Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

553 results about "Triglycidyl isocyanurate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Triglycidyl isocyanurate caused serious eye damage in rabbits, including severe corneal opacity and chemosis. Triglycidyl isocyanurate (commercial grade) was positive for skin sensitization in guinea-pigs in two modified Magnusson and Kligman studies.

Thermosetting acrylic resin for powder coating as well as synthesis method and applications of thermosetting acrylic resin

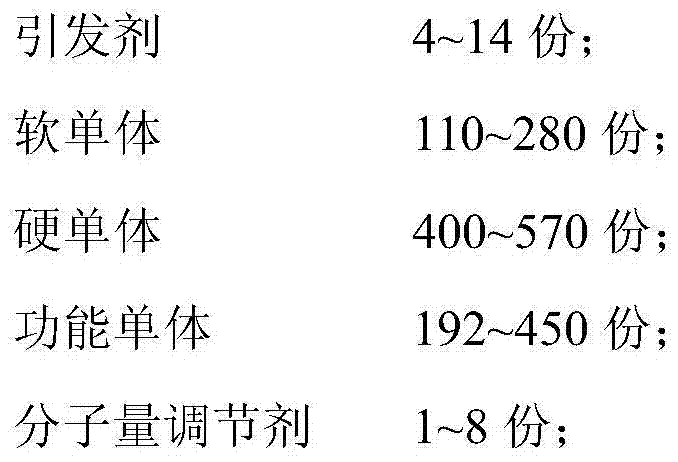

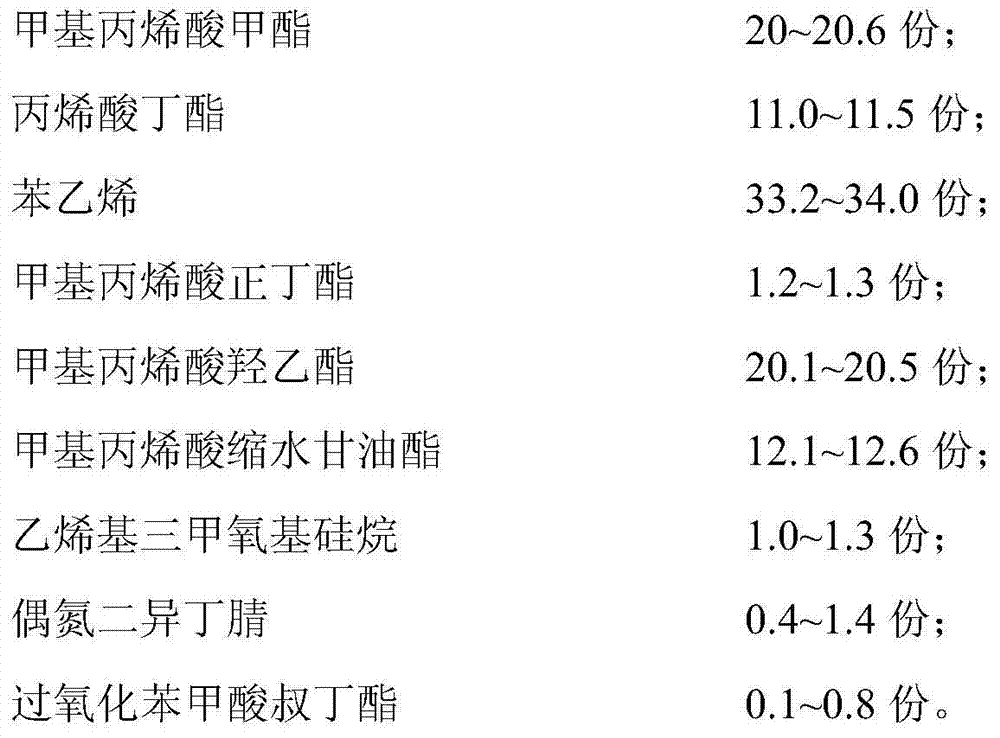

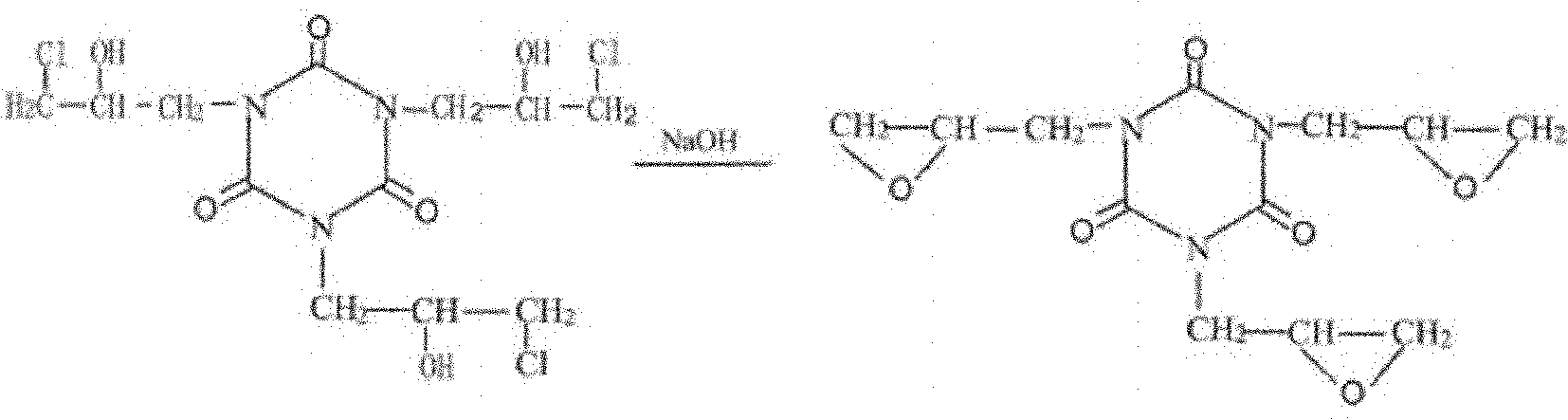

The invention relates to thermosetting acrylic resin for a powder coating. The thermosetting acrylic resin is prepared from the following raw materials in parts by mass: 4-14 parts of an initiator, 110-280 parts of soft monomers, 400-570 parts of hard monomers, 192-450 parts of functional monomers, and 1-8 parts of a molecular weight regulator, wherein the soft monomers refer to acrylic acid alkyl ester compounds, and the hard monomers refer to methacrylate, styrene, or compounds of derivatives of methacrylate and styrene. The acrylic resin contains epoxy functional groups and hydroxyl functional groups simultaneously, wherein the epoxy equivalent is 570-630g / mol and the hydroxyl value is 40-50mgKOH / g; the acrylic resin can react with various substances such as carboxyl, amidogen and isocyanate and can be used for powder coating. A coating film, which is formed after the thermosetting powder coating prepared from the acrylic resin in combination with other materials is sprayed, has excellent weather resistance, good leveling performance, outstanding surface hardness, and high glossiness, durability and decorating performance; the powder coating can be used for indoor or outdoor metal sectional materials or building materials. The thermosetting acrylic resin can substitute for TGIC (triglycidyl isocyanurate) to a certain extent so as to avoid the use of the toxic substances.

