Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

1931results about How to "Improve desulfurization effect" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

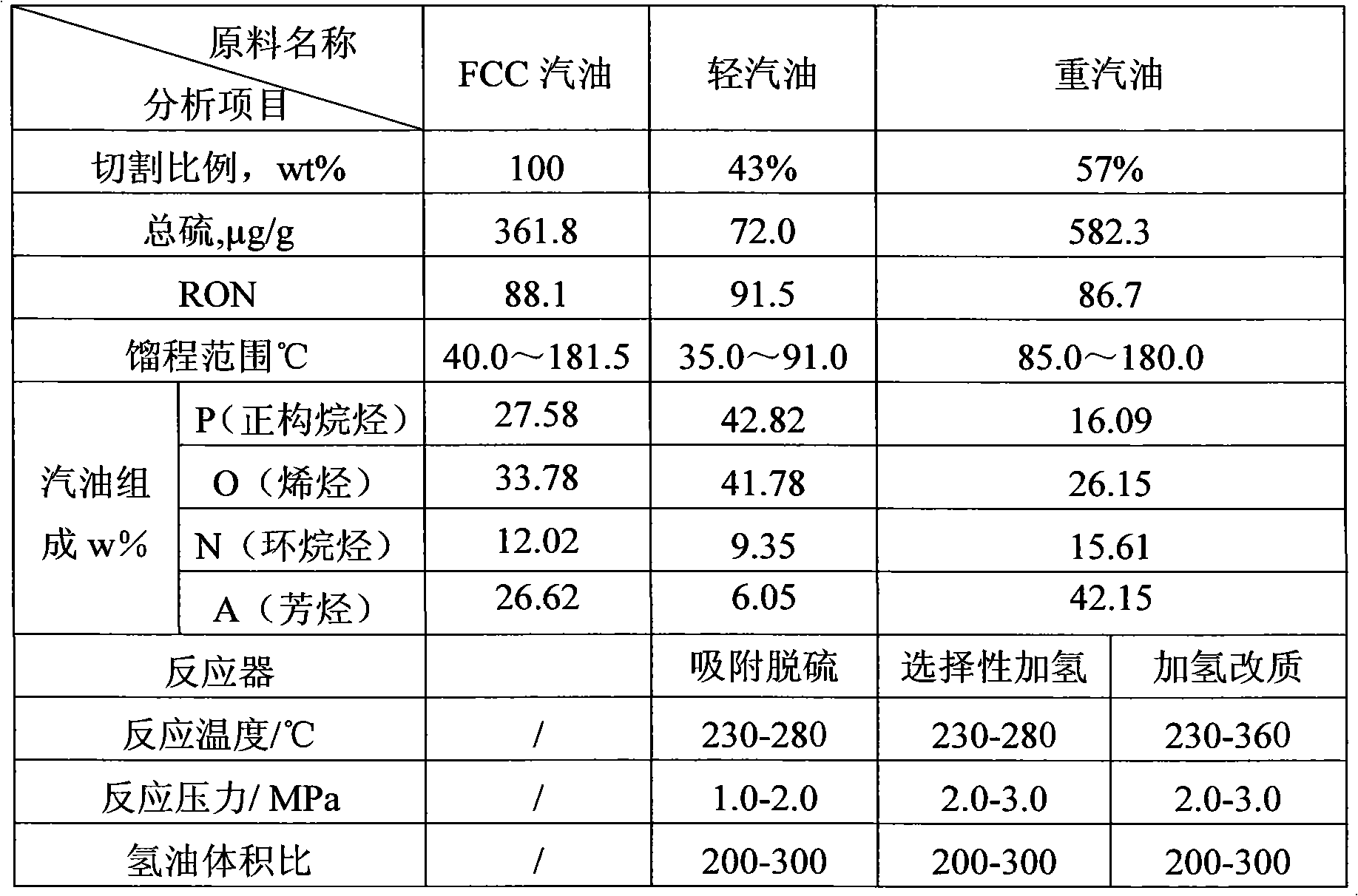

Production method for lowering contents of sulfur and alkene in gasoline

ActiveCN101845322AGuaranteed octane ratingFlexible processTreatment with hydrotreatment processesSulfideAlkane synthesis

The invention relates to a production method for lowering the contents of sulfur and alkene in gasoline; alkadiene is firstly removed from the raw material of FCC gasoline by a pre-hydrogenation reactor, then the FCC gasoline enters a fractionating tower and is cut and fractionated into light gasoline and heavy gasoline, the light gasoline is adsorbed and desulfurized, the heavy gasoline enters a selective hydrogenation and desulphurization reactor, selective hydrogenation and desulphurization is carried out on the heavy gasoline, organic sulfide and part of the alkene in the heavy gasoline are removed, then a reaction effluent enters a hydrogenation and modification reactor and is hydrogenized and modified, the content of the alkene is lowered, and the heavy gasoline after being modified and the light gasoline are blended by an adsorption and desulphurization product or the light gasoline is blended by the adsorption and desulphurization product or the treatment of the process flows of adsorption and desulphurization is carried out after the heavy gasoline and the light gasoline are mixed with light gasoline obtained after cutting and fractionation to obtain clean gasoline meeting the standard requirements; and the process flows are flexible and can be flexibly regulated, the utilization of heat is reasonable, the production meets European IV and compromises European V clean gasoline, the selective deep hydrogenation and desulphurization and the alkene content reduction can be achieved, and the aims of reducing the loss of the octane value and having higher liquid yield can also be achieved.

Owner:PETROCHINA CO LTD

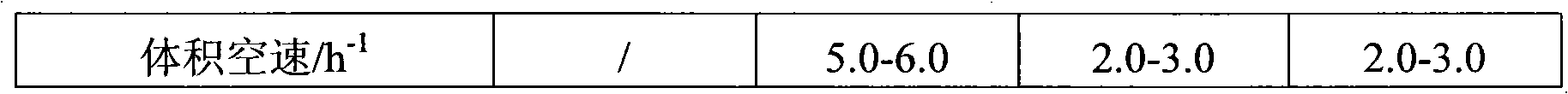

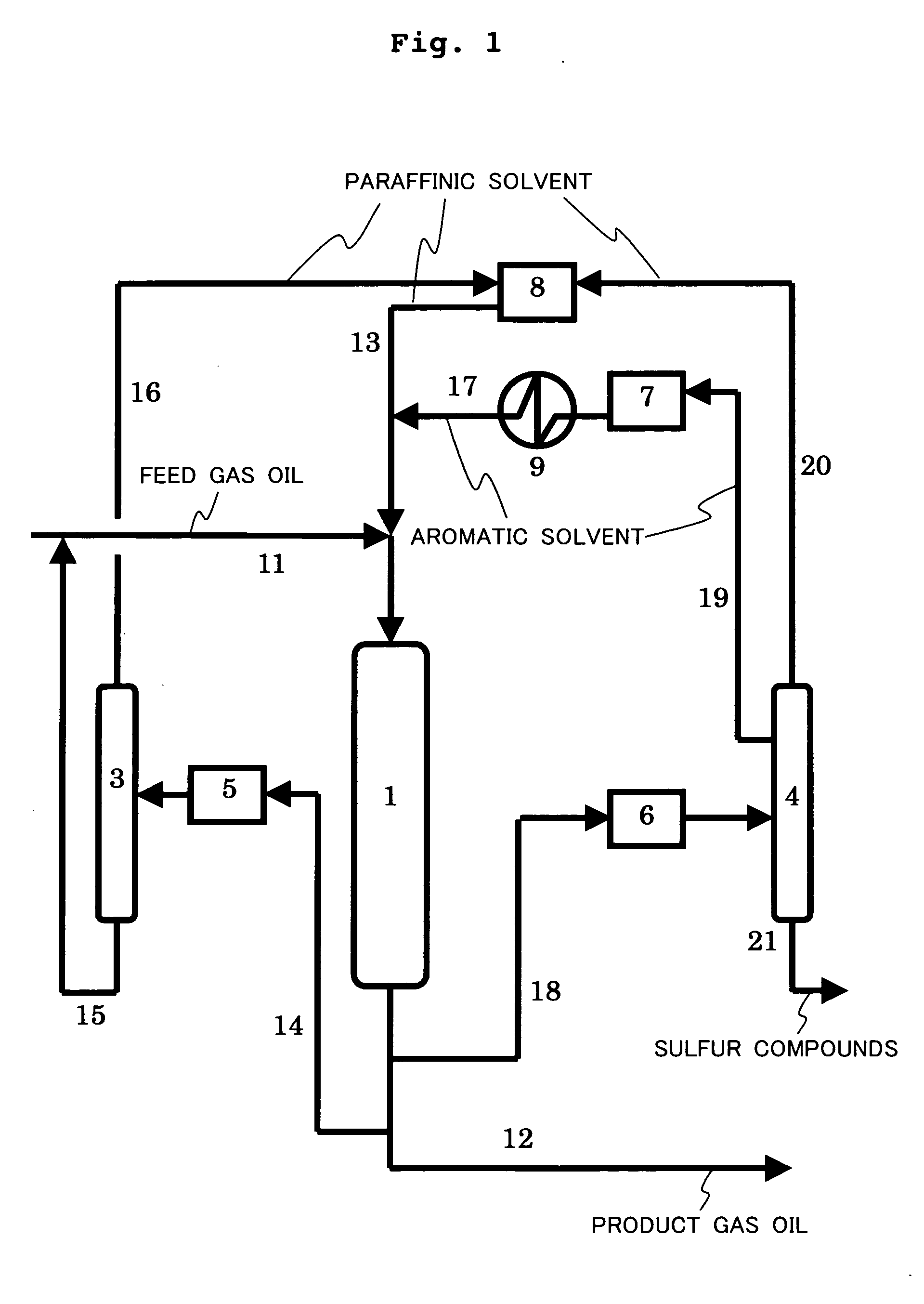

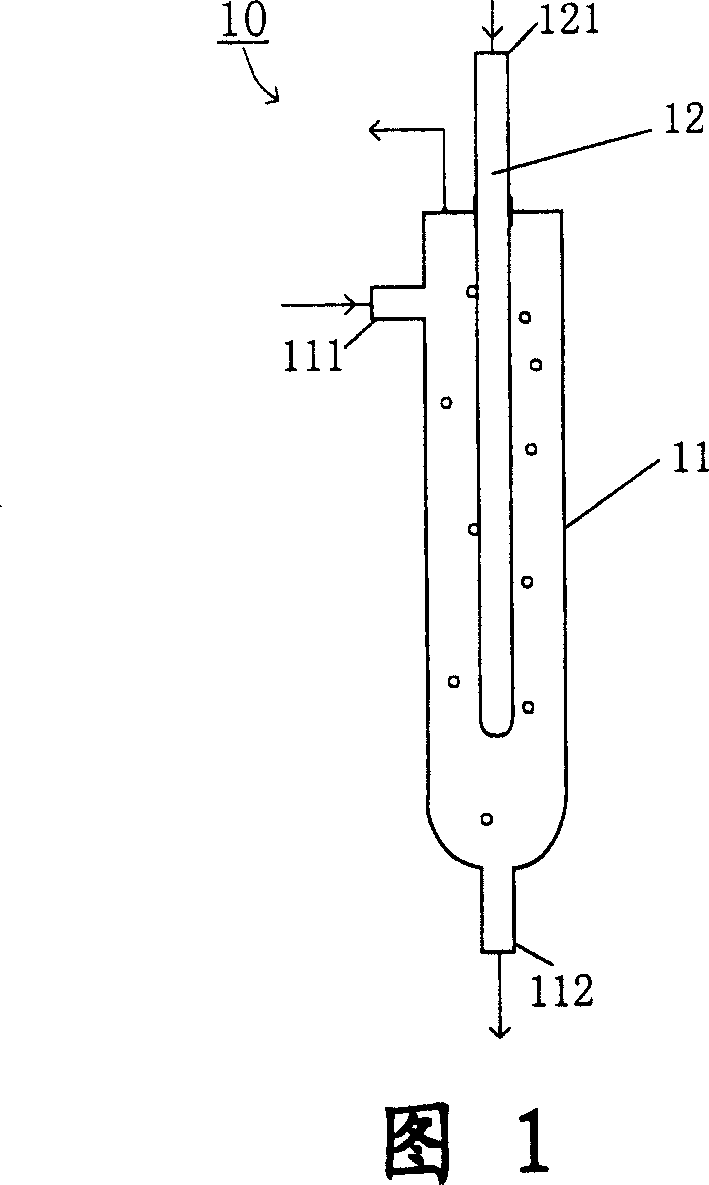

Adsorption desulfurization agent for desulfurizing petroleum fraction and desulfurization method using the same

InactiveUS20050173297A1Reduce equipment costsLow running costOther chemical processesLiquid organic insulatorsDesorptionTower

A desulfurization method for a gas oil which includes a step of removing sulfur compounds contained in a gas oil distillate product by the adsorption with an adsorptive desulfurization agent formed of a fibrous active carbon and provided in an adsorption tower (1), and a desorption regeneration step of washing the used adsorptive desulfurization agent with an aromatic solvent to regenerate the desulfurization agent. The method allows the production of gas oil being satisfactorily freed of sulfur content at relatively low equipment and operation costs over a long period of time, and in the method, difficult-to-remove sulfur compounds, such as 4,6-DMDBT, and polycyclic aromatic compounds having two or more rings are selectively removed.

Owner:JAPAN ENERGY CORP

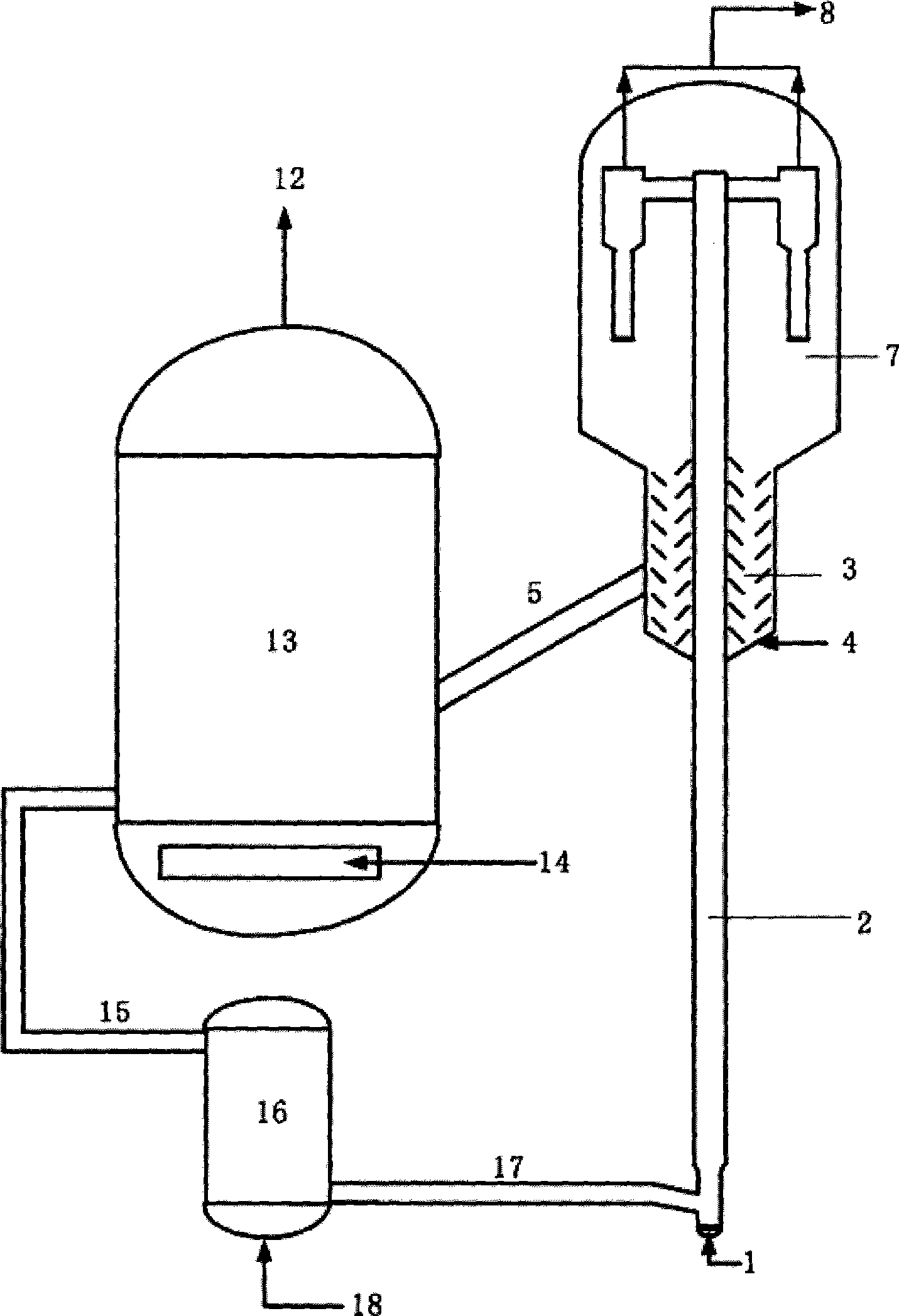

Sorbent for reducing sulfur content of light hydrocarbon oil

ActiveCN101434854AHigh desulfurization activityEvenly distributedHydrocarbon oils refiningSorbentRare earth

The invention provides a sorbent used for reducing the content of sulfur in light hydrocarbon oil. According to weight percentage, the sorbent comprises 1-30 percent of phosphorus-modified rare earth faujasite, 5-40 percent of active metal oxide and 30-94% of carrier; wherein, the carrier comprises alumina and zinc oxide; the rare earth faujasite is modified by phosphorus and is pre-formed into porous heat-resistance solid grains together with carrier mixture; subsequently, the active metal oxide is led into the solid grains, thus preparing the sorbent; the light hydrocarbon oil raw material containing the sulfur and hydrogen donor enter a reactor filled with the sorbent; the materials are separated after reaction; the reaction products are sent to a subsequent separation system so that the product is separated; the sorbent to be regenerated after reaction is stripped, burned and regenerated; and the regenerated sorbent is reduced by the hydrogen donor and subsequently returns to the reactor so as to be circularly used. The sorbent realizes that the sulfur of light hydrocarbon oil is deeply removed, and simultaneously, the octane number of the outcome gasoline is higher, while thebenzene content is lower and the strength is higher.

