Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

69results about How to "Strong sulfur resistance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

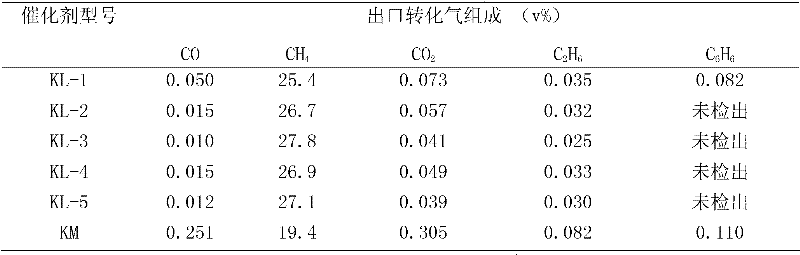

A coke oven gas methanation catalyst and preparation method thereof

ActiveCN102259003AHigh low temperature activityHigh activityHydrocarbon from carbon oxidesMetal/metal-oxides/metal-hydroxide catalystsRare-earth elementMethanation

The invention provides a coke-oven gas methanation catalyst and a preparation method thereof. The coke-oven gas methanation catalyst is prepared by loading a certain amount of active ingredients Ni on composite oxide TiO2-ZrO2-SiO2 serving as a carrier, and using rare-earth elements RE and metal M as aids. The catalyst has the advantages which cannot be achieved by other methanation catalysts. The catalyst has the characteristics of high low-temperature activity, sulfur resistance capacity, good high temperature resistance performance and the like, and the function of hydrocarbon cracking andgood antioxidation performance and the like and is easy to prepare.

Owner:WUHAN KELIN FINE CHEM

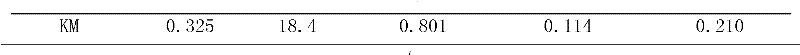

Efficient denitrified integral catalyst of stationary source

InactiveCN101905156AWide operating temperatureImprove out-of-stock efficiencyCatalyst carriersDispersed particle separationIonMolecular sieve

The invention discloses an efficient denitrified integral catalyst of a stationary source, which relates to a control technique of catalytic selective reducing nitric oxides (NOx) in the fields of catalyzation, environmental protection and energy saving and is characterized in that honeycomb cordierite ceramics are used as matrixes; gamma-Al2O3 is used as a first carrier; anatase crystal TiO2 is used as a second carrier; and a manganese oxide molecular sieve (V-OMS) of framework vanadium ions (V<5+>) is used as an active component, wherein contents of the gamma-Al2O3 and the TiO2 are respectively 5wt% to 15wt% and 5wt% to 15wt%; the content of the V-OMS is 5wt% to 20wt%; and the molar ratio of V to Mn is between 0 and 0.20. On a window with wide temperature of 80 DEG C to 450 DEG C, the conversion ratio of the NOx of the integral catalyst of the invention by using NH3 as a reducing agent is not less than 85%; and the selectivity of N2 is larger than 90%. The integral catalyst is suitable for controlling the discharge of nitrogen oxides of the stationary source (boiler).

Owner:唐幸福 +1

High-efficient denitration monolithic catalyst for titanium oxide carried vanadium-molybdenum composite oxide

ActiveCN102247832AImprove out-of-stock efficiencyHigh selectivityDispersed particle separationCatalyst activation/preparationComposite oxideTitanium oxide

The invention relates to a high-efficient denitration monolithic catalyst for titanium oxide carried vanadium-molybdenum composite oxide and a preparation method thereof, and relates to a technology for controlling selective catalytic reduction of nitrogen oxide (NOx) in the fields of catalysis, environmental protection and energy saving. The preparation method provided by the invention is characterized in that a honeycomb cordierite ceramic material is used as a matrix, gamma-Al2O3 is used as a first carrier, Anatase crystalline TiO2 is used as a second carrier, and active components containing V2O5-MoO3 composite oxide are used as the active components, wherein the contents of gamma-Al2O3 and TiO2 are respectively 5-15 wt% and 5-10 wt%, the content of V205-MoO3 is 1-10 wt%, and the mol ratio of V / Mo ranges from 0 to 0.20. The monolithic catalyst provided by the invention has a broad temperature window of 80-450 DEG C; with NH3 as a reducing agent, the transformation rate of NOx is not less than 85%; and the selectivity on N2 is greater than 90%.

Owner:上海复翼环保科技有限公司

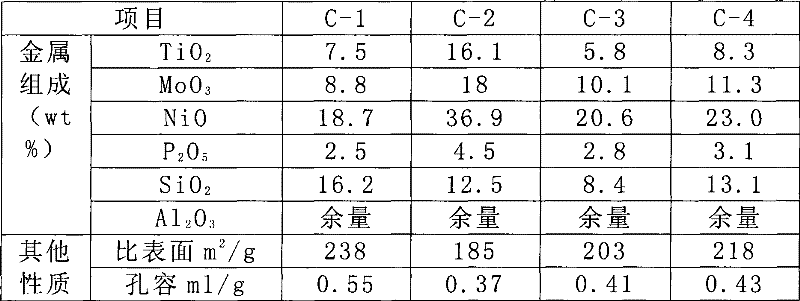

Refined hydrogenation catalyst and its preparation method

ActiveCN1769379ALarger than surfaceConcentrated hole distributionRefining to eliminate hetero atomsHydrogenation processSolvent

Owner:CHINA PETROLEUM & CHEM CORP +1

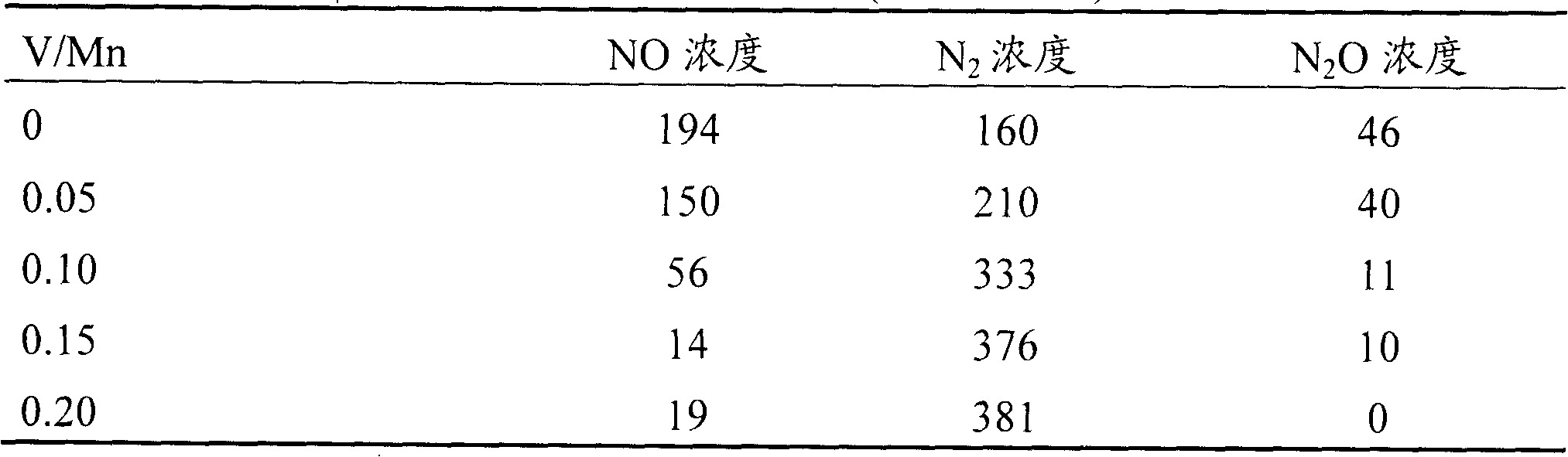

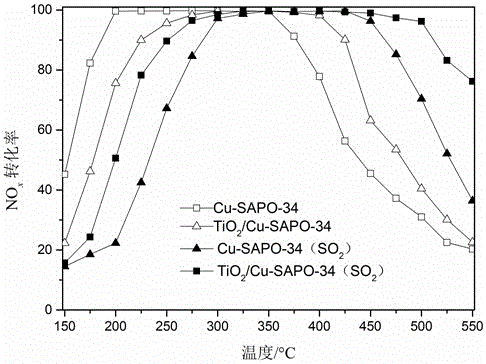

Preparation method of low-temperature NH3-SCR sulfur-resistant denitration catalyst

InactiveCN105944755AImprove purification efficiencyImprove sulfur resistanceMolecular sieve catalystsDispersed particle separationTitanium tetraisopropoxideSulfur

The invention discloses a preparation method of a low-temperature NH3-SCR sulfur-resistant denitration catalyst. The preparation method is characterized in that titanium tetrachloride, titanium(IV) isopropoxide, isopropyl titanate and butyl titanate are used as the titanium sources of the sulfur-resistant denitration catalyst, and a chemical vapor deposition method or aqueous phase method to precipitate a TiO2 sulfur-resistant layer on the surface of a Cu-SAPO-34 catalyst or wrap the surface of the Cu-SAPO-34 catalyst with the TiO2 sulfur-resistant layer so as to form a TiO2 / Cu-SAPO-34 compound catalyst. The prepared catalyst keeps the low-temperature high-activity feature of the Cu-SAPO-34 catalyst and adopts the TiO2 sulfur-resistant layer to evidently enhance of the sulfur resistance. At 300-500 DEG C, SO2 (100-500ppm) is fed into a reaction system, and the conversion rate of NOx in the NH3-SCR reaction is above 80%. Compared with a common catalyst, the compound catalyst is wider in temperature operation window, excellent in low-temperature activity and high in sulfur resistance.

Owner:KUNMING UNIV OF SCI & TECH

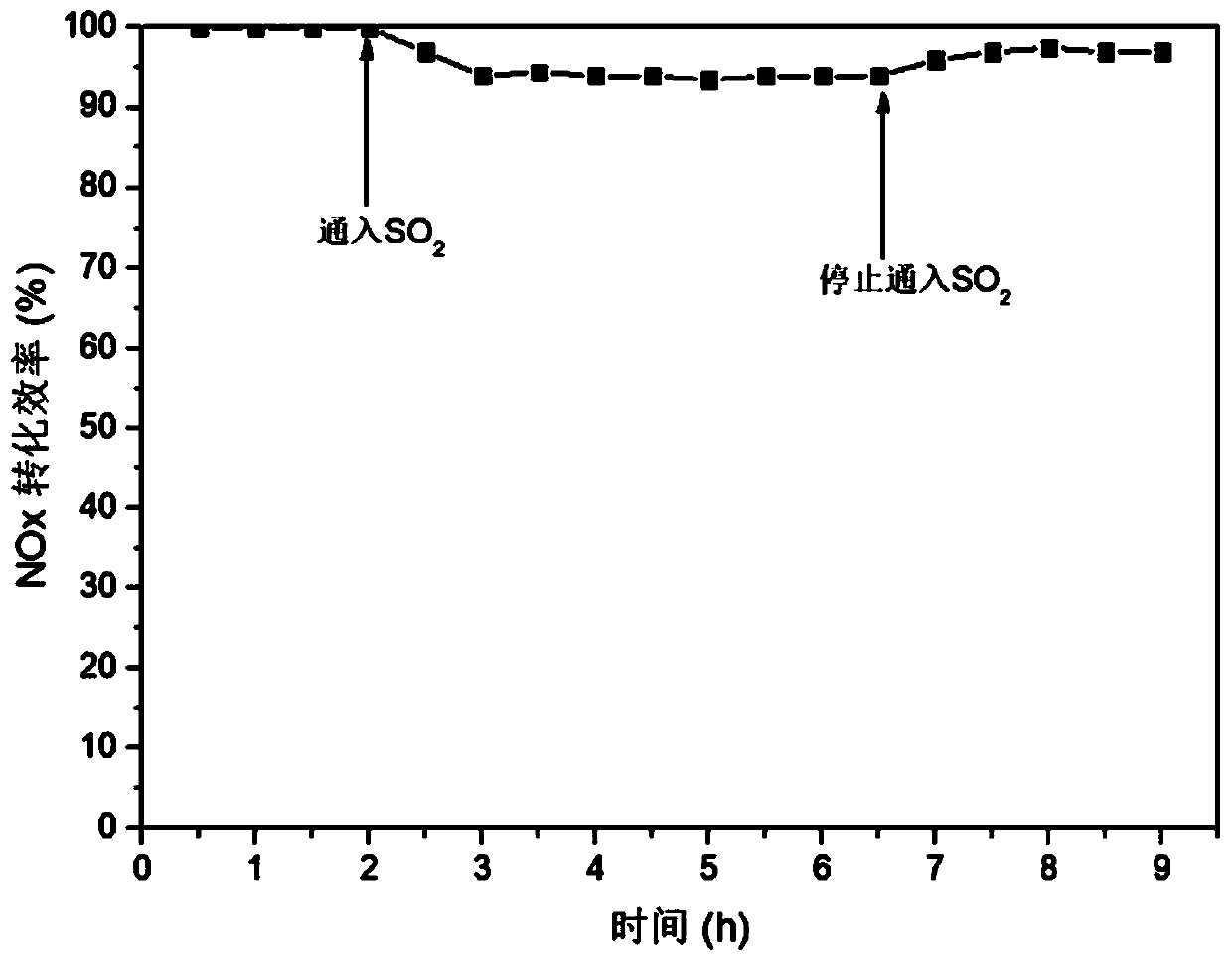

Denitration catalyst for inhibiting SO2 oxidization as well as preparation method and application thereof

InactiveCN106975492ALarge specific surface areaSolve the defect of low temperature sulfur poisoning inactivationGas treatmentHeterogenous catalyst chemical elementsVanadium oxidePollution

The invention belongs to the technical field of atmosphere pollution control and in particular relates to a denitration catalyst for inhibiting SO2 oxidization as well as a preparation method and application thereof. The denitration catalyst takes titanium dioxide as a carrier, takes one or more of cerium oxide, iron oxide and vanadium oxide as active components and takes one or more of barium oxide, molybdenum oxide and tungsten oxide as auxiliary agents. The denitration catalyst has the advantages that the specific surface area of the catalyst is effectively enlarged and the denitration efficiency is remarkably improved; the problem of a traditional vanadium-based catalyst that low-temperature sulfur poisoning suddenly reduces the activity is solved. The denitration catalyst has the specific surface area of 100m<2> / g to 160m<2> / g; the denitration efficiency keeps 95 percent or more under conditions that the temperature is 150 DEG C to 300 DEG C and the air speed is 3,000h<-1> to 100,000h<-1>, and the N2 selectivity is higher than 92 percent; nitrogen oxide flue gas containing 0 to 3000mg / m<3> of SO2 still keeps 90 percent or more, the N2 selectivity is higher than 90 percent and the SO2 oxidization efficiency is less than 1 percent; the denitration catalyst has a high anti-sulfur capability and is especially suitable for nitrogen oxide emission control of flue gas generated in fields of glass, steel, coke ovens for coking and the like.

