Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

1322 results about "Cyanuric acid" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Cyanuric acid or 1,3,5-triazine-2,4,6-triol is a chemical compound with the formula (CNOH)₃. Like many industrially useful chemicals, this triazine has many synonyms. This white, odorless solid finds use as a precursor or a component of bleaches, disinfectants, and herbicides. In 1997, worldwide production was 160 million kilograms.

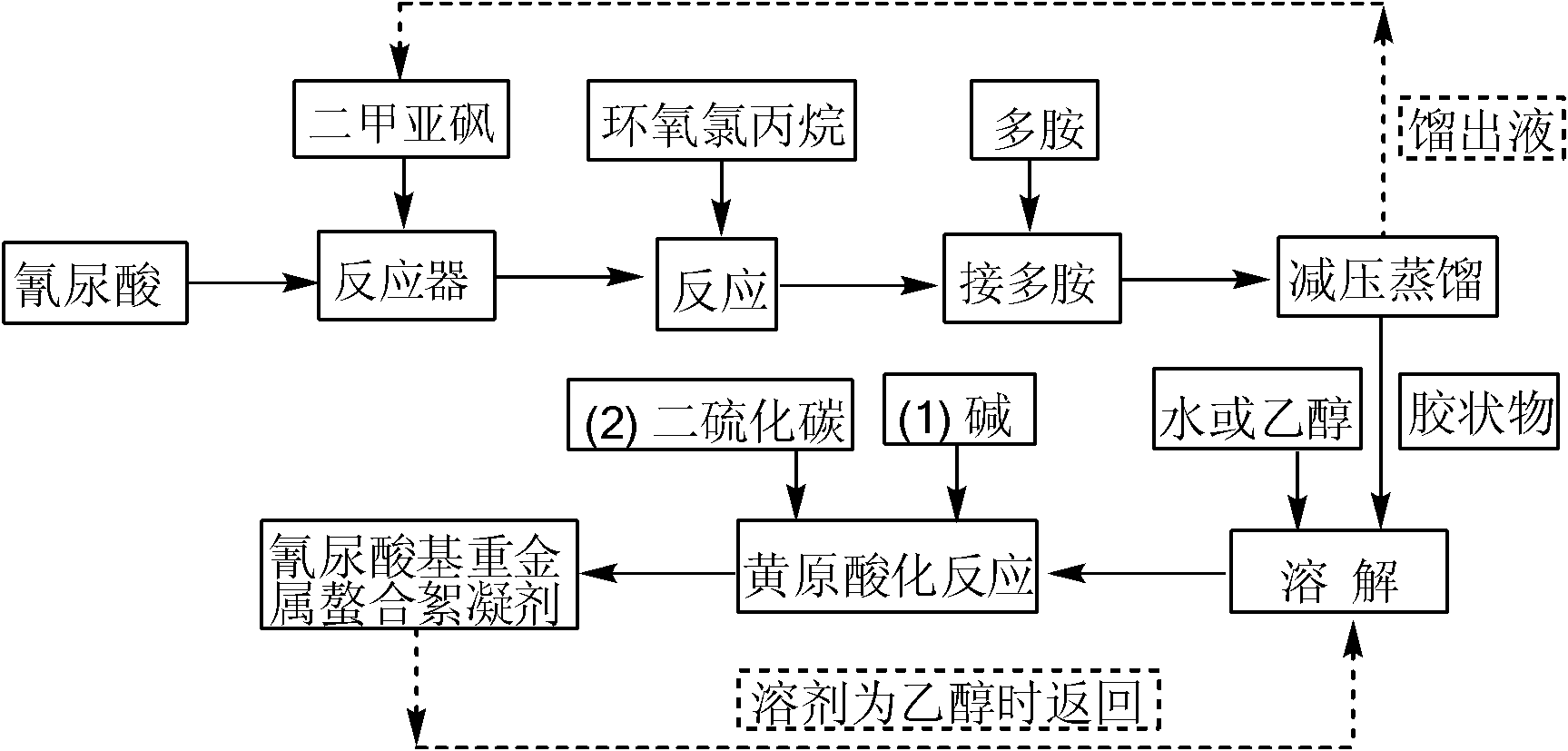

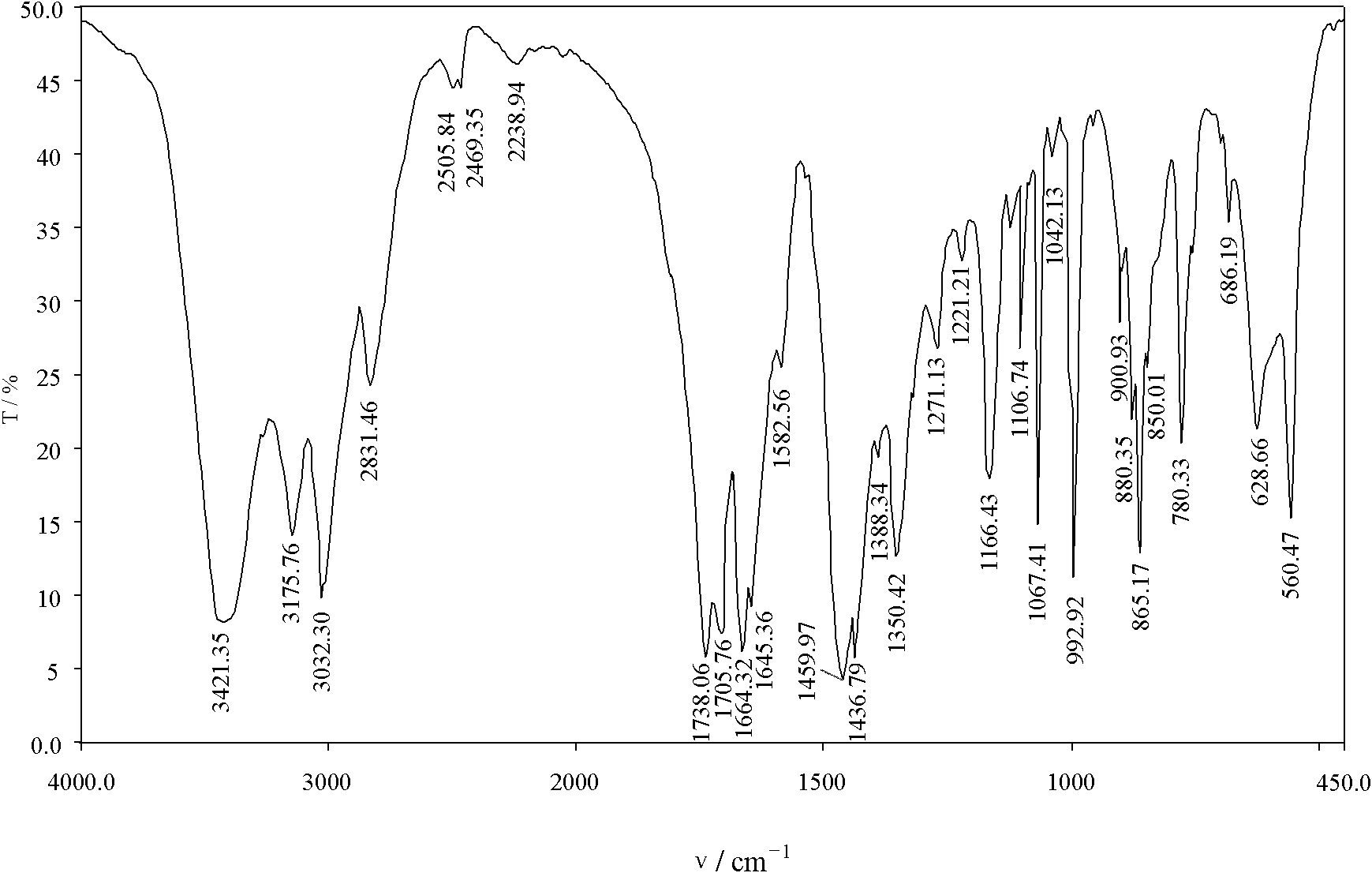

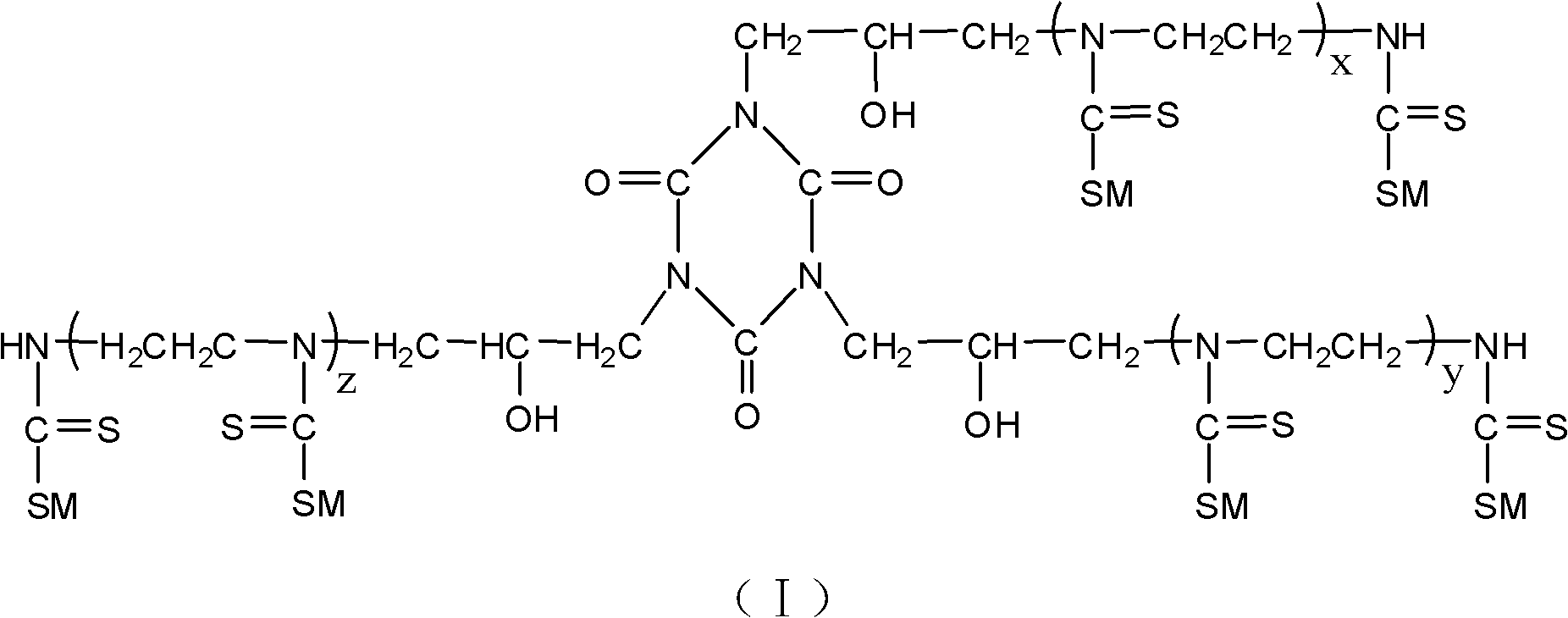

Cyanuric acid-based heavy metal chelating flocculant and preparation method thereof

InactiveCN101863544AOvercome the defect that the ion concentration is difficult to reach the standardIncrease steric hindranceWater/sewage treatment by flocculation/precipitationEpoxyHeavy metal chelation

The invention belongs to the technical field of heavy metal wastewater treatment, and in particular relates to cyanuric acid-based heavy metal chelating flocculant and a preparation method thereof. In the method, cyanuric acid is adopted as a basic framework; and polyamine is connected to a molecule through epoxy chloropropane, and reacts with carbon disulfide in an alkaline condition to prepare the heavy metal chelating flocculant of which the molecule contains a plurality of branches and a plurality of dithio formate functional groups. The method overcomes the defects that the conventional monofunctional flocculant has small flocculating body, and poor precipitation performance, and when polymeric chelant chelates heavy metals, steric clash is great, and the residual heavy metal ion concentration is difficult to meet the standard and the like. The flocculant has the advantages of simple preparation process, mild condition, easy operation and control, high yield, high raw material utilization, less three waste discharge and environmental protection of technical process, convenient popularization and industrialization realization and suitability for treatment of various types of heavy metal wastewater, such as smelting wastewater, electroplating wastewater, nonferrous metals processing wastewater, mining and beneficiating wastewater, printed circuit board wastewater, battery plants and the like.

Owner:HUNAN UNIV OF SCI & TECH

Flame-retardant resin composition

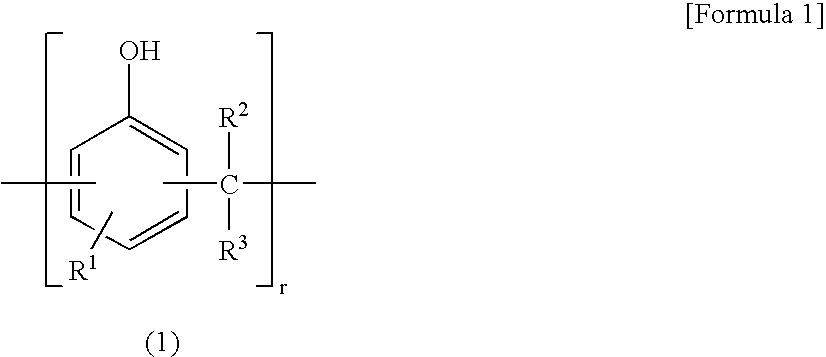

InactiveUS20060247339A1Avoid bleedingProportion of the flame retardant is lowAnti-corrosive paintsGreenhouse cultivationPolymer scienceMetallic sulfide

A flame-retardant resin composition comprises a base resin (e.g., a polyester-series resin), a flame retardant (A) comprising a salt of an amino group-containing triazine compound with a sulfuric acid and / or a sulfonic acid, a flame-retardant auxiliary (B). The flame-retardant auxiliary (B) includes an aromatic resin, acyclic urea-series compound or a derivative thereof [e.g., acetyleneurea, uric acid, a salt of melamine or a condensate thereof (e.g., melam, melem, and melon) with cyanuric acid], an amino group-containing triazine compound (e.g., melamine or a condensate thereof), and / or an inorganic metal-series compound (e.g., a metal salt of an oxygen acid having no sulfur atom, a metal oxide, a metal hydroxide, and a metal sulfide). The present invention provides a flame-retardant resin composition to which flame retardancy is imparted without using a halogen-series flame retardant and an organic phosphorus-series flame retardant.