Owner:CHINA PETROLEUM & CHEM CORP +1

A hydrogenation method for producing diesel oil in low sulphur

ActiveCN101092573AHigh activityLow operating pressureRefining to eliminate hetero atomsLiquid productHydrogen

This invention discloses a hydrogenation method for producing low-sulfur diesel oil. The method comprises: mixing base oil with hydrogen, introducing into a hydrogenation reactor to orderly contact hydrogenation protecting agent, hydrorefining catalyst I, hydrorefining catalyst II and freely selected hydrorefining catalyst III for reactions, cooling the effluent, and separating to obtain hydrogen-rich gas and liquid product. With the synergism of the catalysts, the whole catalyst activity is improved. By the method, high-sulfur, high-nitrogen and high-metal content diesel oil fraction can be treated under mild conditions, and low-sulfur diesel oil that can meet Europe III standard and Europe IV standard can be obtained. The method has such advantages as simple process, low operation pressure, low apparatus investment and low operation cost.

Owner:CHINA PETROLEUM & CHEM CORP +1

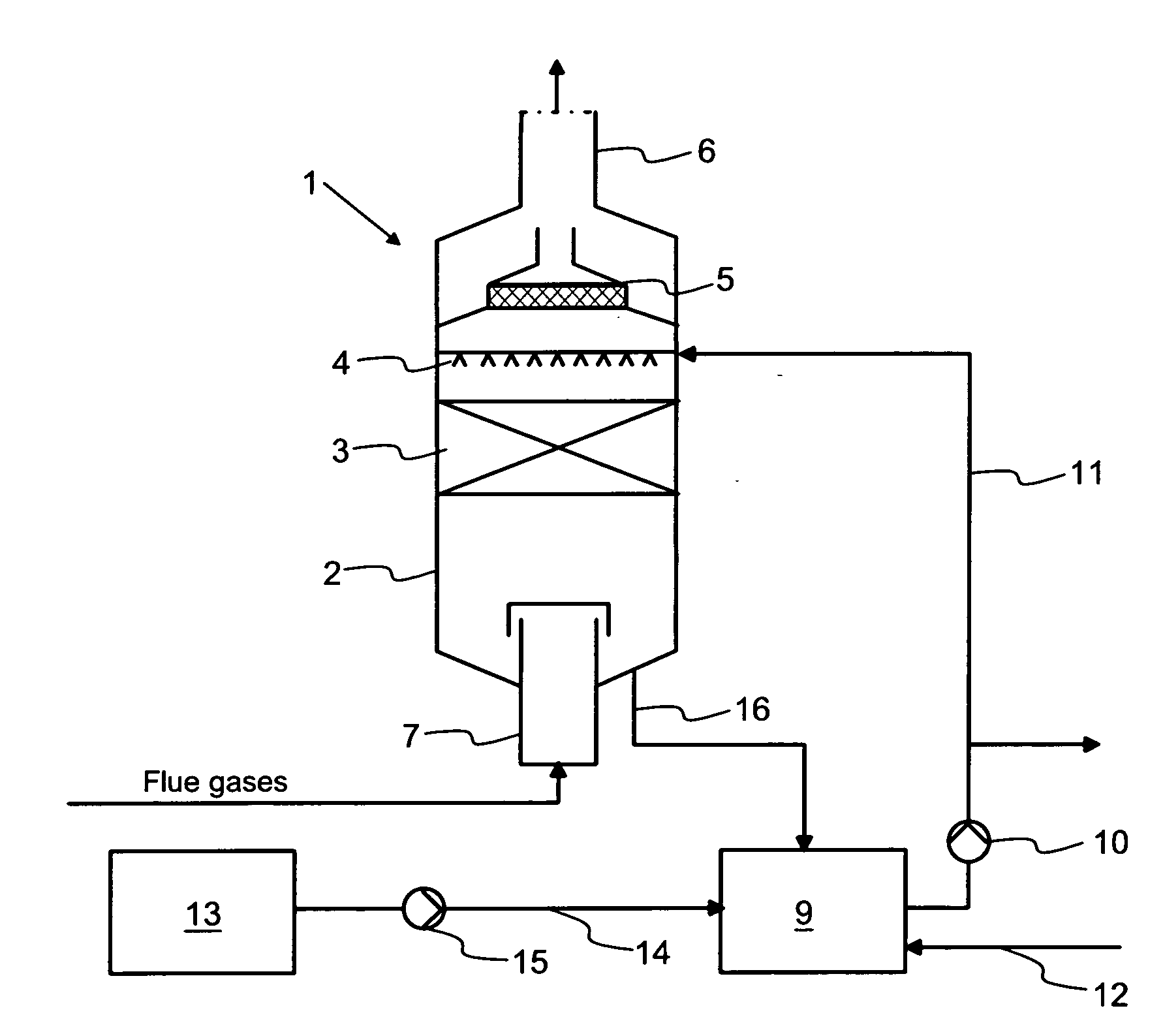

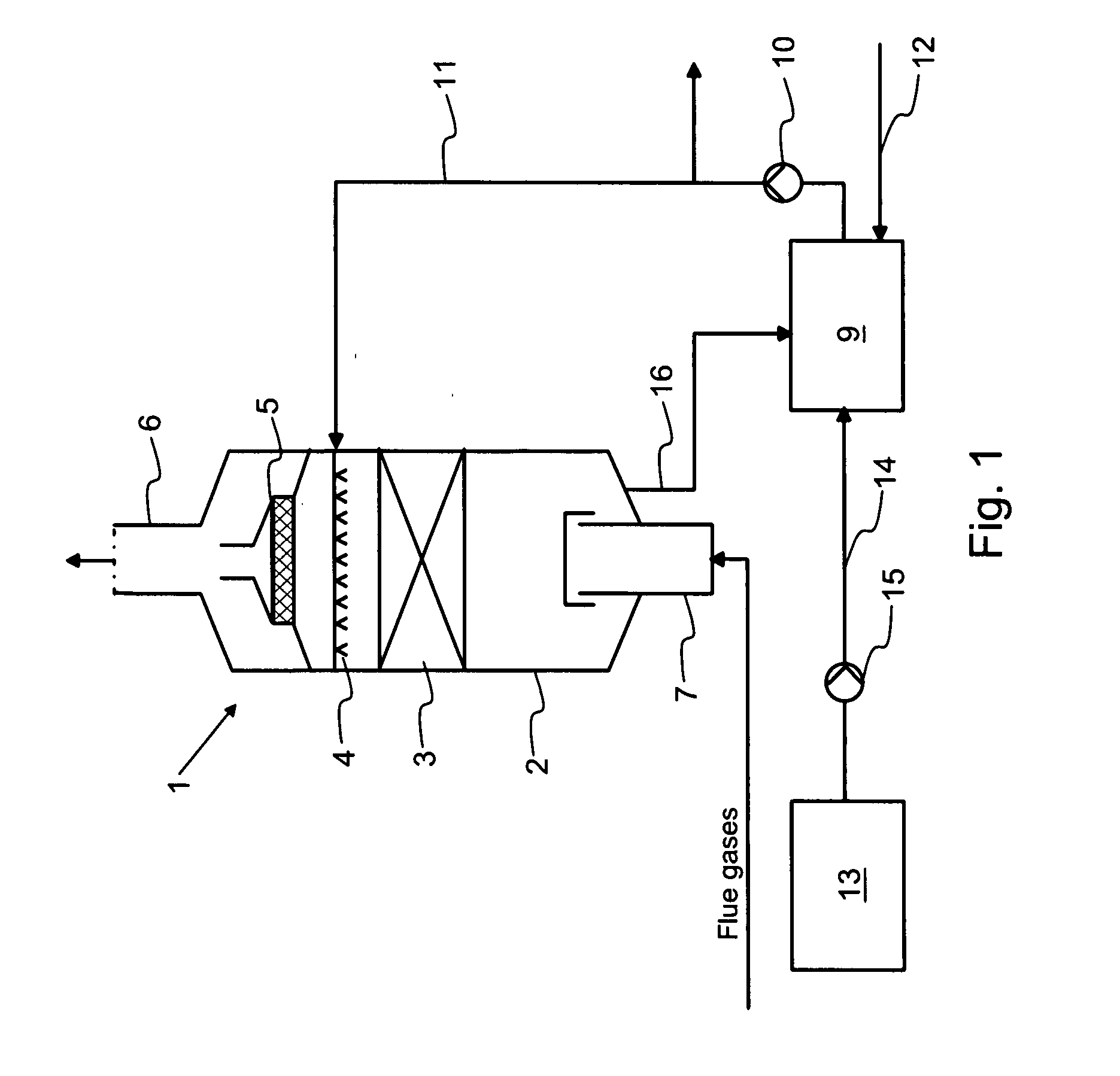

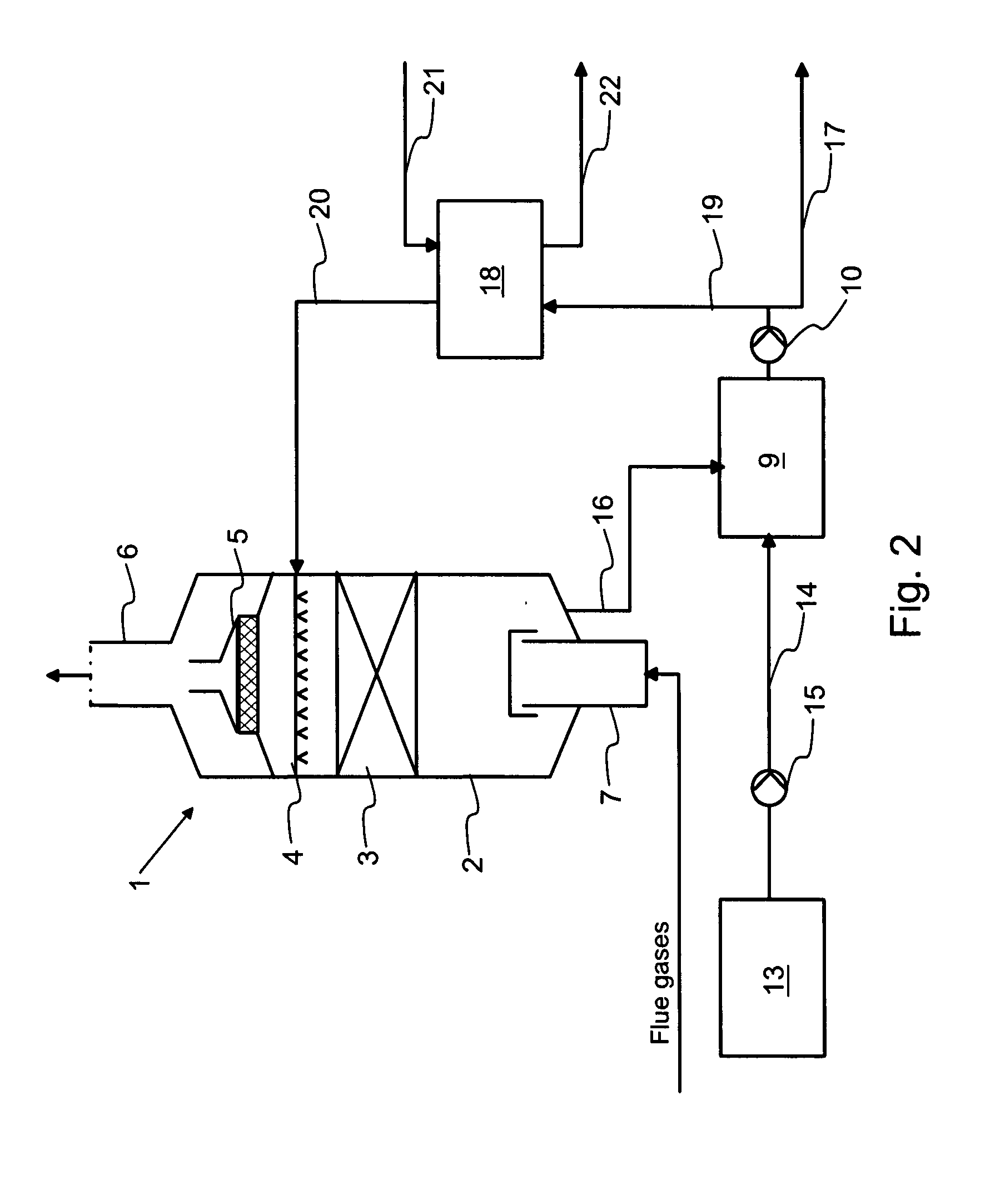

Method and an equipment for reducing the sulphur dioxide emissions of a marine engine

ActiveUS20080044335A1Reduce usageEmission reductionCombination devicesInternal combustion piston enginesSulfurFlue gas

A method and an equipment for reducing sulphur dioxide emissions of a marine engine, wherein flue gases are scrubbed with a scrubbing solution in a scrubber. Fresh water with added sulphur removal reagent is used as the scrubbing solution.

