Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

35results about How to "Improve the ratio of agent to oil" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

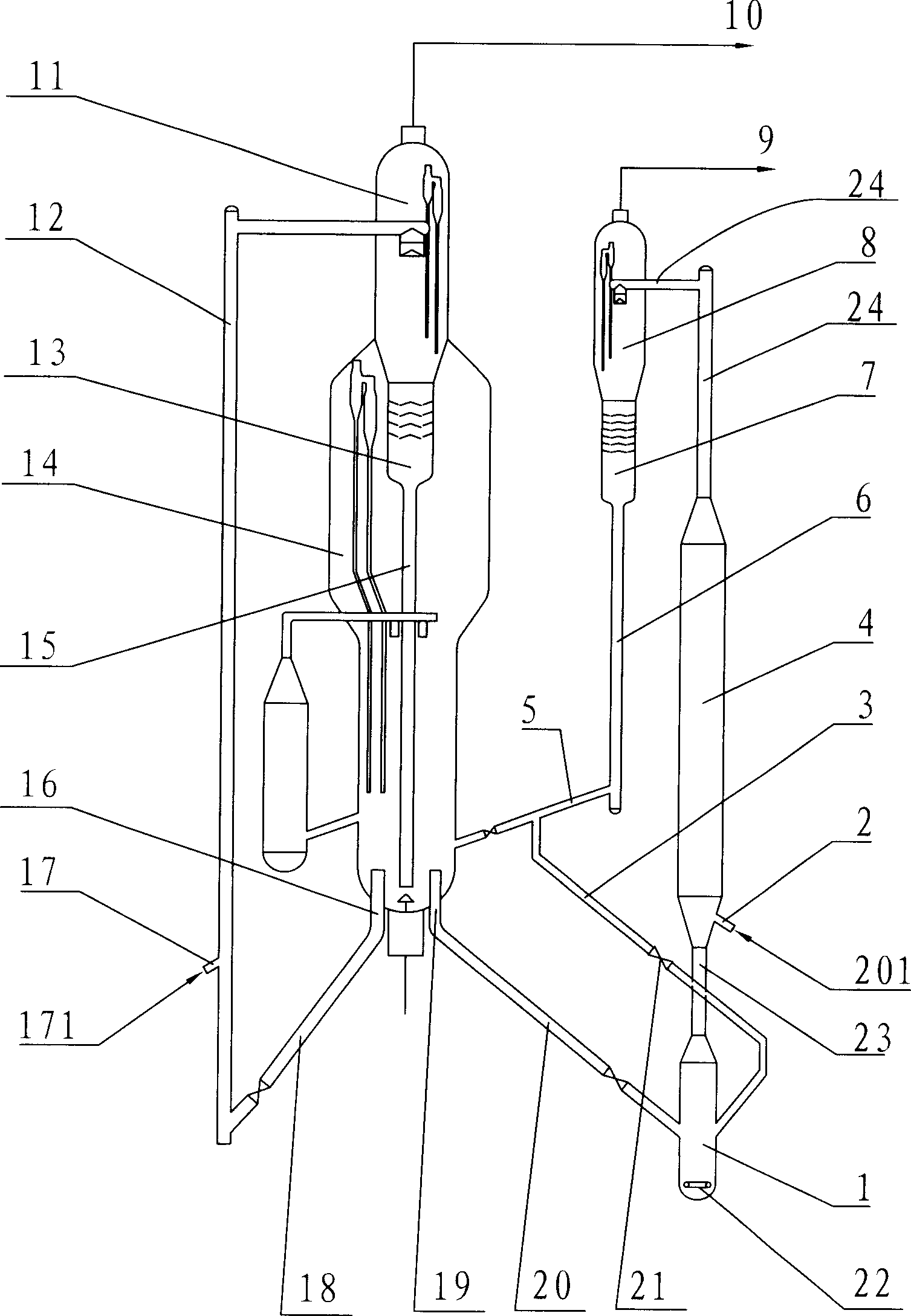

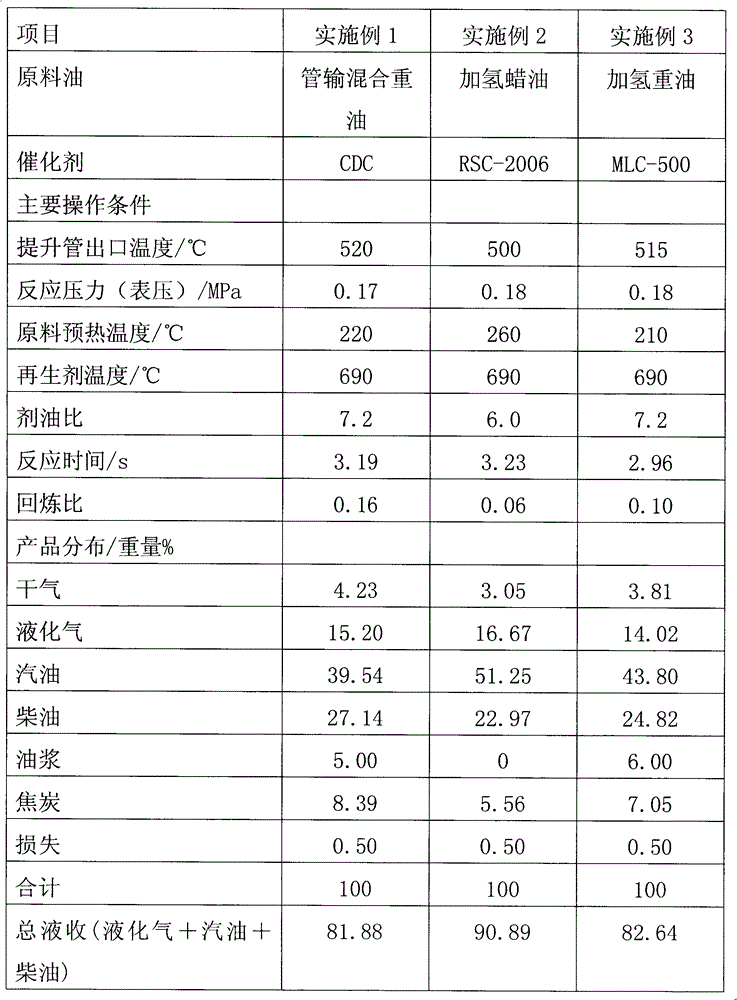

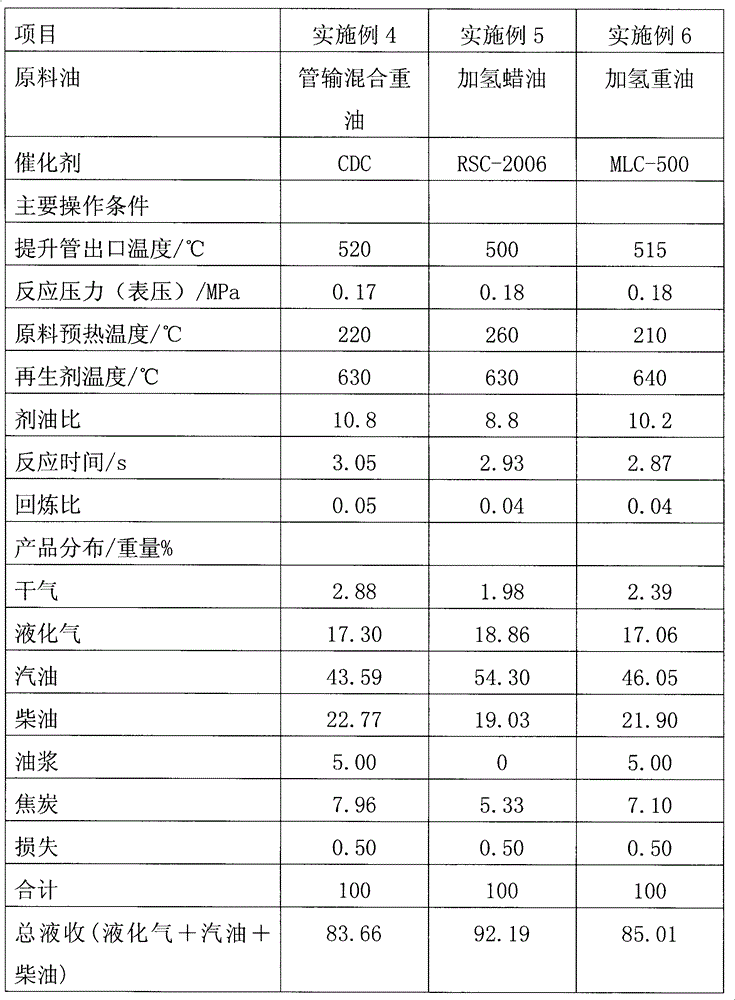

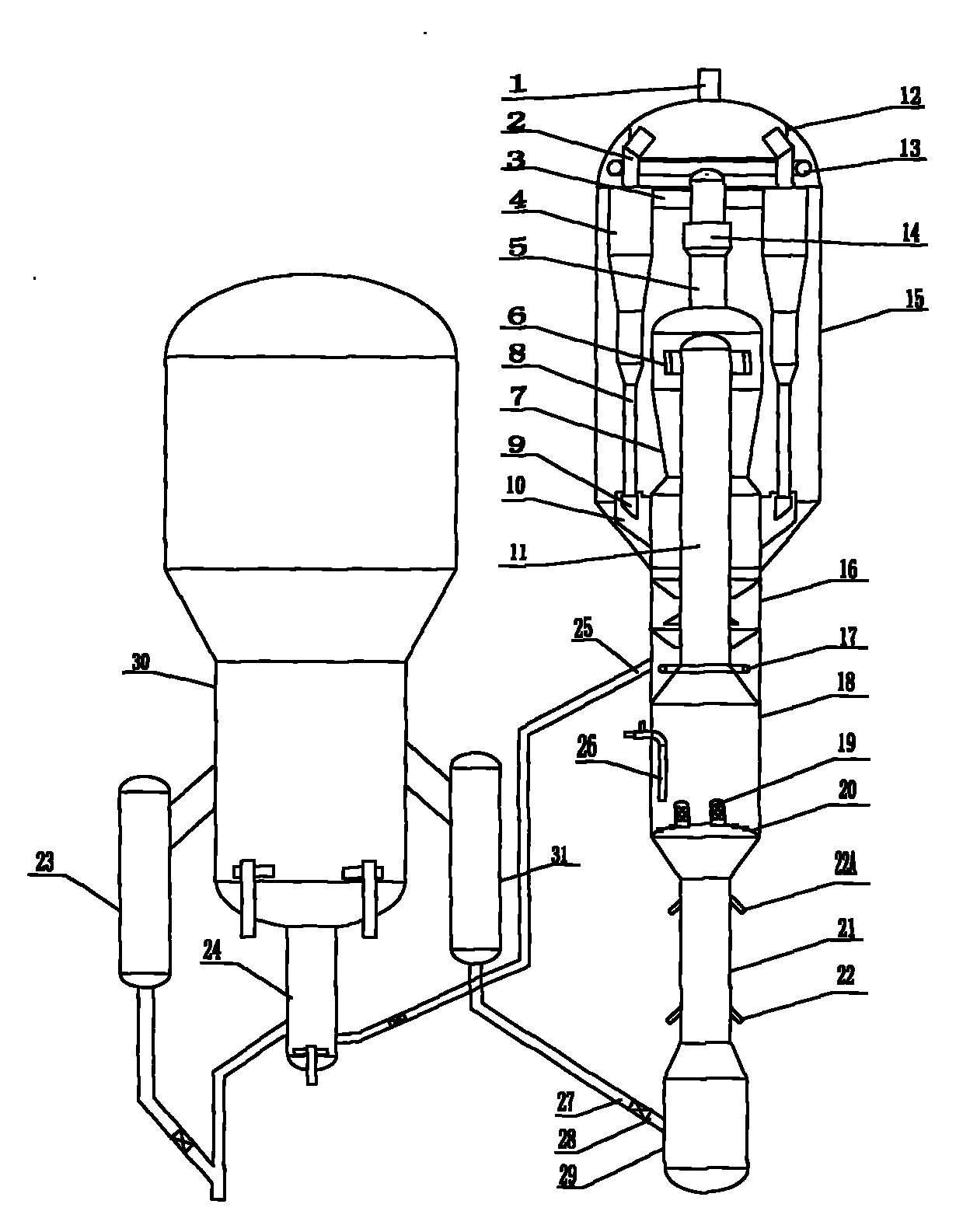

Method for catalytic conversion of heavy oil and device thereof

ActiveCN1664074ARaise the preheat temperaturePromote atomizationTreatment with plural serial stages onlyCatalytic transformationPtru catalyst

The invention provides a method of heavy raw material catalytic conversion and the device, comprising: the heavy hydrocarbon raw material passing through the first and second reaction area of the raiser reactor and contacting with catalyst for first reaction and second reaction, the reactants entering into the settler for the separation of catalyst and oil gas, steam stripping the separated catalyst through stripping section and introducing it to the reactivator for carbon burning reactivation, the reactivated catalyst returning to the raiser reactor after cooled or directly to the raiser reactor for reuse. After the heavy oil passing through the device said above, the volume content of olefin decreases by 10~40%, octane value increases 0.5~1 units, sulfur content in petrol decreases 10~30% by weight. After the poor petrol passing through the device said above, the volume content of olefin decreases by 10~60%, octane value increases 0.5~40 units, sulfur content in petrol decreases 10~50% by weight.

Owner:LUOYANG WEIDA PETROCHEMICAL ENG CO LTD

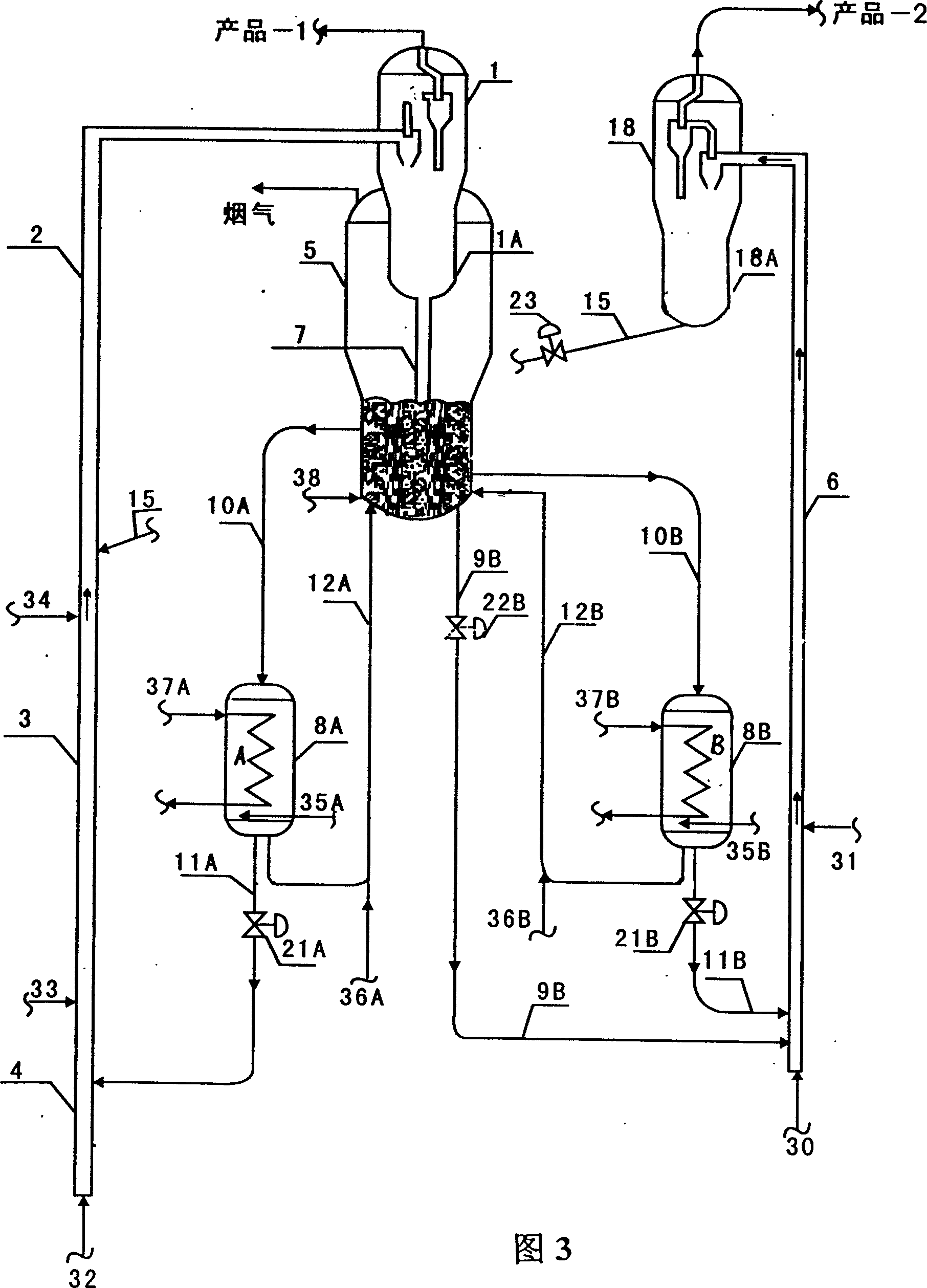

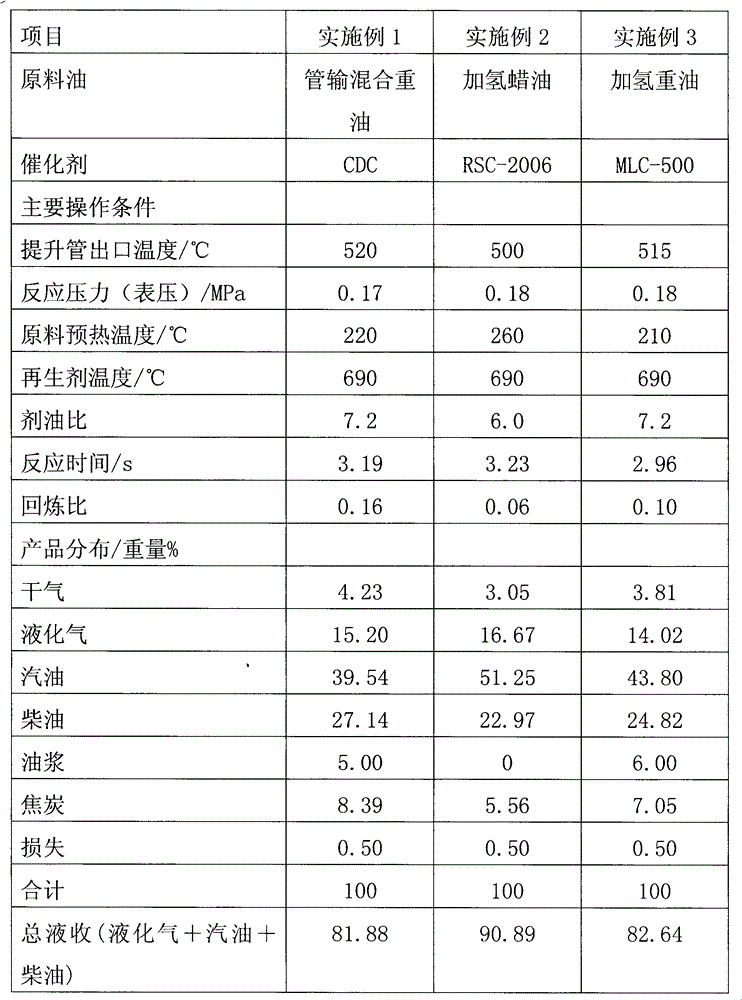

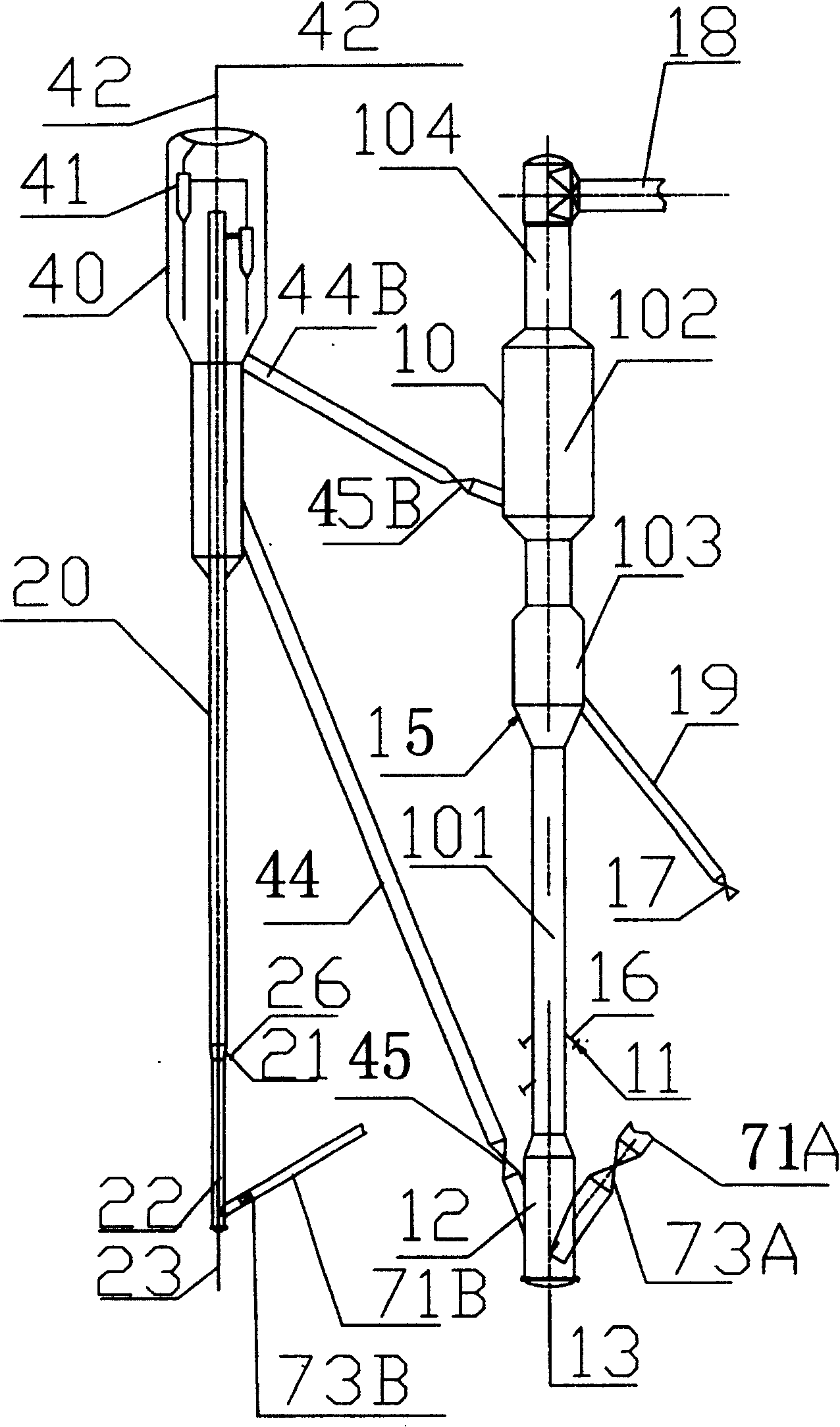

Catalytic conversion method for increasing propylene production

ActiveCN101062885AReduce the temperatureImprove the ratio of agent to oilChemical recyclingBulk chemical productionChemistryPetroleum

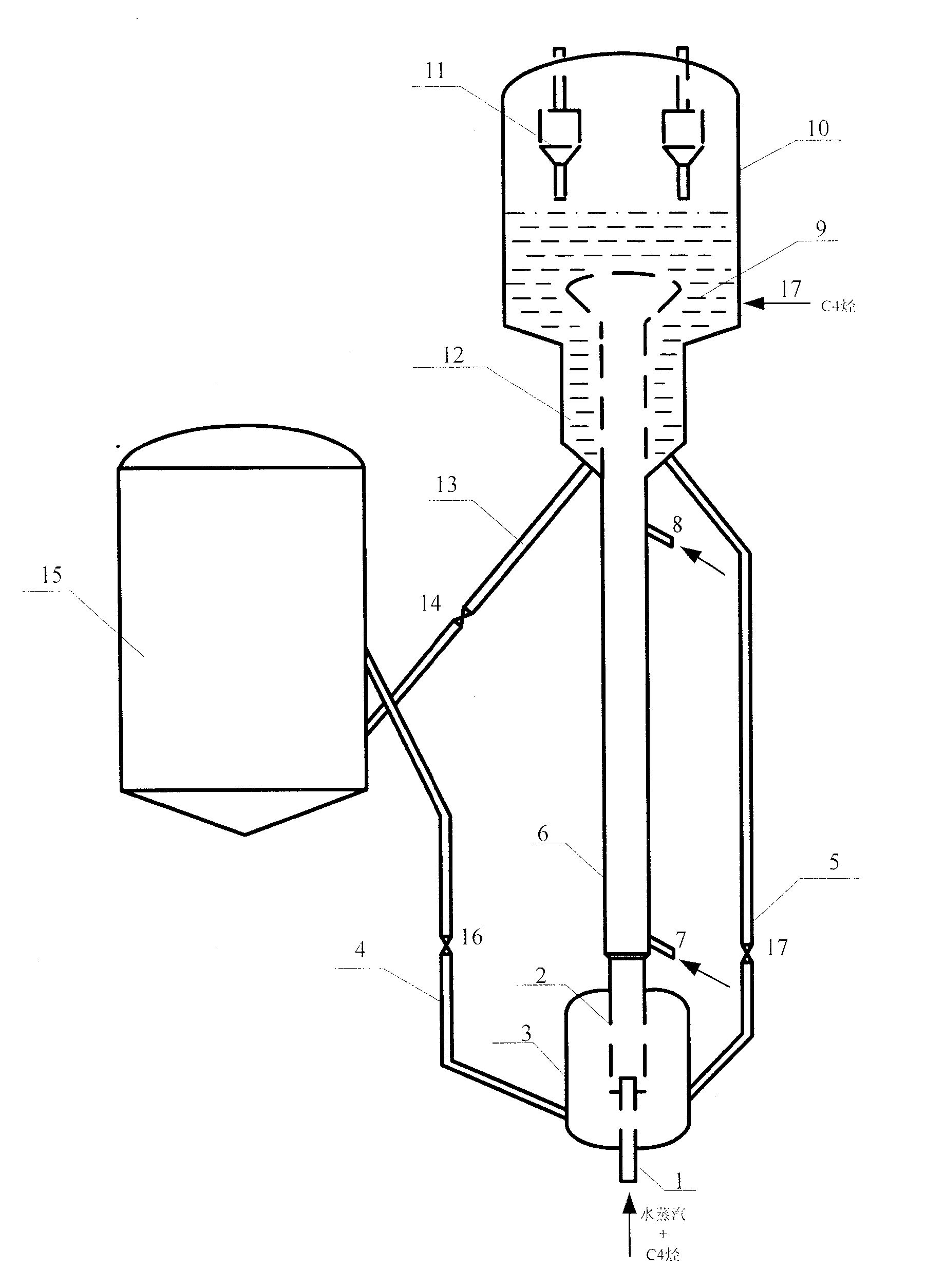

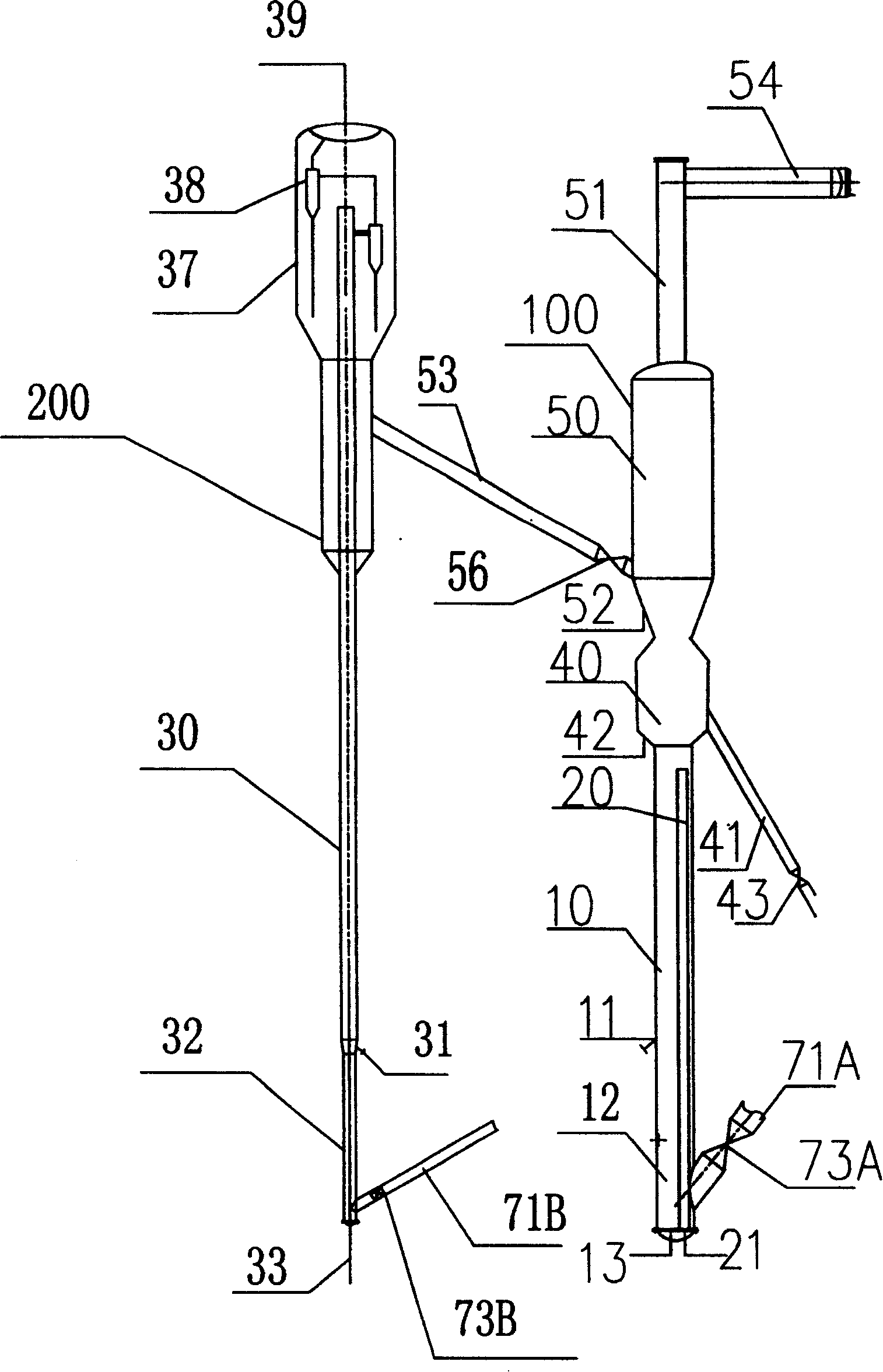

The invention discloses a catalytic conversion method to increase production propylene, which comprises the following steps: proceeding in reactor with dilution zone, lightweight hydrocarbon reaction zone and heavyweight hydrocarbon reaction zone; entering regenerated catalyst and carbon catalyst from stripping section into the dilution zone; mixing; flowing upward under the function of pre-lifting agent; entering into the lightweight hydrocarbon reaction zone; touching with the lightweight hydrocarbon at the lower of the lightweight hydrocarbon reaction zone; reacting; moving upward; touching with heavyweight petroleum hydrocarbon at the upper of the lightweight hydrocarbon reaction zone; reacting; moving upward; forming oil solution mixture; entering into heavyweight hydrocarbon reaction zone; touching continually; reacting; getting the carbon catalyst; entering into the stripping section to strip; getting the carbon agent; backing moiety to mixed zone; using cycle; entering the other moiety into mixed zone; using cycle; leading the reaction oil gas to separation system of subsequent product. This method can get very high productivity of propone low carbon alkene.

