Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

1539results about How to "Improve denitrification efficiency" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Ozone oxidation and denitration method of boiler flue gas

The invention provides a method for processing de-nitration on the boiler smoke, belonging to the environmental protective technique. The method comprises: ejecting ozone O3 into the low-temperature section of smoke channel of boiler whose temperature ranges from 110-150Deg. C; oxygenizing the nitric oxide NO into high-state nitrogen oxide as NO2, NO3 or N2O5; washing the smoke with alkali liquor to remove the nitrogen oxide in the smoke. Compared to other de-nitration method, said invention has higher efficiency, lower cost, and non-secondary pollution, while the absorption effect combined with alkali liquor can reach more than 80%. In addition, the invention can apply variable boiler devices, which is not relative to the burning condition of boiler.

Owner:ZHEJIANG UNIV

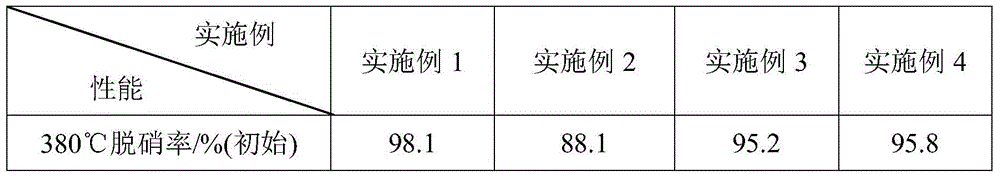

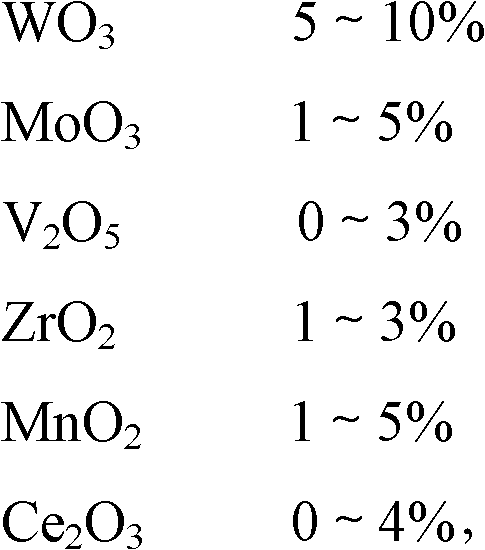

Integral honeycombed catalyst for SCR flue-gas denitration and preparation method therefor

ActiveCN101444727AImprove catalytic performanceIncrease contact areaDispersed particle separationMetal/metal-oxides/metal-hydroxide catalystsSodium BentoniteFlue gas

The invention relates to an integral honeycombed catalyst for SCR flue-gas denitration and a preparation method therefor. Titanium dioxide, bentonite and meerschaum are taken as carries, soaked for loading active components, formed, dried and baked to prepare the integral honeycombed catalyst. The carries comprise titanium dioxide 60-90%, bentonite 0-20% and meerschaum 0-10% by weight; the active components comprise WO3 5.0-10.0% OR MoO3 5.0-9.0%, V2O5 0.3-5.0%, and CeO2 0.0-2.0% or Nb2O5 0.0-1.0% by weight; and the total of the components is 100%. The catalytic activity is high, the denitration efficiency is high, and the service life is long; titanium dioxide, bentonite and meerschaum are taken as the carries, soaked for loading the active components, formed, dried and baked to prepare the integral honeycombed catalyst; and the preparation method is scientific, reasonable, simple and feasible.

Owner:ZHONGCAI HIGH NEW MATERIAL +1

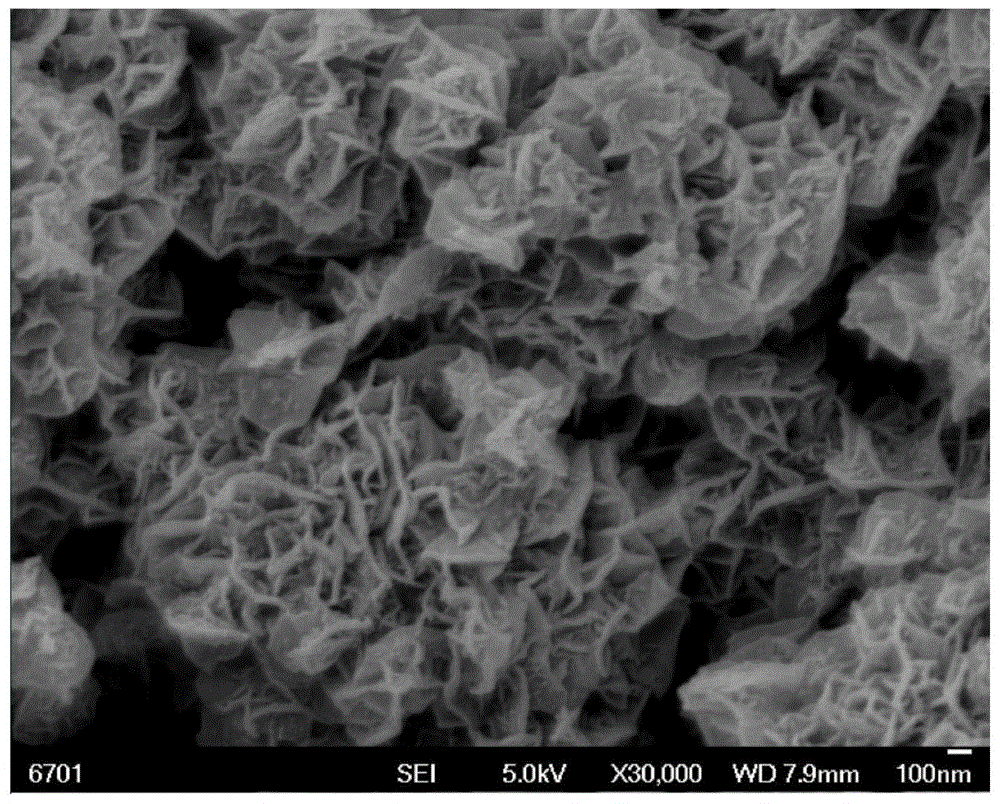

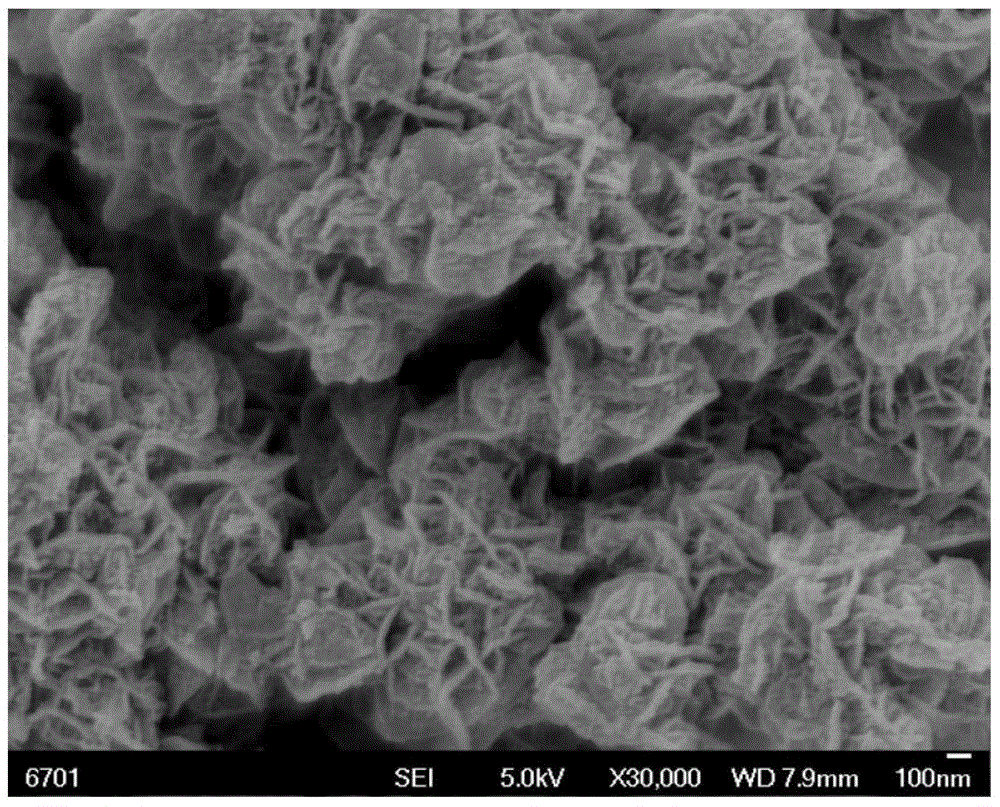

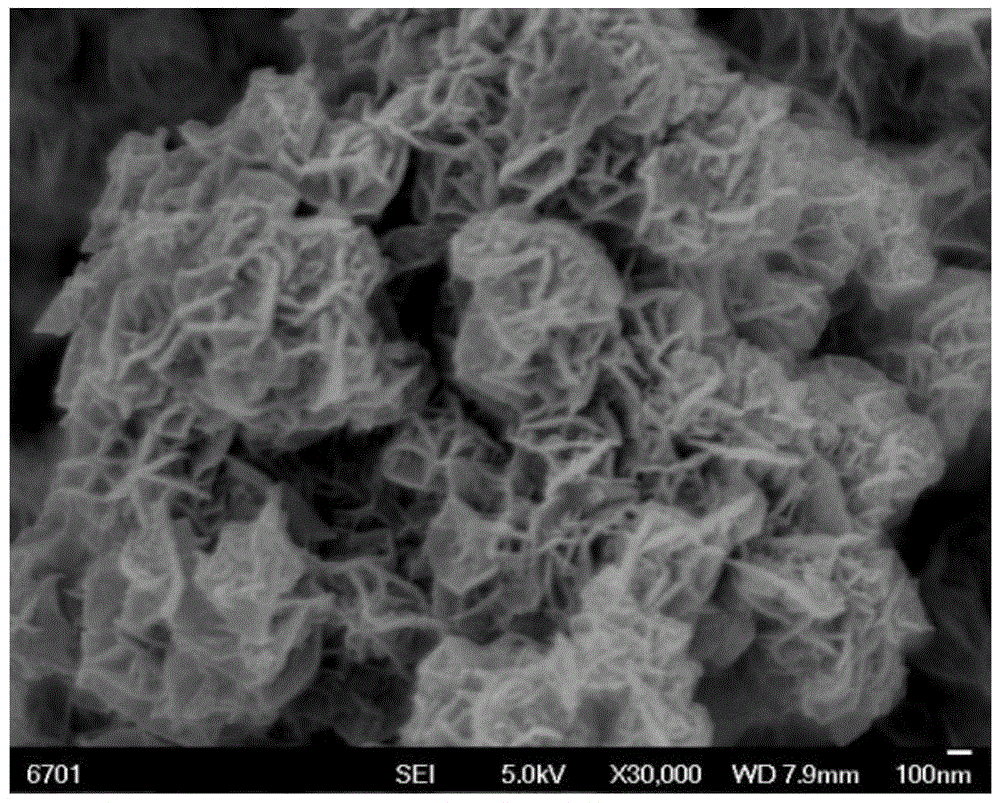

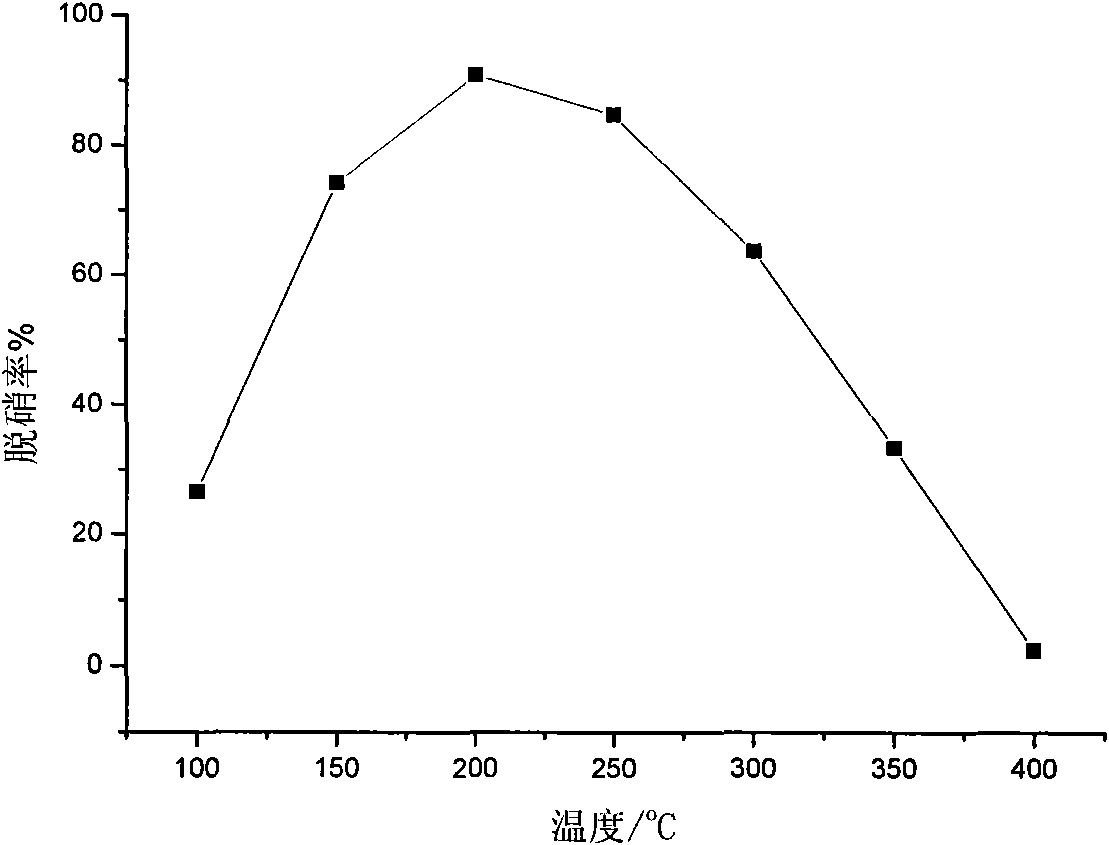

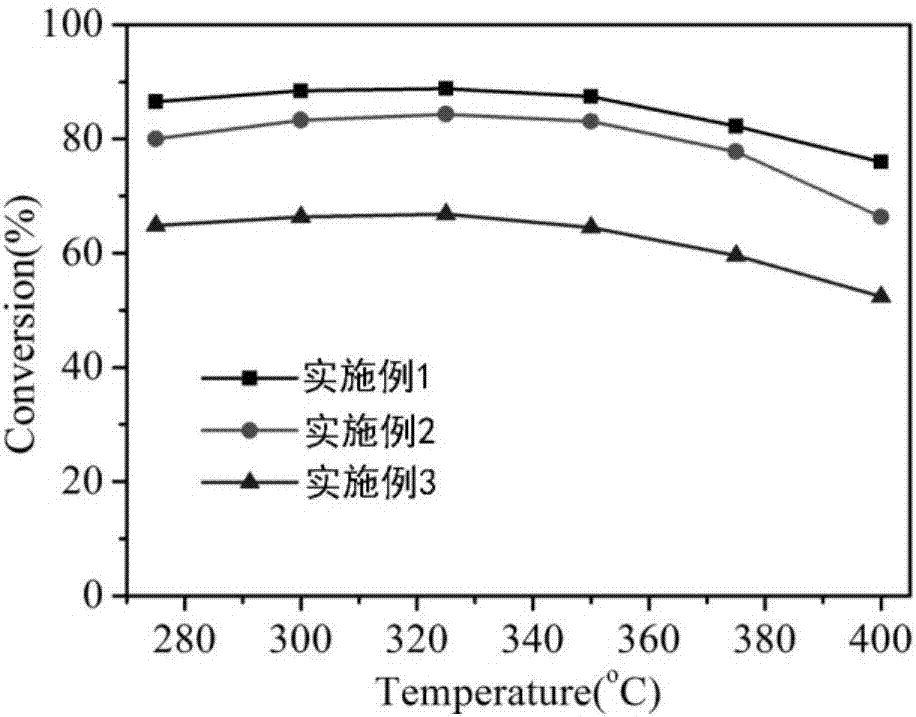

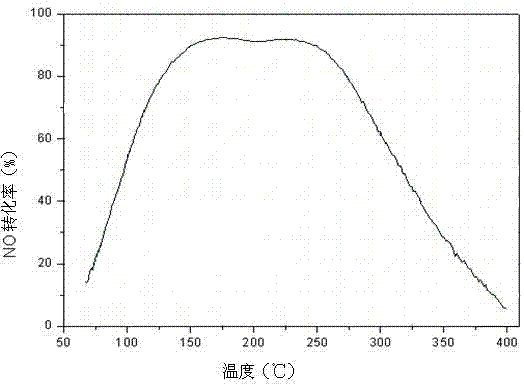

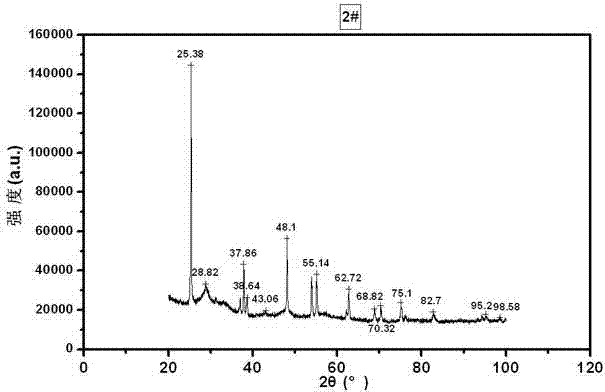

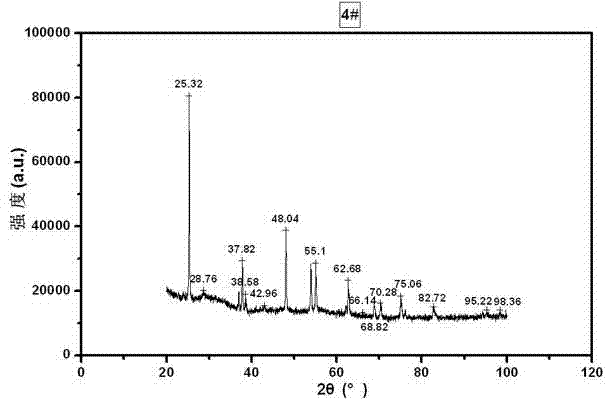

Low-temperature selective catalytic reduction denitration catalyst and preparation method thereof

ActiveCN101658787ALow costWide variety of sourcesDispersed particle separationCatalyst activation/preparationManganese oxideHigh activity

The invention discloses a low-temperature selective catalytic reduction denitration catalyst and a preparation method thereof, wherein the catalyst takes an attapulgite as a carrier to load nano-composite materials of manganese oxide nano-particles; the structure thereof is as follows: manganese oxide particles with the particle diameter of less than 20nm are loaded on the rod-shaped crystal surface of the attapulgite with the diameter of 40-50nm; one or more types from iron, copper and nickel are added as an additive; and calculated according to the mass percentage of manganese, the content of the manganese oxide in the catalyst is 0.1-20. The preparation method comprises the steps of: firstly extruding, drying and crushing the attapulgite clay, and then preparing attapulgite clay powderinto suspension liquid; adding acid solution to wash and remove carbonate impurities, adding manganese salt, and then adding alkali solution for stirring so as to lead the manganese ion to be hydrolyzed and precipitated and loaded onto the crystal surface of the attapulgite, and finally obtaining the product after centrifugal washing, dewatering, drying and calcinations. The catalyst takes ammoniaas a reducing agent, and has higher activity of catalyzing NH3 and reducing NO reaction within the scope of 120 DEG C to 350 DEG C.

Owner:ANHUI WEIDA ENVIRONMENTAL PROTECTION TECH

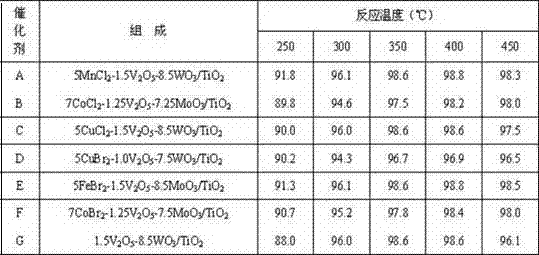

Denitrition catalyst with mercury removal effect and its preparation method

ActiveCN102366722ALess corrosiveReduce processing costsPhysical/chemical process catalystsDispersed particle separationHalogenCoal fired power plant

The invention relates to denitrition catalyst with a mercury removal effect. The catalyst has a chemical general formula of: MXn-V2O5-Y / TiO2, wherein, M is a metallic element selected from Fe, Cu, Mn or Co, X is halogen Cl or Br, Y is WO3 or MoO3, and n=2-4, and the elements are in a weight ratio of: 1-10 of M, 1-1.5 of V, 7.5-8.5 of W or Mo, and 75-100 of TiO2. The catalyst is prepared by the steps of: dipping V2O5-WO3 / TiO2 or V2O5-MoO3 / TiO2 with MCln or MBrn, then conducting frying and calcination. With the catalyst of the invention, catalytic reduction of NOx and catalytic oxidation of Hg<0> can be simultaneously completed in an original flue gas denitrition catalytic reactor, and the generated divalent mercury ions are washed and cured in desulfurized gypsum in a subsequent flue gas wet desulphurization process. Thus, cooperative control of the discharge of NOx and Hg<0> can be realized without increasing flue gas purification facilities of coal-fired power plants.