Owner:POLYPLASTICS CO LTD

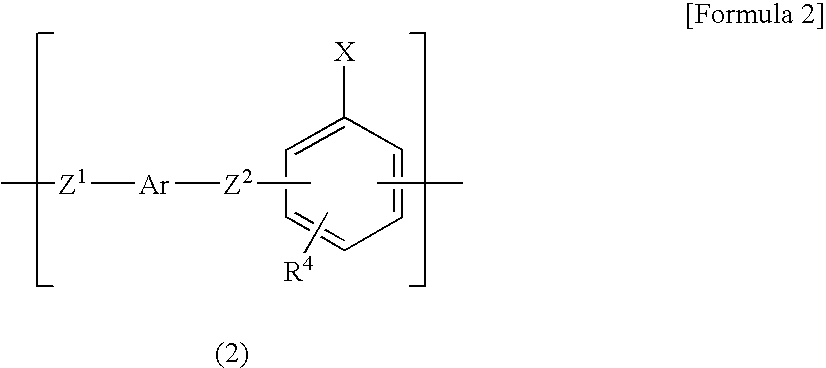

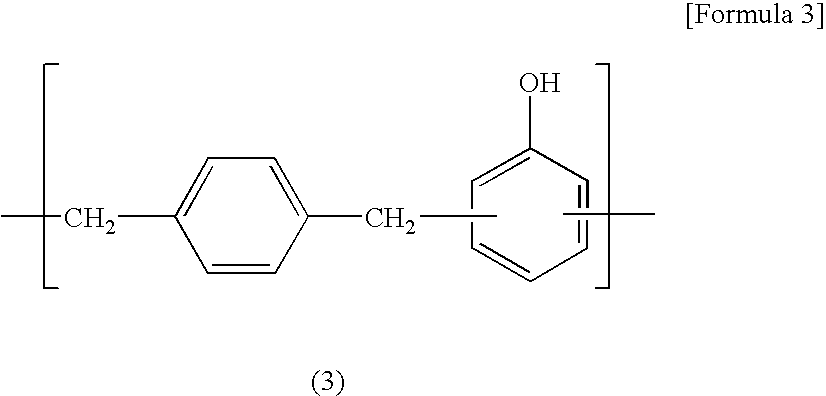

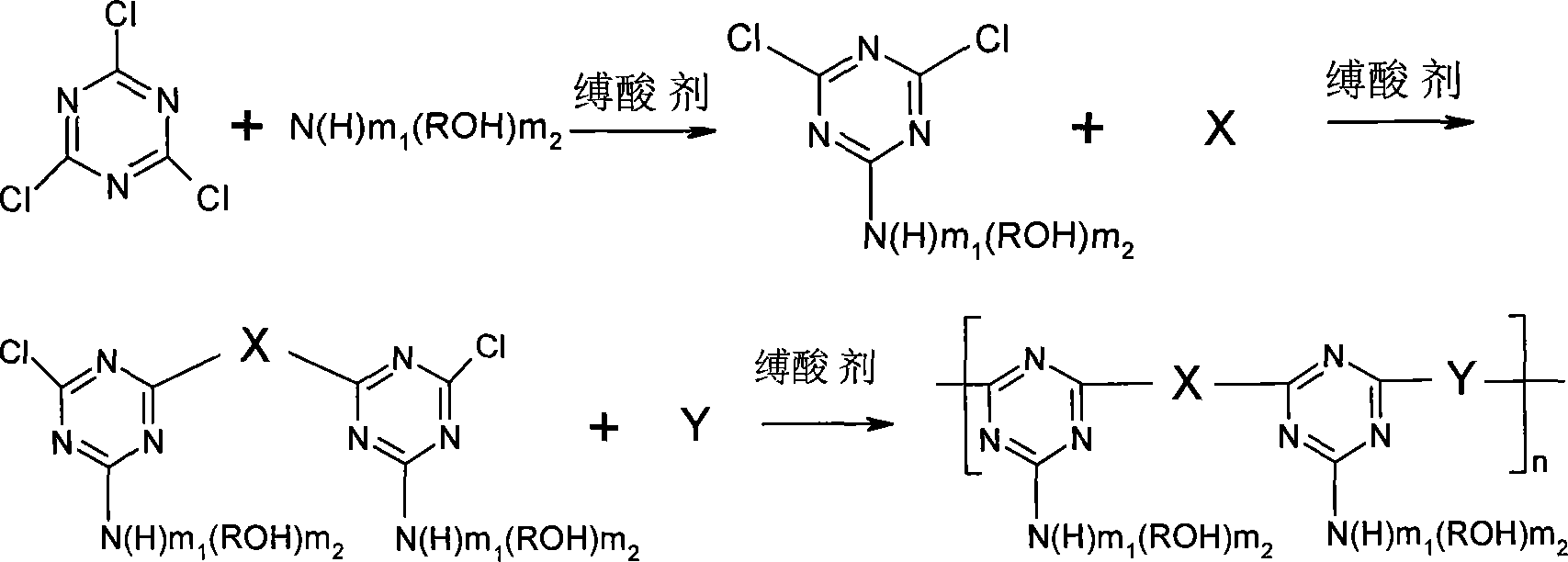

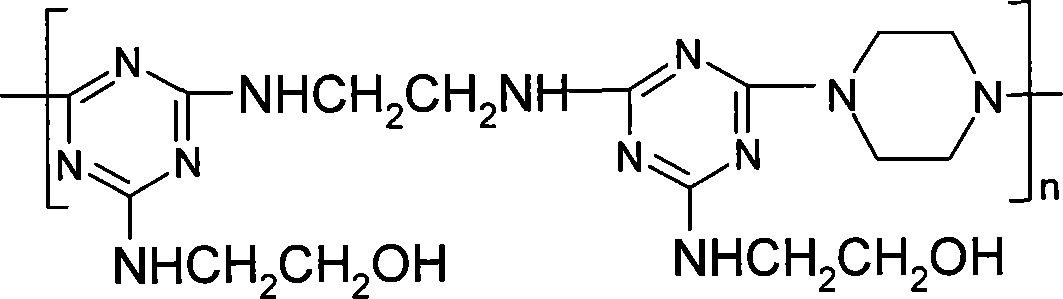

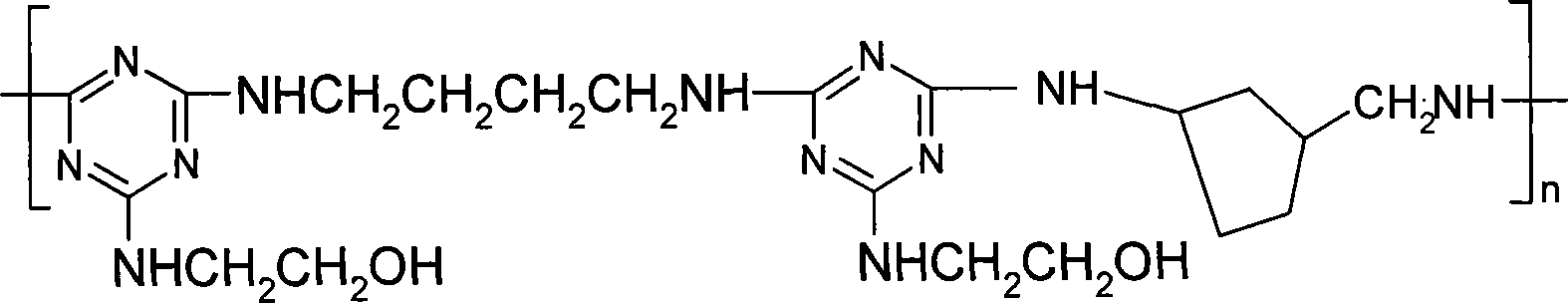

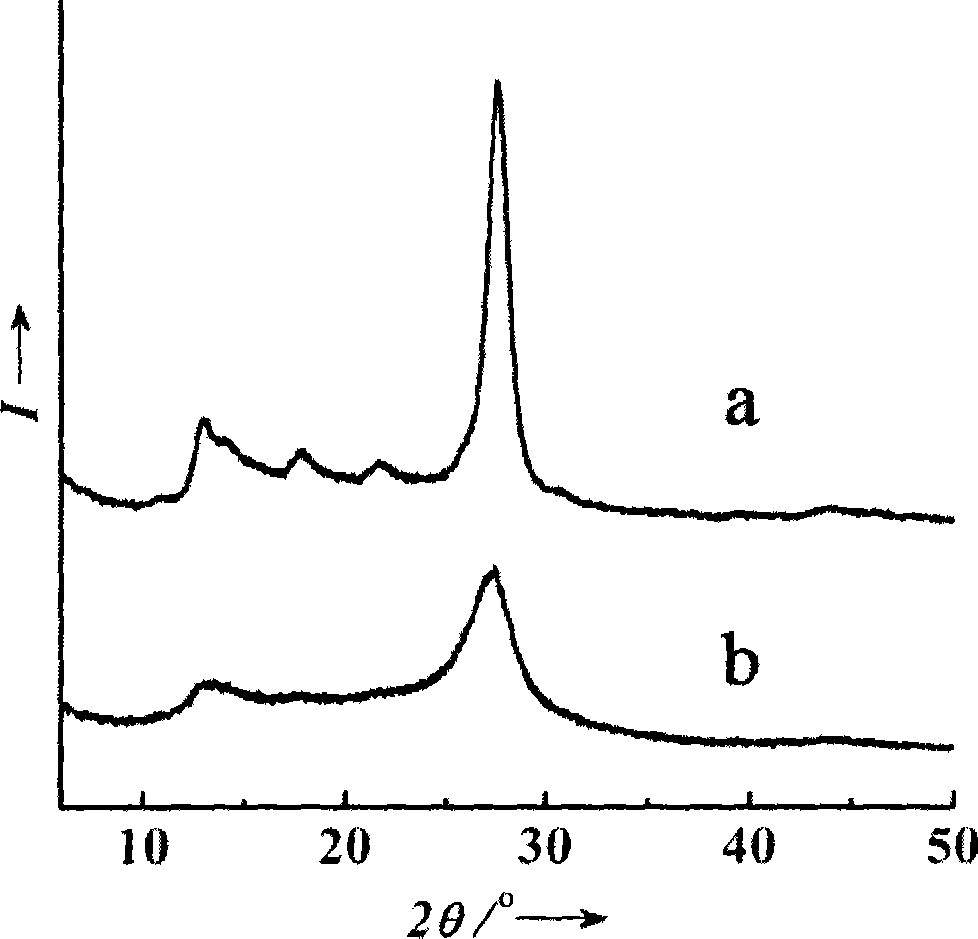

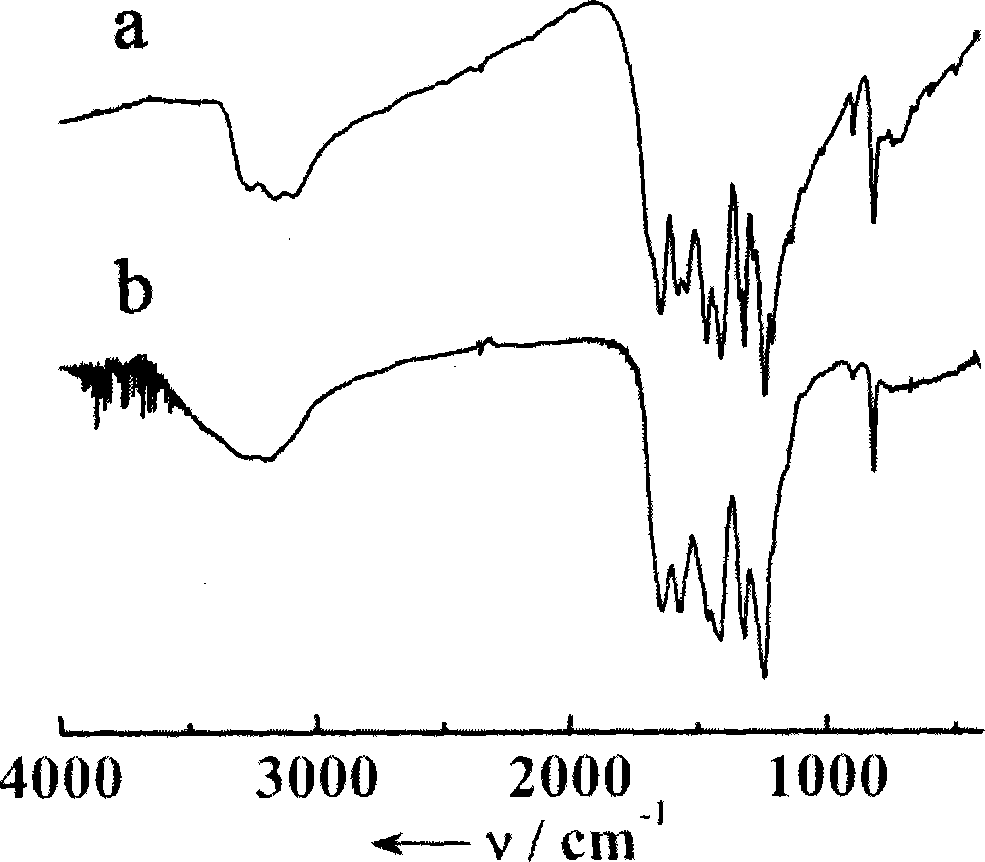

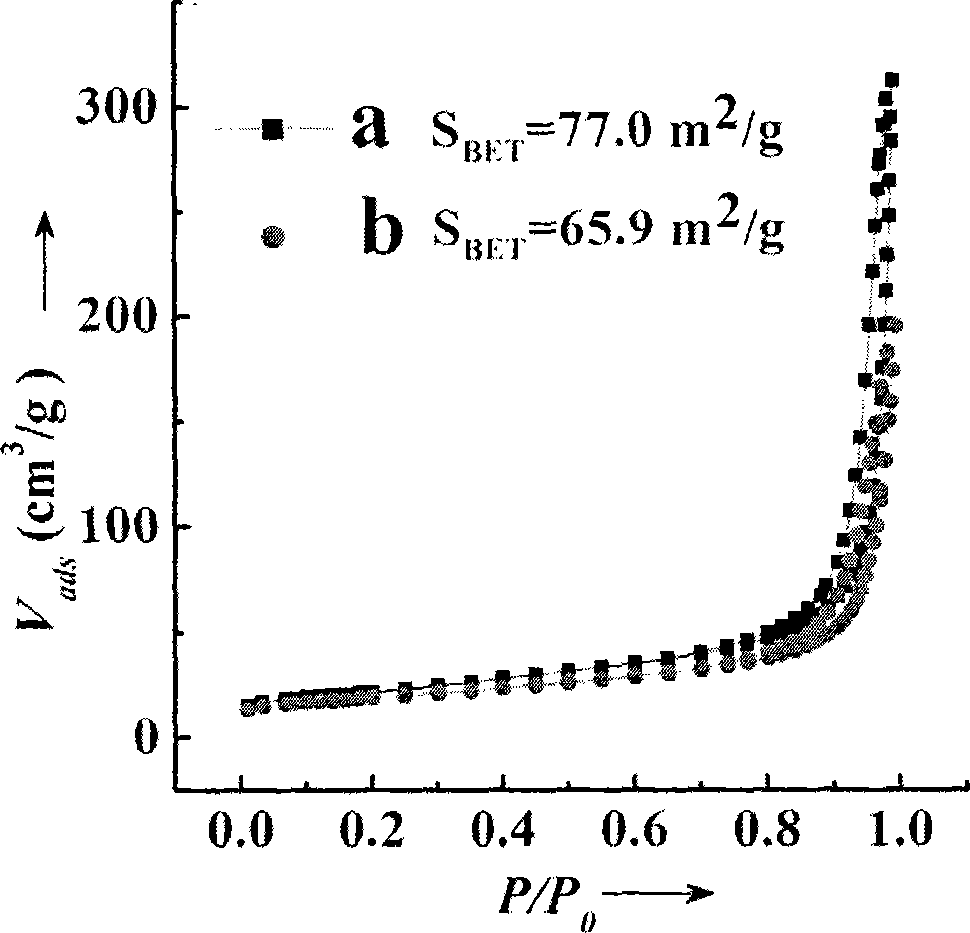

Triazine series oligomer and its synthesizing method

The invention relates to a triazine series oligomer and the compound method. The method has the following steps: adding solvent into cyanuric chloride, dropping alkylol amine and acid roping agent to gain substitute of cyanuric chloride; heating, dropping diamidogen and acid roping agent to gain the substitute of cyanuric chloride; adding diamidogen and acid roping agent into reaction solution, heating, pumping, washing, and drying to gain triazine series oligomer. The invention has strong charring and expanding ability, and good thermal stability. It has advantages of continuously reaction process, short reaction time, simple compounding technology, little organic solvent, and easy to recycle organic solvent.

