Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

39results about How to "Absorb quickly and completely" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

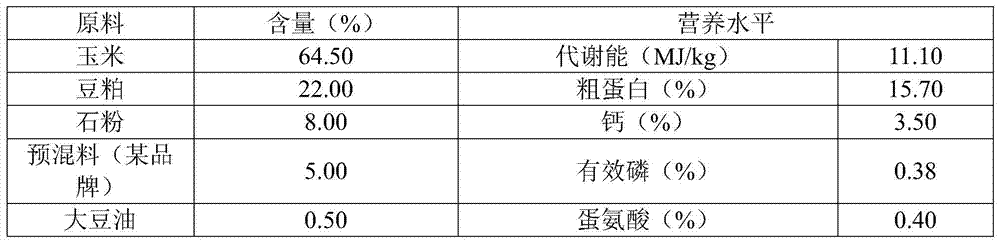

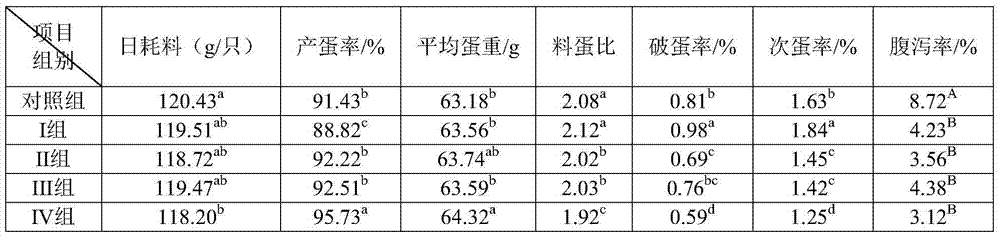

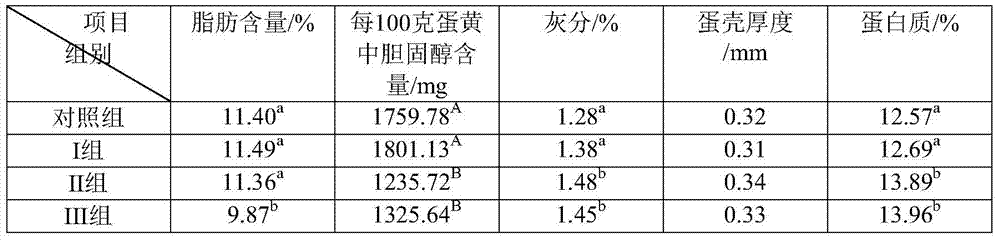

Laying hen compound biological feed additive and preparation method thereof

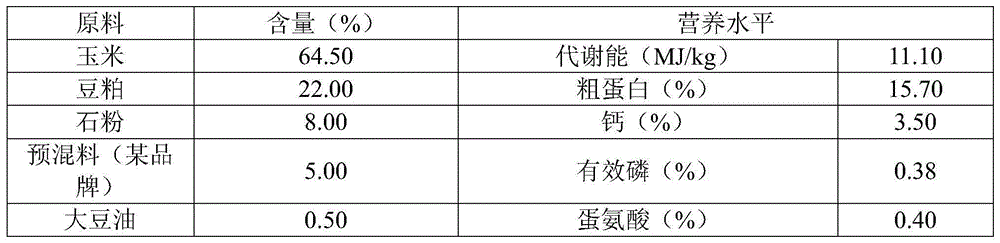

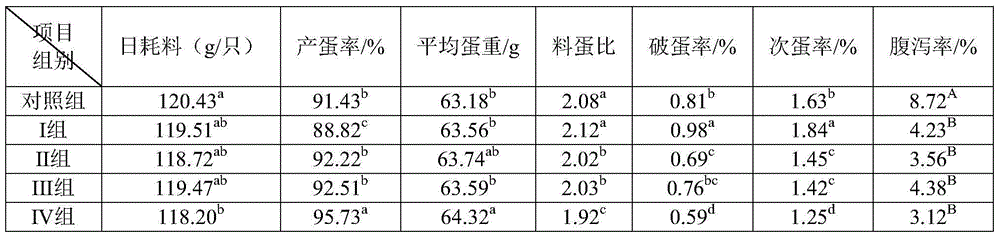

ActiveCN104522433AActivation activityPromote respirationAnimal feeding stuffFood additiveAnti stress

The invention provides laying hen compound biological feed additive, and belongs to the technical field of feed science and feed additives. The feed additive is compoundly prepared by feed grade fluvic acid, worm powder, fermented frass, an extractive compound preparation, a microecologic preparation and carriers by a certain ratio. Premix of the compound biological feed additive is used in the feed of a laying hen. Environment in the digestive tract of livestock and poultry can be regulated and controlled, intestinal flora balance in an organism can be regulated, the organism immunity can be improved, and the feed additive has the properties of being antimicrobial and anti-stress, and improving immunity and production. The feed additive is added into daily ration of the laying hen to improve the laying capacity and the immunity of the laying hen, improve the feed conversion rate, and then to reduce drug residue and improve egg quality. The compound biological feed additive is a safe and reliable and green environmental protection feed additive product, and the application prospect is good.

