Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

244results about How to "Uniform molecular weight" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Thermosetting acrylic resin for powder coating as well as synthesis method and applications of thermosetting acrylic resin

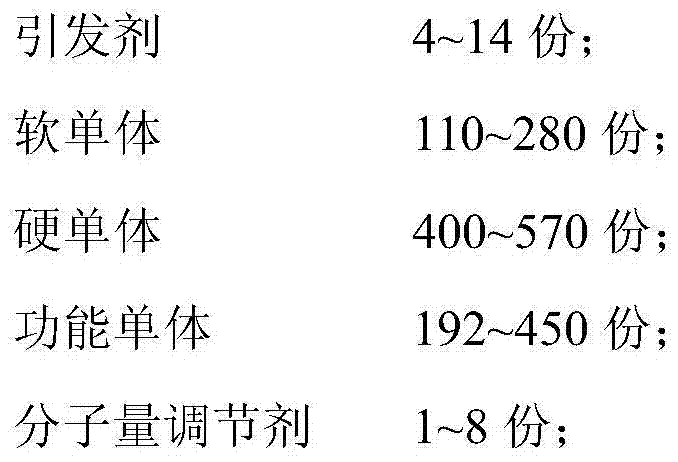

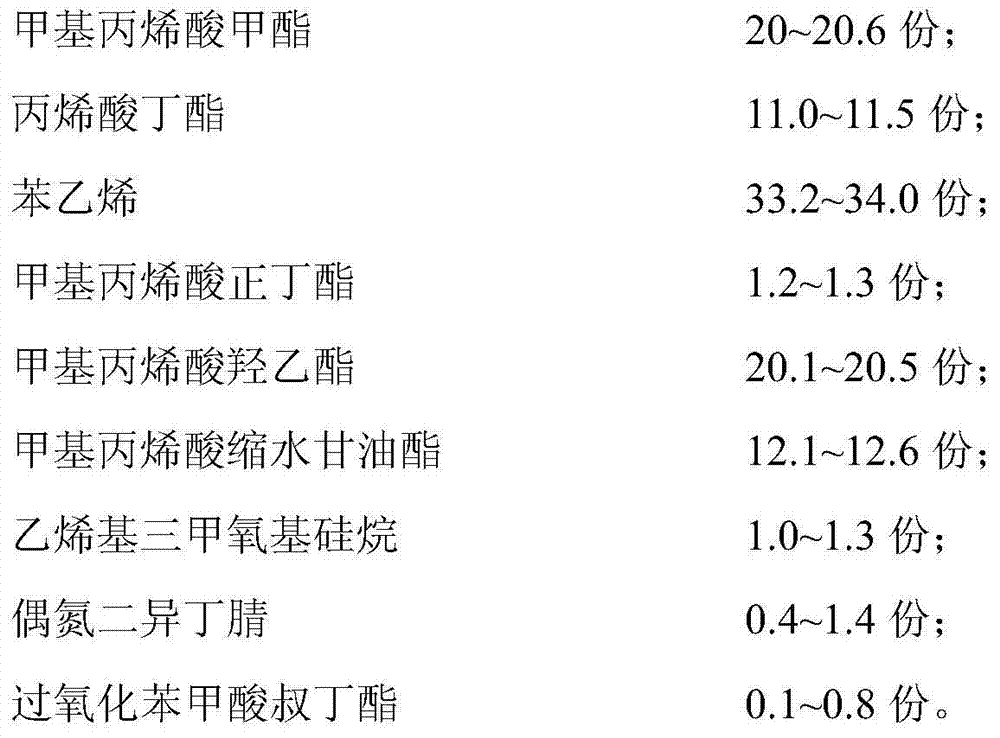

The invention relates to thermosetting acrylic resin for a powder coating. The thermosetting acrylic resin is prepared from the following raw materials in parts by mass: 4-14 parts of an initiator, 110-280 parts of soft monomers, 400-570 parts of hard monomers, 192-450 parts of functional monomers, and 1-8 parts of a molecular weight regulator, wherein the soft monomers refer to acrylic acid alkyl ester compounds, and the hard monomers refer to methacrylate, styrene, or compounds of derivatives of methacrylate and styrene. The acrylic resin contains epoxy functional groups and hydroxyl functional groups simultaneously, wherein the epoxy equivalent is 570-630g / mol and the hydroxyl value is 40-50mgKOH / g; the acrylic resin can react with various substances such as carboxyl, amidogen and isocyanate and can be used for powder coating. A coating film, which is formed after the thermosetting powder coating prepared from the acrylic resin in combination with other materials is sprayed, has excellent weather resistance, good leveling performance, outstanding surface hardness, and high glossiness, durability and decorating performance; the powder coating can be used for indoor or outdoor metal sectional materials or building materials. The thermosetting acrylic resin can substitute for TGIC (triglycidyl isocyanurate) to a certain extent so as to avoid the use of the toxic substances.

Owner:阜阳市诗雅涤新材料科技有限公司

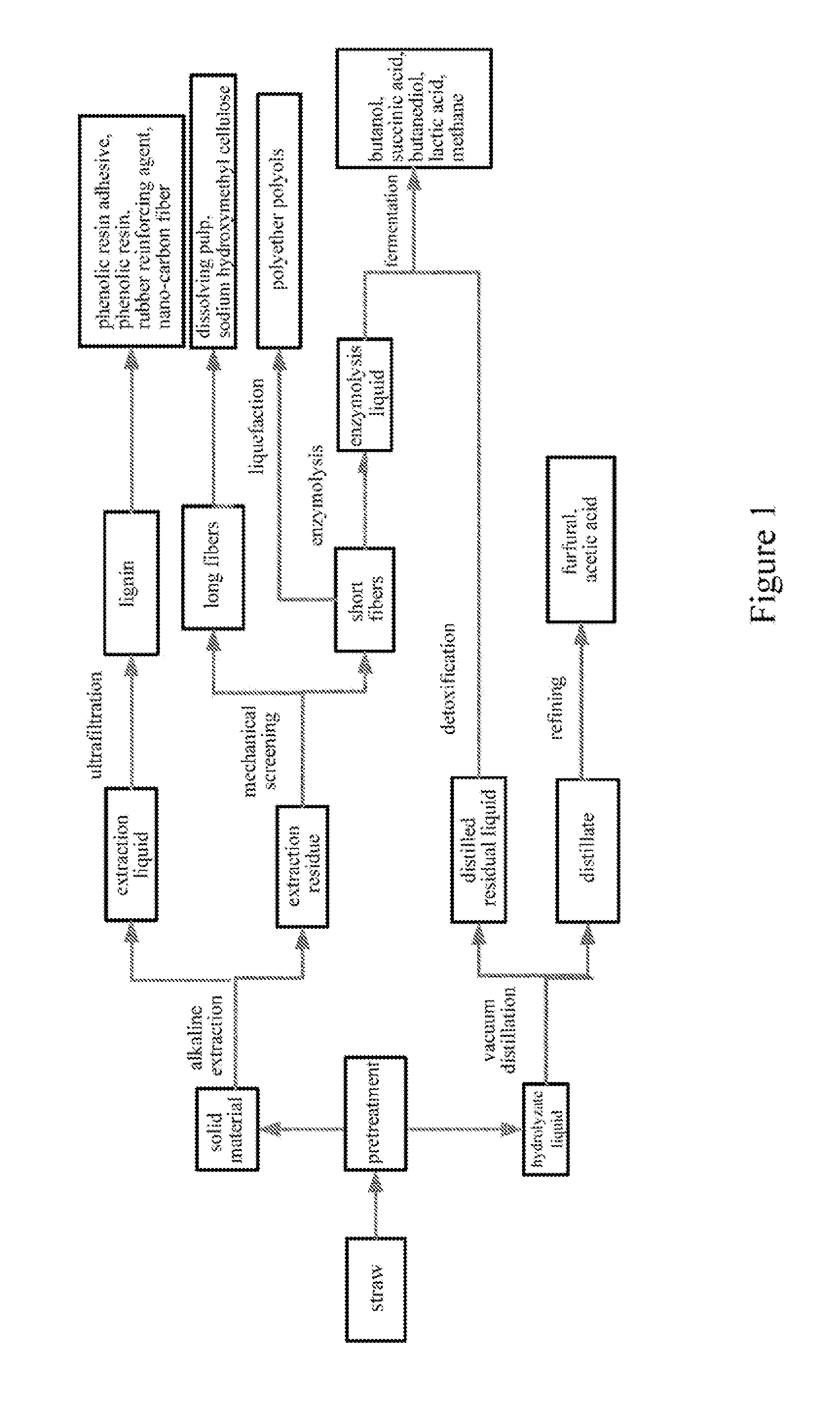

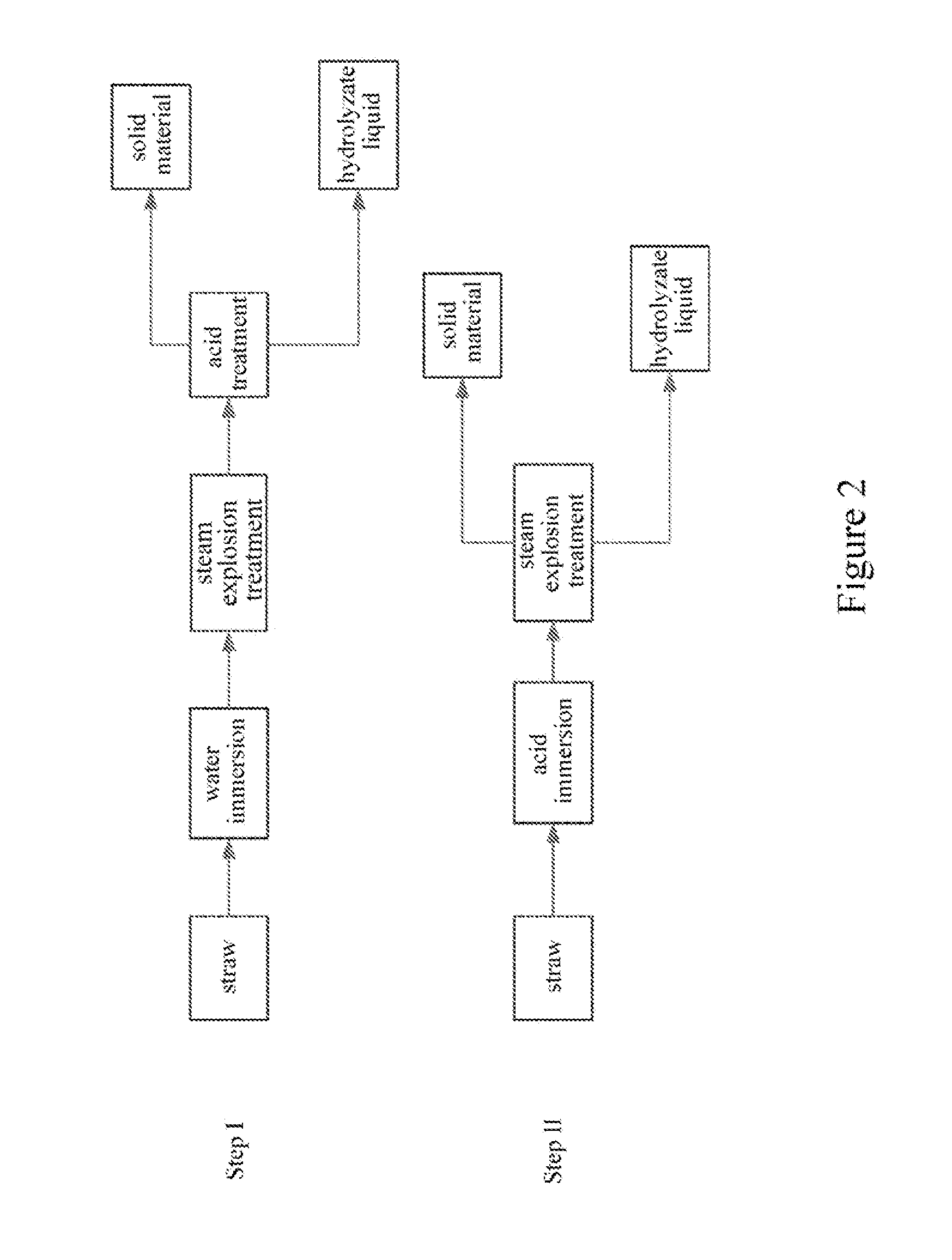

Process for producing bio-based product from straw hemicellulose and fully utilizing the components thereof

ActiveUS20130252293A1Low costHigh value utilizationPretreatment with water/steamBacteriaHigh concentrationSuccinic acid

Provided is a process for producing biomass-based product from straw hemicellulose and utilizing the components thereof thoroughly. Steam-explosion and acid-hydrolysis are combined in the pre-treatment of straw in the process, thus a higher concentration of a sugar liquid can be obtained, and furfural and acetic acid can be recovered. The hemicellulose obtained by the pre-treatment can be used directly as ferment materials for producing butanol, succinic acid, butylene glycol, lactic acid, hydrogen and firedamp, which reduces the cost of these biomass-based products. The cellulose and lignin obtained by extracting the straw with an alkaline solution can produce products, such as sodium hydroxymethyl cellulose etc. In the process, all components in the straw can be utilized thoroughly and waste and pollutant will not be produced.

