Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

57results about How to "Lower contact temperature" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Catalytic cracking method for producing low-carbon olefins and light aromatic hydrocarbons

ActiveCN107971010ALarge specific surface areaHigh and medium pore volumeMolecular sieve catalystsTreatment with plural serial stages onlyMolecular sieveOxide

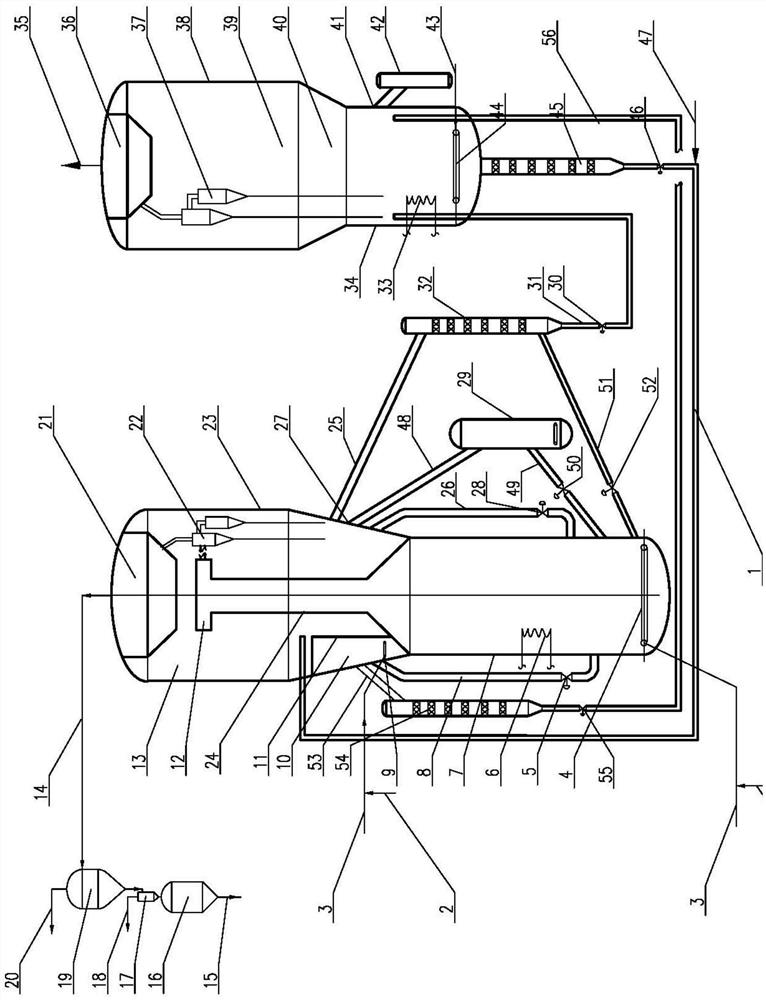

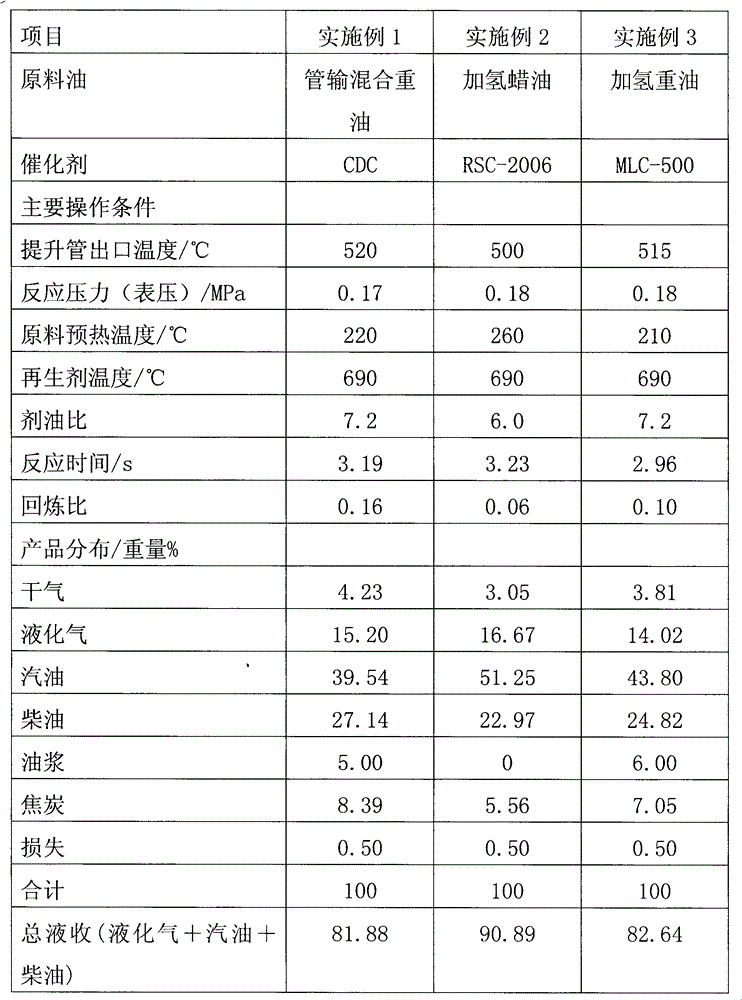

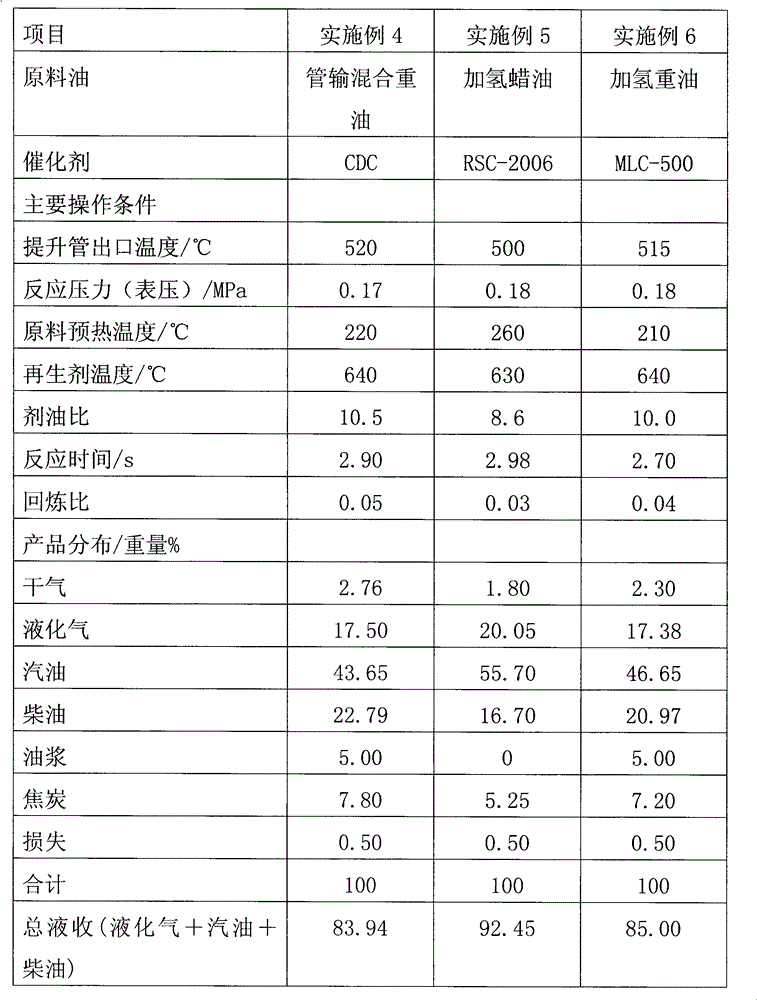

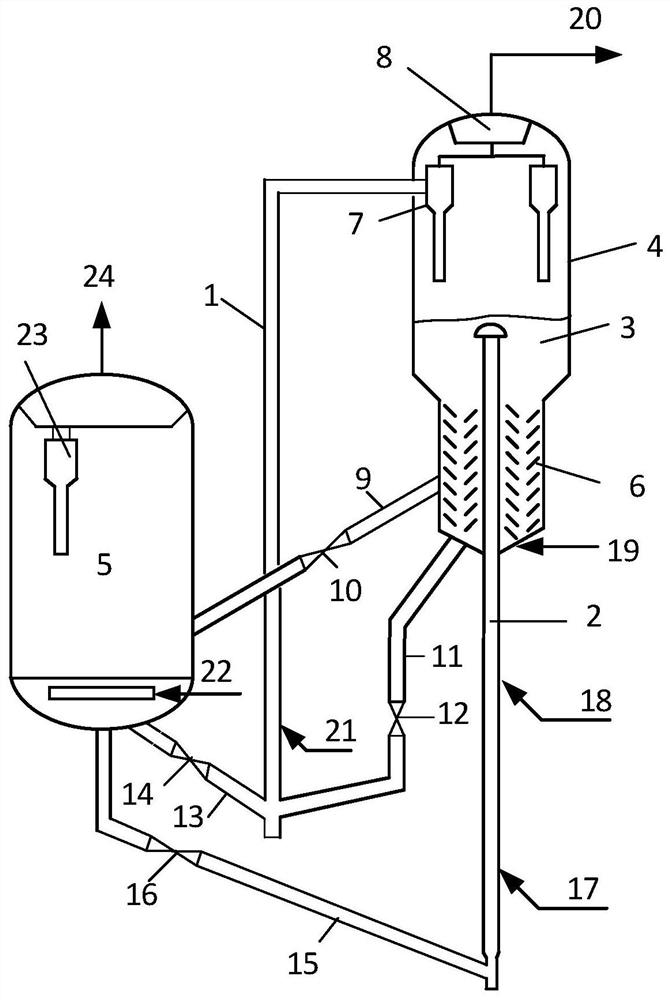

The invention relates to a catalytic cracking method for producing low-carbon olefins and light aromatic hydrocarbons. According to the catalytic cracking method, a heavy raw material and a first catalytic cracking catalyst are subjected to a contact reaction in a first reactor; a lightweight raw material rich in saturated hydrocarbons, a lightweight raw material rich in olefins and a second catalytic cracking catalyst are subjected to a contact reaction in a second reactor and a third reactor; all the reaction oil-gas and the spent catalysts are subjected to gas-solid separation; the reactionoil-gas is further separated to obtain a product containing light-carbon olefins and light aromatic hydrocarbons; and the spent catalysts are subjected to steam stripping, the steam stripped catalysts enter a catalyst regenerator, charring regeneration is performed, and the regenerated catalyst returns to the reactor so as to be recycled, wherein the catalytic cracking catalyst comprises, by weight, 15-65% of natural minerals, 10-60% of an oxide, and 25-75% of a Y-type molecular sieve and a phosphorus-containing IMF structure molecular sieve. With the method of the present invention, the yield of low-carbon olefins is high, and the yield of light aromatic hydrocarbons is high.

