Preparation method of electronic grade triglycidyl isocyanurate

A technology of triglycidyl isocyanurate, applied in the direction of organic chemistry, can solve the problems of low product purity and unsuitability for large-scale industrial production, and achieve the effect of improving product purity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0010] A preparation method of electronic grade triglycidyl isocyanurate, comprising the following steps:

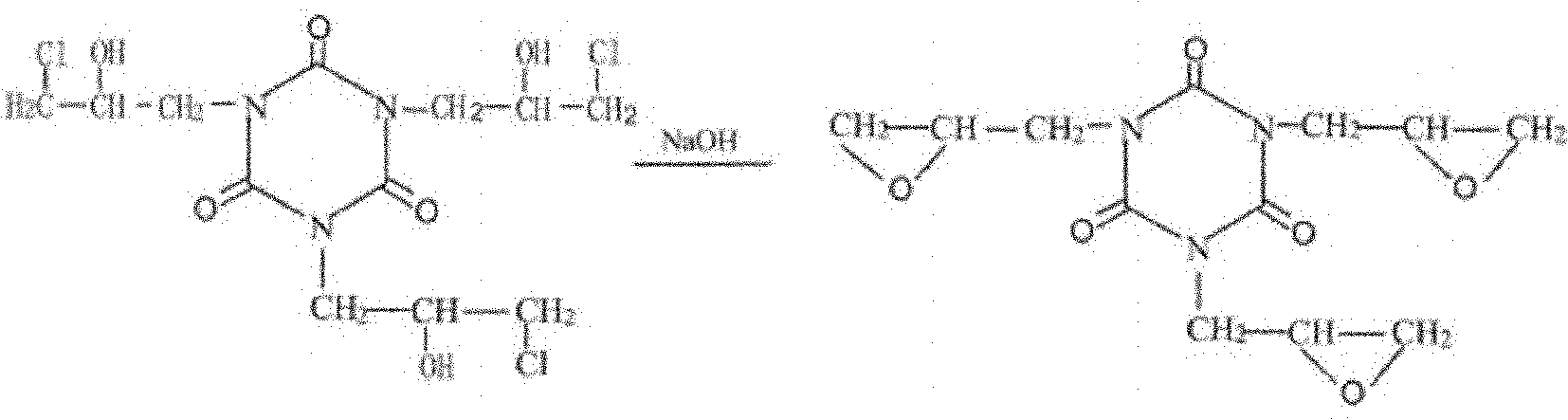

[0011] a, drop into epichlorohydrin, cyanuric acid, quaternary ammonium salt phase transfer catalyst, water in proportion, wherein the molar ratio of cyanuric acid and epichlorohydrin is 1: 11~1: 17, and the quaternary ammonium salt phase transfer catalyst is The mass of cyanuric acid is 4-10%, the water is 5-10% of the volume of epichlorohydrin, the heating temperature is controlled at 80-120°C, and the reaction is stirred for 4-6 hours. Under the excess condition of epichlorohydrin, carry out synthetic reaction, its reaction formula is:

[0012]

[0013] Among them, CA is cyanuric acid, and ECH is epichlorohydrin. Under the condition of stirring, the mixed liquid reacts continuously and gradually becomes clear and transparent, and serves as the raw material for the subsequent cyclization reaction.

[0014] B, add caustic soda in described a reaction system, the mo...

Embodiment 1

[0021] a. Under the condition of excessive epichlorohydrin, input cyanuric acid and tetramethylammonium chloride in proportion, wherein the molar ratio of cyanuric acid and epichlorohydrin is 1:11, and the quality of tetramethylammonium chloride is cyanuric acid 4% of the mass of uric acid, 5% of the volume of epichlorohydrin by water, heating and temperature control at 80° C., and stirring for 4 hours.

[0022] b. Add caustic soda to the reaction system of a, the molar ratio of caustic soda and cyanuric acid is 1:3, the temperature is controlled at 15°C, the reaction time is 100min, and then the solid salt is removed by pressure filtration.

[0023] c. After the reaction is over, under reduced pressure, the cyclization solution is distilled to remove epichlorohydrin through the reaction kettle, and then further removed through high-vacuum thin film evaporator distillation to remove epichlorohydrin, and the crude product is then crystallized, centrifuged, Electronic grade trig...

Embodiment 2

[0025] a. Under the condition of excessive epichlorohydrin, the mixture of cyanuric acid, tetramethylammonium chloride and benzyltriethylammonium chloride is input in proportion, wherein the molar ratio of cyanuric acid and epichlorohydrin is 1 : 17, the quality of the mixture of tetramethylammonium chloride and benzyltriethylammonium chloride is 10% of the mass of cyanuric acid, water is 10% of the volume of epichlorohydrin, heating and temperature control is at 120 ℃, stirring Reaction 6h.

[0026] b. Add caustic soda to the reaction system of a, the molar ratio of caustic soda and cyanuric acid is 1:3.5, the temperature is controlled at 20°C, the reaction time is 150min, and then the solid salt is removed by pressure filtration.

[0027] c. After the reaction is over, under reduced pressure, the cyclization solution is distilled to remove epichlorohydrin through the reaction kettle, and then further removed through high-vacuum thin film evaporator distillation to remove epi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com