Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

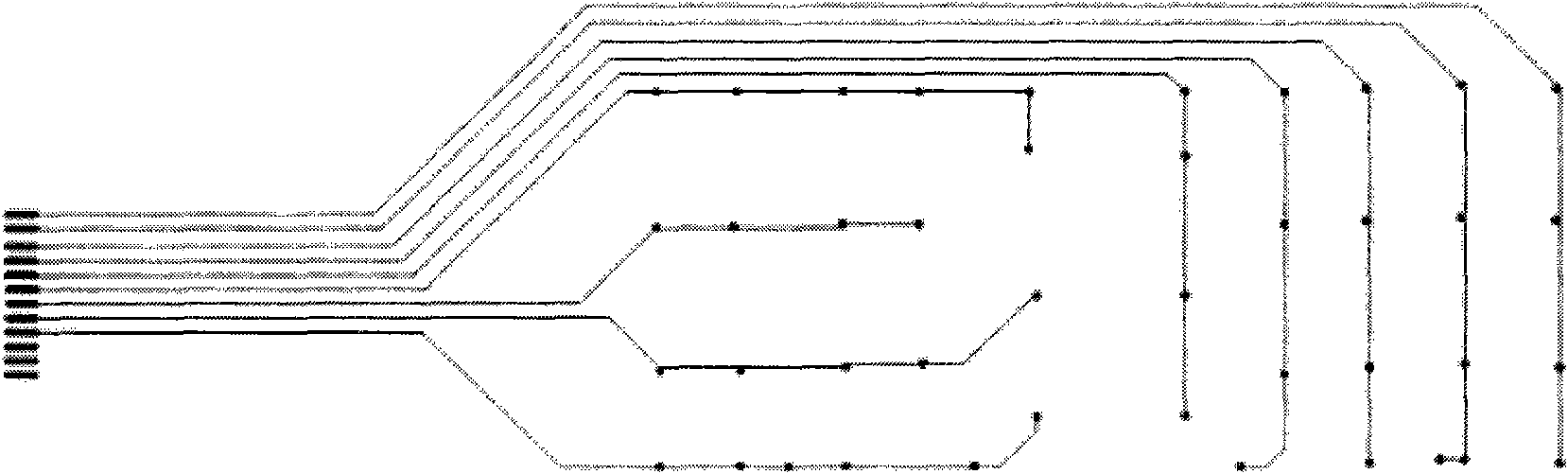

256results about How to "Improve foldability" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

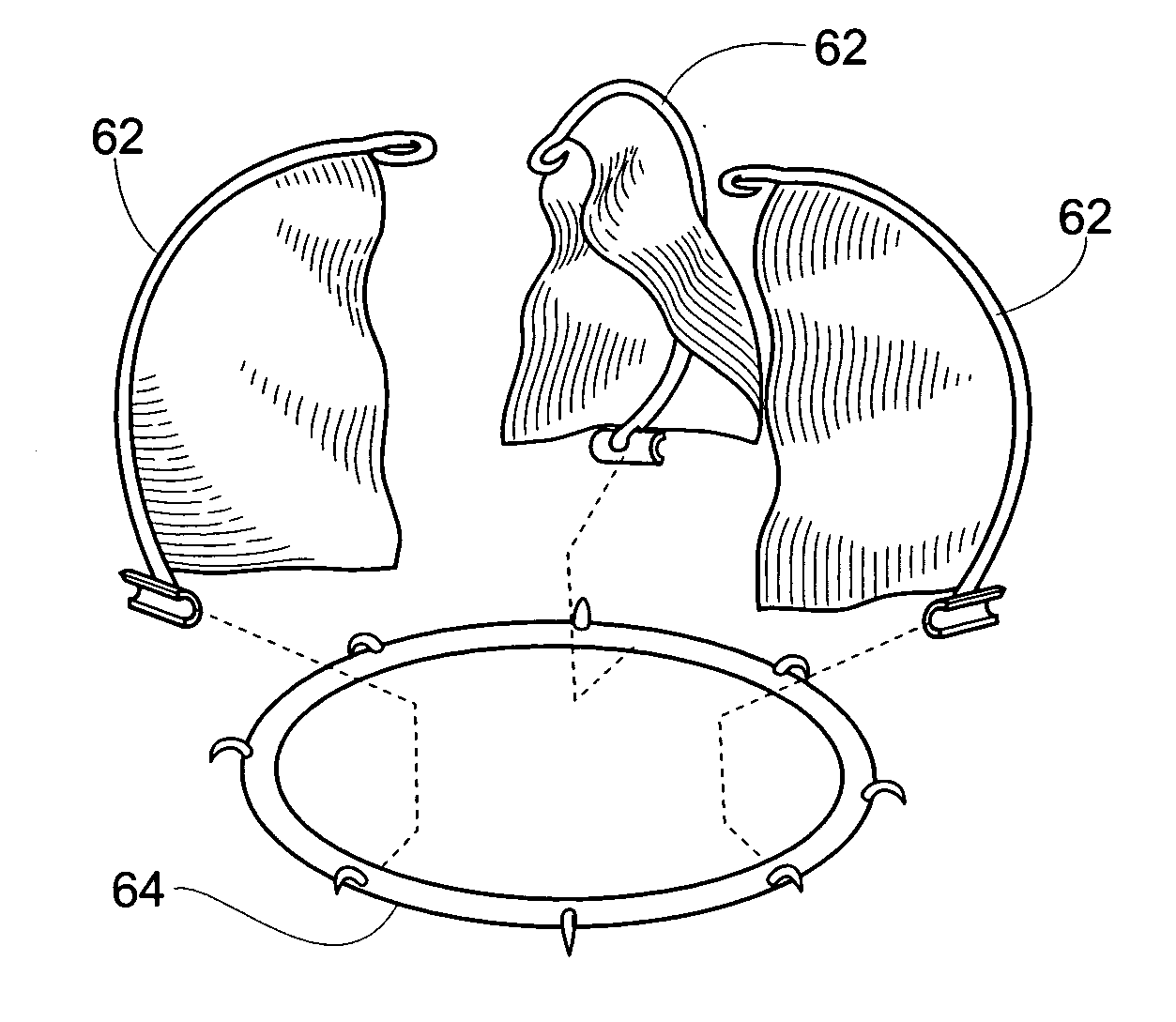

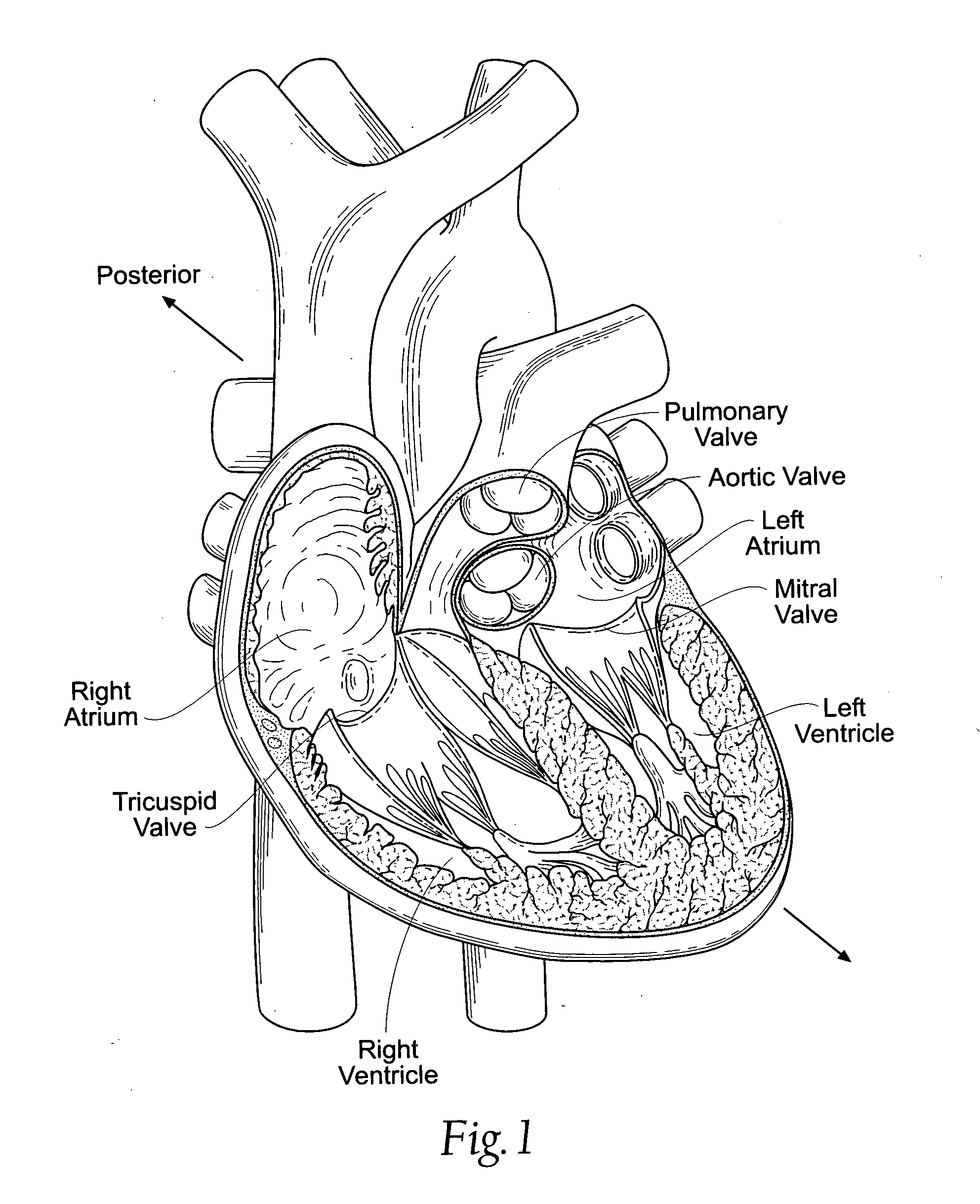

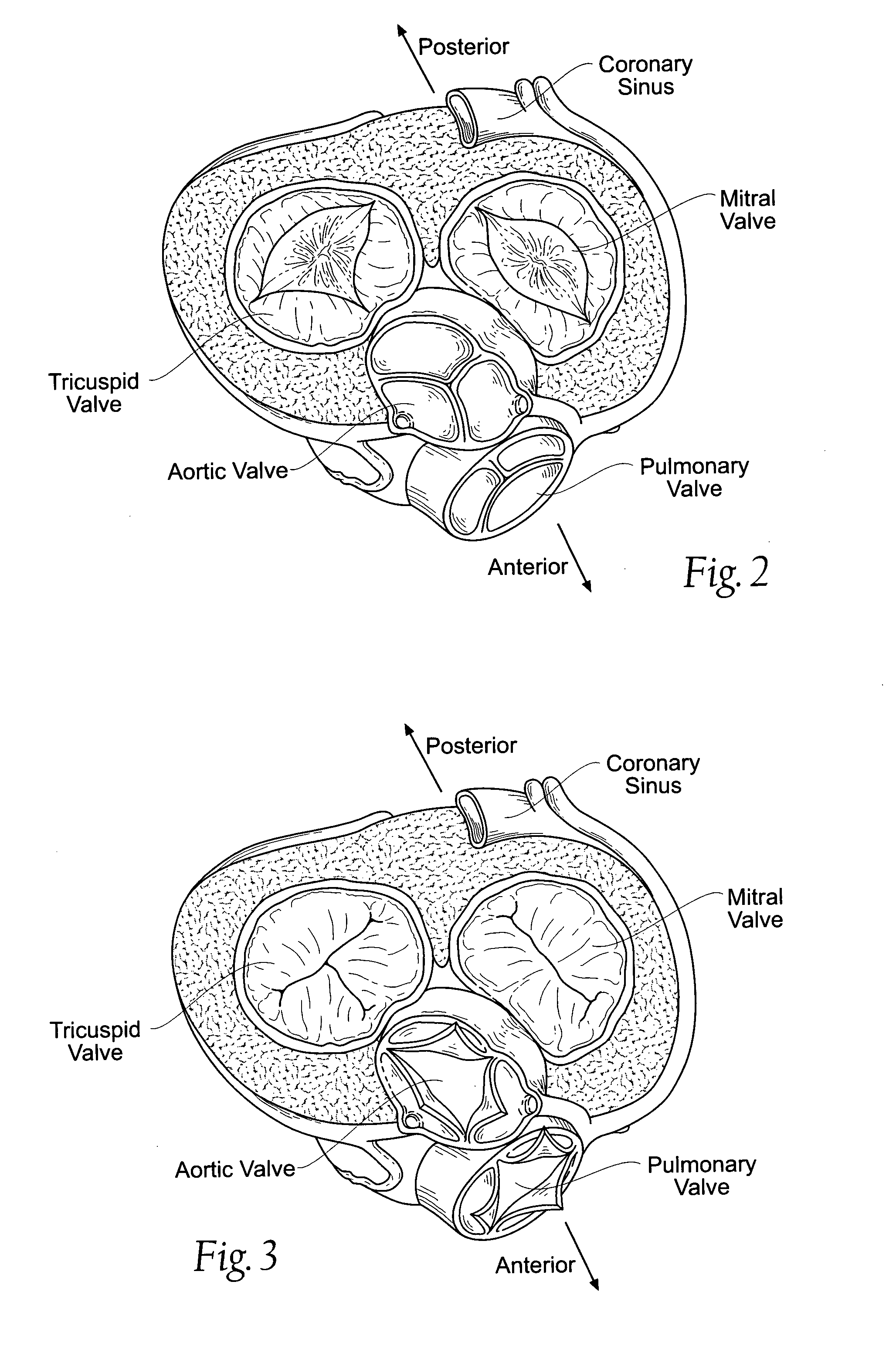

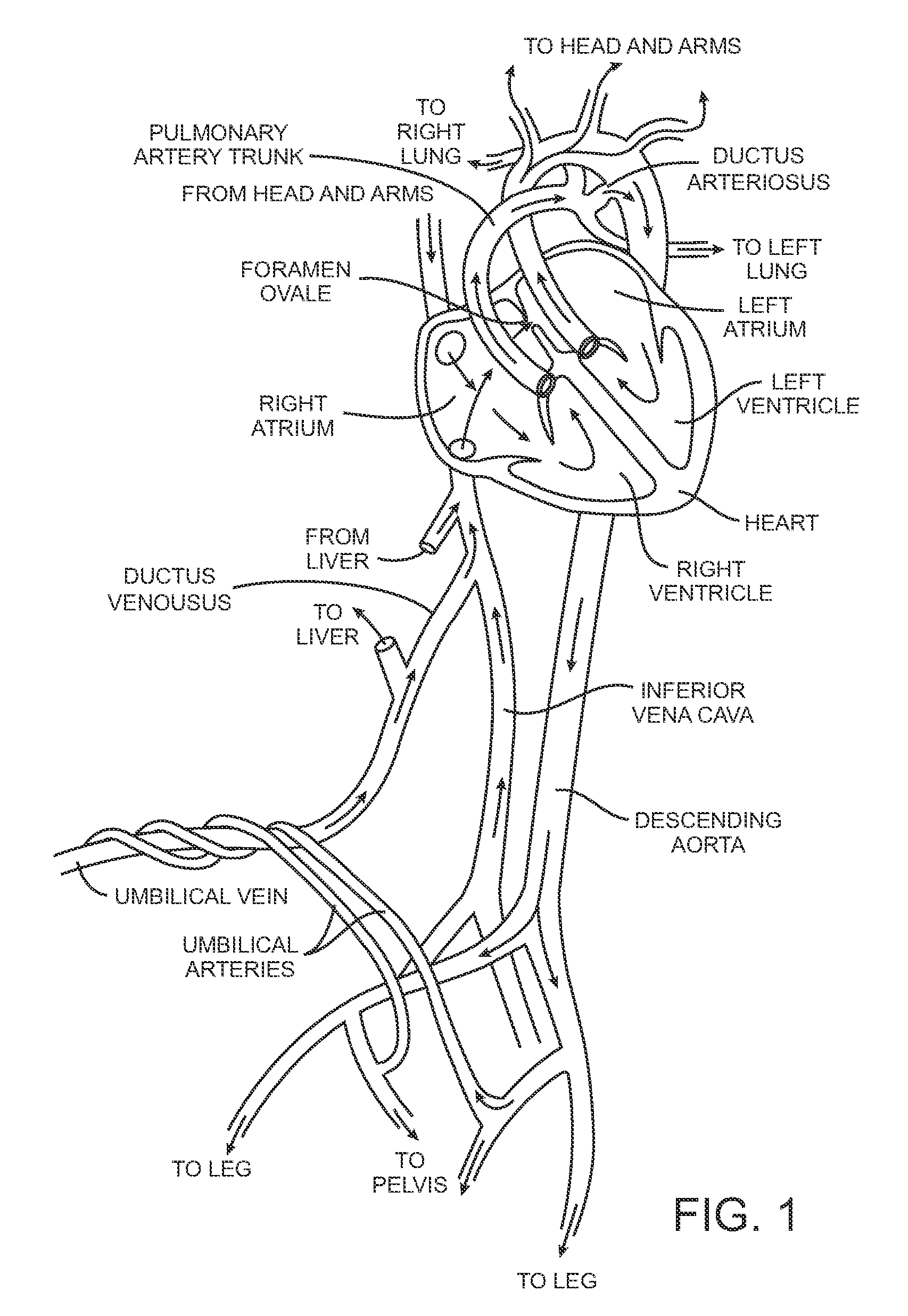

Suspended heart valve devices, systems, and methods for supplementing, repairing, or replacing a native heart valve

InactiveUS20050228495A1Good flexibility and compressibilityImprove foldabilityHeart valvesBlood vesselsHeart chamberBlood vessel

A valve prosthesis is sized and configured to rest within a blood path subject to antegrade and retrograde blood flow. A trestle element on the prosthesis extends across the blood path. A leaflet assembly is suspended from the trestle element and extends into the blood path in alignment with blood flow. At least one mobile leaflet member on the leaflet assembly is sized and configured to assume orientations that change according to blood flow direction. The mobile leaflet member has a first orientation that permits antegrade blood flow and a second orientation that resists retrograde blood flow. The valve prosthesis, when implanted in a heart chamber or great vessel, serves to supplement and / or repair and / or replace native one-way heart valve function.