Owner:CHINA PETROLEUM & CHEM CORP +1

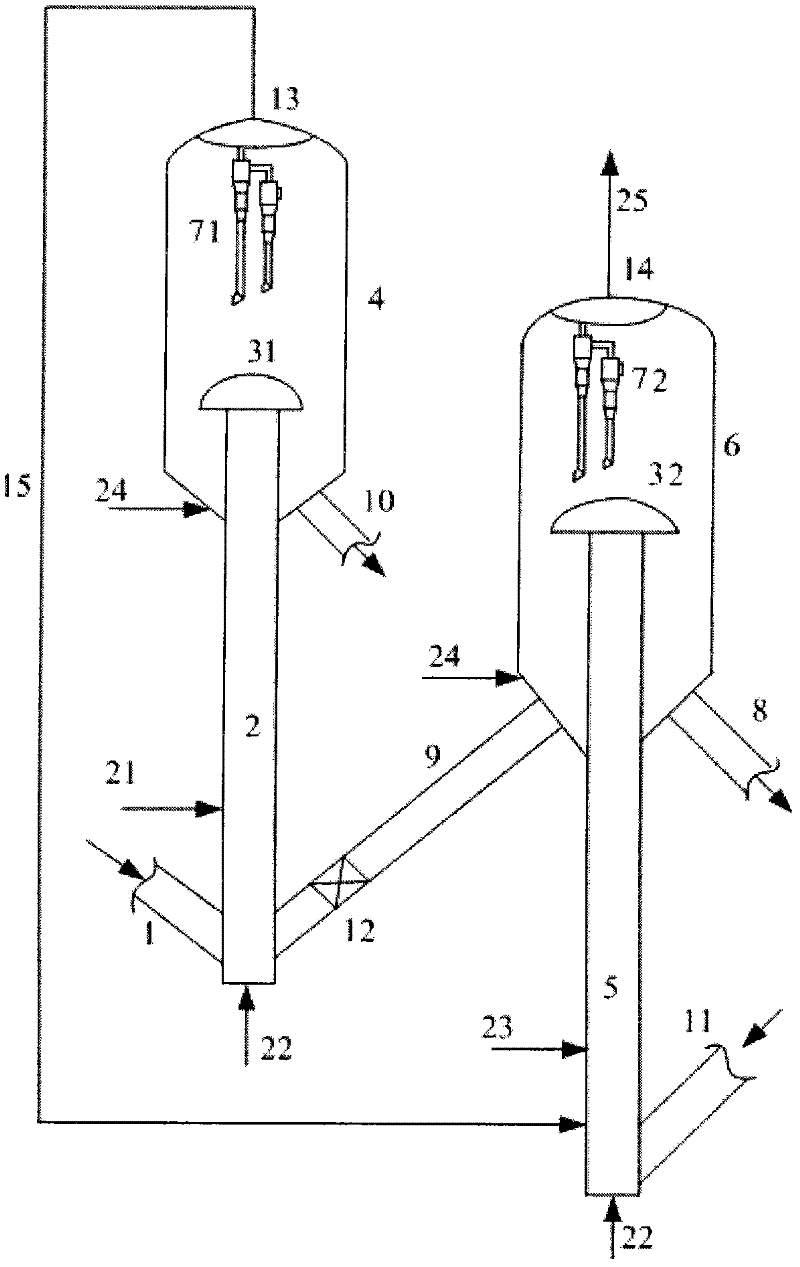

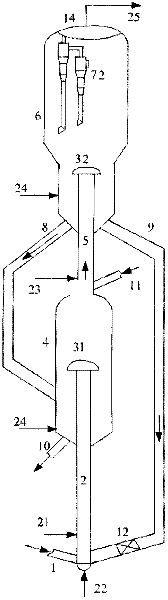

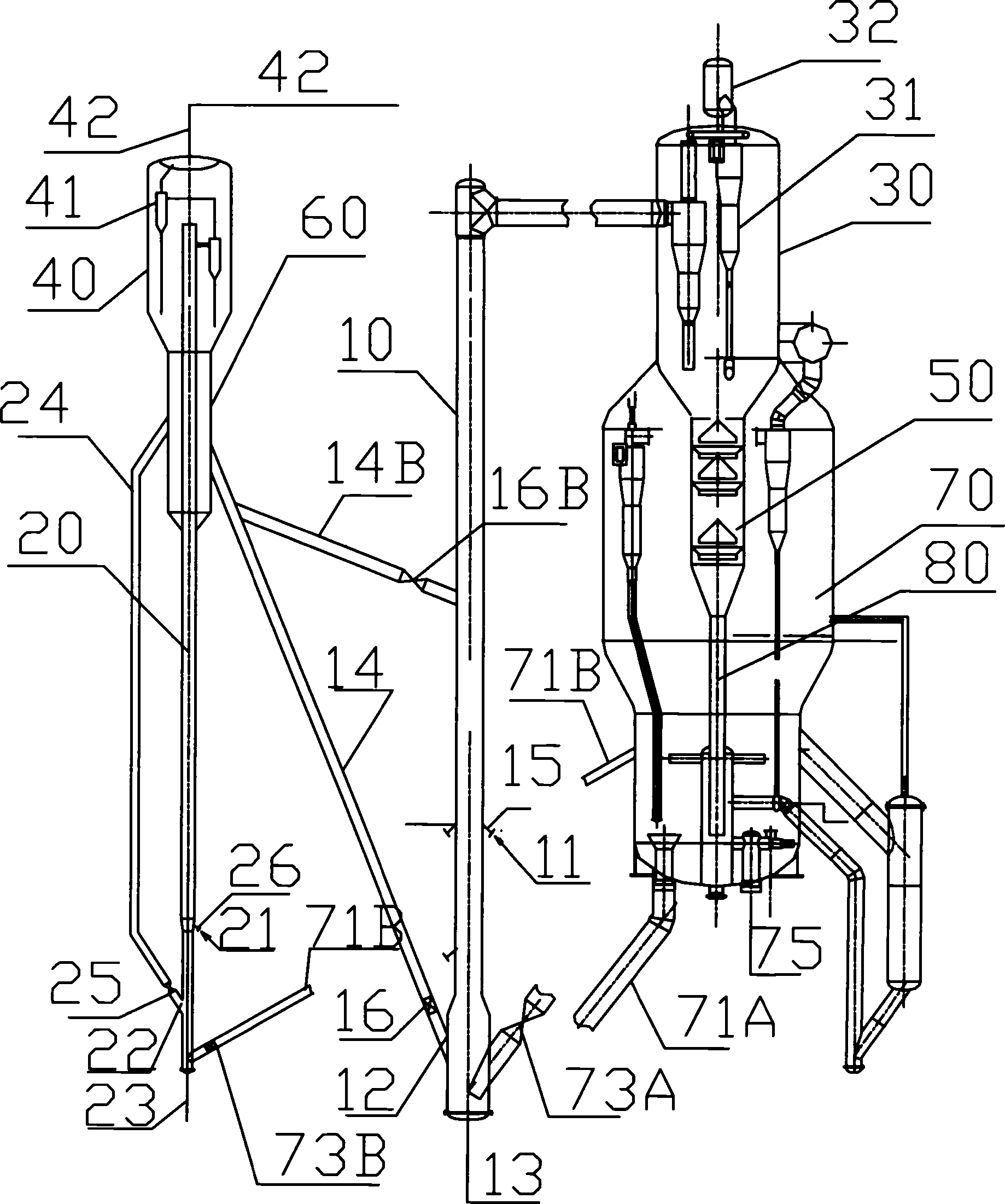

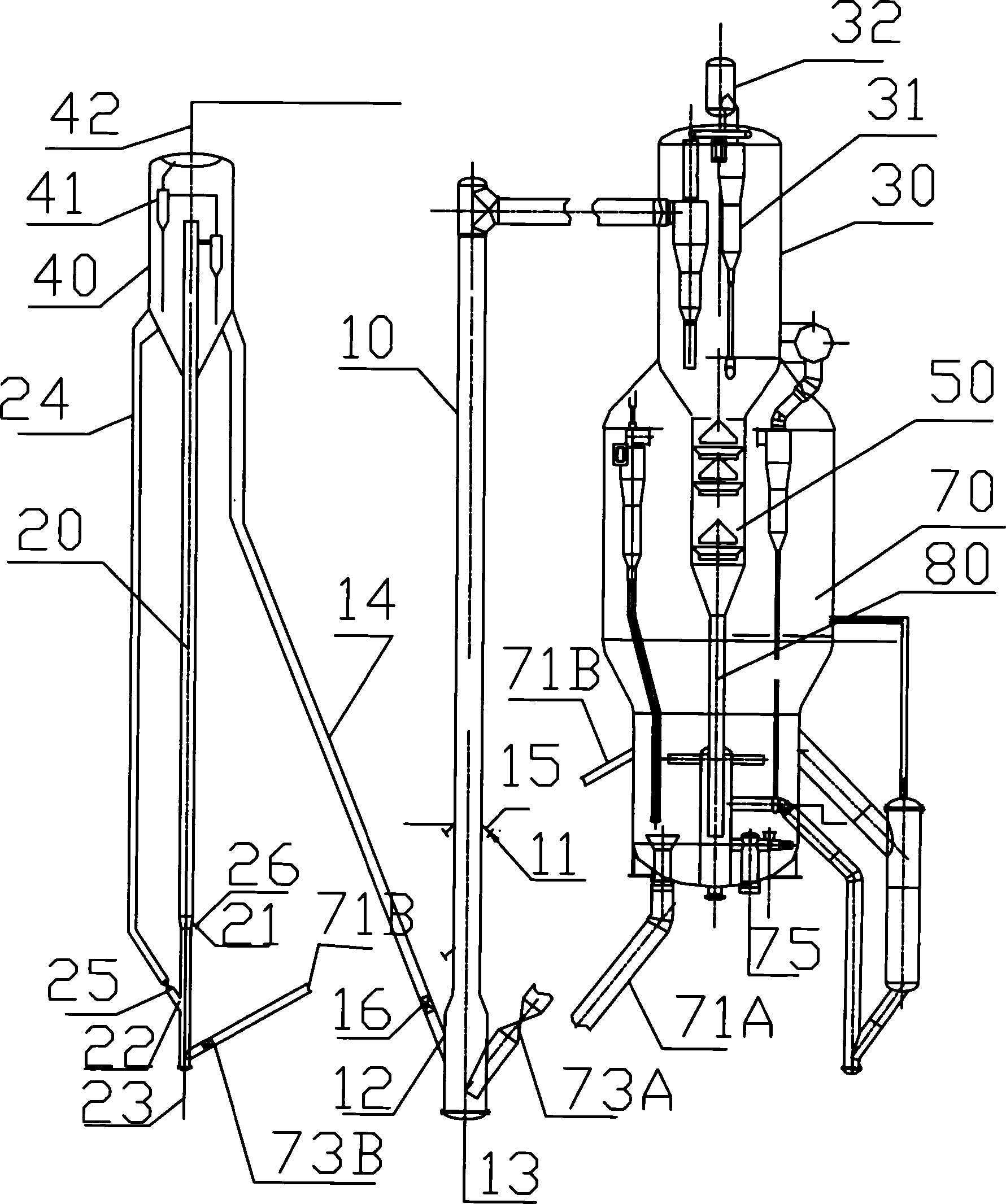

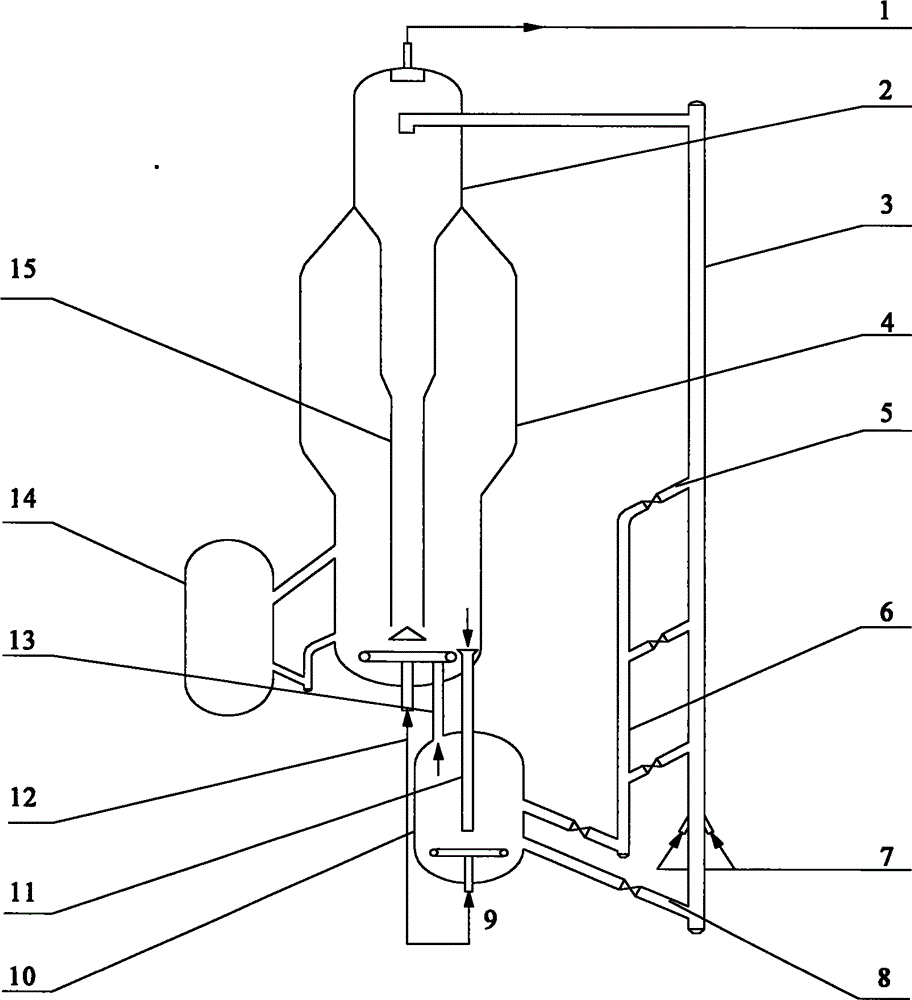

Catalytic cracking method and equipment for hydrocarbon oil

InactiveCN102453500AAvoid the problem of insufficient activityAvoid coolingTreatment with plural serial cracking stages onlyContact reactionHydrocarbon

The invention discloses a catalytic cracking method for hydrocarbon oil. The method is characterized by comprising the following steps of: (1) undergoing a first contact reaction on a hydrocarbon oil raw material and a first cracking catalyst in a first reactor, and performing first oil-agent separation on a mixture of oil gas and the catalyst after the first contact reaction; (2) undergoing a second contact reaction on oil gas obtained after first oil-agent separation and a second newly-added cracking catalyst in a second reactor, and performing second oil-agent separation; and (3) feeding a part of or all of a spent catalyst obtained in the step (2) into the first reactor. The invention further provides catalytic cracking equipment for hydrocarbon oil. Due to the adoption of the method and the equipment, the problem of poor activity in the second reactor caused by great reduction in the activity of the catalyst discharged from the first reactor is solved, and the yields of dry gas and coke can be lowered greatly.

Owner:CHINA PETROLEUM & CHEM CORP +1

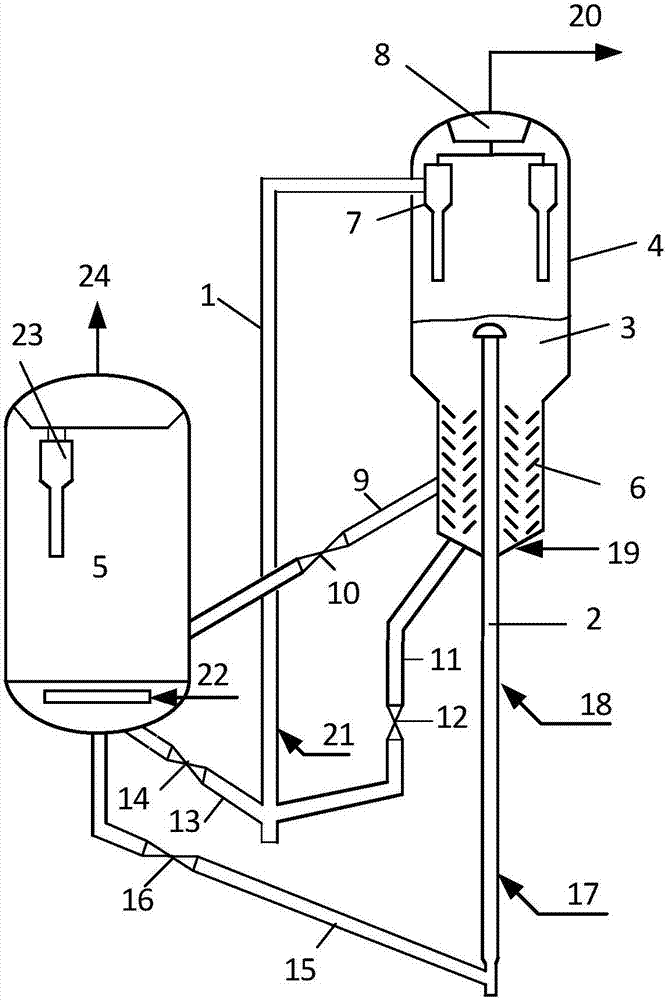

Catalytic conversion method and apparatus

The present invention is catalytic conversion method and apparatus and belongs to the field of petroleum hydrocarbon catalytically converting technology. The catalytic conversion method is that beside the heavy oil reactor of heavy oil reaction-regeneration apparatus, one gasoline reactor sharing the regenerator is connected in parallel, so that catalyst after passing through the gasoline reactor can enter to the heavy oil reactor for being mixed with the regenerated catalyst from the regenerator before reacting with heavy oil. There are one settler set in the outlet of the gasoline reactor and one catalyst conveying pipe set between the settler and the heavy oil reactor. The present invention can raise catalytic cracking yield, improve product quality and, especially, lower the content of olefin in gasoline.

Owner:石宝珍

Low-temperature high agent-oil ratio catalytic conversion reaction method and reactor

InactiveCN1928022AReduce the temperatureOil ratio increaseCatalytic crackingGasolineCracking reaction

The present invention provides catalytic reaction method and reactor capable of improving reaction condition and raising the product yield. The present invention features that catalyst is made to reflux in the reactor and this can lower the temperature of catalyst contacting with reacted material, increase the practical catalyst amount, inhibit thermal cracking reaction, raise product yield, raise the catalyst inventory and catalyst / oil ratio in the second reaction region, improve product distribution and raise product quality. The reactor of the present invention features its catalyst reflux without affecting the operation of the other parts and without needing improving or increasing depositor. The present invention can raise product yield and lower the olefin content in gasoline product.

Owner:石宝珍

Catalytic cracking method for producing low-carbon olefins and light aromatic hydrocarbons

ActiveCN107974286ALarge specific surface areaHigh and medium pore volumeTreatment with hydrotreatment processesHydrocarbon oils treatment productsMolecular sieveNatural mineral

The invention relates to a catalytic cracking method for producing low-carbon olefins and light aromatic hydrocarbons. According to the catalytic cracking method, a heavy raw material and a first catalytic cracking catalyst are subjected to a contact reaction in a first reactor; a lightweight raw material rich in saturated hydrocarbons, a lightweight raw material rich in olefins and a second catalytic cracking catalyst are subjected to a contact reaction in a second reactor and a third reactor; all the reaction oil-gas and the spent catalysts are subjected to gas-solid separation; the reactionoil-gas is further separated to obtain a product containing light-carbon olefins and light aromatic hydrocarbons; and the spent catalysts are subjected to steam stripping, the steam stripped catalysts enter a catalyst regenerator, charring regeneration is performed, and the regenerated catalyst returns to the reactor so as to be recycled, wherein the catalytic cracking catalyst comprises, by weight, 15-65% of natural minerals, 10-60% of an oxide, and 25-75% of a Y-type molecular sieve and a loaded metal-containing IMF structure molecular sieve. With the method of the present invention, the yield of low-carbon olefins is high, and the yield of light aromatic hydrocarbons is high.

Owner:CHINA PETROLEUM & CHEM CORP +1

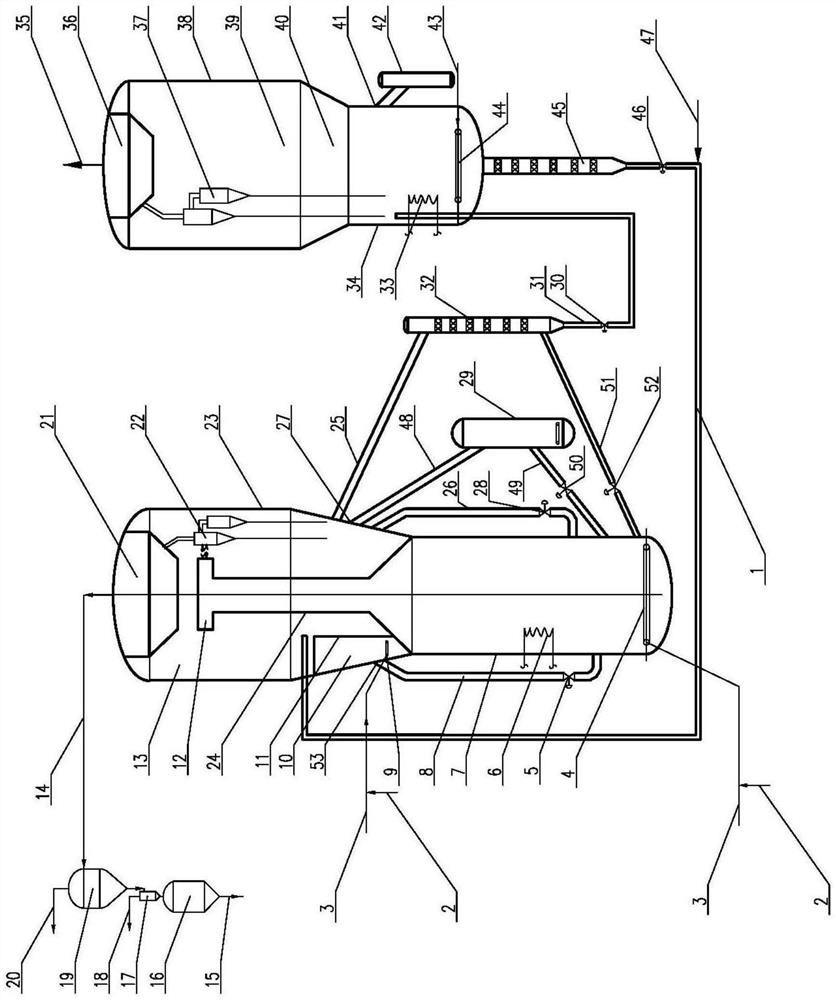

Catalytic cracking conversion method of hydrocarbon raw material and its device

InactiveCN1912066AImprove modification reaction conditionsHigh reaction conversion rateTreatment with plural parallel stages onlyGasolineFuel oil

The invention relates to a hydrocarbon raw material catalytic-cracking converting method and device, belonging to petroleum hydrocarbon catalytic-cracking converting technical field, connecting a gasoline reaction riser in parallel with a heavy oil reaction riser to make the catalyst enter the bottoms of the second or / and first heavy oil reaction regions, so as to take part in modifying reaction in the second heavy reaction region or / and catalytic cracking reaction in the first heavy reaction region, respectively. And it can raise yield of heavy oil reaction by 1-2%, reduce the alkene content in the produced gasoline by 15 percent, and reduce losses of secondary gasoline reaction by 30% above.

