Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

80results about How to "Improve glass strength" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

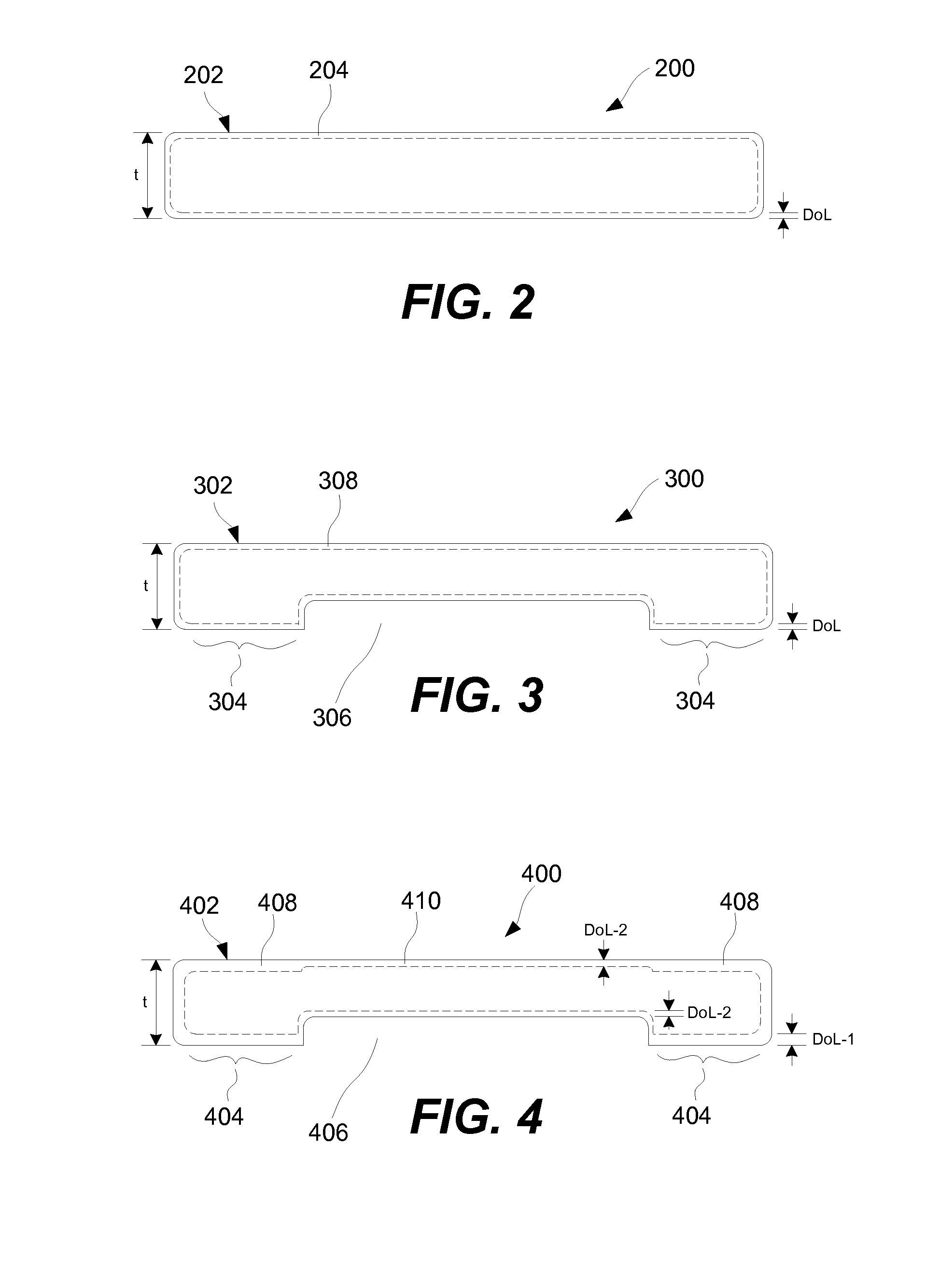

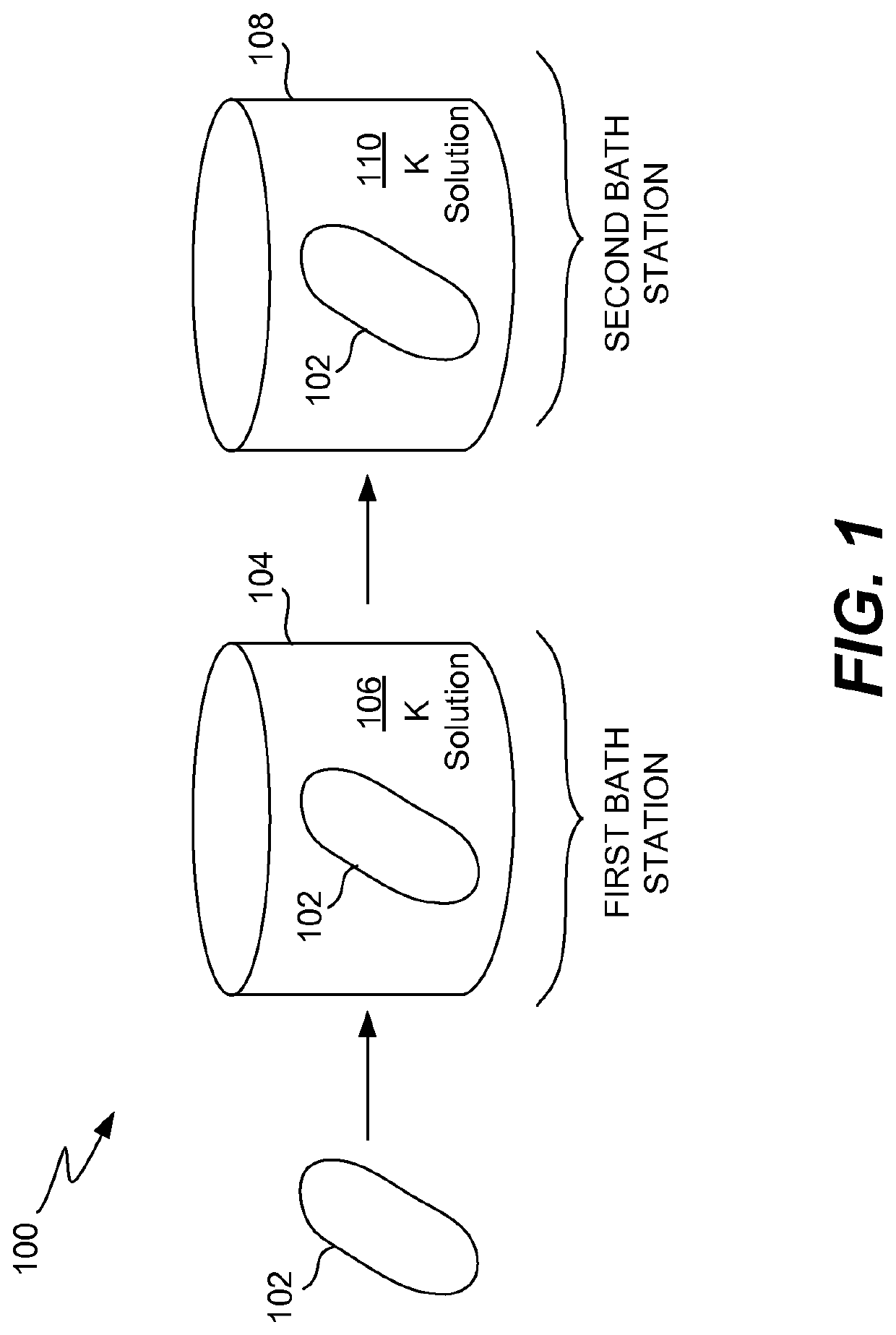

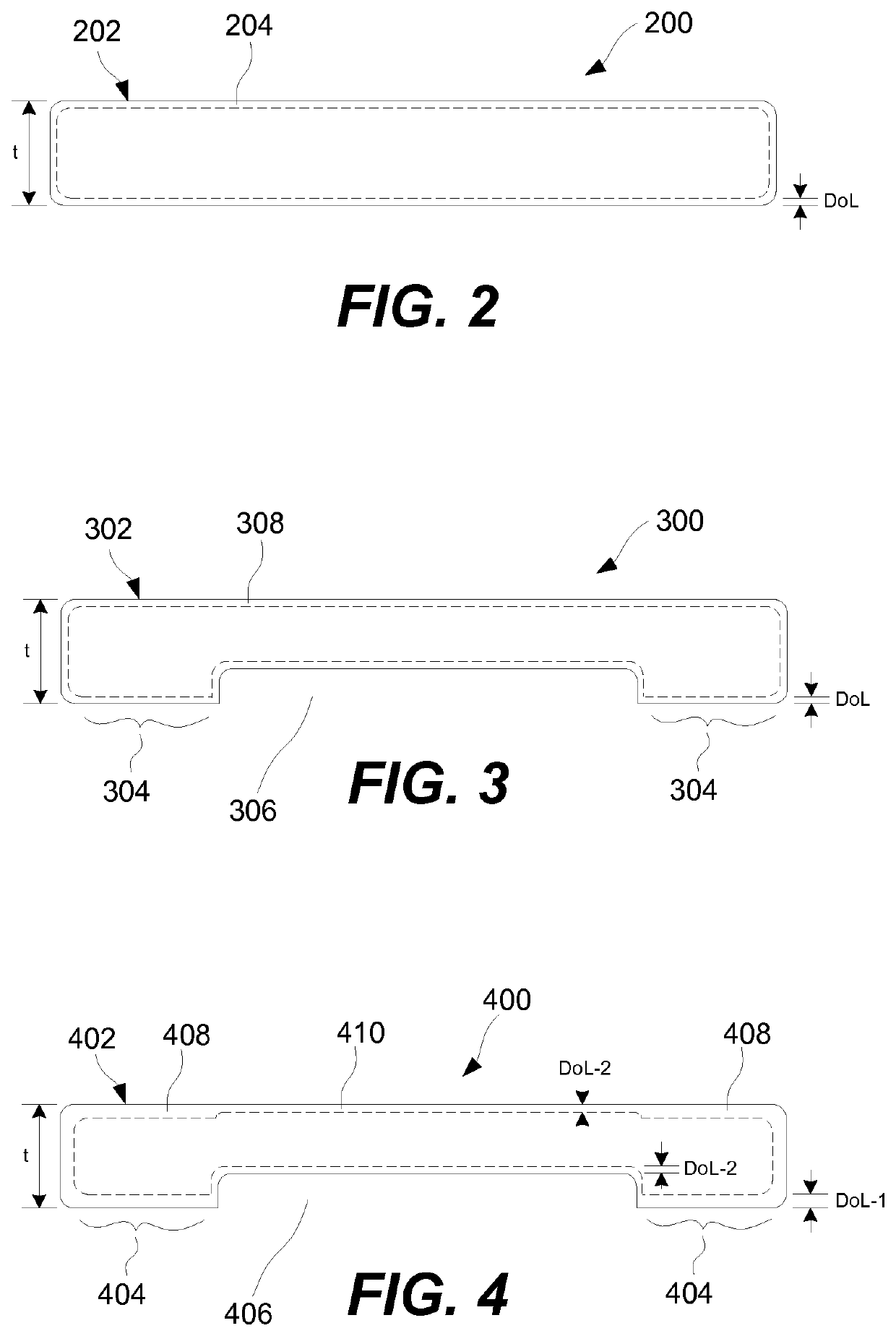

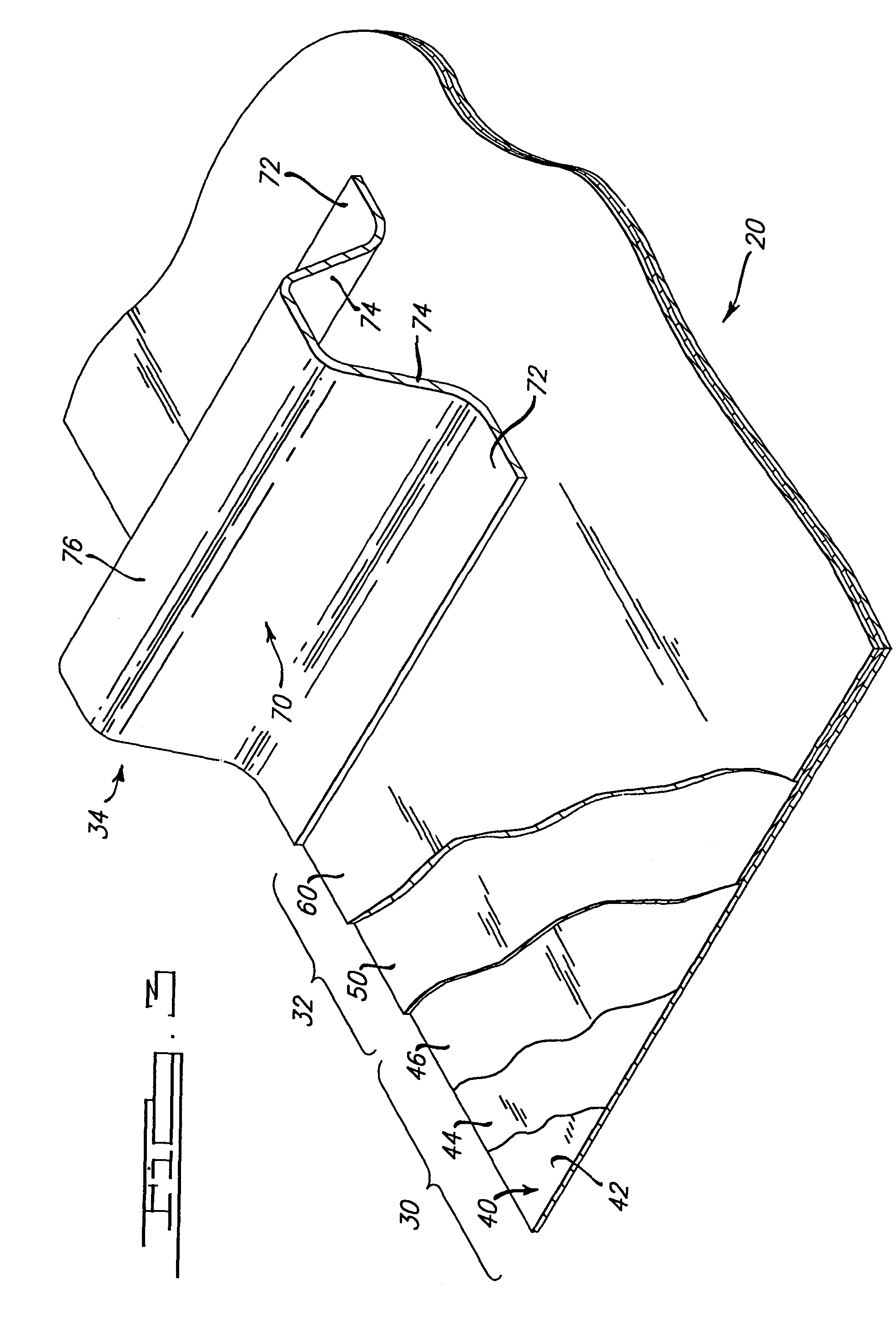

Strengthening variable thickness glass

ActiveUS20120236526A1Improve glass strengthFacilitate controlled chemical strengtheningCircuit arrangements on conductive chasisMaterials scienceElectronic equipment

Apparatus, systems and methods for increasing the strength of glass are disclosed. The use of multi-bath chemical processing for a glass article can facilitate controlled chemical strengthening. Through multi-bath (or multi-step) chemical processing, differing levels of strengthening can be achieved for different portion of glass articles. The multi-bath chemical processing can be achieved through the use of successive chemical baths. Accordingly, glass articles that have undergone multi-bath chemical processing are able to be not only thin but also sufficiently strong and resistant to damage. The strengthened glass articles are well suited for use in consumer products, such as consumer electronic devices (e.g., portable electronic devices). In one embodiment, the glass member can pertain to a glass cover for a housing of an electronic device.

