Hydrogel antifouling fiber, preparation method thereof and preparation method of implanted type high-strength hydrogel antiflouling coating layer

An anti-fouling coating, hydrogel technology, applied in coating, fiber treatment, devices for coating liquid on the surface, etc. Safe and non-toxic, improved antifouling performance and simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

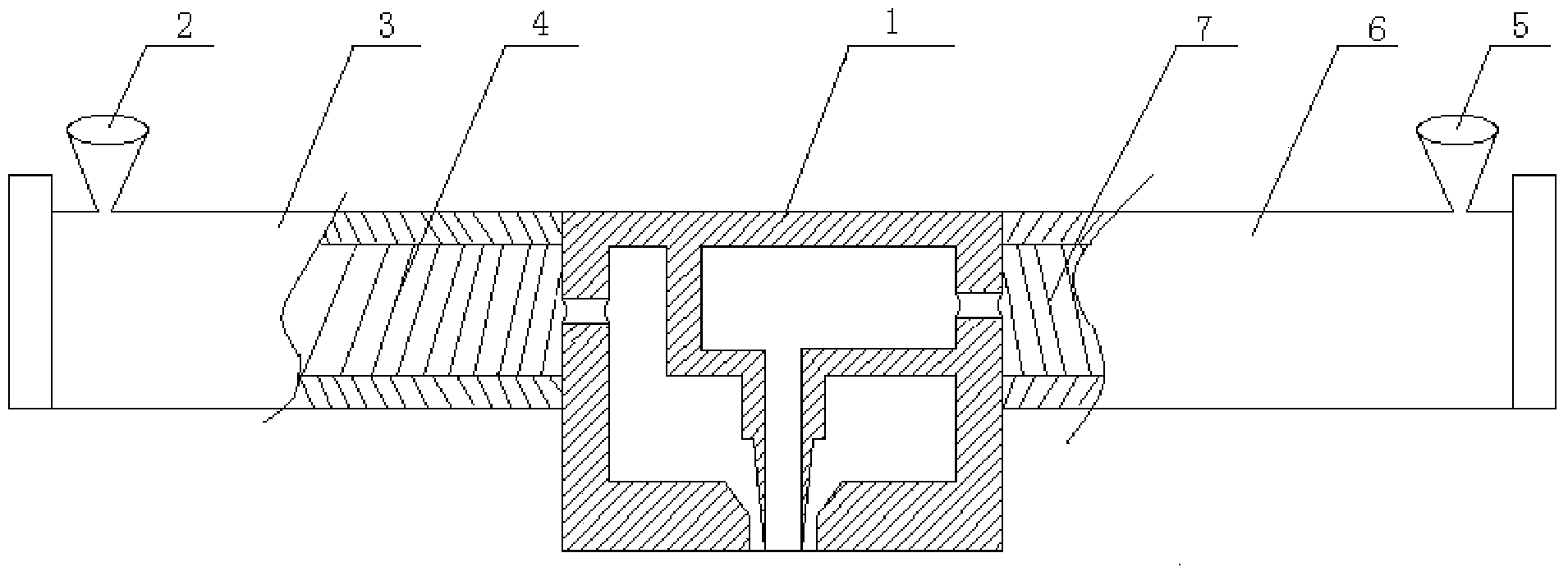

