Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

1249 results about "Coal fired power plant" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Enhanced mercury control in coal-fired power plants

InactiveUS6808692B2Easy to captureEliminate dischargeChloride preparationUsing liquid separation agentPulverized fuel ashElemental mercury

A method of treating a coal combustion flue gas, which includes injecting a molecular halogen or thermolabile molecular halogen precursor, such as calcium hypochlorite, able to decompose to form molecular halogen at flue gas temperature. The molecular halogen converts elemental mercury to mercuric halide, which is adsorbable by alkaline solids such as subbituminous or lignite coal ash, alkali fused bituminous coal ash, and dry flue gas desulphurization solids, capturable in whole or part by electrostatic precipitators (ESPs), baghouses (BHs), and fabric filters (FFs), with or without subsequent adsorption by a liquid such as a flue gas desulphurization scrubbing liquor.

Owner:HAZELMERE RES

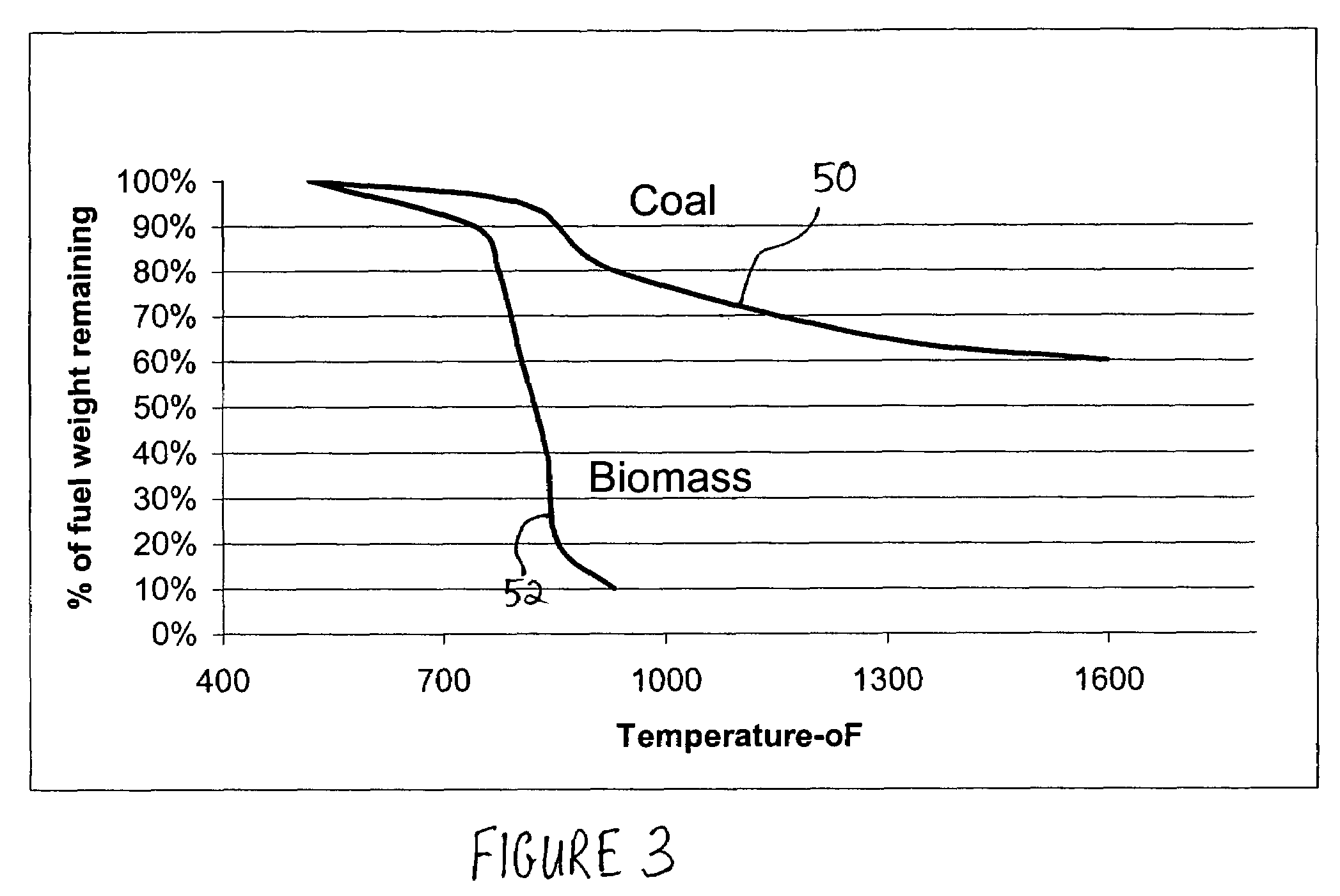

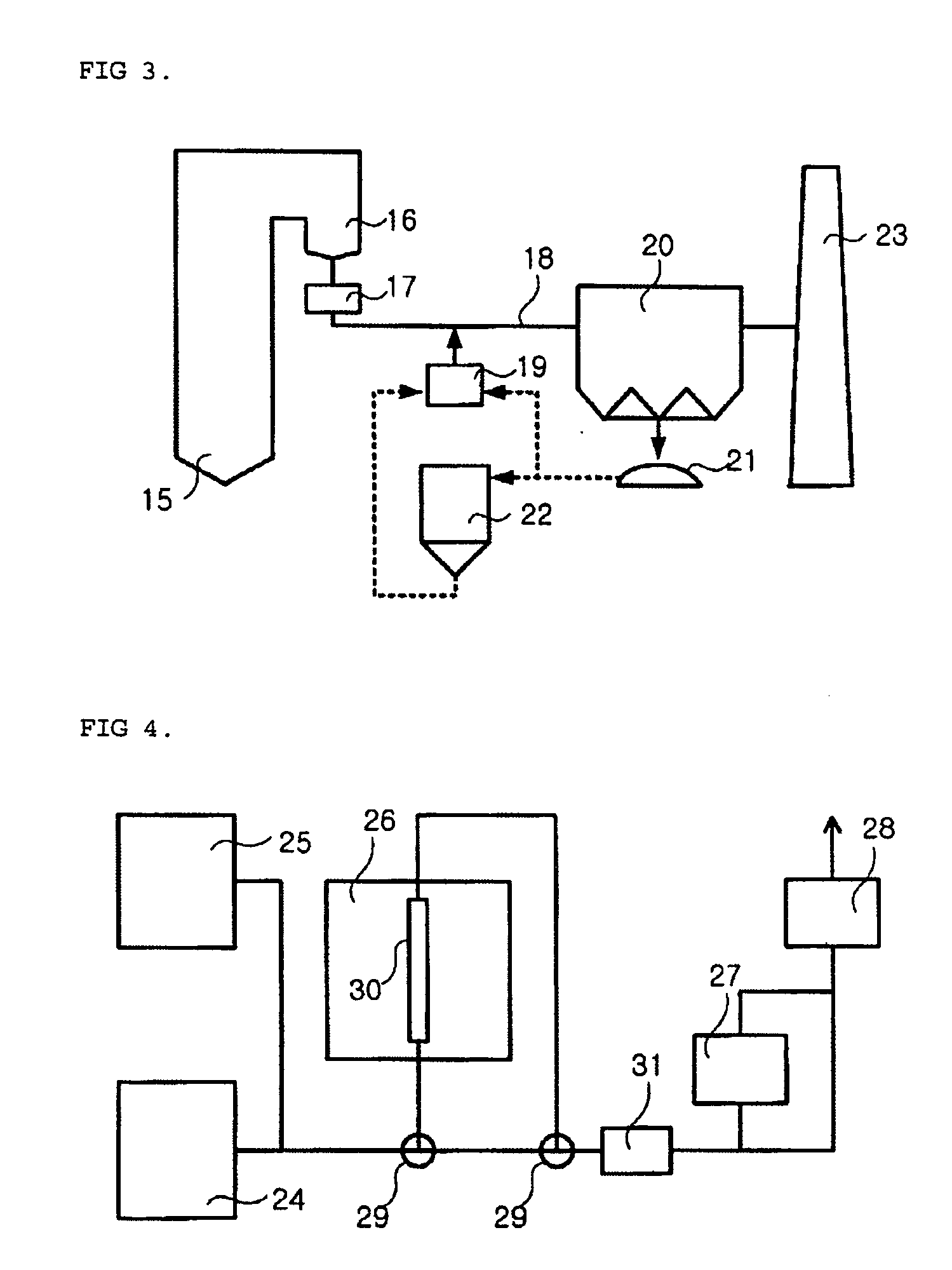

Thief process for the removal of mercury from flue gas

InactiveUS6521021B1Low costQuench oxidationGas treatmentUsing liquid separation agentParticulatesCombustion chamber

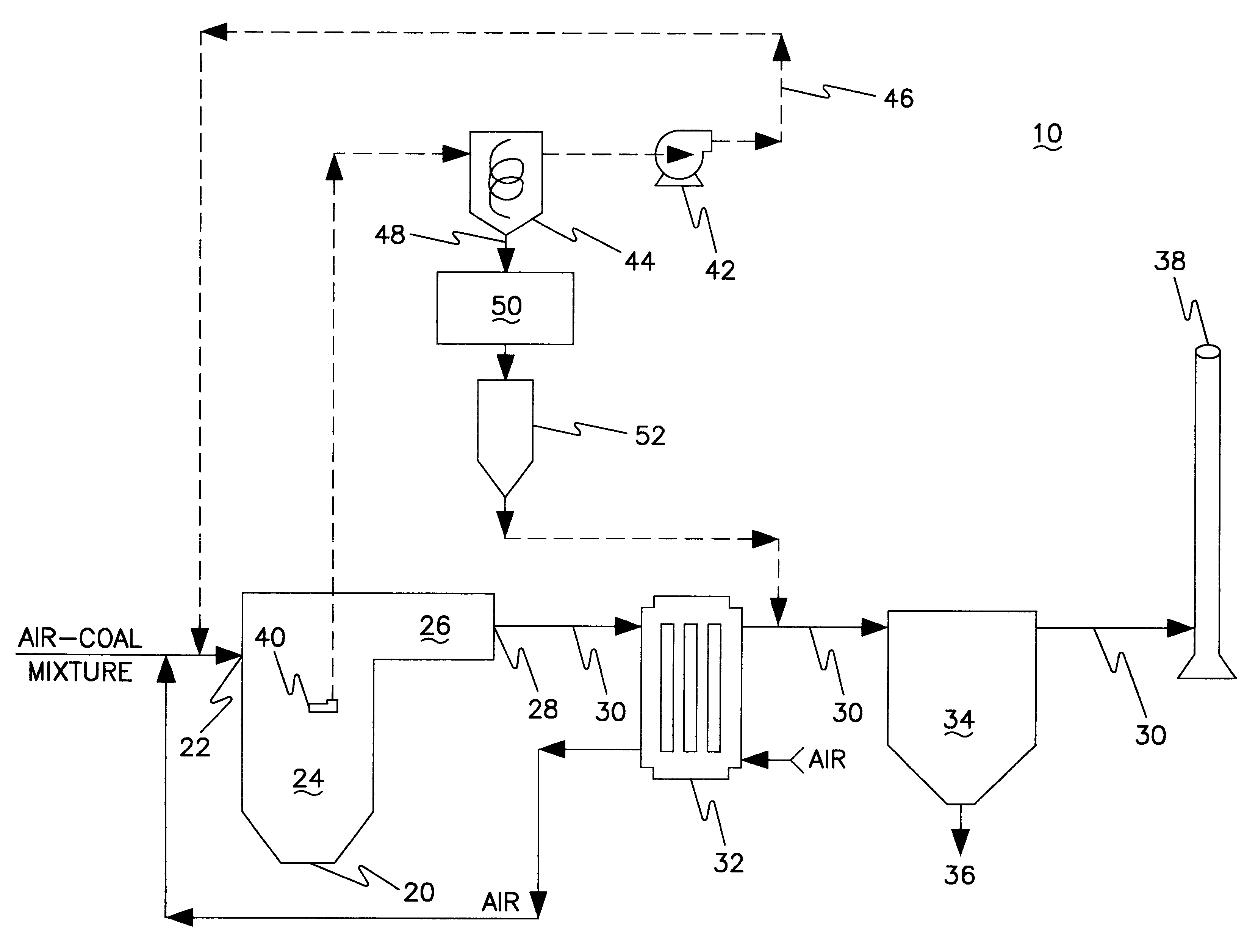

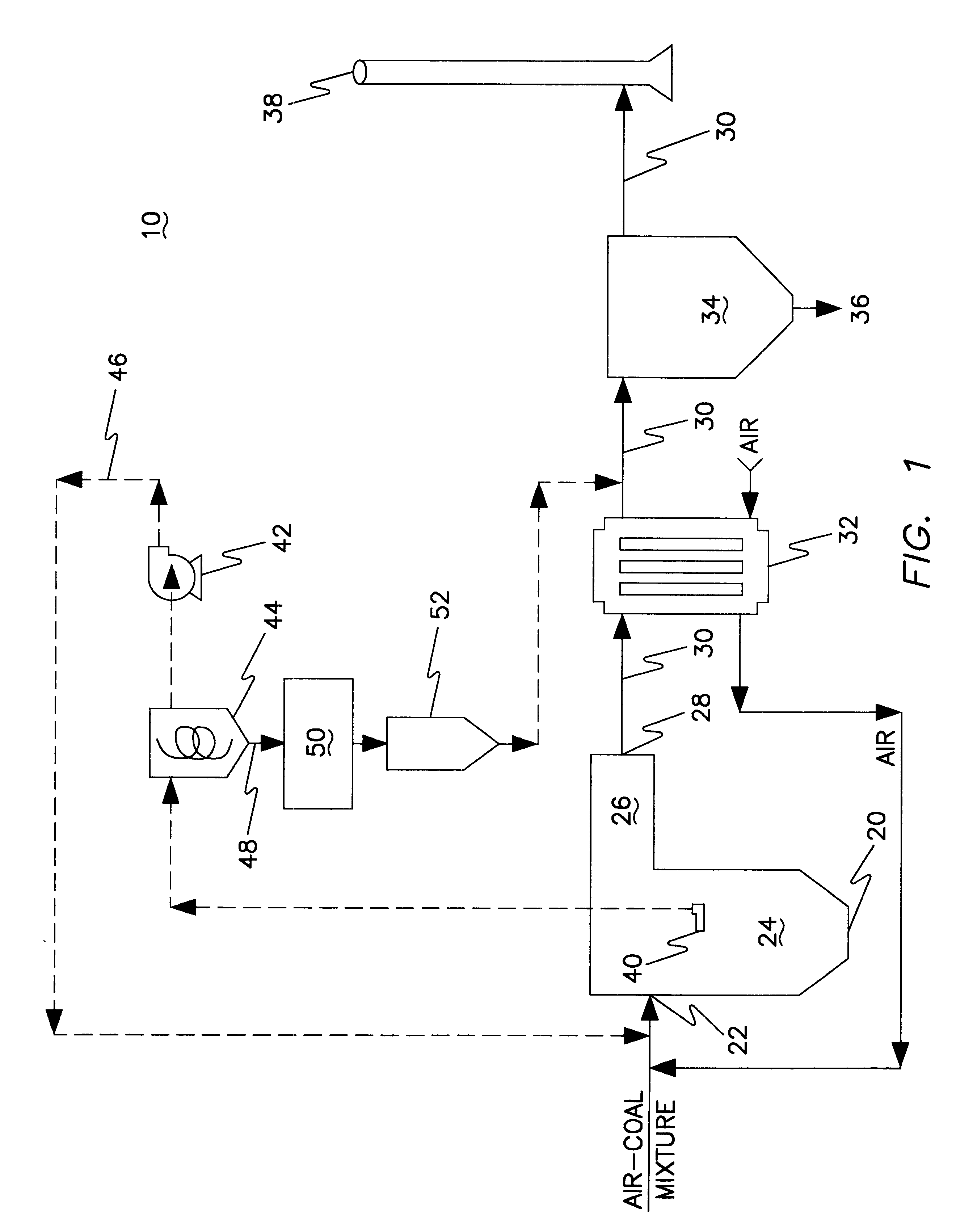

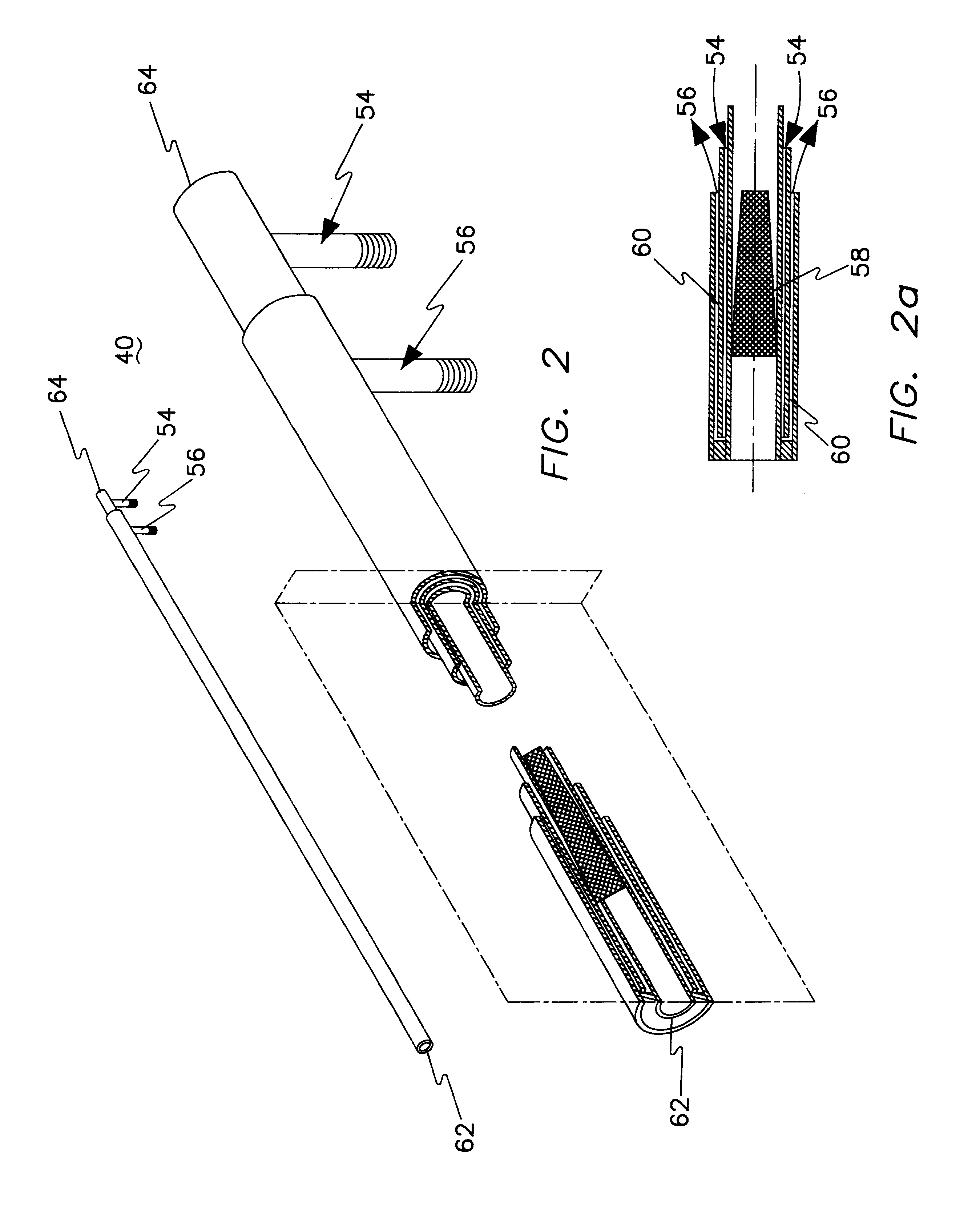

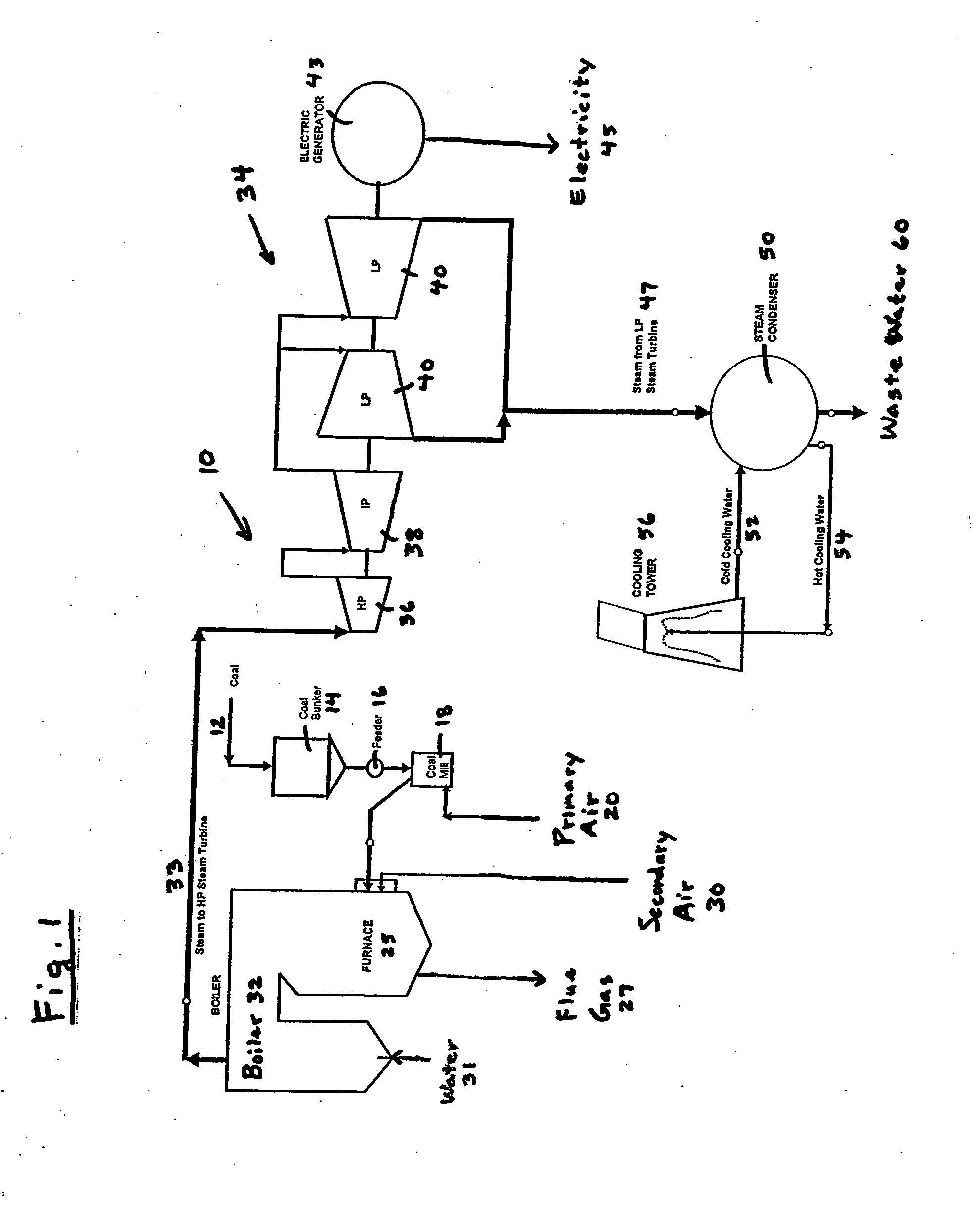

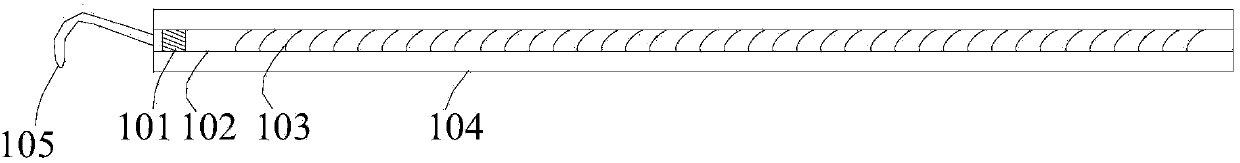

A system and method for removing mercury from the flue gas of a coal-fired power plant is described. Mercury removal is by adsorption onto a thermally activated sorbent produced in-situ at the power plant. To obtain the thermally activated sorbent, a lance (thief) is inserted into a location within the combustion zone of the combustion chamber and extracts a mixture of semi-combusted coal and gas. The semi-combusted coal has adsorptive properties suitable for the removal of elemental and oxidized mercury. The mixture of semi-combusted coal and gas is separated into a stream of gas and semi-combusted coal that has been converted to a stream of thermally activated sorbent. The separated stream of gas is recycled to the combustion chamber. The thermally activated sorbent is injected into the duct work of the power plant at a location downstream from the exit port of the combustion chamber. Mercury within the flue gas contacts and adsorbs onto the thermally activated sorbent. The sorbent-mercury combination is removed from the plant by a particulate collection system.