Owner:ALLLE INC

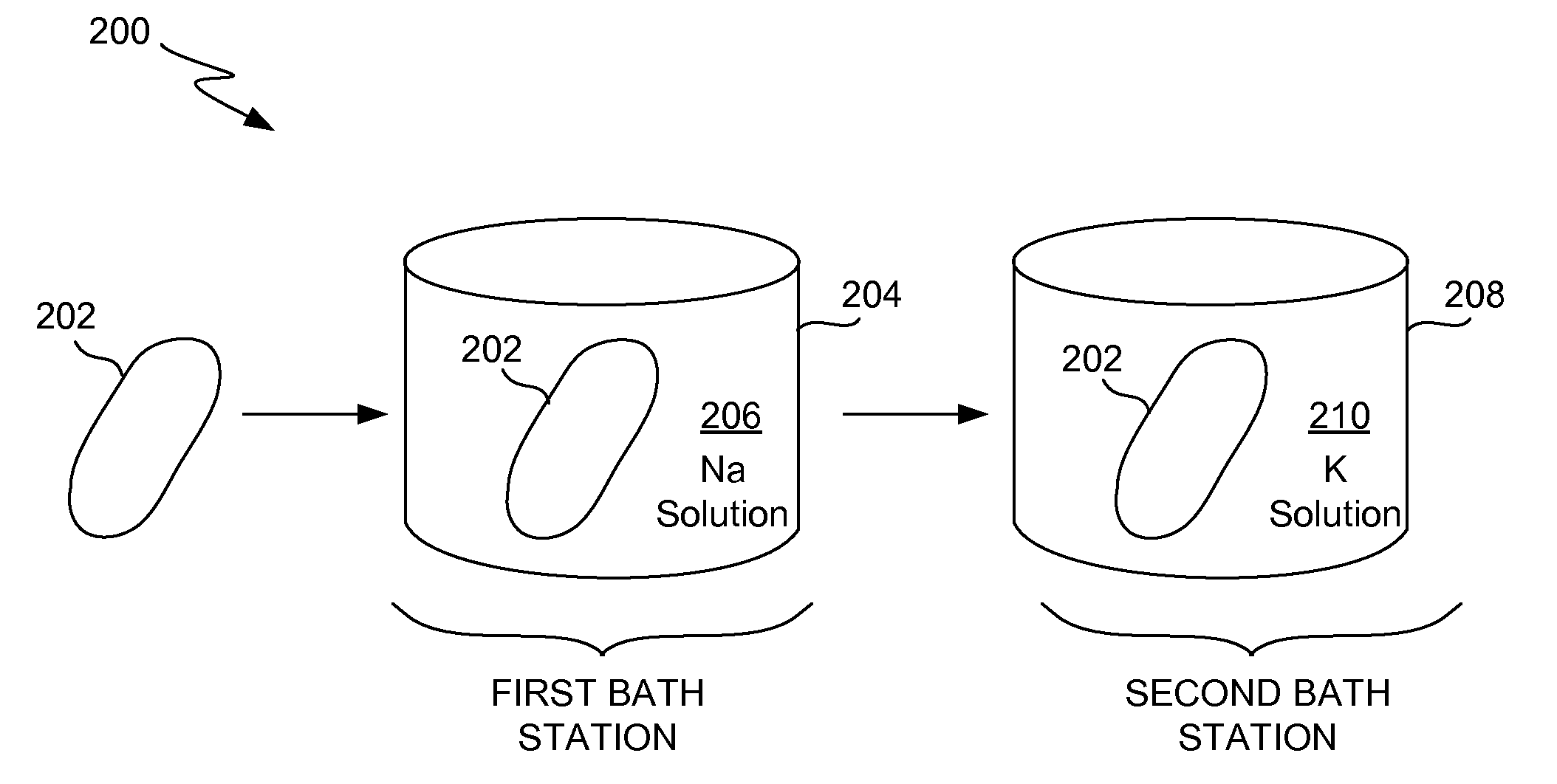

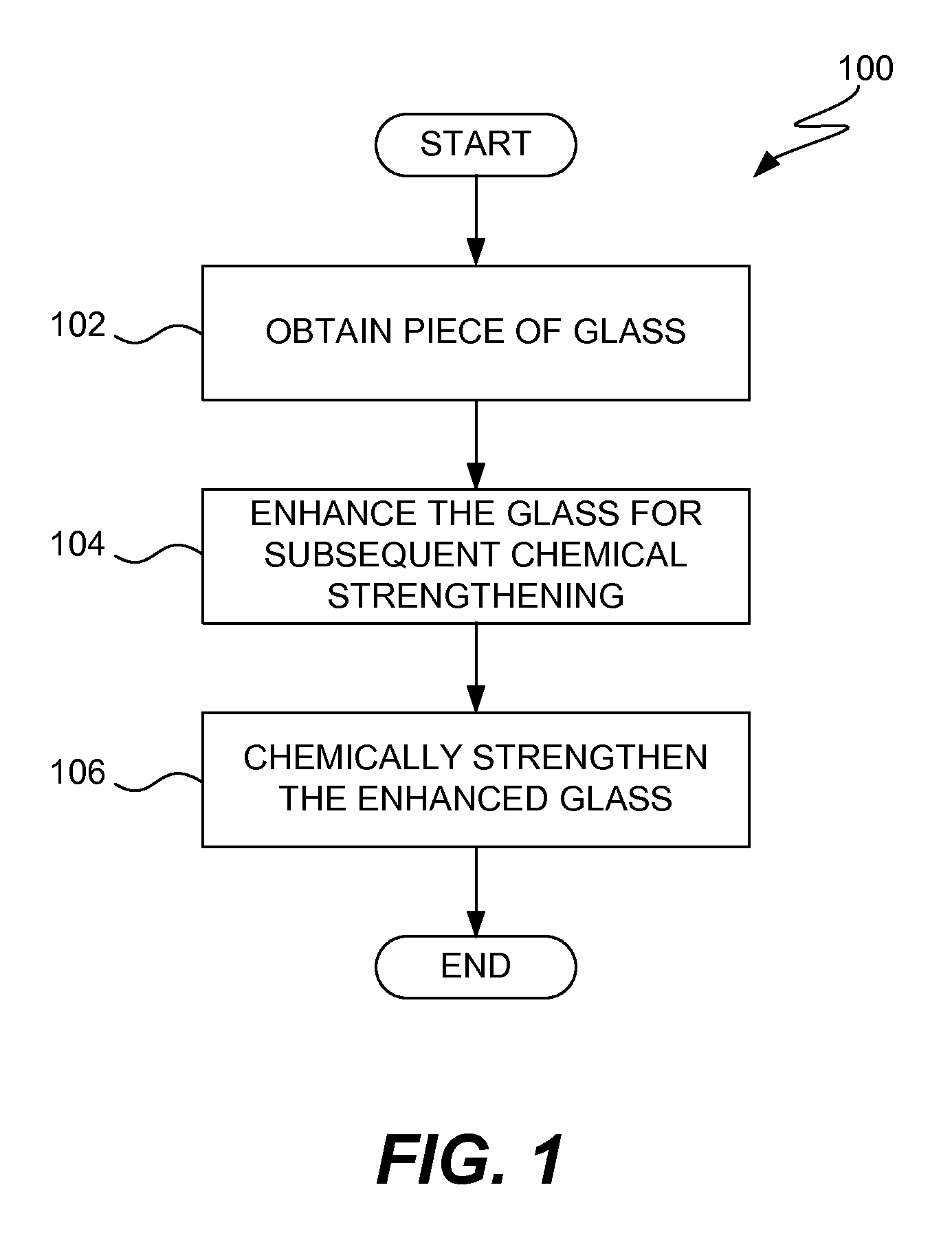

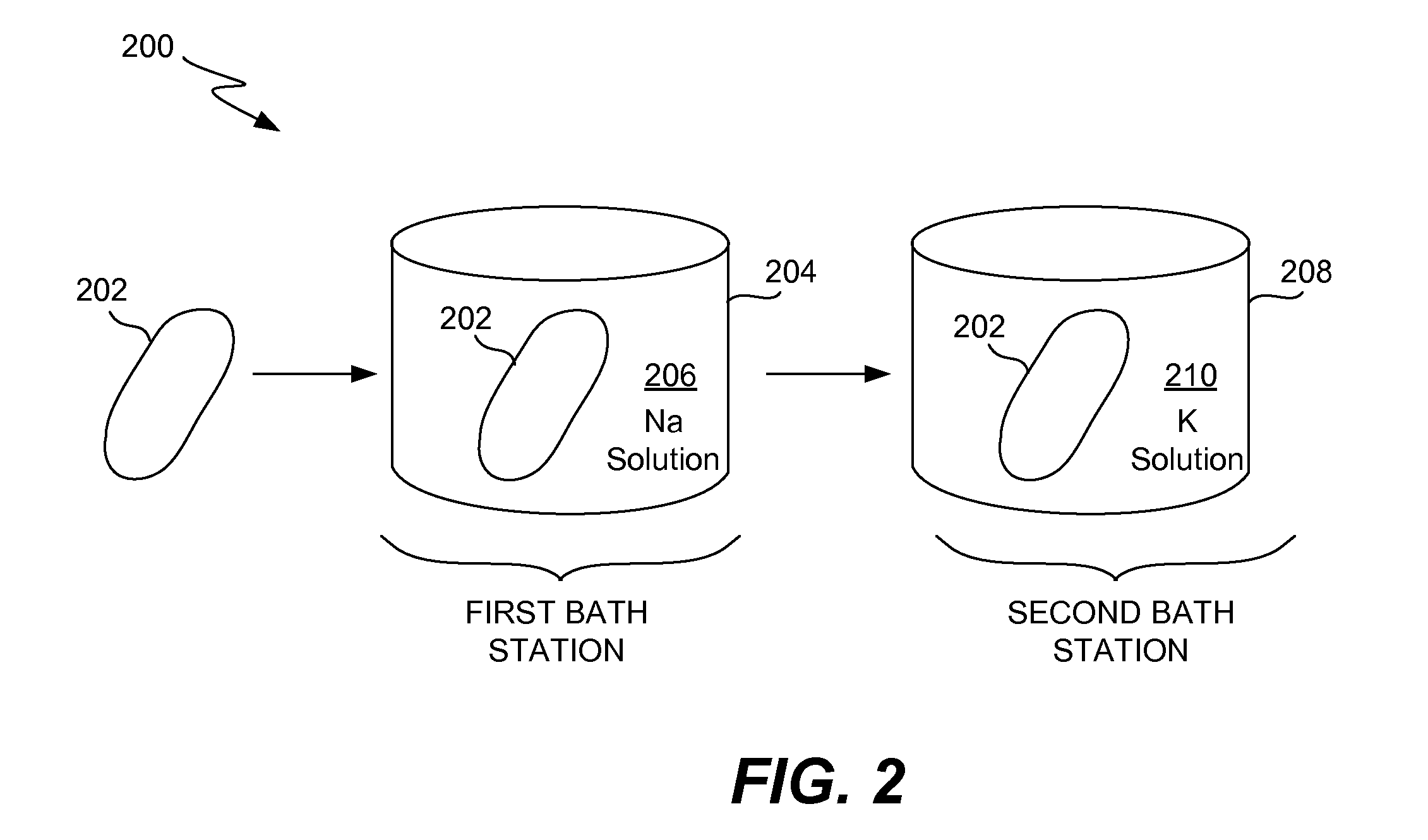

Enhanced Strengthening of Glass

ActiveUS20110067447A1Improve glass strengthImprove the level ofGlass drawing apparatusGlass transportation apparatusChemical treatmentGlass cover

Apparatus, systems and methods for improving strength of a thin glass member for an electronic device are disclosed. In one embodiment, the glass member can have improved strength by using multi-bath chemical processing. The multi-bath chemical processing allows greater levels of strengthening to be achieved for glass member. In one embodiment, the glass member can pertain to a glass cover for a housing of an electronic device.

Owner:APPLE INC

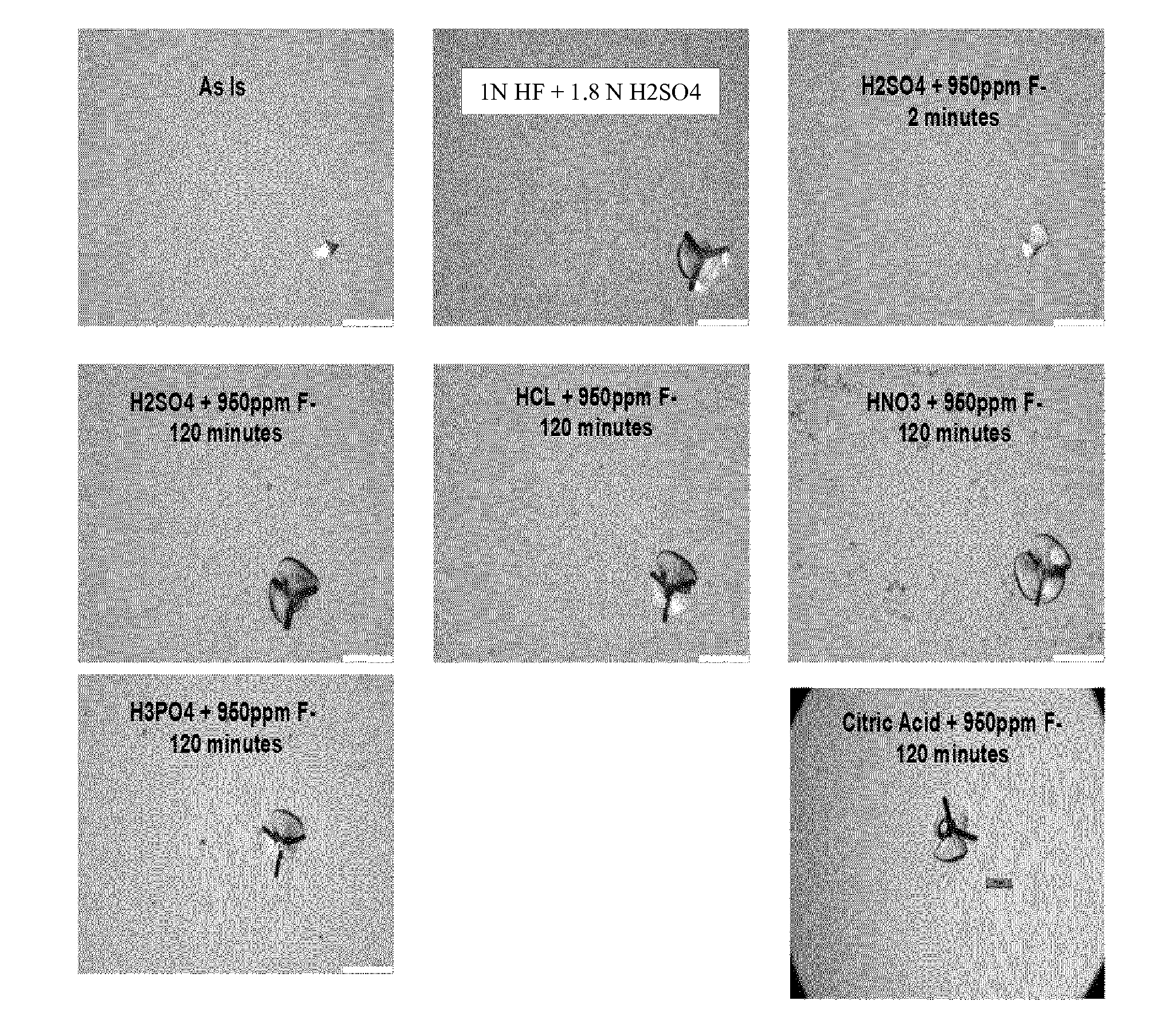

Acid strengthening of glass

ActiveUS20130122306A1Improve glass strengthIncrease in glass article strengthGlass/slag layered productsGlass reforming apparatusComposite materialFluoride

Disclosed herein are methods for strengthening glass articles having strength-limiting surface flaws, together with strengthened glass articles produced by such methods, and electronic devices incorporating the strengthened glass articles. The methods generally involve contacting the glass articles with a substantially fluoride-free aqueous acidic treating medium for a time at least sufficient to increase the rupture failure points of the glass articles.

Owner:CORNING INC

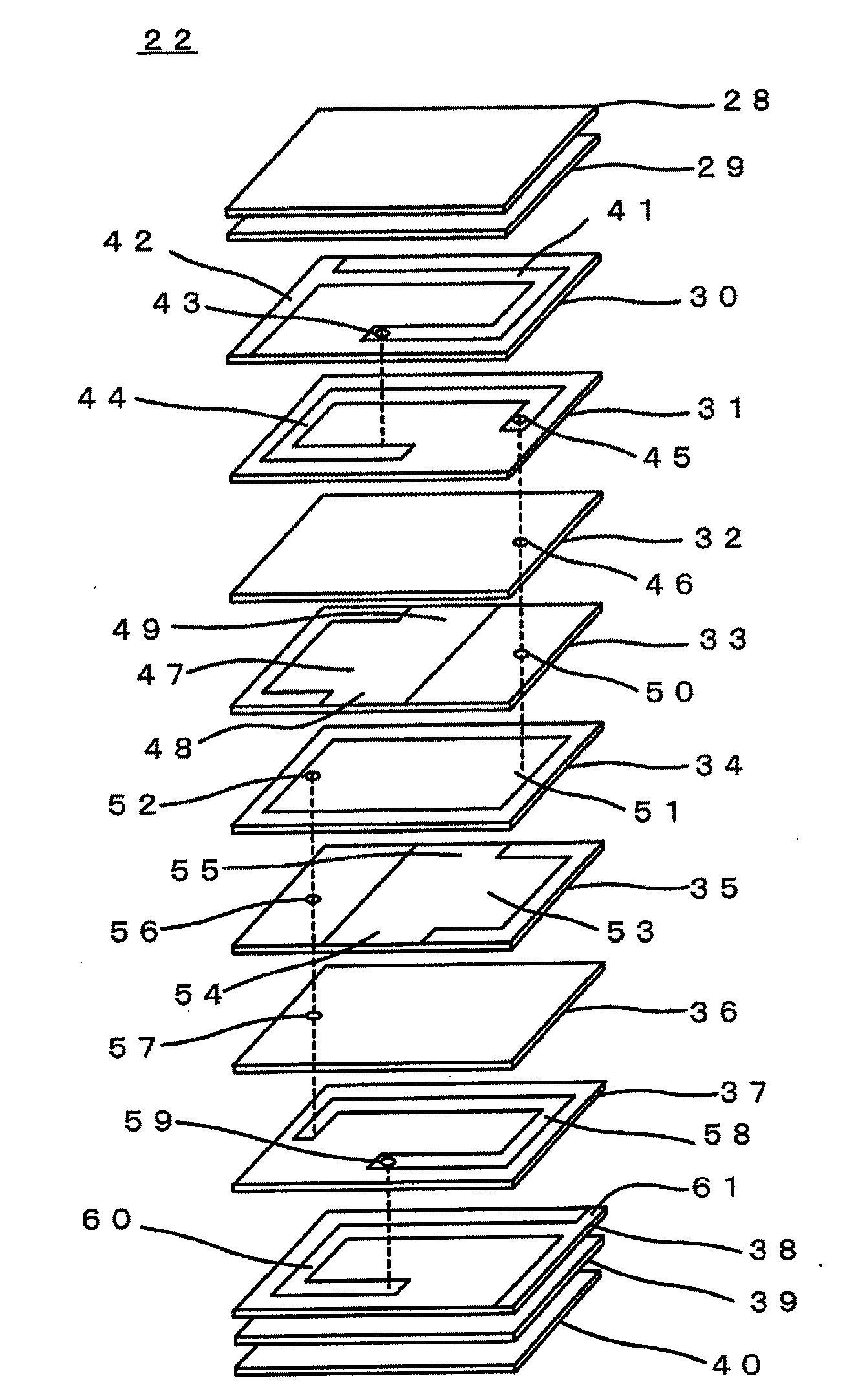

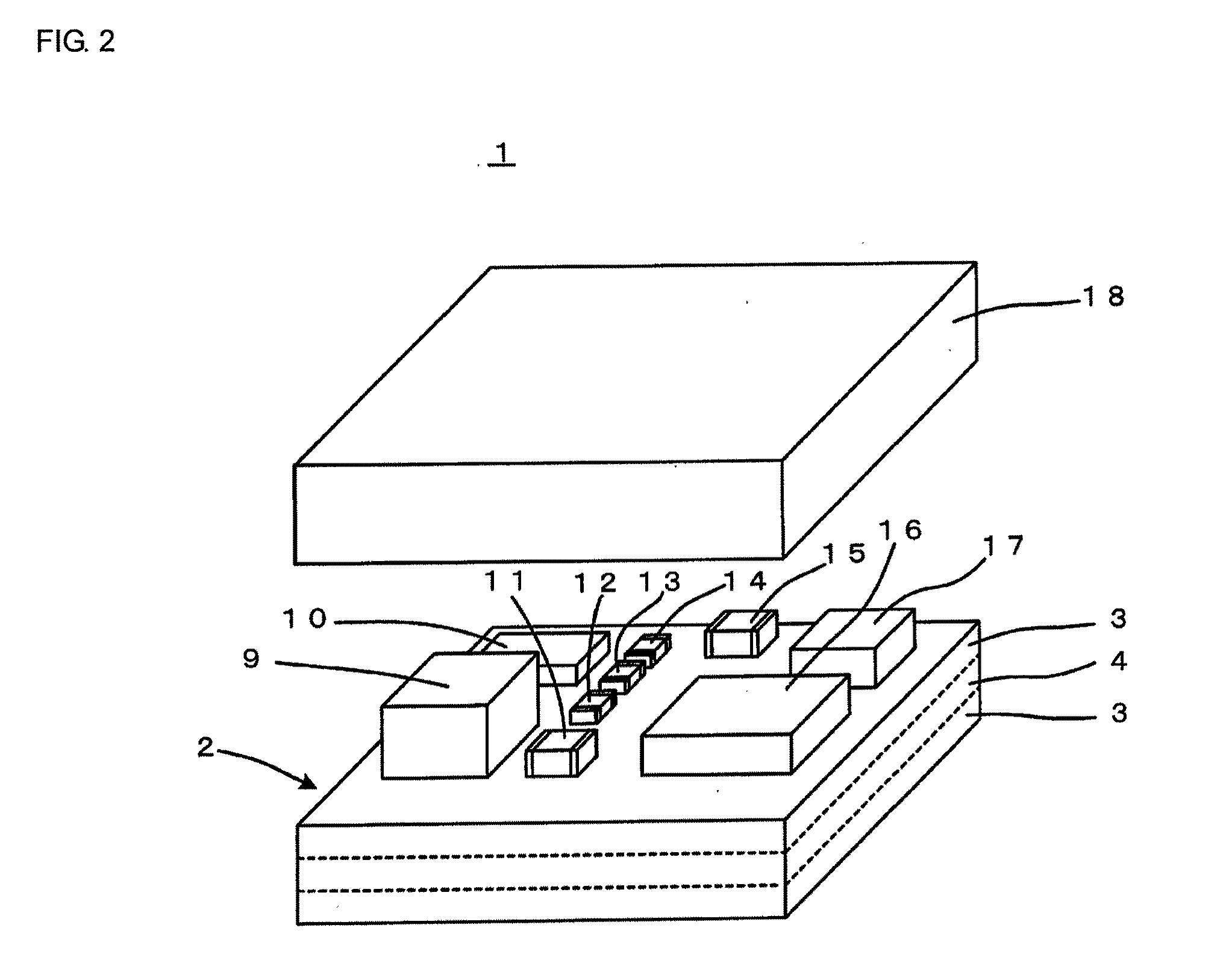

Glass ceramic composition, glass ceramic sintered body, and multilayer ceramic electronic device

ActiveUS20100046137A1Good chemical stabilityLow dielectric constantFixed capacitor electrodesFixed capacitor dielectricCapacitanceFlexural strength

A glass ceramic composition is provided which can be fired at a temperature of 1,000° C. or less to form a sintered body having a low relative dielectric constant, a small temperature coefficient of resonant frequency, a small change in capacitance before and after a loading test, a high Qf value, high electrical insulating reliability, and a high flexural strength. A glass ceramic composition forming glass ceramic layers laminated to each other in a multilayer ceramic substrate is also provided. The glass ceramic composition includes a first ceramic powder containing forsterite as a primary component; a second ceramic powder containing SrTiO3 and / or TiO2 as a primary component; a third ceramic powder containing BaZrO3 as a primary component; a fourth ceramic powder containing SrZrO3 as a primary component; and a borosilicate glass which contains Li2O, MgO, B2O3, SiO2, and ZnO, and also which contains at least one of CaO, BaO, and SrO.

