Coupled catalyst system used for directly producing light olefins with synthetic gas

A low-carbon olefin and synthesis gas technology, applied in molecular sieve catalysts, physical/chemical process catalysts, hydrocarbon production from carbon oxides, etc. Sexual problems, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

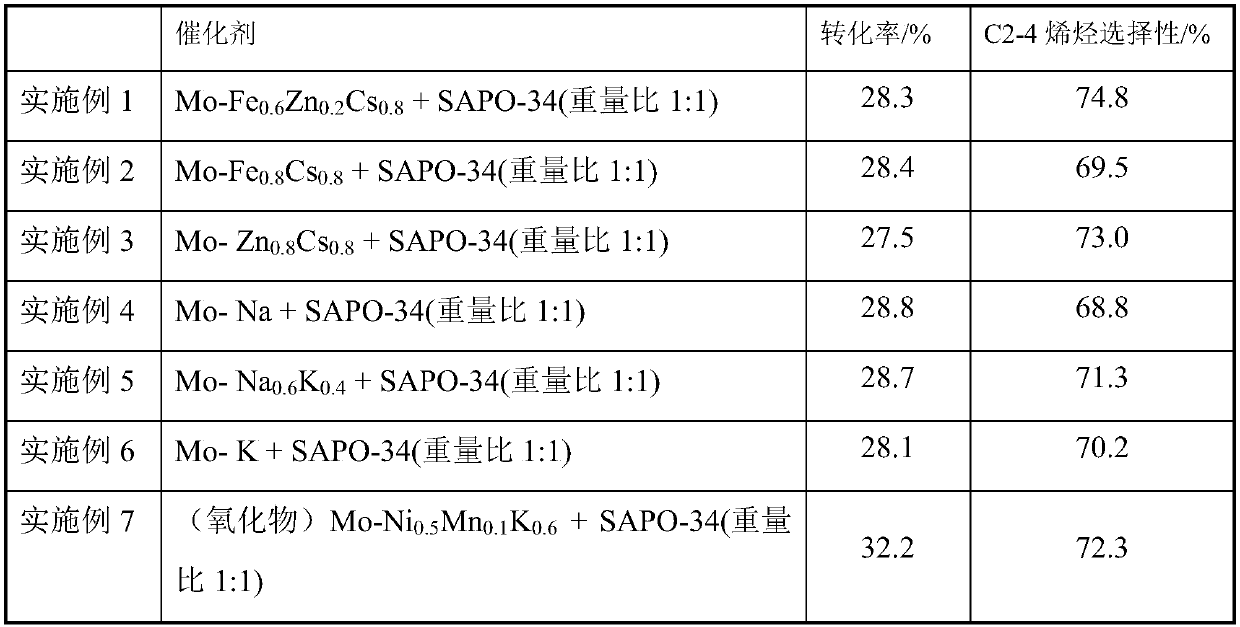

Examples

Embodiment 1

[0038] Mo-Fe 0.6 Zn 0.2 Cs 0.8 Sulfide catalyst is prepared as follows:

[0039] Weigh 0.05 mol of ammonium thiomolybdate and dissolve in water, weigh 0.03 mol of ferric nitrate and 0.01 mol of zinc nitrate and dissolve in water, and co-precipitate the two aqueous solutions in parallel, filter and wash after precipitation. Dry overnight and bake at 500°C for 4h. Sulfide intermediate loaded with 0.02mol of Cs 2 CO 3 , dried overnight at 80°C and calcined at 400°C for 1h to obtain Mo-Fe 0.6 Zn 0.2 Cs 0.8 Sulfide catalyst.

[0040] The SAPO-34 catalyst is prepared according to the following steps: phosphoric acid, pseudoboehmite, ethyl orthosilicate, and morpholine are respectively used as phosphorus source, aluminum source, silicon source, template agent, and the molar ratio Al 2 o 3 :P 2 o 5 : SiO 2 :R:H 2 O=1:1:0.6:3:100, add to the reactor and age for 2 hours, stir and crystallize at 200°C for 24 hours, wash the obtained solid with deionized water until neutral,...

Embodiment 2

[0043] Mo-Fe 0.8 Cs 0.8 Sulfide catalyst is prepared as follows:

[0044] Weigh 0.05mol of ammonium thiomolybdate and dissolve in water, weigh 0.04mol of ferric nitrate and dissolve in water, and co-precipitate the two aqueous solutions in parallel, filter and wash after precipitation, dry at 100°C overnight, and dry at 500°C Under roasting 4h. Sulfide intermediate loaded with 0.02mol of Cs 2 CO 3 , dried overnight at 80°C and calcined at 400°C for 1h to obtain Mo-Fe 0.8 Cs 0.8 Sulfide catalyst.

[0045] The SAPO-34 catalyst was prepared according to [Example 1].

[0046] 0.75 g of prepared Mo-Fe 0.8 Cs 0.8 The sulfide catalyst was mixed with 0.75 gram of prepared SAPO-34, and packed into a quartz reaction tube with an inner diameter of 6 mm, and (n 氢气 :n 一氧化碳 =50:50) into the reaction tube, into the catalytic bed reaction, the reaction temperature is 400 ℃, the reaction system pressure is 4MPa, the gas volume space velocity is 2,000h -1 The reaction of syngas to l...

Embodiment 3

[0048] Mo-Zn 0.8 Cs 0.8 Sulfide catalyst is prepared as follows:

[0049] Weigh 0.05mol of ammonium thiomolybdate and dissolve in water, weigh 0.04mol of zinc nitrate and dissolve in water, and co-precipitate the two aqueous solutions in parallel, filter and wash after precipitation, dry at 100°C overnight, and then dry at 500°C Under roasting 4h. Sulfide intermediate loaded with 0.02mol of Cs 2 CO 3 , dried overnight at 80°C and fired at 400°C for 1h to obtain Mo-Zn 0.8 Cs 0.8 Sulfide catalyst.

[0050] The SAPO-34 catalyst was prepared according to [Example 1].

[0051] 0.75 g of prepared Mo-Zn 0.8 Cs 0.8 The sulfide catalyst was mixed with 0.75 gram of prepared SAPO-34, and packed into a quartz reaction tube with an inner diameter of 6 mm, and (n 氢气 :n 一氧化碳 =50:50) into the reaction tube, into the catalytic bed reaction, the reaction temperature is 400 ℃, the reaction system pressure is 4MPa, the gas volume space velocity is 2,000h -1 The reaction of syngas to l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com