Owner:THE UNITED STATES AS REPRESENTED BY THE DEPARTMENT OF ENERGY

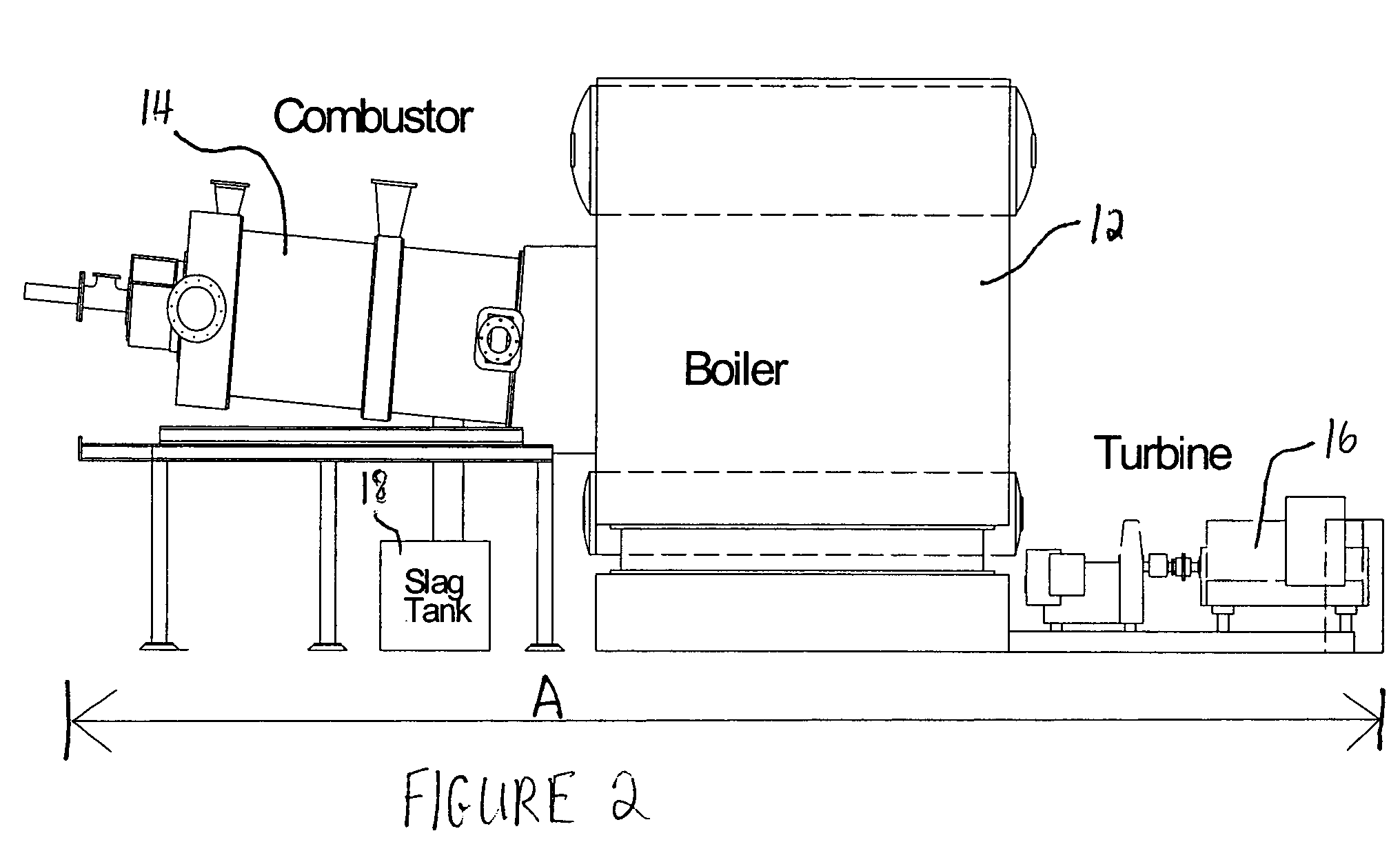

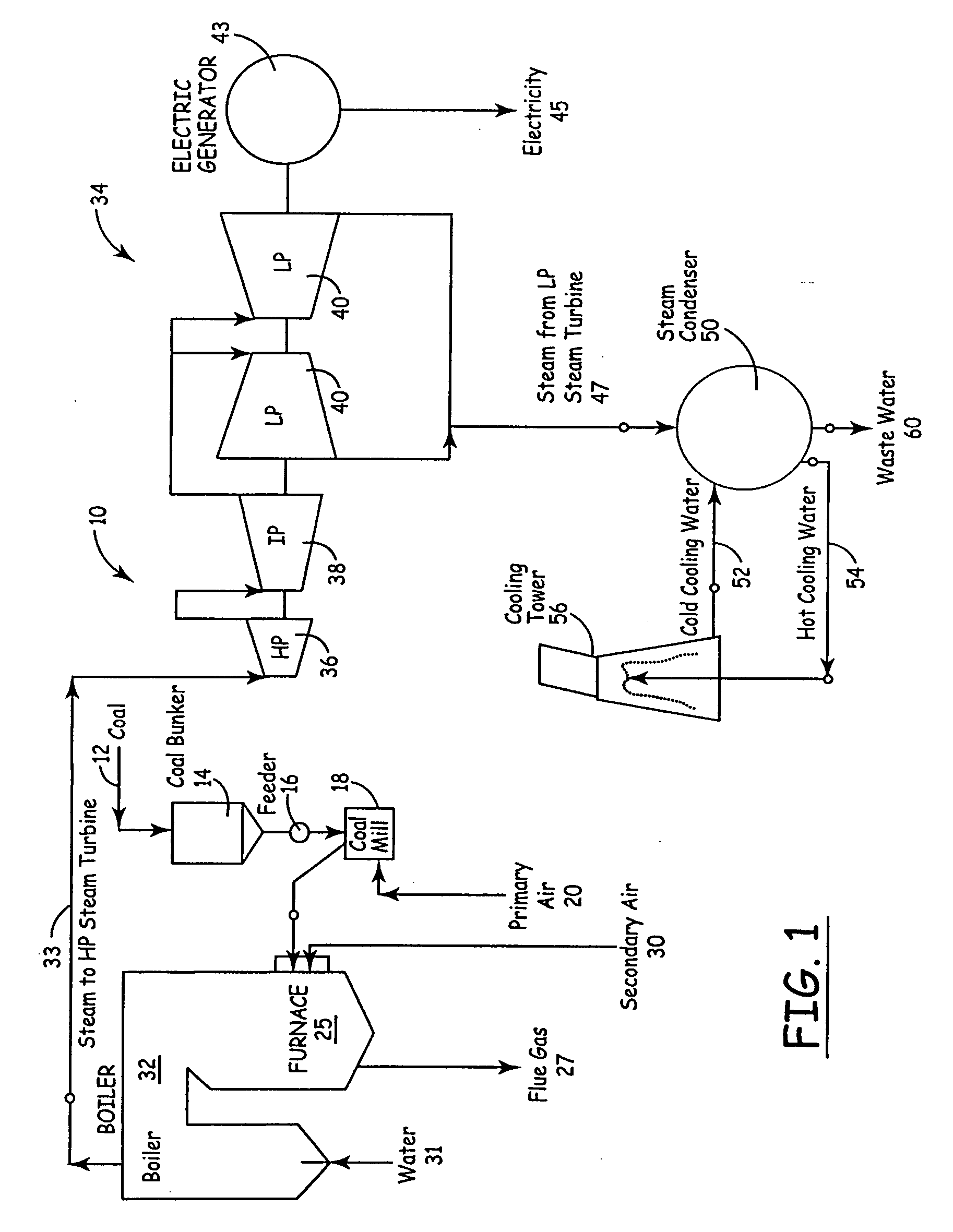

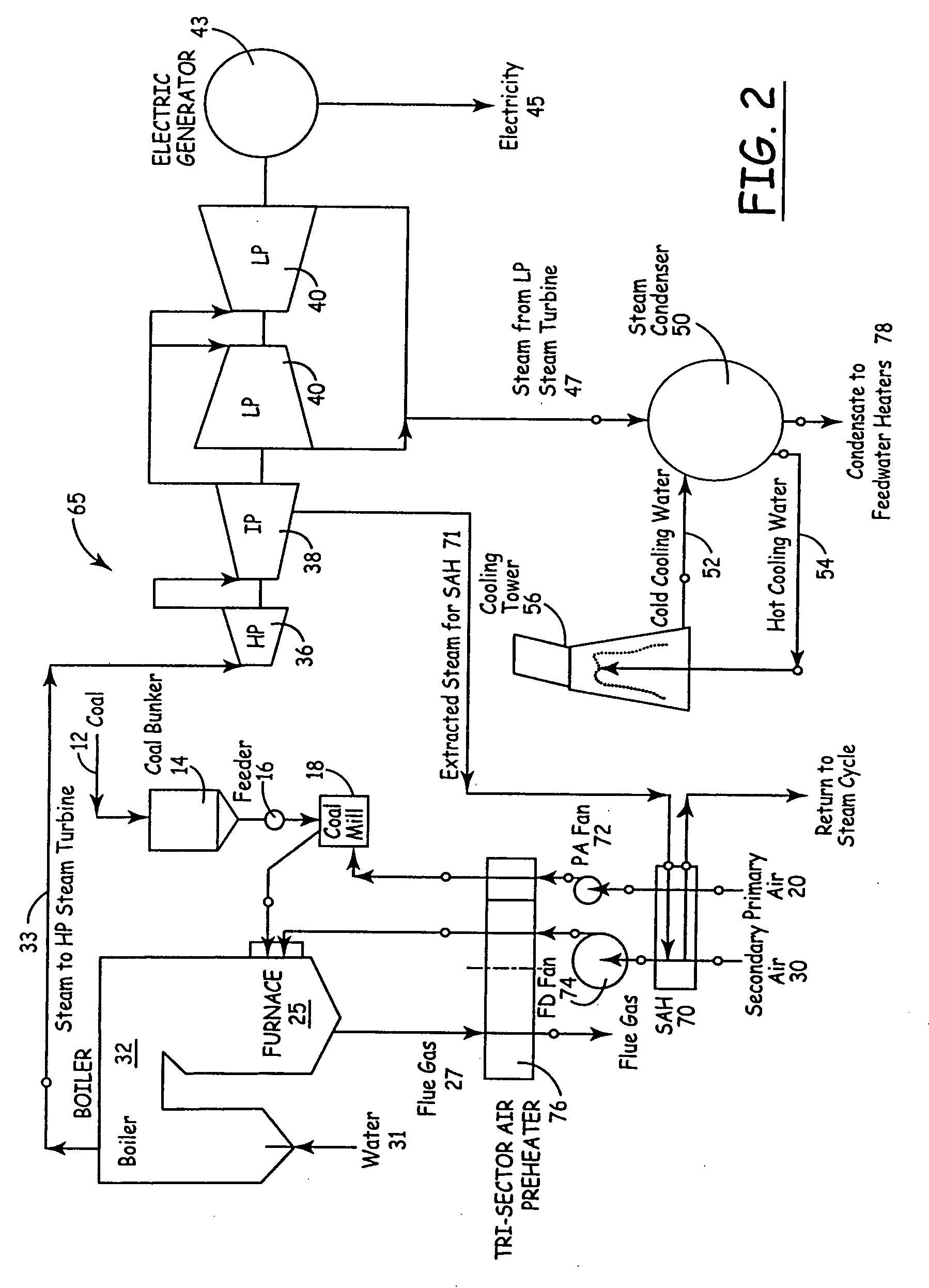

Production of hydrogen and removal and sequestration of carbon dioxide from coal-fired furnaces and boilers

InactiveUS7282189B2Increase ratingsValue maximizationOrganic chemistryNitrogen compoundsHydrogenProcess engineering

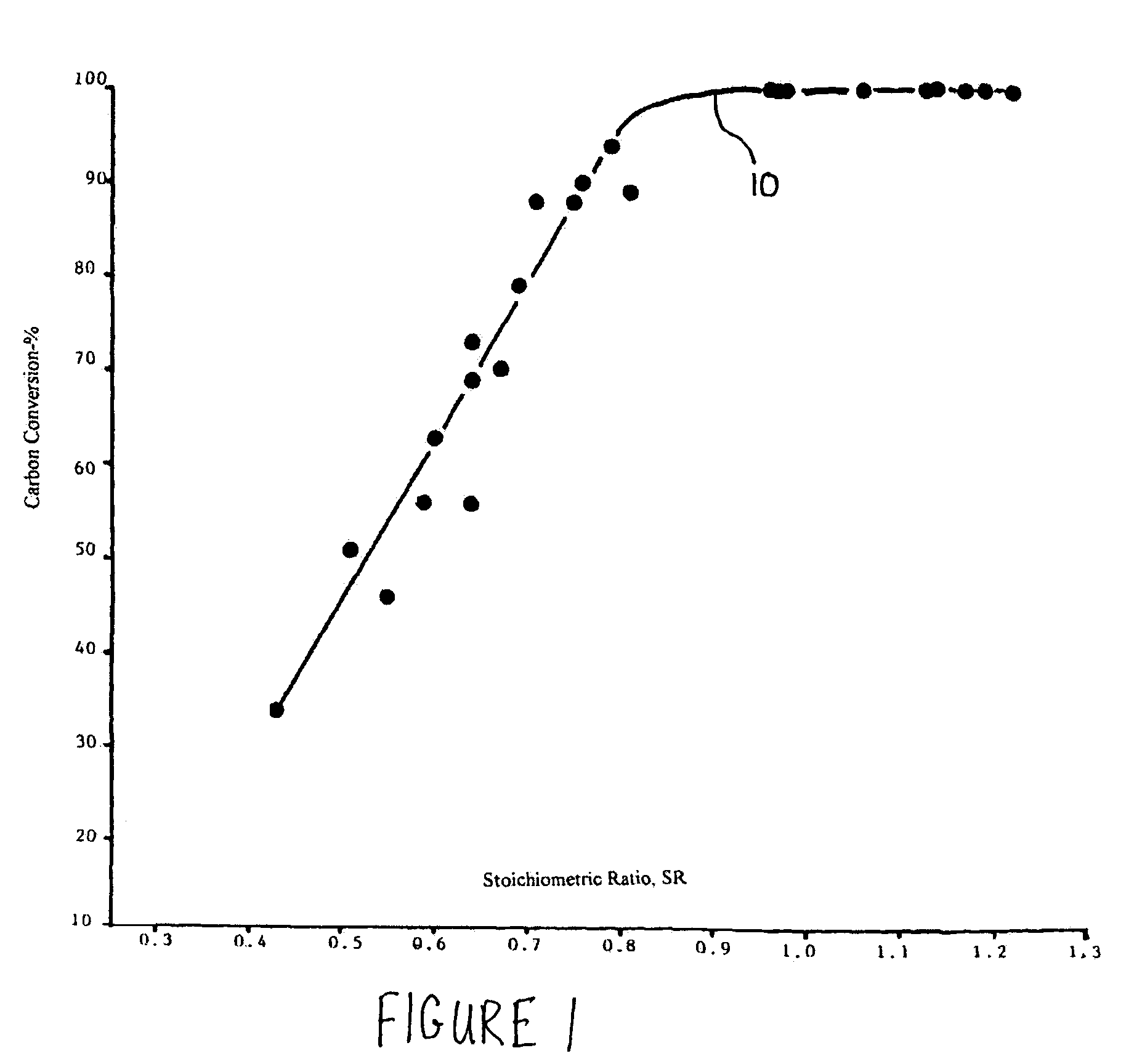

Methods for reducing and eliminating carbon dioxide from the emissions of solid fuel fired power plants, particularly coal fired power plants, and to sequester the carbon dioxide, typically by using existing equipment. In some embodiments, the methods involve pyrolyzing the solid fuel to remove volatile matter and using the volatile matter to produce hydrogen. Additionally, the methods may involve burning the solid fuel or pyrolized solid fuel at very fuel rich stoichiometric conditions. Sequestration may include the production of a carbon dioxide-containing solution and the pumping of the solution into the ground, particularly in areas high in limestone.

Owner:ZAUDERER BERT

Enhanced mercury control in coal-fired power plants

InactiveUS20030161771A1Enhanced capture of mercuryEliminating undesirable dischargeUsing liquid separation agentHalide preparation methodsPulverized fuel ashElemental mercury

A method of treating a coal combustion flue gas, which includes injecting a molecular halogen or thermolabile molecular halogen precursor able to decompose to form molecular halogen at flue gas temperature. The molecular halogen coverts elemental mercury to mercuric halide adsorbable by alkaline solids such as subbituminous or lignite coal ash, alkali fused bituminous coal ash capturable in whole or part by electrostatic precipitators (ESPs), baghouses (BHs), fabric filters (FFs), dry flue gas desulphurization solids, with or without subsequent adsorption by a liquid such as a flue gas desulphurization scrubbing liquor.

Owner:HAZELMERE RES

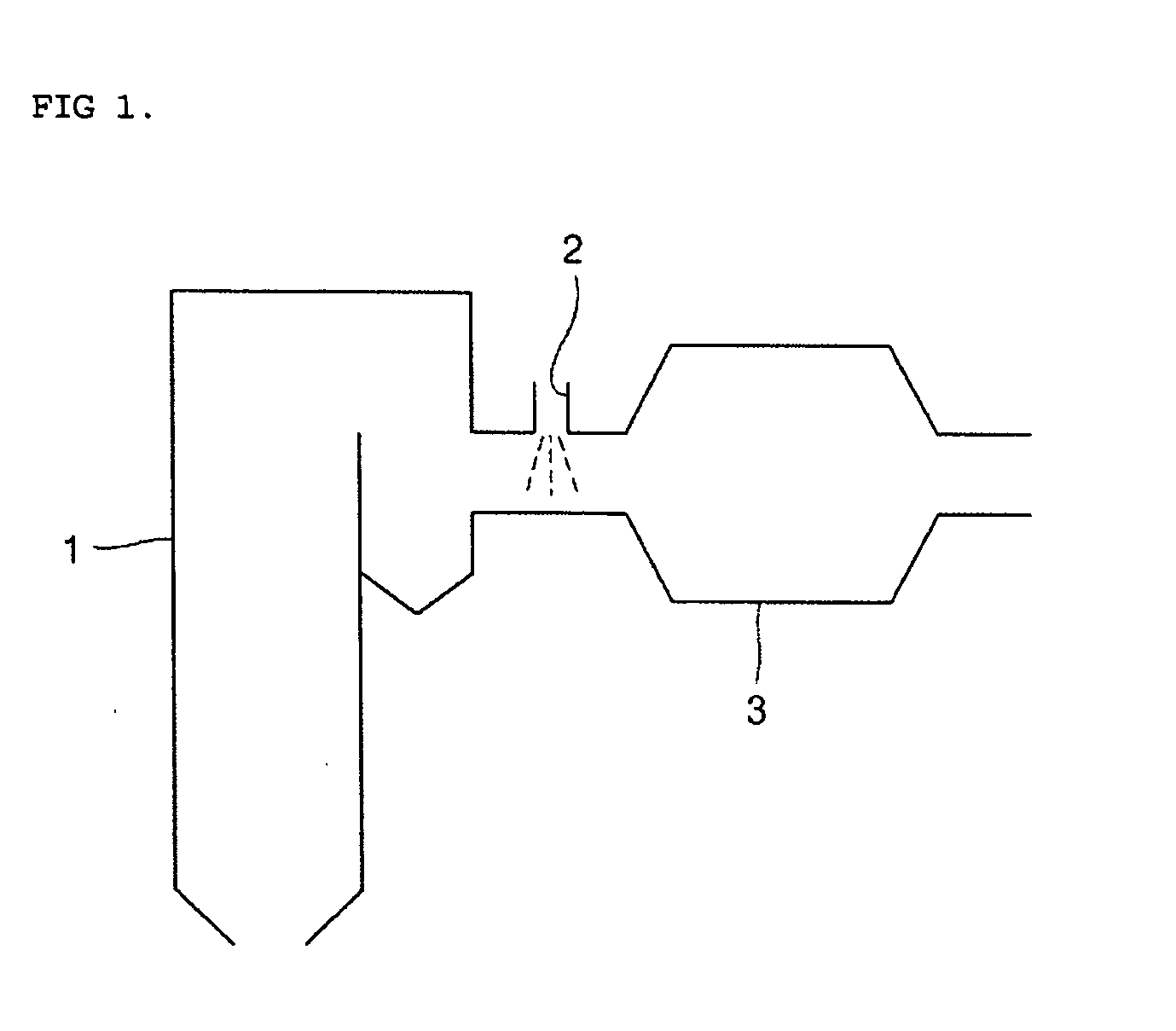

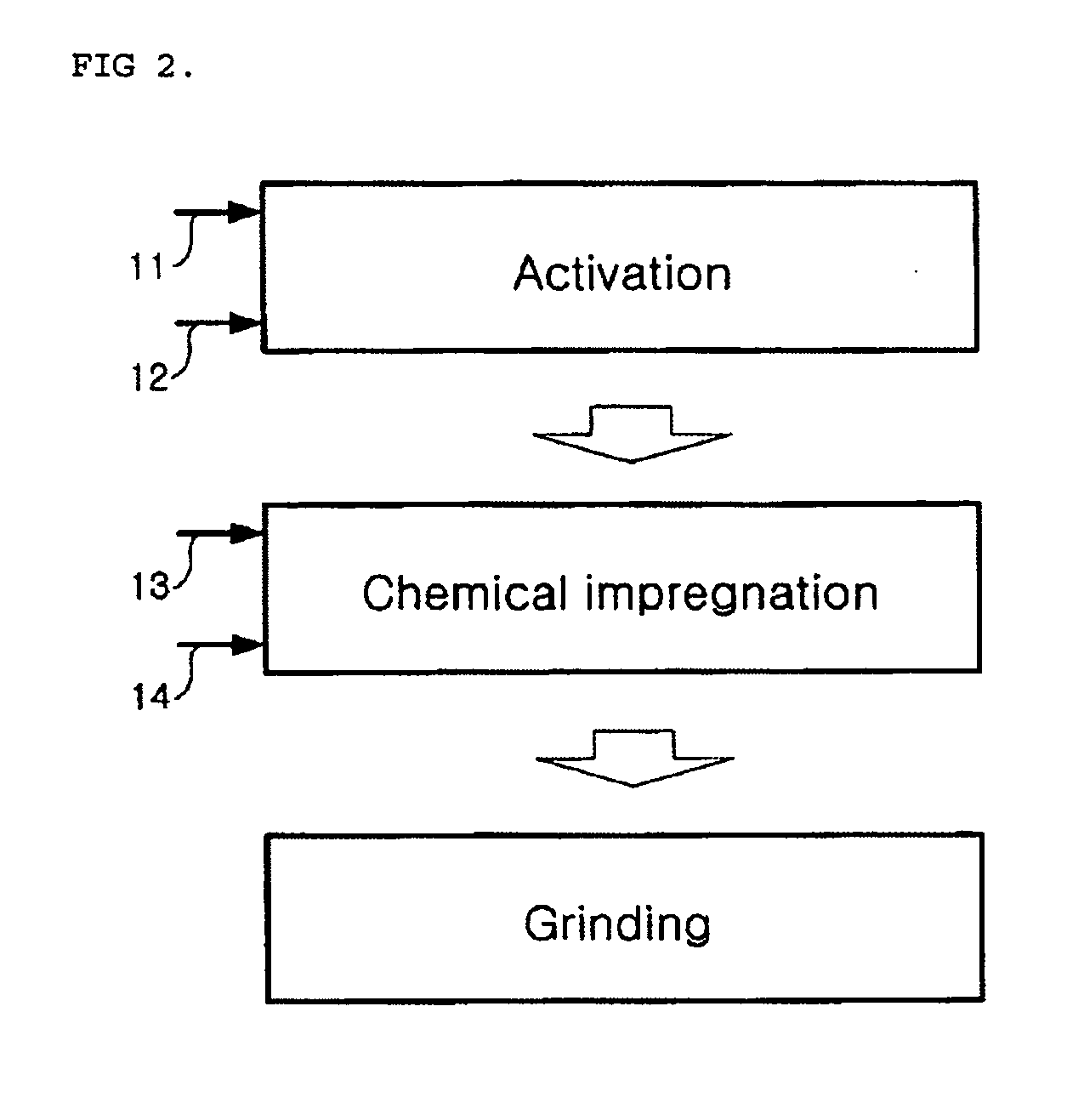

Sorbent for removal of trace hazardous air pollutants from combustion flue gas and preparation method thereof

InactiveUS20070179056A1Low costLow raw material costGas treatmentOther chemical processesSorbentToxic industrial waste

Disclosed is a sorbent for the removal of mercury from combustion flue gas and a preparation method thereof. The sorbent includes an activated heavy oil heavy ash impregnated with 0.1-30% by weight of any chemical substance selected from sulfur, iodine, bromine and chlorine. The sorbent is prepared in an economical manner using heavy oil fly ash, industrial waste generated from heavy oil-fired boilers, and has excellent sorption performance for mercury, so that a low concentration of mercury contained in combustion flue gas discharged from large-scale boilers can be removed by injection of a small amount of the sorbent. Thus, the invention can prevent a reduction in the recycling rate of coal fly ash in coal-fired power plants and minimize operation cost.

