Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

410results about How to "High product content" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

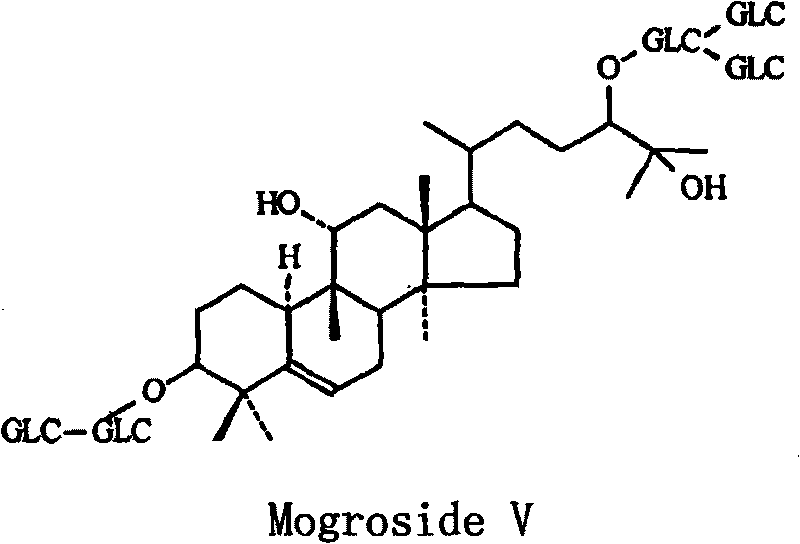

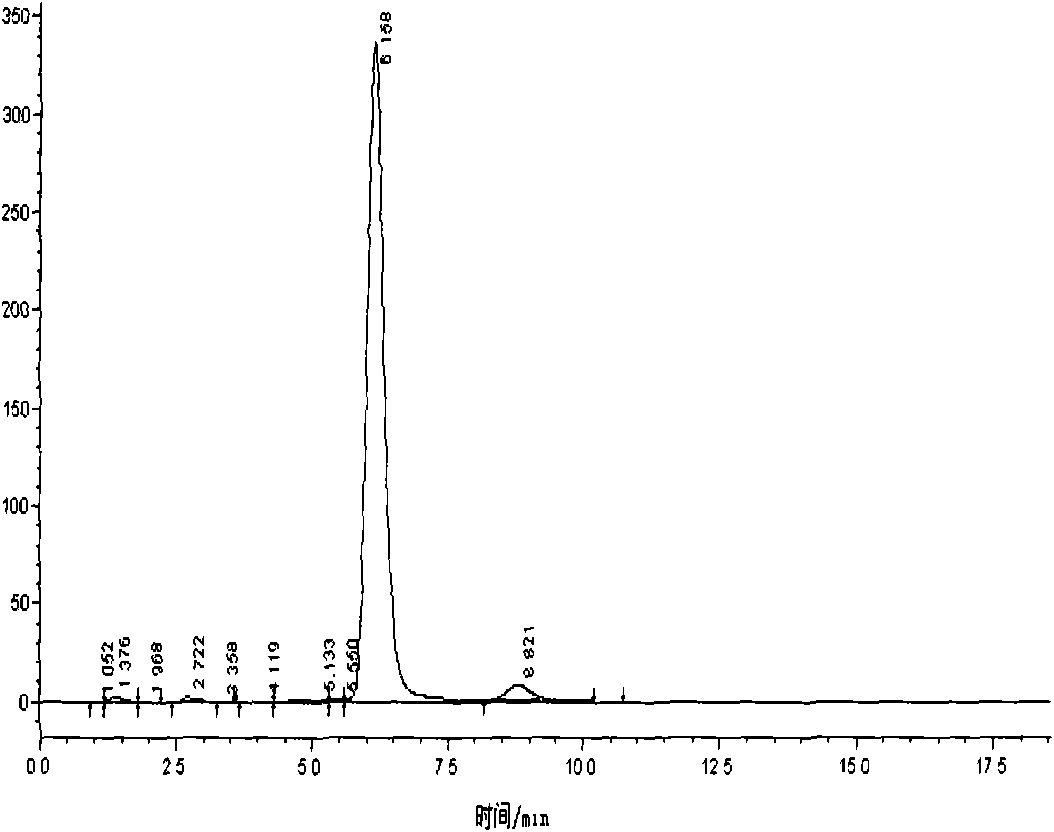

Production method of fructus monordicae extract with over 60% of mogroside V content

ActiveCN101690573APromote leachingEasy to separateCosmetic preparationsToilet preparationsSucroseAdditive ingredient

The invention provides a production method of fructus monordicae extract with over 60% of mogroside V content. In the method, the fresh momordica grosvenori is subjected to the following technique processes: smashing, saccharification, extraction by water, concentration, sedimentation and centrifugation, ion exchange resin refining, macroporous resin refining, concentration, aluminum oxide refining, concentration, spray drying and finishing product. The method can produce high-quality fructus monordicae extract products, reduce material loss, shorten period of production, increase product yield, lower production cost, and is suitable for industrial production. The mogroside V content in the fructus monordicae extract produced by the method is more than or equal to 60%; the fructus monordicae extract has high product purity, single composition, pure white color, good color and taste, fresh and cool sweet taste like that of sugar, simultaneously overcomes the technical problem for industrial production of the high-content and high-quality fructus monordicae extract, and successfully realizes large-scale production.

Owner:YONGZHOU YIDONG BIOTECH

Technology for preparing 1, 1, 2, 3-tetrachloropropene

InactiveCN101955414AHigh product contentIncrease contentPreparation by hydrogen halide split-offChemistryDistillation

The invention discloses a technology for preparing 1, 1, 2, 3-tetrachloropropene, which comprises the following steps of dehydrochlorinating 1, 2, 3-trichloropropene in the existence of alkali solution to prepare 2, 3-dichloropropene; chlorinating the 2, 3-dichloropropene to prepare 1, 2, 2, 3-tetrachloropropene; dehydrochlorinating the 1, 2, 2, 3-tetrachloropropene in the existence of the alkali solution to prepare the 1, 2, 3-trichloropropene; chlorinating the 1, 2, 3-trichloropropene to prepare 1, 1, 2, 2, 3-pentachloropropene; finely distilling and purifying the prepared 1, 1, 2, 2, 3-pentachloropropene; dehydrochlorinating the 1, 1, 2, 2, 3-pentachloropropene in the existence of the alkali solution to prepare the 1, 1, 2, 3-tetrachloropropene which can be directly used for the fine distillation step (6) for synthesizing triallate to prepare the 1, 1, 2, 3-tetrachloropropene. The invention can ensure that the preparation technology is suitable for industrial production and has high content of products.

Owner:CAC NANTONG CHEM

Method for extracting high-content mogroside V from dried momordica grosvenori swingle

The invention discloses a method for extracting high-content mogroside V from dried momordica grosvenori swingle. The extraction technique includes the following steps: extraction, concentration, filtration, adsorption, decoloration, concentration and drying, so that the mogroside V product is obtained. The method adopts the dried momordica grosvenori swingle as material for production, the content of the obtained product is high, the taste and the color are good, the adopted equipment required by the technique is simple, continuous production can be carried out, and moreover, because the used solvents are ethanol and water, no pollution is generated.

Owner:HILL PHARMA

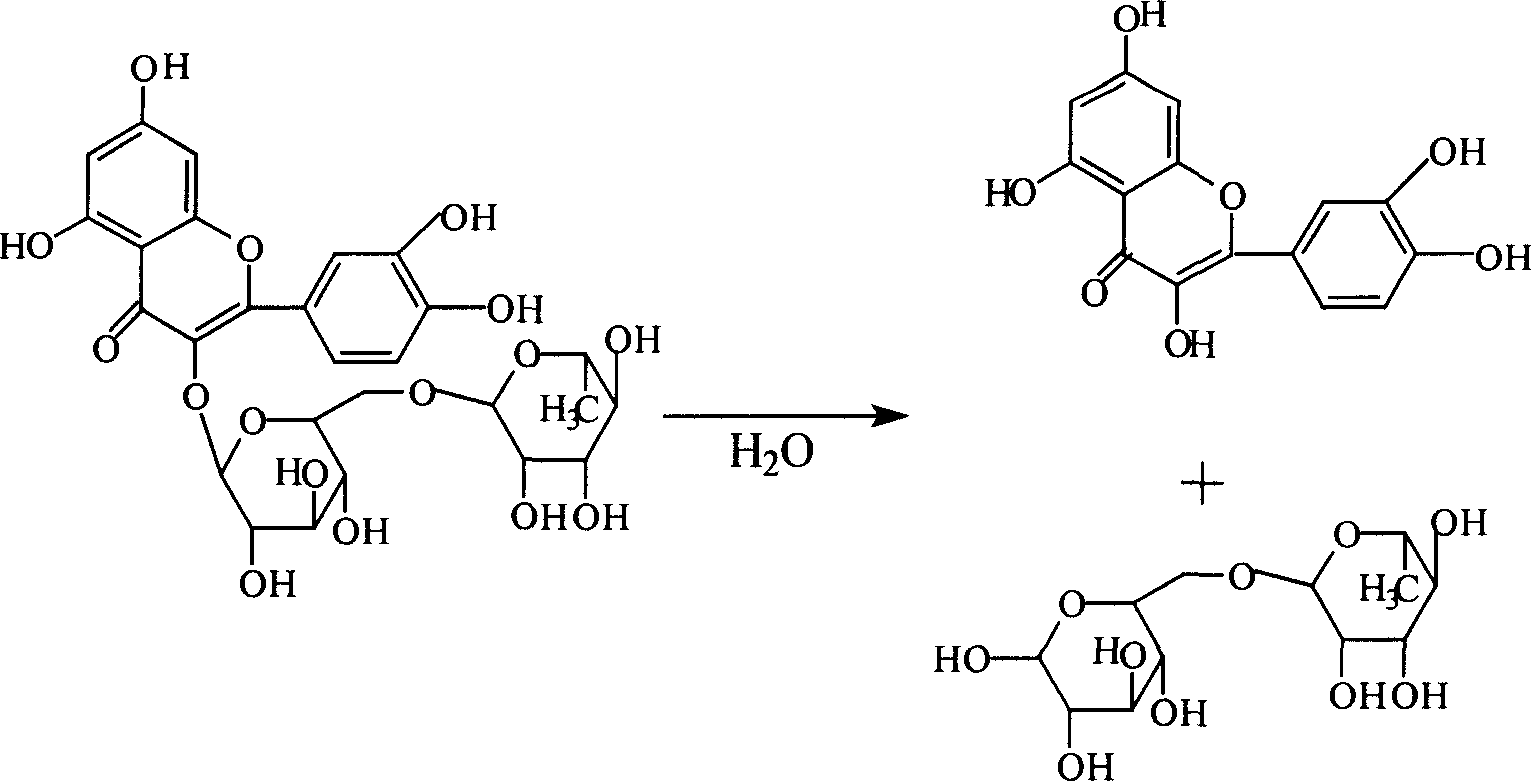

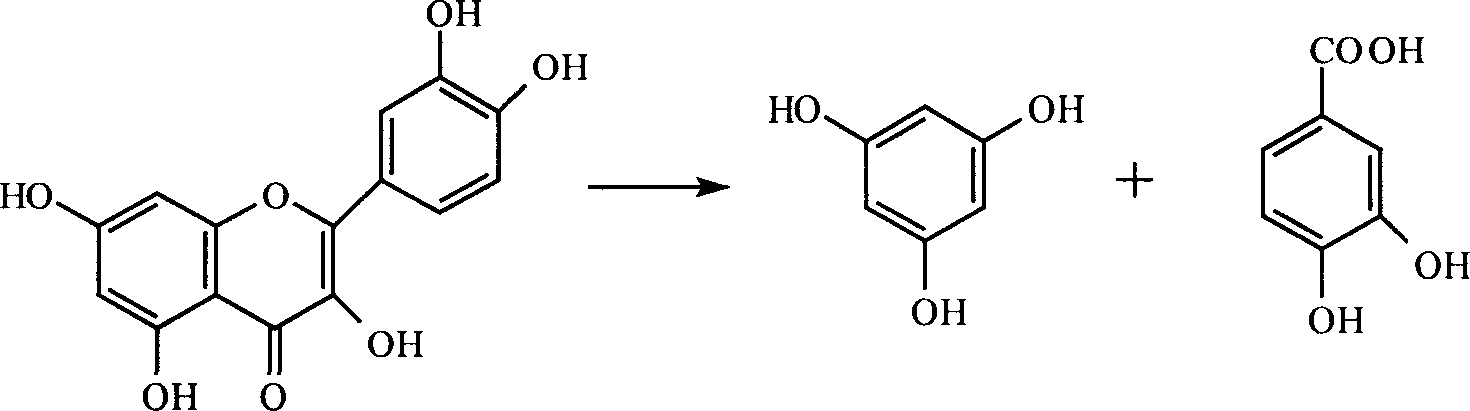

Preparation method for fast separating flavonoid glycosides from oil-tea-cakes with medium pressure column