Owner:洛阳石化设备研究所

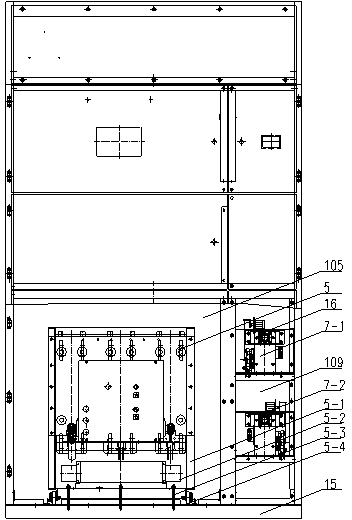

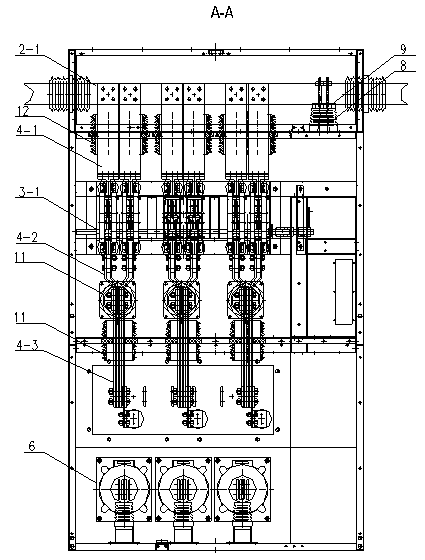

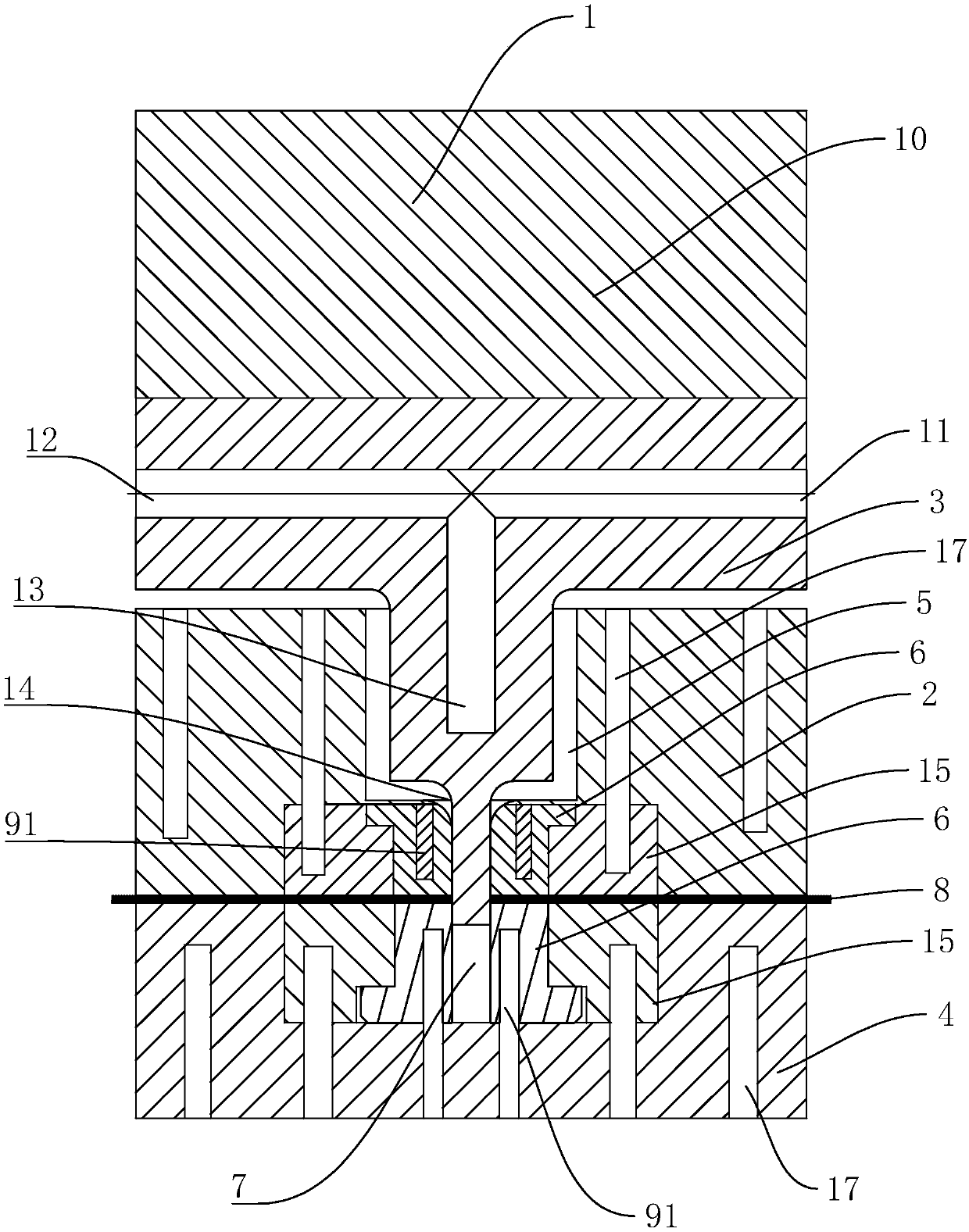

12kV-5000A/63kA armored fixation type double-bus cabinet

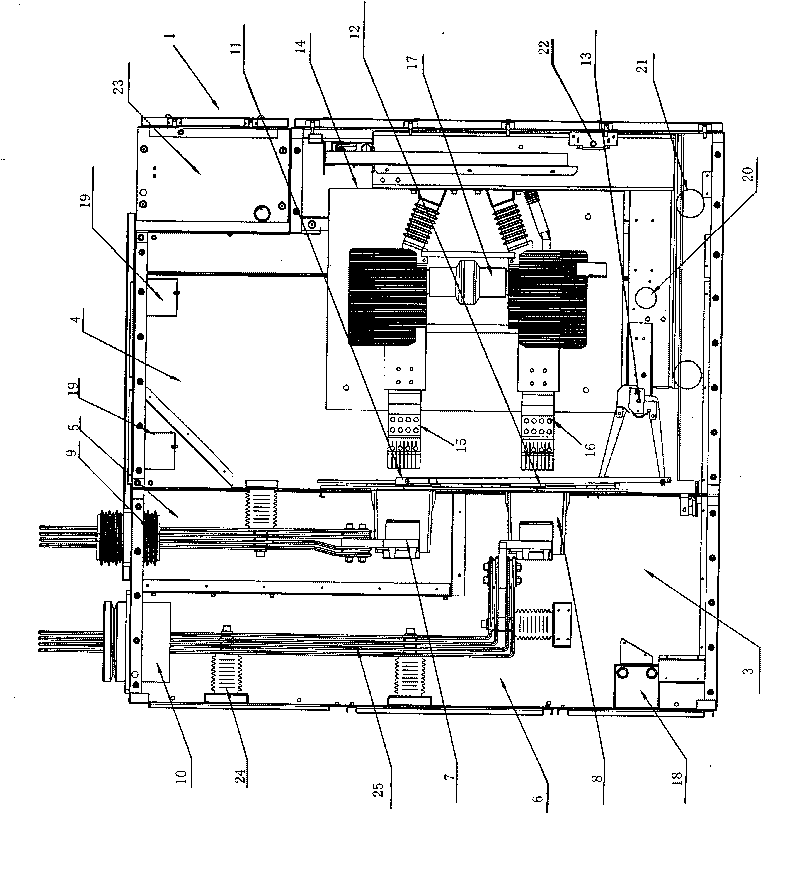

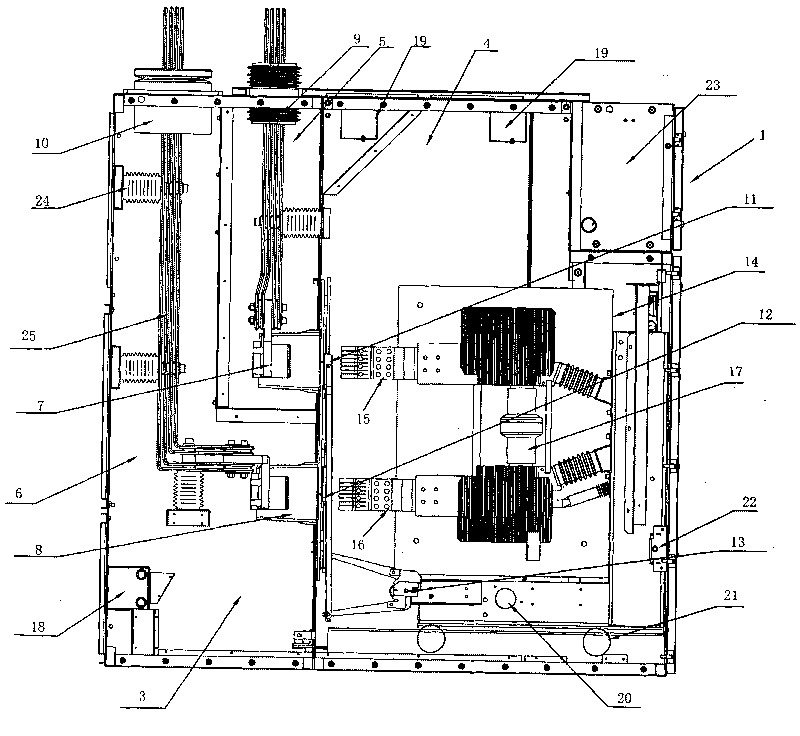

InactiveCN103944081AHigh precisionReduce temperature riseBus-bar/wiring layoutsSubstation/switching arrangement cooling/ventilationPower flowResonance

A 12kV-5000A / 63kA armored fixation type double-bus cabinet overcomes the defects that in the prior art, the cut-off current is small, the precision is low, the pressure relief and heat dissipation effects are poor, the electromagnetic resonance is large and operation is laborsome. The 12kV-5000A / 63kA armored fixation type double-bus cabinet is characterized in that a cabinet body is of a full packaging structure, a work main bus chamber and a standby bus chamber are arranged front and back, an instrument chamber and a small bus chamber are arranged in the middle of the front of the cabinet body, a pressure relief device is installed on the top of the bus chambers and an isolation chamber, black paint is sprayed onto the interior of the main bus chamber and main and branch buses except the lap joint portion, a stainless steel plate is adopted as a partition plate in the bus passing position, an armor clamp is installed on an insulator, a spacer pad is added when the supporting span of the main bus is large, an isolating switch is connected with an electric operating mechanism, and a manual interlocking mechanism is installed at the front end of the electric operating mechanism. The 12kV-5000A / 63kA armored fixation type double-bus cabinet has the advantages that the cut-off current can reach 63kA, the precision is high, the heat dissipation effect is good, temperature rise and energy consumption can be reduced, the electromagnetic resonance is small, the dynamic stability of the buses is smooth and steady, the cabinet can be operated both electrically and manually and is safe and reliable in operation, the buses can be maintained without cutting off the power.

Owner:沈阳华利能源设备制造有限公司

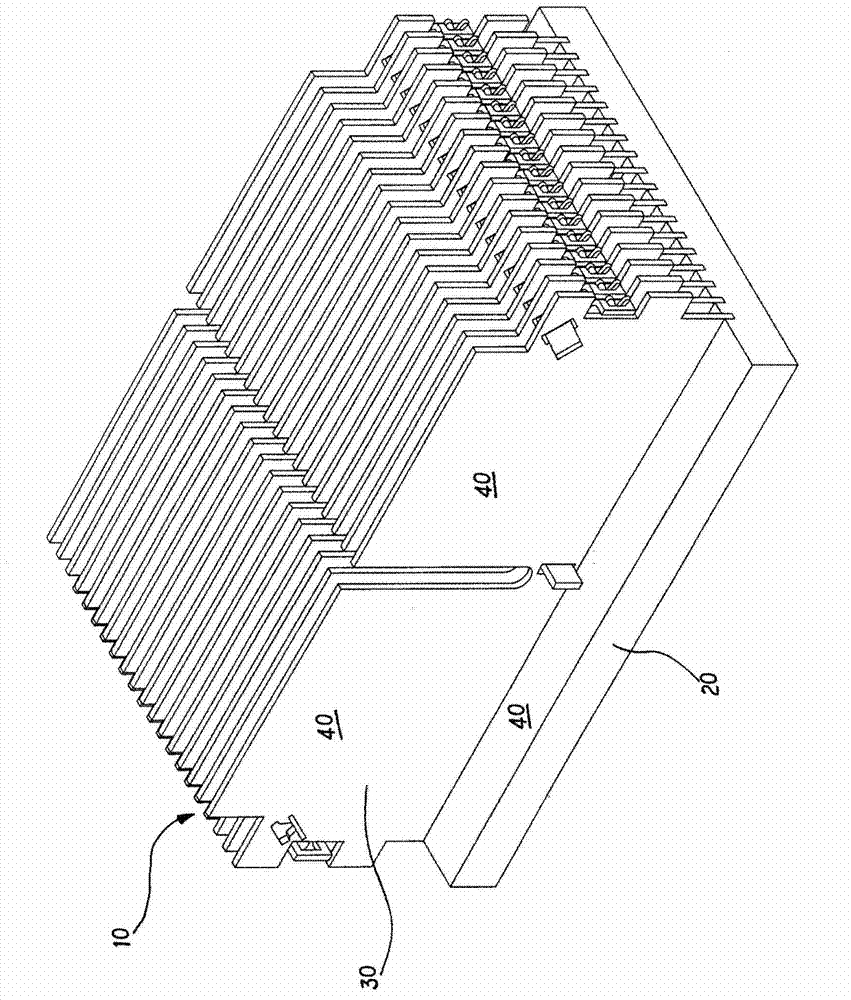

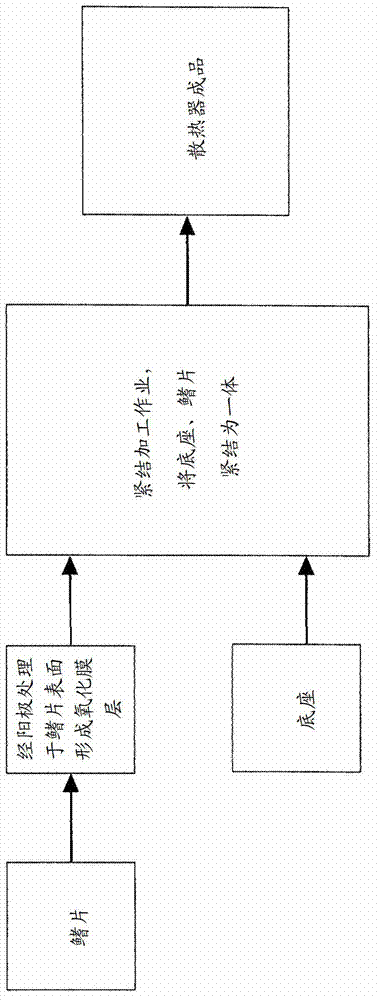

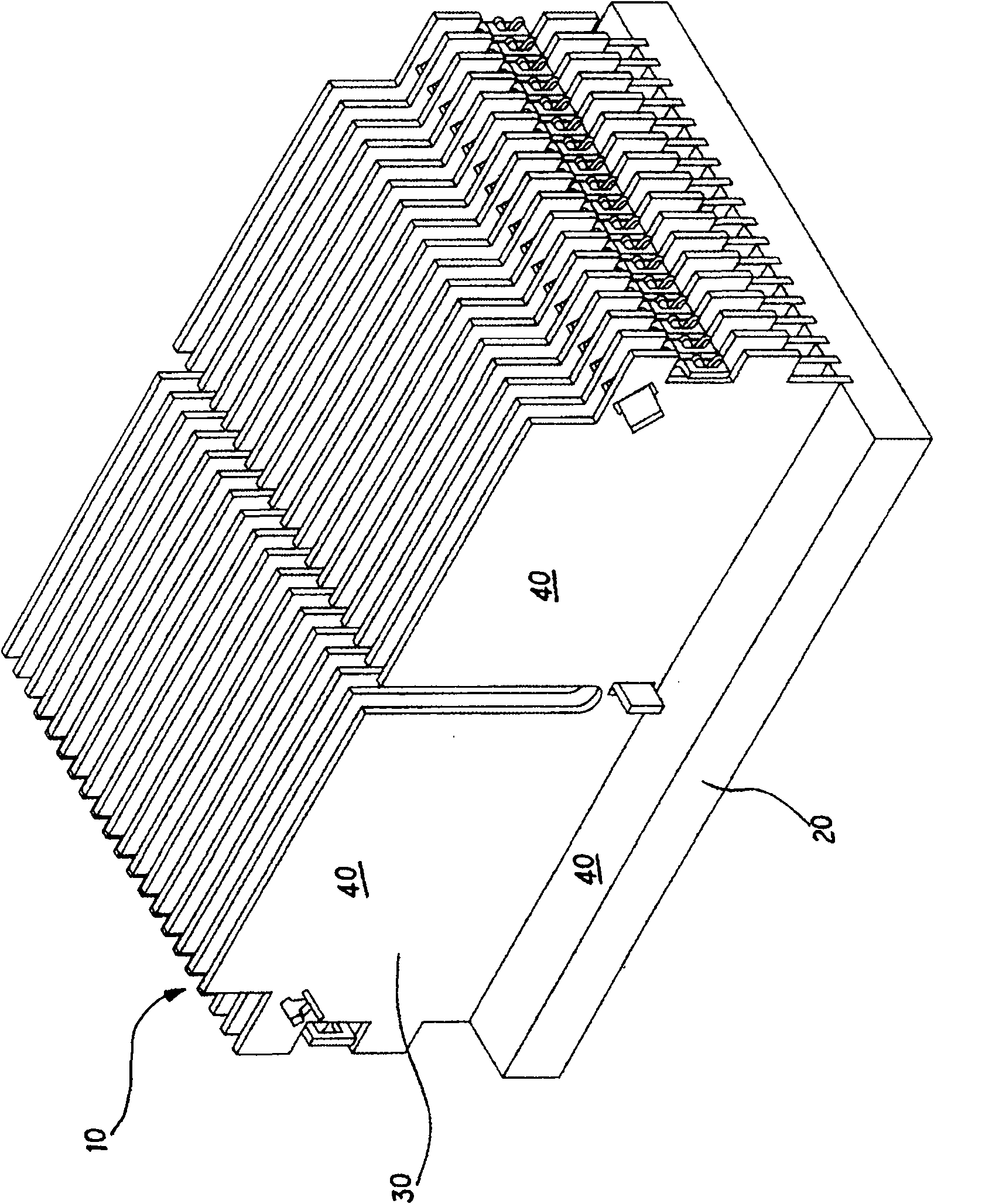

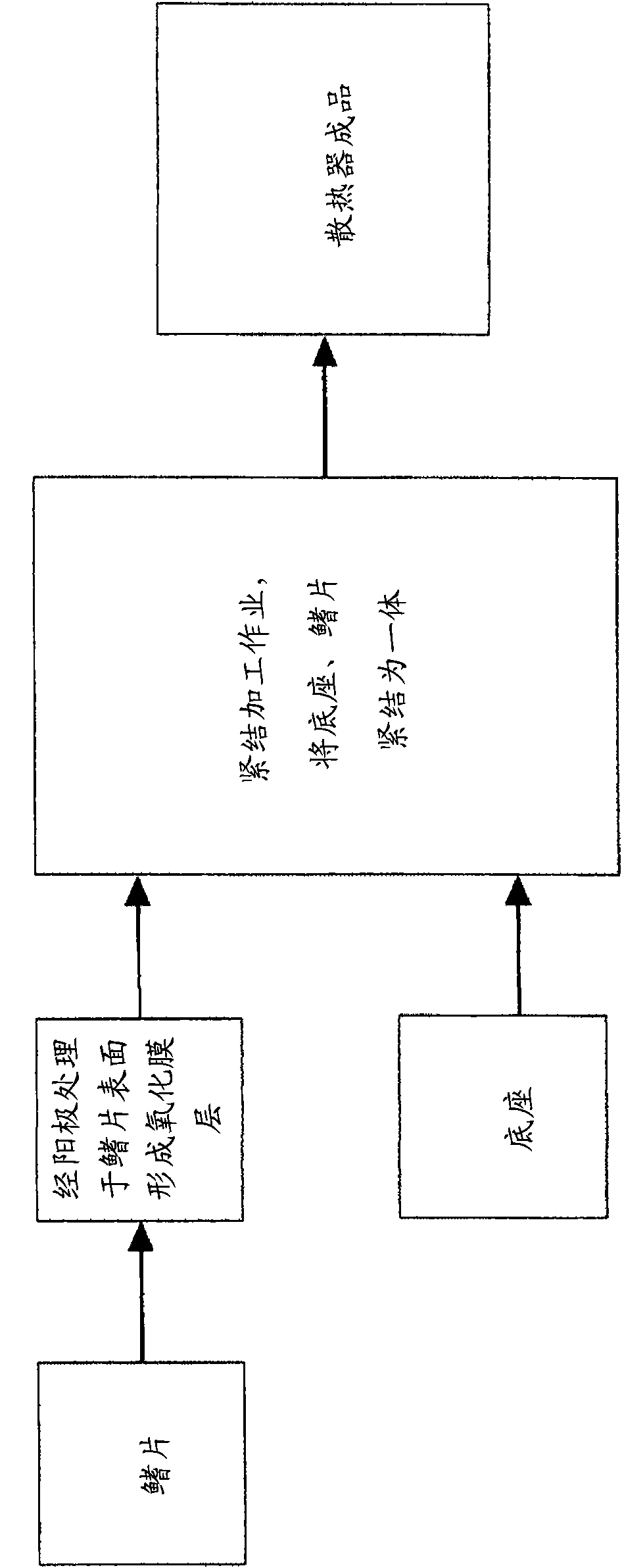

Manufacturing method of high heat transfer efficiency radiators

InactiveCN102877103AHigh thermal radiation emissivityRaise the temperature differenceAnodisationCooling/ventilation/heating modificationsEngineeringHeat transfer efficiency

The invention provides a manufacturing method of high heat transfer efficiency radiators, comprising the following steps: providing a plate-shaped or barrel-shaped base and a plurality of fins combined with the base, wherein the base and the fins are formed by aluminums; and forming an oxidation film layer capable of improving the thermal radiation emission rate of the base or / and fins on the surface of the base or / and fins through an anode processing technology, wherein the high heat transfer efficiency radiator further comprises a heat pipe; the heat energy of the base is rapidly transferred to the fins to radiate by menas of the heat pipe; or the treatment is performed at anodes of the fins by using a radiator type combined by the heat pipe and the fins to form the oxidation film layer. According to the characteristics, the radiator improves the heat transfer efficiency and simultaneously has the functions of beautiful appearance, easy identification and fouling resistance.

