Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

85results about How to "Reduce olefins" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

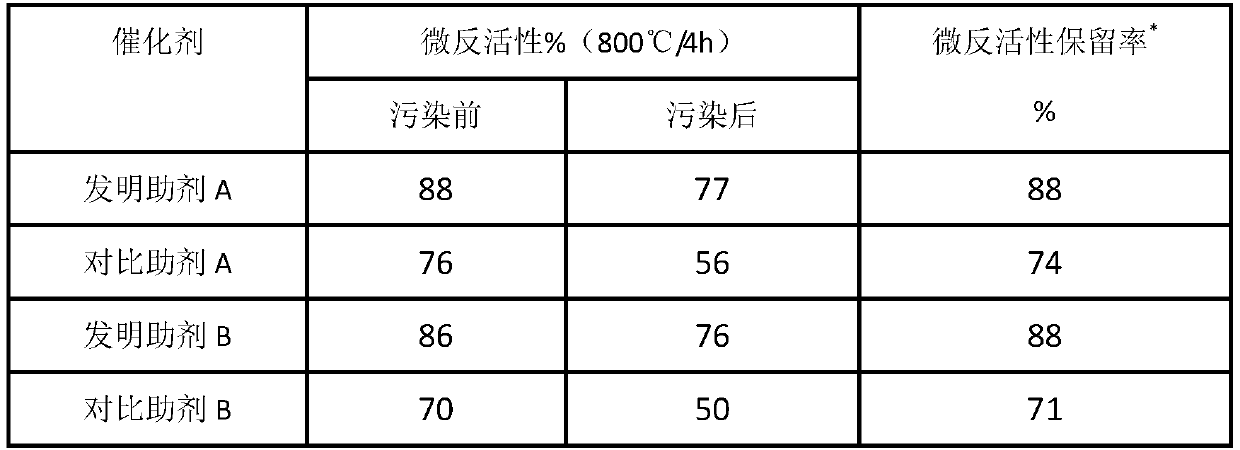

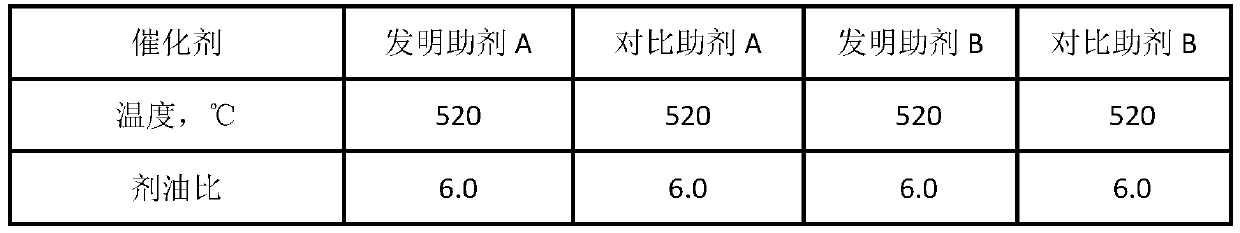

Catalytic cracking auxiliary agent for increasing heavy oil conversion performance and preparation method thereof

The invention provides a catalytic cracking additive for improving the transformation ability of heavy oil and the preparation method. The catalytic cracking additive is produced by spray shaping, roasting, in-situ crystallization and composite elements modification after natural sepiolite is mixed with natural kaolinite mineral or with one or two roasting kaolinite mineral. Provided with high activity, high heavy metal resistance and good selectivity in cracking reaction, the additive can improve the transformation ability of heavy oil and reduce the olefin content and increase gasoline octane number.

Owner:姚华

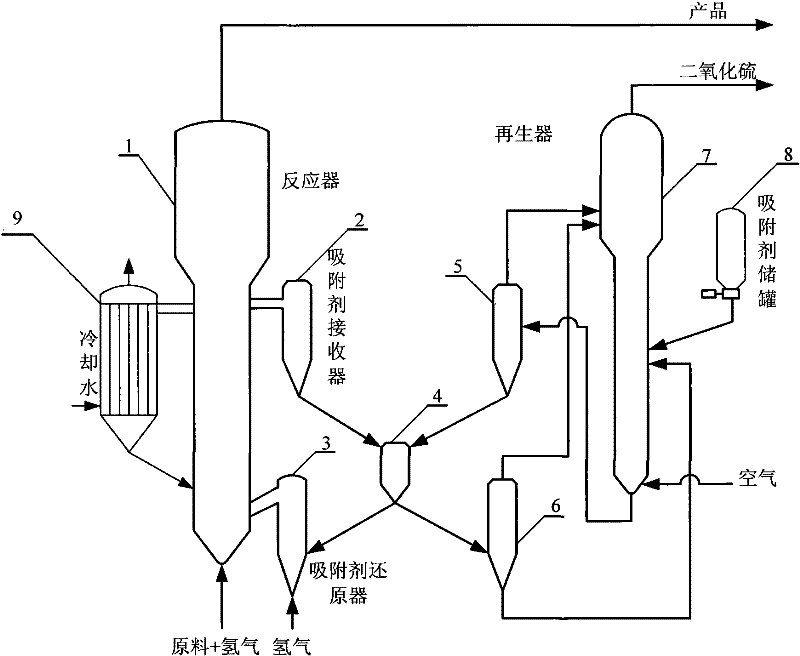

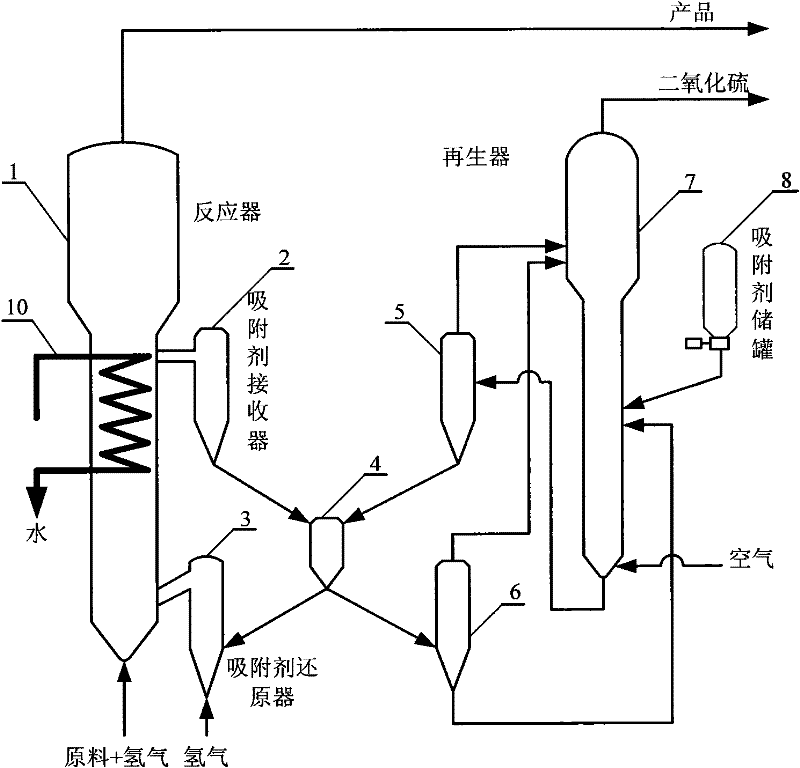

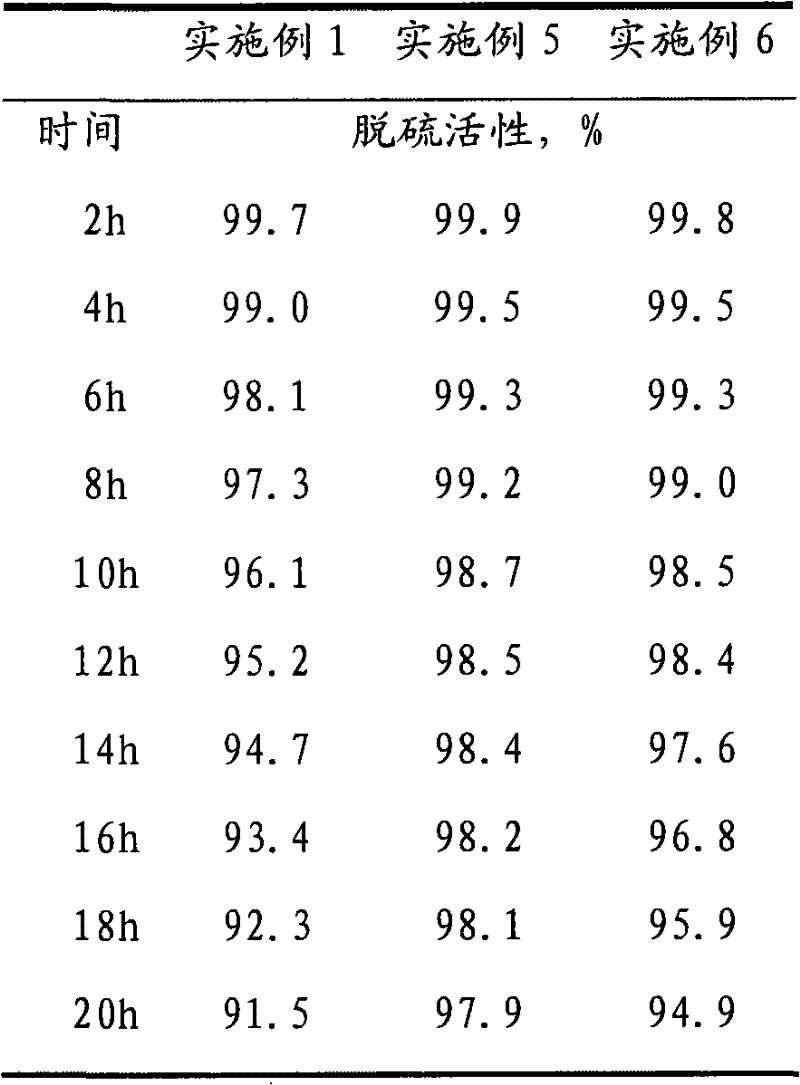

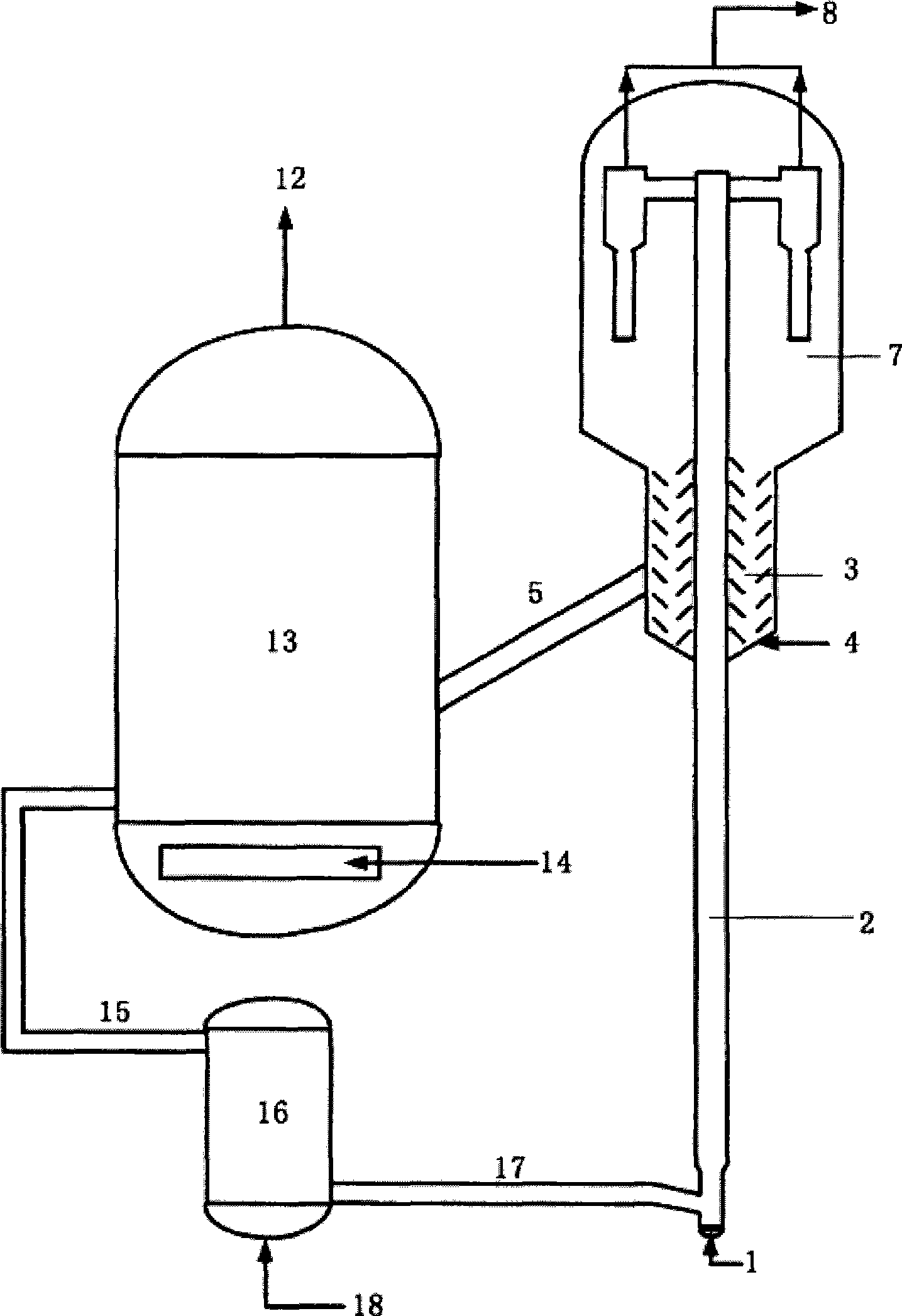

Method for lowering sulfur and olefin content in gasoline

ActiveCN102191080AReduce olefinsReduce sulfur contentHydrocarbon oils treatmentRefining to eliminate hetero atomsFluidized bedSorbent

The invention relates to a method for lowering the sulfur and olefin content in gasoline, which comprises: introducing a preheated gasoline raw material containing more than 35 weight percent of olefin and a hydrogen donor to a fluidized bed reactor to contact the gasoline raw material and the hydrogen donor with an absorber to form desulfurized oil gas and sulfurized absorbent; separating the desulfurized oil gas and sulfurized absorbent; delivering the separated oil gas to a subsequent separation system for product separation; and regenerating and reducing the sulfurized absorbent and returning the sulfurized absorbent to the reactor. The fluidized bed reactor is provided with a heater and / or devices for cooling the reduced absorbent and returning the reduced absorbent to the reactor. When the method is used to process a high-olefin gasoline raw material, deep desulfurization can be realized under a low hydrogen consumption condition, and the olefin content in the gasoline can be lowered considerably.

Owner:CHINA PETROLEUM & CHEM CORP +1

Production of cracking catalyst for qualified gasoline and propylene

It is a preparation method of cracking catalyst which can product high quality petrol and more propene. Making clay, de-ionized water and phosphorated compound well blended to get clay slurry, making molecular screen, de-ionized water and phosphorated compound well blended to get molecular screen slurry, making agglomerant, de-ionized water and optional inorganic acid to get agglomerant slurry. Uniform mixing three kinds of slurry mentioned before with rare-earth compound, and then drying the mixture. Using this kind of cracking catalyst, we can produce the petrol which contains a low level of olefinic hydrocarbon, a high level of isoparaffin, and in the same time produce more propene and isobutene.

