Double-rotation SCR denitration method and apparatus thereof

A double-rotation, denitrification technology, applied in the field of flue gas denitrification, can solve the problems of ammonia escape, catalyst failure, easy ash accumulation, etc., and achieve the effect of uniform flow field, long contact time and good fullness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

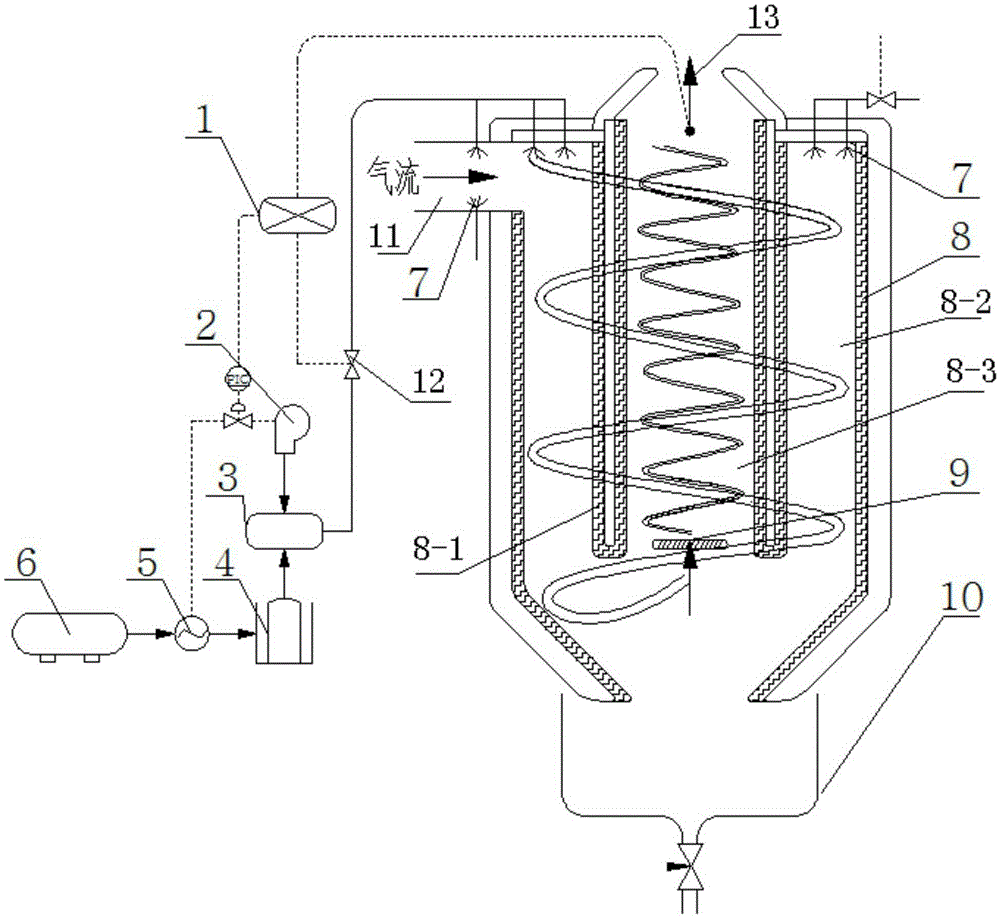

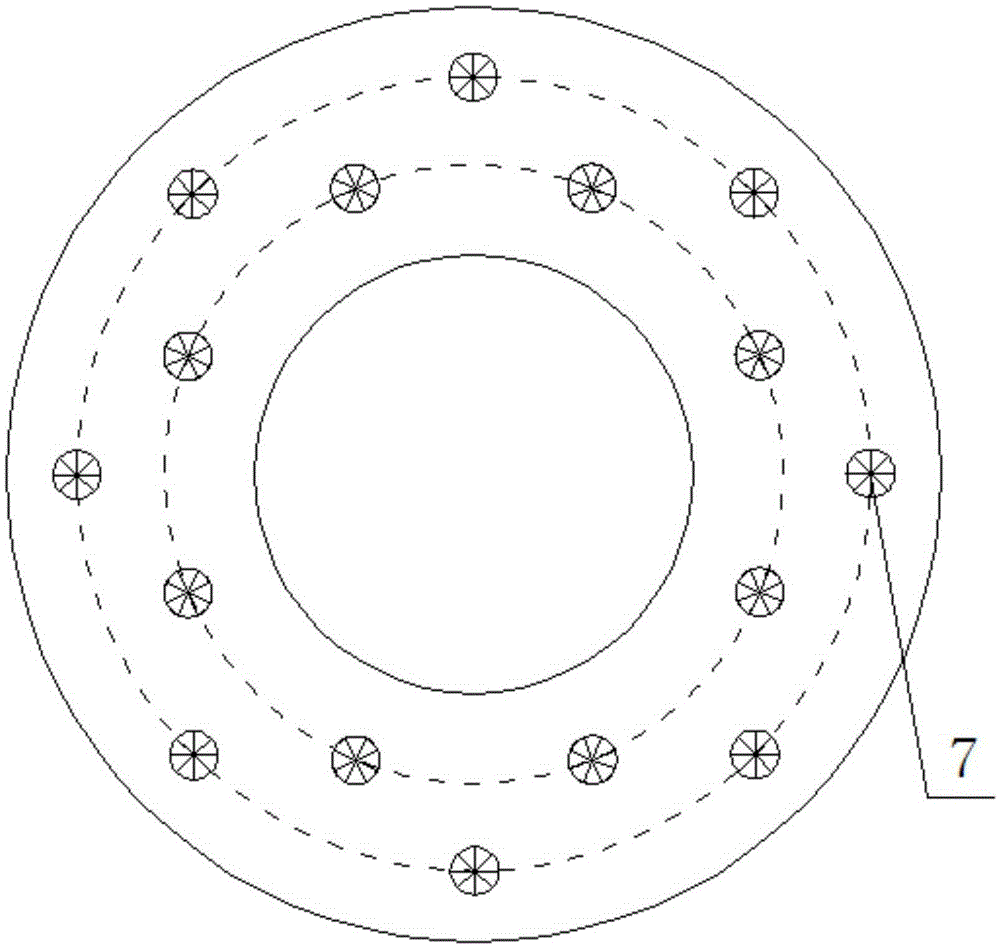

[0034] Such as Figures 1 to 4 shown. The invention discloses a double-rotation SCR denitrification device, comprising a denitrification tower body and a first plate catalyst layer 8 arranged along the inner peripheral surface of the denitrification tower body, and a second plate catalyst layer is arranged in