Owner:CHINA PETROLEUM & CHEM CORP +1

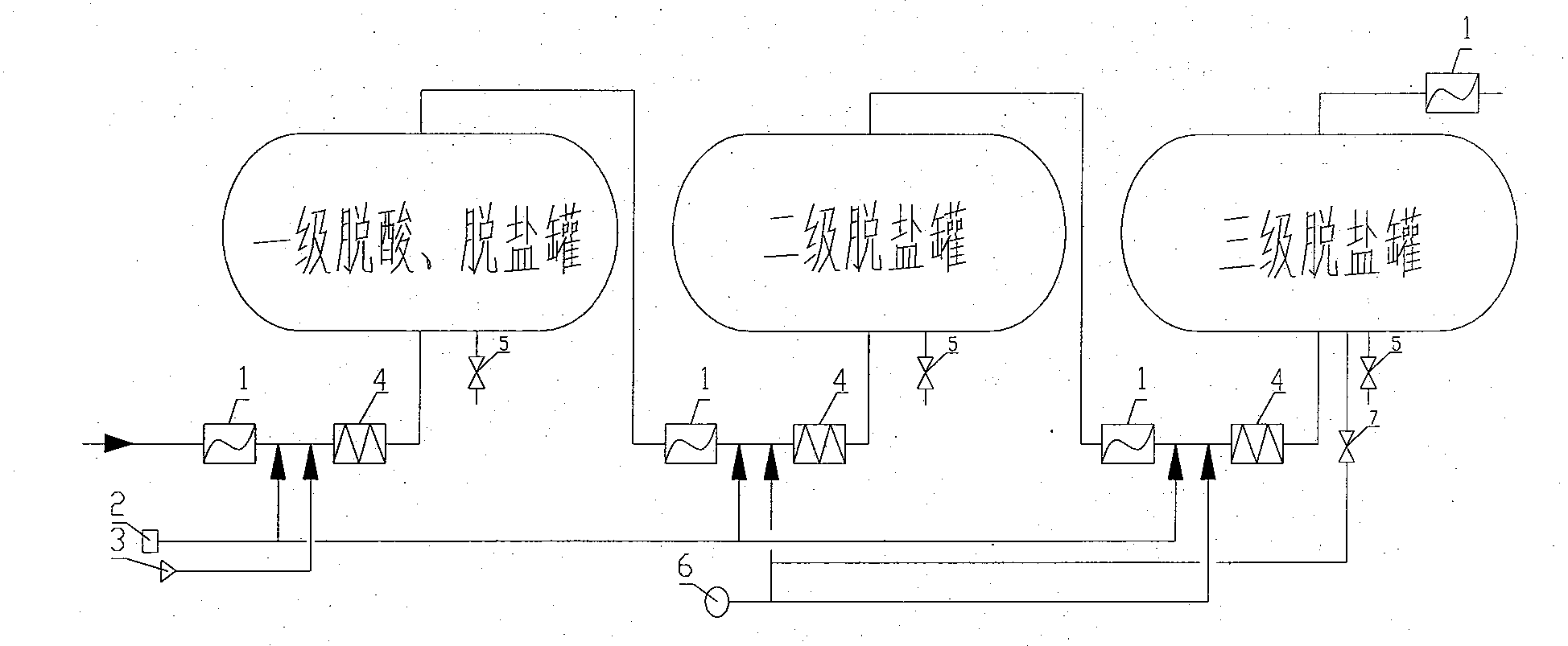

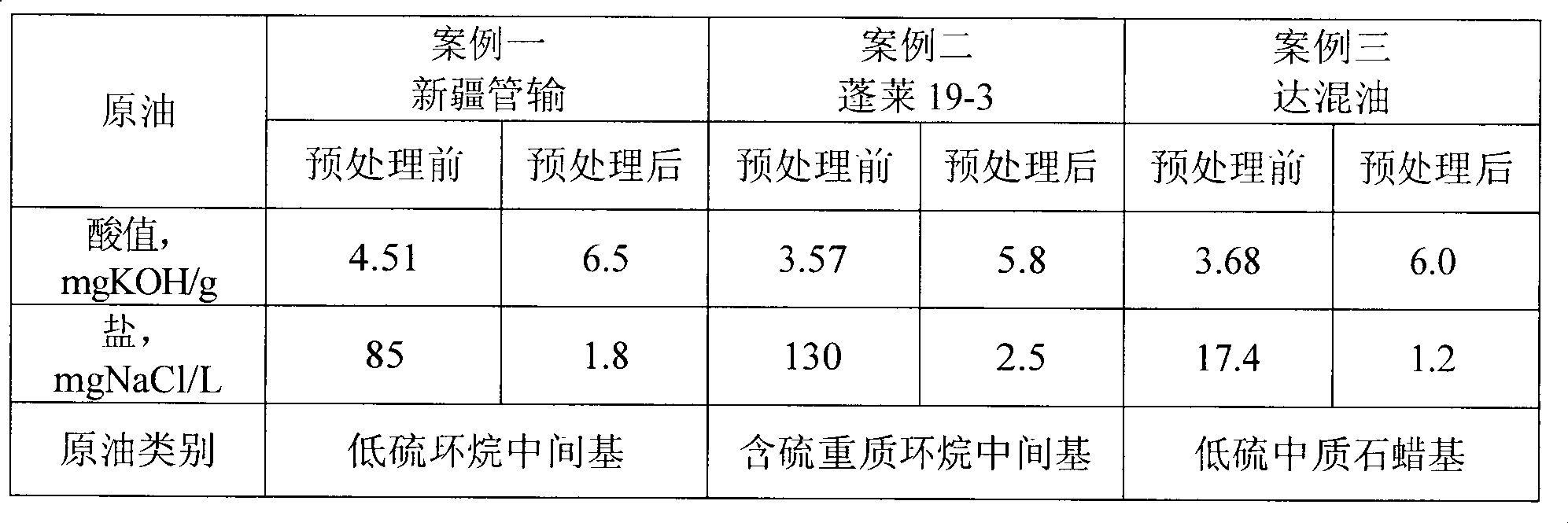

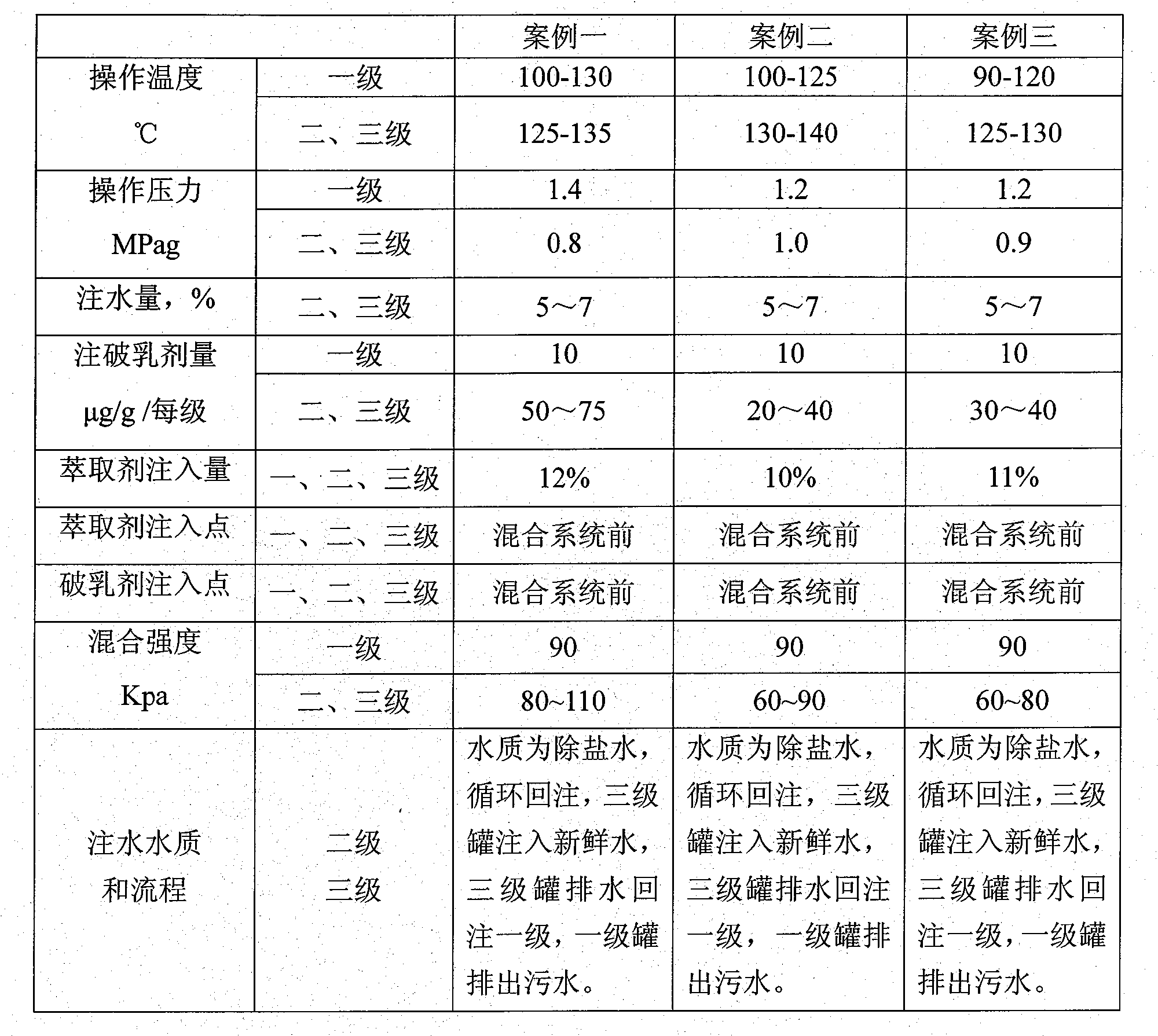

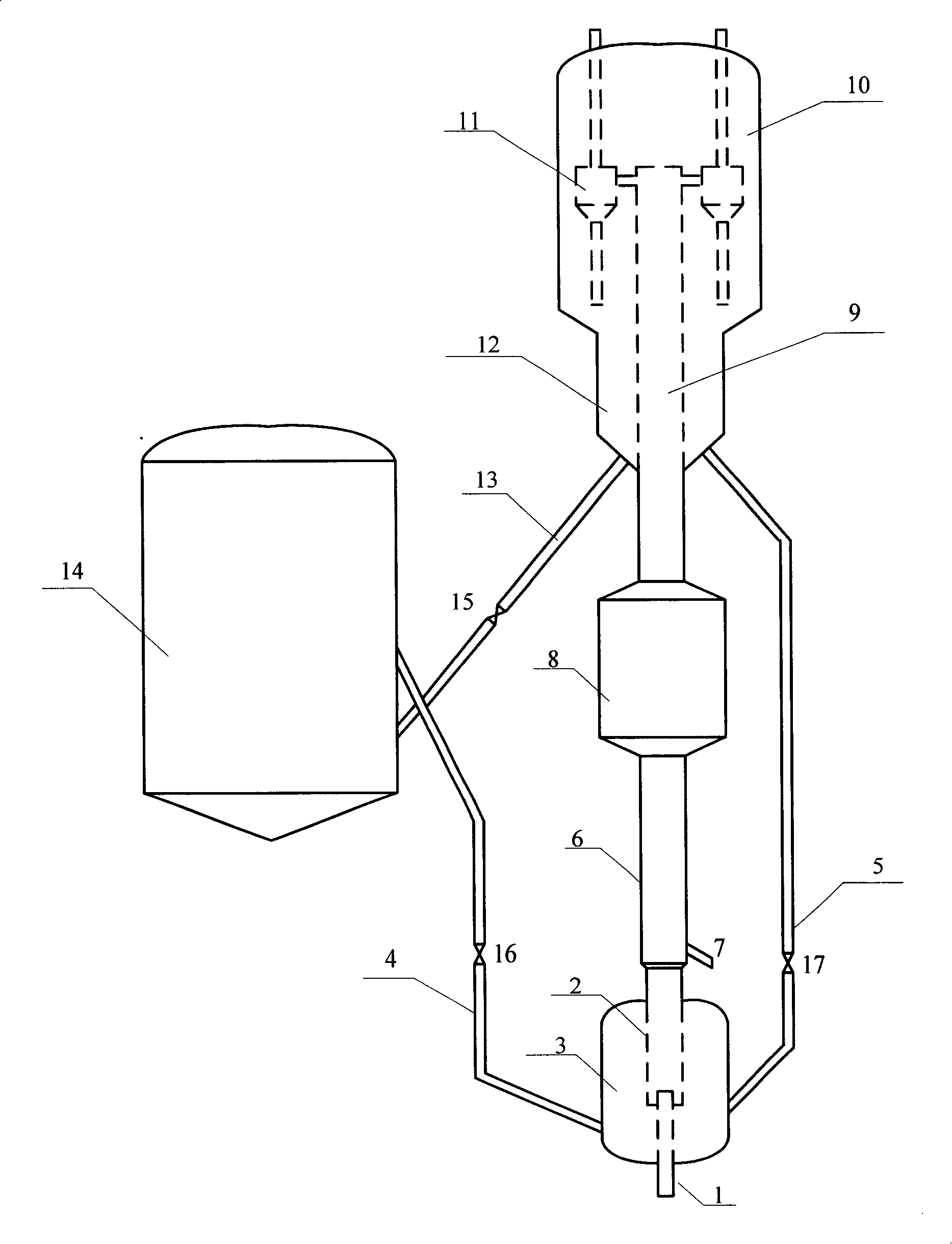

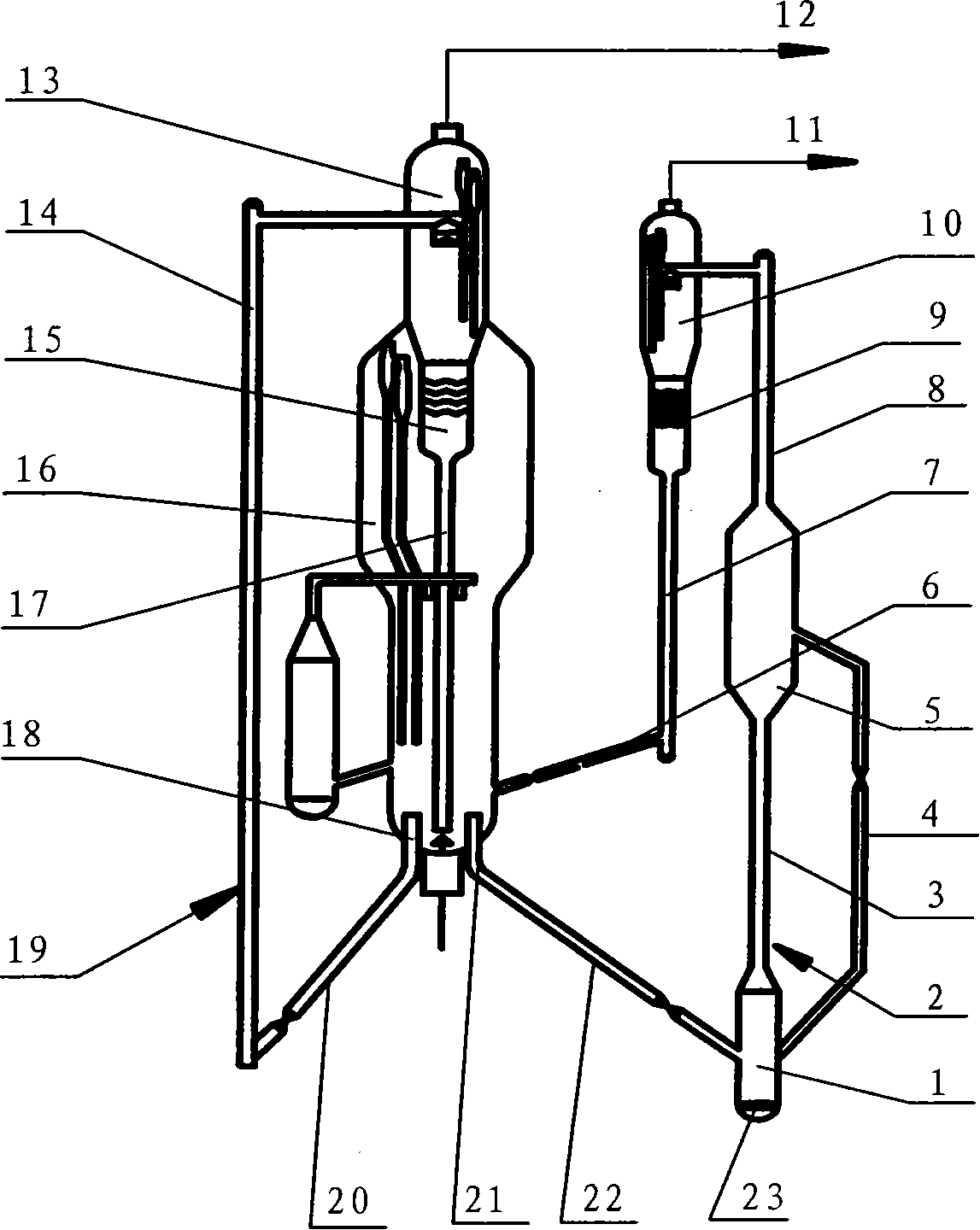

Pre-treatment process method of high acid crude oil

ActiveCN103805227AAvoid corrosionSimple processDewatering/demulsification with electric/magnetic meansRefining with two or more solventsDemulsifierDesalination

The invention relates to a pre-treatment process method of high acid crude oil. The method comprises the following steps that high acid crude oil is treated by coupling deacidification and electro-desalting processes by combining chemical extraction and electro-desalting; a first level tank is taken as a deacidification and electro-desalting tank; a demulsifier and an extractant are injected before a crude oil electro-desalting static mixer; after being fully mixing with crude oil, the mixture enters into the first level desalting tank; generated naphthenate and salt-containing sewage in the crude oil are dissolved in the extractant; treated deacidified oil enters into second and third level desalting tanks after being mixed with the demulsifier and water through the static mixer for desalination and dehydration; treated crude oil enters into a subsequent heat exchange unit; after a period time of operation of an electro-desalting system, impurities such as mud in raw material oil are flushed by a non-stop back purge device to discharge mud-containing sewage out of the tank; an extract phase is acidified to separate out naphthenic acid which is further extracted and purified by light dydrocarbon, and the extractant is purified and recovered and recycled.

Owner:长江三星能源科技股份有限公司

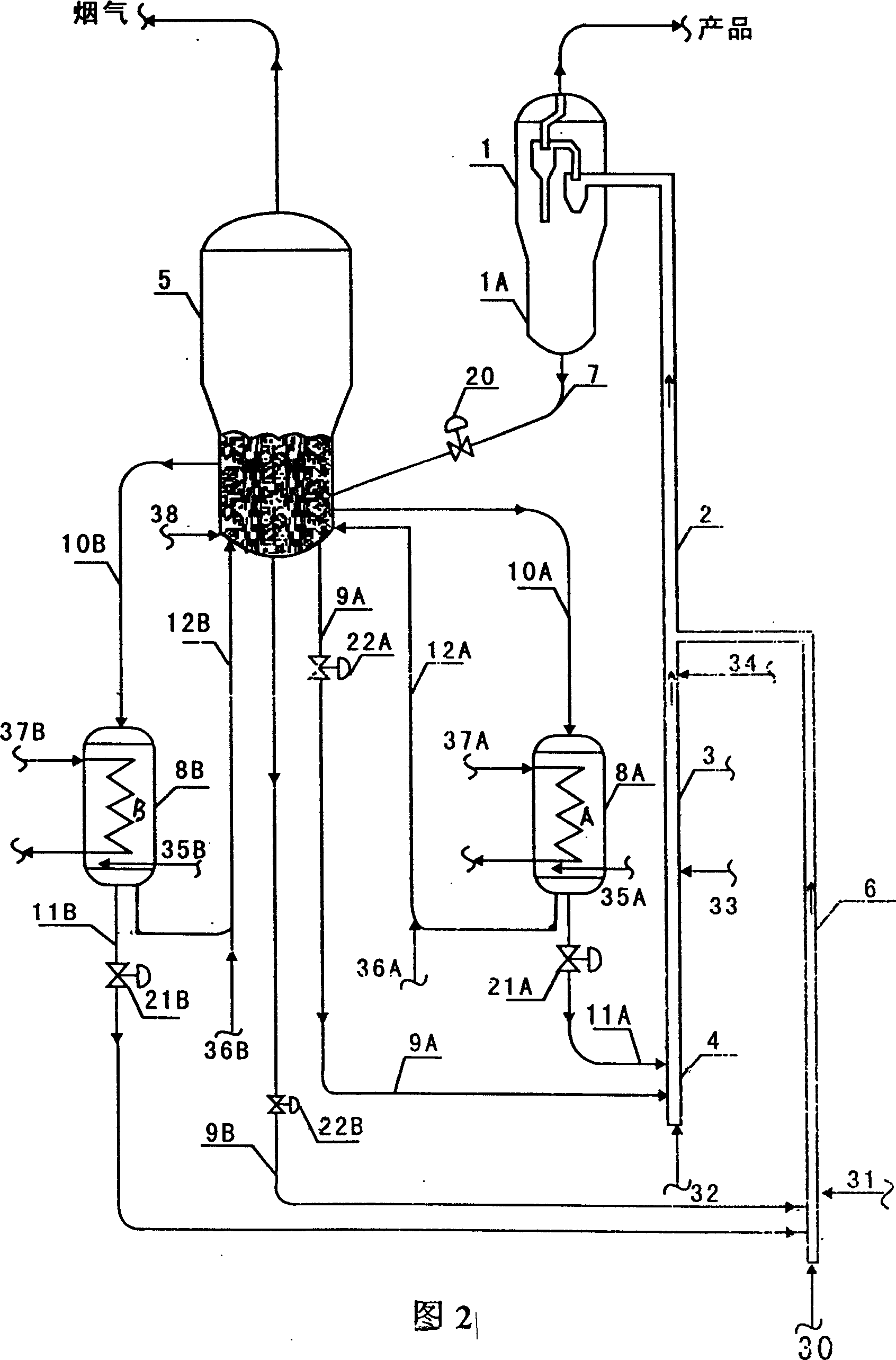

Hydrocarbons catalytic conversion method for preparing low olefin-content gasoline

ActiveCN101205475AReduce the temperatureReduce olefin contentCatalytic crackingComing outCatalytic transformation

The invention relates to a hydrocarbon catalytic conversion method for preparing gasoline with low alkene, wherein, in a reactor comprising a mixing area, a first reaction area and a second reaction area, regenerated catalyst and steam stripped charcoal catalyst enter into the mixing area and are mixed together, and flow upward and enter into the first reaction area under the action of a pre-lifted medium; the mixture contacts and reacts with catalyzing materials at the lower part of the first reaction area and flows upward; the generated oil agent mixture enters into the second reaction area and continue to contact and react fully; the oil agent mixture coming out from the second reaction area enters in a settler through a outlet area of the reactor to perform gas-solid separation, the charcoal catalyst after reaction enters into a stripper section of the settler for steam stripping; at lest one part of the steam stripped charcoal catalyst returns to the mixing area for cycling use, and the remained steam stripped charcoal catalyst is regenerated in a regenerator and then enters into the mixing area for cycling use; the reaction oil-gas after separating the charcoal catalyst is sent to a follow-up product separating system. Under the condition of low dry gas yield, the catalytic gasoline with low alkene can be produced by the method.