Owner:AM DISCOVERY

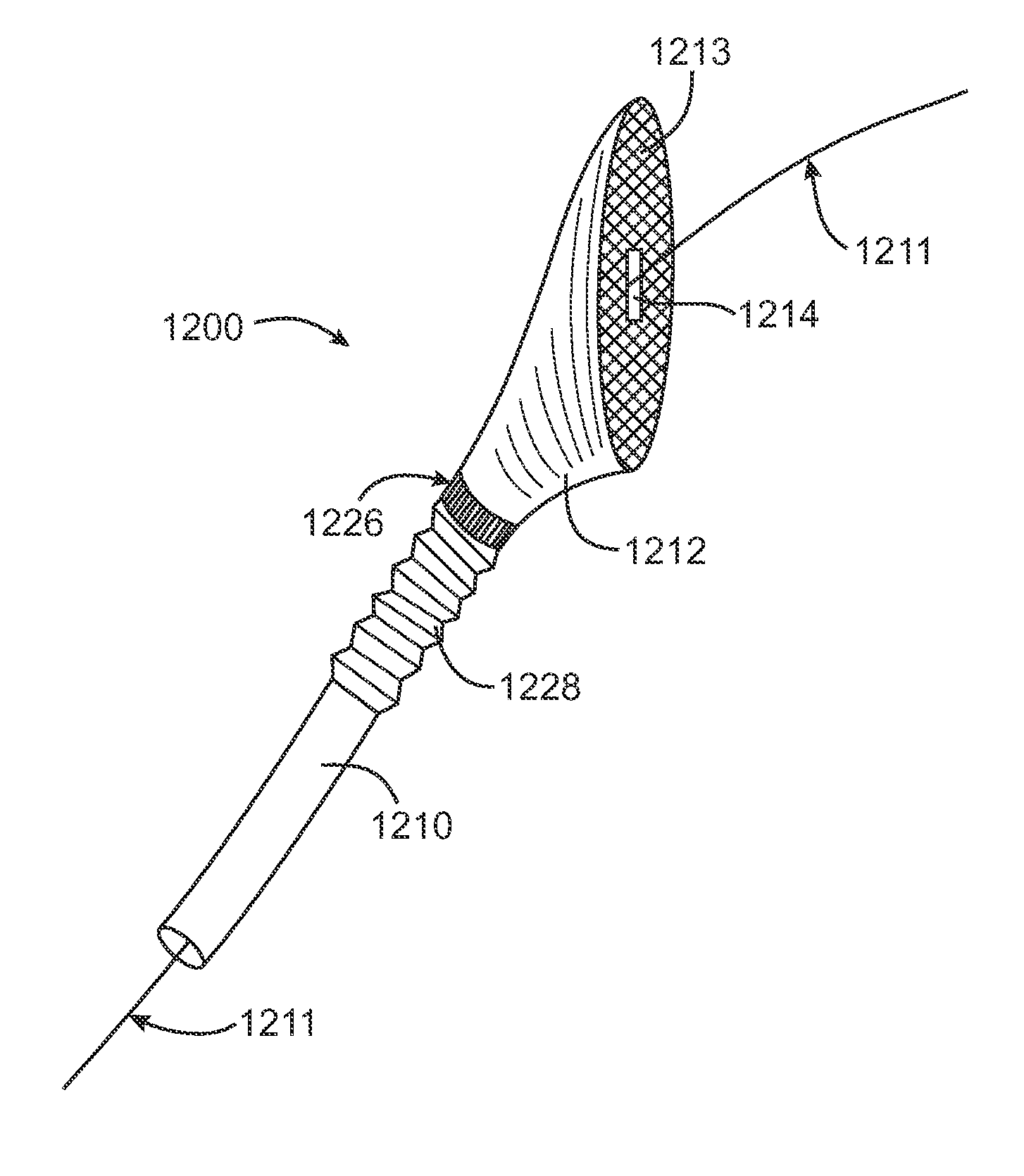

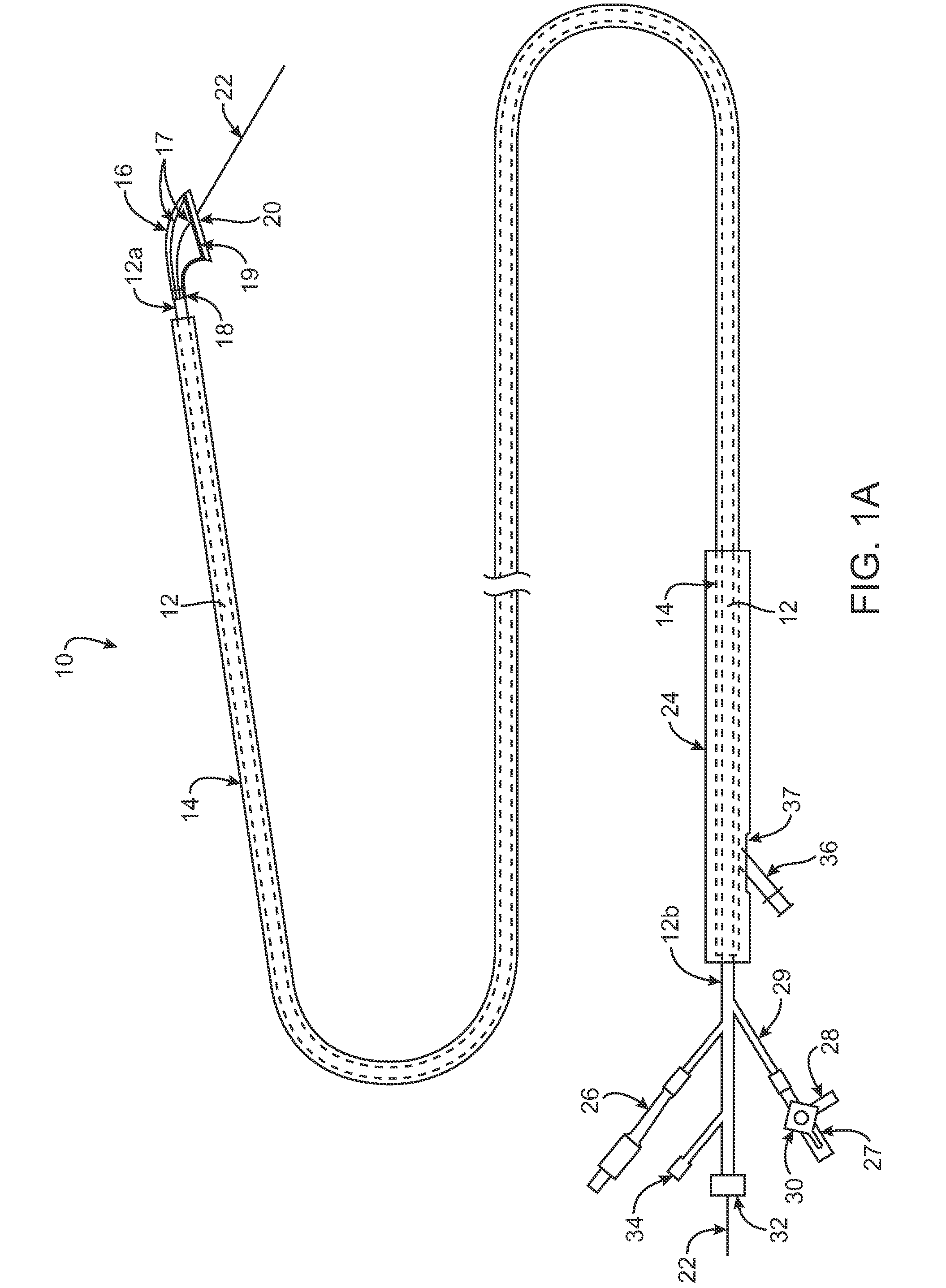

Energy based devices and methods for treatment of anatomic tissue defects

ActiveUS20070287999A1Promote sportsImprove foldabilityCatheterSurgical instrument detailsTissue defectEnergy based

Methods for treating anatomic tissue defects such as patent foramen ovale (PFO) generally involve positioning a distal end of an elongate catheter device at the site of the anatomic defect, exposing an expandable housing and energy transmission member out of the distal end of the catheter device, engaging the housing with tissues at the site of the anatomic defect, applying suction to the tissues via the housing to bring the tissues together; and applying energy to the tissues with the energy transmission member to substantially close the anatomic defect acutely. Apparatus generally include an elongate catheter body, a housing extending from a distal end of the catheter body for engaging tissues at the site of the anatomic defect, and an energy transmission member adjacent a distal end of the housing, the energy transmission member having at least one substantially planar surface.

Owner:TERUMO KK

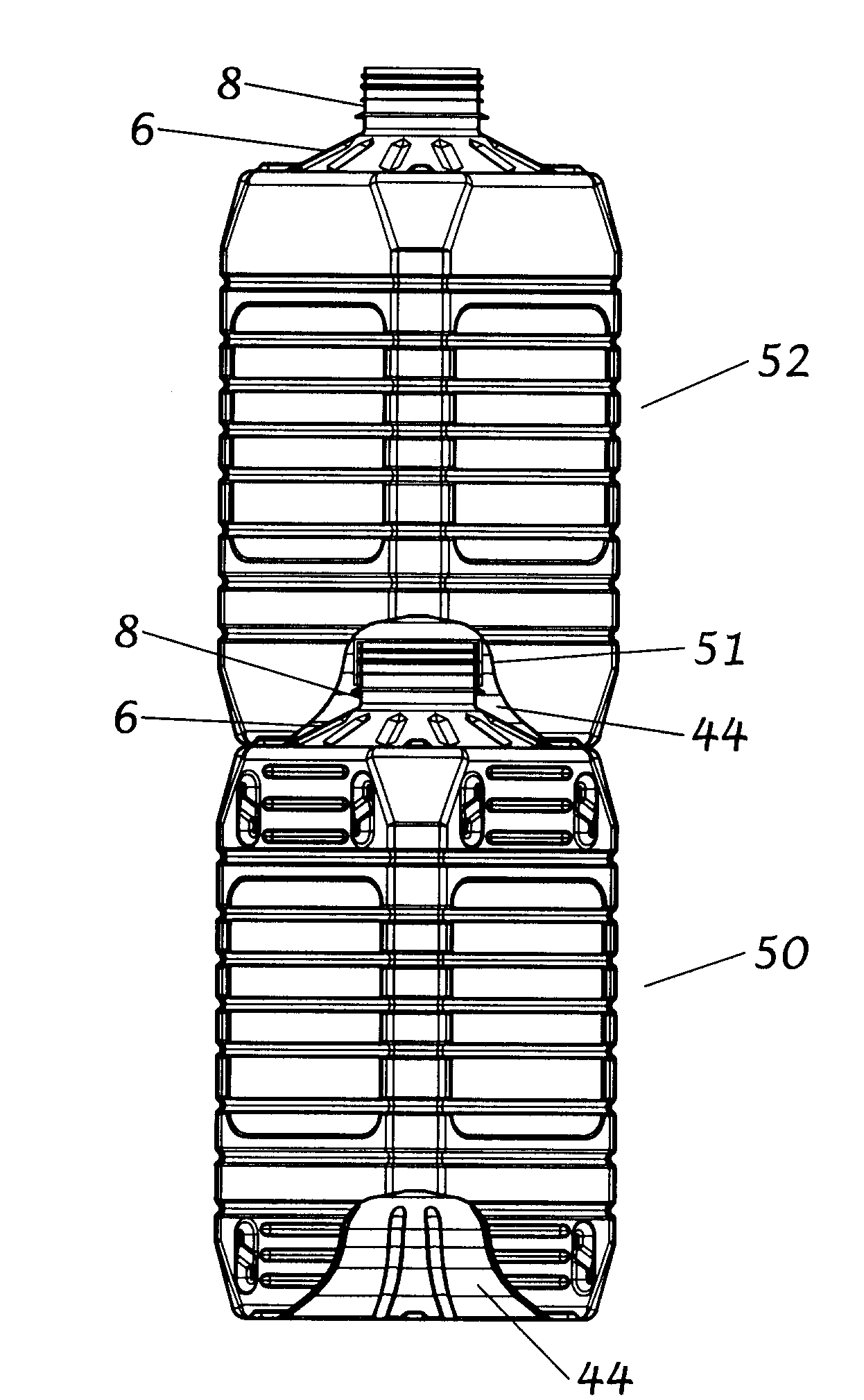

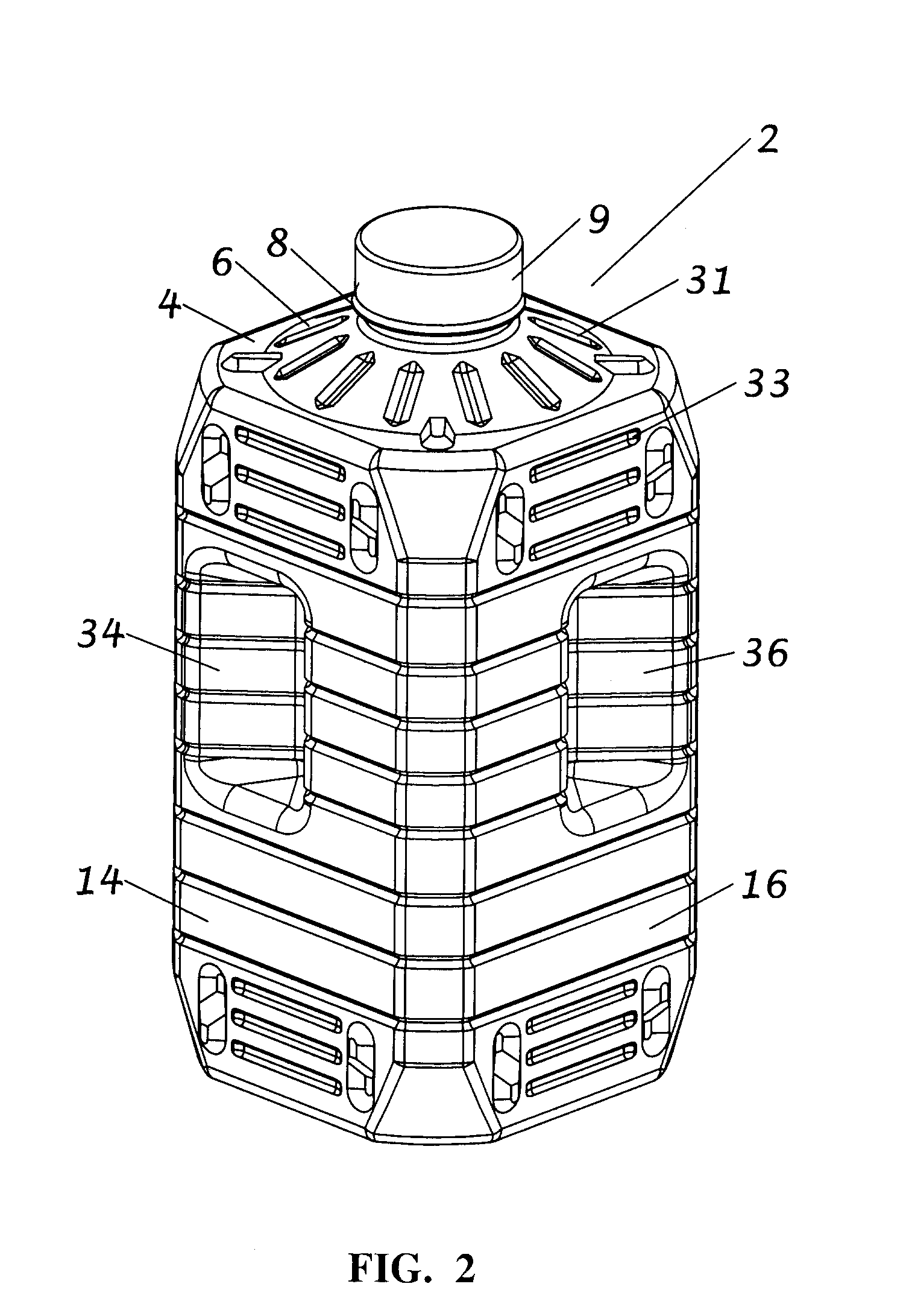

Stackable ribbed bottle system

InactiveUS20090266782A1Improve foldabilityIncrease load capacityBottlesContainer/bottle contructionLoad resistanceEngineering

A bottle having a storage chamber defined by spaced upper and lower surfaces and planar sidewalls; a conical ceiling in said upper surface having an opening at the top thereof; a conical convex recess in said lower surface for receiving the conical ceiling of the next adjacent bottle when stacking said bottles, and means for interlocking the sides and upper and lower surfaces of the bottles when stacked. The bottle may have ribs in the conical ceiling, conical recess and sidewalls for increasing top load resistance. A plurality of bottles may be assembled into a stable bottle stack with minimal packaging material.

Owner:LANE DEAN VINCENT

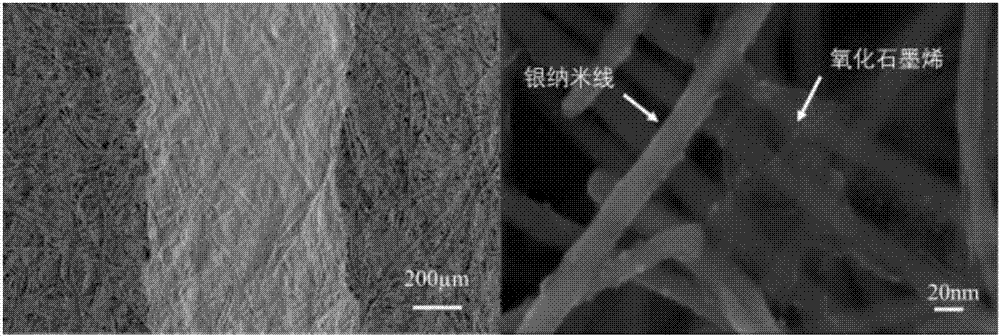

Preparation method and application of conductive ink based on metal nanowire and graphene oxide

ActiveCN106867315AEasy to prepareEasy to operateInksMetallic pattern materialsSurface-active agentsFlashlight

The invention provides a preparation method and application of conductive ink based on metal nanowire and graphene oxide. The graphene oxide is simultaneously used as a dispersing agent, a thickening agent and a stabilizing agent. The metal nanowire, the graphene oxide, the deionized water, the alcohol solvent, the dispersing agent, the surface active agent, the flatting agent and the de-foaming agent are uniformly mixed at a certain mass ratio, so as to acquire the conductive ink product. The acquired ink can be directly written or printed on various substrate materials so as to construct a conductive circuit with high conductivity, stability, flexibility and high adhesion; the constructed conductive circuit is dried for 3-10 minutes under room temperature, so that ultrahigh conductivity is achieved; furthermore, the graphene oxide is reduced and the metal nanowire is sintered according to the methods, such as, selecting sintering temperature at 50-200 DEG C or performing chemical reduction under room temperature or utilizing an xenon flashlight to sinter, so that the conductivity of the conductive circuit is further increased.

