Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

91results about How to "Realize deep desulfurization" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Method for producing the clean diean diesel oil with low sulfur and low arene

InactiveCN1415706AExpand sourceImprove adaptabilityTreatment with hydrotreatment processesSulfurImpurity

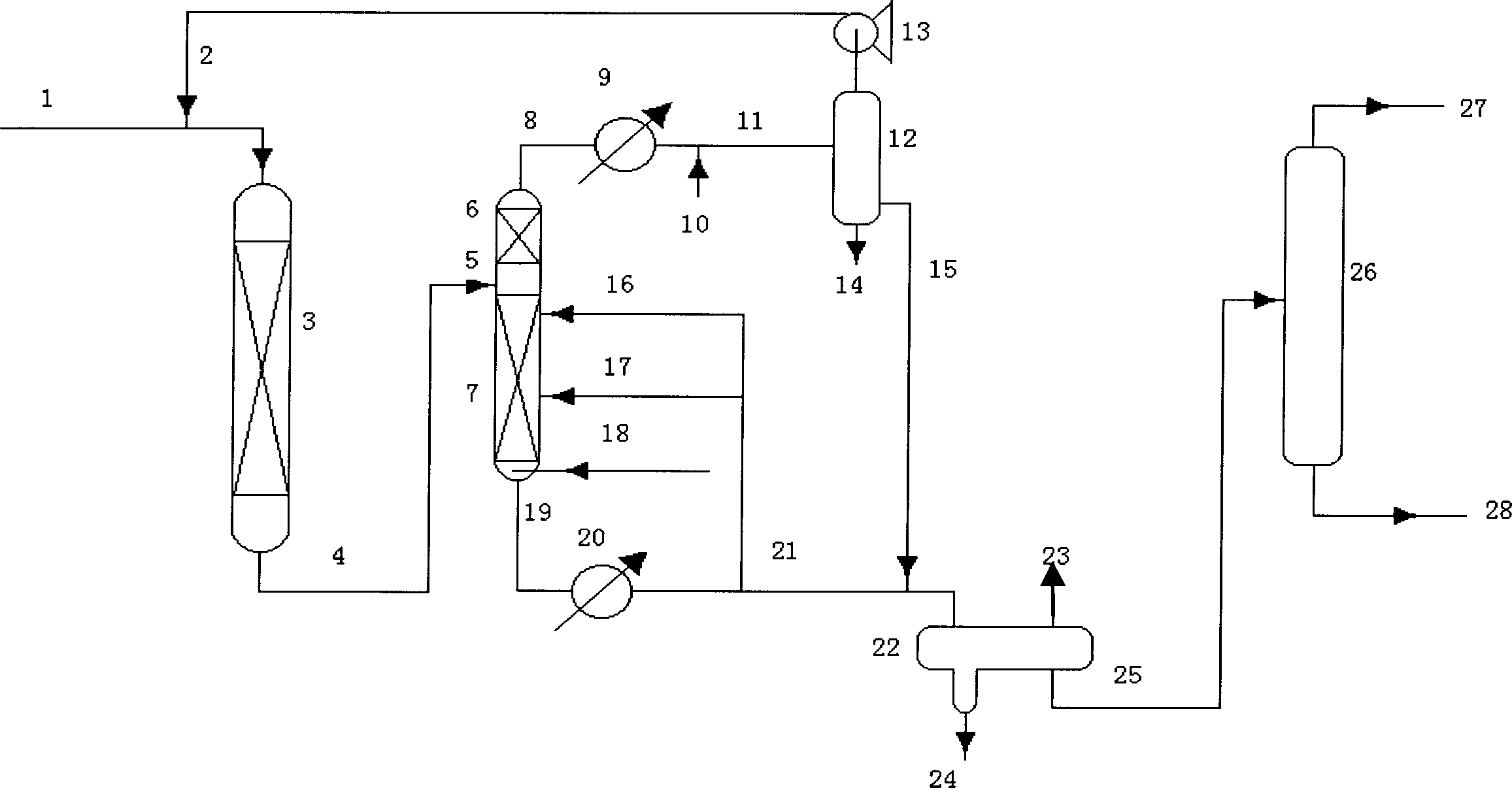

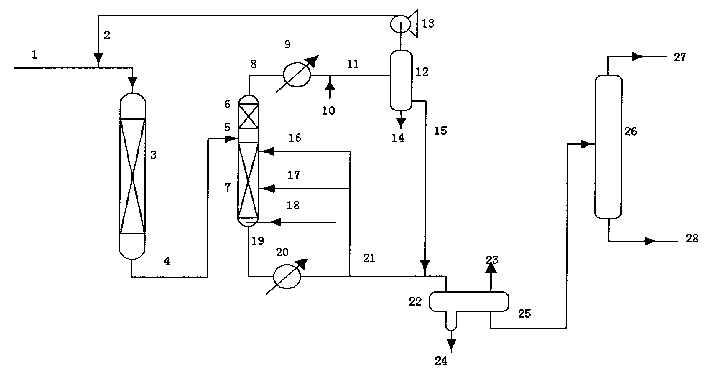

A process for preparing low-sulfur low-arylhydrocarbon clean diesel oil includes such steps as hydrorefining / hydrocracking raw hydrocarbon to obtain intermediate fraction oil, catalytic stripping to separate light fraction from heavy fraction, hydrorefining the light fraction to remove residual S and impurities, and catalytic stripping of heavy fraction for removing sulfure and arylhydrocarbon to obtain final product. Its advantage is cyclic use of two reactino segments for low cost.

Owner:CHINA PETROLEUM & CHEM CORP +1

Gasoline desulfurization method

InactiveCN104673376ARealize deep desulfurizationLow component contentTreatment with hydrotreatment processesGasolineRaw material

The invention provides a gasoline desulfurization method. The gasoline desulfurization comprises the following steps: cutting a gasoline raw material into a light gasoline fraction and a heavy gasoline fraction; performing adsorption desulfurization on the light gasoline fraction to obtain desulfurized light gasoline fraction; and performing selective hydrogenation desulfurization on the heavy gasoline fraction to obtain desulfurized heavy gasoline fraction, wherein the cutting temperature of the light gasoline fraction and the heavy gasoline fraction is 70-110 DEG C. By adopting the gasoline desulfurization method, not only can deep desulfurization of gasoline be realized, but also the octane loss is low.

Owner:CHINA UNIV OF PETROLEUM (BEIJING) +1

Method for lowering sulfur and olefin content in gasoline

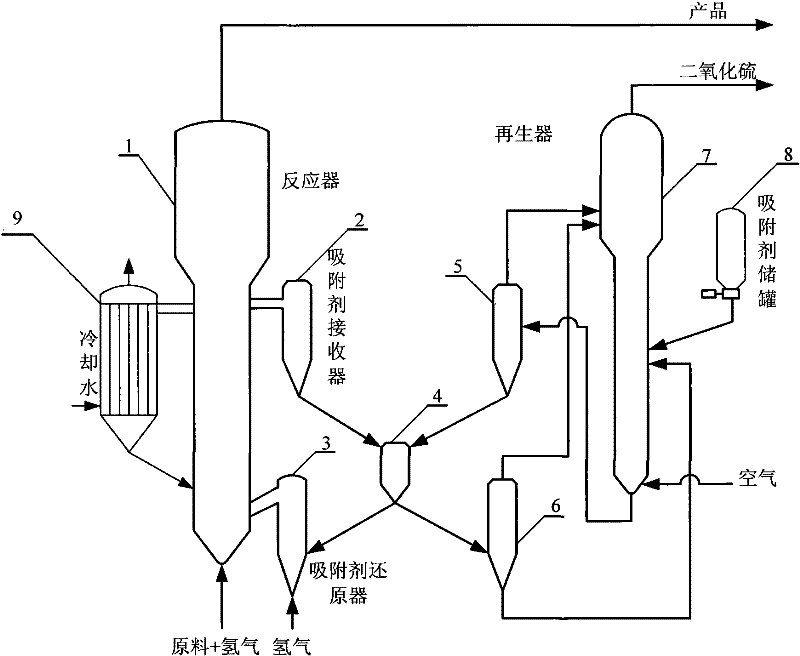

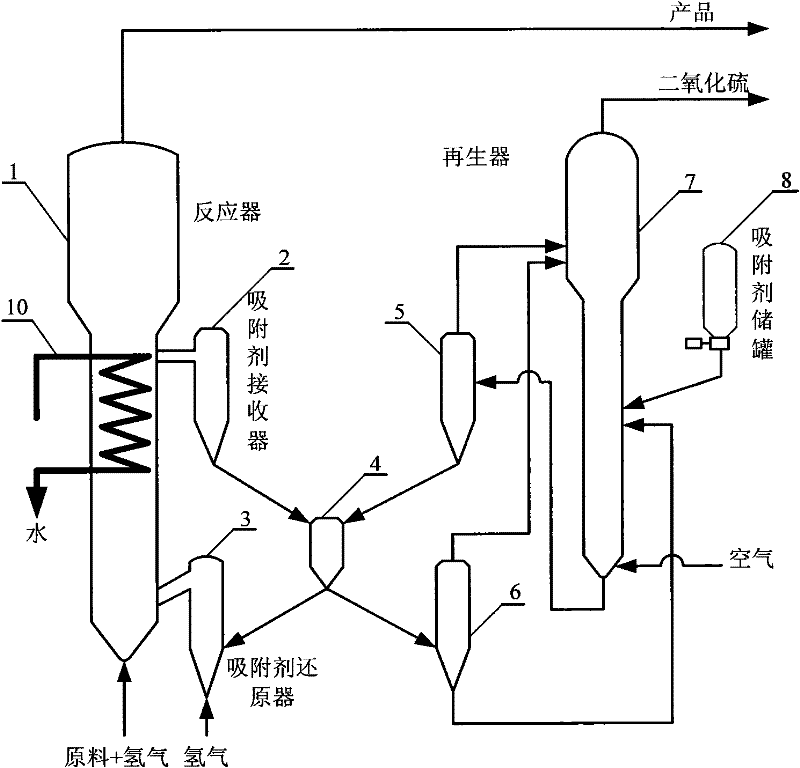

ActiveCN102191080AReduce olefinsReduce sulfur contentHydrocarbon oils treatmentRefining to eliminate hetero atomsFluidized bedSorbent

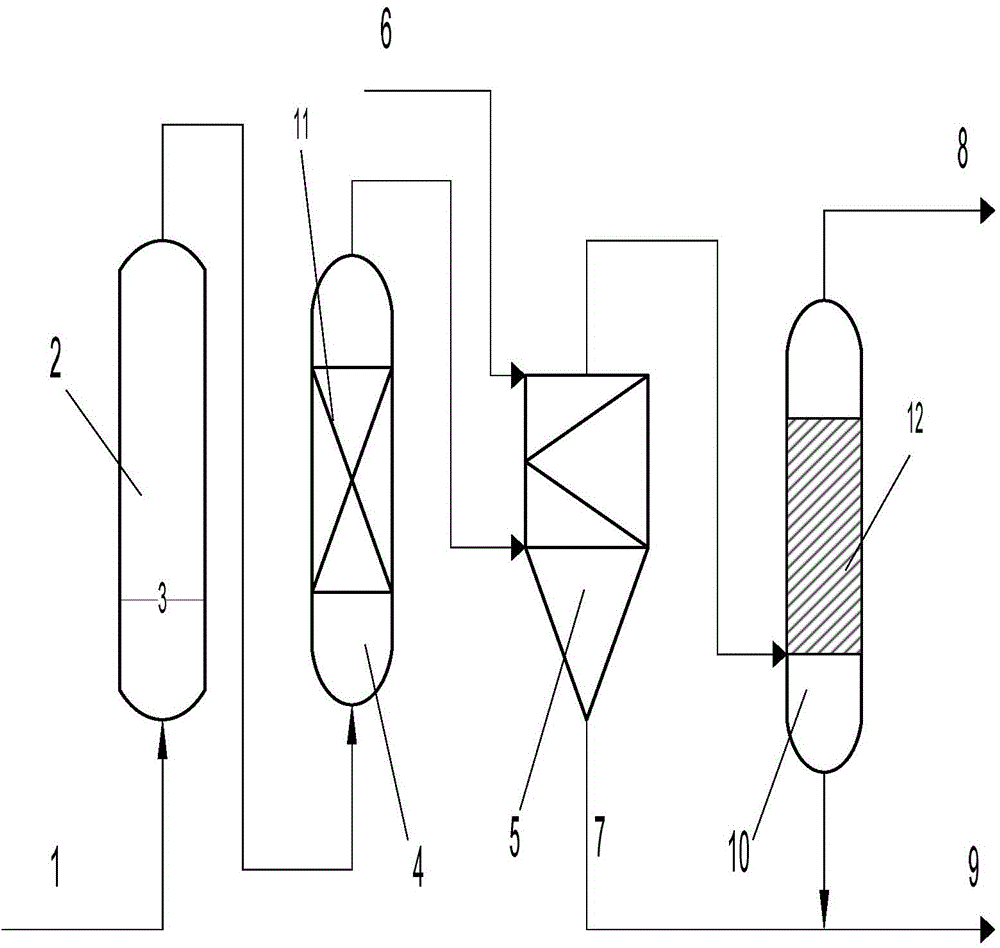

The invention relates to a method for lowering the sulfur and olefin content in gasoline, which comprises: introducing a preheated gasoline raw material containing more than 35 weight percent of olefin and a hydrogen donor to a fluidized bed reactor to contact the gasoline raw material and the hydrogen donor with an absorber to form desulfurized oil gas and sulfurized absorbent; separating the desulfurized oil gas and sulfurized absorbent; delivering the separated oil gas to a subsequent separation system for product separation; and regenerating and reducing the sulfurized absorbent and returning the sulfurized absorbent to the reactor. The fluidized bed reactor is provided with a heater and / or devices for cooling the reduced absorbent and returning the reduced absorbent to the reactor. When the method is used to process a high-olefin gasoline raw material, deep desulfurization can be realized under a low hydrogen consumption condition, and the olefin content in the gasoline can be lowered considerably.

Owner:CHINA PETROLEUM & CHEM CORP +1

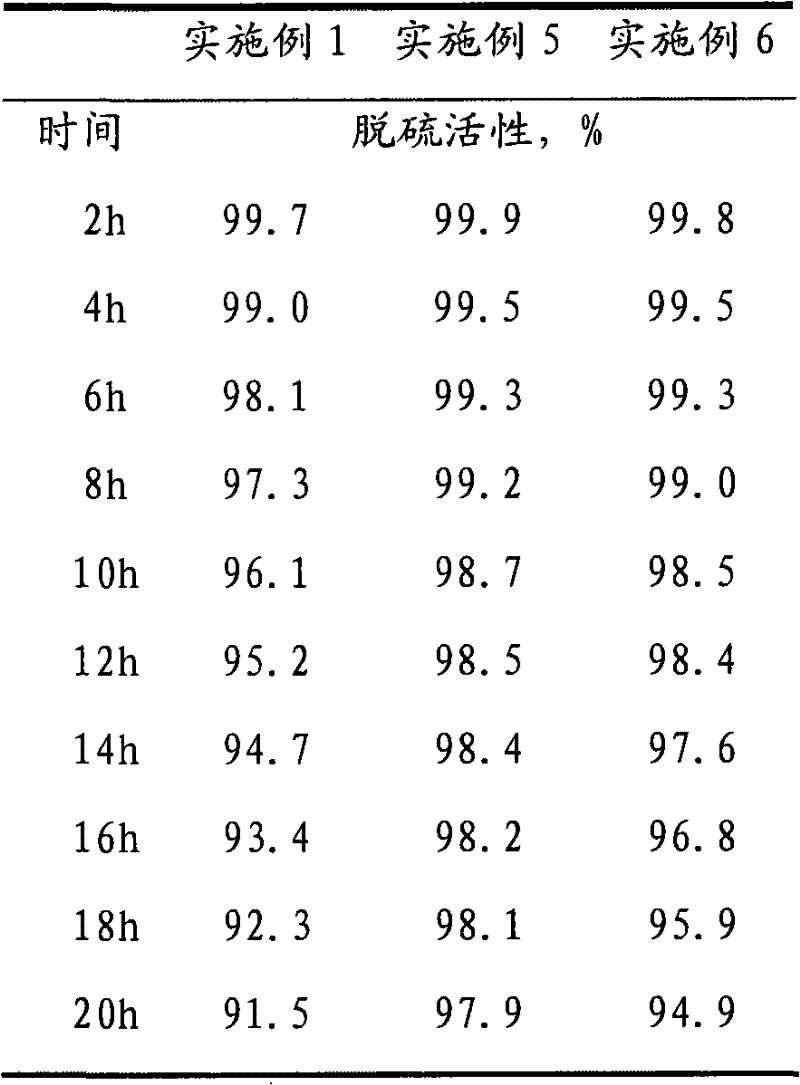

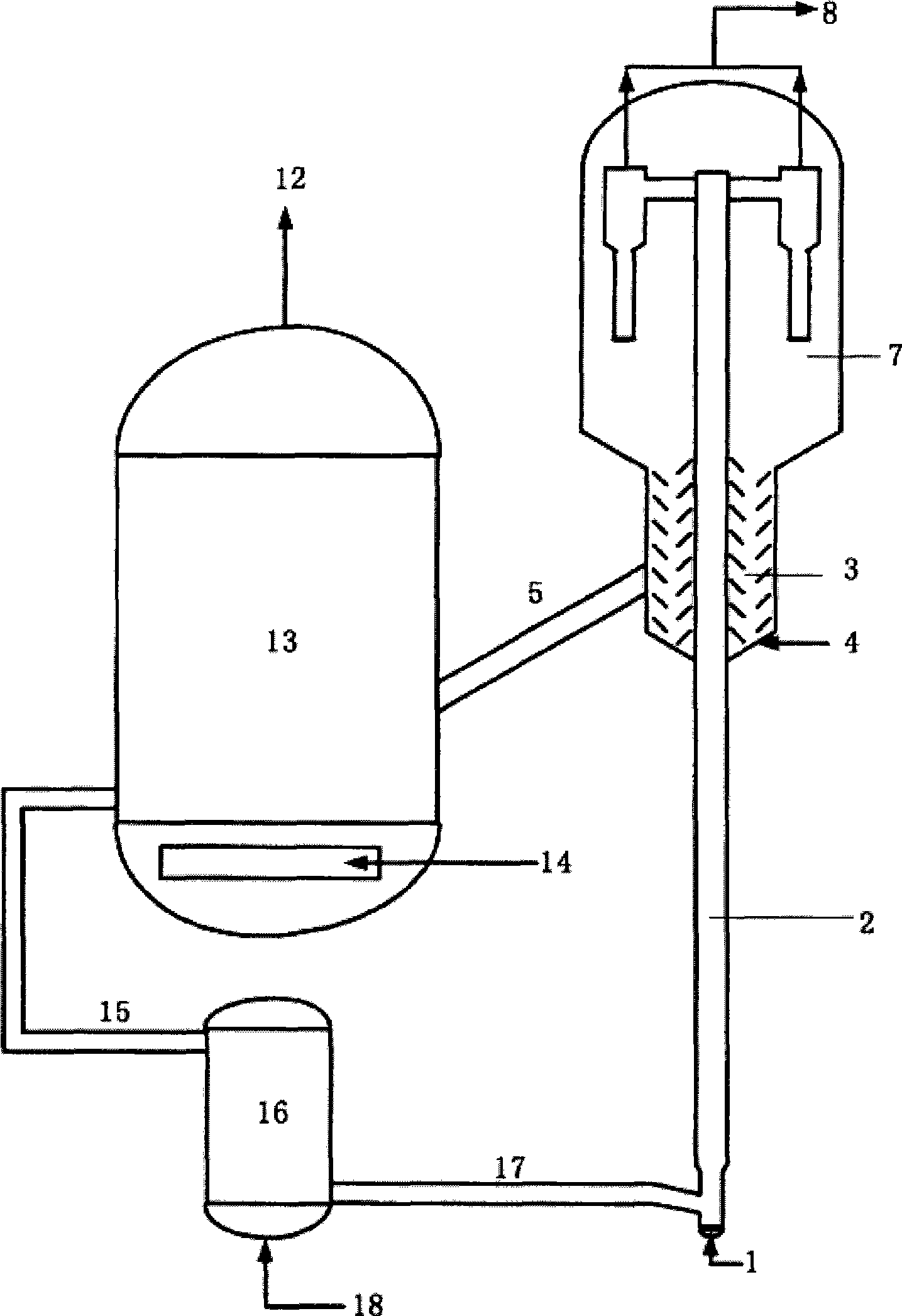

Method for reducing sulfide in light hydrocarbon oil

The invention provides a method used for reducing the content of sulfide in light hydrocarbon oil, which comprises the steps as follows: after being preheated, a hydrocarbon oil raw material containing sulfur, and hydrogen donor enter a reactor filled with a sorbent and a zeolite additive so as to react under the conditions as follows: temperature of 300-500 DEG C, pressure of 0.5-3.5MPa, weight hourly space velocity of raw material oil at 0.5-10h<-1> and weight ratio between total amounts of the sorbent and the hydrocarbon oil raw material at 1-20; the materials are separated after reaction; the reaction products are sent to a subsequent separation system so that the product is separated; the sorbent to be regenerated and the zeolite additive to be regenerated after reaction are stripped, burned and regenerated; and the regenerated sorbent and the zeolite additive are reduced by the hydrogen donor and subsequently returned to the reactor so as to be circularly used. The method adds the zeolite additive during the adsorption desulfurization process, realizes deep desulfurization, leads the removal rate of the sulfur to achieve more than 96wt percent when disposing the gasoline, reduces the olefin of the gasoline, improves the octane number of the outcome gasoline simultaneously, keeps high liquid recovery and has low benzene content in the outcome gasoline.

