Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

399 results about "Steam room" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

A steam room is an enclosed space with large amounts of high-temperature steam, creating a high-humidity environment. People sit in this room in a similar way to a sauna, for relaxation and purported benefits to health and well-being. They can be commonly found in gyms, sanitariums and health resorts. Smaller, standalone steamroom enclosures can also be found in residential buildings. Steam rooms are commonly maintained at a temperature of 41 degrees Celsius or above, with a high humidity of around 100% adding to the sensation. In comparison, saunas are maintained at a much higher temperature due to the lack of humidity in the air. The amount of power required for steam generation varies depending on construction style.

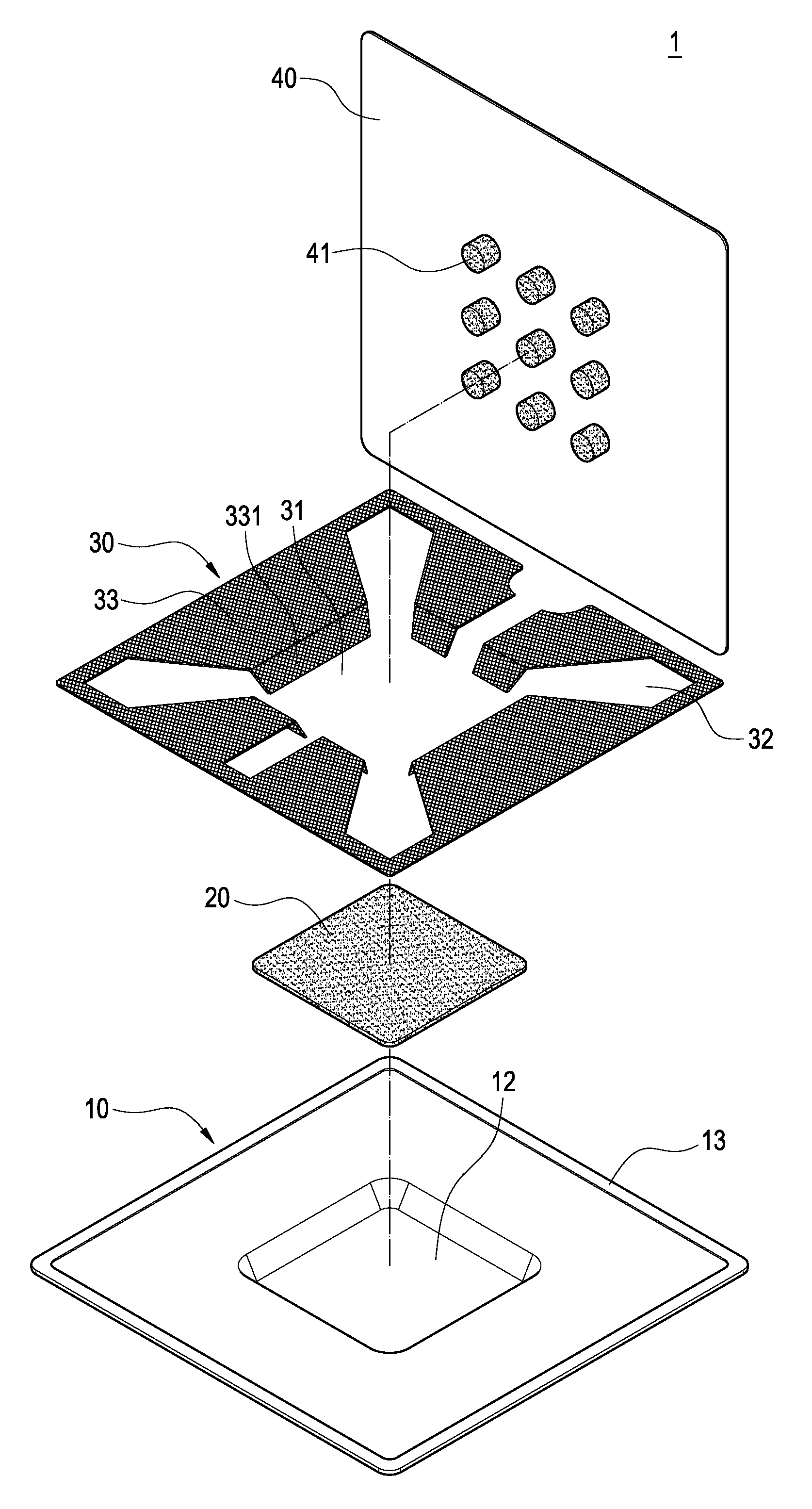

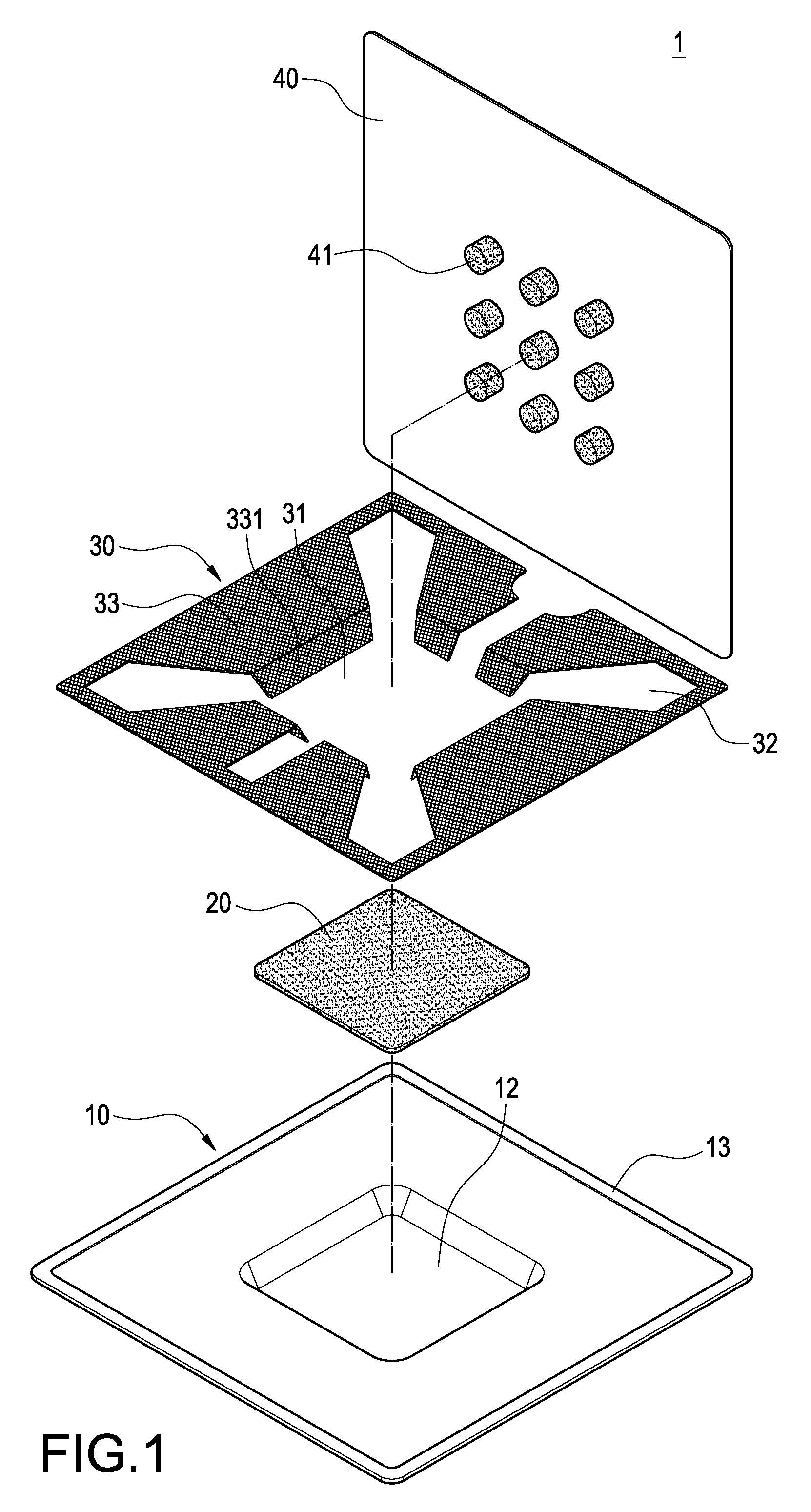

Vapor chamber structure with improved wick and method for manufacturing the same

InactiveUS20090025910A1Improve thermal efficiencySemiconductor/solid-state device detailsSolid-state devicesWorking fluidHeat transfer efficiency

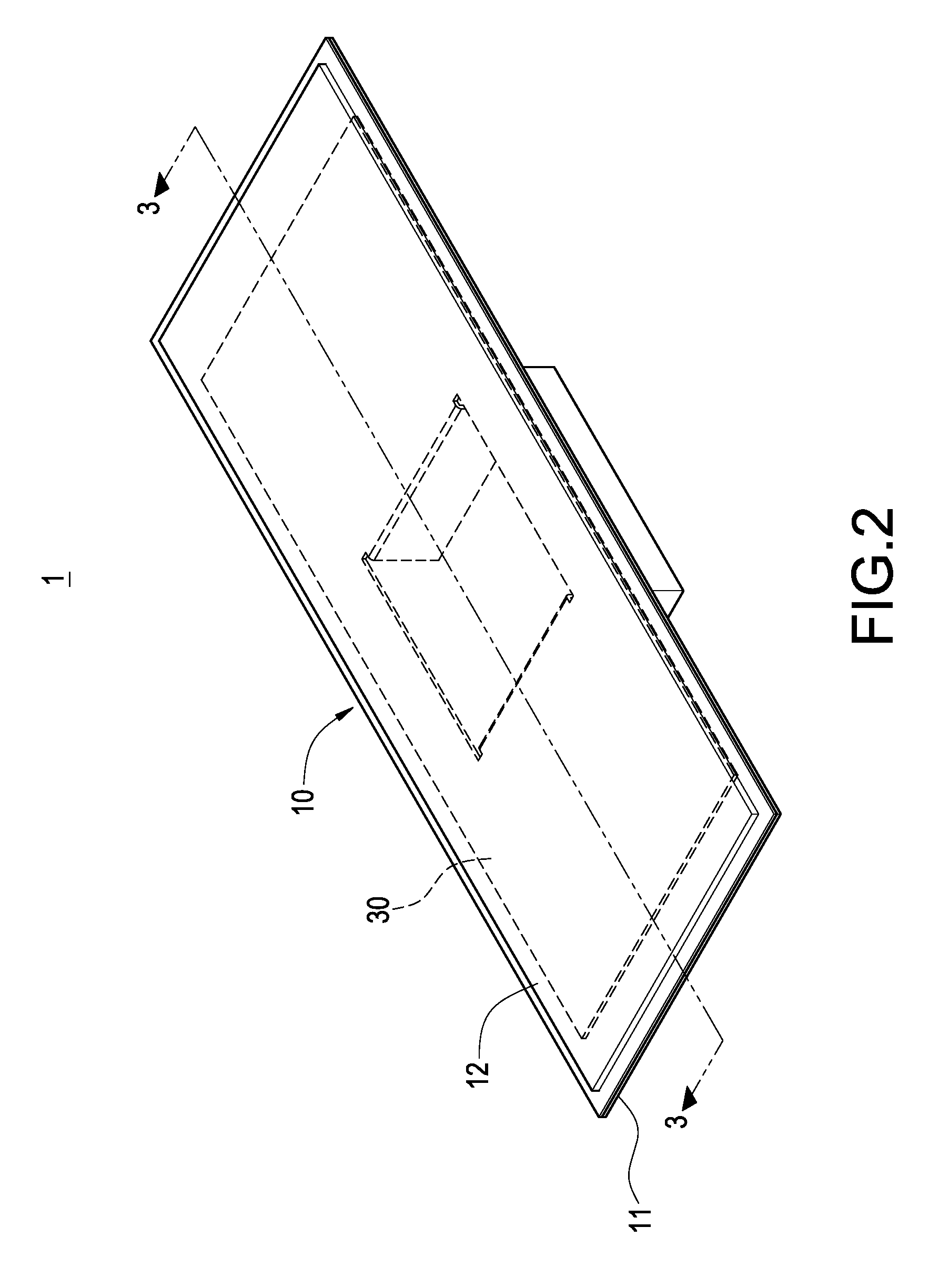

A vapor chamber structure includes a casing, a working fluid, and an improved wick layer. The casing has an airtight vacuum chamber. The working fluid is filled into the airtight vacuum chamber. The wick layer is formed on a surface of the airtight vacuum chamber. Therefore, the present invention can increase the backflow velocity of the working fluid and improve the boiling of the working fluid due to the match of the improved wick structure. Because the backflow velocity and boiling of the working fluid is increased, the heat-transmitting efficiency is increased.