Owner:KOREA ELECTRIC POWER CORP

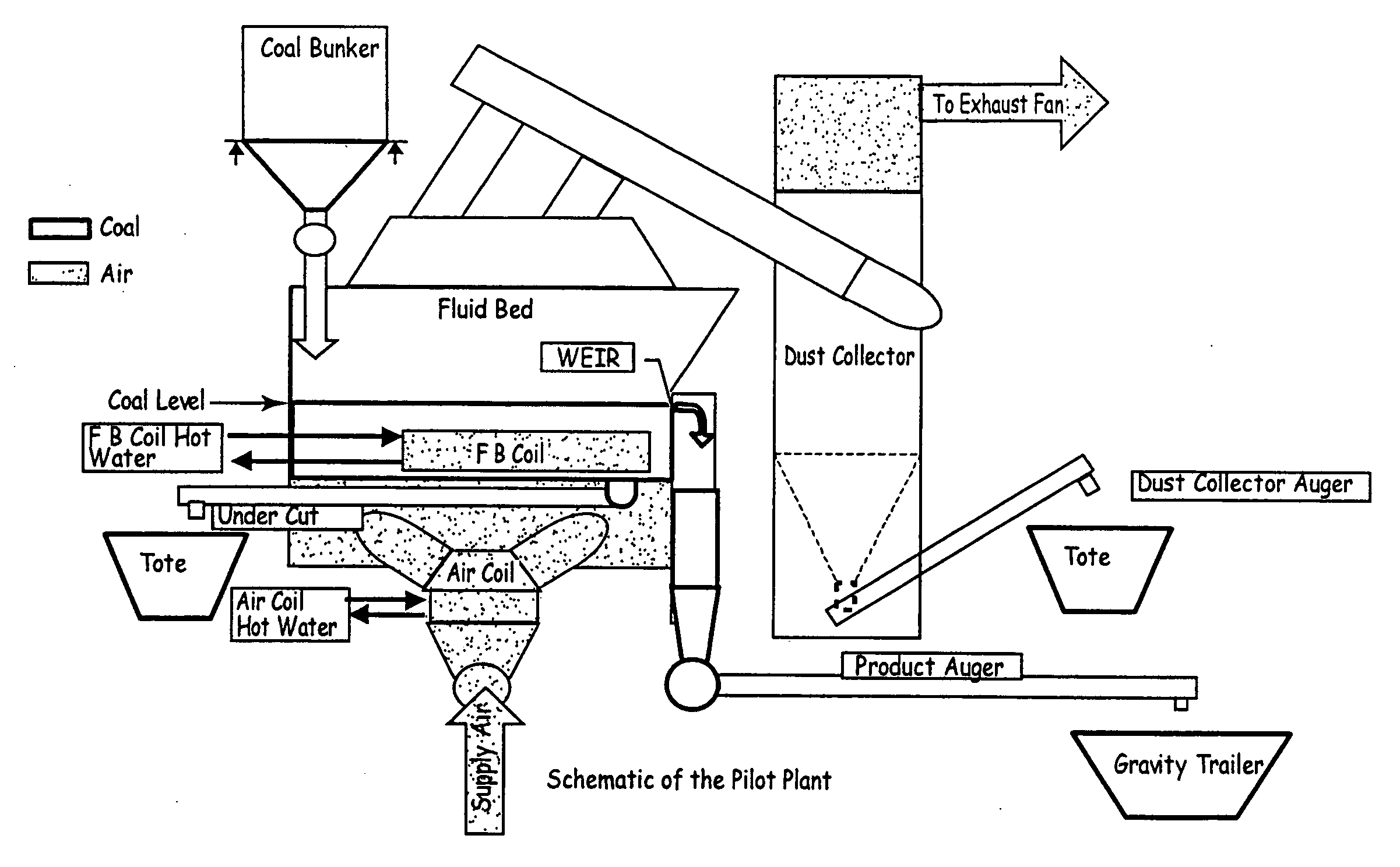

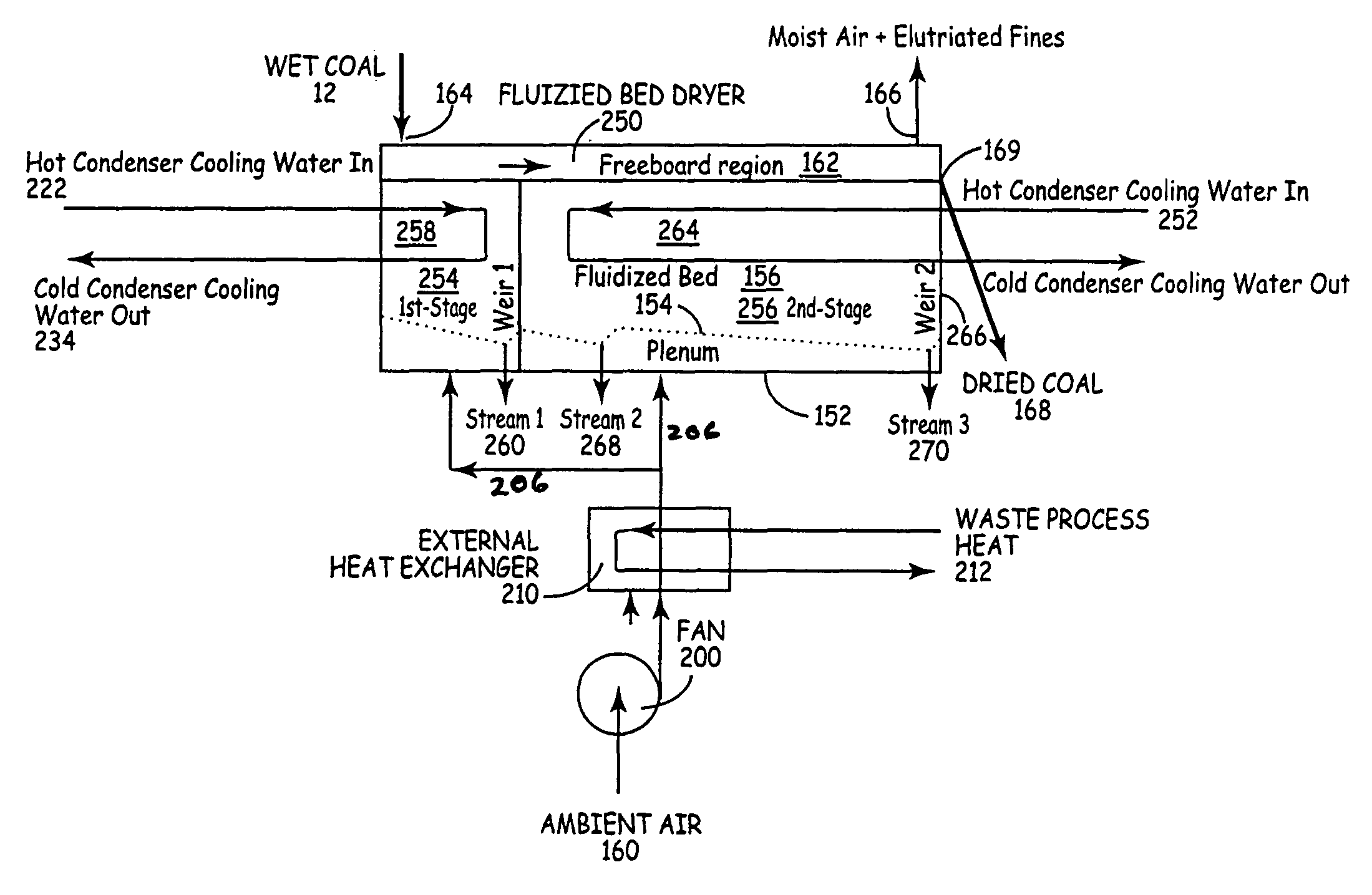

Apparatus and method of enhancing the quality of high-moisture materials and separating and concentrating organic and/or non-organic material contained therein

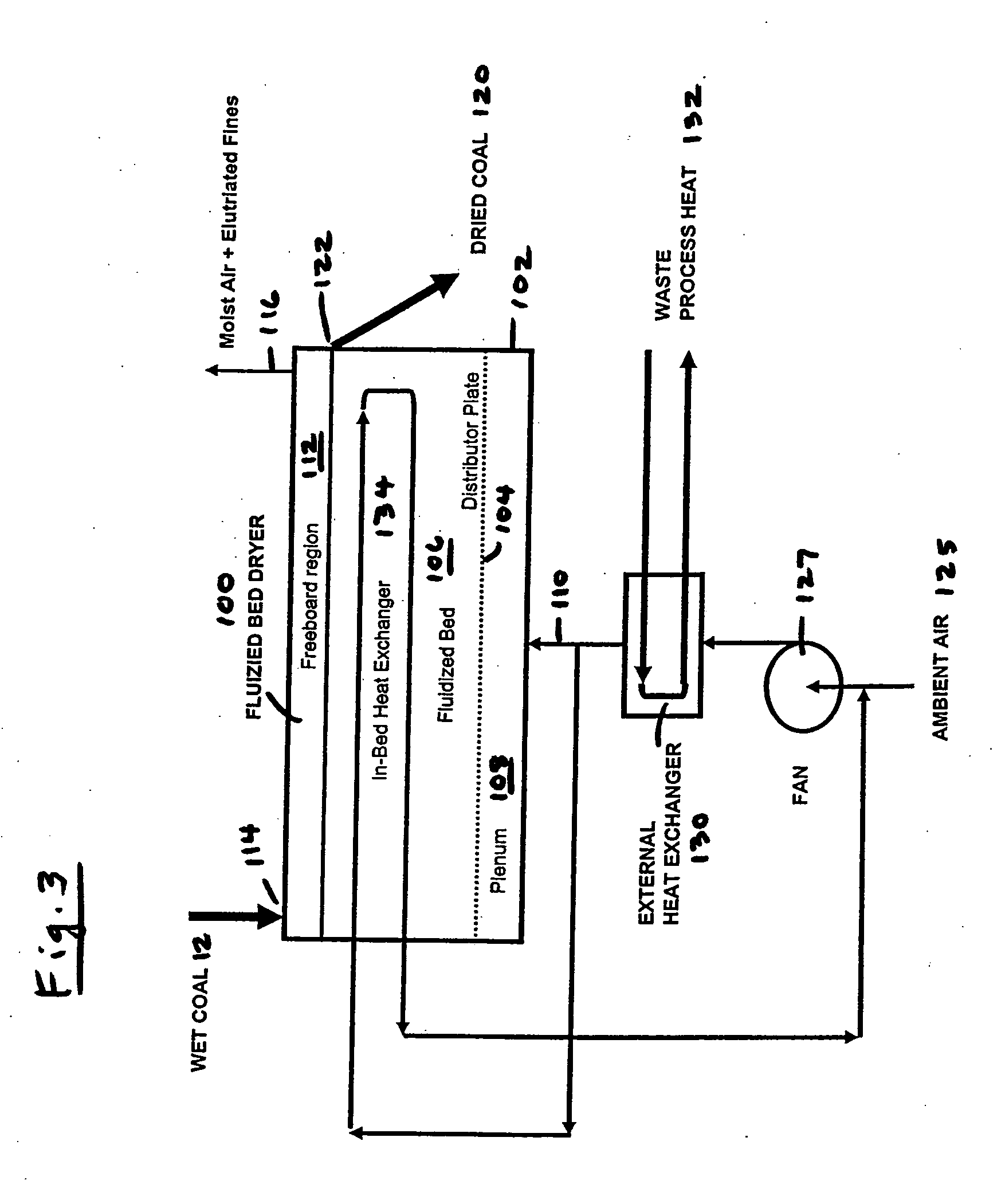

ActiveUS20080201980A1Processed evenly and quicklySignificant environmental benefitsDrying solid materials with heatSolid fuel pretreatmentParticulatesFluidized bed drying

The present invention harvests and utilizes fluidized bed drying technology and waste heat streams augmented by other available heat sources to dry feedstock or fuel. This method is useful in many industries, including coal-fired power plants. Coal is dried using the present invention before it goes to coal pulverizers and on to the furnace / boiler arrangement to improve boiler efficiency and reduce emissions. This is all completed in a low-temperature, open-air system. Also included is an apparatus for segregating particulate by density and / or size including a fluidizing bed having a particulate receiving inlet for receiving particulate to be fluidized. This is useful for segregating contaminants like sulfur and mercury from the product stream.

Owner:RAINBOW ENERGY CENT LLC

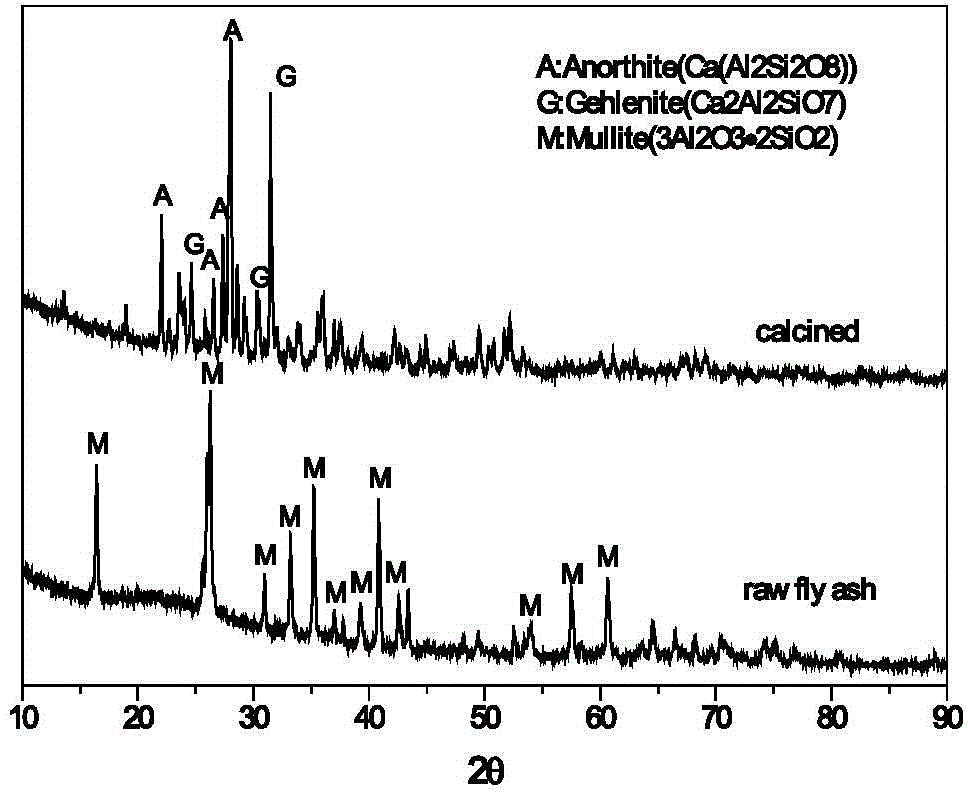

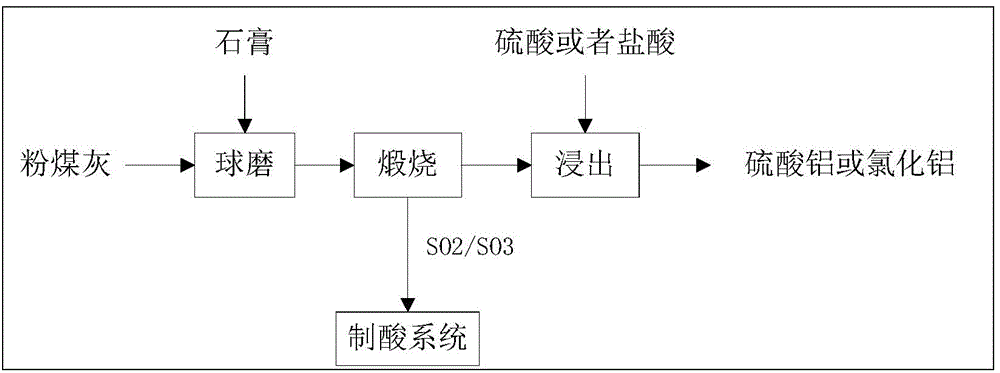

Method for cooperative activation of fly ash and decomposition of gypsum for recovery of sulfur resource

The invention provides a method for cooperative activation of fly ash and decomposition of gypsum for recovery of a sulfur resource. According to the method, solid waste, i.e., fly ash, discharged by a coal-fired power plant or coal-fired boiler is used as a raw material, a certain proportion of desulfurized gypsum discharged by the coal-fired power plant or waste phosphogypsum produced in the phosphorus chemical industry is added and mixed with the fly ash, then the obtained mixture is subjected to ball milling, and activation and calcination at a temperature of 950 to 1450 DEG C are carried out for 5 to 180 min; calcium sulfate in the gypsum are almost totally decomposed after calcination, and produced gas contains sulfur dioxide or sulfur trioxide which can be used as feed gas for preparation of sulfuric acid; and calcination enables solid fly ash to be activated, leaching with a sulfuric acid or hydrochloric acid solution is carried out at a temperature of 50 to 100 DEG C, and the leaching rate of alumina is greater than 80%. The method provided by the invention has the advantages that since all the raw materials are solid waste, the purpose of treating the waste by using the waste is achieved; elemental sulphur in the gypsum can be recovered; and the fly ash can be activated and activity of the fly ash can be improved, so a high alumina recovery rate at a low temperature can be realized. With the method, high-efficiency extraction of alumina in the fly ash is realized; the sulfur resource in the gypsum is recovered; shortage in industrial sulphur in the sulfuric acid industry in China is compensated; and the method has good economic benefits and wide industrial application prospects.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