Owner:阜阳市诗雅涤新材料科技有限公司

Carboxyl-terminated polyester resin for super weather-proof powder coating and preparation method thereof

The invention discloses carboxyl-terminated polyester resin for super weather-proof powder coating. The carboxyl-terminated polyester resin is prepared by the condensation polymerization of the following raw materials in percentage by weight: 23-50% of polyhydric alcohol, 40-65% of aromatic polybasic acid, 0-10% of fatty polybasic acid, 0-2% of branching agent, 10-20% of acidolysis agent and 0.01-0.15% of esterification catalyst. The invention also discloses a preparation method of the polyester resin. The super weather-proof polyester resin disclosed by the invention has proper glass-transition temperature and storage stability; and the prepared powder coating has excellent mechanical performance and weather resistance; and the polyester resin is particularly applicable to the powder coating of the polyester / TGI (triglycidyl isocyanurate) solidifying system.

Owner:GUANGZHOU QINGTIAN INDAL

Powdery paint for aluminum profile and preparation method thereof

ActiveCN102516855AStrong adhesionSimple recipePowdery paintsPolyester coatingsComminutionOrganic matter

The invention discloses a powdery paint for aluminum profile and a preparation method thereof. The powdery paint is composed of carboxyl-terminated saturated polyester resin, triglycidyl isocyanurate (TGIC), titanium dioxide, precipitated barium sulfate, a brightener, a leveling agent and benzoin. The preparation method contains the following steps of: batch mixing, melt extrusion, crushing and ultrafine comminution. The powdery paint for aluminum profile has low curing temperature. By the adoption of the powdery paint, volatilization amount of residual TCIC low molecular organic matter is reduced. The powdery paint is beneficial to environmental protection and the health of human body. In addition, the appearance of the film is more flattening and fine.

Owner:广东华江粉末科技有限公司

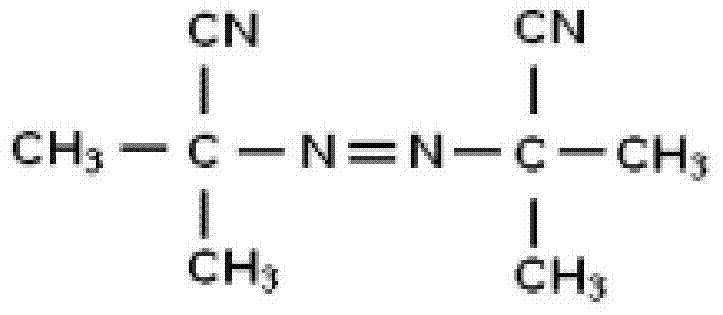

Preparation method of electronic grade triglycidyl isocyanurate

The invention mainly aims to provide a preparation method of electronic grade triglycidyl isocyanurate (TGIC). In order to realize the aim, the technical scheme in the invention is as follows: the preparation method of electronic grade TGIC comprises the following steps: a) adding epichlorohydrin, cyanuric acid, quaternary ammonium salt phase transfer catalyst and water according to a ratio, heating and stirring to react; b) adding flake caustic soda in the reaction system obtained in the step a) to react, then performing pressure filtration to remove solid salt; and c) performing vacuum distillation after the reaction, then using a high vacuum film evaporator to distill and remove epichlorohydrin, crystallizing the coarse product, centrifuging, grinding, and drying to obtain electronic grade TGIC. According to the treatment method provided by the invention, the purity of the TGIC product can be effectively increased, and the purity of TGIC can be increased from 92% to more than 99%, which reaches the electronic grade.

Owner:HUANGSHAN HUAHUI TECH

Polyester resin for triglycidyl isocyanurate (TGIC)-cured weather-resistant heat transfer printing powdery paint and preparation method thereof

ActiveCN102977346AHigh glass transition temperatureHigh softening pointPowdery paintsPolyester coatingsAlcoholPolyol

The invention discloses a polyester resin for a triglycidyl isocyanurate (TGIC)-cured weather-resistant heat transfer printing powdery paint. The polyester resin is prepared by a melt polycondensation reaction of 35 to 40wt% of one or more polyhydric alcohols, 48 to 55wt% of one or more aromatic polybasic acids, 0 to 2wt% of an alicyclic polyol, 0 to 2wt% of one or more alicyclic polybasic acids, 0 to 2wt% of a branching agent, 8 to 15wt% of one or more acidolysis agents, 0.05 to 0.20wt% of an esterification catalyst, 0 to 0.5wt% of one or more main antioxidants, 0 to 0.5wt% of one or more auxiliary antioxidants, and 0 to 0.5wt% of a curing accelerator. The invention also discloses a preparation method of the polyester resin for the TGIC-cured weather-resistant heat transfer printing powdery paint. The polyester resin has a high glass-transition temperature, a high softening point, appropriate melt viscosity and appropriate storage stability. The powdery paint prepared from the polyester resin has excellent heat transfer printing effects, realizes clear heat transfer printed patterns, does not adhere to a transfer paper and realizes easy tearing of the transfer paper.

Owner:GUANGZHOU KINTE IND

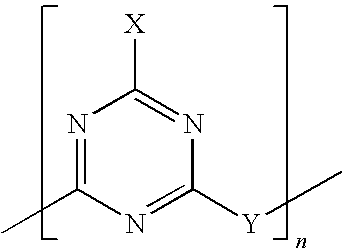

Triazines cross-linking compounds, preparation method and application thereof

InactiveCN101362819AImprove thermal stabilityImprove water resistanceCarbon layerHazardous substance

The invention discloses a triazine crosslinking compound, a preparation method and applications thereof, wherein, the preparation method comprises the following steps: a multi-amidocyanogen compound is added into melt triglycidyl isocyanurate and reacts for 1-3 hours to obtain a pre-polymer, wherein, the molar ratio of the triglycidyl isocyanurate to the multi-amidocyanogen compound is 1:3-1:1; the pre-polymer is placed in an air dry oven at 120-180 DEG C to slake for 4-6 hours, and the triazine crosslinking compound is obtained. Compared with the reported preparations of triazine flame retardants, the preparation method has simple and easy operation, requires no solvent and discharges no harmful substance. The obtained triazine crosslinking compound has good thermal stability and water resistance and can be compounded with ammonium polyphosphate as a carbon source and an air source to generate an intumescent flame retardant which has good inflaming retarding effect when applies to the inflaming retarding of the polymers, and the obtained carbon layer shows a compact and continuous structure.

