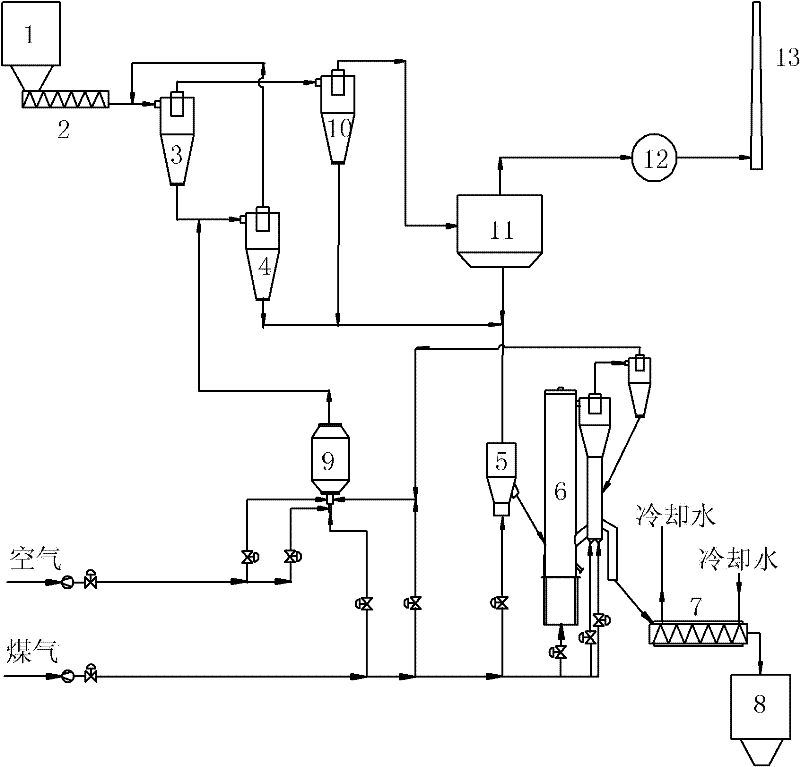

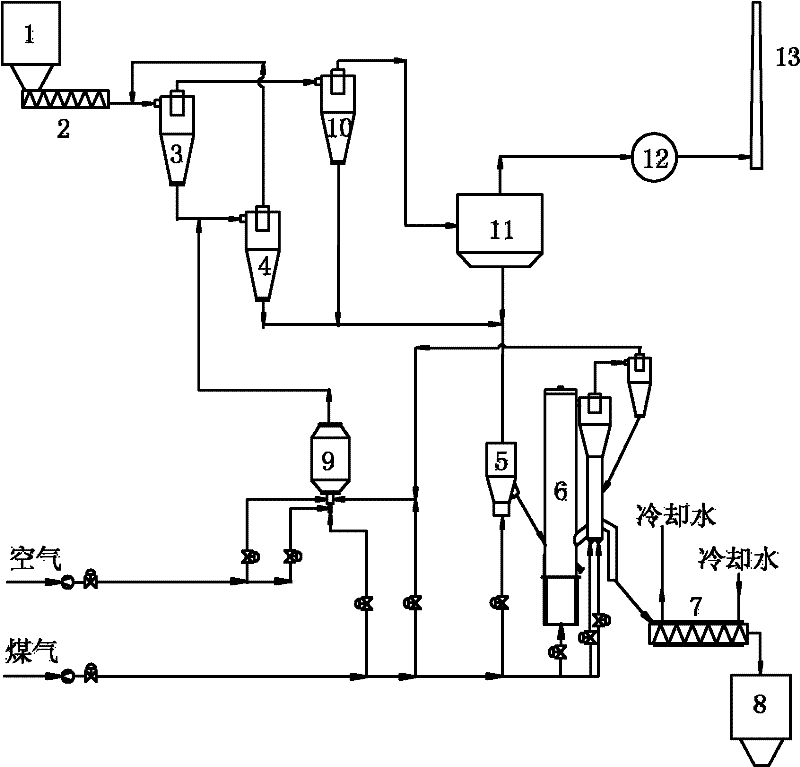

Fluidized low-temperature reduction device and reduction method for powdery manganese oxide ores

A technology of manganese oxide and fluidization, which is applied in the fields of metallurgy and chemical industry, can solve the problems of unfavorable improvement of reduction rate, large internal mass transfer resistance, and low reaction efficiency, so as to avoid manganese-containing phases that are insoluble in sulfuric acid, Small internal mass transfer resistance and high reaction efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0046] Embodiment 1: select Africa Gabon manganese oxide ore, raw ore manganese grade 42%, manganese oxide ore is ground until all pass 60 mesh sieves, wherein, 60~100 mesh80%, 200~200 mesh <10% between 400 meshes; producer gas is used as reducing agent and fuel. The preheating time of manganese oxide ore is controlled at 30-40 seconds, the preheating temperature is controlled at 300-400°C, the dehydration rate after preheating is about 90%, the thermal decomposition rate of manganese oxide is about 5%, and the reduction temperature is controlled at 500-400°C. 550°C, the average reaction residence time is about 15 minutes, after cooling, the temperature of manganese monoxide ore is lower than 80°C. The reduction rate of manganese oxide ore reaches 98%.

Embodiment 2

[0047] Embodiment 2: select Australian manganese oxide ore, raw ore manganese grade 40%, manganese oxide ore is ground until all pass through 100 mesh sieves, wherein, 100~200 order>90%, 200~300 order<10%; Take coke oven gas as Reductant and fuel. The preheating time of manganese oxide ore is controlled at 30-40 seconds, the preheating temperature is controlled at 400-500°C, the dehydration rate after preheating is about 100%, the thermal decomposition rate of manganese oxide is about 10%, and the reduction temperature is controlled at 550-500°C. 600°C, the average residence time of the reaction is about 10 minutes, after cooling, the temperature of manganese monoxide ore is lower than 60°C. The reduction rate of manganese oxide ore is close to 100%.

Embodiment 3

[0048] Embodiment 3: Select Hunan manganese oxide ore, the original ore manganese grade is 21%, grind the manganese oxide ore until all pass through 80 mesh sieve, wherein, 80-100 mesh 70%, 200-400 mesh< 20%; use blast furnace gas as reducing agent and fuel. The preheating time of manganese oxide ore is controlled at 20-30 seconds, the preheating temperature is controlled at 400-500°C, the dehydration rate after preheating is about 94%, the thermal decomposition rate of manganese oxide is about 8%, and the reduction temperature is controlled at 550-500°C. 600°C, the average residence time of the reaction is about 20 minutes, after cooling, the temperature of manganese monoxide ore is lower than 60°C. The reduction rate of manganese oxide ore is close to 100%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com