Owner:FUDAN UNIV

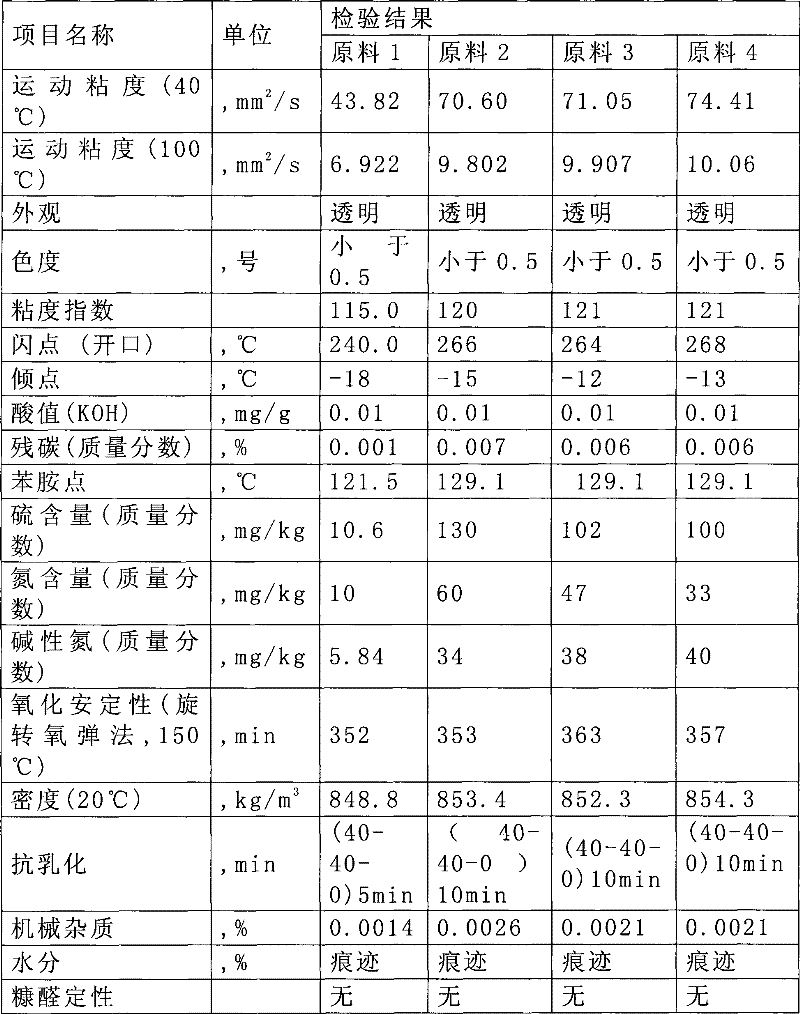

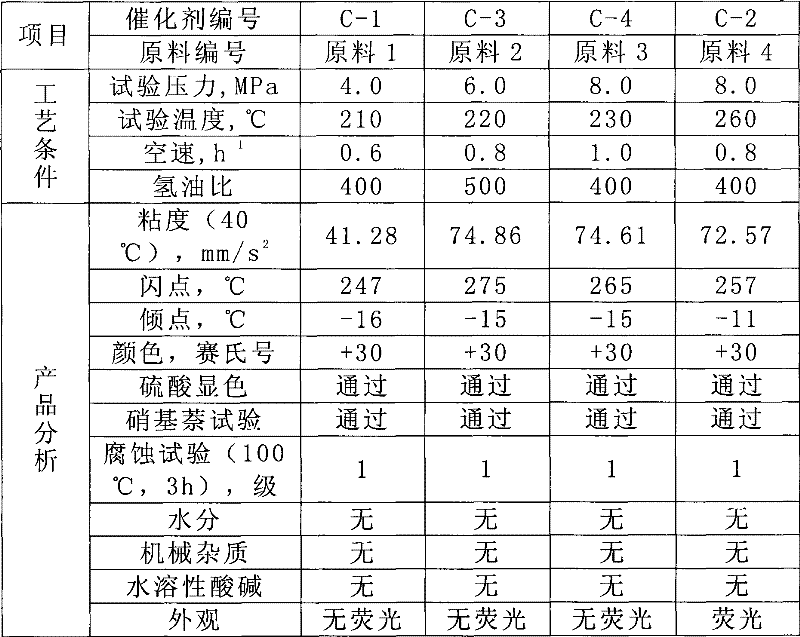

Process for preparing high-viscosity technical white oil

ActiveCN101343558BLarger than surfaceConcentrated hole distributionRefining to eliminate hetero atomsActive componentSulfur

The invention relates to a high viscosity industrial white oil production method, which takes the catalytic cracking mesoplasm lube base oil as the raw material, anti-sulfur catalyst is adopted, the industrial white oil is generated through the first stage hydrogenation, the reaction temperature is 200 DEG C to 320 DEG C, the reaction hydrogen partial pressure is 4.0 MPa to 8.0 MPa, the liquid volume space velocity is 0.3 to 1.5 h-1, and the hydrogen oil volume rate is 200 to 1000; the catalyst carrier is SiO2-Al2O3 modified by TiO2, an active component takes the catalyst weight as the datum, the NiO content is 10 wt percent to 40 wt percent, the MoO3 content is 15 wt percent to 20 wt percent, the TiO2 content is 3 wt percent to 8 wt percent, the surplus is a SiO2-Al2O3 carrier, the catalyst active component content is low, the sulfur-resistant and nitrogen poisoning ability is high, the method is suitable for the impurities, such as sulfur, nitrogen and the like, and the mesoplasm lube base oil with a higher aromatics content, and the superior grade high viscosity industrial white oil is generated by adopting the first stage hydrogenation technology.

Owner:PETROCHINA CO LTD

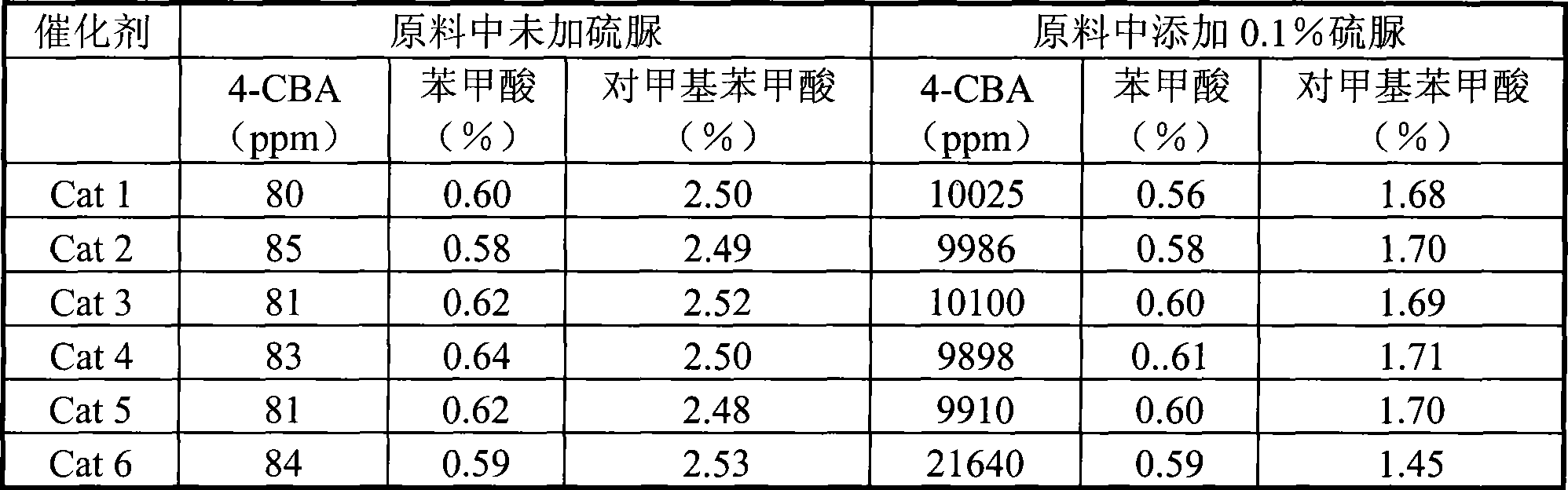

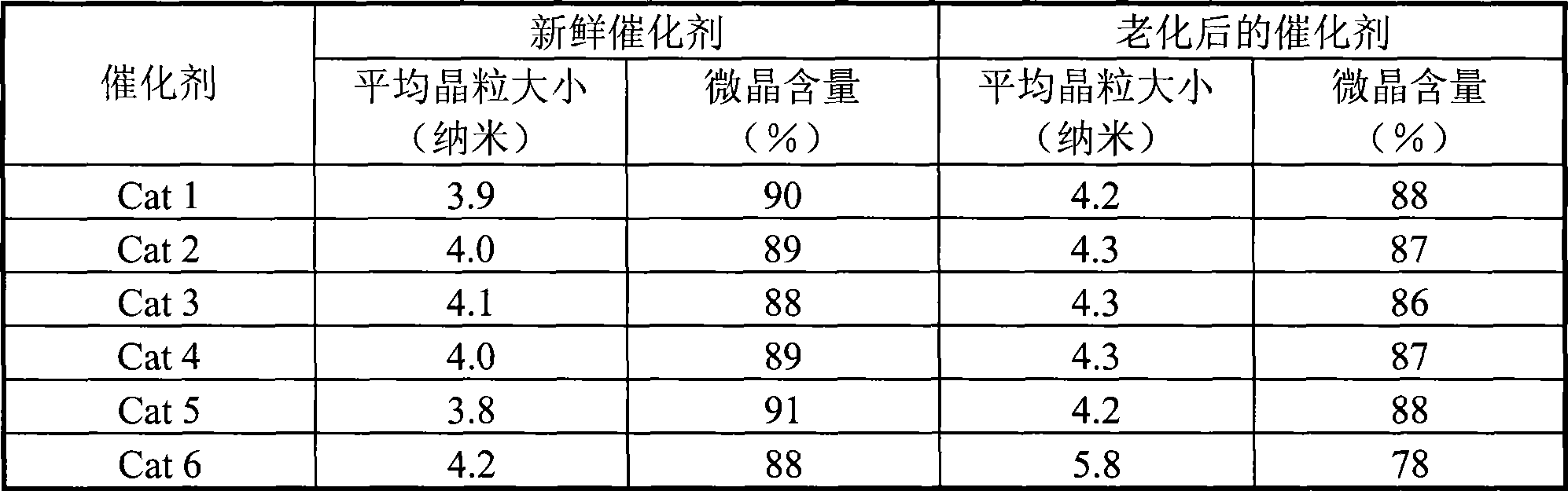

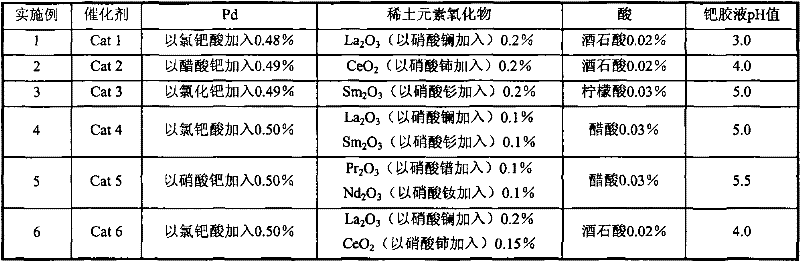

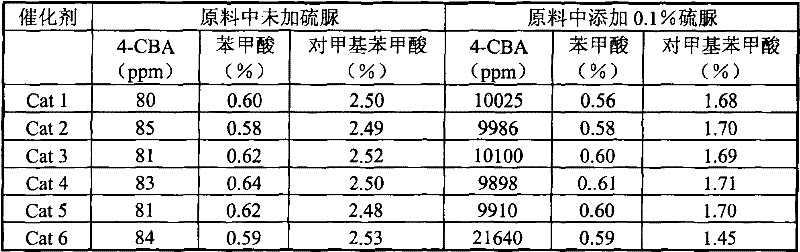

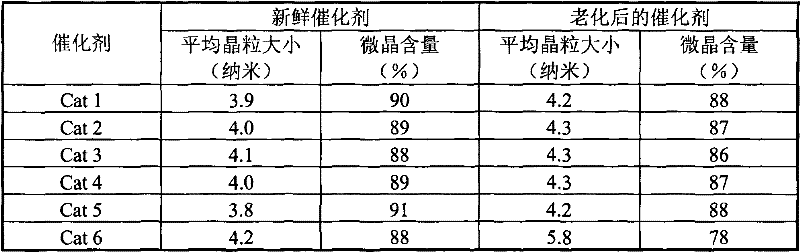

P-benzene dicarboxylic acid hydrogen refining catalyst and preparation method thereof

ActiveCN101428218AStrong sulfur resistanceImprove heat resistanceOrganic compound preparationCarboxylic compound preparationRare-earth elementRare earth

The invention relates to a catalyst used in a hydrofining reaction of terephthalic acid and a preparation method thereof, and mainly solves the problems that the prior Pd-C catalyst has poor sulfur resistance and the Pd grain is liable to grow. The components in weight percentages of the catalyst are as follows: a) 0.3% to 0.8% of Pd; b) 0.01% to 0.5% of oxides of at least one metal selected from rare-earth elements; and c) a carrier in balance amount, wherein the carrier is coconut shell charcoal with a particle size ranging from 4 meshes to 8 meshes and a specific surface area more than 1000 square meter / g; and the Pd and the oxides of rare-earth elements are distributed from the surface of the carrier to the superficial layer (at a depth ranging from 40micrometers to 100 micrometers). With the technical scheme, the catalyst overcomes the problems in the prior art and is applied to the commercial-scale hydrofining of terephthalic acid.