Owner:THERMAL TECH

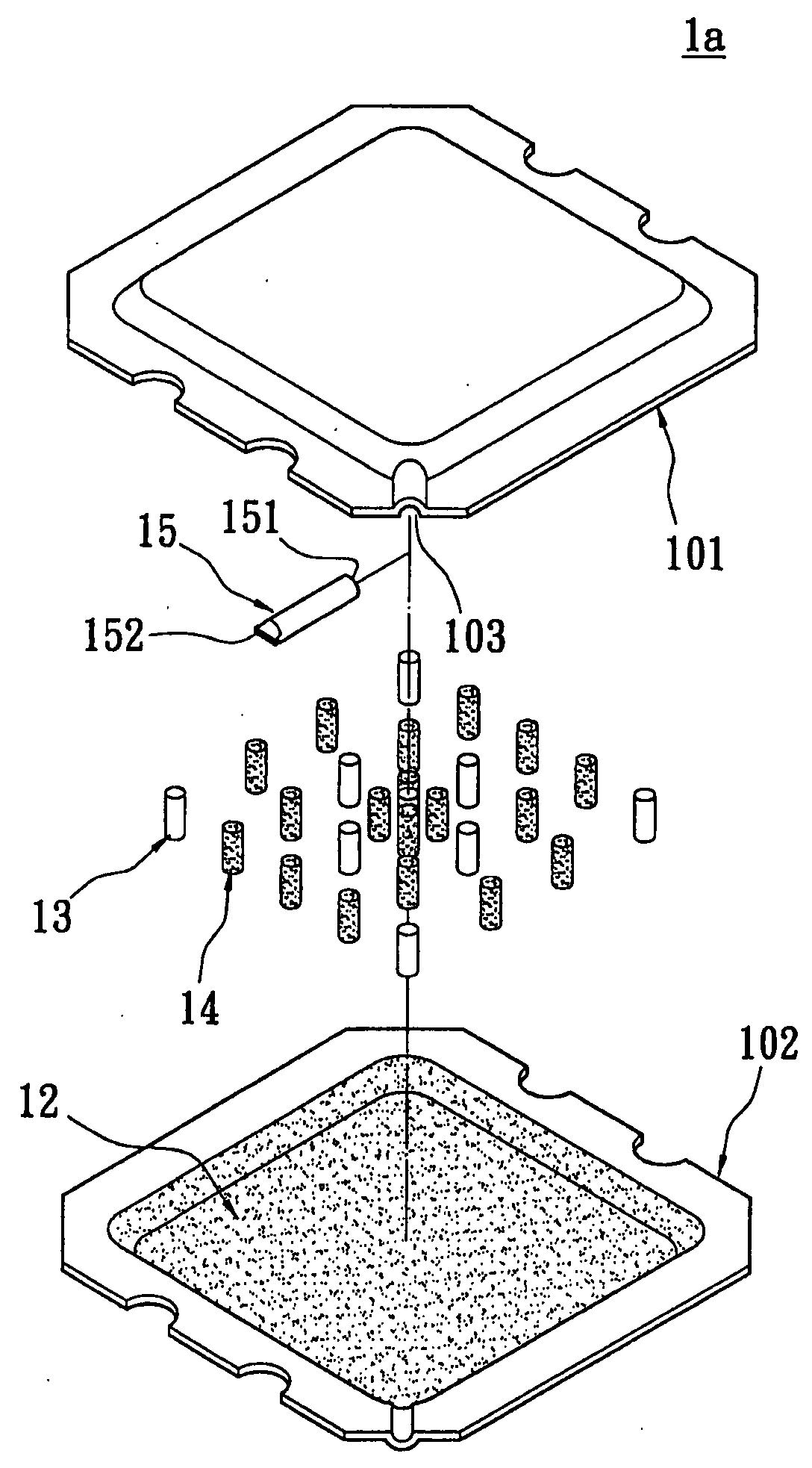

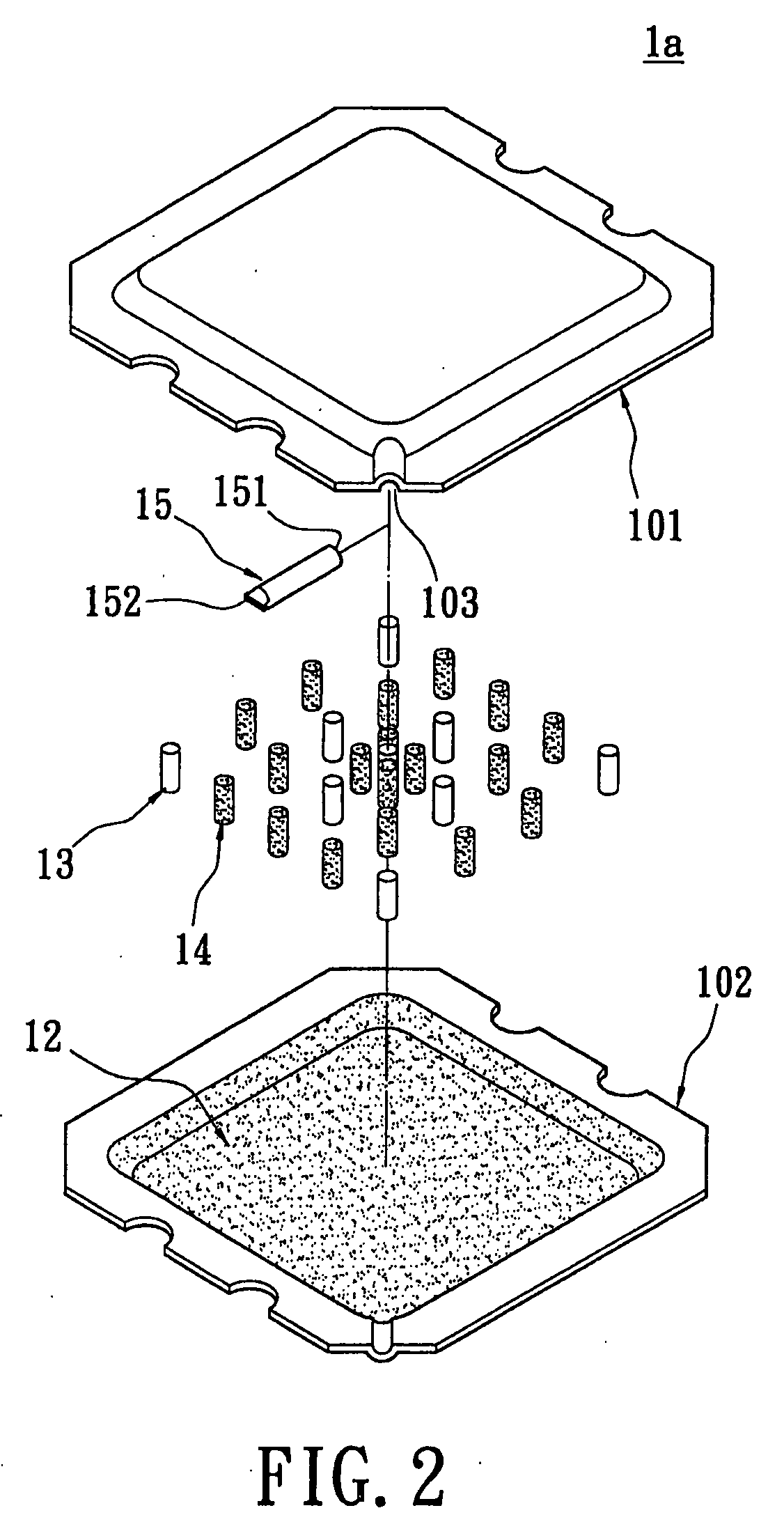

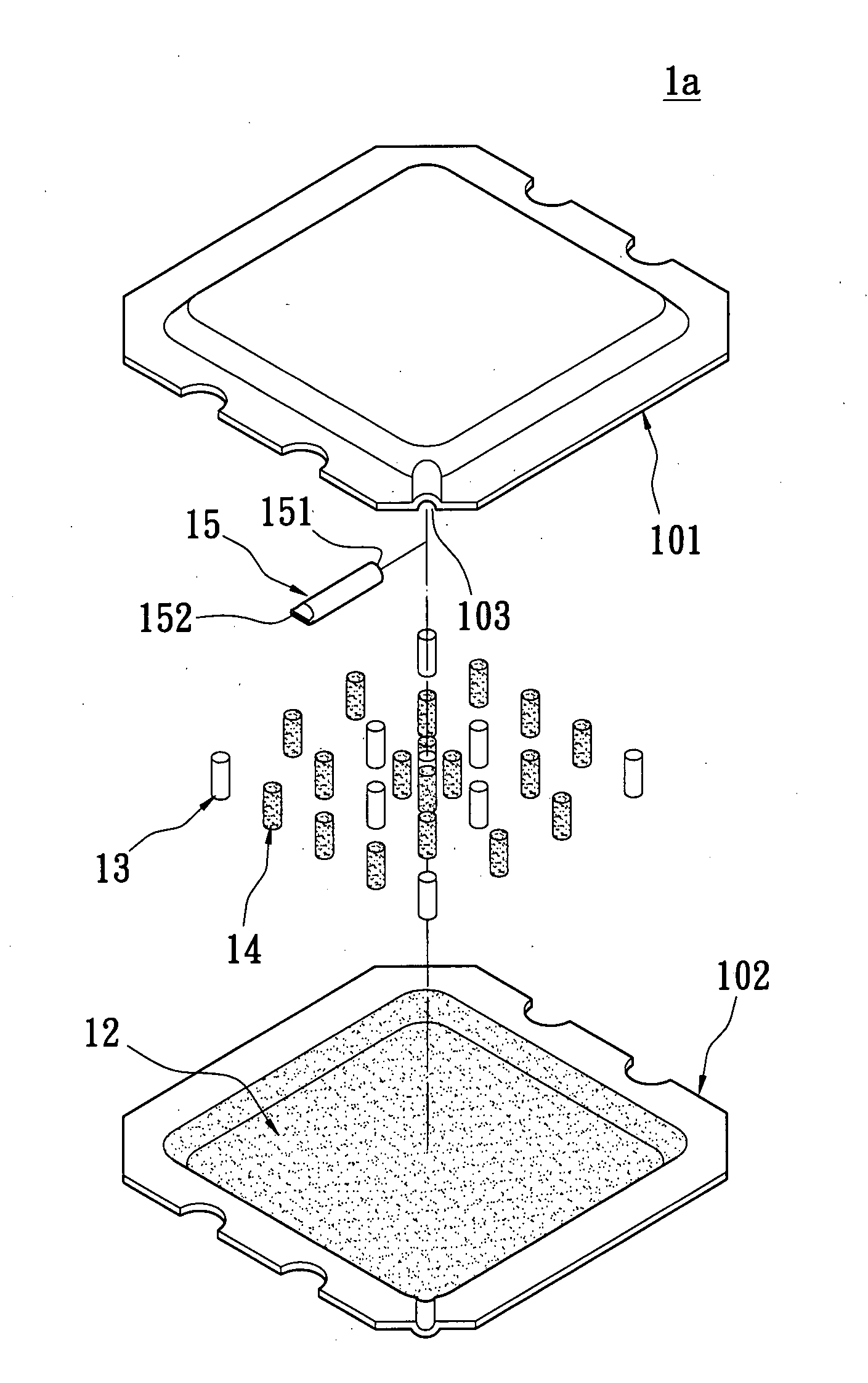

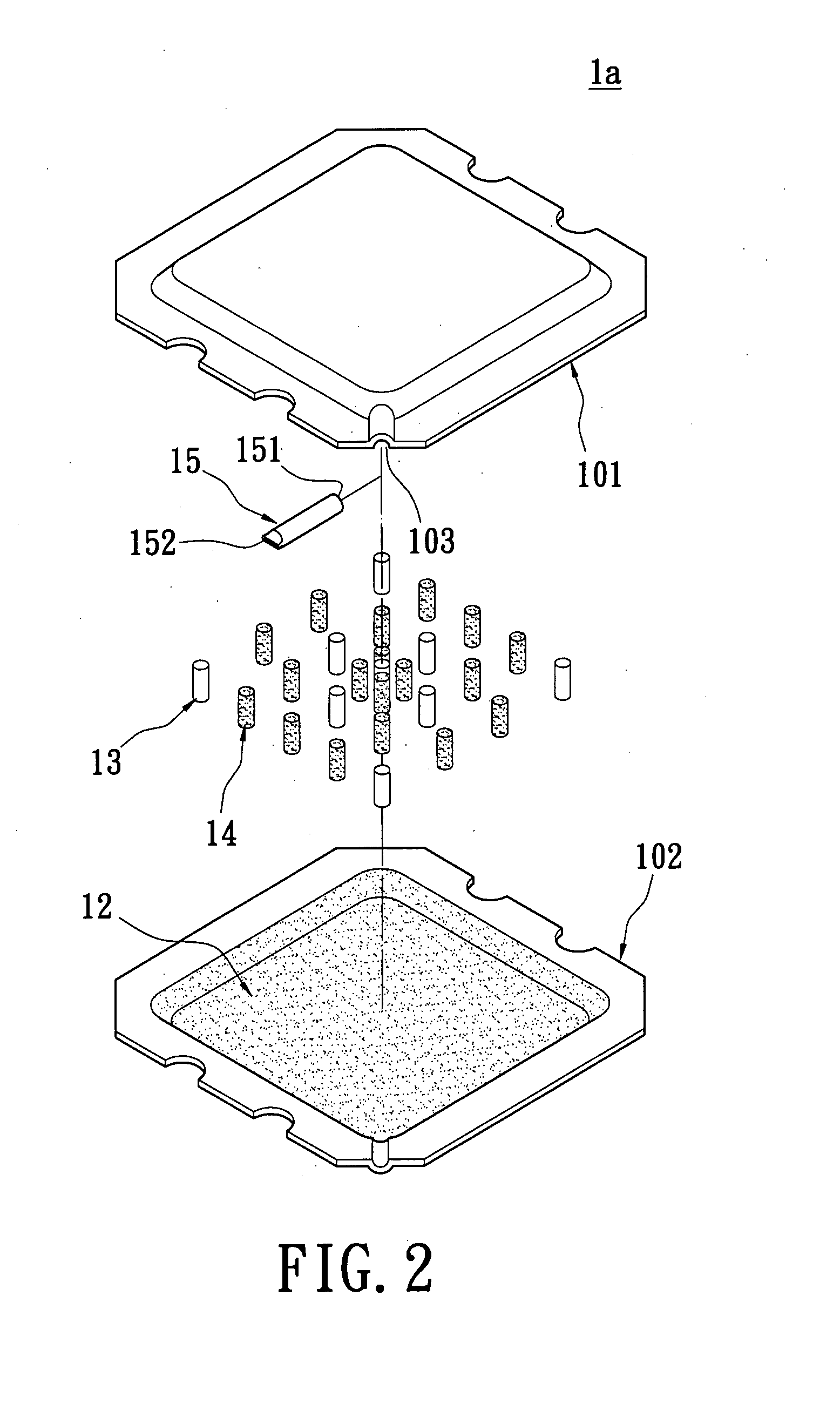

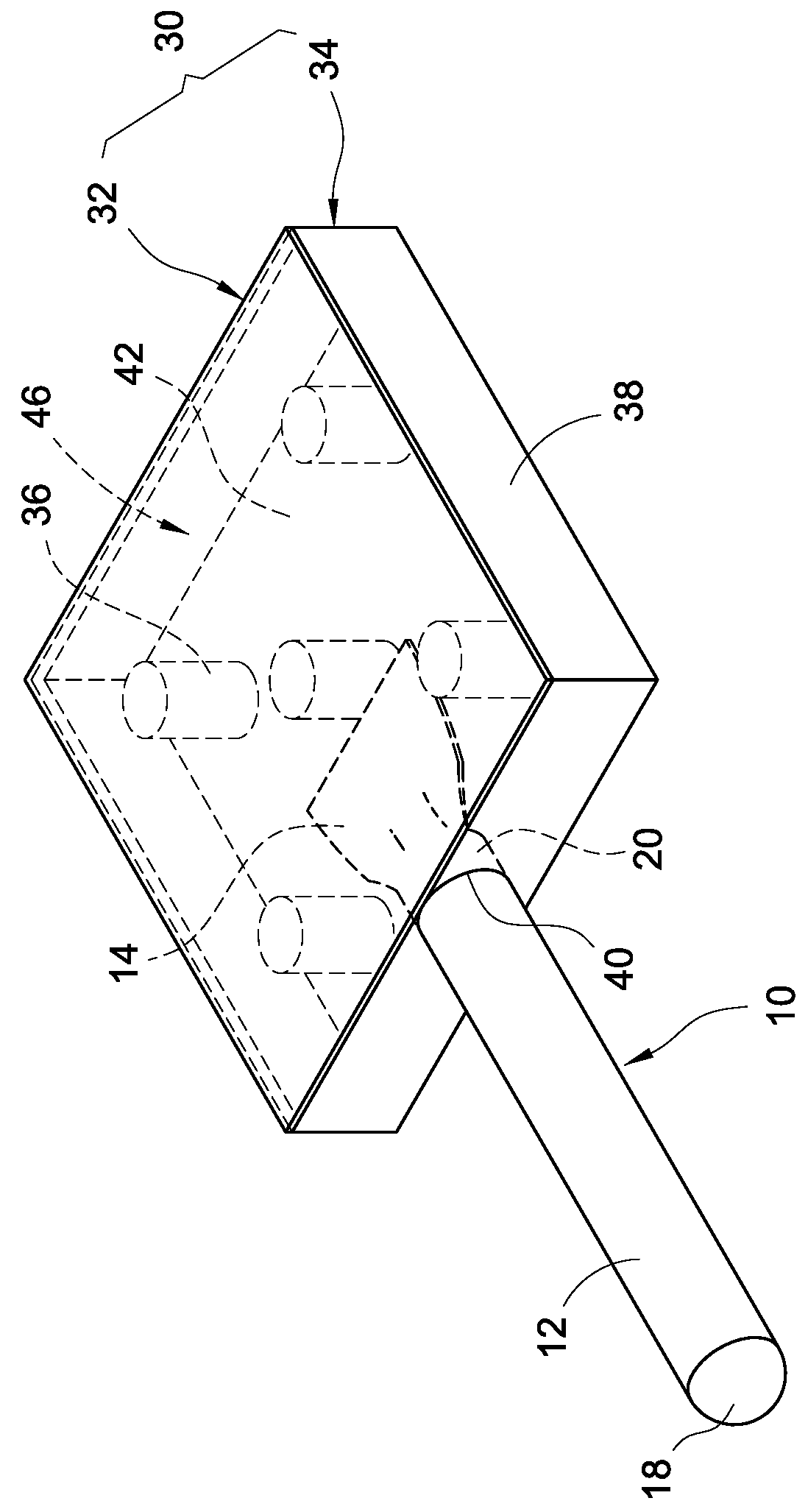

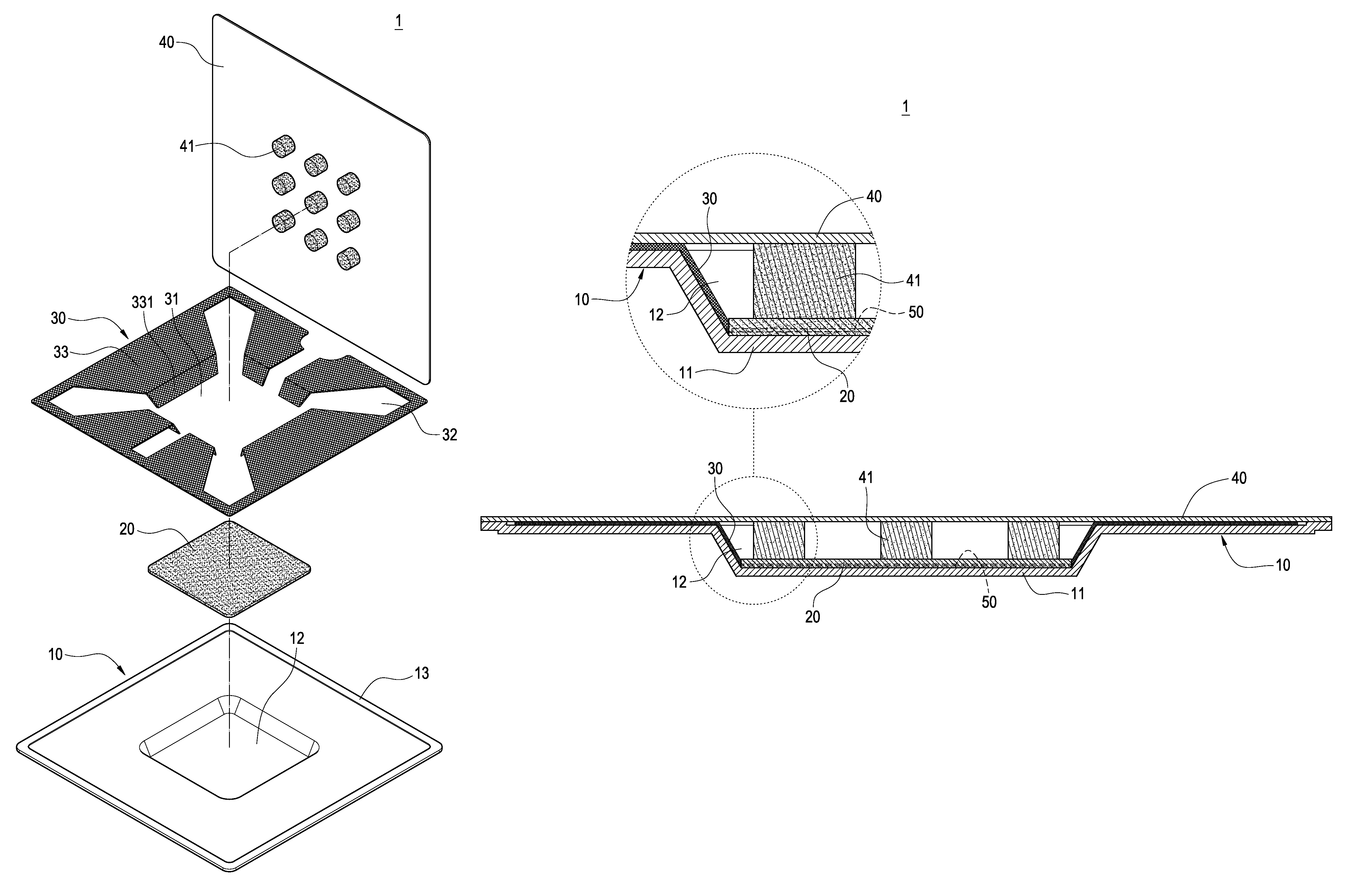

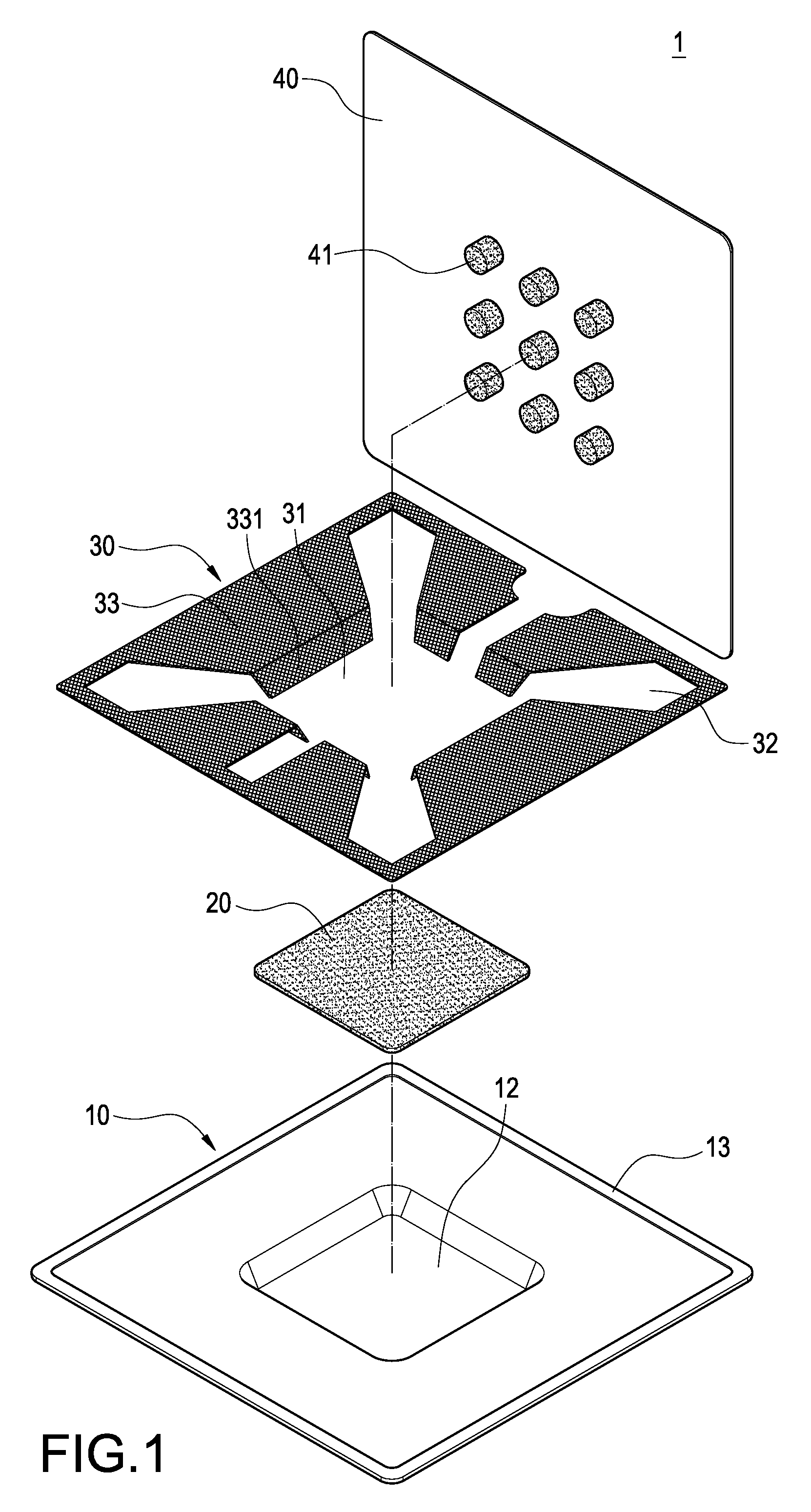

Vapor chamber structure and method for manufacturing the same

InactiveUS20090040726A1Improve structural strengthImprove sealingSpacing meansReinforcing meansWorking fluidEngineering

A vapor chamber structure includes a casing, a working fluid, a wick layer, a plurality of structure strengthening bodies, and a plurality of backflow accelerating bodies. The casing has an airtight vacuum chamber. The working fluid is filled into the airtight vacuum chamber. The wick layer is formed on a surface of the airtight vacuum chamber. The structure strengthening bodies are respectively arranged in the airtight vacuum chamber for supporting the casing. The backflow accelerating bodies are respectively arranged in the airtight vacuum chamber for increasing the backflow velocity of the working fluid. Therefore, the present invention can maintain the completeness of the vapor chamber structure and increase the backflow velocity of the working fluid due to the match of the structure strengthening bodies and backflow accelerating bodies. Because the backflow velocity of the working fluid is increased, the heat-transmitting efficiency is increased.

Owner:THERMAL TECH

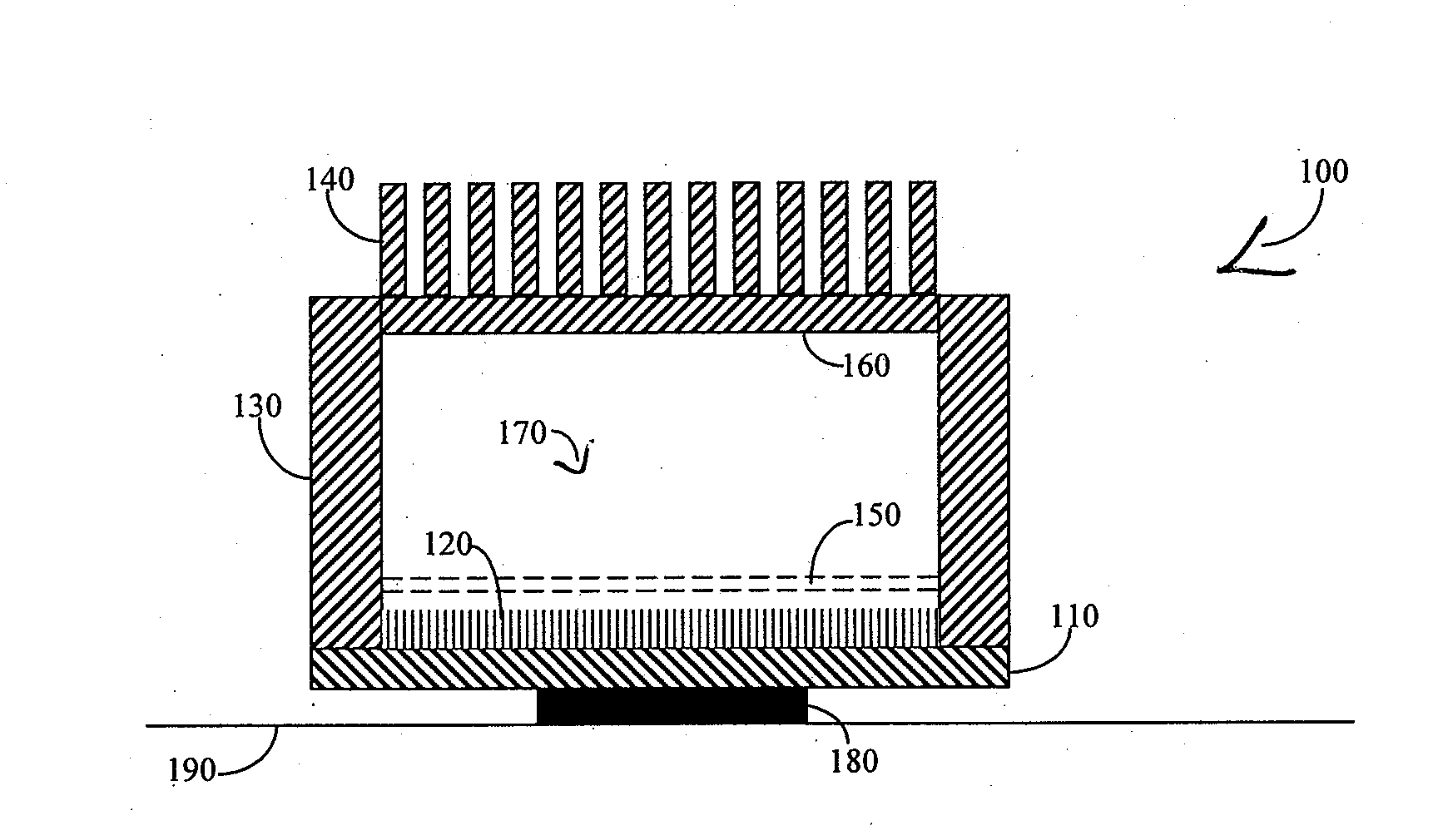

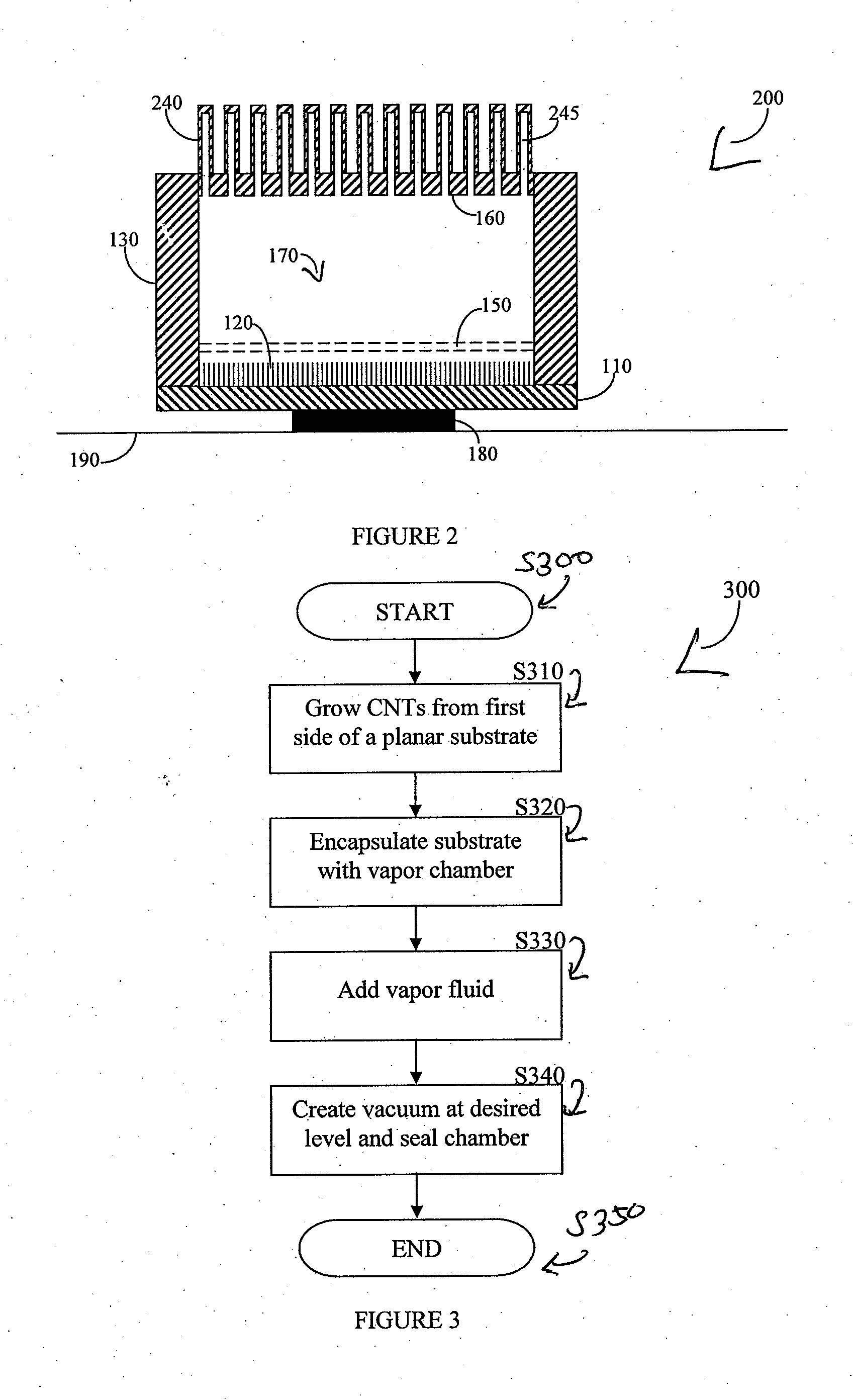

Vapor chamber heat sink having a carbon nanotube fluid interface

An enhanced heat transposer comprised is of a vapor chamber. The surface of the vapor chamber that holds the fluid comprises an array of carbon nanotubes (CNTs) that are grown in a way that enables the fluid to come into maximum contact with the CNTs. The fluid evaporates in the sealed vapor chamber when it is in touch with a hot surface. The vapor comes in contact with a hollow pin-fin structure that provides additional surface area for vapor cooling and heat transfer. The condensed vapor then drops back into the fluid container, and the cycle continues.

Owner:SAMSUNG ELECTRONICS CO LTD

Evaporatively cooled thermosiphon

InactiveUS20070227703A1Increase surface areaImprove heat transfer performanceSemiconductor/solid-state device detailsSolid-state devicesEngineeringRefrigerant

A thermosiphon cooling assembly cools an electronic device with a first refrigerant disposed in the lower boiling chamber of a housing for liquid-to-vapor transformation and a second refrigerant disposed in an upper evaporating chamber of a housing for liquid-to-vapor transformation. The partition separating the lower boiling chamber of the housing from the upper evaporating chamber of the housing creates a series of vapor chambers within the lower boiling portion for condensing vapor boiled off the first refrigerant. The upper evaporating chamber contains a series of refrigerant pockets interleaved vertically with the vapor chambers to increase the surface area for heat transfer between the refrigerant vapor and the second refrigerant for absorbing heat by the second refrigerant for liquid-to-vapor transformation.

