Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

287results about "Alkali metal sulfite preparation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

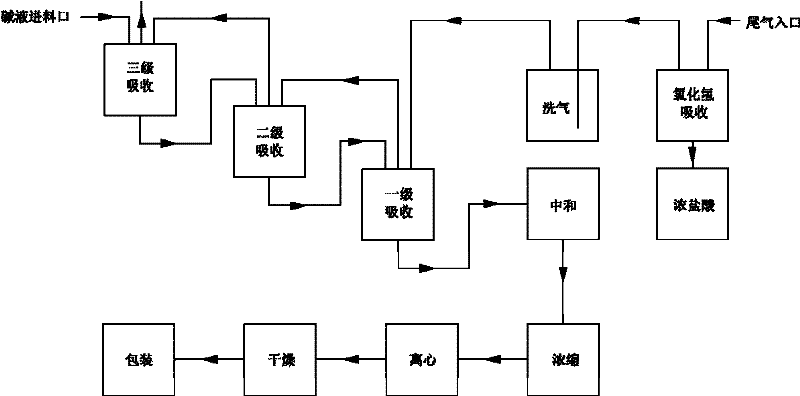

Comprehensive treatment method of sulfur-containing flue gas

ActiveCN101637685AImprove purification qualityAchieving zero emissionsCombination devicesUsing liquid separation agentChemical industryFlue gas

The invention belongs to the technical field of chemical industry, in particular to a comprehensive treatment method of sulfur-containing flue gas. The comprehensive treatment method comprises the following steps: (a) dedusting through a bath tower; (b) desulphurizing through a desulphurizing and absorbing tower, wherein , dewatering the sulfur-containing flue gas after being treated by water washing and dedusting in the step (a). When the method is applied to purify the sulfur-containing flue gas, the efficiency of dedusting and removing sulfur dioxide and hydrogen sulfide reaches 100 percent, thus zero discharge of pollutants in exhaust smoke can be realized.

Owner:CHENGDU DEMEI ENG TECH

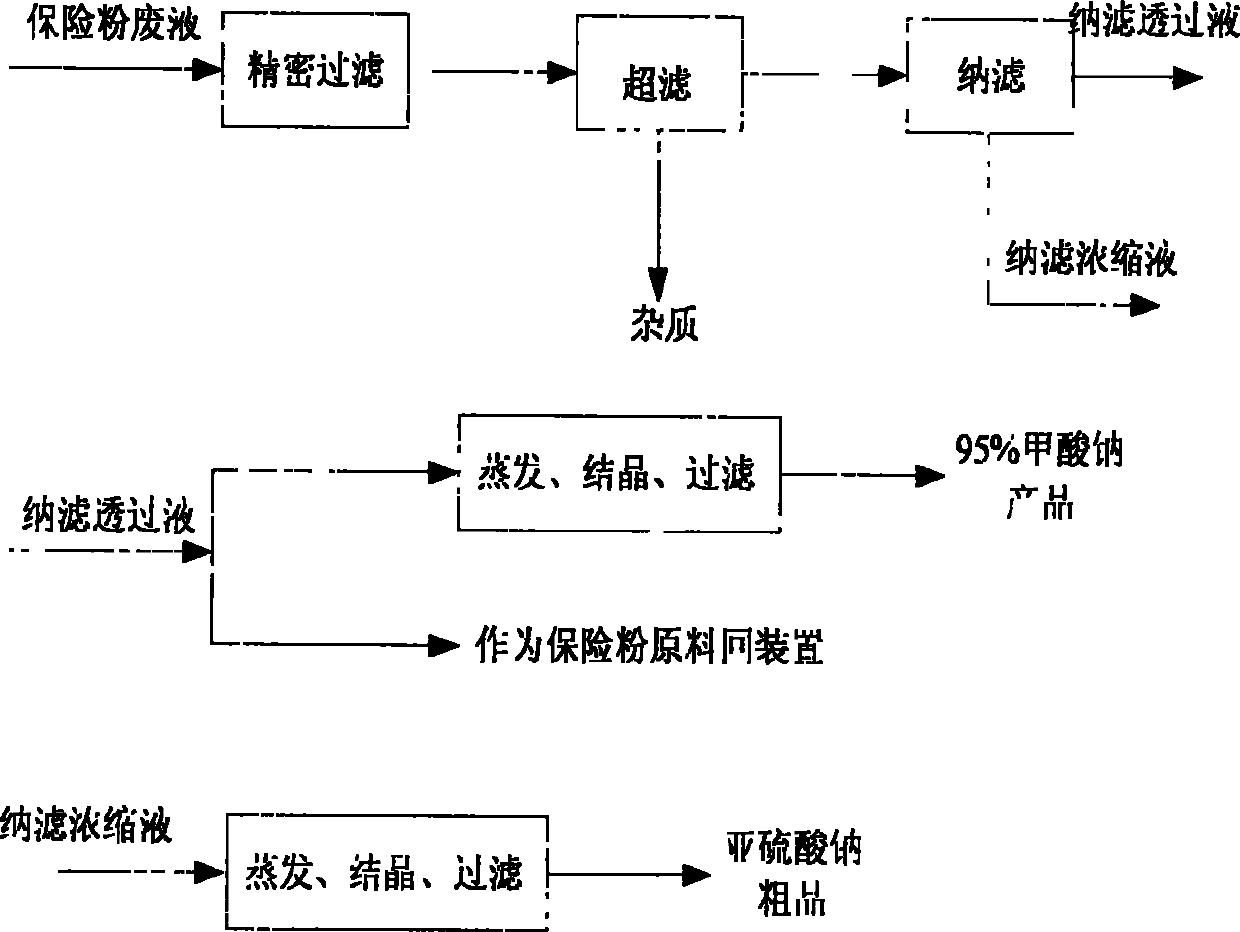

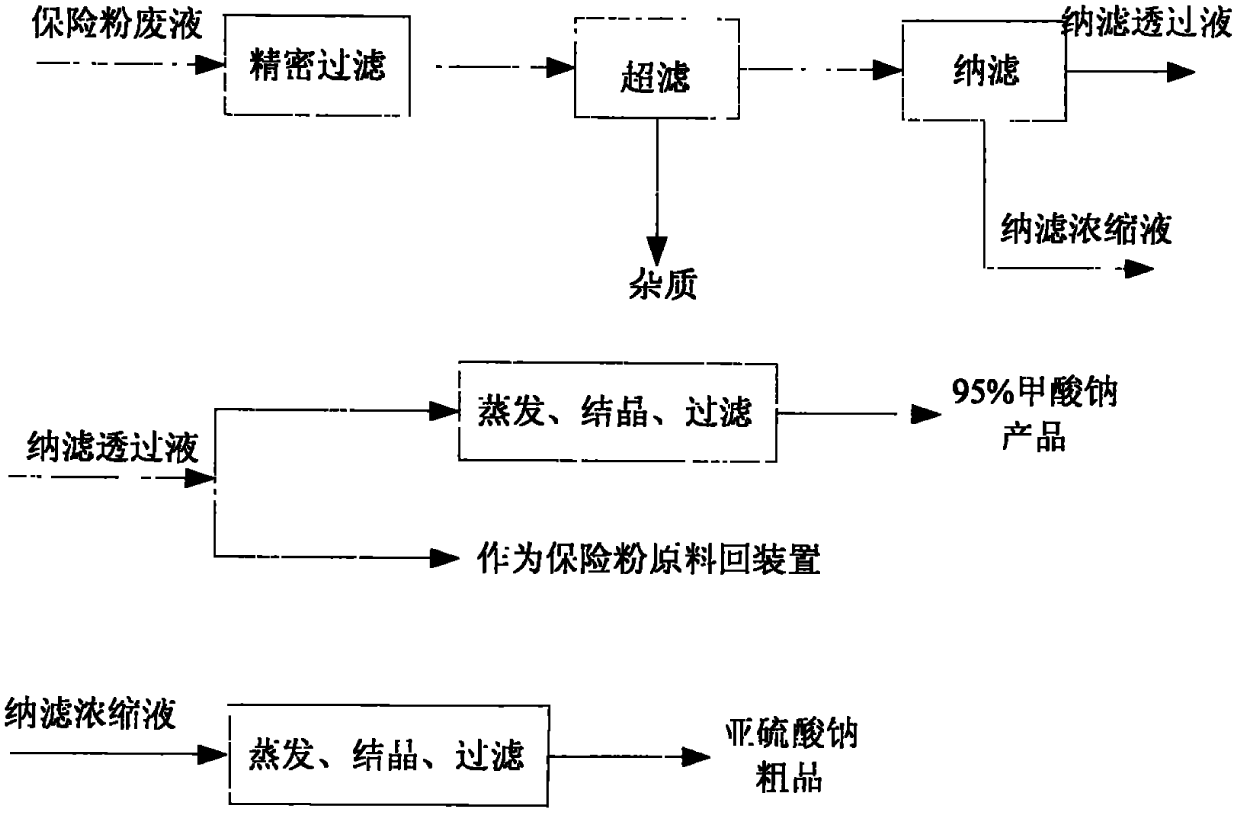

Method for recycling sodium formate and sodium sulfite from waste sodium hydrosulfite liquid with sodium formate method

InactiveCN102050471ANo secondary pollutionHigh purityAlkali metal sulfite preparationMultistage water/sewage treatmentUltrafiltrationFiltration

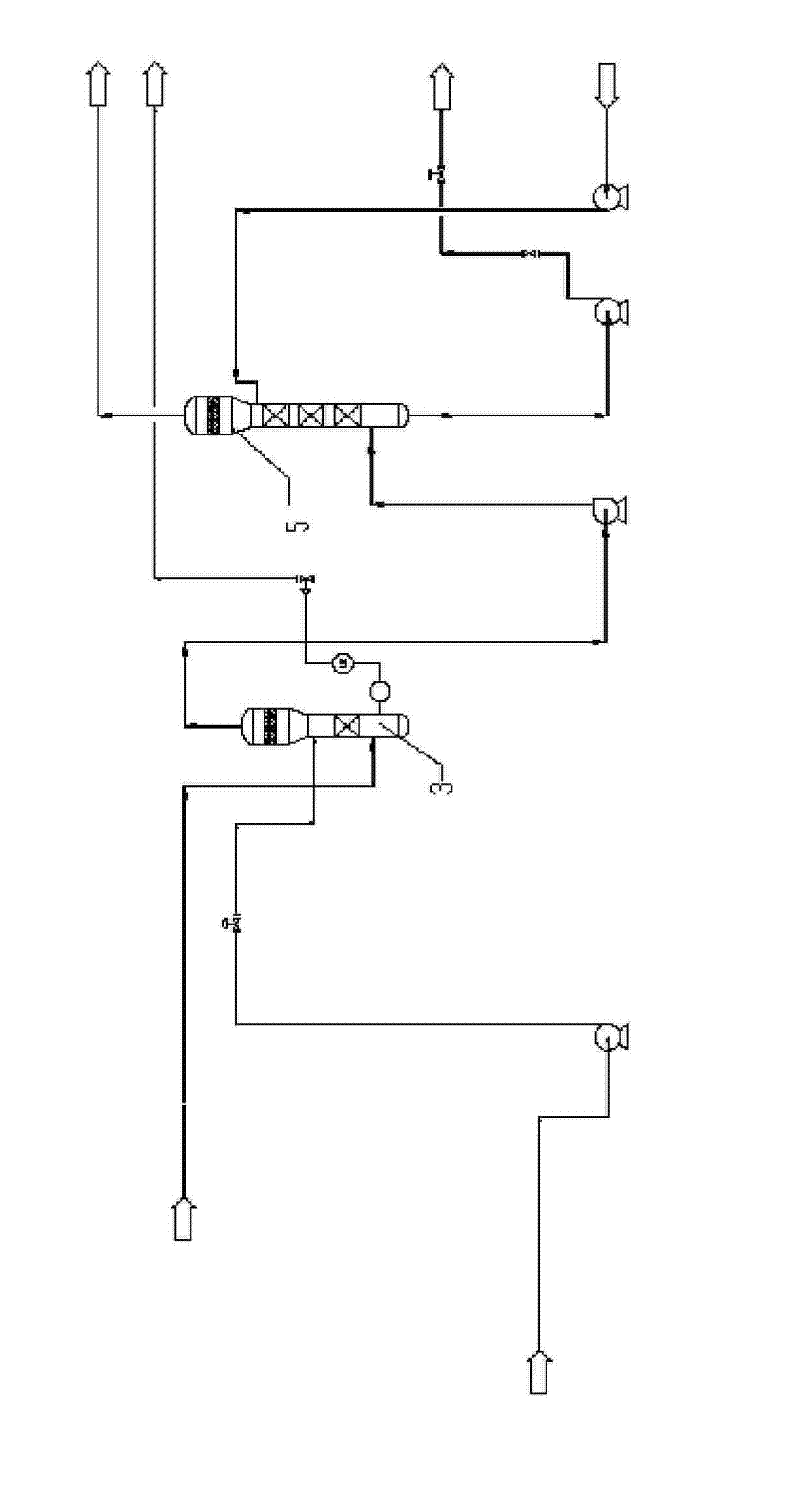

The invention relates to a method for recycling sodium formate and sodium sulfite from waste sodium hydrosulfite liquid with a sodium formate method. The method comprises the following steps of: carrying out precise filtration and ultrafiltration on waste sodium hydrosulfite liquid with the sodium formate method to remove insoluble substances and granular impurities in the liquid; and then introducing the liquid into a nanofiltration device for nanofiltration separation, wherein after being evaporated and concentrated, an obtained nanofiltration permeate solution can be used as a raw material of the sodium hydrosulfite and returned to a sodium hydrosulfite production station, and can also be continuously evaporated, concentrated, crystallized, centrifuged and filtered to obtain a sodium formate product of which the purity is higher than 95 percent; and an obtained nanofiltration concentrated solution can be introduced into an evaporator for concentrating and then is crystallized, centrifuged and filtered to obtain a crude sodium sulfite product. The method has the technical advantages of no secondary pollution, high purity of the sodium formate, simple process and easiness for industrial realization, wherein the purity can be up to higher than 95 percent.

Owner:YANTAI UNIV

Soda wet desulphurization process and system for sintering flue gas

InactiveCN102160960ASimple processImprove desulfurization efficiencyDispersed particle separationAlkali metal sulfite preparationSulfite saltFlue gas

The invention discloses a soda wet desulphurization process and a soda wet desulphurization system for sintering flue gas, and solves the problems of severe pollution and the like in the prior art. Sodium carbonate serves as a desulfurizing agent, and a desulfurization by-product is sodium sulfite; and the process comprises the following steps of: (1) cooling and introducing sulfur-containing flue gas into a desulfurizing tower; and (2) purifying the sulfur-containing flue gas in the step (1) in the desulfurizing tower by taking solution of sodium carbonate or sodium hydroxide as an absorbent, demisting the purified flue gas through a demister and discharging. The process is simple in procedures, high in desulphurization efficiency, high in response speed and high in value of the desulfurization by-product, and saves energy and land.