Owner:CHINA PETROLEUM & CHEM CORP +1

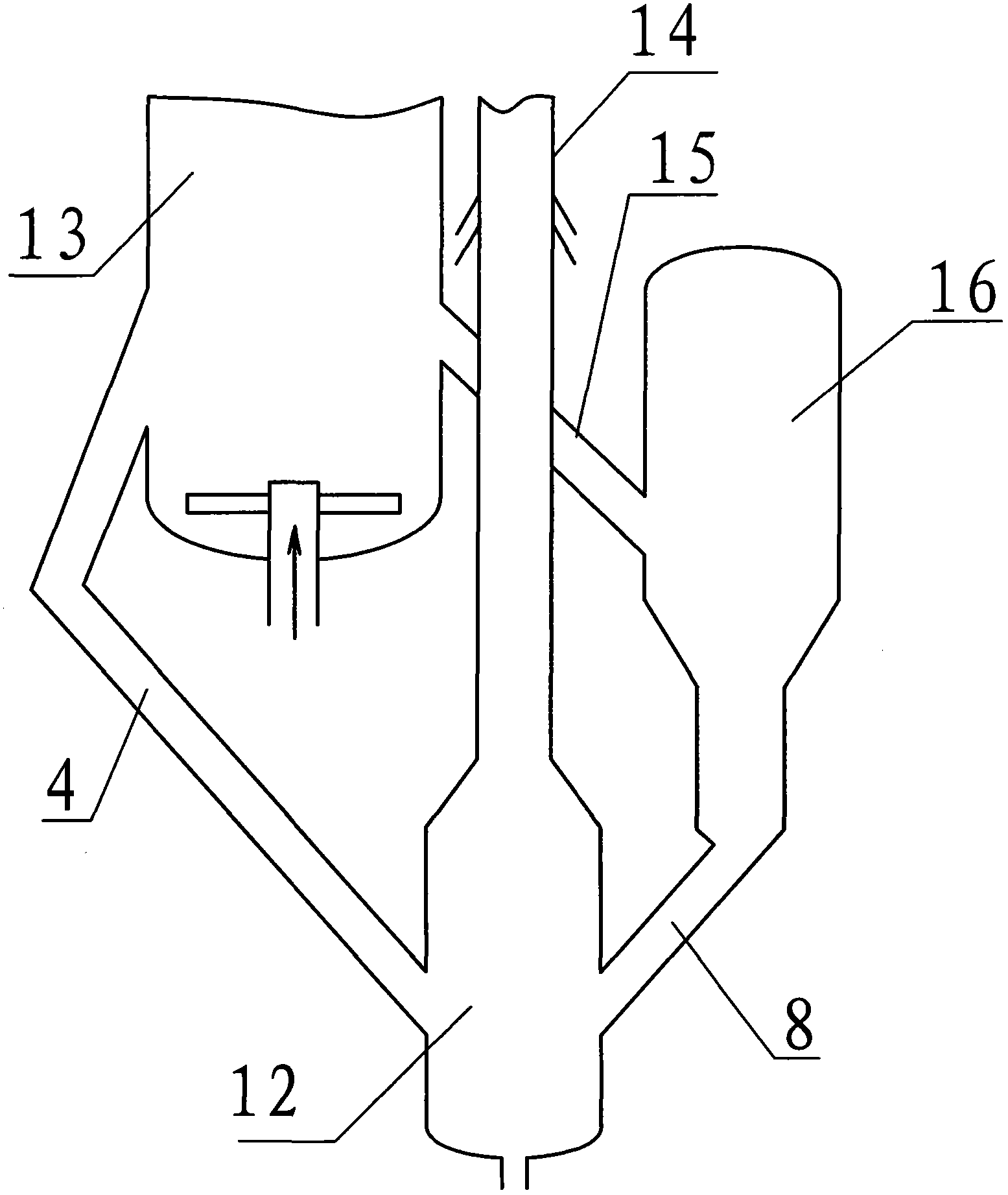

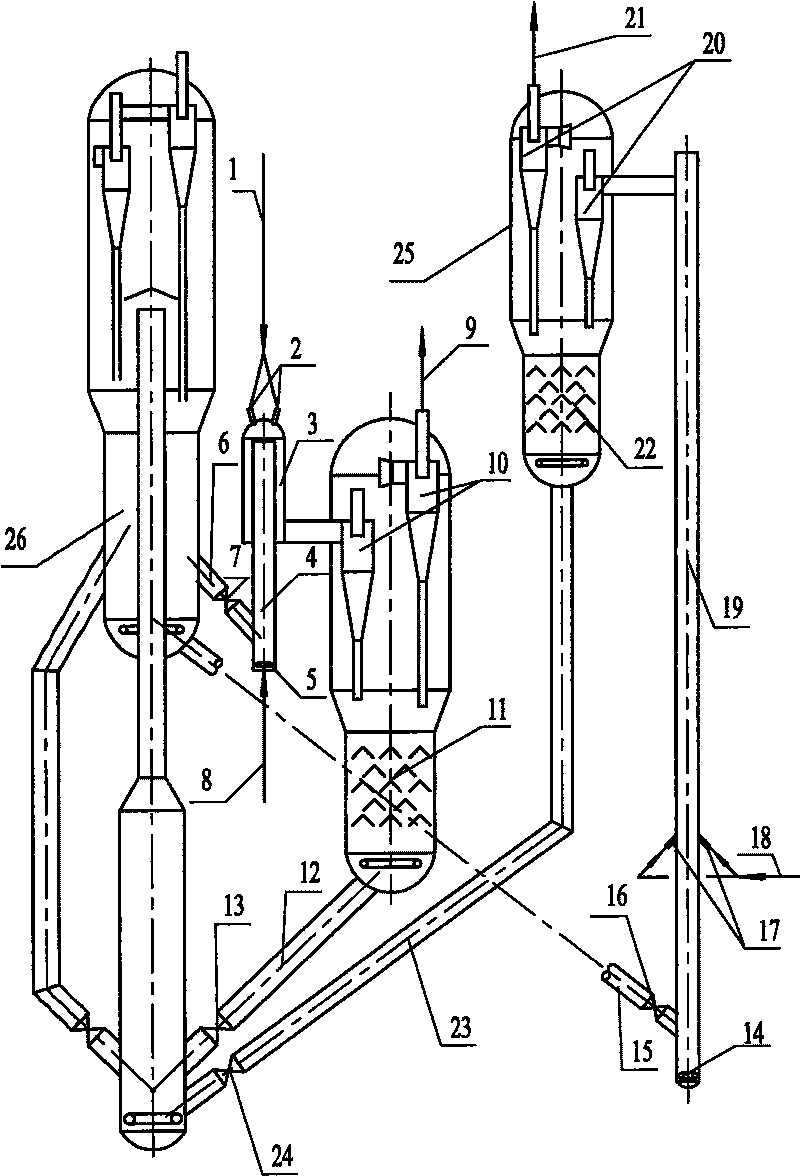

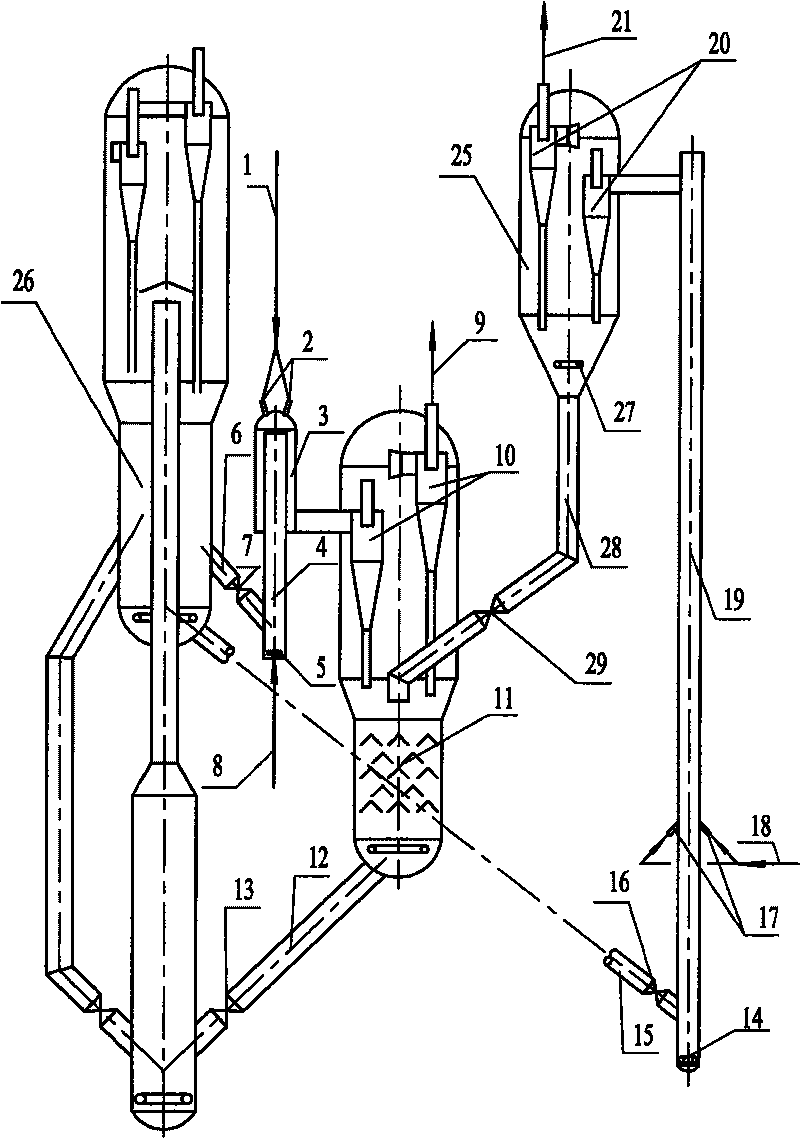

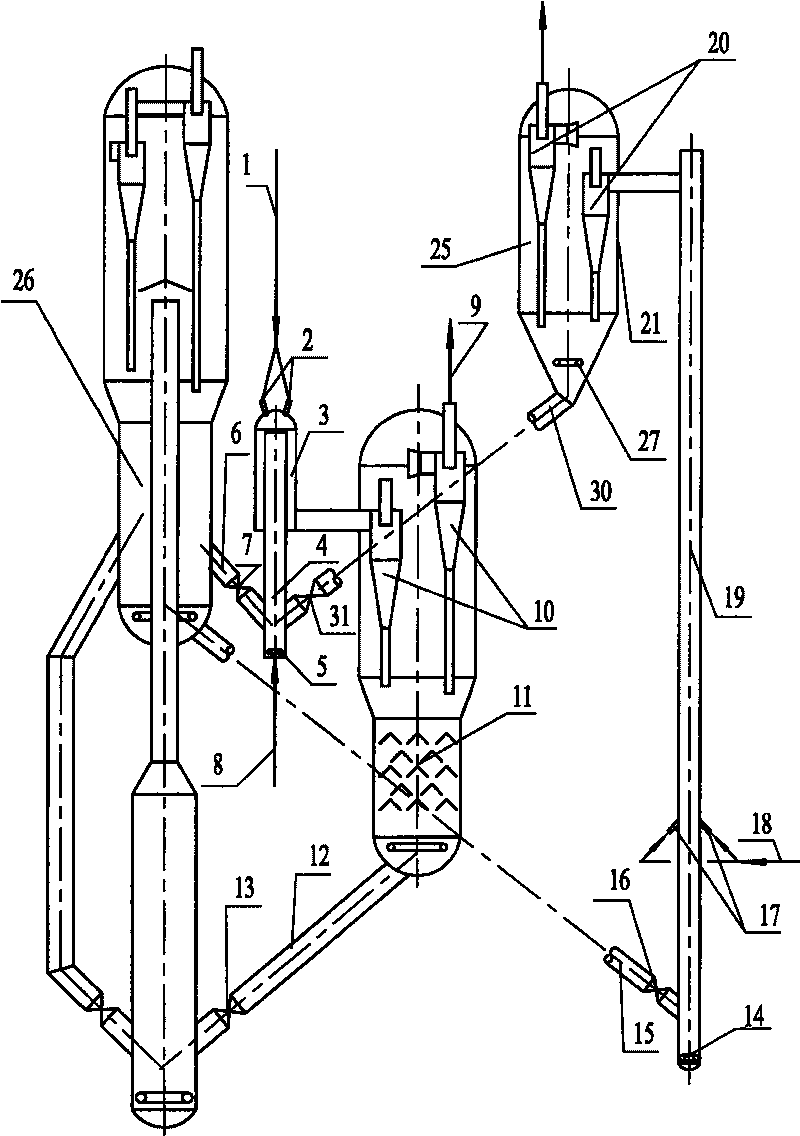

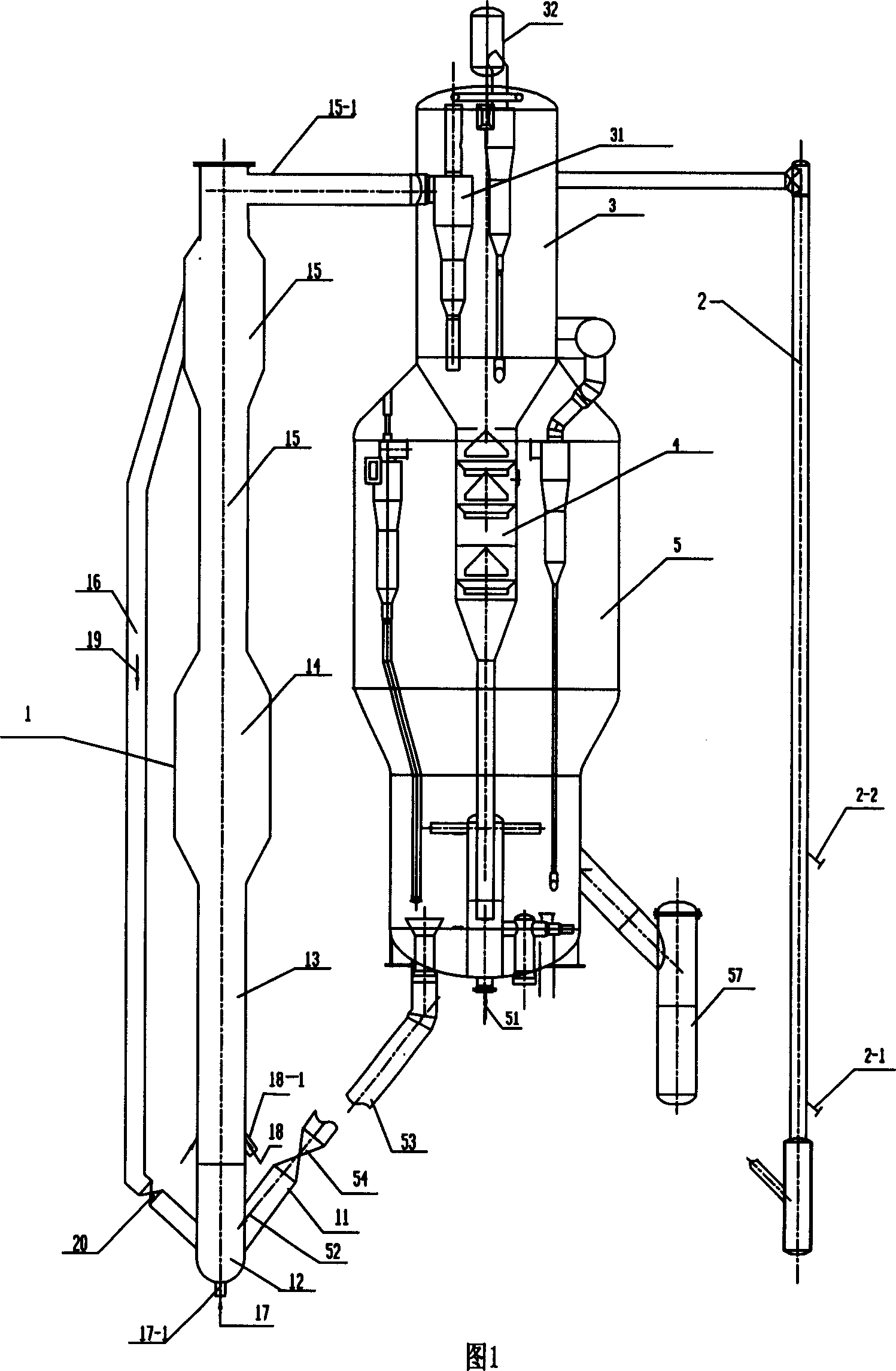

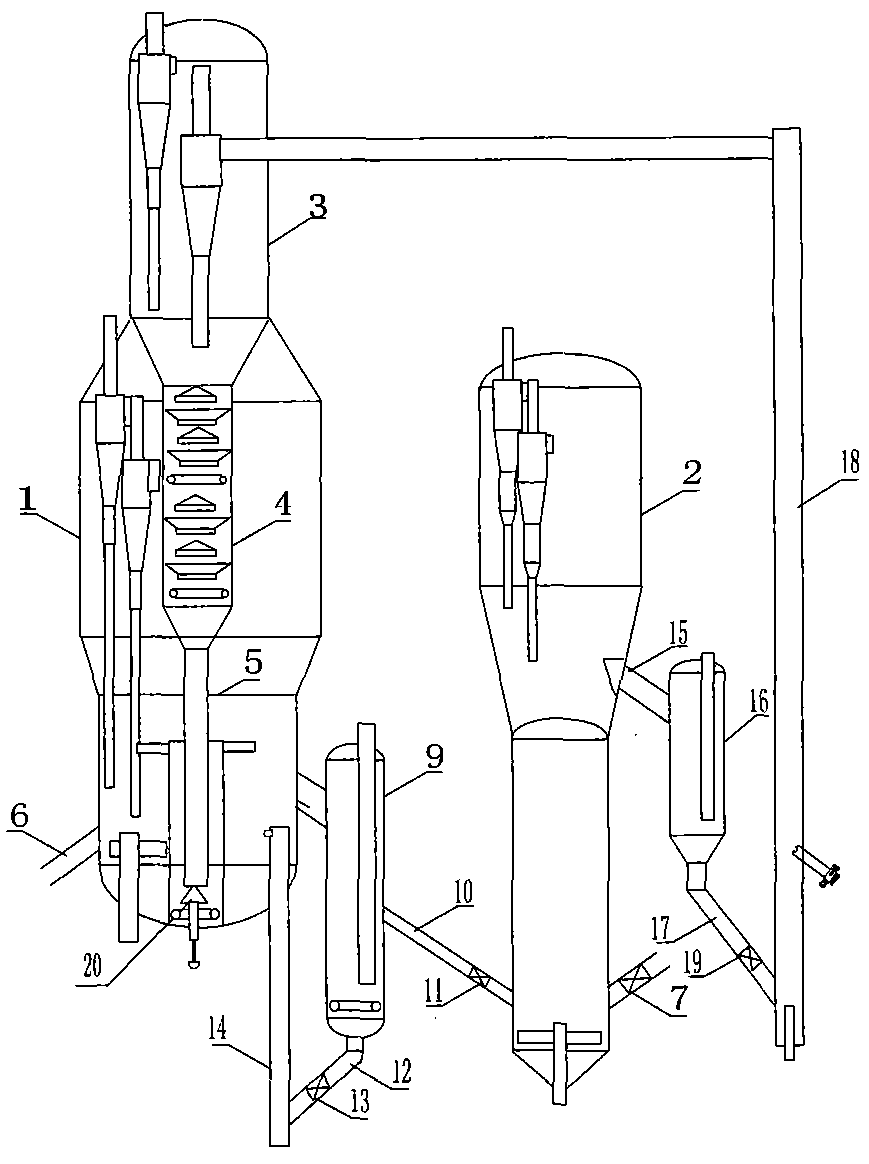

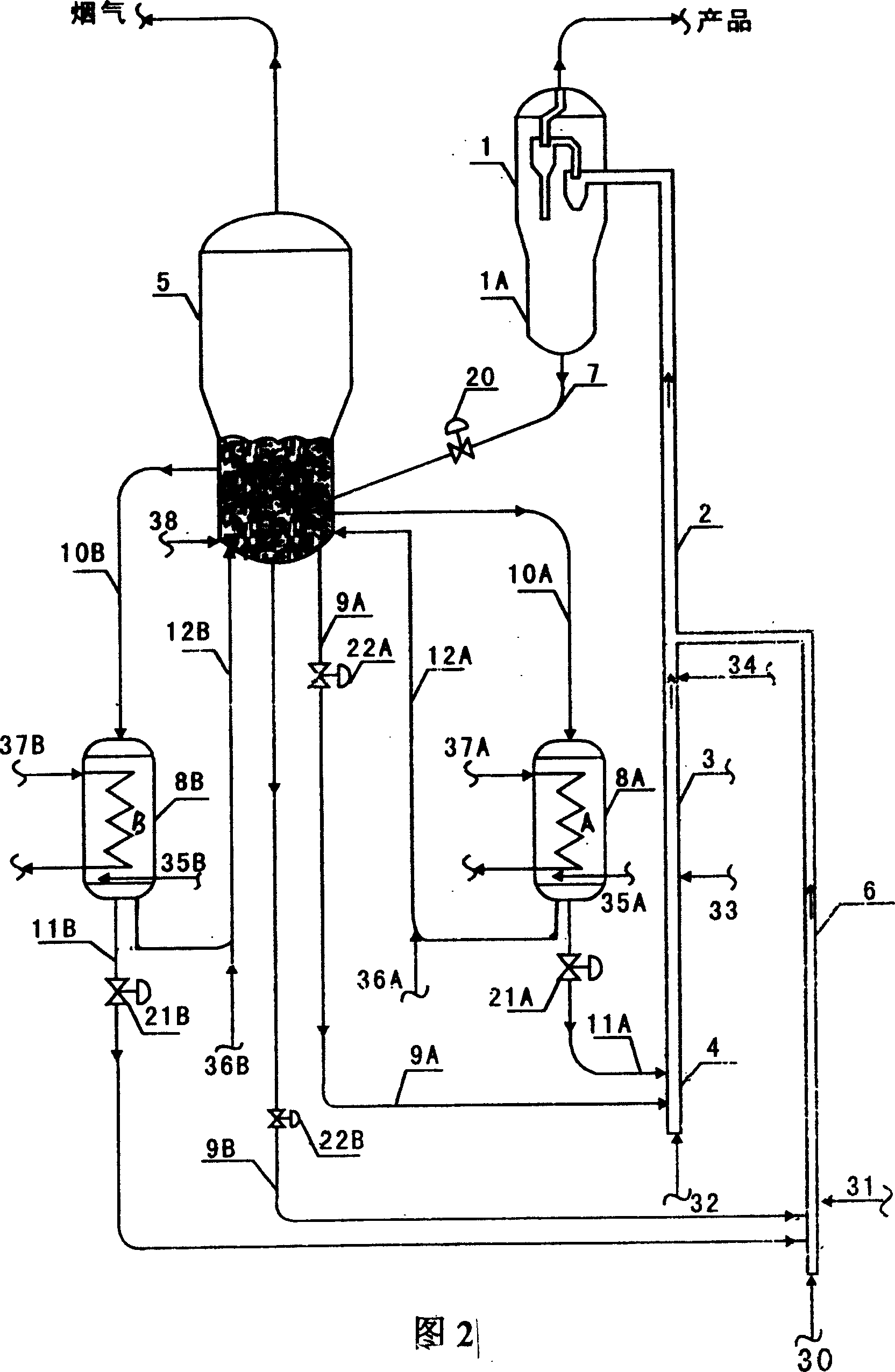

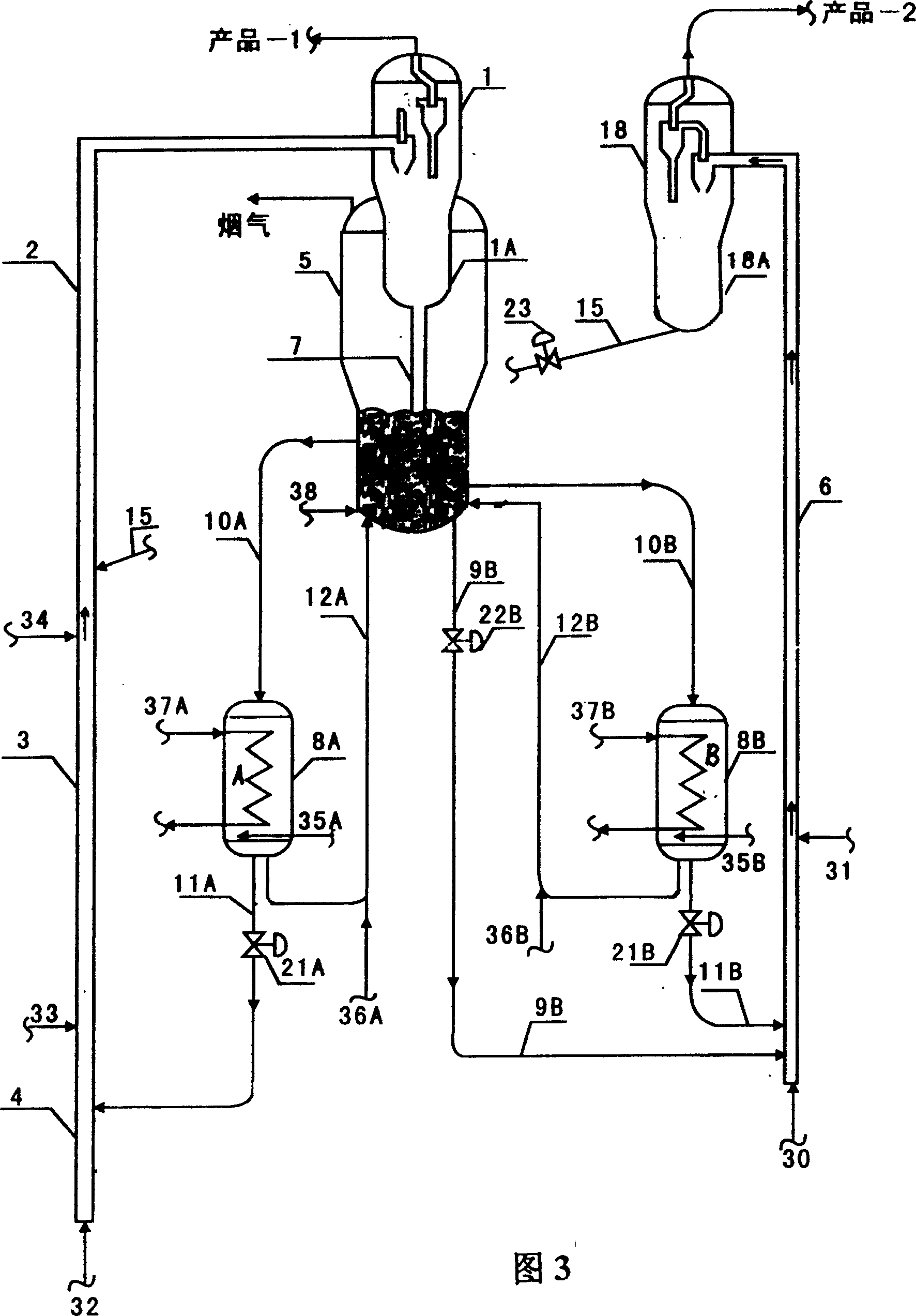

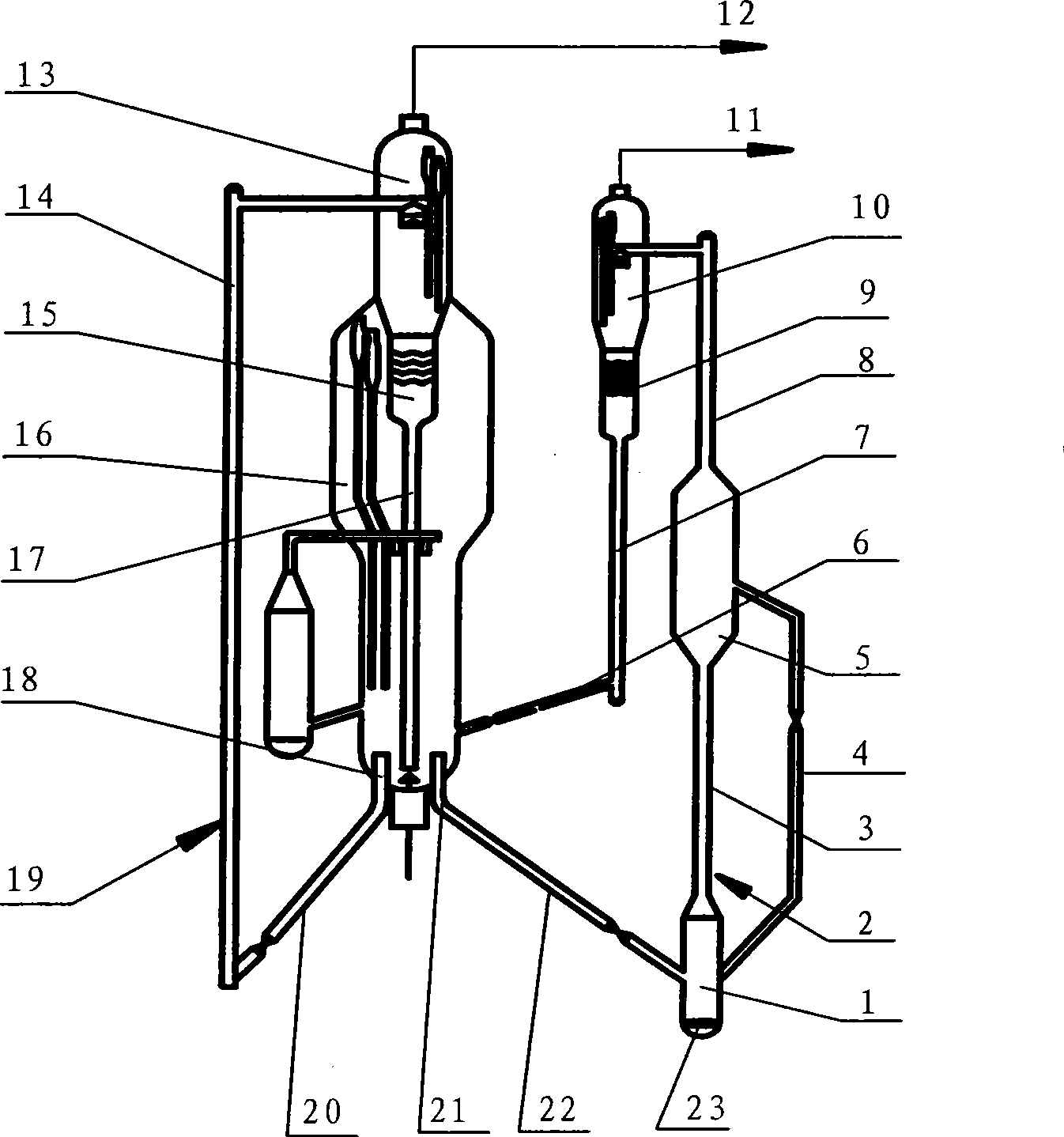

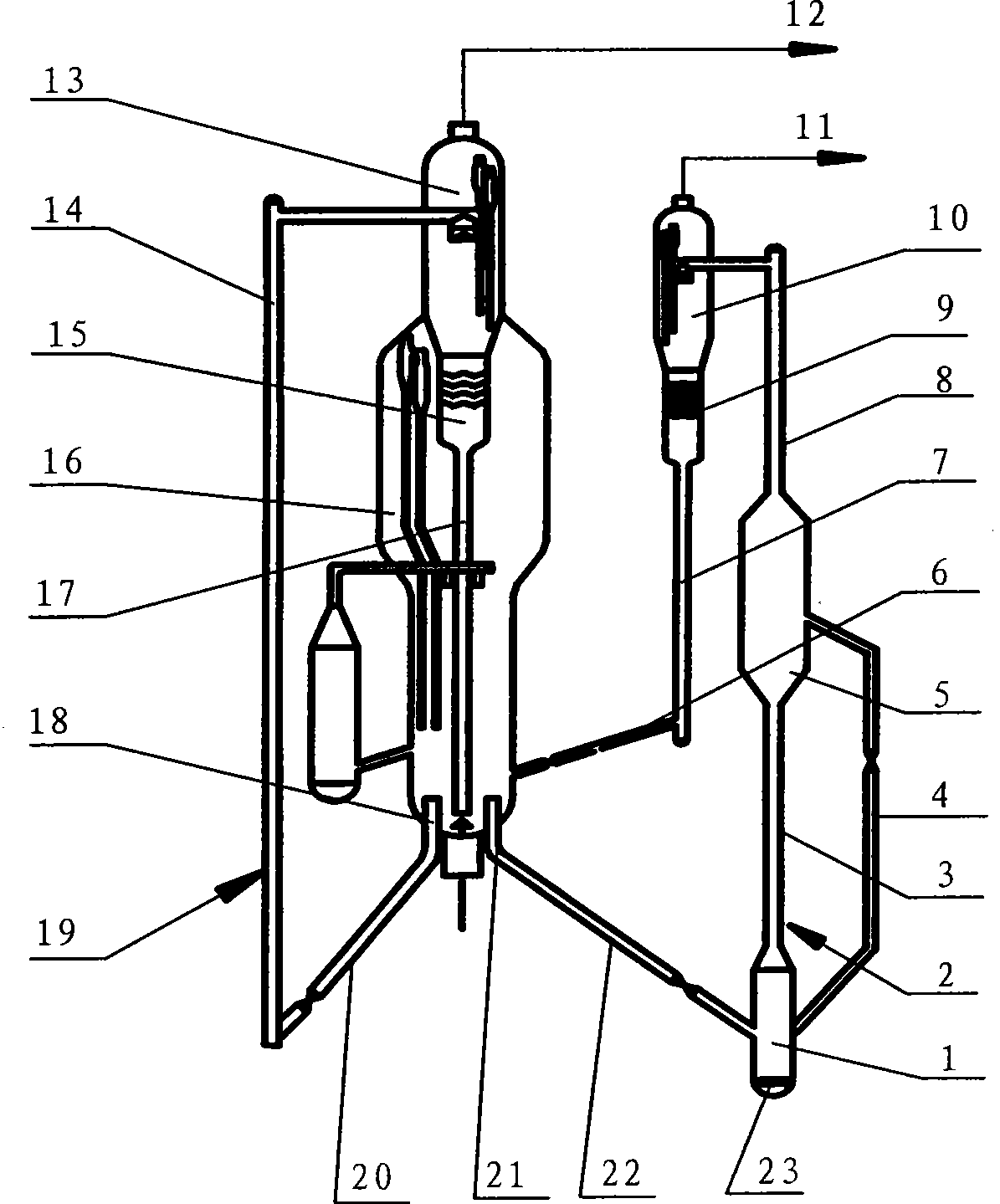

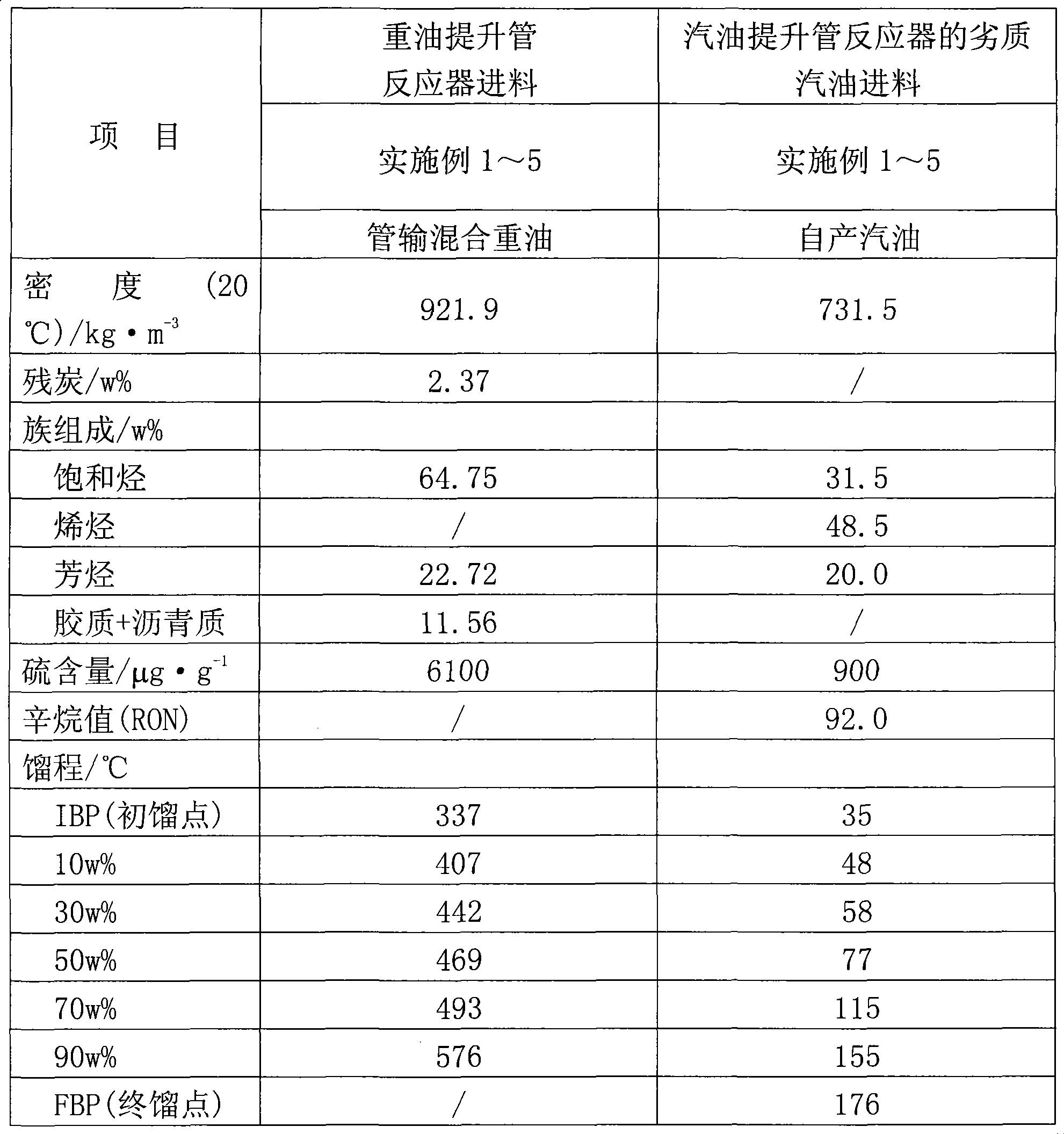

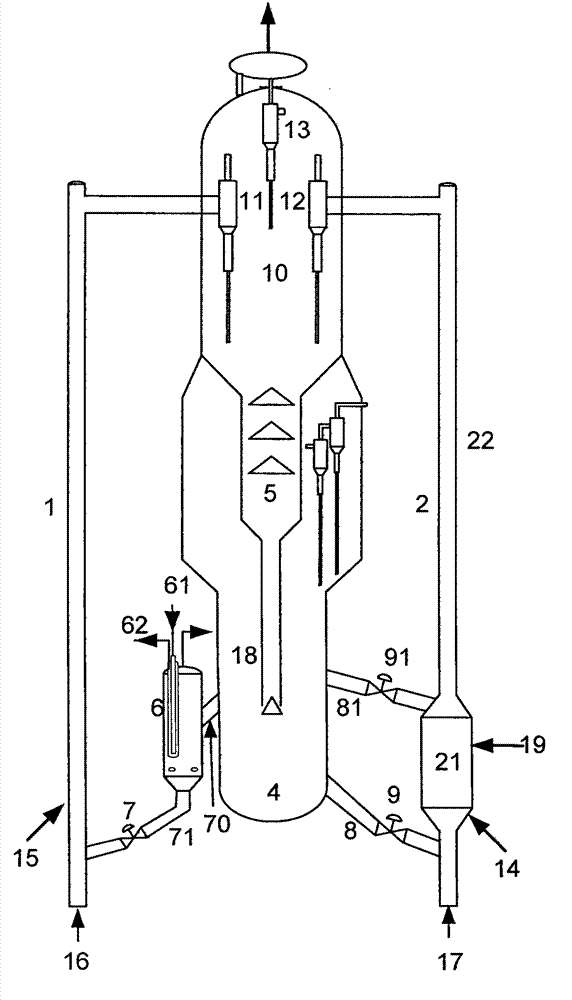

Upgrading method and device for gasoline

ActiveCN101104815AImprove the ratio of agent to oilReduce contentCatalytic crackingHigh energyFractionation

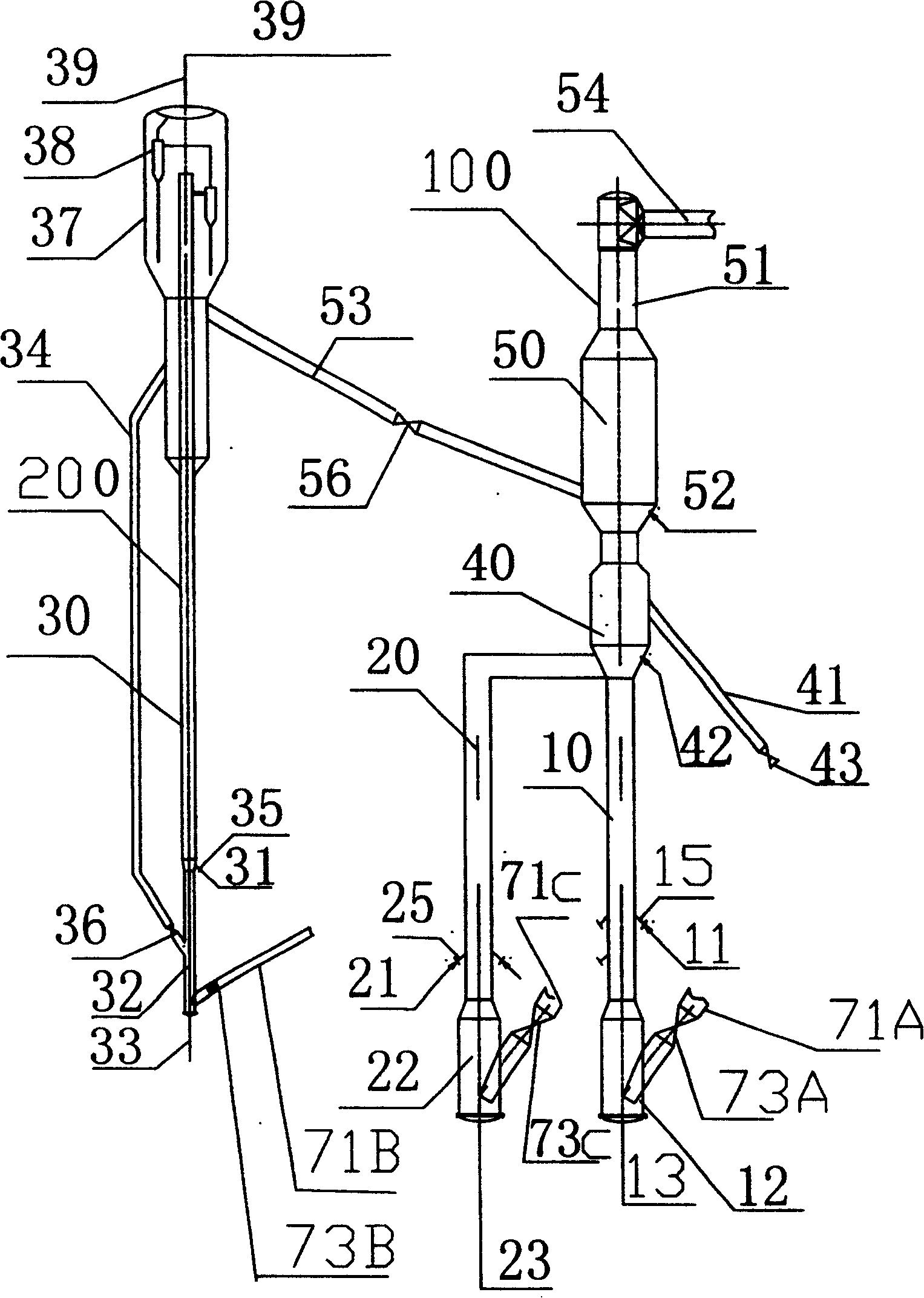

The invention discloses a method and a device for gasoline upgrading, mainly solving the problems of high yield of dry gas and coke and low liquid recovery during the gasoline upgrading reaction in the double-riser catalytic cracking device, high energy consumption of the device and low desulphurization efficiency. The method is mainly characterized by the steps as follows: some of the regenerated catalysts returning to the heavy oil riser reactor; some of the regenerated catalysts mixing with the recycled catalysts from the rapid bed reactor in the catalysts mixer before contacting with the gasoline of poor quality and entering part I of the gasoline riser reactor, the rapid bed reactor, and the part II of the gasoline riser reactor; reactants flowing into a second settler for separation; upgrading reaction oil and gas entering the fractionation system for fractionating; spent catalysts entering the regenerators for coke burning regenerating. The invention can reduce dry gas and coke yield and improve the total liquid yield and meanwhile decrease the energy consumption of the whole device.

Owner:LUOYANG PETROCHEMICAL ENG CORP SINOPEC

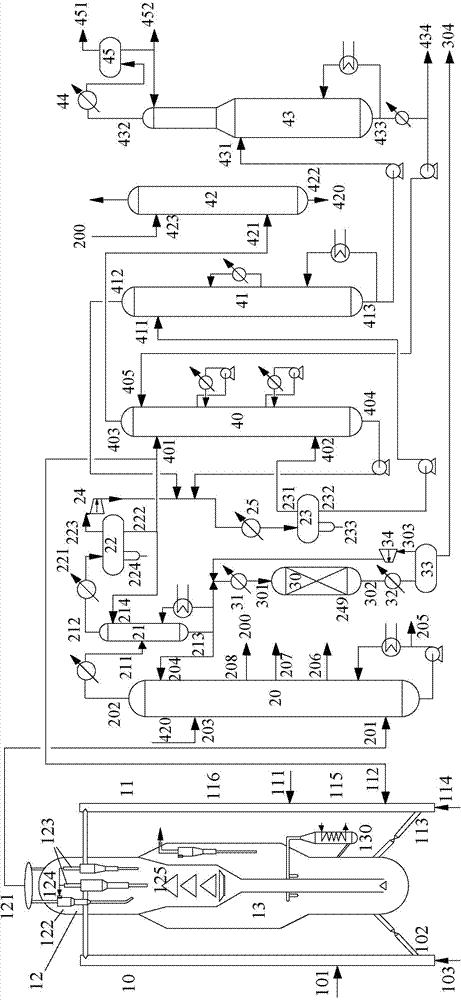

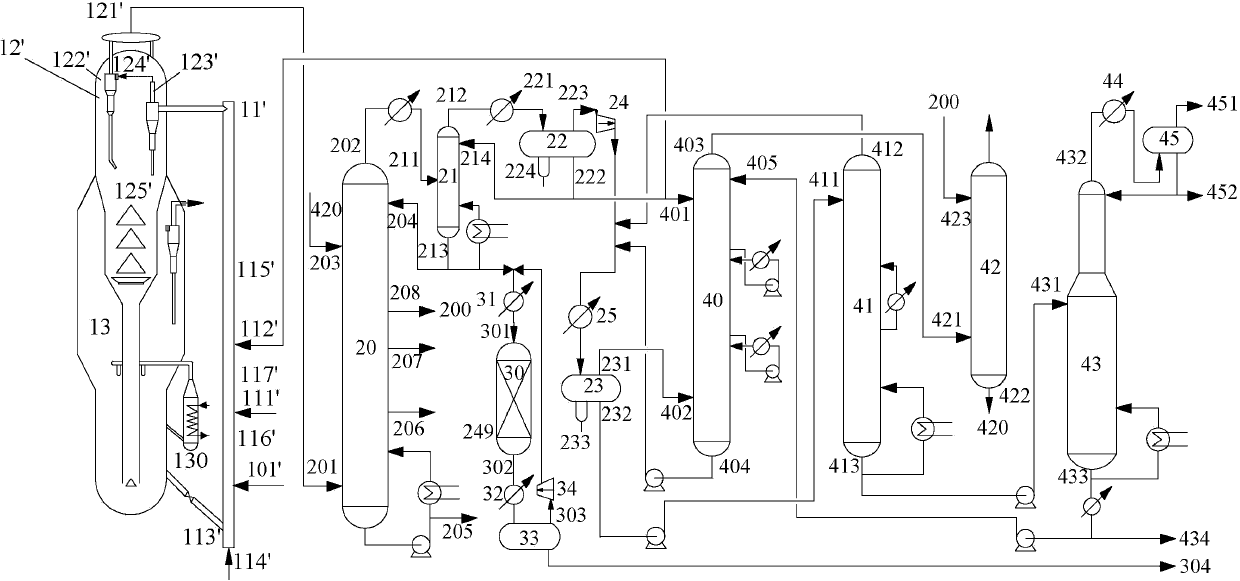

Device and method for producing clean gasoline and increasing propylene yield through catalytic cracking and hydrogenation

InactiveCN103571536APromote absorptionReduce Saturation RequirementsTreatment with hydrotreatment processesGasolineTower

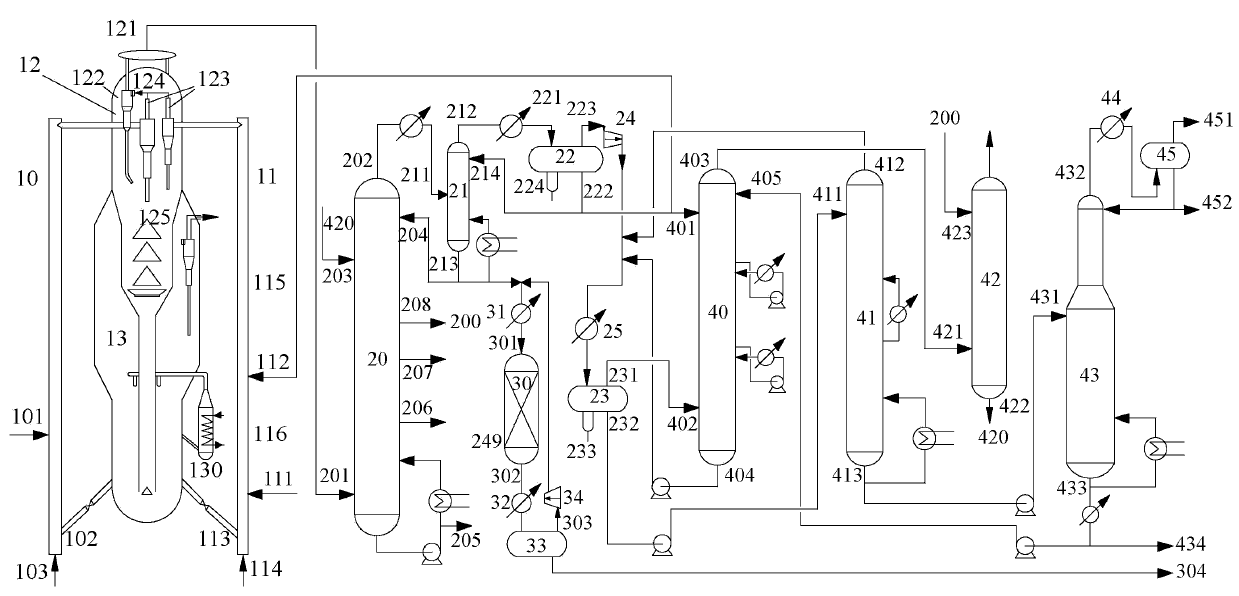

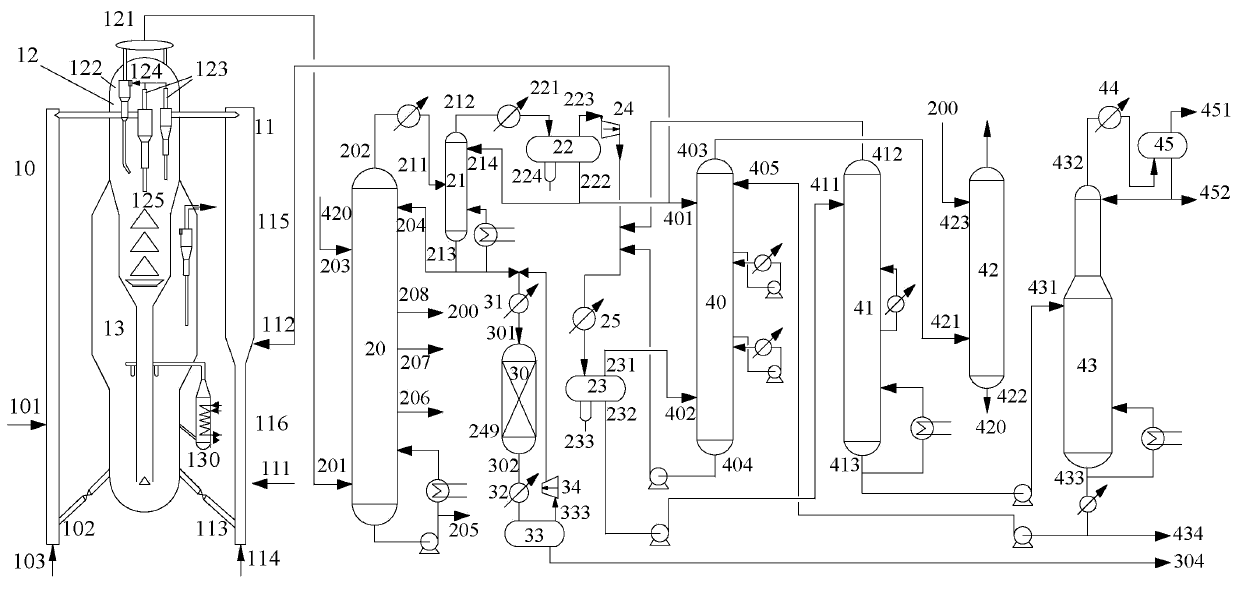

The invention discloses a device and method for producing clean gasoline and increasing propylene yield through catalytic cracking and hydrogenation. The device comprises a reaction-regeneration system, a fractionating system, an absorption stable system and a hydrofining unit. The method comprises the following steps: adding a gasoline fractionating tower to the top of a catalytic cracking fractionating tower to divide crude gasoline into a light fraction and a heavy fraction, wherein the heavy gasoline enters the hydrogenation unit for refining, and one part of the light gasoline enters the absorption stable system to obtain stable light gasoline, and the other part of the light gasoline directly returns to the upper part of a catalytic cracking riser reactor to be cracked to increase the propylene yield under a relatively harsh reaction condition; and finally, blending the stable light gasoline and the modified heavy gasoline to obtain the