Owner:HAINAN SUPER HEALTHY GRAIN CO

Preparation method of polyester resin for mixing type powdery coating

InactiveCN1962717AReduce melt viscosityUniform molecular weightPowdery paintsPolyester coatingsPolymer sciencePolymer resin

Owner:GUANGZHOU QINGTIAN INDAL

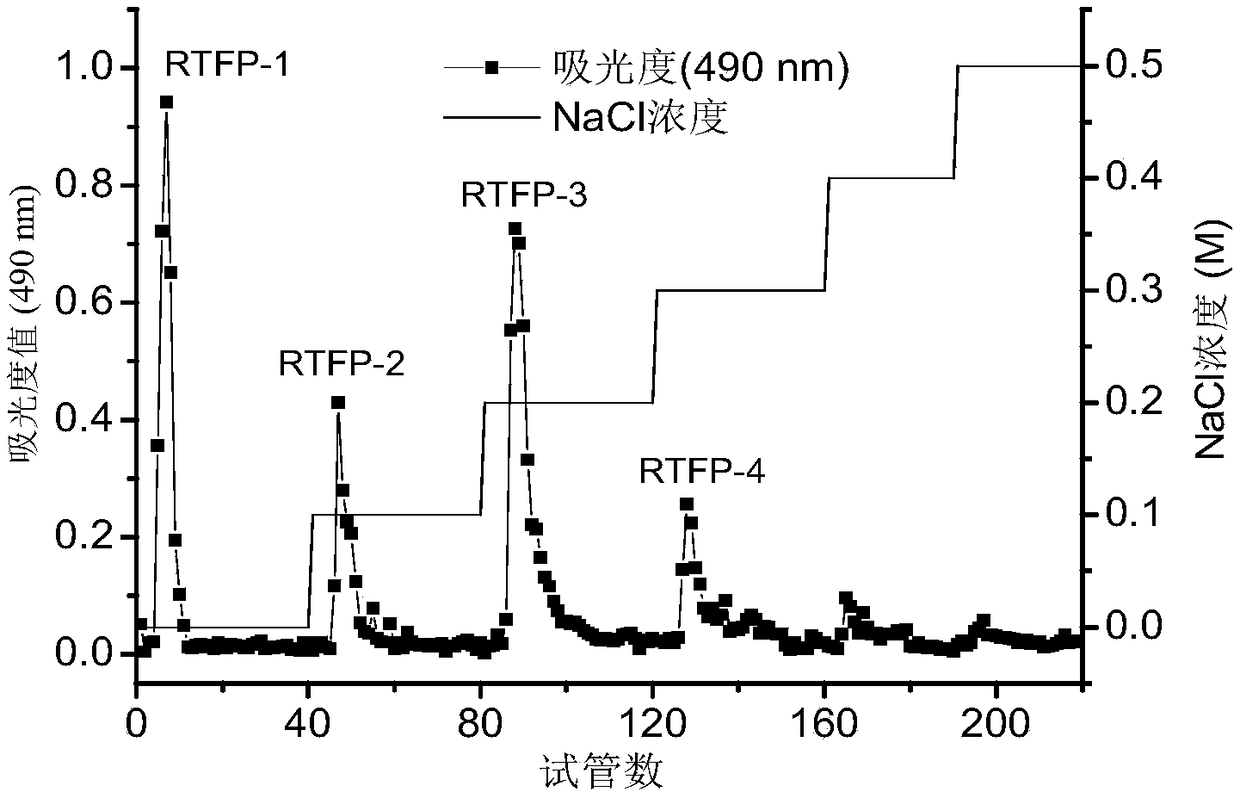

Novel material for use in separation and separating method using the same

InactiveUS20040134846A1Small molecular weightEfficient changeIon-exchange process apparatusComponent separationPhysical contextResponsive polymer

A separatory material comprising a composite material containing a stimulus-responsive polymer and a substance interacting specifically with a target substance, wherein said stimulus-responsive polymer undergoes a structural change upon a physical stimulus so that the interaction of said substance interacting specifically with the target substance is affected by the chemical or physical environmental change, thereby causing a reversible change in the interaction force with the target substance due to the physical stimulus, which separatory material is characterized in that said stimulus-responsive polymer has no affinity with said substance interacting specifically with the target substance.