Owner:陈世明

Catalytic conversion method of double reactor and its device

InactiveCN1948440AAchieve sharingUnaffected by heavy oil reactionsTreatment with plural parallel stages onlyGasolineFuel oil

This invention provides a catalytic cracking method, and it will make sure that raw material oil and petroleum react separately in their own demands by using coupling reactors. In order to improve agent-oil ratio, the accelerant with low temperature from petroleum reaction reenters into the pre-upgrading section of raw material oil reaction. It will low the temperature of accelerant of petroleum reaction and improve agent-oil ratio before low temperature accelerant from petroleum reaction recirculating into petroleum reactor before feeding material. The equipment of this catalytic cracker uses coupling reactor, and the accelerant after the reaction of petroleum will be directly send into the pre-promotion section of heavy oil reactivation from petroleum reactor by accelerant transport pipe between the petroleum reactor and heavy oil reactor. The accelerant recirculating pipe designed with petroleum reactor to make part of the accelerant return to petroleum reactor before feeding material. The catalytic cracking equipment is a settling vessel, which will separate the oil gas from different reactor and enter their own fractionating tower to form the program of single settling vessel and coupling fractionating tower to receive pure petroleum upgrading product.

Owner:石宝珍

Preparation method of high-immune plasma protein powder

InactiveCN105851455AImprove stabilityIncrease G contentProtein composition from bloodAccessory food factorsGlobulin GHigh pressure

The invention relates to a preparation method of high-immune plasma protein powder. According to the method, fresh plasma liquid of healthy slaughtered livestock and poultry as a raw material, a process method including the steps of inorganic membrane filtering, organic membrane concentrating, reducing sugar adding, high-pressure homogenizing and spray drying is adopted, the prepared high-immune plasma protein powder basically has no blood smell, the protein content of the high-immune plasma protein powder reaches 75% or above, and the immune globulin G content of the high-immune plasma protein powder is increased by 40% or above compared with common plasma protein powder; reducing sugar and plasma immune globulin particles are prepared through reducing sugar adding, homogenizing and centrifugal atomization treating, damage of the high temperature to immune globulin in the spray drying process is reduced through the affinity effect of rich hydrophilic hydroxyl groups in reducing sugar to water, therefore, the activity of the immune globulin is guaranteed, and preparation of the high-immune plasma protein powder is achieved.

Owner:HUAIBEI ENBI FEED

Manufacturing method of radiator with high heat transfer efficiency

InactiveCN101837539AHigh thermal radiation emissivityRaise the temperature differenceEmissivityHeat transfer efficiency

The invention provides a manufacturing method of a radiator with high heat transfer efficiency. The radiator comprises a base in a plate shape or a cylindrical part and a plurality of fins which can be combined with the base, wherein the base and the fins are molded from aluminum timbers, and an oxidation film for improving the heat radiation emissivity of the base and the fins is formed on the surfaces of the base or / and the fins through an anodization technology; moreover, the device further comprises a heat pipe by which heat energy on the base can be rapidly transferred to the fins for heat radiation; or, the oxidation film is formed on the fins through anodization by utilizing a radiator type combined by the heat pipe and the fins. By dint of the characteristics, the heat transfer efficiency of the radiator is improved, and meanwhile, the functions of better appearance, easy identification and antifouling are provided.

Owner:陈世明

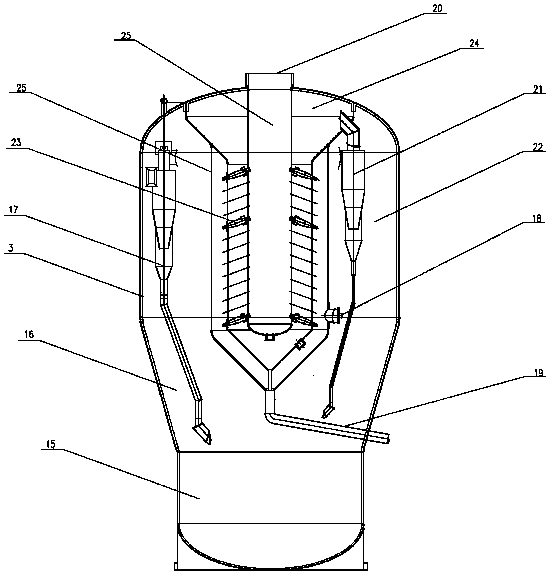

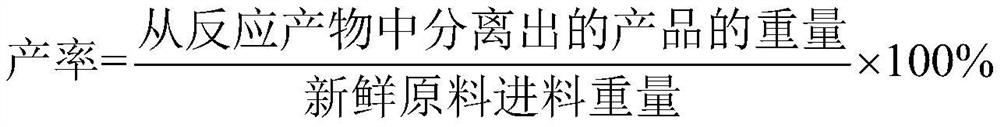

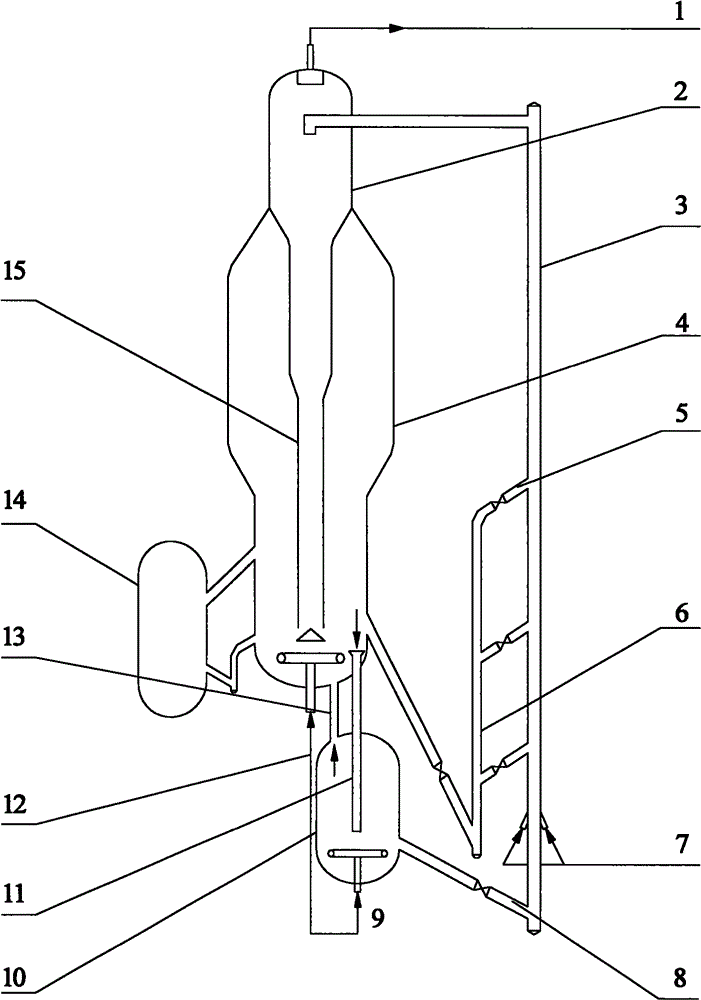

Efficient device for producing low-carbon olefin from oxygen-containing compound

PendingCN111807916AIncrease line speedSmall diameterHydrocarbon purification/separationHydrocarbon from oxygen organic compoundsPetrochemicalOxygen compound

The invention discloses an efficient device for producing low-carbon olefin from an oxygen-containing compound in the technical field of petrochemical engineering. The device meets the requirements for rapid reaction, strong heat release, low catalyst-alcohol ratio, high product selectivity and the like of a process for preparing the low-carbon olefin from the oxygen-containing compound, so that the problem of low selectivity of the low-carbon olefin in the prior art is solved, the advantages of the reaction can be brought into play to the greatest extent, and the selectivity of the low-carbonolefin is improved.

Owner:LUOYANG PETROCHEMICAL ENG CORP SINOPEC

Method and equipment for improving selectivity of low-carbon olefins

ActiveCN110950730AReduce the temperatureReduced activityHydrocarbon from oxygen organic compoundsChemical recyclingPtru catalystProcess engineering

The invention discloses a method and equipment for improving the selectivity of low-carbon olefins. The method comprises the following steps that 1) an oxygen-containing compound raw material enters areactor, contacts with a regeneration catalyst from a pre-reaction section, and is subjected to an exothermic reaction; 2) after the carried catalyst is removed from the reaction gas in the step (1),the obtained reaction gas enters the built-in separation facility of the reactor to remove the carried catalyst, and then is led out; 3) the spent catalyst subjected to carbon deposition after the reaction in the step 1) enters a regenerator, and is subjected to scorching regeneration; 4) the spent catalyst in the step 3) enters a regeneration stream stripping device, and is subjected to steam stripping cooling, and the cooled catalyst enters a pre-reaction section; and 5) a pre-reaction medium is gasified, and the gasified pre-reaction medium enters the pre-reaction section, is subjected toan endothermic reaction with the regenerated catalyst, and then enters the reactor. The method and the equipment provided by the invention have the advantages that by arranging the pre-reaction section, the occurrence of non-target reaction is reduced, and the selectivity of low-carbon olefin is improved; and the bush is arranged in the reactor, so that the dilute phase space of the reactor is shortened, and the selectivity of low-carbon olefin is improved.

Owner:SINOPEC LUOYANG PETROCHEM ENG CORP +1

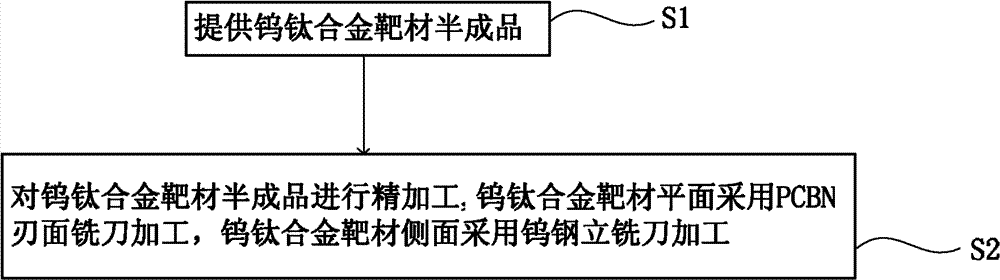

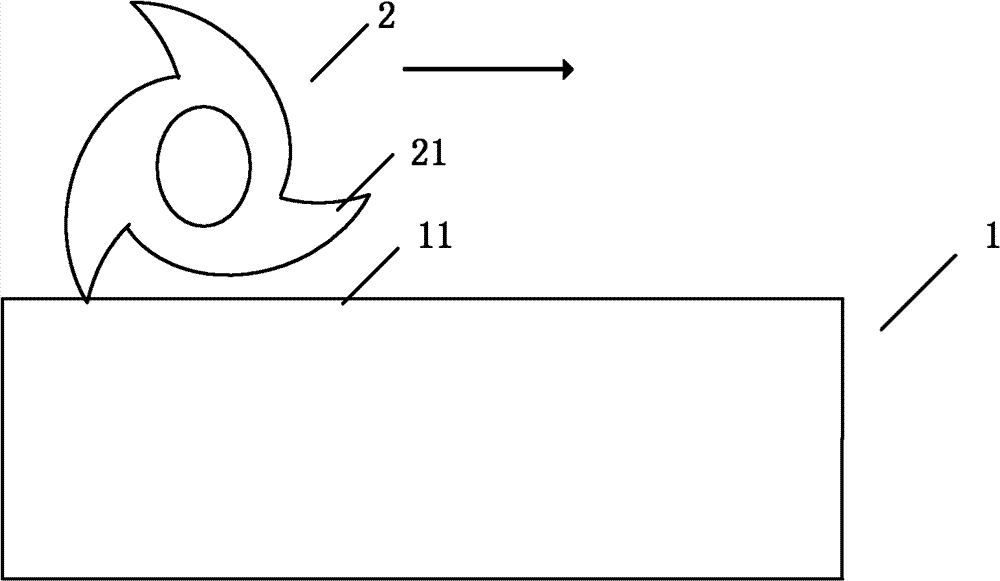

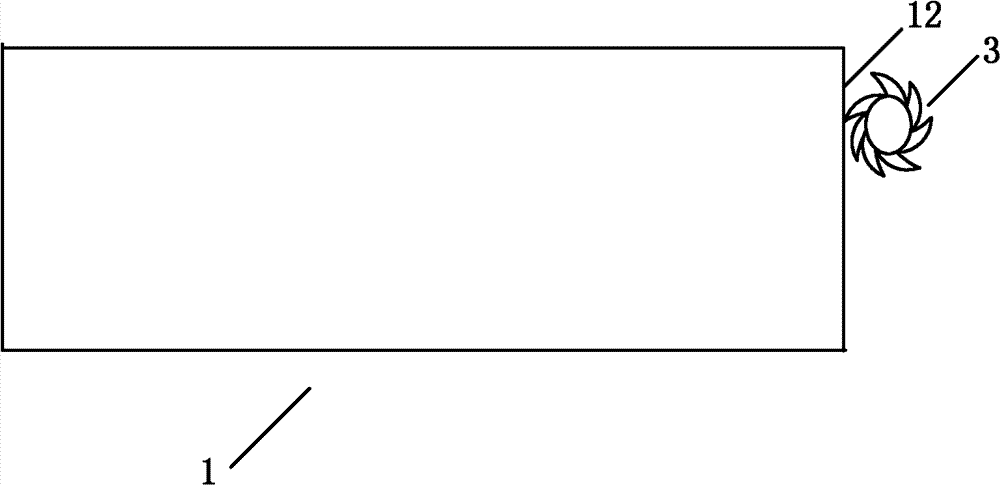

Machining method for milling tungsten alloy target material

ActiveCN102145403BUniform cutting forceAvoid cornersMilling equipment detailsMilling cutterBoron nitride

The invention discloses a machining method for a tungsten alloy target material, which comprises the steps of providing a semi-finished product of the tungsten alloy target material and carrying out finish machining on the semi-finished product of the tungsten alloy target material, wherein in the finish machining step, the plane of the tungsten alloy target material is machined by a PCBN (Polycrystalline Cubic Boron Nitride) face mill, and the side face of the tungsten alloy target material is machined by a tungsten steel end mill. By adopting the machining method for the tungsten alloy target material provided by the invention, the arris defect in the machining process is avoided, the machining of the tungsten alloy target material with complex curved surface can be realized, and the problems of long machining cycle and low production efficiency are solved.

