Method for preparing peroxidized dicarbonate (2-ethylhexyl) ester (EHP) by continuous flow

A technology of dicarbonic acid peroxide and ethylhexyl, applied in the chemical industry, can solve problems such as poor quality stability and reproducibility, uneven temperature distribution, and high labor intensity of workers, so as to achieve stable product quality, low labor intensity, The effect of stable production process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

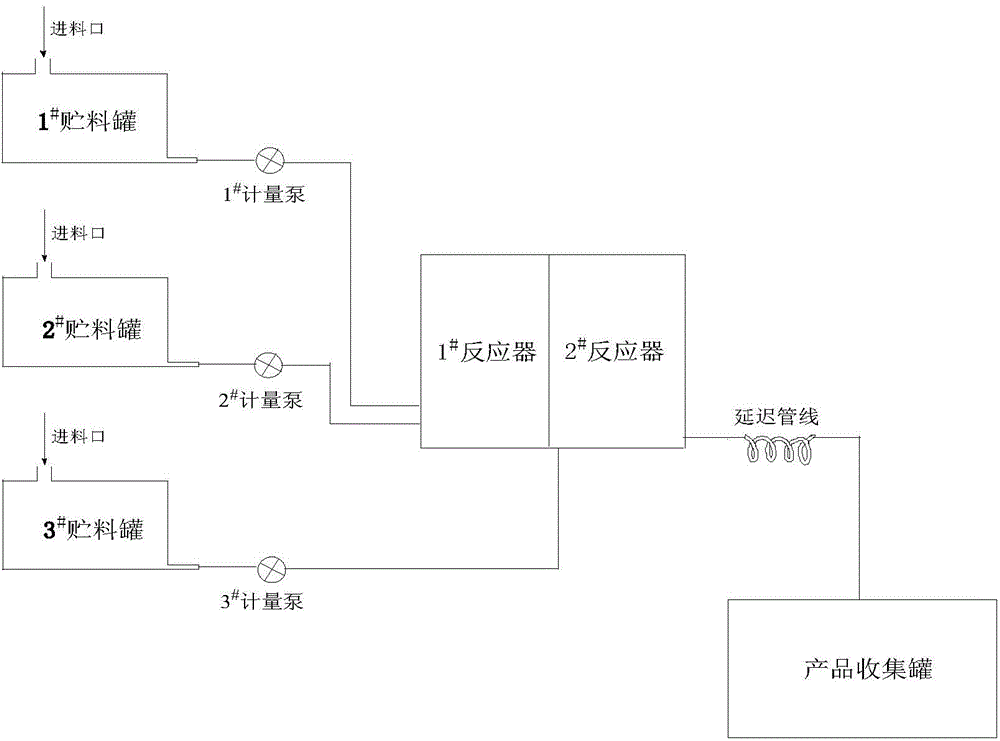

Method used

Image

Examples

Embodiment 1

[0029] (1) solid sodium hydroxide is added into deionized water to be mixed with a 10% sodium hydroxide aqueous solution;

[0030] (2) will 1 # The flow rate of the metering pump is set to 360ml / min, 2 # The flow rate of the metering pump is set to 40ml / min, and 1 # Metering pump, 2 # Metering pump, so that sodium hydroxide aqueous solution and 27.5wt% hydrogen peroxide enter 1 at a steady flow rate respectively # React in the reactor, add the brine of 5wt% concentration simultaneously to control reaction temperature at 10 ℃, then enter 2 # reactor;

[0031] (3) Setting 3 # The flow rate of the metering pump is 130ml / min, 3 # metering pump in 1 # Metering pump, 2 # The metering pump is turned on after 60 seconds, so that the 2-ethylhexyl chloroformate solution of 98wt% purity enters the 2 # The reactor reacts with the product of sodium hydroxide aqueous solution and hydrogen peroxide, adding brine to control the reaction temperature at 25°C;

[0032] (4) The product ...

Embodiment 2

[0034] (1) solid sodium hydroxide is added into deionized water to be mixed with a 15% sodium hydroxide aqueous solution;

[0035] (2) will 1 # The flow rate of the metering pump is set to 420ml / min, 2 # The flow rate of the metering pump is set to 70ml / min, and 1 # Metering pump, 2 # Metering pump, so that sodium hydroxide aqueous solution and 27.5wt% concentration of hydrogen peroxide enter 1 at a steady flow rate respectively # React in the reactor, add the brine of 7wt% concentration simultaneously to control reaction temperature at 15 ℃, then enter 2 # reactor;

[0036] (3) Setting 3 # The flow rate of the metering pump is 180ml / min, 3 # metering pump in 1 # Metering pump, 2 # After the metering pump is turned on for 80 seconds, the chloroformate-2-ethylhexyl ester solution with a purity of 98wt% enters the 2 # The reactor reacts with the product of sodium hydroxide aqueous solution and hydrogen peroxide, adding brine to control the reaction temperature at 30°C; ...

Embodiment 3

[0039] (1) adding solid potassium hydroxide to deionized water to prepare an aqueous potassium hydroxide solution with a concentration of 12.5%;

[0040] (2) will 1 # The flow rate of the metering pump is set to 460ml / min, 2 # The flow rate of the metering pump is set to 80ml / min, and 1 # Metering pump, 2 # Metering pump, so that potassium hydroxide aqueous solution and 27.5wt% concentration of hydrogen peroxide enter 1 at a steady flow rate respectively #React in the reactor, add the brine of 10wt% concentration simultaneously to control reaction temperature at 12 ℃, then enter 2 # reactor;

[0041] (3) Setting 3 # The flow rate of the metering pump is 170ml / min, 3 # metering pump in 1 # Metering pump, 2 # The metering pump is turned on after 50 seconds, so that the 2-ethylhexyl chloroformate solution of 98wt% purity enters the 2 # The reactor reacts with the product of potassium hydroxide aqueous solution and hydrogen peroxide, adding brine to control the reaction t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com