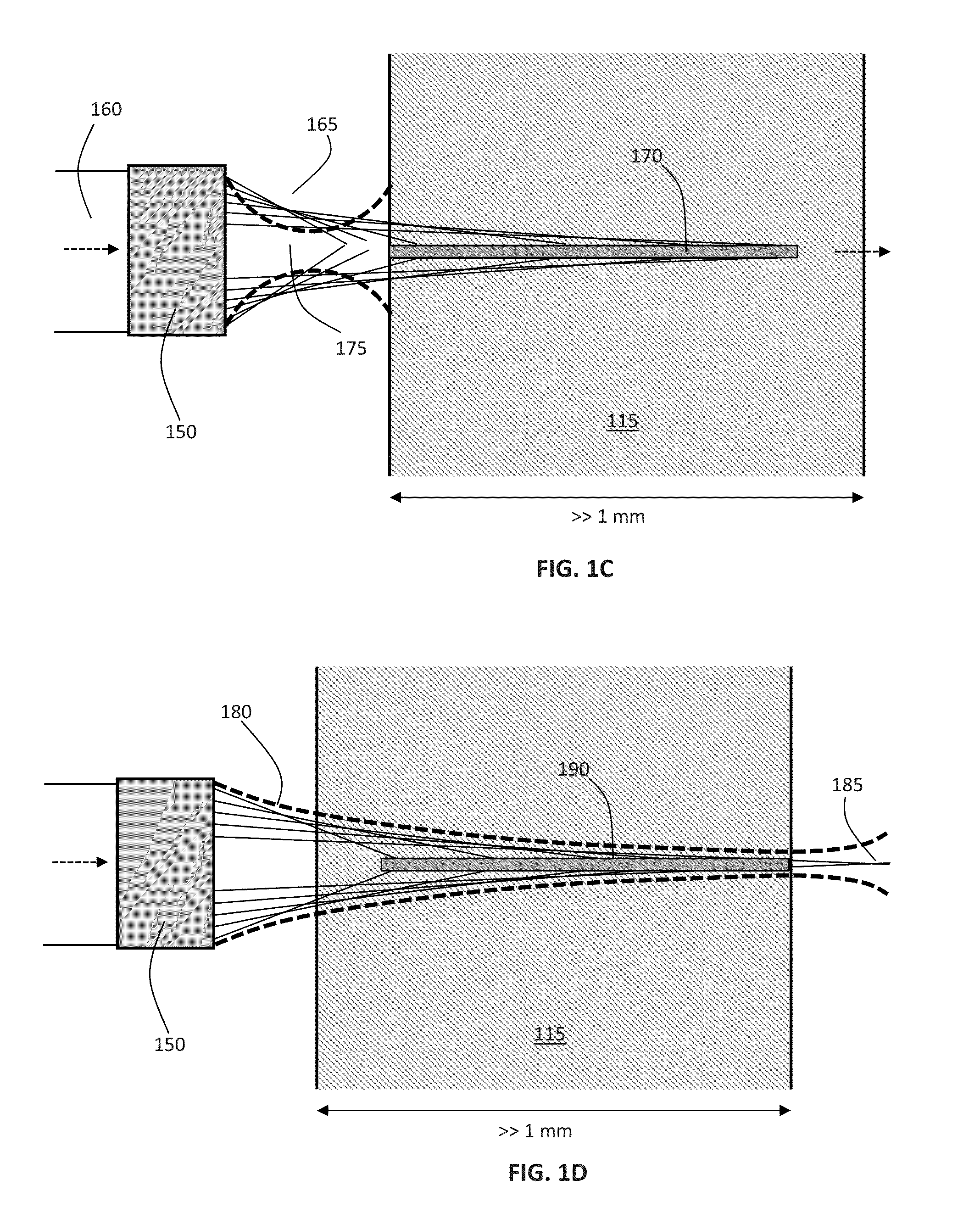

Method and apparatus for performing laser curved filamentation within transparent materials

ActiveUS20160016257A1Improve bending strengthInhibition formationGlass drawing apparatusGlass transportation apparatusFilamentationPlasma channel

Systems and methods are described for forming continuous curved laser filaments in transparent materials. The filaments are preferably curved and C-shaped. Filaments may employ other curved profiles (shapes). A burst of ultrafast laser pulses is focused such that a beam waist is formed external to the material being processed without forming an external plasma channel, while a sufficient energy density is formed within an extended region within the material to support the formation of a continuous filament, without causing optical breakdown within the material. Filaments formed according to this method may exhibit lengths in the range of 100 μm-10 mm. An aberrated optical focusing element is employed to produce an external beam waist while producing distributed focusing of the incident beam within the material. Optical monitoring of the filaments may be employed to provide feedback to facilitate active control of the process.

