Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

309results about How to "Low reduction temperature" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

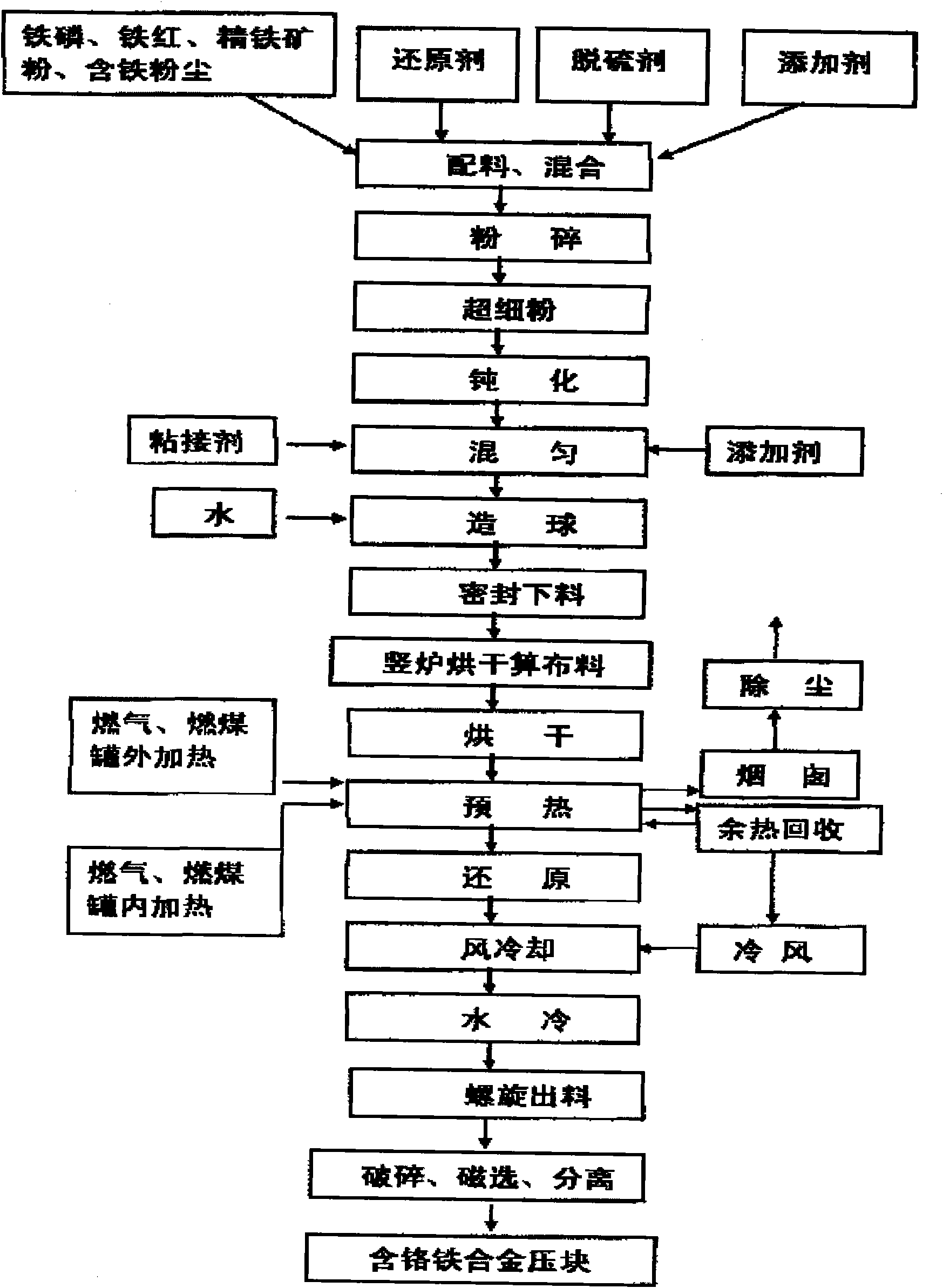

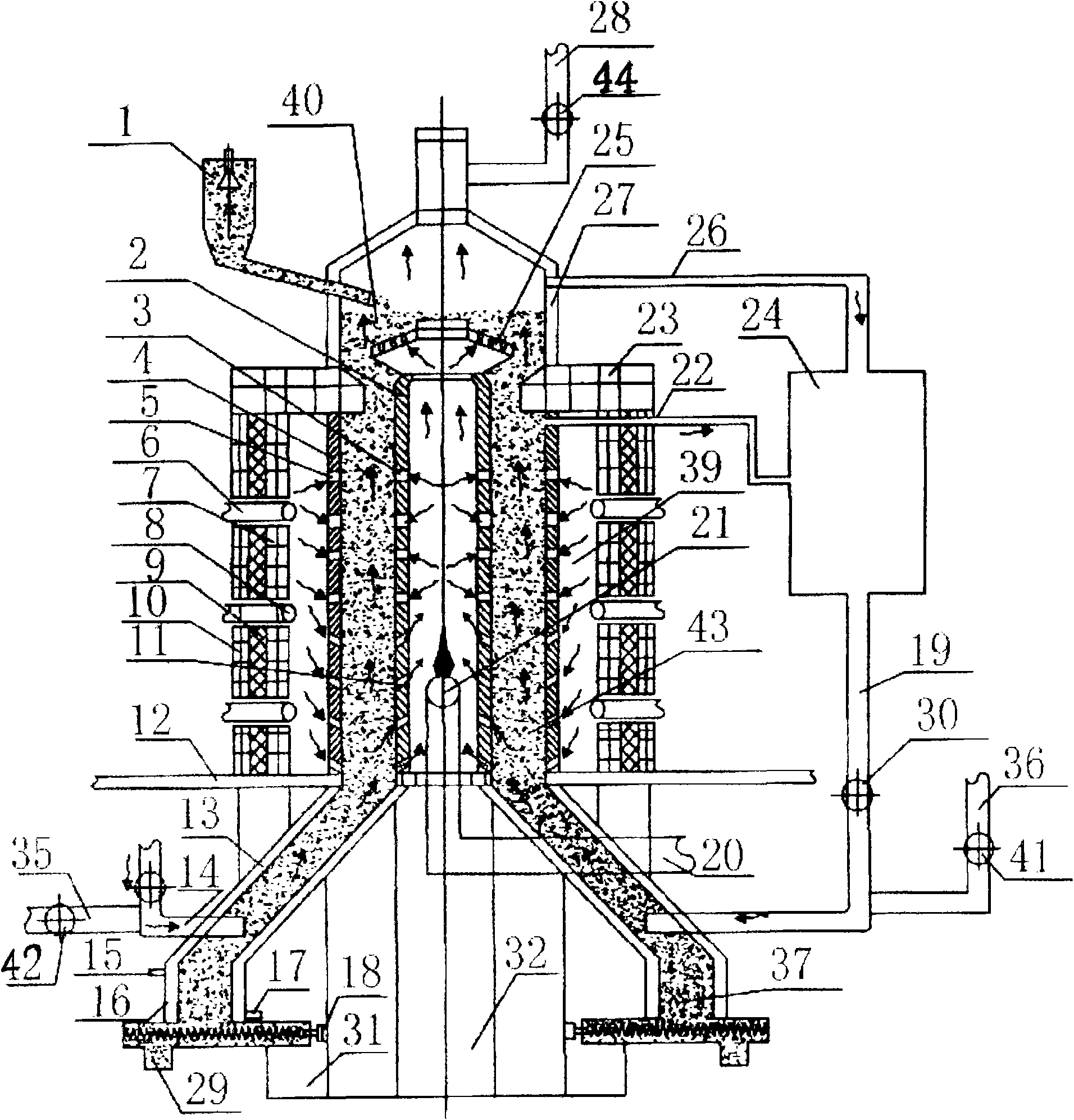

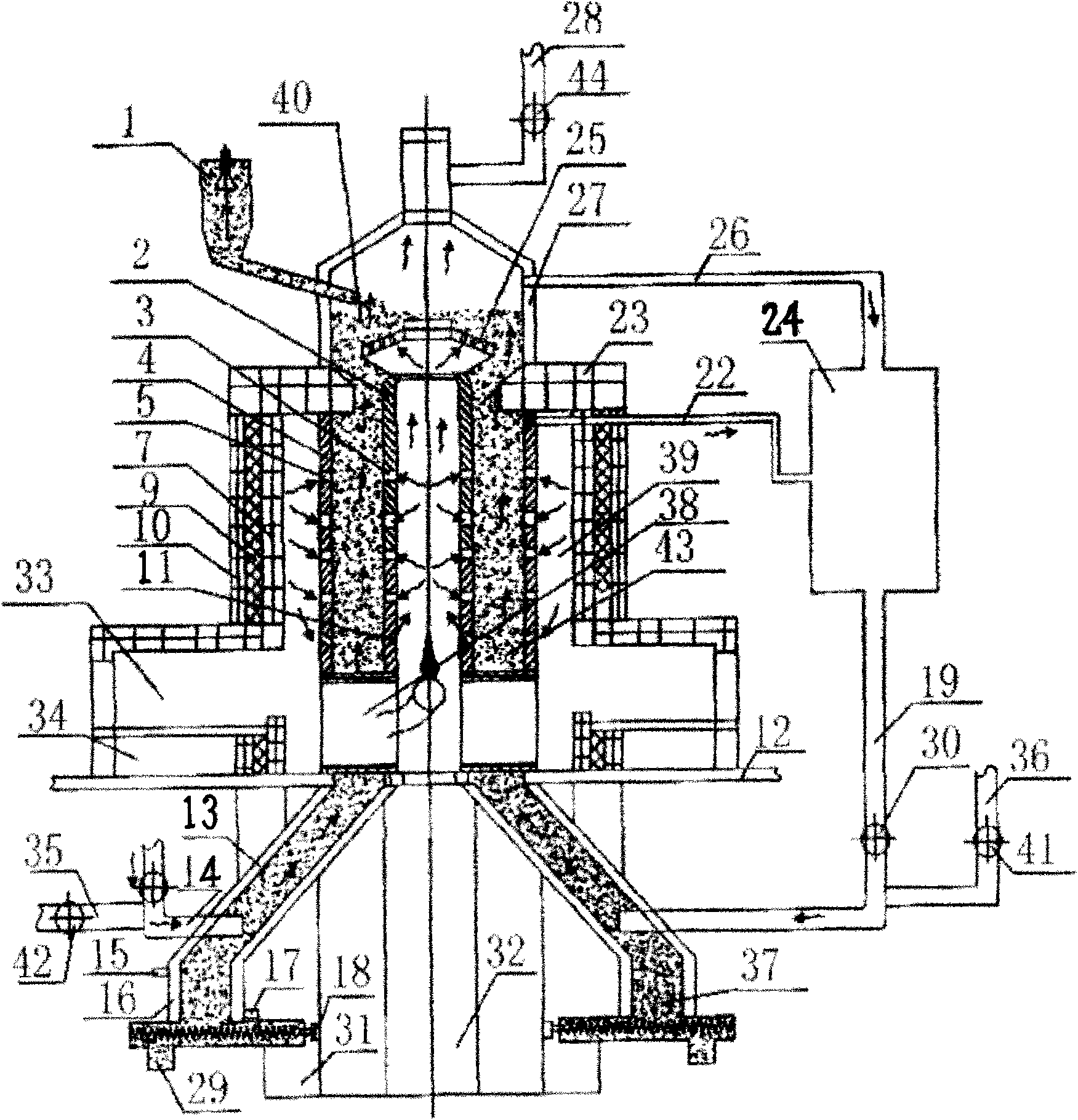

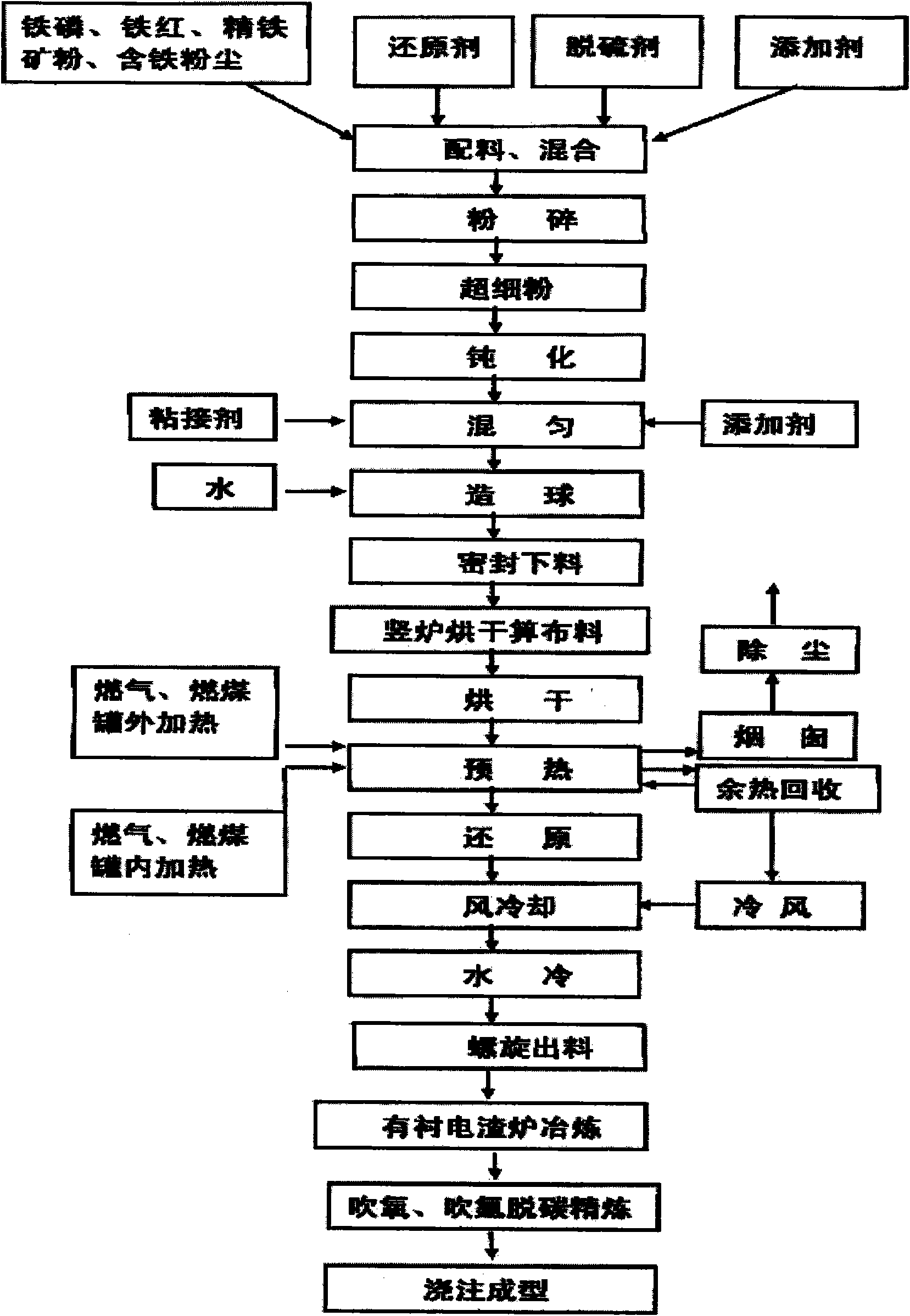

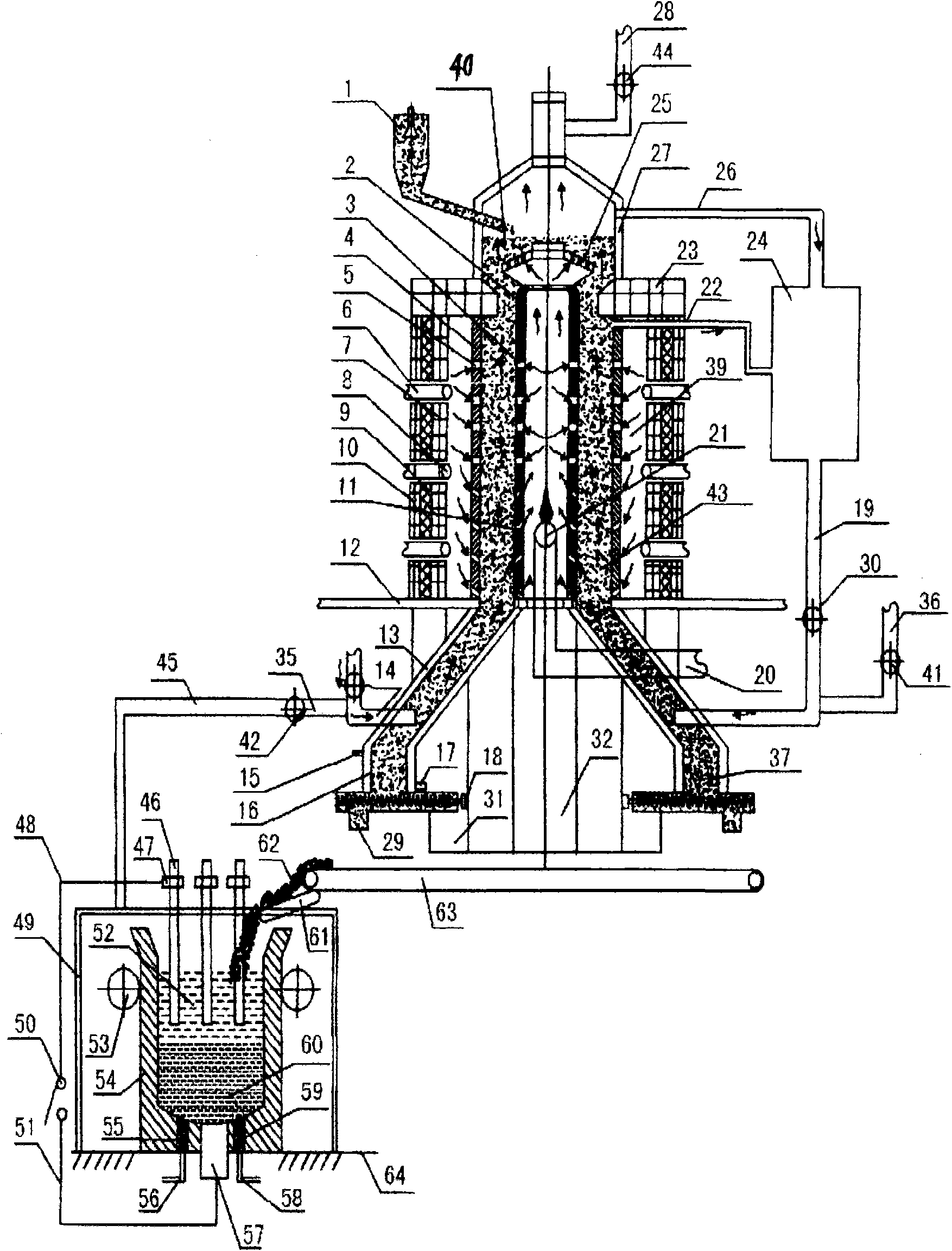

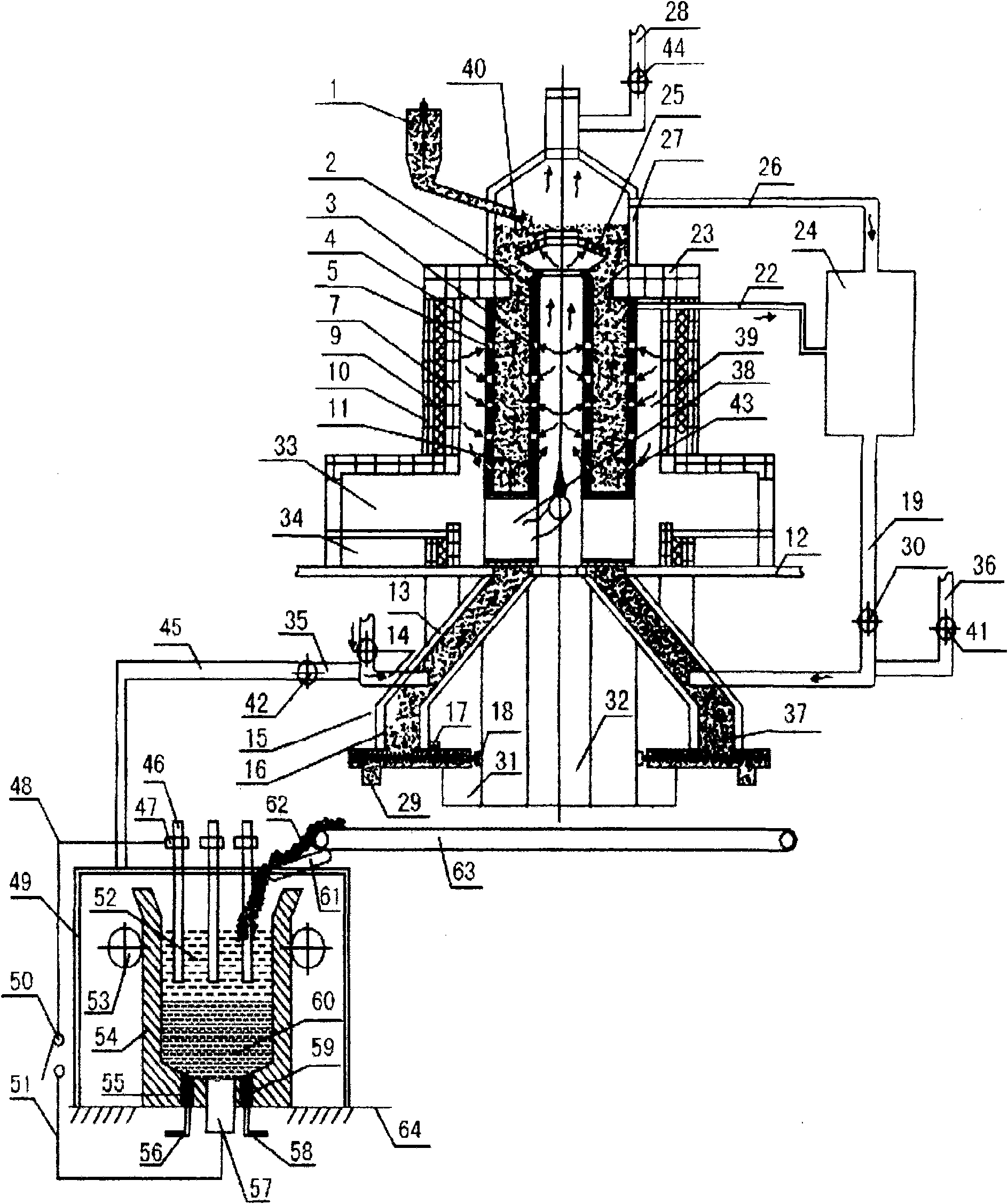

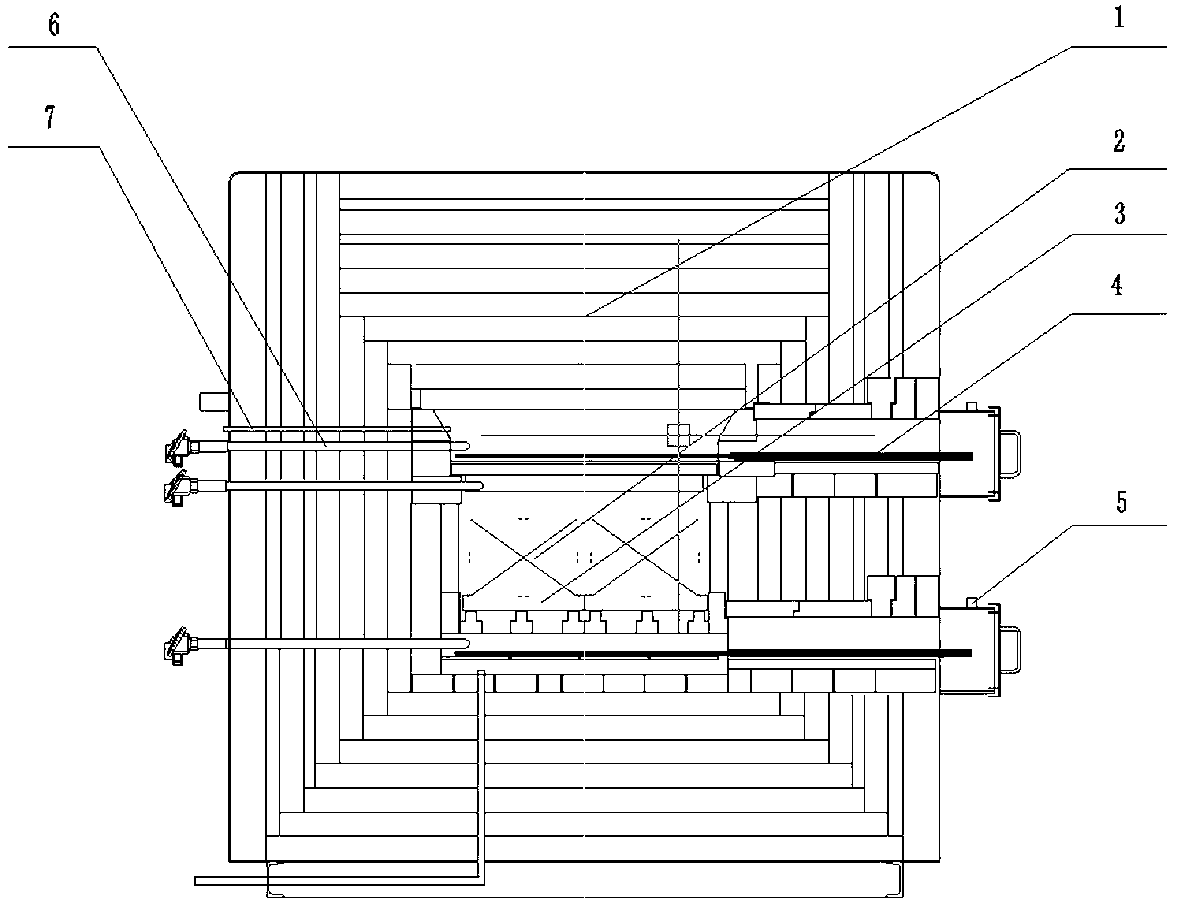

Preparation process and device of sponge iron

InactiveCN101538632AGuaranteed uniformityReduce wasteProcess efficiency improvementShaft furnaceResource consumptionUltra fine

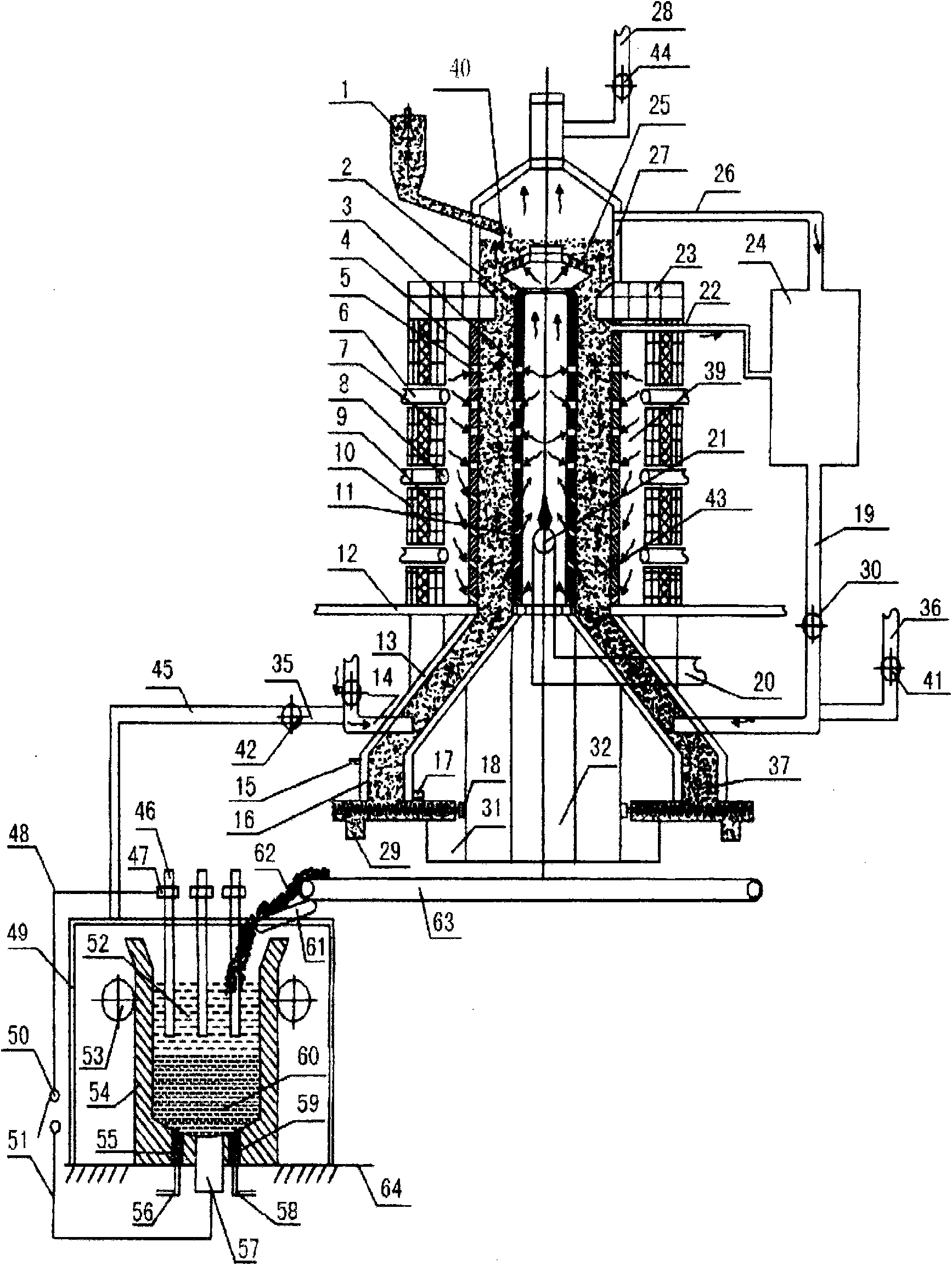

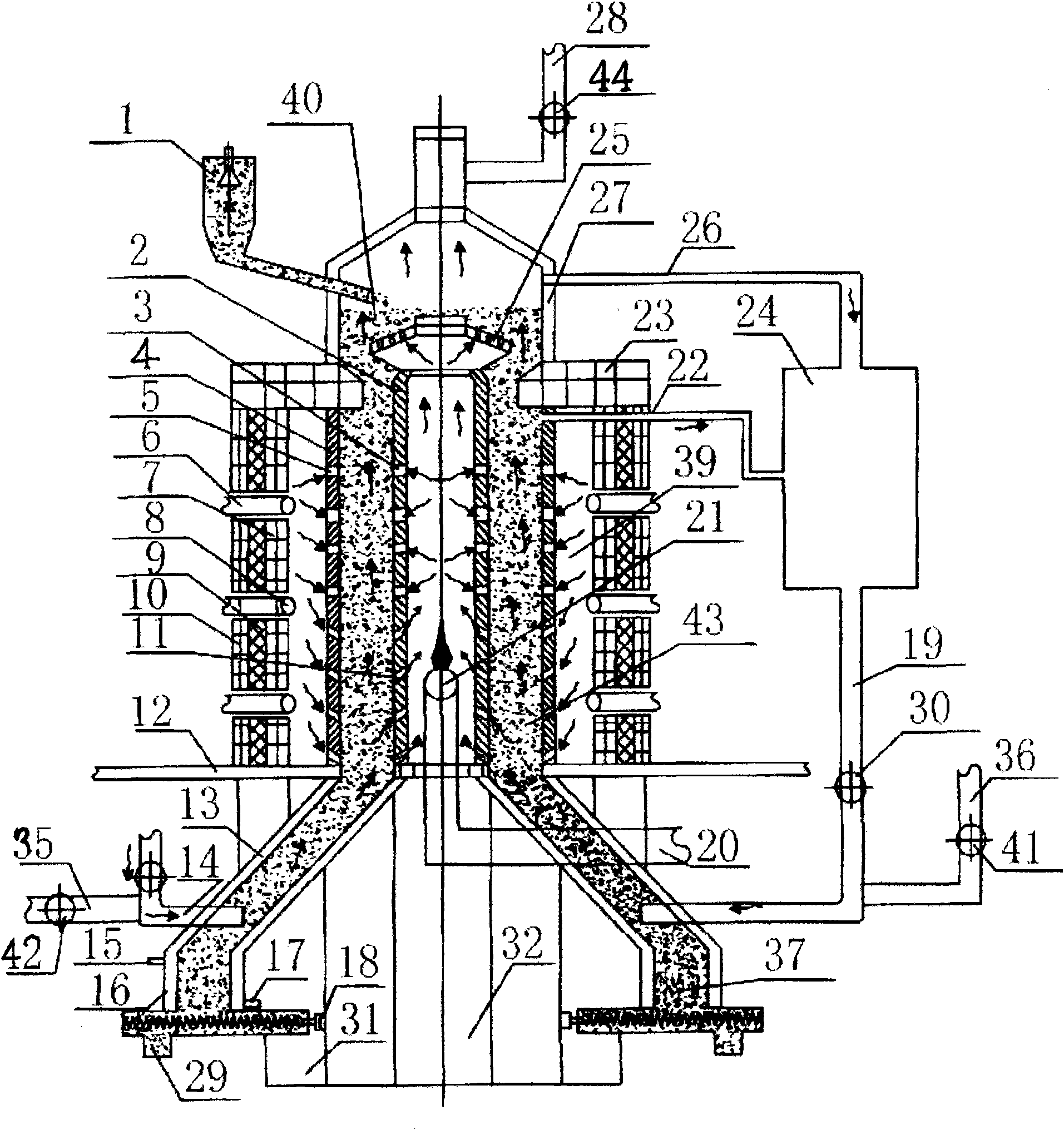

The invention relates to a preparation process and a device of sponge iron, belonging to metallurgical industry steel-making raw material. The process comprises the following steps: mixing iron-containing raw materials with reducing agent, solvent and catalyst to prepare ultra fine powder, passivating and mixing to make pelletizing materials, sending the prepared pelletizing materials into a reducing furnace, drying and roasting, and obtaining sponge iron after the reduction reaction. The reducing device is connected with an upper furnace above a furnace base, a lower furnace body is connected to the downside of the furnace base, the upper end of the upper furnace body is connected with an upper furnace mantle, a drying bed grate is positioned at the upper end in the upper furnace body, a purifying device is connected with the upper furnace body and the lower furnace body through pipelines, and a residual heat circulating device is connected with the lower furnace body. The invention has the advantages that: firstly, the reduction temperature is reduced, the reduction speed is increased, the energy consumption is reduced, the production cost is lowered, the production efficiency is improved, and the uniformity of the quality is ensured; secondly, the degree of mechanization is high, the procedure is simple, the yield is large, the mass production can be performed; thirdly, the waste of raw materials is lowered, the environment pollution is reduced; and fourthly, the waste resource can be recycled so as to save the resource consumption.