Owner:SOUTH CHINA UNIV OF TECH

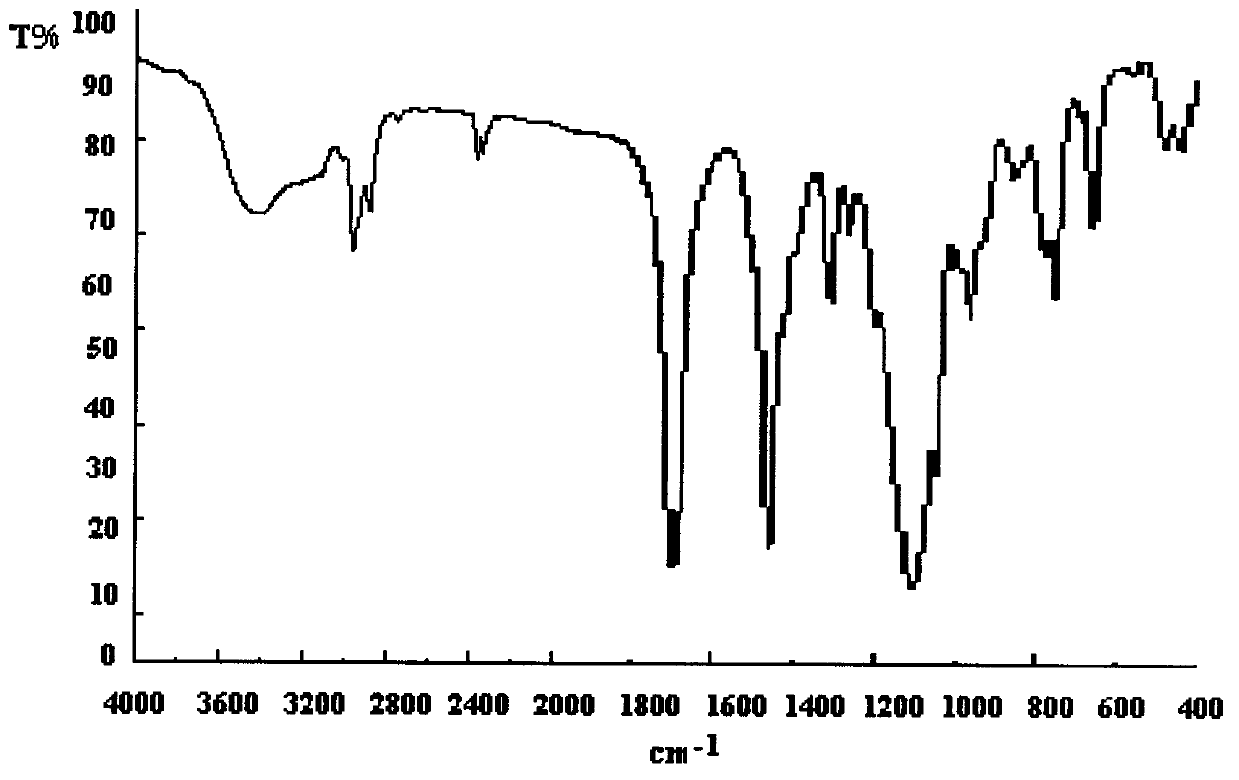

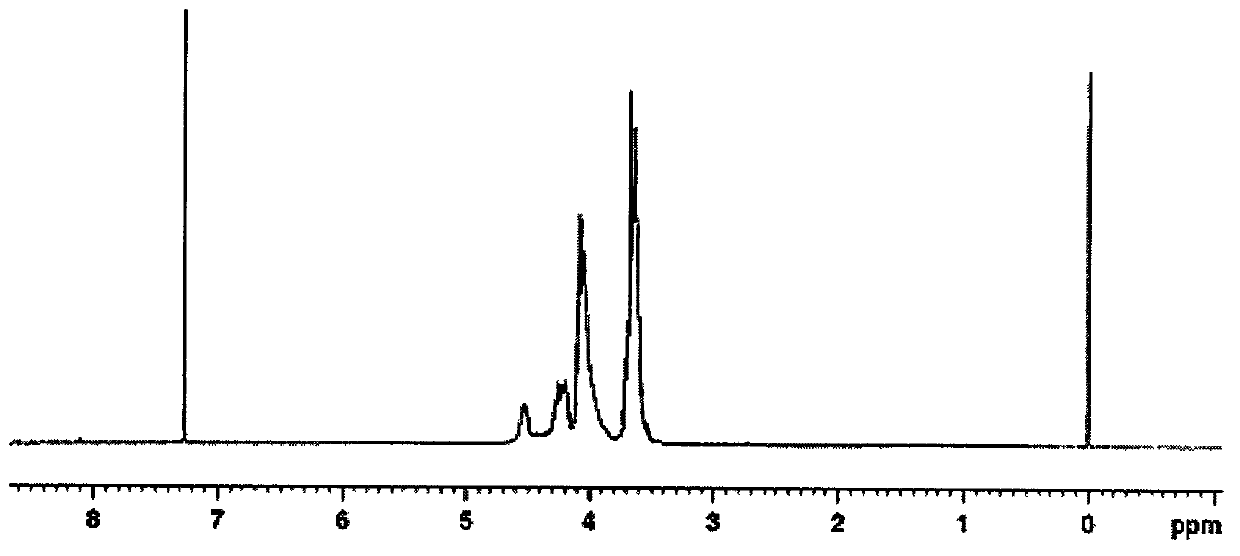

Isocyanurate chloropropyl chloroethyl silicate and preparation method thereof

ActiveCN102731545AGood compatibilityHigh synergistic flame retardant performanceSilicon organic compoundsEpoxyPolyvinyl chloride

The invention relates to a nitrogen, silicon and chlorine thee-element synergic flame retardant tri{2-chloro-3-[tri(chloroethoxy)silicon acyloxy]propyl}isocyanurate compound and a preparation method thereof. The structure of the compound is shown as a formula in the specification. The preparation method comprises the following steps: dripping organic solvent solution of triglycidyl Isocyanurate into silicon tetrachloride, and reacting for 4 to 6 hours at a temperature of between 50 and 70 DEG C; and cooling to 30 DEG C, introducing ethylene oxide under the liquid surface, reacting for 2 to 3 hours at a temperature of between 45 and 55 DEG C, and purifying to obtain the tri{2-chlor-3-[tri(chloroethoxy)silicon acyloxy]propyl}isocyanurate. The compound has good flame retardant plasticization, and is suitable for flame retardant plasticizer such as polyvinyl chloride, polyurethane, epoxy resin, unsaturated resin and the like; and the method has simple production process and low cost, and is easy for industrial production.

Owner:SUZHOU UNIV OF SCI & TECH

Sand pattern powder coating for aluminum profiles as well as preparation method and application thereof

InactiveCN102775888AFeel smoothNot easy to scratchPowdery paintsPolyester coatingsSodium BentoniteRoom temperature

The invention belongs to the technical field of new materials and discloses a sand pattern powder coating for aluminum profiles as well as a preparation method and application thereof. The coating is prepared from the following raw materials in percentage by weight: 50-60% of saturated carboxyl polyester resin, 3.7-4.5% of triglycidyl isocyanurate, 17-27% of titanium dioxide, 13-20% of precipitated barium sulfate, 0.2-1.5% of bentonite, 0.2-0.7% of sand pattern agent, 0.3% of carbon black, 0.1-0.2% of pink and 0.1-0.2% of phthalocyanine blue. The preparation method comprises the following steps of: putting the raw materials into a mixing cylinder and premixing the raw materials; carrying out melt extrusion on the premixed raw materials and then pressing the materials into flakes; cooling the flakes to room temperature, crushing the flakes and then carrying out fine crushing; and screening the finely crushed materials to obtain the product.

Owner:广东华江粉末科技有限公司

Thermosetting powders comprising curing agent adducts of polyesters and strong, flexible powder coatings made therefrom

InactiveUS20080233300A1Improve impact resistanceIncrease flexibilityPretreated surfacesEpoxy resin coatingsGlycolurilPolyester

The present invention provides thermosetting polyester powder or epoxy-containing acrylic powder compositions comprising one or more curing agent adduct of a polyester, preferably a linear polyester, wherein when the said curing agent adduct comprises an adduct of one or more polyepoxy compound, the said polyepoxy compound has an average of 2.01 or more epoxy groups per molecule. The compositions provide flexible coatings, films and capstocks having improved impact resistance, especially for use in automotive and architectural applications. To improve impact strength of coatings and films provided thereby, the compositions comprise curing agent adducts of one or more polyepoxy compound chosen from triglycidyl isocyanurate (TGIC) and triglycidyl trimellitate with a carboxyl functional polyester having a carboxyl equivalent weight of 602 or more. In addition, to further improve the impact strength of coatings and films provided thereby, the compositions may comprise one or more adjunct curing agent, such as glycoluril, an aminoplast resin or a blocked isocyanate.