Owner:CHINA PETROLEUM & CHEM CORP +1

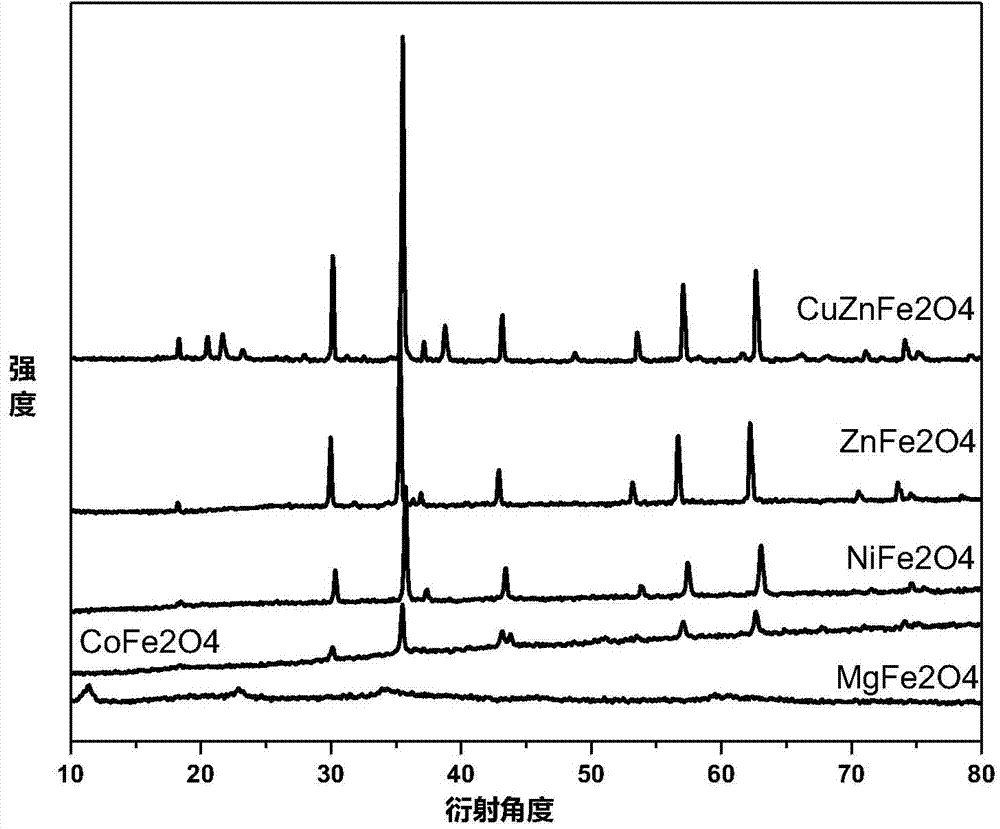

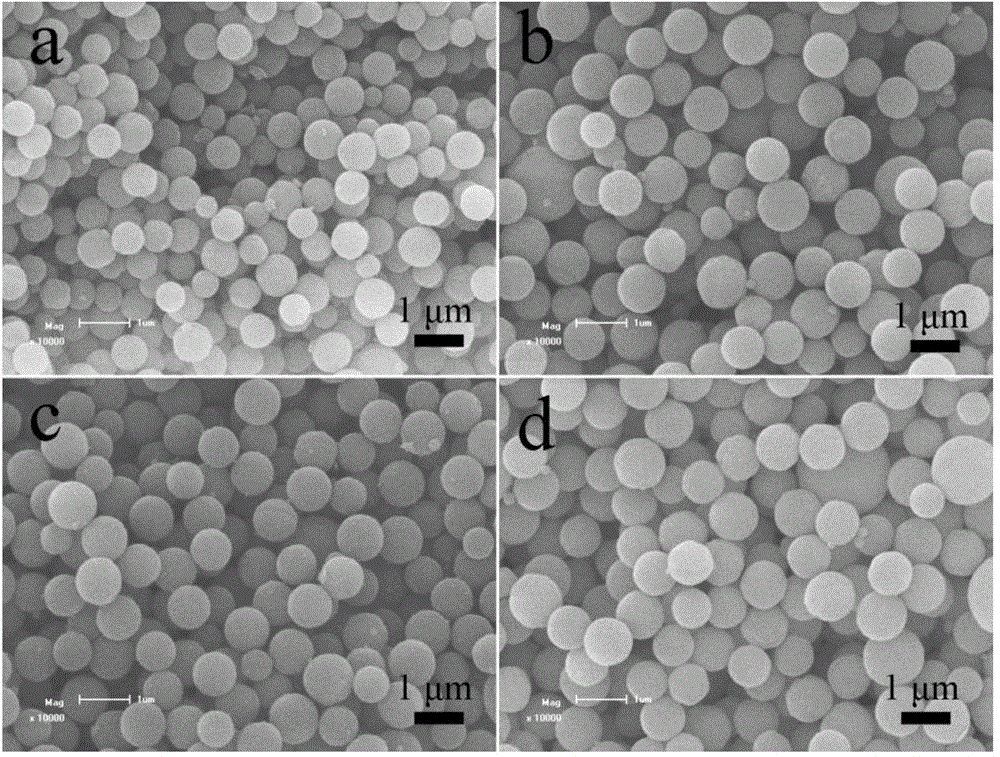

Novel nano ferrite adsorption desulfurization catalyst and preparation method thereof

InactiveCN104741123AHigh desulfurization selectivityRealize deep desulfurizationHydrocarbon oils refiningMetal/metal-oxides/metal-hydroxide catalystsFuel oilPetroleum

The invention belongs to the technical field of fuel processing and petroleum chemical engineering, and relates to a novel nano ferrite adsorption desulfurization catalyst MeFe2O4, wherein Me comprises but not the same with Mg, Zn, Ni, Co and Cu. The preparation method comprises the following steps: dissolving transition metal nitrate, Fe-containing nitrate and fuels in water, heating the obtained solution in a microwave furnace rapidly, decomposing so as to generate a great quantity of combustible gases and emit a great amount of heat, and combusting reactants reaching the spontaneous ignition point; and reacting so as to obtain a solid material, namely the novel nano ferrite adsorption desulfurization catalyst. The novel nano ferrite adsorption desulfurization catalyst is relatively high in desulfurization selectivity, can prevent the loss of octane value and cetane value due to olefins hydrogenation while deeply removing sulfocompound in fuel oil, and has relatively good industrial application prospect.

Owner:DALIAN UNIV OF TECH +1

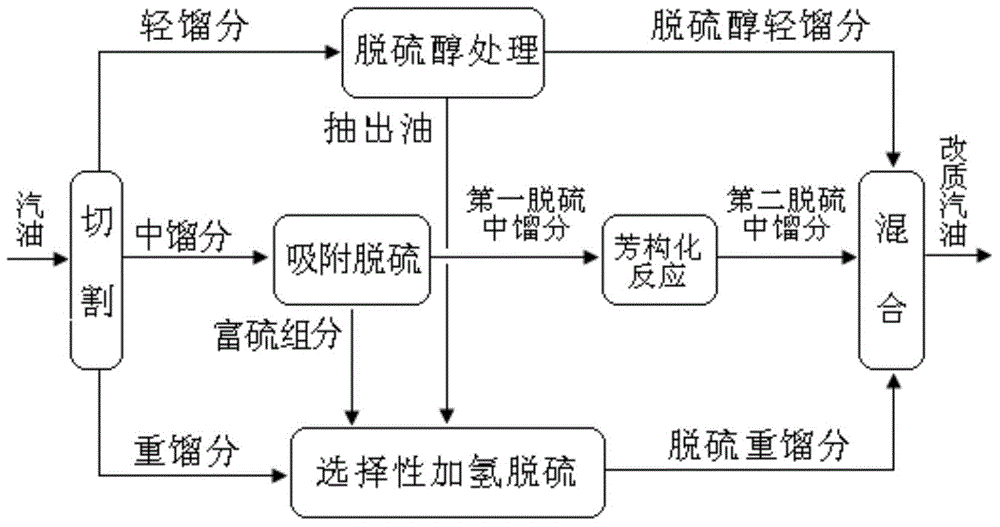

Quality improvement method of catalytic cracking gasoline

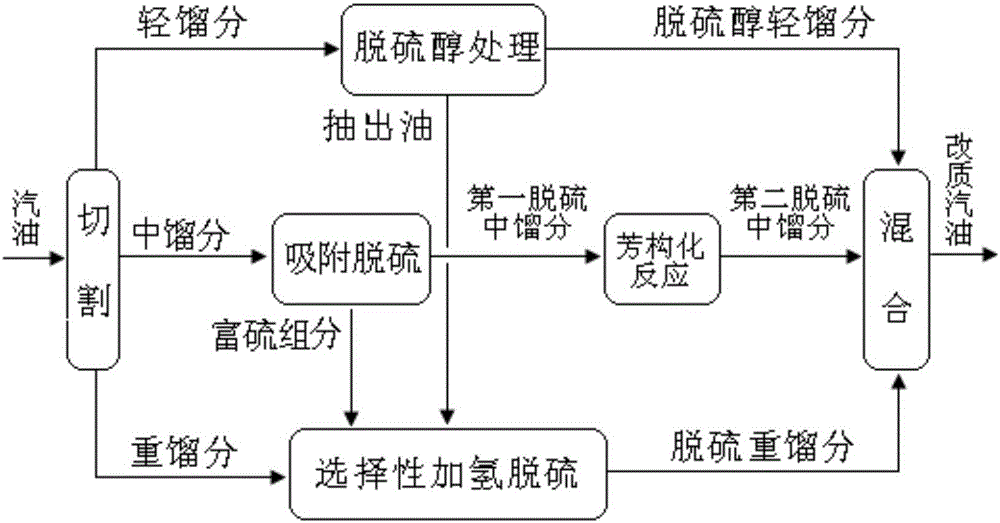

InactiveCN104673377ARealize deep desulfurizationFlexible operationTreatment with hydrotreatment processesHydrocarbon oils treatment productsHydrodesulfurizationAromatization

The invention provides a quality improvement method of catalytic cracking gasoline. The quality improvement method comprises the following steps of: cutting a gasoline raw material into light, medium and heavy gasoline fractions; desulfurizing the medium gasoline fraction to obtain first desulfurized medium gasoline fraction; carrying out aromatization / hydroisomerization reaction on the first desulfurized medium gasoline fraction in the presence of a catalyst to obtain second desulfurized medium gasoline fraction; carrying out selective hydrodesulfurization on the heavy gasoline fraction to obtain desulfurized heavy gasoline fraction; mixing the light gasoline fraction, the second desulfurized medium gasoline fraction and the desulfurized heavy gasoline fraction to obtain quality improved gasoline, wherein the cutting temperature of the light and medium gasoline fractions is 35-60 DEG C, and the cutting temperature of the medium and heavy gasoline fraction is 70-130 DEG C. The quality improvement method provided by the invention can not only realize the deep desulfurization of the catalytic cracking gasoline, but also be used for outstandingly increasing the octane value.

Owner:CHINA UNIV OF PETROLEUM (BEIJING)

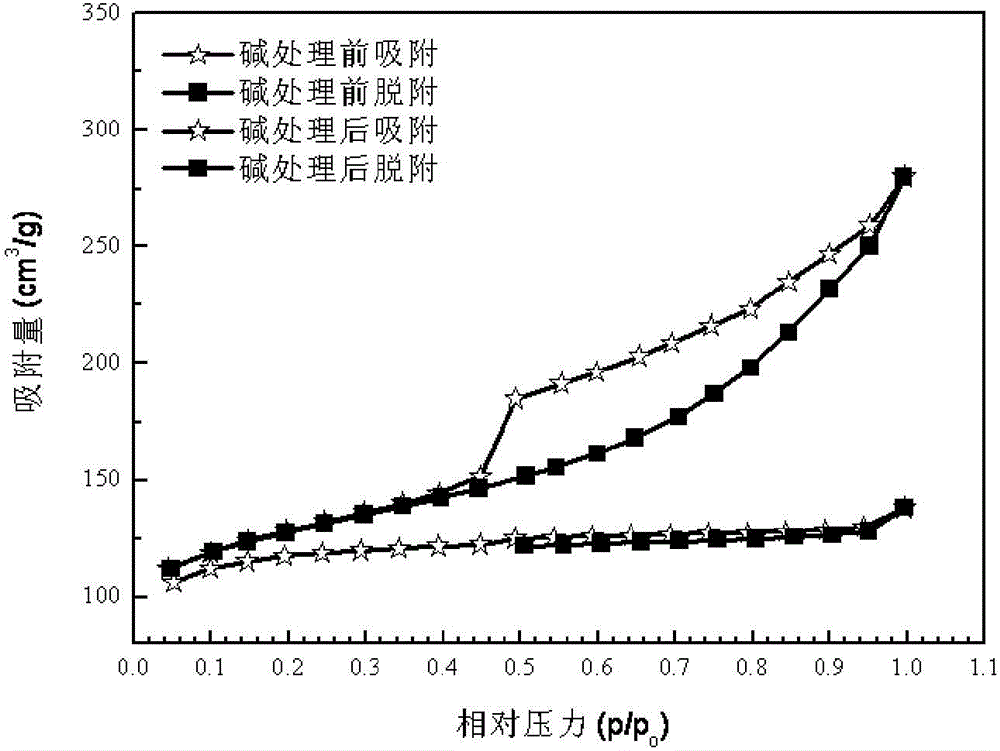

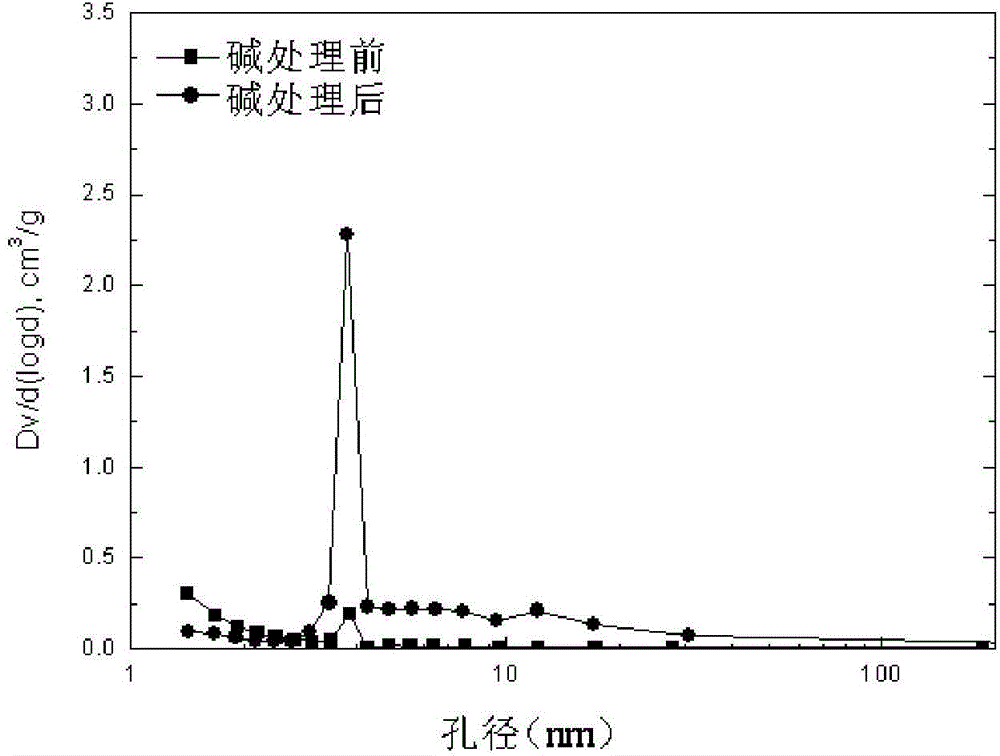

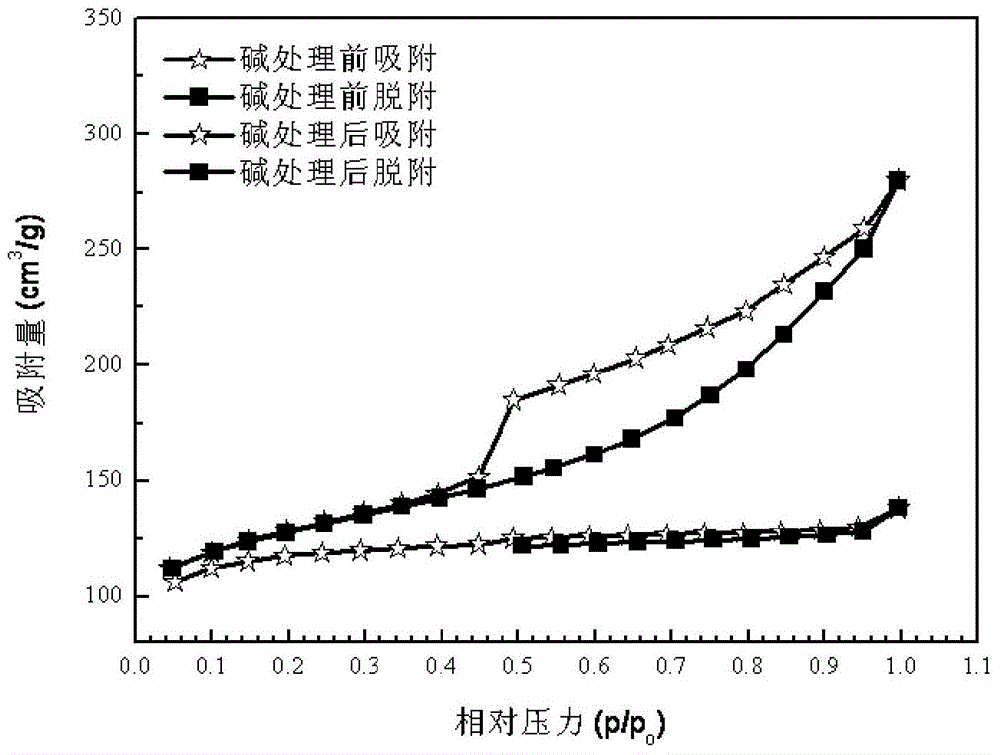

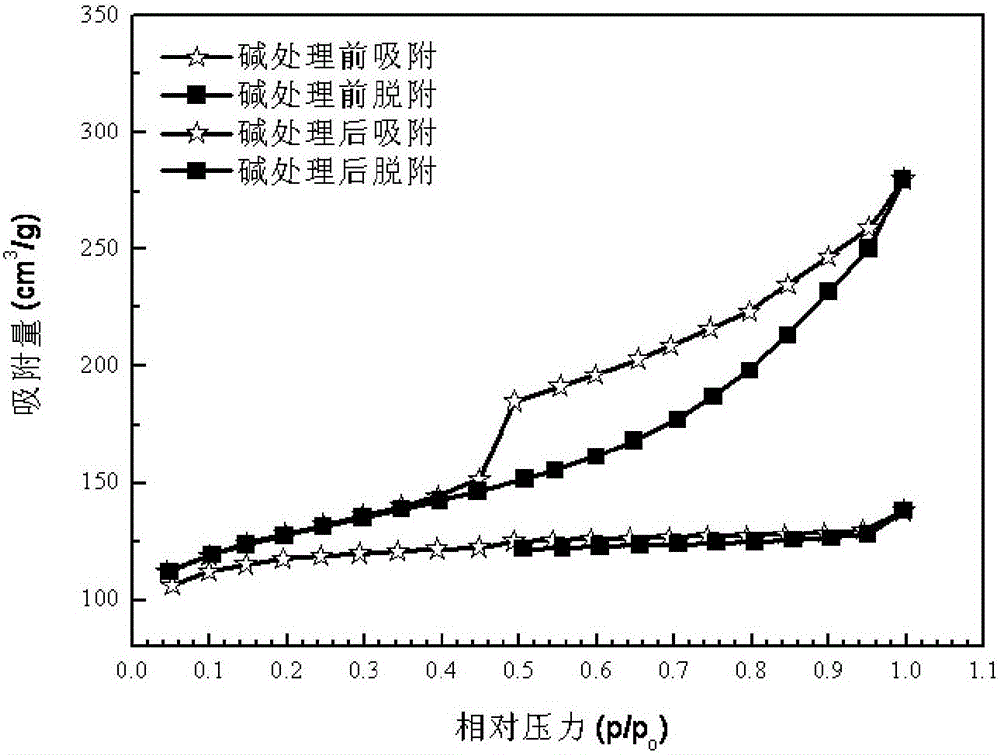

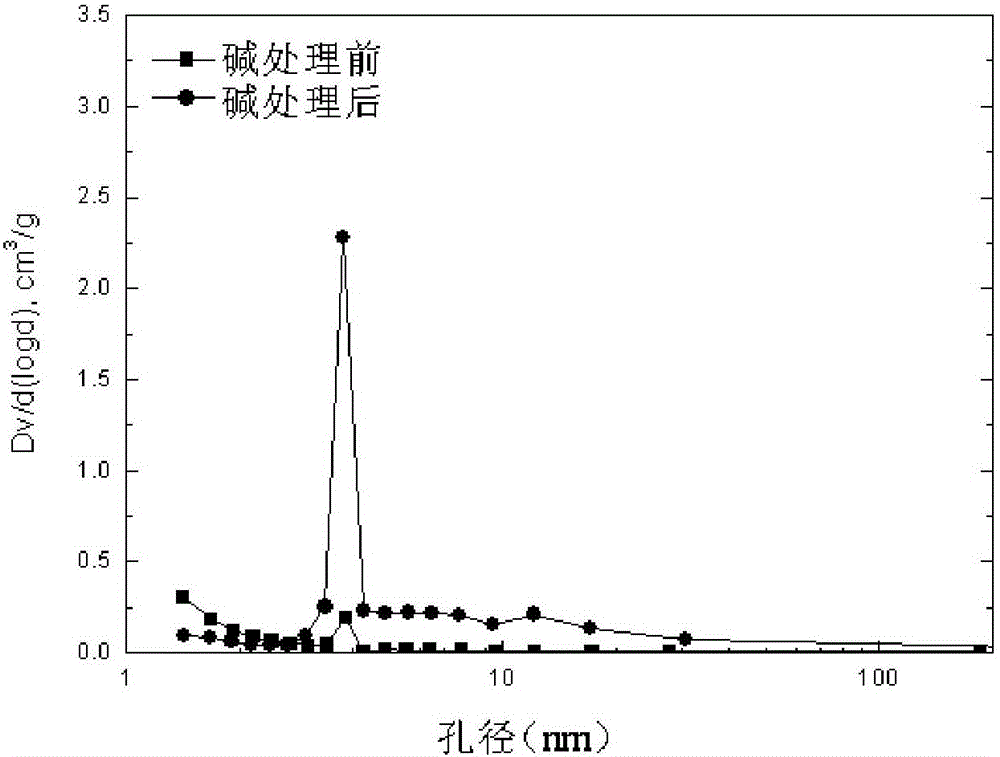

Mesoporous silicon material as well as preparation method and application thereof