Owner:NORTHEAST FORESTRY UNIVERSITY

Method for quickly preparing quasi-graphite-structure carbon nitride material by adopting microwave heating

InactiveCN104415786AOrganic-compounds/hydrides/coordination-complexes catalystsCatalyst activation/preparationThioureaMetallic sulfide

The invention relates to a quick, energy-saving and high-yield preparation method of quasi-graphite-structure carbon nitride catalysis materials and application of the materials, belonging to the field of preparation and application of catalysis materials. According to the preparation process, one or multiple nitrogen-rich small organic molecules of urea, melamine, thiourea, cyanamide, dicyanamide, cyanuric chloride and cyanuric acid is / are taken as raw materials, a simple metal substance, a metallic oxide, a metal sulfide and a metal chloride are taken as microwave absorbers, microwave is taken as a heating source, and under the condition of radiation of microwave, the quasi-graphite-structure carbon nitride material can be quickly prepared. The prepared carbon nitride material has a large specific area and crystallinity and has high photocatalytic water decomposition hydrogen production performance and organic pollutant degradation performance. The preparation method provided by the invention is short in time, small in energy consumption, high in production efficiency and simple in process, does not have harsh preparation conditions, is easy to operate and has wide application prospect.

Owner:ANHUI UNIVERSITY

Sterilization compound containing chloroisobromine cyanuric acid

InactiveCN102823603ADelay drug resistanceExpanded bactericidal spectrumBiocideFungicidesCarbamateMorpholine

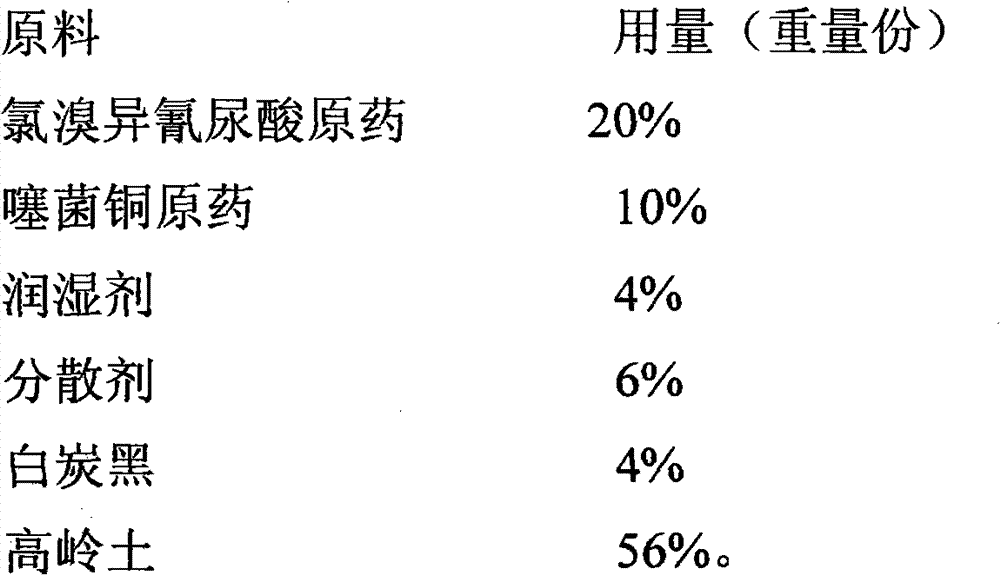

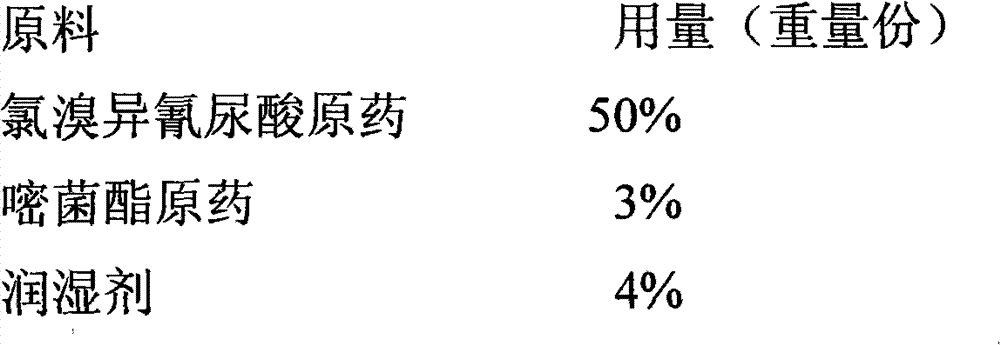

The invention discloses a sterilization compound containing chloroisobromine cyanuric acid, comprising a raw medicine formed by compounding a sterilizing agent A and a sterilizing agent B, wherein the proportion of the sterilizing agent A to the sterilizing agent B is (1-80):(1-80); the sterilizing agent A is the chloroisobromine cyanuric acid; and the sterilizing agent B is any one of the following types of the sterilizing agents: copper preparations, methoxy acrylic esters, triazoles, amides, benzimidazoles, thiocarbamates, substituted benzenes, dicarboximides, phthalimides, imidazoles, morpholines, carbamates, oxazoles and the like. The sterilization compound is formed by compounding the sterilizing agent A and the sterilizing agent B so that not only a sterilization spectrum is enlarged, but also the drug resistance of bacteria is slowed; and the sterilization compound has an obvious lasting synergistic effect.

Owner:王学权

Ethylene propylene rubber cable insulating material for ship and ocean use and manufacturing method thereof

ActiveCN102344612ASmall outer diameterReduce weightPlastic/resin/waxes insulatorsMicrocrystalline waxPolymer science

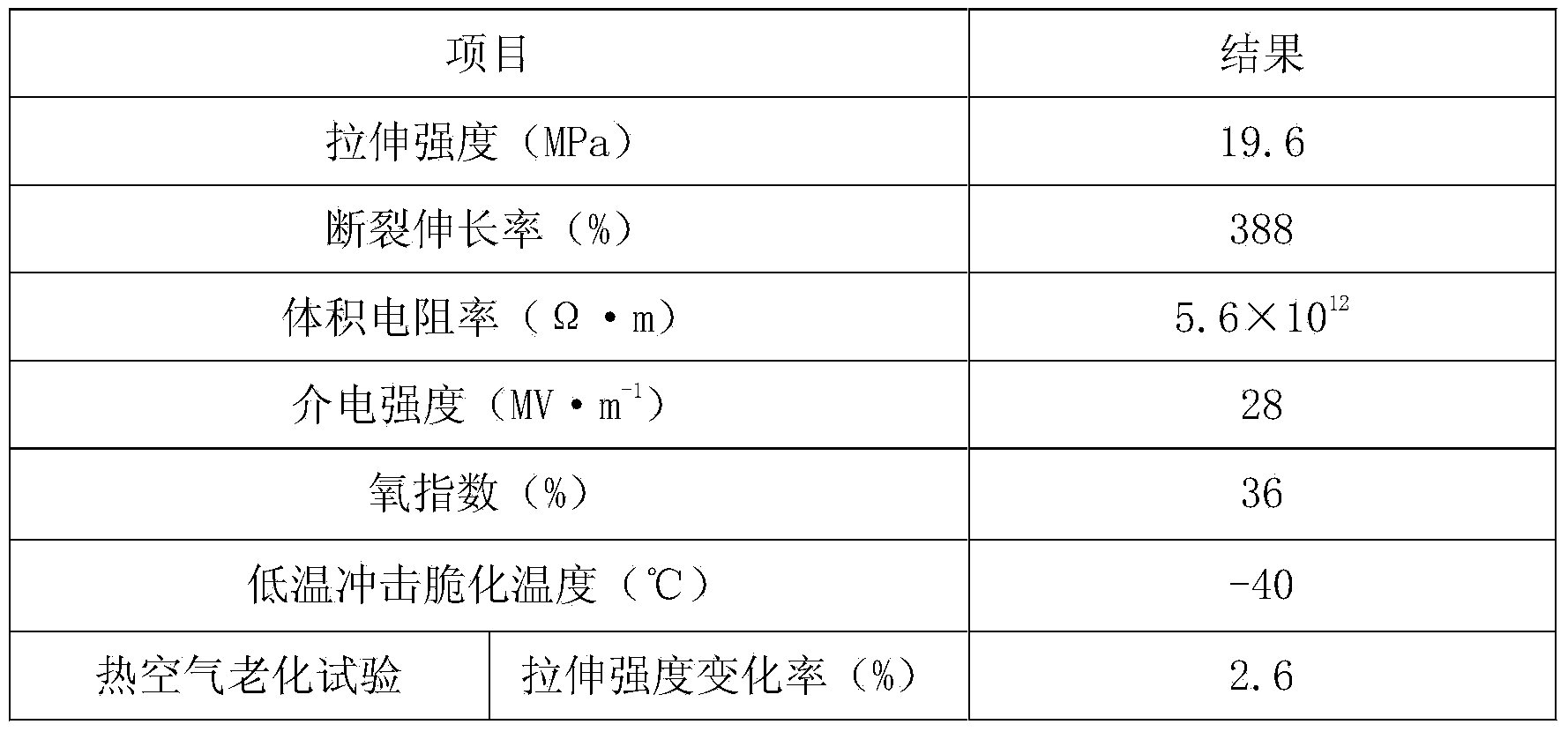

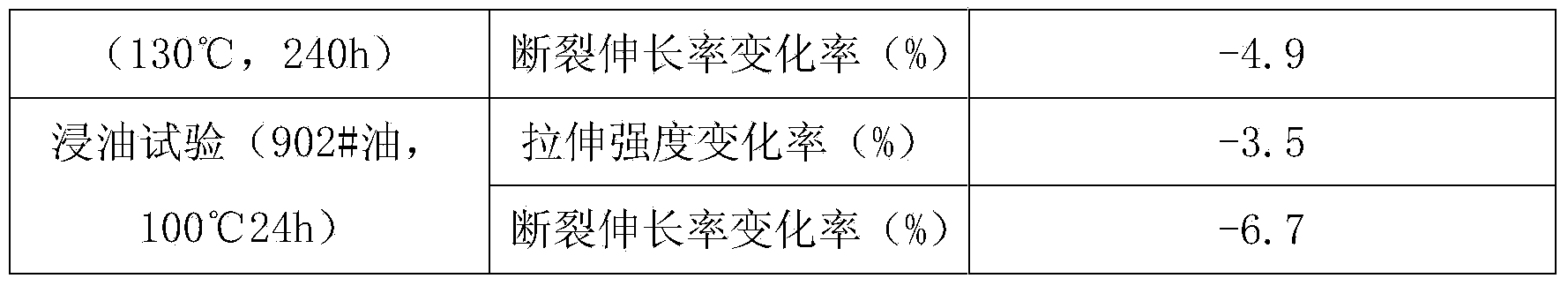

The invention discloses an ethylene propylene rubber cable insulating material for ship and ocean use and a manufacturing method thereof. The insulating material comprises by weight: 11 parts of ethylene propylene rubber 2470; 9 parts of ethylene propylene rubber 4044; 1.0-1.5 parts of high pressure polyethylene; 0.5-1.0 part of dicumyl peroxide; 0.3-0.4 part of triallyl isocyanurate; 0.5-0.8 part of 2-mercaptobenzimidazole; 1-1.5 parts of titanium dioxide; 1.0-1.5 parts of paraffin oil; 1.0-1.5 parts of zinc oxide; 0.6-1.0 part of microcrystalline wax; 0.2-0.5 part of stearic acid; 1-2 partsof white carbon black; 10-15 parts of superfine talc powder; and 12-16 parts of modified calcined argil. The method consists of the steps of: conducting uniform banbury mixing to ethylene propylene rubber and high pressure polyethylene; then adding titanium dioxide and the like in order for uniform mixing; carrying out triangle bag packaging with an open mill for 7 times, then filtering rubber, and putting the filtered rubber in a banbury mixer and adding an antioxidant for mixing well; finally conducting triangle bag packaging in an open mill for 5 times and extruding rubber sheets. The insulating material has the advantages of low smoke, free of halogen, flame retardation, high mechanical strength and high insulation resistance.