Owner:丁家伟 +1

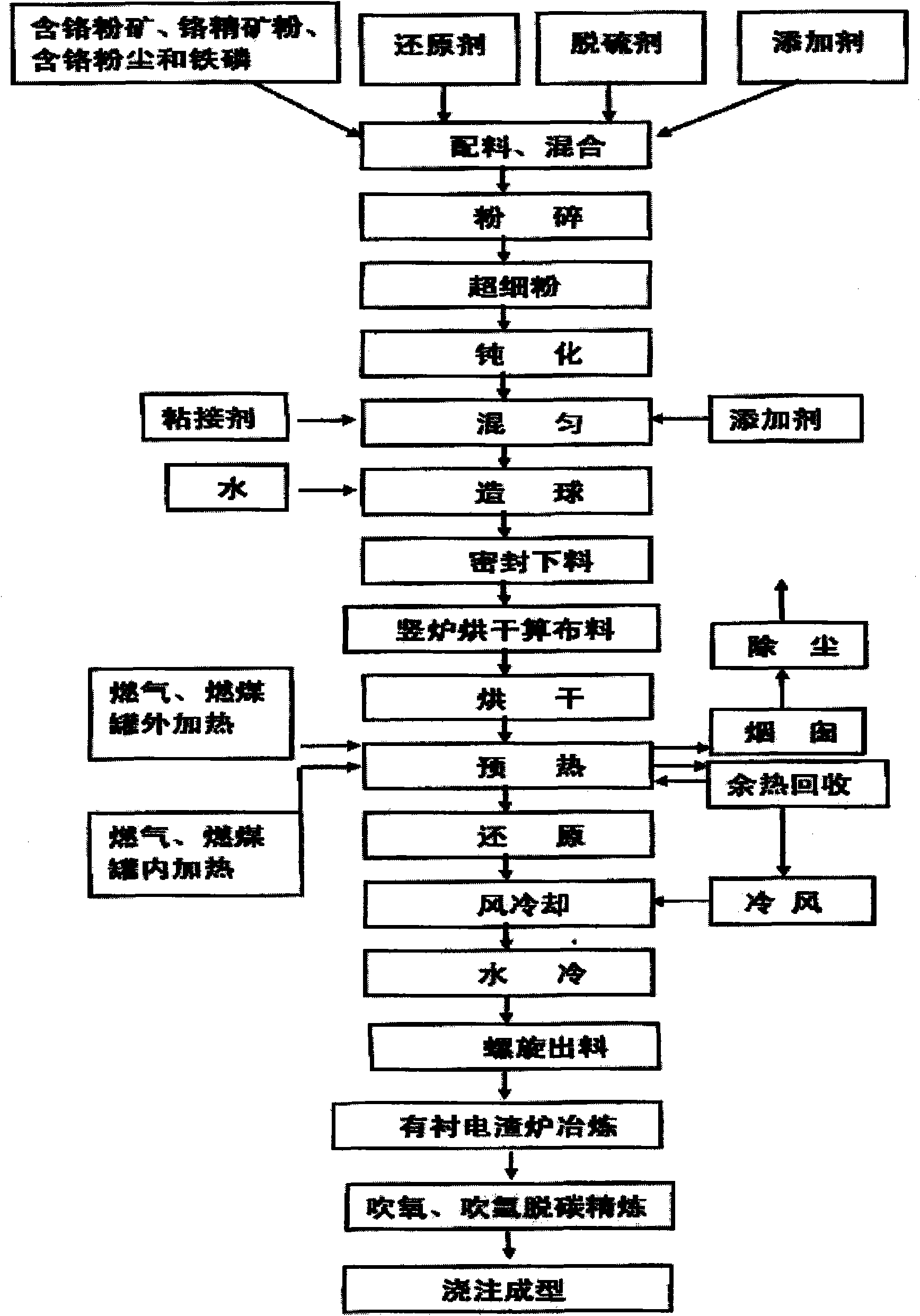

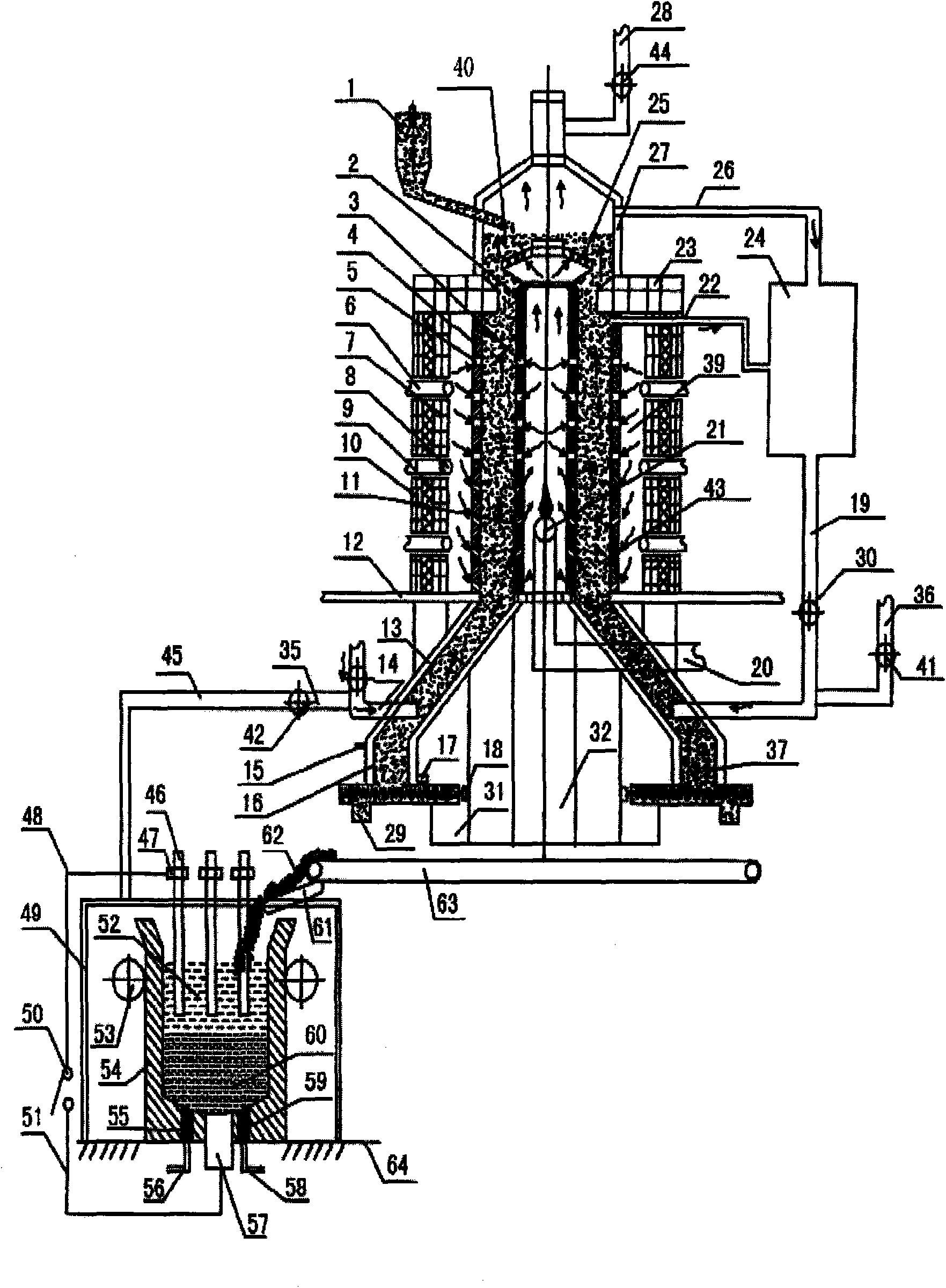

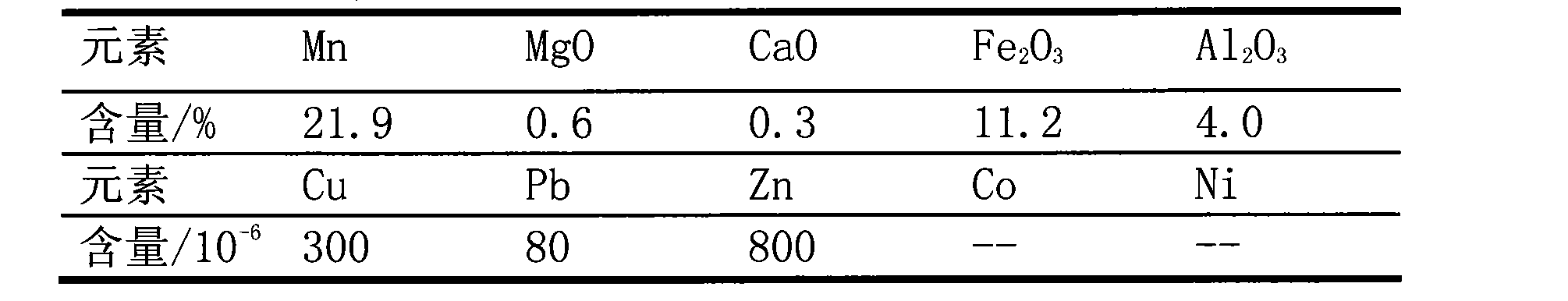

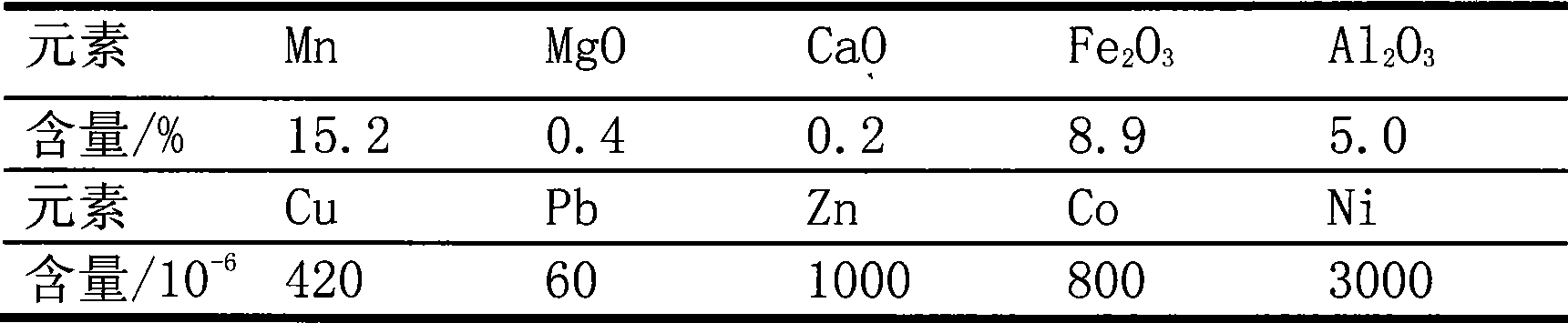

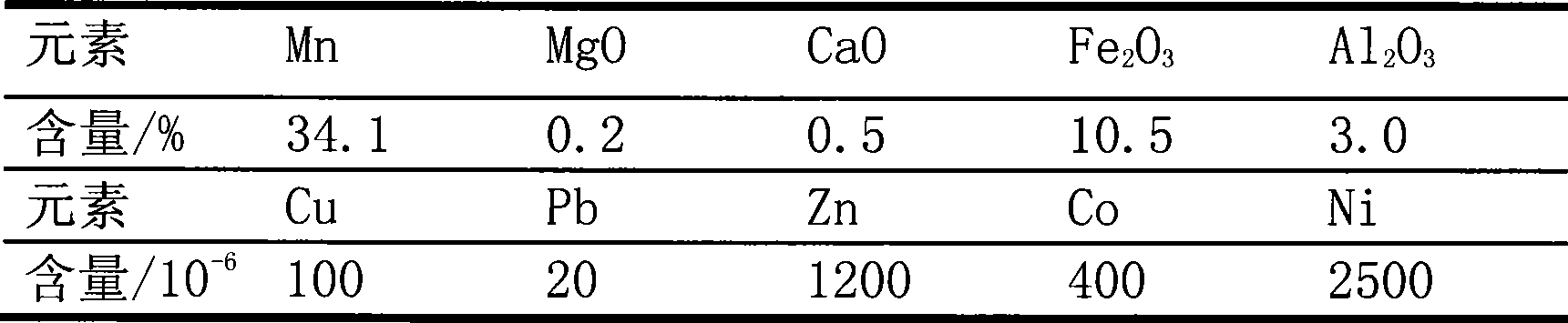

Process and device for smelting chromium irons and chromium-containing molten iron by using chromium ore powder

InactiveCN101538629AImprove applicabilityHigh recovery rateProcess efficiency improvementShaft furnaceUltra fineSolvent

The invention relates to a process and a device for smelting chromium irons and chromium-containing molten iron by using chromium ore powder, which belongs to metallurgical industry steel-making raw material. The process comprises the following steps: mixing chromium iron containing raw materials with reducing agent, solvent and catalyst to prepare ultra fine powder, mixing to make pelletizing materials, sending the pelletizing materials into a reducing furnace, obtaining chromium irons pellets after the reduction reaction, and directly adding reduced pellets into a lining electroslag furnace for being smelted into the chromium-iron alloy or the chromium-containing molten iron. The device comprises an internal-external heating vertical reducing furnace, a lining electroslag furnace and a residual heat recovery system. The invention has the advantages that: firstly, the reduction temperature is low, the speed is high, the energy consumption is reduced, the production cost is lowered, the production efficiency is high, and the uniformity of the quality is good; secondly, the degree of mechanization is high, the procedure is simple, the yield is large, the mass production can be performed; thirdly, the waste of raw materials is reduced, the environment pollution is lowered; fourthly, the source of raw materials adopting the chromium ore powder and chromium-containing waste, the cost is low; fifthly, the waste resource can be recycled so as to save the resource consumption; and sixthly, the high-temperature pellets are directly smelted by adopting the lining electroslag furnace, the heat efficiency is high, the energy consumption is low, the material purity is high and the quality is good, and the device is simple with less investment.

Owner:丁家伟

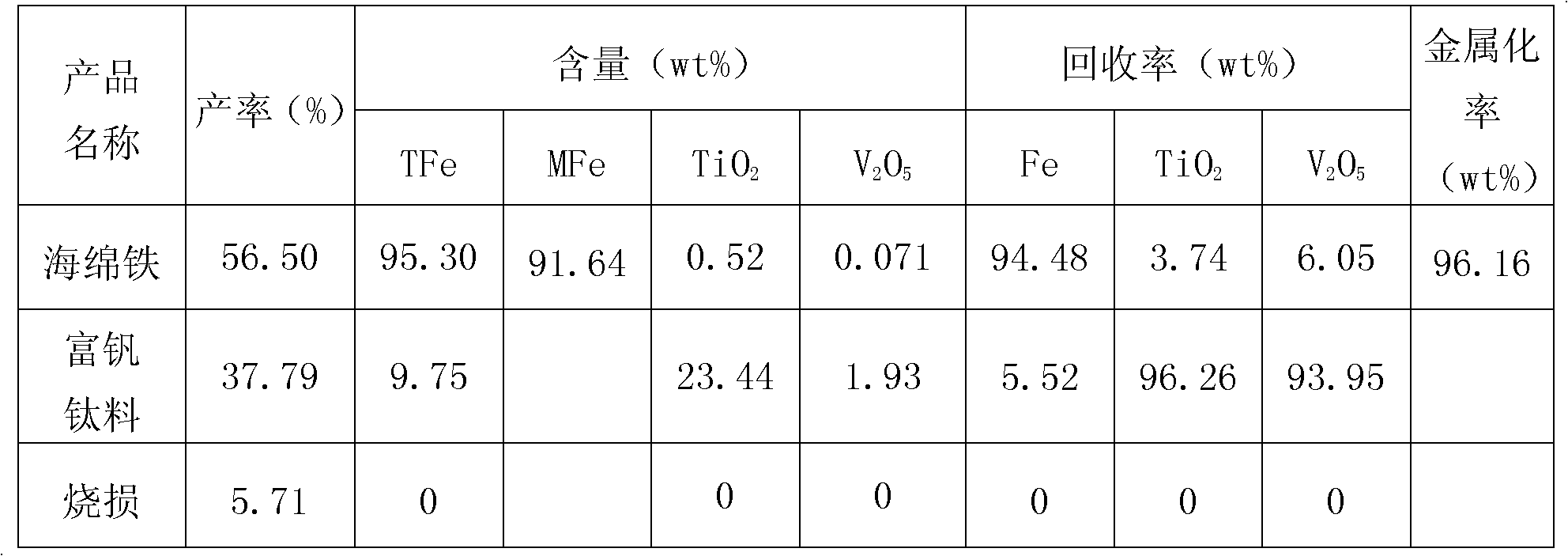

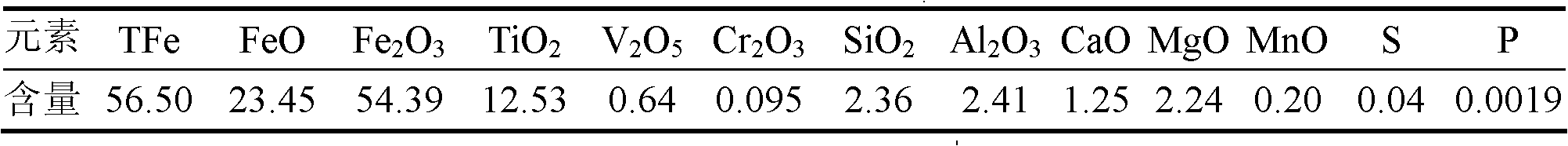

Method for separating iron and vanadium and titanium from vanadium titano-magnetite

InactiveCN102433436ALow reduction temperatureReduce consumptionProcess efficiency improvementGrain treatmentsTunnel kilnIron powder