Owner:CHINA PETROLEUM & CHEM CORP +1

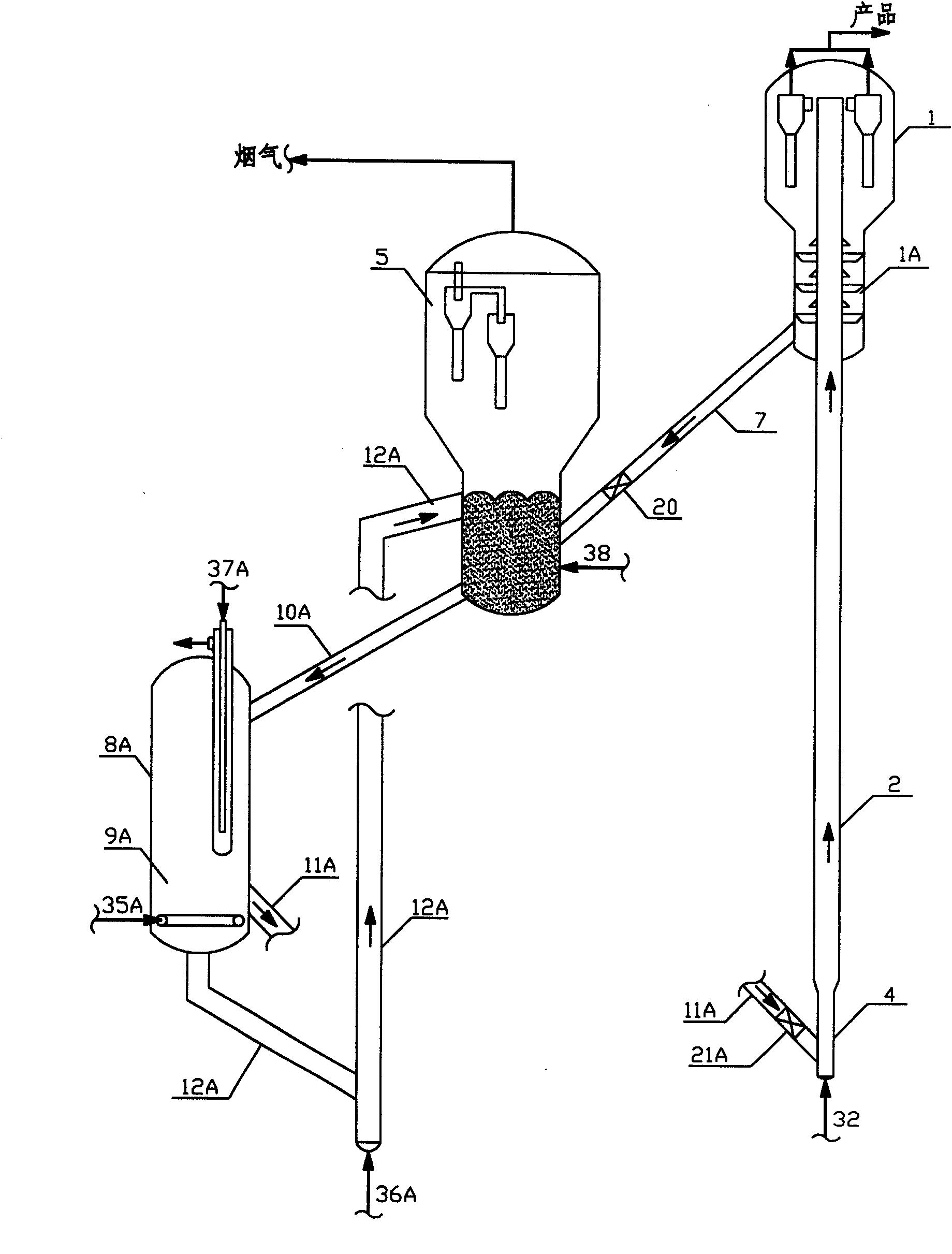

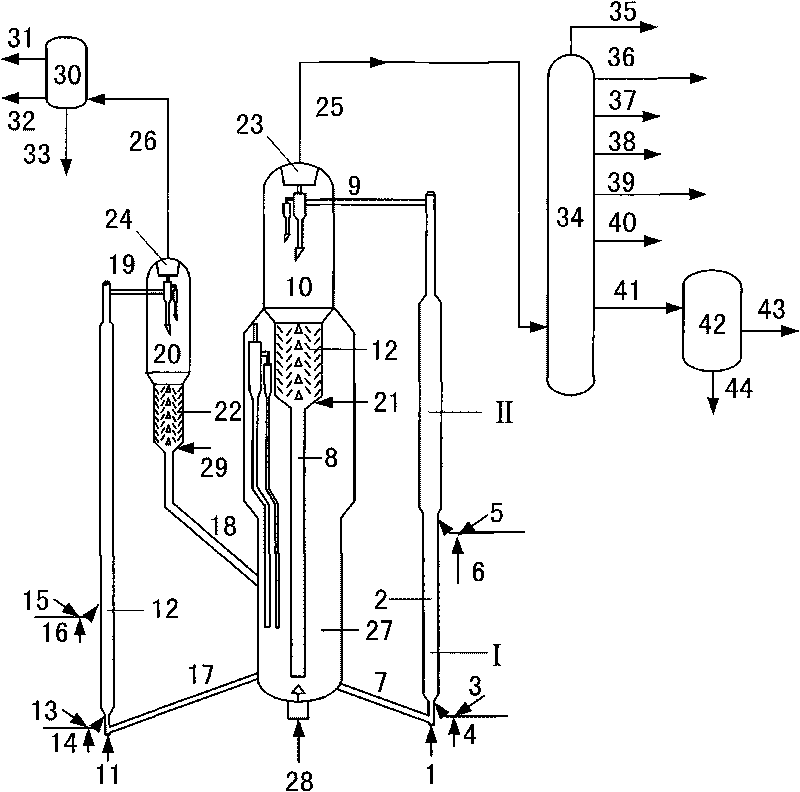

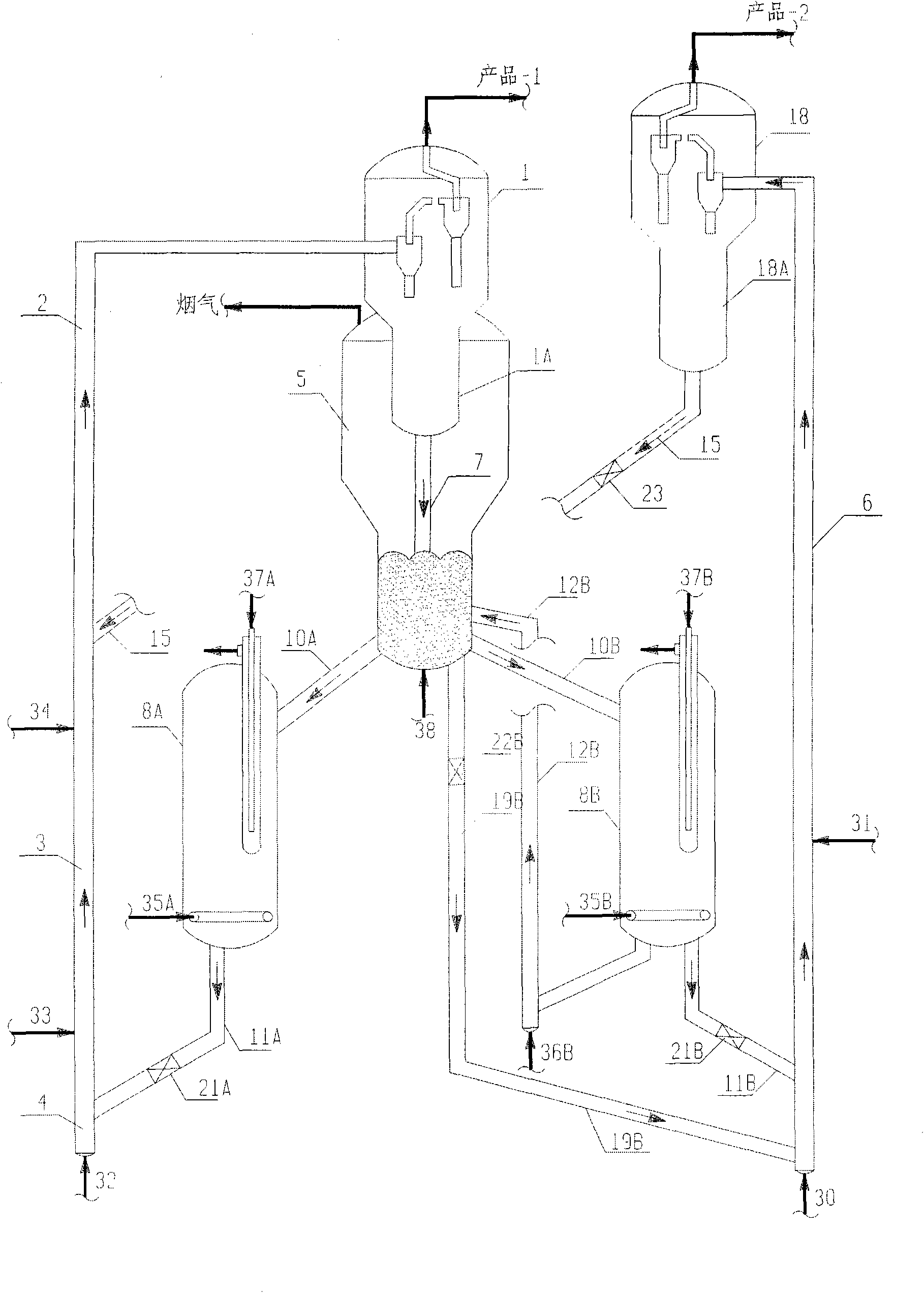

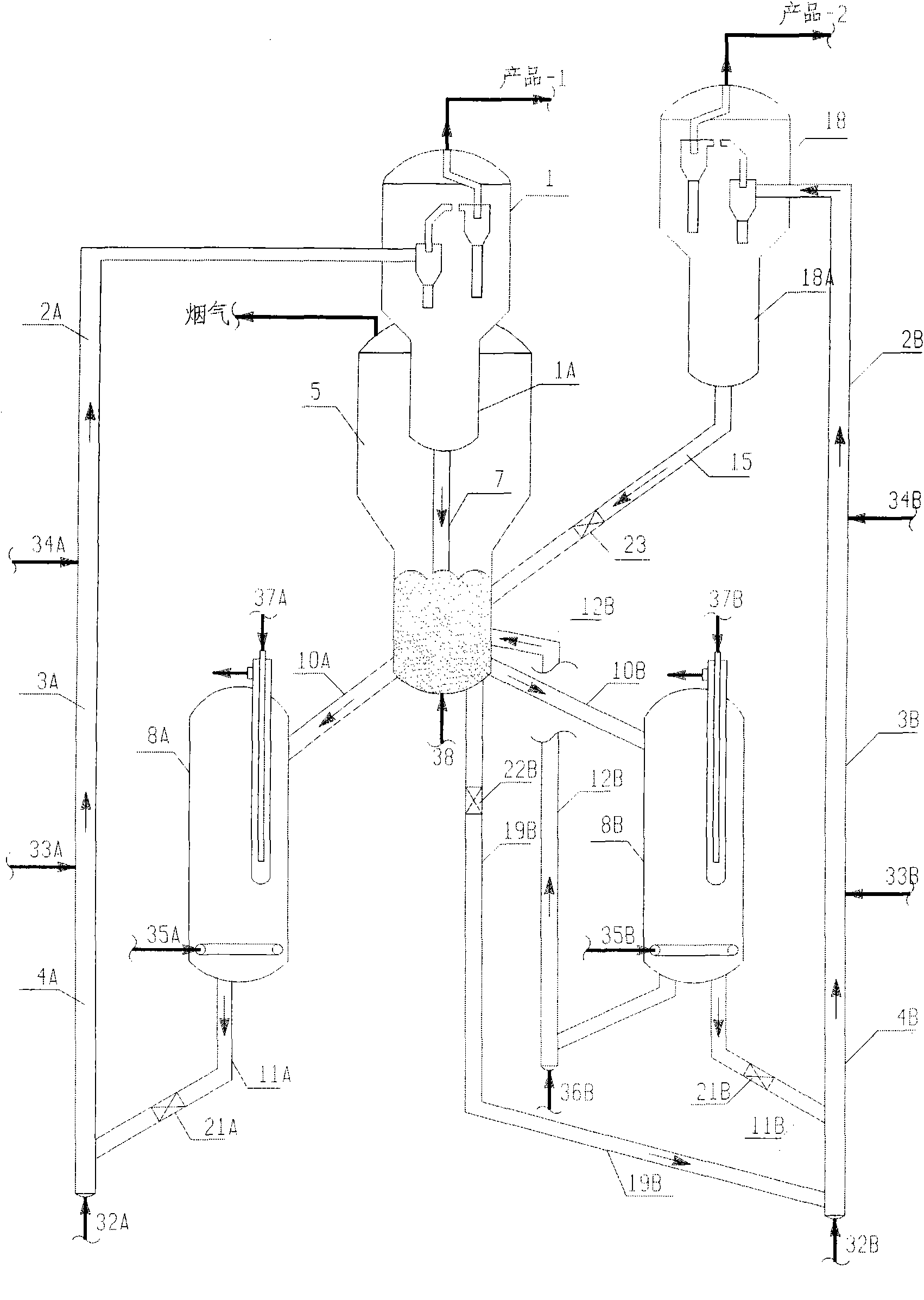

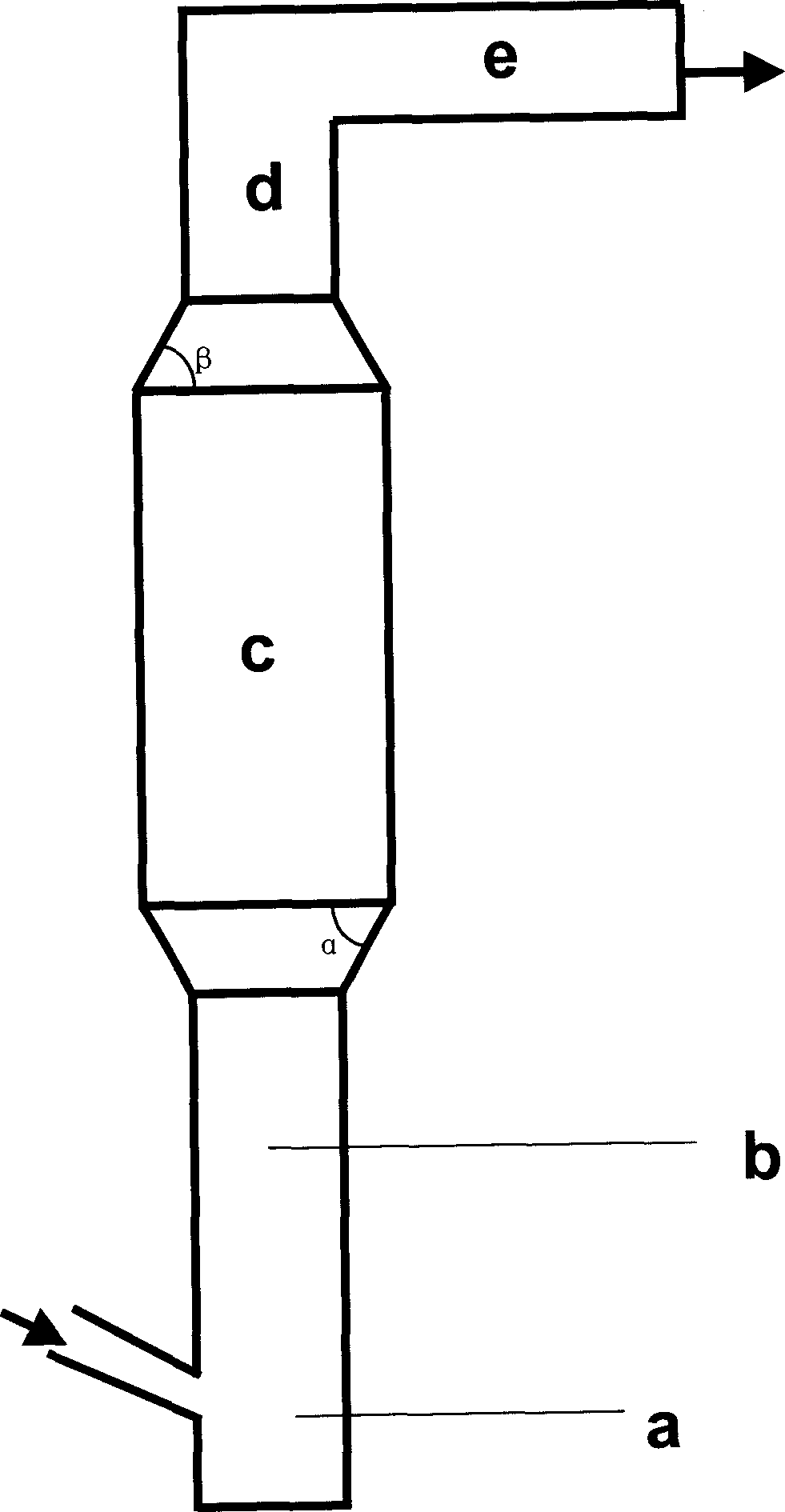

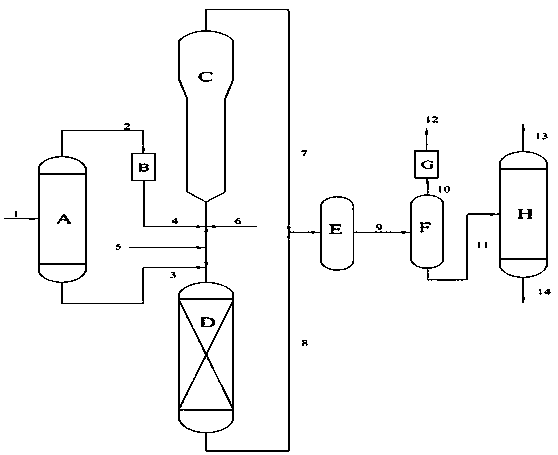

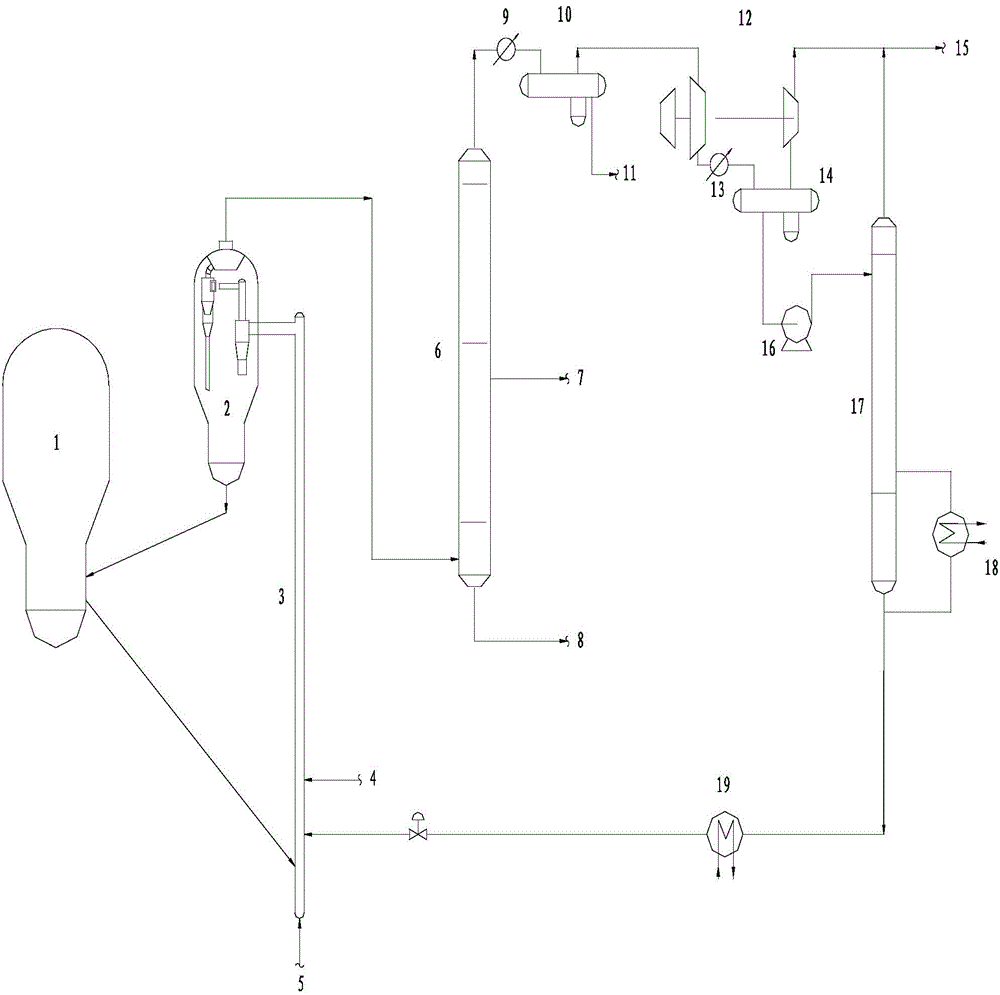

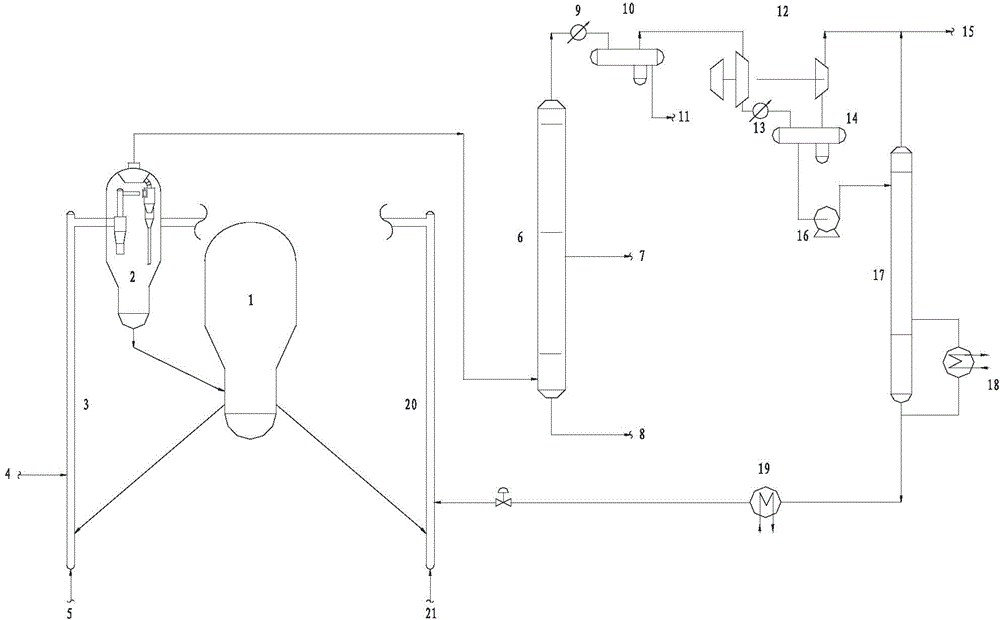

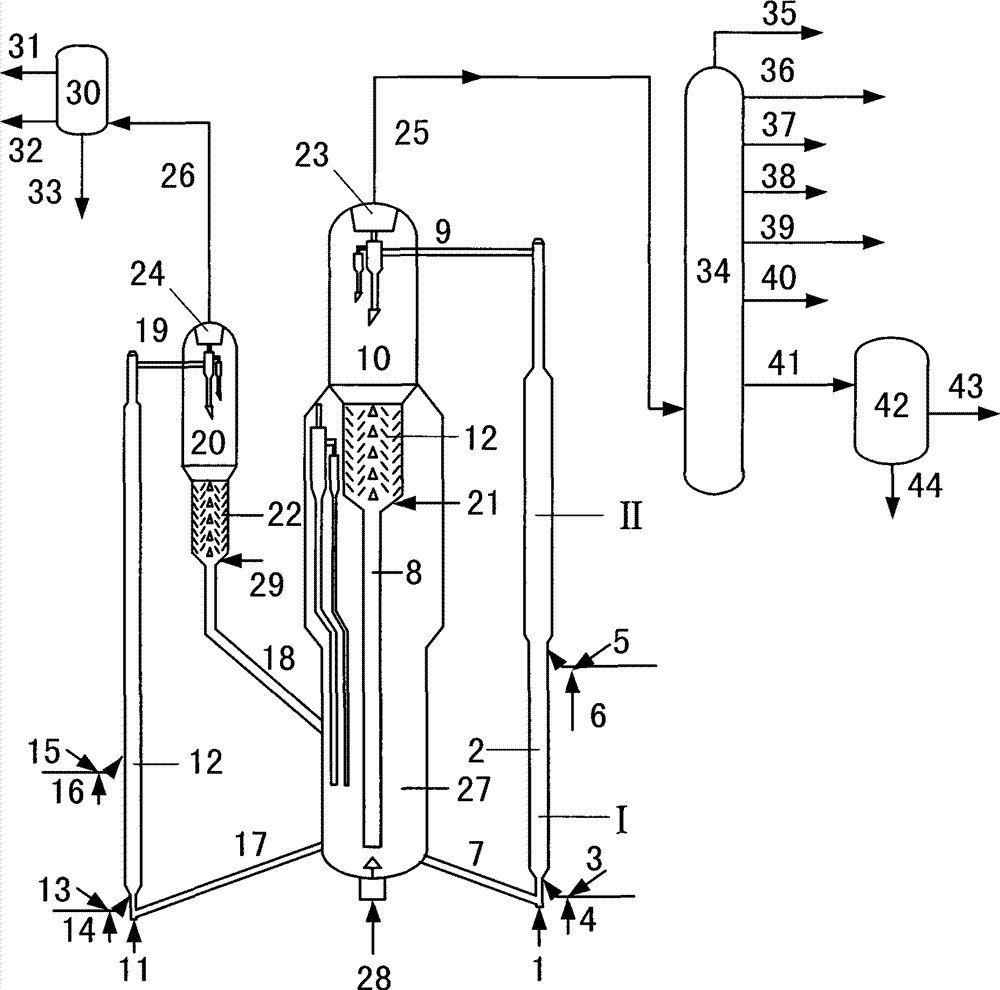

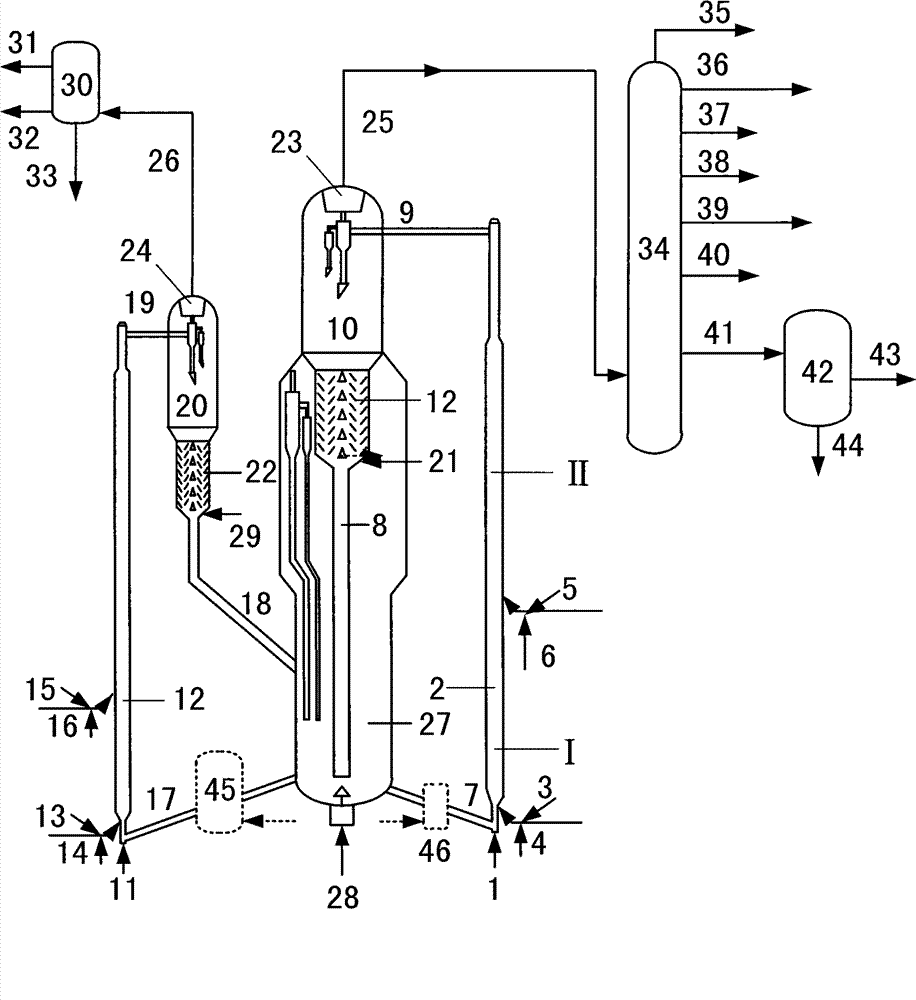

Method for catalytic conversion of heavy oil and device thereof

ActiveCN1664074ARaise the preheat temperaturePromote atomizationTreatment with plural serial stages onlyCatalytic transformationPtru catalyst

The invention provides a method of heavy raw material catalytic conversion and the device, comprising: the heavy hydrocarbon raw material passing through the first and second reaction area of the raiser reactor and contacting with catalyst for first reaction and second reaction, the reactants entering into the settler for the separation of catalyst and oil gas, steam stripping the separated catalyst through stripping section and introducing it to the reactivator for carbon burning reactivation, the reactivated catalyst returning to the raiser reactor after cooled or directly to the raiser reactor for reuse. After the heavy oil passing through the device said above, the volume content of olefin decreases by 10~40%, octane value increases 0.5~1 units, sulfur content in petrol decreases 10~30% by weight. After the poor petrol passing through the device said above, the volume content of olefin decreases by 10~60%, octane value increases 0.5~40 units, sulfur content in petrol decreases 10~50% by weight.