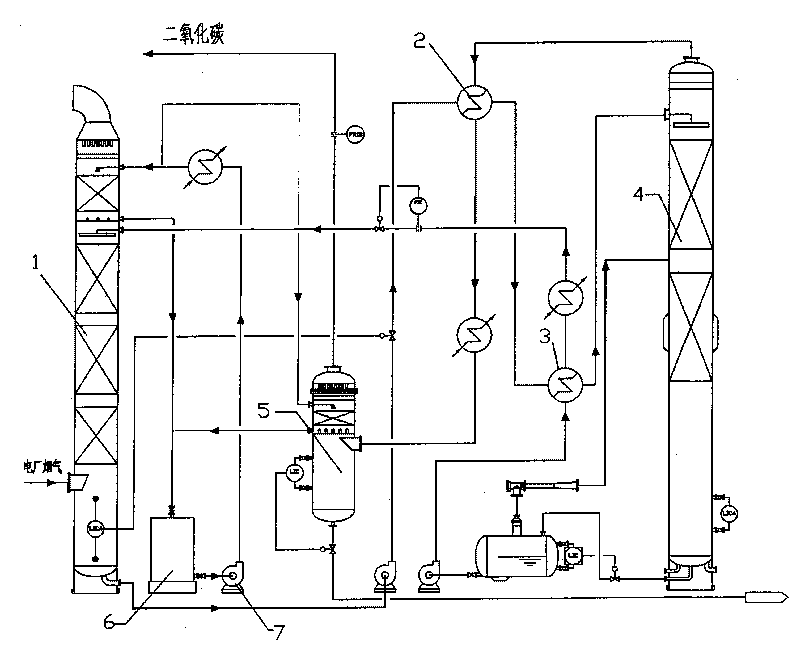

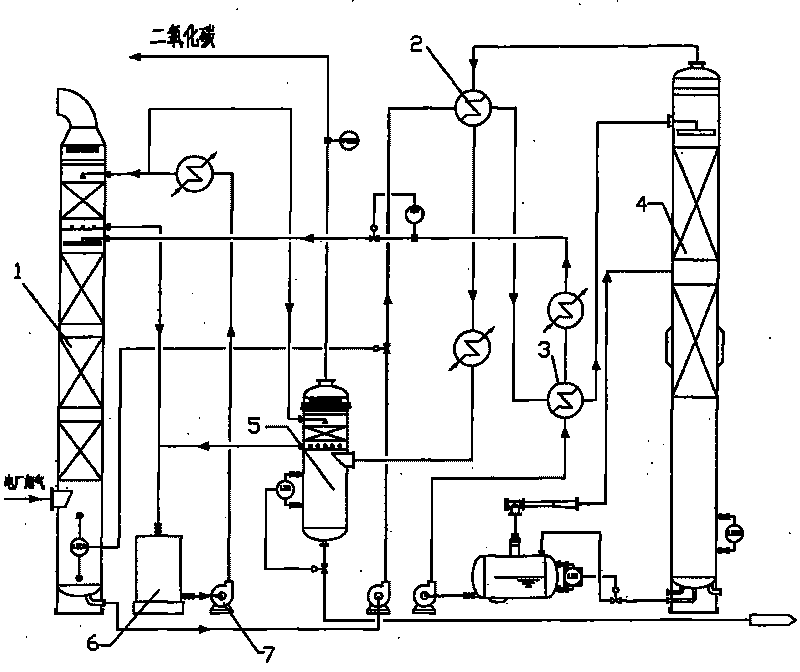

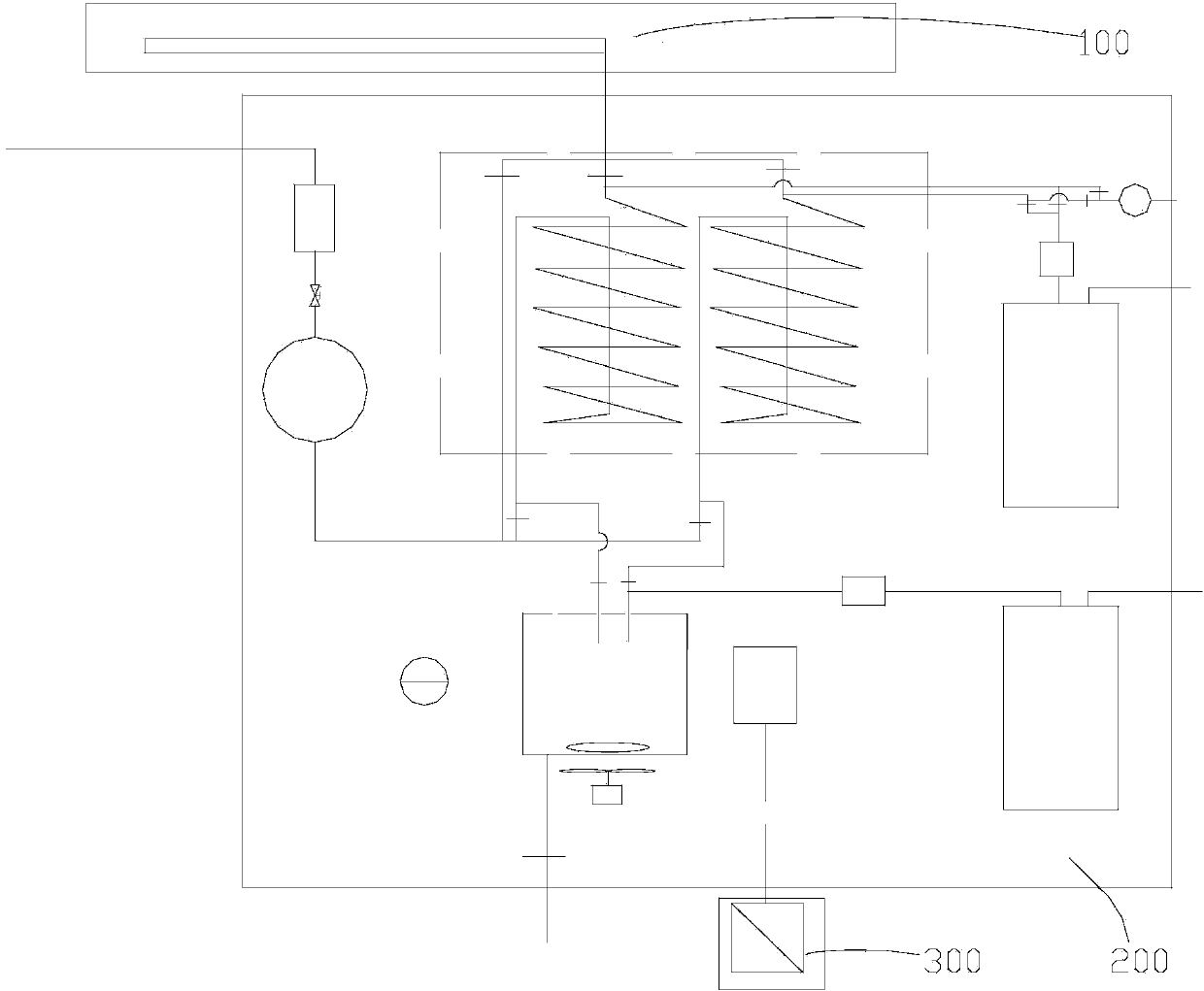

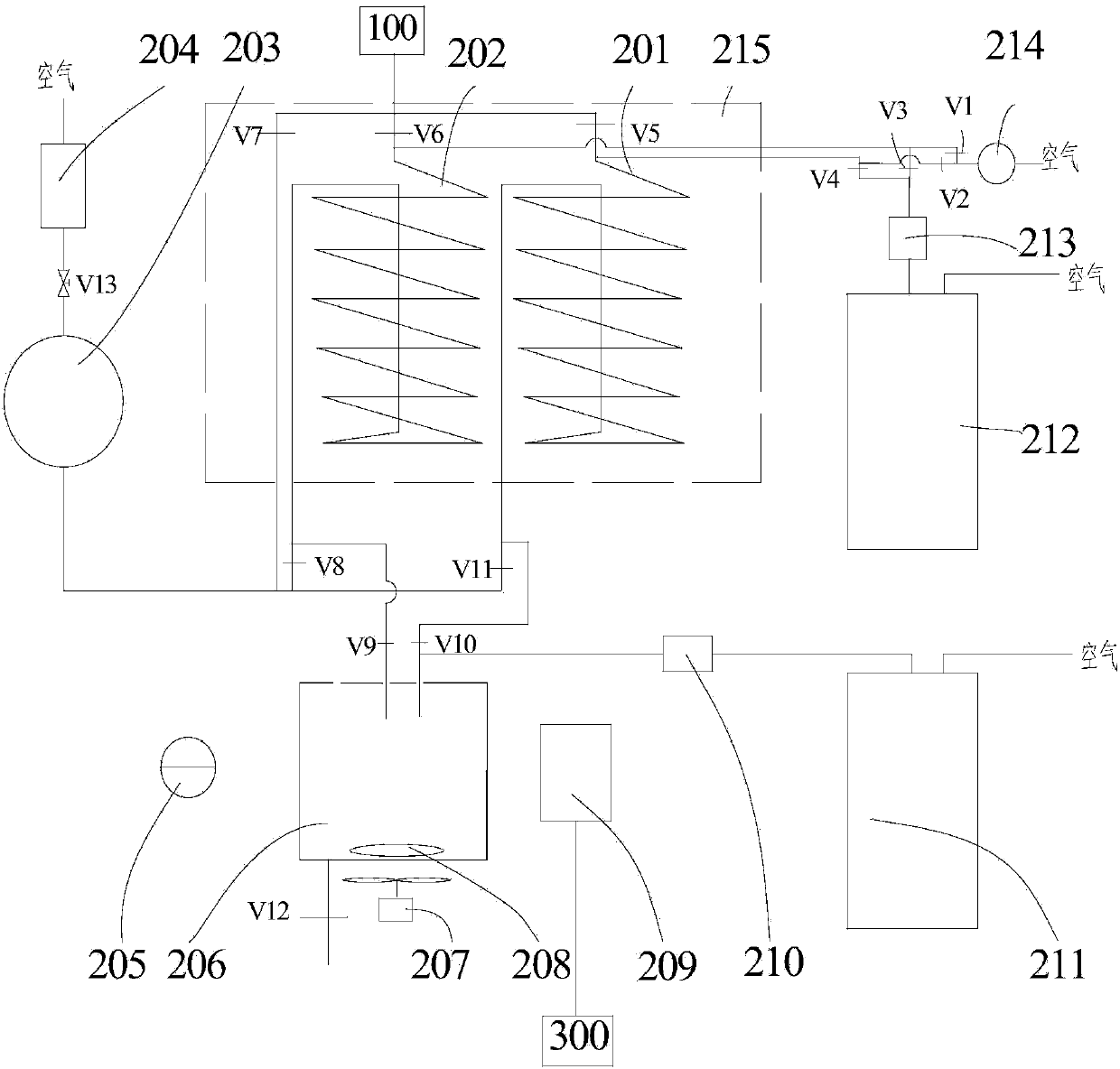

Method and apparatus for collecting carbonic anhydride in coal-fired plant flue gas

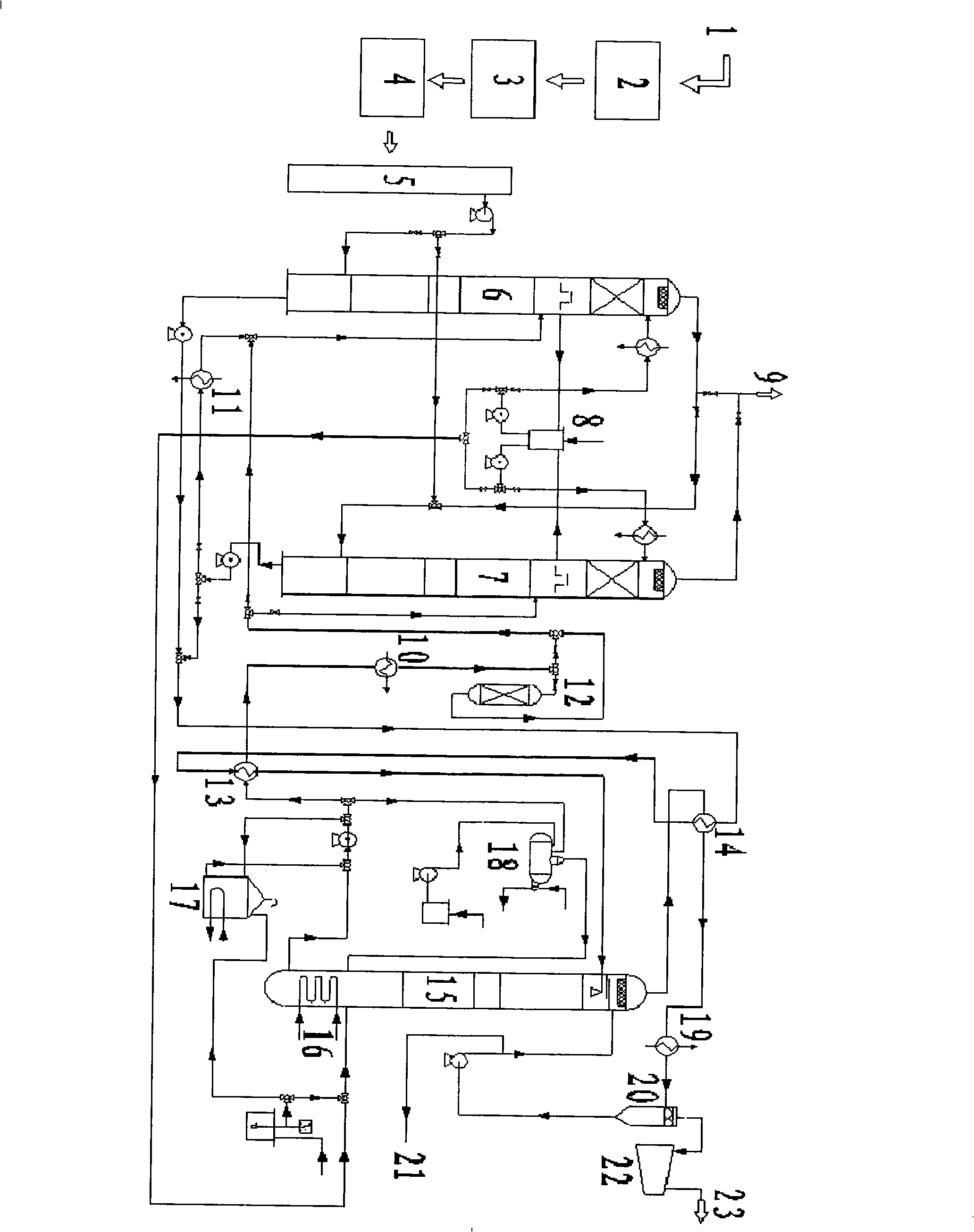

The invention provides a method and a device for collecting carbon dioxide in smoke gas of a coal-fired power plant. The device consists of a smoke gas pretreatment system, absorption towers, a regeneration tower, an exhaust scrubbing system, a solution heating recoverer, a product gas processing system (comprising a condenser, a gas-liquid separator and a compressor). The device is integrated with the prior smoke gas purification device of the coal-fired power plant, and is provided with a high-efficiency whirlcone and a chemical absorption system, so that mass carbon dioxide gas exhausted from a coal-fired boiler can be collected, and the emission of greenhouse gas can be reduced; the special arrangement of double absorption towers ensures more flexible operation of a collecting system, and improves the operational reliability; an absorption solution reclaiming process reduces the consumption of the solution; the arrangement of a lean-rich solution heat exchanger and a product gas rich solution heat exchanger reduces the energy consumption of the collecting system; and the steam consumption can be effectively reduced by adopting a built-in solution boiling unit.

Owner:XIAN THERMAL POWER RES INST CO LTD

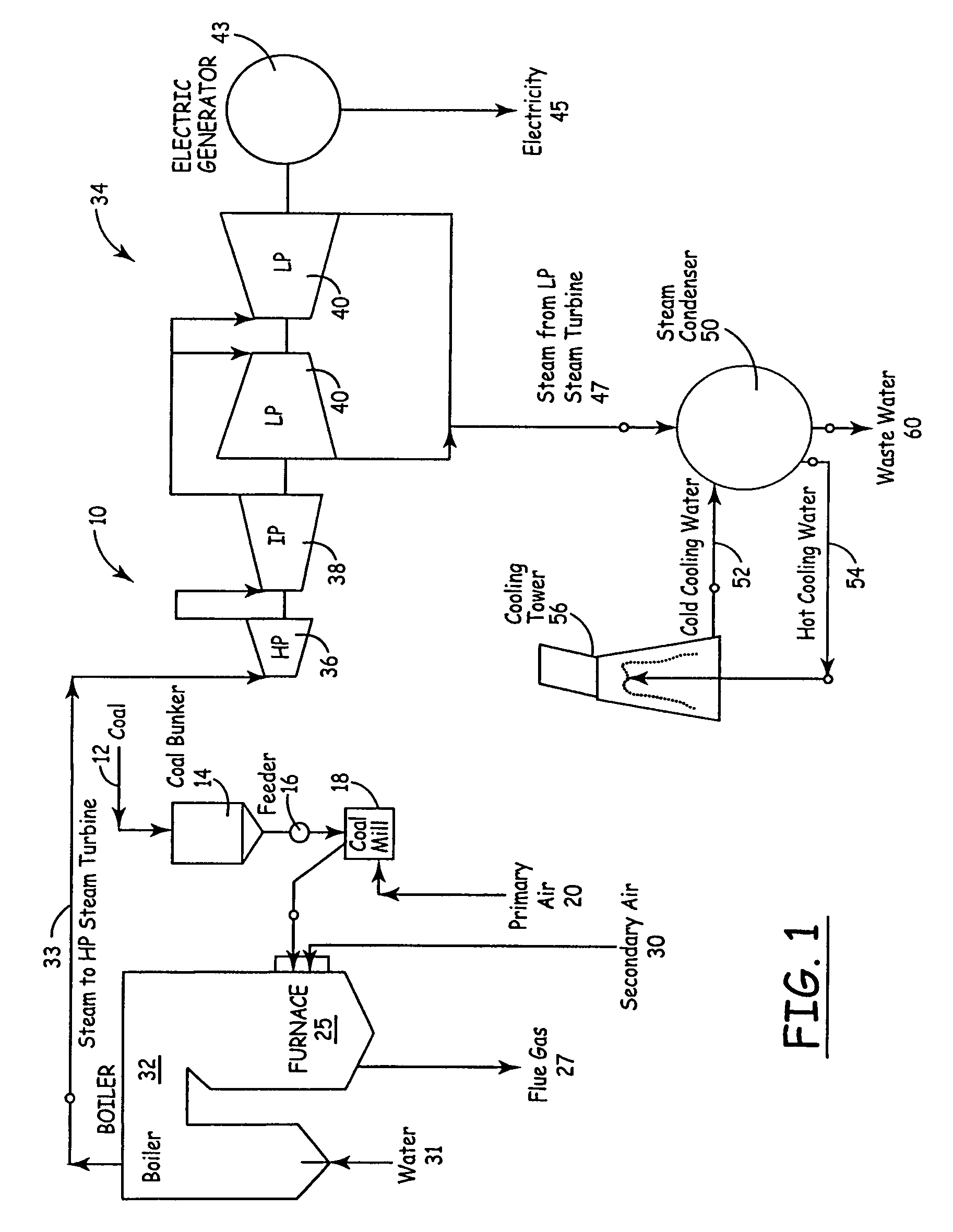

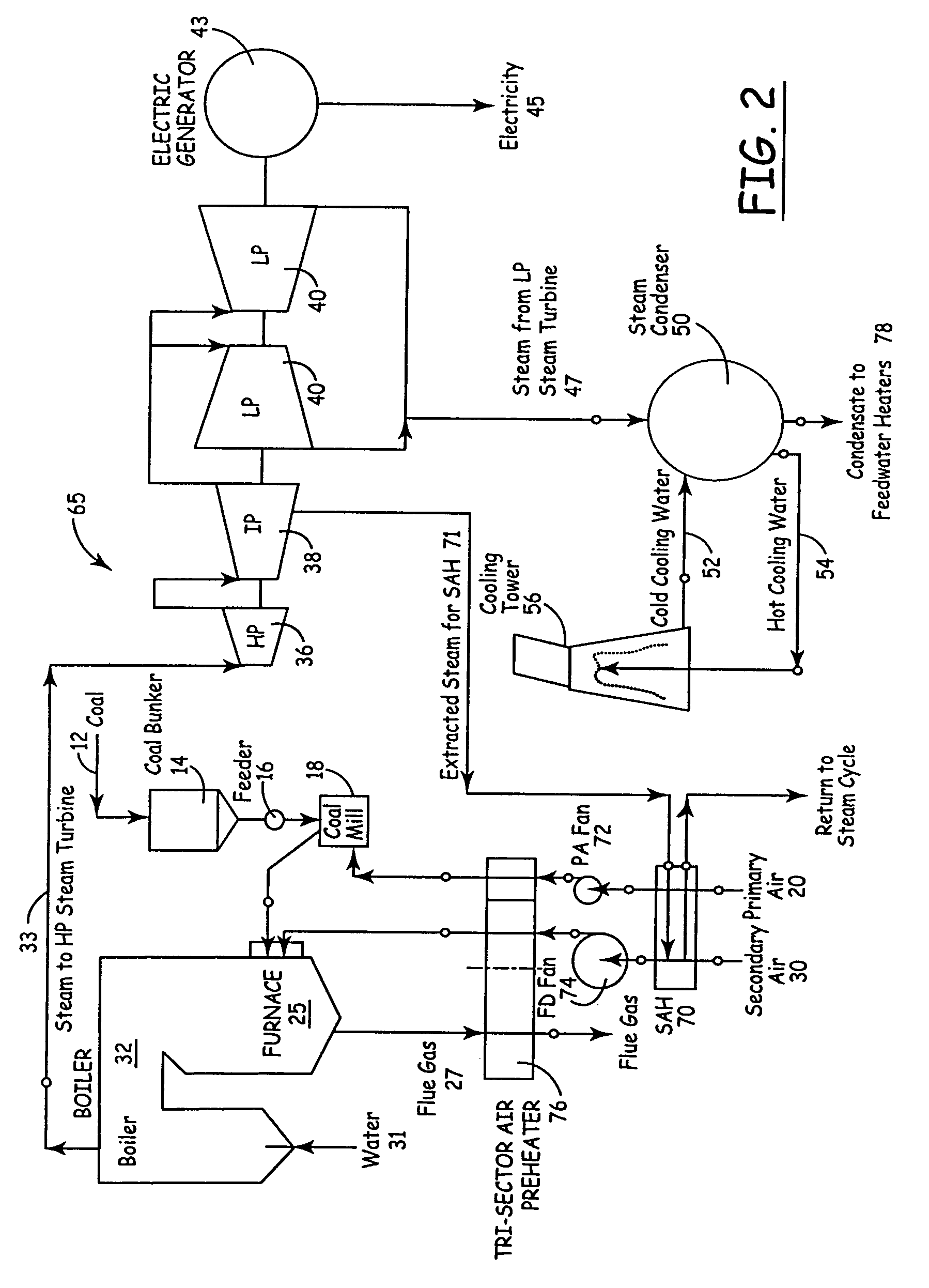

Method of enhancing the quality of high-moisture materials using system heat sources

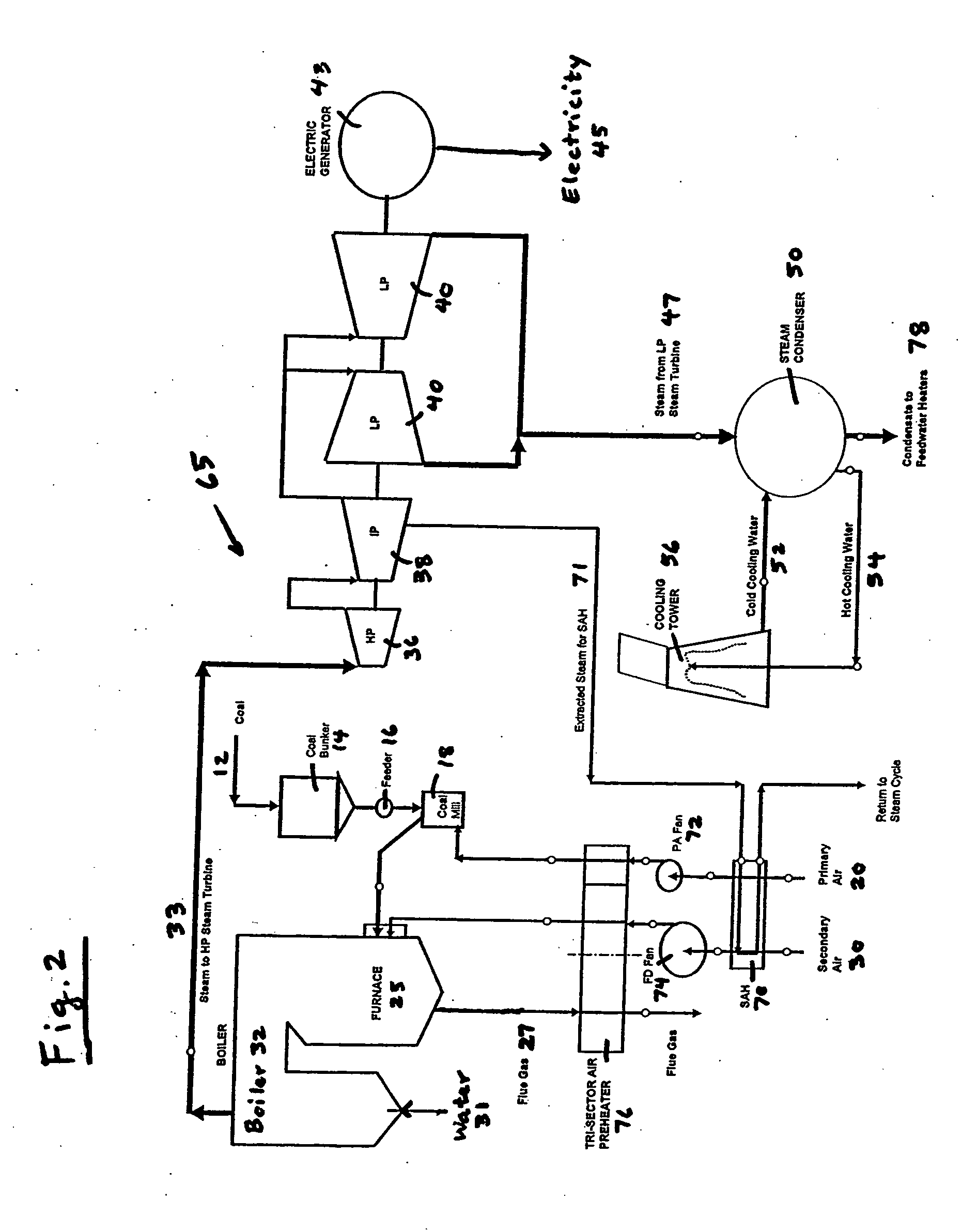

ActiveUS20060075682A1Eliminates potential harmEmission reductionDrying solid materials with heatSolid fuelsFluidized bed dryingHeat flow

The present invention harvests and utilizes fluidized bed drying technology and waste heat streams augmented by other available heat sources to dry feedstock or fuel. This method is useful in many industries, including coal-fired power plants. Coal is dried using the present invention before it goes to coal pulverizers and on to the furnace / boiler arrangement. Coal can be intercepted on current coal feed systems ahead of the pulverizers. Drying fuel, such as coal, is done to improve boiler efficiency and reduce emissions. A two-stage bed utilized in the process first “pre-dries and separates” the feed stream into desirable and undesirable feedstock. Then, it incrementally dries and segregates fluidizable and non-fluidizable material from the product stream. This is all completed in a low-temperature, open-air system. Elevation of fan room air temperature is also accomplished using waste heat, thereby making available to the plant system higher temperature media to enhance the feedstock drying process.

Owner:RAINBOW ENERGY CENT LLC

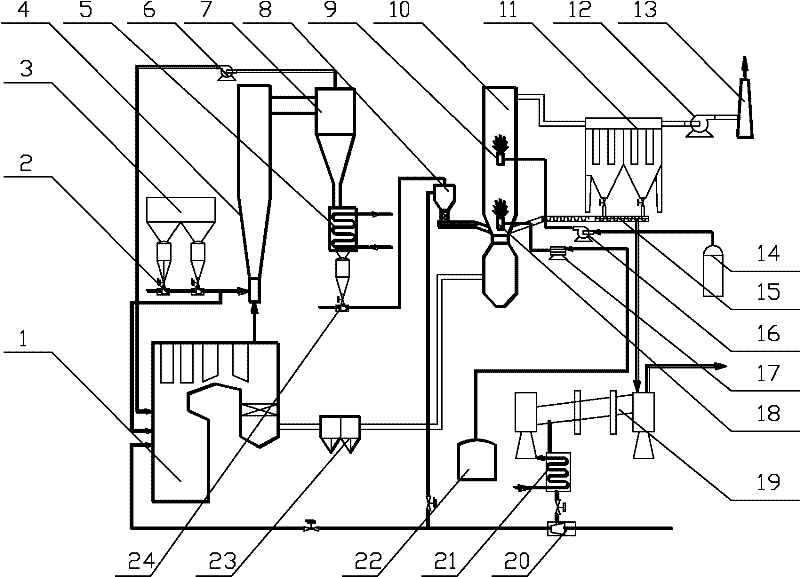

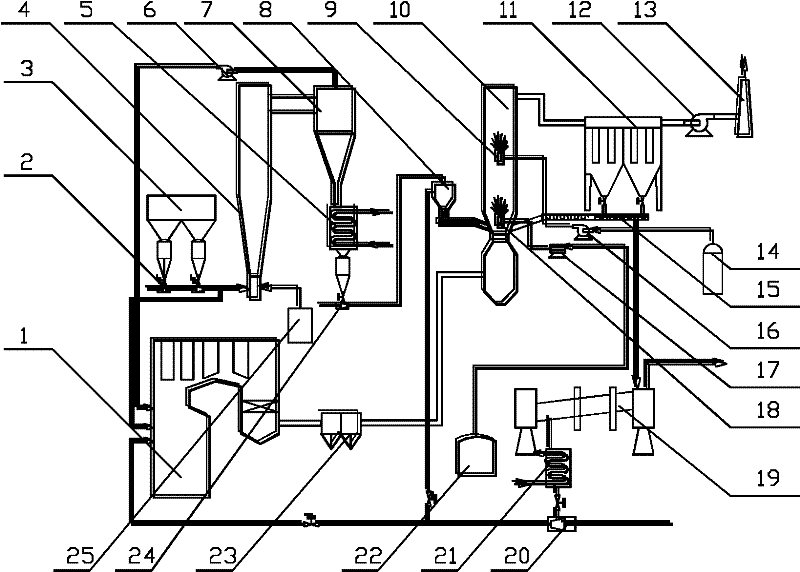

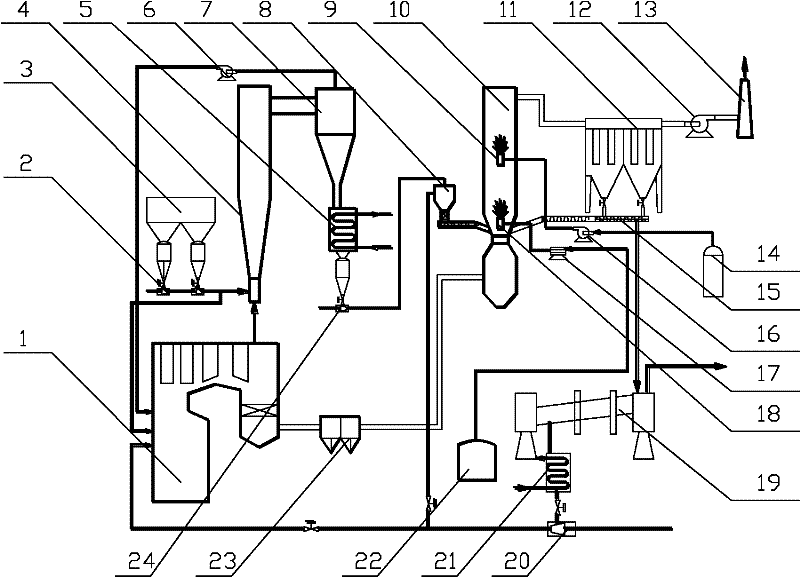

Coal-fired power plant coal dust prepared activated coke flue gas comprehensive purification system and technology

InactiveCN102350214ARealize reburning and denitrificationFull joint removalDispersed particle separationResource utilizationCoal dust

The invention relates to a coal-fired power plant coal dust prepared activated coke flue gas comprehensive purification system and a technology. The technology provided by the invention comprises the following steps of: using coal dust in a coal-fired power plant as a raw material, simultaneously carrying out carbonization and activation on coal dust in an activated coke preparation reactor to obtain powdered activated coke, using pyrolysis gas obtained during the preparation process as reburning fuel and sending it into a boiler so as to remove part of NOx; sending the powdered activated coke into a flue gas adsorption tower, adsorbing pollutants such as sulfur dioxide, mercury and the like at an appropriate temperature, injecting ammonia gas and nitrogen oxide to perform a catalytic reduction reaction so as to remove nitrogen oxide; reusing the adsorbed activated coke after regeneration; sending the activated coke into the boiler for combustion after multiple adsorption / regeneration; regenerating the activated coke after adsorbing sulfur dioxide to obtain high-density sulfur dioxide gas to realize resource utilization. By the utilization of coal resources in a coal-fired power plant, the comprehensive purification of flue gas and the resource utilization of sulfur dioxide are realized without discharge of waste water, exhaust gas and solid waste.