Owner:ROFIN SINAR TECH

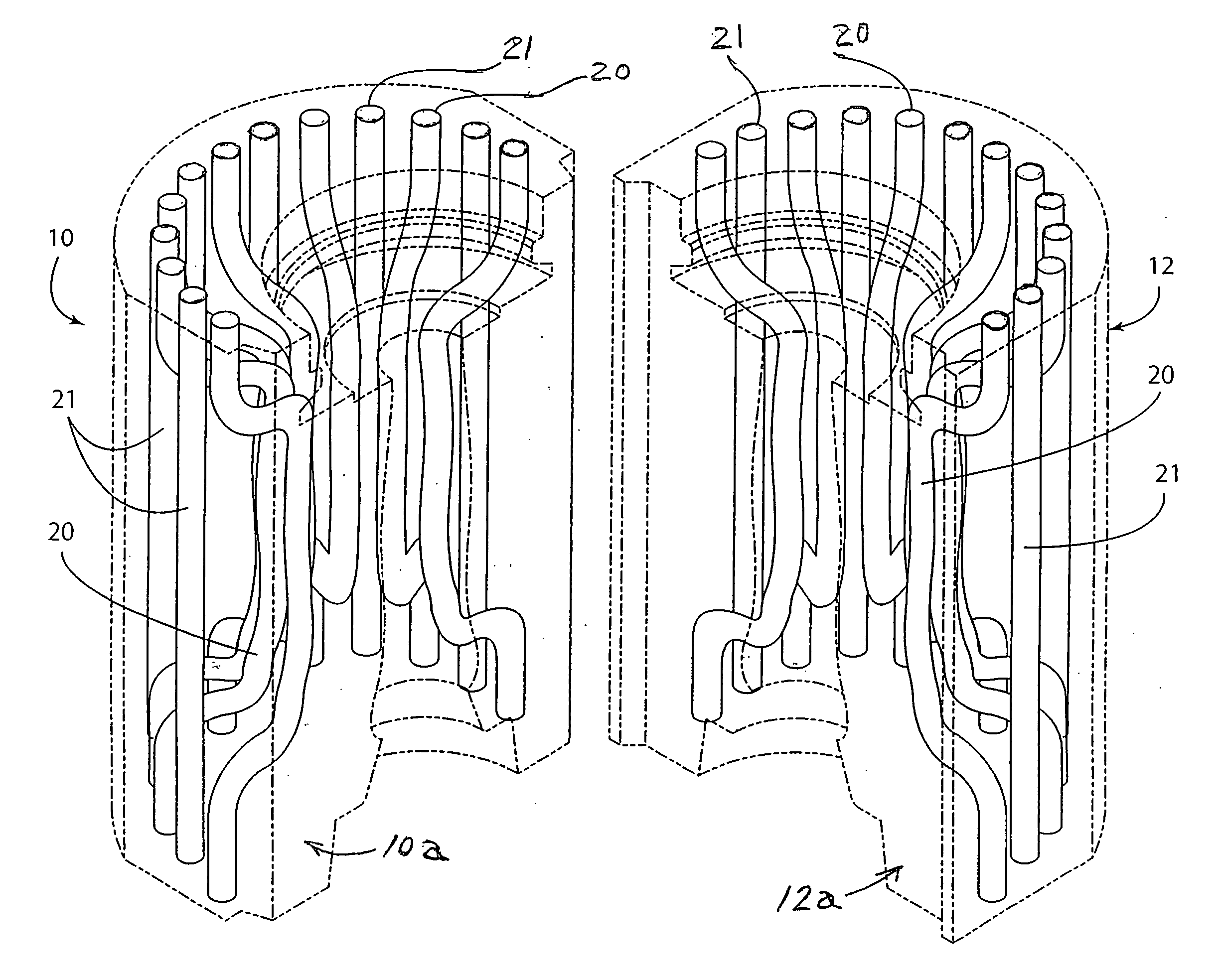

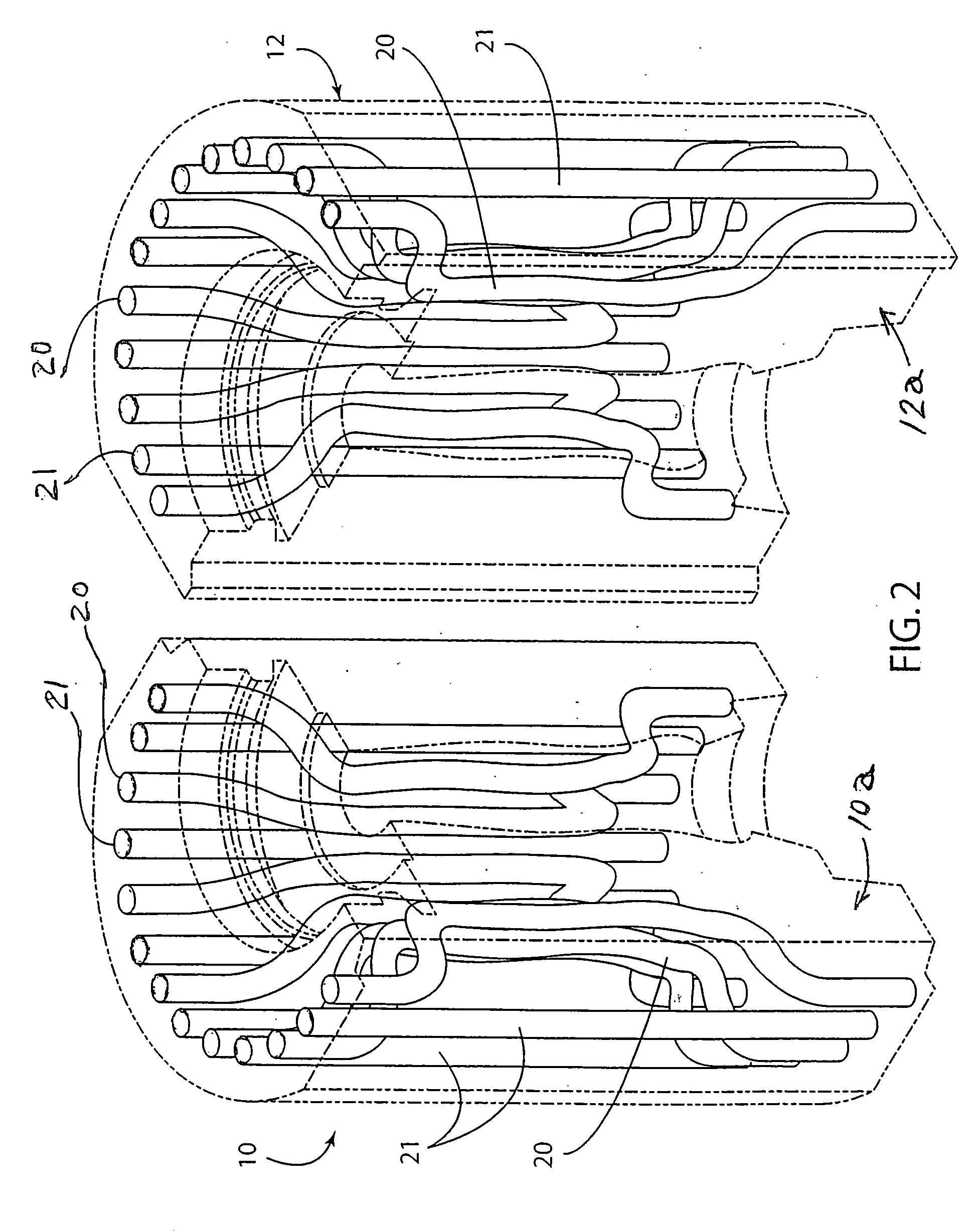

Glass-forming die and method

InactiveUS20060213632A1Easy to controlImprove uniformityGlass drawing apparatusFoundry mouldsTemperature controlEngineering

Glass-forming die, such as a parsain-forming or bottle-forming die, includes a die body having a molding surface with a curved contour to form at least a portion of a glass bottle or other article to be made. The die body has one or more cooling passages inside the body wherein the cooling passages is / are non-linear (non-straight) along at least a portion of their length to improve temperature control of the die during the glass forming operation. To this end, the cooling passages are curved in a manner to generally follow the curved contour along at least a portion of the length of the curved contour, and may include heat radiating or turbulating elements in the cooling passage. The glass-forming die alternately, or in addition, can include integral cooling fins, ribs or other heat radiating element on one or more exterior regions of the die.

Owner:HOWMET CORPORATION

Burner apparatus, submerged combustion melters including the burner, and methods of use