Owner:MURATA MFG CO LTD

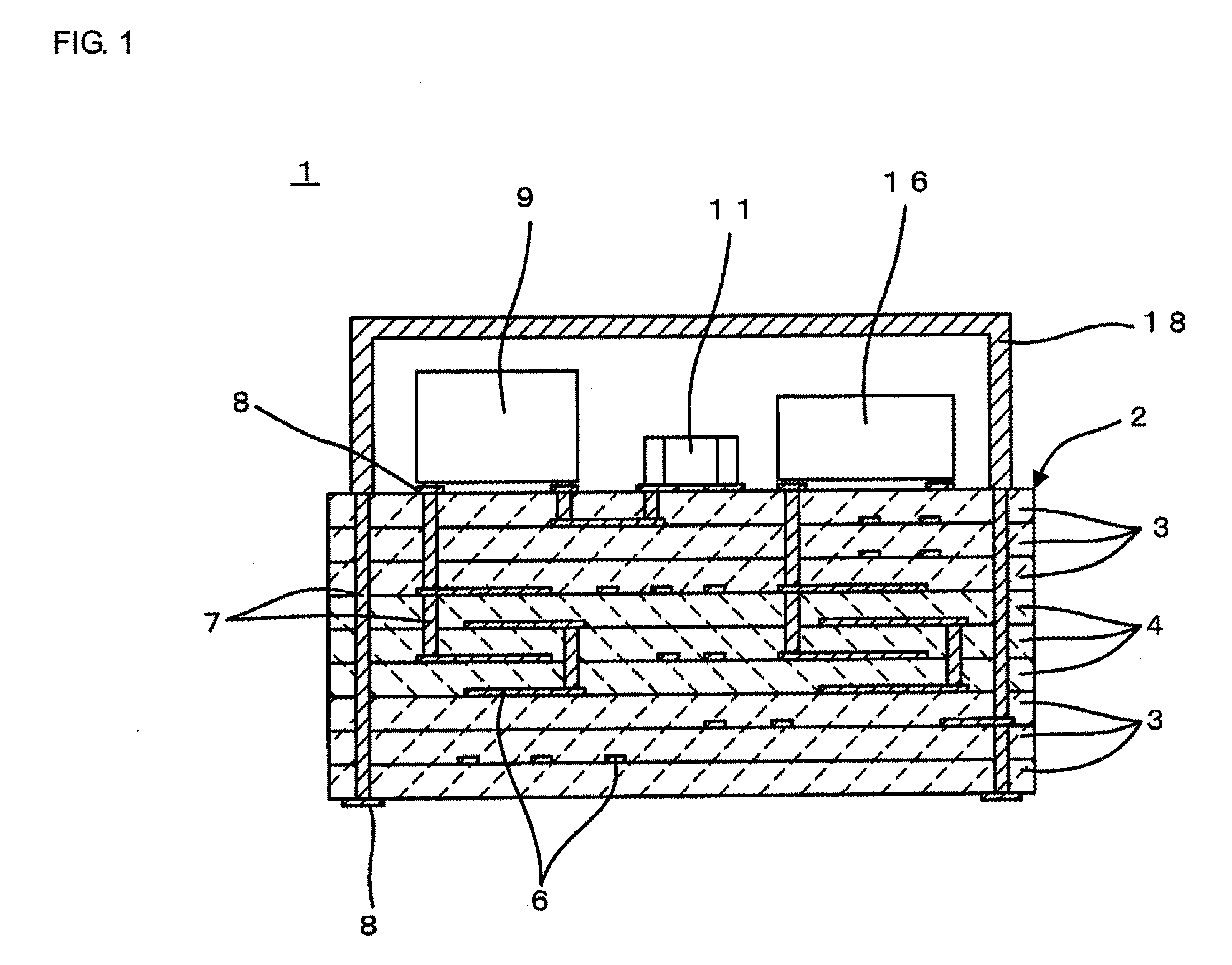

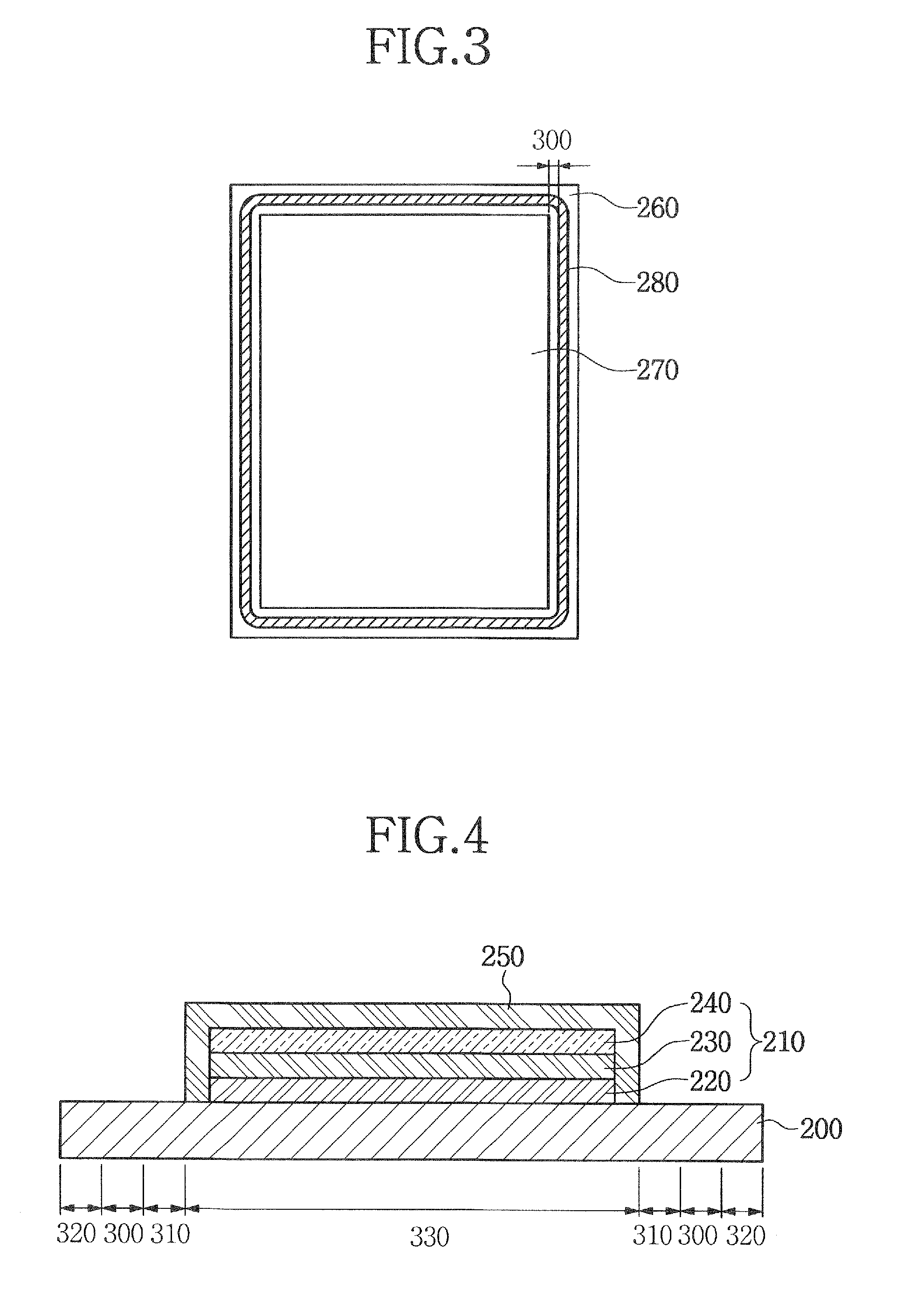

Encapsulation substrate, organic light emitting diode display device having the same and method of fabricating the same

ActiveUS20110031479A1Improve glass strengthSimplify the manufacturing processLiquid surface applicatorsElectroluminescent light sourcesOLEDDisplay device

An organic light emitting diode (OLED) display device and method of fabrication that includes a substrate having a device region, an outer dam region and an encapsulation region. The encapsulation region includes an inner dam region, an outer dam region and an encapsulation region that correspond to the device region. An encapsulation agent is formed in the encapsulation region of the encapsulation substrate, and filling dams are formed of the same material in the outer dam region and the inner dam region of the encapsulation substrate.

Owner:SAMSUNG DISPLAY CO LTD

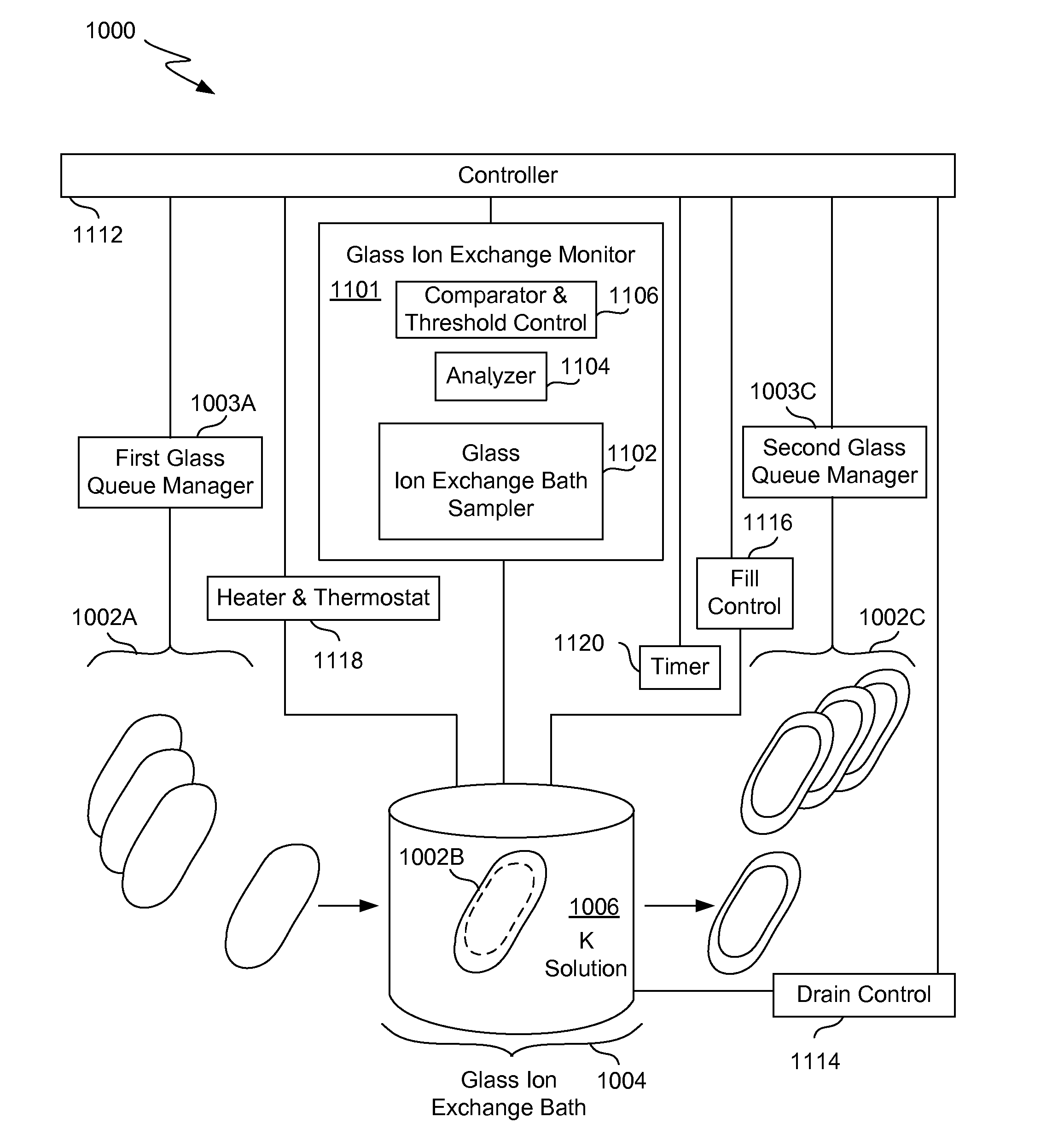

Self-optimizing chemical strengthening bath for glass

InactiveUS20130128416A1Improve glass strengthBlowing machine gearingsDigital data processing detailsIonIon exchange

Apparatus, systems and methods for improving strength of a thin glass member for an electronic device are disclosed. In one embodiment, the glass member can be strengthened chemically using a monitored ion exchange process in which the glass member is disposed in a glass ion exchange bath. In one embodiment, the glass member can pertain to a cover glass for housings of electronic devices.

Owner:APPLE INC

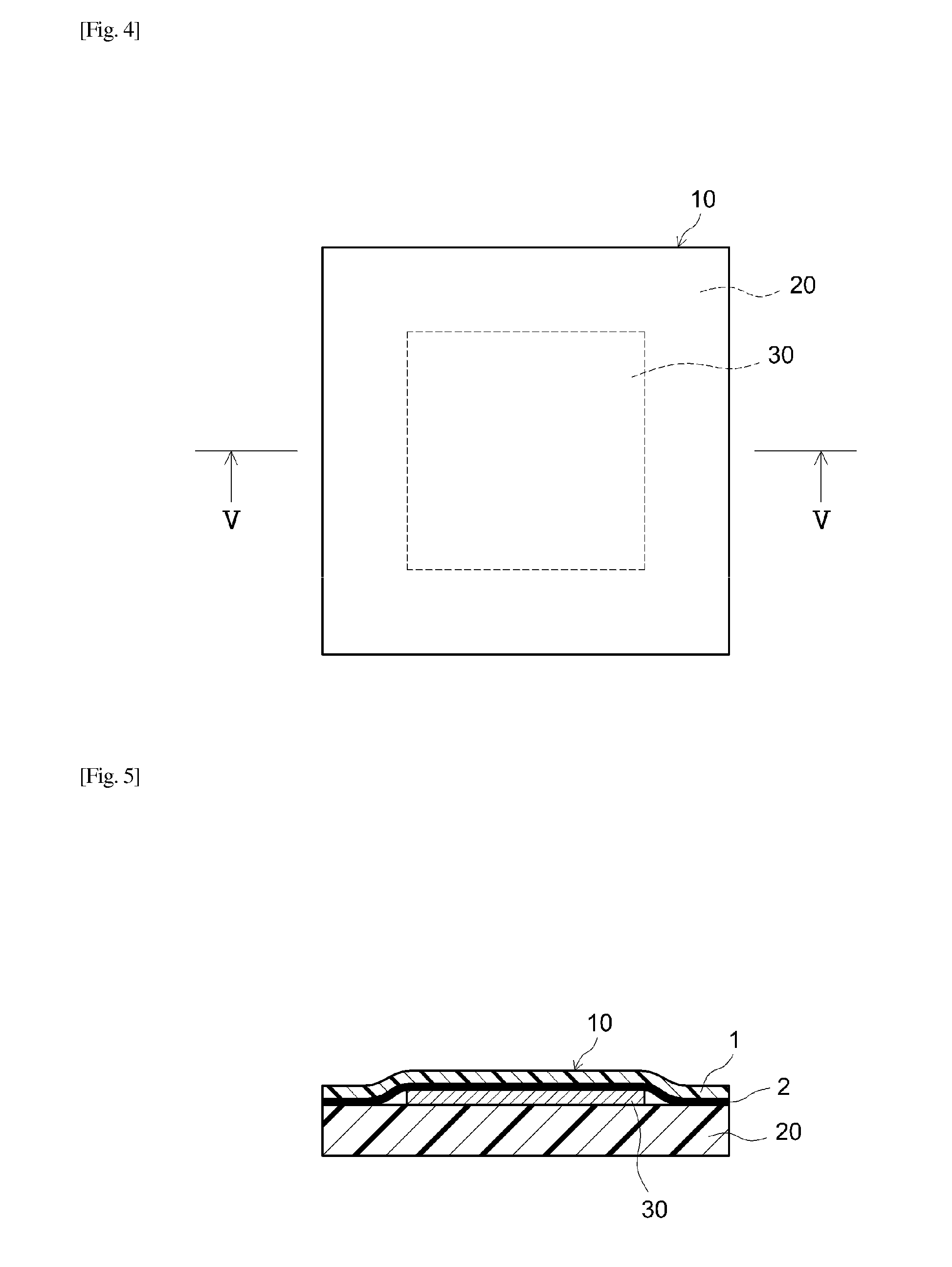

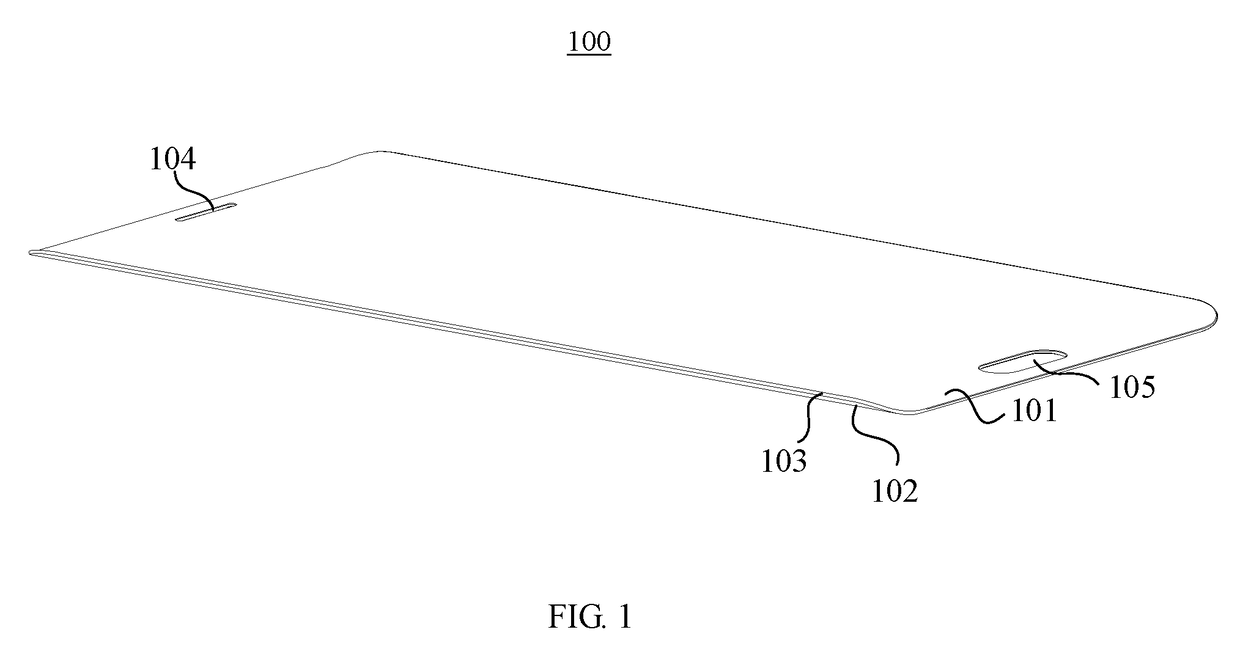

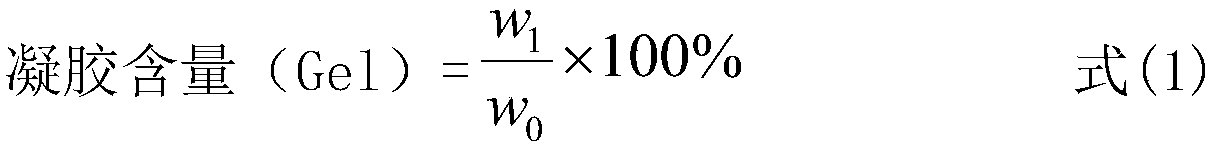

Protective sheet for glass etching

InactiveUS20140158300A1Appropriate hardnessEfficient use ofFilm/foil adhesivesSemiconductor/solid-state device manufacturingHydrogen atomMethyl group

This invention provides a protective sheet for glass etching, having excellent etching solution penetration resistance, non-contaminating property and peeling efficiency. The protective sheet comprises a substrate and a PSA layer provided on one face of the substrate, such that, when the protective sheet is adhered to a non-etching area when etching glass, it protects the non-etching area from an etching solution. The PSA layer is constituted with a PSA having a gel fraction of 60% or higher. The PSA is an acrylic PSA comprising an acrylic polymer as a primary component. The acrylic polymer is synthesized by polymerizing starting monomers comprising, as a primary monomer, a monomer represented by a formula: CH2═CR1COOR2 (R1 is a hydrogen atom or a methyl group, and R2 is an alkyl group). The primary monomer comprises as a primary component a monomer with R2 being an alkyl group having 6 or more carbons.