Owner:CHINA PETROLEUM & CHEM CORP +1

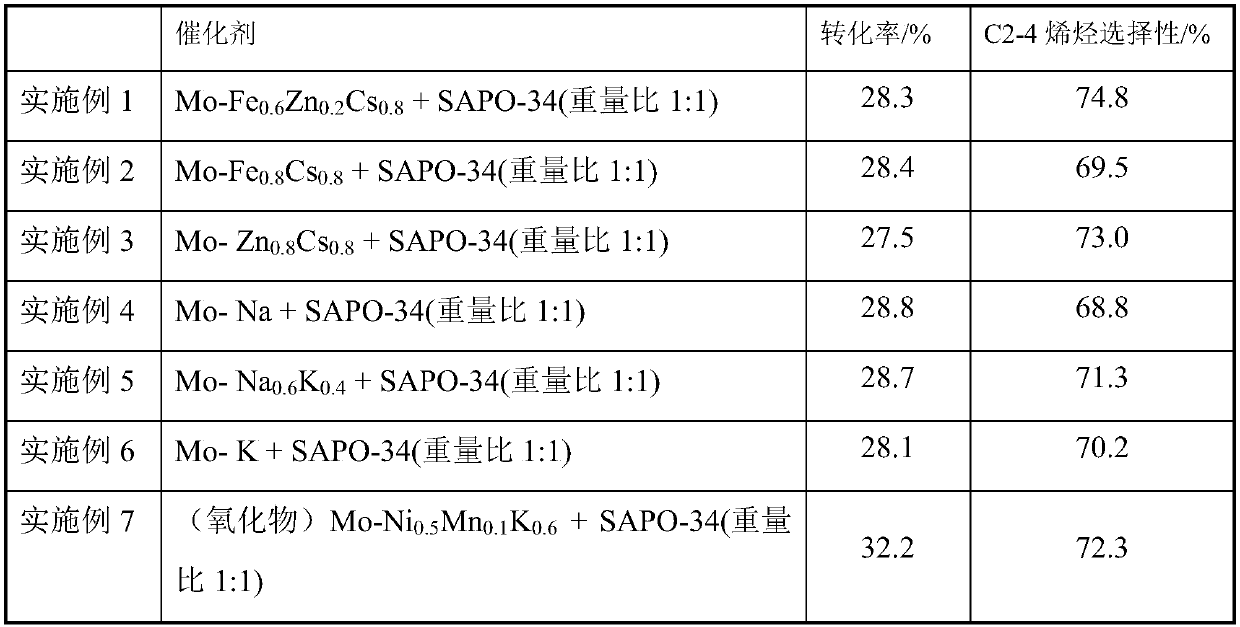

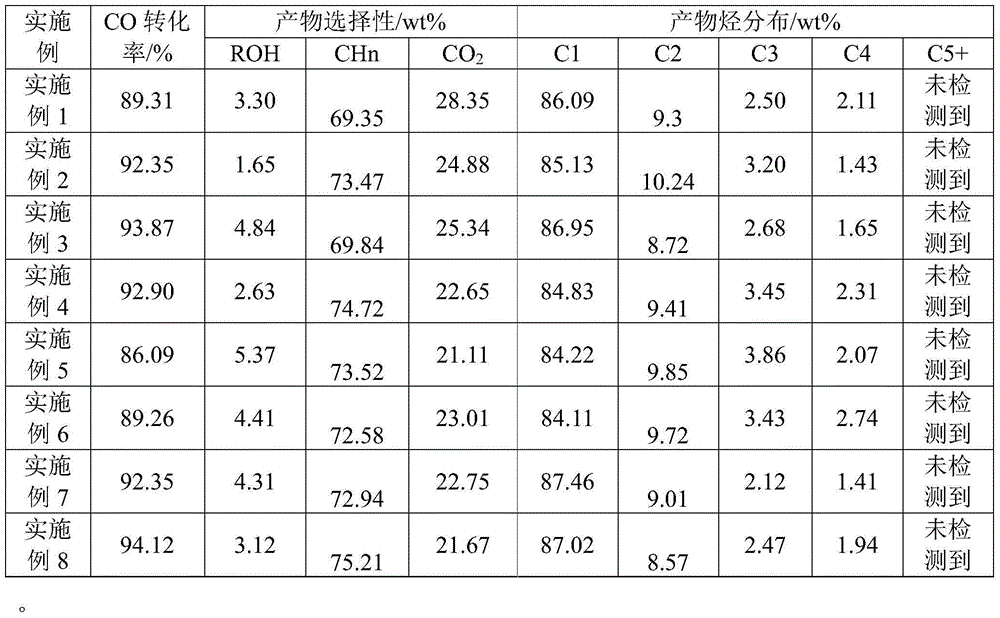

Coupled catalyst system used for directly producing light olefins with synthetic gas

ActiveCN109701630AStrong sulfur resistanceHigh selectivityHydrocarbon from carbon oxidesMolecular sieve catalystsMolecular sieveSyngas

The invention belongs to the technical field of chemistry and chemical engineering and particularly provides a coupled catalyst system used for directly producing light olefins with synthetic gas. Theinvention mainly solves the problem of low selectivity on the light olefins of a catalyst used for preparing light olefins with synthetic gas in the prior art. In the catalyst, a synthetic gas-to-alcohol catalyst and an alcohol-to-olefin catalyst are coupled to achieve the one-step process of directly producing olefins with synthetic gas. The synthetic gas-to-alcohol catalyst is a modified molybdenum-based catalyst had has the molecular general formula of MoTt-XaYbZc, wherein T is at least one selected from S, O or C, the X is one or more of Fe, Co, Ni, Ru, Rh and Pd; the Y is one or more ofCr, Mn, Zn, La, Ce; the Z is one or more selected from alkali metals. The alcohol-to-olefin catalyst is a molecular sieve having a CHA skeleton structure. The catalyst solves the mentioned problems well, can product C2-C4 olefin products high-effectively, continuously and stably, and can be used for industrial production of preparing light olefins with synthetic gas.

Owner:CHINA PETROLEUM & CHEM CORP +1

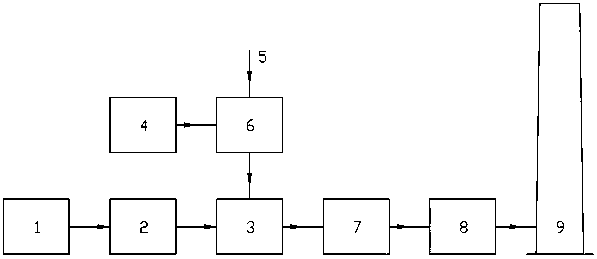

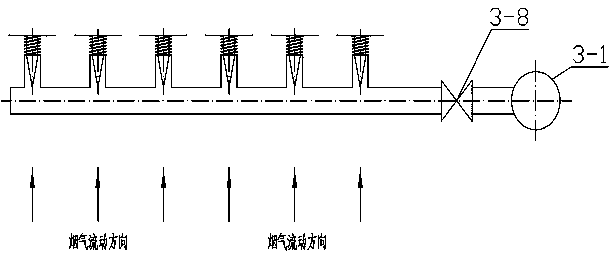

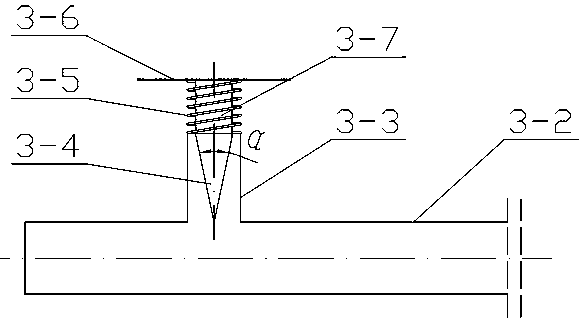

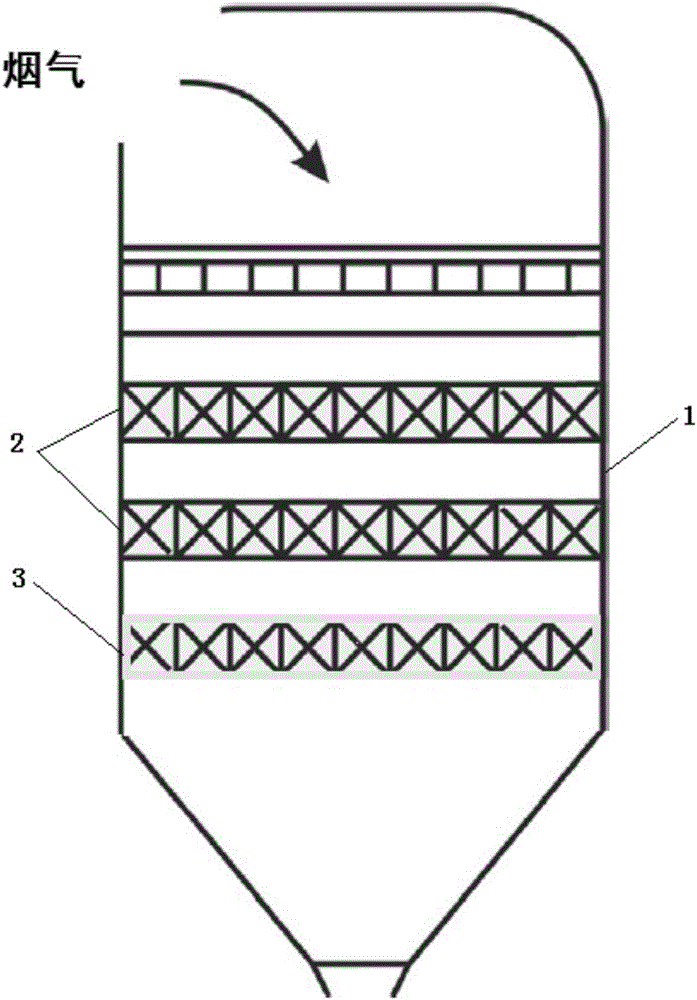

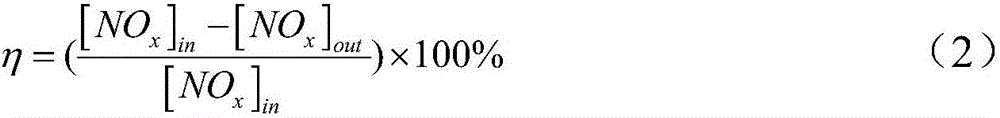

Low-temperature SCR denitration treatment method and device

ActiveCN108939918AGood activity at low temperatureStrong sulfur resistanceDispersed particle separationFlue gasTreatment costs

The invention relates to a low-temperature selective catalytic reduction (SCR) denitration treatment method. The method comprises the following steps: controlling the temperature of NOx-containing flue gas to be 120-300 DEG C through a heat exchange unit, then uniformly mixing the NOx-containing flue gas with ammonia gas sprayed out by an ammonia spraying grid, sending the mixed gas into an SCR denitration reactor, converting the NOx into N2 and H2O under the action of a low-temperature denitration catalyst, and discharging the purified gas after heat is recycled. The low-temperature SCR denitration treatment device provided by the invention is realized by adopting the method. The device provided by the invention has the advantages of good low-temperature activity, high sulfur resistance,good water stability, high anti-poisoning capacity, low treatment cost and the like.