ActiveCN103464140AHigh catalytic activityImprove dispersionHydrocarbon oils refiningMetal/metal-oxides/metal-hydroxide catalystsIonSol-gel

The invention relates to a mesoporous material and particularly relates to a functionalized ordered mesoporous silicon material which is synthesized by taking polyacid-type ionic liquid as a raw material as well as an application of the mesoporous silicon material in oxidation desulfuration of fuel oil. According to the mesoporous silicon material, the polyacid-type ionic liquid is not only used as a template agent of the mesoporous material, but also used as a catalytic activity center, and transition metal is introduced into the mesoporous material structure in situ. A simple and nontoxic synthesis method of the metal-doped green mesoporous material is searched, has a favorable academical research value and also has a wide application prospect in the industrial production. The mesoporous silicon material as well as the preparation method and the application thereof have the advantages that the method is simple in process, and the mesoporous silicon material which is narrow in pore size distribution, regular and ordered in pore duct and good in thermal stability and has the pore size of 2-50nm is self-assembled under the guidance action of inorganic matters and organic matters by adopting a sol-gel method. The purpose of deep desulfuration can be achieved when the mesoporous silicon material is used as a catalyst for an oxidation removing reaction process of organic sulfides.

Owner:泰州市海创新能源研究院有限公司

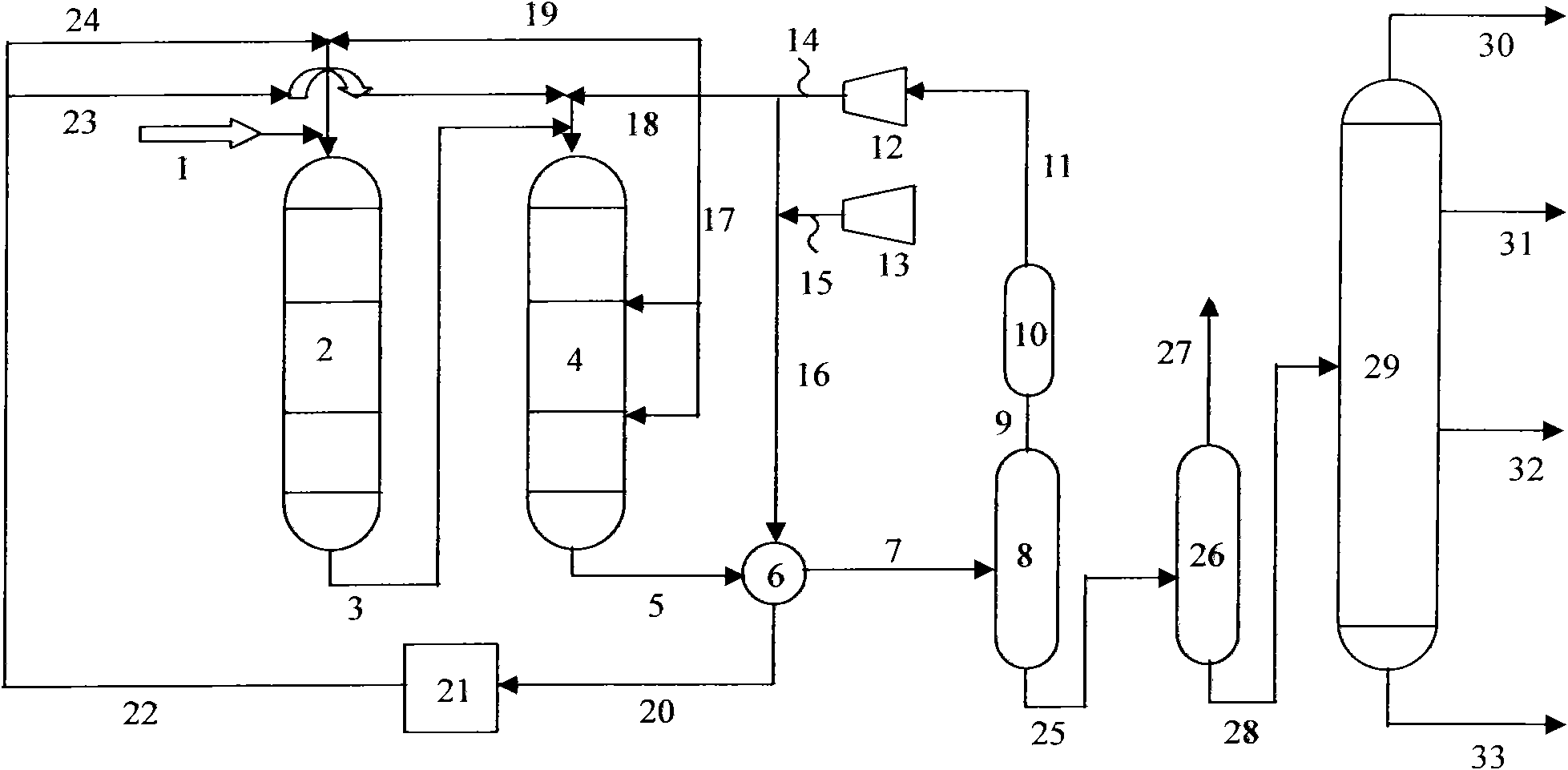

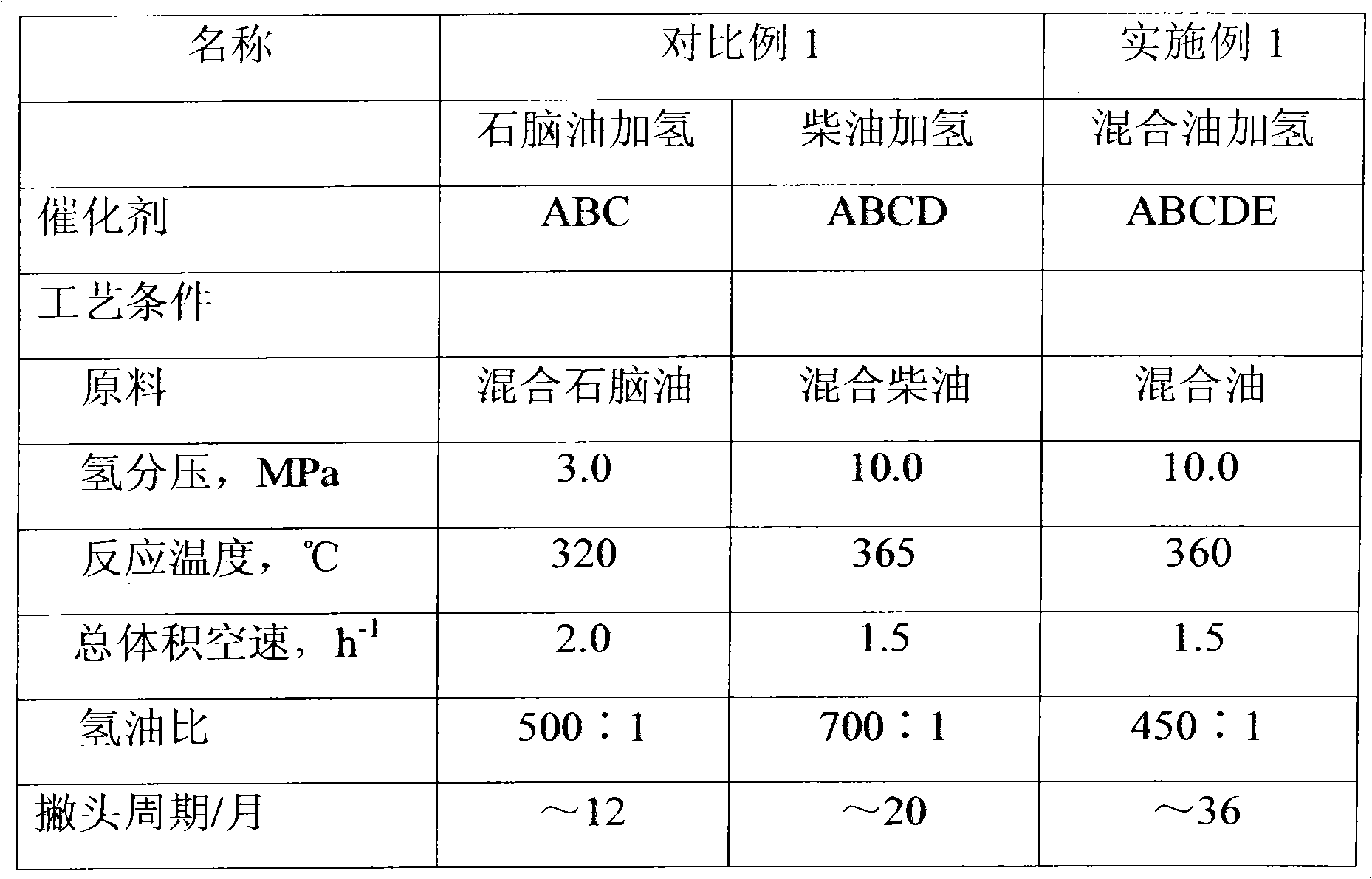

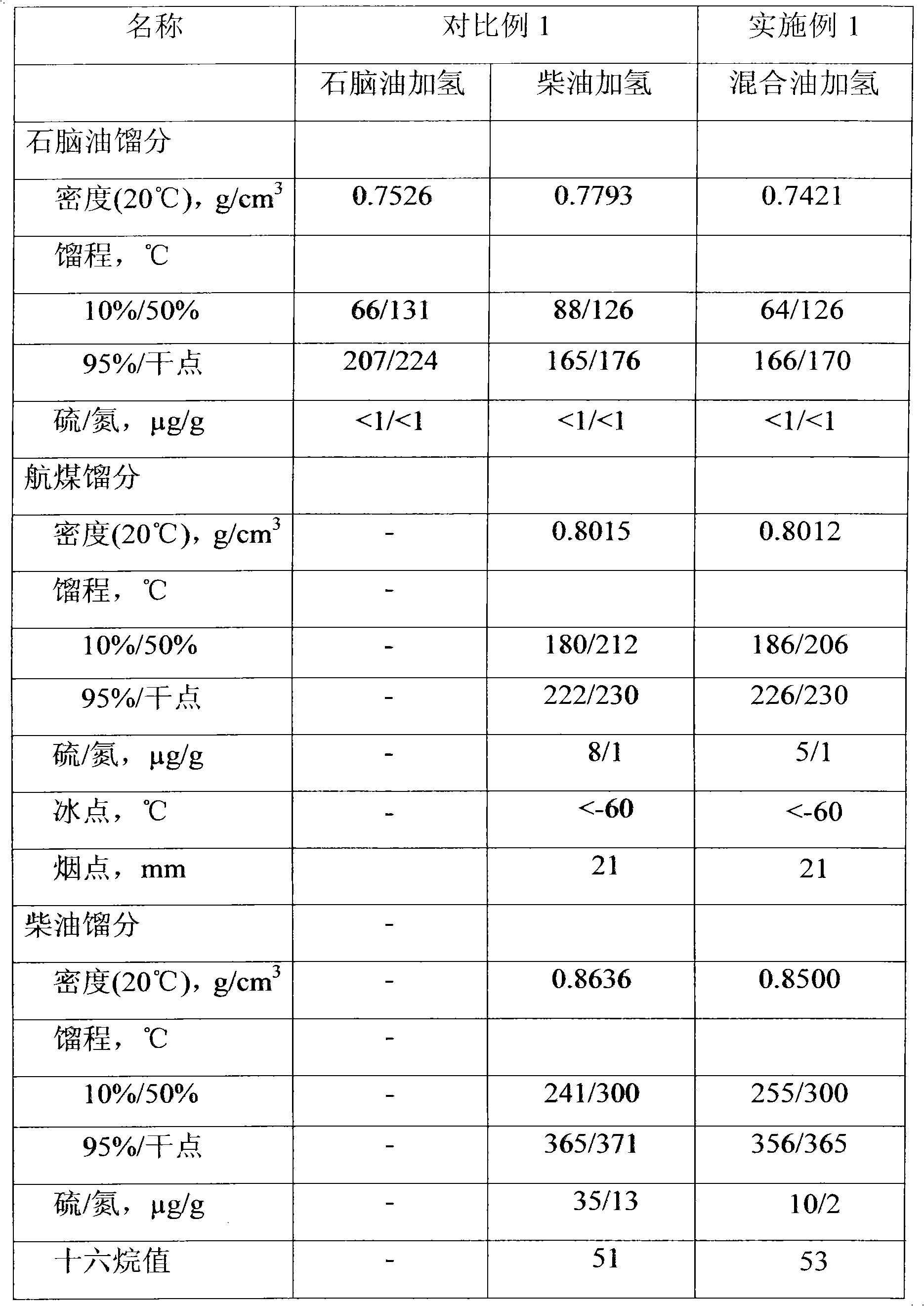

Hydrogenation modification method for coking gasoline and diesel distillates

ActiveCN102465023AAvoid Coking ProblemsFlexible production operationsTreatment with hydrotreatment processesChemistryKerosene

The invention discloses a hydrogenation modification method for coking gasoline and diesel distillates. A coking gasoline and diesel raw material is mixed with heated hydrogen and then introduced to pass through a low-temperature hydrorefining reactor and a hydrogenation modification reactor in sequence; a reaction effluent is separated and modified, and obtained liquid is distilled to obtain gas, gasoline, kerosene and diesel. In the method disclosed by the invention, a process flow of mixing hydrogen behind a furnace is adopted, the heating furnace is only used for heating the hydrogen, the mixed raw material does not pass through the heating furnace, and the temperature of the reactor is controlled based on the quantities of hot hydrogen and cold hydrogen. Compared with the prior art, the hydrogenation modification method disclosed by the invention has the advantage of saving equipment investment and being flexible in production scheme, can be used for flexible production by adjusting process conditions and production distribution according to the differences of raw material properties and product schemes; by implementation of hydrogen mixing behind the furnace, the coking raw material can be effectively prevented from being coked at a furnace tube; and by arrangement of a low-temperature protective agent reactor, olefin saturation is performed at lower temperature so as to reduce coking, meanwhile, coke powder is distributed at a protective agent bed as uniform as possible, so that the long-term operation of a hydrogenation device is ensured.

Owner:CHINA PETROLEUM & CHEM CORP +1

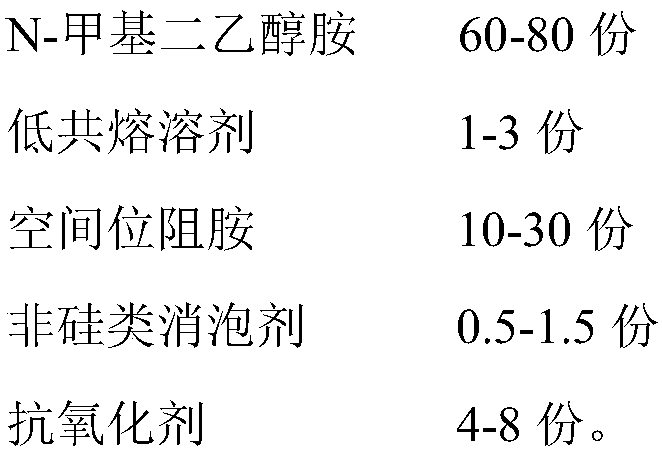

High-selectivity compound desulfurizer and preparation method thereof

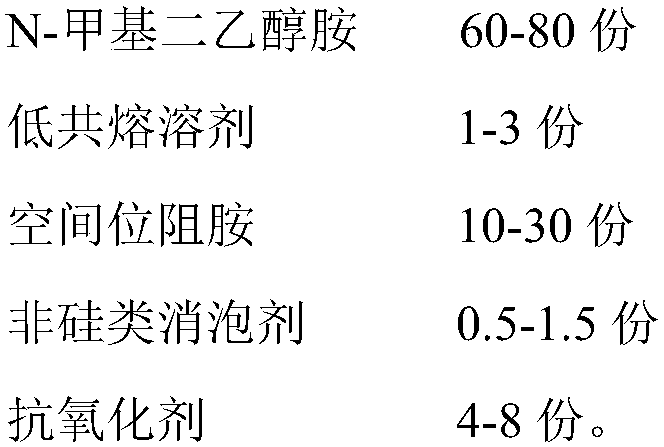

ActiveCN108816196ASimple processLow regeneration energy consumptionGas treatmentOther chemical processesAbsorption capacityAntioxidant

The invention specifically relates to a high-selectivity compound desulfurizer and a preparation method thereof, belonging to the field of gas purification techniques. The high-selectivity compound desulfurizer comprises the following raw materials by weight: 60-80 parts of N-methyldiethanolamine, 1-3 parts of an eutectic solvent, 10-30 parts of sterically hindered amine, 0.5-1.5 parts of a non-silicon defoaming agent and 4-8 parts of an antioxidant. The compound desulfurizer provided by the invention overcomes the shortcomings of current refinery gas desulfurization processes, and is simple in process and applicable to desulfurization of most refinery acidic gases. According to the invention, N-methyldiethanolamine, the eutectic solvent and sterically hindered amine are compounded, and the supplementation effect and synergism of the above three components enhance the respective desulfurization effect of the components; and the high-selectivity compound desulfurizer has high purification depth, large absorption capacity, low energy consumption for regeneration, environment friendliness and other advantages.