the first plate catalyst layer 8 8-1; the cavity between the first plate catalyst layer 8 and the second plate catalyst layer 8-1 is the first swirl catalytic reaction chamber 8-2, and the cavity in the second plate catalyst layer 8-1 is the first Two swirl catalytic reaction chambers 8-3; the bottom end of the second swirl catalytic reaction chamber 8-3 is provided with a cyclone 9; the first swirl catalytic reaction chamber 8-2 and the second swirl catalytic reaction chamber 8-3 The cross section is circular.

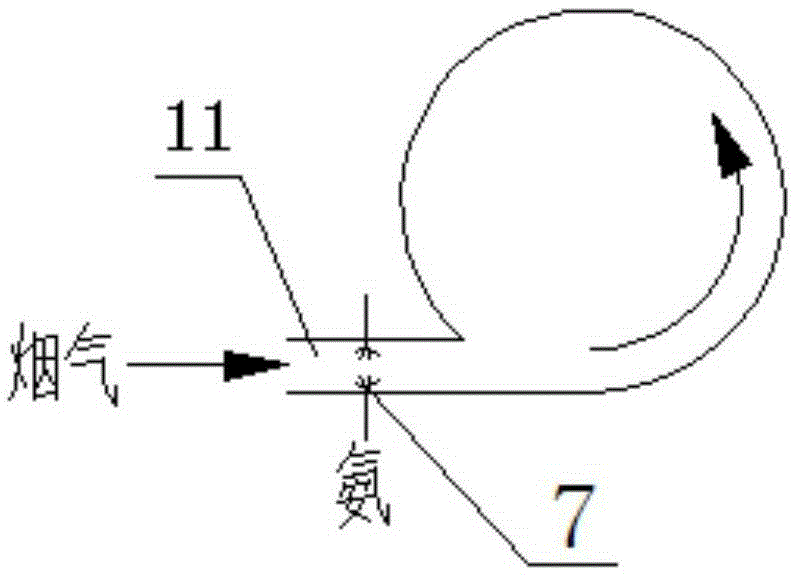

[0035] The top of the first cyclone catalytic reaction chamber 8-2 is sealed, and a flue gas inlet pipe 11 is arranged on the upper side wall of the denitrific...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com