Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

188results about How to "Wide temperature window" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Scr flue gas denitrification catalyst based on tio2-zro2 composite carrier and preparation method

ActiveCN102266761AImprove adsorption capacityExtended service lifeCatalyst carriersDispersed particle separationActive componentFlue gas

The invention mainly relates to a SCR (selective catalyctic reduction) flue gas denitration catalyst based on a TiO2-ZrO2 composite metal oxide carrier, belonging to the field of environment protection and environment catalysis. According to the invention, with the nanometer TiO2-ZrO2 as a carrier, WO3 and CeO2 as assistants and V2O5 as an active component, a low-and-medium temperature flue gas denitration catalyst based on the TiO2-ZrO2 composite carrier is obtained. The nanometer TiO2-ZrO2 substitutes the traditional nanometer TiO2 and is used as a carrier, thus the specific area, the heat stability and the acidity of the catalyst are improved; and denitration activity of the catalyst is improved through mutual action among V2O5, WO3 and CeO2; when the ammonia is used as a reducing agent, the catalyst can show very good catalyzing activity at150-450 DEG C.

Owner:北京华电光大环境股份有限公司

Cu-SSZ-13 catalyst, and preparation method and application thereof

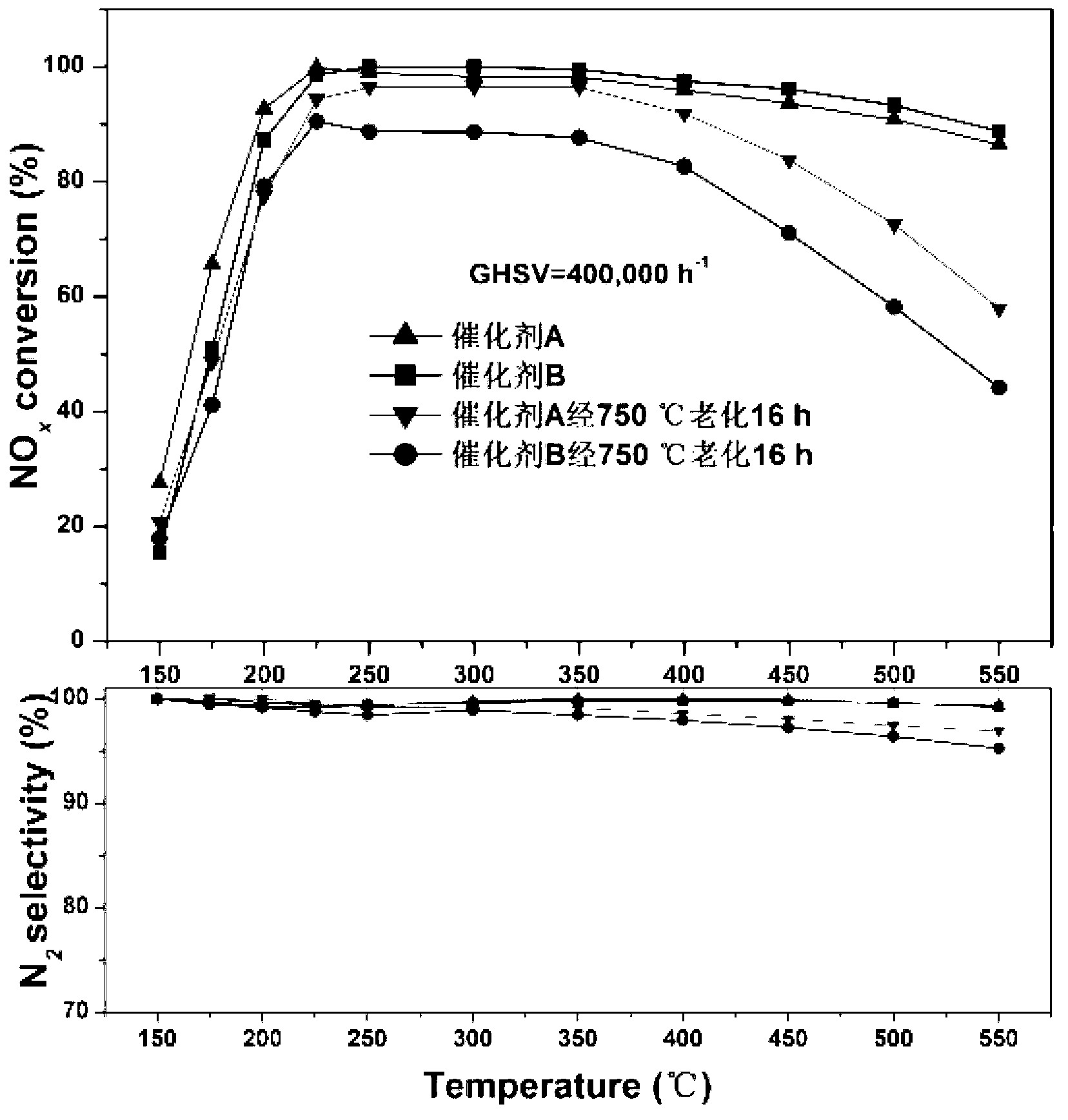

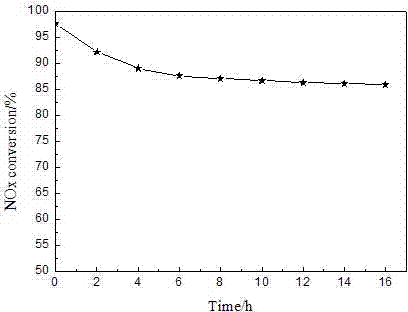

ActiveCN103157505ASolve pollutionImprove activity stabilityMolecular sieve catalystsDispersed particle separationAfter treatmentSynthesis methods

The invention discloses a method for preparing a Cu-SSZ-13 catalyst through an in-situ synthesis method. A Cu-SSZ-13 molecular sieve sample is prepared by taking acid as an exchange reagent and treating through an in-situ synthesis method. Compared with the currently used ammonium nitrate ion exchange method, the after treatment method for the Cu-SSZ-13 molecular sieve prepared through an in-situ synthesis method is more environment-friendly and effective; the activity of the prepared catalyst is higher; and the hydrothermal stability is better. According to the method, the silica-alumina ratio of the molecular sieve structure is increased while the catalyst having high catalytic activity is obtained; and the obtained Cu-SSZ-13 catalyst has excellent hydrothermal stability, wide temperature window and excellent N2 selectivity, and is very applicable to purification of tail gas from diesel cars.

Owner:江西中科鸿虔新材料有限公司

Scr flue gas denitrification catalyst based on mesoporous tio2 carrier and preparation method

ActiveCN102274723ALarge specific surface areaHigh catalytic activityDispersed particle separationMetal/metal-oxides/metal-hydroxide catalystsActive componentFlue gas

The invention belongs to the fields of environmental protection and environment catalysis, and specifically relates to a novel mesoporous TiO2 carrier based SCR flue gas denitration catalyst and a preparation method thereof. According to the invention, the mesoporous TiO2 carrier based SCR flue gas denitration catalyst is obtained by using mesoporous TiO2 as a carrier, WO3 and CeO2 as auxiliary agents, and V2O5 as an active component. The compound catalyst comprises, by weight, 83.5-94.5% of TiO2, 0.5-1.5% of V2O5, 4-10% of WO3 and 1-5% of CeO2. The mesoporous TiO2 is employed as the carrier to substitute traditional nano TiO2, so as to substantially increase a specific surface area of the catalyst; and the interactions among V2O5, WO3 and CeO2 increase denitration activity of the catalyst. Besides, the catalyst shows excellent catalytic activity in a temperature range from 200 to 450 DEG C with ammonia as a reduction agent.

Owner:北京华电光大环境股份有限公司

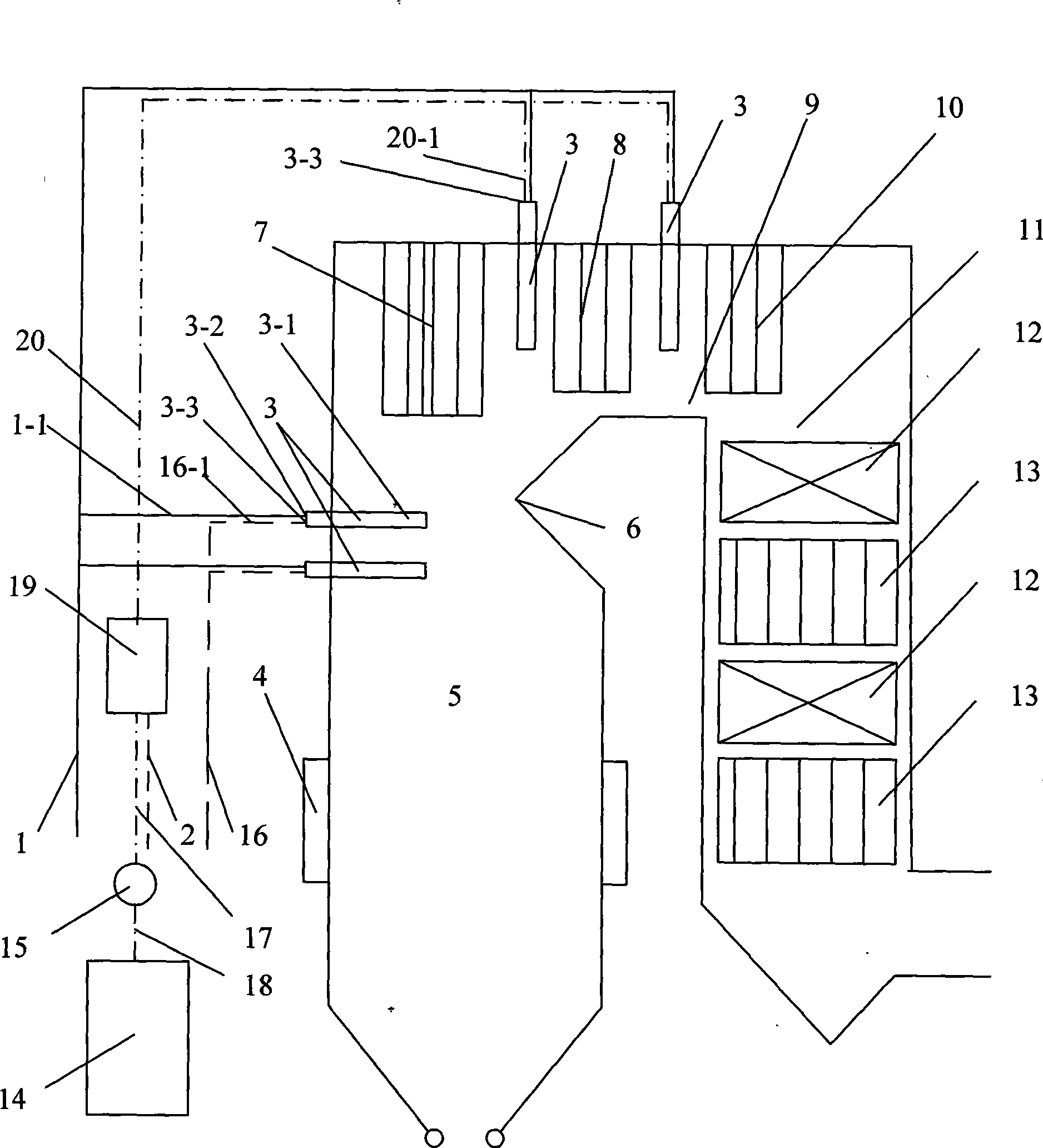

Selective non-catalytic reduction method for gasifying and atomizing biomass and used boiler

InactiveCN101433799AWidely distributedWell mixedLighting and heating apparatusDispersed particle separationProcess engineeringMixed gas

The invention relates to a selective non-catalytic reduction method for gasifying and atomizing biomass and a boiler used by the same, which relate to the selective non-catalytic reduction method and the boiler used by the same. The invention solves the problems that the prior selective non-catalytic reduction method has narrow temperature window, low denitration efficiency at a low temperature region and single effective component in synthesis gas of a reaction additive. The inlet of a gas mixer of the boiler is communicated with a gas additive pipeline and a compressed air pipeline respectively, while the outlet of the gas mixer is communicated with an atomizing medium pipeline. The selective non-catalytic reduction method mixes the biomass gasified gas in the gas additive pipeline with the compressed air through the gas mixer, uses the mixed gas as an atomizing medium for an amino reducing agent solution, and sprays the atomizing medium and the amino reducing agent solution together into a furnace chamber and a horizontal flue in a region with a temperature of between 800 and 950 DGE C through nozzles arranged in the furnace chamber and the horizontal flue. The selective non-catalytic reduction method improves the denitration efficiency and enlarges the temperature window. The boiler system of the invention is simple and has high reliability.

Owner:HARBIN INST OF TECH

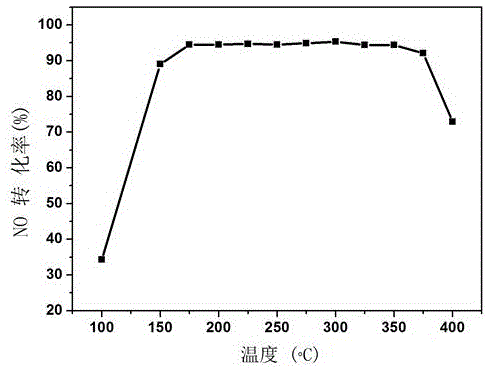

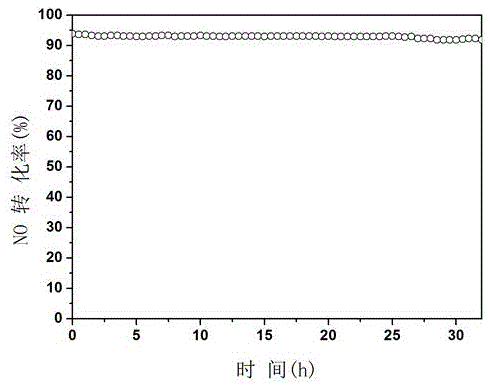

Composite smoke SCR (selective catalytic reduction) denitrification catalyst and preparation method thereof

ActiveCN102950008AWide active temperature windowImprove SCR denitrification efficiencyMolecular sieve catalystsDispersed particle separationActivated carbonMolecular sieve

The invention relates to a composite smoke SCR (selective catalytic reduction) denitrification catalyst. The composite smoke SCR denitrification catalyst takes honeycomb ceramics, activated carbon or a molecular sieve as a carrier. A composite manganese-molybdenum-nickel-loaded metal oxide is an active component, one or more of copper, chromium, cerium, tin and lanthanum are used as cocatalysts, and the total mass of the active components of the catalyst and the cocatalysts accounts for 15-30% of the mass of the carrier, wherein the molar ratio of Mn to Mo to Ni is 1:(0.1-1):(0.1-1), and the molar ratio of manganese to a metallic element of the co-catalyst is 1: (0.1-1). The catalyst provided by the invention is prepared by adopting a dipping method. Compared with the existing denitrification catalyst suitable for the temperature lower than 300 DEG C, the catalyst provided by the invention has the advantages of high denitrification efficiency, low cost, simple production process, long service life, wide active temperature window, high SO2 and H2O poison resistance capability and the like. Within the temperature from 80 DEG C to 300 DEG C, the conversion rate of NO is more than 90%.