Owner:DELPHI TECH INC

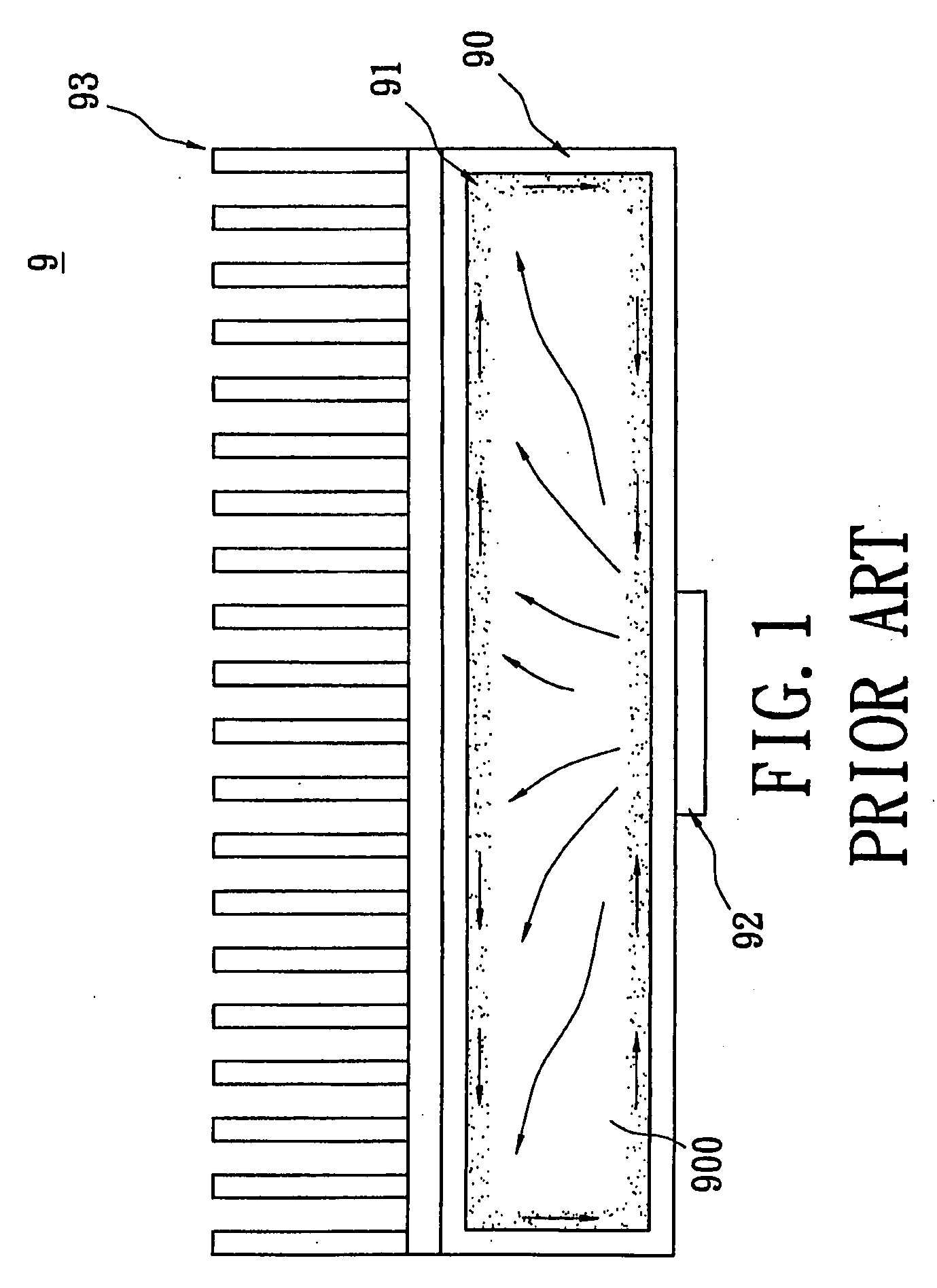

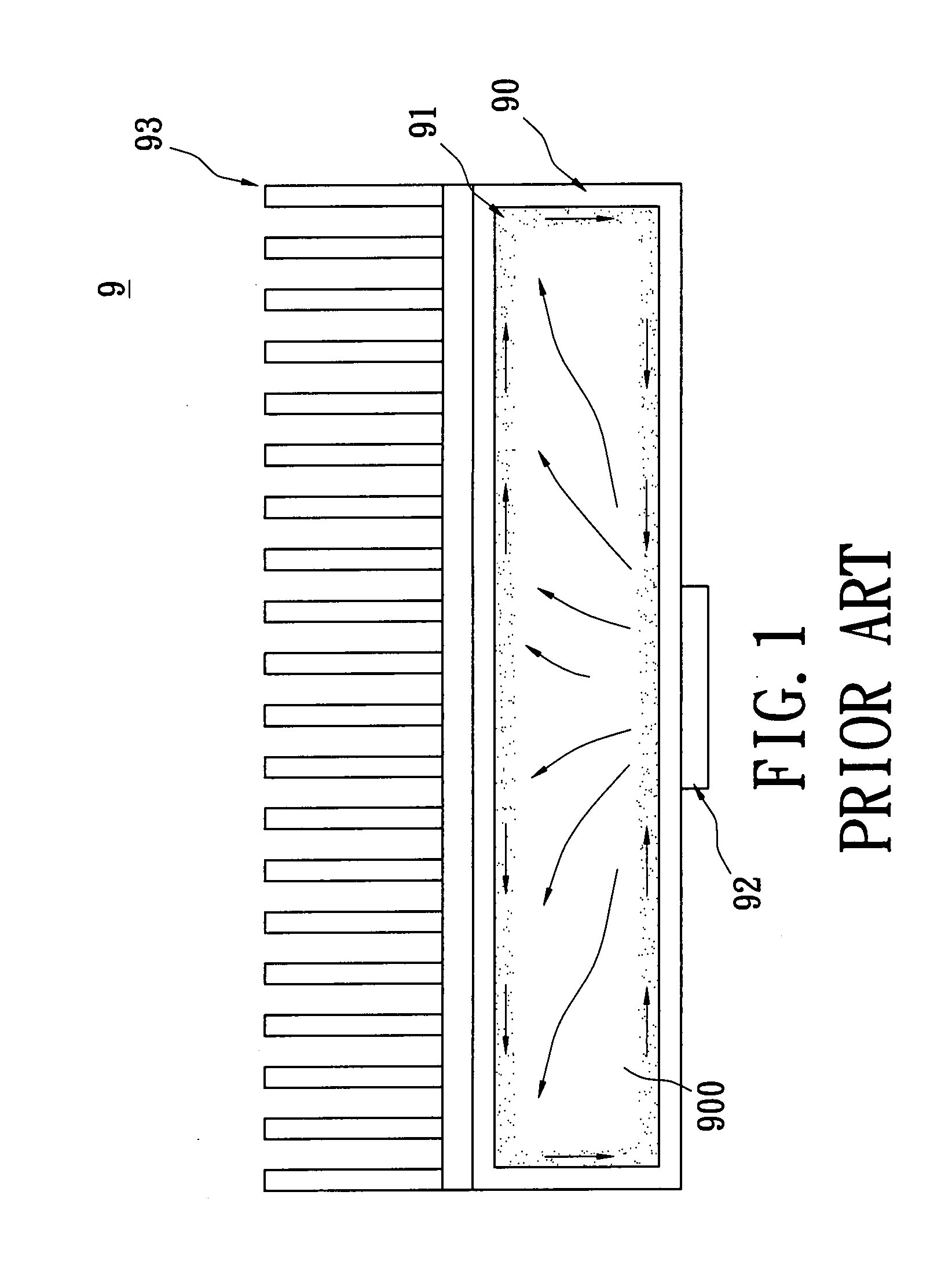

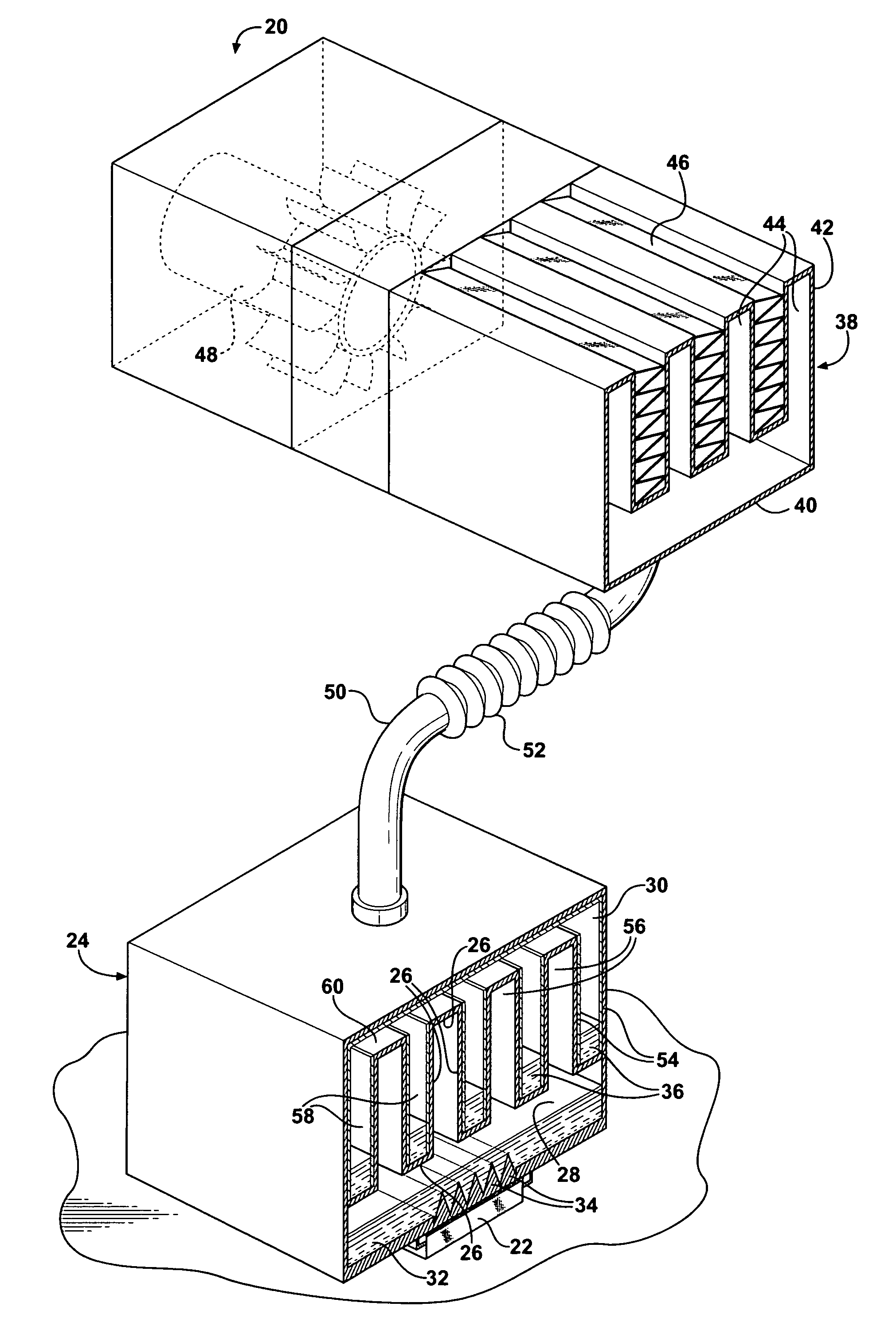

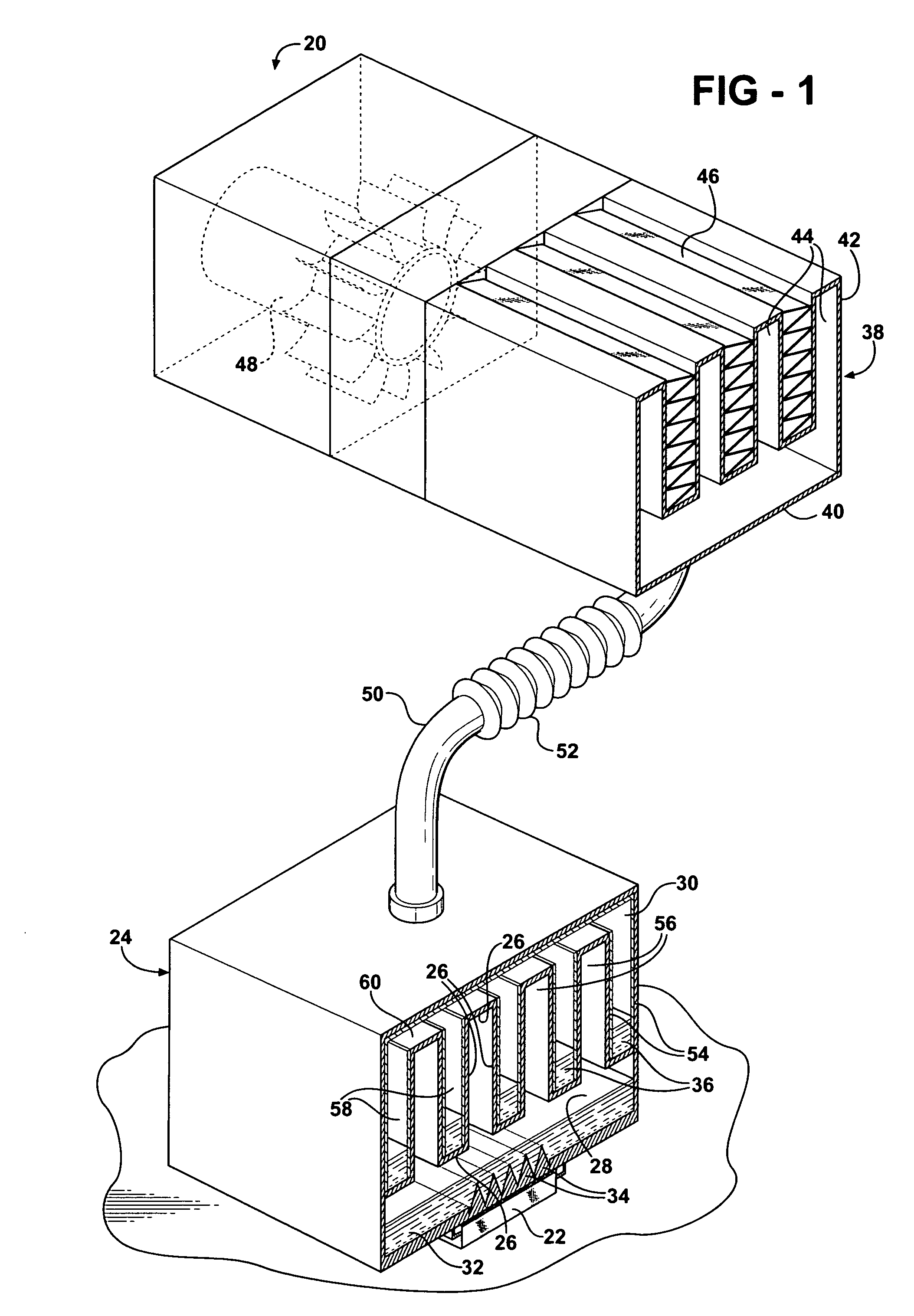

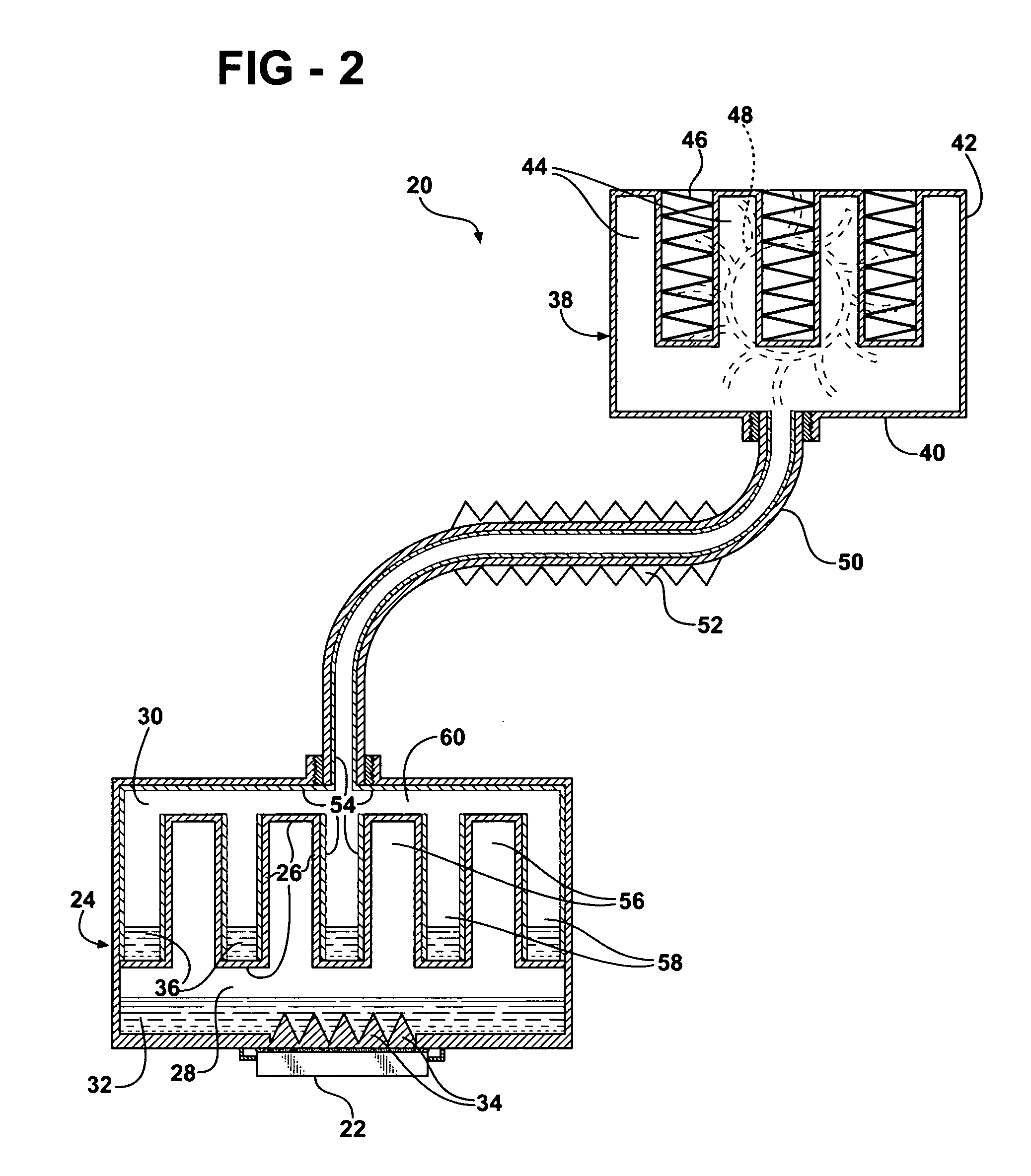

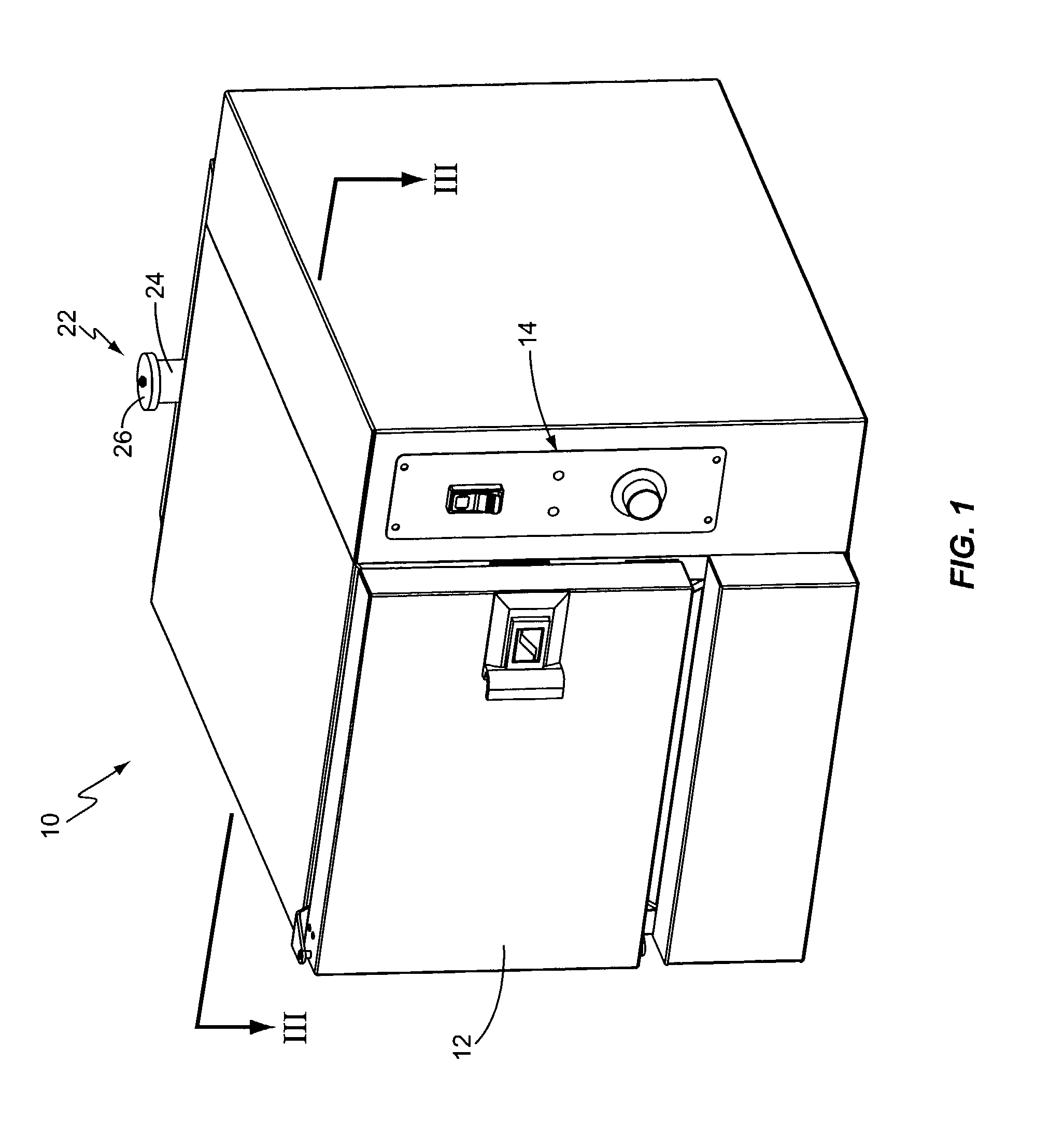

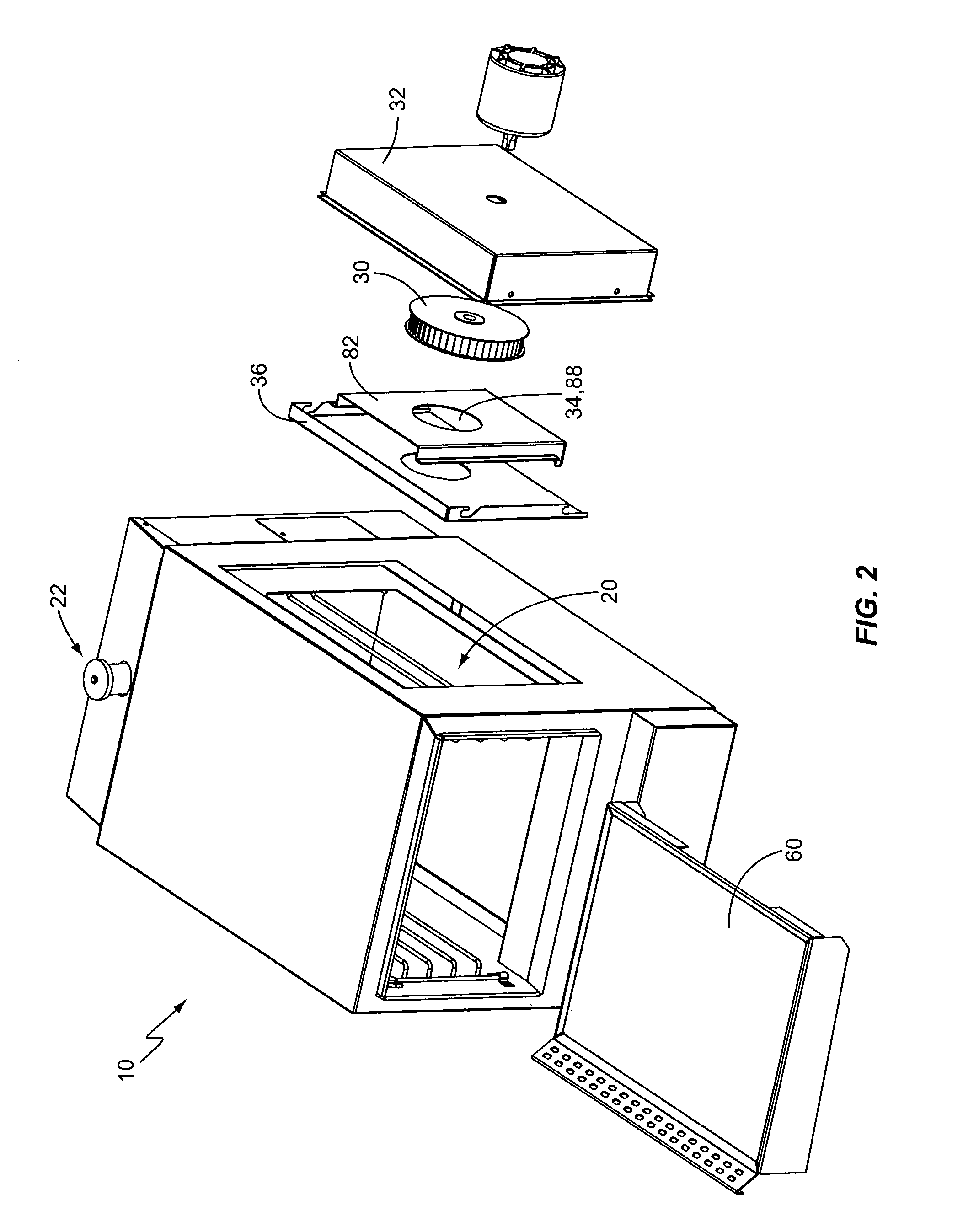

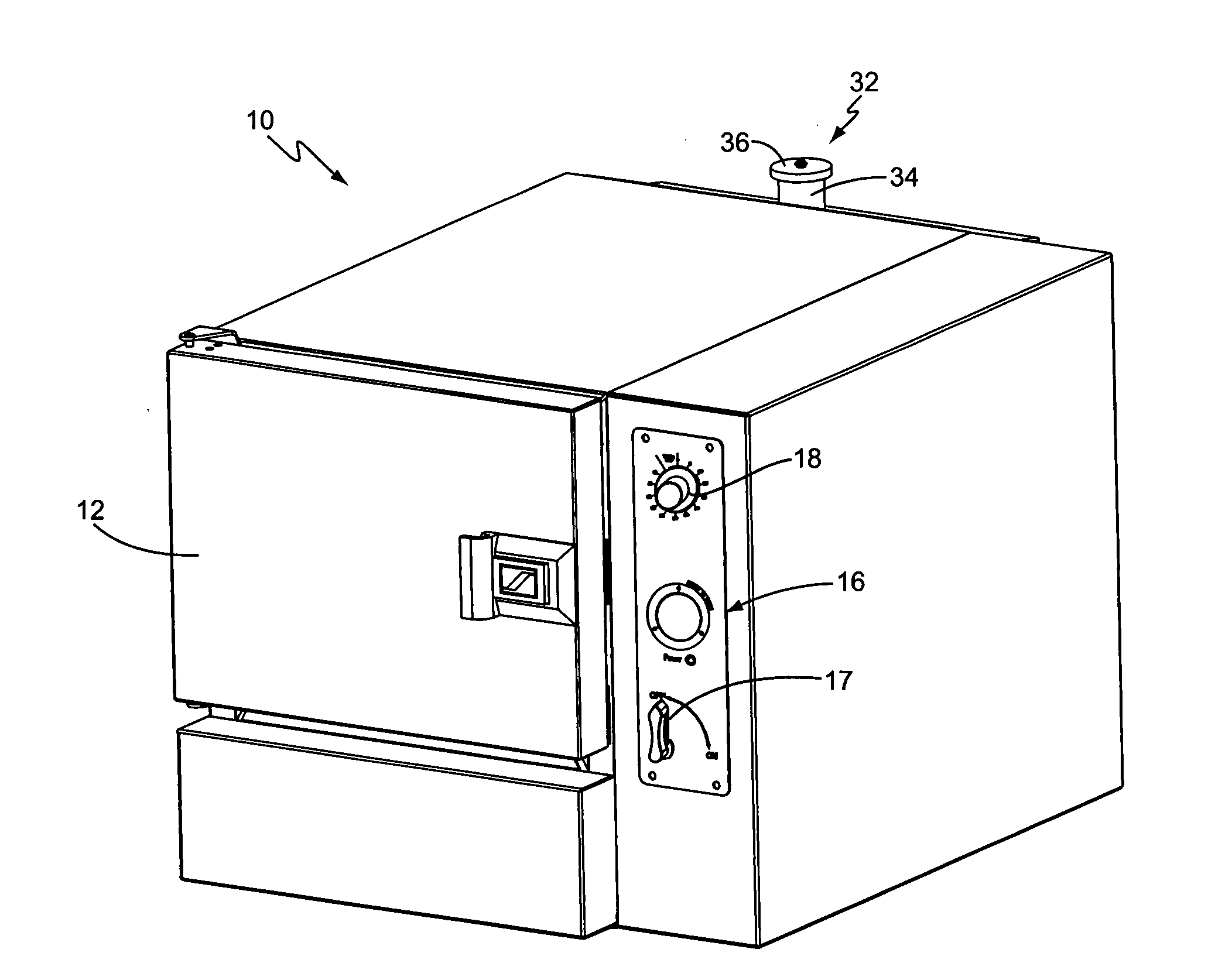

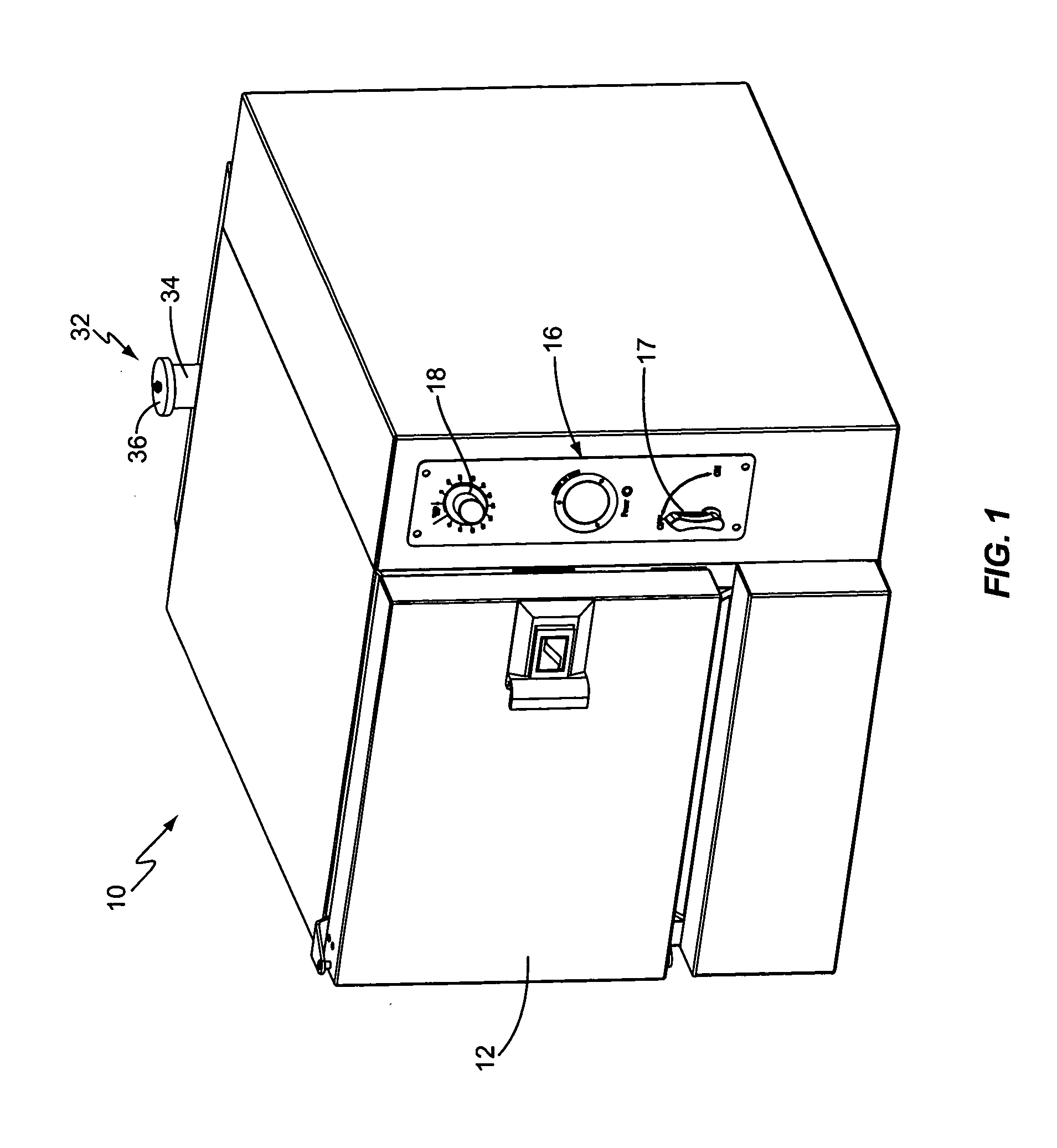

Convection steamer with forced recirculation through steam bath

InactiveUS6904903B1Efficient cookingSelf-cleaning stoves/rangesOven air-treatment devicesSteam cookingEngineering

