Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

3992 results about "Heat transfer efficiency" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Heat transfer is most efficient by convection, then by conduction; radiation is the least efficient and slowest means of heat transfer. Low efficiency of heat transfer means that vacuums make excellent insulation.

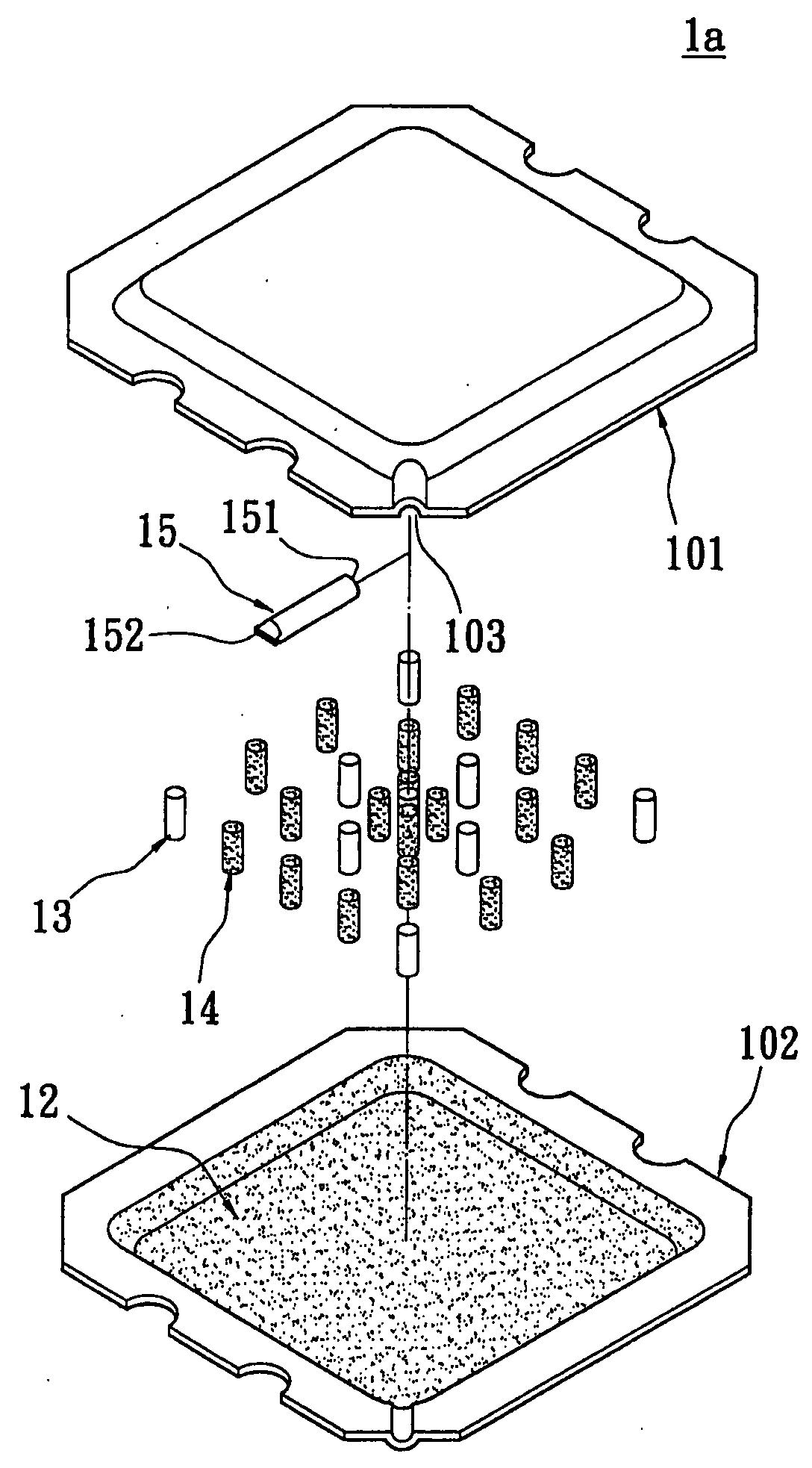

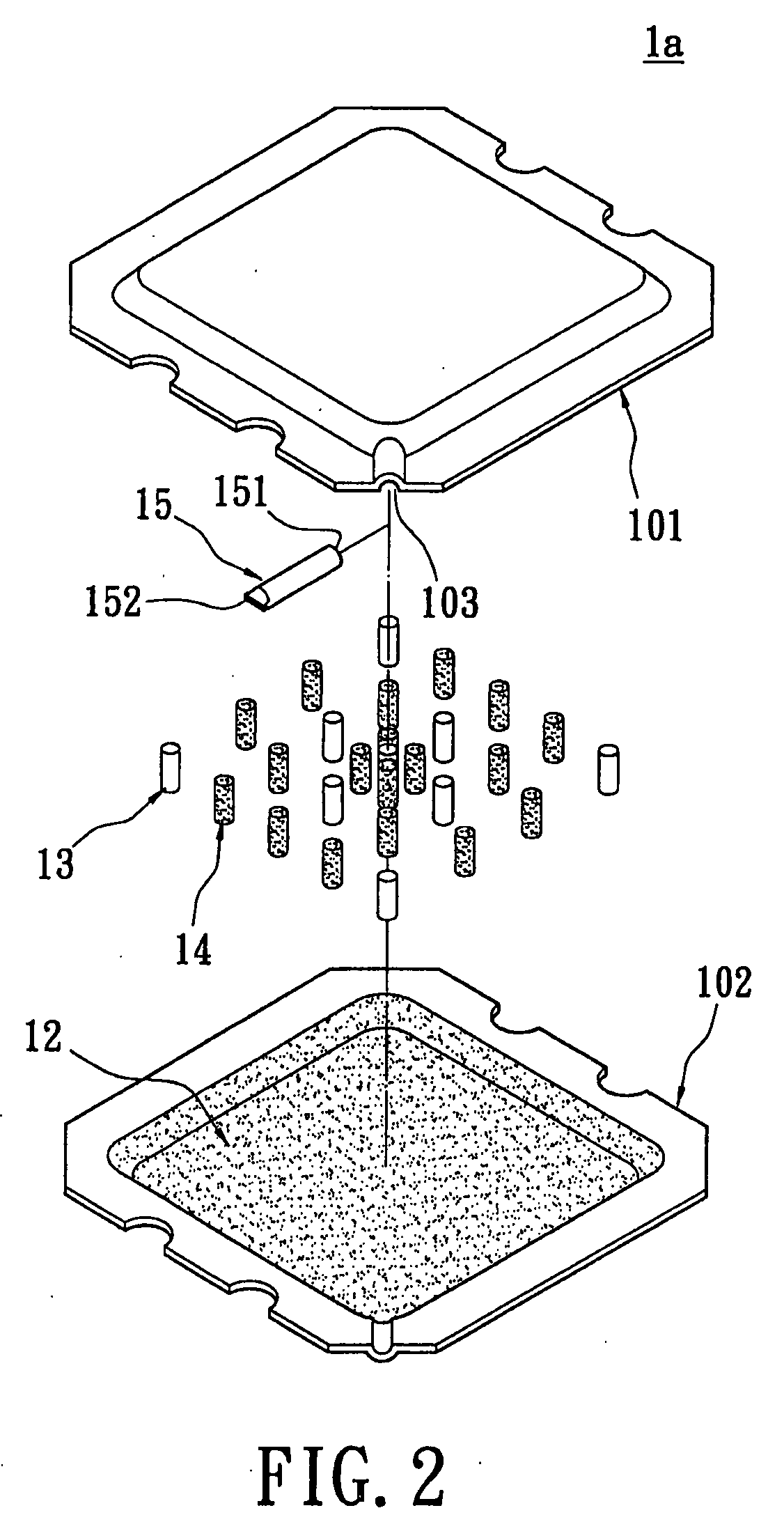

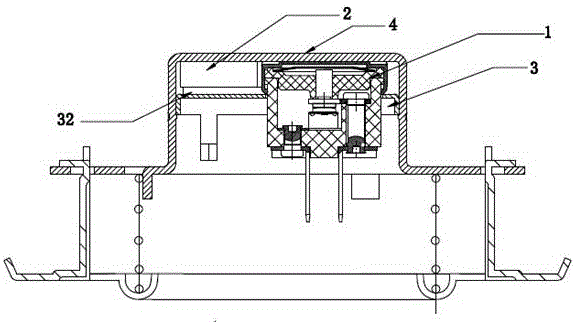

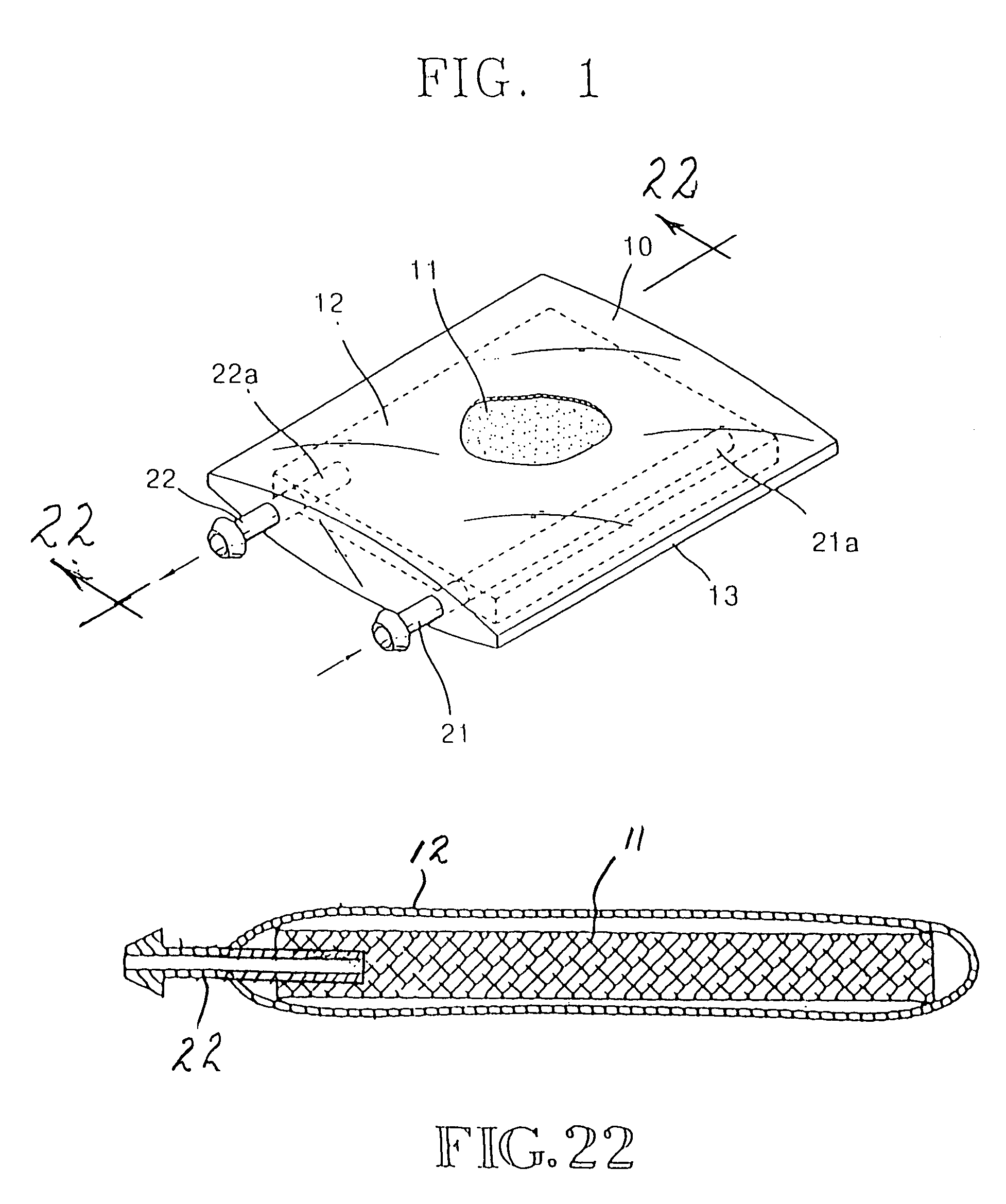

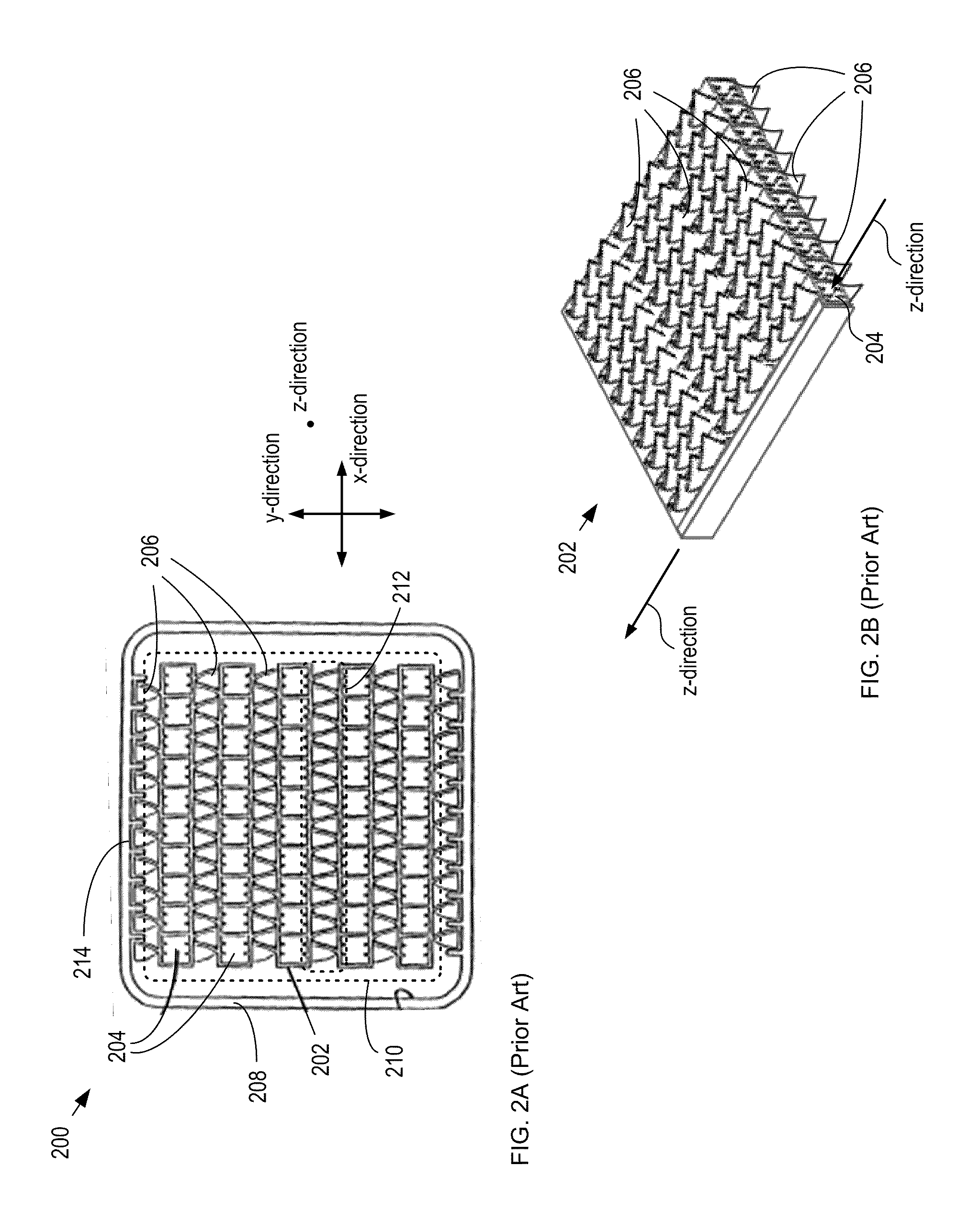

Vapor chamber structure with improved wick and method for manufacturing the same

InactiveUS20090025910A1Improve thermal efficiencySemiconductor/solid-state device detailsSolid-state devicesWorking fluidHeat transfer efficiency

A vapor chamber structure includes a casing, a working fluid, and an improved wick layer. The casing has an airtight vacuum chamber. The working fluid is filled into the airtight vacuum chamber. The wick layer is formed on a surface of the airtight vacuum chamber. Therefore, the present invention can increase the backflow velocity of the working fluid and improve the boiling of the working fluid due to the match of the improved wick structure. Because the backflow velocity and boiling of the working fluid is increased, the heat-transmitting efficiency is increased.

Owner:THERMAL TECH

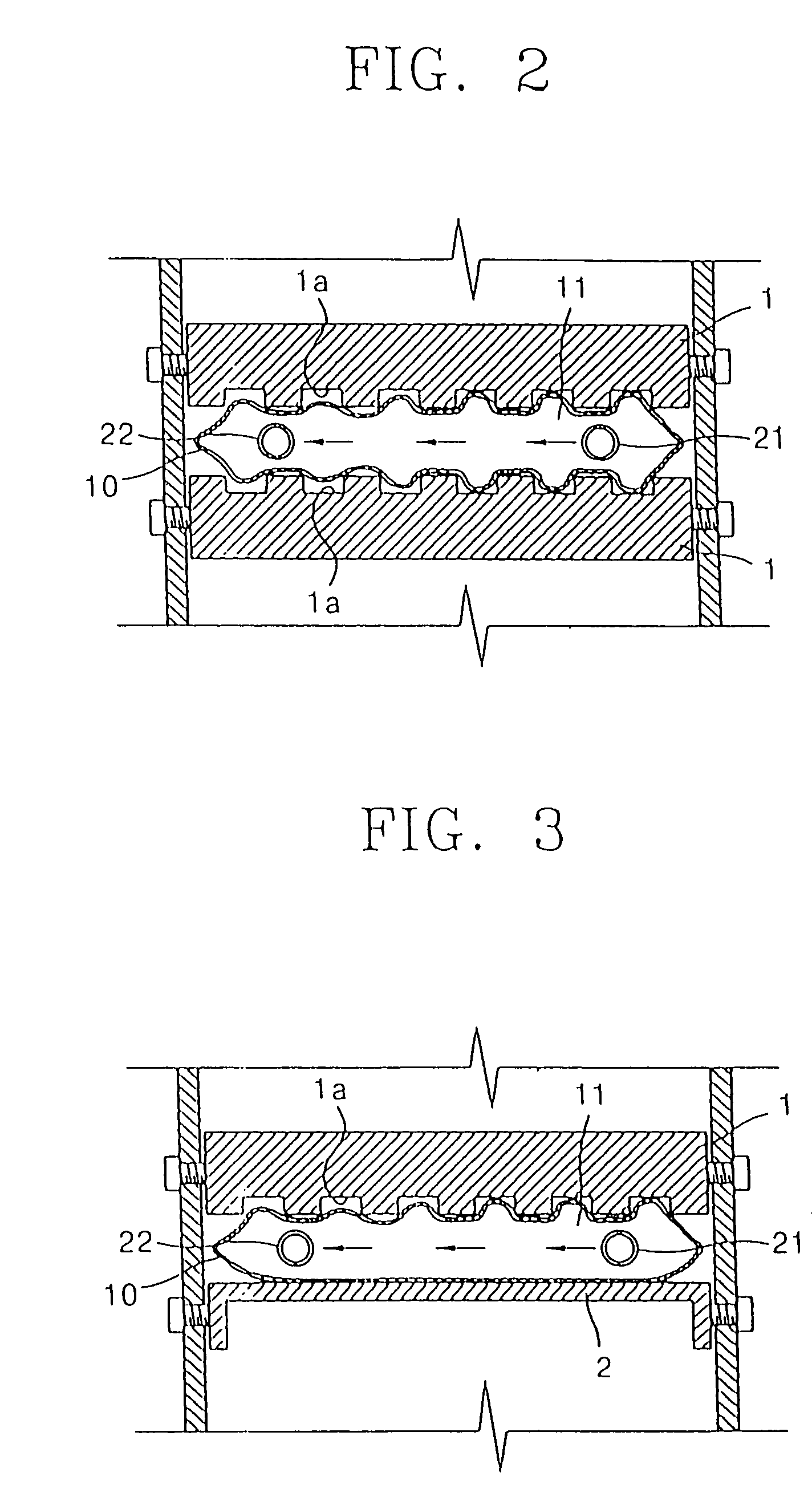

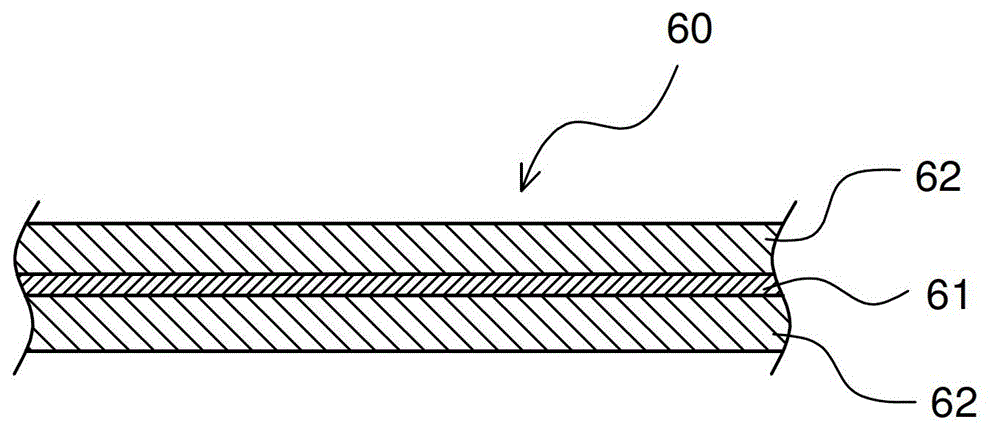

Thermoelectric module with improved heat-transfer efficiency and method of manufacturing the same

InactiveUS6274803B1Thermoelectric device with peltier/seeback effectThermoelectric device manufacture/treatmentHemt circuitsEngineering

A thermoelectric chip with exposed surfaces of N-type and P-type semiconductor elements on its top and bottom surfaces is prepared by arranging the semiconductor elements in a matrix manner such that each of the N-type semiconductor elements is disposed adjacent to the P-type semiconductor element through a space, and filling the space with a first resin material having electrical insulation. A metal layer is formed on each of the exposed surfaces of the semiconductor elements. Then, first electrodes are formed on the top surface according to a first circuit pattern. Similarly, second electrodes are formed on the bottom surface according to a second circuit pattern different from the first circuit pattern. An electrical insulation sheet of a second resin material containing a ceramic powder with high thermal conductivity is bonded to the top and bottom surfaces to obtain the thermoelectric module.

Owner:MATSUSHITA ELECTRIC WORKS LTD

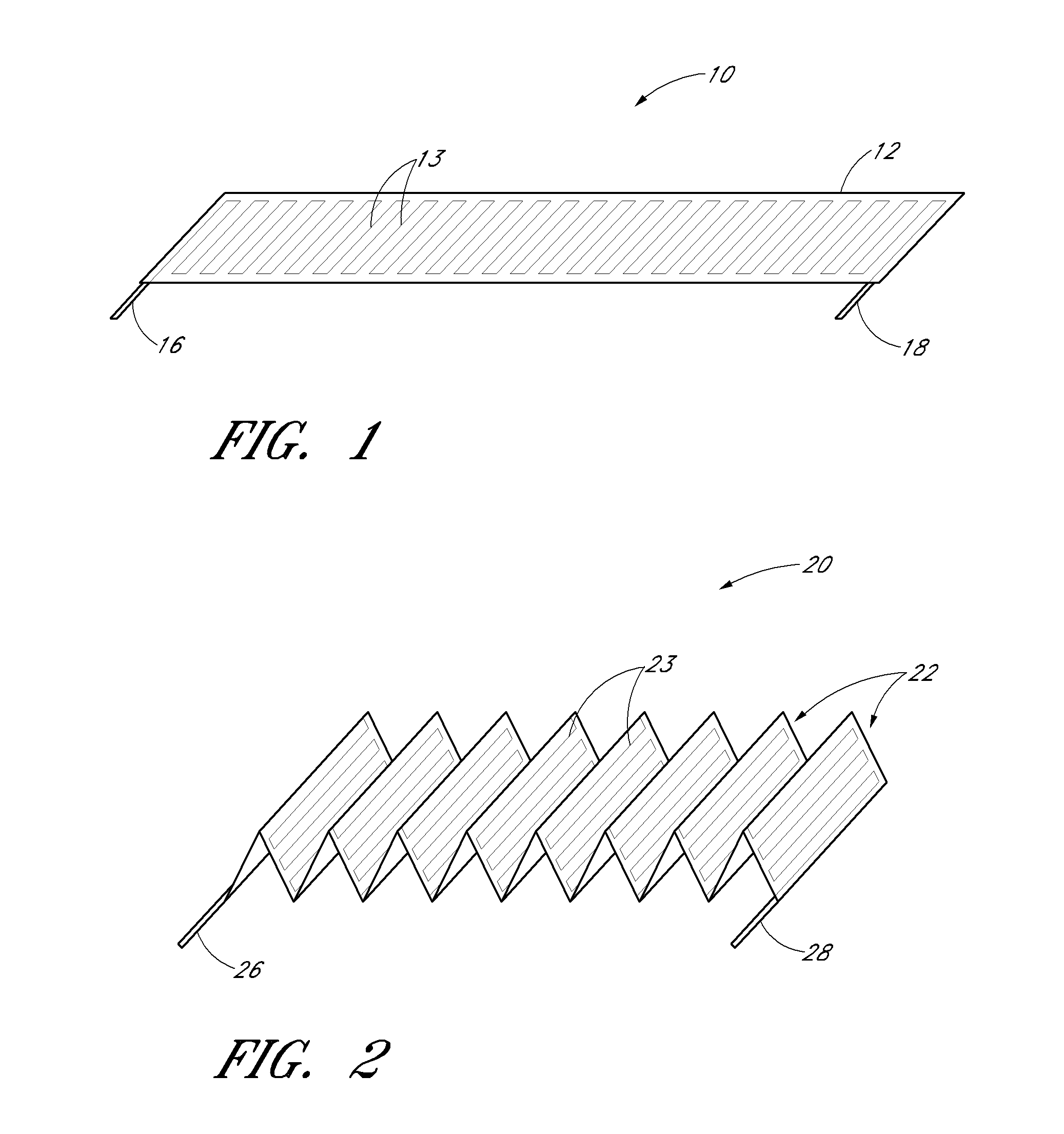

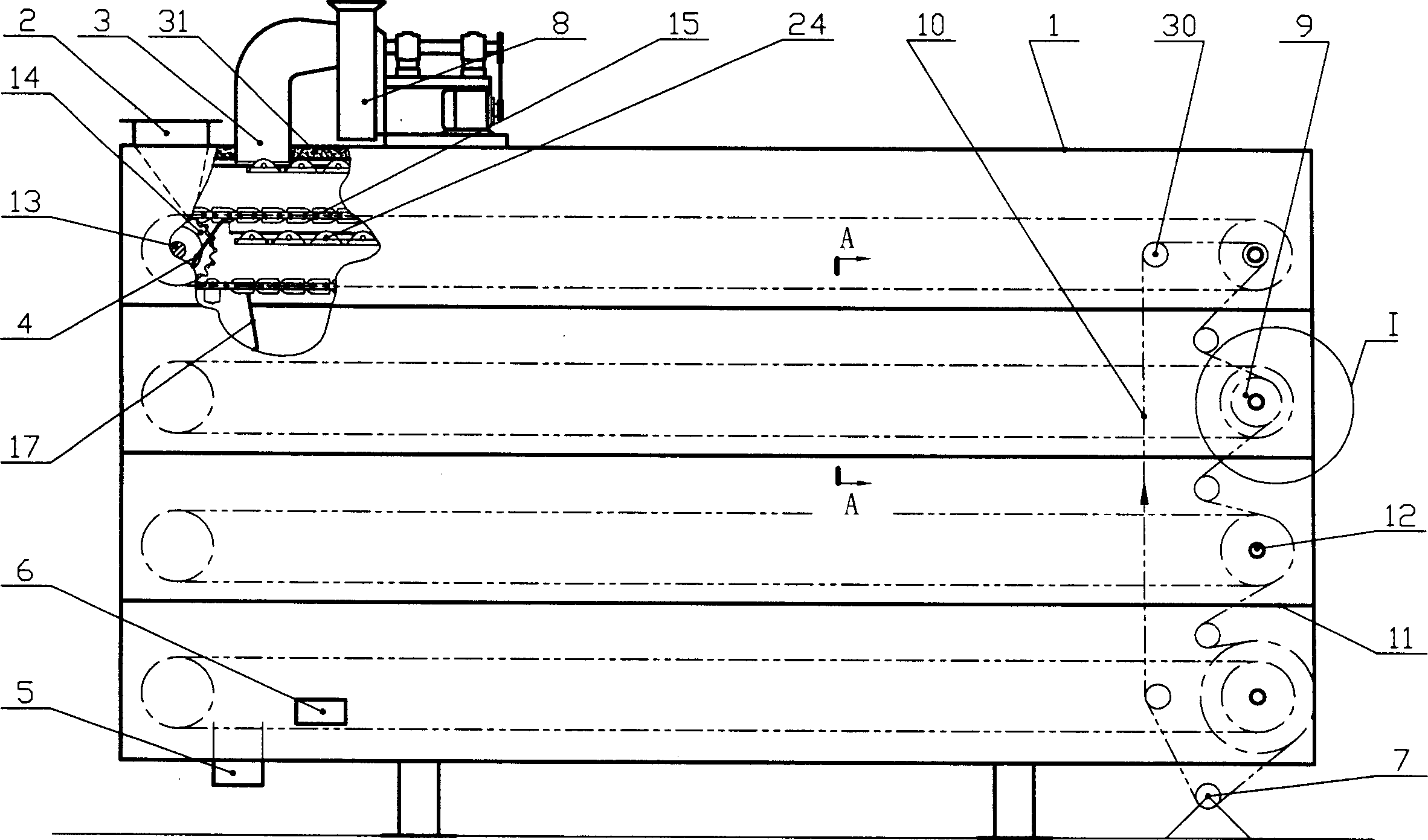

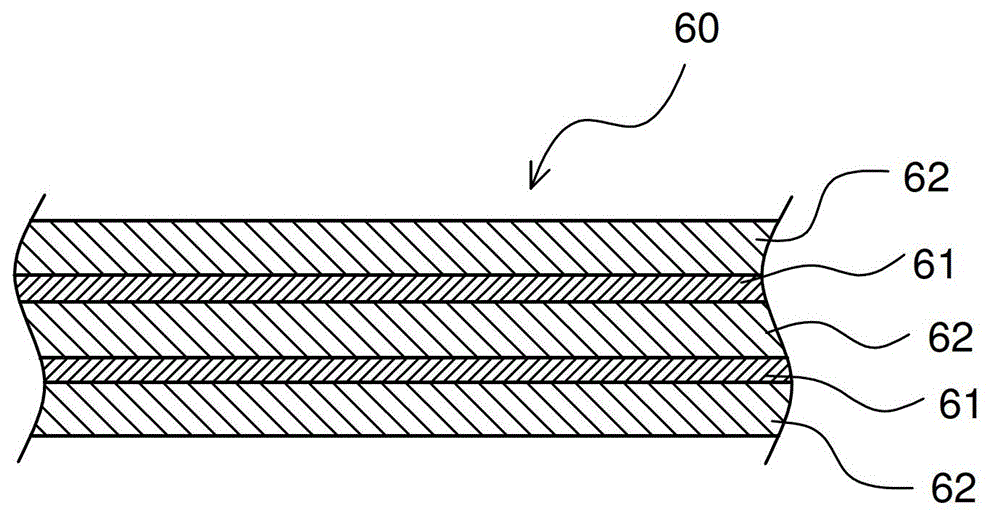

Fluid conditioning device

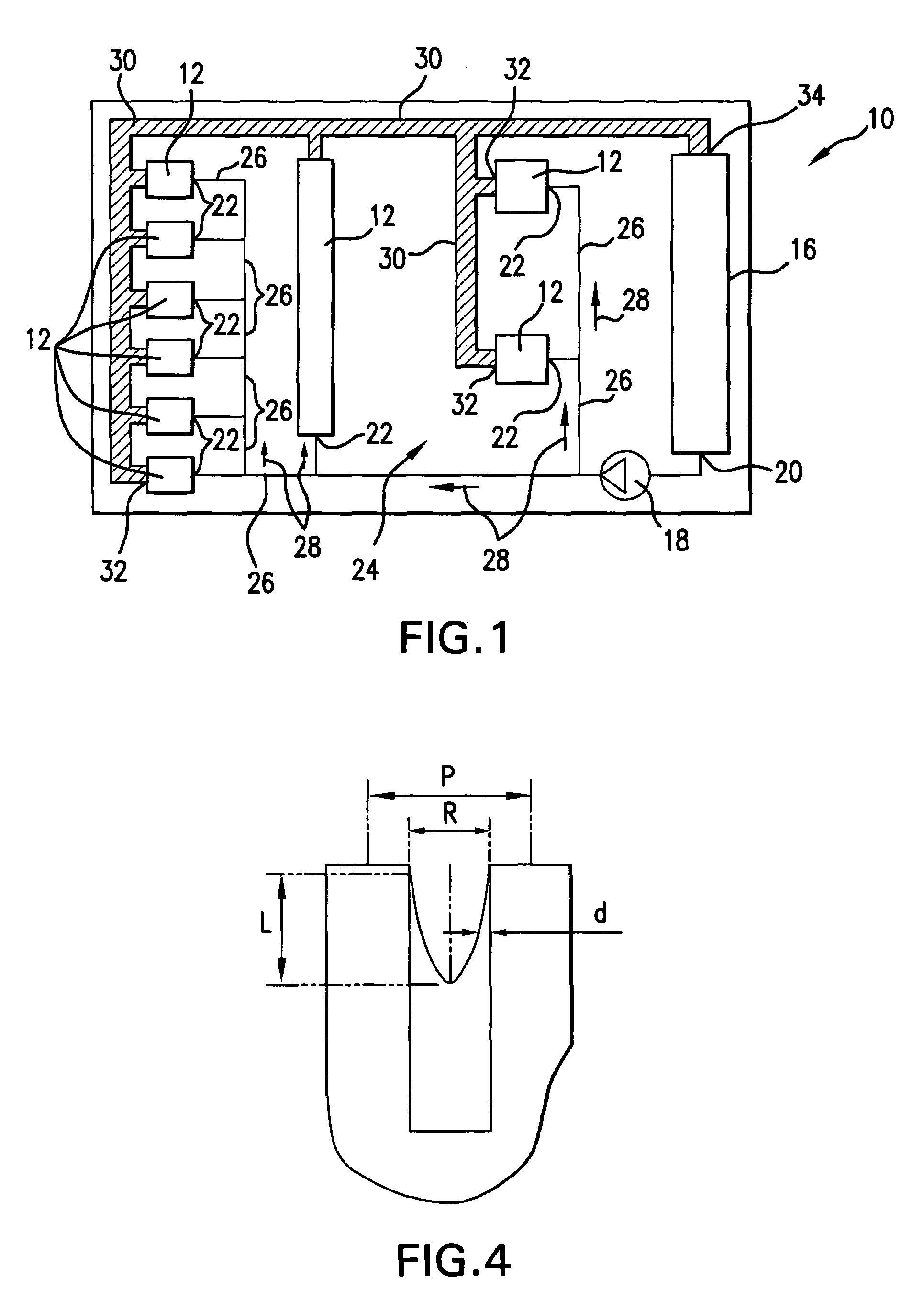

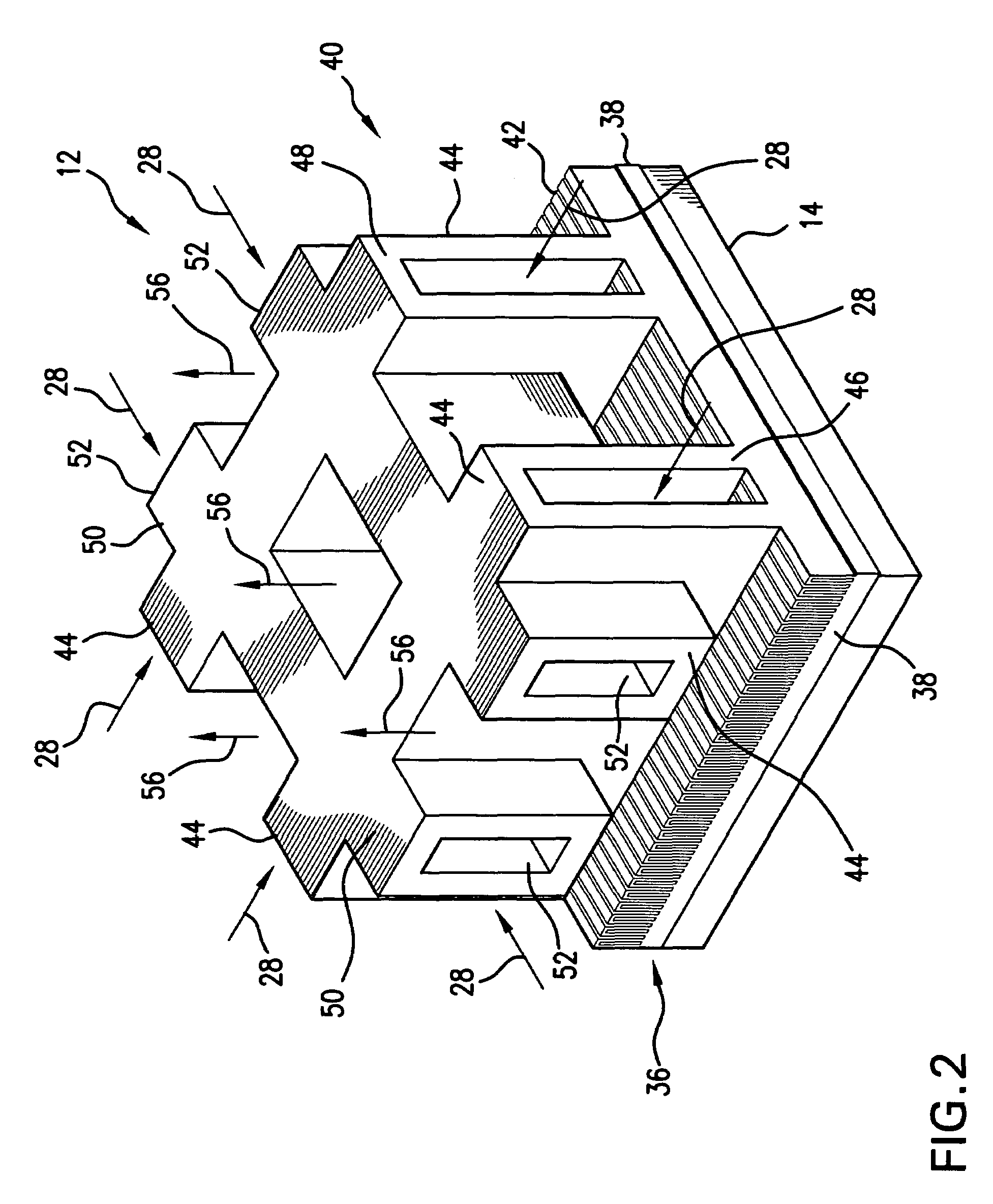

InactiveUS20120261399A1Vehicle seatsOhmic-resistance heating detailsEngineeringHeat transfer efficiency

A heating element includes a plurality of folded surfaces which can be resistively heating using electrical current. The heating element can advantageously function both as a heating source and a heat transfer device, as the need for separate fins or other heat dissipation members is eliminated. In some embodiments, the heating element can be included in a fluid heating system. The fluid heating system can include a fluid transfer device configured to deliver a volume or ambient air or other fluid through the heating element. As air moves past the heated folded surface of the heating element, it is heated. Heated air can then be discharged to one or more desired locations.