Owner:XUZHOU LANOXENE INST CO LTD

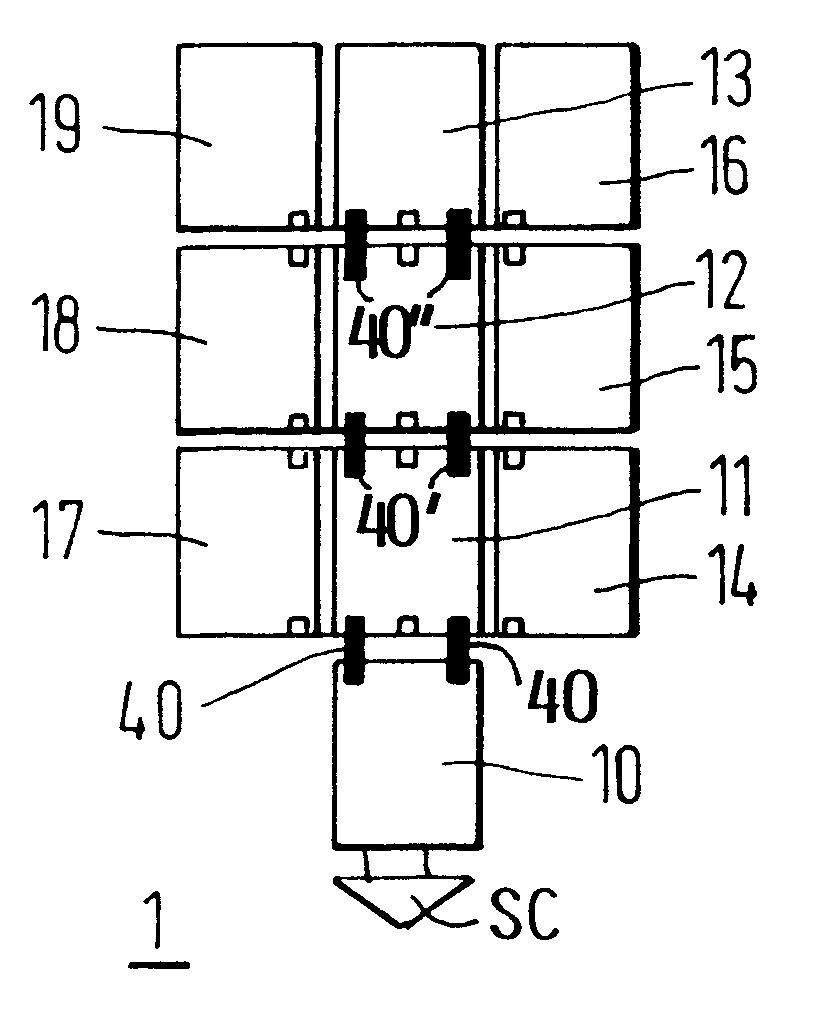

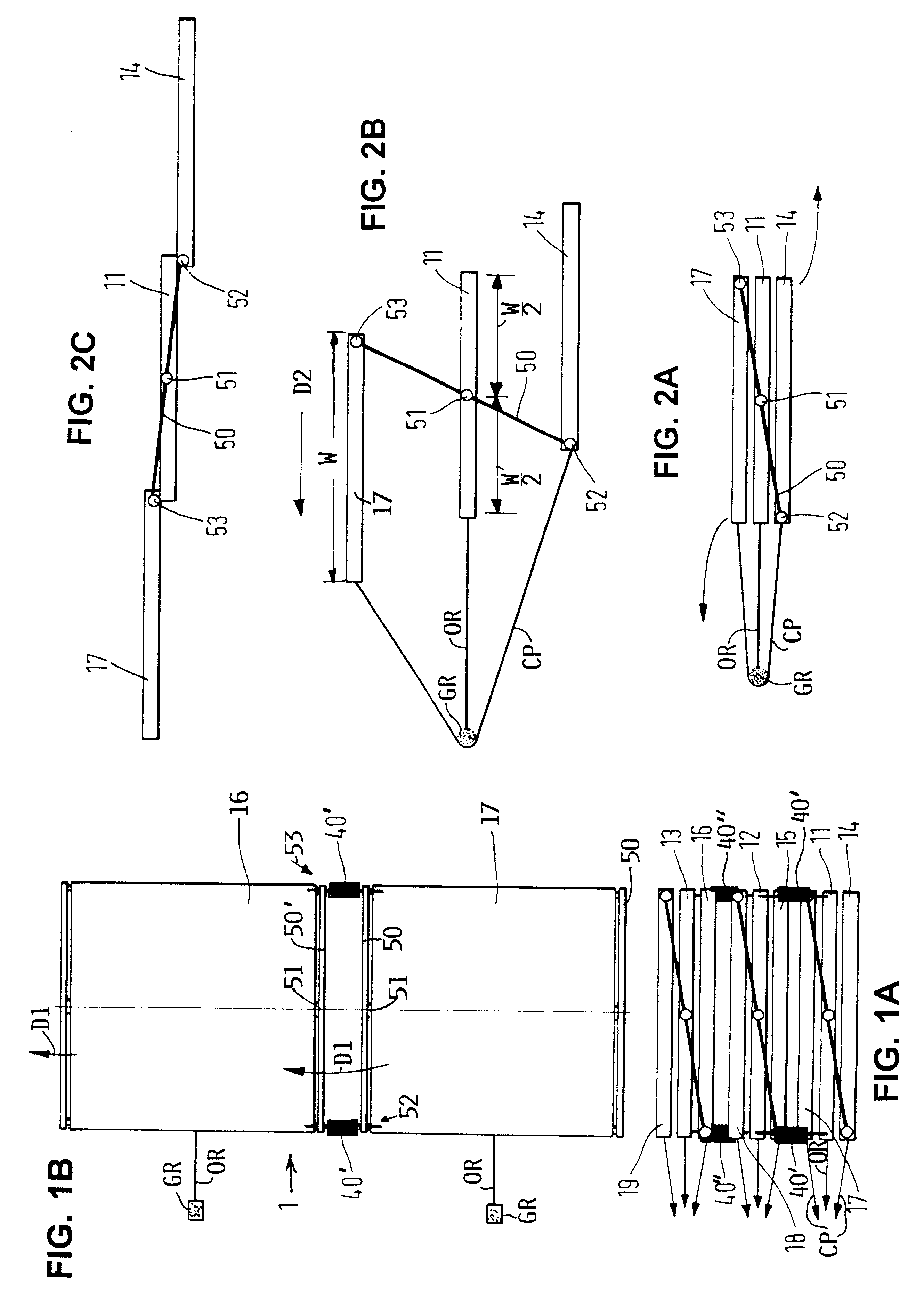

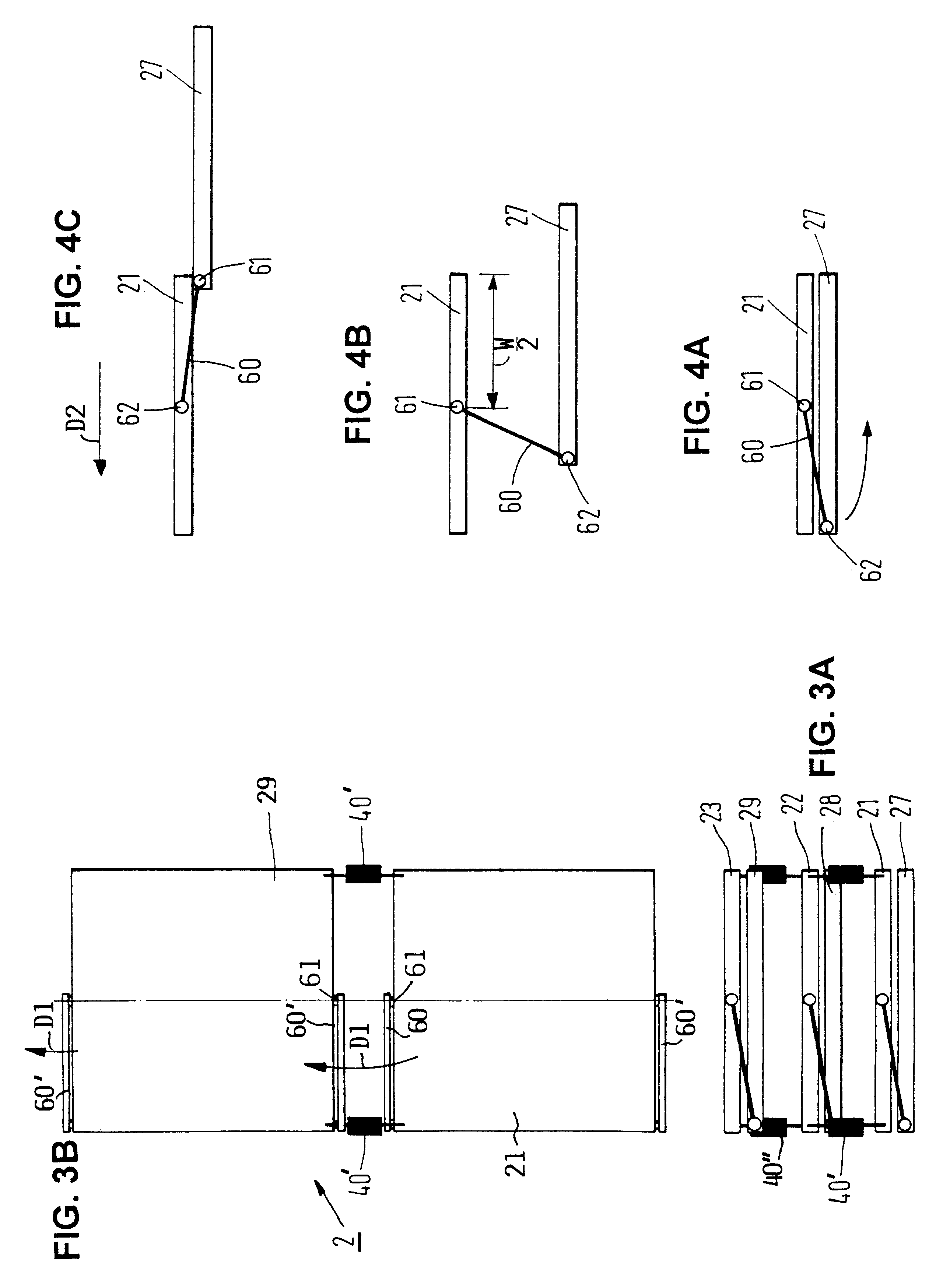

Solar generator with foldable panels especially for a spacecraft

InactiveUS6284967B1Avoid disadvantagesAvoid orCosmonautic vehiclesCosmonautic power supply systemsSolar generatorSpacecraft

A solar generator especially for a spacecraft or space flight body has a plurality of first collector panels hinged to each other in a column extending in a first direction (D1) when the first collector panels are unfolded and a plurality of second panels coupled to the first panels so that the second panels can be unfolded in a second direction (D2) only after the first panels have been unfolded. The second panels are coupled to the first panels by journal struts or by hinges so that at least one first panel forms with at least one second panel, preferably with two or more second panels, a panel packet. The hinges (40) that articulate the first panels to each other permit unfolding the panel packets in said first direction (D1), whereupon the second panels in the individual packets can be unfolded in the second direction (D2).

Owner:DAIMLER AG

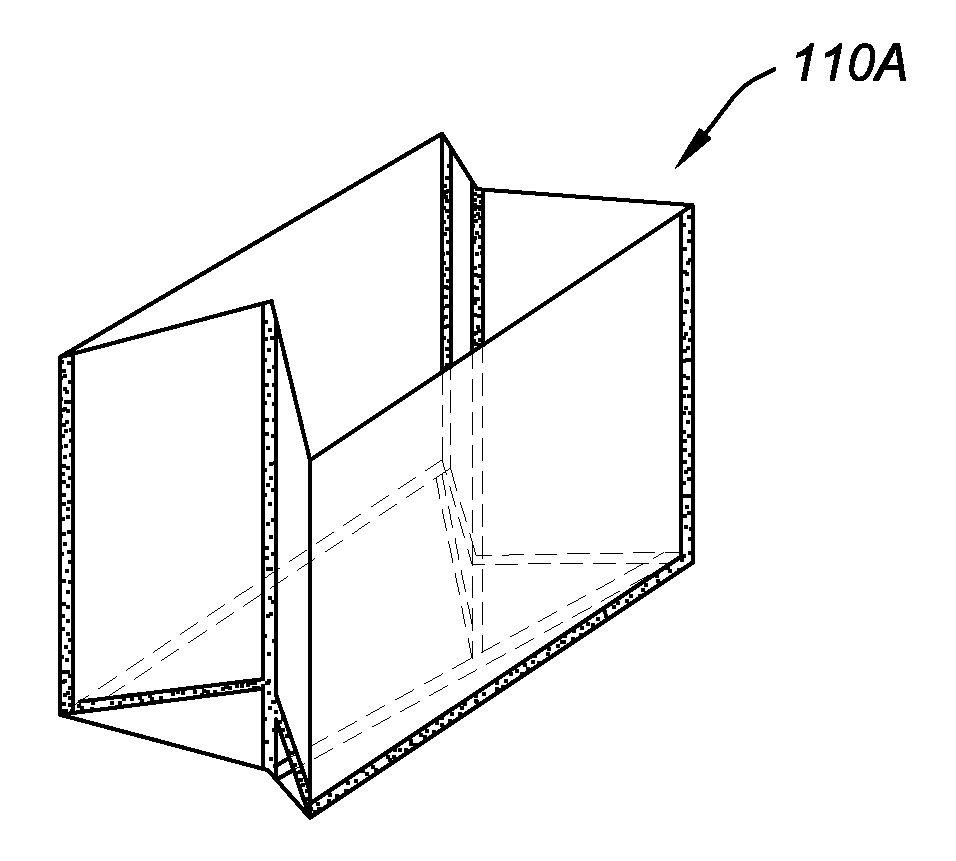

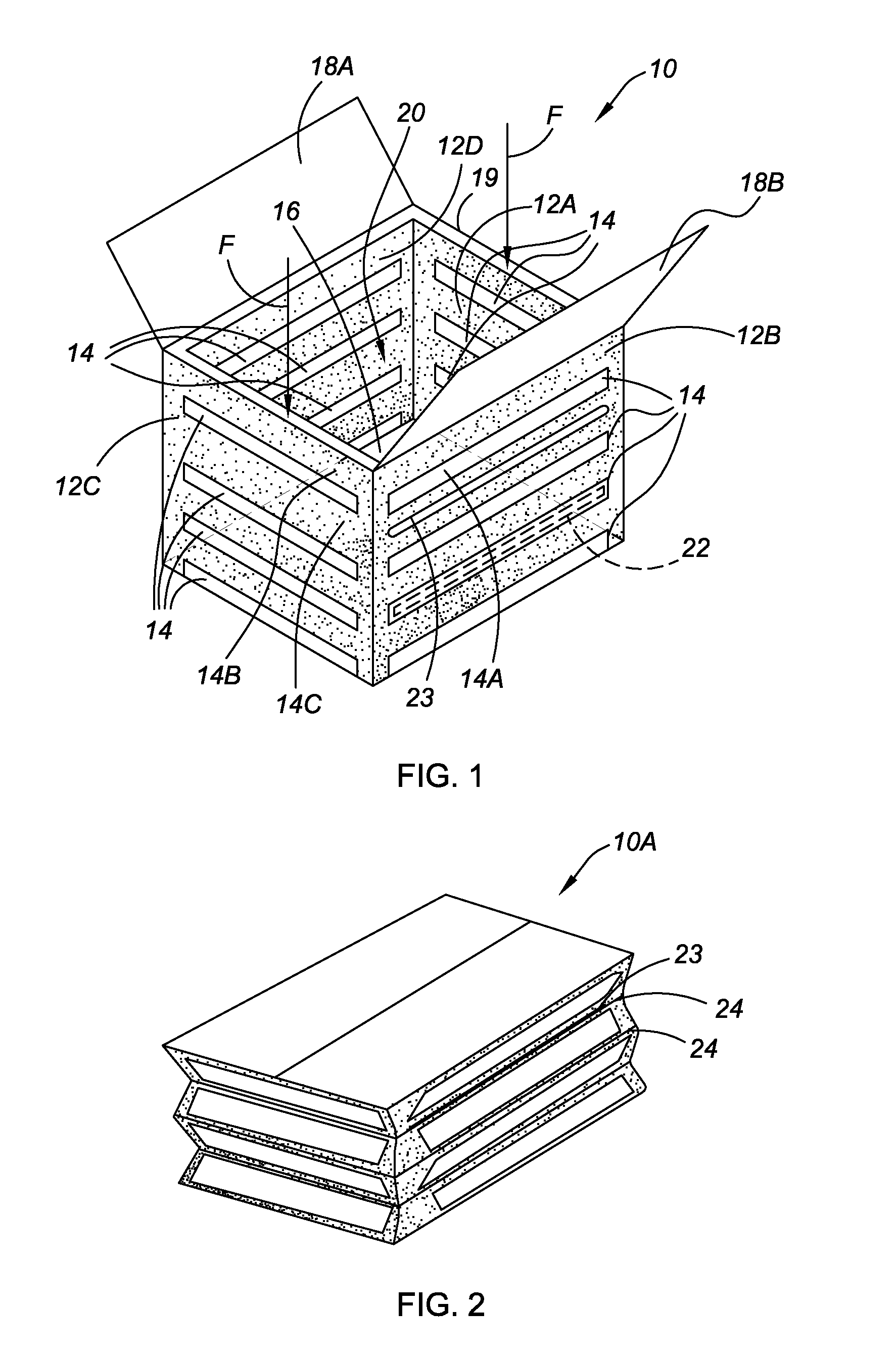

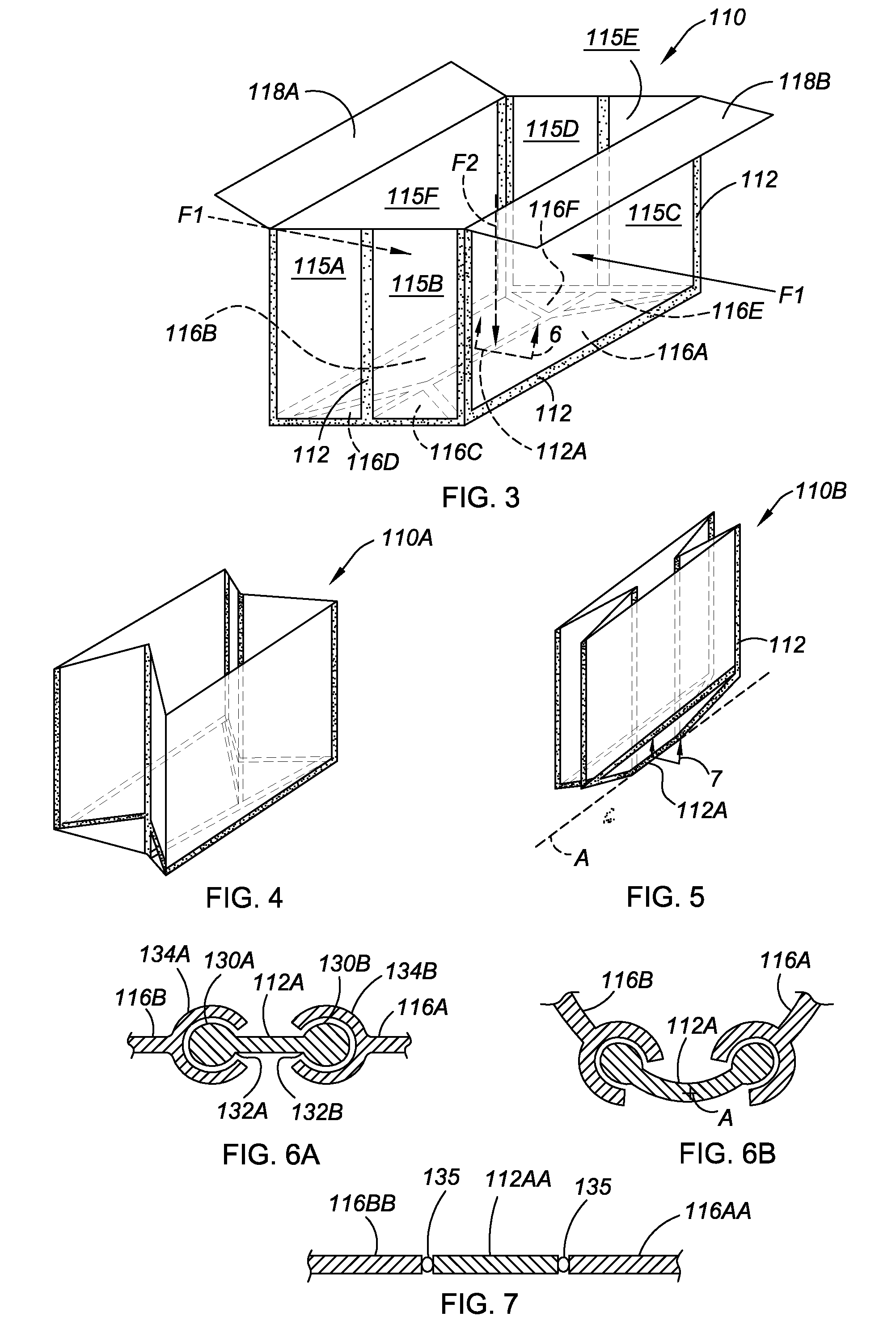

Reconfigurable container and methods of fabrication and use thereof

ActiveUS20080302789A1Improve foldabilityDecrease in modulus of elasticityCapsUmbrellasEngineeringFastener