Owner:SHANDONG UNIV

System for comprehensive utilization of three industrial wastes

InactiveCN101618292AAchieve energy saving and emission reductionReduce manufacturing costDispersed particle separationWater/sewage treatmentElectric powerToxic industrial waste

The invention provides a system for comprehensive utilization of three industrial wastes, mainly relating to the field of energy conservation and emission reduction, in particular to the comprehensive utilization of the three industrial wastes; to realize the objective of energy conservation and emission reduction required by the recycle economy, a system technology targeted at comprehensive utilization of the three industrial wastes of factories is adopted; in the invention, the reactor in the nuclear plant, the boiler in the coal-fired power plant and other types of supercritical boilers are utilized to provide a new cooling and turbine drive mode to solve the issue of industrial discharge of greenhouse gas and other polluting gases; in addition, collected emissions are utilized to produce nuclear fuel, compound chemical fertilizer or feedstuff and other chemical raw materials; moreover, to realize recycling of resources and sustainable utilization of energy, the original three wastes are innovatively applied to nuclear electric power generation. The system is characterized by comprising 10 major links and the beneficial effect thereof lies in utilizing new methods to realize energy conservation and emission reduction and production cost in the late stage of production can be reduced.

Owner:李元胜

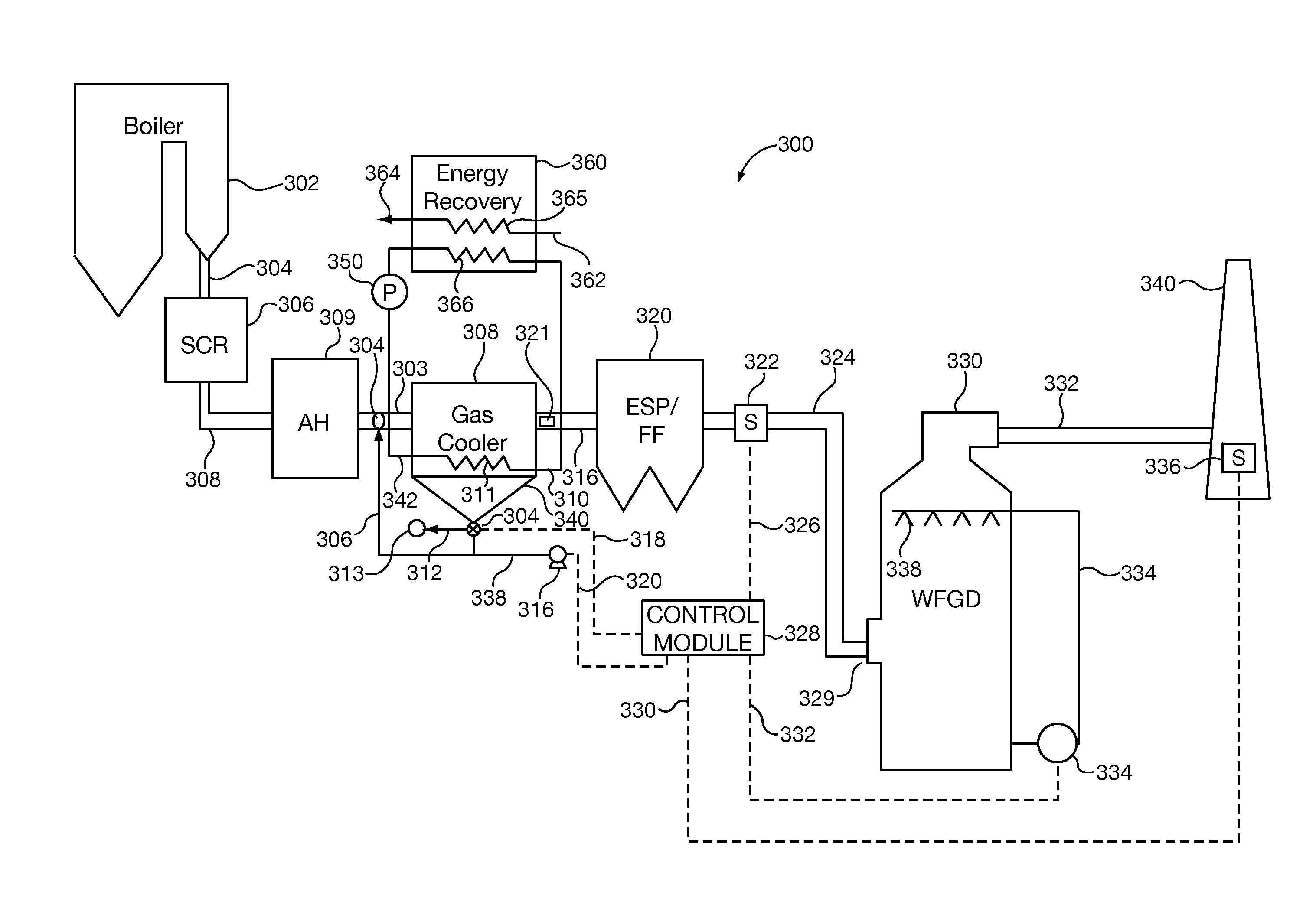

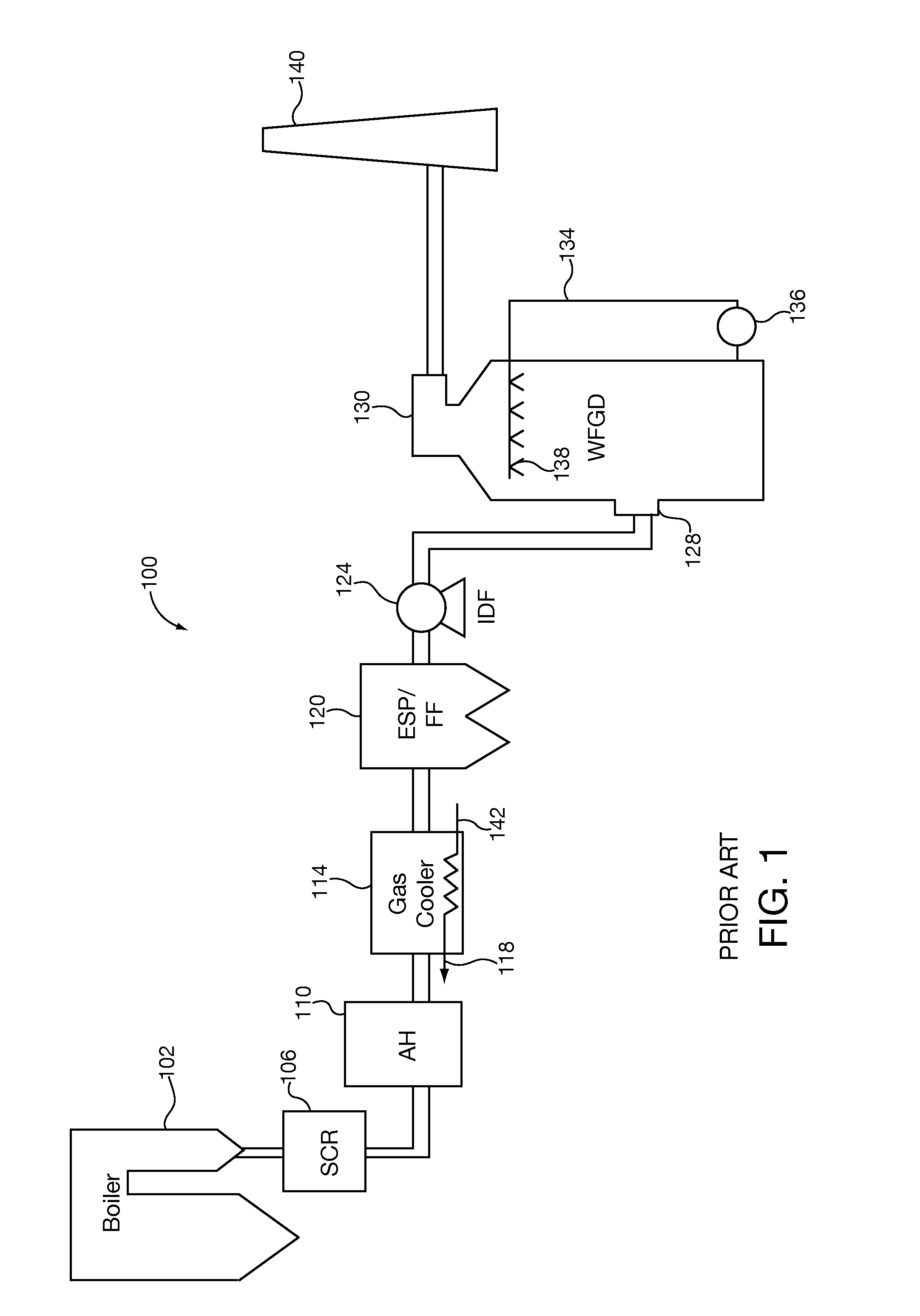

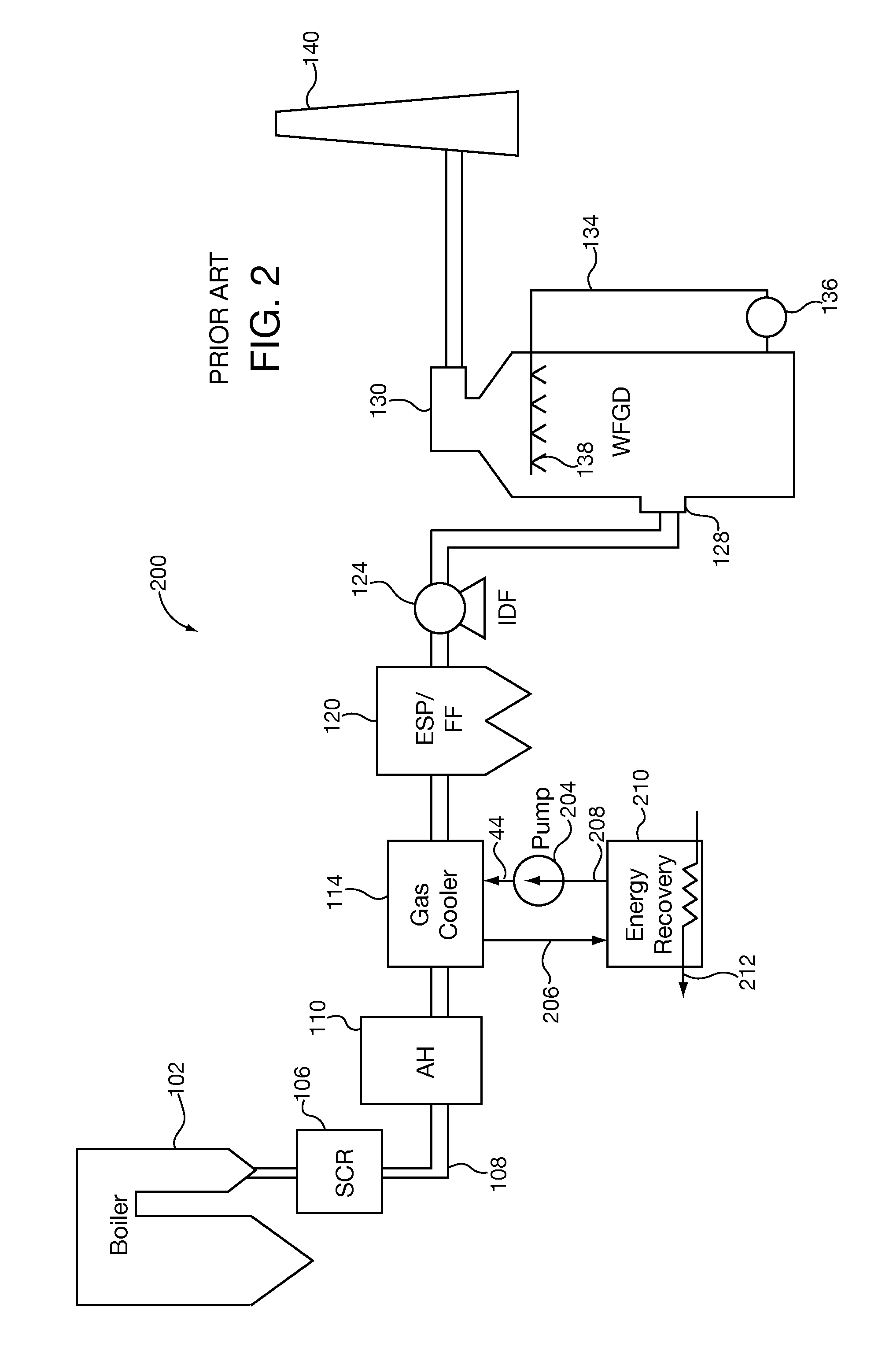

Methods and apparatus for performing flue gas pollution control and/or energy recovery

ActiveUS20090078177A1Improve system efficiencyAvoid and eliminate and reduce any needCombustion using gaseous and pulverulent fuelGas treatmentParticulatesRe introduction

Methods and apparatus for pollution control which are well suited for use in a coal power plant are described. Ash is collected and injected into the flue gas stream at a location upstream of a cooling module. The ash acts as an absorbent and / or reactant material onto which condensate may condense. By re-introducing ash to keep the condensation forming wet areas within the system, lower cost materials which are less corrosion resistant than needed for wet operating conditions can be used. Mercury recovery and SO3 removal is facilitated by the cooling process and re-introduction of collected ash. Activated carbon and / or an alkali absorbent material may be added. Use of a dry ESP and / or fabric filter as opposed to a wet ESP for particulate collection leads to cost benefits. Energy recovered by the cooling of the flue gas may be re-used to heat turbine condensate leading to improved energy efficiency.

Owner:MITSUBISHI POWER AMERICAS INC

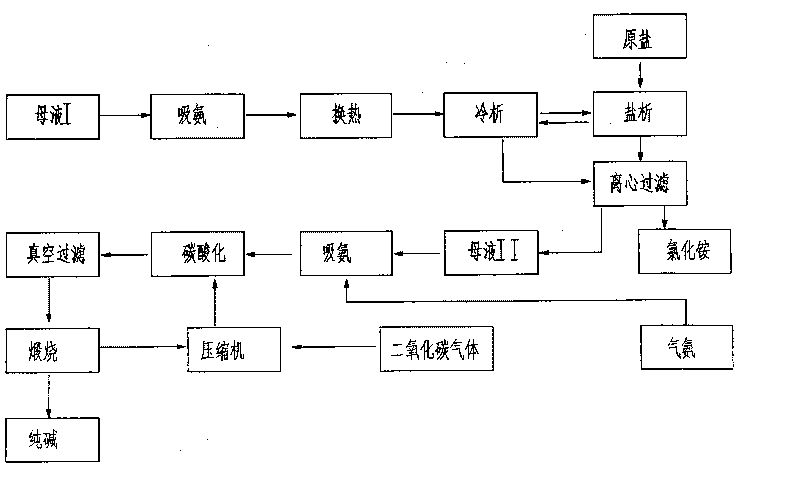

System for trapping carbon dioxide in flue gas of coal-fired power plant and corresponding treatment method

The invention discloses a system for trapping carbon dioxide in flue gas of coal-fired power plant, comprising an absorption tower and a regenerating tower and also comprising a regenerated gas condenser, a poor-rich liquid heat exchanger, a carbon dioxide separator and a carbon dioxide compressor. The invention also discloses a method for trapping and utilizing carbon dioxide in flue gas of coal-fired power plant. In the invention, by coordinate design of the absorption tower and regenerating tower, massive carbon dioxide gas exhausted by boiler of coal-fired power plant can be trapped, and the emission of greenhouse gas is reduced, thus protecting the environment; and in the disclosed method, the trapped carbon dioxide gas directly enters the process flow for preparing soda ash and ammonium chloride by combination system, thus carbon dioxide gas can be timely utilized, the whole production process is optimized, and consumption of carbon dioxide gas is reduced.

Owner:CPI YUANDA ENVIRONMENTAL PROTECTION ENG

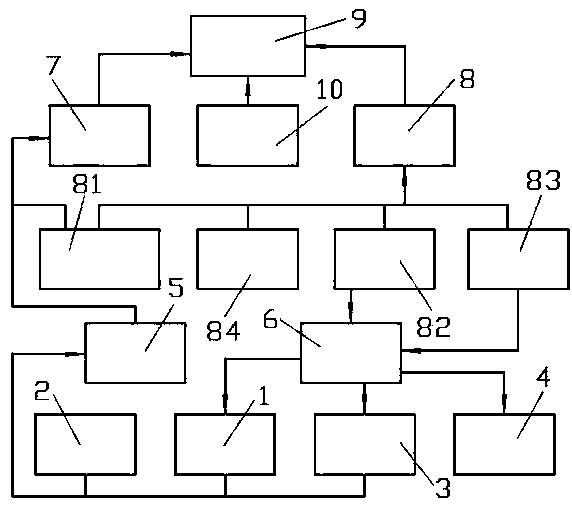

Coal-fired power plant coal yard refined management system and control method thereof

ActiveCN103455901AFast and accurate deliveryAccurate accessSystems intergating technologiesLogisticsInformatizationData acquisition

The invention relates to a coal-fired power plant coal yard refined management system and a control method of the coal-fired power plant coal yard refined management system. The coal-fired power plant coal yard refined management system is characterized by comprising a laser disc coal instrument, an intelligent temperature monitoring meter, a metering device, a stacker-reclaimer, a data acquisition unit, a controller, a data server, an application server and a computer client side. The application server comprises a coal database management module, a real-time stock management module, a coal storage management module and a heat loss evaluation and control module. The control method is characterized by including the following steps that coal pile outline data points and digital signs in a coal yard field are acquired according to the laser disc coal instrument, and three-dimensional reconstruction of coal piles is completed based on a VC++ and OpenGL platform; when coal is transported to a factory, information is input to the coal database management module through an input port in the computer client side. According to the coal-fired power plant coal yard refined management system and the control method, the informatization and intelligentization method is adopted, information is quickly and accurately transmitted, and coal heat loss is reduced.