Owner:NITTO DENKO CORP +1

Glass housing, manufacturing equipment and method thereof

ActiveUS20180037488A1Improve glass strengthEasy to crackDigital data processing detailsCasings/cabinets/drawers detailsEngineering

A glass housing includes an inner surface; an outer surface opposite to the inner surface; and a circumferential surface interconnecting the outer surface and the inner surface, wherein a distance between the inner surface and the outer surface ranges from 0.2 mm to 1 mm, each of the inner surface and the outer surface includes a planar portion and two curved portions extending outwardly from opposite edges of the planar portion toward a side of the inner surface, the curved portion is an arc surface having a radius of curvature ranging from 5 mm to 50 mm. The present disclosure further provides a manufacturing device and manufacturing method of manufacturing the glass housing.

Owner:ANHUI JINGZHUO OPTICAL DISPLAY TECH CO LTD

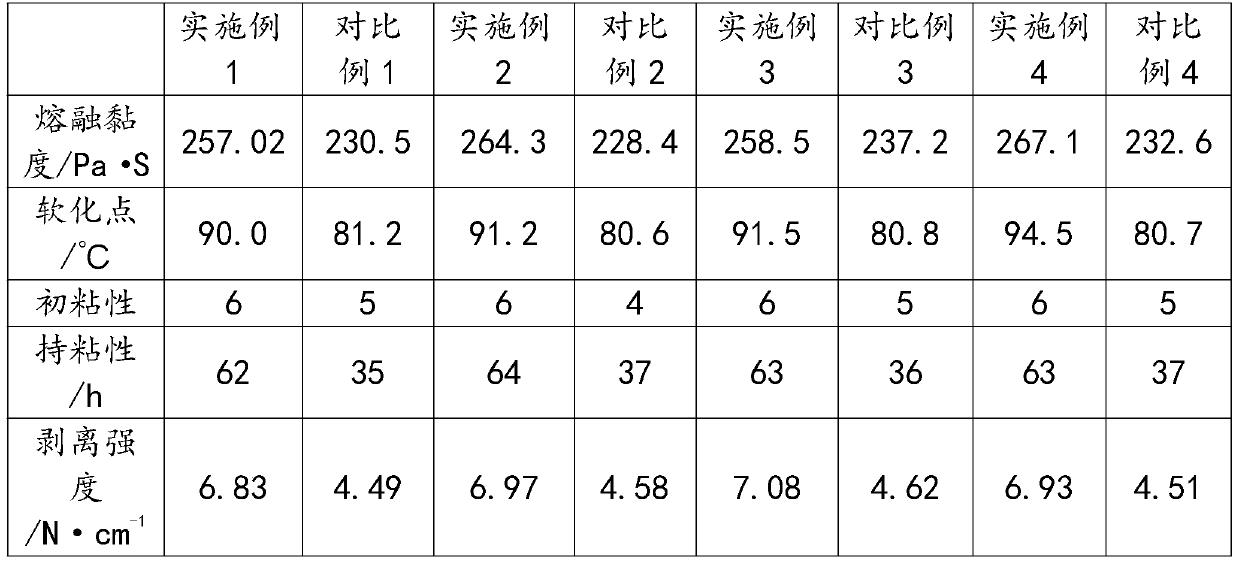

Environmentally-friendly hot-melt pressure sensitive adhesive and preparation method thereof

PendingCN110093128AUniform molecular weightGood solubilityMineral oil hydrocarbon copolymer adhesivesNon-macromolecular adhesive additivesEnvironmental resistanceAntioxidant

The invention discloses an environmentally-friendly hot-melt pressure sensitive adhesive. The environmentally-friendly hot-melt pressure sensitive adhesive is prepared from, by weight, 25-35 parts ofa thermoplastic elastomer, 28-36 parts of modified petroleum resin, 6-10 parts of natural tackifying resin, 12-20 parts of a plasticizer, 2-3 parts of a modifying filler, 0.2-0.3 part of a coupling agent and 0.2-0.3 part of an antioxidant. The present invention also discloses preparation method of the hot-melt pressure sensitive adhesive. The thermoplastic elastomer is used as a matrix for the hot-melt pressure sensitive adhesive, the modified petroleum resin and the natural tackifying resin are used as tackifying resins, and no organic solvent is needed, so the raw materials are safe and environmentally friendly; the petroleum resin is modified, so the compatibility of the petroleum resin and the thermoplastic elastomer is improved, and the thermal stability of the hot-melt pressure sensitive adhesive is improved; and the reinforcing effect of the modifying filler improves the initial viscosity, the glass strength and the thermal stability of the hot-melt pressure sensitive adhesive are improved, so the environmentally-friendly hot-melt pressure sensitive adhesive with excellent performances is prepared.

Owner:黄敏

Glass article and glass substrate for information recording media using the same

InactiveUS6713418B2Easy to useLarge ionic radiusBase layers for recording layersLight beam reproducingHydrofluoric acidWorking temperature

A glass article of the present invention has a rate of dissolution in an acidic liquid of from 10 to 100 nm / min in terms of etching rate in immersing in a 0.1% by weight 50° C. aqueous solution of hydrofluoric acid and an average linear thermal expansion coefficient of 70x10<-7> / ° C. or higher as measured in the range of from -50° C. to 70° C., and the working temperature T4 (° C.) and the liquidus temperature TL (° C.) thereof satisfy the relationship: T4-TL>=-100° C.

Owner:HOYA CORP

Glass cutting method

InactiveUS7836727B2Breakage suppressedSuppress generationOther printing matterLamination ancillary operationsChemical solutionCutting glass

Owner:NISHIYAMA STAINLESS CHEMICAL KK

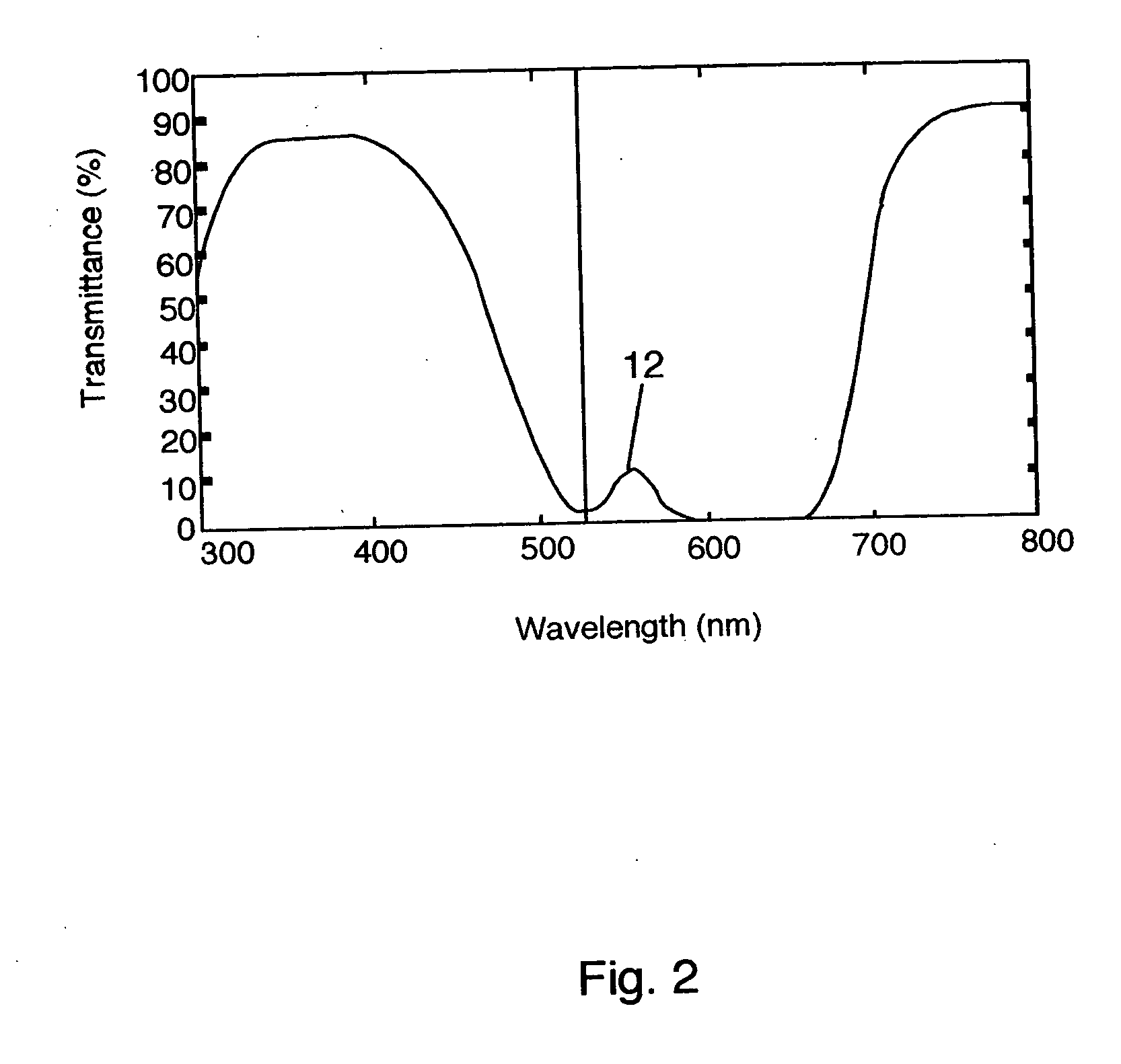

Glass substrate for a magnetic disk, a magnetic disk which can be formed with a stable texture and a magnetic disk device

InactiveUS20050013048A1Good chemical stabilityStable laser textureDead plant preservationMagnetic materials for record carriersRare earthTransmittance

A glass substrate for a magnetic disk contains a transition metal. The substrate, which is subjected to formation of zone texturing by irradiating the substrate with a laser beam, has a high mechanical strength even if it is not chemically strengthened. The glass substrate contains a transition metal element and has a transmittance of 10% of less for light in a wavelength range of 300 to 2000 nm. The surface roughness of an information recording surface portion thereof is 2.0 nm or less. In addition to a transition metal element, the glass substrate may include a rare earth metal element.

Owner:HITACHI GLOBAL STORAGE TECH JAPAN LTD

Glass substrate for cu-in-ga-se solar cell and solar cell using same

InactiveUS20130306145A1Improve glass strengthHigh glass transition temperaturePhotovoltaic energy generationSemiconductor devicesSolar cellMaterials science

A glass substrate for a CIGS solar cell containing specific amounts of SiO2, Al2O3, B2O3, MgO, CaO, SrO, BaO, ZrO2, TiO2, Na2O and K2O, respectively. The glass substrate satisfies the specific requirements regarding MgO+CaO+SrO+BaO, Na2O+K2O, MgO / Al2O3, (2Na2O+K2O+SrO+BaO) / (Al2O3+ZrO2), Na2O / K2O, the relation of Al2O3 and MgO, and the relation of CaO and MgO, respectively. The glass substrate has a glass transition temperature of 640° C. or higher, an average coefficient of thermal expansion within a range of 50 to 350° C. of 70×10−7 to 90×10−7 / ° C., the temperature (T4) of 1,230° C. or lower, the temperature (T2) of 1,650° C. or lower, and a density of 2.7 g / cm3 or less. The glass substrate satisfies the relationship of T4−TL≧−30° C.

Owner:ASAHI GLASS CO LTD

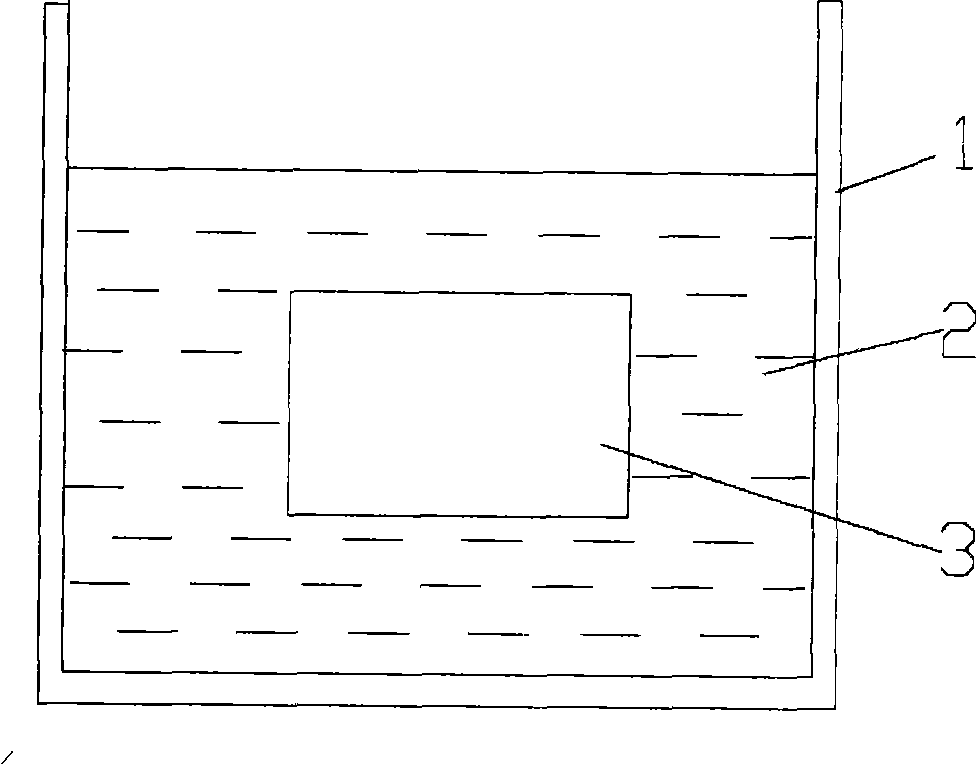

Catalyst for chemically enhancing glass, preparation and use thereof

ActiveCN101372393AIncrease compressive stressImprove glass strengthMolten saltUltimate tensile strength

The invention discloses a catalyst used for strengthening glass, a preparation method and the application thereof. The catalyst is prepared according to the following steps: component B is added into molten salt and melted for 1 to 5 hours, then potassium carbonate and component C are added into the molten salt and melted for 0.5 to 8 hours, finally, component A is added into the molten salt obtained and put statically for 2 to 10 hours. The catalyst of the invention which is used for chemical strengthening of glass can improve the surface compressive stress and the strength of the glass, as well as can prolong the service life of the glass. The invention pertains to the chemical strengthening field of the glass.

Owner:BYD CO LTD

Strengthening variable thickness glass

ActiveUS10781135B2Improve glass strengthEasy to controlCircuit arrangements on conductive chasisChemical treatmentGlass cover

Apparatus, systems and methods for increasing the strength of glass are disclosed. The use of multi-bath chemical processing for a glass article can facilitate controlled chemical strengthening. Through multi-bath (or multi-step) chemical processing, differing levels of strengthening can be achieved for different portion of glass articles. The multi-bath chemical processing can be achieved through the use of successive chemical baths. Accordingly, glass articles that have undergone multi-bath chemical processing are able to be not only thin but also sufficiently strong and resistant to damage. The strengthened glass articles are well suited for use in consumer products, such as consumer electronic devices (e.g., portable electronic devices). In one embodiment, the glass member can pertain to a glass cover for a housing of an electronic device.