Owner:CHINA PETROLEUM & CHEM CORP +1

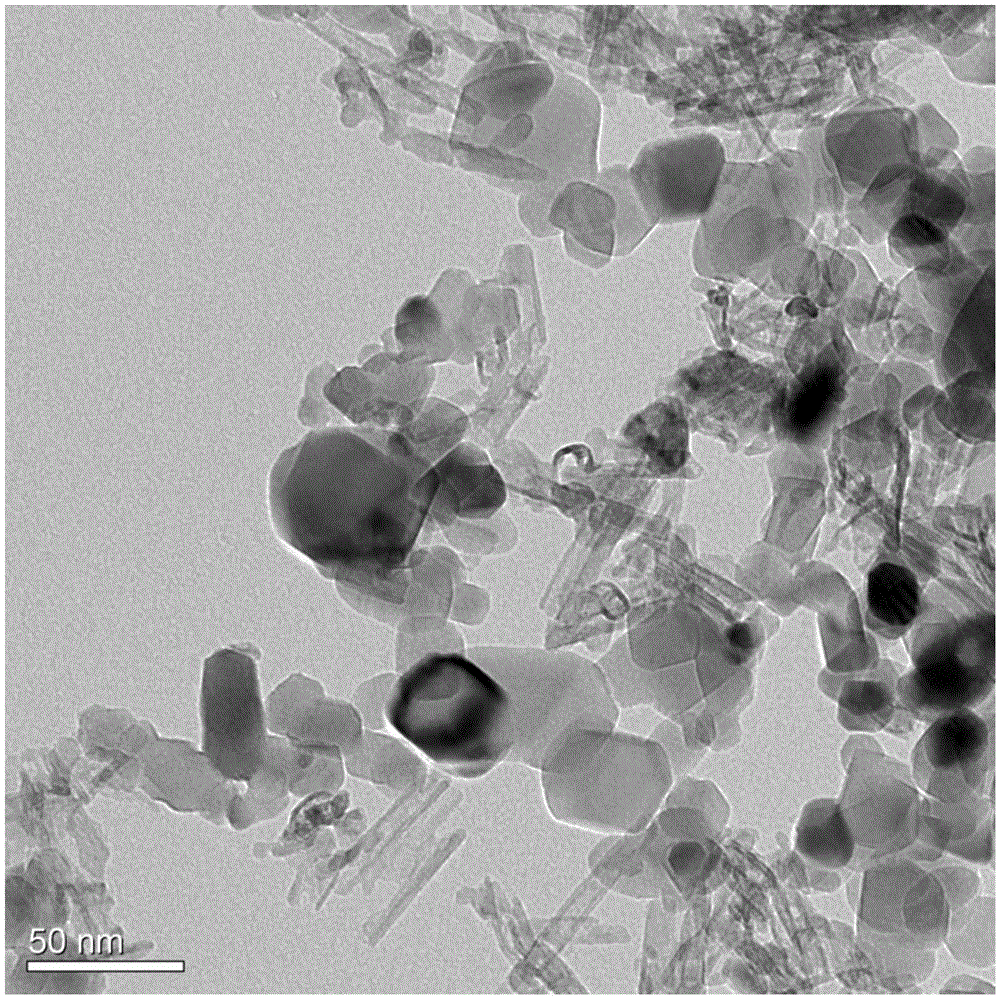

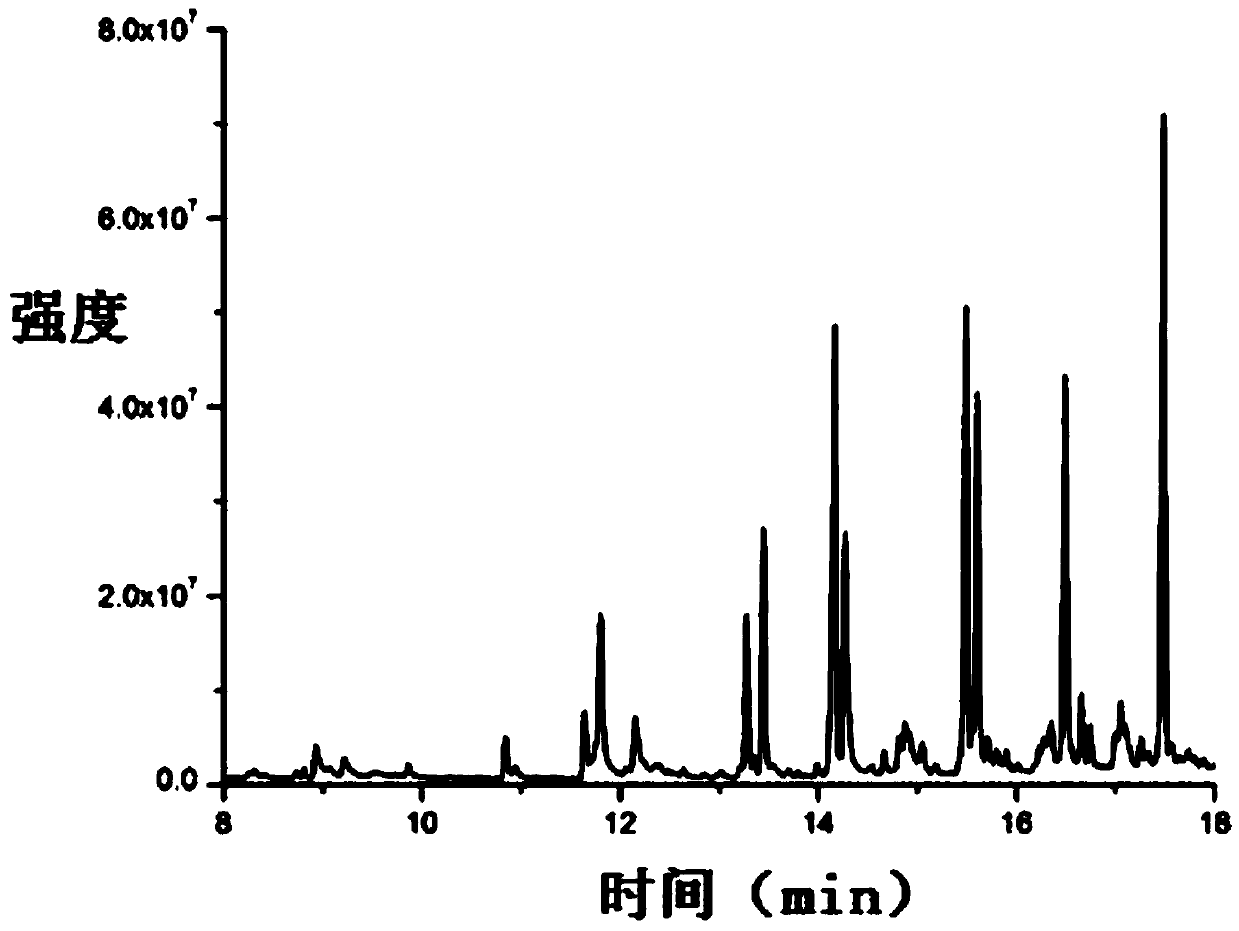

Nano-molybdenum-based sulfur-tolerant methanation catalyst, preparation method and application

ActiveCN105771965ASmall particle sizeNarrow distributionHeterogenous catalyst chemical elementsGaseous fuelsSulfurActive component

A nano-molybdenum-based sulfur-tolerant methanation catalyst takes metal Mo as the main active component.A second active component metal M1 and an additive metal M2 are added on the basis of the main active component, and the catalyst is prepared from, by mass, 5%-55% of M, 2%-50% of M1, 0.2%-20% of M2 and the balance oxygen atoms.The nano-molybdenum-based sulfur-tolerant methanation catalyst has the advantages of being simple in preparation, high in sulfur-tolerant capacity, high in methanation activity, good in stability and free of carbon deposition.

Owner:SHANXI INST OF COAL CHEM CHINESE ACAD OF SCI

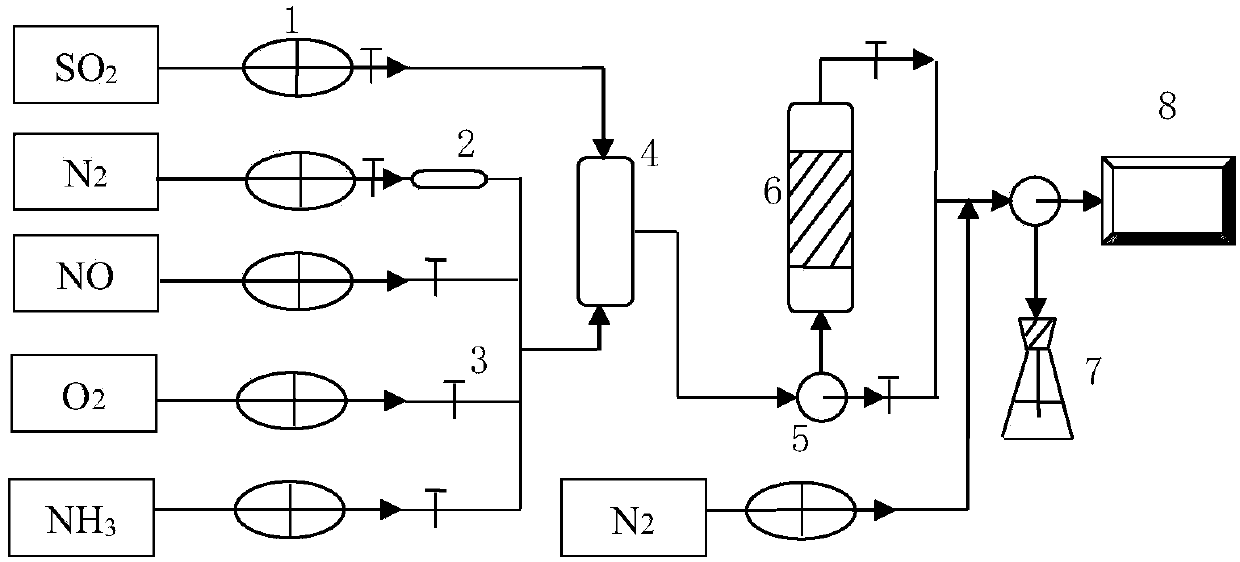

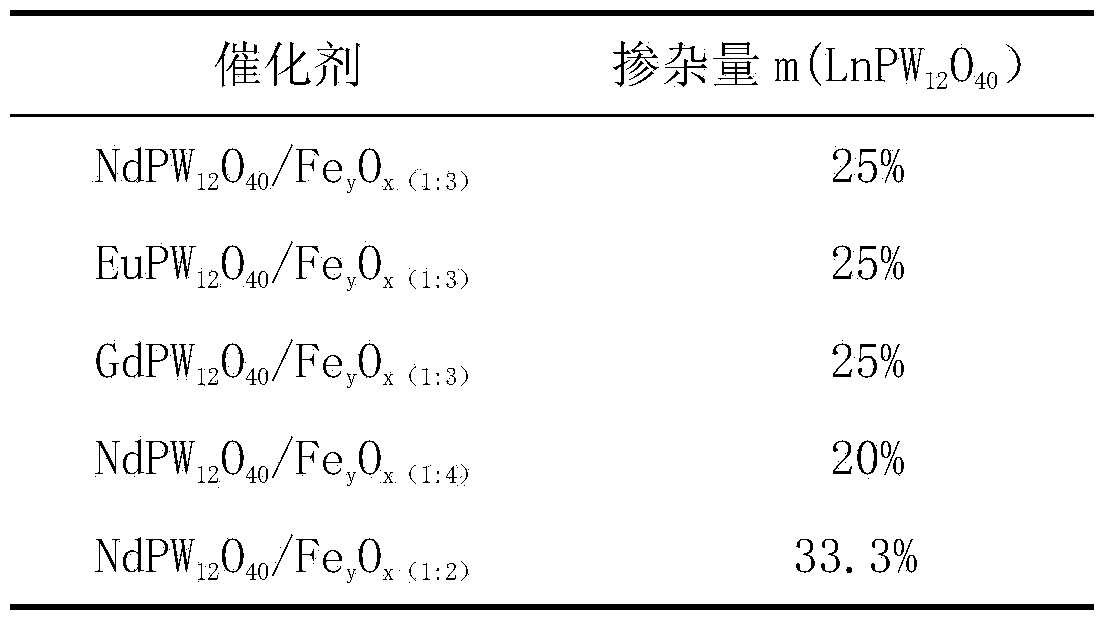

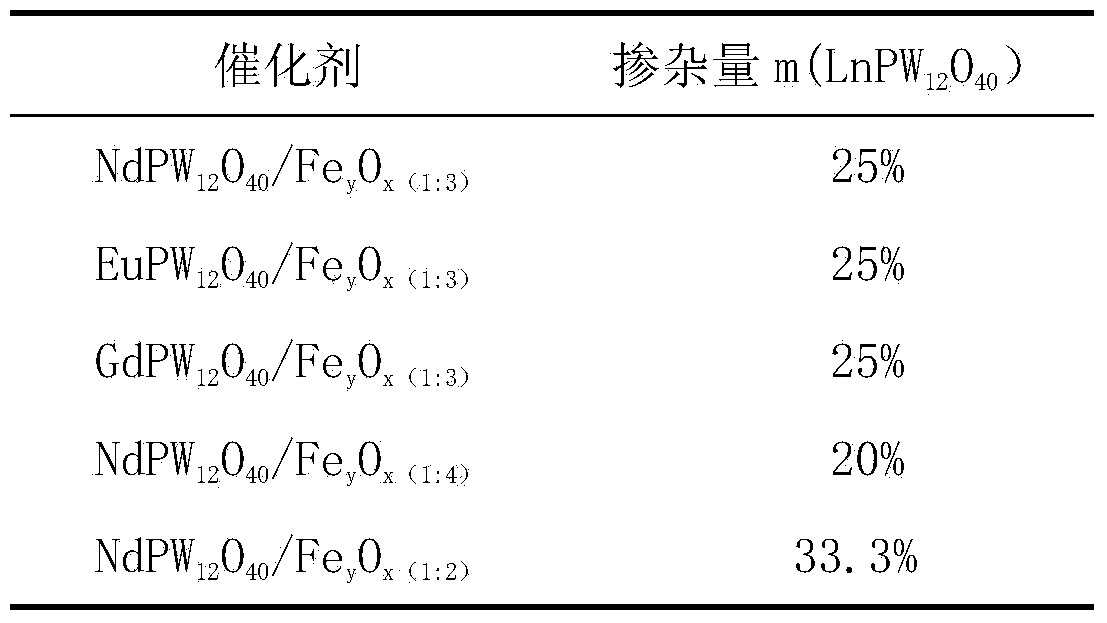

Rare-earth heteropolyacid salt-doped iron-based catalyst and application of catalyst in flue gas denitration

InactiveCN103990480AEasy to prepareNo pollution in the processPhysical/chemical process catalystsDispersed particle separationMass ratioRare earth

The invention discloses a rare-earth heteropolyacid salt-doped iron-based catalyst which is formed by mechanical mixing of rare-earth heteropolyacid salt and iron oxide, wherein mass ratio of rare-earth heteropolyacid salt to iron oxide is 1:2, 1:3 or 1:4; and rare-earth heteropolyacid salt is selected from Keggin structured rare-earth phosphotungstate. The rare-earth heteropolyacid salt-doped iron-based catalyst can be used in selective catalytic reduction of NOx and flue gas denitration. In specific application, ammonia gas is used as a reducing agent and mixed proportionally; and under conditions of a certain space velocity, nitrogen oxide concentration, reaction temperature and normal pressure and in the presence of oxygen, nitrogen oxide in flue gas is removed, and nitrogen oxide is converted to nitrogen. The catalyst provided by the invention has advantages of simple preparation method, no toxicity, no harm, no pollution, high catalytic activity, high stability, high denitration efficiency, high sulfur-resistance performance, simple processing equipment and little investment, and is suitable for industrial popularization.

