Preparation method of vanadium nitride

A vanadium nitride and vanadium oxide technology, applied in chemical instruments and methods, nitrogen-metal/silicon/boron binary compounds, vanadium compounds, etc., can solve problems such as low N content, difficult production and use, and achieve production High efficiency, long service life and small temperature gradient

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0032] The preparation process of vanadium nitride is:

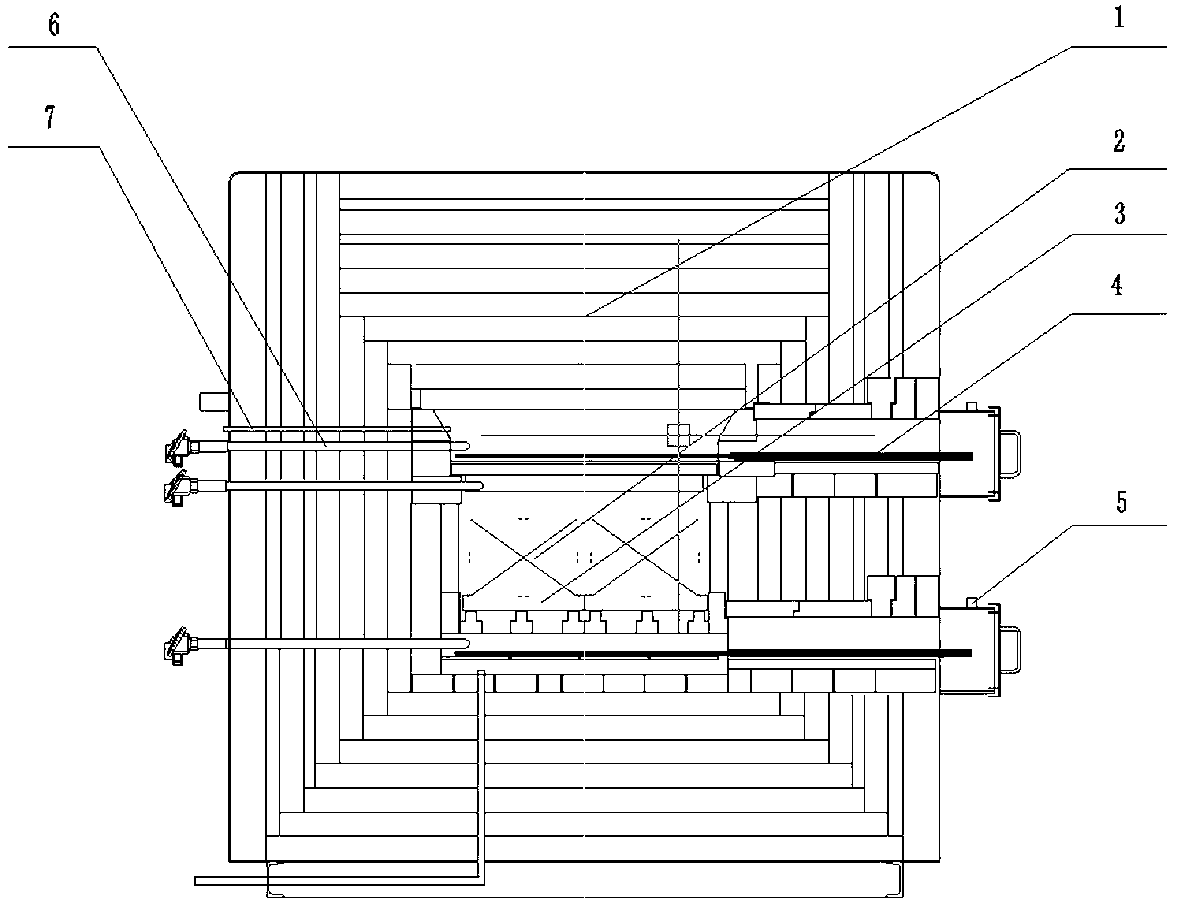

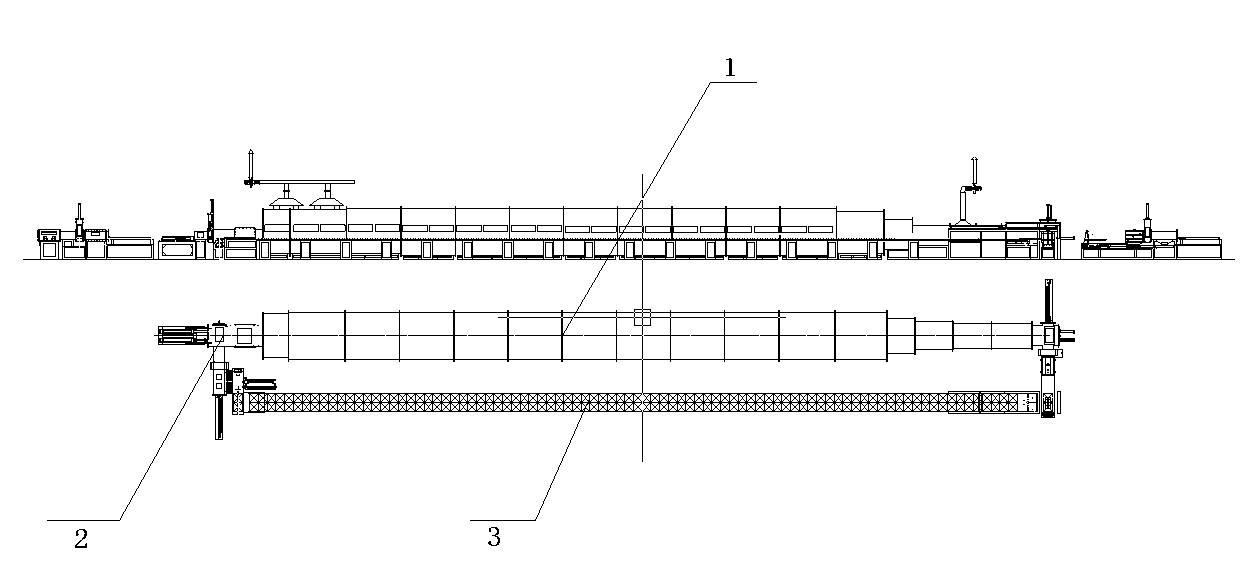

[0033] Powdered vanadium oxide (V 2 o 5 , V 2 o 3 , NH 4 VO 3 or one or any mixture of ammonium polyvanadate) and carbonaceous reducing agent (one or more of carbon black, graphite, activated carbon, pitch and petroleum coke) are mixed according to the weight ratio of 3.4-3:1 , adding a binder with a concentration of 2.0-3.0% (one or more of starch, polyvinyl alcohol, acrylic resin, sucrose, and cellulose) in an amount of 8-25% (percentage by weight), and mixing evenly; then Pressed into diamond-shaped blocks with a size of 45mm×455mm×35mm, the pressing pressure is controlled at 100-150Mpa, the compression ratio is 1.8-2.3; oven drying, the temperature is 100-250°C, and the time is 8-24 hours; after drying, add graphite The crucible is sent into the double-channel pusher kiln. The dual-channel pusher kiln adopts nitrogen protection, and a sealed chamber and a cleaning chamber are designed at the entrance and exit ...

Embodiment 1

