Method for desulphurization and dust removal of flue gas and recycling of sodium sulfite

A sodium sulfite, desulfurization and dust removal technology, applied in the field of air pollution control, can solve the problems of high operating cost of sulfur dioxide, large waste liquid discharge, large water resource consumption, etc., easy to transport and follow-up treatment, low liquid content of filter cake, The effect of reducing equipment investment and floor space

Active Publication Date: 2014-06-18

CHINA PETROCHEMICAL CORP +1

View PDF11 Cites 9 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

To solve the problems of high investment, high energy consumption, large waste liquid discharge, large water resource consumption, and high operating cost per unit of sulfur dioxide in the existing flue gas desulfurization technology

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

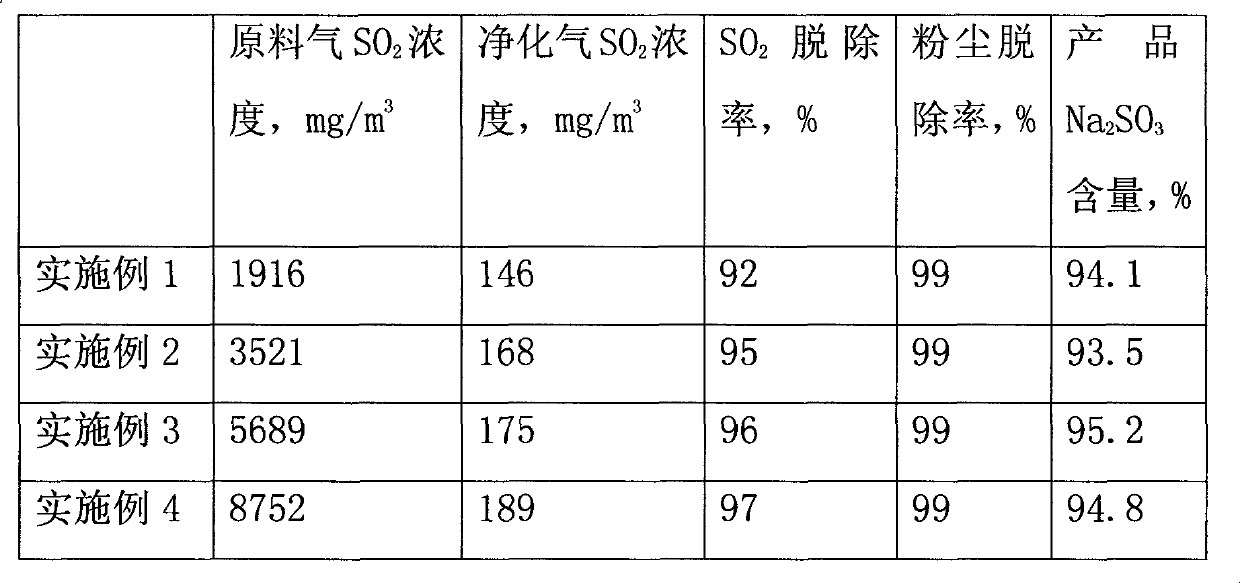

Embodiment 1

[0038] The flue gas inlet temperature is 120°C, and the liquid-gas ratio is 0.5kg / m 3 , the experimental results are shown in Table 1

Embodiment 2

[0040] The flue gas inlet temperature is 180°C, and the liquid-gas ratio is 1.0kg / m 3 , the experimental results are shown in Table 1

Embodiment 3

[0042] The flue gas inlet temperature is 200°C, and the liquid-gas ratio is 1.5kg / m 3 , the experimental results are shown in Table 1

