Composite sulphur dioxide desulfurizing agent and preparation method thereof

A composite material and desulfurization agent technology, applied in chemical instruments and methods, separation methods, dispersed particle separation, etc., to achieve the effect of no secondary pollution, low price, and good desulfurization effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

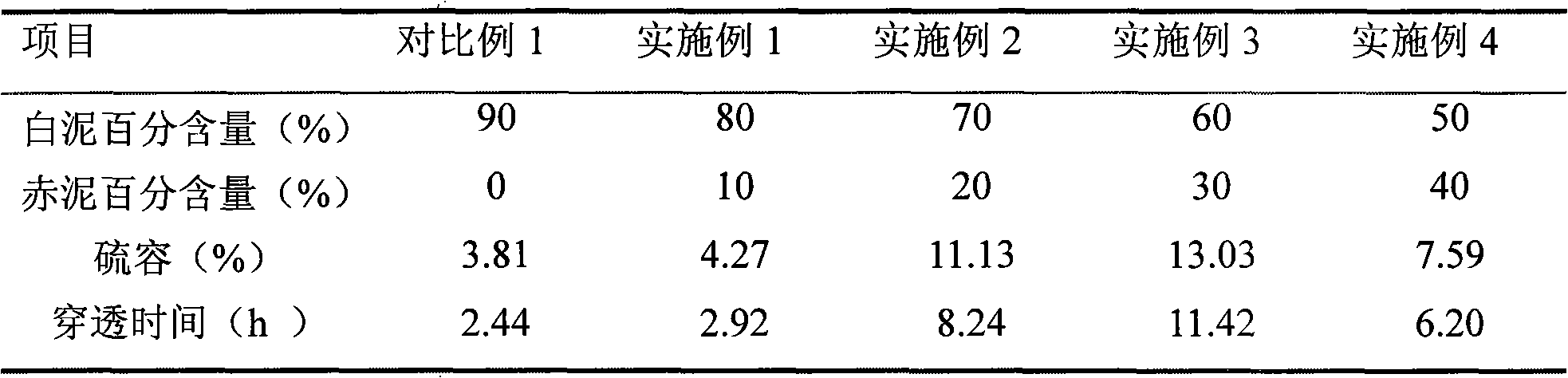

Embodiment 1-4 and comparative example 1

[0023] Mix different percentages of white mud and red mud, then mix them with 5.0% bentonite, 4.9% starch and 0.1% graphite, add water and mix to form a paste, extrude into strips, dry, and finally pass high-temperature roasting treatment , Preparation of several desulfurizers. The white mud and red mud are both 40 mesh, dried at 105°C for 6 hours, the roasting temperature is 500°C, and the roasting time is 2 hours. The prepared desulfurizer was subjected to desulfurization activity evaluation test, and the results are shown in Table 3.

[0024] Table 3 Desulfurization effects of desulfurizers with different ratios (mass ratios)

[0025]

[0026] Experimental conditions: temperature: 400℃; space velocity: 1200h -1 ; SO 2 Concentration: 6290mg / m 3 (2200ppm); O 2 : ~5%; H 2 O(g): 8%.

[0027] It can be seen from the table that when there is only white mud and no red mud, the sulfur capacity of the desulfurizer is the smallest and the desulfurization effect is not good; when the wh...