Owner:JOHNS MANVILLE CORP

Method for forming heated glass sheets

Owner:GLASSTECH

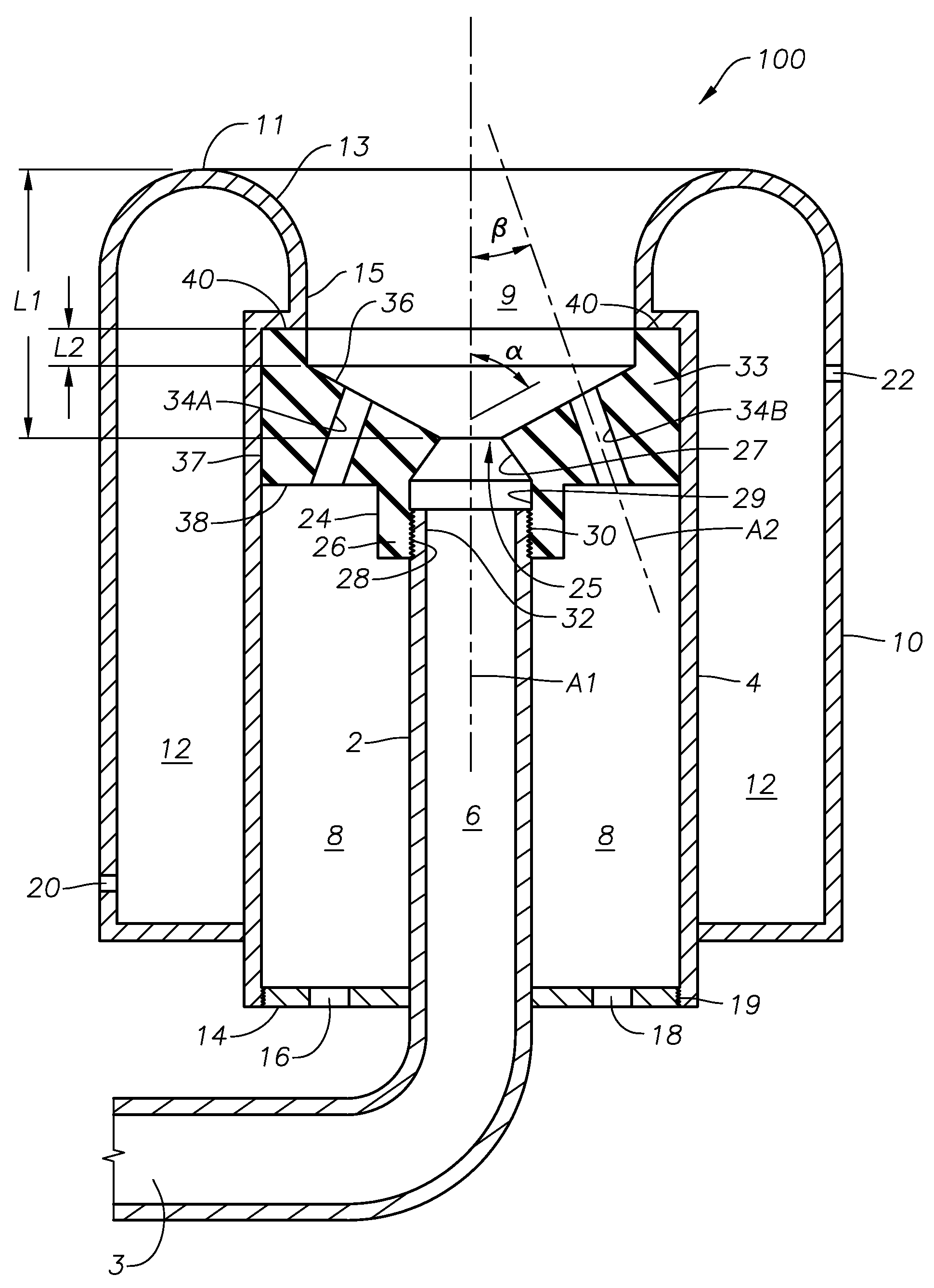

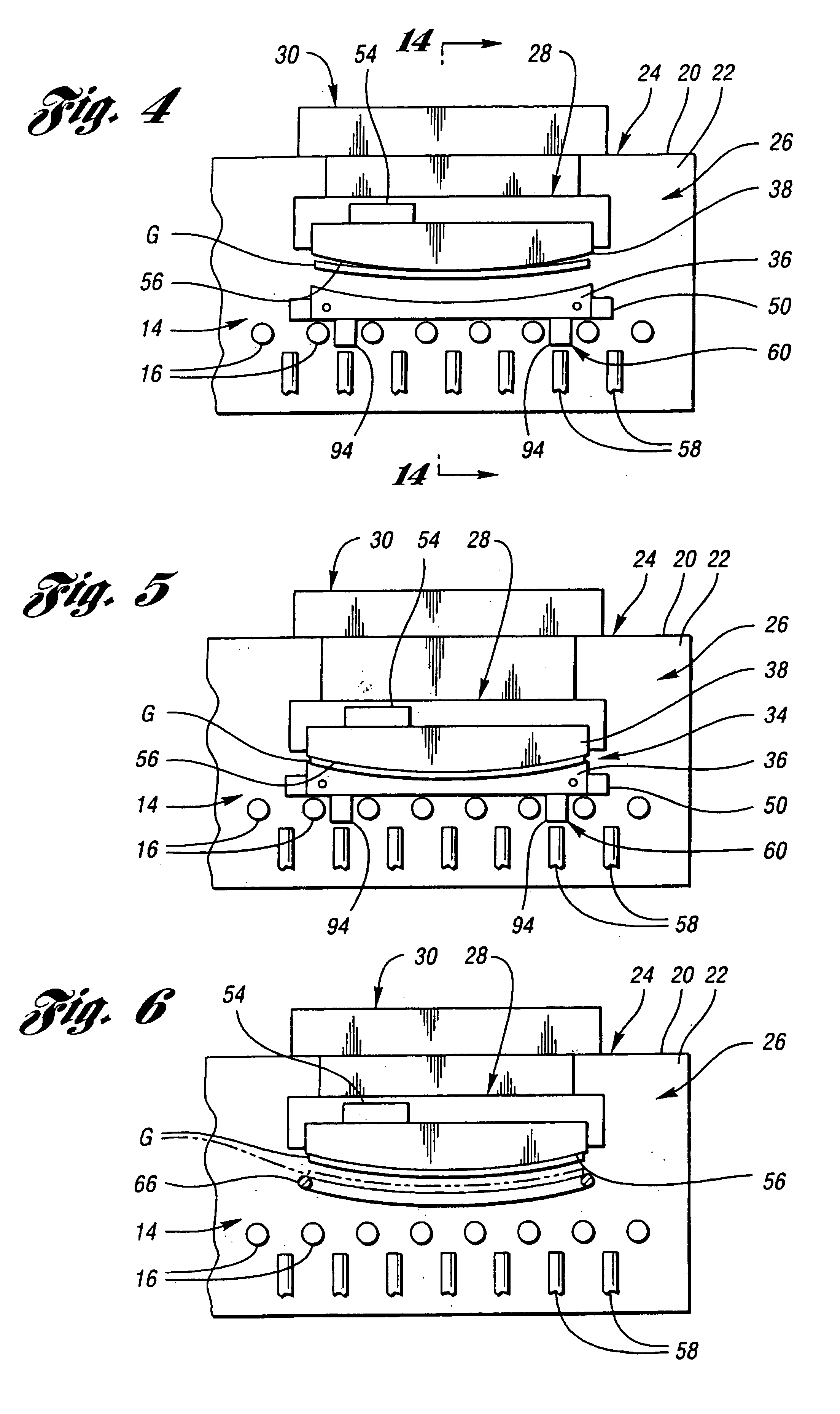

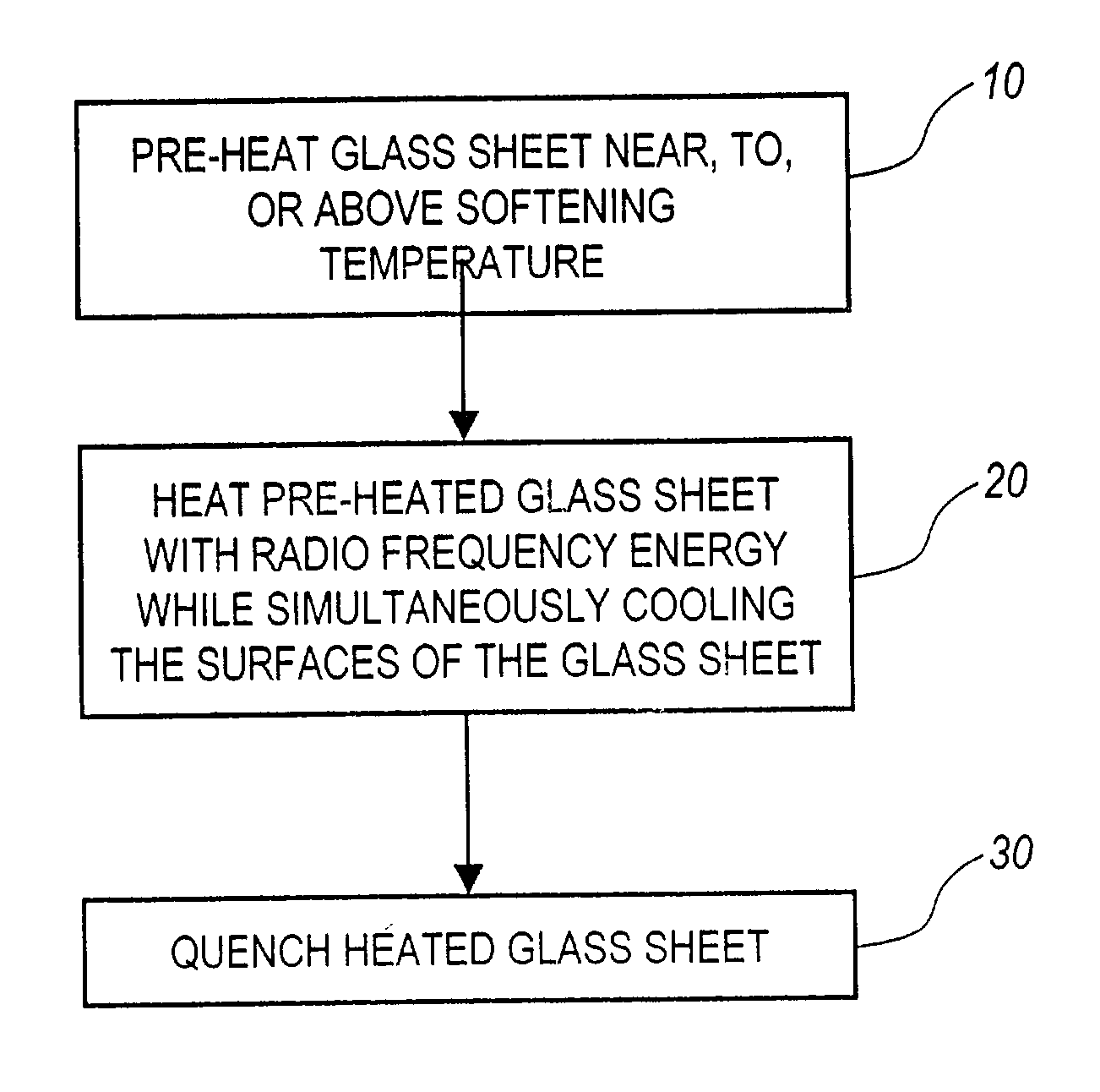

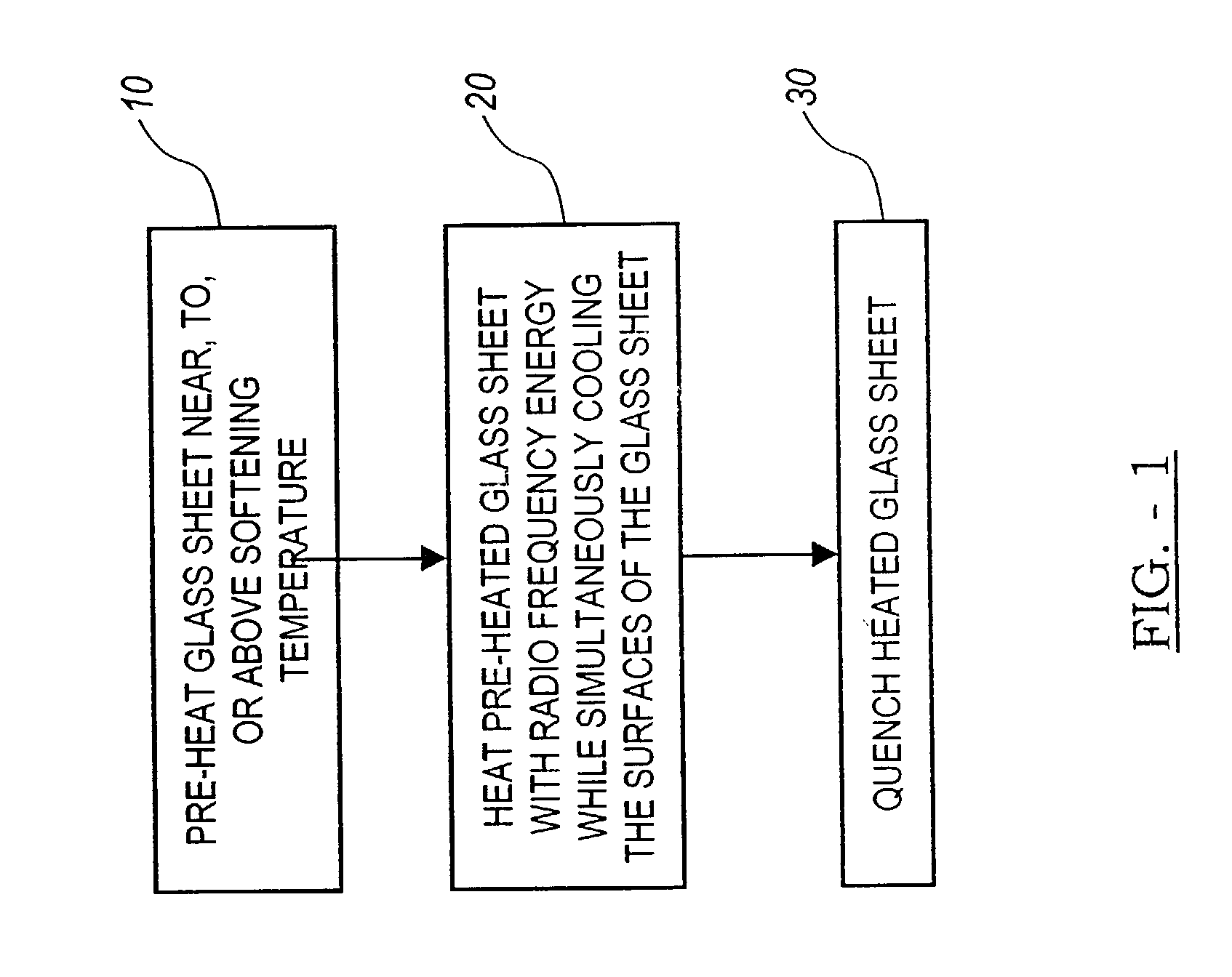

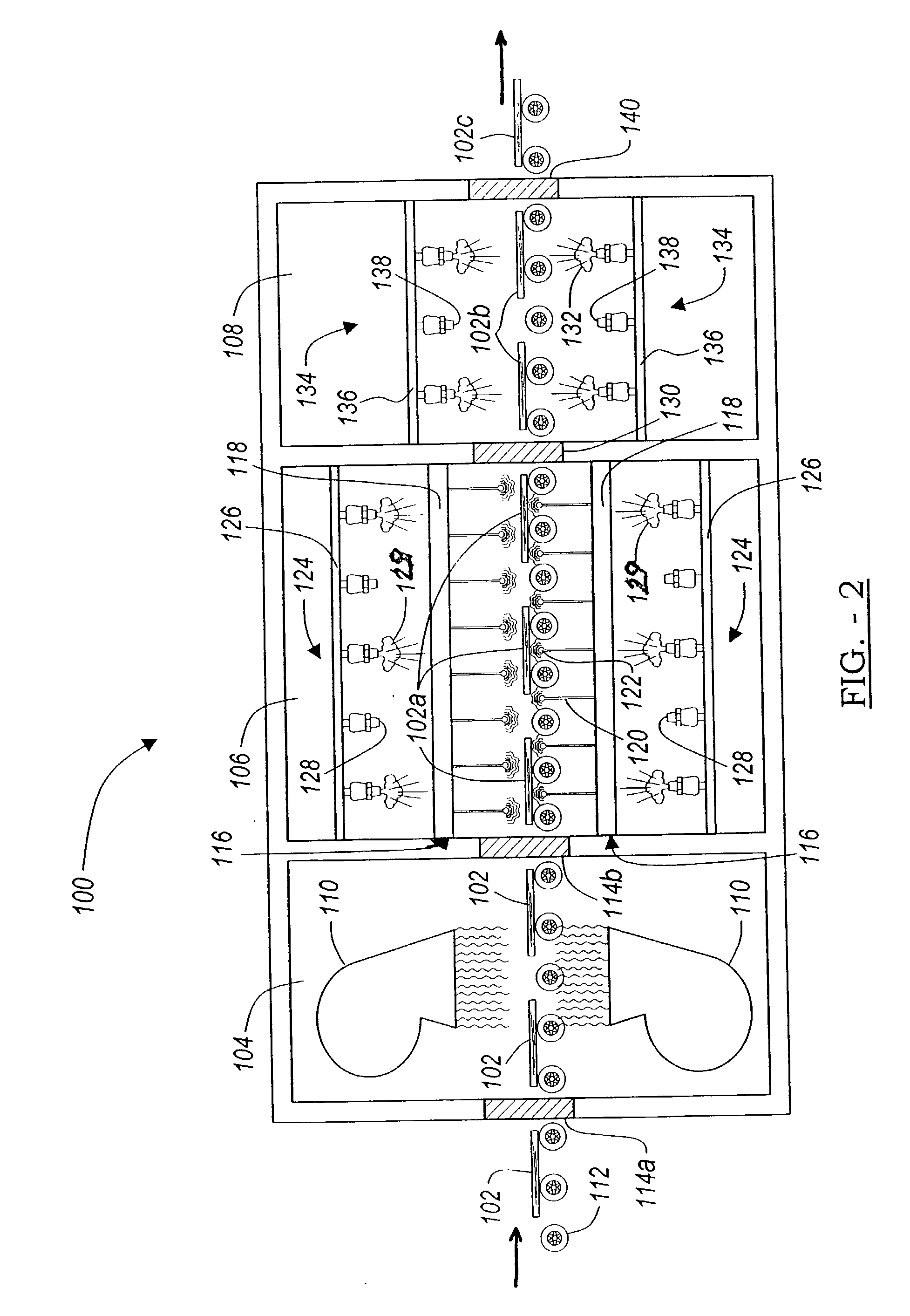

System and method for simultaneously heating and cooling glass to produce tempered glass

InactiveUS20030233846A1Rapidly and efficiently and inexpensively heatThin tempered glassGlass transportation apparatusGlass reforming apparatusSurface coolingRadio frequency energy

A system and method for heating, forming, and tempering a glass sheet includes pre-heating the glass sheet to at least a first predetermined temperature. The system and method includes also applying radio-frequency energy to the glass sheet to heat it to at least a second predetermined temperature and cooling at least one outer surface of the glass sheet to at least a third predetermined temperature to temper the glass sheet.