Owner:嘉兴顾翔制冷设备有限公司

Oil-resistant cold-resistant ultraviolet-proof polyvinyl chloride/nitrile rubber composite cable material and preparation method thereof

InactiveCN103509274AImprove mechanical propertiesImprove toughnessRubber insulatorsPlastic/resin/waxes insulatorsDiethylene glycol monobutyl etherPolymer science

A disclosed oil-resistant cold-resistant ultraviolet-proofpolyvinyl chloride / nitrile rubber composite cable material is prepared from the following raw materials in parts by weight: 60-80 parts of SG-2 type polyethylene, 20-30 parts of POE, 30-50 parts of nitrile rubber, 15-20 parts of fluorubber, 10-15 parts of dioctyl phthalate, 5-10 parts of di(butylcarbitol)adipate, 0.5-1 part of dicumyl peroxide, 2-3 parts of triallyl isocyanurate, 1-2 parts of 2-mercaptobenzimidazole, 4-8 parts of titanium dioxide, 5-10 parts of paraffin oil, 2-3 parts of zinc oxide, 4-8 parts of microcrystalline paraffin and the like. The cable materials of the invention ahs excellent thermoset rubber apparence and thermoplastic elastomer characteristics, and good mechanical properties and low-temperature flexibility; the long-term suitable operation temperature is -40 DEG C to 105 DEG C; the cable material is capable of retarding flame, resisting oil, resisting acid and base, resisting wear, resisting weather, resisting ozone, resisting thermal aging and resisting ultraviolet ray, and is applicable as high-oil-resistance weatherable cable sheath materials.

Owner:安徽天民电气科技有限公司

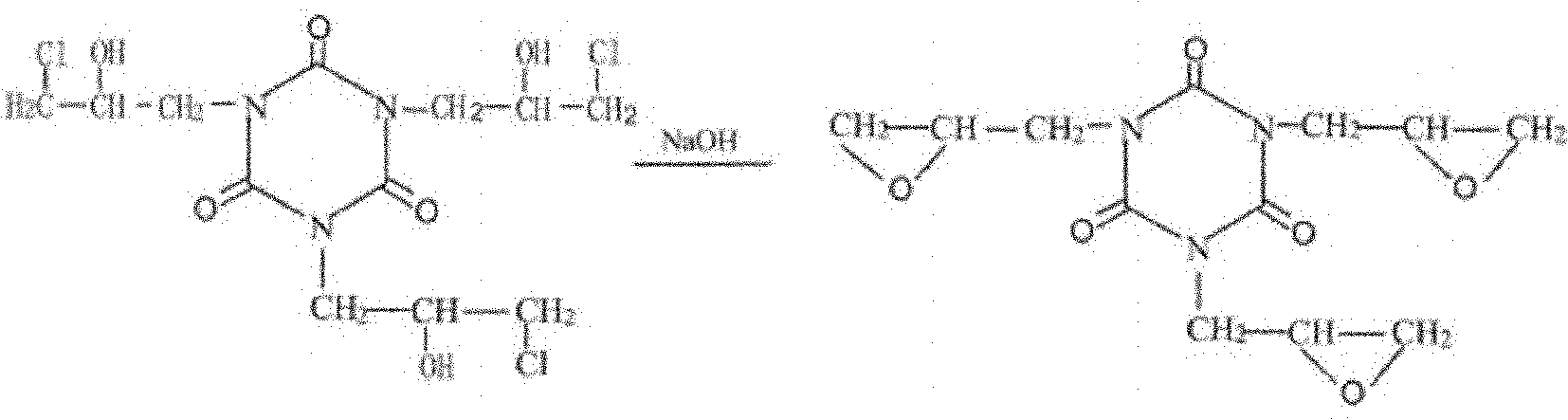

Preparation method of electronic grade triglycidyl isocyanurate

The invention mainly aims to provide a preparation method of electronic grade triglycidyl isocyanurate (TGIC). In order to realize the aim, the technical scheme in the invention is as follows: the preparation method of electronic grade TGIC comprises the following steps: a) adding epichlorohydrin, cyanuric acid, quaternary ammonium salt phase transfer catalyst and water according to a ratio, heating and stirring to react; b) adding flake caustic soda in the reaction system obtained in the step a) to react, then performing pressure filtration to remove solid salt; and c) performing vacuum distillation after the reaction, then using a high vacuum film evaporator to distill and remove epichlorohydrin, crystallizing the coarse product, centrifuging, grinding, and drying to obtain electronic grade TGIC. According to the treatment method provided by the invention, the purity of the TGIC product can be effectively increased, and the purity of TGIC can be increased from 92% to more than 99%, which reaches the electronic grade.

Owner:HUANGSHAN HUAHUI TECH

Flame-retardant agent and flame-retardant resin composition

InactiveUS20140200292A1Improve flame retardant performanceFireproof paintsO-Phosphoric AcidSilicic acid

The present invention provides a composite flame retardant which can be produced without using any toxic metal such as antimony trioxide or any halogen such as bromine and chlorine and can exhibit excellent flame retardancy compared with magnesium hydroxide when added in a smaller amount; and a flame retardant resin composition having excellent flame retardancy and excellent physical properties. The present invention relates to a flame retardant including: (A) 100 parts by mass of a reaction product of piperazine with one phosphorus compound selected from phosphoric acid, pyrophosphoric acid, and polyphosphoric acid; (B) 10 to 1000 parts by mass of a reaction product of melamine with a polyacid selected from cyanuric acid, phosphoric acid, pyrophosphoric acid, and polyphosphoric acid; and (C) 0.1 to 100 parts by mass of a reaction product of calcium or magnesium with silicic acid.

Owner:SAKAI CHEM IND CO LTD

Melamine cyanuric acid red phosphorous-based microcapsule and its preparation method and use

Disclosed are melamine and its preparing method and application, with the characteristics that add 10-300 portions of red phosphorus powder, 100-1000portions of water into reactor with agitator and thermometer, make them to be dispersion in 50-130deg.C, the add into 0-300portions of antiflaming synergistic agent, 50-100 portions of melamine and 50-200 portions of cyanuric acid (emulsion or cream of ), which are stirred for 5 minutes to 2 hours in 50-150deg.C, in the course, can add into 100-1000 portions of water, generate the emulsion or cream of cyanuric acid which are filtered, are centrifugal separated, dried and scattered to be 0.01-500um powder product. The product can be used as flame retardant of polymer or method with other flame retardant.