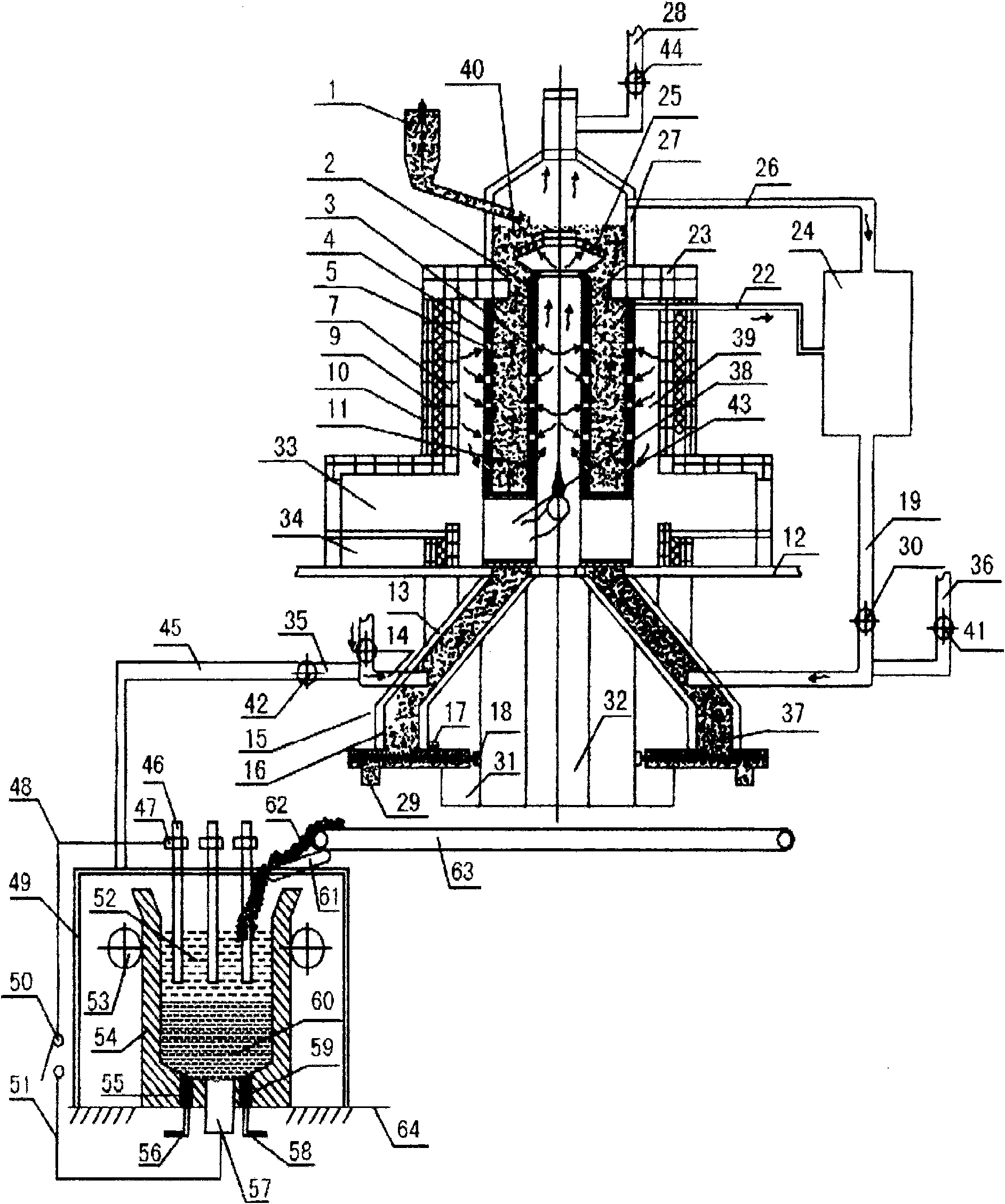

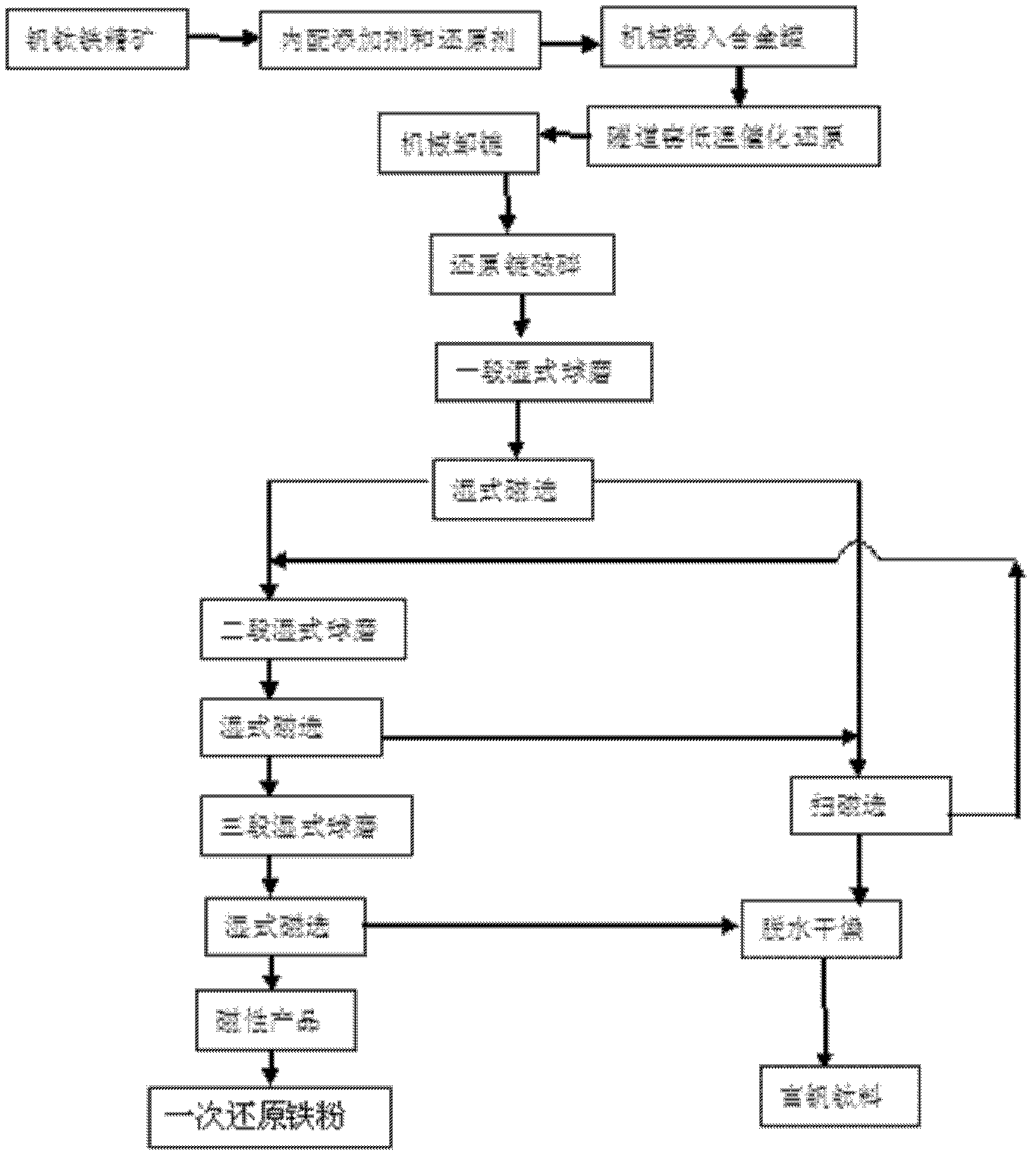

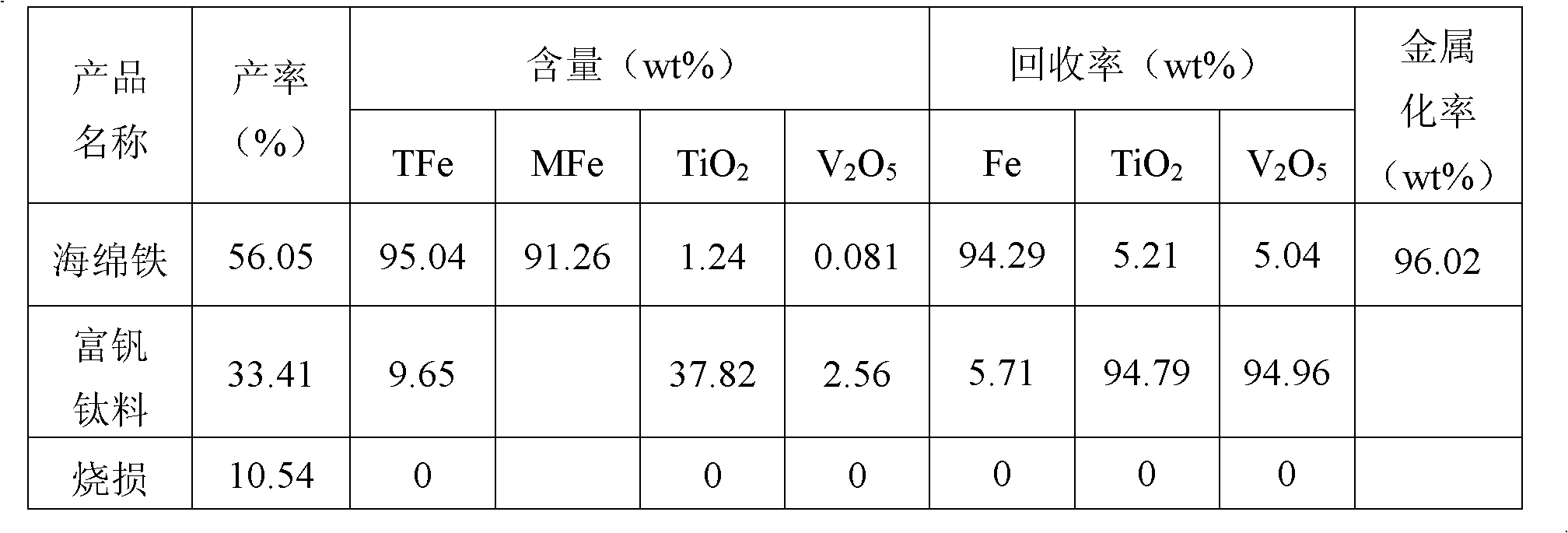

The invention relates to a method for separating iron and vanadium and titanium from vanadium titano-magnetite, which belongs to the technical field of metallurgy. The technical problem to be solved of the invention is to provide a method for separating iron and vanadium and titanium from vanadium titano-magnetite, which has high iron recovering rate. The method for separating iron and vanadium and titanium from vanadium titano-magnetite comprises the following steps of: a, burdening: uniformly mixing 100 parts by weight of vanadium titano-magnetite, 15-20 parts by weight of additive and 15-25 parts by weight of reducing agent, wherein the additive is at least one of sodium chloride, sodium sulfate and sodium carbonate; b, charging and reducing: charging the mixture which is uniformly mixed in the step a, heating to 920-980 DEG C in a tunnel kiln, and preserving heat for 5-60 hours to obtain reduced ingots; and c, separating: crashing the reduced ingots, and separating magnetically toobtain reduced iron powder and a vanadium and titanium-rich material.

Owner:攀枝花鑫润矿业有限公司 +1

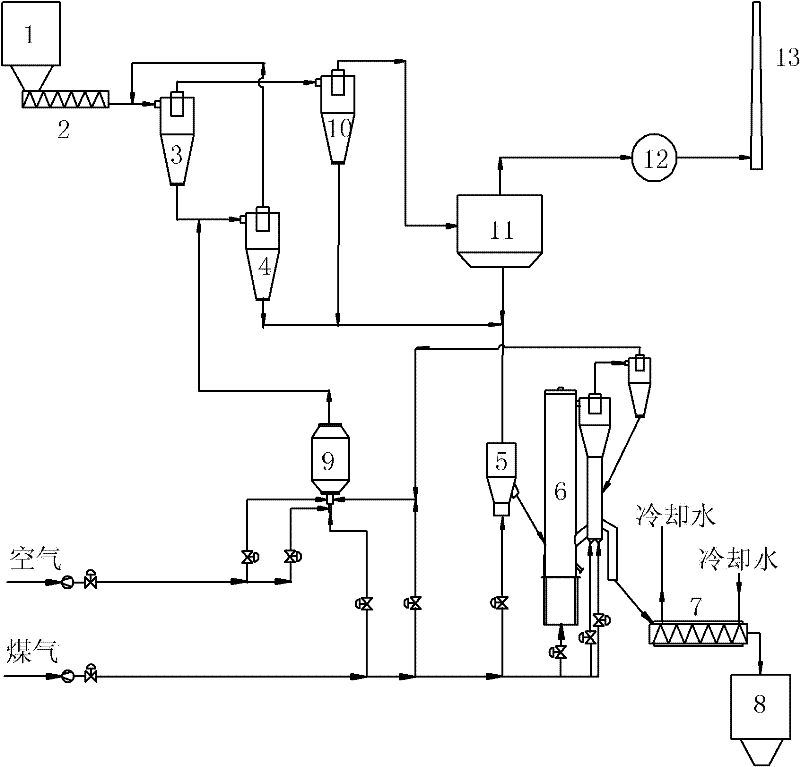

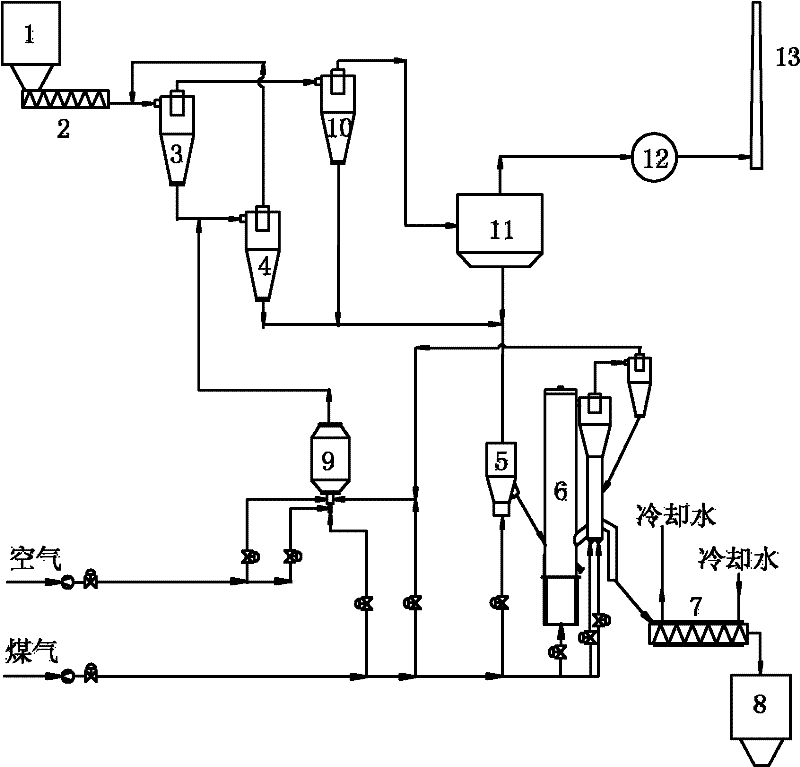

Fluidized low-temperature reduction device and reduction method for powdery manganese oxide ores

The invention relates to a fluidized low-temperature reduction device and a fluidized low-temperature reduction method for powdery manganese oxide ores. The device comprises a feeding unit, a preheating unit, a reduction roasting unit and a cooling unit which are connected from top down, wherein the reduction roasting unit is connected with a combustion chamber; and the combustion chamber is connected below the preheating unit. In the reduction method, tail gas formed in the reduction process enters the combustion chamber combusts with supplementary gas and air to form flue gas; and the flue gas is subjected to countercurrent heat exchange with the manganese oxide ores. The fluidized low-temperature reduction device and the reduction method have the advantages that: the gas can be used as a reducer and also can be used as fuel; and the utilization rate of the gas is 100 percent. In the reduction device, the reduction temperature of the manganese oxide ores is low, so a manganese-containing phase which is insoluble to sulfuric acid is avoided, and heat carried by the manganese oxide ores is reduced by over 30 percent. The manganese oxide ores in a fluidized reduction roasting furnace are in the bubbling fluidized state, the heat transfer efficiency, the mass transfer efficiency and the reaction efficiency are high, the distribution of retention time is uniform, and the reduction rate of the manganese oxide is more than 98 percent.

Owner:深圳中科九台资源科技有限公司

Smelting process and device of pure iron

InactiveCN101538634AImprove applicabilityHigh recovery rateShaft furnaceProcess efficiency improvementUltra fineSolvent

The invention relates to a smelting process and a device of pure iron, belonging to metallurgical industry steel-making raw material. The process comprises the following steps: mixing iron-containing raw materials with reducing agent, solvent and catalyst to prepare ultra fine powder, mixing to make pelletizing materials, sending the prepared pelletizing materials into a reducing furnace, obtaining metallic pellets after the reduction reaction, and directly adding the reduced pellets into a lining electroslag furnace for being smelted into pure iron. The device comprises an internal-external heating vertical reducing furnace, a lining electroslag furnace and a residual heat recovery system. The invention has the advantages that: firstly, the reduction temperature is low, the speed is high, the energy consumption is reduced, the production cost is lowered, the production efficiency is high, and the uniformity of the quality is good; secondly, the degree of mechanization is high, the procedure is simple, the yield is large, the mass production can be performed; thirdly, the waste of raw materials is reduced, the environment pollution is lowered; fourthly, the source of raw materials adopting iron ore concentrate powder and iron-containing metallurgical waste, the cost is low; fifthly, the waste resource can be recycled so as to save the resource consumption; and sixthly, the high-temperature pellets are directly smelted by adopting the lining electroslag furnace, the heat efficiency is high, the energy consumption is low, the material purity is high and the quality is good, and the device is simple with less investment.

Owner:丁家伟 +1

Cuprous modified metal organic skeleton adsorbent, preparation method and application

InactiveCN103752276AEfficient removalImprove recovery rateOther chemical processesHydrocarbon oils refiningSorbentGasoline

The invention discloses cuprous modified metal organic skeleton absorbent, a preparation method and application, belonging to the technical field of fuel oil processing. The absorbent can effectively adsorb sulfide in gasoline. The cuprous modified metal organic skeleton absorbent adopts a metal organic skeleton as a carrier, a cupric precursor is reduced by adopting a reducing agent through a vapor induction reduction method to prepare the metal organic skeleton adsorbent which is loaded with monovalent copper, and the cuprous content is 0.1 to 1mmol / g.