Owner:LUOYANG WEIDA PETROCHEMICAL ENG CO LTD

Catalyst for catalytic cracking of gasoline while reducing olefine and its preparing process

A catalyst for catalytic cracking gasoline while decreasing olefine contains NiSO4 as primary active components, Fe2(SO4)3 or CoSO4 as secondary one, and gamma-Al2O3 as carrier. It is prepared through immersing or kneading. Its advantages are simple preparing process, high activity of decreasing olefine, high output of diesel oil as by-product, and less investment in equipment.

Owner:DALIAN UNIV OF TECH

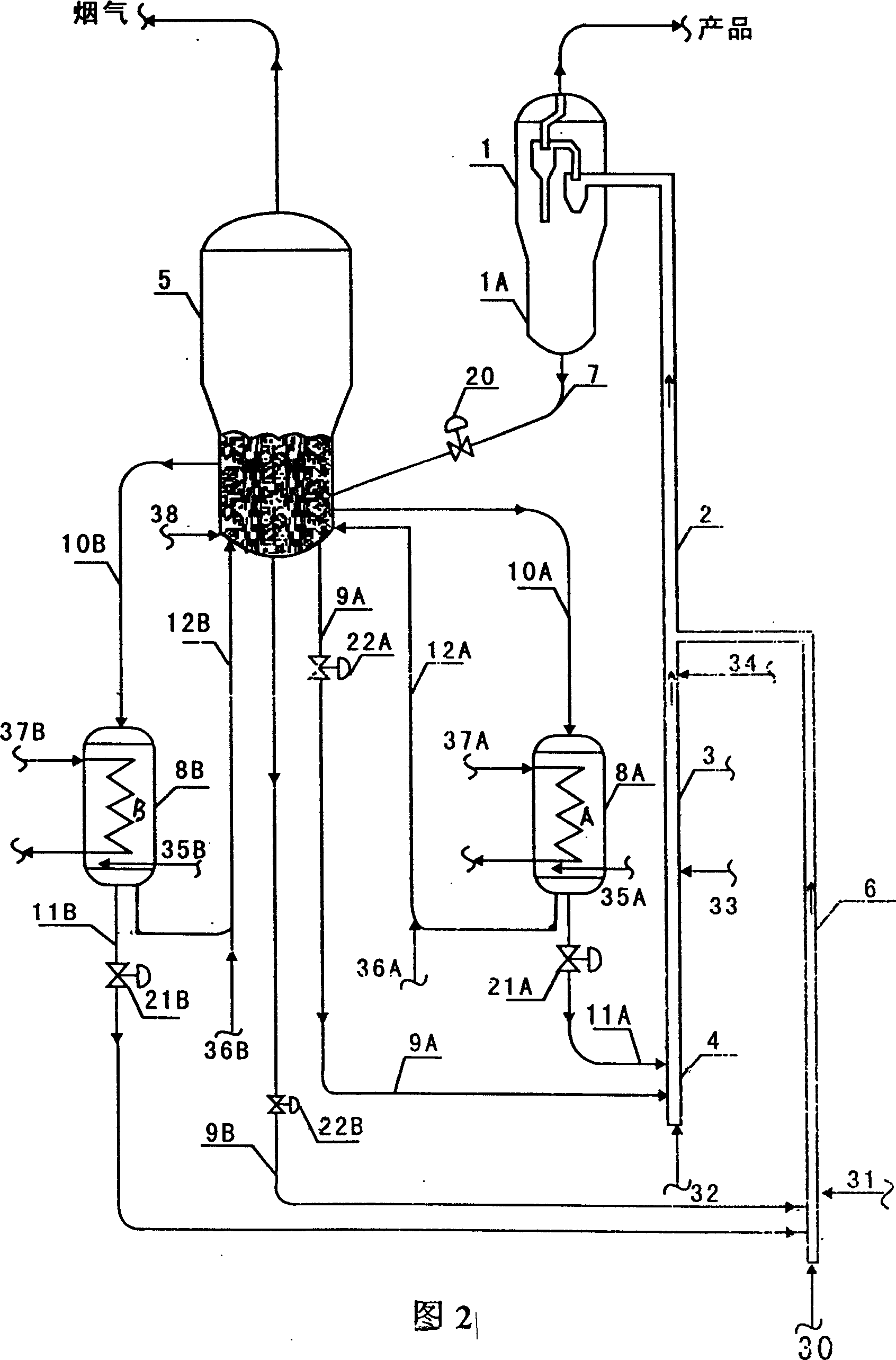

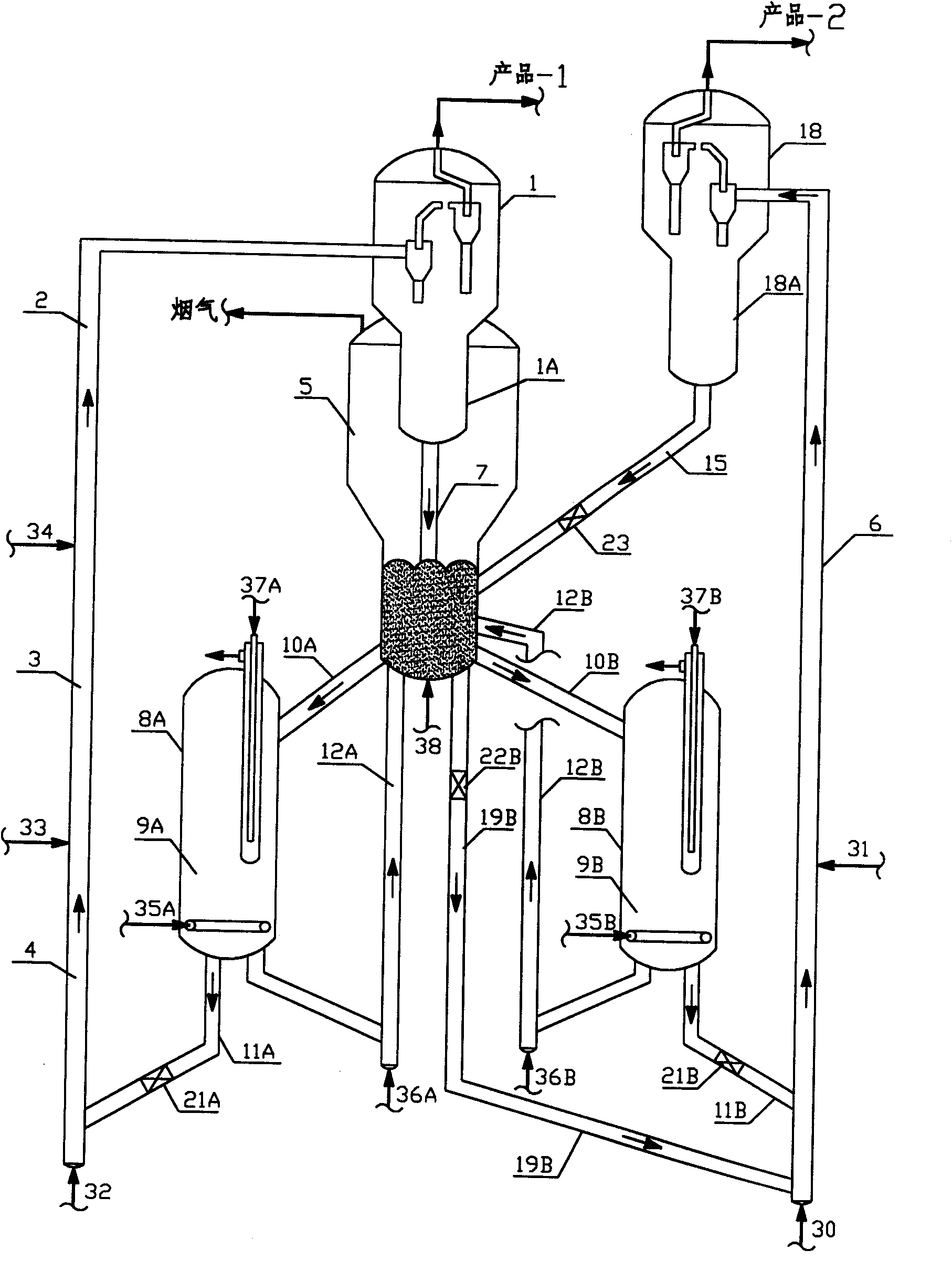

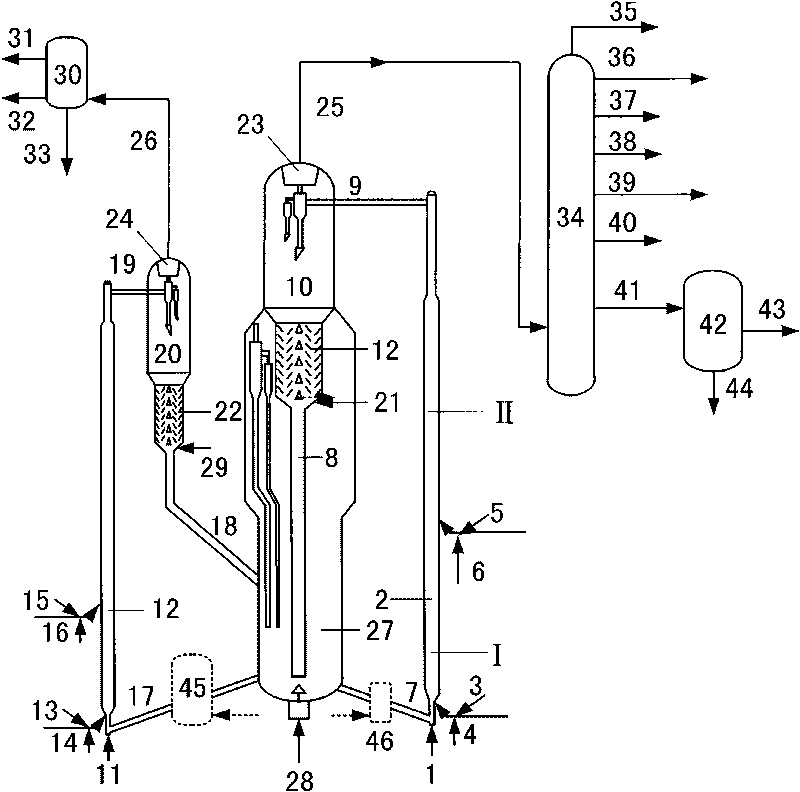

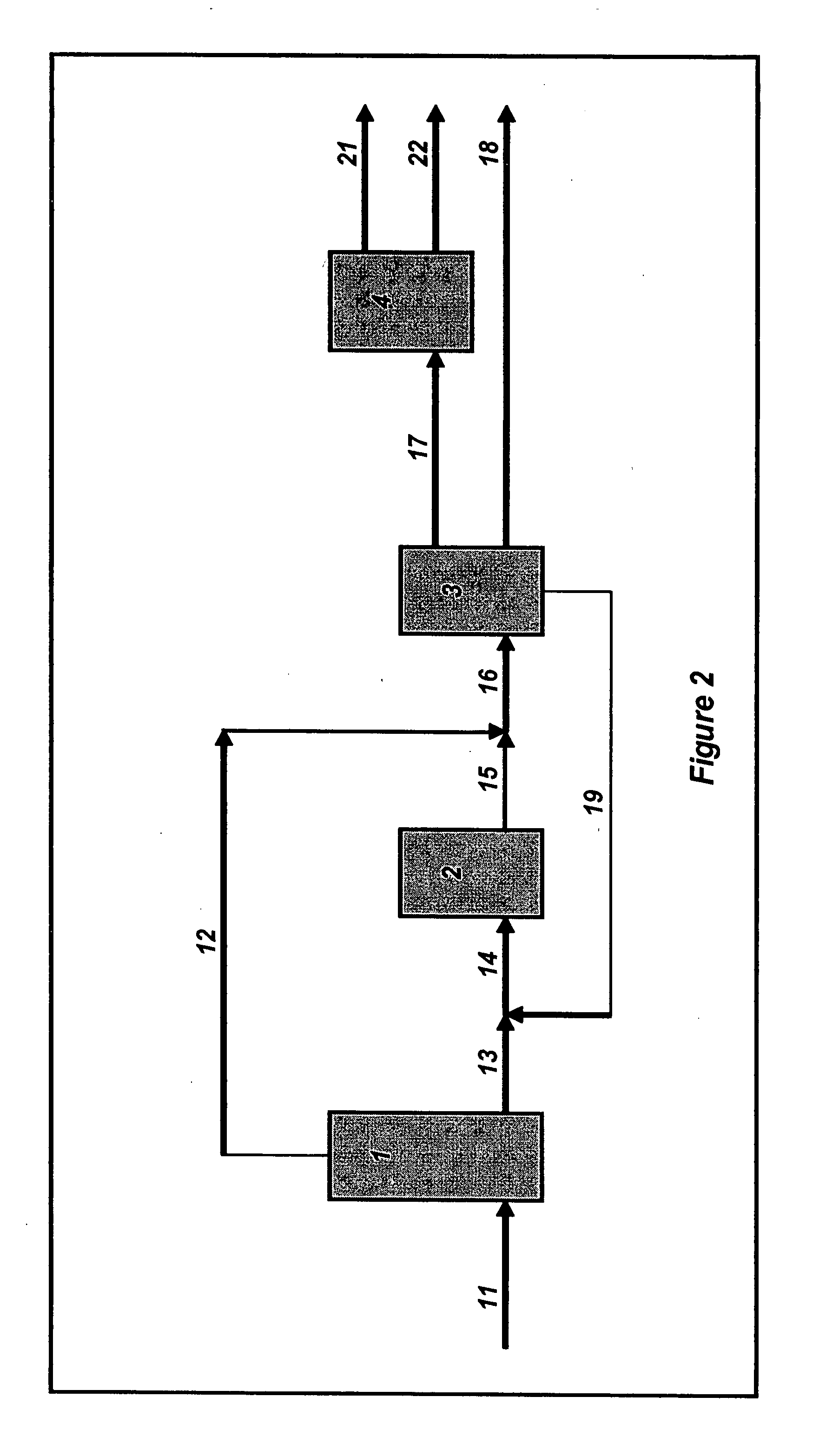

Method and device for circulating cold regenerated catalyst

The invention provides a method for circulating a cold regenerated catalyst and application thereof. A regenerated catalyst from a regenerator is cooled by a catalyst cooler to between 200 and 720DEGC, and is not mixed with a hot regenerated catalyst to directly enter a riser reactor, or is mixed with another part of uncooled hot regenerated catalyst into a mixed regenerated catalyst of which thetemperature is not lower than that of the regenerator to enter the riser reactor; and a hydrocarbon raw material undergoes contact reaction with the catalyst in the riser reactor, the reaction material flow enters a settler for the separation of the catalyst and oil gas, the separated catalyst to be regenerated is subjected to steam stripping in a steam stripping section, and then enters the regenerator for coke burning regeneration, and the regenerated catalyst is cooled and returns to the riser reactor for recycling. The method for circulating the cold regenerated catalyst has wide application, can be used for various fluid catalytic cracking processes comprising resid fluid catalytic cracking, wax oil catalytic cracking, gasoline catalytic conversion upgrading and the like, and also can be sued for other gas-solid reaction processes comprising residual oil pretreatment, fluid coking and the like.

Owner:LUOYANG WEIDA PETROCHEMICAL ENG CO LTD

Method for reducing sulfide in light hydrocarbon oil

The invention provides a method used for reducing the content of sulfide in light hydrocarbon oil, which comprises the steps as follows: after being preheated, a hydrocarbon oil raw material containing sulfur, and hydrogen donor enter a reactor filled with a sorbent and a zeolite additive so as to react under the conditions as follows: temperature of 300-500 DEG C, pressure of 0.5-3.5MPa, weight hourly space velocity of raw material oil at 0.5-10h<-1> and weight ratio between total amounts of the sorbent and the hydrocarbon oil raw material at 1-20; the materials are separated after reaction; the reaction products are sent to a subsequent separation system so that the product is separated; the sorbent to be regenerated and the zeolite additive to be regenerated after reaction are stripped, burned and regenerated; and the regenerated sorbent and the zeolite additive are reduced by the hydrogen donor and subsequently returned to the reactor so as to be circularly used. The method adds the zeolite additive during the adsorption desulfurization process, realizes deep desulfurization, leads the removal rate of the sulfur to achieve more than 96wt percent when disposing the gasoline, reduces the olefin of the gasoline, improves the octane number of the outcome gasoline simultaneously, keeps high liquid recovery and has low benzene content in the outcome gasoline.