ActiveCN101899070ASimple processHigh product contentSugar derivativesSugar derivatives preparationCamellia oleiferaSolvent

The invention discloses a preparation method for fast separating flavonoid glycosides from oil-tea-cakes with a medium pressure column, which comprises the following steps of: decorticating and crushing camellia oleifera abel seeds, degreasing the camellia oleifera abel seeds with non-polar solvents, performing extraction with ethanol water, filtering and condensing the extract to obtain crude extract concrete, performing fast separation with the medium pressure column to obtain an over 90 percent flavonoid glycoside mixture, and further adopting a high performance liquid chromatography to prepare over 95 percent flavonoid glycoside monomers, wherein the flavonoid glycoside monomers are kaemplerol 3-O-[2-O-beta-D-galactose-6-O-alpha-L-rhamnose]-beta-D-glucoside (I) and kaemplerol 3-O-[2-O-beta-D-xylose-6-O-alpha-L-rhamnose]-beta-D-glucoside (II) respectively. The method can be used for batch preparation, and has the advantage of providing quality raw materials for the development of flavonoid glycoside medicaments and healthcare functional products in the oil-tea-cakes.

Owner:INST OF CHEM IND OF FOREST PROD CHINESE ACAD OF FORESTRY

Method for preparing beta-carotin from Blakeslea trispora fermentation broth

The invention relates to a method for preparing beta-carotin from Blakeslea trispora fermentation broth, which comprises the following steps of: filtering Blakeslea trispora fermentation broth to obtain wet mycelia; vacuum-drying the wet mycelia to obtain dry mycelia of which the water content is less than 10%; milling and pulverizing the dry mycelia; screening, leaching the dry mycelia with dichloromethane which is 15-20 times of the dry mycelia by mass, evaporating to concentrate the leaching liquor until the concentration of beta-carotin is not lower than 50000 mu g / ml, keeping the temperature, and filtering to obtain the wet crude product of beta-carotin crystals; and dissolving the wet crude product with dichloromethane, filtering, evaporating to concentrate until the concentration of the beta-carotin is not lower than 50000 mu g / ml, keeping the temperature, filtering, and vacuum-drying to obtain the beta-carotin crystals. The method has the advantages of short technical process,less operation steps, easy control on production process, high product content, low cost, high yield, only one solvent used in the overall process and suitability for industrial production.

Owner:ZHEJIANG MEDICINE CO LTD XINCHANG PHAMACEUTICAL FACTORY

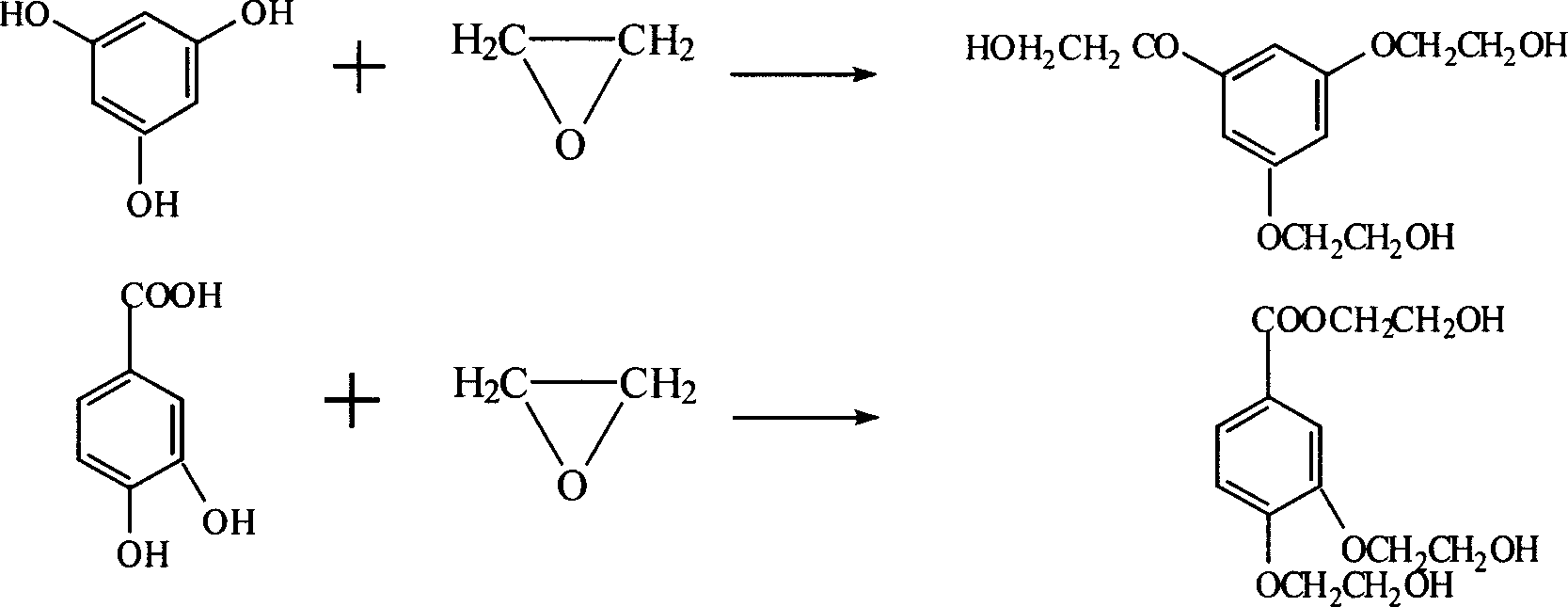

Method for preparing high-content troxerutin drug

ActiveCN1814613AHigh content and yieldReduce dosageOrganic active ingredientsSugar derivativesDrugSodium hydroxide

The invention offers 3', 4', 7-troxerutin synthetic method. It uses rutin and ethylene oxide to do hydroxyethylation reaction under the catalyzing of sodium hydroxide. Its features are that in the reaction, the weight ratio of rutin and water is 1:1-1:3; optimization is 1:1-1:1.5; the weight ratio of rutin and sodium hydroxide is 100:0.82-100:0.85; adding resin when the pH value of the reaction solution is 9.0-9.5 to adjust end point pH value to 9.5-10.3. The method can make high purity and high quality troxerutin. And its 3', 4', 7-troxerutin content is more than 78%; optimization is more than 80%; and the more optimization is more than 85%.

Owner:TOPFOND PHARMA CO LTD

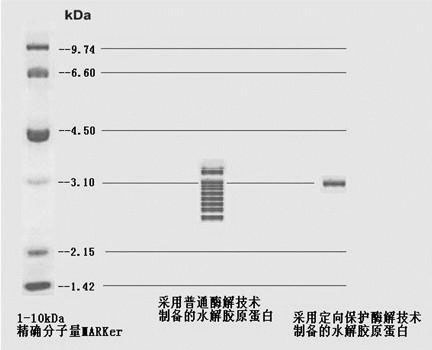

Method for extracting hydrolyzed collagen from bovine cartilage

ActiveCN101948900AAchieve hydrolysisGuaranteed HalalPeptide preparation methodsFermentationBovine CartilageCollagen VI

The invention provides a method for extracting hydrolyzed collagen from bovine cartilage. The method sequentially comprises the following steps of: processing fresh bovine cartilage which is obtained from a Muslim slaughter house and serves as a raw material with solution of sodium hydroxide; adding papain and alkali protease into the obtained product by stages and simultaneously adding a composite enzymolysis protecting agent into the obtained product; raising temperature for inactivating enzyme after two enzymolysis processes; decoloring by oxidation; filtering and performing ultra-filtering; collecting retained solution; and performing spray-drying on the solution to obtain the hydrolyzed collagen. In the method, the bovine cartilage of the Muslim slaughter house is used as a basic rawmaterial, and other animal derived enzyme preparations are not added during the entire process, so that the Muslim property and no pollution of the product can be ensured.

Owner:SHANGHAI AL AMIN BIOTECH

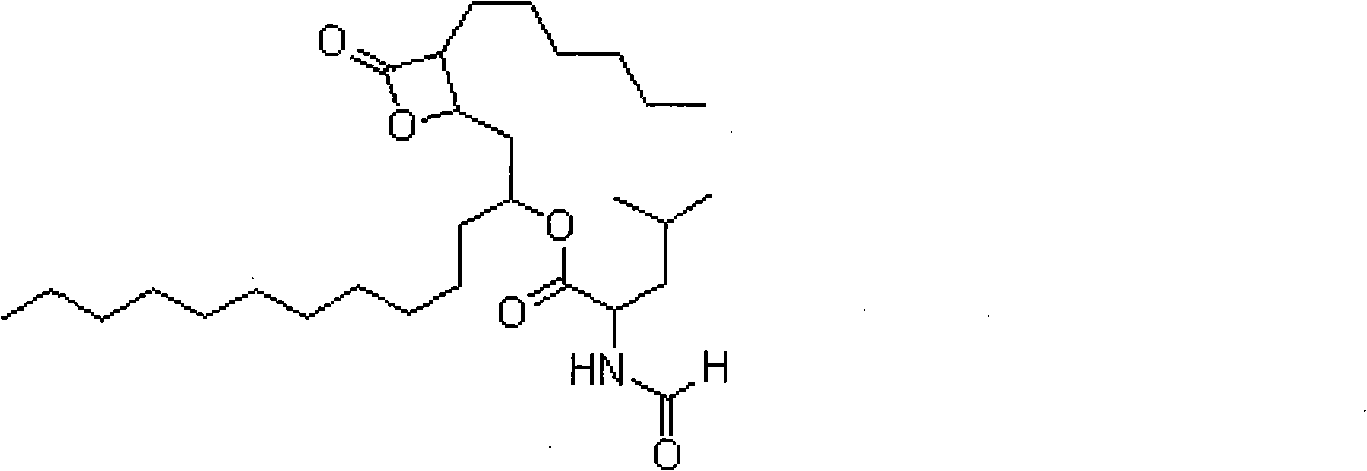

Method for preparing orlistat

The invention belongs to the technical field of medicaments, and particularly relates to a novel method for preparing weight-losing medicament orlistat by a fermentation method. The method for preparing the orlistat comprises the following steps of: extraction and filtering of fermentation solution, chromatographic impurity removal by macroporous absorption resin, silica column chromatography of orlistat after hydrogenation and the like. By method, the effects of better removing impurities and purifying products are achieved.