Owner:NANJING UNIV OF TECH

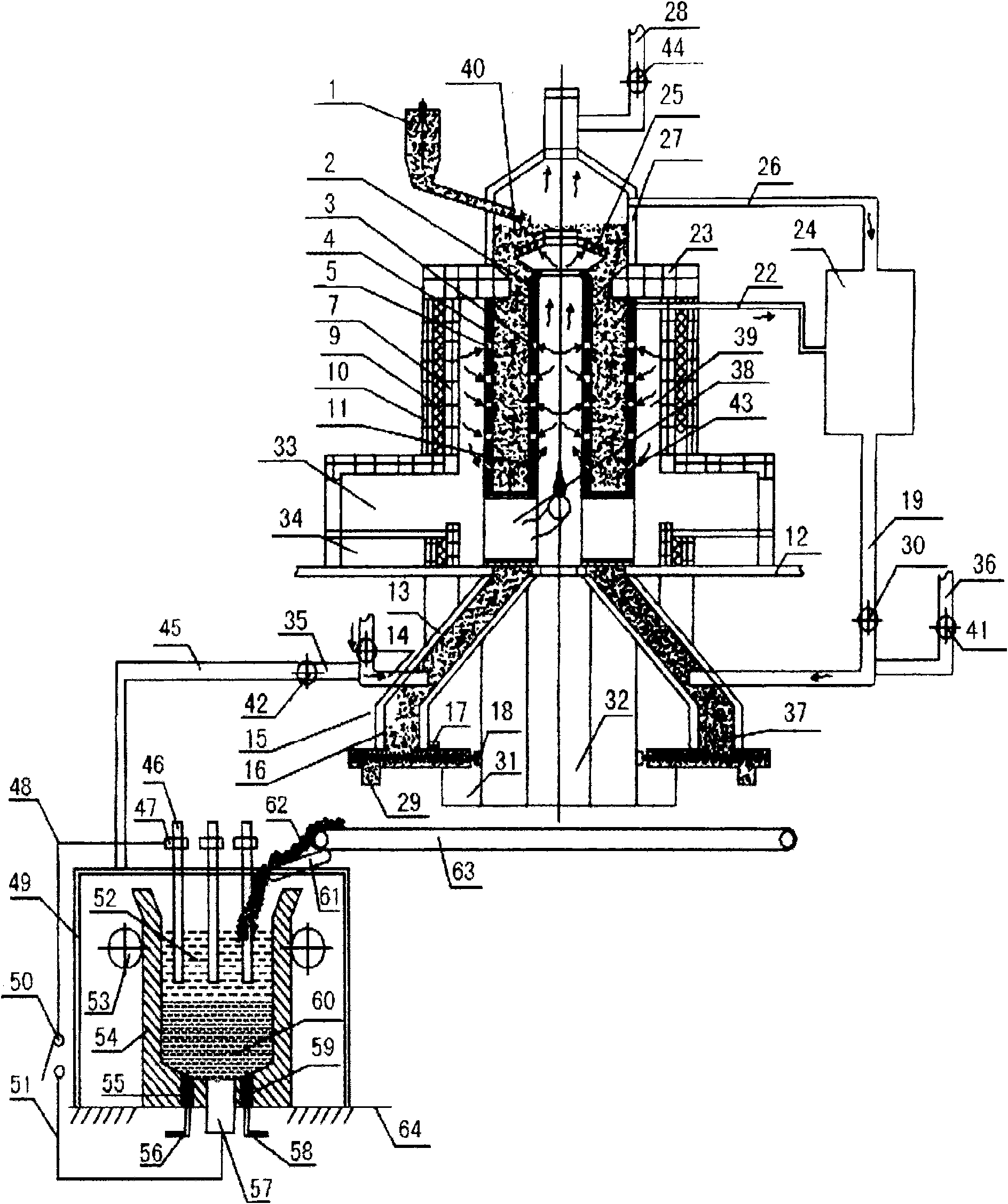

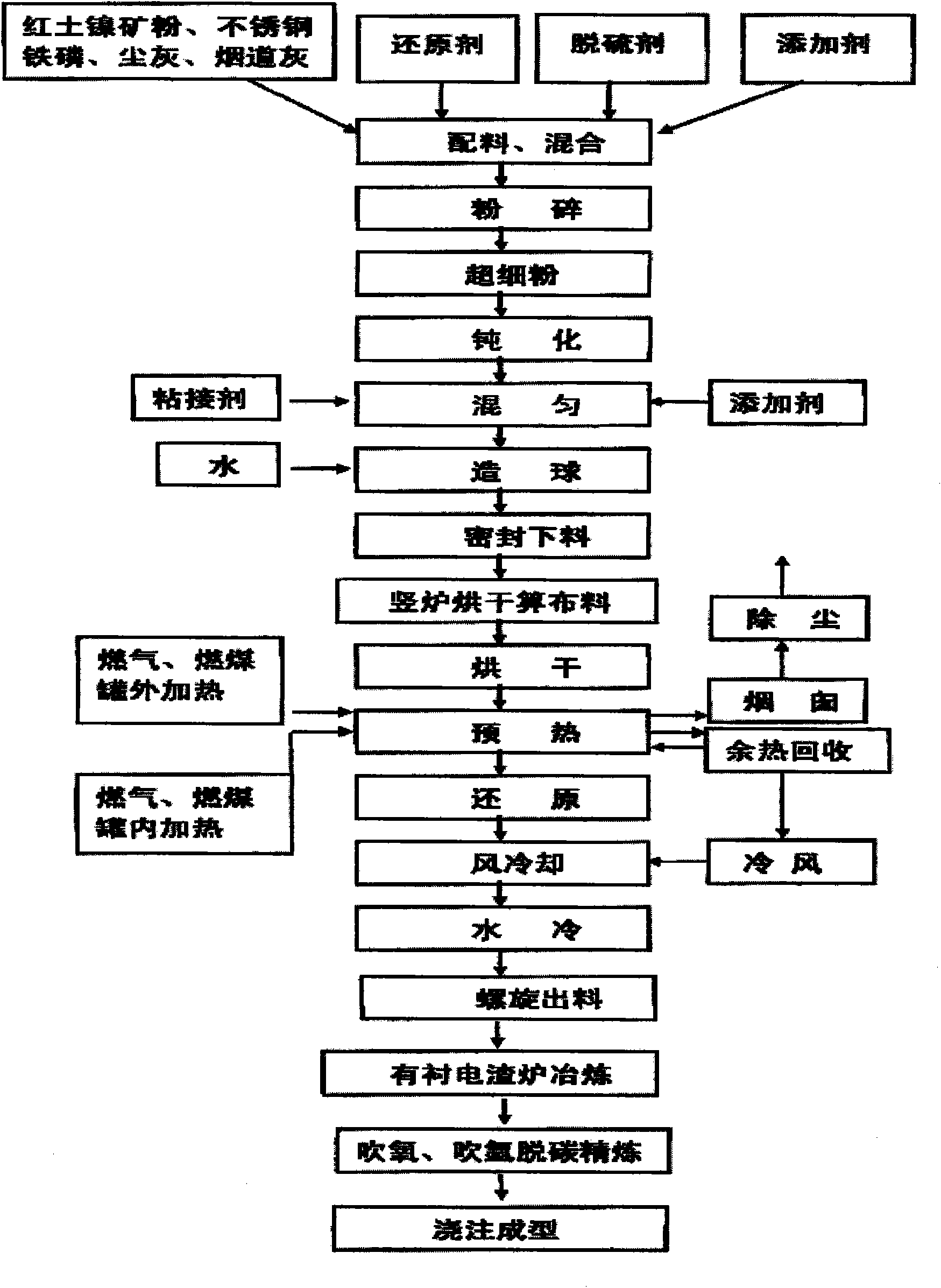

Process and device for smelting ferronickel and nickel-containing molten iron by using lower-nickel materials

InactiveCN101538631AImprove applicabilityHigh recovery rateShaft furnaceSolventMetallurgical industry

The invention relates to a process and a device for smelting ferronickel and nickel-containing molten iron by using lower-nickel materials, which belongs to metallurgical industry steel-making raw material. The process comprises the following steps: mixing ferro nickel containing raw materials with reducing agent, solvent and catalyst to prepare ultra fine powder, mixing to make pelletizing materials, sending the pelletizing materials into a reducing furnace, obtaining chromium irons pellets after the reduction reaction, and directly adding reduced pellets into an lining electroslag furnace for being smelted into ferro nickel alloy or the nickel-containing molten iron. The device comprises an internal-external heating vertical reducing furnace, a lining electroslag furnace and a residual heat recovery system. The invention has the advantages that: firstly, the reduction temperature is low, the speed is high, the energy consumption is reduced, the production cost is lowered, the production efficiency is high, and the uniformity of the quality is good; secondly, the degree of mechanization is high, the procedure is simple, the yield is large, the mass production can be performed; thirdly, the waste of raw materials is reduced, the environment pollution is lowered; fourthly, the source of raw materials adopting nickel oxide ore or nickel-containing waste, the cost is low; fifthly, the waste resource can be recycled so as to save the resource consumption; and sixthly, the high-temperature pellets are directly smelted by adopting the lining electroslag furnace, the heat efficiency is high, the energy consumption is low, the material purity is high and the quality is good, and the device is simple with less investment.

Owner:丁家伟

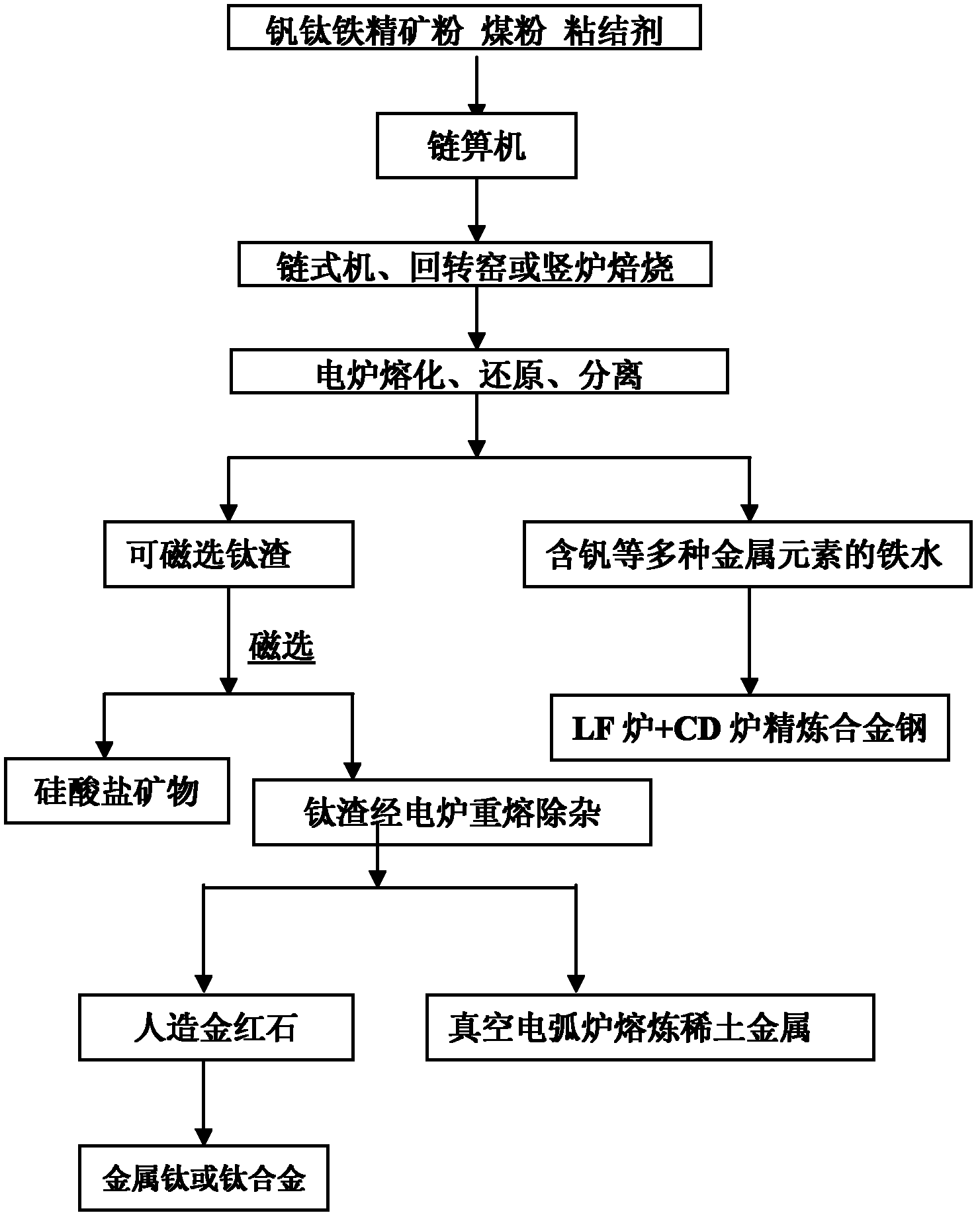

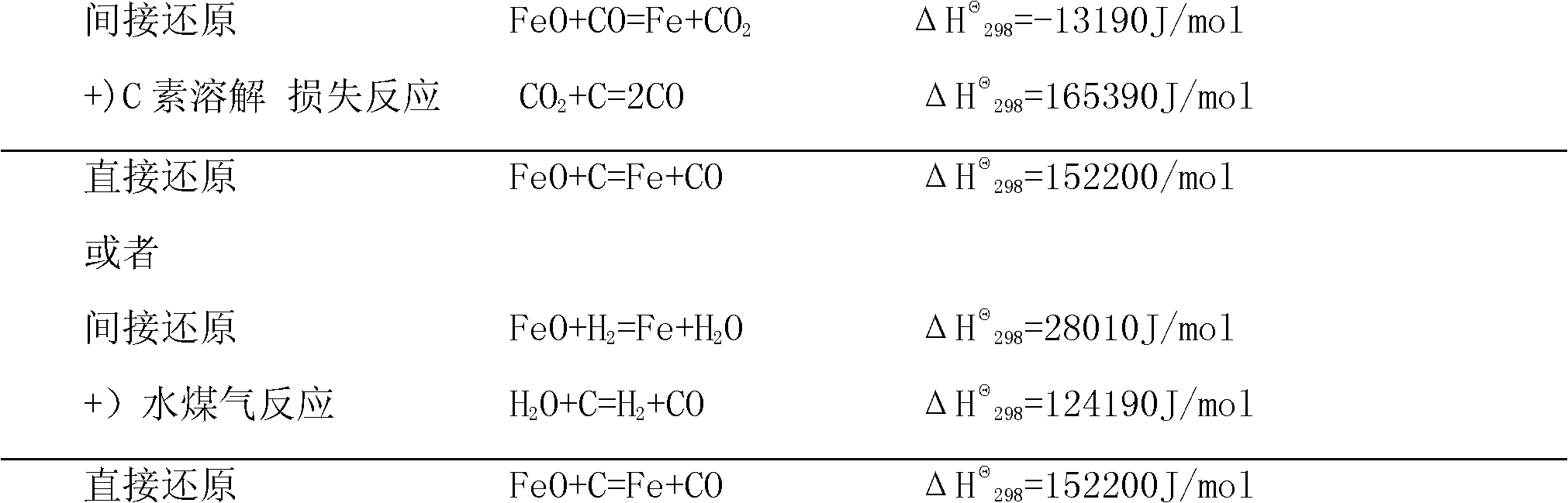

Method for selecting and smelting titanium from vanadium titanomagnetite at low temperature

InactiveCN102352423AQuick restoreIncrease magnetic susceptibilityProcess efficiency improvementElectric furnaceDc arc furnaceTitanium metal

The invention relates to a method for selecting and smelting titanium from vanadium titanomagnetite at low temperature, belonging to the technical field of metallurgy. The method comprises the following steps: 1) roasting at the low temperature of 500-1100 DEG C; 2) adding a solid reductant to the roasted product, carrying out reduction smelting at 1100-1300 DEG C, and separating slag and iron torespectively obtain molten iron and titanium slag; carrying out magnetic separation on the titanium slag to remove impurities, thereby obtaining the titanium-rich material; and 4) adding required metal oxide concentrate into a direct-current arc furnace, and directly alloying the molten iron to obtain alloy steel. The smelting method provided by the invention is a brand new smelting method, and changes the existing iron ore selection into titanium ore selection; the pellet is molten and reduced by roasting at low temperature, and the separated molten iron facilitates the addition of ores withdeficient metal elements so as to directly smelt the alloy steel; the titanium slag is subjected to magnetic separation to obtain the titanium-rich material, and the titanium-rich material is furthersmelted to obtain the titanium alloy or titanium metal; and the smelting slag can be used as the raw material for smelting rare earth metals so as to sufficiently and respectively utilize the elements in the ores in one step.

Owner:攀枝花慧泰金属新材料有限公司

Method for preparing manganese sulfate by biomass self-heating reduction of low grade manganese oxide ore

InactiveCN101439878AAchieving zero emissionsLow reduction temperatureEnergy inputManganese sulfatesManganese oxideCoal

The invention discloses a method for preparing manganese sulfate through the biomass self heating reduction of low-grade manganese oxide ore. The method comprises the following steps: 1) respectively crushing the low-grade manganese oxide ore and biomass material; 2) weighing the low-grade manganese oxide ore, the biomass material and an initiating additive according to the weight ratio of 100:10-30: 0.5-3; 3) mixing evenly and roasting the low-grade manganese oxide ore, the biomass material and the initiating additive; 4) leaching the roasted mass through dilute sulfuric acid at a temperature of between 40 and 80 DEG C, regulating the mixed liquor to make the pH value more than or equal to 6, carrying out solid-liquid separation, and keeping the obtained filtrate for standby; and 5) removing impurities from the filtrate to obtain the manganese sulfate solution. The method adopts renewable energy source of the biomass material to replace coal to reduce the manganese oxide ore and prepare manganese sulfate which can be the raw material for producing electrolytic manganese. The leaching efficiency of manganese can reach more than 95 percent. The method not only saves energy sources, but also reduces the production cost.