Owner:APPLE INC

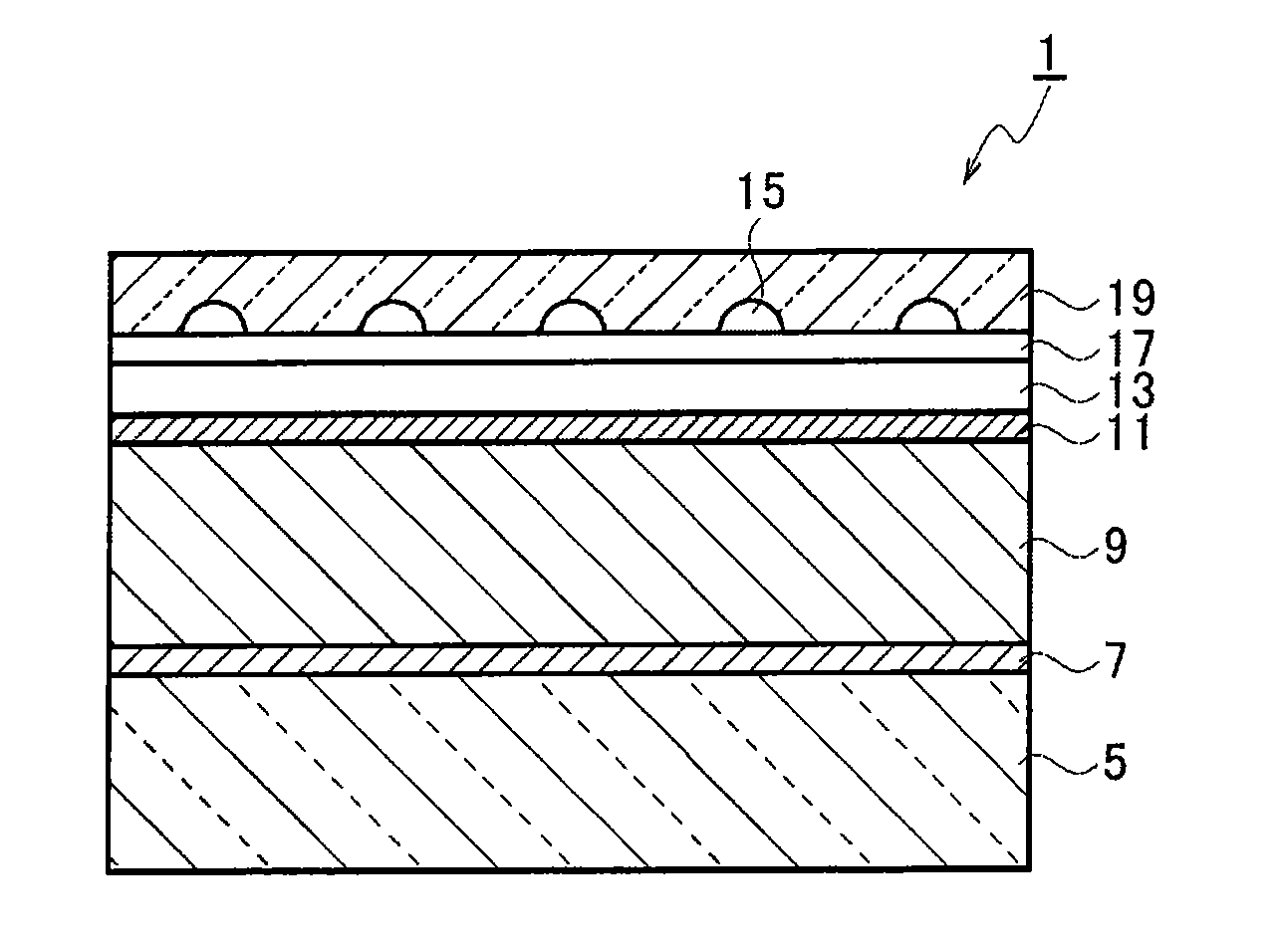

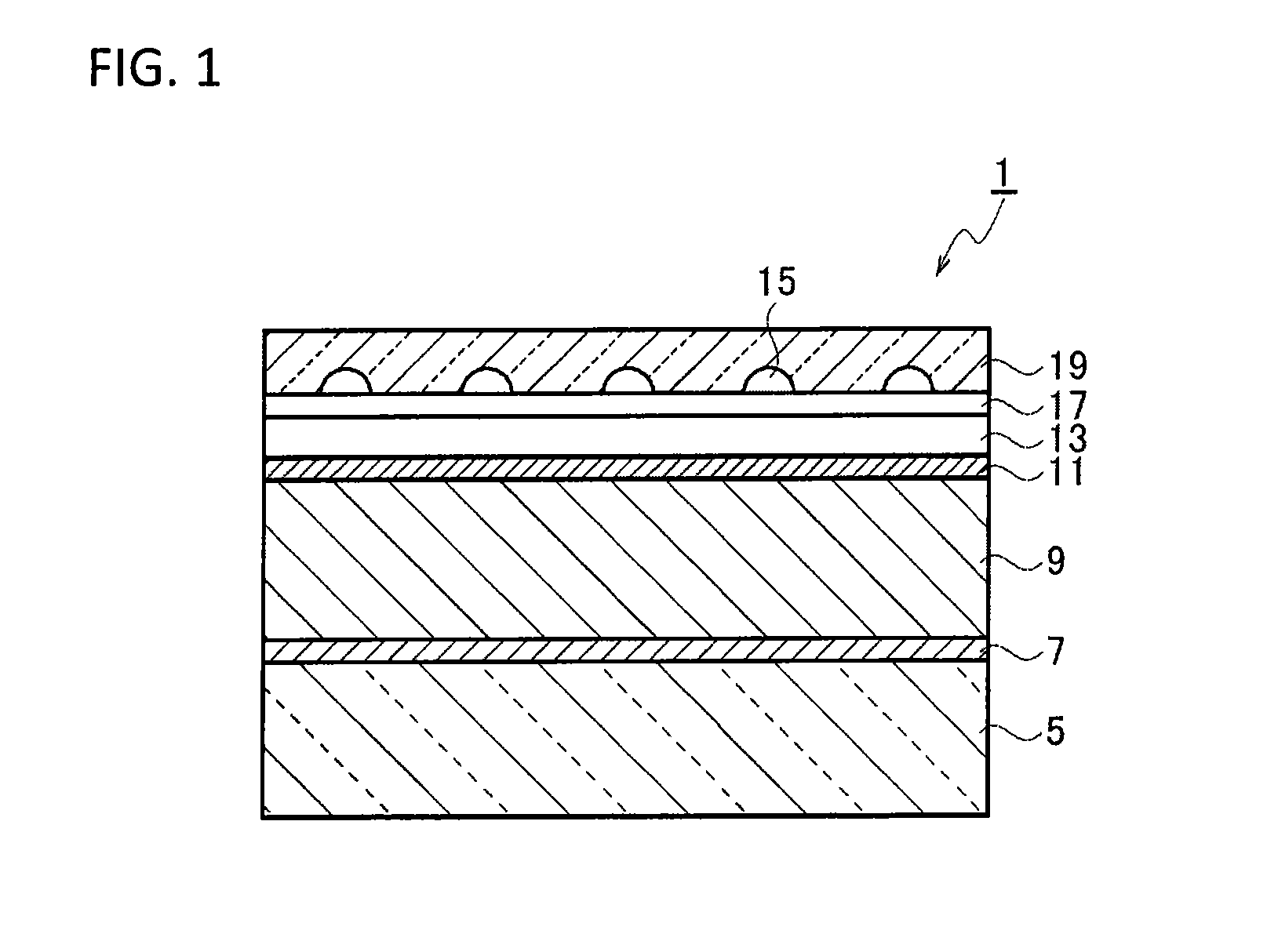

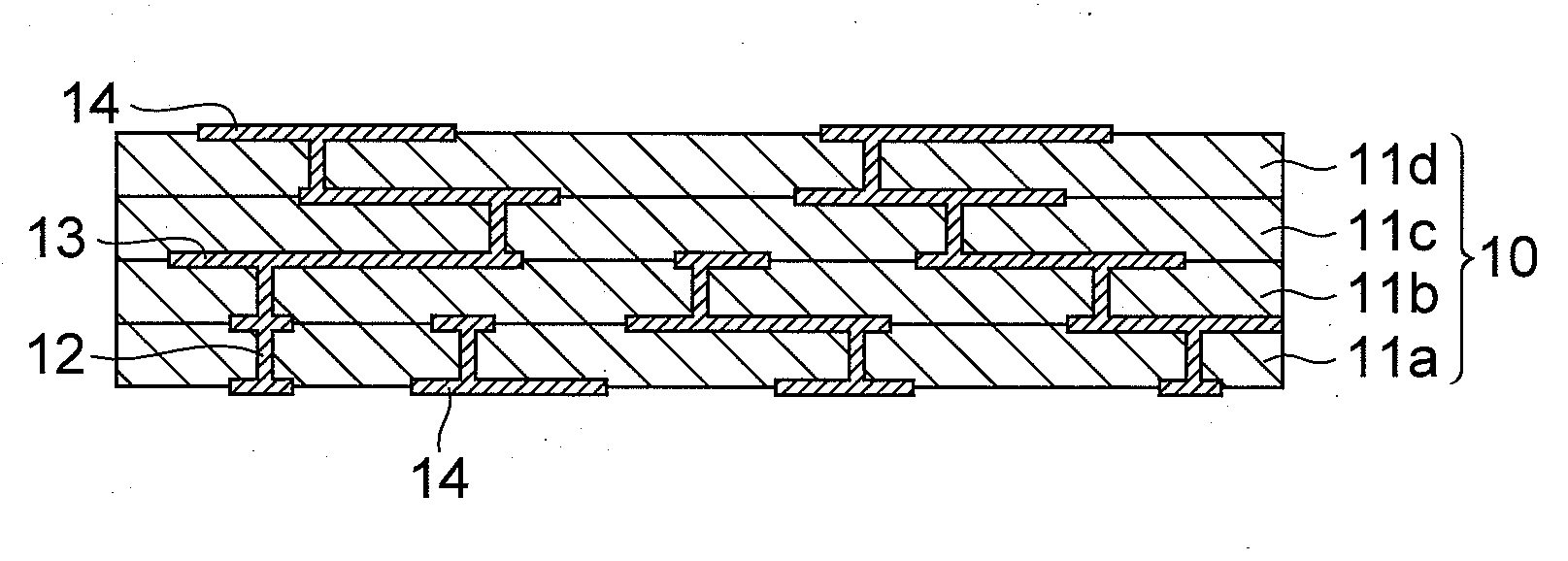

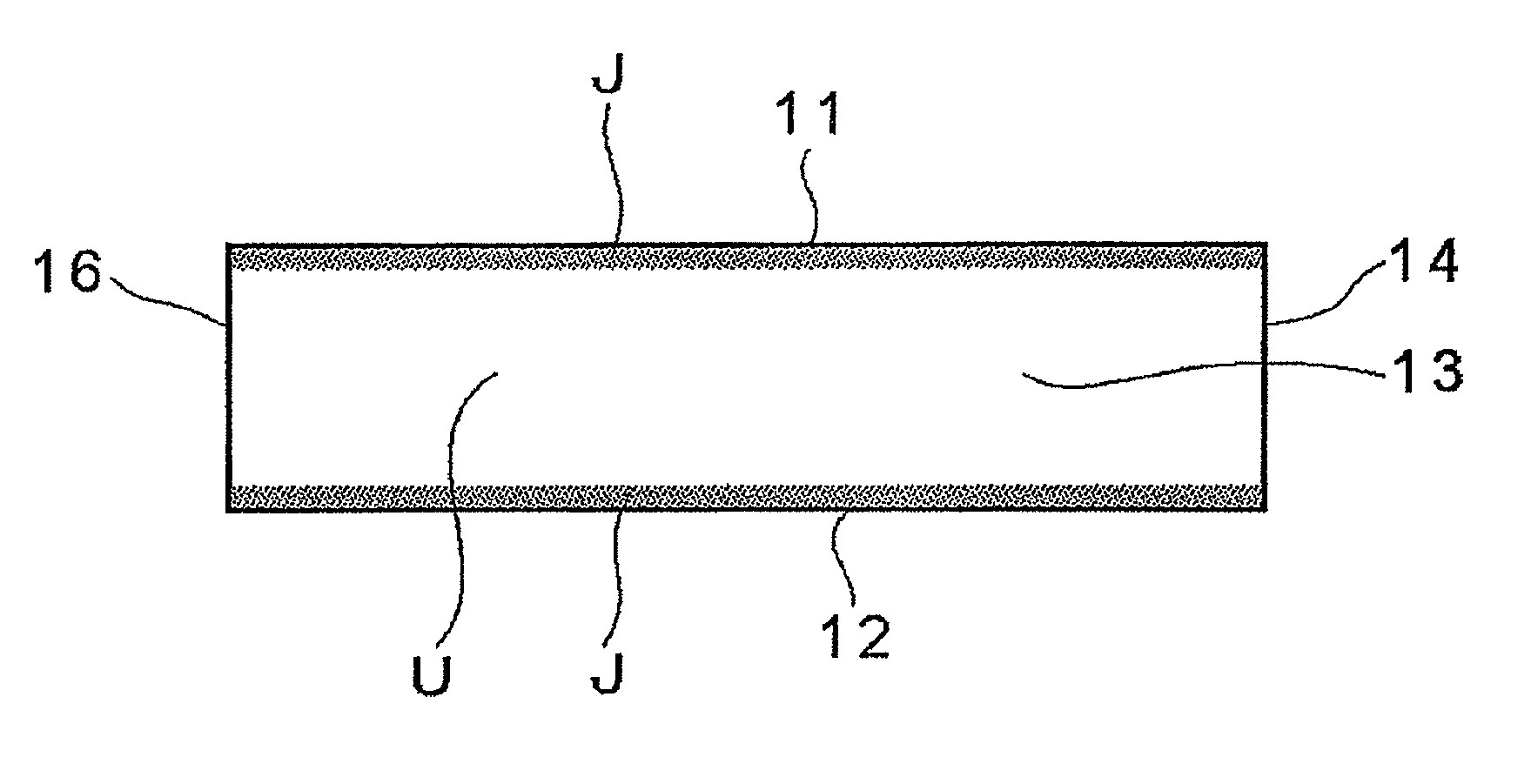

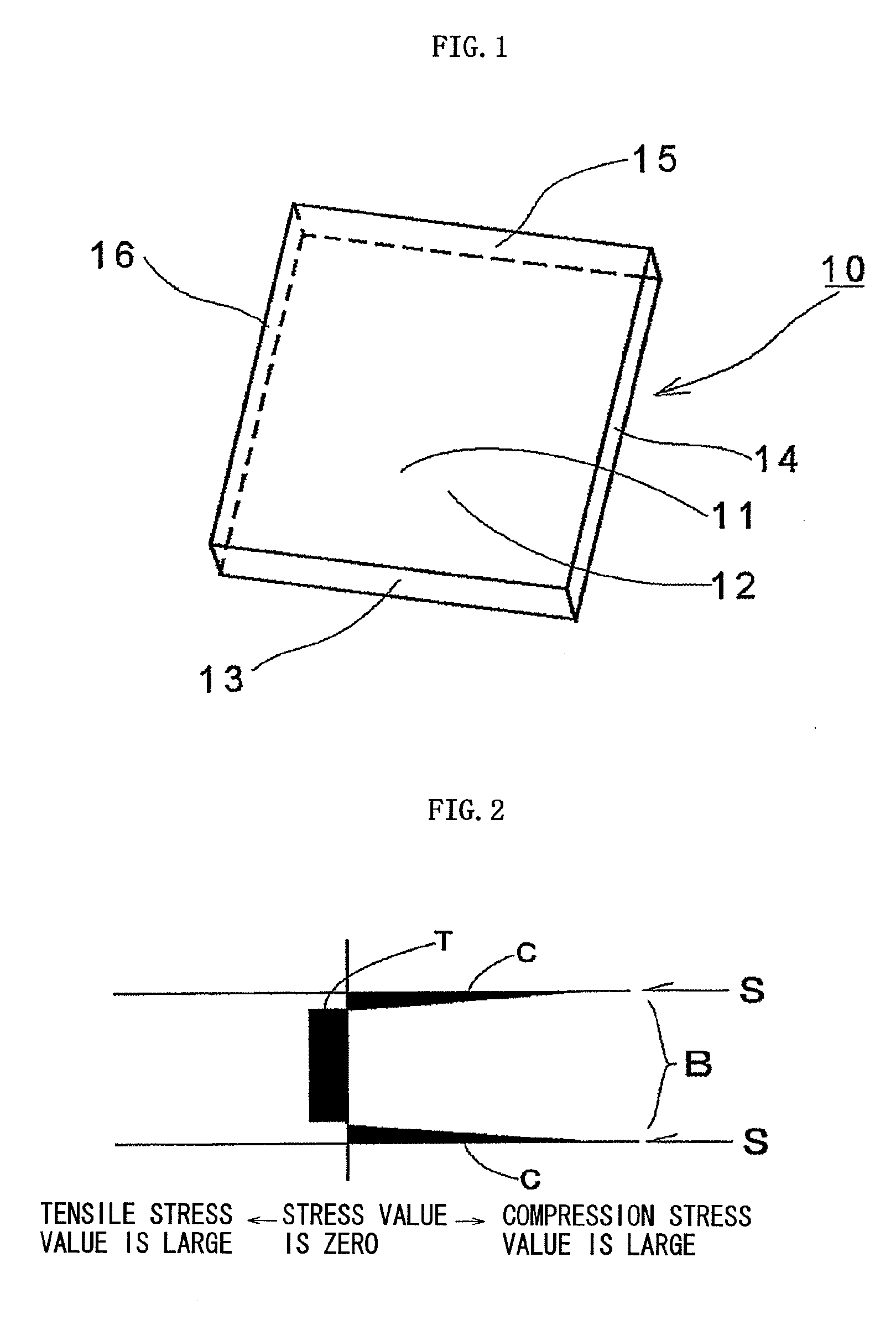

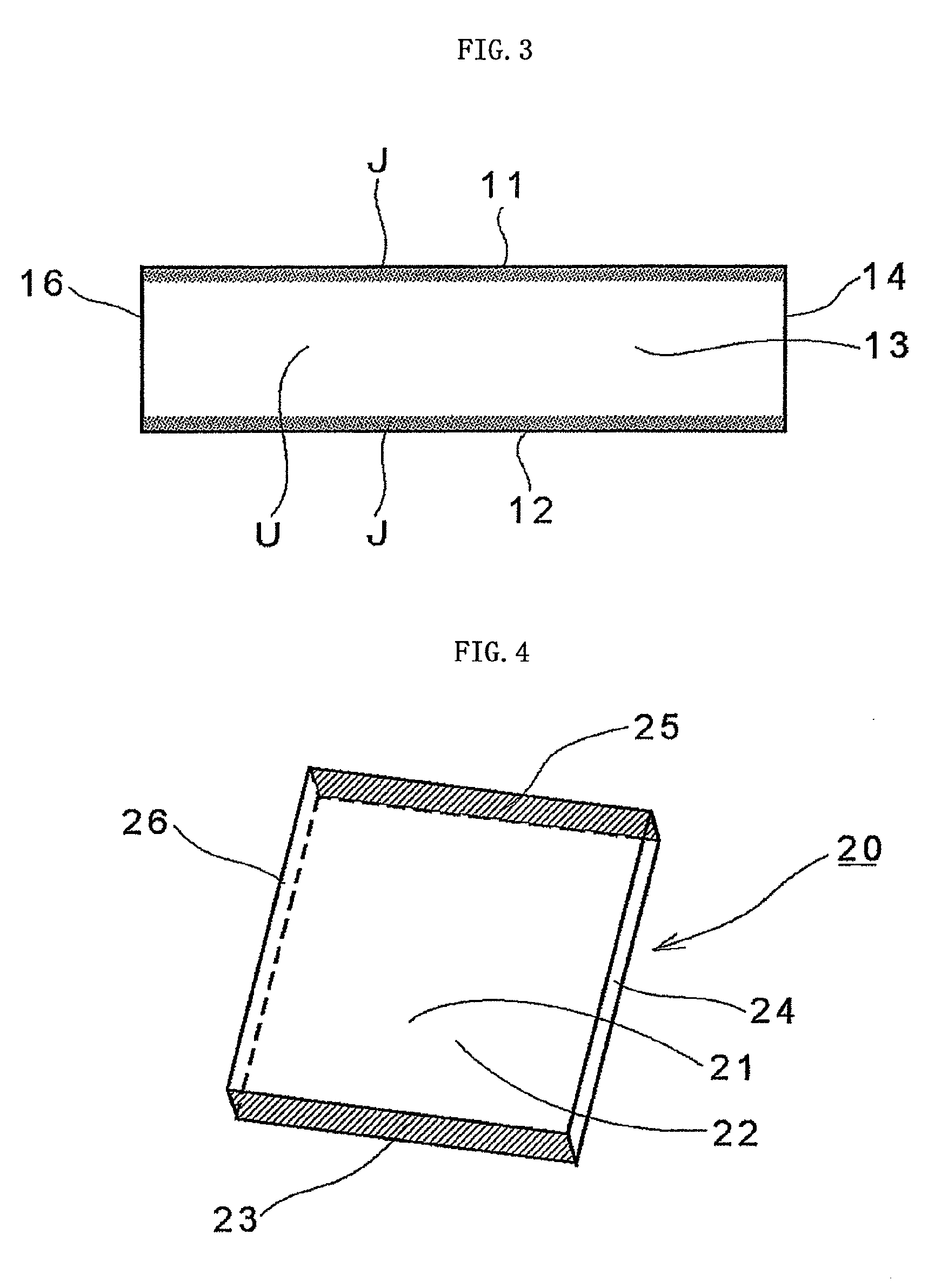

Glass ceramic substrate

InactiveUS20100080981A1High strengthExcellent dispersibility and orientationLayered productsPrinted circuit aspectsGlass-ceramicCeramic substrate

The present invention provides glass ceramic substrates 11a to 11d each containing a glass component and a plate-like alumina filler dispersed in the glass component, wherein the plate-like alumina filler has an average plate diameter of 0.1 to 20 μm and an average aspect ratio of 50 to 80, and wherein the plate-like alumina filler has a content of 22 to 35% by volume based on a total amount of the glass component and plate-like alumina filler.