Owner:SHANDONG UNIV

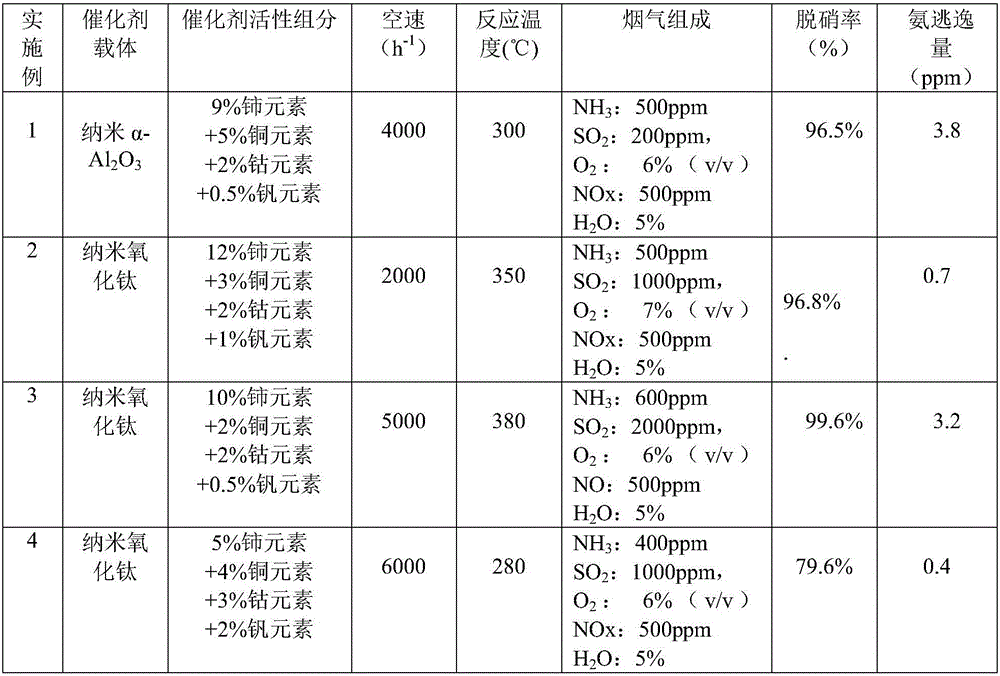

W-firing boiler NOx ultra-clean emission method and SCO ammonia removal catalyst thereof

InactiveCN106807390ALow costStrong sulfur resistanceGas treatmentDispersed particle separationCeriumAmmonium metavanadate

The invention discloses a W-firing boiler NOx ultra-clean emission method and an SCO ammonia removal catalyst thereof. The process is simple, high in denitration efficiency and low in ammonia escape. Meanwhile, the SCO catalyst is simple in preparation, high in activity and low in cost. The SCO ammonia removal catalyst comprises active ingredients and a carrier, wherein the active ingredients are prepared by calcining active ingredient precursors; the active ingredient precursors refer to cerium salts, copper salts, cobalt salts and vanadium salts; the cerium salts, copper salts or cobalt salts refer to nitrate, acetate or sulfate; the vanadium salt refers to ammonium metavanadate or vanadiumoxy acetylacetonate; the carrier is anatase type nano TiO2 or nano alpha-Al2O3; a mass fraction of cerium accounting for the catalyst is 1-20%; a mass fraction of copper accounting for the catalyst is 0-15%; a mass fraction of cobalt accounting for the catalyst is 0-15%; a mass fraction of vanadium accounting for the catalyst is 0.5-5%.

Owner:XIAN THERMAL POWER RES INST CO LTD

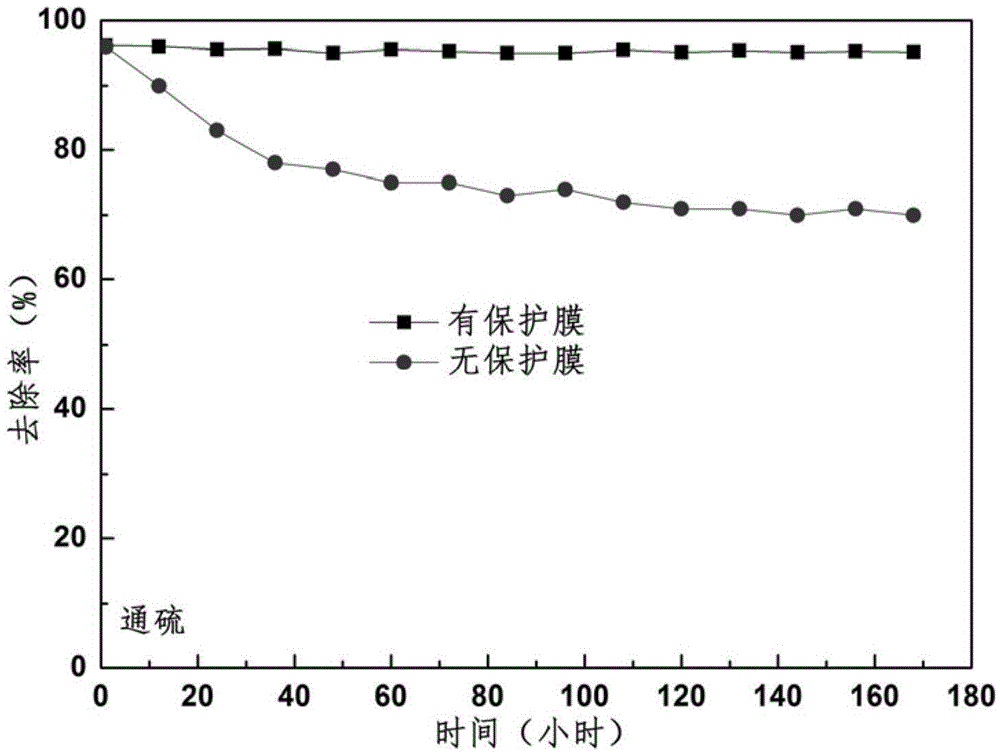

Medium and low temperature denitration catalyst with protective layer and preparation method thereof

ActiveCN105457646AGood water and sulfur resistanceExtended service lifeGas treatmentHeterogenous catalyst chemical elementsTectorial membraneSulfur

The invention discloses a medium and low temperature denitration catalyst with a protective layer and a preparation method thereof. The catalyst is composed of an outer layer protective film and an inner layer catalyst body; the outer layer protective film takes a mixture of titanium dioxide nanoparticles and titanium nanotubes as a substrate material, and V, Ce and Cu composite oxide is doped; the inner layer catalyst body takes the titanium dioxide nanoparticles as carriers, takes V and Ce composite oxide as a main active component and takes trace precious metal as an additive. The catalyst is provided with the protective film with a special structure, the protective film has good medium and low temperature denitration activity by itself, sulfur ammonium salt particles can not enter pore passages of the titanium nanotubes, reaction gas can reach the inner layer catalyst body through the pore passages of the titanium nanotubes, the catalyst shows excellent water-resistant and sulfur-resistant properties, and the service life is effectively prolonged.

Owner:ZHEJIANG TIANLAN ENVIRONMENTAL PROTECTION TECH

High sulfur-resistant catalyst for using syngas to produce methane, preparation method and application

InactiveCN104971712AEasy to makeEasy to operateHydrocarbon from carbon oxidesMetal/metal-oxides/metal-hydroxide catalystsSyngasMethanation

A high sulfur-resistant catalyst for using syngas to produce methane has bimetallic active components, comprising an M oxide as a first active component, an M1 oxide as a second active component and an S oxide as a carrier. The mass percentages of components of the catalyst are: M is 0.5-45%, M1 is 0.2-25% and the remaining component is the oxide carrier S. The high sulfur-resistant catalyst is strong in sulfur resistance, high in methanation activity, low in carbon deposit and simple in preparation.

Owner:SHANXI INST OF COAL CHEM CHINESE ACAD OF SCI

Sulfur-resistant BaFe1-xTixO3 perovskite catalyst, preparation and application

InactiveCN102139216AReduce manufacturing costEasy to dopeDispersed particle separationMetal/metal-oxides/metal-hydroxide catalystsEthylene diamineNitrate

The invention discloses a sulfur-resistant BaFe1-xTixO3 perovskite catalyst, preparation and application, preparation and application, and belongs to a NOx eliminating catalyst technology. The structural formula of the catalyst is BaFe1-xTixO3, wherein X is 0.1-0.3; a preparation method of the catalyst comprises the following steps of: after mixing nitrates of Ba and Fe, using citric acid and EDTA (ethylene diamine tetraacetic acid) as complexing agents to regulate the pH (potential of hydrogen) to be 6, drying the sol after the mixture forms the sol, and dipping the sol in Ti after roasting the gel at a low temperature; roasting the gel at a high temperature to prepare a perovskite sample; performing NOx storage on the sample; and testing the sulfur-resistance and regeneration performance of the sample. The catalyst has the following advantage: a NOx storage catalyst with high sulfur-resistance is prepared through a dipping method. The perovskite catalyst has an excellent sulfur-resistant characteristic and regeneration performance, and is a non-noble metal NOx storage reduction catalyst which has a good development prospect.

Owner:TIANJIN UNIV

Preparation method of sulfur-tolerant palladium-base catalyst

InactiveCN102350347AShort manufacturing timeIncrease the areaMetal/metal-oxides/metal-hydroxide catalystsMicrowaveDistillation

The invention relates to a preparation method of a sulfur-tolerant palladium-base catalyst, belonging to the field of preparation of supported catalysts. The method comprises the following steps: mixing a gamma-Al2O3 carrier, of which the granularity is 0.6-0.9mm, with a cerous nitrate-zirconium nitrate water solution by an isometric impregnation method, impregnating at constant temperature while stirring, drying by distillation, sectionally roasting with microwaves to prepare the CeO2-ZrO2 / gamma-Al2O3 catalyst carrier; and mixing the CeO2-ZrO2 / gamma-Al2O3 catalyst carrier and a PdCl2 solution, impregnating at constant temperature while stirring, drying by distillation, and roasting with microwaves to obtain the Pd-CeO2-ZrO2 / gamma-Al2O3 catalyst. When being used for synthesizing dimethyl ether by a coal-base synthetic gas one-step method, the sulfur-tolerant Pd-CeO2-ZrO2 / gamma-Al2O3 catalyst has higher CO conversion rate and higher selectivity for the product dimethyl ether; and the invention obviously enhances the sulfur-tolerant stability and anti-carbon performance of the catalyst, optimizes the catalyst preparation technique, is simple to operate, and has the advantages of short time consumption, small energy consumption and good repetitiveness.

Owner:CHINA UNIV OF MINING & TECH

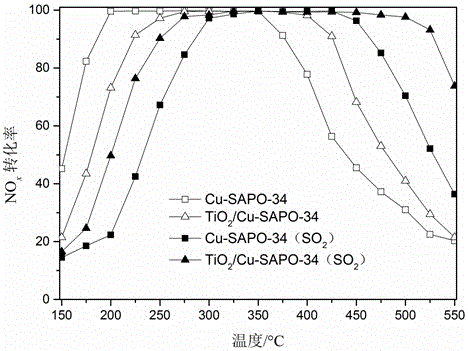

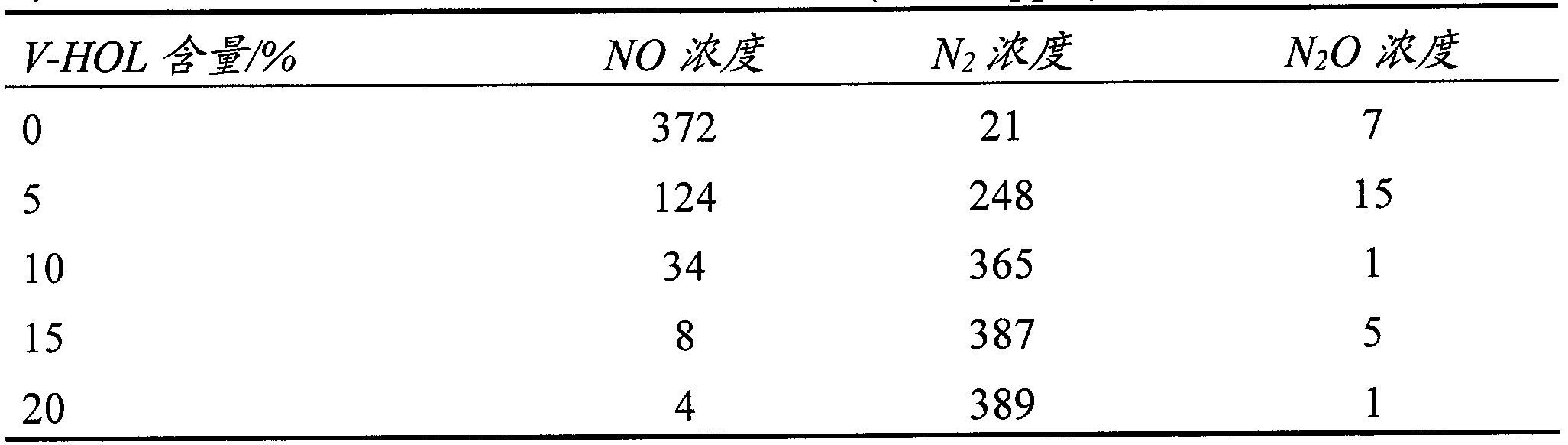

Titanium oxide molecular sieve monolithic catalyst for flue gas denitrification

ActiveCN102284281AWide operating temperatureImprove out-of-stock efficiencyDispersed particle separationMetal/metal-oxides/metal-hydroxide catalystsNitric oxideCordierite

The invention provides a doped Hollandite type titanium oxide ammonia catalytic selective reduction nitrogen oxide (NH3-SCR) denitrified monolithic catalyst, and relates to the environmentally-friendly technology in the field of catalytic science and energy saving. The catalyst is characterized in that: a honeycomb cordierite ceramic material serving as a base material and gamma-Al2O3 serving as a carrier carry Anatase crystal TiO2 powder at first, and then carry Hollandite structured titanium oxide (V-HOL) of an active component framework vanadium ion (V5+), wherein the contents of gamma-Al2O3 and TiO2 are 5-15 weight percent and 5-10 weight percent respectively; the V-HOL is 5-20 weight percent; and the molar ratio of V / Ti is between 0 and 0.20. According to the monolithic catalyst, at a broad temperature window of between 100 and 450 DEG C, the conversion rate to NOx by using NH3 as a reducing agent is more than 85 percent, and the selectivity to N2 is more than 95 percent. The catalyst is suitable for controlling emission of nitric oxides.