Owner:鲁南新时代生物技术有限公司

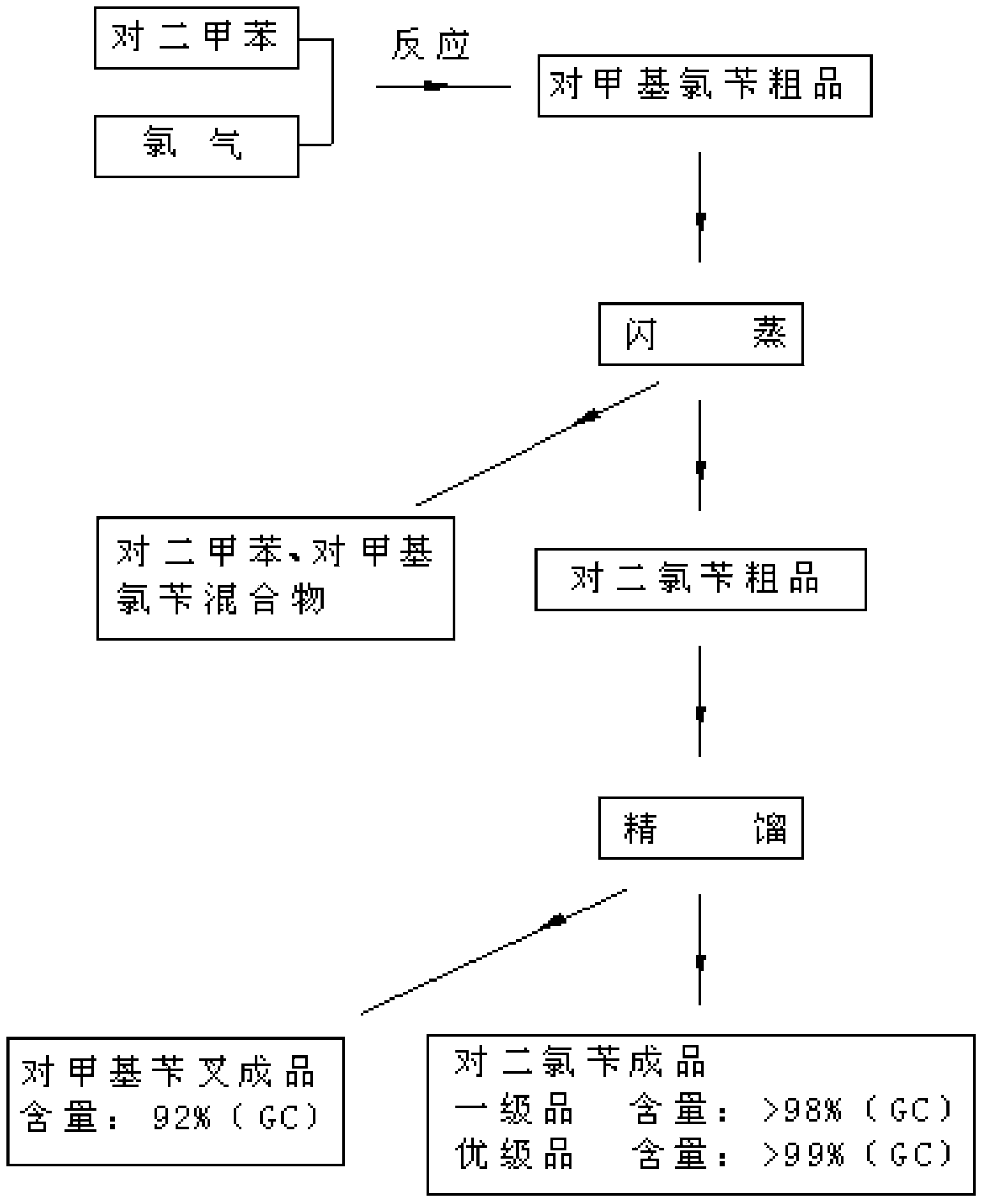

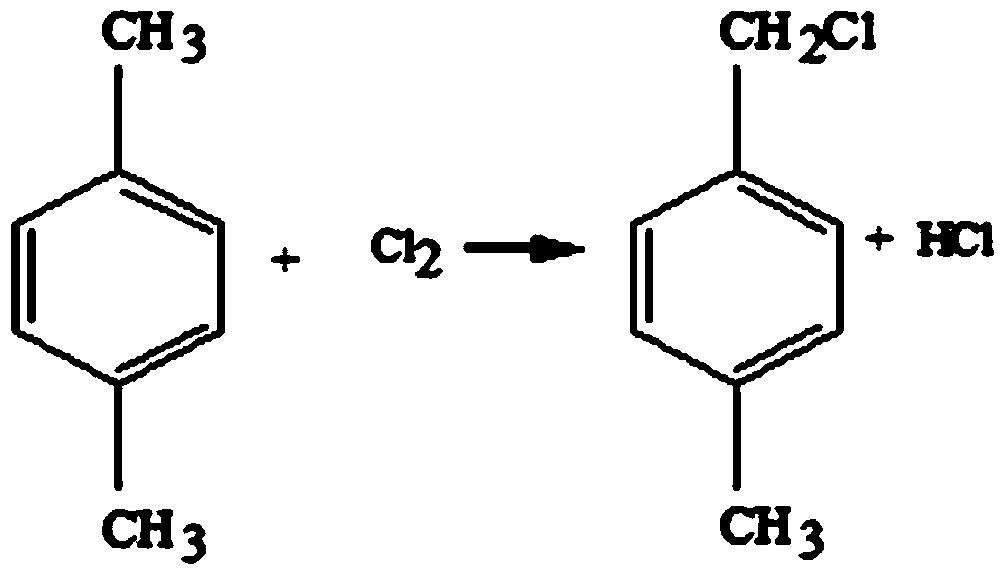

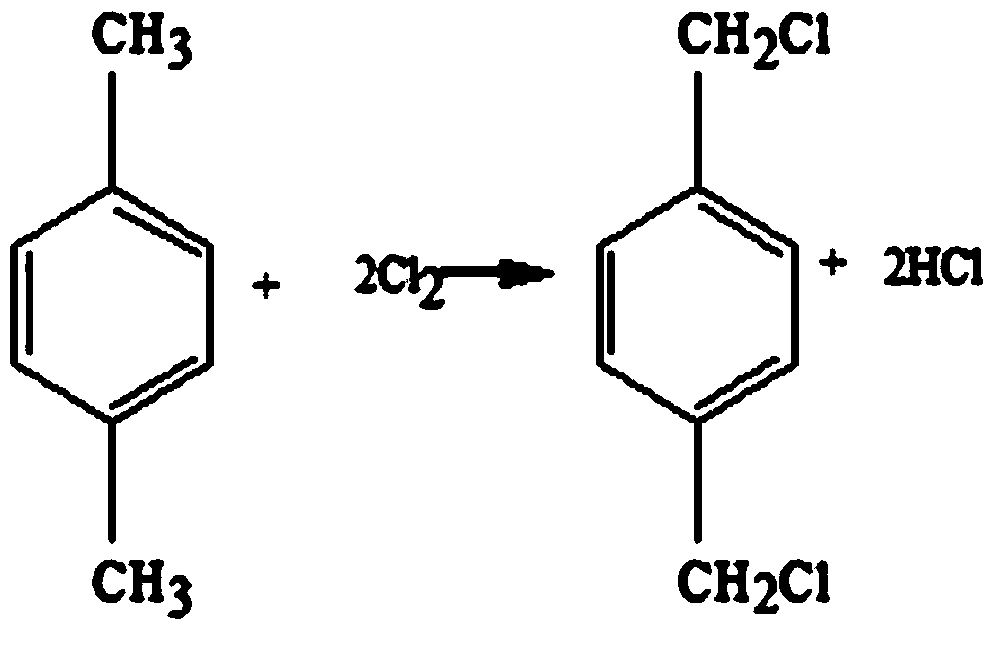

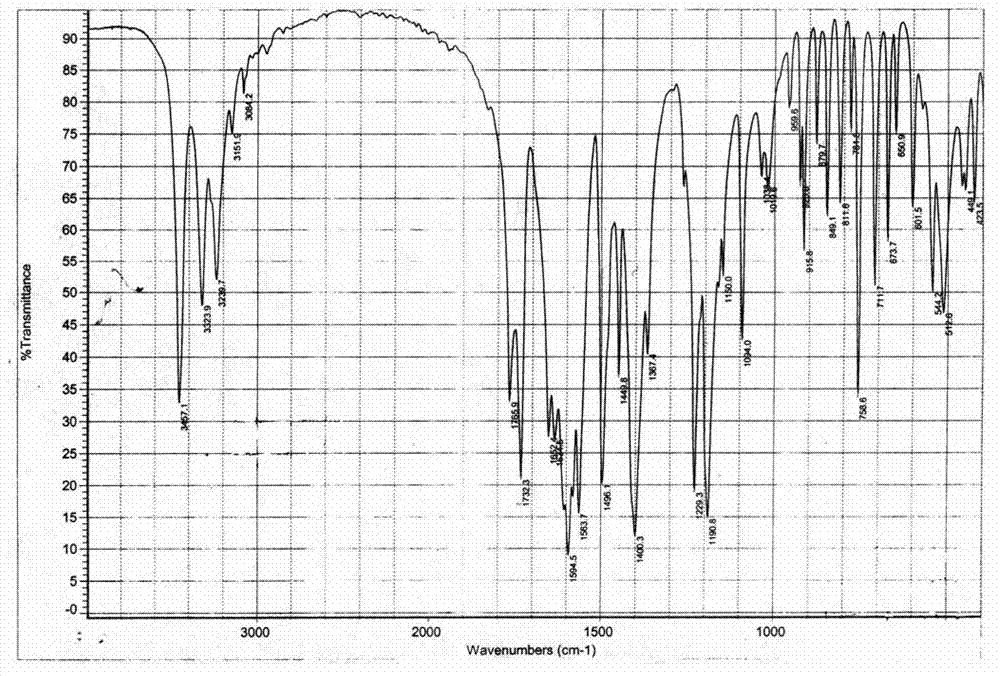

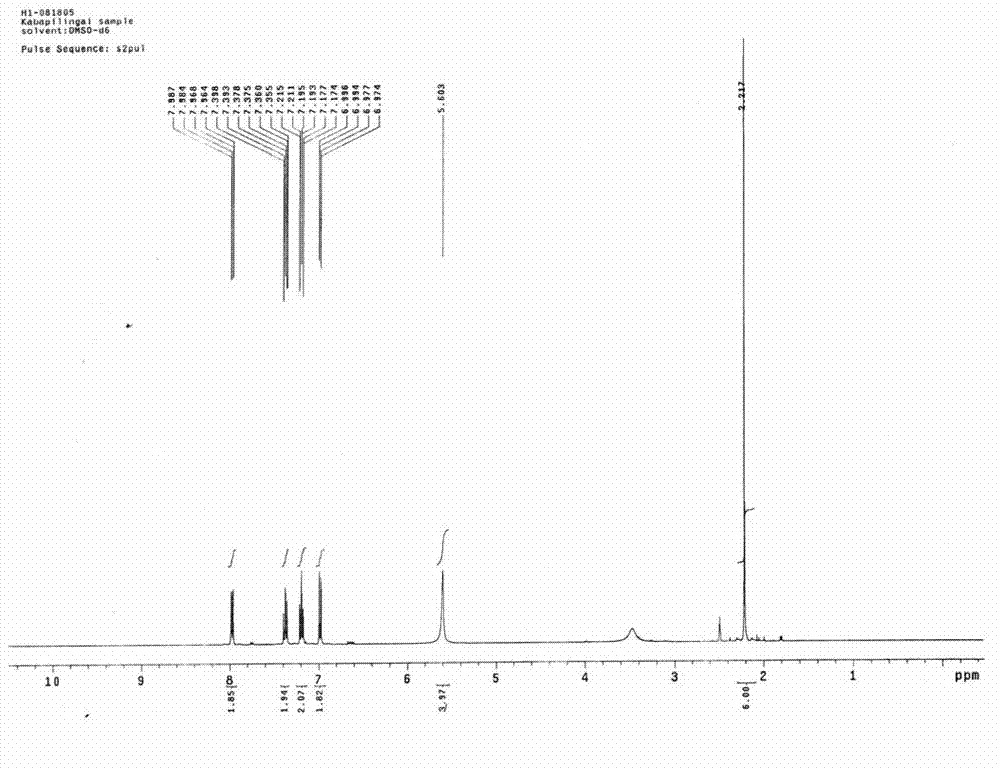

Manufacturing technology of p-xylylene dichloride

InactiveCN104230653AHigh product contentHigh purityHalogenated hydrocarbon preparationXylyleneManufacturing technology

The invention provides a manufacturing technology of p-xylylene dichloride. The manufacturing technology comprises the following steps: (1) reaction: adding p-xylene in a chlorination reactor, turning on a reaction light source, and then turning on jacket steam of a reaction still to begin to heat and raise the temperature; when the temperature is raised to 80 DEG C, stopping steam heating, and introducing Cl2 to the reaction still; two hours after Cl2 introduction, increasing the chlorine flow, sampling to conduct center control analysis, and stopping introduction of the chlorine after meeting the process control requirements; (2) flash evaporation: simply distilling the mixed liquor obtained in the step (1), collecting the mixture of p-xylene and p-methylbenzyl chloride, and centrally collecting the bed charge inside the distillation still; (3) rectification: transferring the bed charge centrally collected in the step (2) to a benzylidene chloride rectifying column to be decompressed and rectified; collecting 4 mm Hg of fraction at 120-125 DEG C to obtain p-methylbenzylidene; collecting 4 mm Hg of fraction at 135-140 DEG C to obtain p-xylylene dichloride. The manufacturing technology disclosed by the invention can increase the yield of the product, achieves higher purity, and is easy for byproduct separation and purification.

