Honeycomb non-vanadium denitration shaping catalyst, preparation method and application thereof

A catalyst and honeycomb-shaped technology, applied in chemical instruments and methods, physical/chemical process catalysts, separation methods, etc., can solve problems such as low mechanical strength, no investigation of water resistance and sulfur resistance, and complex molding process of shaped catalysts

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

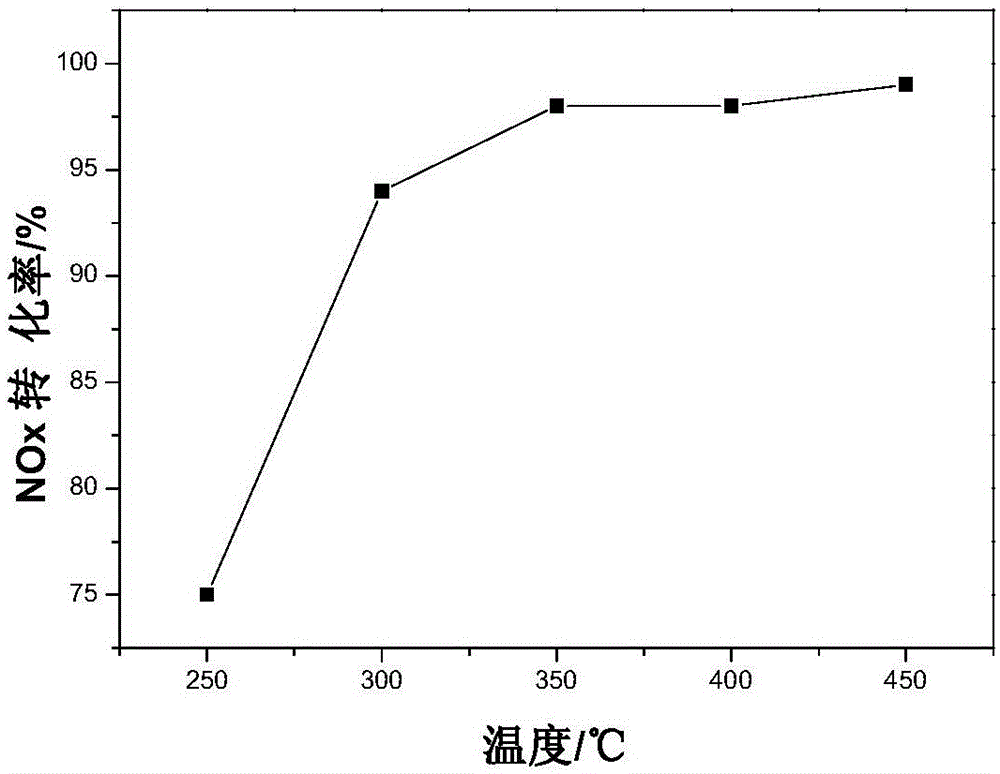

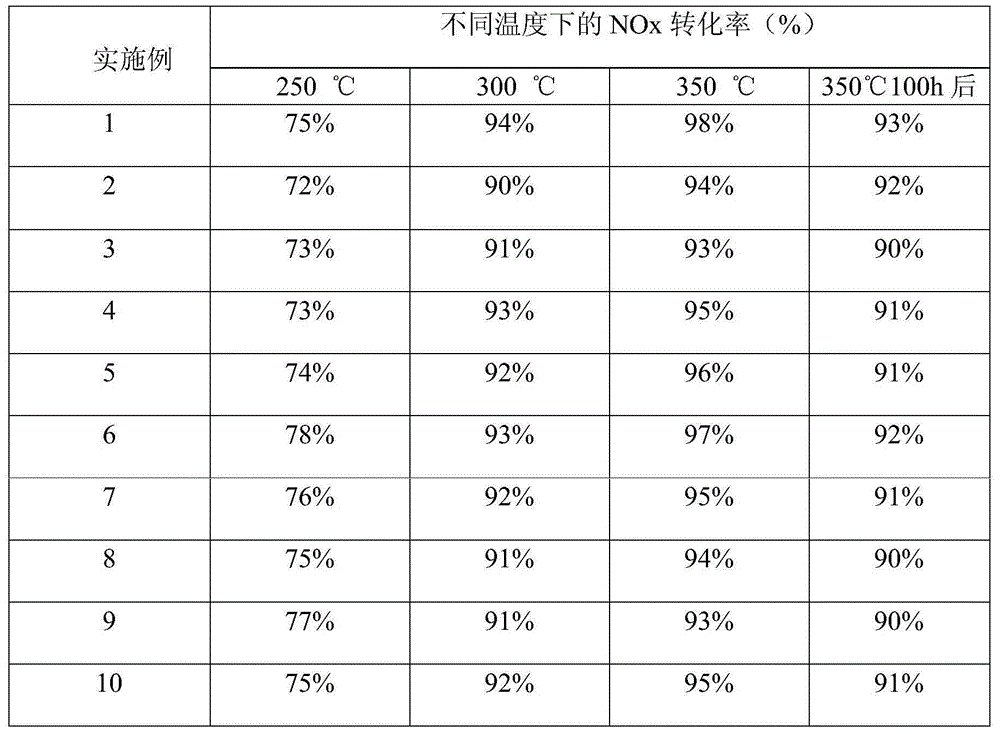

Embodiment 1

[0075] Configure titanyl sulfate, copper nitrate, zirconium oxychloride, nickel nitrate, cerium nitrate solution and 10wt% sodium carbonate solution, mix titanyl sulfate, copper nitrate, zirconium oxychloride, nickel nitrate and cerium nitrate solution evenly to obtain a mixed solution, control the molar ratio of the five elements Ti, Cu, Zr, Ni, and Ce in the mixed solution to be 1:0.01:0.01:0.02:0.1, and add the above-mentioned titanium, copper, and zirconium in a constant temperature water bath at 25°C with sodium carbonate solution dropwise The nickel-cerium salt mixed solution is used to completely precipitate titanium, copper, zirconium, nickel, and cerium ions. After the dropwise addition, the pH is controlled to be 9-11, stirred for 3 hours, filtered, washed, and dried and roasted.

[0076] Weigh the titanium-copper-zirconium-nickel-cerium catalyst powder synthesized by the co-precipitation method, then add solid forming aids glass fiber, activated carbon, and methyl ce...

Embodiment 2

[0079] Configure titanyl sulfate, ferric nitrate, copper nitrate, zirconium oxychloride, nickel nitrate, cerium nitrate solution and 10wt% sodium hydroxide solution, and titanyl sulfate, ferric nitrate, copper nitrate, zirconium oxychloride, nickel nitrate, nitric acid Mix the cerium