Owner:上海复翼环保科技有限公司

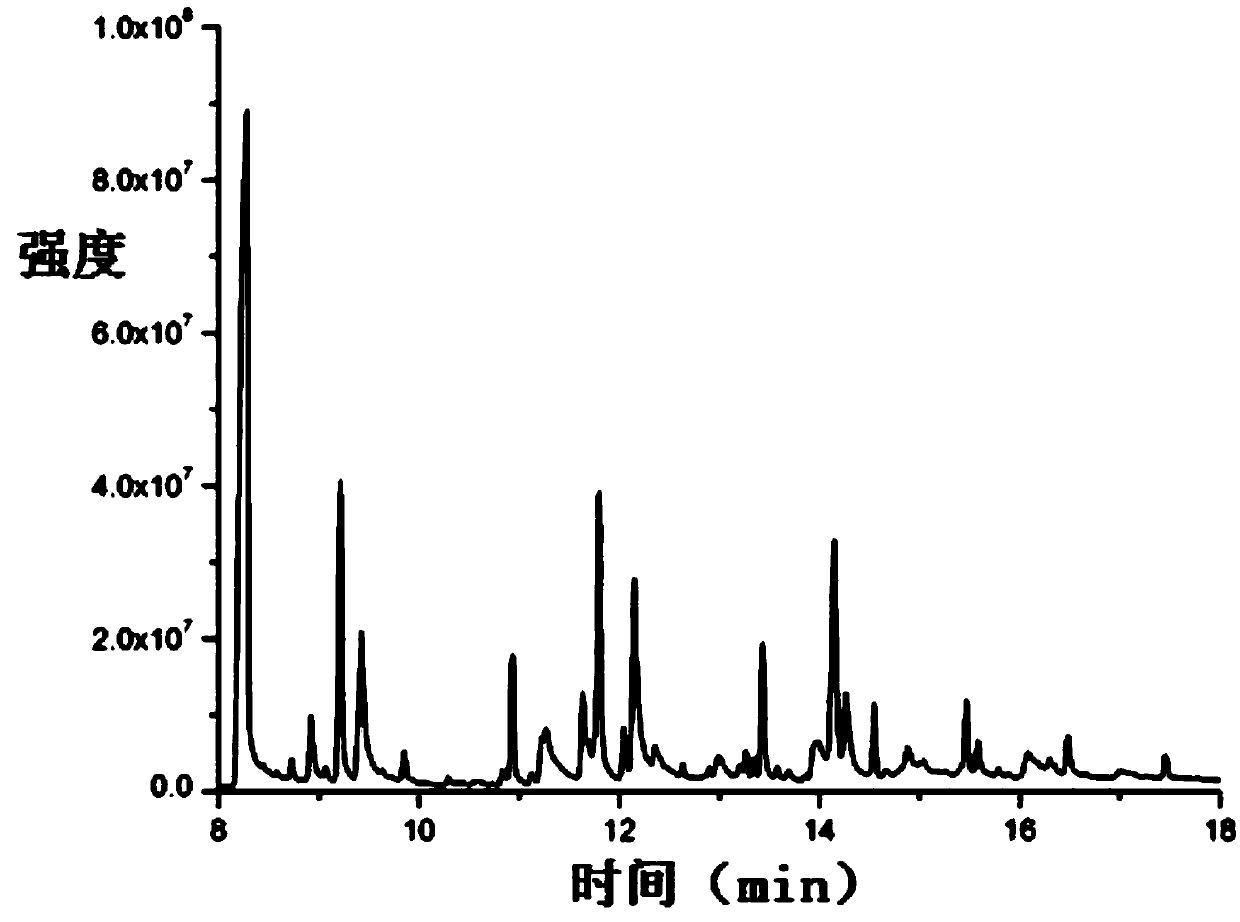

Method for preparing hydrocarbyl phenol by catalytic conversion of phenolic compound in presence of molybdenum-based catalyst

InactiveCN107586255AWide variety of sourcesLow costOrganic chemistryOrganic compound preparationLiquid productSolvent

The invention discloses a method for preparing hydrocarbyl phenol by catalytic conversion of a phenolic compound in the presence of a molybdenum-based catalyst. The method comprises mixing a phenoliccompound, a molybdenum-based catalyst and a reaction solvent, adding the mixture into a sealed reactor, feeding gas into the reactor, heating the mixture to 150-350 DEG C, carrying out stirring for areaction for 0.5-2h, then filtering to remove a solid catalyst and carrying out rotary evaporateion to obtain a liquid product. The phenolic compound has a wide source, a cost is low, product alkyl phenol selectivity is high, an added value is high, alcohol or an alcohol-water mixture is used as a reaction solvent, environmental friendliness is realized, pollution is avoided, any inorganic acids and alkalis are avoided in the reaction process, the common environmental pollution problems in the biomass processing technology are solved, the reaction conditions are mild, the process can be carried out at a low temperature, high-efficiency conversion of the reactants can be realized without consuming hydrogen gas and the method is suitable for large-scale industrial trial production.

Owner:TIANJIN UNIV +1

Organic contaminated soil thermal desorption waste gas catalytic oxidation purification catalyst and preparation method and application thereof

ActiveCN113731409AImprove catalytic performanceImprove the ability to resist chlorine poisoningDispersed particle separationMetal/metal-oxides/metal-hydroxide catalystsPtru catalystCatalytic oxidation

The invention relates to the technical field of catalysts, and provides an organic contaminated soil thermal desorption waste gas catalytic oxidation purification catalyst and a preparation method and application thereof. The catalyst provided by the invention comprises a matrix, a carrier and active components, the matrix is honeycomb cordierite, the carrier is a CeO2-ZrO2 compound or a CeO2-ZrO2-R compound (R is one or more of La2O3, Co3O4, Y2O3 and SiO2), the active components are MnO2 and RuO2, and an auxiliary agent WO3-TiO2 is further loaded on the matrix. The catalyst provided by the invention has high catalytic efficiency in a temperature range of 450-650 DEG C, can completely convert organic contaminated soil thermal desorption waste gas, has good high-temperature stability, strong sintering resistance and carbon deposition resistance, and also has good alkali, alkaline earth and heavy metal resistance, chlorine resistance and sulfur poisoning resistance.