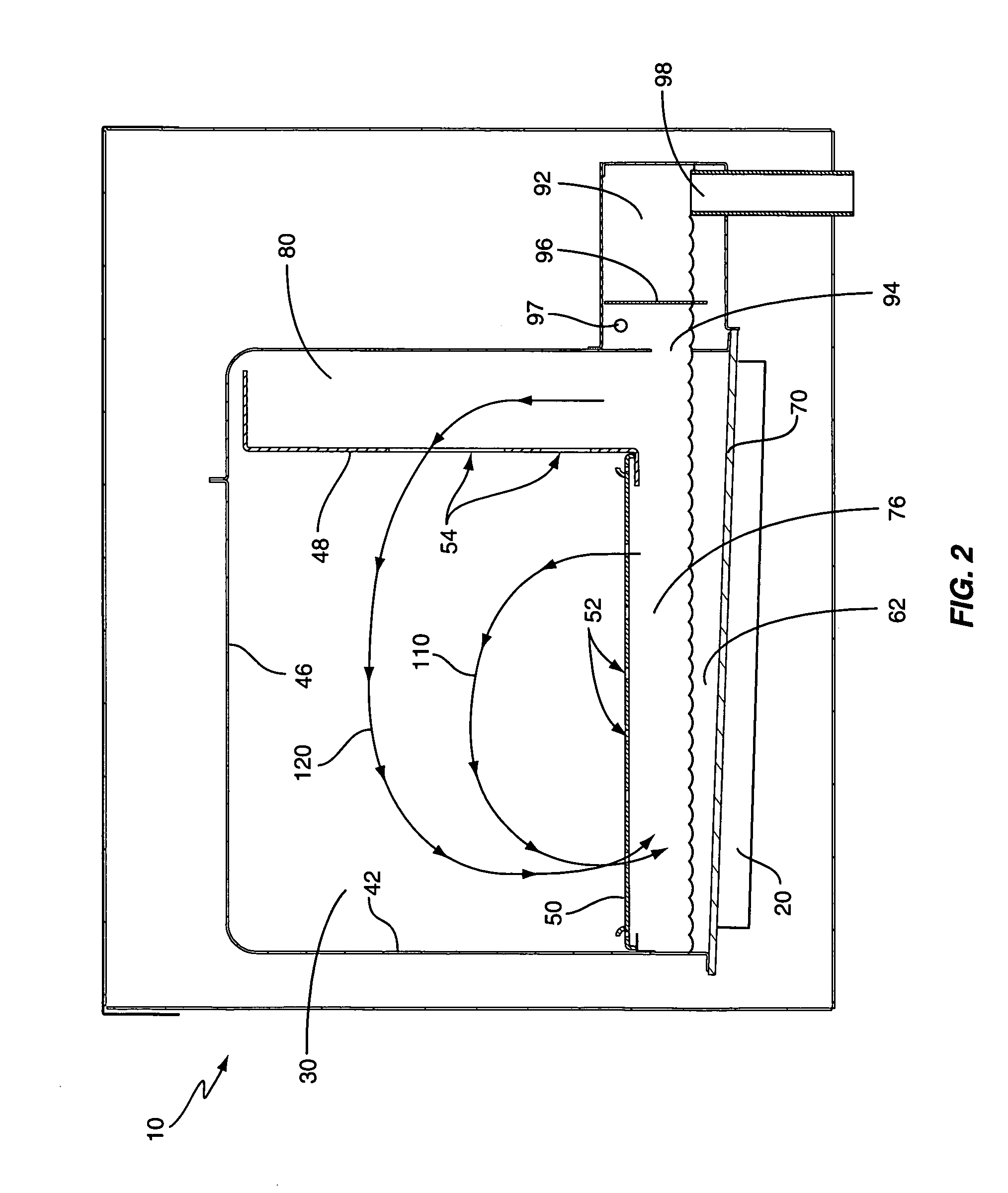

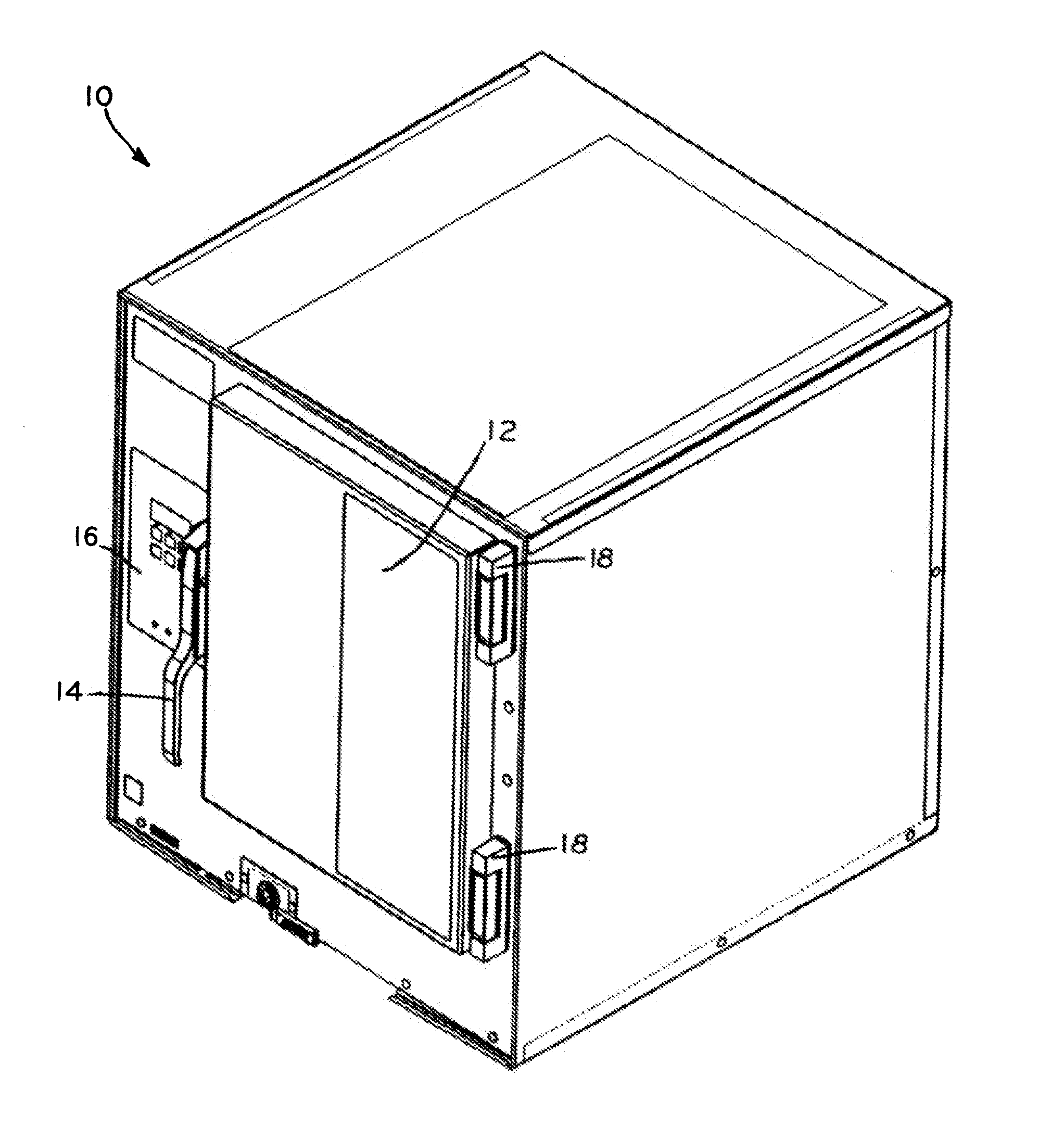

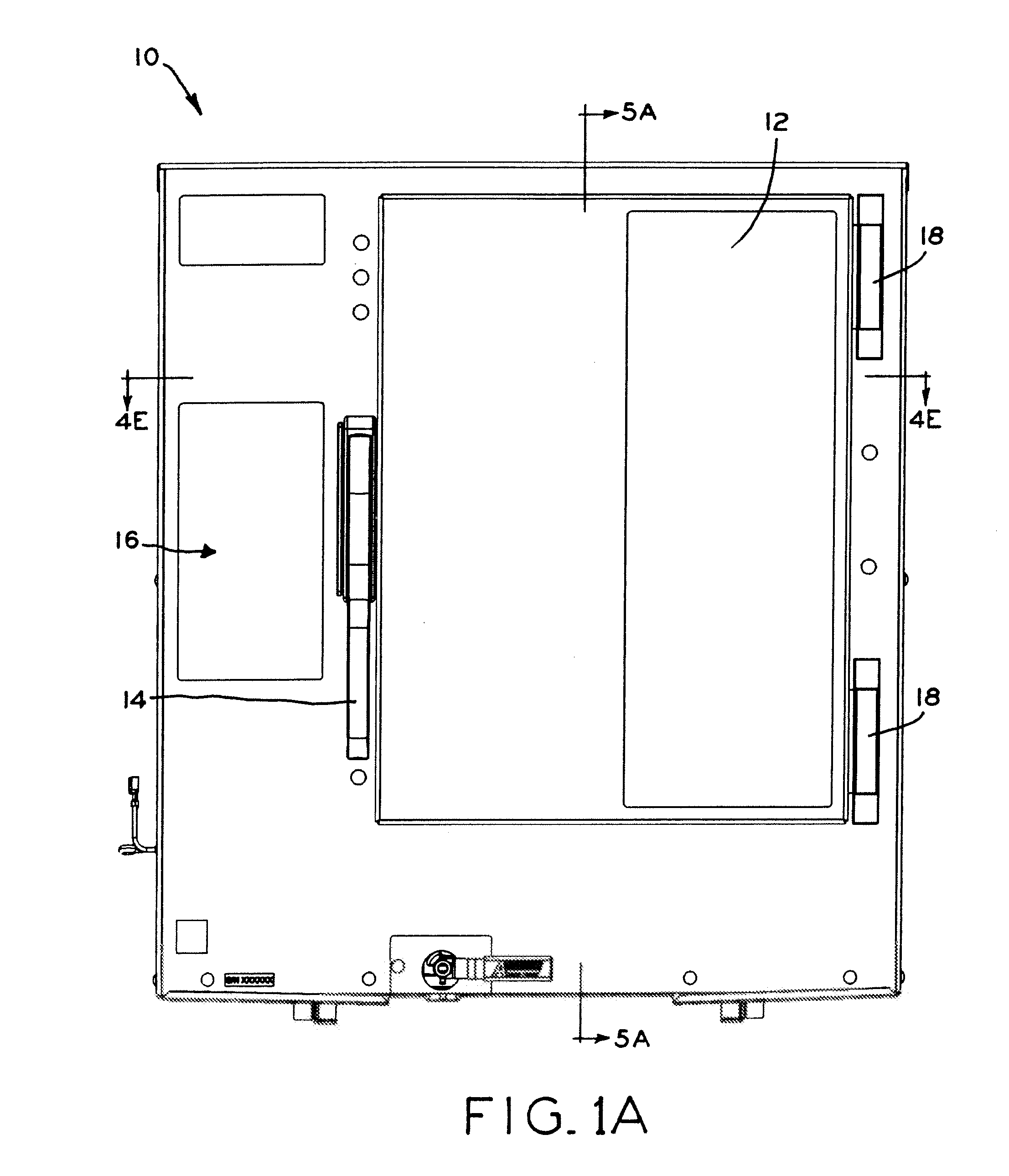

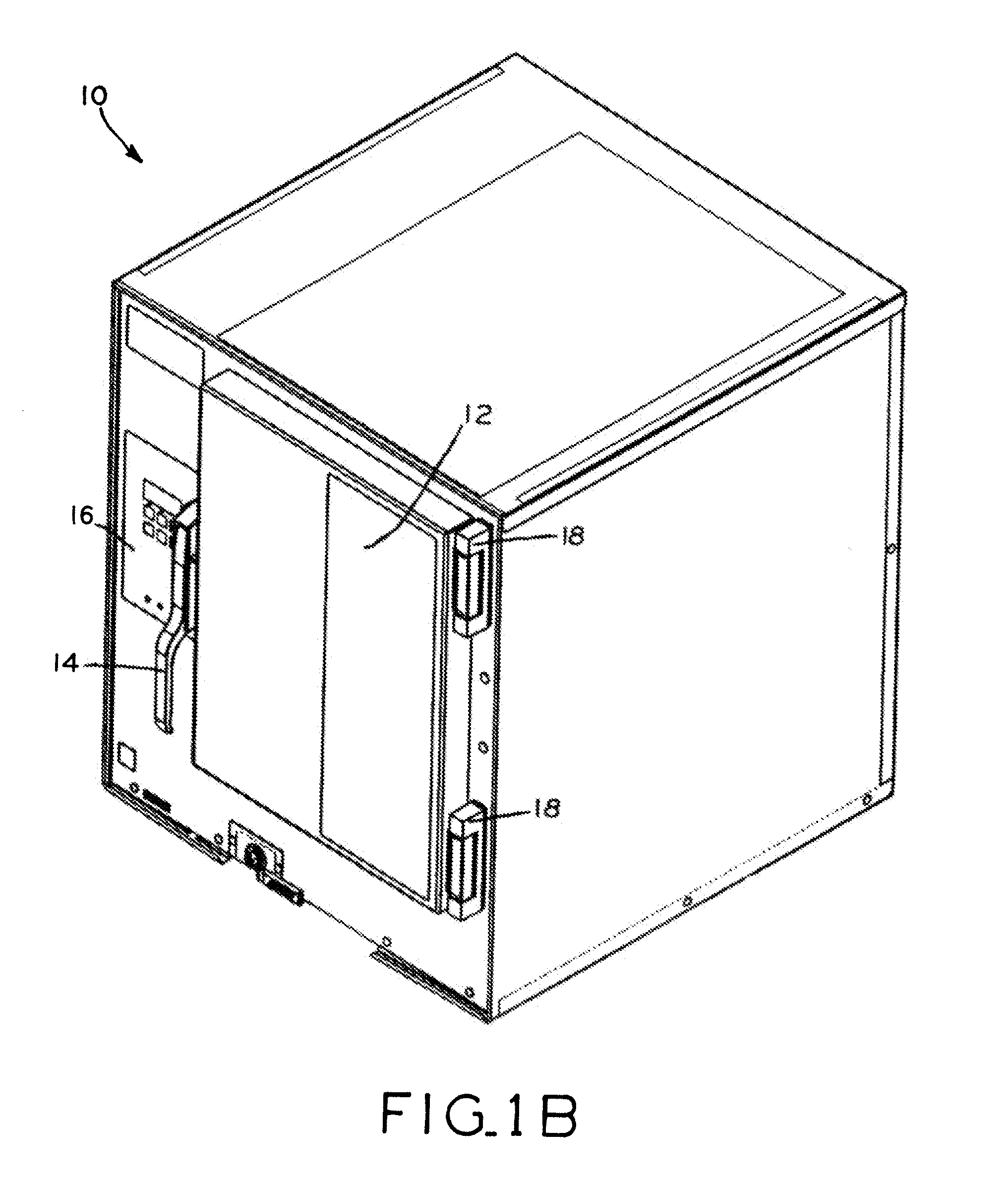

A convection steam cooking device utilizes forced recirculation of gases along a primary recirculation path that extends through a steam chamber so that gases from the cooking cavity flow through the steam chamber and are subjected to a “steam bath” that alters the gases by adding heat and / or moisture. The cooking device includes a cooking cavity, a fan, a steam chamber disposed beneath the cooking cavity with a lower pool area for holding water and an upper steam collecting area disposed directly above the pool area, and a removable baffle disposed between the cooking cavity and the steam chamber with a perforated section remote from the fan and disposed at an upward angle. The primary forced recirculation path extends from the main cooking cavity, through the baffle, substantially across the steam collecting area, through a duct to the fan, and back to the main cavity.

Owner:MIDDLEBY MARSHALL

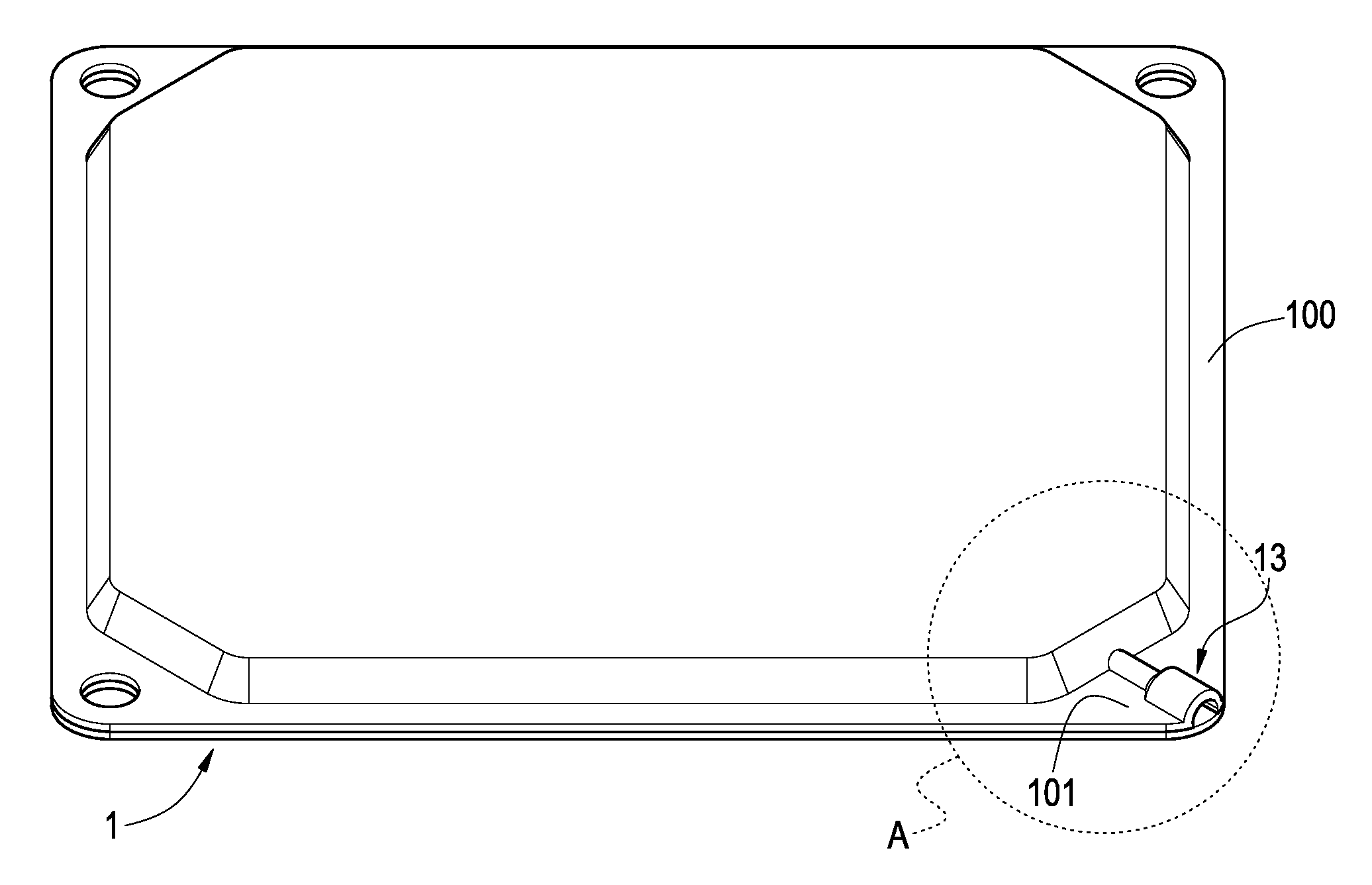

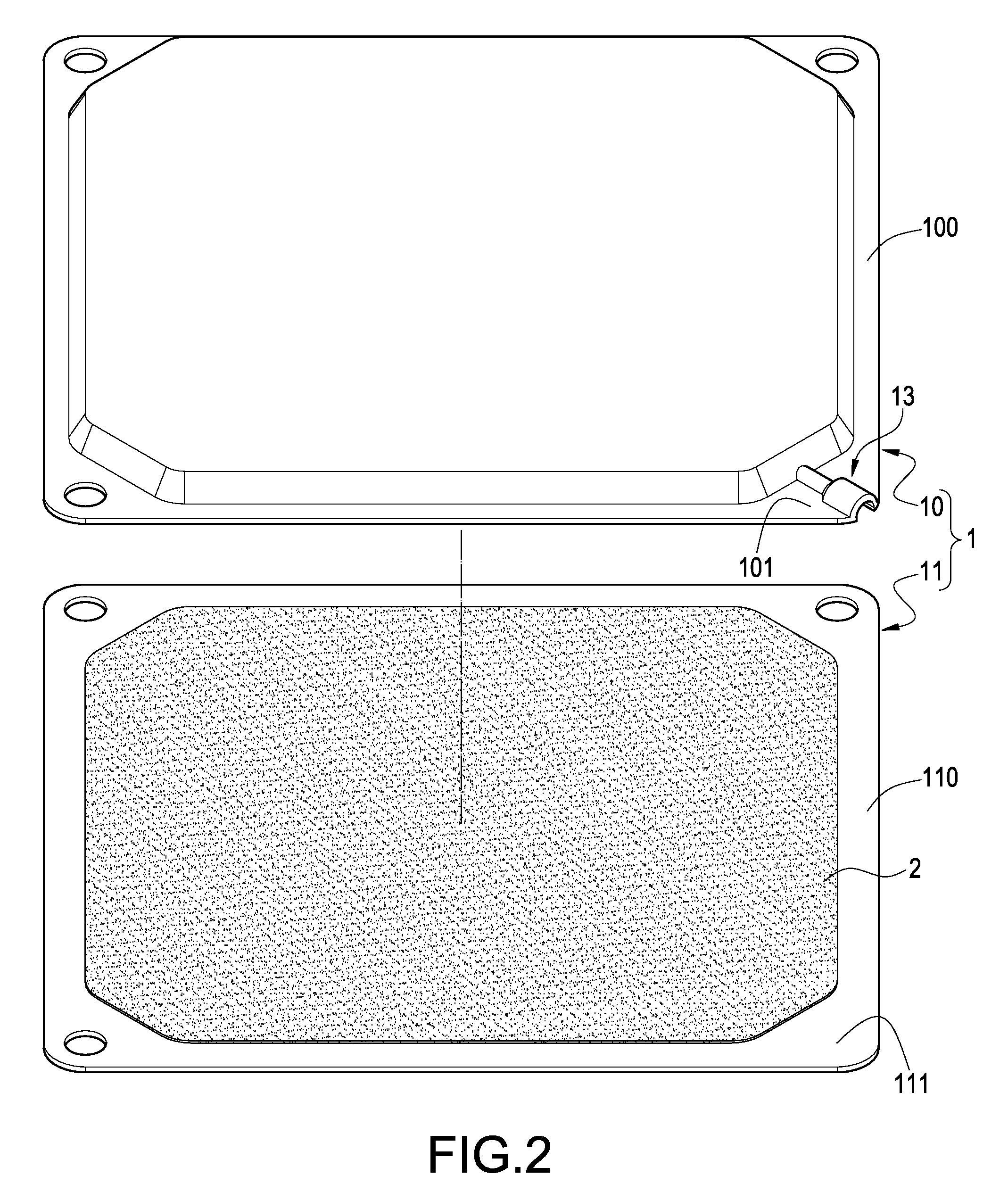

Manufacturing Method of Isothermal Vapor Chamber And Product Thereof

InactiveUS20090178784A1Easy to controlEasy to prepareIndirect heat exchangersLaminated elementsWorking fluidEngineering

A manufacturing method of a isothermal vapor chamber and a product thereof are to use an integrated manner to form an orifice directly on a plate body of a isothermal vapor chamber. Through the orifice, the operations of injecting working fluid and degassing or vacuating can be proceeded. The orifice is functionally similar to a degassing tube or a vacuating tube of the prior arts. However, since the orifice is integrated on the plate body of the isothermal vapor chamber body, it can be pressed to seal the isothermal vapor chamber after an operation of degassing. Therefore, the vacuity in the isothermal vapor chamber and the stored amount of the working fluid, and it is easier for manufacture.

Owner:WANG CHIN WEN +1

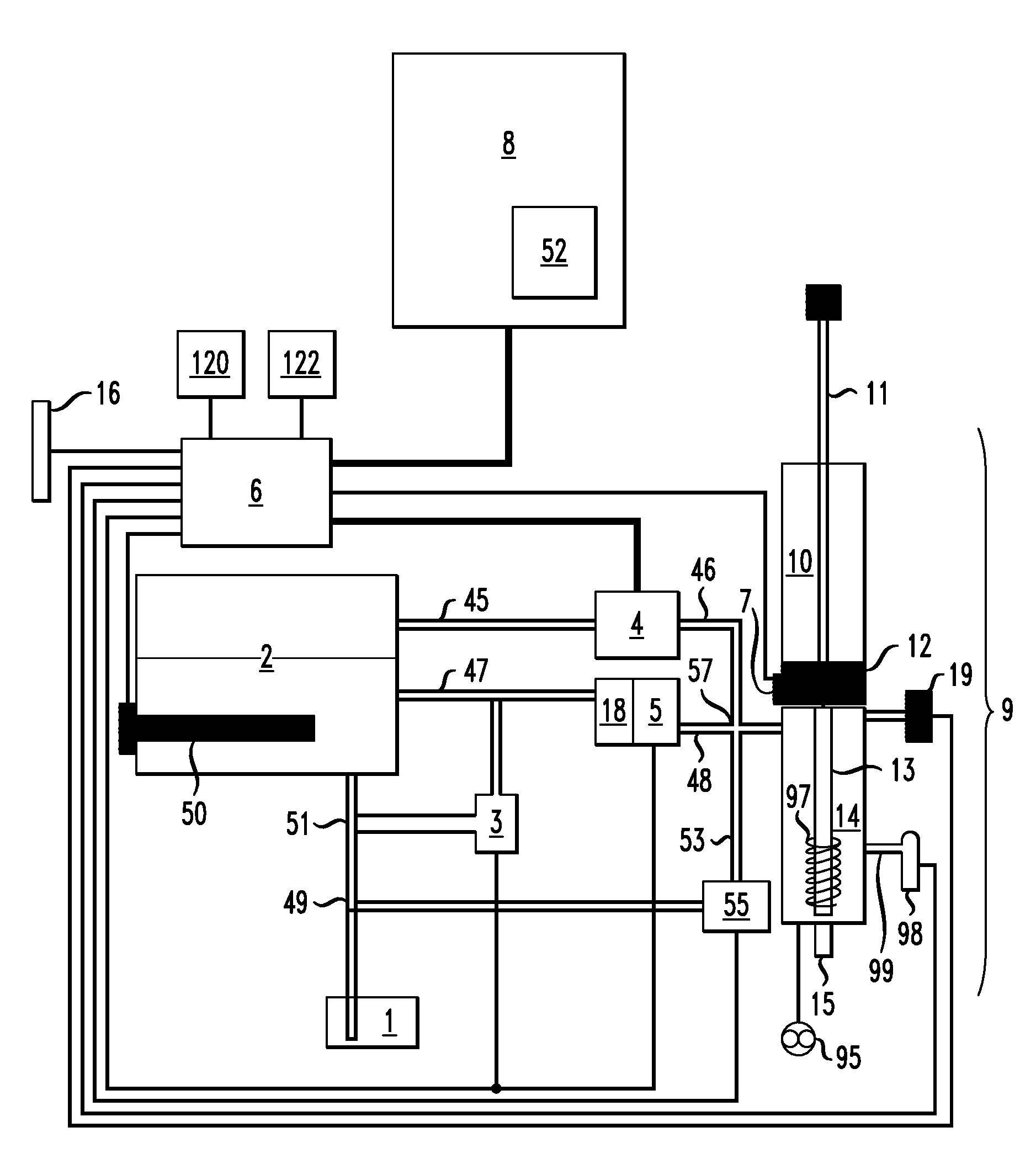

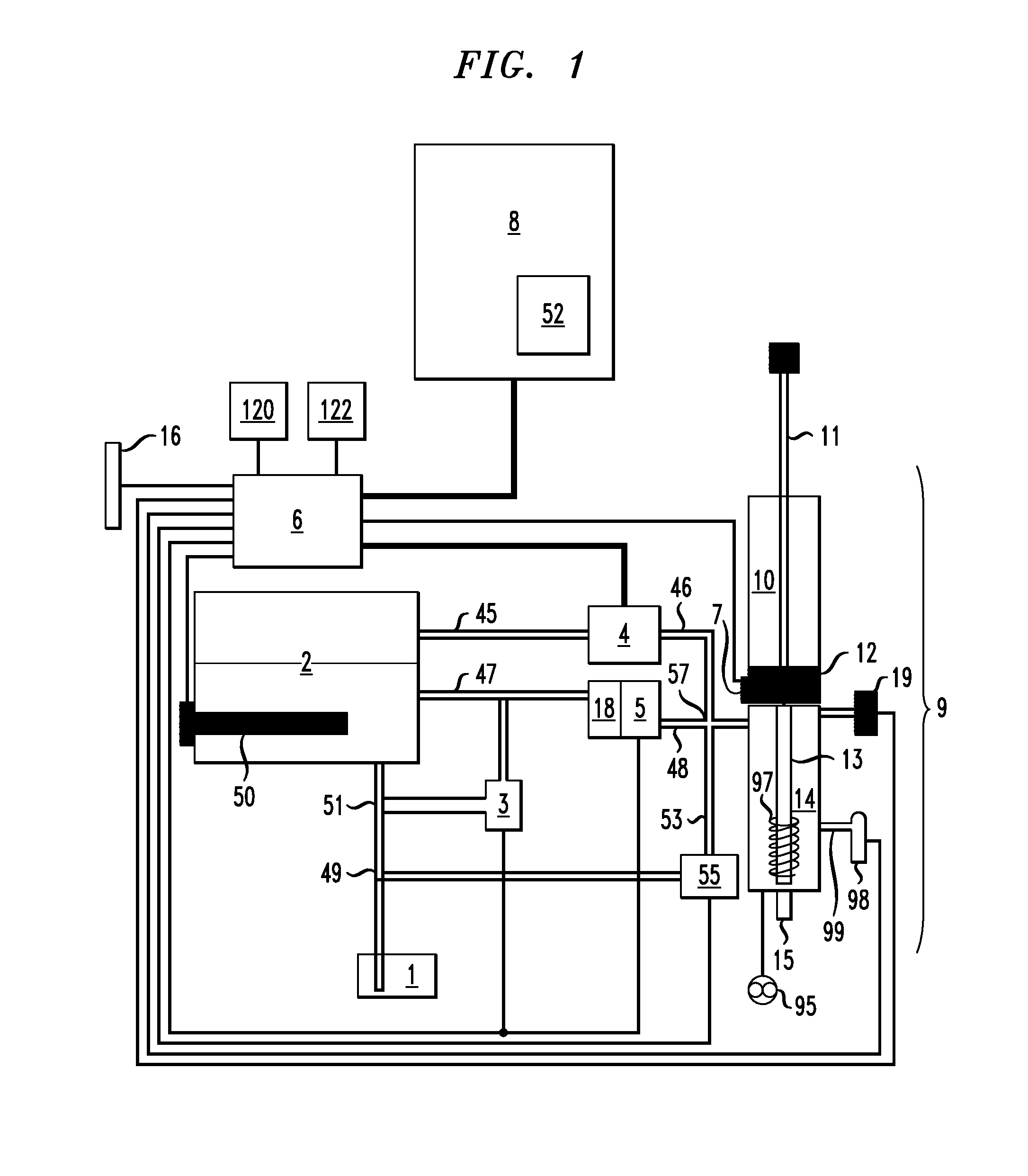

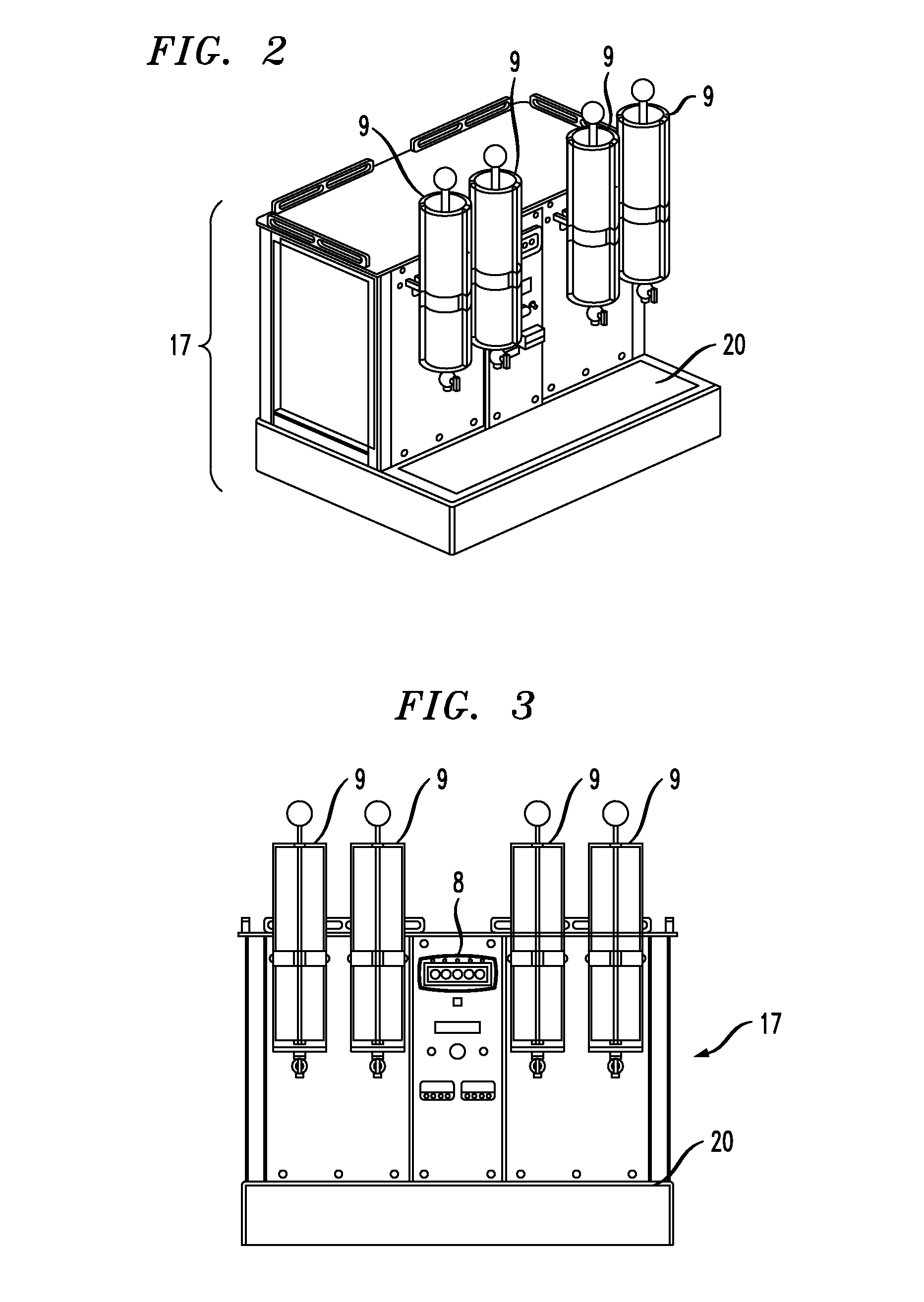

Hot beverage brewing system

In described embodiments, a hot liquid extraction system includes a brew chamber having a brew chamber upper end and a brew chamber lower end. A steam chamber is disposed below the brew chamber. A filtering base is removably inserted into the brew chamber. The filtering base has a diaphragm having a plurality of openings formed therein. The diaphragm is movable via fluid pressure between a first position in which the openings are open, thereby providing fluid communication between the brew chamber and the steam chamber and a second position in which the openings are closed, thereby precluding fluid communication between the brew chamber and the steam chamber.