Owner:SICHUAN UNIV

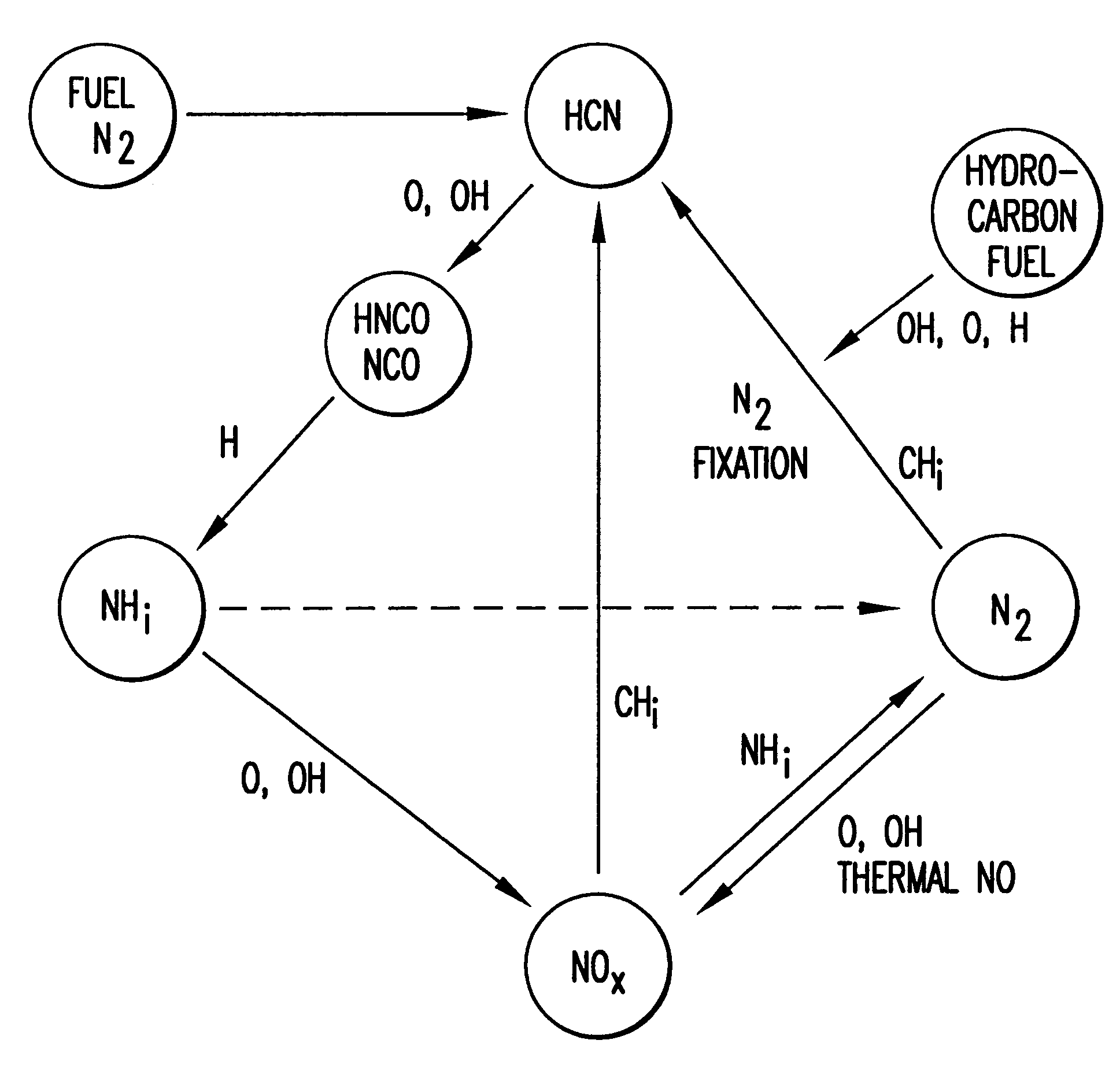

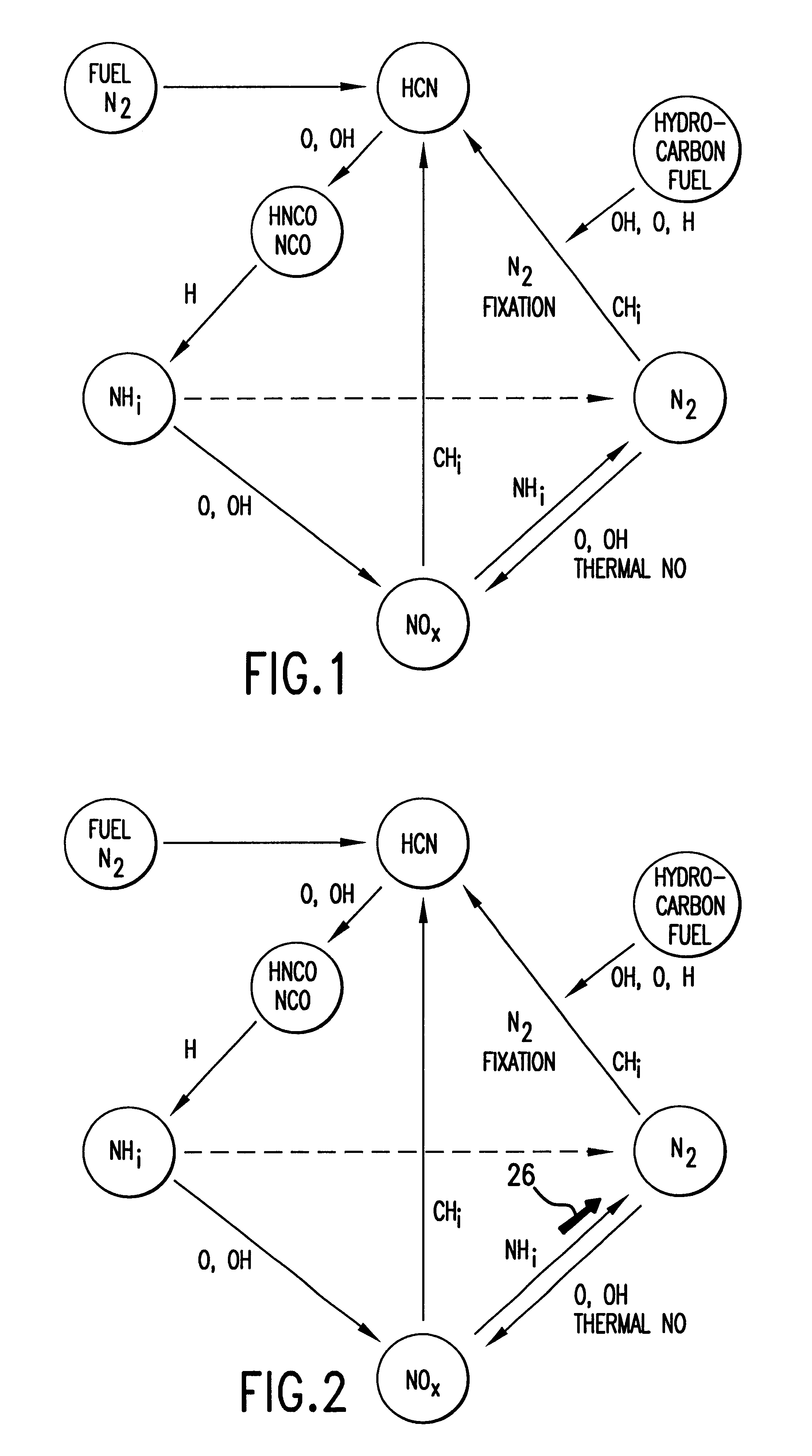

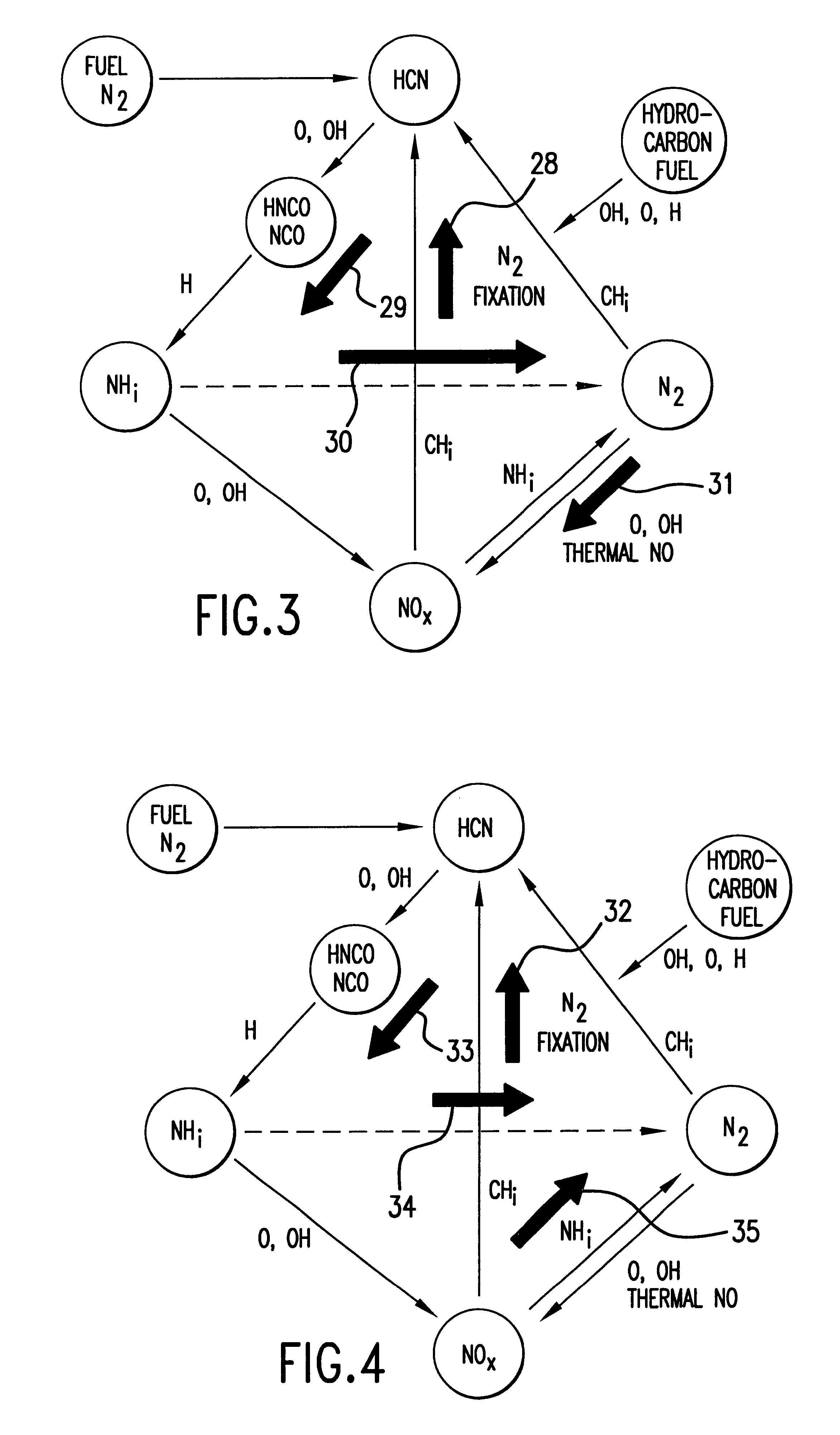

Method and apparatus for NOx reduction in flue gases

InactiveUS6258336B1Low costWide temperature windowNitrogen compoundsDispersed particle separationCombustion productsChemistry

In a furnace having a primary combustion zone for combustion of a fuel and oxidant, an in-furnace method for reducing nitrogen oxides in combustion products generated in the primary combustion zone in which at least one fluid fuel selected from the group consisting of natural gas, hydrogen, CxHy compounds, CxHyOz compounds and mixtures thereof in an amount in a range of about 2.0% to about 25% of a total heat input to the furnace and at least one nitrogenous compound selected from the group consisting of ammonia, amines, urea, cyanuric acid and mixtures thereof are injected into the furnace downstream of the primary combustion zone, forming an overall fuel-lean NOx-reduction zone.

Owner:GAS RES INST

Flame-retardant polybutylene terephthalate resin composition and formed article

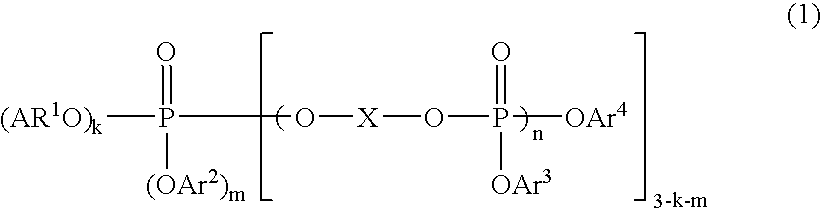

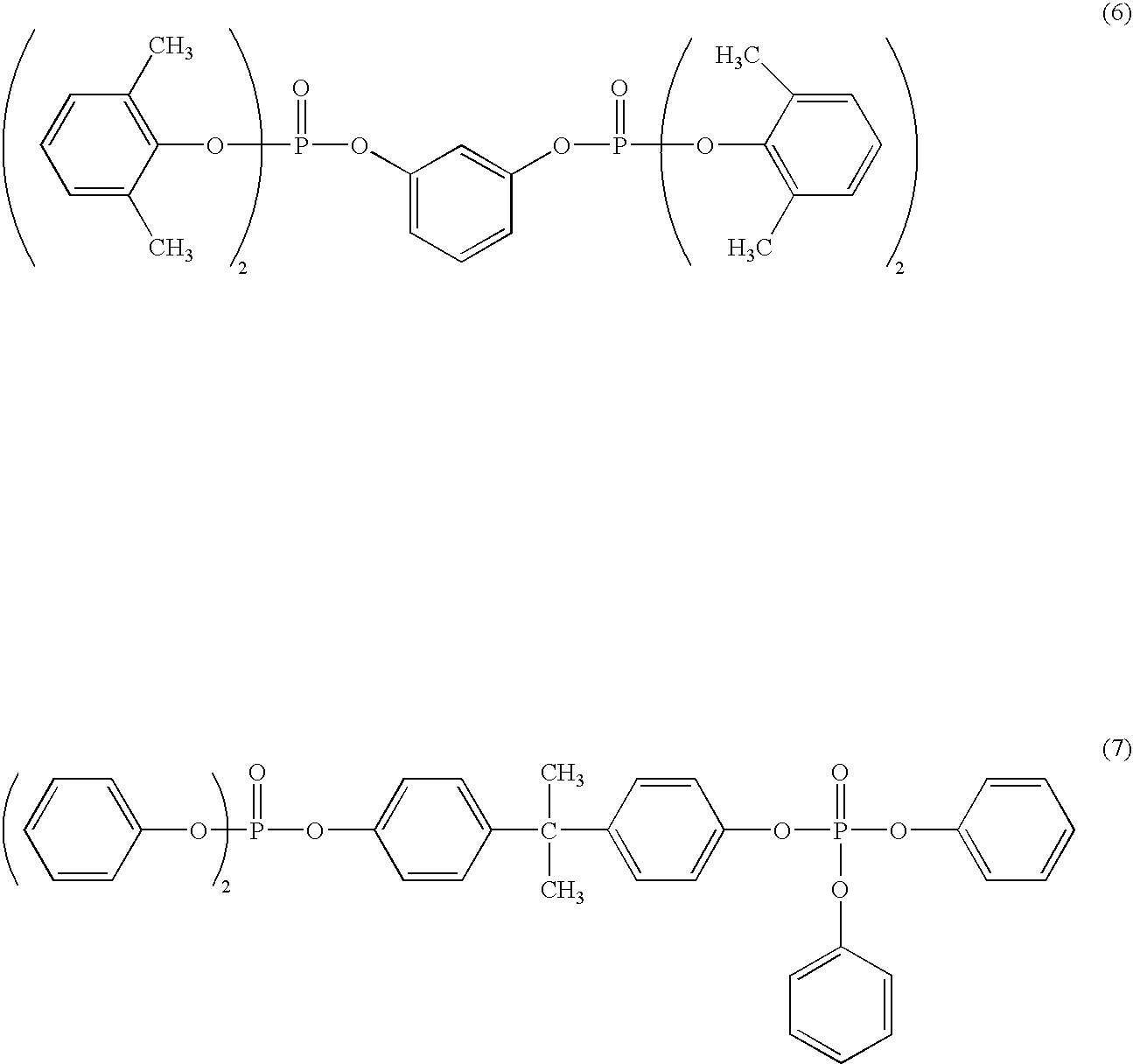

InactiveUS20060142438A1Good effectImprove hydrolysis effectPlastic/resin/waxes insulatorsDyeing processPolytetramethylene terephthalatePhosphoric Acid Esters

A flame-retardant polybutylene terephthalate resin composition wherein (A) 20-70% by weight of a polybutylene terephthalate resin or a mixture of a polybutylene terephthalate resin and a polyethylene terephthalate resin, (B) 1-20% by weight of a vinyl based resin, (C) 1-20% by weight of a phosphoric acid ester, (D) 1-30% by weight of a salt of a triazine based compound and cyanuric acid or isocyanuric acid, and (E) 0.1-5% by weight of an alkaline earth metal compound are compounded, and formed articles thereof have high degrees of flame retardancy and tracking resistance, and are unlikely to allow occurrence of metal pollution or deterioration in hydrolysis resistance due to a phosphoric acid ester, and therefore are suitable for machine component parts, electrical / electronic component parts, and automotive component parts.

Owner:TORAY IND INC

Halogen-free environmentally-friendly power cable material for wind power generation, and its preparation method

The invention discloses a halogen-free environmentally-friendly power cable material for wind power generation, and its preparation method. The cable material comprises the following raw materials, by weight, 90-110 parts of a polyolefin elastomer (POE) 8450 / American DuPont, 50-60 parts of PVC resin powder, 40-60 parts of wollastonite powder, 60-80 parts of nanometer attapulgite, 50-80 parts of ethylene-propylene-diene terpolymer rubber, 40-50 parts of nitrile butadiene rubber, 20-30 parts of nanometer pottery clay, 30-40 parts of aluminum hydroxide, 1-4 parts of precipitated white carbon black, 60-80 parts of light calcium carbonate, 3-5 parts of insoluble sulfur, 1-4 parts of triallyl isocyanurate, 3-5 parts of an antiager TPPD, 4-6 parts of dicumyl peroxide (DCP), 3-8 parts of dibasic lead phosphite, 5-7 parts of an antioxidant 1010, 2-5 parts of monoglycerin stearate and 50-70 parts of antimony trioxide. The cable material has the advantages of simple preparation method, excellent electrical property, good heat, ageing and wear resistances, small swelling deformation at a high temperature, secondary vulcanizing processing benefiting, low smoke and fire resistance, and environmental protection and safety.

Owner:苏州益普敦新材料科技有限公司

Molecular composite trimeric cyanamide cyanurate fire retarder and its preparation method and application

The present invention relates to a molecular compounded trimeric cyanamide cyanurate fire-retarding agent, its preparation method and application. Its preparation includes the folloiwng steps: adding 10-300 portions of recombiner and 100-2000 portions of water in the reactor still with stirrer and thermometer, making them be completely dissolved at 50-130 deg.C, then successively adding 0-300 portions of fire-retarding synergist, 50-100 portions of trimeric cyanamide and 50-110 portions of cyanuric acid, stirring and reacting for 5 min-2 hr, at 50-150 deg.C, in the course of reaction can more adding 100-1000 portions of water so as to obtain the white emulsion or viscous paste-like material of molecular compounded trimeric cyanamide cyanurate.