Owner:JAPAN CHEM INNOVATION INST +1

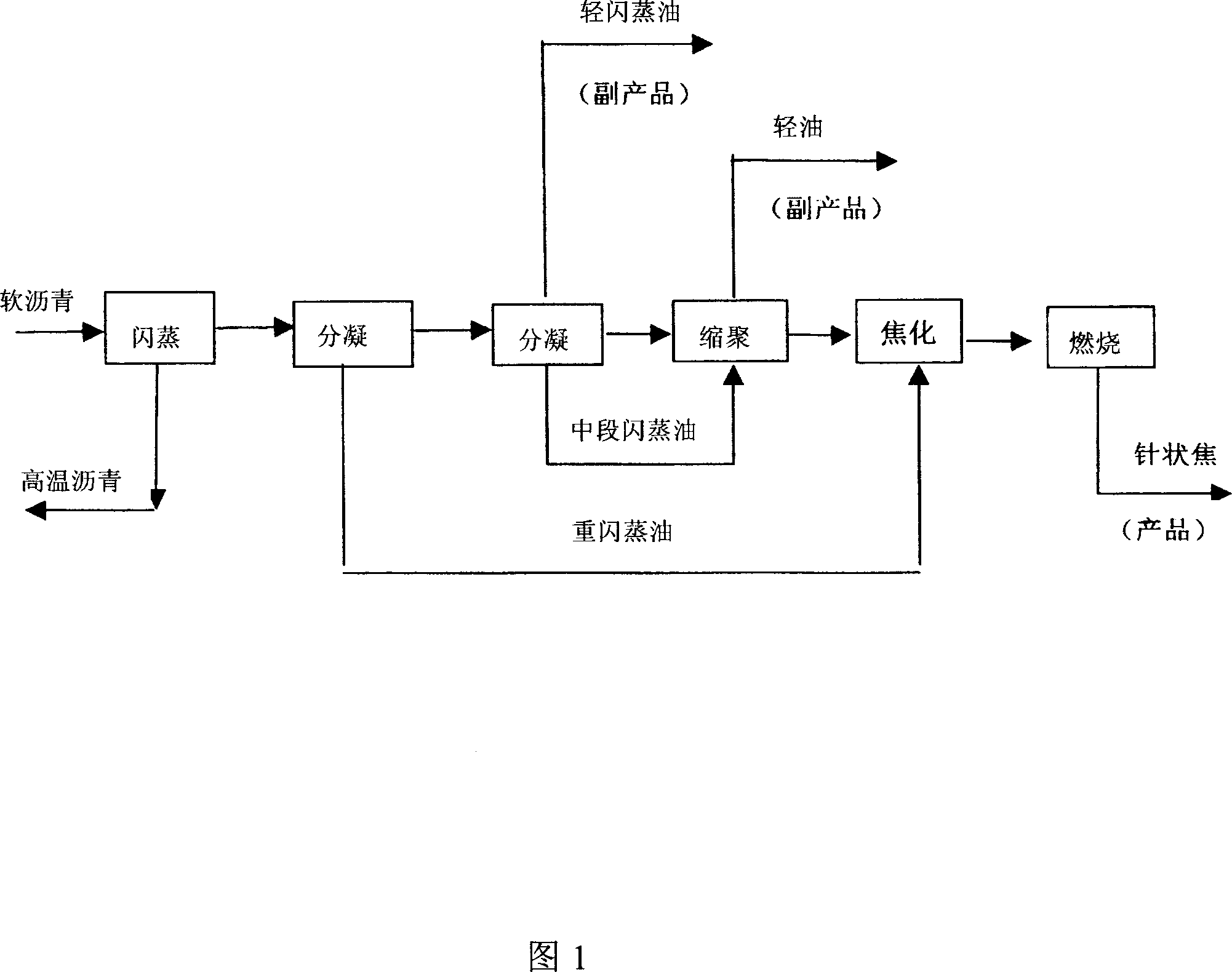

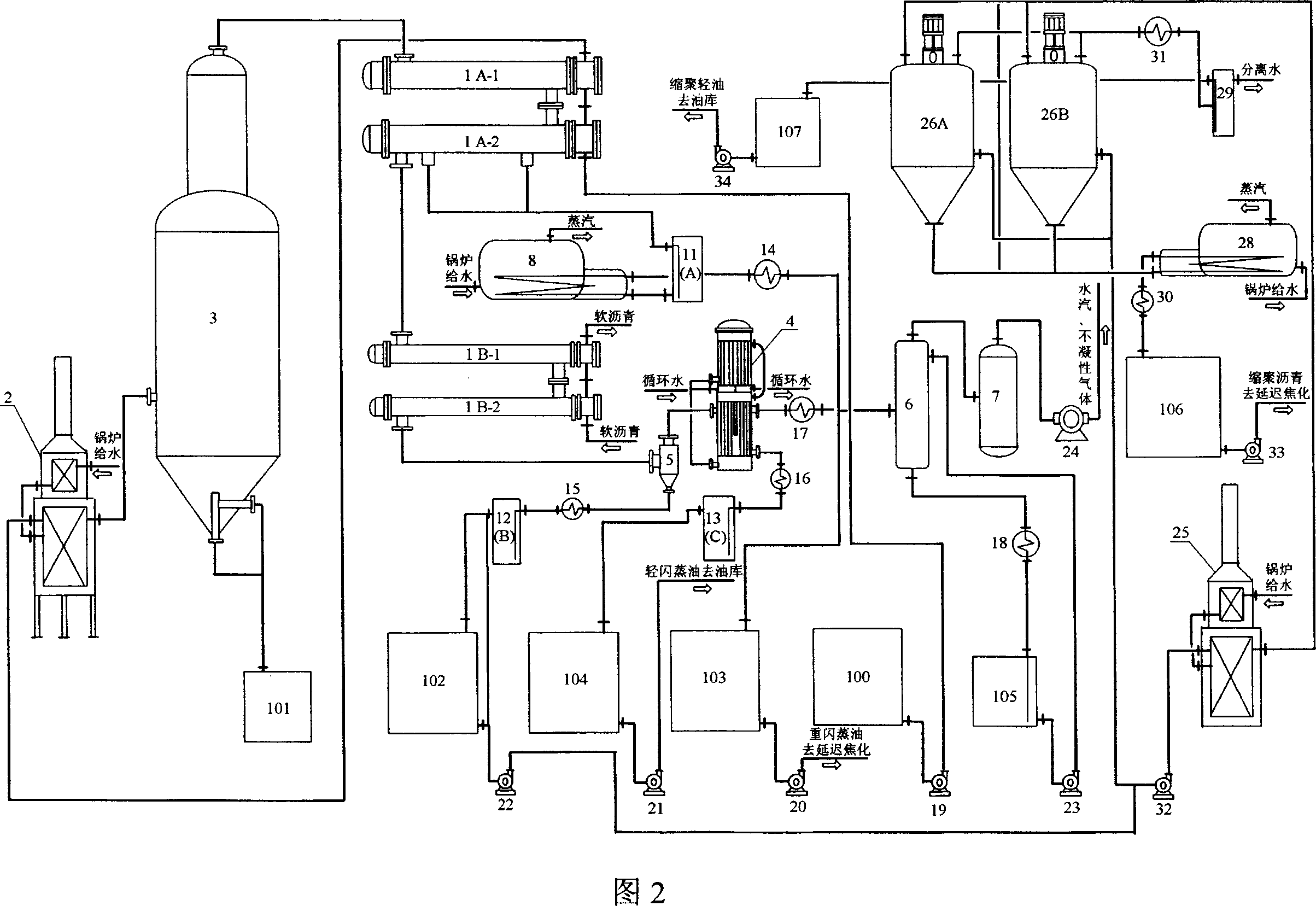

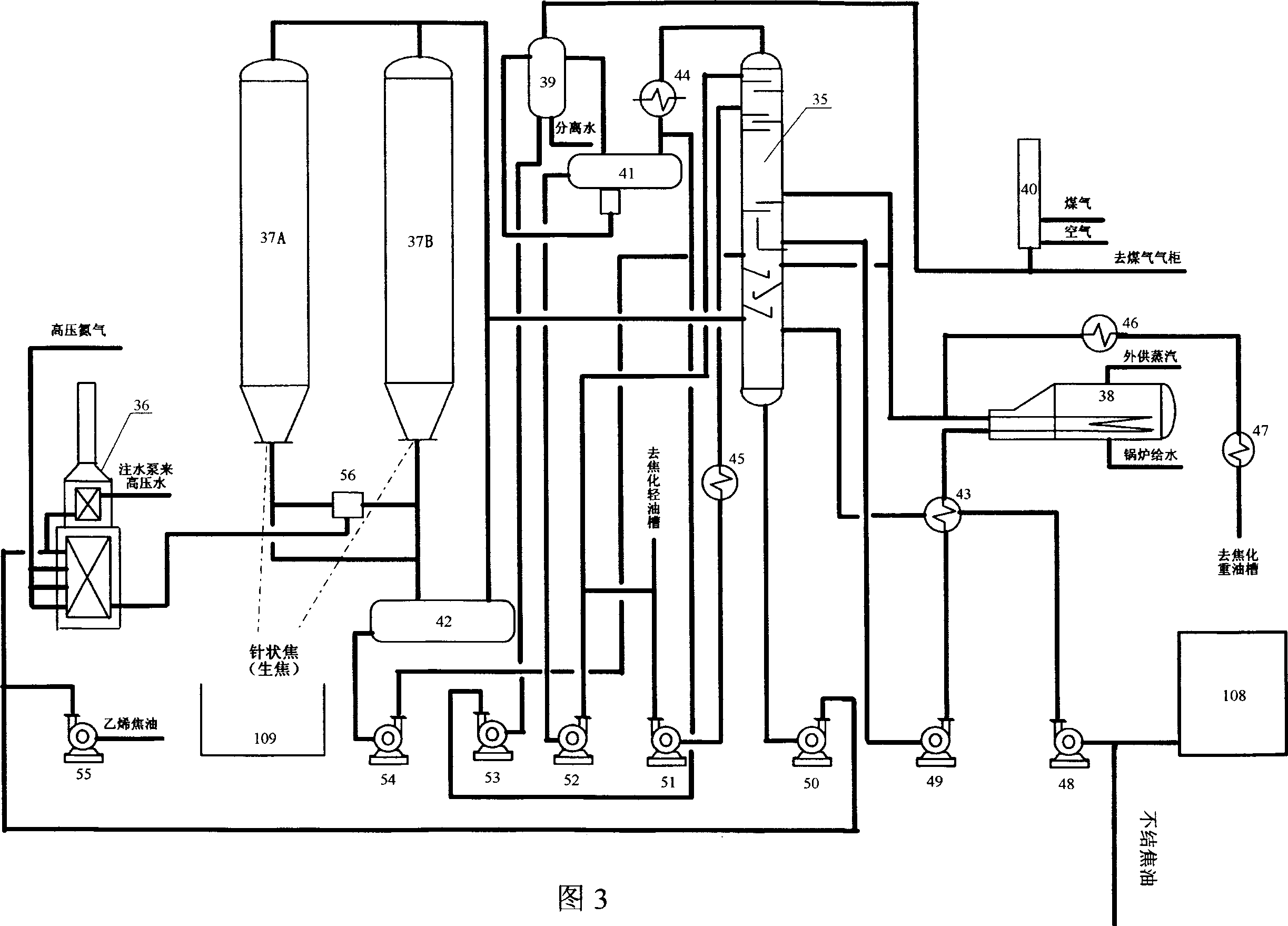

Industrial producing process for coal series needle coke

ActiveCN1944578AHigh molecular weightSmall molecular weightCoking carbonaceous materialsGraphite electrodeGraphite

The industrial producing process of coal series needle coke includes the following steps: stepped condensing the flash oil produced in vacuum flashing of coal tar pitch to obtain three, heavy, medium and light, fractions; polycondensating the medium fraction in an improved pitch circulating process to obtain condensed pitch; delay coking the condensed pitch and the heavy fraction and injecting N2 into the un-coked oil in the later coking stage to perform the final heating and coke drawing of the needle coke forming course; and final high temperature calcining to obtain coal series needle coke. Thus produced coal series needle coke has low thermal expansion coefficient and may be used in producing high power and super high power graphite electrode.

Owner:山西宏特煤化工有限公司

Thermostable organosilicon resin preparation method

The invention discloses a preparing method of high-temperature resistant organic silicon resin, which comprises the following steps: blending methylchlorosilane and phenyl-chloride silicane monomer with composite solvent of PMA, BAC, toluene and anhydrous alcohol; alcoholyzing and hydrolyzing under low temperature; adopting alkaline to neutralize; adding water once; polycondensing; adding silanol; refluxing; adding polymerization inhibitor to obtain the product.

Owner:金小凤

Hydrogel antifouling fiber, preparation method thereof and preparation method of implanted type high-strength hydrogel antiflouling coating layer

InactiveCN103757744AHigh strengthHas superhydrophilic propertiesLiquid surface applicatorsWet spinning methodsFiberPolymer science

The invention discloses a hydrogel antifouling fiber, a preparation method of hydrogel antifouling fiber and a preparation method of an implanted type high-strength hydrogel antiflouling coating layer, and relates to antiflouling materials, preparation methods of the antiflouling materials, and preparation methods of vessel antifouling coating layers, for mainly solving the technical problems that the conventional PVA (Polyvinyl Acetate) fiber implanted type vessel antiflouling coating layer is poor in antifouling effect and short in service life. The hydrogel antifouling fiber disclosed by the invention is a fiber with a core-shell structure, the shell layer of the fiber is made of polyacrylamide, and the core layer is made of carbon nano tube modified polyacrylamide. The preparation method comprises the following steps: 1, preparing polyacrylamide hydrogel, 2, preparing a core layer spinning dope, 3, preparing a shell layer spinning dope, 4, spinning by using a wet method to obtain the hydrogel antifouling fiber. The preparation of the antifouling coating layer comprises the following steps: spraying implantation gel onto a substrate, further implanting the hydrogel antifouling fiber into the substrate through a high-pressure static implantation technique, and drying to obtain the implanted type high-strength hydrogel antifouling coating layer. The coating layer is not changed when being soaked in seawater or industrial water for 6 months, so that the coating layer can be applied to vessel antifouling.

Owner:HARBIN ENG UNIV

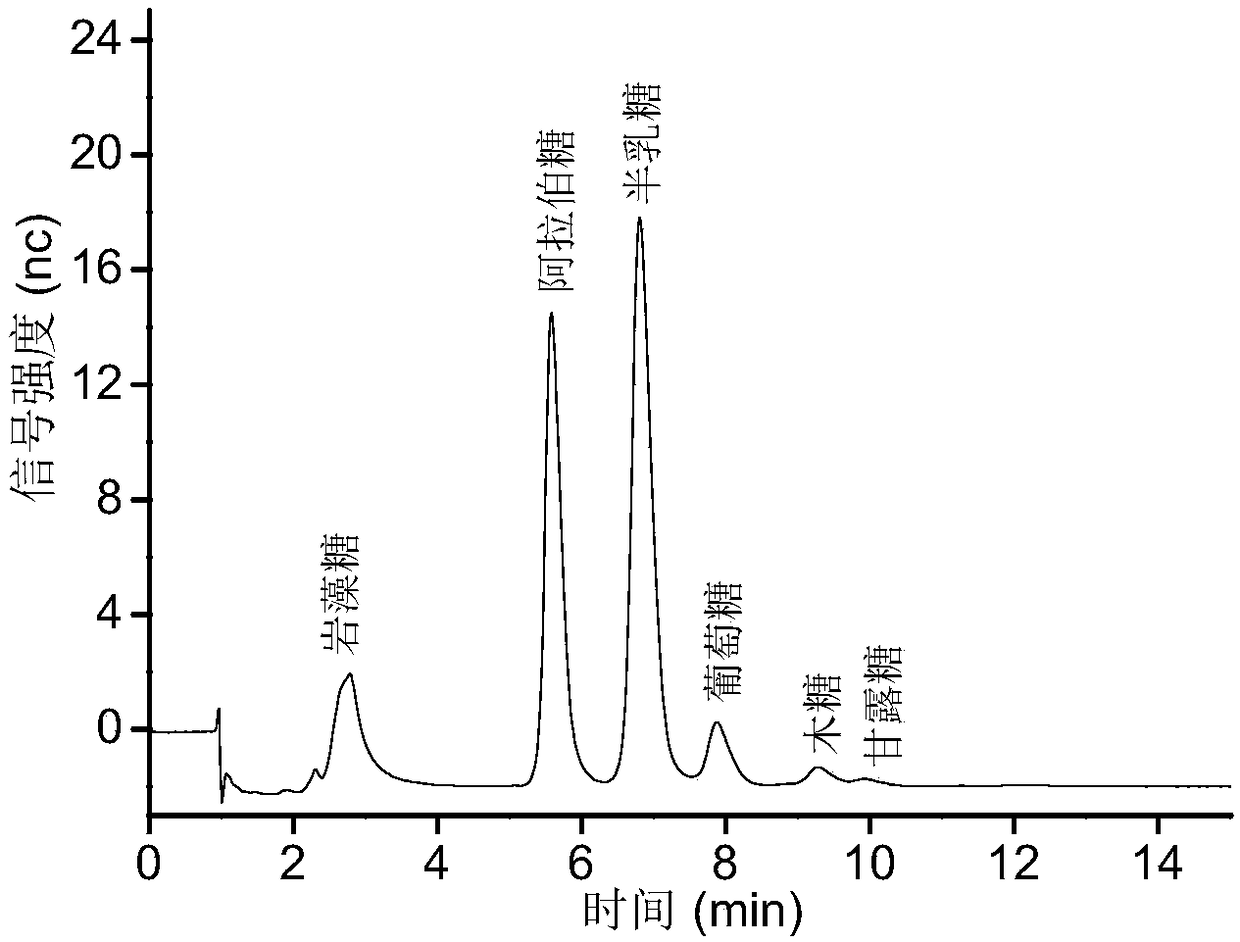

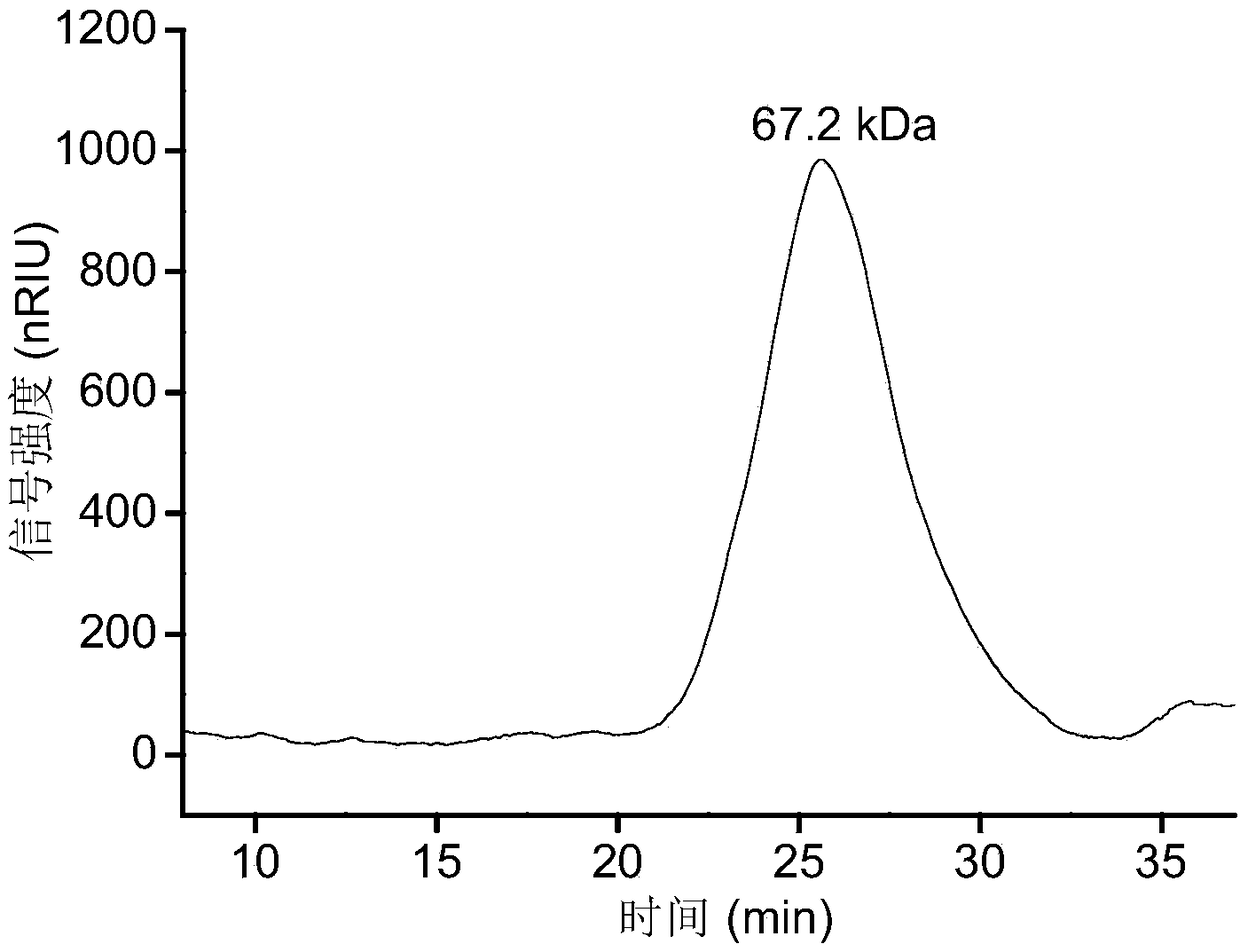

Rosa roxburghii polysaccharide, as well as preparation method and application thereof