Owner:HUATIAN ENG & TECH CORP MCC

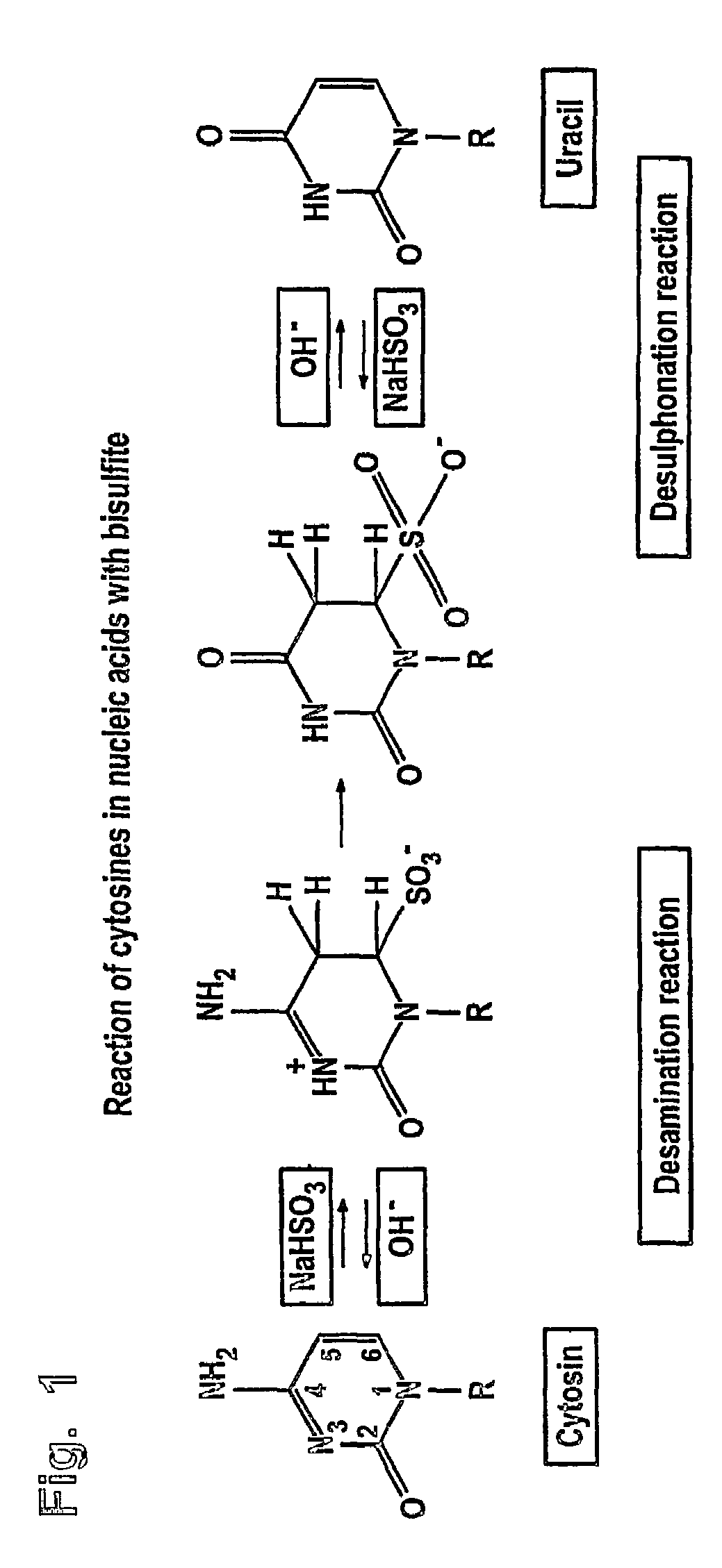

Method for bisulfite treatment

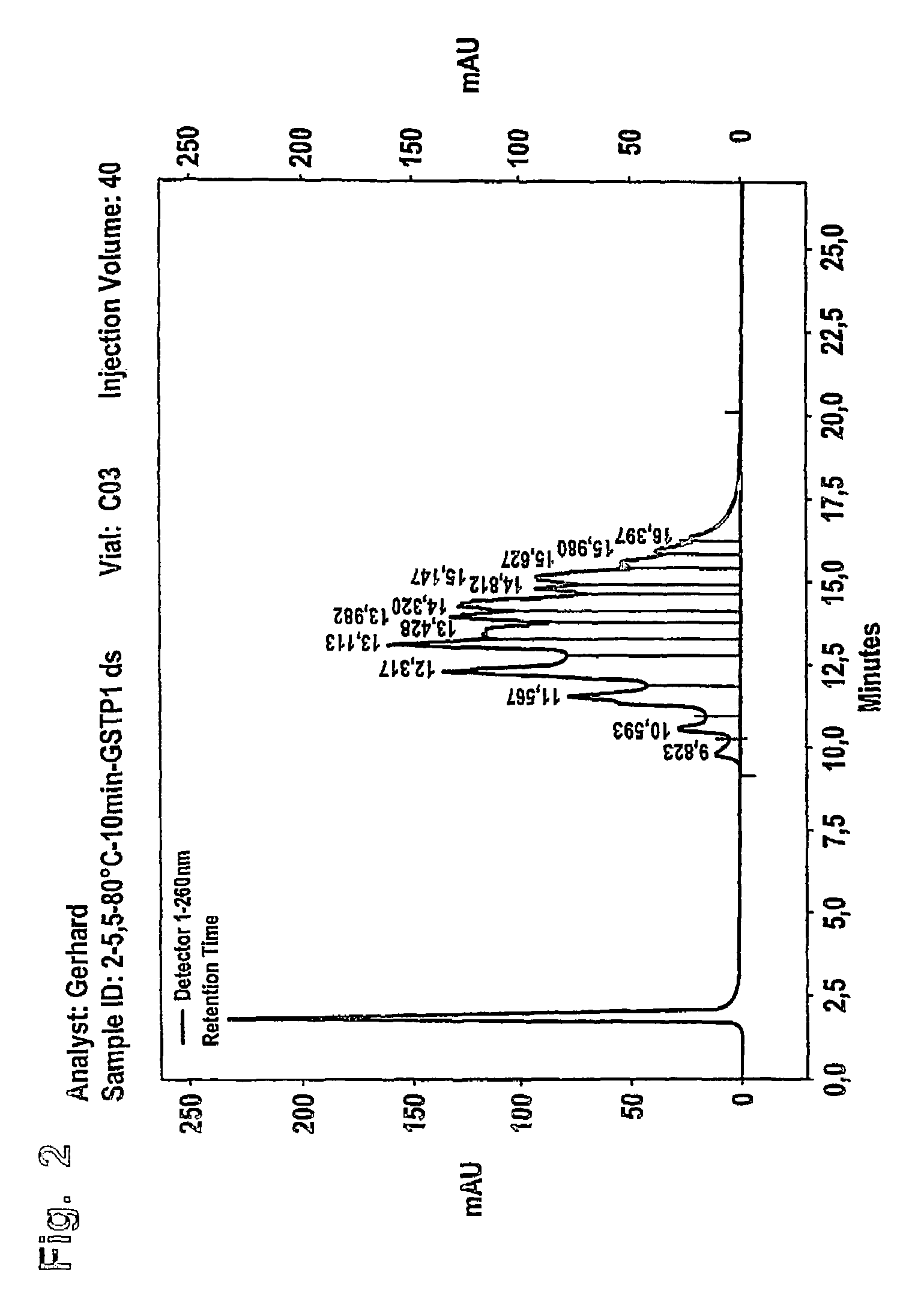

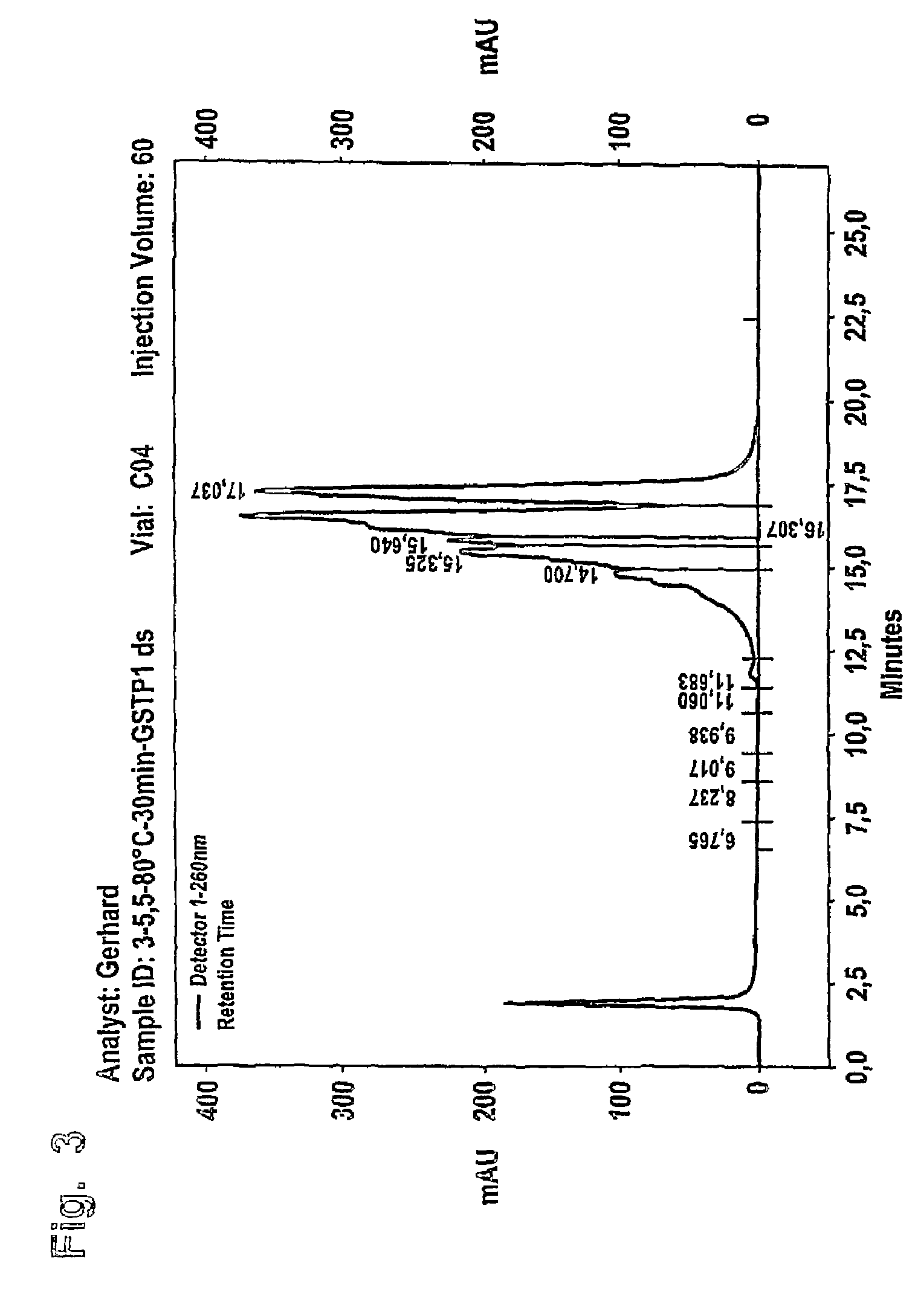

InactiveUS7413855B2Short reaction timeReduce processSugar derivativesMicrobiological testing/measurementCytosineBisulfite

Owner:ROCHE MOLECULAR SYST INC

Recycling process for preparing taurine through ammonolysis of sodium hydroxyethanesulfonate

ActiveCN109020839ASolve the problem of three wastes pollutionIncrease incomeSulfonic acids salts preparationEnergy inputLiquid wasteTaurine

Owner:吴江

Environment-friendly production process of 2-naphthol

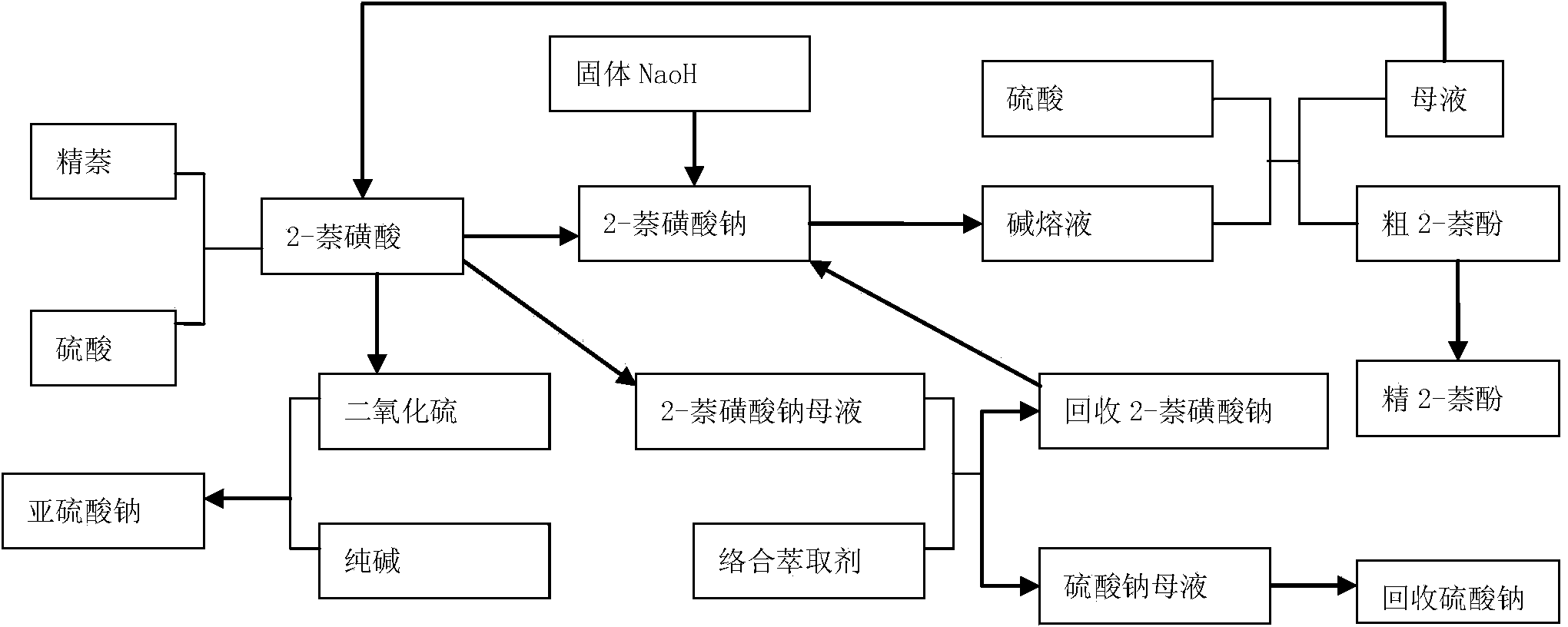

ActiveCN103626637AHigh yieldMeet the needs of industrial productionOrganic chemistryOrganic compound preparationEnvironmental resistanceSulfite salt

The invention relates to an environment-friendly production process of 2-naphthol. The environment-friendly production process of the 2-naphthol comprises the following steps: adding refined naphthalene into a sulfonation kettle, adding concentrated sulfuric acid, heating and performing sulfonation reaction, neutralizing a mixture by using alkali after the reaction is finished, crystallizing, filtering, drying, performing alkali fusion and diluting; neutralizing the diluted alkali fused sulfonation liquid by using sulfuric acid at 70 to 80 DEG C, controlling the pH to be 4 to 7, standing and layering, and separating out crude 2-naphthol; washing, dehydrating and rectifying the separated crude 2-naphthol to obtain refined 2-naphthol; and removing alkali from the separated waste liquid, neutralizing to serve as alkaline liquid, absorbing sulfur dioxide generated by neutralization by using a sodium carbonate aqueous solution to produce sodium sulfite, adjusting the pH value of the waste liquid after 2-sodium naphthalene sulfonate is separated to be 2+ / -1, performing three-stage extraction by using an extracting agent, performing reverse extraction on the extracting liquid by using dilute alkali, diluting sulfonated liquid by using the reverse extraction liquid, oxidizing the water phase by using a Fenton reagent or KMnO4, decoloring by using active carbon, and recovering sodium sulfate by a mechanical vapor recompression (MVR) concentration technology. By the process provided by the invention, no waste water is discharged basically and the production cost is reduced.

