Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

6939 results about "Economic shortage" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

In economics, a shortage or excess demand is a situation in which the demand for a product or service exceeds its supply in a market. It is the opposite of an excess supply (surplus).

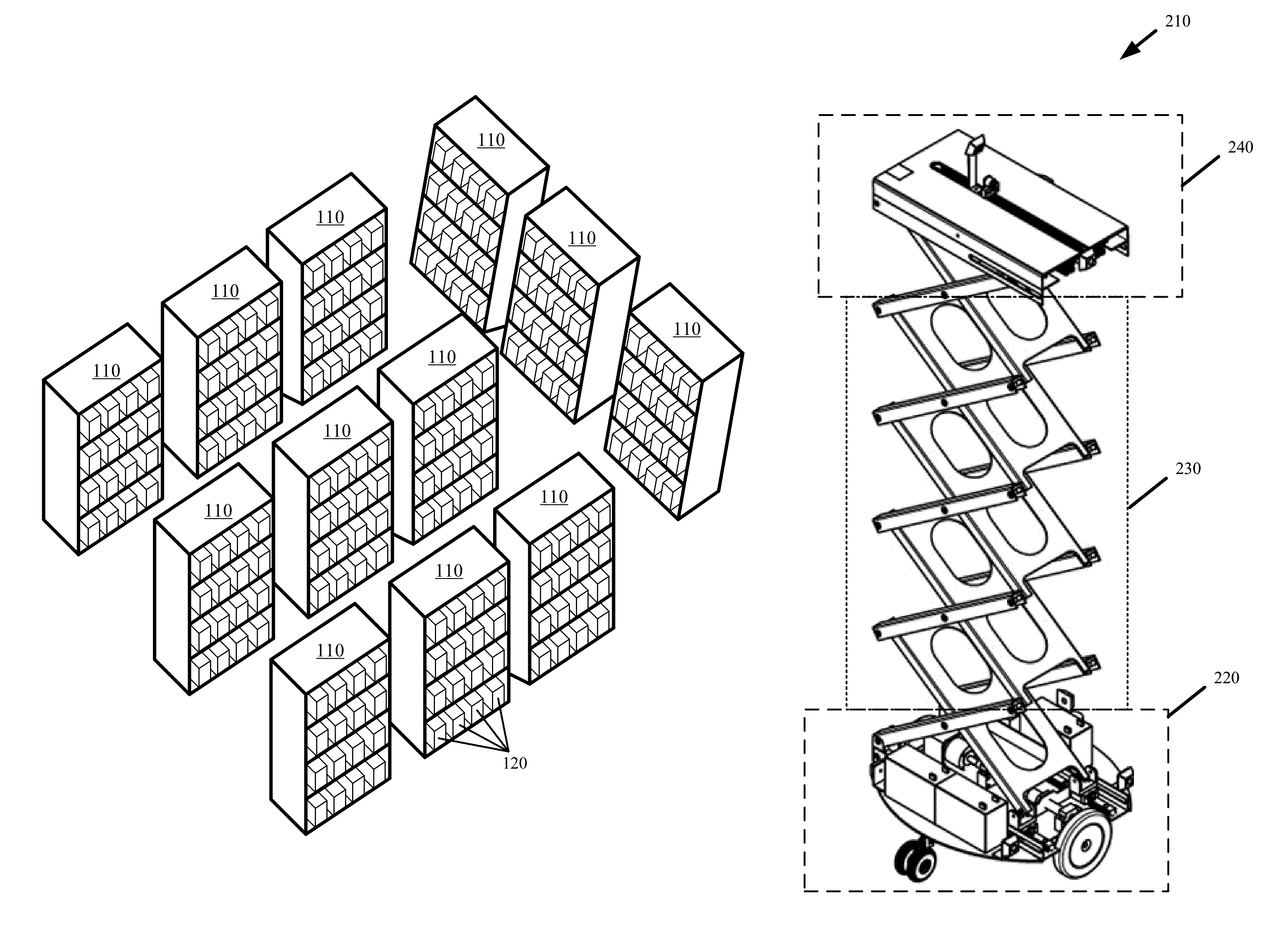

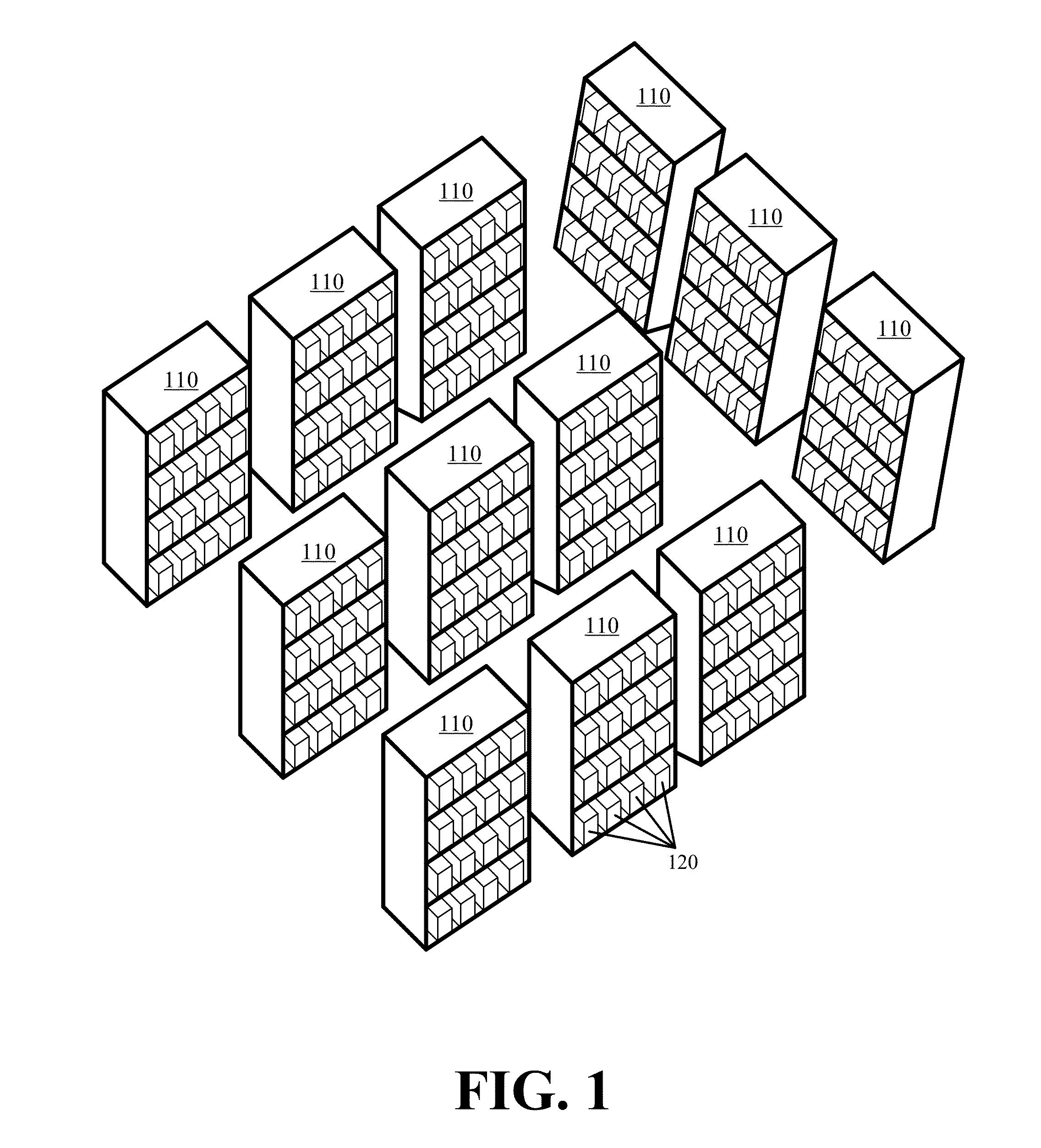

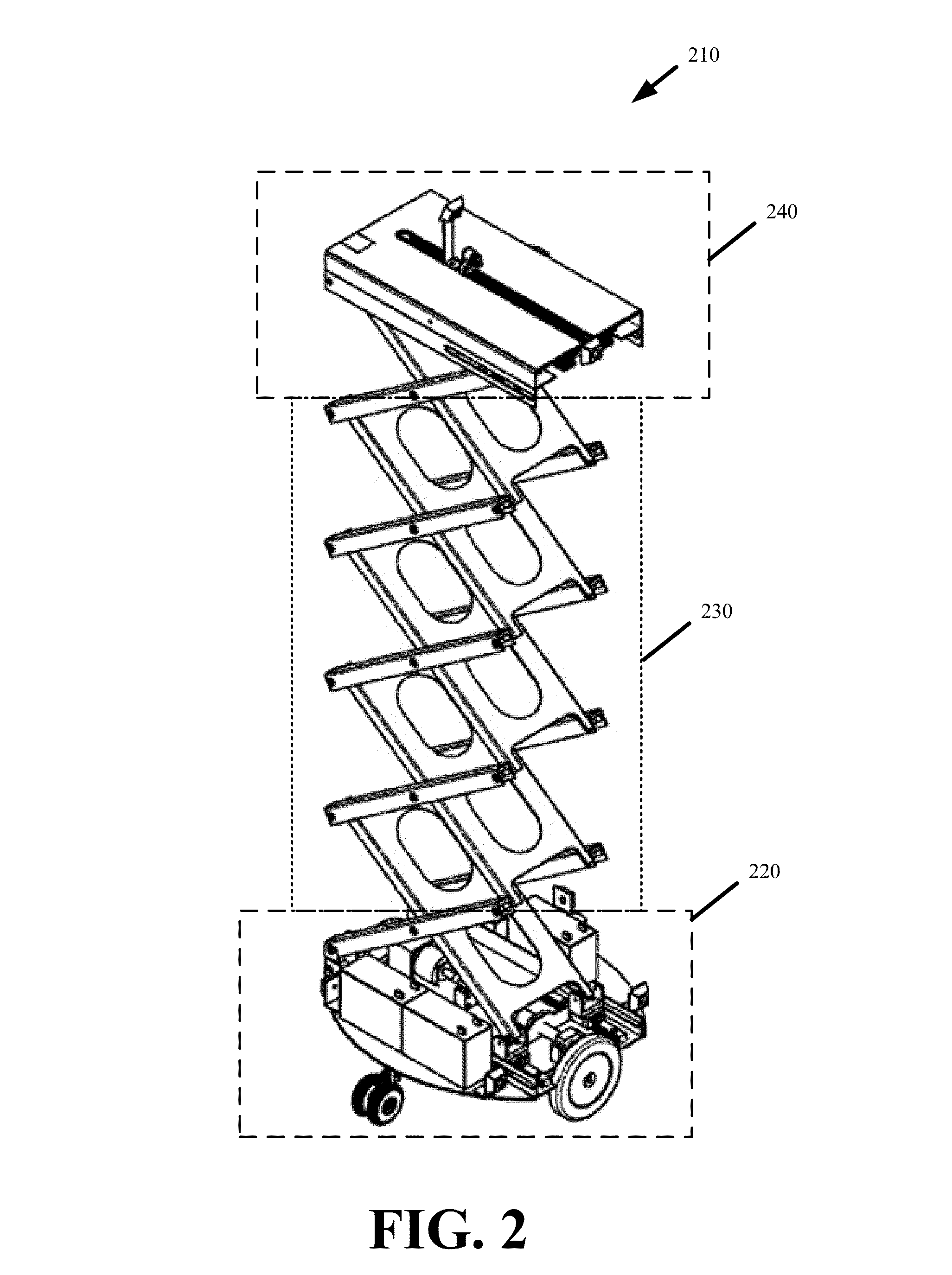

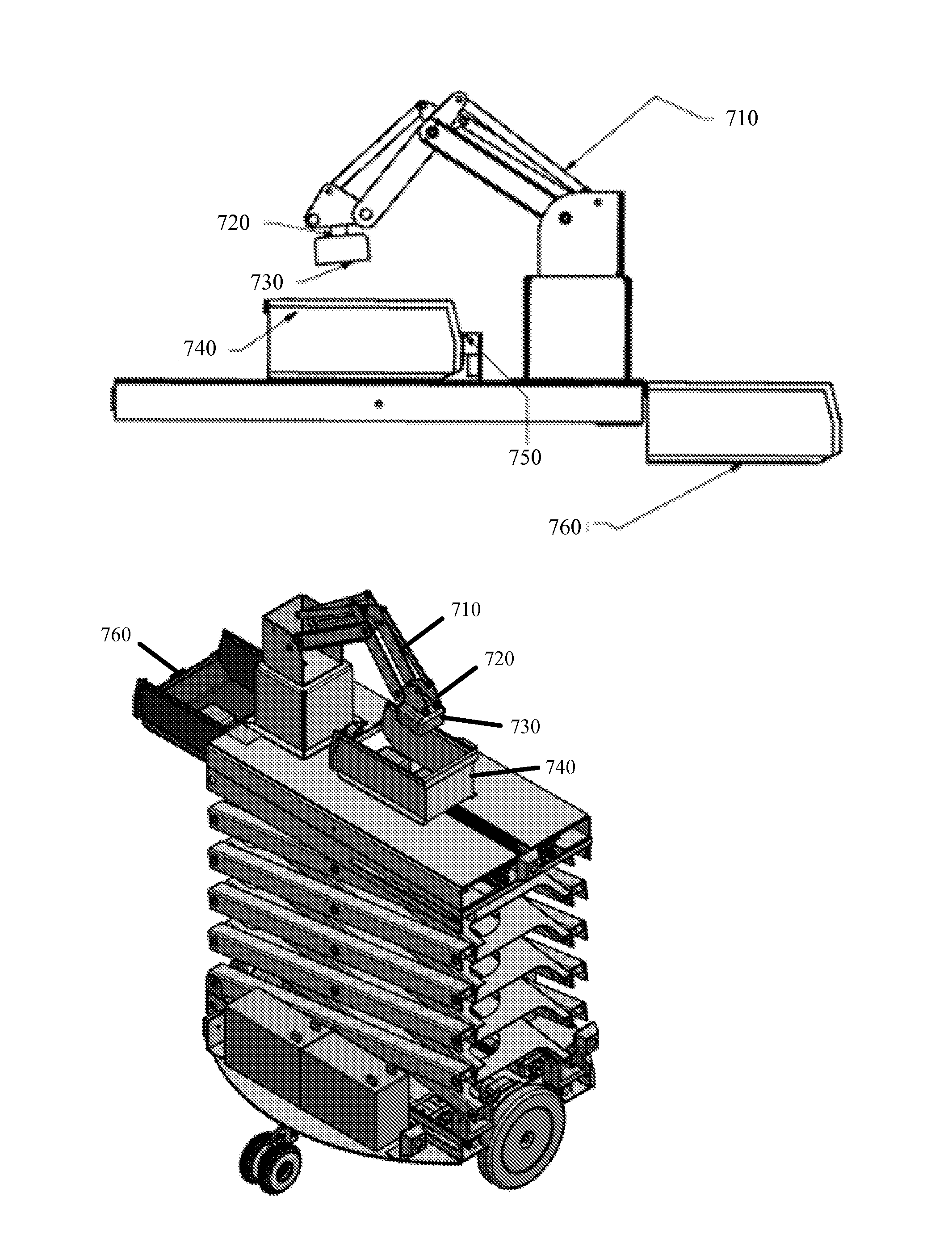

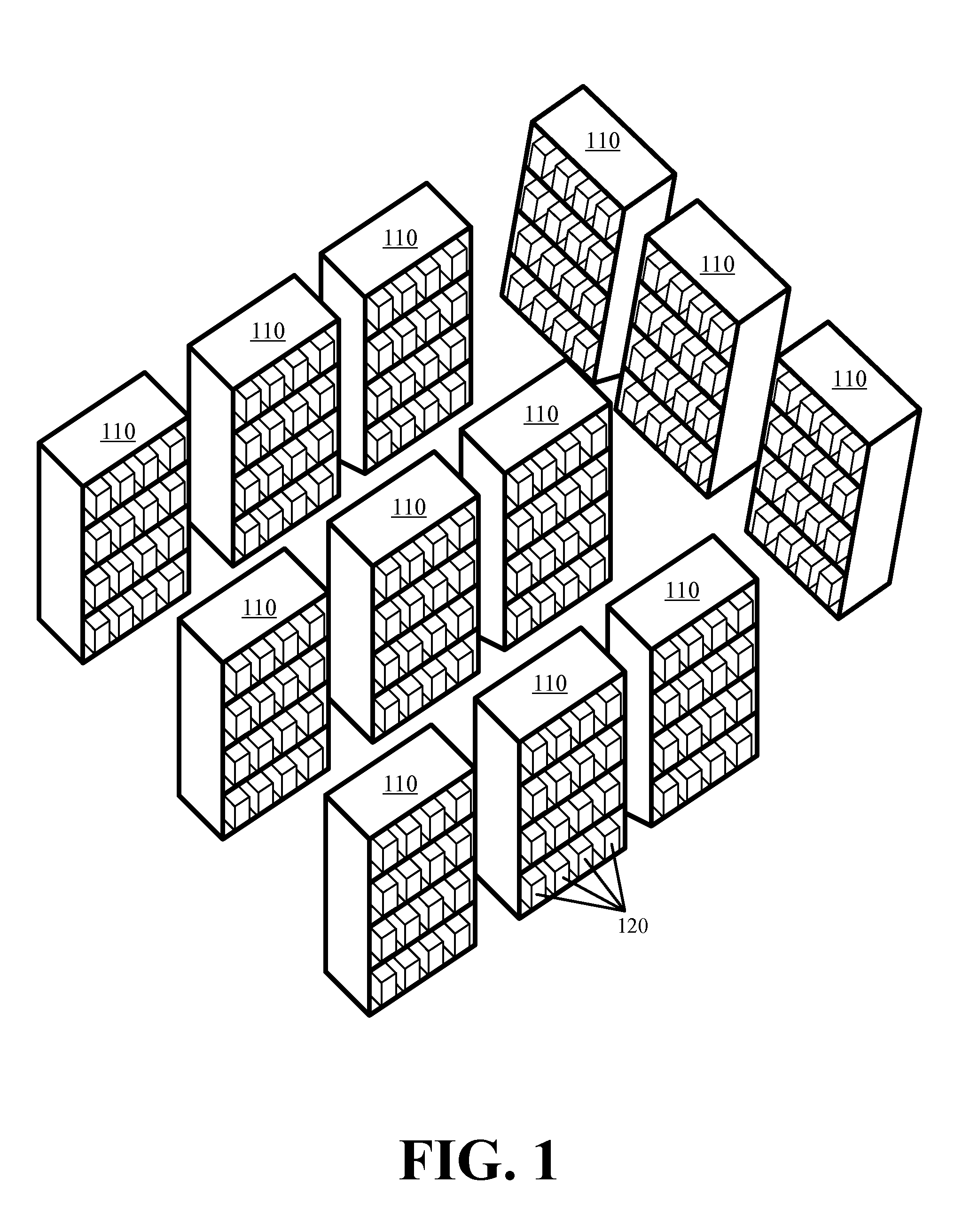

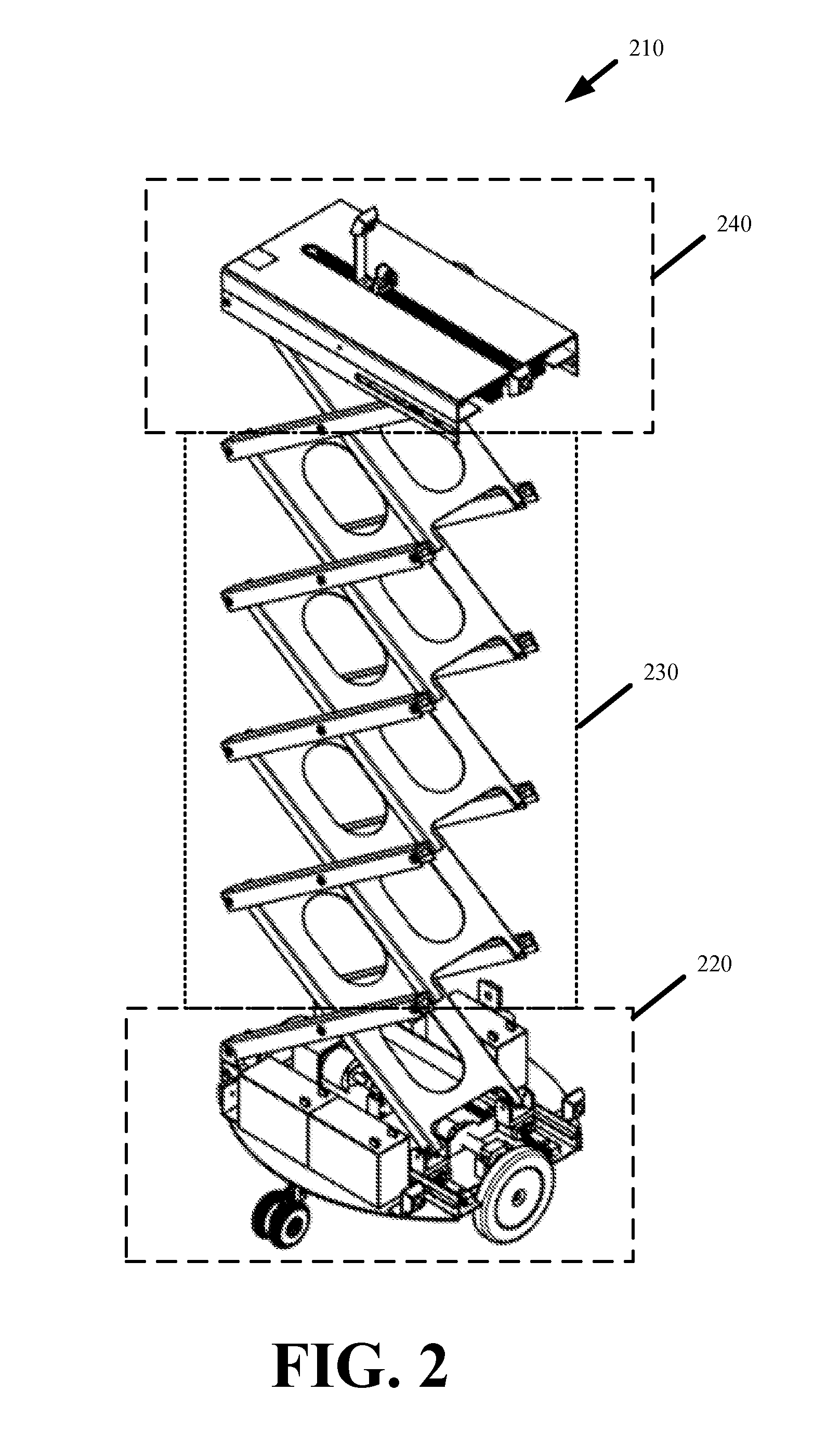

Autonomous order fulfillment and inventory control robots

ActiveUS9120622B1Programme-controlled manipulatorDigital data processing detailsOrder fulfillmentInventory management

Some embodiments provide a system for fully autonomous order fulfillment and inventory management within a distribution site or warehouse. The system operates by autonomous robots directly pulling customer order items from distribution site shelves or pulling individual bins from distribution site shelves and dispensing appropriate quantities of items from the bins until all items of a customer order are retrieved without human involvement. The system further involves the robots autonomously monitoring item quantities within the distribution site, identifying and autonomously responding to shortages, and organizing the items within the distribution site for most efficient order fulfillment.

Owner:INVIA ROBOTICS INC

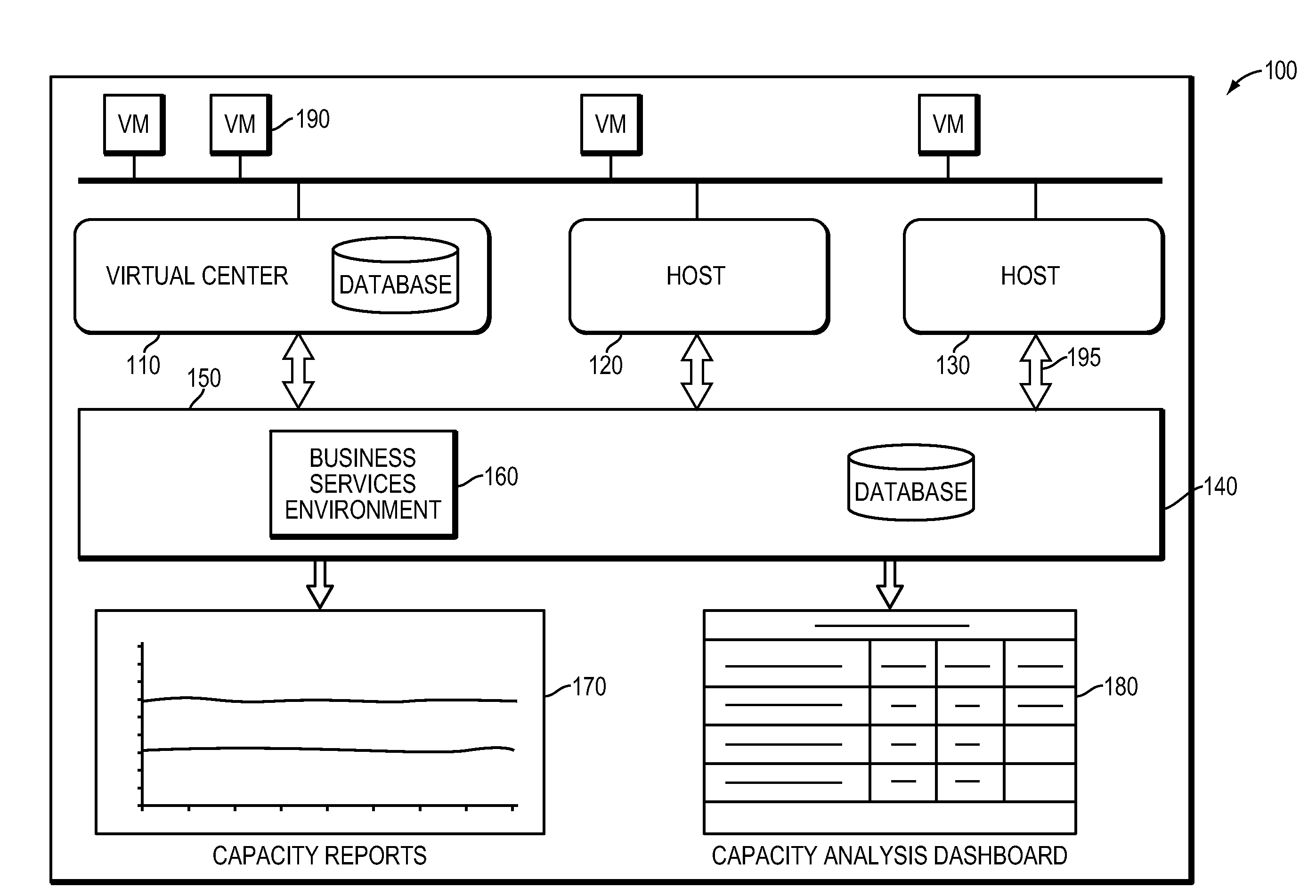

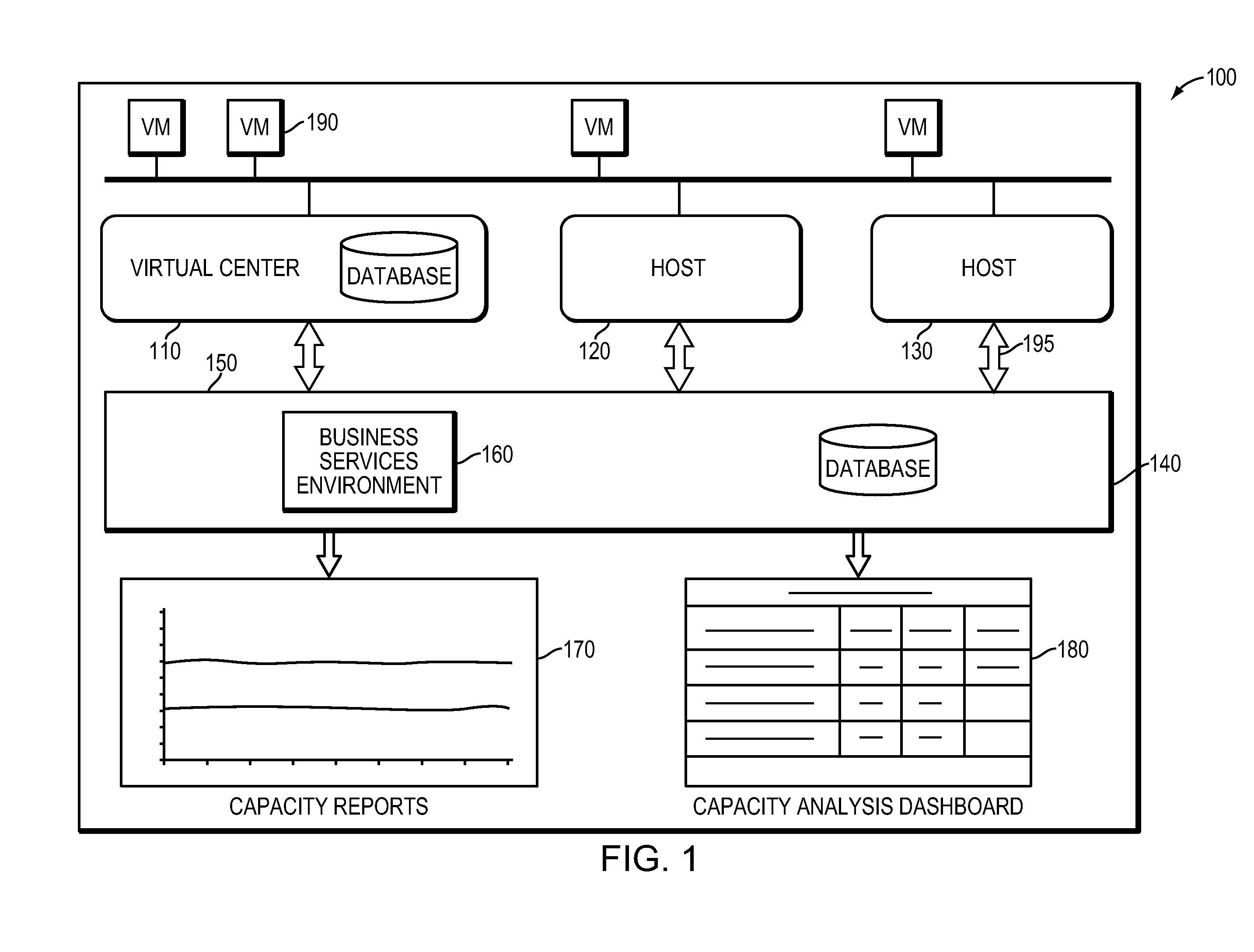

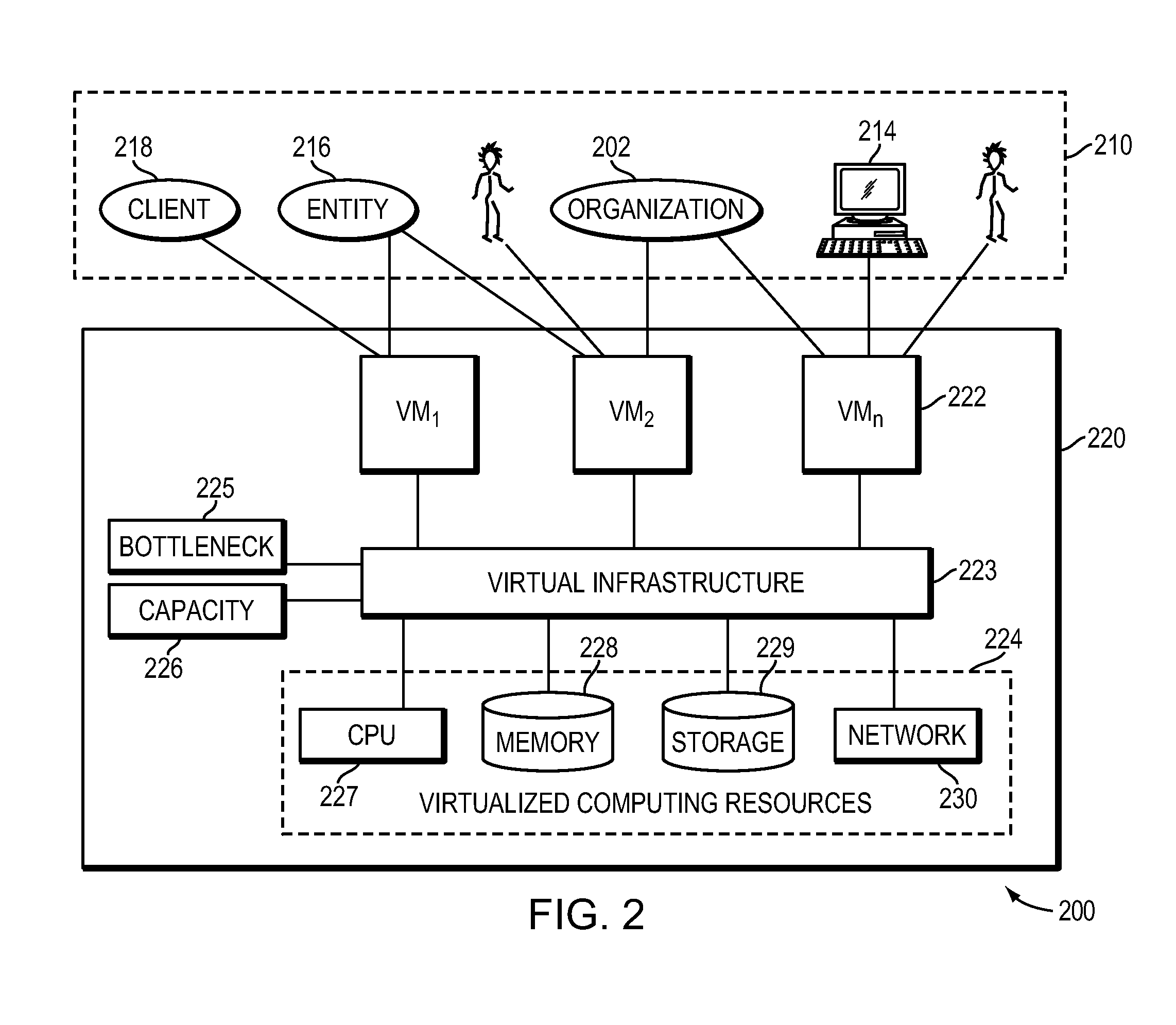

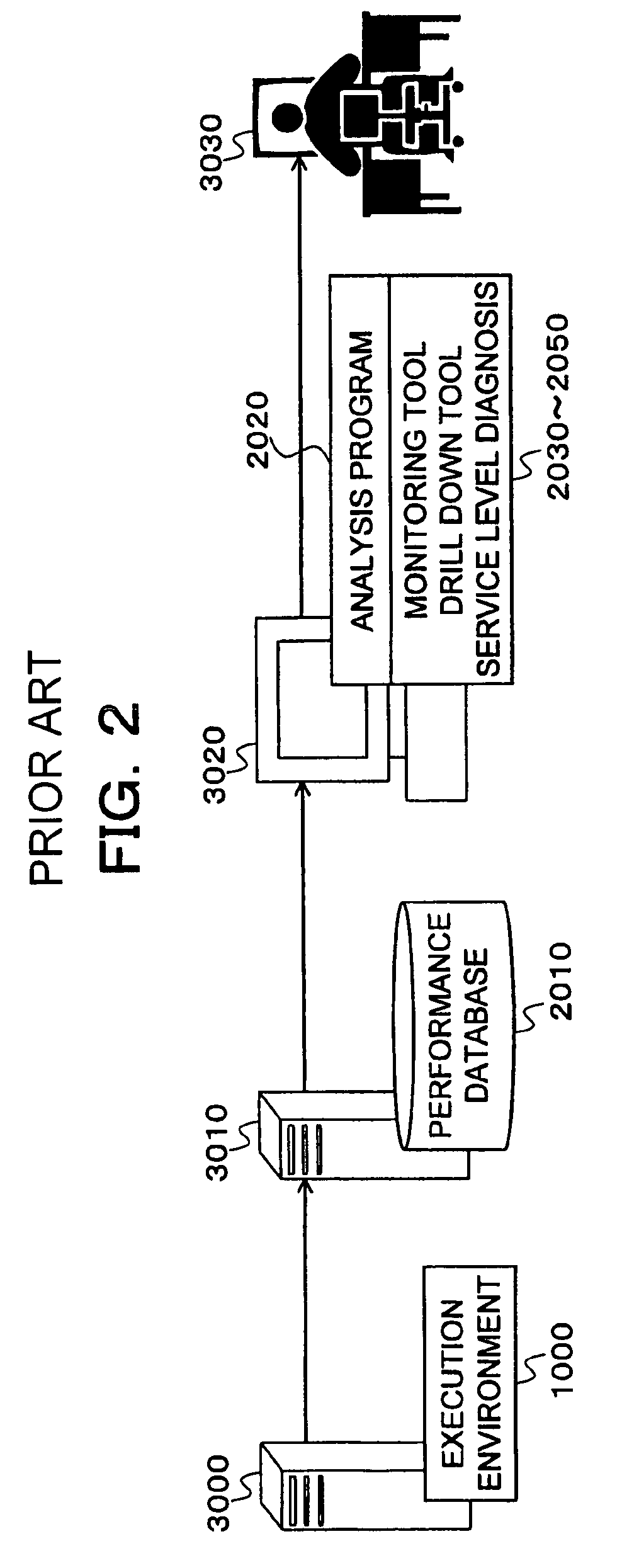

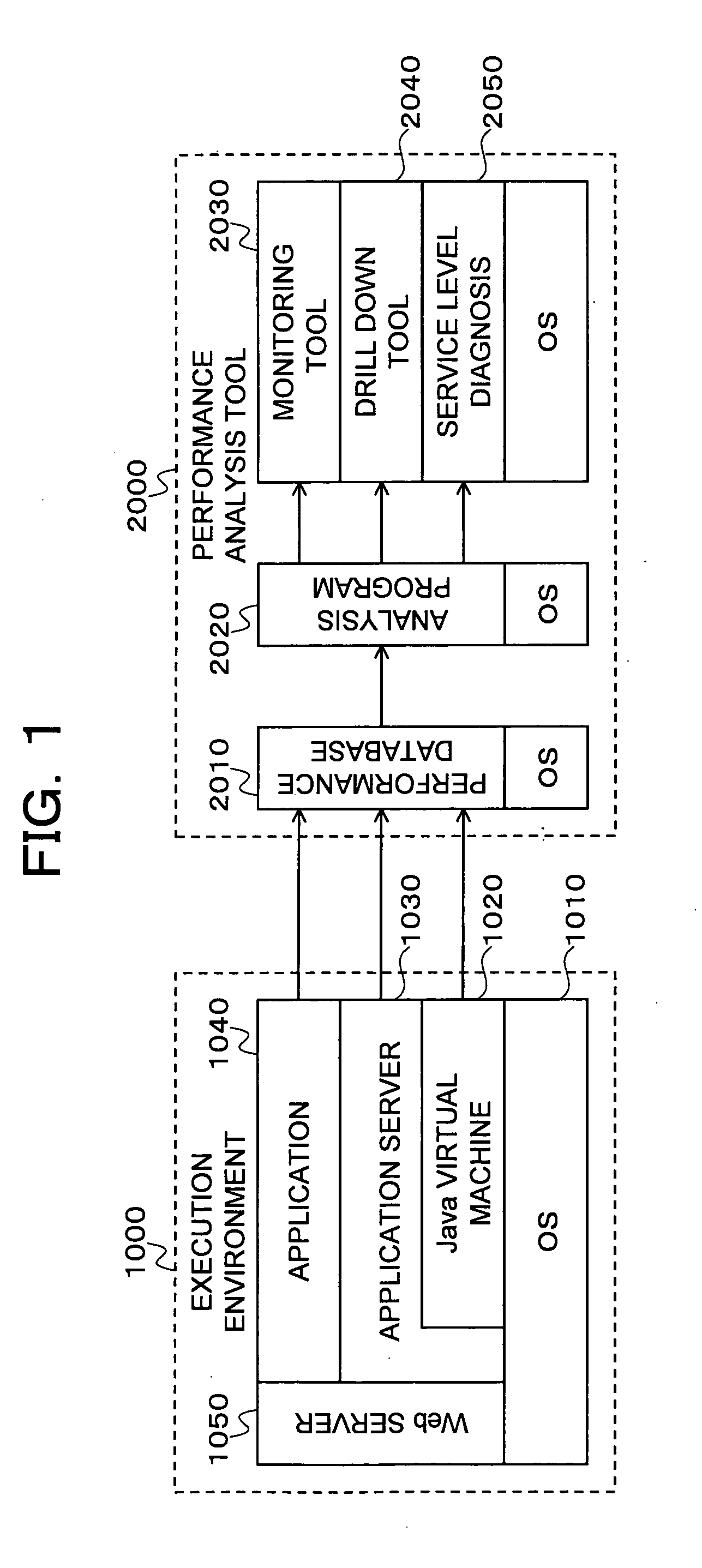

Method, System and Apparatus for Managing, Modeling, Predicting, Allocating and Utilizing Resources and Bottlenecks in a Computer Network

ActiveUS20090300173A1Shorten the timeLow costAnalogue computers for electric apparatusDigital computer detailsVirtualizationResource allocation

A method and apparatus for managing, modeling, predicting, allocating and utilizing resources and bottlenecks in a computer network managing, predicting and displaying of capacity, allocating and utilizing of resources, as well as actual and potential performance-degrading resource shortages in a computer network, is provided. Specifically, exemplary implementations of the present invention provide a method, system and apparatus for calculating, detecting, predicting, and presenting resource allocation, utilization, capacity bottlenecks and availability information, in a computer network, particularly in a virtualized computer environment.