Owner:KONFOONG MATERIALS INTERNATIONAL CO LTD

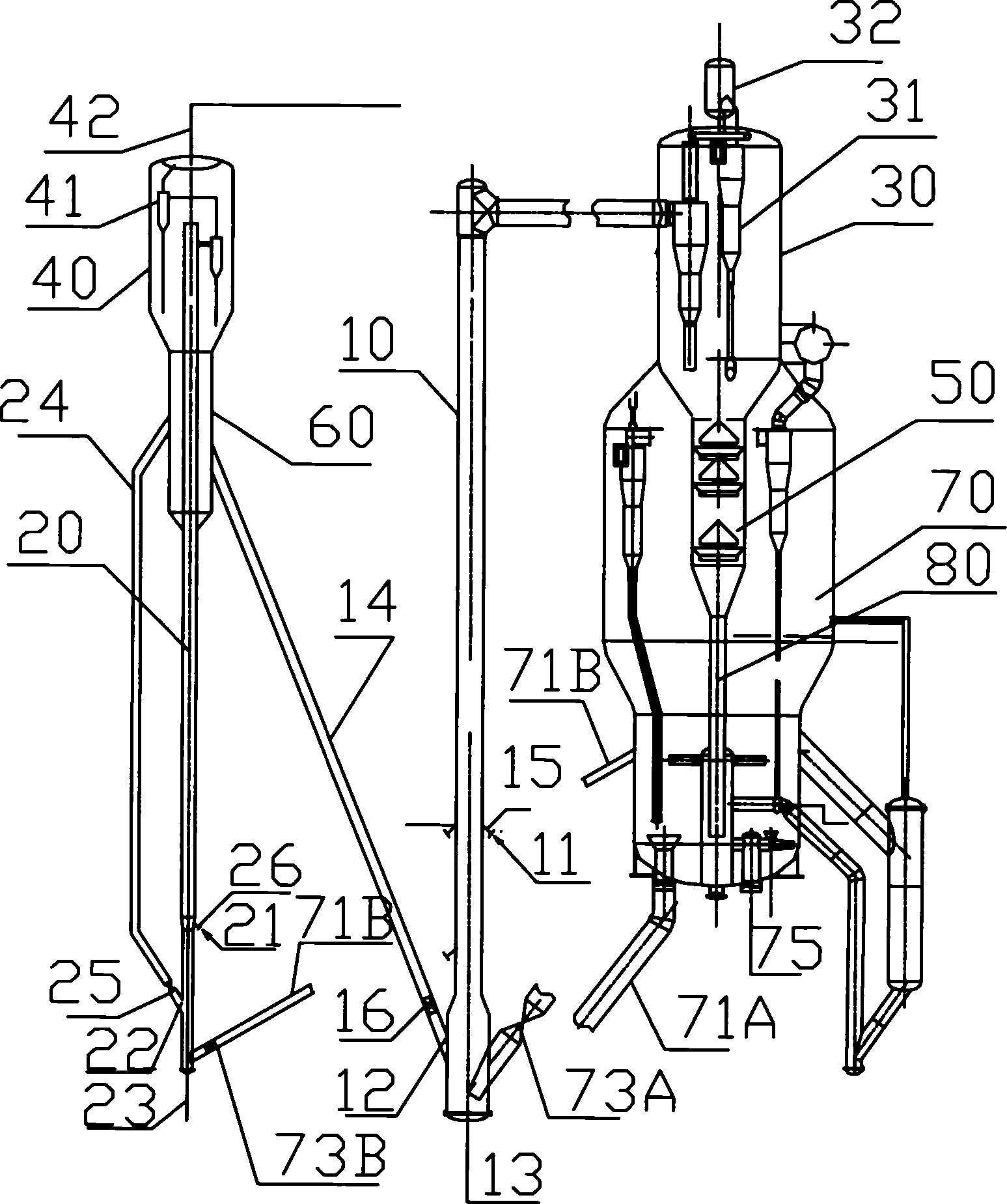

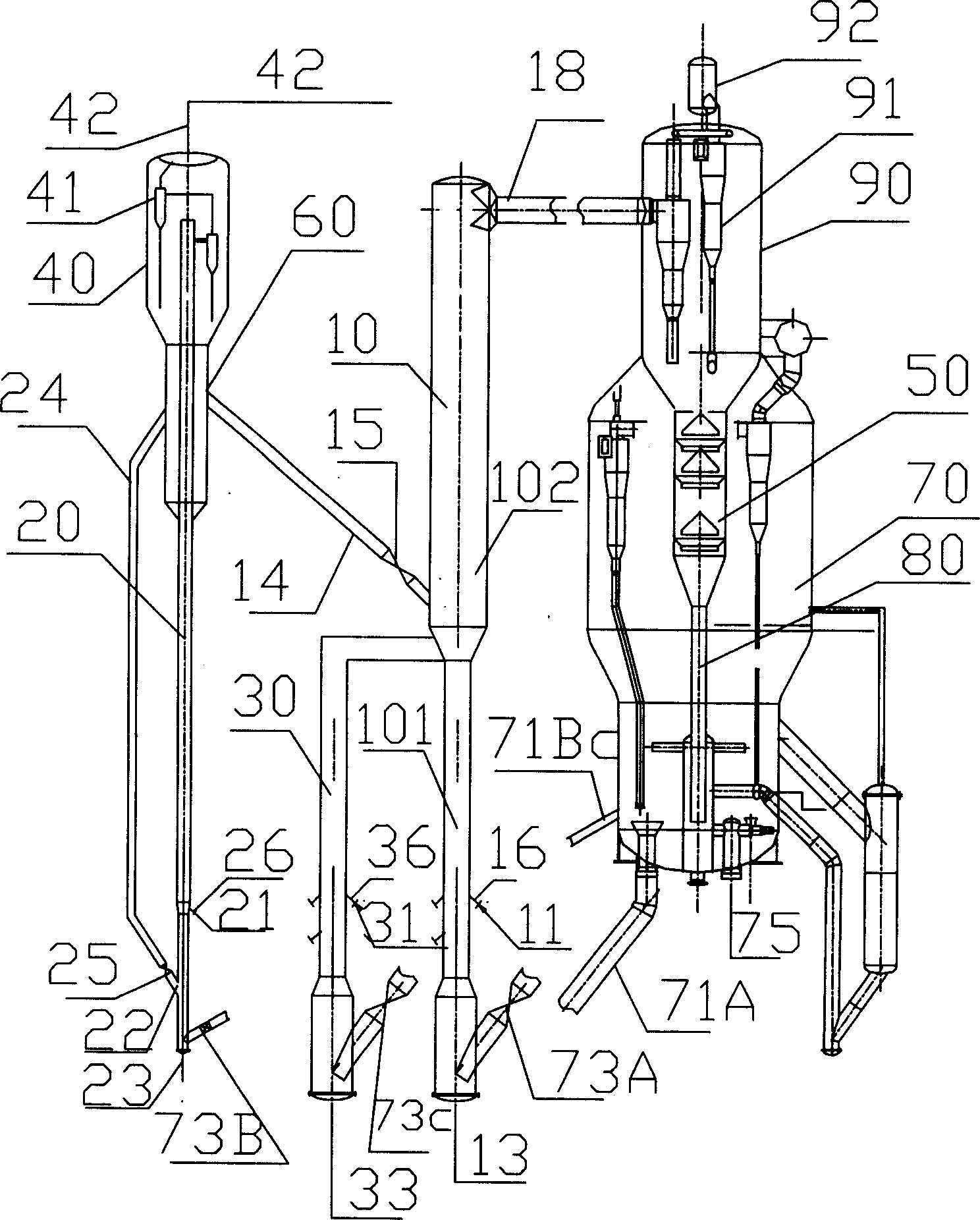

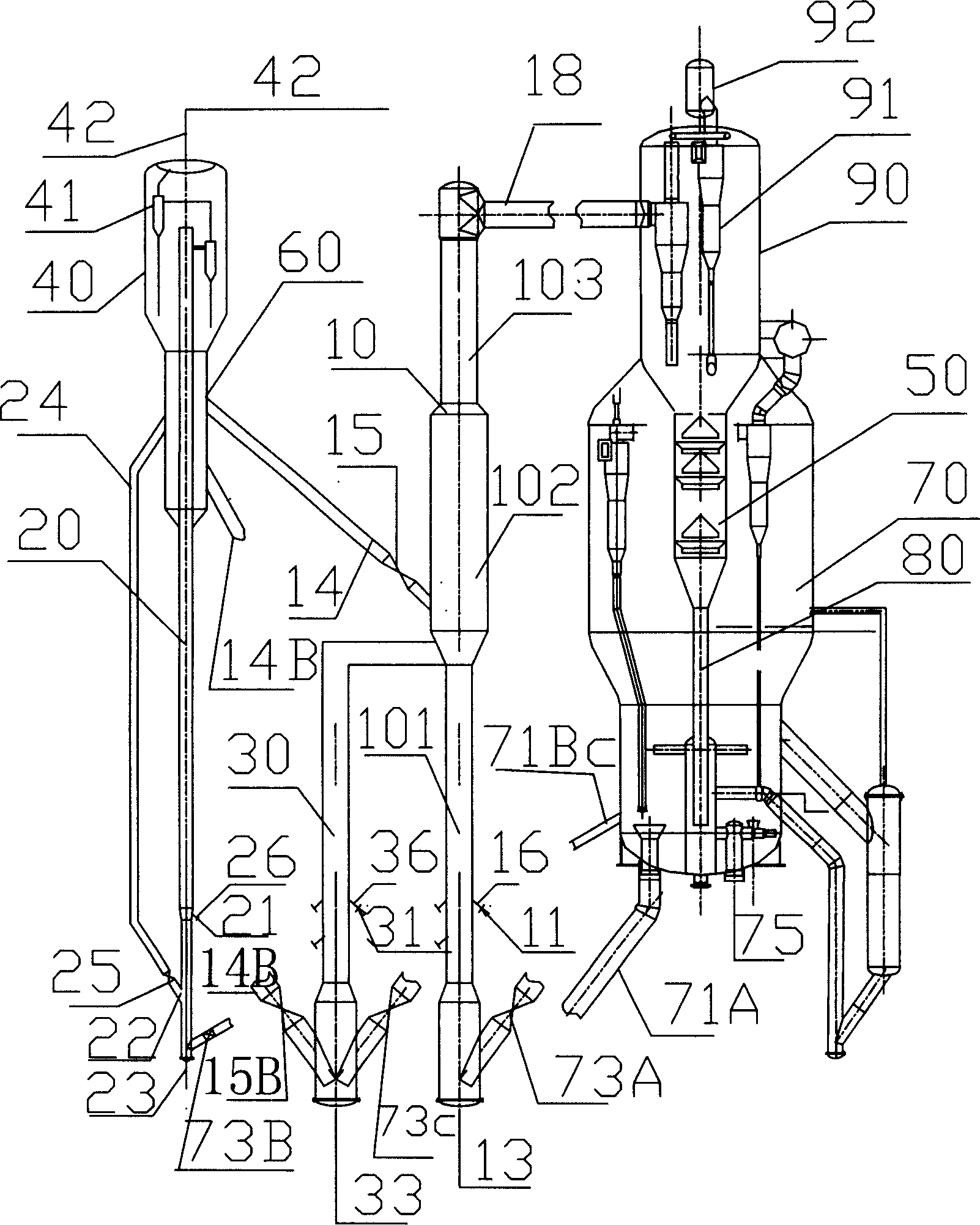

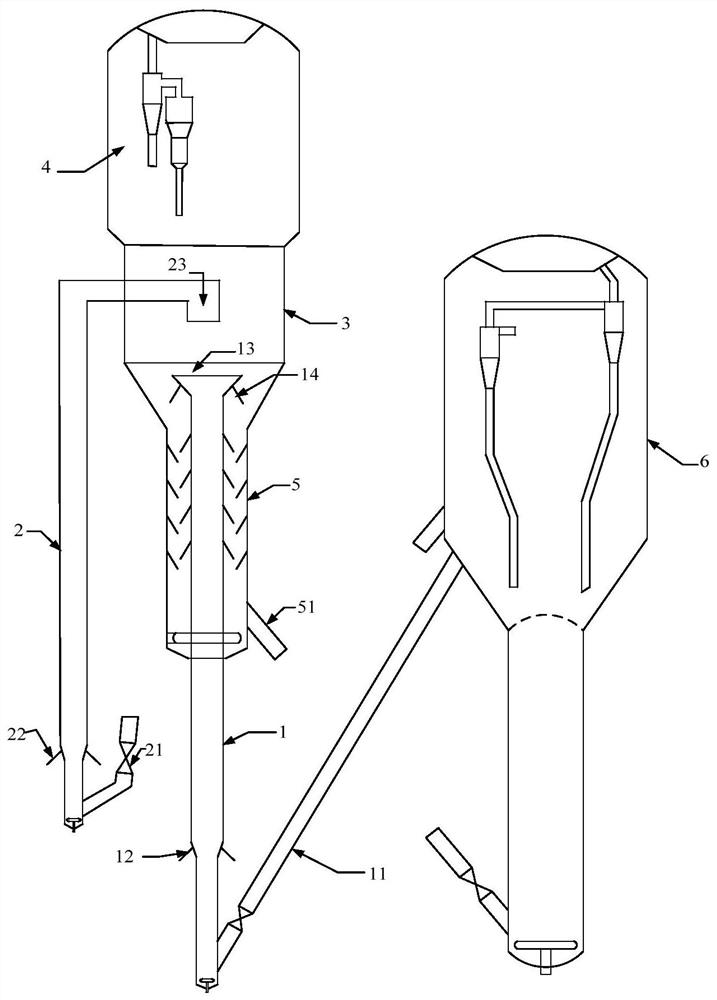

Catalytic conversion method and catalytic conversion device for productive low-carbon olefin

ActiveCN112680247AHigh yieldImprove the reaction environmentLiquid hydrocarbon mixture productionChemical recyclingCatalytic transformationPtru catalyst

The invention relates to a catalytic conversion method and a device for productive low-carbon olefin, and the method comprises the steps: carrying out the contact reaction of a first hydrocarbon raw material and a catalyst from a regenerator in a first riser reactor, and carrying out the contact reaction of a heavy hydrocarbon raw material, a second hydrocarbon raw material and a catalyst from a regenerator in a second riser reactor, introducing the reacted oil mixture into the fluidized bed reactor for continuous reaction, sequentially performing contact reaction on a third hydrocarbon raw material and a catalyst from a regenerator in a first reaction zone and a second reaction zone of a third riser reactor, separating the reacted oil mixture through a separation device, and introducing the catalyst into a stripper for stripping; introducing heavy hydrocarbons into the bottom of the second riser reactor, and selecting the third hydrocarbon raw material from distillate oil with the distillation range of 180-360 DEG C, preferably distillate oil with the distillation range of 200-340 DEG C. The method provided by the invention can obviously improve the yields of ethylene and propylene.

Owner:CHINA PETROLEUM & CHEM CORP +1

Method for producing propylene by catalytic cracking of hydrocarbons

ActiveCN112708450APromote circulationLow selectivityChemical recyclingBulk chemical productionPtru catalystProcess engineering

The invention relates to the field of petroleum refining and petrochemical processing, and discloses a method for producing propylene by catalytic cracking of hydrocarbons, which comprises the following steps: (1) carrying out a first catalytic cracking reaction on heavy raw oil and a first regenerated catalyst to obtain a first oil mixture; (2) carrying out a second catalytic cracking reaction on the light raw oil and a second regenerated catalyst to obtain a second oil agent mixture; and (3) carrying out a third catalytic cracking reaction on the first oil agent mixture and the second oil agent mixture to obtain a third oil agent mixture, and carrying out separation, prerequisite and regeneration for cyclic utilization; wherein the mass ratio of the heavy raw oil to the light raw oil is 0.5-5: 1; the method further comprises the following steps: introducing a first cooling medium into the outlet of the first riser reactor; and / or introducing a second cooling medium into the stripper, and circulating part of the stripped spent catalyst back to the first riser reactor. The method provided by the invention can improve the propylene selectivity and reduce the yields of dry gas and coke.

Owner:CHINA PETROLEUM & CHEM CORP +1

Device for producing low-carbon olefin from oxygen-containing compound

PendingCN111871343AHigh selectivityIncrease line speedHydrocarbon from oxygen organic compoundsEthylene productionOxygen compoundPetrochemical

The invention discloses a device for producing low-carbon olefin by using an oxygen-containing compound in the technical field of petrochemical engineering, which is suitable for the characteristics of quick reaction, strong heat release, lower agent-alcohol ratio, high product selectivity and the like in the process of preparing the low-carbon olefin by using the oxygen-containing compound, so asto solve the problem of low selectivity of the low-carbon olefin in the prior art. Therefore, the advantages of the reaction can be exerted to the greatest extent, and the selectivity of the low-carbon olefin is improved.

Owner:LUOYANG PETROCHEMICAL ENG CORP SINOPEC

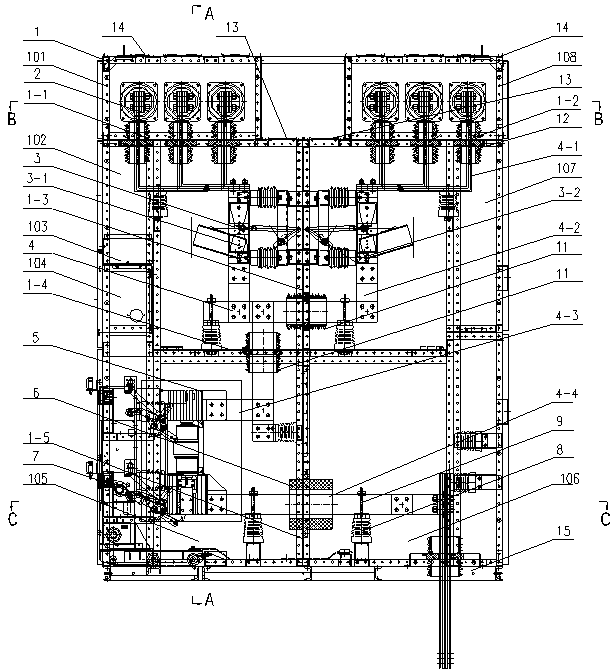

10kv 6300a heavy current armored removable switch cabinet

The invention relates to a 10kV 6300A heavy current armored removable switch cabinet comprising a armored cabinet body (1) which is internally provided with a partition board (2); the partition board (2) is respectively provided with a square high-capacity line incoming static contact (7) and a square high-capacity line outgoing static contact (8); an upper valve (11) and a lower valve (12) which can be linked are installed in positions on the partition board (2), respectively corresponding to the line incoming static contact (7) and the line outgoing static contact (8); the upper valve (11) and the lower valve (12) are respectively connected with a driving device (13) installed at the lower part of a circuit breaker truck (14); a lower air intake fan (18) is installed at the lower part of a line incoming chamber (3), and an upper air exhaust fan (19) is installed on the upper part of a circuit breaker chamber (4); and the circuit breaker truck is also provided with a circuit breaker heat radiating fan (20). The invention has simple structure, good heat radiation effect and small size.