Owner:CHINA PETROLEUM & CHEM CORP +1

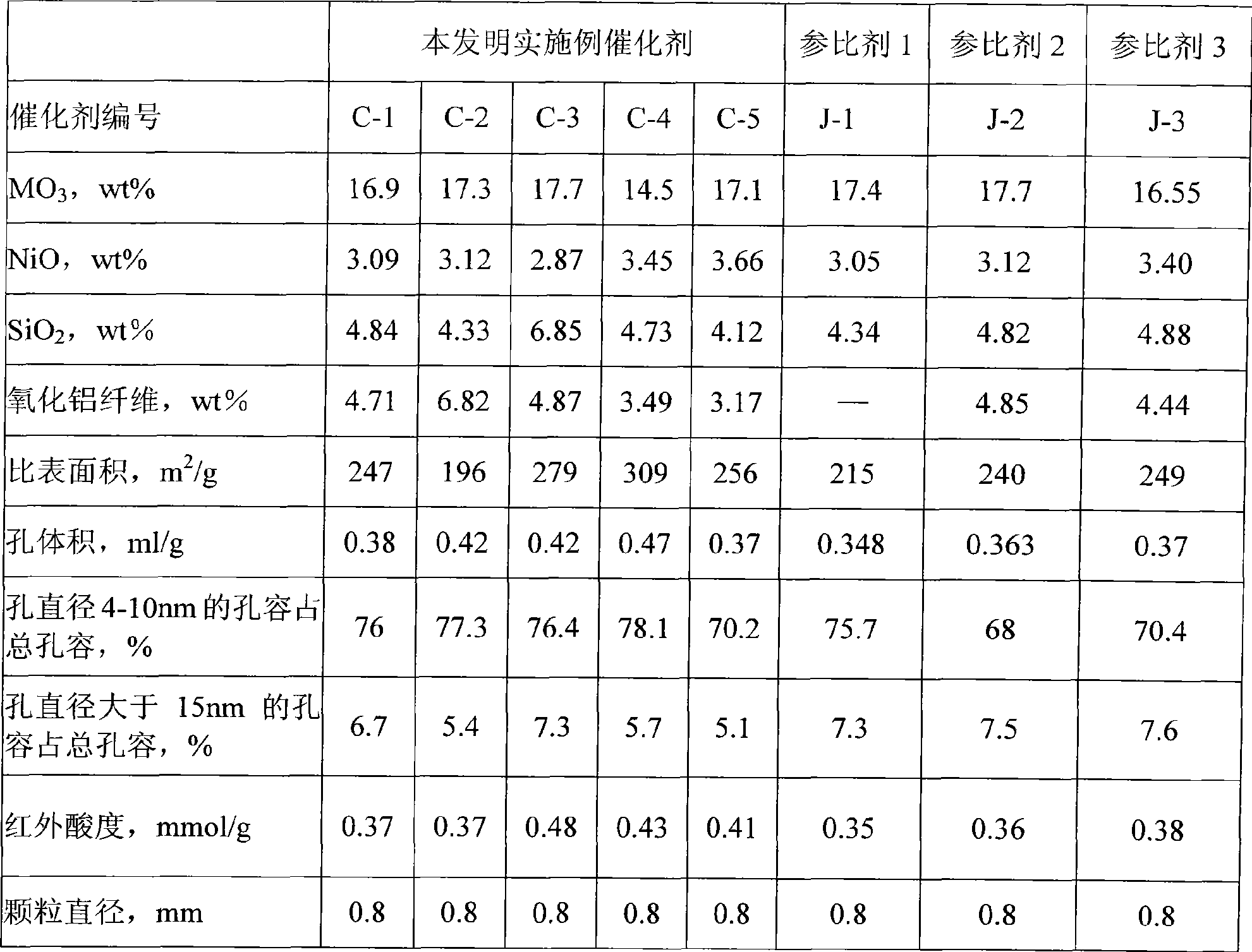

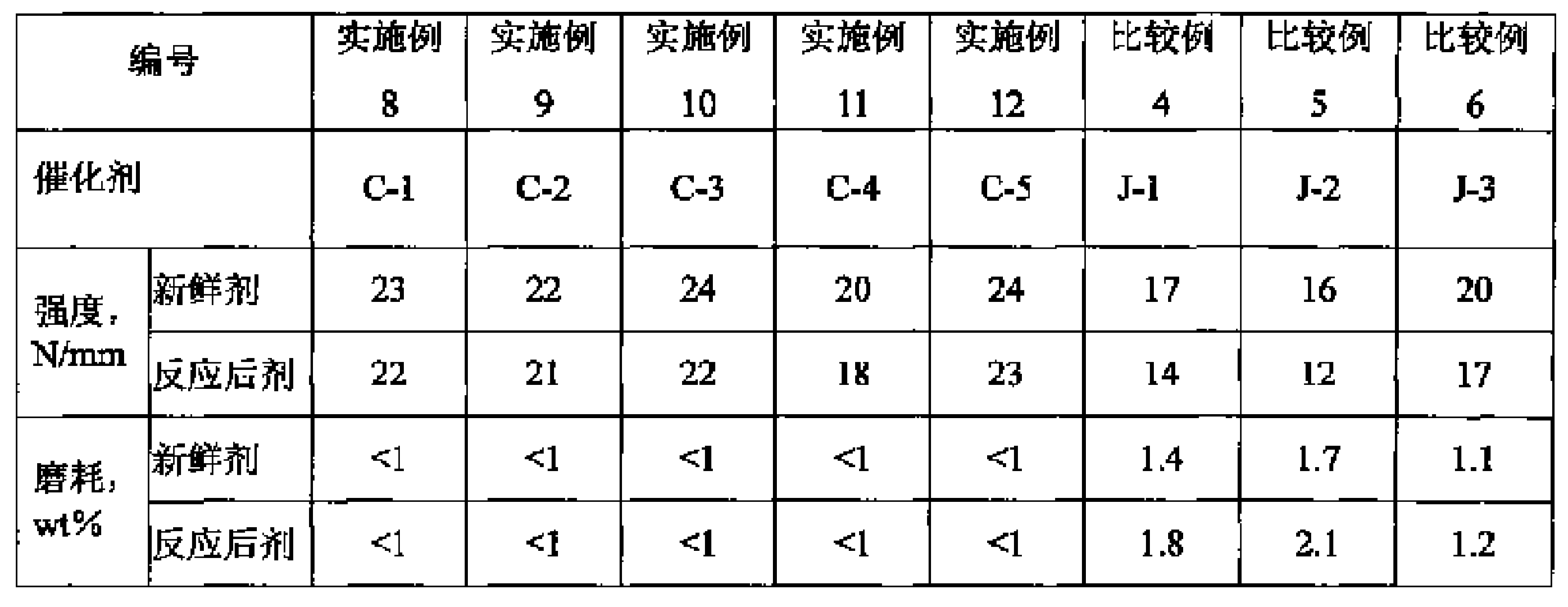

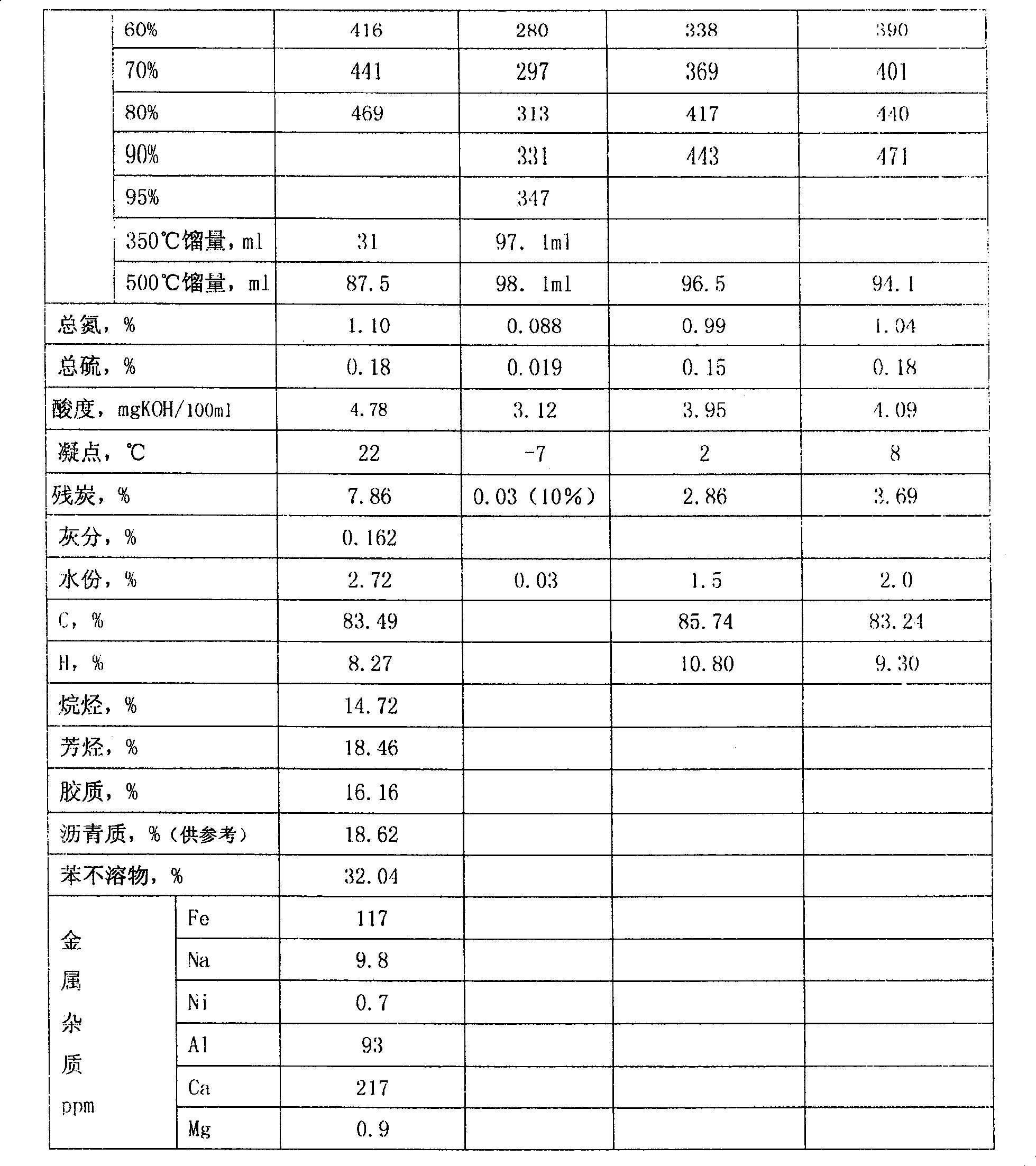

Coal liquefied oil boiling bed hydrogenation technique

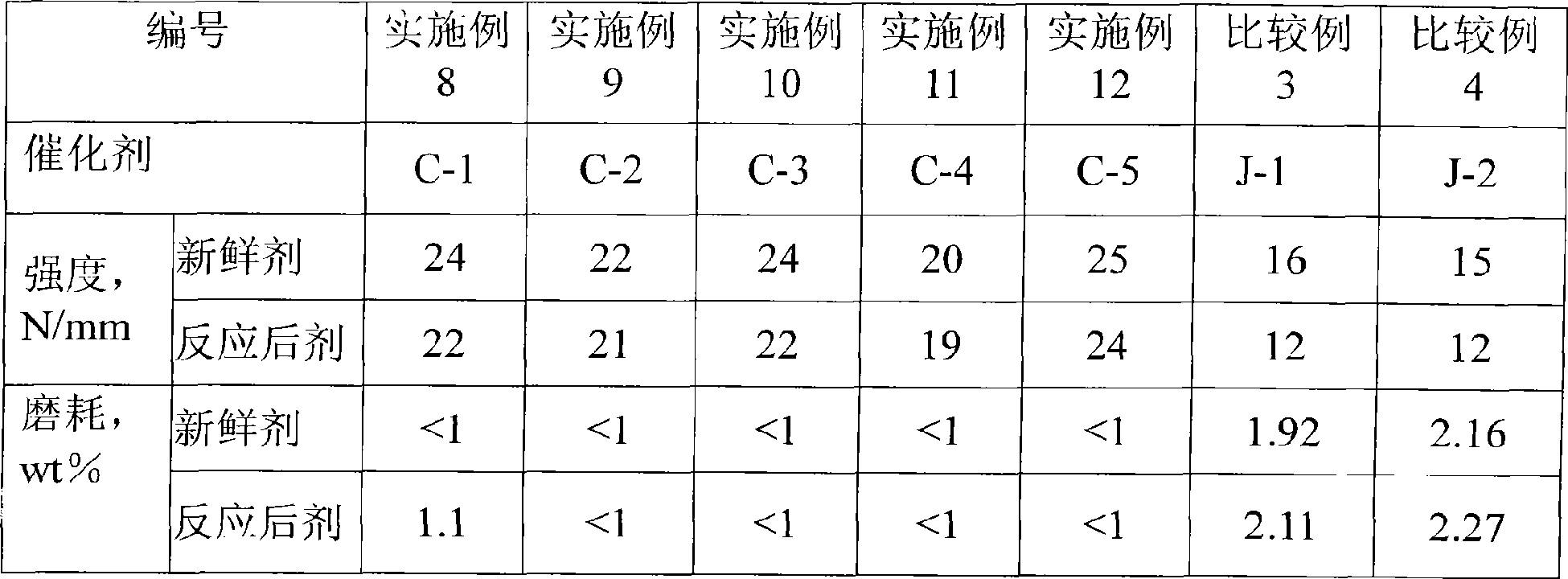

ActiveCN101085933AHigh mechanical strengthImprove wear resistanceRefining to eliminate hetero atomsFiberSulfur

The invention discloses a process of hydrogenation for coal liquification oil on boiling bed. The process employs hydrogenation catalyst which contains fiber adjuvant, the fiber adjuvant content in catalyst is 3- 10 wt%. The mechanical strength and wearing resistance are strong, so it can remove nitrogen and sulfur from coal liquification oil maximumly, reduces olefin and aromatic hydrocarbons content, increases product stability and provides high performance coal liquification solvent oil.

Owner:神华煤制油研究中心有限公司

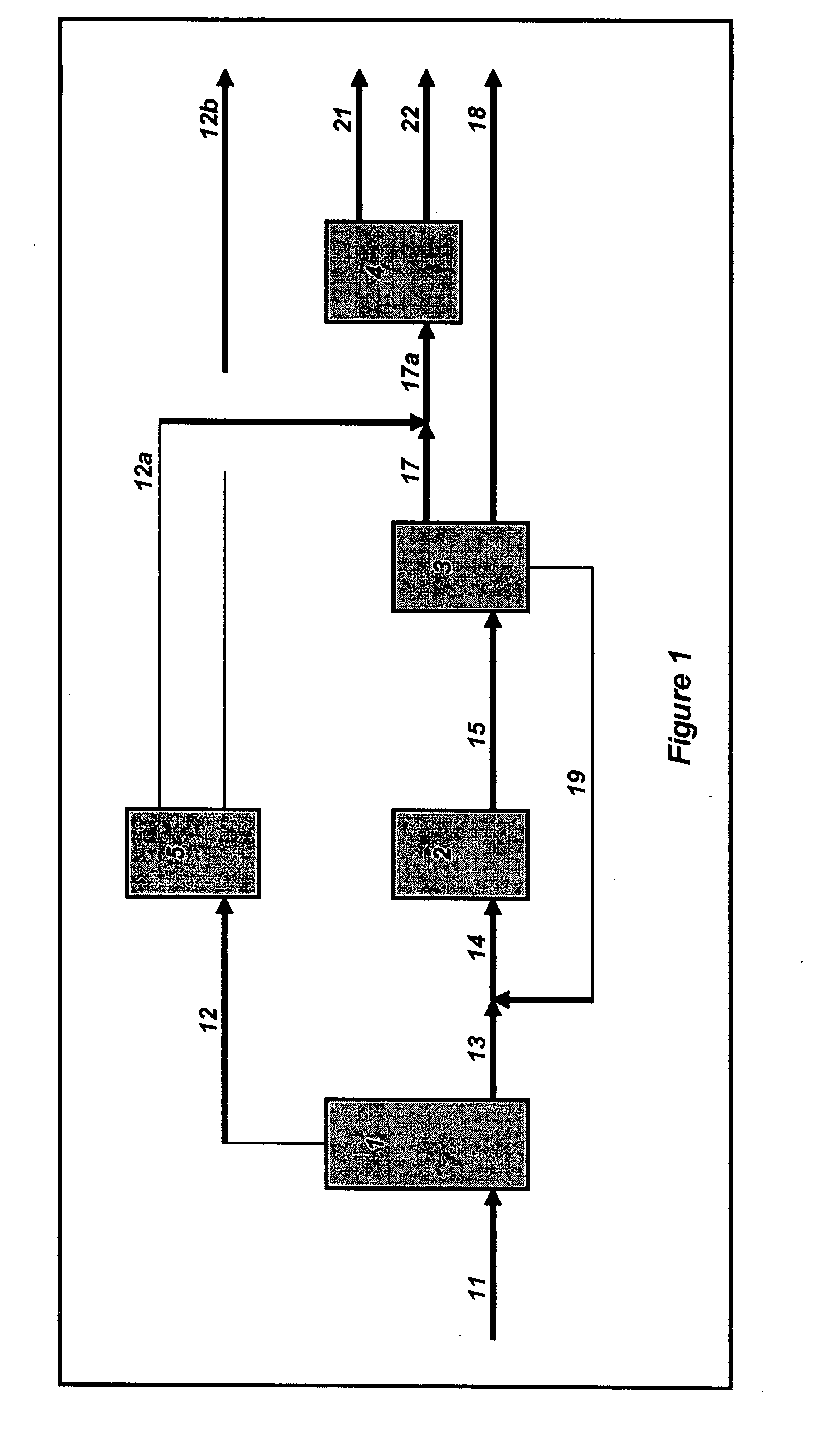

Catalytic conversion method for preparing light fuel oil and propylene

ActiveCN101724431AImprove propertiesExtended operating cycleCatalytic crackingChemical recyclingAlkaneCycloparaffins

The invention relates to a catalytic conversion method for preparing light fuel oil and propylene, comprising: leading inferior crude oil to enter a catalytic conversion reactor to be contacted with catalyst and have reaction; separating the reaction product, and obtaining the product containing the propylene, crude gasoline and catalytic wax oil, wherein leading the crude gasoline to enter another catalytic conversion reactor to be contacted with catalytic conversion catalyst to have reaction; treating the catalytic wax oil by hydrotreating or / and solvent extraction; and taking the catalyticwax oil obtained by hydrotreating or / and raffinate oil of the catalytic wax oil as raw material of the catalytic conversion reactor or other catalytic conversion reactors. In the method, after the catalytic wax oil which is obtained by carrying out mild catalytic conversion on the inferior crude oil is treated by hydrotreating or / and solvent extraction, the obtaining catalytic wax oil obtained byhydrotreating or / and raffinate oil contains alkane or cycloparaffin, and is very suitable for catalytic conversion, thus realizing high efficiency utilization of oil resources.

Owner:CHINA PETROLEUM & CHEM CORP +1

Coal liquefied oil boiling bed hydrogenation treatment catalyst and preparation method thereof

ActiveCN101085934AHigh mechanical strengthImprove wear resistanceRefining to eliminate hetero atomsFiberSulfur

The invention discloses a catalyst for coal liquification oil hydrogenation on boiling bed and the preparation method. Besides normal hydrogenation catalyst, the catalyst aslo contains silicon oxide fiber, the content of which in catalyst is 3- 10wt%. The mechanical strength and wearing resistance of catalyst are strong, which increases catalyst stability and life length. It can remove nitrogen and sulfur from coal liquification oil maximumly, reduces olefin and aromatic hydrocarbons content, increases product stability and provides high performance coal liquification solvent oil.

Owner:神华煤制油研究中心有限公司

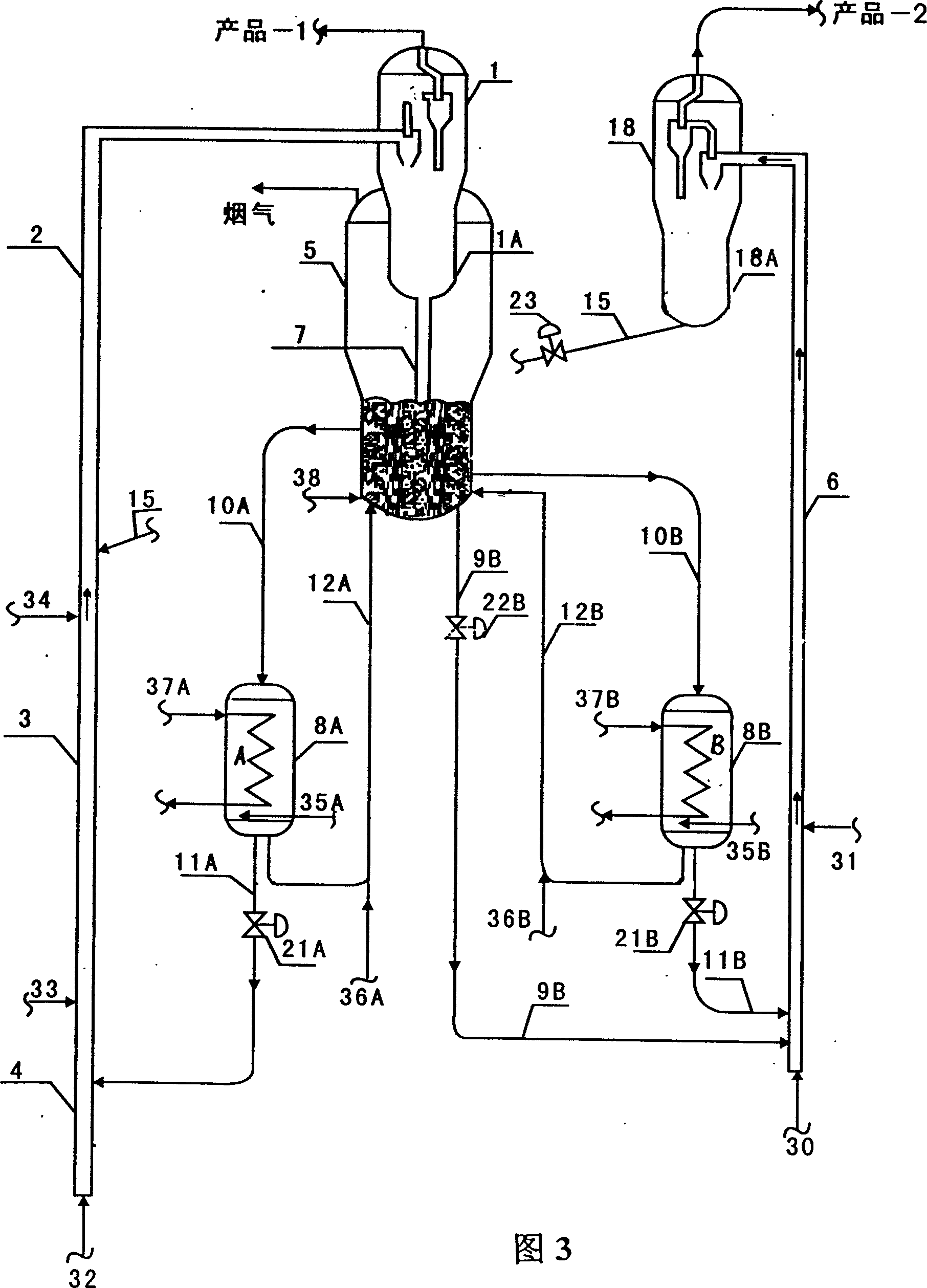

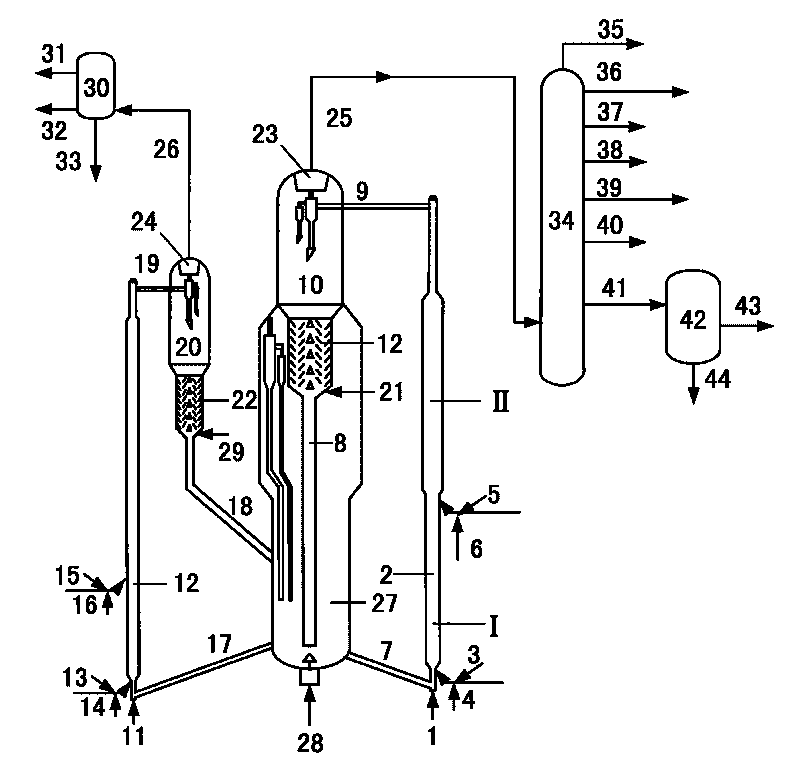

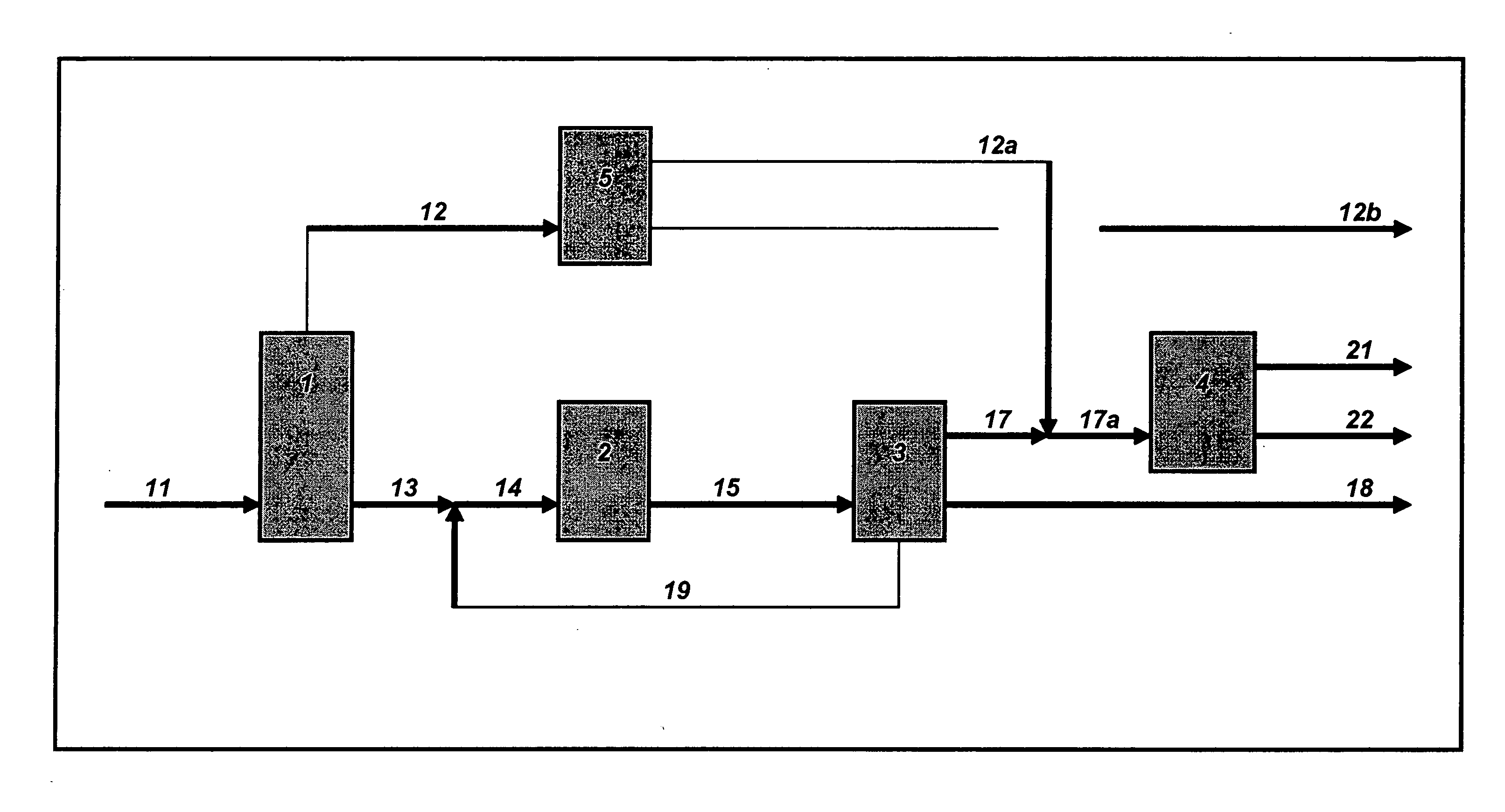

Method and device for fluidized catalytic conversion

ActiveCN101665712AReduce the temperatureRaise the preheat temperatureCatalytic crackingCatalytic transformationContact time

The invention provides a method for catalytic conversion of heavy oil, which comprises a fluidized catalytic conversion process that: heavy hydrocarbon raw materials contacts a catalyst in a riser reactor or fluidized bed reactor to react; the reaction temperature is 400 to 650 DEG C (preferably 480 to 560 DEG C); the reaction pressure is 0.11 to 0.4MPa; the contact time is 0.05 to 5 seconds (preferably 0.1 to 3 seconds); and the weight ratio of the catalyst to the raw materials ( catalyst to oil ratio) generally is 3 to 15, preferably 5 to 12. The reaction products flow in a settler for catalyst and oil gas separation; the separated catalyst to be regenerated is stripped by a stripping section and enters a regenerator for coke burning regeneration; and the regenerated catalyst is cooled or directly returns to the riser reactor to be recycled. The method can solve the problems encountered in the resid-blend ratio improvement and gasoline upgrade and update processes of the prior catalytic conversion.