Owner:AMERIGON INC

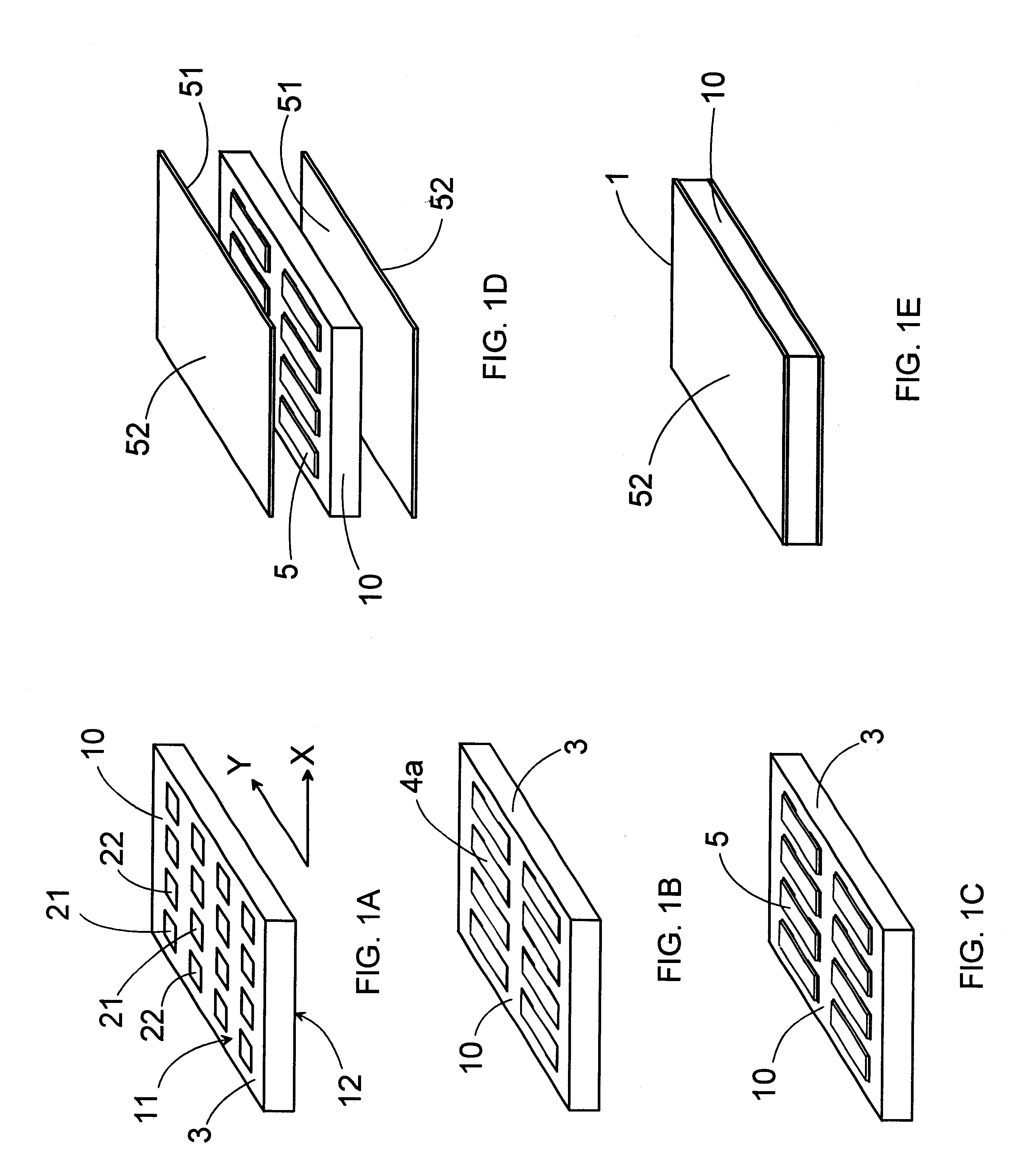

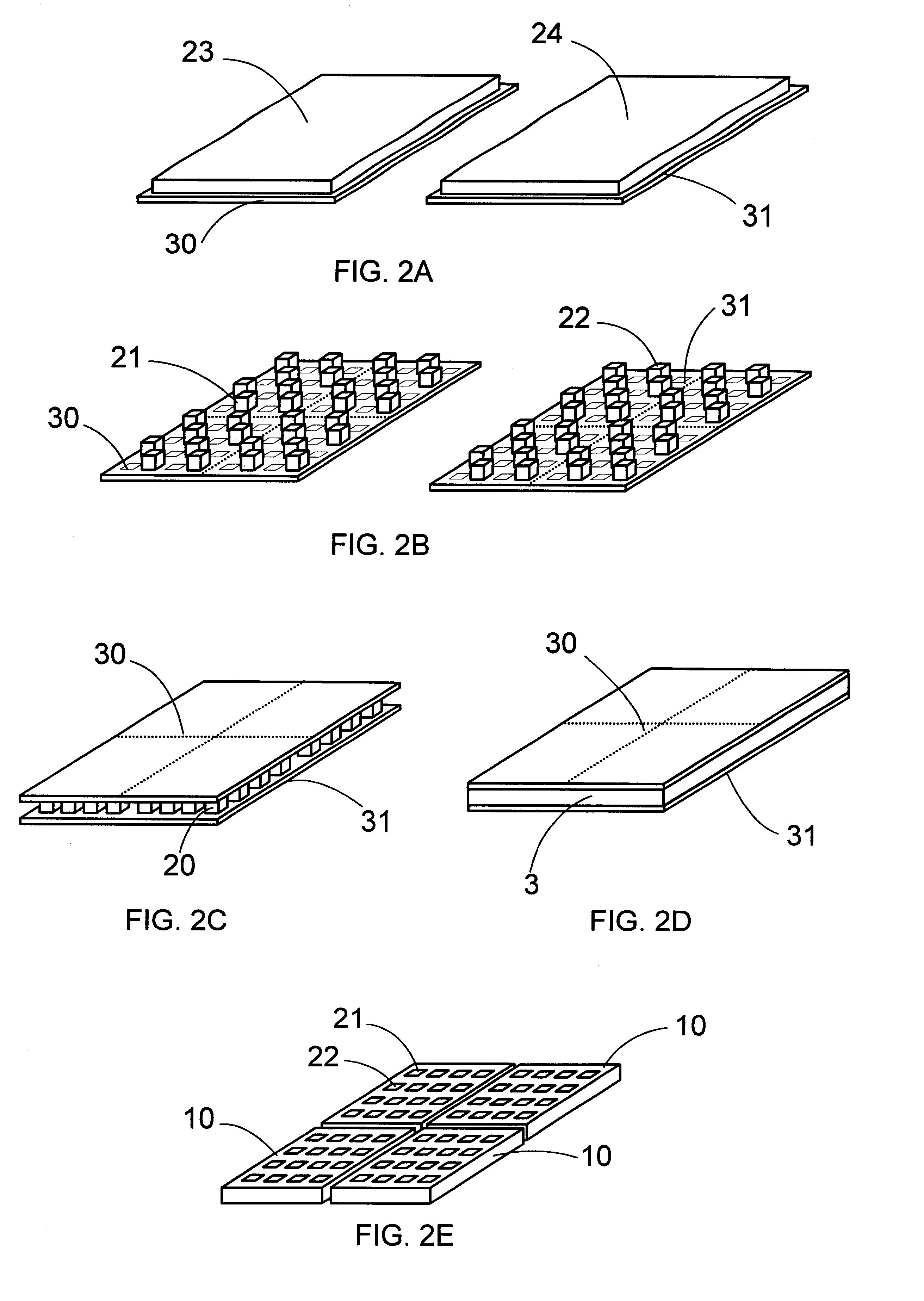

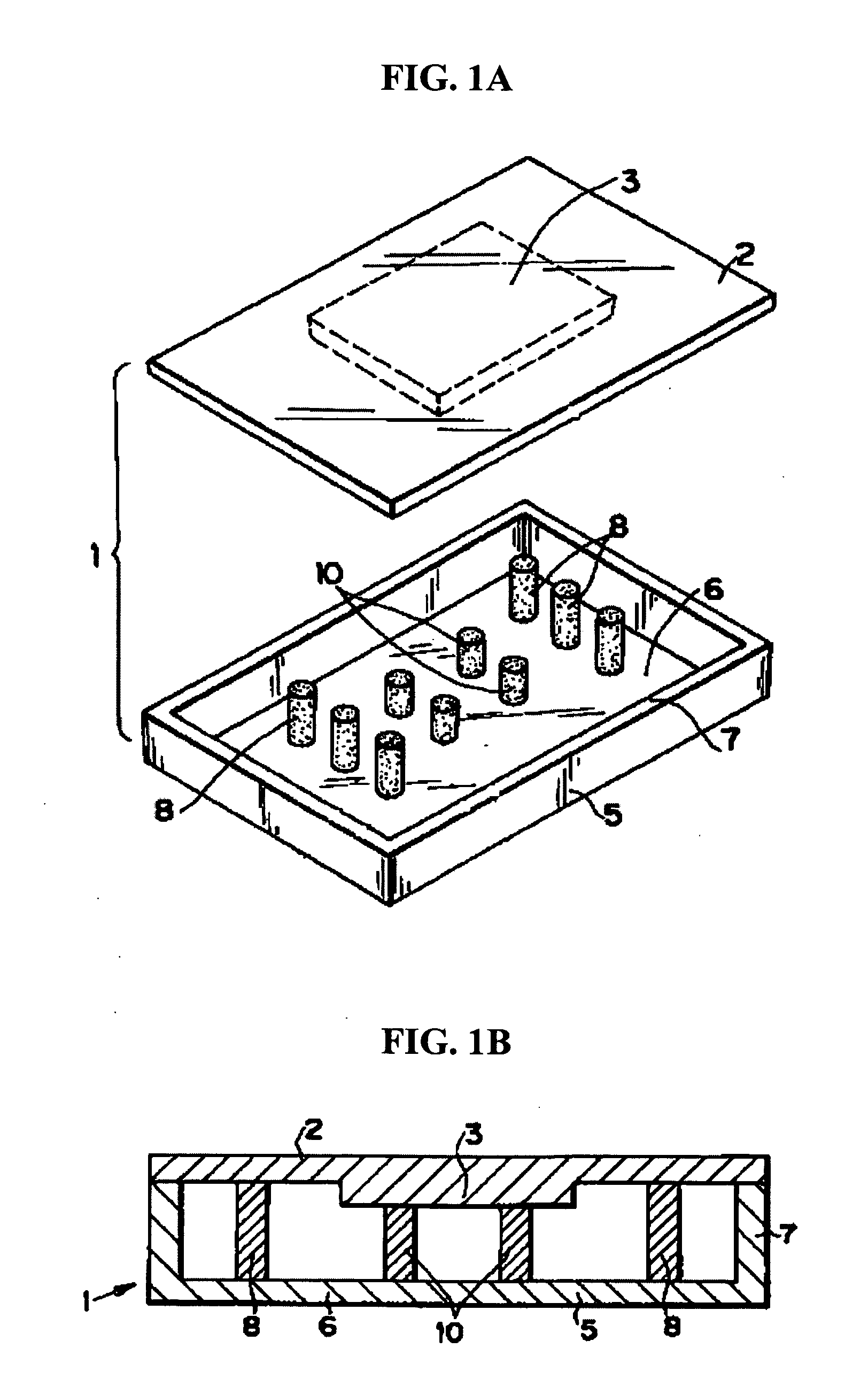

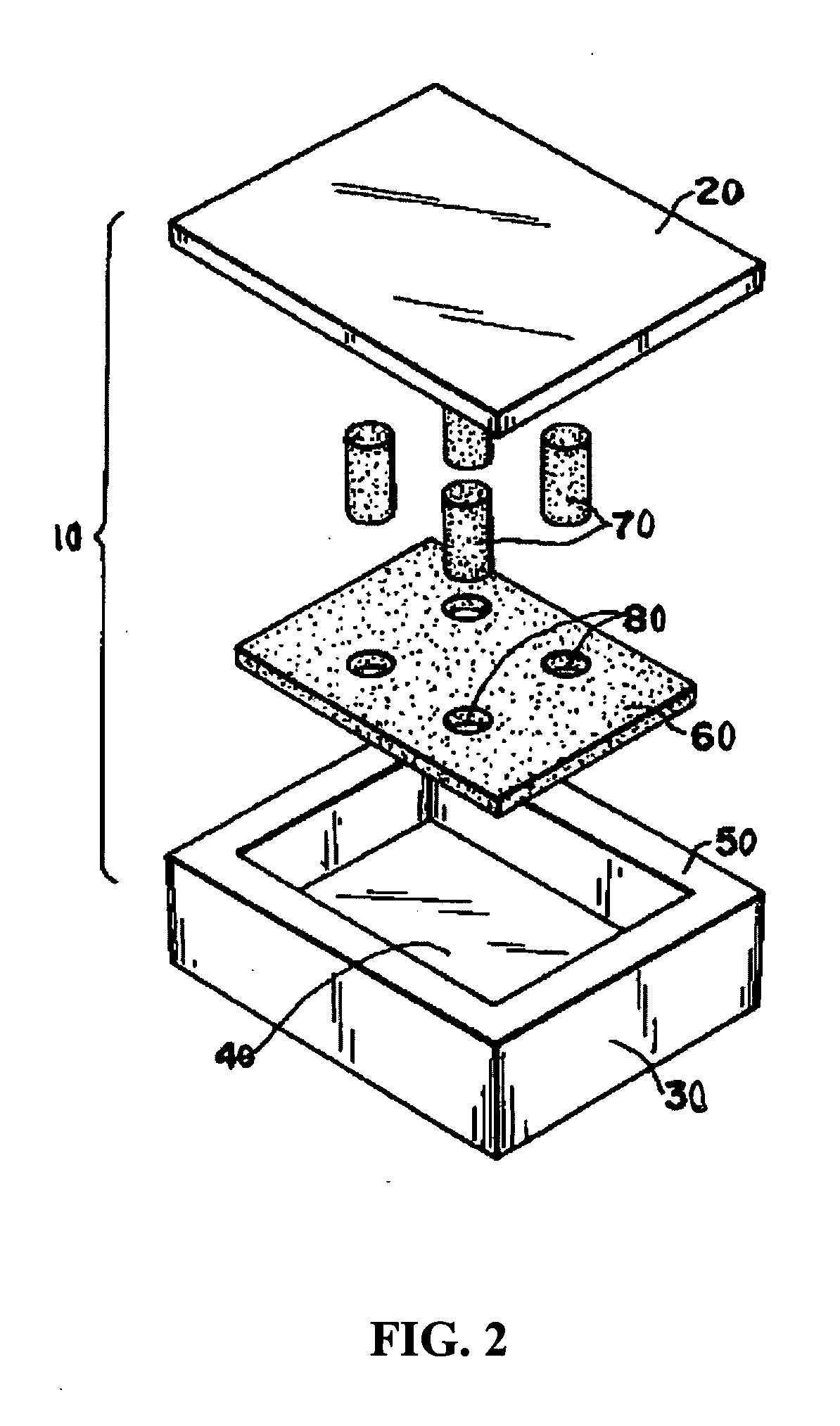

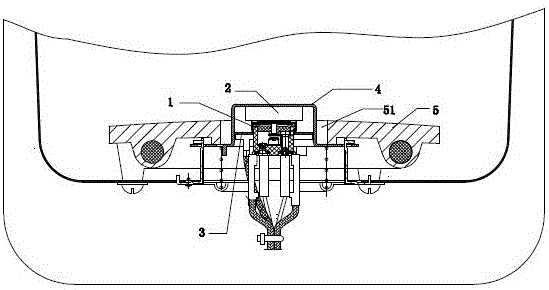

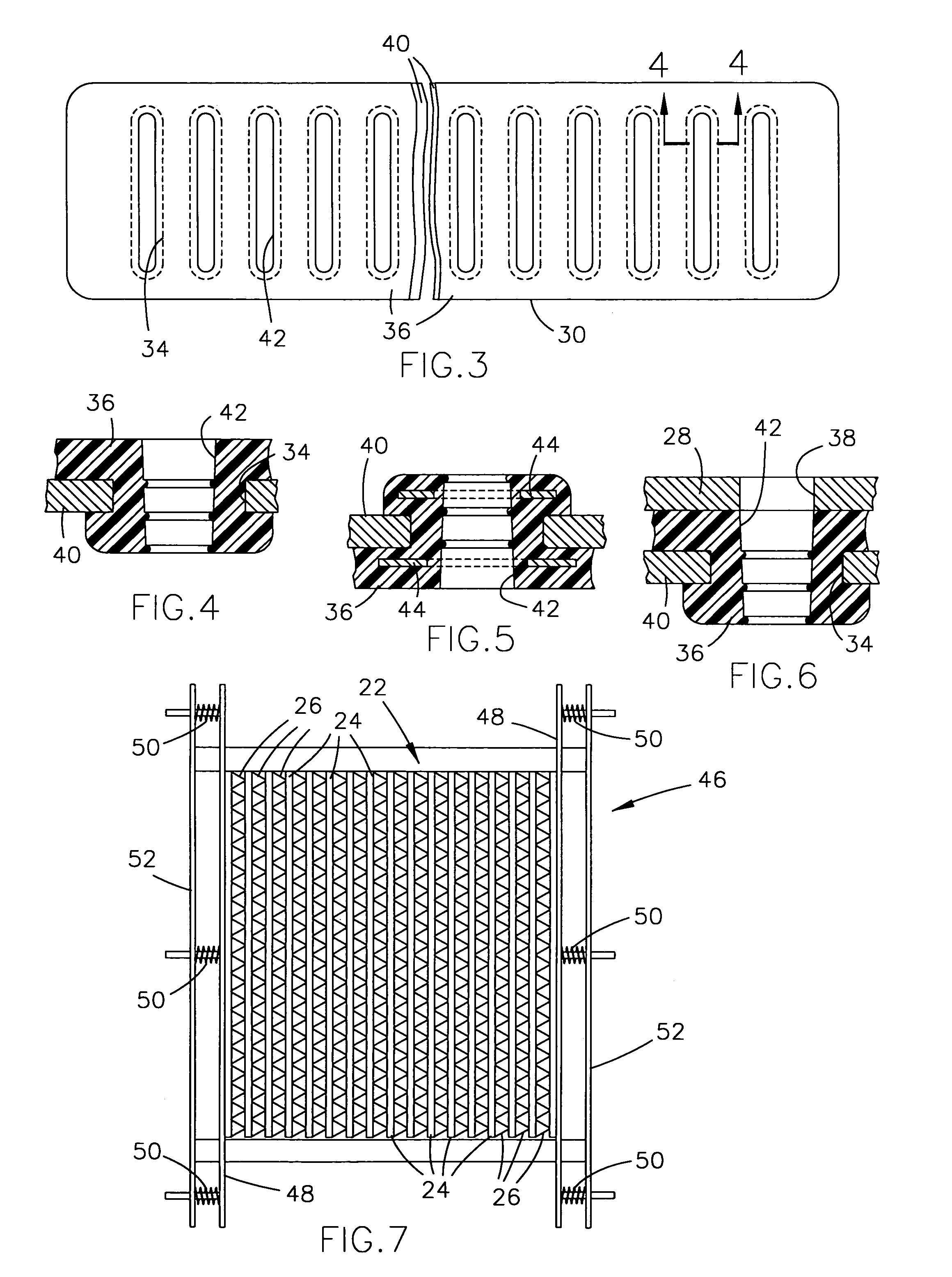

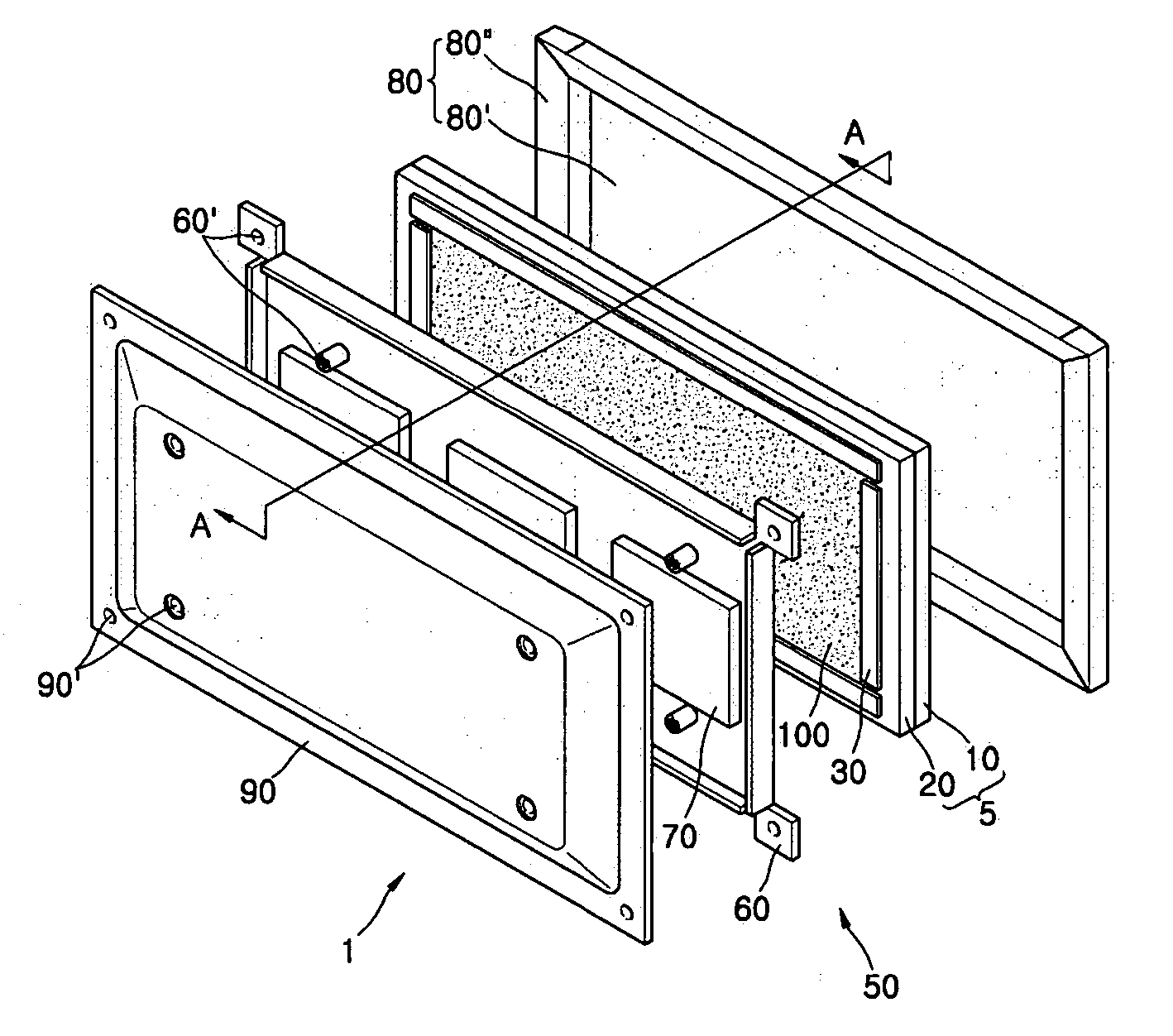

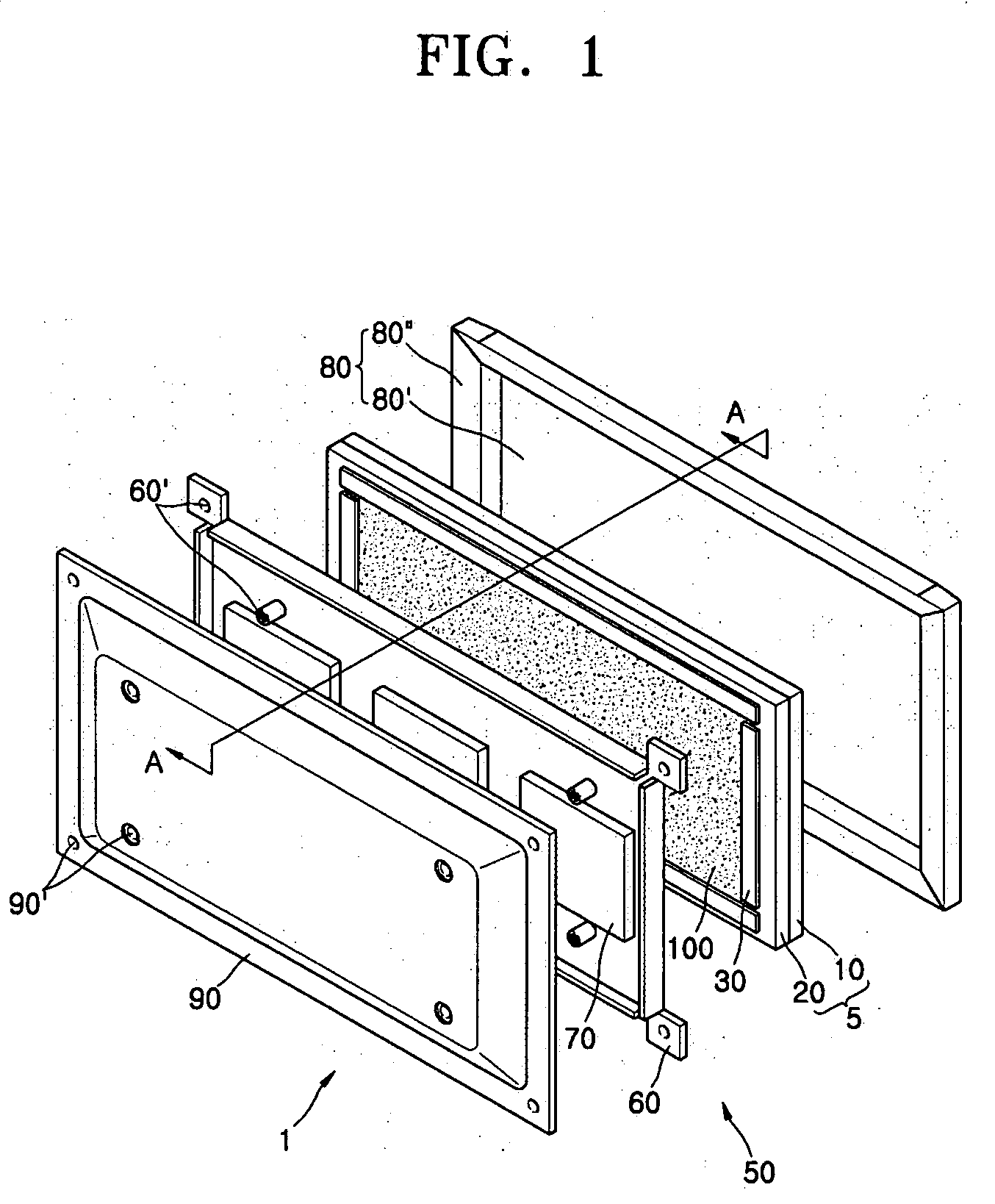

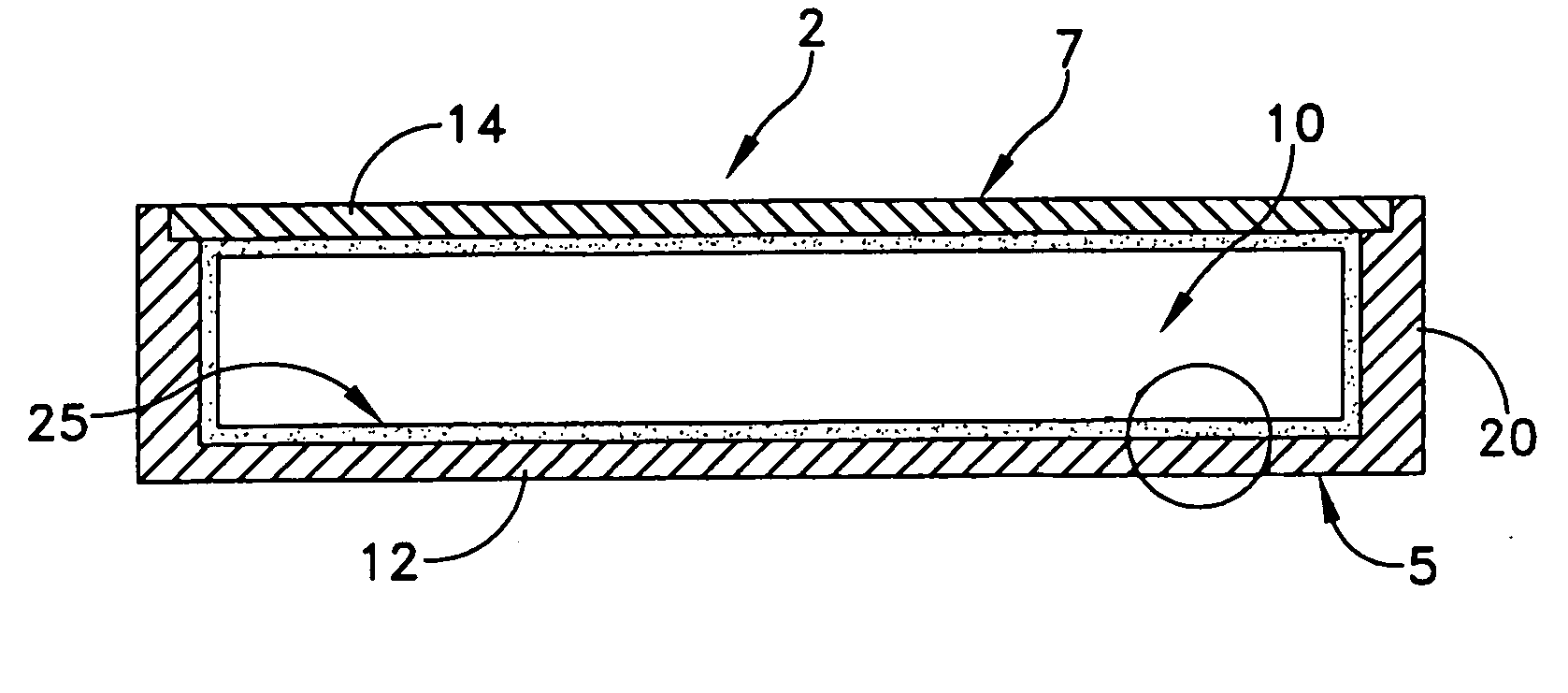

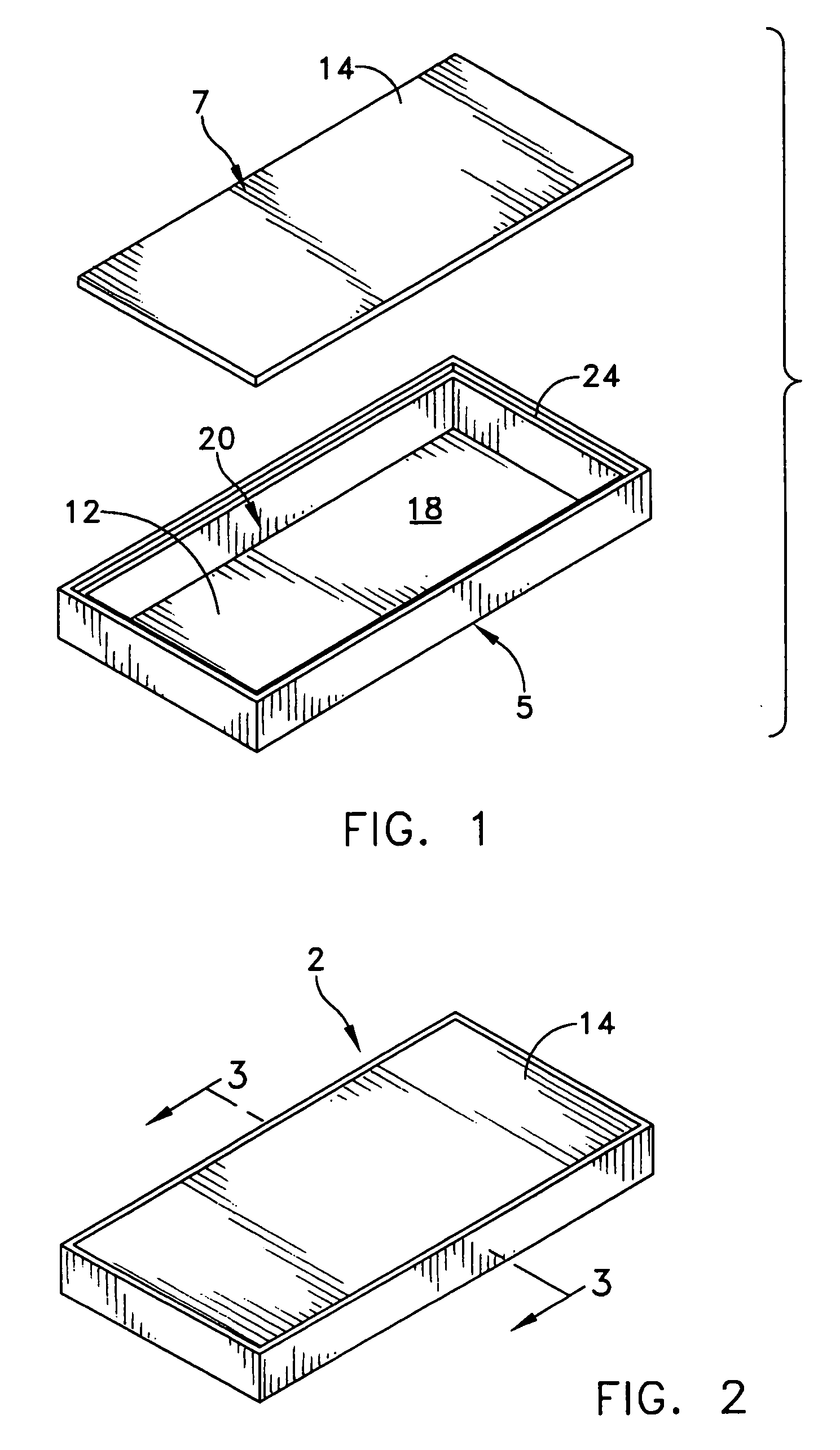

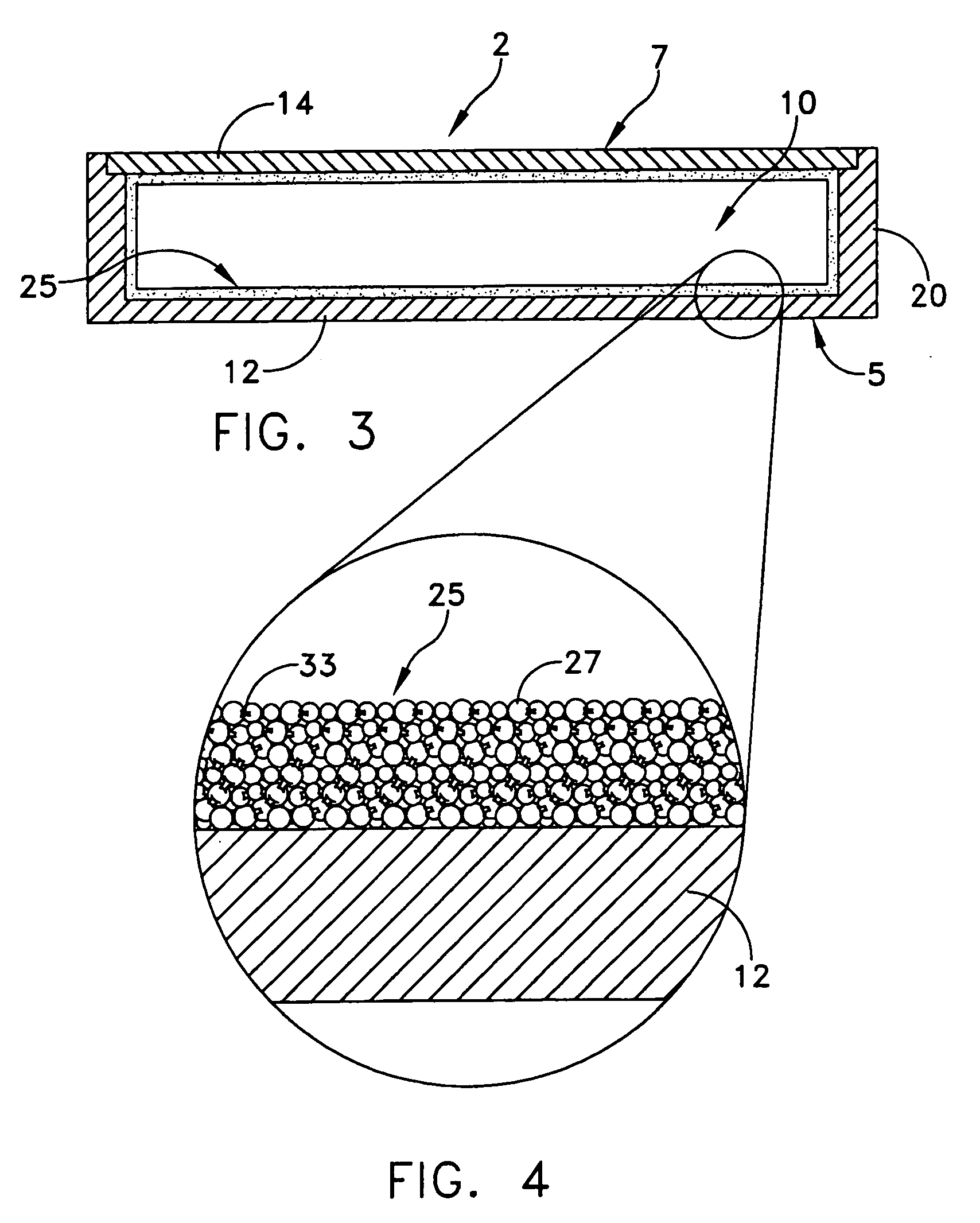

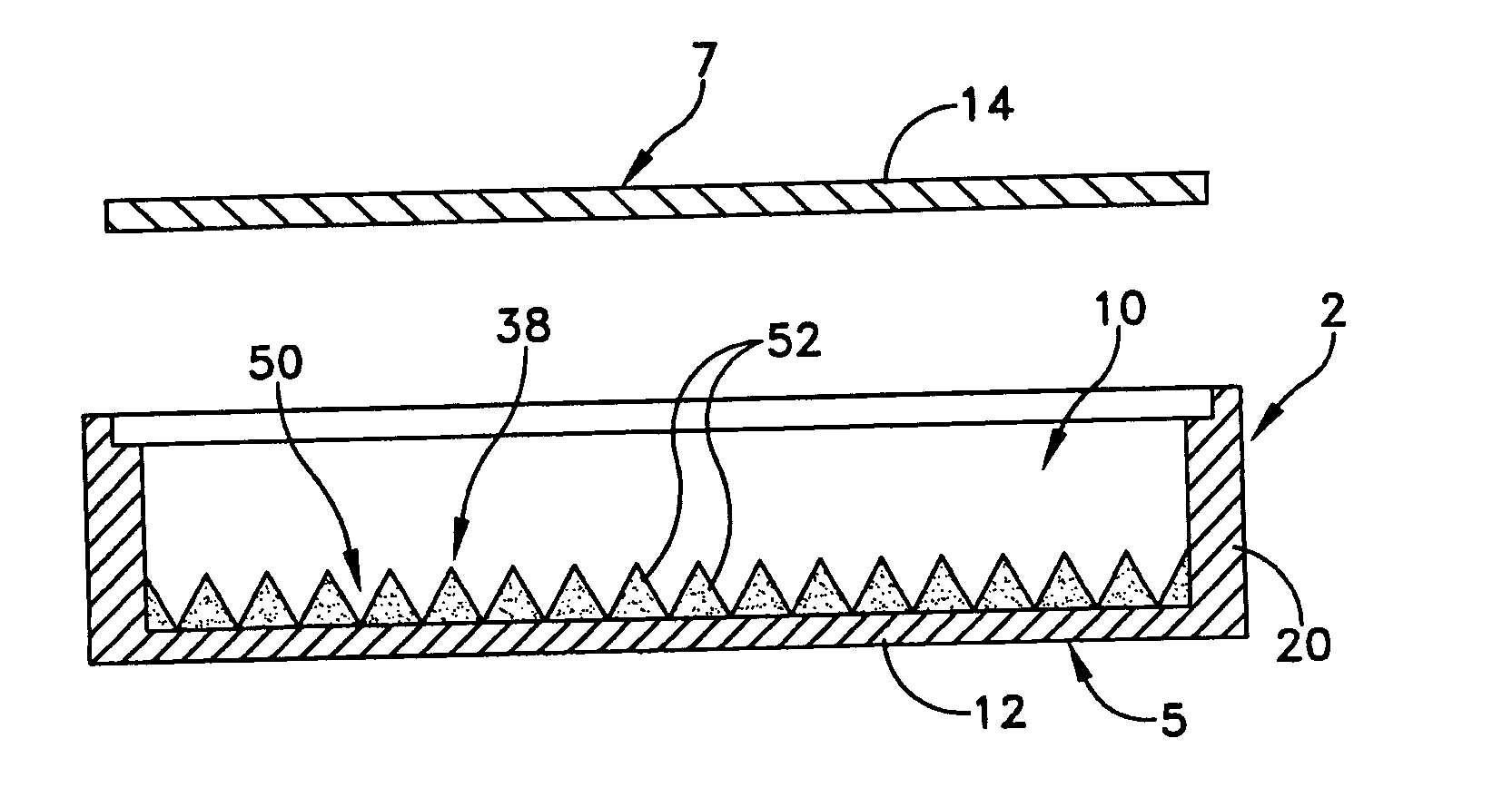

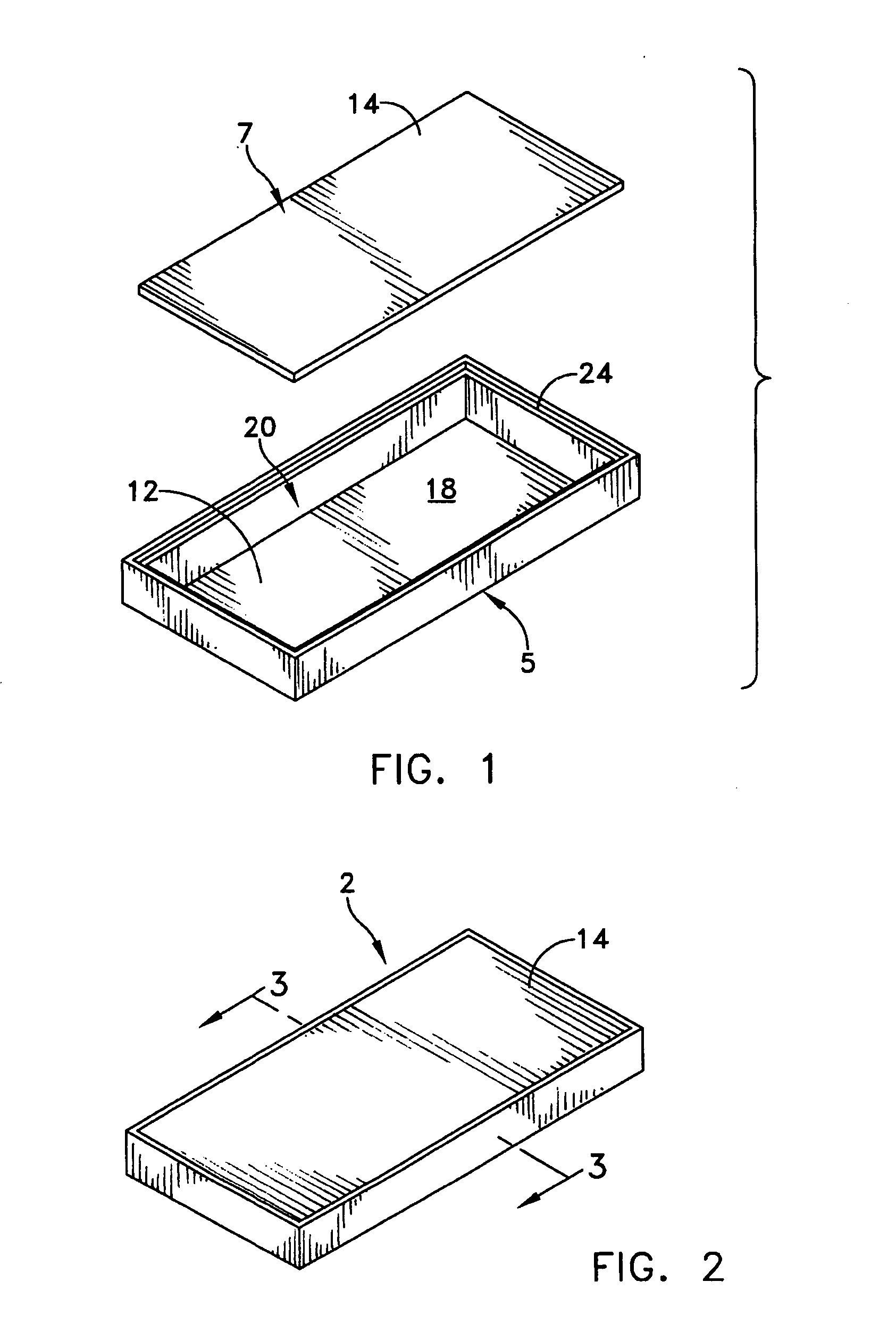

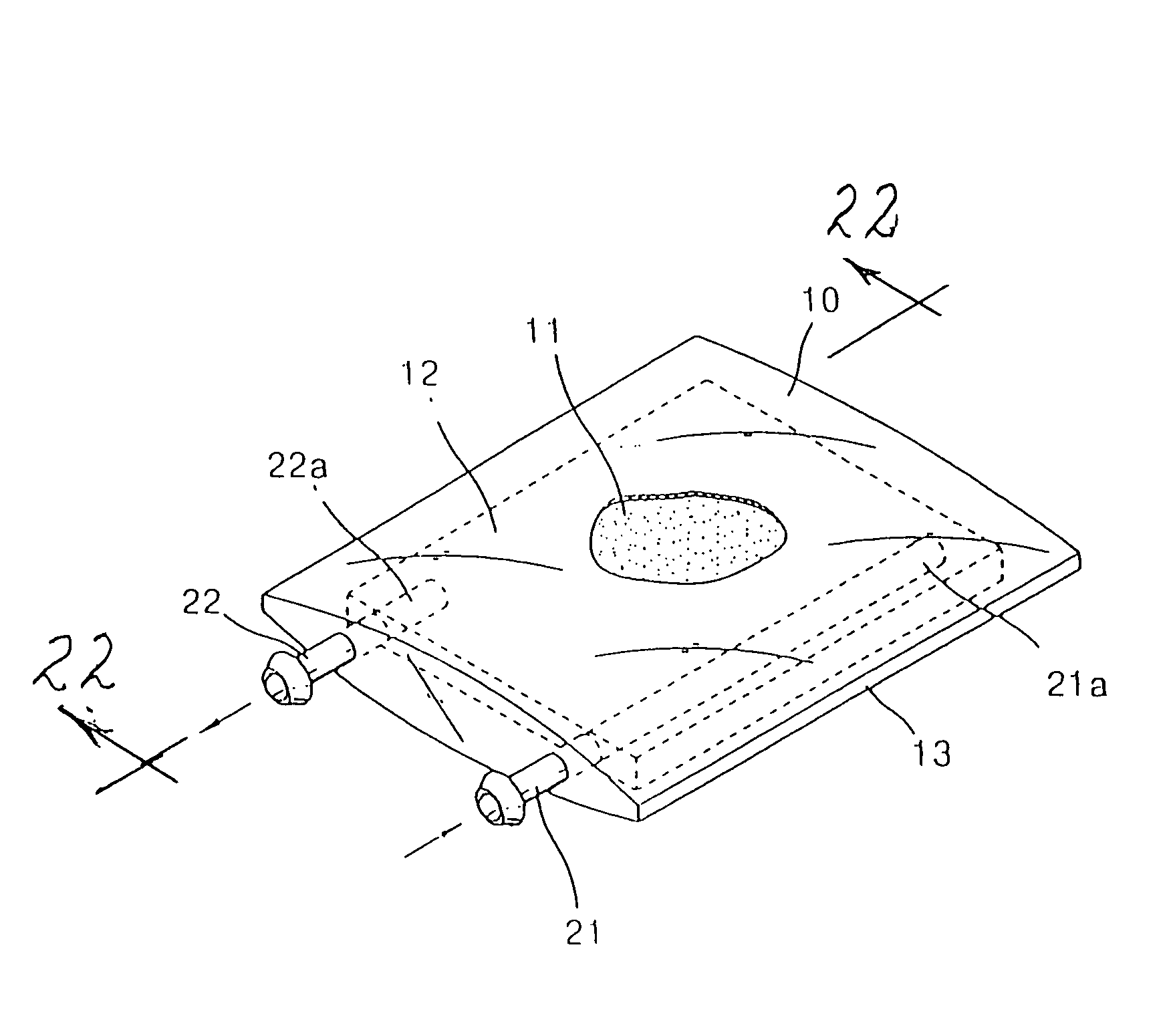

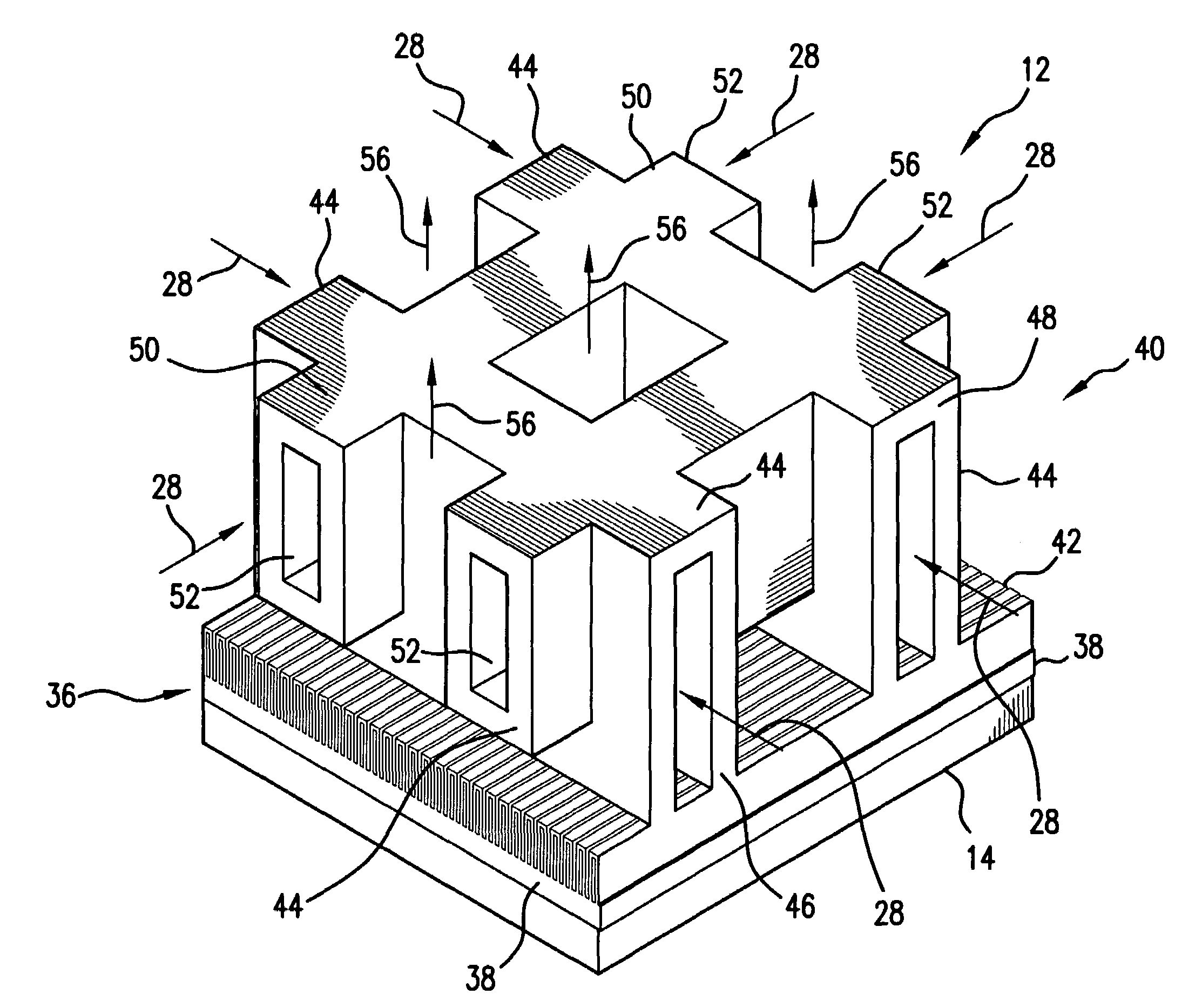

Support structure for a planar cooling device

InactiveUS20070240860A1Digital data processing detailsSemiconductor/solid-state device detailsHeat transfer efficiencySet distance

A support structure for a compact planar cooling device is presented. The support structure allows the cooling device to be made with a simpler structure than most conventional cooling devices. The cooling device includes a planar casing, a wick layer, and the support structure. The support structure includes a flat plate with a portion cut out to form an opening and a spacer on the flat plate. The spacer is made by bending or folding the cut-out portion of the plate. The spacer