Owner:青岛奥盖克化工股份有限公司

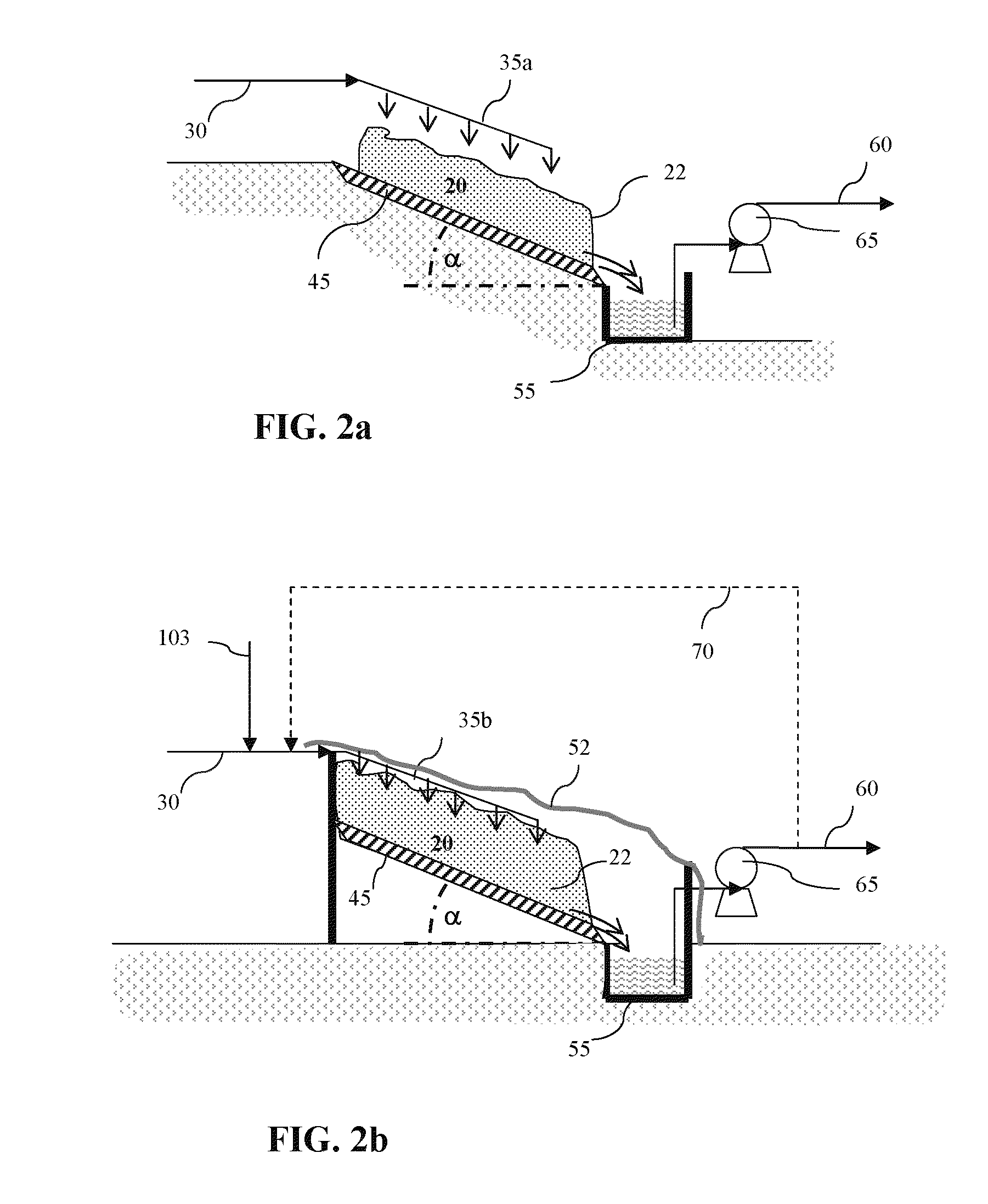

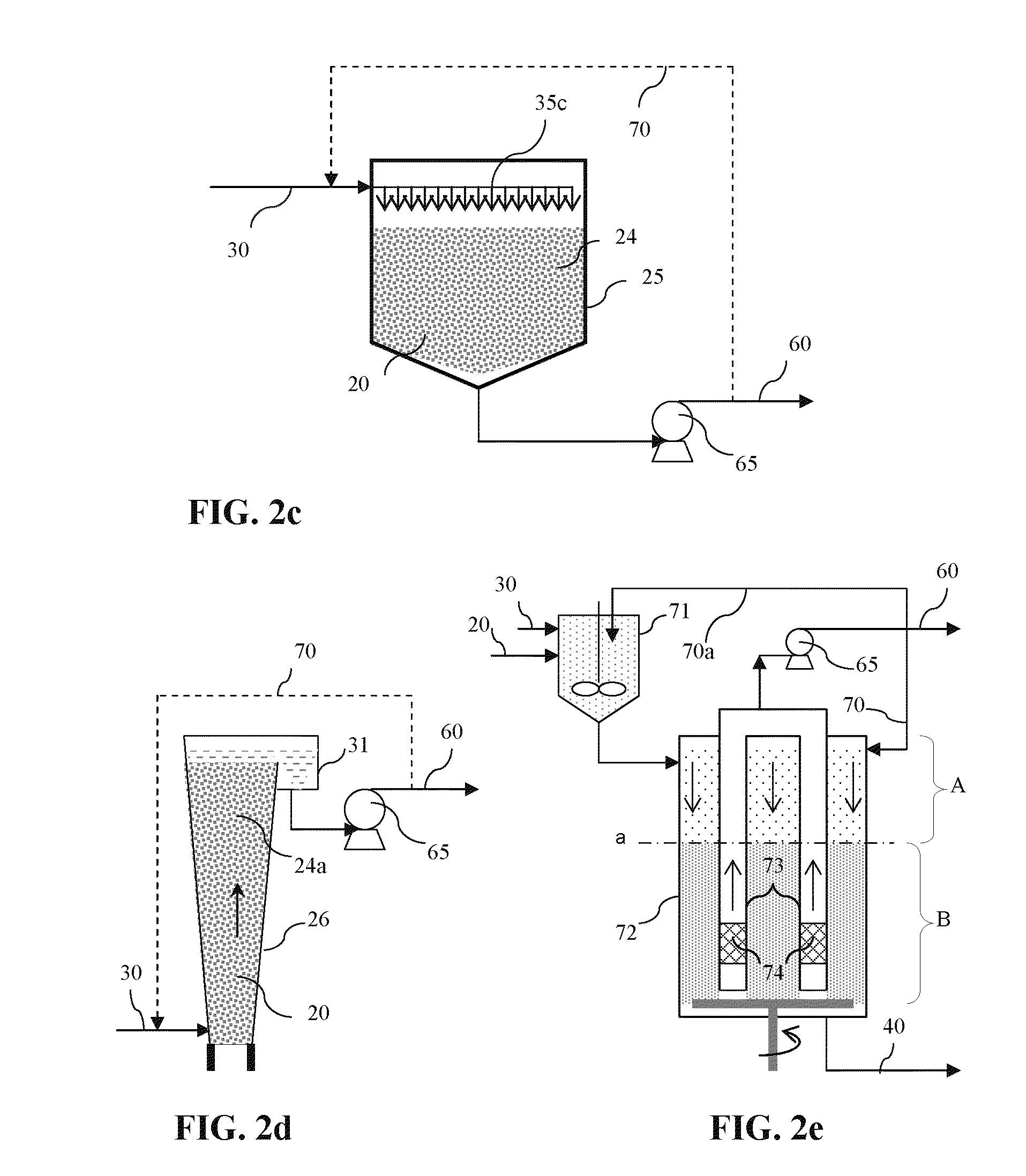

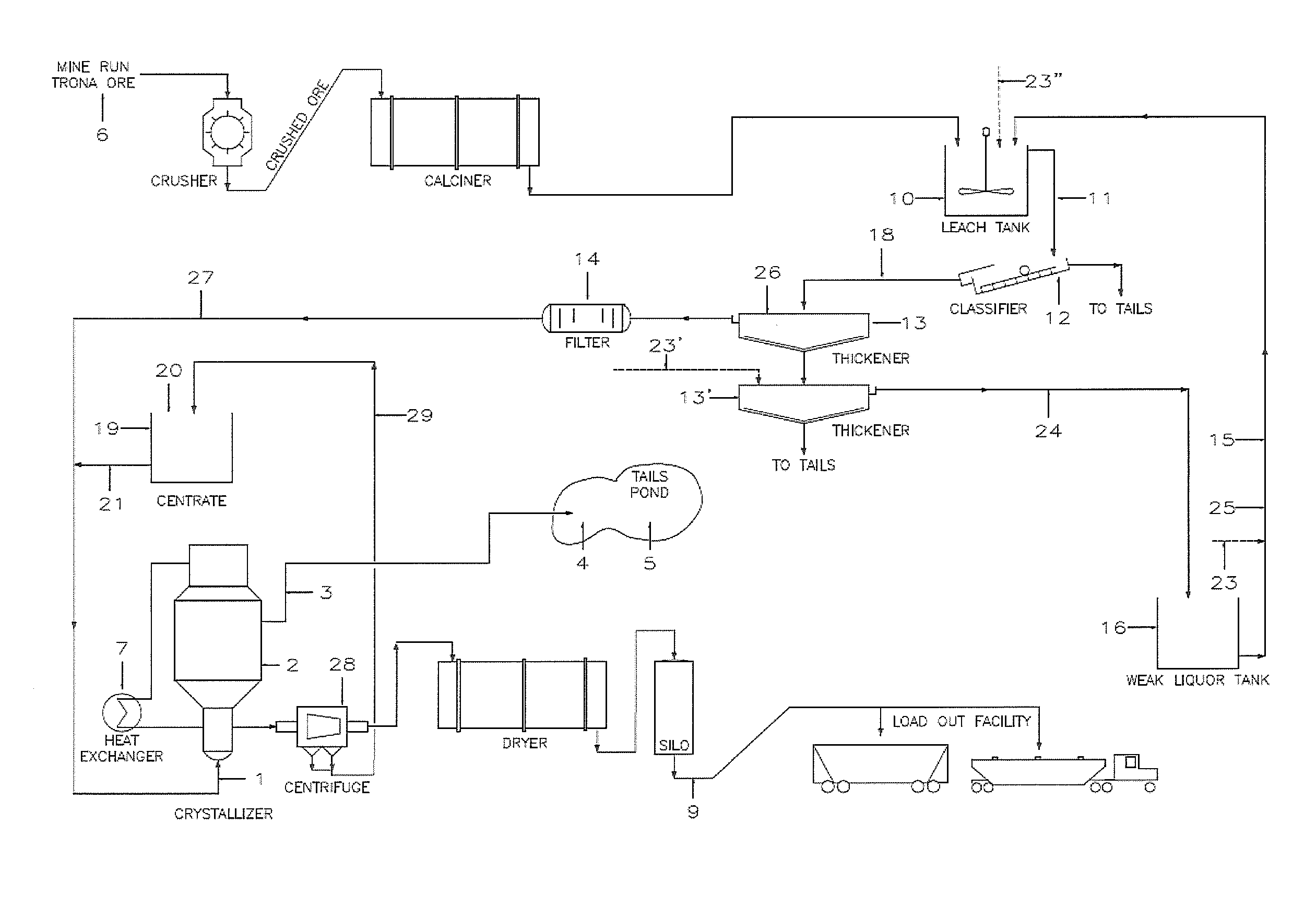

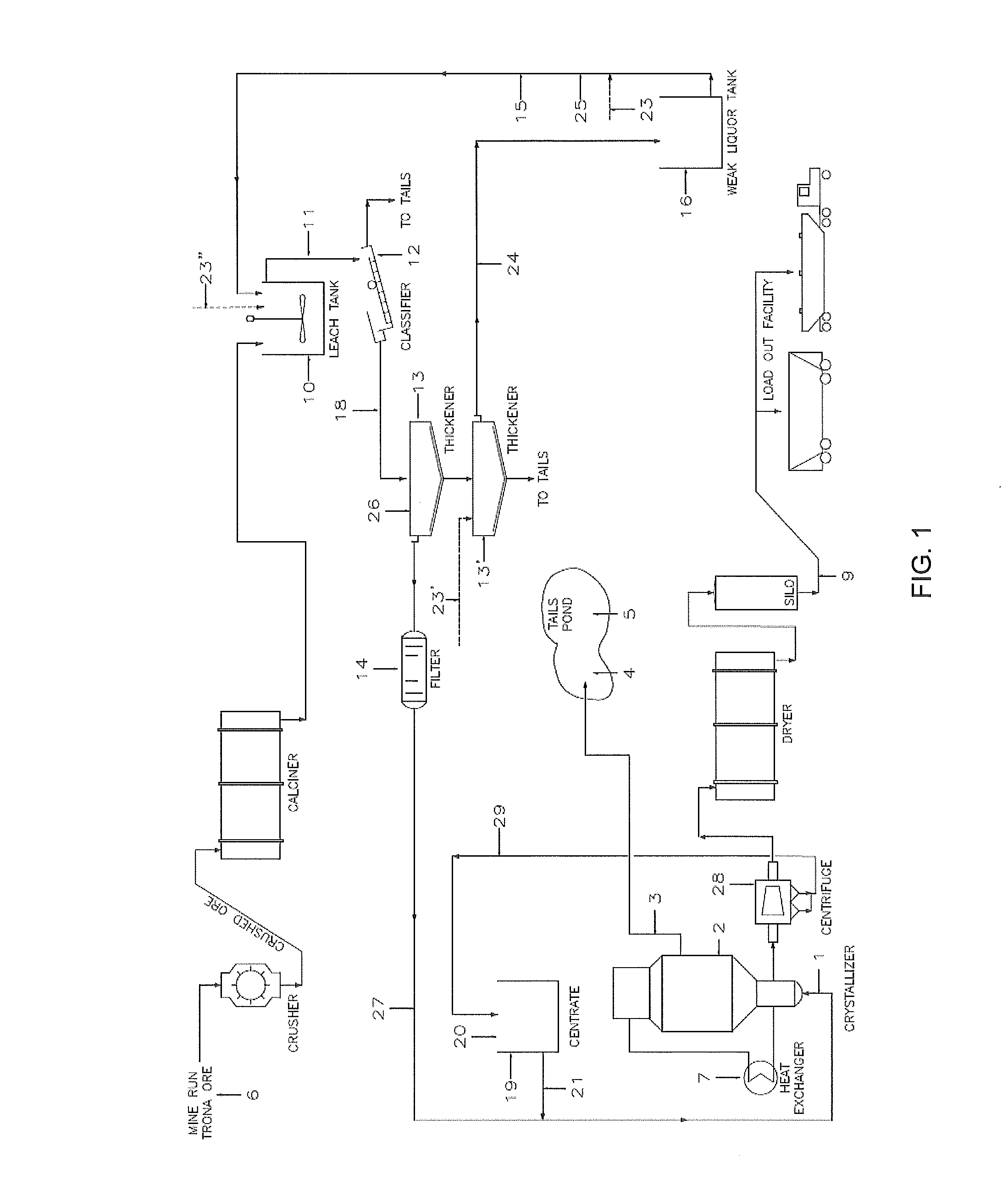

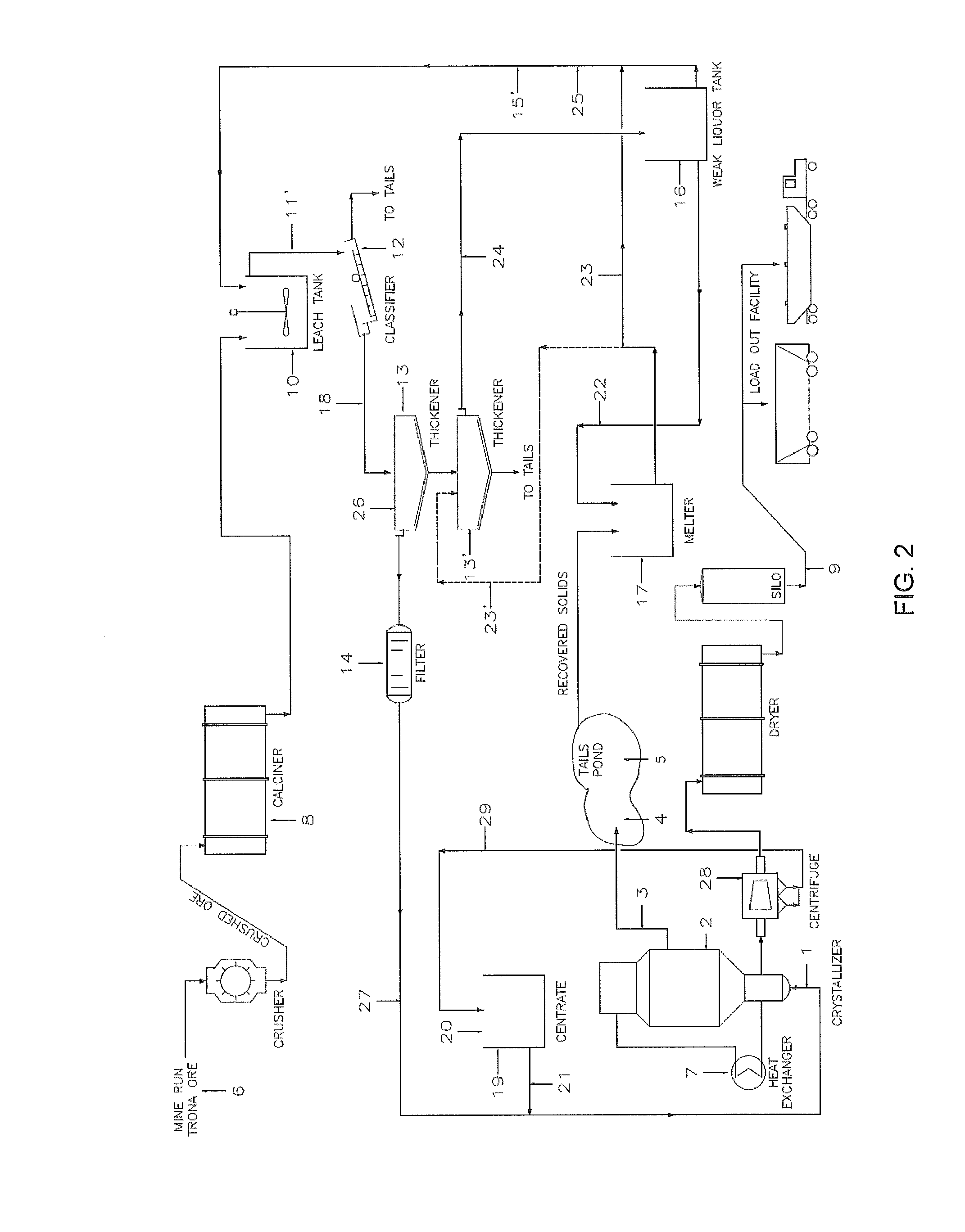

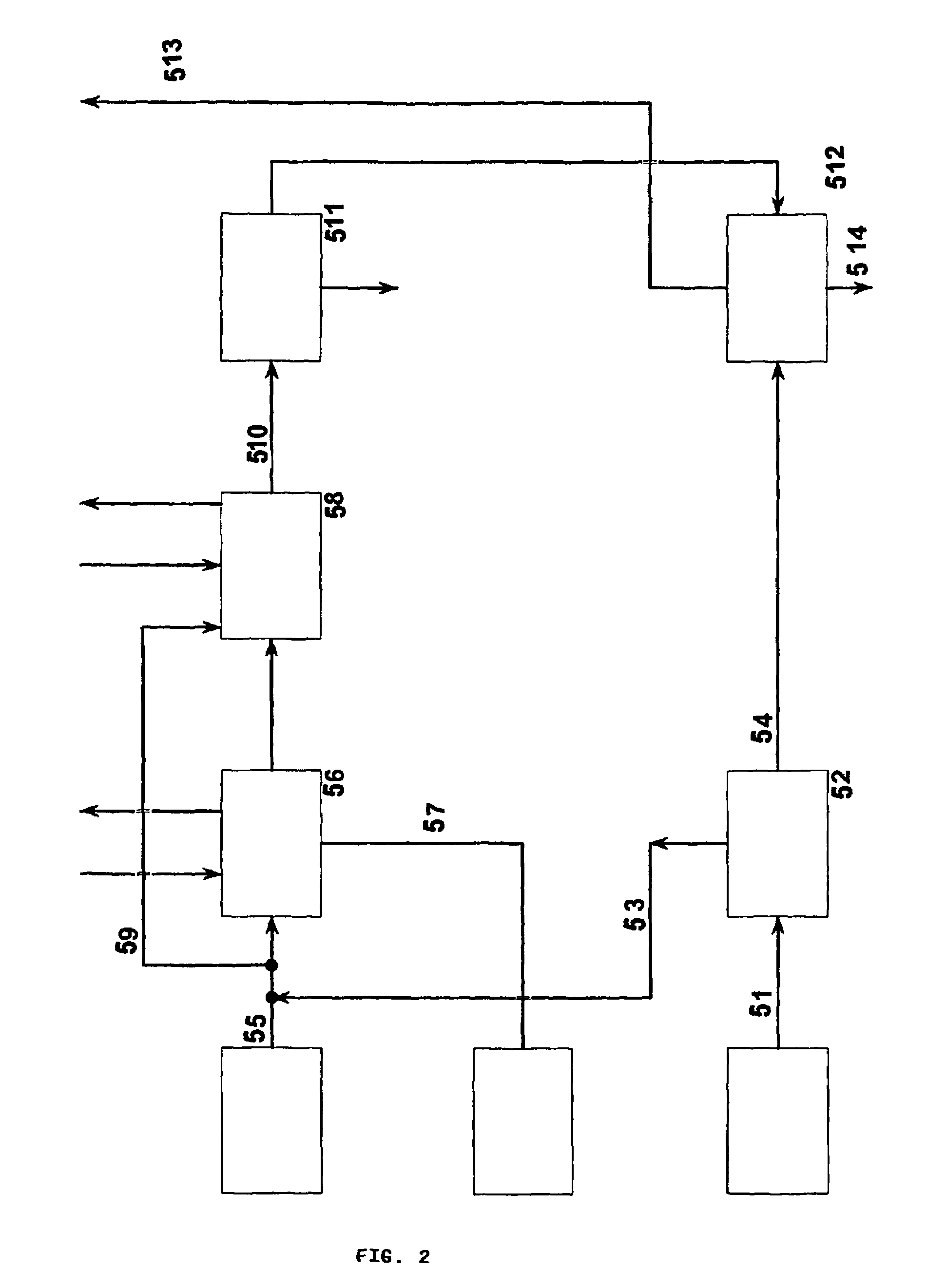

Impurities removal from waste solids in the production of soda ash, sodium bicarbonate and/or other derivatives

ActiveUS20110274599A1Low impurity contentIncrease valueBicarbonate preparationSolvent extractionSodium bicarbonateDissolution

A method for removing impurities from a waste solid to provide at least a portion of a suitable crystallizer feed to a process for making crystalline sodium carbonate, bicarbonate, and / or other derivatives. The method comprises: contacting the waste solid with a leach solution to dissolve at least one impurity and dissolving the resulting leached residue. Leaching may include heap percolation. The leach solution may comprise a crystallizer purge liquor, a process waste effluent, a mine water, or mixtures thereof. The method may further comprise adding a magnesium compound to the resulting leached residue during or after its dissolution to remove another impurity. The waste solid preferably comprises a pond solid containing such impurities. The pond solid may be recovered from a pond receiving crystallizer purge liquor(s) and / or other process waste effluent(s). The pond solid may contain sodium carbonate, any hydrate thereof, sodium bicarbonate, and / or sodium sesquicarbonate. The impurities to be removed may comprise sodium chloride, sodium sulfate, silicates, and / or organics.

Owner:SOLVAY CHEM INC

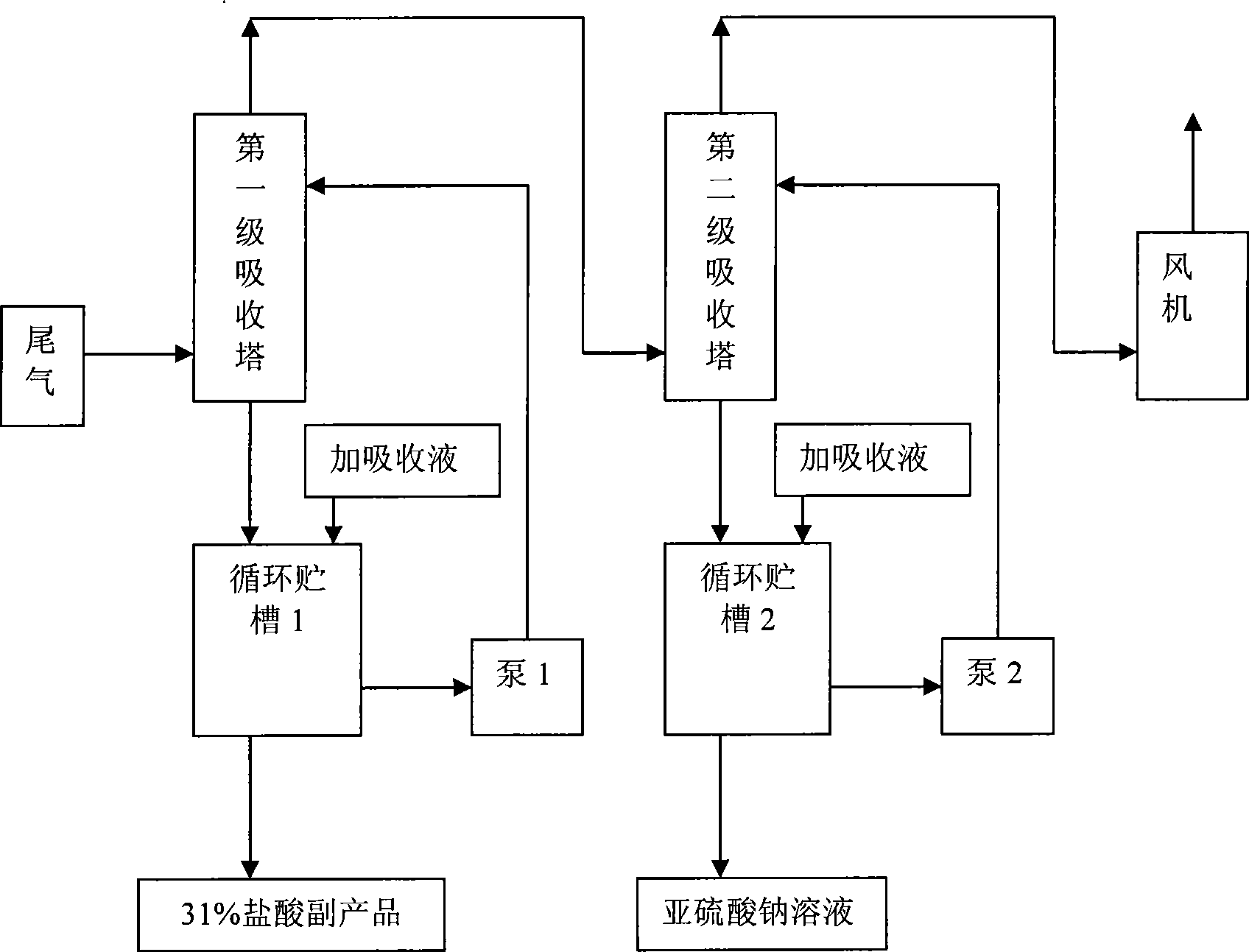

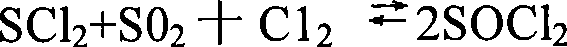

Method for preparing sodium sulphite with tail gas from thionyl chloride synthesis process

ActiveCN101412526ANo pollutionLow costDispersed particle separationAlkali metal sulfite preparationSulfite saltSodium sulfite

The invention provides a method for producing sodium sulfite by-products by utilizing tail gas separated in a filling area, a storage tank, a separator on the top of a rectifying tower and so on during the process of synthesis and rectification of thionyl chloride. The tail gas during the process of the rectification of the thionyl chloride in the method is absorbed by a primary absorption tower; an absorption liquid in the primary absorption tower is clear water or diluted hydrochloric acid; products discharged from the primary absorption tower are approximately 31 percent hydrochloric acid, and can be taken as industrial hydrochloric acid for sale or use; gas exhausted from the primary absorption tower passes through a secondary absorption tower; and an absorption liquid in the secondary absorption tower is an alkaline solution. The method absorbs and utilizes substances in the tail gas during the synthesis and the rectification of the thionyl chloride, so as to reduce environmental pollution during the synthesis of the thionyl chloride.

Owner:JIANGXI SELON INDAL

Removal of impurities in the production of crystalline sodium carbonate, bicarbonate, or sulfite

ActiveUS20100226840A1Reduce contentGood physical propertiesCrystallization separationAlkali metal sulfite/sulfate purificationSodium bicarbonateDicarbonate

A magnesium treatment for removing water-soluble impurities in a process for making crystalline sodium carbonate, bicarbonate, or sulfite. A waste comprising such impurities is treated with a magnesium compound to form water-insoluble matter which is removed to form a purified solution. The treatment may be performed on a solution which contains the waste and optionally dissolved calcined trona. The purified solution may be used as a feedstock to form crystalline soda ash, and / or used as a reactant to produce crystalline sodium sulfite or bicarbonate via reaction with SO2 or CO2. In preferred embodiments, the waste may comprise a purge or weak liquor, a reclaimed solid, or combinations thereof. The water-soluble impurities may be silicates and / or foam-causing impurities, and the waste may contain sodium bicarbonate, sodium sesquicarbonate, and / or one or more sodium carbonate hydrates, such as decahydrate.

Owner:SOLVAY CHEM INC

Comprehensive treatment method of sulfur-containing flue gas

ActiveCN101637685BImprove purification qualityAchieving zero emissionsCombination devicesUsing liquid separation agentChemical industryFlue gas

Owner:CHENGDU DEMEI ENG TECH

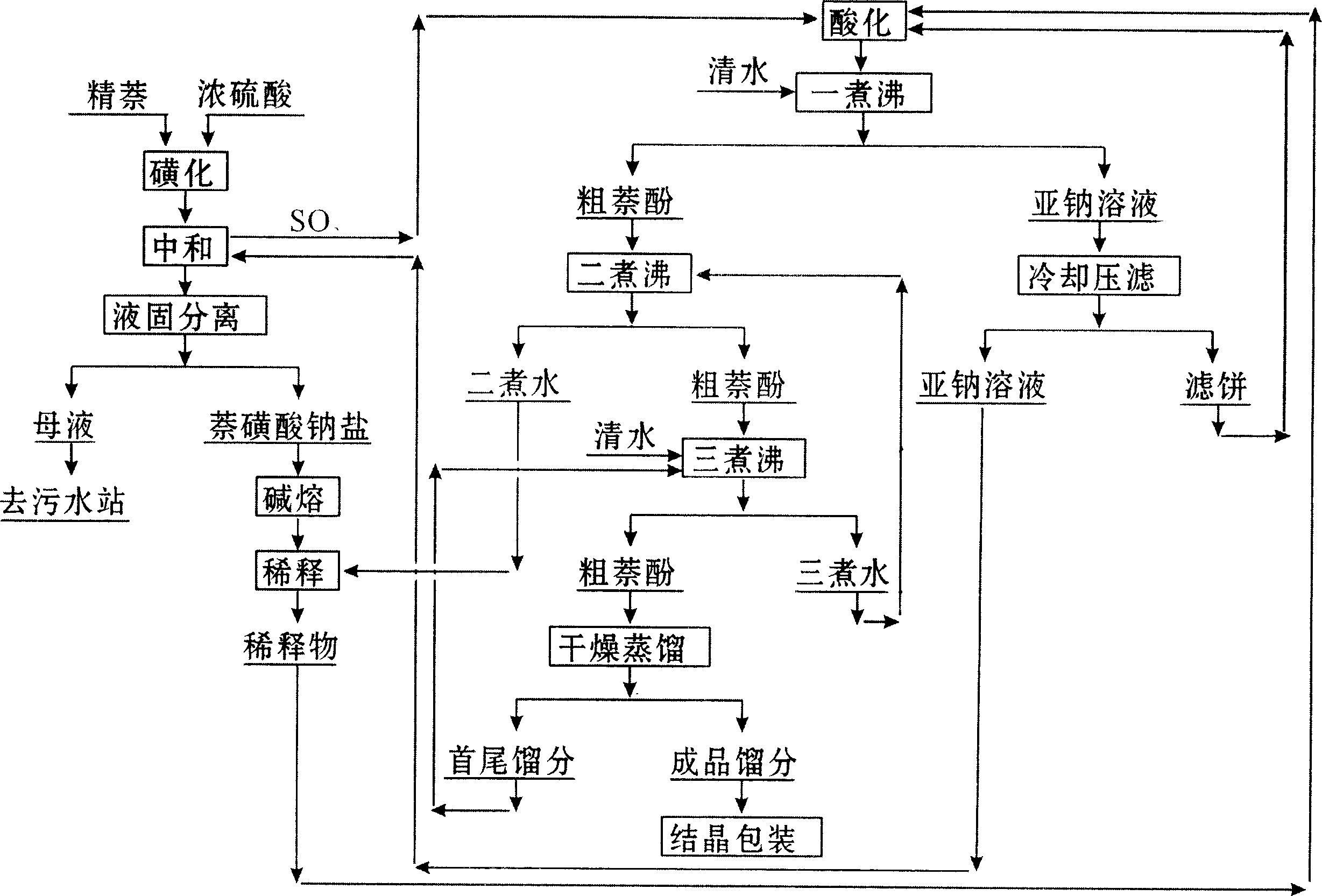

Processing method for mother solution and solium sulfite solution in naphthol production

ActiveCN1858010AReduce consumptionReduce acid consumptionAlkali metal sulfite preparationMultistage water/sewage treatmentDistillationDiluent

The present invention relates to method of treating mother solution and sodium sulfite solution in production process of naphthol including sulfonation, neutralization, liquid-solid separation, alkali fusion, acidification, boiling separation, drying distillation, crystallization and other steps. The present invention features the dilution after alkali fusion with the mother solution after neutralization and liquid-solid separation or the sodium sulfite solution after boiling separation and cooling and pressure filtering as the diluent; and the filtering and washing step set between the diluting step and the acidifying step to separate out solid salt. The present invention has the advantages of the utilization of high temperature heat of the alkali fusion matter for separating out sodium sulfite and other slats, lowered water, steam and sulfuric acid consumption, reduced naphthol loss and raised yield.