Owner:TDK CORPARATION

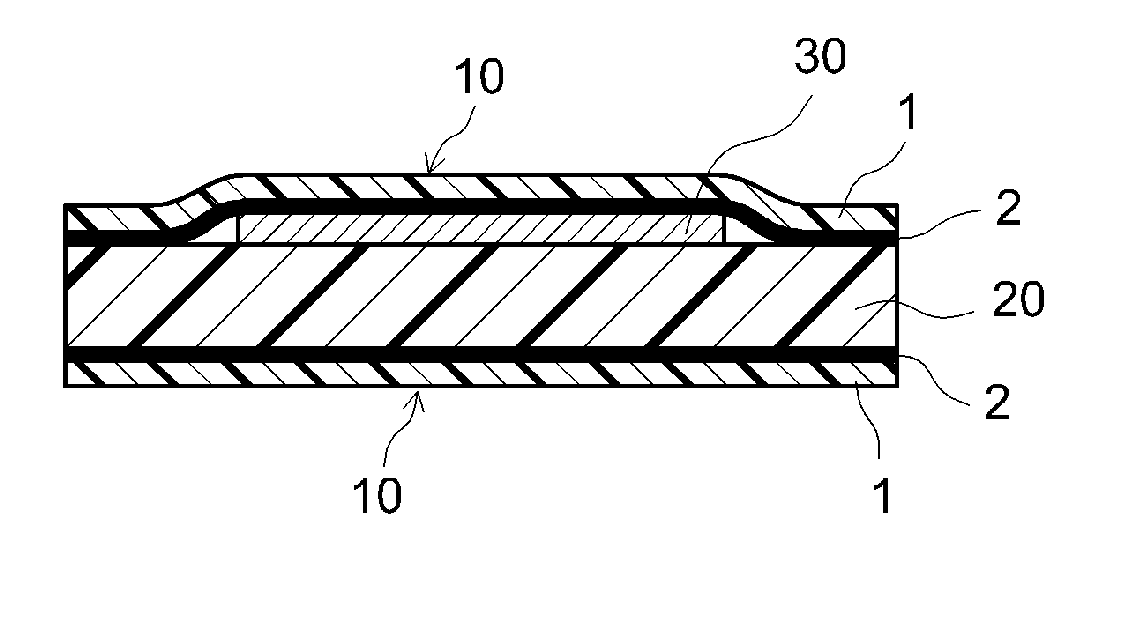

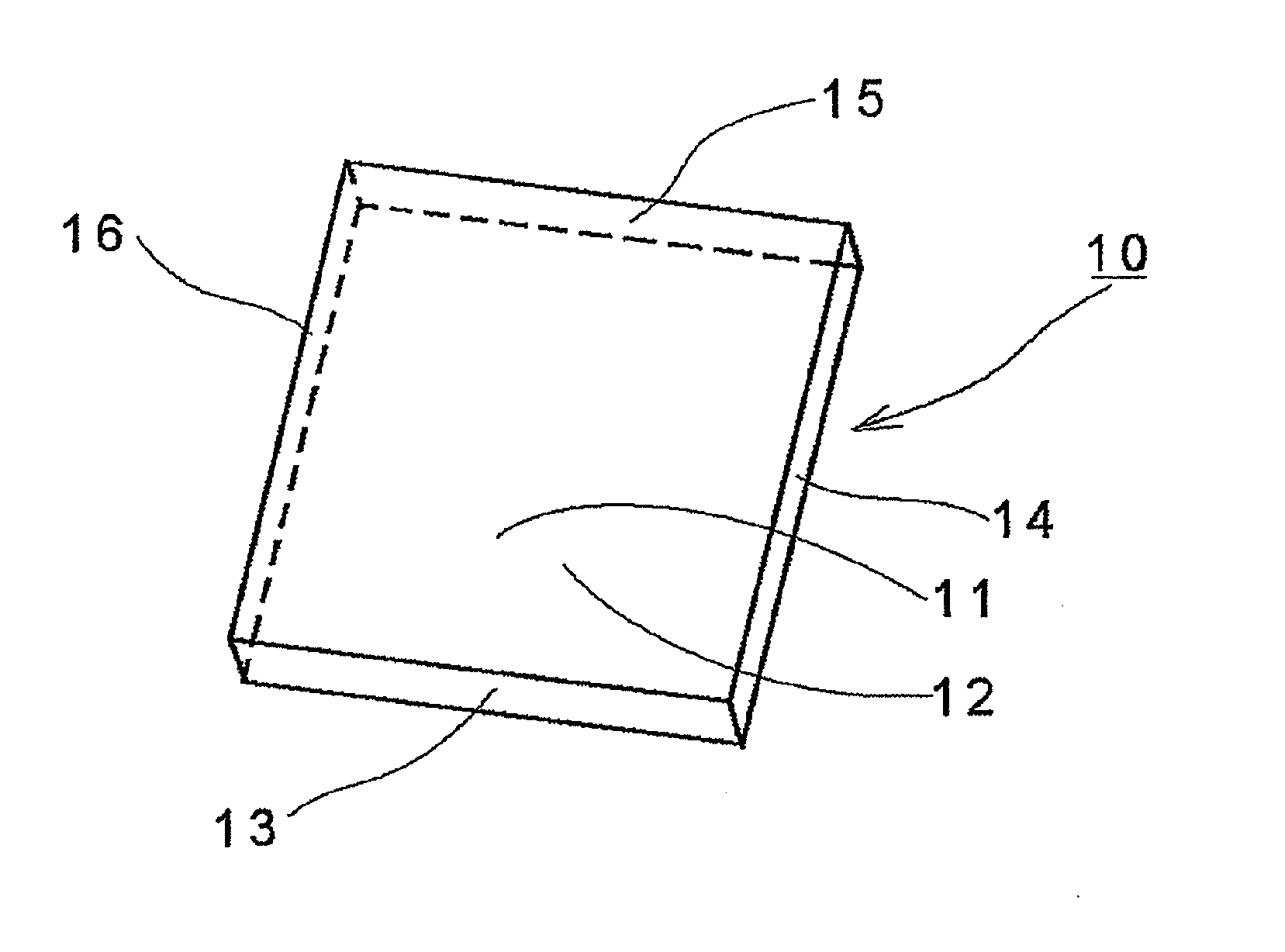

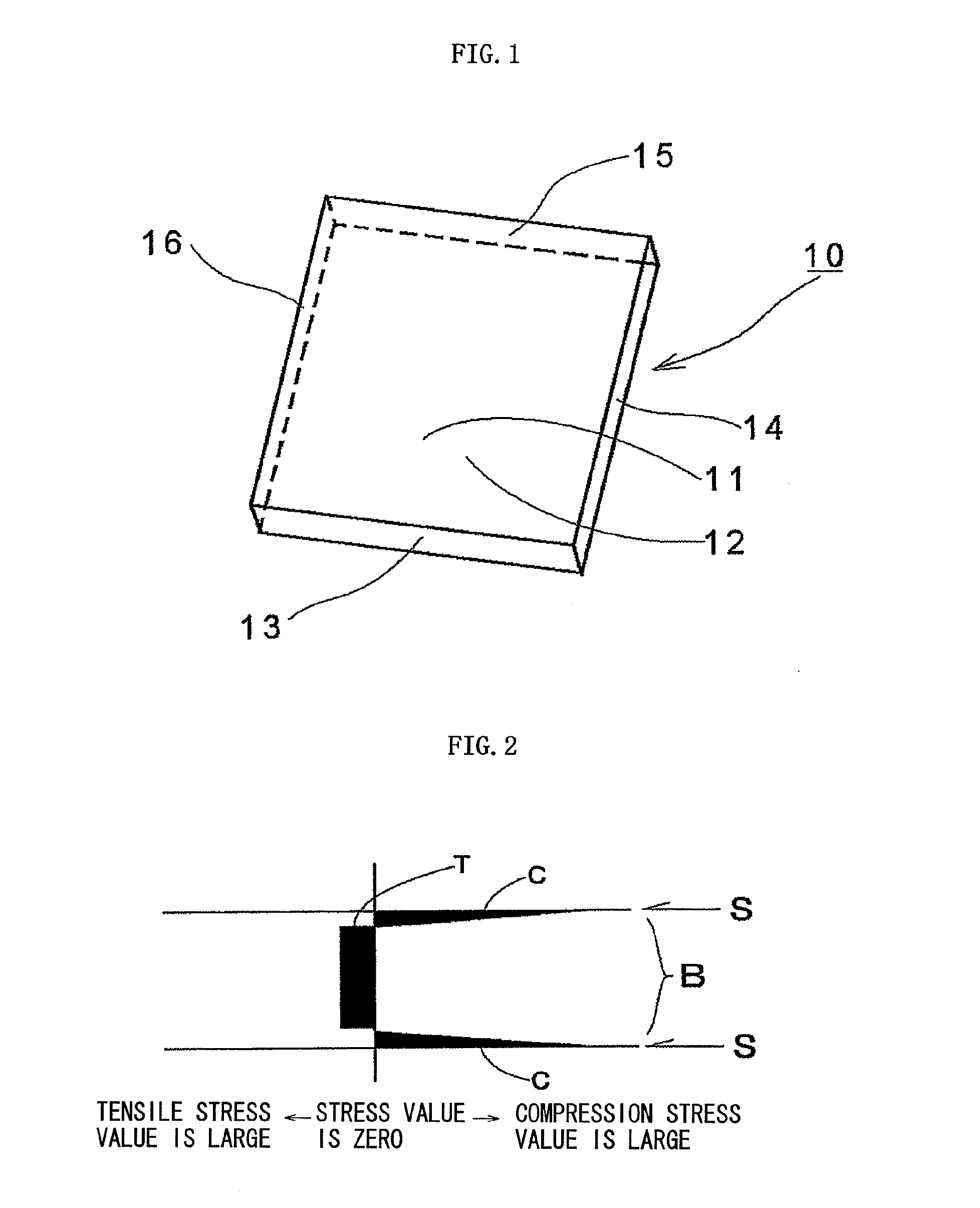

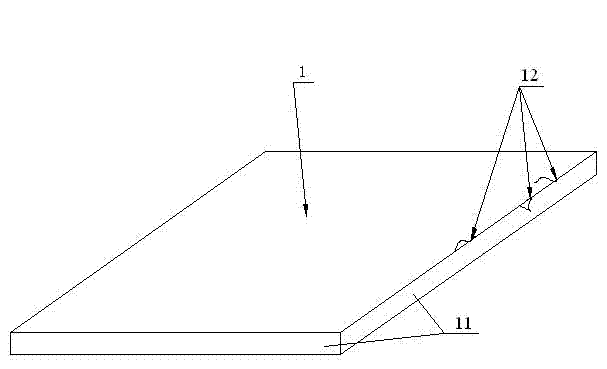

Reinforced plate glass and method for manufacturing the same

ActiveUS9102566B2Quality improvementImprove production efficiencyGlass severing apparatusGlass productionFlat glassUltimate tensile strength

A method of manufacturing a reinforced plate glass by which glass surface strength is sufficiently increased, and a stable quality reinforced plate glass is manufactured at high production efficiency. The reinforced plate glass is formed of an inorganic oxide glass, and is provided with a compression stress layer by chemical reinforcement on plate surfaces opposed to each other in a plate thickness direction. Plate end faces have regions where a compression stress is formed and regions where no compression stress is formed.

Owner:NIPPON ELECTRIC GLASS CO LTD

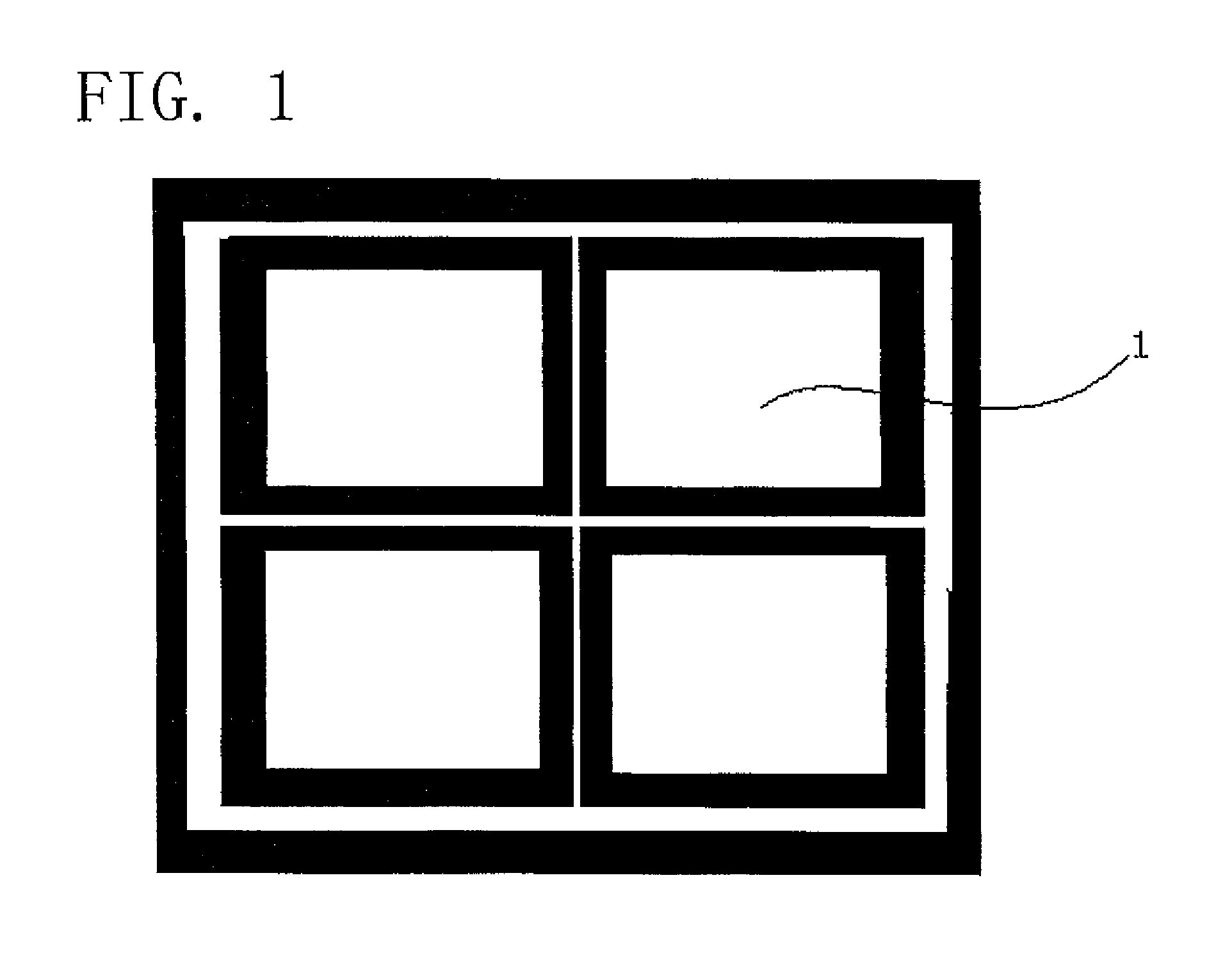

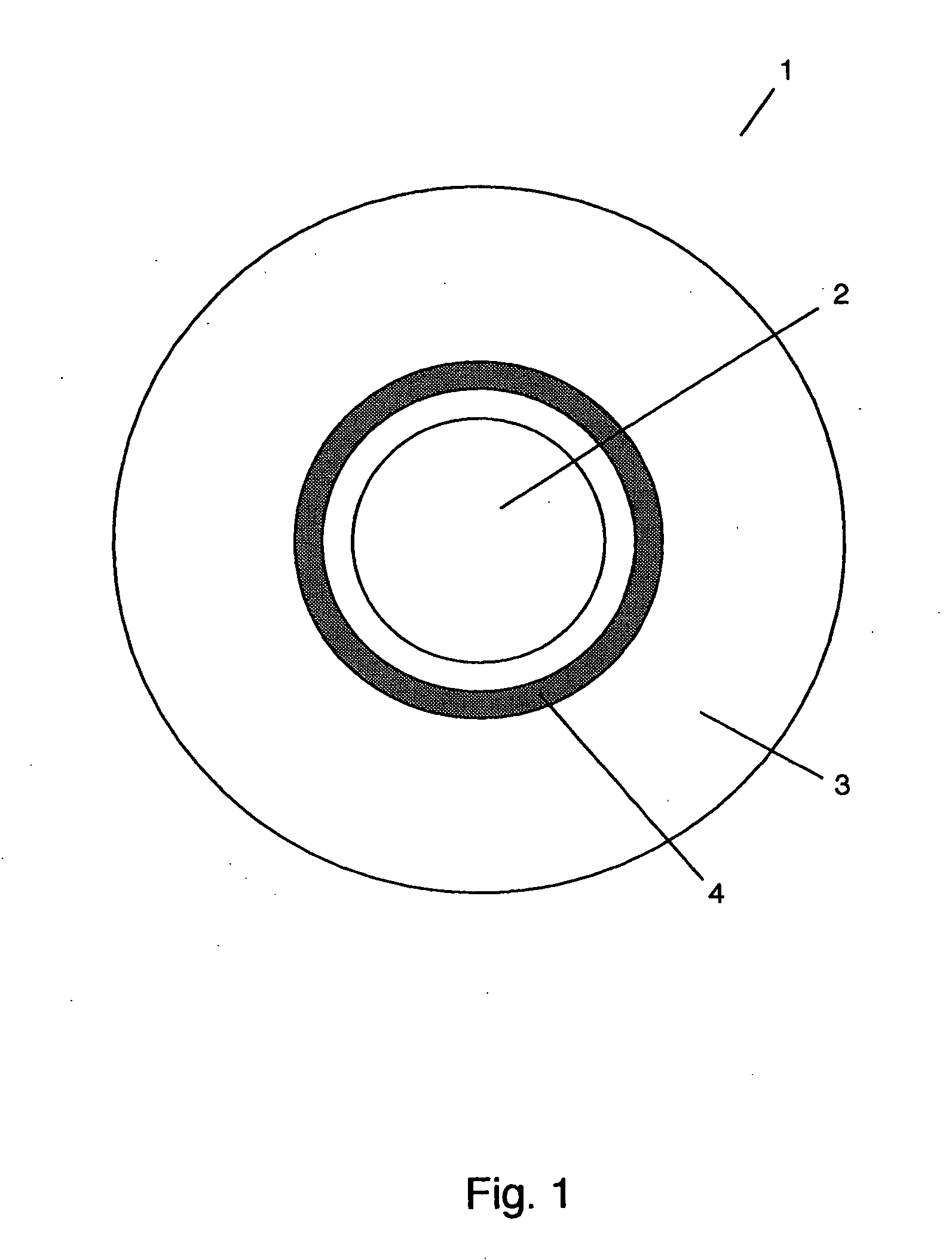

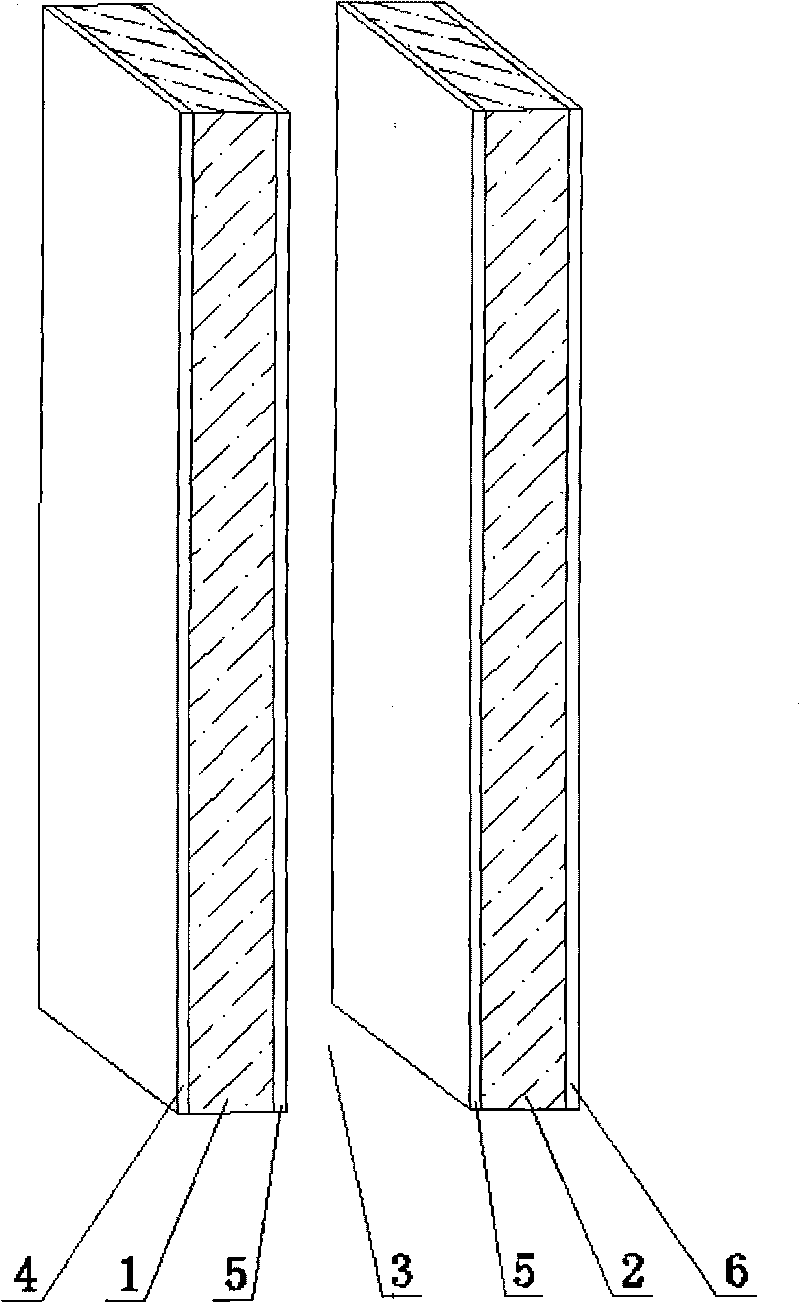

Piece type OGS touch screen and manufacturing method therefor

InactiveCN105335026AImprove glass strengthImprove yieldInput/output processes for data processingPrinting inkEngineering