Owner:METSO POWER OY

Boiler fuel gas dedusting purifying device

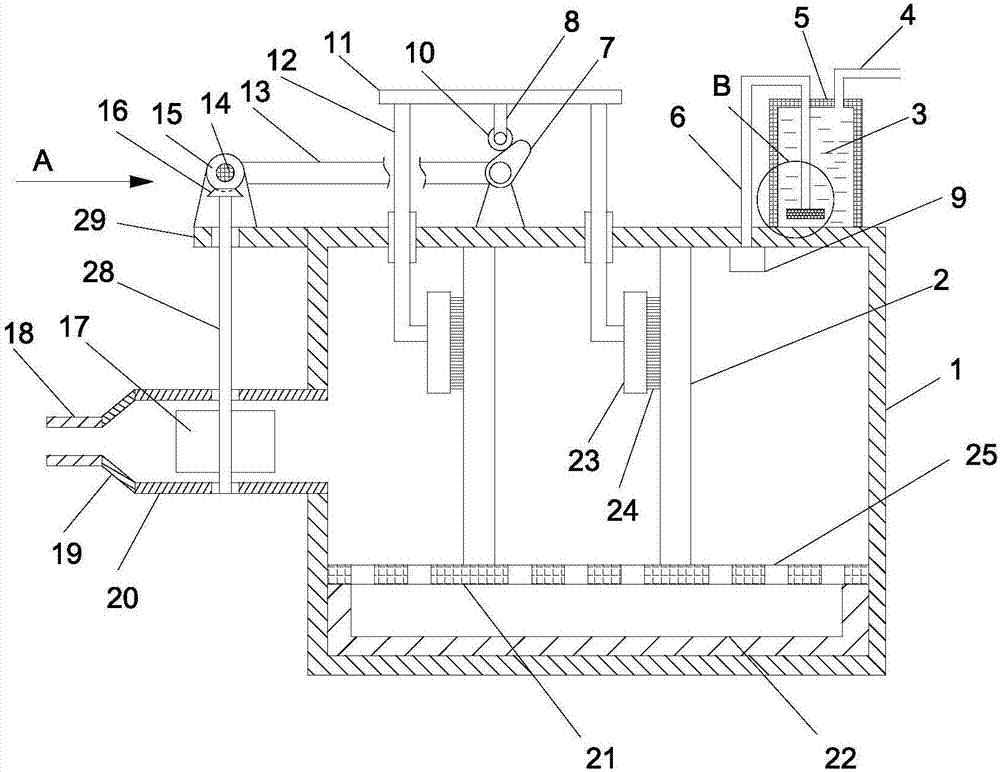

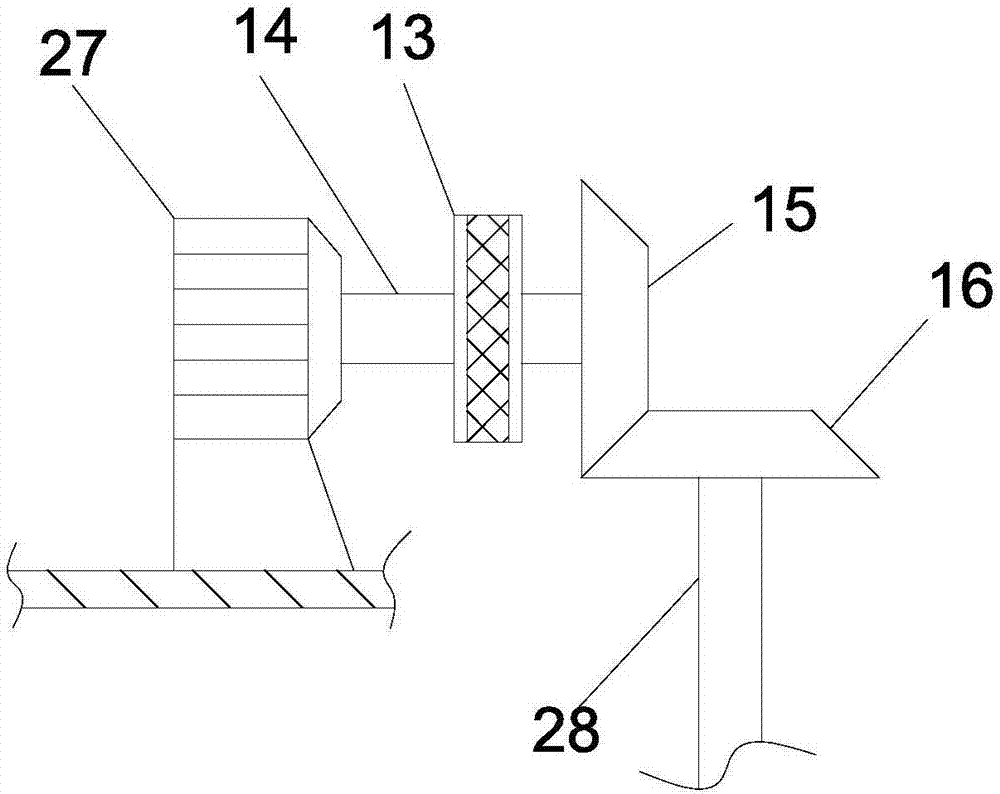

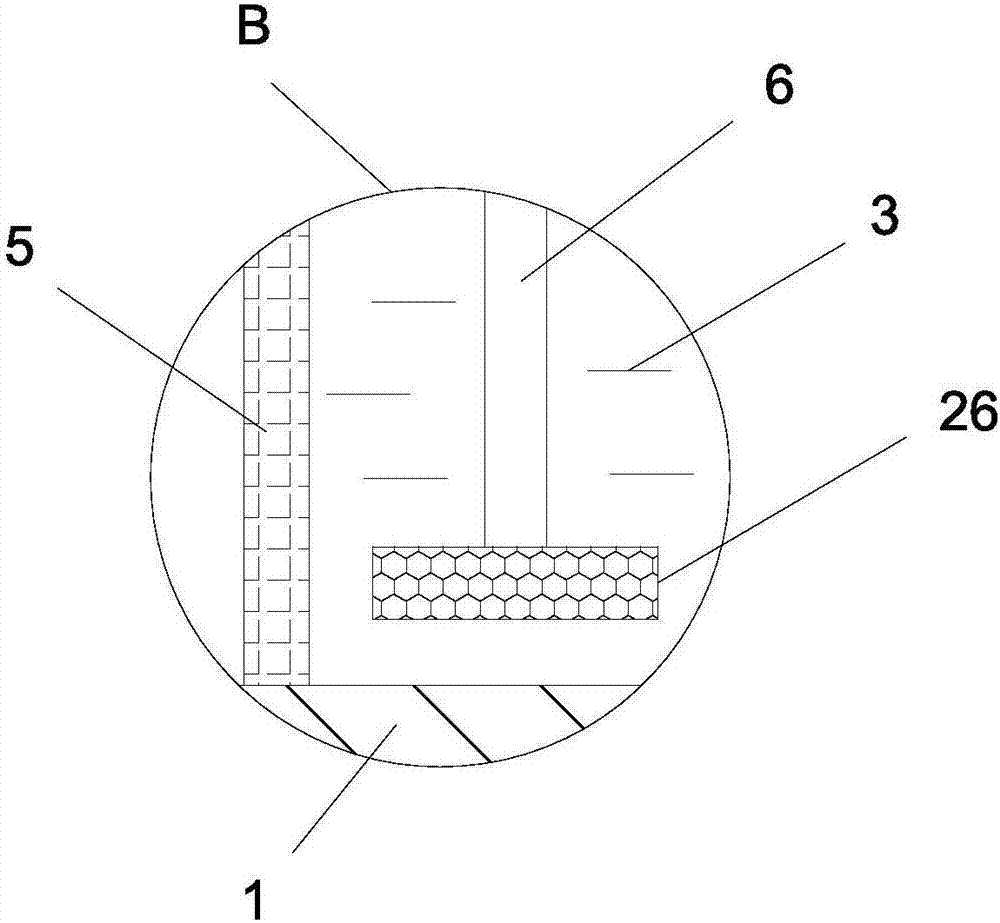

InactiveCN107096361AGood dust removal and filtration effectSpeed up the flowGas treatmentDispersed particle filtrationDrive shaftFlue gas

The invention discloses a boiler fuel gas dedusting purifying device. The boiler fuel gas dedusting purifying device comprises a dedusting chamber; the left side of the dedusting chamber is fixedly provided with an extension board; the extension board is fixedly provided with a driving motor; the driving motor is fixedly provided with a driving shaft; the right end of the driving shaft is fixedly provided with a driving bevel gear; the upper end of a driven shaft is fixedly provided with a driven bevel gear; the driven shaft is fixedly provided with a plurality of blades; the blades are uniformly fixedly arranged on the external surface of the driven shaft along the circumferential direction; two slide bars are arranged on the dedusting chamber; the upper side wall of the dedusting chamber is penetrated by the two slide bars; each of the slide bars is provided with a brushing board; the right side surface of each brushing board is fixedly provided with a hairbrush; the top of the dedusting chamber is provided with a desulphurization tank; one end of a conveyer pipe far from an air pump is provided with an aeration disc; the top of the desulphurization tank is provided with an exhaust pipe. The boiler fuel gas dedusting purifying device is excellent in dedusting filtering effect; flue gas is introduced into the aeration disc for aeration processing, so that sulfides in flue gas are absorbed by a desulfurizer completely, desulphurization effect is excellent; and environment protection emission is realized at last.

Owner:张炳强

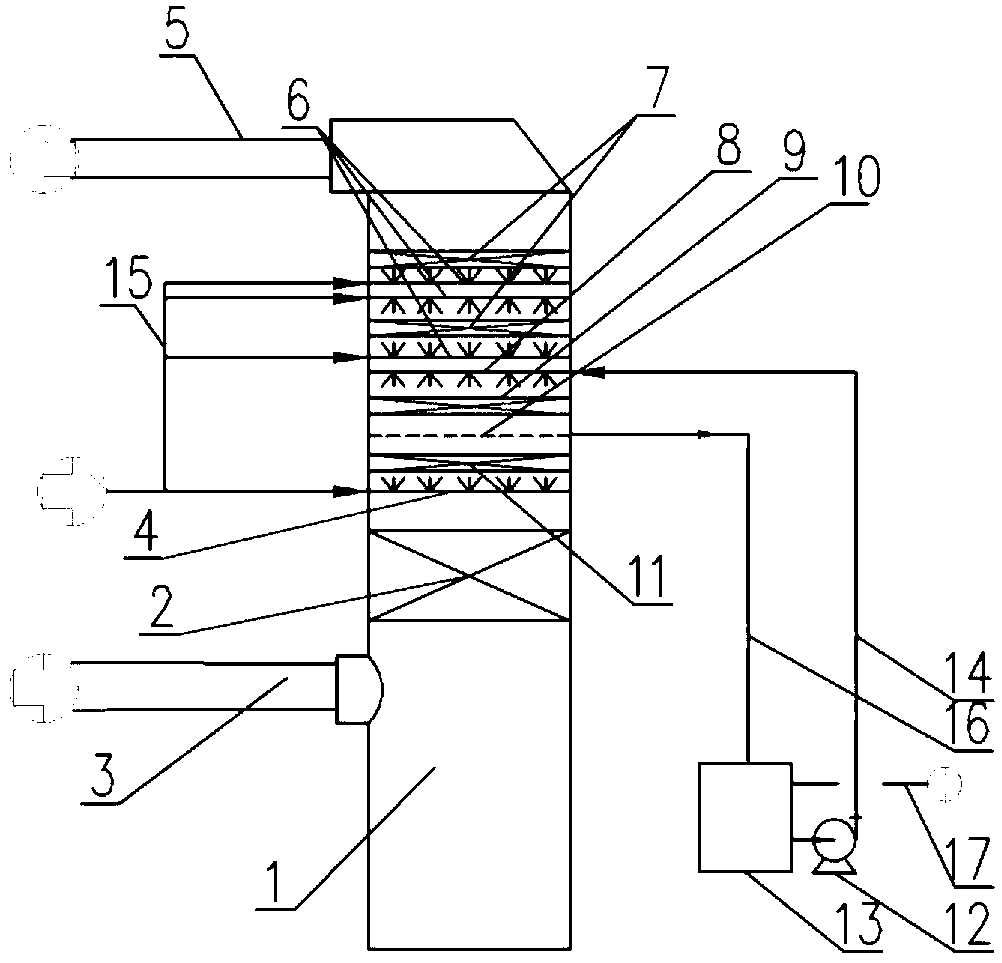

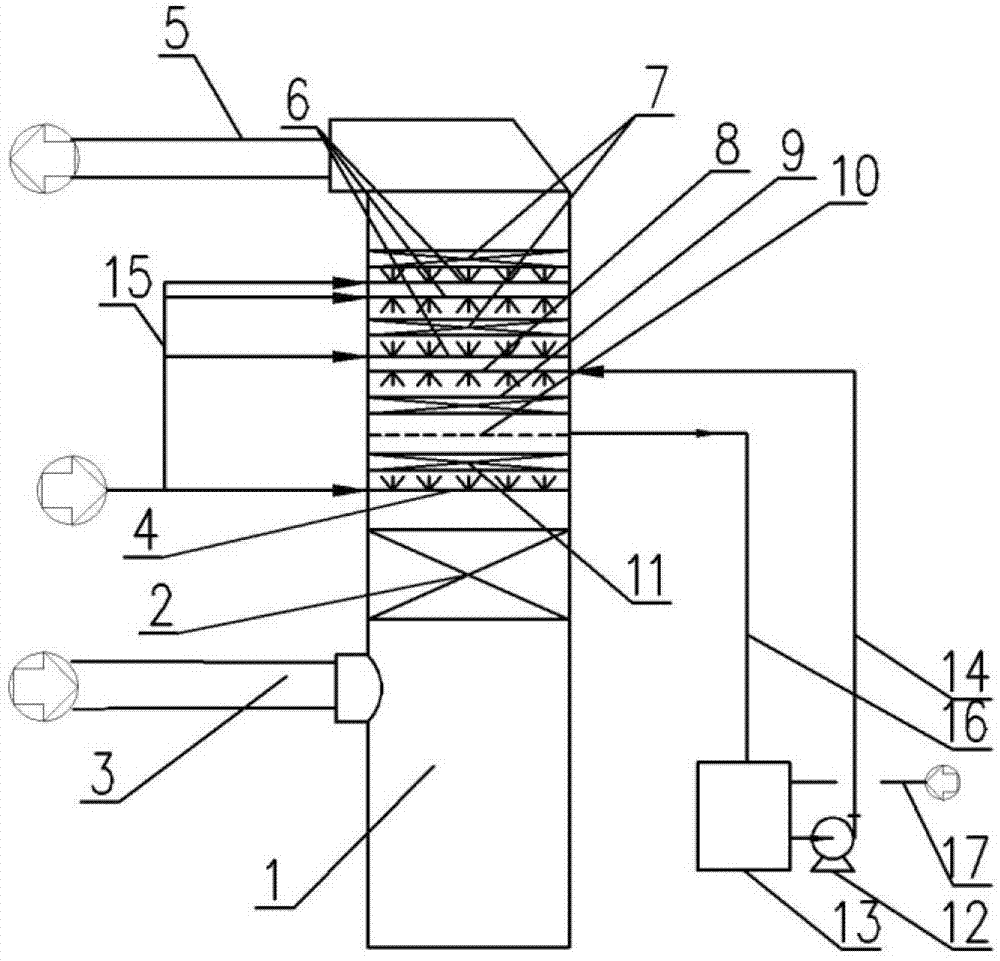

Device and method for controlling fine particulate matter from desulfurized smoke

The invention discloses a device and a method for controlling a fine particulate matter from desulfurized smoke. A raw gas enters an absorption layer (2) from a smoke flue (3) of an absorption tower (1) for desulfurizing smoke; sulfur dioxide in the smoke is absorbed and removed by absorption solution; the smoke with the matters such as absorption solution drops, snoot and an adsorbent ascends inside the absorption tower to enter an absorption solution demister (11) through an absorption solution demister rinsing layer (4); most of liquid drops of which the particle sizes are greater than 10 microns are removed; the smoke enters a washing layer and a gas-liquid distributor (9) and contacts washing solution sprayed from a washing layer distributer (8) through a washing layer partition plate (10); the smoke enters a washing demister (7) to remove liquid drops of which the particle sizes are greater than 10 microns after being washed by a washing demister rinsing layer (6); purified smoke is discharged from a smoke purifying channel (5) at the upper part of a smoke desulfurizing absorption tower after twice rinsing and demisting are orderly carried out. The device is matched with a desulfurizing absorption system. Thus, the device is less in investment and convenient to run.

