Ozone treatment regeneration method and device for vanadium titanium-based flue gas denitration catalyst

A denitrification catalyst and ozone treatment technology, which is applied in catalyst regeneration/reactivation, chemical instruments and methods, physical/chemical process catalysts, etc., can solve problems such as catalyst activity decline, and achieve low regeneration costs, good environmental benefits and economic benefits , Improve the effect of denitrification activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

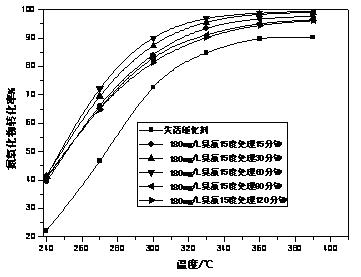

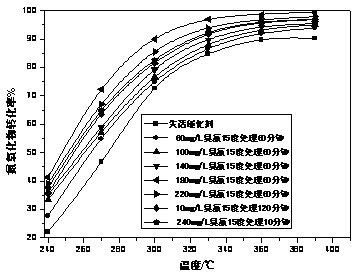

[0036] The ozone regeneration method is used to regenerate the deactivated honeycomb flue gas catalyst. First, the honeycomb catalyst is placed in the flue gas denitration catalyst regeneration reaction bed. At 15°C, an air-ozone mixed gas with an ozone concentration of 60mg / L is used at a flow rate of 1m / min, and enters the reaction bed through a four-way valve. Change the flow direction of the ozone-air mixed gas through the four-way valve at intervals of 10 minutes, so that the mixed gas flows alternately in forward and countercurrent directions. After 60 minutes of oxidation treatment, turn off the ozone generator to complete the regeneration process of the flue gas denitrification catalyst.

Embodiment 2

[0038] The ozone regeneration method is used to regenerate the deactivated honeycomb flue gas catalyst. First, the honeycomb catalyst is placed in the flue gas denitration catalyst regeneration reaction bed. At 15°C, an air-ozone mixed gas with an ozone concentration of 100mg / L is used at a flow rate of 1.5m / min, and enters the reaction bed through a four-way valve. During the period, change the flow direction of the ozone-air mixed gas through the four-way valve at intervals of 10 minutes, so that the mixed gas flows alternately in forward and countercurrent directions. After oxidizing for 60 minutes, turn off the ozone generator to complete the regeneration process of the flue gas denitrification catalyst.

Embodiment 3

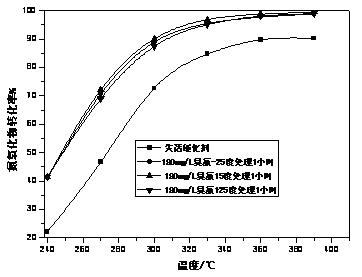

[0040] The ozone regeneration method is used to regenerate the deactivated honeycomb flue gas catalyst. First, the honeycomb catalyst is placed in the flue gas denitration catalyst regeneration reaction bed. At 15°C, an air-ozone mixed gas with an ozone concentration of 140mg / L is used at a flow rate of 2.5m / min, and enters the reaction bed through a four-way valve. During the period, change the flow direction of the ozone-air mixed gas through the four-way valve at intervals of 10 minutes, so that the mixed gas flows alternately in forward and countercurrent directions. After oxidizing for 60 minutes, turn off the ozone generator to complete the regeneration process of the flue gas denitrification catalyst.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com