product of clean gasoline. By adopting the method, the catalytic cracking gasoline is efficiently modified, the propylene yield is increased, and the catalyst-oil ratio of a catalytic cracking device can be increased to promote the conversion of heavy petroleum hydrocarbon; and meanwhile, the load and energy consumption of the absorption stable system are reduced, the process is simplified, the synergistic effect between the two devices of catalytic cracking and hydrofining is enhanced, and the processing cost is lowered.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA) +1

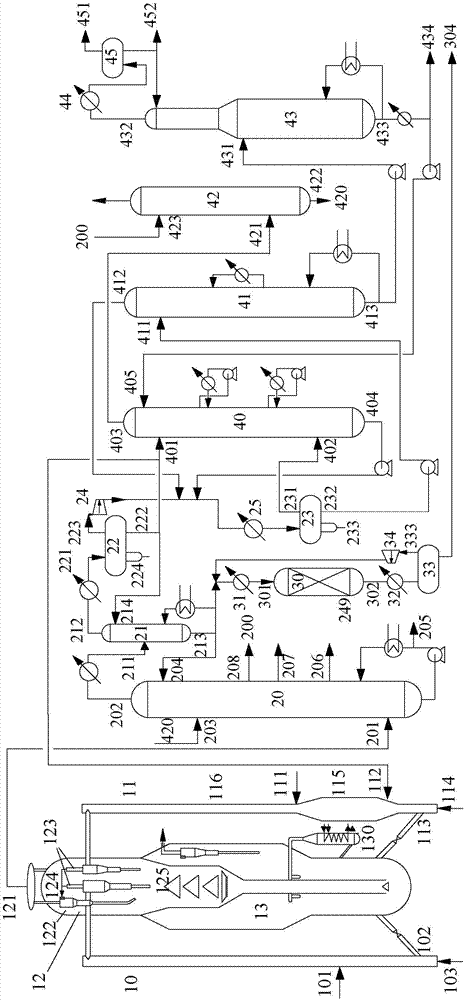

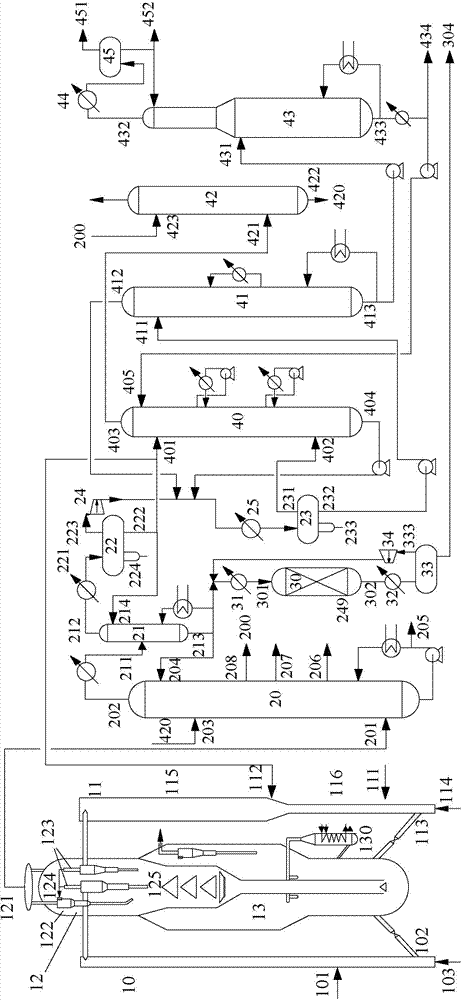

Device and method for producing clean gasoline by combining catalytic cracking and hydrofining

InactiveCN103571534APromote absorptionReduce loadTreatment with hydrotreatment processesGasolineTower

The invention discloses a device and method for producing clean gasoline by combining catalytic cracking and hydrofining. The device comprises a reaction-regeneration system, a fractionating system, an absorption stable system and a hydrofining unit. The method comprises the following steps: adding a gasoline fractionating tower to the top of a catalytic cracking fractionating tower to divide crude gasoline into a light fraction and a heavy fraction, wherein the heavy fraction gasoline enters the hydrofining unit for selective hydrogenation desulfurization, and one part of the light fraction gasoline enters the absorption stable system to obtain stable light gasoline, and the other part of the light fraction gasoline directly returns to a reaction area at the upper part of a catalytic cracking second riser reactor to be modified under a mild condition; and blending the stable light gasoline and the modified heavy gasoline to obtain the product of clean gasoline. By adopting the method, the catalytic cracking gasoline is efficiently modified, and the catalyst-oil ratio of a catalytic cracking device can be increased to promote the conversion of heavy petroleum hydrocarbon; and meanwhile, the load and energy consumption of the absorption stable system are reduced, the synergistic effect between the two devices of catalytic cracking and hydrofining is enhanced, and the processing cost is lowered.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA) +1

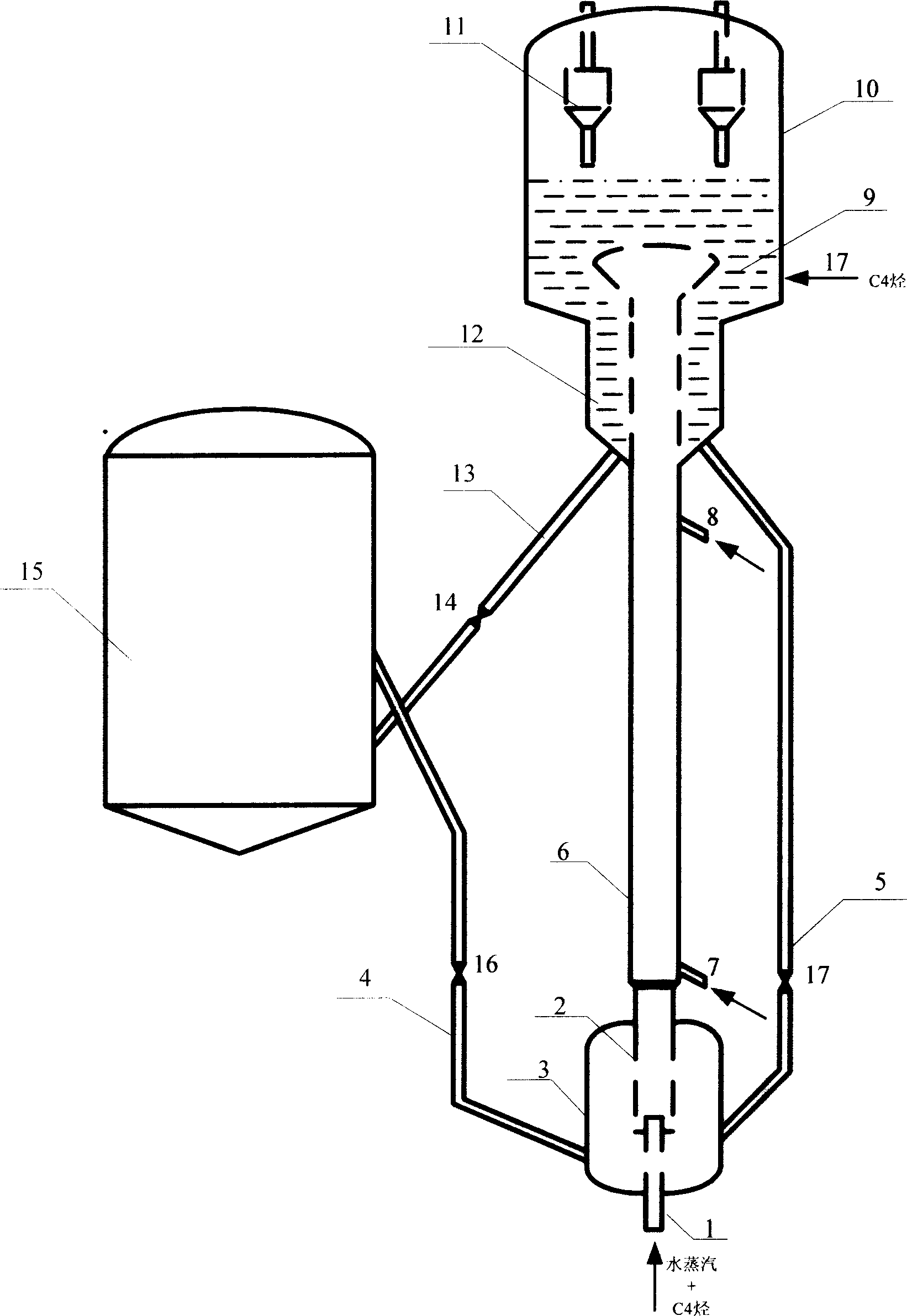

Catalytic cracking desulfur method of faulty gasoline and device thereof

ActiveCN1903989AHigh activityModerate operating conditionsCatalytic crackingOil processingIt equipment

The present invention discloses a catalytic cracking desulfurization method of low-grade gasoline in the field of petroleum processing technology and its equipment. It is characterized by that the invented gasoline upgrading reactor adopts gasoline fast bed reactor with cylindrical structure, a portion of spent catalyst can be passed through spent catalyst coveying pipeline with flow control valve and fed into catalyst mixer, and is mixed together with regenerated catalyst coming from regenerator under the action of aqueous vapor, then fed into gasoline fast bed reactor and is contacted with low-grade gasoline feed so as to make reaction to greatly reduce sulfur content of low-grade gasoline.