Owner:QUEST SOFTWARE INC

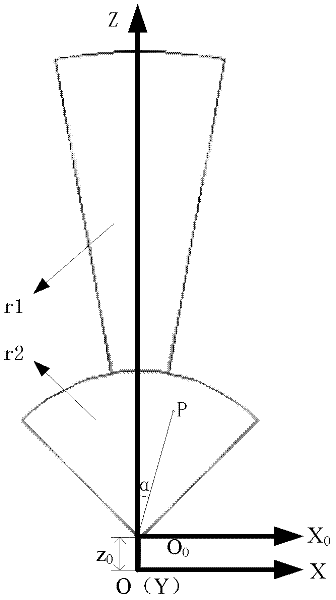

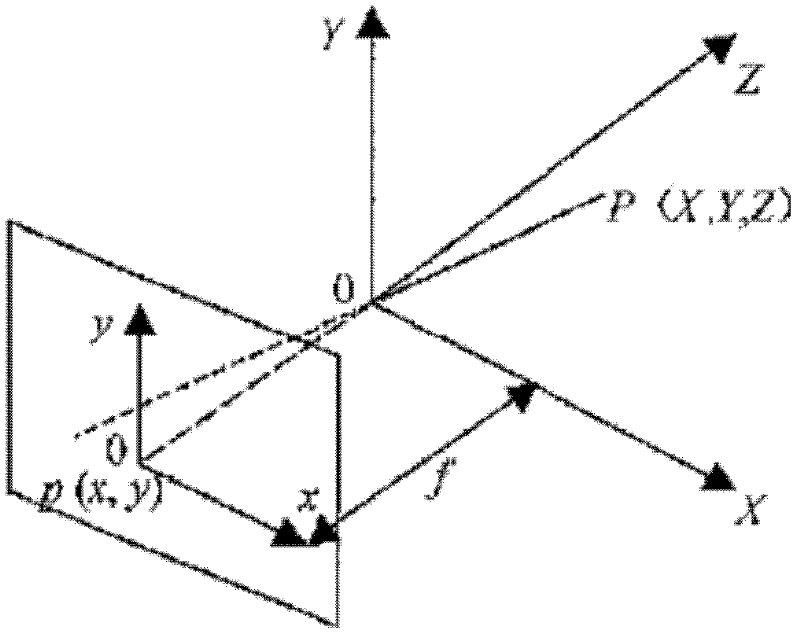

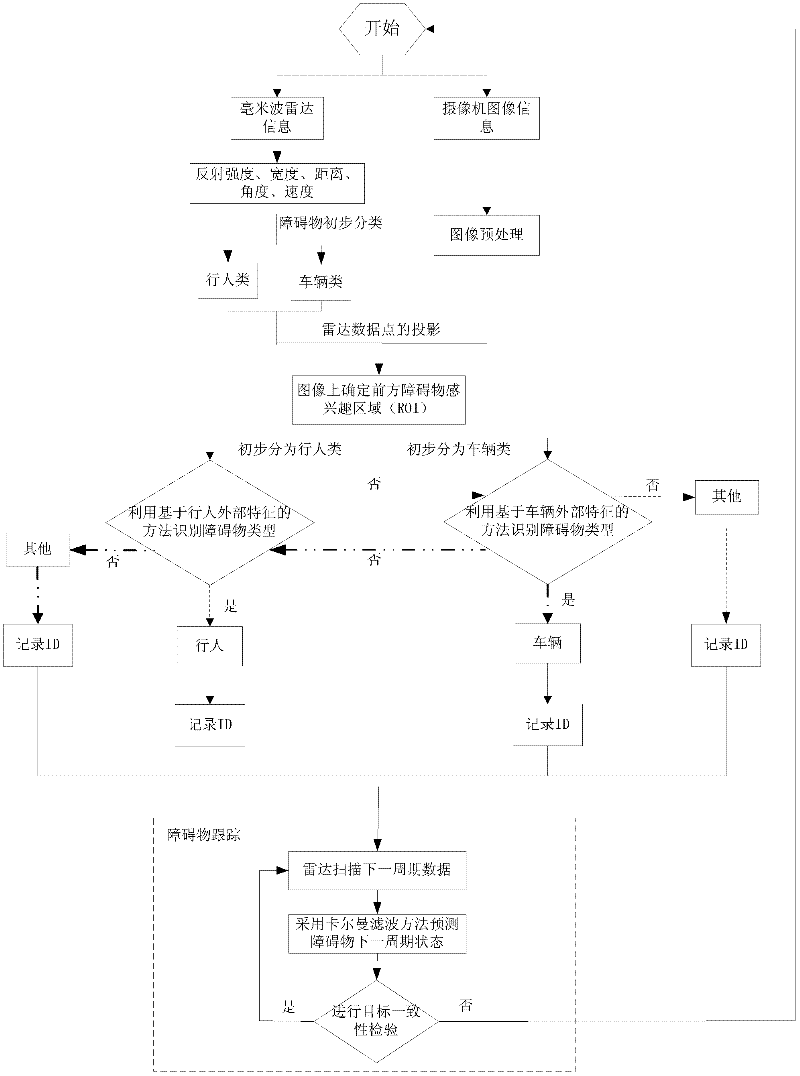

Method for detecting and tracking obstacles in front of vehicle

InactiveCN102508246ASolve problems that are difficult to classify and identify at the same timeSolve elusive problemsPhotogrammetry/videogrammetryCharacter and pattern recognitionCamera imageImaging processing

The invention discloses a method for detecting and tracking obstacles in front of a vehicle, aiming to overcome the defect and shortage in detection and tracking of obstacles in front of the vehicle by using a single-type sensor. The method comprises the following steps of: 1. establishing a relation for realizing data conversion between a millimeter wave radar coordinate system and a camera coordinate system; 2. receiving, resolving and processing the millimeter wave radar data, and carrying out preliminary classification on the obstacles; 3. synchronously collecting a camera image and receiving millimeter wave radar data; 4. classifying the obstacles in front of the vehicle: 1) projecting scanning points of the millimeter wave radar data on a camera coordinate system by combining the methods of millimeter wave radar and monocular vision, and establishing a region of interest (ROI) of the obstacles on the image; 2) carrying out preliminary classification on different obstacles in theROI established on the image, and confirming the types of the obstacles by using different image processing algorithms; and 5. tracking the obstacles in front of the vehicle.

Owner:JILIN UNIV

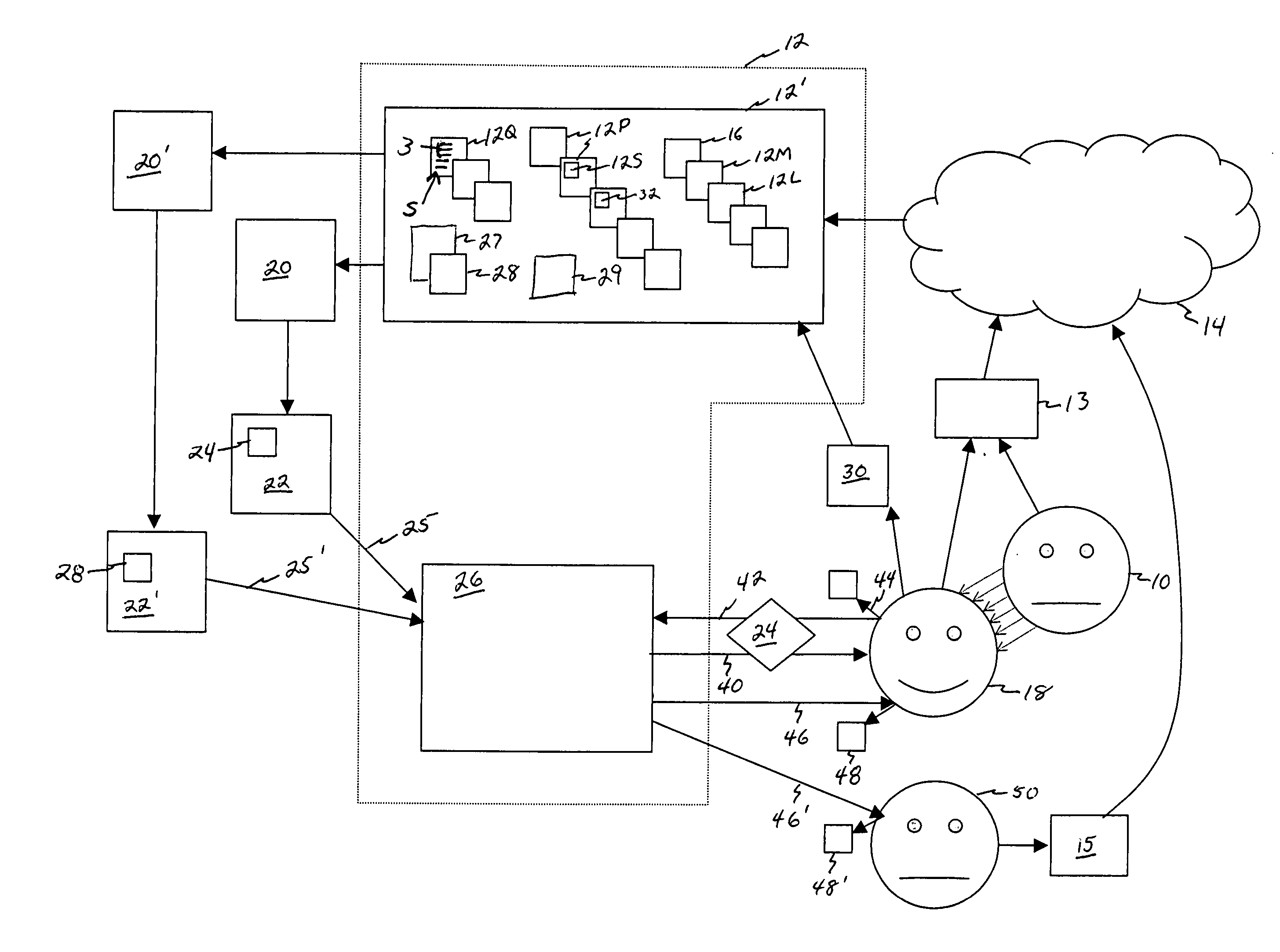

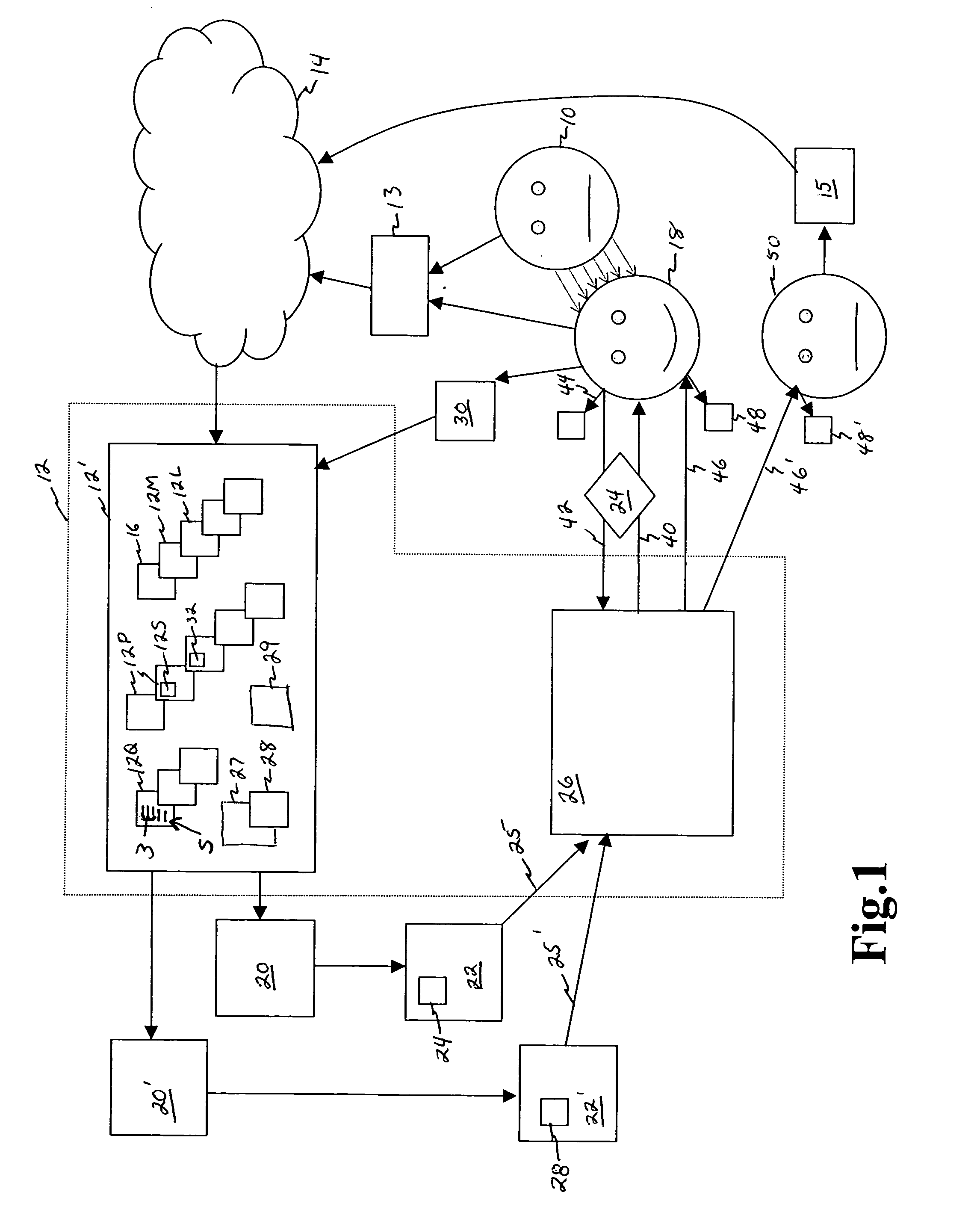

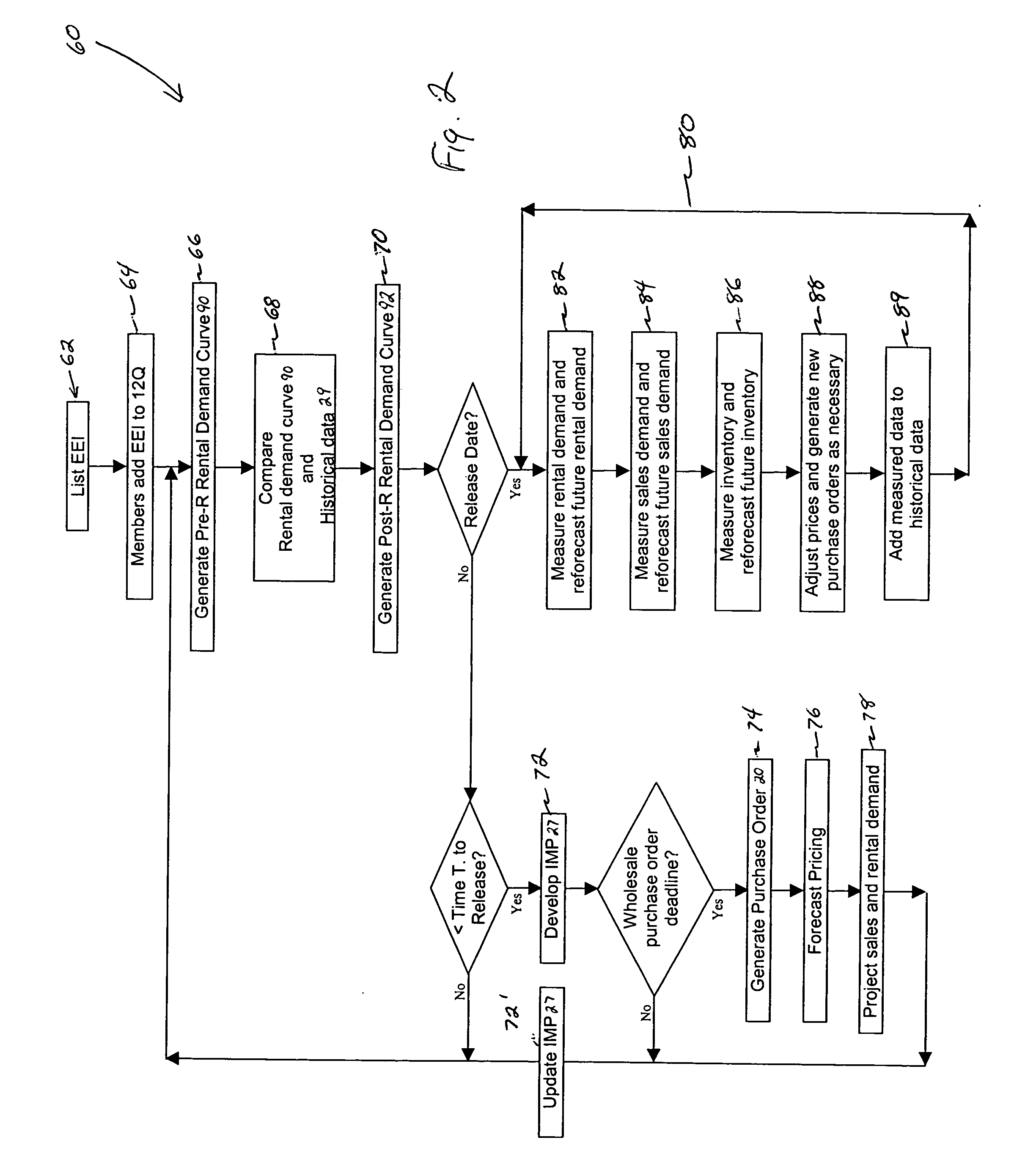

Method and apparatus for managing demand and inventory

InactiveUS20040068451A1Increase salesDecrease stockSpecial data processing applicationsMarketingComputer scienceInventory level

The present invention is directed to a method and system for managing the inventory level of, and the distribution of, electronic media rental units, including but not limited to videogame discs, musical compact disks, or movie VCD / DVDs. More specifically, preferred embodiments of the present invention forecasts future rental and sales demand for a given electronic media, such as a videogame, prior to the release of that electronic media to the general public. The forecast is based on the pre-release demand of the electronic media in that the future rental and sales demand is estimated from the rental and sales demand of previously released electronic media having similar pre-release demand. Furthermore, the preferred embodiments of the present invention allows registered members of a rental user group to keep rented units of the electronic media for a purchase price, which is dynamically controlled to minimize rental shortage and maximize profits.

Owner:GAMEFLY

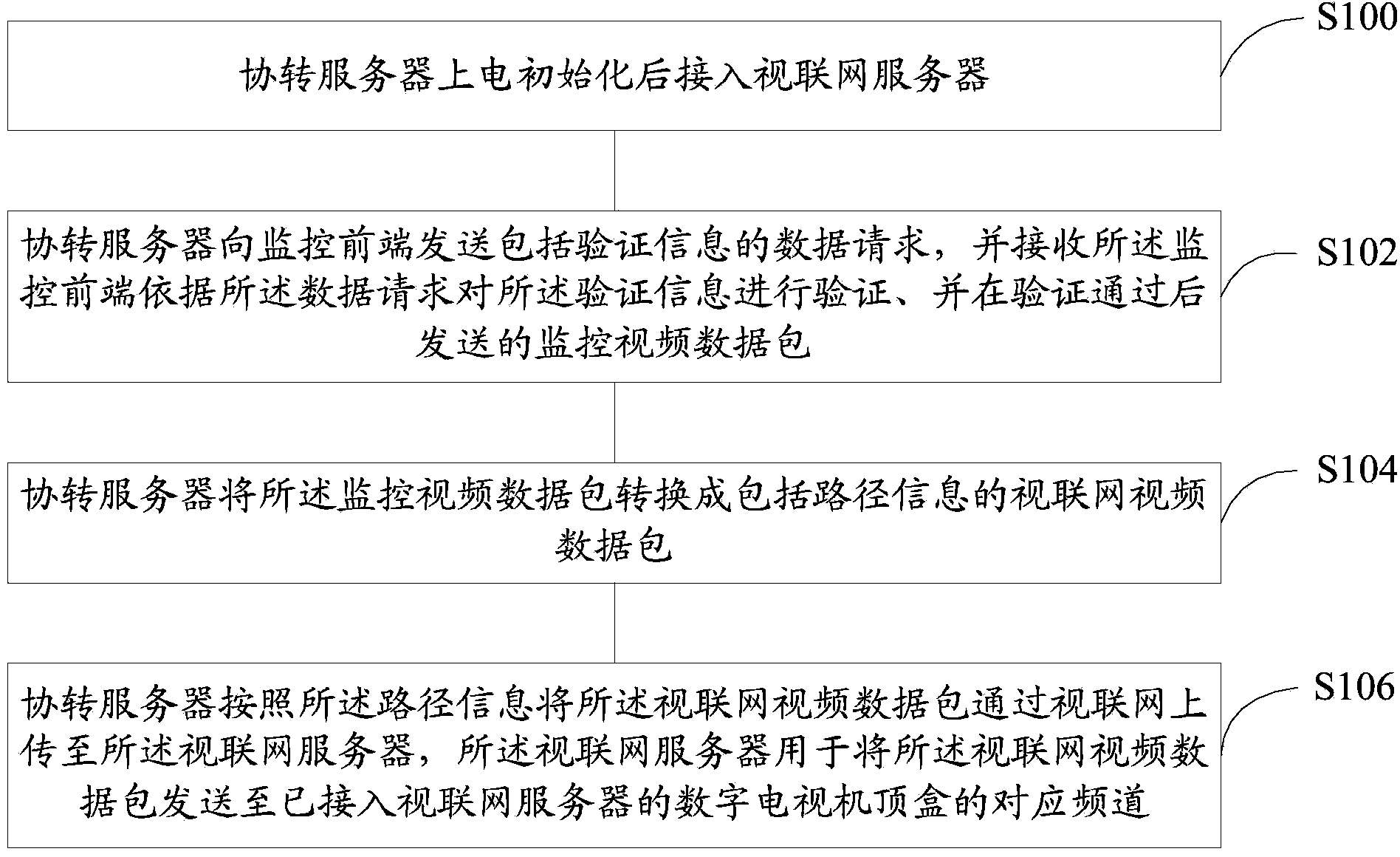

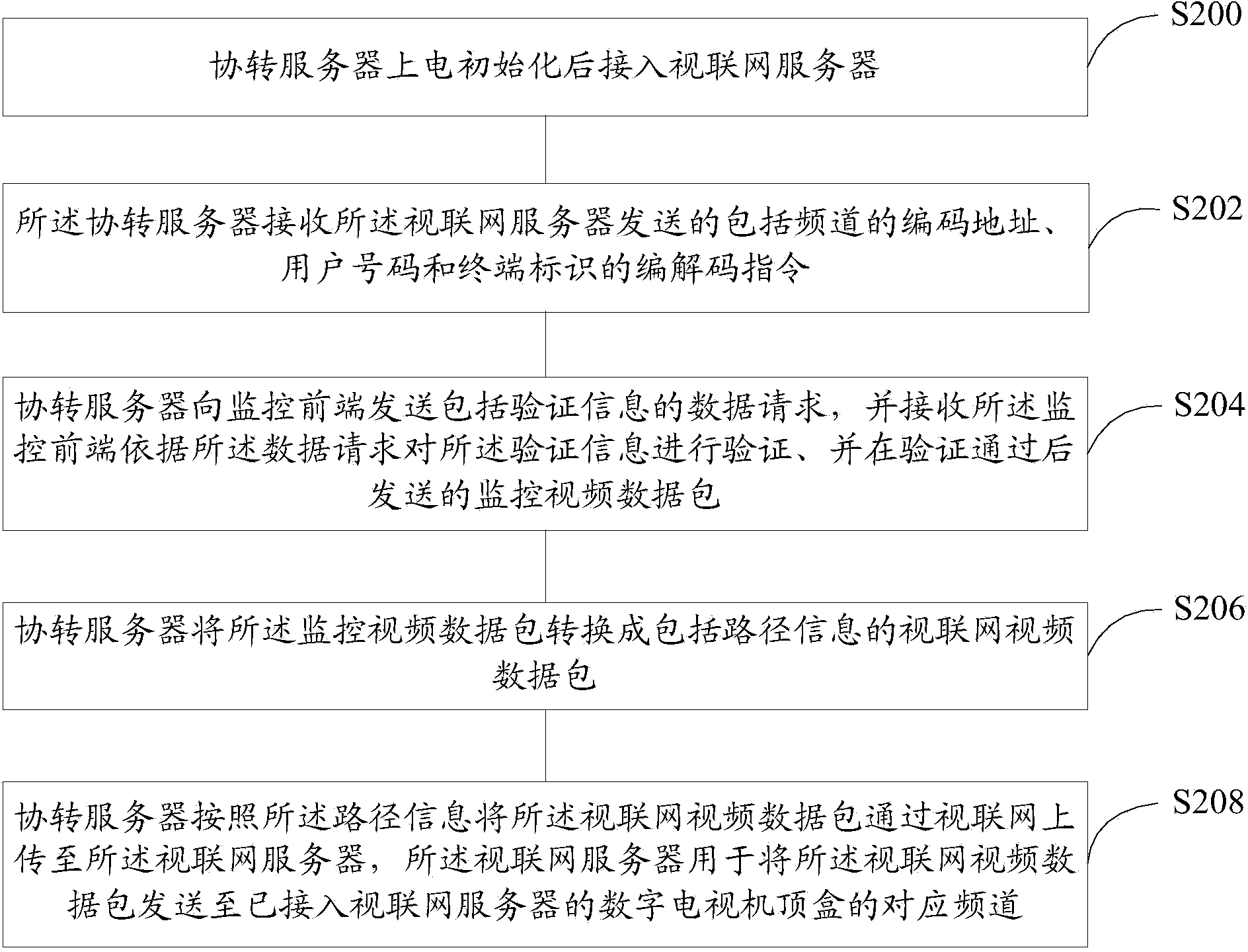

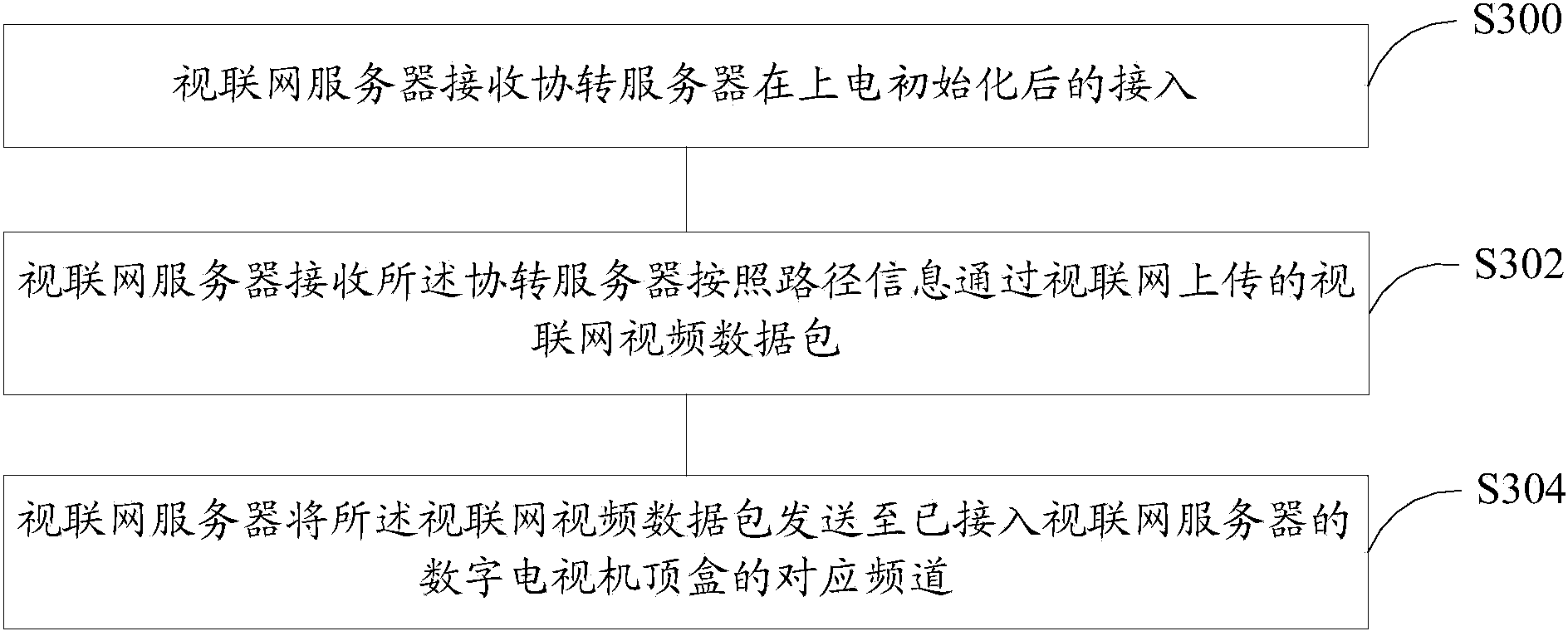

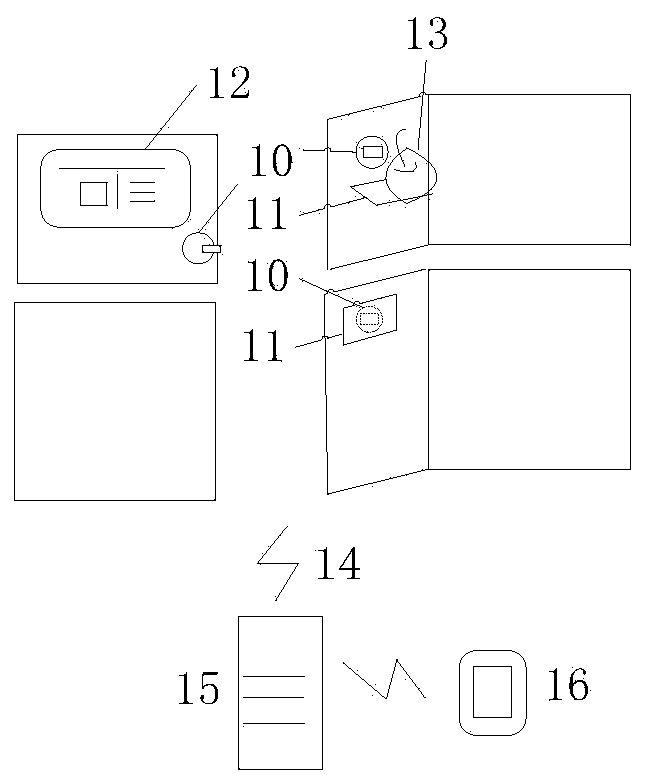

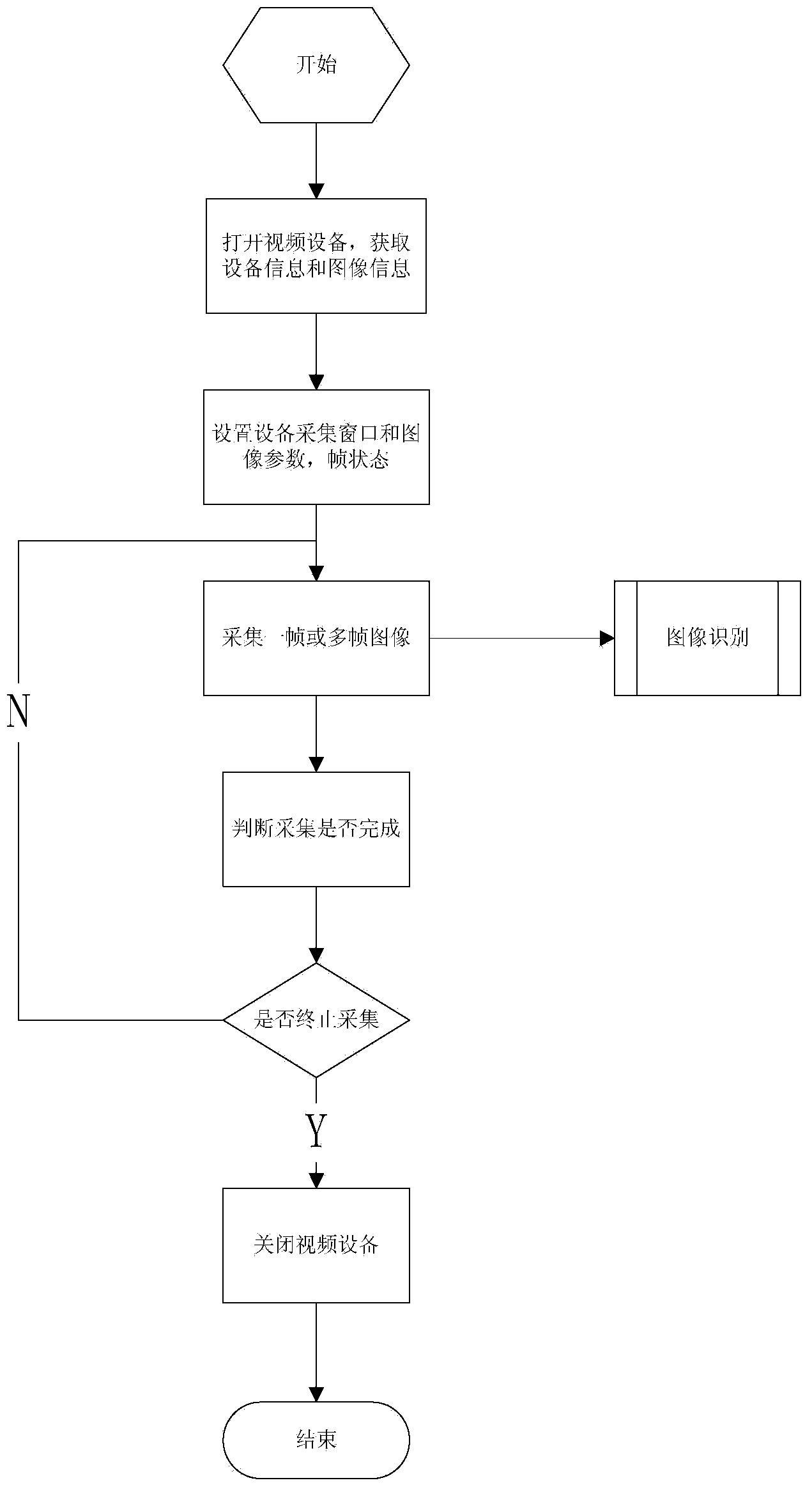

Video internet video monitoring method and system, protocol conversion server, and video internet server

ActiveCN103686072AAvoid delayClosed circuit television systemsSelective content distributionElectricityVideo monitoring

The embodiment of the invention provides a video internet video monitoring method and system, a protocol conversion server and a video internet server, and aims to solve the problem that shortage of staff in a monitoring center results in negligence in viewing monitoring video signals and causes potential safety hazards. The method includes: the protocol conversion server after powering on and initialization is connected with the video network server; a data request including authentication information is sent to a monitoring front-end, and a monitoring video data packet sent by the monitoring front-end is received; the monitoring video data packet is converted into a video network video data packet including path information; and according to the path information, the video network video data packet is through the video network uploaded to the video network server, wherein the video network server is used to send the video network video data packet to a corresponding channel of a digital TV set top box. According to the invention, the staff not belonging to the monitoring center are enabled to watch the monitoring video through the digital television, so that the problem that the shortage of staff in the monitoring center results in negligence in viewing monitoring video signals and causes potential safety hazards is avoided.