Owner:JIANGSU NARI POWER ELECTRIC

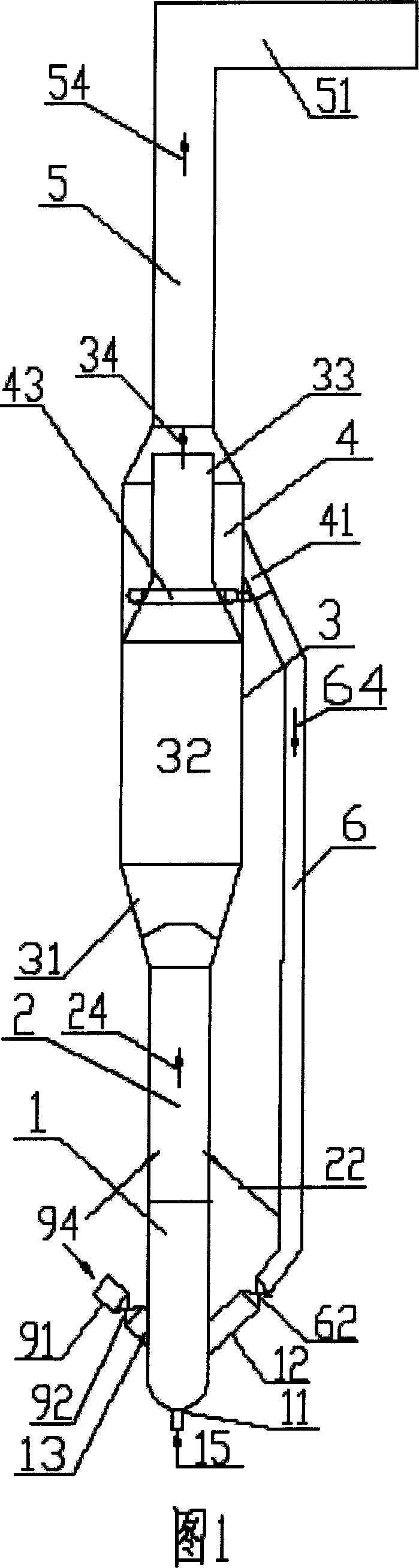

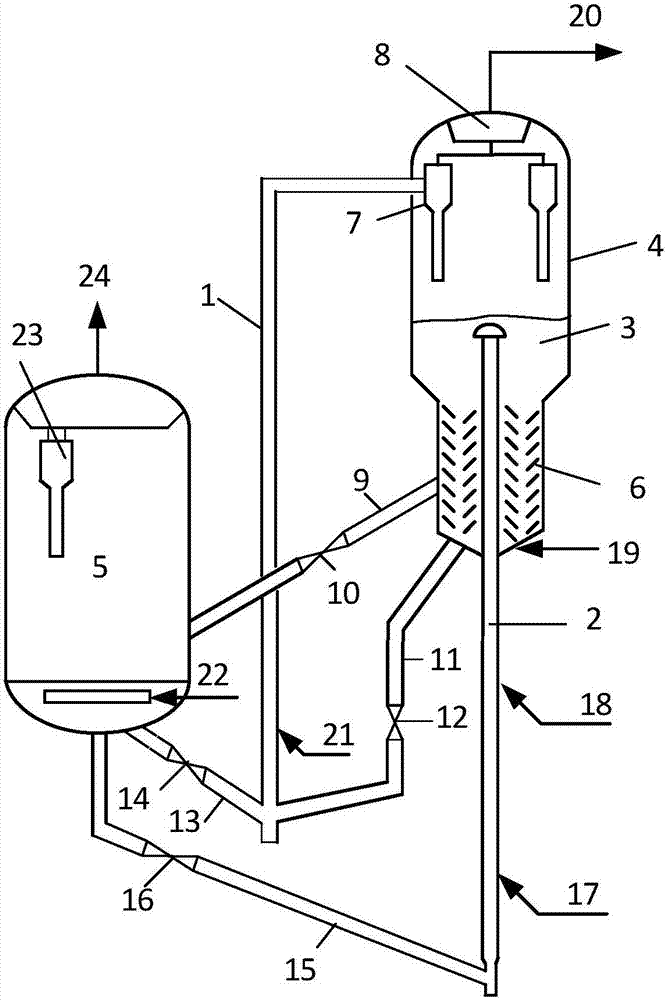

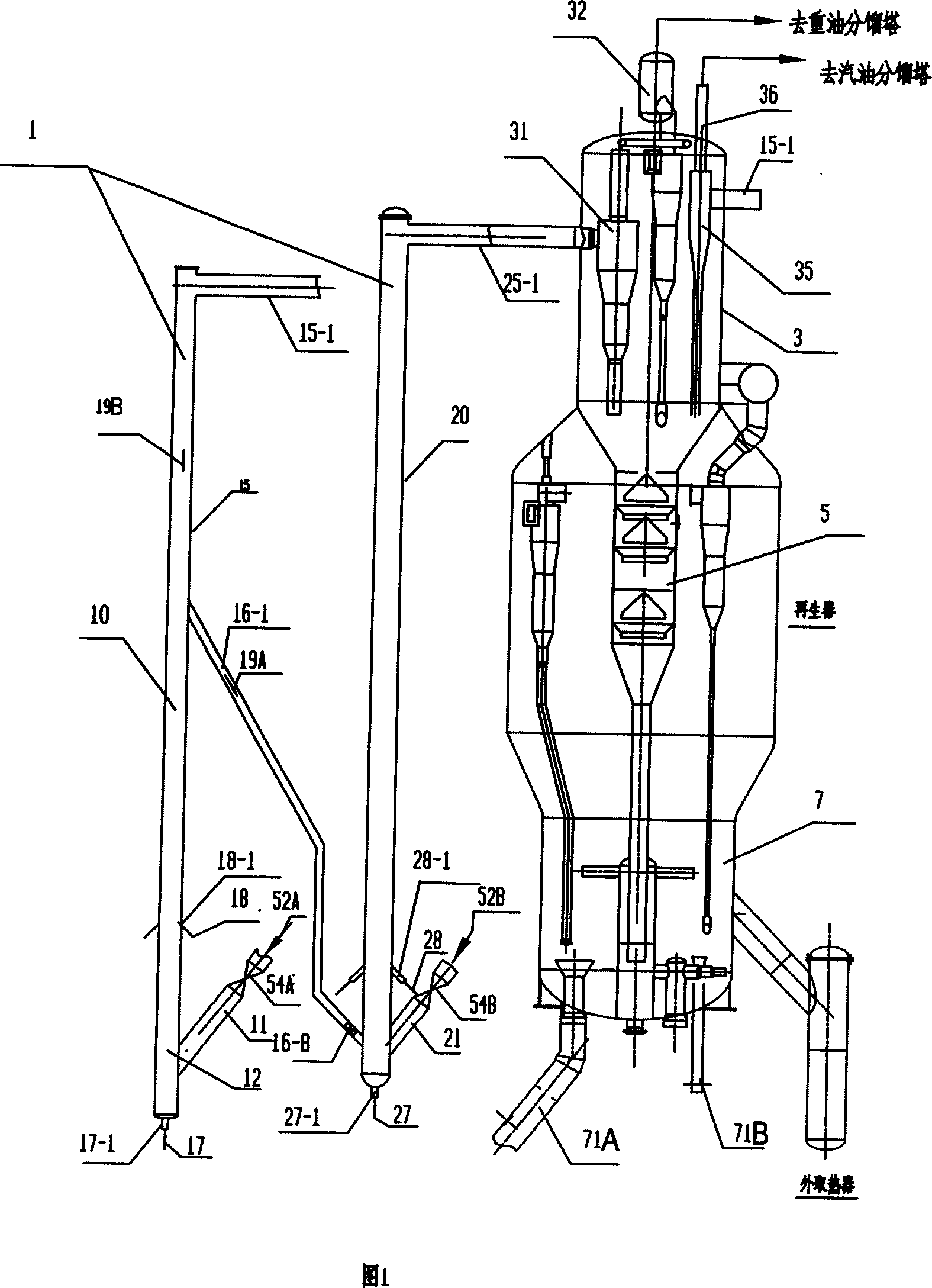

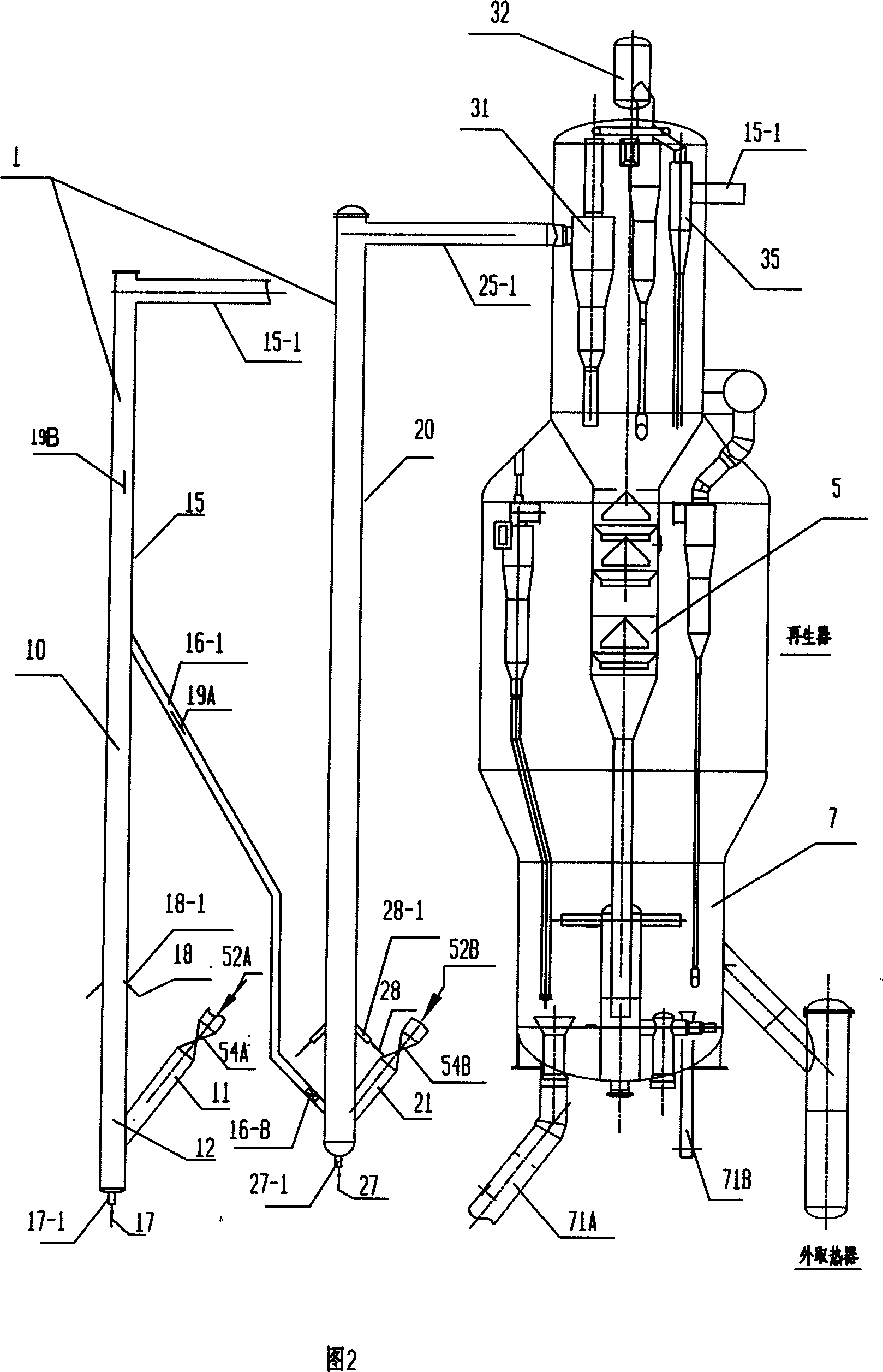

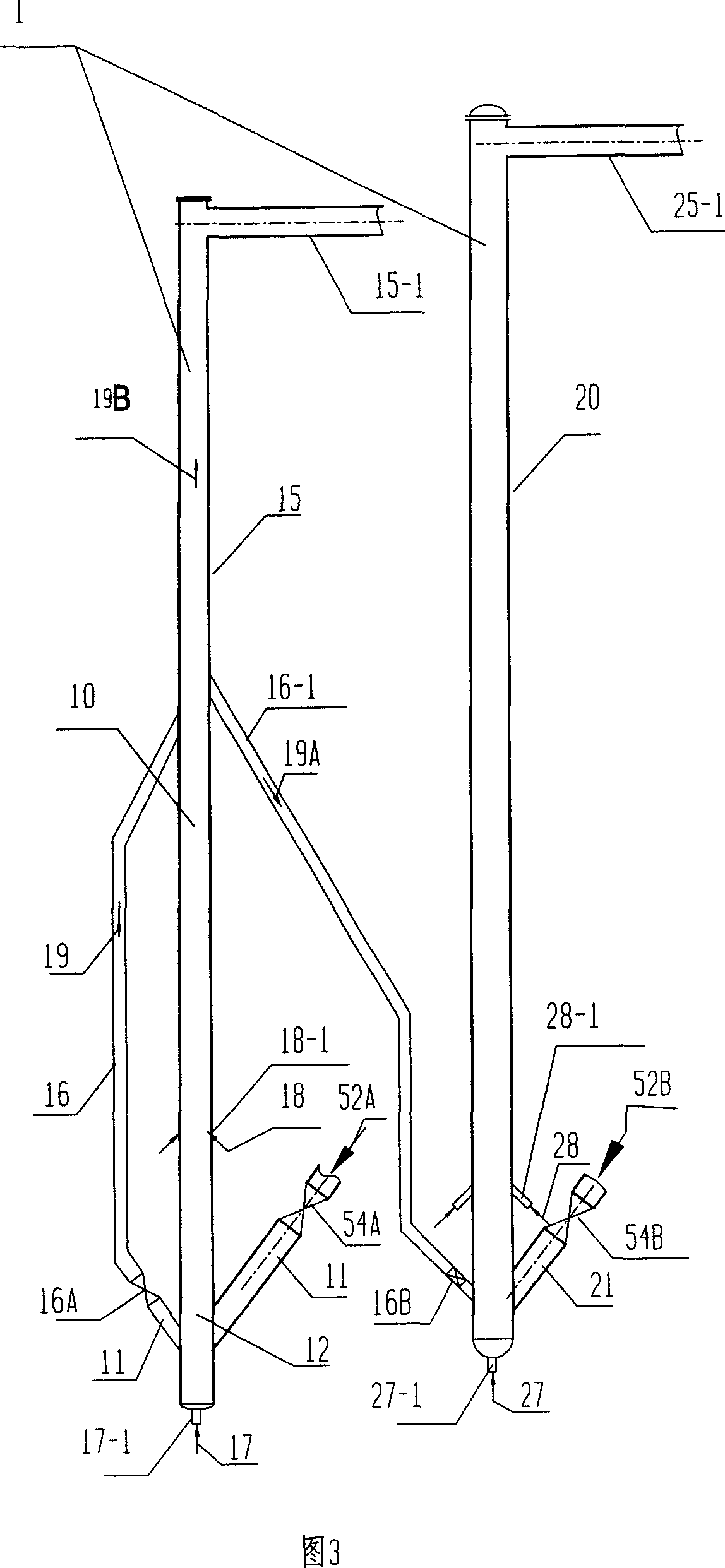

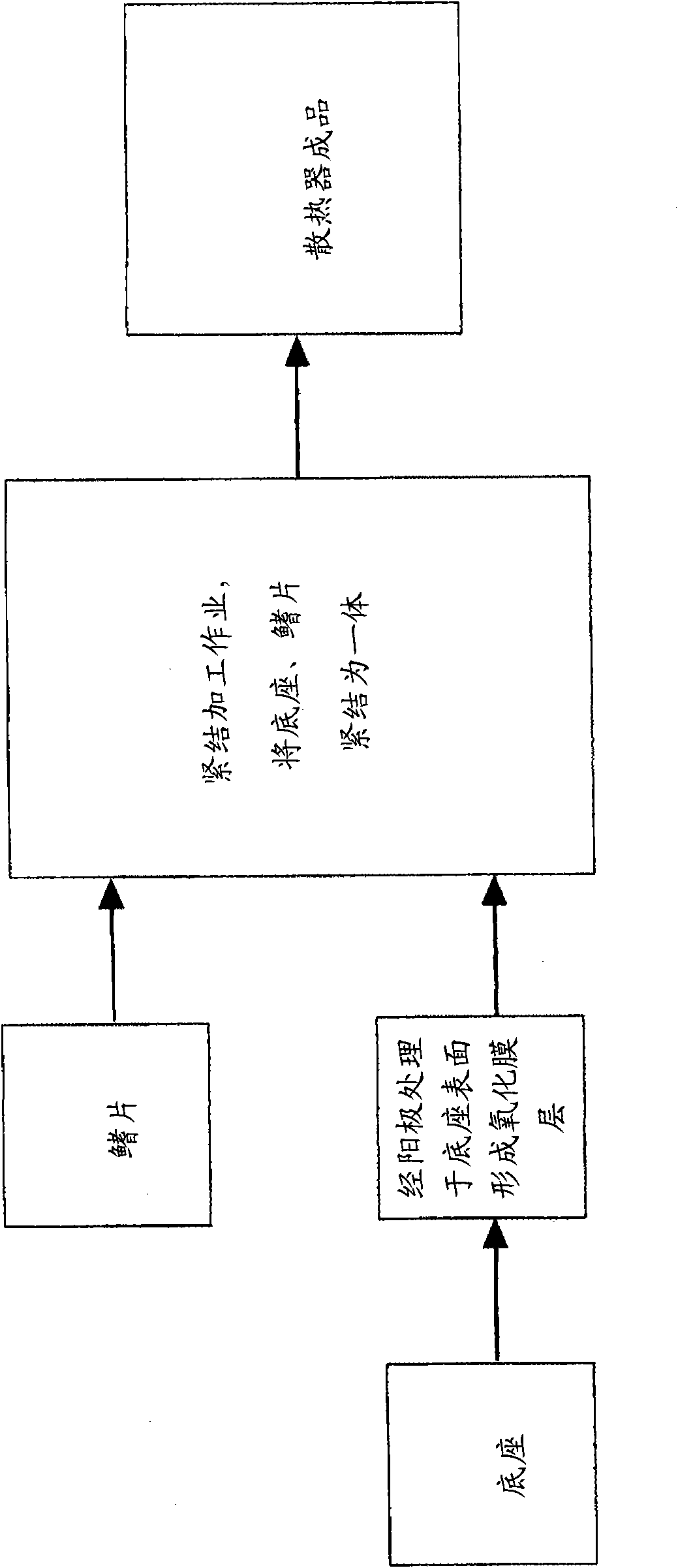

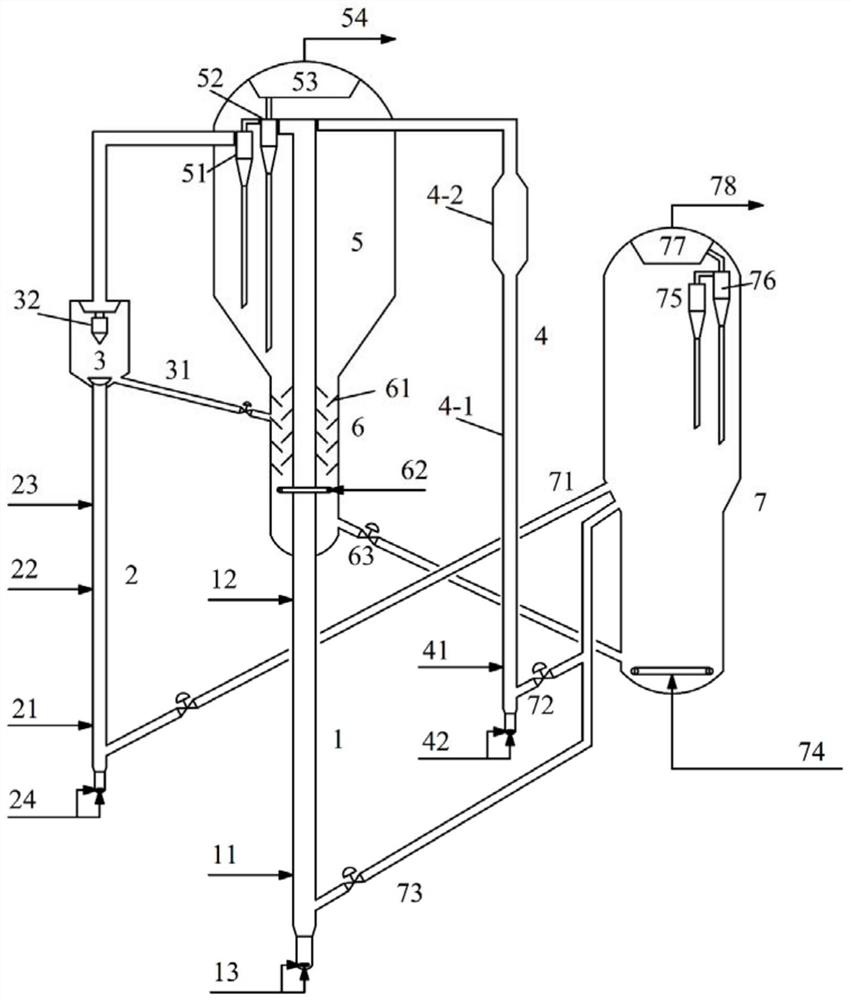

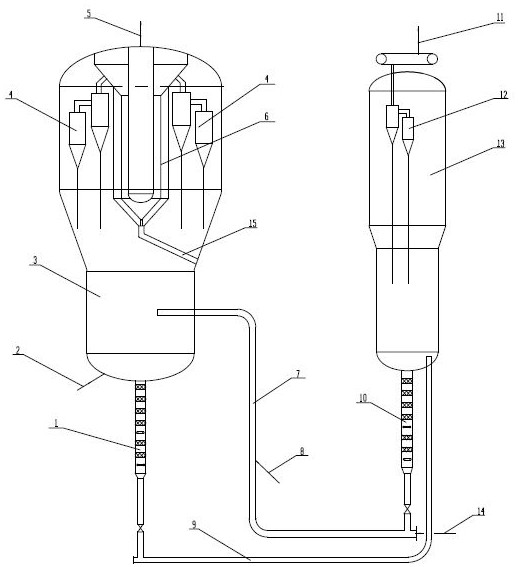

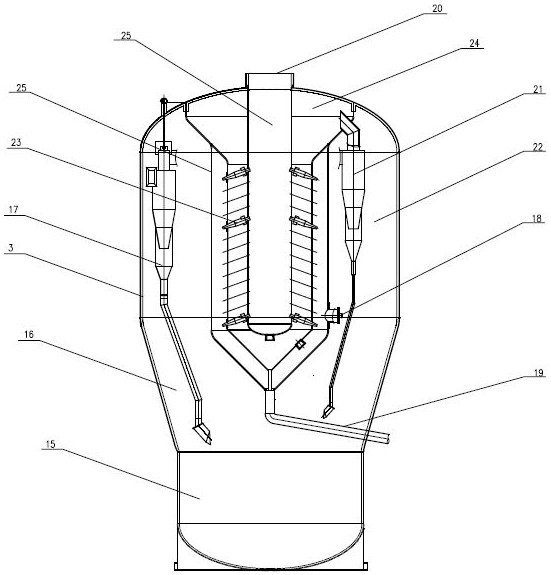

Catalytic cracking method and device

InactiveCN102746893APromote circulationLower contact temperatureCatalytic crackingTreatment with plural serial stages onlyGasolineTower

The invention discloses a catalytic cracking method and device. The method is characterized by comprising the following steps: introducing raw oil into bottom of a riser reactor to contact and react with a catalyst from a catalyst heat exchanger; separating oil gas after the reaction from a coked catalyst; introducing separated reaction oil gas into a fractionating tower; carrying out steam stripping on the separated coked catalyst and sending the coked catalyst into a regenerator for regeneration; sending part of the regenerated catalyst into the riser reactor from different height positions of the riser; and carry out heat transfer on the other part of the regenerated catalyst by a heat exchanger and entering the other part of the regenerated catalyst into bottom of the riser reactor. The method of the invention can lower total yield of dry gas and coke by 0.5-1.5 percentage, increase total liquid yield of liquefied gas, gasoline and diesel by more than 1 percentage, and reduce gasoline olefin volume content by 5-15 percentage.