Owner:BEIJING UNIV OF AGRI

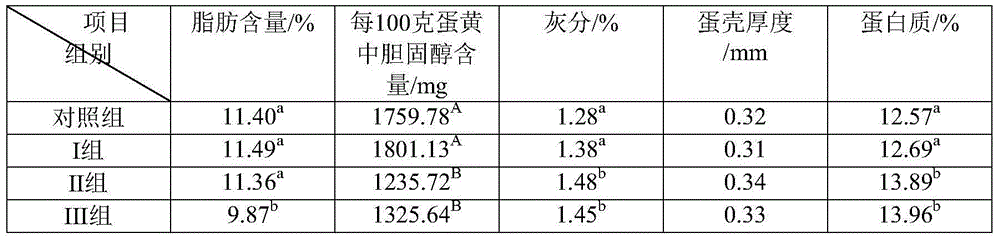

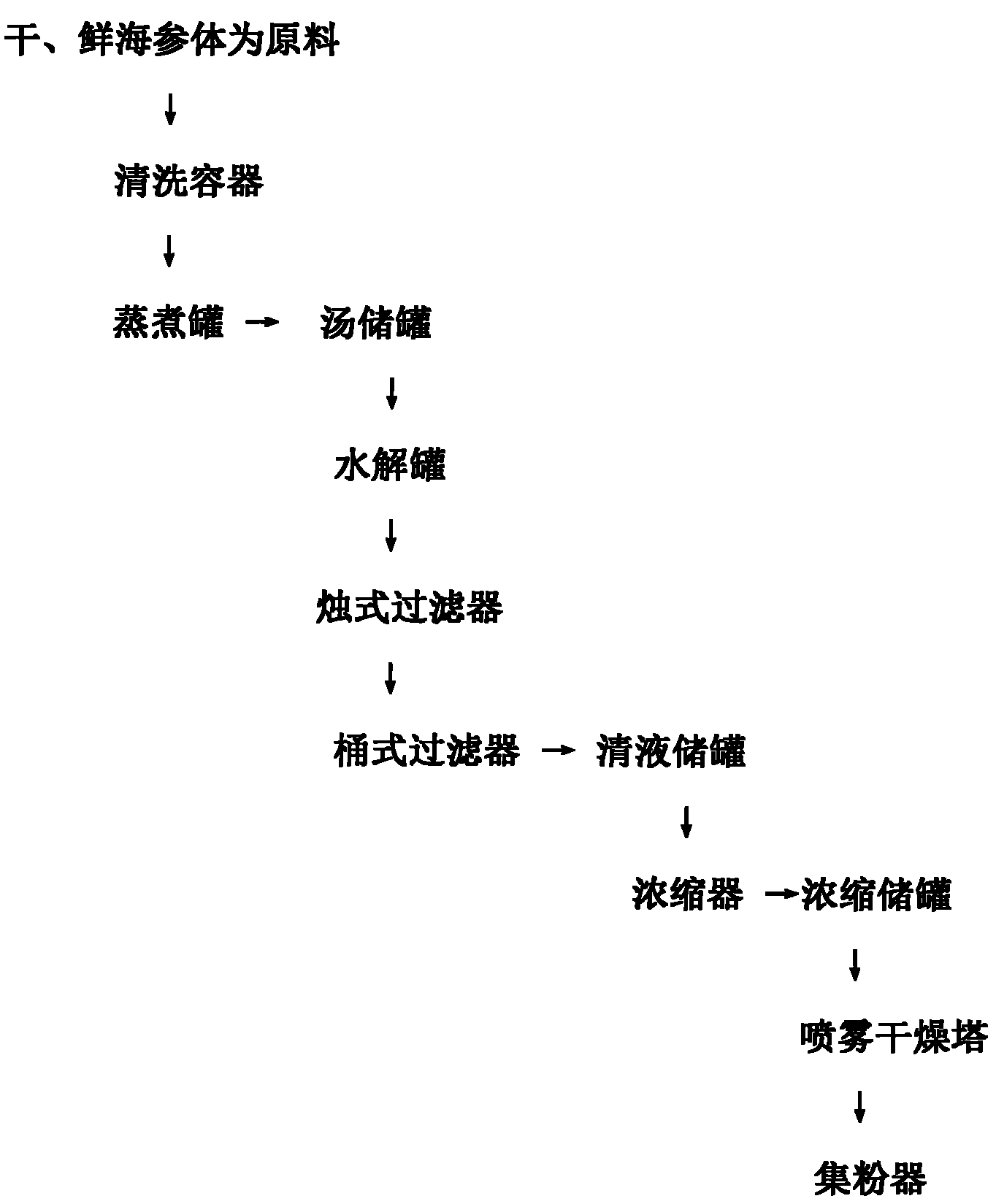

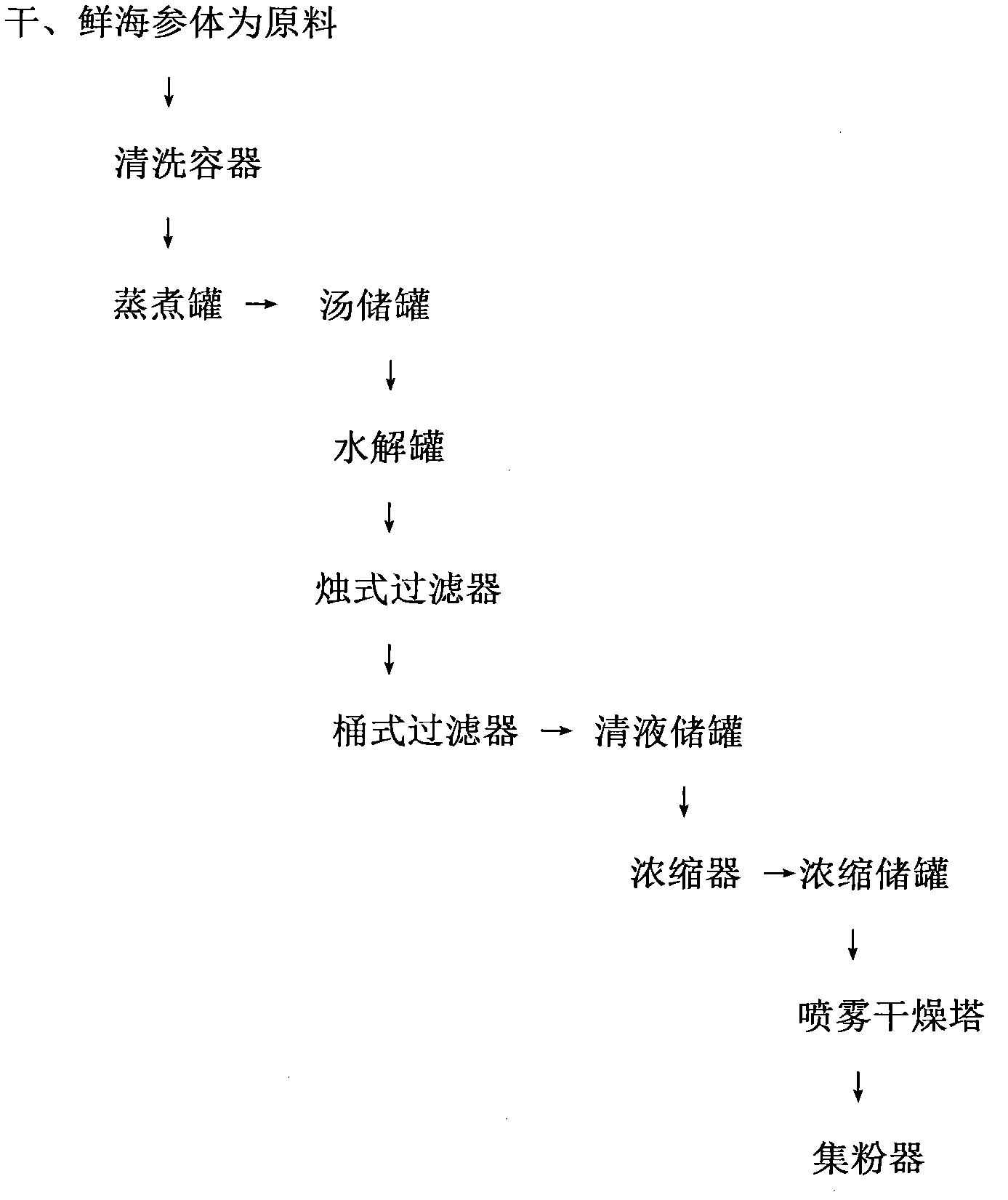

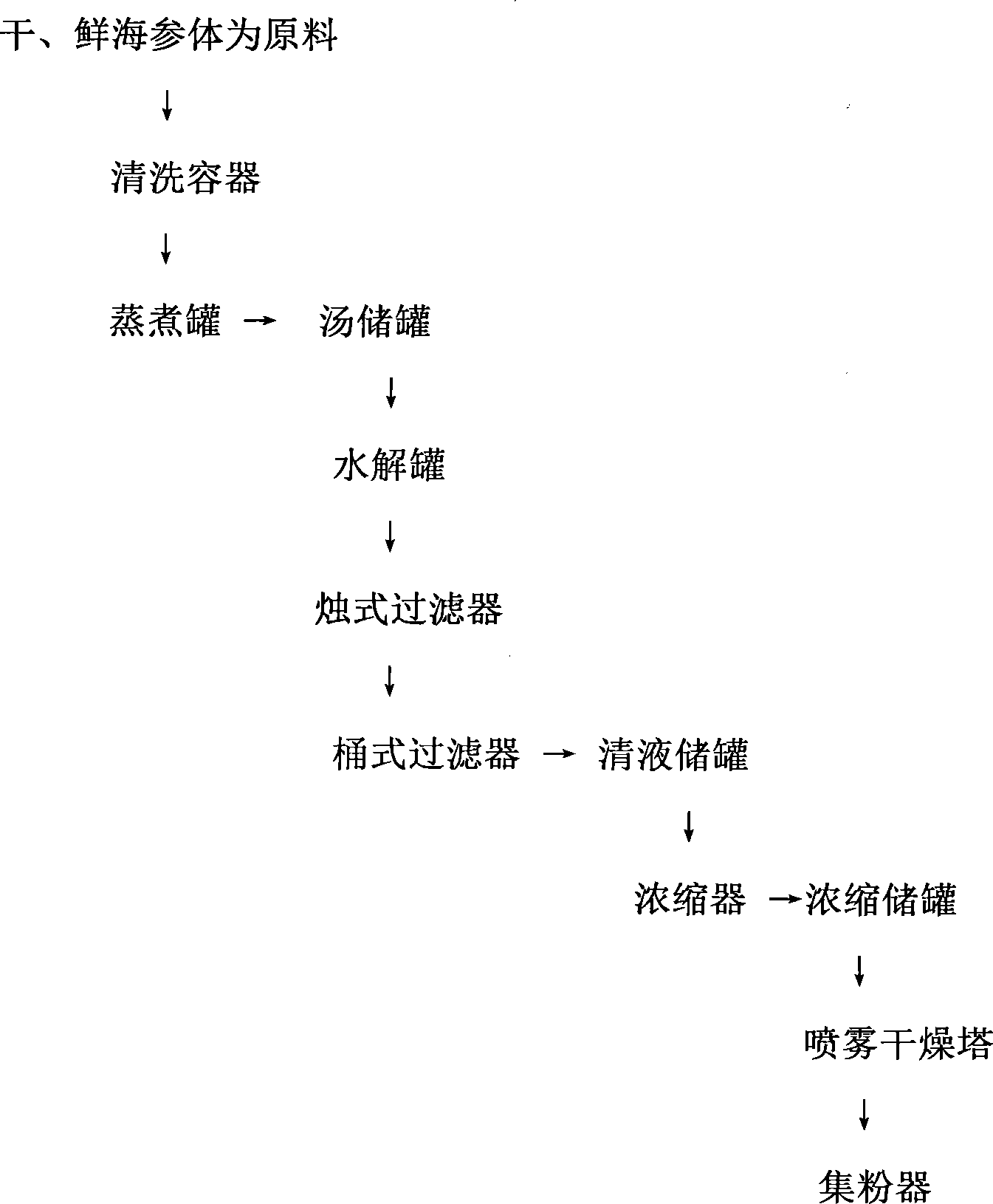

Extraction method of sea cucumber polypeptide

ActiveCN102488073AIndividual smallIncrease elasticityProtein composition from fishHigh pressureStorage tank

An extraction method of sea cucumber polypeptide contains steps of: embathing, high-pressure stewing, enzymatic hydrolysis, deodorizing, filtering, condensation, drying and finished product packaging. The extraction method is characterized in that high-pressure stewing: the temperature is 120-130 DEG C, the pressure is 0.13-0.15 MPa and stewing lasts for 2 hours at constant temperature and constant pressure; enzymatic hydrolysis: the temperature is cooled to 54-56 DEG C after heating and sterilizing, NaOH is added to adjust PH to 7.0 and 0.5% of sea cucumber special-purpose enzyme to perform enzymatic hydrolysis for 6 hours; deodorizing: 17% of active carbon is added for deodorizing; filtering: a standing liquid firstly passes through a candle filter, then passes through a barrel filter and is finally filtered to a clear liquid storage tank; and condensation: condensation pressure is minus 0.04-minus 0.06 MPa, condensation temperature is 75-80 DEG C, and Baume degree determined during the condensation process is controlled at 10. The invention has the following advantages of: sea cucumber is changed into a fully water soluble active component after biological enzyme hydrolysis; the content of small peptides in the product is high, which is more beneficial to the absorption and utilization of the sea cucumber active component; and sea cucumber polypeptide is more acceptable in taste after deodorizing by active carbon. The invention is suitable for the extraction method of sea cucumber polypeptide.

Owner:吴庆林

Medical hemostatic polysaccharide starch microsphere and preparation method thereof

ActiveCN104311870AAbsorb quickly and completelyDisorganized reactionOrganic active ingredientsPotato starchStarch Microspheres

The invention relates to a preparation method and a refining method of medical hemostatic polysaccharide starch. With pretreated potato starch as a raw material and epichlorohydrin as a crosslinking agent, a microsphere adopting a three-dimensional network structure is synthesized by an emulsifying and crosslinking technology. The medical hemostatic polysaccharide starch is high in biocompatibility; the medical hemostatic polysaccharide starch is full with wrinkles on the surface, so that the particle surface area is increased, the water absorbing rate is significantly improved and the hemostatic time is greatly reduced; the medical hemostatic polysaccharide starch is especially applicable to large-area blood seepage, deep bleeding, and bleeding at a part difficult to reach by operative procedures.