Owner:李学军 +2

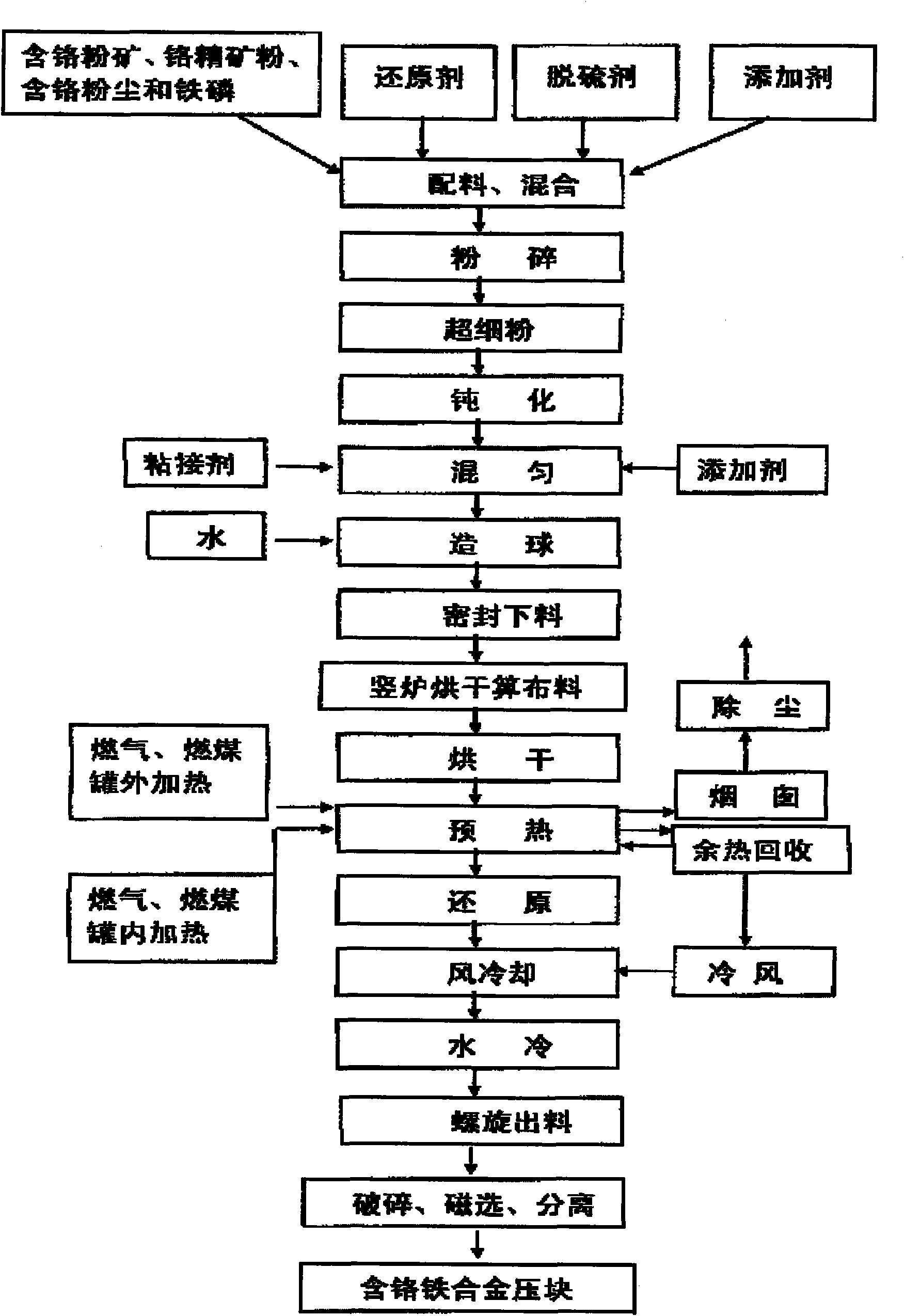

Process and device for preparing chromium iron by using chromium ore powder

InactiveCN101538630AHigh recovery rateGuaranteed uniformityProcess efficiency improvementShaft furnaceResource consumptionSolvent

The invention relates to a process and a device for preparing chromium iron by using chromium ore powder, which belongs to metallurgical industry steel-making raw material. The process comprises the following steps: mixing chromium iron containing raw materials with reducing agent, solvent and catalyst to prepare ultra fine powder, mixing to make pelletizing materials, sending the pelletizing materials into a reducing furnace, drying and roasting, and obtaining chromium irons after the reduction reaction. The reducing device is connected with an upper furnace above a furnace base, a lower furnace body is connected to the downside of the furnace base, the upper end of the upper furnace body is connected with an upper furnace mantle, a drying bed grate is positioned at the upper end in the upper furnace body, a purifying device is connected with the upper furnace body and the lower furnace body through pipelines, and a residual heat circulating device is connected with the lower furnace body. The invention has the advantages that: firstly, the reduction temperature is low, the reduction speed is high, the energy consumption is reduced, the production cost is lowered, the production efficiency is high, and the uniformity of the quality is ensured; secondly, the device is simple with less investment, the degree of mechanization is high, the procedure is simple, the yield is large, the mass production can be performed; thirdly, the waste of raw materials is reduced, the environment pollution is lowered; fourthly, the cost is low because the chromium ore powder and chromium-containing waste are adopted as raw materials; and fifthly, the waste resource can be recycled so as to save the resource consumption.

Owner:丁家伟

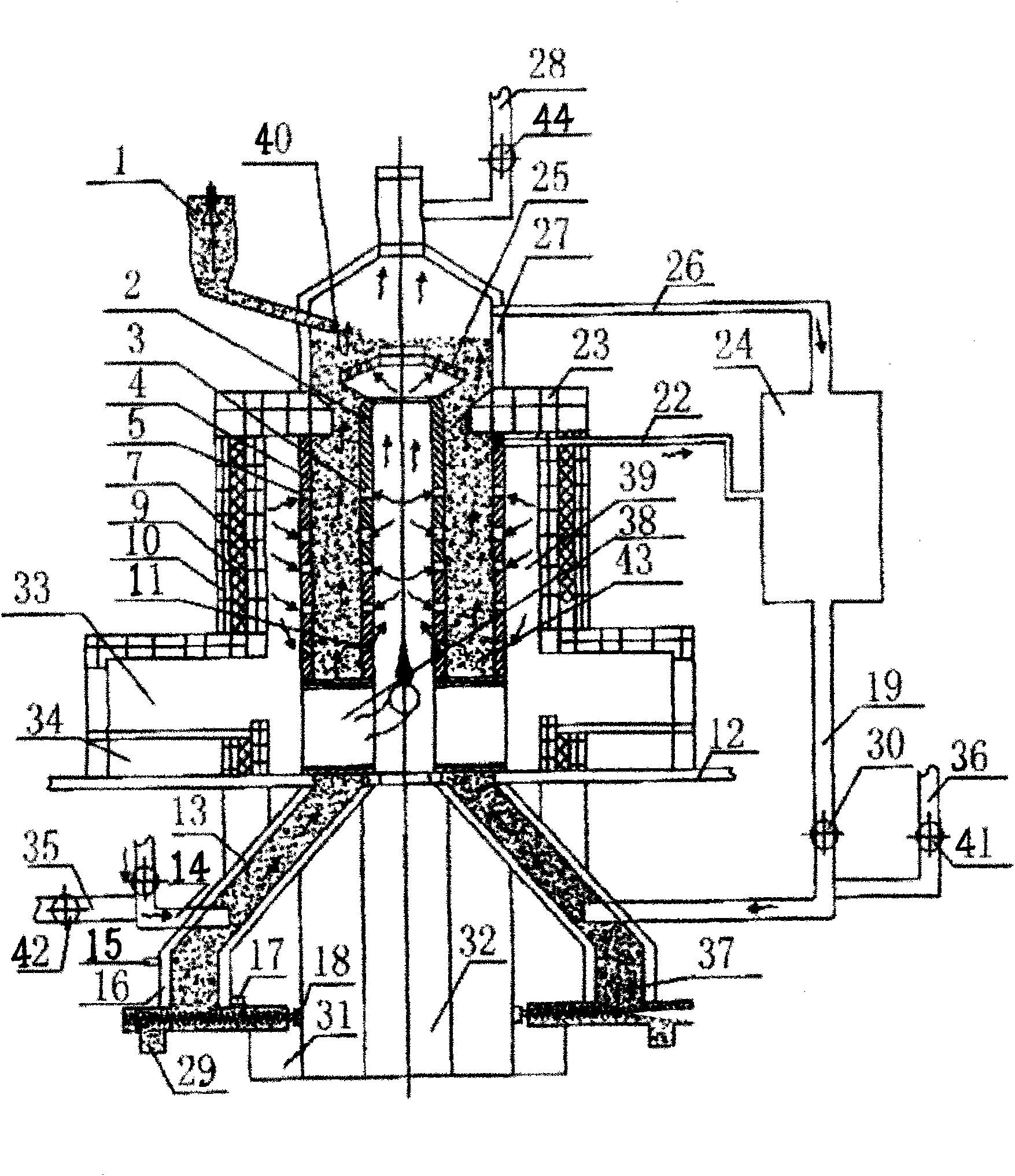

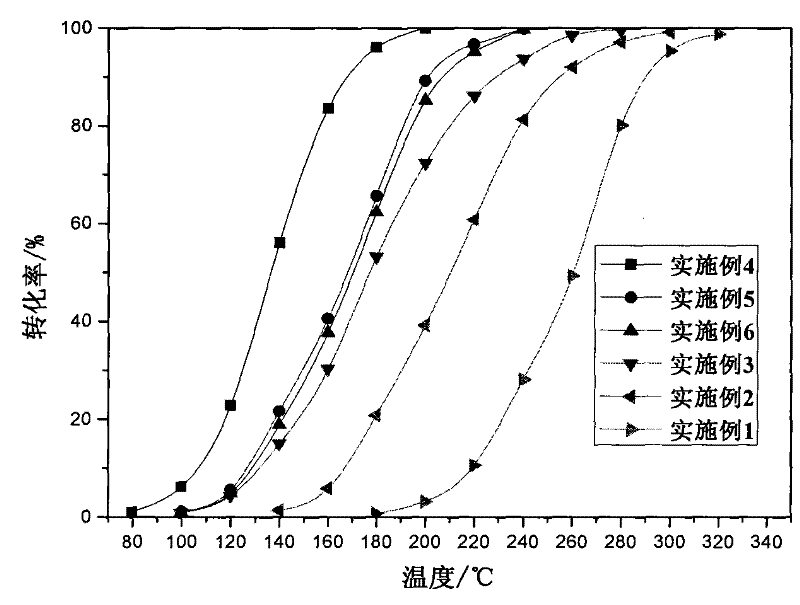

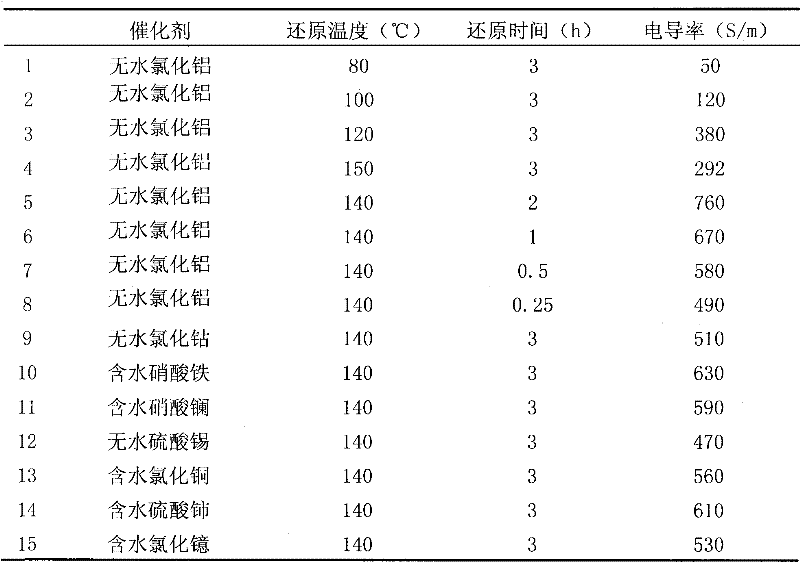

Method for producing nickel/ferrum from nickel laterite ores

The invention relates to a method for producing nickel / ferrum from nickel laterite ores, in particular relates to a fire-wet combined smelting method for metallization reducing roasting-separating of valuable metals, and belongs to the technical field of nickel laterite ore comprehensive utilization. The method comprises steps of: completing the metallization reducing roasting of the nickel laterite ores in a rotary kiln, and carrying out floatation, magnetic separation and reselection on roasted products so as to effectively separate the valuable metals. A fire method effectively combined with a wet method, and the method is a brand-new exploration and development of a nickel laterite ore resource comprehensive utilization technology. By implementing the technology, the energy consumption in a smelting process can be effectively reduced, the smelting production efficiency is increased, and the nickel laterite ore resource comprehensive utilization is realized.

Owner:江苏曦元金属材料有限公司 +1

Method for preparing graphene by low-temperature chemical reduction method

The invention discloses a method for preparing graphene by a low-temperature chemical reduction method, which belongs to the technical field of chemical composition of graphene. In the method, graphene oxide prepared by chemical oxidation is used as a raw material. The method comprises the reduction reaction step of reducing the graphene oxide into graphene; in the reduction reaction step, aluminum iodide is used as a reducer; the reduction of the graphene oxide is realized by controlling the concentration of the reducer and a solvent type at 60 DEG C to 180 DEG C; oxygen-containing functional groups (epoxy group, hydroxyl group, carboxyl group and carbonyl group) on the graphene oxide are removed; the electric conductivity of the graphene is recovered more thoroughly; and the graphene isprepared. The method provided by the invention is a method for preparing the graphene by a low-temperature chemical method, which is suitable for large-scale industrial production. The method has theadvantages of low reduction temperature, mild and controllable reaction, more thorough reduction, environmental-friendly performance, suitability to industrial production, etc.

Owner:TSINGHUA UNIV

Autothermal catalytic marsh gas reforming process of preparing synthetic gas

InactiveCN1468800ASelf-heating reactionHigh activityHydrogenWaste based fuelSyngasCatalytic reforming

The present invention relates to the efficient clean utilization of marsh gas and is especially one new kind of catalyst for reforming methane-CO2 to produce synthetic gas. The present invention is one green process to utilize marsh gas with methane and CO2 as main components to produce synthetic gas via reformation. The present invention is significant for sustained supply of power source and environment protection.

Owner:GUANGZHOU INST OF ENERGY CONVERSION - CHINESE ACAD OF SCI

Method for preparing supported selective hydrogenation catalyst by using microemulsion technology

InactiveCN101757954AHigh strengthLarge volume of waterCatalyst activation/preparationMetal/metal-oxides/metal-hydroxide catalystsNano catalystWater baths

The invention relates to a preparation method for preparing a supported selective hydrogenation catalyst by using microemulsion technology. A microemulsion system containing a surfactant, a cosurfactant, oil phase and a soluble metal salt solution is prepared in constant-temperature water bath to solve problems how to enhance hydrogenation activity and selectivity of the catalyst. Each component of the microemulsion system is prepared at a certain ratio and the system is a microemulsion system with high stable interfacial film strength, without obvious osmosis phenomenon. A nickel nano-catalyst prepared by the microemulsification technology is mainly used for selective catalytic hydrogenation reactions. The invention has the advantages that the prepared catalyst has an active component particle of which the diameter is less than 10nm; the catalyst has good dispersibility and high hydrogenation activity; the reaction temperature is low; and the preparation method is simple and easy to operate.

Owner:CHINA PETROLEUM & CHEM CORP +1

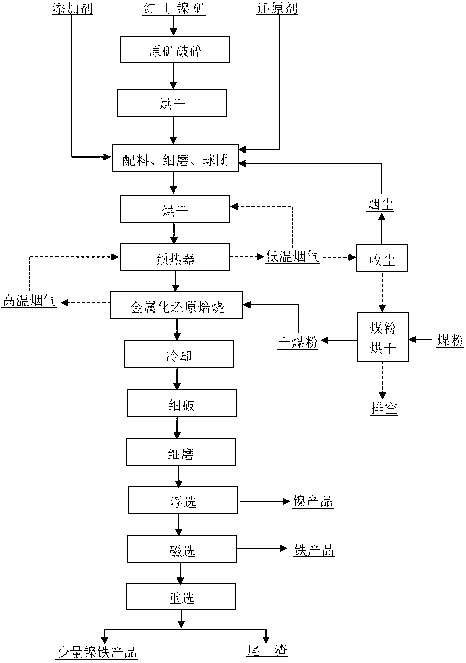

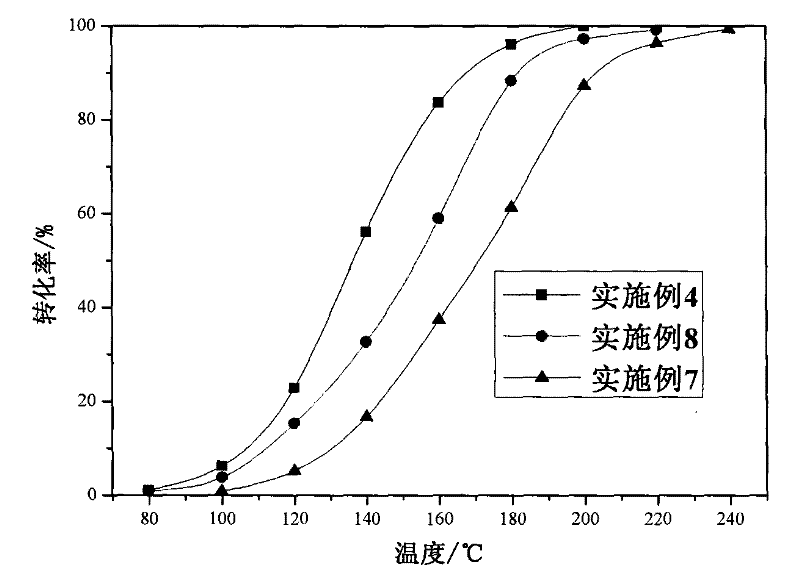

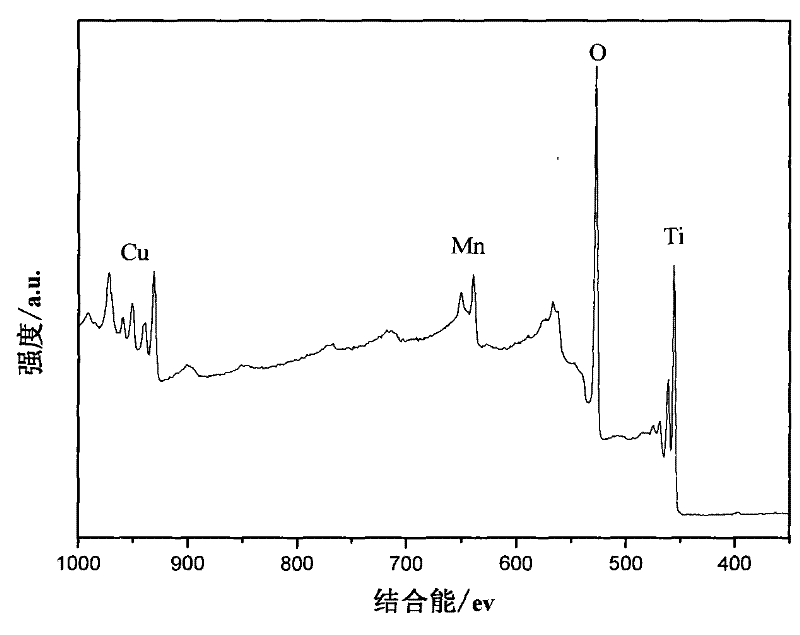

Method for preparing volatile organic compound oxidation catalyst by ultrasound-hydrogen reduction

ActiveCN102172527ALow reduction temperatureGood dispersionDispersed particle separationCatalyst activation/preparationHydrogenSpinel

The invention discloses a method for preparing a volatile organic compound oxidation catalyst by ultrasound-hydrogen reduction, comprising the following steps of: adding TiO2 particles into mixed solution of Cu(NO3)2, Mn(CH3COO)2 and Ce(NO3)3, impregnating in a constant-temperature oscillation bed and then in an ultrasonic wave generator, drying, and roasting, thus solid particles are obtained; and carrying out reduction on the solid particles under the atmosphere of H2, and roasting the solid particles in the air again, thus Cuy1Mny2Cey3Ox / TiO2 / HO catalyst capable of catalyzing oxidation reaction of volatile organic compound is obtained. The catalyst prepared by the invention has low hydrogen reduction temperature, and high-dispersion high-activity spinel structure CuMn2O4 crystalline phase is formed on a porous material carrier; the activity for catalyzing oxidation reaction of the volatile organic compound is high; meanwhile, the method requires no precious metal, thus the cost is greatly reduced compared with that of the method using a precious metal catalyst.