The invention discloses a rosa roxburghii polysaccharide, as well as a preparation method and application thereof. The preparation method mainly comprises raw material pretreatment, extraction, deproteinization, de-coloration, alcohol precipitation, as well as separation and purification, wherein the extraction is to mix pretreated rosa roxburghii dry powder and water in a mass volume ratio of (1to 15) to (1 to 35), and perform extraction at a temperature of 55 to 95 DEG C; perform centrifugal separation to obtain a rosa roxburghii polysaccharide extracting solution, and concentrate the rosaroxburghii polysaccharide extracting solution under reduced pressure to 1 / 3 to 1 / 6 of the original volume to obtain a concentrated solution of the rosa roxburghii polysaccharide. The rosa roxburghii polysaccharide prepared by the invention has the advantages of high purity and uniform molecular weight. Compared with the existing rosa roxburghii polysaccharide, as proved by in-vitro fermentation experiments, the rosa roxburghii polysaccharide disclosed by the invention can promote the generation of short-chain fatty acids such as acetic acid, propionic acid and butyric acid, promote the growthof beneficial bacteria such as lactic acid bacteria and bifidobacterium, and can be taken as prebiotics. Meanwhile, the rosa roxburghii polysaccharide can inhibit the activity of alpha-glucosidase, and can be applied to healthy foods or medicines having auxiliary therapy effects on intestinal diseases and diabetes mellitus.

Owner:SOUTH CHINA UNIV OF TECH

Preparation of wire coated paint of polyester paint and polyester imine paint by using terephthalic acid

InactiveCN1670054AUniform molecular weightLow viscosityPolyester coatingsDimethyl terephthalatePolyester resin

The invention relates to a method for producing polyester, polyurethane glazed wire paint using terephthalic acid, which solves the problems of molecular weight disproportion, paint film continuity in the polyester fibre industrial process and clogging condensator easily, the environmental contamination by byproduct carbinol in the dimethyl terephthalate industrial process. The copper wires used in different standard as well as the polyester enamelled wire paint and polyurethane glazed wire paint allowable different needle speed are produced by controlling exit temperature of the dephlegmating column and other technological parameter strictly,

Owner:杨朝选

Medical hemostatic polysaccharide starch microsphere and preparation method thereof

ActiveCN104311870AAbsorb quickly and completelyDisorganized reactionOrganic active ingredientsPotato starchStarch Microspheres

The invention relates to a preparation method and a refining method of medical hemostatic polysaccharide starch. With pretreated potato starch as a raw material and epichlorohydrin as a crosslinking agent, a microsphere adopting a three-dimensional network structure is synthesized by an emulsifying and crosslinking technology. The medical hemostatic polysaccharide starch is high in biocompatibility; the medical hemostatic polysaccharide starch is full with wrinkles on the surface, so that the particle surface area is increased, the water absorbing rate is significantly improved and the hemostatic time is greatly reduced; the medical hemostatic polysaccharide starch is especially applicable to large-area blood seepage, deep bleeding, and bleeding at a part difficult to reach by operative procedures.

Owner:SHIJIAZHUANG YISHENGTANG MEDICAL SUPPLIES

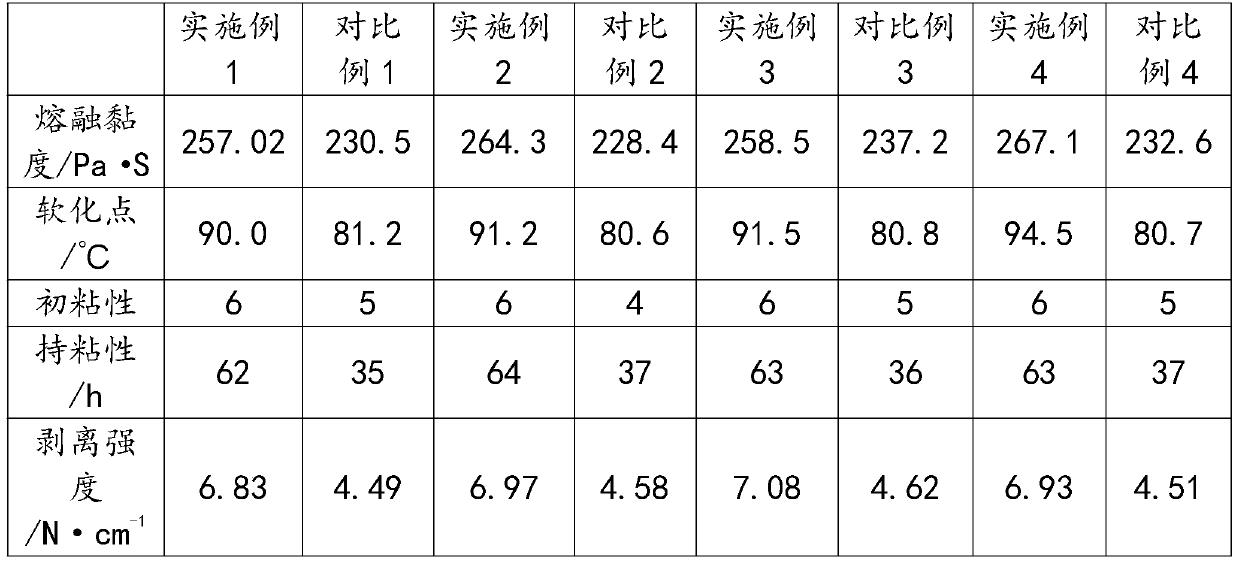

Environmentally-friendly hot-melt pressure sensitive adhesive and preparation method thereof

PendingCN110093128AUniform molecular weightGood solubilityMineral oil hydrocarbon copolymer adhesivesNon-macromolecular adhesive additivesEnvironmental resistanceAntioxidant

The invention discloses an environmentally-friendly hot-melt pressure sensitive adhesive. The environmentally-friendly hot-melt pressure sensitive adhesive is prepared from, by weight, 25-35 parts ofa thermoplastic elastomer, 28-36 parts of modified petroleum resin, 6-10 parts of natural tackifying resin, 12-20 parts of a plasticizer, 2-3 parts of a modifying filler, 0.2-0.3 part of a coupling agent and 0.2-0.3 part of an antioxidant. The present invention also discloses preparation method of the hot-melt pressure sensitive adhesive. The thermoplastic elastomer is used as a matrix for the hot-melt pressure sensitive adhesive, the modified petroleum resin and the natural tackifying resin are used as tackifying resins, and no organic solvent is needed, so the raw materials are safe and environmentally friendly; the petroleum resin is modified, so the compatibility of the petroleum resin and the thermoplastic elastomer is improved, and the thermal stability of the hot-melt pressure sensitive adhesive is improved; and the reinforcing effect of the modifying filler improves the initial viscosity, the glass strength and the thermal stability of the hot-melt pressure sensitive adhesive are improved, so the environmentally-friendly hot-melt pressure sensitive adhesive with excellent performances is prepared.

Owner:黄敏

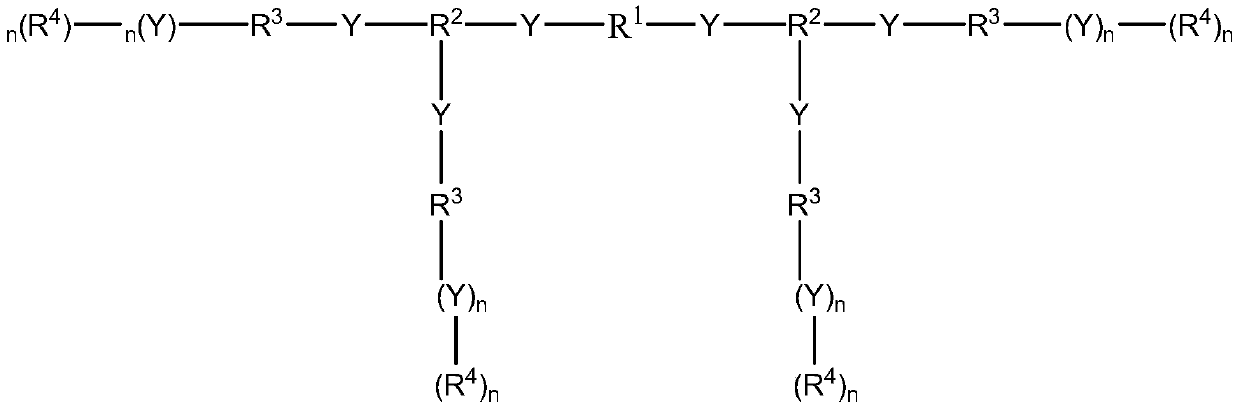

Medical polyurethane adhesive and preparation method thereof

InactiveCN109749694AImproves biological applicabilityImprove performancePolyureas/polyurethane adhesivesPolyurethane adhesiveBiocompatibility Testing

The invention belongs to the field of medical materials and discloses a medical polyurethane adhesive and a preparation method thereof. The preparation method comprises the following steps of mixing the dehydrated polyether polyol with an amine catalyst, an organic solvent and a diisocyanate under the condition of introducing nitrogen gas and stirring, and reacting the mixture to obtain a NCO (Isocyanate)-terminated polyurethane prepolymer; adding a castor oil or a derivative thereof to the obtained NCO-terminated polyurethane prepolymer, and reacting the mixture to obtain a castor oil-modified polyurethane prepolymer solution; adding a polysaccharide substance into the obtained castor oil-modified polyurethane prepolymer solution, and reacting the mixture to obtain a polysaccharide-castoroil modified hyperbranched polyurethane prepolymer solution, wherein the polysaccharide substance is any one or more than two of maltodextrin, amylose and hyaluronic acid; after completion of the reaction, removing the organic solvent to obtain the medical polyurethane adhesive. According to the medical polyurethane adhesive and the preparation method thereof disclosed by the invention, the castor oil or the derivative thereof and the polysaccharide material are used as a bio-based polyol, and the obtained polyurethane adhesive has remarkably improved biocompatibility.

Owner:SOUTH CHINA UNIV OF TECH +1

Method for preparing thickenable dicyclopentadiene unsaturated polyester resin

The invention relates to a preparation method for dicyclopentadiene unsaturated polyester resin which can be thickened. The method is characterized in that reaction material, namely, dibasic acid (anhydride) and deionized water are added into a reactor according to the mol ratio of 1: 1.0 to 1.2, the temperature is raised to 100 to 140 DEG C, and hydrolytic reaction is performed for 0.5 to 1h; 0.4 to 0.8 mol of dicyclopentadiene is titrated at 110 to 180 DEG C for hydrion displacement addition reaction and diolefine addition reaction, and after the titration is finished, reaction is performed again for 1 to 2h at the temperature; 0.3 to 0.7 mol of dibasic alcohol, catalyst accounting for 0.07 to 0.30 percent of the total material weight, and polymerization inhibitor accounting for 0.03to 0.07 percent of the total material weight are added, and the temperature is gradually raised to 200 to 210 DEG C for polycondensation reaction for 0.5 to 1h; after vacuum dehydration, styrene is added for dilution, and then the product can be obtained. The dicyclopentadiene unsaturated polyester resin synthesized through the multi-step synthesis method of the invention can be thickened, and the product is suitable to be used as the substrate resin for unsaturated polyester molding compound.