Owner:LUOYANG PETROCHEMICAL ENG CORP SINOPEC

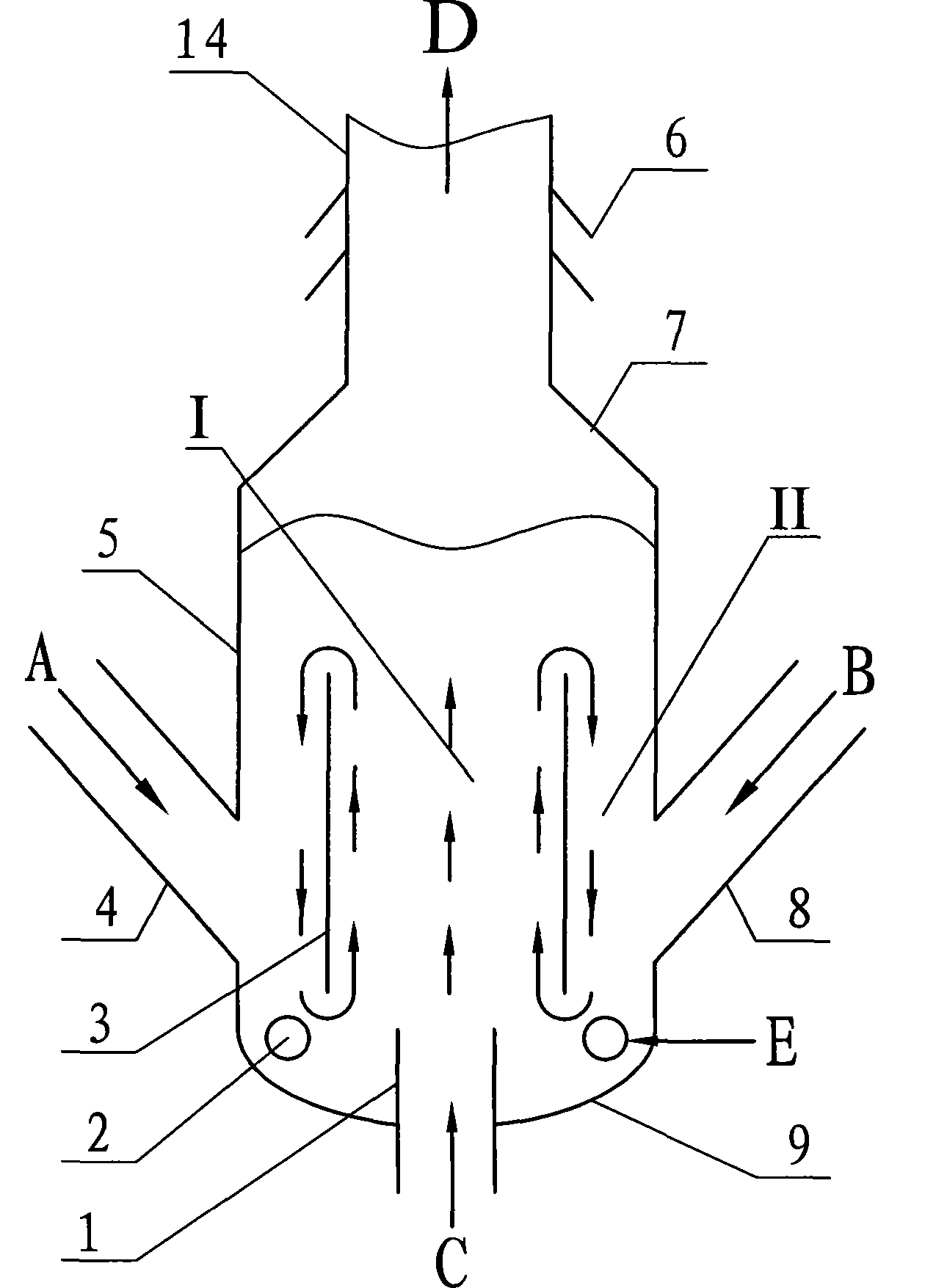

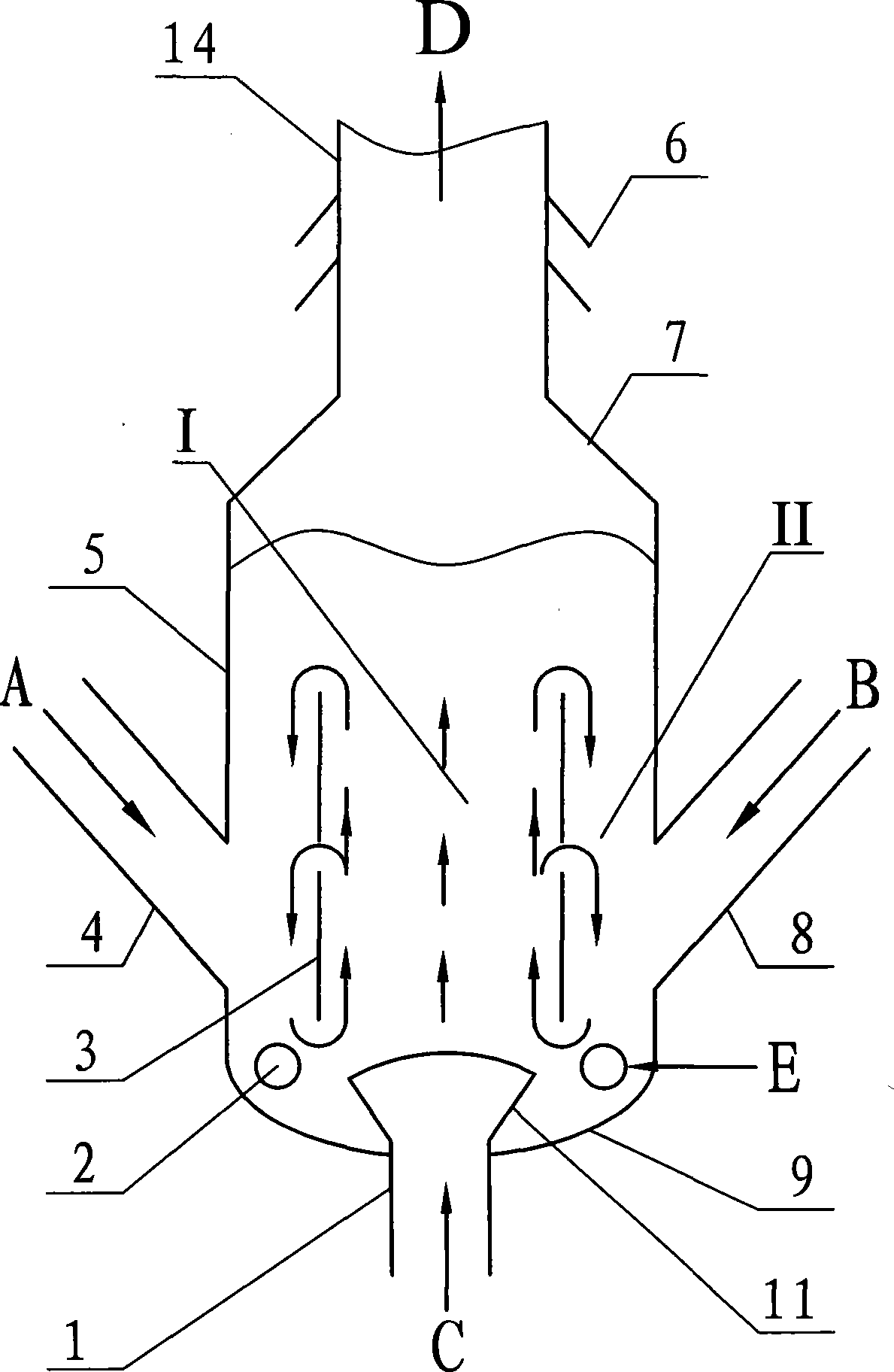

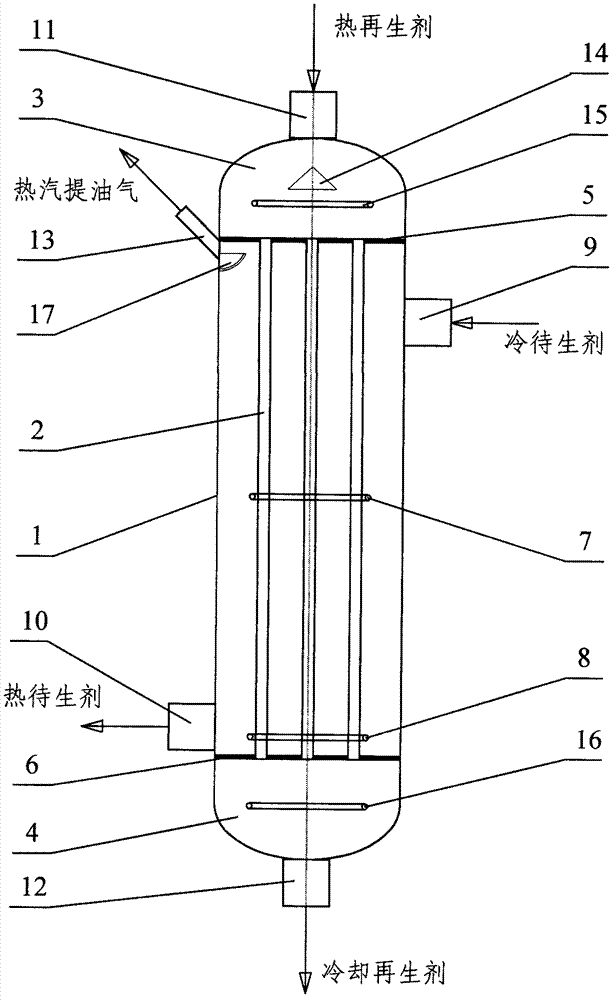

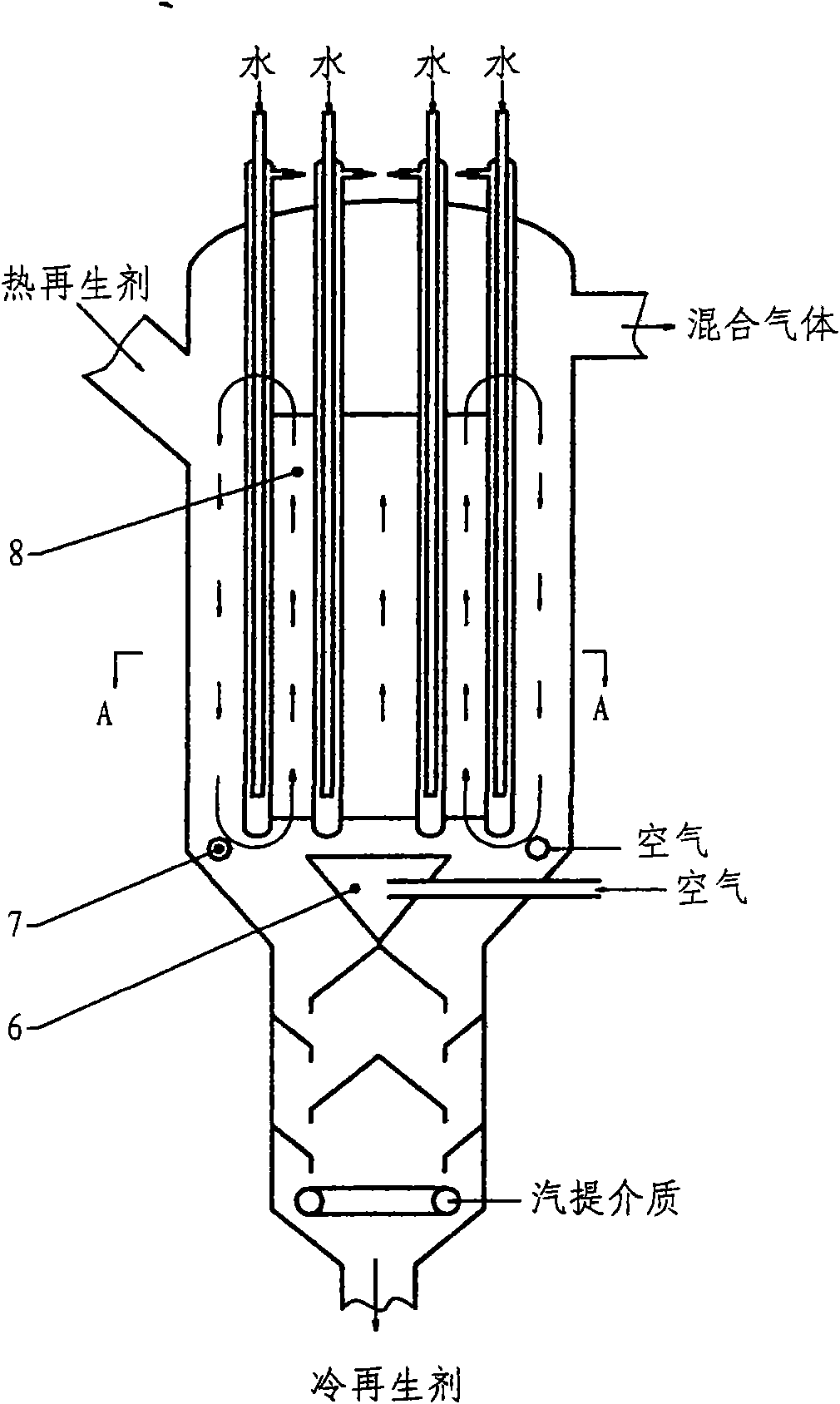

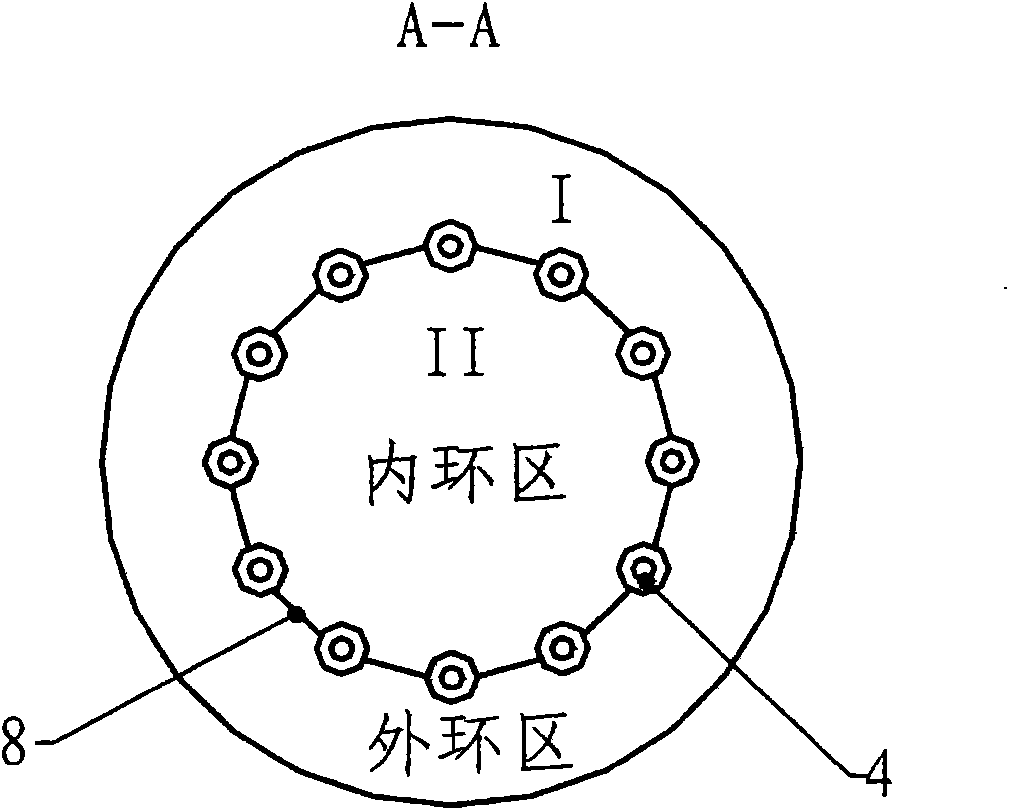

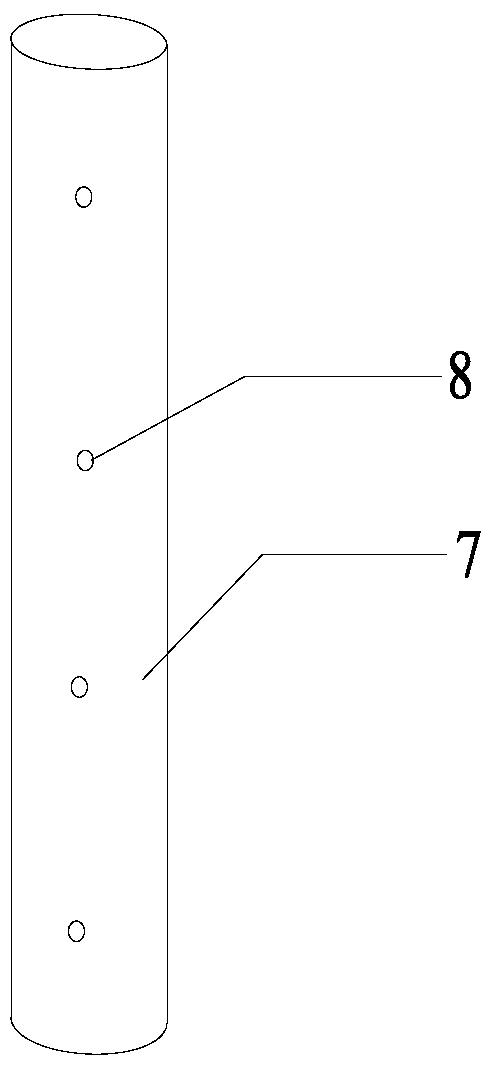

Catalytic cracking cold-hot catalyst pre-lifter

InactiveCN102698661AEnhanced lateral mixingIncrease connection areaCatalytic crackingChemical/physical processesResidence timeCracking reaction

The invention provides a catalytic cracking cold-hot catalyst pre-lifter which is suitable for a catalytic cracking lifting pipe reactor with at least one cold catalyst feeding and one hot catalyst feeding. The pre-lifter comprises a pre-lifting cylinder (5), a hot catalyst feeding pipe (4) and a cold catalyst feeding pipe (8), and is characterized in that a guide cylinder (3) is arranged in the pre-lifting cylinder (5) and divides the pre-lifting cylinder (5) into two communicated areas that is an inner ring (I) and an outer ring (II); and the hot and cold catalyst feeding pipes (4 and 8) are arranged between the upper edge and the lower edge of the guide cylinder. With the adoption of the pre-lifter, the cold catalyst and hot catalyst are uniformly mixed and subjected to heat exchange in a short residence time, so that the requirements of catalytic cracking reactions are satisfied effectively, the catalytic cracking reaction is strengthened and the thermal cracking reaction is inhibited, the conversion rate of the devices is increased and the selectivity of products is enhanced.

Owner:CHINA UNIV OF PETROLEUM (BEIJING)

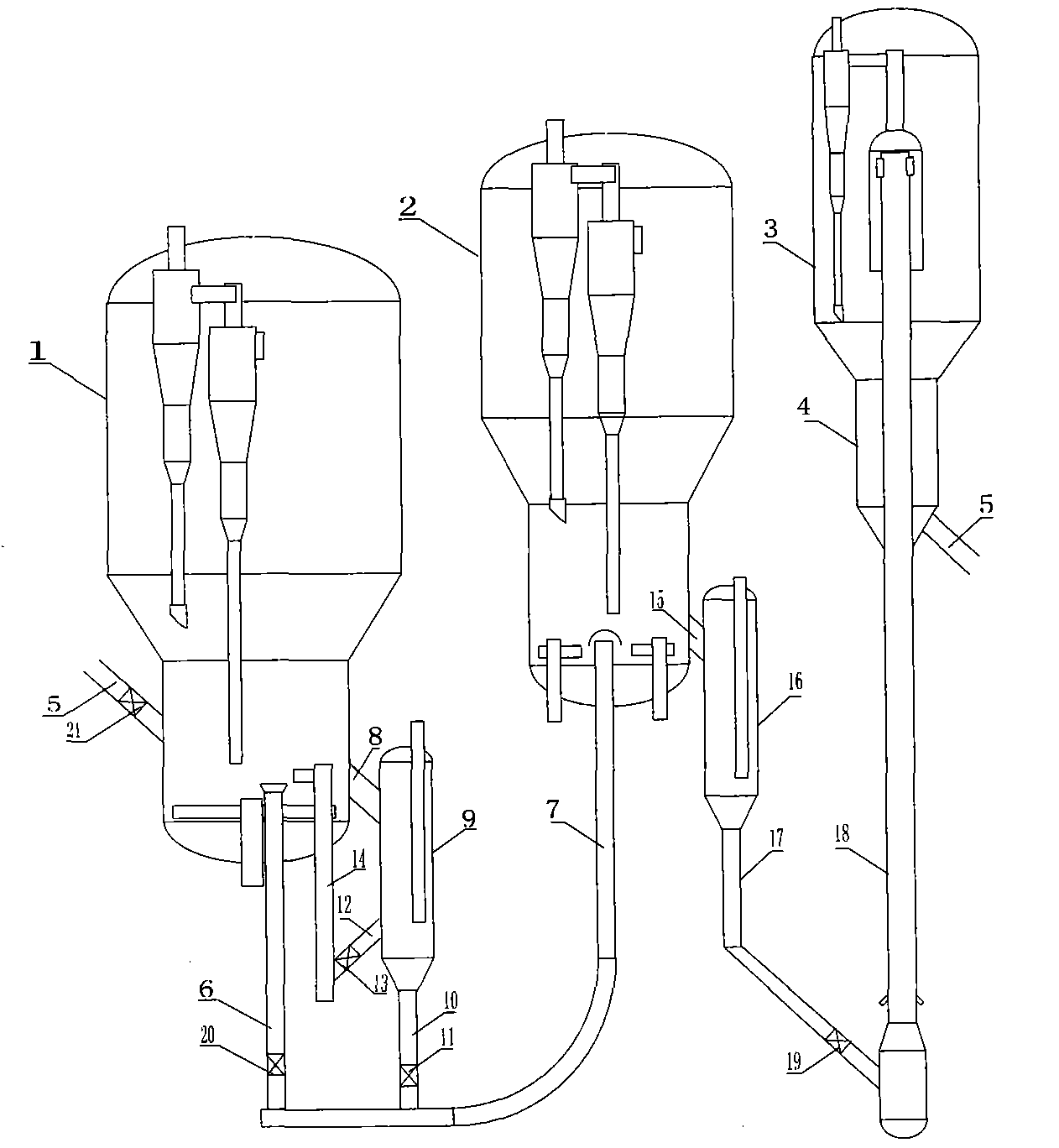

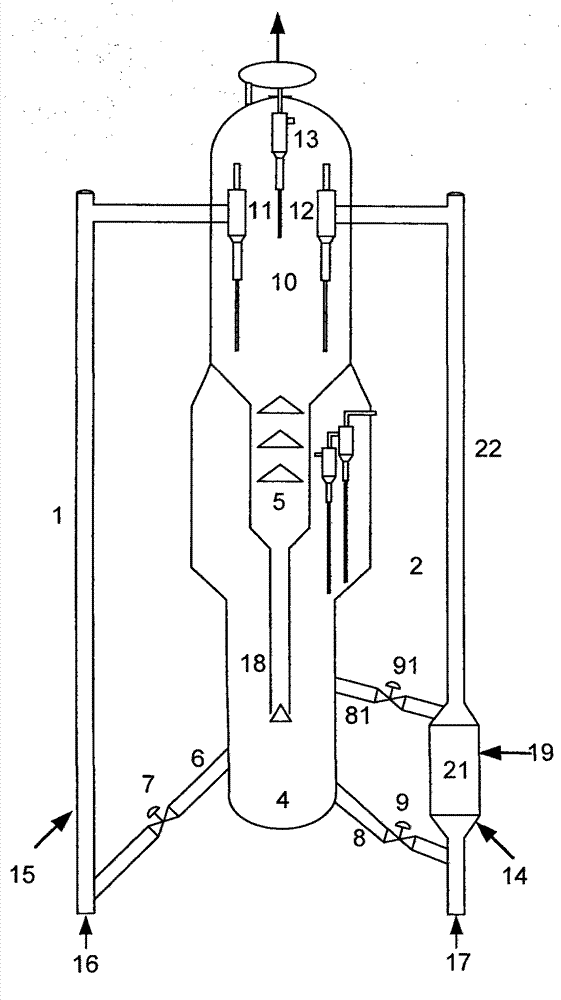

Double lift pipe catalytic cracking method and device for modifying inferior patrol

ActiveCN1298812CReduce olefin contentReduce hydrocarbon contentCatalytic crackingOil processingGasoline