Owner:BOAZ PREMAKARAN T

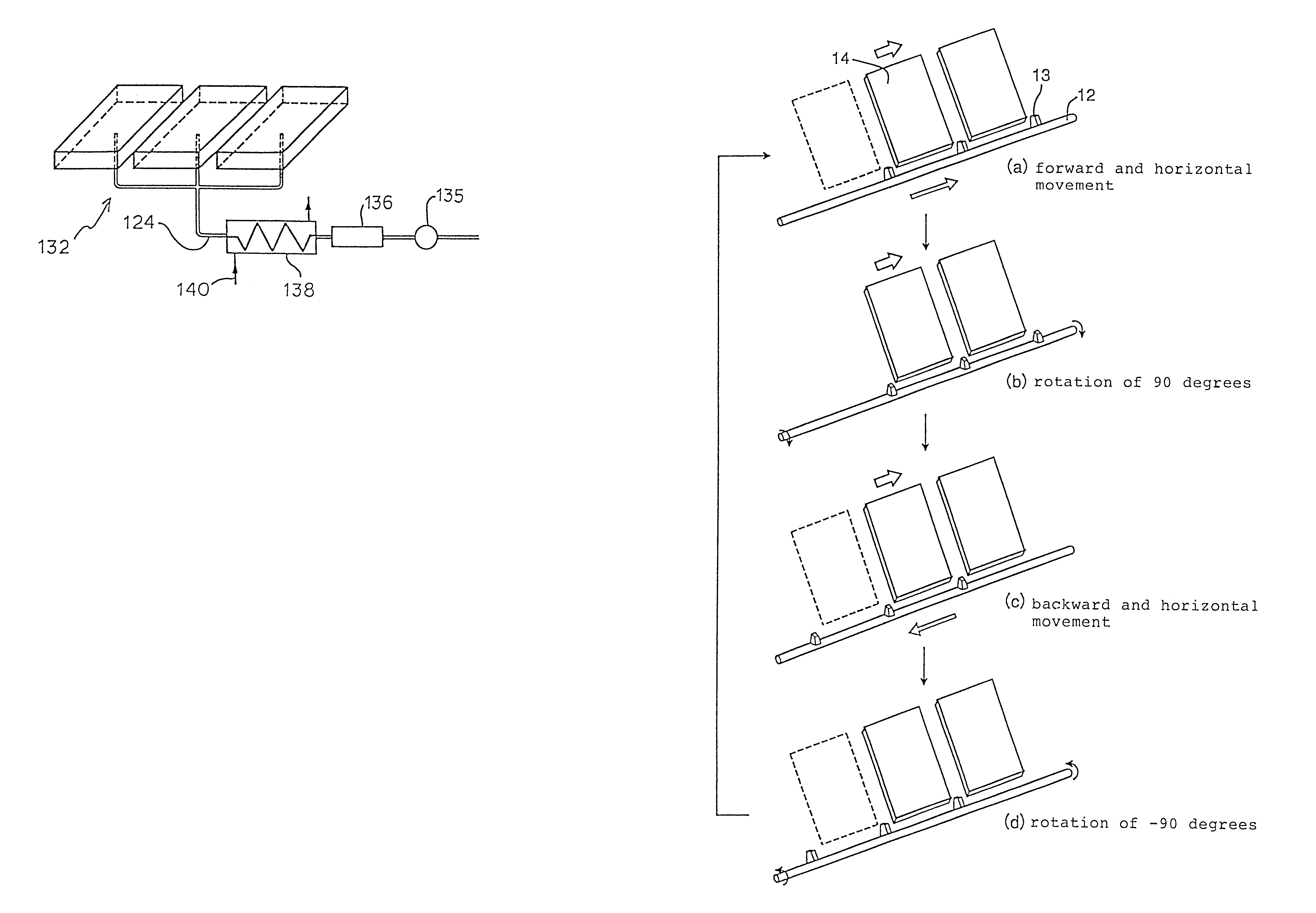

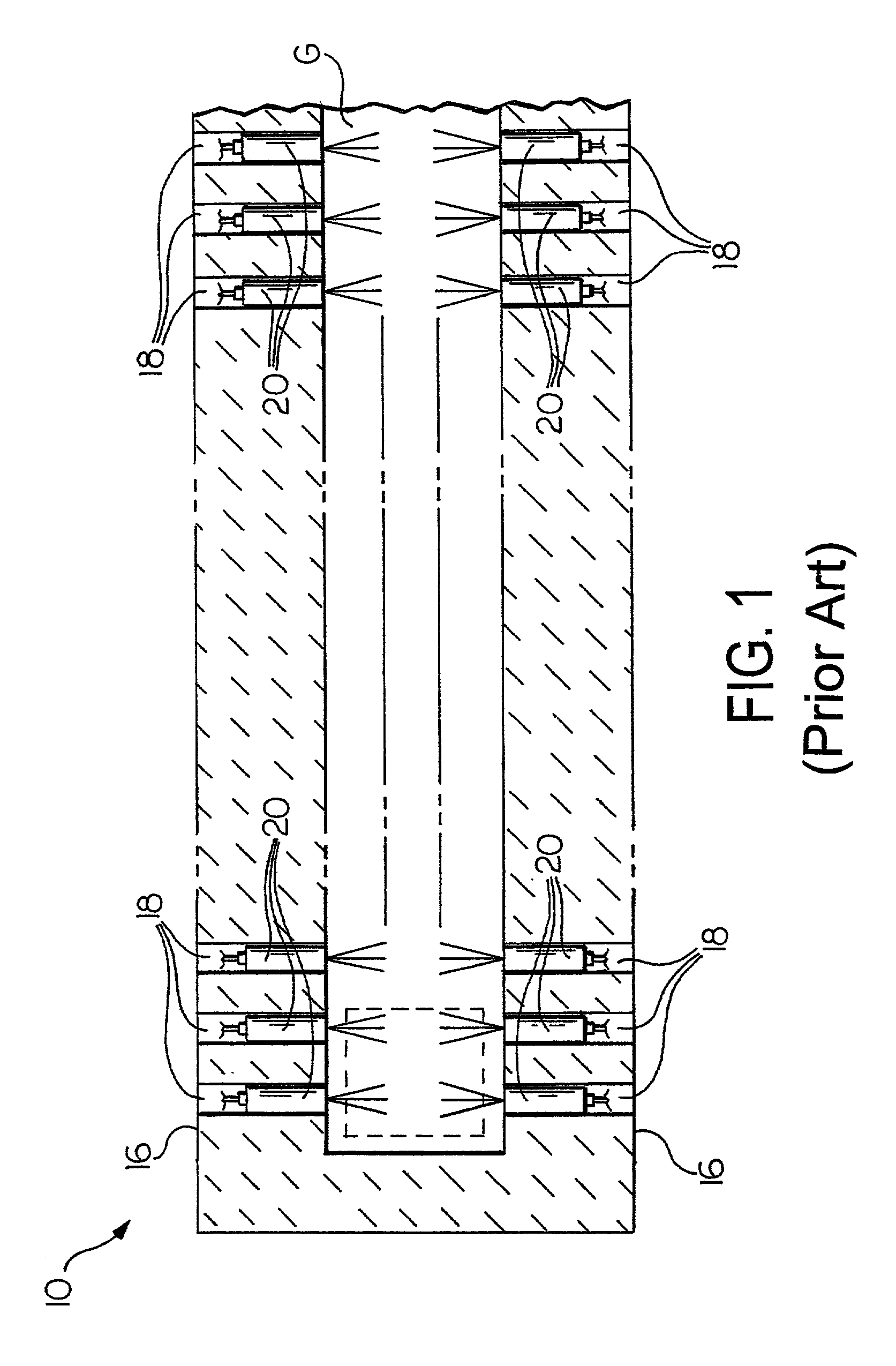

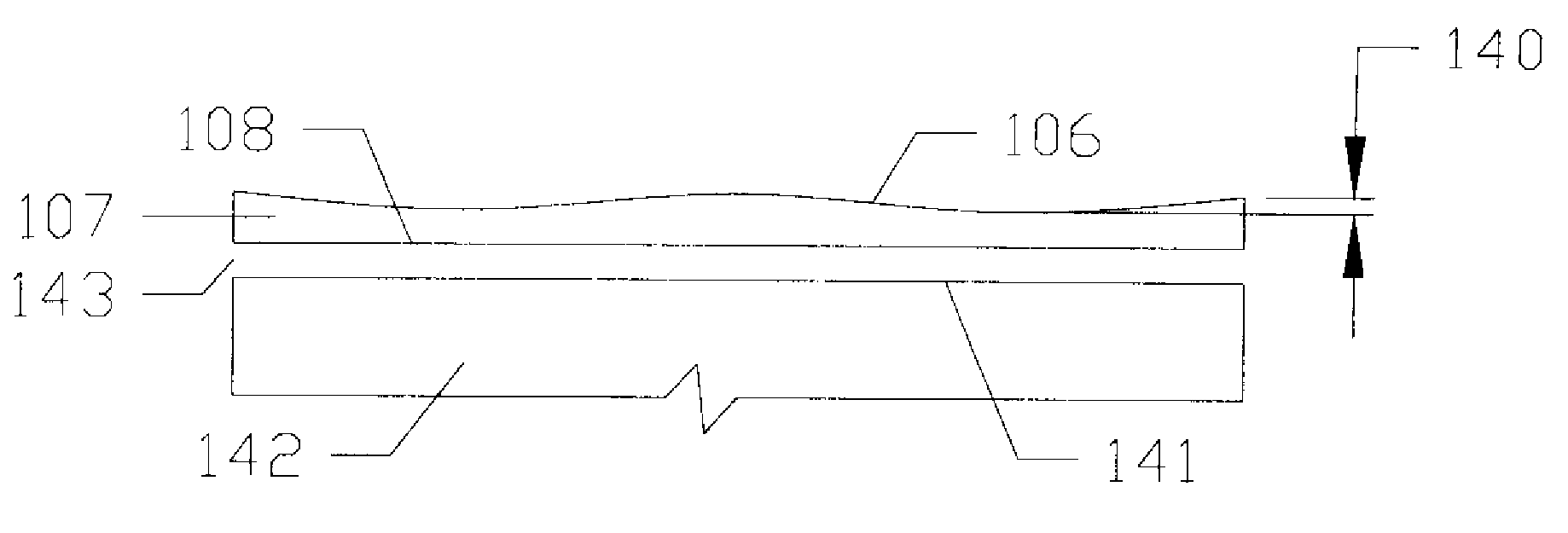

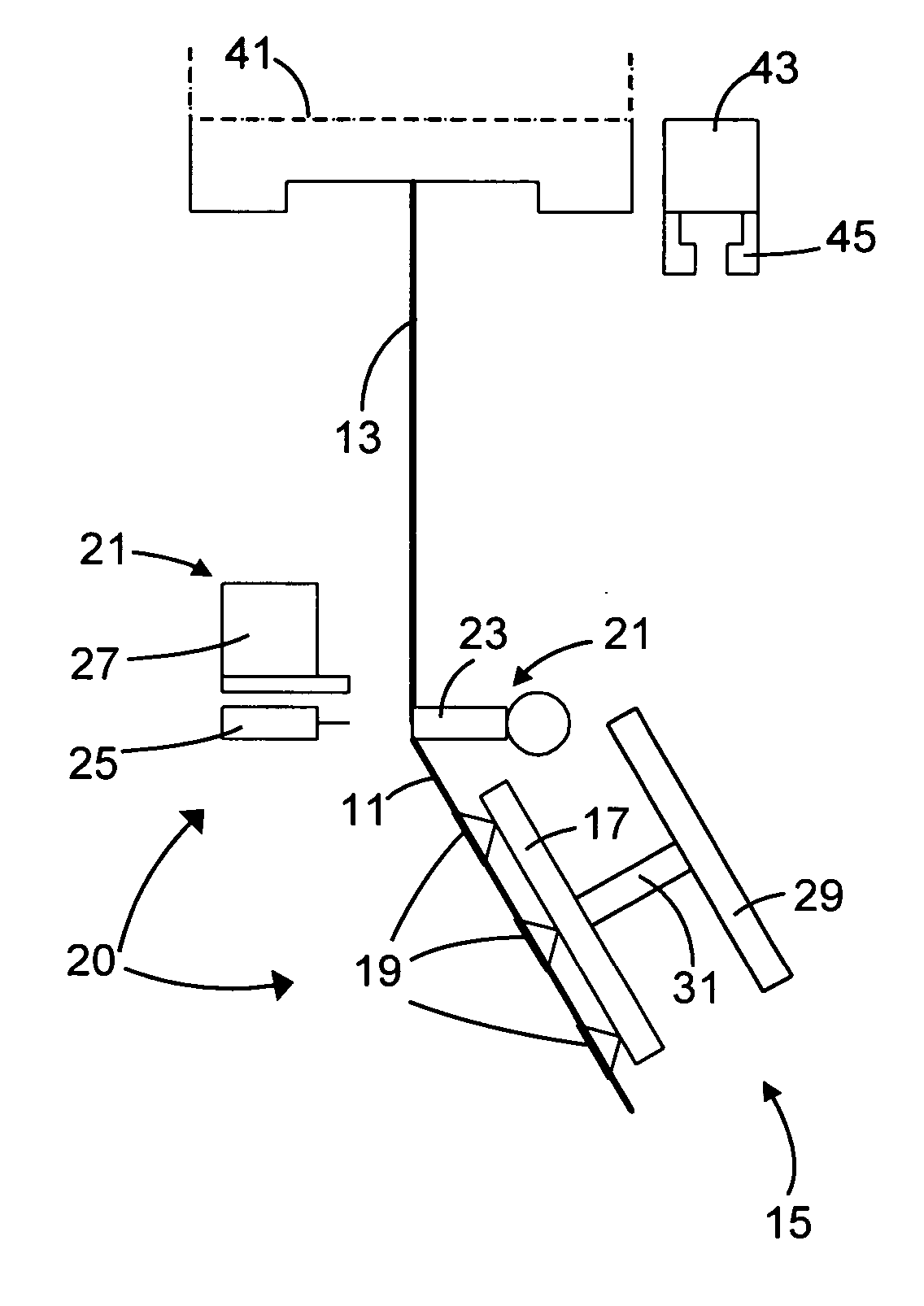

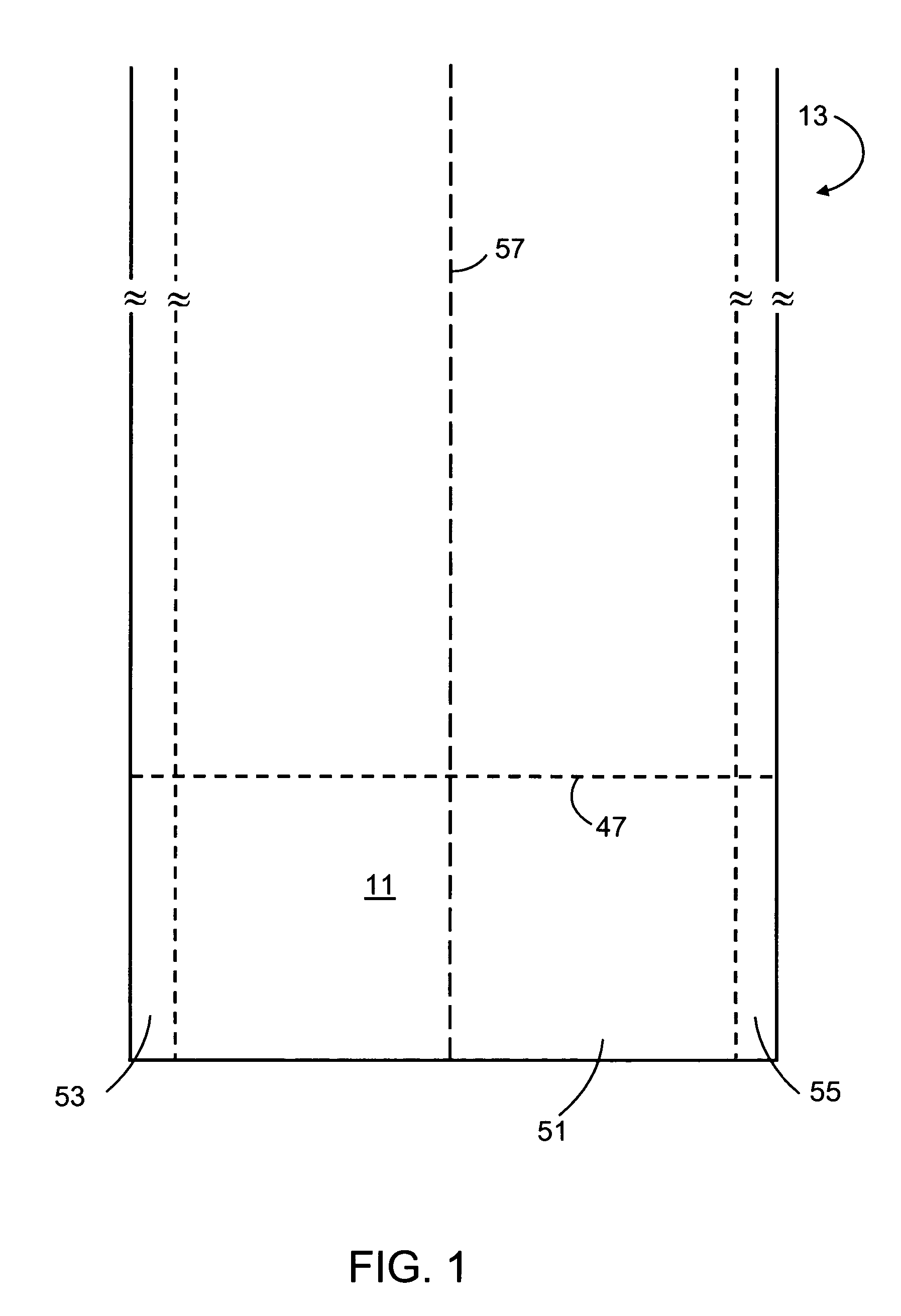

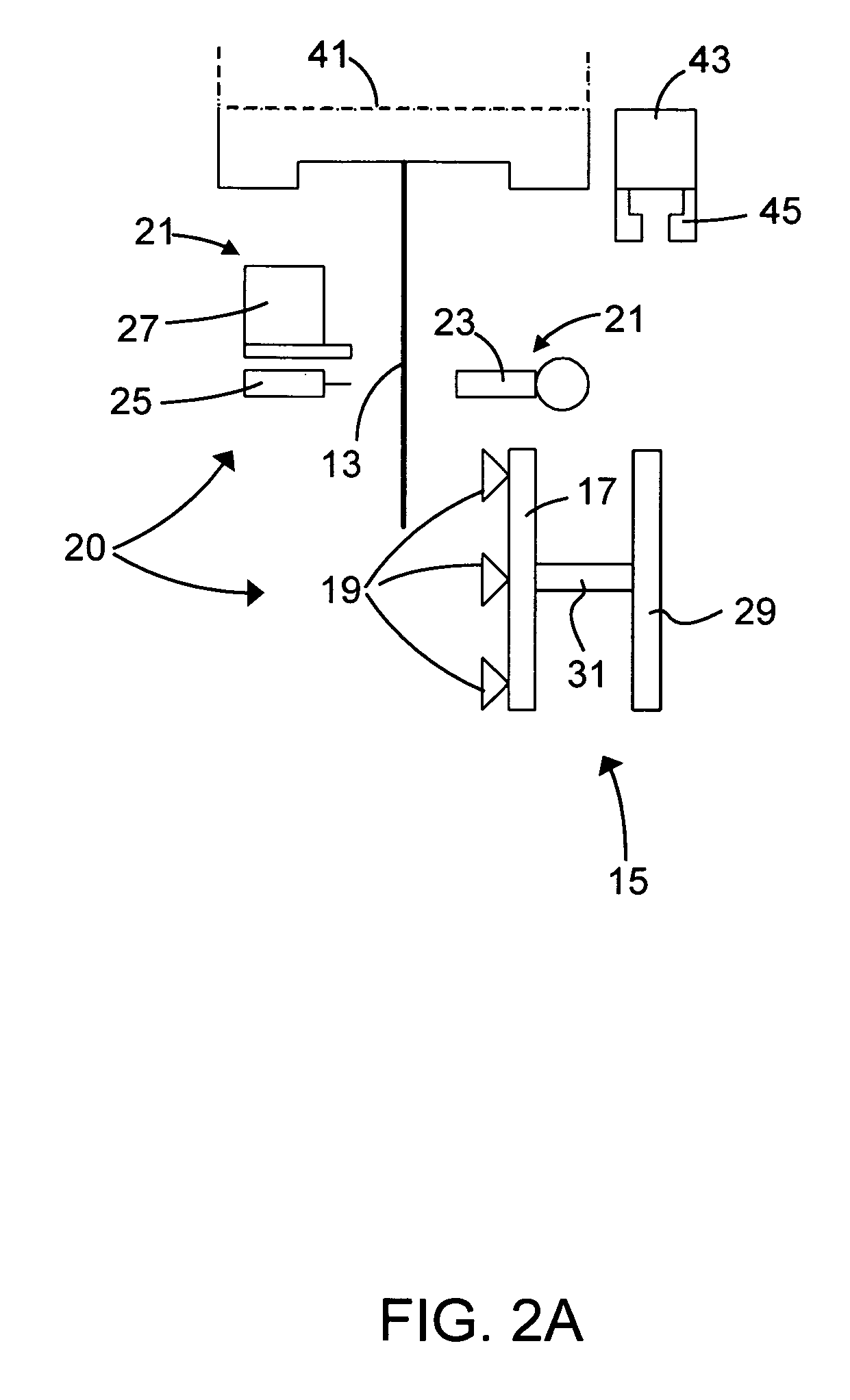

Methods and apparatus for reducing stress variations in glass sheets produced from a glass ribbon

InactiveUS20070095108A1Reduce exerciseStress variationRotary drum furnacesGlass transportation apparatusStress levelStress variation

Apparatus and methods are provided for reducing the variability of stress levels in glass sheets (11) cut from a moving glass ribbon (13). The reductions in variability are achieved by constraining the edge regions (53,55) of the ribbon (13) from movement in a