Dry smoke cleaning process for desulfurizing and denitrating simultaneously and its system

A desulfurization, denitrification, and flue gas technology, applied in the field of flue gas purification, can solve the problems of complex equipment composition, difficult to reuse, long distance, etc., to reduce investment and operating costs, achieve low-cost reuse, and reduce water consumption. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

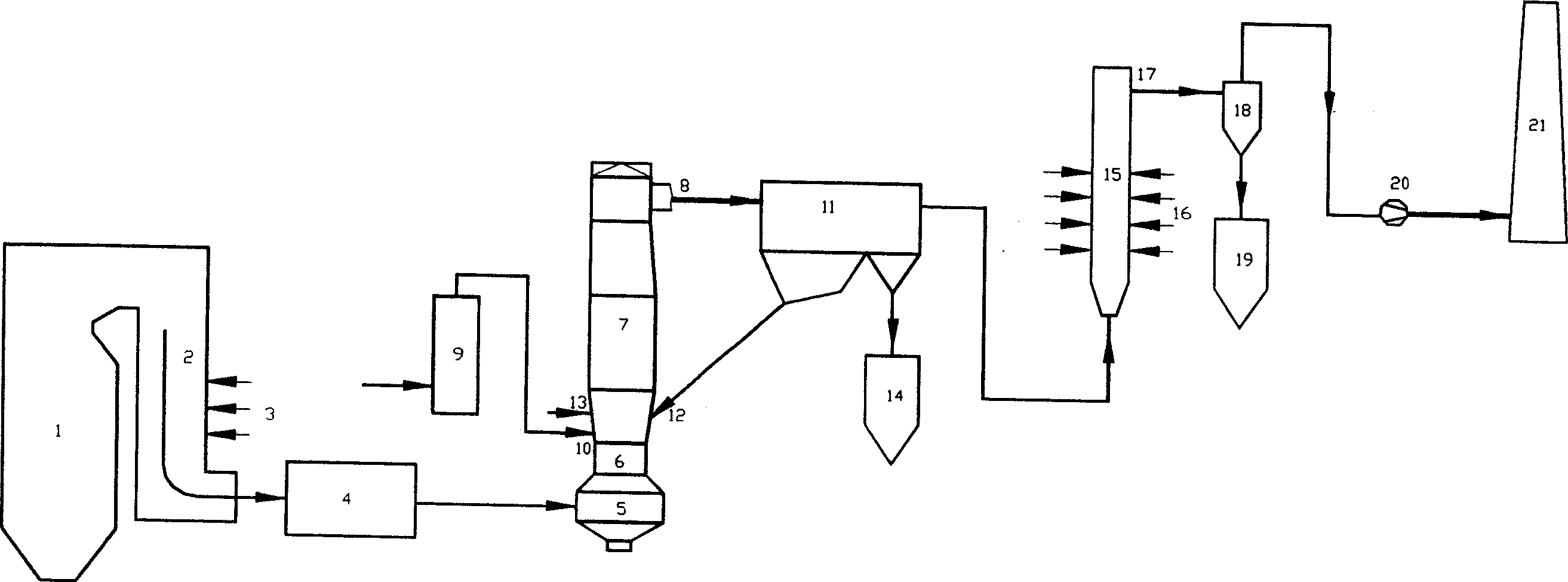

[0026] The following is a further detailed description of the simultaneous desulfurization and denitrification dry flue gas cleaning process and its system of the present invention for a coal-fired boiler generator set in conjunction with the accompanying drawings:

[0027] The dry flue gas cleaning system with simultaneous desulfurization and denitrification shown in the figure has a circulation flow consisting of a desulfurization agent preparation device 9, a desulfurization reaction tower 7, an external desulfurization agent separation and recycling device 11, and a desulfurization product collection slag bin 14. State-based dry flue gas desulfurization system, this part is similar to the prior art, and will not be repeated here. The hydrogen peroxide or methanol additive injection device 3 of this system is arranged on the tail flue 2 of the coal-fired boiler furnace 1, between the hydrogen peroxide or methanol additive injection device 3 and the flue gas inlet of the desu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com