Owner:SINOPEC LUOYANG PETROCHEM ENG CORP

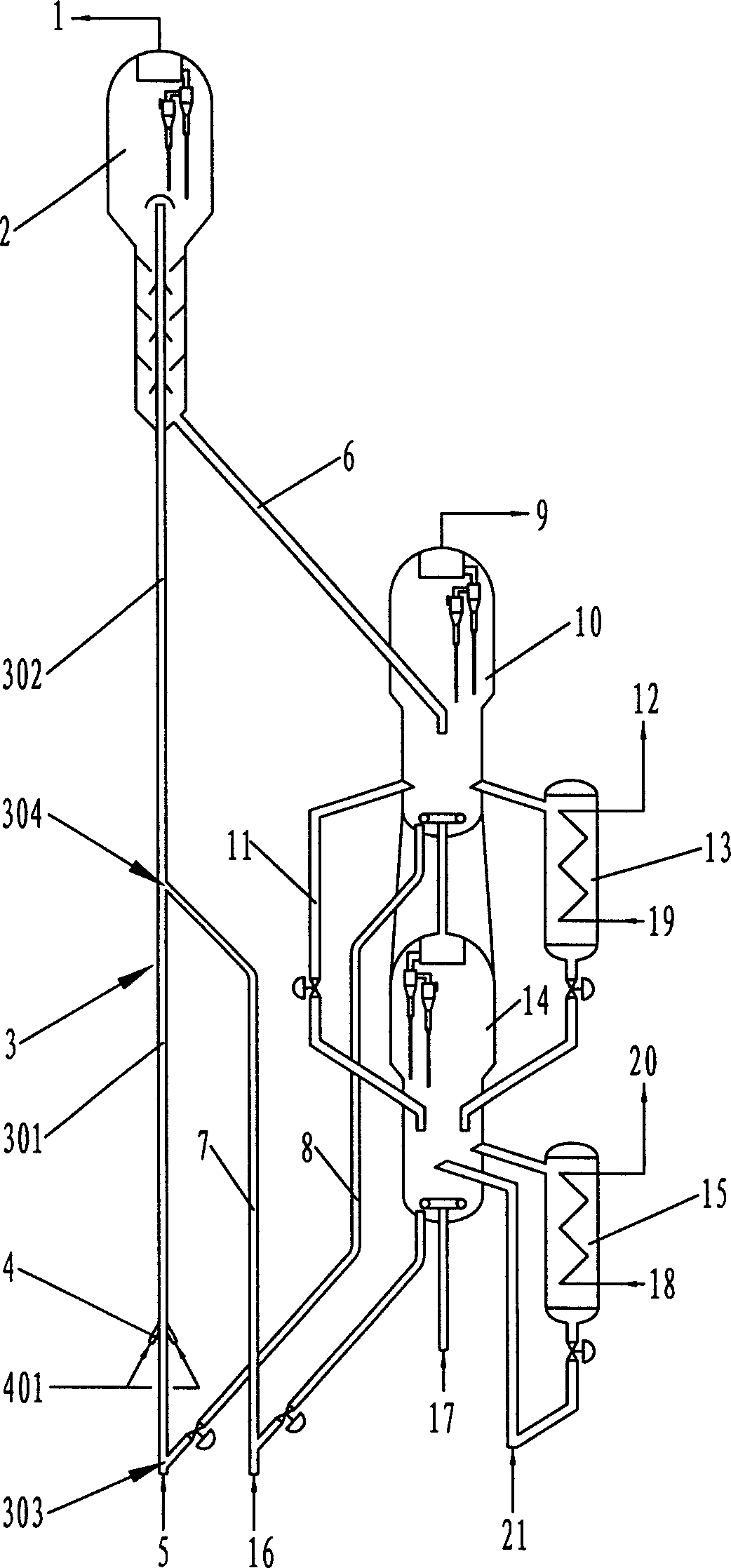

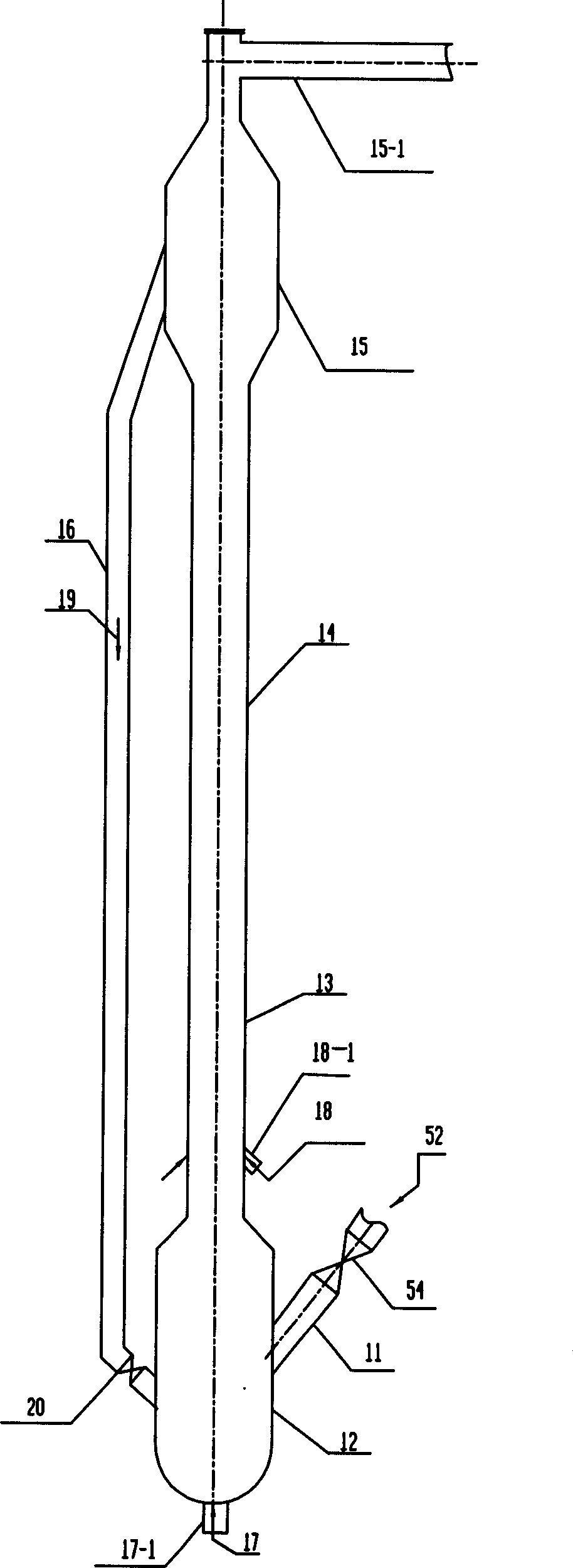

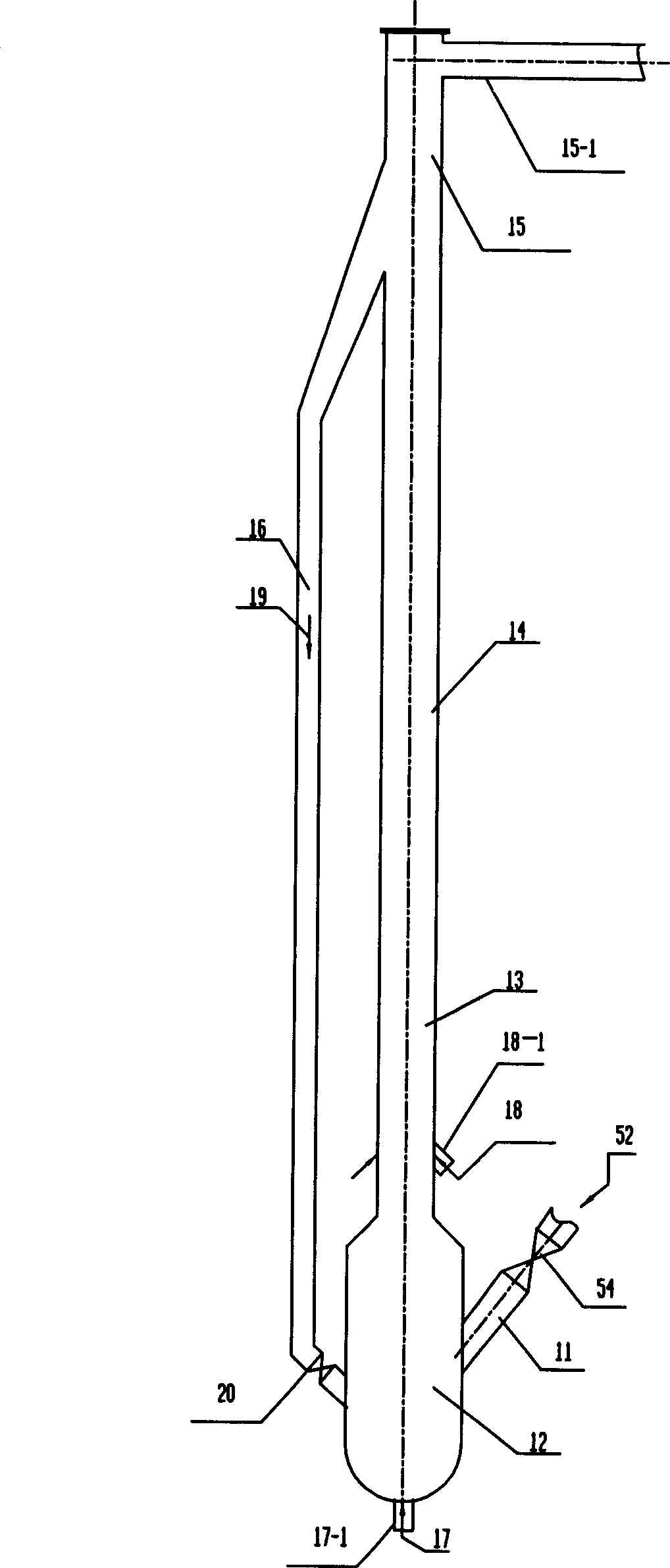

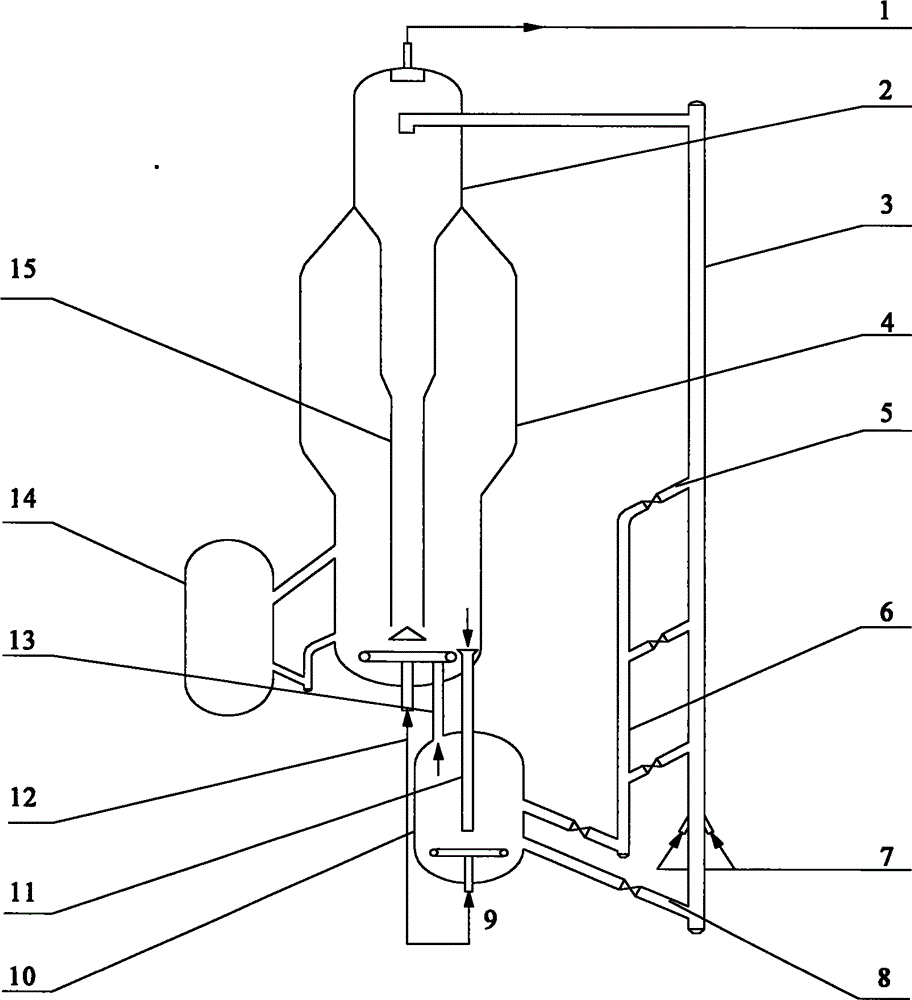

Lift pipe catalytic cracking method and device

The invention discloses a method and a device for catalytic cracking of a riser in a petroleum refining process, which are mainly used to solve the problems of poor catalytic effect in the second half of the existing riser reactor, intensified thermal cracking reaction, and the like. The present invention adopts a two-stage riser reactor, the semi-regenerated catalyst and raw oil (401) with higher temperature from the first regenerator (10) enter the bottom of the riser reactor (3), and along the first reaction section (301) carry out catalytic cracking reaction upward; Introduce the regenerated catalyst from the lower temperature of the second regenerator (14) through the catalyst inlet (304) in the middle of the riser reactor (3), and from the first reaction section (301) The upward catalyst is mixed with oil and gas, enters the second reaction section (302) and continues upward to carry out the catalytic cracking reaction. The invention is mainly used for catalytic cracking processing of petroleum heavy distillates to improve the distribution of cracked products and the quality of cracked gasoline in catalytic cracking units.

Owner:SINOPEC LUOYANG PETROCHEM ENG CORP

Combined catforming of high-production low carbon alkene

ActiveCN101045667BReduce backmixingHigh selectivityChemical recyclingBulk chemical productionAlkeneCracking reaction

A combined catalytic converting process for preparing low-carbon olefin with high output includes such steps as contacting between heavy oil as raw material, regenerated catalyst and carbon depositedcatalyst in flow-down tube reactor, cracking reaction, separating the cracked product from the catalyst to be regenerated, separating low-carbon olefin from cracked product, contacting between rest ofsaid product and regenerated catalyst in flow-up tube reactor, reaction, separating oil gas from catalyst, separating low-carbon olefin from oil gas, and regenerating the catalyst.

Owner:CHINA PETROLEUM & CHEM CORP +1

Catalytic conversion method for increasing propylene yield

ActiveCN100586909CHigh selectivityReduce the proportion of structure reactionChemical recyclingBulk chemical productionReaction zoneAlkene

The invention discloses a catalytic conversion method to increase production propylene, which comprises the following steps: proceeding in reactor with dilution zone, lightweight hydrocarbon reactionzone and heavyweight hydrocarbon reaction zone; entering regenerated catalyst and carbon catalyst from stripping section into the dilution zone; mixing; flowing upward under the function of pre-lifting agent; entering into the lightweight hydrocarbon reaction zone; touching with the lightweight hydrocarbon at the lower of the lightweight hydrocarbon reaction zone; reacting; moving upward; touchingwith heavyweight petroleum hydrocarbon at the upper of the lightweight hydrocarbon reaction zone; reacting; moving upward; forming oil solution mixture; entering into heavyweight hydrocarbon reactionzone; touching continually; reacting; getting the carbon catalyst; entering into the stripping section to strip; getting the carbon agent; backing moiety to mixed zone; using cycle; entering the other moiety into mixed zone; using cycle; leading the reaction oil gas to separation system of subsequent product. This method can get very high productivity of propone low carbon alkene.

Owner:CHINA PETROLEUM & CHEM CORP +1

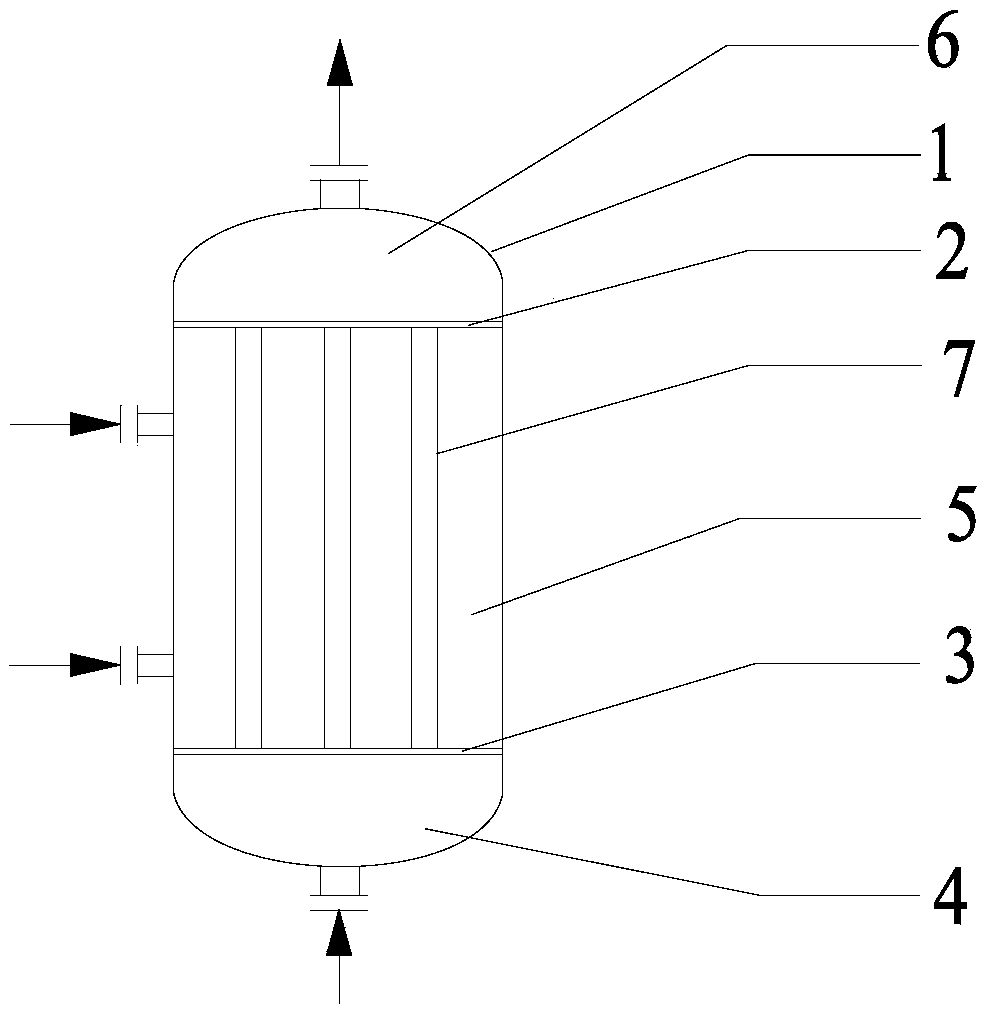

Tube-shell type solid-solid heat exchanger

InactiveCN103289726BGuaranteed thermal balanceGuaranteed to maintain heat balance under the condition of large agent-to-oil ratioCatalytic crackingSolid particleEngineering

The invention relates to a tube-shell type solid-solid heat exchanger without blending between cold and hot solid particles for heat exchange, inner spaces of an upper sealing head (3) and a lower sealing head (4) and the inner space of a heat exchange tube (2) form a tube pass, a space defined by a shell (1), an upper tube plate (5), a lower tube plate (6) and a heat exchange tube (2) forms a shell pass, fluidizers are respectively arranged in the tube pass and the shell pass, the cold and hot solid particles are fluidified and flow in the shell pass and the tube pass respectively, and heat exchange is realized between the cold and hot solid particles by virtue of the heat exchange tube (2). By adopting the tube-shell type solid-solid heat exchanger, heat exchange can be carried out between a thermal regeneration agent and a cold spent agent of a catalytic cracking unit, thus stable operation with high agent-oil ratio is realized, thermal balance of the whole device is maintained, and liquid yield of the tube-shell type solid-solid heat exchanger is increased; and thermal steam stripping on the spent agent can be realized, and benefit of the catalytic cracking unit is increased. The tube-shell type solid-solid heat exchanger provided by the invention can be applied to all the catalytic cracking units and other devices requiring heat exchange between the cold and hot solid particles.

Owner:CHINA UNIV OF PETROLEUM (BEIJING)

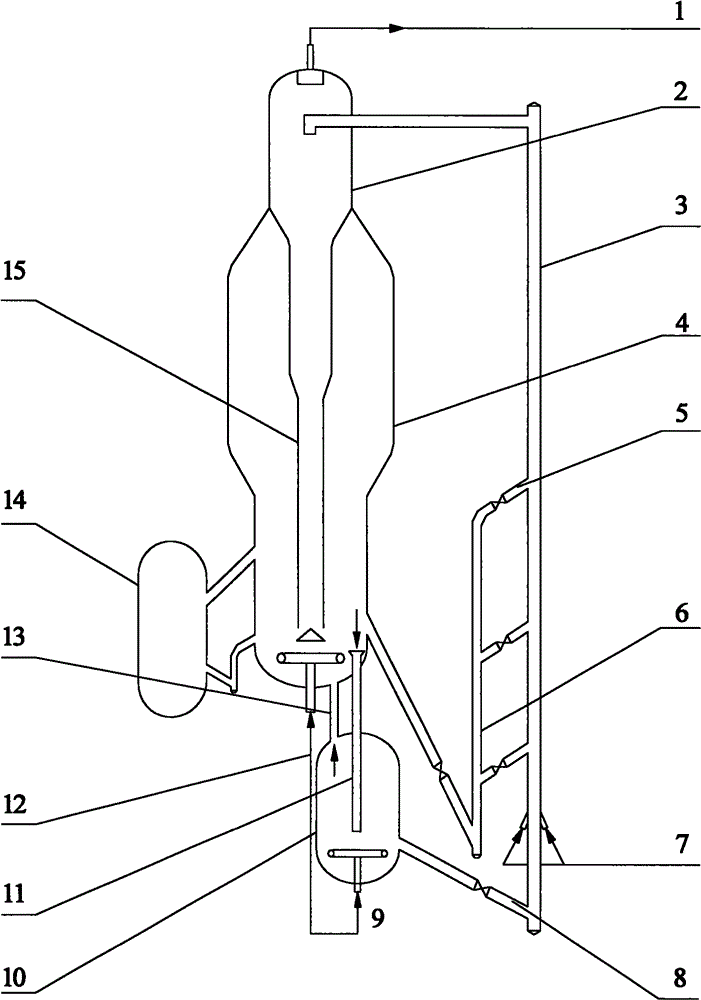

Catalytic cracking method and device

InactiveCN102746893APromote circulationLower contact temperatureCatalytic crackingTreatment with plural serial stages onlyGasolineTower

The invention discloses a catalytic cracking method and device. The method is characterized by comprising the following steps: introducing raw oil into bottom of a riser reactor to contact and react with a catalyst from a catalyst heat exchanger; separating oil gas after the reaction from a coked catalyst; introducing separated reaction oil gas into a fractionating tower; carrying out steam stripping on the separated coked catalyst and sending the coked catalyst into a regenerator for regeneration; sending part of the regenerated catalyst into the riser reactor from different height positions of the riser; and carry out heat transfer on the other part of the regenerated catalyst by a heat exchanger and entering the other part of the regenerated catalyst into bottom of the riser reactor. The method of the invention can lower total yield of dry gas and coke by 0.5-1.5 percentage, increase total liquid yield of liquefied gas, gasoline and diesel by more than 1 percentage, and reduce gasoline olefin volume content by 5-15 percentage.

Owner:CHINA PETROLEUM & CHEM CORP +1

Catalytic cracking method

InactiveCN103087768AImprove the ratio of agent to oilTotal yield dropCatalytic crackingTreatment with plural serial stages onlyFlue gasGasoline

The invention discloses a catalytic cracking method and a catalytic cracking device. According to the invention, raw oil enters the lower part of a riser reactor, and is subjected to a contact reaction with a catalyst from a catalyst pre-lift mixer; oil gas obtained after reaction is separated from spent catalyst; reaction oil gas obtained by separation is delivered into a fractionating tower, and the separated spent catalyst is regenerated; part of high-temperature regenerated catalyst after regeneration enters an external heat remover; part of cooled regenerated catalyst is delivered back to the regenerator, another part of the cooled regenerated catalyst enters the catalyst pre-lift mixer, and a third part of the cooled regenerated catalyst enters the riser reactor from different height positions of the riser. The method provided by the invention can be used for reducing dry gas and coke total yield. A total liquid yield is increased by more than 1.5 percentage points; gasoline olefin volume content is reduced by 5-15 percentage points; and SOx content in flue gas is reduced by more than 30%.

Owner:CHINA PETROLEUM & CHEM CORP +1

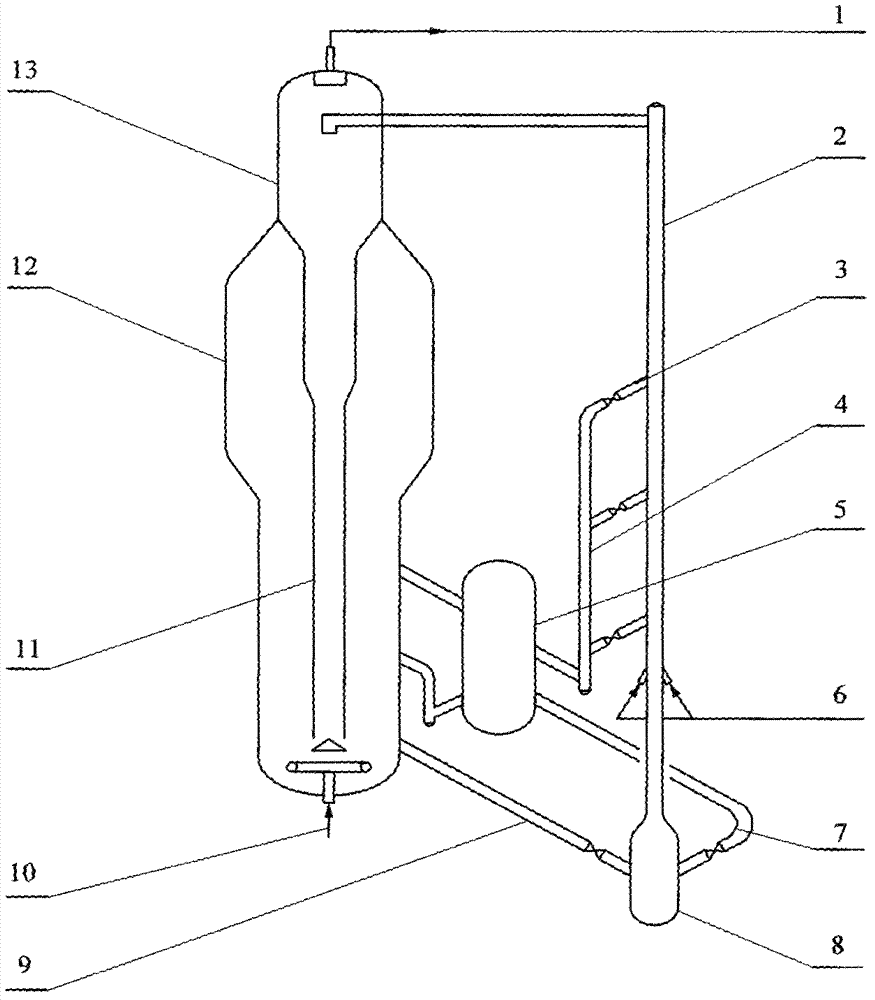

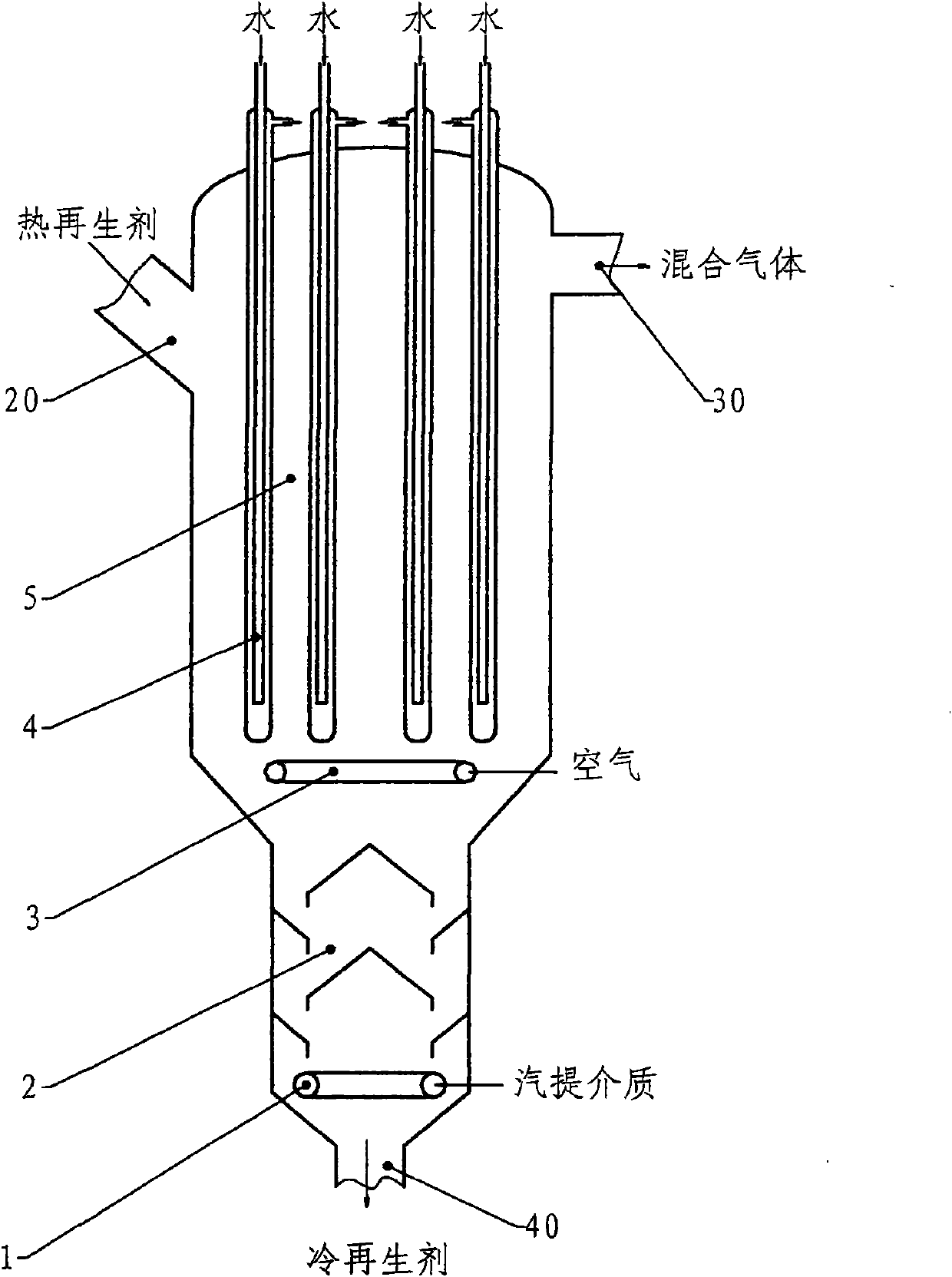

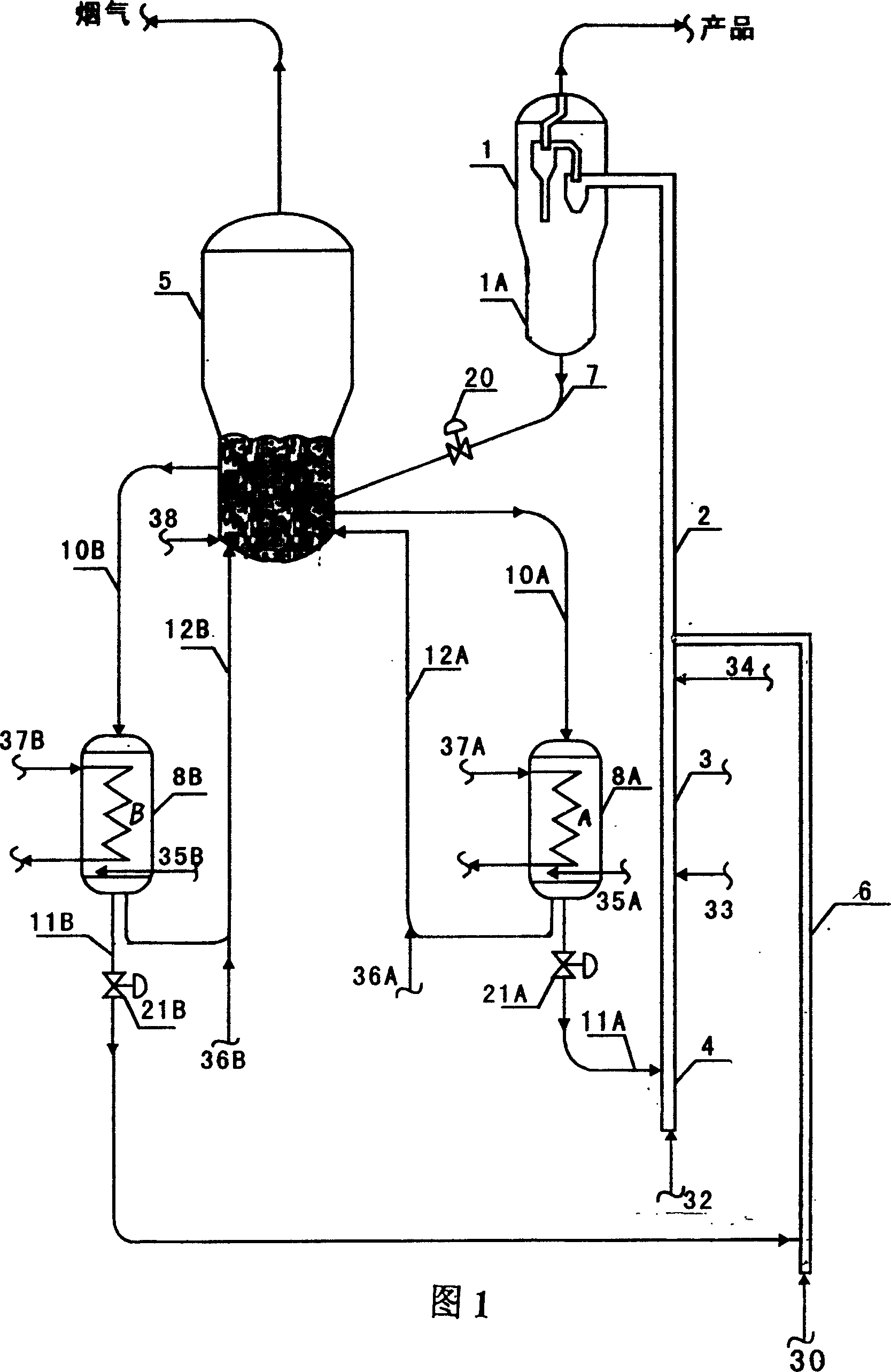

Coupling equipment for realizing temperature adjustment and stripping of catalytic cracking regenerant

InactiveCN101760229BRealize the function of removalInhibitory inactivation effectCatalytic crackingFlue gasGas compressor

The invention provides coupling equipment for realizing the temperature adjustment and the stripping of catalytic cracking regenerant, which comprises a temperature adjustment section arranged at the upper part and a stripping section arranged at the lower part; the temperature adjustment section is provided with a built-in heat exchange component and at least an air distributor; and the temperature adjustment section extends downwards and reduces the circulation area to form the stripping section. By coupling the stripping area with quite small circulation area at the lower part of the temperature adjustment section, the invention can realize the function of flue gas removal without or only with a small amount of stripping steam, and can best inhibit the inactivation of the regenerant under the steam atmosphere. The coupling equipment of the invention can be arranged in a regenerant circulating pipeline of a catalytic cracker, so that the regenerant directly enters a rise reactor after the temperature is adjusted and the flue gas is removed, thereby not only significantly improving the oil ratio, the regeneration temperature and the raw material pre-heating temperature of the catalytic cracker and facilitating the improvement of product distribution, but also having the function of glue gas removal and reducing the load of a rich gas compressor and the energy consumption of the device.