solution evenly to obtain a mixed solution. Control the molar ratio of the six elements Ti, Fe, Cu, Zr, Ni and Ce in the mixed solution to 1:1.0:0.01:0.1:0.01:1.0 in a constant temperature water bath at 25°C. Add the above-mentioned mixture of titanium, iron, copper, zirconium, nickel and cerium salts dropwise with sodium hydroxide solution to completely precipitate titanium, iron, copper, zirconium, nickel, and cerium ions. Wash, dry and roast.

[0080] Weigh the titanium-iron-copper-zirconium-nickel-cerium catalyst powder synthesized by the co-precipitation method, then add solid forming additives glass fiber, titanium dioxide, pseudo-boehmite, celadon powder, and polyvinyl alcohol for stirring ...

Embodiment 3

[0083] Configure titanyl sulfate, copper nitrate, zirconium oxychloride, cobalt nitrate, cerium nitrate solution and 10wt% sodium carbonate solution; mix titanyl sulfate, copper nitrate, zirconium oxychloride, cobalt nitrate and cerium nitrate evenly to obtain a mixed solution , control the molar ratio of the five elements Ti, Cu, Zr, Co, and Ce in the mixed solution to be 1:1.0:0.01:0.01:0.2; in a constant temperature water bath at 25°C, add the above-mentioned titanium copper zirconium cobalt dropwise with sodium carbonate solution For the cerium mixed solution, the titanium, copper, zirconium, cobalt, and cerium ions are completely precipitated. After the dropwise addition, the pH is controlled to be 9-11, stirred for 3 hours, filtered, washed, dried and roasted.

[0084] Weigh the titanium-copper-zirconium-cobalt-cerium catalyst powder synthesized by co-precipitation method, and then add solid forming additives glass fiber, titanium dioxide, water glass, activated carbon, h...

PUM

| Property | Measurement | Unit |

|---|---|---|

| compressive strength | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com