enhances coolant circulation inside the cooling device by pushing the wick layer against the inner surface of the casing and maintaining a set distance between the support structure and the casing to allow unimpeded coolant movement. The cooling device can be made cost-effectively without compromising heat transfer efficiency.

Owner:CELSIA TECH KOREA

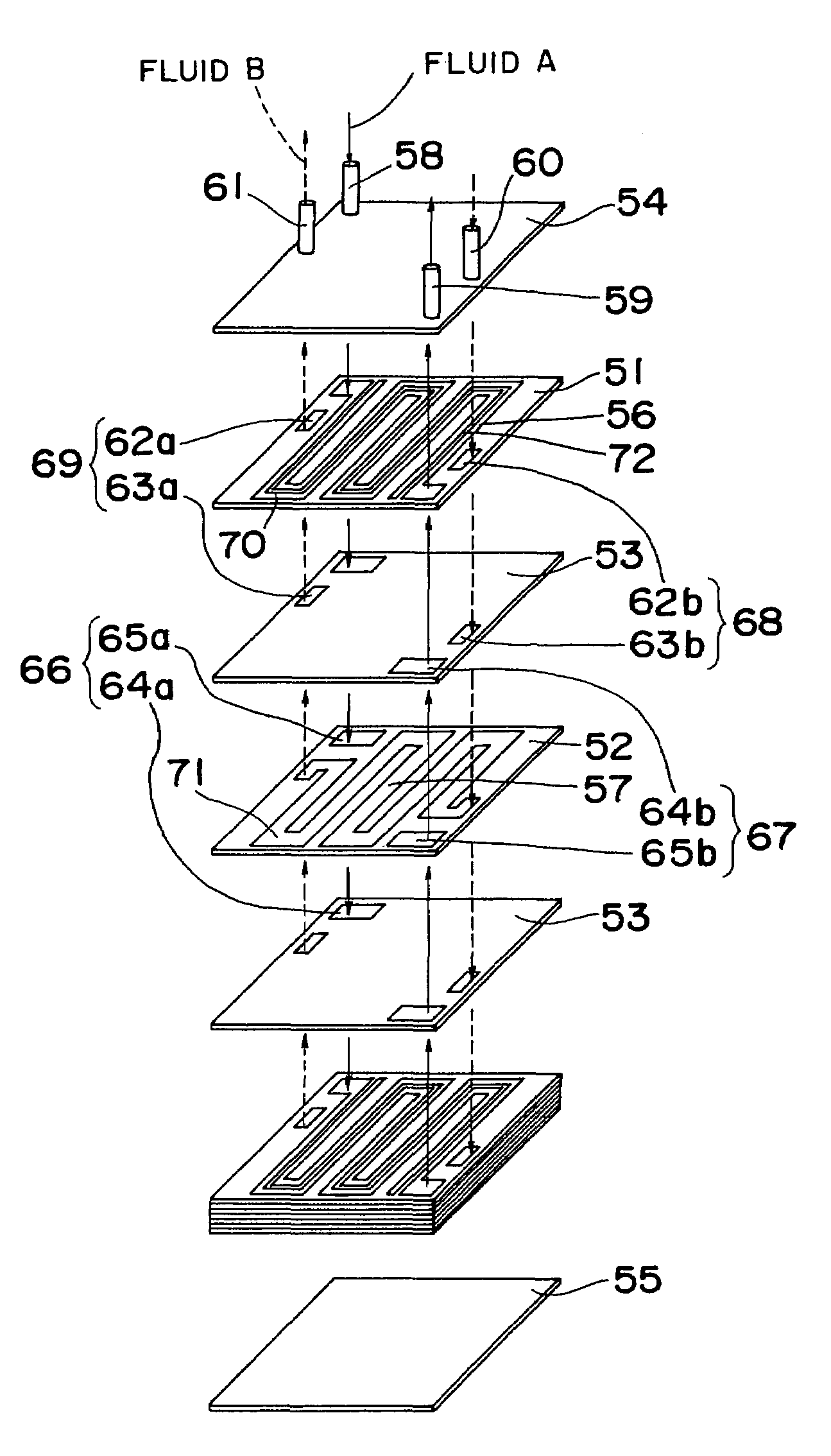

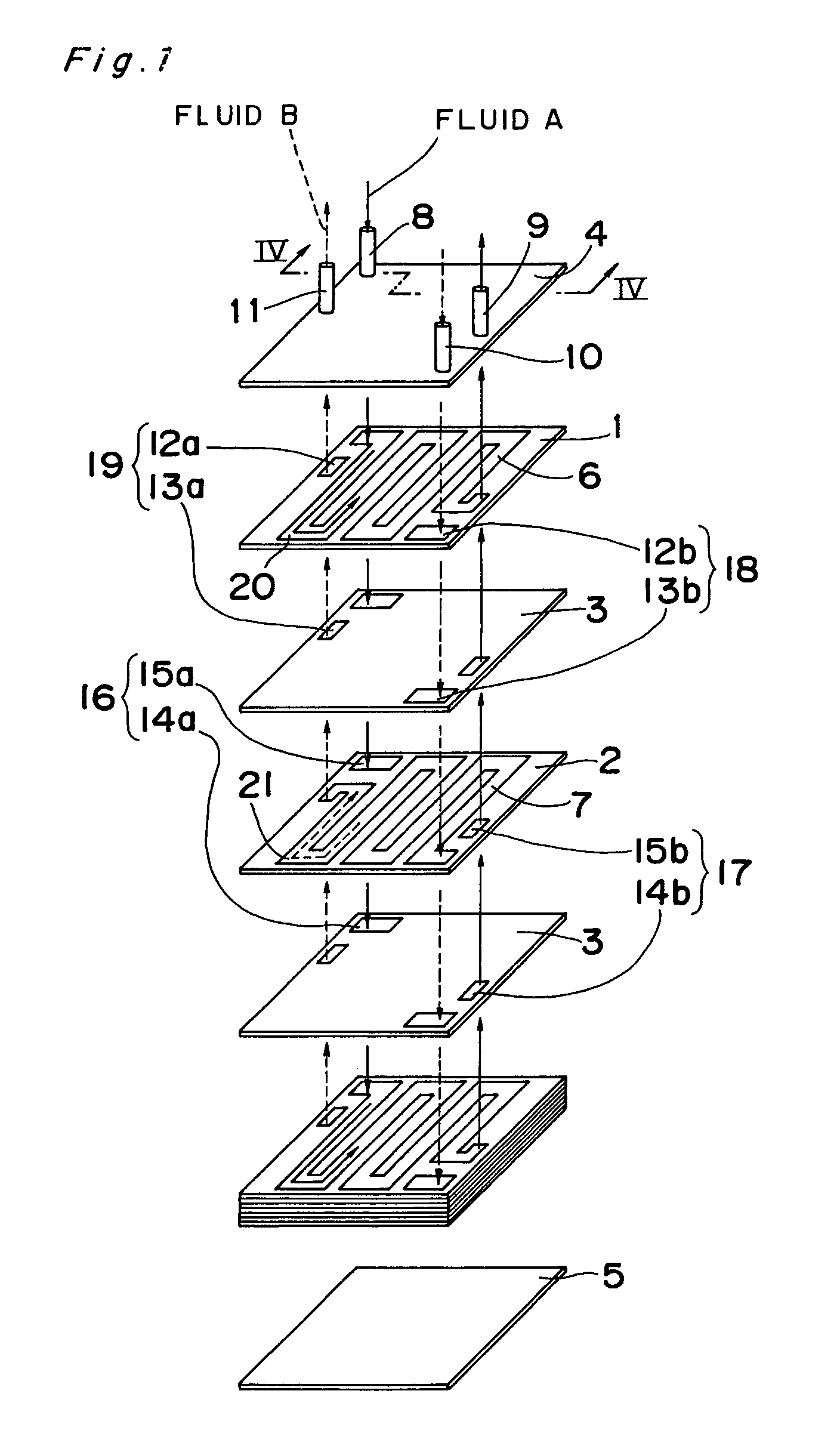

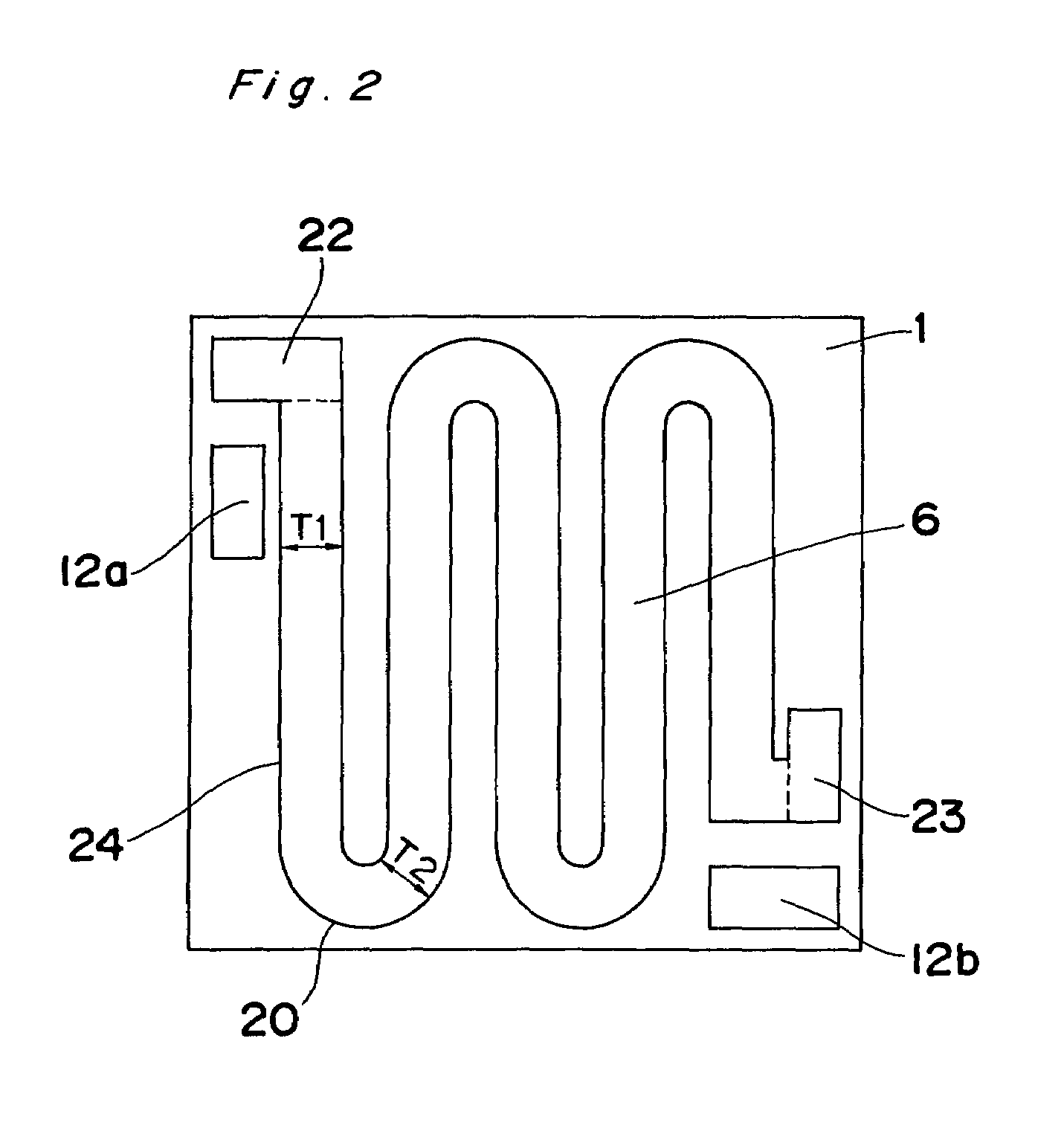

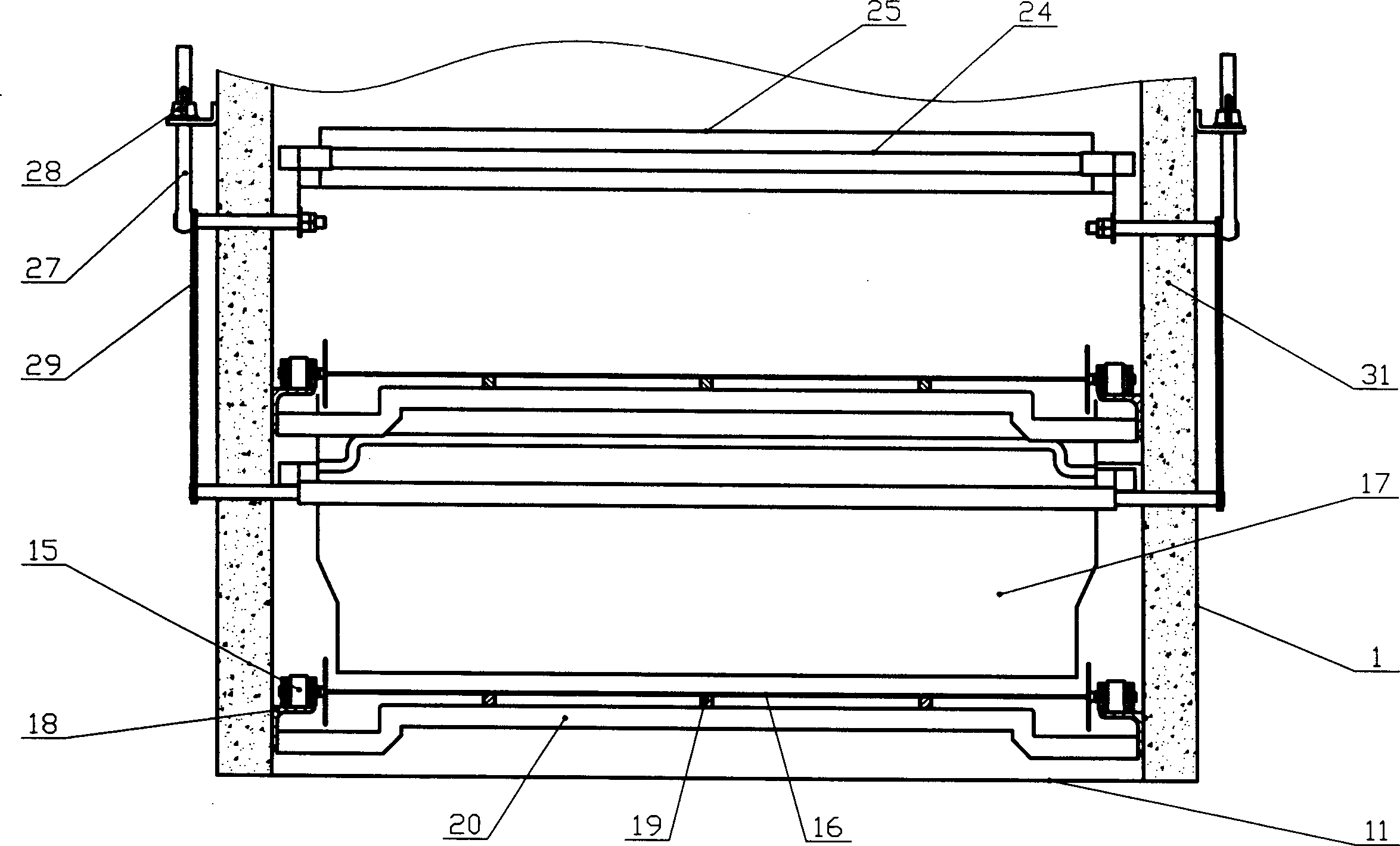

Plate type heat exchanger and method of manufacturing the heat exchanger

InactiveUS6959492B1Smooth connectionReliable and reliableHeat transfer modificationWelding apparatusEngineeringHeat transfer efficiency

A plate heat exchanger includes a plurality of plates sandwiched between a pair of end plates. Each of the plurality of plates has two passageways defined therein that are not in fluid communication with each other. Alternatively, some of the plurality of plates have a passageway, while some of the remaining plates have another passageway. Two fluids flow through the two passageways in a countercurrent fashion. Because the countercurrent flows are superior in heat transfer efficiency, it is possible to enhance the performance and reduce the size of the plate heat exchangers.

