Method for preparing anhydrous sodium sulfite using industrial by-product anhydrous sodium sulfate

A technology of anhydrous sodium sulfite and anhydrous sodium sulfate, which is applied in the field of preparation of anhydrous sodium sulfite, can solve problems such as social hazards, waste of resources, and environmental pollution, and achieve the effects of increasing economic benefits, strengthening environmental protection, and reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

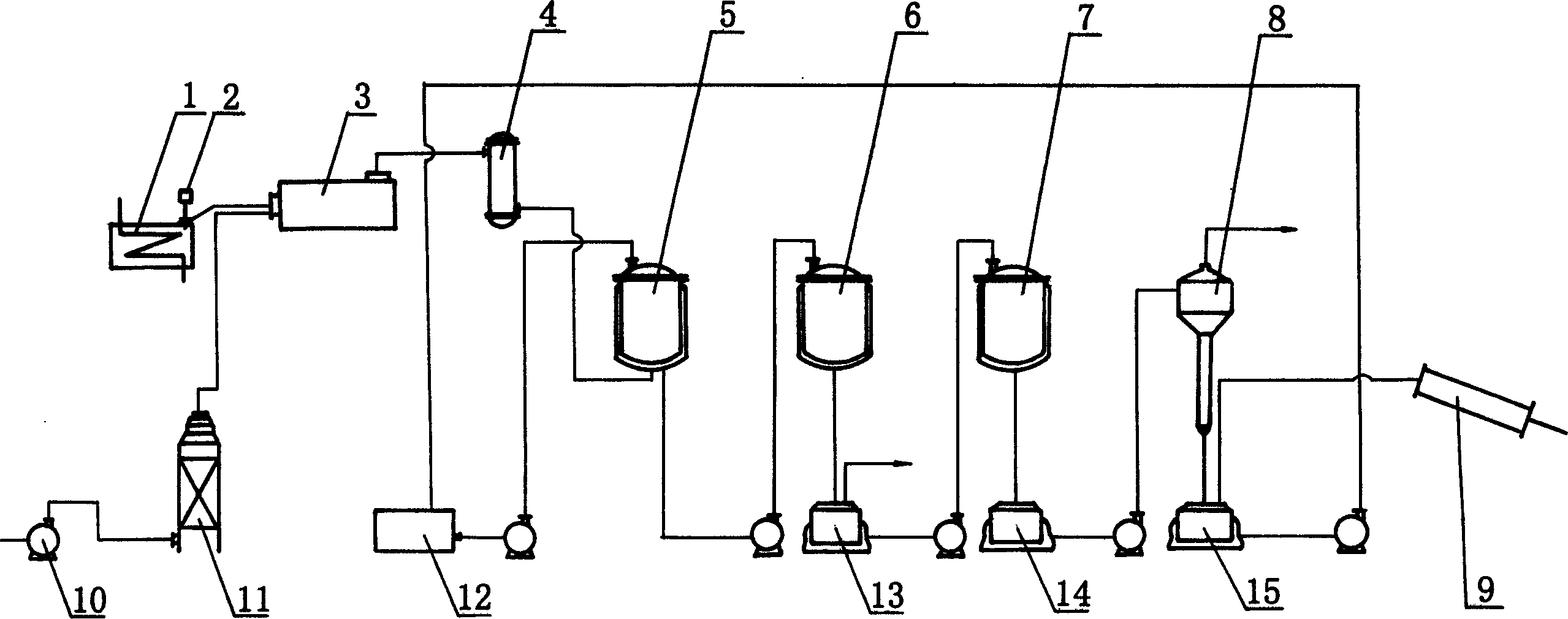

[0028] Refer to attached picture Firstly, industrial sulfur is put into the molten sulfur tank 1 to be melted to a liquid state, and kept warm to 135-140°C, and then the sulfur pump is used to pass through the filter device 2 to the sulfur furnace 3 in the form of mist, and after being dried by the air blower 10 and the dryer 11, it is passed through the furnace. Enter the air of sulfur incinerator 3 to carry out mixed combustion together, the weight of its sulfur is 1 kilogram, and air is 380 cubic meters, and control temperature is at 800~1000 ℃, makes the volume content of sulfur dioxide in furnace gas at 19~21%, then will The furnace gas is cooled and purified by the cooler 4, and the temperature of the furnace gas is controlled at 40-50°C; then 390 kg of sodium sulfite mother liquor, 3,300 kg of evaporated condensed water and quicklime are mixed and digested into the ash reduction device 12 to form a suspension of ash. The ash suspension contains calcium hydroxide Ca(OH) ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com