Owner:AKZO NOBEL COATINGS INT BV

Preparation method of polyester resin capable of being used for outdoor dry mixed extinction powder coating

InactiveCN102719180ANo post-processingEasy material selectionPowdery paintsPolyester coatingsPolymer sciencePolyol

The invention relates to a preparation method of polyester resin capable of being used for an outdoor dry mixed extinction powder coating. The preparation method is characterized by comprising the following steps of: adding polybasic acid or anhydride, polyatomic alcohol, a catalyst and an antioxidant according to a mass ratio into a reaction kettle for mixing; introducing nitrogen; heating to a temperature of 100-300 DEG C until a reaction solution is completely clarified to obtain A-component polyester resin; adding polybasic acid or anhydride, polyatomic alcohol, a catalyst and an antioxidant into the reaction kettle to be mixed; introducing nitrogen; heating to a temperature of 100-300 DEG C until a reaction solution is completely clarified; and carrying out vacuum condensation polymerization on the clarified reaction solution until an acid value is 10-50 mg KOH / g and a viscosity is 30-100 P to obtain B-component polyester resin; mixing the A-component polyester resin with triglycidyl isocyanurate, barium sulfate, titanium dioxide, a flatting agent, a brightener and benzoin according to a mass ratio to obtain a powder coating I; mixing the B-component polyester resin with triglycidyl isocyanurate, barium sulfate, titanium dioxide, a flatting agent, a brightener and benzoin to obtain a powder coating II; and mixing the powder coating I with the powder coating II to obtain the powder coating with low brightness. The preparation method has the advantages of stable extinction effect of outdoor dry mixed extinction polyester, better coating property and the like.