Owner:淄博凯美可工贸有限公司

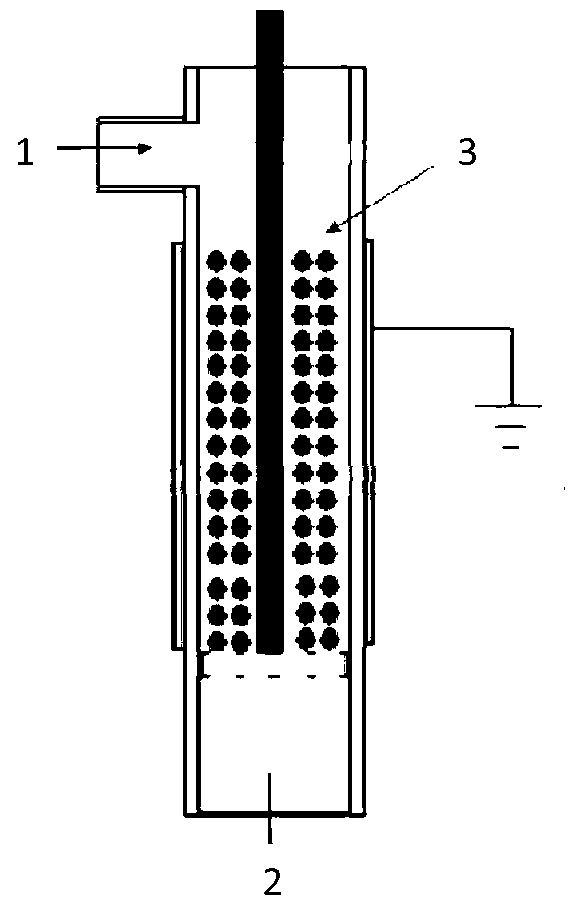

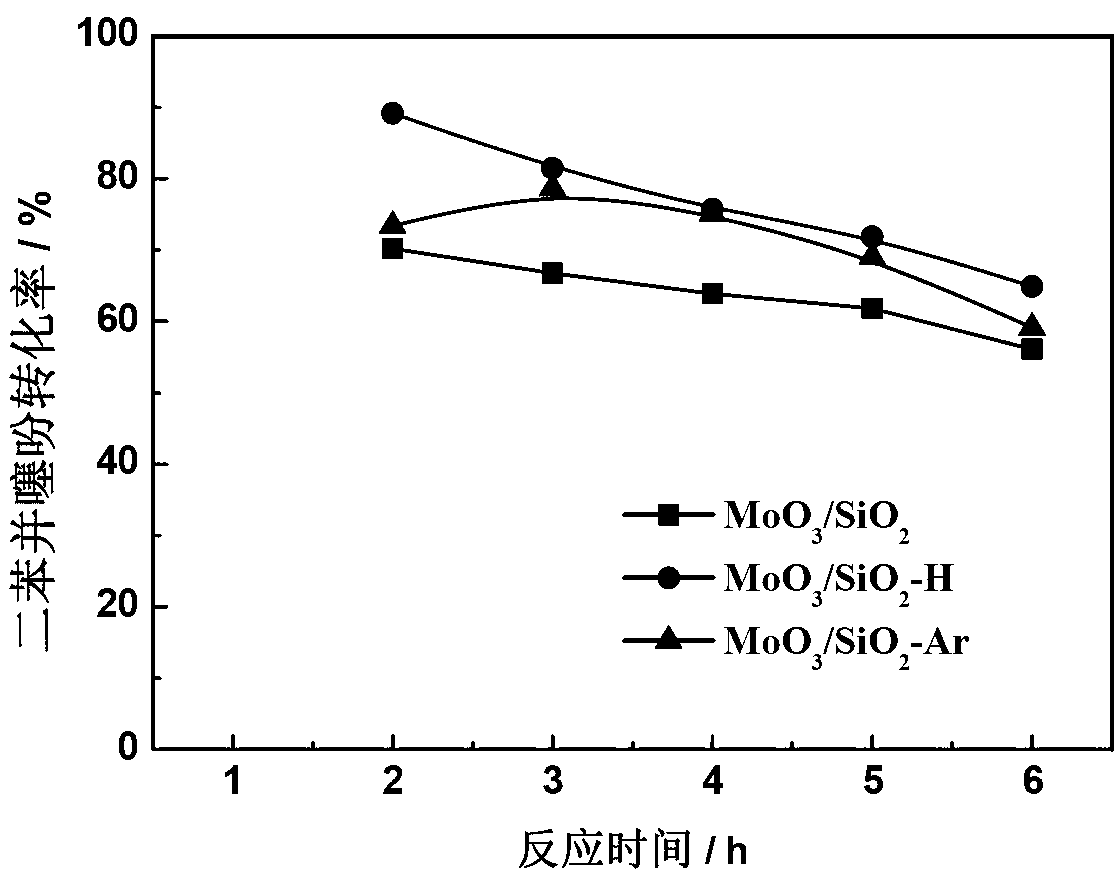

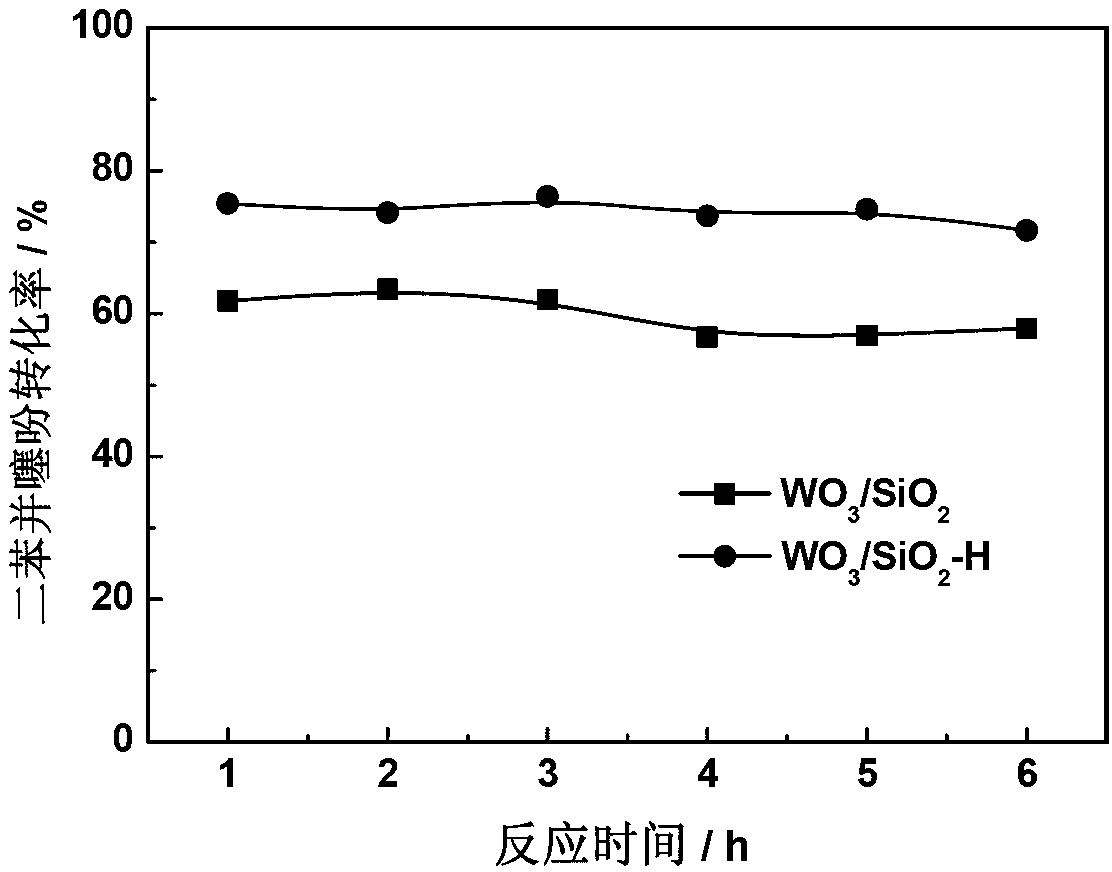

Method for preparing supported molybdenum-oxide-based and tungsten-oxide-based oxidation desulfurization catalysts

InactiveCN103240076AHigh activityReduce sulfur contentMetal/metal-oxides/metal-hydroxide catalystsOil processingHydrogen

The invention discloses a method for preparing supported molybdenum-oxide-based and tungsten-oxide-based oxidation desulfurization catalysts, belonging to the technical fields of coal processing, petroleum processing and petrochemical industry and relating to a method for preparing catalysts for removing thiophene-type heteroaromatic sulfide-containing solids from distillate oil and chemical materials by oxidation. The method is characterized by preparing the catalysts in a way of implementing plasma treatment on the molybdenum-oxide-based or the tungsten-oxide-based catalyst supported by a porous supporter under a hydrogen or inert gas atmosphere. The method has the effect and the benefit of remarkably enhancing the oxidation desulfurization activity of the supported molybdenum-oxide-based and tungsten-oxide-based catalysts, and has wide application prospect in the field of deep desulfurization.

Owner:DALIAN UNIV OF TECH

Catalytic oxidizing method for deeply removing suifide in petrol

InactiveCN1554730AMild reaction conditionsSimple equipmentTreatment with plural serial refining stagesSolventMolecular sieve

The present invention provides catalytic oxidizing process for deeply removing sulfide in petrol. The process adopts solid titanium contaniing molecular sieve as catalyst and hydrogen peroxide solution as oxidant to oxidize main sulfide in petrol at 40-80 deg.c and normal pressure without H2 consumption; and the oxidized product is removed via extraction with methanol, acetonitrile, butanol, water or their mixture. The said process can eliminate 80-90% of sulfide from petrol and lower the sulfur content of FCC petrol from 136 ppm to 18 ppm. The process of the present invention has mild reaction condition, simple apparatus and easy-to-recover catalyst and can realize deep desulfurizing.

Owner:DALIAN UNIV OF TECH

Attapulgite clay-supported heteropoly acid phase-transfer catalyst for oxidative desulfurization of fuel

InactiveCN101987299AImprove the effect of oxidation desulfurizationReduce dosageOrganic-compounds/hydrides/coordination-complexes catalystsRefining with oxygen compoundsHeteropoly acidBULK ACTIVE INGREDIENT

The invention discloses an attapulgite clay-supported heteropoly acid phase-transfer catalyst for oxidative desulfurization of fuel. The attapulgite clay is used as a catalyst support, wherein the active ingredients consist of quaternary ammonium salt and heteropoly acid; and the catalyst comprises the following raw materials in part by mass: 10 to 50 parts of quaternary ammonium salt, 10 to 60 parts of heteropoly acid and 20 to 80 parts of attapulgite clay. The catalyst can realize deep desulfurization of the fuel.

Owner:LANZHOU INST OF CHEM PHYSICS CHINESE ACAD OF SCI

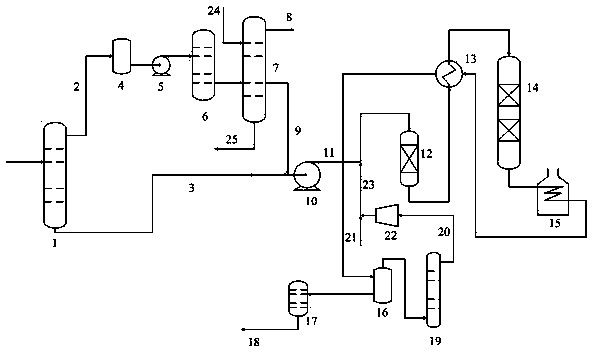

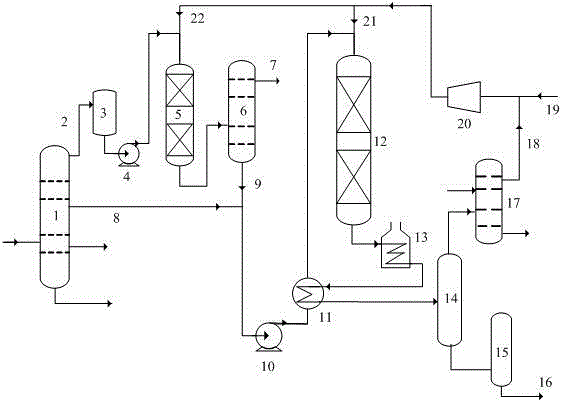

Method used for catalytic gasoline deep hydrodesulfurization

ActiveCN103805269AReduce total sulfur contentFreedom from abnormally rapid rises in pressure dropTreatment with hydrotreatment processesChemistrySulfur content

The invention discloses a method used for catalytic gasoline deep hydrodesulfurization. The method comprises following steps: catalytic gasoline is delivered into a prefrationation tower firstly; an appropriate separation point is adopted, light gasoline fraction and middle gasoline fraction are discharged through the top of the prefrationation tower, and heavy gasoline fraction is discharged through the bottom of the prefrationation tower; the light gasoline fraction and the middle gasoline fraction are subjected to alkali-free deodorization, and are delivered into a hydrogenation prefrationation tower so as to separate light gasoline and middle gasoline, wherein catalytic cracking hot diesel oil extracted from a main fractionate tower side line is also delivered into the hydrogenation prefrationation tower; separated middle gasoline and heavy gasoline are mixed, and are subjected to selective hydrogenation, and an obtained distillate is mixed with light gasoline obtained via alkali-free deodorization so as to obtain clean gasoline products. Compared with existing catalytic gasoline hydrodesulfurization method, the method and equipment of the invention is capable of reducing energy consumption greatly, octane value loss of the gasoline products is less, sulfur content of the gasoline products is less than 10<mu>g / g, and economic benefits of oil refining enterprises are improved.

Owner:CHINA PETROLEUM & CHEM CORP +1

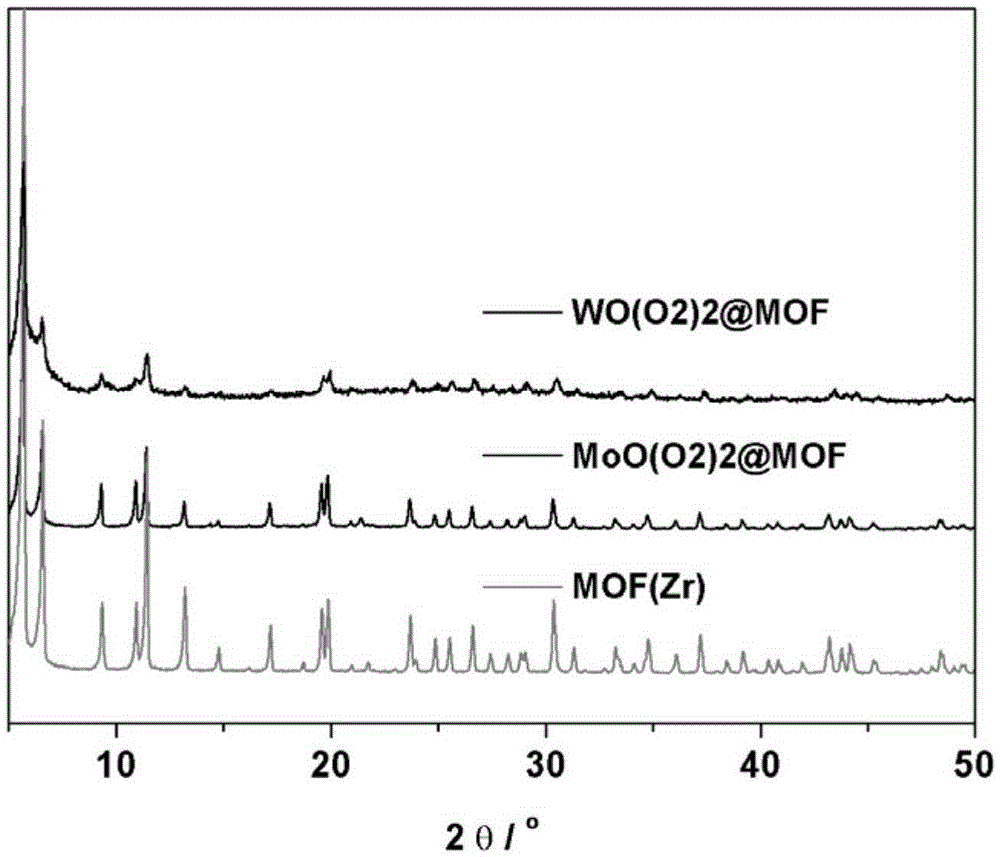

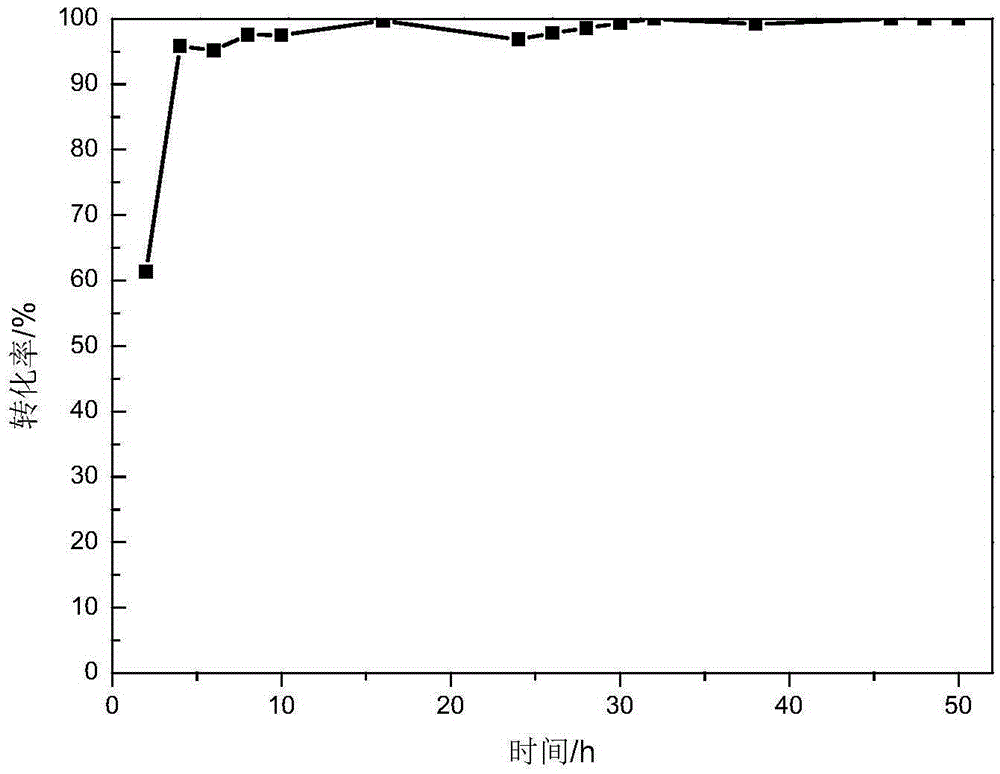

MOF supported metal peroxide catalyst

InactiveCN105289732AHigh activityAvoid churnOrganic-compounds/hydrides/coordination-complexes catalystsRefining with oxygen compoundsCatalytic oxidationMetal-organic framework

The invention provides an MOF supported metal peroxide catalyst. The catalyst comprises a metal organic skeleton carrier and a metal peroxide species MO(O2)2, wherein M represents Mo6 or W6+. The catalyst is prepared in the mode that in the metal organic skeleton material synthesizing process, MO(O2)2 with catalytic oxidation activity is anchored to a metal organic skeleton material through a pre-modification or post-modification method. According to the catalyst, metal peroxide is highly dispersed on a crystal skeleton, and the metal peroxide species is coordinated with organic ligand based on dipyridyl chelation locus, so that high stability is kept; when applied to an oxidation sweetening reaction, high activity and stability are kept, and the catalyst has important industrial application value.

Owner:DALIAN UNIV OF TECH

A kind of upgrading method of catalytic cracking gasoline

InactiveCN104673377BRealize deep desulfurizationFlexible operationTreatment with hydrotreatment processesHydrocarbon oils treatment productsHydrodesulfurizationGasoline

The invention provides a quality improvement method of catalytic cracking gasoline. The quality improvement method comprises the following steps of: cutting a gasoline raw material into light, medium and heavy gasoline fractions; desulfurizing the medium gasoline fraction to obtain first desulfurized medium gasoline fraction; carrying out aromatization / hydroisomerization reaction on the first desulfurized medium gasoline fraction in the presence of a catalyst to obtain second desulfurized medium gasoline fraction; carrying out selective hydrodesulfurization on the heavy gasoline fraction to obtain desulfurized heavy gasoline fraction; mixing the light gasoline fraction, the second desulfurized medium gasoline fraction and the desulfurized heavy gasoline fraction to obtain quality improved gasoline, wherein the cutting temperature of the light and medium gasoline fractions is 35-60 DEG C, and the cutting temperature of the medium and heavy gasoline fraction is 70-130 DEG C. The quality improvement method provided by the invention can not only realize the deep desulfurization of the catalytic cracking gasoline, but also be used for outstandingly increasing the octane value.

Owner:CHINA UNIV OF PETROLEUM (BEIJING)

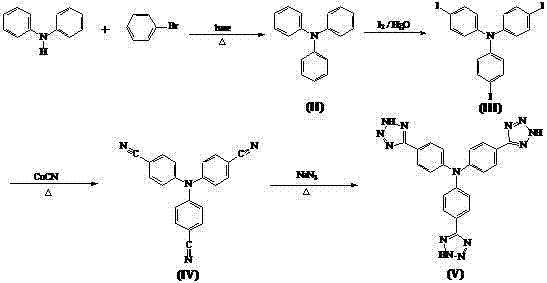

Synthesis method of tris-(4-tetrazolyl-phenyl)amine

The invention relates to a synthesis method of tris-(4-tetrazolyl-phenyl)amine, belonging to the field of material chemistry. The technical scheme of the invention is as follows: reacting diphenylamine with halo-benzene under a basic condition to obtain triphenylamine, carrying out substitution reaction on triphenylamine with iodine to generate tris-(4-iodophenyl)amine, then reacting tris-(4-iodophenyl)amine with CuCN to generate tris-(4-cyanophenyl)amine, and finally reacting tris-(4-cyanophenyl)amine with sodium azide to generate tris-(4-tetrazolyl-phenyl)amine. The porous material built by reacting obtained tris-(4-tetrazolyl-phenyl)amine with a metal has the stability of carboxylic acid porous frames, achieves intra-pore functionalization, and has pores in a mesoporous size. The adsorption capacity with respect to specific sulfur-containing small molecules shows that the porous material has potential application value in developing high-performance petrochemical products.