Owner:KUNMING UNIV OF SCI & TECH

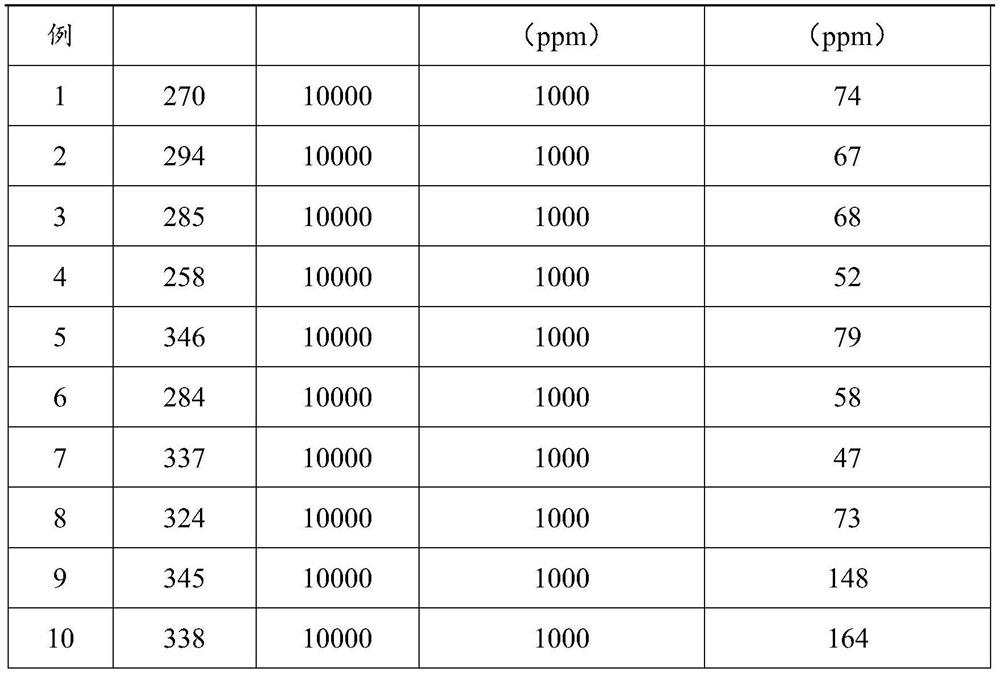

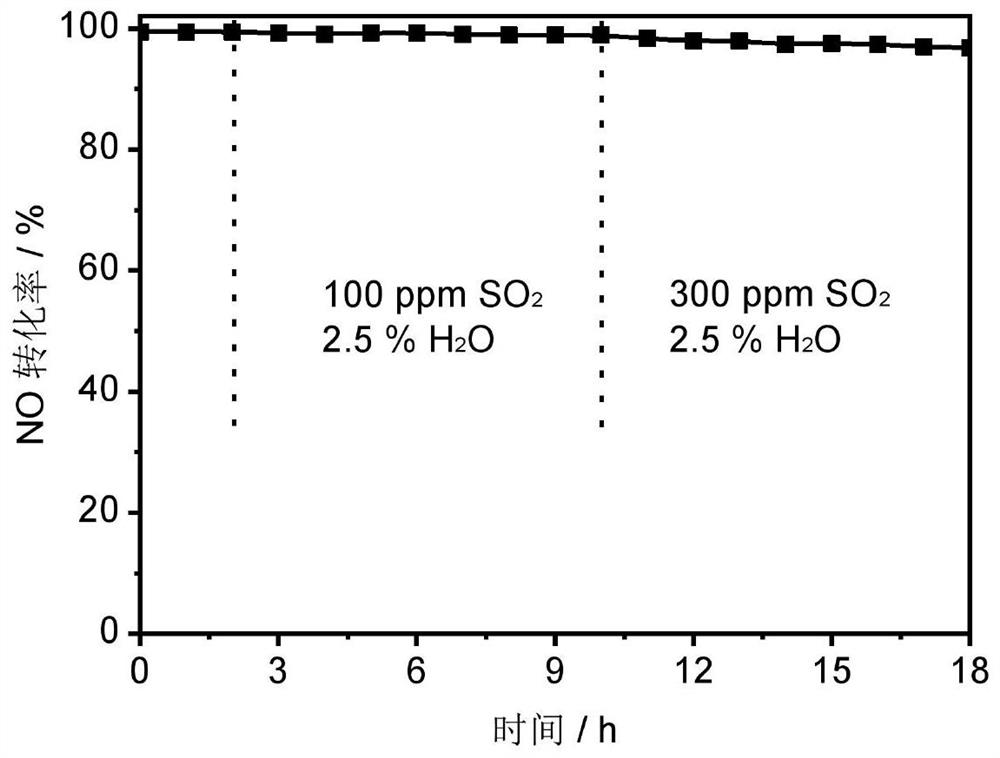

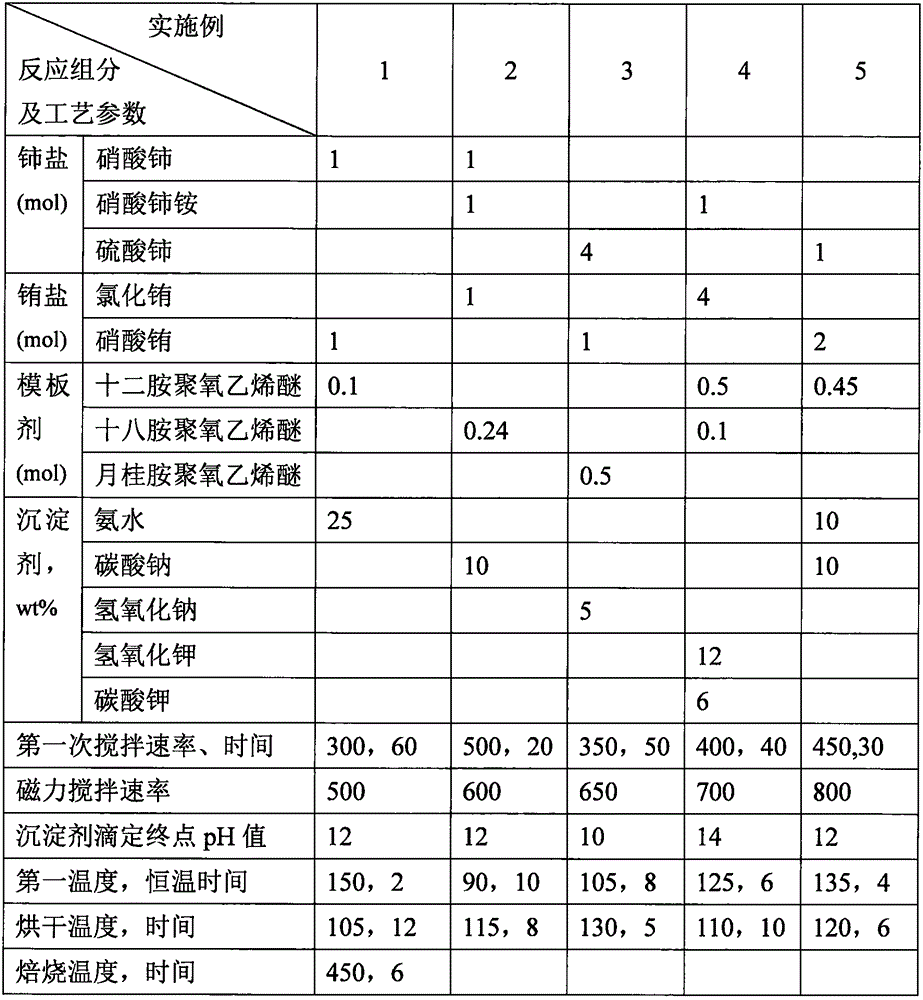

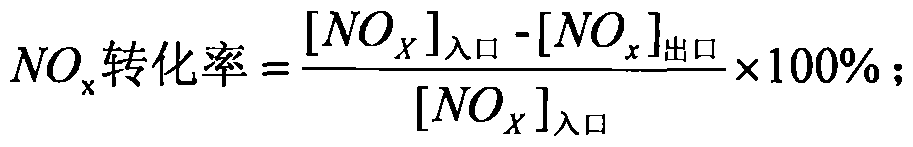

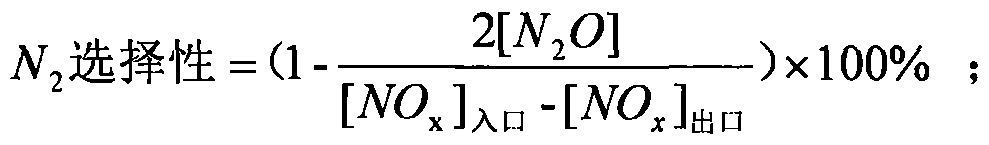

Cerium-based denitrification catalyst and preparation method and application thereof

InactiveCN109731568AImprove denitrification activityStrong sulfur resistanceDispersed particle separationMetal/metal-oxides/metal-hydroxide catalystsCeriumReaction temperature

A preparation method of a cerium-based denitrification catalyst includes the steps of dissolving Ce, Sn and Ti salts separately in deionized water, stirring until clarification, and mixing the three salt solutions to obtain a mixed salt solution; dropwise adding ammonia water solution as a precipitating agent into the mixed salt solution, stirring until PH of the mixed solution is 9-11 to generatewhite precipitate, stopping adding ammonia water, ad allowing to stand for aging; washing the white precipitate, filtering to obtain a catalyst precursor, and calcining the dried catalyst precursor to obtain Ce-Sn-TiOx composite oxide SCR (selective catalytic reduction) catalyst, with x ranges from 1 to 4. The SCR catalyst prepared via the preparation method herein has catalytic efficiency whichmay reach 90% and above in the reaction temperature range of 200-450 DEG C under the reaction condition of high space velocity (60000 h<-1>).

Owner:TIANJIN UNIV

P-benzene dicarboxylic acid hydrogen refining catalyst and preparation method thereof

ActiveCN101428218BStrong sulfur resistanceImprove heat resistanceOrganic compound preparationCarboxylic compound preparationBenzeneRare-earth element

The invention relates to a catalyst used in a hydrofining reaction of terephthalic acid and a preparation method thereof, and mainly solves the problems that the prior Pd-C catalyst has poor sulfur resistance and the Pd grain is liable to grow. The catalyst comprises the following components by weight percentages: a) 0.3% to 0.8% of Pd; b) 0.01% to 0.5% of oxides of at least one metal selected fromrare-earth elements; and c) balance of carrier, wherein the carrier is coconut shell charcoal with a particle size ranging from 4 meshes to 8 meshes and a specific surface area more than 1000 square meter / g; and the Pd and the oxides of rare-earth elements are distributed from the surface of the carrier to the superficial layer (at a depth ranging from 40micrometers to 100 micrometers). With the technical scheme, the catalyst overcomes the problems in the prior art and is applied to the commercial-scale hydrofining of terephthalic acid.

Owner:CHINA PETROLEUM & CHEM CORP +1

Preparation method of low-cost sulfur palladium alloy resisting composite film

ActiveCN108097065ALow costImprove stabilityMembranesSemi-permeable membranesComposite filmChemical plating

The invention provides a preparation method of a low-cost sulfur palladium alloy resisting composite film. The low-cost sulfur palladium alloy resisting composite film is prepared from a palladium alloy film or a palladium double-alloy composite film on the surface of a porous supporting body; a palladium composite film on the surface of the porous supporting body is subjected to disposable alloying to prepare a Pd-Ag / Pd / Pd-Cu double-alloy composite film. The preparation method comprises the following steps: firstly, chemically plating Ag by adopting a continuous chemical plating method; depositing an Ag film on the surface of the porous supporting body; secondly, chemically plating Pd; depositing a Pd film on the Ag film on the surface of the porous supporting body; finally, chemically plating Cu and depositing the Cu on the Ag / Pd film on the surface of the porous supporting body; after all film plating processes are finished, putting the porous supporting body containing the Ag / Pd / Cufilm into a film assembly and carrying out alloying operation.

Owner:新疆裕隆丰源气体有限公司

Titanium oxide molecular sieve monolithic catalyst for flue gas denitrification

ActiveCN102284281BWide operating temperatureImprove out-of-stock efficiencyDispersed particle separationMetal/metal-oxides/metal-hydroxide catalystsCordieriteNitric oxide

The invention provides a doped Hollandite type titanium oxide ammonia catalytic selective reduction nitrogen oxide (NH3-SCR) denitrified monolithic catalyst, and relates to the environmentally-friendly technology in the field of catalytic science and energy saving. The catalyst is characterized in that: a honeycomb cordierite ceramic material serving as a base material and gamma-Al2O3 serving as a carrier carry Anatase crystal TiO2 powder at first, and then carry Hollandite structured titanium oxide (V-HOL) of an active component framework vanadium ion (V5+), wherein the contents of gamma-Al2O3 and TiO2 are 5-15 weight percent and 5-10 weight percent respectively; the V-HOL is 5-20 weight percent; and the molar ratio of V / Ti is between 0 and 0.20. According to the monolithic catalyst, at a broad temperature window of between 100 and 450 DEG C, the conversion rate to NOx by using NH3 as a reducing agent is more than 85 percent, and the selectivity to N2 is more than 95 percent. The catalyst is suitable for controlling emission of nitric oxides.