Owner:CHINA PETROLEUM & CHEM CORP +1

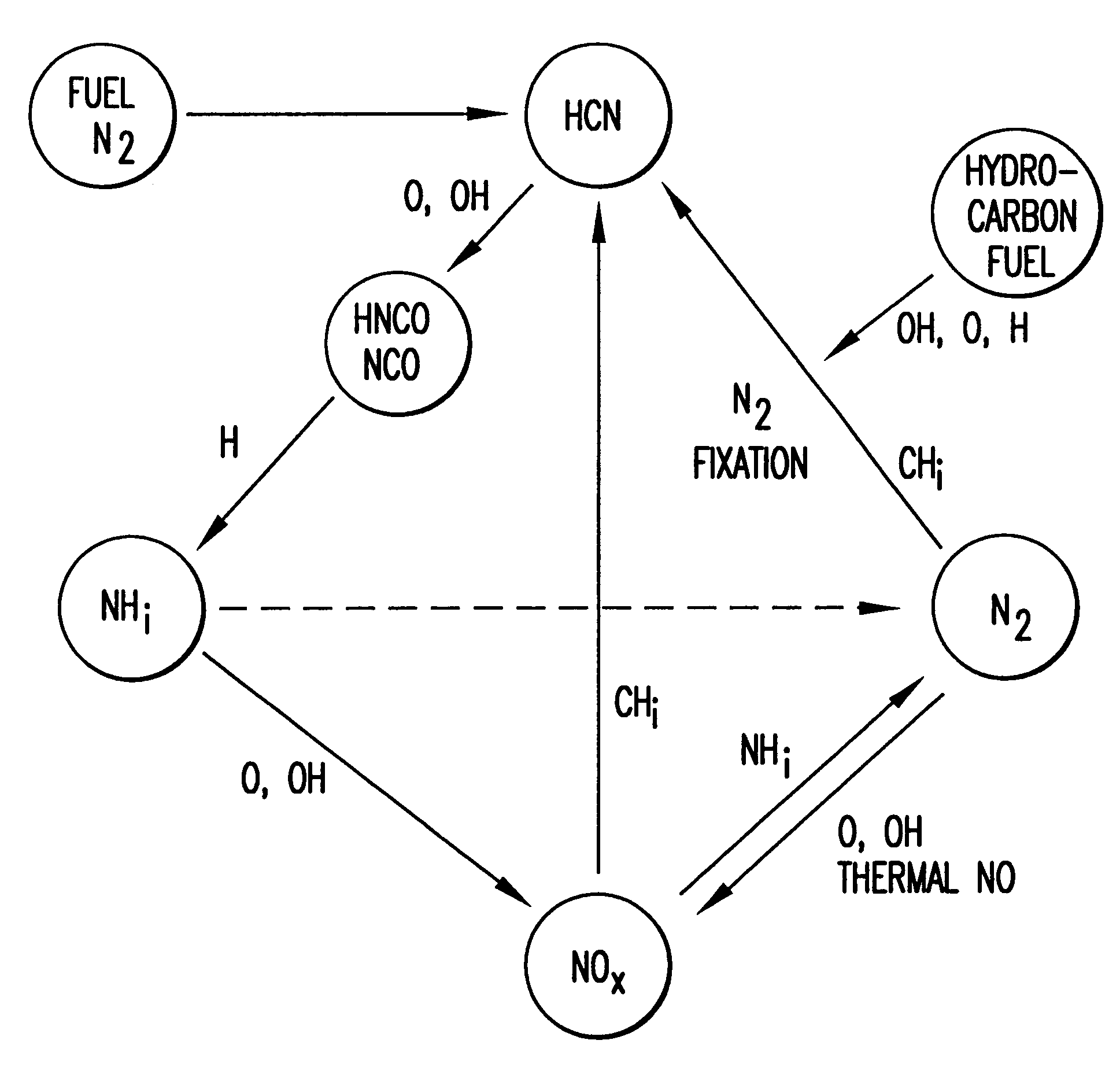

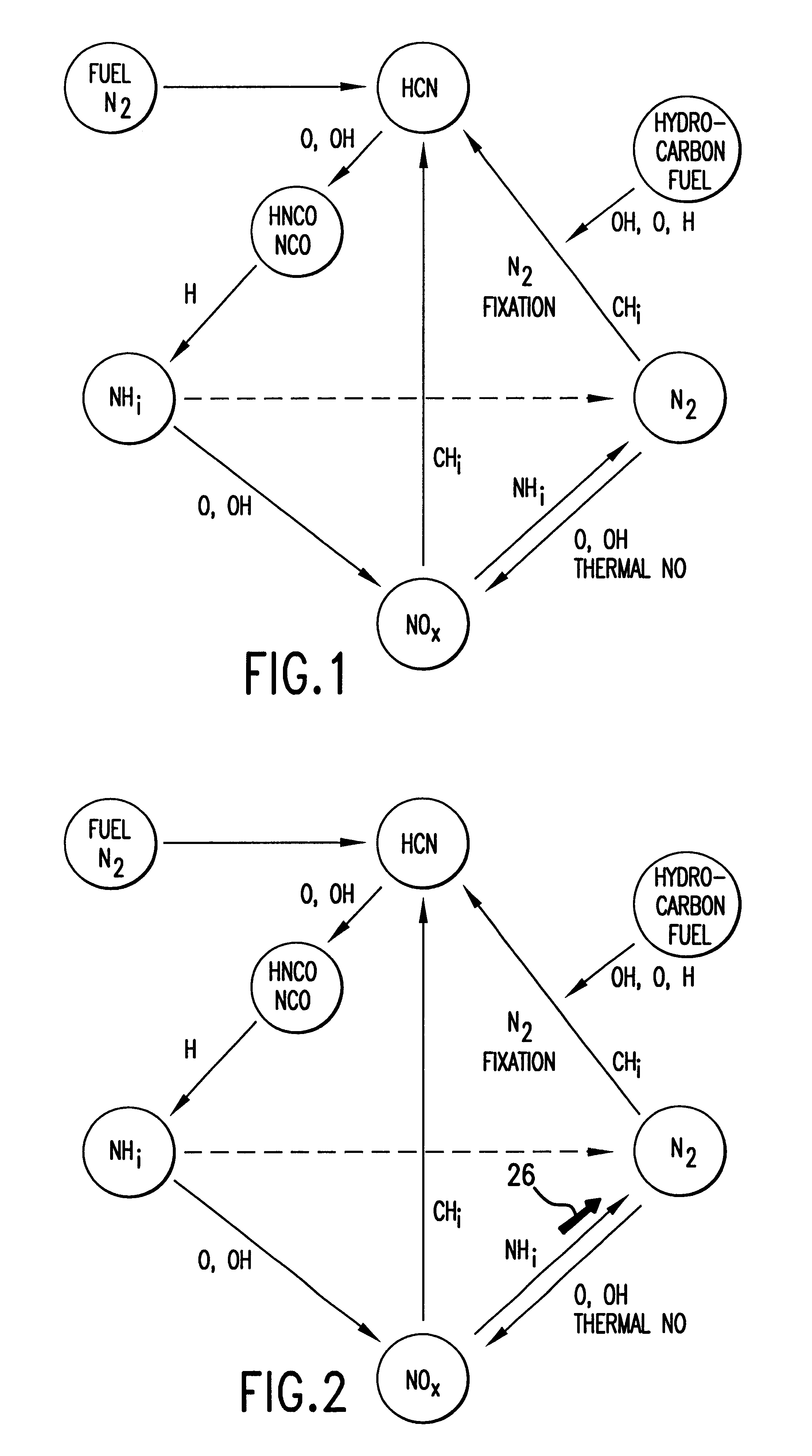

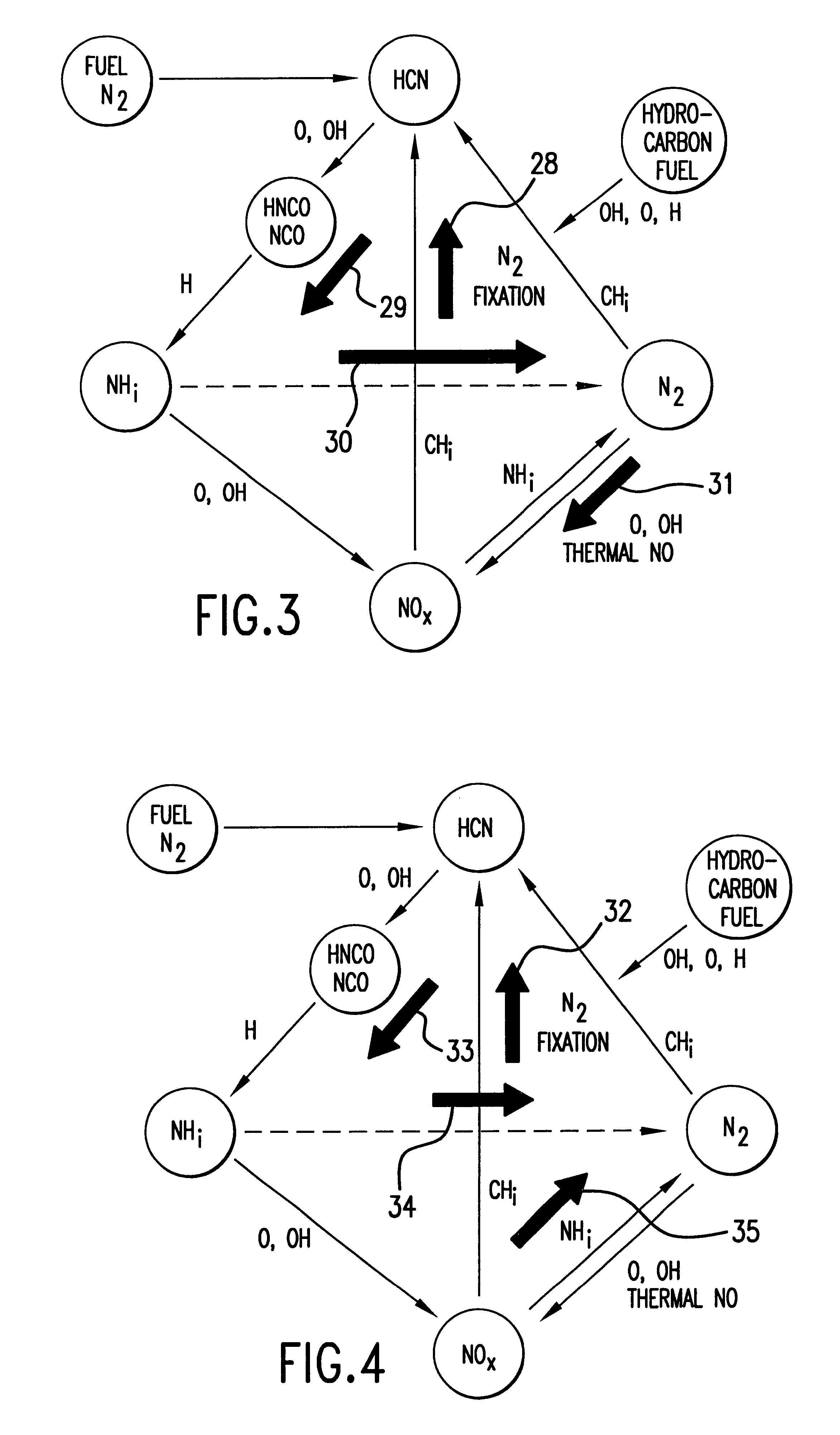

Method and apparatus for NOx reduction in flue gases

InactiveUS6258336B1Low costWide temperature windowNitrogen compoundsDispersed particle separationCombustion productsChemistry

In a furnace having a primary combustion zone for combustion of a fuel and oxidant, an in-furnace method for reducing nitrogen oxides in combustion products generated in the primary combustion zone in which at least one fluid fuel selected from the group consisting of natural gas, hydrogen, CxHy compounds, CxHyOz compounds and mixtures thereof in an amount in a range of about 2.0% to about 25% of a total heat input to the furnace and at least one nitrogenous compound selected from the group consisting of ammonia, amines, urea, cyanuric acid and mixtures thereof are injected into the furnace downstream of the primary combustion zone, forming an overall fuel-lean NOx-reduction zone.