Owner:CONSOL SYST +1

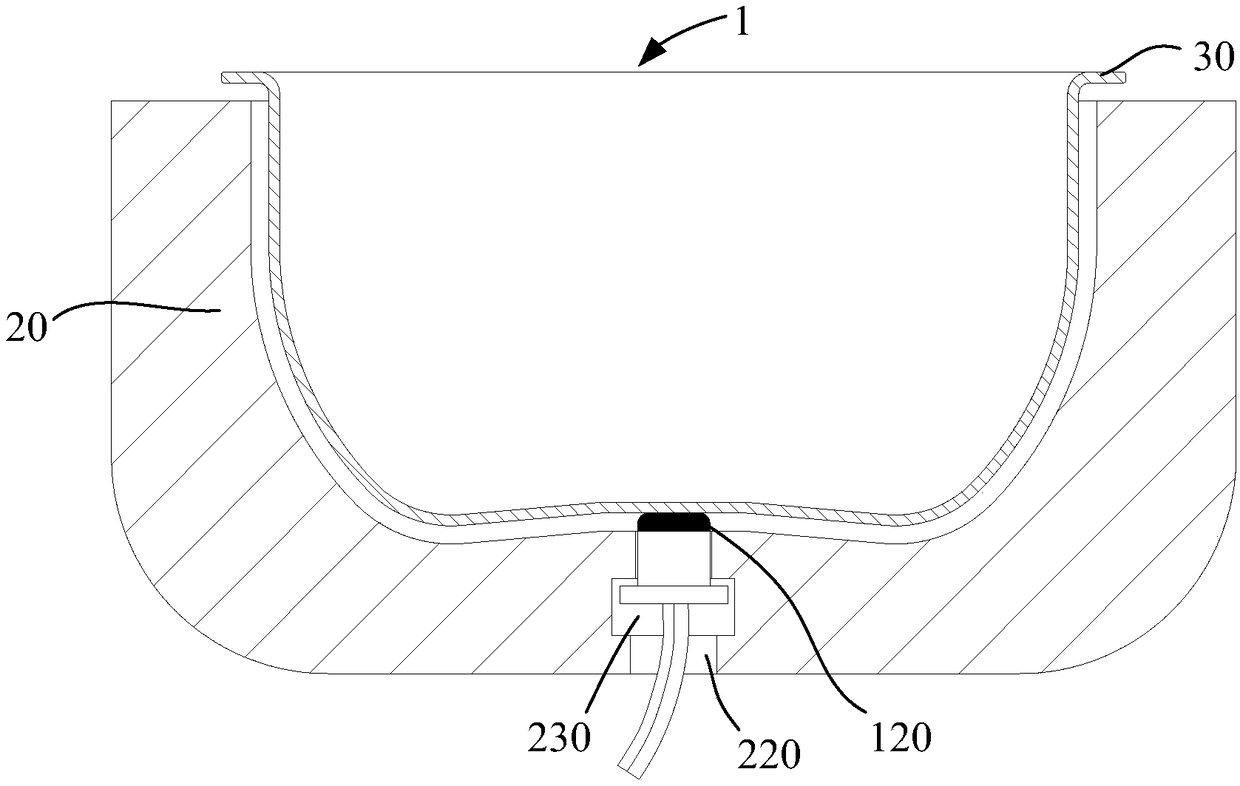

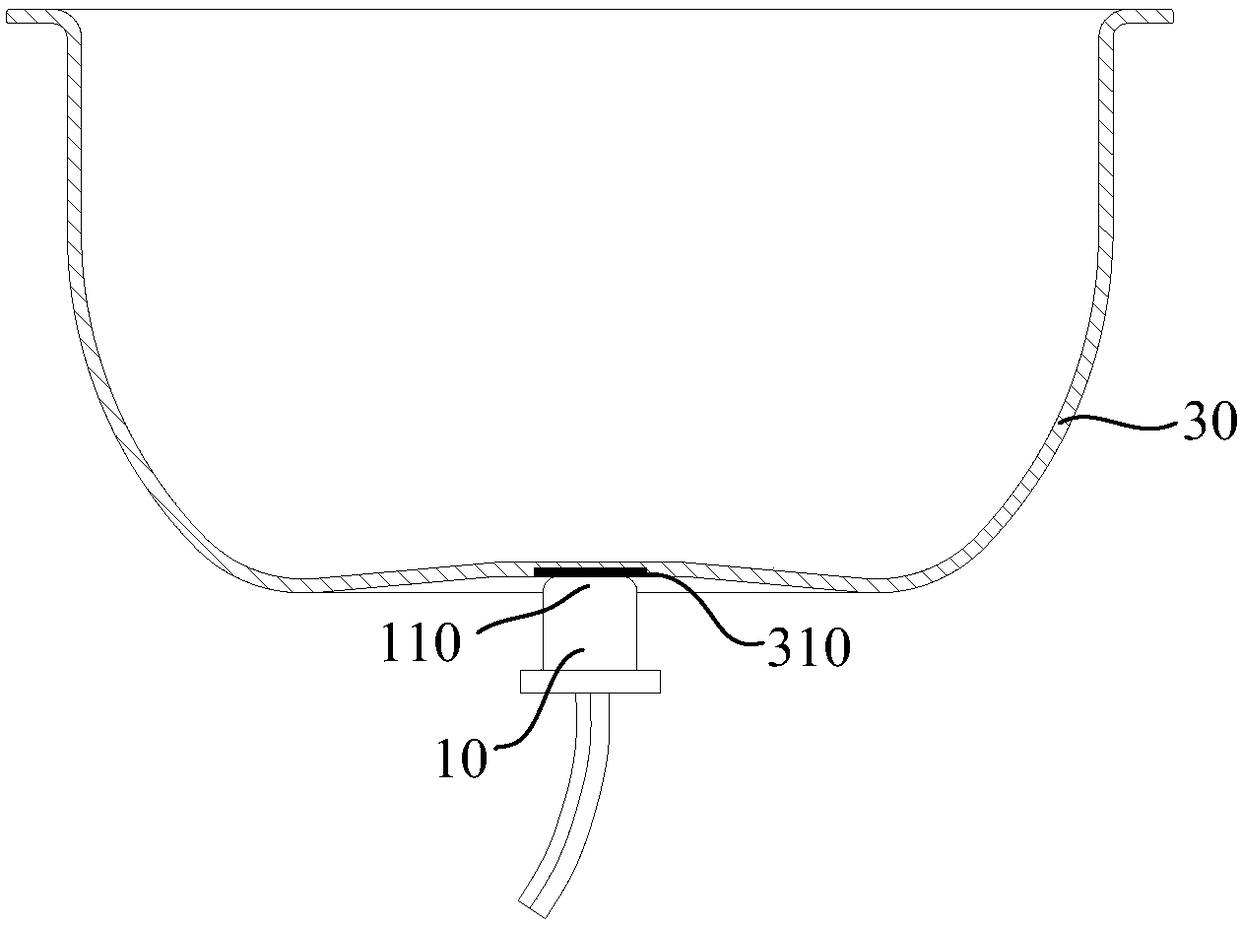

Novel electric cooker temperature control assembly and electric cooker using same

InactiveCN105662112ARealize the insulation functionRealize anti-dry functionTemperature control using plurality of sensorsVessels with intergral heatingTemperature controlThermal insulation

The invention provides a novel electric cooker temperature control assembly which is high in PTC heater heat transfer efficiency and stable in performance.The temperature control assembly comprises a kick type temperature controller, a PTC heater, a support and a heat conduction cover, wherein the upper heat dissipation surface of the PTC heater is tightly attached to the inner top surface of the heat conduction cover, and the kick type temperature controller and the PTC heater are pressed and fixed into the heat conduction cover through the support.The invention further provides an electric cooker using the temperature control assembly.The electric cooker further comprises a heating disc and a liner.A skirt extends outwards from the open portion of the heat conduction cover, an elastic component is arranged on the lower portion of the heat conduction cover, the heating disc is provided with a heat conduction cover installation hole, the heat conduction cover upwards penetrates through the heat conduction cover installation hole, the skirt of the heat conduction cover is sustained by the elastic component so as to be in close contact with the heating disc, and the PTC heater and the kick type temperature controller are connected in parallel and then connected with the heating disc in a power circuit of the electric cooker in series.The electric cooker adopting the temperature control assembly can achieve automatic temperature limitation, heat insulation and dry heating prevention.

Owner:梁炜畅 +1

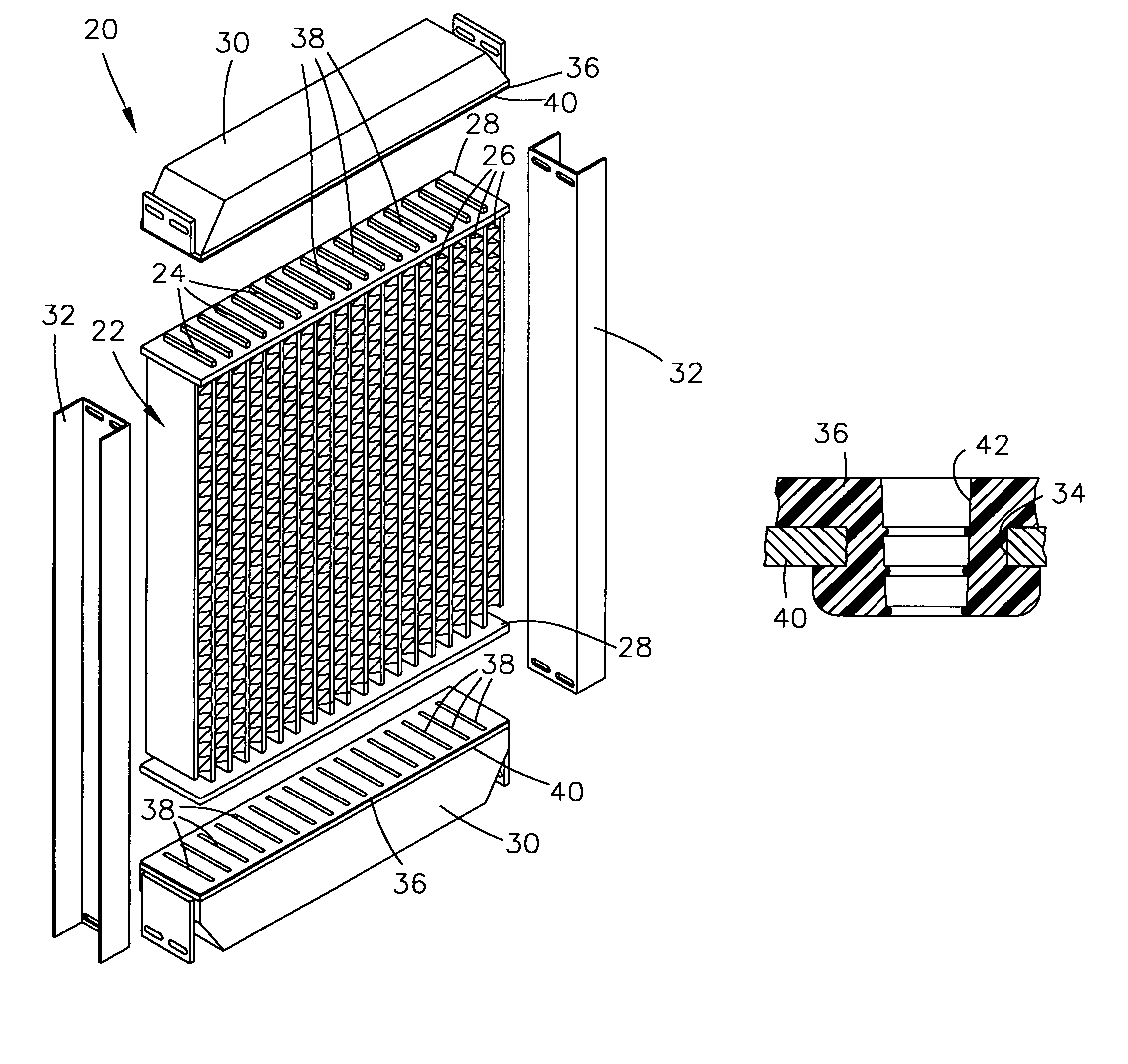

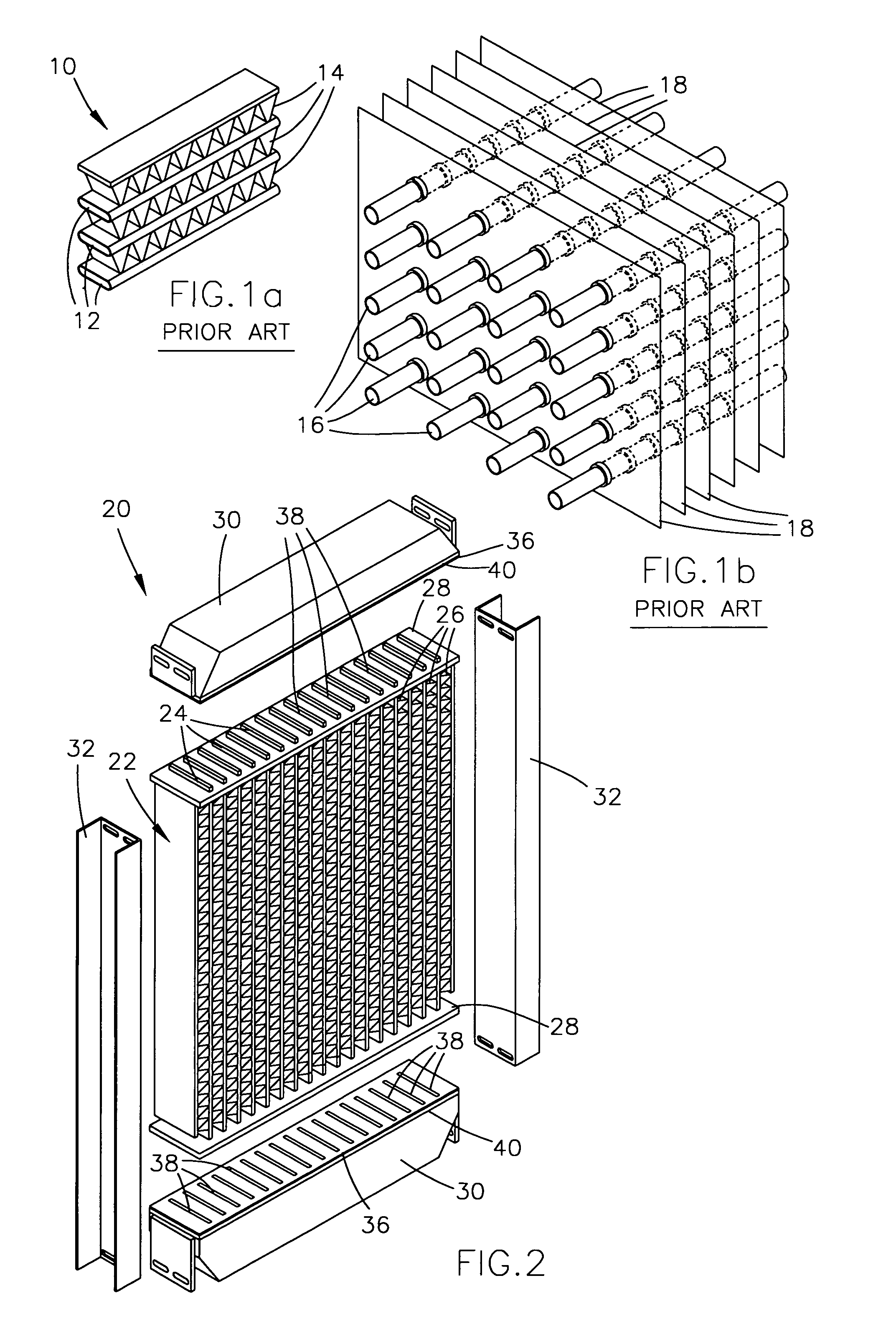

Modular heat exchanger having a brazed core and method for forming

InactiveUS7234511B1Improve heat transfer efficiencyReadily dismantled and rebuiltReinforcing meansSafety devices for heat exchange apparatusPosition toleranceNuclear engineering

An improved modular heat exchanger suitable for automotive applications, and particularly radiators for heavy duty equipment, and methods for forming the modular heat exchanger. The modular heat exchanger construction incorporates a brazed core assembly composed of flat-type cooling tubes and sinusoidal centers. The ability to use a brazed core assembly within a modular heat exchanger construction promotes enhanced heat transfer efficiencies associated with the use of flat tubes and sinusoidal centers, as compared to mechanically-joined round tubes and fins. The required positional tolerances of the tubes for mating with the remainder of the heat exchanger are maintained within the brazed core assembly by eliminating core shrinkage attributable to the use of clad aluminum alloy components to construct the core assembly. In two embodiments, core shrinkage is physical suppressed through the use of an expandable brazing fixture or the inclusion of sub-headers in the brazed core assembly. In a third embodiment, a clad slurry containing a braze alloy is deposited prior to brazing on a core assembly composed of unclad tubes and centers.

Owner:LESAGE PHILIP GEORGE

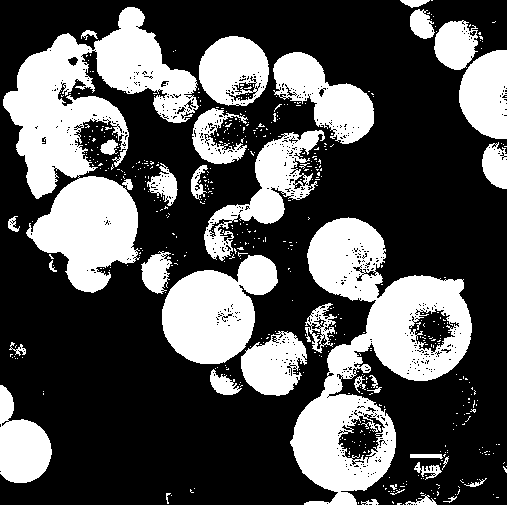

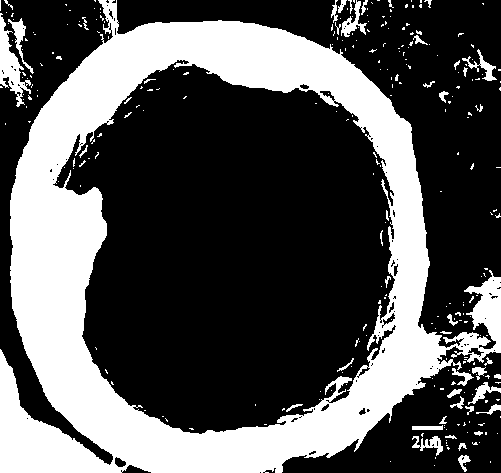

Method for preparing hollow polymer microsphere coated with phase change material

ActiveCN103285793ASmall particle sizeIncrease coverageHeat-exchange elementsMicroballoon preparationPolymer scienceMicrosphere

The invention belongs to the technical field of preparation of phase change materials and microcapsules, and specifically relates to a method for preparing a hollow polymer microsphere coated with a phase change material. The method comprises the following steps of: performing surface modification on hydrophilic inorganic nanoparticles by an ionic surfactant, and adding the phase change material and monomers to the modified inorganic nanoparticles, which are taken as a stabilizer, to prepare the hollow polymer microsphere coated with the phase change material through a Pickering suspension polymerization method. The preparation process is simple, the raw materials are cheap and easily available, the inner wall of the prepared hollow polymer microsphere is made from polymers, the outer layer of the prepared hollow polymer microsphere is made from the inorganic nanoparticles, and the organic phase change material is coated inside the prepared hollow polymer microsphere. The prepared microsphere has a small size, the coating rate of the phase change material is high, and the outer inorganic nanoparticle layer enhances thermal stability, heat transfer efficiency, sealing performance and mechanical properties of the microsphere.

Owner:FUDAN UNIV

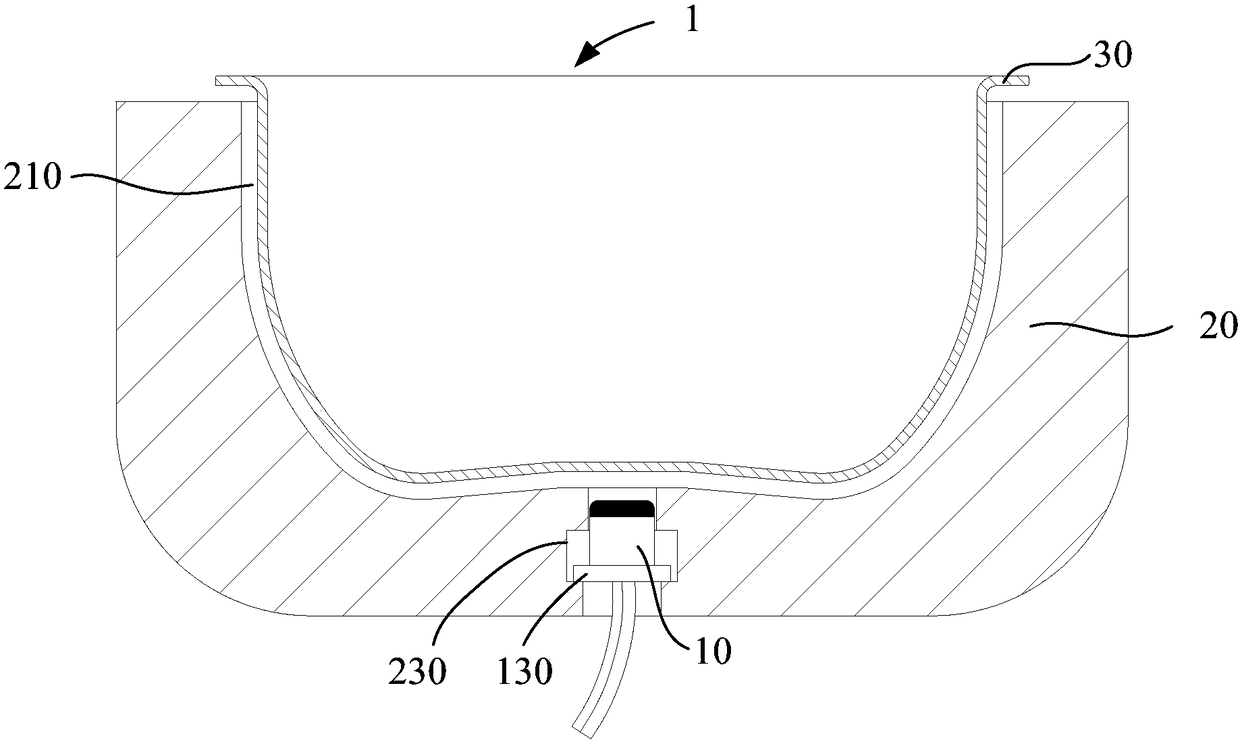

Electric cooking appliance

PendingCN108937525APrecise temperature controlFit tightlyPressure-cookersWarming devicesElectricityHeat transfer efficiency

The invention discloses an electric cooking appliance. The electric cooking appliance comprises a pot body, a heating device and a temperature controller, wherein the pot body is provided with an inner pot cavity, and the inner pot cavity is internally provided with an inner pot; the heating device is arranged in the pot body and used for heating the inner pot; the temperature controller is arranged in the pot body and magnetically attracted on the outer wall face of the inner pot. According to the technical scheme, the temperature controller is magnetically attracted on the outer wall face ofthe inner pot, and more tightly fits the outer wall face of the inner pot under the action of magnetic field force, the fit gap between the temperature controller and the inner pot is smaller, and the heat transfer efficiency between the inner pot and the temperature controller is improved, so that the temperature at a temperature sensor is closer to the actual temperature of the inner pot, thereby reducing the error of the detection temperature of the temperature sensor, and being beneficial to the precise control over the temperature of the inner pot.

Owner:FOSHAN SHUNDE MIDEA ELECTRICAL HEATING APPLIANCES MFG CO LTD

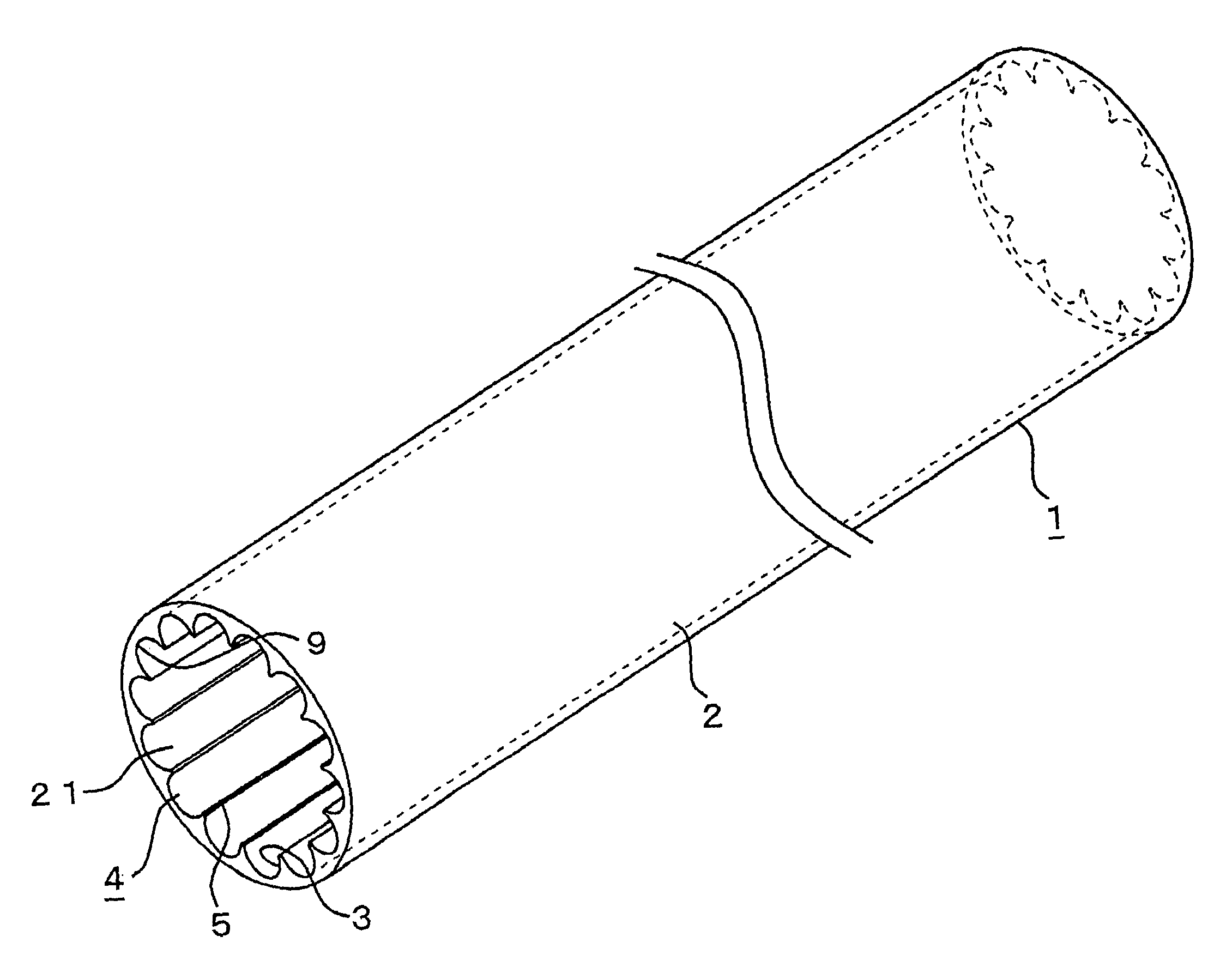

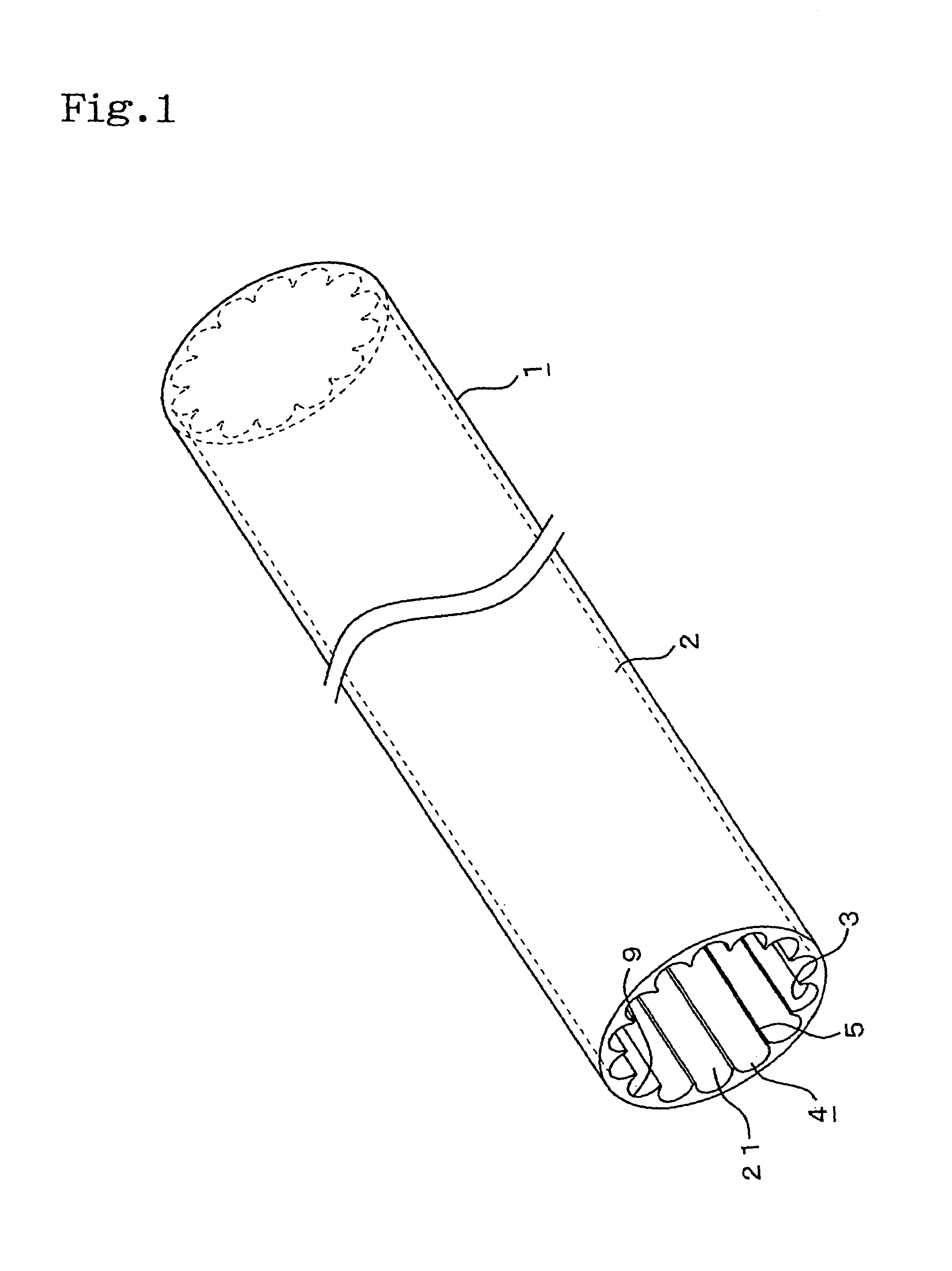

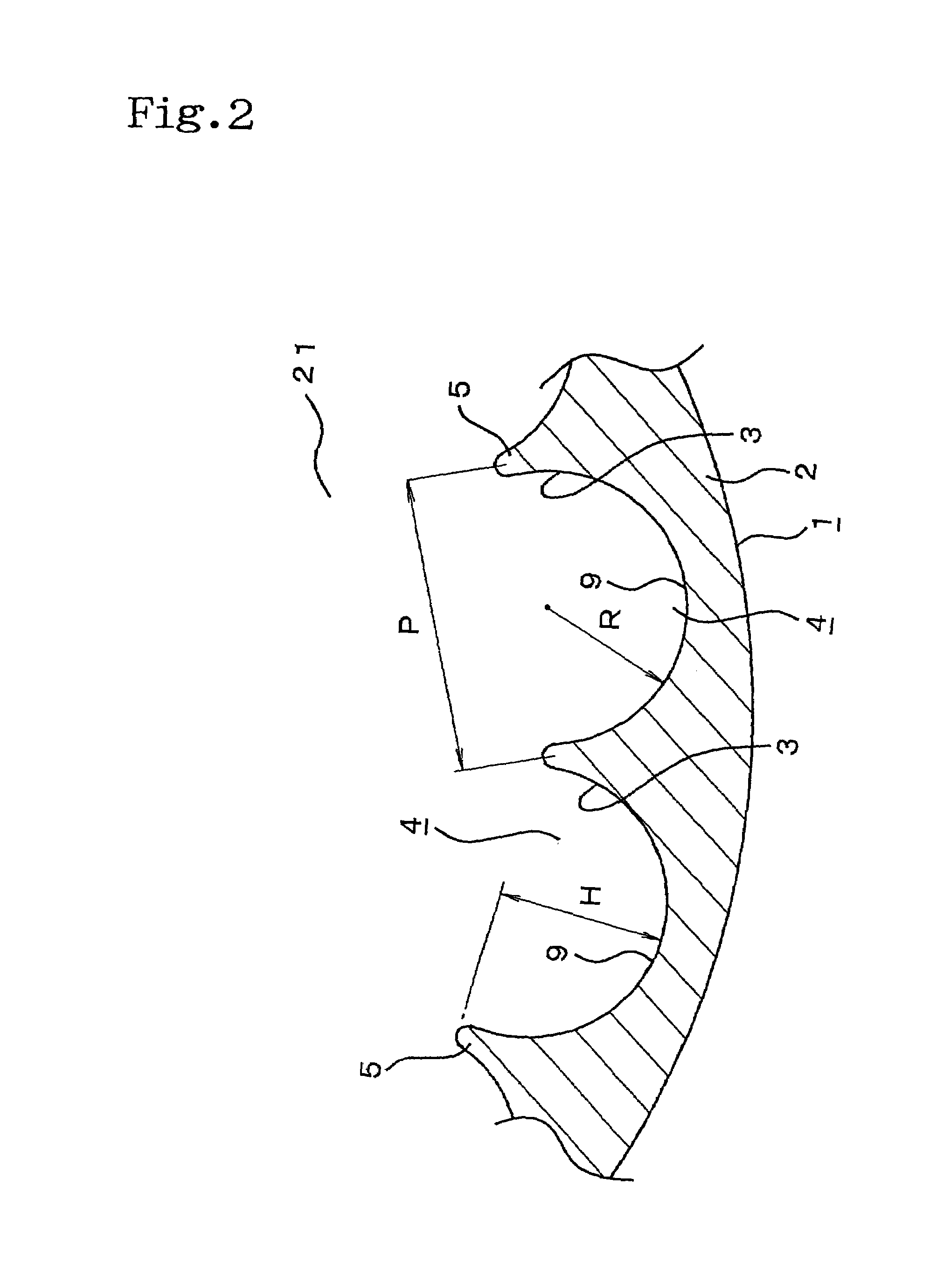

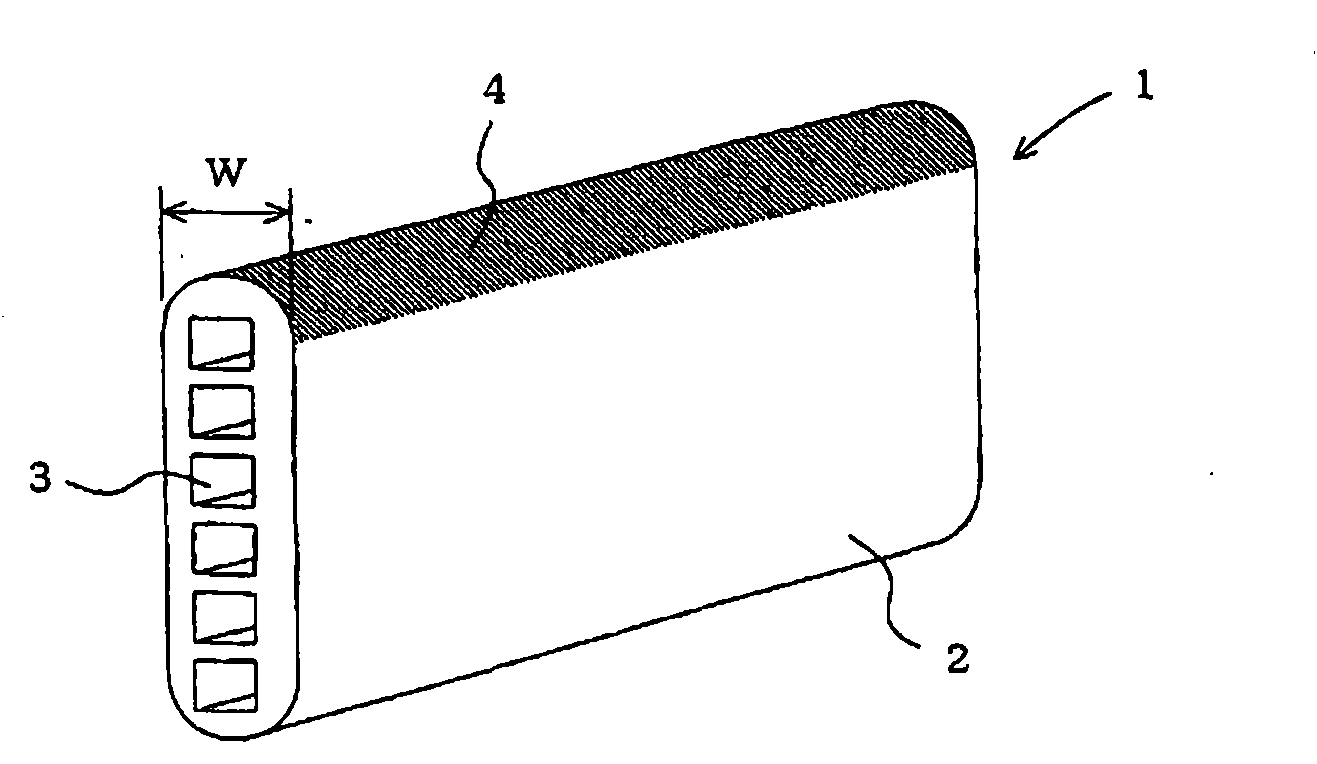

Heat transfer pipe and heat exchange incorporating such heat transfer pipe

InactiveUS7044210B2Facilitate conductionLarge heat exchange surfaceCorrosion preventionHeat exhanger finsPlate heat exchangerHeat transfer efficiency

Soot adhering to the inner surface of a heat transfer pipe can be removed without lowering the heat transfer efficiency that is the inherent object of the heat transfer pipe or without stopping the cooling operation of the heat transfer pipe. Further, this soot removal can be effected when the amount of soot adhering to the inner surface of the heat transfer pipe is small, thus minimizing the soot-caused lowering in the heat transfer efficiency of the heat transfer pipe. A heat transfer pipe (1) wherein the inner peripheral surface of an element pipe (2) through which fluid can flow is formed with longitudinal grooves (4) as recessed grooves (3) of cross-section with a given depth such that the longitudinal grooves are parallel with the pipe axis and circumferentially continuous, and a partition wall (5) of given thickness is formed between the longitudinal grooves (4): and a heat exchanger incorporating this heat transfer pipe (1).

