Method for reducing sulfide in light hydrocarbon oil

A technology of sulfide and hydrocarbon oil, applied in the direction of refined hydrocarbon oil, petroleum industry, etc., can solve the problems of insufficient deep desulfurization and loss of octane number of gasoline products, and achieve the effect of low hydrogen consumption and high desulfurization efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

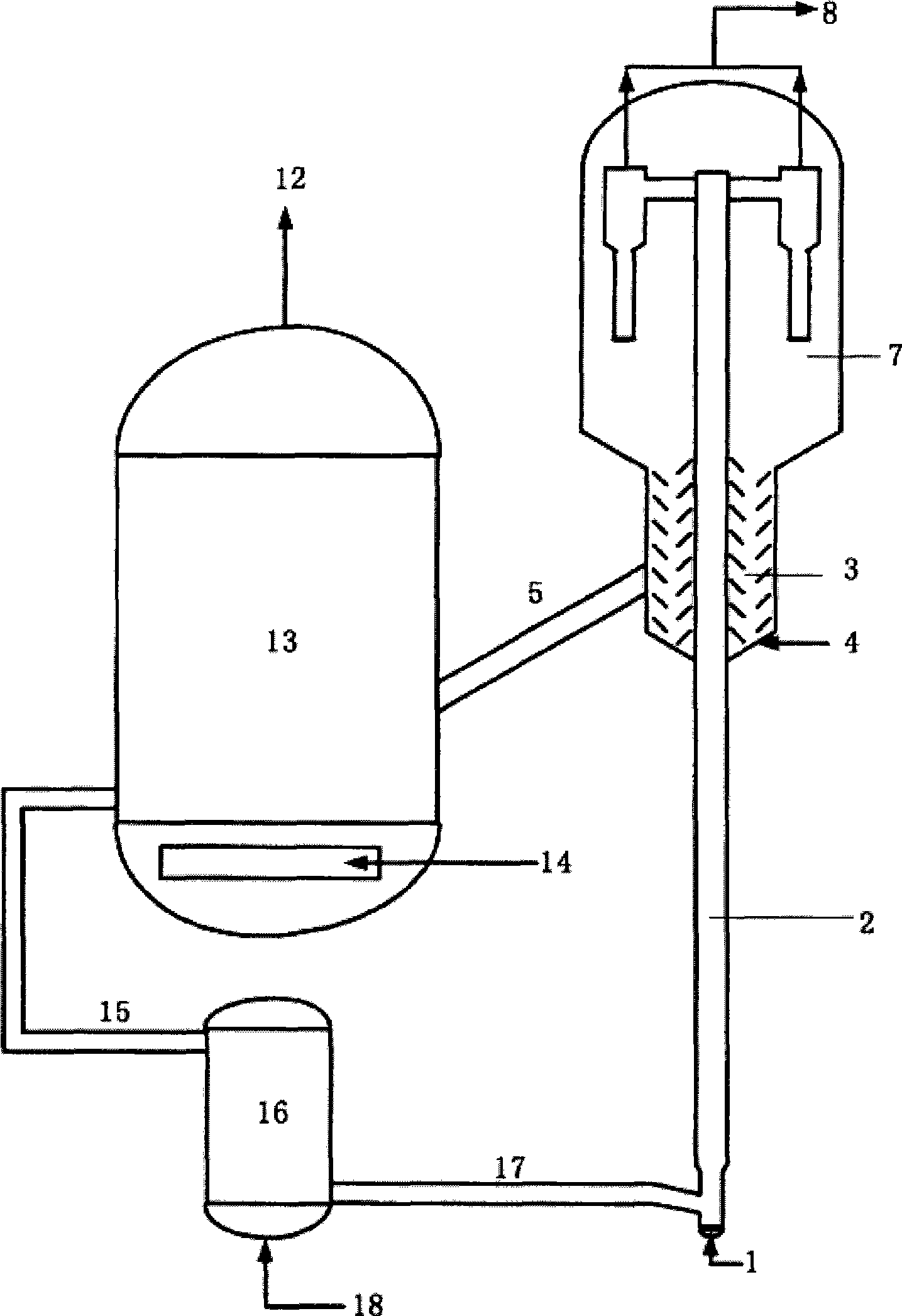

Image

Examples

preparation example Construction

[0033] The preparation of the additive solid particle that embodiment adopts is as follows:

[0034] Respectively 2.9 kilograms of ZRP zeolite (silicon-aluminum ratio 50) and 8.0 kilograms of NaY zeolite (silicon-aluminum ratio) produced by Qilu Petrochemical Company Catalyst Factory, according to zeolite: ammonium nitrate: the weight ratio of deionized water=1:1:20 in Ion exchange at 90°C for 2 hours, filter, wash with water, and repeat the exchange once to obtain ammonium-type shape-selective zeolite, whose Na 2 The O content is not more than 0.15% by weight. At room temperature, the above-mentioned ammonium-type zeolite was respectively mixed with 2.31 kilograms and 0.38 kilograms of rare earth chloride (produced by Inner Mongolia Baotou Rare Earth Factory, with a dry basis of 48% by weight, wherein the dry basis content of each component is La 2 o 3 25.0%, Ce 2 o 3 6.0%, Pr 2 o 3 5.0%, Nd 2 o 3 10.0%) aqueous solution prepared by stirring and impregnating for 2 ...

Embodiment 1

[0037] This example illustrates the application of adding rare earth modified zeolite in the adsorbent in gasoline desulfurization.

[0038] Taking the raw gasoline A in Table 1 as the raw material, the adsorption reaction desulfurization of the raw gasoline raw material was investigated when 10% by weight of REZRP (accounting for the total amount of adsorbent) was added to the adsorbent S-1 in a small fluidized bed reactor. The loading capacity of the adsorbent is 500 grams, and it is reduced for 60 minutes with hydrogen at a temperature of 360° C. and a hydrogen flow rate of 1.5 liters / hour before use. The reaction product, steam and raw adsorbent mixture are separated in the settler, and the reaction product is separated to obtain gas products and liquid products, while the raw adsorbent and zeolite additive are stripped by water vapor to remove the hydrocarbon products adsorbed on the raw adsorbent mixture . The stripped adsorbent and zeolite additive are regenerated in c...

Embodiment 2

[0044] This example illustrates the application of adding faujasite additive to the adsorbent S-2 in gasoline desulfurization.

[0045] Taking the raw material gasoline B in Table 1 as the raw material, the adsorption reaction desulfurization of the raw material gasoline was investigated when 1% by weight of REY zeolite (accounting for the total weight of the adsorbent) was added to the adsorbent S-2 in a small fluidized bed reactor. . The loading capacity of the adsorbent is 500 grams, and it is reduced for 60 minutes with hydrogen at a temperature of 360° C. and a hydrogen flow rate of 1.5 liters / hour before use. The reaction product, steam and raw adsorbent mixture are separated in the settler, and the reaction product is separated to obtain gas products and liquid products, while the raw adsorbent and zeolite additive are stripped by water vapor to remove the hydrocarbon products adsorbed on the raw adsorbent mixture . The stripped adsorbent and zeolite additive are rege...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com