Owner:李阳 +1

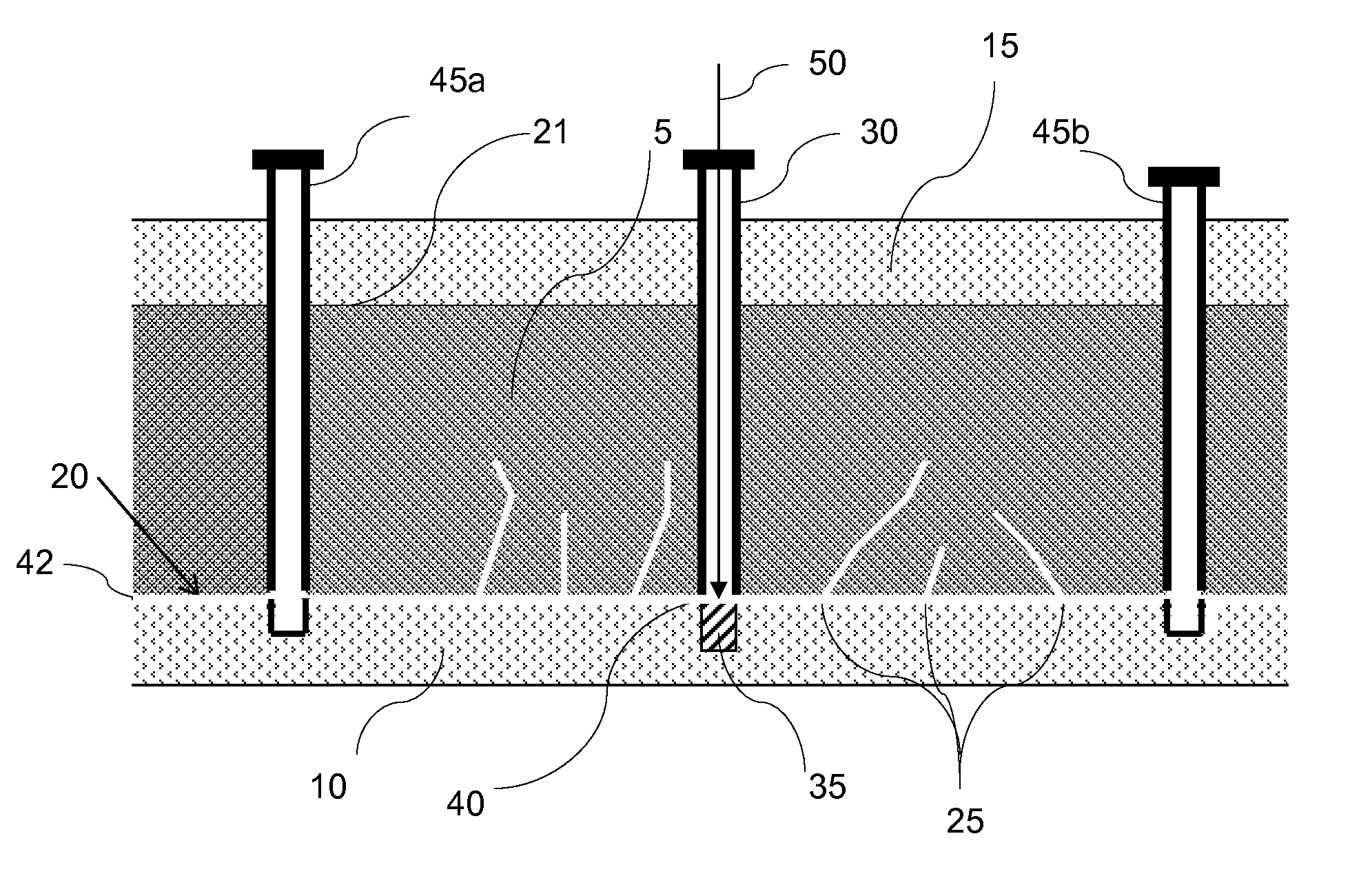

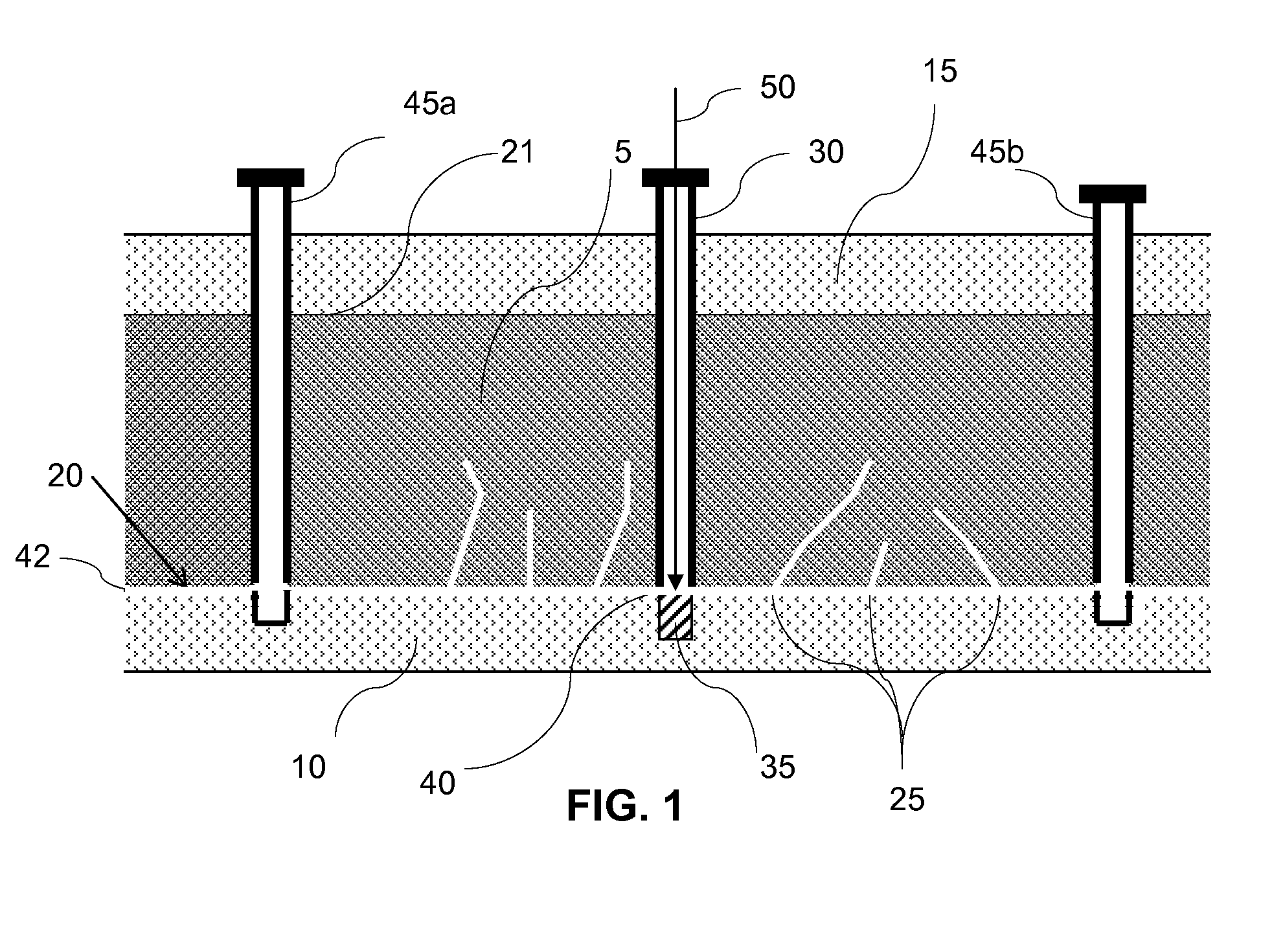

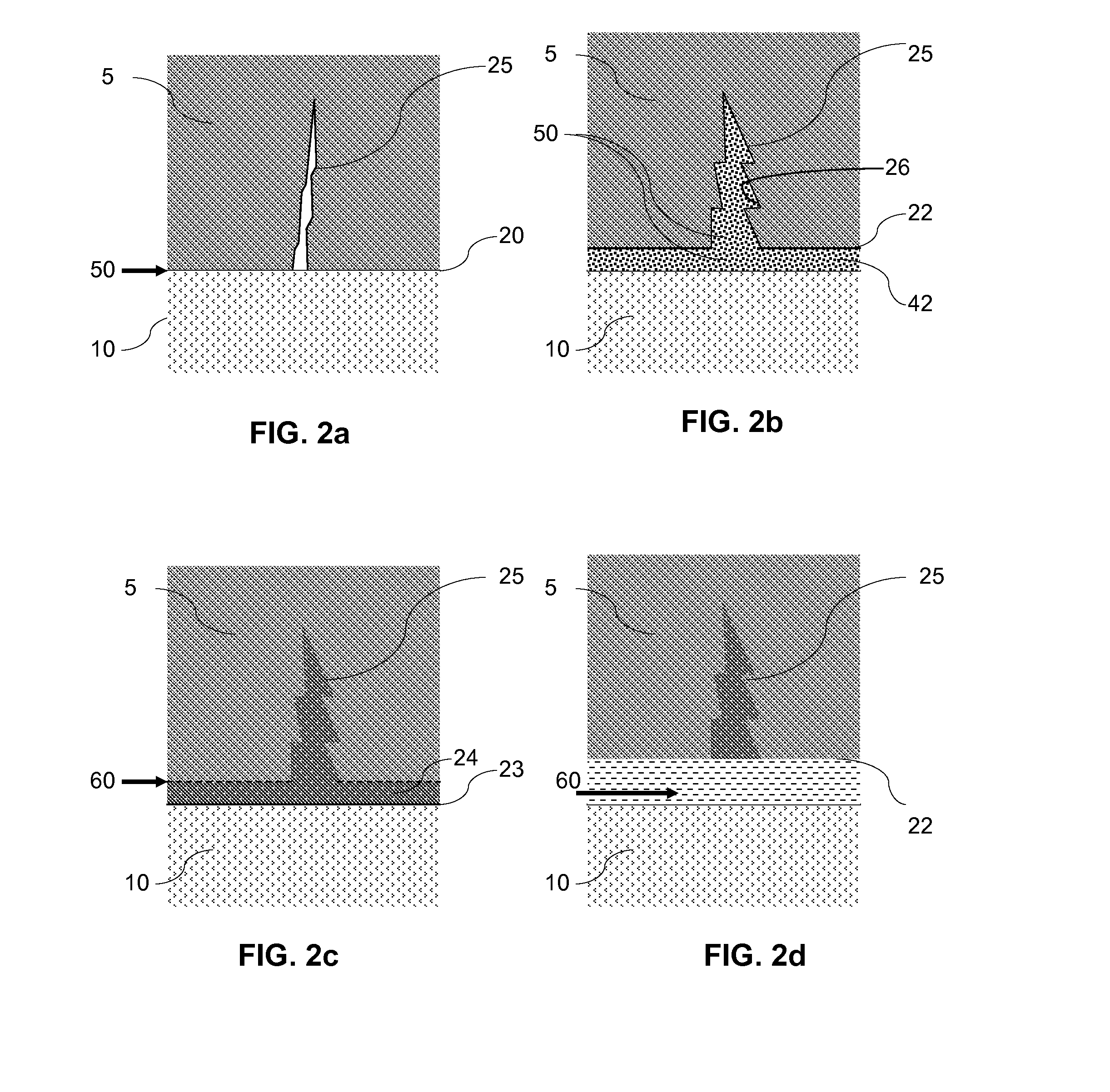

In situ method for sealing undesirable transverse fractures under hydraulic pressure during lithological displacement of an evaporite deposit

Methods for sealing undesirable transverse fractures enlarged and / or created during lithological displacement of an underground water-soluble evaporite stratum by hydraulic pressure greater than overburden pressure at an evaporite / non-evaporite strata interface, comprising injecting and maintaining a sealing agent into these undesirable fractures to form a solidified matter in situ and ultimately seal them, while forming a main free surface at the interface suitable for initiating solution mining of the evaporite stratum. The solidified matter may be crystallized, precipitated, compacted, agglomerated, cross-linked, coagulated, water-swollen, and / or cemented matter, or may include a wall-building matter with the mineral on fracture faces. The sealing agent may comprise at least one component of the mineral and / or the non-evaporite. The evaporite stratum is preferably a trona stratum overlying an oil shale stratum. The sealing agent may comprise dissolved and / or solid trona, trona tailings particles, and / or water-swelling particles.

Owner:SOLVAY SA

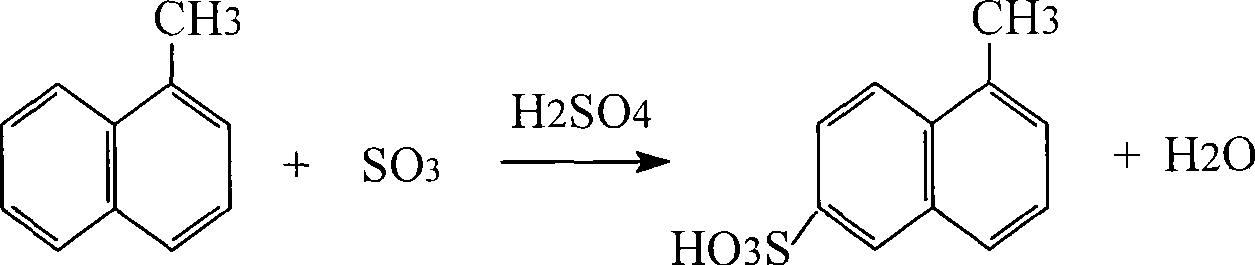

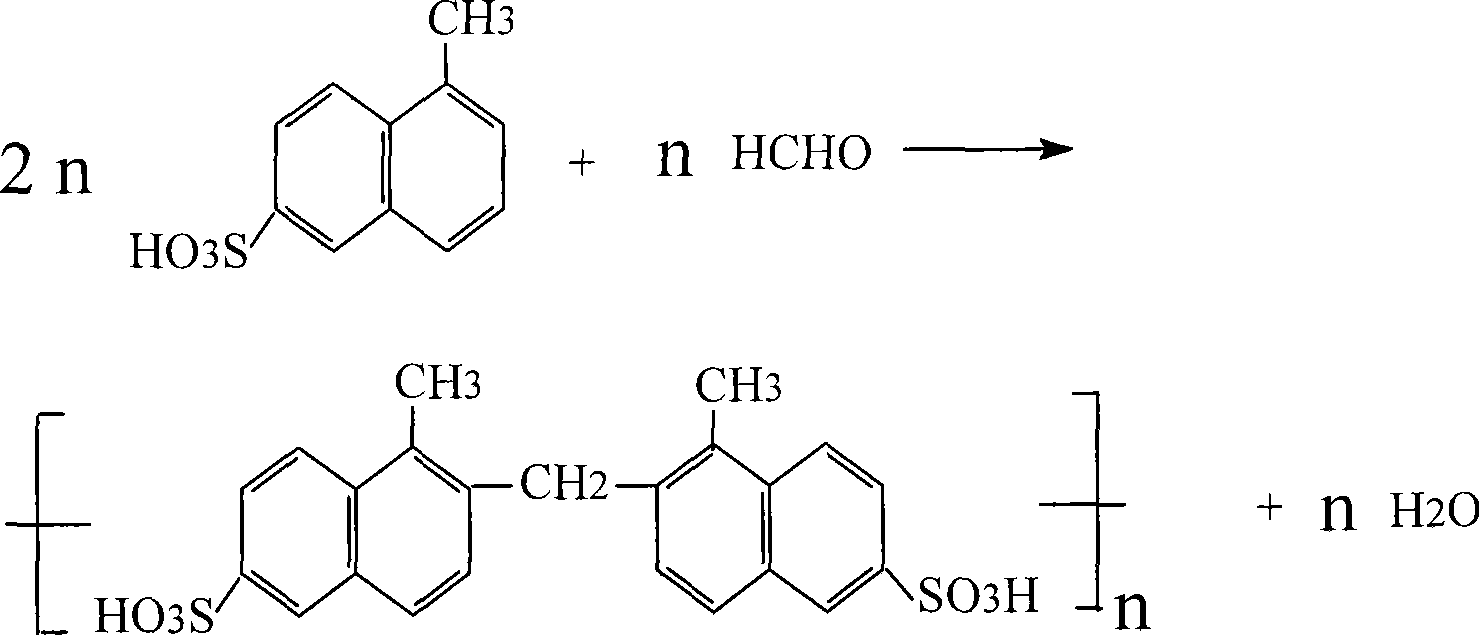

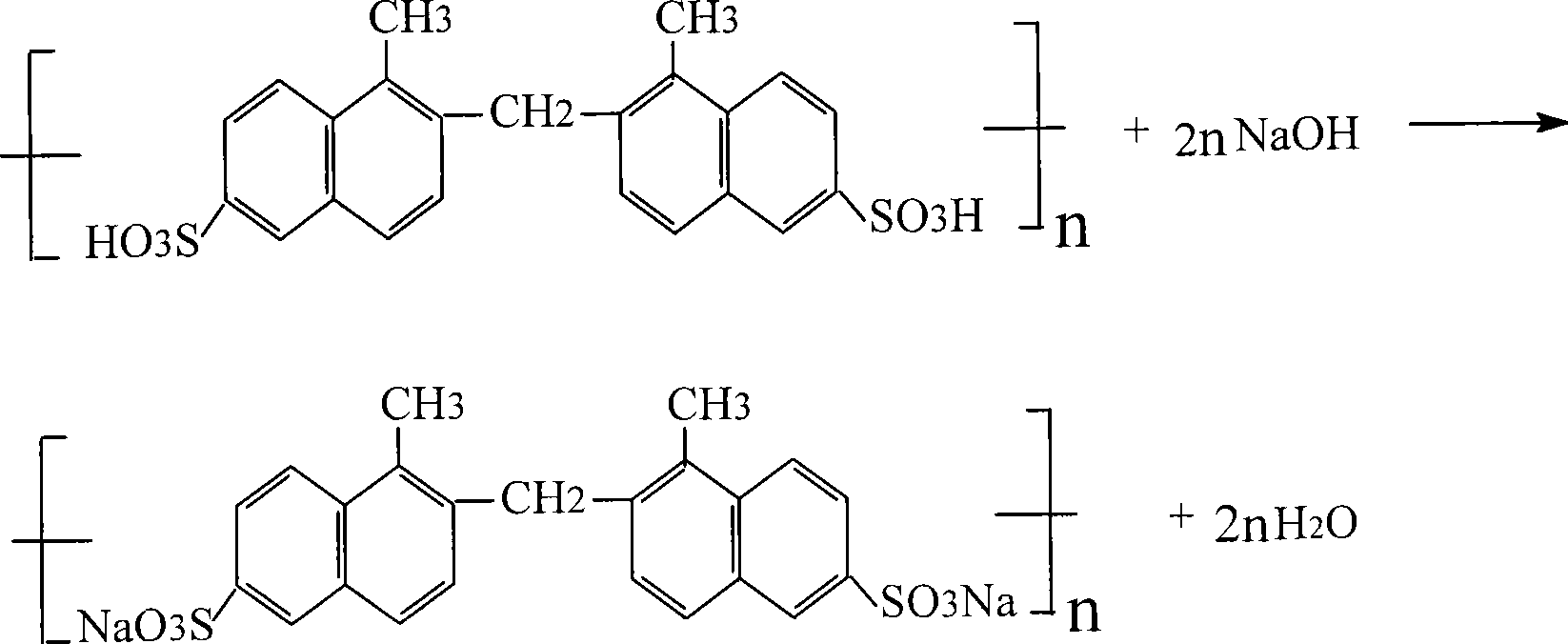

Method for coproduction of dispersants MF and sodium sulphite

ActiveCN101376639ANo pollutionSimple processAlkali metal sulfite preparationSulfonic acid preparationSulfite saltSulfate

The invention discloses a method for preparing dispersant MF in combination with sodium sulfite. The method comprises the following steps: adding more than 95% of sulfuric acid to the methylnaphthalene raw material, charging sulfur trioxide to carry out sulfonation reaction thoroughly, heating, evacuating, and continuously reacting to reach the total acidity of the solution of 22-27%; absorbing sulfur dioxide gas generated by sulfonation reaction with alkali liquor for preparing sodium sulfite; and regulating condensation acidity to 14% to 20% with water, adding formaldehyde aqueous solution for condensation, diluting, and regulating pH to 7 with alkali to obtain dispersant MF. In the method, lime is not required to neutralize so that solid waste such as calcium sulfate can not be generated and the dispersant MF reaches Chinese quality standard GB9294-88. Meanwhile, sulfur oxide waste gas is reasonably reutilized, with the characteristic of low energy consumption; and is a clean environment friendly production process.