Owner:GAS RES INST

Honeycomb non-vanadium denitration shaping catalyst, preparation method and application thereof

ActiveCN105107514AHigh mechanical strengthImprove denitrification efficiencyDispersed particle separationMetal/metal-oxides/metal-hydroxide catalystsWater vaporCopper oxide

The invention relates to a honeycomb non-vanadium denitration shaping catalyst, a preparation method and application thereof. The shaping catalyst is mainly obtained by shaping catalyst powder and forming additives. The catalyst powder comprises titanium dioxide and additives as main components, wherein the additives are combinations of any four or more than four of copper oxide, zirconium oxide, molybdenum oxide, iron oxide, nickel oxide, cobalt oxide, tungsten oxide and cerium oxide. The forming additives mainly comprise combinations of an enhancer, an inorganic binder, an organic binder, a pore forming agent and a lubricant. The shaping catalyst has excellent anti-SO2 and water vapor poisoning performance, and excellent denitration efficiency and high mechanical strength, and can be used in nitrogen oxide purification of stationary sources (such as a coal-fired power plant and oil catalytic cracking exhaust thereof) and mobile sources (such as diesel exhaust).

Owner:张鑫

Scr flue gas denitrification catalyst and preparation method based on tio2 carrier promoted by sulfate radical

ActiveCN102259009AStrong oxygen storage-release capacityStrong oxidation-reduction propertiesPhysical/chemical process catalystsDispersed particle separationSulfate radicalsFlue gas

The invention relates to a sulfate radical promoted nanometer TiO2 carrier based SCR (Selective Catalytic Reduction) flue gas denitration catalyst and a preparation method thereof, belonging to the fields of environmental protection and environmental catalysis. In the invention, a SO42- / TiO2 carrier based medium / low-temperature flue gas denitration catalyst is obtained through taking sulfate radical promoted nanometer TiO2 (SO42- / TiO2) as the carrier, taking WO3 and CeO2 as auxiliaries and taking V2O5 as an active component, wherein in the composite catalysis, the mass percentage of the V2O5 is 0.5-1.5%; the mass percentage of the WO3 is 4-10%; the mass percentage of the CeO2 is 1-5%; and the balance is SO42- / TiO2. The acidity of the catalyst is obviously increased after nanometer TiO2 issubject to sulfating treatment; the denitration activity of the catalyst is increased through interacting with the V2O5, the WO3 and the CeO2; and very good catalytic activity is showed through taking ammonia as a reducing agent at a temperature of 150-450 DEG C.

Owner:北京华电光大环境股份有限公司

Anti-water and anti-sulfur denitration catalyst, preparation method and application thereof

ActiveCN105056923AImprove denitrification activityGood water and sulfur resistanceDispersed particle separationCatalyst activation/preparationWater vaporCopper oxide

The invention relates to an anti-water and anti-sulfur denitration catalyst, a preparation method and application thereof. The catalyst includes titanium dioxide and an additive, both of which are used as the main components, wherein the additive is a combination of any four or more of zirconium oxide, copper oxide, molybdenum oxide, cerium oxide, iron oxide, nickel oxide, cobalt oxide, and tungsten oxide; the surface of the catalyst is coated with a silica coating; the catalyst can be used in the selective catalytic reduction (NH3-SCR) and purification processes of the nitrogen oxides in the flue gas of a stationary source and mobile source. The catalyst adopts non-toxic and harmless raw materials, and has the advantages of being simple and convenient in preparation method, high in catalytic activity, wide in active window, resistant to SO2 poisoning and vapor poisoning for a long time, and environment-friendly.

Owner:张鑫

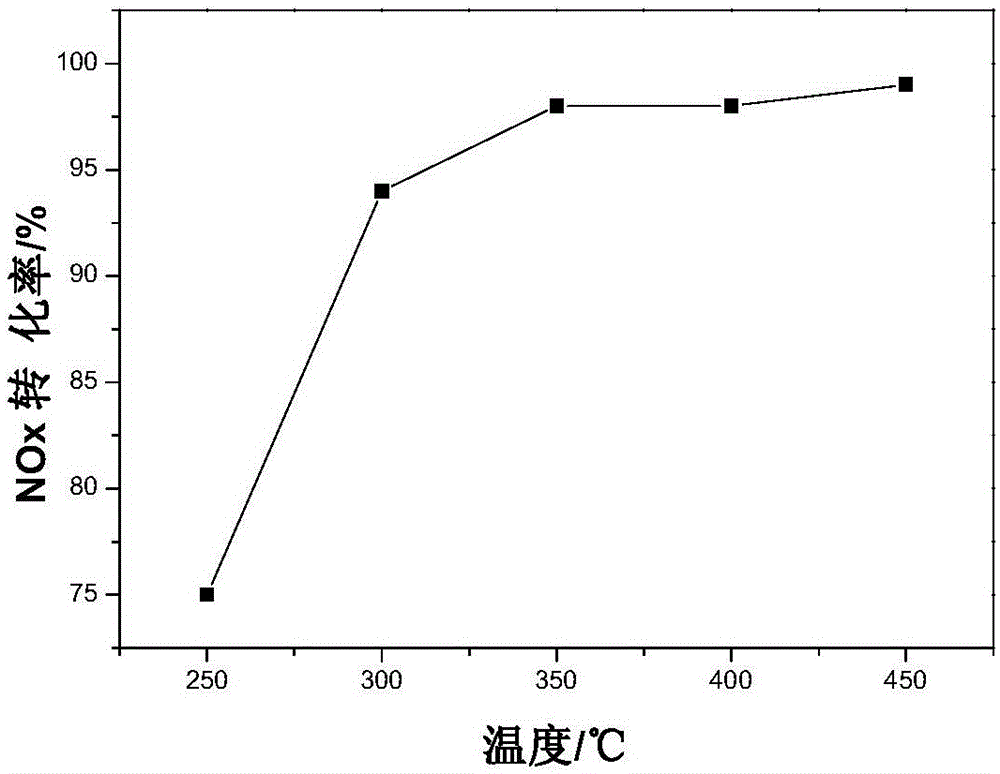

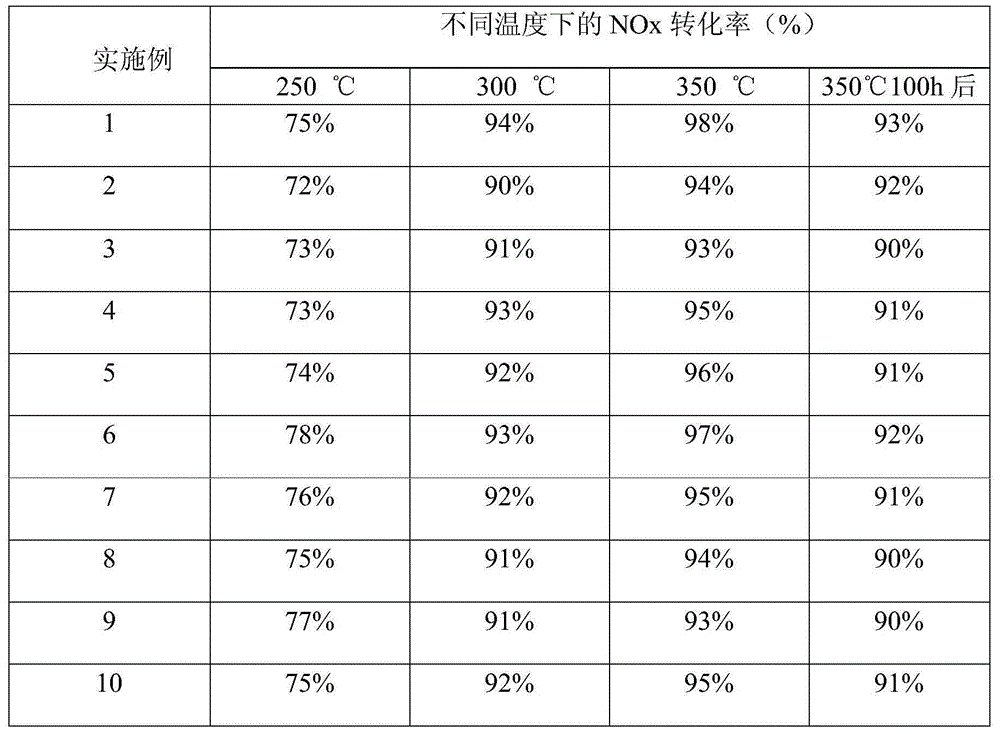

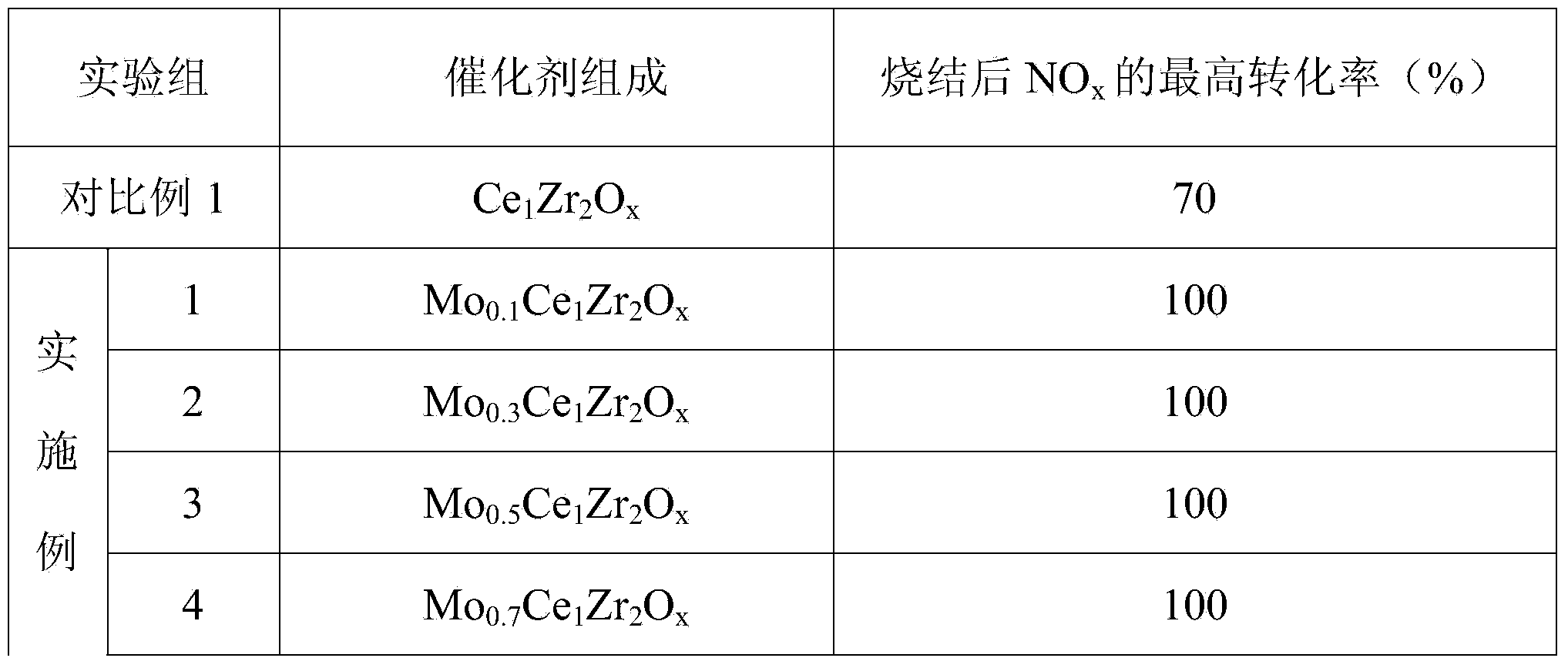

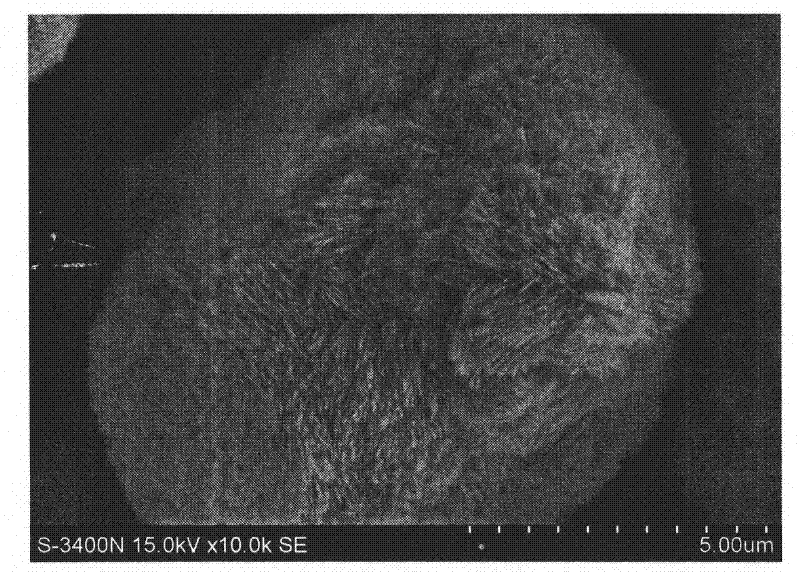

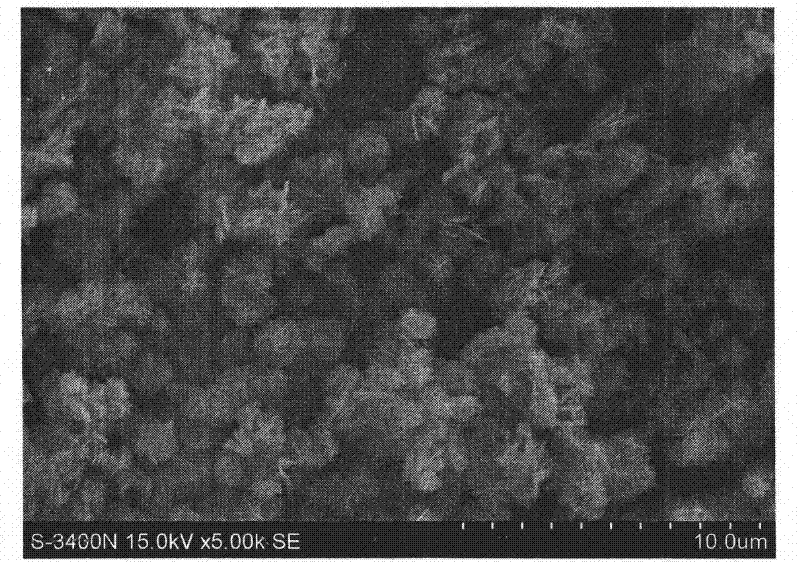

Cerium-molybdenum-zirconium composite oxide catalyst, and preparation method and application thereof

ActiveCN103816891AImprove thermal stabilityImprove conversion rateGas treatmentHeterogenous catalyst chemical elementsCeriumNitrogen oxide

The invention relates to a cerium-molybdenum-zirconium (Ce-Mo-Zr) composite oxide catalyst. The molar ratio of Zr to Ce in the catalyst is 1:2, and the molar ratio value of Mo to Ce is 0.1-1.5. By the adjustment of the ratio of the three elements, namely cerium, molybdenum and zirconium, the catalyst which is wide in temperature window, high in conversion rate and excellent in temperature resistance and sintering resistance, and is used for converting nitrogen oxides is obtained; the preparation process is simple, the cost is low, and the realization of the industrialization is facilitated.