Owner:上海复翼环保科技有限公司

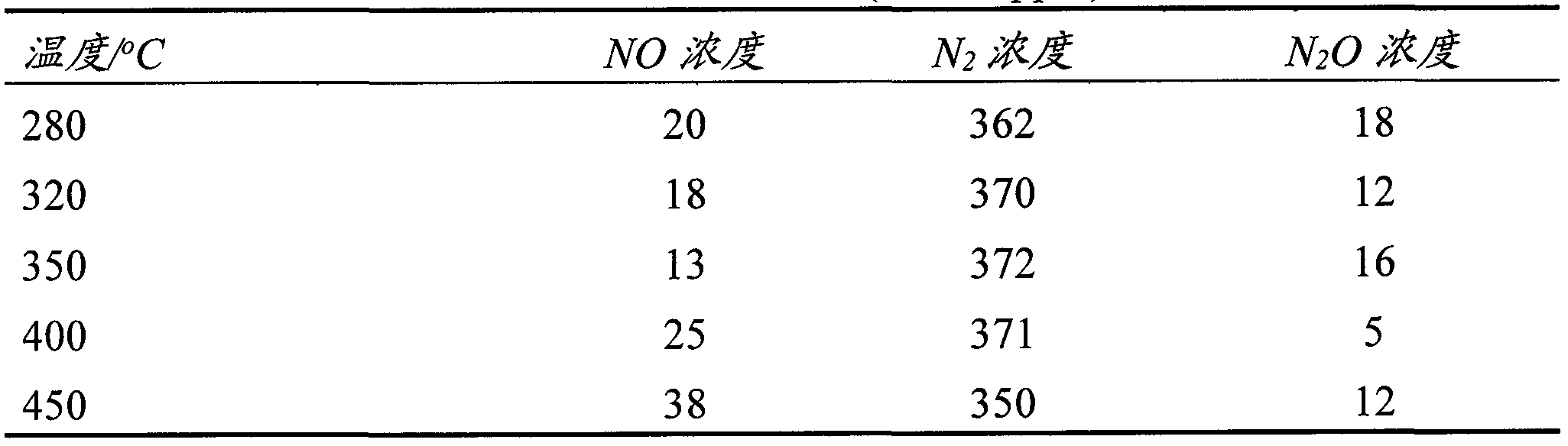

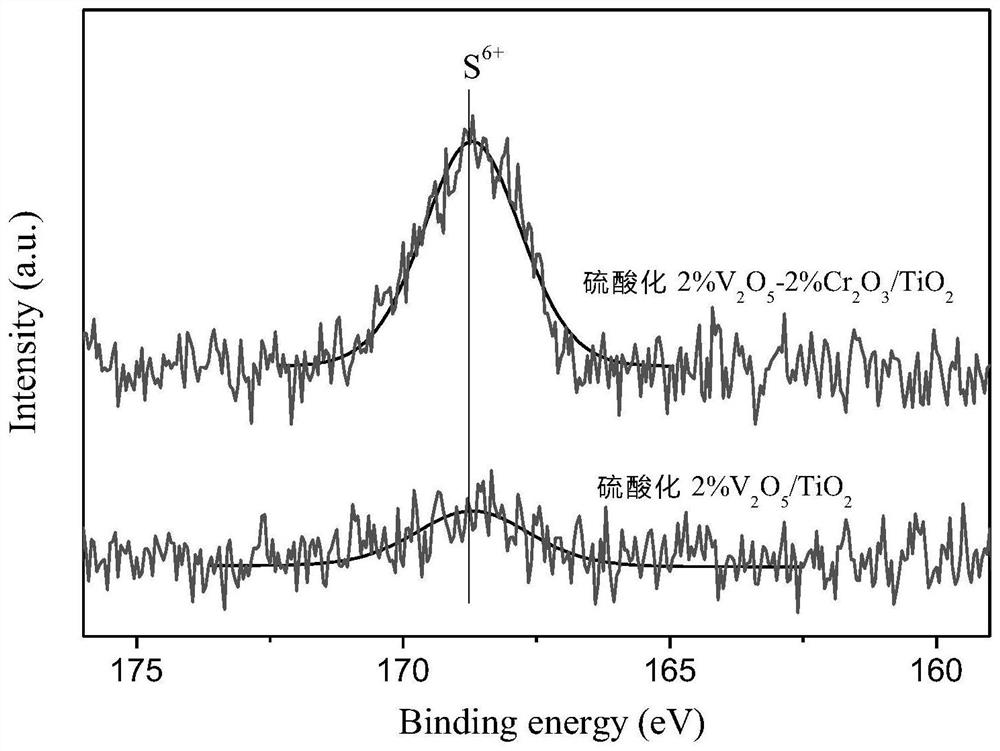

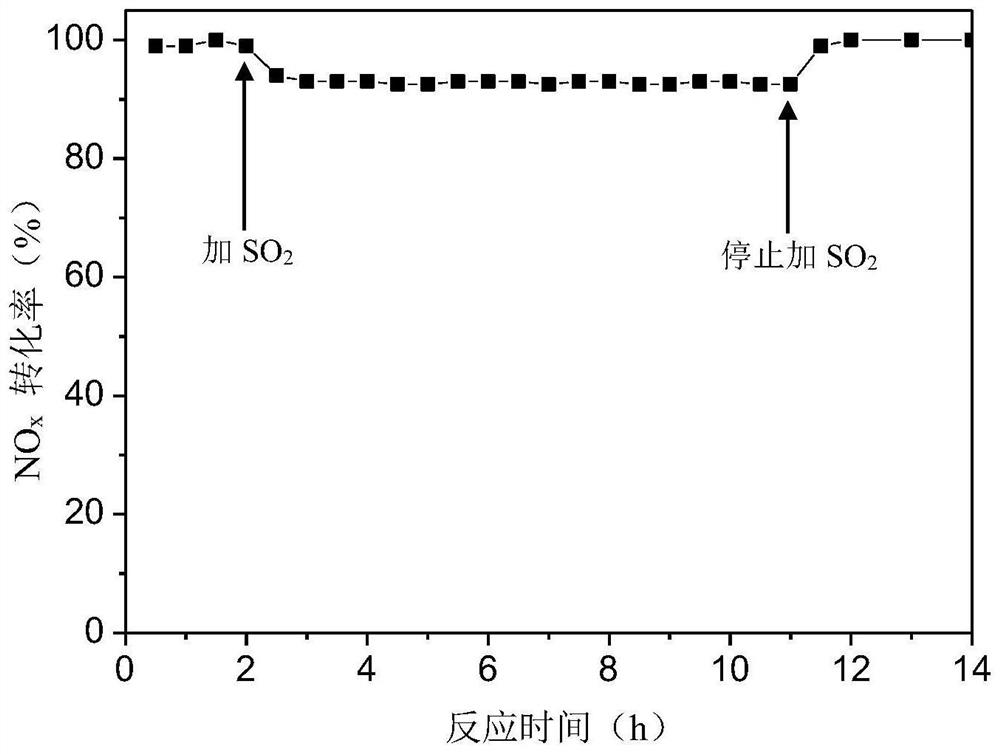

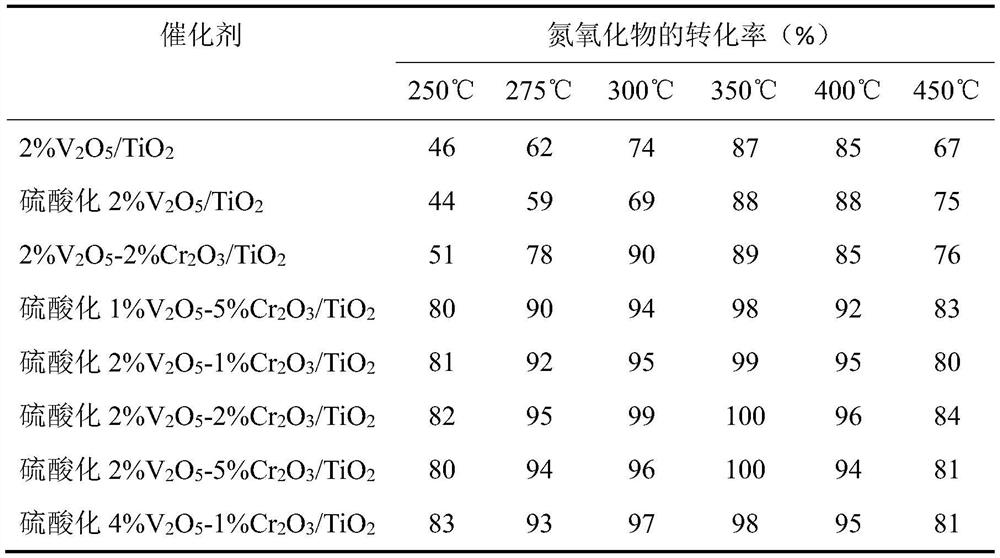

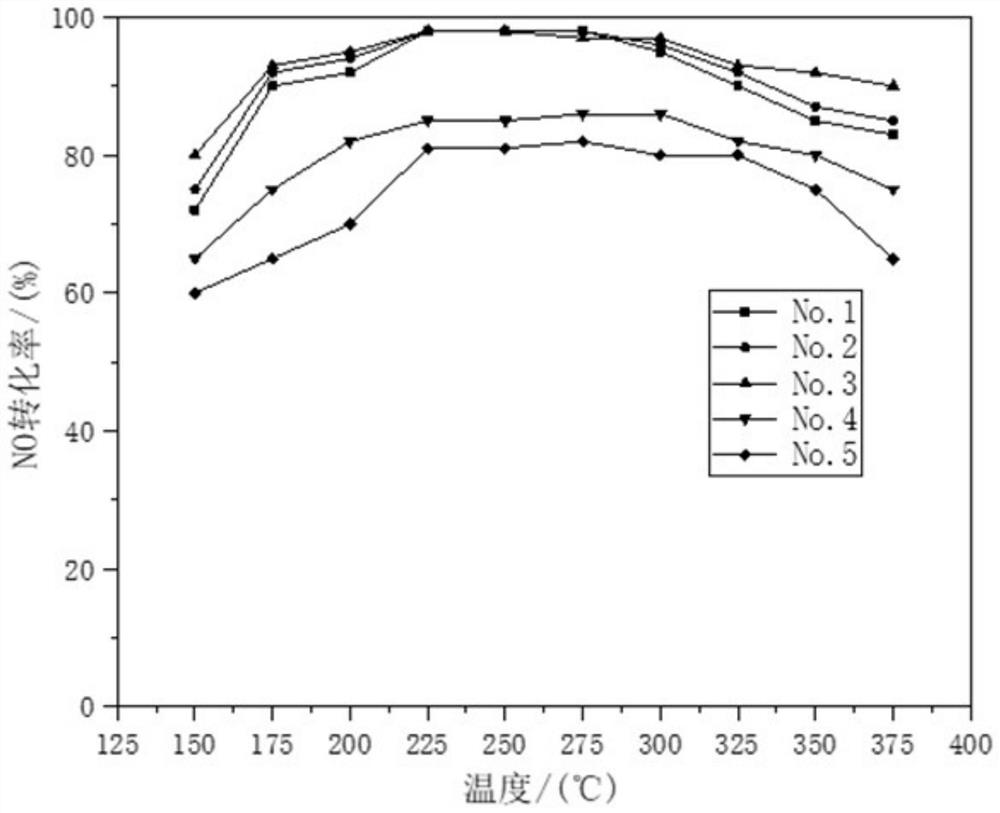

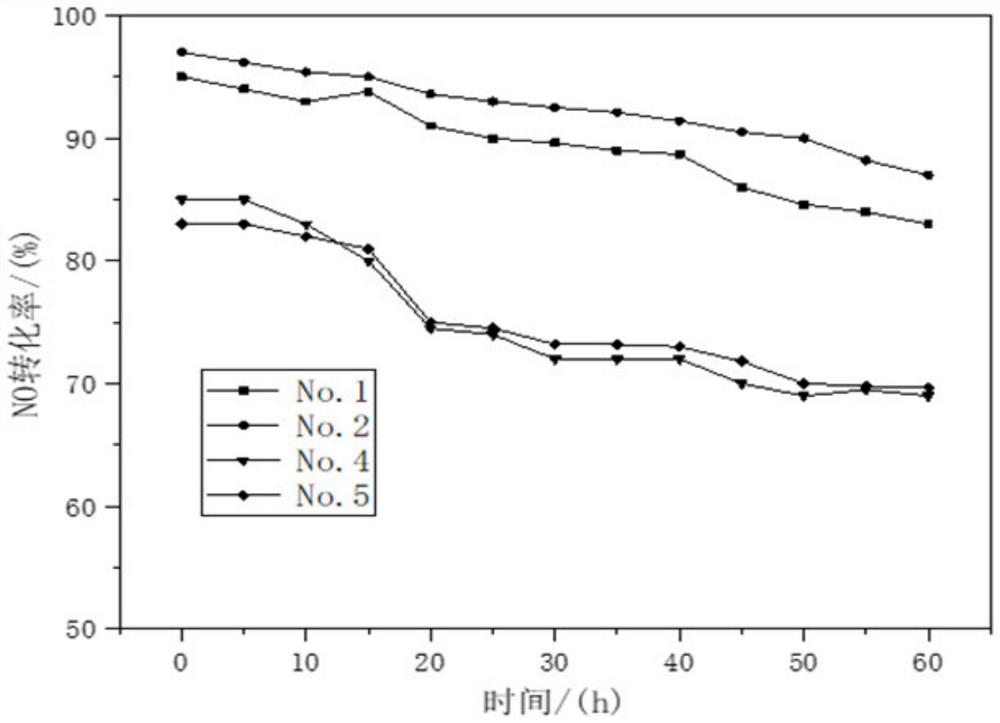

Sulfated vanadium-chromium-titanium denitration catalyst as well as preparation method and application thereof

ActiveCN113385199APromotes sulfationImprove oxidation-reductionGas treatmentInternal combustion piston enginesPtru catalystFlue gas

The invention relates to a sulfated vanadium-chromium-titanium denitration catalyst as well as a preparation method and application thereof, and belongs to the fields of air pollution control technology and environmental catalysis. The catalyst is obtained by sulfating with titanium dioxide serving as a carrier, V2O5 serving as a main active component and Cr2O3 serving as an auxiliary agent. The sulfated vanadium-chromium-titanium catalyst prepared by the method has good activity in the ammonia selective catalytic reduction NOx reaction, the NOx conversion rate is 80% or above within the range of 250-450 DEG C and the air speed is 100000 h<-1>, and the sulfated vanadium-chromium-titanium catalyst has good sulfur resistance. The catalyst disclosed by the invention can be used for efficiently removing NOx in stationary source flue gas and diesel vehicle tail gas.

Owner:BEIJING UNIV OF CHEM TECH

Low-temperature sulfur-tolerant denitration catalyst and preparation method and application thereof

ActiveCN112007654AImprove thermal stabilityImprove mechanical propertiesHeterogenous catalyst chemical elementsDispersed particle separationPtru catalystPhysical chemistry

The invention provides a low-temperature sulfur-tolerant denitration catalyst and a preparation method and application thereof. The catalyst consists of an active component, an auxiliary agent and a carrier. The active component has a perovskite structure and is a composite oxide containing La, Ni, Co and Mn elements, the auxiliary agent is oxide of Ce and P, and the carrier is a mixture containing iron oxide, titanium oxide and zirconium oxide. The catalyst is prepared by a method of combining chemical precipitation, chemical complexing and impregnation, and the preparation method is simple,mild in condition and low in cost. The NO conversion rate of the catalyst reaches up to 90% within the temperature range of 200-300 DEG C, and the catalyst has excellent sulfur resistance and water resistance.

Owner:DALIAN MARITIME UNIVERSITY

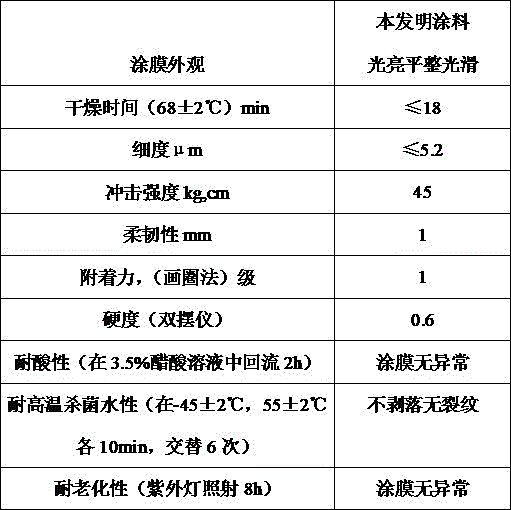

Inner-wall paint for liquid food can with high-temperature resistant sterilization

InactiveCN106318157AExcellent sulfur resistanceImprove salt toleranceFireproof paintsAntifouling/underwater paintsShellacSolvent

The invention discloses inner-wall paint for liquid-food can with high-temperature resistant sterilization. The paint is prepared from the following compositions: modified polyester resin, ethyl acrylate, shellac resin, starch gel powder, stuffing, adjuvant, and solvent. Compared with other existing inner-wall paint for liquid-food can, the present inner-wall paint for liquid-food can is capable of greatly enhancing the storage stability of canned food. The paint film has long life, and is 2-3 times higher than the life of normal canned food inner-wall paint. The paint layer formed after coatings of the inner-wall paint for canned food is firm, with greater brightness, strong adhesion, acid resistant, sulfur resistant, strong salt resistant, stable in functionality, hard to be corroded, and non-discoloring. The present paint has good high-temperature resistant ability and sterilization ability; it can adapt to most of the high-temperature sterilizations at different temperature levels on the market; meanwhile the paint is not harmful to environment, does no harm to human bodies, and is beneficial for green environmental protection.

Owner:蚌埠飞浦科技包装材料有限公司

Rare earth heteropoly acid salt doped iron-based catalyst and its application in flue gas denitrification

InactiveCN103990480BEasy to prepareNo pollution in the processPhysical/chemical process catalystsDispersed particle separationMass ratioRare earth

Owner:SHANDONG UNIV

High-sulfur-resistance metal sulfate denitration catalyst and preparation method thereof

PendingCN112844423AExcellent SCR activityAvoid depositionPhysical/chemical process catalystsDispersed particle separationMetal sulfateNitrogen oxides

The invention discloses a high-sulfur-resistance metal sulfate denitration catalyst and a preparation method thereof, and belongs to the field of thermocatalytic material preparation and atmosphere control. According to the method, 1-20wt% of metal sulfate is anchored on a carrier by a rotary evaporation impregnation method, so that the metal sulfate is uniformly distributed on the carrier, and then drying and high-temperature calcination are performed to obtain the catalyst. The catalyst disclosed by the invention has the advantages of excellent SCR activity, super-strong sulfur resistance, relatively good durability and cycling stability, simplicity and convenience in preparation, easiness in obtaining and the like. The catalyst can be used for catalytic treatment of nitrogen oxides in tail gas generated by various stationary pollution sources such as coal-fired power plants, biomass power plants and waste incineration boilers.

Owner:SHANGHAI UNIV

Flue gas denitration catalyst and preparation method thereof

ActiveCN105688880ASimple production processEasy to operateGas treatmentDispersed particle separationSulfurFlue gas

The invention relates to a flue gas denitration catalyst and a preparation method thereof, characterized in that this catalyst is a solid solution composed of cerium oxide and curopium oxide; a molar ratio of cerium and curopium in the solid solution is 1:10-10:1, preferably 1:4-4:1. The catalyst is prepared by the co-precipitation and hydrothermal joint treatment. The prepared catalyst has mass orderly mesoporous and macroporous structures, is high in NH3-SCR catalytic activity, has wide operation temperature range, is good in water tolerance and sulfur resistance and is high in stability.

Owner:NANTONG CHUNGUANG AUTOMATIC CONTROL EQUIP ENG

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com