Owner:扬州三友合成化工有限公司

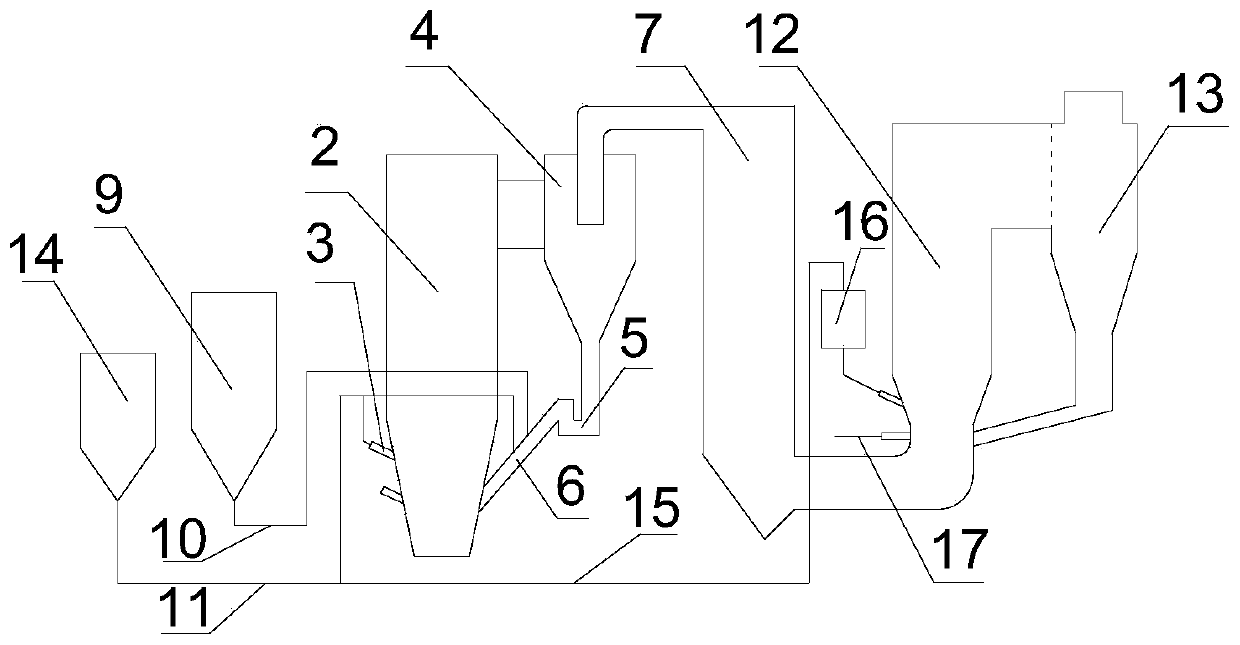

Circulating fluidized bed boiler and desulfurization method

InactiveCN109718660AHigh calcium oxideAchieve ultra-low emissionsFluidized bed combustionDispersed particle separationFluidized bedFlue gas

The invention provides a circulating fluidized bed boiler and a desulfurization method. The circulating fluidized bed boiler comprises an in-furnace desulfurization system and an out-furnace desulfurization system which are communicated in sequence, wherein the in-furnace desulfurization system comprises a hearth; the hearth is provided with a first inlet, the circulating fluidized bed boiler further comprises a limestone conveying pipeline and a quicklime conveying pipeline, and the limestone conveying pipeline and the quicklime conveying pipeline are communicated with the first inlet. In thewhole process of starting the circulating fluidized bed boiler, when the boiler does not reach the optimal temperature range of the limestone reaction, quicklime (calcium oxide) as a desulfurizing agent is first directly adopted for directly reacting with sulfur dioxide in flue gas in the hearth for desulfurization reaction; when the optimal reaction temperature range of the in-furnace limestonedesulfurization system reaches in the boiler, an out-furnace circulating fluidized bed ash circulation system is established, limestone is fed into by the limestone conveying pipeline for desulfurization of sulfur-containing flue gas, high calcium oxide content in the hearth can be kept all the time so as to achieve the efficient desulfurization effect in the furnace.

Owner:CHINA SHENHUA ENERGY CO LTD +2

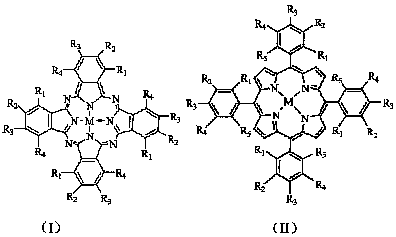

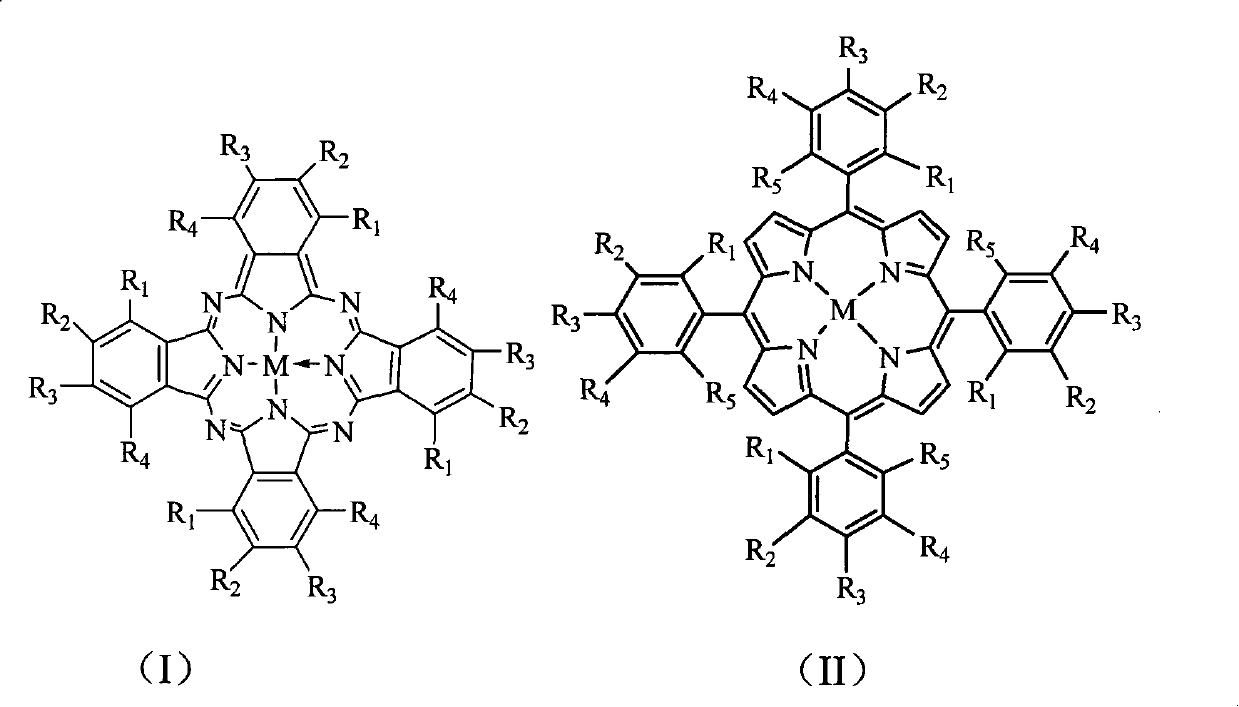

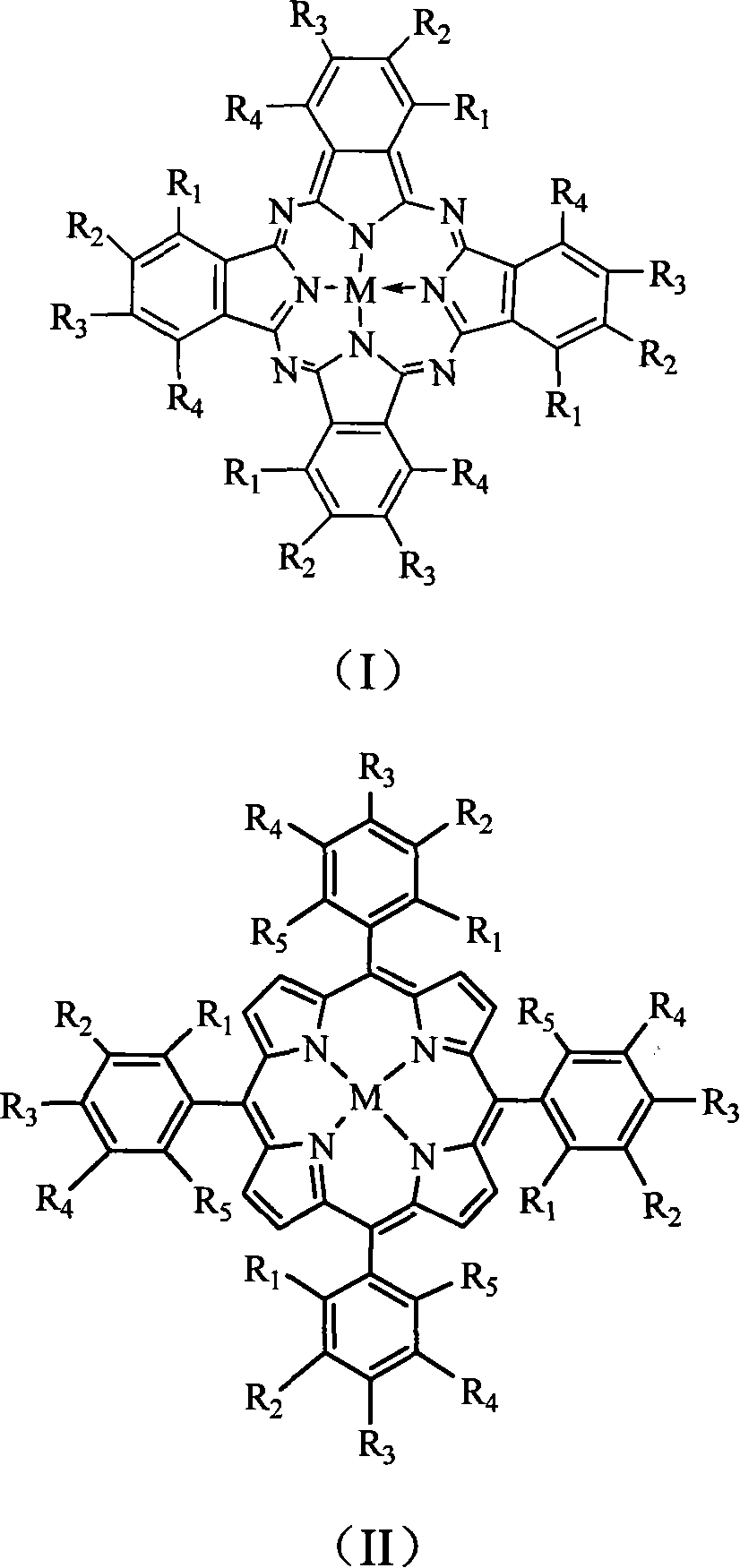

Method for bionically catalyzing and oxidizing thiophen compounds

InactiveCN101301627BReduce dosageRealize deep desulfurizationOrganic compounds purification/separation/stabilisationOrganic-compounds/hydrides/coordination-complexes catalystsReaction temperaturePorphyrin

The invention discloses a biomimetic catalytic oxidation method of thiophene compound, characterized by the structure of the biomimetic catalyst of formula I and formula II, wherein, M is Fe, Co or Mn; R1 is NO2, NH2, Cl, F, SOH3 or H; R2 is NO2, NH2, Cl, F, SOH3 or H; R3 is NO2, NH2, Cl, F, SOH3 or H, R4 is NO2, NH2, Cl, F, SOH3 or H; and R5 is NO2, NH2, Cl, F, SOH3 or H. Due to the application of metal phthalocyanine compound and metal porphyrins as the catalyst, the invention has the benefits of transferring and activating oxygen molecule, and catalytic oxidating organics with high selectivity under a mild condition. The reaction system of the invention has low use level of the catalyst, reduced cost, low reaction temperature and reaction pressure, no oil corrosion, is friendly to environment, can be recycled, as well as can achieve deep desulfurization of oil product, without requiring any cooxidation agent.

Owner:DALIAN UNIV OF TECH

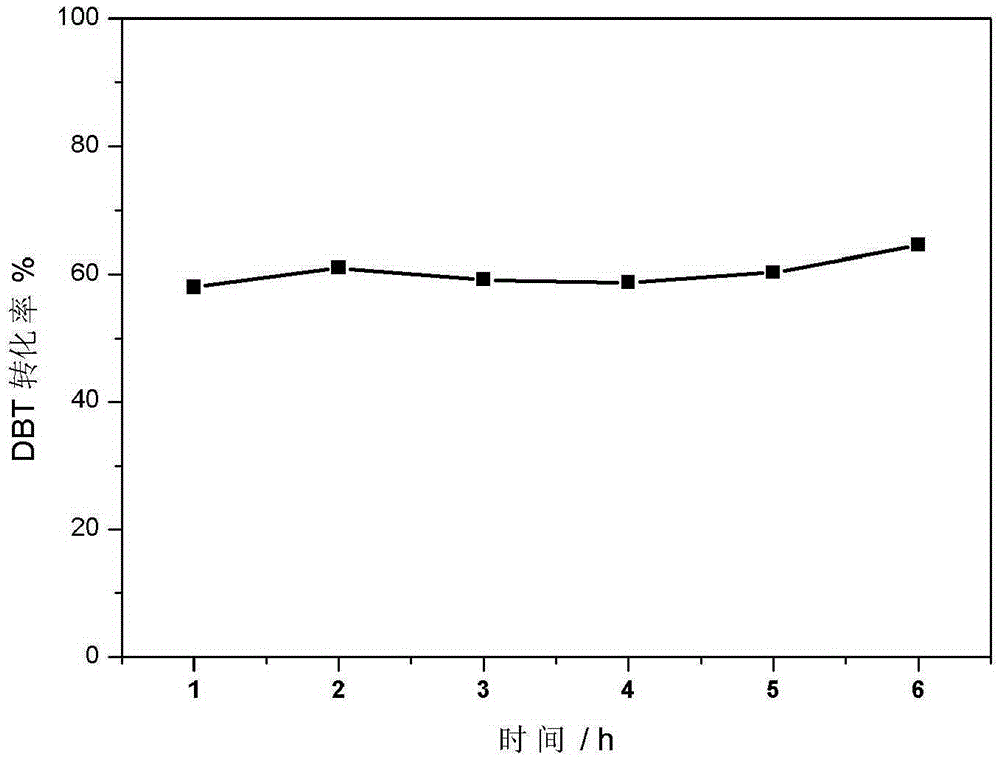

Desulfurization method by catalytic oxidation for fuel oil

InactiveCN103074099AReduce dosageHigh recovery rateOrganic-compounds/hydrides/coordination-complexes catalystsRefining with oxygen compoundsCatalytic oxidationFuel oil

The invention provides a desulfurization method by catalytic oxidation for fuel oil. The method comprises the steps of taking low-concentration, non-toxic, cheap and readily accessible hydrogen peroxide as an oxidizer, taking immobilized double-layer ionic liquid-phosphotungstate as a catalyst, and separating desulfurized fuel oil by catalytic oxidation extraction. The method can effectively reduce metal contamination in an oil product, is good in desulfurization effect, high in oil product recovery and mild in reaction condition, and can particularly realize deep desulfurization of benzothiophene (BT) sulfide or dibenzothiophene (DBT) and a derivative of BT sulfide or DBT; and the catalyst is simple in preparation method, small in use amount and high in activity, and can be recycled after being filtered and washed simply, so that the material cost is lowered. The method is simple in technology, readily accessible in raw material, low in operating cost, mild in reaction condition, few in byproduct, small in environmental contamination, suitable for industrial application, and good in application prospect.

Owner:SHAANXI NORMAL UNIV

Treatment method for alkali liquor oxidation regeneration tail gas containing mercaptide

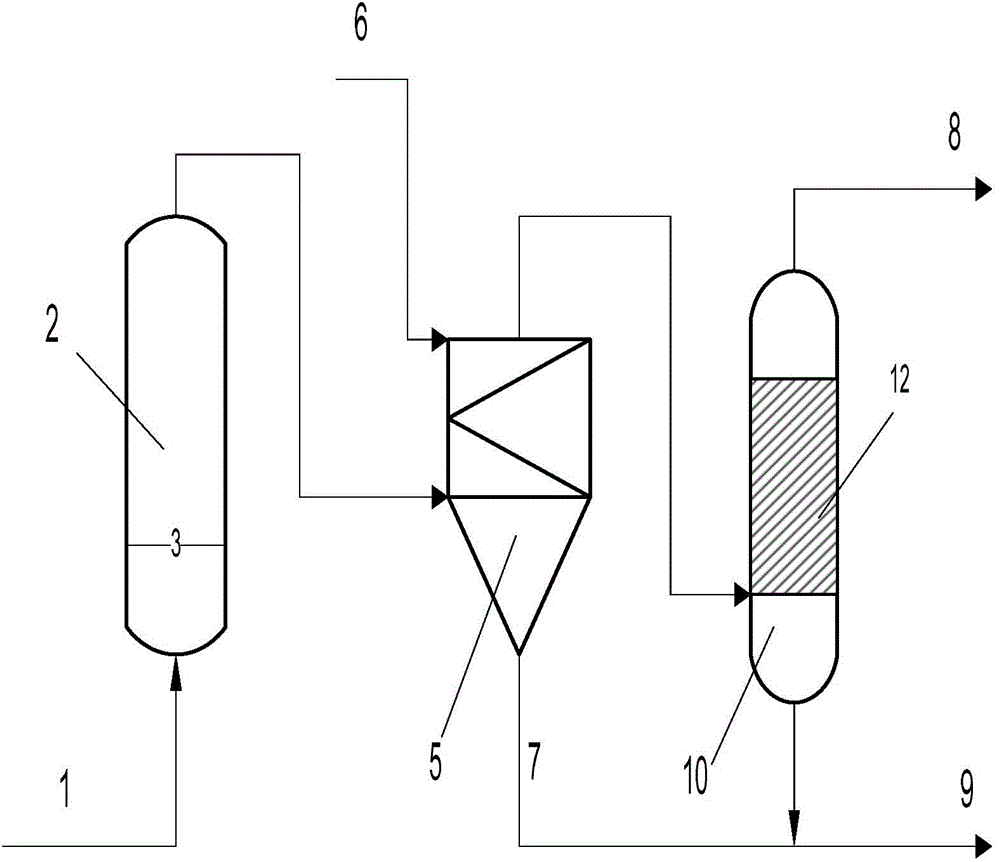

ActiveCN104624019AAchieve recyclingRealize deep desulfurizationDispersed particle separationGas phaseLiquid gas

The invention relates to a treatment method for an alkali liquor oxidation regeneration tail gas containing mercaptide. The treatment method comprises the following steps: feeding a to-be-treated alkali liquor oxidation regeneration tail gas containing mercaptide from the bottom of a washing tank, penetrating though a gas distribution plate in the tank, discharging from an exhaust gas pipe at the top of the washing tank, and feeding to an air inlet in the bottom of a dewatering tank; drying through a drying agent in the dewatering tank, feeding into a supergravity separator, contacting diesel oil fed from a liquid-phase inlet of the supergravity separator, and feeding into a gasoline and diesel oil separation recovery tank from a gas-phase outlet of the supergravity separator, wherein a crane of the supergravity separator is a rotary packing bed which is operated in a gas-liquid countercurrent, cocurrent flow or baffle flow form; and the operation ranges of the supergravity separator are as follows: the gas-liquid ratio is (5-2,000) to 1, the operation gage pressure is 0-0.3MPa and the operation temperature is 10-60 DEG C. According to the method, ultra-low sulphur emission of a liquefied gas alkali liquor oxidation regeneration tail gas is reached; desulfurization treatment can be carried out on absorbent diesel oil in a hydrogenation device; and the total sulfur emission in three wastes of factories is effectively reduced.

Owner:PETROCHINA CO LTD

Preparation and application method of oil-soluble oil oxidation desulfurizing agent

InactiveCN101717358AOxidative desulfurization process is simpleReduce desulfurization costOrganic chemistryTreatment with plural serial refining stagesOxygenOil soluble

The invention discloses a preparation and application method of an oil-soluble oil product oxidation desulfurizing agent, relating to a preparation and application method of an oil product desulfurizing agent, and solving the problems of poor intermiscibility of a traditional diesel oil oxidation desulfurizing agent with diesel oil and complex desulfurizing process. The preparation method of the oil-soluble oil oxidation desulfurizing agent comprises the step of leading low-carbon aldehyde compound and oxygen into a trickle bed reactor for reaction under trace amount of catalyst to obtain the oxidation desulfurizing agent which is structurally an organic peroxide, wherein the molar ratio of the low carbon aldehyde compound to the oxygen is 2:1-1:10. The desulfurizing method comprises the following steps of: under normal pressure and temperature, directly adding the oxidation desulfurizing agent into an oil product; stirring for reacting for 5-100 minutes; and then extracting sulphone and / or sulfoxide which are generated from the reaction by using a polar extracting agent. By using the oil-soluble oil oxidation desulfurizing agent, a deep desulfurization of the oil product can be realized and sulphur content in the oil product is reduced below 10 mg / g.