Owner:RES CENT FOR ECO ENVIRONMENTAL SCI THE CHINESE ACAD OF SCI

CuO loaded CeO2 catalyst for CO preferential oxidation

InactiveCN102407123ALow priceEasy to manufactureHydrogen separation using solid contactMetal/metal-oxides/metal-hydroxide catalystsHydrogenCopper nitrate

The invention discloses a CuO loaded CeO2 catalyst for CO preferential oxidation in hydrogen-rich gas and application thereof, especially a ballflower-shaped or petal-shaped CuO loaded CeO2 catalyst. The invention takes copper nitrate as raw material, prepares ballflower-shaped or petal-shaped CuO, and takes it as carrier to synthesize ballflower-shaped or petal-shaped CuO loaded CeO2 catalyst for CO preferential oxidation by isovolumetric dipping method. The preparation process of the catalyst is simple and feasible. The raw material cost is comparatively low. CO preferential oxidation rate and selectivity are high. Temperature window of CO complete conversion is wide.

Owner:INNER MONGOLIA UNIVERSITY

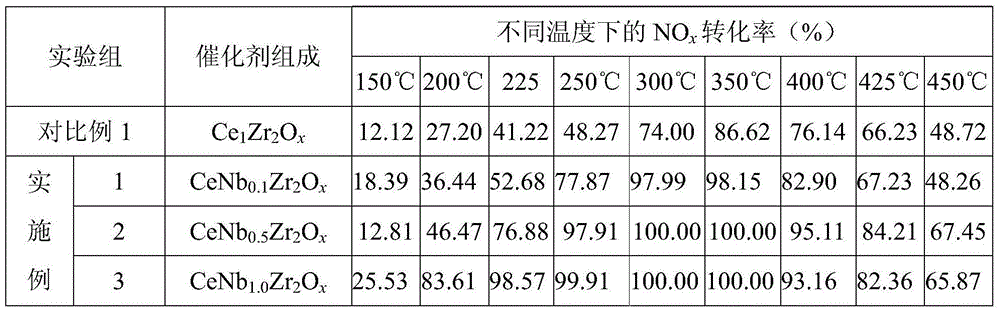

Cerium-niobium-zirconium composite oxide catalyst, preparation method and uses thereof

ActiveCN104368329AHigh low temperature activityWide temperature windowDispersed particle separationMetal/metal-oxides/metal-hydroxide catalystsChemical compositionNiobium

The present invention relates to a cerium-niobium-zirconium composite oxide catalyst, a preparation method and uses thereof. The catalyst has the following chemical composition: CeNbaZr2Ox, wherein a is 0-1.0 and does not include 0. The method comprises: (1) preparing a mixed aqueous solution comprising a cerium source and a zirconium source; (2) adding a niobium source aqueous solution and an excess urea precipitation agent to the mixed solution in the step (1) to completely precipitate cerium, niobium and zirconium; (3) carrying out suction filtration and washing on the obtained precipitated product to obtain the filter cake; and (4) drying and calcining the filter cake to obtain the cerium-niobium-zirconium composite oxide catalyst, wherein the catalyst has characteristics of excellent low-temperature activity, wide operation temperature window, high N2 selectivity and high NOx conversion rate, and can be used for the NH3-SCR reaction.

Owner:RES CENT FOR ECO ENVIRONMENTAL SCI THE CHINESE ACAD OF SCI

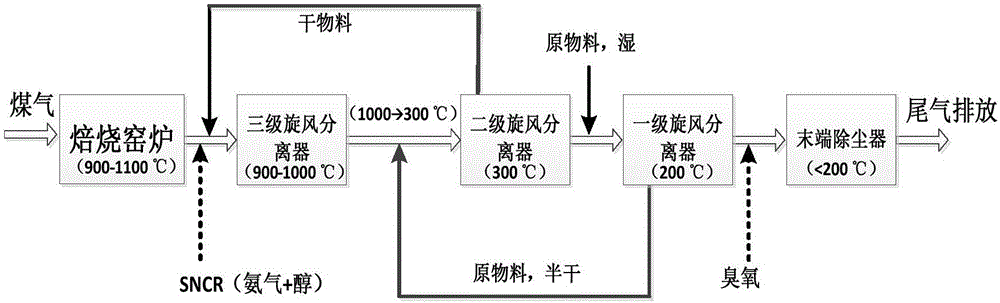

Combined denitrification system and method for alumina baked fuel gas

ActiveCN106215652AReduce usageReduce escapeCombination devicesGas treatmentReaction temperatureNitric oxide

The invention relates to a combined denitrification system and method for alumina baked fuel gas. The combined denitrification system comprises the following steps: (1), a mixed gas containing gasified ammonia water and an alcohol organic matter is added into a high temperature section gas duct at the outlet of a roasting kiln from a first purified gas inlet, so as to remove part of nitric oxide from the flue gas; (2), ozone is added into a low temperature section gas duct from a second purified gas inlet, and the rest nitric oxide in the fuel gas is further converted to NO2; (3), wet raw materials enter into a gas duct from a wet raw material dry inlet, and then are changed to be half-dried raw materials and dried materials in sequence through fuel gas drying, during the wet raw material drying process, NO2 in the fuel gas is synchronously absorbed, and a secondary denitration effect is achieved. Compared with the prior art, the method provided by the invention has the advantages that the fuel gas denitrification effect is good, broadening a reaction temperature window is facilitated, the usage amount of ammonia gas in a conventional process is reduced, the ammonia escape frequency is reduced, and potential interference and the like caused on aluminium oxide products by ammonia can be avoided.

Owner:SHANGHAI JIAO TONG UNIV

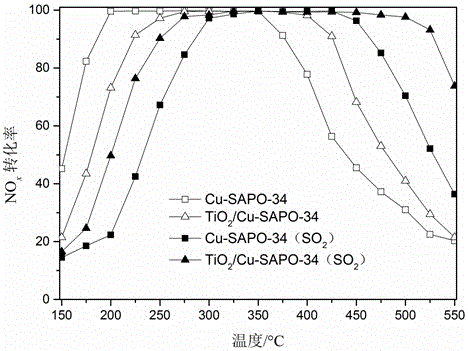

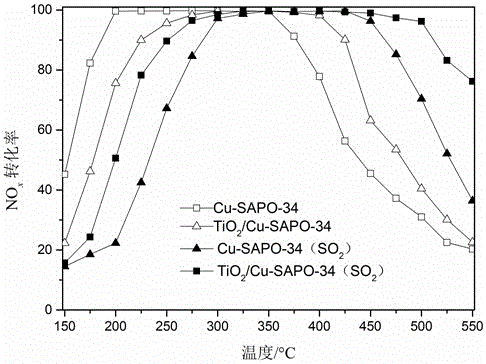

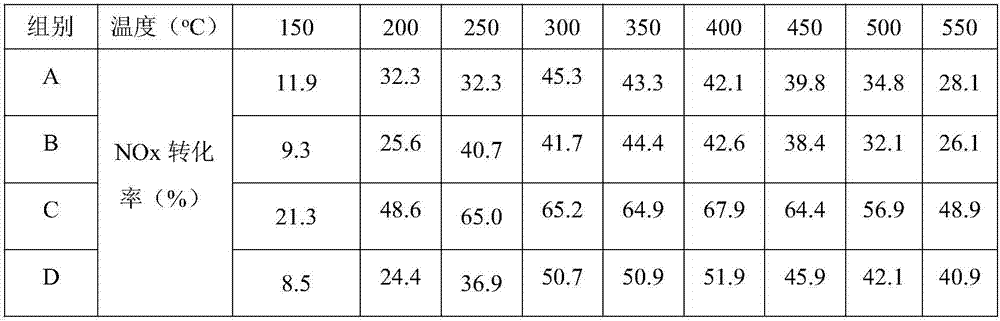

Preparation method of low-temperature NH3-SCR sulfur-resistant denitration catalyst

InactiveCN105944755AImprove purification efficiencyImprove sulfur resistanceMolecular sieve catalystsDispersed particle separationTitanium tetraisopropoxideSulfur

The invention discloses a preparation method of a low-temperature NH3-SCR sulfur-resistant denitration catalyst. The preparation method is characterized in that titanium tetrachloride, titanium(IV) isopropoxide, isopropyl titanate and butyl titanate are used as the titanium sources of the sulfur-resistant denitration catalyst, and a chemical vapor deposition method or aqueous phase method to precipitate a TiO2 sulfur-resistant layer on the surface of a Cu-SAPO-34 catalyst or wrap the surface of the Cu-SAPO-34 catalyst with the TiO2 sulfur-resistant layer so as to form a TiO2 / Cu-SAPO-34 compound catalyst. The prepared catalyst keeps the low-temperature high-activity feature of the Cu-SAPO-34 catalyst and adopts the TiO2 sulfur-resistant layer to evidently enhance of the sulfur resistance. At 300-500 DEG C, SO2 (100-500ppm) is fed into a reaction system, and the conversion rate of NOx in the NH3-SCR reaction is above 80%. Compared with a common catalyst, the compound catalyst is wider in temperature operation window, excellent in low-temperature activity and high in sulfur resistance.

Owner:KUNMING UNIV OF SCI & TECH

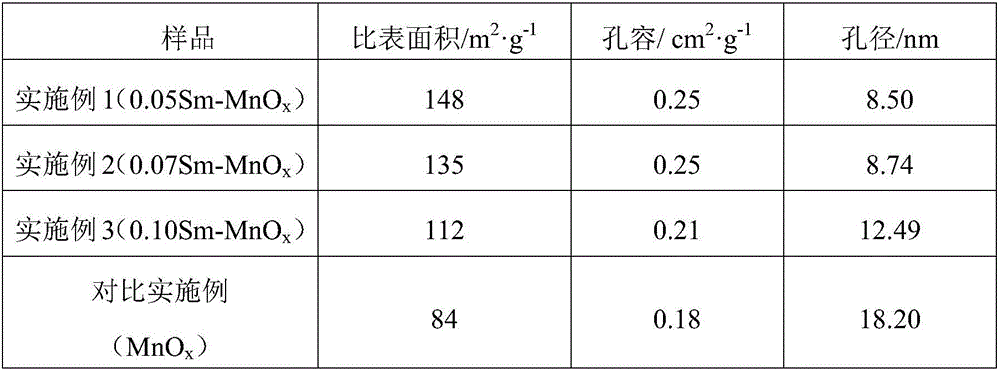

Samarium-doped MnOx low-temperature SCR (Selective Catalytic Reduction) catalyst as well as preparation method and application thereof

InactiveCN106268787ALarge specific surface areaSmall particle sizeHeterogenous catalyst chemical elementsDispersed particle separationDispersityMischmetal

The invention relates to a samarium-doped MnOx low-temperature SCR (Selective Catalytic Reduction) catalyst as well as a preparation method and application thereof. A proper amount of rare-earth metal samarium is doped into a manganese-based catalyst to obtain the samarium-doped MnOx low-temperature SCR catalyst; compared with a single manganese-based catalyst, the specific surface area of the catalyst is enlarged and the grain diameter of MnOx is reduced; the dispersity of manganese oxide in the catalyst is improved, and reaction activity of the MnOx at low temperature is effectively facilitated; an SCR denitration activity temperature window is expanded, and a modification effect on an MnOx catalyst is very good; the samarium-doped MnOx low-temperature SCR catalyst has relatively high catalytic activity at the low temperature.

