Preparation method of low-temperature NH3-SCR sulfur-resistant denitration catalyst

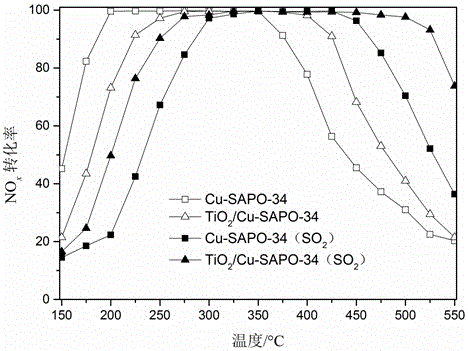

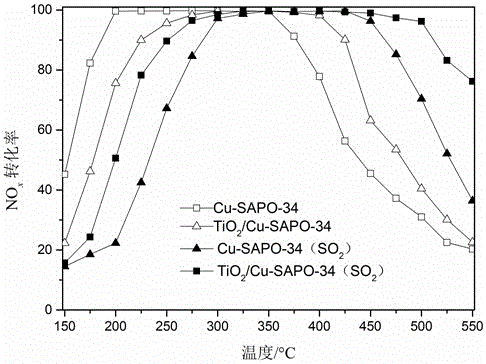

A technology of NH3-SCR and denitrification catalysts, applied in physical/chemical process catalysts, molecular sieve catalysts, chemical instruments and methods, etc., can solve the problems of strong biological toxicity, no catalytic activity, etc., and achieve strong sulfur resistance and wide temperature window Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] (1) Preparation of Cu-SAPO-34 catalyst: the prepared ion concentration is 0.1mol.L -1 Cuprous chloride solution, soak SAPO-34 molecular sieves in cuprous chloride solution for 2 hours, then stir in a 70°C water bath for 5 hours, dry, and roast to obtain Cu-SAPO- with a Cu loading of 0.5%. 34 catalyst;

[0029] (2) Put 2g of the Cu-SAPO-34 catalyst prepared in step (1) into a quartz tube, raise the temperature of the CVD reactor to 150°C, and use 150mL / min N 2 Purge 2h;

[0030] (3) with N 2 As a carrier gas, the titanium tetraisopropoxide precursor placed in a water bath at 80°C is introduced into a condensation reflux device at 60°C to obtain saturated titanium tetraisopropoxide vapor;

[0031] (4) The titanium tetraisopropoxide vapor obtained in step (3) was mixed with N 2 After mixing, it is passed into the quartz tube, and with the additionally introduced O 2 Together (carrier gas flow rate 150mL / min), heat deposition at 400°C for 3h, anneal at 500°C for 0.5h, ...

Embodiment 2

[0034] (1) Preparation of Cu-SAPO-34 catalyst: the prepared ion concentration is 0.3mol.L -1 Copper chloride solution, soak SAPO-34 molecular sieves in copper chloride solution for 3 hours, then stir in a water bath at 60°C for 6 hours, dry, and roast to obtain a Cu-SAPO-34 catalyst with a Cu loading of 1%. ;

[0035] (2) Put 2g of the Cu-SAPO-34 catalyst prepared in step (1) into a quartz tube, raise the temperature of the CVD reactor to 175°C, and use 150mL / min N 2 Purge for 1.5h;

[0036](3) Using He as the carrier gas, the titanium tetrachloride precursor placed in a water bath at 80°C was introduced into a condensation reflux device at 60°C to obtain saturated titanium tetrachloride vapor;

[0037] (4) Combine the titanium tetrachloride steam obtained in step (3) with N 2 Pass into the quartz tube after mixing, and NH introduced separately 3 Together (carrier gas flow rate 150mL / min), heat deposition at 550°C for 1h, annealing at 450°C for 2h, and then cool down to ro...

Embodiment 3

[0040] (1) Cu-SAPO-34 catalyst preparation: SAPO-34 molecular sieve and 0.2mol.L -1 Mix the cuprous chloride solution evenly, HNO 3 Adjust the pH to 2, then ion-exchange in a water bath at 80°C for 12 hours, wash, dry, and calcinate to obtain a Cu-SAPO-34 catalyst with a Cu loading of 4%.

[0041] (2) Put 2g of the Cu-SAPO-34 catalyst prepared in step (1) into a quartz tube, raise the temperature of the CVD reactor to 200°C, and use 150mL / min N 2 Purge lh.

[0042] (3) with N 2 / He mixed gas is the carrier gas, and the isopropyl titanate precursor placed in a water bath at 80°C is introduced into a condensation reflux device at 60°C to obtain saturated isopropyl titanate vapor;

[0043] (4) Combine the isopropyl titanate vapor obtained in step (3) with N 2 After mixing, pass it into a quartz tube, heat deposition at 650°C for 0.5h together with water vapor introduced separately (carrier gas flow rate 150mL / min), anneal at 500°C for 1h, and then cool down to room temperatur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com