Owner:HARBIN UNIV OF SCI & TECH

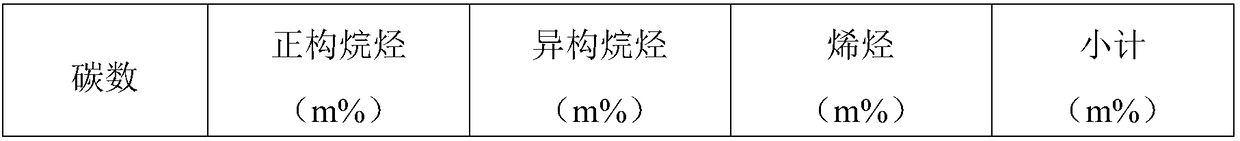

Low-energy consumption catalytic gasoline hydrodesulfurization method

ActiveCN103059957AAchieve pre-separationLow investment costTreatment with hydrotreatment processesHydrogenHydrodesulfurization

The invention discloses a low-energy consumption catalytic gasoline hydrodesulfurization method. The method comprises: adjusting the operating conditions of a catalytic cracking device fractionating tower, and adopting an appropriate cutting point to perform pre-separation in an FCC (fluid catalytic cracking) fractionating tower so as to obtain light fractions and heavy fractions; subjecting the mercaptan in the light fractions to hydroconversion to form a heavy sulfide, making the treated light fractions enter a hydrogenation prefractionator to fractionate light gasoline and medium gasoline, mixing the medium gasoline with the heavy fractions generated by the FCC fractionating tower, letting the mixture enter a hydrodesulfurization reactor to undergo deep desulfurization, conducting steam stripping on the obtained refined heavy gasoline, and mixing it with the light gasoline, thus obtaining a clean gasoline product or a blending component. Compared with the existing catalytic gasoline hydrodesulfurization technologies, the method provided in the invention has the advantages that: the equipment energy consumption is significantly reduced, the gasoline octane number loss is small, the gasoline product quality can meet the quality requirement for a sulfur content of less than 10 micrograms / g, and the economic benefits of oil refining enterprises are improved.

Owner:CHINA PETROLEUM & CHEM CORP +1

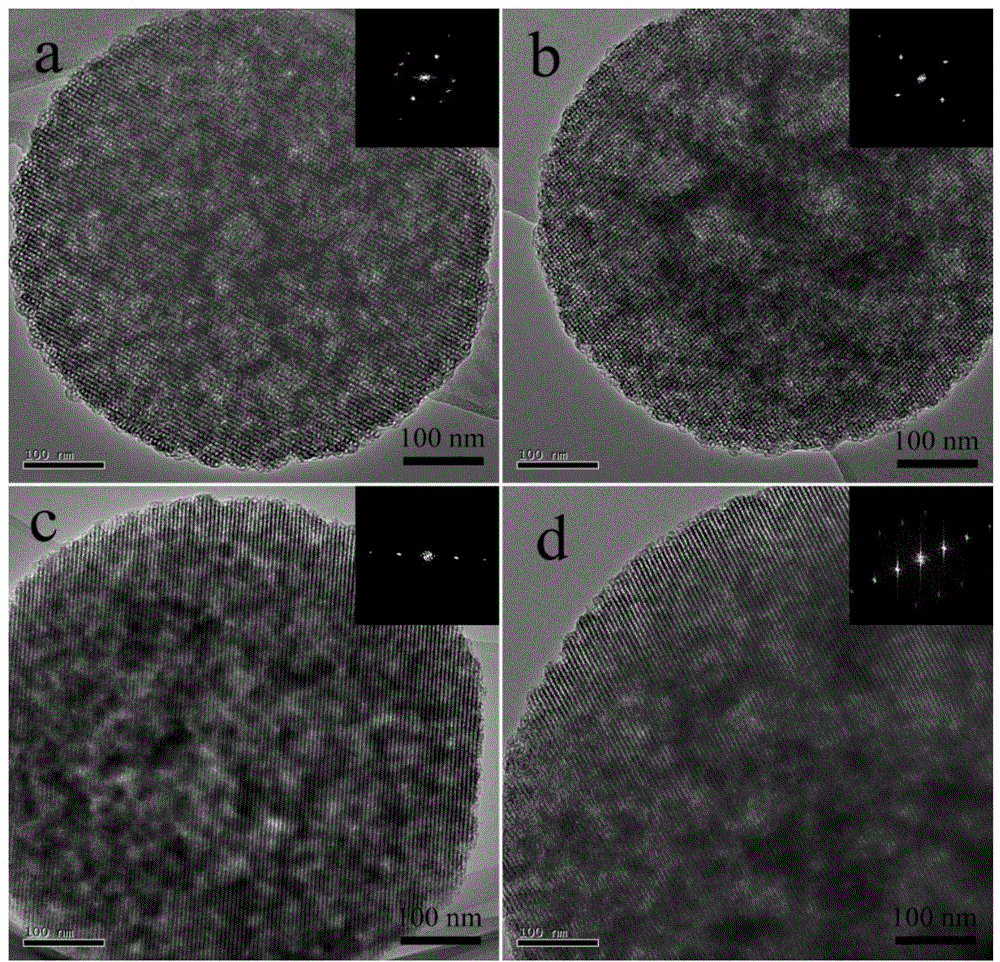

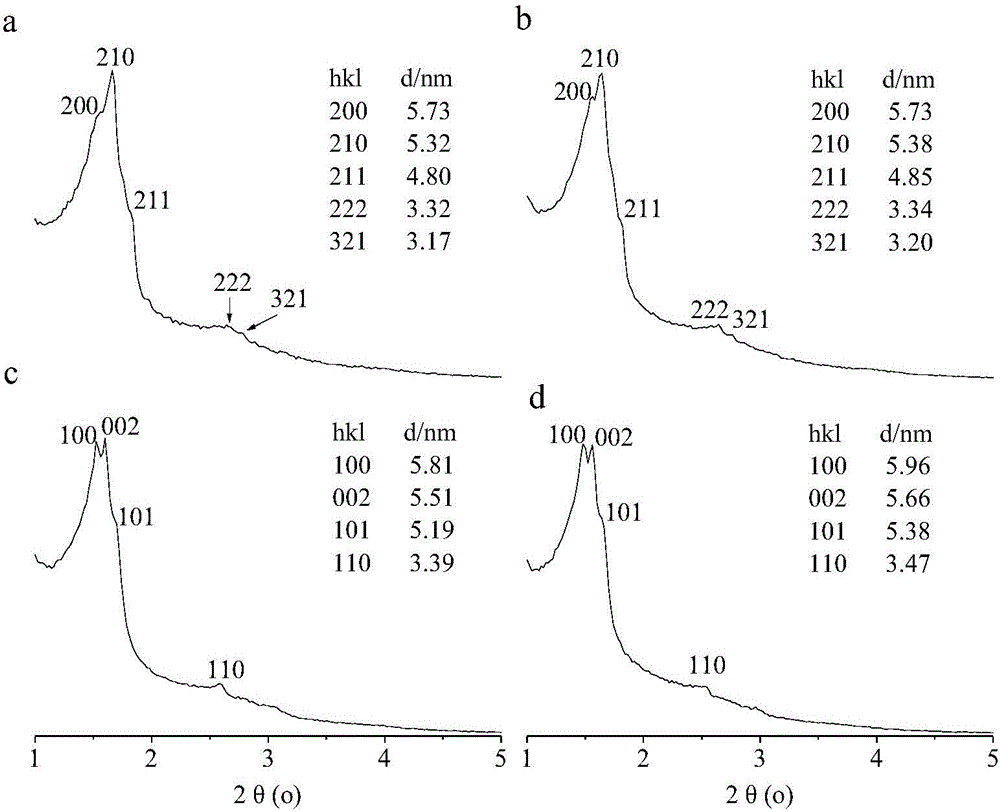

Preparation method for titanium-containing hierarchical porous structure mesoporous molecular sieve catalyst

InactiveCN104874420ASimple processRealize deep desulfurizationMolecular sieve catalystsHydrocarbon oils refiningPolyelectrolyteMolecular sieve

The invention discloses a preparation method for titanium-containing hierarchical porous structure mesoporous molecular sieve catalyst. The preparation method for the titanium-containing hierarchical porous structure mesoporous molecular sieve catalyst uses peroxotitauium acid as titanium source and uses mesoscopic compound composed of cationic surface active agent-hexadecyl trimethyl ammonium bromide (CTAB) and anionic polyelectrolyte (PAA) as a dynamic template to synthesize to form a hierarchical porous structure mesoporous titanium silicalite molecular sieve; the prepared titanium-containing hierarchical porous structure mesoporous molecular sieve catalyst is used for the oxidative desulfurization reaction which uses dibenzothiophene (DBT) as model sulfide. The preparation method for the titanium-containing hierarchical porous structure mesoporous molecular sieve catalyst has advantages that the catalyst is capable of catalyzing the oxidizing reaction of the thiophene sulfur compound under a low temperature and realizing deep desulfurization; the catalyst preparation method is simple in technique, easy to implement and good for industrial production.

Owner:NANKAI UNIV

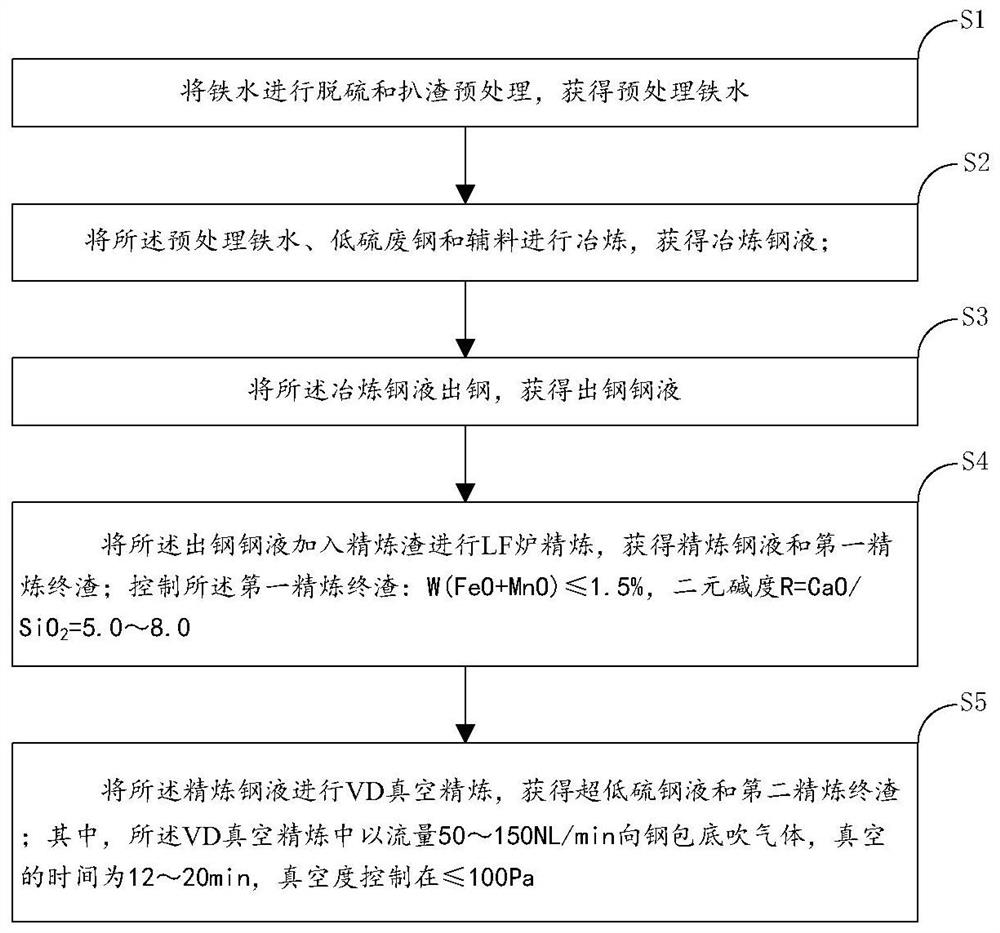

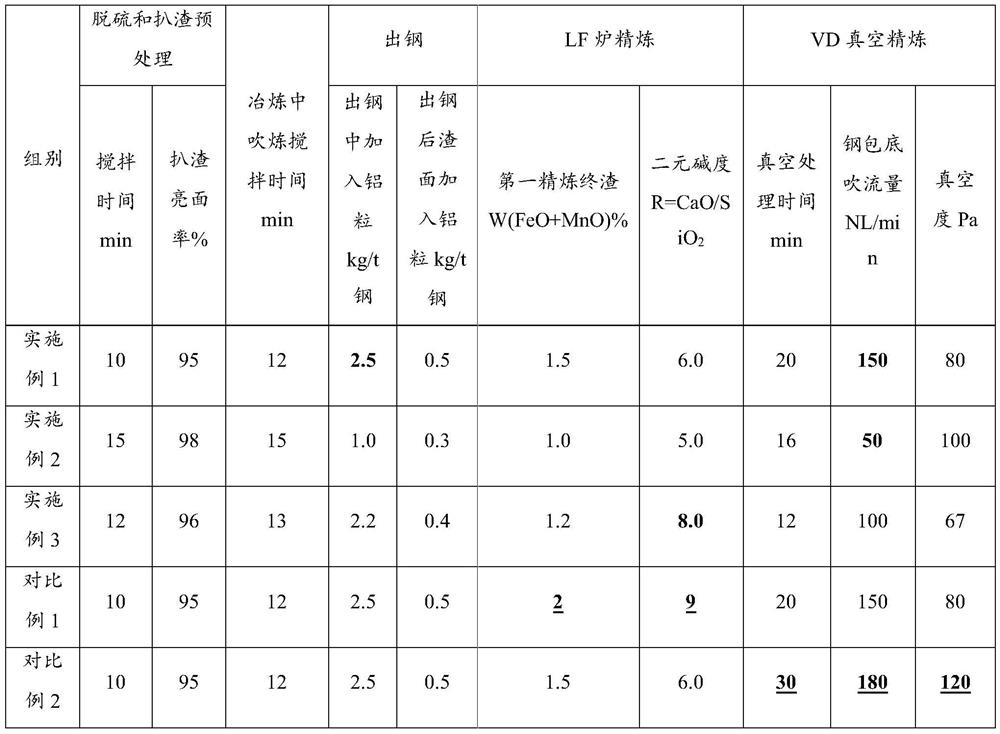

Method for producing ultralow-sulfur steel by using LF and VD duplex technology

ActiveCN112961961ASmelting to achieveControl Al contentProcess efficiency improvementSmeltingMolten steel

The invention discloses a method for producing ultralow-sulfur steel by using an LF and VD duplex technology. The method comprises the following steps: carrying out desulfurization and slagging-off pretreatment on molten iron to obtain pretreated molten iron; smelting the pretreated molten iron, low-sulfur waste steel and auxiliary materials to obtain smelted molten steel; carrying out tapping of the smelting molten steel to obtain the tapped molten steel; adding refining slag into the tapped molten steel for LF furnace refining to obtain refined molten steel and first refined final slag; controlling the first refining final slag, wherein W (FeO + MnO) is less than or equal to 1.5%, and the binary alkalinity R = CaO / SiO2 = 5.0-8.0; and subjecting he refined molten steel to VD vacuum refining to obtain ultralow-sulfur molten steel and second refined final slag, wherein the vacuum treatment time is 12-20 min, the bottom blowing flow of a steel ladle is 50-150 NL / min, and the vacuum degree is controlled to be less than or equal to 100 Pa; Stable control of ultralow sulfur less than or equal to 0.0010% is achieved by using the LF and VD duplex technology.