Owner:SICHUAN UNIV

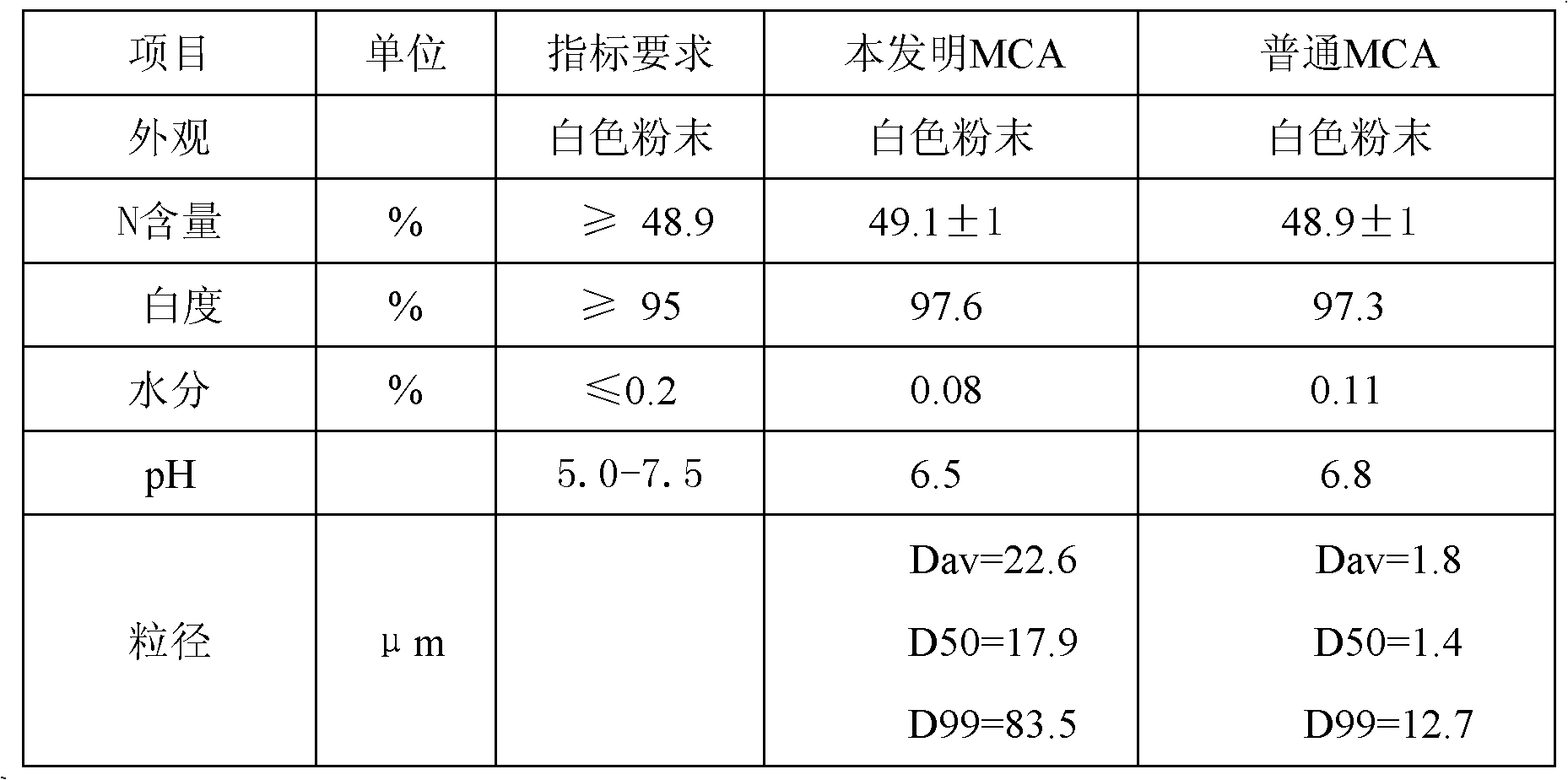

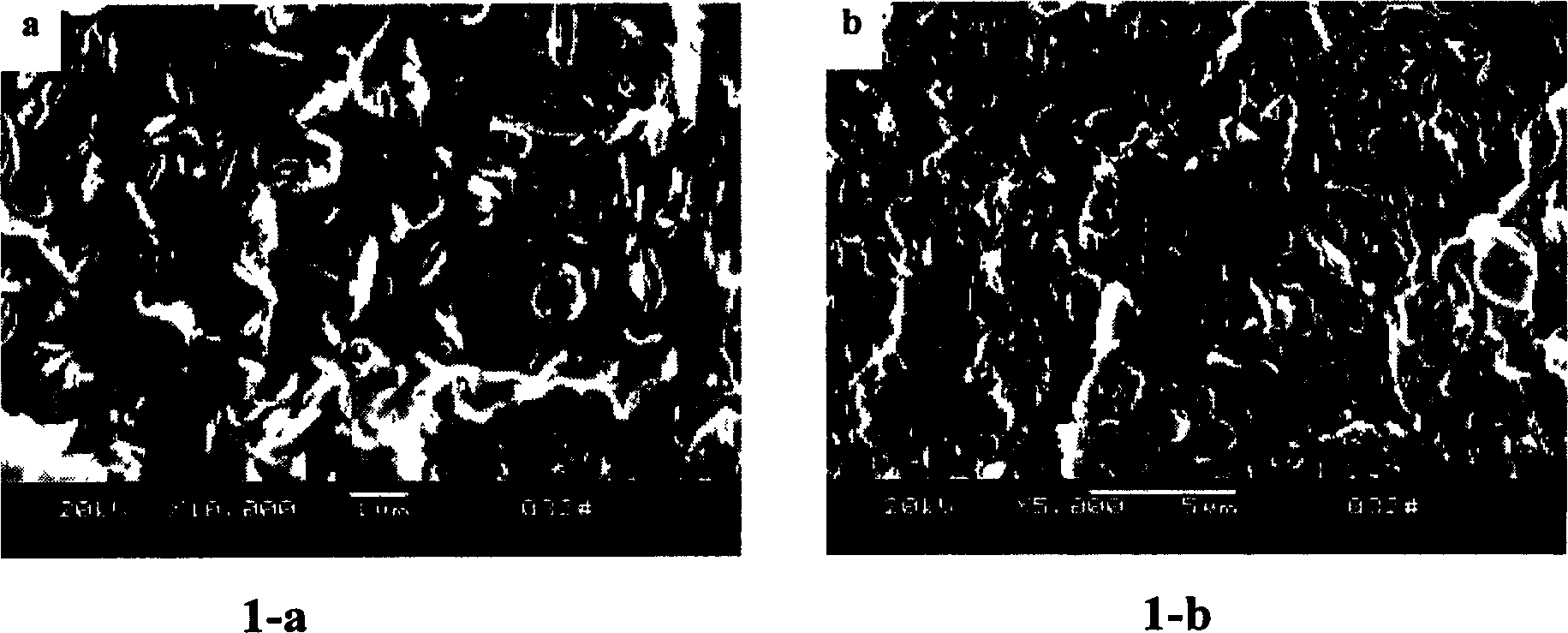

Method for preparing melamine cyanurate with large particle size and wide distribution

The invention discloses a method for preparing melamine cyanurate with large particle size and wide distribution, and belongs to the technical field of preparation of flame retardants. The method comprises the following steps of: preparing raw materials, namely melamine and cyanuric acid in a molar ratio of 1:1.05, adding a solvent, namely water in an amount which is 3 to 6 times the total mass of the melamine and the cyanuric acid into a reaction kettle, adding the cyanuric acid into the reaction kettle, and heating to the temperature of between 60 and 110 DEG C with stirring; adding the melamine and a macromolecular nucleating agent, and reacting at the temperature of between 95 and 110 DEG C for 1.5 to 5 hours with stirring to obtain white slurry; and performing pressure filtering on the slurry, drying, and grinding to prepare white powdered melamine cyanurate with the particle size of 15 to 100mu m. The melamine cyanurate with large particle size and wide distribution is easily subjected to suction filtering and dried, so that production efficiency is improved; and the melamine cyanurate serving as a flame-retardant additive has high dispersibility in a macromolecular materialsubstrate, and the flame-retardant effect and mechanical property of the substrate material are improved.

Owner:JINAN TAIXING FINE CHEM

Macromolecular dry denitrifying agent, preparation method thereof, denitrifying technology and denitrifying equipment

InactiveCN108187490AImprove denitrification efficiencyLower activation energyLighting and heating apparatusDispersed particle separationSodium BentoniteRaw material

The invention discloses a macromolecular dry denitrifying agent. The agent is prepared from components of raw materials in parts by weight as follows: 40-50 parts of urea, 10-20 parts of melamine and / or cyanuric acid, 20-30 parts of organic activated carbon powder, 10-15 parts of magnesium oxide, 10-15 parts of sodium carbonate, 20-25 parts of bentonite, 10-20 parts of quicklime and 1.0-1.2 partsof a catalyst. Meanwhile, the invention also provides a preparation method of the macromolecular dry denitrifying agent as well as a denitrifying technology and denitrifying equipment using the macromolecular dry denitrifying agent. The denitrifying agent obtained with the technical scheme is simple to prepare and low in cost. The dry denitrifying technology and denitrifying equipment using the denitrifying agent can treat flue gas with wider temperature ranges, have high denitrifying efficiency, have no ammonia escape and other side effects and have good application prospects.

Owner:HEBEI YAO YI ENERGY SAVING & ENVIRONMENTAL MFG CO LTD

Trimeric cyanamide cyanureate fire retarding polyamide nano-composite meterial and its preparation method

The present invention relates to a melamine cyanurate (MCA) fire-resisting polyamide nano composite material and its preparation method. It is characterized by that it uses melamine (MEL) and cyanuric acid (CA) as raw material, uses polyamide as base body resin and uses water as dispersion medium, under the action of molecular recombiner and water-tying plasticizer, in the course of extrusion it can in-situ synthesize MCA and prepare fire-resisting polyamide nano composite material.

Owner:SICHUAN UNIV

Preparation method of composite material for inorganic modified melamine chlorinated isocyanurate flame-retardant nylon 6

The invention discloses a preparation method of a composite material for inorganic modified melamine chlorinated isocyanurate flame-retardant nylon 6. The preparation method is characterized in that melted caprolactam is taken as a reaction medium; melamine and cyanuric acid react under the conditions of certain temperature and certain pH value; during the reaction process, water, an inorganic modified component and / or a precursor for generating the inorganic modified component, and other blending agents are added to prepare inorganic modified melamine chlorinated isocyanurate compound flame retardant; and then the composite material for the inorganic modified melamine chlorinated isocyanurate flame-retardant nylon 6 is prepared through in-situ polymerization under the conditions of certain temperature and certain pressure. During the whole preparation process, melted caprolactam not only serves as a resolvent for preparation of inorganic modified melamine chlorinated isocyanurate, but also serves as a polymerization monomer of the nylon 6; and synthesis and modification of modified melamine chlorinated isocyanurate and polymerization of the nylon 6 are accomplished at one step. The composite material for the flame-retardant nylon 6 has the characteristics of small additive amount of flame retardant, excellent overall performance of the composite material, and the like.

Owner:HUNAN UNIV OF TECH

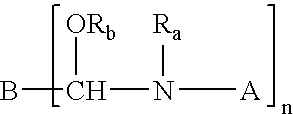

Crosslinking composition

This invention relates to a crosslinking composition comprising a compound having the structure of Formula I:A′-NRA—RDwhere A′ is a moiety derived from the group consisting of linear or cyclic ureas, cyanuric acid, substituted cyanuric acids, linear or cyclic amides, glycolurils, hydantoins, linear or cyclic carbamates and mixtures thereof, or a moiety comprising the structure:where RA is RD, hydrogen, an alkyl of 1 to 20 carbon atoms, or taken together with A′ forms a cyclic compound; RD is —CHRC ORB, wherein RB is hydrogen, alkyl, aryl, aralkyl or an alkaryl having from 1 to about 24 carbon atoms and RC is an alkyl, halogenated alkyl, aryl, aralkyl, halogenated aralkyl, alkoxyalkyl or an alkaryl having from 1 to about 24 carbon atoms; A is a moiety derived from the group consisting of linear or cyclic ureas, cyanuric acid, substituted cyanuric acids, linear or cyclic amides, glycolurils, hydantoins, linear or cyclic carbamates and mixtures thereof; B is a residue of a poly(alkylaldehyde) with n aldehyde groups; n is an integer of 2 to about 8; Ra is Rd, hydrogen, an alkyl of 1 to about 20 carbon atoms, or taken together with A forms a cyclic compound; where Rd is CHRcORb orwhere Rb is hydrogen, alkyl, aryl, aralkyl or an alkaryl having from 1 to about 24 carbon atoms and Rc is an alkyl, halogenated alkyl, aryl, aralkyl, halogenated aralkyl, alkoxyalkyl or an alkaryl having from 1 to about 24 carbon atoms; and where the alkyl or aryl groups in each radical may optionally have heteroatoms in their structure. This invention also relates to a process for producing the crosslinking composition by reacting an amino compound containing amino groups; a mono(alkylaldehyde) and / or a poly(alkylaldehyde), and an alcohol; where said amino compound is selected from the group consisting of: linear or cyclic ureas, cyanuric acid, substituted cyanuric acids, linear or cyclic amides, glycolurils, hydantoins, linear or cyclic carbamates and mixtures thereof.

Owner:ALLNEX NETHERLANDS BV

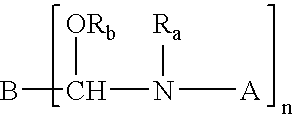

High-glowing filament anti-soaking separate-out-free halogen-free inflaming retarding polypropylene materials and preparation method thereof

The invention discloses high-glowing filament anti-soaking separate-out-free halogen-free inflaming retarding polypropylene materials which comprise the following components: by weight, 40-80 parts of polypropylene (PP) resins, 20-40 parts of compound halogen-free flame retarding agents, 0.5-5 parts of flame retardant synergists, 0-30 parts of inorganic fillers, 0.1-0.5 part of antioxidants, and 0.4-1 part of lubricating agents. The compound halogen-free flame retarding agents are composed of the following components: by weight, 30-50 parts of silane-wrapped organic or inorganic hypophosphite, 35-50 parts of melamine formaldehyde resin (MF)-wrapped halogen-free organic phosphate ester or the ramification thereof, and 15-40 parts of melamine cyanuric acid ester. The compound halogen-free flame retarding agents are easy to disperse in the process of processing, so that processing is convenient. The halogen-free inflaming retarding polypropylene materials prepared by the method have high-glow filaments, and have the advantages of being anti-soaking, separate-out-free and the like. In addition, the production process is simple, so that industrial production can be achieved.

Owner:聚石化学(苏州)有限公司

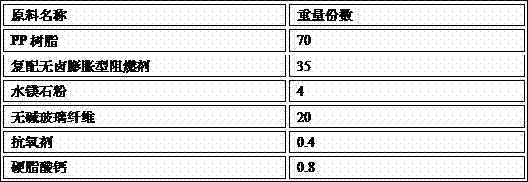

Ethylene vinyl acetate (EVA) glue film for encapsulating solar battery

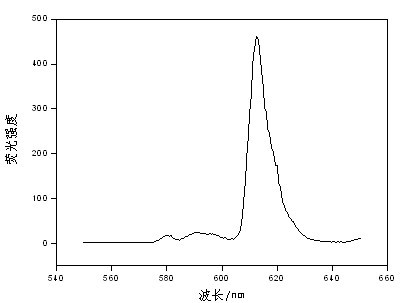

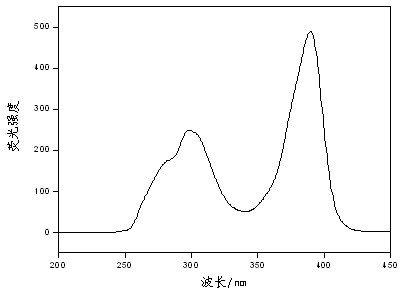

InactiveCN102559079AAvoid churnGuaranteed service lifeNon-macromolecular adhesive additivesFilm/foil adhesivesFluorescenceSilanes

The invention discloses an ethylene vinyl acetate (EVA) glue film for encapsulating a solar battery. The EVA glue film comprises the following components in part by mass: 100 parts of ethylene-vinyl acetate copolymer, 0.7 to 1.1 parts of crosslinking curing agent, 0.4 to 0.8 part of crosslinking aid, 0.4 to 0.8 part of coupling agent, 0.1 to 0.5 part of antioxidant and 0.1 to 0.5 part of fluorescence complex, wherein the mass percentage of the ethylene-vinyl acetate copolymer is 20 to 40 percent; the crosslinking curing agent is tert-butyl peroxide 2-ethyl hexyl carbonic ester; the crosslinking aid is triene propyl isocyanate trimer; and the coupling agent is gamma-(methyl propylene acyloxy)propyl trimethoxy silane. After the battery pack is heated and encapsulated, the olefinic bond of the fluorescence complex and the EVA perform copolymerization, so that the fluorescence complex is firmly fixed in the crosslinking cured EVA glue film through the chemical bond, loss of the fluorescence complex is effectively avoided, the service life of the battery pack is guaranteed, and ultraviolet light is effectively utilized.

Owner:SUZHOU TECHN SOLAR FILM MATERIAL

Burnthrough-resistant water-based fire retardant glue for spinning

The invention provides burnthrough-resistant water-based fire retardant glue for spinning. The burnthrough-resistant water-based fire retardant glue is prepared from the following components in parts by weight: 100 parts of a water-based adhesive, 10 to 100 parts of a halogen flame retardant, 3 to 100 parts of a synergistic flame retardant, 0 to 30 parts of an auxiliary and 0 to 100 parts of water, wherein the water-based adhesive is prepared from ethylene-vinyl acetate copolymer emulsion and an auxiliary adhesive; the solid content of the ethylene-vinyl acetate copolymer emulsion is 20 to 56 percent; the weight ratio of the water-based adhesive to the halogen flame retardant is (1 to 8) to 1; the halogen flame retardant is prepared from one or more of decabromodiphenyl ether, decabromodiphenyl ethane, tri(2,3-dibromo propyl) isocyanuric acid ester, tri(tribromophenyl) cyanurate, ethylene bis (tetrabromophthalimide), tetrabromo bisphenol A, hexabromocyclododecane, octo-bromo-ether, chlorine ester resin, ploy (vinylidene chloride) resin, brominated styrene, brominated epoxy resin, polyvinyl chloride, chlorinated paraffin and methyl chloride.