Owner:QIANJIANG XINYIHONG ORGANIC CHEM

Preparation method of carbasalate calcium

ActiveCN102924335AHigh product contentImprove stabilityUrea derivatives preparationOrganic compound preparationAlcoholFiltration

The invention relates to a preparation method of carbasalate calcium. The preparation method comprises the following steps: (1) dispersing aspirin, calcium nitrate and urea into alcohol, adding ammonia water under a stirring condition at 0-5 DEG C, then heating up to 25-35 DEG C, and reacting for 2-2.5 hours; and (2) cooling the reaction solution obtained in step (1) to 0-5 DEG C, standing for growing crystals, and then performing suction filtration and drying to obtain carbasalate calcium. The preparation method of arbasalate calcium is characterized by high product content, low content of impurities (related substances), good stability, concise process and low production cost; and the requirement on equipment is lowered, and the method is suitable for industrial production.

Owner:QILU ANIMAL HEALTH PROD +1

Extraction technique of high-purity phlorizin

InactiveCN101392008ARaw materials are easy to getSimple extraction processSugar derivativesSugar derivatives preparationCentrifugationGradient elution

The invention discloses an extraction process of a high purity phlorizin, comprising the following steps: (1) the raw materials are added with 4-8 times pure water, marinated for 1-3 hours, heated to boiling and micro boiling is kept for 2-3 hours so as to obtain an extracting solution; residue is heated to boiling by using 2-6 times pure water and micro boiling is kept for 2-3 hours so as to obtain a secondary extracting solution; the extracting solutions are merged, cooled and filtered and then the filtered liquid is collected; (2) the filtered liquid is adsorbed by macroporous resin and subjected to gradient elution by using 20 DEG and 50 DEG ethanol; the effluent liquid is collected in subsection, concentrated in vacuum, placed in a quiescence way and cooled, dissolves out crystal at 0-4 DEG C, and dehydrates by high-speed centrifugation; and (3) re-dissolving of pure water, vacuum concentration, re-crystallization, high-speed centrifugation dehydration and drying are carried out so as to obtain the finished product. By adopting pure water for extraction, the organic-residue is decreased and simultaneously the product content is more than 99 percent.

Owner:XINGHUA GL STEVIA CO LTD

Synthesis method of photoinitiator 2-hydroxy-2-methyl-1-phenyl-1-propyl ketone

ActiveCN103613492AReduce consumptionQuick responseOrganic compound preparationCarbonyl compound preparation by condensationKetone synthesisCatalytic effect

The invention relates to a synthesis method of a photoinitiator 2-hydroxy-2-methyl-1-phenyl-1-propyl ketone, which comprises the following steps: reacting high-purity gas phosgene with isobutyric acid to synthesize isobutyryl chloride; and carrying out chlorine substitution reaction by a cascade technique: exhaust of a first reaction kettle after chlorine introduction is connected into a second reaction kettle in cascade, and hydrogen chloride and chlorine in the exhaust released by the first reaction enter the second reaction kettle to catalyze the absorption and utilization. The method can well enhance the purity of isobutyryl chloride and further enhance the purity and yield of the product 2-hydroxy-2-methyl-1-phenyl-1-propyl ketone; and the catalytic action of hydrogen chloride in the exhaust is utilized to increase the reaction speed, lower the chlorine consumption and enhance the product content. The generated exhaust is recycled after innocent treatment, thereby solving the problem of environmental pollution of the exhaust.

Owner:岳阳市国发植物用药工程技术研究中心有限公司

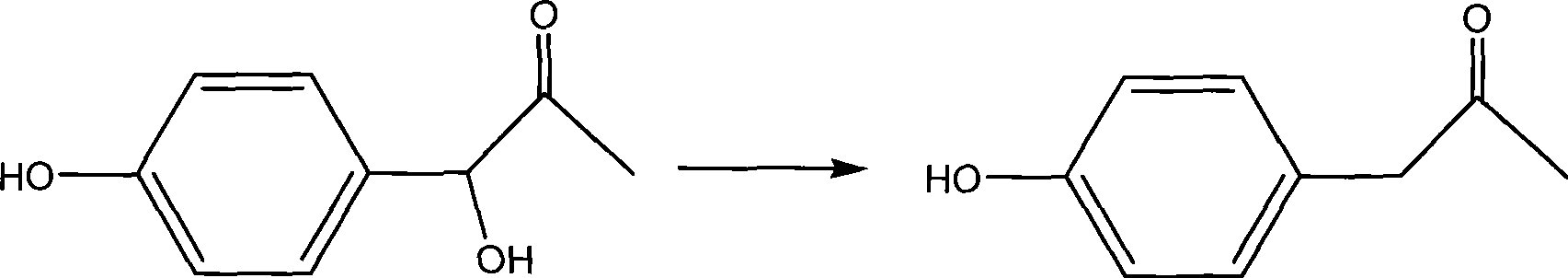

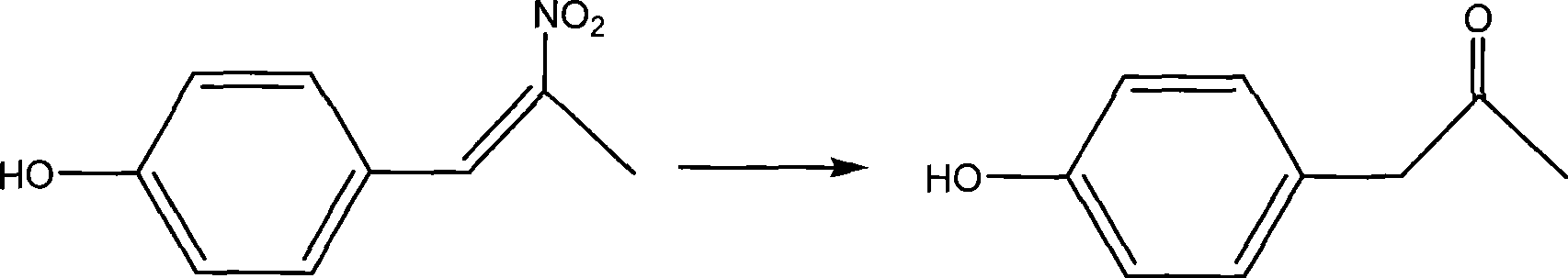

Synthesis method of medical midbodies of para(ortho)-hydroxybenzoic acetone

InactiveCN101544552AEasy to industrializeReduce processing costsOrganic compound preparationCarbonyl compound preparationAcetic acidSynthesis methods

The invention relates to the field of medical chemical engineering, in particular to a synthesis method of medical midbodies of para-hydroxybenzoic acetone and ortho-hydroxybenzoic acetone. The method comprises the following steps: adding para-methoxybenzoic acetone or ortho-methoxybenzoic acetone to solvent; adding an acidolysis agent for acidolysis refluence; concentrating after a reaction; adding water into concentrate for dissolution; using ethyl acetate to extract; and concentrating and rectifying an extracting solution. The invention has easily obtainable raw materials, mild reaction conditions, simple reaction procedures, high product content larger than 99 percent, product yield larger than 70 percent and low production cost and is suitable for industrialized mass production.

Owner:CHANGZHOU RUIMING PHARMA

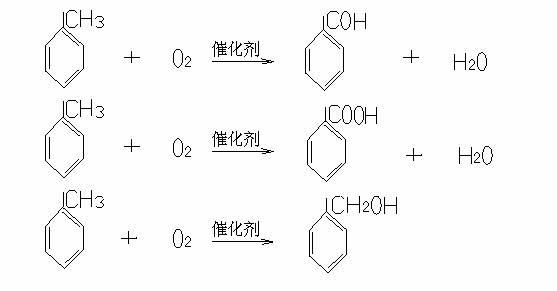

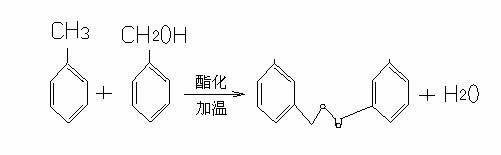

Method for preparing benzaldehyde, benzyl alcohol and benzyl benzoate through air catalytic oxidation of methylbenzene

InactiveCN102219662AHigh product contentIncrease contentPreparation by oxidation reactionsOrganic compound preparationBenzyl benzoatBenzoic acid

The invention discloses a preparation method which can improves the content of high added-value product benzaldehyde, benzyl alcohol and benzyl benzoate while not using an organic solvent and producing benzoic acid with high yield on the condition of not changing the existing benzoic acid production process and equipment. The invention has the advantages that through adjusting proportion of a catalyst, under the condition of best proportion of the catalyst, the conversion rate of the benzaldehyde is about 10 percent, the selectivity of the benzoic acid is 40 percent, the selectivity of the benzaldehyde is 30 percent, and the selectivity of the benzyl alcohol is 30 percent; and the content of the high added-value product benzaldehyde and benzyl alcohol are both high, and the catalyst can be repeatedly used, easy to regenerate, so that the production cost is lowered, and the economic benefits of benzoic acid production factories are greatly improved.

Owner:武汉万园寺药业有限公司 +1

Production method of triethyl phosphite

ActiveCN101624400AIncrease production capacityImprove product qualityGroup 5/15 element organic compoundsAmmonium halidesTriethylphosphiteDistillation

The invention relates to a production method of triethyl phosphite, which belongs to the technical field of chemical production. Absolute ethyl alcohol, phosphorous trichloride are taken as main material, pure benzol is taken as solvent, triethylamine is taken as acid-binding agent, liquid ammonia is taken as reducing agent, and the triethyl phosphate is prepared through the processes of three-complex liquor preparing, synthetic reaction, water scrubbing reaction, layering, drying, crude distillation, rectifying, recovering and ammonia recovery and the like. The method adopts continuous production process of triethylamine, the material charging and the product discharging are continuous, the production capacity is strong, and the product quality is stable. With equal equipment and investment, the capacity of the method can be 6 to 7 times as the capacity of intermittent method. The method solves the problems of the prior production method that the production capacity is small, the production cycle of the product is long, the material consumption is large, the quality is unstable, the discharge amount of 'three wastes' is large, and the yield can not be guaranteed. The method has the advantages that the liquid ammonia is taken as reducing agent, the cost is low, the recovery factor of excess ammonia can reach more than 90 percent, the recovered ammonium chloride can be used as the crude product of ammonium fertilizer, the production cost is lowered, and the environmental pollution is reduced.

Owner:荆州三才堂化工科技有限公司

Method for preparing high-purity resveratrol from fresh giant knotweed rhizome

InactiveCN101760483AReduce lossesHigh yieldOrganic chemistryOrganic compound preparationFiltration membraneAqueous solution

Then invention relates to a method for preparing resveratrol, which comprises: fresh giant knotweed rhizome is taken as the raw material; after being grinded, the fresh giant knotweed rhizome is heated and soaked by saturation lime water solution for extraction; the pH of extraction liquid can be adjusted; macromolecule purities are removed by adopting an ultra-filtration membrane; the solution is concentrated by adopting a nano-filtration membrane; biological enzyme is added into the concentrated solution for heat preservation and enzymolysis for 9-12h; the obtained crude product can be dissolved by ethanol; the impurities in the crude product are removed by adopting alumina resin; and then water can be added in the crude product for crystallization. The product prepared by adopting the method has the advantages of high content, high yield and low cost. The process is easy to be enlarged and industrialized.

