Continuous casting machine and small square billet soft reduction device

A light reduction and billet technology, applied in the field of metallurgical continuous casting, can solve problems such as large changes in casting speed range, influence on billet quality, billet center segregation, etc., to achieve center porosity and center segregation control, Effect of improving density and improving reduction efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] In order to make the above objects, features and advantages of the present invention more comprehensible, the present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

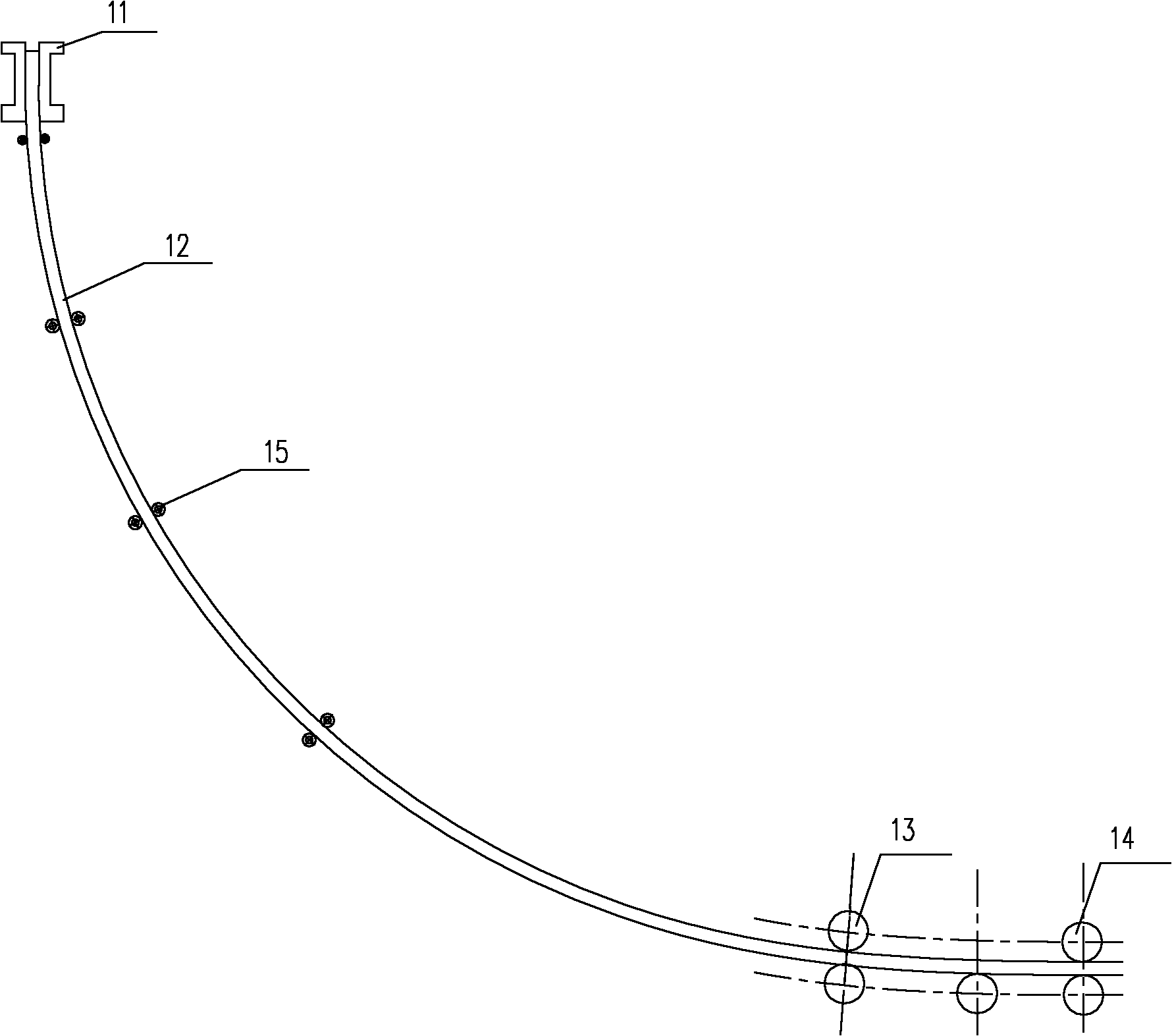

[0029] see figure 2 , shows the continuous casting machine of the present invention, including a crystallizer 11, a roller table 12, a light reduction device 23 and a tension leveler 14. The soft reduction device 23 is arranged at the end of the strand and includes six groups of soft reduction units, each group of soft reduction units is composed of an upper pressing roll 231 and a lower pressing roll 232 arranged on a frame (not shown in the figure) . The upper pressure roller 231 and the lower pressure roller 232 are arranged on a frame, and the roller spacing of each group of the upper pressure roller 231 and the lower pressure roller 232 can be made smaller in mechanical structure, and the upper pressure roller 231 and the l...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com