Owner:GUODIAN SCI & TECH RES INST

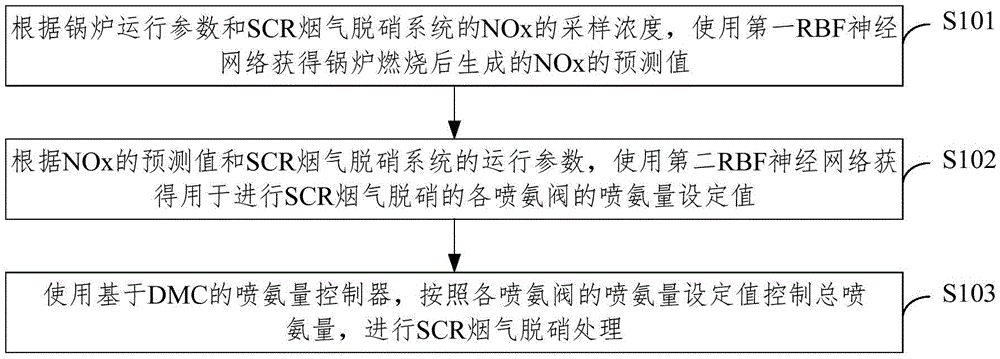

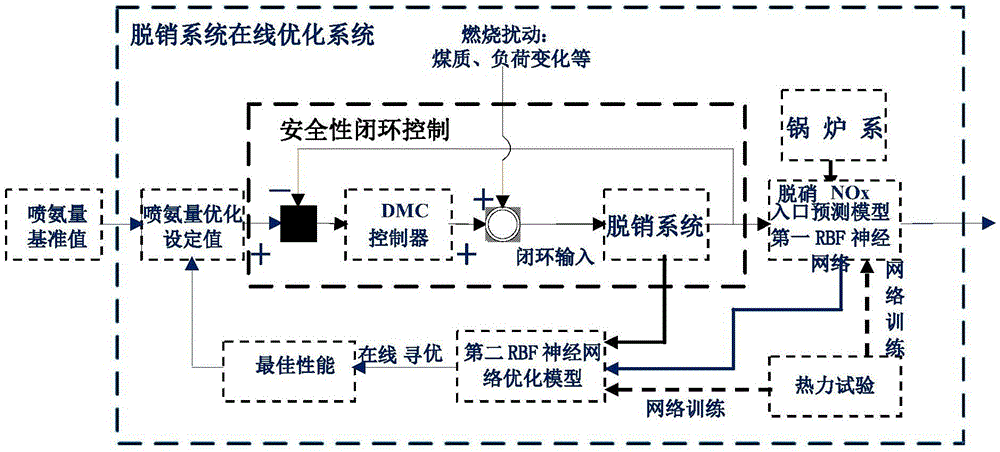

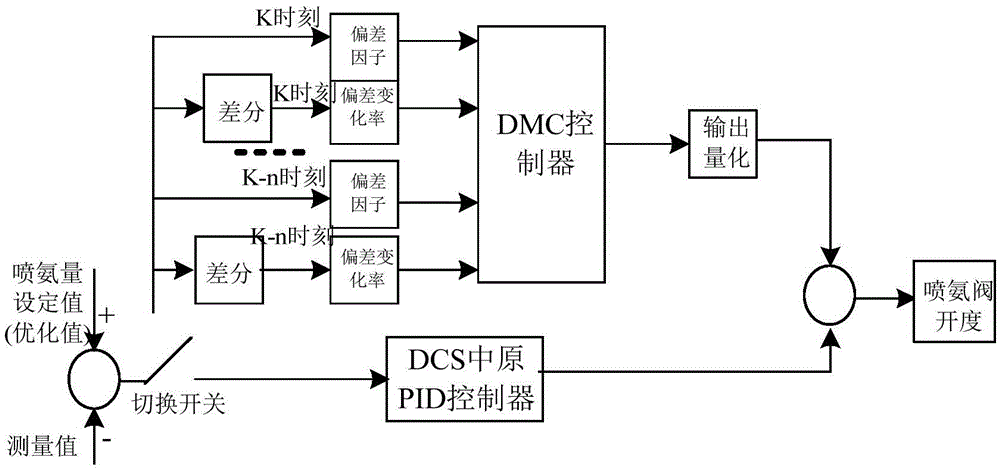

SCR (Selective Catalytic Reduction) flue gas denitration system control method and apparatus

The invention discloses an SCR (Selective Catalytic Reduction) flue gas denitration system control method and apparatus. The SCR flue gas denitration system control method includes the following steps that: a first RBF neural network is adopted to obtain the predicted value of NOx generated after boiler combustion according to boiler operating parameters, the sampling concentration of NOx of an SCR flue gas denitration system; a second RBF neural network is adopted to obtain ammonia spray amount set values of ammonia spray valves for SCR flue gas denitration according to the predicted value of the NOx and the operating parameters of the SCR flue gas denitration system; and a DMC (Dynamic Matrix Control)-based ammonia spray amount controller is adopted to control total ammonia spray amount according to the ammonia spray amount set values of the ammonia spray valves so as to perform SCR flue gas denitration treatment. With the method and apparatus of the invention adopted, denitration efficiency can be effectively improved, and the escape rate of NH3 of the exit of the SCR denitration system can be reduced.

Owner:INNER MONGOLIA RUITE TECH

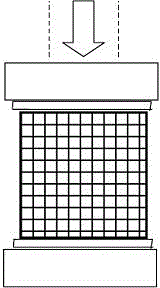

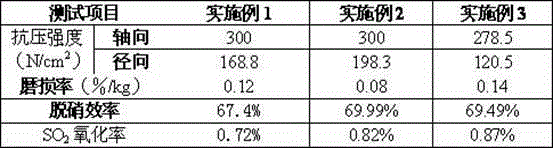

Honeycomb flue gas denitrification catalyst and preparation method thereof

ActiveCN103143396AHigh mechanical strengthWear-resistantOrganic-compounds/hydrides/coordination-complexes catalystsDispersed particle separationCellulosePtru catalyst

The invention relates to a honeycomb flue gas denitrification catalyst and a preparation method thereof, belonging to the technical field of inorganic new materials. The honeycomb flue gas denitrification catalyst is mainly prepared by carrying out extrusion molding and sintering on the following raw materials in parts by weight: 68-92.8 parts of nano TiO2, 3-10 parts of nano SiO2, 2-10 parts of glass fiber, 0.1-0.5 part of extrusion aid, 0.1-0.2 part of carboxymethyl cellulose, 0.1-0.3 part of polyoxyethylene and 0.1-0.2 part of sesbania powder. The preparation method comprises the following steps: (1) weighing the nano TiO2 and nano SiO2 powder, adding the extrusion aid, adding water while stirring to obtain paste, and adding ammonia water to regulate the pH value to 7-11; (2) adding the rest of raw materials, evenly mixing, and extruding with an extruding machine to obtain a honeycomb blank; (3) drying the blank at 30-70 DEG C under the relative humidity of 20-100% for 7-15 days; and (4) calcining the dried blank at 250-300 DEG C for 8-15 hours, calcining at 380-420 DEG C for 5-10 hours, and calcining at 580-620 DEG C for 8-12 hours to obtain the finished product.

Owner:河南康宁特环保科技股份有限公司

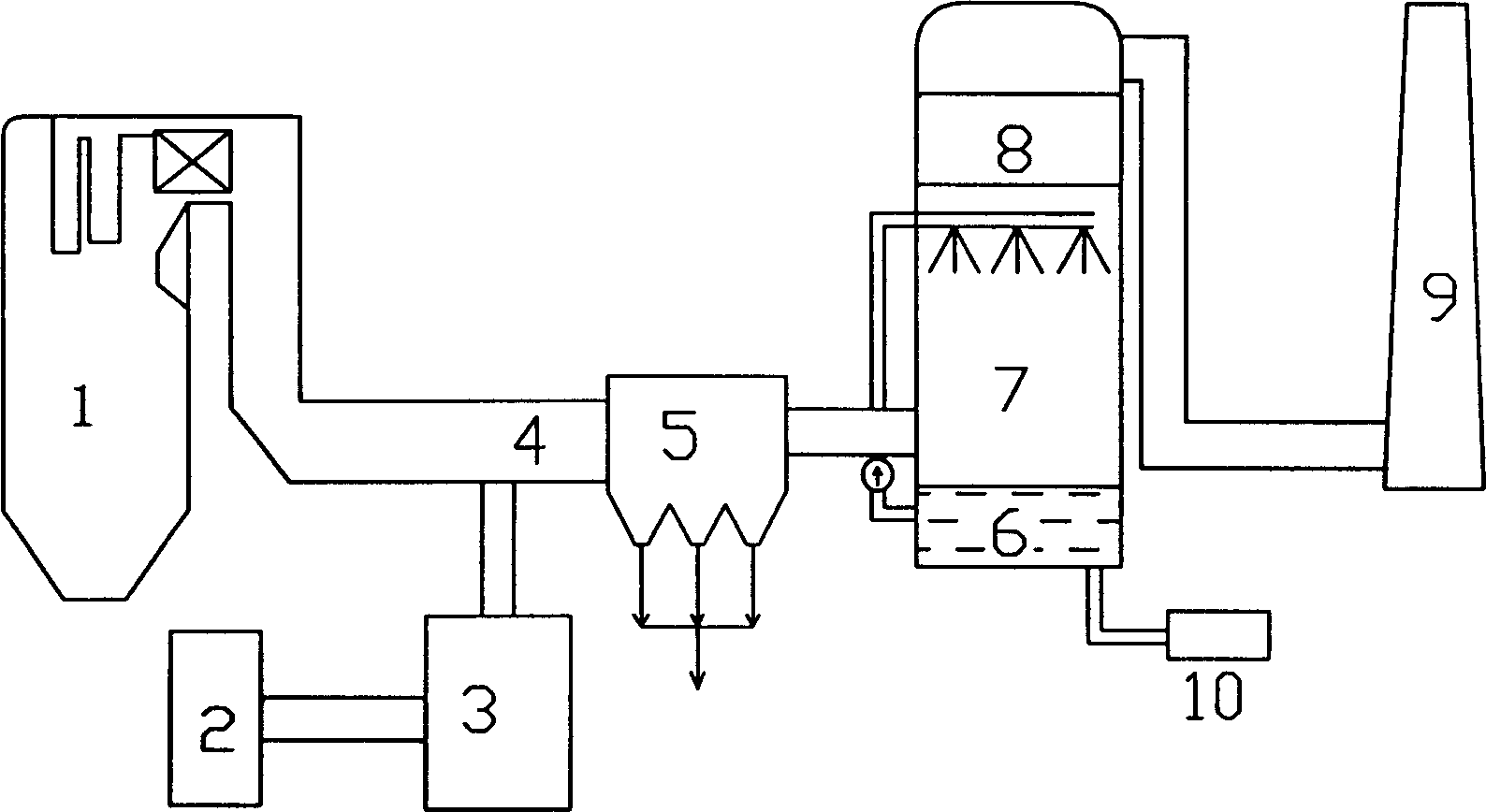

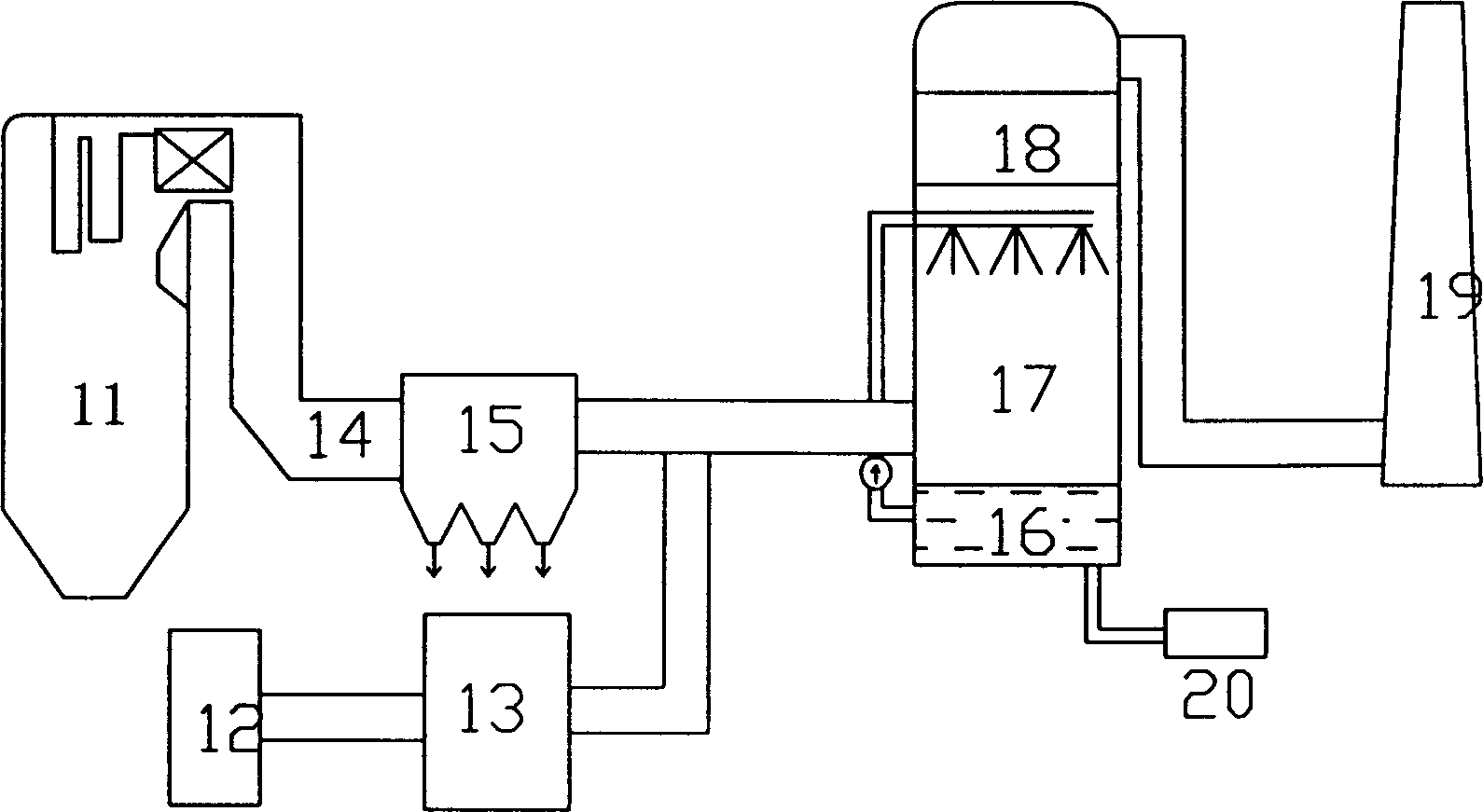

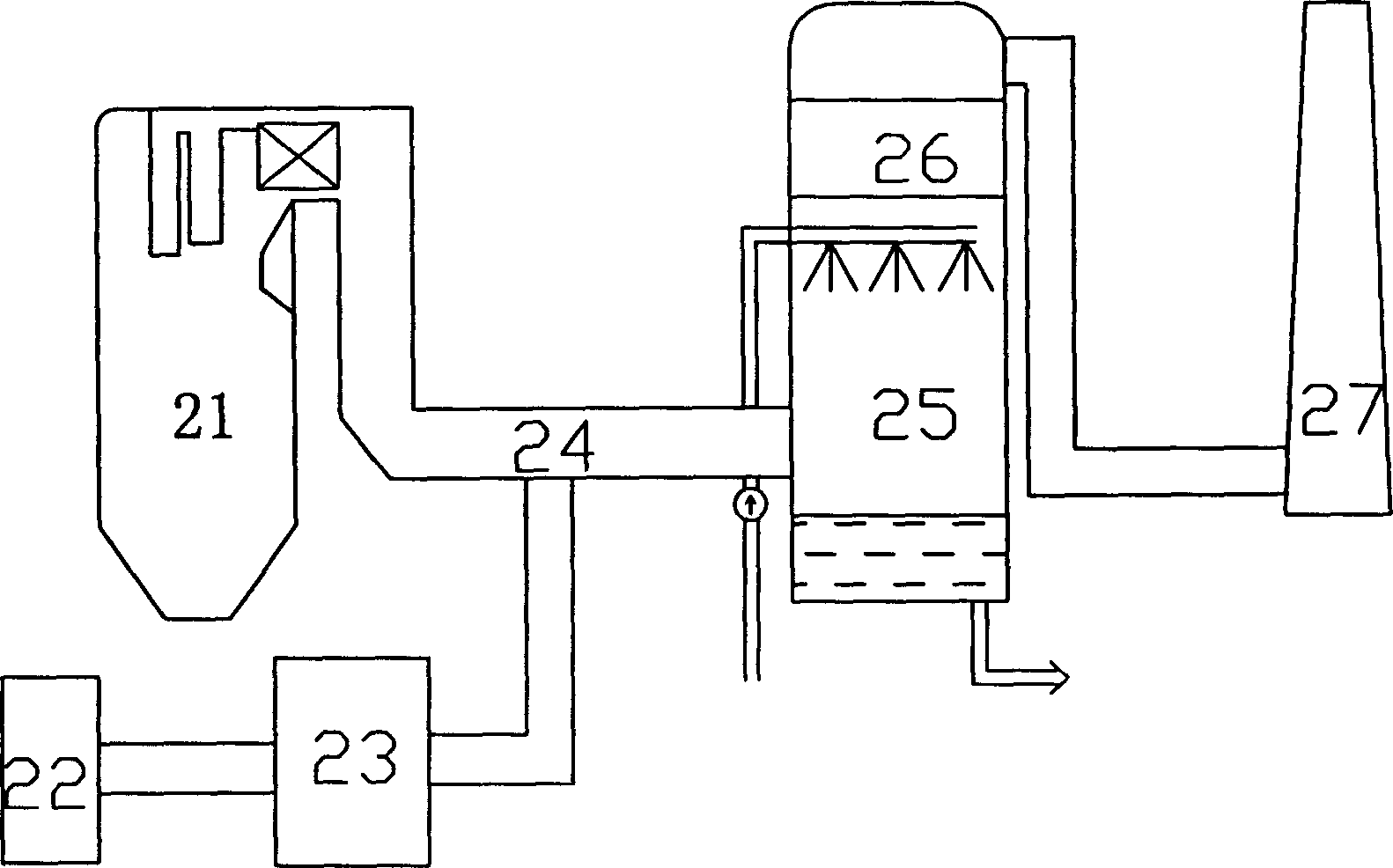

Dry smoke cleaning process for desulfurizing and denitrating simultaneously and its system

InactiveCN1589954ASimplify stand-alone removal systemsSimple processDispersed particle separationSprayerNitric oxide

A dry method for simultaneously desulfurizing and denitrating fume includes using H2O2 or methanol to convert the NO in fume to NO2, using Ca-base particles as desulfurizing agent to react with SO2 to obtain calcium sulfate, and using ammonia water or urea as denitrating agent to react with NO2 to obtain ammonium nitrate and clean fume. Its apparatus is composed of additive sprayer, desulfurizing system and denitrating system.

Owner:WUHAN KAIDI ELECTRIC POWER CO LTD

Low-temperature sulfur-resistant denitration catalyst and preparation method thereof

InactiveCN105727936AHigh activityImprove sulfur resistanceNitrous oxide captureHeterogenous catalyst chemical elementsCopper oxideManganese oxide

The invention discloses a preparation method of a catalyst for removing NOx in coke oven tail gas through low-temperature sulfur-resistant catalytic reduction.The catalyst is prepared by taking titanium oxide as a carrier, taking one or two of cerium oxide, zirconia oxide and lanthanum oxide as an auxiliary, taking one or more than two of manganese oxide, cobalt oxide, copper oxide and ferric oxide as an active ingredient and adopting a precipitation-deposition method, wherein two or three of TiO2, ZrO2, CeO2, La2O2, MgO, CaO and BaO can be adopted as the carrier.In the low-temperature sulfur-resistant denitration catalyst, the loading quantity of the active ingredient is 5 wt%-20 wt%, and the loading quantity of the auxiliary is 0.5%-5%.According to the preparation method, the active ingredient prepared by achieving precipitation and deposition sodium carbonate and oxidizing and loading the active ingredient manganese dioxide through potassium permanganate is mainly distributed in the surface area of the carrier, and the dosage of the active ingredient can be effectively decreased.The catalyst is high in activity and sulfur poisoning resisting capacity and particularly suitable for catalytic removal of the NOx in the coke oven tail gas, and the denitration effect of the catalyst also can be expanded to the low-temperature denitration process of other tail gases.

Owner:GANSU TIANLANG CHEM TECH CO LTD +1

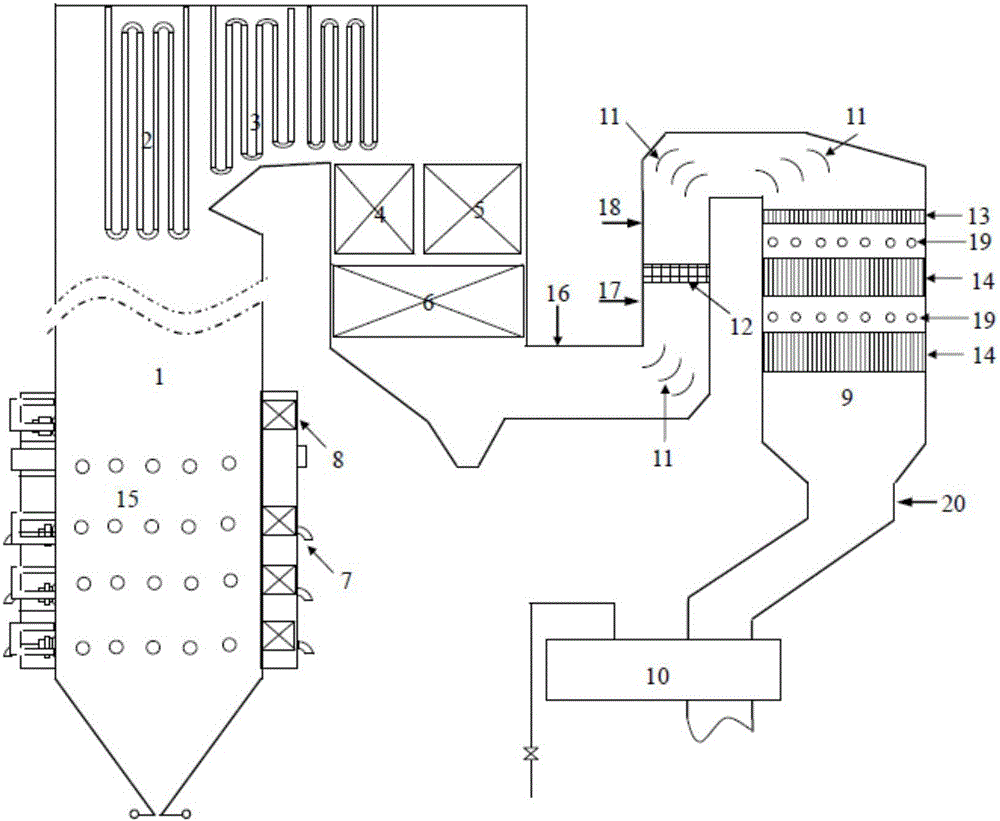

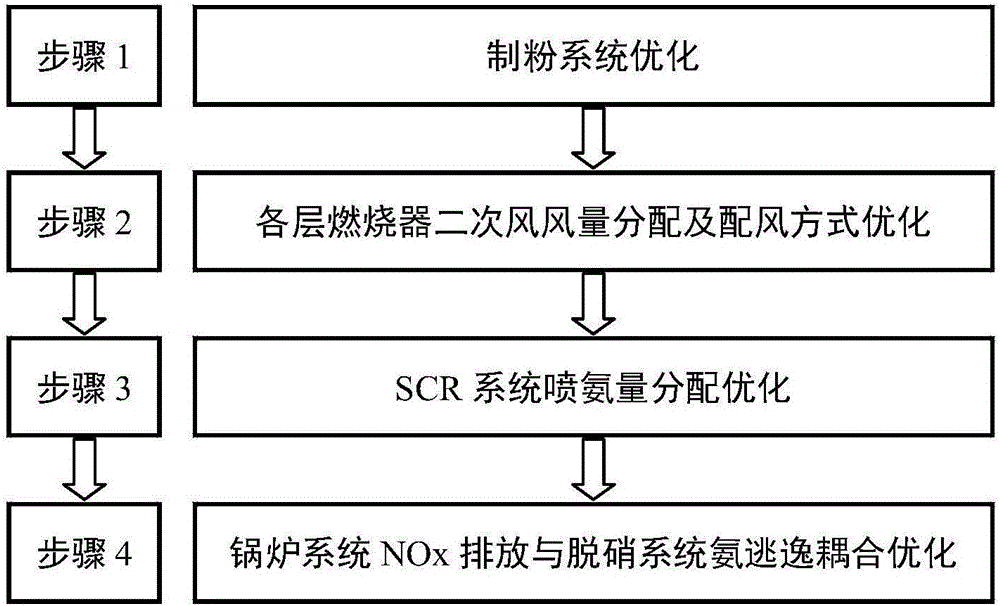

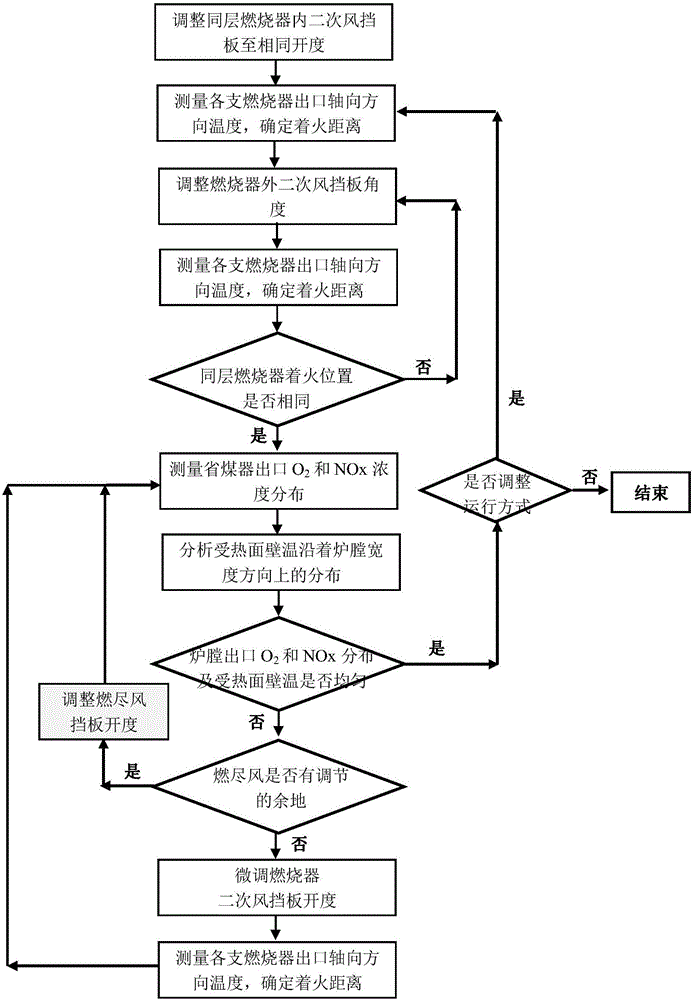

Coal-fired power plant boiler system and denitration system operation collaborative optimization method