Owner:VISIONVERA INFORMATION TECH CO LTD

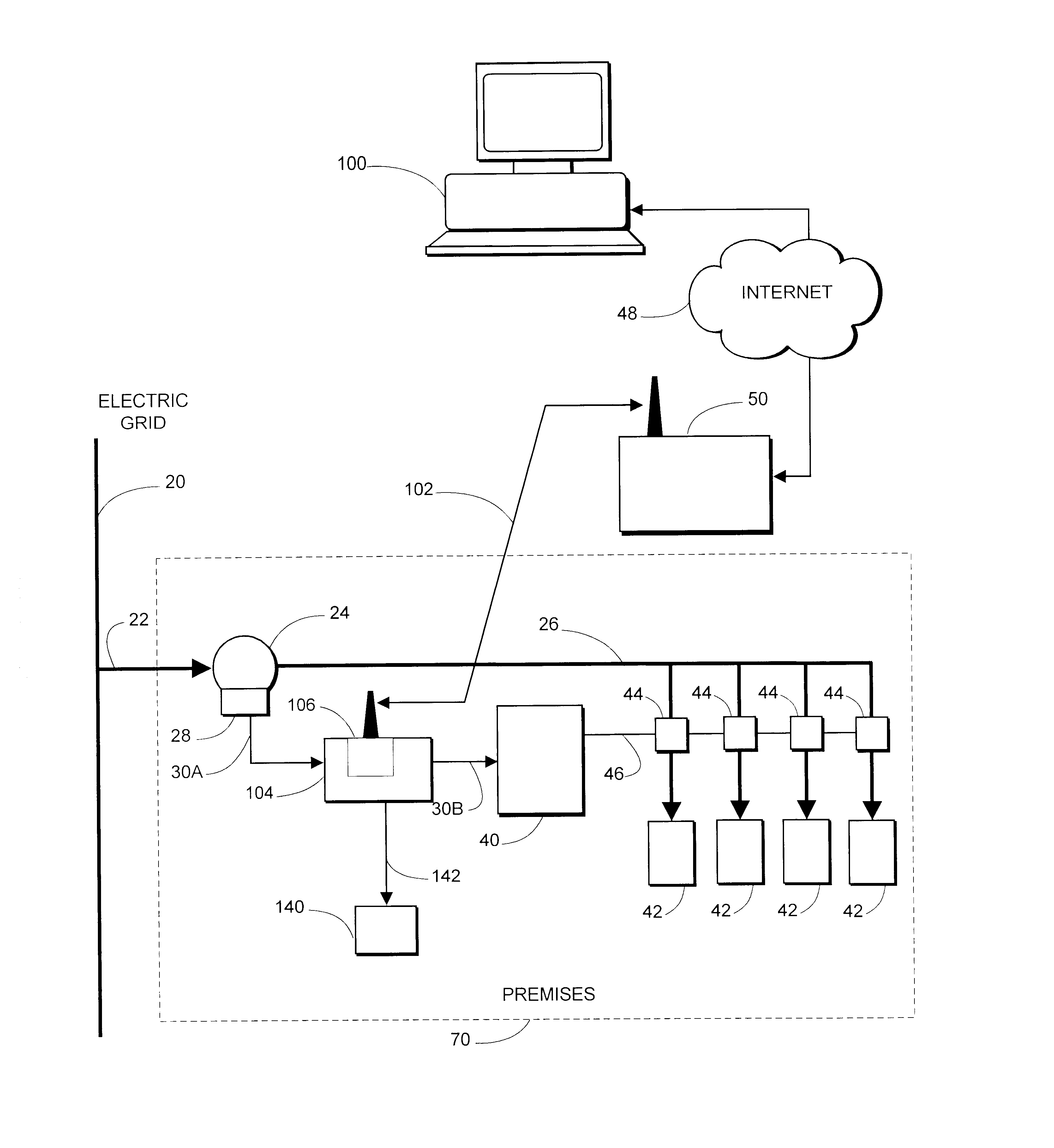

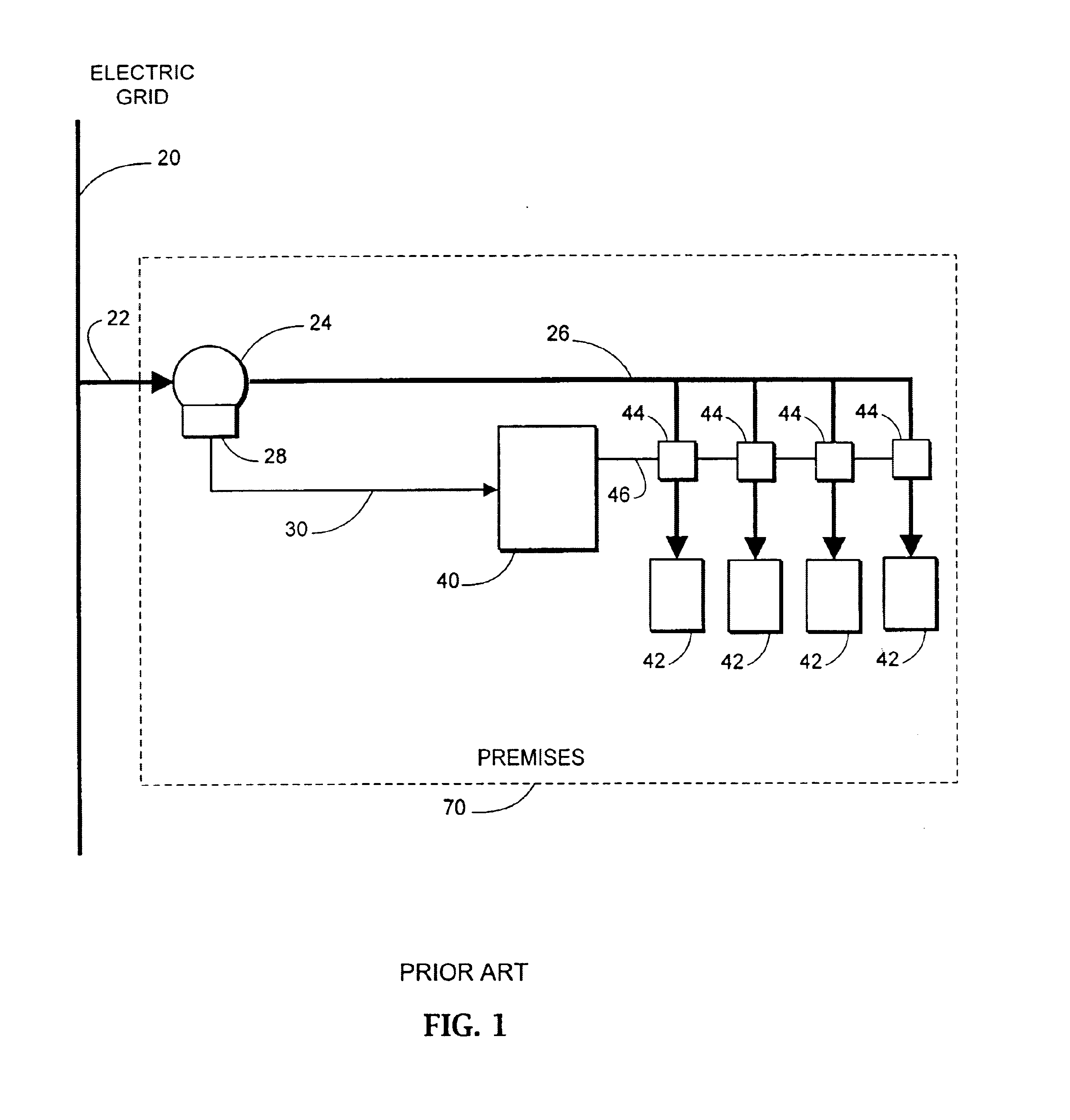

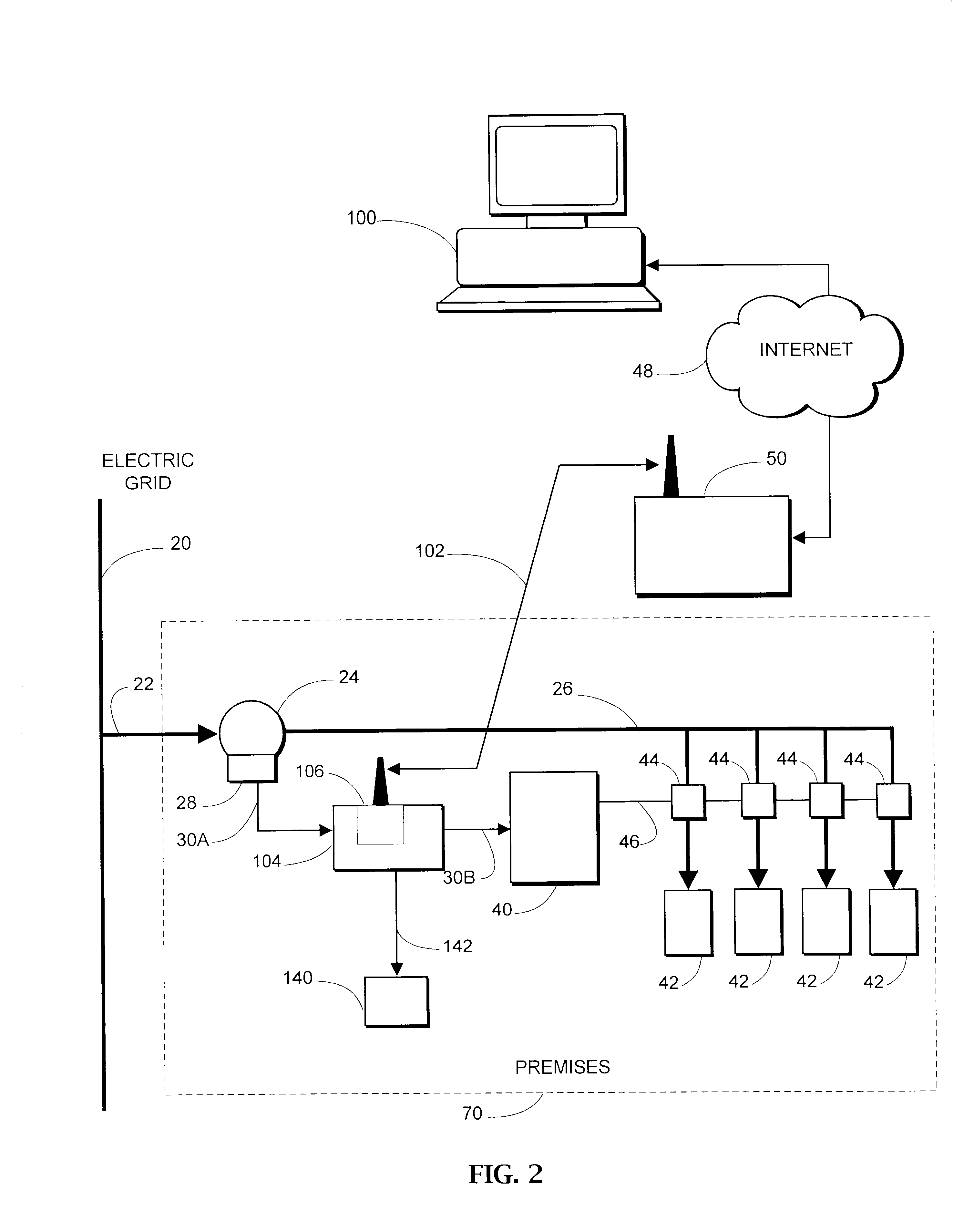

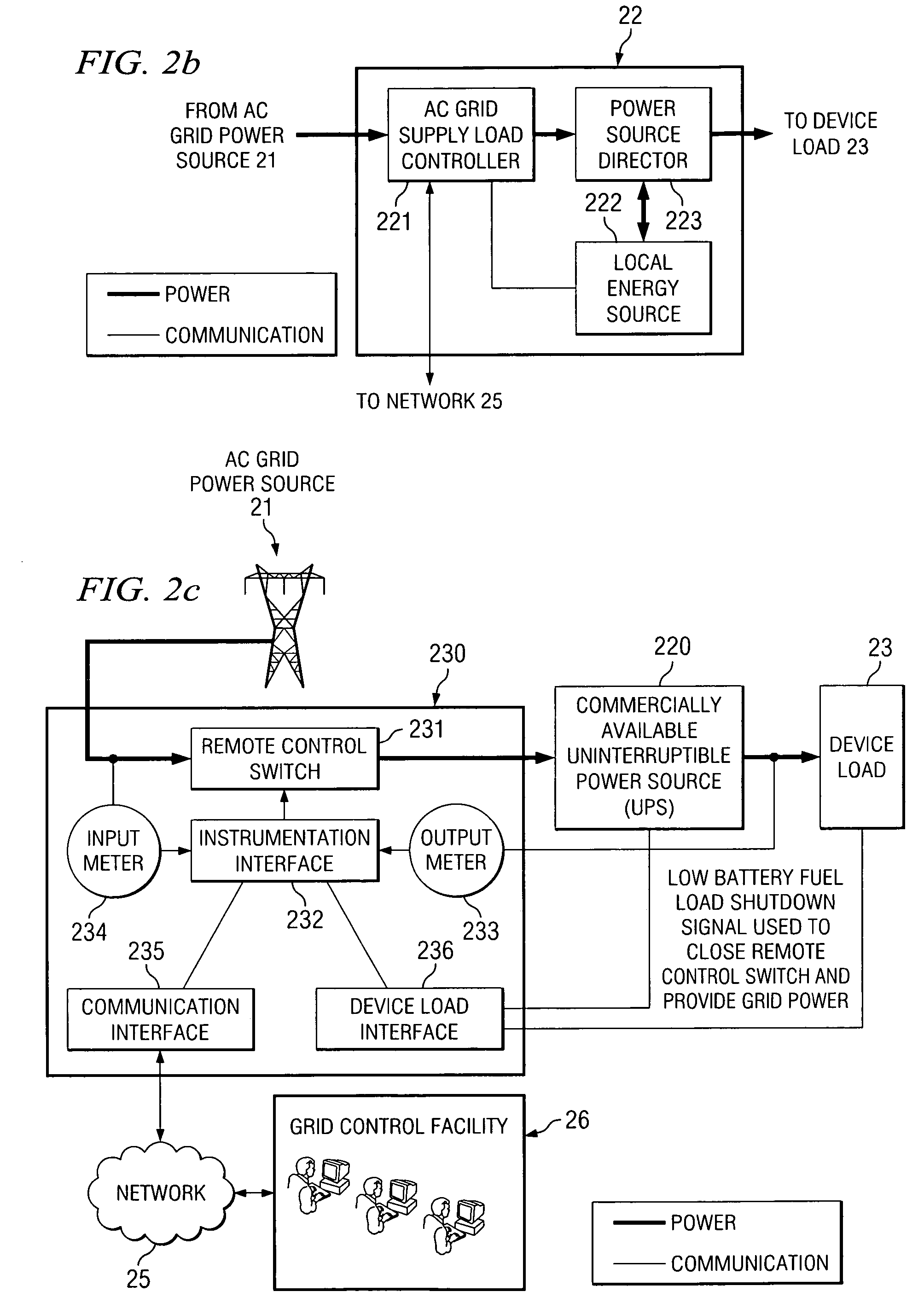

Device for curtailing electric demand

InactiveUS6621179B1Dc source parallel operationConstant-current supply dc circuitPower gridEnergy management system

A device for curtailing electric demand is suitable as a tool for responding to the real-time pricing of electrical energy or for reducing demand during power shortages. The device (104) according to the present invention works in conjunction with an energy management system (40), which receives demand signals from an electric meter (24). Upon executing a curtailment command sent to the device (104) through a communications network (48, 50, 102), device intercepts and biases the signal going to the energy management system (40), which, in effect, coerces it to reduce the demand upon the meter (24) and upon the electric grid (20).

Owner:HOWARD JOHN E

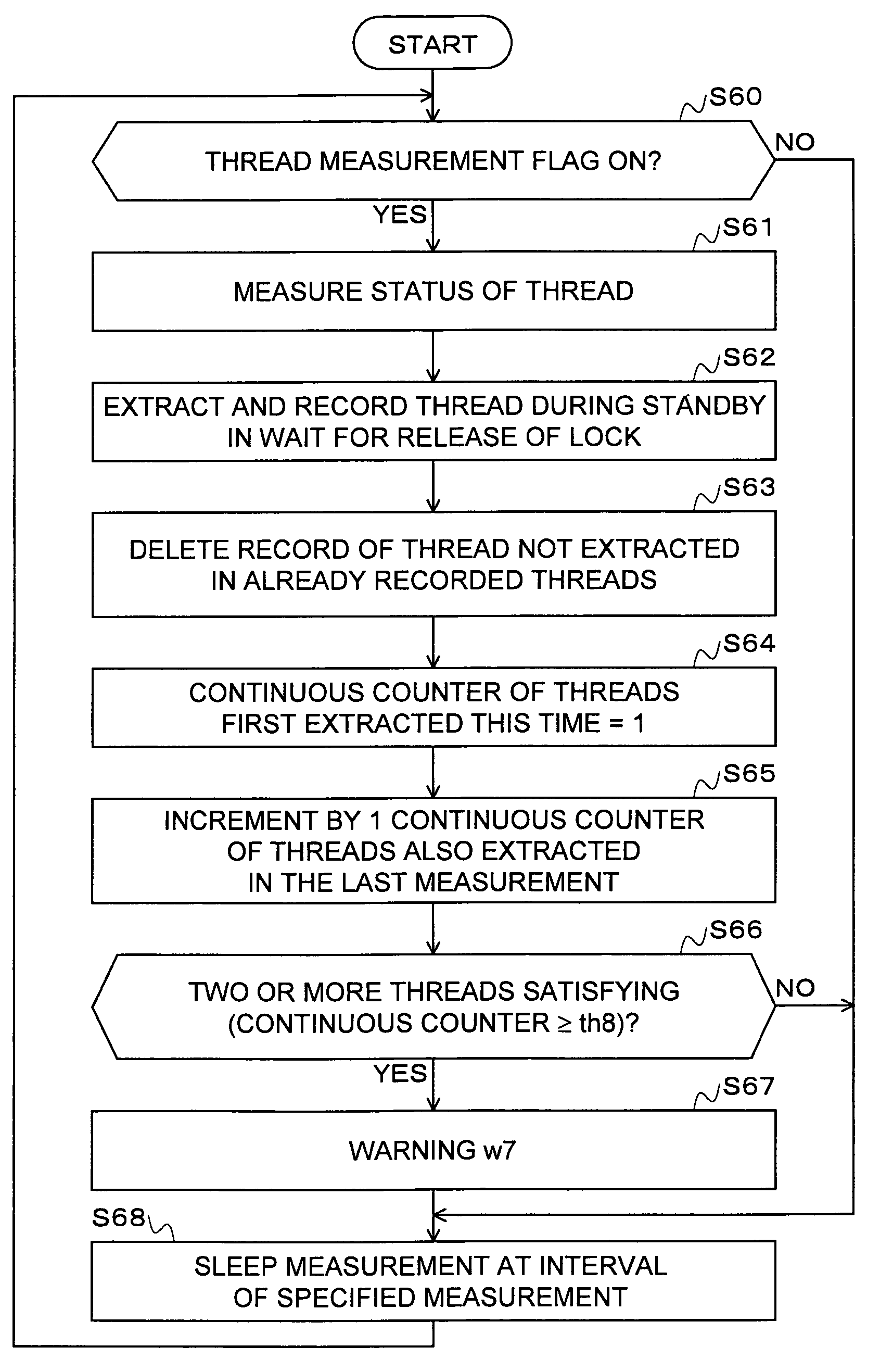

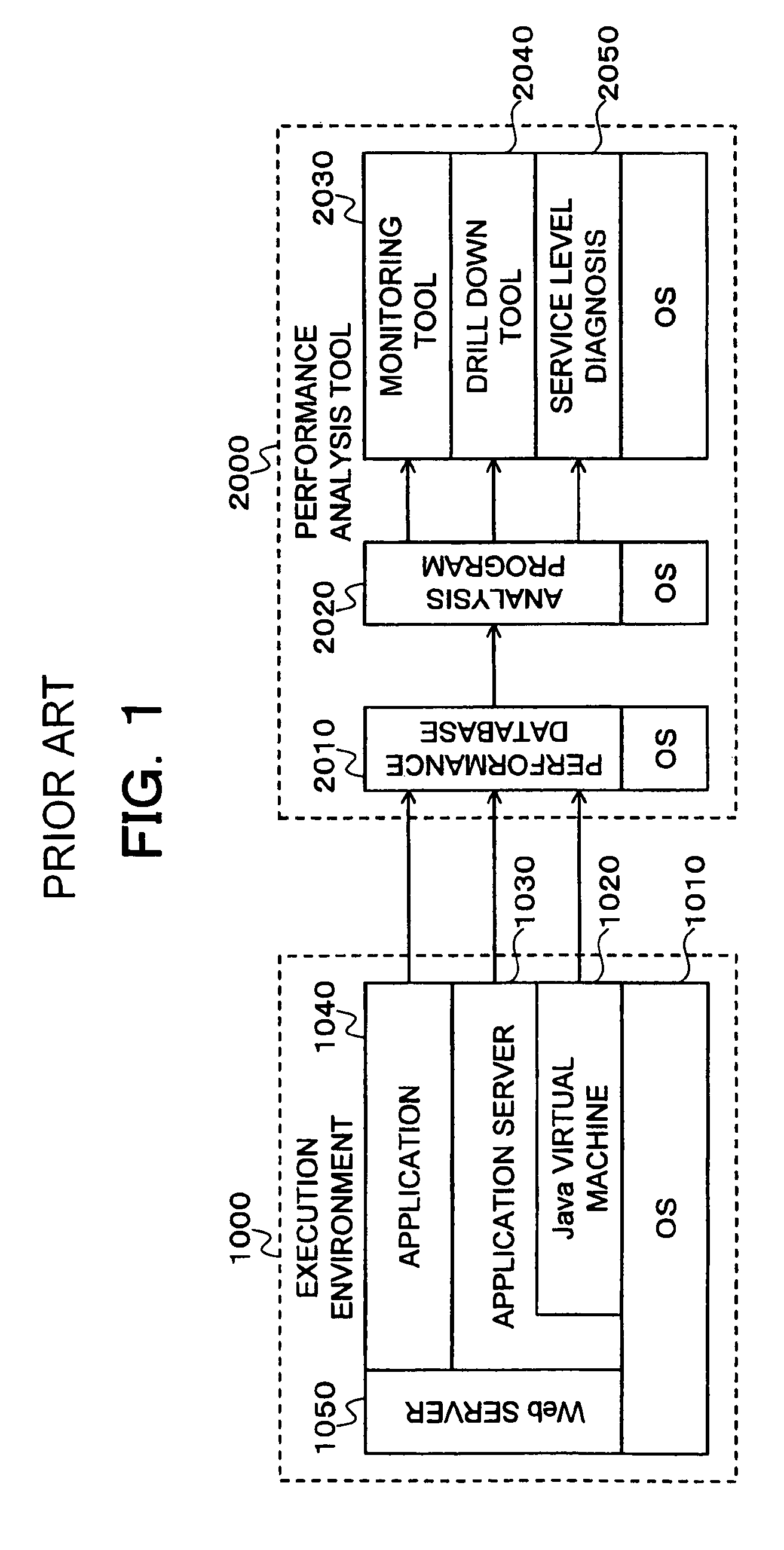

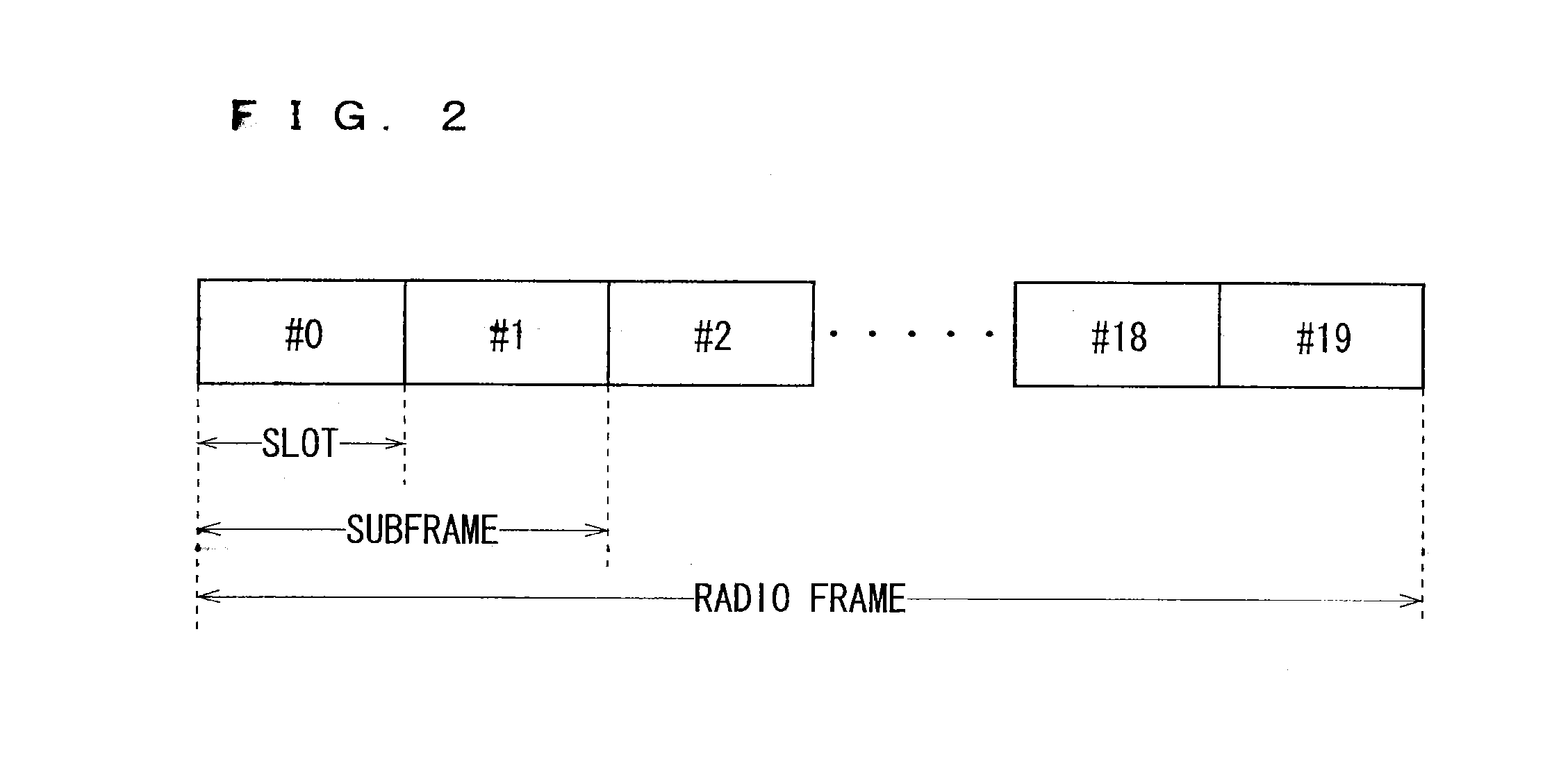

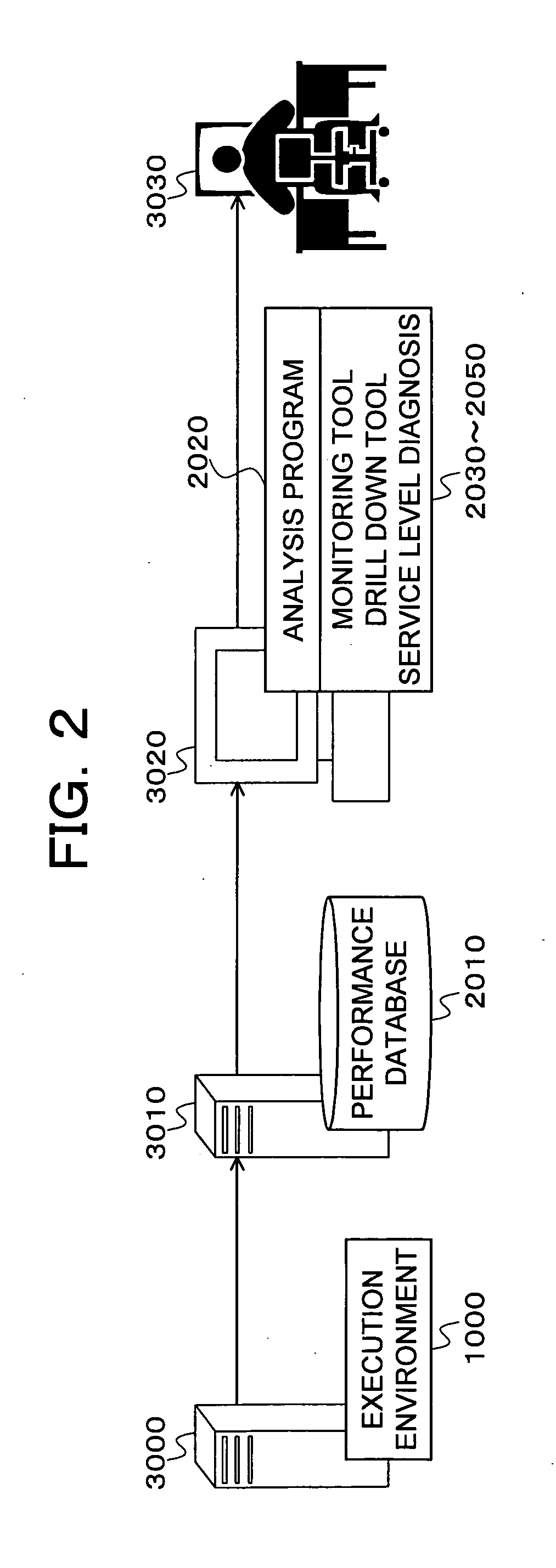

Method for predicting and avoiding danger in execution environment

InactiveUS7516292B2Reduce loadShort timeData processing applicationsMemory adressing/allocation/relocationApplication serverParallel computing

Measurement / analysis unit in a Java virtual machine has the function of measuring data when an event of garbage collection occurs, and the function of periodically measuring data. The measurement / analysis unit analyzes the measured data and predicts a danger of a memory shortage, and predicts a danger using an algorithm depending on the type of garbage collection used by the Java virtual machine. An application server is notified of a warning of the predicted danger of a memory shortage by an analysis result notification means by an inter-process communication, or the like. The measurement / analysis unit calculates a memory capacity required to avoid the predicted danger of a memory shortage, and the calculated memory capacity is transmitted to the application server by the analysis result notification means by an inter-process communication, or the like in the same way as the warning.