Owner:WUHAN UNIV OF TECH

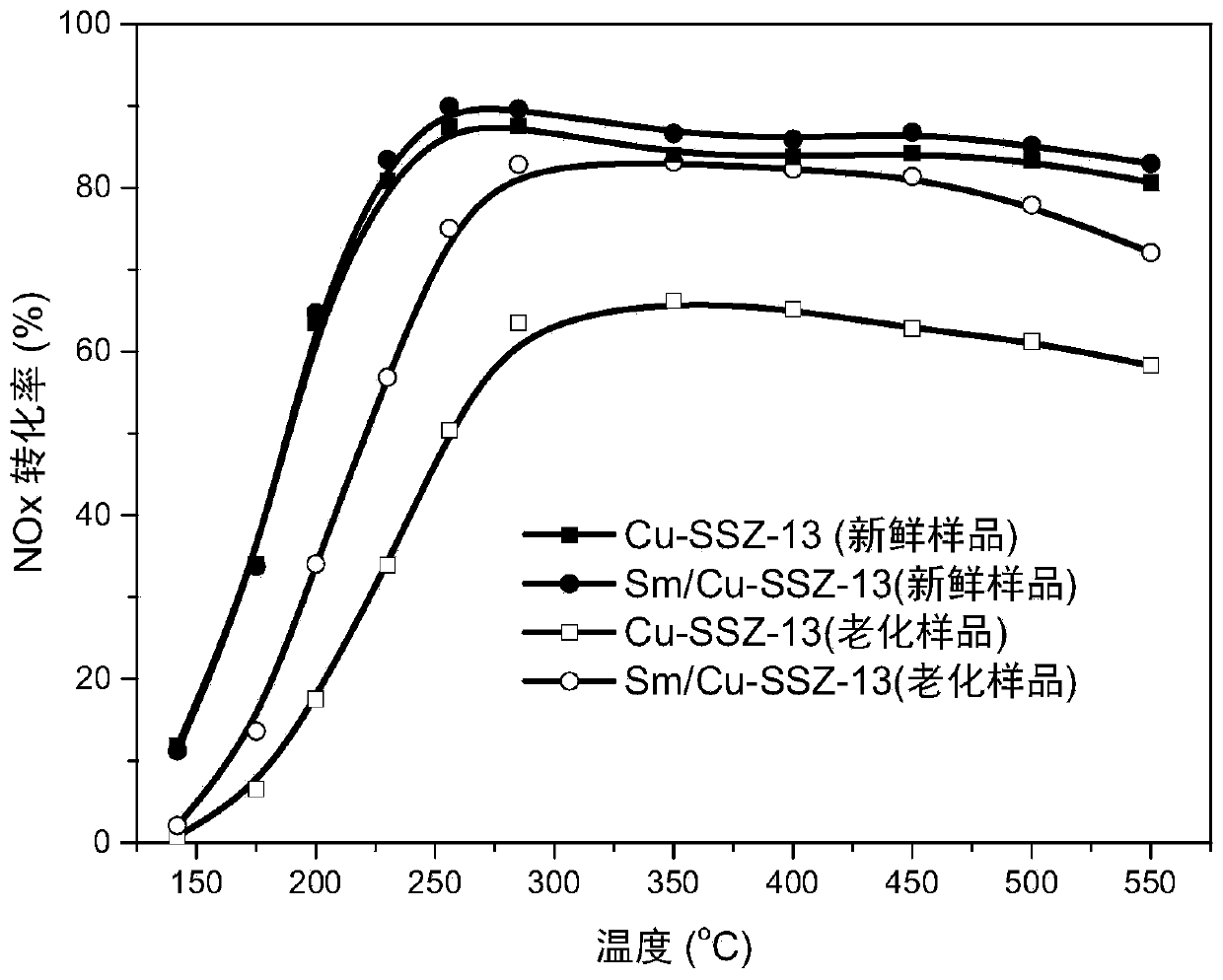

Rare earth metal modified Cu-SSZ-13 molecular sieve and preparation method and application thereof

ActiveCN111135860AMitigation of dealuminationImprove stabilityMolecular sieve catalystsDispersed particle separationMolecular sieveMischmetal

The invention discloses a rare earth metal modified Cu-SSZ-13 molecular sieve and a preparation method and application thereof. The rare earth metal modified Cu-SSZ-13 comprises a Cu-SSZ-13 molecularsieve which is prepared after ion exchange of a Cu-SSZ-13 molecular sieve prepared by a one-step synthesis method and with a silica-alumina ratio of 3-5, and rare earth metal ions modified at ion exchange sites in a skeleton of the Cu-SSZ-13 molecular sieve. According to the invention, the used raw materials are non-toxic and harmless, the preparation method is simple, and the synthesized catalysthas characteristics of good NH3-SCR catalytic activity, good nitrogen selectivity, good hydrothermal stability and high space velocity resistance, and is suitable for diesel exhaust nitrogen oxide removal and stationary source flue gas denitrification.

Owner:RES CENT FOR ECO ENVIRONMENTAL SCI THE CHINESE ACAD OF SCI

SCR (Selective Catalyctic Reduction) smoke denitration catalyst based on TiO2-SnO2 composite barrier and preparation method thereof

InactiveCN102205240AImprove adsorption capacityExtended service lifeCatalyst carriersDispersed particle separationActive componentThermal stability

The invention belongs to the field of environment friendliness and environment catalysis, in particular relates to an SCR (Selective Catalyctic Reduction) smoke denitration catalyst based on a TiO2-SnO2 composite barrier. The medium-low temperature smoke denitration catalyst based on the TiO2-SnO2 composite barrier is prepared by using nanometer TiO2-SnO2 as a carrier, WO3 and CeO2 as additives and V2O5 as an active component. By adopting the nanometer TiO2-SnO2 for replacing the traditional nanometer TiO2 as the carrier, the specific surface area, the thermal stability and the acidity of the catalyst are increased, the denitration activity of the catalyst is improved through interaction among the V2O5, the WO3 and the CeO2; and when ammonia is used as a reducing agent, better catalytic activity is expressed within a temperature range of 150-450 DEG C.

Owner:NORTH CHINA ELECTRIC POWER UNIV (BAODING)

Preparation method and slurry of denitration integral type catalyst

InactiveCN102151564AReduce manufacturing costImprove denitrification activityCatalyst carriersDispersed particle separationOrganic solventSlurry

The invention provides slurry for preparing a denitration integral type catalyst, which comprises a catalyst, silica gel and water. The invention also provides a method for preparing the denitration integral type catalyst by using a dipping method. Compared with the prior art, the slurry of the invention does not include any organic solvent, is simple and environmental-friendly and can reduce theproduction cost. The prepared integral type catalyst has higher denitration activity and wider temperature window, the coating amount of the catalyst can be realized by adjusting the concentration ofthe catalyst in the slurry liquor and the target coating amount can be obtained by only one-time coating so that the preparation process is greatly shortened, the production cost is greatly reduced and large-scale production can be carried out.

Owner:广州市威格林环保科技有限公司

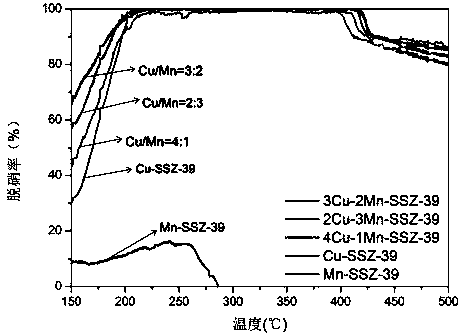

Cu/Mn-SSZ-39 catalyst, preparation method and application thereof

InactiveCN109433256AImprove denitrification rateLow temperature activeMolecular sieve catalystsDispersed particle separationMolecular sieveActive component

The invention discloses a Cu / Mn-SSZ-39 catalyst, a preparation method and the application thereof. The catalyst is characterized by the catalyst taking H-SSZ-39 molecular sieve as a carrier, and active components comprise copper and manganese. Through the synergistic effect between copper and manganese, the catalyst ensures that the denitration ratio is 42 to 66 percent at 150 DEG C, and reaches 100 percent at 200 to 420 DEG C, and shows excellent SCR activity at 150 to 500 DEG C. The Cu / Mn-SSZ-39 catalyst formed through an ion exchange method not only has low-temperature activity and high denitration ratio, but also has a wide activity temperature window, and the preparation method is simple, can be completely used for catalytic reduction of oxynitride, can eliminate oxynitride in dieselvehicle tail gas, and is applicable to diesel vehicle tail gas purification systems.

Owner:GUANGDONG UNIV OF TECH

Preparation method of SCR (Selective Catalytic Reduction) vanadium-series catalyst used in denitration of tail gas of diesel vehicle

InactiveCN102416321AEasy to optimizeGood modification effectInternal combustion piston enginesDispersed particle separationDesorptionNitrogen oxide

The invention discloses a preparation method of an SCR (Selective Catalytic Reduction) vanadium-series catalyst used in denitration of tail gas of a diesel vehicle. Active ingredients are introduced into the catalyst by adopting a simple soaking method, and a catalyst carrier or the catalyst is baked at different temperatures, so that the catalytic performance of the obtained SCR vanadium-series catalyst is improved remarkably, the catalytic activity is greatly increased, and the intensity of the catalyst is greatly increased. The vanadium-series denitration catalyst provided by the inventionhas high denitration efficiency and a wide temperature window, and is suitable for the field of desorption of nitrogen oxides in the tail gas of the diesel vehicle. As proved by the simulated tail gas evaluation of the diesel vehicle in a laboratory, the NOx removing rate of the SCR vanadium-series catalyst prepared with the method is over 90 percent under the condition that the space speed is 30,000 h<-1>, the NO content is 500 ppm and the H2O content is 4 percent at the temperature of 170-469 DEG C.

Owner:广州市威格林环保科技有限公司

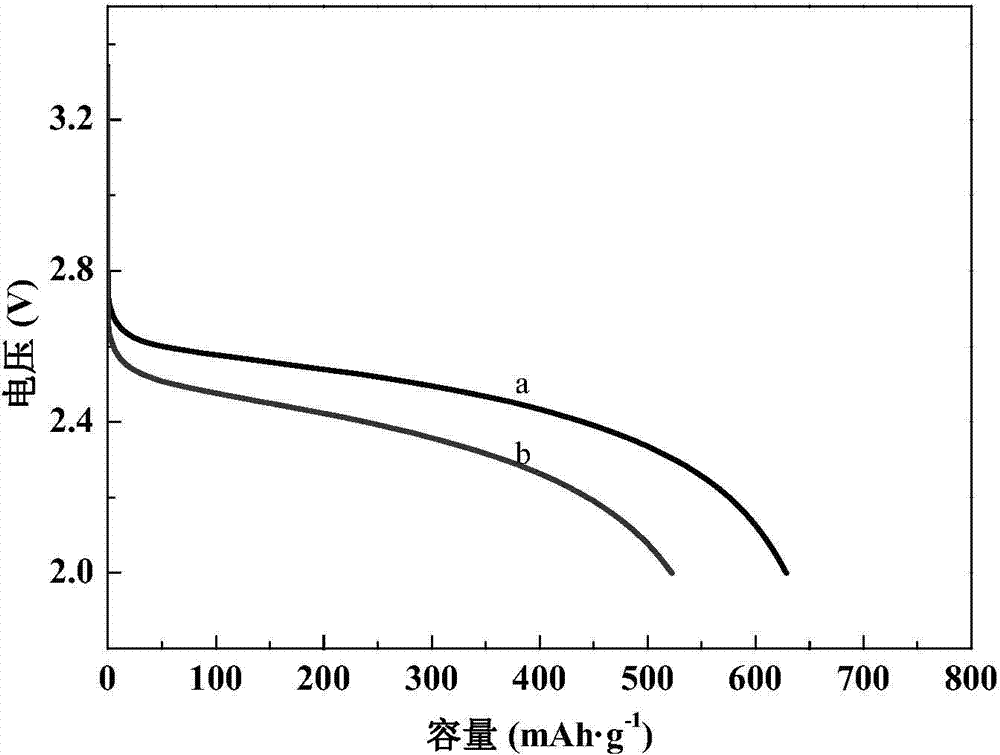

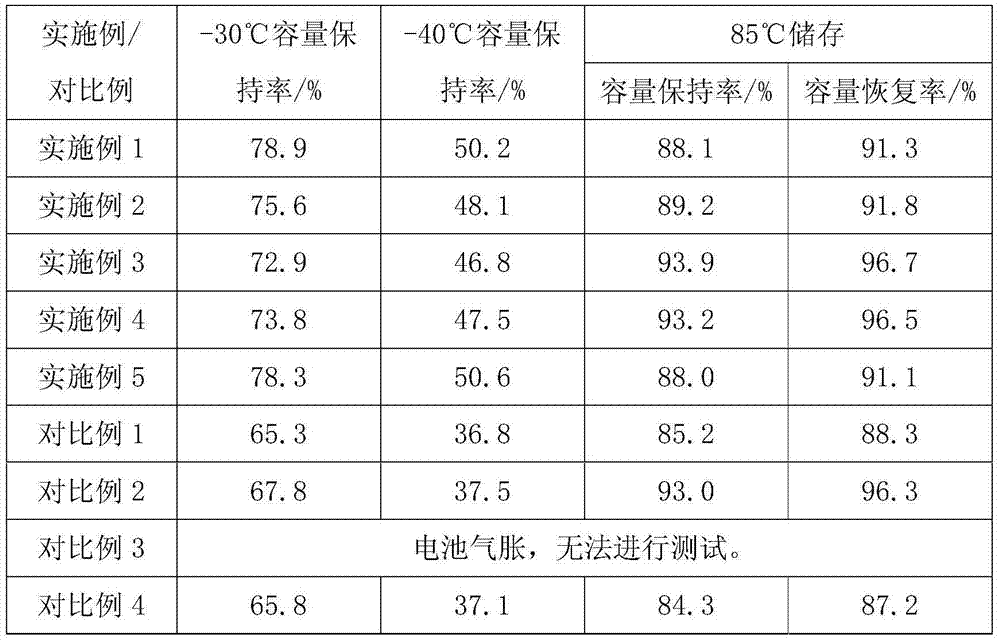

Electrolyte solution of lithium ion battery

The invention discloses electrolyte solution of a lithium ion battery, and aims to provide electrolyte solution of a lithium ion battery with high discharging performance and larger operating temperature windows. The electrolyte solution of the lithium ion battery comprises a solvent and lithium salt, wherein the solvent comprises 60 to 90 weight percent of cyclic carboxylic ester gamma-butyrolactone and 10 to 40 weight percent of linear carboxylic ester. The cyclic carboxylic ester gamma-butyrolactone solvent has a low melting point, a high boiling point and lower viscosity, can expand the temperature window of the electrolyte solution, improves the high-temperature and low-temperature performance of the electrolyte solution and improves the discharging performance of the lithium ion battery, so that the lithium ion battery can be operated in an environment at the temperature of between -40 and 50 DEG C; therefore, the battery has the high discharging performance and the larger operating temperature windows.

Owner:ZHUHAI SMOOTHWAY ELECTRONICS MATERIALS

Honeycomb-like cerium-zirconium-titanium-based denitration catalyst and preparation method thereof

InactiveCN105435769AHigh activityImprove pollutionDispersed particle separationMetal/metal-oxides/metal-hydroxide catalystsFlue gasFiltration

The present invention provides a honeycomb-like cerium-zirconium-titanium-based denitration catalyst and a preparation method thereof, and the honeycomb-like cerium-zirconium-titanium-based denitration catalyst is prepared by the steps of preparation of a mud material, filtration and pre-squeezing, preparation of a denitration mud blank, and calcination. The honeycomb-like cerium-zirconium-titanium-based denitration catalyst is non-toxic and environmentally friendly, the boiler flue gas NOx removal rate can reach 90% in a 150-420 DEG C temperature window.

