Method for cooperative activation of fly ash and decomposition of gypsum for recovery of sulfur resource

A fly ash and sulfur recovery technology, applied in chemical instruments and methods, aluminum chloride, aluminum halide, etc., can solve problems such as environmental threats, technology in the research and development stage, and low utilization rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

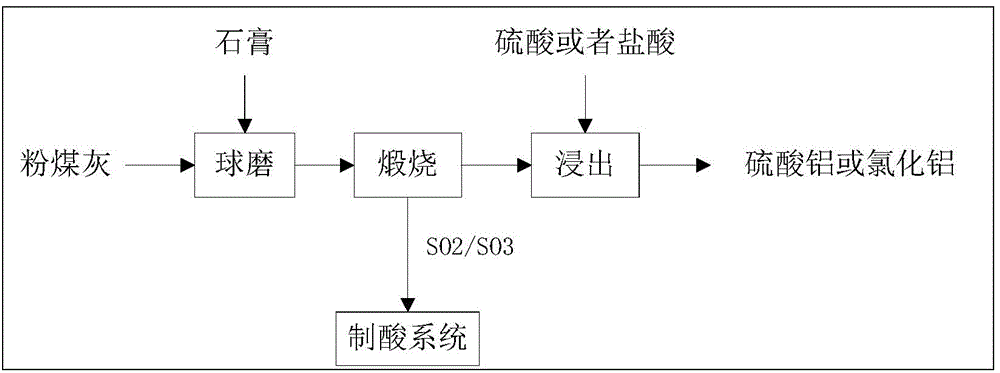

[0029] The fly ash and desulfurized gypsum of the coal-fired power plant are selected in this embodiment, wherein the content of alumina in the fly ash is 47.8%, and the content of calcium sulfate in the desulfurized gypsum is 65.4%. The specific process is as follows:

[0030] (1) Fly ash and gypsum are mixed in a certain proportion so that the calcium-aluminum molar ratio (Ca / Al) is 1.05 / 1 to obtain a mixture of fly ash and gypsum;

[0031] (2) ball milling the solid mixture obtained in step (1) so that its particle size is less than 100 mesh;

[0032] (3) Calcining the mixture obtained in (2) for 120 minutes at 1300° C.;

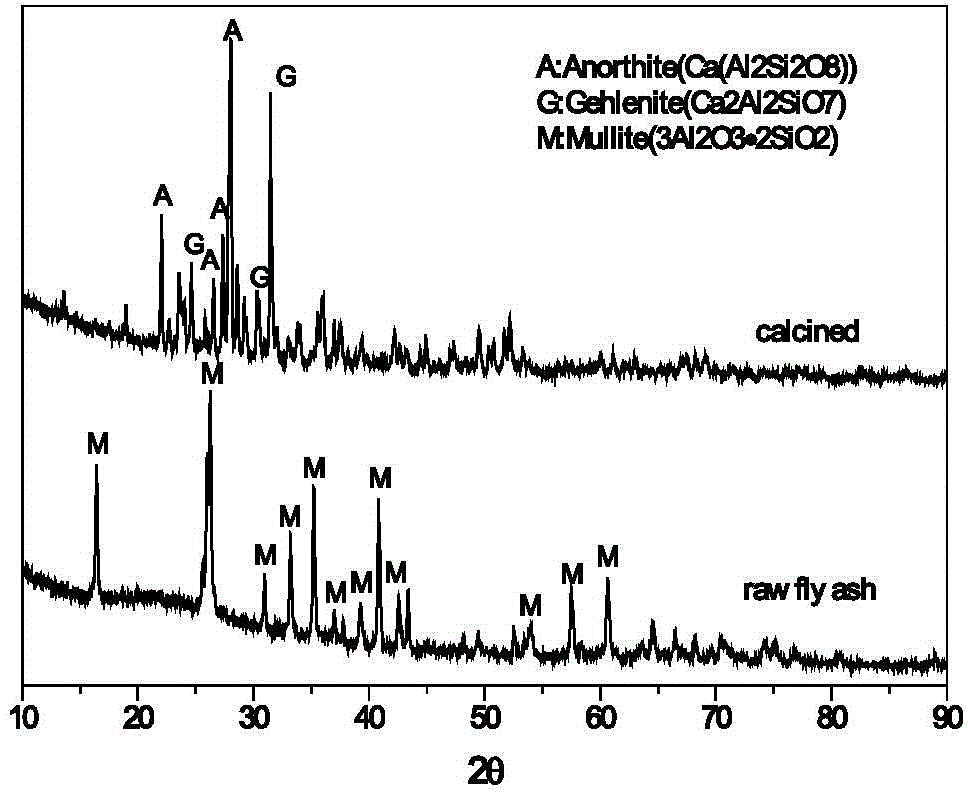

[0033] (4) The sulfur content of the (3) product after calcination was detected to be 0.36%, indicating that the desulfurization gypsum was almost completely decomposed; XRD analysis showed that the mullite phase in the fly ash had transformed into an anorthite and anorthite phase;

[0034] (5) Leach the clinker after calcined in (3), and use 0.5mol / L hy...

Embodiment 2

[0036] In this embodiment, the fly ash from a coal-fired power plant and the phosphogypsum from a phosphorus chemical enterprise are selected, wherein the alumina content in the fly ash is 40.3%, and the calcium sulfate content in the phosphogypsum is 73.8%. The specific process is as follows:

[0037] (1) Fly ash and gypsum are mixed in a certain proportion so that the calcium-aluminum molar ratio (Ca / Al) is 2.1 / 1 to obtain a mixture of fly ash and gypsum;

[0038] (2) ball milling the solid mixture obtained in step (1) so that its particle size is less than 300 mesh;

[0039] (3) calcining the mixture obtained in (2) at 1450° C. for 100 min;

[0040] (4) The sulfur content of the (3) product after calcination was detected to be 0.49%, indicating that the desulfurization gypsum was almost completely decomposed; XRD analysis showed that the mullite phase in the fly ash had transformed into a calcium alumina feldspar phase;

[0041] (5) Leach the calcined clinker in (3), and u...

Embodiment 3

[0043] In this embodiment, the fly ash from a coal-fired power plant and the phosphogypsum from a certain phosphorus chemical enterprise are selected, wherein the alumina content in the fly ash is 35.3%, and the calcium sulfate content in the phosphogypsum is 70.8%. The specific process is as follows:

[0044] (1) Fly ash and gypsum are mixed in a certain proportion so that the calcium-aluminum molar ratio (Ca / Al) is 0.4 / 1 to obtain a mixture of fly ash and gypsum;

[0045] (2) ball milling the solid mixture obtained in step (1) so that its particle size is less than 200 mesh;

[0046] (3) calcining the mixture obtained in (2) for 180 min at 950° C.;

[0047] (4) The sulfur content of the (3) product after calcination was detected to be 1.08%, indicating that the desulfurized gypsum was almost completely decomposed; XRD analysis showed that the mullite phase in the fly ash had transformed into an anorthite phase;

[0048] (5) Leach the calcined clinker in (3) with 0.5mol / L su...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com