Owner:SOUTH CHINA UNIV OF TECH

Method of preparing synthetic rutile from ore type ilmenite concentrate

InactiveCN1923703AEliminate the hidden danger of loopingImprove reducibilityTitanium dioxideIlmeniteTitanium

The invention discloses an artificial rutile preparing method through rock ilmenite concentrate, which comprises the following steps: preheating rock ilmenite concentrate in the rotary kiln to reduce directly; separating the corrosion of reduced ilmenite; immersing material with titanium in the diluted acid to remove impurity to prepare the artificial rutile.

Owner:CENT SOUTH UNIV

Process for preparing graphene by cryochemical method

ActiveCN102452650AConductivity recoveryLow reduction temperaturePhysical/chemical process catalystsGrapheneEpoxyChemical synthesis

The invention discloses a process for preparing graphene by a cryochemical method, belonging to the technical field of chemical synthesis of graphene. The process uses graphene oxide prepared by chemical oxidation as a raw material, and comprises the step of reducing reaction in which graphene oxide is reduced into graphene. The reducing reaction step implements reduction of the graphene oxide at80-150 DEG C by using sodium borohydride as a reducer by the aid of a catalyst, oxygen-containing functional groups (epoxy group, hydroxy group, carboxy group and carbonyl group) on the graphene oxide are removed, and the electric conductivity of the graphene is thoroughly recovered, thereby preparing the graphene. The process disclosed by the invention is suitable for large-scale industrial production. The process has the advantages of low reduction temperature, mild and controllable reaction, thorough reduction, environment friendliness and the like, and is suitable for industrial production.

Owner:TSINGHUA UNIV

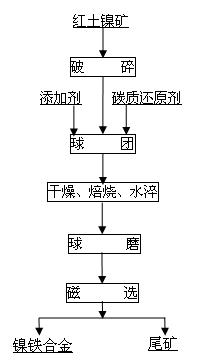

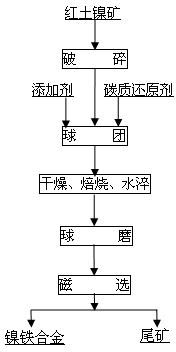

Method for producing ferronickel from lateritic nickel ores

The invention relates to a method for producing ferronickel from lateritic nickel ores, particularly a method for producing ferronickel from lateritic nickel ores by metallizing reduction roasting-magnetic separation. The method is characterized by comprising the following steps: adding additives and a carbonaceous reducing agent into lateritic nickel ores, carrying out reduction roasting, quenching with water, grinding, and carrying out magnetic separation to obtain the ferronickel alloy. In the method, the magnetic separation is directly carried out to obtain the ferronickel alloy powder with high nickel grade; the additives are added to lower the reduction temperature; not all the materials need to be heated to 1500 DEG C, thereby lowering the energy consumption; and the technique has slight influence on the environment, and thus, is an economical method for producing ferronickel from lateritic nickel ores, thereby having wide application prospects.

Owner:BEIJING GENERAL RES INST OF MINING & METALLURGY

Industrial production method for directly producing iron and vanadium-titanium-aluminum alloy from iron concentrate

InactiveCN101487066AImprove recycling ratesIncrease productivityProcess efficiency improvementProduction rateSlag

The invention discloses a commercial manufacturing method for directly producing iron and titanium aluminum alloy from iron ore concentrate, and comprises the following procedures: first, carrying out pellet preparation to the iron ore concentrate extracted from the vanadium-titanium magnetite rock and mineral; then, drying the pellets, reducing and fractional melting, and screening and extracting the block iron; last, adopting an aluminothermic reducing method to vanadium-titanium bearing slag so as to obtain vanadium-titanium aluminum alloy. The content of the block iron obtained in the method is about 95 percent; the recycling rates of iron, vanadium and titanium are 90 percent, 85 percent and 85 percent respectively. The commercial manufacturing method has the advantages of high iron, vanadium and titanium integrated recycling and utilization rate, high production rate and no pollution to environment, thus being easy for industrialization promotion and having obvious social and economical efficiency.

Owner:北京金坤宏宇矿业科技有限公司 +1

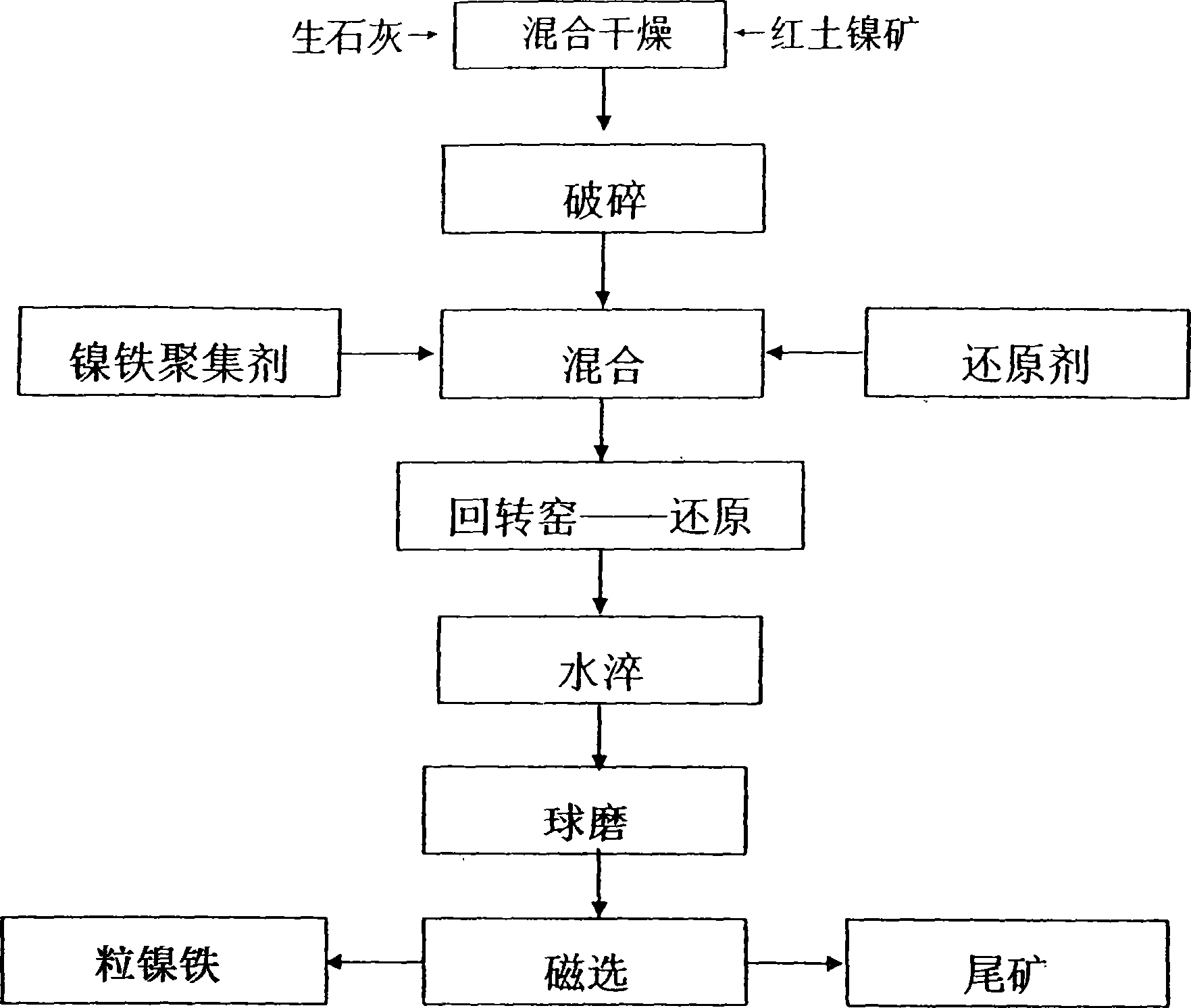

Method for directly reducing grain nickel iron in rotary kiln by using laterite nickle mine

InactiveCN101418389AReduce production processReduce environmental pollutionMagnetic separationQuenchingRotary kiln

The invention relates to a method for directly reducing granular ferronickel by using nickeliferous laterite ore in a rotary kiln, which comprises the following steps: firstly, adding desiccant in the nickeliferous laterite ore containing adsorption water, stirring and blending the mixture evenly, and dehydrating and drying the mixture; secondly, crushing the mixture, adding reducing agent and ferronickel aggregation agent, blending the mixture evenly and then sending the mixture to the rotary kiln to reduce and bake; and finally, water quenching, cooling, crushing, ball milling and magnetically separating the reduced and baked material, so as to obtain high grade granular ferronickel alloy. The method has the advantages of simple production, convenient operation, energy consumption saving, low cost, and high recycling ratio of nickel. The produced granular ferronickel alloy grains can be directly used as a high-quality raw material for smelting stainless steel. The method is suitable for the nickeliferous laterite ores with various grades and different types.

Owner:毛黎生

Method for preparing graphene/polymer composite material based on infrared irradiation

The invention discloses a method for preparing a graphene / polymer composite material based on infrared irradiation. The method comprises the following steps: 1) mixing a graphite oxide solution with a polymer solution or polymer emulsion to obtain a mixed solution, casting or spinning, and drying until the weight percentage of the total solvent is less than or equal to 50 percent so as to obtain a composite product; and 2) removing the solvent from the composite product under the irradiation of an infrared heating lamp, and performing reduction reaction of graphite oxide to obtain the graphene / polymer composite material. By the preparation method, the graphene / polymer composite material is prepared under the irradiation of the infrared heating lamp, the process is simple and convenient, the production cost is low, the method is suitable for large-scale industrial production, different polymers can be selected for preparing different graphene / polymer composite materials so as to meet the production and use requirements, and the graphene / polymer composite material has a wide application prospect in the fields such as conductive polymer composite materials, films and fibers.