Owner:SHANGHAI LANGT AUTOCATALYST +1

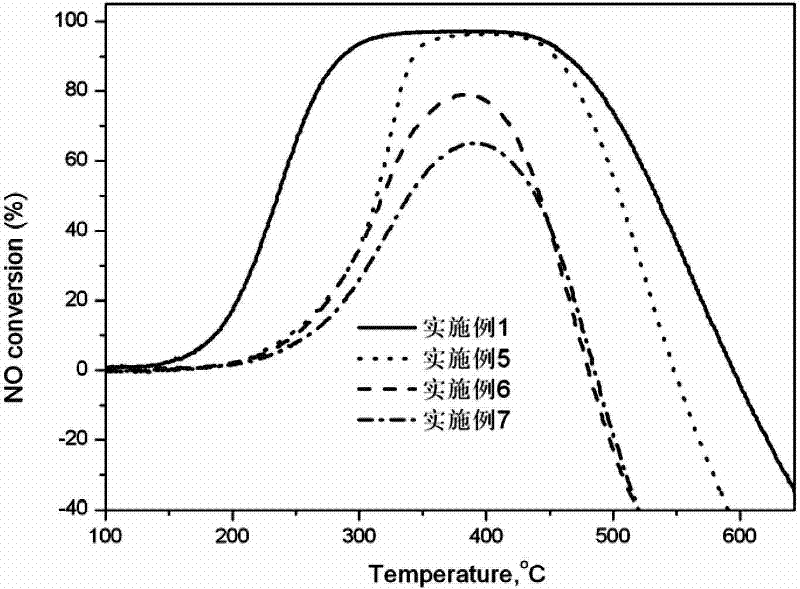

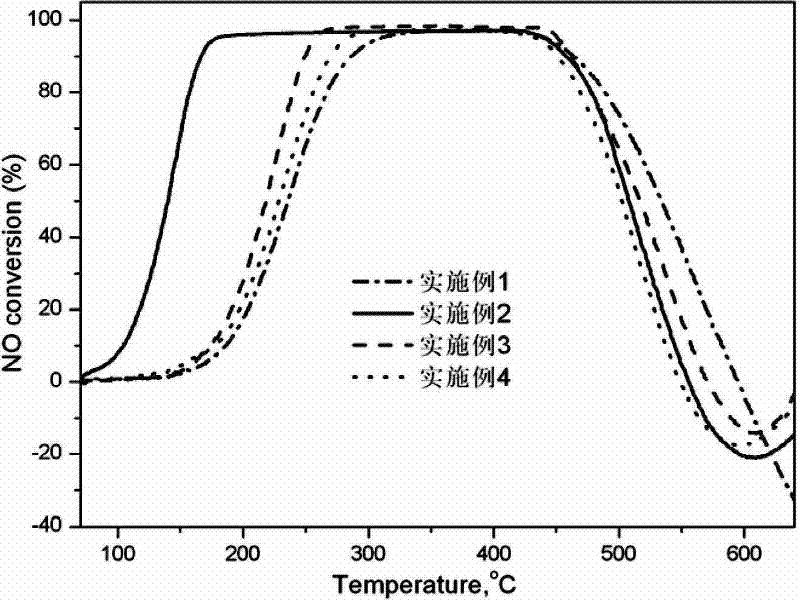

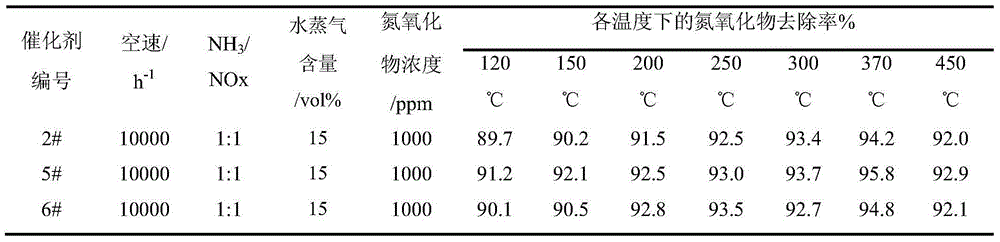

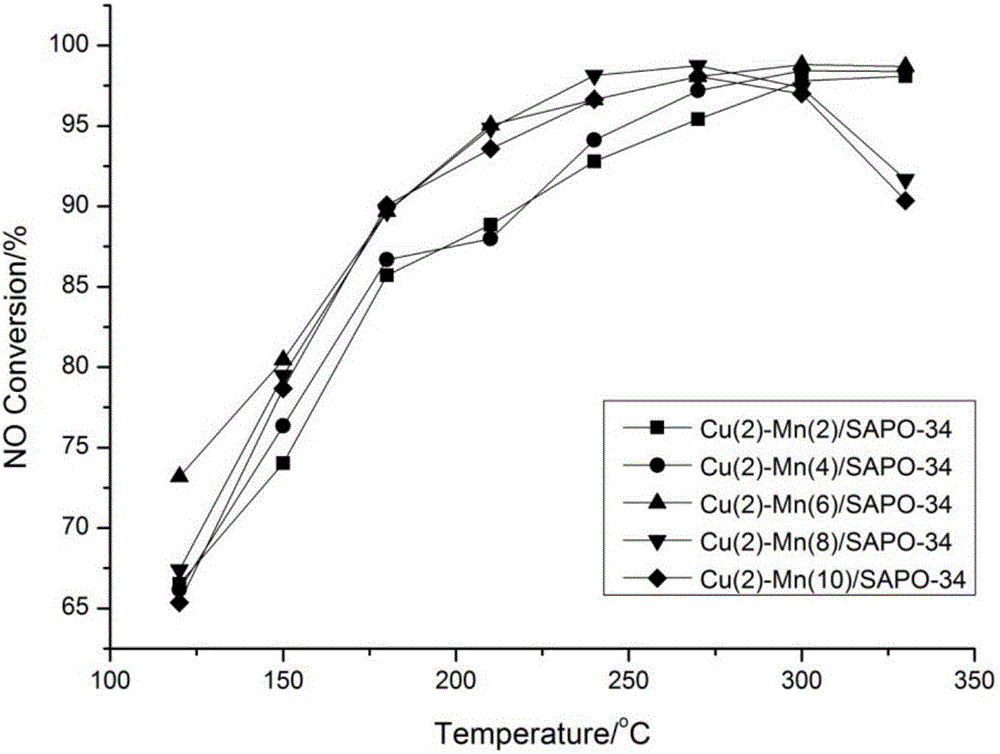

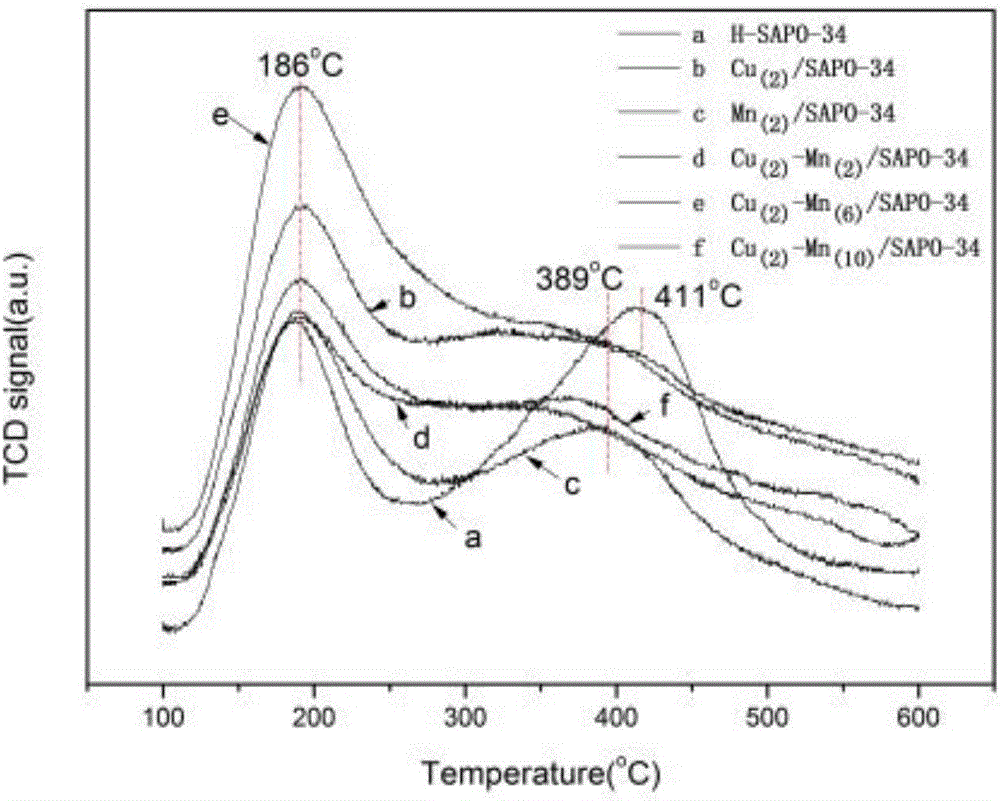

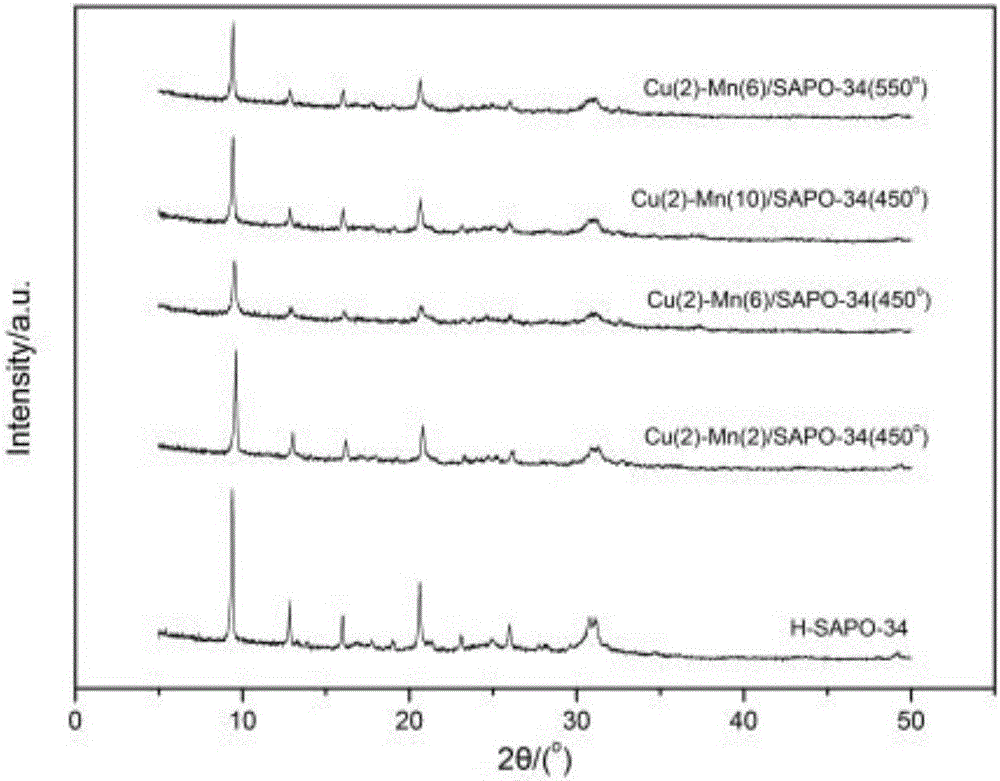

Cu-Mn bimetallic composite type low-temperature denitration catalyst and preparation method thereof

InactiveCN105854932ALow starting temperatureLower the temperature of the denitrification reactionMolecular sieve catalystsMolecular sieveActive component

The invention discloses a Cu-Mn bimetallic composite type low-temperature denitration catalyst and a preparation method thereof. The catalyst is prepared by using an immersion method. A chabasite molecular sieve H-SAPO-34 is taken as a carrier, and active components are composite oxides of transition metals Cu and Mn, wherein the weight percentages of the active components Cu and Mn are 2% to 10% respectively. According to the SCR catalyst disclosed by the invention, compared with a Cu-based or Mn-based catalyst of a single component, the denitration efficiency and heat stability of the catalyst are improved obviously by using a bimetallic synergistic effect, and the active temperature window of the catalyst is effectively widened; at the temperature of 180-350 DEG C, the conversion rate of NO can reach 90% or more.