Owner:NANJING ZELANG MEDICAL TECH

Method for preparation of loganin from traditional Chinese medicine Cornus officinalis

InactiveCN104447910AEasy to operateHigh product contentSugar derivativesSugar derivatives preparationChemistryColumn chromatography

The invention discloses a method for preparation of loganin from Cornus officinalis. The method uses traditional Chinese medicine Cornus officinalis as a raw material, and comprises the steps of ethanol heating extraction, macroporous adsorption resin purification, silica gel column chromatography separation, and recrystallization, so as to obtain loganin with purity greater than 95% and extraction of 70.5-75.2%.

Owner:LANZHOU INST OF CHEM PHYSICS CHINESE ACAD OF SCI

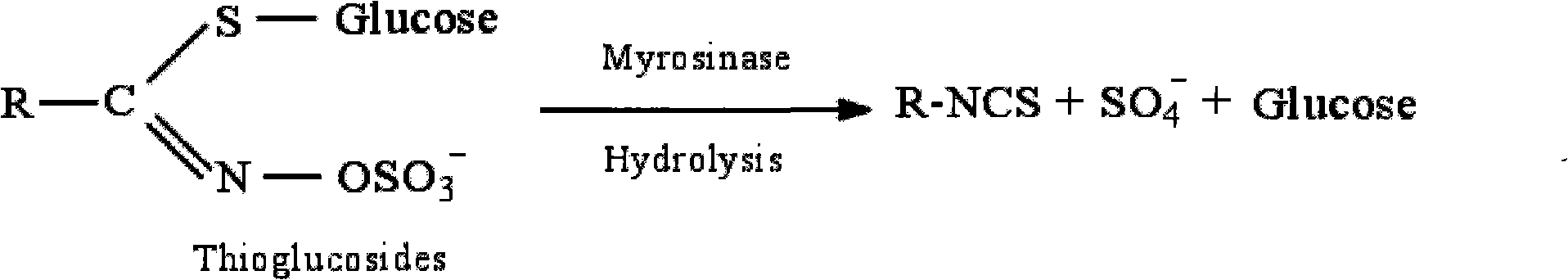

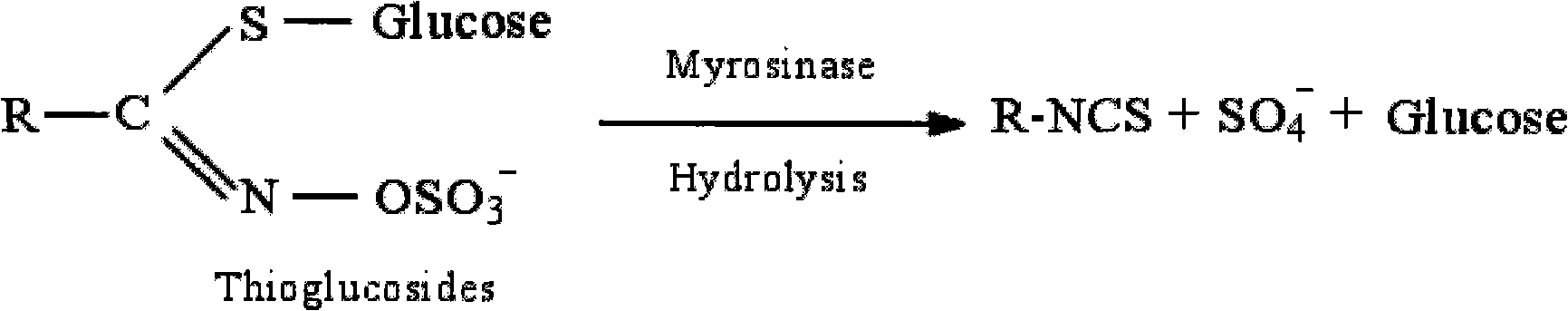

Method for extracting athomin with mustard seeds as raw material

The invention relates to a method for extracting athomin with mustard seeds as the raw material. The method comprises the following steps: taking mustard seeds in brassica in cruciferae as the processing raw material, soaking the raw material in water after being crushed, and then rapidly and effectively obtaining crude product of athomin by a subcritical water extraction method. Because the subcritical water extraction technology is a novel environment-friendly extraction technology not using or rarely using organic solvent, when being in the subcritical state, water has certain dissolving capacity to semi-polar and non-polar organisms, the polarity, the surface tension and the viscosity of water can be changed by controlling the temperature and the pressure of subcritical water, so that the dissolving capacity of the subcritical water to the organisms can be greatly imoroved, therefore, the extraction efficiency is greatly improved, and the content of allyl isothiocyanate product in athomin is high. Compared with the prior art, the method has the advantages of simple technological line, reasonable technological condition, simple and safe reaction and operation, short reaction time, low solvent loss, low technological cost, and high implementation value and social and economic benefit.

Owner:北京农鹰现代农业技术研究院 +3

Method of preparing 4-amino-3-phenyl butyric hydrochloride

InactiveCN101033195AHigh product yieldGood product purityOrganic compound preparationAmino-carboxyl compound preparationChemistryFormate

This invention relates to a preparation method for 4-amido-phenyl butyrate including: mixing benzene formate and methyl alcohol with nitromethane to be reacted at heat preservation, cooled and crystallized, separated for solid and liquid to be dried to get nitrobenzene ethane, which is put into a methanol solution together with diethyl malonate to be reacted to generate alpha-carbomethoxy-beta-phenyl-gamma-nitryl methyl butyrate, then Ni and H2 are added into a methanol solution to carry out hydrogenation reaction to get alpha-carbomethoxy-beta-phenyl-gamma tetrahydroketopyrrolidine, which is added with HCl to be hydrolyzed dried to get a product of 4-amido-phenyl butyrate.

Owner:安徽省郎溪县科联实业有限公司 +1

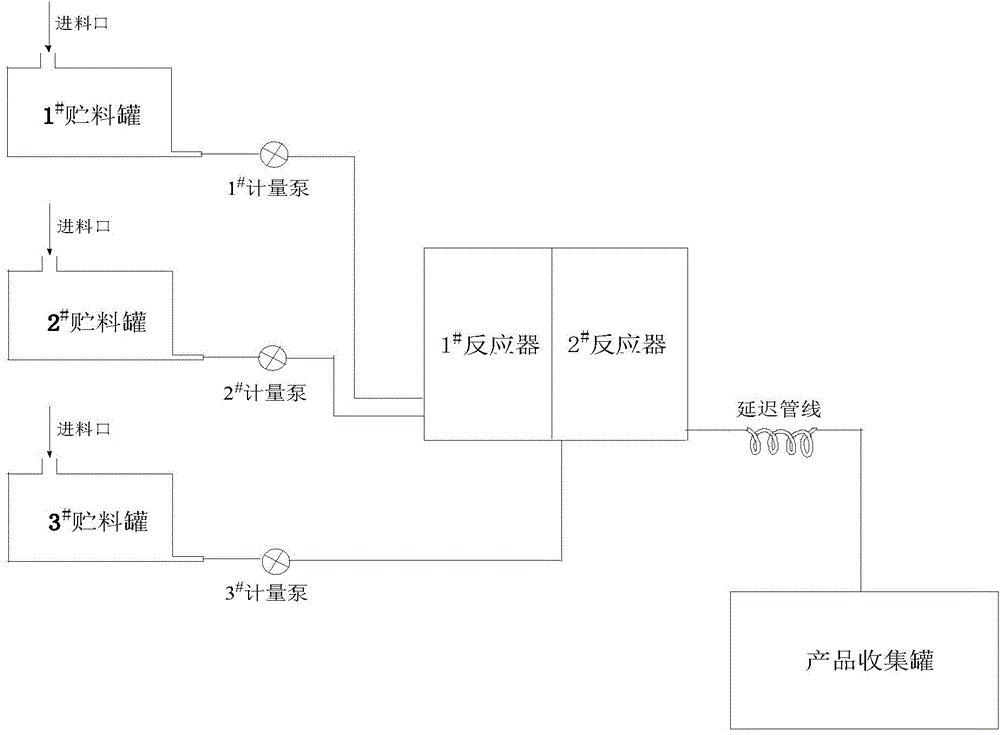

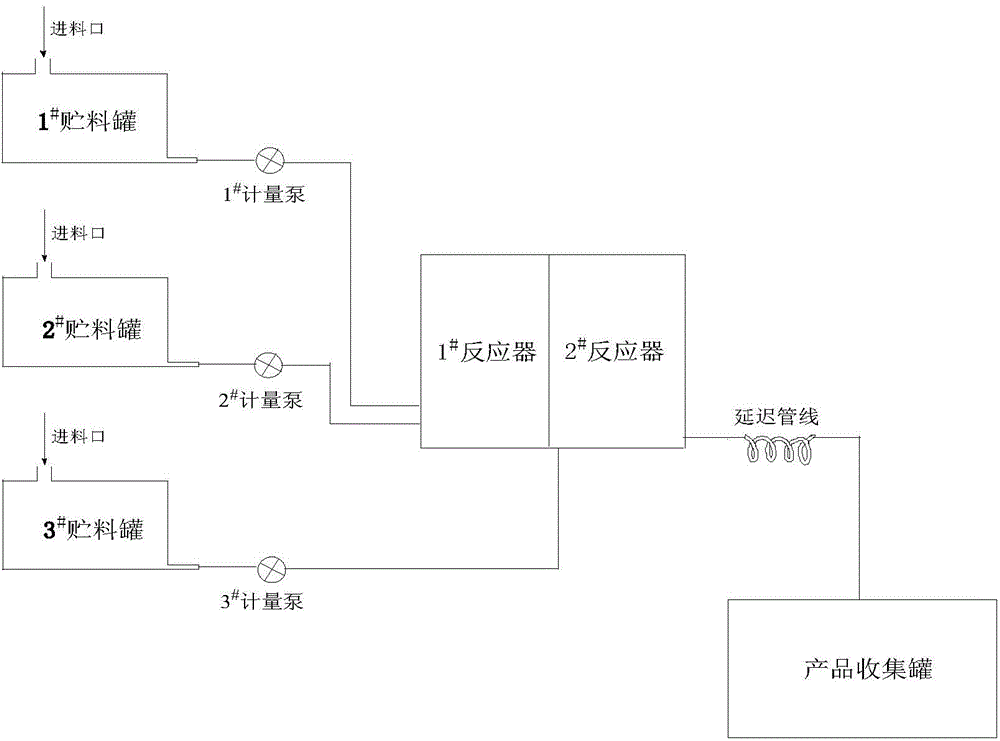

Method for preparing tert-butyl peroxyneodecanoate (BNP) through continuous flow

InactiveCN104592080AEmission reductionReduce labor intensityOrganic compound preparationPeroxy compound preparationEmulsionContinuous flow

The invention provides a method for preparing tert-butyl peroxyneodecanoate (BNP) through a continuous flow, wherein the method includes an alkaline aqueous solution is prepared, the alkaline aqueous solution and a tert-butyl hydrogen peroxide aqueous solution are subjected to a reaction in a reactor, a neodecanoyl chloride solution and the product of the alkaline aqueous solution and the tert-butyl hydrogen peroxide aqueous solution are subjected to a reaction, and the product is subjected to further full reaction through a delay pipeline to obtain the product, wherein the reaction process is carried out in a micro-reactor. With adopting of the prepared solvent-type or emulsion-type tert-butyl peroxyneodecanoate (BNP), the product quality is stable, and the reproducibility is good; because the reaction is carried out in the micro-reactor, the process flow is simplified, the reaction is continuously carried out under mild, safe and environmental-protection conditions, the amount and the yield of the product are greatly improved, and the yield can reach above 98%.