ActiveCN105953259AEconomic operation modeGuaranteed operational safetyFuel supply regulationFuel feeding arrangementsOperation modeOxygen

The invention provides a coal-fired power plant boiler system and denitration system operation collaborative optimization method. The method comprises the following steps: the operation of a powder preparation system is optimized and adjusted; the operation of a combustion system is optimized and adjusted; the operation of a denitration system is optimized and adjusted; the coal-fired boiler NOx emission control and the SCR denitration system ammonia escape control are coupled for optimization and adjustment; an optimal operation oxygen quantity range of a coal-fired boiler under different loads and an optimal openness range of a burnt wind nozzle in the optimal oxygen quantity operation range are determined by combining the reductive atmosphere distribution characteristics in a near wall area of a hearth water cooling wall and the denitration ammonia escape conditions; and an optimal denitration efficiency range of the denitration system under different loads is determined. The three system operation collaborative optimization methods, provided by the invention, see the boiler system and the denitration system as a large system; the mutual correlation and influence among the three systems are decoupled from the angle of the large system; and the most economical and safest operation mode of the large system is obtained through optimization.

Owner:GUODIAN NANJING ELECTRIC POWER TEST RES CO LTD

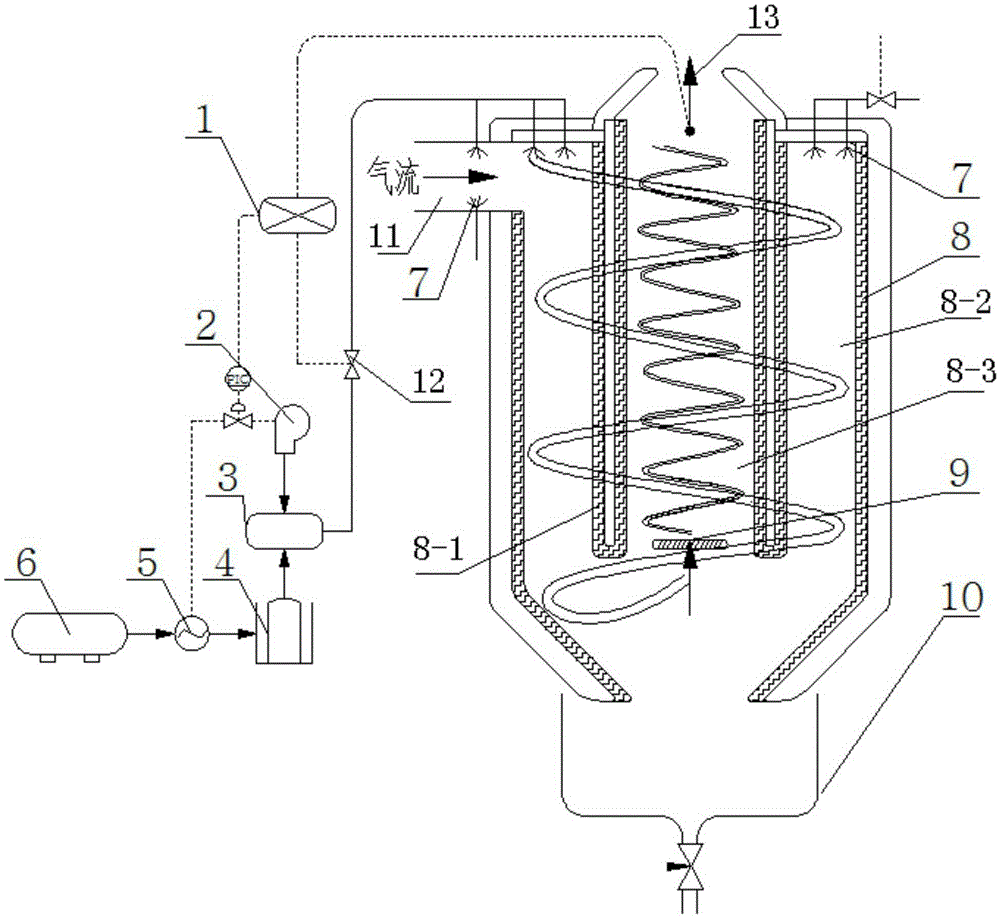

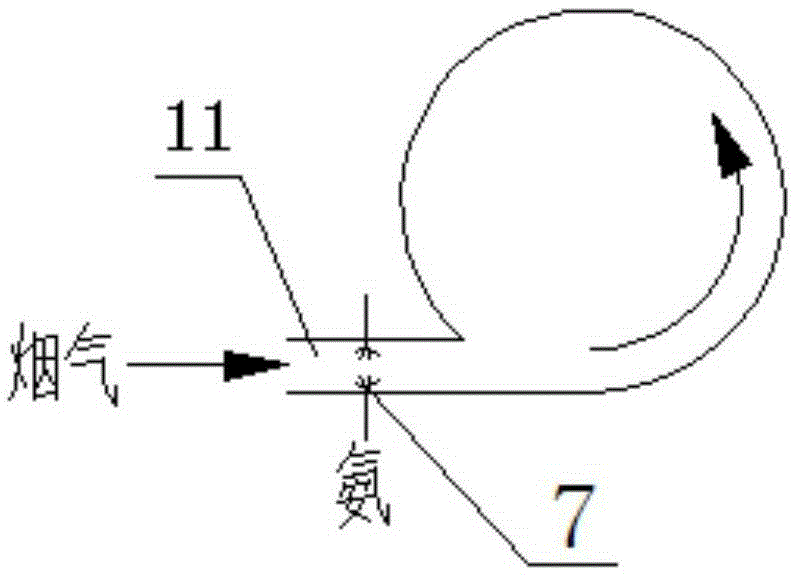

Selective non-catalytic reduction method for gasifying and atomizing biomass and used boiler

InactiveCN101433799AWidely distributedWell mixedLighting and heating apparatusDispersed particle separationProcess engineeringMixed gas

The invention relates to a selective non-catalytic reduction method for gasifying and atomizing biomass and a boiler used by the same, which relate to the selective non-catalytic reduction method and the boiler used by the same. The invention solves the problems that the prior selective non-catalytic reduction method has narrow temperature window, low denitration efficiency at a low temperature region and single effective component in synthesis gas of a reaction additive. The inlet of a gas mixer of the boiler is communicated with a gas additive pipeline and a compressed air pipeline respectively, while the outlet of the gas mixer is communicated with an atomizing medium pipeline. The selective non-catalytic reduction method mixes the biomass gasified gas in the gas additive pipeline with the compressed air through the gas mixer, uses the mixed gas as an atomizing medium for an amino reducing agent solution, and sprays the atomizing medium and the amino reducing agent solution together into a furnace chamber and a horizontal flue in a region with a temperature of between 800 and 950 DGE C through nozzles arranged in the furnace chamber and the horizontal flue. The selective non-catalytic reduction method improves the denitration efficiency and enlarges the temperature window. The boiler system of the invention is simple and has high reliability.

Owner:HARBIN INST OF TECH

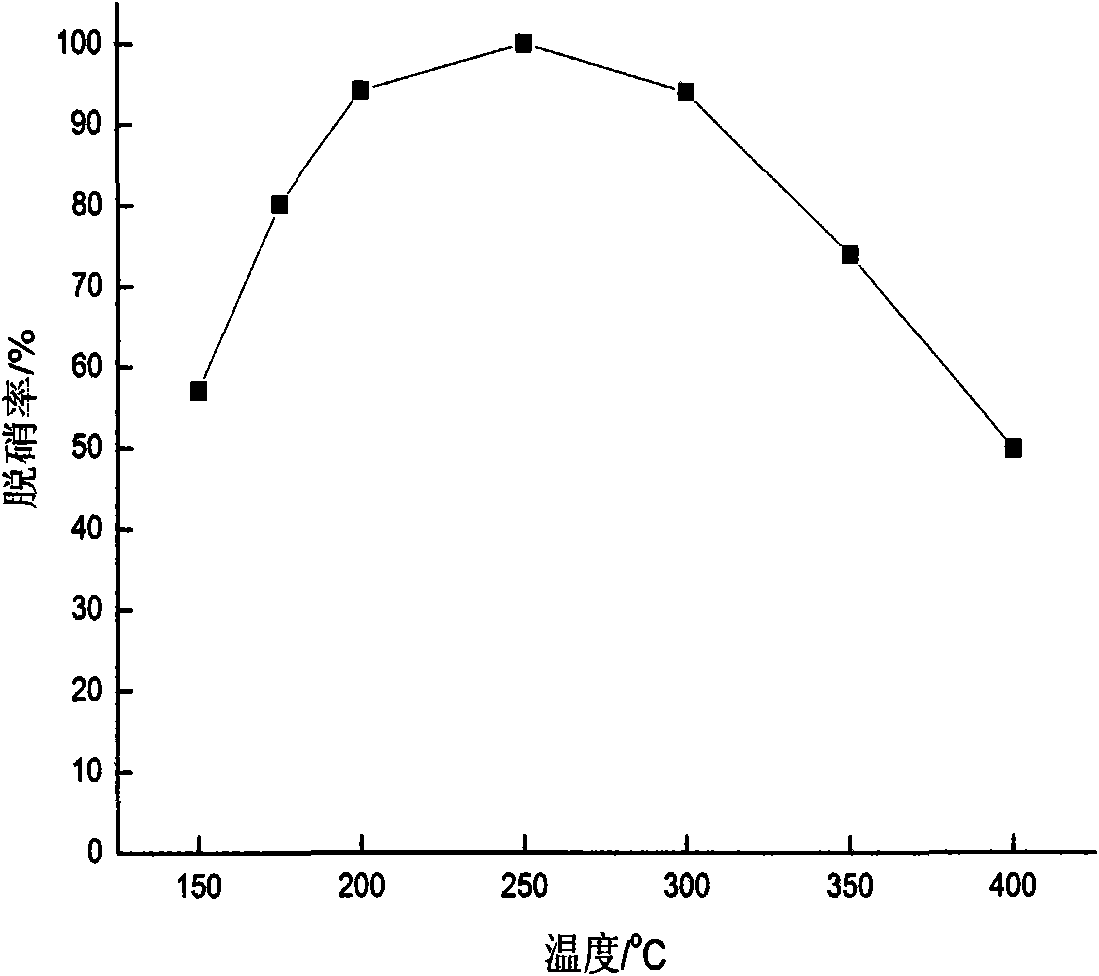

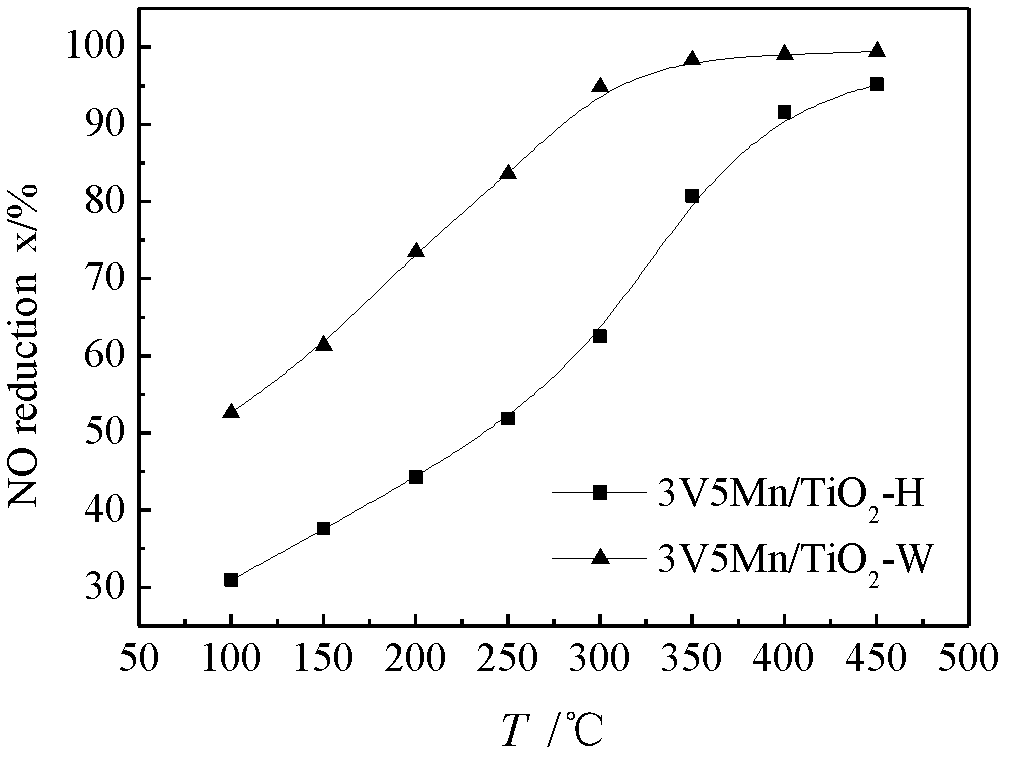

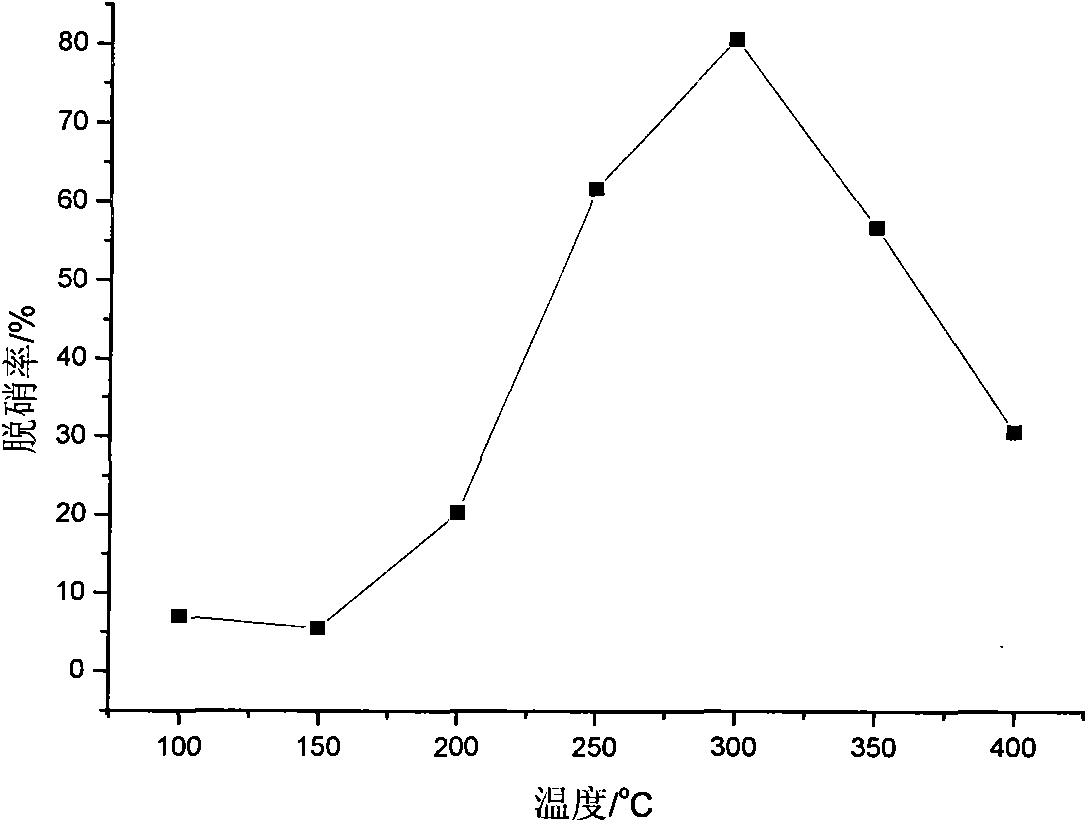

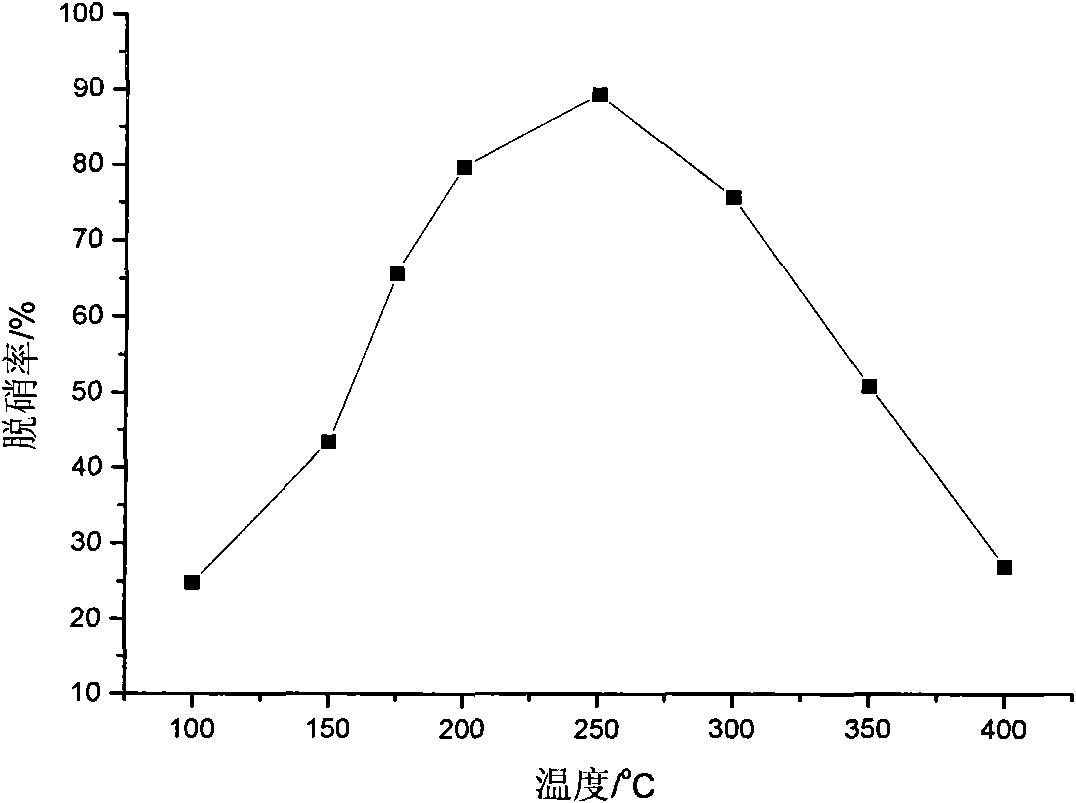

Method for preparing flue gas SCR (Selective Catalytic Reduction) denitration catalyst

InactiveCN102553574AShorten drying timeReduce energy consumptionDispersed particle separationCatalyst activation/preparationWater bathsAmmonium metavanadate

The invention relates to a method for preparing a flue gas SCR (Selective Catalytic Reduction) denitration catalyst. The method comprises the following steps of: mixing ammonium metavanadate, oxalic acid, manganese salt and water for preparing a mixture solution, adding titanium dioxide powder into the mixture solution, heating in water bath and stirring, and obtaining mixed sol by standing at room temperature; putting the mixed sol into a microwave oven, heating and drying by utilizing microwave radiation; and putting dried solid into a muffle furnace for burning. According to the method disclosed by the invention, a temperature window of the SCR catalyst can be broadened to a low-temperature direction, the problems of low denitration efficiency at low temperature and narrow temperature window of a commercial catalyst are solved; compared with the traditional drying method, the microwave radiation heating and drying method has the advantages that low-temperature SCR denitration activity of the composite catalyst can be increased to a large extend, when the activity temperature is up to 250 DEG C, the denitration efficiency of the catalyst prepared by the traditional drying method is up to 51.9%, and the denitration efficiency of the catalyst can be increased by 31.7 percentage points and can be up to 83.6% by the microwave radiation heating and drying method.