Owner:ALPHA DOMINCHE HLDG INC

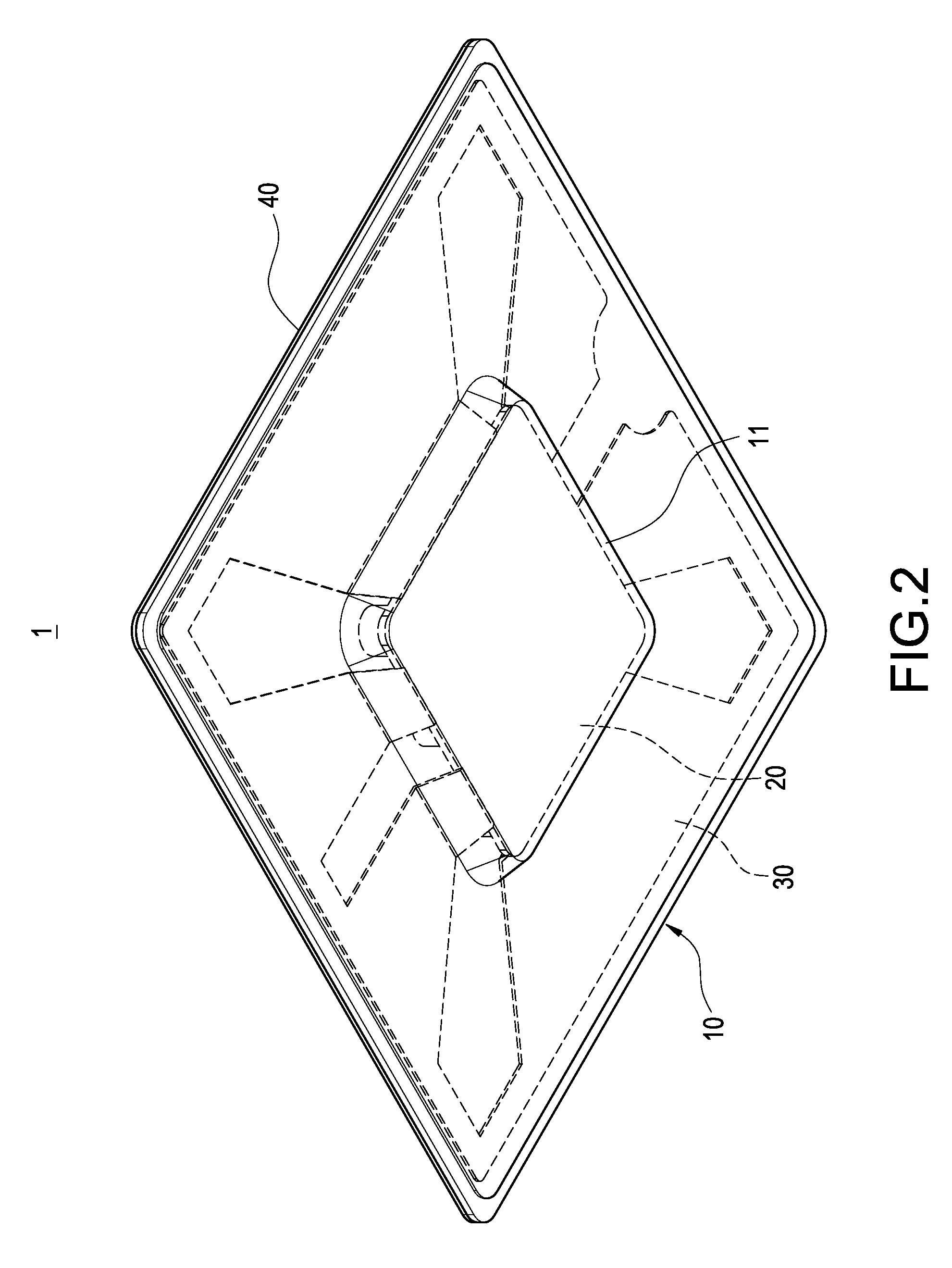

Vapor chamber having heated protrusion

InactiveUS20130025829A1Improve efficiencyLow production costIndirect heat exchangersWorking fluidHeat conducting

A vapor chamber is configured to conduct heat generated by a heat-generating element and includes a bottom plate, a first wick structure, a second wick structure, a cover plate and a working fluid filled between the cover plate and the bottom plate. One side of the bottom plate has a heated protrusion in thermal contact with the heat-generating element, and the other side is formed with an accommodating trough corresponding to the heated protrusion. The first wick structure is provided in the accommodating trough. The second wick structure is disposed on the bottom plate and provided with an opening and a plurality of airflow channels in communication with the opening. The cover plate tightly covers the bottom plate. The supporting posts are sandwiched between the cover plate and the first wick structure. By this arrangement, the mounting and heat-conducting of the heat-generating element can be achieved.

Owner:KUNSHAN JUZHONG ELECTRONICS

Natural convection steam cooking device

InactiveUS20060081592A1Domestic stoves or rangesOven air-treatment devicesSteam cookingNatural convection

A natural convection steam cooking device with a cooking cavity having a floor defining a lower boundary thereof and a sidewall defining a side boundary thereof, the floor having a plurality of first holes therein, the sidewall having a plurality of second holes therein; a steam chamber disposed below the cooking cavity and along the sidewall, the steam chamber having a pool disposed below the floor; wherein the steam enters the cooking cavity from the steam chamber via both the first holes and the second holes; and wherein the steam circulates within the device in an unforced manner by natural convection. The first holes and the second holes may have a ratio of cross-sectional areas of approximately 2:3. And method(s) of providing steam to, and design of steam flow for, a cooking cavity of a commercial steam cooking device.

Owner:MIDDLEBY MARSHALL

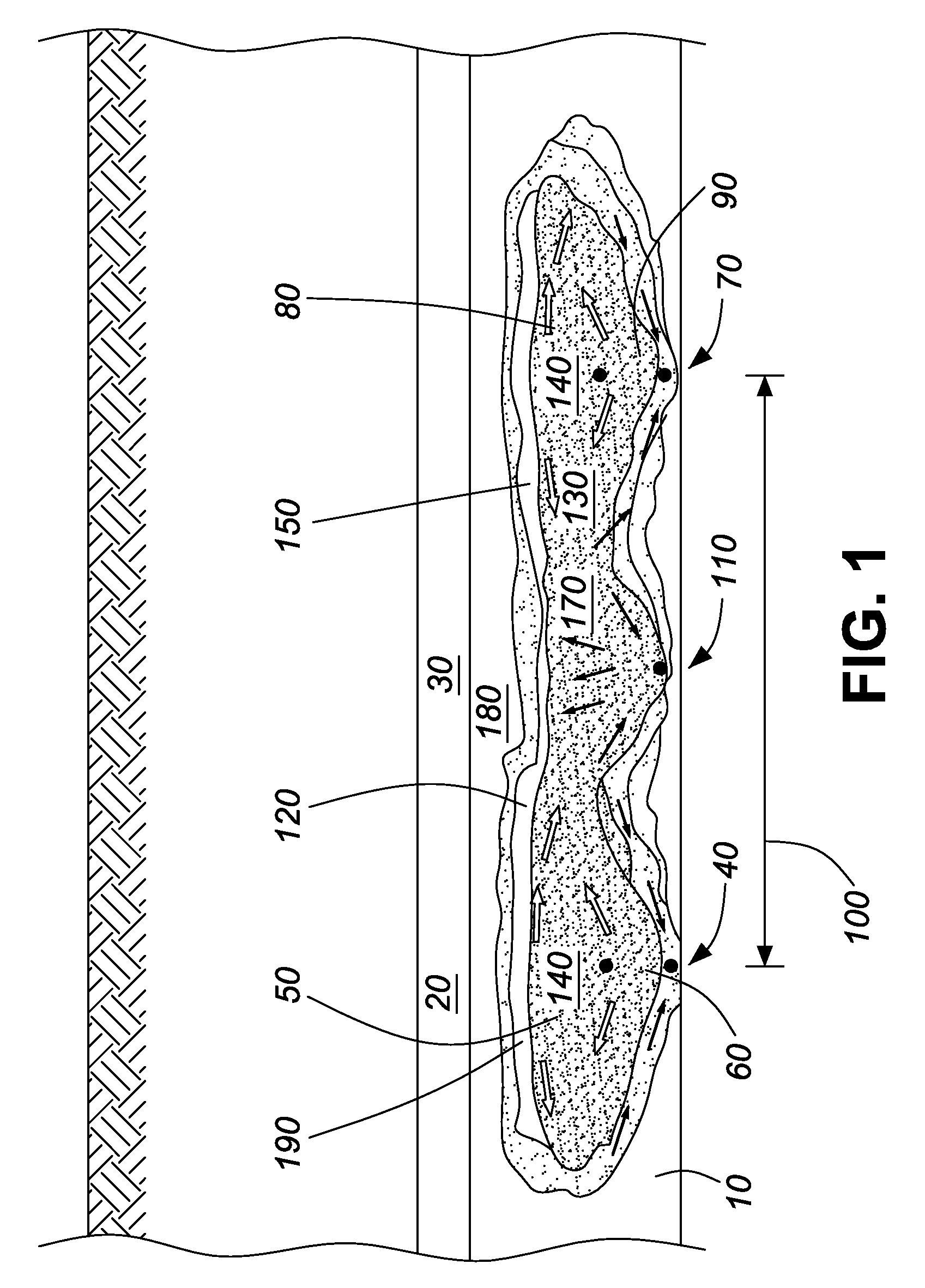

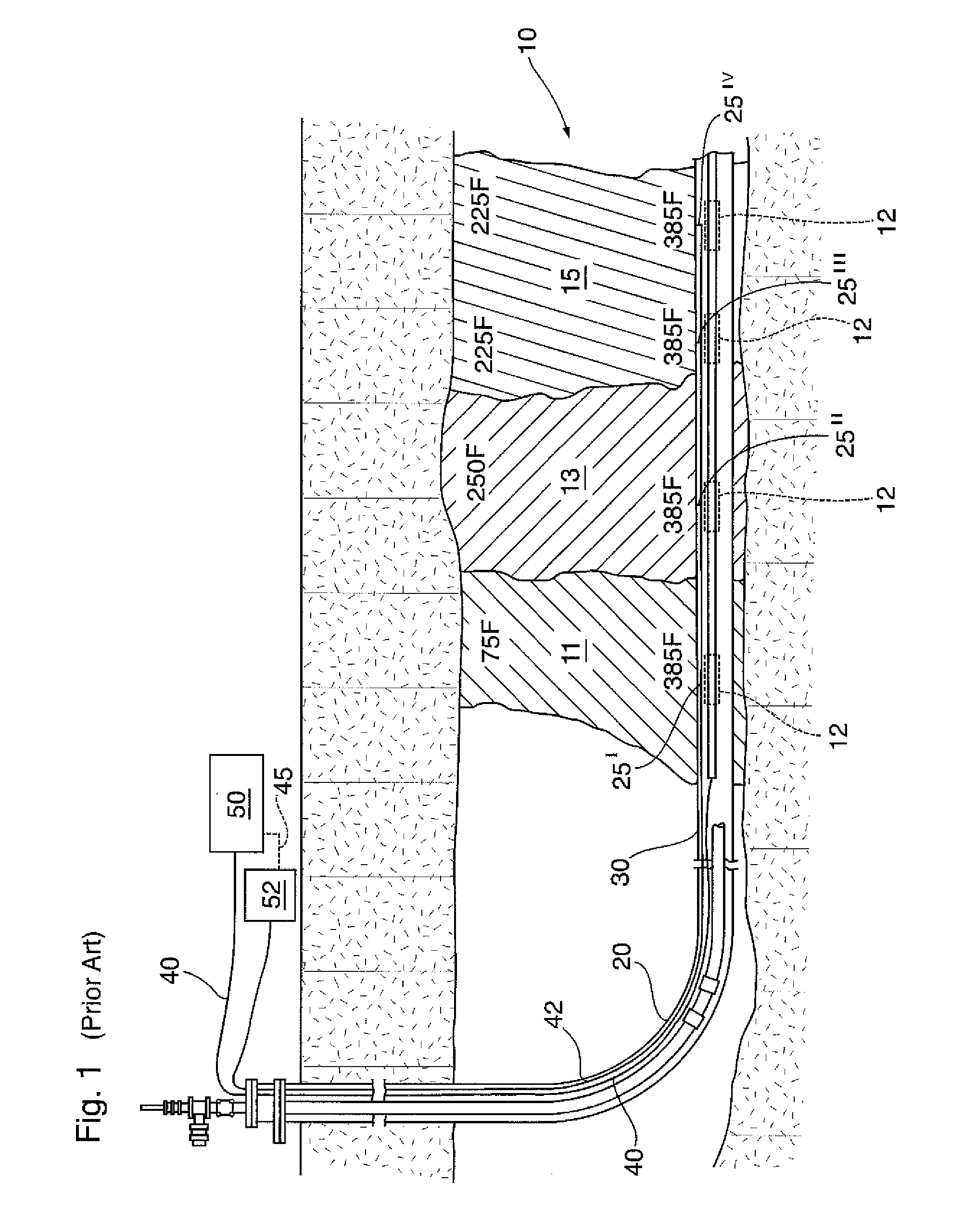

In situ heating for reservoir chamber development

Methods and apparatus relate to systems and methods of recovering oil from a formation. In operation, a steam chamber develops as a result of steam injection into the formation and the recovery of fluids including the oil through a production well. An auxiliary well spaced in a lateral direction from the production well helps ensure development of the steam chamber as desired. The auxiliary well may enable heating of the formation through establishing an electric potential between the auxiliary well and the production well or by resistive heating of material forming the auxiliary well. Further, the auxiliary well may provide a flow path for solvent or gas injection to facilitate the recovery through the production well.

Owner:CONOCOPHILLIPS CO

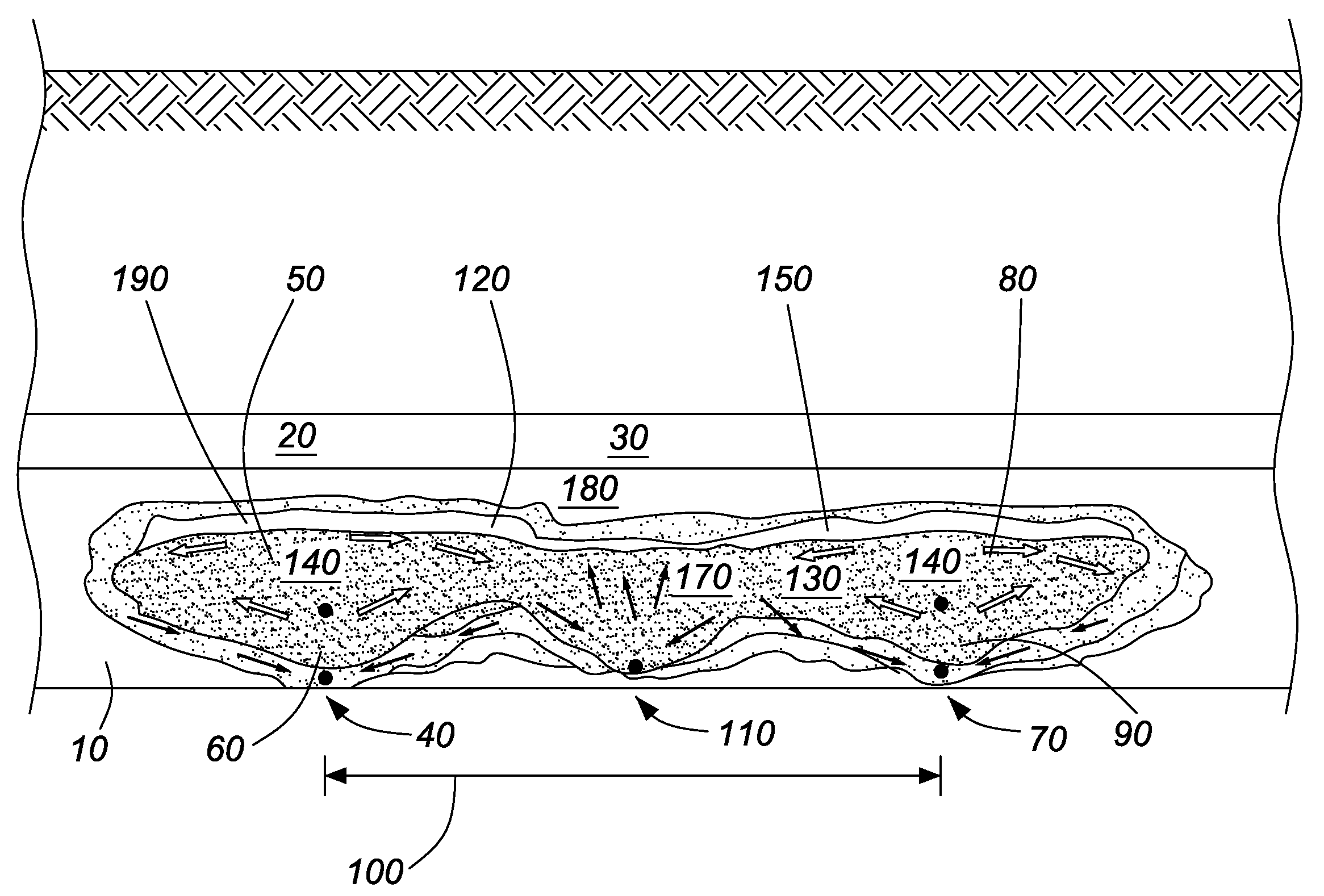

Low pressure recovery process for acceleration of in-situ bitumen recovery

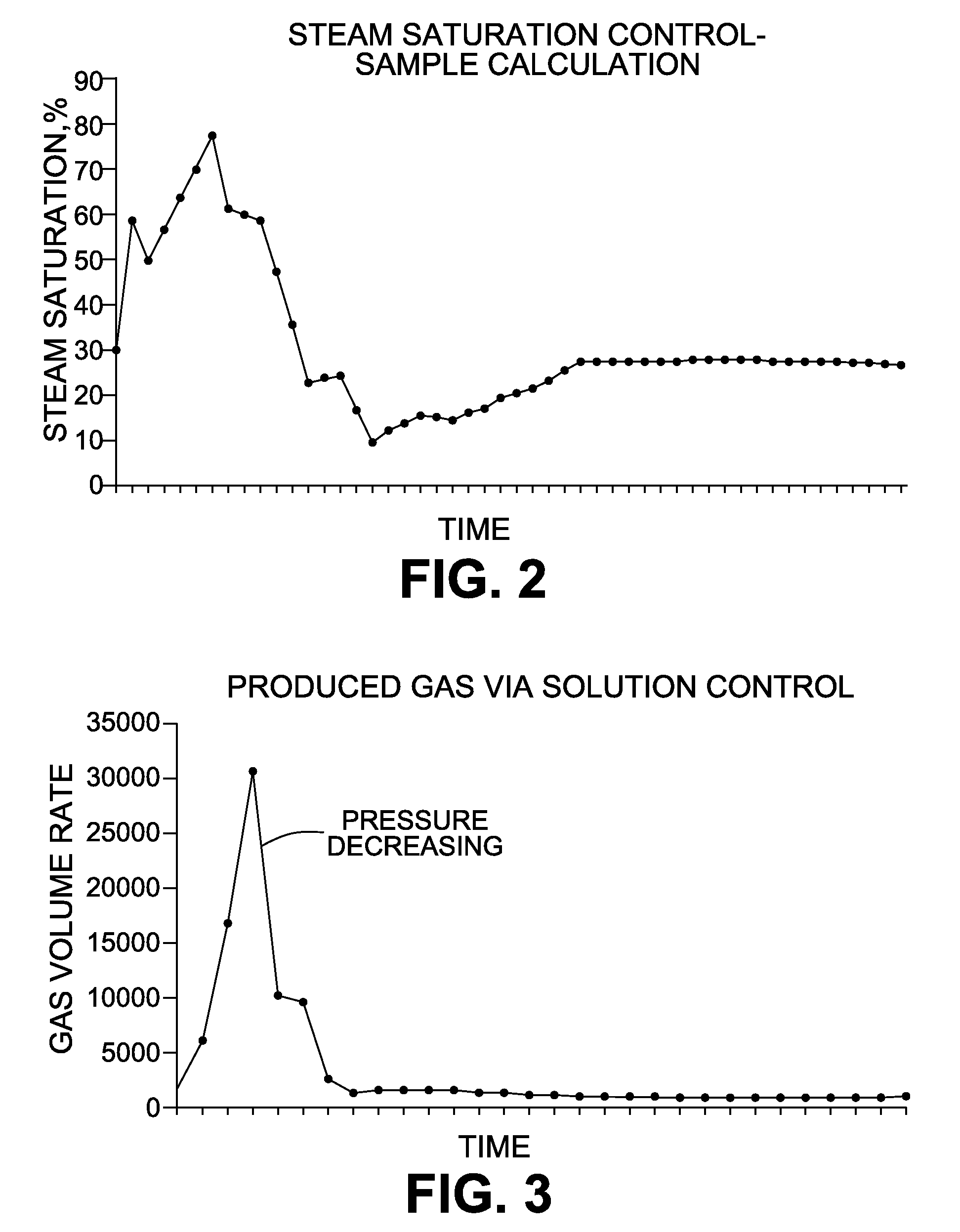

A method for recovery of hydrocarbons from a subterranean reservoir by operating adjacent injector producer well pairs under conditions of steam assisted gravity drainage (SAGD) with a lateral drainage well between and substantially parallel to them; the lateral drainage well is operated under conditions of intermittent steam injection and alternating oil, water and gas production; NCG is co-injected with steam into both the injector wells and the lateral drainage well at selected intervals, and in selected quantities in order to control the steam saturation of the SAGD steam chamber and the rise of the steam chamber, and to encourage lateral fluid communication between the adjacent well pairs and the LD well; controlling gas injection and production in order to control the rise of the steam chamber to improve production of oil; operating the well pairs and the LD well under conditions of a steam chamber pressure that is initially and briefly high to establish a steam chamber, but thereafter may be reduced to as low as 200 kPa; operating this low pressure SAGD in reservoirs that are at low pressure, due to factors such as depleted gas caps, regional geology, lack of cap rock, thief zones, or other low pressure zone or loss zones.