Owner:JIANGSU NEW CENTURY JIANGNAN ENVIRONMENTAL PROTECTION

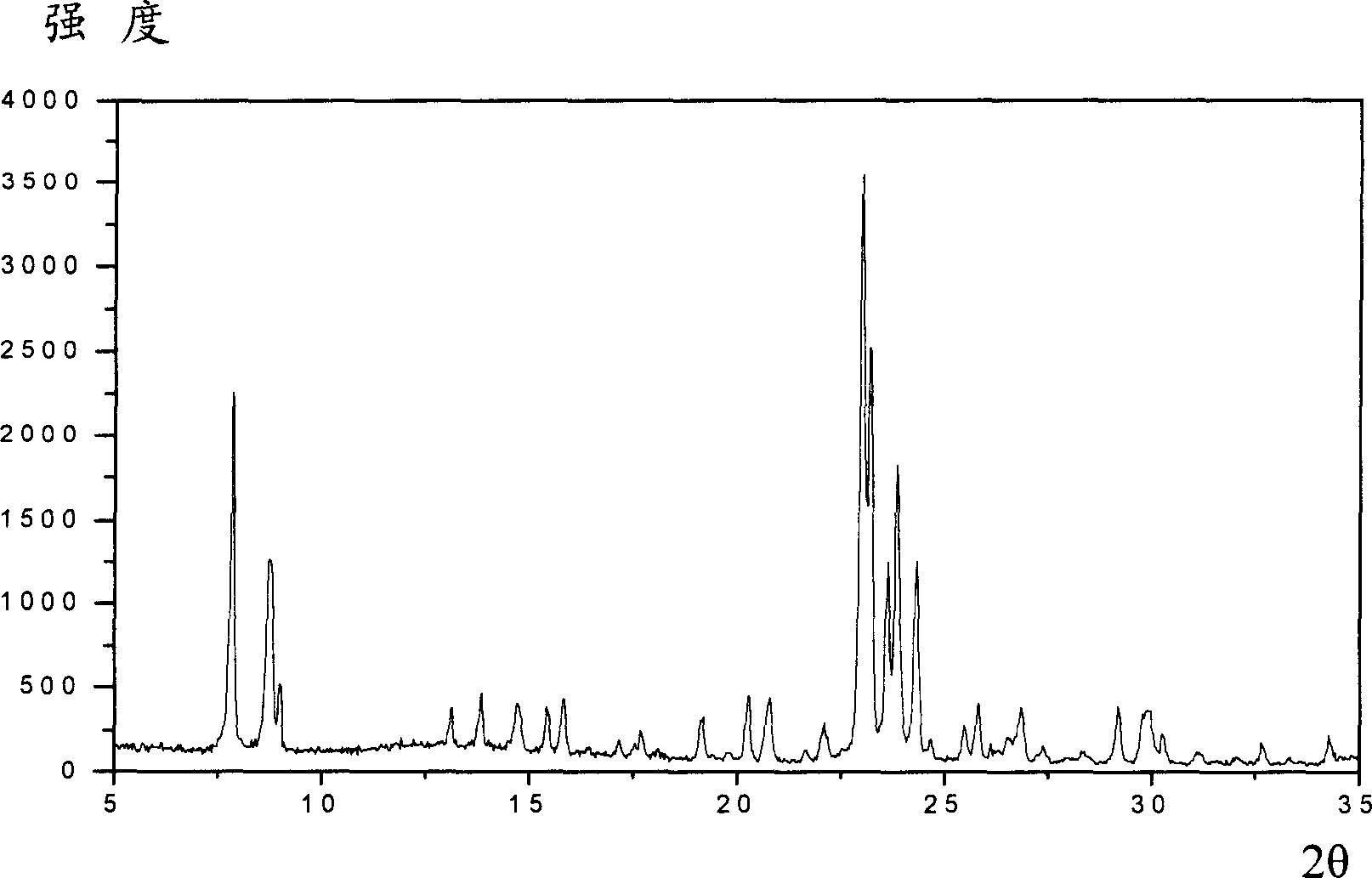

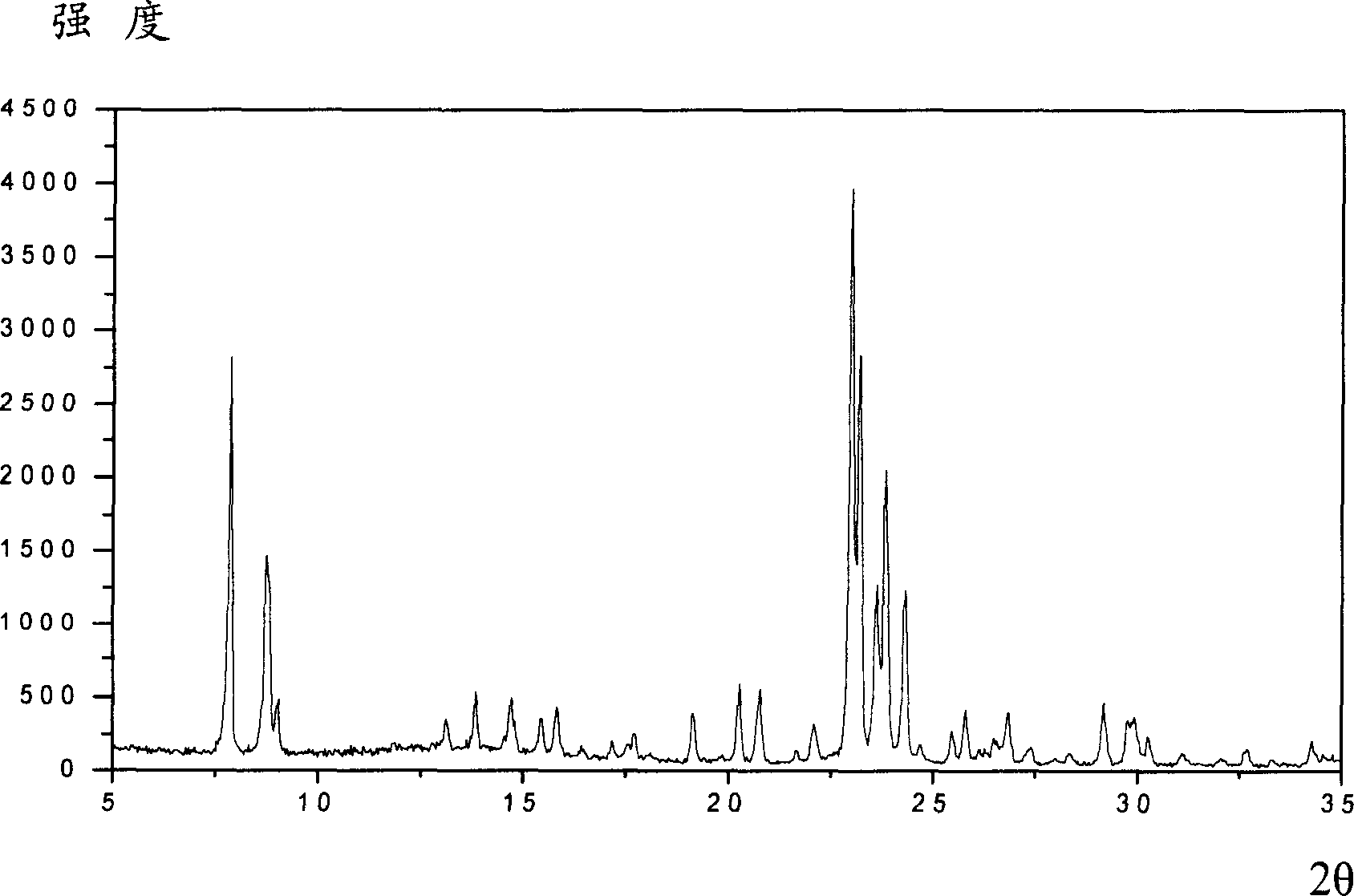

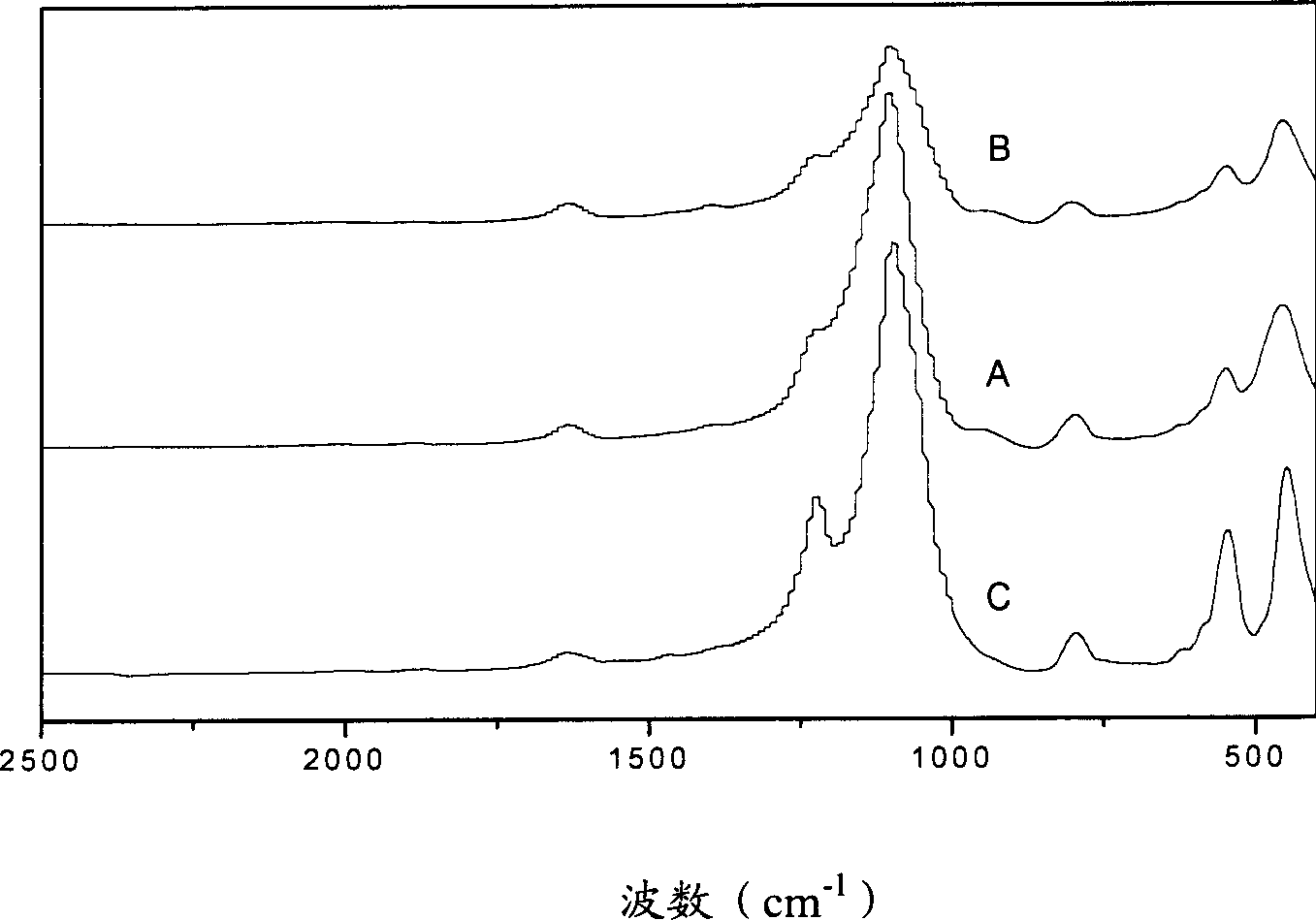

Method for preparing vanadium-silicon molecular sieve

ActiveCN1840477AReduce manufacturing costMolecular sieve vanadium content adjustableMolecular sieve catalystsCrystalline aluminosilicate zeolitesMolecular sieveSilicon

The preparation method for V-Si molecular sieve with MFI structure comprises: mixing Si source, V source, the template agent by n-butyl amine and / or triethylamine with mole ratio to SiO2 as 0.04-0.5:1, the inorganic alkali, and water; crystallizing in sealed kettle to obtain the product.

Owner:CHINA PETROLEUM & CHEM CORP +1

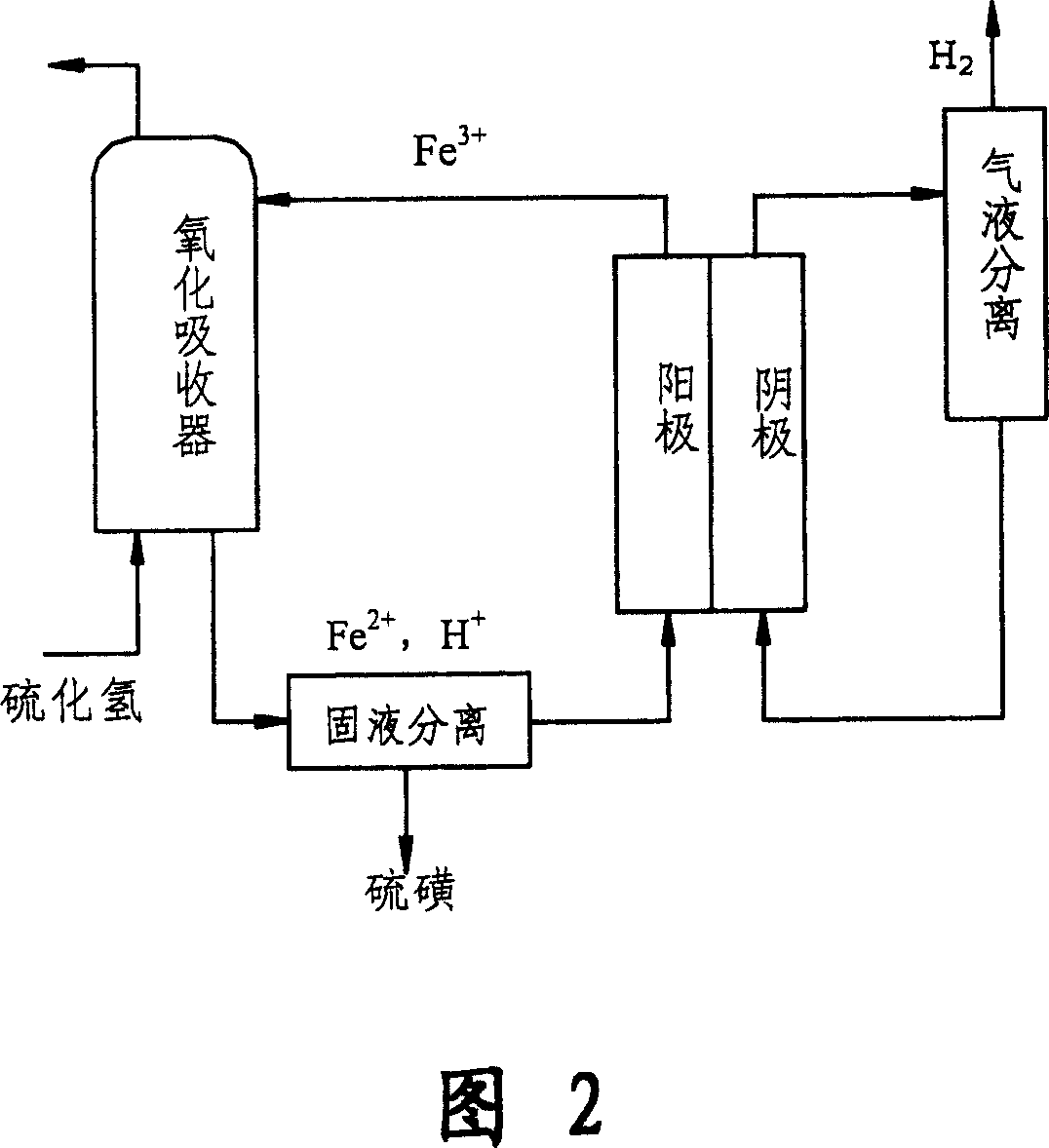

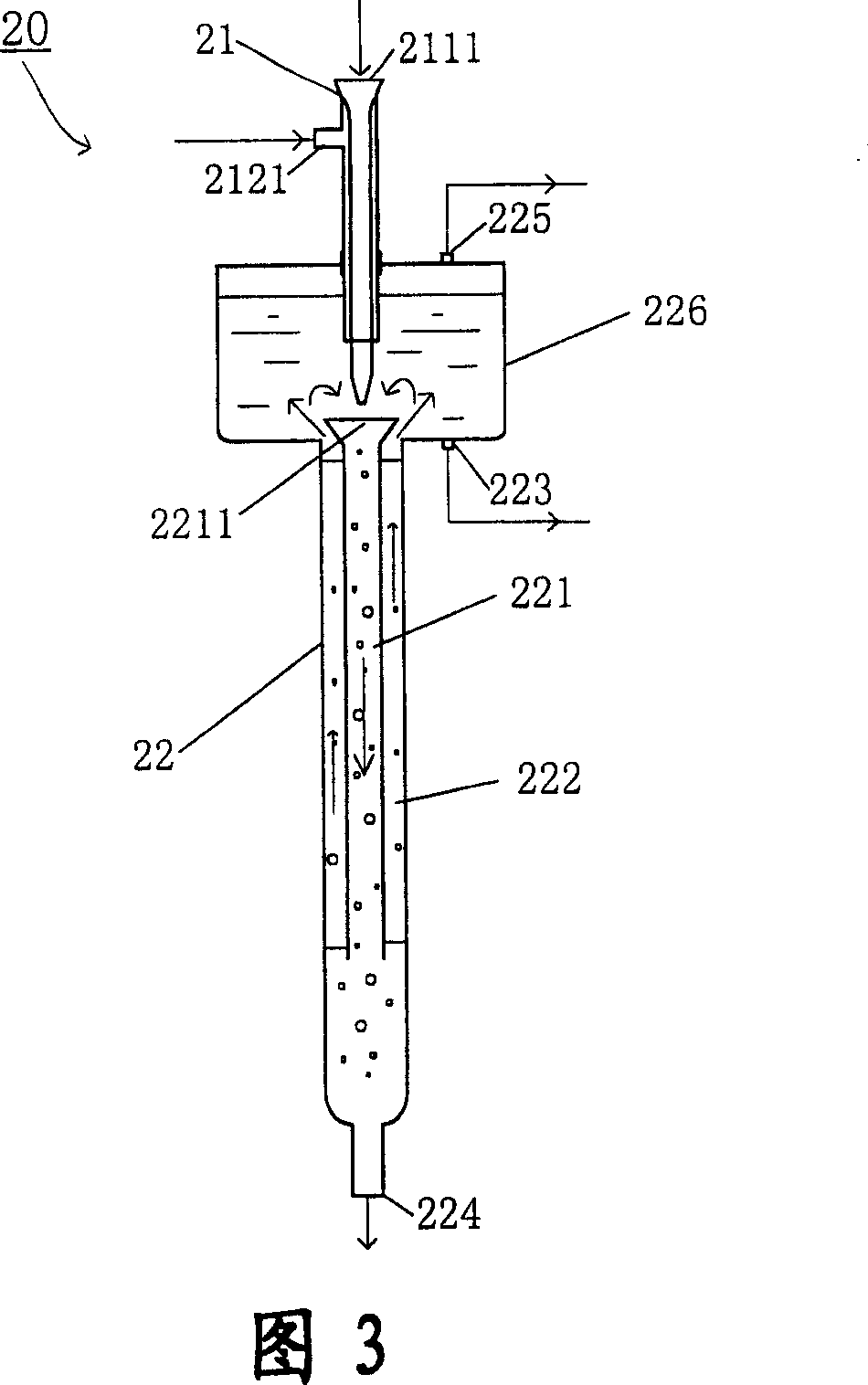

Method for recovering sulfur and making hydrogen from hydrogen sulfide

InactiveCN101028920AIncrease contact timeAvoid cloggingElectrolysis componentsSulfur preparation/purificationCyclic processHydrogen

A process for recovering sulfur and preparing H2 from the hydrogen sulfide at same time is characterized by that an internal circulation absorption type reactor and an electrolyzing reactor with dual electrode plates are simultaneously used for the oxidizing absorption reaction and electrolytic regeneration reaction.

Owner:CHINA UNIV OF PETROLEUM (BEIJING)

Preparation method of modified active carbon-based gasoline desulfurization adsorbent

InactiveCN103143322ACarrier is easy to getLow priceOther chemical processesHydrocarbon oils refiningSorbentAdsorption selectivity

The invention discloses a preparation method of a modified active carbon-based gasoline desulfurization adsorbent, and relates to a preparation method of a gasoline deep desulfurization adsorbent. The adsorbent is a Fe ion-loaded active carbon adsorbent; and the preparation method comprises the following steps of: performing cleaning pretreatment of the raw material of the adsorbent carrier particles; drying the pretreated carrier particles, mixing the carrier particles with a nitric acid solution, performing backflow and electromagnetic stirring; washing the oxidized carrier particles; drying the carrier particles; roasting to modify the dried particles; and steeping the carrier particles and a soluble ferric salt solution; drying the steeped carrier particles; and roasting to activate the dried particles. The preparation process is simple and easy to implement and realizes easy regeneration; the service life of the adsorbent is long; the adsorbent has high adsorption capacity and adsorption selectivity on thiophene and derivatives thereof in gasoline; the adsorption process is performed in a normal-temperature normal-pressure condition, and the operation cost is low; and no pollutant is generated in the adsorption process, good economic practicability is realized, and environmental protection requirements are met.

Owner:SHENYANG INSTITUTE OF CHEMICAL TECHNOLOGY

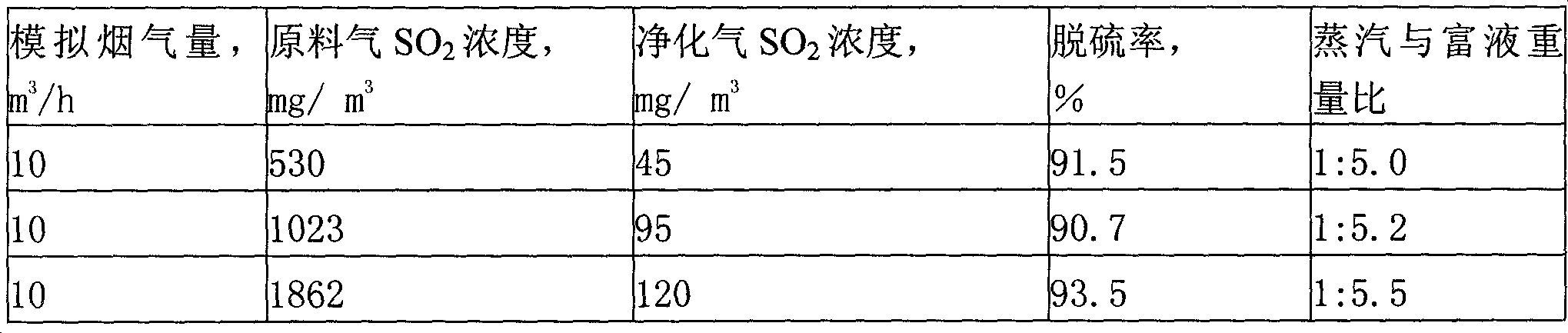

Steelmaking and slagging method

The invention provides a steelmaking and slagging method. The method comprises the following steps of: adding semisteel from which vanadium is extracted into a steel refining furnace; blowing oxygen into the steel refining furnace and blowing; in two minutes after the blowing is started, adding 9 to 11kg of lime, 9 to 11kg of high-magnesium lime, 3 to 8kg of fluxing agent, and 11 to 14kg of acid composite slag into the steel refining furnace based on one ton of semisteel from which vanadium is extracted; and in 9 minutes after the first slag is formed and blowing is started, adding 9 to 11kg of lime and 9 to 11kg of high-magnesium lime into the steel refining furnace based on one ton of semisteel from which vanadium is extracted, and continuously blowing to obtain molten steel and final slag. The fluxing agent is refined steel slag. Slagging is performed by the method, the slag can be formed quickly, the consumption of an iron and steel material is reduced, smelting time is shortened and steelmaking cost is saved.

Owner:PANGANG GROUP VANADIUM TITANIUM & RESOURCES +3

Desulfurated and denitrated activated coke and preparation method thereof

PendingCN101993066ALow costReduce manufacturing costCarbon compoundsOther chemical processesTarCopper oxide

The invention provides desulfurated and denitrated activated coke and a preparation method thereof. The desulfurated and denitrated activated coke is prepared from lignite and coking coal which are crushed into certain fineness, pitch, tar, vanadium pentoxide, copper oxide and water through kneading, shaping, drying, charring and activating. The desulfurated and denitrated activated coke prepared from the raw materials by the method not only has good desulfuration and denitration effect but also has low cost, simplicity in preparation and strong practicability.