Owner:SHANDONG UNIV

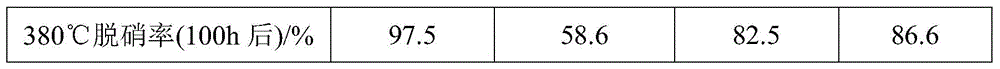

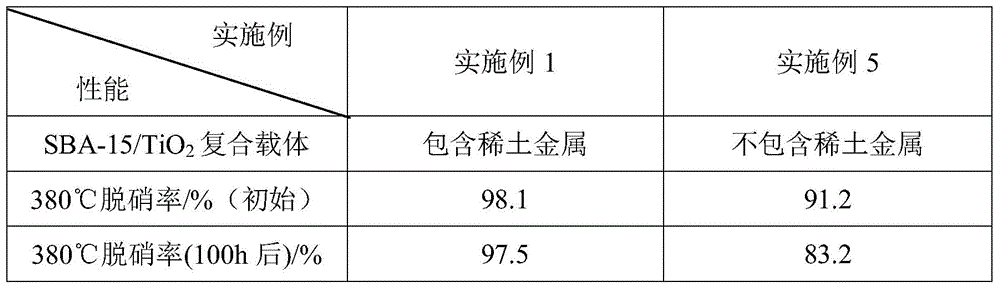

Denitration catalyst with SBA-15/TiO2 serving as carrier and preparing method thereof

ActiveCN105688974ALarge specific surface areaEnhanced mass transferMolecular sieve catalystsGlass fiberMolecular sieve

The invention discloses a denitration catalyst with SBA-15 / TiO2 as a carrier and a preparing method thereof.The denitration catalyst comprises 36wt%-85wt% of SBA-15 molecular sieves, 10wt%-40wt% of TiO2, 0.1wt%-1wt%V2O5, 1wt%-10wt% of active assistant, 1wt%-8wt% of glass fibers and 0.5wt%-5wt% of forming assistant.The preparing method includes the steps that after a titanium salt solution and an electrolyte solution are mixed, SBA-15 molecular sieves with skeletons containing rare-earth metal are added to be soaked, and a series of reactions are carried out to obtained the SBA-15 / TiO2 carrier; the carrier, an ammonium-metavanadate active assistant, glass fibers and a forming assistant are mixed to obtain the denitration catalyst.The denitration catalyst and the preparing method have the advantages that the prepared denitration catalyst is large in specific surface area, high in hydrothermal stability, wide in active temperature window and high in denitration efficiency; meanwhile, the preparing method is simple.

Owner:DATANG NANJING ENVIRONMENTAL PROTECTION TECH

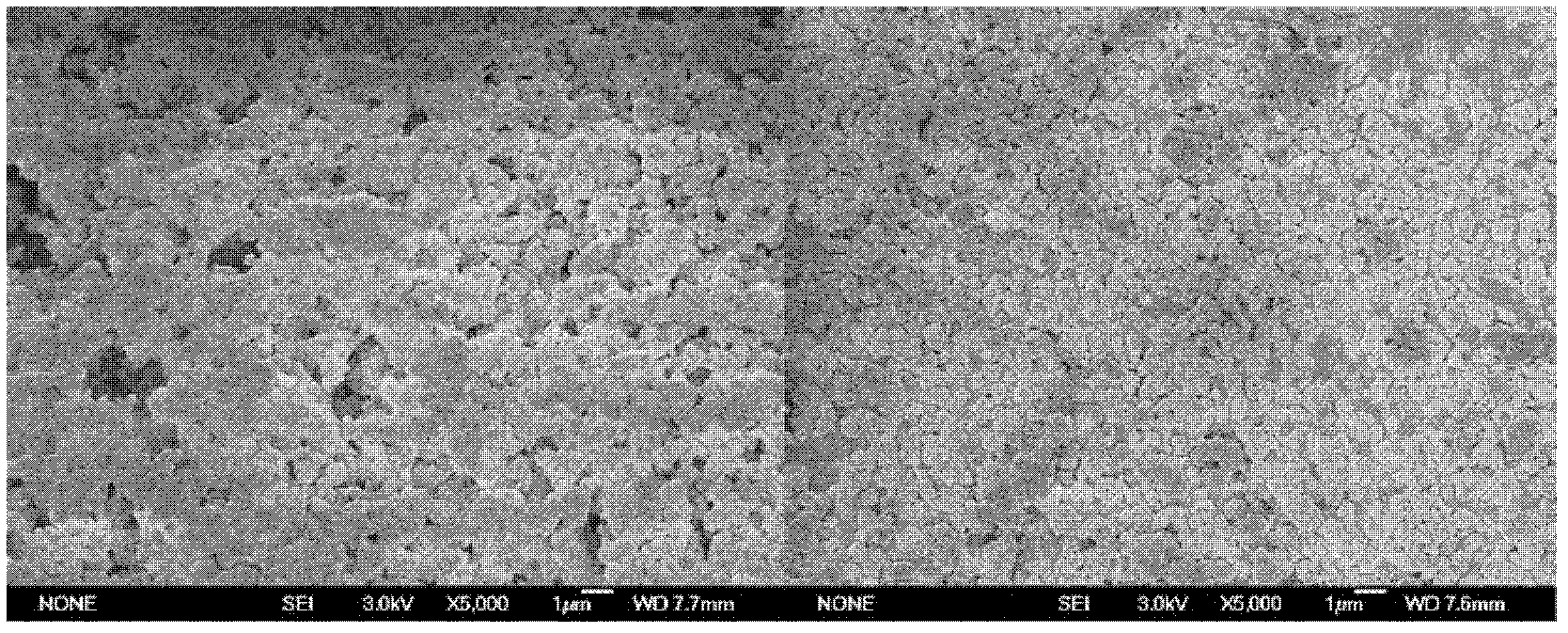

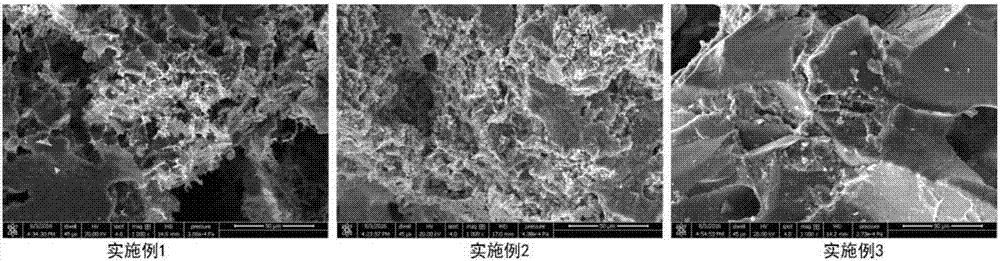

Low-temperature manganese-based denitration catalyst and preparing method thereof

InactiveCN103381362AImprove denitrification efficiencyImprove performanceDispersed particle separationMetal/metal-oxides/metal-hydroxide catalystsAir pollutionPtru catalyst

The invention discloses a low-temperature manganese-based denitration catalyst and a preparing method thereof and relates to the catalyst used in the technical field of air pollution control and a preparing method thereof. The catalyst uses industrial TiO2 as a carrier and carries transition metal M dosed manganese and cerium active components, wherein molar ratio of the components is, Ti: Mn: Ce: transition metal M= 1: (0.05-2): (0.05-.1): (0.01-0.1), and the transition metal M is W, La, Pr, Zr and Y. By means of the preparing method, the catalyst is prepared in an ultrasonic immersing method, so that dispersibility of the active components on the carrier is improved, and the preparing period of the catalyst is reduced. The prepared catalyst is used for reduction reactions of low-temperature NOx, has lasting sulfur poisoning resisting performance and is suitable for the environment-protection fields of tail gas denitration of power plants and large coal consuming enterprises.

Owner:HARBIN INST OF TECH

Power plant flue-gas SCR denitration catalyst capable of preventing sulfur trioxide poisoning and preparation method thereof

InactiveCN101396656ASimple preparation processEasy to operateDispersed particle separationMetal/metal-oxides/metal-hydroxide catalystsAmmonium paratungstateSlurry

The invention belongs to the chemical material field, in particular to an SO3 poisoning resisting power plant flue gas SCR denitrification catalyst and a preparation method thereof. Tungsten doped titanium pigment which is synthesized from domestic metatitanic acid slurry and ammonium paratungstate oxalic acid solution is adopted by the catalyst as a carrier. Vanadium is used as a main catalyst, and oxide of germanium or zinc is added as additive for lowering the oxidization of the vanadium on SO2. Through drying, calcining and sieving, the catalyst is obtained. The catalyst comprises 80-95wt percent of TiO2, 3-15wt percent of WO3, 1-8wt percent of V2O5 and 1-8wt percent of GeO2 or ZnO2. The preparation method has the advantages of simple preparation process, easy operation, low cost and good denitrification effect. The SCR catalyst prepared by the method is tested to prove high denitrification efficiency and good SO3 poisoning resistance. Added SO2 has almost no influence on the activity of the catalyst.

Owner:TSINGHUA UNIV +1

Coal ash and attapulgite compound SCR denitration catalyst and preparation method thereof

InactiveCN102000564AHigh mechanical strengthImprove thermal stabilityDispersed particle separationMetal/metal-oxides/metal-hydroxide catalystsPolymer scienceActive component

The invention discloses a coal ash and attapulgite compound SCR denitration catalyst and a preparation method thereof. Coal ash and attapulgite compound are used as catalyst carriers for carrying the compound material of manganese oxide. The preparation method comprises the following steps: mixing the coal ash with the attapulgite, making the mixture into coal ash and attapulgite compound catalyst carrier by scoring, molding, drying and burning, using the isopyknic immersion method to carry the compound carrier on the catalyst precursor, drying and burning so as to acquire the finished product. In the invention, the coal ash and the attapulgite cheaply obtained are used as the catalyst carriers, so the cost of the catalyst and the environmental loading of the catalyst are reduced, the mouldability and the heat stability are better, and the low-temperature activity of the catalyst is better because of the loading of manganese active component.

Owner:HEFEI UNIV OF TECH

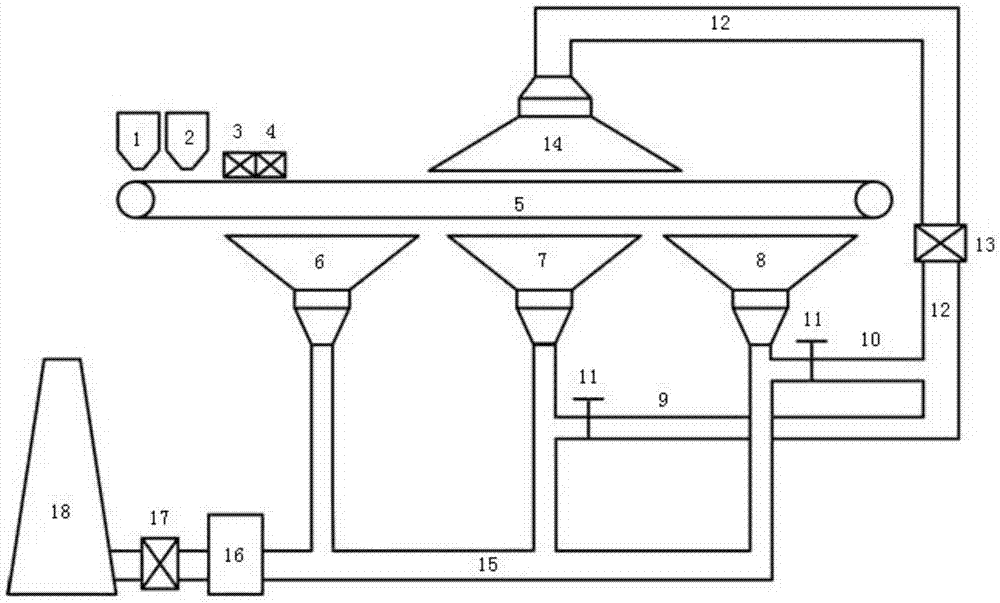

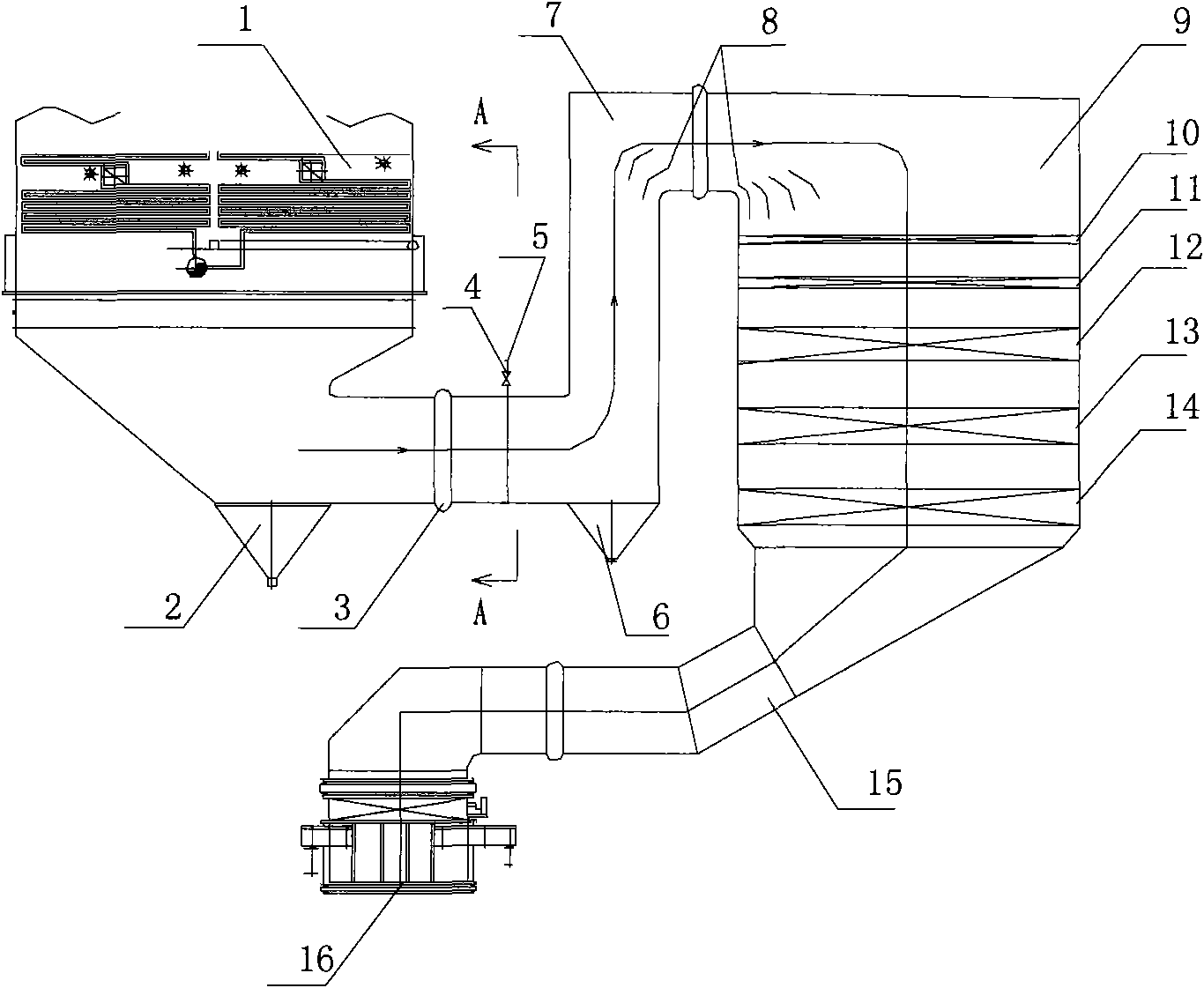

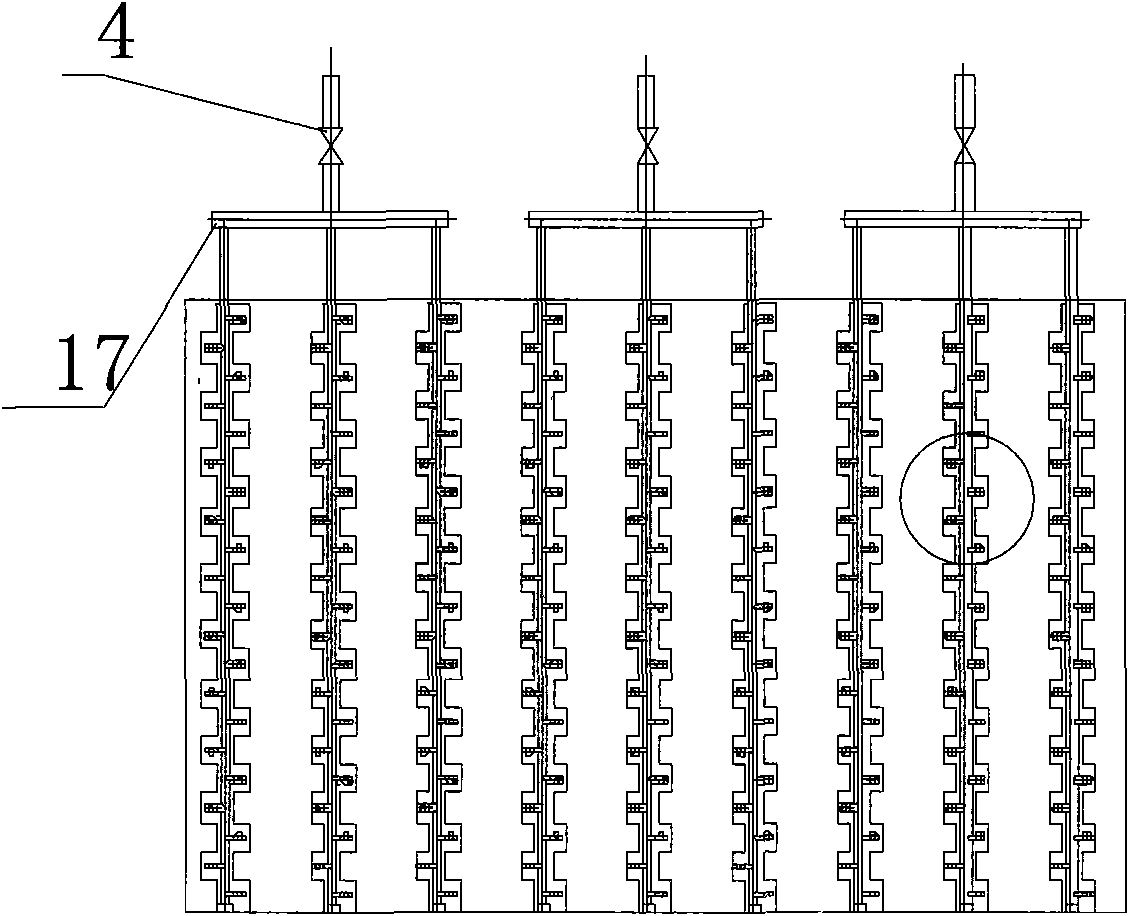

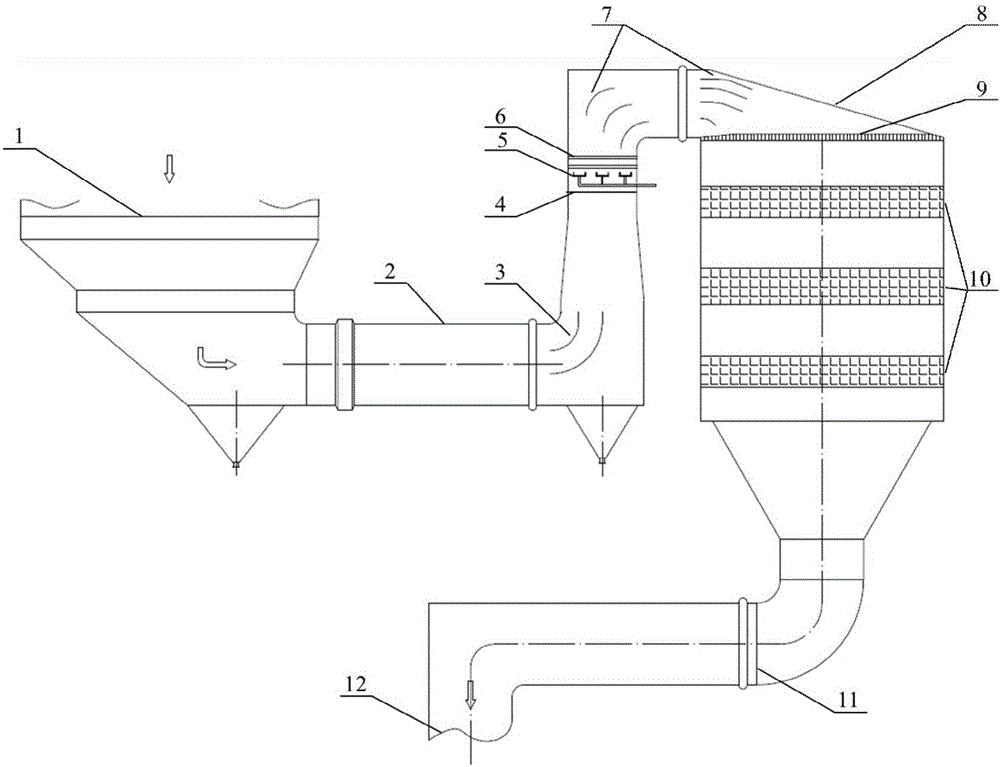

Flue gas circulation system and method for sintering machine flue gas recirculation denitration

The invention discloses a flue gas circulation system and method for sintering machine flue gas recirculation denitration. The flue gas circulation system is composed of a sintering machine, a branch pipe I, a branch pipe II, regulating valves, a recirculation flue, a recirculation draught fan and a top-suspended flue gas hood. The method comprises the steps that the recirculation draught fan is utilized to extract flue gas in the middle section and the rear section of a wind box of the sintering machine, recirculation flue gas enters the recirculation flue through the branch pipe I and the branch pipe II, enters the top-suspended flue gas hood, and enters a high-temperature combustion zone of a trolley again from the top of the sintering machine, NOx in the flue gas is restored to be N2 through coke, and the NOx is removed. According to the flue gas circulation system and method for the sintering machine flue gas recirculation denitration, on the premise that the combustion mode of the sintering machine and the sinter quality are not changed, the NOx is removed efficiently, the changes to a system are less, the operating cost is low, the operation is simple, convenient and flexible, and the denitration efficiency is high; the flue gas circulation system and method for the sintering machine flue gas recirculation denitration have wide application prospect in the field of sintering machine flue gas denitration.