Owner:FUJITSU LTD

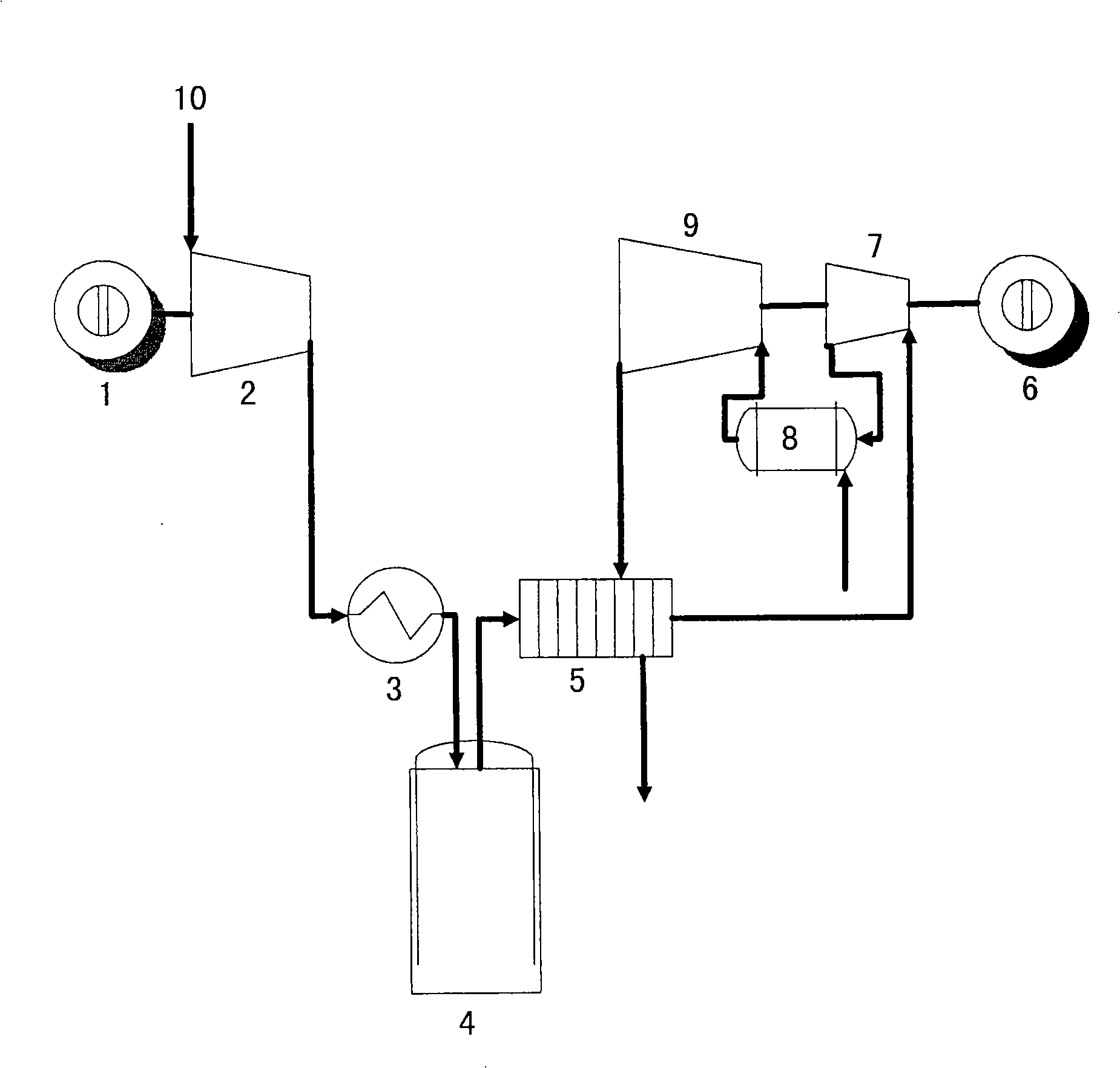

Compressed-air energy-storage system

The invention discloses a compressed air energy storage system, in particular to a compressed air energy storage system for an electric power system. The compressed air energy storage system disclosed by the invention has reasonable structure, flexible layout, high energy conversion efficiency, good economical efficiency and peakload regulation performance, rapid startup, safety and reliability. The compressed air energy storage system applying the invention can be used for despicking and valley filling of the electric power system, energy storage of renewable energy source and power supply when the renewable energy source is in supply intermission or in shortage in an electric network, and can be used as an emergency power station, an energy accumulator of distributed energy resource and other equipment for electric power energy storage.

Owner:INST OF ENGINEERING THERMOPHYSICS - CHINESE ACAD OF SCI

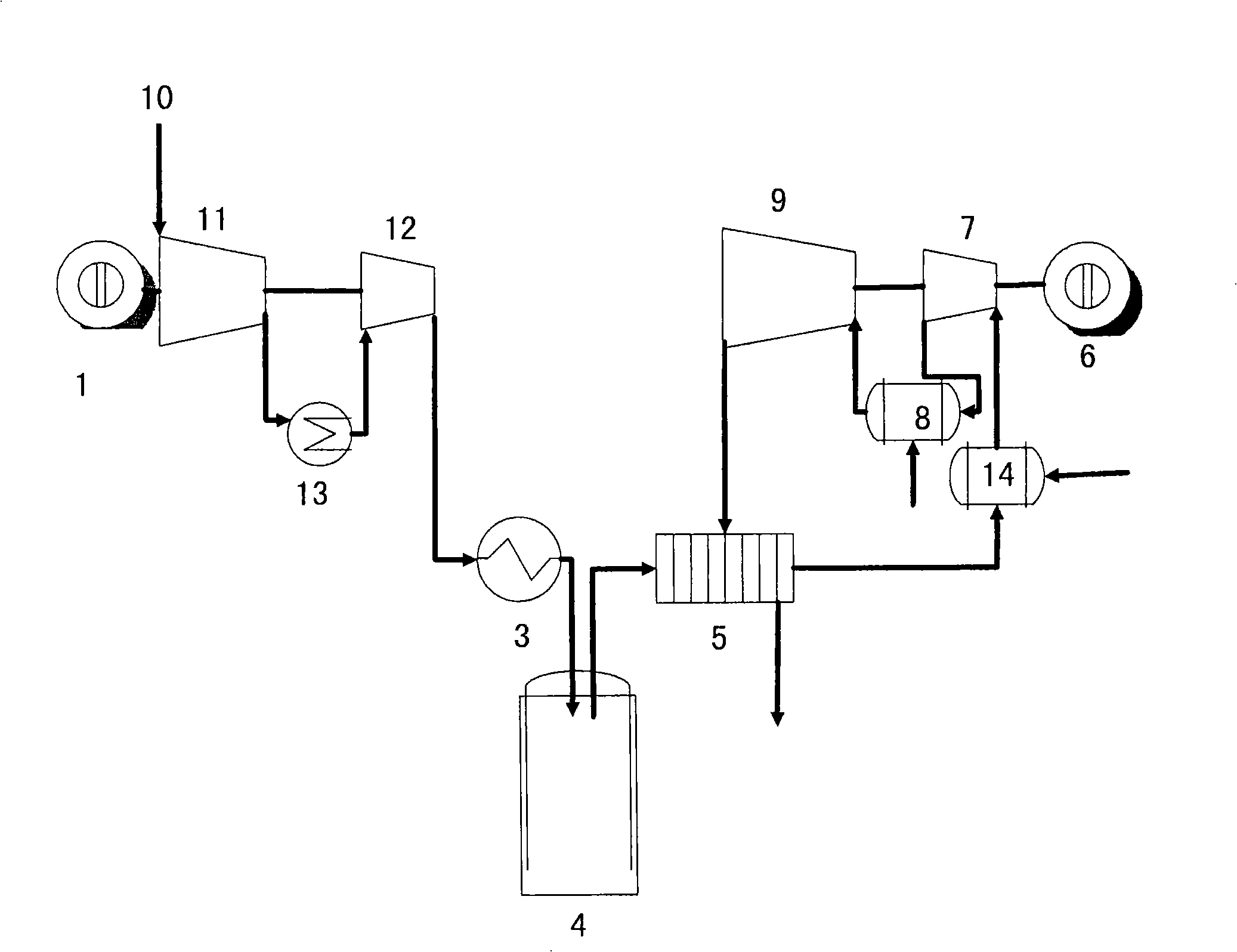

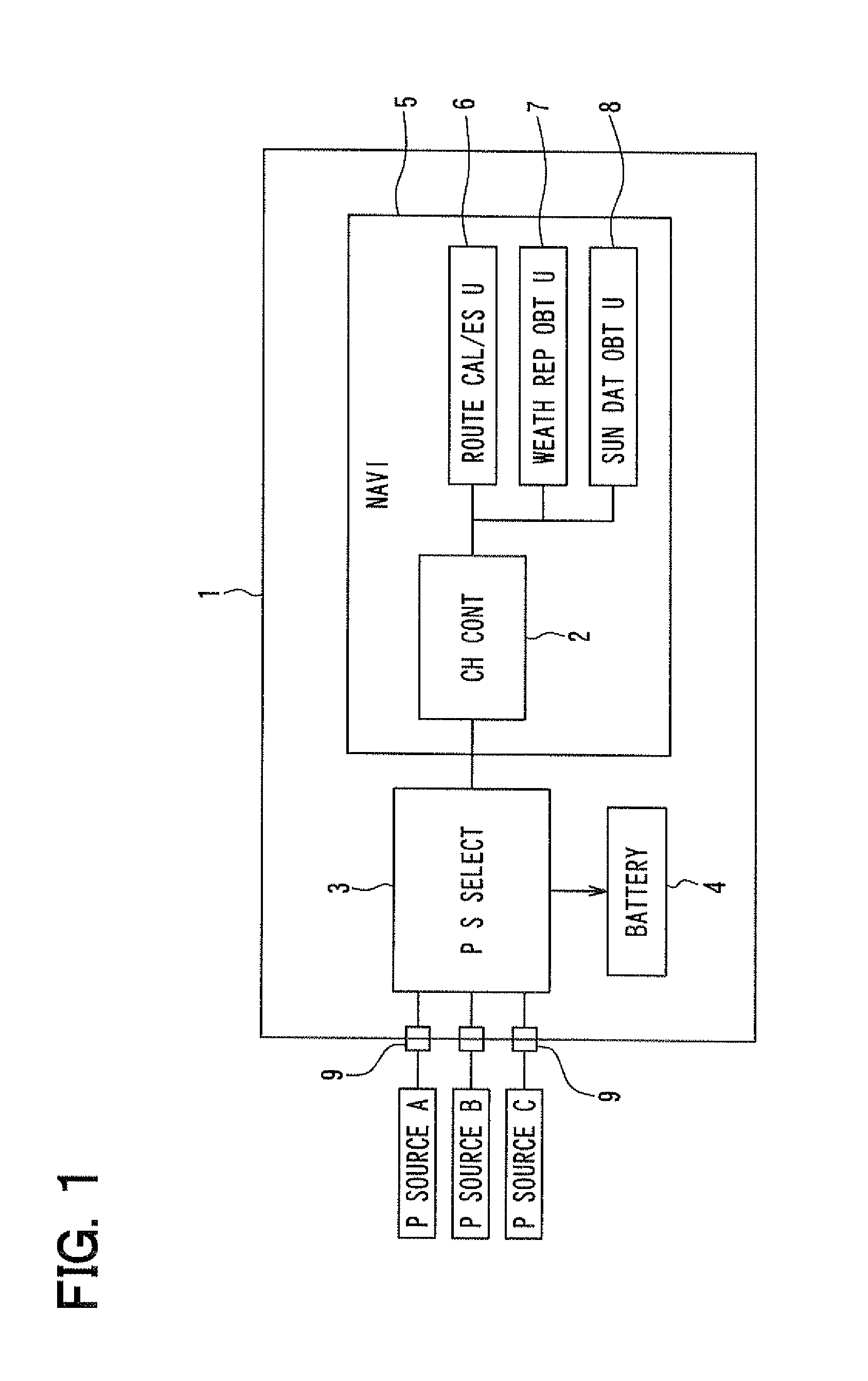

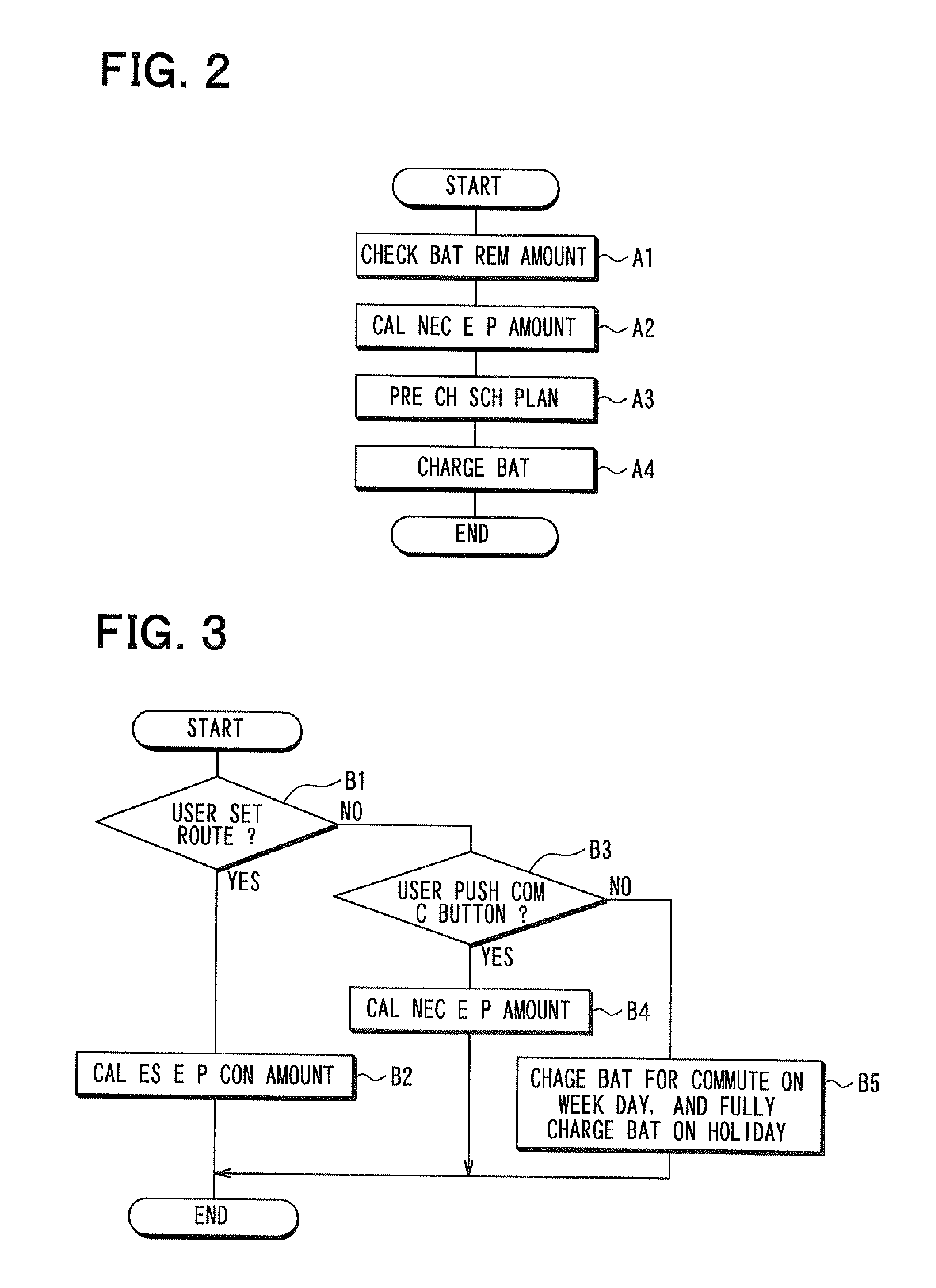

Charge controller and navigation device for plug-in vehicle

ActiveUS20110202221A1Reduce charging costsFully chargedHybrid vehiclesBatteries circuit arrangementsElectrical batteryElectric power system

A charge controller for charging a battery of a plug-in vehicle with a plurality of electric power sources includes: a driving route estimation element; an estimated electric power consumption amount calculator; a weather information obtaining element; a sunshine information obtaining element; a solar photovoltaic generation electric power amount calculator; an electric power shortage amount calculator for calculating an electric power shortage amount when the solar photovoltaic generation electric power amount is smaller than an estimated electric power consumption amount; a charge schedule preparation element for preparing a charge schedule, which represents a first charge time for charging the battery with a solar photovoltaic generation system and a second charge time for charging the battery by the electric power shortage amount with another electric power source; and a charge control element for controlling to charge the battery according to the charge schedule.

Owner:DENSO CORP

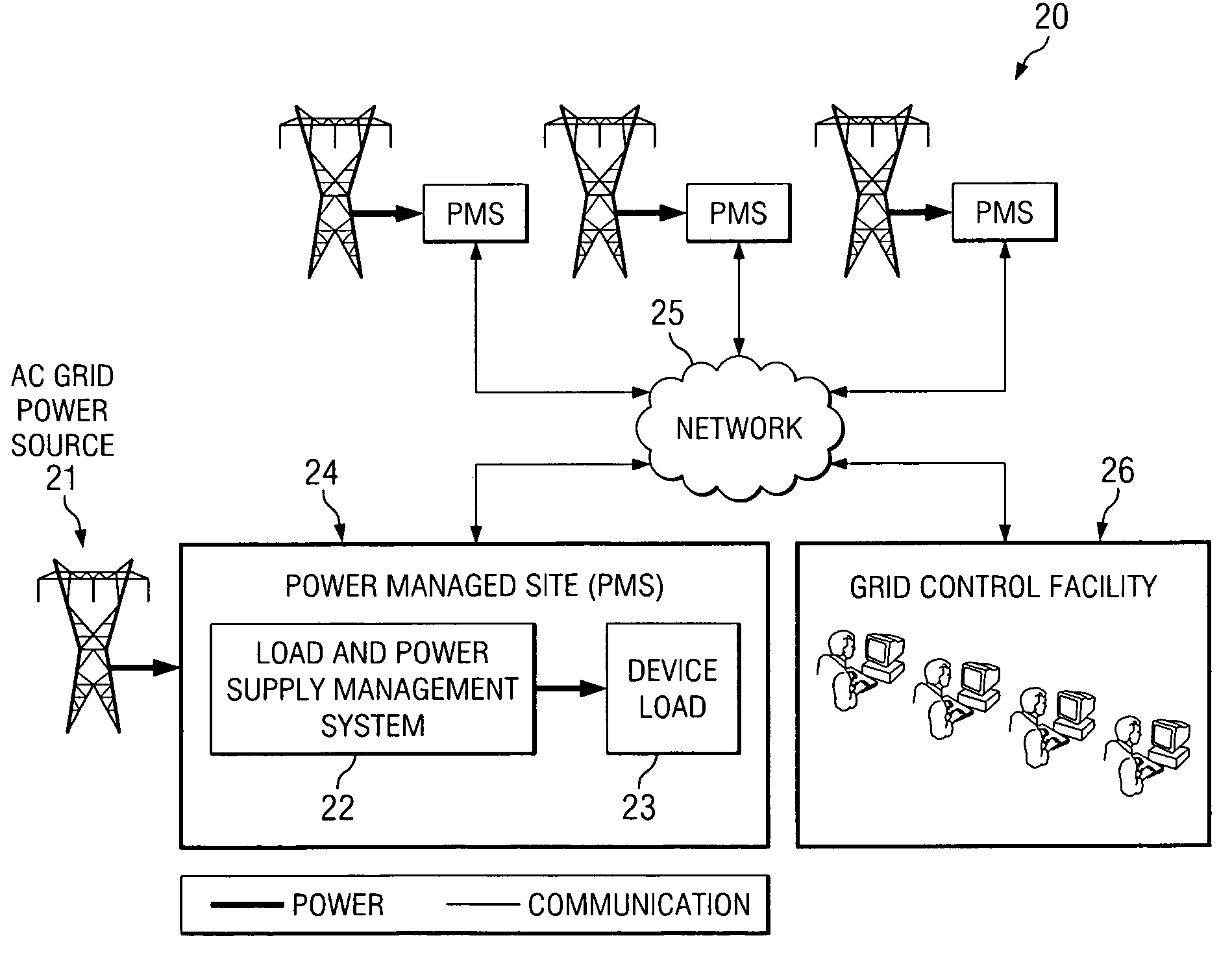

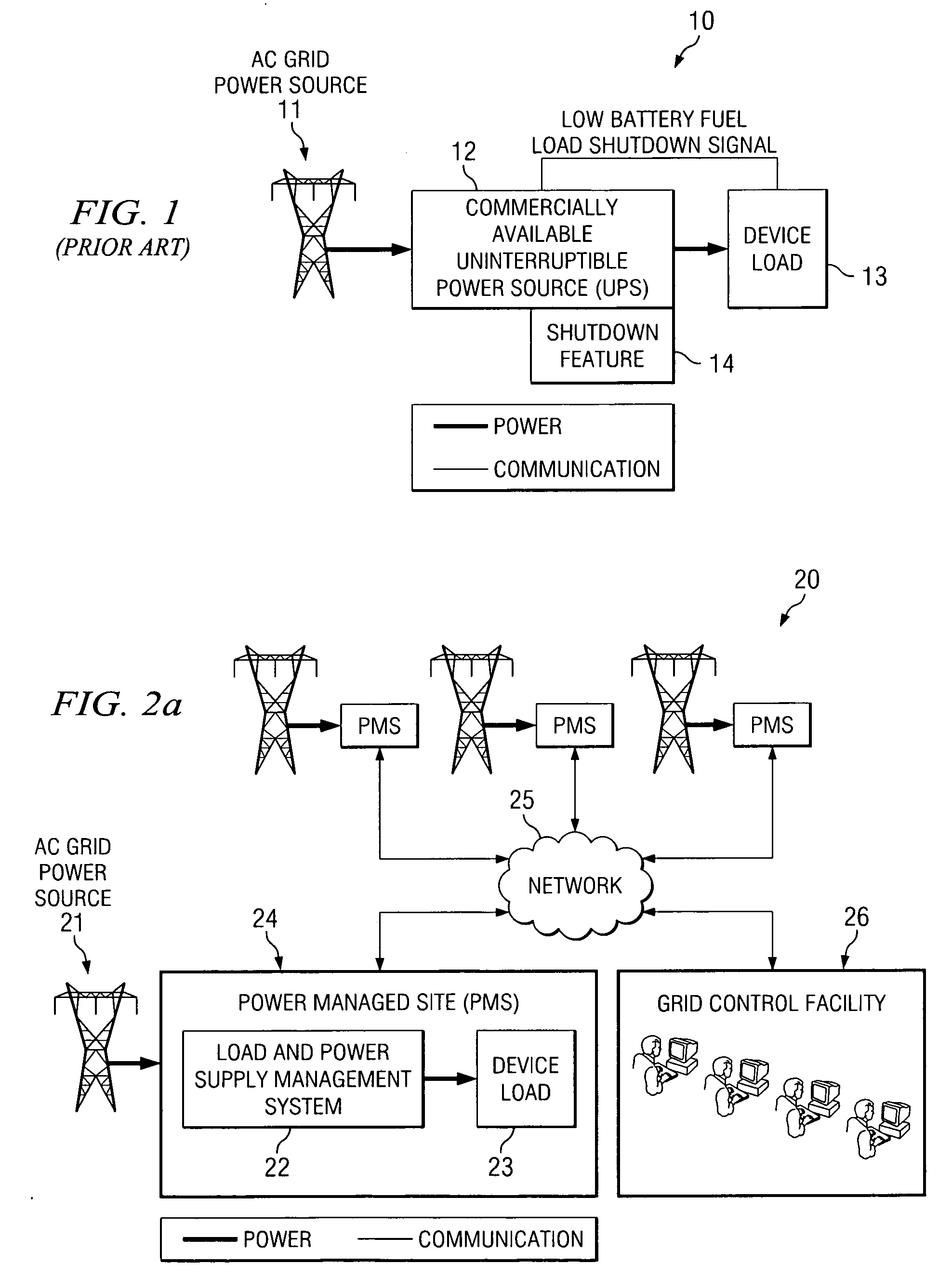

Fast acting distributed power system for transmission and distribution system load using energy storage units

InactiveUS20070005192A1The method is accurate and reliableReduce dependenceMechanical power/torque controlLevel controlDistribution power systemElectric power

An electric power load management system and method that uses a multiplicity of remote power supplies in a controlled manner such that the aggregate system has the capacity to offset critical power company peak electric demand periods thereby preventing severe and detrimental power shortages and interruptions.

Owner:OPTIMAL INNOVATIONS INC

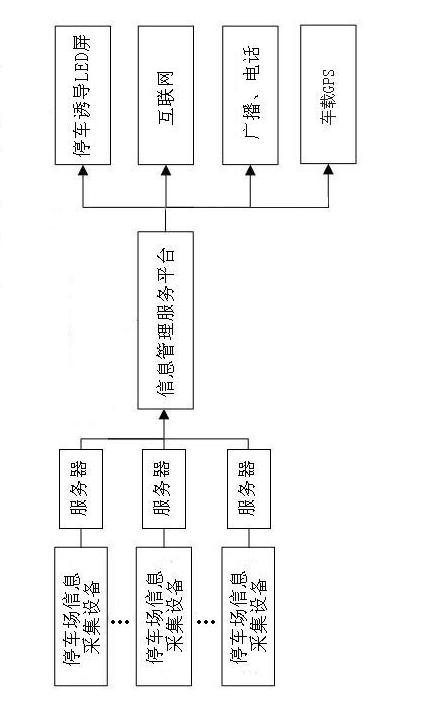

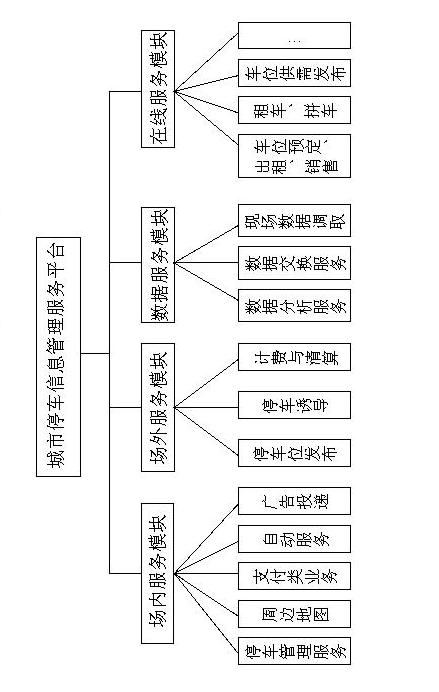

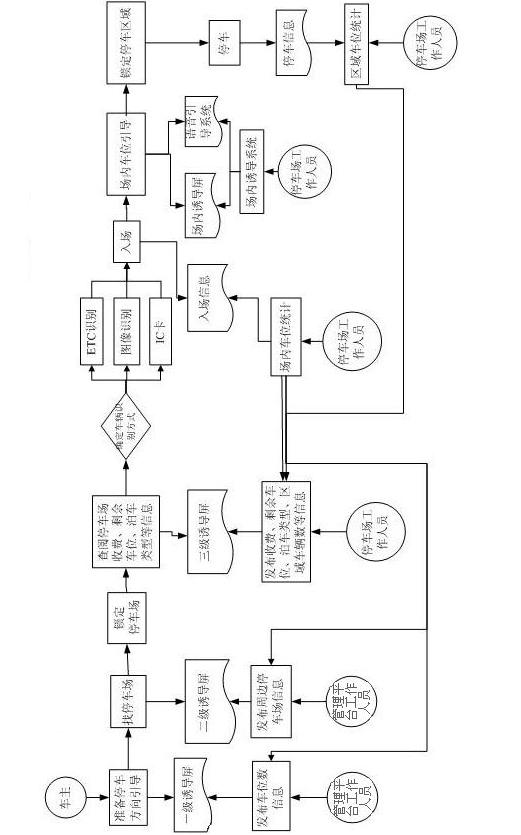

Intelligent parking-place public service system

ActiveCN102622871ATo achieve transparent useEasy to operateData processing applicationsIndication of parksing free spacesInformatizationParking space

The invention relates to the field of application systems orienting to industry and enterprise informatization in electronic information and provides an intelligent parking-place public service system. The intelligent parking-place public service system comprises parking-place information acquisition equipment, a parking-place internal parking data server, an information management service platform and an information issuing terminal. The intelligent parking-place public service system provided by the invention has the advantages that the intelligent parking-place public service system orienting to cities is reformed into a component of a smart city, so that shortage resources of parking spots can be fully shared, the decision-making basis is provided for the urban parking planning of a government, guidance is provided for trip parking of a vehicle owner, further the traffic can be eased, data support is provided for public safety management, and simultaneously the parking place that the vehicle owner often comes in and goes out is reformed into a service channel, so that the vehicle owner can enjoy the service nearby.

Owner:WUHAN ID TECH CO LTD

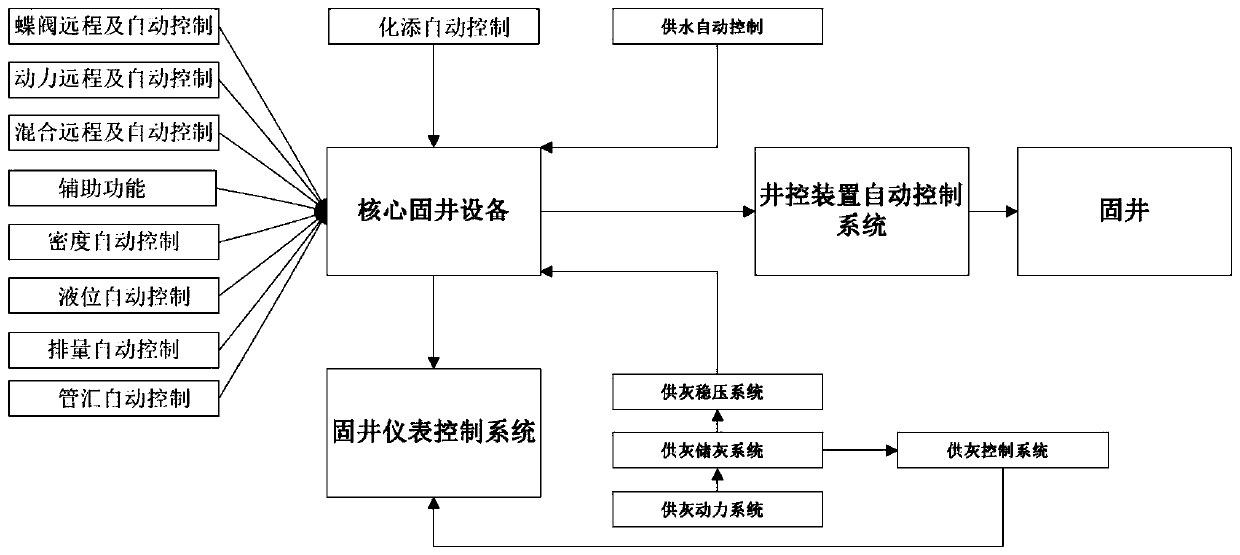

Full-automatic cementing complete set control method

InactiveCN110159225ARaise the advanced levelSolve labor shortageSealing/packingTotal factory controlAutomatic controlControl system

The invention discloses a full-automatic cementing complete set control method, and relates to the related technical field of petroleum equipment. The method comprises the steps of intelligent full-automatic cementing key control, matching control, an automatic power control system, a slurry mixing control system, an automatic premixing function, automatic liquid level control, automatic manifoldcontrol, a hydraulic pneumatic control system, a lime supply automatic control system, a chemical additive automatic control system, a water supply automatic control system and a well control device automatic control system. According to the operating method, intelligent full-automatic control over cementing operation is achieved, and breakthrough of the automatic manifold control technology is achieved successfully; through the lime supply automatic control technology and the full-automatic control technology, the advanced level of equipment and technologies of the company is improved greatly; a new mode of future cementing operation is created, and a new era of a smart oil field is started; through achievement of the intelligent full-automatic cementing operation technology, the problems, that customers face at present, of shortage of labor forces and labor resources can be solved; and the intelligent operation is achieved.

Owner:YANTAI JEREH PETROLEUM EQUIP & TECH CO LTD

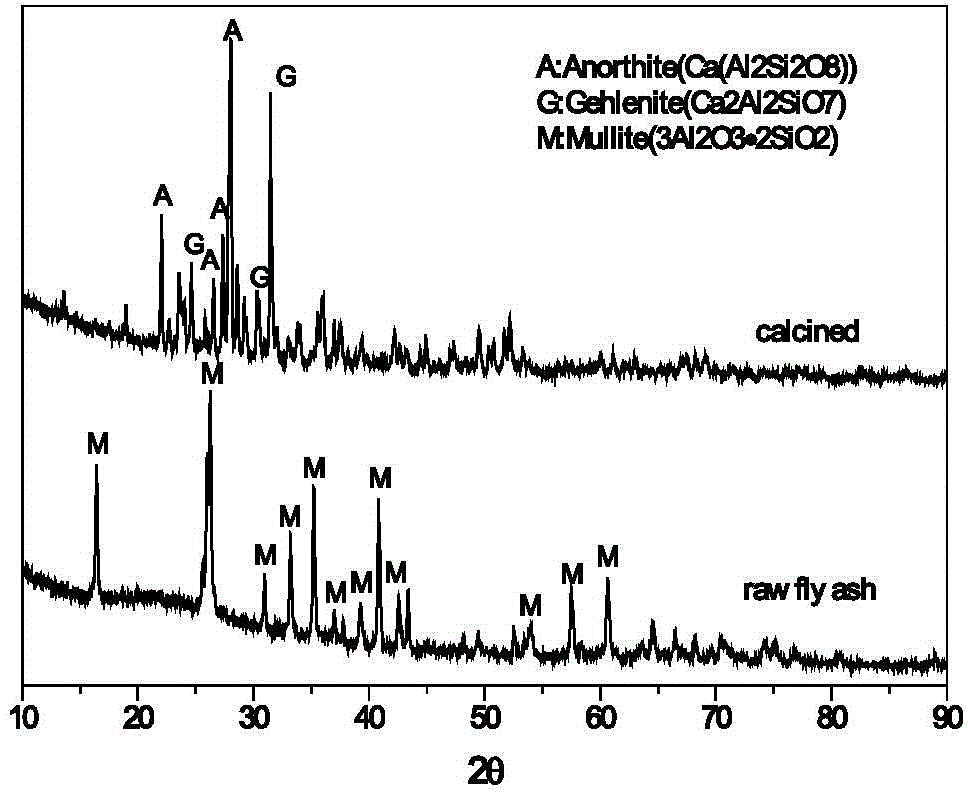

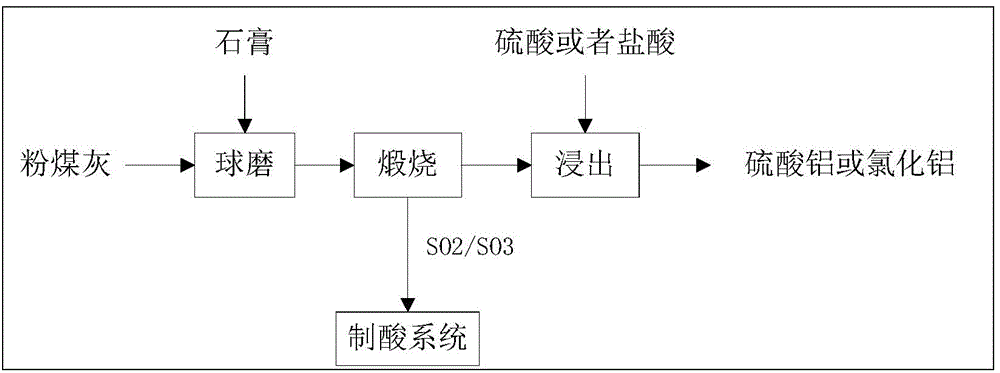

Method for cooperative activation of fly ash and decomposition of gypsum for recovery of sulfur resource

The invention provides a method for cooperative activation of fly ash and decomposition of gypsum for recovery of a sulfur resource. According to the method, solid waste, i.e., fly ash, discharged by a coal-fired power plant or coal-fired boiler is used as a raw material, a certain proportion of desulfurized gypsum discharged by the coal-fired power plant or waste phosphogypsum produced in the phosphorus chemical industry is added and mixed with the fly ash, then the obtained mixture is subjected to ball milling, and activation and calcination at a temperature of 950 to 1450 DEG C are carried out for 5 to 180 min; calcium sulfate in the gypsum are almost totally decomposed after calcination, and produced gas contains sulfur dioxide or sulfur trioxide which can be used as feed gas for preparation of sulfuric acid; and calcination enables solid fly ash to be activated, leaching with a sulfuric acid or hydrochloric acid solution is carried out at a temperature of 50 to 100 DEG C, and the leaching rate of alumina is greater than 80%. The method provided by the invention has the advantages that since all the raw materials are solid waste, the purpose of treating the waste by using the waste is achieved; elemental sulphur in the gypsum can be recovered; and the fly ash can be activated and activity of the fly ash can be improved, so a high alumina recovery rate at a low temperature can be realized. With the method, high-efficiency extraction of alumina in the fly ash is realized; the sulfur resource in the gypsum is recovered; shortage in industrial sulphur in the sulfuric acid industry in China is compensated; and the method has good economic benefits and wide industrial application prospects.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