Owner:SHIJIAZHUANG YISHENGTANG MEDICAL SUPPLIES

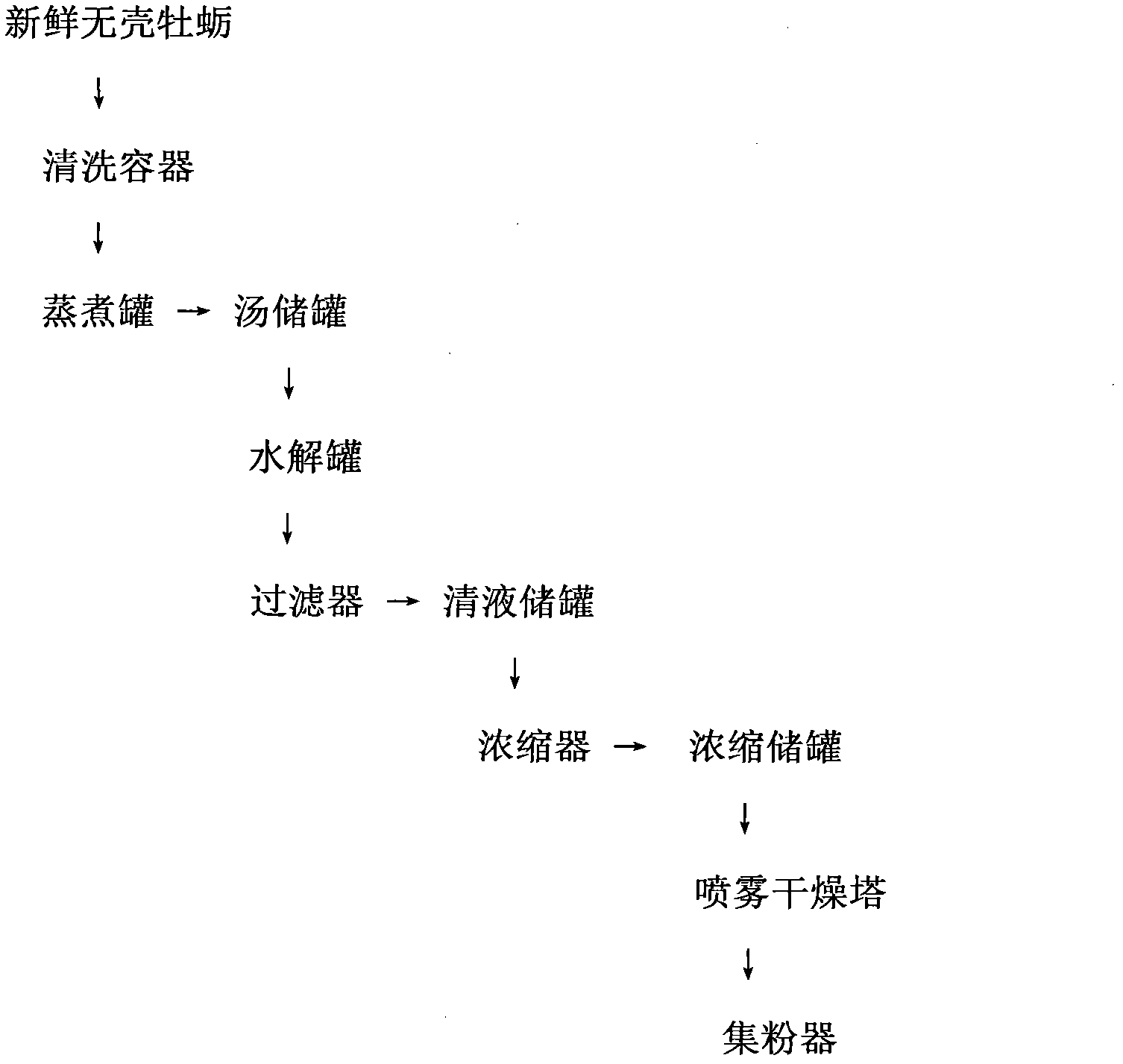

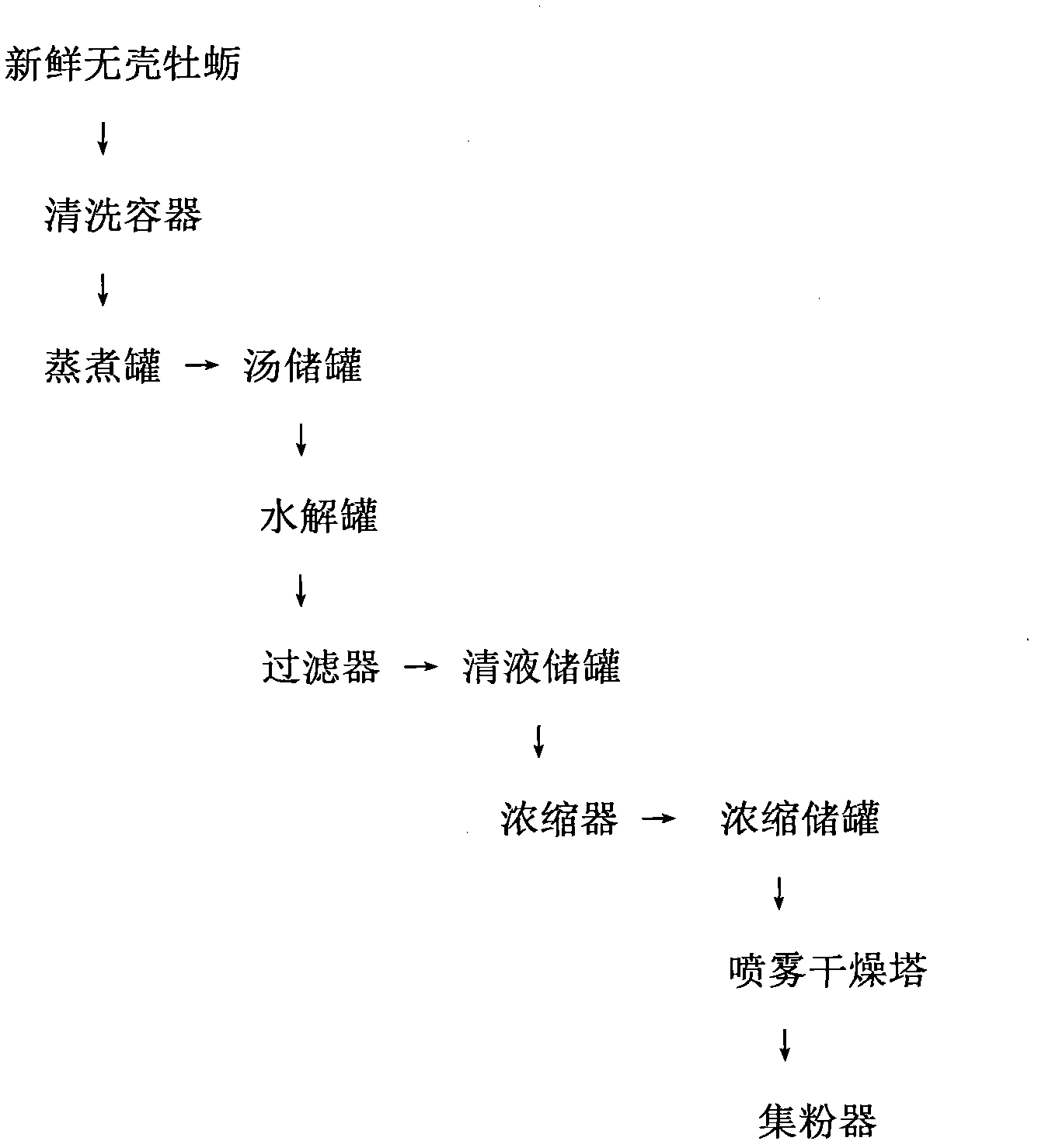

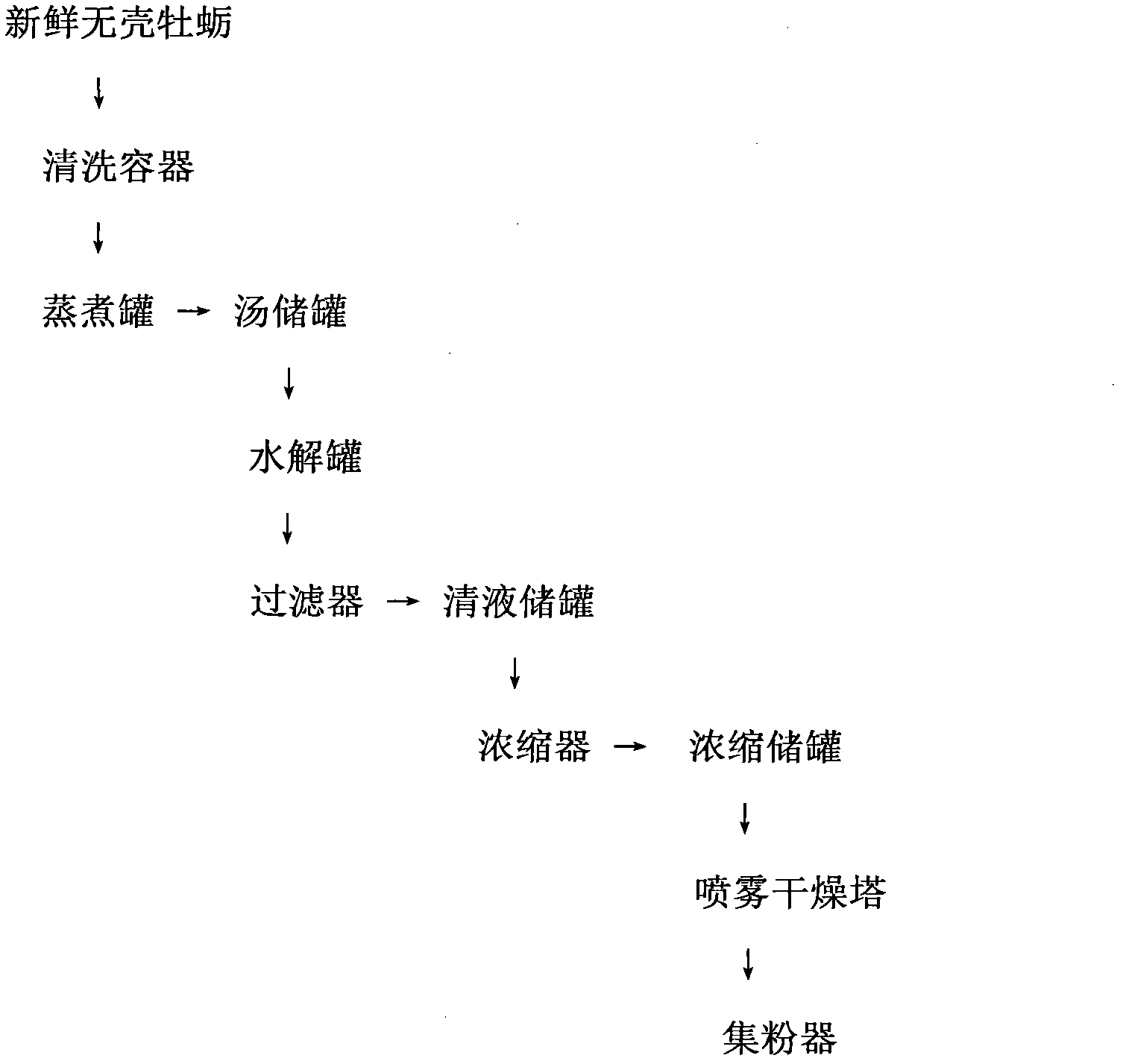

Method for extracting oyster peptide

ActiveCN102488074AFull of nutritionHigh extraction rateProtein composition from fishActivated carbonSmall peptide

The invention provides a method for extracting oyster peptide, which comprises the following steps: cleaning, steaming and boiling under high pressure, carrying out enzymatic hydrolysis, removing the flavour, filtering, concentrating, drying and carrying out finished product package. The method is characterized in that when the boiling process under the high pressure is carried out, the employed temperature is 120 DEG C-130 DEG C, the pressure is 0.13-0.15 MPa, and the boiling time under constant temperature and constant pressure is 2 hours; when the enzymatic hydrolysis step is carried out, the cooling step is carried out to the temperature of 52-54 DEG C after heating and disinfecting, then NaOH is added for regulating the pH value to 7.0, 0.5% special enzyme used for oyster is added, the enzymatic hydrolysis step is carried out for 3 hours, during the enzymatic hydrolysis step, stirring is carried out for 2 minutes every 1 hour, so that the enzymatic hydrolysis can be uniformly and fully carried out; when the flavour is removed, because an oyster extract possesses little fishy smell, 12% active carbon is added after the enzymatic hydrolysis step is finished for removing the fishy smell. The method of the invention has the advantages that by using a biological enzymatic hydrolysis technology, the oyster can be changed through biological enzyme hydrolysis to active components capable of solving in water, the product small peptide possesses high content, which is in favor of absorption and utilization of the oyster active components; the mouthfeel of the oyster peptide after removing the flavour by the active carbon is easier to be accepted. The invention is suitable for the method by taking the fresh shellless oyster as a raw material for extracting the oyster peptide.

Owner:吴庆林

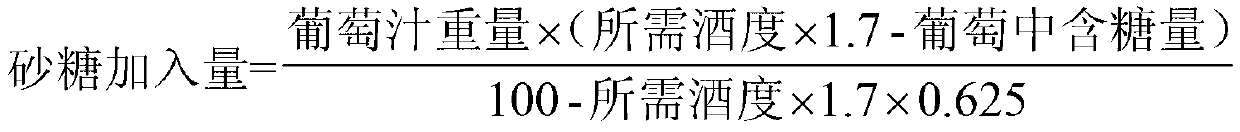

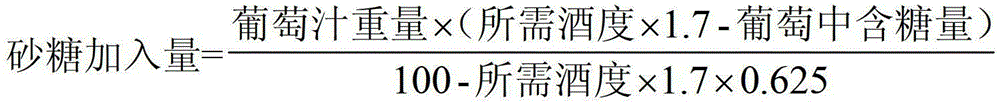

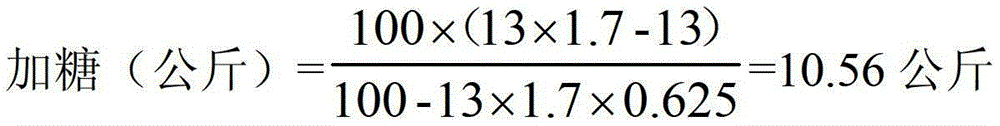

Wine containing SOD (Superoxide Dismutase) component and preparation method thereof

ActiveCN103122294AAgingAnti agingMicroorganism based processesWine preparationProanthocyanidinInternational unit

The invention relates to a wine and a preparation method thereof, and in particular relates to a wine containing an SOD (Superoxide Dismutase) component and a preparation method thereof. The preparation method of the wine containing the SOD component comprises the following steps of: (1) preparing phyllanthus emblica wine juice; (2) preparing phyllanthus emblica fermenting juice; (3) blending and disinfecting; and (4) bottling and packaging. The prepared wine per liter contains 800-1200 thousand international units of SOD. The original anthocyanin in percentage by weight in the wine is 0.01-0.0375%. The wine containing the SOD component prepared by the preparation method not only maintains taste of wine, but also increases various nutritional substances and SOD, and has the edible, beautifying and health-care functions.

Owner:霍全胜

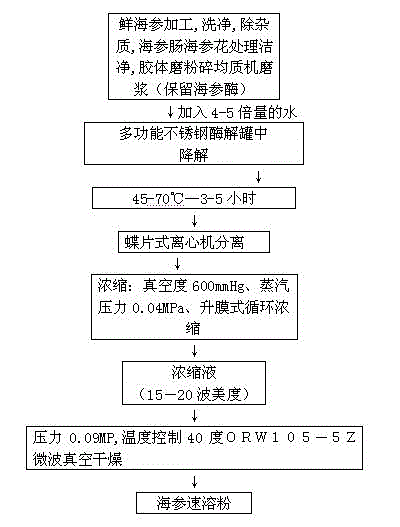

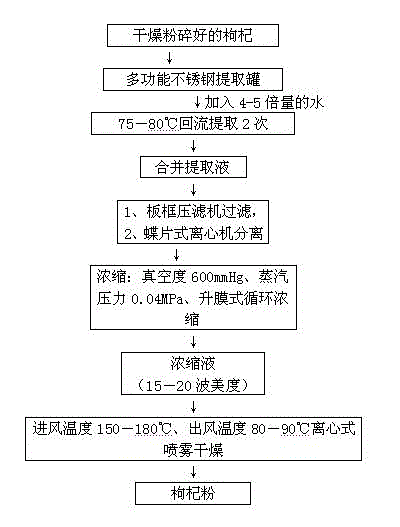

Sea cucumber effervescent tablet and preparation technique thereof

InactiveCN102972843AImprove immunityImprove disease resistanceFood preparationDiseaseSodium bicarbonate

The invention provides a sea cucumber effervescent tablet and a preparation technique thereof. The sea cucumber effervescent tablet comprises the following ingredients by weight parts: 10-20 parts of sea cucumber instant powder, 4-15 parts of medlar powder, 2-5 parts of thinleaf glossogyne herb powder, 3-16 parts of lactose, 3-25 parts of mannitol, 19.5-24.5 parts of sodium bicarbonate, 20-25 parts of citric acid, 3-4 parts of lubricant, 0.5-0.8 part of blackcurrant flavor or blueberry flavor, and 18-26 parts of binder, and is prepared by the processes of preparing sea cucumber instant powder, medlar powder and thinleaf glossogyne herb powder, selecting materials according to the proportion, respectively pelletizing the acidic material and the alkali material, and then conducting tableting to prepare the sea cucumber effervescent tablet. According to the sea cucumber effervescent tablet, solid beverage having functions of enhancing immunity and enhancing human body disease resistance is prepared by the compatibility of medicines of sea cucumber, and medlar and thinleaf glossogyne herb complemented with the sea cucumber. The sea cucumber effervescent tablet prepared by the invention as the solid beverage is excellent in mouth feel and convenient to use at optional situations; in addition, the nutritional ingredient of the sea cucumber can be easily dissolved into water and can be rapidly and completely adsorbed after being eaten, so that the healthcare effect is significant.