Owner:SOUTHEAST UNIV

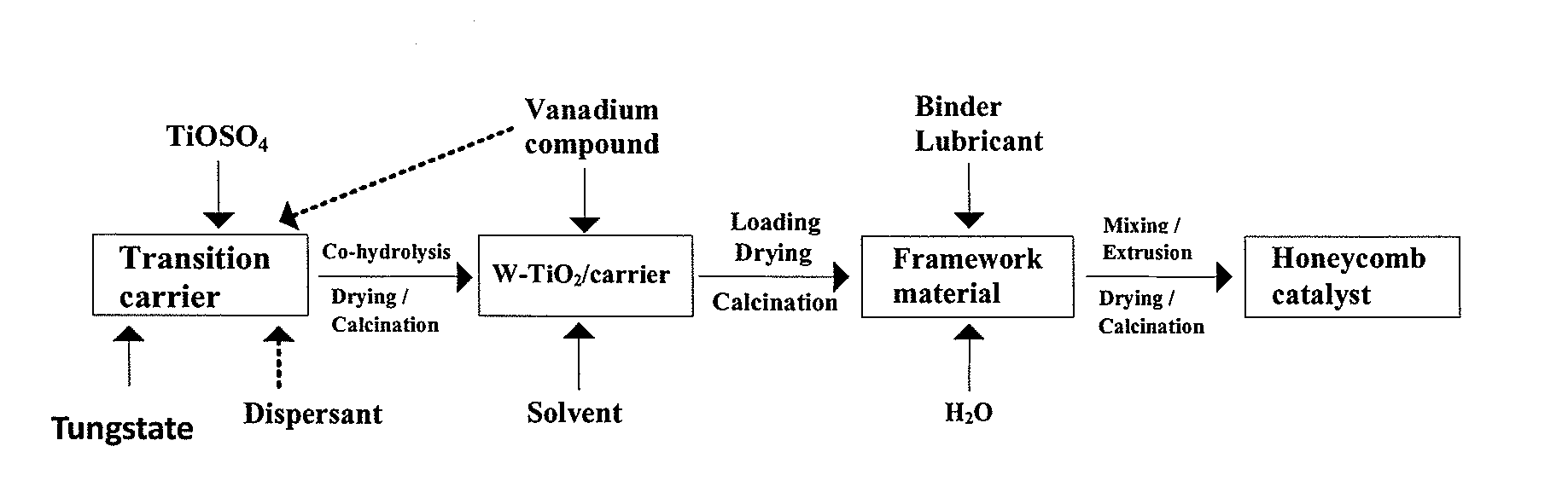

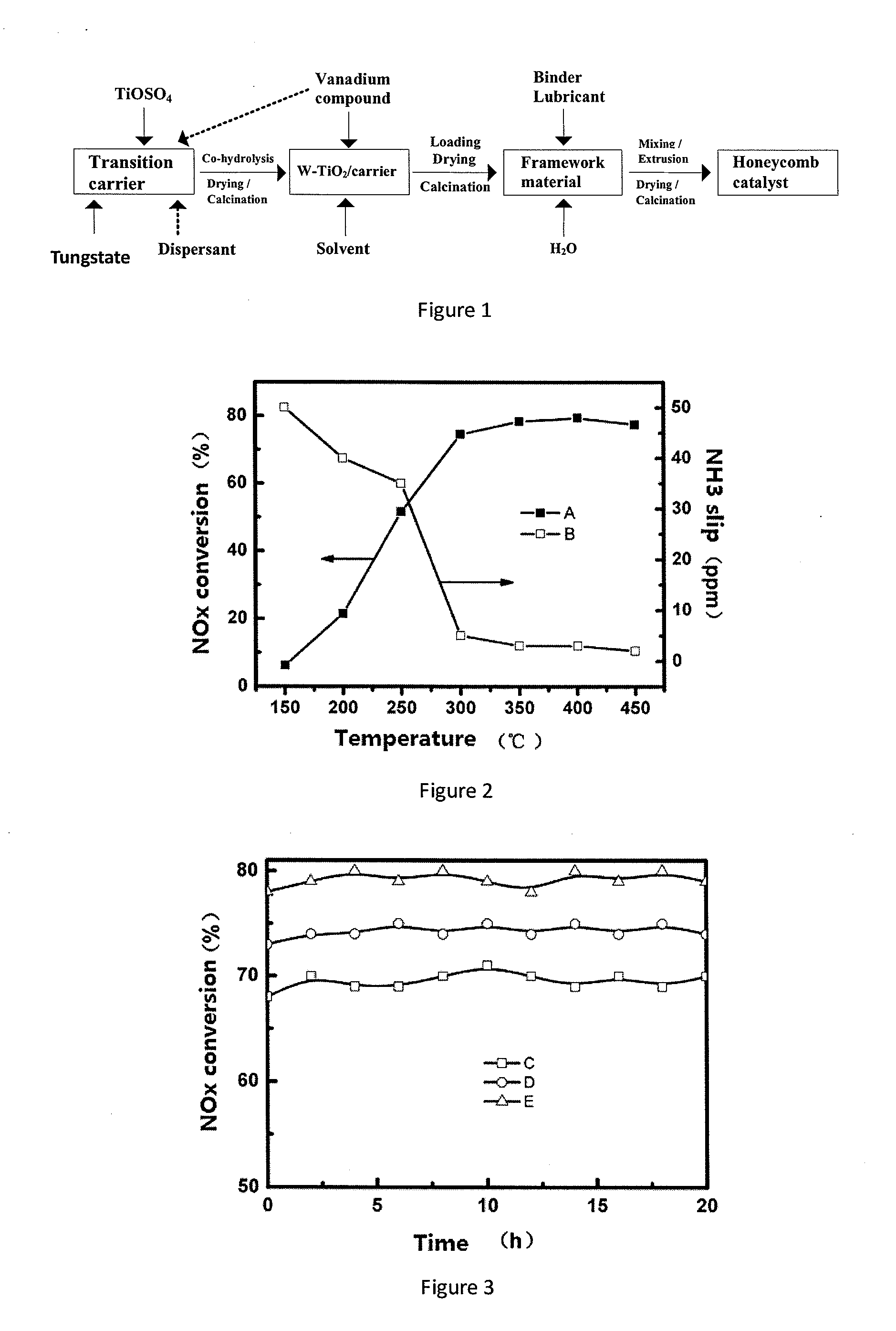

Surface Deposition-Type Honeycomb Catalyst For Flue Gas Denitrification and Preparation Method Thereof

InactiveUS20140113802A1Low costMaximize interactionDispersed particle separationCatalyst activation/preparationFlue gasHoneycomb

This invention relates to the cleaning of flue gas released from various combustion processes, particularly a surface deposition NH3—SCR honeycomb catalyst and its preparation method. The catalyst is composed of framework material, TiO2, V2O5 and WO3, wherein the framework material is composed of clay, coal ash, mineral waste residue or their mixture. The mass fractions for framework material, TiO2, V2O5, and WO3 are 60 wt. % to 80 wt. %, 13 wt. % to 33 wt. %, 1 wt. % to 5 wt. %, and 0.1 wt. % to 2 wt. %, respectively. The nano V2O5—WO3—TiO2 particles were deposited on the surface of particle pore or honeycomb, and the performance of the catalyst could be greatly improved

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

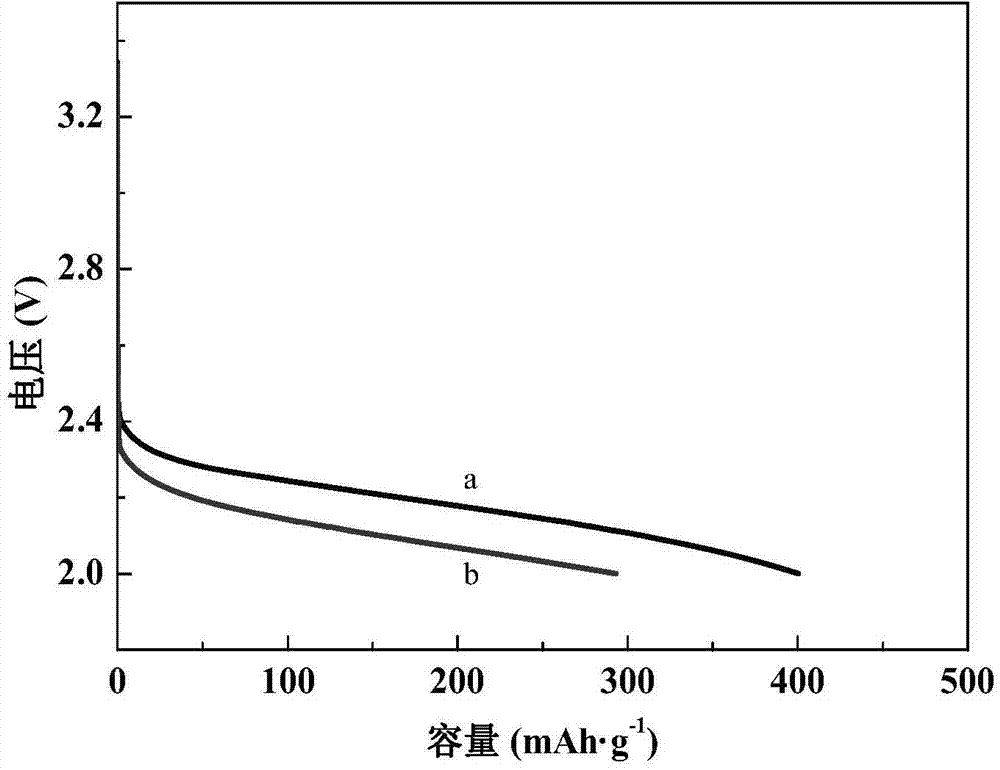

Lithium-ion battery electrolyte

ActiveCN104124469AWide temperature windowLow freezing pointSecondary cellsHigh temperature storageLithium-ion battery

The invention discloses a lithium-ion battery electrolyte relating to a lithium ion battery. The lithium-ion battery electrolyte comprises an organic solvent, a lithium salt and an additive, wherein the organic solvent comprises propylene carbonate, chain carboxylic ester and chain carbonic ester, wherein the content of propylene carbonate is 24-58 percent, the content of chain carboxylic ester is 9-58 percent, the content of chain carbonic ester is 0-26 percent, the content of the lithium salt is 9-16 percent, and the content of the additive is 2-10 percent; and the additive is selected from vinylene carbonate, fluoroethylene carbonate, vinyl vinylene carbonate, glycol sulfite, vinyl glycol sulfite, propylene sulfite, dimethyl sulfate or trimethylene sulfate. Propylene carbonate is used for completely replacing ethylene carbonate, and is low in melting point and high in boiling point, thus a temperature window of the electrolyte can be enlarged; and chain carboxylic ester is low in melting point and low in viscosity, thus the solidifying point and the viscosity of the electrode can be reduced, and the conductivity of the electrode is increased. PC (Poly Carbonate) co-block is inhibited by using the additive in the electrolyte, thus the film-forming property for the surface of a negative electrode can be improved, and the high-temperature storage property is improved.