Owner:佛山市顺德区伊诗德新材料科技有限公司

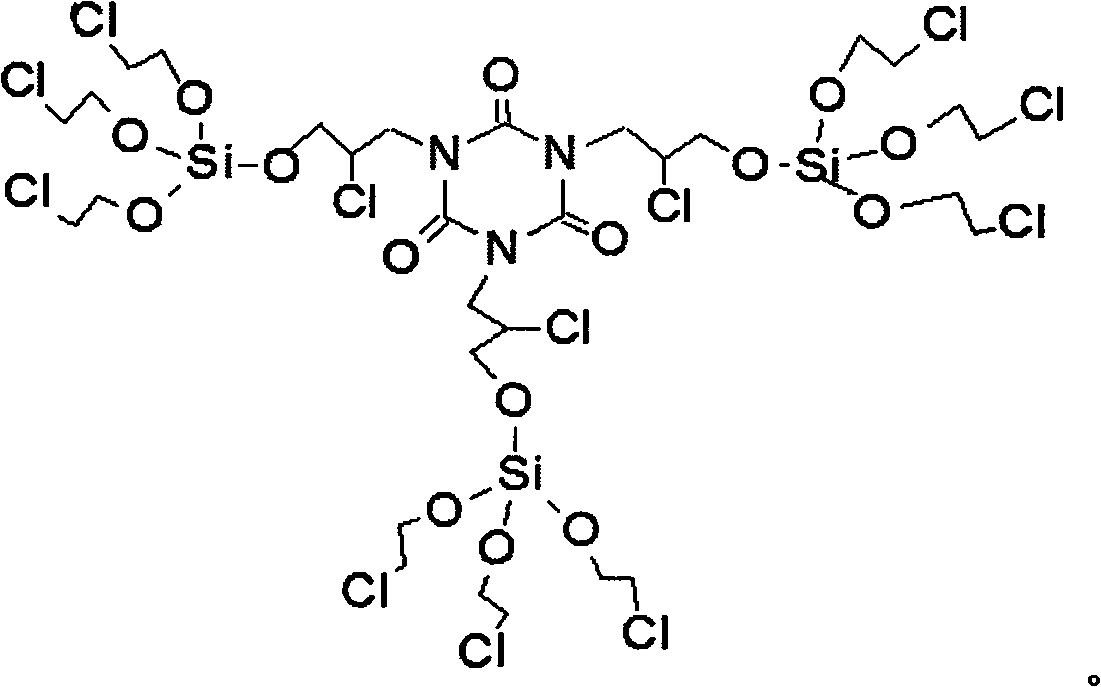

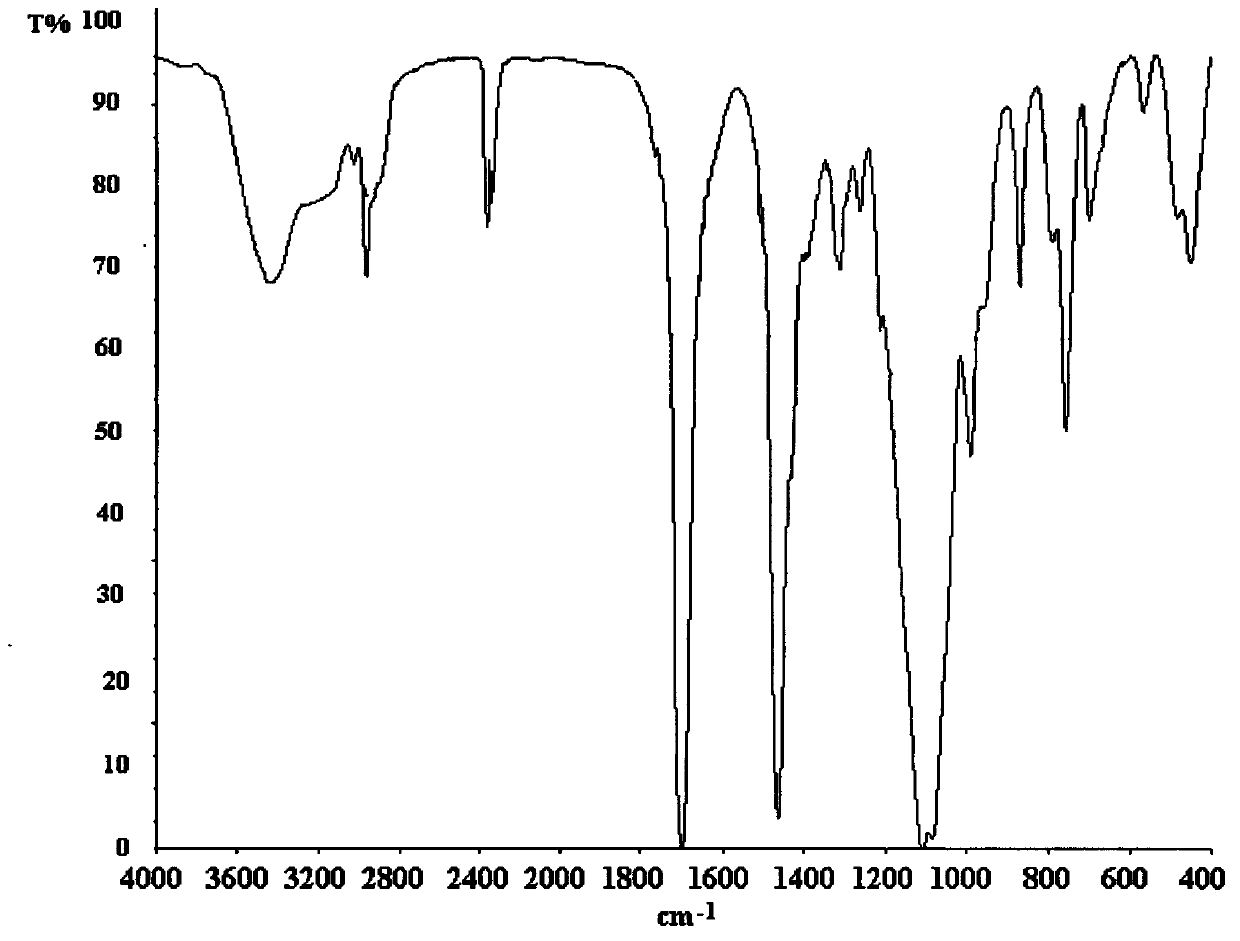

Nitrogen-containing chloro-polysilicate compound and preparation method thereof

The invention relates to a tri{2-chloro-3-[tri(dichloropropoxy)silicon acyloxy]propyl}isocyanurate compound and a preparation method thereof. The structure of the compound is shown in the specification. The preparation method comprises the steps of adding triglycidyl isocyanurate in a certain molar ratio to silicon tetrachloride, preserving heat at 60 DEG C and reacting for 4-5 hours, then dropwise adding epoxy chloropropane in a certain molar ratio, preserving heat at 70-90 DEG C and reacting for 6-8 hours to obtain tri{2-chloro-3-[tri(dichloropropoxy)silicon acyloxy]propyl}isocyanurate through purification treatment. The compound is an excellent flame-retardant plasticizer; and the preparation method is simple in production process and low in equipment investment and is easy for industrial production.

Owner:张家港市乐余科创园投资发展有限公司

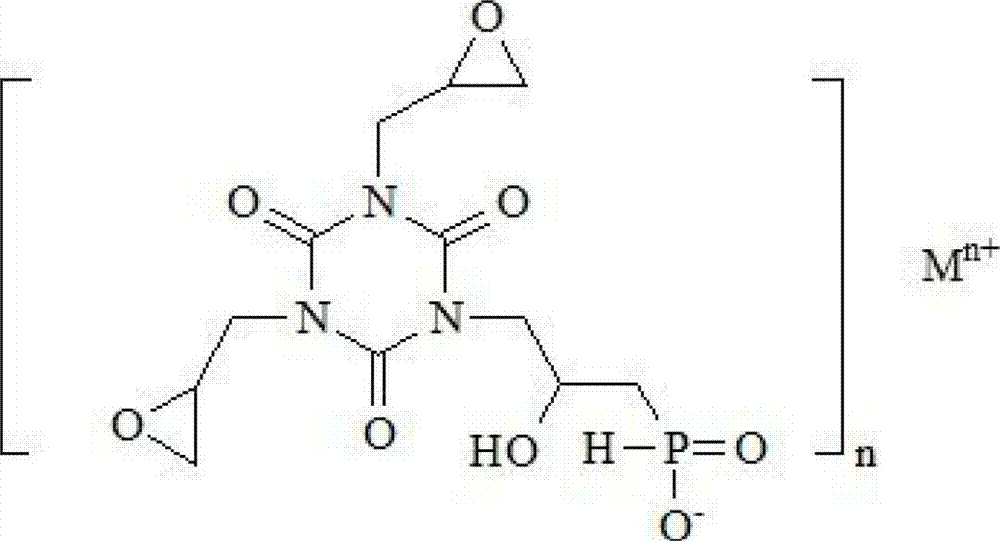

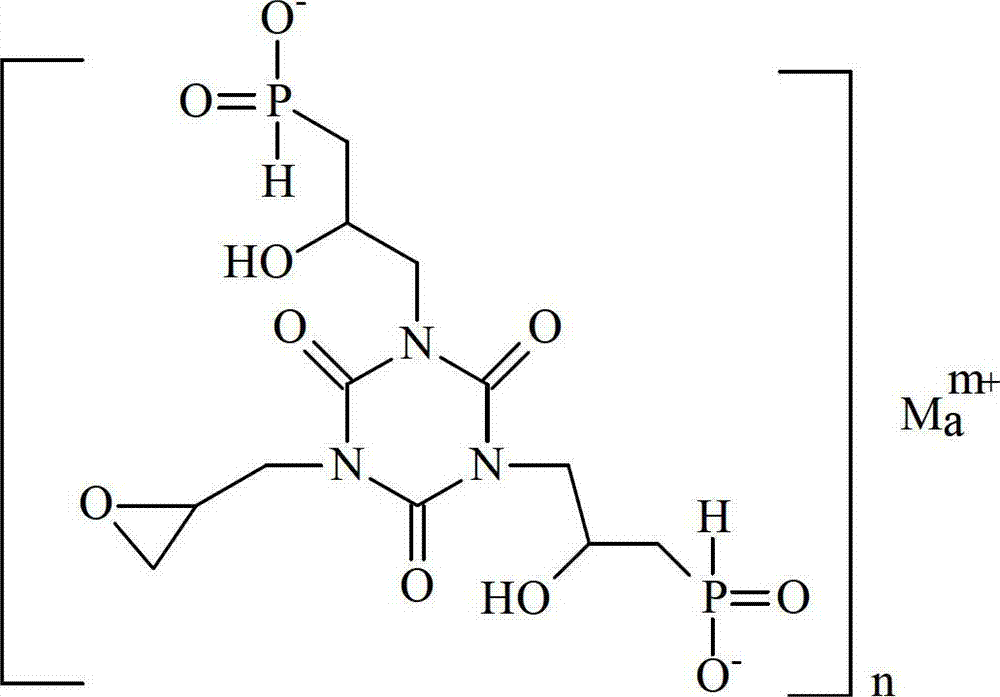

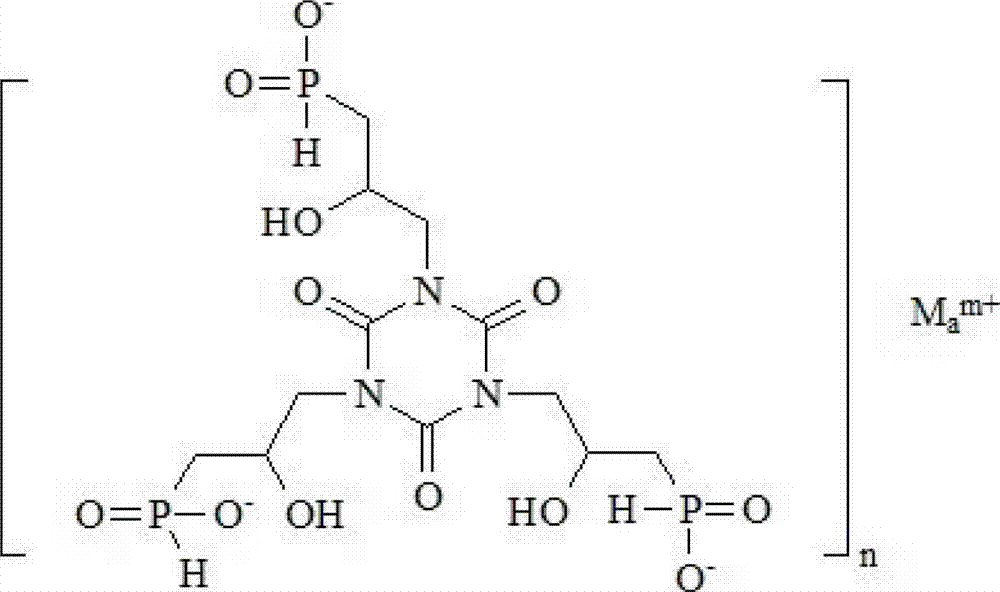

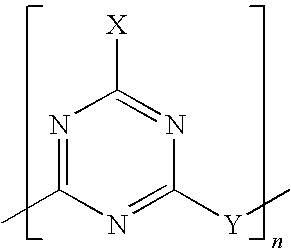

Halogen-free flame retardant and preparation method thereof

ActiveCN103030836AImprove flame retardant performanceIn line with the trend of non-halogenationGroup 5/15 element organic compoundsPolyethylene terephthalate glycolPolymer science