Owner:SICHUAN DONGFANG INSULATING MATERIAL

Preparation method of asphalt based carbon fiber

ActiveCN106435840AWide source and low costImprove compositionFibre chemical featuresHydrogen pressureDistillation

The invention relates to a preparation method of asphalt based carbon fiber. The method comprises the following steps that 1, catalytic slurry oil is adopted as a raw material; 2, high pressure hydrogenation pretreatment is performed, the hydrogen pressure is 12-18 MPa, the reaction temperature is 420-450 DEG C, the reaction is performed for 1-3 h, and a pretreatment product is obtained; 3, reduced pressure distillation is performed to obtain a fraction with the temperature not lower than 400 DEG C, and a co-carbonization component is added into the fraction, wherein deasphalted oil of naphthenic base vacuum residues or a 450-550 DEG C fraction in the naphthenic base vacuum fraction or a catalytic cracking slurry hydrogenation reduction product 450-550 DEG C fraction and the co-carbonization accounts for 10-45% that of the hydrogenation product component with the temperature not smaller than 400 DEG C, a co-carbonization high pressure condensation polymerization is performed, the reaction condition is an inert gas or nitrogen atmosphere, the reaction pressure is 1-6 MPa, the reaction temperature is 460-500 DEG C, and the reaction is performed for 6-8 h; 4, the pressure is decreased to the normal pressure, the negative pressure condensation polymerization is performed at the nitrogen flow rate of 6-10 L / (s.kg), the reaction temperature is 450-500 DEG C, the reaction is performed for 4-6 h, and high-quality spinnable mesophase asphalt is obtained; 5, melt spinning of the mesophase asphalt is performed to obtain the asphalt base carbon fiber.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

Method for preparing seaweed plant growth regulator by using whole biological enzymolysis method

InactiveCN107236766AImprove retentionHigh purityBiocidePlant growth regulatorsGrowth plantHydrolysate

The invention relates to a method for preparing a seaweed plant growth regulator by using a whole biological enzymolysis method. The method comprises the nine steps of preparation before production, pre-treatment of material, primary enzymolysis, enzymatic hydrolysate edulcoration, enzymatic hydrolysate homogenization, secondary enzymolysis, post-treatment, separation and purification of somatotropin and final fertilizer configuration. According to the method provided by the invention, commodity complex enzyme is used for performing enzymolysis on the seaweed, complexity of pre-treatment of enzymolysis technology, such as seaweed soaking, cleaning, edulcorating and grinding and the disadvantage that active material is lost due to caused by the pre-treatment are overcome, the fresh seaweed or the dried seaweed are directly, integrally, tenderly and efficiently softened and enzymatically decomposed, active material in the seaweed is furthest reserved, and effect and quality of seaweed fertilizer are ensured.

Owner:YELLOW SEA FISHERIES RES INST CHINESE ACAD OF FISHERIES SCI +1

Preparation method of powdery polyacrylic acid thickener

InactiveCN103183765ASimple manufacturing processEasy to dry and removeCross-linkReaction temperature

A preparation method of a powdery polyacrylic acid thickener comprises the following steps: at room temperature, adding organic solvent, polymeric monomers, comonomers, neutralizers and cross linking agents in a reaction kettle in sequence, introducing nitrogen to remove all oxygen, starting stirring to cause the reactants to be uniformly mixed, rising the temperature to the reaction temperature, dissolving initiators in the organic solvent having the same reaction system as the initiators, dripping off for 15-30 min, preserving the reaction temperature for 3-6 hours, cooling, filtering, washing with the organic solvent, removing unreacted raw materials in the product, and vacuum-drying a filter cake for 24-48 hours at the temperature of 40-50 DEG C to obtain white powder. The preparation method has the advantages of simple preparation process, environmental friendliness, low energy consumption and low cost.

Owner:CHINA RES INST OF DAILY CHEM IND

Alkyd resin for amino baking paint and preparation method thereof

The invention discloses alkyd resin for amino baking paint and a preparation method thereof. The alkyd resin for amino baking paint is prepared from the following components: 10 to 15 parts of dry or half-dry vegetable oil acid, 10 to 15 parts of triatomic alcohol with side chains, 5 to 10 parts of dihydric alcohol with side chains, 20 to 30 parts of phthalic anhydride, 1 to 3 parts of adipic acid, 0.05 to 0.2 part of esterification catalyst, 1 to 5 parts of dimethylbenzene, and 30 to 40 parts of organic solvent. The compositions and the proportions of the raw materials are screened through a lot of experiments, the component proportion is scientific and reasonable, and the alkyd resin for the amino baking paint has good flexibility, shock resistance, rigidity and weather resistance, and is wide in application range. The preparation method of the alkyd resin for amino baking paint is low in production cost, high in preparation efficiency, reasonable in whole process design, strong in operability and easy to implement.

