Preparation method of sea cucumber peptides

A technology of sea cucumber peptides and sea cucumbers, which is applied in the field of preparation of sea cucumber peptides, can solve problems such as hindering the deep development of products, high salinity in marine organisms, and affecting the appearance of products, so as to facilitate absorption and utilization, rich in nutrients, and health care and health preservation good effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

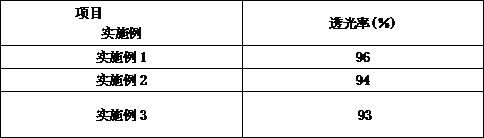

Embodiment 1

[0023] A preparation method of sea cucumber peptide, comprising the following steps::

[0024] (1) Fresh sea cucumbers are cleaned of silt, removed from the viscera, cut into small pieces, and refined to obtain sea cucumber puree;

[0025] (2) Mix sea cucumber puree with deionized water at a ratio of 1:1, heat to 90°C and maintain for 15 minutes to moderately denature sea cucumber protein. After cooling, add soluble compound protease for enzymolysis. The compound protease consists of papain and trypsin Composition, the ratio is 2:1, the amount of compound protease added is 1000U, the enzymatic hydrolysis condition is pH8.0, the temperature is 35°C, and the time is 5h;

[0026] (3) After enzymatic hydrolysis, add 17% of the dry matter weight activated carbon to deodorize, then adjust the pH=6.0-7.0, heat up to sterilize the enzyme, then cool down to 73°C, and let it stand for 4 hours;

[0027] (4) The sea cucumber peptide clarified filtrate is filtered with an inorganic nanofi...

Embodiment 2

[0031] A preparation method of sea cucumber peptide, comprising the following steps::

[0032] (1) Fresh sea cucumbers are cleaned of silt, removed from the viscera, cut into small pieces, and refined to obtain sea cucumber puree;

[0033] (2) Mix sea cucumber puree with deionized water at a ratio of 1:1, heat to 95°C and maintain for 13 minutes to moderately denature sea cucumber protein. After cooling, add soluble compound protease for enzymolysis. The compound protease consists of papain and trypsin Composition, the ratio is 3:1, the amount of compound protease added is 700U, the enzymatic hydrolysis condition is pH8.0, the temperature is 35°C, and the time is 3h;

[0034] (3) After enzymatic hydrolysis, add 17% of the dry matter weight activated carbon to deodorize, then adjust the pH=6.0-7.0, heat up to sterilize the enzyme, then cool down to 74°C, and let it stand for 4 hours;

[0035] (4) The sea cucumber peptide clarified filtrate is filtered with an inorganic nanofil...

Embodiment 3

[0039] A preparation method of sea cucumber peptide, comprising the following steps:

[0040] (1) Fresh sea cucumbers are cleaned of silt, removed from the viscera, cut into small pieces, and refined to obtain sea cucumber puree;

[0041] (2) Mix sea cucumber puree with deionized water at a ratio of 1:1, heat to 100°C and maintain for 10 minutes to moderately denature sea cucumber protein. After cooling, add soluble compound protease for enzymolysis. The compound protease consists of papain and trypsin Composition, the ratio is 5:1, the amount of compound protease added is 1000U, the enzymatic hydrolysis condition is pH8.0, the temperature is 30°C, and the time is 5h;

[0042] (3) After enzymatic hydrolysis, add 17% of the dry matter weight activated carbon to deodorize, then adjust the pH to 6.0-7.0, heat up to sterilize the enzyme, then cool down to 75°C, and let it stand for 4 hours;

[0043] (4) The sea cucumber peptide clarified filtrate is filtered with an inorganic nan...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com