The invention relates to a halogen-free flame retardant and a preparation method thereof. The flame retardant is formed by combining one or two of the following three organic hypophosphite compounds containing triazine ring structures at any mass ratio. The preparation method of the halogen-free flame retardant comprises the following steps of adding triglycidyl isocyanurate and hypophosphite into a reaction vessel, taking ethanol, ethylene glycol or glacial acetic acid as a solvent, heating slowly and maintaining a reaction, conducting suction filtration, washing and drying after the reaction is finished, and obtaining the halogen-free flame retardant. The halogen-free flame retardant is prepared by taking hypophosphite and triglycidyl isocyanurate (TGIC) as main raw materials, and has the characteristics that the raw materials are easy to obtain, a process is simple and easy to run, and the production and the operation are safe. The prepared halogen-free flame retardant and a composition are good in thermostability and excellent in comprehensive property; various colors can be blended; the halogen-free flame retardant and the composition can be applied to flame retarding PBT (polybutylece terephthalate) engineering plastics, PA6 (polyamide6) or PET(polyethylene terephthalate) and the like, and are good in application prospect.

Owner:湖南美莱珀科技发展有限公司

Boil-resistant polyester powder coating, and preparation method and application thereof

ActiveCN103146292APrevent shrinkageThe role of preventing exposurePolyurea/polyurethane coatingsPolyester coatingsAcid valuePermeation

The invention relates to a boil-resistant polyester powder coating which comprises the following components: a high-acid-value polyester resin particle system containing high-acid-value polyester resin, curing agents A and stuffing A, and a low-acid-value polyester resin particle system containing low-acid-value polyester resin, curing agents B and stuffing B. The curing agents A and the curing agents B are mutually-independent mixed curing agent systems of hydroxyalkyl acidamide (HAA) and isocyanic acid ester. The stuffing A and the stuffing B are mutually-independent aluminum hydroxides or hydrophobic stuffing. According to the boil-resistant polyester powder coating, the hydrophobic stuffing is added into the high-acid-value polyester resin particle system and the low-acid-value polyester resin particle system, so that water permeation is effectively blocked, and therefore the polyester powder coating is protected. The boil-resistant property of the boil-resistant polyester powder coating is even more than that of a polyester powder coating which is curded by means of triglycidyl isocyanurate (TGIC) curing agents.

Owner:NINGBO SOUTH SEA CHEM

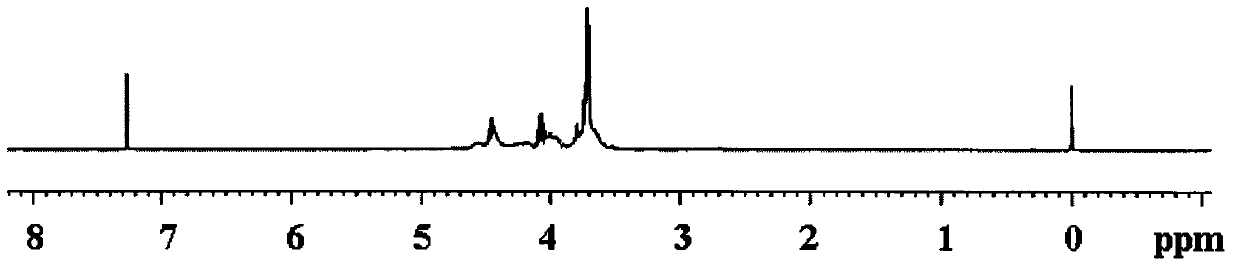

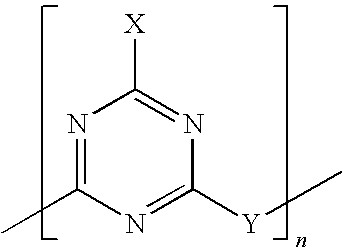

Organic hypophosphite containing triazine ring structure and method for preparing same

ActiveCN102977144AImproved blending dispersibilityImprove flame retardant performanceGroup 5/15 element organic compoundsThermal stabilityMetal

The invention relates to an organic hypophosphite containing a triazine ring structure and a method for preparing the same. The organic hypophosphite containing the triazine ring structure is prepared from the hypophosphite and the triglycidyl isocyanurate which serve as the main raw materials. The method comprises the following steps: subjecting the triglycidyl isocyanurate and the hypophosphite to reaction in a solvent system for a certain time at a certain temperature; filtrating; washing; drying; and grinding to obtain the organic hypophosphite containing the triazine ring structure. The method has the characteristic of readily-available raw materials, simple process and safe production and operation. The organic hypophosphite prepared by adopting the method has good thermal stability and excellent overall performance, can be used as the flame retardant, rare metal ion extractant and scale and corrosion inhibitor and has a good application prospect.

Owner:湖南美莱珀科技发展有限公司

High-temperature-resistant powder coating with good gloss-retention performance and production method thereof

InactiveCN103965752AReduce sheddingReduce oxidationPowdery paintsPolyester coatingsPhosphoric Acid EstersFirming agent

The invention relates to a high-temperature-resistant powder coating with good gloss-retention performance. The high-temperature-resistant powder coating is characterized by comprising the following constituents in mass percentage: 58-62 parts of polyester resin, 4-5 parts of TGIC (Triglycidyl Isocyanurate) curing agent, 0.2-0.5 part of wax powder, 0.3-1 part of organic soil, 1.5-2.5 parts of ammonium polyphosphate temperature resistant auxiliary, 0.3-0.6 part of phosphite ester antioxidant, 0.1-0.3 part of a sand ripple agent, 0.6-1.2 parts of carbon black, 20-30 parts of precipitated barium sulphate, and 2-5 parts of asbestos powder.

Owner:ZHANGJIAGANG JIANGNAN POWDER COATING

Process for preparing triglycidyl isocyanurate

InactiveCN101367796AReduce consumptionHigh yieldOrganic chemistryPowdery paintsDistillationFirming agent

The present invention relates to a production method of powder coating firming agent, in particular to a production method of tris (2, 3-epoxy propyl) isocyanurate, and belongs to the technical field of chemical production. Two catalysts used in the production method effectively control the side reaction, thereby greatly improving the yield rate and quality of the product; when the distillation is performed, the vacuum degree can be increased to reduce the distillation temperature so as to process the synthesized materials at the low temperature, the raw material epichlorohydrin can be reclaimed, the consumption of the raw material is reduced from original 1.55 tons to 1.3 tons. The present invention overcomes the defects in the old technology. The experiments on batch production prove that the process conditions are mature and feasible, the conversion is high, the quality of the product is stable, the yield is above 80 percent, the consumption of raw materials is less, and the present invention has broad market prospects.