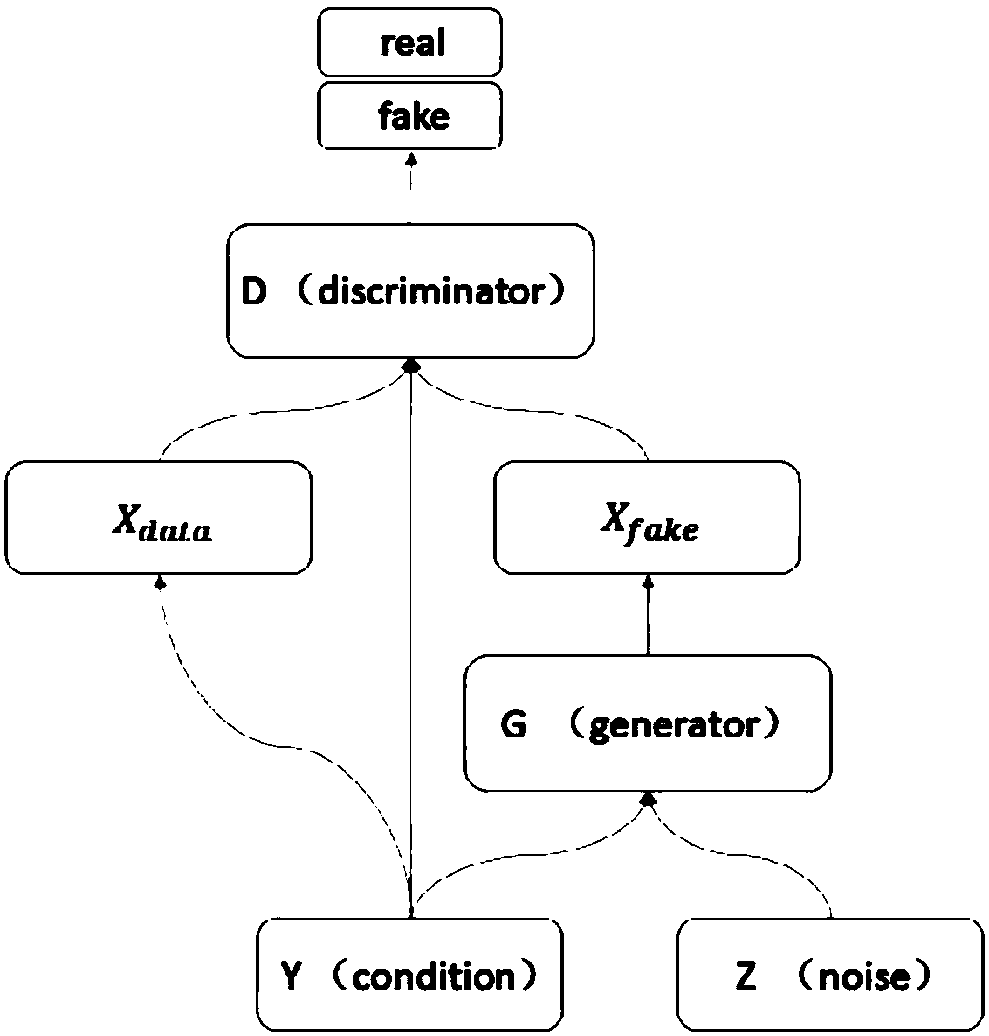

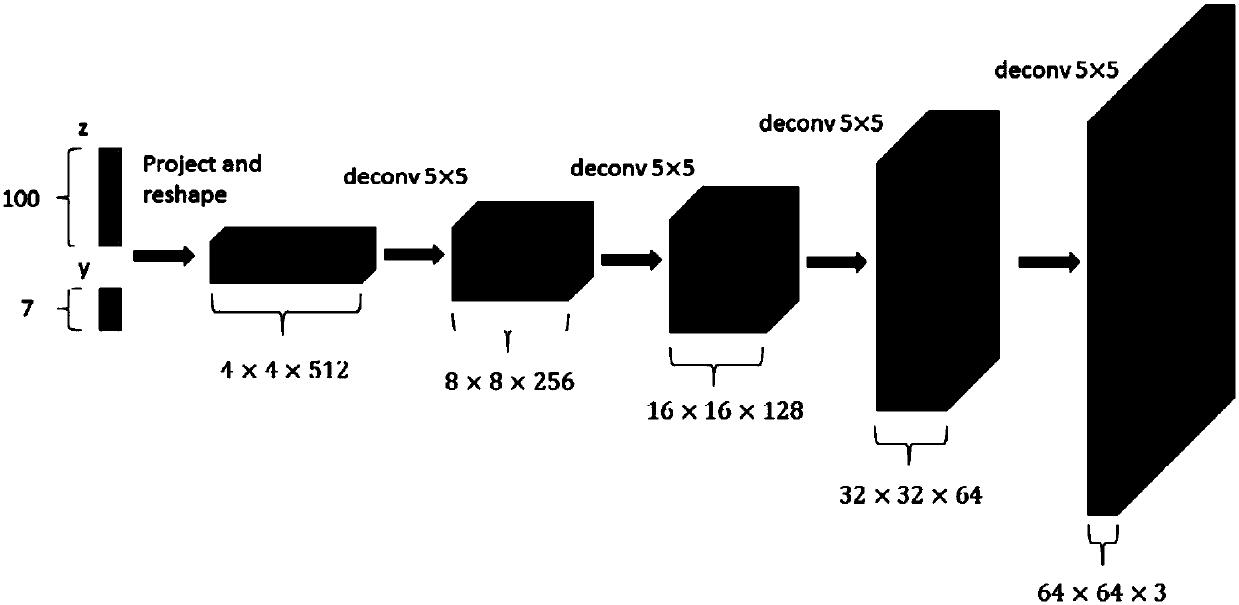

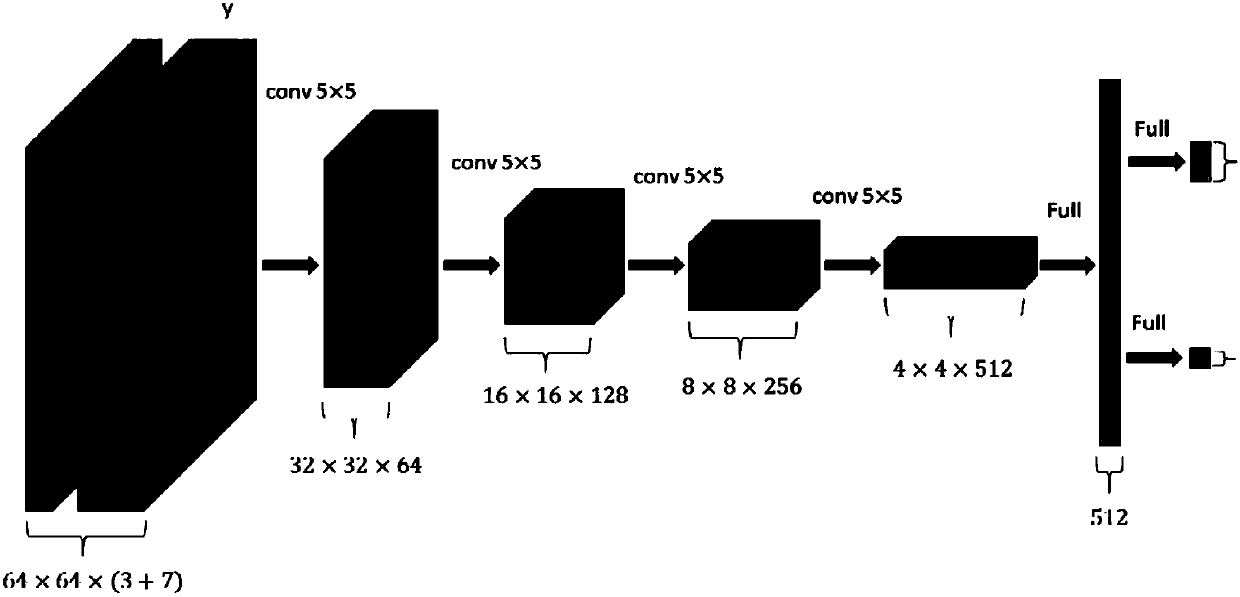

Generative adversarial network-based multi-pose face generation method

ActiveCN107292813AImprove recognition rateImprove the problem of lack of large-scale dataGeometric image transformationCharacter and pattern recognitionTraining phaseAttitude control

The present invention discloses a generative adversarial network-based multi-pose face generation method. According to the generative adversarial network-based multi-pose face generation method, in a training phase, the face data of various poses are collected; two deep neural networks G and D are trained on the basis of a generative adversarial network; and after training is completed, the generative network G is inputted on the basis of random sampling and pose control parameters, so that face images of various poses can be obtained. With the method of the invention adopted, a large quantity of different face images of a plurality of poses can be generated, and the problem of data shortage in the multi-pose face recognition field can be solved; the newly generated face images of various poses are adopted as training data to train an encoder for extracting the identity information of the images; in a final testing process, an image of a random pose is inputted, and identity information features are obtained through the trained encoder; and the face images of various poses of the same person are obtained through the trained generative network.

Owner:ZHEJIANG UNIV

Method for recycling silica powder and carborundum powder from cut waste mortar

The invention discloses an extracting method of high-purity silicon powder and carborundum powder from waste slurry of monocrystalline silicon cutting or grinding course, which comprises the following steps: separating solid from liquid for the waste slurry; using organic solvent to remove suspending agent and adhesive; doing gas float for solid sand; obtaining certain purity silicon powder; doing liquid float and gravity sorting for the silicon powder further; acidifying the silicon powder through acid; obtaining high-purity silicon powder; doing magnetic float for the composite powder of carborundum-metal through gravity; obtaining the pure carborundum powder. The invention can recycle high-purity silicon from waste slurry in the silicon bar cutting manufacturing course effectively, which changes waste into value with high receiving rate to solve the problem of resource shortage of high-purity silicon.

Owner:XI AN JIAOTONG UNIV

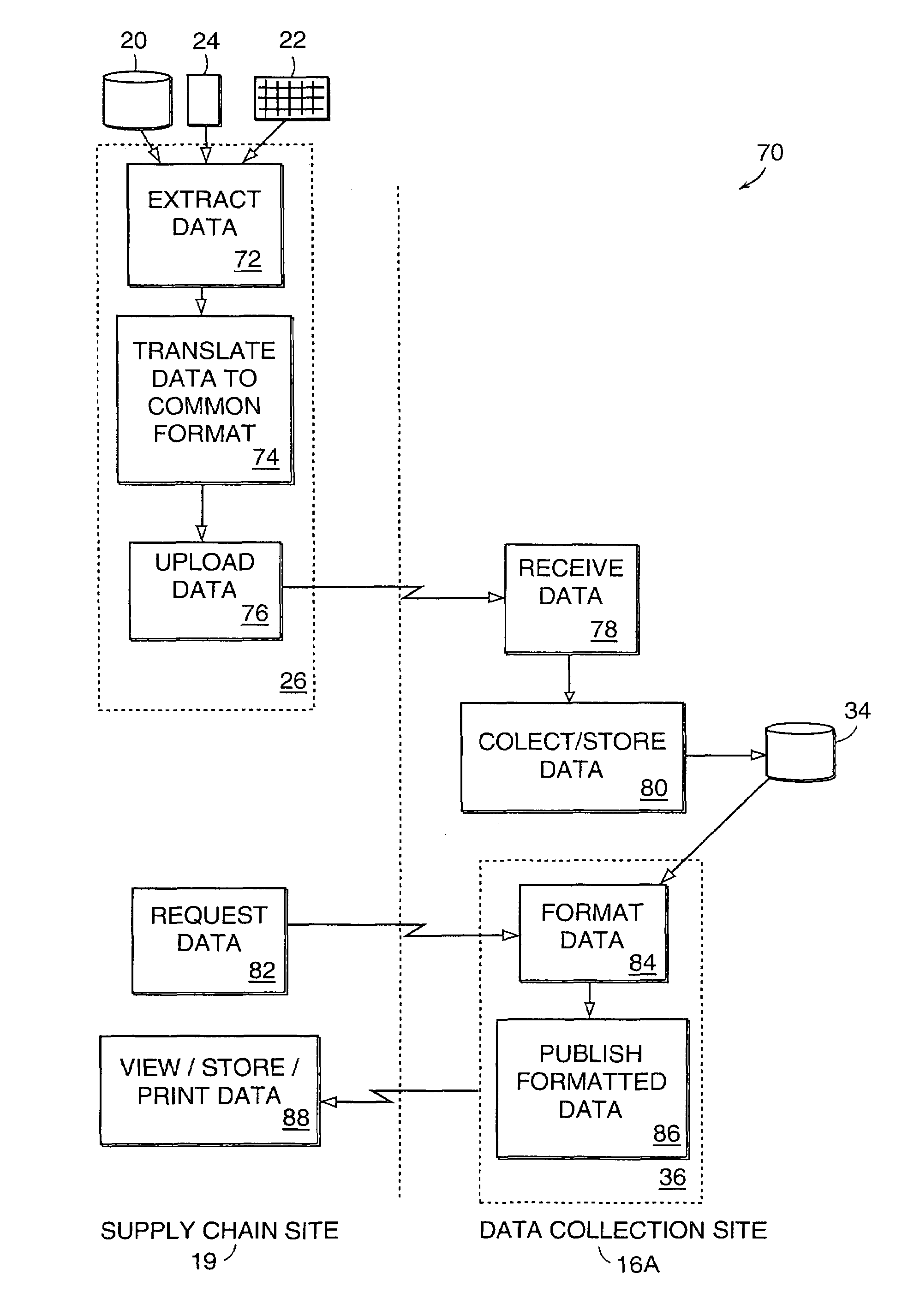

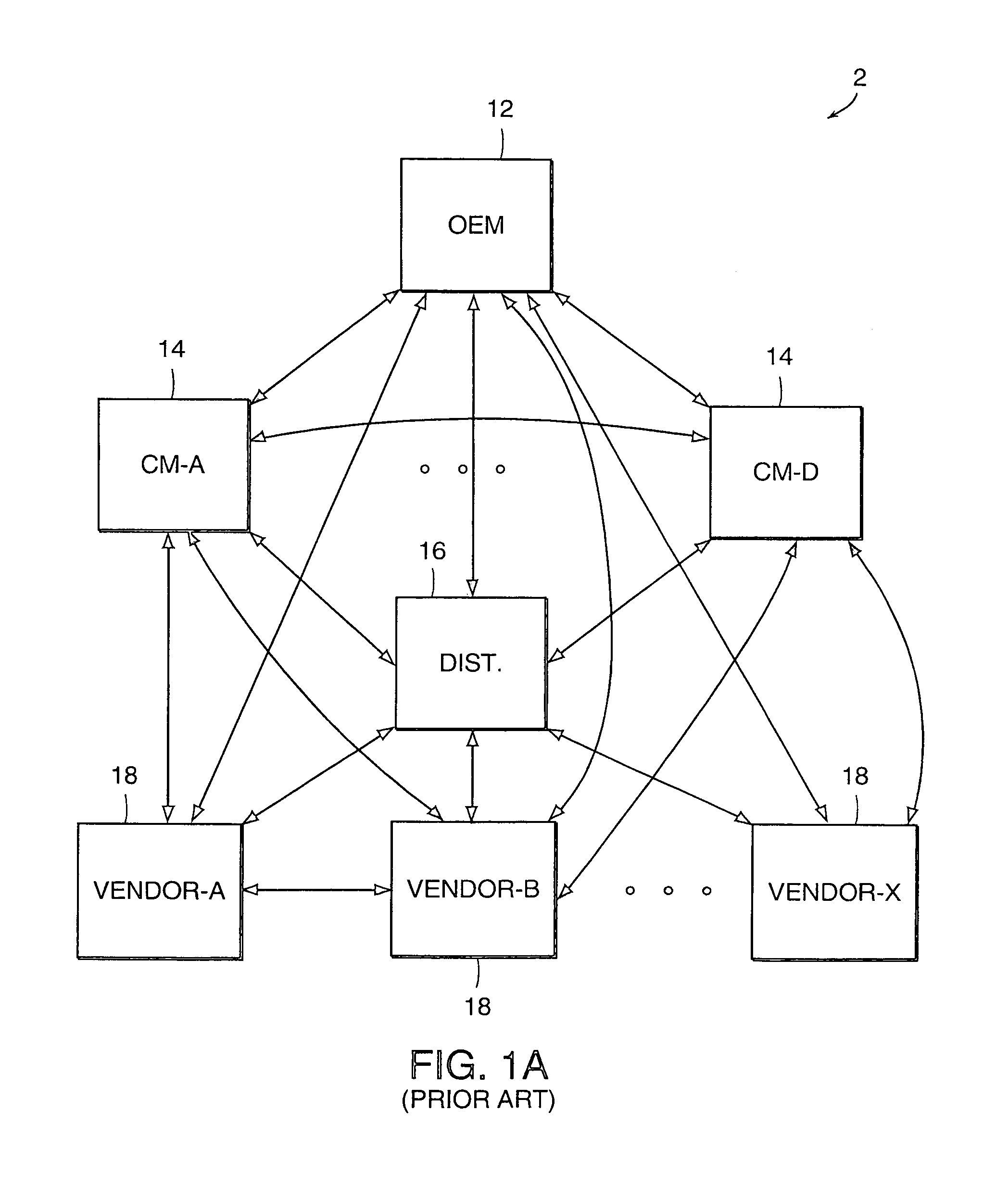

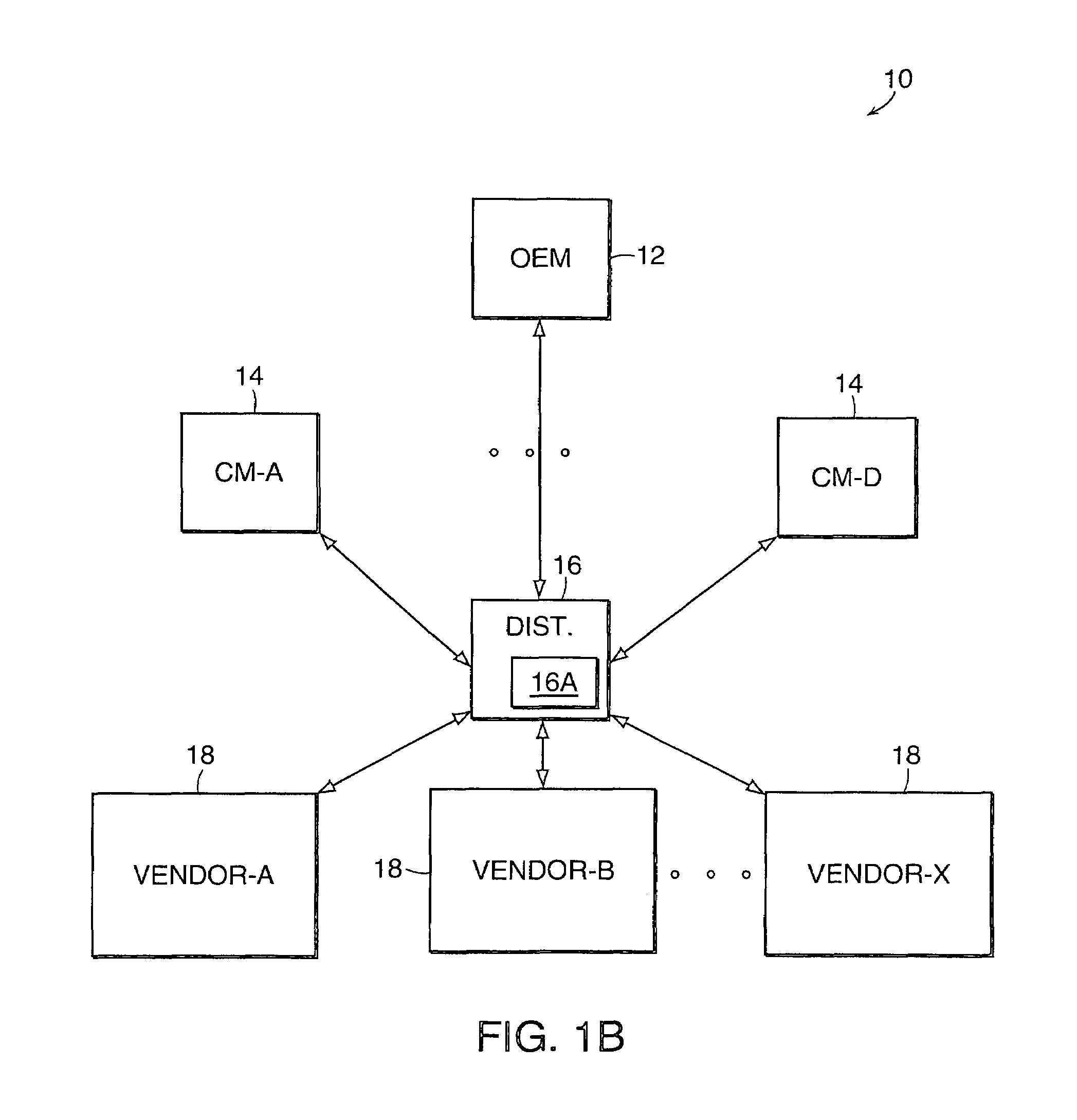

Method and system for monitoring a supply-chain

InactiveUS6947903B1More confusionImprove relationshipStatic storageResourcesData transformationData view

A method of monitoring supply chain activity throughout a plurality of supply chain sites includes extracting, at each supply chain site, supply-related data to be monitored. The data is maintained in plural formats at the supply chain sites, and translated the data to a common format. The extracted data is then uploaded to and collected, from each supply chain site, to a data collection center or site. Upon a user request, a portion of the collected data is formatted, at the data collection site, into one of a plurality of views, responsive to criteria selected by the user, for presentation to the user, the portion of formatted data being dependent on access rights granted to the user's supply chain site. Finally, the formatted data view is published to the user's supply chain site. The data collection center comprises a data collector in which the uploaded data is stored, and a publisher for publishing data from the data collector upon request. Each supply chain site has a data storage device for maintaining its own supply-chain data, a data transfer engine (DTE), for transferring the supply-chain data to the data collection center, input means for allowing a user to query the data collector, and a display for displaying data published by the publisher in response to a query. The inbound data received from the multiple supply chain sites is monitored at the data collection site. If a problem condition is detected, such as a forecasted or present shortage or surplus, an alert is asserted, for example, by highlighting an Alert indicator, such as an Alert tab, on a user screen. Upon selection of the highlighted Alert indicator by a user, details of the detected problem condition are displayed.

Owner:ELCOMMERCE COM

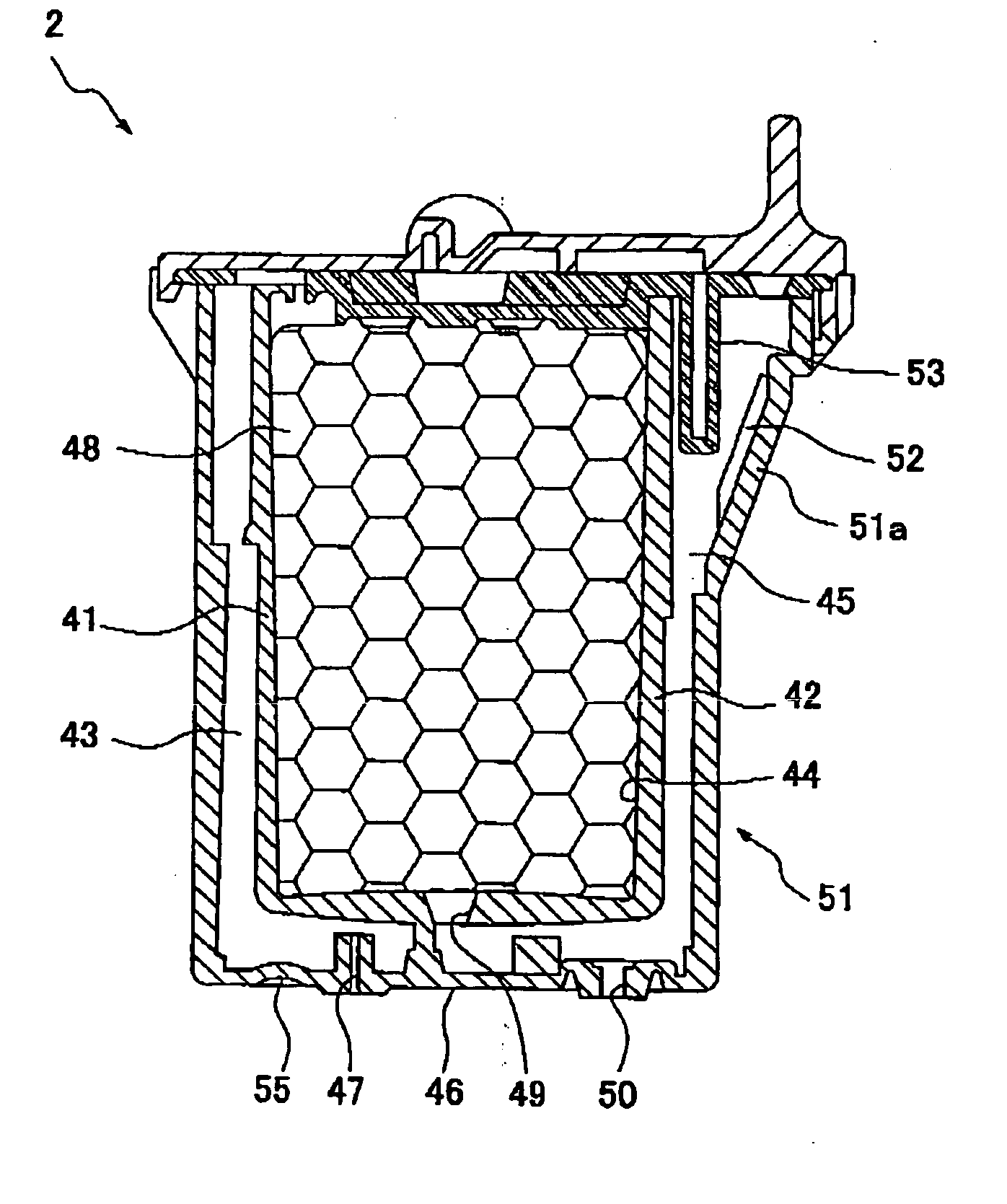

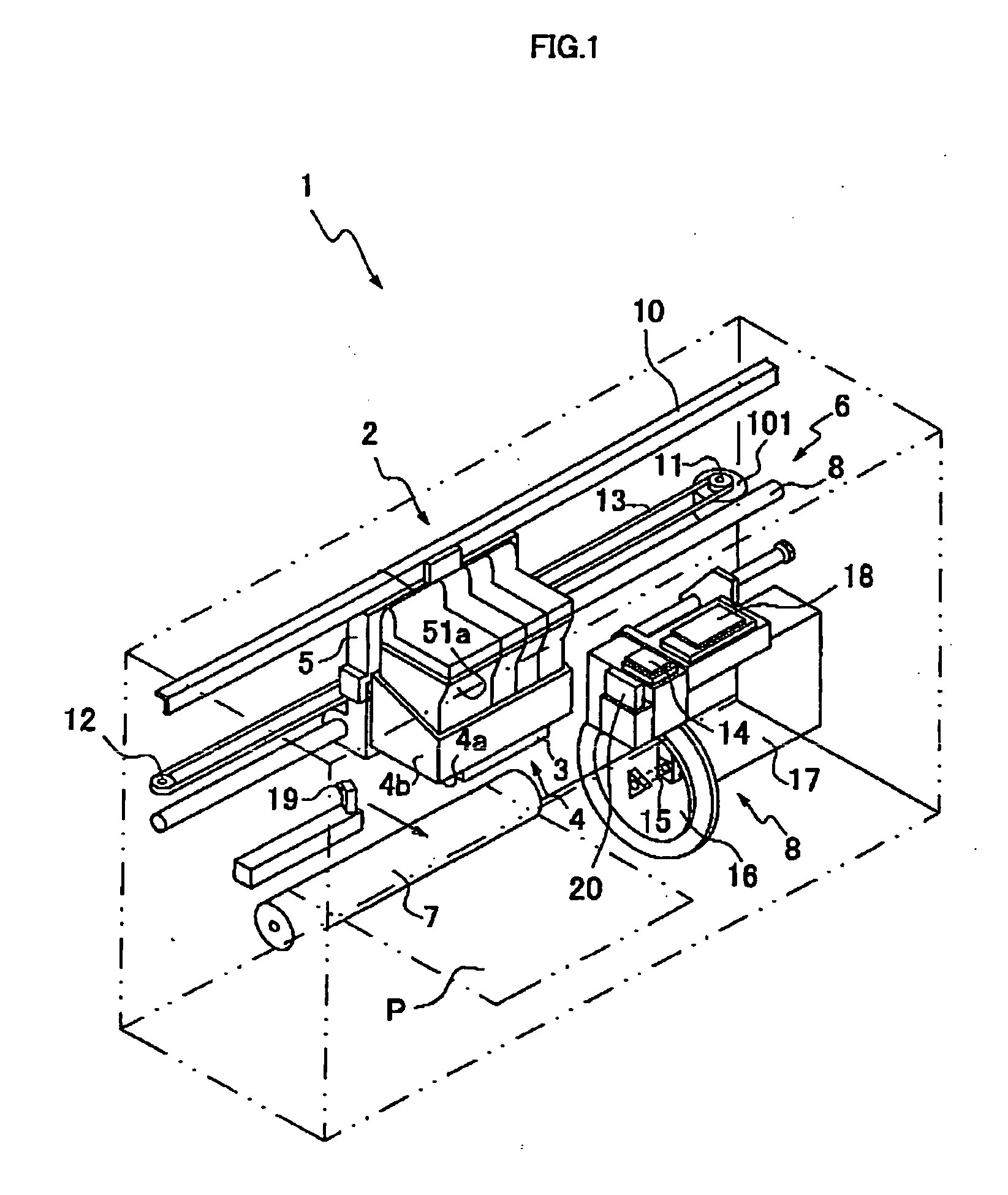

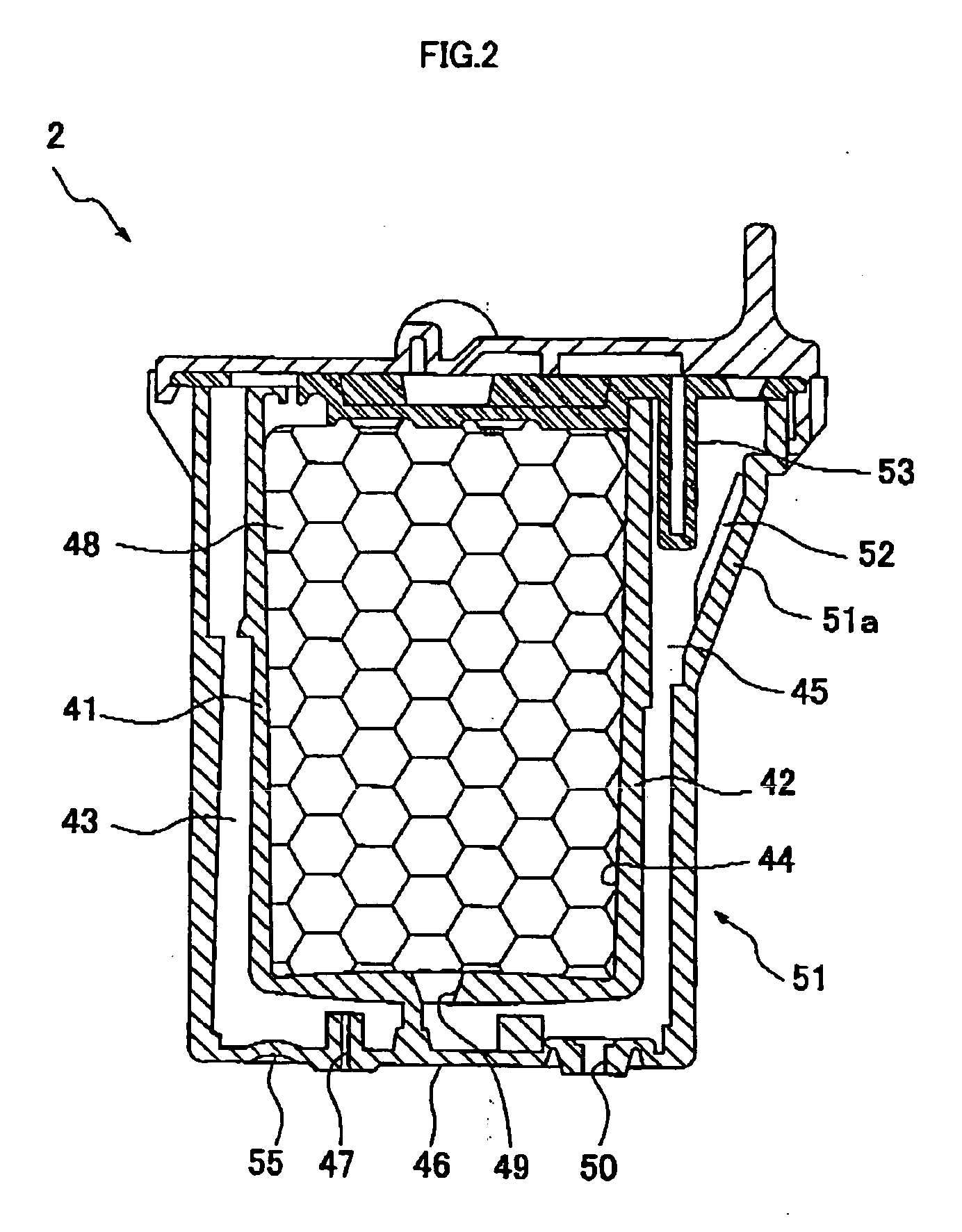

Ink cartridge, detection device for cartridge identification and ink level detection, and image formation apparatus comprising thereof

InactiveUS20050024454A1Ink levelIncrease the areaOther printing apparatusPrintingImage formationEngineering

The ink cartridge has a first detection target portion for detecting ink level and a second detection target portion for identifying the type of an ink cartridge. The ink level detection device uses an optical sensor to scan the first and second detection target portions of the ink cartridge, and detects ink level and the type of the ink cartridge, that is, whether the ink cartridge is containing standard amount of ink or large amount of ink. Therefore, the number of image formation on recording media can be estimated, and failure in image formation due to a shortage of ink in the middle of image formation can be inhibited.