The present invention discloses a piece type OGS touch screen. The OGS touch screen comprises a transparent substrate (1), an ink layer (2), an ITO electrode layer (3) and an ITO protective layer (4) which are successively stacked. The present invention also provides a manufacturing method for a piece type OGS touch screen. The method comprises: printing ink on a transparent substrate (1) to form an ink layer (2); applying a piece type ITO coating to the ink layer (2), and performing laser dry etching to form an ITO electrode layer (3); and printing ink on the ITO electrode layer(3) to form an ITO protective layer (4). The method provided by the present invention can significantly improve glass strength of the OGS touch screen, and reduce and optimize OGS process steps, thereby reducing production costs, improving the yield rate of the OGS touch screen, and facilitating environmental protection.

Owner:深圳市合力泰光电有限公司

Reinforced plate glass and method for manufacturing the same

ActiveUS20130199241A1Quality improvementImprove production efficiencyGlass severing apparatusGlass productionFlat glassUltimate tensile strength

Owner:NIPPON ELECTRIC GLASS CO LTD

Safety energy-saving hollow glass and coating film as well as preparation method

InactiveCN101705781AImprove glass strengthPurify indoor airClimate change adaptationWindows/door improvementBenzeneRadioactive gas

The invention discloses safety energy-saving hollow glass, which comprises an internal layer of glass and an external layer of glass between which a cavity is kept; a coating film with the function of heat insulation and preservation is arranged outside the external layer glass; coating films with the functions of enhancing glass strength are arranged inside the external layer of glass and outside the internal layer of glass, insulating sound wave and filtering ultraviolet rays; and a coating film with the functions of absorbing, purifying and decomposing indoor radioactive and poisonous gases is arranged inside the internal layer of glass. The structure of the invention has the functions of obviously improving heat insulation and preservation property, increasing anti-seismic and anti-impact intensity, purifying indoor air, and absorbing, purifying, and decomposing radioactive gas radon, volatilizing gases of methyl aldehyde, benzene and methylbenzene, and bacterial viruses in building decoration materials.

Owner:HEBEI RUIHUI GLASS PRODS

Composite packaging adhesive film for solar packaging material and preparation method of composite packaging adhesive film

ActiveCN109294455AInhibitionAchieving high efficiency of cross-linking and curingNon-macromolecular adhesive additivesOrganic non-macromolecular adhesiveElastomerCross-link

The invention discloses a composite packaging adhesive film for a solar packaging material. The composite packaging adhesive film is composed of an ethylene vinyl acetate (EVA) adhesive film layer anda polyolefin elastomer (POE) adhesive film layer, and the EVA adhesive film layer is prepared from the following raw materials in parts by weight: 100 parts of EVA resin, 0.5-1.6 parts of a compositecross-linking agent, 0.5-1 part of a co-crosslinking agent, 0.05-0.2 part of an ultraviolet absorbent, 0.03-0.1 part of an antioxidant and 0.1-0.5 part of a tackifier, wherein the composite cross-linking agent comprises a peroxide and an crosslinking control agent. The invention further discloses a preparation method of the composite packaging adhesive film for the solar packaging material, and the preparation method comprises the following steps: melt extrusion of POE resin, melt extrusion of EVA resin and co-extrusion. According to the composite packaging adhesive film disclosed by the invention, the problems of bubbles and too low gel content of a cured film are solved, and meanwhile, the composite packaging adhesive film has the characteristics of good light transmittance and high glass strength. The preparation method can meet the requirements of process stability, laminating process stability and cross-linking curing efficiency during film preparation by casting at a same time.

Owner:JIANGSU LUSHAN PHOTOVOLTAIC TECH +1

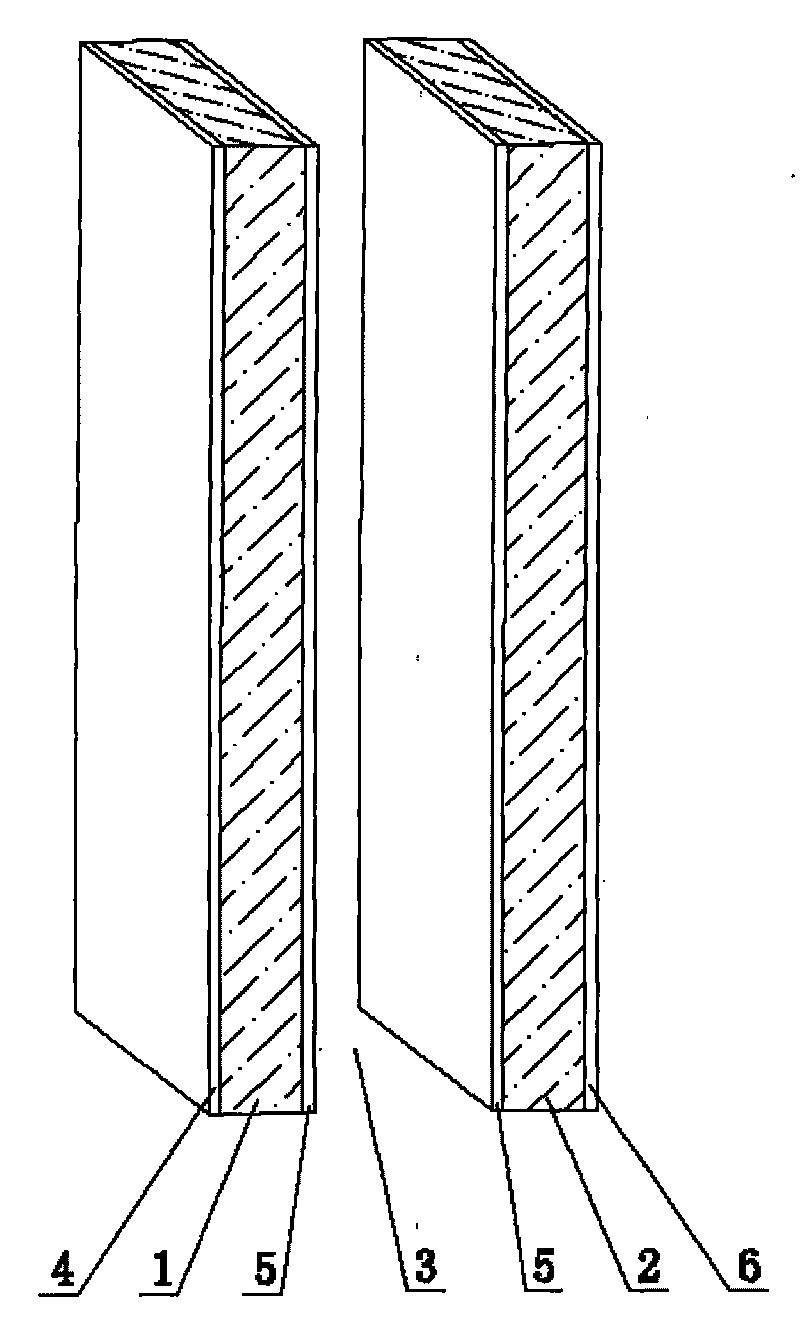

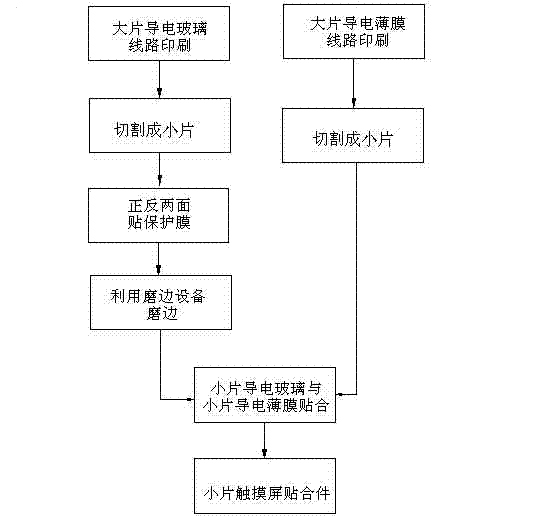

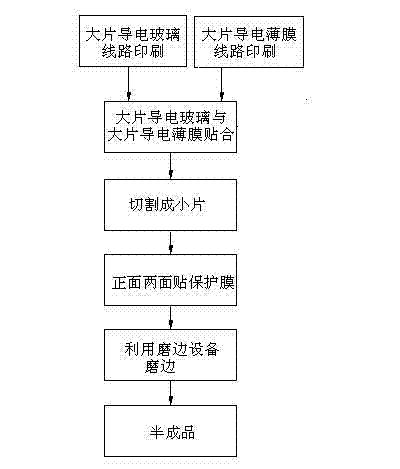

A method of manufacturing touch screen bonding parts

InactiveCN102298464ALow costImprove drop resistanceInput/output processes for data processingTouch panelEngineering

The invention relates to a manufacturing process of a touch screen bonding part. The bonding part is formed by bonding conductive glass and a conductive film. A touch screen uses a small bonding part, and a large bonding part contains a plurality of uncut small bonding parts. Fittings; in the process of making the fittings, the edging equipment is used to grind the cutting surface of each edge of the conductive glass in the small fittings into a frosted curved surface. The touch screen laminating part produced by the invention avoids the problems of stress concentration points and poor drop resistance in the cut surface of the ITO conductive glass substrate in conventional laminating parts. After the touch screen is made by using the invention, the stress when the touch screen falls can be effectively dispersed, and the qualified rate of products in the production of the touch screen can be improved. At the same time, because no strengthened glass substrate is used, the production cost is greatly reduced.

Owner:NANJING WALLY ELECTRONICS TECH

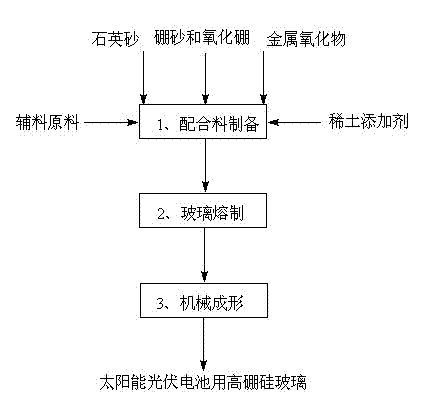

Preparation method of high borosilicate glass for solar photovoltaic batteries

The invention especially relates to a preparation method of high borosilicate glass for solar photovoltaic batteries. The method comprises the following steps: 1, batch preparation: adding a rare earth element additive to present high borosilicate glass, wherein visible light is formed through converting infrared light and ultraviolet light by a conversion luminescence effect through applying an up-conversion luminescence principle, and illuminates; the rare earth additive is simultaneously used as a clarificant, a color complementation agent and a conversion luminescence couplant to improve the visible light transmittance of glass; and rare earth element borate glass has a high refractive index and a low chromatic dispersion, and is novel optical glass; 2, glass melting: carrying out high temperature melting of the glass batch in an electric melting furnace to form molten glass, carrying out clarification homogenizing, and cooling to form liquid glass; and 3, mechanical shaping: processing the liquid glass through adopting a float process production technology to form flat glass. The glass prepared through the method provided by the invention has a high visible light transmittance, and can be used as a glass matrix material and a packaging material for the solar photovoltaic batteries.

Owner:YANGZHOU TONGHE GLASS

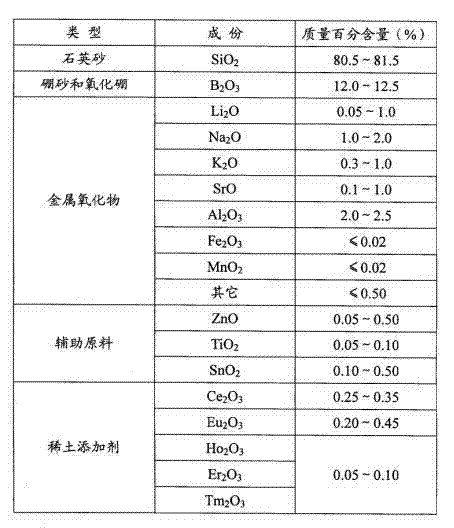

Composite backed prestressed mirror for solar facet

InactiveUS7309398B2Light weightReduce manufacturing costSolar heating energyMirrorsHeliostatPre stress

A glass structure, such as a mirror facet, having a glass member, a composite structure and a support structure. The composite structure includes a rigid interlayer which is bonded to the glass member and exerts a compressive force thereon to place the glass member in compression. The support structure is used to mount the glass structure and prevents the glass member from collapsing due to the compressive force exerted by the rigid interlayer. The glass structure is particularly well adapted for use in forming heliostats, parabolic dishes, trough concentrators, or other like elements for use in solar power systems, and does not suffer from the limitations or prior forms of such devices.

Owner:THE BOEING CO

Tempered sheet glass and preparation method thereof

ActiveCN107056046AEfficient processIncrease the amount of participationGlass furnace apparatusGlass shaping apparatusRoom temperatureMolten salt

The invention relates to tempered sheet glass and a preparation method thereof. The method comprises the steps as follows: step 1, a mixture formed after mixing is accurately weighed according to the mass fraction of the mixture; step 2, cullet accounting for 30%-55% of the mass fraction of the mixture is added and uniformly mixed, and a batch is obtained; step 3, a formed glass sheet is prepared after the batch is molten; step 4, the formed glass sheet is annealed at 700-750 DEG C for 30-60 min and cooled to 450 DEG C, and sheet glass is obtained; step 5, tempering materials are weighed for later use according to the mass fraction; step 6, the tempering materials are kept at the constant temperature of 410-450 DEG C for 1-2 h and uniformly mixed molten salt is formed; step 7, the sheet glass at 450 DEG C is placed in the uniformly mixed molten salt, kept at the constant temperature of 410-450 DEG C for 1-6 h and taken out; step 8, the sheet glass taken out of the molten salt is dried, naturally cooled to the room temperature, washed and dried, and the tempered sheet glass is obtained.