Reconfigurable containers which may adopt two stable configurations are described. In the first configuration, the container is suitable for the storing and transport of goods. When in a second, collapsed configuration, the container occupies a lesser volume than the first configuration and thus requires less shipping space. This is accomplished through the use of at least one deformable active material member that is preferably a shape memory polymer and, optionally, releasable fasteners.

Owner:GM GLOBAL TECH OPERATIONS LLC

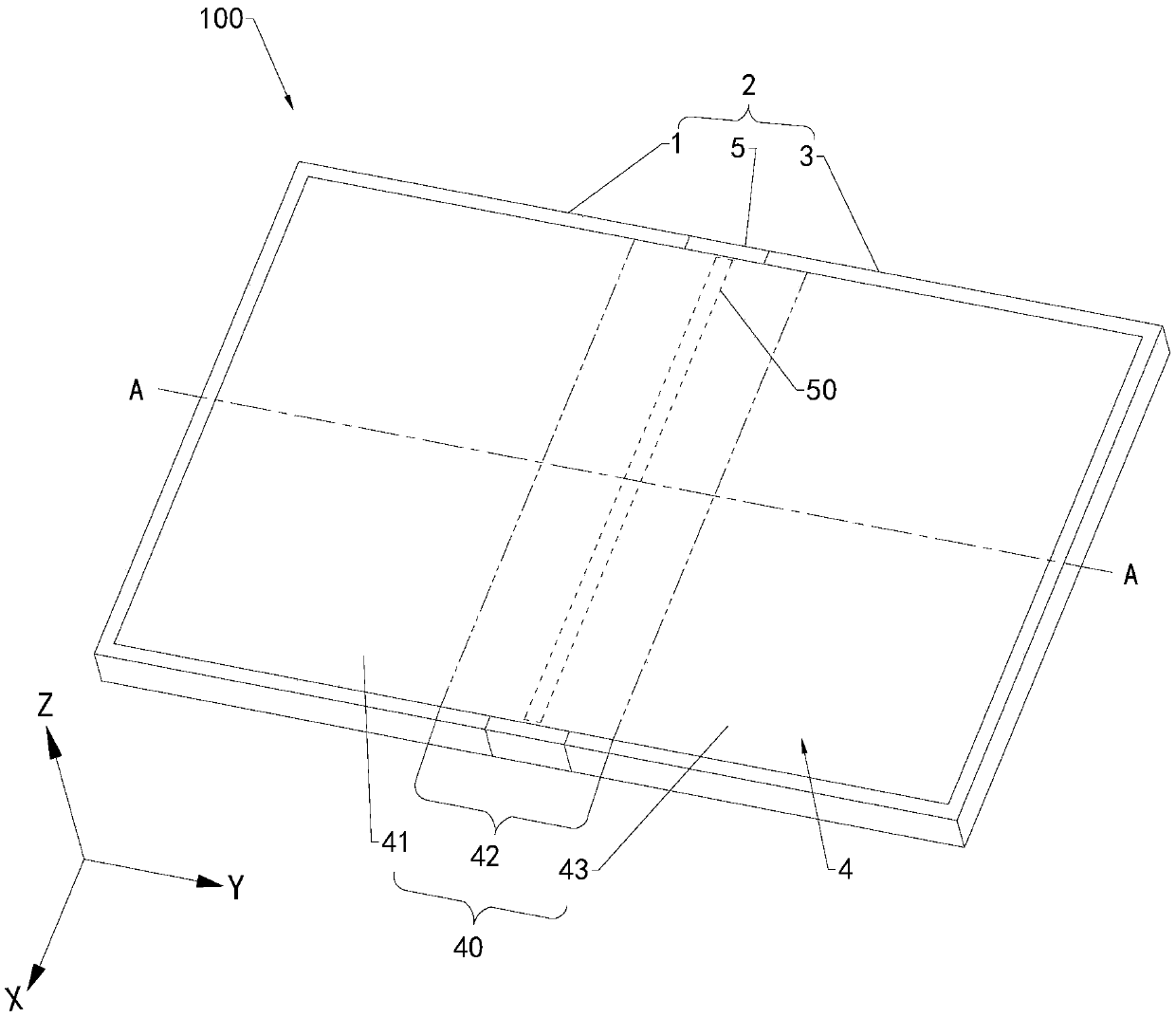

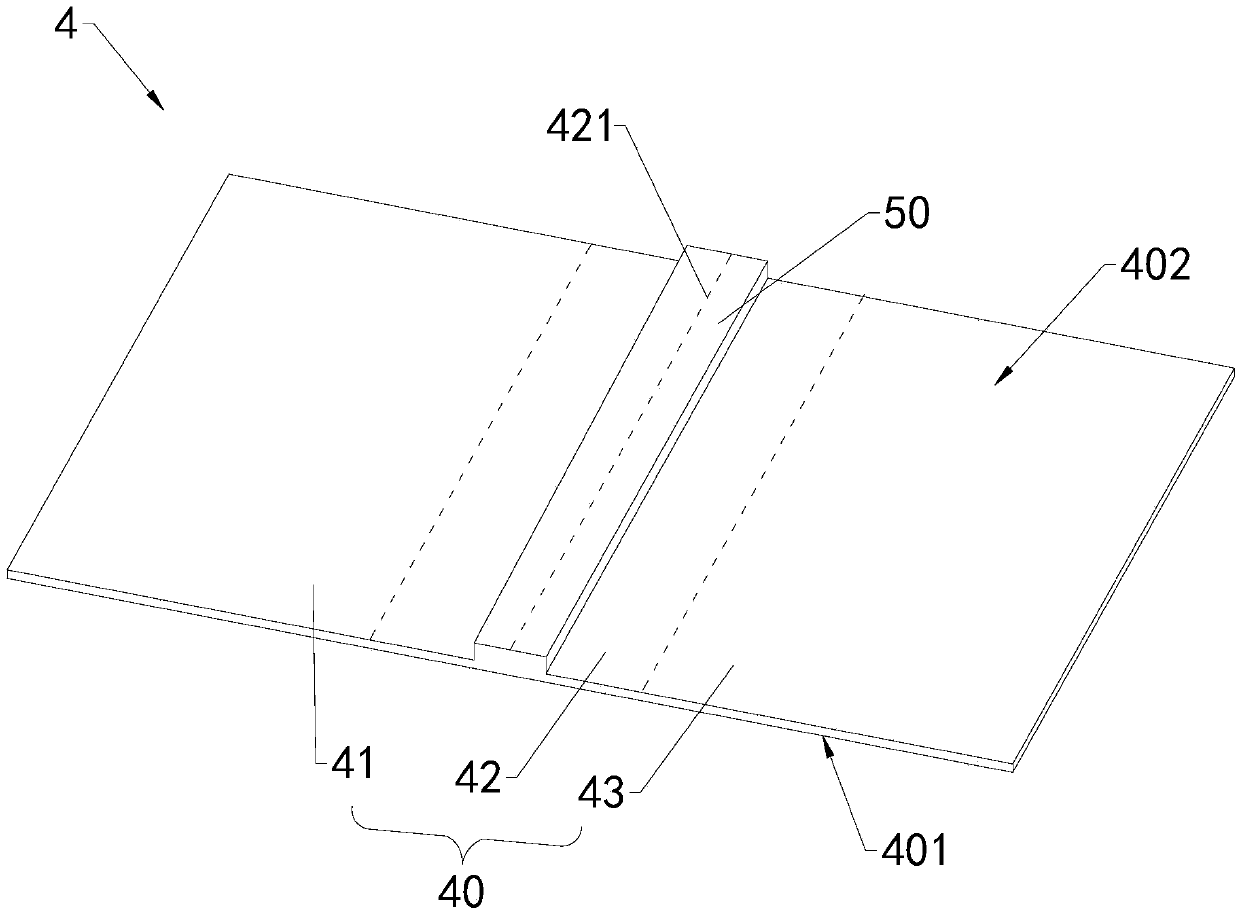

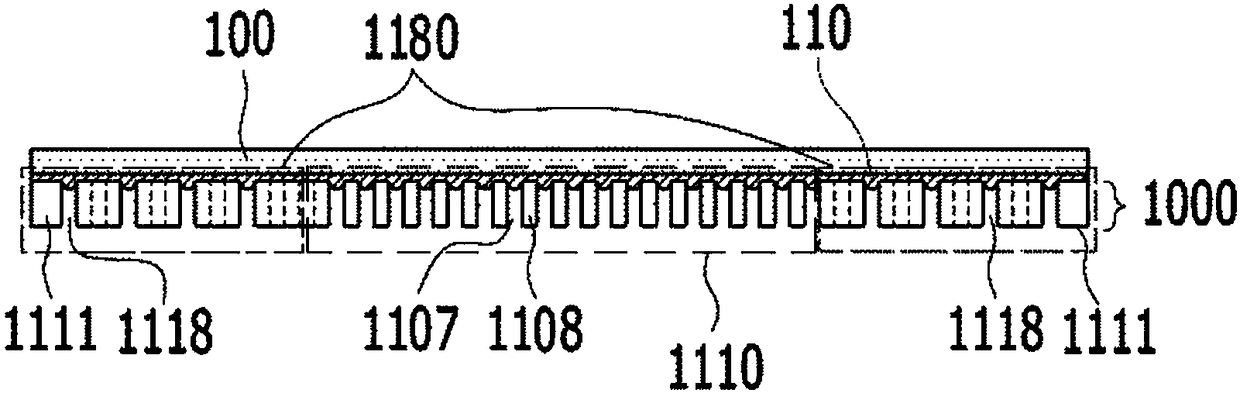

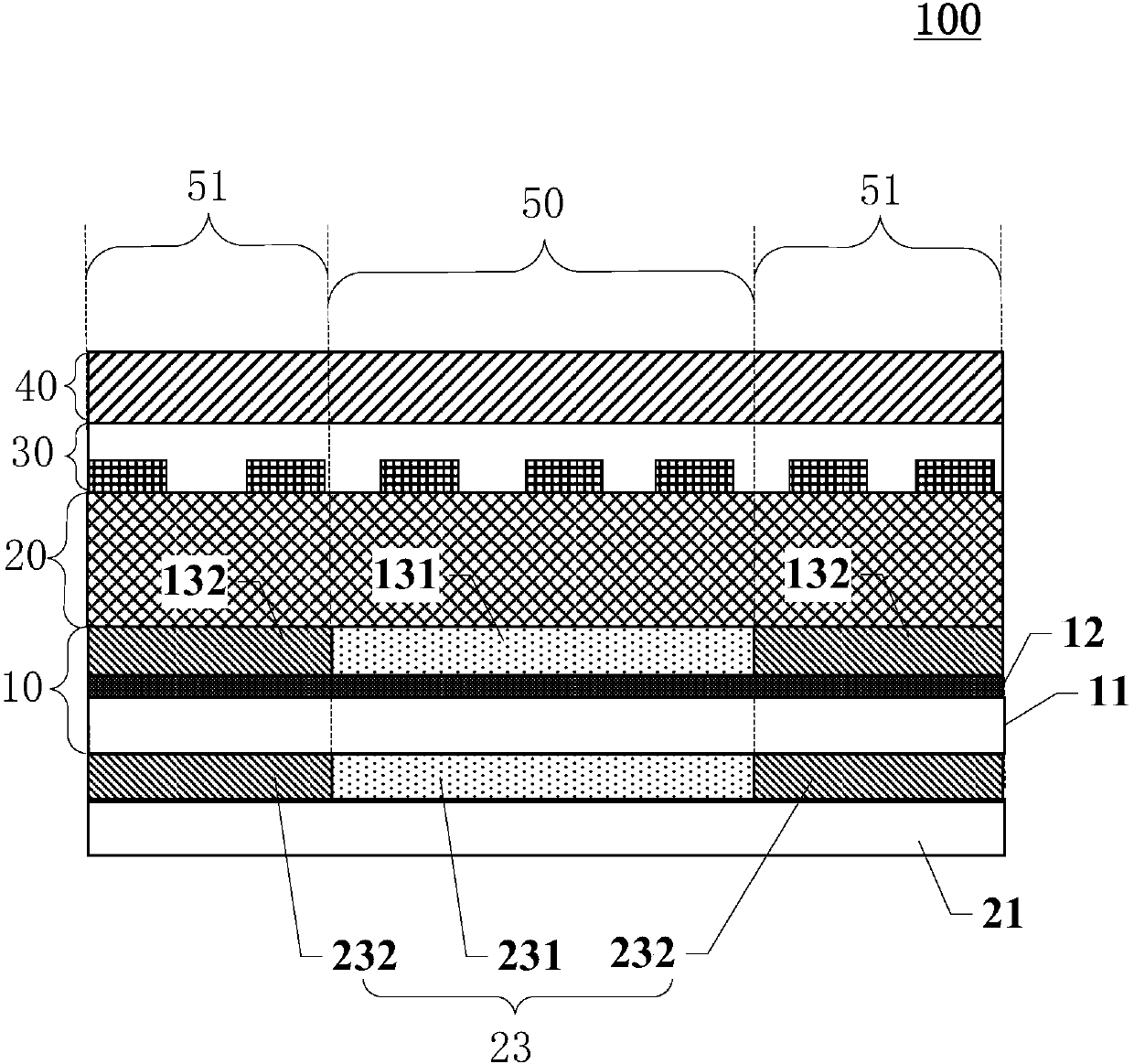

Flexible screen and electronic device

ActiveCN109658826AImprove foldabilityIncrease stressInput/output processes for data processingIdentification meansMechanical engineeringEngineering

Owner:GUANGDONG OPPO MOBILE TELECOMM CORP LTD

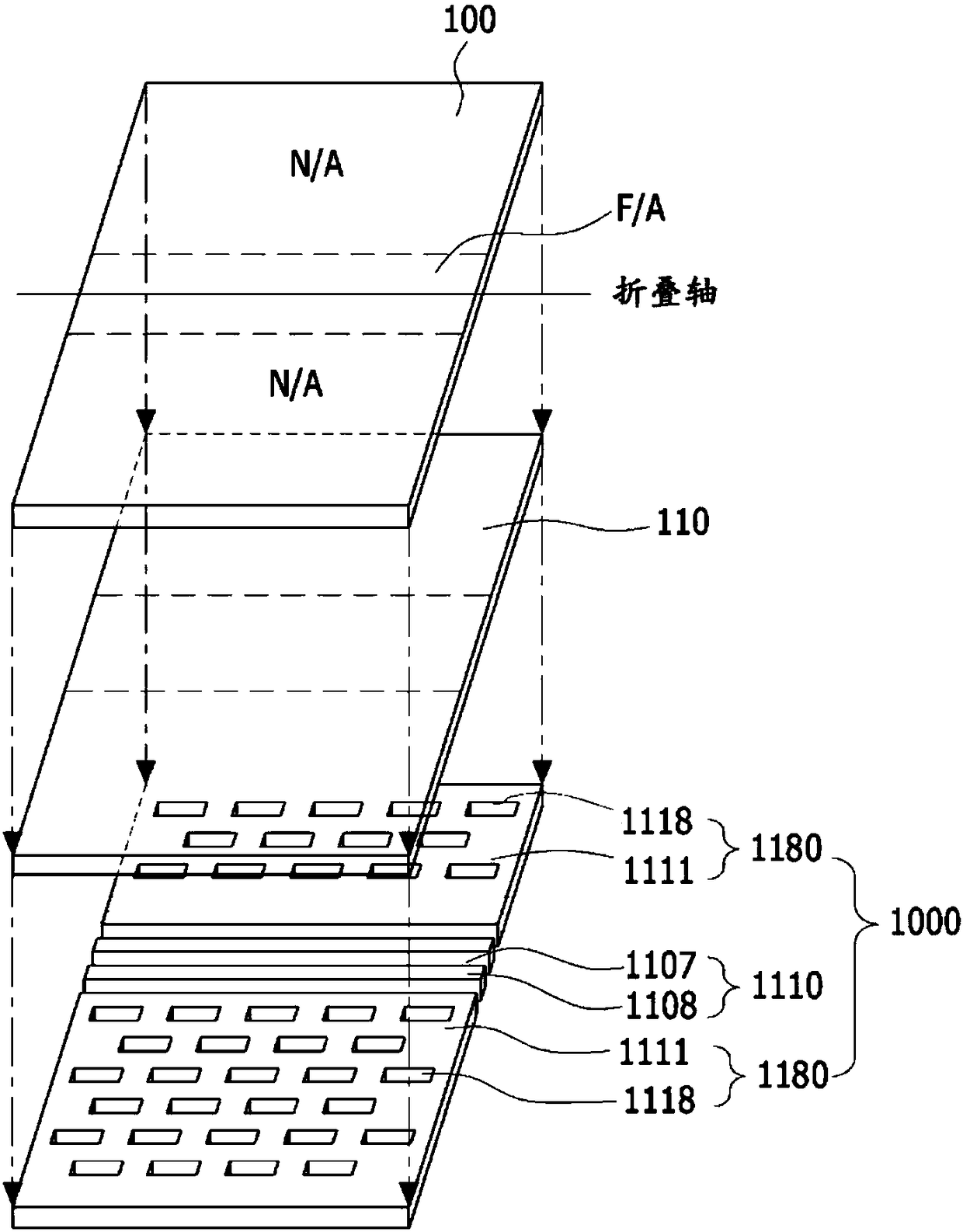

Foldable display device

ActiveCN108268170APrevent saggingReduce transferDigital data processing detailsElectrical equipmentDisplay deviceStructural engineering

Disclosed is a foldable display device capable of preventing distortion of a folding part of a display screen due to deformation of the folding part. The foldable display device includes a display panel including a folding part and non-folding parts, and a back cover attached to the rear surface of the display panel via an adhesive layer, wherein the back cover includes folding patterns and open patterns, both of which are disposed at the folding part, and unevenness compensation patterns disposed on areas of a surface of the back cover contacting the adhesive layer, the areas of the surface of the back cover corresponding to the non-folding parts. The unevenness compensation patterns may be a plurality of open patterns, which are fully formed through the back cover, or may be a pluralityof grooves, which are not fully formed through the back cover.