Owner:ZHEJIANG RUNTU +1

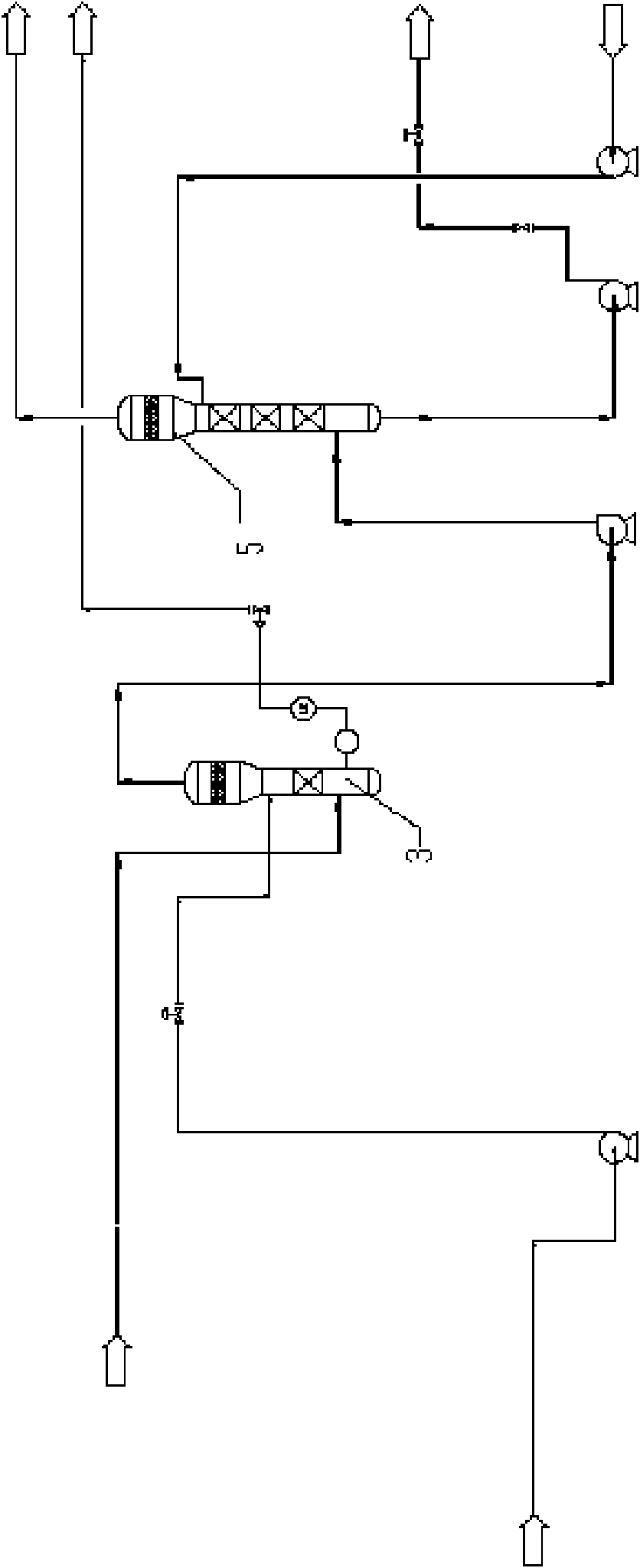

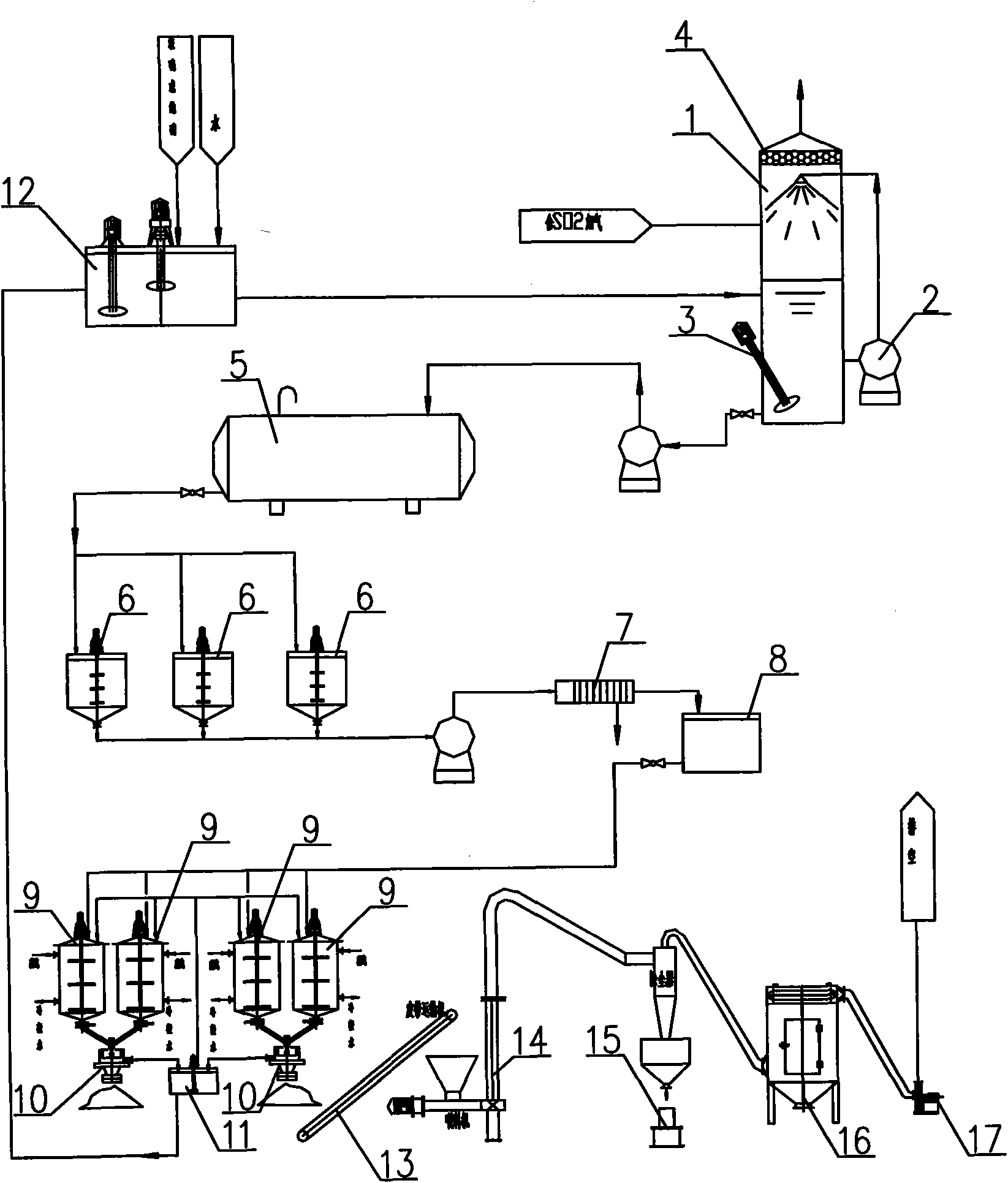

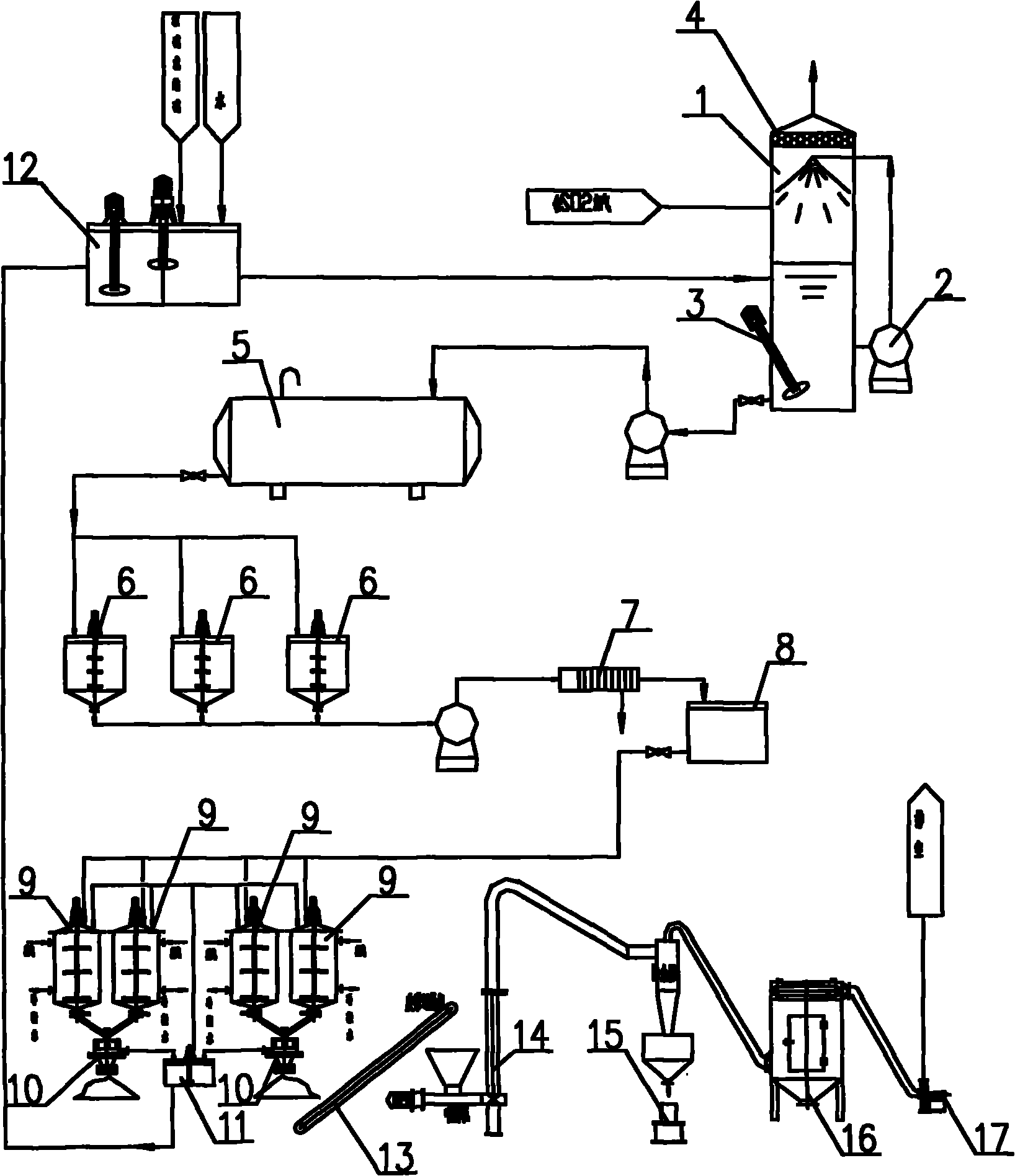

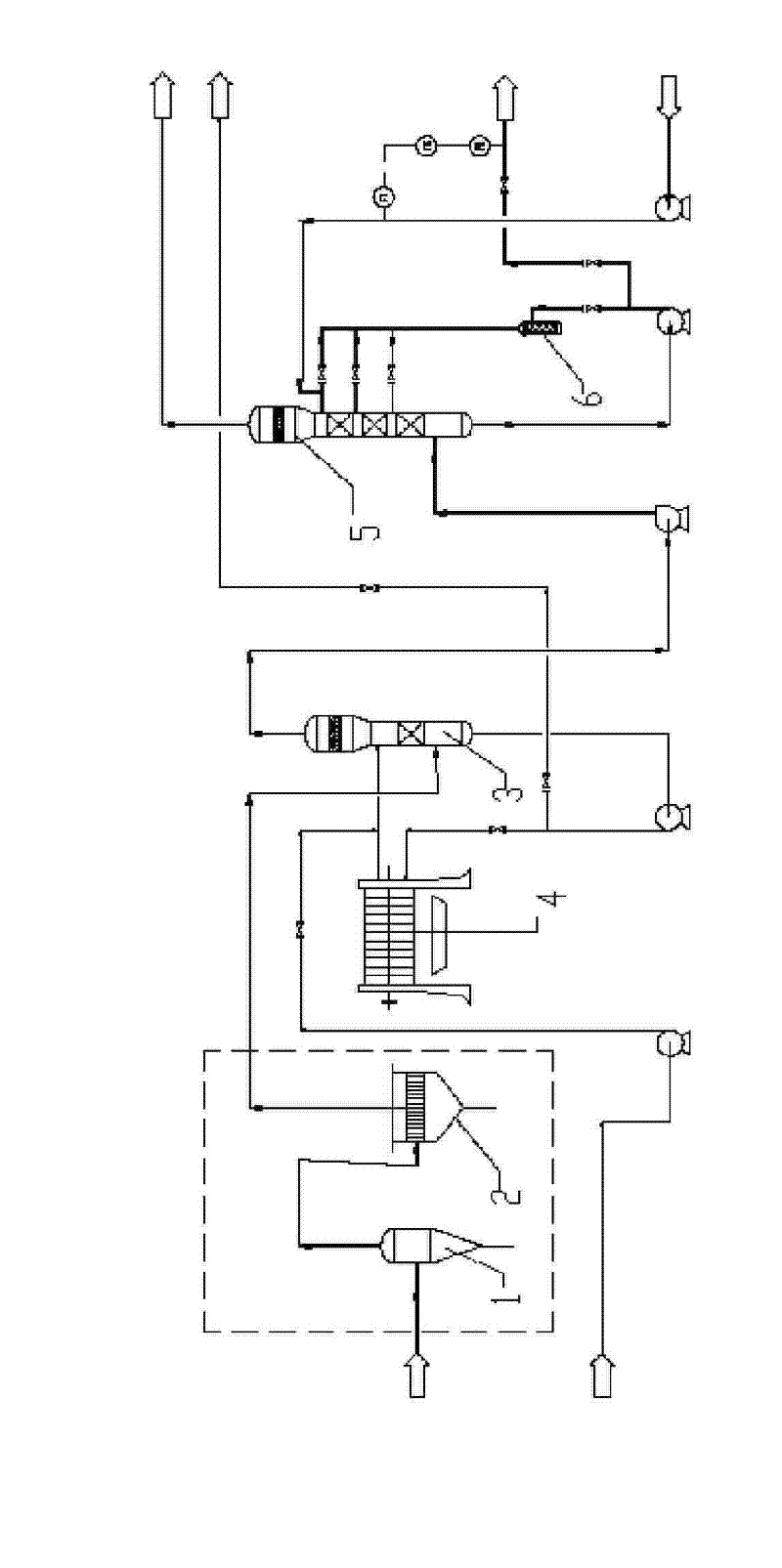

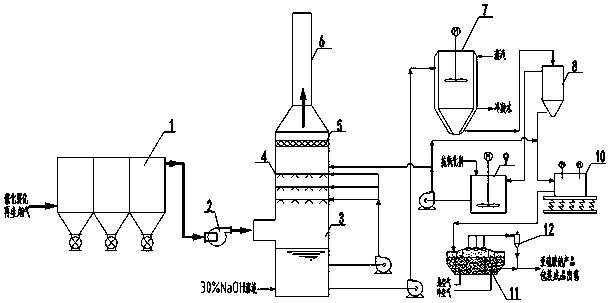

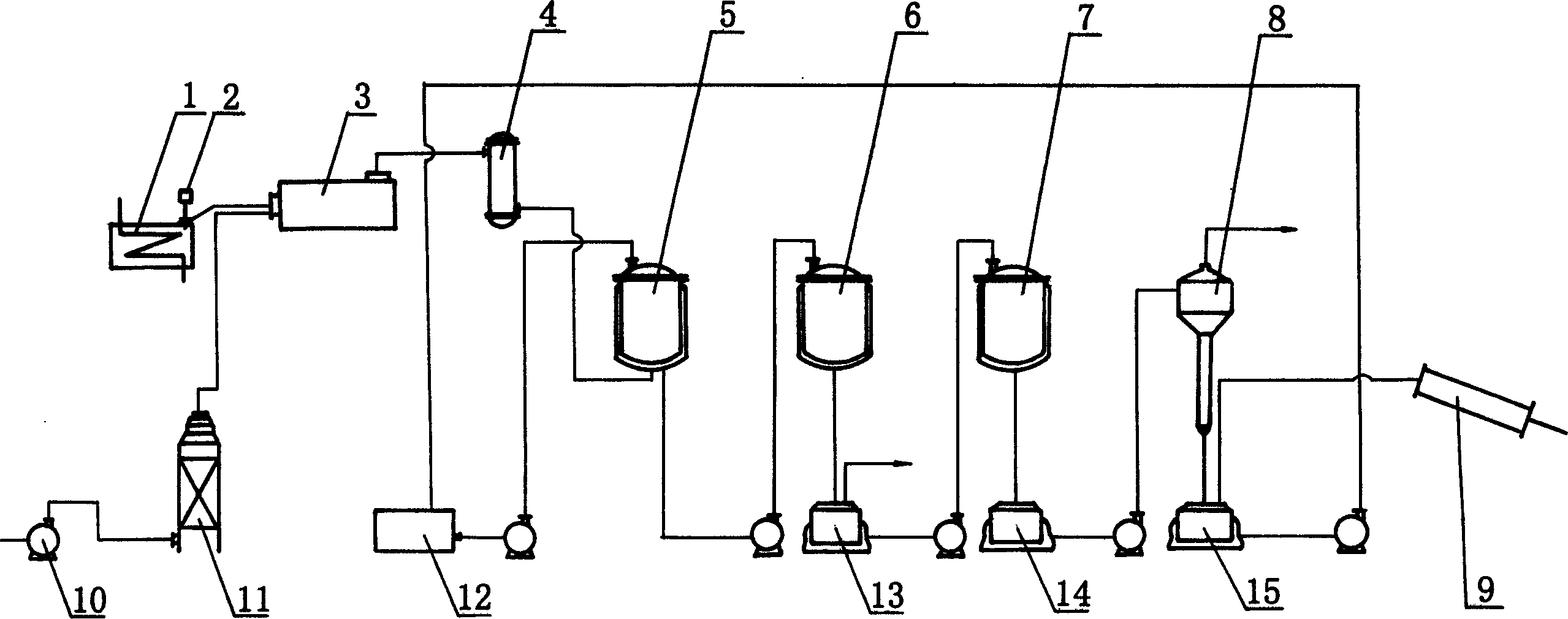

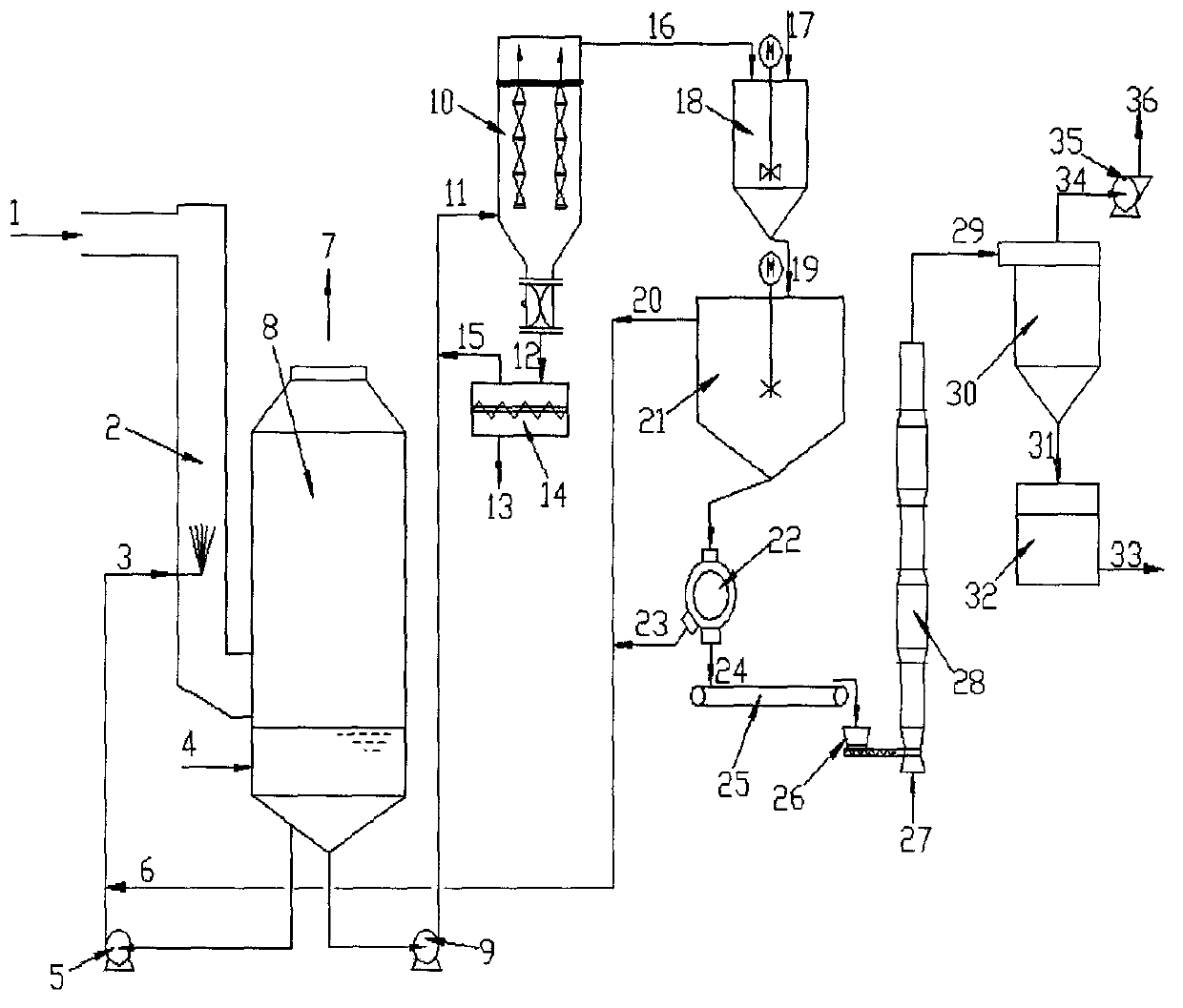

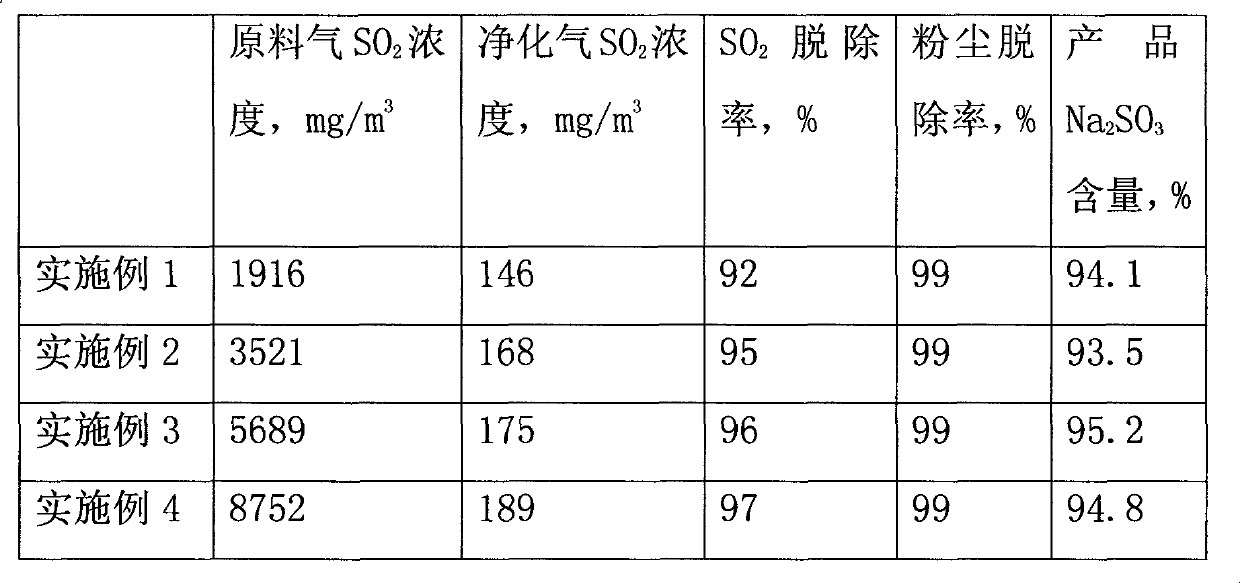

Catalytic crackingflue gas dust removal, desulfurization and sodium sulfite recovery process

InactiveCN107648948AHigh purityAvoid oxidation reactionsGas treatmentDispersed particle filtrationFluidized bed dryingSulfite salt

The invention discloses a catalytic crackingflue gas dust removal, desulfurization and sodium sulfite recovery process which adopts a dust removal system, a desulfurization system and a sodium sulfiterecovery system. The dust removal system is a bag type dust collector 1. The desulfurization system is a desulfurization tower 3, the desulfurization tower 3 comprises a spraying layer 4, a demister5 and a chimney 6 are arranged above the spraying layer 4. The bag type dust collector 1 is connected with the desulfurization tower 3 through a booster fan 2. The sodium sulfite recovery system comprises a crystallizer 7, a thickening device 8 and a centrifugal machine 10, wherein the thickening device 8 is arranged before the centrifugal machine 10, the crystallizer 7, the thickening device 8 and the centrifugal machine 10 are sequentially connected through pipes, and a fluidized-bed dryer 11 and a cyclone separator 12 are sequentially connected behind the centrifugal machine 10. The thickening device 8 is also connected with an overflow buffer tank 9, and the overflow buffer tank 9 is also connected with the desulfurization tower 3. The process is high in sodium sulfite recovery rate while meeting current environmental protection standard, obtained products are high in purity, almost no wastewater is discharged, and the catalytic crackingflue gas dust removal, desulfurization and sodium sulfite recovery process has the advantages of being low in operation cost, obvious in economic and environmental benefit and the like.