Owner:ATHABASCA OIL CORPORATION

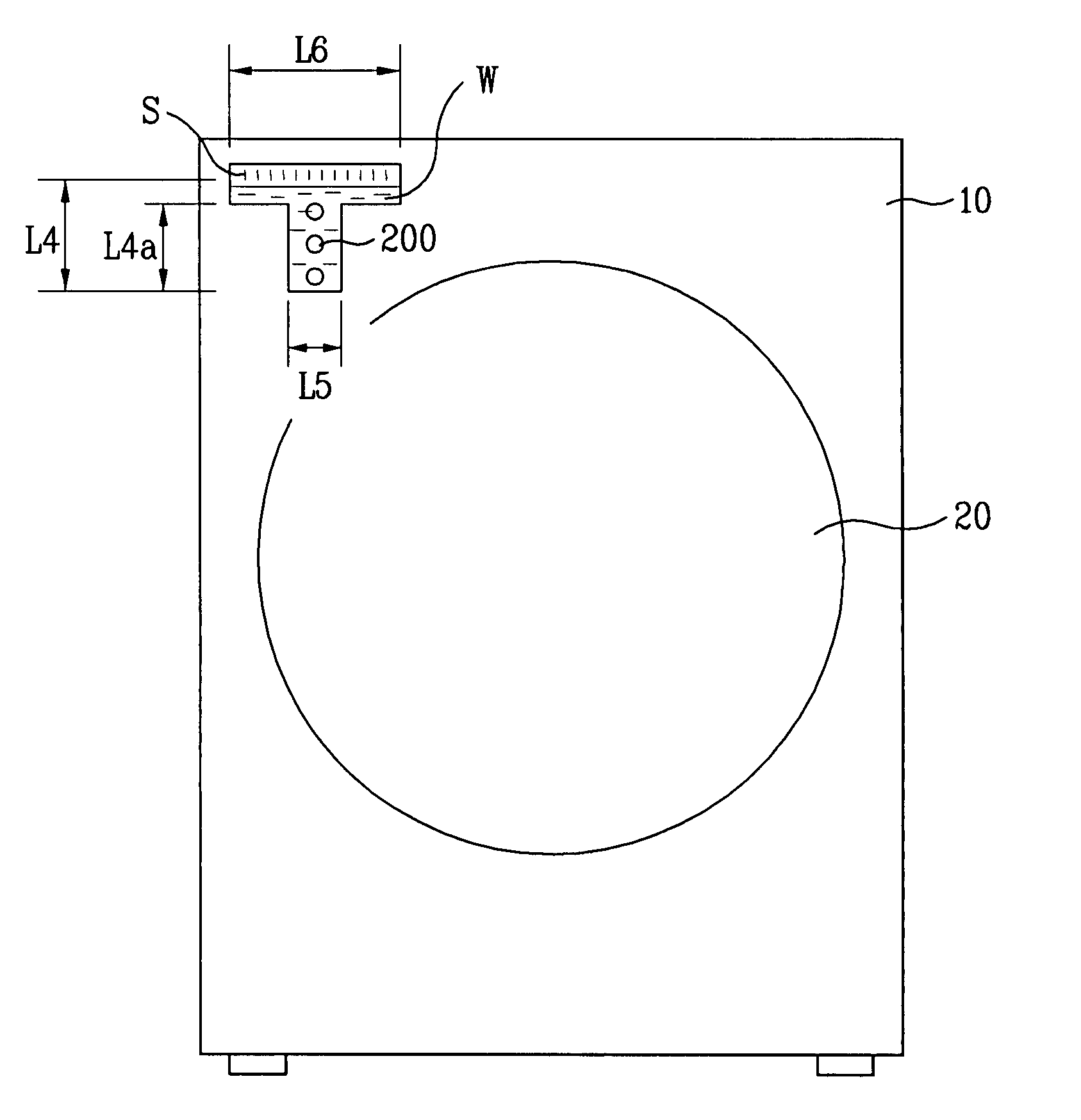

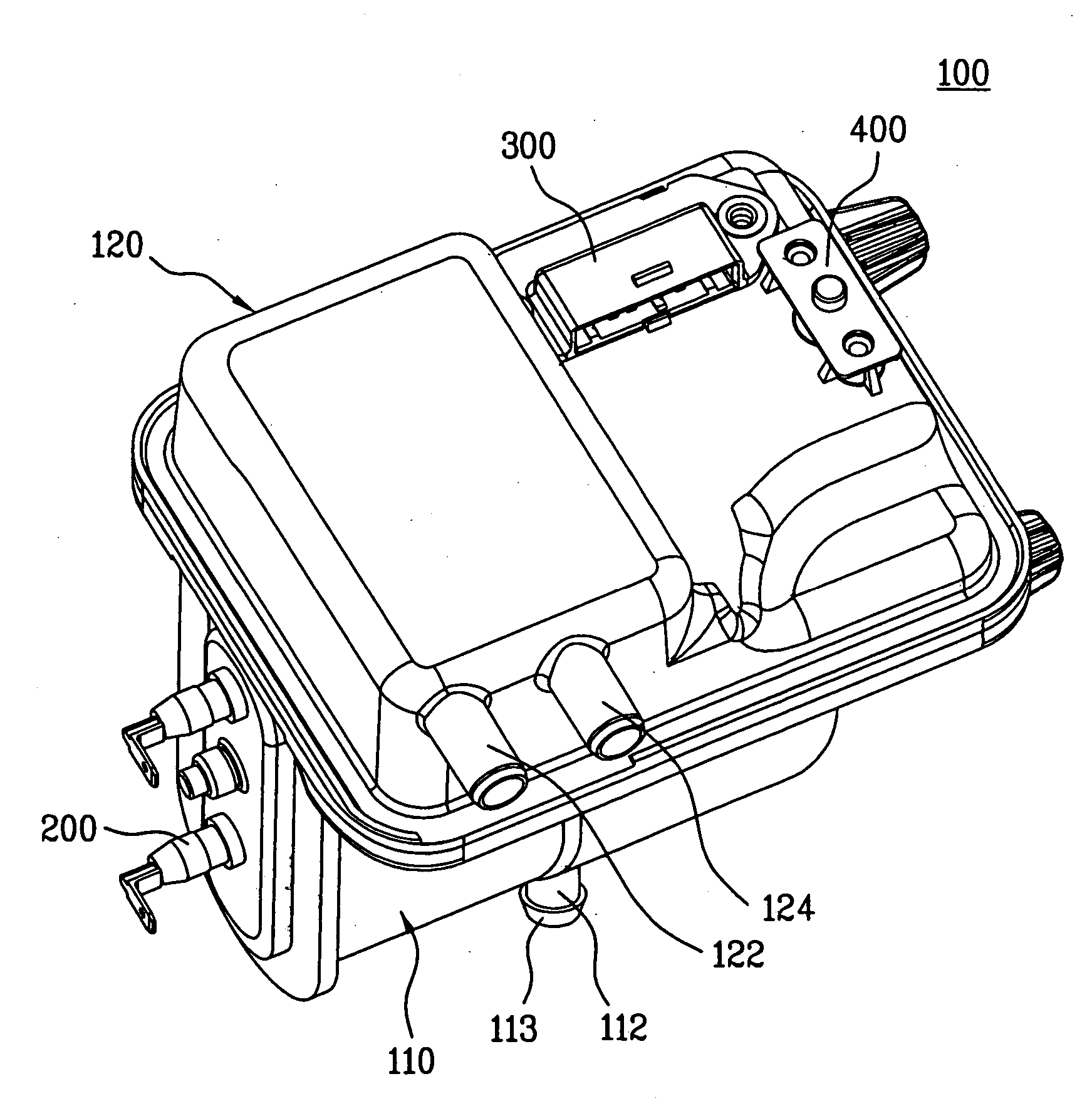

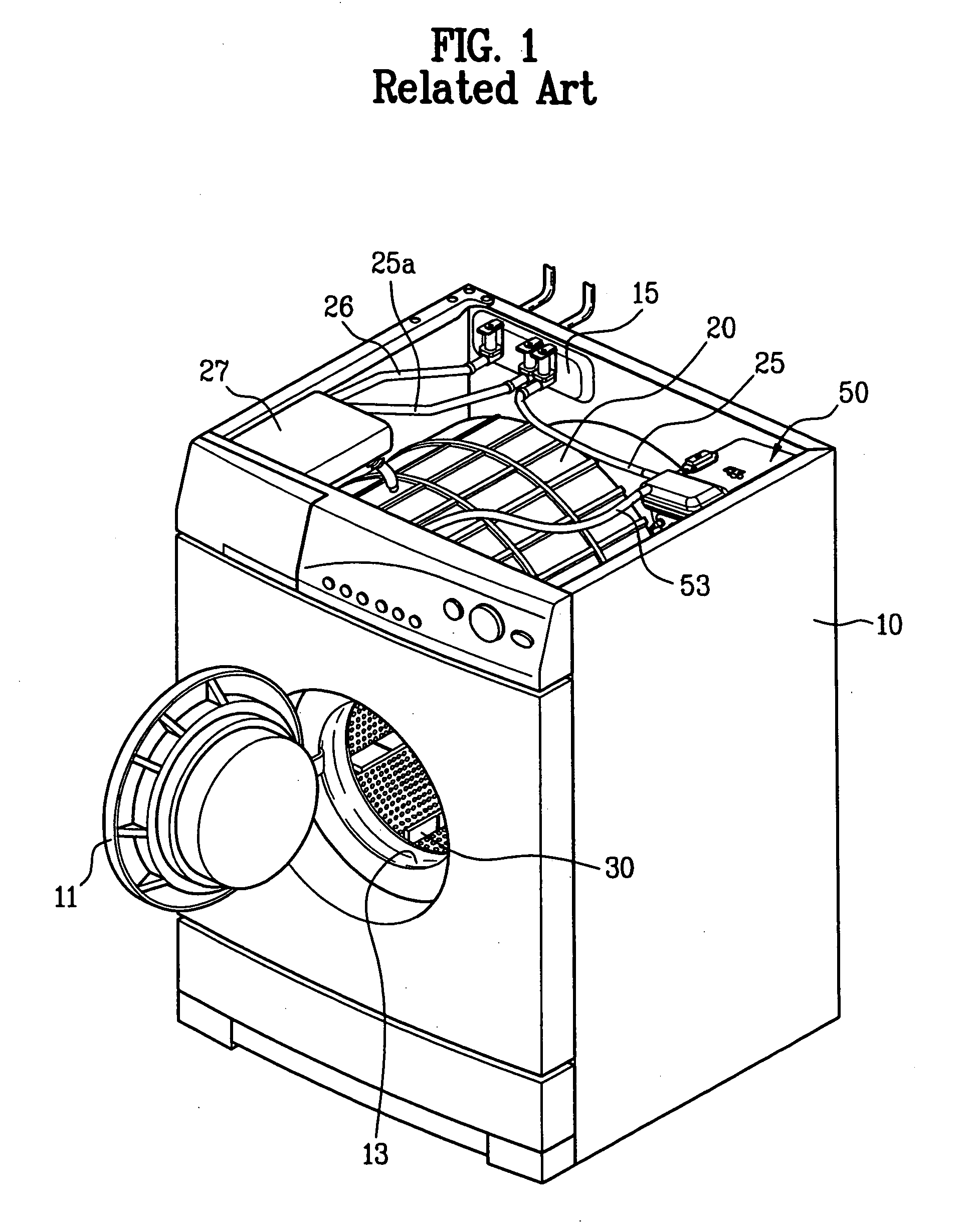

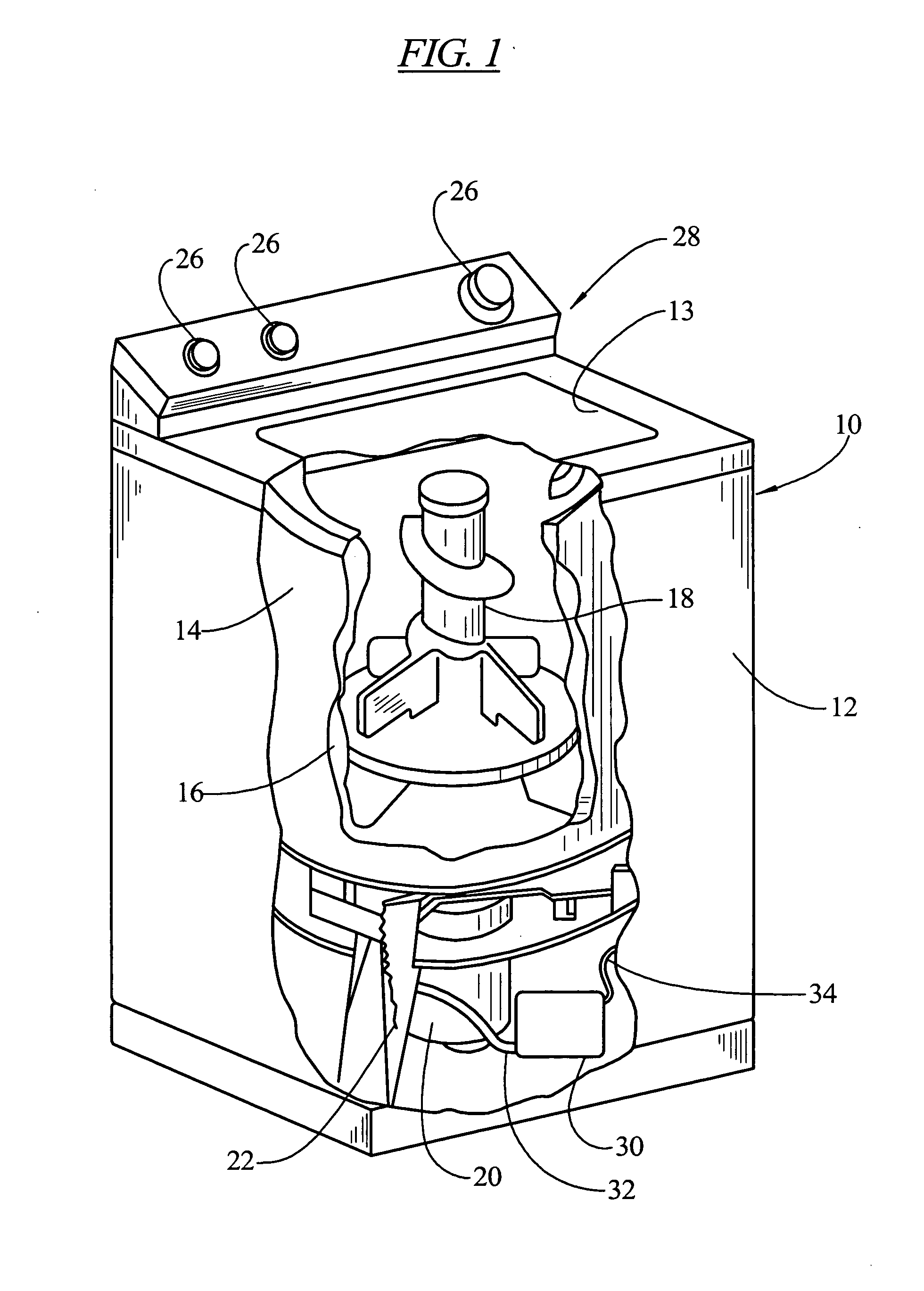

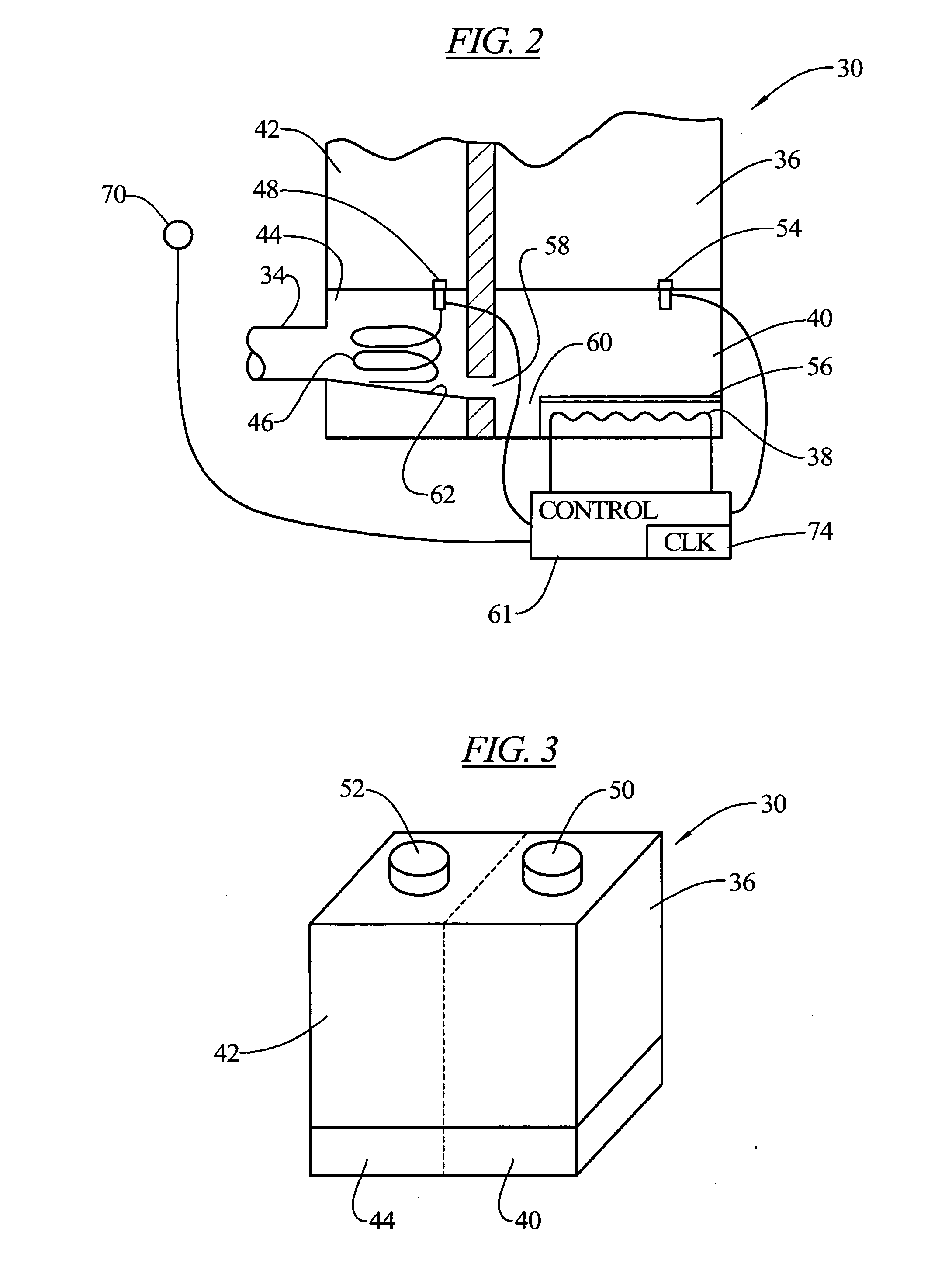

Steam generating device and washing machine having the same

ActiveUS20080006063A1Easy to installImprove performanceSteam generation heating methodsOther washing machinesEngineeringWater level

A steam generating device and a washing machine having the same are disclosed. The steam generating device includes a lower housing including a main portion for receiving a heater, and connecting portions extending outwardly from the main portion, the lower housing defining a water chamber for containing water, an upper housing connected to the connecting portions, the upper housing defining a steam chamber for containing steam, a water level sensor for sensing a level of water contained in the water chamber, and a receptacle for protecting the water level sensor. The receptacle has an opening for allowing water to be introduced into the receptacle, and is substantially aligned with an inner surface of the lower housing or is arranged at a position spaced apart from the heater by a longer distance than the inner surface of the lower housing.

Owner:LG ELECTRONICS INC

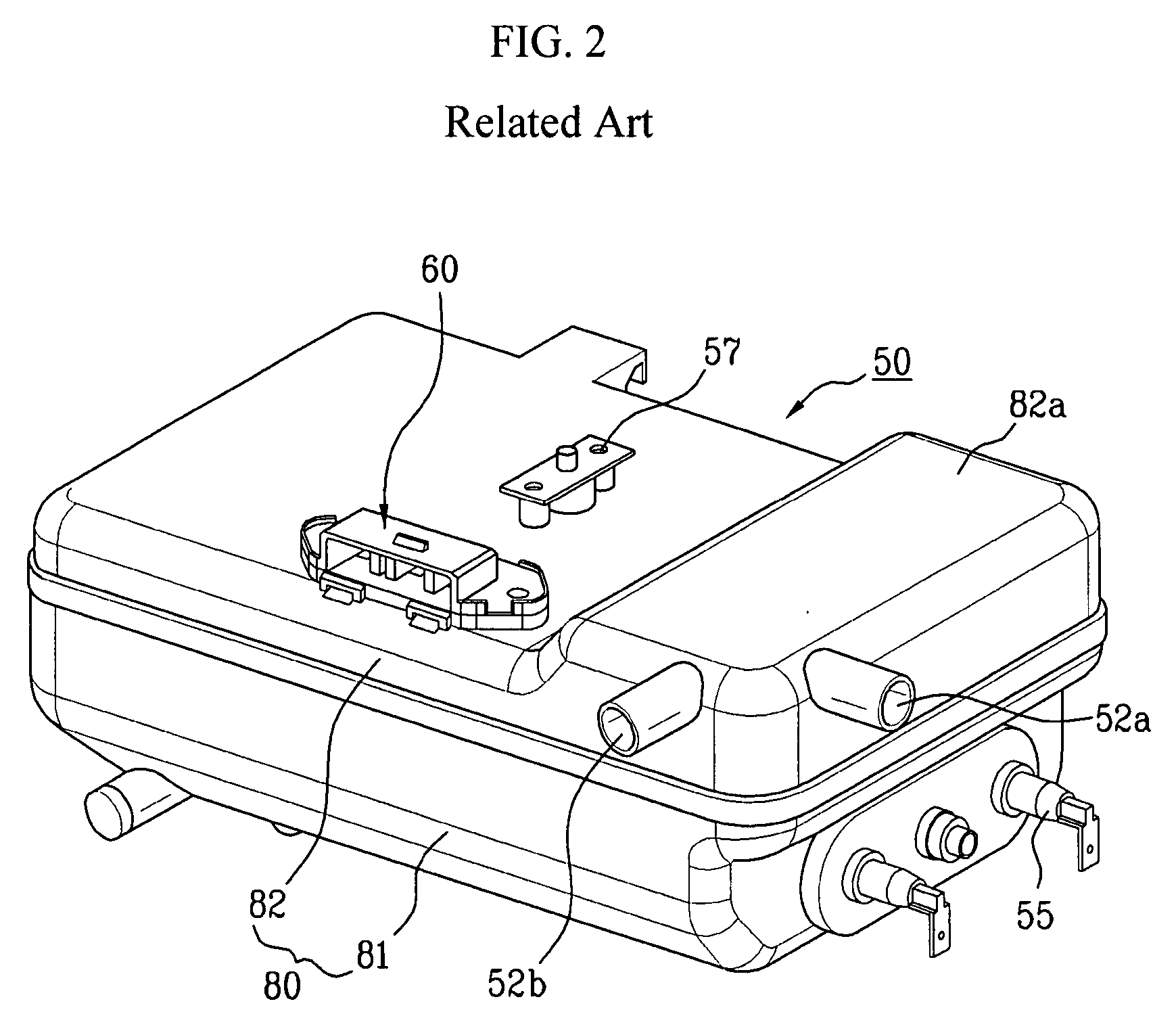

Steam generator and washing machine therewith

ActiveUS20070186592A1Easy to installImprove performanceSteam generation heating methodsOther washing machinesEngineeringSteam room

The present invention relates to a steam generator and a washing machine therewith. The present invention provides a steam generator including a water chamber for holding water, the water chamber having a heater mounted thereto for heating the water, and a steam chamber for holding steam generated as the water is heated, wherein the steam chamber has a steam discharge opening for discharging the steam wherein the steam discharge opening is provided with a separator for isolating a steam discharge area from other areas; and a washing machine therewith.