Owner:CHINA PETROLEUM & CHEM CORP +1

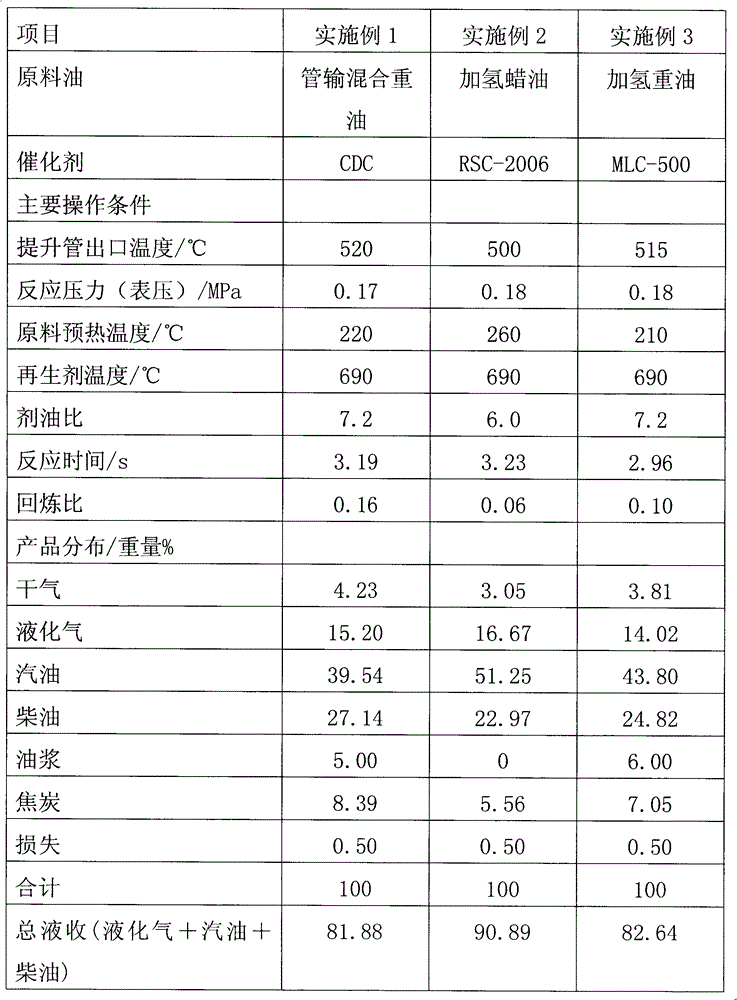

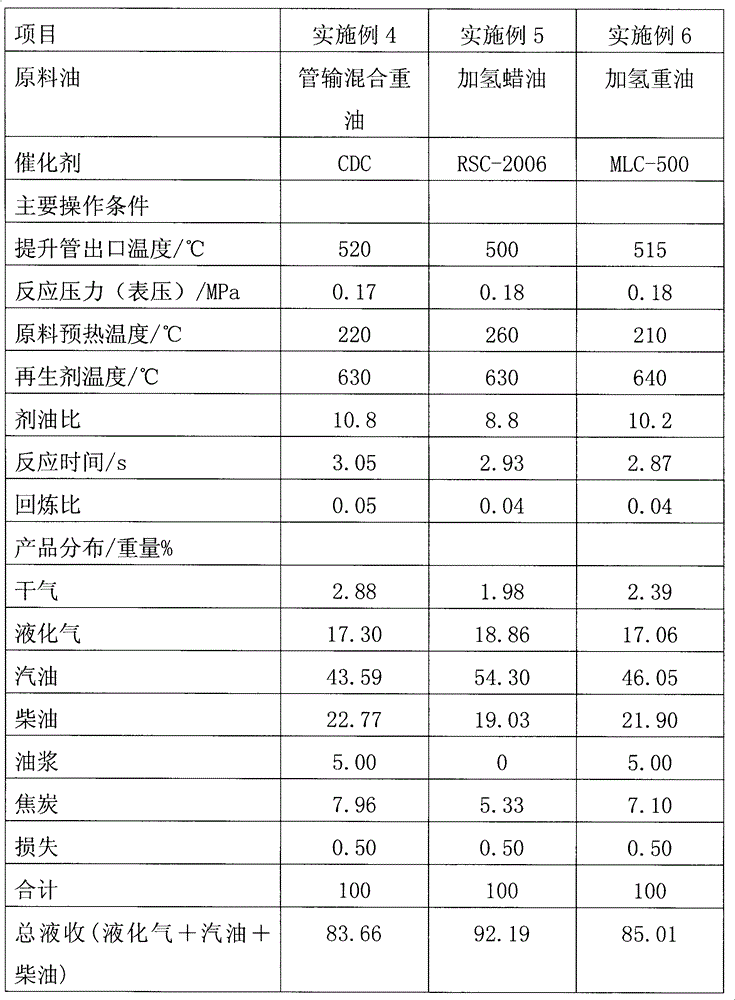

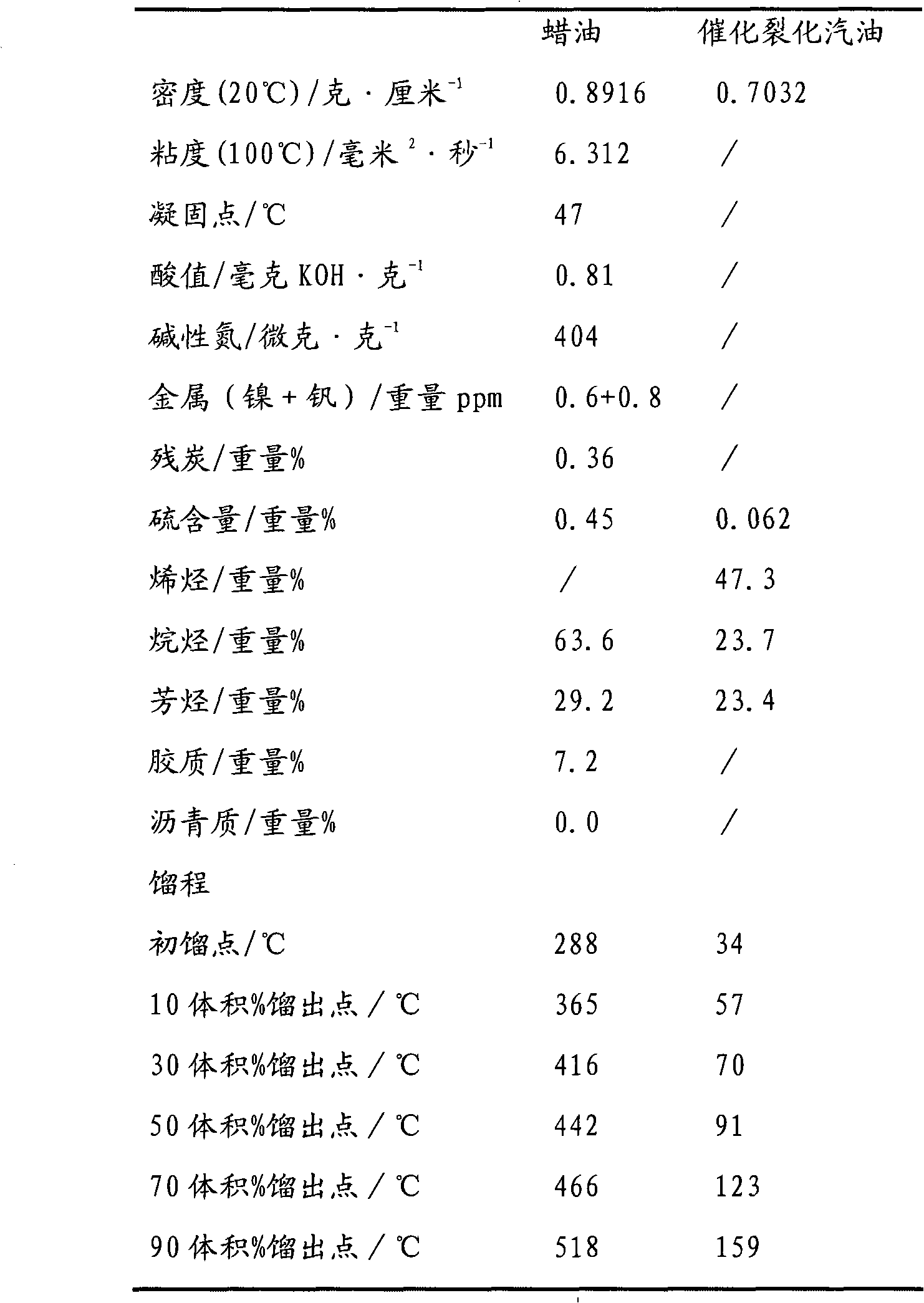

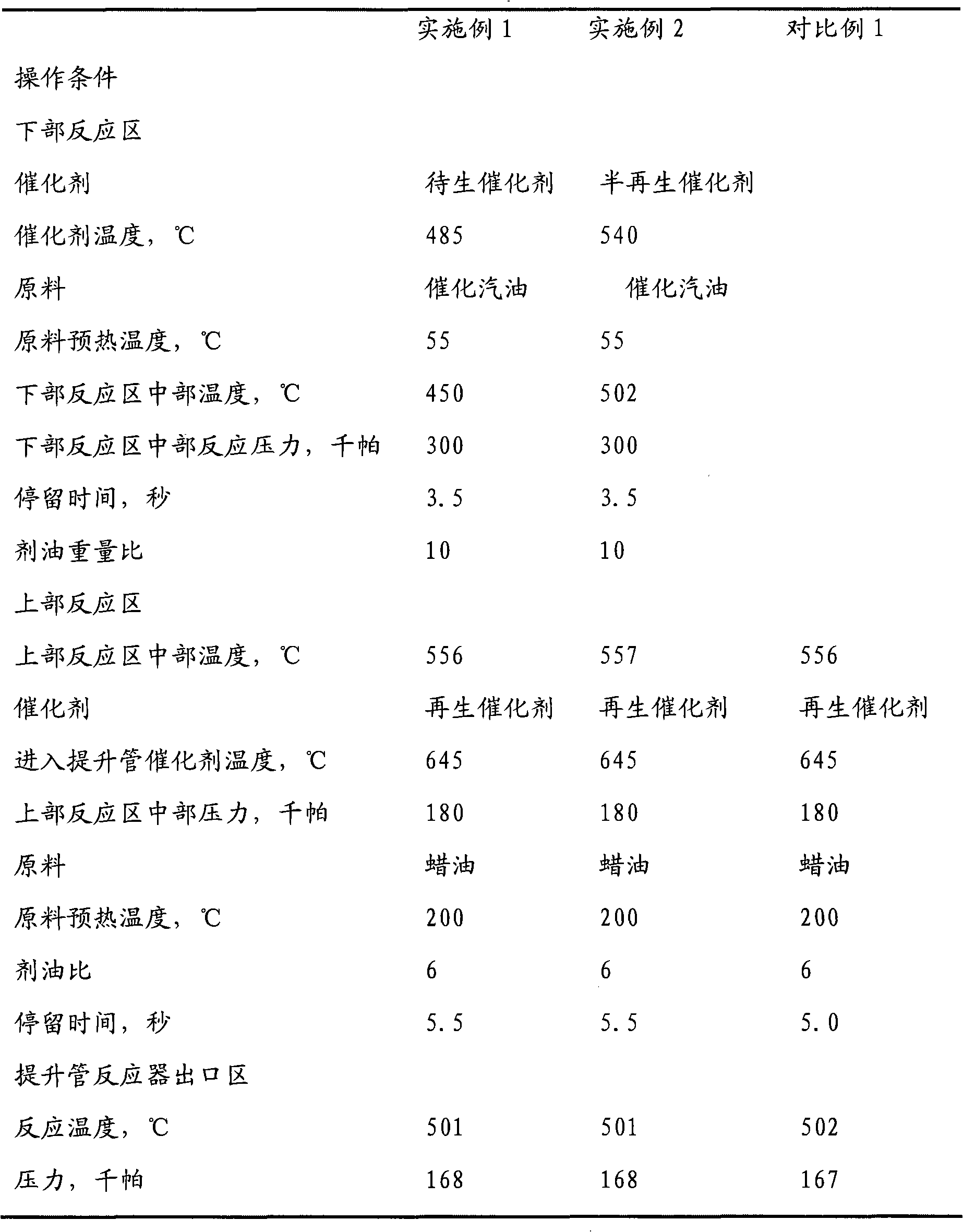

Catalytic cracking method of hydrocarbon oil

ActiveCN101928589AReduce sulfur contentReduce olefin contentCatalytic crackingPtru catalystFluidized bed

The invention relates to a catalytic cracking method of hydrocarbon oil. The processes are carried out in a riser tube or a fluidized bed reactor at least comprising upper and lower reaction zones. The method comprises the following steps: leading raw gasoline and a spent catalyst and / or a semi-regenerated catalyst in the lower reaction zone to carry out contact reaction; and leading heavy raw materials and a regenerated catalyst in the upper reaction zone to carry out contact reaction with the oil and gas and the catalyst from the lower reaction zone. The method can increase the yield of theliquid and simultaneously improve the quality of the gasoline.

Owner:CHINA PETROLEUM & CHEM CORP +1

Efficient method for producing low-carbon olefin from oxygen-containing compound

PendingCN111875464AIncrease line speedSmall diameterHydrocarbon from oxygen organic compoundsHydrocarbonsPtru catalystPetrochemical

The invention discloses an efficient method for producing low-carbon olefin from an oxygen-containing compound in the technical field of petrochemical engineering, which comprises the following steps:preheating a reaction raw material in an auxiliary reaction zone and introducing the preheated reaction raw material into the auxiliary reaction zone through a feeding distributor at the bottom of the auxiliary reaction zone, so that the reaction raw material directly contacts with a high-temperature catalyst from a regenerator, and quickly reacts under the action of the catalyst. The method disclosed by the invention is suitable for the characteristics of rapid reaction, strong heat release, relatively low agent-alcohol ratio, high product selectivity and the like of a process for preparingthe low-carbon olefin from the oxygen-containing compound, so that the problem of relatively low selectivity of the low-carbon olefin in the prior art is solved, the advantages of the reaction are brought into play to the greatest extent, and the selectivity of the low-carbon olefin is improved.

Owner:LUOYANG PETROCHEMICAL ENG CORP SINOPEC

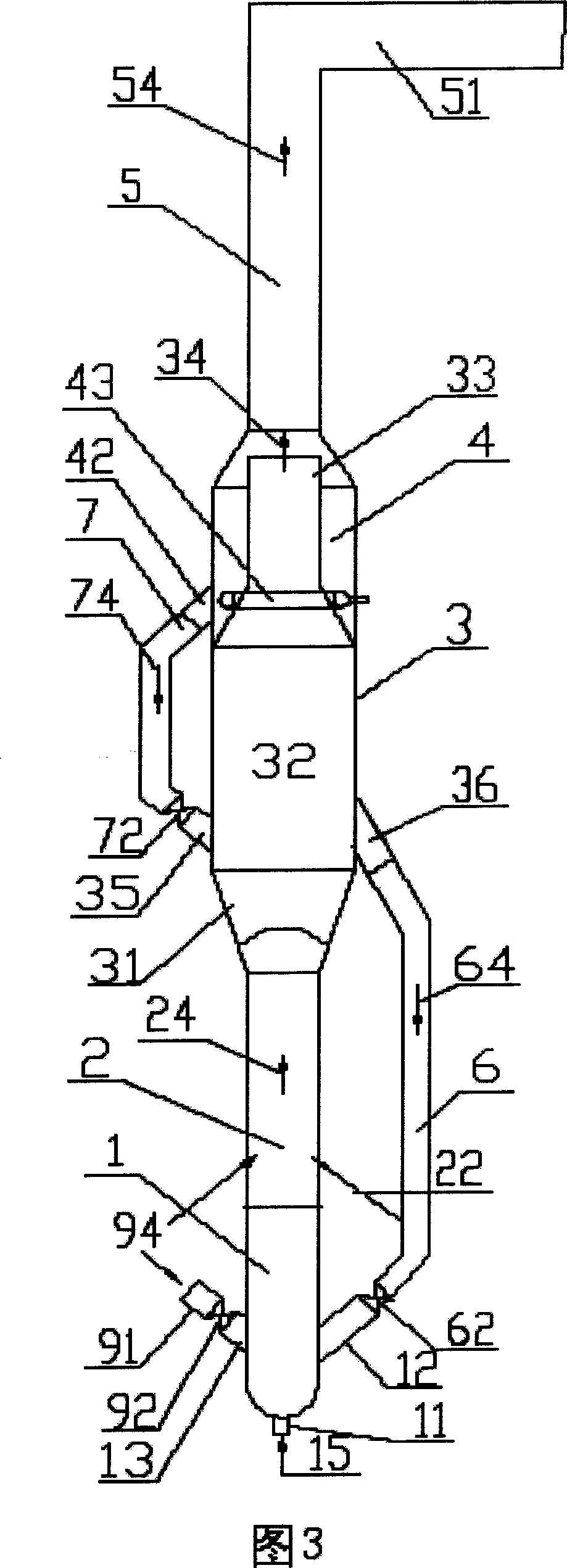

Catalytic cracking method and device

InactiveCN102746892APromote circulationLower contact temperatureCatalytic crackingTreatment with plural serial stages onlyPartial systemGlobal wind patterns

The invention discloses a catalytic cracking method and device. The method comprises the following steps: introducing raw oil into a lower part of a riser reactor to contact and react with a catalyst from a catalyst heat exchanger; separating oil gas after the reaction from a coked catalyst; introducing separated reaction oil gas into a fractionating tower; carrying out steam stripping on the separated coked catalyst and sending the coked catalyst into a regenerator for regeneration; carrying out heat transfer and cooling on the regenerated catalyst and part of system prevailing wind within the catalyst heat exchanger; sending part of the regenerated catalyst into the riser reactor from different heights of the riser; and sending the other part of the regenerated catalyst into the lower part of the riser reactor. The method can reduce total yield of dry gas and coke by 0.8-2 percentage, increase total liquid yield of liquefied gas, gasoline and diesel by 1.2 percentage, and reduce volume content of gasoline olefin by 5-15 percentage.