Owner:WEIHAI YUXINTANG BIOLOGICAL SCI & TECH CO LTD

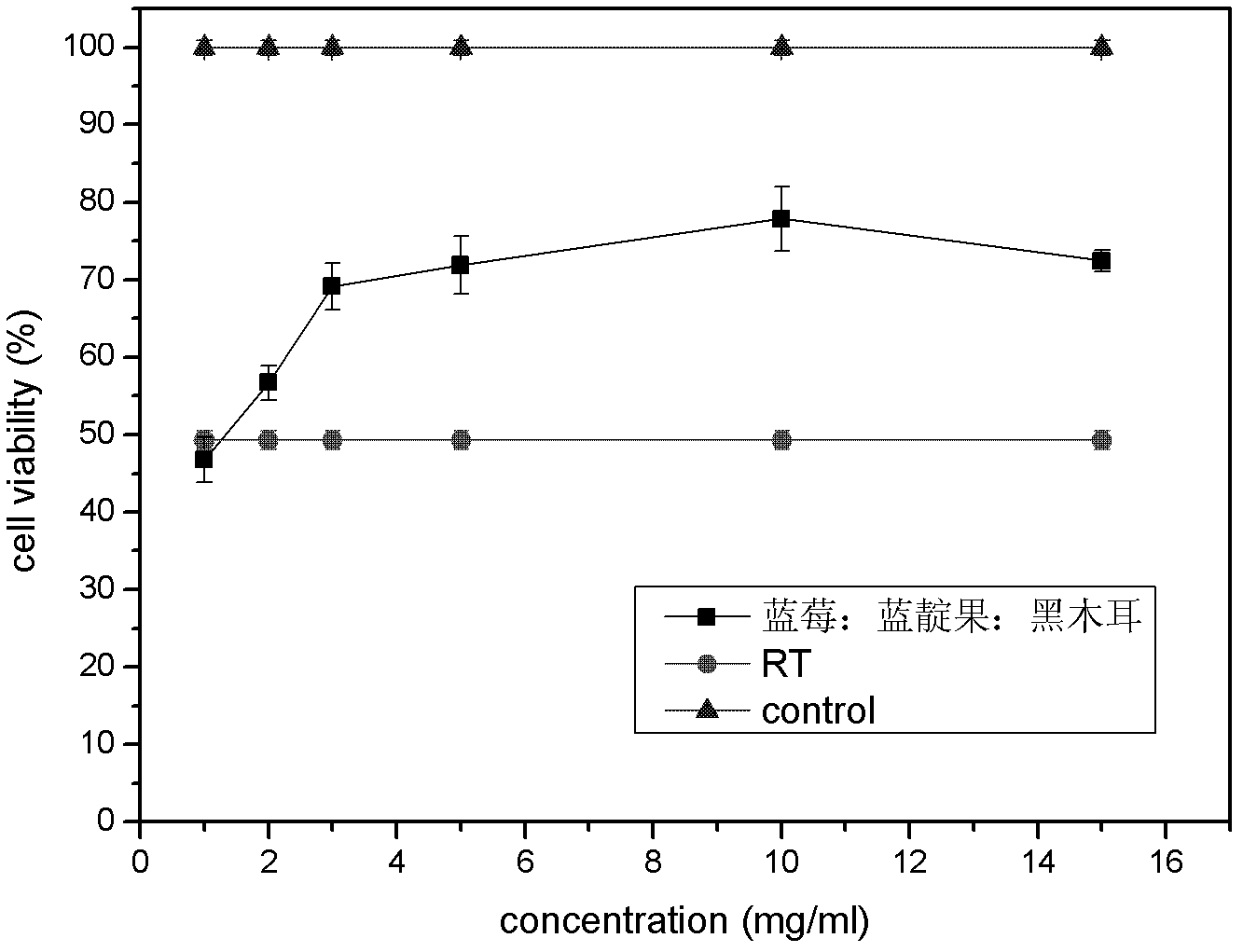

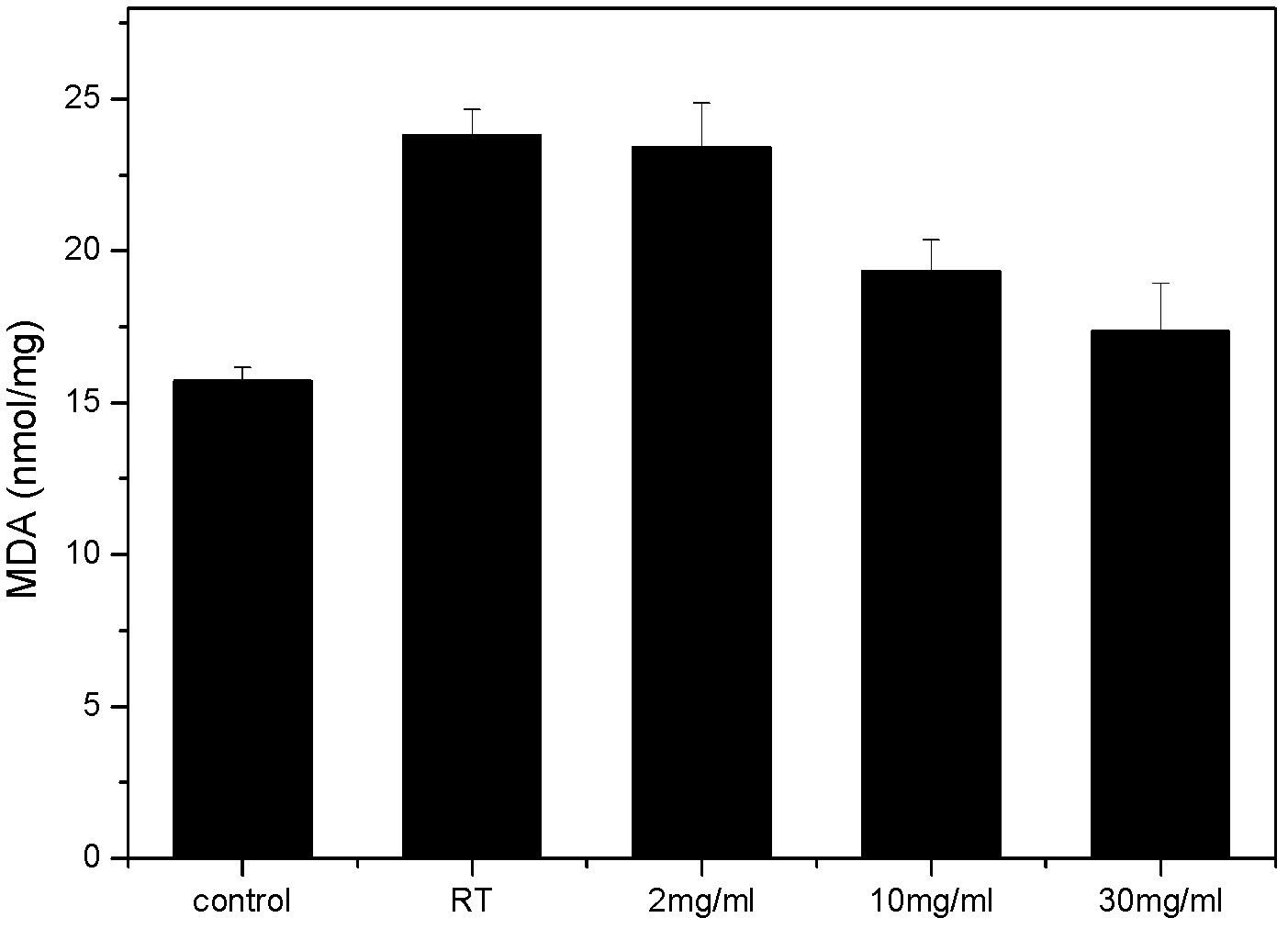

Radiation-resisting medicament and preparation method thereof

InactiveCN102657675AEasy to takeAbsorb quickly and completelyOrganic active ingredientsAntinoxious agentsActive componentMedicine

A radiation-resisting medicament and a preparation method thereof relate to a health care product with a radiation-resisting function and a preparation method thereof. In order to solve the problem that the existing radiation-resisting product contains various plant extracts, is unsatisfactory in radiation-resisting effect and complicated in production process due to the fact that various components are contained The radiation-resisting medicament is prepared by main raw materials of blueberry anthocyanin, indigo fruit anthocyanin and auricularian extractives. The preparation method includes: choosing materials, weighing, extracting effective active components and mixing the extractives. The radiation-resisting medicament and the preparation method of...are simple in production process, have the advantages of strengthening immunity, resisting radiation and being convenient to take and fast and complete in absorbing due to the electuary and capsule type proved by cell experiments, and are suitable for all crowd and wide in market prospect.