Owner:ZHEJIANG UNIV

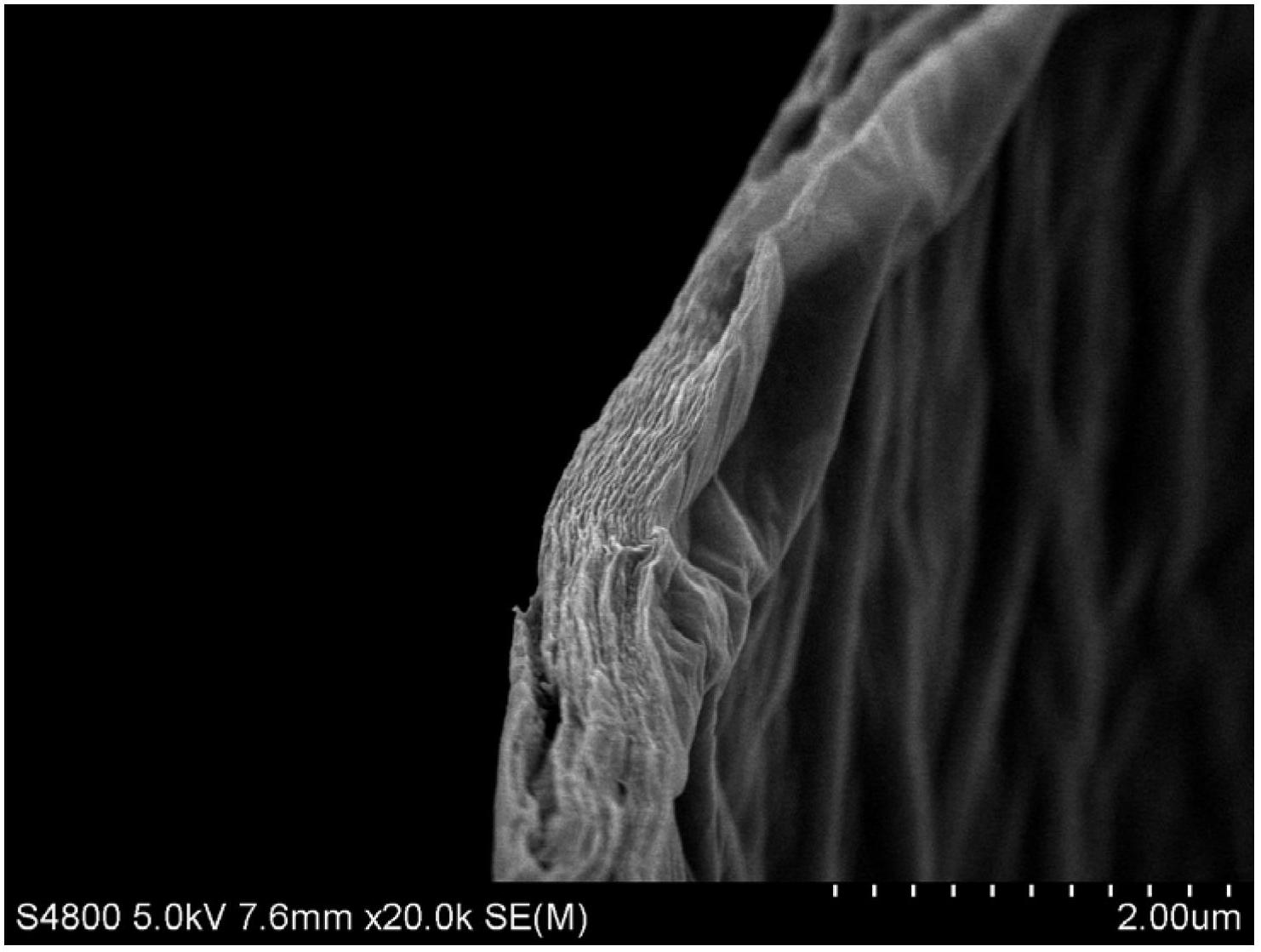

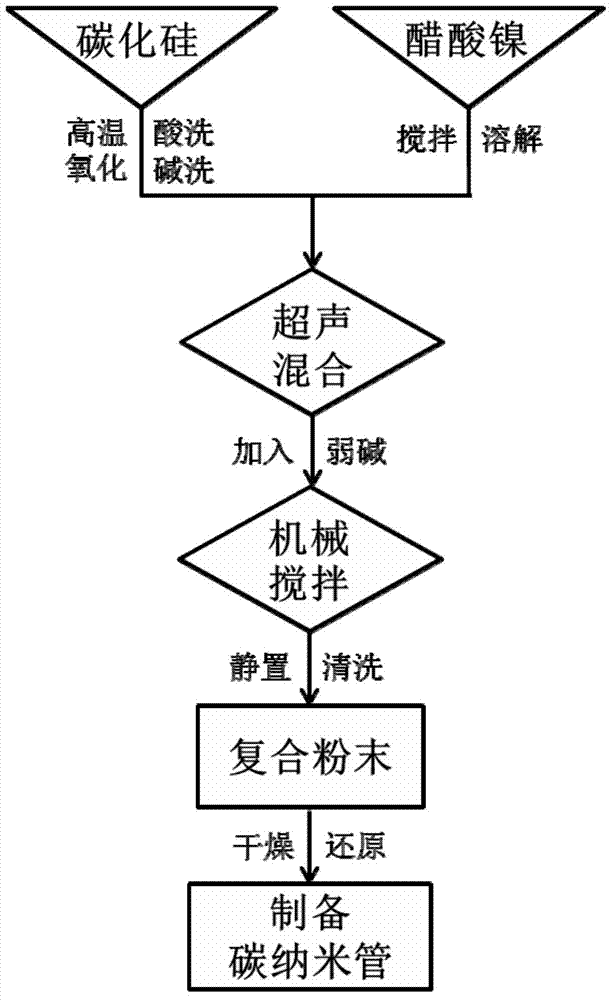

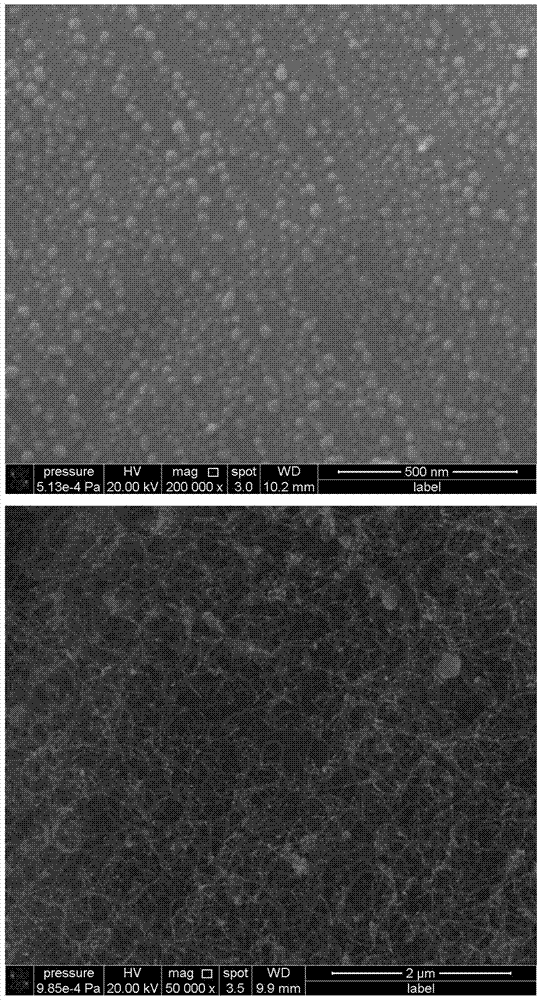

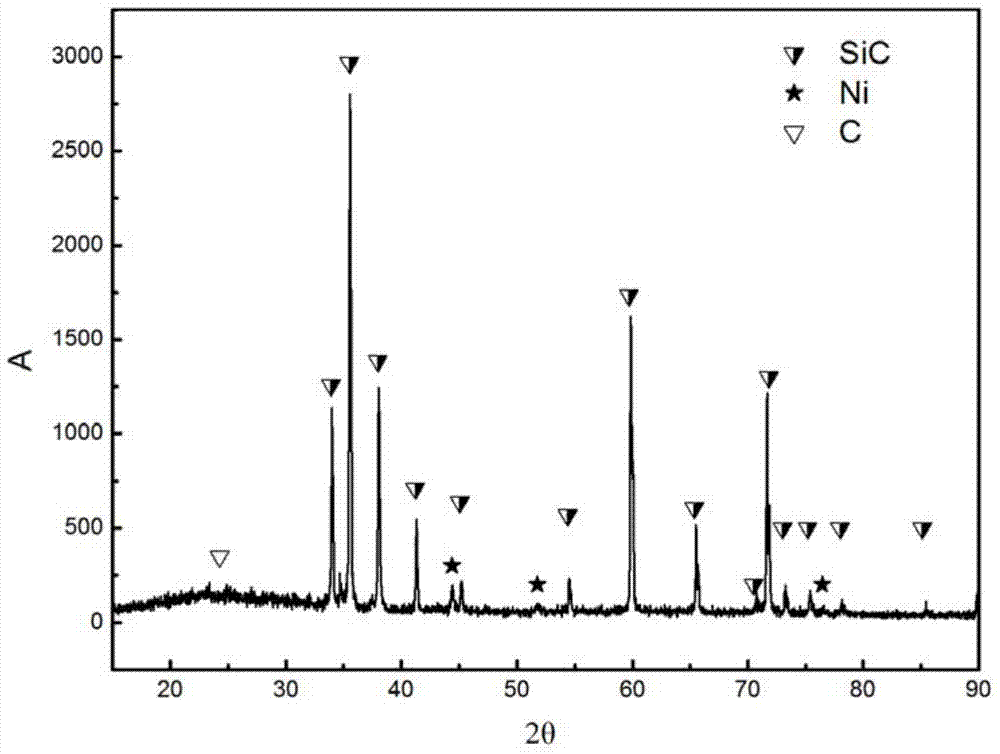

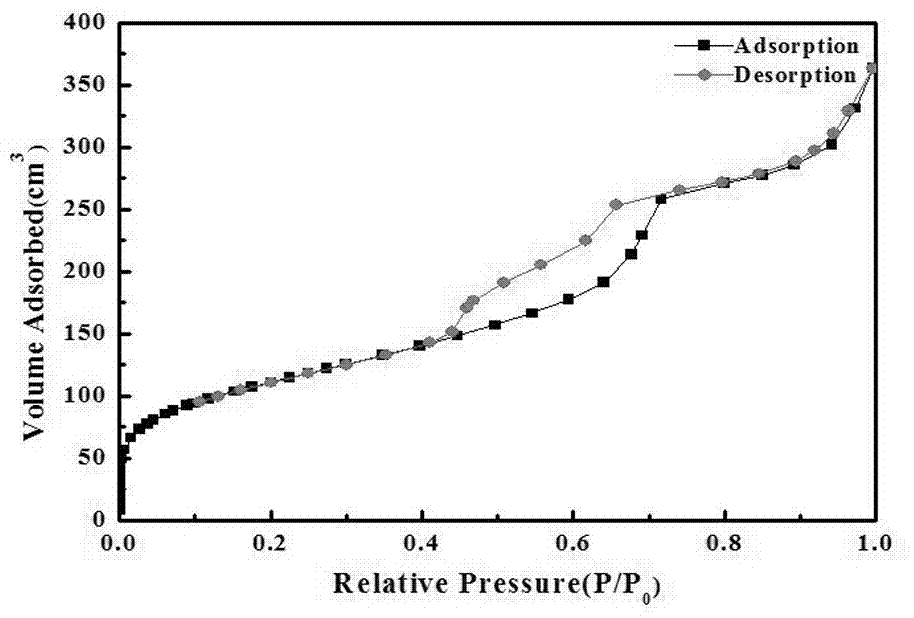

Method for preparing carbon nano tubes on surfaces of silicon carbide particles through in-situ synthesis

ActiveCN103754878AImprove adsorption capacityCalcination temperature is lowMaterial nanotechnologySilicon carbideNano catalystGas phase

The invention provides a method for growing multi-walled carbon nano tubes on the surface of micron silicon carbide powder in situ. The method comprises the steps of firstly oxidizing, acid-washing and alkali-washing the surface of the silicon carbide powder to remove silicon oxide and other impurities on the surface; secondly wrapping the surface of silicon carbide with a layer of uniformly distributed nano-catalyst particles by adopting the method of chemical codeposition, then putting the powder into a quartz tube furnace, and preparing the carbon nano tubes on the surface of silicon carbide in situ through catalytic cracking by utilizing the method of chemical vapor deposition. By adopting the method, uniform distribution of the carbon nano tubes on the surface of micron silicon carbide can be achieved, the difficulty that the carbon nano tubes are easy to agglomerate is solved, and a basis is provided for preparing high-performance multi-scale composite materials. The method is simple and has high feasibility. The prepared carbon nano tubes are uniformly dispersed on the surface of silicon carbide and are controllable in quantity.

Owner:深圳优越科技新材料有限公司

Carbon self-supported metal phosphide catalyst, and preparation method and application thereof

ActiveCN109772385AStrong complexing abilityLow reduction temperaturePreparation by dehalogenationPhysical/chemical process catalystsCarbon filmMicrowave oven

The invention discloses a preparation method of a carbon self-supported metal phosphide catalyst. The preparation method comprises the following steps: dispersing a transition metal element or a transition metal compound in distilled water to form a transition metal dispersion; uniformly mixing the transition metal dispersion with phytic acid, placing the obtained mixture in an oven, drying the mixture to form a colloidal material, and calcining the colloidal material in a microwave oven to obtain a catalyst precursor; and placing the catalyst precursor in a tubular furnace, carrying out calcining reduction in a H2 atmosphere, cooling the obtained material to a passivation temperature, introducing an inert gas containing low-concentration oxygen, and carrying out calcining passivation to obtain the carbon self-supported metal phosphide catalyst. In the present invention, the phytic acid can rapidly absorb microwaves, the transition metal phosphate precursor can be quickly obtained during microwave calcining, the phytic acid is carbonized when absorbing the microwaves and being rapidly heated in order to coat the transition metal phosphate precursor, and carbon wraps the carbon self-supported metal phosphide catalyst which is obtained by the reduction to form a slight carbon film in order to prevent the catalyst from being oxidized.

Owner:ZHEJIANG UNIV OF TECH

Preparation method of ordered mesopore molybdenum carbide

ActiveCN107311176AFacilitated DiffusionHigh activityTungsten/molybdenum carbideDistillationCarbonization

The invention relates to a preparation method of ordered mesopore molybdenum carbide, which belongs to the field of ordered mesopore material preparation. The preparation method comprises the following steps of adopting a hard template method, adopting saccharose as a carbon source and an SBA-15 molecular sieve as a template, stirring, carrying out ultrasound, drying and carbonizing, roasting, and acid pickling to obtain an ordered mesopore carbon material; then soaking the ordered mesopore carbon material into an ammonium molybdate solution (a molybdenum source), stirring, drying by distillation, and roasting to obtain an ordered mesopore carbon / molybdenum trioxide compound; mixing the ordered mesopore carbon / molybdenum trioxide compound with magnesium powder, and carrying out magnesiothermic reduction reaction in a tube furnace to obtain the ordered mesopore molybdenum carbide material. During the preparation process, the carbonization reduction temperature is greatly reduced; the molybdenum carbide prepared at a low temperature condition is concentrated in bore diameter and large in specific surface area; the rich mesoporous structure is beneficial to diffusion of reactants and exposure of active sites, so that the activity and the stability of a molybdenum carbide catalyst are improved. The preparation method is advanced in process, low in cost, easy for getting raw materials, reasonable in match ratio, and stable in products, and is an advanced method for preparing the ordered mesopore molybdenum carbide.

Owner:TAIYUAN UNIV OF TECH

Preparation method of vanadium nitride

InactiveCN102910596AImprove reduction efficiencyLow reduction temperatureNitrogen-metal/silicon/boron binary compoundsVanadium compoundsVanadium nitrideVanadium atom

The invention relates to a preparation method of vanadium nitride. The preparation method comprises the following steps: uniformly mixing powdered vanadium oxide, a carbonaceous reducing agent and a binding agent aqueous solution; compacting to prepare into blocks; drying the block materials; continuously adding in a double-channel push plate kiln; carrying out reduction, sintering, nitrogenization and cooling in each temperature region in the kiln under the condition of 10Pa to 100Pa of pressure in the kiln and gas protection; and finally producing the vanadium nitride product with contents of 77-80% of V (vanadium), 11-18% of N (nitrogen) and 2-8% of C (carbon), and production density of 3.2g / cm<3> to 4.1g / cm<3> is obtained. With the adoption of the preparation method provided by the invention, the continuous production is achieved, and the preparation method has the following advantages of stable technology process, high production efficiency, high reducing efficiency, low reaction temperature, high heating efficiency, low energy consumption and so on.

Owner:CNMC NINGXIA ORIENT GRP

Method for preparing alsifer from high-alumina fly ash and magnetic beads

ActiveCN101469378AEvenly distributedHigh activityMagnetic separationResource utilizationMagnetic bead

The invention discloses a method for preparing AL-Si-Fe alloy by utilizing high-aluminum fly ash and magnetic beads, which relates to the technical field of nonferrous metallurgy. The method comprises the following steps: 1) a bauxite raw material and a reducing agent-bituminous coal are crushed, and the crushed materials and raw materials (the high-aluminum fly ash and the magnetic beads) are sent into a mixing pan; 2) an adhesive-clay and a certain amount of water are added into the mixing pan to mixedly roll the materials; 3) the materials which are mixedly rolled evenly enter a twinroller machine for granulation; 4) pellets which come from the twinroller machine enter a drying kiln for drying; 5) the dried pellets are added into a submerged arc furnace for high-temperature smelting; and 6) molten iron is taken out of the furnace, and an ingot mold is cast to obtain the AL-Si-Fe alloy. The method has the advantages of broad raw material source, low production cost, good performance of the pellets containing fly ash, even furnace-entering smelting constituents, and complete reaction, makes the submerged arc furnace keep good furnace condition, ensures that the produced AL-Si-Fe alloy has steady performance, and realizes the resource utilization of waste.

Owner:TONGFANG ENVIRONMENT

Flexible graphene film capable of being repeatedly folded, preparation method of flexible graphene film and flexible device comprising flexible graphene film

ActiveCN106698407AGood flexibilityImprove foldabilityHybrid capacitor electrodesGrapheneReduction treatmentOptoelectronics

The invention provides a flexible graphene film capable of being repeatedly folded, a preparation method of the flexible graphene film and a flexible device comprising the flexible graphene film. The graphene film is obtained by carrying out reduction treatment on a graphene oxide film; a porous structure is formed in the thickness direction of the graphene film; after the graphene film is folded, the graphene film can be recovered and folds are not formed; the thickness of the graphene oxide film is 0.01mu m to 500mu m; compared with the thickness of the graphene oxide film, the expanding multiple of the thickness of the graphene film is 2 to 30 times. The flexible graphene film provided by the invention has the advantages that the porous structure is formed in the thickness direction of the graphene film and the surface of the thin film is smooth and flat; the film has excellent flexible and foldable performance and can be rapidly recovered and has no folds after being folded singly or doubly for a plurality of times; after the film is treated at high temperature, the flexibility can still be kept. The preparation method provided by the invention is simple and convenient to operate and has the advantages of relatively low reduction temperature, small dosage of a reducing agent and small pollution to environment.

Owner:BEIJING UNIV OF CHEM TECH

An industrial production method for separating valuable elements from aluminum-vanadium-titanium-iron-silicon composite symbiotic ore for recovery and utilization

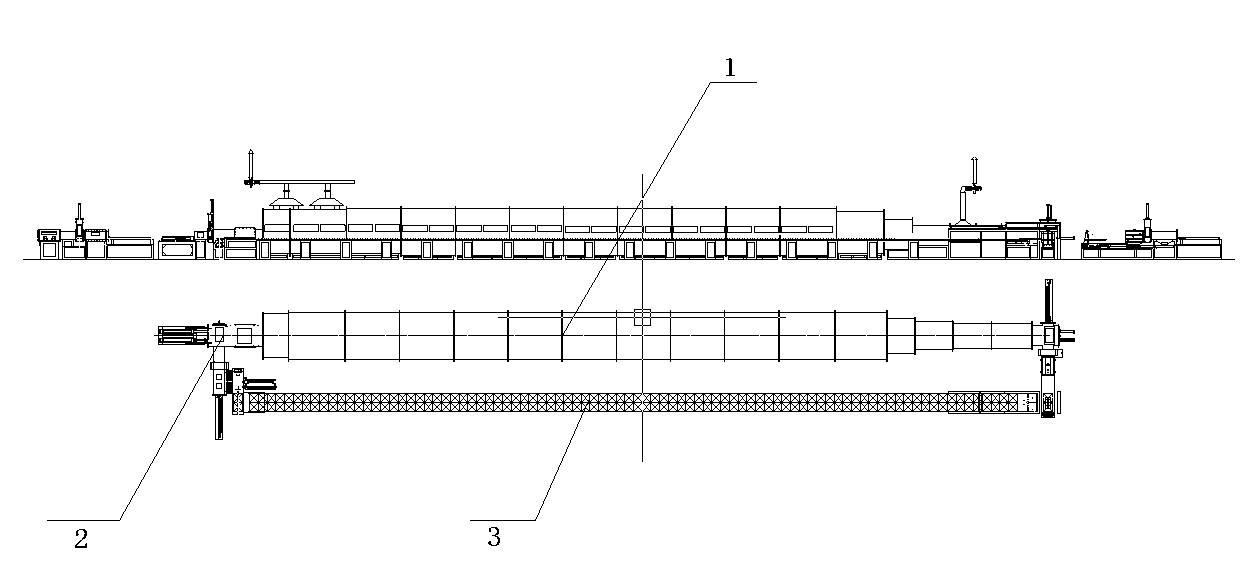

The invention discloses an industrial production method of separating valuable elements from composite paragentic mineral of aluminum-vanadium-titanium-iron-silicon for cyclic utilization. The method comprises the following steps: employing the technique of gradient magnetic separation to separate aluminum-silicon-iron products, vanadium-titanium-iron products and sulfur concentrate from composite paragentic mineral of aluminum-vanadium-titanium-iron-silicon; carrying out flash suspension smelting on the aluminum-silicon-iron products to obtain ferrosilicon alloy and aluminum slag which is used as a raw material for production of alundum; employing the technique of rectilinearly movable bed prereduction-shaft furnace smelting to prepare the vanadium-titanium-iron products into vanadium iron intermetallic compounds and titanium slag. Smelting separation and flash suspension smelting and rectilinearly movable bed prereduction-shaft furnace smelting are combined in the method provided inthe invention, which enables the recovery rate of raw ores to be enhanced.

Owner:陕西延长石油中陕金属矿业有限公司 +1

Supported cuprous oxide adsorbent as well as preparation method, application and regeneration method thereof

ActiveCN103007874AEasy to controlLow reduction temperatureOther chemical processesDispersed particle separationOxidation reductionAlkane

The invention discloses a supported cuprous oxide adsorbent for separating olefin and alkane. The supported cuprous oxide adsorbent is prepared mainly through an oxidation-reduction reaction between copper oxide on a carrier and reducing agent steam at a low temperature and effectively used for separating olefin and alkane. The supported cuprous oxide adsorbent disclosed by the invention is an adsorbent prepared by using a steam induced reduction method and adopts cuprous oxide as the active component.

Owner:NANJING UNIV OF TECH

Method of recovering platinum group metals based on copper capture

InactiveCN104988314AEfficient recyclingHigh recovery rateProcess efficiency improvementPetrochemicalMetal recycling

The invention discloses a method of recovering platinum group metals based on copper capture. The method comprises the steps that platinum group metal contained waste is proportionally mixed with a copper capturing agent, an additive and a binding agent, and is subjected to fine grinding and then water adding to be pelletized, dried, placed in a crucible, and reduced at a certain temperature after certain reducing coal is added; metallized pellets obtained by reduction are broken, and the broken metalized pellets are subjected to ball milling and then gravity separation; and obtained ore concentrate is metal copper powder containing the platinum group metals, thereby realizing the recovery of the platinum group metals. The method is simple in technological process; and the reduction temperature is low; used equipment is conventional metallurgy and ore-dressing equipment, so that the method is easy to implement; a recovery rate of the platinum group metals is greater than 99%; the content of the platinum group metals in gravitation separation tailings is less than 10g / t; with the adoption of the method, the platinum group metals can be effectively recovered from spent auto-catalysts, catalysts for petrochemical industry and catalysts for fine chemicals; no harmful gas is discharged; the tailings can serve as raw building materials; and the whole process is clean and pollution-free.

Owner:KUNMING INST OF PRECIOUS METALS

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com