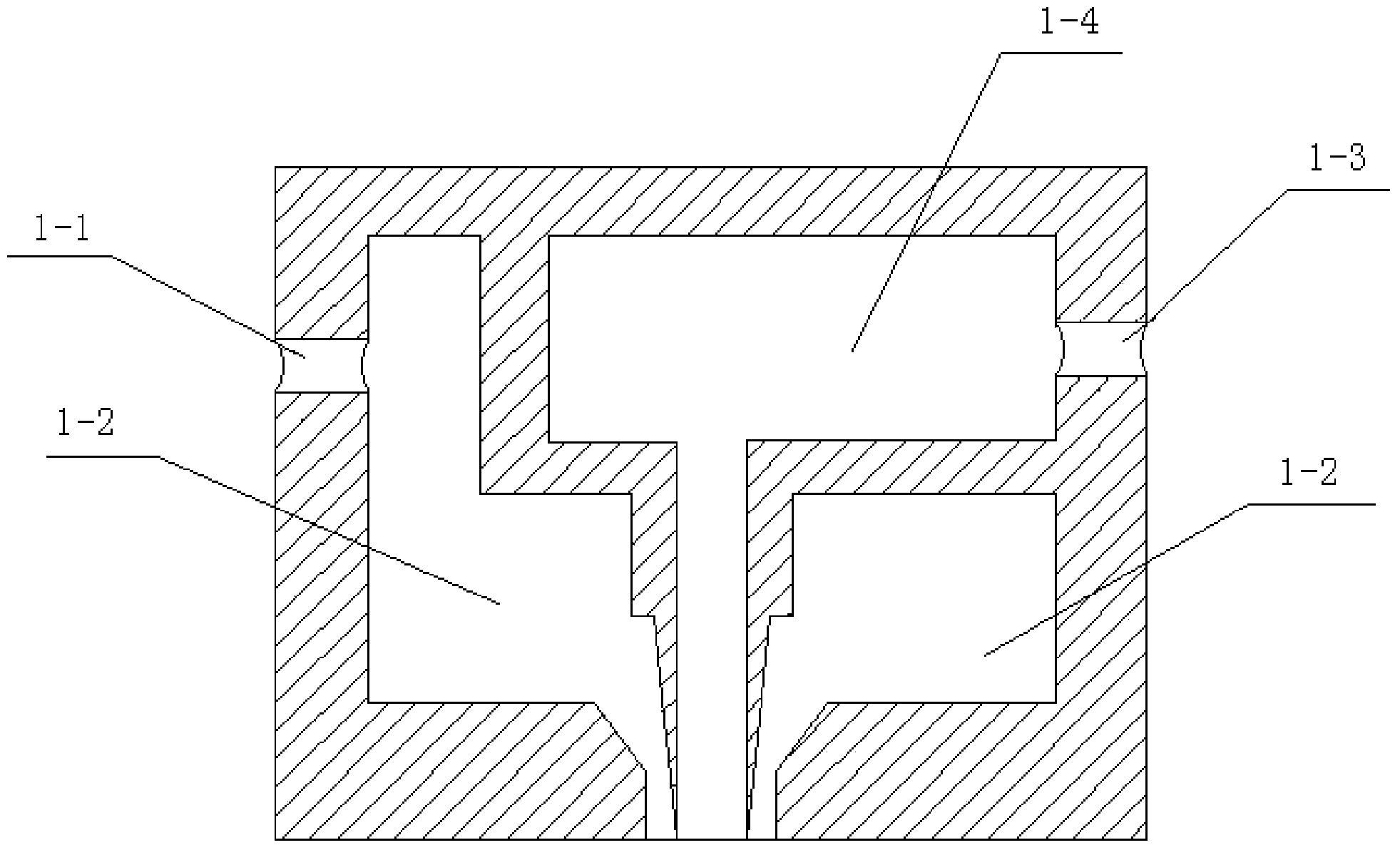

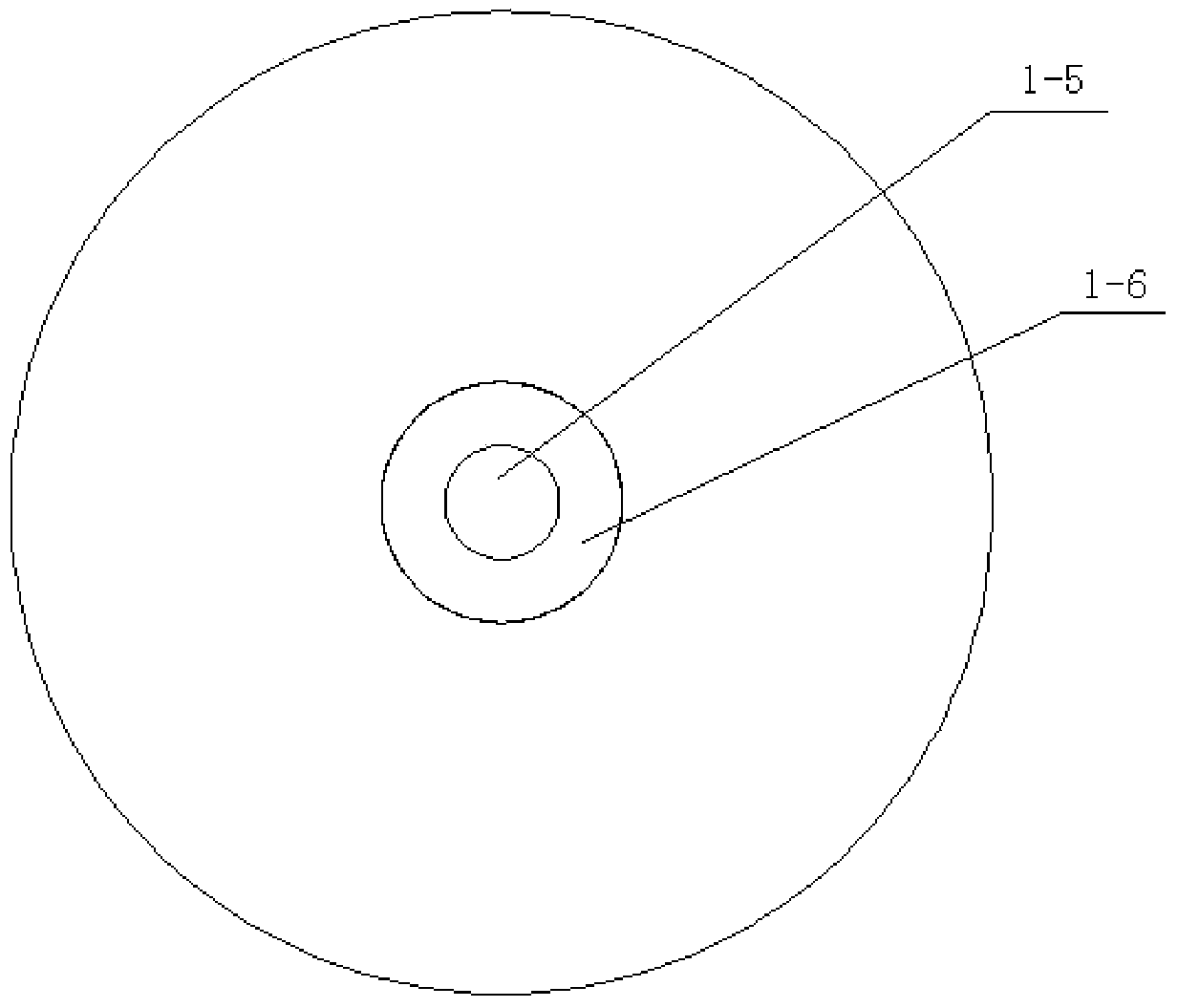

[0032] Embodiment 1: A hydrogel antifouling fiber of this embodiment has a core-shell structure, the shell layer is polyacrylamide, and the core layer is carbon nanotube (CNT) modified polyacrylamide.

specific Embodiment approach 2

[0033]Embodiment 2: This embodiment differs from Embodiment 1 in that the outer diameter of the hydrogel antifouling fiber is 20-60 μm, and the thickness of the shell layer is 10-30 μm. Others are the same as in the first embodiment.

specific Embodiment approach 3

[0034] Embodiment 3: This embodiment differs from Embodiments 1 to 3 in that the water absorption rate of the hydrogel antifouling fiber is 50% to 300%. Others are the same as in the first embodiment.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com