Owner:HARBIN INST OF TECH

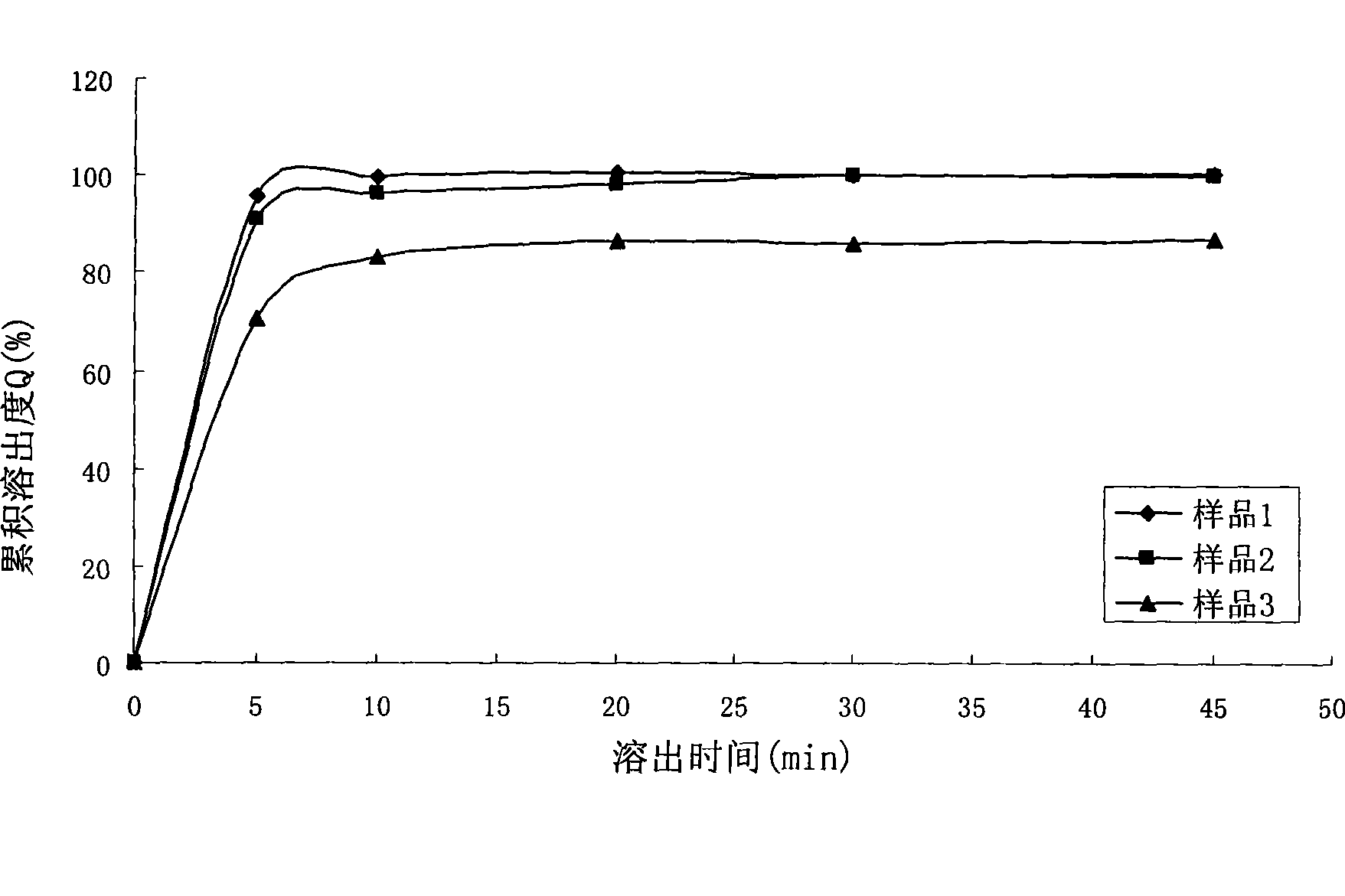

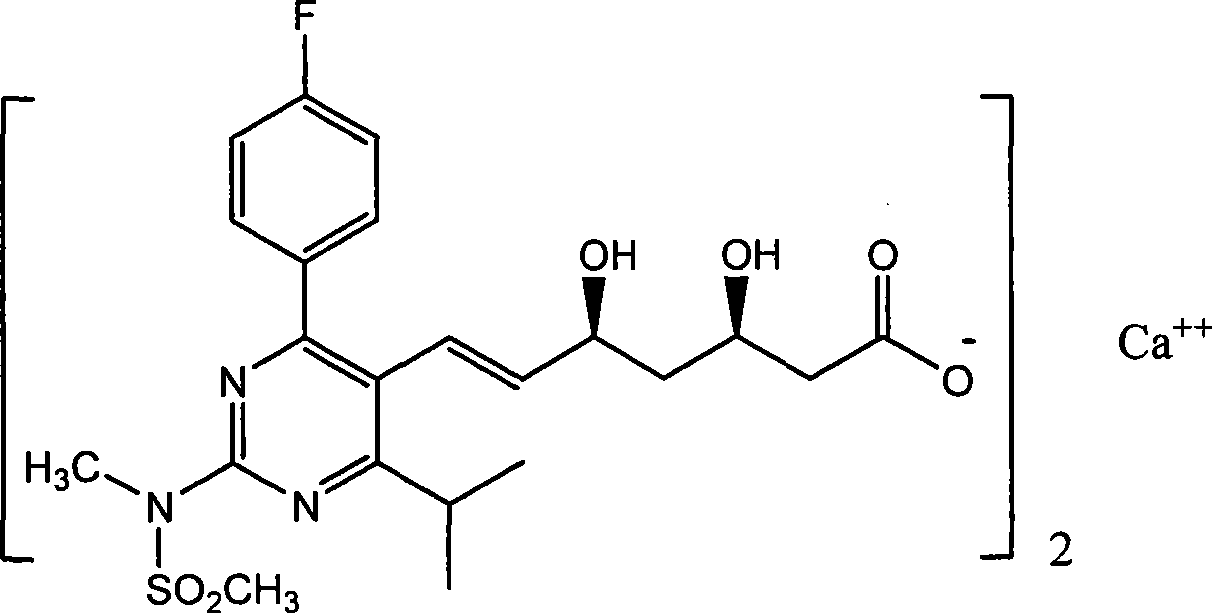

Stable medicine combination

ActiveCN101336920BSimple processImprove controllabilityOrganic active ingredientsMetabolism disorderAdjuvantPharmaceutical drug

The invention relates to a stable oral pharmaceutical composition, particularly to a pharmaceutical composition comprising rosuvastatin calcium, micropowder silica gel and pharmaceutically-acceptable adjuvants, and a preparation method and an application thereof.

Owner:NANJING CHIA TAI TIANQING PHARMA

Lucid ganoderma refined powder compound soft capsule and preparation method thereof

ActiveCN103340919ALow costImprove utilizationHydrocarbon active ingredientsAntipyreticBiotechnologyLycopersene

The invention relates to the technical field of health products, and in particular relates to a lucid ganoderma refined powder compound soft capsule and a preparation method thereof. The lucid ganoderma refined powder compound soft capsule comprises 1 to 300 parts of lucid ganoderma refined powder, 1 to 50 parts of lycopene, 1 to 50 parts of grifolan, and 1 to 500 parts of safflower oil. According to the lucid ganoderma refined powder compound soft capsule, the lucid ganoderma refined powder, lycopene, grifolan and safflower oil which are different in molecular structure are used in common and have some same pesticide effects and also have individual outstanding pesticide effects; and after being organically combined in proportion, the four materials complement and promote one another on curative effect and maximize the effects individually. A preparation in form of the soft capsule can cover the discomfort smell of the contents and effectively improve the stability of the lycopene and safflower oil, enables quick and complete intake and absorption of the healthcare components, and give full play to inflammation resistance, pain alleviating, poisonousness reducing, wound repair promoting, immunoregulation, tumor inhibition, resisting to cancer, three highs (high blood pressure, high blood sugar and high blood lipid) and cardiovascular disease, senescence delaying, improvement of liver function, organism balancing and adjusting and other effects.

Owner:东莞市味菇坊生物科技有限公司

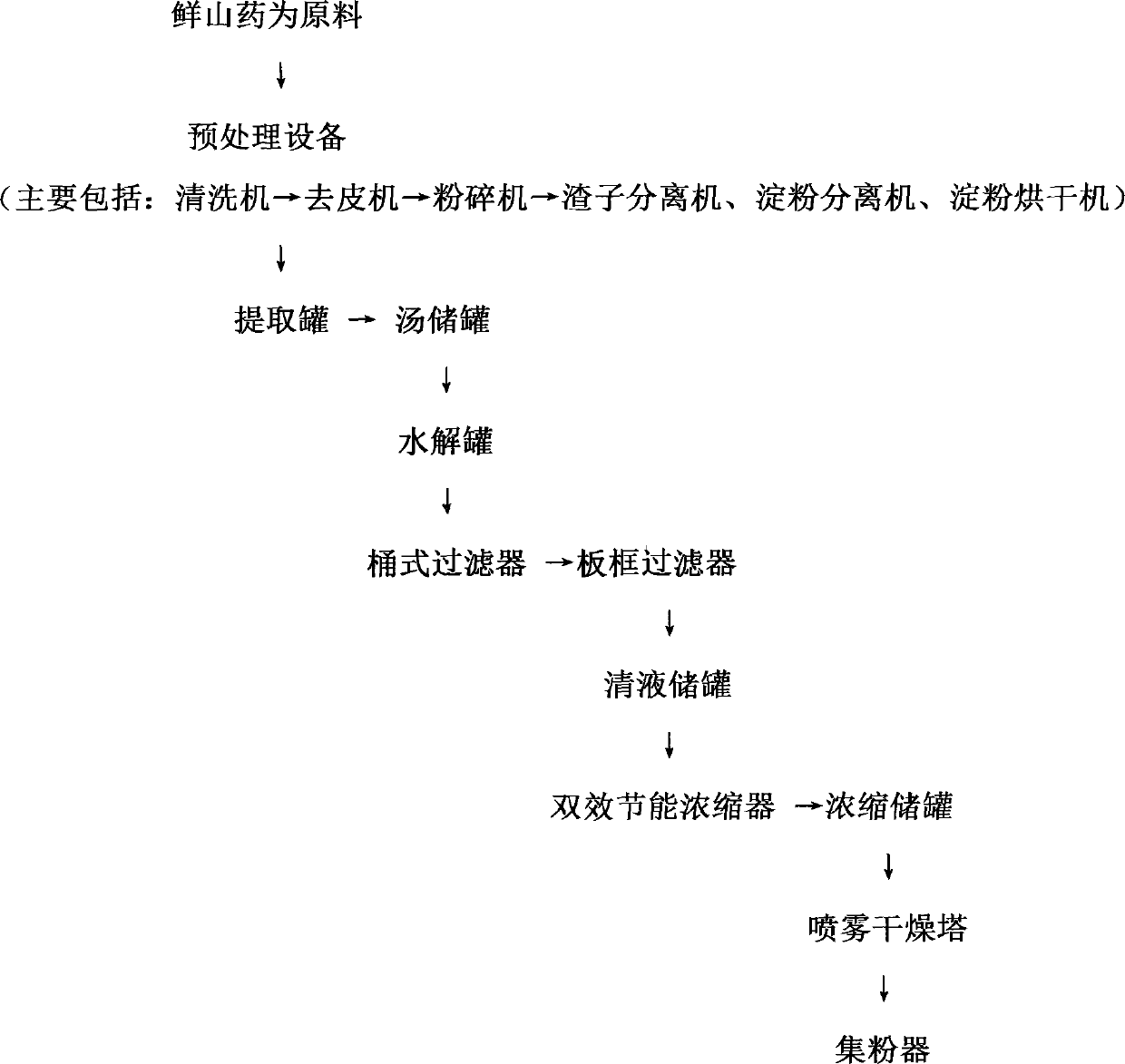

Extraction method of Chinese yam small molecule peptides

InactiveCN103388016AFill research gapsAdapt to market demandPeptide preparation methodsFermentationNeutral proteaseAdditive ingredient

The invention provides an extraction method of Chinese yam small molecule peptides. The extraction method is characterized in that a Chinese yam pretreatment step mainly comprises sieving, cleaning, peeling, grinding, soaking, scum separation, starch separation and drying and has a direct relation with the purity of the Chinese yam small molecule peptides; during extraction by steaming with micro-high pressure, the temperature is 110 DEG C, the pressure is 0.05Mpa, and the extraction is carried out for 20 minutes at a constant temperature and a constant pressure; during enzymatic hydrolysis, after sterilization by heating, the temperature is reduced to 53 DEG C, NaOH is added so as to adjust the pH to 7.0, then 0.6% of neutral protease is added, and the enzymatic hydrolysis is carried out for 3.5 hours; during adsorption, 1.5% of activated carbon is added for adsorption; during filtration, a standing liquid firstly passes through a barrel-type filter, then passes through a sheet frame serving as a protective filter and finally is filtered to a clear liquid storage tank; during concentration, the concentration pressure ranges from minus 0.06Mpa to minus 0.08Mpa, the concentration temperature ranges from 85 DEG C to 70 DEG C, and the baume degree is measured in a concentration process. The Chinese yam small molecule peptides extracted by the method have high purity and nourishing and heath preservation effects and contain natural nutritional ingredients of Chinese yams. The extraction method is suitable for the extraction of the Chinese yam small molecule peptides.

Owner:吴庆林

Solid beverage having health-care efficacy for female skin and preparation method of solid beverage

InactiveCN108308497ARevitalizationAbsorb quickly and completelyFood dryingFood ingredient functionsVitamin CFruit juice

The invention relates to a solid beverage having health-care efficacy for female skin and a preparation method of the solid beverage, and belongs to the technical field of solid beverages. The solid beverage comprises the following raw materials in parts by weight of 20-30 parts of collagen powder, 2.5-5.5 parts of grape fruit juice powder, 1.5-4.5 parts of blueberry fruit juice powder, 35-40 parts of xylitol, 8-12 parts of fructo-oligosaccharide, 15-17 parts of maltodextrin, 3.5-4.5 parts of calcium lactate, 0.008-0.012 part of vitamin A, 0.15-0.25 part of vitamin C, 0.008-0.012 part of vitamin E, 0.10-0.15 part of ferrous gluconate, 0.10-0.15 part of zinc gluconate, 0.3-0.5 part of white fungus polysaccharide and 0.5-1 part of edible essence. The solid beverage disclosed by the inventionis good in mouth feel, and has excellent health-care efficacy on female skin; and besides, the invention provides a simple and practicable preparation method.