Owner:BROTHER KOGYO KK

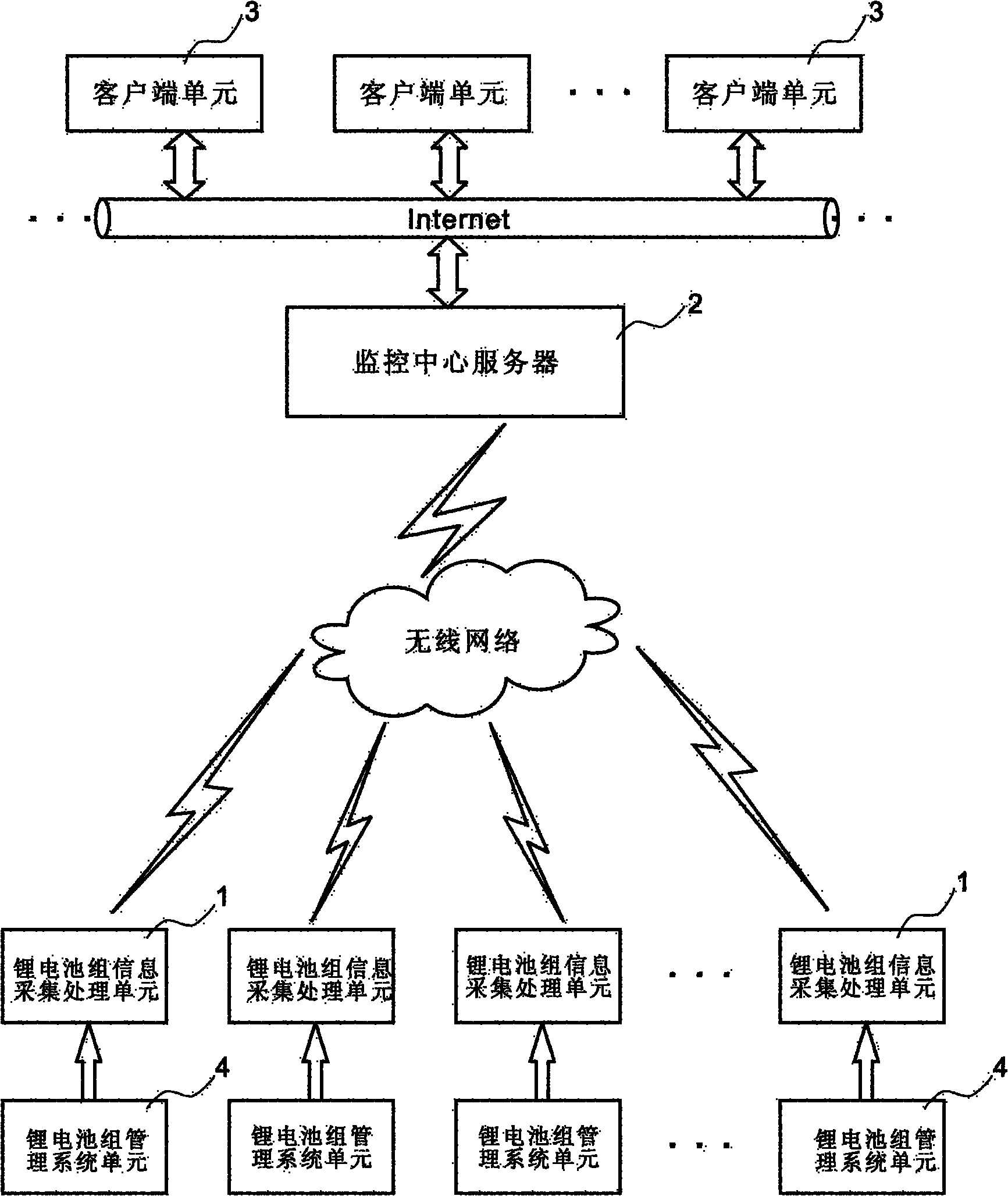

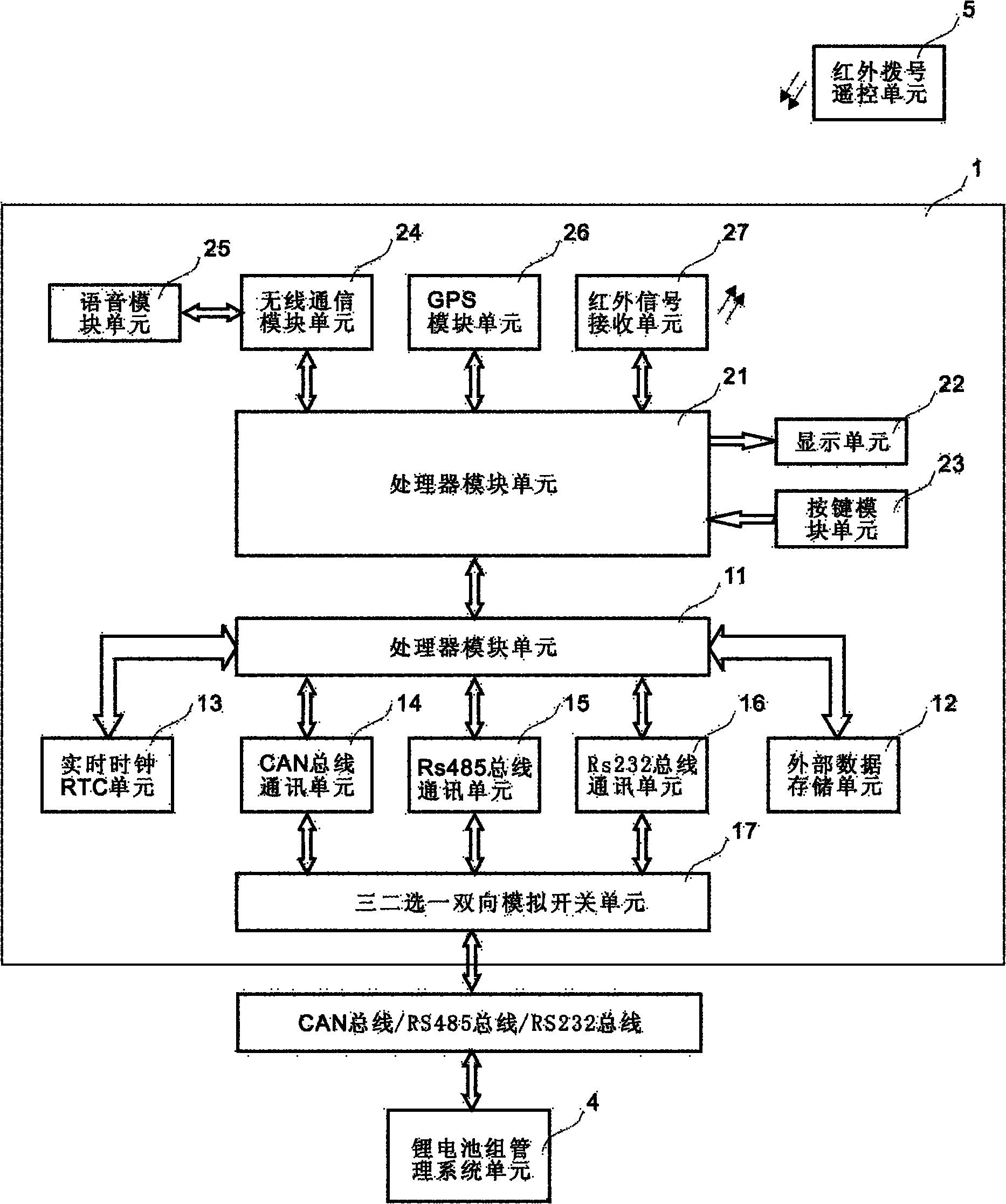

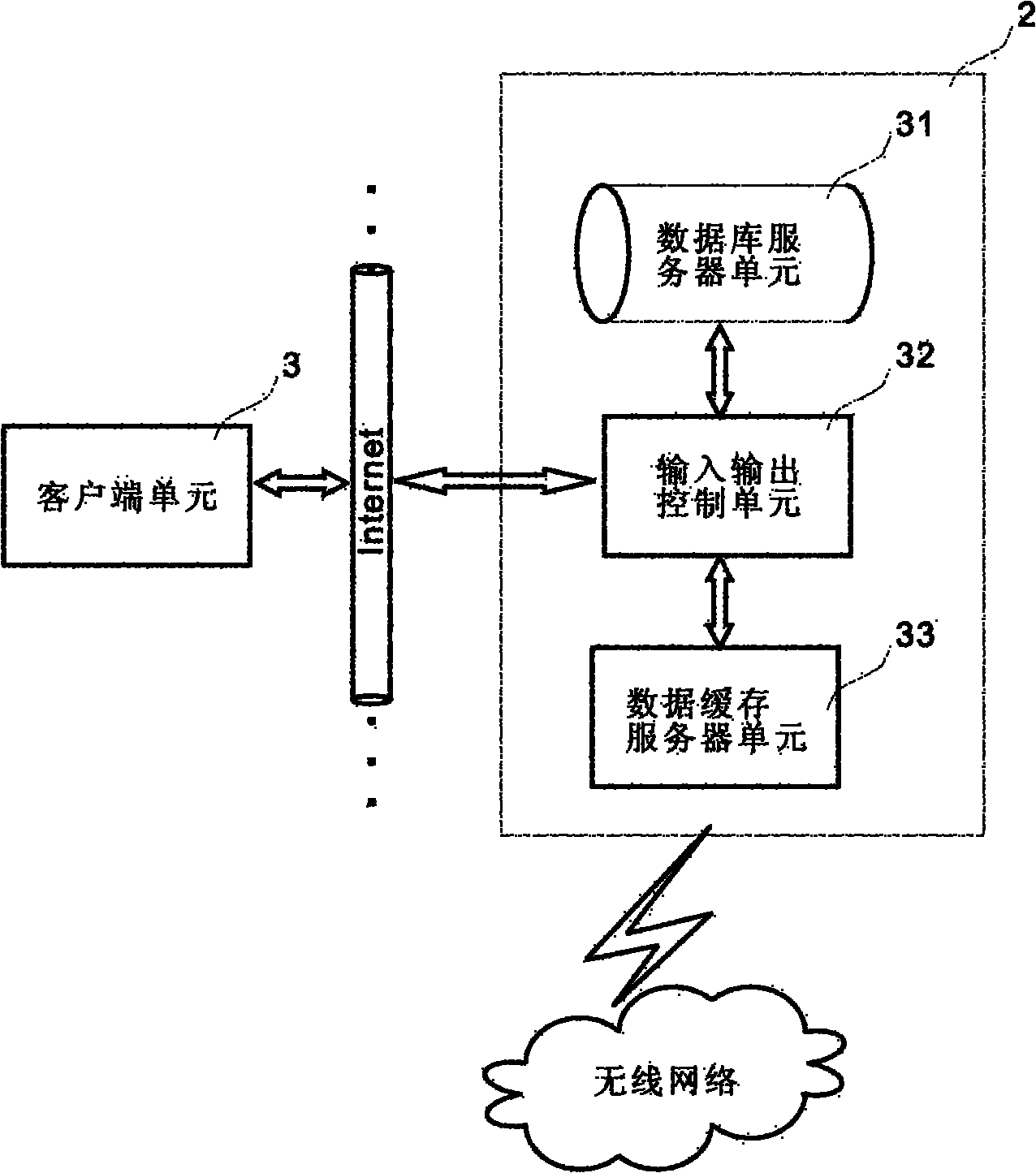

Remote monitoring system for lithium battery pack

InactiveCN102142186AReliable dataAvoid Unrecoverable FailuresTransmission systemsElectrical testingData acquisitionState of charge

The invention discloses a remote monitoring system for a lithium battery pack. The remote monitoring system comprises a lithium battery pack management system unit, a lithium battery pack information collecting and processing unit, a monitoring center server unit and a client unit, wherein, voltage, current, temperature, state of charge and fault information of the lithium battery pack is monitored and collected by the lithium battery pack management system unit in real time and then is transferred into the lithium battery pack information collecting and processing unit for data processing; then the processed data is transmitted to the monitoring center server unit through a wireless network so as to be stored; and the client unit is connected with the monitoring center server unit through Internet. The remote monitoring system can be used for solving the problems of the lithium battery pack such as low data collection efficiency, poor fault early-warning real-time property and shortage of failure analysis data in the prior art.

Owner:HEFEI GUOXUAN HIGH TECH POWER ENERGY

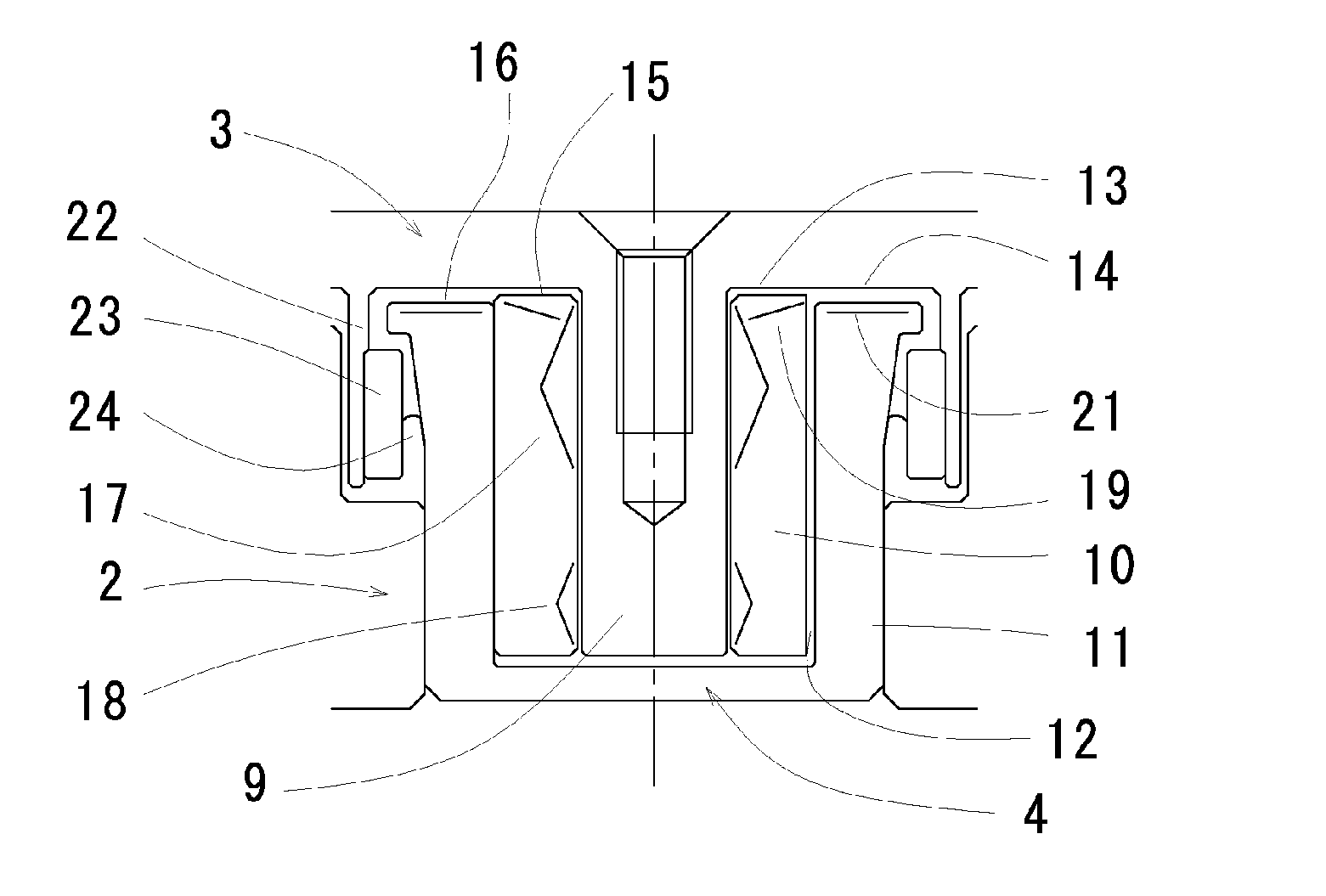

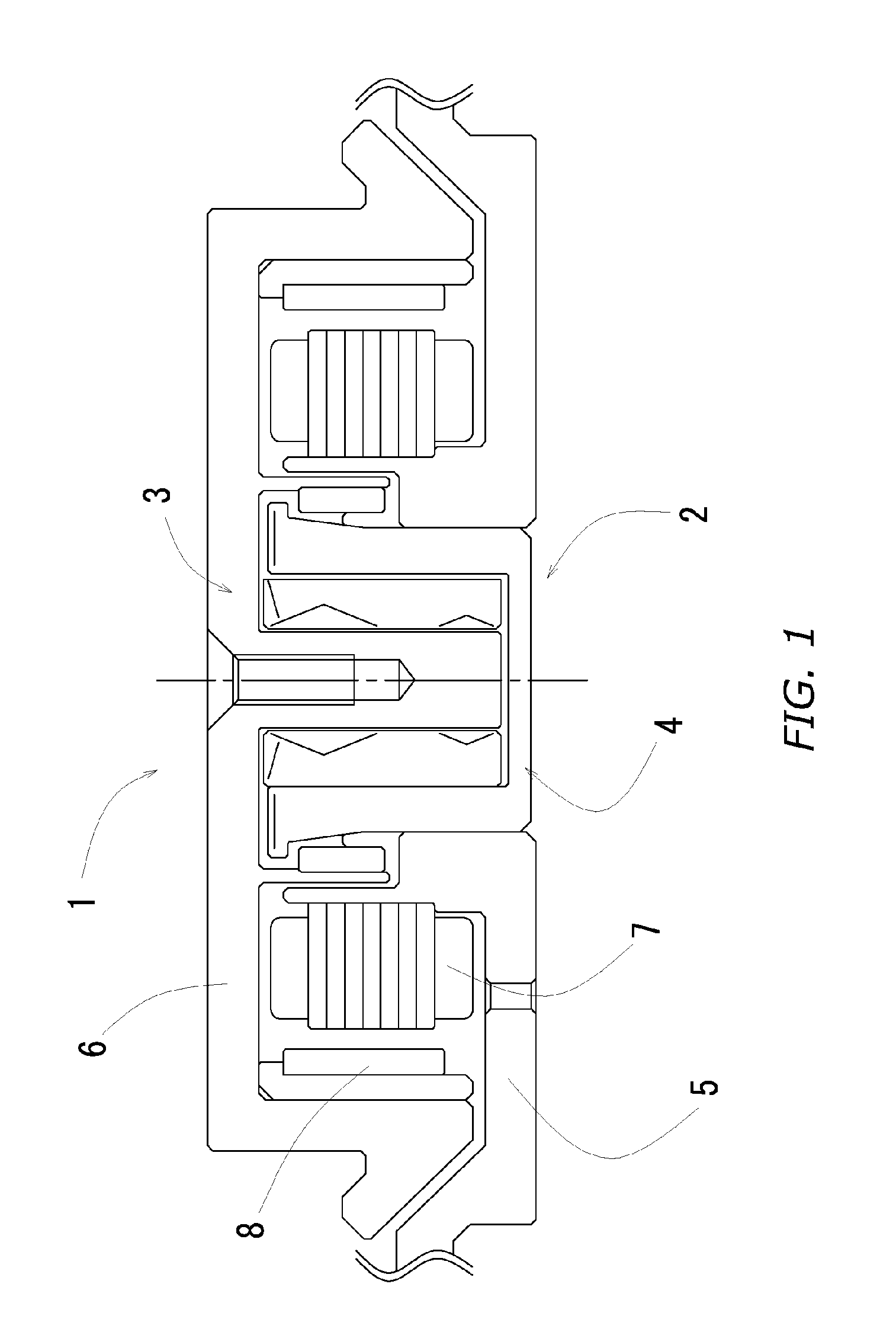

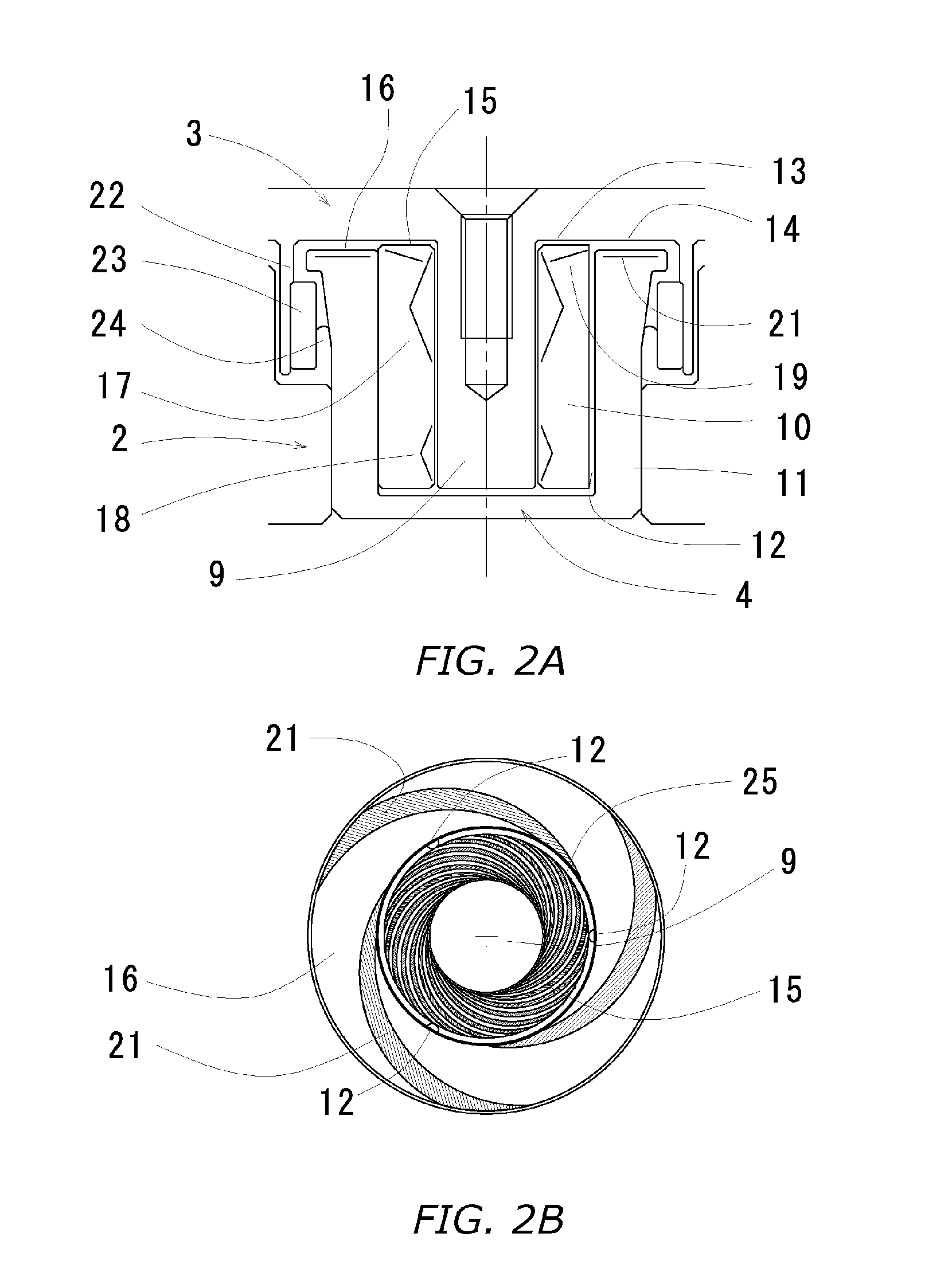

Fluid Dynamic-Pressure Bearing Device and Spindle Motor

ActiveUS20060051001A1Easy maintenanceReduce the overall heightBearing assemblyShaftsEngineeringDynamic pressure

Owner:NIDEC CORP

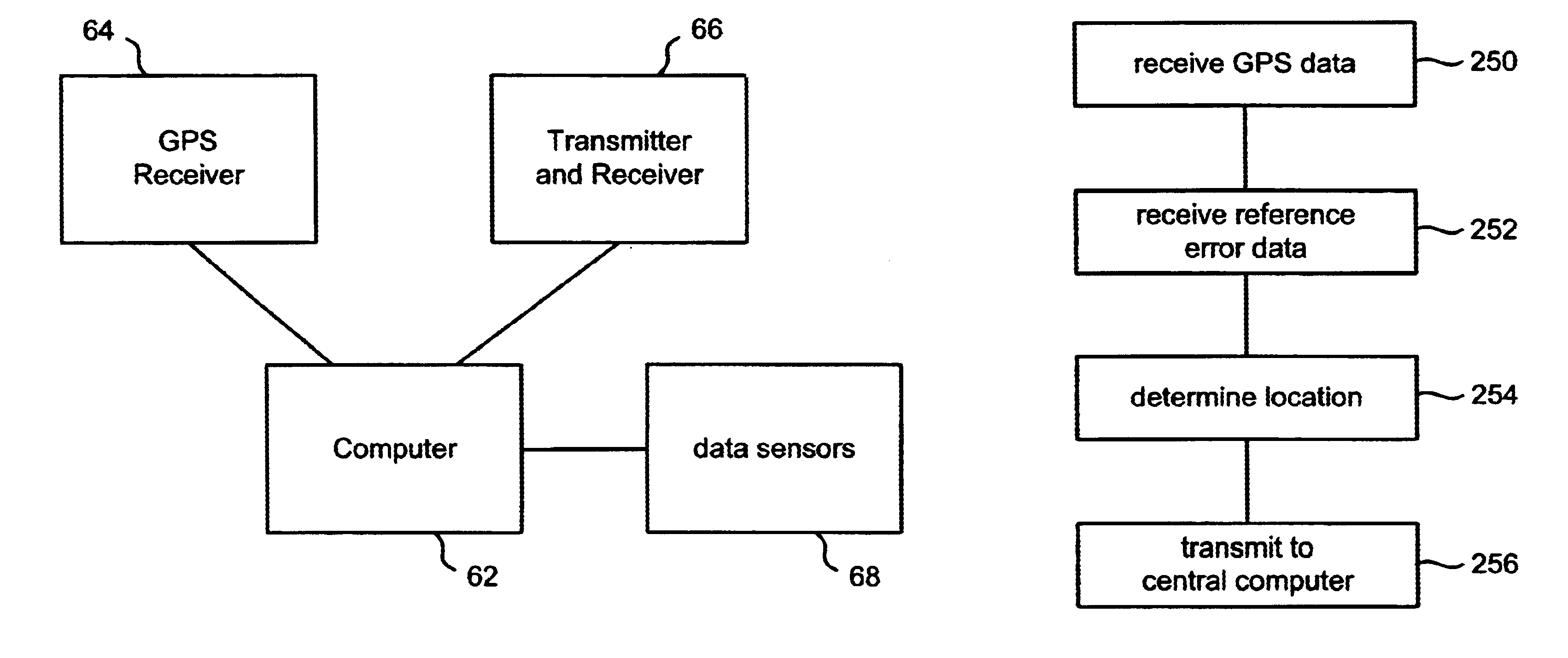

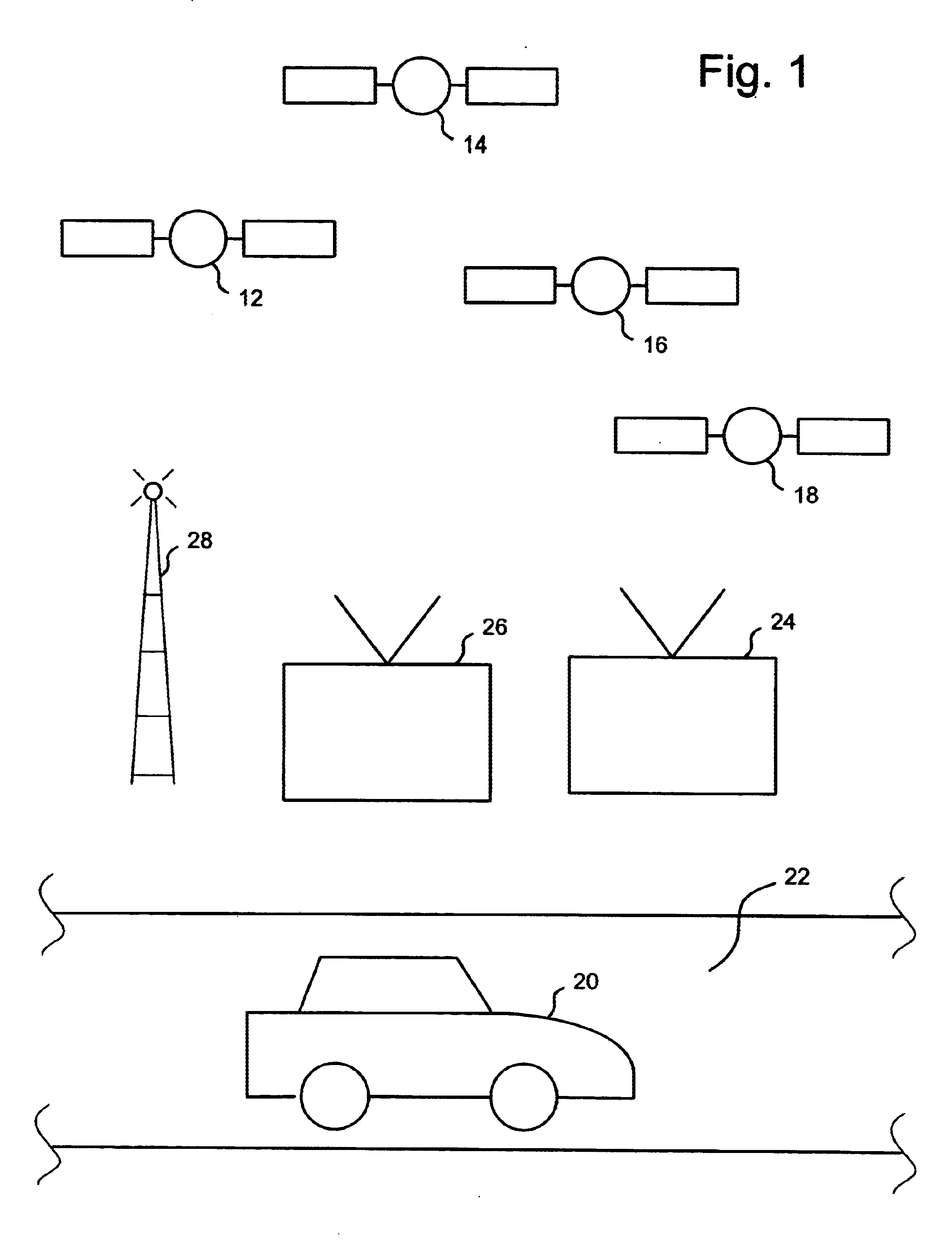

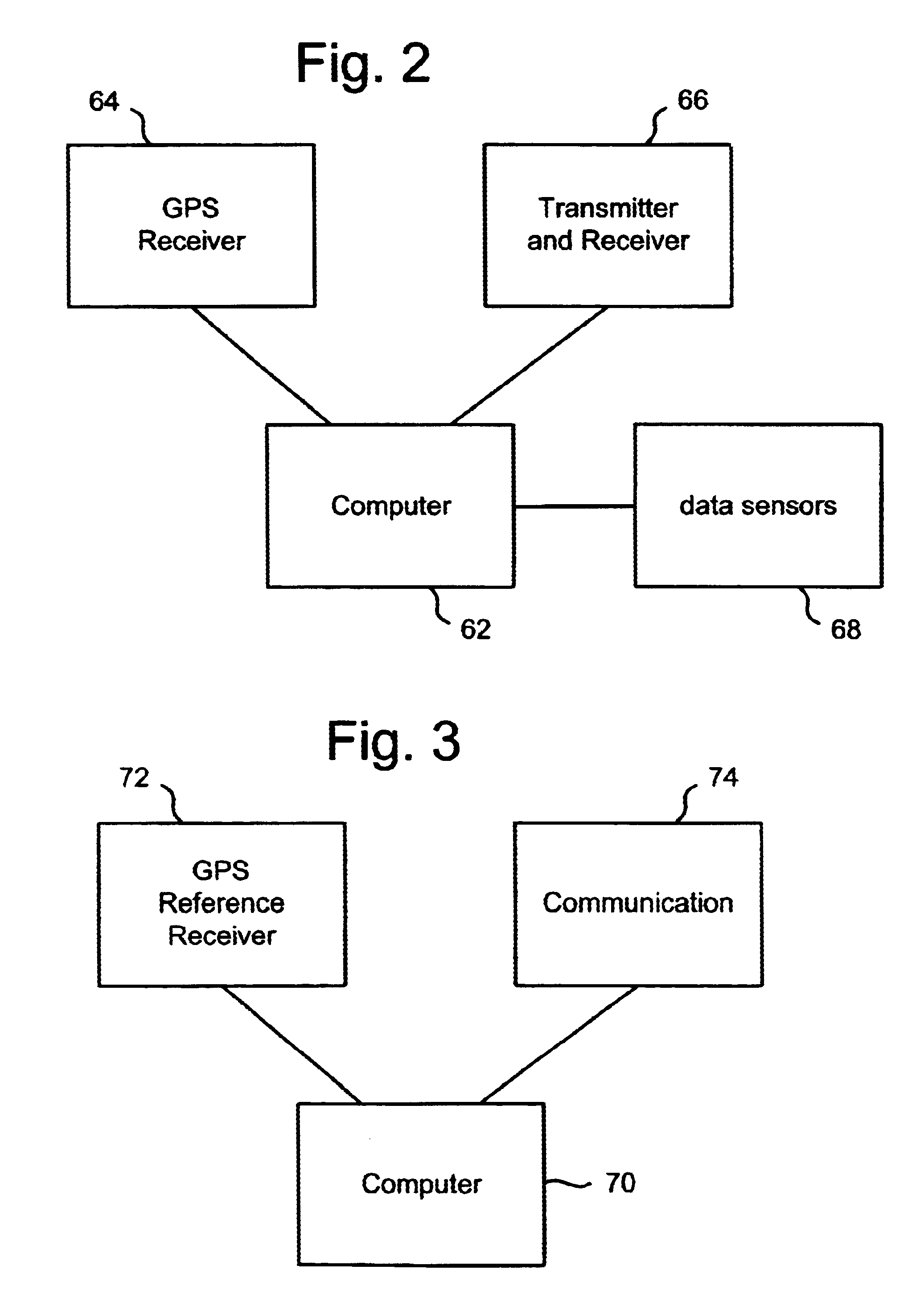

Locating an object using GPS with additional data

A system is disclosed that uses GPS and additional data to determine the location of an object. Typically, GPS receivers need valid data from four satellites to accurately determine a three dimensional location. If a GPS receiver is receiving valid data from fewer than four satellites, then additional data is used to compensate for the shortage of satellites in view of the GPS receiver. Examples of additional data includes a representation of the surface that the object is traveling on, an accurate clock, an odometer, dead reckoning information, pseudolite information, and error correction information from a differential reference receiver. An exemplar use of the disclosed system is to concurrently track a set of one or more automobiles during a race. The determined locations of the automobile can be used to provide route information, to generate statistics and / or to edit video of one or more of the automobiles.

Owner:SPORTSMEDIA TECH CORP

Autonomous Order Fulfillment and Inventory Control Robots

ActiveUS20160304281A1Programme-controlled manipulatorGripping headsOrder fulfillmentInventory management

Some embodiments provide a system for fully autonomous order fulfillment and inventory management within a distribution site or warehouse. The system operates by autonomous robots directly pulling customer order items from distribution site shelves or pulling individual bins from distribution site shelves and dispensing appropriate quantities of items from the bins until all items of a customer order are retrieved without human involvement. The system further involves the robots autonomously monitoring item quantities within the distribution site, identifying and autonomously responding to shortages, and organizing the items within the distribution site for most efficient order fulfillment.

Owner:INVIA ROBOTICS INC

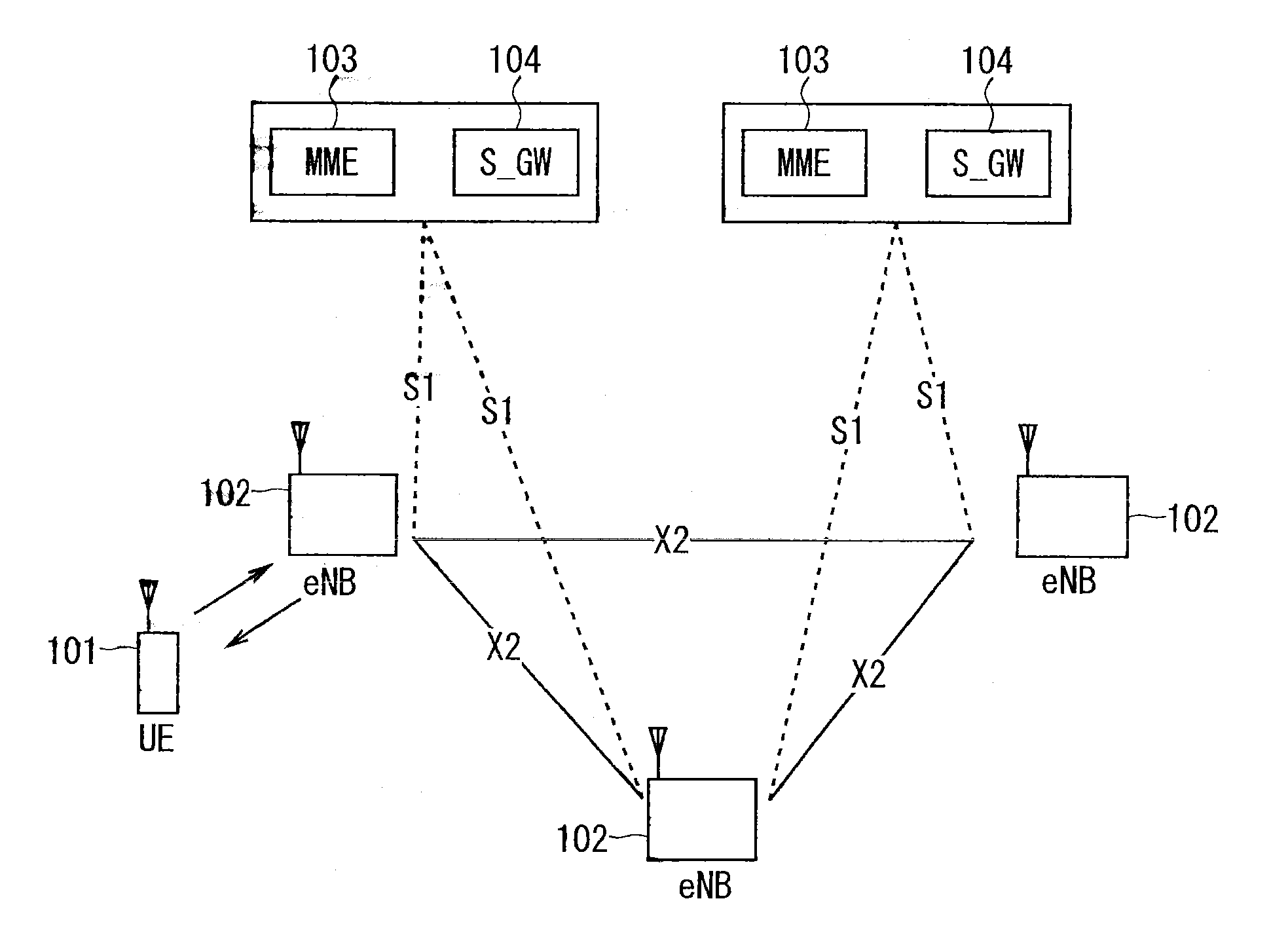

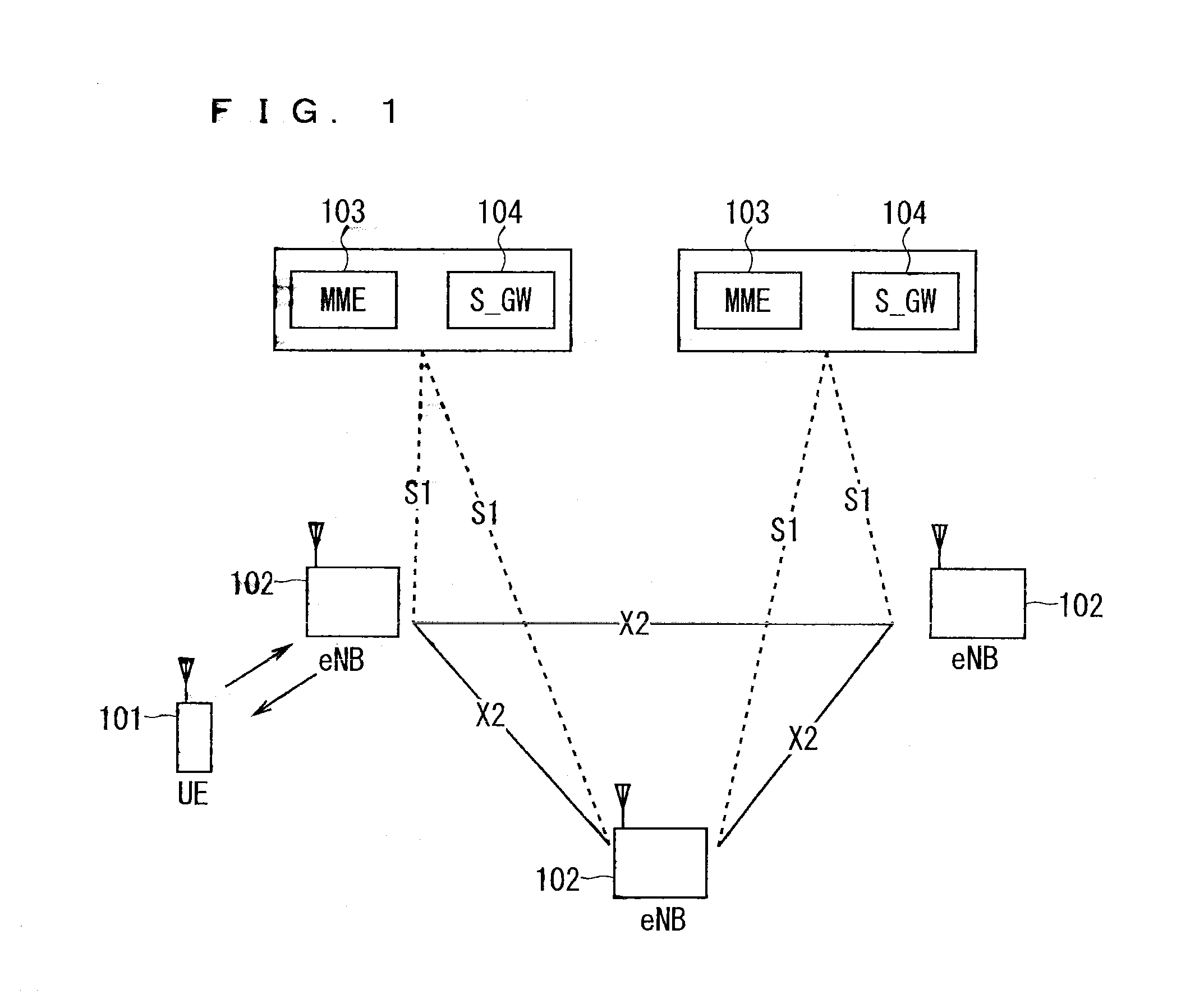

Communication system

ActiveUS20130203450A1Avoid congestionAvoid communicationNetwork topologiesMachine-to-machine/machine-type communication serviceCommunications systemUser equipment

The present invention has an object to provide a communication system capable of avoiding congestion in downlink communication or uplink communication and a shortage of radio resources arising therefrom. In the present invention, in a communication system including a normal user equipment (normal UE) that performs human to human communication and a machine type communication device (MTCD) that performs machine to machine communication, a base station device transmits a paging message to the normal UE and the MTCD for calling the normal UE and the MTCD. The paging message contains, for example, an equipment identity (UE-ID). A maximum number of equipment identities (UE-IDs) that can be accommodated within this paging message is set individually for the normal UE and the MTCD. Alternatively, the paging message contains a calling indicator in place of the equipment identity of the MTCD (UE-ID of MTCD).