Owner:赵建勋

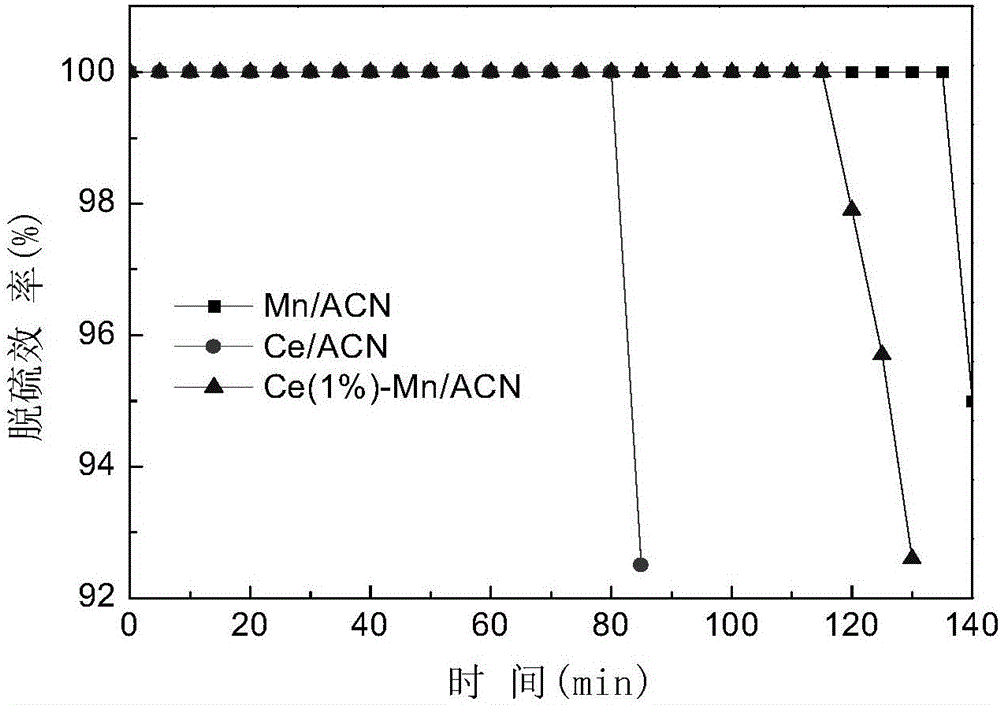

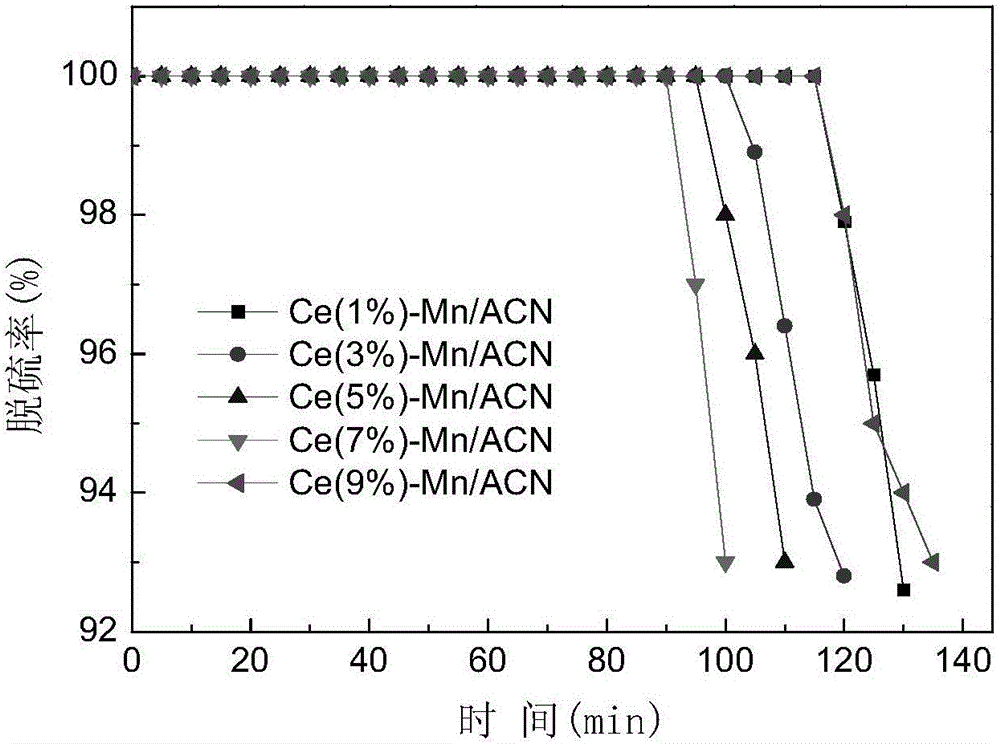

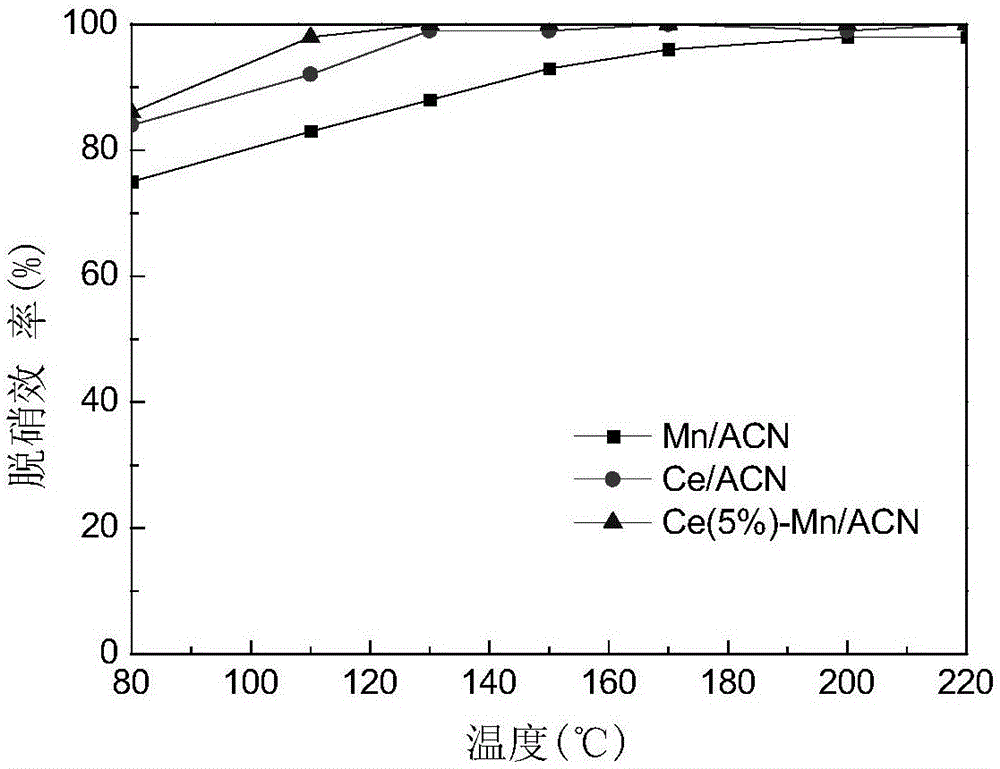

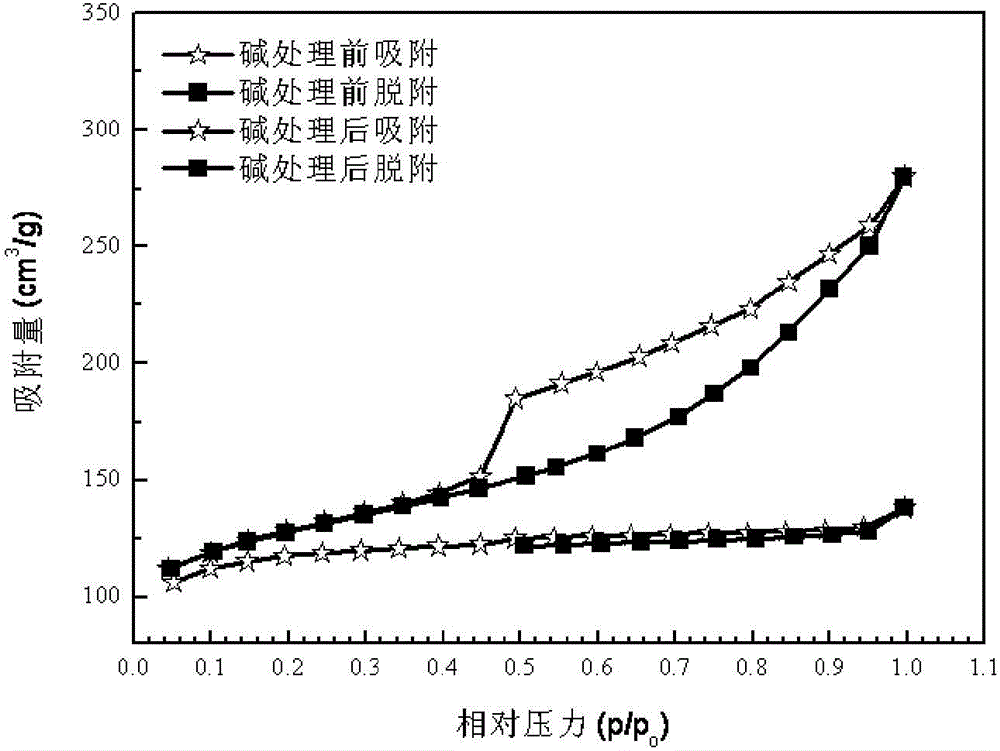

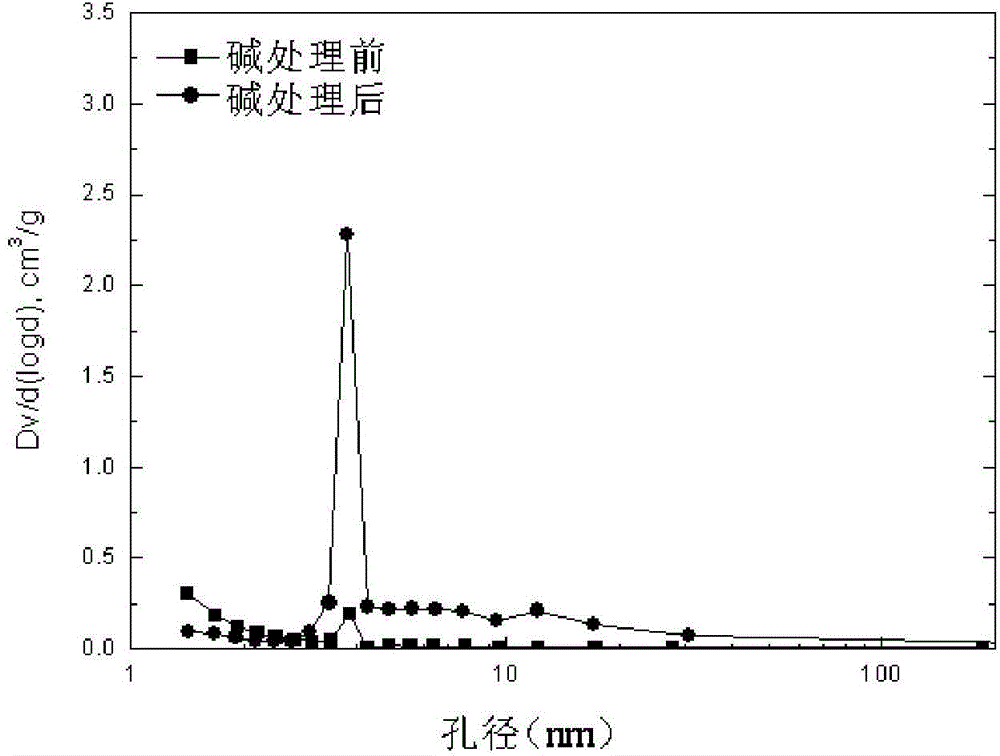

Catalyst used for low temperature desulphurization and denitration of flue gas and preparation method thereof

ActiveCN105032403AImprove denitrification activityDischarge directlyDispersed particle separationMetal/metal-oxides/metal-hydroxide catalystsRare-earth elementActivated carbon

The invention discloses a catalyst used for low temperature desulphurization and denitration of flue gas and a preparation method thereof. The catalyst uses active carbon modified by nitric acid as a carrier and the transition metal Mn and / or the rare earth element as active components; the active components are loaded on the carrier through dipping and high temperature roasting; and the load amount of Mn is 0 to 7 wt% of the weight of the catalyst, the load amount of Ce is 0 to 9 wt% of the weight of the catalyst, and the total load amount of the active components is no less than 3 wt% of the weight of the catalyst. The preparation method for the catalyst comprises the following steps: soaking active carbon in nitric acid for modification, soaking the carbon modified by nitric acid in a manganese nitrate solution or / and cerium nitrate solution and evaporating a liquid phase to dryness so as to allow the modified active carbon to be infiltrated by Mn and / or Ce; and fully roasting the modified active carbon infiltrated by Mn and / or Ce in a roasting apparatus so as to obtain the active-component-loaded catalyst used for low temperature desulphurization and denitration of flue gas. The catalyst has high desulphurization and denitration efficiency in a temperature range of 80 to 220 DEG C.