Owner:SHANDONG SHENGHAI HEALTH PROD CO LTD

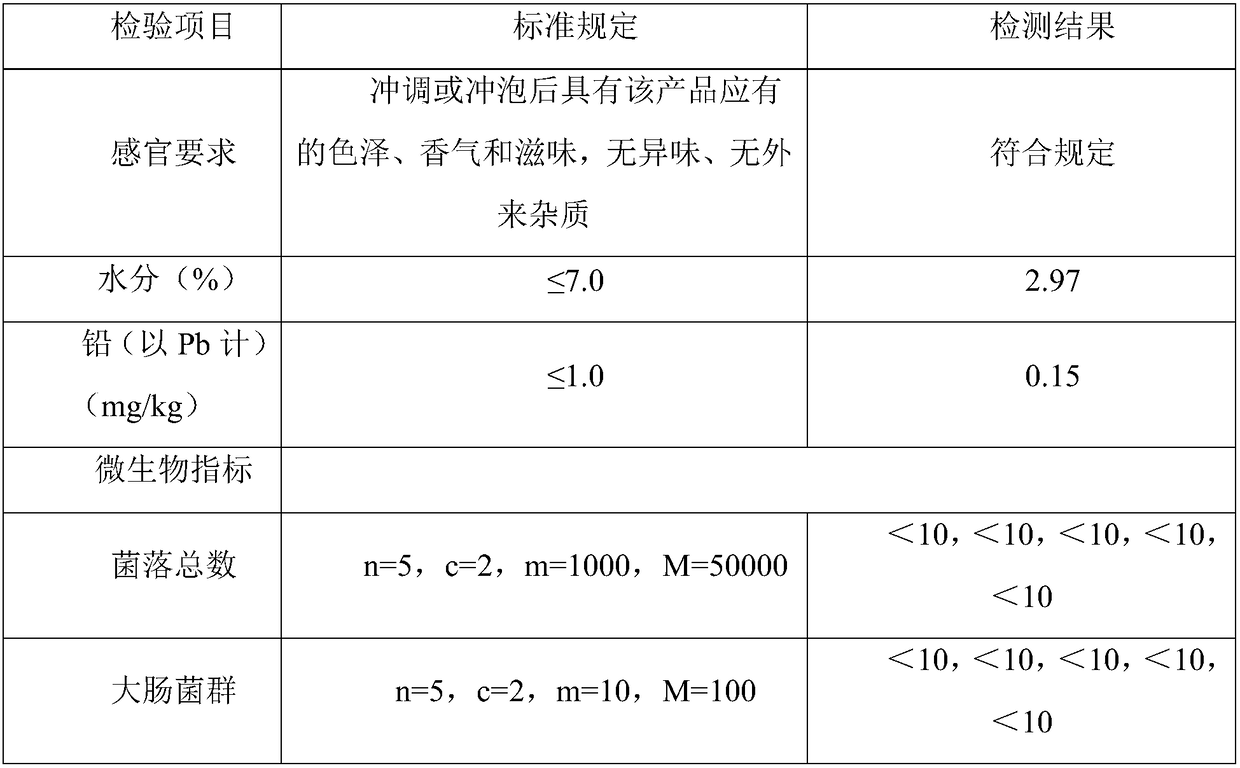

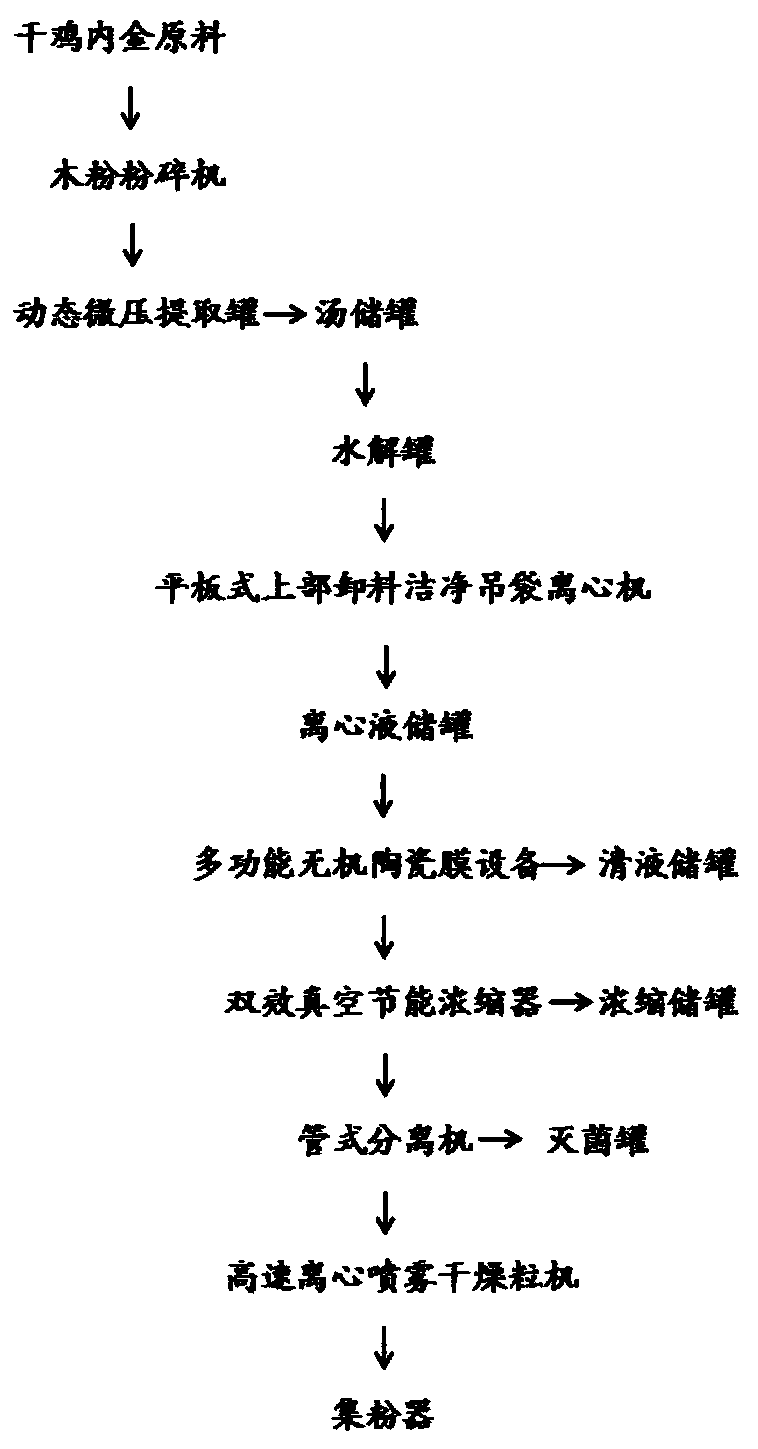

Extraction method and application of endothelium corneum gigeriae galli small molecule peptide

PendingCN110272934AHigh product contentAbsorb quickly and completelyChemical industryPeptide preparation methodsEnzymatic hydrolysisWater soluble

The invention belongs to the technical field of biology, and particularly relates to an extraction method and application of an endothelium corneum gigeriae galli small molecule peptide. The extraction method of the endothelium corneum gigeriae galli small molecule peptide comprises the following steps that after a dry endothelium corneum gigeriae galli raw material is pre-pulverized, pulp is dynamically extracted, and then enzymatic hydrolysis and purification are carried out in sequence to obtain an endothelium corneum gigeriae galli small molecule peptide solution. The invention researches and develops the method for extracting the endothelium corneum gigeriae galli small molecule peptide through the steps of enzymatic hydrolysis and like for the first time. The method makes up for the research and development gap of the endothelium corneum gigeriae galli small molecule peptide, and adapts to the market demand and development. Through biological enzymatic hydrolysis and other technologies, endothelium corneum gigeriae galli protein is converted into a water-soluble active ingredient small molecule peptide through biological enzymatic hydrolysis, the product content is high, the absorption is complete and rapid, the operation process steps are simple and convenient, each link is easy to control, the processing cost is low, and the method can be used for industrial production.

Owner:山西原生肽科技有限公司

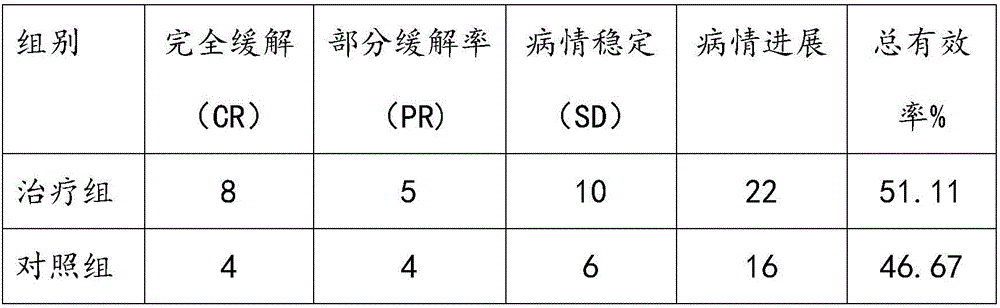

Medicine for treating advanced non-small-cell lung cancer and preparation method of medicine

ActiveCN106620391AInhibit aggregationGrowth inhibitionUnknown materialsAntineoplastic agentsLife qualityFritillaria thunbergii

The invention discloses a medicine for treating advanced non-small-cell lung cancer and a preparation method of the medicine. The medicine for treating advanced non-small-cell lung cancer is prepared from raw materials in parts by weight as follows: 20-40 parts of hedyotis diffusa, 20-40 parts of scutellaria barbata, 20-40 parts of herba houttuyniae, 10-20 parts of dried tangerine peel, 20-30 parts of fructus trichosanthis, 10-20 parts of semen coicis, 20-30 parts of semen lepidii, 10-20 parts of radix scutellariae, 10-20 parts of rhizoma anemarrhenae, 10-20 parts of semen armeniacae amarae, 10-20 parts of bulbus fritillaria thunbergii, 20-30 parts of carapax trionycis, 10-20 parts of prunella vulgaris, 20-40 parts of radix astragali, 10-20 parts of codonopsis pilosula, 10-20 parts of rhizoma phragmitis, 10-20 parts of semen persicae, 10-15 parts of fructus perillae and 5-10 parts of radix glycyrrhizae preparata. The medicine has the effects of clearing heat, removing toxins, reducing phlegm, removing blood stasis, tonifying qi and nourishing yin and has functions of resisting tumor, relieving cough, eliminating phlegm and enhancing body immunity. The medicine capsules can relieve symptoms of patients, have exact curative effect and can prolong lifetime of the patients and improve the life quality.

Owner:平阴县中医医院

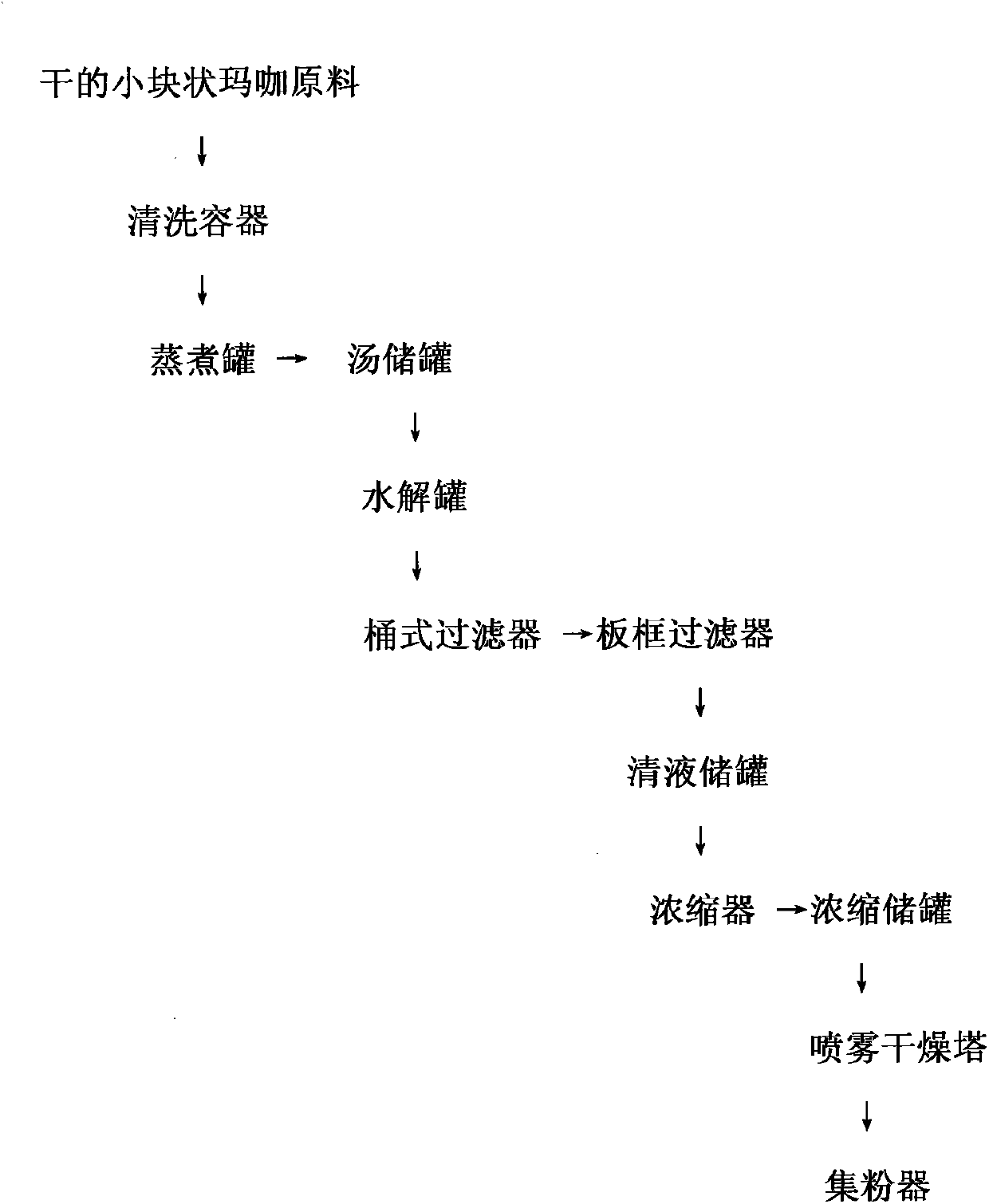

Method for extracting maca peptide

InactiveCN103725741AAbsorb quickly and completelyEasy to separatePeptide preparation methodsFermentationActivated carbonFiltration