Owner:CHANGZHOU NIUTANG CHEM PLANT CO LTD

Polyester resin for weather-proof and impact-resisting powder coating and preparation method of polyester resin

InactiveCN104356369AModerate glass transition temperatureGood storage stabilityPolyurea/polyurethane coatingsPowdery paintsAlcoholWeather resistance

The invention discloses polyester resin for a weather-proof and impact-resisting powder coating. The polyester resin is mainly prepared through polycondensation and synthesis of raw materials in percentage by weight as follows: 34%-40% of polyhydric alcohol, 50%-60% of polyatomic acid, 0.1%-0.5% of a branching agent, 0.05%-1.0% of an esterification catalyst, 5%-10% of an acidulation agent, 0.05%-1.0% of a curing accelerator and 0.4%-0.8% of an antioxidant. The invention further discloses a preparation method of the polyester resin. The polyester resin has excellent weather resistance and impact resistance, simultaneously has good levelling property, appropriate glass transition temperature and better storage stability and is applicable to a TGIC (triglycidyl isocyanurate)-polyester powder curing system.

Owner:GUANGZHOU KINTE IND

Antibiotic powdery paint for aluminium profile and preparation method thereof

InactiveCN102516854ASimple recipeReduce manufacturing costAntifouling/underwater paintsPaints with biocidesEnd-groupMildew

The invention discloses an antibiotic powdery paint for aluminium profile and a preparation method thereof. The antibiotic powdery paint comprises carboxyl end group saturated polyester resin, triglycidyl isocyanurate (TGIC), titanium dioxide, precipitated barium sulfate, antibiotic mildew inhibitor, brightener, levelling agent and benzoin. A preparation method comprises steps of batch mixing, fusion extrusion, fragmentation and fine crushing. The antibiotic powdery paint for aluminium profile prepared by the method of the invention has good antibiotic and mildew-resistant effects, long-lasting antibiotic and mildew-resistant effects, good compatibility with main film forming substances in powdery paint and no influence on decorative effect of powdery paint.

Owner:广东华江粉末科技有限公司

Decorative metal powder paint

InactiveCN103509447AImprove the decorative effectGood weather resistancePowdery paintsPolyester coatingsSodium PyrithioneSulfonate

A disclosed decorative metal powder paint is composed of the following raw materials in parts by weight: 70 parts of 196 unsaturated polyester resin, 12 parts of high-density polyethylene, 3 parts of polybenzimidazoles, 5 parts of quartz sand, 18 parts of triglycidyl isocyanurate, 0.7 part of zinc pyrithione, 3 parts of dibutyltin dilaurate, 2.5 parts of petroleum sodium sulfonate, 2 parts of pentaerythritol, 0.6 part of silver powder, 3 parts of waste iron filings, 1 parts of zinc powder and 20 parts of a composite filling material. The powder paint of the invention is painted in one time for film forming, is low in construction cost, good in decorative effect and good in weatherability, and is especially applicable outdoors.

Owner:ANHUI KING AUTO ELECTRONICS TECH CO LTD

Halogen-free flame-proofing agent

ActiveUS20100298474A1Improve flame retardant performanceLow water solubilityFireproof paintsTriazine derivativeTriallyl isocyanurate

Halogen-free flame retardant for incorporation into a polymer matrix, wherein the flame retardant contains at least ammonium polyphosphate(s) and / or derivatives thereof and an oligomeric or polymeric 1,3,5-triazine derivative or mixtures of several thereof and at least one compound selected from monozinc phosphate, zinc borate, trizinc phosphate, zinc pyrophosphate, zinc polyphosphate, zinc hydroxystannate, zinc stannate, boron phosphate, monoaluminium phosphate, trialuminium phosphate, aluminium metaphosphate and mixtures thereof, precondensed melamine derivatives, melamine salts and adducts, ethylenediamine phosphate, piperazine phosphate, piperazine polyphosphate, 1,3,5-trihydroxyethyl isocyanurate, 1,3,5-triglycidyl isocyanurate and triallyl isocyanurate.

Owner:CHEM FAB BUDENHEIM AG

Flame-proofed polymer material

ActiveUS20100227952A1Improve flame retardant performanceLow water solubilityFireproof paintsPhosphateTriazine derivative

The invention relates to a polymer material comprising a halogen-free flame-proofing agent incorporated into the polymer matrix, the flame-proofing agent comprising at least ammonium polyphosphate(s) and / or derivatives thereof and an oligomer or polymer 1,3,5-triazine derivative or mixtures of a plurality thereof and at least one compound selected from phosphates, pyrophosphates, polyphosphates, organic and inorganic phosphonates, organic and inorganic phosphinates, stannates, molybdates or borates of the elements of the main groups II, III, IV or of the sub-group elements Fe, Zn, Ti, Mn, Zr, Mo, pre-condensed melamine derivatives, melamine salts and addition compounds, ethylene diamine phosphate, piperazine phosphate, piperazine polyphosphate, 1,3,5-trihydroxyethyl isocyanurate, 1,3,5-triglycidyl isocyanurate and triallyl isocyanurate. The weight ratio of constituents A to constituents B is 10:1 to 1:1, constituents A and B together amounting to between 60 and 99 wt. % and constituents C and D to between 1 and 40 wt. % of the total weight of constituents A, B, C and D. The polymer material is a thermoplastic elastomer (TPE).

Owner:CHEM FAB BUDENHEIM AG

Fluorine resin-modified polyester powder coating for aluminum profile and preparation method for fluorine resin-modified polyester powder coating

ActiveCN103849298AAdvantages of design principleMeet needsPowdery paintsPolyester coatingsVinyl etherIsophorone diisocyanate

The invention discloses a fluorine resin-modified polyester powder coating for an aluminum profile. The fluorine resin-modified polyester powder coating comprises multiple auxiliaries and pigments such as carboxyl-terminated saturated polyester resin, TGIC (triglycidyl isocyanurate), FEVE (fluoroethylene vinyl ether) fluorine resin, an isophorone diisocyanate tripolymer, a flatting agent, a brightening agent, benzoin and precipitated barium sulphate. A preparation method for the powder coating comprises the following steps of premixing the raw materials of the powder coating, and performing melted extrusion, tabletting, crushing and screening to obtain a finished product. The weather resistance of the powder coating can be greatly improved, the heat resistance and cold resistance of a film can also be improved, influence on decoration effects and the preparation method of the powder coating is avoided, and the price of the powder coating can be accepted by domestic users.

Owner:广东华江粉末科技有限公司

TGIC (triglycidyl isocyanurate) cured polyester resin with high toughness and ultrahigh weather fastness for powder coating and preparation method of polyester resin

InactiveCN107266665AReduce viscosityImprove impact performancePowdery paintsPolyester coatingsVitrificationAntioxidant

The invention relates to TGIC (triglycidyl isocyanurate) cured polyester resin with high toughness and ultrahigh weather fastness for a powder coating and a preparation method of polyester resin in order to realize that polyester resin has higher glass-transition temperature and a prepared powder coating film has excellent dynamic mechanical properties, high surface decoration performance and ultrahigh weather fastness. According to the technical scheme, TGIC cured polyester resin with high toughness and ultrahigh weather fastness for the powder coating is prepared from following raw materials through melt condensation polymerization: polyalcohol, polyacid, an acidulate agent, an esterification catalyst, an antioxidant and a curing accelerator. The preparation method of the TGIC cured polyester resin with high toughness and ultrahigh weather fastness for the powder coating comprises steps as follows: 1), required polyalcohol is added to a reaction kettle according to the proportion, the temperature is rapidly increased, and esterified water is produced and distilled off; 2), the temperature is increased step by step, and materials keep clear; 3), a sample is taken for detection; 4), negative-pressure condensation polymerization is performed; 5), the temperature is reduced, the antioxidant and the curing accelerator are added, and a mixture is cooled and discharged after being stirred and dispersed.