Owner:LG ELECTRONICS INC

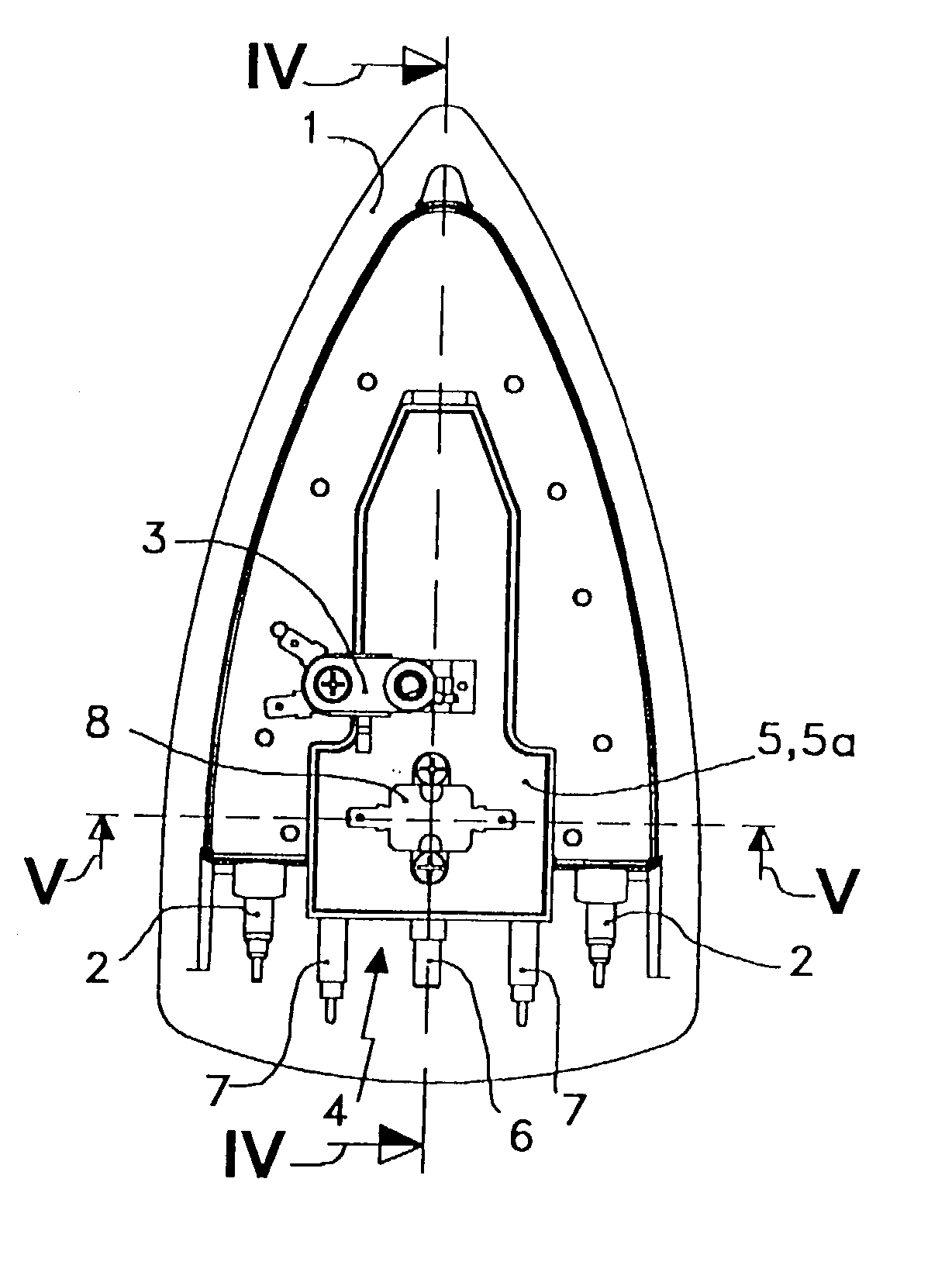

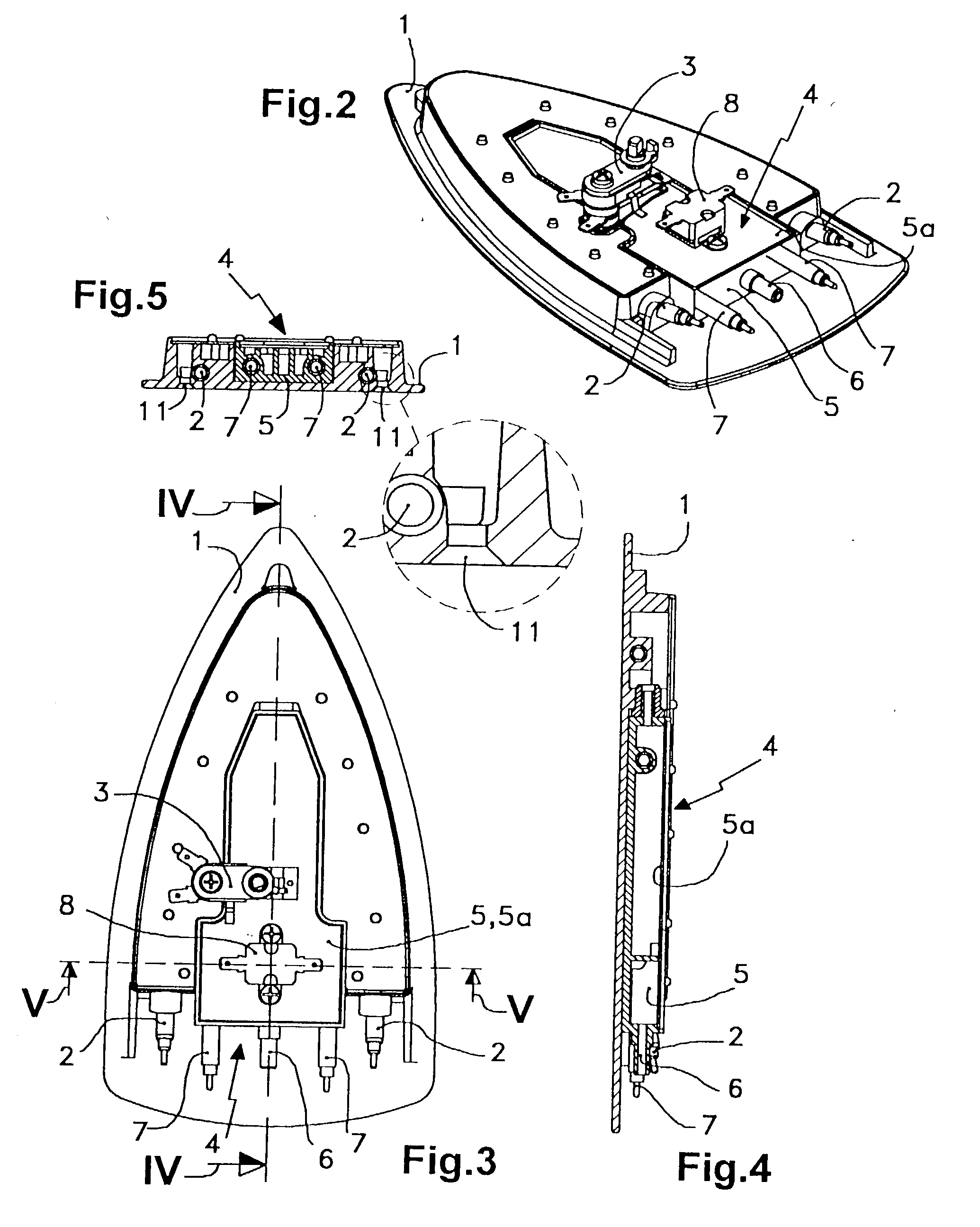

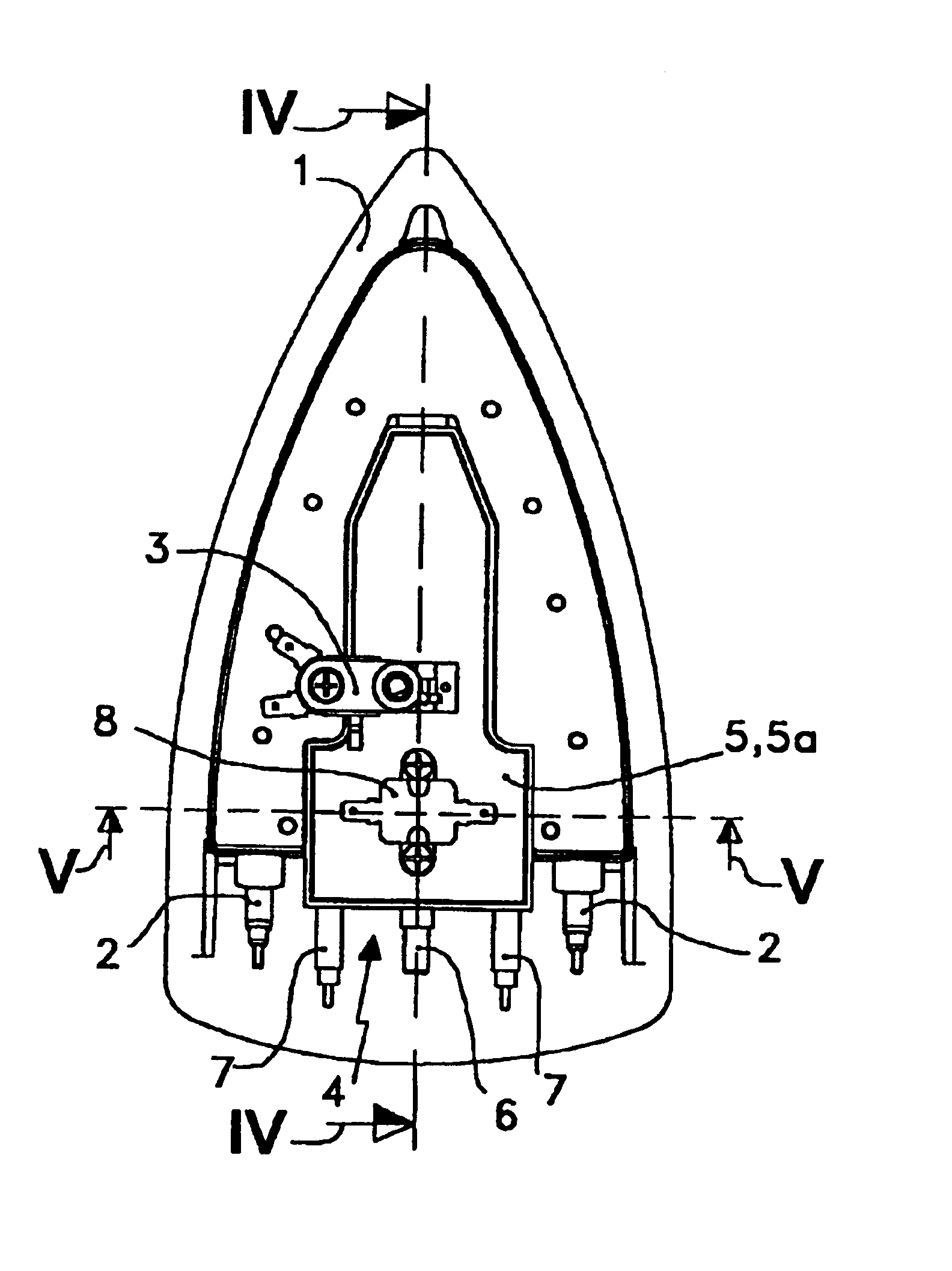

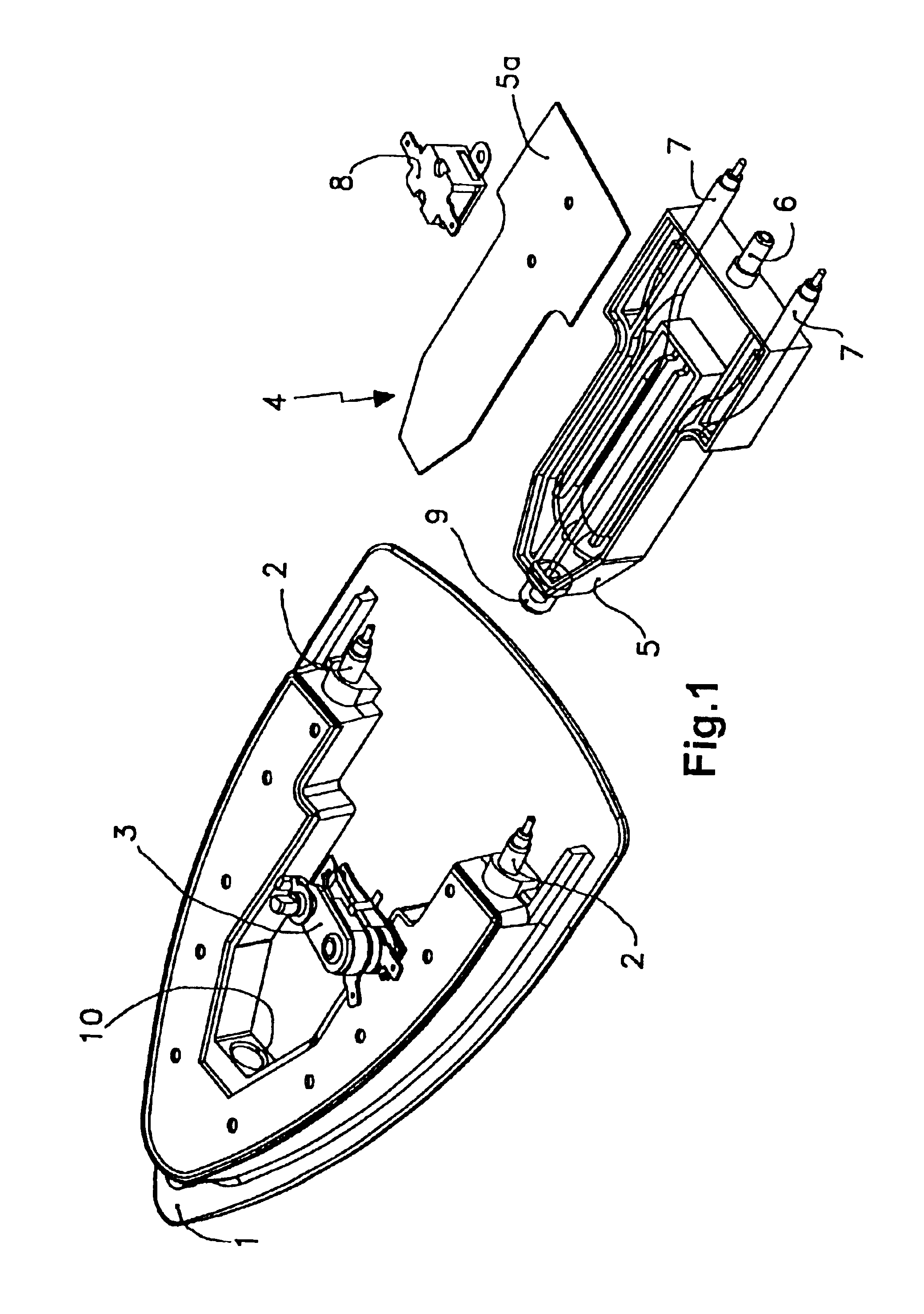

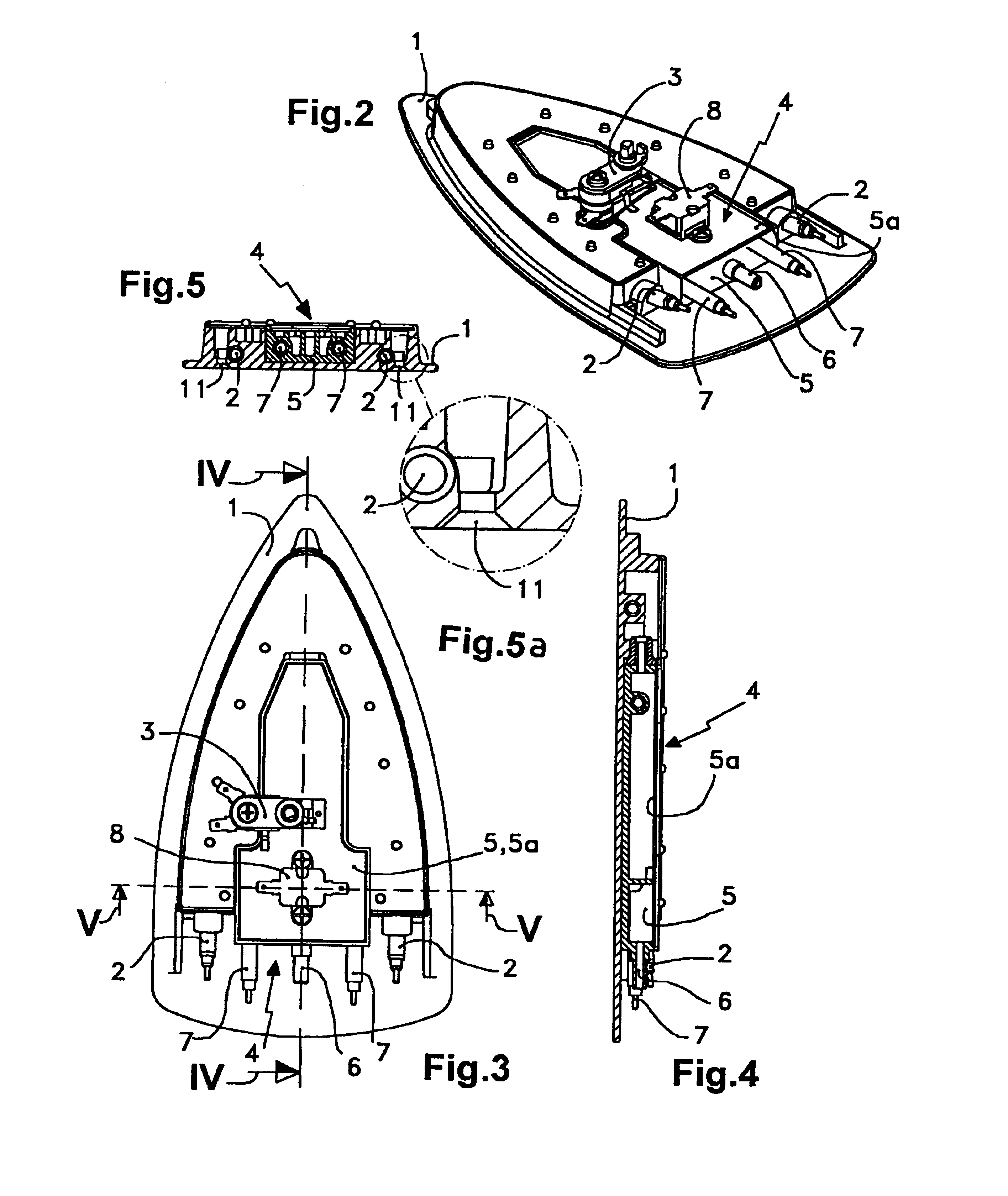

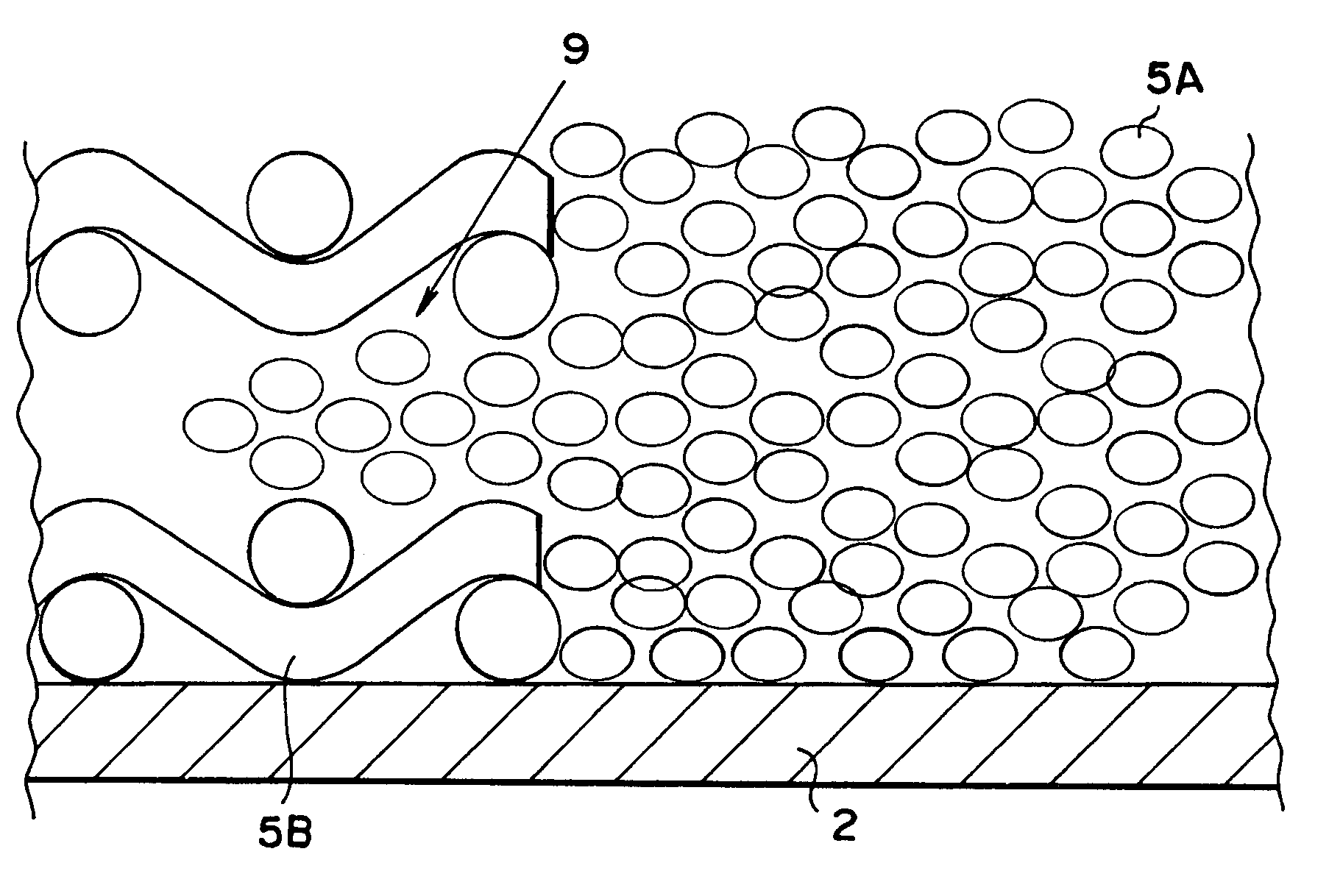

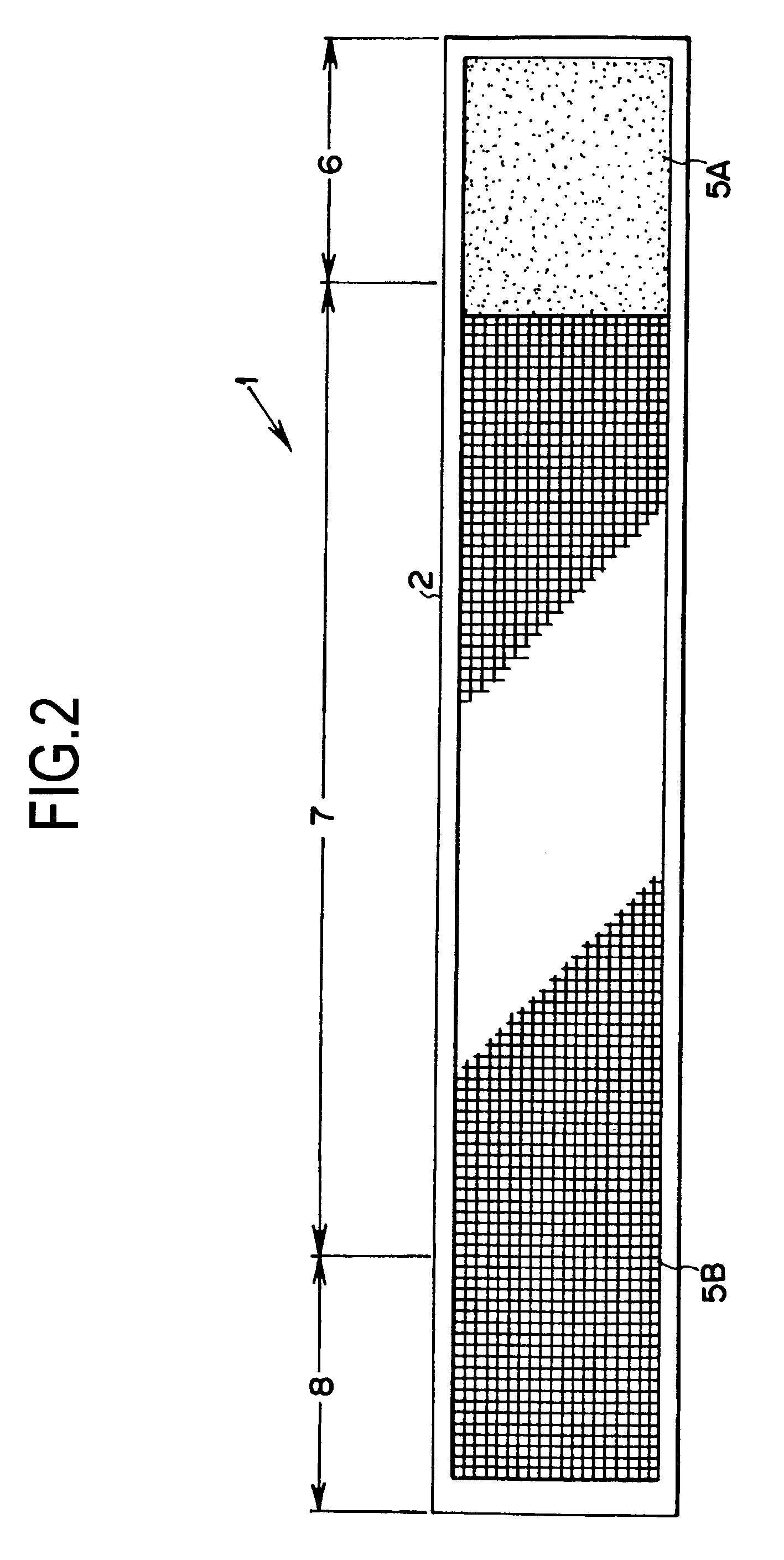

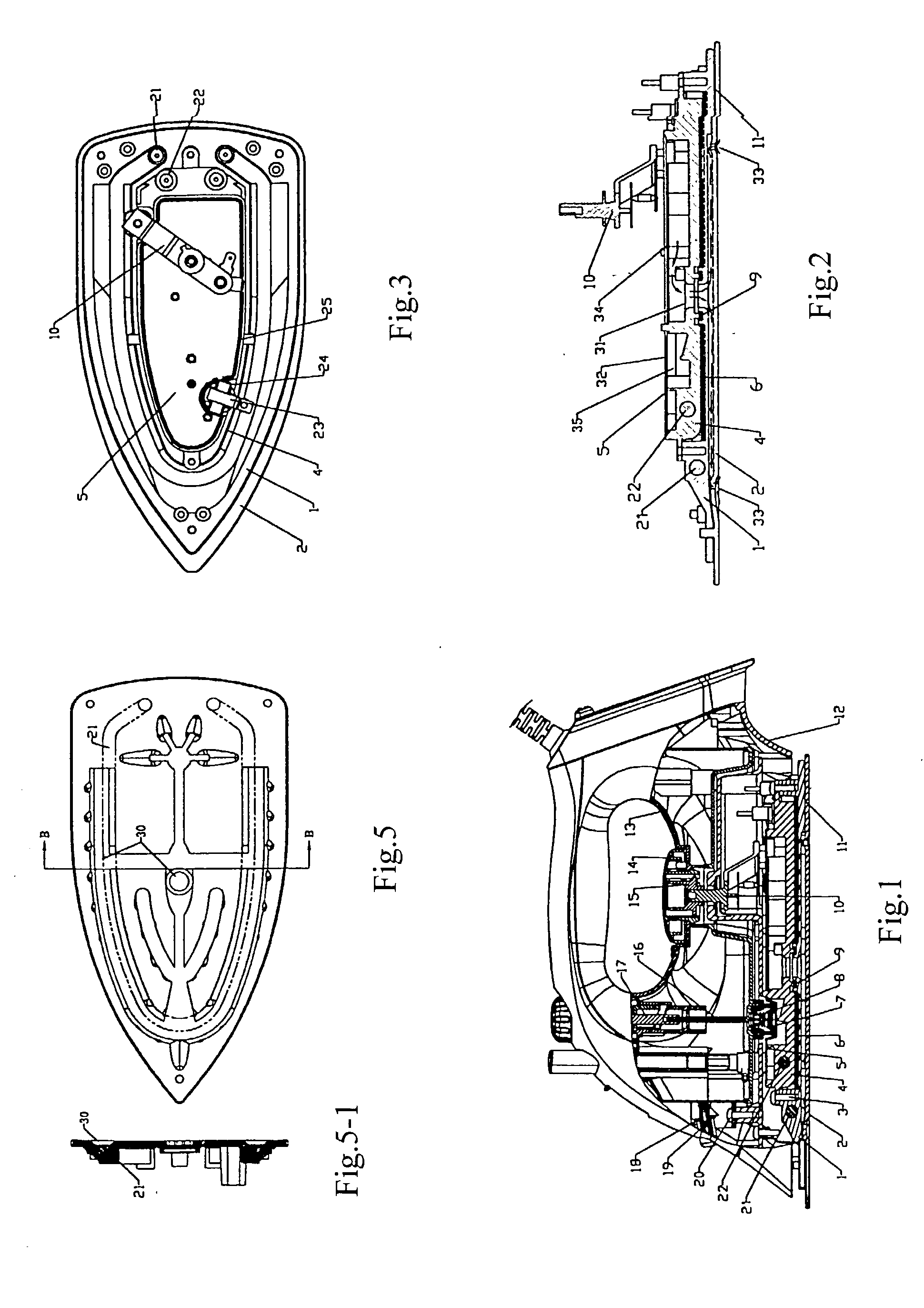

Soleplate of domestic steam iron

InactiveUS20030094445A1Quality improvementDelicate ironingHand ironTextiles and paperEngineeringThermostat

Soleplate of domestic steam iron, basically constituted by a an ironing element (1), which is that which comes into contact with the item to be ironed, and a heating element (2) which heats said ironing element (1) by means of a thermostatic element (3) which regulates the ironing temperature, which independently of the assembly of ironing element (1), heating element (2) and thermostatic element (3), the soleplate of domestic steam iron (1-2) according to the invention incorporates an autonomous steam assembly (4) which is composed of a steam chamber (5) which has a water supply conduit (6) connected to the reservoir of the domestic iron, and whose steam chamber (5) has a separate heating element (7) which has its own thermostat (8) which regulates the temperature in that steam chamber (5); the steam assembly (4) has a steam outlet (9) connected to a complementary steam intake (10) which exists in the ironing element (1) for the correct passage of steam to the outlet holes.

Owner:POLNE

Domestic steam iron with autonomous steam assembly heated by separate heating element

InactiveUS6953912B2Quality improvementDelicate ironingHand ironTextiles and paperEngineeringThermostat

Soleplate of domestic steam iron, basically constituted by a an ironing element (1), which is that which comes into contact with the item to be ironed, and a heating element (2) which heats said ironing element (1) by means of a thermostatic element (3) which regulates the ironing temperature, which independently of the assembly of ironing element (1), heating element (2) and thermostatic element (3), the soleplate of domestic steam iron (1-2) according to the invention incorporates an autonomous steam assembly (4) which is composed of a steam chamber (5) which has a water supply conduit (6) connected to the reservoir of the domestic iron, and whose steam chamber (5) has a separate heating element (7) which has its own thermostat (8) which regulates the temperature in that steam chamber (5); the steam assembly (4) has a steam outlet (9) connected to a complementary steam intake (10) which exists in the ironing element (1) for the correct passage of steam to the outlet holes.

Owner:POLNE

Vapor chamber

ActiveUS7137442B2Good heat transfer performanceIncrease pressureIndirect heat exchangersWorking fluidCapillary pressure

A vapor chamber, in which a condensable fluid, which evaporates and condenses depending on a state of input and radiation of a heat, is encapsulated in a hollow and flat sealed receptacle as a liquid phase working fluid; and in which the wick for creating the capillary pressure by moistening by the working fluid is arranged in said sealed receptacle, comprising: a wick for creating a great capillary pressure by being moistened by said working fluid, which is arranged on the evaporating part side where the heat is input from outside; and a wick having a small flow resistance against the moistening working fluid, which is arranged on the condensing part side where the heat is radiated to outside.

Owner:THE FUJIKURA CABLE WORKS LTD +1

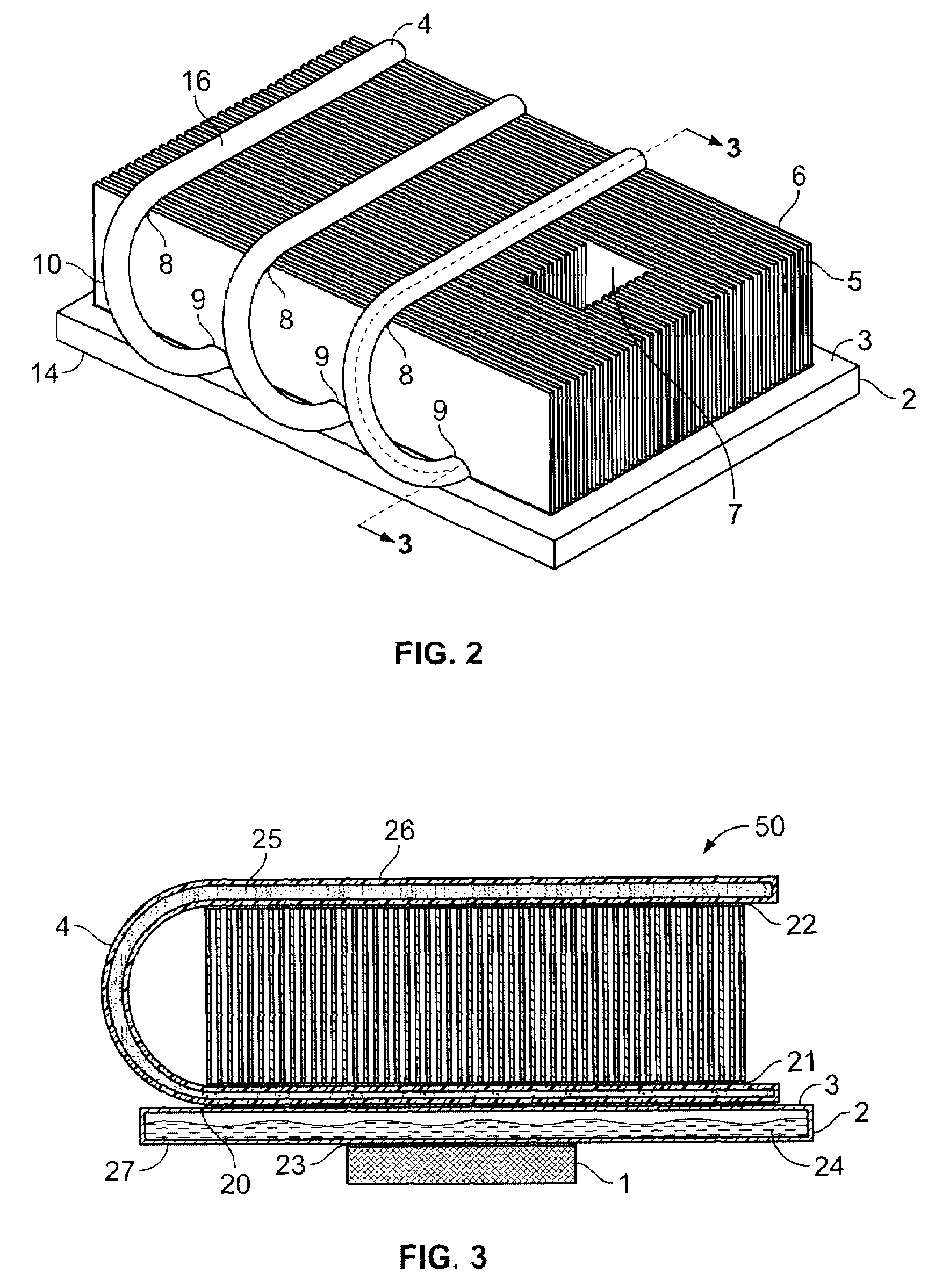

Three-Dimensional Thermal Spreading in an Air-Cooled Thermal Device

ActiveUS20080043437A1Semiconductor/solid-state device detailsSolid-state devicesWater vaporEngineering

The present disclosure relates to heat transfer thermal management device utilizing varied methods of heat transfer to cool a heat generating component from a circuit assembly or any other embodiment where a heat generating component can be functionally and operatively coupled. In a proposed embodiment, at least one heat pipe is used to transfer heat from the condensation portion of a vapor chamber to cool a bottom portion of a finned heat dissipation space and transfer the heat to a colder location on the heat fins. In another proposed embodiment, the water vapor chamber is placed in a heat sink and is adapted to thermally connect to at least one heat pipe.

Owner:ATI TECH INC

Video live steaming method and device

ActiveCN106604046AImprove the level of intelligenceSelective content distributionSteam roomMultimedia

The present invention provides a video live steaming method and device. The method includes the following steps that: a new live steaming room template is determined according to a user instruction, wherein the new live steaming room template is a template different from a live steaming room template used by a user terminal currently; and live steaming data to be displayed are arranged and displayed according to the new live steaming room template. According to the video live steaming method and device of the invention, a live steaming room template replacement function is provided, so that a user can replace live steaming room templates; a live steaming room template which the user is fond of can be adopted to arrange and display live steaming data to be displayed; and therefore, the intelligent level of the user terminal can be improved, and conveniences can be brought to the user.

Owner:广州方硅信息技术有限公司

Heat-conducting module and heat-dissipating device having the same

InactiveUS20110297355A1Improve thermal conductivityIncrease contact areaSemiconductor/solid-state device detailsSolid-state devicesHeat conductingEngineering

Owner:CELSIA TECH TAIWAN INC

Preparation method of rapid silane cross-linked polyethylene special material

InactiveCN101608031AOvercome the defect of boiling to cross-linkPromote environmental protectionCross-linkSilanes

The invention relates to a preparation method of a rapid silane cross-linked polyethylene special material, the composition of the special material comprises: 60-95 parts by weight of polyethylene, 0-35 parts by weight of ethylene-vinyl acetate copolymer, 1-5 parts by weight of unsaturated silane, 0.1-1 part by weight of water-absorbing agent, 0.5-5 parts by weight of cross-linking assistant agent, 0.1-0.5 part by weight of antioxidant and 0.5-2 parts by weight of lubricant, and the special material is obtained by fully mixing all the raw materials and carrying out granulation by an extruder. The special material is extruded for preparing a pipeline or a cable insulating layer and then placed at room temperature of 23 DEG C for 24 hours, thereby automatically completing the cross-linking process and leading the degree of cross-linking to be above 65%; and the preparation method overcomes the shortcoming that the prior silane cross-linked plastic can only be cross-linked by water boiling under the environment of a warm water pool or a steam room, thereby greatly saving production cost for a manufacturer.

Owner:尤伟兴

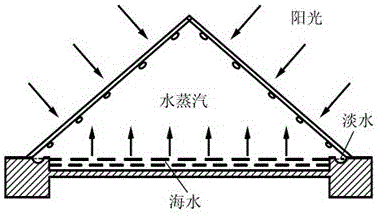

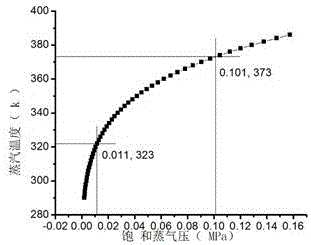

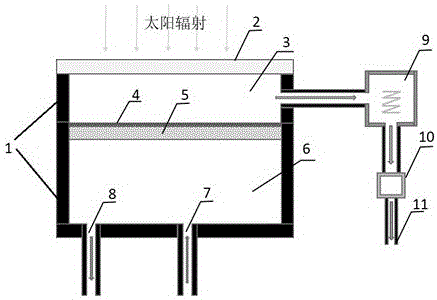

Low-temperature low-pressure solar local-thermal-process seawater desalination system

InactiveCN106365235AFast evaporationAchieving the desalination processGeneral water supply conservationSeawater treatmentThermal energySteam condensation

The invention discloses a low-temperature low-pressure solar local-thermal-process seawater desalination system which comprises a steam generation system and a steam condensation collection system, wherein the steam generation system comprises a box body and a steam generator; the steam generator divides the box body into a steam chamber and a seawater compensating chamber which are respectively the upper and lower part structures; the top of the steam chamber is provided with a solar receiving window; the bottom of the seawater compensating chamber is provided with a seawater water inlet pipe and a concentrated brine water outlet pipe; the steam generator comprises a capillary pore layer and a solar energy absorbing coating deposited on the upper surface of the capillary pore layer; the solar energy absorbing coating is used for absorbing the solar energy and converting the solar energy into the heat energy; the capillary pore layer is used for delivering the seawater to the solar energy absorbing coating; the steam condensation collection system comprises a condenser, a vacuum pump and a fresh water outlet which are connected through pipelines; and an inlet of the condenser is connected with the steam chamber through a pipeline. The system only heats the seawater surface to form partial high temperature, so that the seawater is quickly evaporated. The non-evaporated part of the seawater is still kept in the low-temperature state, so the solar conversion efficiency is high.

Owner:WUHAN UNIV

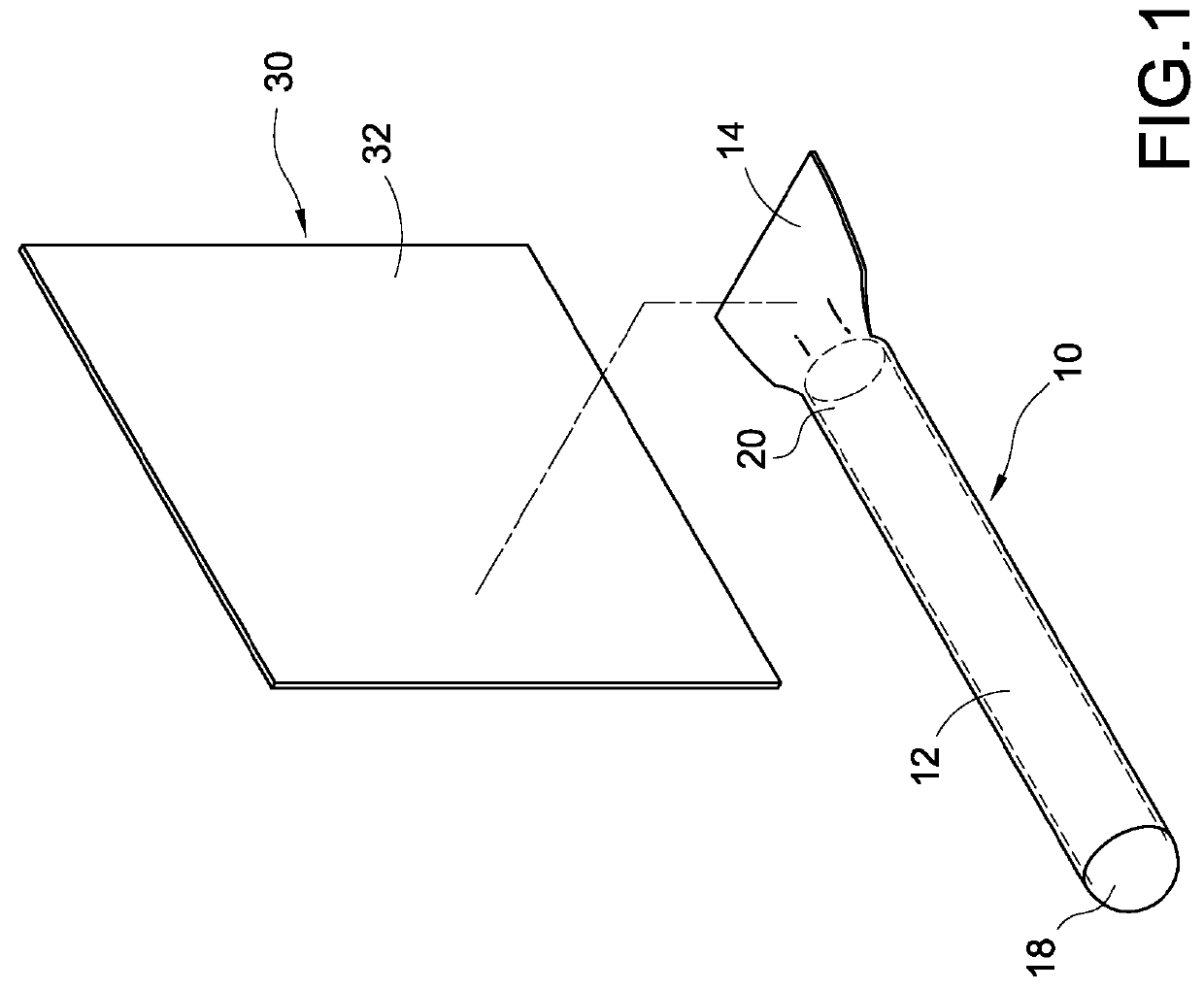

Vapor chamber and heat pipe combined structure and combining method thereof

ActiveUS20180106552A1Increase return speedImprove conduction abilitySemiconductor/solid-state device detailsIndirect heat exchangersWorking fluidLiquid state

A vapor chamber and heat pipe combined structure and method; the vapor chamber and heat pipe combined structure includes a heat pipe, a vapor chamber and a working fluid. The heat pipe includes a pipe body, a fixing section, and a first capillary tissue. The vapor chamber includes an upper metal casing, a lower metal casing, a containing chamber and a second capillary tissue installed in the containing chamber. The working fluid is filled into the containing chamber, and the fixing section of the heat pipe is coupled to the upper metal casing, so that the first capillary tissue is coupled to the second capillary tissue. The combined structure facilitates the connection and fixation of the heat pipe and improves the reflux speed of the liquid-state working fluid.