The invention discloses a method for extracting maca peptide. The method comprises the steps of high-pressure cooking, enzymolysis, adsorption, filtration, concentration, drying and finished product package, and is characterized in that during high-pressure cooking, the temperature is 124 DEG C, the pressure is 0.14MPa, and constant-temperature and constant-pressure cooking is performed for 1 hour; during enzymolysis, the temperature is reduced to 53 DEG C after heating sterilization, NaOH is added to adjust the pH value to be 7.0, and 0.5% of a maca special enzyme consisting of an incision enzyme, an excision enzyme and a flavor enzyme is added to perform enzymolysis for 3.5 hours; during adsorption, 4% of active carbon is added to perform adsorption; during filtration, a standing solution is filtered through a barrel filter, then passes through a sheet frame serving as a protection filter, and finally is filtered into a clear solution storage tank; during concentration, the concentration pressure is minus 0.5MPa, the concentration temperature is 80 DEG C, and the Baume degree is determined during concentration. The method disclosed by the invention is simple in process and high in extraction rate, and is suitable for extracting the maca peptide.

Owner:冯启训

Preparation method of sea cucumber peptides

InactiveCN112790392APromote absorptionEfficient use ofPeptide preparation methodsFermentationActivated carbonSmall peptide

The invention belongs to the technical field of deep processing of marine products, and relates to a preparation method of sea cucumber peptides, which comprises the following steps: (1) grinding sea cucumbers into pulp; (2) uniformly mixing the sea cucumber primary pulp with deionized water, heating until denaturation, cooling, and adding compound protease for enzymolysis; (3) after the enzymolysis is finished, adding activated carbon to remove odor, then adjusting the pH value to 6.0-7.0, and heating to inactivate the enzyme; (4) filtering by adopting an inorganic nanofiltration ceramic membrane; (5) freeze drying; and (6) preparing granules. The process is simple, the extraction rate is high, and the enzymolysis condition control and the improvement of the taste of the sea cucumber peptides are facilitated; enzymolysis is thorough, the content of small molecule peptides is high, the peptide content in the product components reaches 80% or above; and the peptide molecular weight distribution result is that the content of peptides with a size of 1000Da or above is 6%, and the content of small molecule peptides with a size of 1000Da or below is 94%. Through a biological enzymolysis technology, the sea cucumbers are hydrolyzed by biological enzymes to form active ingredients which are all soluble in water, the active ingredients are absorbed completely and rapidly, the content of small peptides in the product is high, and absorption and utilization of the active ingredients of the sea cucumbers are facilitated.

Owner:王朝辉

Method for preparing dendrobium officinale peptide

InactiveCN105861604AImprove efficacyHigh absorption rate in human bodyFermentationWater bathsFiltration

The invention discloses a method for preparing dendrobium officinale peptide. The method comprises the following steps: 1) taking dried dendrobium officinale as a processing raw material, and soaking in warm water; 2) fishing out the cleaned dendrobium officinale, draining off the water on the surface, and performing low-temperature treatment in low-temperature freezing equipment; 3) taking out the dendrobium officinale after low-temperature treatment, cutting into dendrobium officinale fragments of 0.5-20mm, adding pure water which is 0.5 times of the weight of the dendrobium officinale, and kneading in a kneading machine together; 4) taking out the kneaded dendrobium officinale fragments, performing superfine crushing, screening by using a medicine sieve of 100-400 meshes, and uniformly mixing with pure water in the kneading machine in the step 3); 5) feeding the wet dendrobium officinale powder into microwave treatment equipment, and performing intermittent microwave treatment at the microwave frequency of 2450MHz and the power of 500W; 6) adding water into the wet dendrobium officinale powder after microwave treatment in a weight ratio of 1:(12-18), soaking for 1.5 hours in a water bath of 75 DEG C, adding papain, and performing extraction for 1-4 hours so as to obtain an extraction liquid; 7) performing vacuum filtration by using a circulating water type multi-purpose vacuum pump so as to obtain a peptide liquid after suction filtration; and 8) performing spray-drying on the peptide liquid, thereby obtaining the dendrobium officinale peptide.

Owner:JINZHAI JINLIYUAN BIOTECH CO LTD

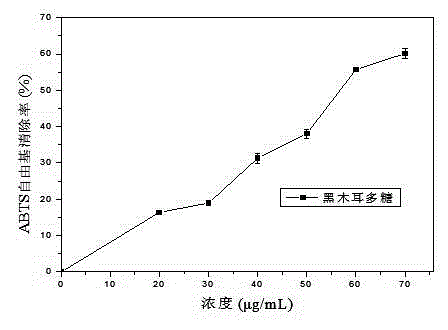

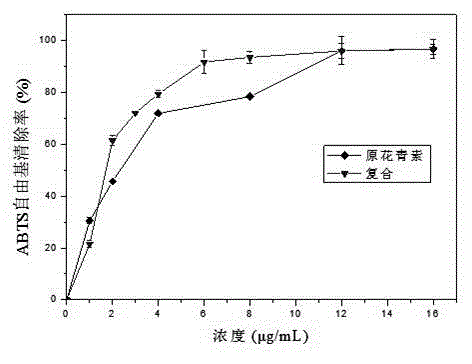

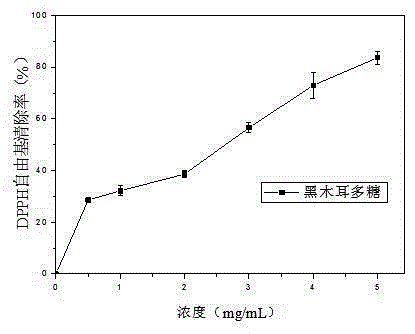

Black fungus polysaccharide and grape pip procyanidine composite antioxidant capsule

InactiveCN103142636AEasy to takeSimple production processOrganic active ingredientsAntinoxious agentsBetacyaninsActive component

The invention discloses a black fungus polysaccharide and grape pip procyanidine composite antioxidant capsule, and relates to an antioxidant product. The black fungus polysaccharide and grape pip procyanidine composite antioxidant capsule is prepared by mixing 100g of starch and 6-12g of black fungus polysaccharide extract and grape pip procyanidine composition, wherein the black fungus polysaccharide extract and grape pip procyanidine composition is prepared from 40-60 parts by weight of black fungus polysaccharide extract and 40-60 parts by weight of procyanidine extract. The preparation method comprises the following steps of: firstly, selecting materials and weighing; then, extracting effective active components; mixing the extract with starch to prepare powder; and finally, packaging according to different specifications. The capsule is simple in production process. In vitro experiments show that the composite capsules have the adding, synergistic interaction and antioxidant effect. The capsules have the characteristics of convenience in administration in form and quick and complete absorption, so that the capsules are suitable for all crowds to take, and have wide market prospect.

Owner:HARBIN INST OF TECH

Preparation technology capable of improving difference of filling amount of bovine colostrum freeze-dried powder capsules

InactiveCN109330890APromote growth and developmentPromote healingMilk preparationCapsule deliveryFreeze-dryingMicroparticle

The invention discloses a preparation technology capable of improving the difference of the filling amount of bovine colostrum freeze-dried powder capsules. Each capsule is filled with content including 190-210 mg of bovine colostrum freeze-dried powder. The production technology is advanced and simple, due to the small particle form, the capsules are quickly and completely absorbed, the functionsare given full play to that the immunity is adjusted, the intestinal flora is adjusted, growth and development of the gastrointestinal tract are promoted or healing of intestinal tissue wound is promoted, senescence is delayed, and growth and development are promoted, and the bovine colostrum freeze-dried powder capsules are suitable for various sub-healthy and postoperative crowds. The functionsof active immunoglobulins in the bovine colostrum freeze-dried powder can be effectively ensured, the functions are added that the immunity is adjusted, the intestinal flora is adjusted, growth and development of the gastrointestinal tract are promoted or healing of intestinal tissue wound is promoted, senescence is delayed, and growth and development are promoted, and the health-care effects ofthe product are greatly improved.

Owner:康道生物(南通)有限公司

Method for extracting oyster peptide

ActiveCN102488074BFull of nutritionHigh extraction rateProtein composition from fishAdditive ingredientBoiling process

The invention provides a method for extracting oyster peptide, which comprises the following steps: cleaning, steaming and boiling under high pressure, carrying out enzymatic hydrolysis, removing the flavour, filtering, concentrating, drying and carrying out finished product package. The method is characterized in that when the boiling process under the high pressure is carried out, the employed temperature is 120 DEG C-130 DEG C, the pressure is 0.13-0.15 MPa, and the boiling time under constant temperature and constant pressure is 2 hours; when the enzymatic hydrolysis step is carried out, the cooling step is carried out to the temperature of 52-54 DEG C after heating and disinfecting, then NaOH is added for regulating the pH value to 7.0, 0.5% special enzyme used for oyster is added, the enzymatic hydrolysis step is carried out for 3 hours, during the enzymatic hydrolysis step, stirring is carried out for 2 minutes every 1 hour, so that the enzymatic hydrolysis can be uniformly and fully carried out; when the flavour is removed, because an oyster extract possesses little fishy smell, 12% active carbon is added after the enzymatic hydrolysis step is finished for removing the fishy smell. The method of the invention has the advantages that by using a biological enzymatic hydrolysis technology, the oyster can be changed through biological enzyme hydrolysis to active components capable of solving in water, the product small peptide possesses high content, which is in favor of absorption and utilization of the oyster active components; the mouthfeel of the oyster peptide after removing the flavour by the active carbon is easier to be accepted. The invention is suitable for the method by taking the fresh shellless oyster as a raw material for extracting the oyster peptide.

Owner:吴庆林

Method for preparing poria cocos peptide

InactiveCN105734101ASignificant anti-inflammatory health effectsGood treatment effectFermentationDry matterPeptide

A method for preparing poria cocos peptide includes the following steps that firstly, fresh poria cocos is harvested, cleaned, diced and conveyed into a low-temperature cold air drying device to be dried; secondly, the dried poria cocos dices are conveyed into a rubbing machine to be rubbed continuously for 20 min; thirdly, the poria cocos dices are conveyed into a tumbling machine to be tumbled; fourthly, the tumbled poria cocos dices are subjected to superfine smashing and screened by a 100-400-mesh sifter, the poria cocos dices are frozen for 40 min in the temperature of minus 15 DEG C, the poria cocos dices are taken out, water is added for stirring, and a wet material is obtained; fifthly, the wet material is conveyed into a microwave processing device for interval microwave processing; sixthly, the wet material subjected to microwave processing is soaked for 1.5 h in water bath at the temperature of 75 DEG C, papain is added for stirring, extraction is conducted for 1-4 h at the temperature of 40-60 DEG C, and an extraction solution is obtained; seventhly, vacuum suction filtration is conducted by means of a circulating water type multi-purpose vacuum pump to obtain a peptide solution subjected to suction filtration; eighthly, the raw material peptide solution is subjected to vacuum spraying and drying, and dried matter is collected as the poria cocos peptide.