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

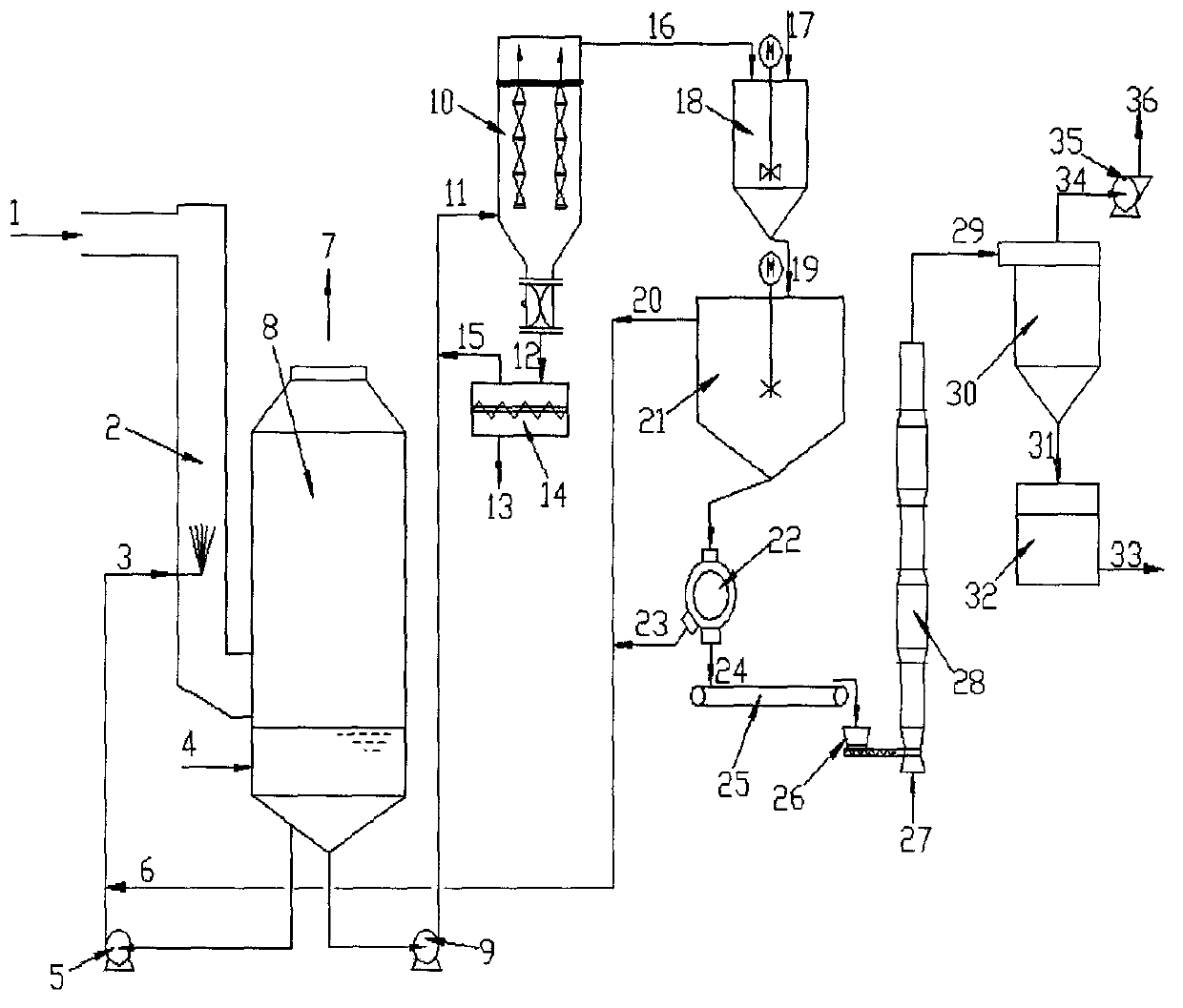

The invention belongs to the field of atmospheric pollution governance, relates to a method for desulfurization and dust removal of flue gas, and particularly relates to a low-energy-consumption method for desulphurization and dust removal of the flue gas and recycling of sodium sulfite. The technical problems to be solved comprise the problems of high investment, large energy consumption, large waste liquid emission load, large water resource consumption, high operating cost of per unit of sulfur dioxide and the like existing in a conventional fuel gas desulfurization technology, and the invention provides a process route comprising the steps of taking a sodium sulfite / sodium hydrogen sulfite mixed solution as a desulfurization agent, washing and purifying the sulfur-containing flue gas, and recycling the anhydrous sodium sulfite product.

Description

technical field [0001] The invention belongs to the field of air pollution control, and in particular relates to a flue gas desulfurization method. Background technique [0002] With the increase of human demand for energy, the SO formed in the process of burning coal, fuel oil and oil refining x Emissions are increasing day by day. SO x is one of the main air pollutants, SO in the atmosphere x It seriously endangers the human living environment in the form of acid rain. Over the years, SO x Governance has received extensive attention at home and abroad, and has become an important part of protecting the environment and controlling air pollution. [0003] There are many flue gas desulfurization technologies researched and developed by various countries in the world, some of which have been industrialized. The desulfurization principle is basically the same, that is, to use the alkaline absorbent and the acidic SO generated during the fuel combustion process. x The rea...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): B01D53/18B01D47/00C01D5/14

Inventor 陈卫红李朝恒裴旭东郭荣群郭玉涛涂先红张凡王秀珍

Owner CHINA PETROCHEMICAL CORP

Who we serve

- R&D Engineer

- R&D Manager

- IP Professional

Why Patsnap Eureka

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com