Owner:USUI KOKUSAI SANGYO KAISHA LTD

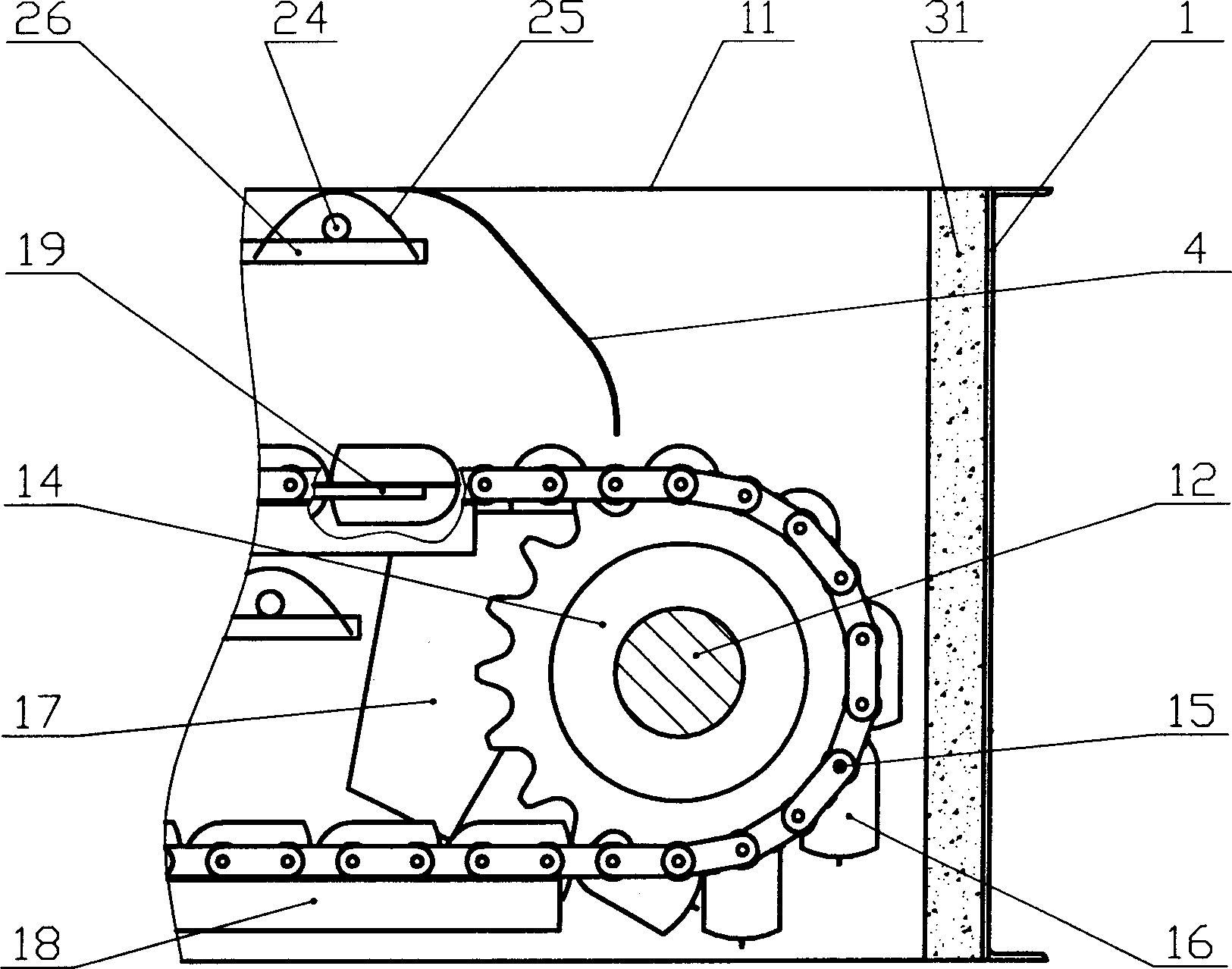

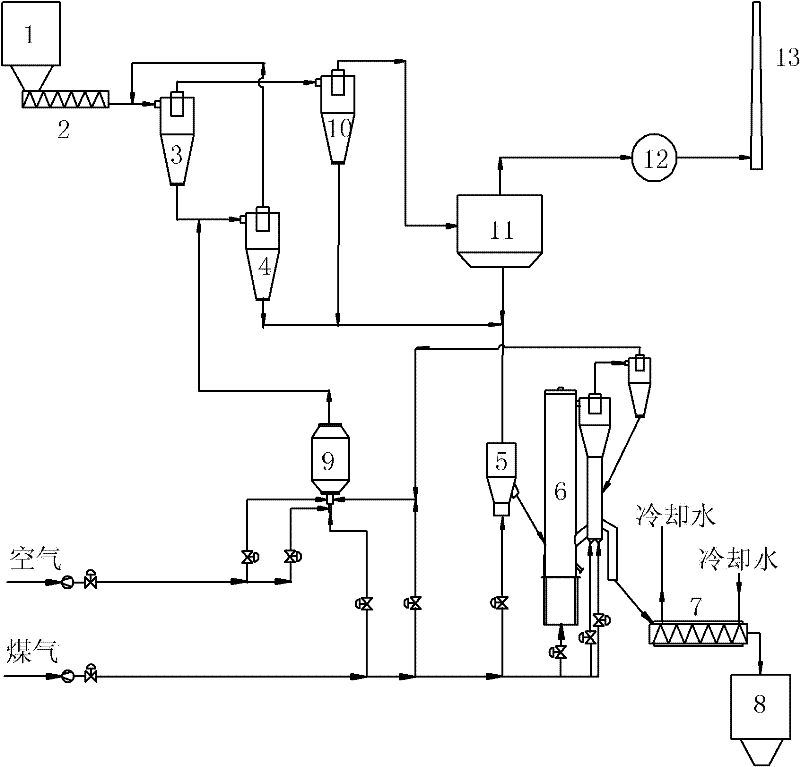

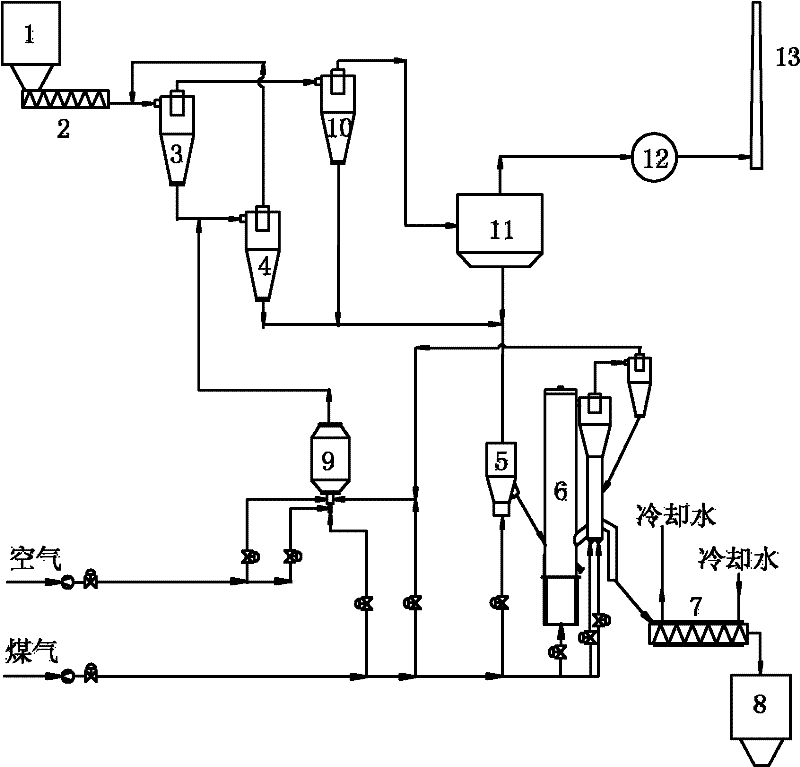

Sludge drying and incinerating treatment process

InactiveCN1931753AAvoid pollutionAvoid harmSludge treatment by oxidationByproduct vaporizationChemical compositionSludge

The present invention relates to environmental protection engineering technology, and is especially sludge drying and incinerating treatment process. The present invention has effective utilization of heat energy, no exhaust of harmful gas and bad smell, no exhaust of dangerous clinker, simple structure and high burning efficiency of the sludge incinerating system, no need of auxiliary fuel and other advantages.

Owner:BEIJING CHINA SCI GENERAL ENERGY & ENVIRONMENT CO LTD

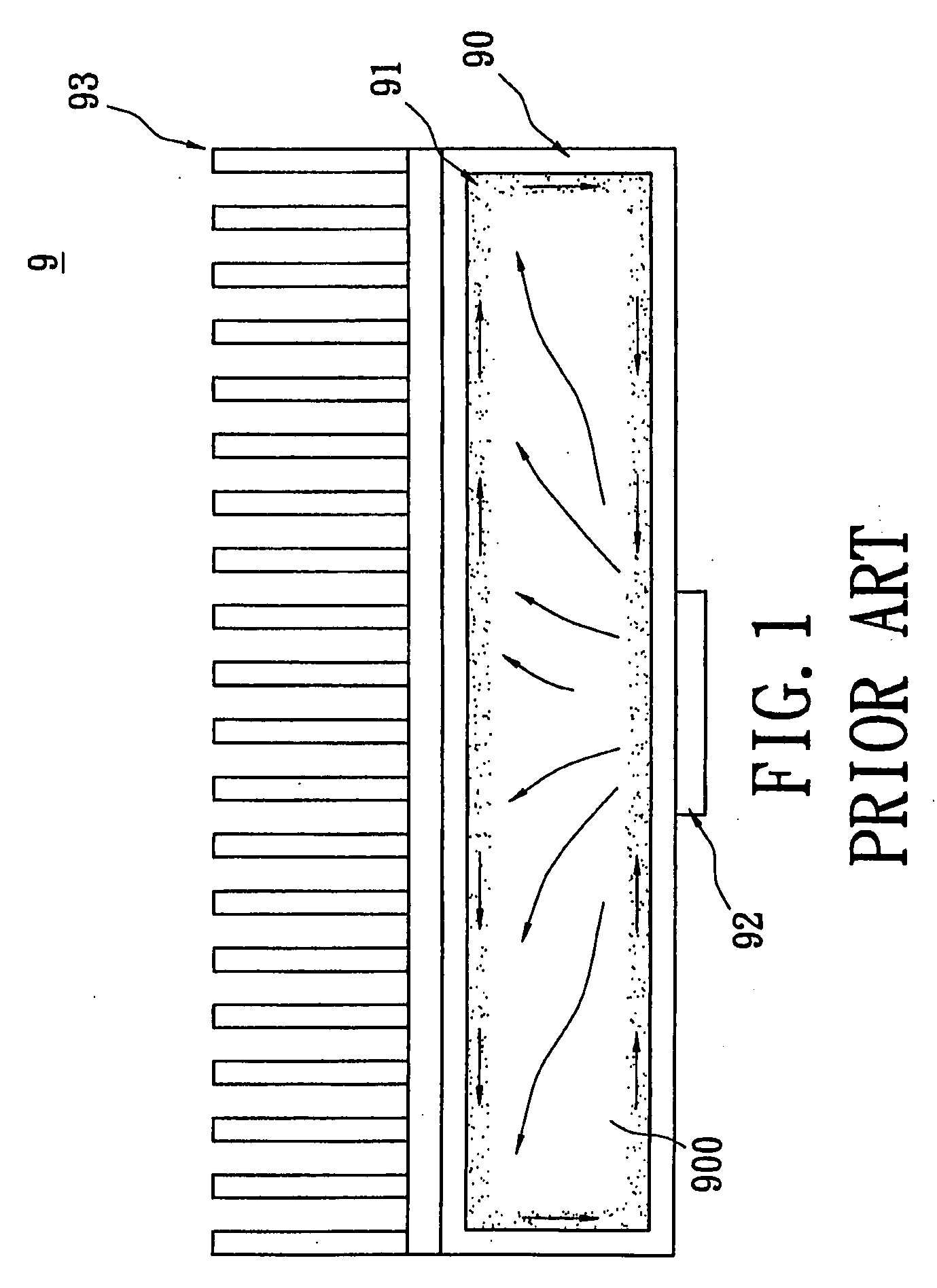

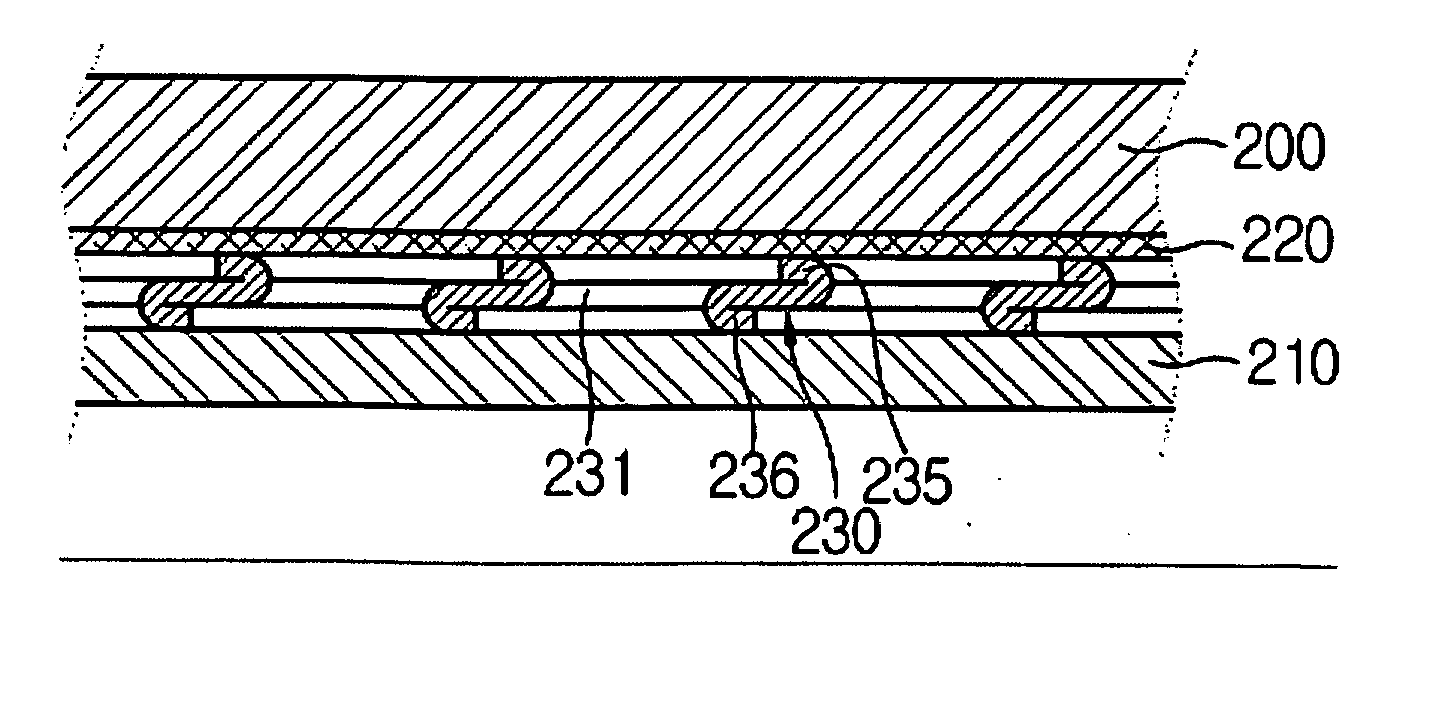

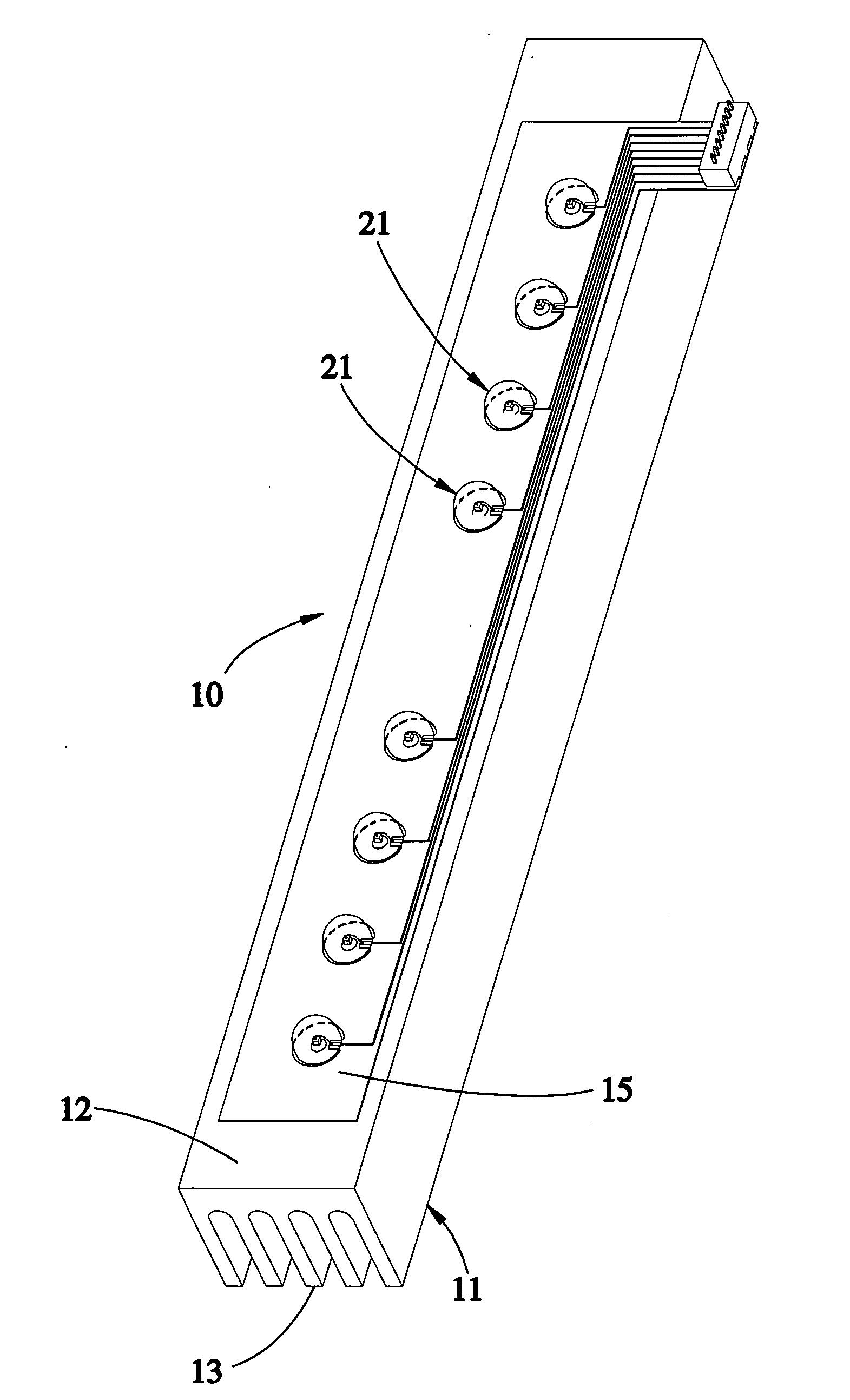

Plasma display panel and plasma display device having the same

InactiveUS20050077822A1Improve heat transfer efficiencySimple structureAlternating current plasma display panelsDischarge tube main electrodesEngineeringHeat transfer efficiency

A plasma display panel having improved heat transfer efficiency and temperature distribution, and a plasma display device including the same are disclosed. The plasma display device includes a plasma display module that includes a plasma display panel on which an image is displayed, a chassis base facing the plasma display panel, a circuit unit disposed at a back side of the chassis base for driving the plasma display panel, a front cover and a back cover that house the plasma display module, and at least a heat radiation coating layer formed between the front cover and the back cover. The heat radiation layer reduces a conventional heat dissipation sheet unnecessary, and thus reduces process times and manufacturing costs.

Owner:SAMSUNG SDI CO LTD

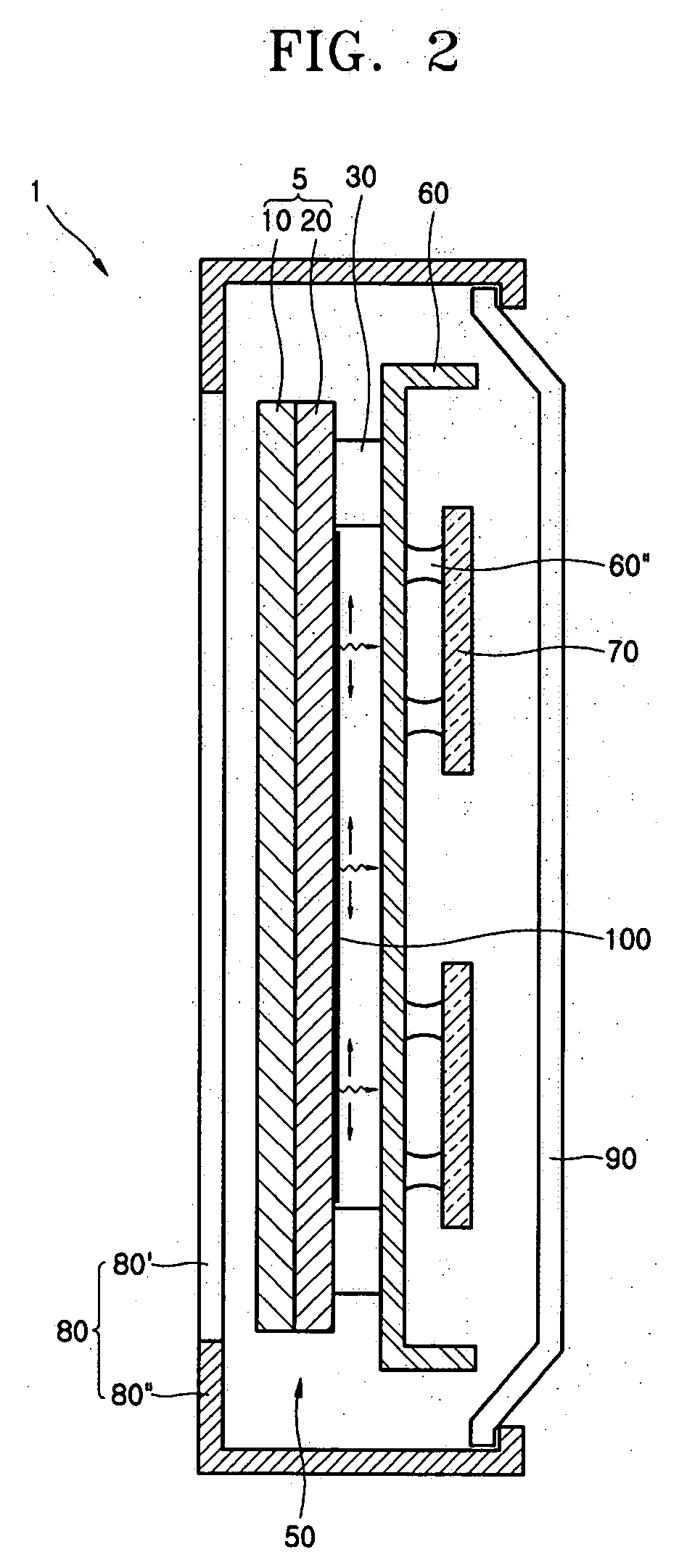

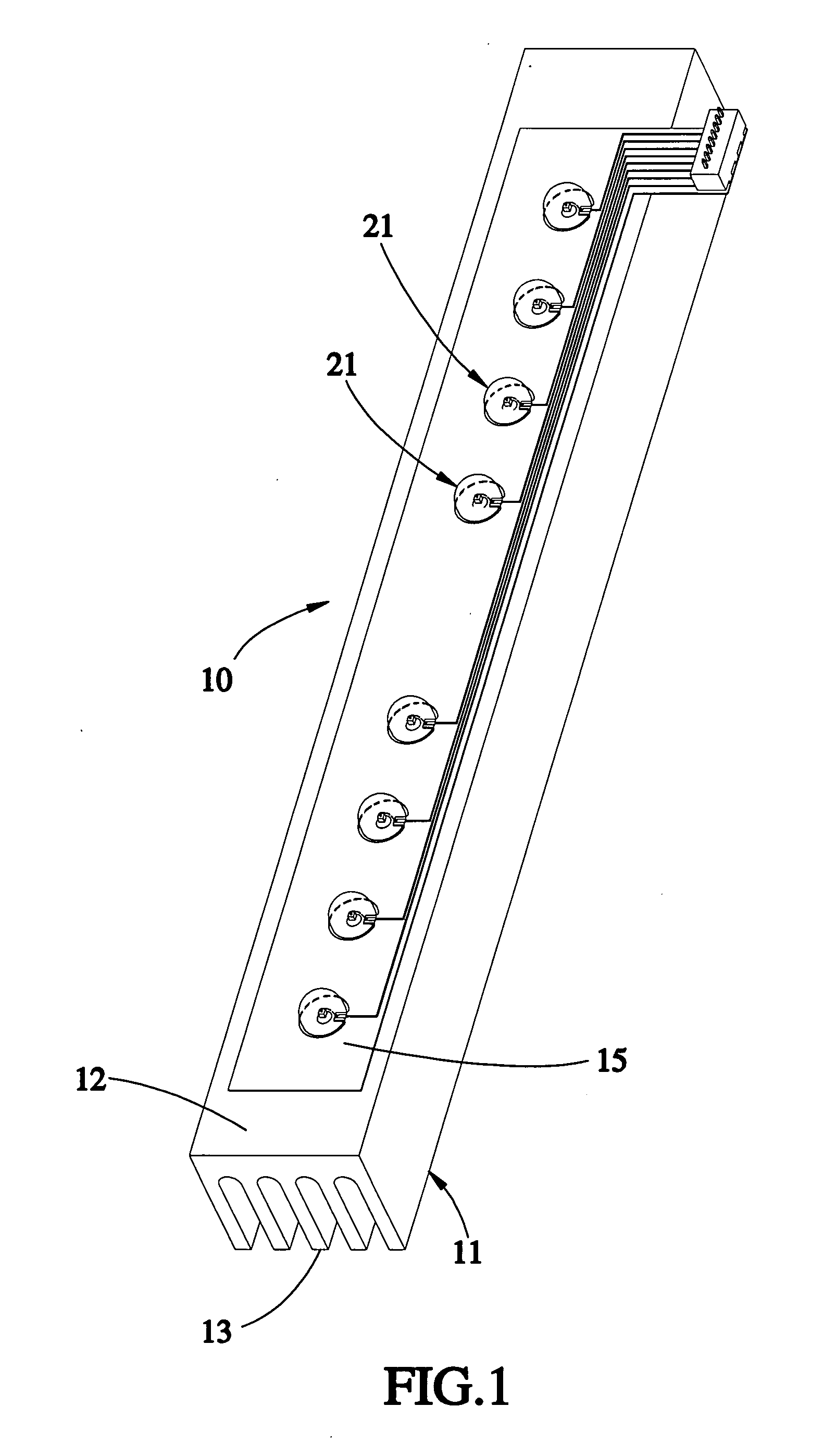

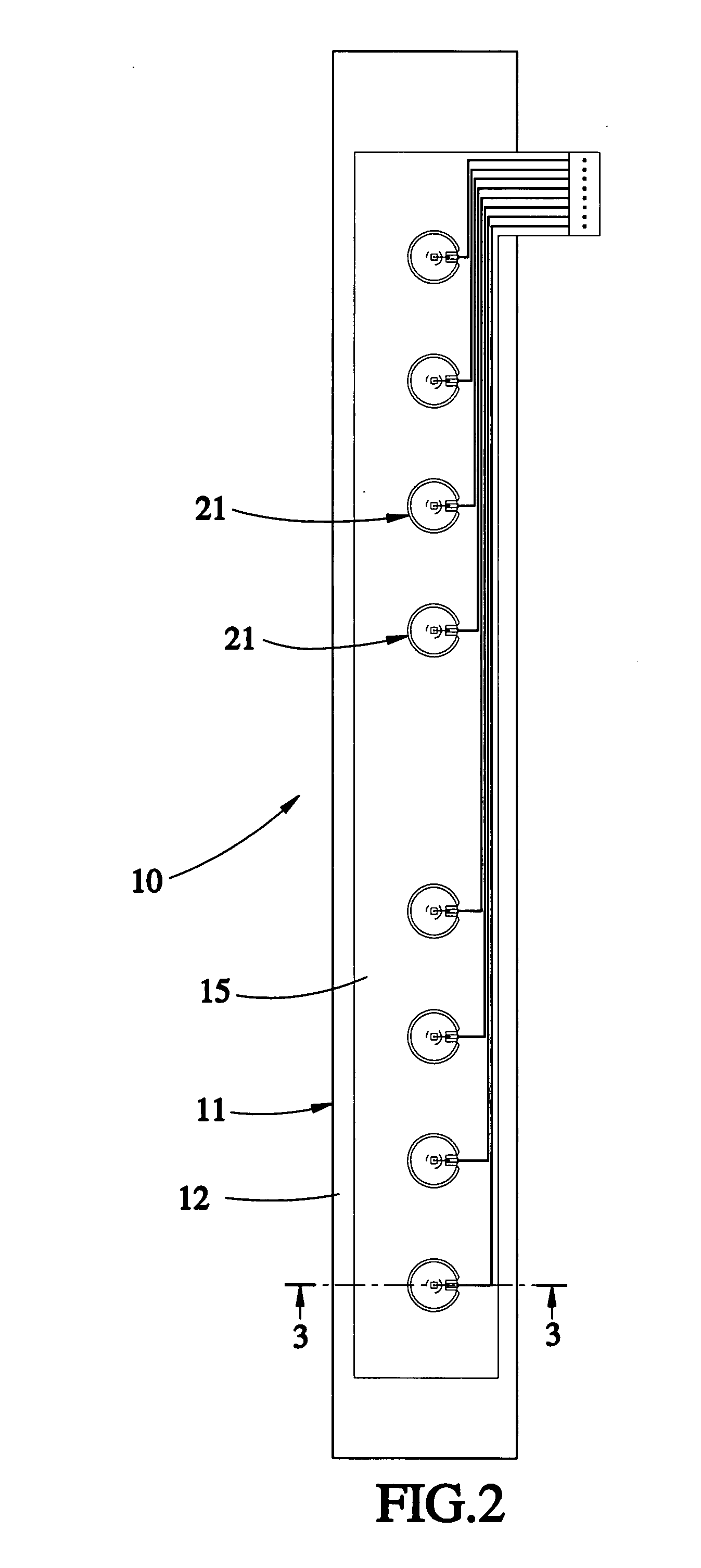

Combination assembly of led and heat sink

InactiveUS20080170371A1Improve transmission efficiencyPoint-like light sourceLighting heating/cooling arrangementsHeat transmissionHeat transfer efficiency

A combination assembly of LED and heat sink includes a heat sink having a substrate and a plurality of fins, a circuit board provided on the substrate and at least one LED unit provided on the heat sink and electrically connected to the circuit board. The heat of the LED unit may be transmitted to the heat sink directly for heat transmission. The present invention has a greater heat transmission efficiency.