Owner:LINZIZHENGHUA ACCESSORY INGREDIENT ZIBO

Method for preparing peroxidized dicarbonate (2-ethylhexyl) ester (EHP) by continuous flow

InactiveCN104370789AEmission reductionReduce labor intensityOrganic compound preparationPeroxy compound preparationDicarbonateEmulsion

The invention provides a method for preparing peroxidized dicarbonate (2-ethylhexyl) ester (EHP) by a continuous flow. The method comprises the following steps: preparing an alkaline aqueous liquid; carrying out reaction on the alkaline aqueous liquid and hydrogen peroxide in a reactor; adding a chloroformic acid-2-ethyl caproate liquid to react with a product of the alkaline aqueous liquid and hydrogen peroxide; and further carrying out full reaction on the product to obtain a product by virtue of a delayed pipeline, wherein the reaction process is carried out in a micro-reactor. The solvent or emulsion type peroxidized dicarbonate (2-ethylhexyl) ester (EHP) prepared by the method provided by the invention is stable in product quality and good in repeatability. As reaction is carried out in the micro-reactor, the process flow is simplified, so that the reaction is continuously carried out under mild, safe and environment-friendly conditions. Therefore, the product content and yield are greatly improved, and the yield can reach over 98%.

Owner:LINZIZHENGHUA ACCESSORY INGREDIENT ZIBO

Method for comprehensively extracting dye lignin and kaempferol from sophora fruit

ActiveCN102875511AHigh product contentReduce manufacturing costOrganic chemistryOrganic solventHydrogen

The invention provides a method for comprehensively extracting dye lignin and kaempferol from sophora fruit. The technical concept is shown in the steps as follows: 1, crushing raw materials, hydrolyzing through acid water, and extracting acidolysis slag through an organic solvent; 2, combining an extracting liquid, and concentrating and filtering the extracting liquid to obtain precipitate which is a mixture of kaempferol and dye lignin; 3, extracting the obtained precipitate through alkaline liquid, and centrifugally separating to obtain the precipitate which is kaempferol and obtain the supernate which is dye lignin; 4, dissolving the obtained precipitate through the organic solvent, and adding an absorbent to be purified, and filtering, concentrating, and centrifugally separating to obtain faint yellow powder which is kaempferol; and 5, discoloring the supernate obtained in step 3 through the absorbent, and filtering, then adjusting the pH (Potential Of Hydrogen), standing and precipitating, and centrifugally separating to obtain the white powder which is the dye lignin. With the adoption of the method provided by the invention, the problem of the prior art that the resource is wasted because two products cannot be comprehensively developed can be overcome, the extracting step is optimized, the producing cost is reduced, and the operability is improved.

Owner:SHAANXI JIAHE PHYTOCHEM

Method for extracting and separating silver linden glycoside from oriental paperbush flower

The invention provides a process for preparing tiliroside from oriental paperbush flowers, which comprises the following steps, (1) lixiviating or backflow extracting from oriental paperbush flower in extraction solvent, decompression concentrating the extract liquid, obtaining concentrate, the extraction solvent is 60-100% of hydrophilic solvent, (2) washing the concentrate, backflow extracting with medium and low polarity fat-dissolving solvent, thus obtaining filter cakes, (3) finally recrystallizing the filter cakes.

Owner:ZHEJIANG UNIV OF TECH

Method for preparation of moxidectin

ActiveCN104277050AReduce the difficulty of purificationReduce the number of analysisOrganic chemistryNemadectinTert butyl

The invention relates to a method for preparation of moxidectin. The method includes subjecting Nemadectin to protective reaction, oxidation reaction, oximation reaction and deprotection reaction in order, thus obtaining moxidectin. Specifically, the protective agent employed in the protective reaction is tert-butyl dimethylchlorosilane, and after the oximation reaction, the solid form crude product obtained by the oximation reaction is subjected to crystallization, and then the deprotection reaction is carried out on the obtained crystal. The method provided by the invention increases the product content, further reduces the difficulty for follow-up utilization of macroporous resin for purification, and improves the column loading amount, reduces the number of column chromatography, maintains or even improves the purity of the final product, and lowers the production cost.

Owner:NEW FOUNDER HLDG DEV LLC +2

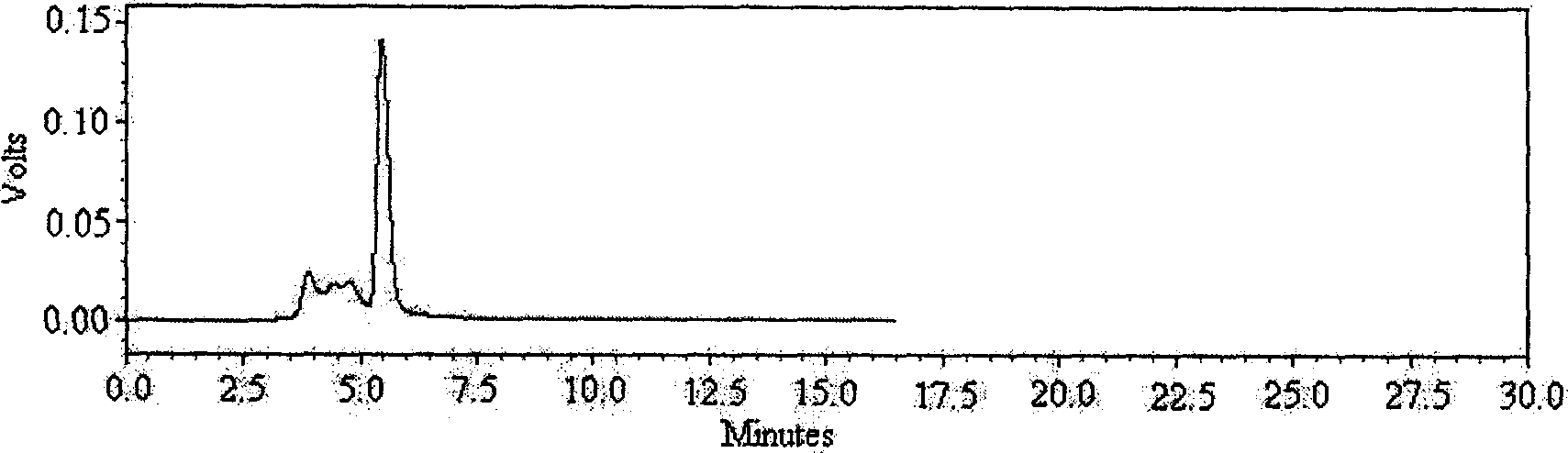

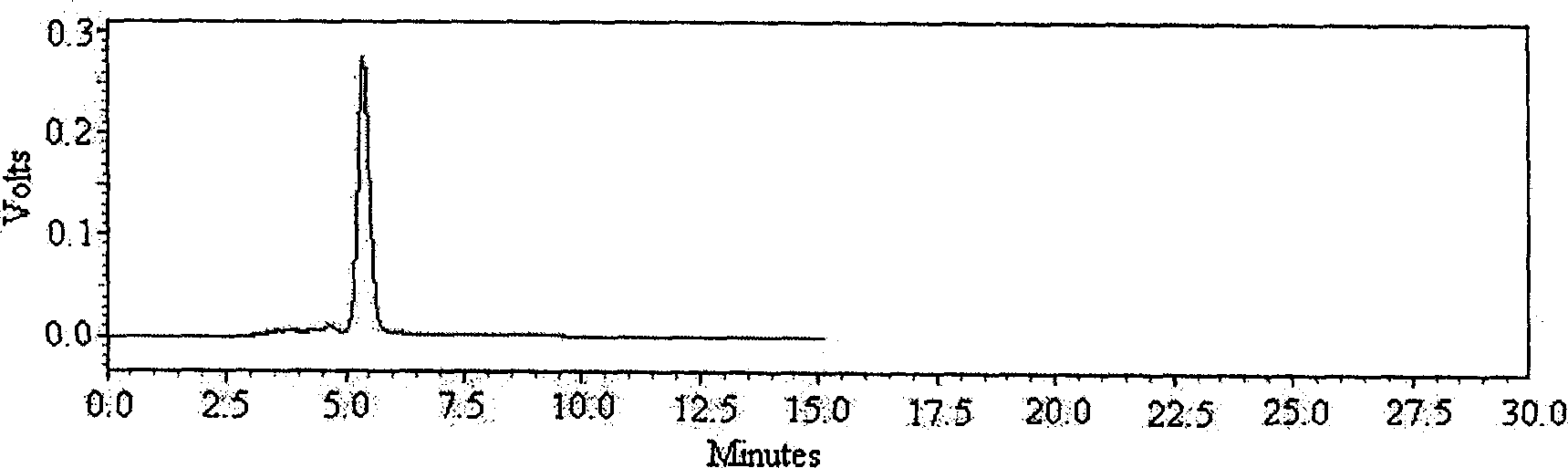

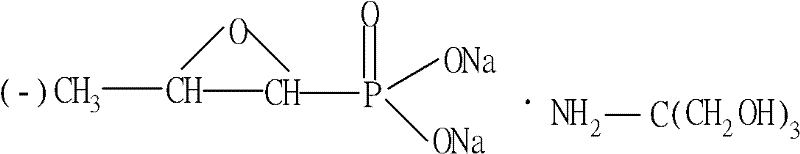

Preparation method of fosfomycin monoamine butantriol

InactiveCN102351902AImprove responseHigh product contentGroup 5/15 element organic compoundsOrganic solventMedicinal chemistry

The invention provides a preparation method of fosfomycin monoamine butantriol. The method comprises the following steps of: adding fosfomycin diamine butantriol salt into methanol, adding acid to adjust the pH to be between 4 and 7 at the temperature of between 5 DEG C below zero and 30 DEG C, filtering, removing filter residue, adding an organic solvent into the filtrate to separate out crystal, filtering, drying, and thus obtaining a fosfomycin monoamine butantriol finished product. The method is simple in reaction, the yield can reach 85 to 90 percent, the product content (the detection content can reach over 99 percent) is high, and the method is suitable for industrialized production and has great application value.

Owner:SHANXI C&Y PHARMACEUTICAL GROUP CO LTD

Method for preparing high-purity chondroitin sulfate

The invention discloses a method for preparing chondroitin sulfate, which comprises the following steps: boiling animal cartilage, performing enzymolysis and filtering to obtain enzymolysis liquid; subjecting the enzymolysis liquid to ultrafiltration concentration to obtain primary concentrate; passing the primary concentrate through cation exchange resin, and collecting effluent; washing the cation exchange resin with water, and collecting and mixing effluent; subjecting the effluent to ultrafiltration concentration to obtain secondary concentrate; and precipitating the secondary concentrate in ethanol, dewatering and drying to obtain chondroitin sulfate. The method disclosed by the invention has the advantages of high selectivity, high product purity, high yield, low energy consumption, low ethanol consumption, mild process conditions, simple operation and the like.