Owner:MITSUBISHI ELECTRIC CORP

Method for predicting and avoiding danger in execution environment

InactiveUS20050240641A1Reduce loadShort timeData processing applicationsMemory adressing/allocation/relocationApplication serverOut of memory

Measurement / analysis unit in a Java virtual machine has the function of measuring data when an event of garbage collection occurs, and the function of periodically measuring data. The measurement / analysis unit analyzes the measured data and predicts a danger of a memory shortage, and predicts a danger using an algorithm depending on the type of garbage collection used by the Java virtual machine. An application server is notified of a warning of the predicted danger of a memory shortage by an analysis result notification means by an inter-process communication, or the like. The measurement / analysis unit calculates a memory capacity required to avoid the predicted danger of a memory shortage, and the calculated memory capacity is transmitted to the application server by the analysis result notification means by an inter-process communication, or the like in the same way as the warning.

Owner:FUJITSU LTD

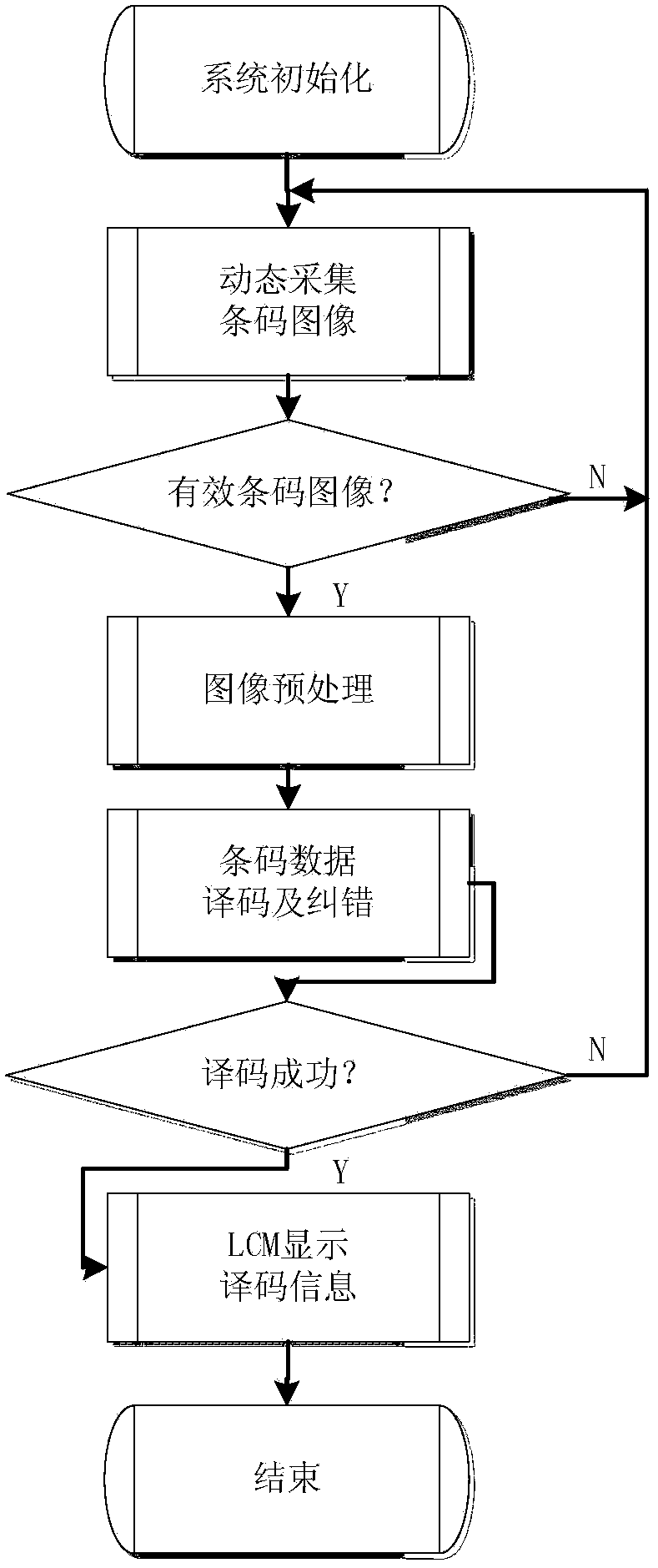

Auxiliary method and auxiliary system of intelligent refrigerator

ActiveCN104361041AImprove usabilityImprove practicalityDomestic cooling apparatusLighting and heating apparatusNetwork connectionAuxiliary memory

The invention discloses an auxiliary method of an intelligent refrigerator. The auxiliary method can be used in food material management, recipe recommendation, purchase assistance, and the like. The invention further discloses an auxiliary system of the intelligent refrigerator. The auxiliary system consists of embedded equipment, a server and mobile equipment, wherein the embedded equipment is embedded into the outer side of a refrigerator door. In the embedded equipment, food material information is written into the system in modes of manual operation, bar codes and camera acquisition. The embedded equipment is connected with the server through a network and is used for performing high-precision recognition and other processing; the mobile equipment is interconnected with the server and is used for acquiring system information; system auxiliary information, that is, shortage alert made according to the number of the food materials, is fed back to the embedded equipment and the mobile equipment. The auxiliary method has the advantages of low cost, low power consumption, high use easiness and the like.

Owner:SOUTH CHINA UNIV OF TECH

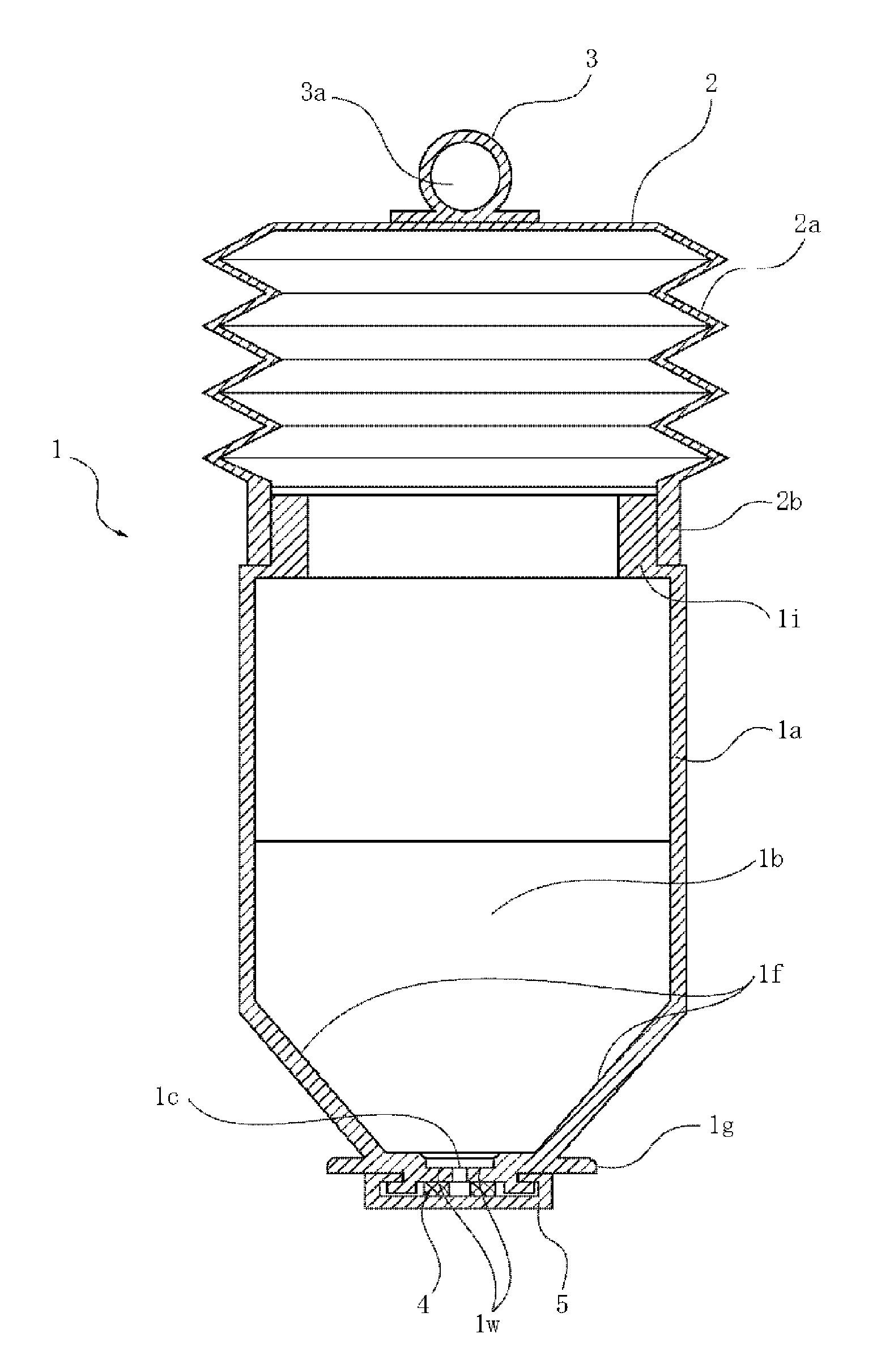

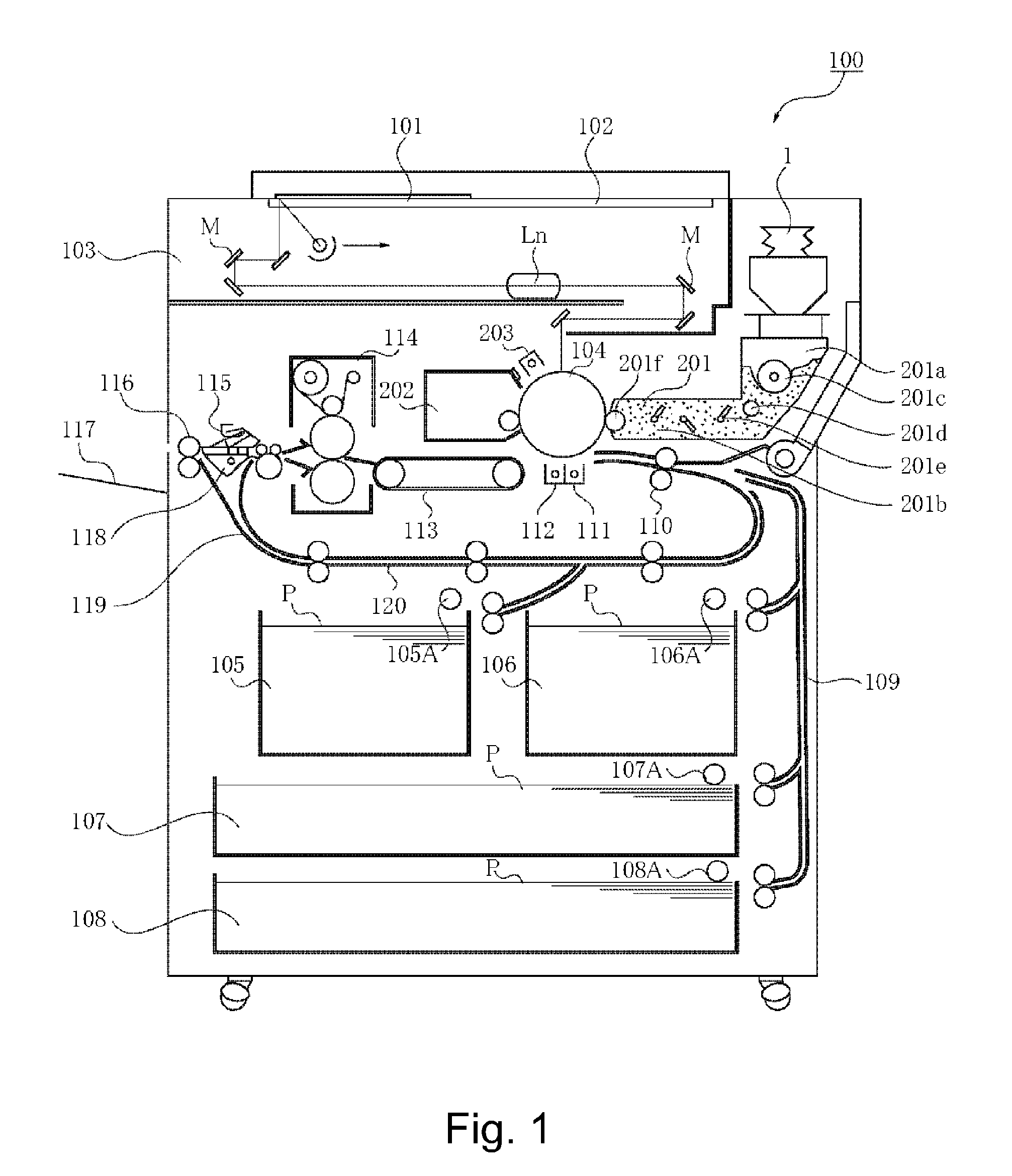

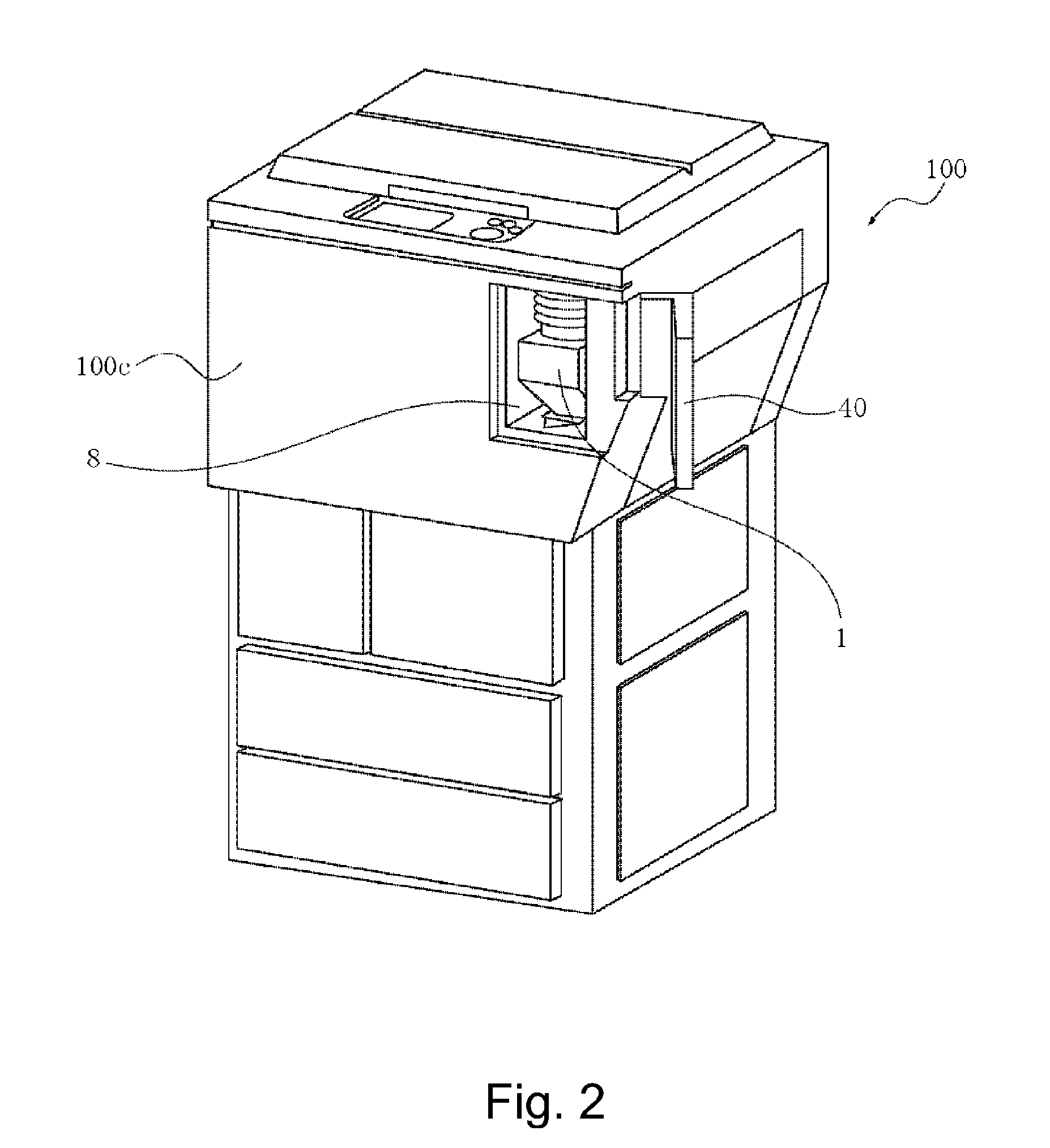

Developer supply container and developer supplying system

Conventionally, the developer in the developer supply container is discharged by an air-supply pump and a suction pump which are provided in the main assembly side of the image forming apparatus, and therefore, the developer is compacted by the increase of the internal pressure of the developer supply container resulting from the air-supply. Therefore, the proper suction of the developer from the developer supply container becomes difficult with the result of shortage of the developer amount to be supplied.A bellow-like pump is provided on the side of the developer supply container, and the pump alternately repeats the suction operation and the discharging operation through the discharge opening by a driving force inputted from the image forming apparatus side. By this, the developer can be sufficiently loosened, thus properly discharging the developer.

Owner:CANON KK

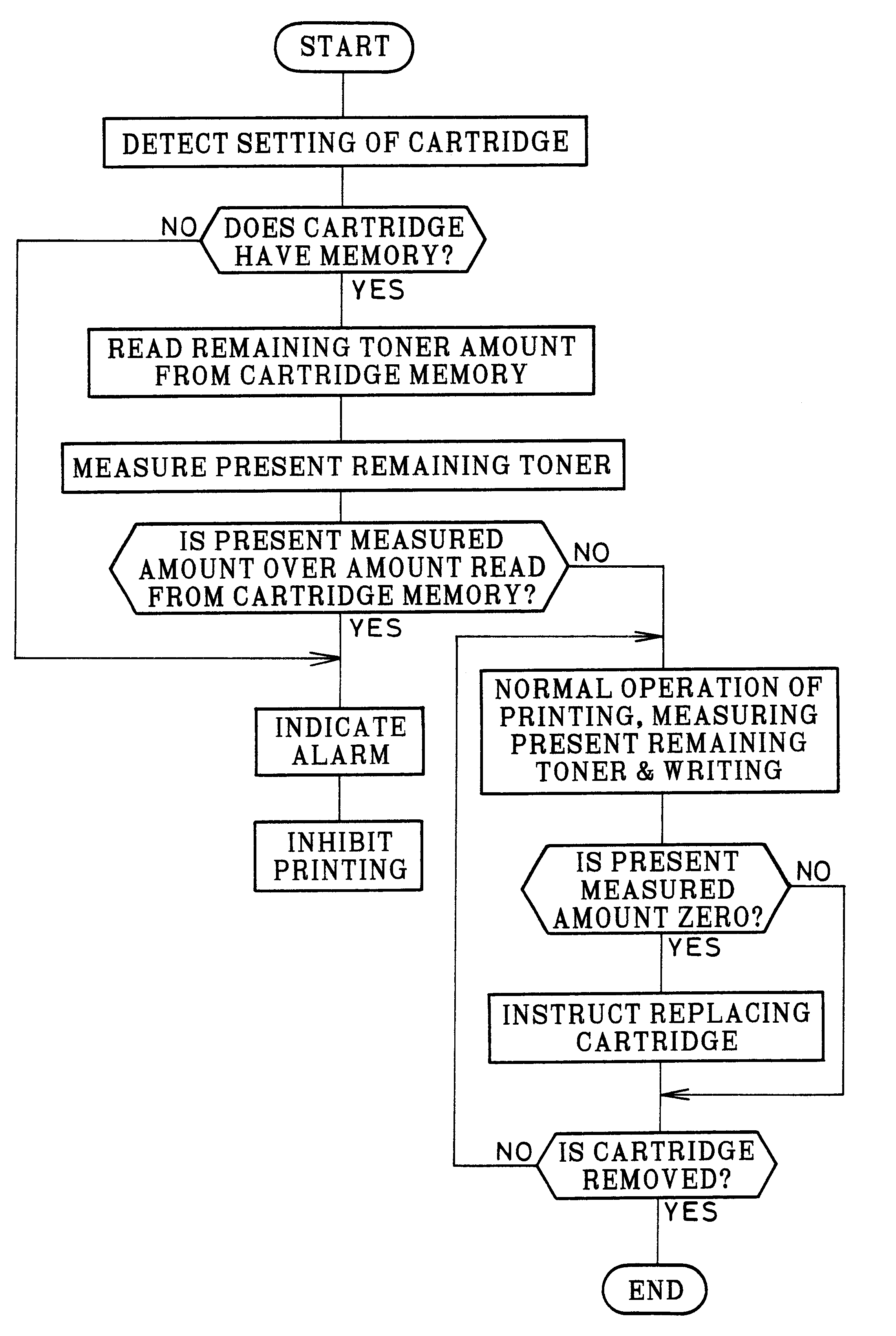

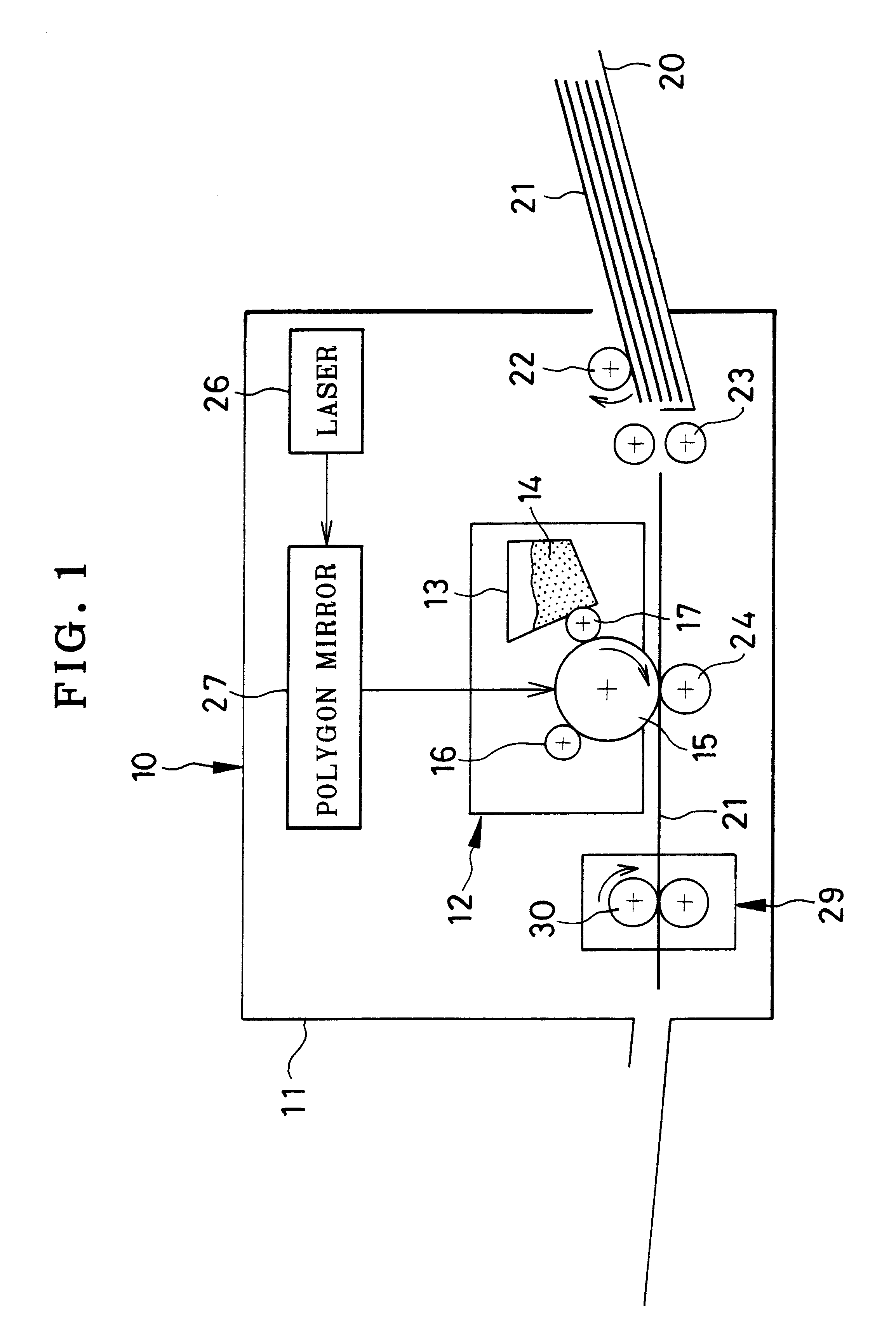

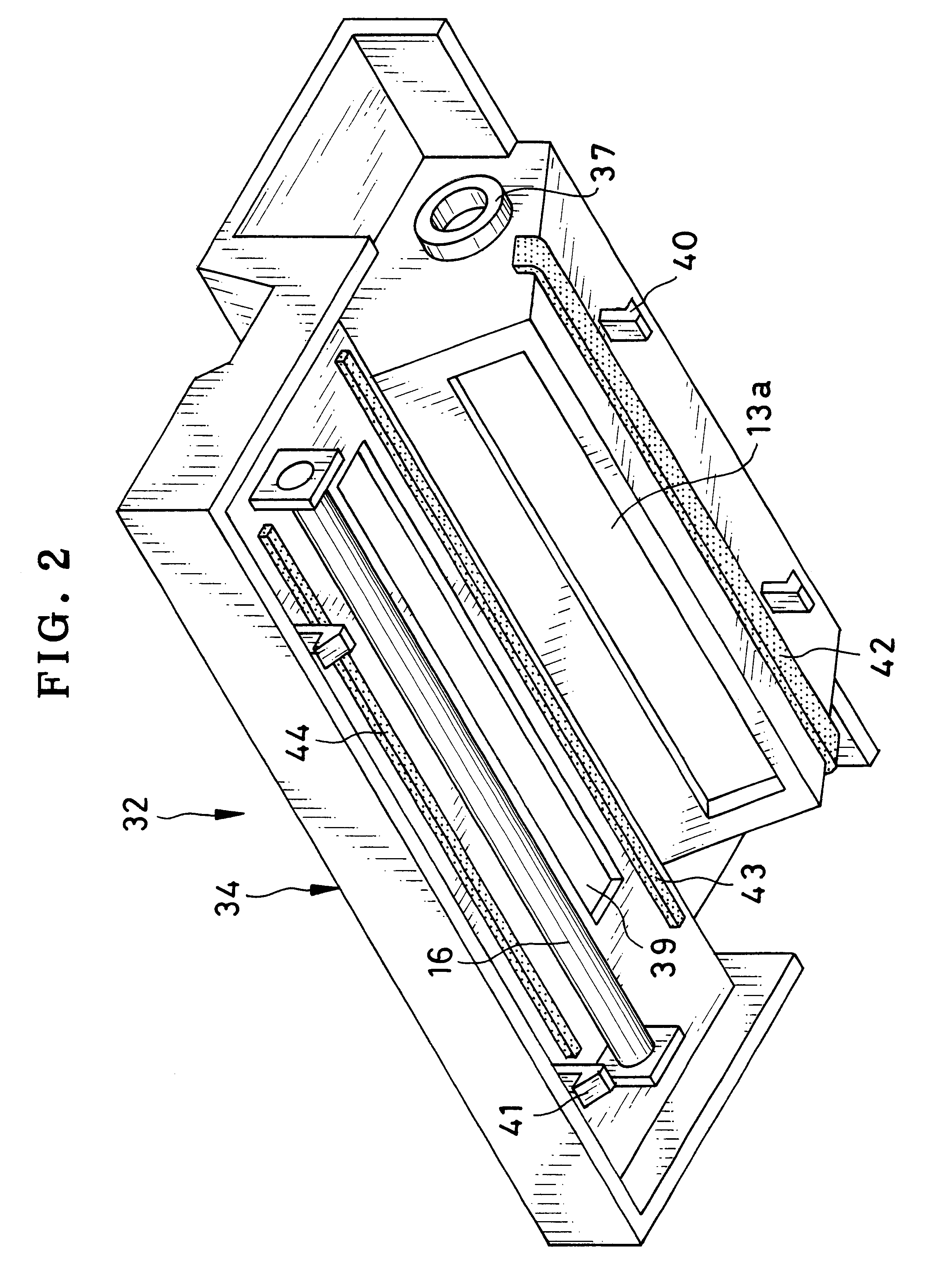

Method, device, system and recording medium for detecting improper cartridge, and cartridge

InactiveUS6658219B1Accurate measurementEasy to detectElectrographic process apparatusEngineeringReference range

A cartridge is set in a printer main unit, and has a remaining toner measurer which measures toner in a toner chamber upon setting of the cartridge. A cartridge memory stores information of a remaining toner amount measured previously. CPU compares the remaining toner amount measured newly with the remaining toner amount measured previously and read from the cartridge memory. If there is an increase in the toner, the cartridge is determined as improper cartridge reloaded with the toner. An alarm signal is generated. Also, printing is inhibited. In another preferred embodiment, shortage information is assigned to the cartridge upon using up the toner. The cartridge, if it has the shortage information, is determined as improper. If a characteristic of the toner is not within a reference range, the cartridge is determined improper. In another preferred embodiment, an upper limit of the number of times of toner reloading is predetermined. The cartridge is determined improper if the reloading time number comes up to the upper limit. The improper cartridge is set in a state in which operation is inhibited. Also, when the cartridge is disassembled, the improper cartridge is inhibited from operating.