Owner:TAI SOL ELECTRONICS

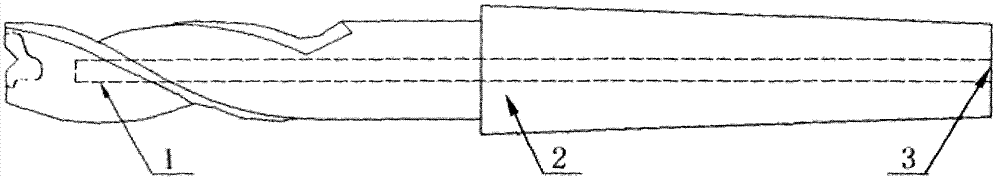

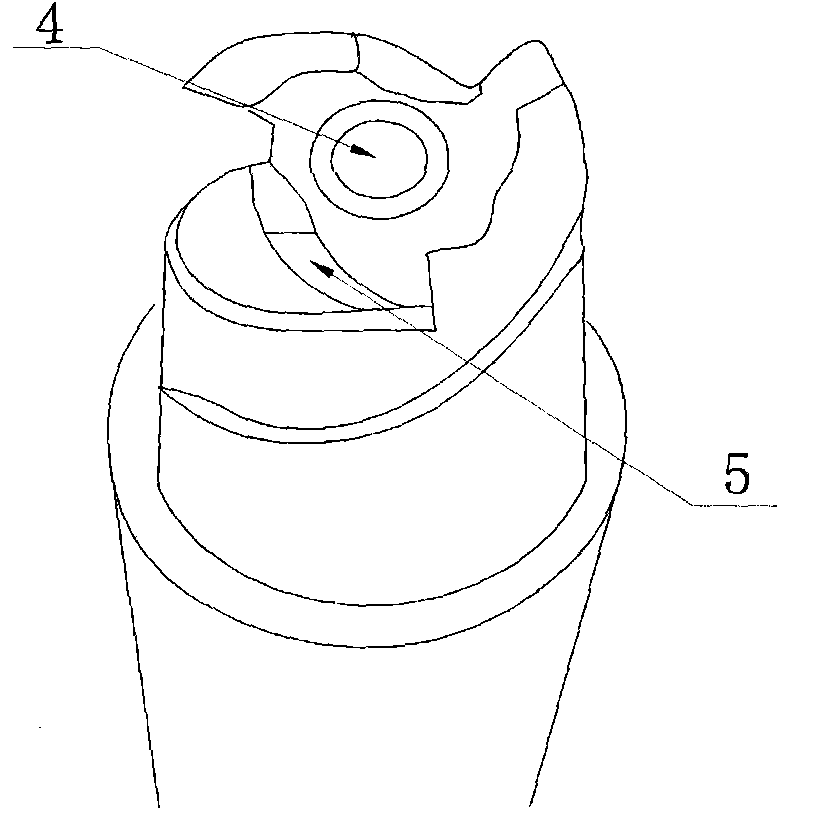

Method for prolonging service life of face milling cutter based on heat pipe phase changes

InactiveCN103537950AImprove heat transfer efficiencyNo personal injuryMilling cuttersMaintainance and safety accessoriesMilling cutterHeat transfer efficiency

The invention provides an environment-friendly method for prolonging the service life of a face milling cutter based on heat pipe phase changes, so durability of the face milling cutter can be remarkably improved under a milling especial for high-speed milling machining condition. The method comprises a novel face milling cutter. The novel face milling cutter comprises a heat pipe, a face milling cutter shank, a face milling cutter body and a face milling head. The face milling head is arranged at one end of the face milling cutter body, the face milling cutter shank is arranged at the other end of the face milling cutter body, the heat pipe is implanted into the face milling cutter body from the face milling cutter shank in the direction parallel with the axis of the face milling cutter body and is close to the main cutting edge part on the face milling head, and the heat pipe is filled with a liquid absorption core. Heat pipe phase change heat transferring is adopted in the method, so the heat pipe is higher than cutting fluid in heat transfer efficiency. A heat pipe technology is adopted, the cutting temperature of the face milling cutter is lowered, the heat pipe is more environment-friendly than the cutting fluid, and personal injuries to operation staff do not exist. In addition, the heat pipe adopted in the method is cheaper than the cutting fluid in market price, and therefore manufacturing cost of products of enterprises can be reduced.

Owner:ANHUI AGRICULTURAL UNIVERSITY

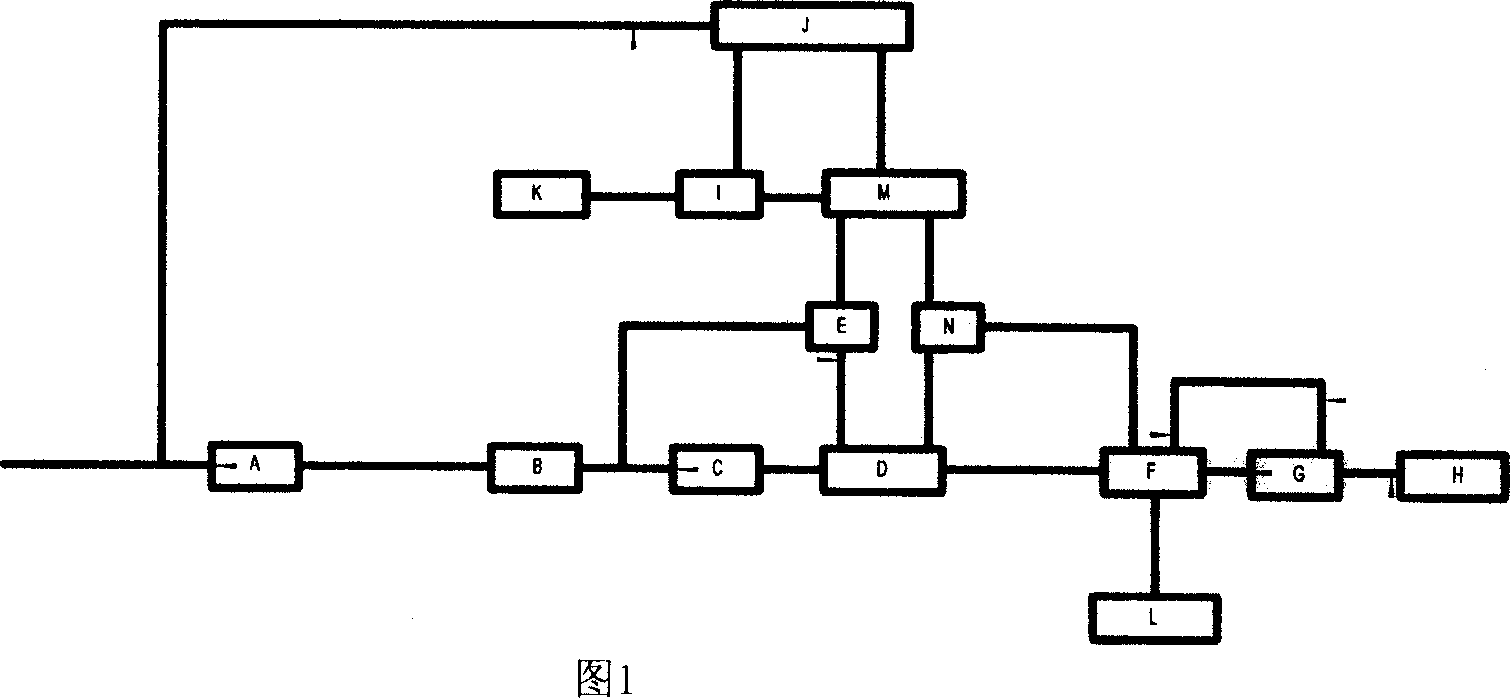

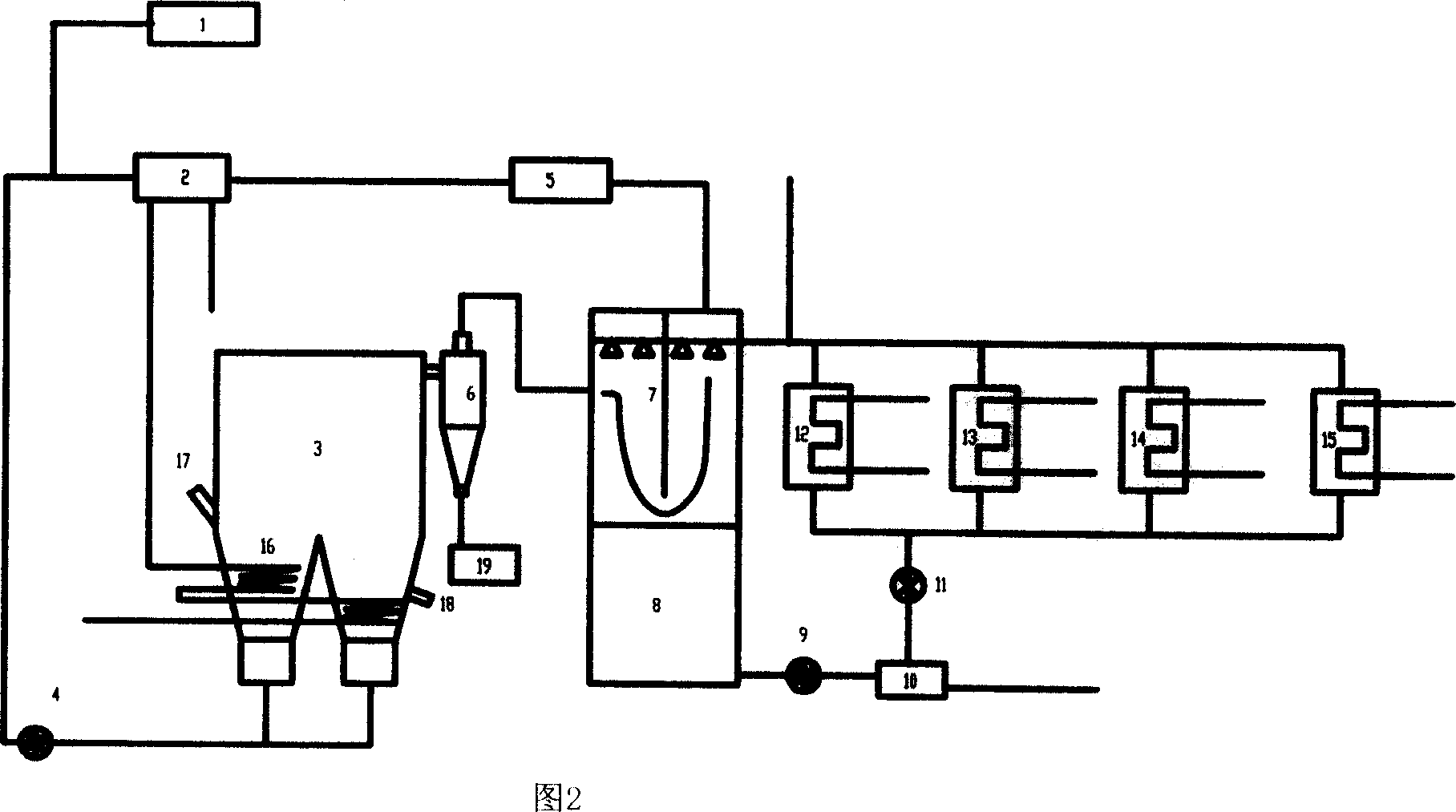

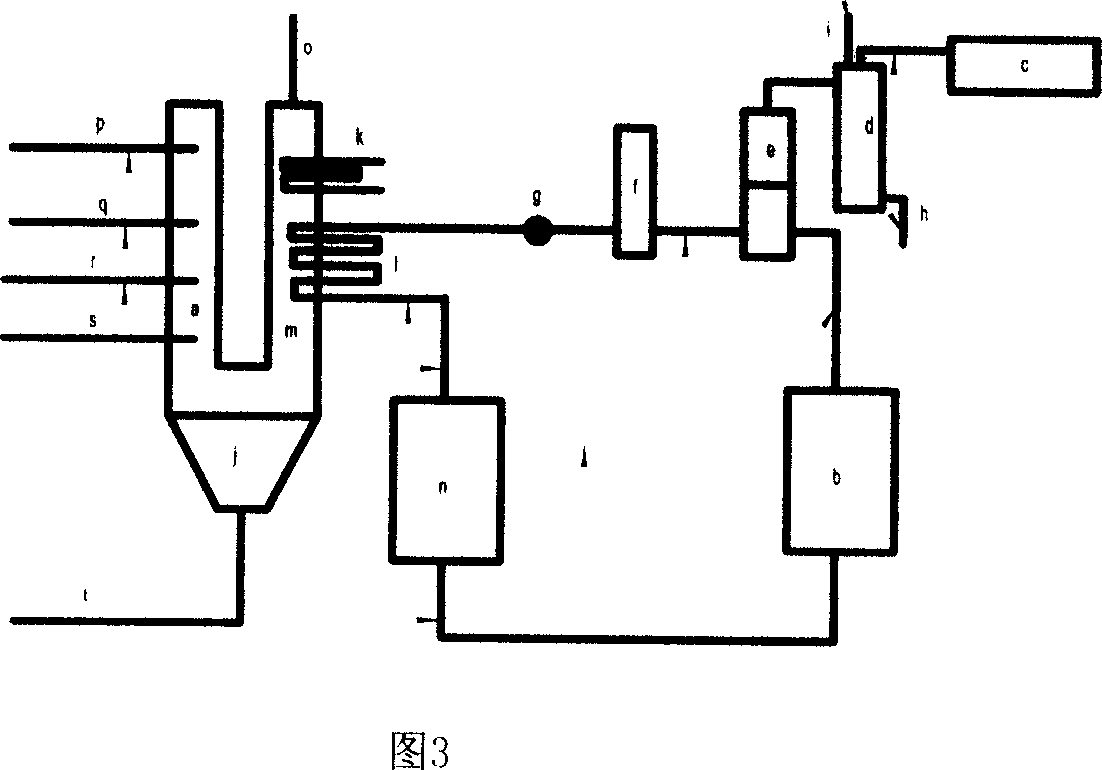

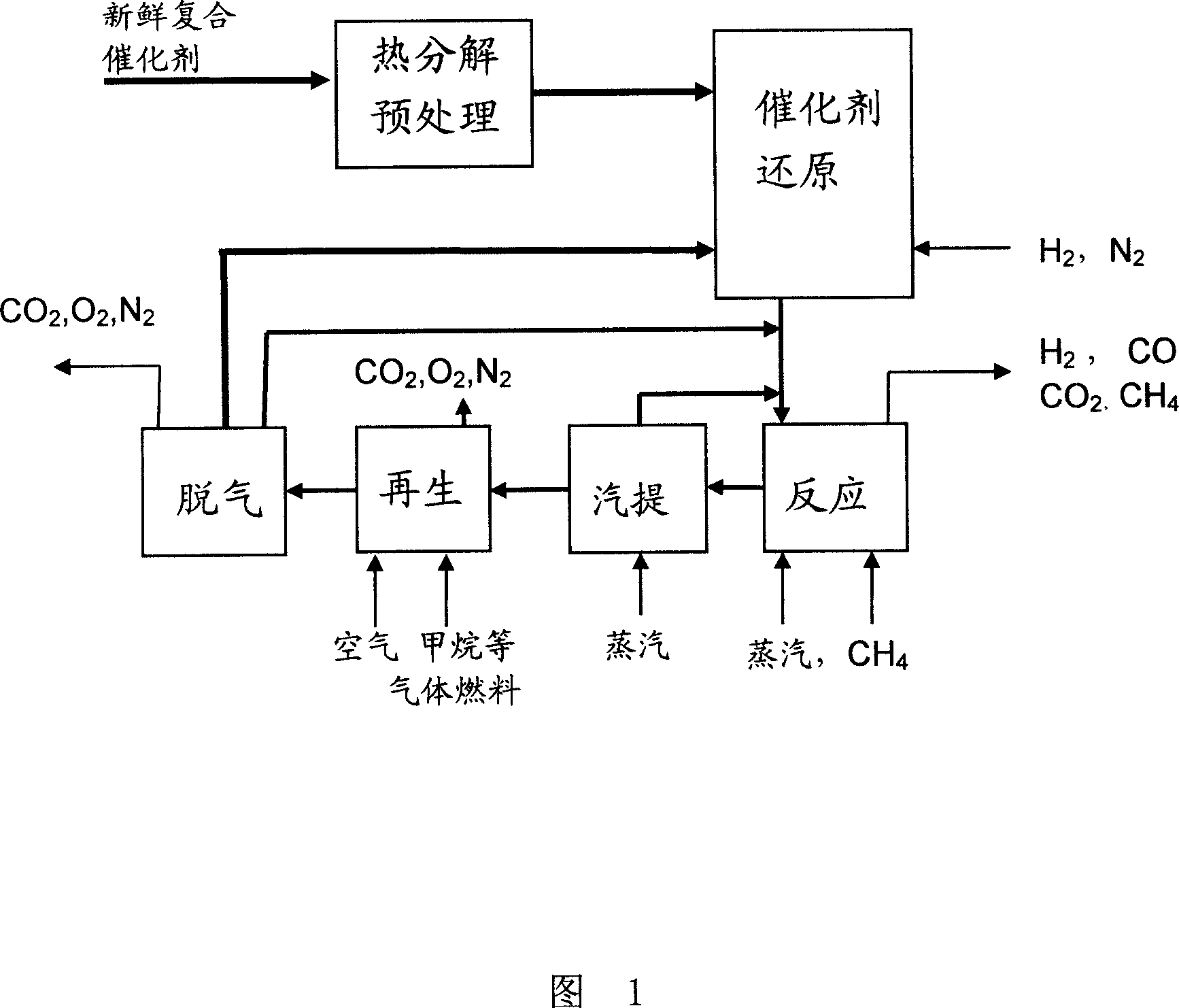

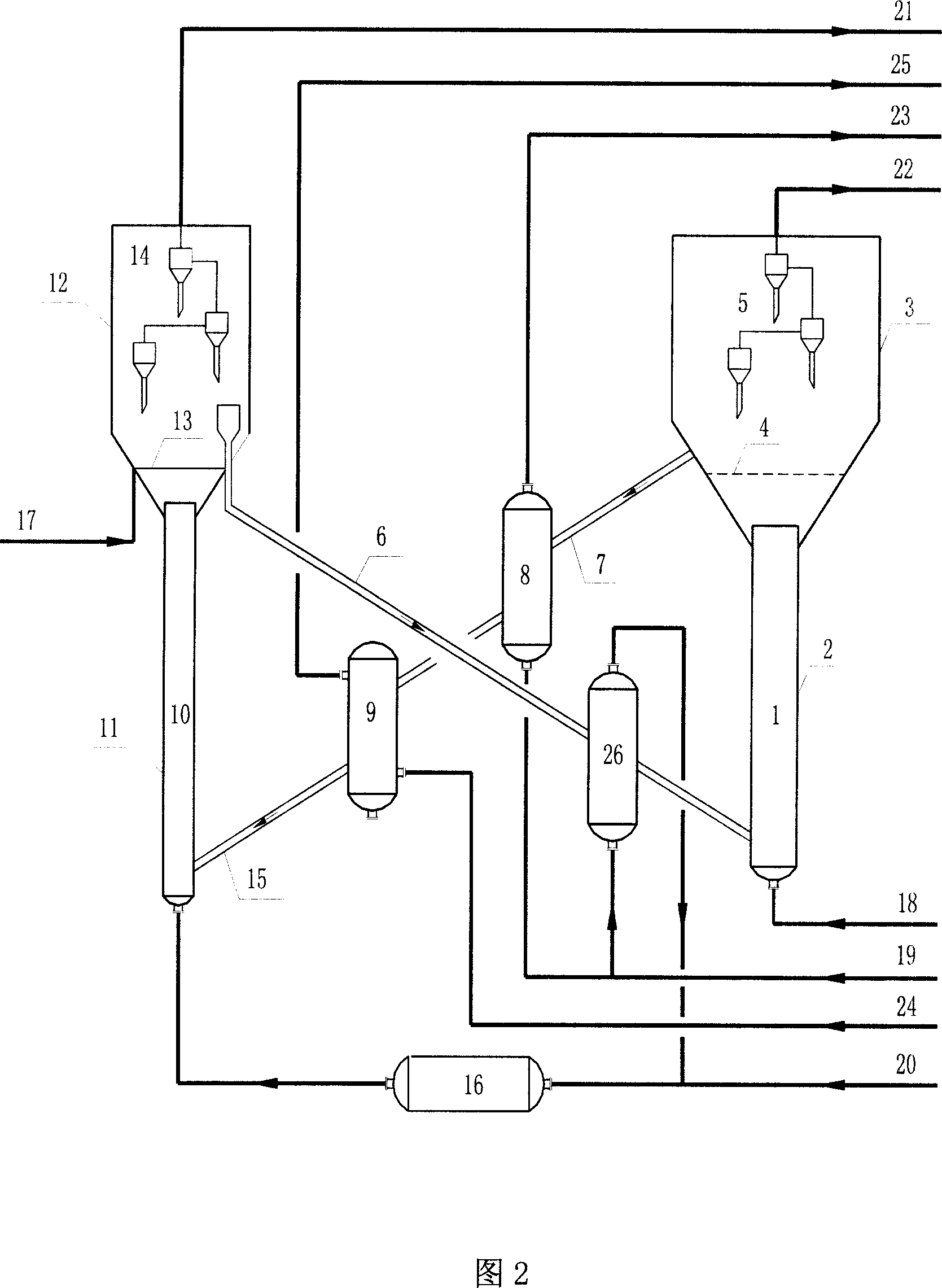

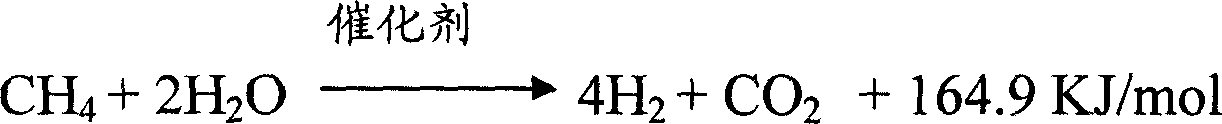

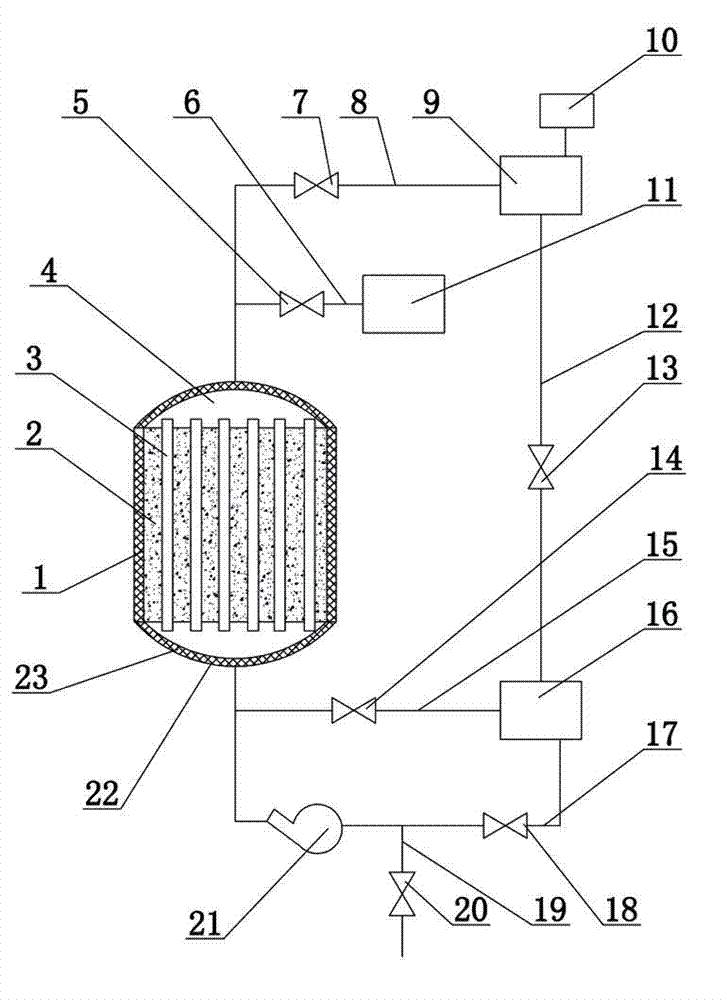

Adsorption forced methane steam reforming hydrogen manufacturing process and apparatus using circulating fluidized bed

The invention discloses a hydrogen preparing process of strengthening methane steam reforming by cyclic fluidized bed adsorption, comprising: transporting 5-200 micron composite catalyst grains into a regenerator for pretreating; degasifying the pretreated composite catalyst and tranfering it to a fluidized bed reactor for reducing; charing methane and steam into the fluidized bed reactor in the water-carbon ratio of 2-10, and making the fluidized composite catalyst perform reforming hydrogen preparing reaction with methane and steam at the same time, and finally transferring the composite catalyst into regnerator to be regenerated and recycled, where the reacting time is 1s-5min, the reacting gas speed is 0.3-1.0m / s, and the ratio of composite catalyst to methane is 10 : 1-0.002 : 1 in g / ml. And it also discloses a device of implementing the above process. And the process can implement stable and continuous operation of fluidized bed reactor, and has advantages of high mass and heat transfer efficiencies.

Owner:CHINA PETROLEUM & CHEM CORP +1

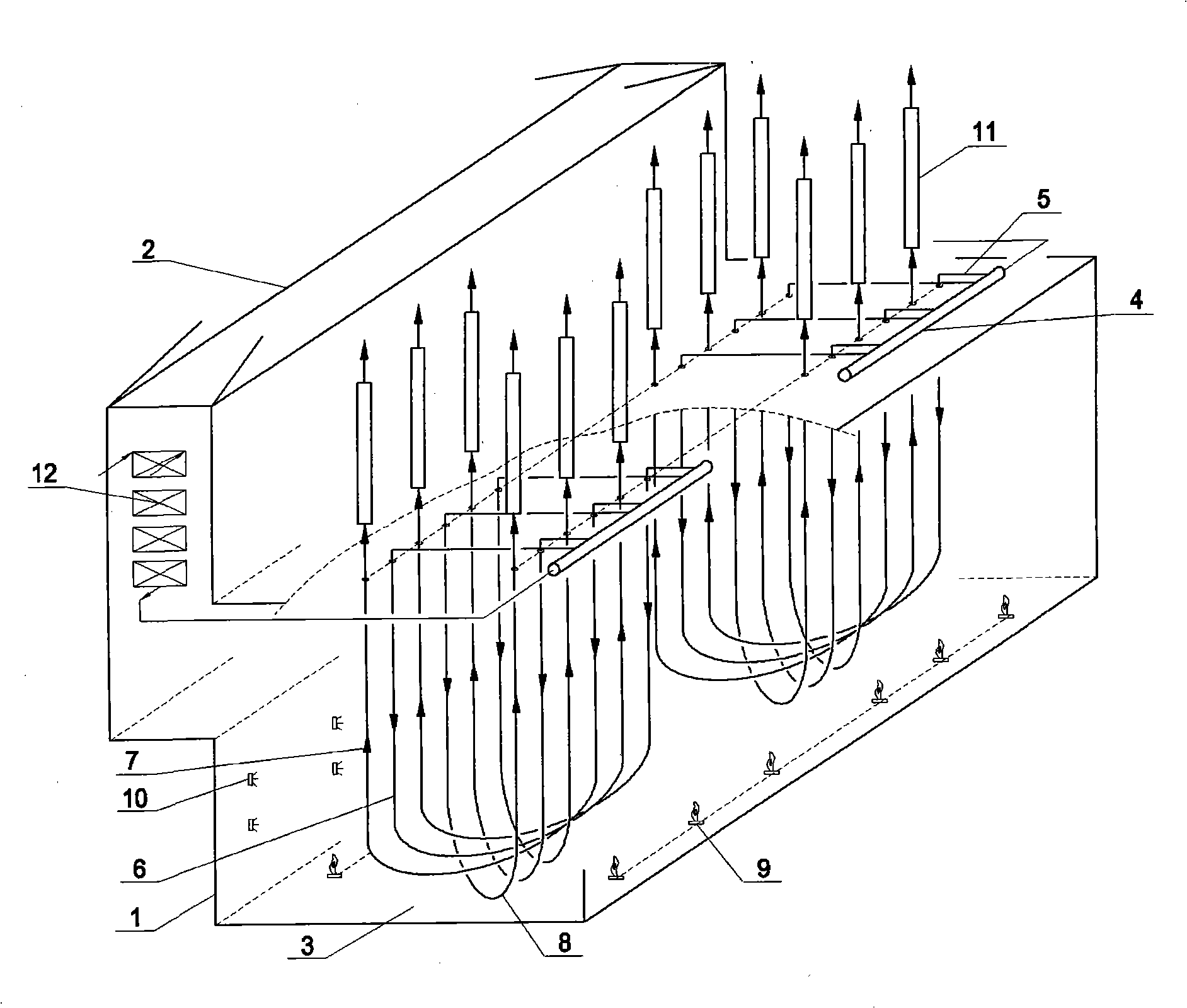

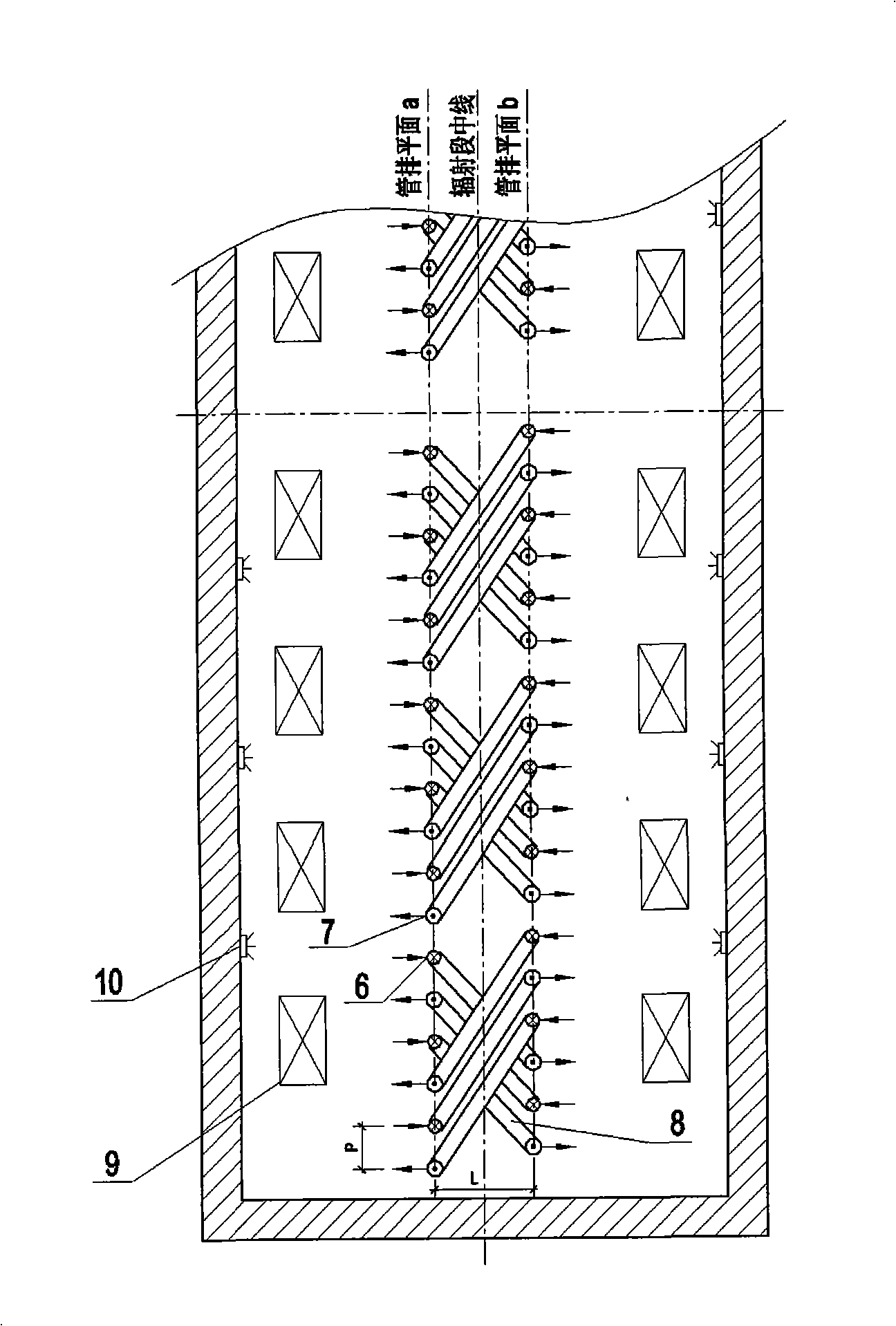

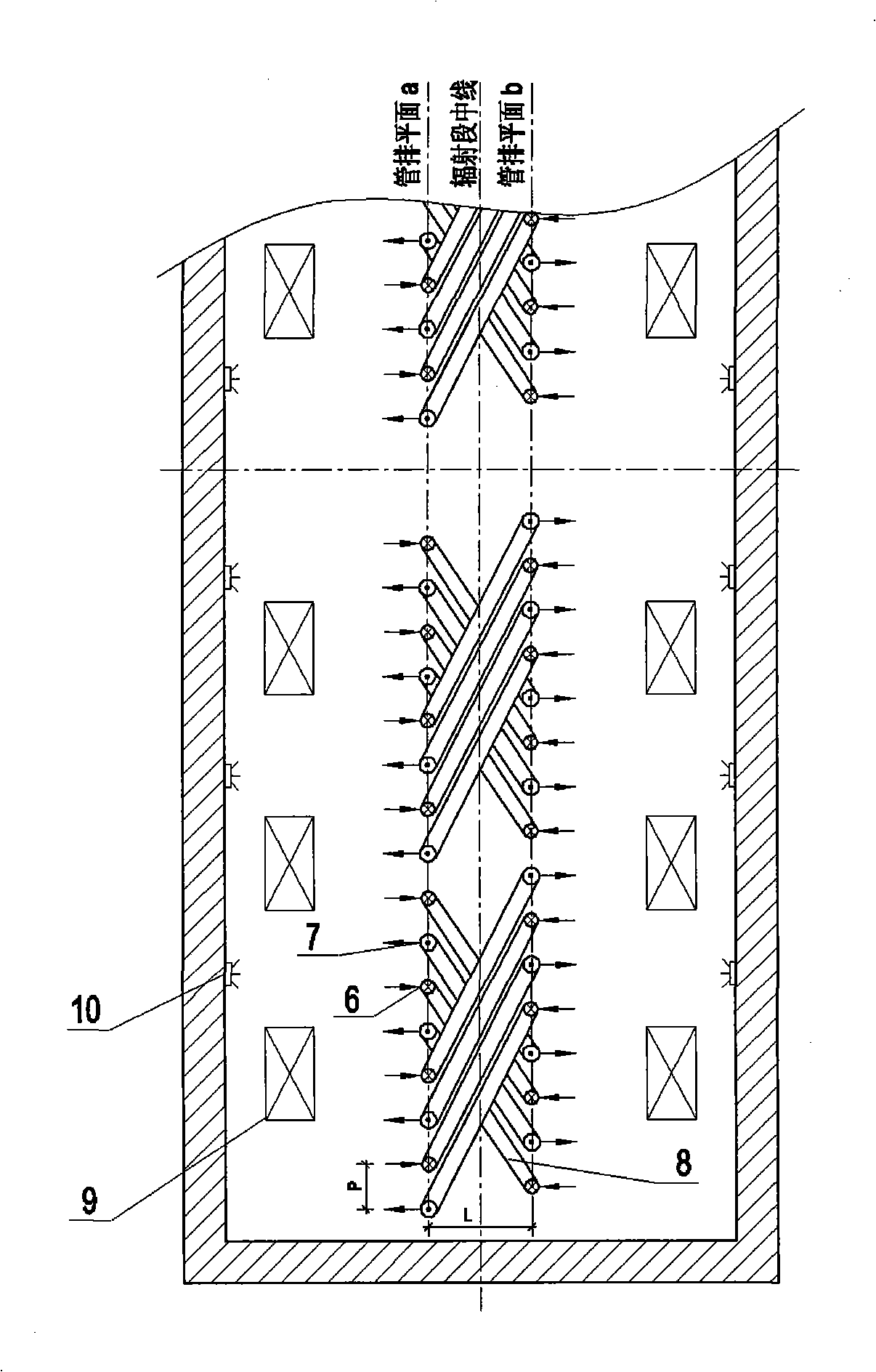

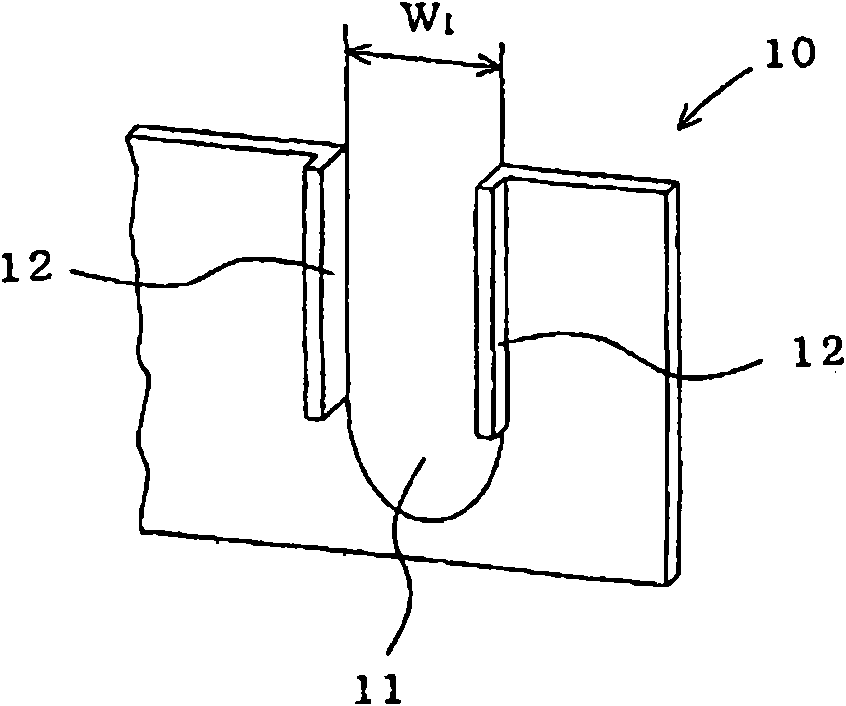

Ethylene pyrolysis furnace

ActiveCN101333147AEvenly heatedExtended operating cycleThermal non-catalytic crackingHydrocarbon by hydrocarbon crackingCombustorHeat transfer efficiency

An ethylene cracking furnace comprises a radiation segment, a convection segment, a bottom burner, sidewall burners and a quench boiler; the radiation segment is provided with a radiation room; radiation furnace tubes used for the pyrolysis of hydrocarbons and petroleum distillate are arranged inside the radiation room; each radiation furnace tube is composed of an inlet tube and an outlet tube; each inlet tube and each outlet tube are respectively provided with one channel; at least a radiation room 3 is arranged in the radiation segment of the cracking furnace; the radiation furnace tubes are arranged in two rows in the radiation room; each row of radiation furnace tubes forms a tube row plane; an inlet tube 6 and an outlet tube 7 of a radiation furnace tube are in two different tube row planes in an alternating interval way; the bottom parts of the inlet tube 6 and the outlet tube 7 are connected together through a symmetrical U-connector 8. The invention achieves a large-scale cracking furnace; the furnace tube arrangement way of the invention improves the radiation heat transfer efficiency of the radiation furnace tubes so as to prolong the operating cycle of the cracking furnace and reduce energy consumption of products.