Owner:SHOUGANG CORPORATION

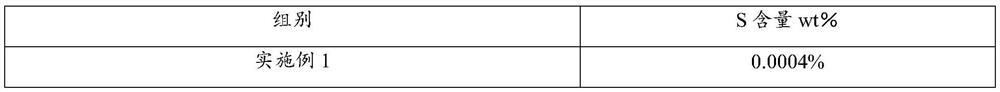

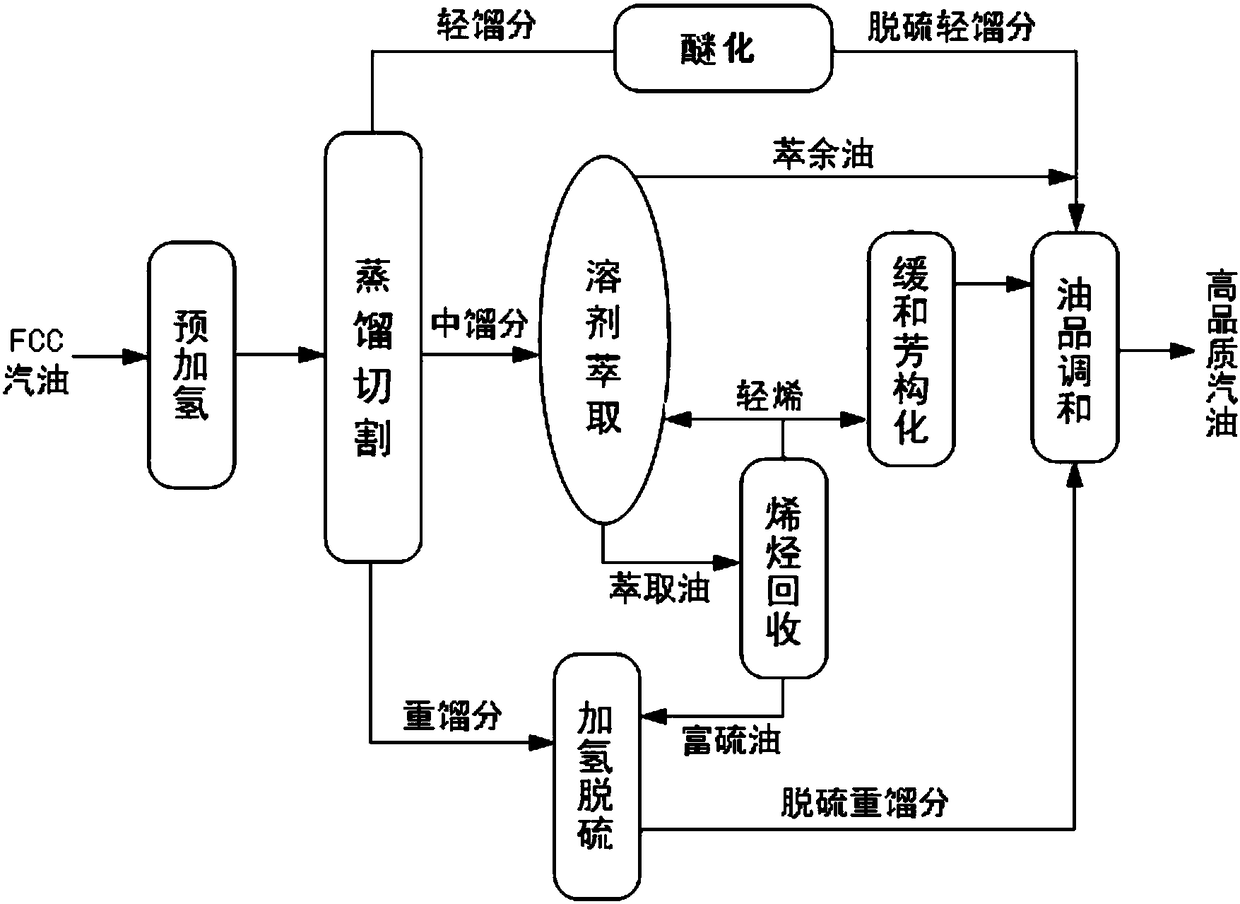

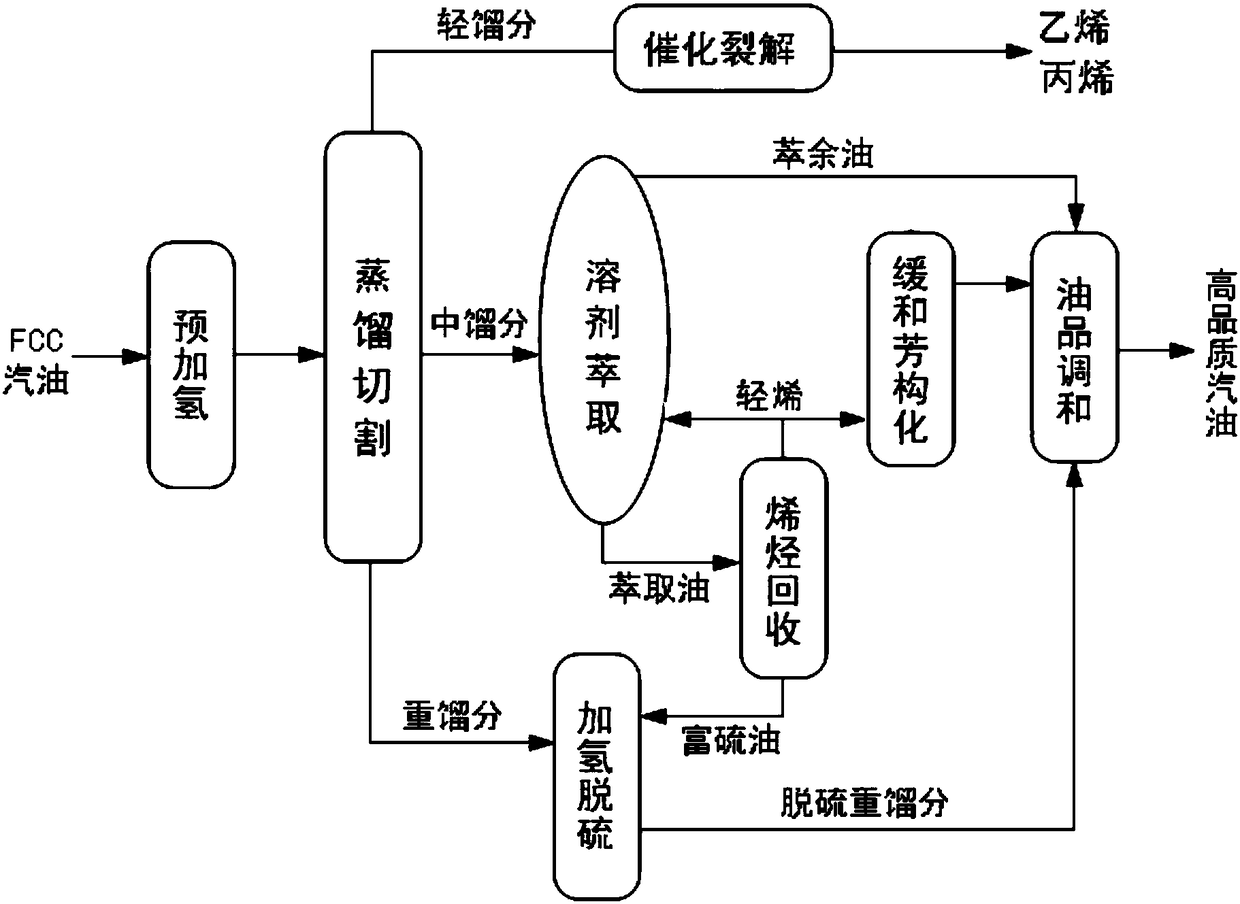

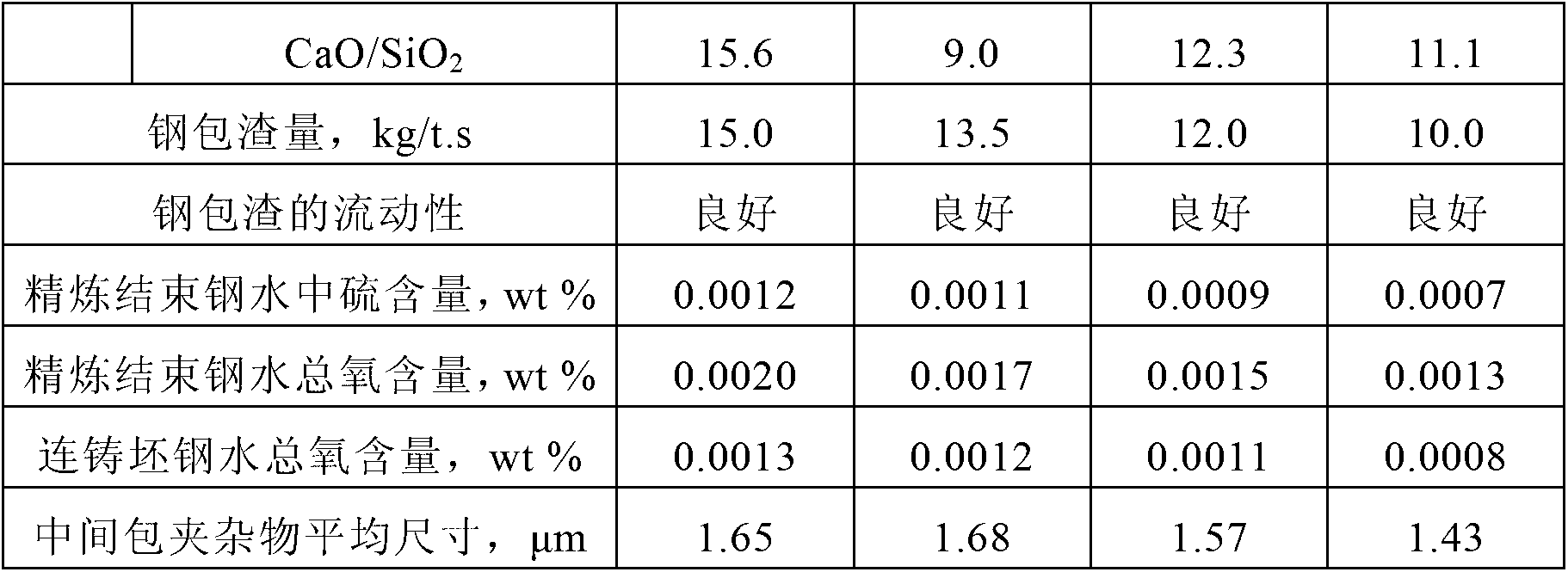

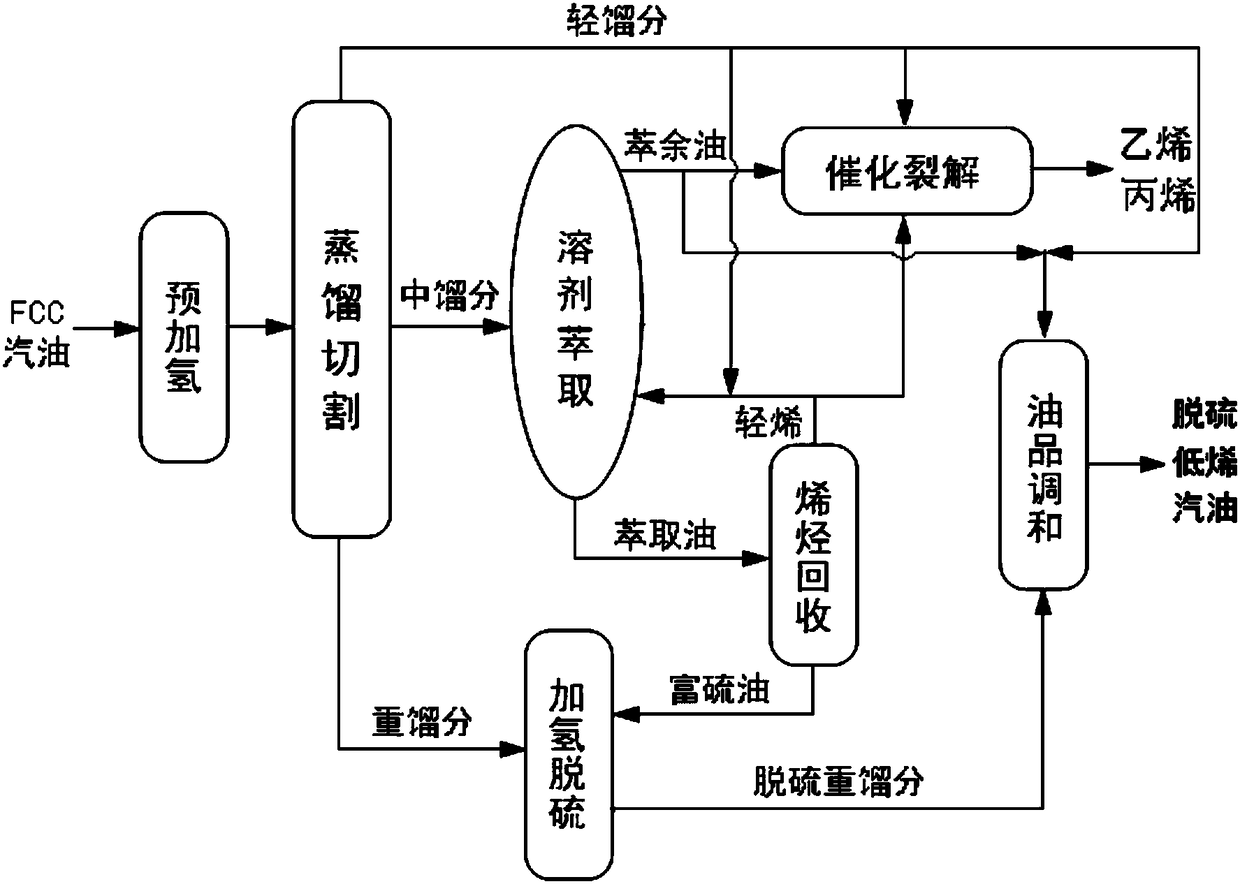

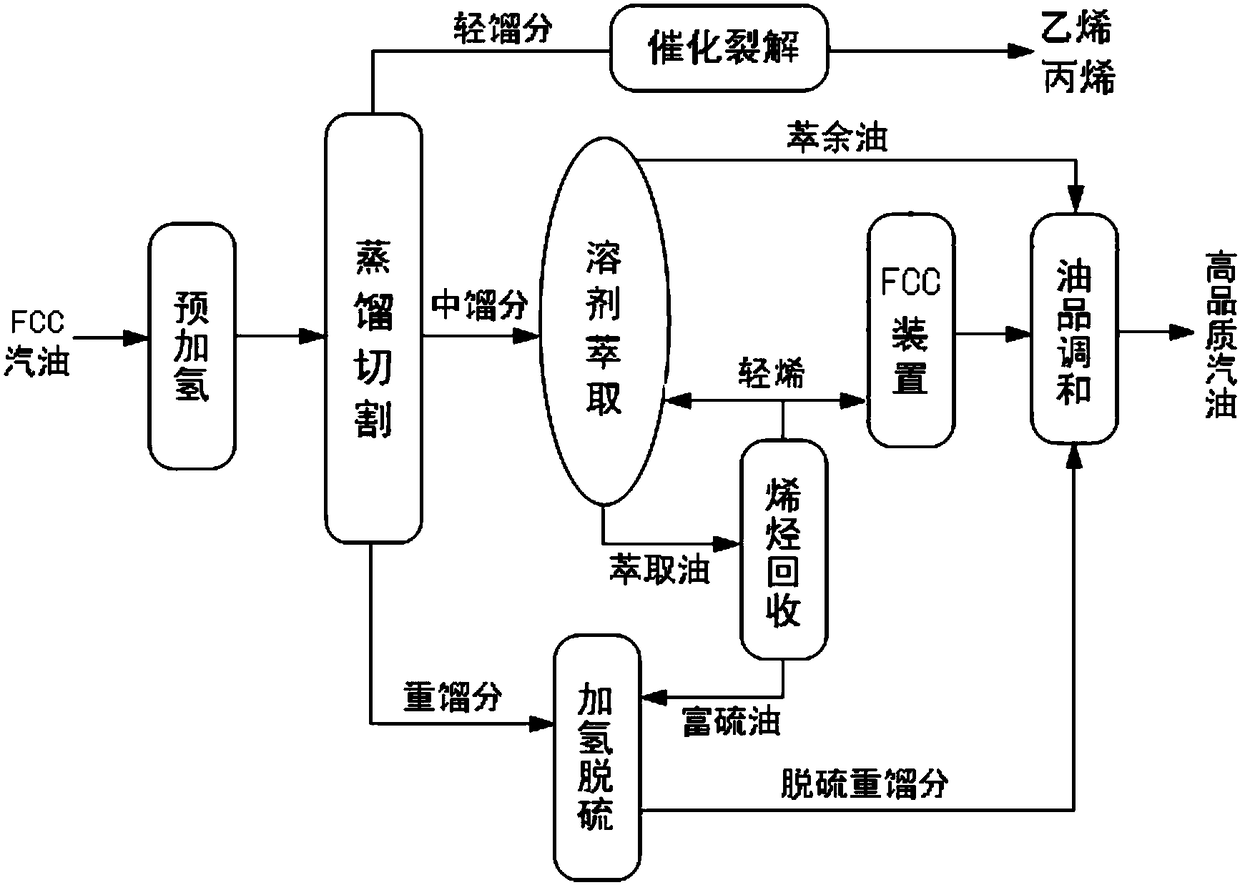

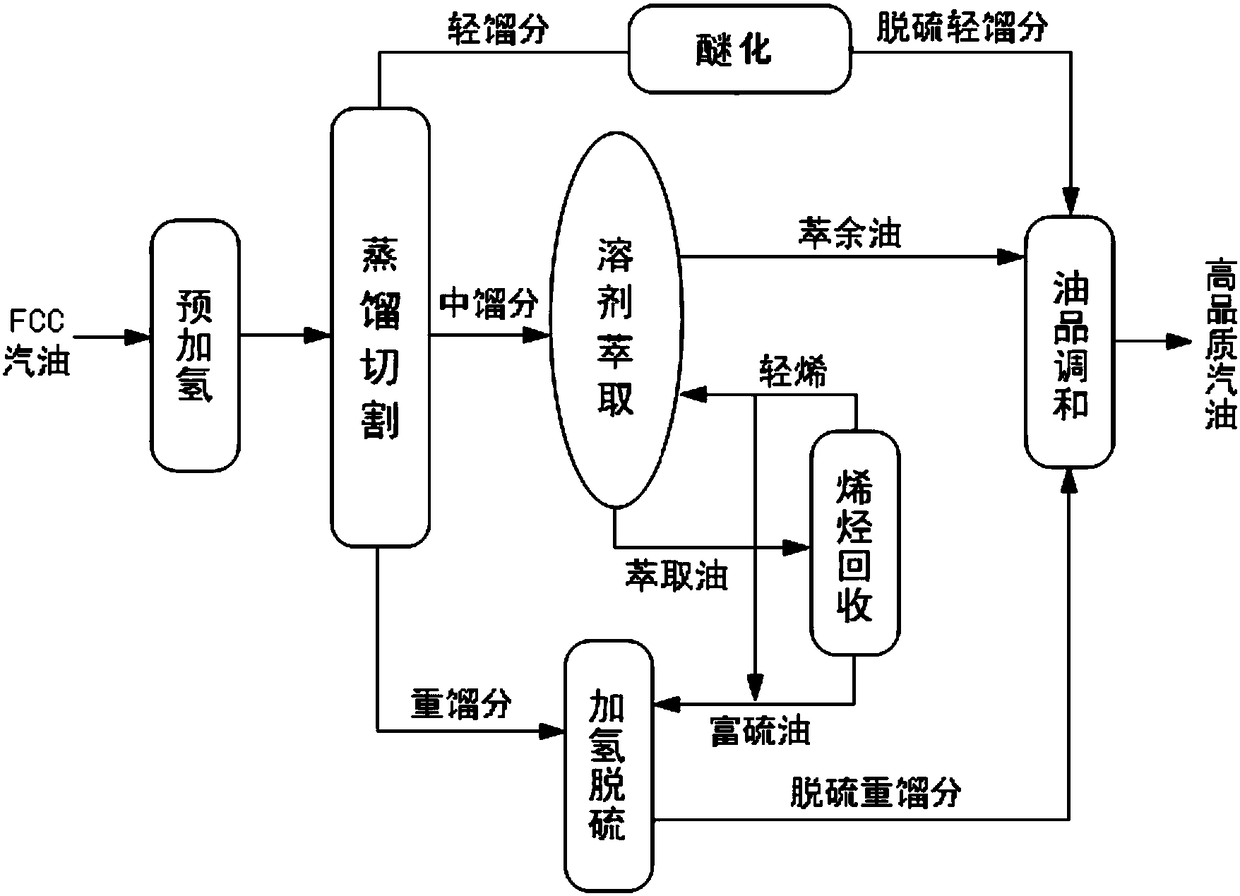

Quality upgrading method for high olefin catalytic cracking gasoline

ActiveCN108424787AImprove qualityReduce sulfur contentTreatment with hydrotreatment processesHydrocarbon oils treatment productsHydrodesulfurizationAromatization

The invention provides a quality upgrading method for high olefin catalytic cracking gasoline. The method includes the steps of: conducting prehydrogenation on catalytic cracking gasoline to obtain prehydrogenated catalytic cracking gasoline; cutting the prehydrogenated catalytic cracking gasoline into light fraction, medium fraction and heavy fraction; conducting etherification or catalytic cracking on the light fraction; subjecting the medium fraction to solvent extraction to obtain olefin-rich raffinate oil and aromatic hydrocarbon-rich extracted oil; conducting light olefin recovery on theextracted oil to obtain light olefin and sulfur-rich oil; returning at least a part of the light olefin to the solvent extraction system for backwashing; conducting mitigated aromatization on at least one of the raffinate oil and the other part of the light olefin; and subjecting the heavy fraction and sulfur-rich oil to selective hydrodesulfurization, thus obtaining desulfurized heavy fraction.The method provided by the invention can improve the octane number of gasoline products while lowering the sulfur content and olefin content.

Owner:CHINA UNIV OF PETROLEUM (BEIJING)