Owner:江苏三木化工股份有限公司

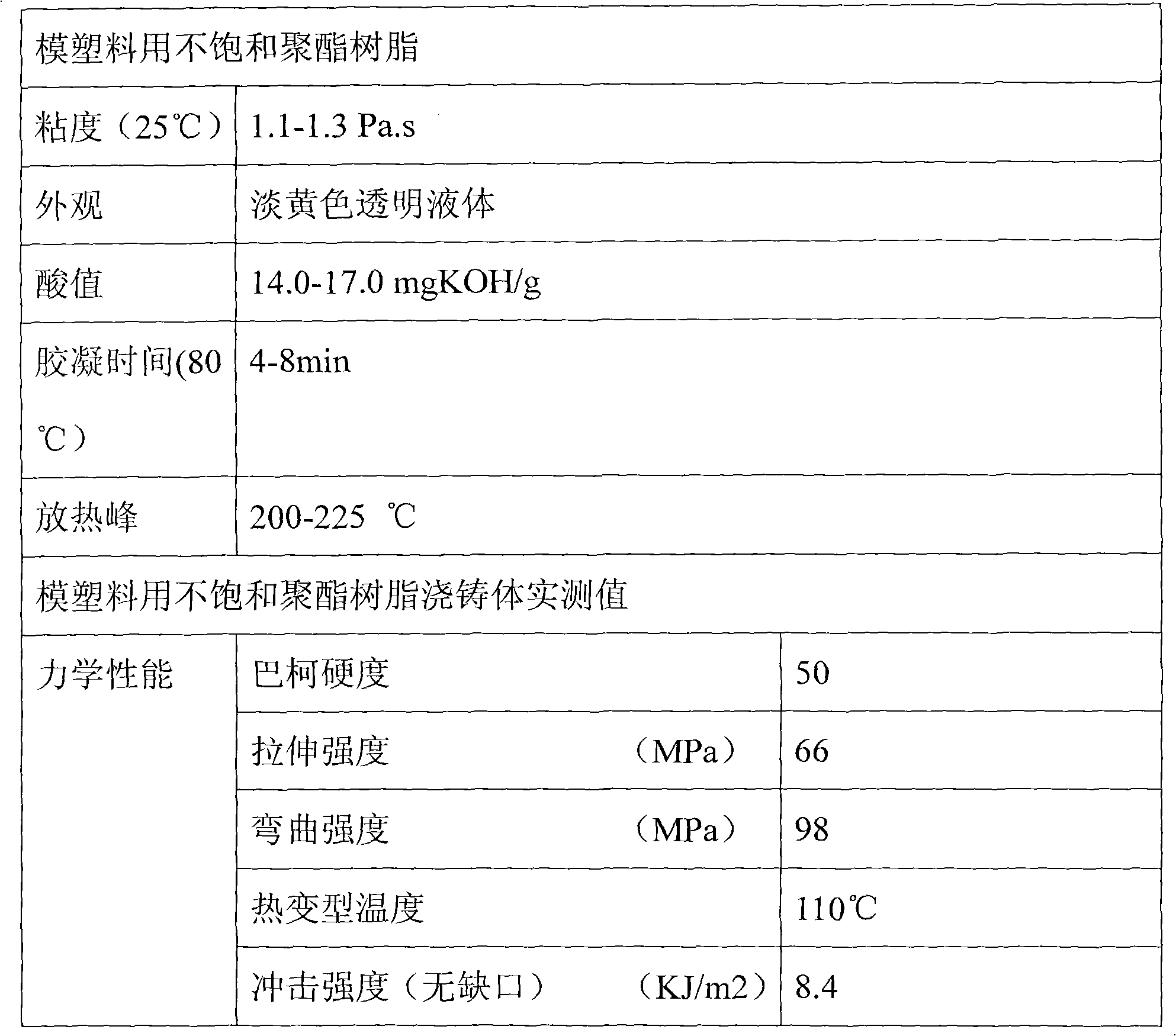

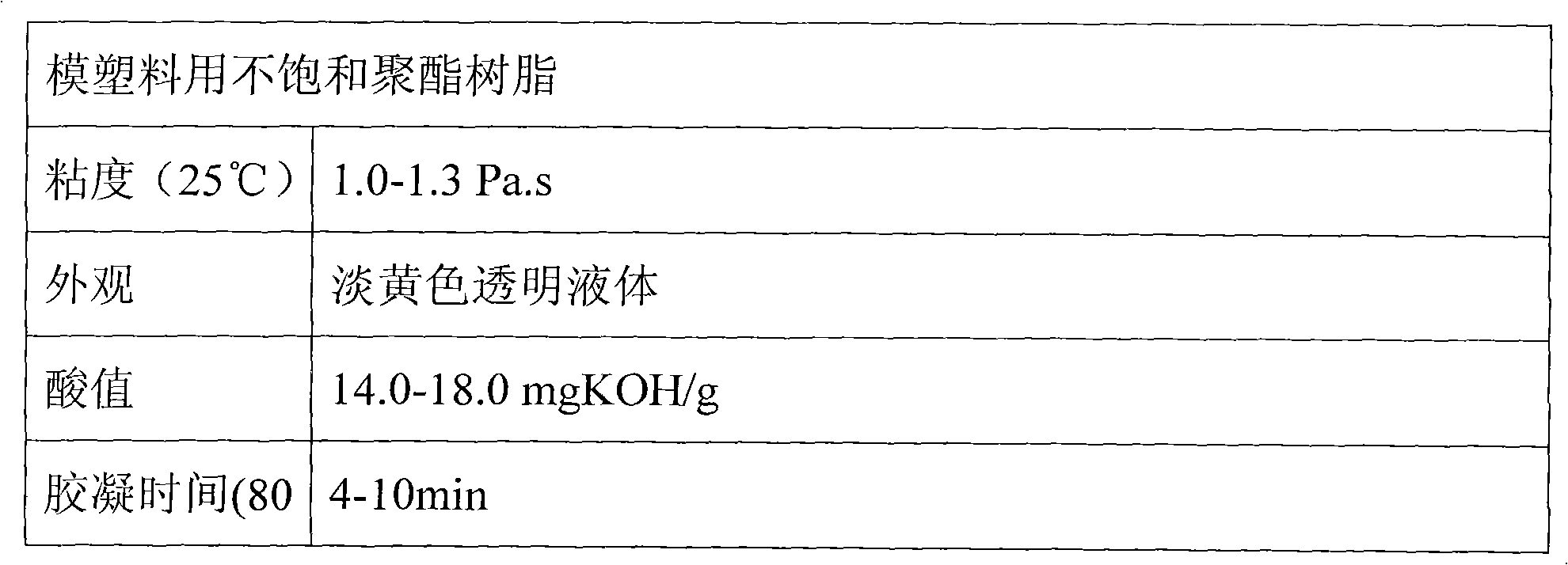

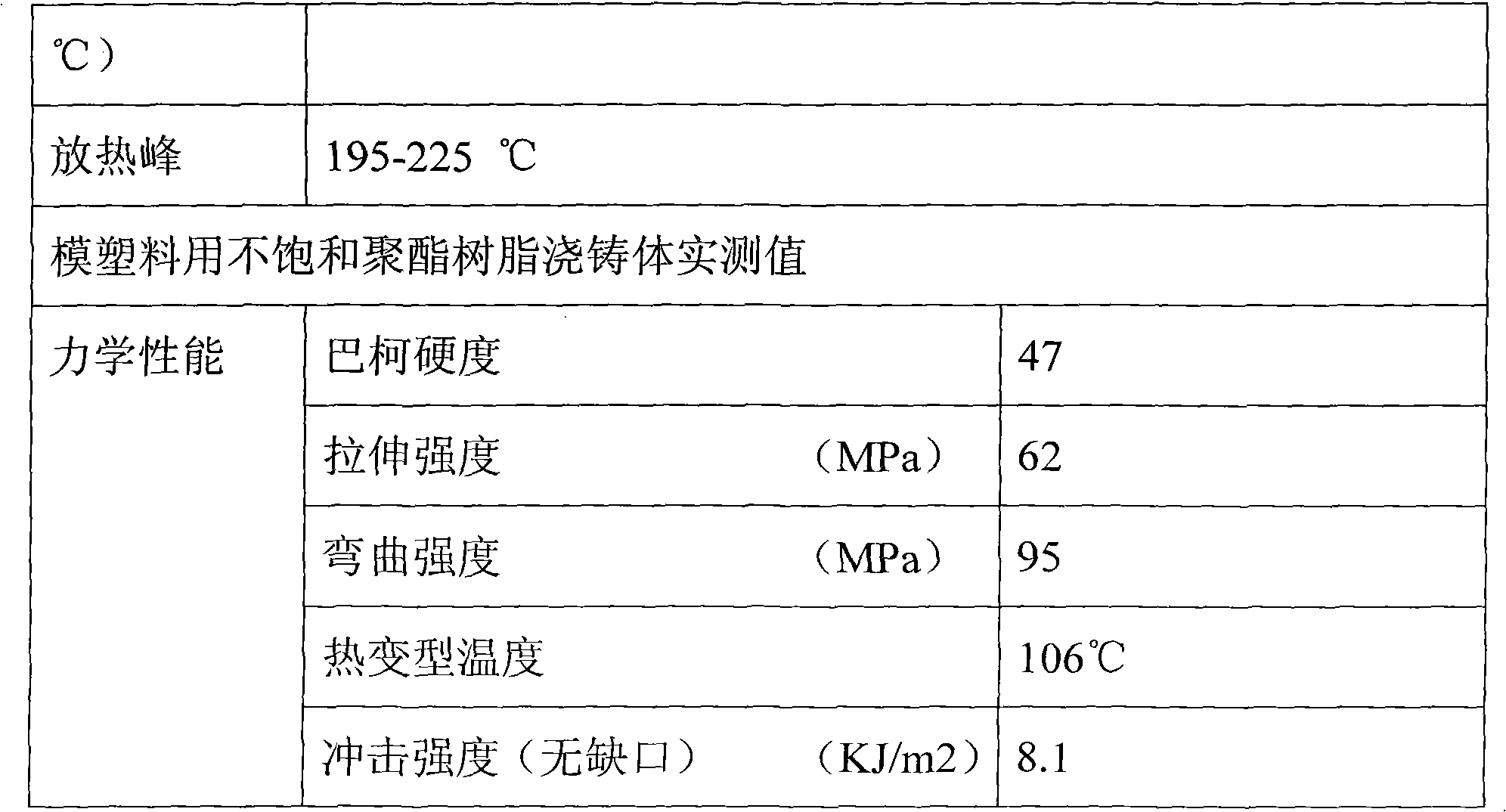

Unsaturated polyester resin for molding compound of auto parts and manufacturing method thereof

The invention relates to a high molecular compound, in particular to an unsaturated polyester resin for molding compound of auto parts, which is prepared by dissolving a reaction product of the condensation reaction of propylene qlycol, diethylene qlycol, dipropylene glycol, phthalic anhydride and cis-butenedioic anhydride into styrene after the condensation reaction is completed. The invention has the advantages that: (1) the resin has good water resistance and flexibility through optimization combination on the premise that the cost of raw materials of the resin is not greatly increased, and products made of the resin have good anti-wet capacity and good mechanical property; (2) the reactivity of the resin is greatly enhanced so as to ensure that the surface of molding compound products after hot press molding has higher luster; (3) the resin is used together with a proper low-profile agent, and enables produced products to achieve zero shrinkage so as to ensure the accuracy of the size of the products; and the resin also can be used together with low-shrinkage agents in polystyrene so as to enhance stainability of the products; and (4) the reaction time can be shortened as well as the energy consumption and the manufacturing cost of the resin can be reduced by adopting phthalic anhydride.

Owner:CHANGZHOU HUARUN COMPOSITE MATERIALS +1

Method of modifying protein alpha-amido by carbowax

InactiveCN1687106AIncrease response rateUniform molecular weightPeptide preparation methodsPolyethylene glycolNitrogen

The present invention provides a method for modifying protein alpha-amino group by using polyethuylene glycol. Said method includes the following steps: utilizing amino protective agent to close lysine epsilon amino group capable of reacting with PEG in the protein, using activated PEG with dominant response with alpha amino group to make amino modification, then removing amino protective agent so as to obtain nitrogen end specific PEG modified protein derivative. The conversion rate of product obtained by said method is high, can be up to 90%-95%.

Owner:山东格兰百克生物制药有限公司

Ionizing radiation degradation method for sea cucumber polysaccharide

The invention discloses an ionizing radiation degradation method for sea cucumber polysaccharide. The method sequentially comprises the following steps of: 1) completely dissolving the sea cucumber polysaccharide into distilled water to obtain an aqueous solution of the sea cucumber polysaccharide; 2) performing ionizing radiation degradation on the aqueous solution of the sea cucumber polysaccharide at normal temperature by adopting 60 Co, wherein the absorbed dose is 2 to 200kGy; and 3) standing and settling or centrifuging the obtained product in the 2) to remove non-degradable settlement and obtain a clear solution, drying the clear solution, and thus obtaining an oligosaccharide with low molecular weight. The product obtained by adopting the method has uniform and centralized molecular weight, the molecular weight distribution index is close to 1, and the product has good uniformity.

Owner:ZHEJIANG UNIV

Semi-continuous preparation method for solution of heterocycle-containing aromatic polyamide copolymer

The invention relates to a semi-continuous preparation method for solution of heterocycle-containing aromatic polyamide copolymer, which comprises the following steps of: dissolving p-phenylenediamine and 5(6)-amino-2-(4-aminophenyl)benzimidazole in a mixed solvent system and cooling to -20 to 10 DEG C; adding terephthaloyl chloride (TPC) with stirring to obtain prepolymer; and adding the prepolymer into a double-screw extruder and retaining in the double-screw extruder at the temperature of between 40 and 100 DEG C for 10 to 25 minutes to obtain the solution of heterocycle-containing aromatic polyamide copolymer. The double-screw extruder is taken as a main reactor, so that a reaction interface can be updated, the heat transfer problem of the system can be solved, the low-temperature solution polycondensation of the heterocycle-containing aromatic polyamide copolymer is semi-continuous, the side reaction is reduced, and the molecular weight of the polymer is effectively improved.

Owner:DONGHUA UNIV

Preparation method and use of active low molecular weight fucosan

ActiveCN103554293AImprove controllabilityUniform molecular weightFood preservationAlgluceraseSulfate radicals

The invention discloses a preparation method and use of active low molecular weight fucosan. The method comprises the following steps: hydrolyzing the fucosan by using beta-galactosidase and beta-glucosaccharase to obtain an oligomerized fucosan aqueous solution with different molecular fragments; separating through an ultrafiltration membrane to obtain the low molecular weight fucosan at 5000-100000 Da. The preparation method of enzymatically preparing the low molecular weight fucosan is mild in reaction condition, strong in controllability, and high in retention rate of sulfate radicals which are the key active groups of the low molecular weight fucosan; the obtained low molecular weight fucosan has a good antibacterial effect and antibacterial stability. The prepared low molecular weight fucosan is a safe and environment-friendly product applied to antibacteria, and can be used for food fresh keeping and storage, and the use of pesticides and antibiotics is reduced so as to improve the security of the food.

Owner:厦门百拓生物工程有限公司

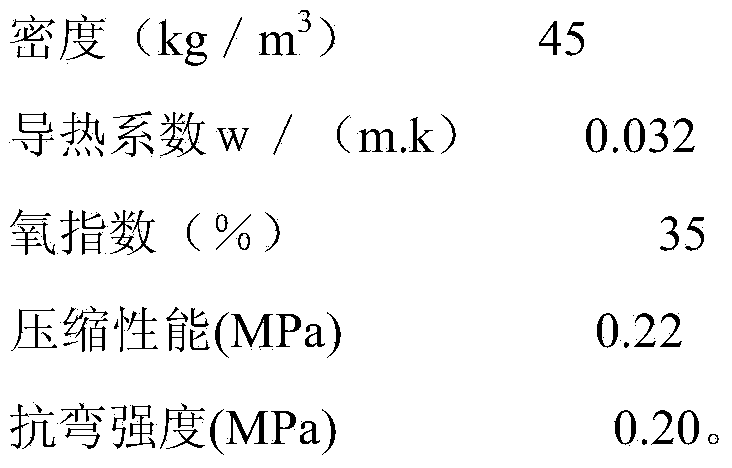

Method for producing low-hydroxyl value high-temperature sulfuration silicon rubber raw rubber

InactiveCN101173045ASolve the problem of poor uniformitySolve uneven heatingDecompositionWeight distribution

The invention relates to the field for producing silicon rubber, in particular to a preparation method of sulfuration silicon rubber crude rubber with low hydroxyl value high temperature. The invention adopts the method that: firstly, all materials are dehydrated before preparation and then the polyreaction is conducted; after the catalyzer loses activity caused by decomposition, the material which can react with a SiOH group is added. The silicon rubber crude rubber prepared by the invention has narrow molecular weight distribution and extremely micro-hydroxy-terminated. The invention also discloses a double-pair screw belt scraping wall type stirrer.

Owner:JIANGSU HONGDA NEW MATERIAL

Monocomponent polyurethane coating and preparation method thereof

InactiveCN104987826AGood compatibilityFast curingWax coatingsPolyurea/polyurethane coatingsButyl acetateMethyl isobutyl ketone

The invention provides a monocomponent polyurethane coating, and relates to the field of coating. The monocomponent polyurethane coating comprises, by weight, the following components of 20 to 40 parts of diisocyanate, 40 to 65 parts of polyether, 50 to 75 parts of chlorcosane, 35 to 60 parts of chlorcosane, 20 to 50 parts of xylene, 15 to 25 parts of butyl acetate, 50 to 90 parts of padding, 10 to 20 parts of curing agent and 40 to 80 parts of catalyst. The acid value of the chlorcosane is smaller than 12 mg KOH / g, and the curing agent is a mixture of acetone-ethidene diamine condensation compound and methyl isobutyl ketone-ethanol amine condensation compound. The provided monocomponent polyurethane coating has the advantages that the curing speed is high, blistering in the crosslinking process and the storage process can be avoided effectively, and the practicability is high. The invention further provides a preparation method for the monocomponent polyurethane coating.

Owner:四川珍福堂商贸有限公司

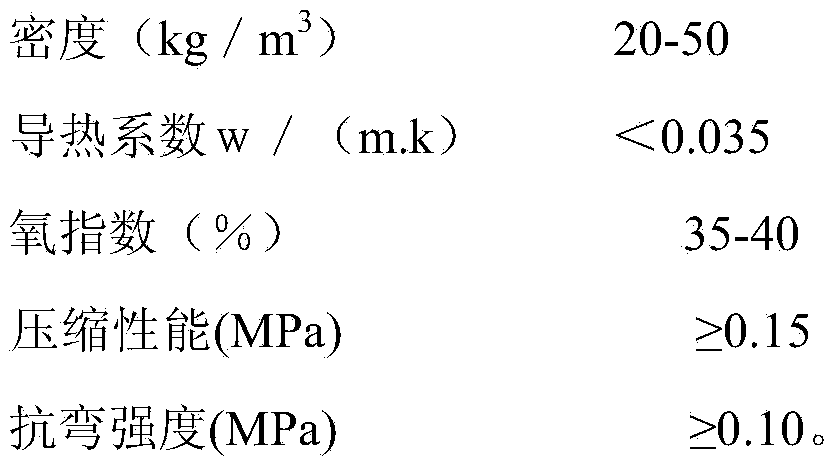

Synthetic method of resin for hard melamine foam material

The invention belongs to the field of polymer materials, and in particular relates to a synthetic method of a resin using a hard melamine foam material. The method is as below: conducting a hydroxymethylation reaction on melamine and formaldehyde in with a solvent of water at the pH of 8.0-9.0 to generate polyhydroxy melamine; adding acid into the polyhydroxy melamine to adjust the pH value to 5.5-7.0, and adding alcohol to carry out a three-dimensional network polymerization. The alcohol is one or a mixture of methanol, ethanol, ethylene glycol and polyethylene glycol 400. According to the invention, the polyhydroxy melamine is added with acid and then alcohol, so that the resin gains good stability to facilitate storage and utilization. By adjusting the proportion of melamine and formaldehyde and controlling the reaction conditions, the obtained resin has uniform molecular weight. Weak acid conditions are employed to control the speed of a resin cross-linking reaction, so as to effectively prevent the problem that the resin coagulates into a block due to fast cross-linking.