Owner:TSINGHUA UNIV

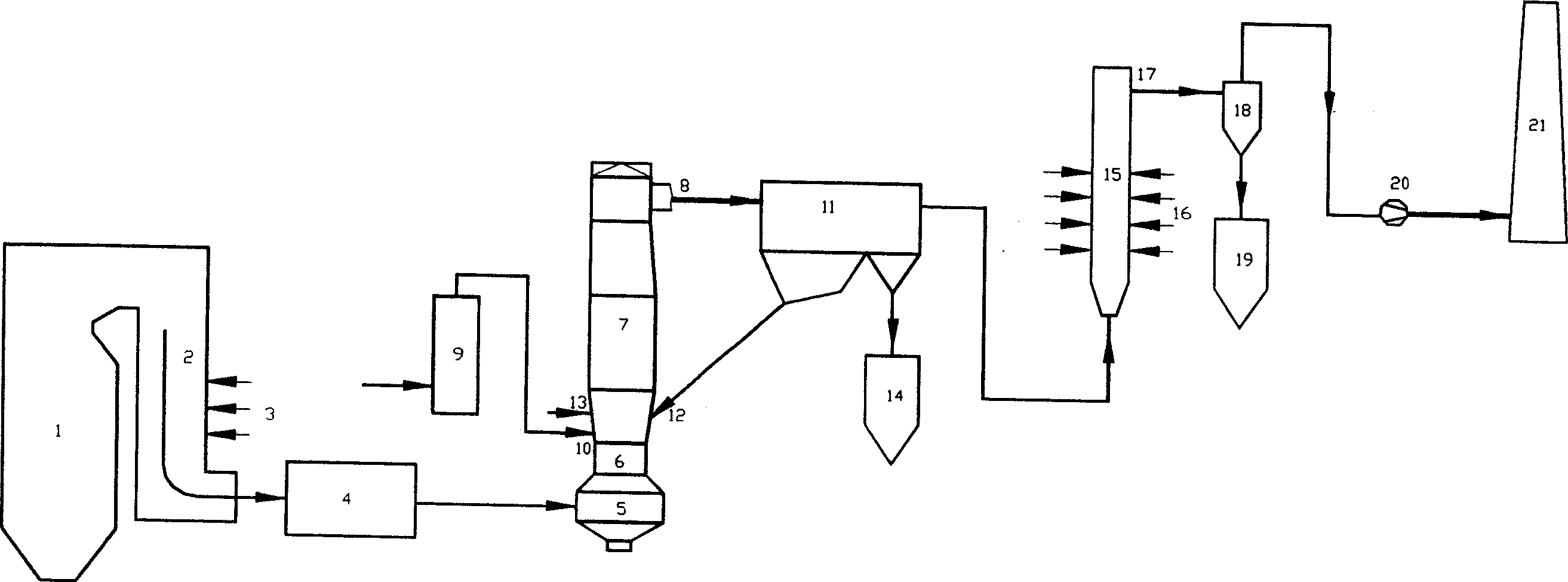

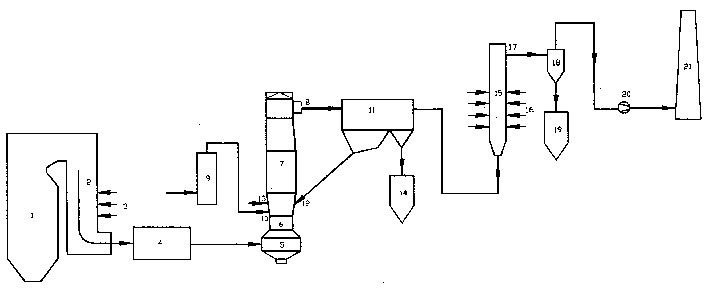

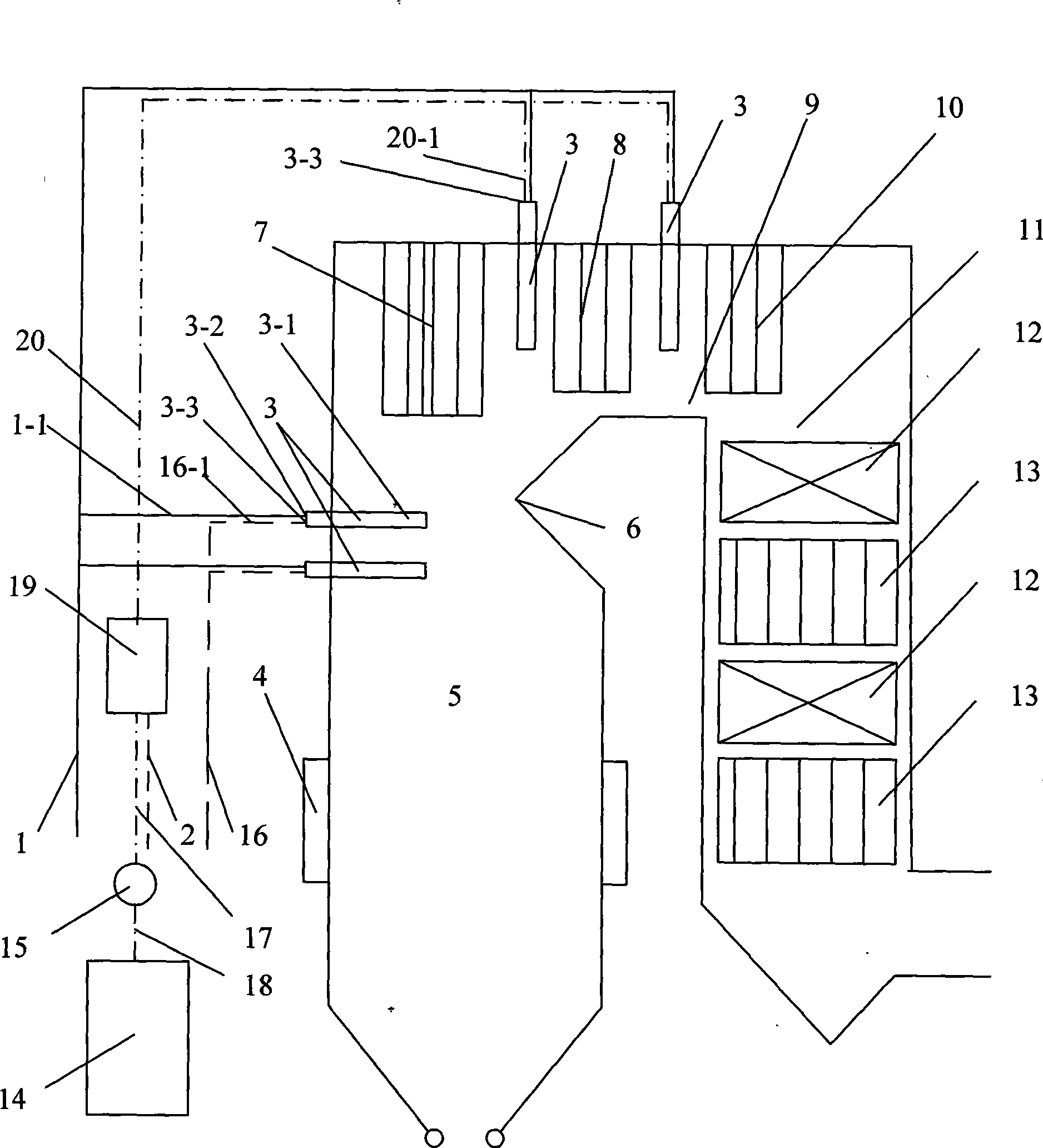

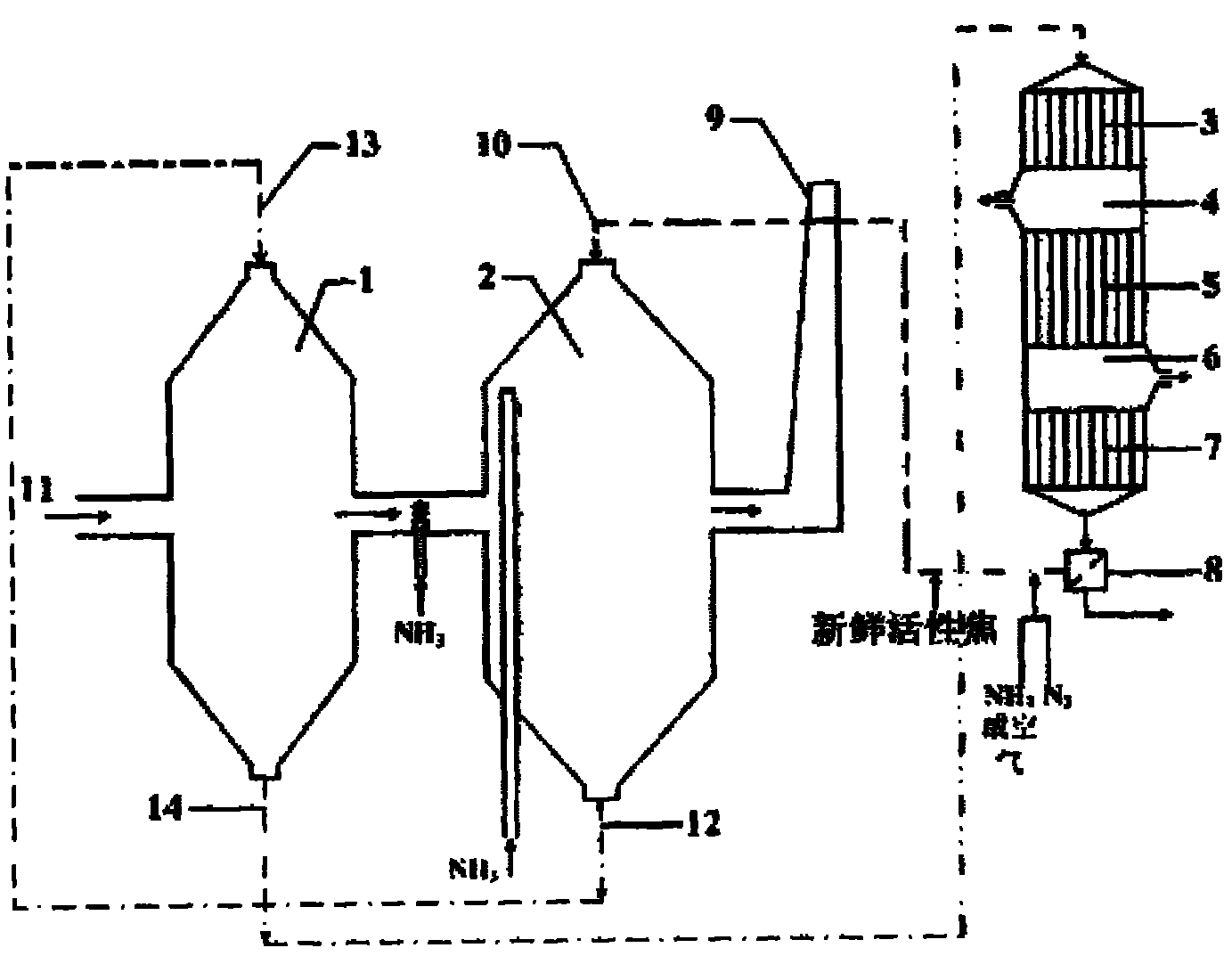

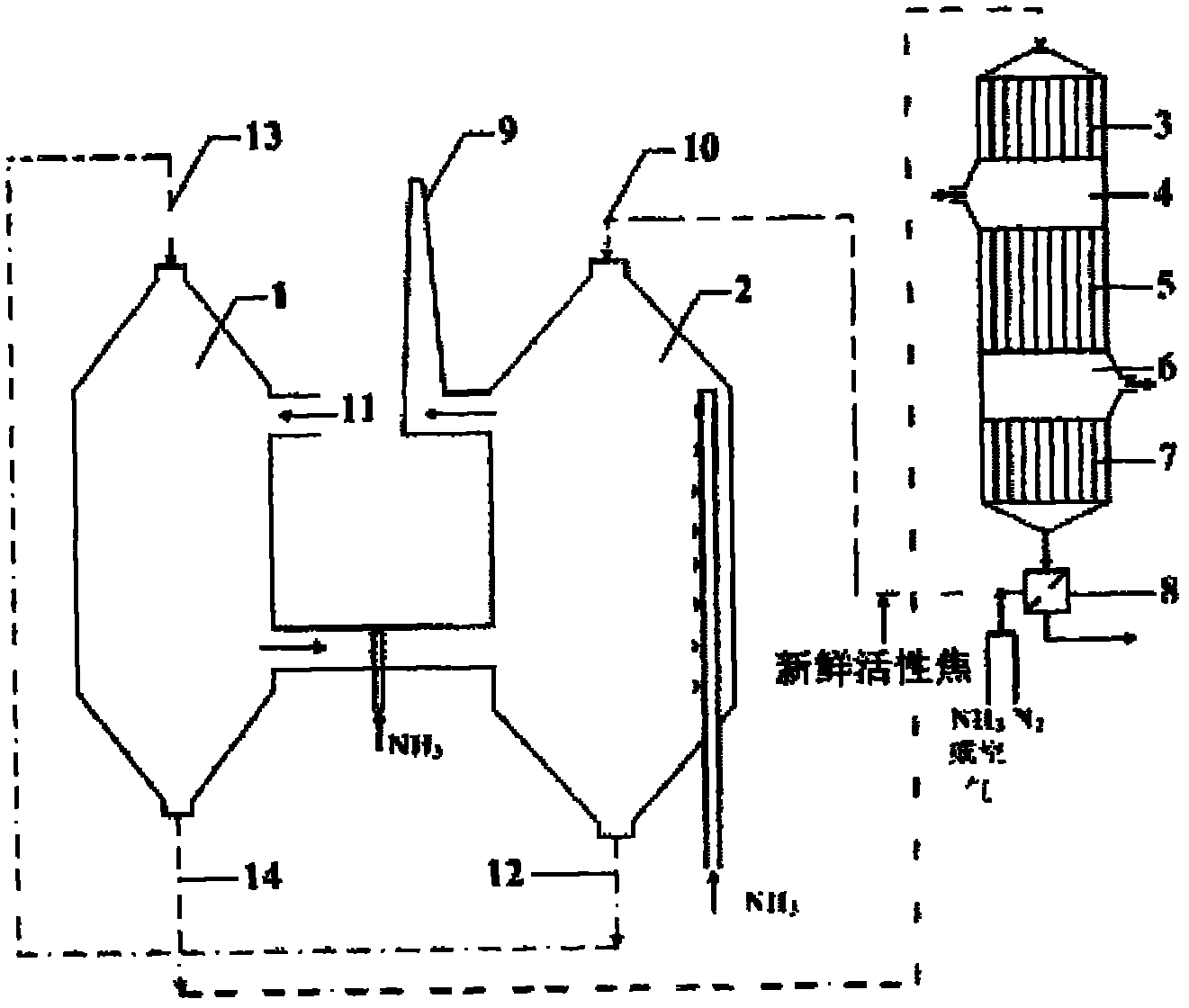

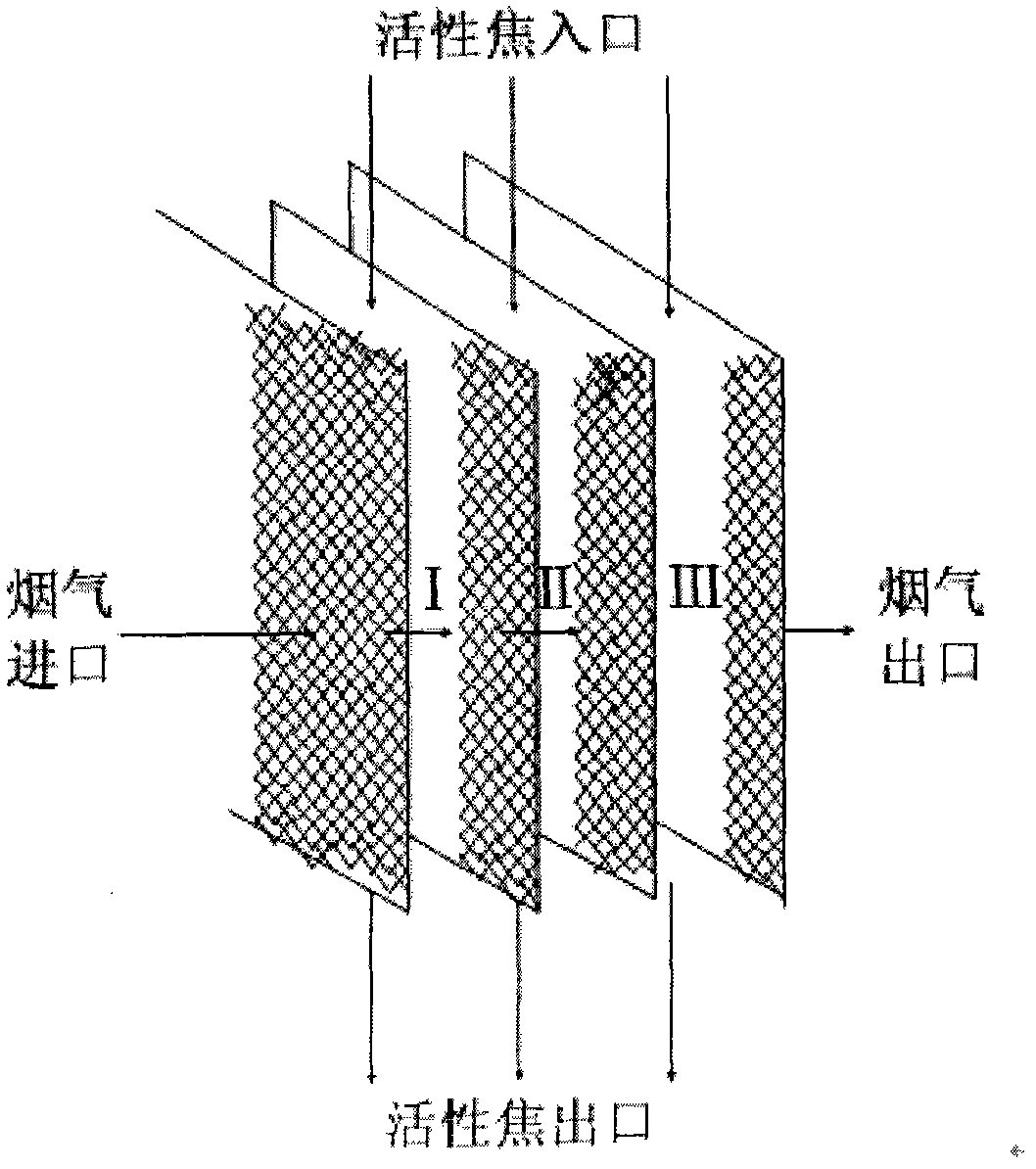

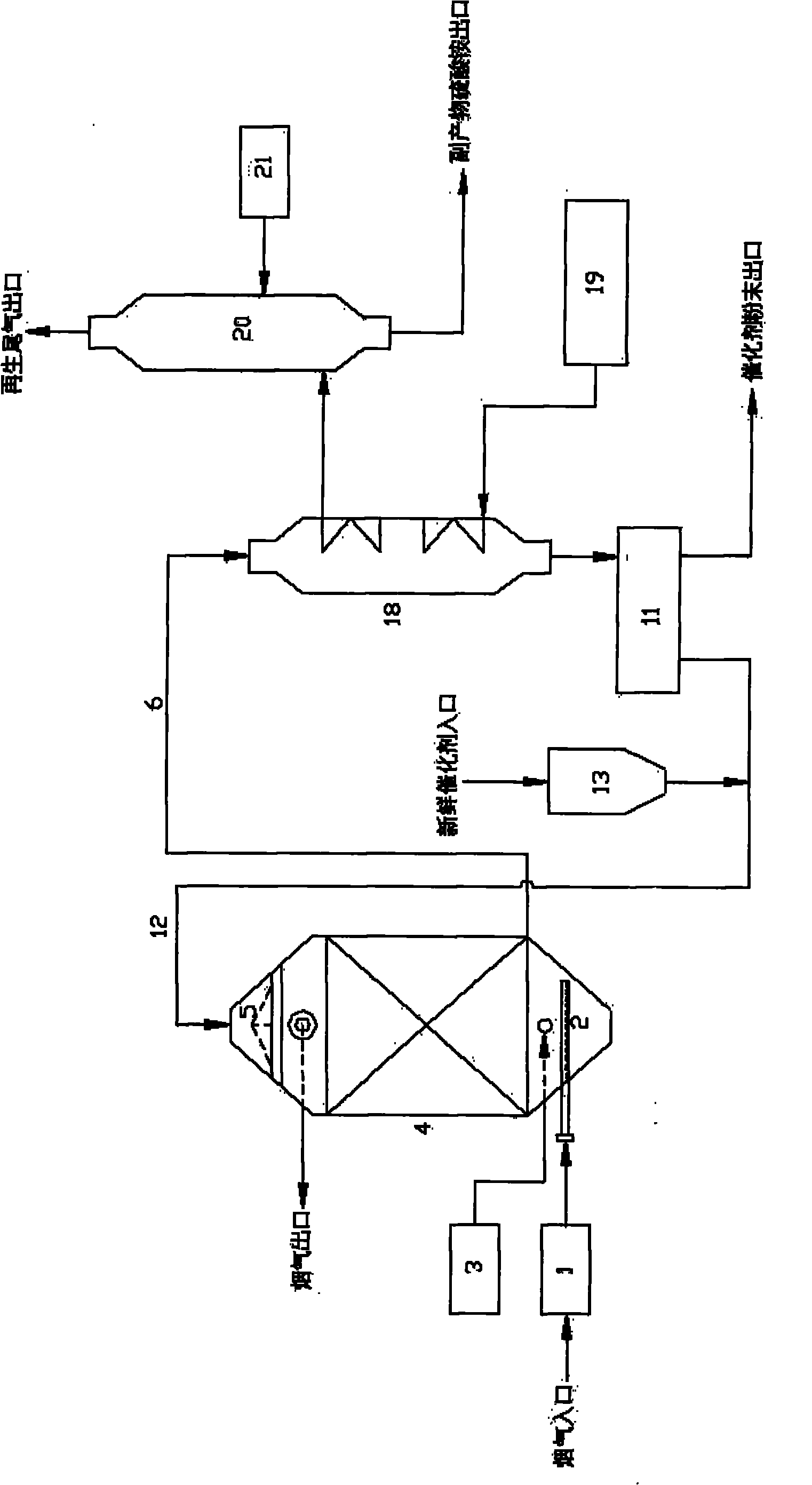

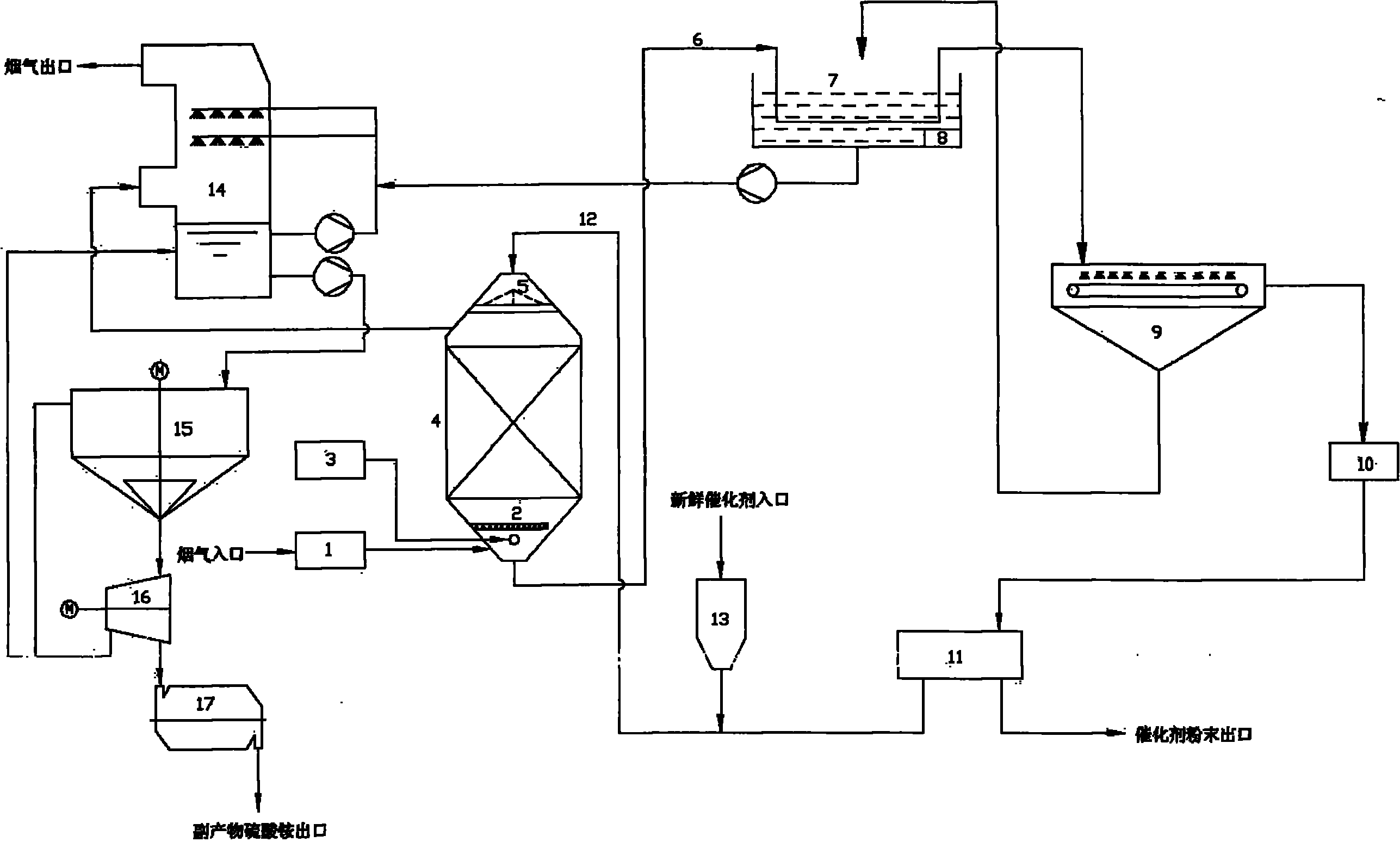

Flue gas-based combined desulfuration and denitration method and special device for method