Owner:FUJIFILM HLDG CORP +1

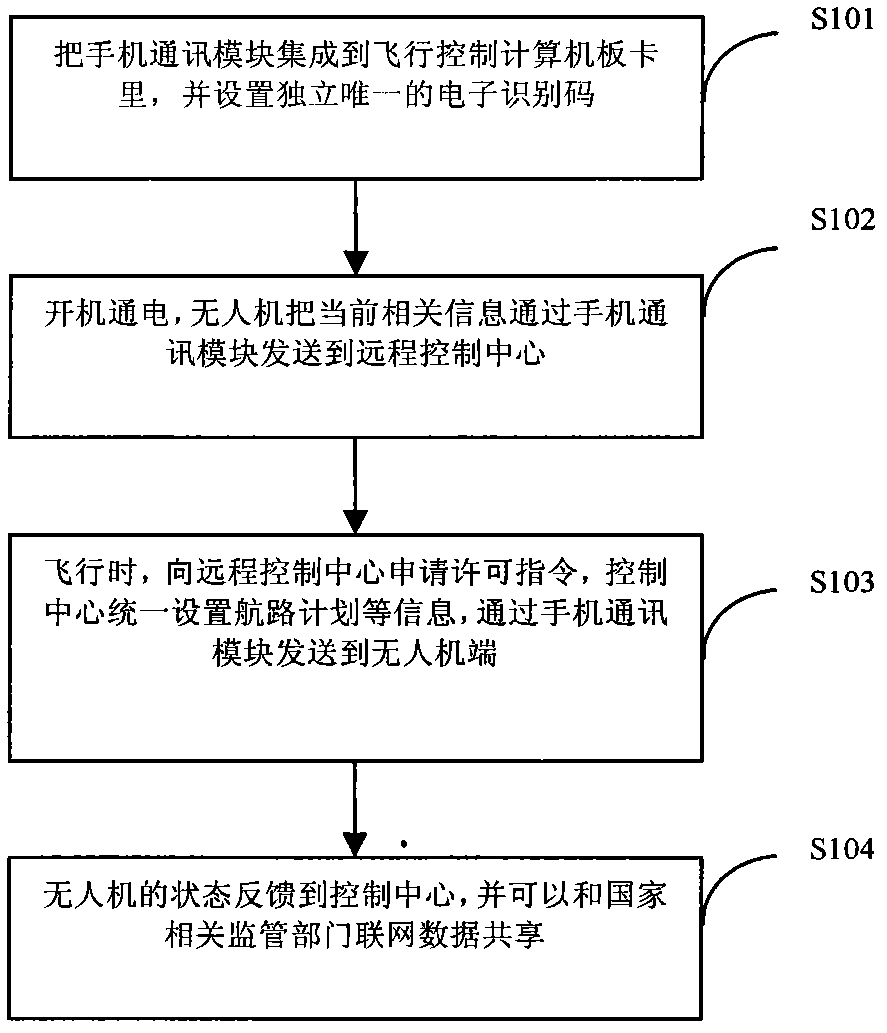

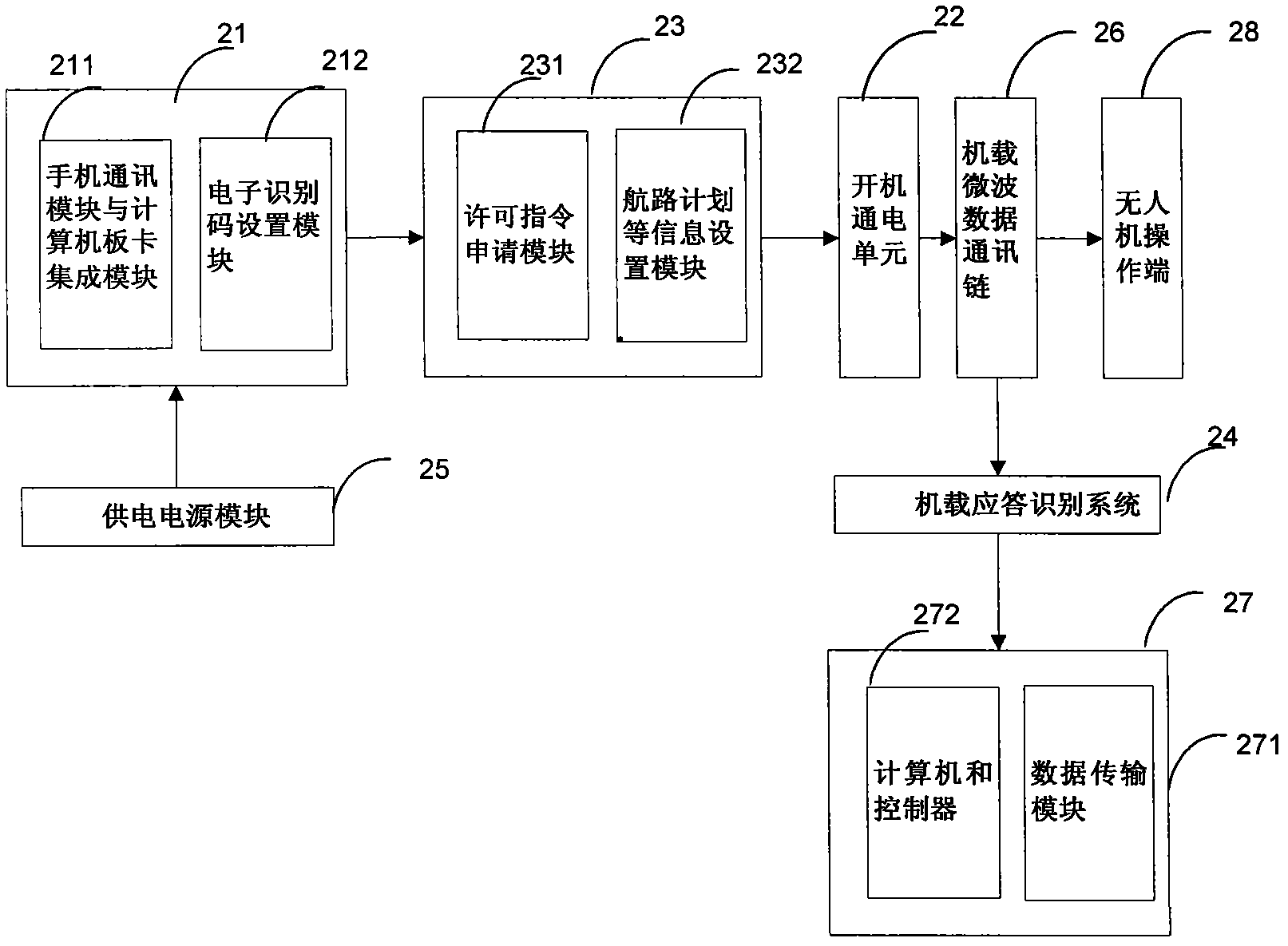

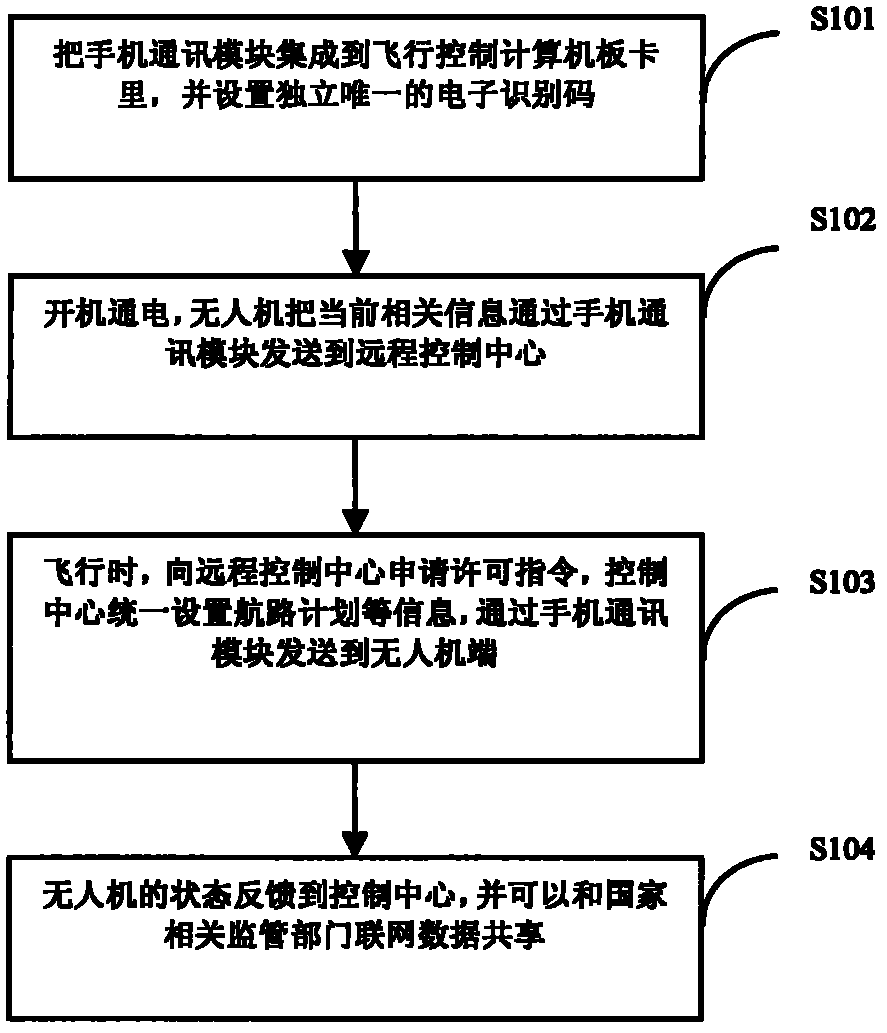

Remote unmanned aerial vehicle cluster control method and system based on 3G (the 3rd Generation Telecommunication) and GPRS (General Packet Radio Service) cell phone communication

InactiveCN102637023AEnsure safety and controlUnified supervision and dispatchSubstation equipmentTotal factory controlGeneral Packet Radio ServiceElectronic identification

The invention provides a remote unmanned aerial vehicle cluster control method and system based on 3G (the 3rd Generation Telecommunication) and GPRS (General Packet Radio Service) cell phone communication and belongs to the technical field of unmanned aerial vehicles. Each unmanned aerial vehicle is provided with an independent unique electronic identification code by integrating a cell phone communication module into a flight control computer board card; as long as the system is started and electrified, the current relevant information of the unmanned aerial vehicle is transmitted to a remote control center; a permission instruction is necessarily applied from a control center for each flight; information such as an airway plan is made uniformly in the control center; and the information is transmitted to an operation terminal of the unmanned aerial vehicle through a cell phone communication module. Consequently the unmanned aerial vehicle cannot fly away without a headquarter control instruction. The state of each unmanned aerial vehicle is fed back to the control center and can be shared with networked data of relevant national supervision departments so as to play roles in unified supervision and scheduling. In addition, the on-site operation personnel do not need professional knowledge such as airway point setup; and the unmanned aerial vehicle can be operated by common people subjected to simple training, so that the problem of staff shortage in unmanned aerial vehicle control is solved.

Owner:WUHAN AI BIRD UAV

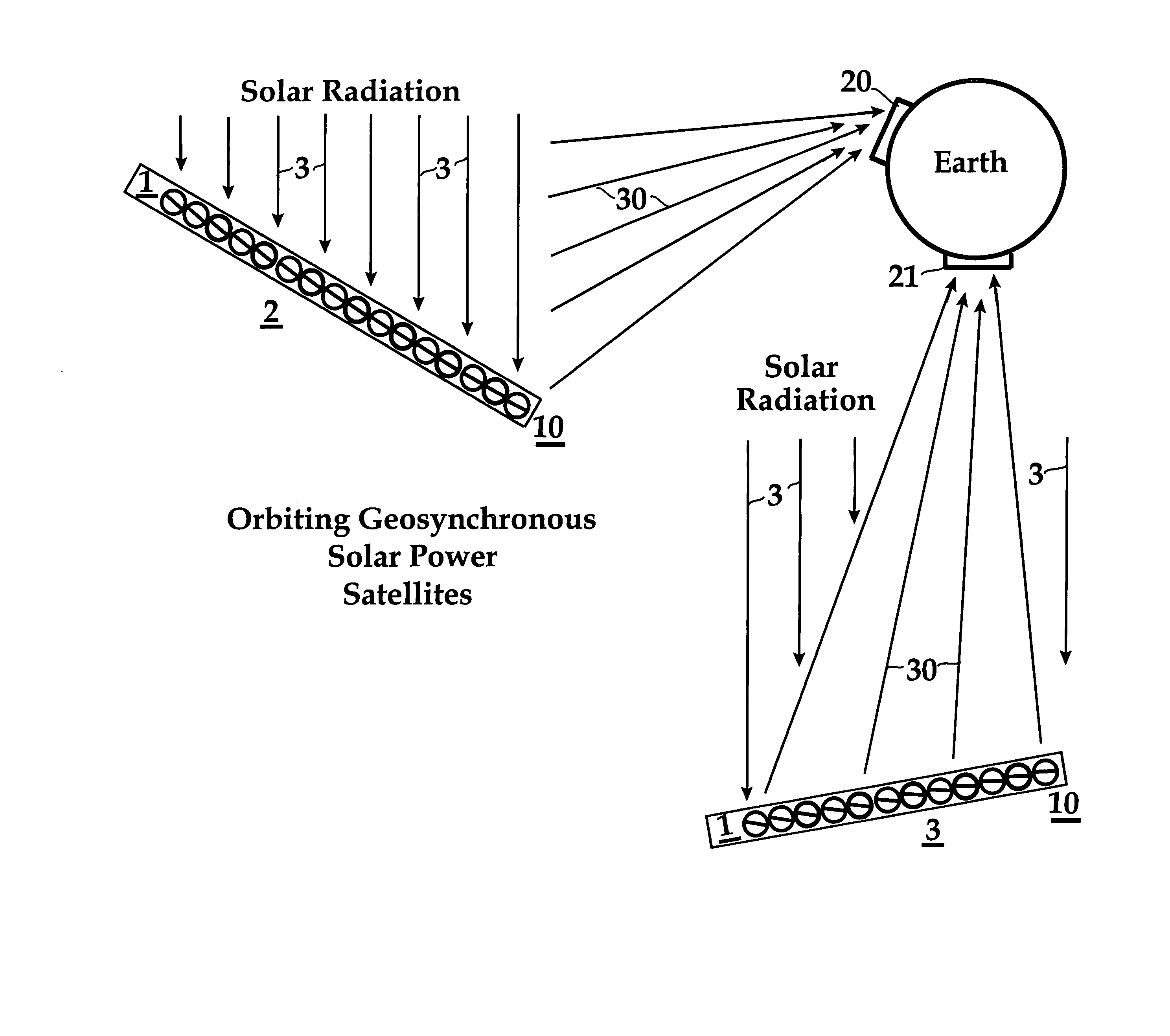

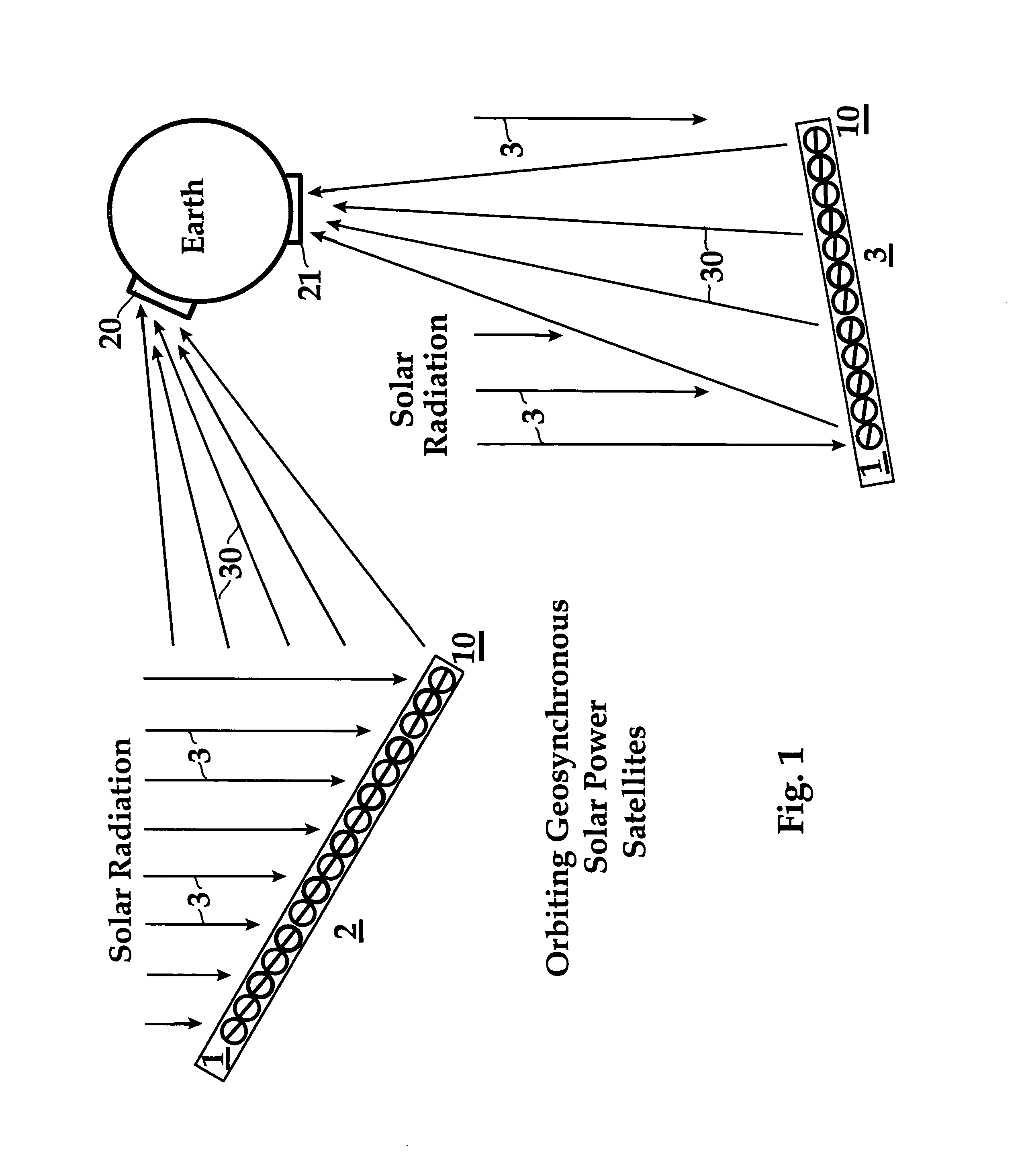

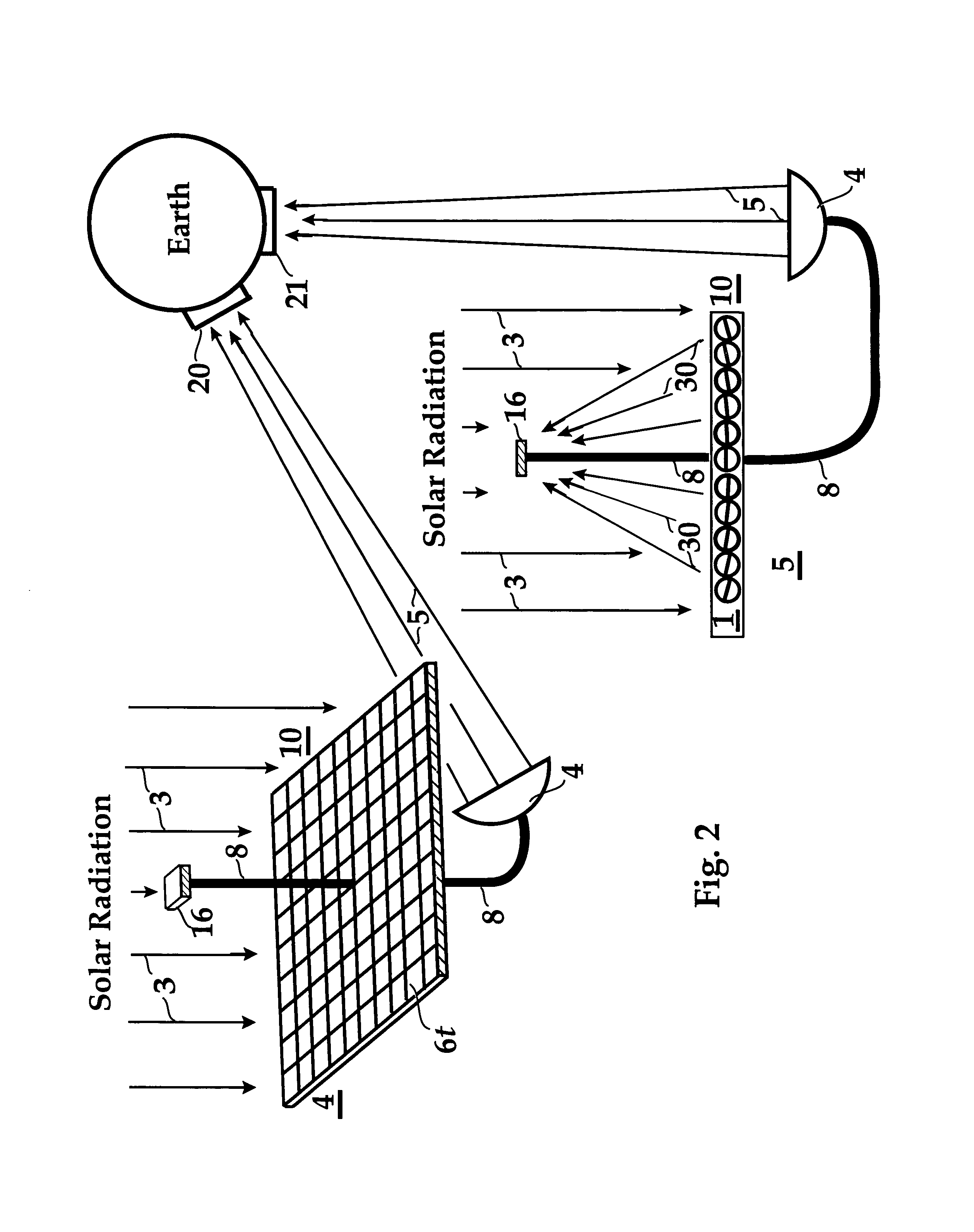

Micro-optics concentrator for solar power satellites

InactiveUS7077361B1Low costAffordable solar energySolar heating energyCosmonautic vehiclesSolar powerSolar power satellites

There is an increasingly intense need to harness solar energy due to an ever growing shortage of conventional energy sources, The instant invention is concerned with method and apparatus for solar concentrator micro-mirrors on solar power satellites and the moon to focus and reflect large quantities of solar energy. Method and apparatus are taught for directly reflecting solar energy to the Earth; reflecting solar energy to a microwave converter in space which transmits microwave energy to the Earth; and reflecting solar energy to a laser radiation converter which beams laser radiation to the Earth. The concentrated energy received at the Earth may be converted directly to electricity or indirectly by thermo-mechanical means. The advantages and disadvantages of the different means of sending such concentrated energy to the Earth are discussed. A particularly important objective of this invention is the focussing of sunlight for solar power conversion and production. The instant invention can contribute to the goal of achieving environmentally clean solar energy on a large enough scale to be competitive with conventional energy sources.

Owner:RABINOWITZ MARIO

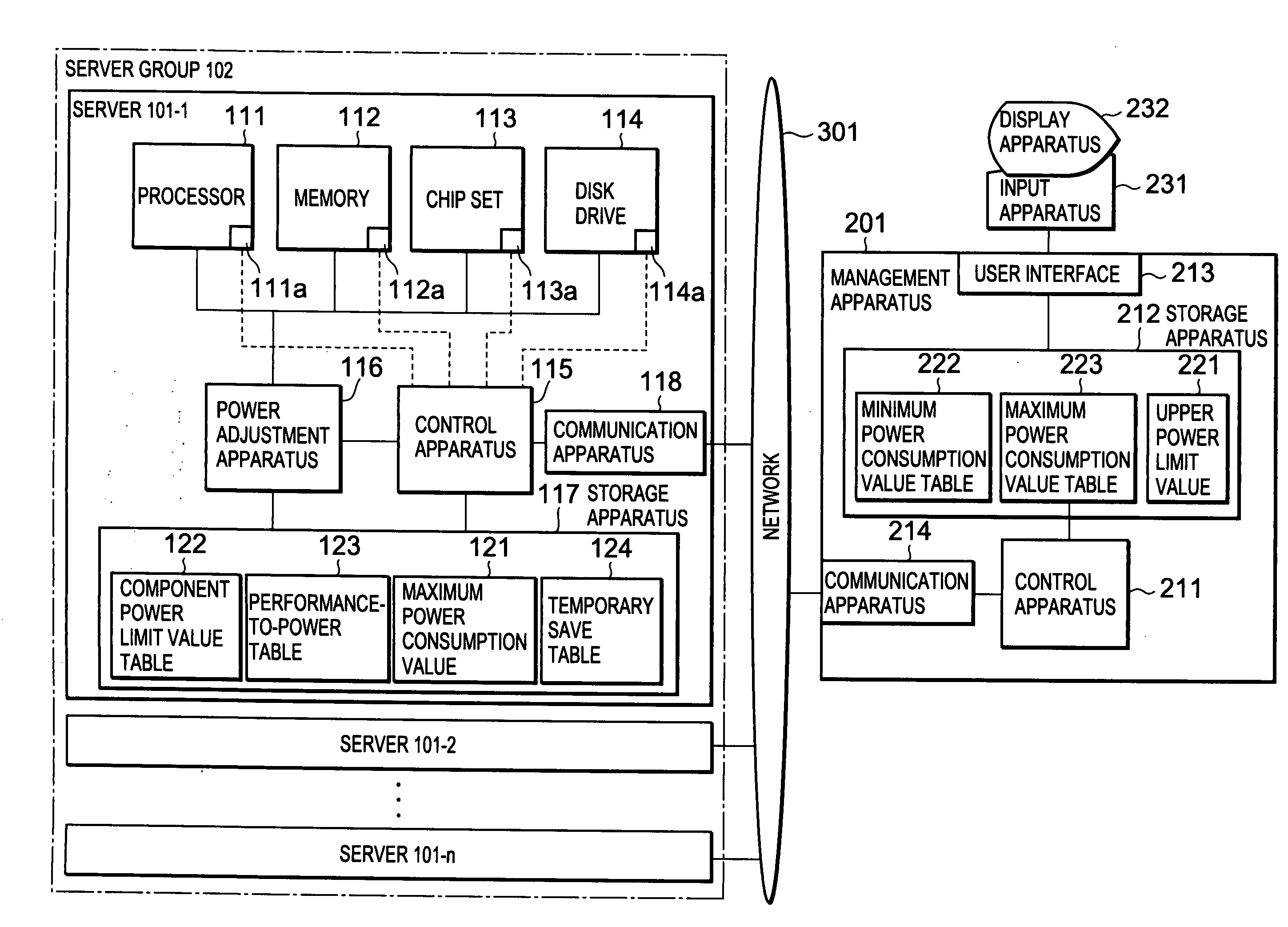

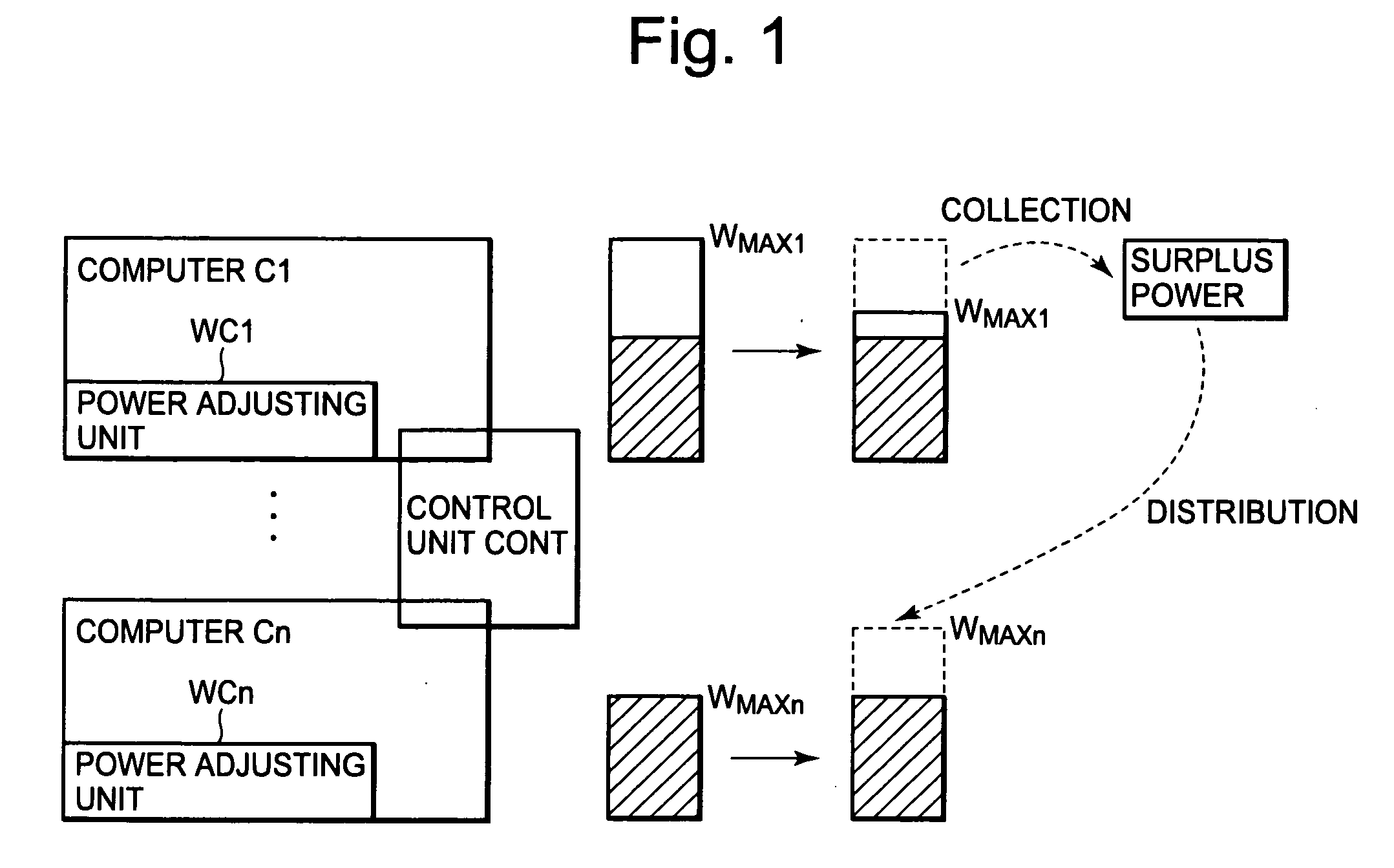

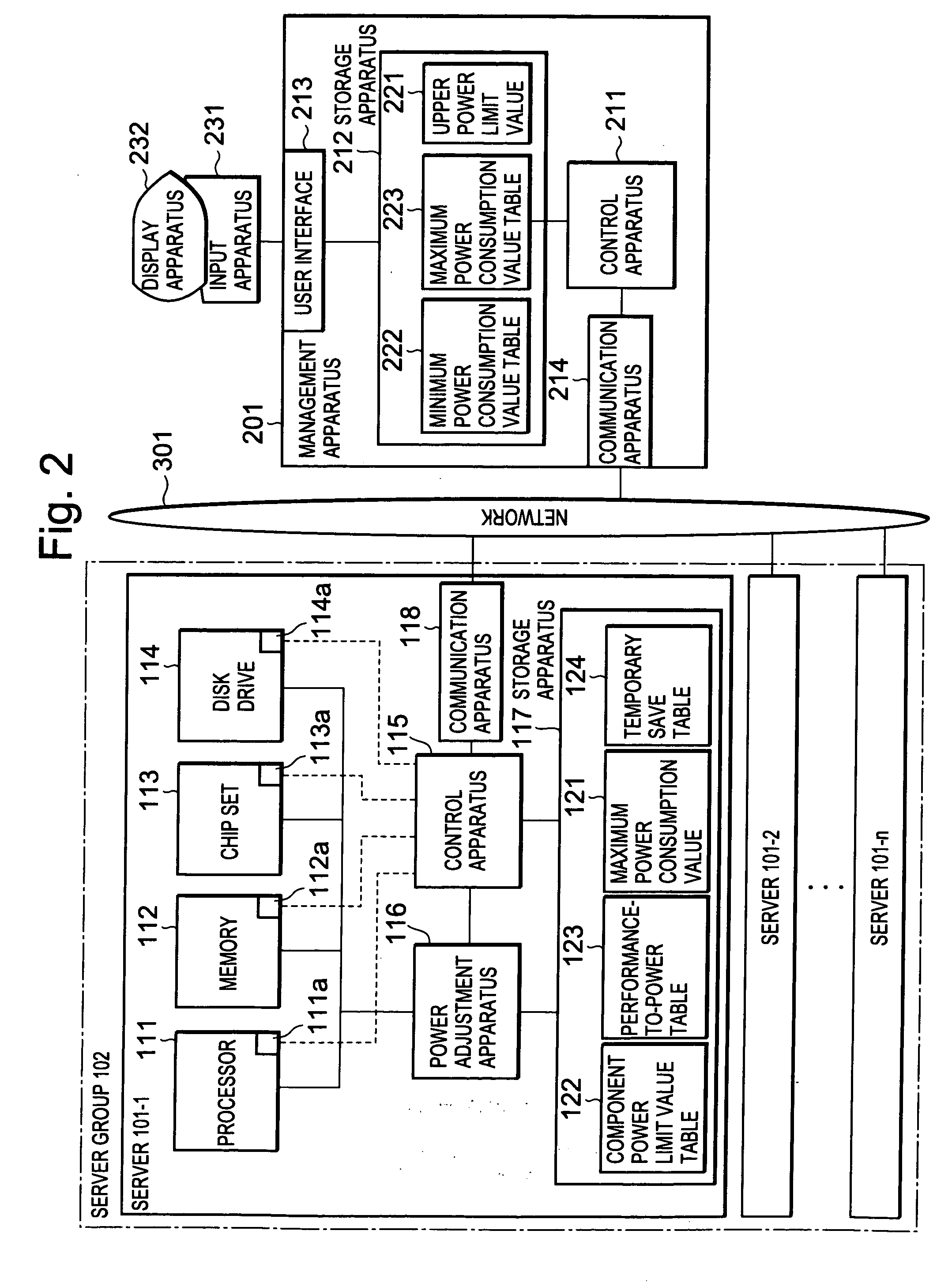

Apparatus, system and method for power management

InactiveUS20090077407A1Power supplyAdjust power consumptionVolume/mass flow measurementHardware monitoringEngineeringPower management

An apparatus which communicates with another apparatus includes a control unit which monitors a power consumption of the apparatus, supplies a power to the another apparatus when the power consumption includes a surplus, and requests the another apparatus to supply the power when the power consumption includes a shortage, and an adjusting unit which adjusts the power consumption of the apparatus according to an operation of the control unit.

Owner:NEC CORP

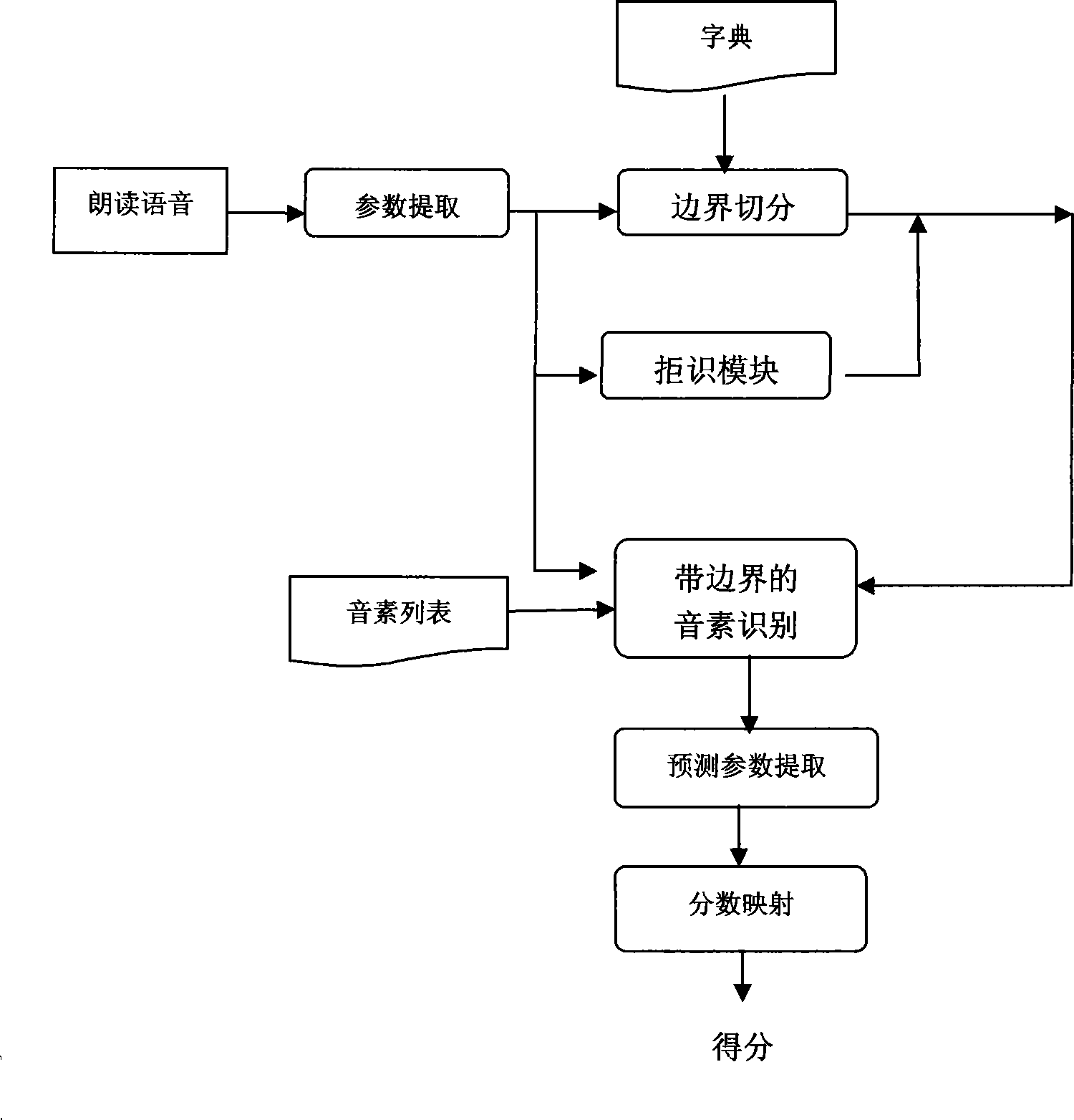

Automatic spoken English evaluating and learning system

The invention relates to an automation oral English evaluation and learning system, comprising a testing part, an grading part and a guiding part; the invention is realized by the following procedures that: (1) a standard pronunciation people corpus is set up; (2) an oral English evaluation corpus is collected; (3) the oral English evaluation corpus is labeled; (4) a standard sound acoustic model is built; (5) the error detection parameter of the sound is calculated; (6) an error detection mapping model for error detection parameter-toward pronunciation error labeled by experts is created; (7) an evaluation parameter-toward expert grading mapping model is created; (8) the oral error is guided to be corrected. The invention has the advantages of good interactivity and no limit on place, and overcomes the shortage of the teacher resource and resolves the limitation problem in the practicability aspect that more teachers are needed for teaching.

Owner:IFLYTEK CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com