Owner:LG DISPLAY CO LTD

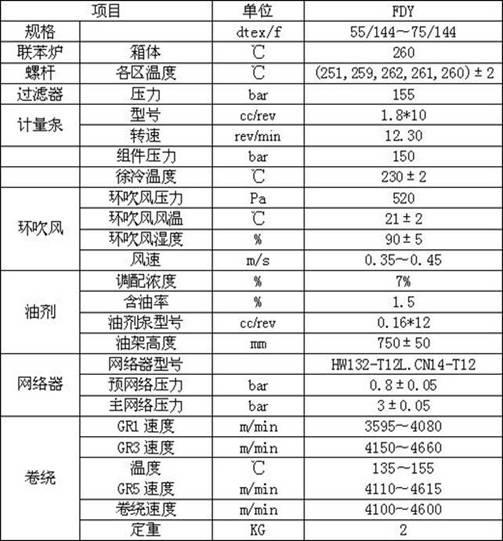

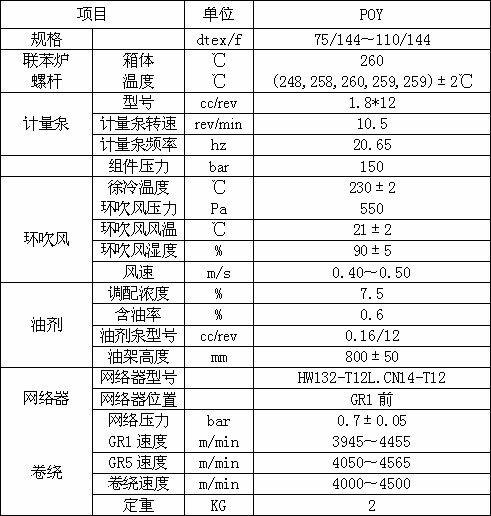

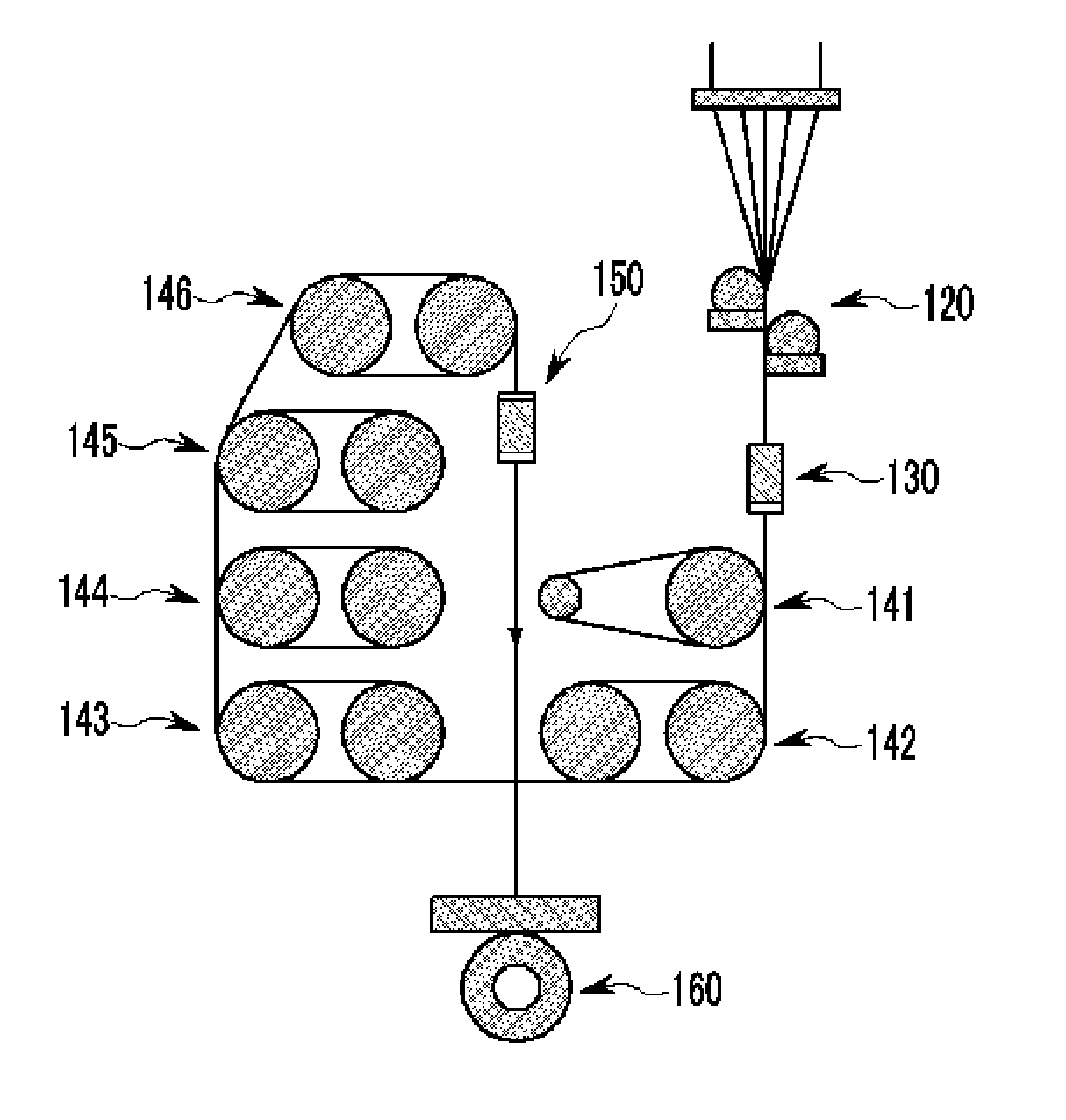

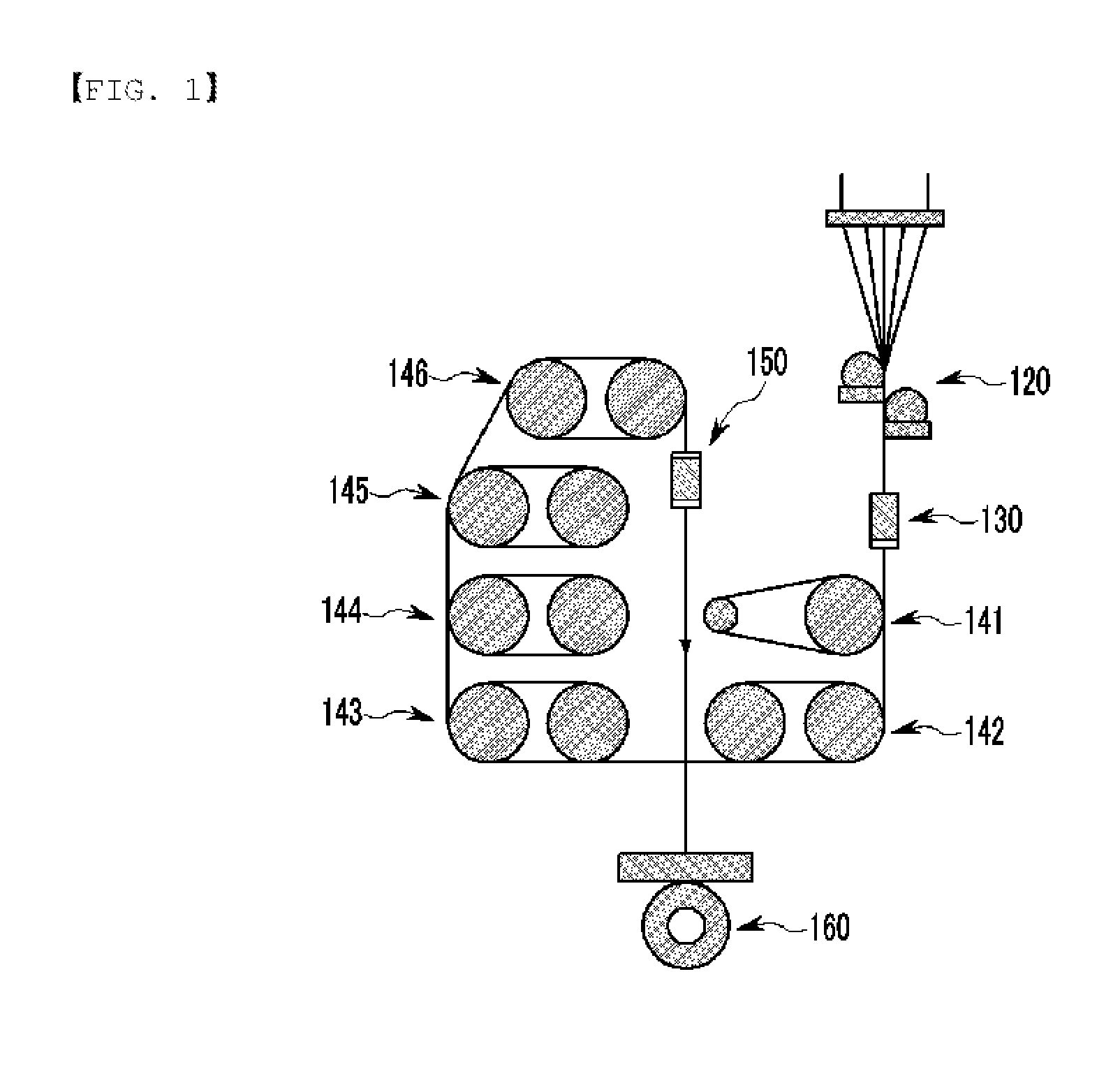

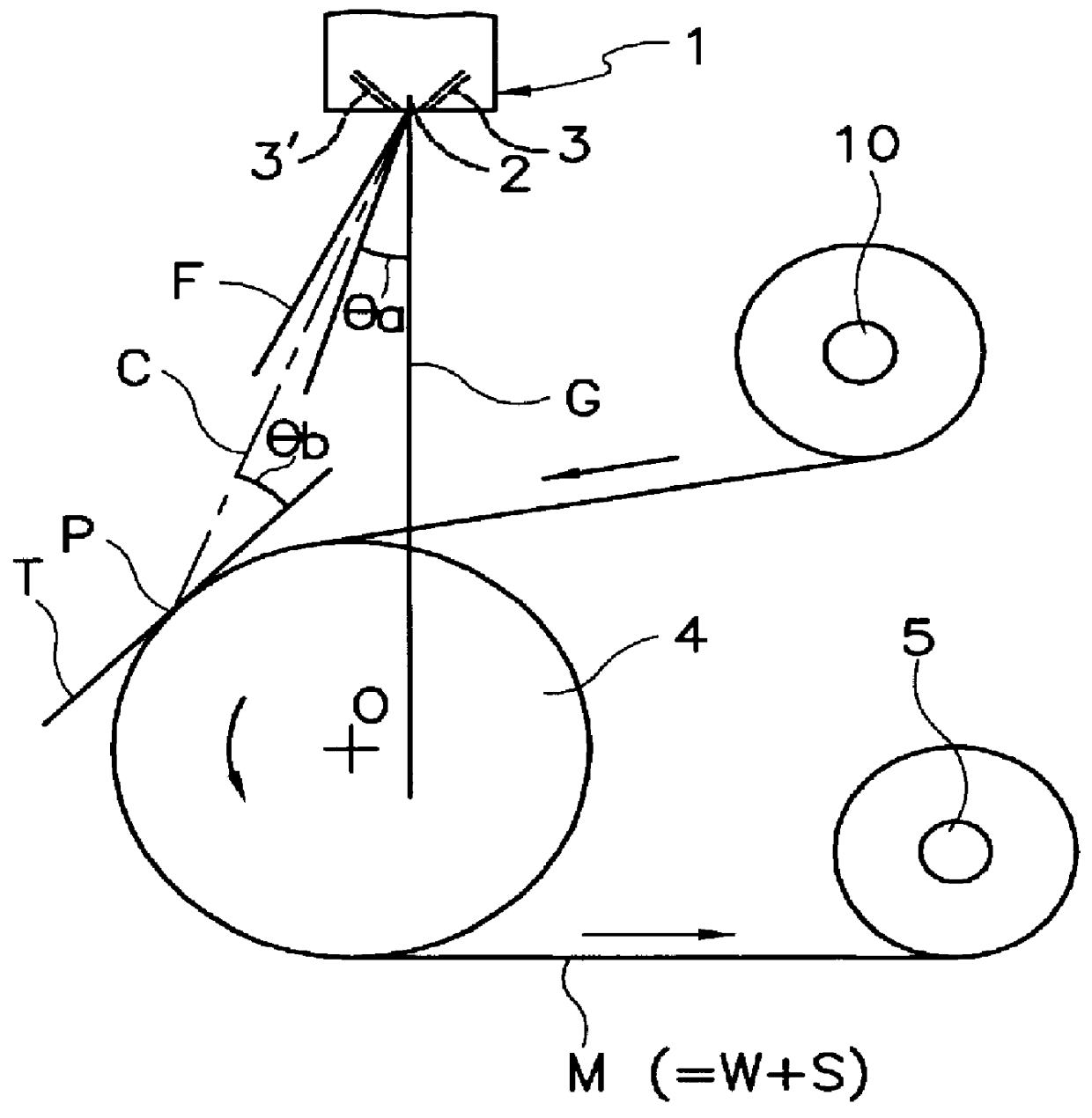

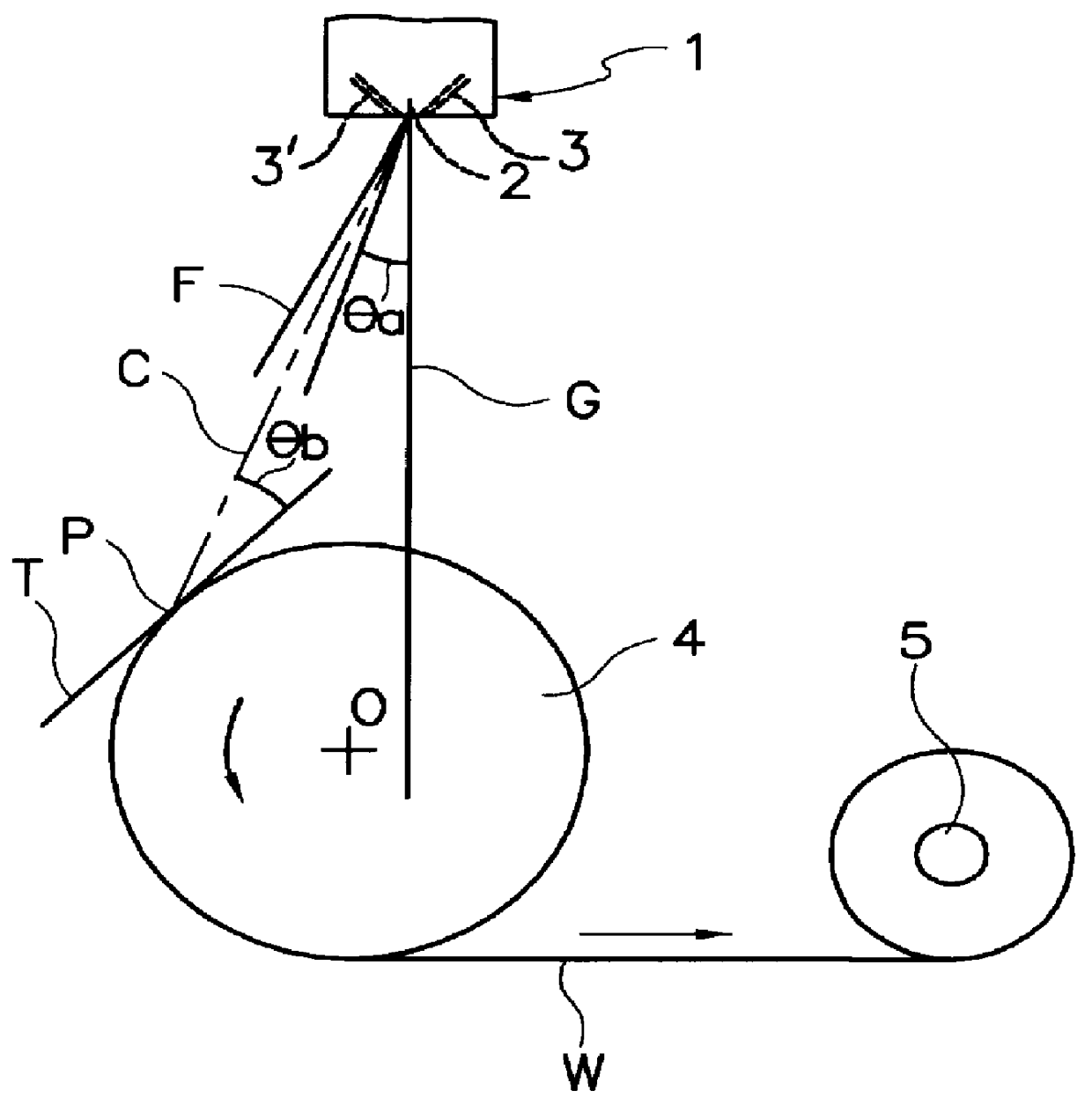

Porous superfine polyamide 6 fully-drawn yarn, preparation method thereof, and equipment thereof

InactiveCN102493016AImprove mixing uniformityImproved pressure stabilityFilament forming substance formingArtificial thread manufacturing machinesYarnAir velocity

The invention relates to a porous superfine polyamide 6 fully-drawn yarn, a preparation method thereof, and equipment thereof. According to the invention, existing FDY production equipment is adopted. A raw material polyamide 6 is sliced and dried; an additive is added on line; the material is subject to screw extrusion and melt extrusion; the material is then cured with a gradually cooling manner and a circular air blow cooling manner; with a reasonably selected spinning temperature of 259-262 DEG C, an air temperature in the circular air blowing process of 19-23 DEG C, a humidity of 85-95%, an air velocity of 0.35-0.45m / s, an oiling and clustering position of 700-800mm, and a winding speed of 4100-4600m / min, the porous superfine polyamide 6 fully-drawn yarn product with a specification of 55dtex / 144f-75dtex / 144f is prepared. Flexible operation is adopted in the preparation method. The preparation method is advantaged in simple technology and low production cost. The product is advantaged in stable performance, good yarn evenness, and good coloration property.