ActiveCN102019135AImprove distributionImprove denitrification efficiencyDispersed particle separationFlue gasProcess engineering

The invention discloses a flue gas-based desulduratoin and denitration method and a special device for the flue gas-based desulduratoin and denitration method. The special device comprises a denitration reactor body and a desulphurization reactor body, wherein the side wall of the desulphurization reactor body is provided with a flue inlet; the desulphurization reactor body and the denitration reactor body are communicated in parallel; the volume of the denitration reactor body is 1-2 times that of the desulphurization reactor body; the communicating position of the desulphurization reactor body and the denitration reactor body is provided with a device for spraying NH3; the top of the denitration reactor body is provided with a denitration reactor inlet for active coke; the bottom of thedenitration reactor is provided with a denitration reactor outlet for the active coke; the top of the desulphurization reactor is provided with a desulphurization reactor inlet for the active coke; the bottom of the desulphurization reactor is provided with a desulphurization reactor outlet for the active coke; and the denitration reactor outlet for the active coke is communicated with a desulphurization reactor inlet for the active coke through a pipeline, and the desulphurization reactor outlet for the active coke is communicated with a regeneration reactor. The invention also provides a method for flue gas desulfurization and denitration by using the device.

Owner:CCTEG CHINA COAL RES INST

Chloric strong oxidant enhanced wet combined urea desulfurizing and denitrifying process

InactiveCN1986033AIncrease the degree of oxidationImprove denitrification efficiencyDispersed particle separationAir quality improvementNitrogen oxideSodium chlorite

The wet combined fume desulfurizing and denitrifying process with chloric strong oxidant enhanced urea has the fume to be treated contacted sufficiently with the mixed absorbent liquid containing urea and chloric strong oxidant inside the absorbing reactor so as to eliminate NOx and SO2 through absorption before being exhausted. The chloric strong oxidant is sodium chlorite, sodium hypochlorite, bleaching powder or their mixture. The process has high denitrifying efficiency, high fume purifying effect, simple structure, easy operation and small occupied land. The said process can reach NOx eliminating rate of 75-98 % and desulfurizing efficiency over 95 %.

Owner:ZHEJIANG TIANLAN ENVIRONMENTAL PROTECTION TECH

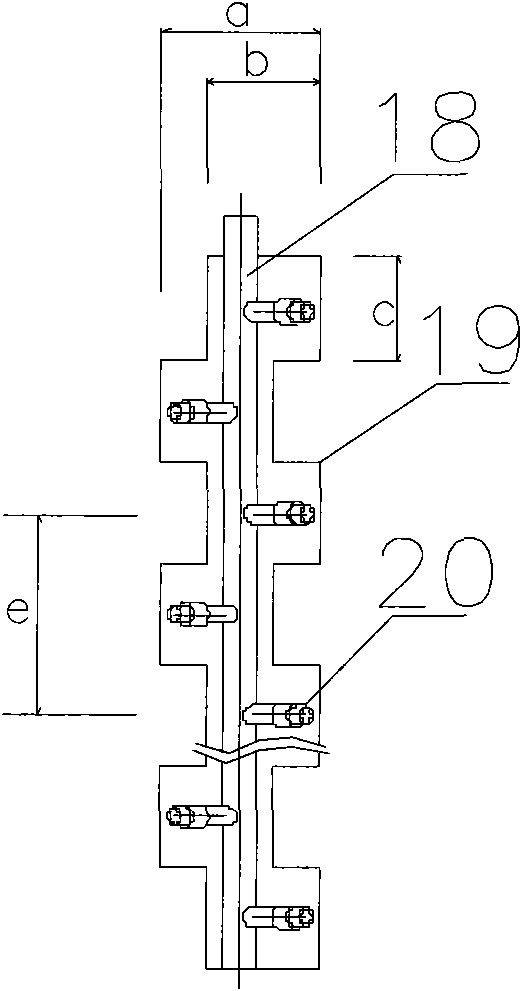

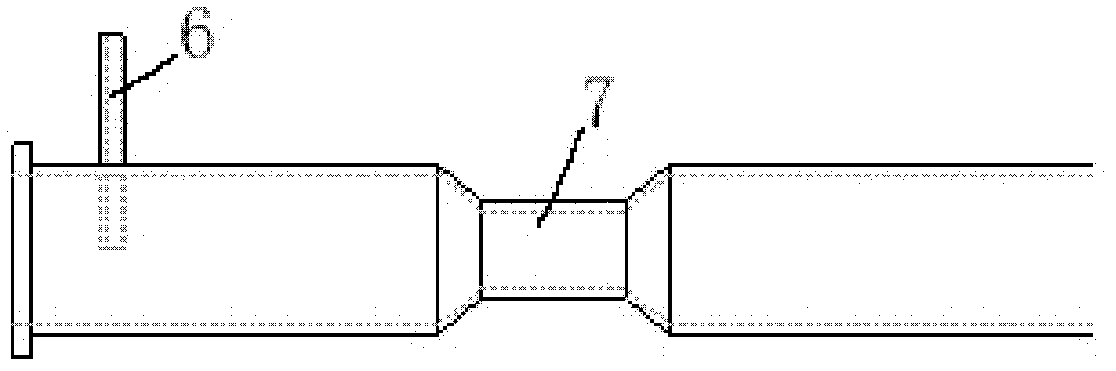

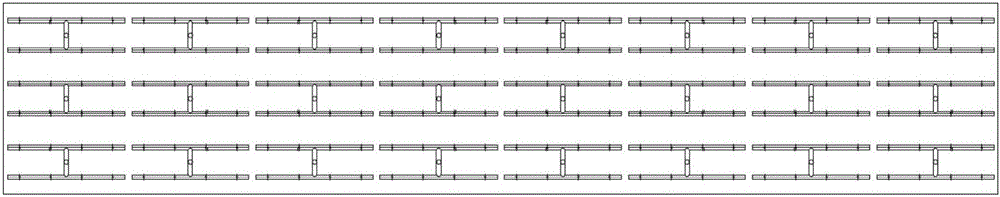

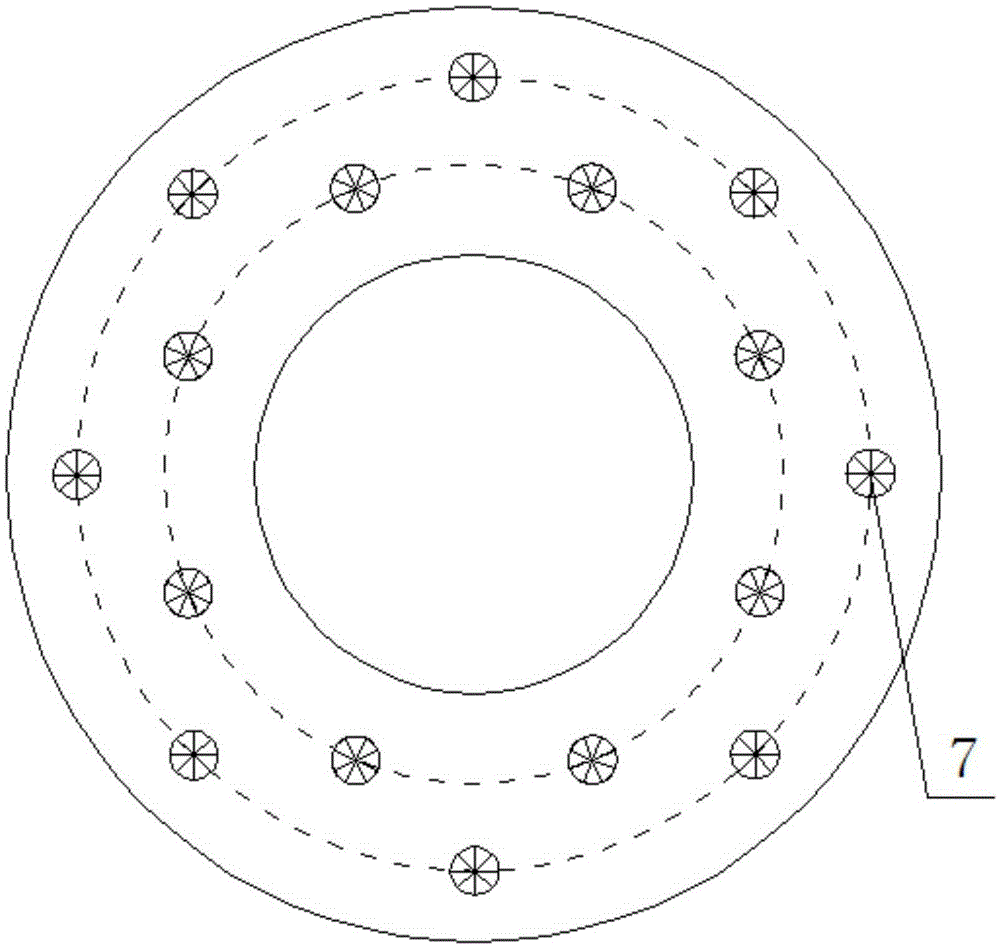

Ammonia-spraying grid device for SCR-method flue gas denitrification, and SCR-method flue gas denitrification process

ActiveCN101601965ASolve the resistanceReduce resistanceNitrous oxide captureDispersed particle separationFlue gasProduct gas

The invention discloses an ammonia-spraying grid device for SCR-method flue gas denitrification, which comprises an ammonia-spraying grid consisting of bundles of metal pipes, wherein each metal pipe is provided with a nozzle in the radial direction; the nozzle is communicated with the metal pipe; and the included angle between the opening direction of the nozzle and the flow direction of flue gas is between 0 and 90 degrees. The invention also discloses an SCR-method flue gas denitrification process adopting the ammonia-spraying grid device. The process adopts the ammonia-spraying grid to distribute ammonia / air gas mixture sprayed into an inlet flue of a denitrification reactor, and adjusts ammonia spray distribution according to the concentration of NOx in the inlet flue of the reactor so as to mix the NOx in the flue gas with NH3 sprayed in well, thus the mixing effect of the NH3 and the flue gas as well as denitrification efficiency can be effectively improved. A grid-type ammonia spraying-distributing-mixing device of the invention has the advantages of simple structure, low mixture resistance, good distribution effect, insusceptibility to ash deposition, capability of effectively protecting ammonia-spraying grid nozzles from wear, reducing the mixture distance of ammonia and the flue gas in an inlet of the denitrification reactor, improving the utilization rate of denitrification catalysts, reducing the height of the denitrification reactor and reducing the resistance of a flue gas denitrification system, thereby greatly reducing the unit cost of flue gas denitrification.

Owner:HUADIAN ENVIRONMENTAL PROTECTION ENG & TECH

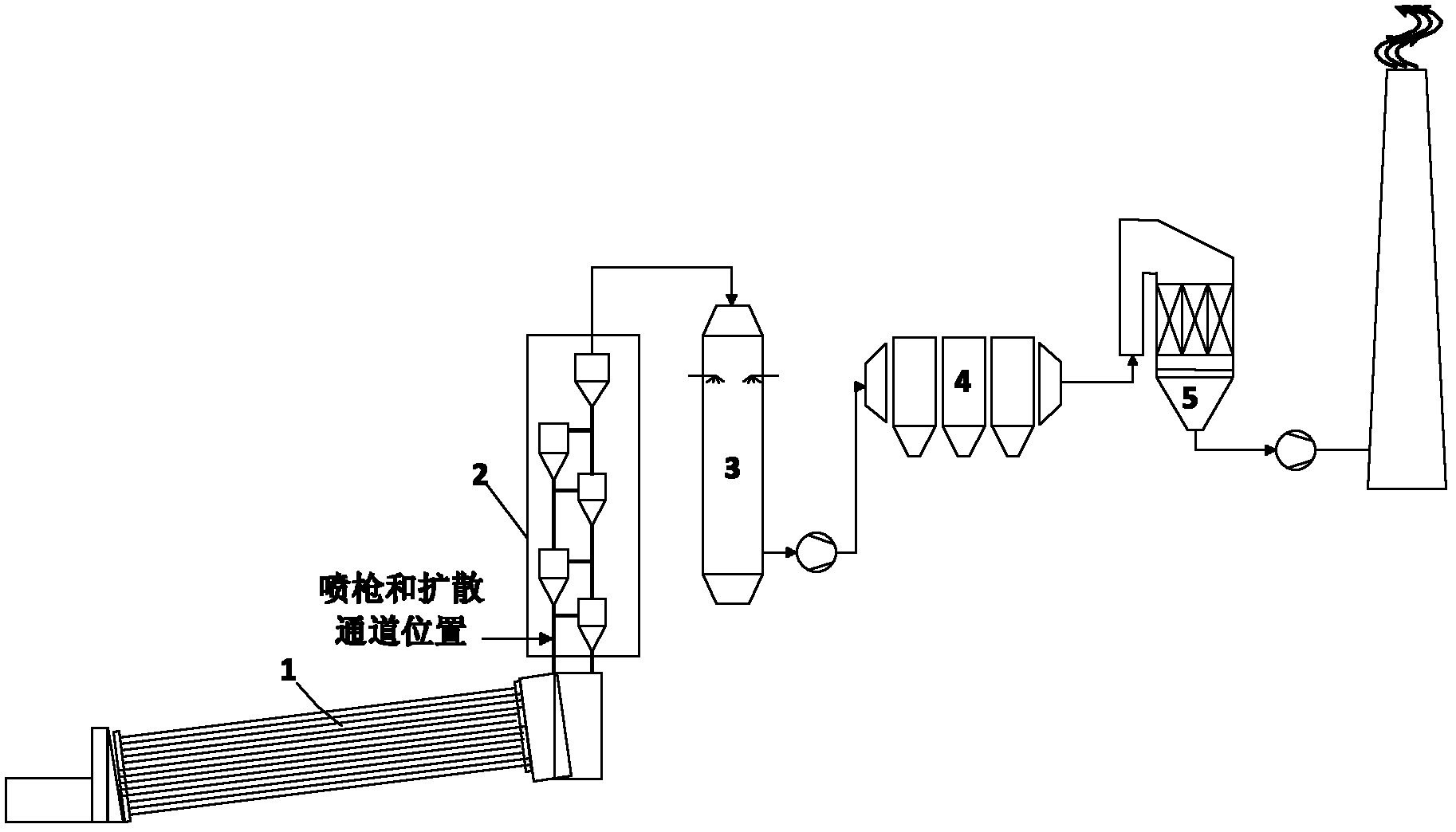

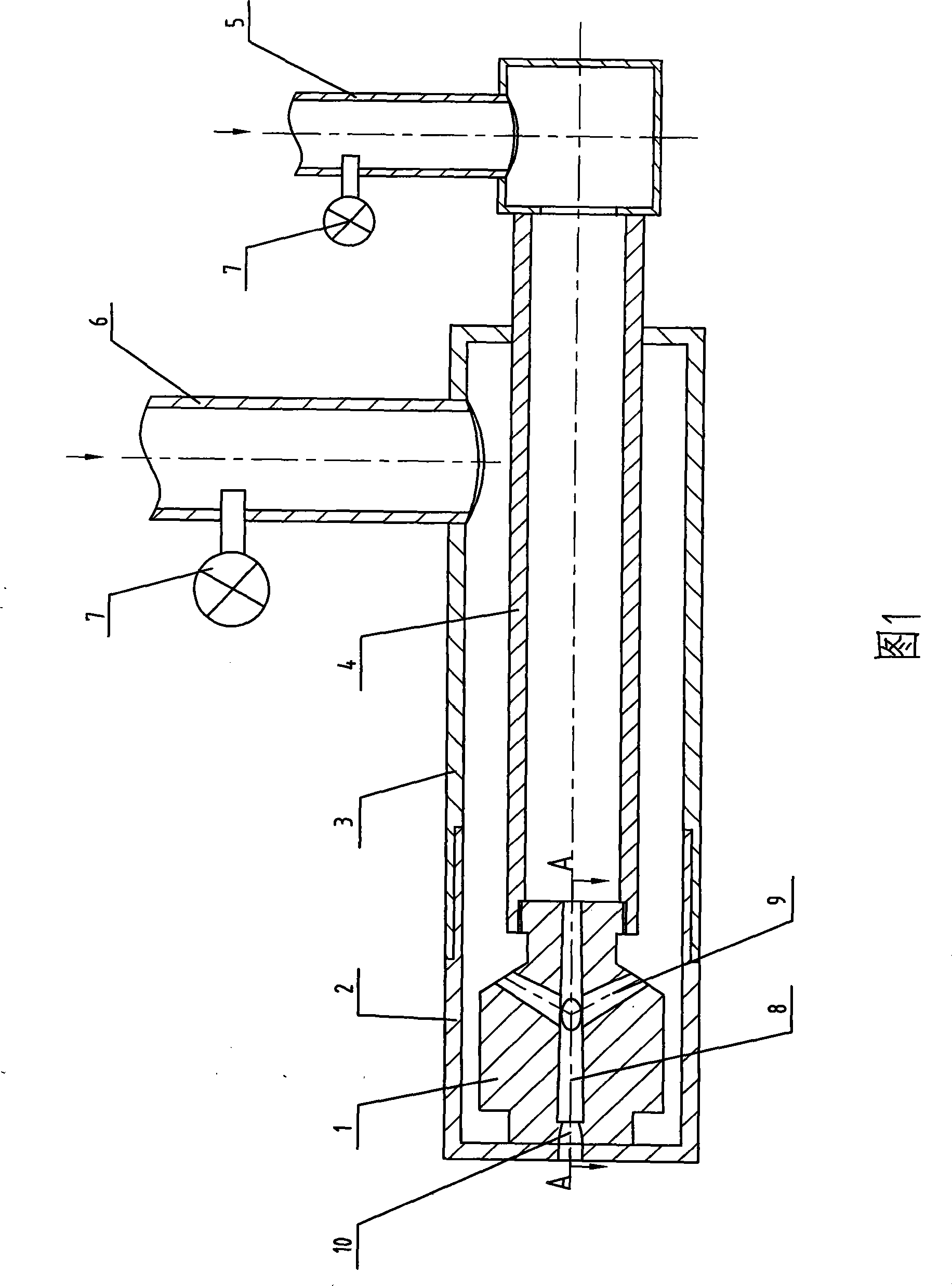

Denitration process and denitration apparatus for cement kiln flue gas

ActiveCN102512925AImprove denitrification efficiencyReduce escape rateGas treatmentDispersed particle separationDecompositionEscape rate

The invention discloses a denitration process for cement kiln flue gas. According to the process, liquefied ammonia, ammonia water or urea is used as a reducing agent and is injected into cement decomposition kiln flue gas in a temperature range of 750 to 1100 DEG C by a spray gun for a selective uncatalyzed reaction, and then the reducing agent and unreacted nitrogen oxides in the flue gas pass through an SCR reaction system installed behind a humidifying tower and a deduster together and undergo a selective uncatalyzed reaction on the surface of a specially-produced low temperature catalyst so as to realize secondary denitration. The invention also discloses a denitration apparatus used for realizing the denitration process. According to the invention, through installation of an SCR denitration system at the tail of a system, the escape rate of ammonia in an SNCR system is reduced; meanwhile, through former SNCR preliminary denitration, the volume of an SCR reactor and usage amount of the catalyst are reduced, thereby reducing cost of one-shot investment for the denitration system and improving denitration efficiency of the system. The denitration process and denitration apparatus provided in the invention are applicable to removal of nitrogen oxides in cement kiln flue gas and have wide market and application prospects.

