Cerium-based denitrification catalyst and preparation method and application thereof

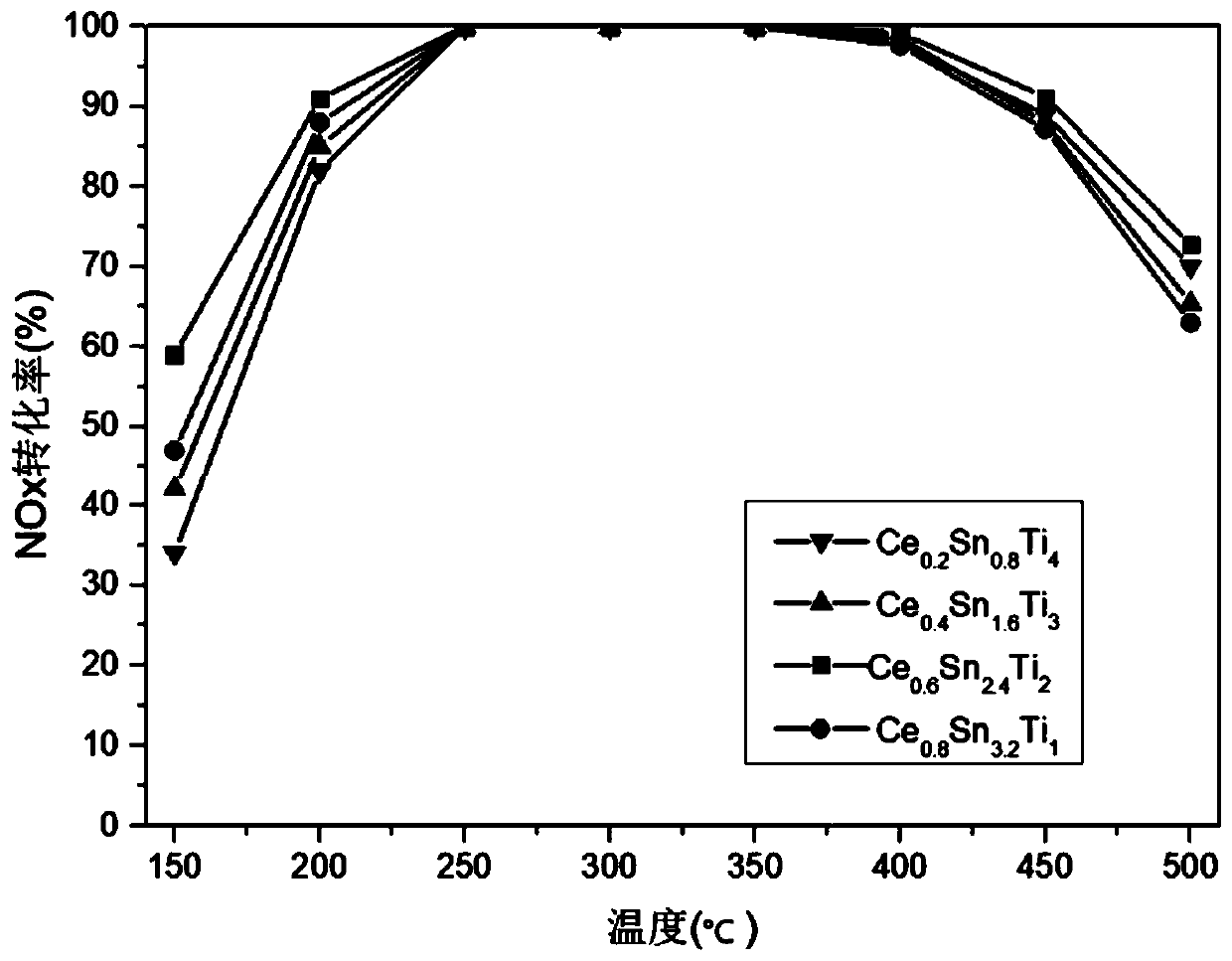

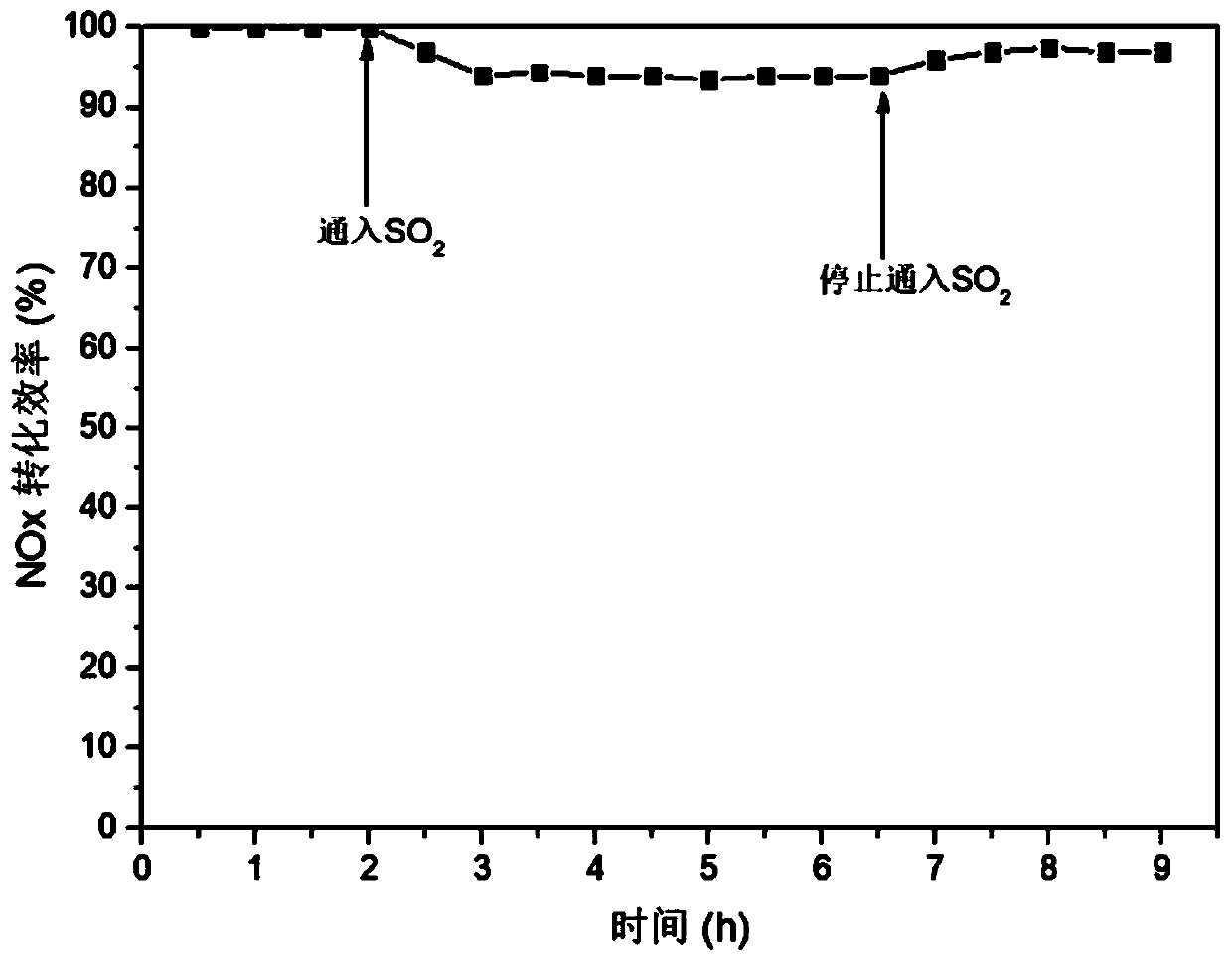

A denitration catalyst and catalyst technology are applied in the field of cerium-based denitration catalyst and its preparation, which can solve the problems of poor sulfur resistance and water resistance, increase the cost of flue gas treatment, and low denitration efficiency, and achieve strong sulfur resistance and good application. Foreground effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0025] According to the basic idea of the present invention, there is provided a preparation method of cerium-based denitration catalyst, which is characterized in that it comprises the following steps: respectively dissolving the salt containing Ce, Sn and Ti in deionized water and stirring to a clear solution, and then respectively Mix the three salt solutions to obtain a mixed salt solution; configure ammonia solution as a precipitating agent; drop the ammonia solution into the mixed salt solution and stir until the pH value of the mixed solution is between 9 and 11, forming a white precipitate, Stop the dripping of ammonia water, and place it for aging; wash and filter the obtained white precipitate to obtain the catalyst precursor, and then dry it; after calcining the dried catalyst precursor, obtain Ce-Sn-TiOx composite oxide SCR catalysts where x is between 1 and 4.