Owner:ZHEJIANG CHUANHUA TIANSONG NEW MATERIAL CO LTD

Special anticorrosive powder coating for high-decorativeness pure polyester aluminum section and preparation method of powder coating

ActiveCN104263211AGood weather resistanceImprove performanceAnti-corrosive paintsPowdery paintsMelt extrusionIsocyanuric acid

The invention discloses a special anticorrosive powder coating for a high-decorativeness pure polyester aluminum section and a preparation method of the powder coating. The powder coating comprises the following raw materials: carboxyl-terminated polyester resin, triglycidyl isocyanurate, titanium dioxide, ultrafine barium sulfate, a charging additive, a dry flow additive, benzoin, a leveling agent and a brightening agent. The preparation method mainly comprises the following steps: firstly, uniformly premixing the raw materials; secondly, performing melt extrusion; finally, performing crushing and ultrafine grinding. The powder coating prepared by the method is strong in adaptability to different thickness of coatings, and has relatively good leveling effects on thick coating (not less than 120 microns) and thin coating (not more than 60 microns); especially, the phenomena of melt falling and non-uniform thickness of powder applied to a workpiece due to influence of gravity on the powder product sprayed by vertical spraying equipment at the construction site in baking and curing processes are greatly reduced, and a paint film is excellent in appearance and free of particle phenomenon during thin coating.

Owner:西北永新涂料有限公司

Curable resin composition and cured product thereof

ActiveUS20140332987A1Excellent heat resistance and transparency and flexibilityExcellent reflow resistanceSemiconductor/solid-state device detailsSolid-state devicesHeat resistanceTriallyl isocyanurate

Provided is a curable resin composition capable of forming a cured product which has excellent heat resistance, transparency, and flexibility and particularly excels in reflow resistance and barrier properties to a corrosive gas. The curable resin composition includes a ladder-type polyorganosilsesquioxane and an isocyanurate compound such as a triglycidyl isocyanurate compound, a monoallyl diglycidyl isocyanurate compound, a diallyl monoglycidyl isocyanurate compound, or a triallyl isocyanurate compound.

Owner:DAICEL CHEM IND LTD

Method for preparing electronic grade triglycidyl isocyanurate

ActiveCN106008482AReduce feed usageImprove recycling efficiencyOrganic chemistryTwo stepReaction step

The invention belongs to the technical field of preparation of chemical preparations and in particular relates to a novel method for preparing electronic grade triglycidyl isocyanurate. The method for preparing electronic grade triglycidyl isocyanurate provided by the invention uses a conventional two-step method in the prior art for preparation; commonly used cyanuric acid and epichlorohydrin are selected as reaction raw materials; methanol as a co-solvent is creatively added to the synthesis reaction steps, to promote the heterogeneous reaction between a solid phase cyanuric acid and a liquid phase ECH; methanol is added in a cyclization reaction step to effectively reduce the dosage of ECH, thereby greatly improving the ECH recovery efficiency and reducing the unit consumption and production energy consumption of ECH.

Owner:HUANGSHAN HUAHUI TECH

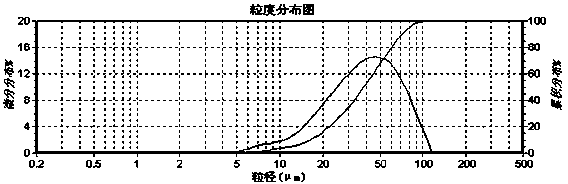

Triglycidyl isocyanurate melting granulating technology and production line thereof

ActiveCN101773806AImprove working environmentSolve environmental problemsOrganic chemistryGranulation on conveyor beltsChemistryTriglycidyl isocyanurate

The invention relates to the technical field of triglycidyl isocyanurate melting granulation, in particular to a triglycidyl isocyanurate melting granulating technology and a production line thereof. In the melting granulating technology, a distillation still is used at different temperatures to carry out atmospheric distillation and reduced pressure distillation, and after an organic solvent is steamed out completely, materials in the distillation still are uniformly put onto a band type cooling conveyer and are ground and screened after being cooled, and the production line consists of the distillation still, a condenser, an organic solvent recovery tank, a vacuum pump, the band type cooling conveyer arranged under the distillation still, a grinder, a screening machine, a packaging machine, a steam pipeline connected with an interlayer of the distillation still and a cooling water pipeline. The invention has the advantages of complete recovery of the organic solvent, working environment improvement, production cost reduction, stable and safe process and high product yield. Because the product density is large, the storage and transportation space is reduced, and the storage and transportation cost is reduced.

Owner:ANSHAN RUNDE FINE CHEM

Liquid photo-imageable electrostatic-spraying solder mask and preparation and spraying methods thereof

InactiveCN105131703AImprove adhesionGood resistance to tin sprayingPretreated surfacesInksEpoxyPolymer science

The invention discloses a liquid photo-imageable electrostatic-spraying solder mask for a PCB. The liquid photo-imageable electrostatic-spraying solder mask consists of a main agent and a curing agent at the mass ratio of 3: 1, wherein the main agent consists of photosensitive resin, NA, melamine, a photoinitiator, a photosensitizer, an additive, talcum powder, barium sulfate, a dibasic ester solvent and tetramethylbenzene; the curing agent consists of novolac epoxy resin, light curing monomers, 1,3,5-triglycidyl isocyanurate, barium sulfate, dipropylene glycol monomethyl ether and a dibasic ester solvent. The liquid photo-imageable electrostatic-spraying solder mask is suitable for an automatic electrostatic spraying drying line, and has favorable resolution, excellent adhesion and extremely good solder coating resistance and chemical resistance, a liquid photo-imageable electrostatic-spraying solder mask film subjected to high-temperature hardening has high insulativity, high water resistance and gold and tin immersion resistance, and the liquid photo-imageable electrostatic-spraying solder mask is suitable for the conventional PCB solder mask operation procedure.

Owner:江门市阪桥电子材料有限公司

Powder coating material composition and method for producing same

The present invention relates to a layer separation type powder coating material composition which has good weather resistance and is reduced in the production cost. The present invention specifically relates to a powder coating material composition which contains a fluororesin containing a hydroxyl group or a carboxyl group, a polyester resin containing a hydroxyl group or a carboxyl group, and a curing agent that is selected from the group consisting of beta-hydroxyalkyl amide, triglycidyl isocyanurate and isocyanate compounds, and which is capable of forming a coating film that comprises a fluorine coating film layer and a polyester coating film layer.

Owner:DAI NIPPON TORYO CO LTD

Preparation method of triglycidyl isocyanurate

The invention relates to a preparation method of triglycidyl isocyanurate (I). The preparation method of triglycidyl isocyanurate is characterized by comprising the following steps: stirring triallyl isocyanurate in the presence of alcohol, acid carbonate and nitrile; adding 30% of hydrogen peroxide and stirring the mixture at 25-60 DEG C to keep the reaction for 6-10 hours, and then completing the reaction; performing aftertreatment on the reaction liquid to obtain the triglycidyl isocyanurate. The yield is more than 80.0%.

Owner:HUNAN UNIV +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com