Owner:SUZHOU UNIV

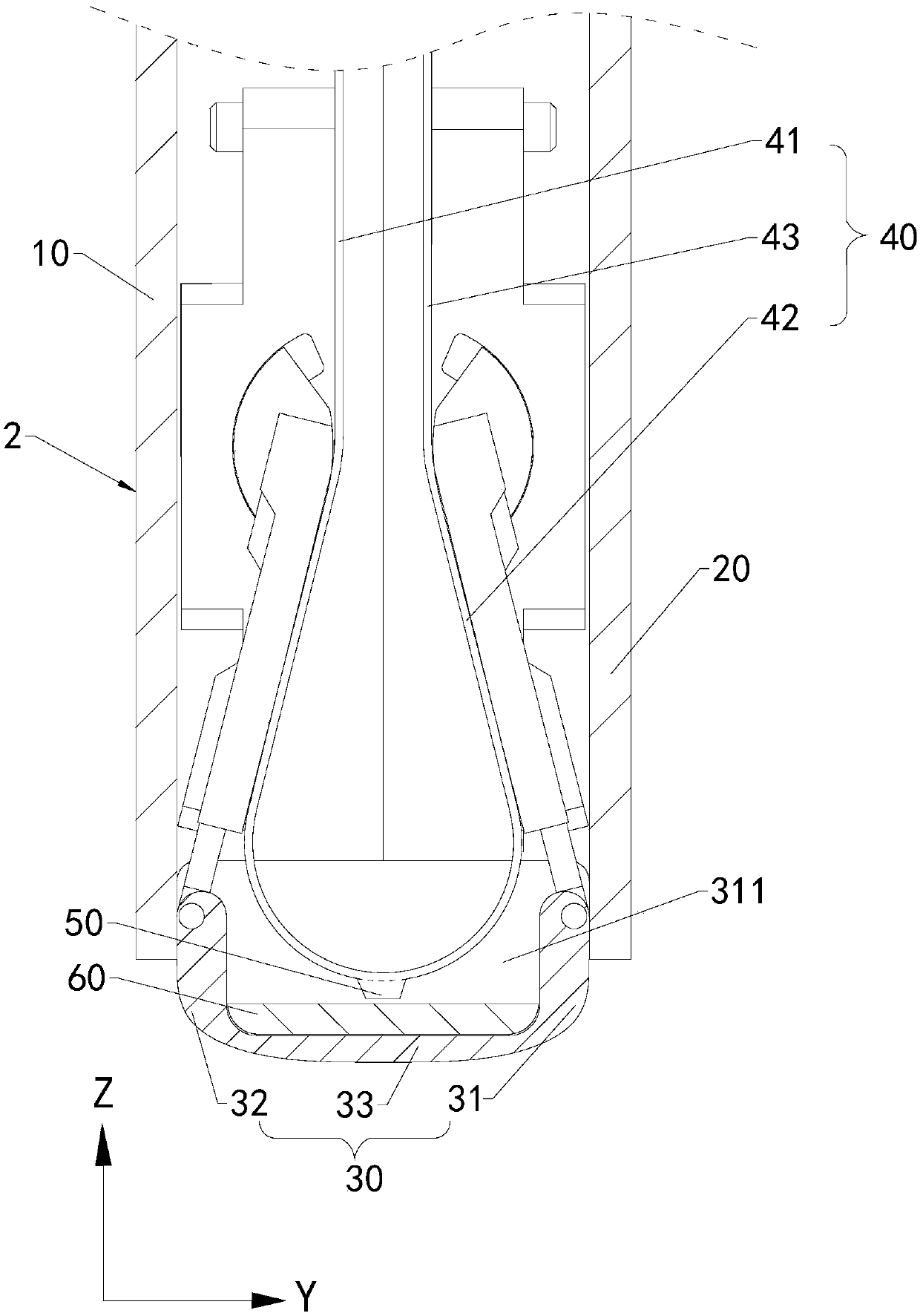

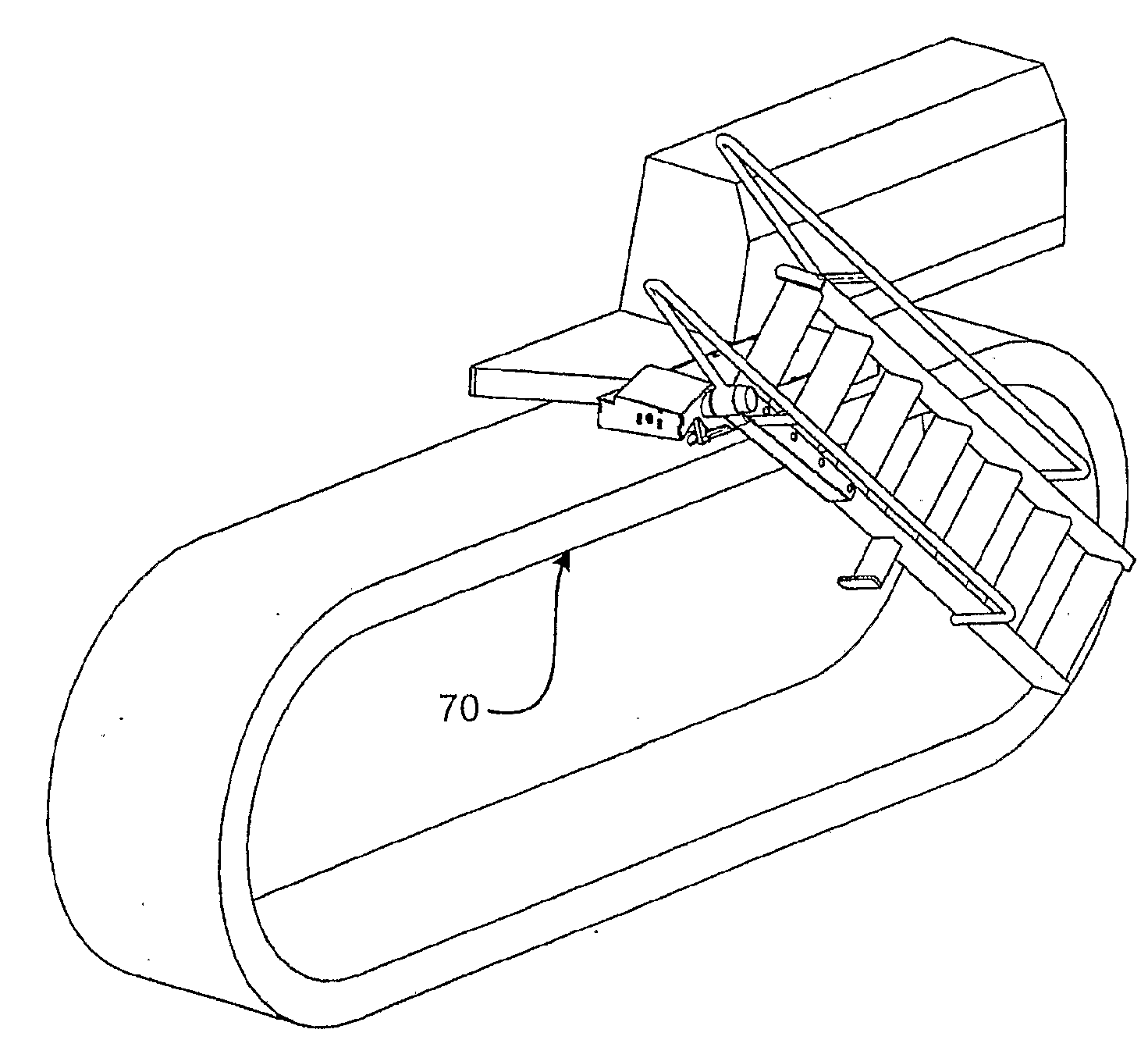

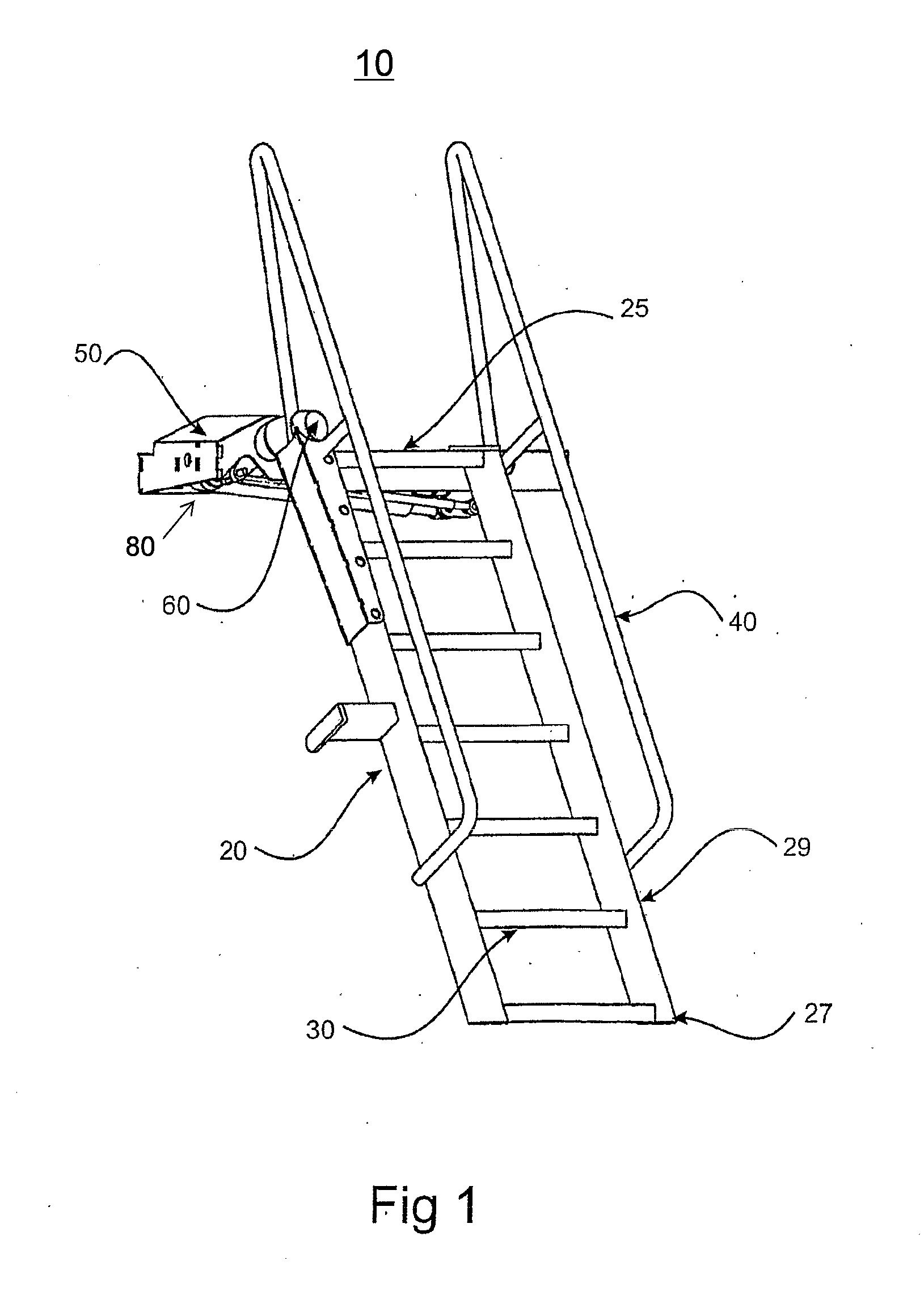

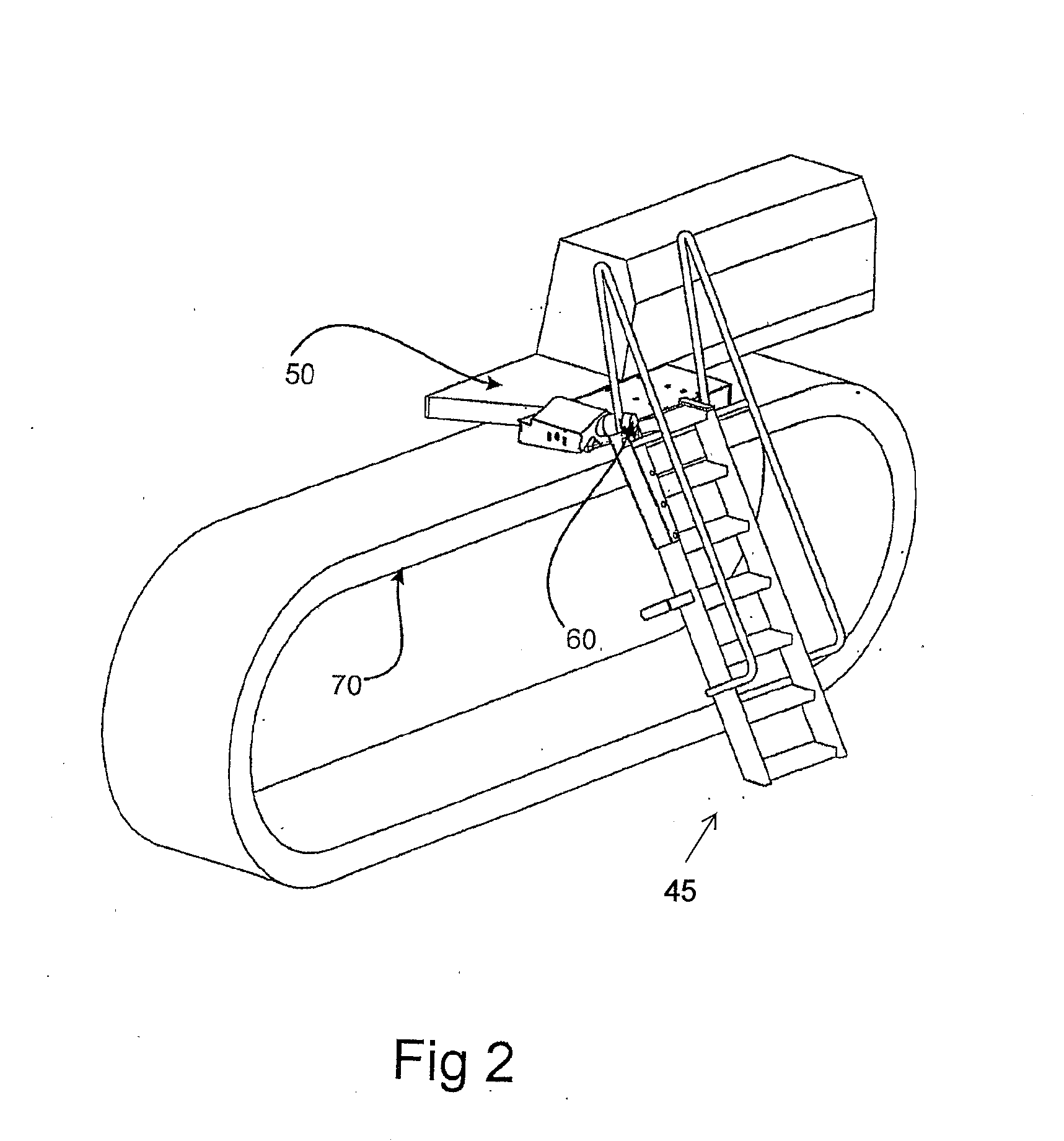

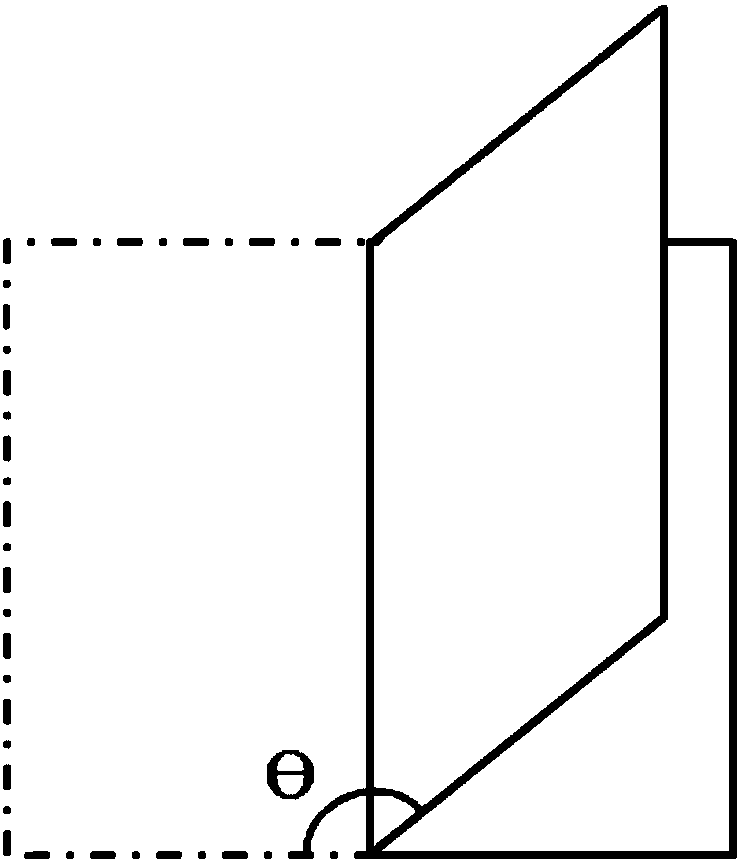

Access device

ActiveUS20090065301A1Minimising overhangEasy and safe accessSoil-shifting machines/dredgersSteps arrangementEmbedded systemGround level

An access system (10) for earthmoving equipment to allow a person to move from ground level to an elevated position, said access system having an access means (20) mounted to the earthmoving equipment via a pivot, and a retraction mechanism (50) therefor, said pivot allowing the access means to be retracted through a compound angle from a downwardly and outwardly deployed position to a retracted position generally adjacent and aligned beside the vehicle, the access means may be collapsible, such as with steps (30) pivotably mounted to the sides of the access means via secondary pivots (62).

