Method for quickly preparing quasi-graphite-structure carbon nitride material by adopting microwave heating

A technology of graphite structure and carbon nitride, which is applied in the direction of catalyst activation/preparation, chemical instruments and methods, chemical/physical processes, etc., can solve the problems of time-consuming and energy-consuming, and achieve simple process, high-efficiency and rapid preparation, and high-degradation organic The effect of pollutant performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] Example 1: Rapid preparation of graphite-like structure carbon nitride material by microwave heating

[0033] Weigh 6g of urea into a 25mL alumina crucible, cover the 25mL crucible mouth-to-mouth with a 50mL alumina crucible, and then seal the junction of the two crucibles with aluminum silicate felt. Put the sealed crucible containing urea into a 200mL large alumina crucible, then bury the crucible containing urea with copper oxide, react for 18 minutes at a microwave power of 1000W, take out the buried crucible after cooling, that is Carbon nitride materials are available.

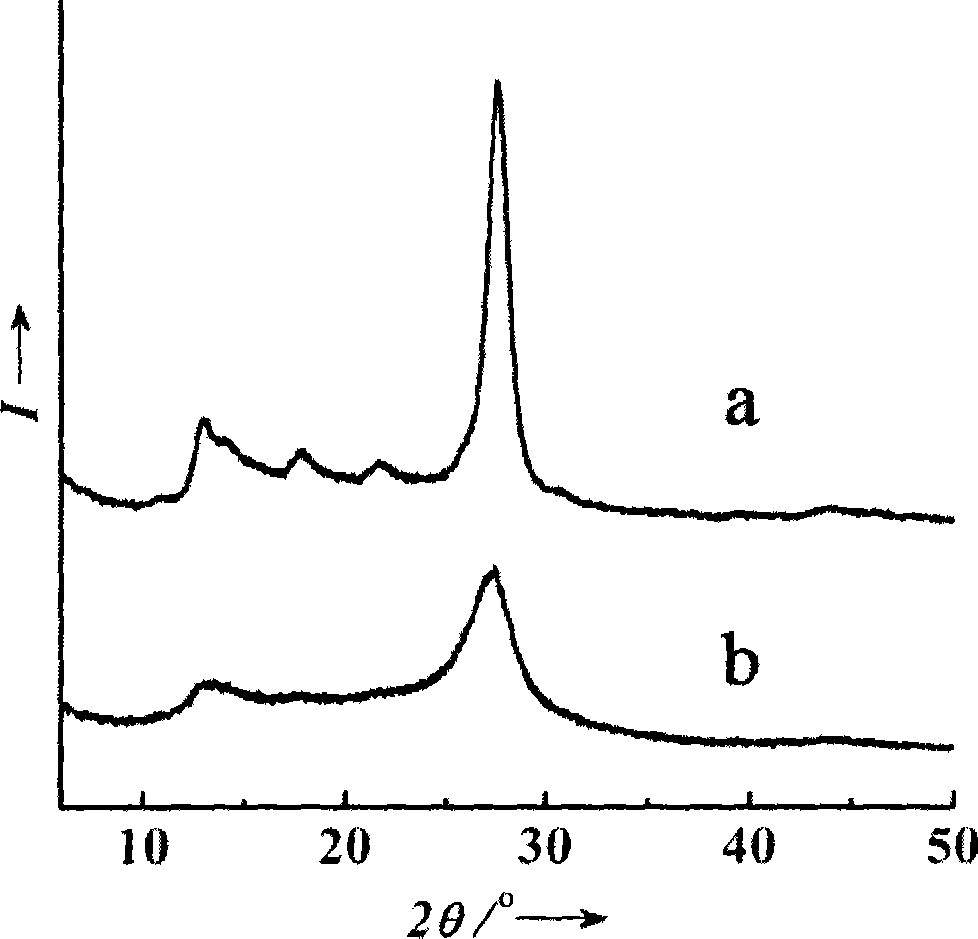

[0034] The XRD diffraction pattern of the carbon nitride material prepared in the present embodiment is as follows figure 1 , indicating that the prepared material is carbon nitride.