Owner:CAIHONG GRP SHAOYANG SPECIAL GLASS CO LTD

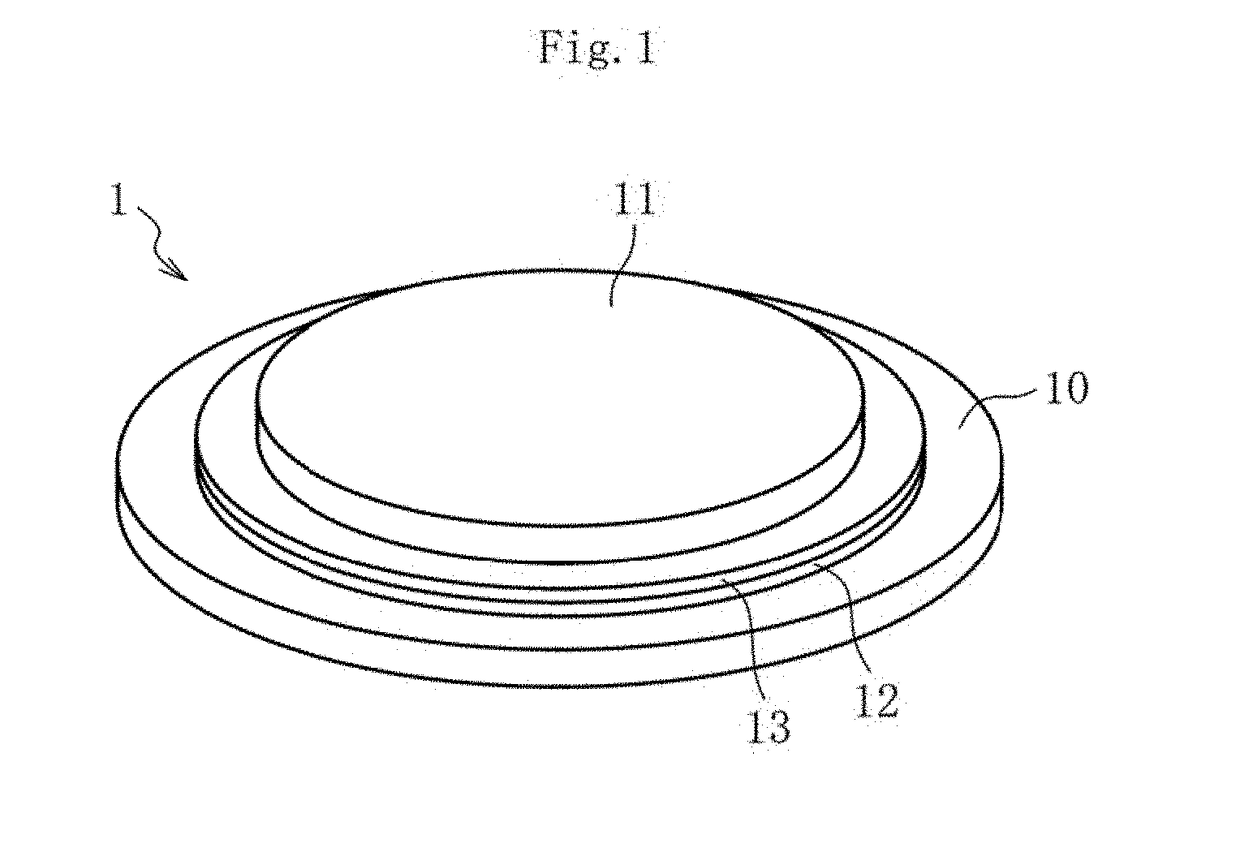

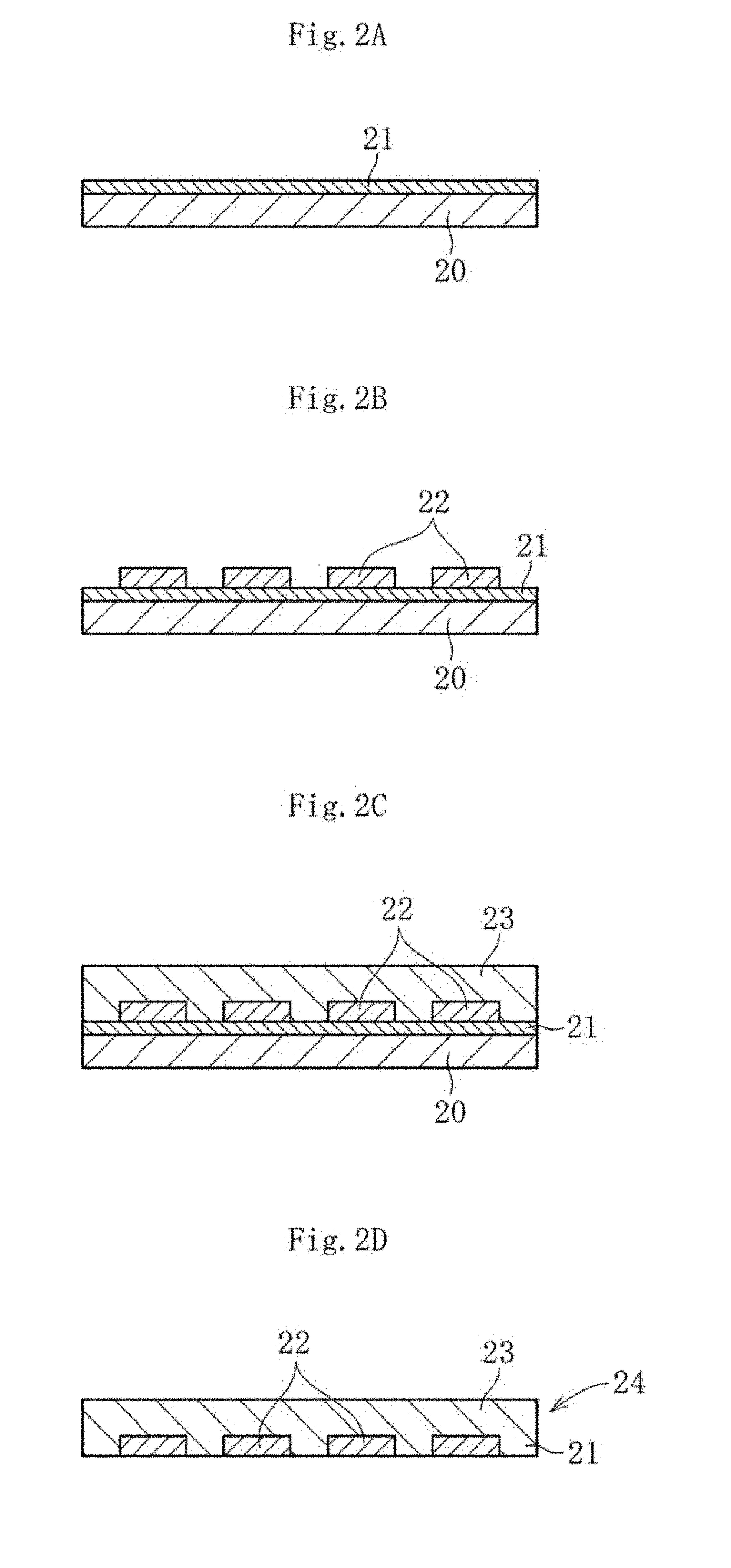

Glass substrate and laminate using same

ActiveUS20180339929A1Increase stiffnessImprove deformationSemiconductor/solid-state device detailsSolid-state devicesHigh densityTechnical object

A technical object of the present invention is to devise a glass substrate that is suitable for supporting a substrate to be processed to be subjected to high-density wiring and enables correct recognition of production information and the like, and a laminate using the glass substrate. In order to achieve the technical object, the glass substrate of the present invention has a total thickness variation of less than 2.0 μm and includes an information identification part formed of a plurality of dots.

Owner:NIPPON ELECTRIC GLASS CO LTD

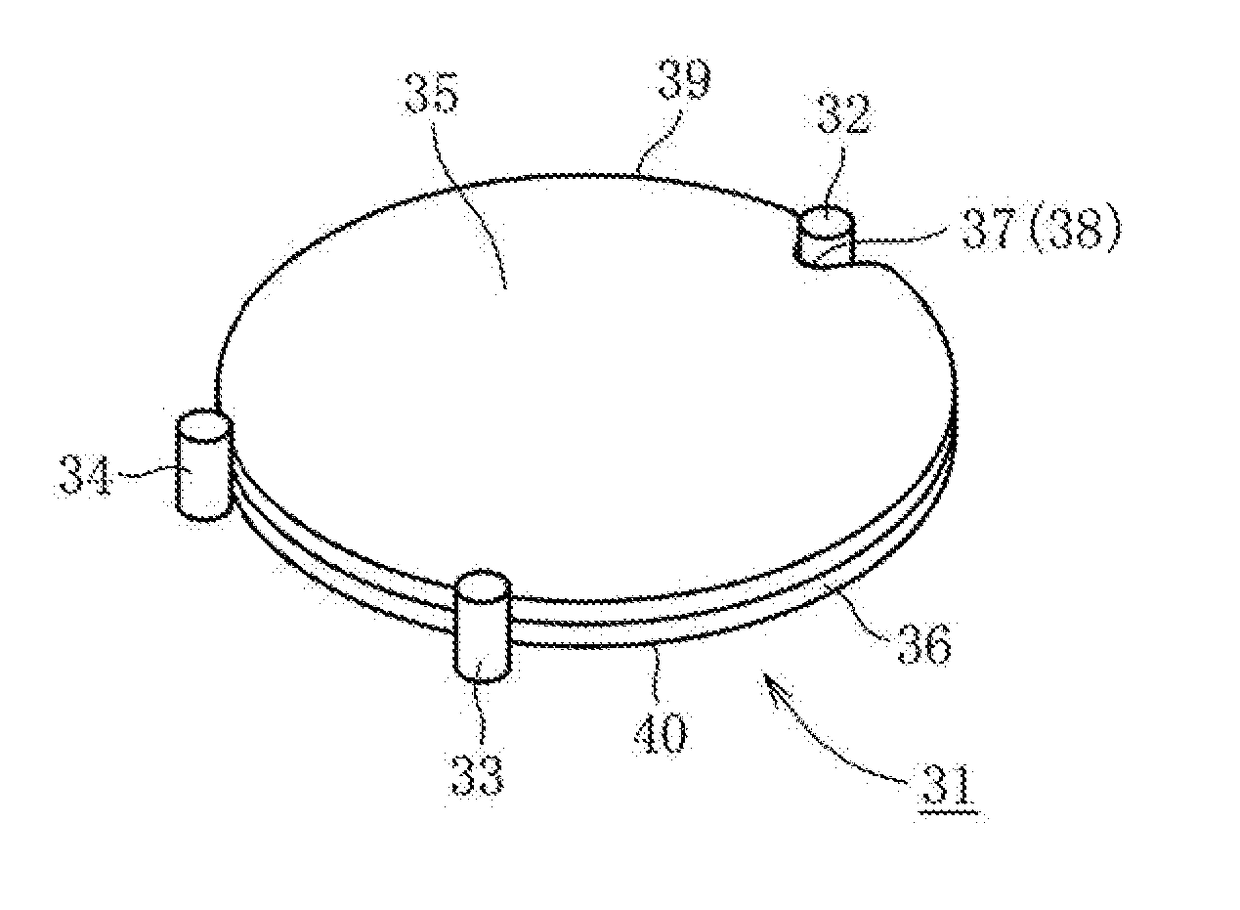

Glass sheet

ActiveUS20170334773A1Avoid changeSupported strongly and accuratelySemiconductor/solid-state device detailsSolid-state devicesTechnical objectMaterials science

A technical object of the present invention is to devise a glass sheet that facilitates position alignment with a substrate to be processed and is less liable to be broken during conveyance, or processing treatment of the substrate to be processed, to thereby contribute to an increase in density of a semiconductor package. In order to achieve the technical object, the glass sheet of the present invention includes, in a contour thereof: a contour portion; and a position alignment portion, in which all or part of an end edge region of the position alignment portion where a surface thereof and an end surface thereof intersect is chamfered.

Owner:NIPPON ELECTRIC GLASS CO LTD

Fluorescent lamp made of glass and having particular composition

InactiveUS8093793B2Prevent goodIncrease resistanceDischarge tube luminescnet screensLamp detailsRare-earth elementLiquid-crystal display

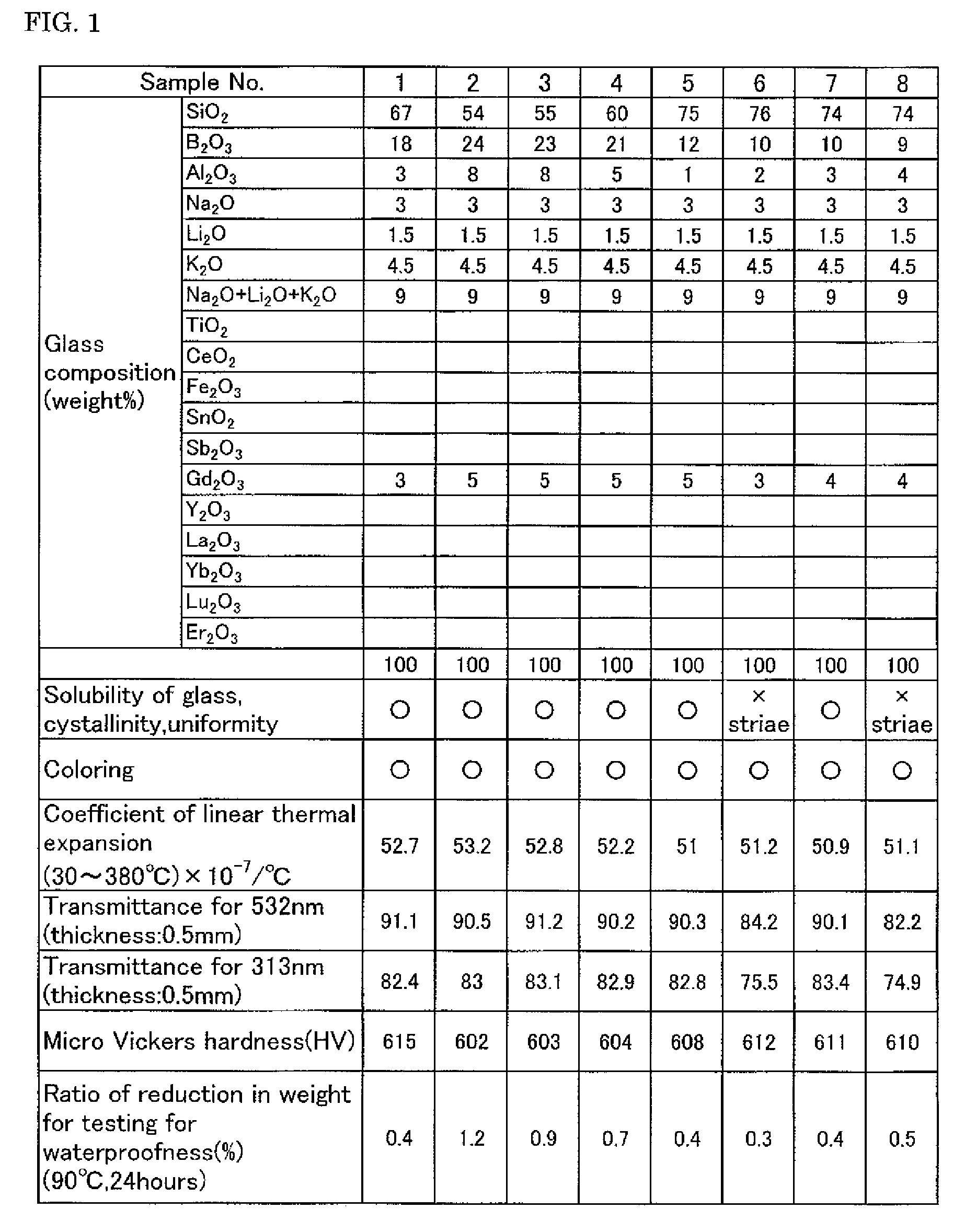

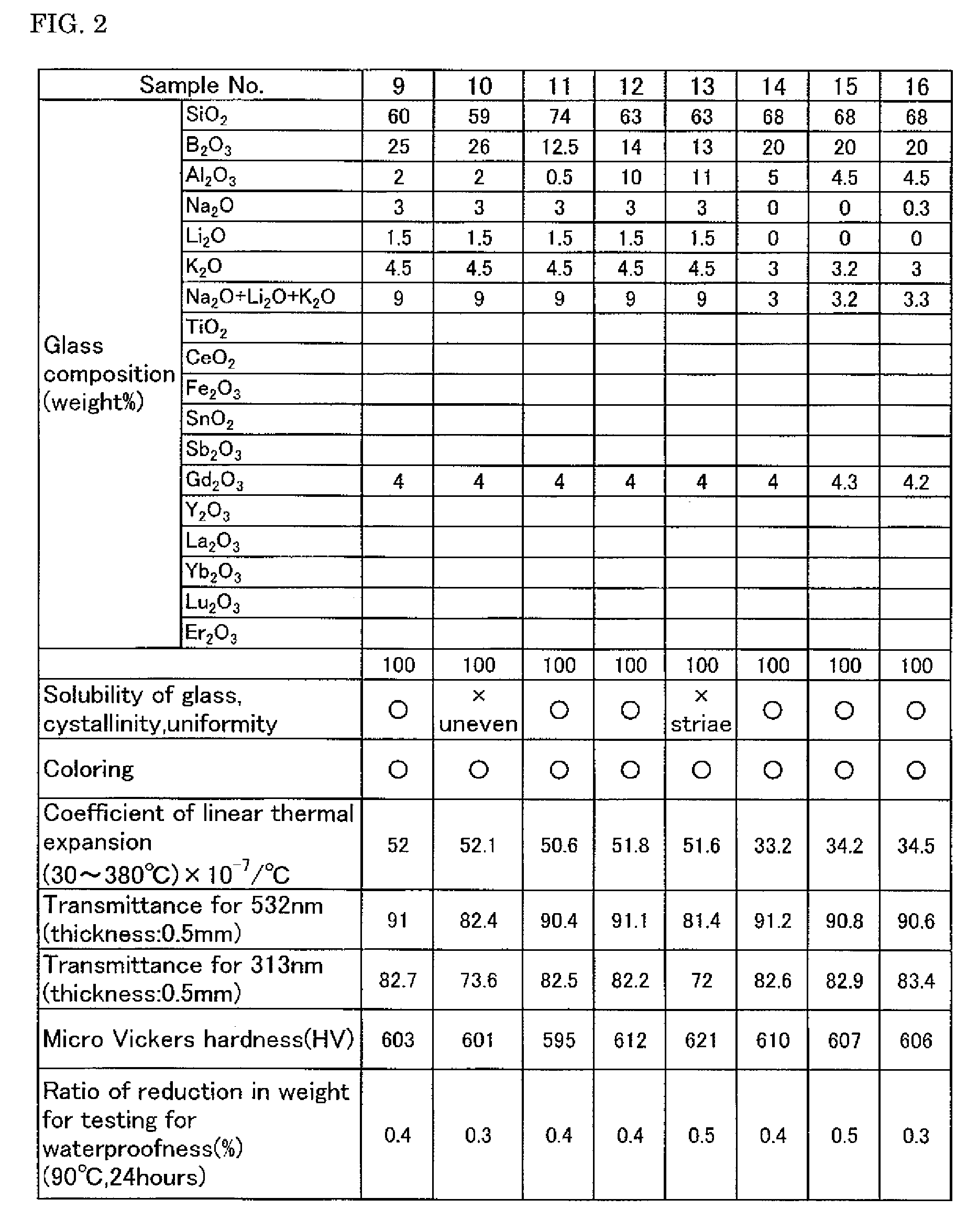

An object of the present invention is to provide fluorescent lamps used as a light source for liquid crystal display devices, which have excellent characteristics in terms of preventing solarization, the properties for blocking ultraviolet rays, and the physical and thermal strength, and preventing scratching. The present invention provides fluorescent lamps made of glass containing 55.0% to 75.0% of SiO2; 10.0% to 25.0% of B2O3; 1.0% to 10.0% of Al2O3; 0% to 3.8% of Na2O; 0% to 3.0% of Li2O; 3.0% to 10.0% of K2O; 3.2% to 16.0% of Na2O+Li2O+K2O; 0.5% to 8% of TiO2; 0.1% to 5% of CeO2; 0.6% to 8.1% of TiO2+CeO2; 0.001% to 0.05% of Fe2O3; 0% to 0.7% of Sb2O3; 0.1% to 3.0% of SnO2; and 0.5% to 10.0% of at least one rare earth element selected from the group consisting of Gd, Y, La, Yb and Lu by weight, and is characterized in that the coefficient of linear expansion in a temperature range of 30° C. to 380° C. is 34×10−7 / ° C. to 58×10−7 / ° C.

Owner:PANASONIC LIQUID CRYSTAL DISPLAY CO LTD

Special formula for lightweight glass packaging material

The invention discloses a special formula for a lightweight glass packaging material. The lightweight glass packaging material is prepared from the following raw materials in parts by weight: 900-1100 parts of quartz sand, 110-150 parts of lepidolite, 260-360 parts of soda, 260-360 parts of limestone, 4000-4300 parts of cullet, 18-22 parts of barite, 4-7 parts of chromite ore powder, 28-32 parts of anhydrous sodium sulfate, 17-21 parts of sodium fluosilicate, 0.8-1.2 parts of chrome green and 0.8-1.2 parts of carbon powder. According to the special formula disclosed by the invention, with sodium-calcium-silicate glass as a basic skeleton, alumina, magnesium oxide and barium oxide are auxiliary filled, and a part of sodium oxide is replaced by lithia and potassium oxide, so that the structure is ensured to be stable, and the strength of the glass is strengthened; by virtue of the evenness of a batch of above 95.8 percent, a lightweight bottle (L=0.44*bottle weight / brimful capacity (0.81)), produced by the special formula, with the lightweight degree to be small than or equal to 1 has the impact resistance to be larger than or equal to 0.4J, the internal pressure resistance to be larger than or equal to 1.4MPa and the vertical load to be larger than or equal to 4000N and exceeds the European standard.

Owner:SHANDONG JINGYAO GLASS GRP

Tempered glass and manufacturing method for the same

ActiveUS9388064B2Improve glass strengthHigh mechanical strengthGlass forming apparatusThin material handlingTransmittanceLength wave

A tempered glass of the present invention having a compression stress layer is characterized in that a β-OH value is 0.01 to 0.5 / mm. Here, the “β-OH value” is a value obtained from the following equation by measuring the transmittance of glass by FT-IR.β-OH value=(1 / X)log 10(T1 / T2)X: thickness of glass (mm)T1: transmittance (%) at a reference wavelength of 3,846 cm−1 T2: minimum transmittance (%) at a hydroxyl group absorption wavelength of around 3,600 cm−1.

Owner:NIPPON ELECTRIC GLASS CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com