Owner:成都达奇科技股份有限公司

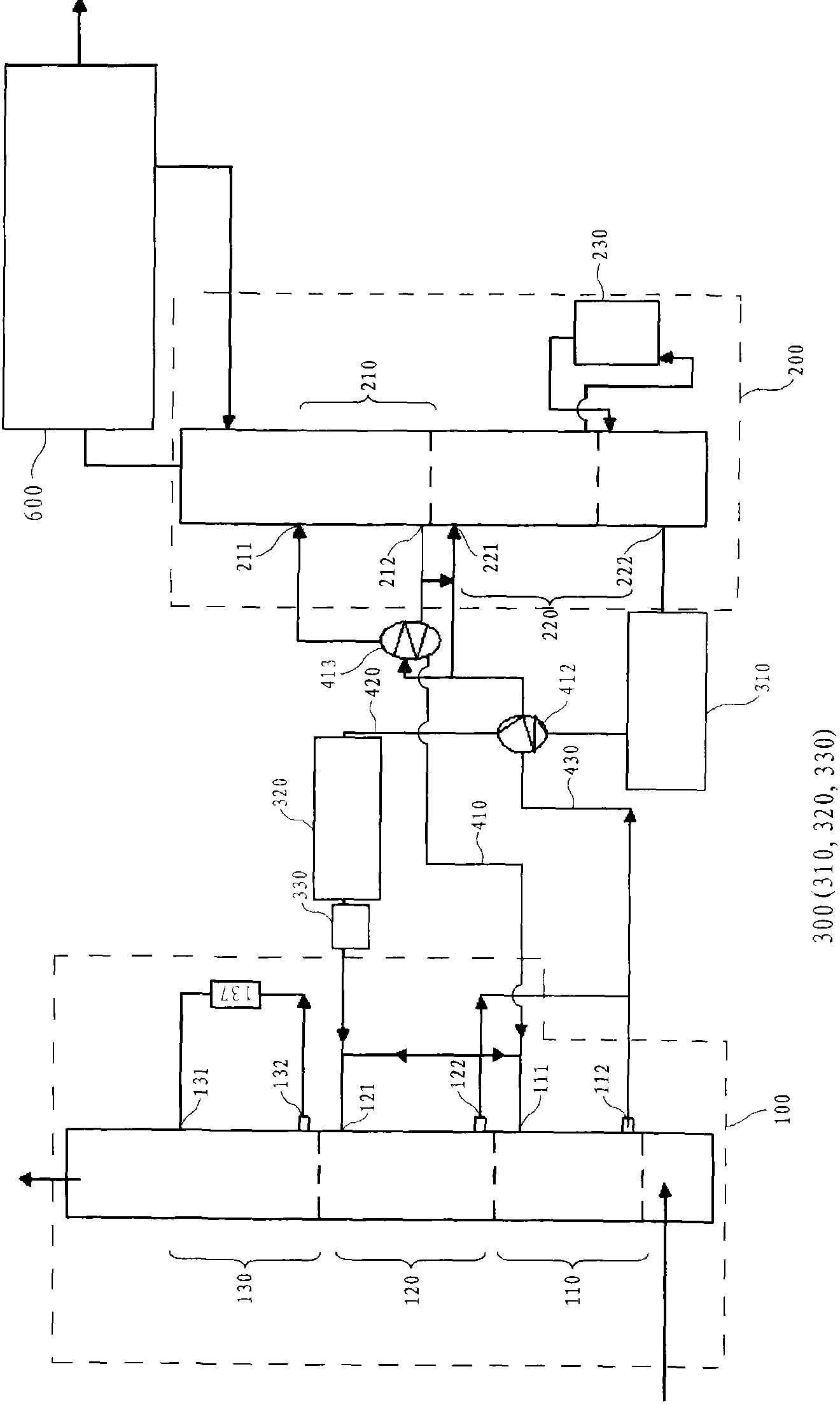

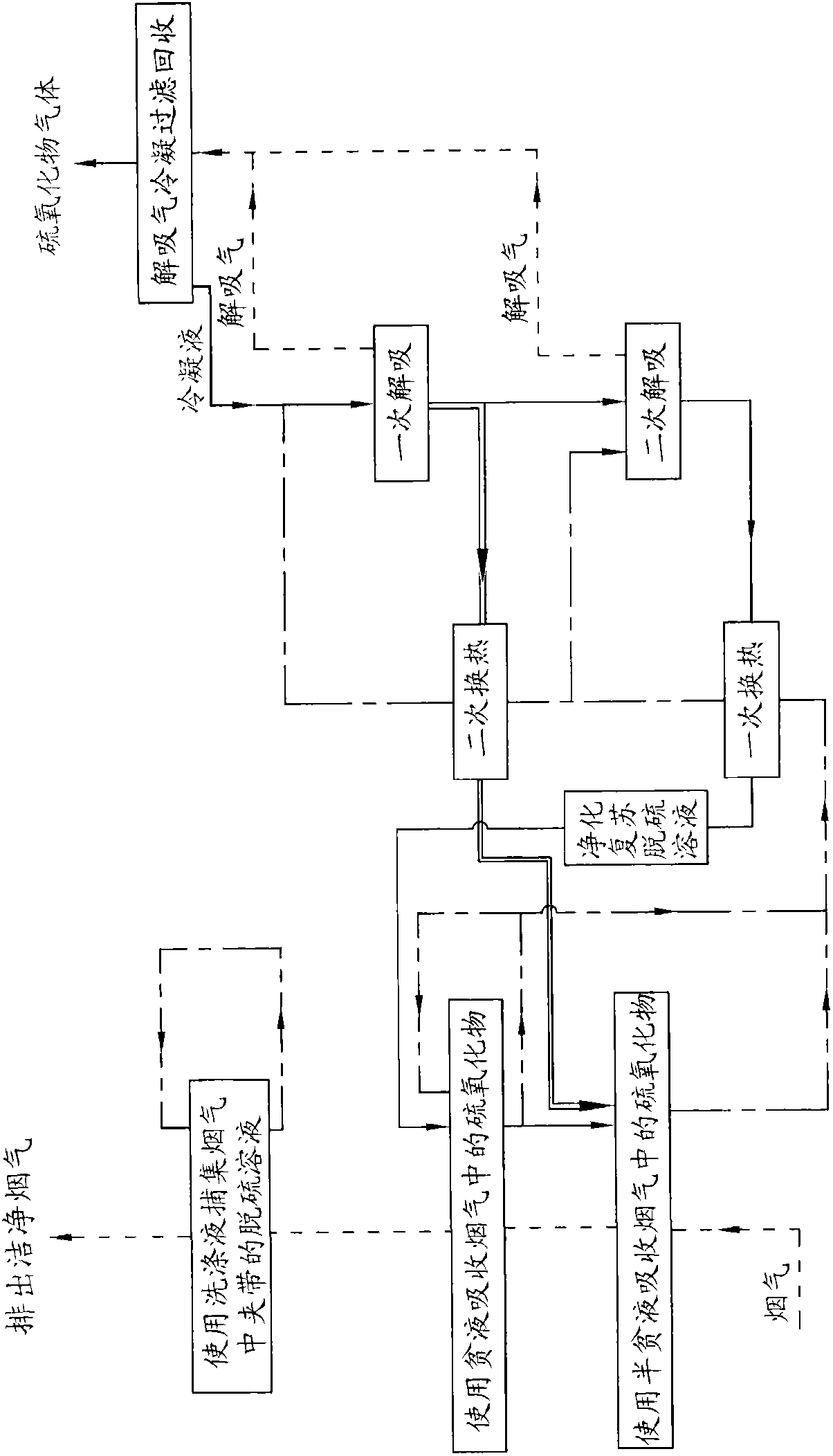

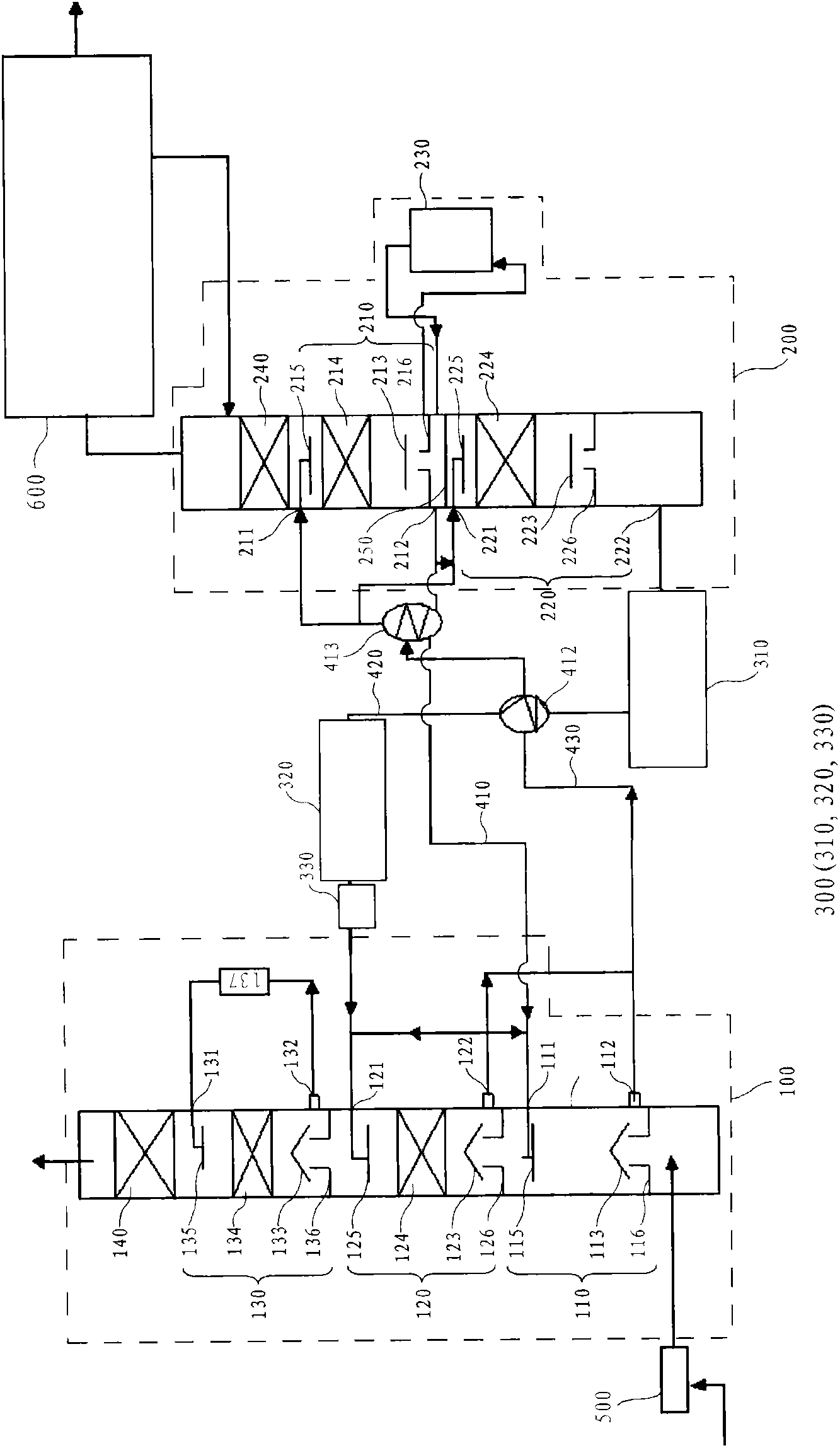

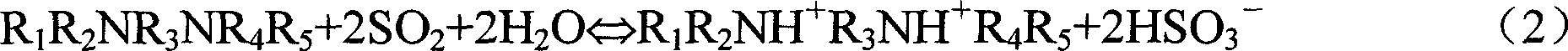

Renewable flue gas desulphurization process

ActiveCN102302894AImprove desulfurization effectReduce desorption energy consumptionDispersed particle separationFlueIndustrial waste

The invention provides a renewable flue gas desulphurization process. The renewable flue gas desulphurization process comprises an absorption process and a desorption process. In the absorption process, the following steps are sequentially carried out according to the flowing direction of flue gas: absorbing oxysulfide in the flue gas by using a half-lean solution to form a first pregnant solution; further absorbing the oxysulfide in the flue gas by using a lean solution to form a second pregnant solution; catching a desulfuration solution carried in the flue gas by using a detergent; and discharging clean flue gas. The desorption process comprises the following steps of: carrying out first desorption on part of the first pregnant solution to form a half-lean solution and desorption gases; simultaneously carrying out second desorption on part of the first pregnant solution and part of the half-lean solution to form a lean solution and desorption gases; condensing and recycling oxysulfide in the desorption gases; and respectively supplying the other part of the half-lean solution and the lean solution for the absorption process so as to realize the circulation of the desulfuration solution between the absorption process and the desorption process. The renewable flue gas desulphurization process is suitable for processing various oxysulfide-contained flue gases or industrial waste gases.

Owner:PANGANG GRP PANZHIHUA STEEL & VANADIUM +2

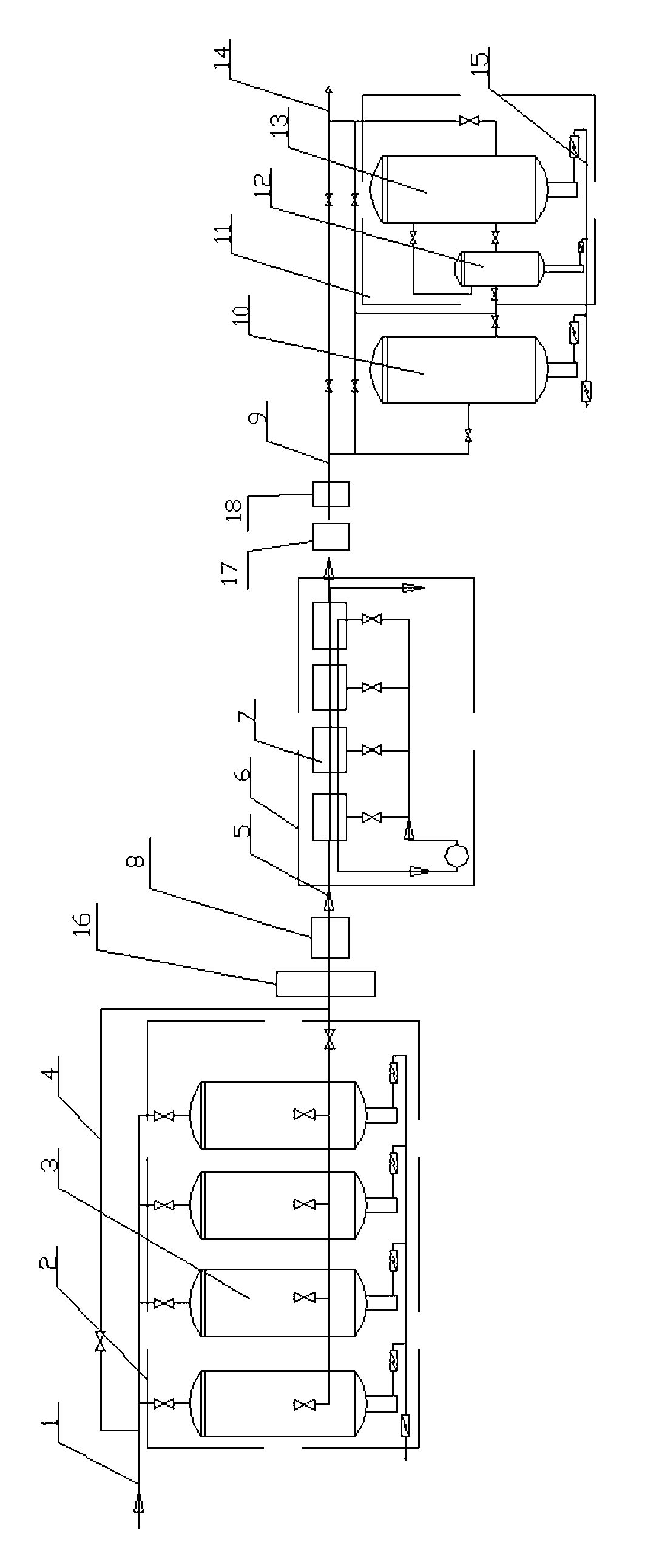

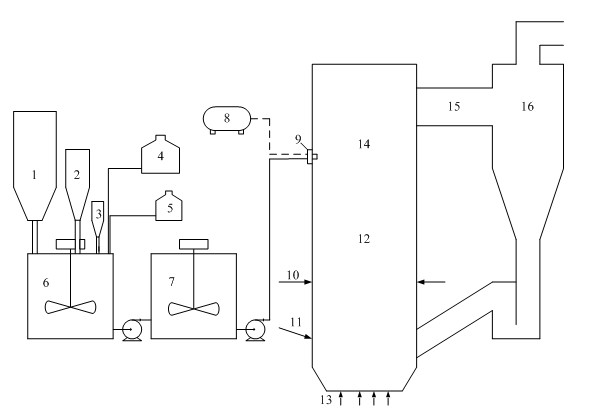

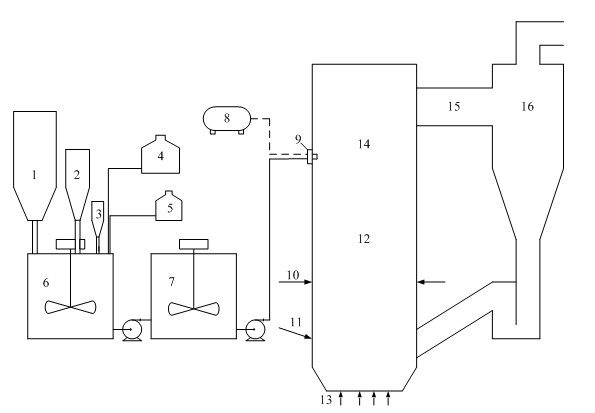

Gas turbine generating coke oven gas comprehensive purification system and purification method thereof

InactiveCN102994171AGood desulfurization effectGood purification effectCombustible gas purificationCoke oven gasProcess engineering

The invention relates to a gas turbine generating coke oven gas comprehensive purification system and a purification method thereof. The gas turbine generating coke oven gas comprehensive purification system is characterized in that coke oven gas in a gas pipe enters into a gas turbine by virtue of a desulphurization system, a compressor filtering system and a coal oven gas filtering system sequentially, wherein the desulphurization system is formed by connecting four dry desulphurizing towers on the gas pipe in parallel, and the compressor filtering system is formed by connecting four compressor filters on a first gas pipe from the desulphurization system in series; and the purification method utilizing the coke oven gas comprehensive purification system comprises the following steps of: a, desulphurizing coal oven gas; b, filtering and compressing the coal oven gas obtained by the step a; c, carrying out isobaric warming on the coal oven gas obtained by the step b; d, carrying out primary filtering on the coal oven gas obtained by the step c; and e, carrying out fine filtering on the coal oven gas obtained by the step d, so that the coal oven gas meeting the requirement of a gas turbine is obtained. According to the gas turbine generating coke oven gas comprehensive purification system provided by the invention, on the basis of crude benzene purification treatment, four dry desulphurization towers are additionally arranged, a desulphurization effect is good, the compressor filtering system and the coal oven gas filtering system are optimized, and quality of the coal oven gas is improved.

Owner:HENAN LIYUAN CHAR GROUP

Device and method for controlling fine particles in desulfurization flue gas

The invention discloses a device and a method for controlling a fine particulate matter from desulfurized smoke. A raw gas enters an absorption layer (2) from a smoke flue (3) of an absorption tower (1) for desulfurizing smoke; sulfur dioxide in the smoke is absorbed and removed by absorption solution; the smoke with the matters such as absorption solution drops, snoot and an adsorbent ascends inside the absorption tower to enter an absorption solution demister (11) through an absorption solution demister rinsing layer (4); most of liquid drops of which the particle sizes are greater than 10 microns are removed; the smoke enters a washing layer and a gas-liquid distributor (9) and contacts washing solution sprayed from a washing layer distributer (8) through a washing layer partition plate (10); the smoke enters a washing demister (7) to remove liquid drops of which the particle sizes are greater than 10 microns after being washed by a washing demister rinsing layer (6); purified smoke is discharged from a smoke purifying channel (5) at the upper part of a smoke desulfurizing absorption tower after twice rinsing and demisting are orderly carried out. The device is matched with a desulfurizing absorption system. Thus, the device is less in investment and convenient to run.

Owner:JIANGSU NEW CENTURY JIANGNAN ENVIRONMENTAL PROTECTION

Gasoline desulfurization method

InactiveCN104673376ARealize deep desulfurizationLow component contentTreatment with hydrotreatment processesGasolineRaw material

The invention provides a gasoline desulfurization method. The gasoline desulfurization comprises the following steps: cutting a gasoline raw material into a light gasoline fraction and a heavy gasoline fraction; performing adsorption desulfurization on the light gasoline fraction to obtain desulfurized light gasoline fraction; and performing selective hydrogenation desulfurization on the heavy gasoline fraction to obtain desulfurized heavy gasoline fraction, wherein the cutting temperature of the light gasoline fraction and the heavy gasoline fraction is 70-110 DEG C. By adopting the gasoline desulfurization method, not only can deep desulfurization of gasoline be realized, but also the octane loss is low.

Owner:CHINA UNIV OF PETROLEUM (BEIJING) +1

Slurry for desulfuration and denitration of recirculating fluidized bed boiler

ActiveCN102179161AImprove desulfurization effectRealize comprehensive utilizationLighting and heating apparatusDispersed particle separationFluidized bedProcess engineering

The invention discloses slurry for desulfuration and denitration of a recirculating fluidized bed boiler, which comprises desulfurizing agent slurry and a denitrfying agent solution. Composite desulfurizing and denitrfying agent slurry is prepared by adopting a calcium based absorbing agent, an additive, a co-additive and an amino reducing agent according to a certain proportion and programs and used for being atomized and sprayed into a region at the top of the recirculating fluidized bed boiler through a nozzle to react with SO2 and NOx in smoke to generate sulfate and N2. By applying the slurry disclosed by the invention, the problems of low desulfuration efficiency of calcined limestone doped in the recirculating fluidized bed boiler and low utilization rate of the desulfurizing agent are solved, desulfuration and denitration are realized simultaneously, the desulfuration efficiency reaches 85-95 percent and the denitration efficiency reaches 50-70 percent. The slurry has the advantages of low investment and operation costs and convenience for implementation.

