Method for producing lead oxide by recovering waste lead-acid batteries based on atom economy way

A lead-acid battery and lead oxide technology, applied in the direction of improving process efficiency, etc., can solve problems such as difficulty in obtaining relatively pure PbO, achieve significant environmental value, improve recovery efficiency, and save huge amounts of energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

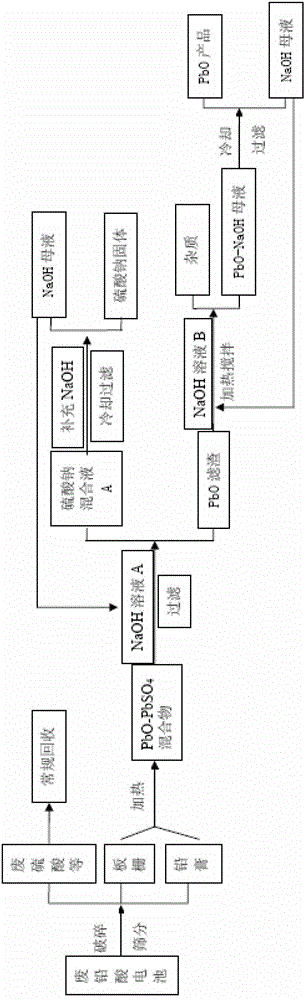

Method used

Image

Examples

Embodiment 1

[0026] Get 2 pieces of 12V, 12Ah ordinary electric vehicle waste lead-acid batteries purchased on the market, and the total weight of the battery pack is 9.2 kg. The specific implementation process is as follows:

[0027] (1) After routine crushing and separation of waste lead-acid batteries, lead paste, grids, waste sulfuric acid, separators and casings are obtained.

[0028] (2) Pulverize the separated lead paste and sieve it with a 120-mesh stainless steel screen. Larger lead paste particles will continue to be transferred to the pulverizer for crushing until all the lead paste passes through the screen.

[0029] (3) After the waste grid is crushed, it is screened with a 120-mesh stainless steel screen, and the larger lead particles continue to be transferred to the crusher for crushing until all the lead particles pass through the screen for later use.

[0030] (4) Prepare NaOH solutions with concentrations of 3mol / L (density 1.12g / ml), 8mol / L (density 1.28g / ml) and 10mol...

Embodiment 2

[0040] (1) Obtain crushed lead paste and lead powder, and recovered NaOH mother liquor A, mother liquor B and mother liquor C according to Example 1.

[0041] (2) Mix 0.96 kg of lead paste and 0.04 kg of lead powder in solid phase, then heat to 390°C for 15 minutes of redox reaction to obtain 0.99 kg of a mixture mainly containing lead oxide and lead sulfate;

[0042] (3) Desulfurize the reaction product obtained in the process of (2) in 500ml of mother liquor A, maintain the reaction conditions of 150 rpm stirring speed and constant temperature of 50°C, and filter after 10 minutes of reaction to obtain lead oxide-based filter residue and filtrate A;

[0043] (4) Put the filter residue of step (3) into 13 liters of mother liquor B, and heat at 110°C, so that all the lead oxide in the filter residue is dissolved in mother liquor B;

[0044] (5) Filtrate the mother liquor B in the process of (4) while it is hot to obtain filtrate B and filter residue dissolved with lead oxide; ...

Embodiment 3

[0050] (1) Take 2 kg of the paste slurry on the lead-acid battery plate discarded in the lead-acid battery workshop and put it into a pulverizer for continuous crushing and screening to obtain a 120-mesh lead paste powder.

[0051] (2) Prepare 100 liters of NaOH solution with a concentration of 3.3mol / L (density 1.121g / ml), 10mol / L NaOH solution containing 30g / L PbO (density 1.331g / ml) and 11mol NaOH solution containing 35g / L PbO The NaOH solution (density 1.35g / ml) of / L is recorded as NaOH solution A, B and C respectively, is put in the bucket for subsequent use;

[0052] (3) Mix 2 kg of lead plaster and 0.1 kg of lead powder, then heat to 500°C for 9 minutes for redox reaction to obtain 2.08 kg of solid mixture mainly composed of lead oxide and lead sulfate;

[0053] (4) Desulfurize the reaction product obtained in (3) in 1 liter of NaOH solution A, maintain the reaction conditions of 150 rpm stirring speed and constant temperature of 50 ° C, react for 5 minutes and filter ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Density | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com