Owner:WISON ENG

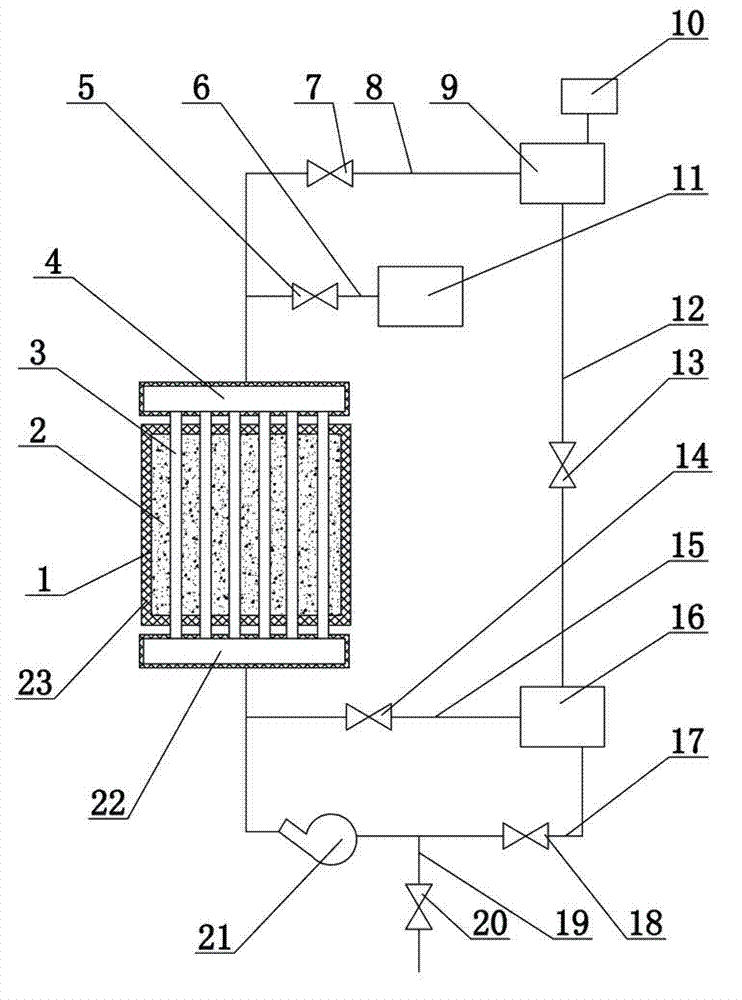

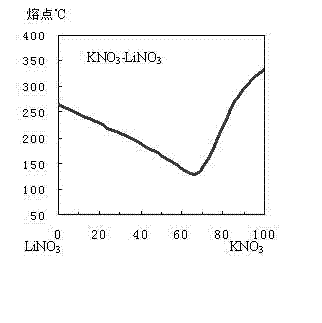

Phase change heat accumulation system for generating steam directly and preparation method of phase change heat accumulation agent

InactiveCN102777874AImprove efficiencyImprove heat transfer coefficientHeat storage plantsChemical industryPorous mediumToxic industrial waste

The invention relates to a phase change heat accumulation system for generating steam directly and a preparation method of a phase change heat accumulation agent. A phase change material is enhanced with graphite foam, and is absorbed in a porous medium of the graphite foam, so that a binary eutectic salt / graphite foam material is prepared and is used as a composite phase change material of a heat accumulation device, the composite phase change material is high in heat conduction coefficient, therefore under the same design condition, the phase change heat accumulation system provided by the invention is applied to systems of a focusing type solar thermal power generation system, an industrial waste heat recovery system and the like, and has the characteristics of high heat transfer efficiency, small volume, low cost and the like. In addition, the phase change heat accumulation system for generating steam directly can flexibly adopt a parallel connection or serial connection mode according to the temperature of high-temperature waste heat steam and the requirement of a steam user; and during serial connection, the binary eutectic salt / graphite foam composite phase change material can be combined in a cascaded manner according to a melting point, thus the efficiency of an energy accumulation system is increased, and the energy can be greatly accumulated.

Owner:ZHENGZHOU UNIV

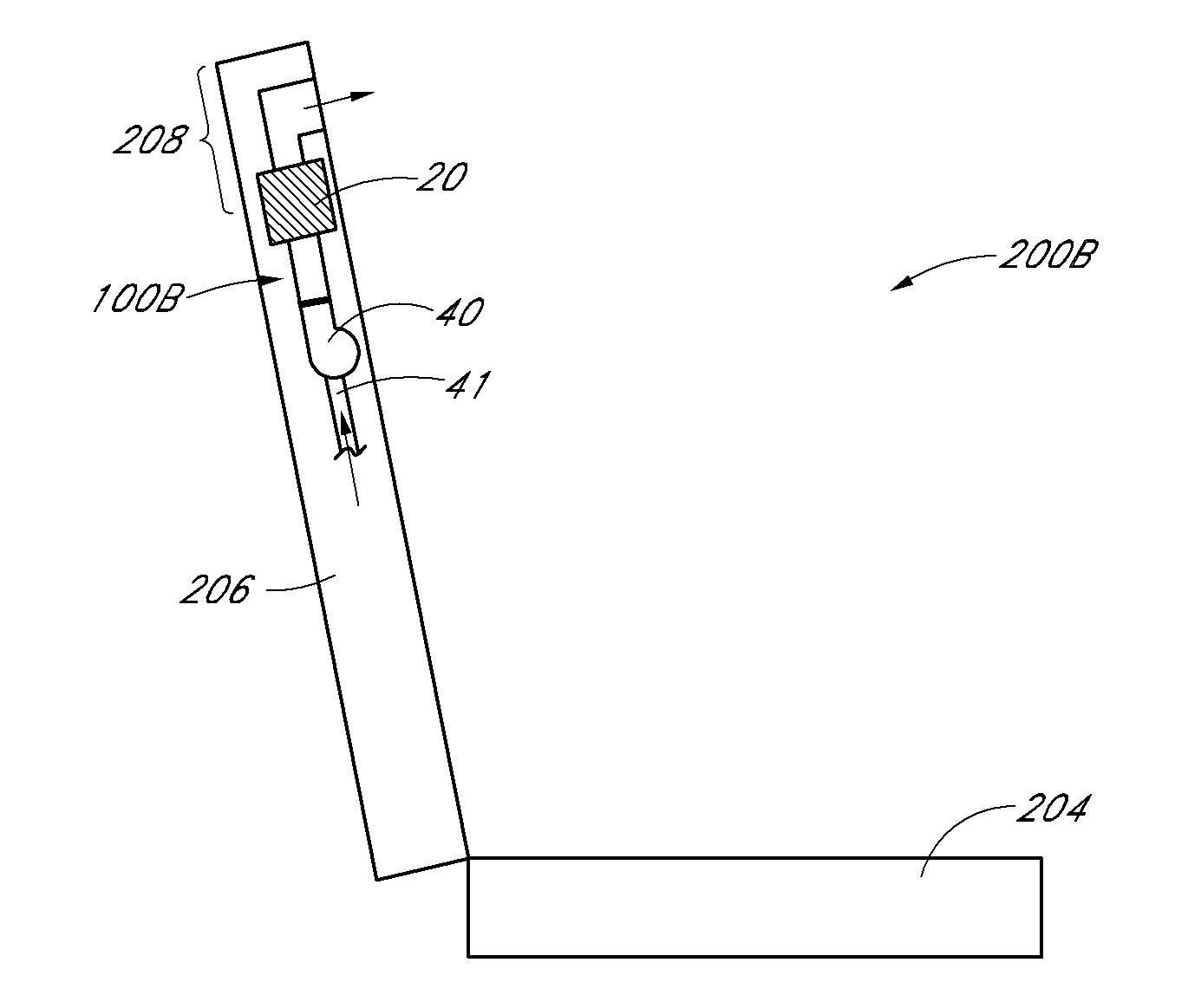

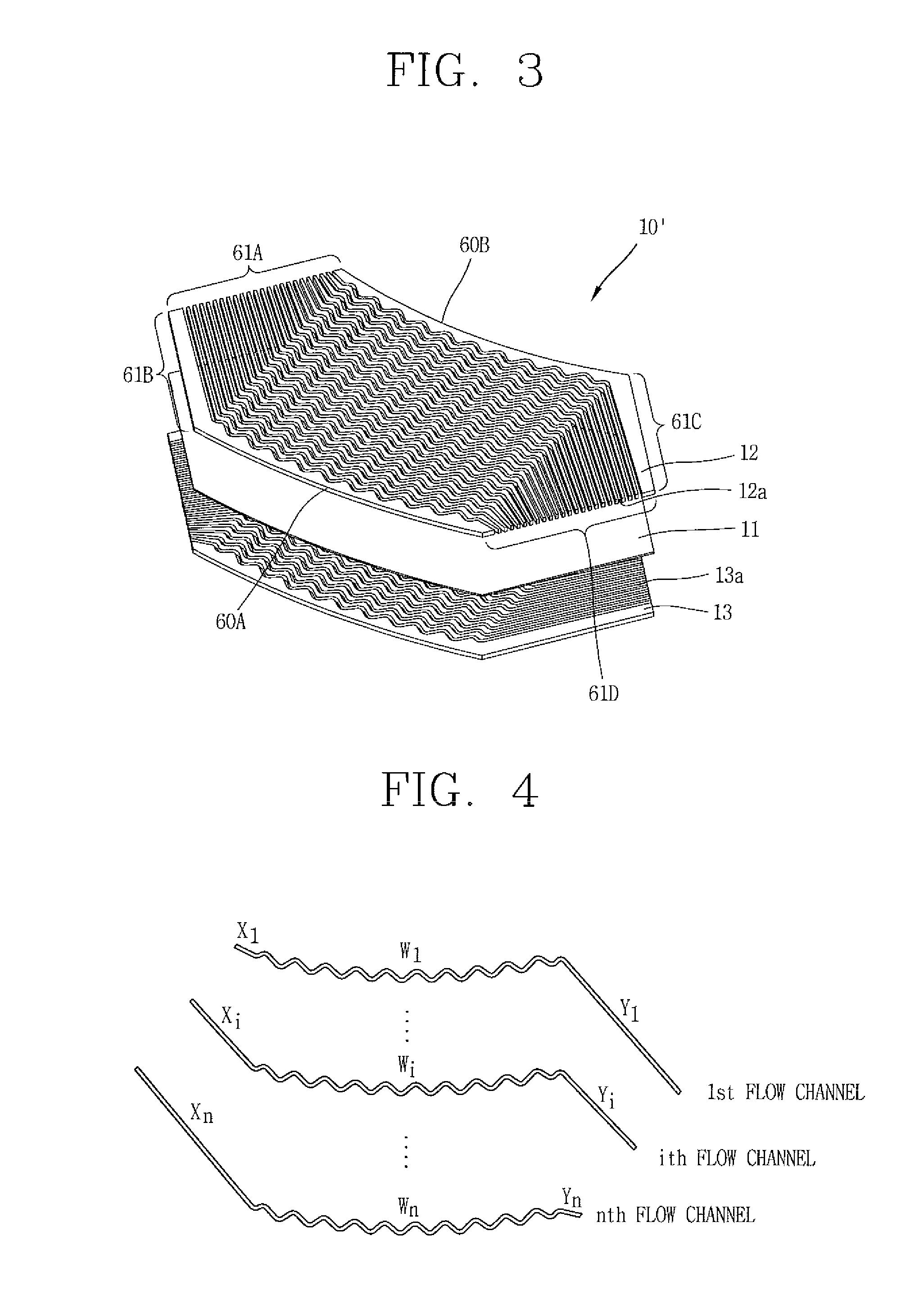

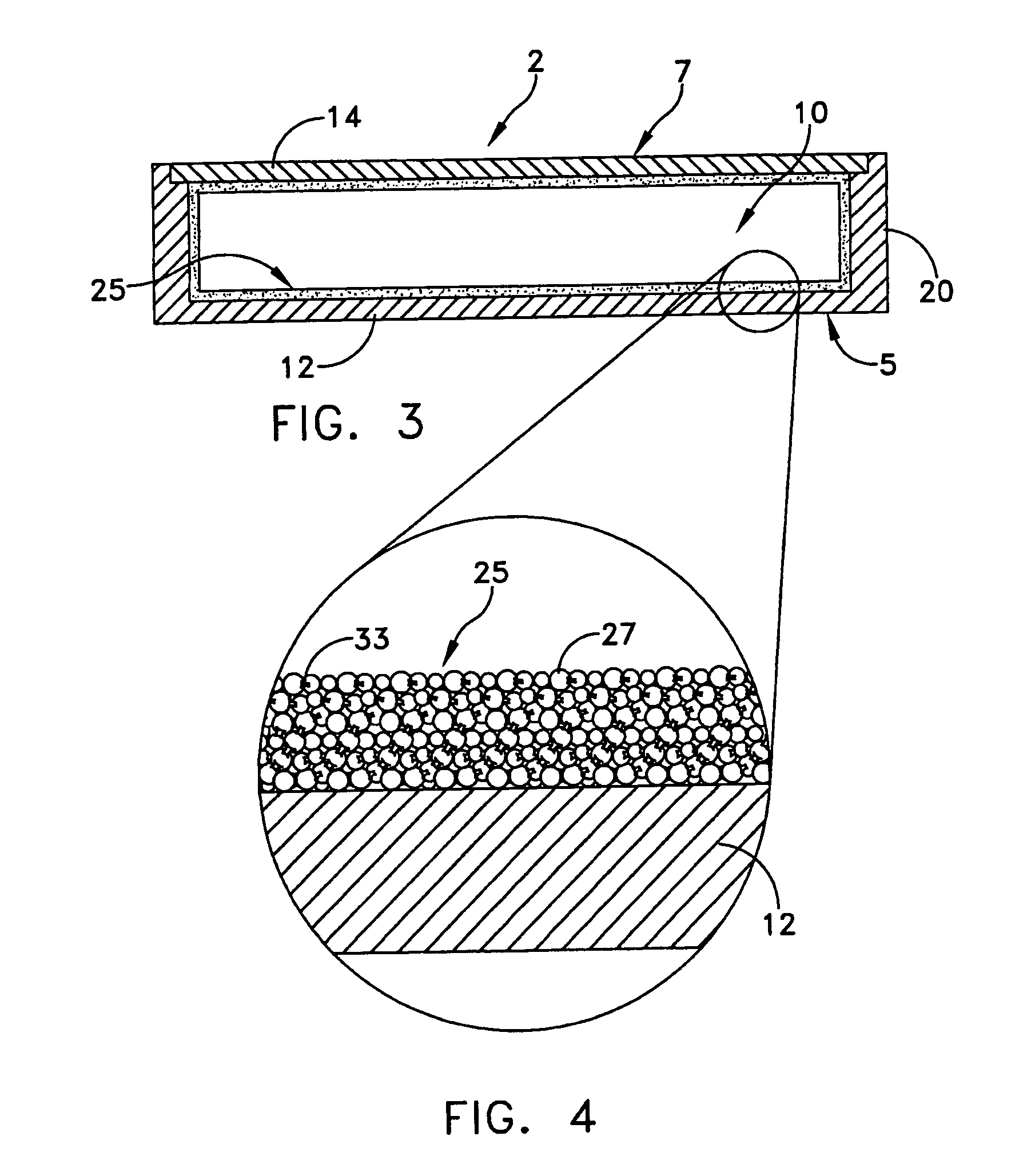

Heat transfer device and method of making same

InactiveUS20060124281A1Enhanced capillary structureImprove heat transfer efficiencySemiconductor/solid-state device detailsSolid-state devicesWorking fluidCompound (substance)

A capillary structure for a heat transfer device, such as a heat pipe is provided having a plurality of particles joined together by a brazing compound such that fillets of the brazing compound are formed between adjacent ones of the plurality of particles and one or more vapor vents are defined in the capillary structer. In this way, a network of capillary passageways are formed between the particles and vapor-vents through the capillary structure so as to aid in the transfer of working fluid by capillary action, while the plurality of fillets provide enhanced thermal transfer properties between the plurality of particles so as to greatly improve over all heat transfer efficiency of the device. A method of making the capillary structure according to the invention is also presented.

Owner:ROSENFELD JOHN H +1

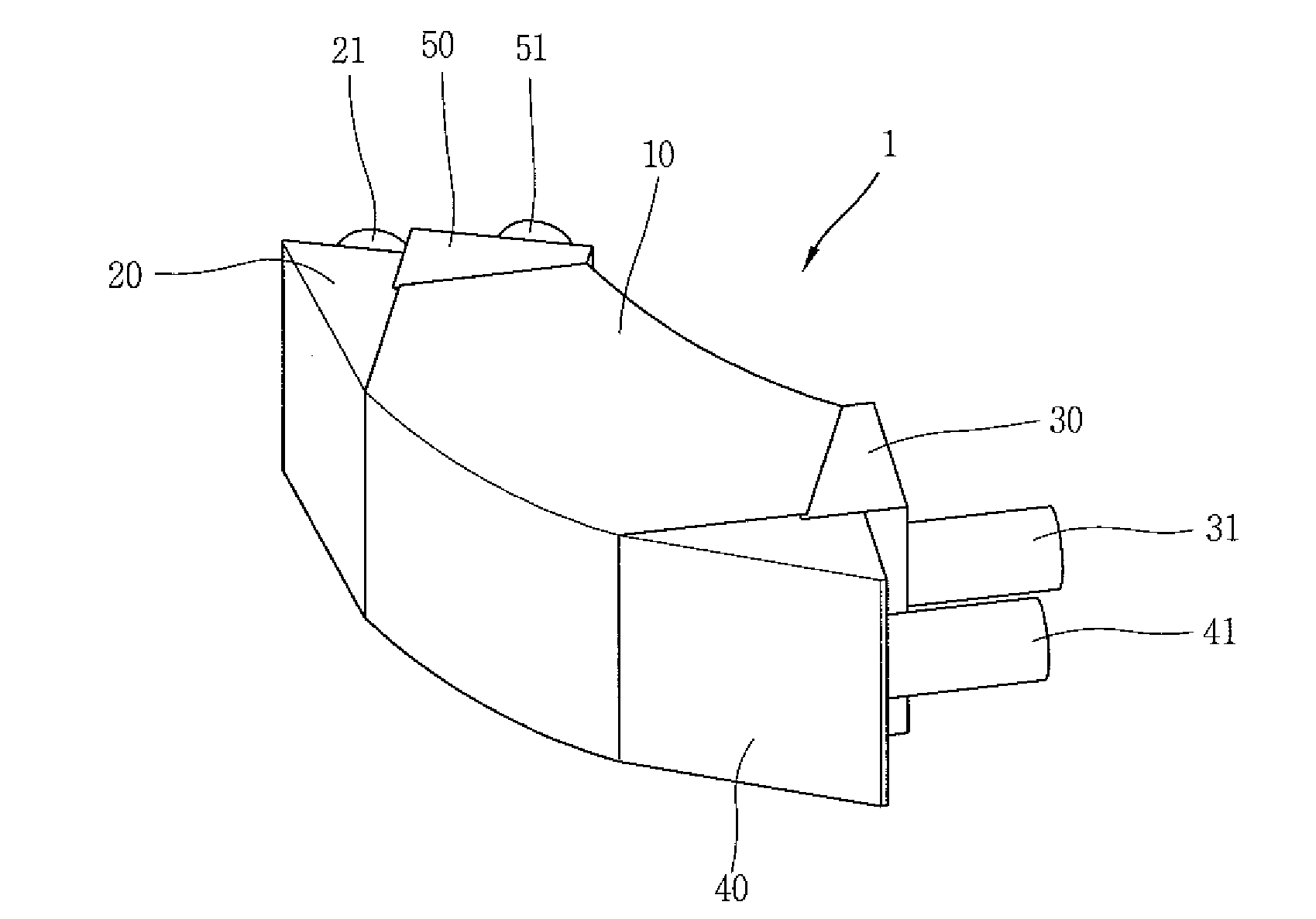

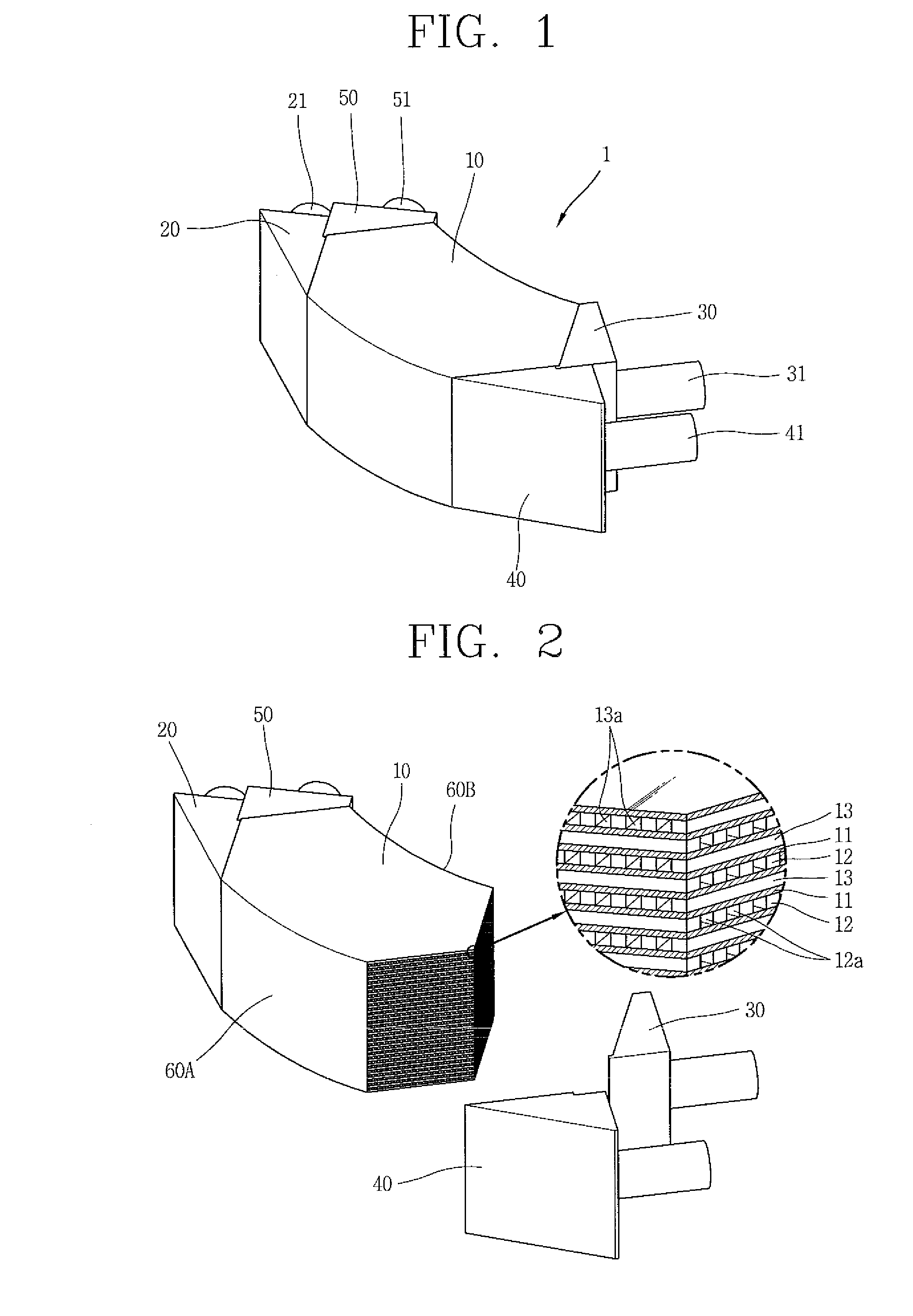

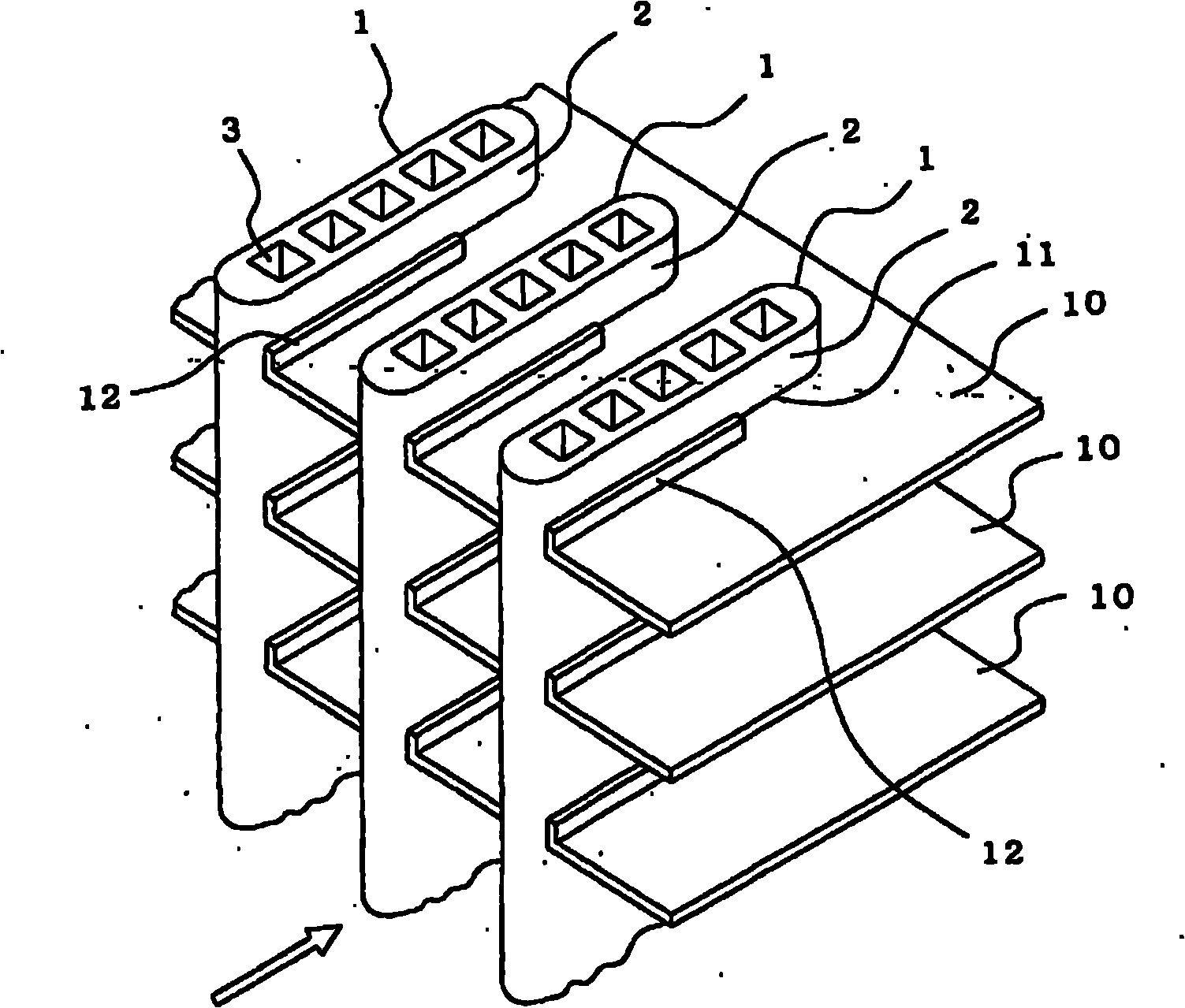

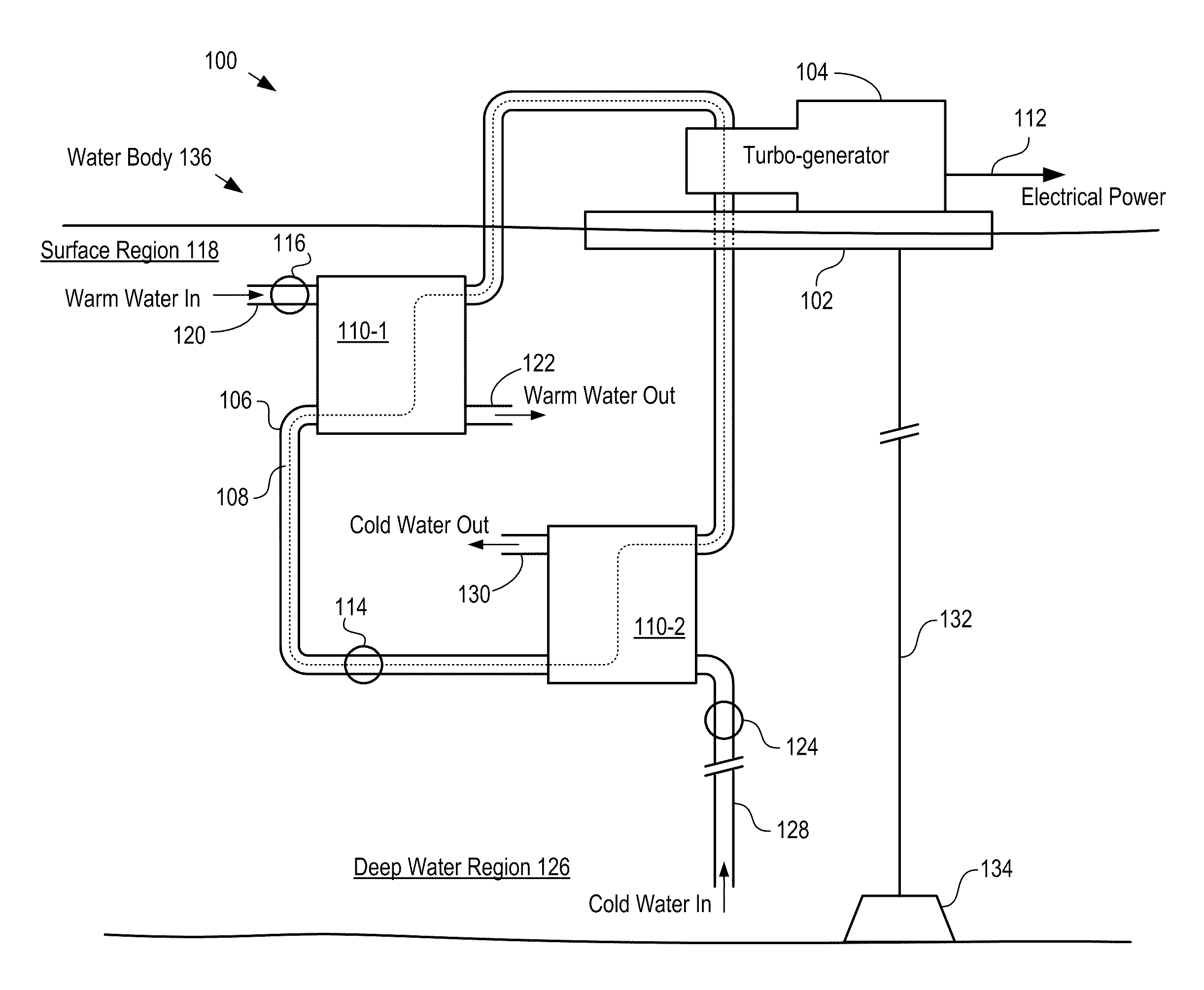

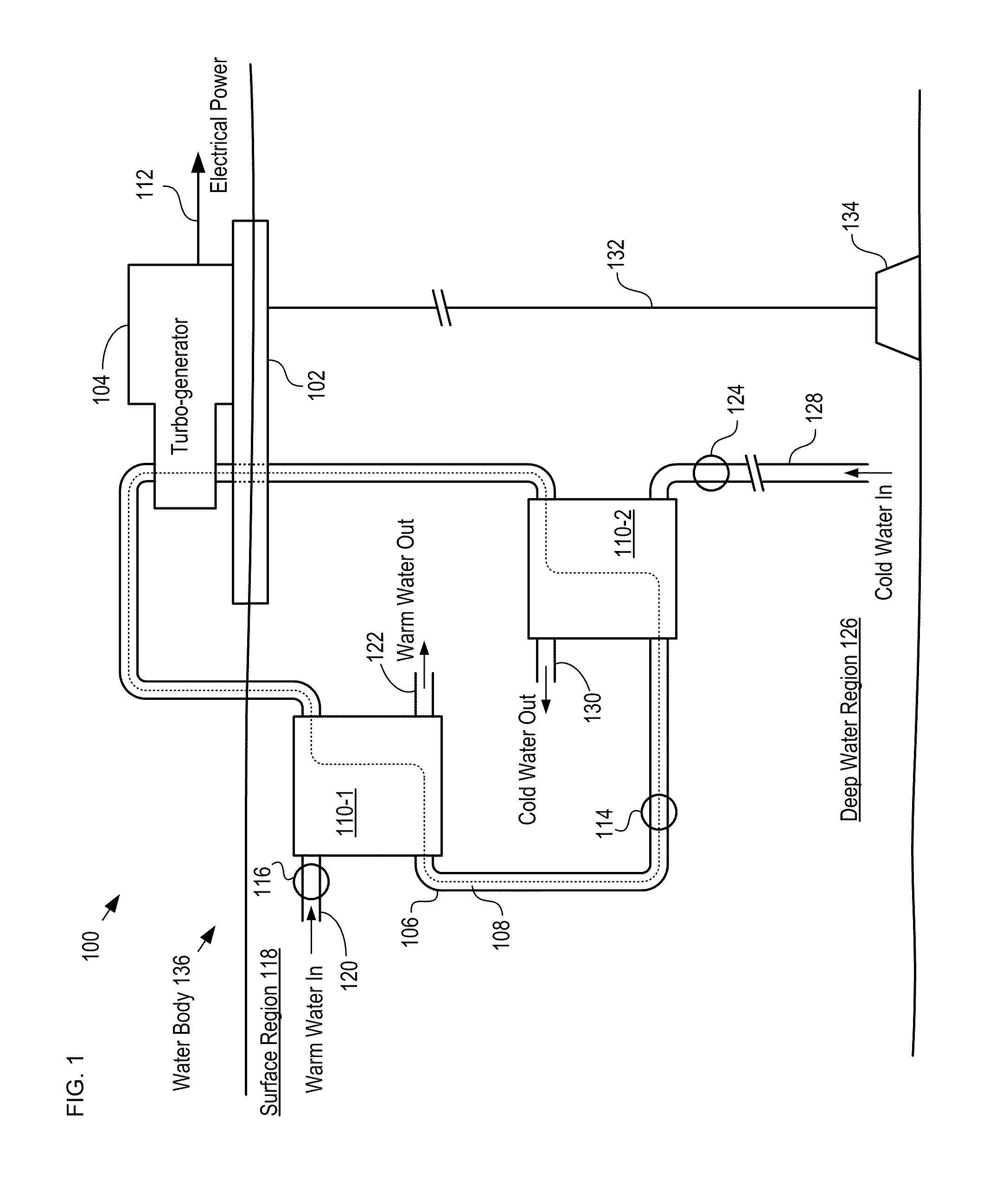

Heat exchanger having micro-channels

InactiveUS20100314088A1Improve performanceImprove heat transfer efficiencyStationary conduit assembliesHeat transfer modificationHeat transfer efficiencyEngineering

Disclosed is a heat exchanger configured by laminating layers having micro-channels by adapting a micromachining, wherein the micro-channels having uniform length and cross section are constructed within a heat exchanger body in a curved outer shape, thereby minimizing deviation for each channel and improving heat transfer efficiency.