[0036] Mix 1000kg of vanadium pentoxide powder and 325kg of carbon black, add polyvinyl alcohol aqueous solution with a concentration of 2.5%, the solution ratio is 8%, after mixing evenly, briquette under a pressure of 120Mpa, the material compression ratio is 1.8, and dry at 125°C for 12 hours , and then put the molded and dried material in the feeding bin of the pusher kiln. The material is controlled by PLC, and the material is automatically circulated in and out of the pusher kiln. At the same time, nitrogen is introduced into the pusher kiln to keep the kiln pressure above the atmospheric pressure of 10- 100pa, the material is kept at 1500°C for 6 hours, cooled to 1200°C for 2 hours for nitriding treatment, and then continues to cool to 120°C to be automatically released from the furnace, and the content is 78.32%V, 15.2%N, 4.7%C, 0.83% O, 0.01% S vanadium nitride, its product density is 3.8g / cm 3 .

Embodiment 2

[0038] Mix 1000kg of vanadium pentoxide and 335kg of carbon black evenly, add polyvinyl alcohol aqueous solution with a concentration of 2%, the solution ratio is 15%, after mixing evenly, briquette under a pressure of 150Mpa, the material compression ratio is 2.0, and dry at 150°C for 12 hours , and then put the molded and dried material in the feeding bin of the pusher kiln. The material is controlled by PLC, and the material is automatically circulated in and out of the pusher kiln. At the same time, nitrogen is introduced into the pusher kiln to keep the kiln pressure above the atmospheric pressure of 10- 100pa, the material is kept in the temperature range of 1480°C for 6h, cooled to 1200°C for 2h for nitriding treatment, and then continued to cool to 120°C to be automatically released from the furnace, and the content is 78.22%V, 13.8%N, 5.9%C, 0.72% O, 0.01% S vanadium nitride, its product density is 3.8g / cm 3 .

PUM

| Property | Measurement | Unit |

|---|---|---|

| yield strength | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com