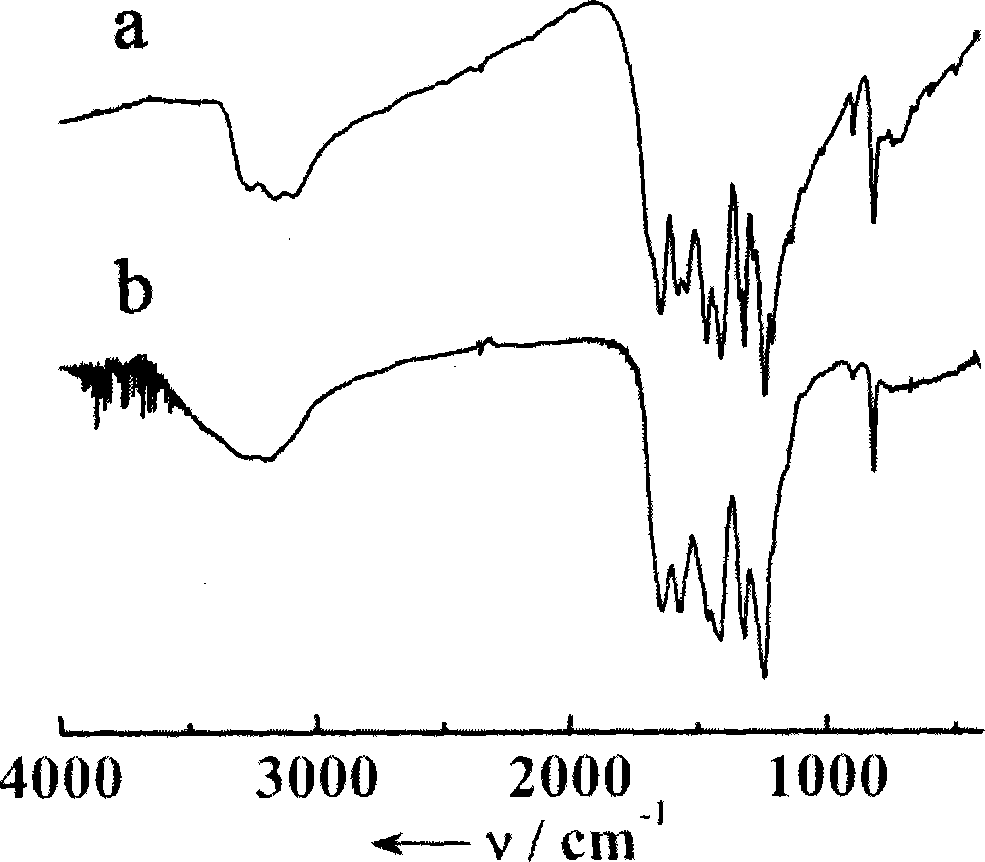

[0035] The infrared spectrogram (FT-IR) of the carbon nitride material prepared in the present embodiment is as follows figure 2 As shown, it shows that the prepared material is carbon nitride material.

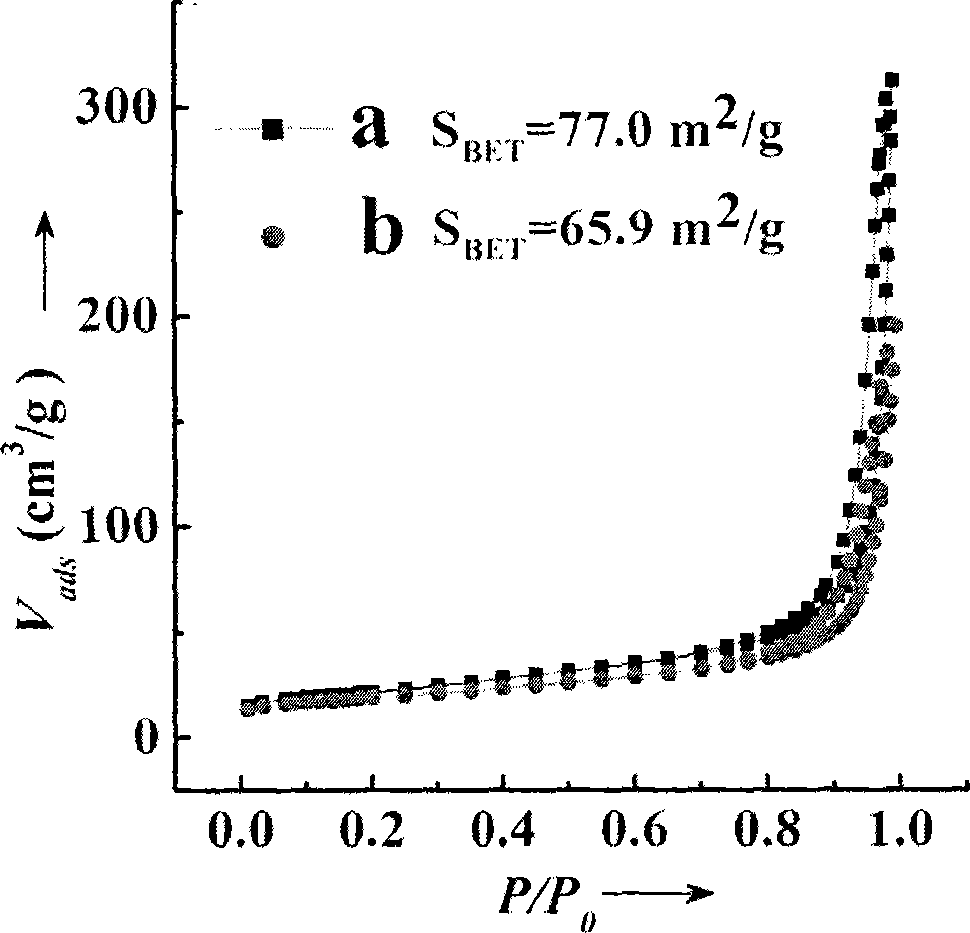

[0036...

Embodiment 2

[0039] Example 2: Rapid preparation of graphite-like structure carbon nitride material by microwave heating

[0040] Weigh 6g of urea into a 25mL alumina crucible, cover the 25mL crucible mouth-to-mouth with a 50mL alumina crucible, and then seal the junction of the two crucibles with aluminum silicate felt. Put the sealed crucible containing urea into a large alumina crucible of 200mL, then bury the crucible containing urea with copper oxide, react at a microwave power of 660W for 18 minutes, take out the buried crucible after cooling, that is Carbon nitride materials are available.

[0041] The XRD diffraction pattern of the carbon nitride material prepared in the present embodiment is as follows Figure 6 , indicating that the prepared material is carbon nitride.

Embodiment 3

[0042] Example 3: Rapid Preparation of Carbon Nitride with Graphite Structure by Microwave Heating

[0043] Weigh 3g of melamine and put it into a 25mL alumina crucible, cover the 25mL crucible mouth-to-mouth with a 50mL alumina crucible, and then seal the junction of the two crucibles with aluminum silicate felt. Put the sealed crucible containing urea into a 200mL large alumina crucible, then bury the crucible containing urea with copper oxide, react for 15 minutes at a microwave power of 1000W, take out the buried crucible after cooling, that is Carbon nitride materials are available.

[0044] The XRD diffraction pattern of the carbon nitride material prepared in the present embodiment is as follows Figure 7 , indicating that the prepared material is carbon nitride.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com