Owner:WUJIANG HONGYUAN SPRAY WEAVING CO LTD

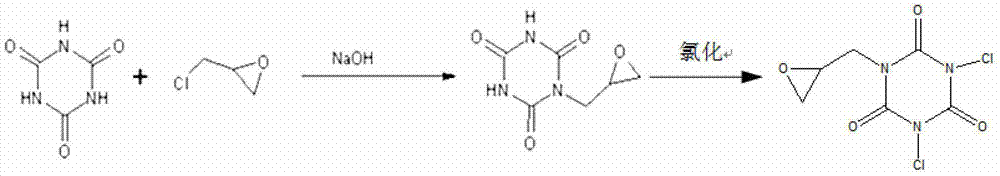

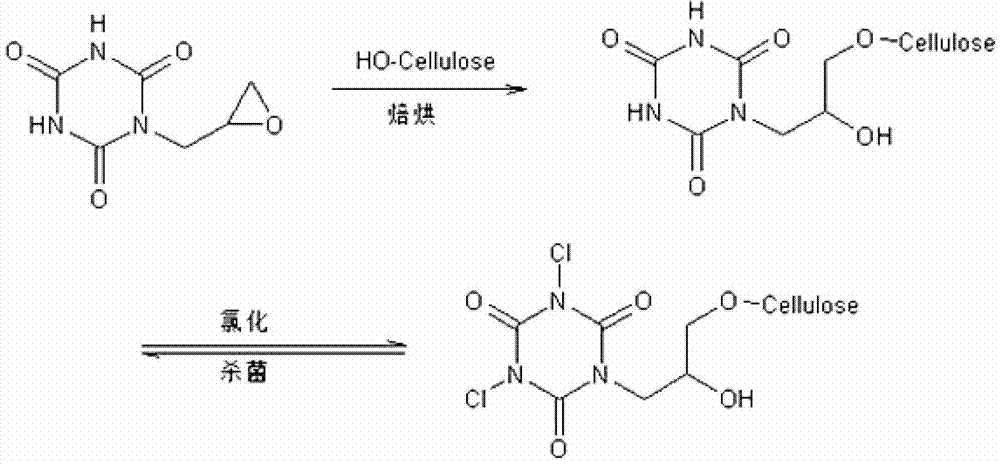

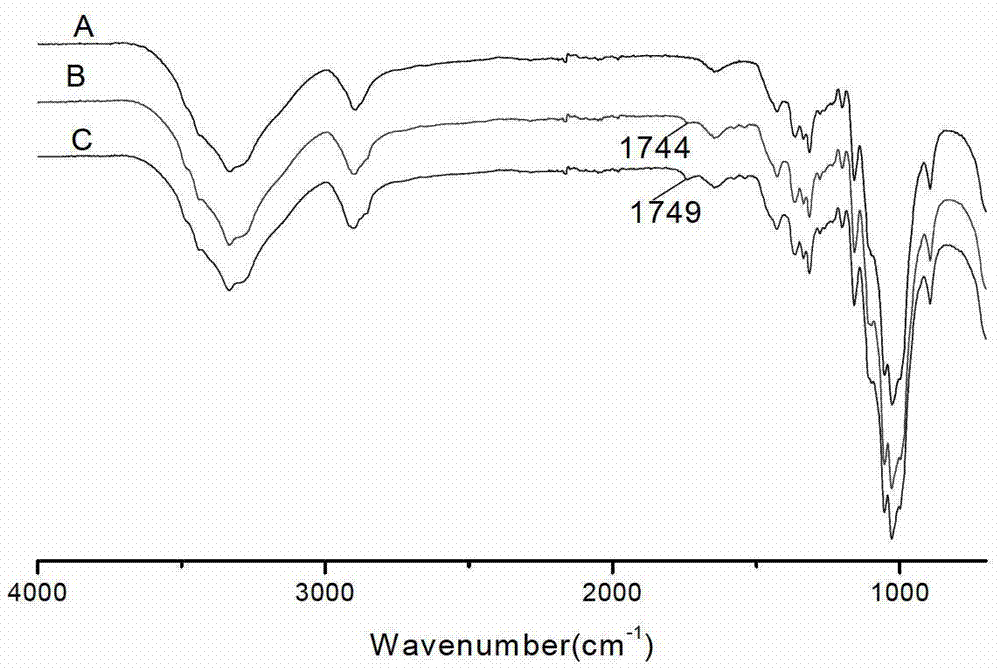

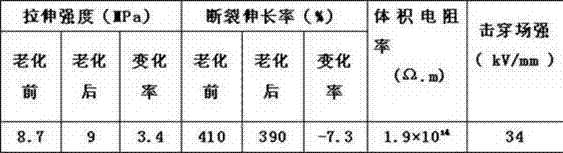

Halamine antibacterial agent and synthetic method and application thereof

InactiveCN102875536AReduce manufacturing costMild reaction conditionsBiocideOrganic chemistryCyanuric acidWater soluble

The invention provides a halamine antibacterial agent and a synthetic method and application thereof. The halamine antibacterial agent is a compound with a structure which is shown as a formula (I) or a formula (II). The synthetic method comprises the following steps of: reacting by taking epoxy chloropropane and cyanuric acid or a derivative of the cyanuric acid as synthetic raw materials at the temperature of between 5 and 50 DEG C for 6 to 12 hours, filtering, removing impurities to obtain a halamine antibacterial agent precursor with a structure which is shown as a formula (III) or a formula (IV), and performing halogenating reaction to obtain a finished product of the halamine antibacterial agent. According to the application of the halamine antibacterial agent to the preparation of an antibacterial material, the antibacterial material is prepared by the following steps of: treating a material to be treated by a working solution prepared from the halamine antibacterial agent precursor, taking the material out, drying, treating at the temperature of between 80 and 200 DEG C for 3 to 60 minutes, and performing halogenating reaction. According to the method, reaction condition is mild, a process is simple, and raw materials are low in cost and readily available; and the halamine antibacterial agent synthesized by the method and the halamine antibacterial agent precursor are water-soluble, high in yield, safe and non-toxic, and can be prepared into antibacterial textiles with high antibacterial performance.

Owner:JIANGNAN UNIV

Light curing adhesive for splicing capacitive touch screen and preparation method of light curing adhesive

InactiveCN103184029AHigh refractive indexHigh light transmittancePolyureas/polyurethane adhesivesRubber derivative adhesivesVinyl etherPolymer science

The invention discloses a light curing adhesive for splicing a capacitive touch screen. The light curing adhesive is prepared from the following components by weight percent: 30-50% of main body resin, 20-40% of auxiliary resin, 10-30% of an active monomer, 0.5-5% of a photoinitiator, and 0.1-5% of an auxiliary agent, wherein the main body resin is aliphatic urethane acrylate resin; the auxiliary resin is one substance or a mixture of more substances: cyanuric acid resin modified by acrylic ester, liquid nitrile rubber, liquid polybutadiene rubber and liquid isoprene rubber; the active monomer is one or a mixture of more of a vinyl ether monomer and an acrylate monomer; the photoinitiator is one or a mixture of two of a free radical initiator and a cationic photoinitiator; and the auxiliary agent is one or mixture of two of a silane coupling agent and a flatting agent. The light curing adhesive for splicing the capacitive touch screen has the advantages of high refractive index, high light transmittance, low color brightness, low hardness, low cure shrinkage rate, good reliability, good yellowing resistance and the like.

Owner:SHENZHEN FISHER NEW MATERIALS CO LTD

Medium-voltage ethylene propylene rubber insulating material and preparation method thereof

The invention discloses a medium-voltage ethylene propylene rubber insulating material and a preparation method thereof. The medium-voltage ethylene propylene rubber insulating material comprises the following components in percentage by weight: 15-30 percent of ethylene-propylene-diene rubber, 9-20 percent of ethylene-propylene rubber, 4-10 percent of linear low-density polyethylene, 4-7 percentof zinc oxide, 0.1-0.4 percent of stearic acid, 5-35 percent of superfine talc powder, 4-7 percent of paraffin hydrocarbon oil, 0.5-3 percent of paraffin, 10-30 percent of calcining clay, 0.1-0.9 percent of surface active agent gamma-aminopropyltriethoxysilane, 0.4-1.8 percent of antiager 4,4'di(alpha,alpha dimethylbenzyl)diphenylamine, 0.5-1.5 percent of vulcanizer dicumyl peroxide and 0.3-1.4 percent of vulcanizing agent triallyl cyanurate. By synthesizing the performance of various materials and learning from strengths to offset their weaknesses, the aims of reducing the cost and improvingthe electric performance are achieved. Tests prove that the medium-voltage ethylene propylene rubber insulating material disclosed by the invention has the volume resistivity of 1014 ohm.m and the breaking-down field strength of larger than 30KV / mm and has the advantages of excellent electric performance, higher thermal ageing performance and physical and mechanical performance, simple preparation process and strong operability.

Owner:JIANGSU HENGTONG POWER CABLE +1

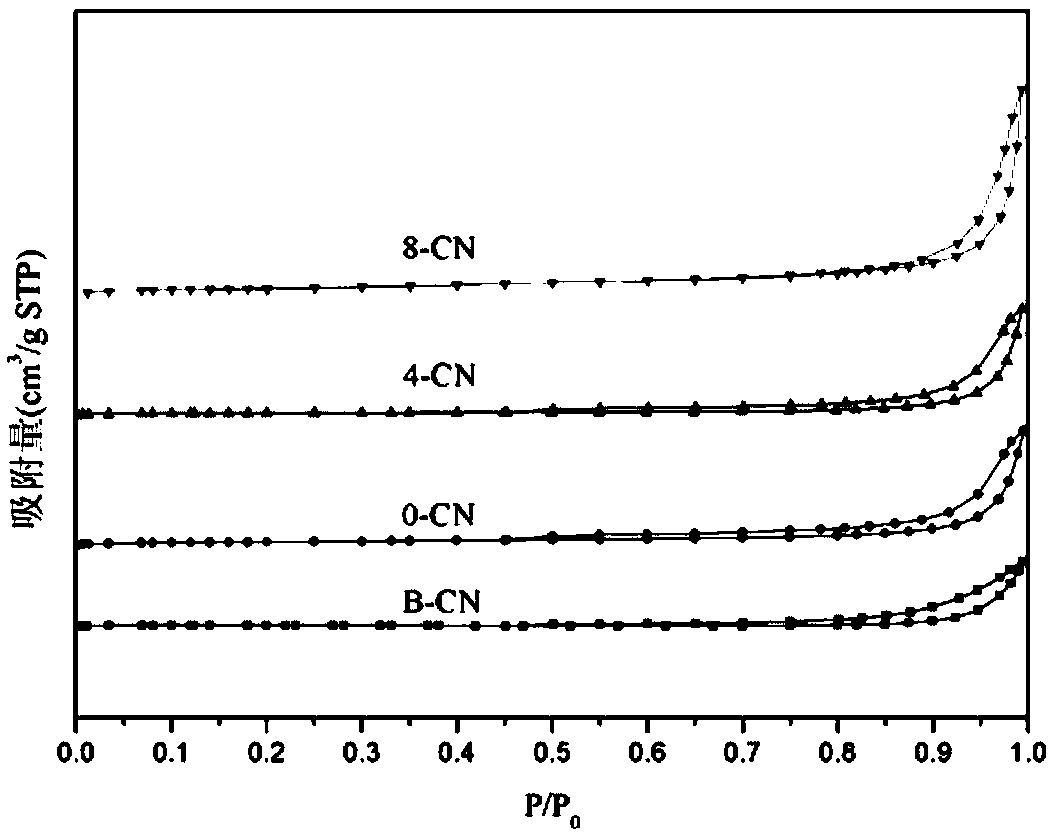

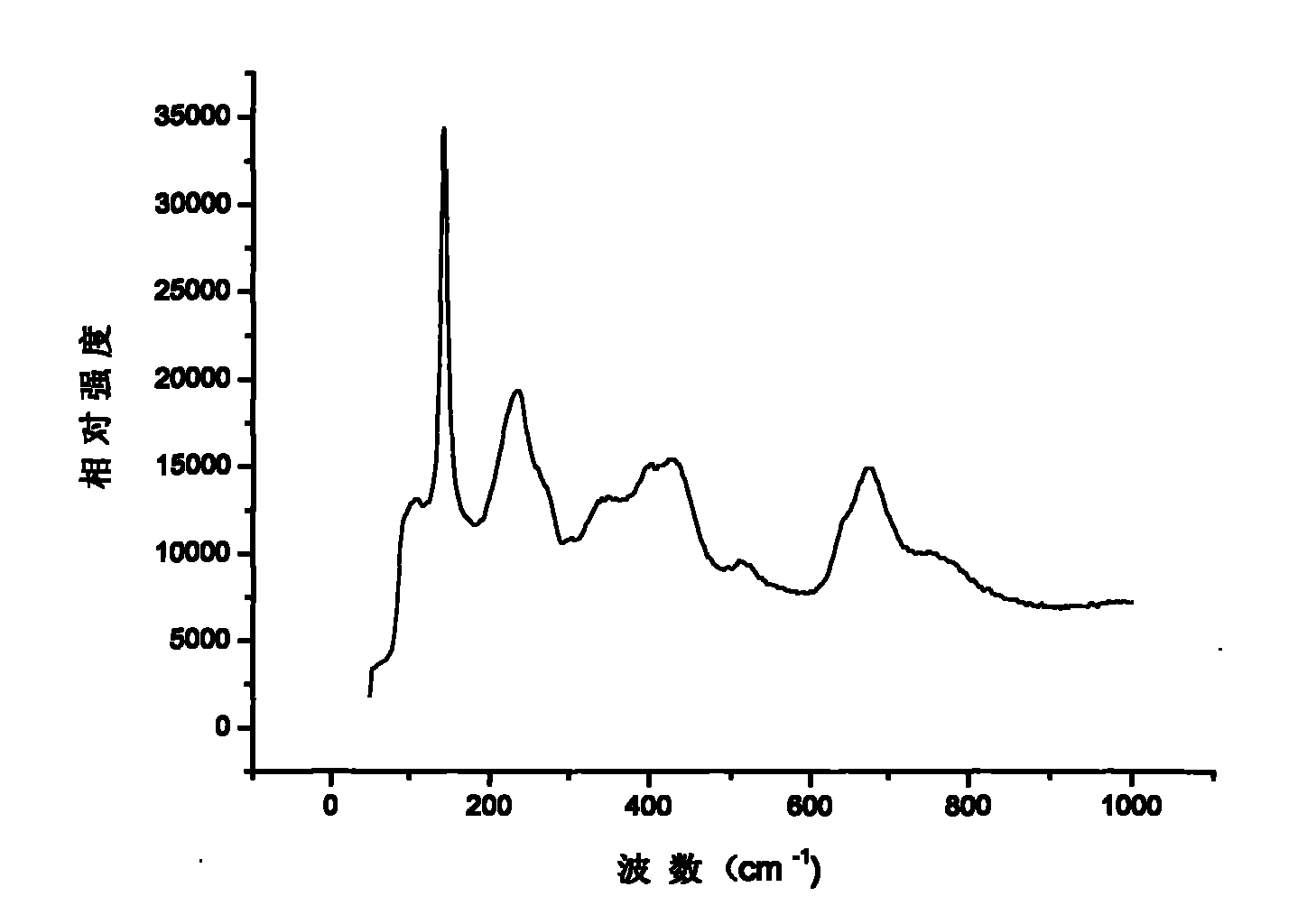

Mesoporous graphite phase carbon nitride and preparation method and application thereof

InactiveCN109046428AActive photocatalytic activityWater/sewage treatment by irradiationWater treatment compoundsSupermoleculeHeat treated

The invention belongs to the field of functional materials, and discloses a mesoporous graphite phase carbon nitride and a preparation method and application thereof. Ammonium salt is utilized as a pore-forming agent and a hydrothermal inducer and melamine is taken as a precursor, so that controllable mesoporous g-C3N4 is prepared. Ammonium salt is hydrolyzed in water, an acidic environment is provided, melamine is partially converted into cyanuric acid under the acidic condition, melamine and cyanuric acid are connected through hydrogen bonds between molecules to form supermolecules, the supermolecules are then roasted, cyanuric acid in the supermolecules is decomposed in the process of roasting to produce a great deal of gas (serving as a bubble template), meanwhile, voids are left over,so that rich pore structures are produced in the process of forming carbon nitride by the pyrocondensation polymerization of melamine, ammonium chloride which remains after hydrothermal treatment also plays the role of the bubble template, and ultimately, the mesoporous graphite phase carbon nitride with high catalytic performance is obtained.