Embodiment 5-8 and comparative example 2

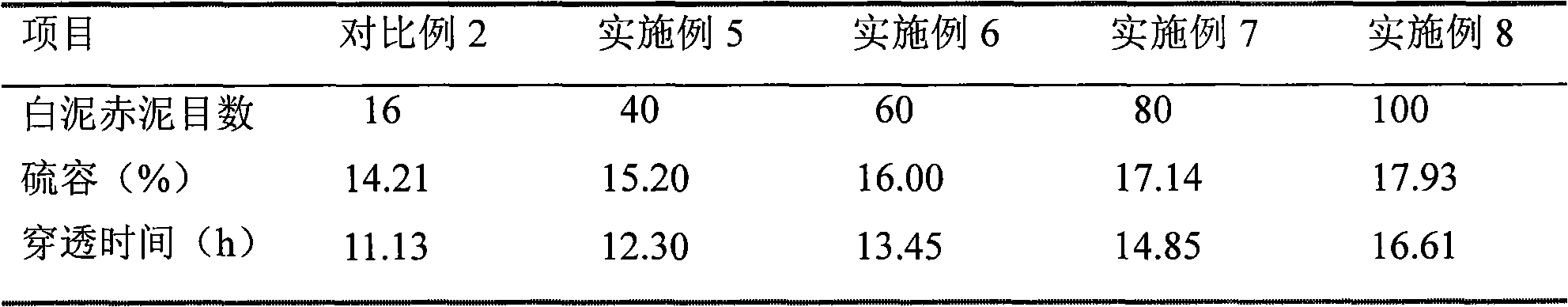

[0029] Mix the white mud and red mud at 60% and 30% respectively, and then add 5.0% bentonite, 4.9% starch, and 0.1% graphite. After mixing, add water and mix into a paste, extruded into a strip, dried, and finally passed high temperature. In the roasting process, several desulfurizers are prepared according to the different meshes of the white mud and red mud. Among them, it was dried at 105°C for 6 hours, the calcination temperature was 400°C, and the calcination time was 2 hours. The meshes of the white mud and red mud were 16, 40, 60, 80, and 100 meshes respectively. The prepared desulfurizer is subjected to desulfurization activity evaluation test. The results are shown in Table 4.

[0030] Table 4 Desulfurization effect of desulfurizers prepared with different meshes

[0031]

[0032] Experimental conditions: temperature: 400℃; space velocity: 1200h -1 ; SO 2 Concentration: 6290mg / m 3 (2200ppm); O 2 : ~5%; H 2 O(g): 8%

[0033] It can be seen from the table that as the numbe...

Embodiment 9-12

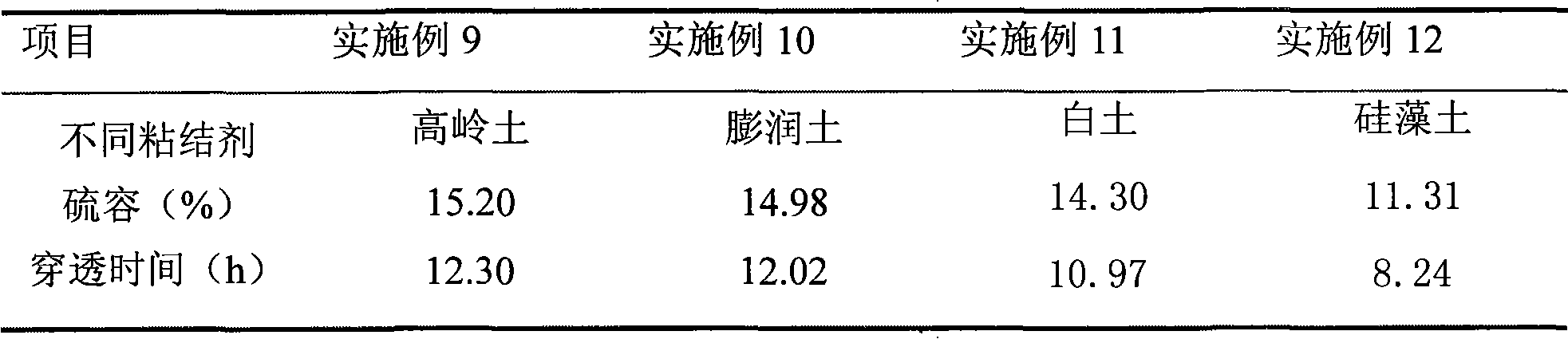

[0035] Mix the white mud and red mud at 60% and 30% respectively, then add 5% different binders, 4.9% starch as a pore former, mix with 0.1% graphite, add water and mix into a paste, extrude Forming, drying, and finally high-temperature roasting treatment to prepare several desulfurizers. The white mud and red mud are both 40 mesh, dried at 105°C for 6 hours, and the roasting temperature is 500°C and the roasting time is 2 hours. The binders are kaolin, bentonite, clay, and diatomite. The prepared desulfurizer is subjected to desulfurization activity evaluation test. The results are shown in Table 5.

[0036] Table 5 Comparison of desulfurization effects of desulfurizers prepared with different binders

[0037]

[0038] Experimental conditions: temperature: 400℃; space velocity: 1200h -1 ; SO 2 Concentration: 6290mg / m 3 (2200ppm); O 2 : ~5%; H 2 O(g): 8%

[0039] It can be seen from the table that the binder has a great effect on increasing the sulfur capacity of the desulfurize...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com