Owner:HUADIAN ELECTRIC POWER SCI INST CO LTD

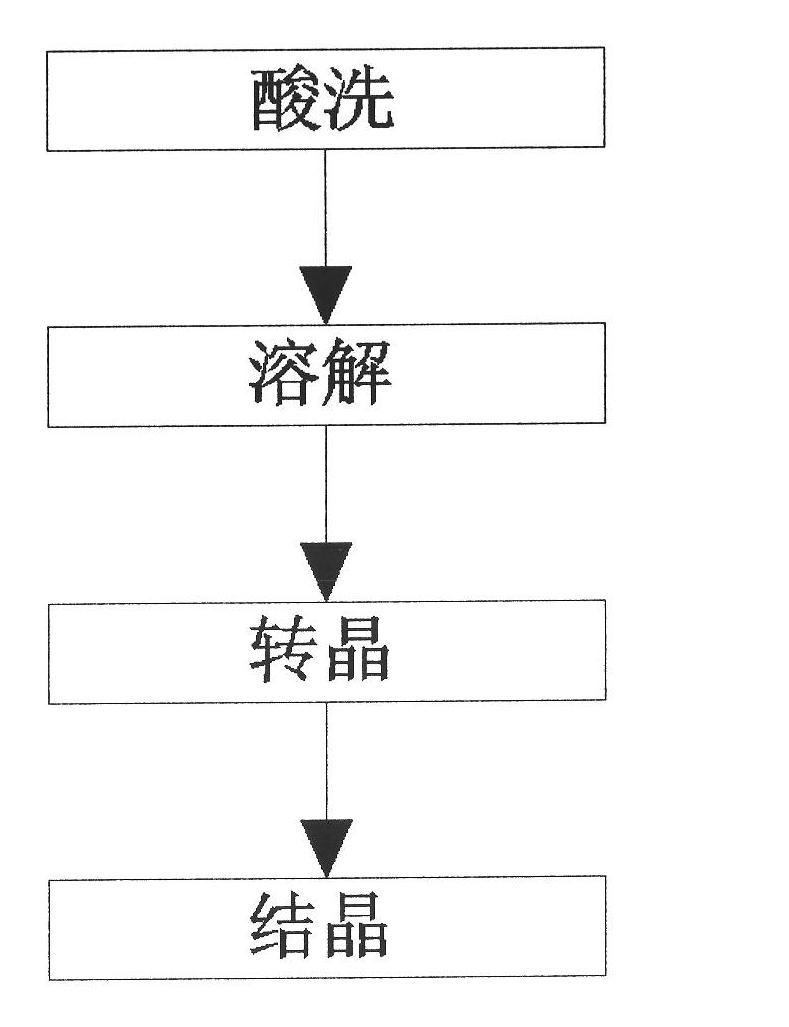

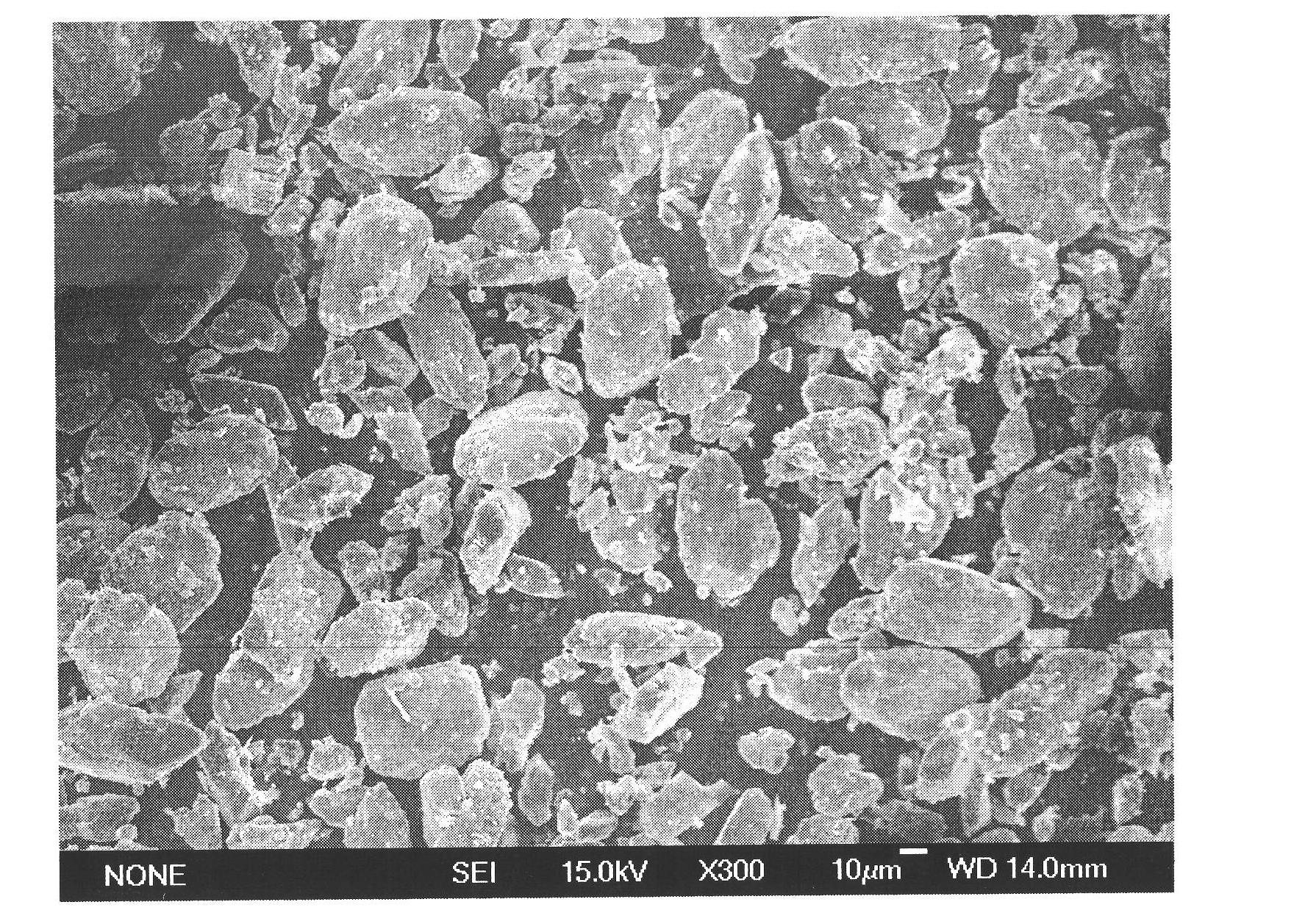

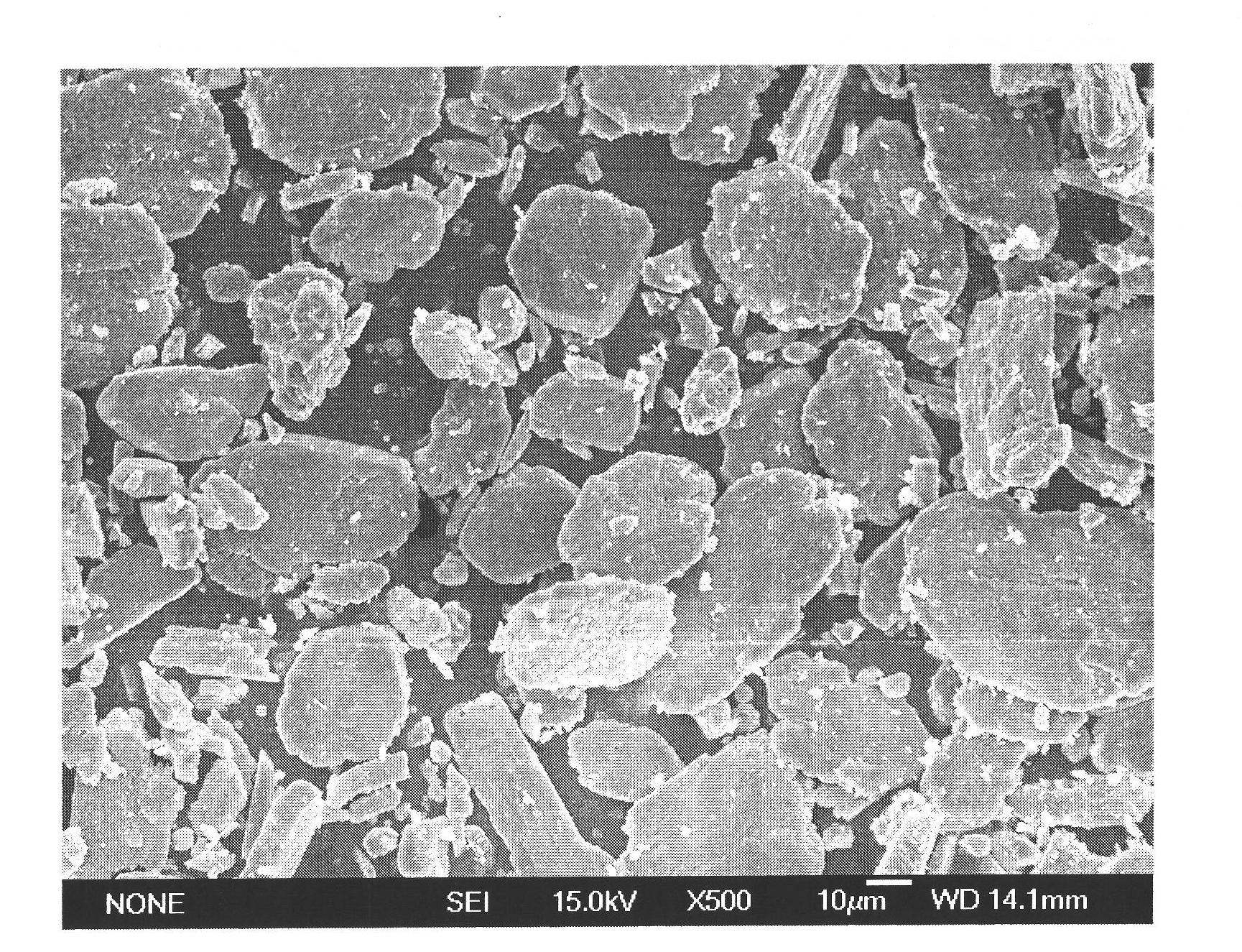

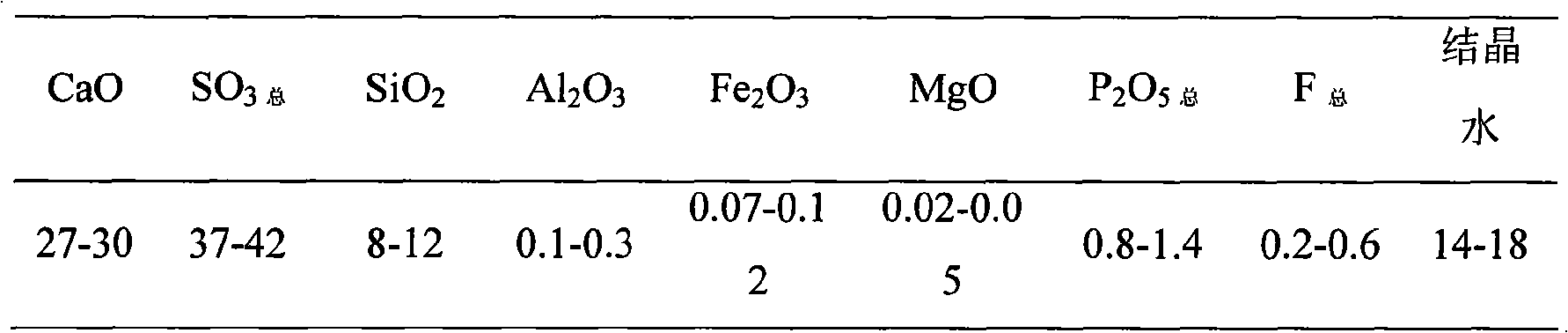

Method for preparing calcium sulfate crystal whiskers from desulfurized gypsum under normal pressure

ActiveCN102352535ASimple manufacturing processEasy to implementPolycrystalline material growthFrom normal temperature solutionsDispersityCalcium sulfate crystals

The invention discloses a method for preparing calcium sulfate crystal whiskers from desulfurized gypsum under normal pressure. The method comprises the following steps: 1) pickling; 2) dissolving; 3) rotating crystal; and 4) crystallizing, after crystallizing, carrying out solid-liquid separation, washing filter cake with water, and drying to obtain calcium sulfate crystal whiskers. The method disclosed by the invention has the advantages that: the preparation process is simple and is easy to achieve, and the production efficiency is high; higher-purity and higher-whiteness calcium sulfate crystal whiskers are prepared by adopting a normal-pressure recrystallization method, controlling related process conditions and utilizing the characteristic that the dissolubility of main component calcium sulfate dihydrate of desulfurized gypsum in specific solution changes obviously along with the temperature; obtained calcium sulfate crystal whisker product has regular morphology, low agglomeration and good dispersity; and in addition, inorganic acid solution used for recrystallization can be recycled, and inorganic acid solution is not consumed in the reaction process, thereby creating better economic benefit, environmental benefit and social benefit, reducing the burden of coal-fired power plant and increasing enterprise benefits.

Owner:上海大学浙江嘉兴新兴产业研究院

Anti-static polytetrafluoroethylene filter bag and preparation method thereof

InactiveCN103191602AHigh temperature resistantCorrosion resistantDispersed particle filtrationSynthetic resin layered productsChemical industryEngineering

The invention discloses an anti-static polytetrafluoroethylene filter bag and a preparation method thereof. The anti-static polytetrafluoroethylene filter bag comprises a bag head, a bag body and a bag bottom, wherein the bag head is made from a polytetrafluoroethylene filter material; the polytetrafluoroethylene filter material comprises a base cloth; the base cloth is weaved through warps and wefts by twisting polytetrafluoroethylene filament fibers and stainless steel fibers; the upper surface and lower surface of the base cloth are symmetrically covered with non-woven layers; the non-woven layers are prepared by blending polytetrafluoroethylene fibers or one or more of the polytetrafluoroethylene fibers, polyphenylene sulfide fibers, polyamide fibers, polyamide-imide fibers and glass fibers; and the overlapped edge of the bag body is provided with a stainless steel wire mesh layer. The filter material prepared through the method disclosed by the invention has the advantages of good high temperature resistance, corrosion resistance and electric conductivity and persistent static elimination, reduces the fire hazard or explosion generated due to electrostatic sparks and can be widely applied to the high-temperature fire prevention, explosion prevention and dust removal in the fields of iron and steel smelting, refuse burning, a coal-fired power plant, cement, chemical industry, and the like.

Owner:南京际华三五二一环保科技有限公司

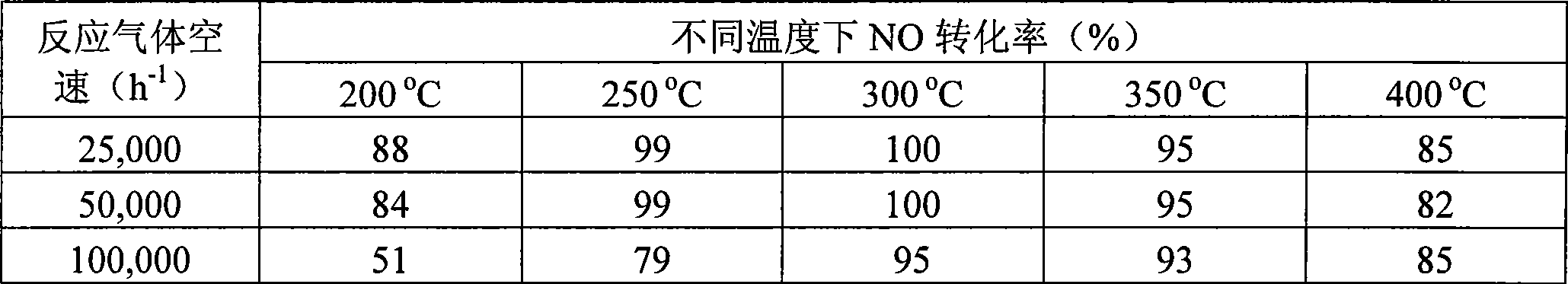

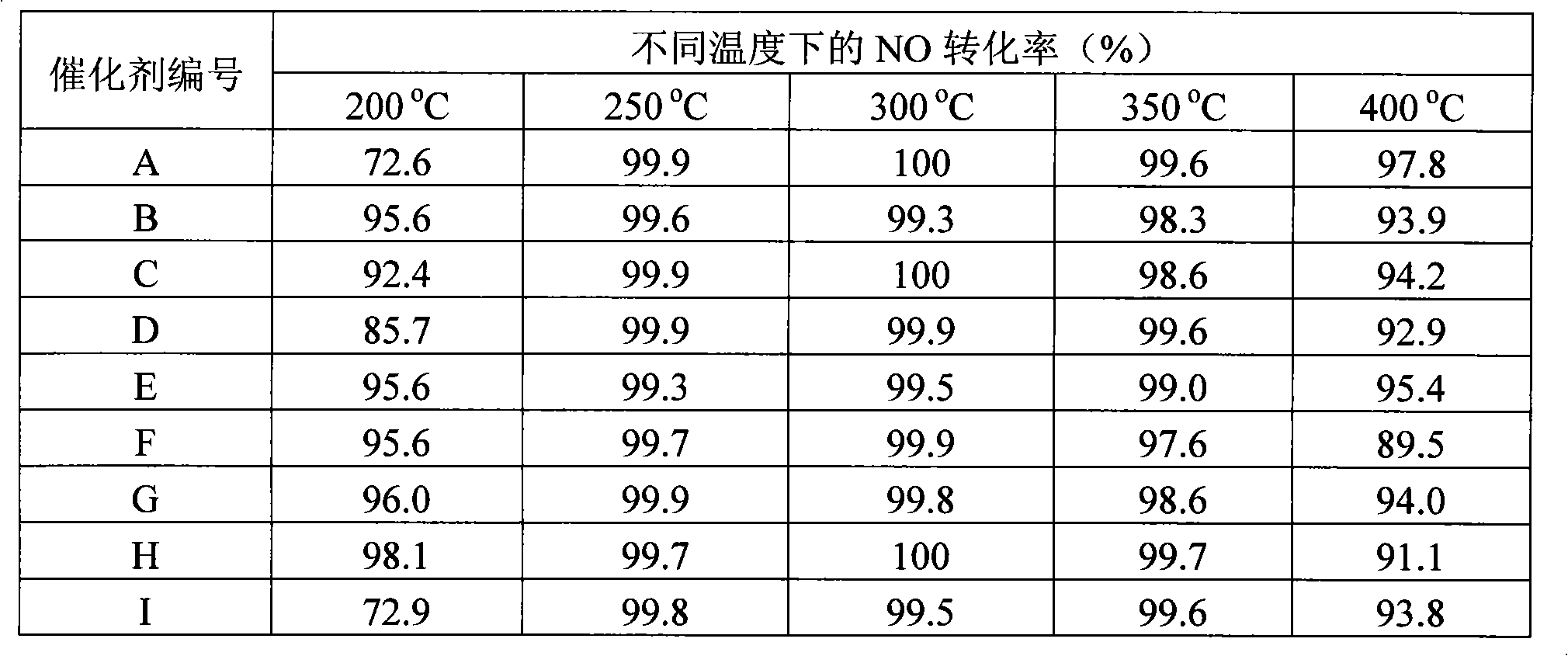

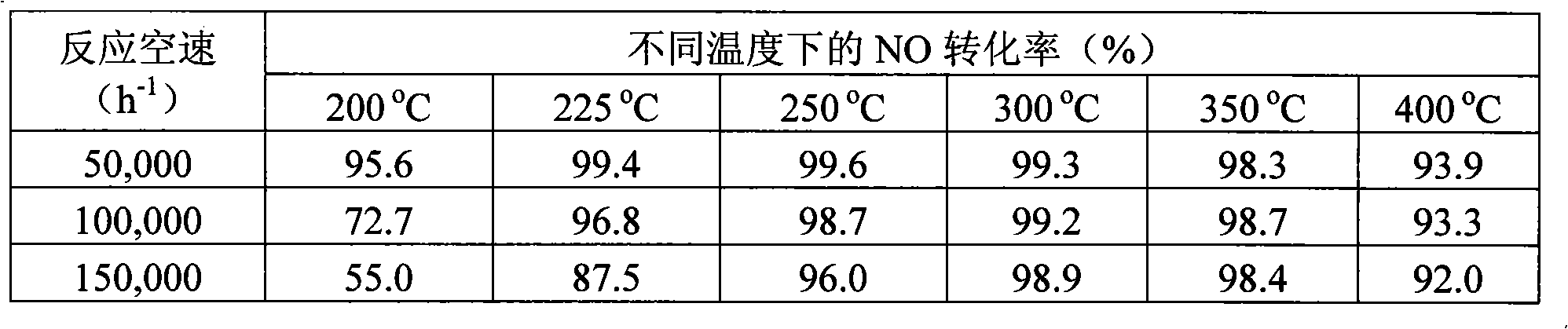

Cerium-zirconium-tungsten composite oxide catalyst as well as preparation method and usage thereof

ActiveCN103240079AWide operating temperature windowExtended service lifeDispersed particle separationMetal/metal-oxides/metal-hydroxide catalystsCeriumNitric oxide

The invention relates to a cerium-zirconium-tungsten composite oxide catalyst used for carrying out selective catalytic reduction on nitric oxide by ammonia, as well as a preparation method and usage thereof. The catalyst is a composite metal oxide formed by three types of metal including cerium, zirconium and tungsten. The catalyst adopts non-toxic and harmless raw materials; the cerium-zirconium-tungsten composite oxide catalyst which can adapt to high space velocity reaction condition and has the characteristics of being excellent in catalytic activity, high in N2 generation selectivity, wide in operating temperature window and the like can be prepared by using a simple and practicable method; and the cerium-zirconium-tungsten composite oxide catalyst is suitable for a nitric oxide catalytic purification device used for a moving source represented by diesel exhaust and a fixed source represented by flue gas of a coal-fired power plant.

Owner:RES CENT FOR ECO ENVIRONMENTAL SCI THE CHINESE ACAD OF SCI

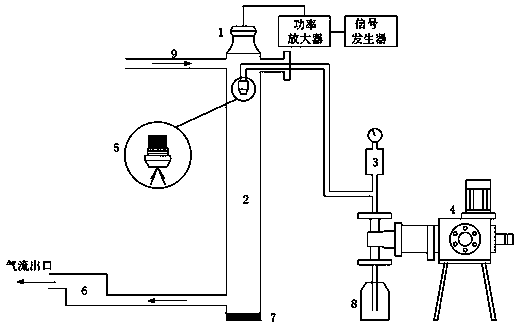

Device for removing fine particles by joint action of acoustic agglomeration and mist spray and method of device

ActiveCN103706219AImprove dust removal efficiencyImprove the efficiency of sonic agglomerationAuxillary pretreatmentUsing liquid separation agentSound sourcesFine particulate

The invention discloses a device for removing fine particles by joint action of acoustic agglomeration and mist spray and a method of the device. A compressed drive sound source is arranged at the top of a main agglomeration chamber body, and connected with a power amplifier and a signal generator sequentially; a smoke inlet is formed in the lateral wall of the upper part of the main agglomeration chamber body; a nozzle is arranged inside the upper part of the main agglomeration chamber body, and connected with a buffer tank, a plunger type metering pump and a storage tank respectively; an induced draft fan is arranged at the lateral wall of the lower part of the main agglomeration chamber body; a sound-absorbing sponge is arranged at the bottom of the main agglomeration chamber body. Fine particles in dust-containing airflow such as discharged smoke from a coal-fired power plant are preprocessed by using joint action of acoustic agglomeration and mist spray, so that the acoustic agglomeration efficiency of the fine particles is greatly improved, and the target of efficiently removing particulate matter 2.5 (PM2.5) is achieved by combining with subsequent traditional dust removers. Thus, emission of the PM2.5 is controlled. The sound pressure level required by the method of combining acoustic wave with mist spray is much lower than that of the method only adopting the acoustic wave, so that the energy consumption of acoustic agglomeration is effectively reduced.