Owner:CHINA UNIV OF PETROLEUM (BEIJING)

Gasoline catalytically converting method and reactor

InactiveCN1888026AImprove the ratio of agent to oilAchieve reflowTreatment with hydrotreatment processesRefluxSulfur

The gasoline catalytically re-converting method and reactor belongs to the field of petroleum refining technology. Before the catalyst and reacted oil-gas flow is discharged from the reactor, partial catalyst is led out, returned through the reflux pipe to the bottom of the gasoline reactor and mixed with regenerated catalyst to lower the temperature of the regenerated catalyst, so that inferior gasoline is made to contact with low temperature and high activity catalyst in high catalyst / oil ratio and for relatively long time for catalytically converting to modify or to convert into low carbon olefin. The modifying section of the reactor may be a convenient riser, a fluidized bed or their combination. The present invention can lower the content of olefin in gasoline to below 20 % and eliminate sulfur of 70 %.

Owner:洛阳石化设备研究所

Catalytic cracking method and device

InactiveCN102746892APromote circulationLower contact temperatureCatalytic crackingTreatment with plural serial stages onlyPartial systemGlobal wind patterns

The invention discloses a catalytic cracking method and device. The method comprises the following steps: introducing raw oil into a lower part of a riser reactor to contact and react with a catalyst from a catalyst heat exchanger; separating oil gas after the reaction from a coked catalyst; introducing separated reaction oil gas into a fractionating tower; carrying out steam stripping on the separated coked catalyst and sending the coked catalyst into a regenerator for regeneration; carrying out heat transfer and cooling on the regenerated catalyst and part of system prevailing wind within the catalyst heat exchanger; sending part of the regenerated catalyst into the riser reactor from different heights of the riser; and sending the other part of the regenerated catalyst into the lower part of the riser reactor. The method can reduce total yield of dry gas and coke by 0.8-2 percentage, increase total liquid yield of liquefied gas, gasoline and diesel by 1.2 percentage, and reduce volume content of gasoline olefin by 5-15 percentage.

Owner:CHINA PETROLEUM & CHEM CORP +1

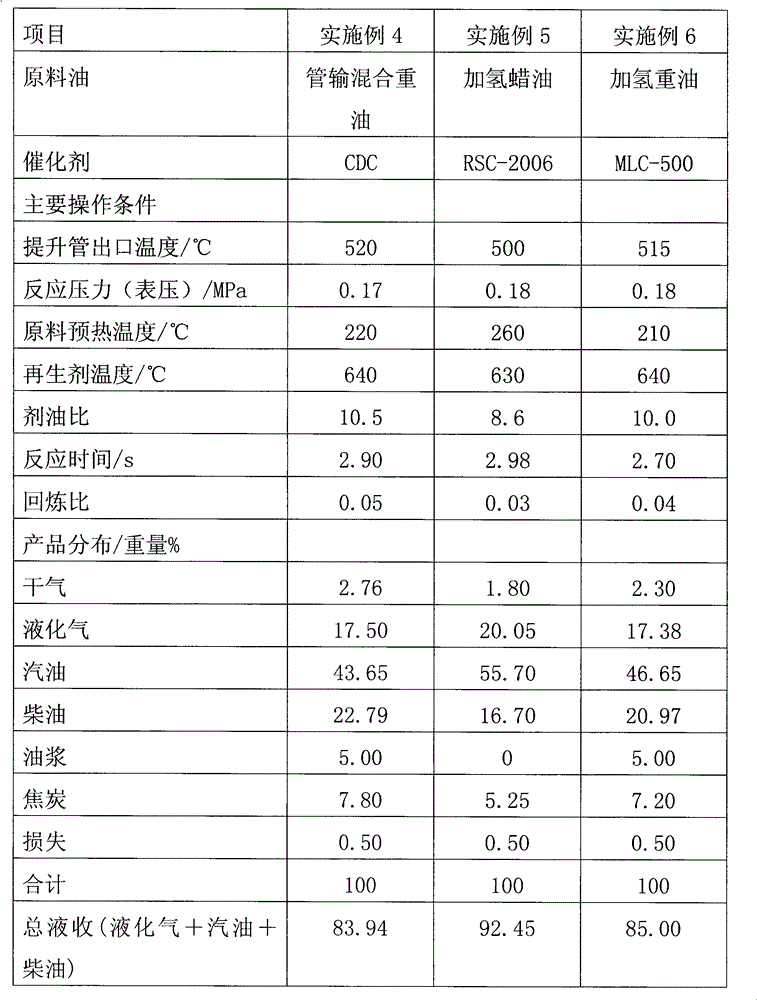

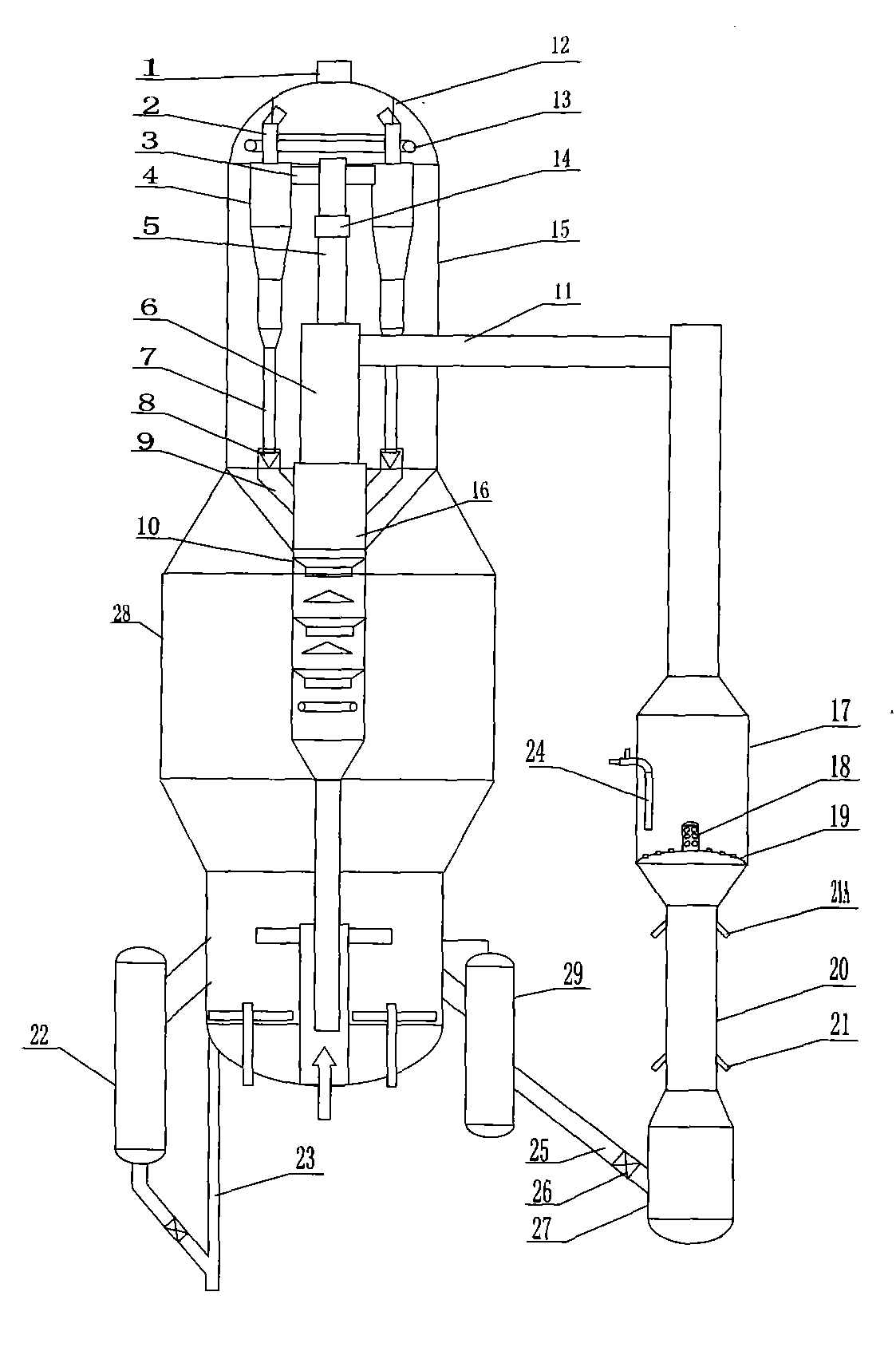

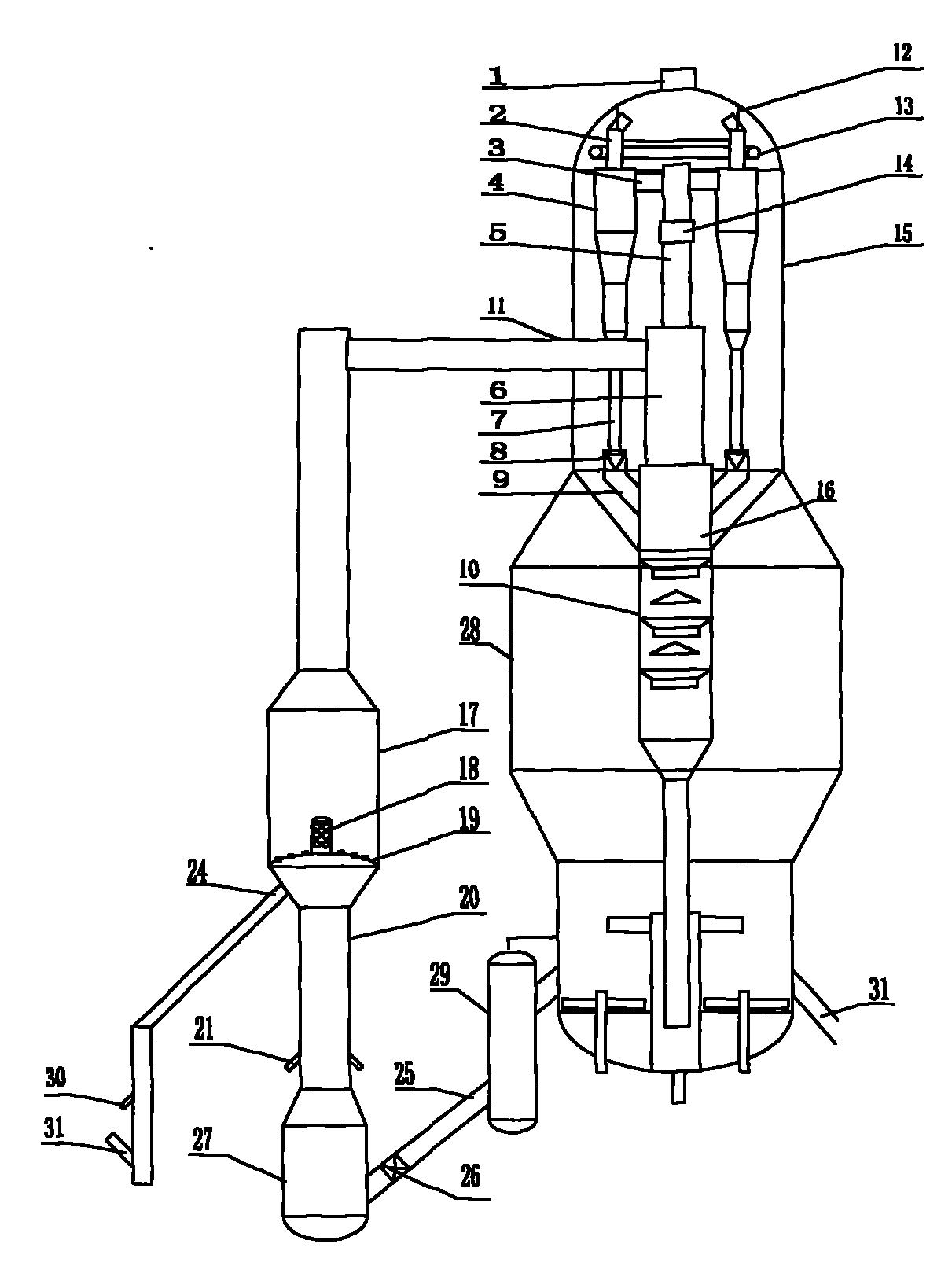

Method and device of heavy oil two stage catalytic cracking reforming and gasoline upgrade coupling