Owner:JINZHAI JINLIYUAN BIOTECH CO LTD

Soft capsule with freckle removing function

The invention relates to a soft capsule with a freckle removing function, which comprises the following raw materials as contents in percentage by weight: 9-15% of hawthorn extract, 9-15% of Chinese angelica extract, 8-13% of natural vitamin E, 25-35% of hippophae oil and 35-45% of soybean oil. The soft capsule has the function of removing freckles and is suitable for various types of crowds with freckles.

Owner:JIUSAN OILS & GRAINS IND GRP CO LTD

Medicine for treating common cold and its preparation method

InactiveCN1446559AAbsorb quickly and completelyEasy to administerUnknown materialsAntiinfectivesMedicinal herbsCommon cold

A Chinese medicine in the form of aerosol for treating cold is prepared from 4 Chinese-medicinal materials: giant knotweed rhizome, scutellaria root, bupleurum root and agastache through pretreating,crushing, immersing in water decocting several times, collecting decoction, centrifugal deposition, filtering to obtain supernatant, and preparing aerosol.

Owner:曾宽生

Health food for removing chloasma and preparation method of health food

InactiveCN110250514AHealth function achievedElimination of health functionOrganic active ingredientsMammal material medical ingredientsSide effectFreeze-drying

The invention discloses a health food for removing chloasma and a preparation method of the health food. The health food for removing the chloasma comprises the following active ingredients in parts by weight: 200-280 parts of Embryo cervi freeze-dried powder, 1000-1400 parts of Radix Salviae Miltiorrhizae, 1000-1400 parts of Radix Puerariae, 600-1000 parts of Radix Paeoniae Alba and 20-30 parts of soybean isoflavone. The health food prepared by the invention has the characteristics of no toxic or side effect, obvious freckle removing effect and difficulty in recurrence.

Owner:北京采瑞医药科技有限公司

Wine containing SOD (Superoxide Dismutase) component and preparation method thereof

ActiveCN103122294BRich in nutrientsKeep the tasteMicroorganism based processesWine preparationInternational unitSuperoxide dismutase

The invention relates to a wine and a preparation method thereof, and in particular relates to a wine containing an SOD (Superoxide Dismutase) component and a preparation method thereof. The preparation method of the wine containing the SOD component comprises the following steps of: (1) preparing phyllanthus emblica wine juice; (2) preparing phyllanthus emblica fermenting juice; (3) blending and disinfecting; and (4) bottling and packaging. The prepared wine per liter contains 800-1200 thousand international units of SOD. The original anthocyanin in percentage by weight in the wine is 0.01-0.0375%. The wine containing the SOD component prepared by the preparation method not only maintains taste of wine, but also increases various nutritional substances and SOD, and has the edible, beautifying and health-care functions.

Owner:霍全胜

Method for extracting wheat oligopeptide from wheat

InactiveCN105961819AAbsorb quickly and completelyImprove extraction efficiencyFood scienceSurface moistureMicrowave

The invention relates to a method for extracting wheat oligopeptide from wheat. The method comprises the following specific steps: (1) thoroughly rinsing harvested fresh wheat kernels with water, draining surface moisture, and then placing the drained wheat kernels in a fresh keeping warehouse for storage for 2-6 hours; (2) taking out the wheat kernels from the fresh keeping warehouse, sending the wheat kernels taken from the fresh keeping warehouse into a crusher for coarse crushing, performing screening with a 30-40-mesh sieve so as to obtain coarse wheat kernel powder, sending the coarse wheat kernel powder into microwave treatment equipment, and performing interval microwave treatment; (3) sending the coarse wheat kernel after microwave treatment into a grinding machine, performing continuous grinding for 4 hours, performing screening with a 120-180-mesh sieve plate, then putting screened wheat kernel powder into a stainless steel container, and adding warm water for diluting the screened wheat kernel powder so as to obtain wheat kernel paste; (4) heating the wheat kernel paste to 45 DEG C, adding papain to the paste, performing uniform stirring, maintaining the temperature at 40-60 DEG C, and performing leaching for 1-4 hours so as to obtain an extracting solution for standby application; (5) taking the extracting solution, and performing vacuum sucking filtration with a circulating water type multi-purpose vacuum pump so as to obtain a peptide solution after sucking filtration; and (6) performing vacuum spray drying on the raw material peptide solution, and collecting drying substances namely the wheat oligopeptide.

Owner:CHAOHU XINYU BREEDING FARMER PROFESSIONAL COOP

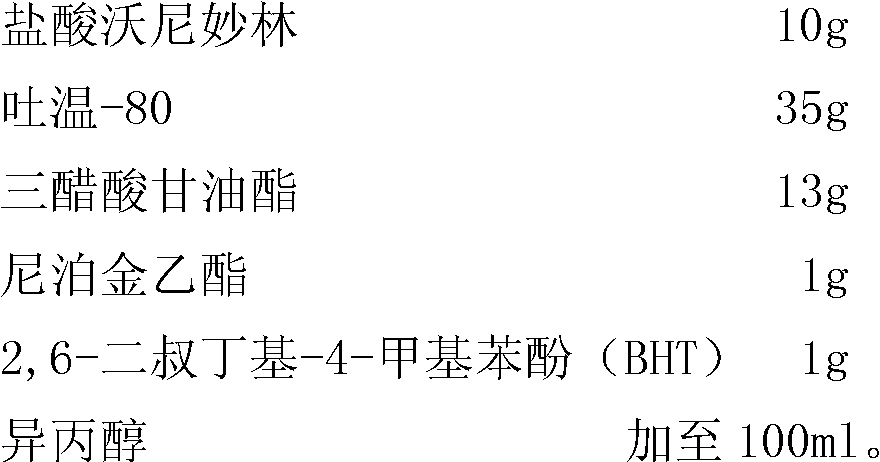

Valnemulin hydrochloride self-emulsified oral nano emulsion for veterinary use and preparation method thereof

ActiveCN102415996BImprove oral bioavailabilityImprove palatabilityAntibacterial agentsEmulsion deliveryActive agentVeterinary Drugs

The invention discloses valnemulin hydrochloride self-emulsified oral nano emulsion for veterinary use and a preparation method thereof. The valnemulin hydrochloride self-emulsified oral nano emulsion for veterinary use comprises the following components: valnemulin hydrochloride, oil, surfactant, preservative, antioxygen and auxiliary surfactant. After disintegrating in water and being stirred slightly or being taken orally and moving with intestine movement, the self-emulsified emulsion can spontaneously form emulsion with emulsion droplet size of 10 to 100 nanometers; the drawbacks of decomposition of valnemulin during long standing and content reduction of the valnemulin or valnemulin hydrochloride nano emulsion prepared in the prior art are overcome and the content stability of the product is increased; the palatability of the valnemulin product is improved; and the preparation process is simple, and the valnemulin hydrochloride self-emulsified oral nano emulsion is suitable to be produced in large scale by veterinary medicine enterprises.

Owner:QILU ANIMAL HEALTH PROD

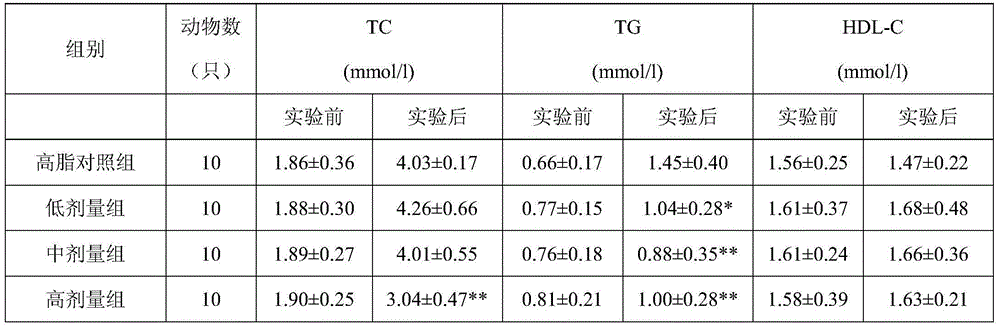

Soft capsule with auxiliary function of reducing blood fat and preparation method thereof

ActiveCN102078365BEasy to takeAbsorb quickly and completelyOrganic active ingredientsMetabolism disorderPreservativeMedicine

The invention relates to a soft capsule with an auxiliary function of reducing blood fat and a preparation method thereof. The soft capsule comprises contents and capsule materials, wherein the contents comprise the following raw materials in percentage by weight: 60-75% of black currant oil, 10-15% of fish oil, 10-20% of soybean lecithin and 0.5-2% of natural vitamin E; and the capsule materialscomprise the following raw materials in percentage by weight: 40-55% of gelatin, 10-25% of glycerol and 30-45% of water. The preparation method comprises the following steps: respectively stirring the raw materials of the contents and the raw materials of the capsule materials proportionally and uniformly to prepare uniform and stable contents and capsule materials; and then, pressing pills, shaping, washing the pills, airing the pills, internally packaging, and externally packaging to prepare a soft capsule with an auxiliary function of reducing blood fat. In the invention, no pigments and preservatives are added into the capsule materials, thus the safety is good; and in addition, the production process is advanced and simple, and the soft capsule is convenient to take and can be absorbed quickly and completely. The soft capsule provided by the invention has the functions of regulating blood fat, improving memory and the like, and is suitable for all people with high blood fat.

Owner:JIUSAN OILS & GRAINS IND GRP CO LTD

Seal oil soft capsule

ActiveCN103800435BAdvanced and simple production technologyEasy to takeOrganic active ingredientsNervous disorderSide effectCholesterol

The invention relates to a health-care capsule capable of reducing blood fat, and particularly relates to a seal oil soft capsule. The capsule is prepared from pure natural seal oil imported from Canada as a main material, and naturally extracted purple perilla seed oil, lecithin and natural vitamin E. The seal oil soft capsule is pure natural, free of a side effect, convenient to take, and rapid and complete to absorb, has the effects of obviously reducing blood fat, reducing blood pressure, and reducing cholesterol.

Owner:SHANDONG TIANDIJIAN BIOLOGICAL ENG COMPANY

Extraction method of sea cucumber polypeptide

ActiveCN102488073BIndividual smallIncrease elasticityProtein composition from fishHigh pressureStorage tank

An extraction method of sea cucumber polypeptide contains steps of: embathing, high-pressure stewing, enzymatic hydrolysis, deodorizing, filtering, condensation, drying and finished product packaging. The extraction method is characterized in that high-pressure stewing: the temperature is 120-130 DEG C, the pressure is 0.13-0.15 MPa and stewing lasts for 2 hours at constant temperature and constant pressure; enzymatic hydrolysis: the temperature is cooled to 54-56 DEG C after heating and sterilizing, NaOH is added to adjust PH to 7.0 and 0.5% of sea cucumber special-purpose enzyme to perform enzymatic hydrolysis for 6 hours; deodorizing: 17% of active carbon is added for deodorizing; filtering: a standing liquid firstly passes through a candle filter, then passes through a barrel filter and is finally filtered to a clear liquid storage tank; and condensation: condensation pressure is minus 0.04-minus 0.06 MPa, condensation temperature is 75-80 DEG C, and Baume degree determined during the condensation process is controlled at 10. The invention has the following advantages of: sea cucumber is changed into a fully water soluble active component after biological enzyme hydrolysis; the content of small peptides in the product is high, which is more beneficial to the absorption and utilization of the sea cucumber active component; and sea cucumber polypeptide is more acceptable in taste after deodorizing by active carbon. The invention is suitable for the extraction method of sea cucumber polypeptide.

Owner:吴庆林

A kind of compound biological feed additive for laying hens and preparation method thereof

ActiveCN104522433BActivation activityPromote respirationAnimal feeding stuffAccessory food factorsAnti stressAnimal science

The invention provides a compound biological feed additive for laying hens, which belongs to the technical field of feed science and feed additives. The feed additive of the invention comprises: feed-grade fulvic acid, insect meal, fermented insect excrement, extract compound preparation, microbe Ecological preparations and carriers are compounded according to a certain proportion. The premix of the compound biological feed additive is used in the feed of laying hens, which can not only regulate the internal environment of the digestive tract of livestock and poultry, regulate the balance of the intestinal flora of the body, enhance the immune function of the body, and has the functions of antibacterial, anti-stress, enhancing immunity, improving In terms of production performance, the feed additive of the present invention is added to the diet of laying hens to improve the production capacity and self-immunity of laying hens, improve the feed conversion rate, thereby reducing drug residues and improving the quality of eggs. It is a new type of safe, reliable, green and environmentally friendly feed additive product. , the application prospect is good.

Owner:BEIJING UNIV OF AGRI

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com