Owner:ZHEJIANG UNIV

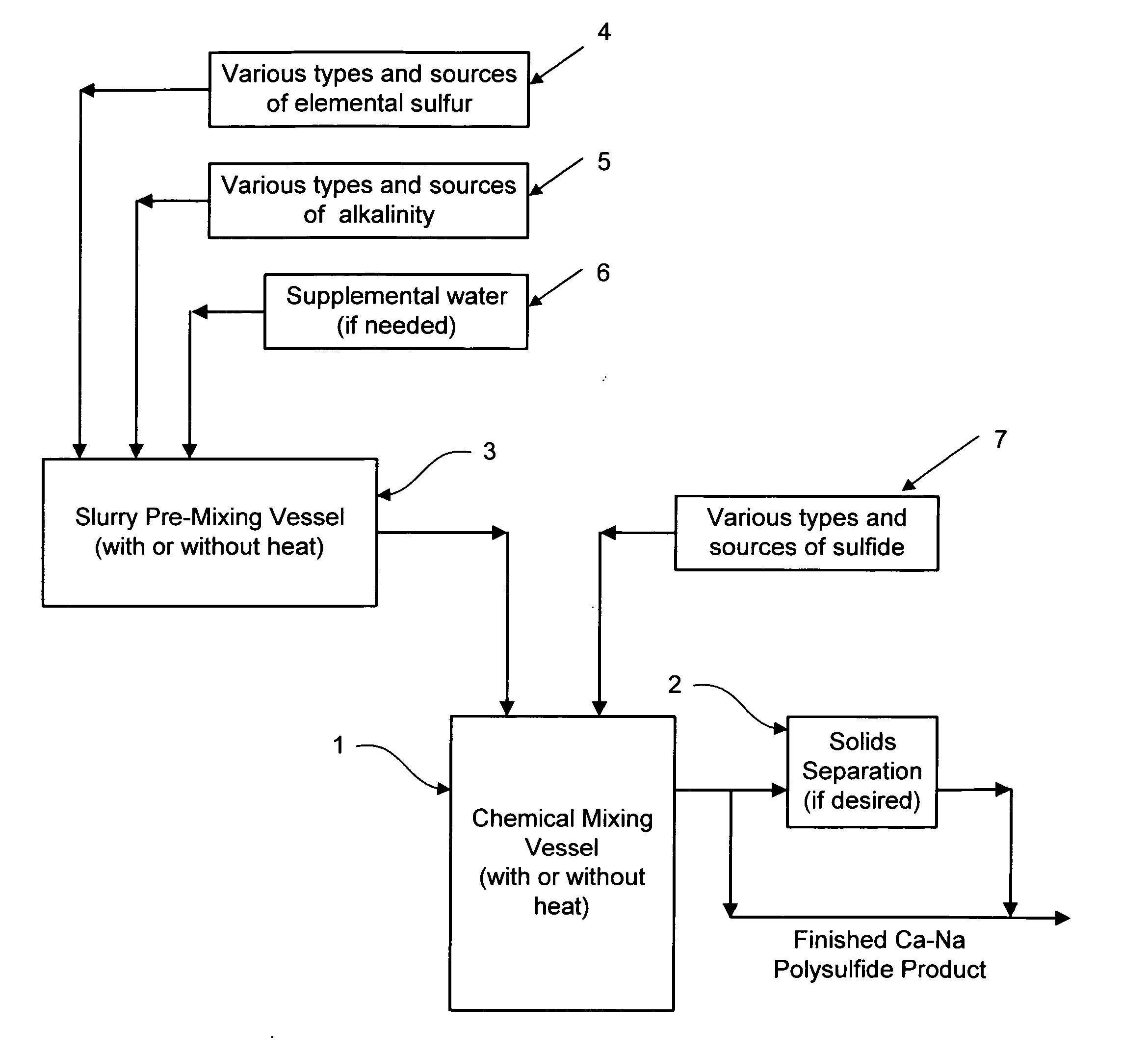

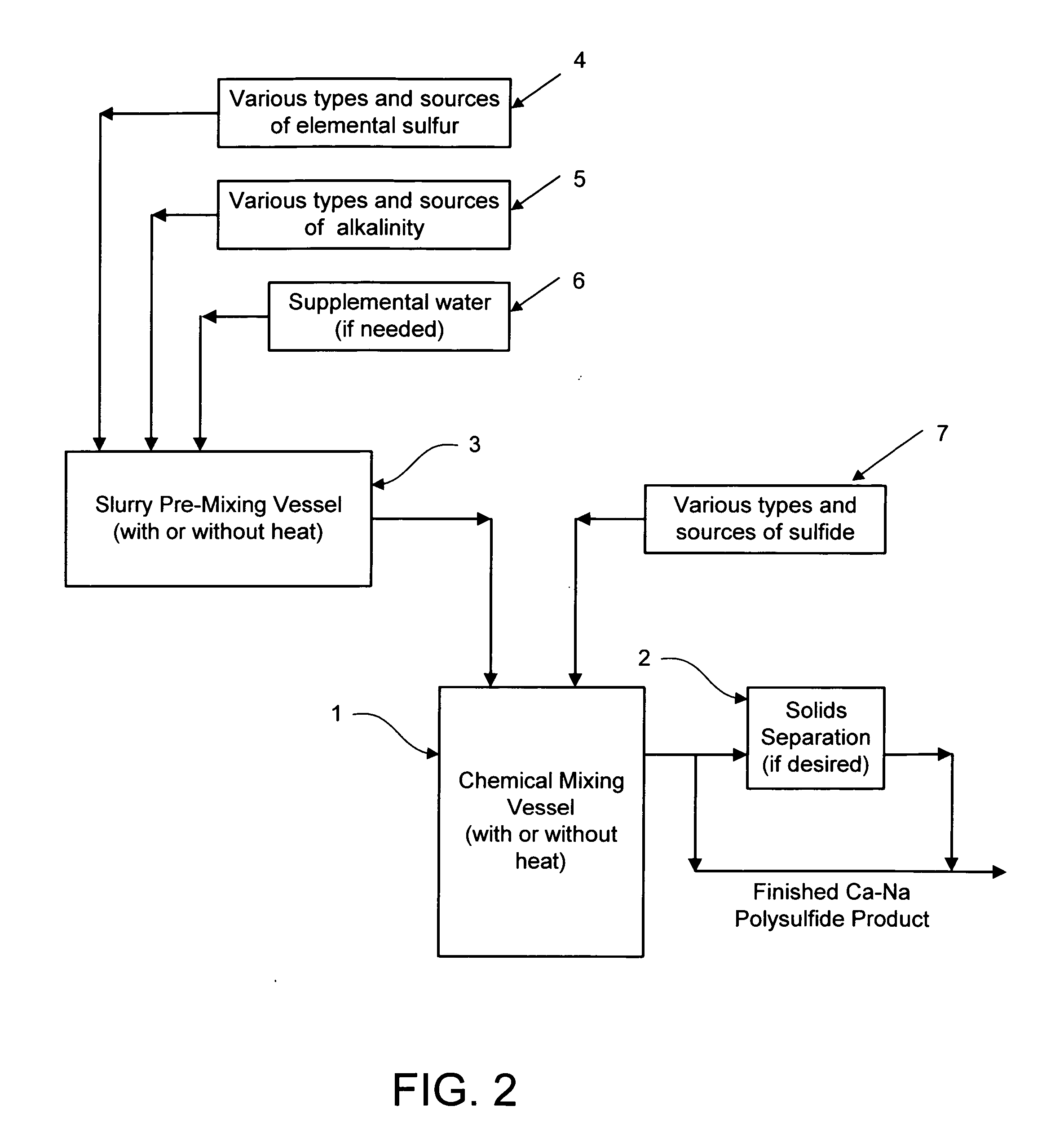

Calcium-sodium polysulfide chemical reagent and production methods

Owner:REDOX TECH GRP

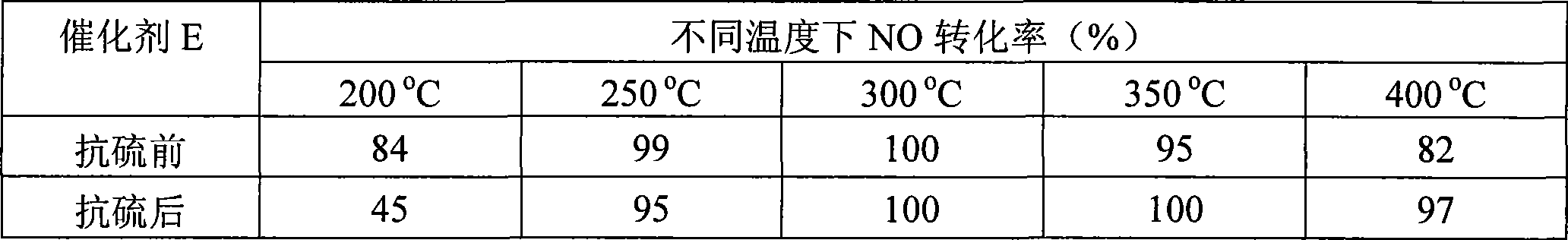

Ferrotitanium composite oxides catalyst for ammonia selective reduction nitric oxides

ActiveCN101380578ALow priceSimple preparation processDispersed particle separationMetal/metal-oxides/metal-hydroxide catalystsNitric oxideHigh activity

The invention relates to a catalyst of selective reduction of nitrogen oxide by ammonia, which mainly solves the existing problems that the commonly used NH3-SCR catalyst system is toxic to environment and human body, the anti-SO2 poisoning ability of the catalyst system is poor in the reference and the catalyst system can not adapt to the conditions of high space velocity. The invention adopts cheap and non-toxic raw materials to prepare a Fe-Ti oxide catalyst with high activity, selectivity, stability and anti-S2 poisoning ability by the simple and practicable co-precipitation method, which can better solve the existing technical problems. If the catalyst is loaded on honeycomb ceramics after being made into pulp, the catalyst is hopeful to be put into practical application of flue gas denitrification of coal-fired power plants.

Owner:江西中科鸿虔新材料有限公司

Device and method for detecting sulfur trioxide in flue gas on line

ActiveCN103472061ARealize online measurementTake convenienceMaterial analysis by observing effect on chemical indicatorWithdrawing sample devicesGas phaseEngineering

The invention discloses a device and a method for detecting sulfur trioxide (SO3) in flue gas on line. The device comprises a flue gas collecting unit, a gas liquid separator, a gas phase detection unit, a first solution tank, a liquid phase detection unit and a digital control unit, wherein the gas liquid separator is used for condensing SO3 in the flue gas from a flue gas sampling unit into sulfuric acid liquid drops and separating the sulfuric acid liquid dropsfrom gas phase; the gas phase detection unit is used for measuring the flow of the gas phase from the gas liquid separator; the first solution tank is used for providing an absorption liquid to the gas liquid separator and mixing the absorption liquid with the sulfuric acid liquid drops to form mixed liquid; the liquid phase detection unit is used for measuring the mass of the transformed SO3 in the mixed liquid from the gas liquid separator; and the digital control unit is used for calculating the SO3 concentration of the flue gas according to the detection results of the gas phase detection unit and the liquid phase detection unit. According to the device and the method, on-line measurement of the SO3 of the flue gas is realized, the SO3 of the flue gas is sampled and the SO3 content is analyzed, so that a coal-fired power plant can take corresponding measures conveniently, the SO3 content of the flue gas is controlled, the corrosion to a flue and equipment is reduced, and the heat loss due to exhaust smoke of a boiler is reduced to the maximum degree.

Owner:ZHEJIANG UNIV

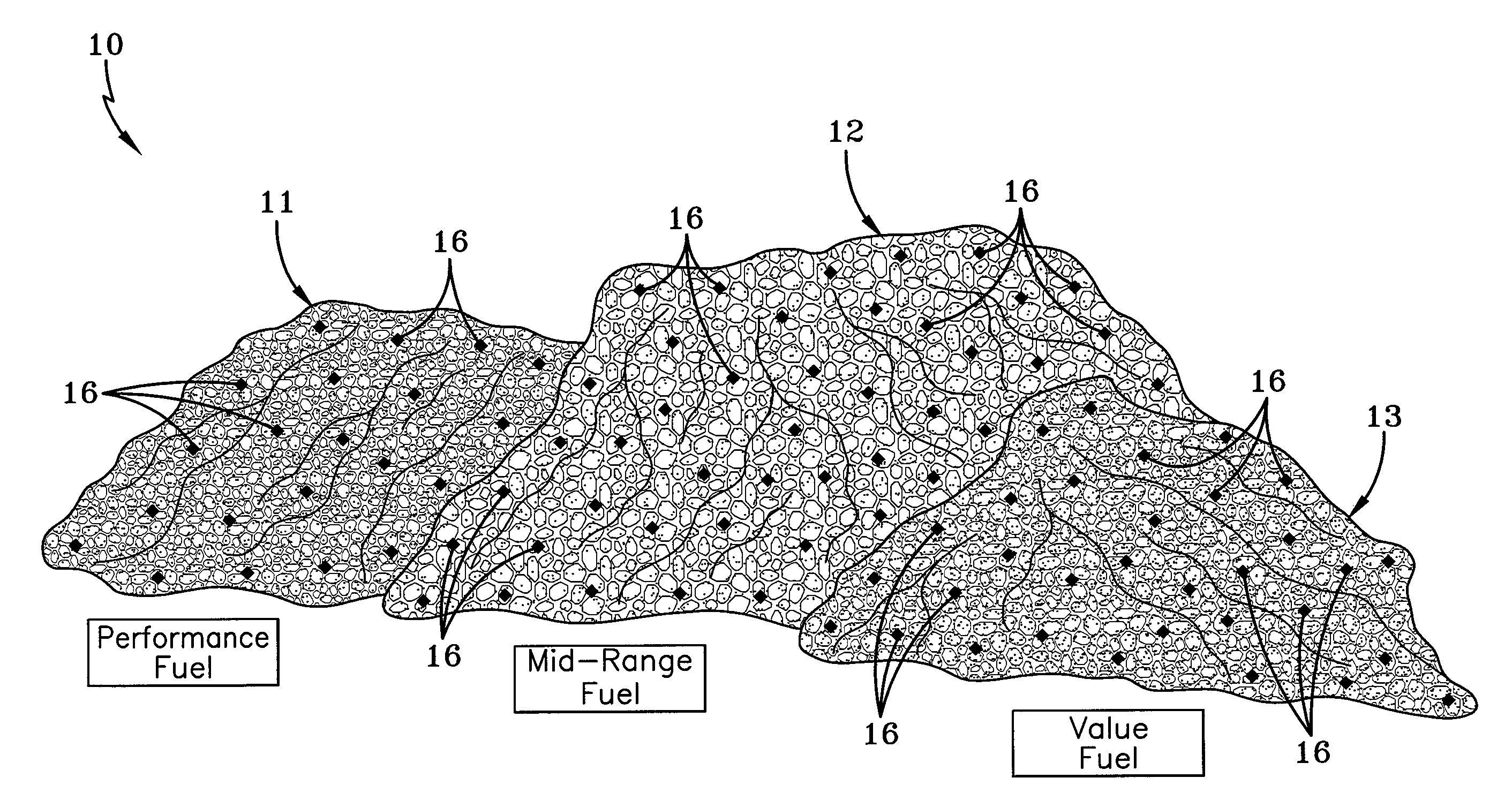

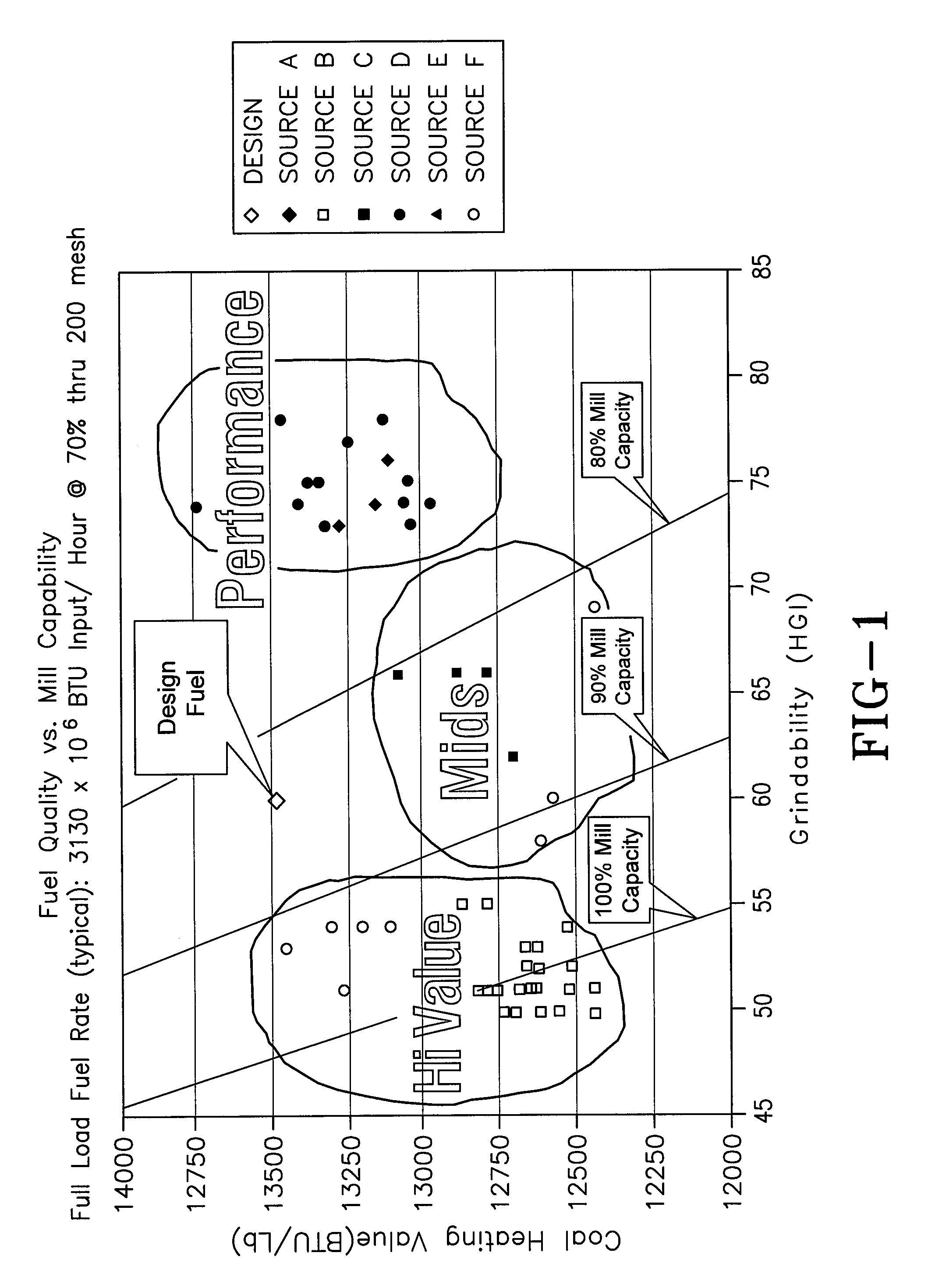

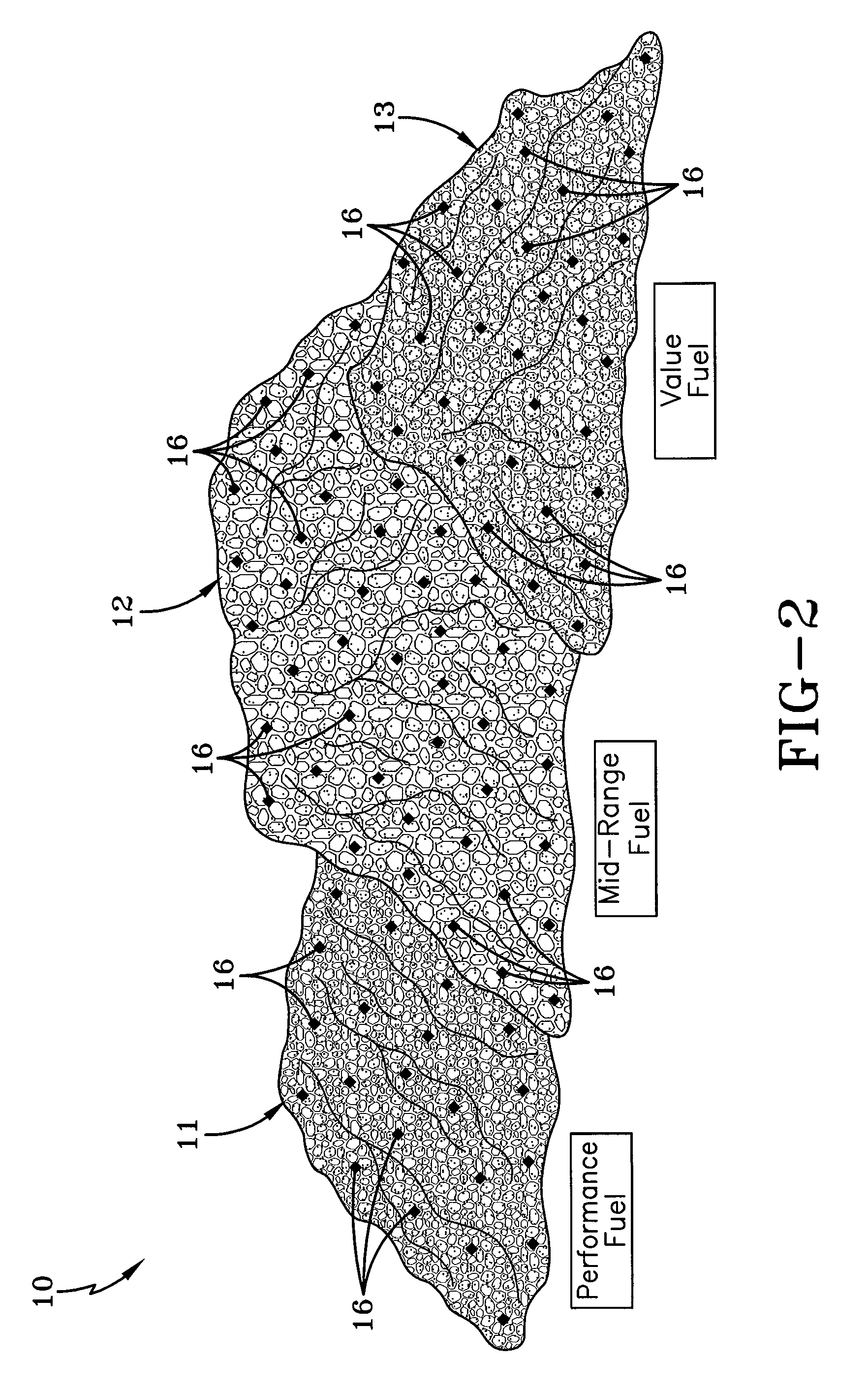

Tracking and properties control system for bulk materials

The invention provides a system of devices and a set of methods for accurately characterizing, tracking and controlling bulk material flows. Measurements of input material properties, dynamical measurements involving identifiable tags, and fast, discrete simulations are combined to predict and control the composition of bulk material exiting a container, such as a silo, bunker or hopper. In one embodiment, a system is provided for a coal-fired power plant where the properties of coal are assessed, then the coal is marked and tracked to provide the plant's operators improved control over the coal mixture and target bulk properties as it makes its way from a coal receiving station to delivery for combustion in a furnace.

Owner:ENG CONSULTANTS GROUP

Apparatus and method of enhancing the quality of high-moisture materials and separating and concentrating organic and/or non-organic material contained therein

ActiveUS8062410B2Processed evenly and quicklySignificant environmental benefitsDrying solid materials with heatGas current separationParticulatesFluidized bed drying

The present invention harvests and utilizes fluidized bed drying technology and waste heat streams augmented by other available heat sources to dry feedstock or fuel. This method is useful in many industries, including coal-fired power plants. Coal is dried using the present invention before it goes to coal pulverizers and on to the furnace / boiler arrangement to improve boiler efficiency and reduce emissions. This is all completed in a low-temperature, open-air system. Also included is an apparatus for segregating particulate by density and / or size including a fluidizing bed having a particulate receiving inlet for receiving particulate to be fluidized. This is useful for segregating contaminants like sulfur and mercury from the product stream.

Owner:RAINBOW ENERGY CENT LLC

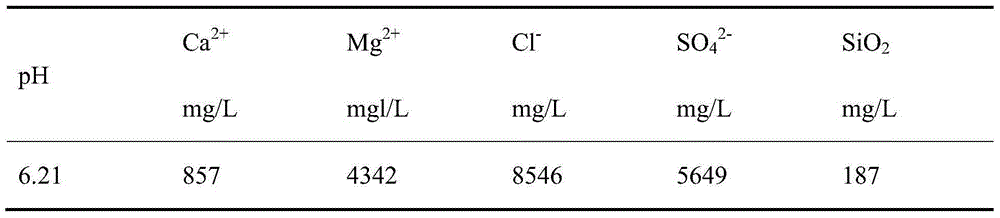

System and method for softening treatment of desulfurization wastewater of coal-fired power plant

ActiveCN105060545AReduce ammonia nitrogenReduce ammonia nitrogen contentWaste water treatment from gaseous effluentsMultistage water/sewage treatmentSulfateEconomic benefits

The invention discloses a system and a method for softening treatment of desulfurization wastewater of a coal-fired power plant. A primary reaction tank, a primary clarification tank, a secondary reaction tank and a secondary clarification tank are arranged, lime milk, sodium sulfate, polymeric ferric sulfate and polyacrylamide are added to the primary reaction tank for a primary reaction and clarified through the primary clarification tank, Mg(OH)2 and CaSO4*2H2O in the wastewater after the primary reaction are removed, the mixture has a secondary reaction in the secondary reaction tank, smoke is fed into the secondary reaction tank and is settled in the secondary clarification tank, CaCO3 is settled, and softening treatment of the desulfurization wastewater of the coal-fired power plant is completed. The system is simple in structure and easy to implement and facilitates industrial production; when the softening treatment effect is met, that is, the content of Mg<2+> is smaller than or equal to 5 mg / L and the content of Ca<2+> is smaller than or equal to 5 mg / L, the adding amount of chemical is reduced, and the chemical operation cost is reduced, so that the operation cost of a zero discharging system for the desulfurization wastewater of the coal-fired power plant is reduced, and the system has important economic benefits and environmental benefits.

Owner:XIAN TPRI WATER & ENVIRONMENTAL PROTECTION

Process for producing calcium carbonate by absorbing carbon dioxide with ardealite decompose slag

InactiveCN101337685ARealize resource utilizationEmission reductionCalcium/strontium/barium carbonatesSlagDecomposition

The invention relates to a method for producing calcium carbonate by using phosphogypsum decomposition slag to absorb carbon dioxide, and provides a process for synthesizing calcium carbonate through comprehensive utilization of phosphogypsum and CO2 gas resources. The method comprises the steps of decomposing mixed phosphogypsum and coal at the temperature of 950-1200 DEG C to generate a gas which is used as sulfur to produce a feed gas; placing solid slag in a carbonizer after colling; introducing CO2 into the carbonizer for reaction under normal pressure and at the temperature of 25-80 DEG C to obtain similar strong argillo calcareous limestone with 75%-85% of CaCo3; further purifying to obtain a high purity calcium carbonate product; or directly using the similar argillo calcareous limestone as building material. Aiming at the solid waste of phosphogypsum in phosphoric acid manufacture industries, the comprehensive utilization of industrial resources in coal-fired power plants, ammonium phosphate production, etc. which has large emission of CO2, the method not only solves the pollution problem of the solid waste of phosphogypsum and recycles sulfur resources, but also recycles carbon resources and reduces CO2 emission in combination with the problem of large emission of CO2 in ammonium phosphate production in phosphoric acid industries.