Owner:中钢集团天澄环保科技股份有限公司

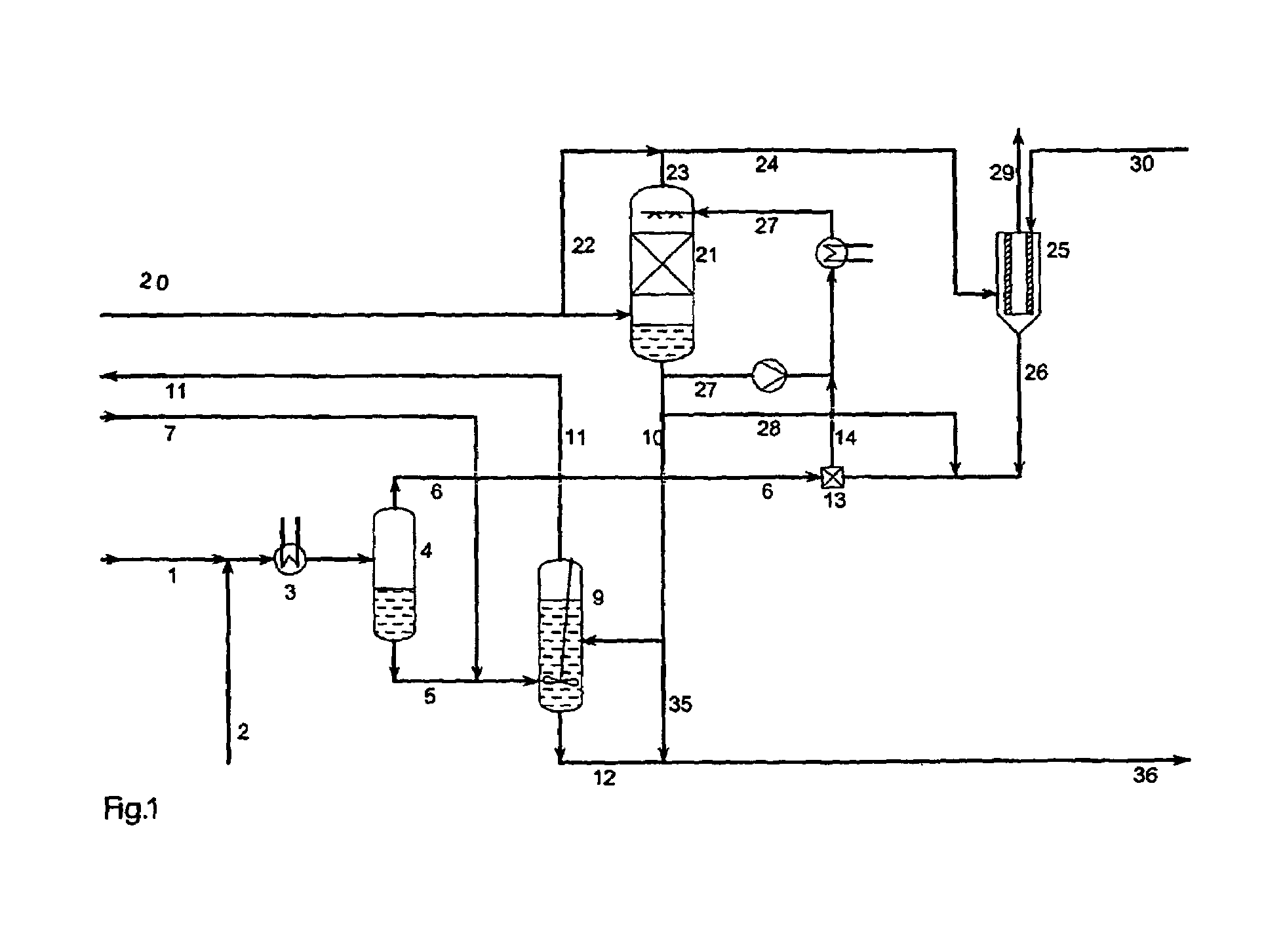

Process for production of ammonium thiosulphate

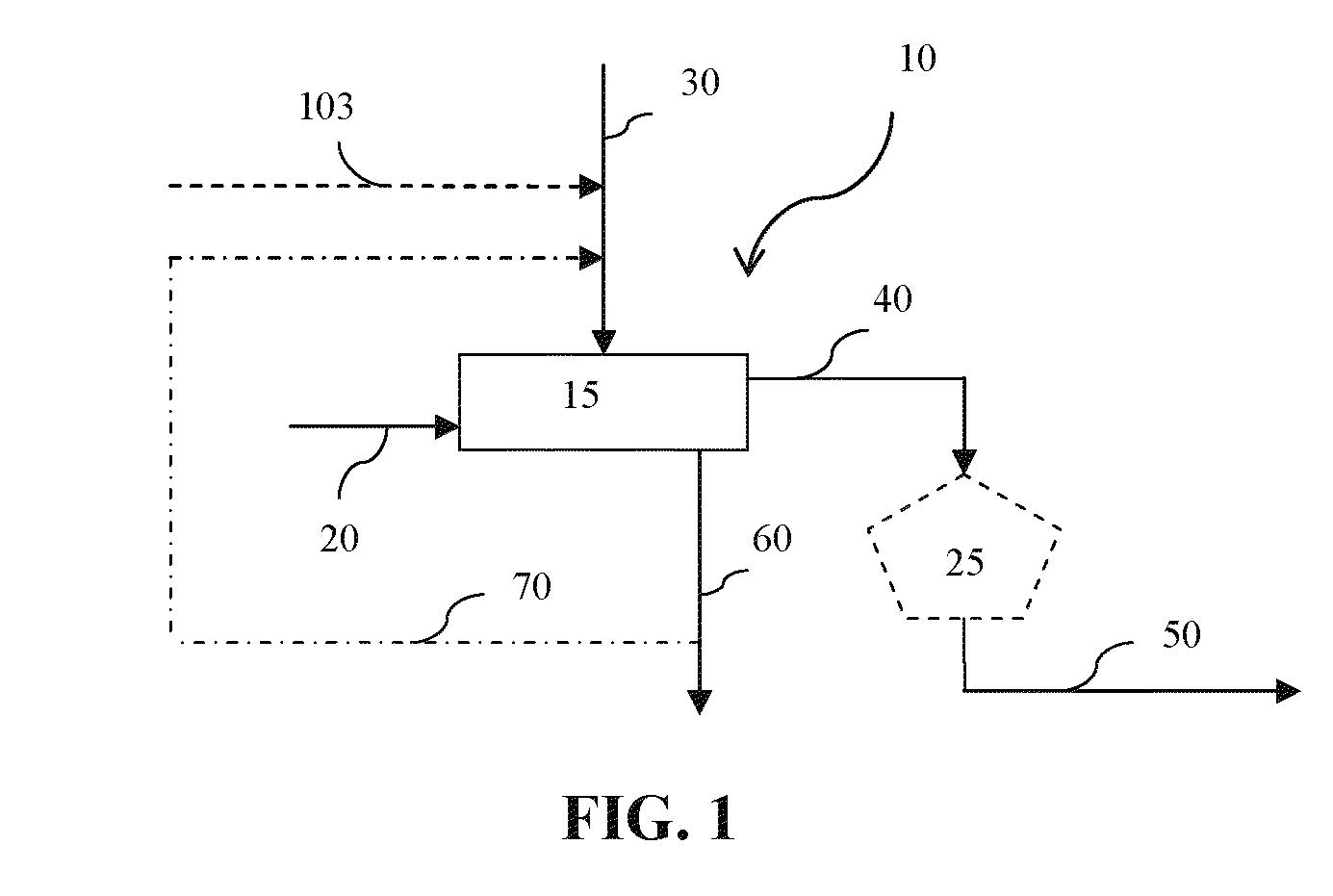

InactiveUS20030223930A1Speed up the processThiosulfates/dithionites/polythionitesSulfite preparationAqueous solutionAmmonium thiosulfate

A process for continuous production of ammonium thiosulphate, (NH4)2S2O3 (ATS) from NH3, H2S and SO2 comprising steps of: (a) partial condensation in a partial condenser 4 of a first gaseous or partial liquid feed stream comprising H2O, H2S and NH3 with a molar H2S:NH3 ratio <0.4; (b) passing the aqueous condensate comprising NH4HS and NH3 from the partial condenser 4 to a reactor 9 in which said condensate is contacted with a third feed gas stream 7 comprising H2S and with an aqueous solution 10 comprising NH4HSO3 and (NH4)2SO3 under formation of an aqueous solution of (NH4) 2S2O3; (c) passing the gas stream comprising NH3 and H2S from the partial condenser 4 to a mixing device 13 in which said gas stream is completely dissolved in the water drained off from the aerosol filter 25; (d) passing a second feed gas stream 20 comprising approximately 2 / 3 mole SO2 per mole of NH3 contained in the first feed stream to a SO2 absorber 21 and the aerosol filter 25; (e) passing the aqueous solution produced in mixing device 13 to the SO2 absorber 21; (f) passing the off gas from the absorber 21 to the aerosol filter 25 and (g) adding to the aerosol filter 25 a balance amount of water required for obtaining approximately 40-65 wt % (NH4)2S2O3 in the aqueous of solution of (NH4)2S2O3 being withdrawn from the reactor 9.