Owner:BARJOH

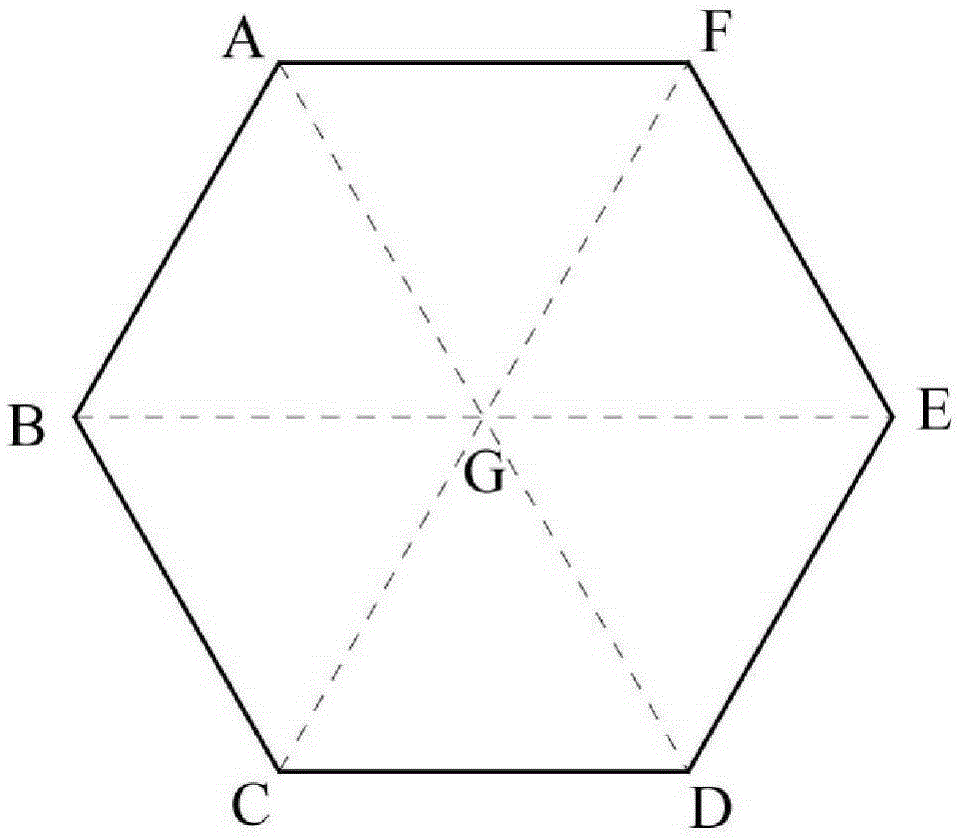

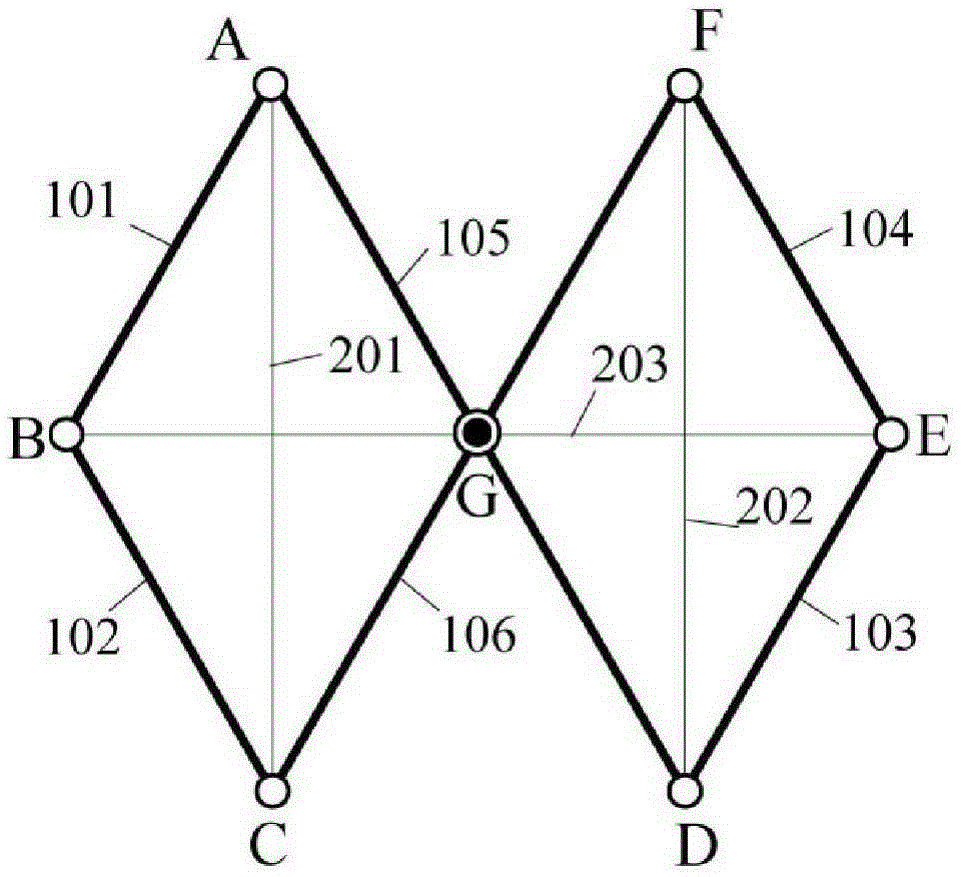

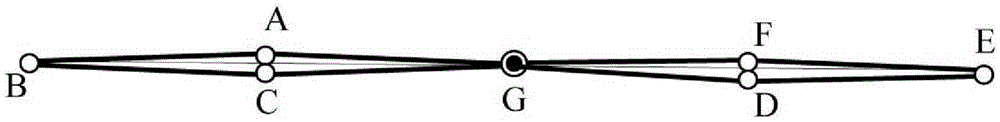

Foldable cable bar structural unit based on hexagonal geometry

ActiveCN105297902ALow utilization efficiencyImprove utilization efficiencyBuilding constructionsHexagonal geometryEngineering

The invention discloses a foldable cable bar structural unit based on hexagonal geometry. The structural unit is composed of six hinging nodes, one pivoting node, three stay cables and six pressure bars. The six hinging nodes are respectively located at the six vertexes of a two-dimensional hexagonal geometry, and the pivoting node is located at the central point of the hexagonal geometry. The four first-type pressure bars are symmetrically arranged on the two sides of the hexagon, and coincide with the four edges of the hexagon. The other two second-type pressure bars are located inside the hexagon, and form a scissor-like hinge through the pivoting node. The three stay cables are located inside the hexagon, and the six hinging nodes are connected in pairs by the three stay cables. When all the stay cables are pre-tensioned, pre-pressure exists in all the pressure bars, and the structural unit is a self-balancing cable bar system. When the first-type stay cable or the third-type stay cable is loosened, the structural unit can be folded to form a compact bundle shape. The foldable cable bar structural unit has a good application prospect in foldable / scalable cable bar structural systems.

Owner:SOUTHEAST UNIV

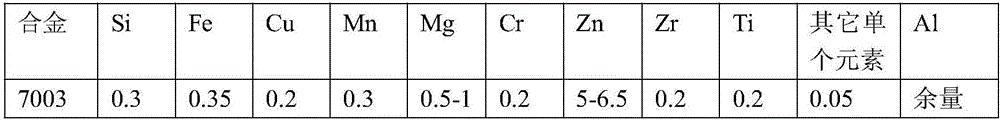

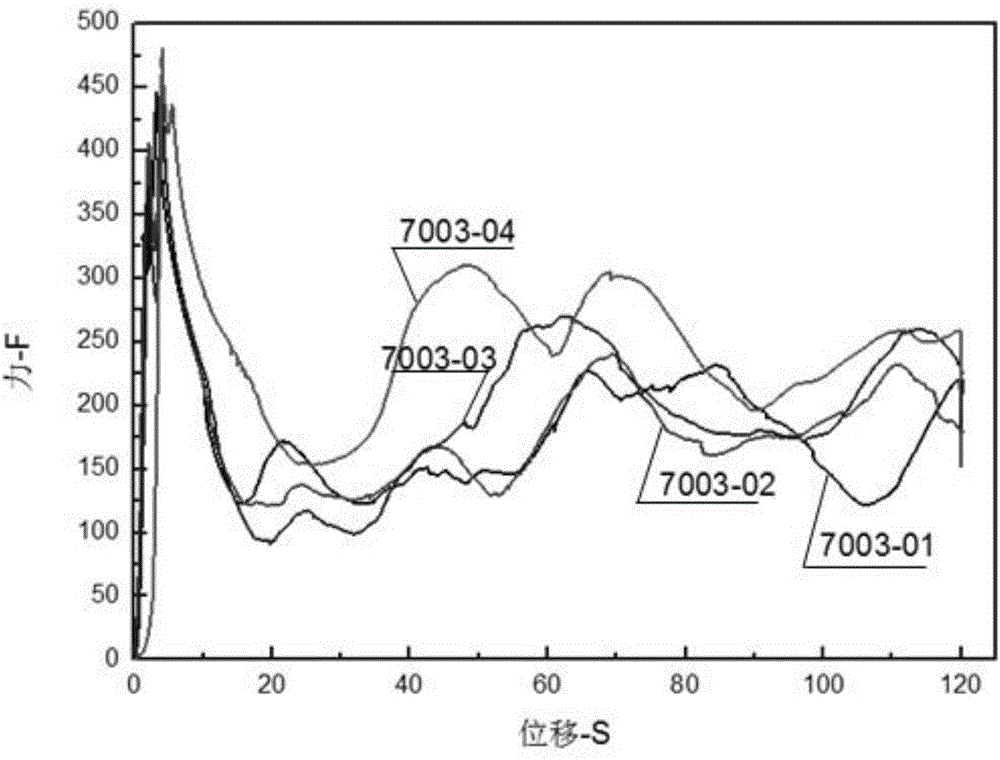

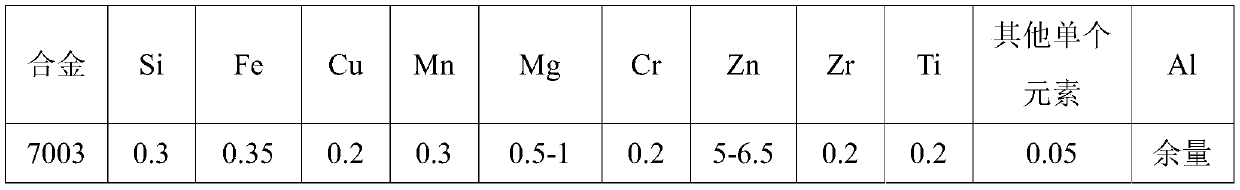

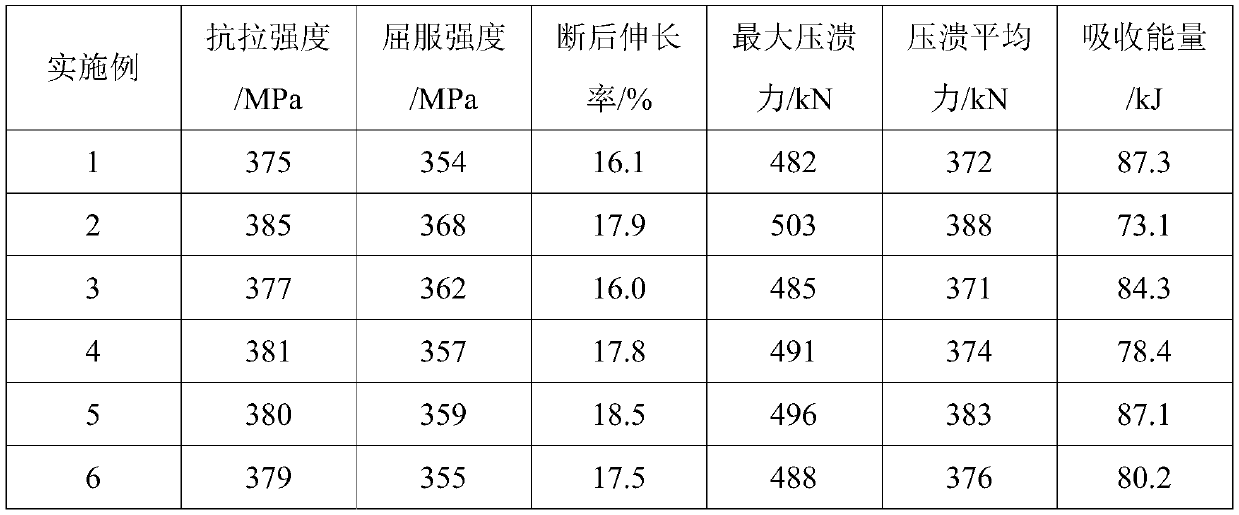

Manufacturing method of 7000-series aluminum alloy section for vehicular bodies

The invention discloses a manufacturing method of a 7000-series aluminum alloy section for vehicular bodies. The 7000-series aluminum alloy section comprises alloy elements including, by mass, 0.145%-0.155% of Si, 0.145%-0.155% of Fe, 0.09%-0.11% of Cu, 0.045%-0.055% of Mn, 0.58%-0.8% of Mg, 0.019%-0.021% of Cr, 5.5%-5.8% of Zn, 0.15%-0.19% of Zr, 0.028%-0.031% of Ti and the balance aluminum, wherein other single element content is smaller than or equal to 0.045%, other element total content is smaller than or equal to 0.15%, and a Zn / Mg ratio is controlled to be 7-10. The manufacturing method includes procedures of smelting, purification, casting for rod forming, homogeneous annealing, extruding, stretching, natural aging, manual aging treatment and the like, great static collision effects of materials can be achieved, the 7000-series aluminum alloy section is especially suitable for manufacturing of aluminum alloy energy absorption boxes and longitudinal beams for vehicular bumper systems, and comprehensive requirements of light weight of the vehicular bodies and energy absorption in low-speed and high-speed collision can be met.

Owner:CYMA PRECISION ALUMINUM

Porous microfine denier polyamide 6 pre-oriented yarn, its preparation method and device

ActiveCN102517679AImproved post-stretch propertiesAdjust and manage stressArtificial thread manufacturing machinesArtifical filament manufactureYarnMethacrylate

The invention, relating to a melt spinning technique of a high-molecular polymer, provides a porous microfine denier polyamide 6 pre-oriented yarn, its preparation method and device. Random copolymer additive of methacrylate, maleic anhydride and styrene are added in the screw melt extrusion step, and the obtained pre-oriented yarn has the breaking tenacity of 3.20-3.70 cN / dex and the breaking elongation of 60-100 %. According to the invention, a routine FDY device and related production technology conditions are improved, the aggregation structure adjustment, high order orientation, and crystalline supramolecular structure in the stretch forming process of a spinneret are effectively controlled, the melt mixing uniformity and pressure stability are further increased, the winding tensile stress and unevenness of the yarn are effectively adjusted and controlled, and the after-stretching performance of the porous microfine denier polyamide 6 pre-oriented yarn is raised. According to the product provided by the invention, the maximum benefits of the enterprise can be achieved.

Owner:WUJIANG YATAI CHEM TEXTILE

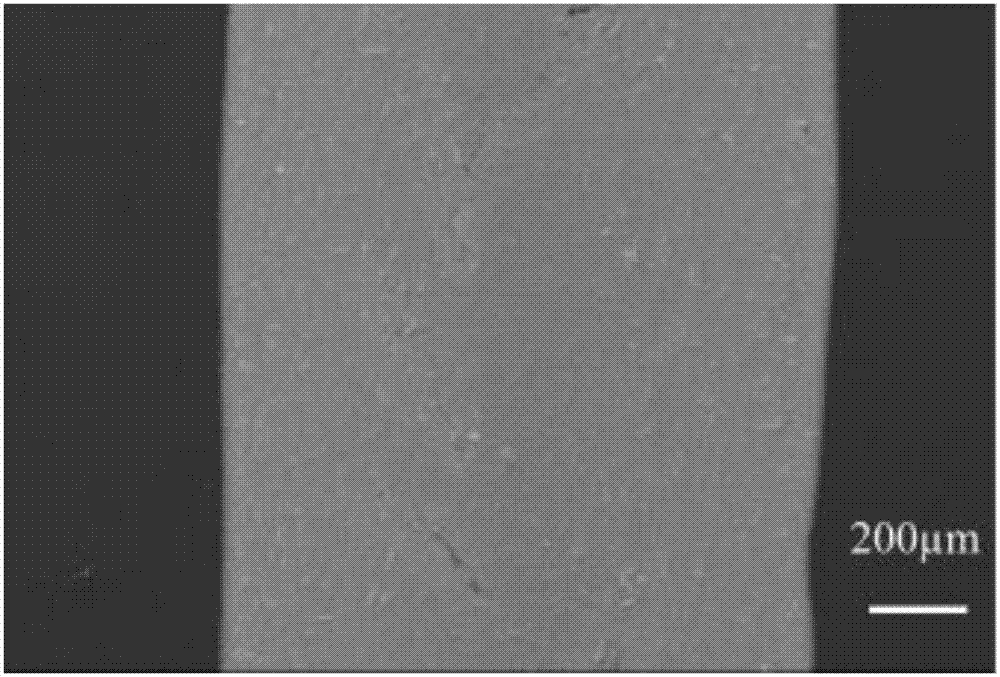

Flexible graphene film capable of being repeatedly folded, preparation method of flexible graphene film and flexible device comprising flexible graphene film

ActiveCN106698407AGood flexibilityImprove foldabilityHybrid capacitor electrodesGrapheneReduction treatmentOptoelectronics

The invention provides a flexible graphene film capable of being repeatedly folded, a preparation method of the flexible graphene film and a flexible device comprising the flexible graphene film. The graphene film is obtained by carrying out reduction treatment on a graphene oxide film; a porous structure is formed in the thickness direction of the graphene film; after the graphene film is folded, the graphene film can be recovered and folds are not formed; the thickness of the graphene oxide film is 0.01mu m to 500mu m; compared with the thickness of the graphene oxide film, the expanding multiple of the thickness of the graphene film is 2 to 30 times. The flexible graphene film provided by the invention has the advantages that the porous structure is formed in the thickness direction of the graphene film and the surface of the thin film is smooth and flat; the film has excellent flexible and foldable performance and can be rapidly recovered and has no folds after being folded singly or doubly for a plurality of times; after the film is treated at high temperature, the flexibility can still be kept. The preparation method provided by the invention is simple and convenient to operate and has the advantages of relatively low reduction temperature, small dosage of a reducing agent and small pollution to environment.