Owner:TAIWAN MICROLOOPS CORP

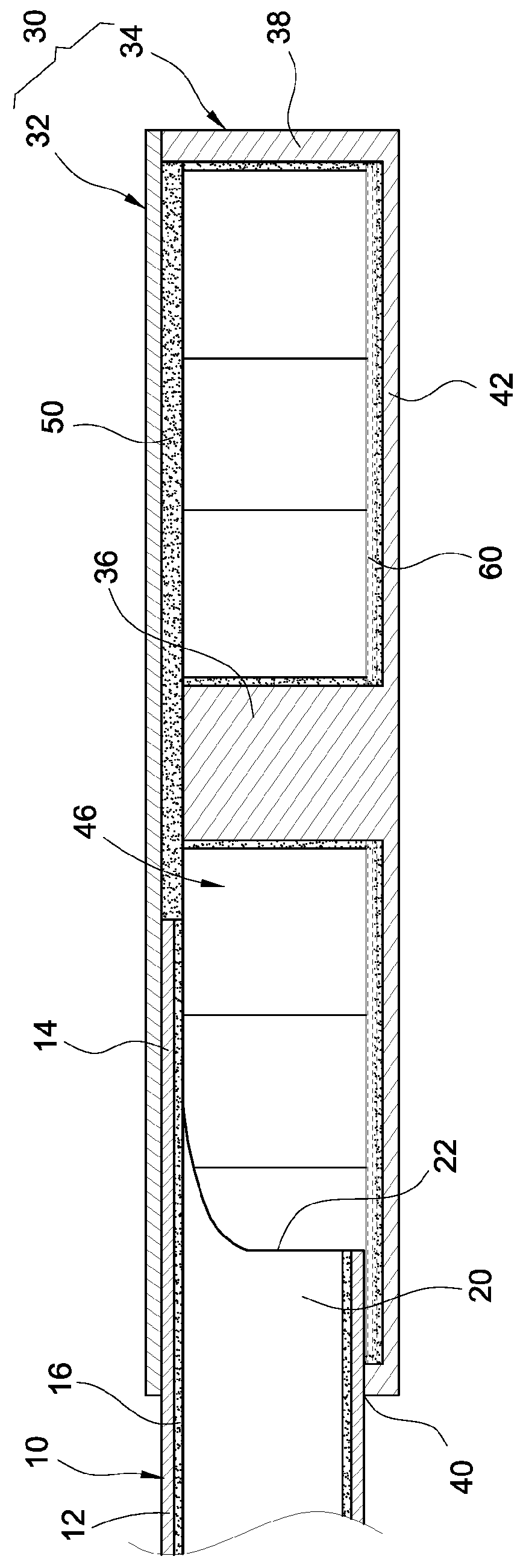

Vapor chamber with separator

InactiveUS20100326629A1Improve cooling effectAvoid interferenceSemiconductor/solid-state device detailsSolid-state devicesWorking fluidSteam room

A vapor chamber with separator includes shell, capillary tissue, separator, supporting structure and working fluid. The shell includes inter-sealed lower and upper shell plates. Partial section of the lower shell plate projects downwardly and forms accommodating room therein. The capillary tissue is arranged by distributing over inner wall of the lower shell plate. The separator overlapped the capillary tissue is arranged penetrating trough corresponding to the accommodating room. Liquid passage is formed between the lower shell plate and the separator. The supporting structure is accommodated in the shell with upper and lower sides respectively inter-abutted against the upper shell plate and the separator. Vapor passage formed between the upper shell plate and the separator is communicated to the liquid passage. The working fluid is filled into the shell. Since the vapor and liquid working fluids are separated by the separator to avoid interference, the cooling performance is thus boosted.

Owner:CELSIA TECH TAIWAN INC

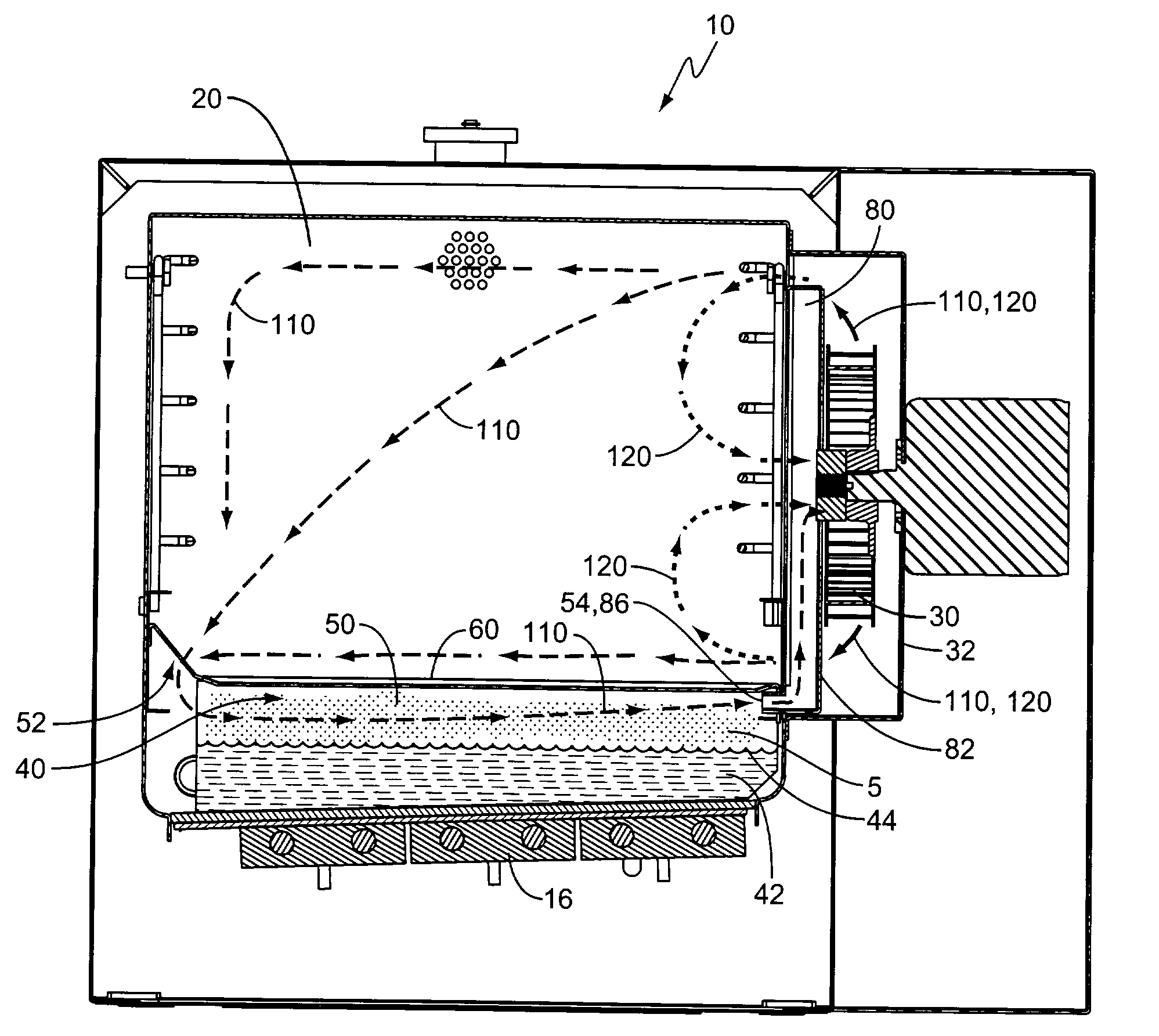

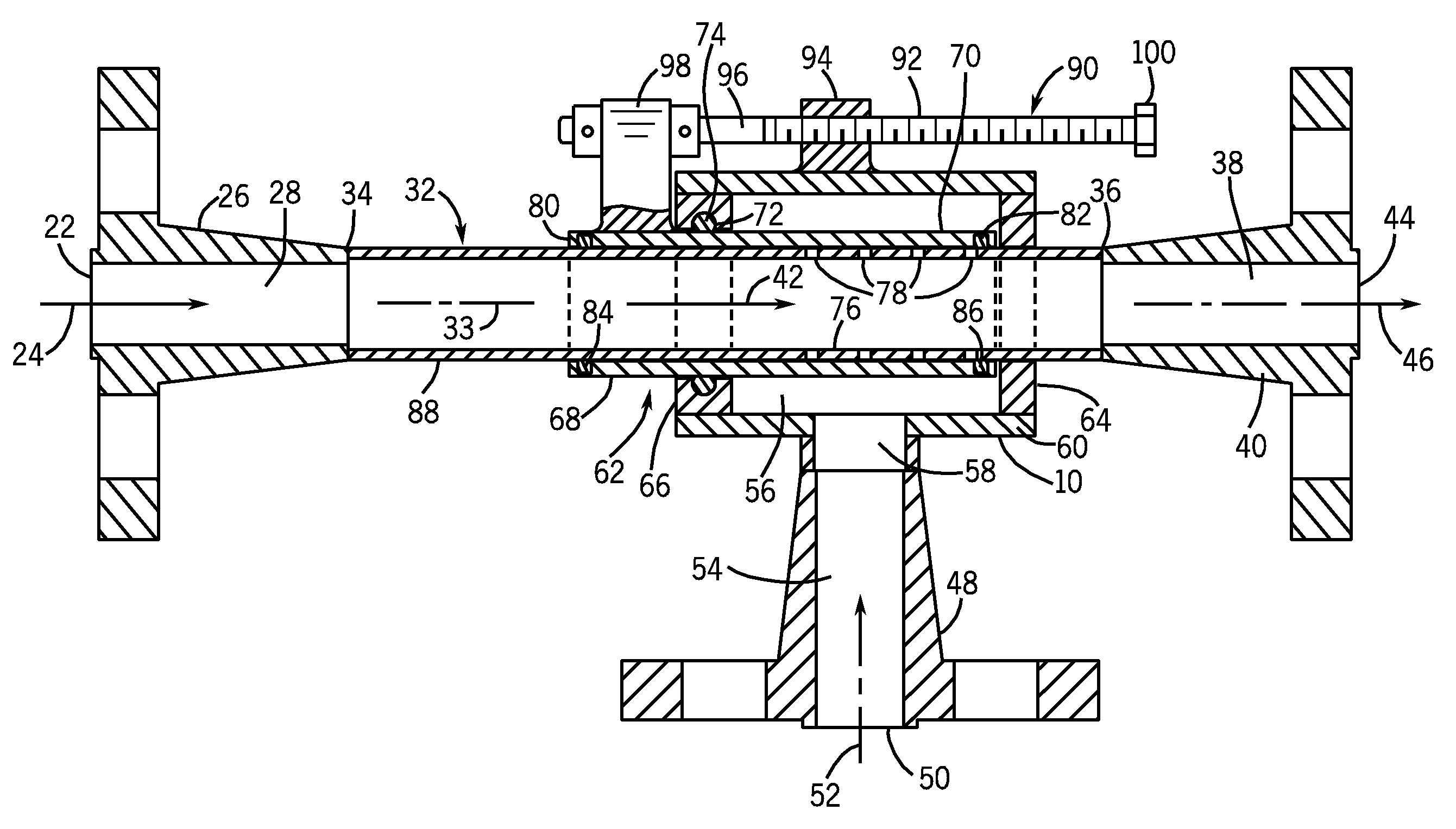

Method and apparatus for directing steam distribution in a steam cooker

ActiveUS20100199860A1No noise during operationImprove uniformityMilk treatmentOven air-treatment devicesEngineeringDistributor

The present invention relates to a method and apparatus for directing steam distribution in a steam cooker. In one exemplary embodiment, steam is directed through a steam cooker by a plenum that is in fluid communication with a steam chamber. As steam is generated within the steam chamber, the steam fills the chamber where it is directed to the plenum. In one exemplary embodiment, the plenum is formed to extend vertically along an interior wall of the steam cooker. In one exemplary embodiment, the plenum is defined between an interior wall of the steam cooker and a steam distributor that has a plurality of openings formed therein. The openings in the steam distributor allow for steam rising within the plenum to exit into the cooking chamber by passing through the openings. A pressure switch may be utilized to turn off the steam generator in the steam cooker.

Owner:ACCUTEMP PRODS

Electrical heating method for a hydrocarbon formation, and improved thermal recovery method using electrical pre-heating method

InactiveUS20140246193A1Improve oil mobilityImprove mobilitySurveyConstructionsThermal energyElectricity

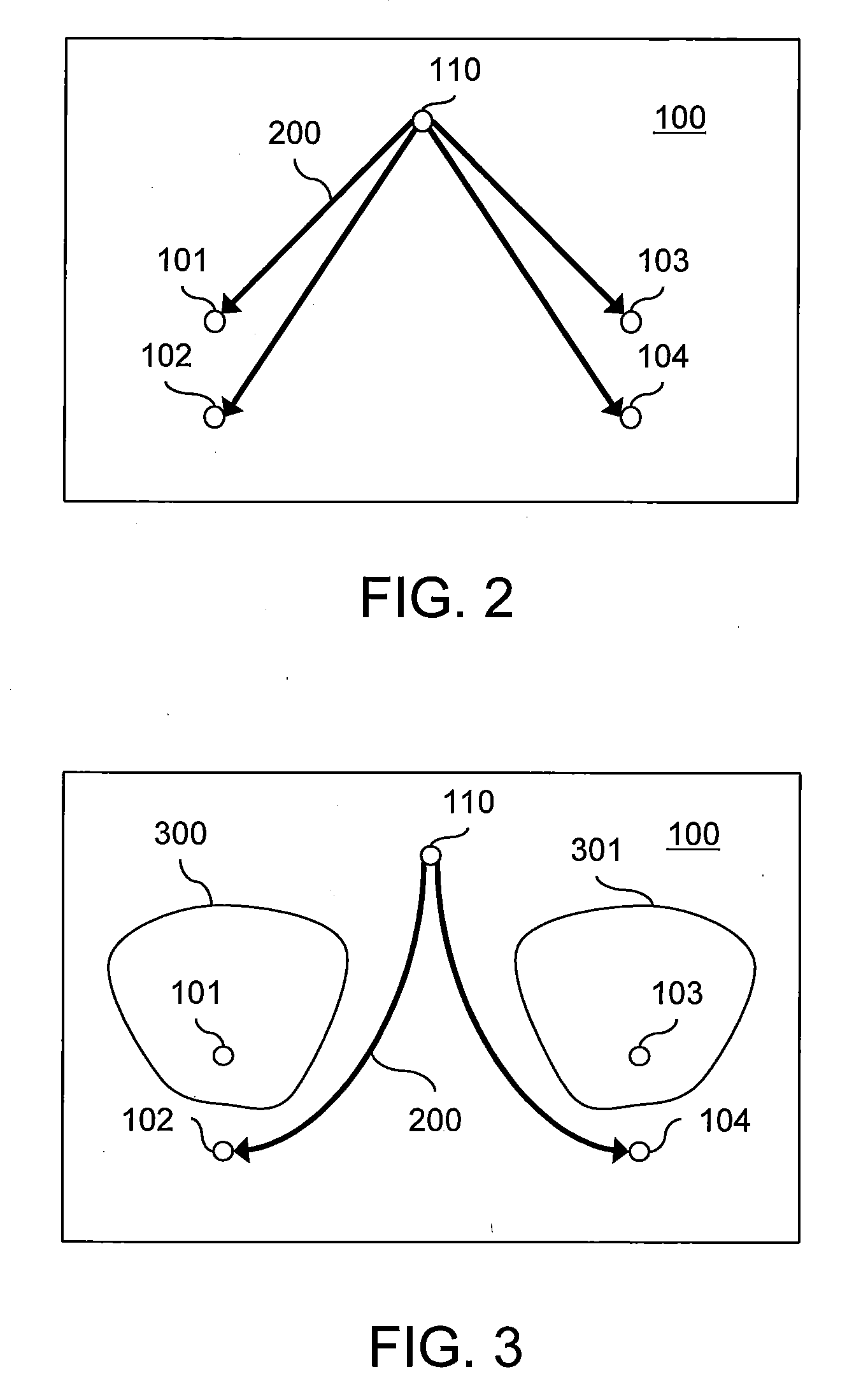

A thermal recovery method employing an electrical pre-heating method to condition the hydrocarbon-bearing formation as a means of improving recovery when steam injection is later applied. In addition, a method of comparing the applied electrical flux and resulting temperature profile to determine the heat transfer properties of each of a plurality of reservoir regions along the length of a horizontal well is disclosed. Advantageously, the heat flux supplied to each of the regions may be varied relative to each other region to compensate for different thermal transfer properties which may exist in the formation within each of the regions. Such controlled variation in thermal energy transfer, compensating for variances in fluid mobility and thermal properties in the reservoir allows for a more even steam chamber development and therefore optimized oil recovery.

Owner:HUSKY OIL OPERATIONS

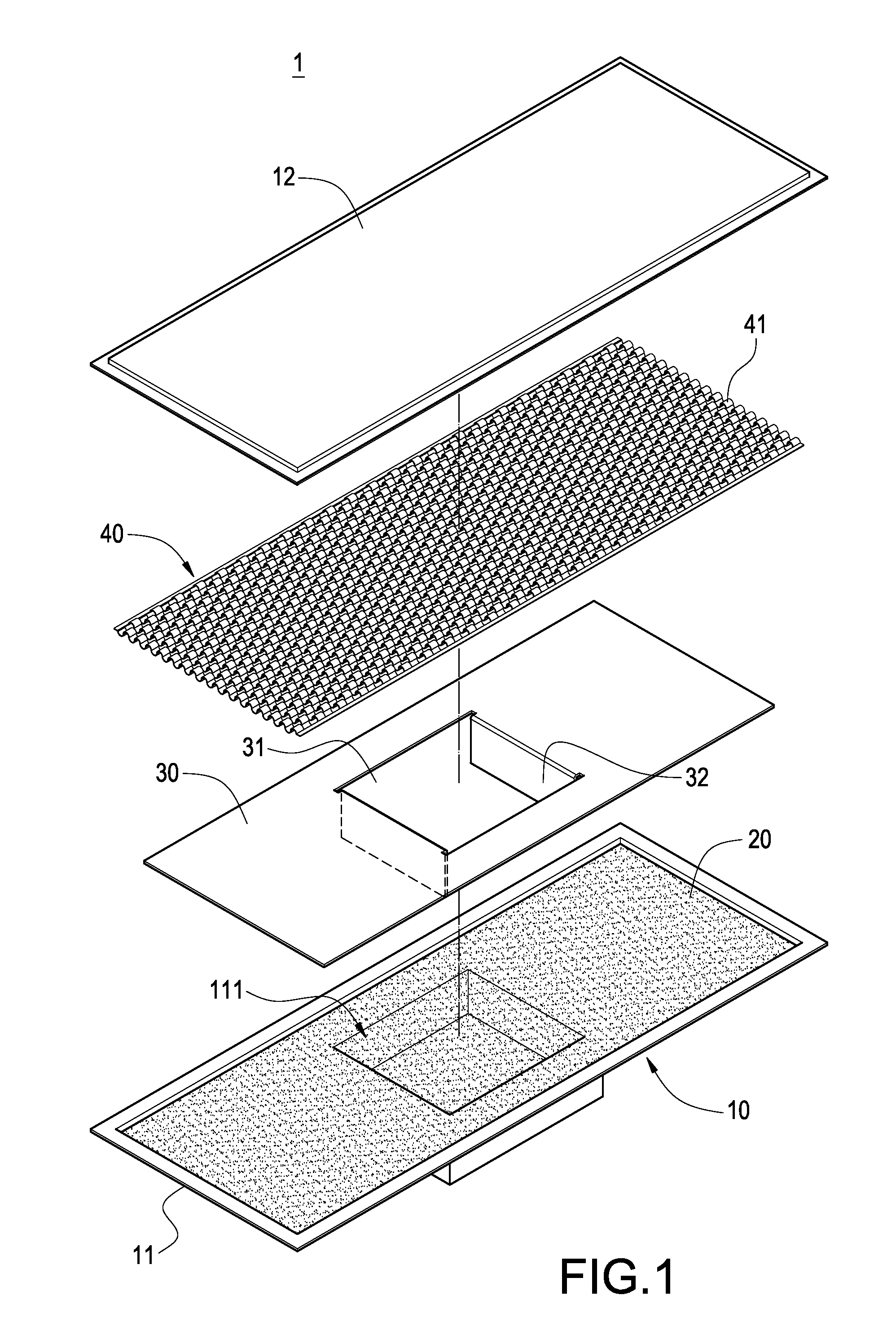

Thermal spreader for simultaneously enhancing capillary effect and structural strength

InactiveUS8047269B2Semiconductor/solid-state device detailsSolid-state devicesWorking fluidEngineering

A thermal spreader comprises: a casing having a first side contacted with a heat source and a second side secured with a heat sink, and having a vapor chamber defined in an interior in the casing; and a crosslinking capillary lattice retained in the casing and occupying the vapor chamber in the casing, whereby upon evacuation to form vacuum in the vapor chamber and filling of a vaporizable working fluid in the vapor chamber, the working fluid will be repeatedly vaporized and condensed through the crosslinking capillary lattice to absorb and remove heat from the first side of the casing and to dissipate heat outwardly from the second side of the casing.

Owner:TAMKANG UNIVERSITY

Vapor chamber having heated protrusion

InactiveUS8857502B2Effective structureLow costIndirect heat exchangersCooling/ventilation/heating modificationsWorking fluidHeat conducting

A vapor chamber is configured to conduct heat generated by a heat-generating element and includes a bottom plate, a first wick structure, a second wick structure, a cover plate and a working fluid filled between the cover plate and the bottom plate. One side of the bottom plate has a heated protrusion in thermal contact with the heat-generating element, and the other side is formed with an accommodating trough corresponding to the heated protrusion. The first wick structure is provided in the accommodating trough. The second wick structure is disposed on the bottom plate and provided with an opening and a plurality of airflow channels in communication with the opening. The cover plate tightly covers the bottom plate. The supporting posts are sandwiched between the cover plate and the first wick structure. By this arrangement, the mounting and heat-conducting of the heat-generating element can be achieved.

Owner:KUNSHAN JUZHONG ELECTRONICS

Radial flow steam injection heater

ActiveUS20100085833A1High trafficImprove efficiencyFlow mixersTransportation and packagingEngineeringSteam room

A radial flow steam injection heater that injects a selected amount of steam into a product flow to heat the product flow. The steam injection heater includes a mixing tube that receives the product flow to be heated. The mixing tube includes a series of steam injection holes that are positioned within a steam chamber defined by the heater body. Pressurized steam within the steam chamber flows into the mixing tube in a direction transverse to the flow axis through the steam injection holes. A regulating member is selectively movable relative to the mixing tube to expose the steam injection holes to the steam chamber to control the amount of steam utilized to heat the product flow.

Owner:HYDRO THERMAL

Kind of low-temperature steam electric iron

A kind of low-temperature steam electric iron, which is consisted of ironing plate, temperature-adjusting plate and temperature adjustable circuit, steam room and its temperature auto-adjusting circuit, wherein there is a heat insulation layer between the temperature-adjusting plate and the steam room, and a steam passage is formed between the temperature adjusting plate and the ironing plate. The temperature auto-adjusting circuit in the steam room can immediately sense the temperature variation in the steam room and adjust that, making sure that the water in the steam room can be fully evaporated, so the low-temperature fabric material can be ironed.

Owner:ELEC TECH INT CO LTD

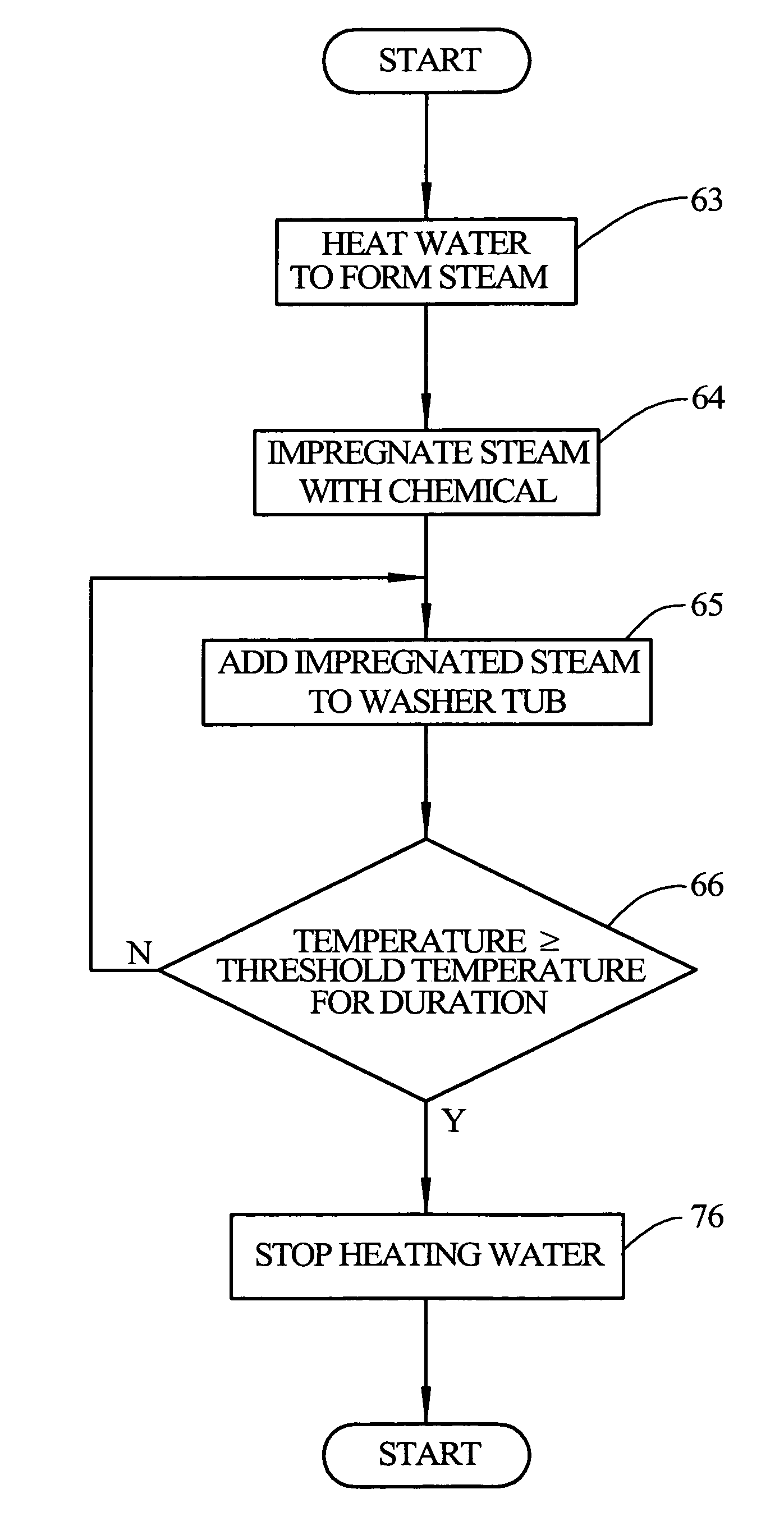

Washer with bio prevention cycle

InactiveUS20080092602A1Killing microorganismAircraft power plantsTextile treatment machine partsCompound (substance)Engineering

An appliance having an enclosure arranged to receive articles to be treated also includes a water container and a steam chamber with a steam outlet. A water dispenser is arranged to dispense water from the water container to the steam chamber. A heating element is thermally associated with the steam chamber. A control is arranged to selectively operate the heating element. A steam path extends between the steam outlet and the enclosure. A chemical dispenser is positioned along the steam path. The heating element heats water in the steam chamber to create steam, and the chemical dispenser adds a chemical to the steam as the steam passes through the steam path.

Owner:WHIRLPOOL CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com