Owner:HOLITECH TECH CO LTD

Preparation method for high molecular weight cationic polyacrylamide

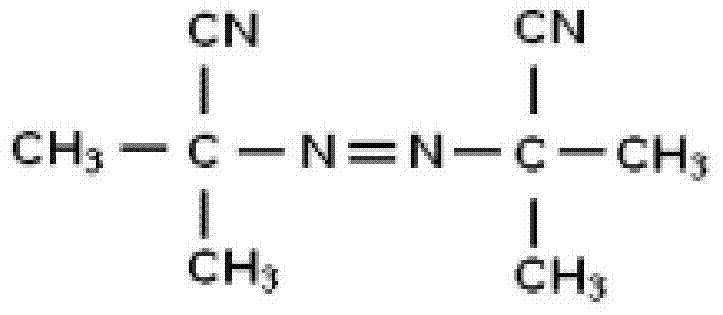

A preparation method for high molecular weight cationic polyacrylamide includes following steps: uniformly mixing acrylamide, acryloyloxyethyl trimethylammonium chloride and deionized water to obtain homogeneous solution, then sequentially adding complexant and defoamer, stirring well until the solution is clear and adjusting the pH value with weak acids to obtain homopolymerized solution; pumping the homopolymerized solution into a polymerizer after cooling, adding azodiisobutyronitrile, feeding high-purity nitrogen, sequentially adding solutions respectively prepared by oxidant, azo-oxidant, reductant and auxiliary reductant, continuing to feed high-purity nitrogen and stopping after all the solutions are added, and controlling the temperature for polymerization reaction and aging reaction for hours to obtain transparent elastic rubber brick; and taking out the rubber brick, cutting, pelleting, drying, smashing and screening to obtain white powdery cationic polyacrylamide. The high molecular weight cationic polyacrylamide prepared by the method can be widely applicable to fields of organic wastewater treatment, papermaking auxiliaries and dispersant, oil field auxiliaries and the like.

Owner:ANHUI JUCHENG FINE CHEM

Method for preparing high temperature resistant silicone resin

The invention relates to a method for preparing organic silicone resin, in particular to a method for preparing heat-resistant organic silicone resin, wherein methyl chlorosilane monomers and phenyl chlorosilane monomers are mixed, added into a mixed solvent of PMA, BAC, toluene and anhydrous alcohol, subjected to alcoholysis and hydrolysis at a low temperature synchronously, neutralized by alkali, subjected to water scrubbing for one time, subjected to polycondensation, silanol, reflux and synthesis, and added with a polymerization inhibitor finally to prepare the heat-resistant organic silicone resin. The method solves the problems of smoke formation of the prior organic silicone resin at a high temperature and faded color of coating at a high temperature of more than 600 DEG C, and the organic silicone resin prepared by the method can be applied to prepare heat-resistant lacquer with various colors which can resist the high temperature of more than 600 DEG C and applied to manufacture open-fire coke ovens, grills, heat-insulated steelmaking furnaces, electric furnace discs, electric barrettes, non-smoking exhaust pipes and so on.