Owner:ZHEJIANG TIANLAN ENVIRONMENTAL PROTECTION TECH

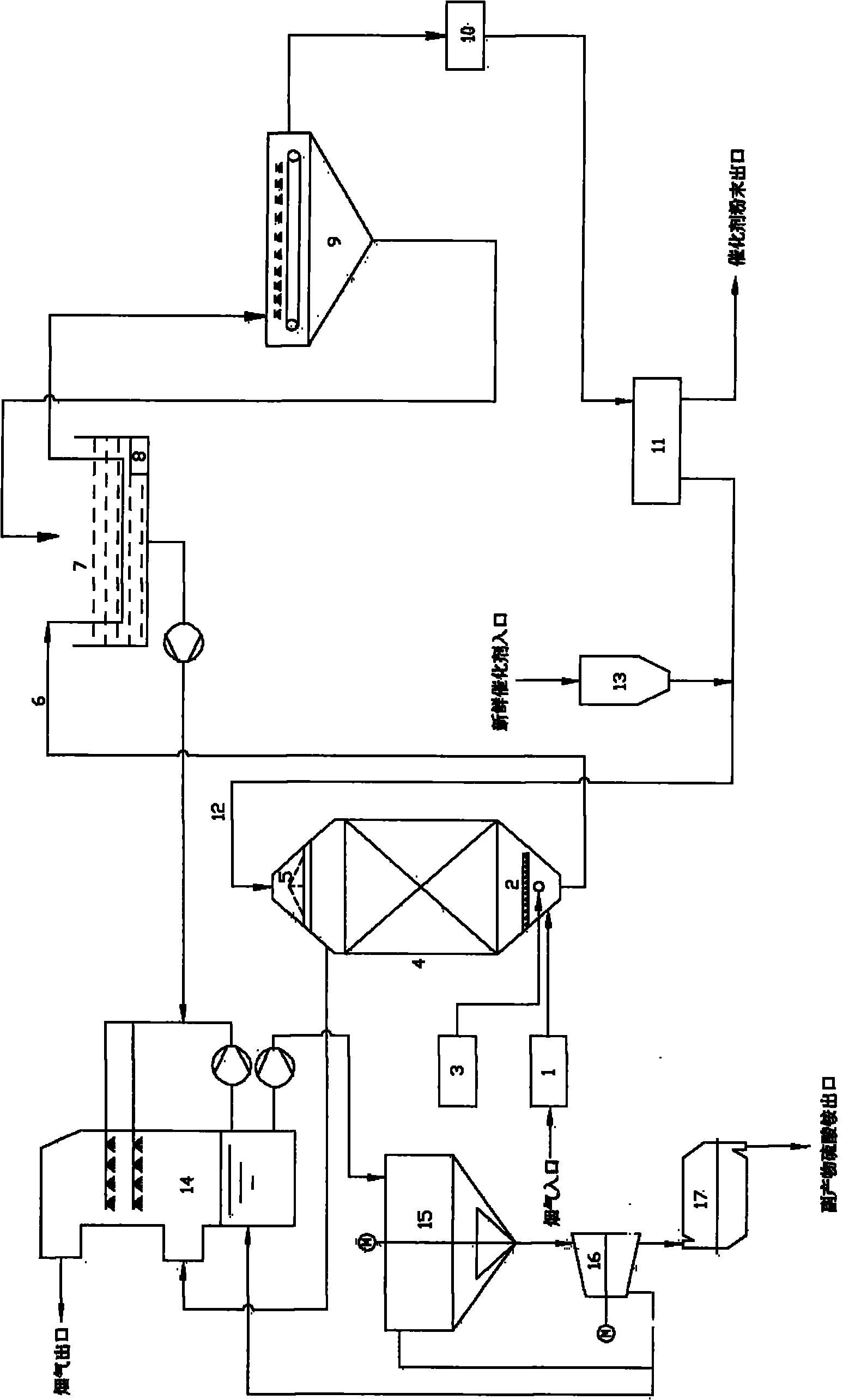

Low temperature SCR moving bed flue gas denitration method for coal-fired boiler

InactiveCN102008893AImprove denitrification performanceImprove denitrification efficiencyDispersed particle separationProcess engineeringFlue gas

The invention relates to a low temperature selective catalytic reduction (SCR) moving bed flue gas denitration method for a coal-fired boiler. Boiler flue gas subjected to dust removal and a denitration reducer NH3 are introduced into a denitration reactor respectively; a low temperature SCR catalyst is continuously input from one end of the denitration reactor and continuously output from the other end of the denitration reactor to form a moving bed; the flue gas and the NH3 are in gas-solid contact with the catalyst which moves directionally in a countercurrent or crosscurrent mode in the reactor; NOx and NH3 in the flue gas are reacted with each other and the generated N2 and water vapor are discharged out of the denitration reactor along with the denitrified flue gas; in the process, parts of SO2 and NH3 in the flue gas are reacted with each other and the generated sulfate is deposited on the catalyst; and an inactivated catalyst which is continuously output from the denitration reactor enters a regenerative process, the regenerated catalyst returns to the reactor and the steps are continuously and repeatedly circulated by the method. By continuously regenerating the catalyst, the method solves the problem of catalyst poisoning and improves the denitration efficiency and running stability of a system.

Owner:GUODIAN SCI & TECH RES INST +1

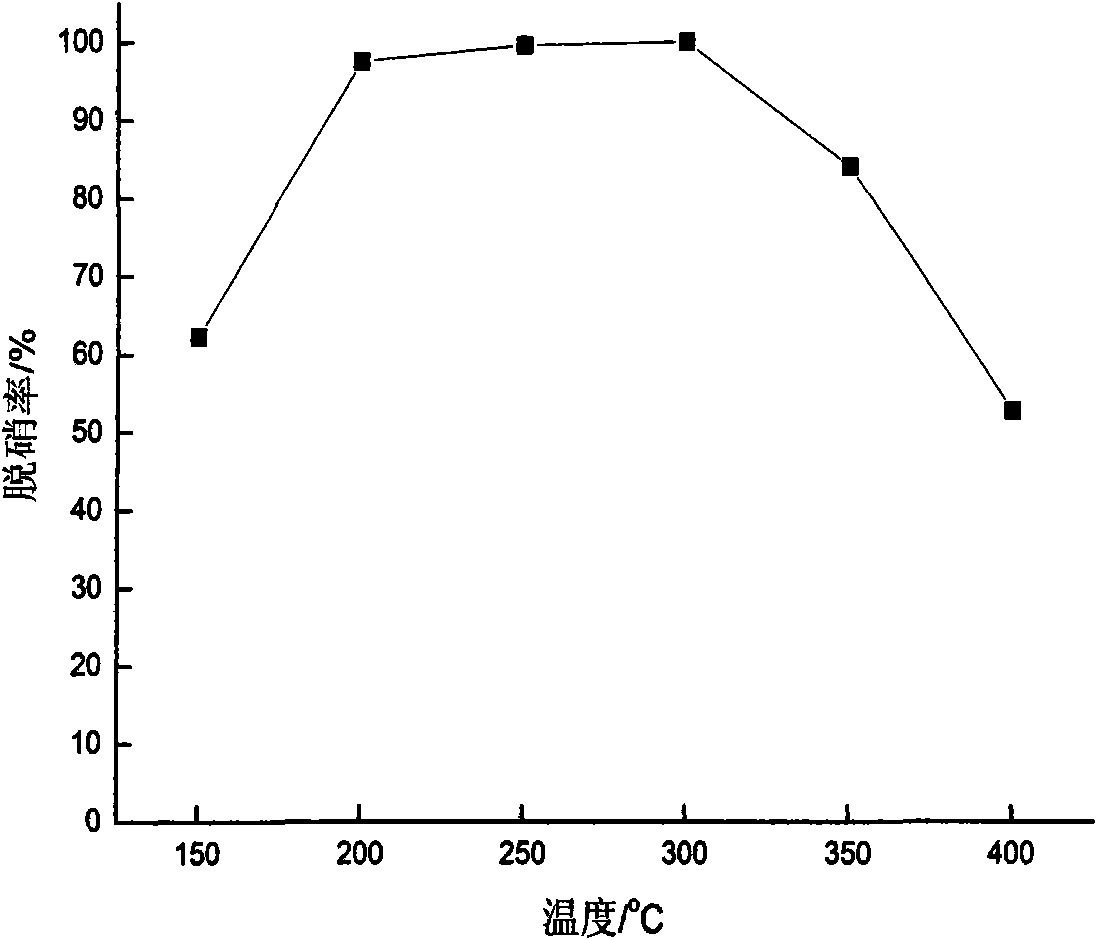

Flue gas dust removal and denitration integrated catalytic ceramic filter

ActiveCN107243256APrevent clogging and abrasionIncrease working temperatureGas treatmentDispersed particle filtrationComposite oxideSol-gel

The invention discloses a flue gas dust removal and denitration integrated catalytic ceramic filter which takes porous ceramics coated and adhered or wound with ceramic fiber composite membranes as carriers; iron, copper, cerium, manganese and titanium oxides or composite oxides are loaded in pores of the porous ceramics as denitration active components; a preparation method of the flue gas dust removal and denitration integrated catalytic ceramic filter can be realized by adopting a synchronous vacuum impregnation method, a step-by-step vacuum impregnation method, a co-precipitation method, a sol-gel method and other methods. The filter disclosed by the invention can remove dust and nitrogen oxides in high-temperature flue gas at the same time, is hypotoxic or non-toxic and wide in applicable temperature range and prevents the dust in the flue gas from blocking and abrading the active components. The best denitration efficiency can be achieved at different temperatures within the temperature range of 150-400 DEG C, so that the working temperature of denitration is greatly expanded. The flue gas dust removal and denitration integrated catalytic ceramic filter disclosed by the invention can be used for controlling the discharge of the dust and the nitrogen oxides in the processes of thermal power, steel, glass, ceramics, cement, nonferrous metals, petrochemical, chemical, waste incineration and the like.

Owner:ZHEJIANG UNIV +1

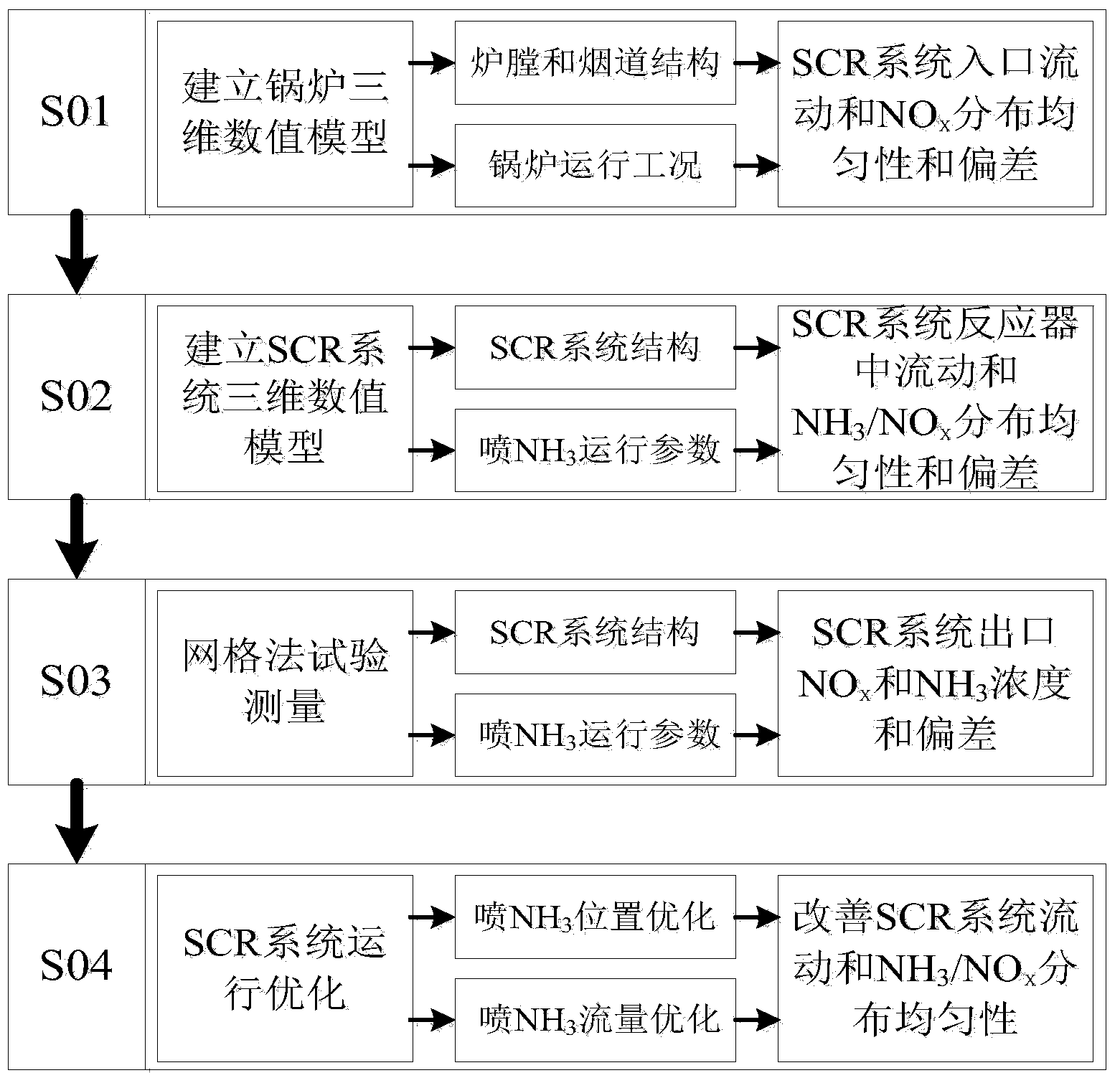

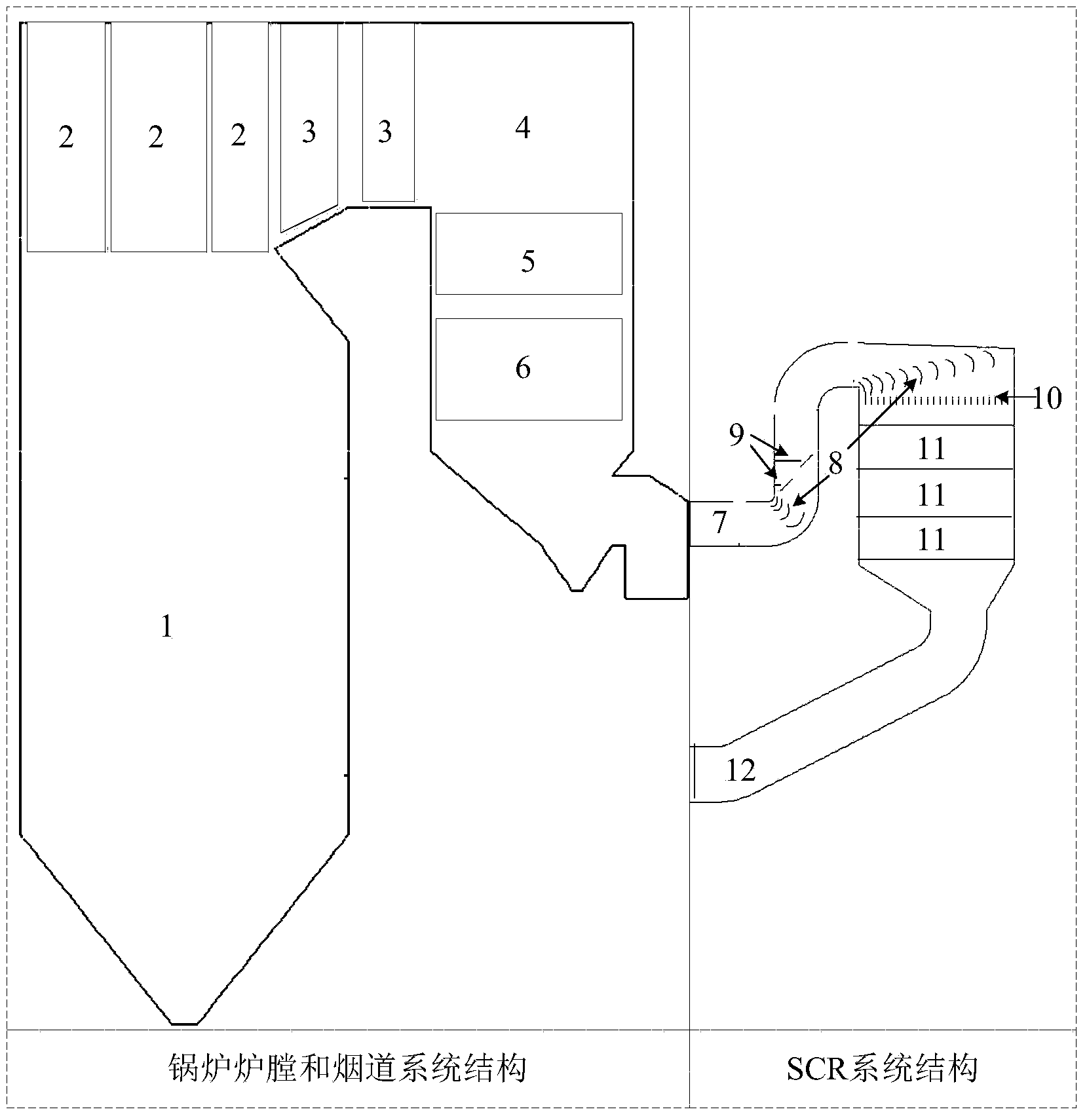

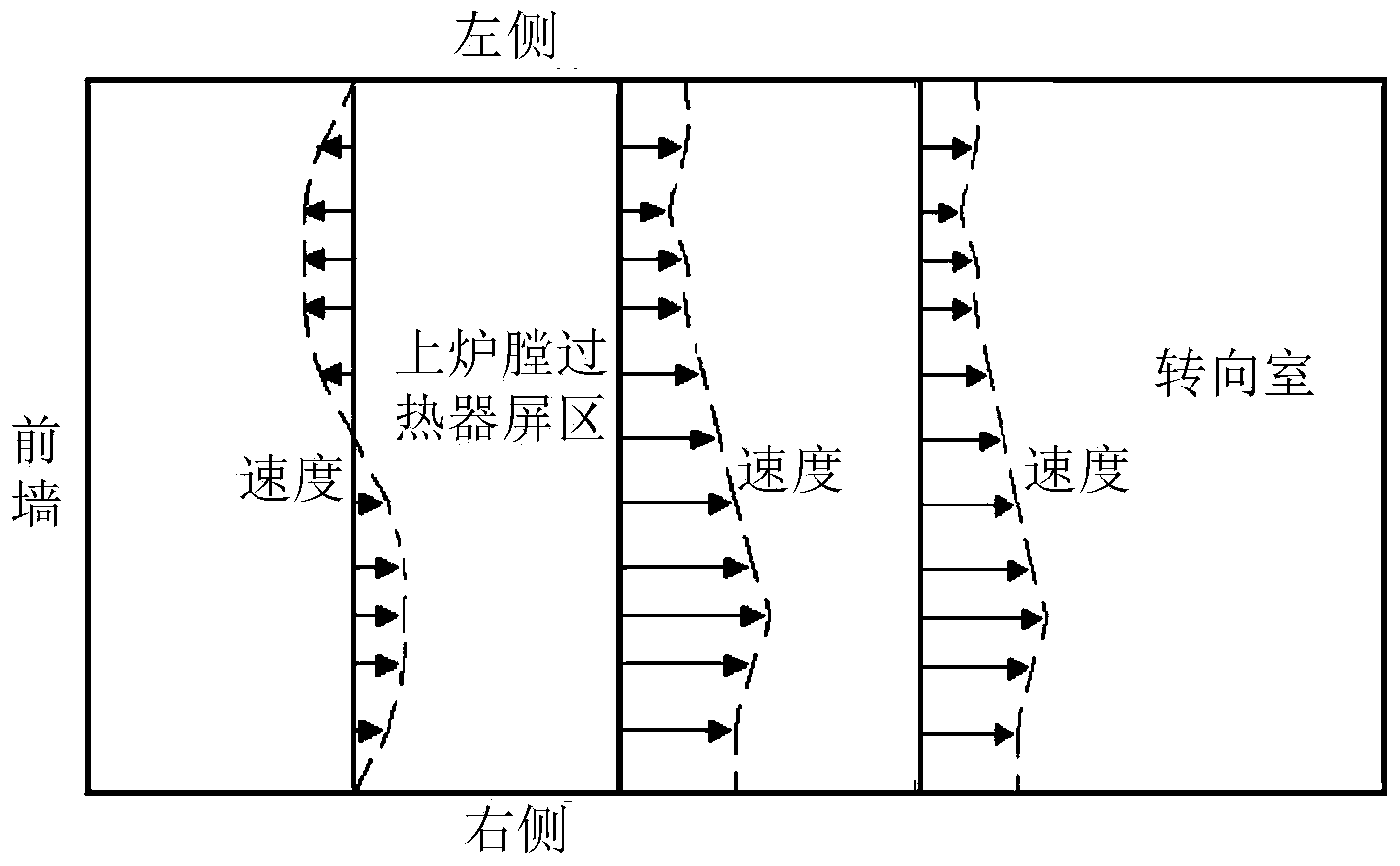

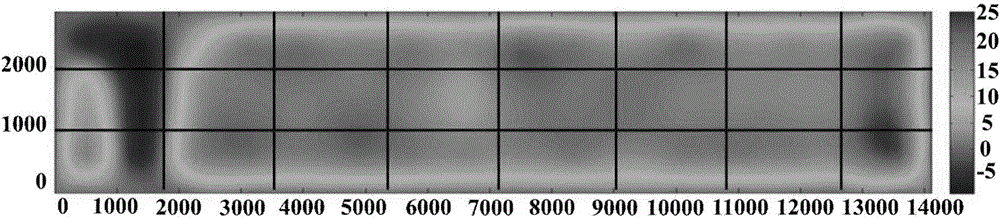

Denitration operation optimization method for SCR (Selective Catalytic Reduction) system of tangential firing pulverized coal boiler

InactiveCN103752170AOptimal adjustment of ammonia injection flow rateIncrease the flow rate of ammonia injectionDispersed particle separationEngineeringStreamflow

The invention discloses a denitration operation optimization method for an SCR (Selective Catalytic Reduction) system of a tangential firing pulverized coal boiler. The denitration operation optimization method comprises the special steps of using a numerical simulation method; obtaining a velocity of flue gas, an NOx concentration distribution uniformity and a deviation of an outlet of the boiler by means of considering the structure and the operation condition of the boiler as a boundary condition of an inlet of the SCR system; obtaining the velocity of the flue gas, an NH3 / NOx distribution uniformity and a deviation inside the SCR reactor; optimizing and adjusting an ammonia spraying flow of an ammonia spraying nozzle on a flue of the SCR system according to the velocity of the flue gas and the NH3 / NOx; increasing the ammonia spraying flow of the ammonia spraying nozzle corresponding to an area with the larger velocity of the flue gas, and decreasing the ammonia spraying flow of the ammonia spraying nozzle corresponding to an area with the smaller velocity of the flue gas; and increasing the ammonia spraying flow of the ammonia spraying nozzle corresponding to an area with the smaller NH3 / NOx, and decreasing the ammonia spraying flow of the ammonia spraying nozzle corresponding to an area with the larger NH3 / NOx. The denitration operation optimization method provided by the invention can be used for optimizing and adjusting by comprehensively considering the structures and the operation conditions of the boiler and the SCR system, so that the denitration efficiency of the SCR system is improved; the spraying amount and the release rate of ammonia can be reduced; the security, the economical efficiency and the environmental friendliness of the operation of the boiler unit can be improved.