Owner:KUNMING UNIV OF SCI & TECH

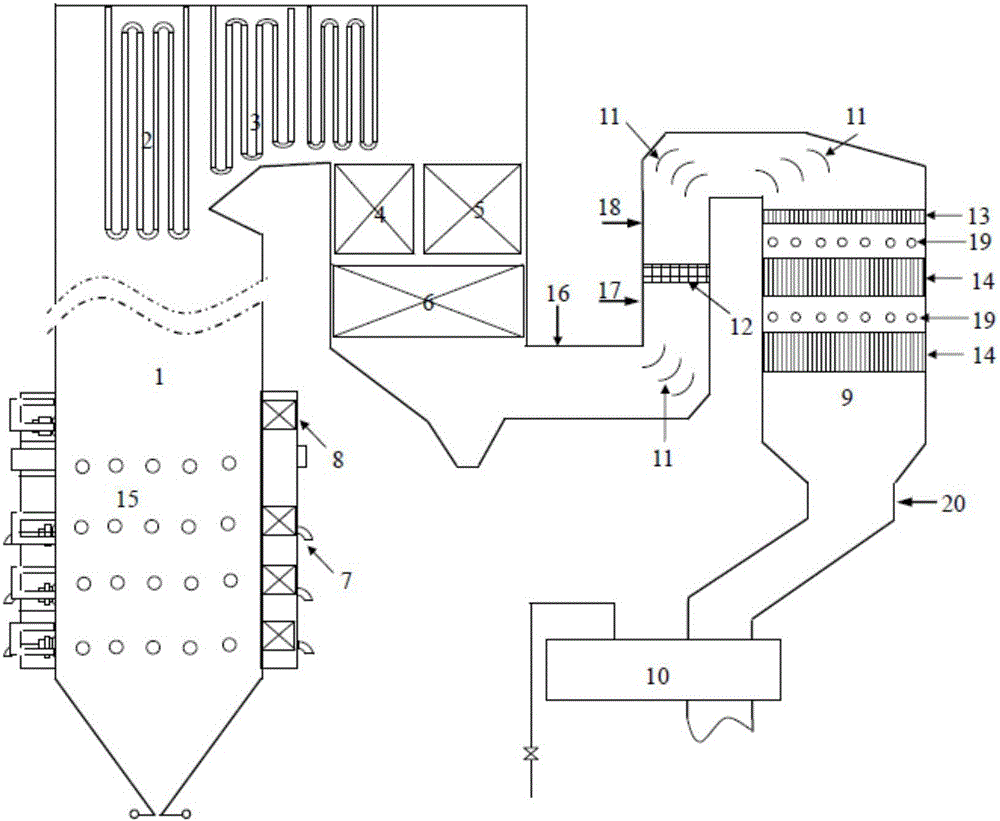

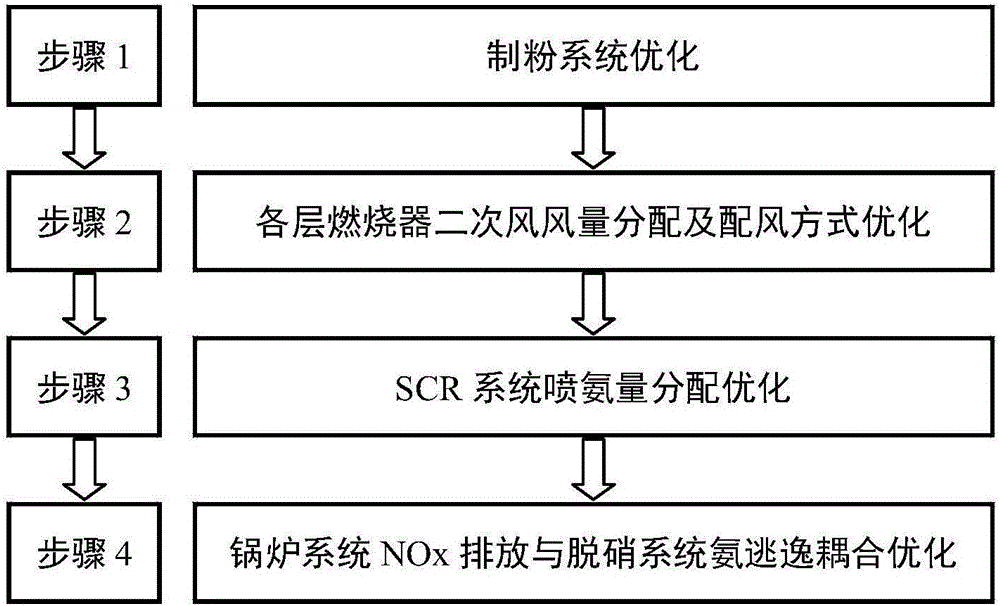

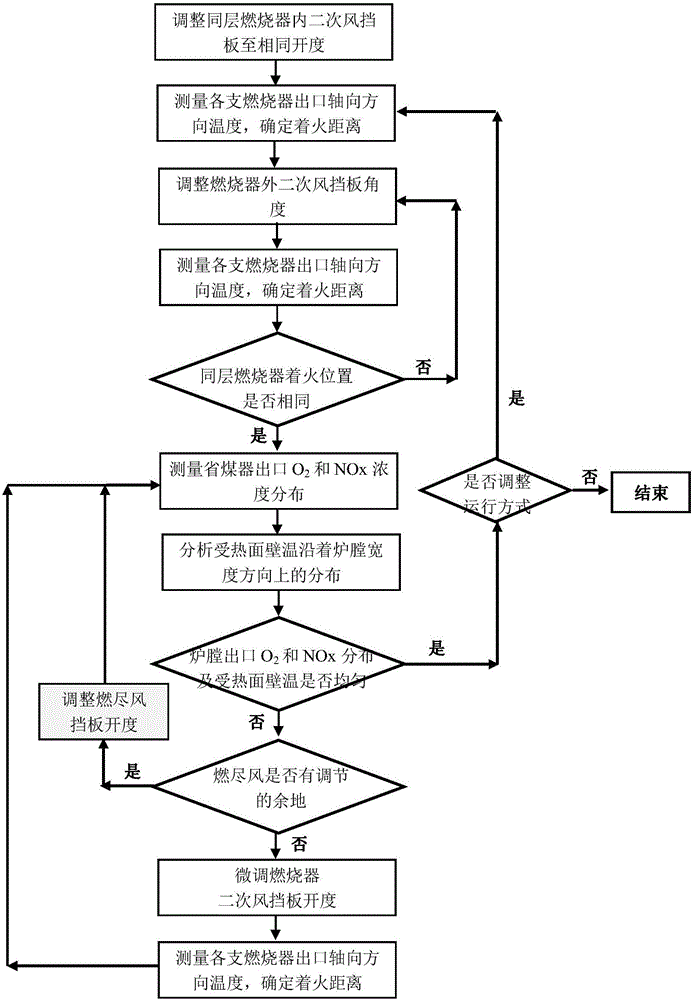

Coal-fired power plant boiler system and denitration system operation collaborative optimization method

ActiveCN105953259AEconomic operation modeGuaranteed operational safetyFuel supply regulationFuel feeding arrangementsOperation modeOxygen

The invention provides a coal-fired power plant boiler system and denitration system operation collaborative optimization method. The method comprises the following steps: the operation of a powder preparation system is optimized and adjusted; the operation of a combustion system is optimized and adjusted; the operation of a denitration system is optimized and adjusted; the coal-fired boiler NOx emission control and the SCR denitration system ammonia escape control are coupled for optimization and adjustment; an optimal operation oxygen quantity range of a coal-fired boiler under different loads and an optimal openness range of a burnt wind nozzle in the optimal oxygen quantity operation range are determined by combining the reductive atmosphere distribution characteristics in a near wall area of a hearth water cooling wall and the denitration ammonia escape conditions; and an optimal denitration efficiency range of the denitration system under different loads is determined. The three system operation collaborative optimization methods, provided by the invention, see the boiler system and the denitration system as a large system; the mutual correlation and influence among the three systems are decoupled from the angle of the large system; and the most economical and safest operation mode of the large system is obtained through optimization.

Owner:GUODIAN NANJING ELECTRIC POWER TEST RES CO LTD

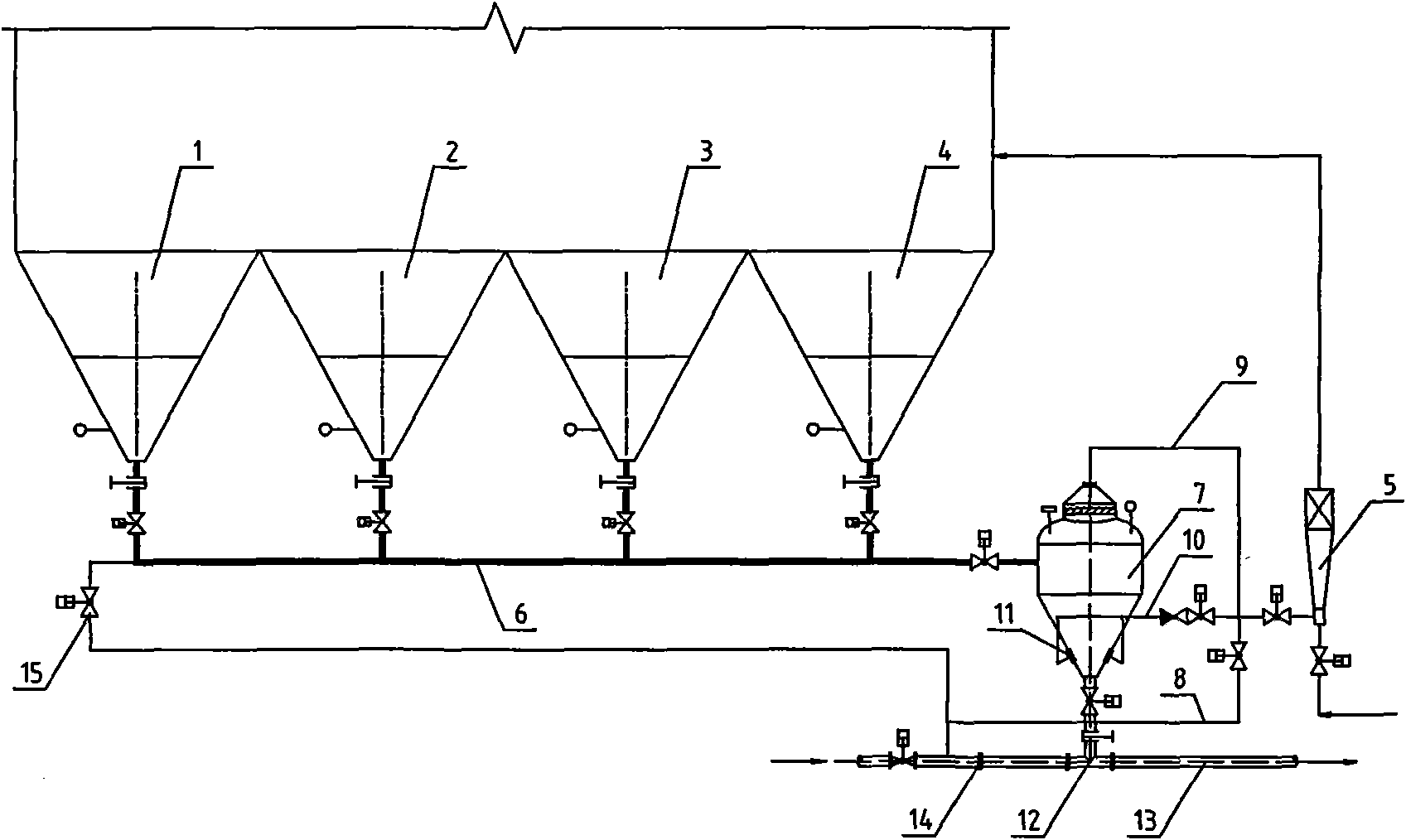

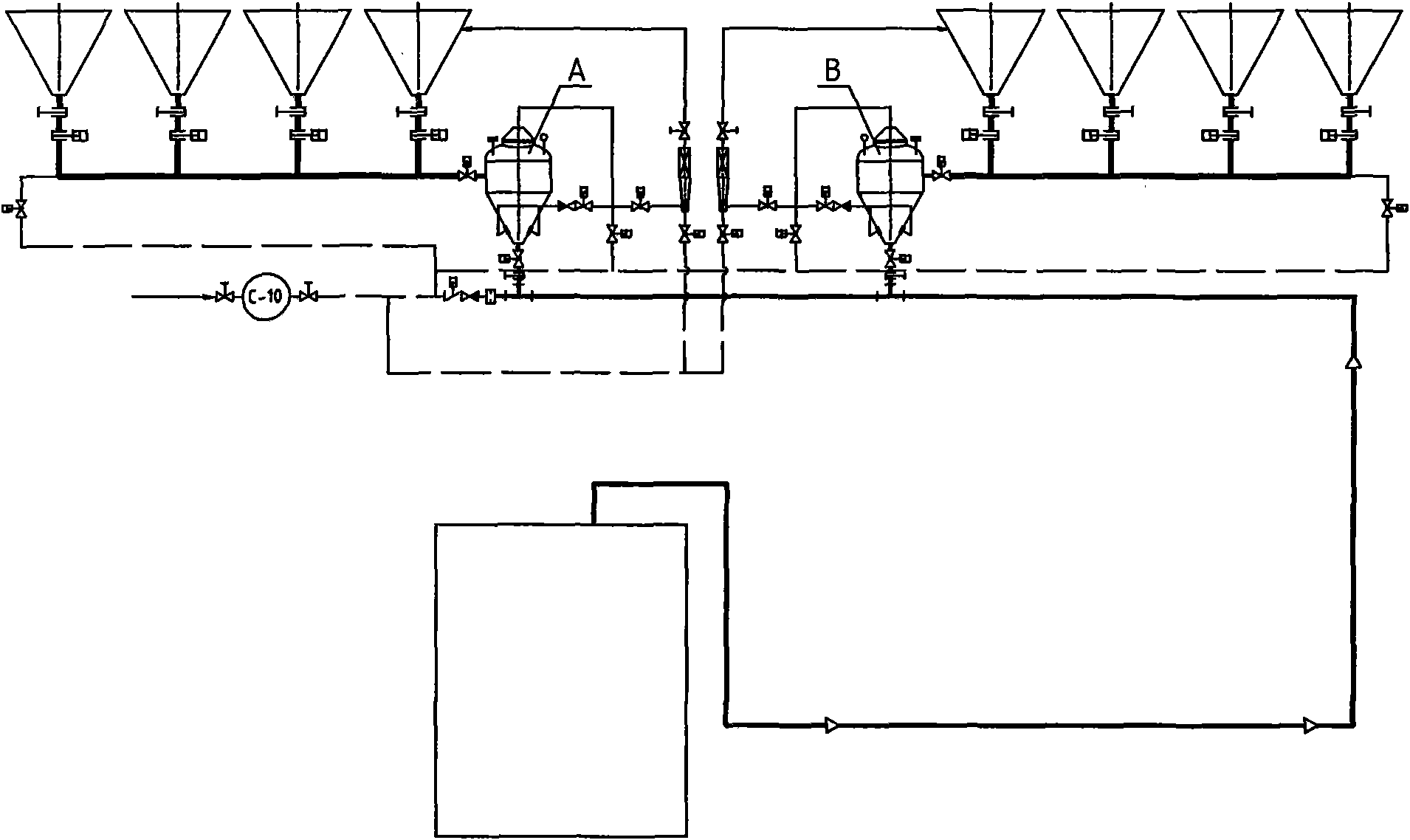

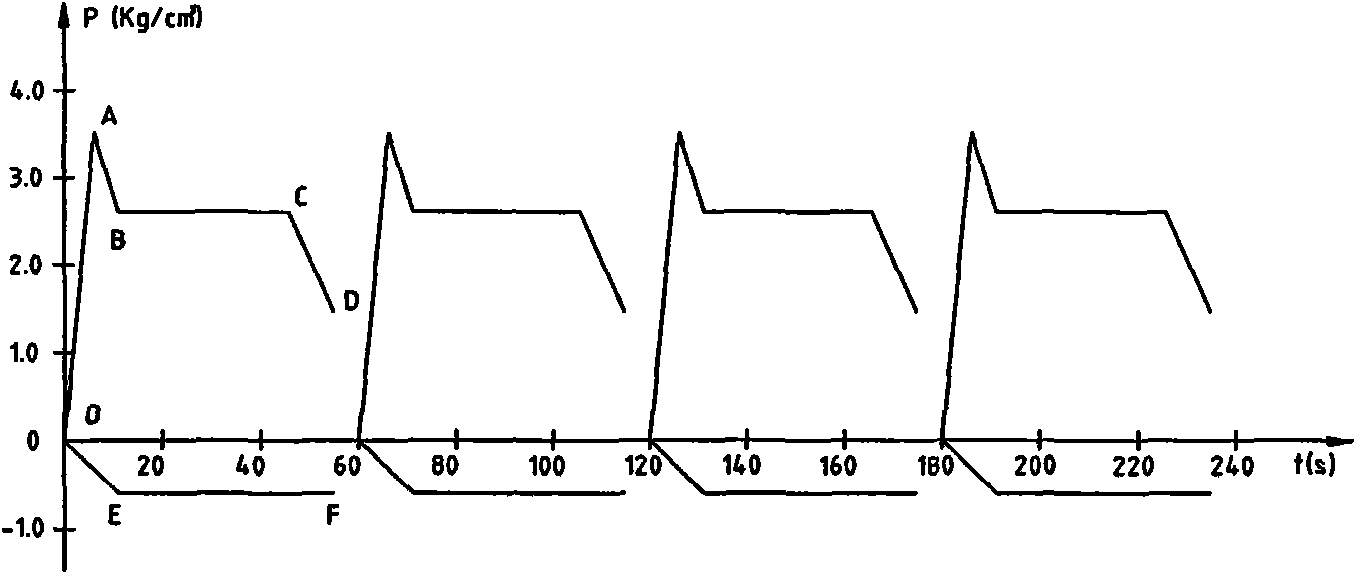

Pneumatic conveying method for powder materials

The invention relates to a pneumatic conveying method for powder materials, in particular to a pneumatic conveying method for pneumatic ash handling for large and medium-sized coal-fired power plants and limestone powder of a flue gas desulfurization system of a boiler. The pneumatic conveying method comprises two steps of negative-pressure ash loading and positive-pressure conveying and is economic and practical. One set of multi-function warehouse pump can be used for conveying ashes in a plurality of ash buckets, and therefore a lot of equipment and materials are saved. The multi-function warehouse pump can complete negative-pressure feeding and positive-pressure conveying, so that the integral structure is simplified, and reliability is enhanced. Meanwhile, the ashes are conveyed to a final ash silo once, a middle ash silo is saved, and a lot of warehouse pumps and valves are also saved. As a positive-pressure conveying pipeline is provided with a flow adjusting device and is separated from a fluidization pressurization pipeline, the ash handling speed is conveniently controlled, the conveying efficiency is increased and the pipe blocking probability is reduced.

Owner:ZHENJIANG CITY POWER STATION AUXILIARY MACHINERY PLANT

Method for regenerating inactivation SCR denitration catalyst by using antitoxic renewable liquid

ActiveCN102974367AImprove adhesionHigh mechanical strengthCatalyst regeneration/reactivationMetal/metal-oxides/metal-hydroxide catalystsOil freeOxygen

A method for regenerating an inactivation SCR denitration catalyst of coal-fired power plants by an antitoxic renewable liquid includes: S1 air purging the catalyst with oil-free dry compressed air for 10-30 minutes; S2 impregnating in a cleaning fluid for ultrasonic processing for 10-30 min and drying at 80-110 DEG C for 60-180 min; S3 impregnating in the antitoxic renewable liquid for 60-80 min, drying at 80-110 DEG C for 60-180 min for at least twice; S4 discharging for 30 minutes under the atmosphere of 25 ml / min oxygen under 45 kV voltage in dielectric barrier discharge reaction gas; and S5 roasting for 3-12h at 300-500 DEG C. After the regeneration, the activity of the catalyst is recovered by more than 90%, the catalyst mechanical properties and antitoxic performance are effectively improved, and the service life is prolonged.

Owner:ELECTRIC POWER RES INST OF GUANGDONG POWER GRID

Nanocrystalline Ce-Ti composite oxide catalyst used for selective catalytic reduction of nitric oxide by utilizing ammonia

InactiveCN101785994AExtended service lifeReduce usageDispersed particle separationMetal/metal-oxides/metal-hydroxide catalystsCeriumNitric oxide

The invention relates to a preparation method of a nanocrystalline Ce-Ti composite oxide catalyst used for the selective catalytic reduction of nitric oxide by utilizing ammonia and an application thereof. The preparation method of the catalyst is the homogeneous precipitation method, namely, the required cerium salt and titanium salt are prepared to mixed solution, and the molar ratio of cerium and titanium is 0.1-1.0; the solution is continuously stirred for 6-10h at the temperature of 90-95 DEG C by taking excessive urea as the precipitator and then is pumped, filtered, washed and dried; and finally, the catalyst is obtained by roasting the processed solution for 4-6h in the air at the temperature of 400-500 DEG C. In the invention, the nanocrystalline Ce-Ti composite oxide catalyst is prepared by taking non-toxic and harmless raw materials and adopting the simple and easy method, which has the characteristics of high catalytic activity, good N2 selection, wide temperature window, good adaptability of high airspeed condition, good SO2 intoxication resistance and the like. The catalyst is applicable to various tail gas sources including fixed combustion devices in an engine of a diesel vehicle, a coal-fired power plant and the like.

Owner:RES CENT FOR ECO ENVIRONMENTAL SCI THE CHINESE ACAD OF SCI

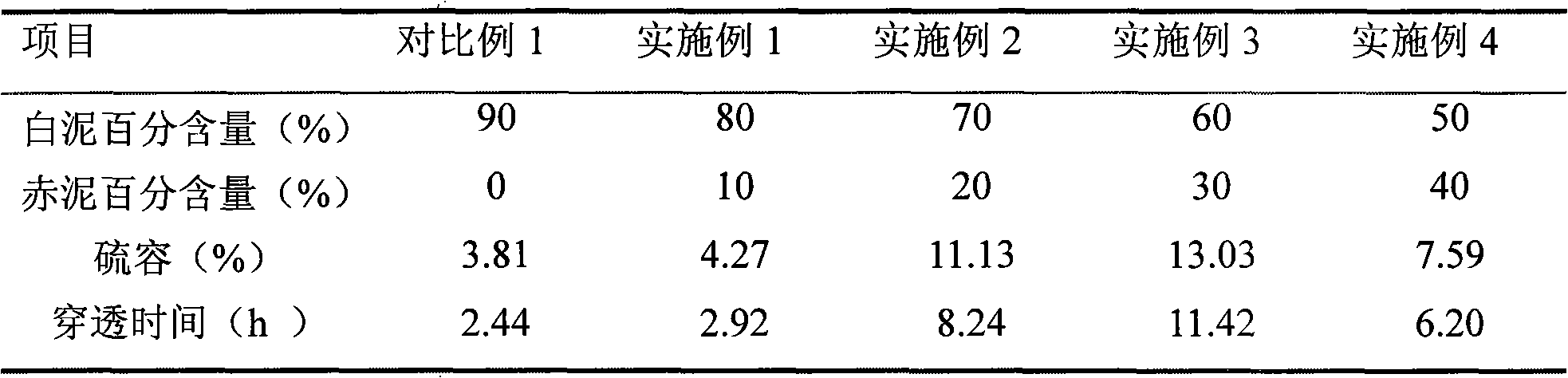

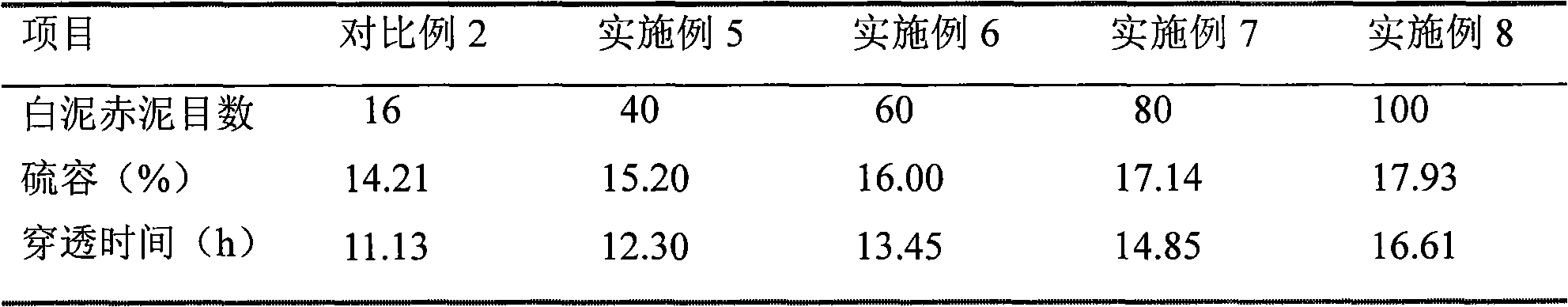

Composite sulphur dioxide desulfurizing agent and preparation method thereof

The invention discloses a desulphurizer for sulfur dioxide in composite material, which is characterized in that the desulphurizer comprises the following compositions in a mass percentage of 50- 80% of white mud in an alkali factory, 10-40% of red mud in a steel plant, 5.0- 8.0% of binder, 3.0% - 8.0% of pore-forming agent and 0.1- 1.0% of lubricant. A preparation method is as follows: firstly, the white mud in the alkali factory and the red mud in the steel plant are smashed into a particle above 40 meshes and are mixed with the binder, the pore-forming agent and the lubricant in a proportion above-mentioned; and then the water is added to mix evenly into a pasty state for the extrusion molding and the drying; finally the desulphurizer is obtained by high-temperature roasting. The invention has the advantages that industrial waste material such as the white mud and the red mud are utilized to prepare the desulphurizer which has the advantages of good desulphurizing effect, extensive material source, low price and no secondary pollution; the products of desulphurization can also be used for building sea dams and paving, etc., thereby being extensively used for the desulphurization and the purification of exhaust gas in a coal-fired power plant, a coal-burning boiler and a coal-fired furnace in the environmental protection industries.

Owner:OCEAN UNIV OF CHINA

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com