Owner:金小凤

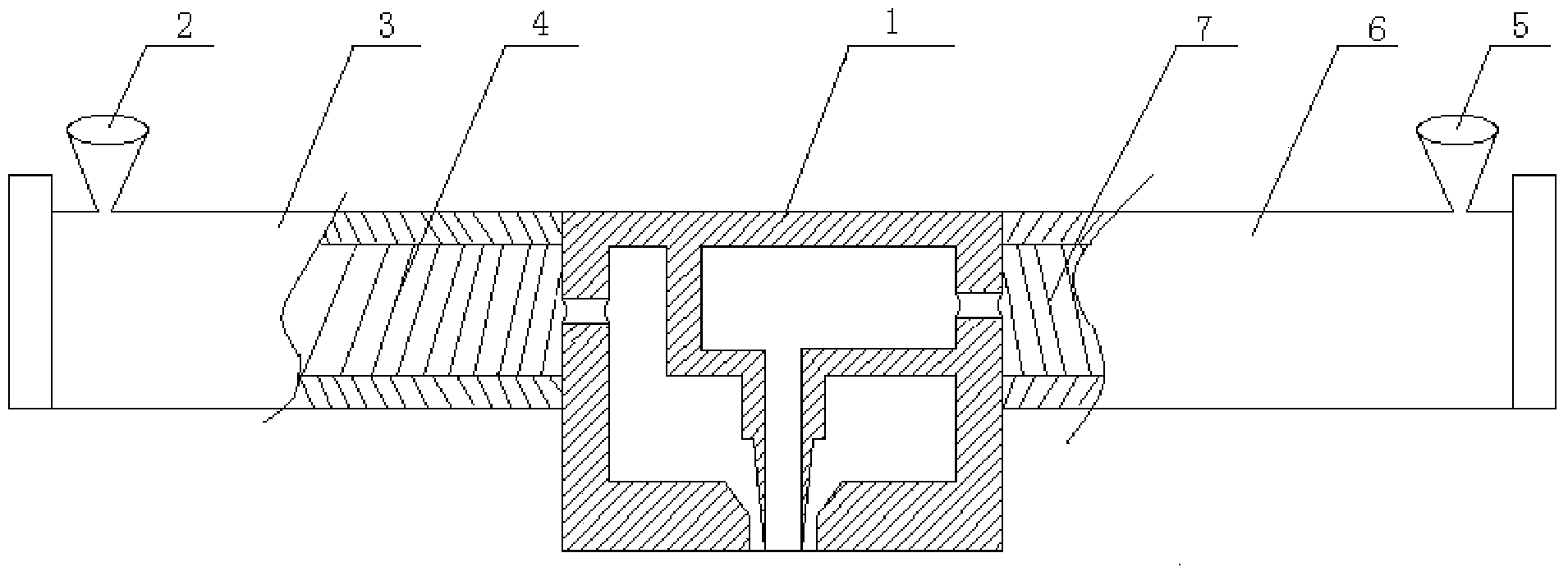

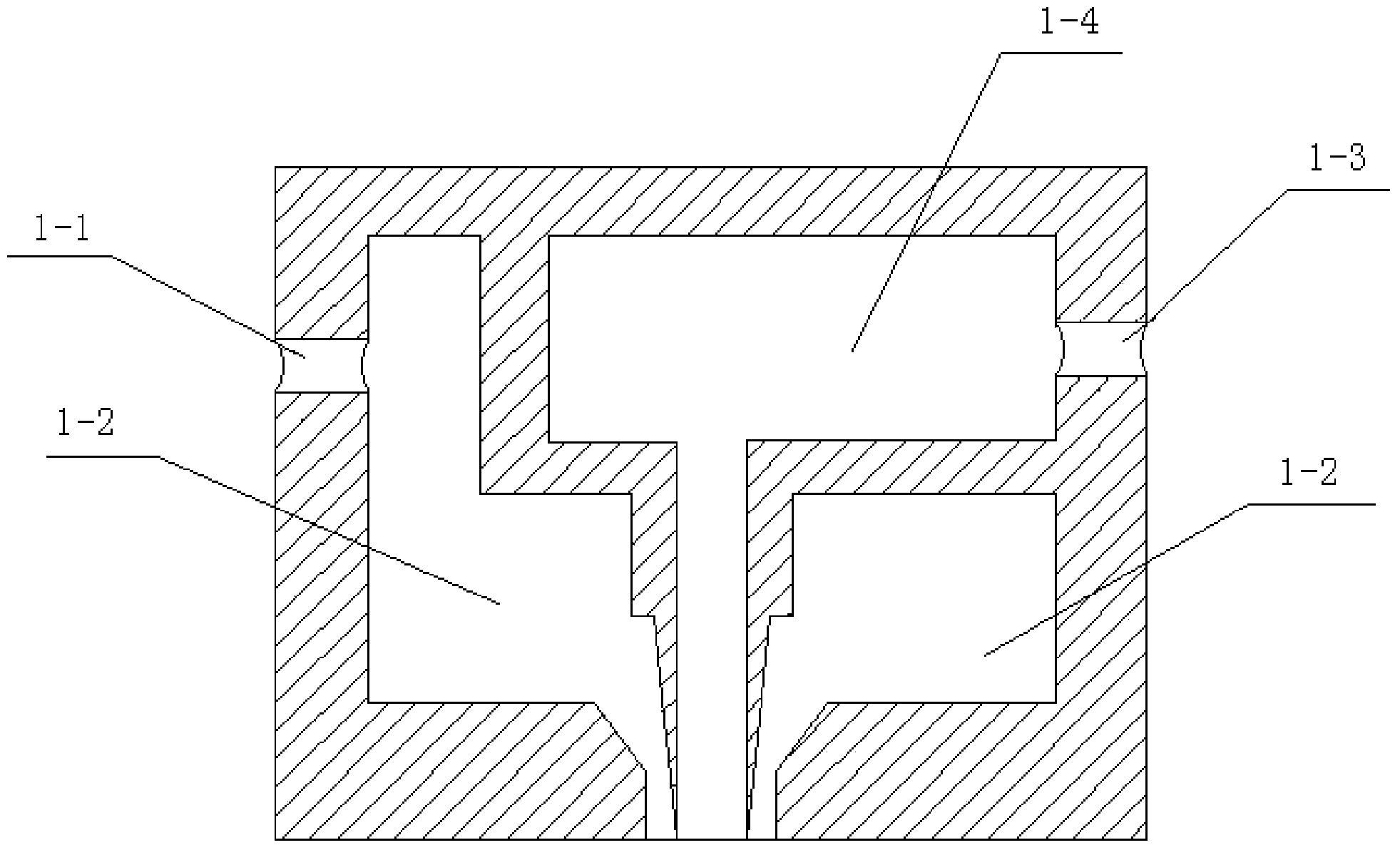

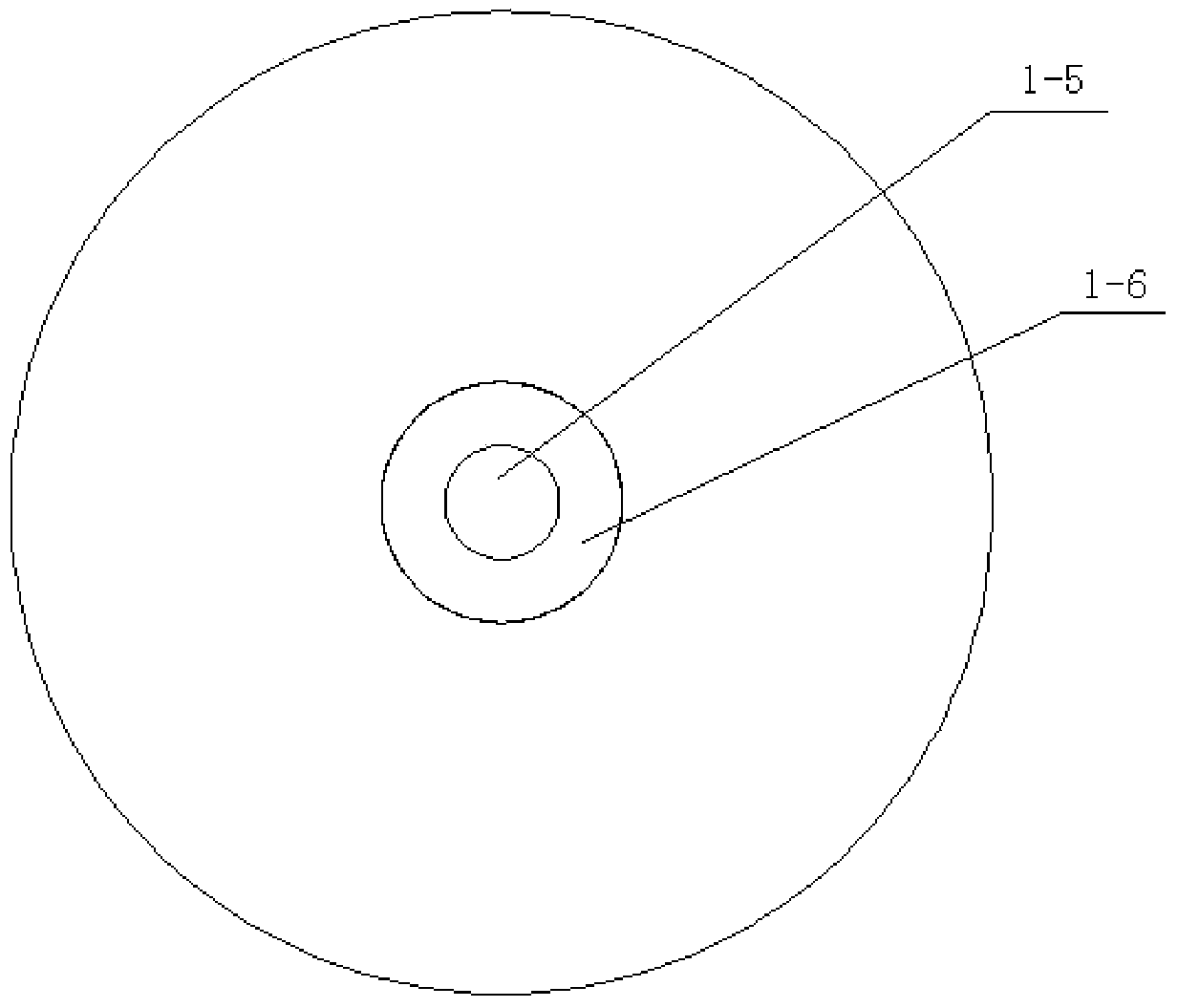

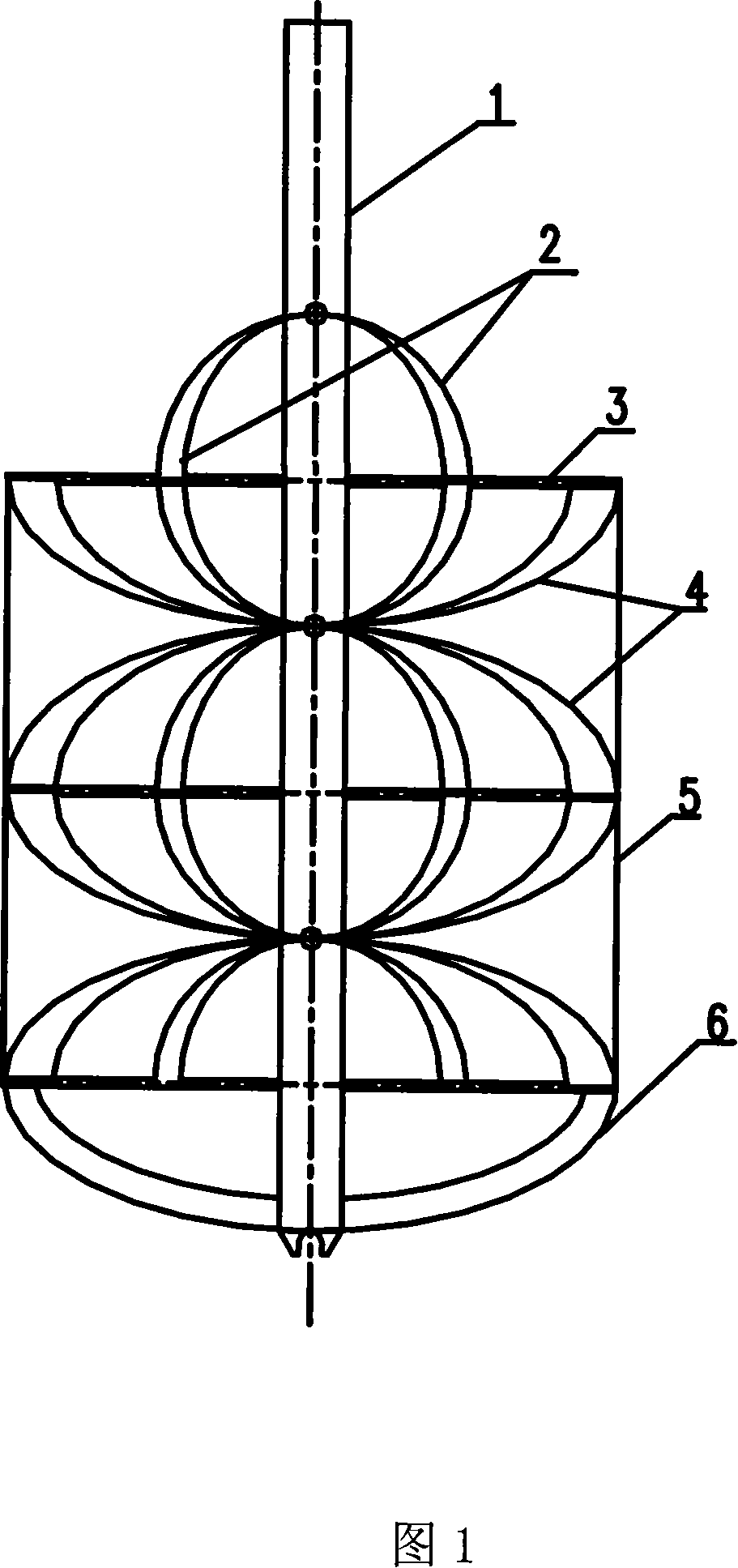

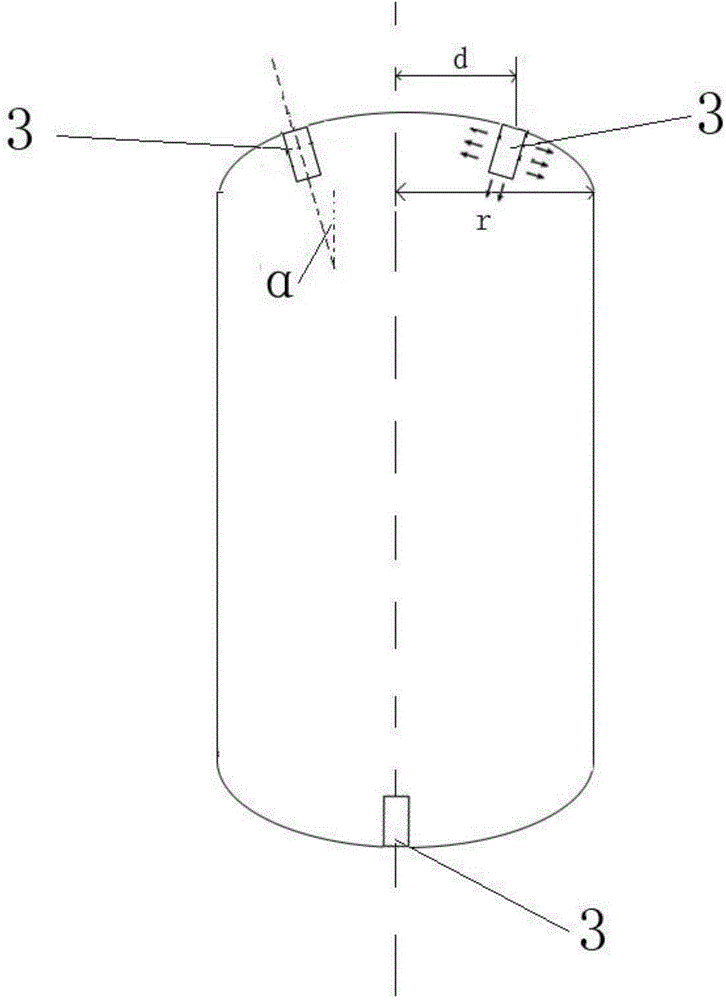

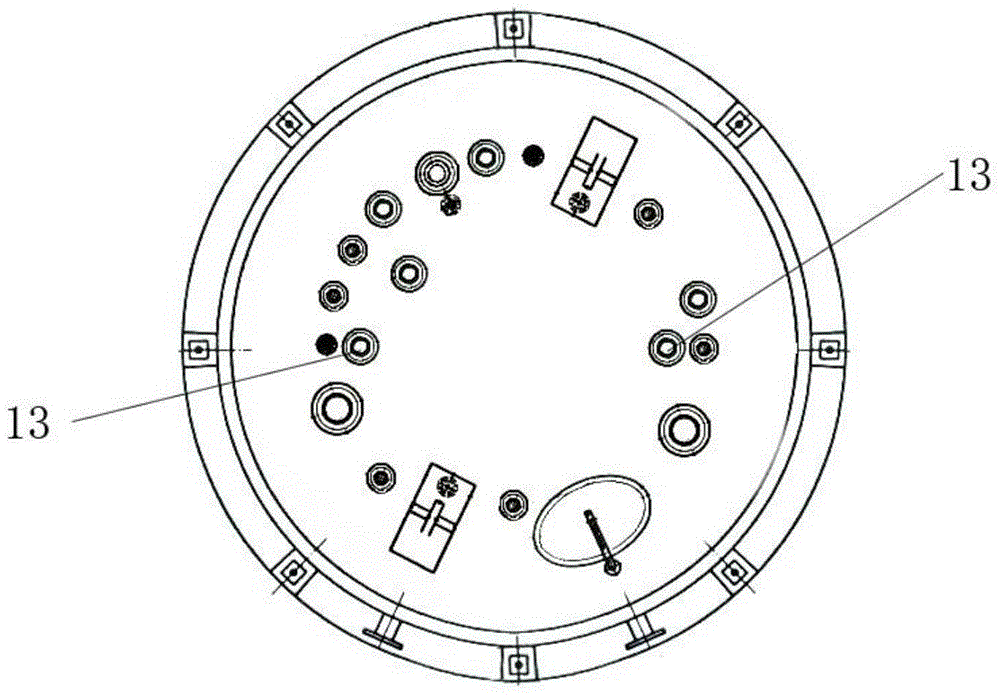

Reaction container

ActiveCN104923145AIncrease profitUniform particle sizeMixersChemical/physical/physico-chemical stationary reactorsEngineeringNoise reduction

The invention relates to a reaction container. Steam firstly enters a steam introduction cavity from an opening, then enters a steam buffer cavity through a first through hole and passes through a second through hole in the outer wall of the buffer cavity and finally enters a tank body. In the process that the steam passes through the steam introduction cavity and the steam buffer cavity, a steam disperse part carries out noise reduction treatment on the steam. Moreover, the steam is dispersed into a plurality of small streams of steam through the first and second through holes and plays a role of stirring a liquid mixture in the tank body, so that the stirring effect is improved. When the small streams of steam move in the liquid mixture, the steam releases heat and is liquefied to become a part of the liquid mixture, so that heat contained in the steam is fully transferred into the liquid mixture, and therefore, the utilization ratio of the heat energy and the steam is increased. As the stirring effect is improved, the grain size or the molecular weight of high-molecular polymers produced by adopting the reaction container is uniform and the proportion of the high-molecular polymers with large grain size or high molecular weight is reduced.

Owner:ZHEJIANG TIANCHEN PLASTIC IND

Method for preparing polyester polyol by taking waste polyester bottles as main raw materials

The invention provides a method for preparing polyester polyol by taking waste polyester bottles as main raw materials, comprising the step of introducing the polyols of tri(alpha-hydroxyethyl) isocyanurate, triethanolamine, sorbitol and the like and performing alcoholysis on waste polyester to prepare polyester polyol, wherein a new way for recycling polyester bottle waste materials is developed, and the reaction endpoint of the alcoholysis can be conveniently and effectively controlled by adopting a thin-layer chromatography method. The polyester polyol prepared by the method disclosed by the invention has a hydroxyl value of 150-310 mgKOH / g, a number-average molecular weight of 5000-7000 (which is measured by a gel permeation chromatography method, and with a mobile phase of tetrahydrofuran), and a molecular weight distribution index of 1.7-2.5; and the production cost is 65-80% of the production cost of the existing similar products.

Owner:华大化学(安徽)有限公司

Method for preparing high-branch low-aromatic oligopeptides

ActiveCN106566858AReduce manufacturing costEasy to operateChemical industryFermentationFreeze-dryingHydrolysate

A method for preparing high-branch low-aromatic oligopeptides belongs to the technical field of separation and purification. The preparation method adopting dry vegetable protein powder as a raw material comprises the following steps: preparing a vegetable protein alkaline protease hydrolysate, preparing an aromatic amino acid hydrolysate with a C end, preparing a C end-removed aromatic amino acid hydrolysate, preparing an ultrafiltration separation liquid, preparing an aromatic amino acid-removed oligopeptide solution, preparing high-branch low-aromatic oligopeptide freeze-dried powder, and preparing a regenerated macro-porous adsorption resin column to prepare the high-branch low-aromatic oligopeptides with the F value reaching up to 21-26. Macro-porous adsorption resin of a styrene-based skeleton substitutes active carbon to separate aromatic amino acids and the aromatic amino acid-containing oligopeptides, so the method has the advantages of high separation efficiency, high precision and repeated use; the method adopting various modern chemical technologies and devices has the characteristics of convenience in operation, mild conditions, energy saving and low production cost; and the method realizes full utilization of the raw material, does not generate three wastes, is a typical green production process, and is convenient for being promoted and applied.

Owner:CHONGQING UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com