Owner:AGENCY FOR DEFENSE DEV

Brazed wick for a heat transfer device and method of making same

InactiveUS20050022975A1Improve thermal conductivityImprove heat transfer efficiencySemiconductor/solid-state device detailsSolid-state devicesWorking fluidEngineering

A capillary structure for a heat transfer device, such as a heat pipe is provided having a plurality of particles joined together by a brazing compound such that fillets of the brazing compound are formed between adjacent ones of the plurality of particles. In this way, a network of capillary passageways are formed between the particles to aid in the transfer of working fluid by capillary action, while the plurality of fillets. provide enhanced thermal transfer properties between the plurality of particles so as to greatly improve over all heat transfer efficiency of the device. A method of making the capillary structure according to the invention is also presented.

Owner:THERMAL

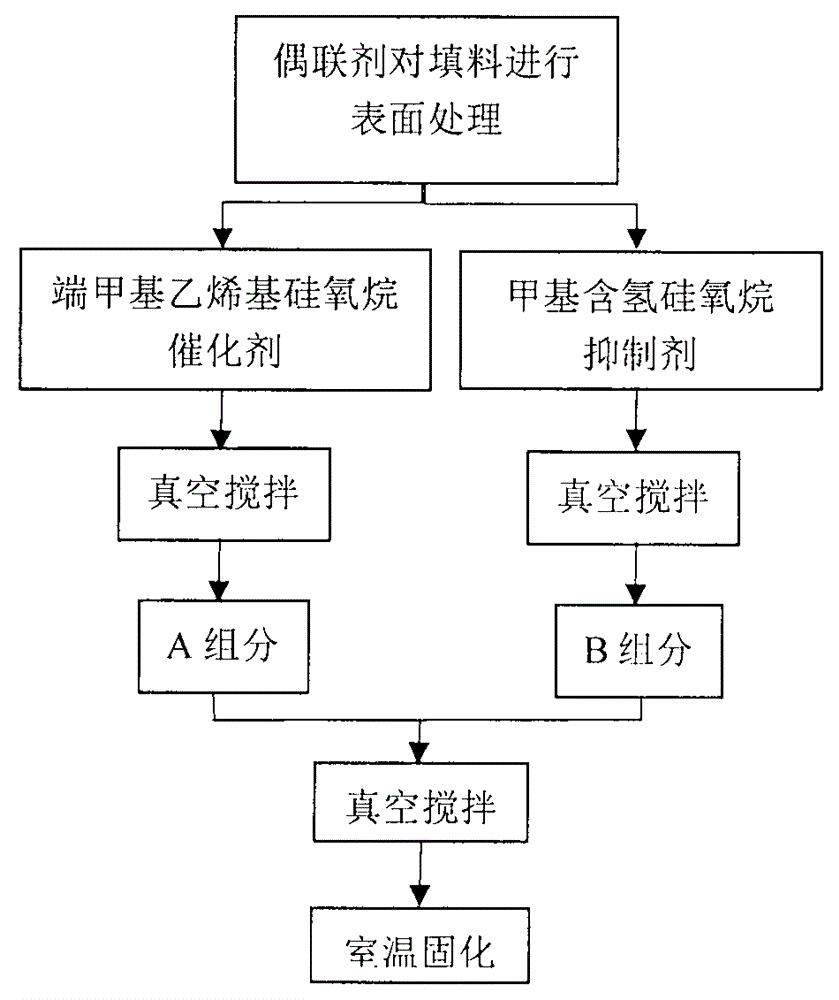

Heat-conducting adhesive for LED (light-emitting diode) lamp packaging and preparation method thereof

InactiveCN104017537AImprove thermal conductivitySimple preparation processNon-macromolecular adhesive additivesSemiconductor devicesHeat conductingAdhesive

The invention discloses a heat-conducting adhesive for LED (light-emitting diode) lamp packaging and a preparation method thereof. The heat-conducting adhesive for LED packaging is prepared by thoroughly mixing and curing methylvinyl-terminated siloxane composed of components A and B as a base material, methyl hydrogen siloxane as a crosslinking agent, an inhibitor, a catalyst and a coupled heat-conducting filler at room temperature, and the curing time can be regulated according to the addition amount of the catalyst. The method comprises the following steps: putting the heat-conducting filler and base material into a vacuum stirrer, and thoroughly and uniformly mixing at room temperature until the heat-conducting filler forms effective distribution in the base material, thereby preparing the heat-conducting adhesive with excellent performance. The method aims to enhance the heat conductivity of the heat-conducting adhesive, lower the thermal resistance between the base plate and radiator in the LED lamp, improve the problems of curing time and curing temperature, and enhance the heat transfer efficiency. The heat-conducting adhesive has the advantages of higher heat conductivity, simple preparation technique and lower cost, can completely satisfy the requirements of heat dissipation for the LED lamp, and has favorable market prospects.

Owner:南京工大光电材料研究院有限公司

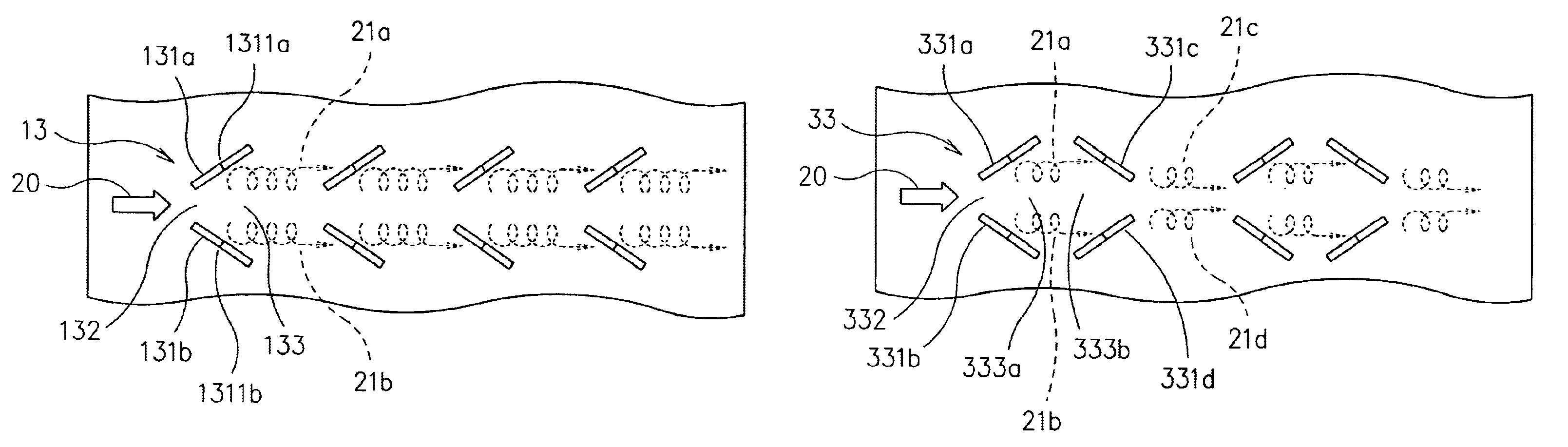

Cold plate with vortex generator

InactiveUS6929058B2Improve heat transfer effectSemiconductor/solid-state device detailsSolid-state devicesEngineeringHeat transfer efficiency

The present invention discloses a cold plate with vortex generator for fluid going through defined an inlet and an outlet according to the flowing directions of the fluid, comprising: a base having a groove, one end of the groove is connected to the inlet and another end is connected to the outlet; a body installed on the base; at least one vortex generator mounted on a surface of the body toward the groove of the base, wherein two unparallel and symmetrical ribs form the vortex generator, one end of the unparallel ribs is a contraction end with a shorter gap, another end is an expansion end with a longer gap, coolant can pass through the gap between the ribs, due to each rib having a sharp portion, an appearance of the rib is a triangle geometric figure. The vortexes increase the liquid mixture and improve the heat transfer on the cold plate, but not cause much pressure drop, therefore the heat transfer of the entire system is more efficient.

Owner:IND TECH RES INST

Soft cooling jacket for electronic device

InactiveUS7167366B2Increase heat transfer areaMaximize heat transfer efficiencyDigital data processing detailsHeat exchange apparatusManufacturing cost reductionHard disc drive

Provided is a water cooling type cooling jacket for an electronic device including a pouch body formed of a soft, loose elastic material that is deformable to closely contact heat-generating elements having various shapes due to a contact pressure and accommodating and a coolant, and a coolant inlet tube and a coolant outlet tube formed at one side of the pouch body to allow the coolant to circulate inside the pouch body and connected to coolant circulation lines for circulating the coolant. Therefore, the water cooling type jacket for an electronic device can be adapted to various shapes of heat-generating elements having uneven surfaces and various shapes of installation spaces beyond electrical and mechanical limitation to increase a heat transfer area and maximize a heat transfer efficiency and can be installed at various electronic devices such as hard disk drives, video cards or memory cards and a PCB without spatial limitation. Also, the water cooling type, soft cooling jacket for an electronic device can reduce a fabrication cost by simplifying the structure while maintaining close adhesion and can safely protect various elements by distributing pressure applied to the elements.

Owner:CHEON KIOAN

Far infrared unit for dewatering vegetable

InactiveCN1689416AImprove qualityImprove quality, drying speedDrying solid materials with heatFood processingPulp and paper industryHeat transfer efficiency

The far infrared vegetable dewatering apparatus includes drying cabinet, transmission mechanical,, conveying mechanism and heater. The drying cabinet has material feeding port and induced draft port in the top and discharge port and air intake in the bottom. The present invention features that the drying cabinet is separated with partition boards into several layers with separated conveying mechanism, transmission mechanism, heating unit and guide board. The present invention has small size, convenient operation, fast drying speed, high heat efficiency and low power consumption, and the dried vegetable product has bright color and high quality.

Owner:SHANDONG UNIV OF TECH

Fluidized low-temperature reduction device and reduction method for powdery manganese oxide ores

The invention relates to a fluidized low-temperature reduction device and a fluidized low-temperature reduction method for powdery manganese oxide ores. The device comprises a feeding unit, a preheating unit, a reduction roasting unit and a cooling unit which are connected from top down, wherein the reduction roasting unit is connected with a combustion chamber; and the combustion chamber is connected below the preheating unit. In the reduction method, tail gas formed in the reduction process enters the combustion chamber combusts with supplementary gas and air to form flue gas; and the flue gas is subjected to countercurrent heat exchange with the manganese oxide ores. The fluidized low-temperature reduction device and the reduction method have the advantages that: the gas can be used as a reducer and also can be used as fuel; and the utilization rate of the gas is 100 percent. In the reduction device, the reduction temperature of the manganese oxide ores is low, so a manganese-containing phase which is insoluble to sulfuric acid is avoided, and heat carried by the manganese oxide ores is reduced by over 30 percent. The manganese oxide ores in a fluidized reduction roasting furnace are in the bubbling fluidized state, the heat transfer efficiency, the mass transfer efficiency and the reaction efficiency are high, the distribution of retention time is uniform, and the reduction rate of the manganese oxide is more than 98 percent.

Owner:深圳中科九台资源科技有限公司

Heat exchanger, method of manufacturing a heat exchanger and air conditioner with the heat exchanger

InactiveCN101769689AEasy to manufactureLow costEvaporators/condensersSoldering apparatusPlate heat exchangerHeat transmission

The present invention provides a heat exchanger, which is improved in terms of heat transfer efficiency and space saving, which can be manufactured with simplified steps and at a reduced cost, and which ensures improved reliability when used, a method for manufacturing the heat exchanger, and an air conditioner including the heat exchanger. The heat exchanger includes: a plurality of plate fins, made of an aluminum alloy, subjected to a hydrophilic film forming treatment, and stacked at predetermined intervals to allow air to flow therebetween; and a flat heat transmission tube, made of an aluminum alloy and provided with a plurality of refrigerant flow paths arranged in a major axis direction of the tube so as to extend in a longitudinal direction of the tube; wherein the heat transmission tube is fitted into grooves provided in the plate fins, and a solder layer provided on an outer surface of the heat transmission tube at a front edge thereof is melted such that the heat transmission tube is fixedly secured to the plate fins by the solder.

Owner:MITSUBISHI ELECTRIC CORP

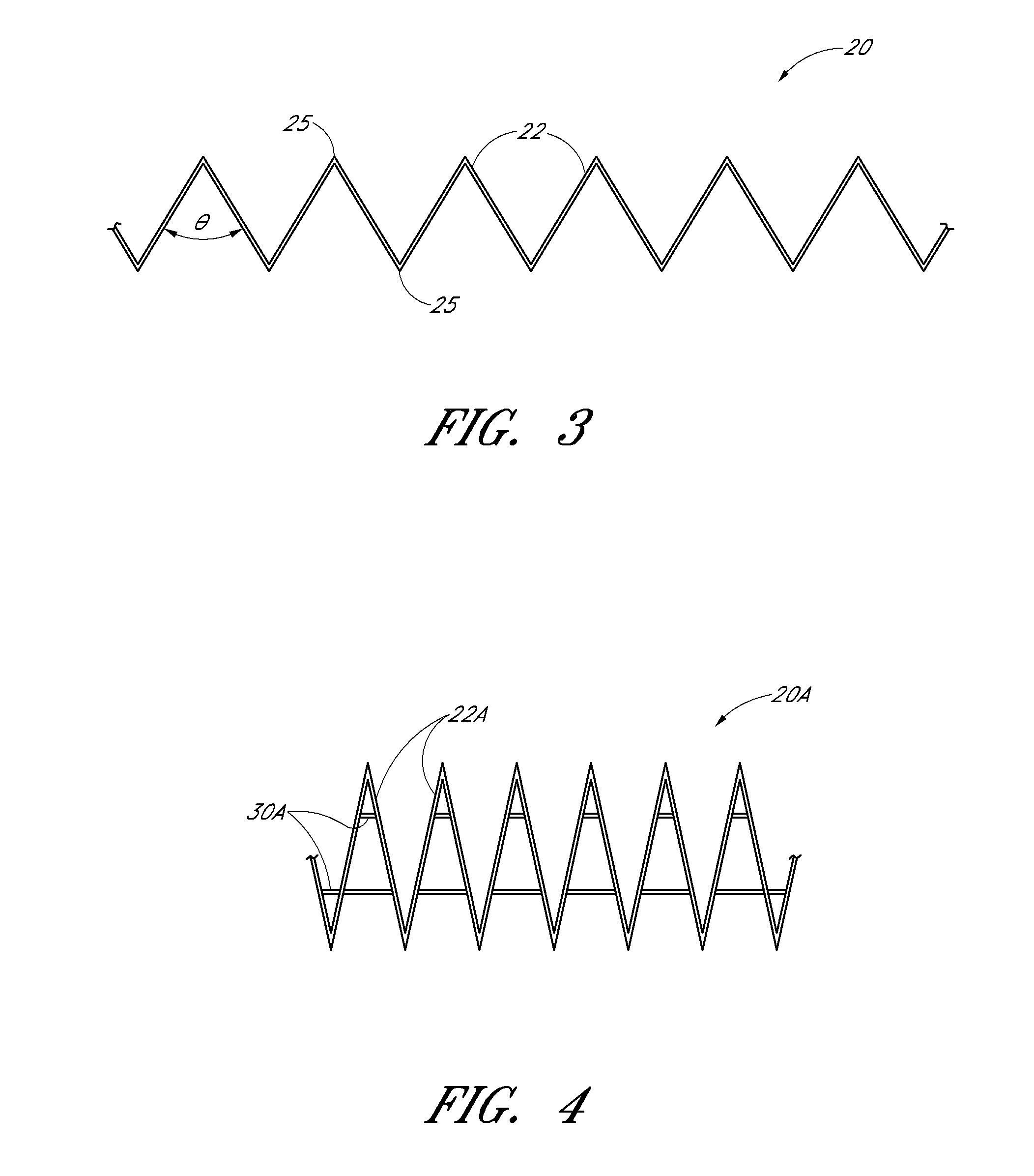

Heat Exchanger Comprising Wave-shaped Fins

InactiveUS20110127022A1Enhanced convective heat transferIncrease back pressureMachines/enginesStationary conduit assembliesWave shapeEngineering

A heat exchanger for exchanging heat between a first fluid and a second fluid is disclosed; wherein the heat exchanger has improved thermal efficiency and low fluid back pressure. The heat exchanger comprises conduits for conveying the first fluid, wherein the conduits include a plurality of flow passages. The flow passages are defined by a plurality of fins that are continuous along the direction of flow of the first fluid. Each fin includes a wave-shaped region, and adjacent fins sub-divide each flow passage into first and second sections that are interposed by a third section. The wave-shape of the fins creates a continuously varying cross-sectional area for each third section. The variation of the cross-sectional area of the third section, coupled with the wave-shape of the fins, induces a swirl flow between the third section and each of the first and second sections. This swirl flow improves the efficiency of the overall convection heat transfer in each conduit. Further, the overall cross-sectional area of each conduit remains constant even as the cross-sectional areas of individual flow passages changes, which mitigates the development of back pressure in the flow of the first fluid.

Owner:LOCKHEED MARTIN CORP

Thermal interface material and semiconductor packaging structure

InactiveCN102867793AHigh planar thermal conductivityUniform heat conductionSemiconductor/solid-state device detailsSolid-state devicesIndiumSemiconductor package

The invention discloses a thermal interface material and a semiconductor packaging structure. The semiconductor packaging structure comprises a substrate, a chip and a heat dissipation plate. The chip is arranged on the substrate, and the heat dissipation plate is arranged on the chip. The thermal interface material is contained between the chip and the heat dissipation plate; the thermal interface material comprises a grapheme layer and two low-melting-point metal layers; the two low-melting-point metal layers are covered on the grapheme layer from top to bottom. According to the thermal interface material and the semiconductor packaging structure, the flat heat-transfer efficiency between the chip and the heat dissipation plate can be improved through the grapheme material with high thermal conductivity; and the cost is lower than that of the thermal interface material using pure indium.

Owner:ADVANCED SEMICON ENG INC

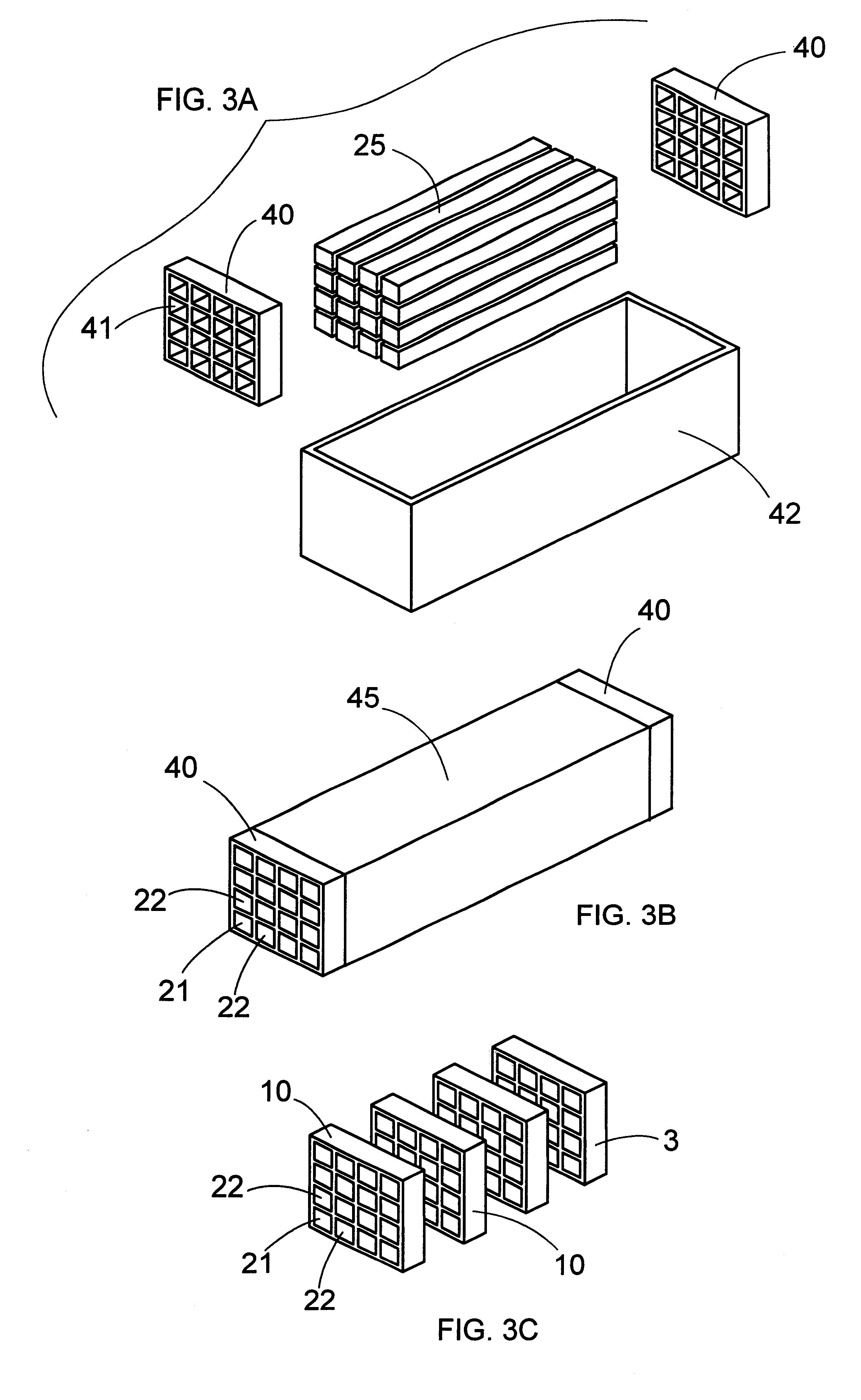

Compact heat exchanging device based on microfabricated heat transfer surfaces

InactiveUS7571618B2Improve heat transfer performanceLower overall pressure dropDomestic cooling apparatusSemiconductor/solid-state device detailsWorking fluidEvaporation

A lightweight compact self-contained microchannel heat exchanger includes a multi-sided heat transfer member having an array of parallel microgrooves (or rows of micropins) on each of the side, and positioned in thermal contact with the heat generating object to be cooled. A fluid distribution unit having a developed system of feed channels and exhaust channels is mounted to the micropatterned surface for guiding an incoming cold working fluid to remove heat from the microgrooves (or micropins). The heat exchanging device includes in one embodiment a pair of double-sided heat transfer plates having an array of microgrooves extending on each of its opposed surfaces, the fluid distribution unit being sandwiched between the double-sided heat transfer plates. The heat transfer plates and distribution units may be stacked to form a multi-layered cooling system with improved pressure drop and increased heat transfer efficiency. The device may be used in several modes of operation such as single phase convection, thin film evaporation, and forced-feed boiling, and may operate with or without a pump depending on heat transfer requirements.

Owner:MARYLAND UNIV OF

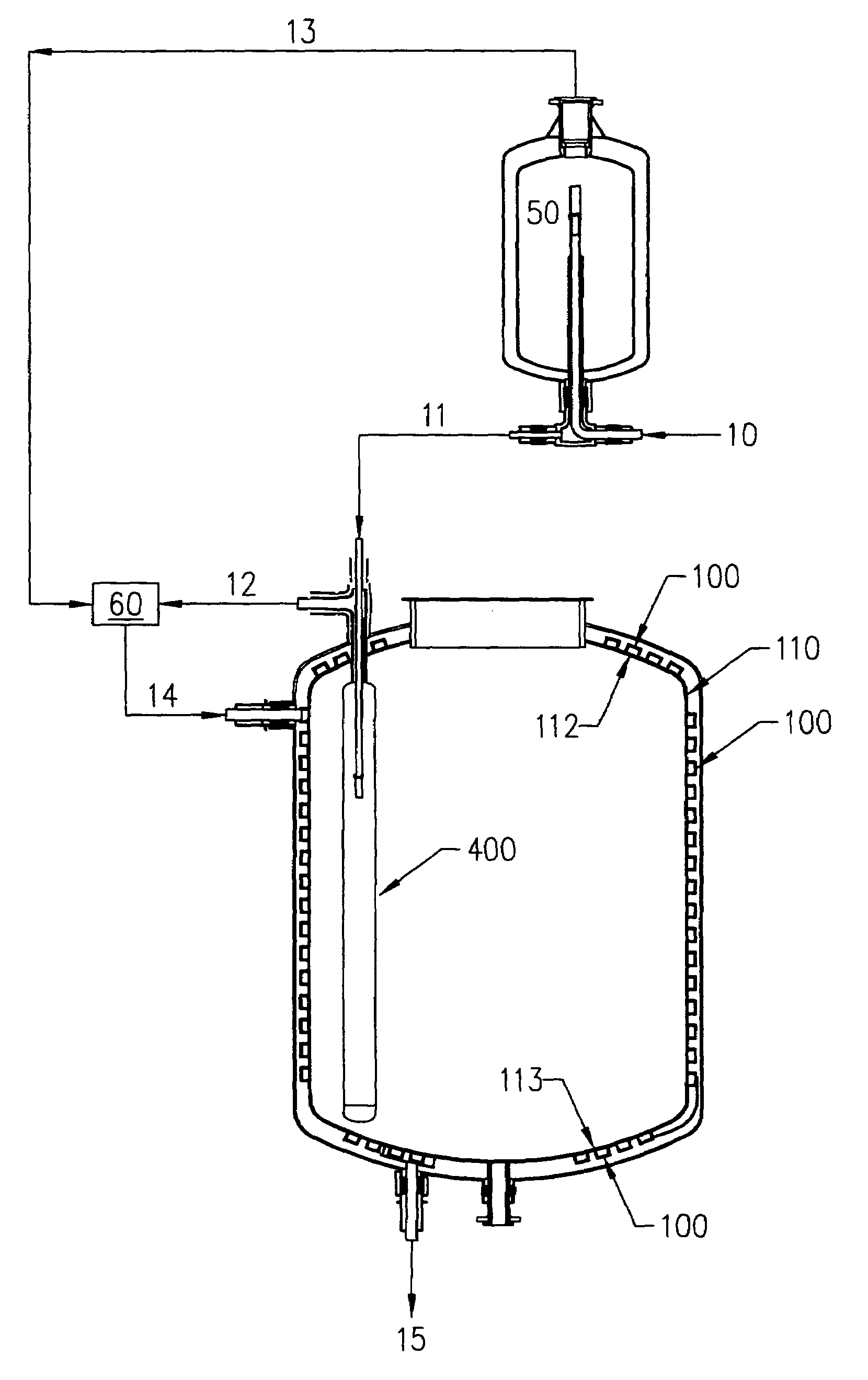

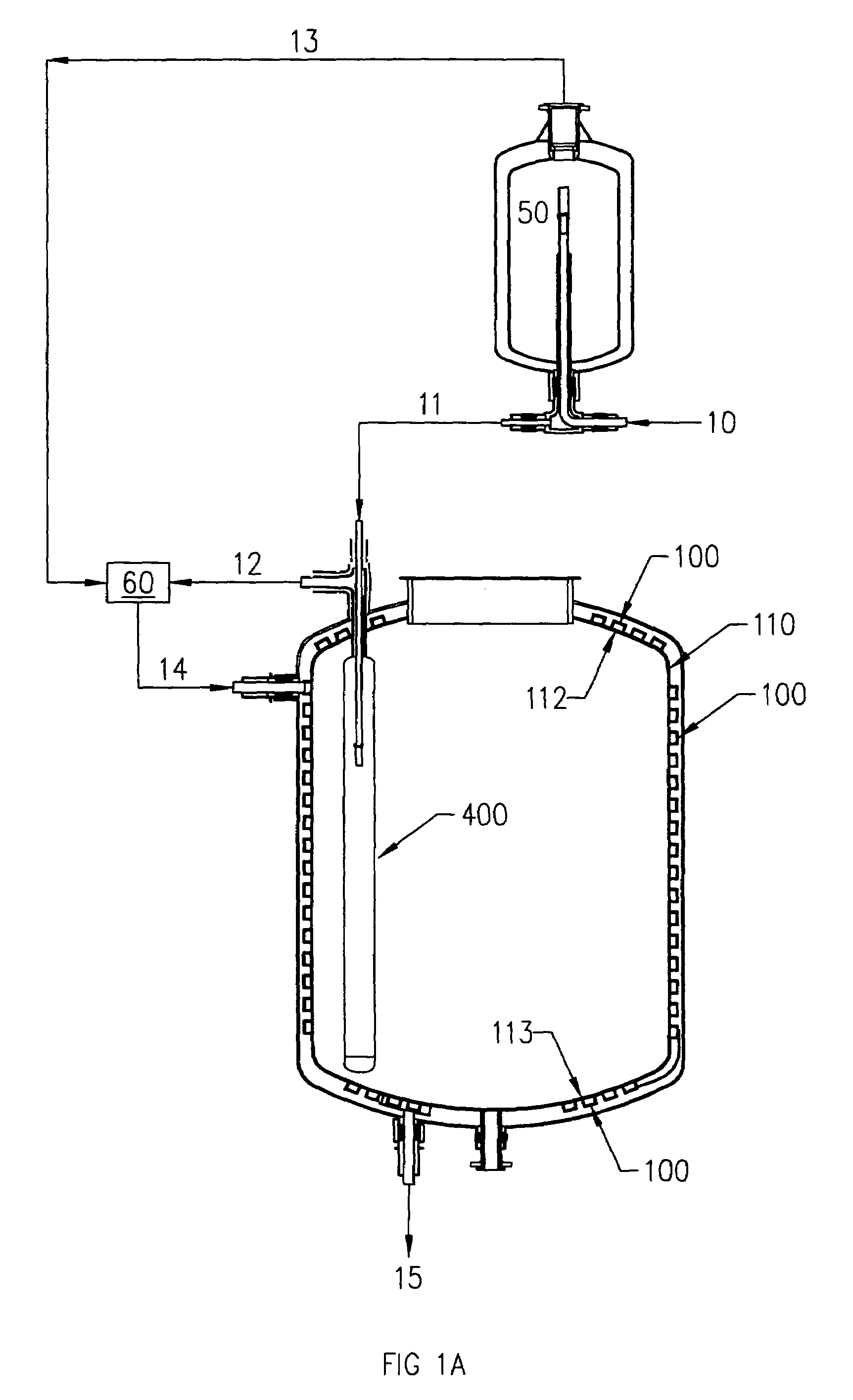

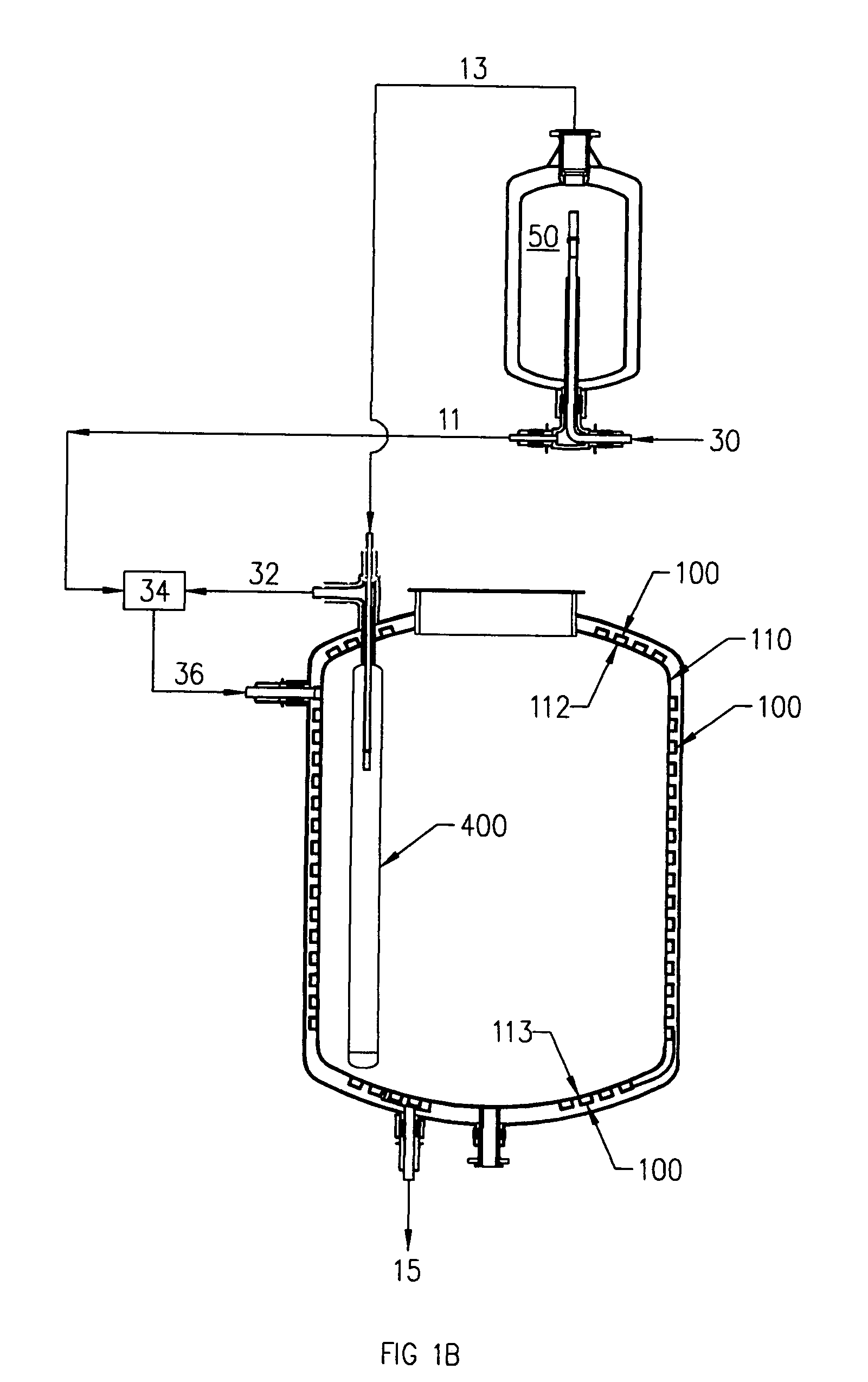

Temperature controlled reaction vessel

InactiveUS6955793B1Increases section modulusHigh mechanical strengthCombination devicesPressurized chemical processTemperature controlHeat transfer efficiency

A reaction vessel which includes internally placed temperature controlling mixing baffles in which liquid is boiled, resulting in an isothermal heat sink. The energy of vaporization is supplied by the reaction vessel contents. The vapor produced by the boiling is directed to channel coils which surround the outside of the reaction vessel wall. The channel coils contact the outside wall of the reaction vessel perpendicularly, and provide mechanical support for the reaction vessel. The mechanical support from the channel coils allows for a decrease in the thickness of the reaction vessel wall and corresponding increased heat transfer efficiency between the channel coil contents and the reaction vessel contents. The entire above described apparatus is enclosed within an evacuated shell to provide additional insulation. The apparatus includes a gravitationally powered device that ensures that saturated or sub-cooled liquid enters the isothermal mixing baffles, thus guaranteeing that isothermal phase change will occur therein.

Owner:ARENCIBIA ASSOCS

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com