Owner:SHANDONG UNIV

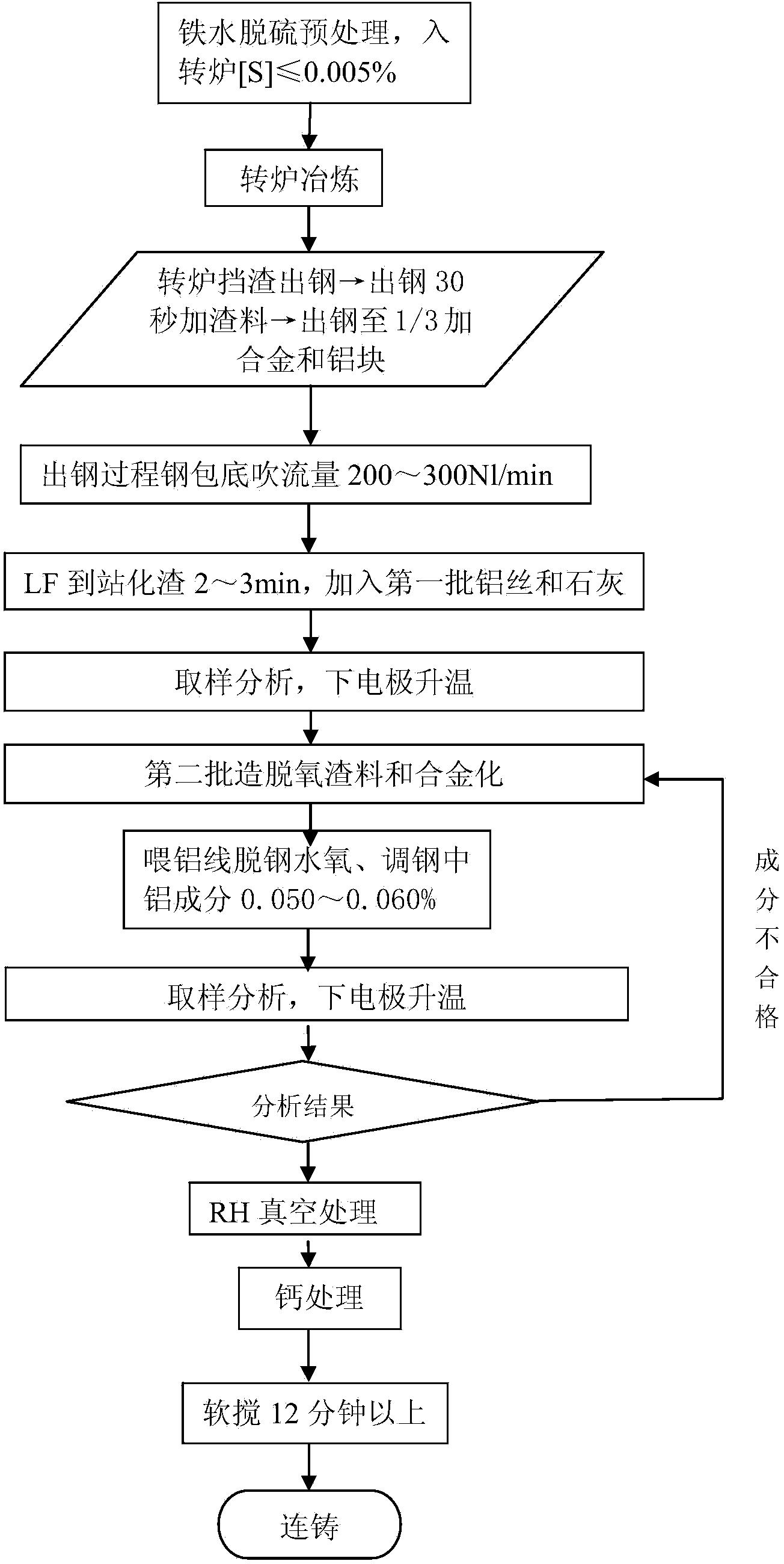

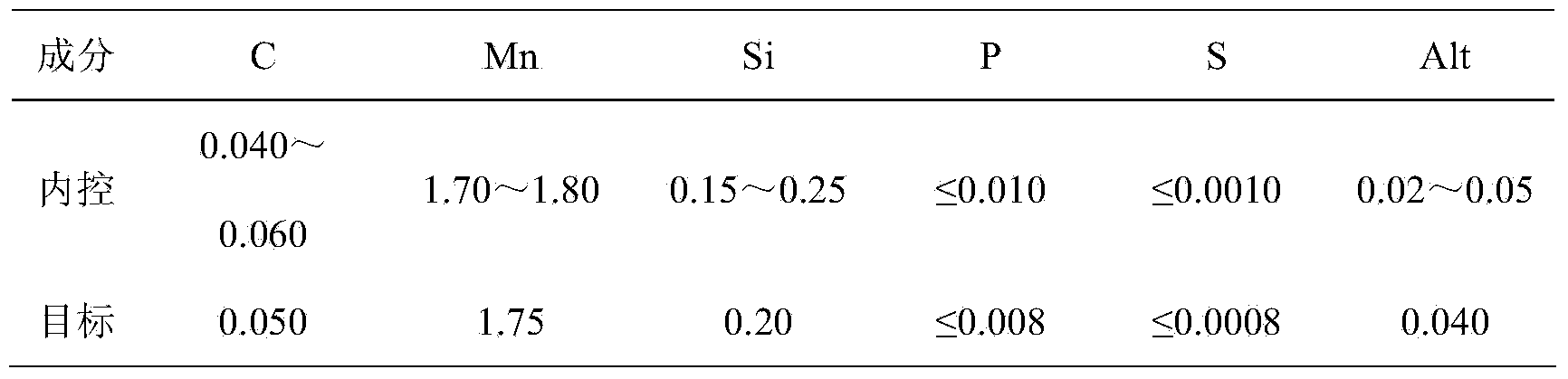

Ultralow sulfur steel quick smelting method

ActiveCN103898269AObvious slag desulfurization effectStable controlManufacturing convertersSmelting processMolten steel

The invention discloses an ultralow sulfur steel quick smelting method. The difficult points of slagging, deoxidizing and desulfurating in the smelting process of the ultralow sulfur steel ([S] is not more than 0.0010%) are successfully solved. The method comprises the following steps: pretreating molten steel to desulfurate and remove slag, deeply deoxidizing tapping aluminum block through a converter, modifying composite refined top slag, deoxidizing aluminum wire through a LF refining furnace, slagging through lime and feeding aluminum wire to trimming aluminum molten steel, combining the whole reasonable argon bottom blowing control in the smelting process of the LF furnace, fully playing the metallurgical thermodynamics and thermodynamics and kinetics of desulfuration, organically combining the diffusion deoxidization and sediment deoxidization, sufficiently evacuating deoxidization and desulfuration potential of the slag so that the sulfur content in the molten steel within 40min can be reduced to within 0.0010% through the LF refining furnace and the full oxygen content of casting blank is controlled within 0.0010%. The sulfur content control of the molten steel is stable, the casting blank is good in quality, the steel plate flaw detection yield can achieve above 99%, the ultralow sulfur steel production requirement is completely satisfied, and the smelting production rhythm and the continuous casting pouring furnace are guaranteed.

Owner:NANJING IRON & STEEL CO LTD

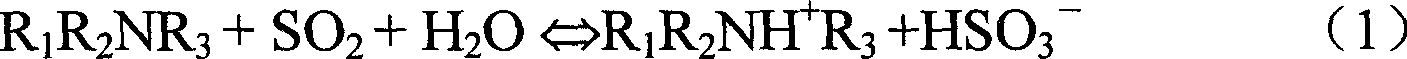

Renewable flue gas desulfuration agent and applications thereof

ActiveCN103801182AImprove desulfurization effectImprove the desorption effectDispersed particle separationDiamineIon

The invention discloses a renewable flue gas desulfuration agent and applications thereof, which aim at overcoming the defects that an adsorbent in the prior art is easily oxidized to generate heat stable salt, and thus the capability of the adsorbent in absorbing SO2 is lost, and the like. The desulfurization agent comprises the following compositions in percentage by weight: (A) 5-60% of diamine compounds containing ethoxyl or hydroxypropyl; (B) 2-40% of desorption auxiliaries; (C) 0.1-0.5% of an antioxidant; (D) 0.5-1% of a corrosion inhibitor; and (E) 5-90% of deionized water. The desulfurization agent can be used in the fields of coal-fired power plants, refinery enterprises, nonferrous metallurgy enterprises and the like, is low in energy consumption, capable of being recycled and free from secondary pollution, and heat stable salts are generated slowly.

Owner:CHINA PETROCHEMICAL CORP +1

Biomass power plant flue gas purification treatment process and system based on dry-process desulfurization and low-temperature denitration

The invention relates to a biomass power plant flue gas purification treatment process and system based on dry-process desulfurization and low-temperature denitration (low-temperature SCR (Selective Catalytic Reduction)). The biomass power plant flue gas purification treatment process based on the dry-process desulfurization and the low-temperature denitration comprises the following steps: firstly, carrying out primary dust removal on dust-containing flue gas generated by combusting biomasses in a boiler, and keeping temperature of gas which is pre-treated by a cyclone dust collector (1) at about 215 DEG C; secondly, carrying out dry-process desulfurization purification treatment on the flue gas, which is subjected to the primary dust removal, in a desulfurization device (2); thirdly, treating the desulfurized flue gas by adopting a bag type dust collector (3); fourthly, conveying the gas into an SCR system (4) and carrying out denitration reaction to generate harmless nitrogen gas and steam; after recycling residual heat through a heat exchanger (5) and conveying the gas into a chimney (9) through a draught fan (8) and discharging to the atmosphere; fifthly, inputting smoke ash separated from the cyclone dust collector and the bag type dust collector into a concentrated ash silo (7) through a first bin pump pneumatic ash removal device (61) and a second bin pump pneumatic ash removal device (62) and storing.

Owner:SHANGHAI ELECTROMECHANICAL DESIGN & RES INST CO LTD

Method for producing silicon deoxygenation low-sulfur high-carbon steel through LF refining double slag method

The invention relates to a method for producing silicon deoxygenation low-sulfur high-carbon steel through an LF refining double slag method. An electric furnace-LF-VD continuous casting technology isadopted. The method includes the steps that in the electric furnace tapping process, carbon powder is mixed firstly, then a silicon alloy and a manganese alloy are added for conducting deoxygenationalloying treatment, and lime, calcium carbide and aluminum-free refining slag are added for conducting modification treatment; secondly, after an LF enters a station, lime, calcium carbide, silicon iron and aluminum-free refining slag are added into the furnace for making high-alkalinity reducing refining slag; thirdly, low-alkalinity reducing slag is made, and the content of components in moltensteel is adjusted; and fourthly, the LF withdraws from the station after refining, VD and continuous casting processes are conducted in sequence, and the silicon deoxygenation low-sulfur high-carbon steel is obtained. The method is simple, reliable, high in operability and easy to achieve, the production cost of the whole process is reduced, the sulfur removing efficiency is high, the cleanlinesslevel of molten steel is high, the problem that when a non-molten-steel pretreatment sulfur removing process is adopted for producing high-quality silicon deoxygenation low-sulfur high-carbon steel, sulfur removing is difficult is solved well, and therefore the product quality is improved, and the economic benefits of a steel enterprise are increased.

Owner:CENT IRON & STEEL RES INST

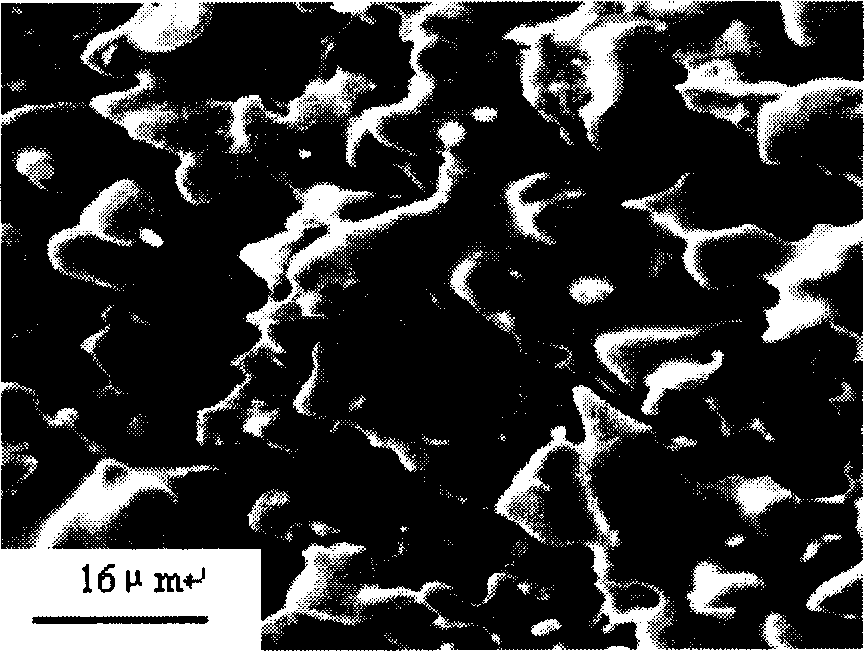

Gasoline desulfurization adsorbent and preparation method thereof

ActiveCN103394322AAvoid reunionIncrease the areaOther chemical processesHydrocarbon oils refiningSorbentGraphene flake

The invention provides a gasoline desulfurization adsorbent and a preparation method thereof, overcoming the defect that graphene in the prior art is easy to agglomerate in the using process. The gasoline desulfurization adsorbent takes attapulgite and graphene as carriers and cuprous oxide and manganese dioxide as active ingredients. The preparation method comprises the following steps of: (1) adding graphite and copper nitrate to concentrated sulfuric acid, then slowly adding potassium permanganate, then adding attapulgite slurry with concentration of 0.5-3g / L, and carrying out ultrasonic dispersion; adding an alkali solution to regulate the pH value, thus preparing composite suspension; and (2) adding a reducing agent solution under the condition of stirring, reacting, filtering, washing and drying, thus preparing the composite desulfurization adsorbent. The gasoline desulfurization adsorbent and the preparation method have the beneficial effects that one-dimensional rod-like attapulgite can be inserted between graphene oxide sheet layers, and attapulgite monocrystals are intercalated into graphene to prevent mutual superimposition of the graphene sheets so as to avoid the problem that graphene is easy to agglomerate in the using process.

Owner:江苏纳欧新材料有限公司

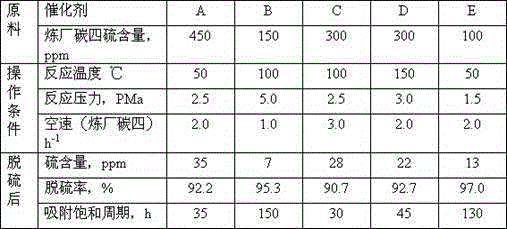

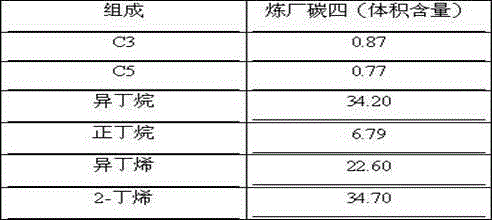

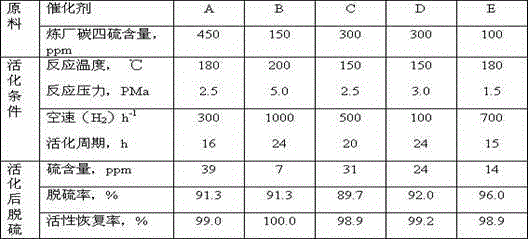

Deep desulfurization method of refinery C4

InactiveCN104557388APromote regenerationCause changeHydrocarbonsAdsorption purification/separationHydrogenActive component

The invention discloses a deep desulfurization method of refinery C4, which comprises the following steps that at least two fixed bed reactors are adopted; a C4 fraction is subjected to adsorption desulfurization by the action of an adsorbent loaded with a hydrogenated active component; the C4 fraction is switched to another reactor for the adsorption desulfurization after adsorption saturation; hydrogen is supplied to the adsorption saturated fixed bed reactor for a hydrogenated desulfurization reaction; and the adsorbent loaded with the hydrogenated active component is regenerated. Refinery C4 desulfurized by the method can directly serve as a raw production material of MTBE (methyl tert-butyl ether), and isobutylene in the C4 fraction is sufficiently protected and utilized.

Owner:CHINA PETROLEUM & CHEM CORP +1

Desulphurization sorbent

ActiveCN101433817AEvenly distributedHigh strengthOther chemical processesHydrocarbon oils refiningAdditive ingredientSorbent

The invention discloses a desulfurization adsorbent, which comprises 1 to 30 weight percent of rare earth-zeolite mixture, 5 to 40 weight percent of active metal oxide and 30 to 94 weight percent of carrier, wherein the carrier comprises alumina and zinc oxide; the rare earth-zeolite mixture and a carrier mixture are preformed into porous heat-resistant solid particles, and then active metal ingredients are introduced on the solid particles to obtain the adsorbent; and a light hydrocarbon oil raw material containing sulfur and a hydrogen donor enter a reactor filled with the adsorbent, materials remained after the reaction are separated, a reaction product is sent into a subsequent separation system for product separation, a spent adsorbent after the reaction is steam-stripped and then is subject to coke-burning regeneration, and the regenerated adsorbent is reduced by the hydrogen donor and is returned to the reactor for cyclic use. The adsorbent realizes the deep removal of sulfide in light hydrocarbon oil, and the produced gasoline has higher octane number, lower benzene content, and higher strength at the same time.