Owner:HALDOR TOPSOE AS

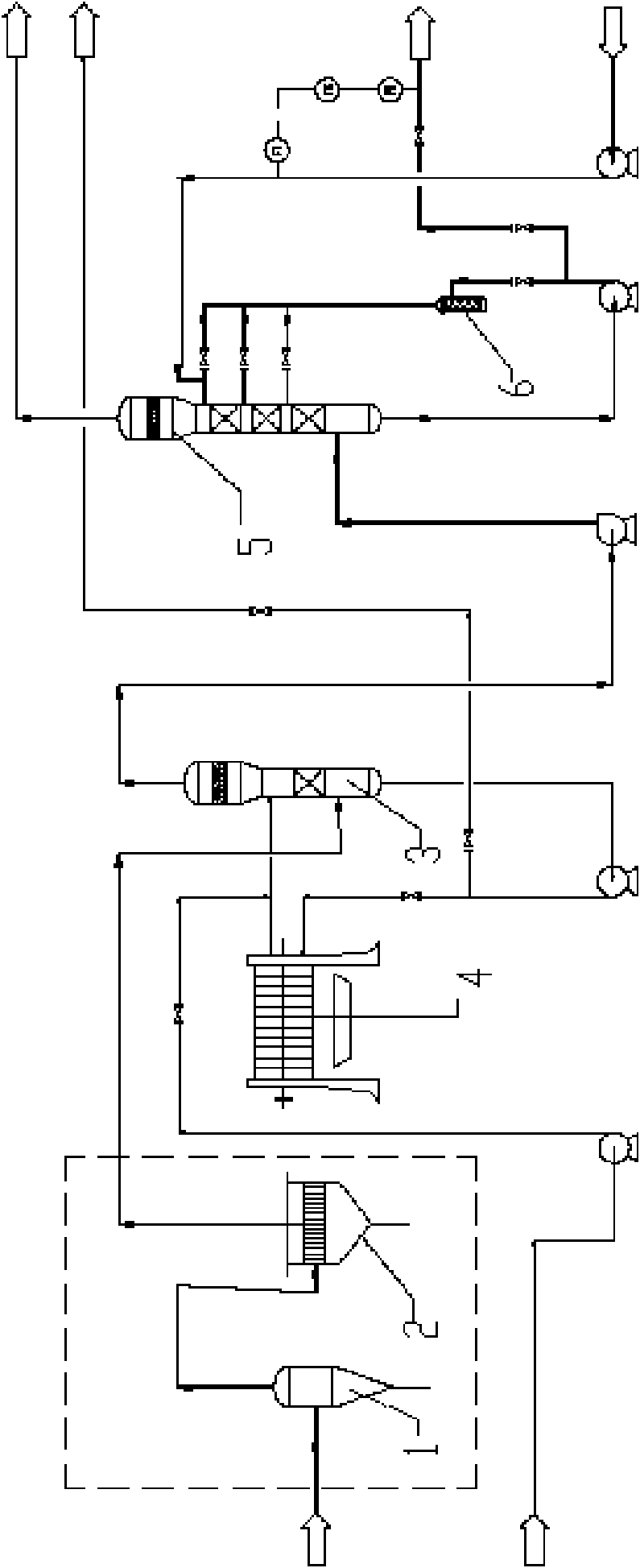

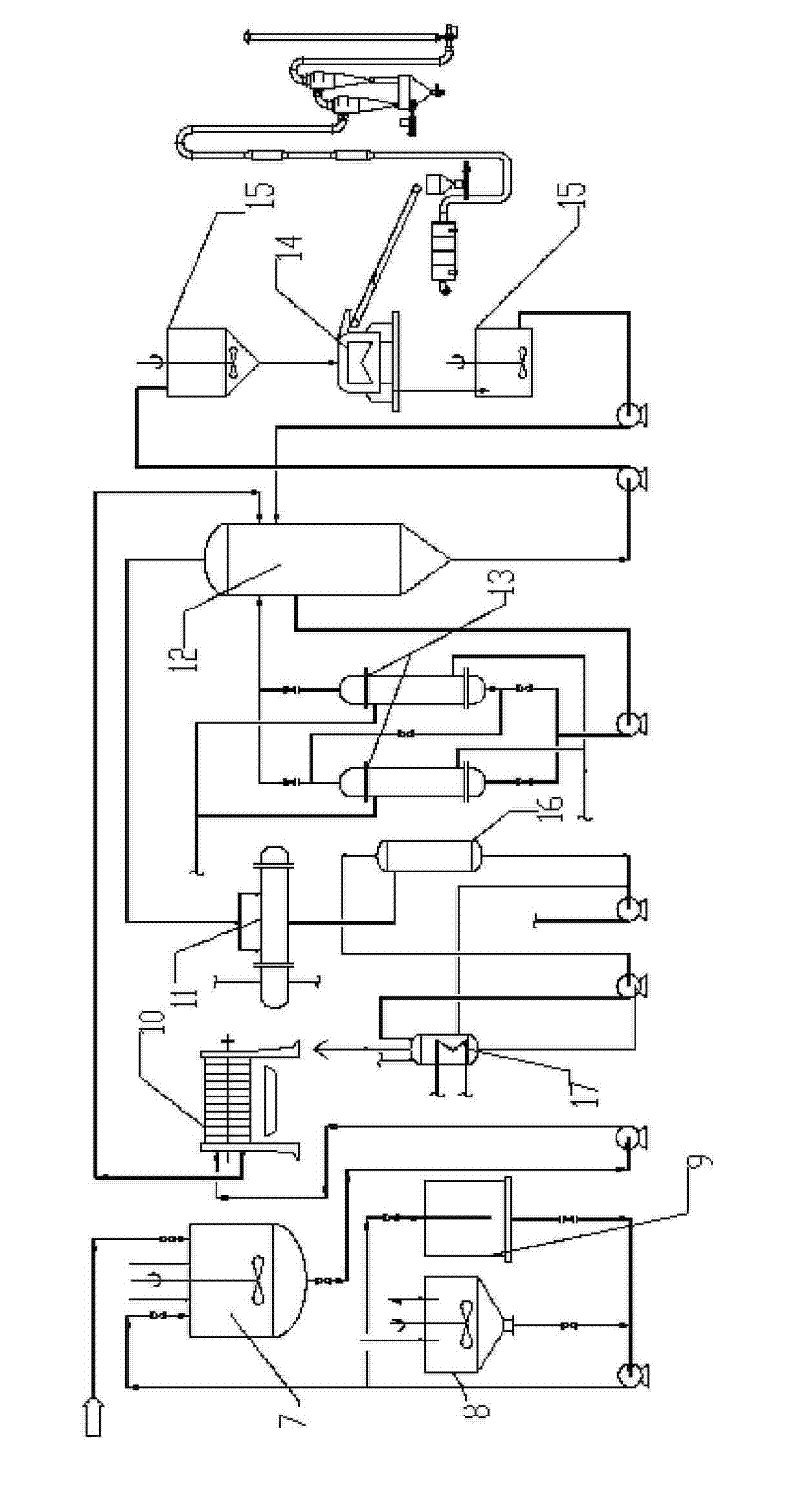

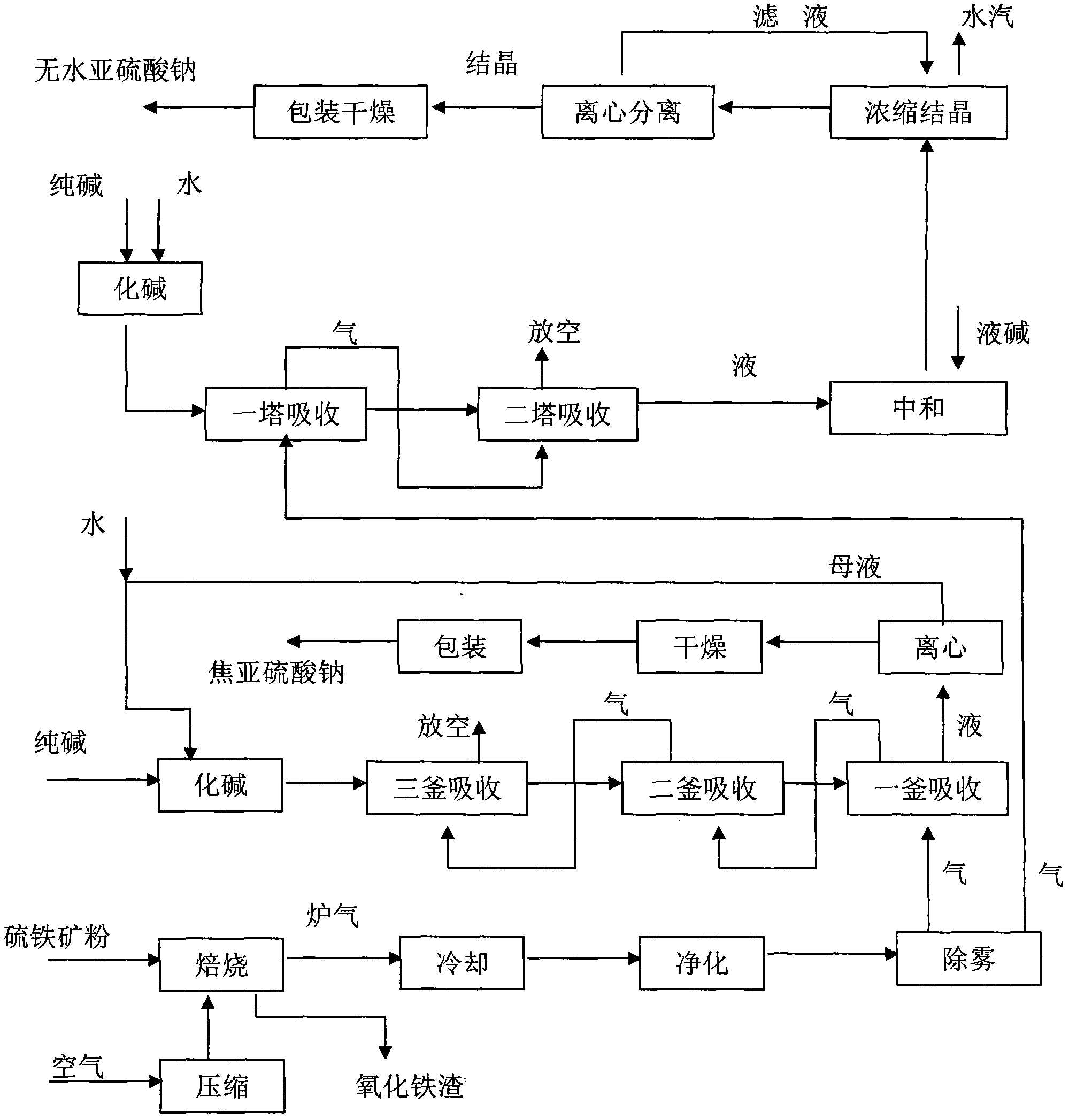

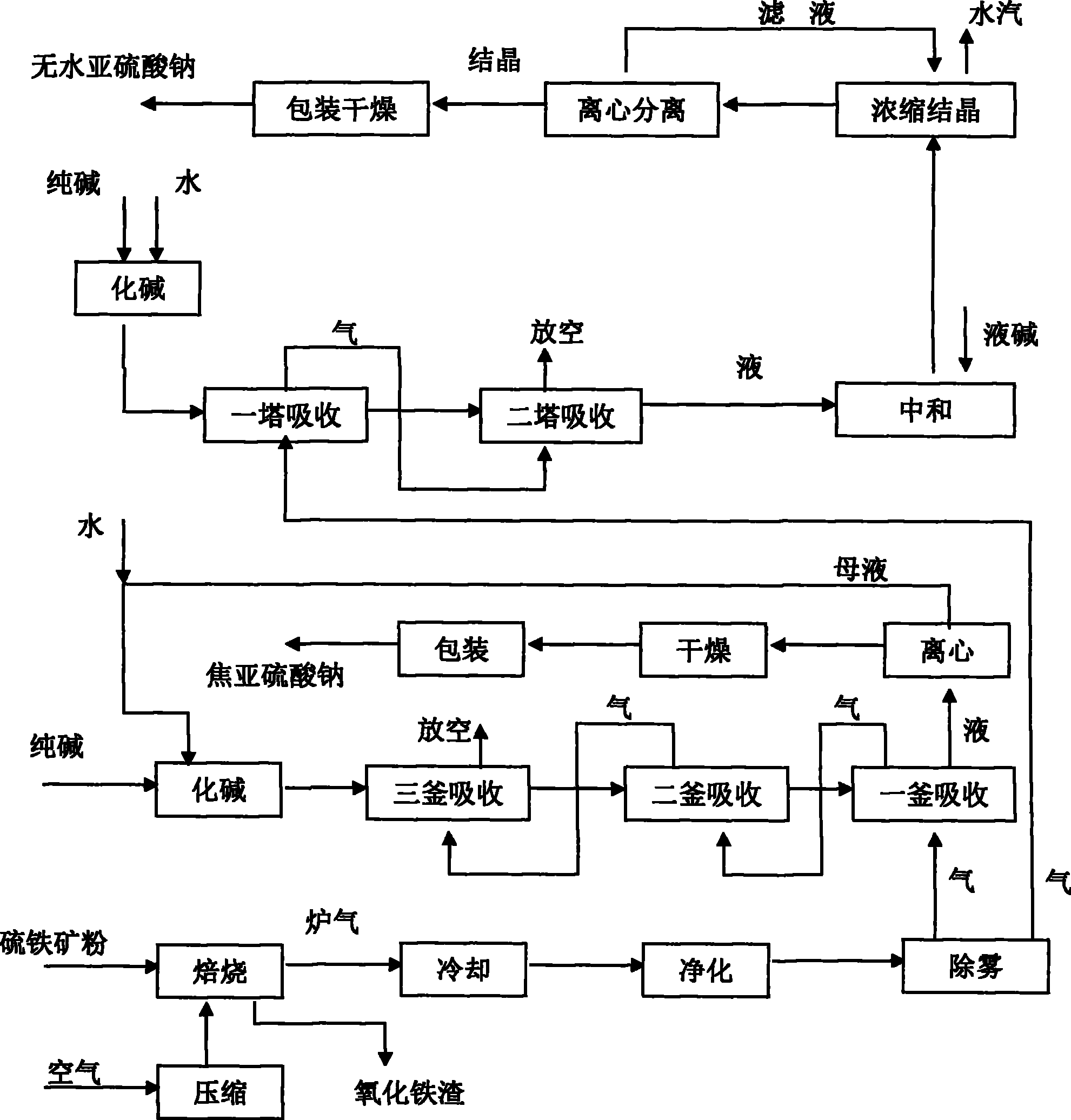

Preparation device and preparation method of sodium pyrosulfite and anhydrous sodium sulphite

InactiveCN102659142AIncrease profitReduce manufacturing costAlkali metal sulfite preparationSodium metabisulfiteSulfur

The invention provides a preparation device of sodium pyrosulfite and anhydrous sodium sulphite, comprising a roasting system, a sodium pyrosulfite preparation system and an anhydrous sodium sulphite preparation system, wherein the sodium pyrosulfite preparation system and the anhydrous sodium sulphite preparation system are respectively connected with the roasting system. A preparation method comprises the following steps: first carrying out fluidized roasting on pyrite powder to let sulfur in the powder be oxidized by the air to SO2 and to produce SO2 as a gas, and carrying out a range of processes such as dedusting purification and alkali absorption on the furnace gas to produce sodium pyrosulfite and anhydrous sodium sulphite. The main component of the roasting slag is iron oxide, and is directly sold to building materials factories or cement mills. According to the invention, the utilization rate of pyrite resource is raised, the production cost is simultaneously reduced, and the advantage of environmental protection is achieved.

Owner:伍立君

Dechlorinating tablet and method of manufacture

InactiveUS20050139805A1Decreases friability of tabletProlong dissolution timeOther chemical processesSpecific water treatment objectivesSulfite saltSodium sulfite

A dehalogenating agent is disclosed that is useful for treating aqueous media. The agent contains at least one sulfite salt, such as sodium sulfite. In the agent, the salt is in mixture with a lubricant, an excipient and a saccharide binder. Then a dry, blended mixture of the agent components is directly compressed to form tablets not only of desirable strength and hardness, but also of desirably controlled dissolution rate.

Owner:EXCEL TECH INT CORP

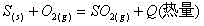

Process for producing anhydrous sodium sulfite using smelting smoke

InactiveCN1587051AAvoid pollutionReduce manufacturing costAlkali metal sulfite preparationSulfite saltSodium sulfite

The present invention relates to sodium hydroxide absorption process of utilizing sodium hydroxide in absorbing low density smelting fume to produce anhydrous sodium sulfite. The present invention features that in the absorption tower, fume containing SO2 after being purified is made to countercurrent contact with sodium hydroxide solution to absorb SO2 to pH 5-6, sodium hydroxide is added to regulate pH to 9-10, sodium sulfate solution is added to eliminate iron, and through further filtering in filtering machine, solid-liquid separation and concentration, coarse sodium sulfite product of 42-45 % concentration is obtained, and the anhydrous sodium sulfite product is produced through further hot air contact drying and dewatering. The present invention reduces environmental pollution while producing stable sodium sulfite product.

Owner:JINCHUAN GROUP LIMITED

Method for preparing anhydrous sodium sulfite using industrial by-product anhydrous sodium sulfate

InactiveCN1762809AReduce manufacturing costImprove protectionAlkali metal sulfite preparationSulfite saltVacuum evaporation

The process of preparing anhydrous sodium sulfite with industrially co-produced anhydrous sodium sulfate includes: introducing SO2 gas produced through burning sulfur in air into the acidifying unit for reaction with suspension inside the acidifying unit, adding industrially co-produced anhydrous sodium sulfate in certain amount, filtering out calcium sulfate precipitate to obtain sodium sulfite, adding certain amount of sodium carbonate via stirring to obtain sodium sulfite solution, centrifugally separating to eliminate impurity to obtain refined sodium sulfite solution, vacuum evaporation to concentrate, crystallization, separating mother liquid and vacuum drying to obtain anhydrous sodium sulfite product, and reusing the condensated water and mother liquid. The process utilizes the industrially co-produced anhydrous sodium sulfate effectively, and is environment friendly.

Owner:吕国锋

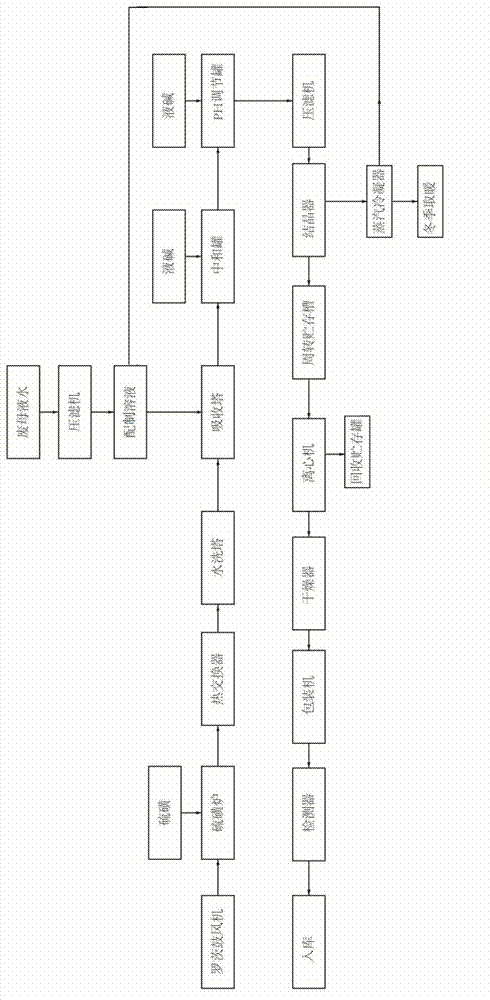

Method for producing anhydrous Na2SO3 by using alkali-containing waste mother liquor

InactiveCN102887533ASolve the problem of purification treatmentReduce investmentAlkali metal sulfite preparationSulfite saltEvaporation

The invention provides a method for producing anhydrous Na2SO3 by using waste mother liquor generated in the production process of soda ash dense. The method is characterized by comprising the following steps of: performing primary treatment on alkali-containing waste mother liquor; generating sulfur dioxide and washing with water; absorbing sulfur dioxide by the alkali-containing waste mother liquor which is subjected to the primary treatment; adding alkali to adjust pH value to be 8 to 14 at high temperature; standing, filter-pressing and decolorizing, and removing residues; performing vacuum concentration and evaporation on a saturated sodium sulfite solution from which the residues are removed; and performing centrifugal dewatering on sodium sulfite crystal substances and drying; and detecting the dried anhydrous sodium sulfite, metering, packaging and putting in storage. The alkali-containing waste mother liquor is used as a raw material, and the waste mother liquor absorbs sulfur dioxide so as to prepare the anhydrous sodium sulfite; therefore, the alkali-containing waste mother liquor can be purified completely; the whole process is simple, low in investment, low in energy consumption, and easy to popularize and apply, and has obvious social and economic benefits; and wastes and secondary pollution can be avoided.

Owner:TIANJIN ZHONGKE CHEM

Potassium sulfite/potassium bisulfite (ks/kbs) liquid as starter, side-dress, broadcast, foliar and fertigation fertilizers

ActiveUS20120255335A1Low indexReduce drug damageBiocideSulfite preparationSulfur productPhytotoxicity

The present invention provides a new liquid fertilizer comprised of potassium sulfite and potassium bisulfite, with neutral to slightly alkaline pH, relatively lower salt index and potentially lower phytotoxicity damage compared to other sources of potassium and sulfur products applied in equal amounts as a starter fertilizer. More specifically, the present invention further relates to methods for fertilizing using a composition of potassium sulfite and potassium bisulfite, particularly as a starter fertilizer, in-furrow fertilizer, side dress fertilizer, and for foliar, broadcast, soil injection and fertigation applications. The fertilizer composition is comprised primarily of potassium sulfite (with the fertilizer grade of 0-0-23-8S).

Owner:TESSENDERLO KERLEY INC

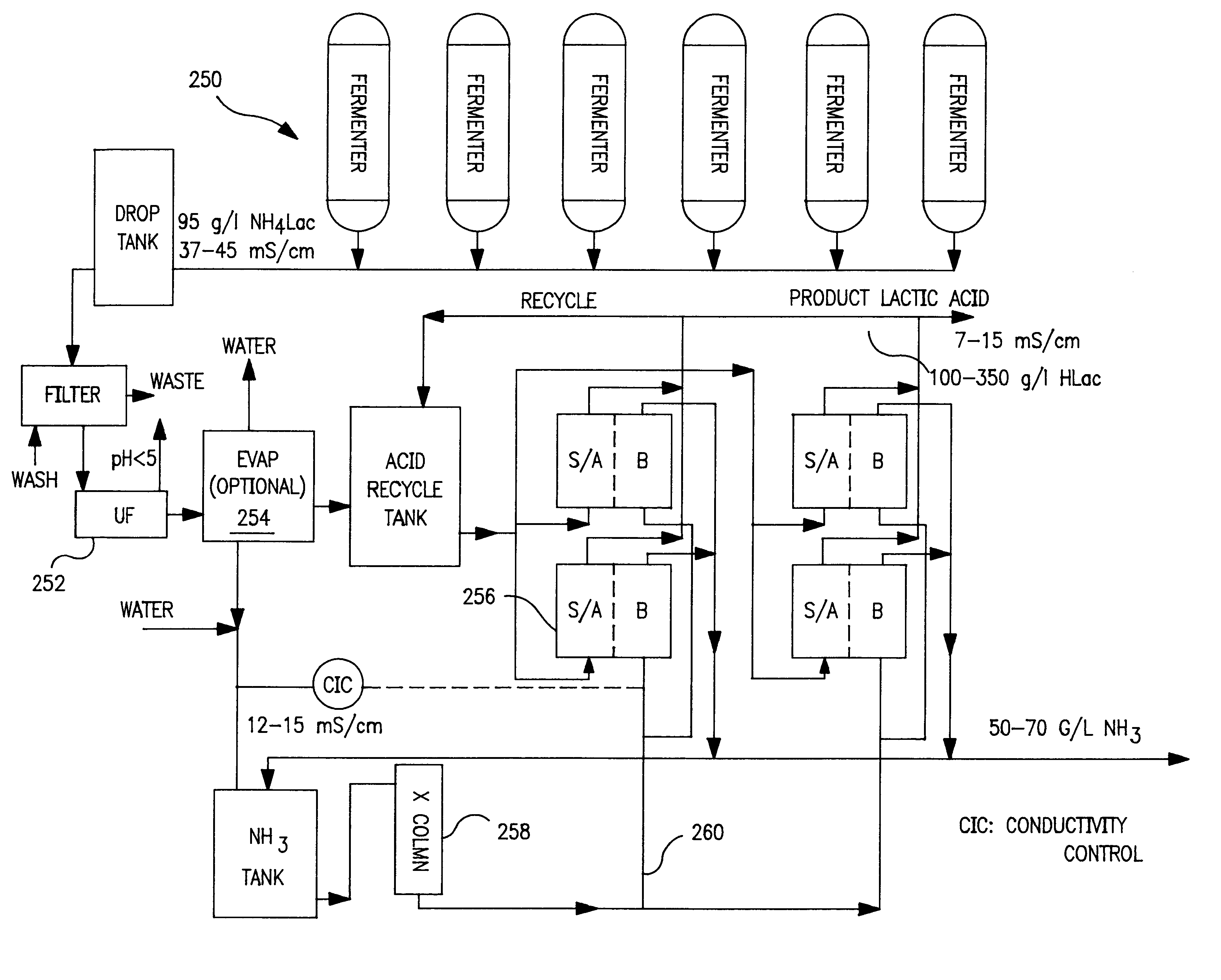

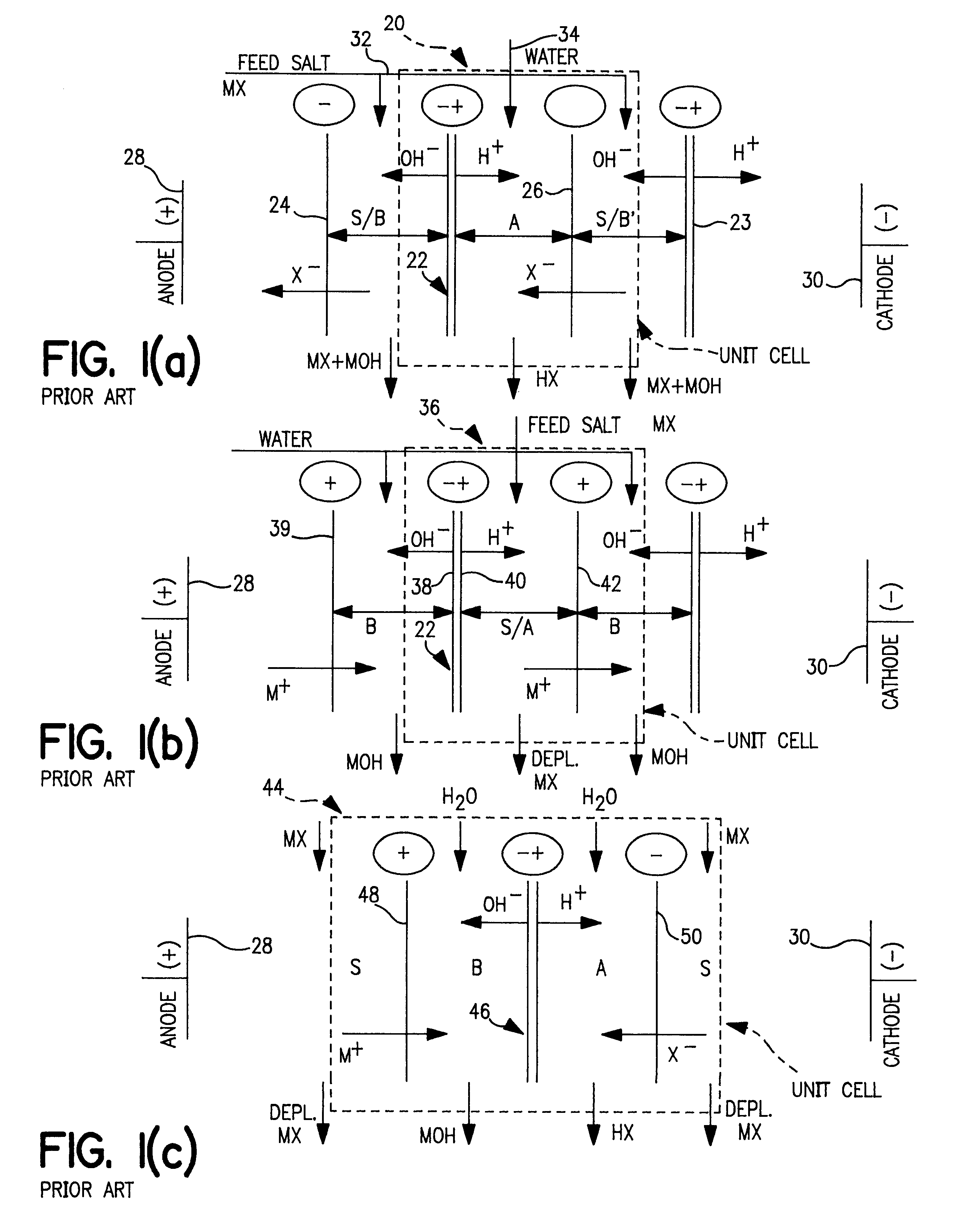

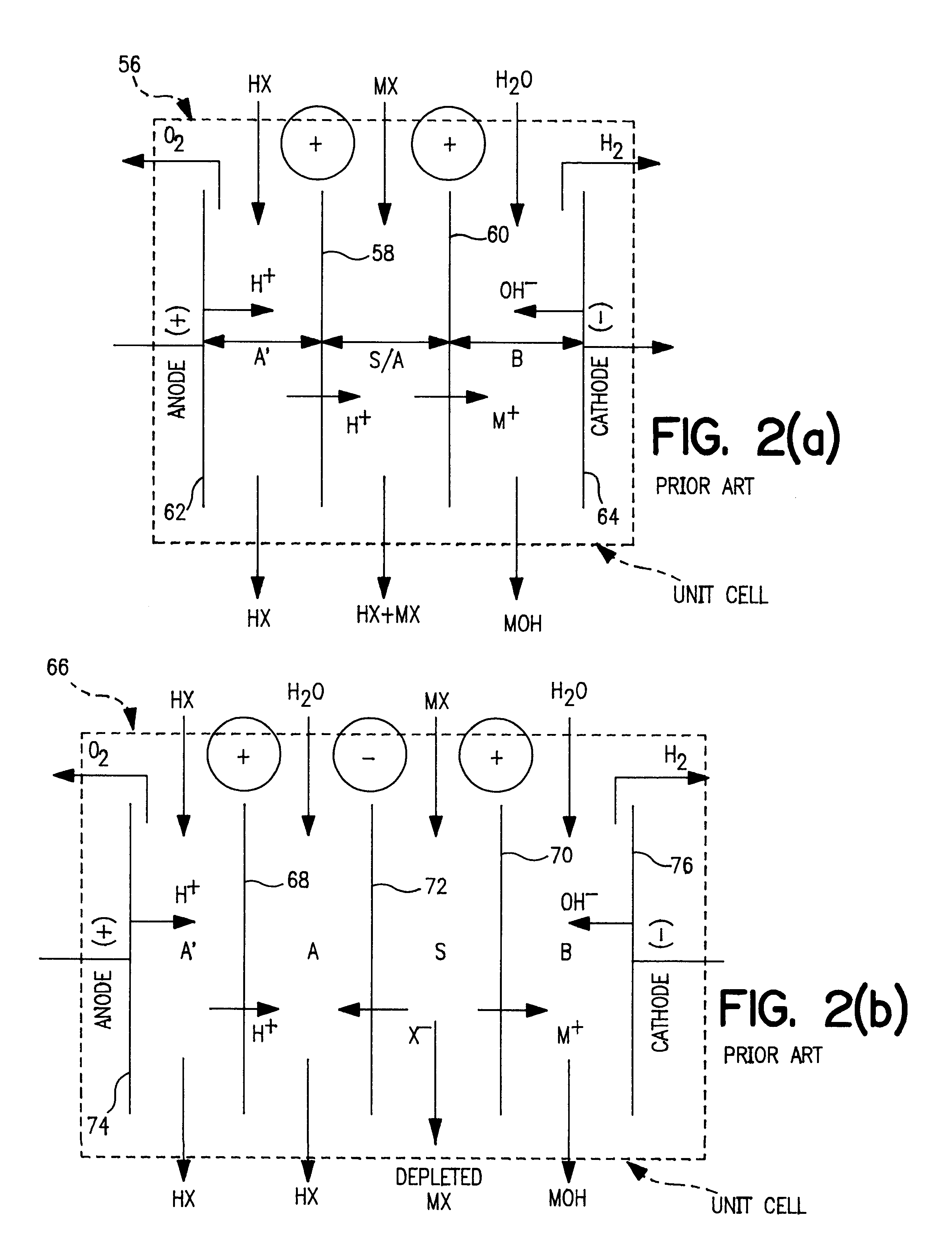

Apparatus and process for electrodialysis of salts

InactiveUS6224731B1Preparation from carboxylic acid saltsElectrolysis componentsElectricityIon exchange

An apparatus and process produces salts by an electrodialysis operation. The basic electrodialysis apparatus is a cell having a number of compartments separated by membranes. A DC source is connected to drive a current through a feed stream passing through the cell which splits the salt stream into an acid and a base. The incoming feed may be nanofiltered to remove divalent metal. The base loop may be in communication with an ion exchange column packed with a material that removes multivalent cations. Depending upon the material being processed and the desired end result either or both the nanofiltration and the ion exchanged column may be used in the apparatus.