Owner:XIAMEN UNIV

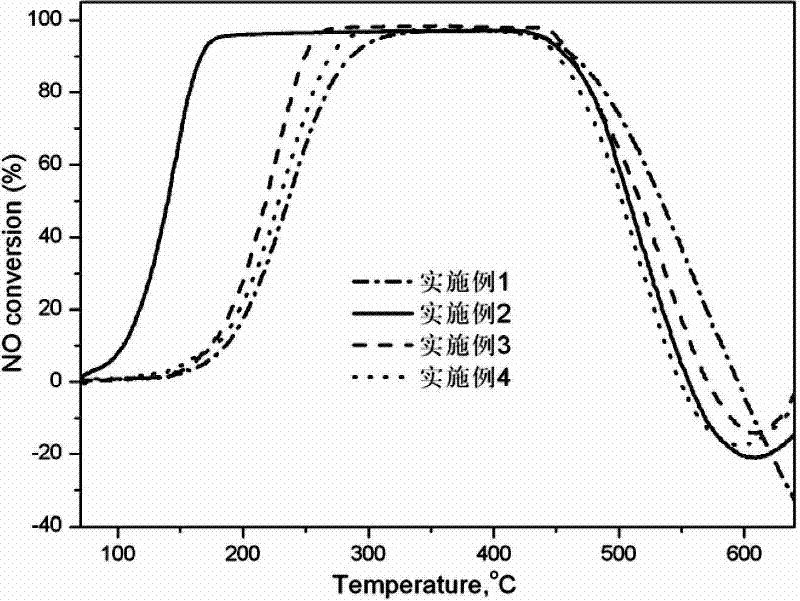

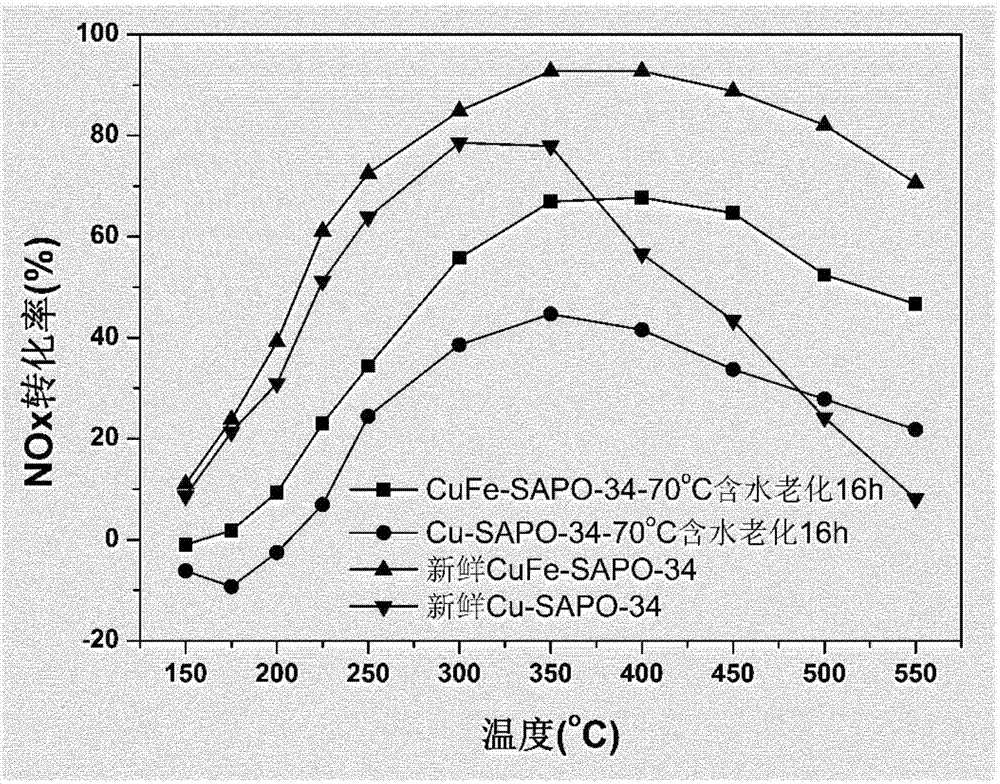

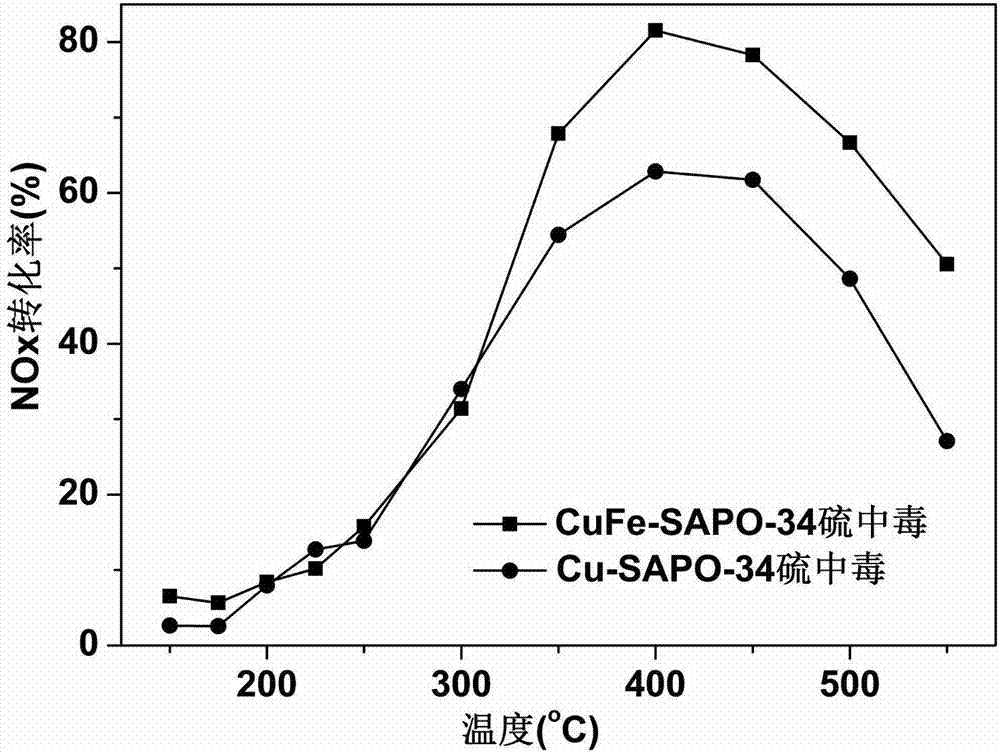

In-situ synthesis method and applications of CuFe-SAPO-34 catalyst

InactiveCN107126973ASave resourcesWide temperature windowGas treatmentMolecular sieve catalystsIonMolecular sieve

The invention discloses an in-situ synthesis method and applications of a CuFe-SAPO-34 catalyst, and belongs to the technical field of catalysis. The method comprises the following steps: adding pseudo-boehmite into deionized water, stirring to dissolve pseudo-boehmite, then adding ortho-phosphoric acid and fumed silica, evenly mixing, then adding copper salts and tetraethylene pentamine, fully stirring, then adding Fe salts and n-propylamine; adding fully stirred gel into a hydrothermal reactor to carry out crystallization, after crystallization reactions, cooling to the room temperature, separating solid crystals from the mother liquor, washing the solid crystals by deionized water until the solid crystals become neutral, drying, and finally burning the solid crystals in the air to obtain the CuFe-SAPO-34 microporous molecular sieve catalyst. The CuFe-SAPO-34 catalyst is synthesized in one step; the loading amount of Fe is optimized; and the catalytic performance and low temperature water resisting performance of the CuFe-SAPO-34 catalyst are prominently improved.

Owner:JIANGNAN UNIV

Zirconium doped cerium vanadate denitration catalyst, preparation method and application

ActiveCN105032395AHigh activityWide temperature windowDispersed particle separationMetal/metal-oxides/metal-hydroxide catalystsPtru catalystNitrogen oxides

The invention discloses a zirconium doped cerium vanadate denitration catalyst which is characterized in that the denitration catalyst is a nano material having a rodlike or granular structure, wherein the mole ratio of zirconium doping amount to metal cerium is x:(1-x), and x is larger than 0.05 and less than 0.8. The invention also discloses a preparation method and application of the zirconium doped cerium vanadate denitration catalyst. The catalyst is prepared by adopting a hydrothermal process, is wide in operating temperature window, can reach NOx removing rate of 80% or above at the temperature of 150-375 DEG C, also has the advantages of good thermal stability, excellent H2O and SO2 poisoning resistance, simple preparation process, low cost and the like, is suitable for treatment of nitric oxide in a fixed source and a moving source and is applicable to practical application.

Owner:SHANGHAI UNIV

Coke oven flue gas denitration catalyst and preparation method thereof

ActiveCN106984349ALower surface energyGood dispersionPhysical/chemical process catalystsDispersed particle separationWater bathsPhosphate

The invention discloses a coke oven flue gas denitration catalyst and a preparation method thereof. The preparation method utilizes ammonium metavanadate as an active precursor, chromium nitrate as an auxiliary agent and oxalic acid and hydrochloric acid as reducing agents, and utilizes phosphoric acid to adjust and control the surface acidity of an active component. The preparation method comprises stirring, water bath heating, drying, calcining to obtain a Cr-doped oxyvanadium phosphate active component, adding the Cr-doped oxyvanadium phosphate active component and anatase TiO2 as a carrier with a specific surface area of greater than or equal to 250 m<2> / g into distilled water according to a ratio, carrying out stirring mixing, and carrying out water bath drying and calcining to obtain the catalyst. The catalyst utilizes phosphoric acid to adjust and control the surface acidity of the catalyst, and utilizes aid chromic nitrate to form an intercalation structure and promote formation of adjacent V<5+> and V<4+>. The catalyst has good low temperature denitration activity and strong SO2 and steam poisoning resistance and is suitable for industrial coke oven flue gas denitrification.

Owner:马鞍山方信环保科技有限公司

Preparation method of NH3-SCR flue gas desulfurization catalyst and catalyst thereof

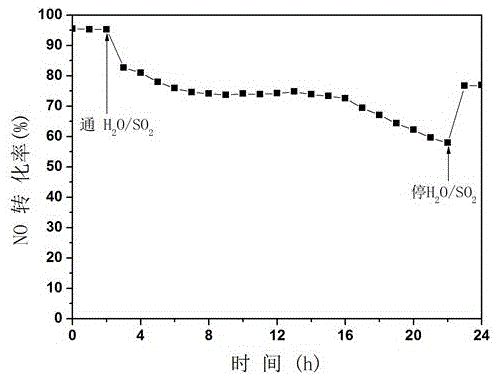

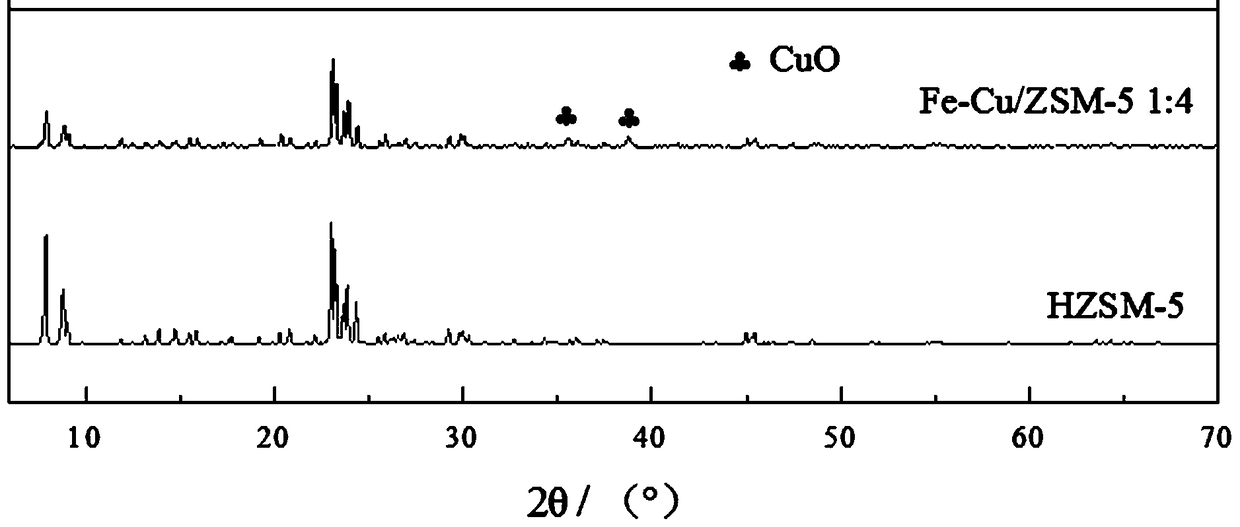

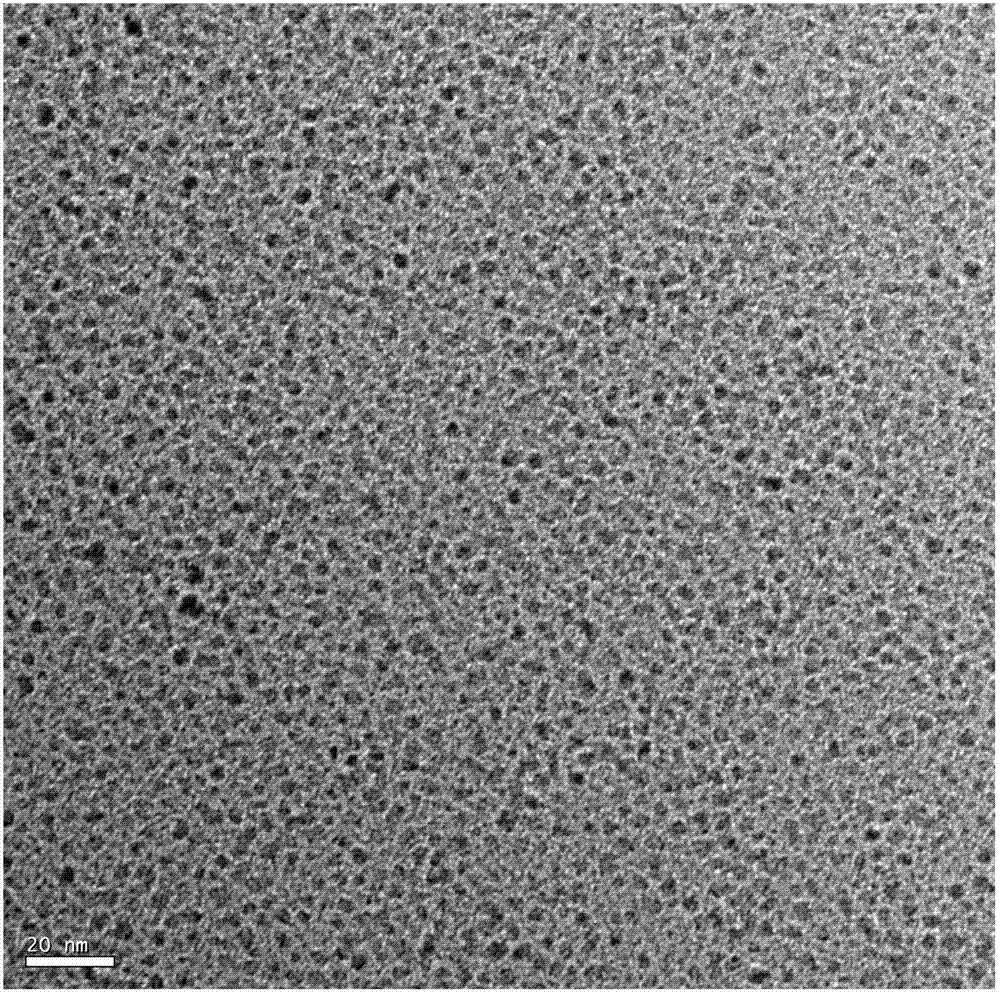

InactiveCN108816274AImprove water and sulfur resistanceLarge specific surface areaGas treatmentMolecular sieve catalystsNitrateCopper nitrate

The invention relates to the technical field of the flue gas desulfurization catalyst, and specifically relates to a preparation method of an NH3-SCR flue gas desulfurization catalyst and the catalystthereof. The preparation method of the catalyst comprises the following steps: dispersing ZSM-5 zeolite carrier into a composite solution of ferric nitrate and copper nitrate, wherein the mole ratioof Fe atoms to Cu atoms in the composite solution is 1:4, the mass of the Fe element is 10% of the mass of the ZSM-5 carrier, and the dispersing method comprises stirring for 4-6h at 50-60 DEG C by adopting a magnetic stirrer, and ultrasonically oscillating for 40min; discarding supernatant after stratification of the dispersion system, drying a precipitate in an electric constant-temperature blast air oven, grinding the precipitate into powder after drying, then roasting in a muffle furnace, and repeatedly grinding into powder after roasting, thereby obtaining the flue gas desulfurization catalyst. The catalyst prepared with the method disclosed by the invention has a relatively wide active temperature window, and has the advantages of being low in price, environmentally-friendly and thelike.

Owner:HENAN UNIV OF SCI & TECH

Cerium/molecular sieve catalyst used for selective catalytic reduction of nitrogen oxides and preparation method thereof

ActiveCN102814192ANon-toxicRaw materials are readily availableMolecular sieve catalystsDispersed particle separationEcological environmentSynthesis methods

The invention discloses a cerium / molecular sieve catalyst used for selective catalytic reduction of nitrogen oxides and a preparation method thereof. The invention overcomes the technical problems of a narrow operating temperature window, poor selectivity at a high temperature and potential harm to the ecological environment and human health of a vanadium-based catalyst system. The catalyst provided by the invention comprises a cerium oxide nanoparticle and a molecular sieve, wherein the molecular formula of the cerium oxide nanoparticle is CeO2, the molecular sieve is MCM56 (n(SiO2) / n(Al2O3)=15-30), and the mass ratio of the cerium oxide nanoparticle to the molecular sieve is 1:19 to 3:1. The invention also provides a preparation method for the catalyst. The preparation method comprises the following steps: synthesizing the cerium oxide nanoparticle by using a hydro-thermal synthesis method; and loading the cerium oxide nanoparticle on the molecular sieve MCM56 for removal of nitrogen oxides through NH3-SCR. The supported catalyst prepared by using the method has the advantages of uniformly dispersed active components, high activity, a wide temperature range and good stability.

Owner:CHANGCHUN INST OF APPLIED CHEMISTRY - CHINESE ACAD OF SCI

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com