Owner:LUOYANG WEIDA PETROCHEMICAL ENG CO LTD

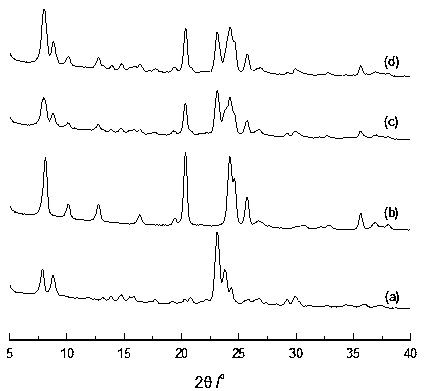

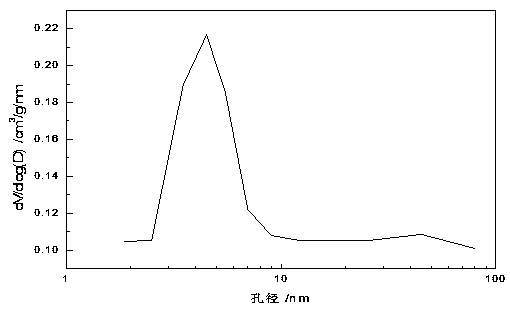

Preparation of bubbling bed hydrotreating catalyst

ActiveCN101376832AReduce olefinsLow aromatic contentRefining to eliminate hetero atomsPhosphateOxide

The invention discloses a preparation method of a boiling bed hydrotreatment catalyst. During the preparation method of the catalyst, alumina fibers and aluminum dihydrogen phosphate are added, thus improving the mechanical intensity of the catalyst, improving the service life of the catalyst and reducing the product cost. In the method, the aluminum dihydrogen phosphate with better acidity is preferably added into a bond, thus being capable of easing the strong mutual effects between an acid and a refractory porous inorganic oxide as well as the alumina fibers and reducing the loss of pore volumes and specific surface area. Besides, as the aluminum dihydrogen phosphate contains 6 hydroxide radicals, the aluminum dihydrogen phosphate is easy to form a complex compound with metals and is beneficial to improving the mutual effect between a carrier and active metals, thereby improving the activity of the catalyst.

Owner:CHINA PETROLEUM & CHEM CORP +1

Bubbling bed hydrotreating catalyst and preparation thereof

ActiveCN101376829AImprove mechanical strength and wear resistanceExtended service lifeRefining to eliminate hetero atomsPhosphateNitrogen

The invention discloses a boiling bed hydrotreatment catalyst and a preparation method thereof. The catalyst adopts an alumina carrier which contains alumina fibers and an accessory ingredient of phosphorus; wherein, the accessory ingredient of phosphorus is partially or completely led in the form of aluminum dihydrogen phosphate. During the preparation process, the alumina fibers and the aluminum dihydrogen phosphate are added in the catalyst, thus being capable of improving the mechanical intensity and the wear resistance of the catalyst, improving the stability of the catalyst, prolonging the service life of the catalyst and reducing the product cost. When the catalyst is used for the heavy oil products of boiling bed hydrotreatment, the impure atoms like nitrogen, sulfur in the oil products can be removed to the largest extent, the contents of olefin and aromatic hydrocarbon can be reduced and the product stability can be improved.

Owner:CHINA PETROLEUM & CHEM CORP +1

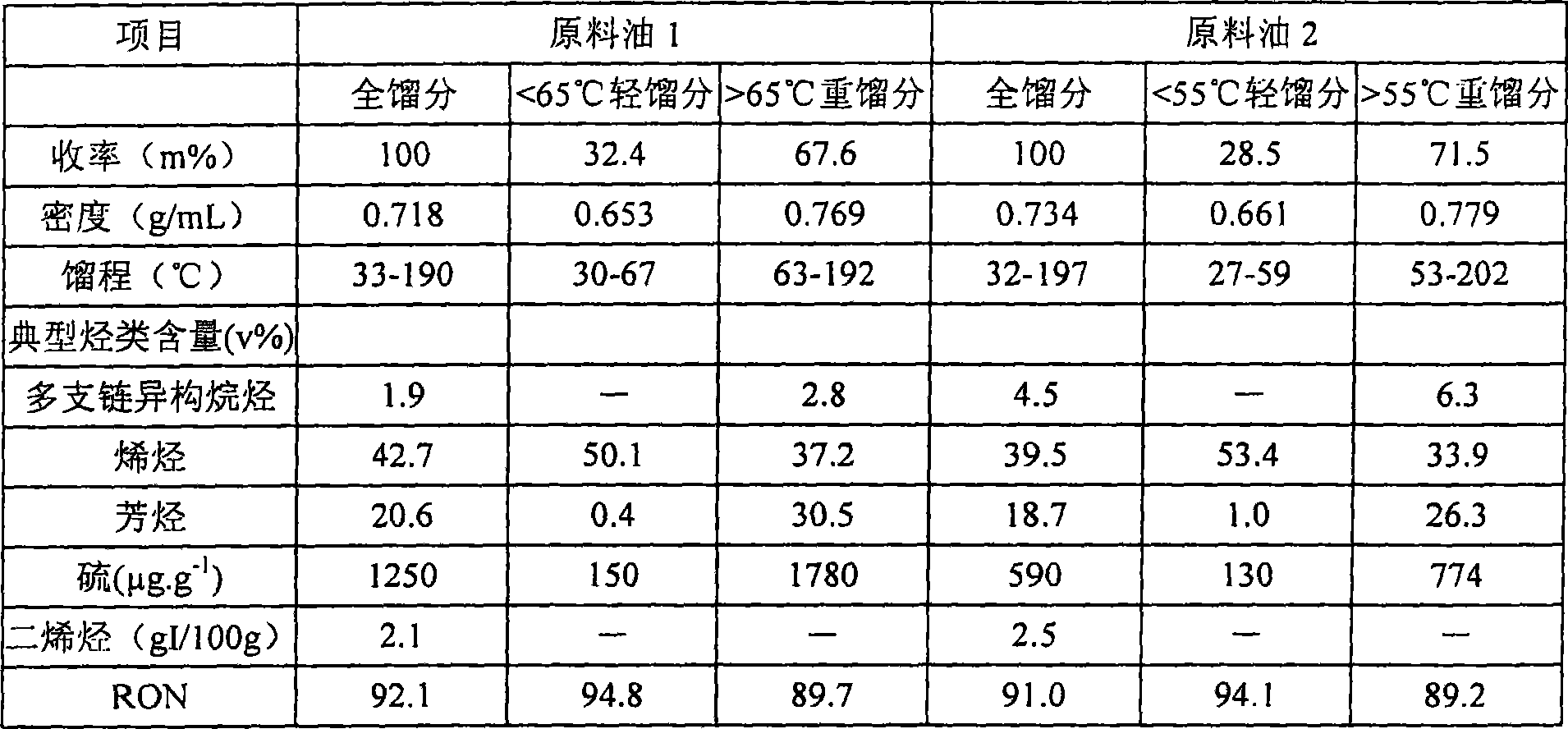

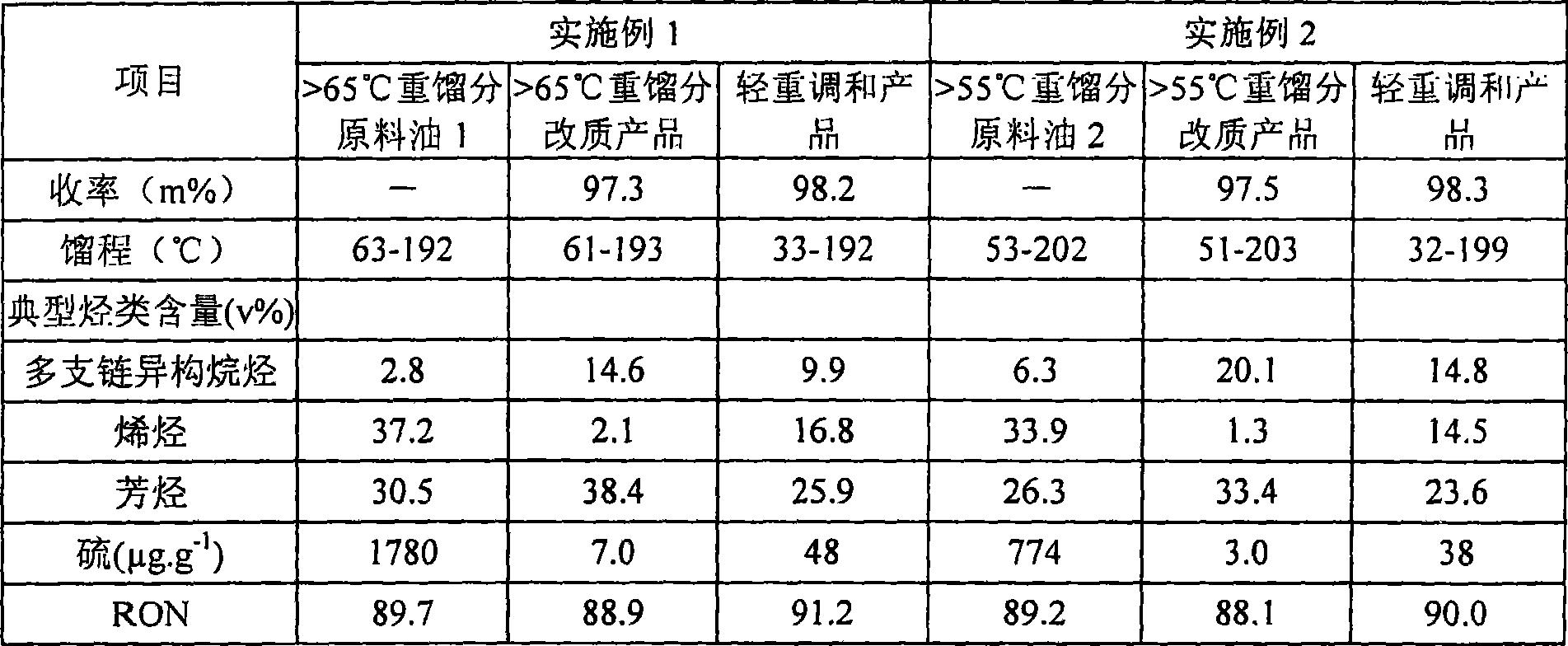

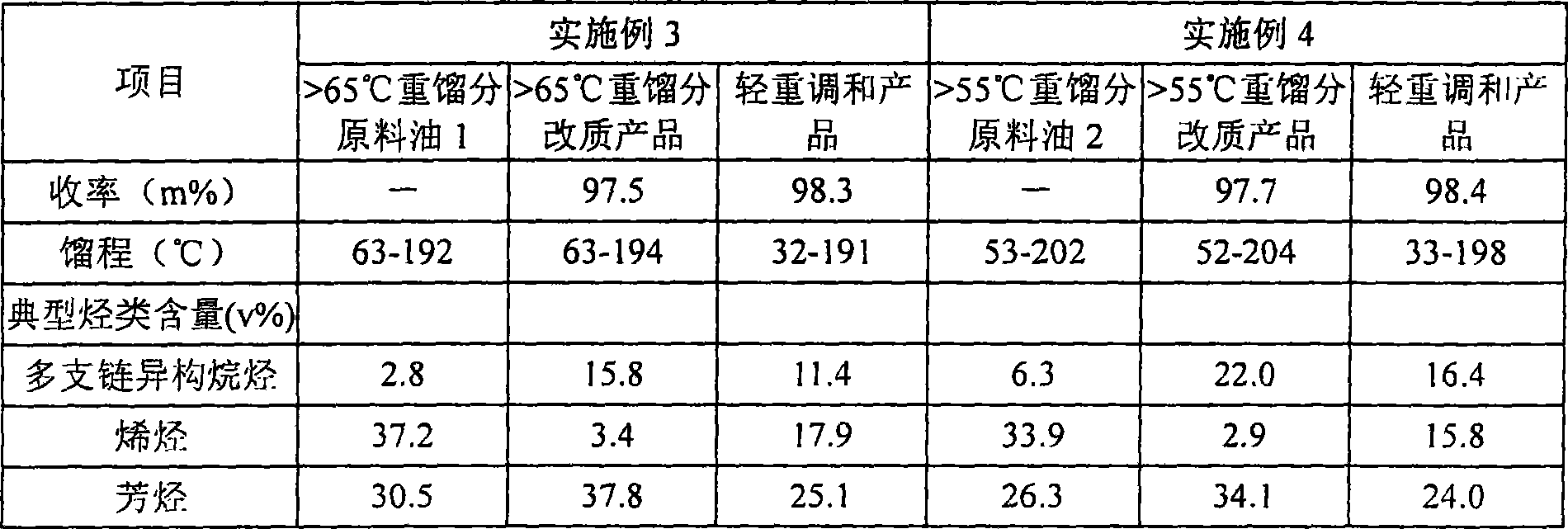

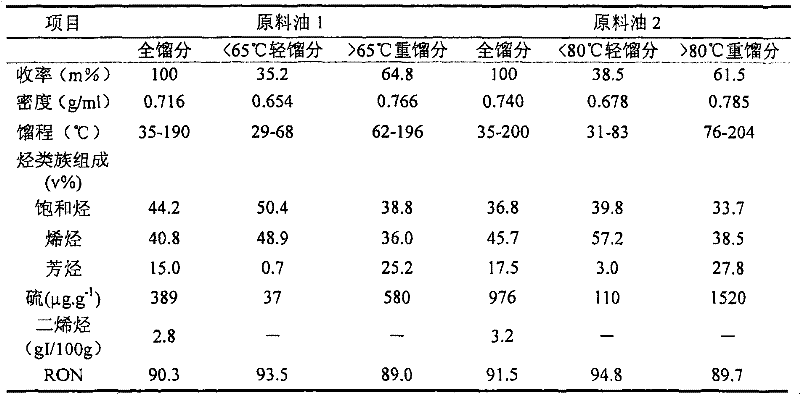

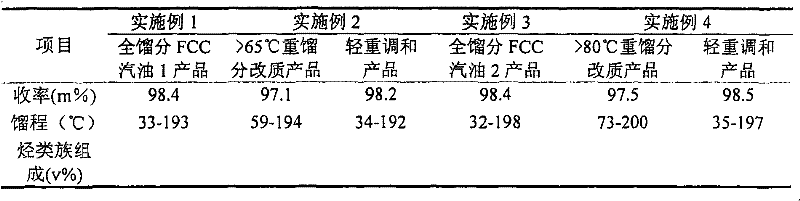

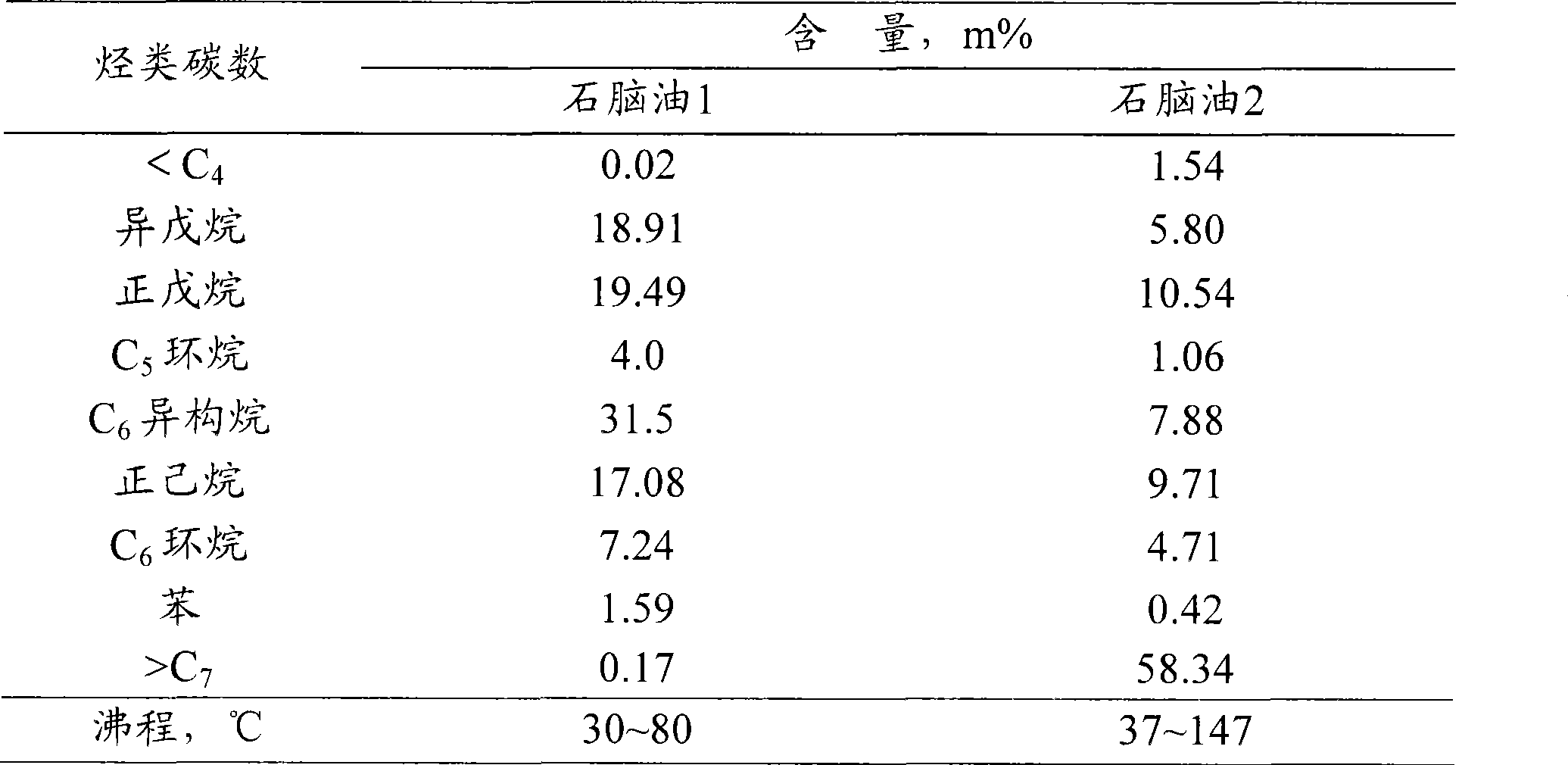

Hydrogenation modification method for faulty gasoline

ActiveCN101508911AAffect the service lifeSolve the problem of difficult removal of sterically hindered sulfidesTreatment with hydrotreatment processesHydrodesulfurizationSulfur

The invention relates to a hydro-upgrading method of poor gasoline. The invention provides a hydro-upgrading method of ultra-deep desulfurization and octane number preservation of poor gasoline, including the followings: poor full range gasoline is divided into light range gasoline and heavy range gasoline; the weight range gasoline is contacted with selective hydrobon catalyst in the first-stage reaction zone so that the reaction effluent in the second-stage reaction zone is contacted with desulfuration-hydrocarbon multibranched hydroisomeric catalyst and the reaction effluent in the third-stage reaction zone is contacted with supplementary desulfuration-hydrocarbon monobranched isomeric / aromatizing catalyst; and then the reaction effluent and the light range gasoline are mixed according to a proportion so as to obtain ultra clean gasoline product. The hydro-upgrading method is applied to hydro-upgrading for poor gasoline, particularly for ultra-high-sulfur and high-olefin poor catalytically cracked gasoline, can maintain or improve the product octane number and keep higher product liquid yield while greatly reducing the contents of olefin and sulfur, and can produce ultra clean gasoline of national IV or even higher standard.

Owner:CHINA UNIV OF PETROLEUM (BEIJING)

Catalytic converting method for improving petrol octane number

Owner:CHINA PETROLEUM & CHEM CORP +1

Stable hydrogenation process for liquefied coal coil

InactiveCN1141362CReduce olefinsLow aromatic contentHydrocarbon oils refiningHydrogenation processHigh pressure

A stable hydrogenation process of liquefied coal oil includes filtering the liquefied coal oil, adding it along with hydrogen gas to stable hydrogenation reactor, contacting with hydroprotector and hydrorefining catalyst, flowing in its product through high-pressure separator, low-pressure separator and fractional tower to respectively obtain hydrogen-enriched airflow, light fraction and tail oil fraction, mixing said hydrogen-enriched airflow with fresh hydrogen, and returning the mixture back to said stable hydrogenation reactor. It has high effect on removing impurities from liquefied oil to maximum.