Owner:石宝珍

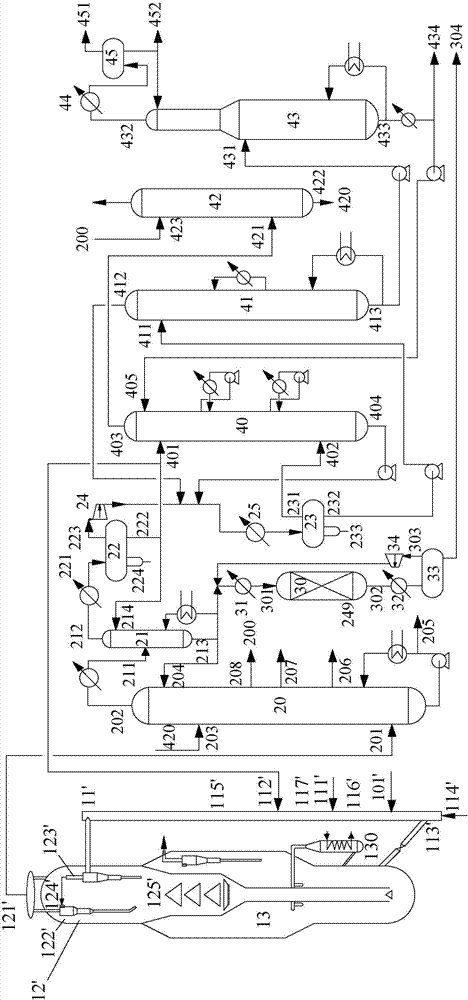

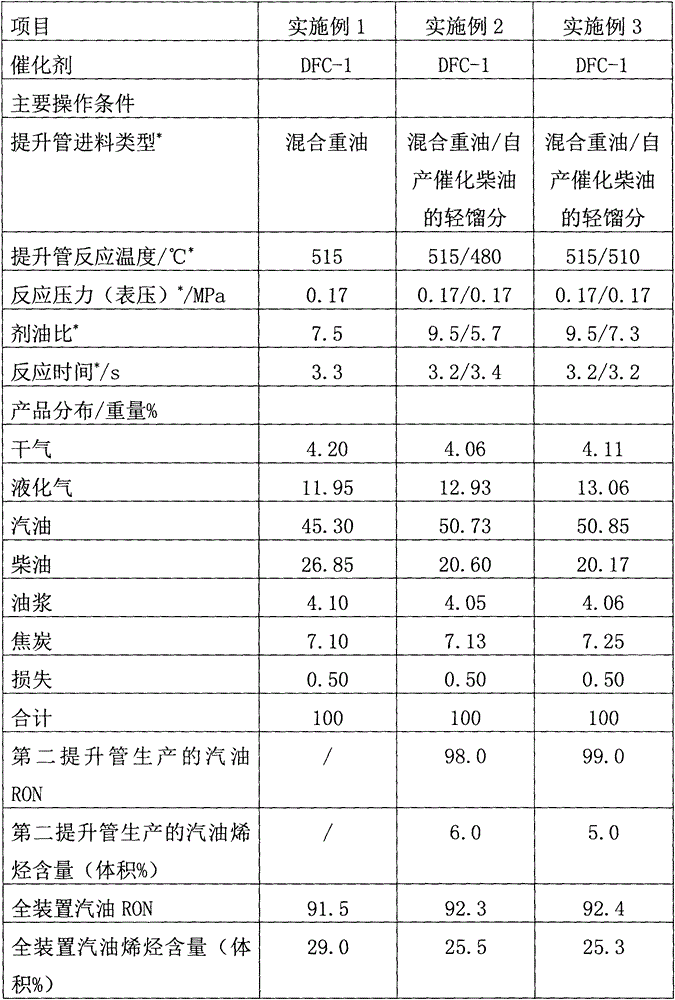

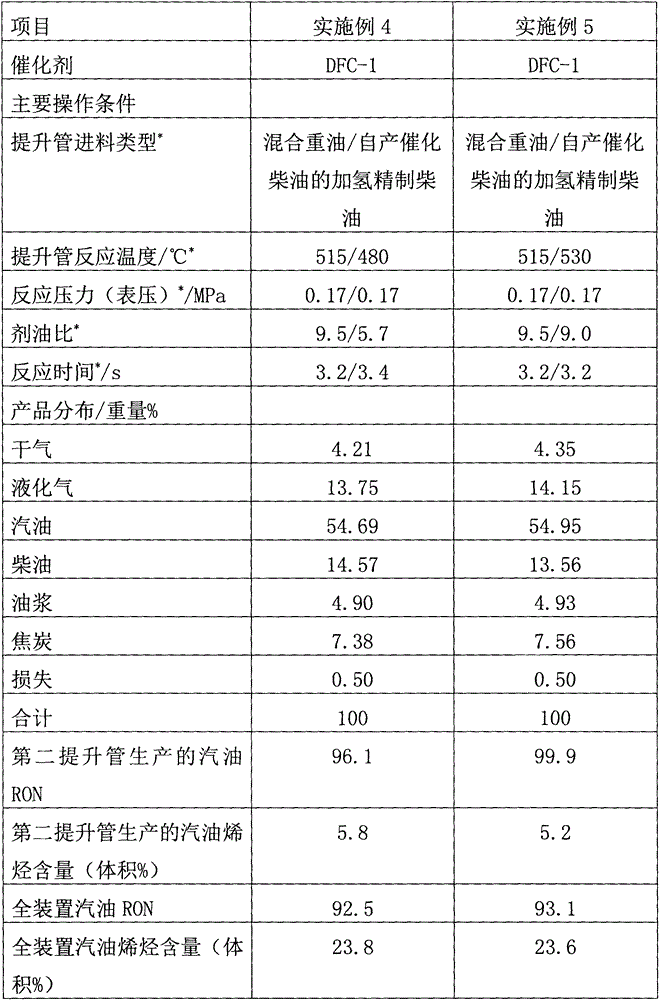

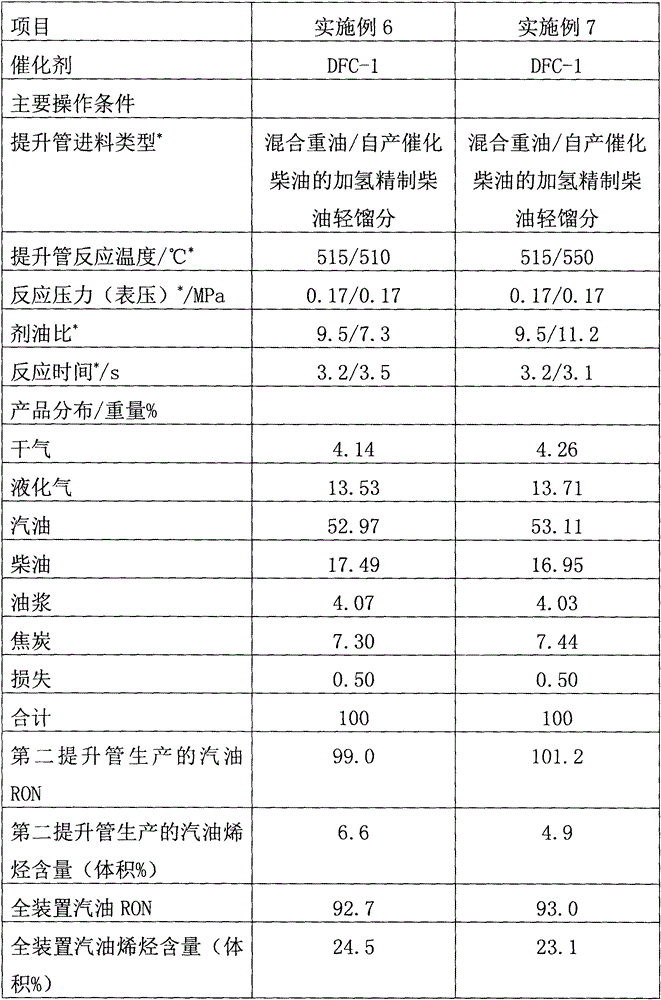

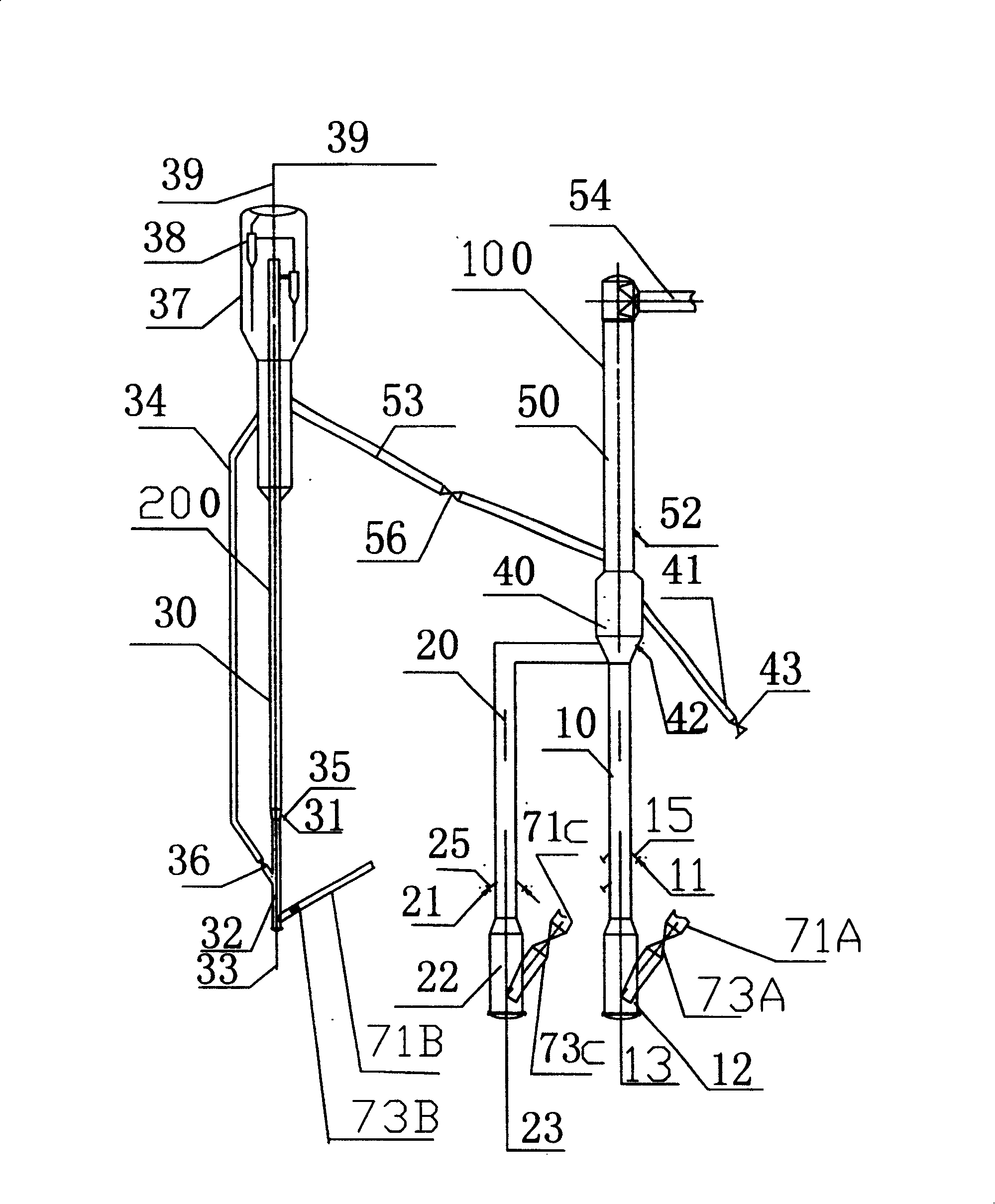

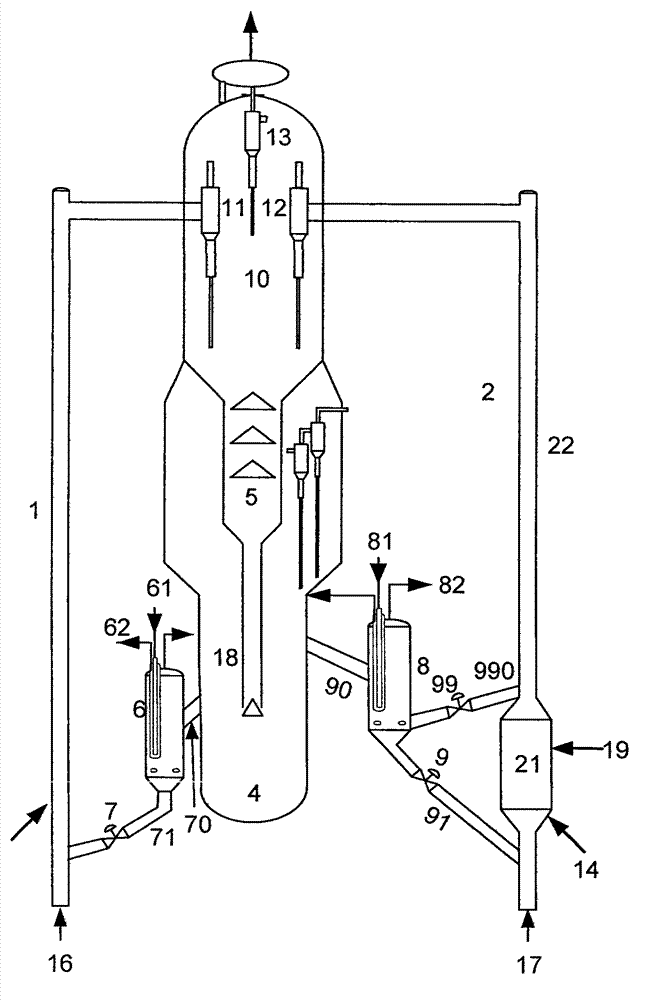

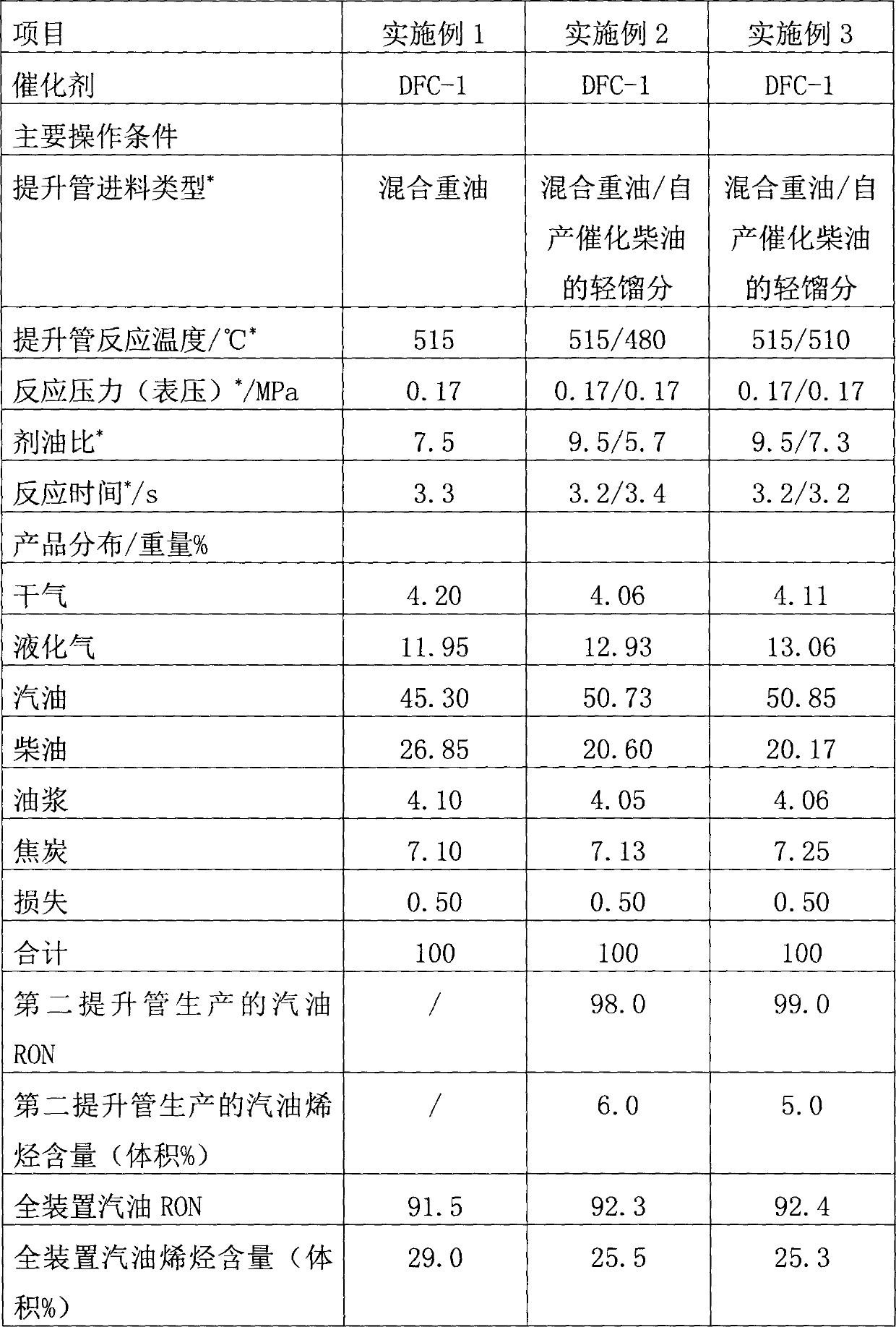

Catalytic cracking method of increasing gasoline yield

ActiveCN104974787AReduce the temperatureReduce contact reactionTreatment with plural serial stages onlyProcess engineeringDirect production

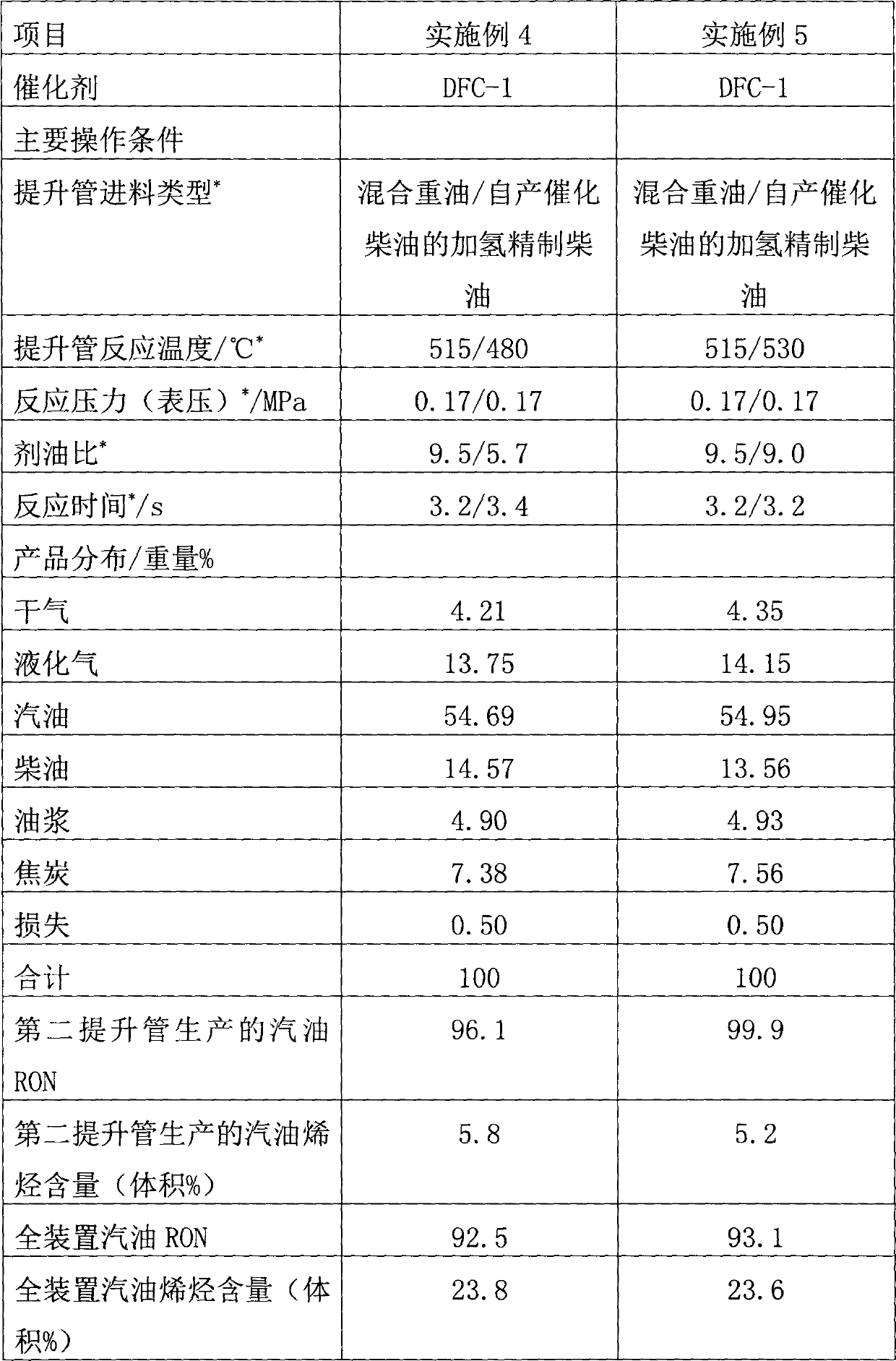

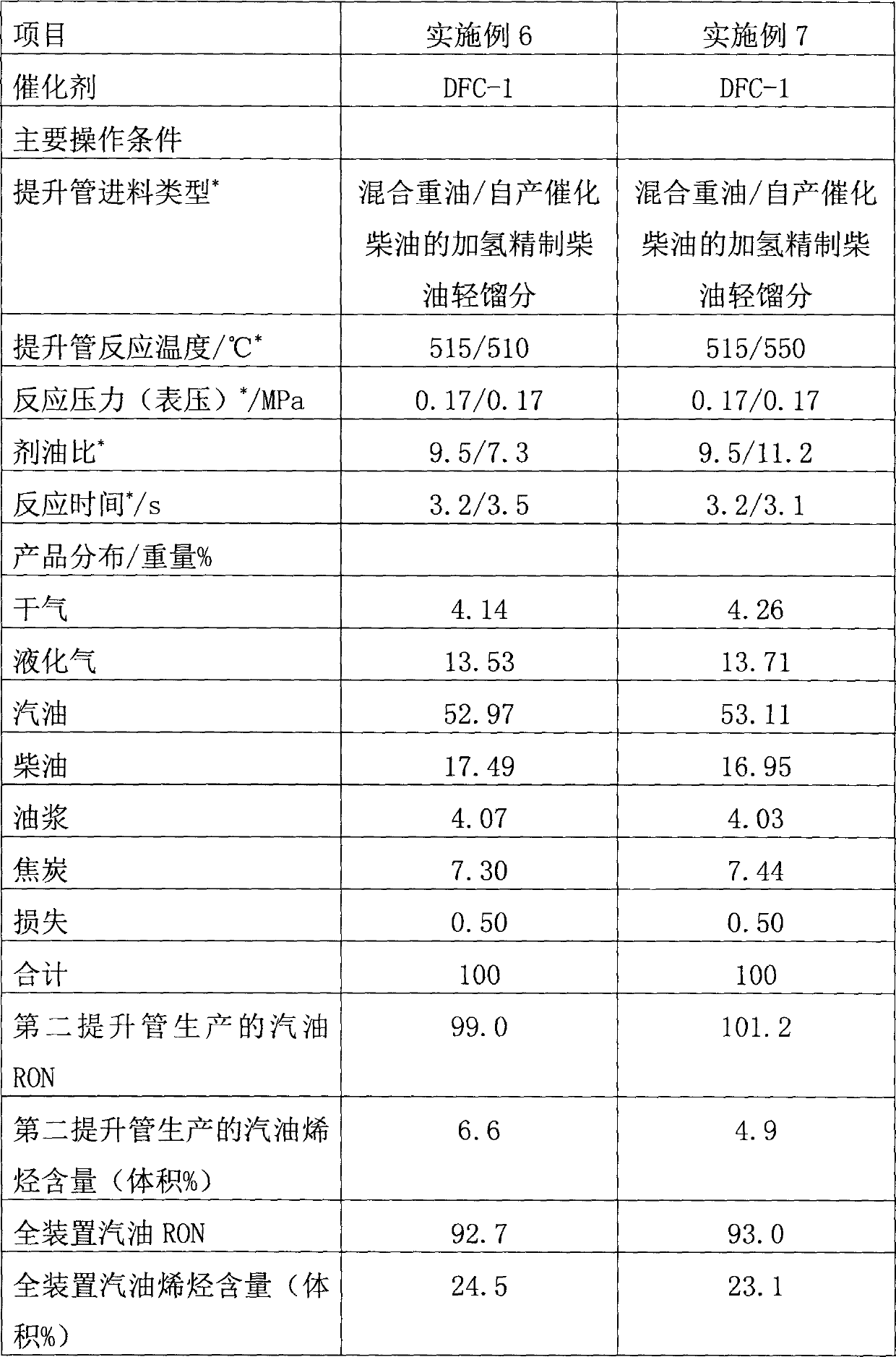

The invention discloses a catalytic cracking method of increasing gasoline yield, which comprises the following steps: (A) feeding raw material oil to the lower part of a first lifting tube reactor and carrying out a contact reaction to the raw material oil with a catalyst from a pre-lifting mixer; (B) feeding a to-be-regenerated catalyst from the first lifting tube reactor into a steam stripping part of a main precipitator, performing steam stripping and regenerating the catalyst in a regenerator; (C) feeding catalytic diesel or hydrotreated catalytic diesel into the lower part of a second lifting tube reactor and carrying out a contact reaction with the catalyst from the regenerator; (D) feeding the to-be-regenerated catalyst from the second lifting tube reactor into a steam stripping part of a sub precipitator; (E) performing air stripping to the to-be-regenerated catalyst from the steam stripping part of the sub precipitator, feeding one part of the catalyst into the regenerator and regenerating the catalyst, and feeding the other one part of the catalyst into the pre-lifting mixer and mixing the catalyst with the regenerated catalyst from the regenerator; and (F) feeding the mixed catalyst into the lower part of the first lifting tube reactor and carrying out a contact reaction with the raw material oil. By means of the method, the catalytic cracking device is increased by 3-20% in gasoline yield, is increased by more than 0.5 units in RON of gasoline and is reduced in the content of olefin by more than 3% by volume. The gasoline directly produced in the second lifting tube reactor is higher than 96 in RON and is less than 10% in the content of olefin.

Owner:LUOYANG PETROCHEMICAL ENG CORP SINOPEC +1

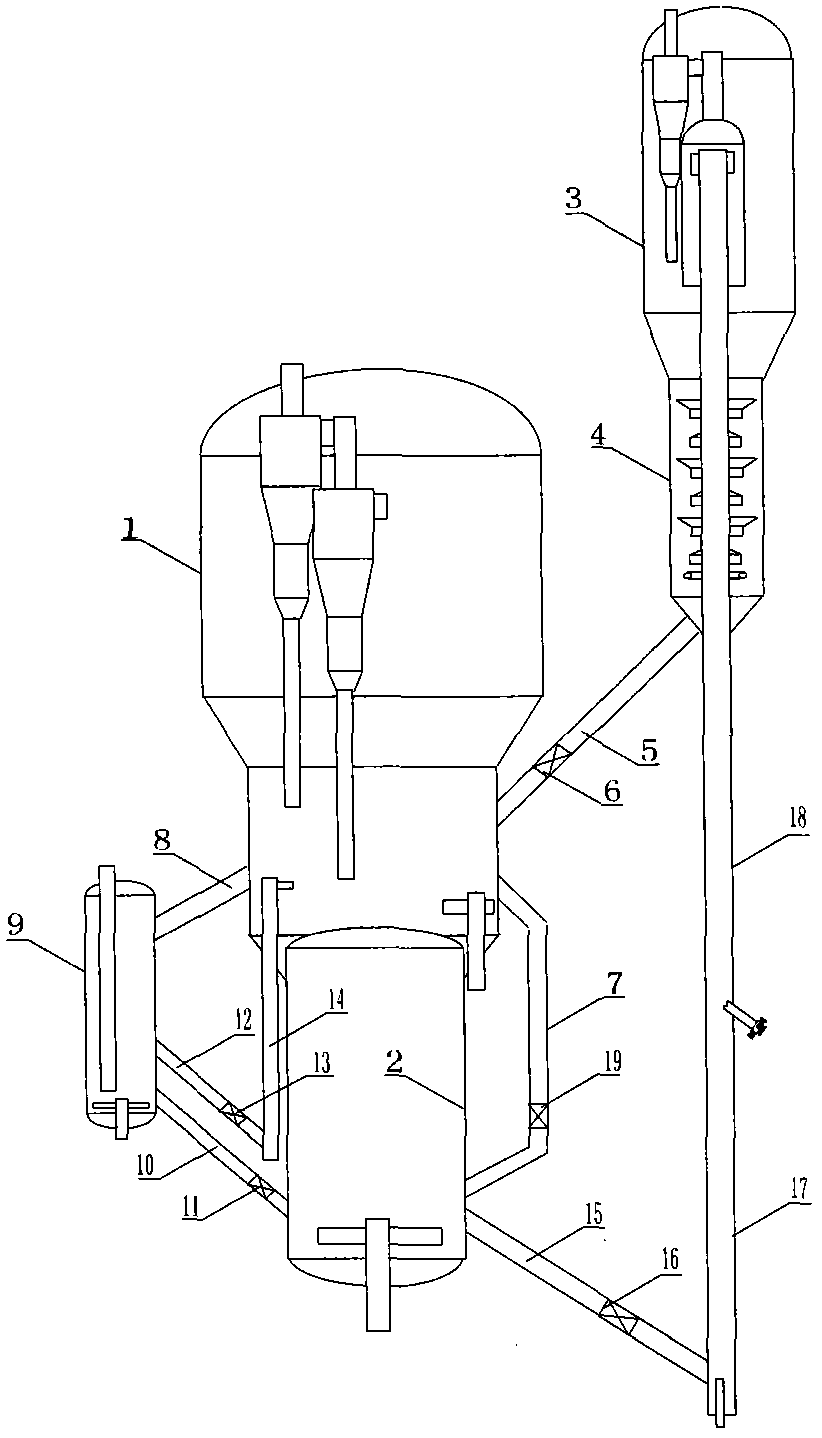

Catalytic cracking conversion method with relay use of catalyst curd its device

InactiveCN100393848CReduce the temperatureReduce energy consumptionHydrocarbon oils treatmentGasolineFuel oil

The invention is a catalyst relay catalytic cracking conversion method and device, belonging to petroleum refining technical field, making raw oil and back-refined oil firstly perform catalytic cracking reaction in the respective risers, successively merging and extracting deactivated catalyst, where the reacting oil gas changes to contact with low temperature catalyst used in the gasoline reaction and continue reaction; a heavy oil reactor is connected in parallel with a gasoline reactor; the gasoline and catalyst complete reaction in the gasoline reactor and then can make gas-solid separation in a gasoline settler, where the oil gas is discharged through pipeline, the extracted catalyst is fed into the position below heavy oil modifying reaction stage and cracking reaction stage to continue heavy oil reaction and can also be fed into a gas-solid separator arranged in the heavy oil modifying reaction stage for separating, where the gasoline gas is directly drawn out and the catalyst takes part in the reaction in this stage; a catalyst return pipe is arranged between the gasoline settler and gasoline reactor bottoms to make a part of catalyst used in the gasoline reaction return to the gasoline reactor bottom so as to take part in the gasoline reaction again.

Owner:石宝珍

Device and method for producing clean gasoline by combining catalytic cracking and hydrofining

InactiveCN103571534BPromote absorptionReduce loadTreatment with hydrotreatment processesHydrodesulfurizationGasoline

The invention discloses a device and method for producing clean gasoline by combining catalytic cracking and hydrofining. The device comprises a reaction-regeneration system, a fractionating system, an absorption stable system and a hydrofining unit. The method comprises the following steps: adding a gasoline fractionating tower to the top of a catalytic cracking fractionating tower to divide crude gasoline into a light fraction and a heavy fraction, wherein the heavy fraction gasoline enters the hydrofining unit for selective hydrogenation desulfurization, and one part of the light fraction gasoline enters the absorption stable system to obtain stable light gasoline, and the other part of the light fraction gasoline directly returns to a reaction area at the upper part of a catalytic cracking second riser reactor to be modified under a mild condition; and blending the stable light gasoline and the modified heavy gasoline to obtain the product of clean gasoline. By adopting the method, the catalytic cracking gasoline is efficiently modified, and the catalyst-oil ratio of a catalytic cracking device can be increased to promote the conversion of heavy petroleum hydrocarbon; and meanwhile, the load and energy consumption of the absorption stable system are reduced, the synergistic effect between the two devices of catalytic cracking and hydrofining is enhanced, and the processing cost is lowered.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA) +1

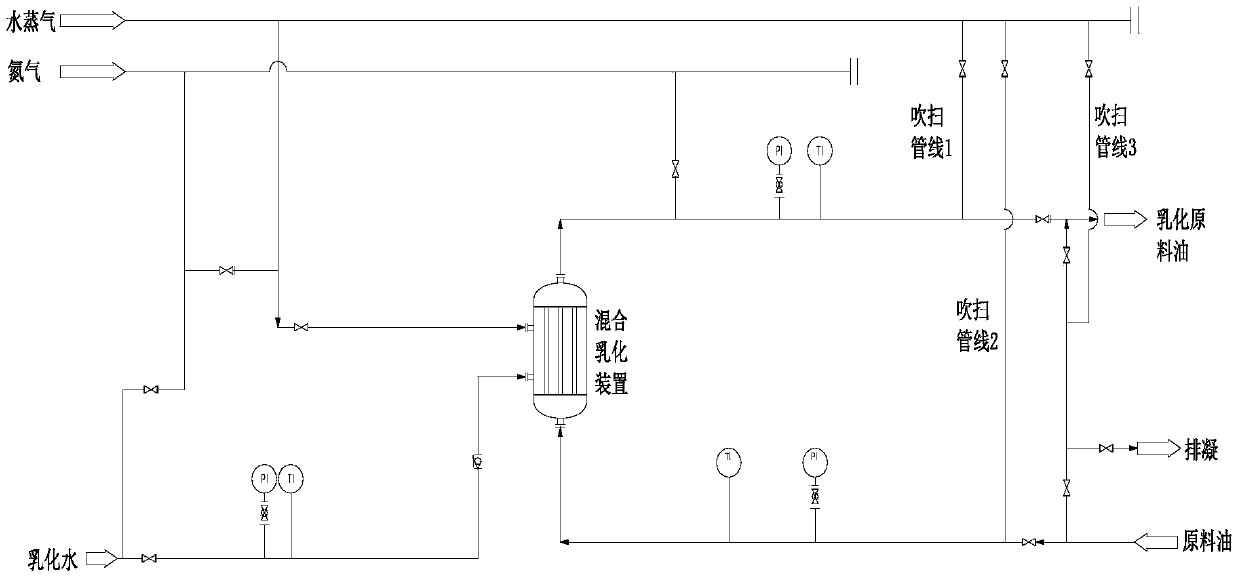

A kind of mixing emulsification method and feeding method of catalytic feed oil

ActiveCN107583481BIncreased dispersionIncrease contact areaCatalytic crackingMixing methodsCokeProcess engineering

The invention discloses a mixing emulsification method and a feeding method of catalytic feed oil. The mixing emulsification method includes: using emulsified water to perform water-in-oil emulsification of the catalytic feed oil, so that the particle size of the oil droplets in the obtained emulsified feed oil is less than 50 Micron. Feeding the emulsified raw oil emulsified by the mixed emulsification method of the present invention into the riser reactor can increase the yield of light oil and reduce the yield of coke and dry gas.

Owner:CHINA PETROLEUM & CHEM CORP +3

Two-stage regeneration catalytic cracking method and device

InactiveCN104277864AGuaranteed burnt effectReduce the coke rate of the deviceCatalytic crackingSolventPetrochemical

The invention relates to a two-stage regeneration catalytic cracking method, belonging to the technical field of petrochemical industry and aiming at solving the problem that the traditional two-stage regeneration catalytic cracking is unsuitable for regulating solvent-oil ratio within a large range. The two-stage regeneration catalytic cracking method comprises the steps of reaction coking, catalyst deactivation and two-stage catalyst regeneration. The two-stage regeneration catalytic cracking method is characterized in that heat removal is set in two-stage regeneration processes; when the solvent-oil ratio is regulated within a large range, by regulating the heat removal of the two-stage regeneration, the invariable main air quantity of the two-stage regeneration can be realized, the temperature of the two-stage regeneration can be controlled to ensure the coking effect, and a regenerated catalyst with temperature of 620-700 DEG C is provided for a reaction process. The invention also provides a device for realizing the method. The device comprises a first regenerator, a second regenerator, a regenerant cooler and an outer combined heat removing device. The two-stage regeneration catalytic cracking method disclosed by the invention can be used for a heavy oil catalytic cracking device and can enhance the solvent-oil ratio of the device, reduce the coking rate of the device and increase the product yield.

Owner:刘英聚

Method for catalytic conversion of heavy oil and device thereof

ActiveCN1324116CRaise the preheat temperaturePromote atomizationCatalytic crackingTreatment with plural serial stages onlyCatalytic transformationGasoline

The invention provides a method of heavy raw material catalytic conversion and the device, comprising: the heavy hydrocarbon raw material passing through the first and second reaction area of the raiser reactor and contacting with catalyst for first reaction and second reaction, the reactants entering into the settler for the separation of catalyst and oil gas, steam stripping the separated catalyst through stripping section and introducing it to the reactivator for carbon burning reactivation, the reactivated catalyst returning to the raiser reactor after cooled or directly to the raiser reactor for reuse. After the heavy oil passing through the device said above, the volume content of olefin decreases by 10~40%, octane value increases 0.5~1 units, sulfur content in petrol decreases 10~30% by weight. After the poor petrol passing through the device said above, the volume content of olefin decreases by 10~60%, octane value increases 0.5~40 units, sulfur content in petrol decreases 10~50% by weight.

Owner:LUOYANG WEIDA PETROCHEMICAL ENG CO LTD

Heavy oil catalytic cracking method and device

InactiveCN104342192AIncrease mixing temperatureHigh activityCatalytic crackingChemical industryCatalytic pyrolysis

The invention discloses a heavy oil catalytic cracking method, belongs to the technical field of petroleum chemical industry, is used for processing heavy oil, can improve the catalyst-to-oil ratio, reduces coke and dry gas yields, improves product yield, and solves reactor coking. The heavy oil catalytic cracking method includes the processes of catalyst feeding, raw material oil feeding, raw material oil vaporization, gas-solid contact, catalytic cracking reaction and gas-solid separation, and is characterized in that through arrangement of temperature reduction with a regeneration agent, heat collection with a pre-lifting device, and heat collection at the middle part of a lifting pipe reactor, the catalyst-to-oil ratio is increased, a mixing temperature of a feeding section is improved, the catalyst activity in the catalytic cracking process is improved, and the feeding heavy oil vaporization rate is improved; through arrangement of a closed fast separation system, the oil and gas residence time in a settler is shortened. The method can reduce the dry gas and coke yields, increase the product yield, improve the product quality and solve the problem of coking of the lifting pipe reactor and the settler. A device for realizing the method is also provided, includes a regeneration agent temperature reducer, the pre-lifting device, a heat collector, a lifting pipe middle-part heat collection facility and a closed fast separation facility, and is the catalytic cracking and catalytic pyrolysis device applied for processing the heavy oil.

Owner:刘英聚

Upgrading method and device for gasoline

ActiveCN101104815BImprove the ratio of agent to oilReduce contentCatalytic crackingPtru catalystGasoline

The invention discloses a method and a device for gasoline upgrading, mainly solving the problems of high yield of dry gas and coke and low liquid recovery during the gasoline upgrading reaction in the double-riser catalytic cracking device, high energy consumption of the device and low desulphurization efficiency. The method is mainly characterized by the steps as follows: some of the regenerated catalysts returning to the heavy oil riser reactor; some of the regenerated catalysts mixing with the recycled catalysts from the rapid bed reactor in the catalysts mixer before contacting with thegasoline of poor quality and entering part I of the gasoline riser reactor, the rapid bed reactor, and the part II of the gasoline riser reactor; reactants flowing into a second settler for separation; upgrading reaction oil and gas entering the fractionation system for fractionating; spent catalysts entering the regenerators for coke burning regenerating. The invention can reduce dry gas and coke yield and improve the total liquid yield and meanwhile decrease the energy consumption of the whole device.

Owner:SINOPEC LUOYANG PETROCHEM ENG CORP

Heavy oil catalytic cracking method and device by double-area coupling and catalyst tandem

InactiveCN102102030BHigh yieldSolve the problem of increasing inferiorityTreatment with plural parallel cracking stages onlyReactive systemFuel oil

Owner:CHINA UNIV OF PETROLEUM (BEIJING)

A kind of catalytic cracking method of prolific gasoline

ActiveCN104974787BReduce the temperatureReduce contact reactionTreatment with plural serial stages onlyGasolineDirect production

The invention discloses a catalytic cracking method for producing gasoline. The steps are: the feedstock oil enters the lower part of the first riser reactor to contact and react with the catalyst from the pre-lift mixer, the raw catalyst in the first riser reactor enters the stripping section of the main settler for stripping, and then enters the regenerator for regeneration. Catalyzed diesel or hydrotreated catalytic diesel enters the lower part of the second riser reactor to contact and react with the catalyst from the regenerator, and the ungenerated catalyst in the second riser reactor enters the stripping section of the secondary settler After being stripped, part of the spent catalyst enters the regenerator for regeneration, and the other part enters the pre-lift mixer to mix with the regenerated catalyst from the regenerator, and the mixed catalyst enters the lower part of the first riser reactor to contact with the raw material oil for reaction. By using the method of the invention, the gasoline yield of the catalytic cracking unit can be increased by 3-20 percentage points, the gasoline RON can be increased by more than 0.5 units, and the gasoline olefin content can be reduced by more than 3 volume percentage points. The RON of gasoline directly produced in the second riser reactor is above 96, and the volume content of olefins is below 10%.

Owner:SINOPEC LUOYANG PETROCHEM ENG CORP +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com