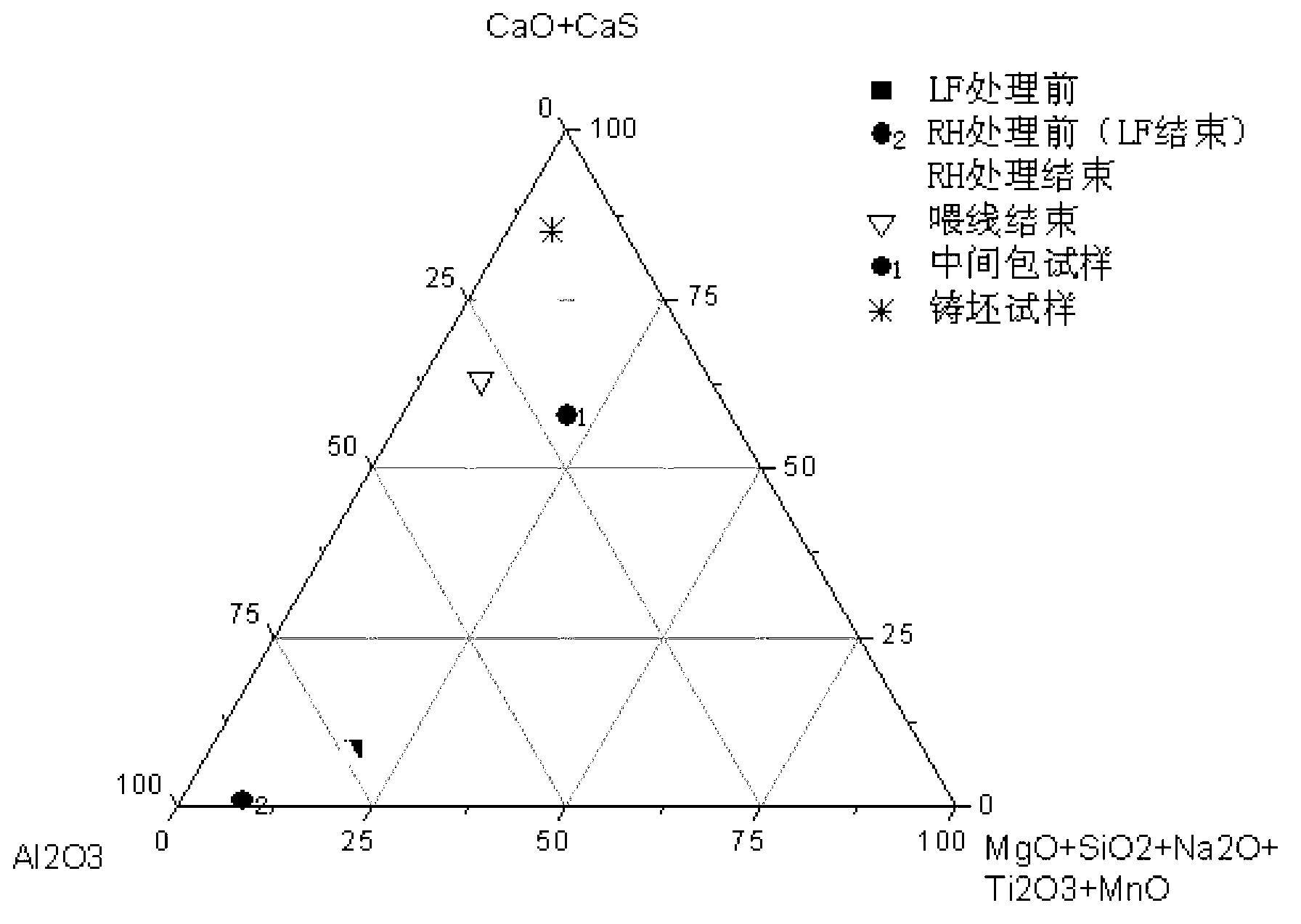

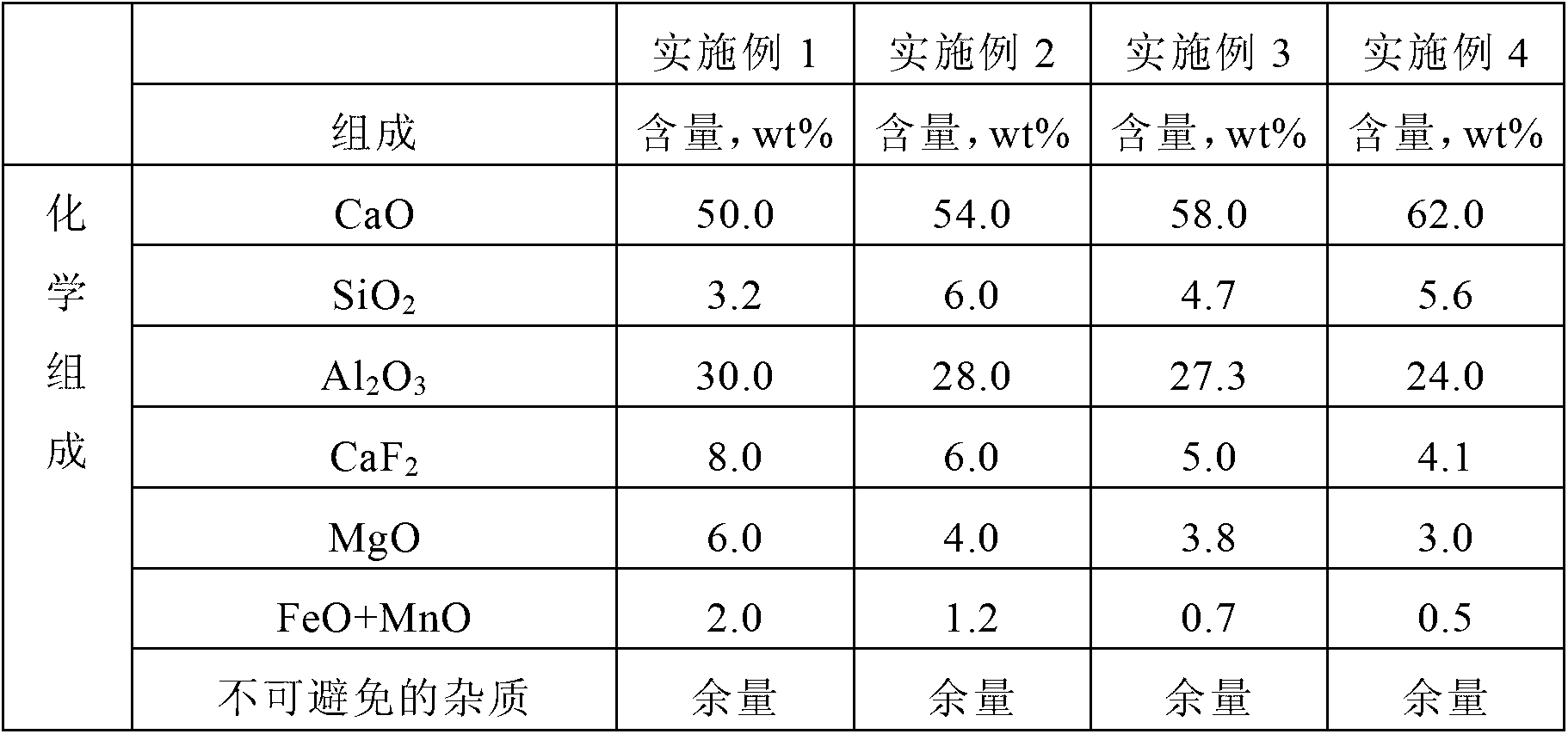

Slag for controlling impurities of pipeline steel

InactiveCN103060526AQuality improvementGood liquidityProcess efficiency improvementSlagDeoxygenation

The invention discloses slag for controlling the impurities of pipeline steel. The slag comprises the following components in weight percentage: 50-62% of CaO, 3.2-6.0% of SiO2, 24-30% of Al2O3, 3-8% of CaF2, 3-6% of MgO, 0.3-2.0% of FeO+MnO, and the balance of unavoidable impurities; and the ratio of CaO / SiO2 is 9-16. The slag for controlling the impurities of the pipeline steel is the slag for refining a steel ladle, which has a high basicity, low aluminum oxide content, low oxidability and good fluidity; the slag can control the basicity of steel ladle slag and the content of the components including the Al2O3 and the like, and reduces the oxidability, so that the steel ladle slag has the functions of improving liquid steel cleanness and controlling the impurities in the steel; the desulfuration and the deoxygenation of the liquid steel, and the control of the impurities are realized; and the quality of the liquid steel is improved.

Owner:BAOSHAN IRON & STEEL CO LTD

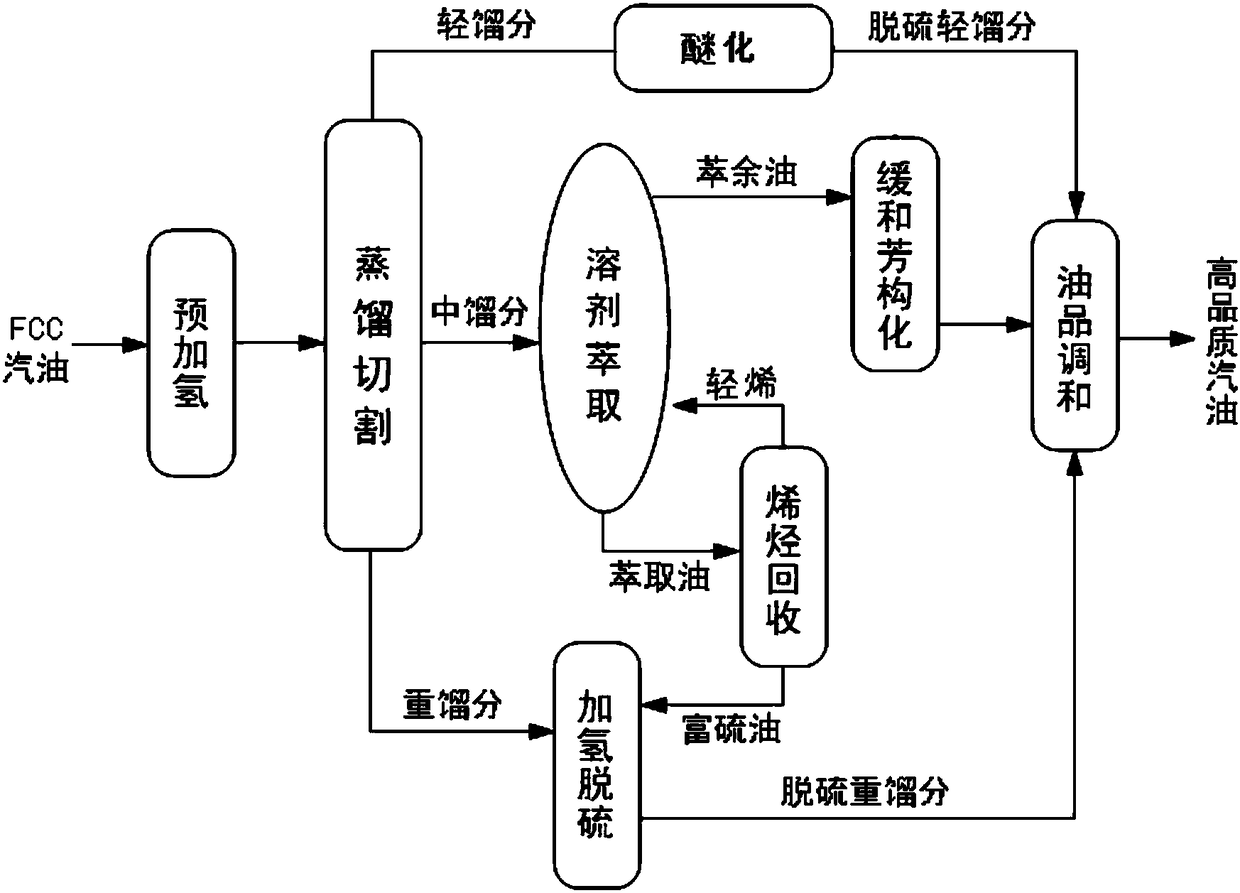

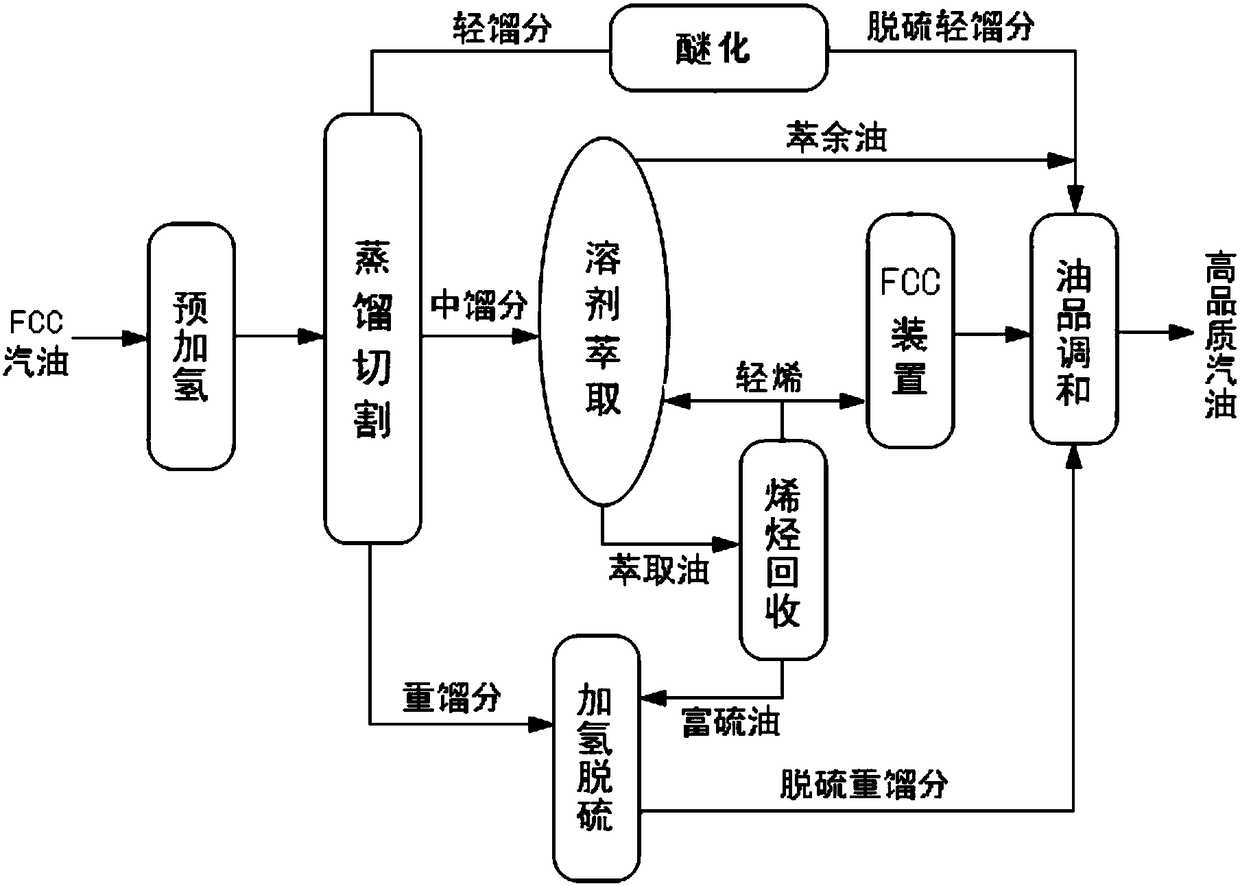

Method for combined production of desulfurized low-alkene gasoline and chemical product by using catalytic gasoline

ActiveCN108329944AReduce sulfur contentBoost octaneTreatment with hydrotreatment processesHydrocarbon oils treatment productsHydrodesulfurizationSulfur

The invention provides a method for combined production of desulfurized low-alkene gasoline and a chemical product by using catalytic gasoline. The method comprises the following steps: pre-hydrogenation is carried out on the catalytic gasoline to obtain the pre-hydrogenation catalytic gasoline; the pre-hydrogenation catalytic gasoline is cut to a light fraction, a middle fraction and a heavy fraction; the middle fraction is subjected to solvent extraction to obtain raffinate oil containing alkene and raffinate oil containing arene; at least a part of the light fraction and / or at least a partof the raffinate oil are subjected to mitigated aromatization or catalytic cracking to obtain the chemical product; the raffinate oil is subjected to the lightweight alkene recovery, lightweight alkene and sulfur-rich oil are obtained, at least a part of the lightweight alkene is returned to a solvent extraction system for backwashing, and the heavy fraction and the sulfur-rich oil are subjected to selective hydrodesulfurization to obtain the desulfurized heavy fraction. The method can efficiently convert the catalytic gasoline to the chemical product having the high value, and performs combined production of a high-quality desulfurized low-alkene gasoline component.

Owner:HEBEI REFINING TECH CO LTD +1

Catalytic gasoline hydrodesulfurization method

ActiveCN103059950AAchieve pre-separationLow investment costTreatment with hydrotreatment processesHydrodesulfurizationProcess engineering

The invention discloses a catalytic gasoline hydrodesulfurization method. The method comprises: adjusting the operating conditions of a catalytic device fractionating tower, adding a lateral line, conducting cutting at an appropriate cutting temperature so as to obtain light fractions at the tower top and heavy fractions at the lateral line; subjecting the light fractions to an alkali extraction treatment, and then separating light gasoline and medium gasoline through a hydrogenation prefractionator; and carrying out moderate selective hydrodesulfurization on the medium gasoline, and carrying out deep selective hydrodesulfurization on the heavy gasoline, subjecting the obtained two refined products to gas stripping, and then mixing them with alkali extracted light gasoline, thus obtaining a clean gasoline product. Compared with the existing catalytic gasoline hydrodesulfurization technologies, the method provided in the invention can significantly reduce equipment energy consumption, the gasoline octane number loss is small, the obtained gasoline product quality can meet the quality requirement for a sulfur content of less than 10 micrograms / g, and the economic benefits of oil refining enterprises are substantially improved.

Owner:CHINA PETROLEUM & CHEM CORP +1

Method for upgrading high-olefin FCC (fluid catalytic cracking) gasoline

ActiveCN108359495ABoost octaneComprehensive modificationTreatment with hydrotreatment processesHydrocarbon oils treatment productsHydrodesulfurizationGasoline

The invention provides a method for upgrading high-olefin FCC (fluid catalytic cracking) gasoline. The method comprises the following steps: prehydrogenating FCC gasoline to obtain prehydrogenated FCCgasoline; cutting the prehydrogenated FCC gasoline into light fraction, medium fraction and heavy fraction; performing etherification or catalytic cracking on the light fraction; performing solvent extraction on the medium fraction to obtain olefin-rich raffinate and arene-rich extracted oil; recovering light olefins from the extracted oil to obtain light olefins and sulfur-rich oil; returning one part of light olefins to a solvent extraction system for backwashing, and performing catalytic cracking reprocessing or selective hydrodesulfurization on the other part of light olefins; performingselective hydrodesulfurization on the heavy fraction and the sulfur-rich oil to obtain desulfurized heavy fraction. With adoption of the method, octane number of a gasoline product can be increased while sulfur content and olefin content are reduced.

Owner:CHINA UNIV OF PETROLEUM (BEIJING)

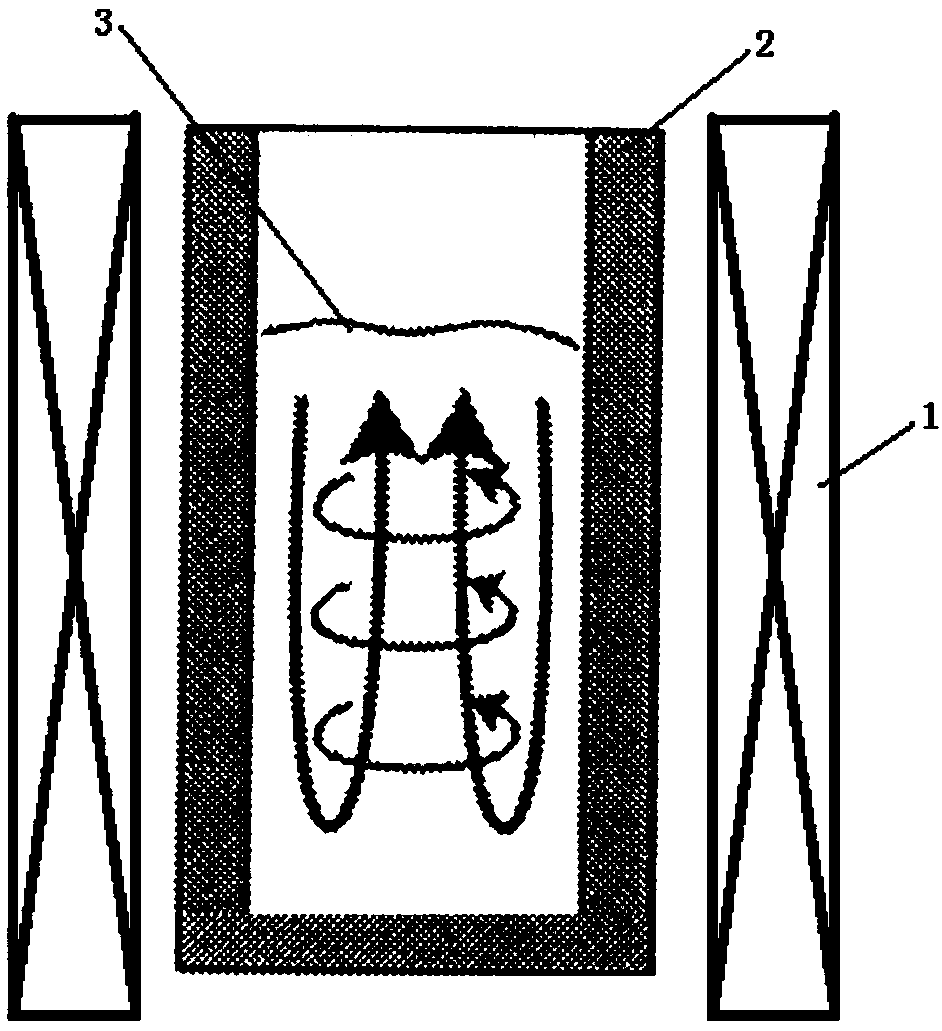

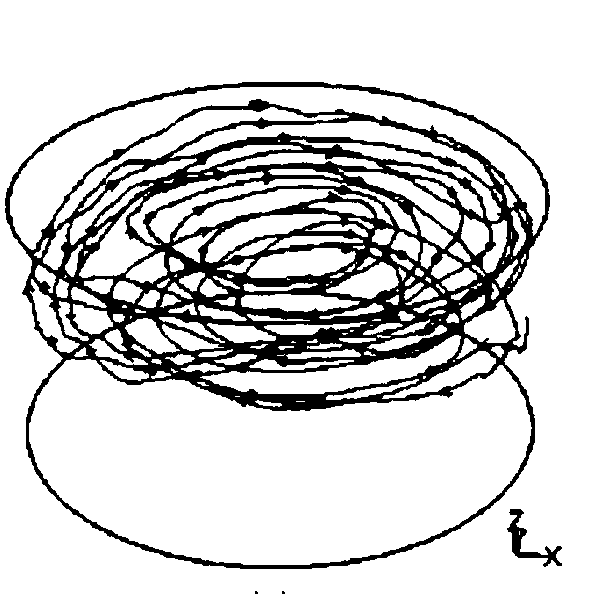

Deoxidizing alloying agent capable of purifying molten steel and preparation method thereof

The invention provides a deoxidizing alloying agent capable of purifying molten steel and a preparation method thereof. The components of the deoxidizing alloying agent include, by weight percentage,30-50% of aluminum, 2-6% of silicon carbide, 2-6% of calcium aluminate, and 5-45% of one or more of niobium, vanadium, titanium, manganese, nickel, chromium, copper, molybdenum and silicon; and particle sizes are 5-50 mm. During preparation, metal aluminum and industrial pure iron can be melted in an induction furnace crucible according to the finished product content; the metal niobium, vanadium,titanium, manganese, nickel, chromium, copper, molybdenum and silicon can be added; spiral electromagnetic stirring can be simultaneously applied, the current of the spiral electromagnetic stirring is 150-250 A, and the frequency is 2.5-4 Hz; the silicon carbide and calcium aluminate fine powder can be added after the added metal is completely melted; the power supply of the induction furnace canbe stopped after 5-10 min of stirring; the spiral electromagnetic stirring can be continued until alloy is solidified; and a crusher can be utilized to crush alloy ingots into small pieces with a particle size of 5-50 mm, and packaging can be performed for later use. The full uniformization of the alloy and the silicon carbide and calcium aluminate fine powder can be guaranteed by adopting a spiral electromagnetic stirring technology; the full purifying molten steel of the calcium aluminate can be guaranteed; and deoxidizing alloying time can be saved.

Owner:ANGANG STEEL CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com