[0026] In some embodiments, in the salt containing Ce, Sn and Ti, the mass ratio of Ce and Sn is 1:4,...

Embodiment 1

[0034] Weigh 2.83g of Ce(NO3 )·6H 2 O, 10.38g of SnCl 4 ·5H 2 O and 4.2g of Ti (SO 4 ) 2 , respectively add 6.5ml, 30ml and 17.5ml of deionized water to dissolve, stir until the colorless and transparent solution, then add the three solutions into a beaker. Measure 37.5ml of concentrated ammonia water, pour it into a volumetric flask, and then add an appropriate amount of deionized water to prepare a 0.5mol / L ammonia solution. Place the beaker containing the mixed salt solution on a magnetic stirrer, then pour the prepared ammonia water into the conical separating funnel, drop it into the beaker of the mixed solution at a constant speed, and keep stirring, measure with PH test paper Mix the pH value of the solution until the pH value of the mixed solution is between 9 and 11, a white precipitate is generated, close the conical separatory funnel, stop the dripping of ammonia, continue to stir for 2 hours, close the magnetic stirrer, and The mixed solution was left to age f...

Embodiment 2

[0036] According to the preparation method of Example 1, Ce(NO 3 )·6H 2 O and SnCl 4 ·5H 2 The mass of O was reduced to 2.12g and 7.78g, respectively, and Ti(SO 4 ) 2 The quality of is increased to 8.4g, is dissolved in the deionized water of 5ml, 22.25ml and 35ml respectively, other parameters are unchanged, obtained Ce 0.6 sn 2.4 Ti 2 composite oxide catalyst.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com