Owner:CHINA PETROLEUM & CHEM CORP +1

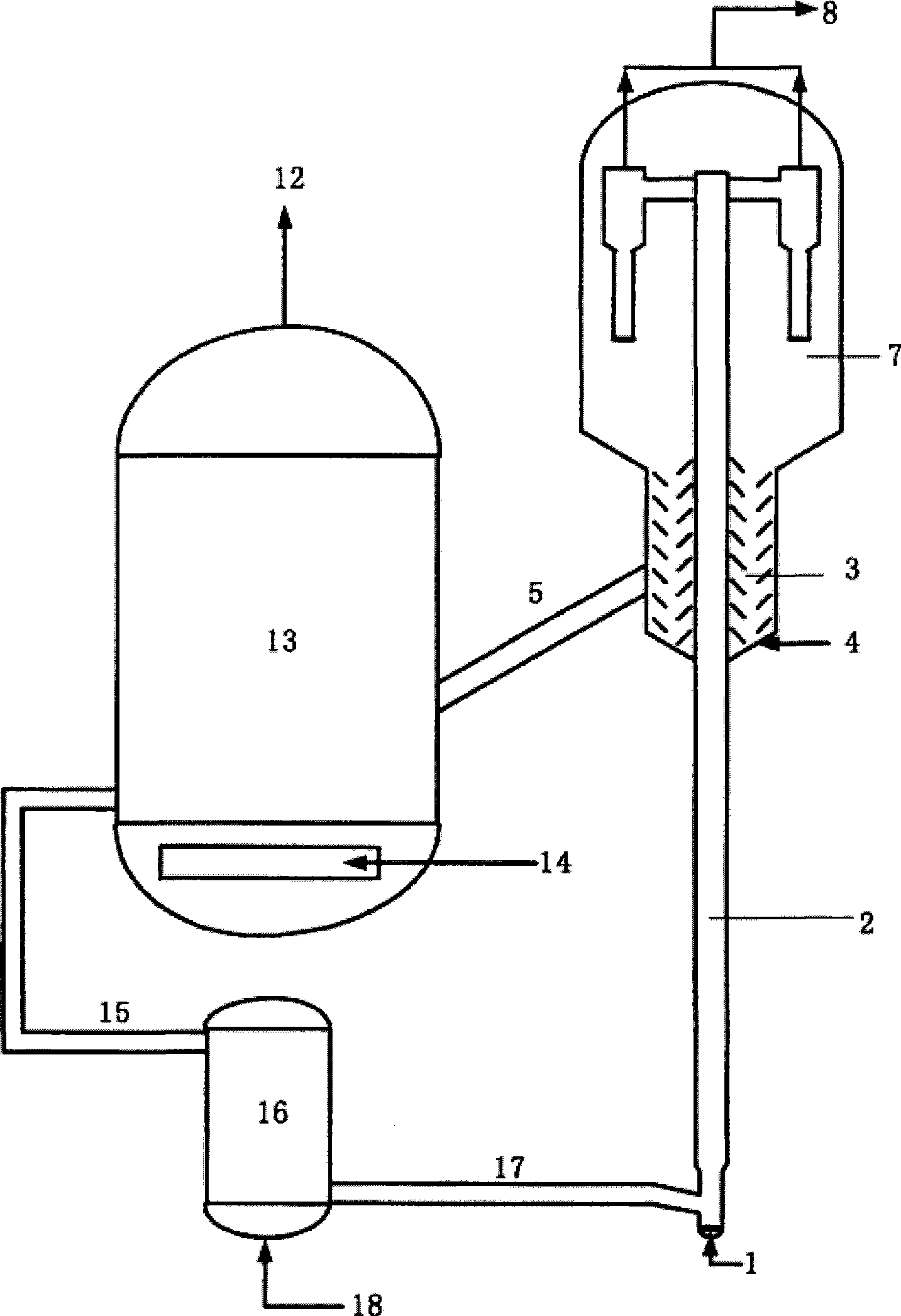

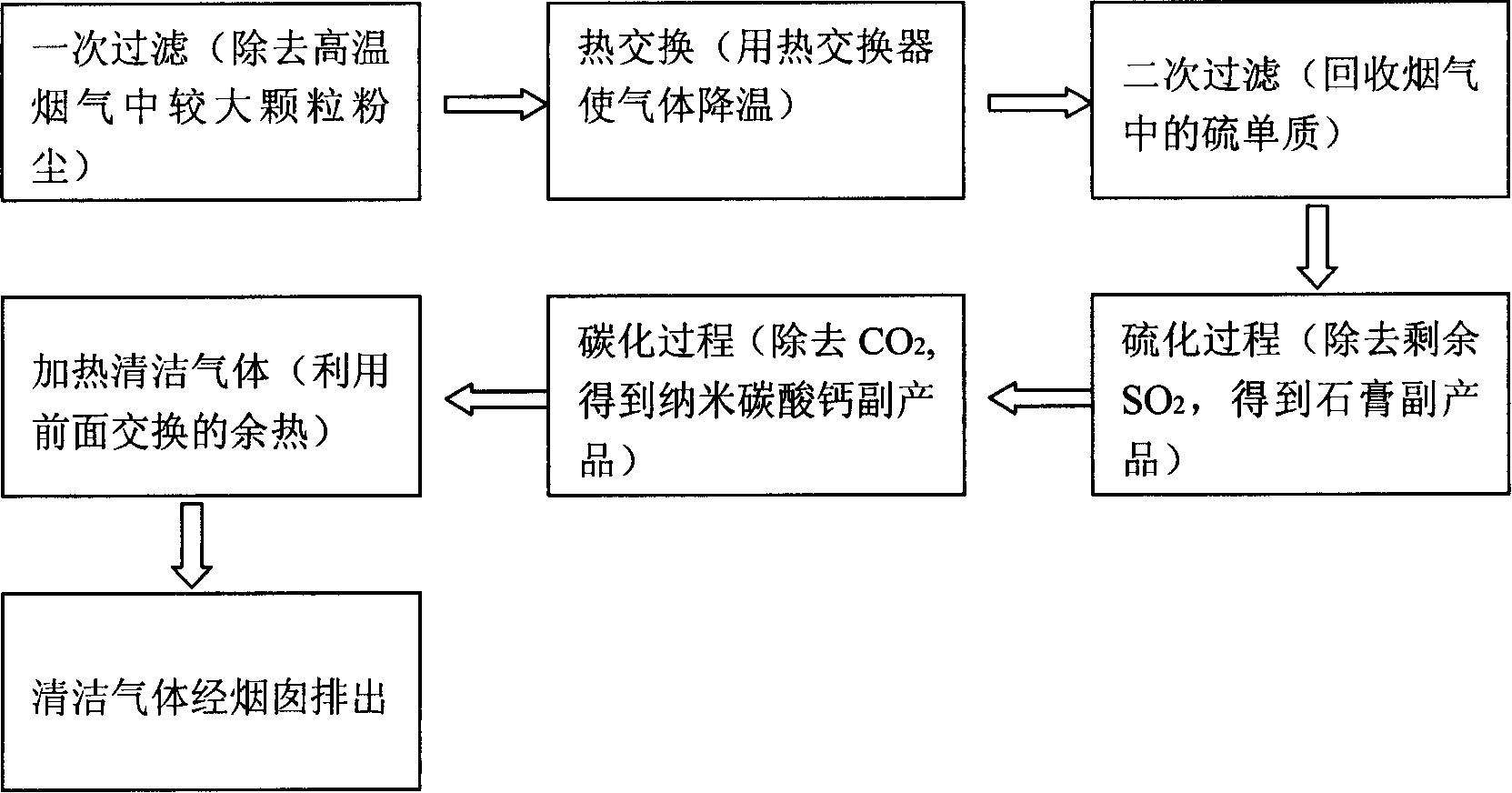

A processing method and apparatus of coal-firing gas

InactiveCN101157005AImprove heat exchange efficiencyGood desulfurization effectCombination devicesLighting and heating apparatusChemistryDust particles

The invention relates to a processing method for coal flue gas. Smoke dust particles and sulfur are removed from the coal flue gas through dry filtration, and sulfur dioxide is removed through a wet process, wherein, the dry filtration process comprises the steps that the coal flue gas passes through ceramic filtering materials; the process for removing the sulfur dioxide with a wet method has the steps that the sulfur dioxide is removed through the reaction of the coal flue gas after being processed with a dry method and calcium carbonate serosity. The invention has evident desulfation effect, and a formed accessory substance has very high added value; the invention can rationally use the residual heat of the high temperature coal flue gas; the invention realizes the removing of an element S and the recovery of the high purity, simultaneously performs the decarbonization process, and avoids the environmental pollution; the equipment adopted by the invention is easy to be assembled and disassembled, cleaned, and maintained; the invention resolves the contradiction between the operating costs and the operating effects of the desulfation and the decarbonization, and has huge economic interest and huge application foreground.

Owner:ZHENGZHOU UNIV

Preparation and application of catalyst for selective hydrodesulfurization of gasoline

ActiveCN101905165AHigh desulfurization activityInhibit carbon depositionCatalyst activation/preparationRefining to eliminate hetero atomsEthylene diamineHydrodesulfurization

The invention relates to preparation and application of a catalyst for selective hydrodesulfurization of gasoline. The catalyst comprises the following components in percentage by weight: 6 to 20 percent of CoO+MoO, 0.1 to 5 percent of K2O, 0.1 to 5 percent of MgO, 0.1 to 5 percent of P2O5, and the balance of ZrO2-Al2O3 composite carrier, wherein the ZrO2 accounts for 0.1 to 20 percent of the weight of the composite carrier. The preparation of the catalyst comprises the following steps of: preparing the composite carrier by adopting a complex precipitation method; adding sylvite, sesbania powder and de-ionized water into the composite carrier, uniformly mixing and kneading, extruding and drying the mixture at the temperature of between 100 and 150 DEG C and roasting the mixture at the temperature of between 450 and 550 DEG C to prepare a catalyst carrier; adding ammonia, EDTA (Ethylene Diamine Tetraacetic Acid) complexing agent to prepare stable Co-Mo co-immersion liquid which contains phosphorus and magnesium; and preparing the catalyst by using an isometric spraying immersion method. The catalyst has high selectivity and stability, and can reduce saturation of olefin to the utmost extent, and has a good desulfurization effect.

Owner:PETROCHINA CO LTD

Convertor tapping washing fining furnace fast desulfurization method

The invention relates to a method for rapidly desulfurizing a slag washing and refining furnace for converter tapping, which belongs to the steelmaking technical field and is used to solve the problem that the converter tapping is rapidly refined and desulfurized. The method comprises two steps of steel ladles slag-washing and LF refining and is characterized in that pre-melted slag and white lime 3-5Kg / t are added according to the ratio of 7-12Kg / t in the step of the steel ladles slag-washing, the pre-melted slag is added according to the ratio of 3-5Kg / t in the step of LF refining, and fluxing medium is added according to the following ratio: lime 3-5Kg / t, calcium carbide 2-4Kg / t and ferrosilicon powder 2-4Kg / t, the components of the pre-melted slag is combined according to following weight units: CaO 46-52, Al2O3 38-45, CaF2 5-7, SiO2<=10, Fe2O3 <=2, H2O<= 0.5, and the pre-melted slag melting point <=1350DEG C. The invention can increase the rear furnace slug washing of a high converter under the condition that aluminum is added to deoxidize in refining and refining slag is rapidly produced under the weak oxidation condition, and the requirements for producing low sulphur steel are satisfied.

Owner:HANSTEEL

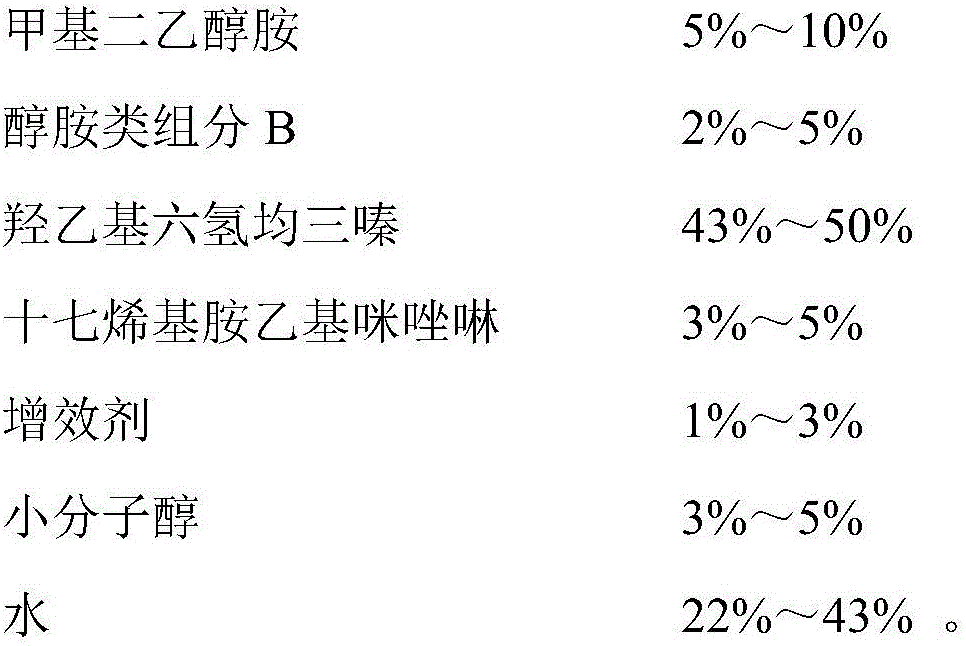

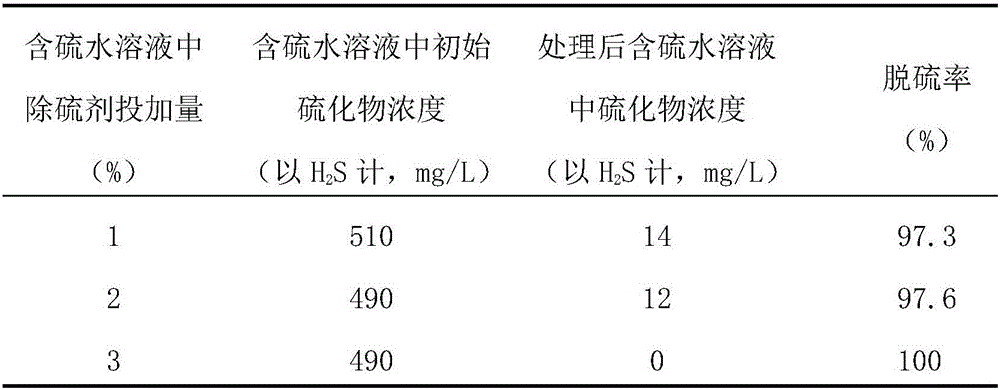

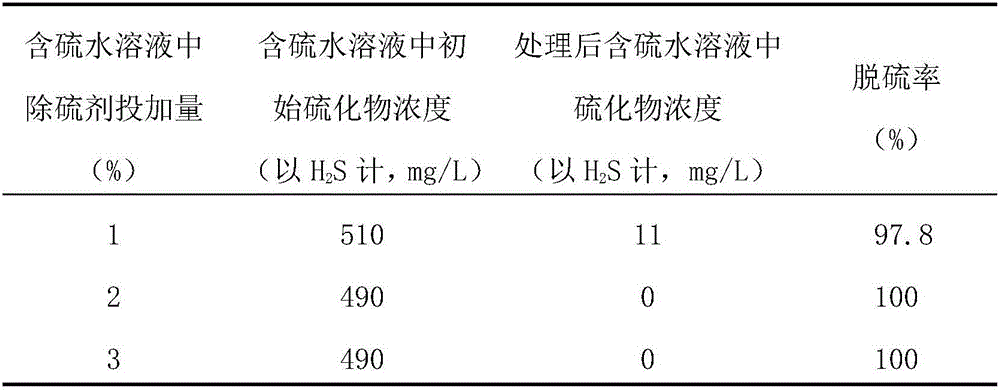

Organic composite efficient sulfur removal agent for oil-gas field and preparation method and application of organic composite efficient sulfur removal agent

ActiveCN106479468AEfficient removalReduce contentGaseous fuelsDrilling compositionDecompositionGlycerol

The invention discloses an organic composite efficient sulfur removal agent for oil-gas field and preparation method and application of the organic composite efficient sulfur removal agent. The sulfur removal agent is characterized in that water serves a solvent and comprises an alcohol amine component A, an alcohol amine component B, a triazine derivative, inhibiter, synergist and low-molecular mass alcohols; the alcohol amine component A refers to methyldiethanolamine, the alcohol amine component B refers to one of triethanolamine and diethanolamine or a mixture of triethanolamine and diethanolamine; triazine derivative refers to hexahydro-1,3,5-tris-s-triazine; the inhibiter refers to seventeen alkenyl amide ethyl imidazoline; the synergist refers to sulfolane; the low-molecular mass alcohols refer to one of ethylene glycol and glycerol or a mixture of ethylene glycol and glycerol. The sulfur removal agent has the advantages of good selectivity on sulfuretted hydrogen, small dosage, quick effect, high sulfur removal efficiency, no corrosion of steel, stable product performance, difficulty in heating decomposition, capability of being biodegradable and the like; sulfide like sulfuretted hydrogen existing in extraction of an oil-gas well can be effectively removed or reduced to safety threshold value range in content, corrosion of sulfide on pipelines and equipment is inhibited, and safety on the equipment and operation personnel is guaranteed.

Owner:陕西森瑞石油技术开发有限公司

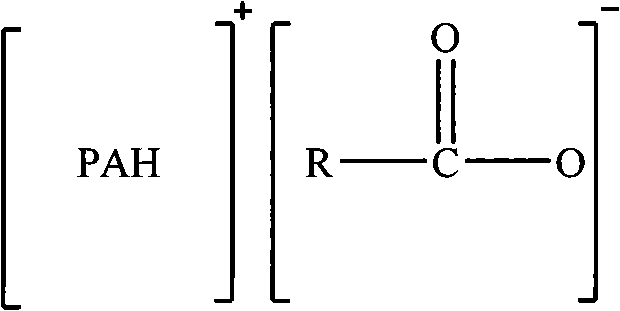

Recyclable sulfur dioxide gas absorbent and preparation method thereof

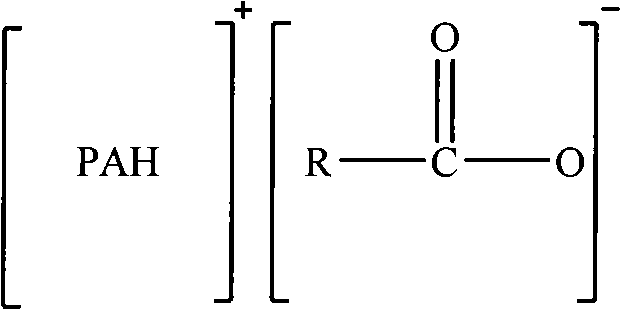

InactiveCN101537300ASynthetic conditions are mildShorten the timeDispersed particle separationDesorptionCarboxylic acid

The invention provides a recyclable sulfur dioxide gas absorbent and a preparation method thereof, wherein the absorbent is an ion liquid with a cation belonging to a multi-nitrogen straight chain amine, which is shown by a chemical formula at the right side, wherein PA is a multi-nitrogen straight chain amine matter and R is H or C1-C2 alkyl. The preparation method of the absorbent is characterized in that t the multi-nitrogen straight chain amine matter and the short chain carboxylate as raw materials and the reaction is carried out in a solvent or carried out directly without a solvent. The absorption amount of the SO2 is increased with the increment of the amount of the functional nitrogen; furthermore, the absorbent can be circularly used repeatedly by desorption, can achieve balanced absorption and desorption quickly, and desorption rate within 1 hour is more than 95% and the absorbent can be used for acidic gasses such as SO2, and the like.

Owner:HEFEI UNIV OF TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com