Owner:HUAZHONG UNIV OF SCI & TECH +1

SCR denitration system ammonia spraying optimization method based on weight valve regulation and control

InactiveCN105126616AMake targeted adjustmentsReduce escapeDispersed particle separationConstant loadFlue gas

The invention discloses an SCR denitration system ammonia spraying optimization method based on weight valve regulation and control. The method is divided into four steps: measurement of flue gas flow field characteristics, analysis of flue gas flow field regional flow characteristics, determination of ammonia spraying weight valves and pertinence adjustment of opening degrees of the ammonia spraying valves. The method comprises the particular steps: firstly, measuring the flue gas flow field characteristics of a flue transverse section in front of an ammonia spraying grille of an SCR denitration system under a condition of constant load; then combining with a distribution condition of spray nozzles of the ammonia spraying grille, and analyzing flue gas flow field regional flow continuous distribution characteristics matched with the ammonia spraying spay nozzle distribution; according to the flue gas flow field regional flow characteristics under various load conditions, obtaining the weights of the ammonia spraying valves; and finally, adjusting the opening degrees of all the valves according to the valve weight difference, simultaneously, with the help of a flue gas analyzer, measuring the NOx outlet concentration on an outlet section of the SCR denitration system, and timely feeding back the adjustment effect of the opening degrees of the ammonia spraying valves. The method can ensure good ammonia nitrogen mixing equivalent ratio, effectively improves the denitration efficiency, decreases the ammonia escape and reduces the ammonia amount.

Owner:南京奥麦科仪器自动化有限公司

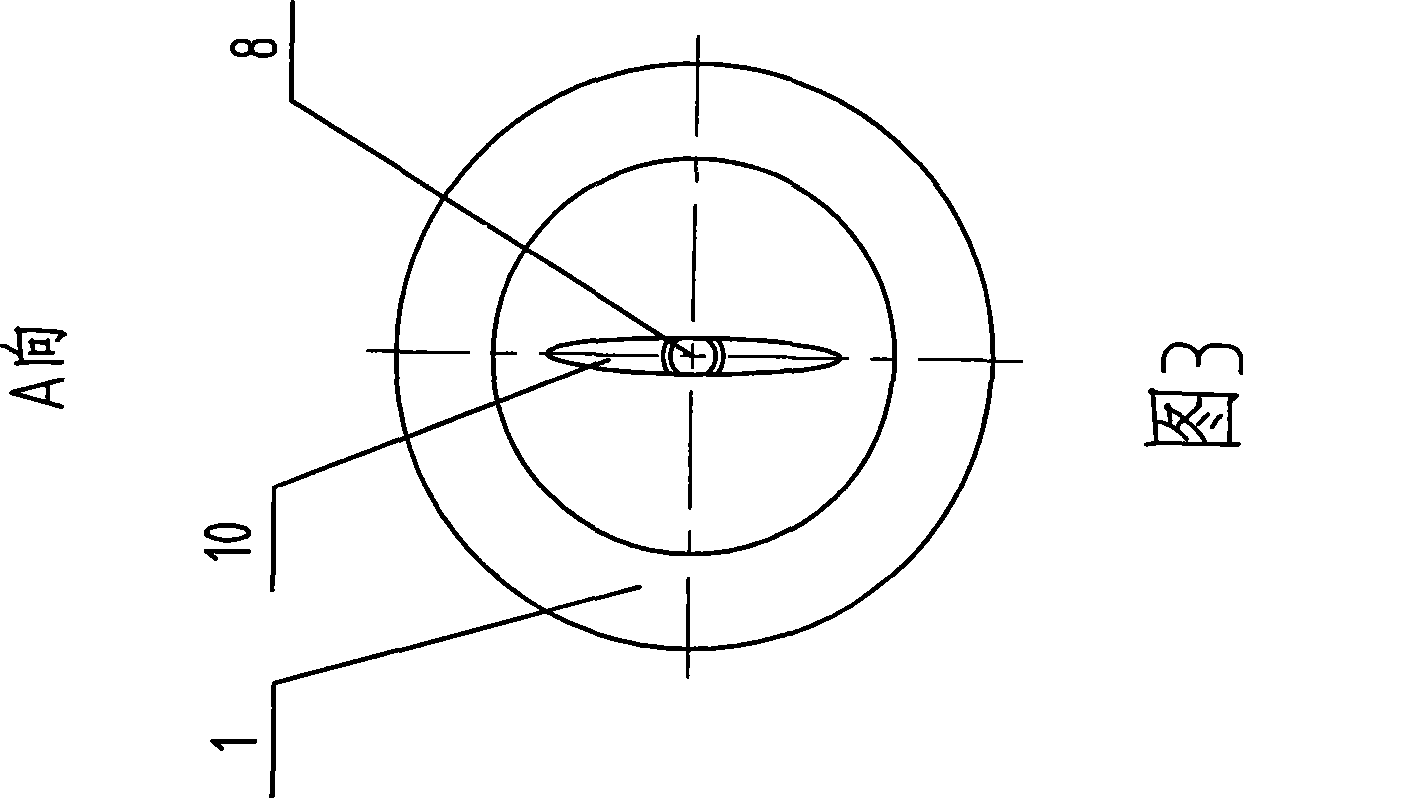

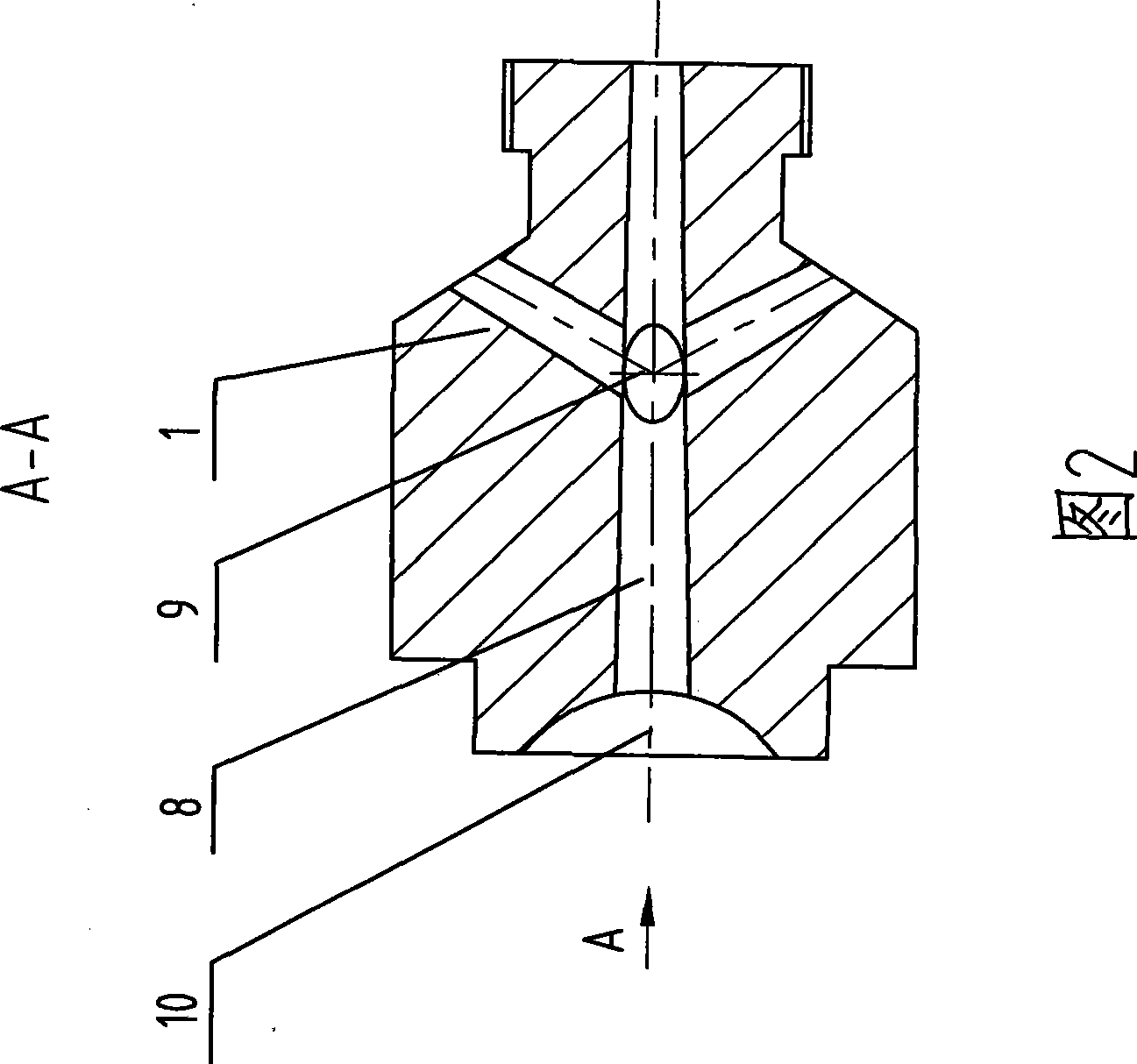

Reducing reagent nozzle for denitration by SNCR method

InactiveCN101371969ANarrow temperature rangeStrong penetrating powerDispersed particle separationSpray nozzlesGranularityReducer

The present invention provides a reducer nozzle used for denitration by an SNCR method. The reducer nozzle comprises a main pipe, an accessory pipe, a cutting ferrule, liquid pipes and a nozzle. The cutting ferrule is connected with the accessory pipe by screw threads to form a relative closed space. The front end of the main pipe is equipped with the nozzle and is arranged in the accessory pipe. The front end of the nozzle is contacted with the cutting ferrule. The back end of the main pipe is communicated with the liquid pipe I which is provided with a manometer. The accessory pipe is communicated with the liquid pipe II which is provided with the manometer. The nozzle is provided with a mixing hole which runs through the main pipe axially and is provided with a plurality of branch holes of the accessory which are communicated with the mixing hole and the accessory pipe. Olivary spray ports are arranged at the nozzle at a liquid outlet of the mixing hole and the cutting ferrule. The reducer nozzle has reasonable structure; when reducer penetrates an oven, the temperature range is narrow, the penetrable performance is good, and the spray distance is long; the reducer nozzle can also effectively control the granularity of atomized particles of the reducer and the vaporizing time of atomized liquid drops; and the reducer is mixed with NOx in smoke uniformly to improve the efficiency of denitrating the smoke.

Owner:JIANGSU ZHONGKE ENERGY SAVING ENVIRONMENTAL PORTECTION TECH

Double-rotation SCR denitration method and apparatus thereof

ActiveCN105289301AImprove denitrification efficiencyIncrease contact timeDispersed particle separationCycloneFlue gas

The invention discloses a double-rotation SCR denitration method and an apparatus thereof. According to the invention, a first eddy flow catalytic reaction chamber and a second eddy flow catalytic reaction chamber are arranged along a denitrating tower body; a flue gas introduction pipeline is arranged on a sidewall of the denitrating tower body; several eddy flow atomizing nozzles are respectively arranged on inner periphery of the flue gas introduction pipeline and the inner periphery at top of the first eddy flow catalytic reaction chamber; when flue gas is introduced into the flue gas introduction pipeline, the flue gas and ammonia gas injected by the eddy flow atomizing nozzle are mixed, and a mixture enables spiral sinking along circumference of the first eddy flow catalytic reaction chamber from up to down in a tangent circle mode, under effect of a cyclone, and then the mixture enable spiral rise along circumference of the second eddy flow catalytic reaction chamber from down to up in the tangent circle mode. Under prerequisite that high efficiency denitration is ensured, catalyst amount is less, operation of technical means is simple and easy, compared with the prior art, a denitrating tower structure is simple, cost of the apparatus is low, denitration efficiency is high, energy consumption is low, escapement ratio of ammonia is reduced, denitration cost is greatly reduced, and economic benefit is obviously increased.

Owner:SOUTH CHINA UNIV OF TECH

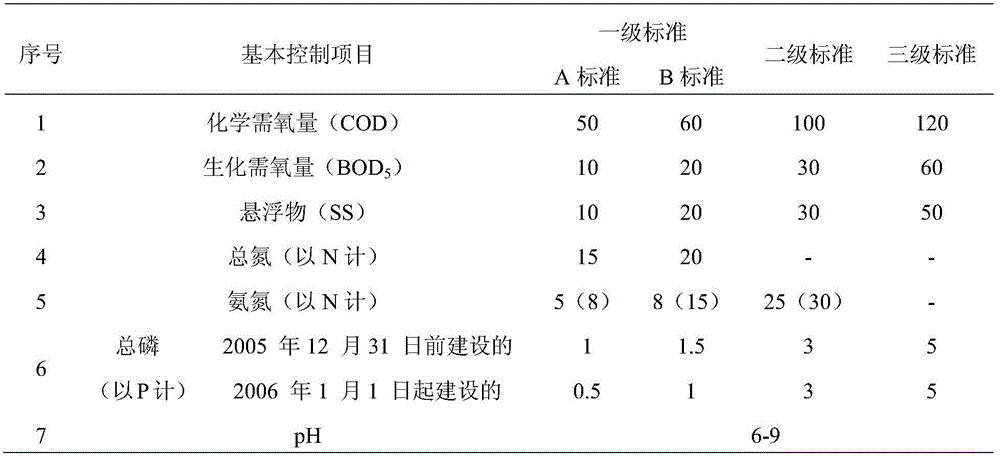

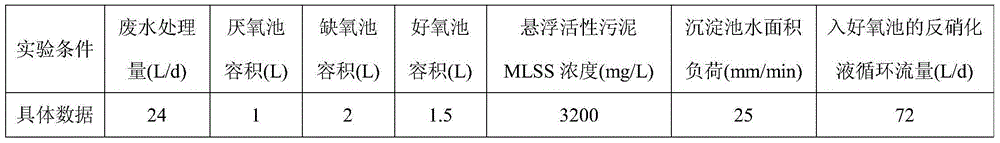

Efficient biochemical nitrogen and phosphorus removal method for waste water

ActiveCN104556572AImprove mud life and recycling rateReduce stepsTreatment using aerobic processesWater contaminantsChemistryIon adsorption

The invention discloses an efficient biochemical nitrogen and phosphorus removal method for waste water. Ammonia nitrogen and phosphorus in waste water are efficiently removed by combining a modified A2 / O biological nitrogen and phosphorus removal technology and a chemical method, namely, zeolite adsorbing ammonia nitrogen method; the denitrification liquid flowing out from an anoxic denitrification tank enters an aerobic nitration tank to form internal circulation; the residual denitrification liquid directly enters a sedimentation tank for solid-liquid separation; phosphorus-accumulating bacteria directly flows back to an anaerobic tank from the sludge of a sedimentation tank, and then enters the anoxic nitration tank. Ion adsorption and biological regeneration treatment are combined; water outlet total nitrogen is less than or equal to 5 mg / L; the removal ratio of total nitrogen and total phosphorus is more than 90%; requirements that water outlet total nitrogen in Taihu basin chemical engineering zone is superior to the primary standard, namely, the A standard, of the urban sewage treatment plant pollutant discharge standard (GB18918-2002) are met stably.

Owner:江苏艾特克环境工程设计研究院有限公司 +1

Iron-based low-temperature SCR denitration catalyst and preparation method thereof

InactiveCN104722307AObvious cost advantageLow costDispersed particle separationMetal/metal-oxides/metal-hydroxide catalystsAir atmosphereCerium nitrate

The invention provides an iron-based low-temperature SCR denitration catalyst and a preparation method thereof. Iron and cerium compounds are taken as active components, or iron, manganese and cerium compounds are taken as active components, titanium oxide is taken as a carrier, the molar ratio of iron, manganese and cerium is 1:(0.5-4):(0.5-1.5), and the molar ratio of iron and titanium oxide is 0.15-0.25. The preparation method comprises the steps of dissolving iron nitrate, manganese nitrate and cerium nitrate in deionized water, adding the titanium oxide, stirring intensely so as to mix the above compounds thoroughly, then performing ultrasonic mixing, putting the mixture into an oven for drying, calcining in an air atmosphere, and then grinding the mixture into powder. The iron-based low-temperature SCR denitration catalyst provided by the invention has an obvious advantage in cost, and meanwhile, the iron-based low-temperature SCR denitration catalyst has higher denitration efficiency under a medium and low temperature.

Owner:STATE GRID CORP OF CHINA +2

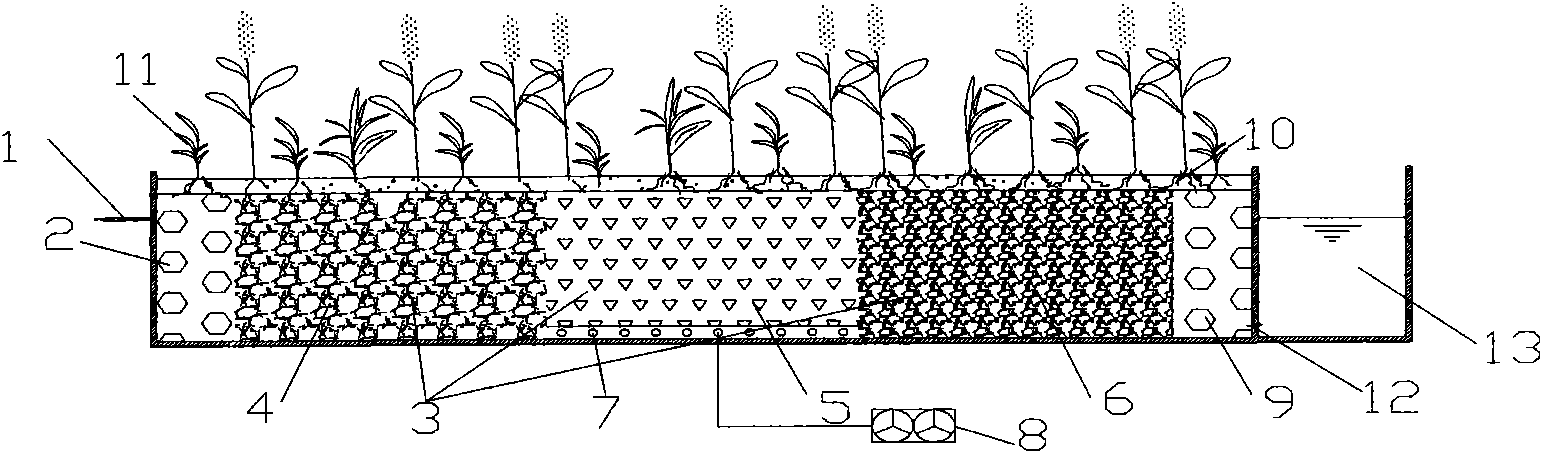

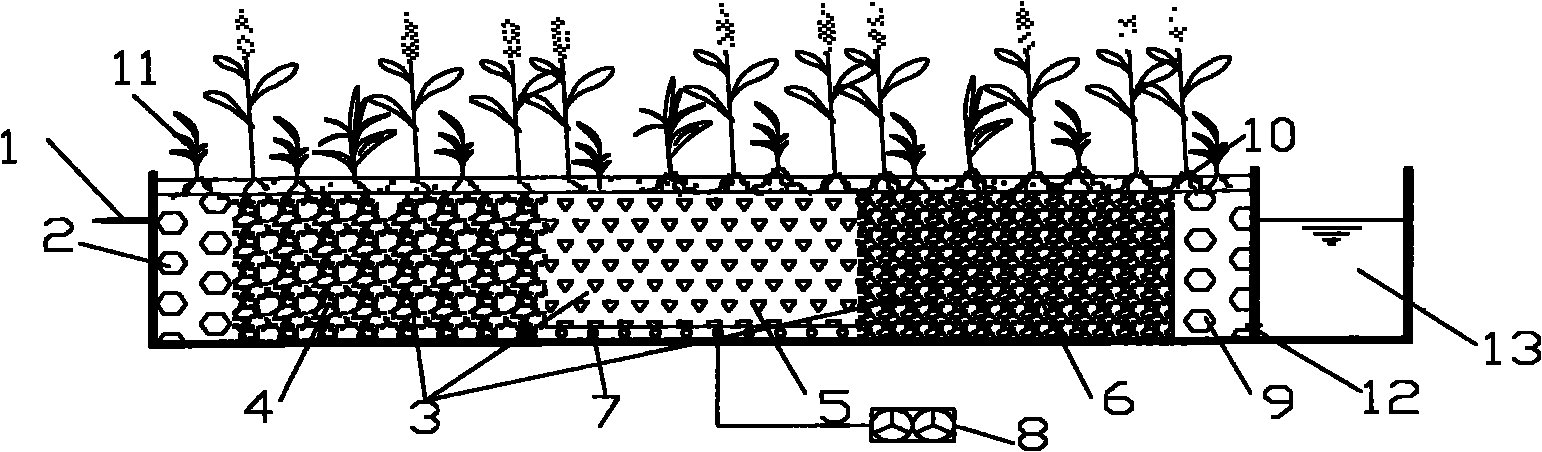

Horizontal underflow constructed wetland capable of strengthening denitrification at low temperature

InactiveCN101987760ASolve the problem of low denitrification efficiency at low temperature in winterImprove nitrogen removal efficiencySustainable biological treatmentBiological water/sewage treatmentConstructed wetlandNitrogen removal

The invention relates to a horizontal underflow constructed wetland capable of strengthening denitrification at a low temperature. The constructed wetland consists of a water distribution region, a filling region, an aeration device, a water collecting region and wetland plants, wherein large-grain detritus is positioned in the water distribution region and the water collecting region; the filling region is arranged between the water distribution region and the water collecting region; medium-grain detritus, medium-grain zeolite and fine-grain detritus are positioned in the filling region sequentially; and aeration pipes are laid on the bottom layer of a zeolite segment and the aeration quantity is adjustable. Sewage is subjected to pretreatment, so that suspended matters and part of pollutant are removed, and then the sewage is subjected to constructed wetland purification treatment. The horizontal underflow constructed wetland can greatly improve the dissolved oxygen concentration of the sewage and the ammonia nitrogen adsorption capacity of regenerated zeolite in the horizontal underflow constructed wetland and can maintain high-efficiency and stable nitrogen removal rate of a system.

Owner:LIAONING BEIFANG ENVIRONMENTAL PROTECTION +1

Honeycomb non-vanadium denitration shaping catalyst, preparation method and application thereof

ActiveCN105107514AHigh mechanical strengthImprove denitrification efficiencyDispersed particle separationMetal/metal-oxides/metal-hydroxide catalystsWater vaporCopper oxide

The invention relates to a honeycomb non-vanadium denitration shaping catalyst, a preparation method and application thereof. The shaping catalyst is mainly obtained by shaping catalyst powder and forming additives. The catalyst powder comprises titanium dioxide and additives as main components, wherein the additives are combinations of any four or more than four of copper oxide, zirconium oxide, molybdenum oxide, iron oxide, nickel oxide, cobalt oxide, tungsten oxide and cerium oxide. The forming additives mainly comprise combinations of an enhancer, an inorganic binder, an organic binder, a pore forming agent and a lubricant. The shaping catalyst has excellent anti-SO2 and water vapor poisoning performance, and excellent denitration efficiency and high mechanical strength, and can be used in nitrogen oxide purification of stationary sources (such as a coal-fired power plant and oil catalytic cracking exhaust thereof) and mobile sources (such as diesel exhaust).

Owner:张鑫

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com