Owner:CHINA PETROLEUM & CHEM CORP +1

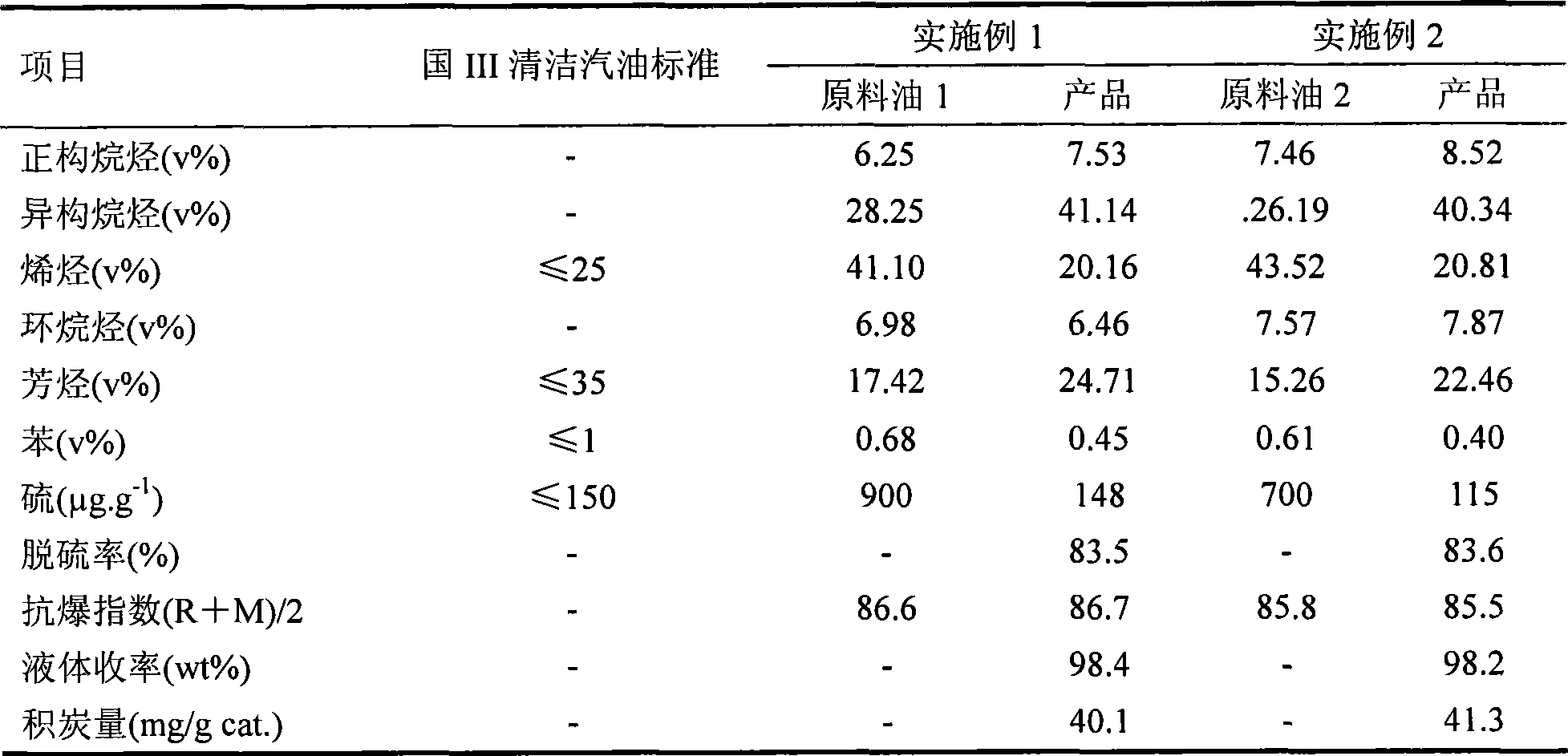

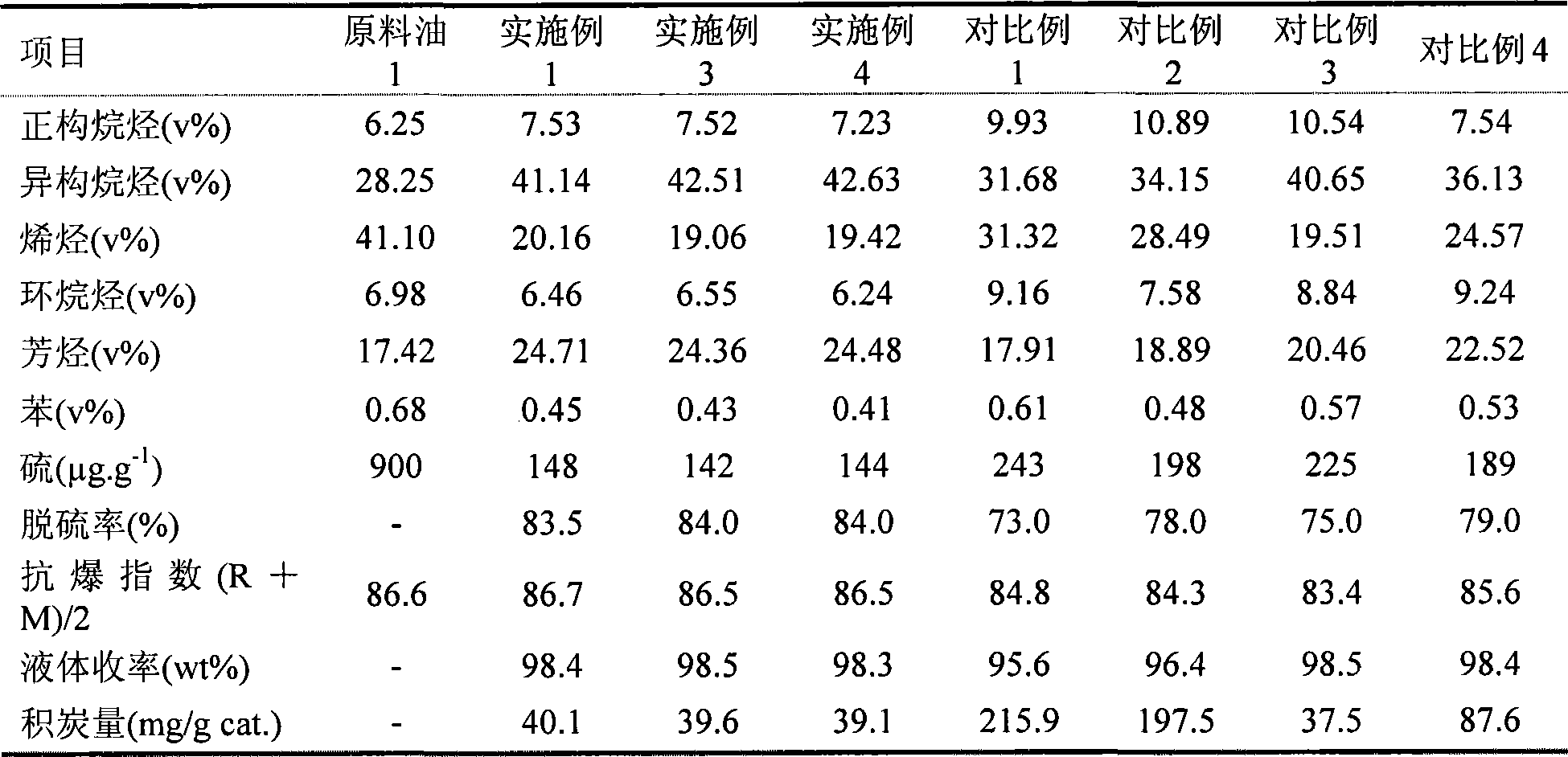

Hydro-upgrading method for FCC gasoline

ActiveCN101440305AAffect the service lifeImprove desulfurizationTreatment with hydrotreatment processesSulfurAlkene

The invention relates to a hydrogenated and modification method for catalytically cracked gasoline. The method adopts two-section reaction to treat FCC gasoline in order that the FCC gasoline has catalytic reaction with two different catalysts in reaction regions of two sections. The reaction region of the first section has a low temperature and adopts a selective hydrogenation diolefin-removal catalyst to mainly remove unstable diolefin in the gasoline; and the reaction region of the second section has high temperature and adopts a modified HZSM-5 zeolite-based catalyst after modification treatment through hydrothermal and citric acid so as to mainly realize the targets of desulfurizing, reducing olefin, restoring the octane number of a product and antiknock index. The method is suitable for hydrogenated modification of the FCC gasoline, can obtain good hydrogenated modification effect on inferior FCC gasoline with high sulphur and high olefin in particular, can reduce the contents of olefin and sulphur, reduce the loss of the antiknock index and keeps high product liquid yield.

Owner:CHINA UNIV OF PETROLEUM (BEIJING)

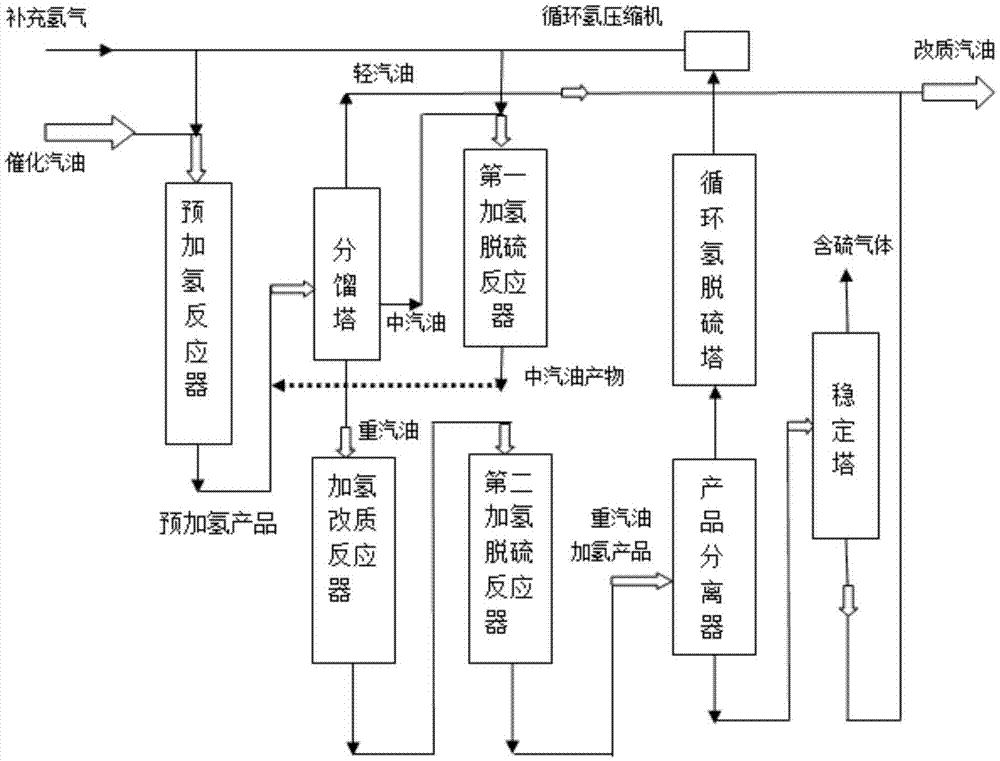

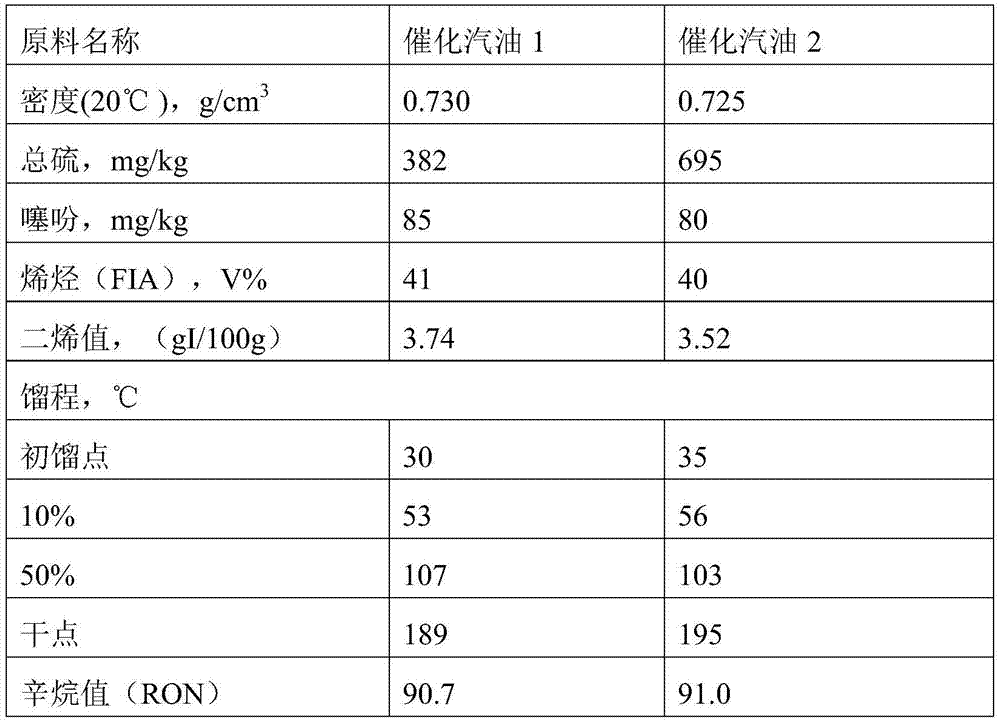

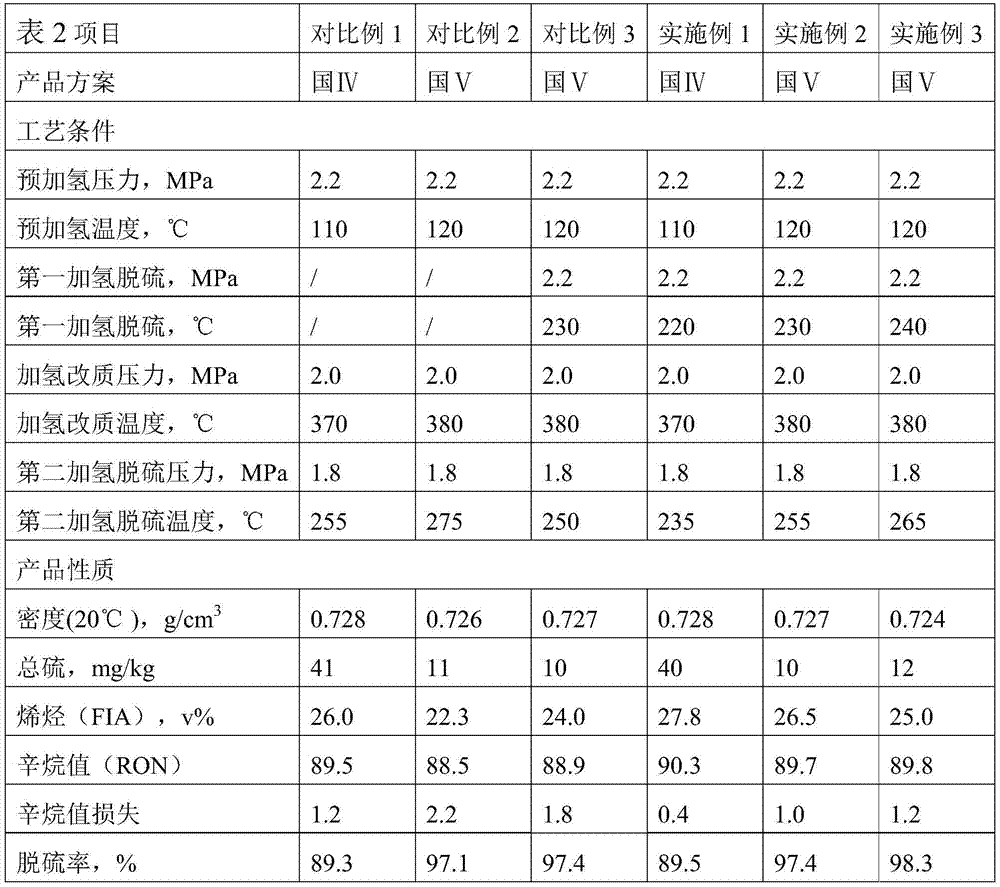

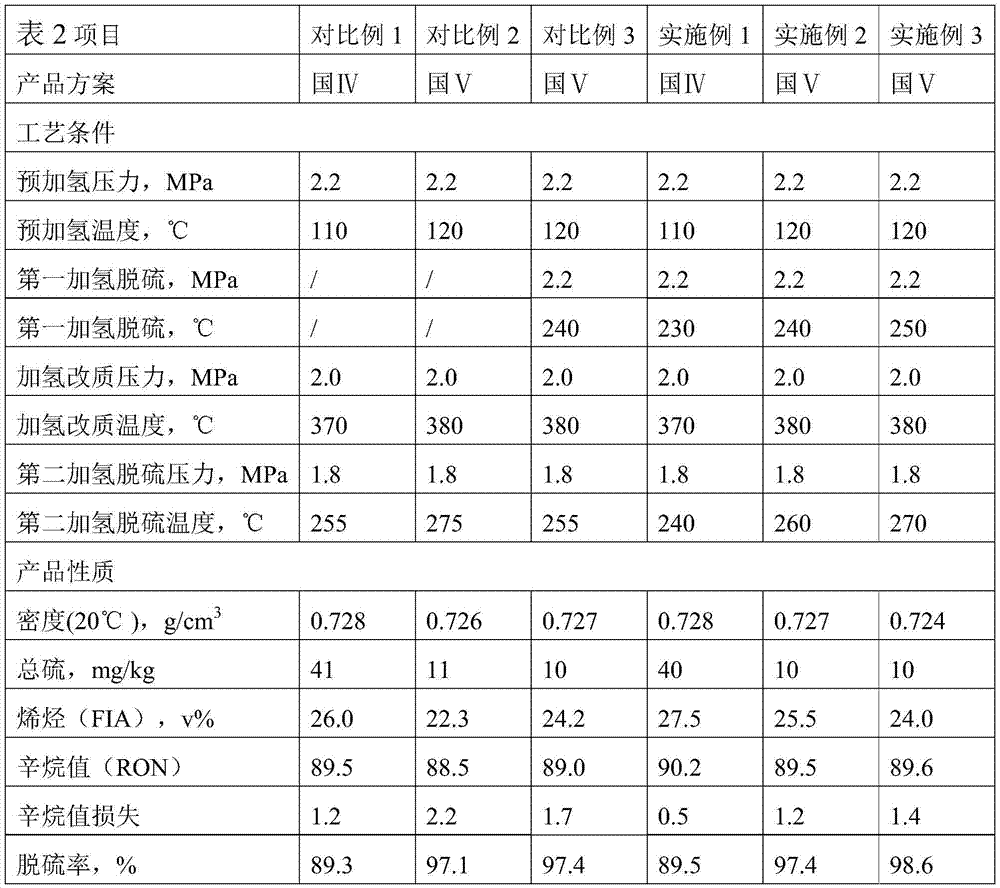

Method for hydro-upgrading inferior catalytic gasoline

ActiveCN106929098AReduced mercaptan contentLower Diene ContentTreatment with hydrotreatment processesChemistryProduct gas

The invention discloses a method for hydro-upgrading inferior catalytic gasoline. The method comprises the following steps: (1) mixing catalytic gasoline and hydrogen and feeding the mixture into a pre-hydrogenating reactor; (2) feeding a product of the step (1) into a fractionating tower and dividing the product into a light gasoline component, a medium gasoline component and a heavy gasoline component; (3) taking the light gasoline component discharged from the top of the fractionating tower as an upgraded gasoline blending component, mixing the medium gasoline component discharged from a side line and the hydrogen, feeding the mixture into a first hydrogen desulfurization reactor, reacting and then returning the product to the fractionating tower; (4) mixing the heavy gasoline component discharged from the bottom of the fractionating tower and the hydrogen, feeding the mixture into a hydro-upgrading reactor and reacting; (5) feeding the product of the step (4) into a second hydrogen desulfurization reactor and reacting; and (6), after the product of the step (5) is cooled down, feeding the product into a product separator and carrying out gas-liquid separation, recycling the hydrogen on the top, feeding a liquid phase at the bottom into a stabilizer to remove sulfurous gas, and mixing the liquid phase with light gasoline to obtain the upgraded gasoline product. According to the method, while the content of olefin and the content of sulphur are greatly reduced, loss of octane value in hydro-upgrading of the catalytic gasoline is reduced.

Owner:PETROCHINA CO LTD

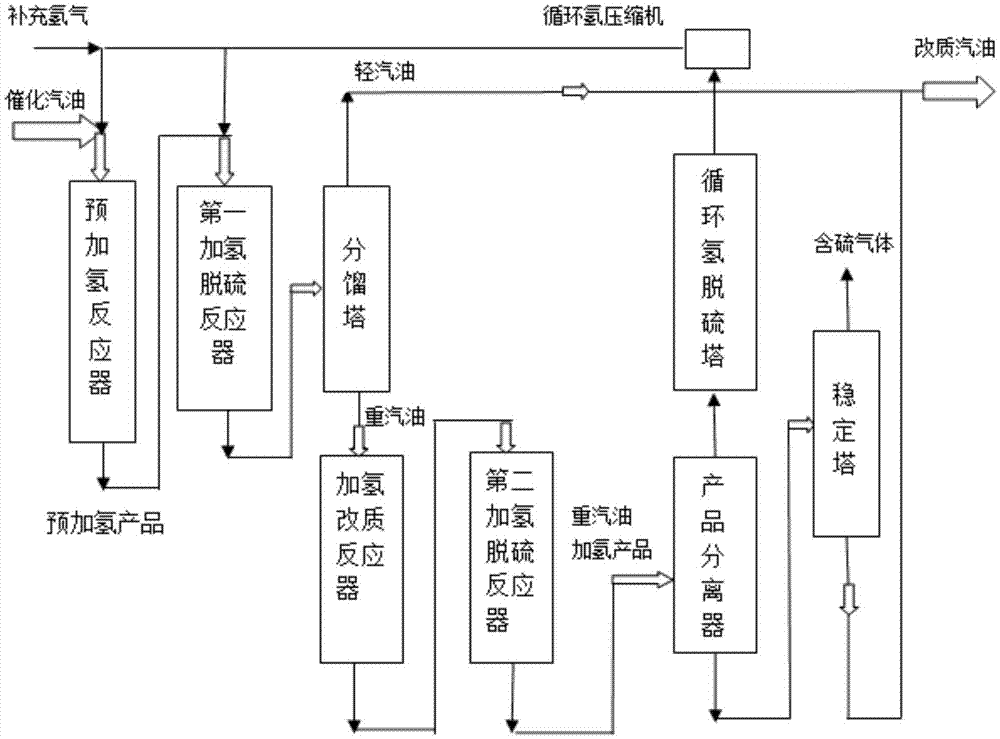

Method for hydro-upgrading inferior gasoline

ActiveCN106929099AReduced diene contentReduced mercaptan contentTreatment with hydrotreatment processesHydrocarbon oils treatment productsHydrogenSulfur

The invention discloses a method for hydro-upgrading inferior gasoline. The method comprises the following steps: (1) mixing catalytic gasoline and hydrogen, feeding the mixture into a pre-hydrogenating reactor and reacting; (2) mixing a pre-hydrogenated product and hydrogen, feeding the mixture into a first hydrogen desulfurization reactor and reacting; (3) feeding the product of the step (2) into a fractionating tower, and dividing the product into a light gasoline component and a heavy gasoline component; (4) taking the light gasoline component discharged from the top of the fractionating tower gas an upgraded gasoline blending component, mixing the heavy gasoline component discharged from the bottom of the tower and hydrogen, then feeding the mixture into a hydro-upgrading reactor and reacting; (5) feeding the product of the step (4) into a second hydrogen desulfurization reactor and reacting; and (6) after the product of the step (5) is cooled down, feeding the product into a product separator and carrying out gas-liquid separation, recycling the hydrogen discharged from the top of the product separator, feeding a liquid phase at the bottom into a stabilizer to remove sulfurous gas, and mixing the liquid phase with light gasoline to obtain the upgraded gasoline product. According to the method, while the content of olefin and the content of sulphur are greatly reduced, loss of octane value in hydro-upgrading of the catalytic gasoline is reduced.