Owner:ZHEJIANG UNIV OF TECH +1

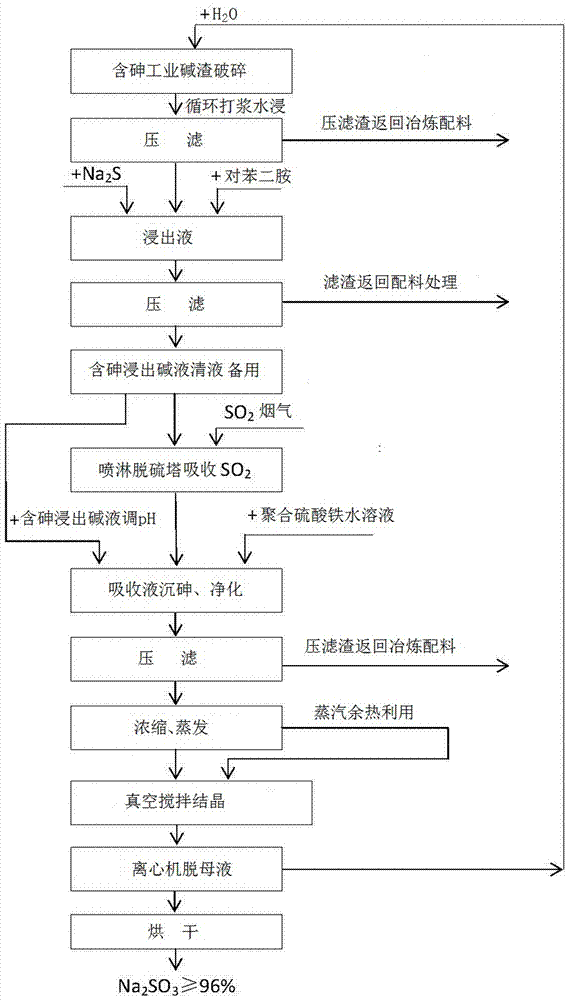

Technique for producing sodium sulfite products by absorption of SO2 flue gas through arsenic-containing industrial alkali residue water alkali liquor and arsenic removal purification

InactiveCN107963642AHigh product contentIncrease contentAlkali metal sulfite preparationSulfite saltFiltration

A kind of technological method of using arsenic-containing industrial alkali slag to absorb SO2 flue gas, remove arsenic and purify to produce sodium sulfite product. After treatment with p-phenylenediamine, press filter to obtain arsenic-containing leaching lye for later use, pump the clear liquid into the spray desulfurization tower to absorb SO2 flue gas, reduce the pH value of the absorption solution to 6.2-6.4, and then add arsenic-containing leaching lye After adjusting the pH value of the clear liquid to 10.5-11.5, adding polyferric sulfate aqueous solution for arsenic precipitation, pressure filtration for liquid-solid separation, clear liquid crystallization after concentration and evaporation, and drying after separating the mother liquor to obtain sodium sulfite products with a mass concentration ≥ 96% . This method starts with industrialized stable production, increases the content of sodium sulfite products as much as possible, optimizes the technical process and parameter selection, and has achieved obvious technological progress. Based on the annual output of 20,000 tons of alkali slag in the country, it can increase economic benefits by about 35 million The total amount of arsenic that can be removed and harmlessly treated is As 6%×20000=1200 tons / year, and the desulfurization is 4250 tons / year, resulting in huge environmental benefits.

Owner:YAN XIN ENVIRONMENTAL PROTECTION & TECH CO LTD

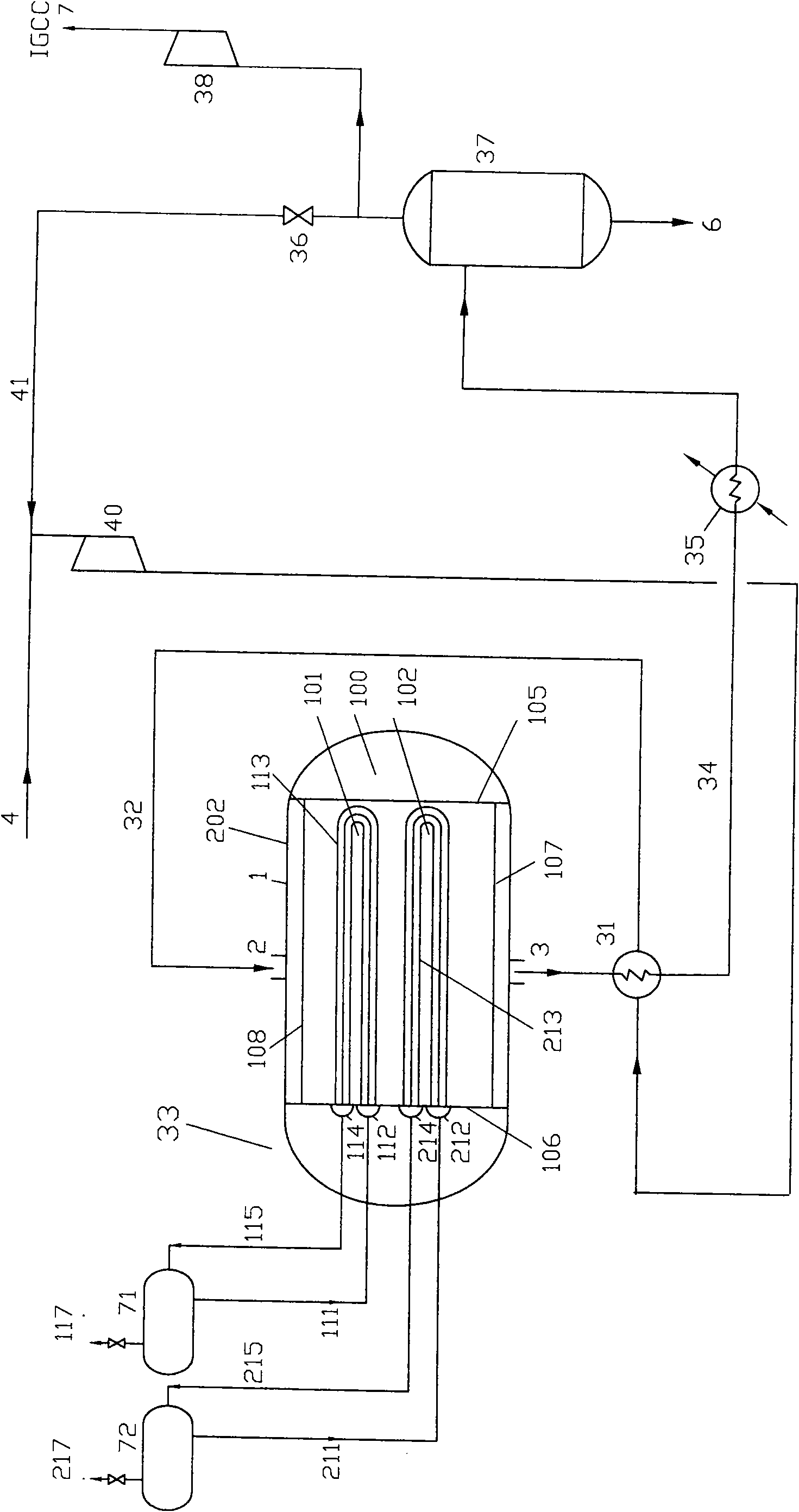

Chemical-electric poly-generation method and equipment

ActiveCN101659879AReduce power consumptionReduce consumptionInternal combustion piston enginesOrganic compound preparationChemical synthesisCompound (substance)

The invention discloses a synthetic gas gasified by carbon-contained raw materials through gasifying agents such as water, oxygen, carbon dioxide and the like. The synthetic gas is chemically synthesized to obtain a chemical product; the synthetic gas not synthesized is used as fuel to be transmitted to an IGCC fuel gas / steam combined circulating generating system; and the synthetic gas is also transmitted into the steam for generating power in gasification, purification and chemical synthesis by the steam produced by reaction heat. The invention obviously enhances the energy utilization rate,increases the productivity, reduces investment and cost and obviously enhances the economic benefit.

Owner:杭州林达化工技术工程有限公司

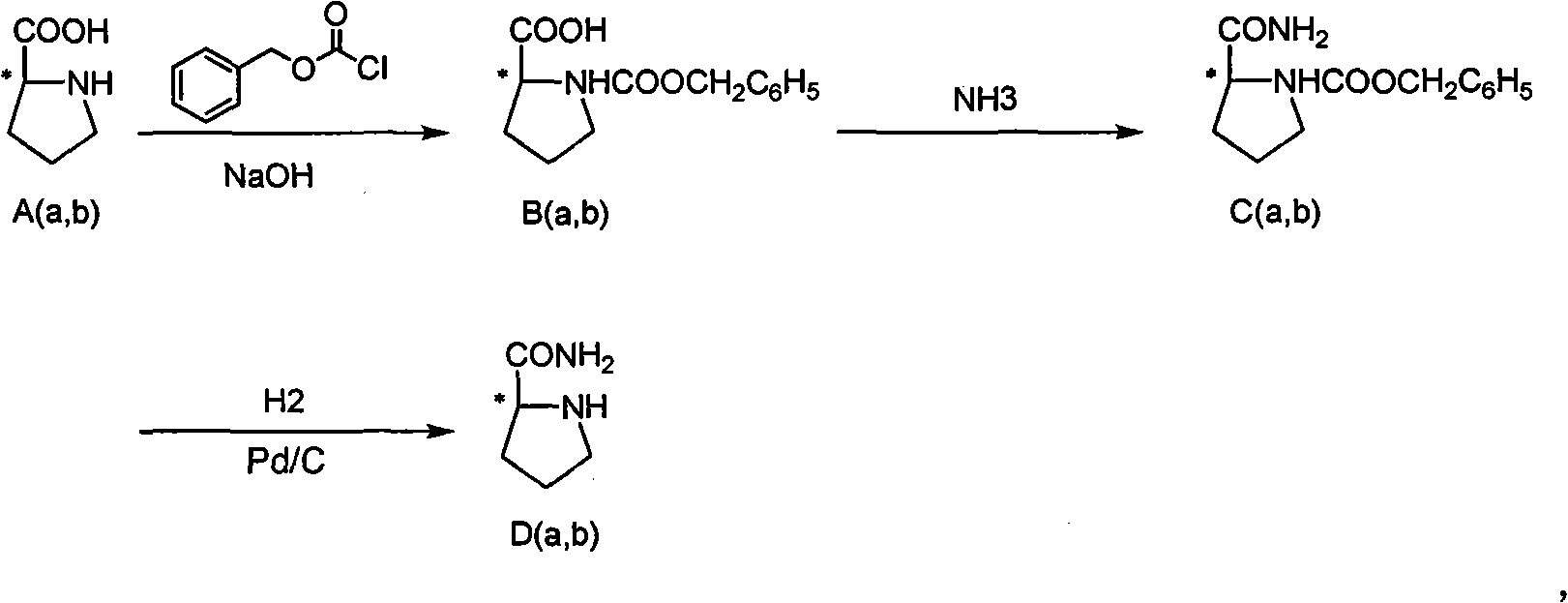

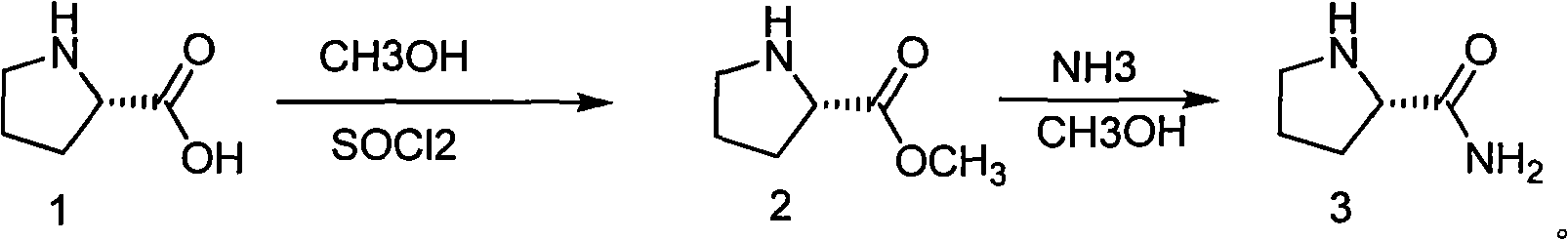

Method for refining prolinamide

The invention relates to a method for refining prolinamide, which includes the following steps: (a) dissolving prolinamide coarse product in an organic solvent, wherein the prolinamide coarse product contains ammonium chloride, prolinamide hydrochloride or mixture thereof; (b) adding inorganic alkali for treatment; and (c) separating to obtain the prolinamide. The method for refining prolinamide is simple, the content and optical purity of the obtained product are high, and the method is very suitable for industrial production.