horizontal plane at at least one location below the location where a separating assembly (20) forms a separation line (47) in the ribbon (13). Sets of vertically arranged wheels (35) which engage the edge regions (53,55) of the ribbon (13) can be used to provide the horizontal constraint without compromising the central, quality area (51) of the glass ribbon (13).

Owner:CORNING INC

Optical glass, press-molding glass gob and optical element

ActiveUS20040145815A1Reduce colorHigh refractive indexGlass transportation apparatusMountingsRefractive indexOptical glass

An optical glass whose refractive index is high and whose coloring is decreased comprising, by weight %, 2 to 45% of B.sub.2O.sub.3, 0 to 30% of SiO.sub.2 provided that the content of B.sub.2O.sub.3>the content of SiO.sub.2, 10 to 50% of La.sub.2O.sub.3, 0 to 30 % of TiO.sub.2, 0 to 15% of ZnO, 0 to 15% of ZrO.sub.2, 0 to 35% of Nb.sub.2O.sub.5, 0 to 35% of BaO, 0 to 5% of SrO, 0% or more but less than 8% of CaO, 0% or more but less than 13% of MgO, provided that the total content of BaO, SrO, CaO and MgO is 0 to 40%, 0 to 20% of Gd.sub.2O.sub.3, 0 to 15% of Y.sub.2O.sub.3, 0 to 18% of Ta.sub.2O.sub.5, 0% or more but less than 0.5% of WO.sub.3, 0 % or more but less than 1.5% of a total of Na.sub.2O, K.sub.2O and Li.sub.2O, 0 to 10% of GeO.sub.2, 0 to 20% of Bi.sub.2O.sub.3, 0 to 10% of Yb.sub.2O.sub.3, 0 to 10% of Al.sub.2O.sub.3, 0% or more but less than 2% of Sb.sub.2O.sub.3 and 0 to 1% of SnO.sub.2.

Owner:HOYA CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com