Owner:PETROCHINA CO LTD

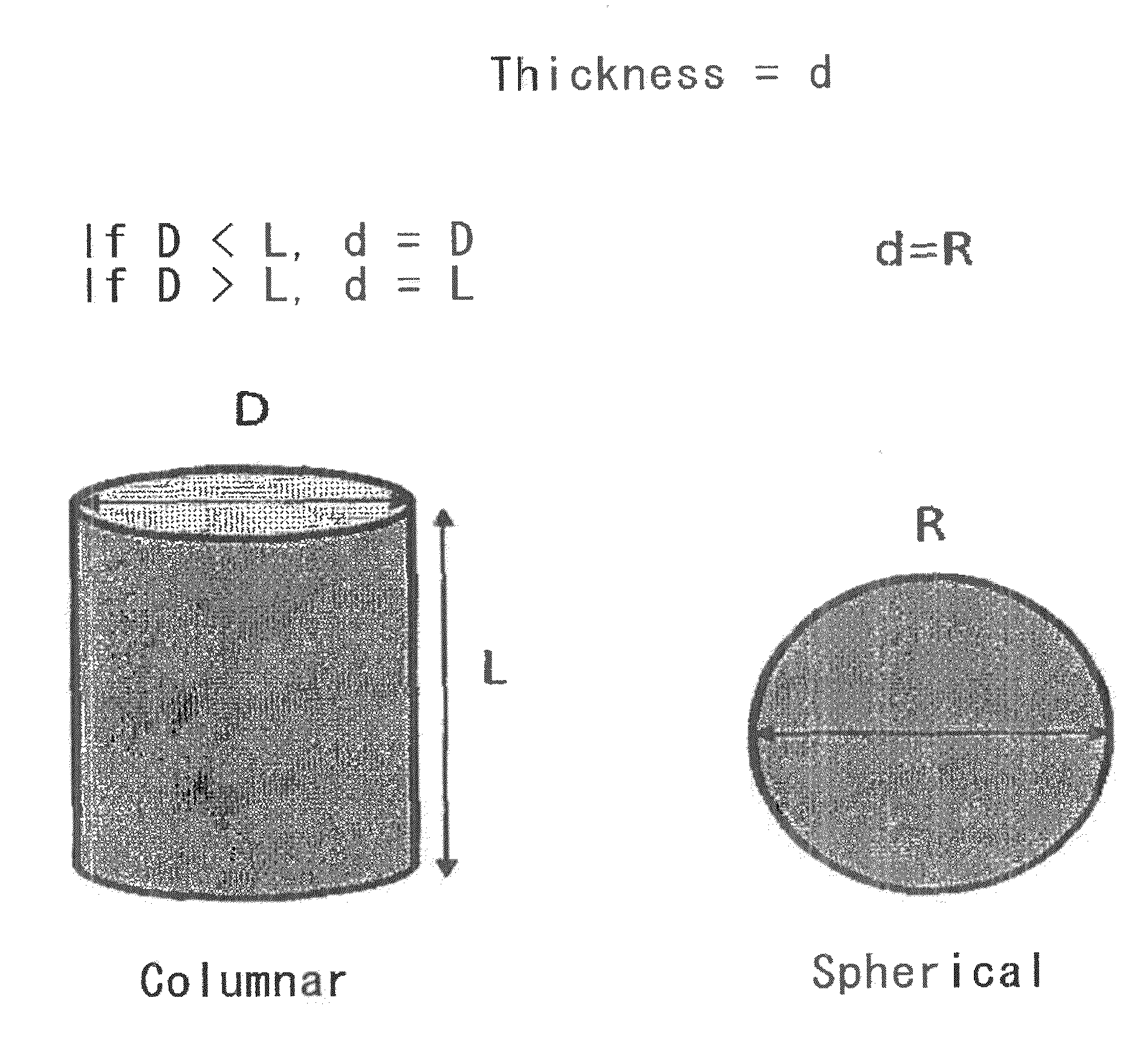

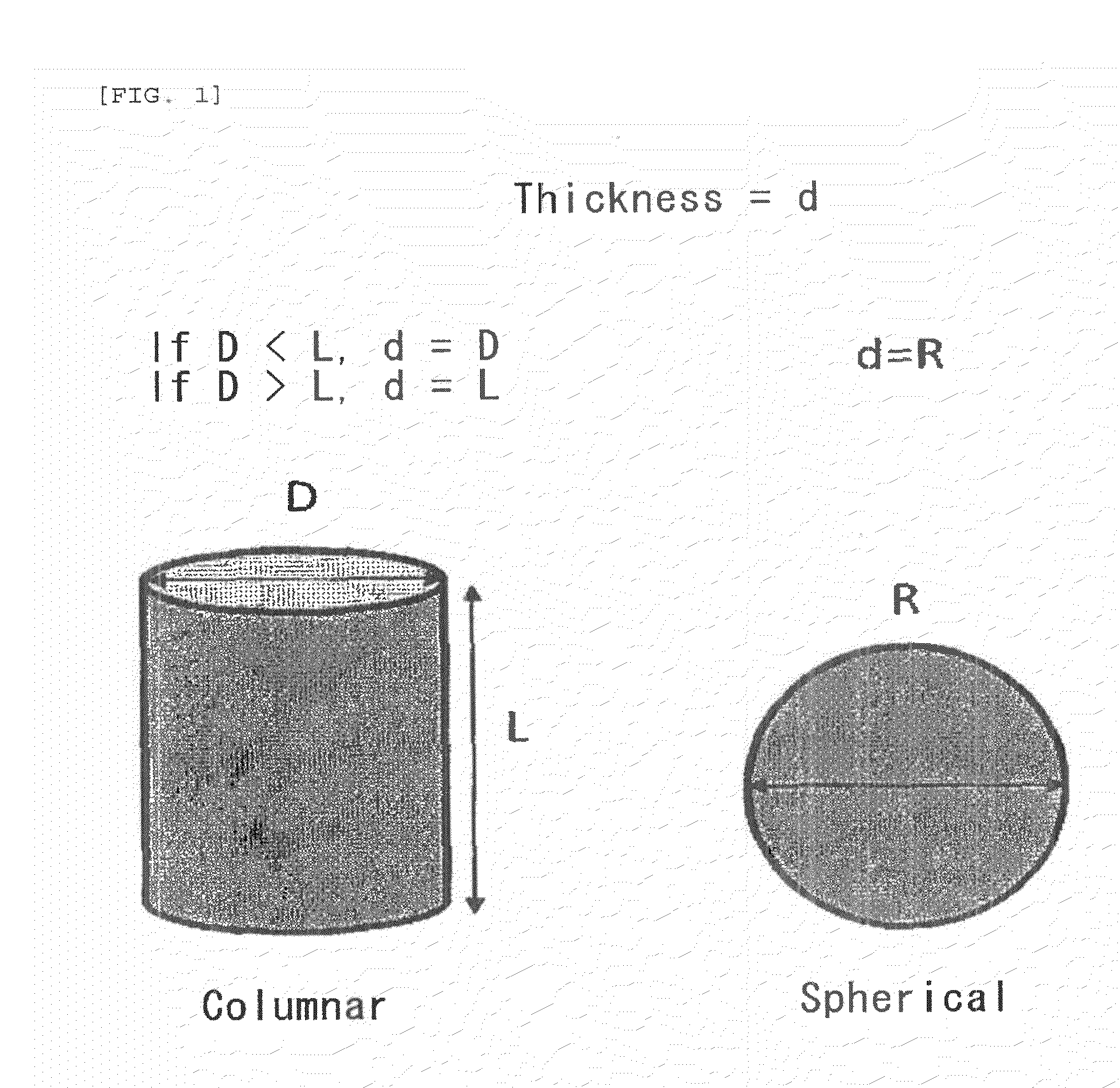

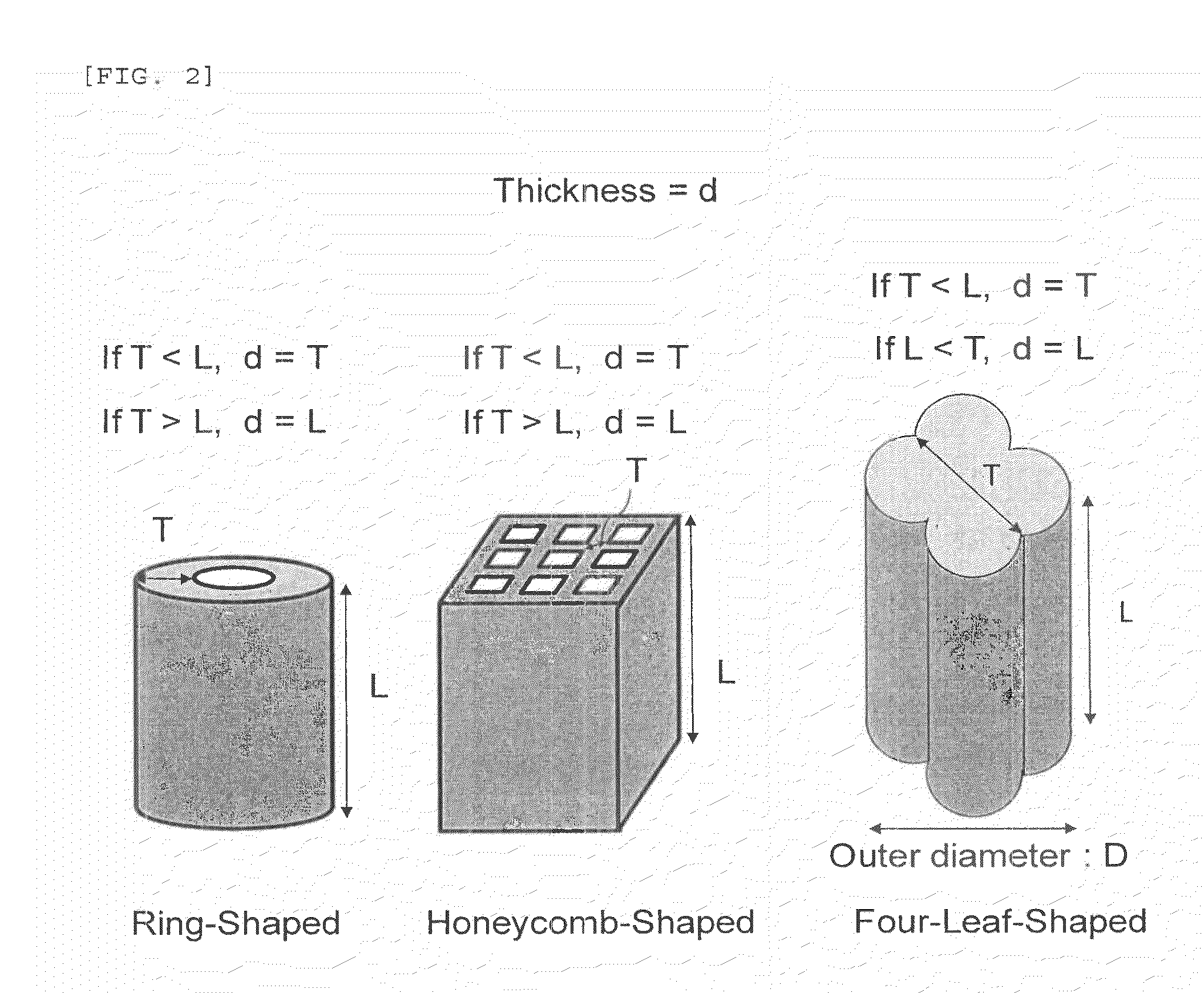

Lower olefins producing catalyst and method for producing lower olefins using same

ActiveUS20120116143A1High catalytic activityLong catalyst lifeMolecular sieve catalystsMolecular sieve catalystChemistrySolid-state

A lower olefin producing catalyst which has high olefin production efficiency and maintains its activity for a long period of time when lower olefins are produced from an oxygen-containing compound, which is a solid catalyst used in producing lower olefins from an oxygen-containing compound, includes a solid-state catalyst component containing an MFI-type zeolite, in which, at a position where the shortest distance to the outer surface is maximum among all positions inside a structure of the solid catalyst, the thickness defined as a distance twice the shortest distance from the point to the outer surface is in a range of from 0.1 to 2.0 mm, and a method for producing lower olefins.

Owner:MITSUBISHI CHEM CORP +1

Process for the preparation of and composition of a feedstock usable for the preparation of lower olefins

InactiveUS20070203386A1Low yieldReduce olefinsThermal non-catalytic crackingLiquid carbonaceous fuelsPolymer scienceAlkene

The invention provides a process for the preparation of lower olefins by a thermal cracking process, a process for the preparation of a synthetic hydrocarbon feedstock for such a process, and a composition of a high performance feedstock usable in said process.

Owner:SASOL TEKHNOLODZHI PROPRIEHJTEHRI LTD

Method of producing fuel oil by coal tar hydrogenation modifying

ActiveCN100532509CReduce temperature riseReduce coking rateTreatment with hydrotreatment processesGasoline stabilisationLow nitrogenSulfur

The present invention relates to a method for producing fuel oil by utilizing coal tar. It is characterized by that said method includes the following steps: after the whole coal tar in which the moisture and ash are removed and diluting oil are mixed according to a certain mixing ratio, making the obtained mixture be successively passed through a shallow hydrogenation unit with hydrogenation protecting agent and prehydrogenation catalyst and a deep hydrogenation unit with main hydrogenation catalyst, then making the product obtained after deep hydrogenation undergo the processes of high-pressure separation, low-pressure separation and fractionation so as to obtain light-oil fraction, medium-oil fraction and tail-oil fraction, namely obtain low-sulfur low-nitrogen fuel oil and light oil product.

Owner:HUNAN CHANGLING PETROCHEM SCI & TECH DEV CO LTD

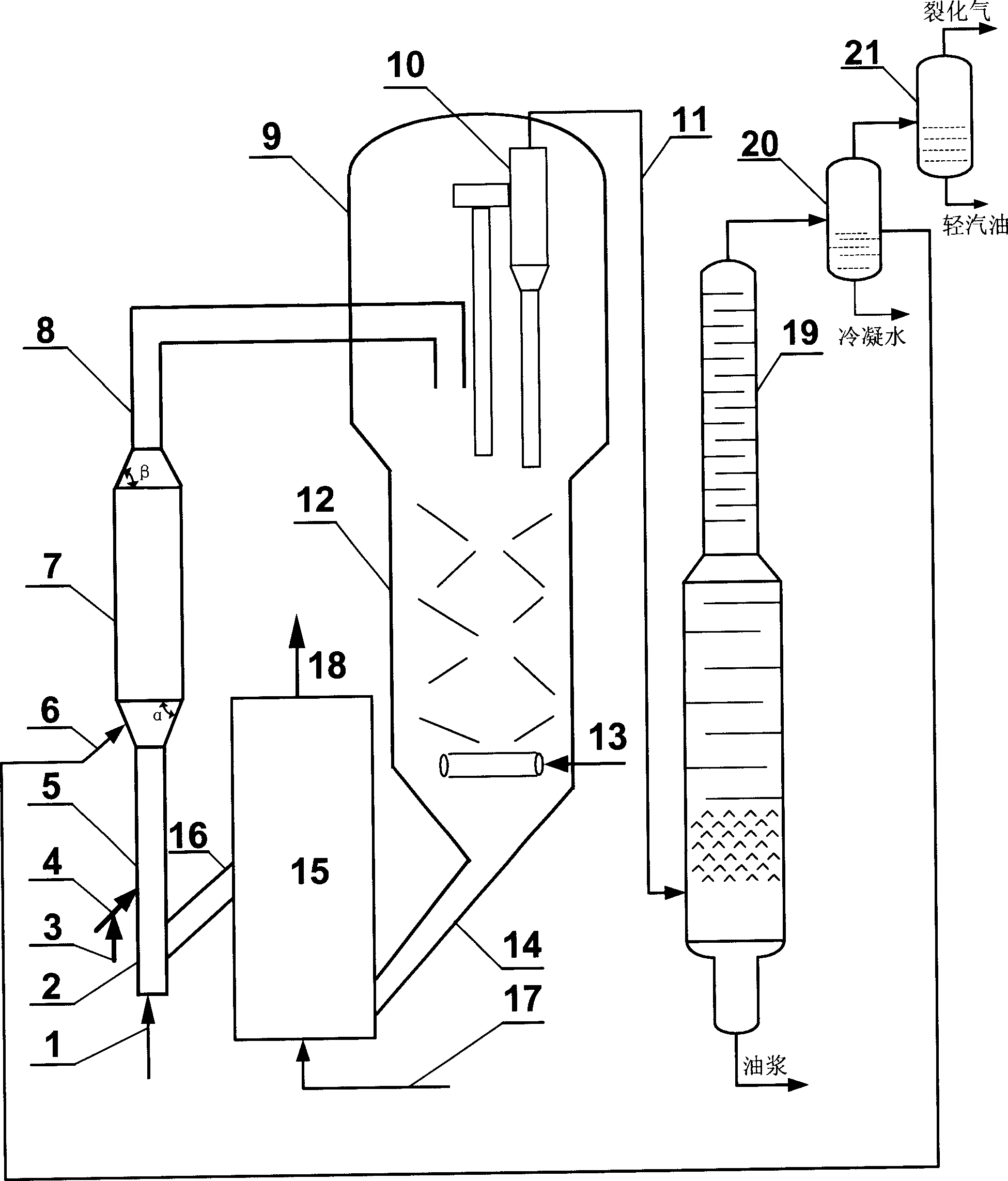

Preparation method of clean gasoline

ActiveCN111073687AReduce olefin contentBoost octaneMolecular sieve catalystsHydrocarbon oils treatment productsPtru catalystHydrodesulfurization

The invention discloses a preparation method of clean gasoline, wherein rich gas from the top of the fractionating tower of a catalytic cracking device and crude gasoline are used as reaction raw materials. The preparation method comprises the following steps: cutting the crude gasoline from the fractionating tower of a catalytic cracking unit to obtain light fraction gasoline and heavy fraction gasoline; carrying out alkali-free deodorization treatment on the light fraction gasoline, feeding the light fraction gasoline and rich gas into a first fluidization reactor, and carrying out an aromatization reaction with an aromatization catalyst to obtain an aromatization product; feeding the heavy fraction gasoline into a hydrodesulfurization reactor, and carrying out a selective hydrodesulfurization reaction on the heavy-fraction gasoline and a selective hydrogen desulfurization catalyst to obtain a heavy fraction gasoline desulfurization product; and mixing the aromatization product and the heavy fraction gasoline desulfurization product to obtain a clean gasoline product. According to the method, the absorption-stabilization system in the conventional catalytic cracking device can beomitted, low-sulfur and low-olefin clean gasoline can be produced, and the gasoline yield and the octane number are increased.

Owner:CHINA PETROLEUM & CHEM CORP +1

Improved catalytic cracking technology method

ActiveCN104650962AHigh yieldImprove product qualityTreatment with plural serial stages onlyHydrocarbon oils treatment productsCarbon numberVapor–liquid separator

The invention relates to an improved catalytic cracking technology method. In the method, oil gas at the top of a fractionation column in a catalytic cracking device passes through a condensation cooler to decrease the temperature to 30-60 DEG C. Rich gas being not condensed is compressed by a two-stage gas compressor, wherein the rich gas is firstly fed into a first stage of the gas compressor and is compressed under an absolute pressure of 0.02-1.0 MPa. The compressed rich gas is cooled to 30-60 DEG C and is separated in a gas-liquid separator. A separated inter-stage condensate is fed into a propylene removal column and is subjected to desorption under the absolute pressure of 1.4-1.8 MPa to remove low-carbon olefins being not more than 3 in carbon number. Oil from the bottom of the column, as recycle condensed oil, is fed into a riser for performing recycle, wherein the composition and the flow rate of the recycle condensed oil are controlled by adjusting the temperature of the oil gas at the top of the fractionation column before the oil gas being fed into the gas compressor and after the condensation cooling. By means of recycle of the inter condensed oil in the gas compressor, the content of olefin in catalytic gasoline can be reduced, the yield of the low-carbon olefin can be increased and meanwhile the energy consumption of the catalytic cracking device is effectively reduced.

Owner:PETROCHINA CO LTD +1

Catalytic cracking aid for improving heavy oil conversion capability, and preparation method thereof

PendingCN111135813AQuality improvementReduce olefinsCatalytic crackingMolecular sieve catalystsAdhesiveKaolinite

The invention discloses a catalytic cracking aid for improving heavy oil conversion capability, and a preparation method thereof. The catalytic cracking aid comprises a natural mineral raw material, adispersant and an adhesive, and the natural mineral raw material is one or two of natural sepiolite, natural kaolinite mineral and roasted kaolinite mineral. The sepiolite and / or kaolinite mineral isused as the main raw material, the kaolin type catalytic cracking aid is prepared by adopting an in-situ crystallization technology, the characteristics that sepiolite is rich in silicon, large in specific surface area and pore volume and contains a magnesium oxide component resistant to heavy metal are utilized, the aid prepared from sepiolite and / or kaolinite mineral has very strong capacity inthe aspect of heavy oil cracking, improves the distribution of the product, improves the quality of gasoline, reduces gasoline olefin, and inreases the octane number of gasoline, and the aid is suitable for heavy oil with high heavy metal content, and is suitable for catalytic cracking of petroleum and various fractions thereof.