Owner:ARCHER DANIELS MIDLAND CO

Process for production of ammonium thiosulphate

InactiveUS7052669B2Thiosulfates/dithionites/polythionitesSulfite preparationAqueous solutionAmmonium thiosulfate

Owner:HALDOR TOPSOE AS

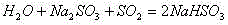

Method for preparing sodium hydrosulphite by utilization of tail gas from acyl chloride production

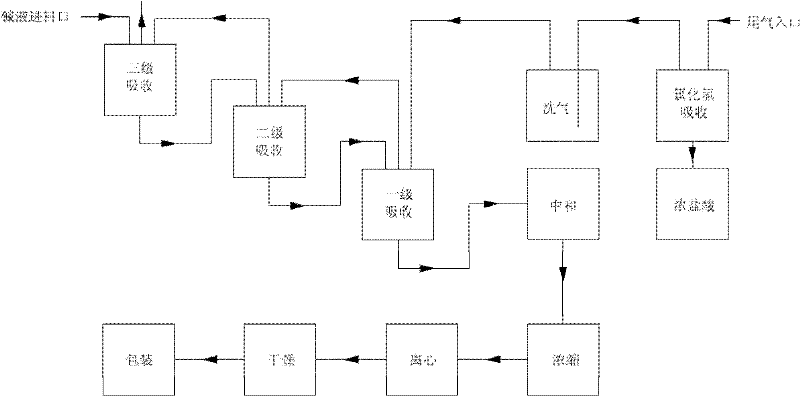

ActiveCN102512931AIncrease throughputIncrease productionDispersed particle separationAlkali metal sulfite preparationHigh absorptionSulfite salt

The invention relates to a method for preparing sodium hydrosulphite by the utilization of tail gas from acyl chloride production. The method has advantages of high absorptivity of sulfur dioxide, high absorption efficiency of sulfur dioxide, good sodium hydrosulphite product quality and product quality stability. The method comprises the following steps of: (1) absorbing the tail gas from acyl chloride production through water and removing HCl gas; (2) removing a few HCl gas from sulfur dioxide by the use of a saturated sodium bisulfite solution; (3) allowing the acyl chloride production tail gas processed from the step (2) to enter into a continuous feeding and continuous discharging absorption kettle filled with a sodium carbonate solution, carrying out three-stage continuous absorption of sulfur dioxide at normal pressure at 40-110 DEG C to generate a sodium bisulfite containing feed solution, discharging the feed solution, and controlling pH of the discharged feed solution within 3.9-5.9; and (4) neutralizing the discharged feed solution from the step (3) by the use of alkali until pH is within 8.0-10.0 to obtain a neutralizer, wherein the alkali is a NaOH solution or a Na2CO3 solution.

Owner:YANTAI TAYHO ADVANCED MATERIALS CO LTD +1

Method for producing sodium metabisulfite or sodium sulphite by using gypsum as raw material

ActiveCN102659143AReduce pollution impactImprove the efficiency of decomposition reactionsAlkali metal sulfite preparationSodium metabisulfiteSodium sulfite

The invention relates to a method for producing sodium metabisulfite or sodium sulphite. The method comprises the following steps of: firstly calcining the gypsum and coke serving as raw materials in a rotary kiln to prepare gas sulphur dioxide; then generating the gas sulphur dioxide subjected to purification treatment into a suspension liquid of the sodium metabisulfite or sodium sulphate, controlling the pH value of the suspension liquid to be 3.8-4.1, carrying out centrifugal dehydration on the suspension liquid by using a centrifugal machine, then drying and separating to obtain the finished product sodium metabisulfite or sodium sulphite, and absorbing tail gases by using a tail gas washing tower; and in the preparation process of the gas sulphur dioxide, controlling the content of O2 of the tail gases in the rotary kiln to be 0.05%-1.0% and the content of CO to be less than 0.4% according to the weight percentage content. The purities of sodium metabisulfite and sodium sulphite product prepared by using the method can respectively reach up to 97.5%-98.5wt% and more than 93wt% and is completely in line with national standards. According to the method, the route of raw materials for producing the sodium metabisulfite is widened.

Owner:CHONGQING SANSHENG IND CO LTD

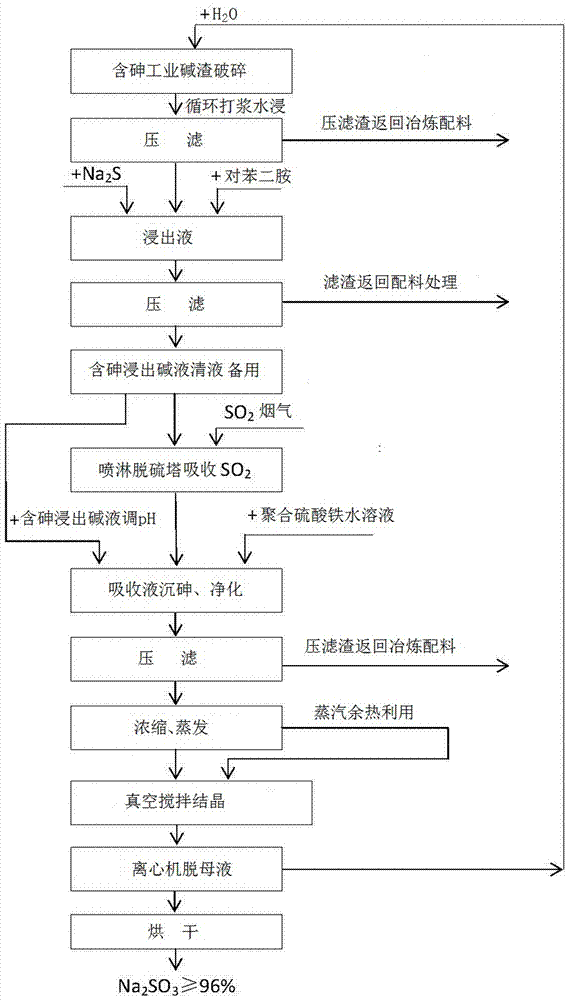

Technique for producing sodium sulfite products by absorption of SO2 flue gas through arsenic-containing industrial alkali residue water alkali liquor and arsenic removal purification

InactiveCN107963642AHigh product contentIncrease contentAlkali metal sulfite preparationSulfite saltFiltration

A kind of technological method of using arsenic-containing industrial alkali slag to absorb SO2 flue gas, remove arsenic and purify to produce sodium sulfite product. After treatment with p-phenylenediamine, press filter to obtain arsenic-containing leaching lye for later use, pump the clear liquid into the spray desulfurization tower to absorb SO2 flue gas, reduce the pH value of the absorption solution to 6.2-6.4, and then add arsenic-containing leaching lye After adjusting the pH value of the clear liquid to 10.5-11.5, adding polyferric sulfate aqueous solution for arsenic precipitation, pressure filtration for liquid-solid separation, clear liquid crystallization after concentration and evaporation, and drying after separating the mother liquor to obtain sodium sulfite products with a mass concentration ≥ 96% . This method starts with industrialized stable production, increases the content of sodium sulfite products as much as possible, optimizes the technical process and parameter selection, and has achieved obvious technological progress. Based on the annual output of 20,000 tons of alkali slag in the country, it can increase economic benefits by about 35 million The total amount of arsenic that can be removed and harmlessly treated is As 6%×20000=1200 tons / year, and the desulfurization is 4250 tons / year, resulting in huge environmental benefits.

Owner:YAN XIN ENVIRONMENTAL PROTECTION & TECH CO LTD

Method for producing high-purity sodium sulfite and sodium sulfate by desulfurizing coal-fired flue gas through alkaline method

ActiveCN103961995AReduce desulfurization burdenSimple processDispersed particle separationAlkali metal sulfite preparationSulfite saltFlue gas

The invention discloses a method for producing high-purity sodium sulfite and sodium sulfate by desulfurizing coal-fired flue gas through an alkaline method. A two-stage desulfurization process is adopted; first-stage desulfurization refers to coarse desulfurization in which sulfate is left in first-stage desulfurizing liquid, sodium sulfate is produced, and most of sulfur dioxide in flue gas enters second-stage desulfurization; the second-stage desulfurization refers to main desulfurization in which flue gas can be exhausted up to standard, and the desulfurizing liquid can be directly concentrated and crystalized to produce high-purity sodium sulfite. The method has the advantages of being simple in process and easy to implement; sulfur dioxide in low-concentration flue gas is recycled by adopting the two-stage desulfurization process, so that secondary pollution caused by desulfurization and zero emission are eliminated completely; 95-percent high-purity sodium sulfate and 95-percent high-purity sodium sulfite are produced by using sulfur dioxide flue gas, and sodium sulfite accounts for 90-95 percent, so that the conventional treatment way of pure resource consumption is changed, the desulfurization burdens of enterprises are relieved greatly, and even desulfurization is turned into value-added production, thus remarkable technical and economical effects are achieved.

Owner:TIANJIN UNIVERSITY OF TECHNOLOGY +1

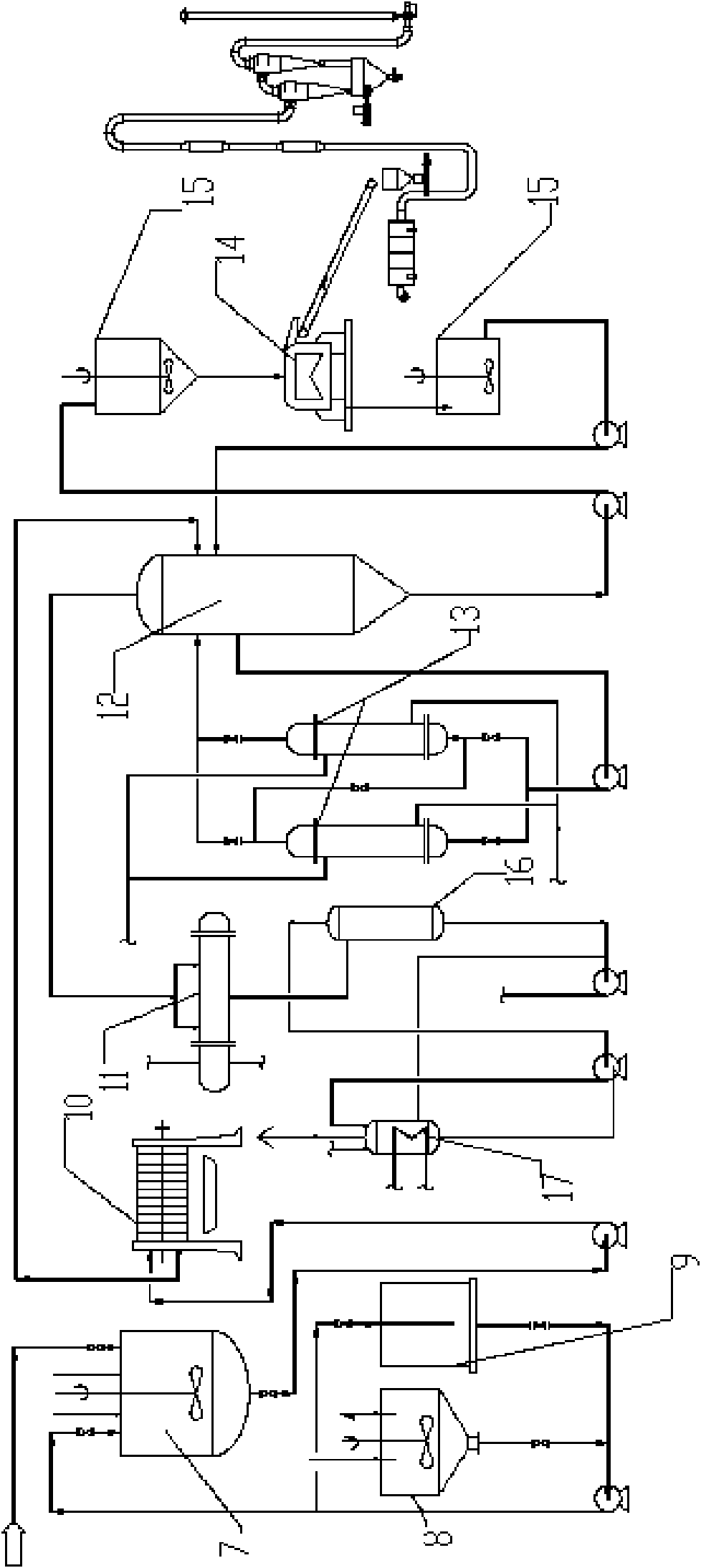

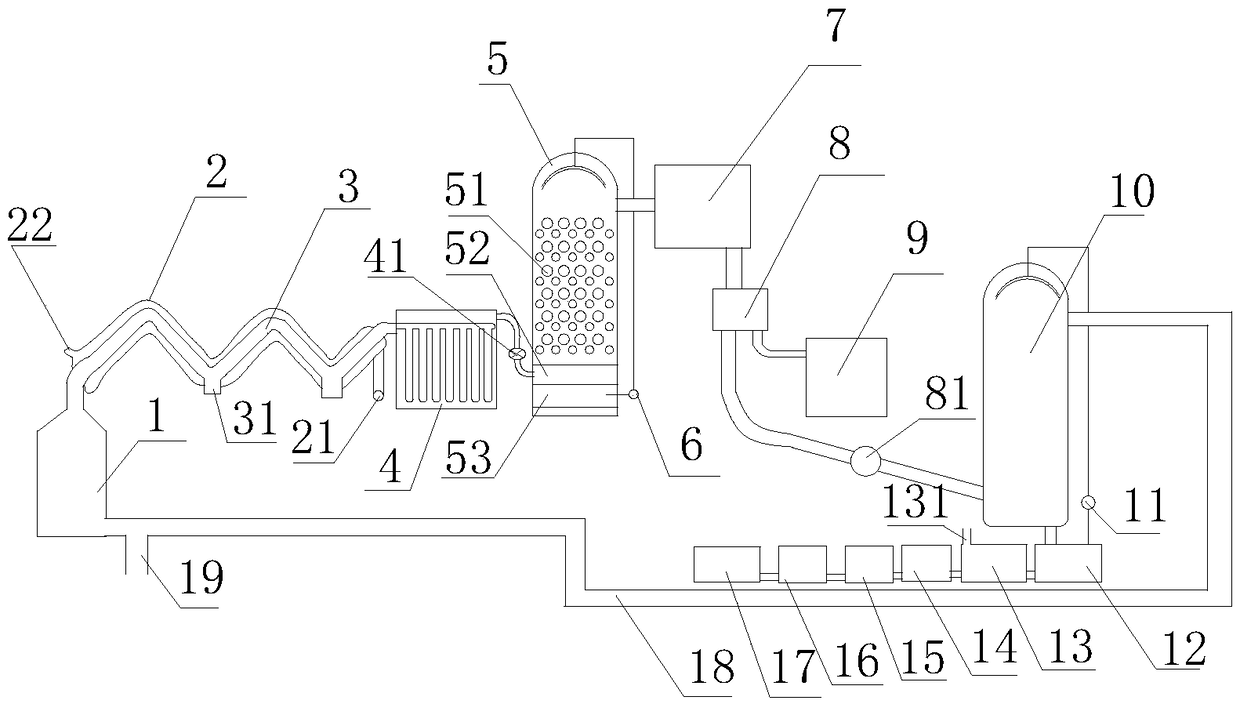

Zero emission circulating system for sealing treatment of regenerated lead smelting tail gas

InactiveCN108889069AEmission reductionReduce consumptionCombination devicesProductsSolubilityLead smelting

The invention discloses a zero emission circulating system for sealing treatment of regenerated lead smelting tail gas. A smelting furnace, a gravity dust collector, a bag type dust collector, a waterwashing dust collecting tower, an air compressor, a gas-liquid separator, an alkali washing desulfurizing tower and a circulating pipe are successively arranged according to a flowing direction of the smelting tail gas. By adopting multiple processes to collect dust first, carrying out pressurizing and liquefying to recover CO2 by means of a physical method, carrying out desulfurization and denitrification by means of a chemical method and finally, and supplementing O2 to residual gas to return to a smelting furnace, the smelting tail gas circulates in a closed system and is not discharge toair, so that the desulfurization cost is reduced greatly, the carbon recovery benefit is increased, and meanwhile, solid-liquid separation can be carried out to reduce lead dust residues by means of good solubility of a desulfurization product. The desulfurization product is treated harmlessly favorably. The process does not need high precision removal of sulfur and dust, so that the flue gas treatment difficulty is reduced greatly and the process is the most economical, cleanest and environment-friendly process.

Owner:JIESHOU JINGHUA TECH INFORMATION CONSULTING SERVICE CO LTD

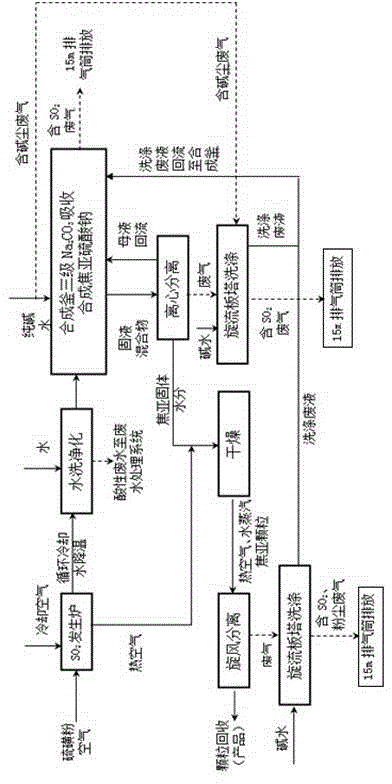

Method for desulphurization and dust removal of flue gas and recycling of sodium sulfite

ActiveCN103861426AReduce investmentReduced footprintUsing liquid separation agentAlkali metal sulfite preparationLiquid wasteAtmospheric pollution

The invention belongs to the field of atmospheric pollution governance, relates to a method for desulfurization and dust removal of flue gas, and particularly relates to a low-energy-consumption method for desulphurization and dust removal of the flue gas and recycling of sodium sulfite. The technical problems to be solved comprise the problems of high investment, large energy consumption, large waste liquid emission load, large water resource consumption, high operating cost of per unit of sulfur dioxide and the like existing in a conventional fuel gas desulfurization technology, and the invention provides a process route comprising the steps of taking a sodium sulfite / sodium hydrogen sulfite mixed solution as a desulfurization agent, washing and purifying the sulfur-containing flue gas, and recycling the anhydrous sodium sulfite product.

Owner:CHINA PETROCHEMICAL CORP +1

Production process of sodium pyrosulfite

InactiveCN104150512AIncrease profitHigh yieldAlkali metal sulfite preparationSodium metabisulfiteSulfur

The invention discloses a production process of sodium pyrosulfite. The production process comprises the following steps: combusting fluidized sulfur powder in the air to generate mixed SO2 gas; washing out sulfur steam and SO3 in the mixed gas by using clear water; reacting the purified SO2 gas with a pure alkali solution to obtain a sodium pyrosulfite oversaturated solution; centrifugally separating the oversaturated solution by using a centrifuging machine; recycling the centrifuged mother solution; drying the centrifuged solid by using hot air to obtain a sodium pyrosulfite product; and packing and warehousing the product to obtain commodity sodium pyrosulfite. The product produced by using the production process is high in yield, the product purity is high, and the raw material utilization ratio is high; and moreover, the process flow is simple, the mother solution and energy are recycled repeatedly, the energy consumption in a production process is lowered greatly, the aims of saving energy and reducing emission are fulfilled, the production cost is lowered, and the economical benefit is remarkably increased.

Owner:梅州联进化工有限公司

Popular searches

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com