Owner:CHINA PETROLEUM & CHEM CORP +1

A catalytic cracking method for producing light olefins and light aromatics

ActiveCN107974286BLarge specific surface areaHigh and medium pore volumeTreatment with hydrotreatment processesHydrocarbon oils treatment productsMolecular sievePtru catalyst

The invention relates to a catalytic cracking method for producing low-carbon olefins and light aromatic hydrocarbons. According to the catalytic cracking method, a heavy raw material and a first catalytic cracking catalyst are subjected to a contact reaction in a first reactor; a lightweight raw material rich in saturated hydrocarbons, a lightweight raw material rich in olefins and a second catalytic cracking catalyst are subjected to a contact reaction in a second reactor and a third reactor; all the reaction oil-gas and the spent catalysts are subjected to gas-solid separation; the reactionoil-gas is further separated to obtain a product containing light-carbon olefins and light aromatic hydrocarbons; and the spent catalysts are subjected to steam stripping, the steam stripped catalysts enter a catalyst regenerator, charring regeneration is performed, and the regenerated catalyst returns to the reactor so as to be recycled, wherein the catalytic cracking catalyst comprises, by weight, 15-65% of natural minerals, 10-60% of an oxide, and 25-75% of a Y-type molecular sieve and a loaded metal-containing IMF structure molecular sieve. With the method of the present invention, the yield of low-carbon olefins is high, and the yield of light aromatic hydrocarbons is high.

Owner:CHINA PETROLEUM & CHEM CORP +1

Catalytic conversion method and device for prolific production of low-carbon olefins

ActiveCN112680247BHigh yieldImprove the reaction environmentLiquid hydrocarbon mixture productionChemical recyclingCatalytic transformationPtru catalyst

Owner:CHINA PETROLEUM & CHEM CORP +1

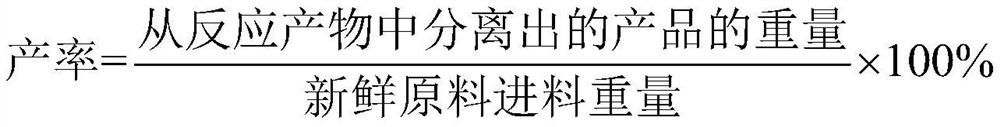

Thermoforming die in-mold punching equipment with heating devices

PendingCN110893436ALower contact temperatureExtended useful lifeShaping toolsPerforating toolsEngineeringHeater Rod

The invention discloses thermoforming die in-mold punching equipment with heating devices, and aims to provide the heating devices which are used for heating the periphery of a punching hole to a certain temperature when the temperature is too low in the production process during punching in a thermoforming die, so that a punch is not prone to breaking during punching. The in-mold punching equipment is characterized in that female die linings and a supporting seat are provided with the heating devices; each heating device comprises a heating rod, a temperature sensor and a heating control system; the heating rods and the temperature sensors are connected with the heating control systems; and the heating rods penetrate through the supporting seat and extend into the female die linings. According the in-mold punching equipment, the heating rods and the temperature sensors are arranged on the female die linings, so that the temperature of the female die linings and a pressing plate is detected through the temperature sensors at any time; and when the temperature is lower than a certain value, the heating control systems control the heating rods to increase the temperature to make thewhole female die linings and the pressing plate stabilized at a stable temperature, so that a part is not cooled too quickly when making contact with the female die linings, thus the strength of the part is not increased too quickly, and the punch is not prone to breaking during punching.

Owner:WUXI LANGXIAN LIGHTWEIGHT TECH CO LTD

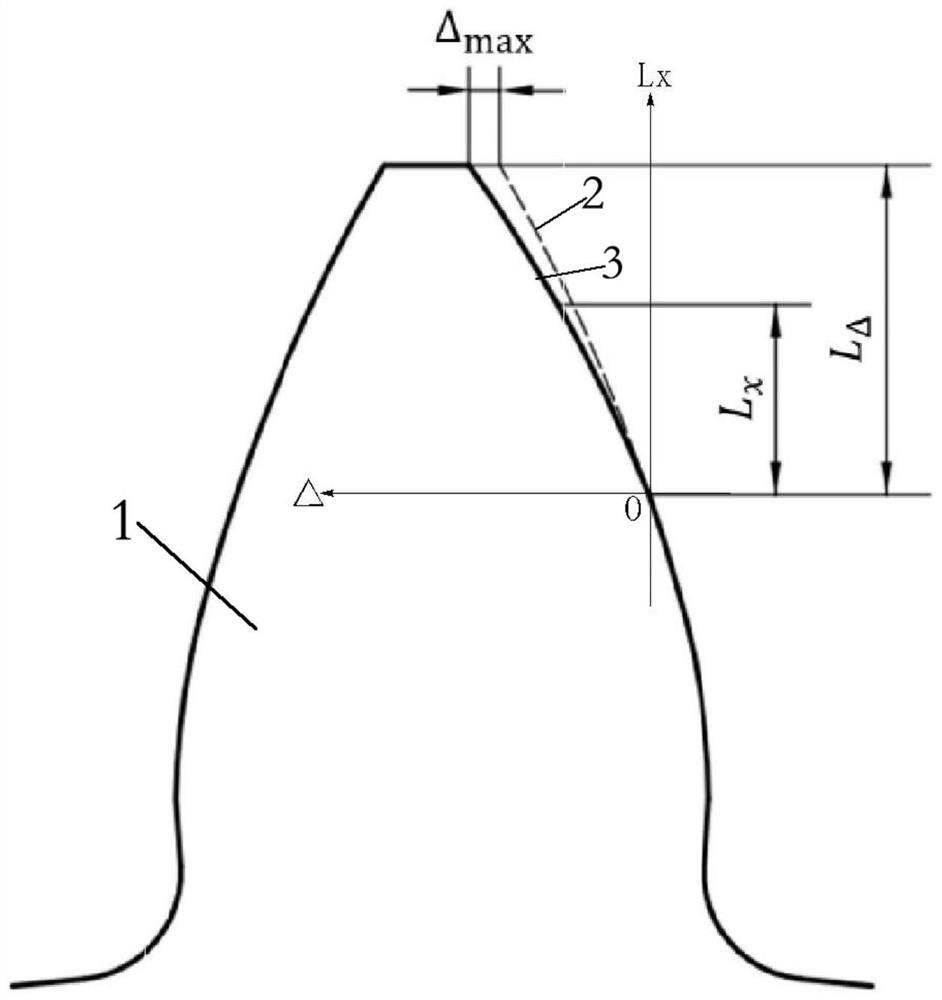

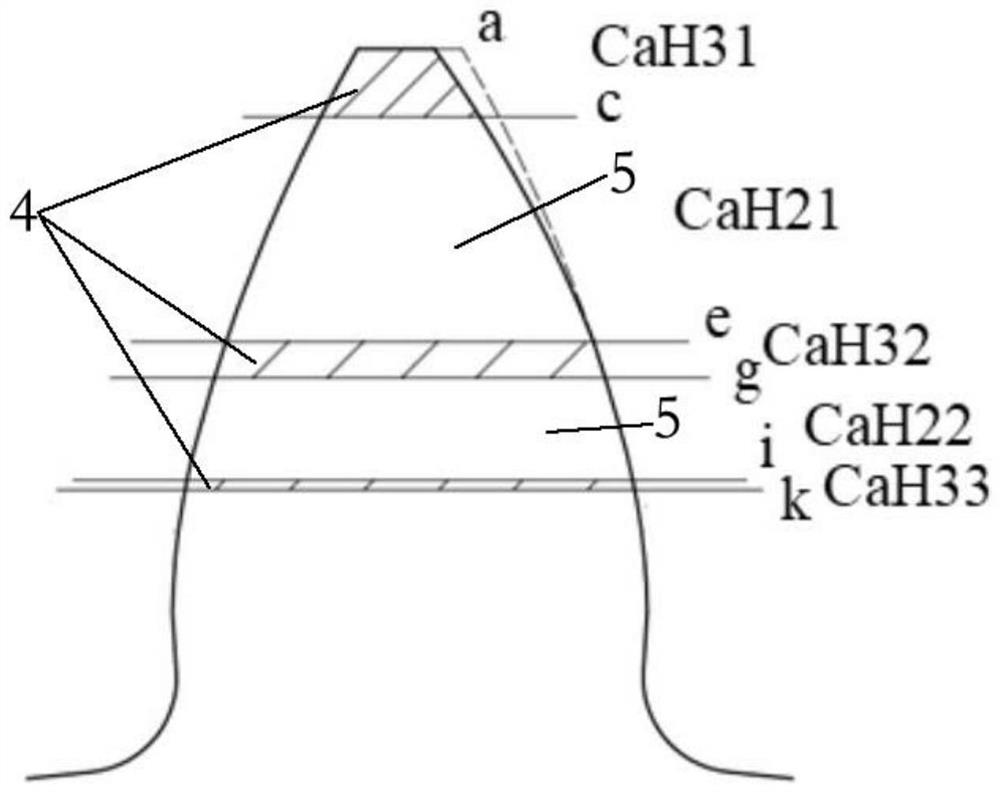

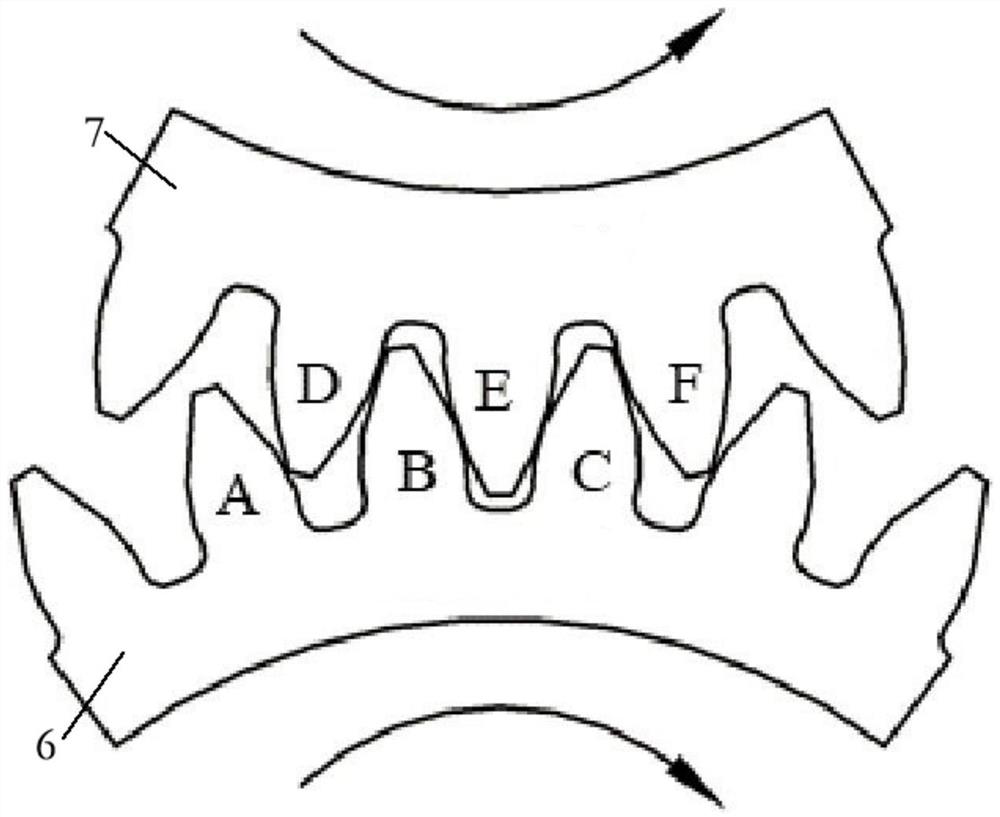

A gear modification method for reducing the contact temperature of gear tooth surfaces

ActiveCN113464624BImprove glue resistanceReduce mutationGeometric CADPortable liftingRectangular coordinatesGear wheel

The invention relates to the technical field of gear modification, in particular to a gear modification method for reducing the contact temperature of the gear tooth surface, comprising the following steps: S1: selecting the three-tooth meshing area closest to the tooth tip and the corresponding two-tooth meshing area The tooth profile of the tooth profile to be modified is used as the tooth profile to be modified; S2: The plane rectangular coordinate system (O-L X Δ), the plane Cartesian coordinate system (O-L X Δ) of the ordinate axis L X Parallel to the radial direction of the gear, the abscissa axis of the plane rectangular coordinate system is the modification amount Δ; S3: Calculate the maximum modification amount Δ of the end point relatively close to the tooth tip on the tooth profile to be modified max ; S4: Select a modification curve, the equation of the modification curve is: In the above formula, L Δ It is the ordinate of the end point relatively close to the tooth tip on the tooth profile to be modified. The invention can reduce the maximum tooth surface contact temperature when the gear teeth are meshed, and reduce or even eliminate the sudden change of the load in each meshing area of the meshing gear.

Owner:UNIV OF JINAN +1

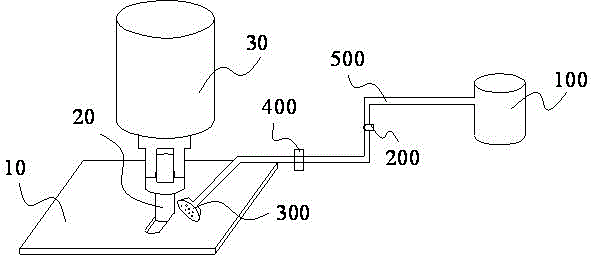

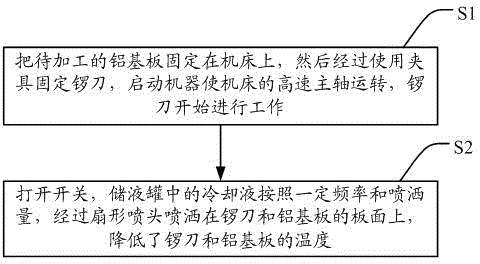

Heat dissipation device and heat dissipation method for aluminum substrate gong plate

ActiveCN103009185BSimple structureLow costPrinted circuit manufactureMilling equipment detailsEngineeringAluminum substrate

The invention discloses a radiating device and a radiating method of an aluminum substrate end-mill. The radiating device comprises a liquid storing tank, an automatic motor, a fan-shaped spray head, a switch and a guide pipe, wherein the liquid storing tank is used for storing a cooling liquid, and is connected with the fan-shaped spray head through the guide pipe; the switch and the automatic motor are arranged on the guide pipe; and the fan-shaped spray head is used for spraying the cooling liquid onto the end-mill and an aluminum substrate and adjusting the spraying time and frequency of the cooling liquid through the automatic motor and the switch. The cooling liquid is sprayed onto the end-mill and an aluminum substrate surface at a certain frequency, so that high temperature and plate surface contact temperature caused by high-speed rotation of a main shaft are lowered, residual aluminum scraps are prevented from sticking to an end-mill scrap discharging groove, the scrap discharging capability of the end-mill scrap discharging groove is ensured, and discarding caused by high temperature is improved; and meanwhile, the radiating device of the aluminum substrate end-mill further has the advantages of simple structure, low cost and the like, and has a good market popularization prospect.

Owner:SHENZHEN KINWONG ELECTRONICS

A kind of preparation method of nylon 6 cool jade fiber

ActiveCN103757738BElimination of useless impurities and toxic substancesFully excludeArtifical filament manufactureMonocomponent polyamides artificial filamentFiberNylon 6

The invention discloses a preparation method of a chinlon 6 cool jade fiber. The fiber is prepared by the steps of adopting an extraction technology and a nanotechnology, allowing jade and other beneficial mineral materials such as aluminum, silicon, titanium, zirconium and other elements to reach the sub-nanometer particle size, then fusing into a chinlon 6 melt, and carrying out spinning processing to obtain the fiber. The chinlon 6 cool jade fiber has the strength equivalent to a conventional chinlon 6 fiber, has strong wear resistance, has strong cool feel compared with an ordinary silk woven fabric, and is simple in spinning process and high in practicability.

Owner:FUJIAN JINJIANG TECH

Hops adding method of low-bitterness wort

InactiveCN111793535AReduce contact timeLower contact temperatureWort preparationEngineeringProcess engineering

The invention relates to the field of beer brewing, in particular to a hops adding method of low-bitterness wort. The method specifically comprises the following steps: crushing raw material barley malt, performing acid restoration, carrying out heat preservation for 30 minutes at 35 DEG C, carrying out protein decomposition, carrying out heat preservation for 60 minutes at 50 DEG C, carrying outstarch decomposition, carrying out heat preservation for 60 minutes at 65 DEG C, carrying out enzyme deactivation at 78 DEG C, carrying out heat preservation for 10 minutes, performing filtering, boiling wort for 60 minutes, cooling the wort to 75 DEG C, adding mosaic hops, carrying out rotary precipitation for 30 minutes, and cooling obtained liquid to 8 DEG C. The technical scheme provided by the invention has the beneficial effects that: the content of isoalpha acid obtained by isomerizing alpha acid in the final finished wort product is also greatly reduced, the bitterness of the final finished beer product is also greatly reduced compared with that of beer produced by a traditional wort preparation process, and the final finished product is easily accepted by consumers.

Owner:山东迈拓啤酒设备有限公司

Method and equipment for improving selectivity of light olefins

ActiveCN110950730BReduce the temperatureReduced activityHydrocarbon from oxygen organic compoundsChemical recyclingPtru catalystPhysical chemistry

The invention discloses a method and equipment for improving the selectivity of low-carbon olefins, which are composed of the following steps: 1) the oxygen-containing compound raw material enters the reactor and contacts with the regenerated catalyst from the pre-reaction section for exothermic reaction; 2) in step 1) The reaction gas enters the built-in separation facility of the reactor to remove the entrained catalyst after removing the catalyst carried; 3) In step 1), the coke-deposited catalyst after the reaction enters the regenerator for charred regeneration; 4) Step 3) The regenerated catalyst enters the regenerated stripper for stripping and cooling, and then enters the pre-reaction section; 5) The pre-reaction medium enters the pre-reaction section after gasification, undergoes an endothermic reaction with the regenerated catalyst, and then enters the reactor. The advantages of adopting the method and equipment provided by the present invention are: by setting the pre-reaction section, the occurrence of unintended reactions is reduced, and the selectivity of low-carbon olefins is improved; by the built-in sleeve in the reactor, the dilute phase space of the reactor is shortened , improving the selectivity of low carbon olefins.

Owner:SINOPEC LUOYANG PETROCHEM ENG CORP +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com