Owner:ZHEJIANG HUAHAI PHARMACEUTICAL CO LTD

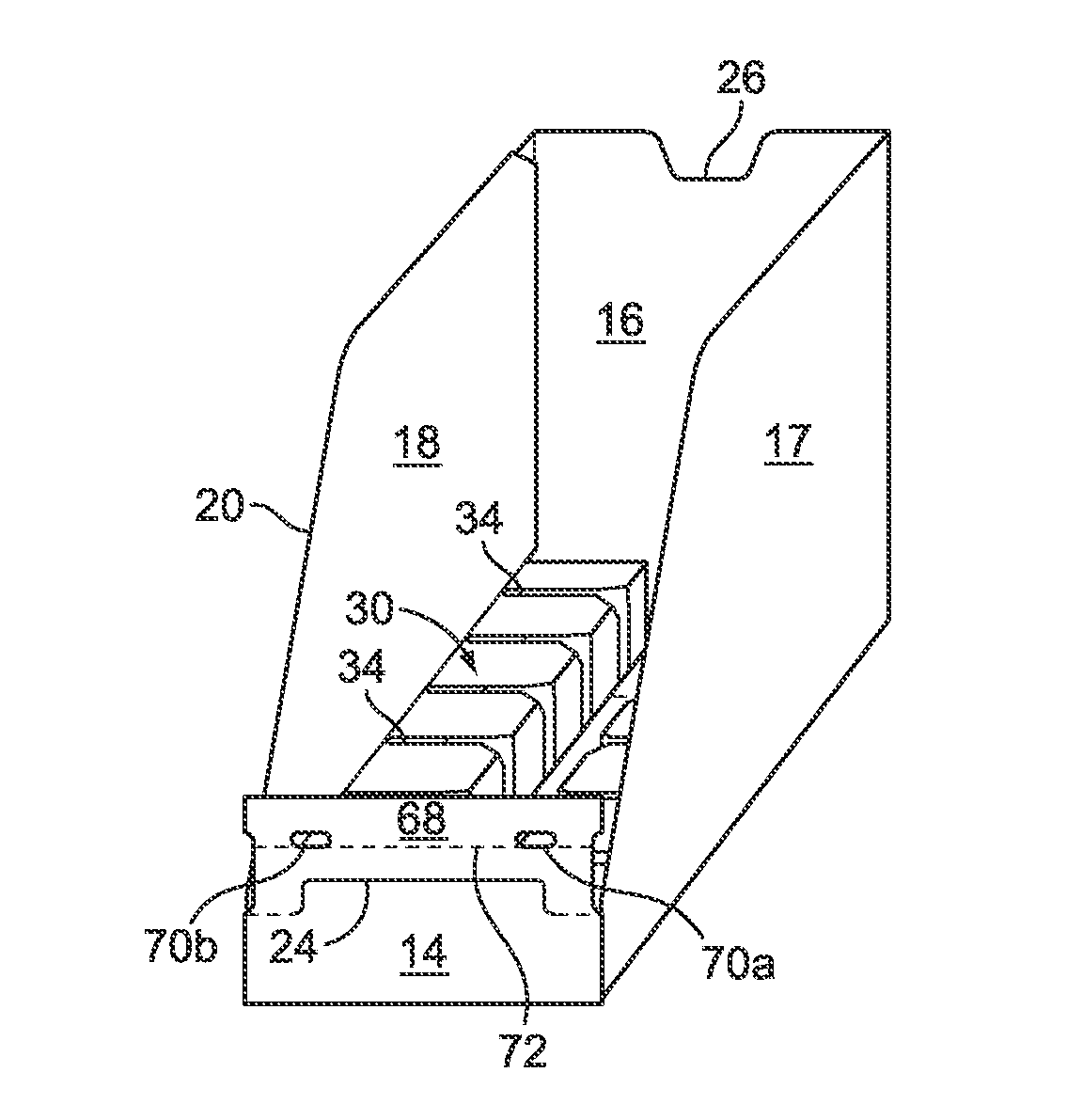

Shipping and display tray with article support

ActiveUS8281927B2Easy removal and possible replacementEffective timeOther accessoriesTray containersCardboardDisplay device

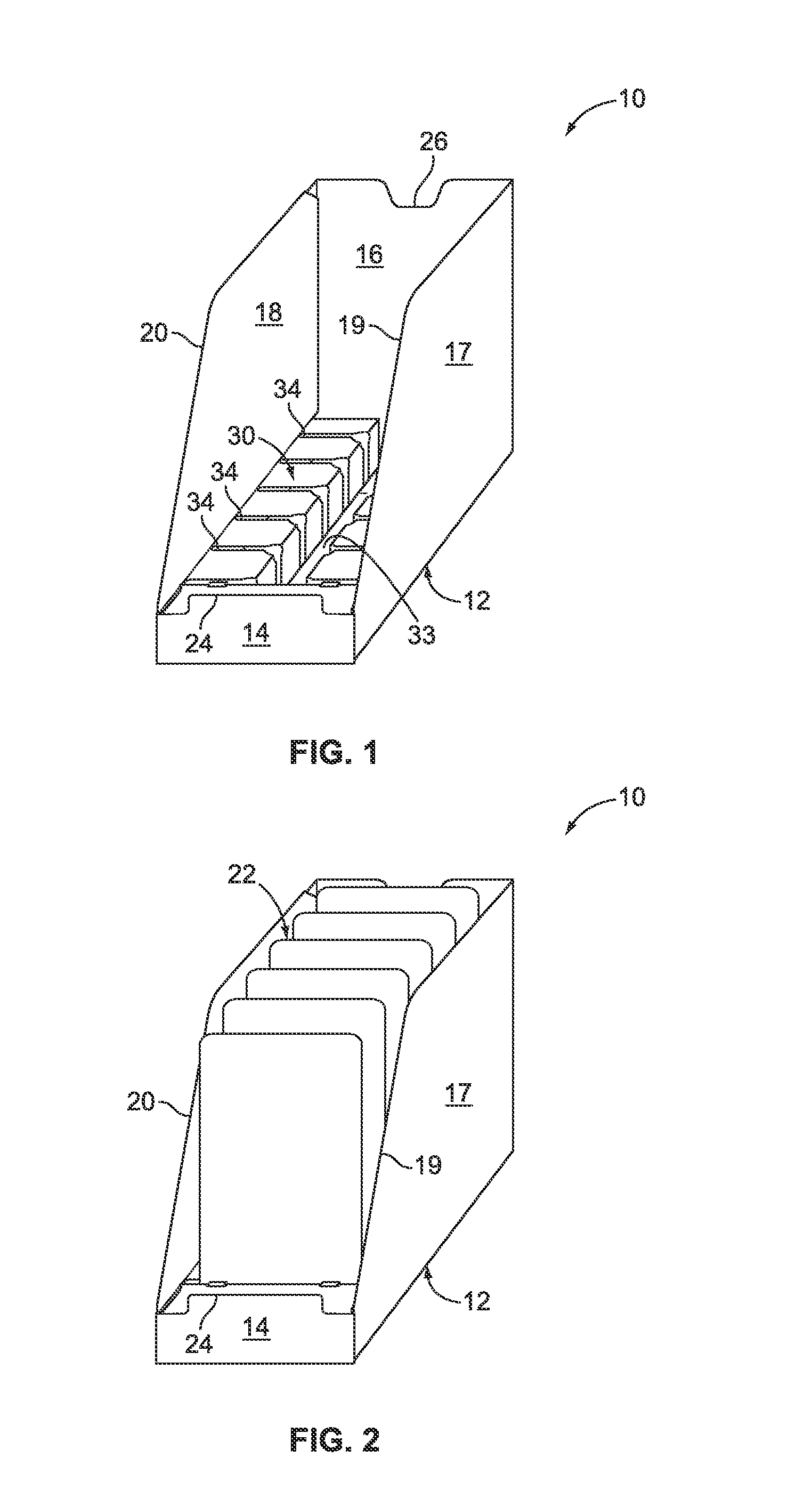

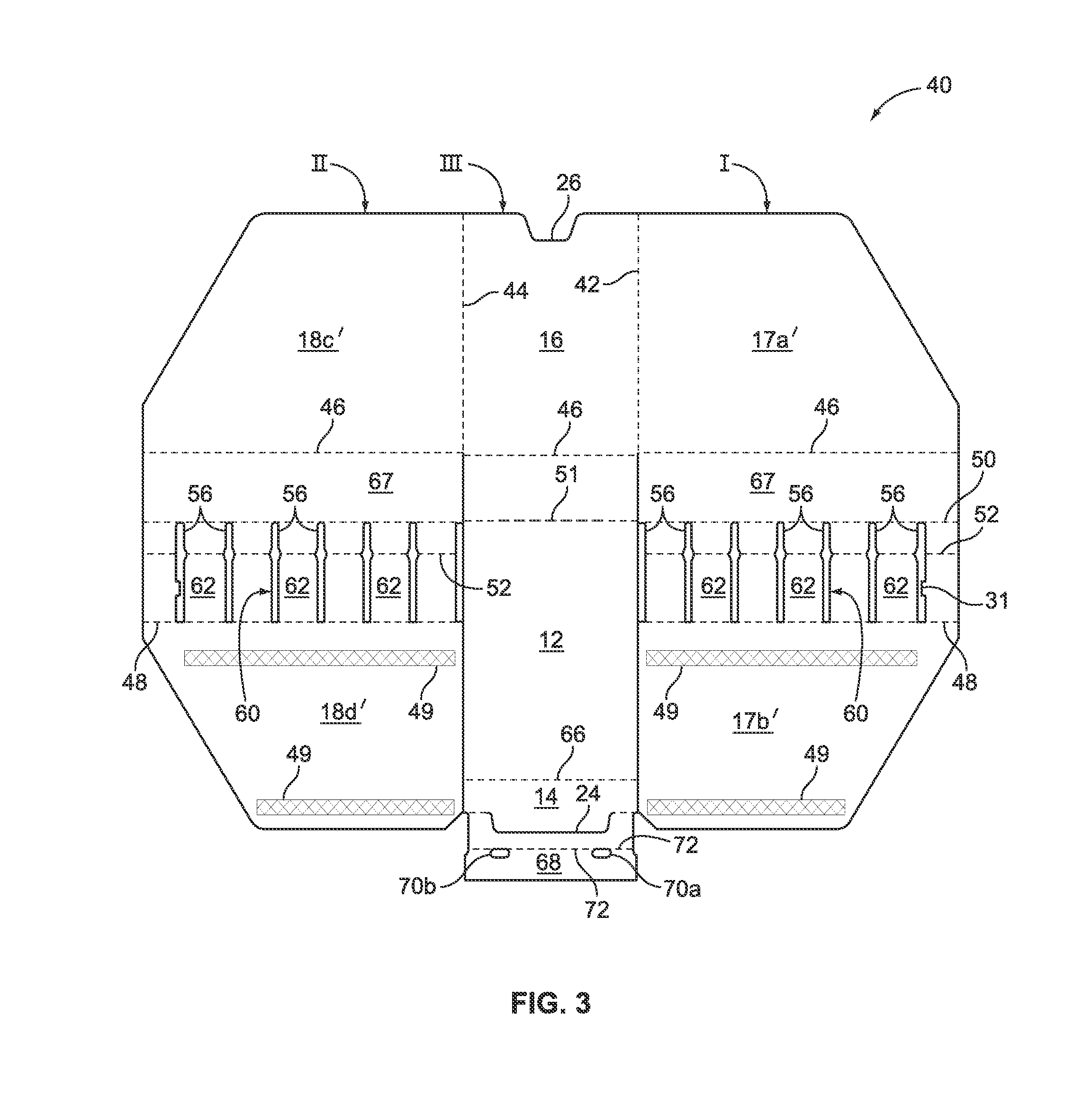

The present invention is directed to a shipping and display tray for holding a plurality of articles contained therein in an upright position at a point of sale. The shipping and display tray is made of paperboard and defined by a one-piece shallow tray having a bottom wall, a front wall, a back wall, and opposite side walls foldably joined with one another. A plurality of parallel spaced apart bumpers are foldably joined to the respective opposite side walls and forming two rows, an aisle, and a plurality of channels when positioned on the bottom wall. The plurality of the channels engages with bottom edges of the plurality of articles to hold the article in standing upright position and prevent the articles from falling over when one of the articles is removed from the display tray. The front wall of the tray includes a flap panel foldably joined thereto and has a pair of openings used to engage with the bumpers.

Owner:INT PAPER CO

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com