Owner:HUNAN JULI CATALYST

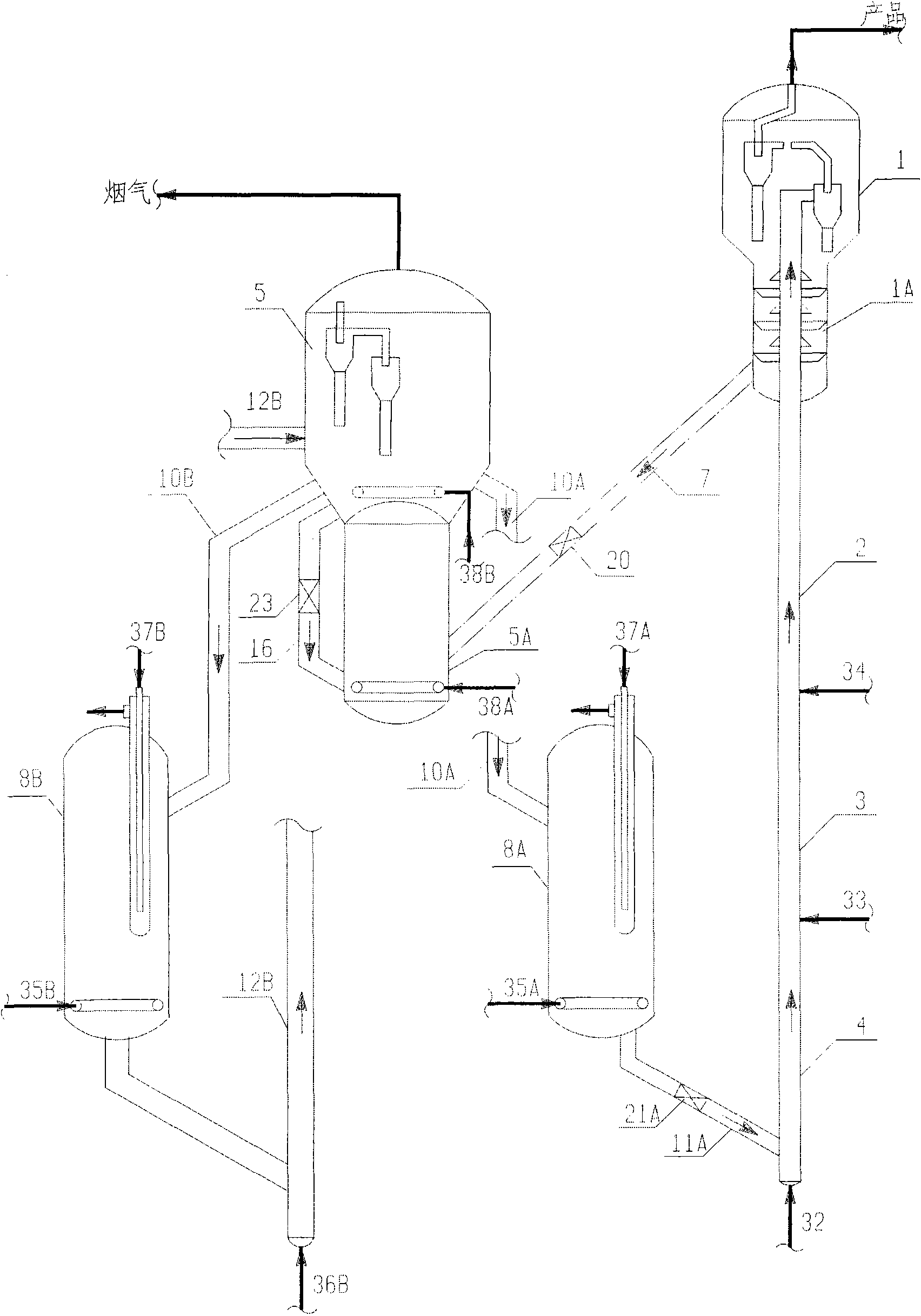

Catalytic conversion method for preparing light fuel oil and propylene

ActiveCN101724431BImprove propertiesExtended operating cycleCatalytic crackingChemical recyclingAlkaneCycloparaffins

The invention relates to a catalytic conversion method for preparing light fuel oil and propylene, comprising: leading inferior crude oil to enter a catalytic conversion reactor to be contacted with catalyst and have reaction; separating the reaction product, and obtaining the product containing the propylene, crude gasoline and catalytic wax oil, wherein leading the crude gasoline to enter another catalytic conversion reactor to be contacted with catalytic conversion catalyst to have reaction; treating the catalytic wax oil by hydrotreating or / and solvent extraction; and taking the catalyticwax oil obtained by hydrotreating or / and raffinate oil of the catalytic wax oil as raw material of the catalytic conversion reactor or other catalytic conversion reactors. In the method, after the catalytic wax oil which is obtained by carrying out mild catalytic conversion on the inferior crude oil is treated by hydrotreating or / and solvent extraction, the obtaining catalytic wax oil obtained byhydrotreating or / and raffinate oil contains alkane or cycloparaffin, and is very suitable for catalytic conversion, thus realizing high efficiency utilization of oil resources.

Owner:CHINA PETROLEUM & CHEM CORP +1

Deep desulfurization-octane value recovery hydrogenation modification method for low grade gasoline

ActiveCN101508912BFlexible operationWide adaptabilityTreatment with hydrotreatment processesOrganic acidHydrodesulfurization

The invention relates to a hydro-upgrading method of ultra-deep desulfurization and octane number preservation of poor gasoline. In the method, the poor gasoline is treated by using coupling of two-stage reaction so that the poor gasoline is contacted and reacted with two different catalysts in two-stage reaction zones. The temperature of the first-stage reaction zone is low, and unstable diene and difficultly deprived sulfur compound are deprived from the gasoline by using Al-Ti-Mg complex carrier catalyst having double functions of diene deprivation and high-selective hydrodesulfurization; the temperature of the second-stage reaction zone is high, and modified HZSM-5 zeolite by comprehensive treatment of hot water, organic acid-organic acid and the catalyst of Ti-Al compound carrier realize further desulfuration, diene reducing and product octane number preservation. The method can obtain better hydro-upgrading effect particularly for medium-sulfur and high-olefin poor FCC gasoline,can reduce octane number loss and keep higher product liquid yield while greatly reducing the contents of olefin and sulfur.

Owner:CHINA UNIV OF PETROLEUM (BEIJING)

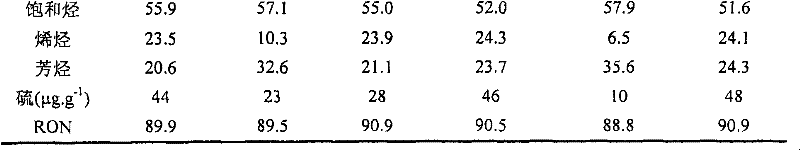

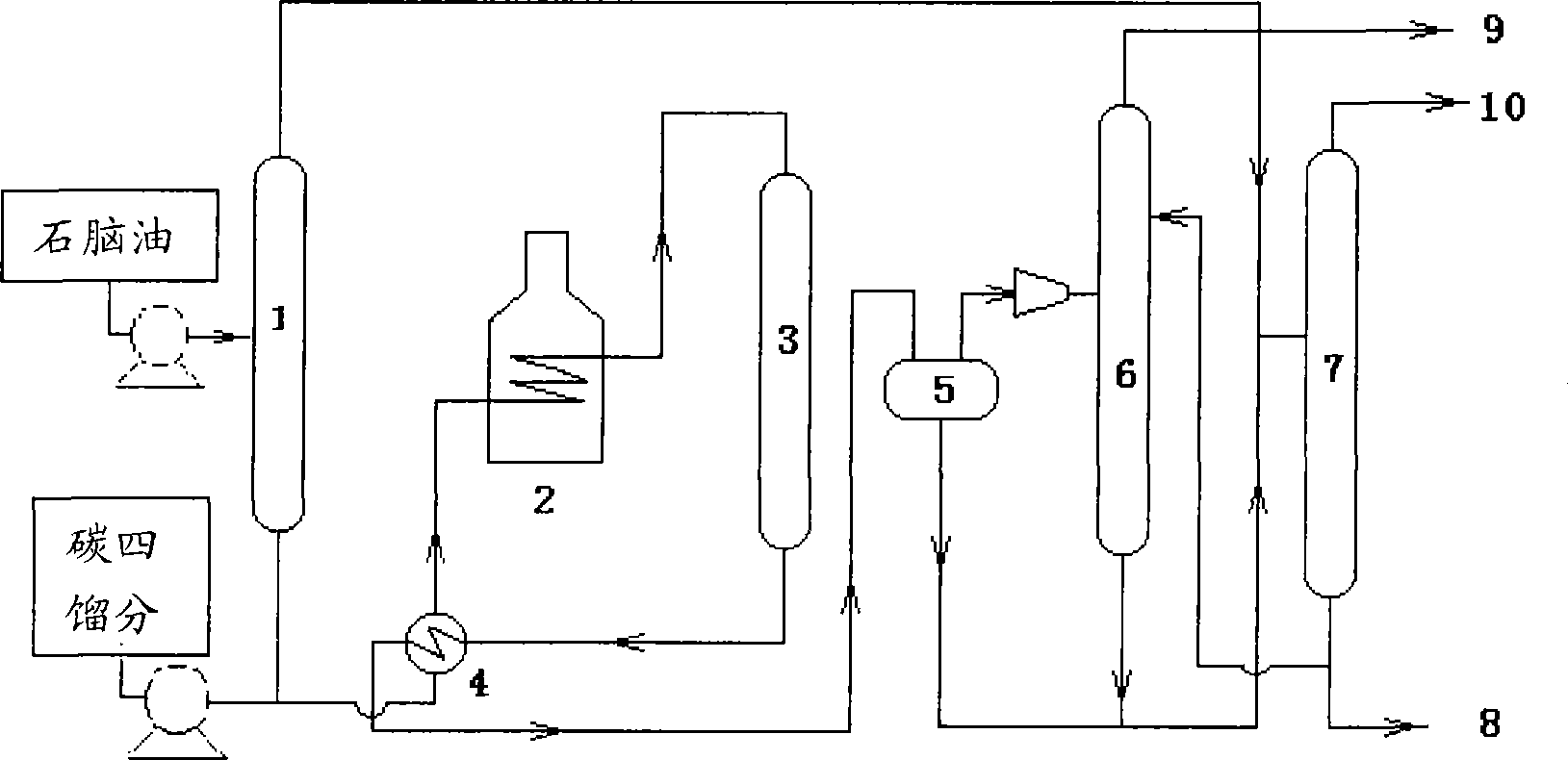

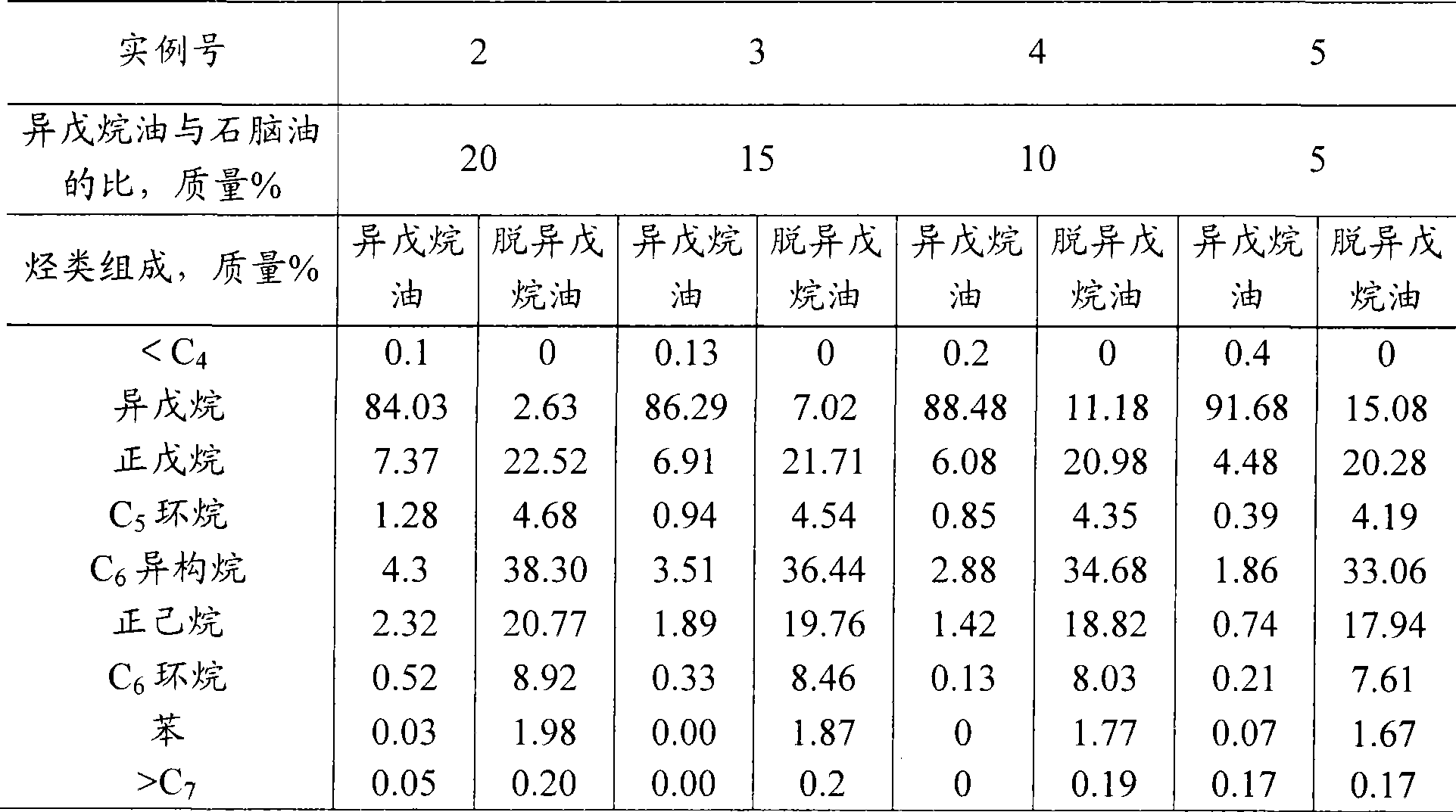

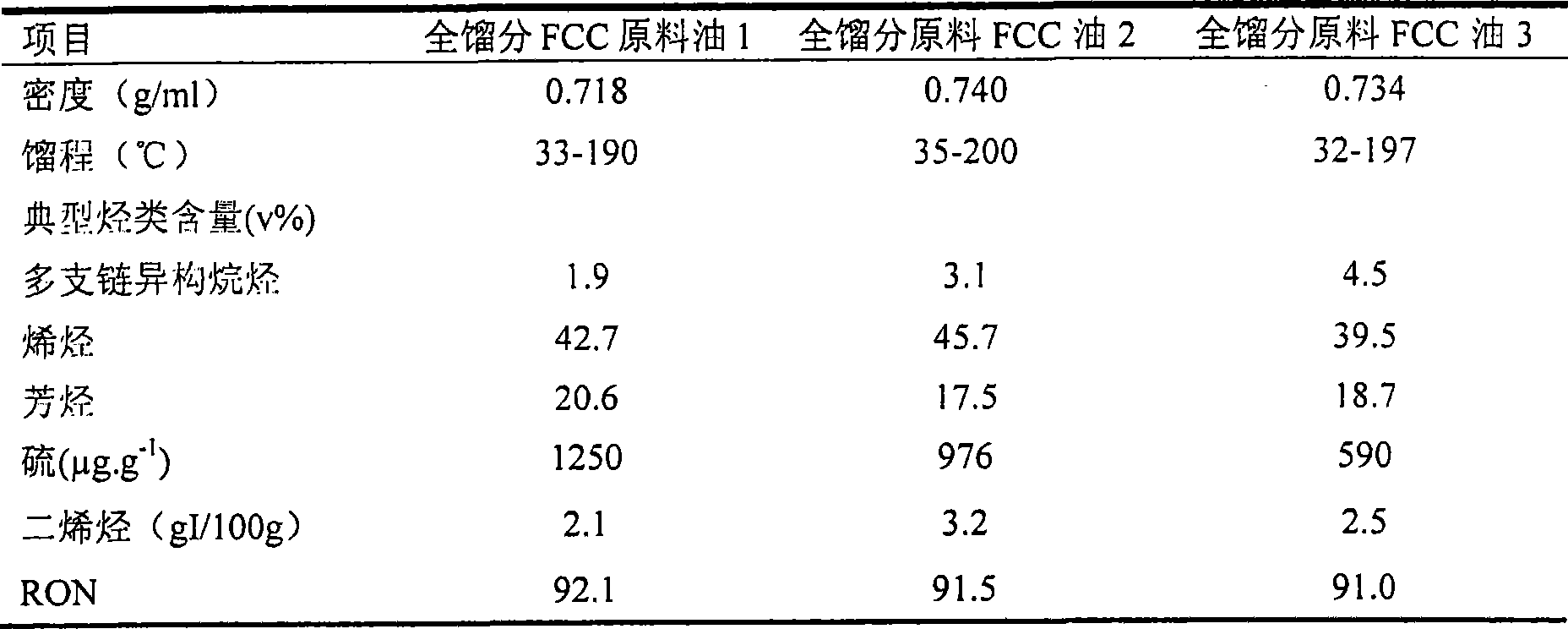

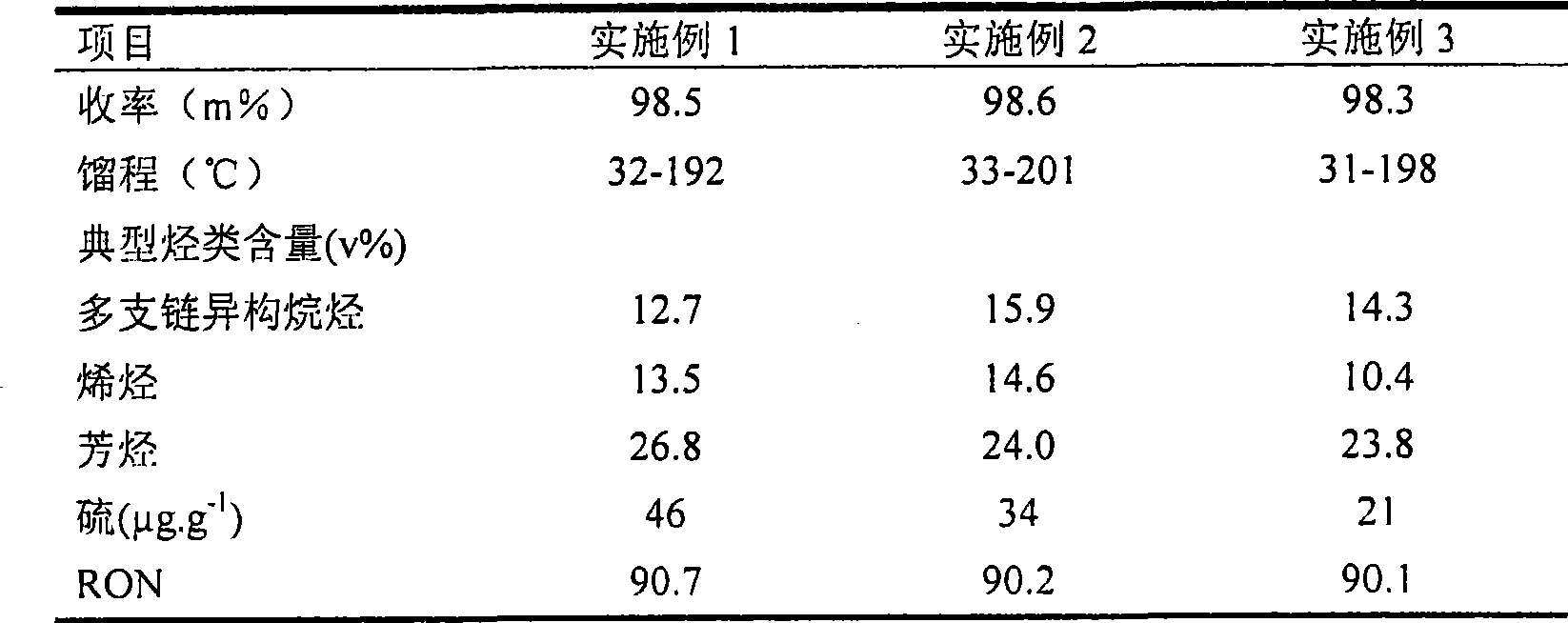

Method for producing clean gasoline by naphtha upgrading

The present invention relates to a method for producing clean gasoline by upgrading naphtha. The method includes the following steps: naphtha is fractionated in order to separate out isopentane oil and de-isopentane oil, and with the existing of catalyst, the de-isopentane oil is upgraded without hydrogen, so that clean gasoline and liquefied gas are produced. The method can increase the liquid yield of the upgrading reaction and the treatment capacity of a reacting device. In particular, after the isopentane oil is bended with the upgraded gasoline, the liquid yield of the whole reaction canbe greatly increased, and the content of the aromatic hydrocarbon of the blended oil can be greatly reduced.

Owner:CHINA PETROLEUM & CHEM CORP +1

Deep desulfurization-octane value recovery hydrogenation modification combined method for faulty full-distillation gasoline

ActiveCN101508913AIncrease liquid collectionLow fluid yieldTreatment with hydrotreatment processesDistillationHydrodesulfurization

The invention relates to a hydro-upgrading method of ultra-deep desulfurization and octane number preservation of full range poor gasoline. The poor full range gasoline is contacted and reacted with three different catalysts in three-stage reactions zones. The reaction temperature of the first stage is low, and difficultly deprived sulfur compound is deprived by using high-selective hydrodesulfurization catalyst and olefin is saturated to the minimum; the reaction temperature of the second stage is high, and supplementary desulfuration-hydrocarbon monobranched isomeric / aromatizing catalyst is used for exhaustively depriving sulfur compound and further reducing the content of olefin; the reaction temperature of the third stage is low, and multibranched isomery of remaining olefin and straight-chain paraffin is carried out by using hydrocarbon multibranched hydroisomeric catalyst, thereby improving the octane number of products. The method can obtain better hydro-upgrading effect particularly for medium-sulfur and high-olefin poor catalytically cracked gasoline, can maintain or improve the product octane number and keep higher product liquid yield while greatly reducing the contents of olefin and sulfur, and can produce clean gasoline of national IV or even higher standard.

Owner:CHINA UNIV OF PETROLEUM (BEIJING)

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com