Owner:GUANGZHOU UNIVERSITY

Method for preparing lithium titanate/titanium nitride composite material

The invention belongs to the field of battery materials, and particularly relates to a cathode material for a lithium battery. The invention discloses a method for preparing a lithium titanate / titanium nitride composite material, which comprises the following steps of: grinding titanium dioxide serving as a titanium source, lithium titanate and solid nitrogen source uniformly in a disperse medium, drying at the temperature of between room temperature and 120 DEG C, and grinding; and firing under the protection of vacuum or inert gas, and then naturally cooling to obtain the lithium titanate / titanium nitride composite material, wherein the nitrogen source is selected from one or mixture of more than two (comprising two) of urea, biuret, cyanamide, dicyandiamide, melamine, cyanuric acid monamide and cyanuric acid diamide. The method for directly preparing the Li4Ti5O12 / TiN composite electrode material by adding the solid nitrogen source into the raw materials for preparing Li4Ti5O12 does not increase the preparation process, has low cost, simple process and low energy consumption, and is easy to realize scale production.

Owner:SUZHOU UNIV

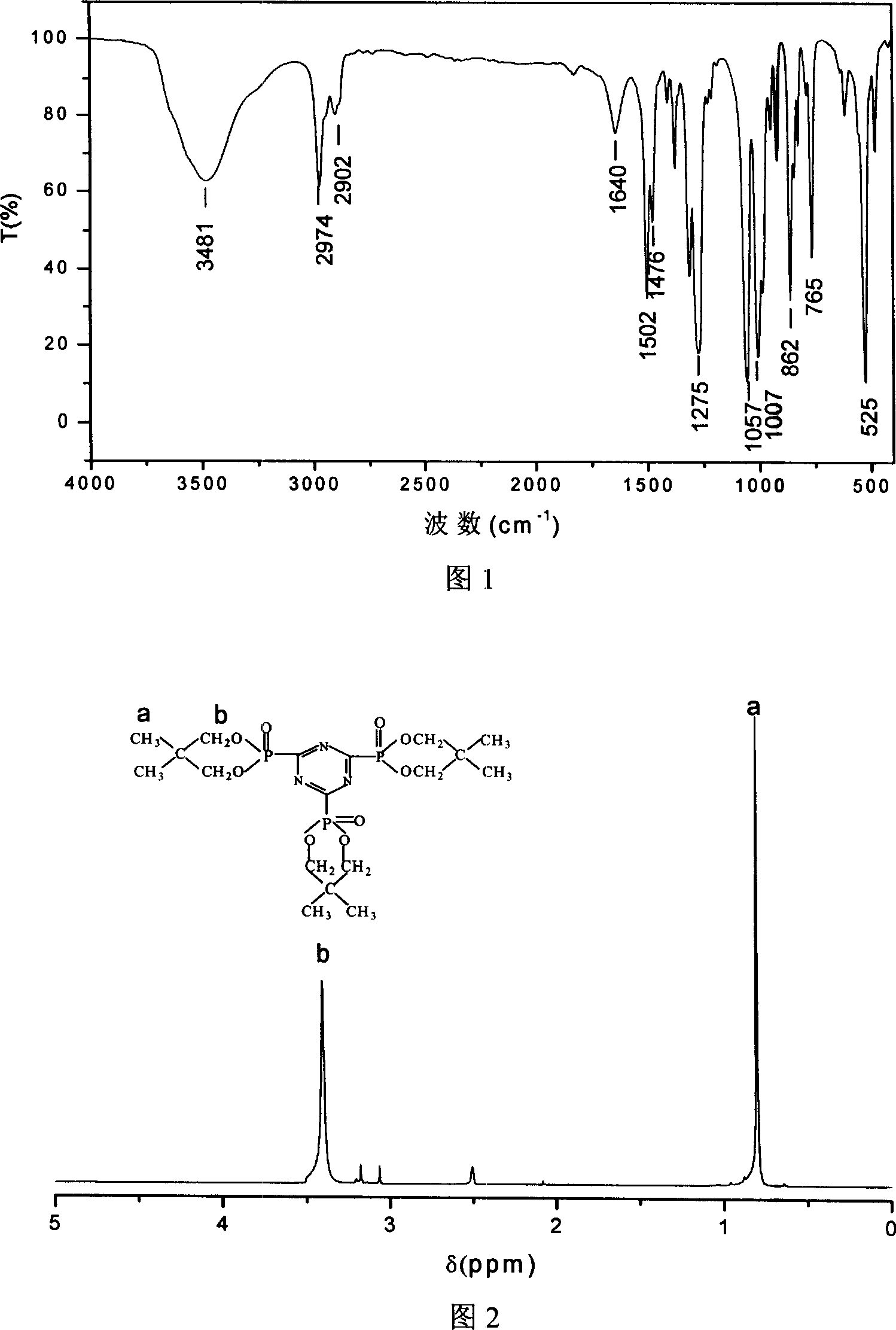

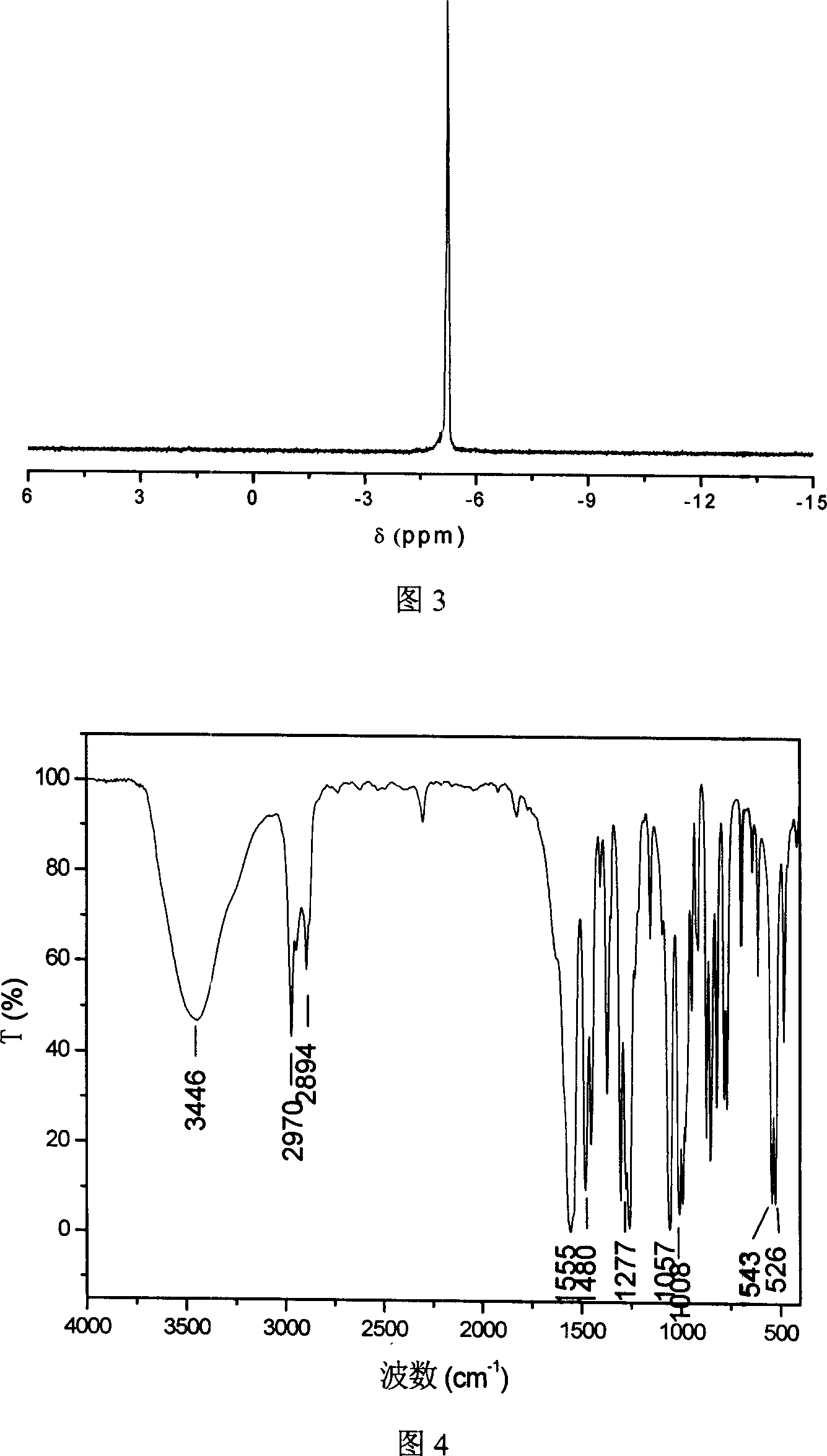

Triazine ring combustion inhibitor containing phosphorus and its preparing process

InactiveCN101007953AImprove thermal stabilityHigh decomposition temperatureGroup 5/15 element organic compoundsPhosphateReaction temperature

The invention discloses a phosphoric triazine radical containing fire retarding agent and the preparing method. The method comprises following steps: putting neopentyl glycol phosphite ester and cyanuric acid of same equivalent weight in organic solvent, reacting for 2- 10 hours at normal temperature to 140 Deg. C, getting 1, 3, 5- triazine neopentyl glycol phosphate; then putting got 1, 3, 5- triazine neopentyl glycol phosphate and diamine of same equivalent weight in inert liquid for replace reaction and getting phosphoric triazine radical containing fire retarding agent, the reacting temperature is from normal temperatur to 160 Deg. C, reacting time is 6- 72 hours. The number average molecular weight of product is 2000- 20000, and the decompostion temperature is 240- 400 Deg. C. The invention increases the fire retarding agent's decompostion temperature, which enables it not to decompose during macromolecular material processing; and the expanded fire retarding agent ploymer prepared in this invention contains P, N and C element, which is multifunctional.

Owner:SOUTH CHINA UNIV OF TECH

Flame-retardant resin composition

InactiveUS7498368B2Avoid bleedingProportion of the flame retardant is lowAnti-corrosive paintsGreenhouse cultivationPolyesterMetallic sulfide

A flame-retardant resin composition comprises a base resin (e.g., a polyester-series resin), a flame retardant (A) comprising a salt of an amino group-containing triazine compound with a sulfuric acid and / or a sulfonic acid, a flame-retardant auxiliary (B). The flame-retardant auxiliary (B) includes an aromatic resin, acyclic urea-series compound or a derivative thereof [e.g., acetyleneurea, uric acid, a salt of melamine or a condensate thereof (e.g., melam, melem, and melon) with cyanuric acid], an amino group-containing triazine compound (e.g., melamine or a condensate thereof), and / or an inorganic metal-series compound (e.g., a metal salt of an oxygen acid having no sulfur atom, a metal oxide, a metal hydroxide, and a metal sulfide). The present invention provides a flame-retardant resin composition to which flame retardancy is imparted without using a halogen-series flame retardant and an organic phosphorus-series flame retardant.

Owner:POLYPLASTICS CO LTD

Formulation of high-concentration ozone resistant rubber tube

InactiveCN101555327AImprove performanceMaintain physical and mechanical propertiesHigh concentrationPolymer science

The invention relates to a formulation of a high-concentration ozone resistant rubber tube, which comprises the following compositions by mass parts: 100 parts of butyronitrile PVC rubber, 20 to 40 parts of fast extruding furnace black (FEF), 20 to 40 parts of MT-N990, 5 to 15 parts of diphenyl octyl phosphate(DOP), 5 to 15 parts of light magnesium oxide, 4 to 10 parts of zinc oxide ( ZnO ), 1.5 to 3 parts of dibenzothiazyl disulfide, 1.5 to 3 parts of 1, 4-bis(tert-butyl peroxy diisopropyl) benzene, 1.5 to 2.5 parts of trially isocyanurate, 0.2 to 0.4 part of sulfur, 3 to 5 parts of coumarone, 1 to 3 parts of stearic acid, 1 to 2 parts of microcrystalline wax, 1 to 2 parts of N-isopropyl-N'-diphenyl-para-phenylene diamine, and 1 to 2 parts of 2, 2, 4-trimethyl-1, 2-dihyaroquinoline polymer. Compared with the traditional formulation, the formulation of the invention improves the function of high-concentration ozone resistance of butyronitrile PVC rubber and leads the butyronitrile PVC rubber to be suitable to the extrusion processing for producing the rubber tube of fuel tank filler, thereby improving the service life of the rubber tube of an automobile fuel tank filler and better satisfying the requirements of fuel resistance and ozone resistance of the rubber tube of the automobile fuel tank filler.

Owner:TIANJIN PENGYI GRP CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com