Owner:BEIJING UNIV OF CHEM TECH

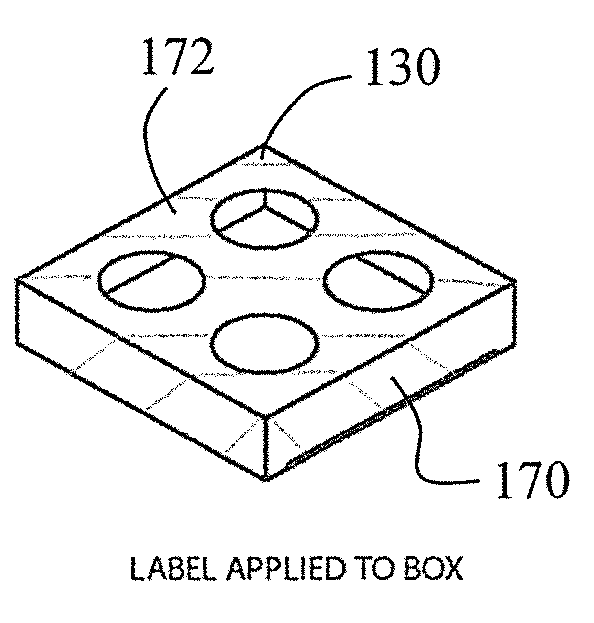

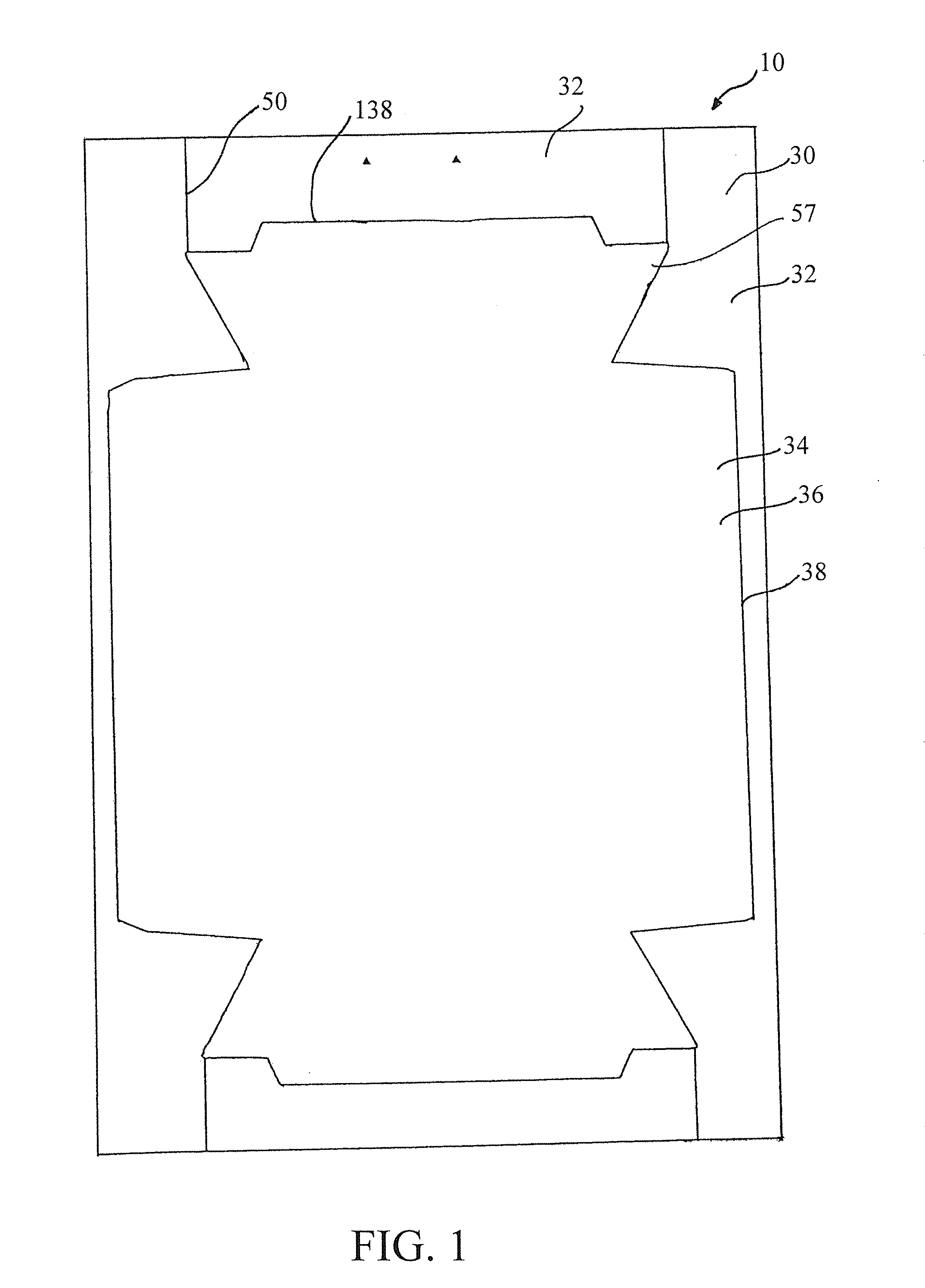

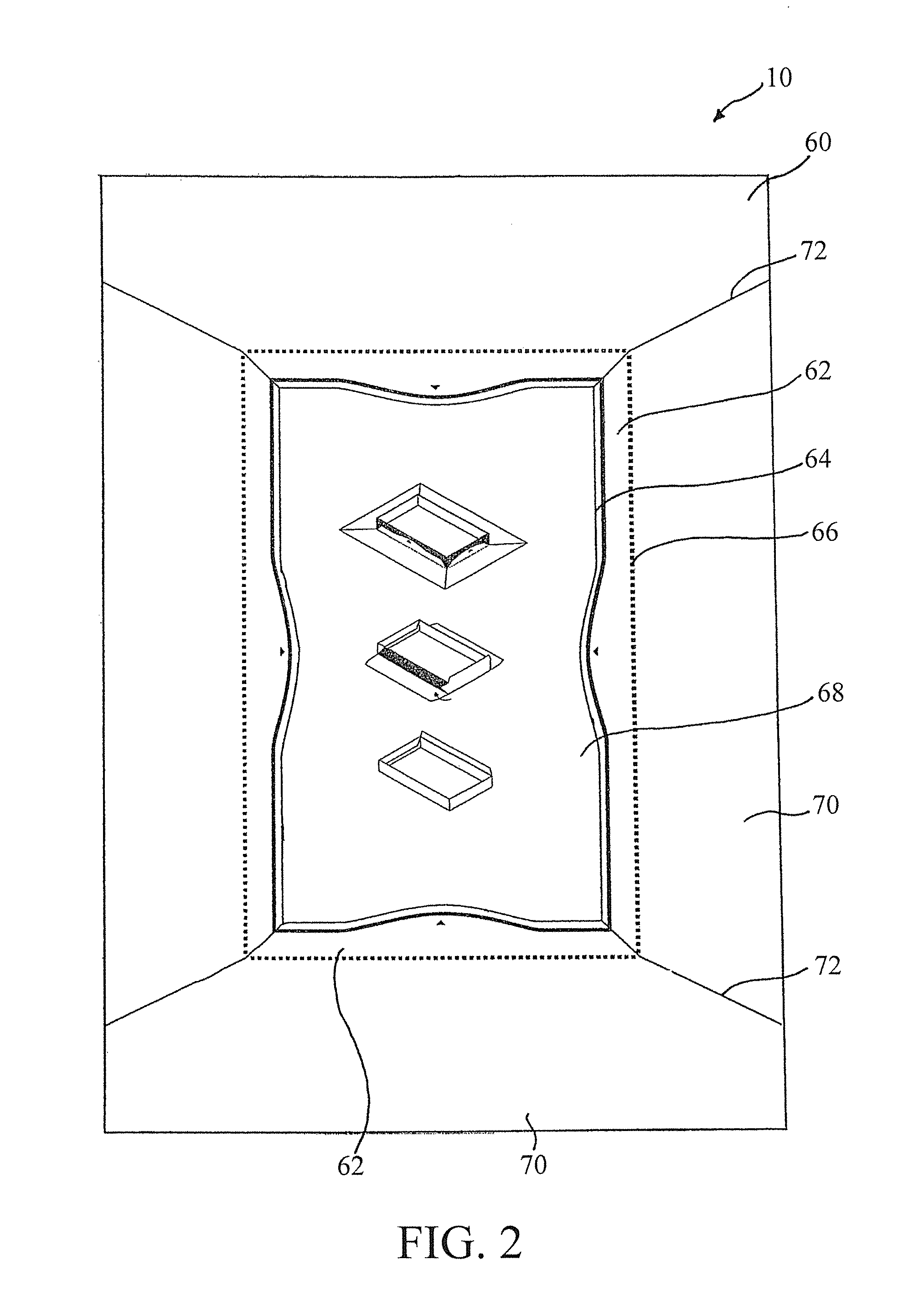

Customizable gift box label assembly

ActiveUS20140209496A1Improve foldabilityFacilitates alignment and placementStampsOther accessoriesSoftware engineeringMechanical engineering

A label assembly for a customizable gift box. The label assembly includes a label and a back sheet having alignment tabs for aligning the box blank to the label. The alignment tabs are raised to expose adhesive material of the label. The box portion is aligned on the adhesive with the tabs, and then the partially adhered label can be fully exposed and wrapped around the box portion. The label can be used as a box bottom or top wrapping, or can form a top for a bottom box portion.

Owner:FLYNN TIMOTHY J

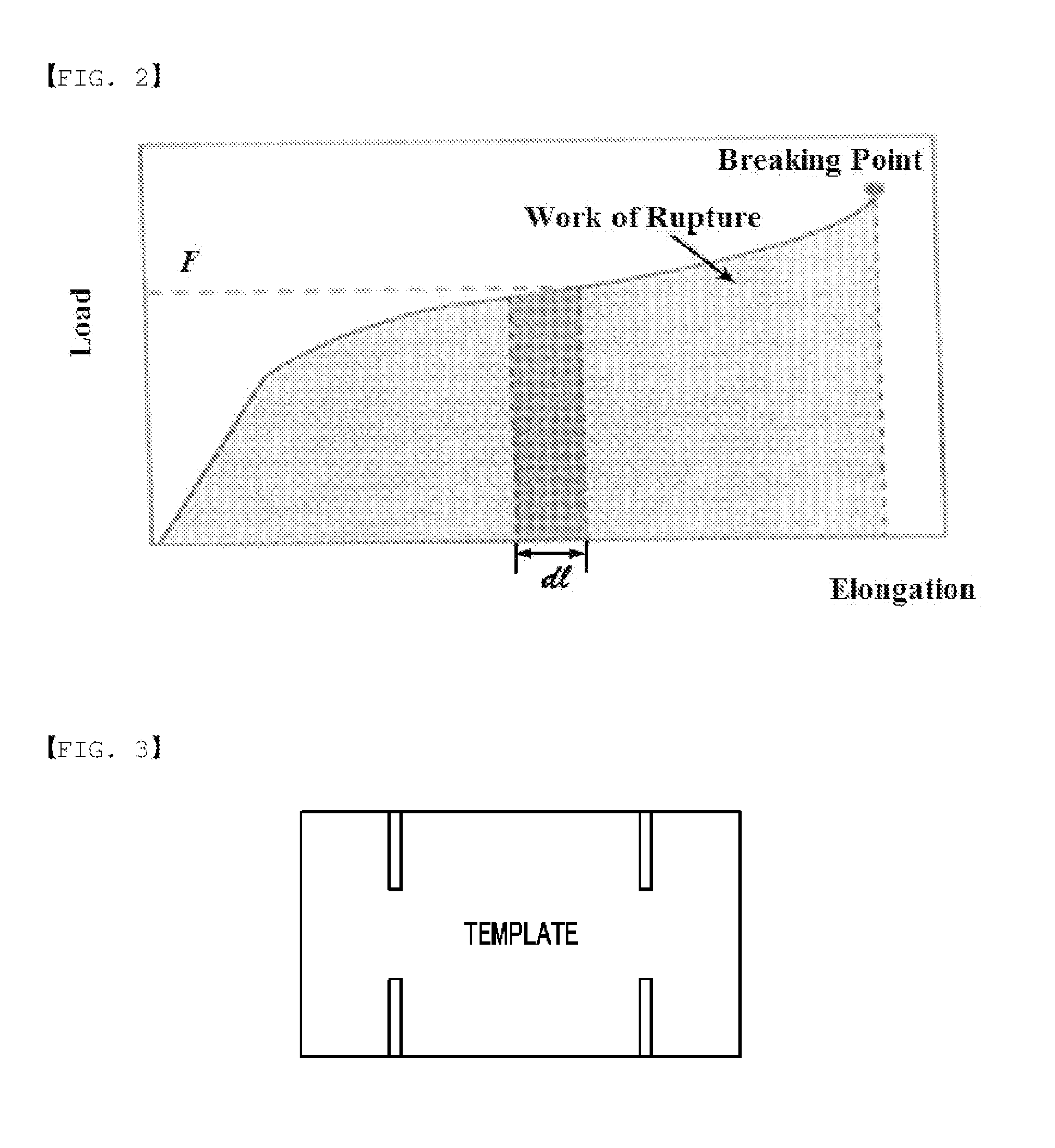

Polyester yarn and a production method therefor

InactiveUS20130187367A1Increase flexibilityImprove foldabilityPedestrian/occupant safety arrangementSynthetic resin layered productsPolyesterYarn

Disclosed is a polyester yarn, wherein a room-temperature strength-elongation index (X0) indicating a ratio (T0 / S0) of tensile strength (T0) to tensile elongation (S0) of the polyester yarn, measured at room temperature, and a primary high-humidity strength-elongation index (X1) indicating a ratio (T1 / S1) of tensile strength (T1) to tensile elongation (S1) of the polyester yarn, measured after heat-treating the polyester yarn under conditions of a temperature of 85° C. and a relative humidity (RH) of 95±5% for 168 hours, are optimized in a predetermined range.

Owner:KOLON IND INC

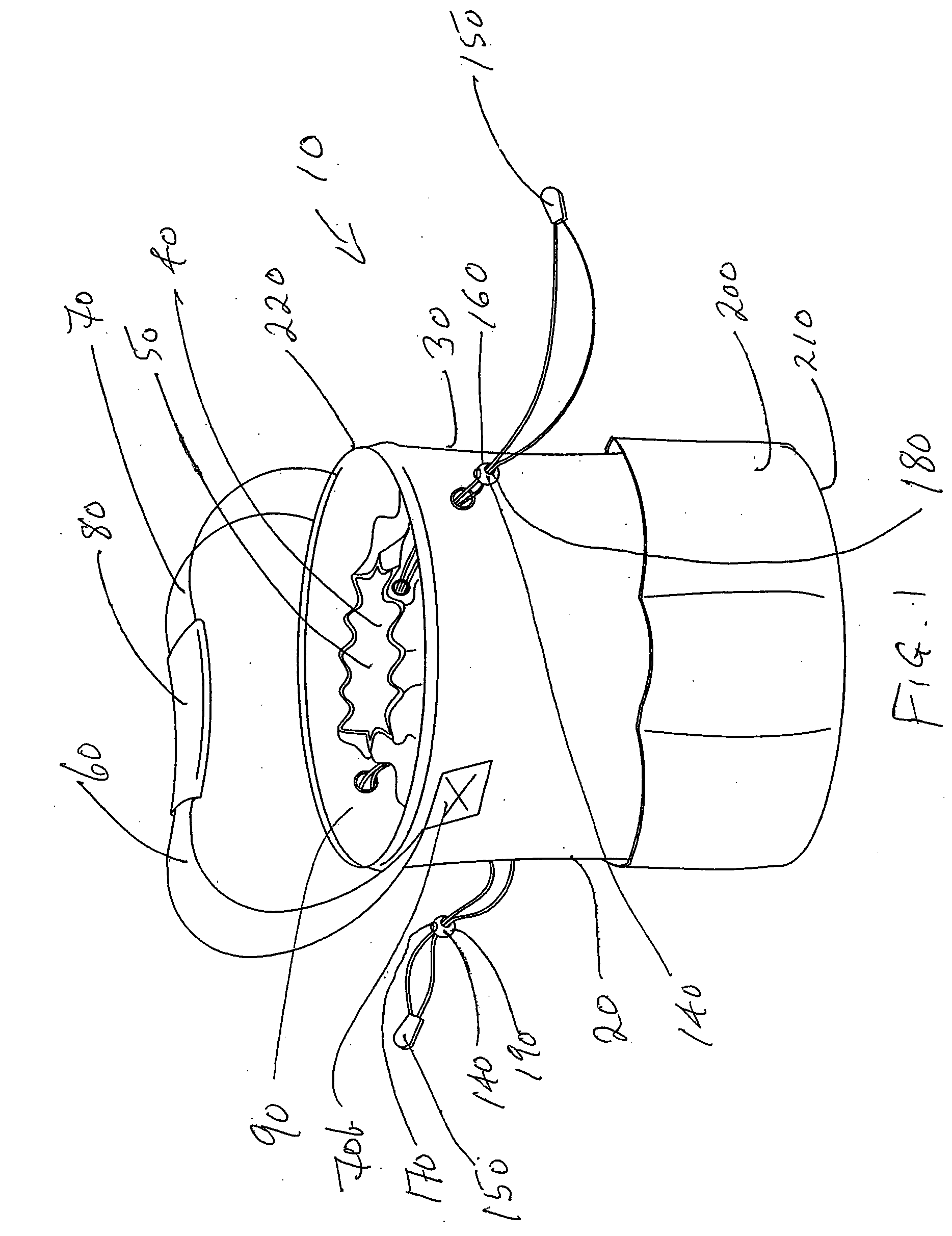

Semirigid, collapsible, cinchable utility sack with pockets

InactiveUS20070241145A1Low profilePrevent overflowTravelling sacksTravelling carriersArchitectural engineeringBuilding construction

A semirigid, collapsible, cinchable utility sack with pockets, wherein the utility sack is of generally cylindrical construction having a cinchable cover, a handle, and pockets disposed on the exterior of the bag. The interior of the utility sack may receive liquids, solids (dry or wet), and / or variously shaped articles, wherein the cinchable cover may thereafter be tightened to secure the materials contained within the utility sack.

Owner:LF CENTENNIAL

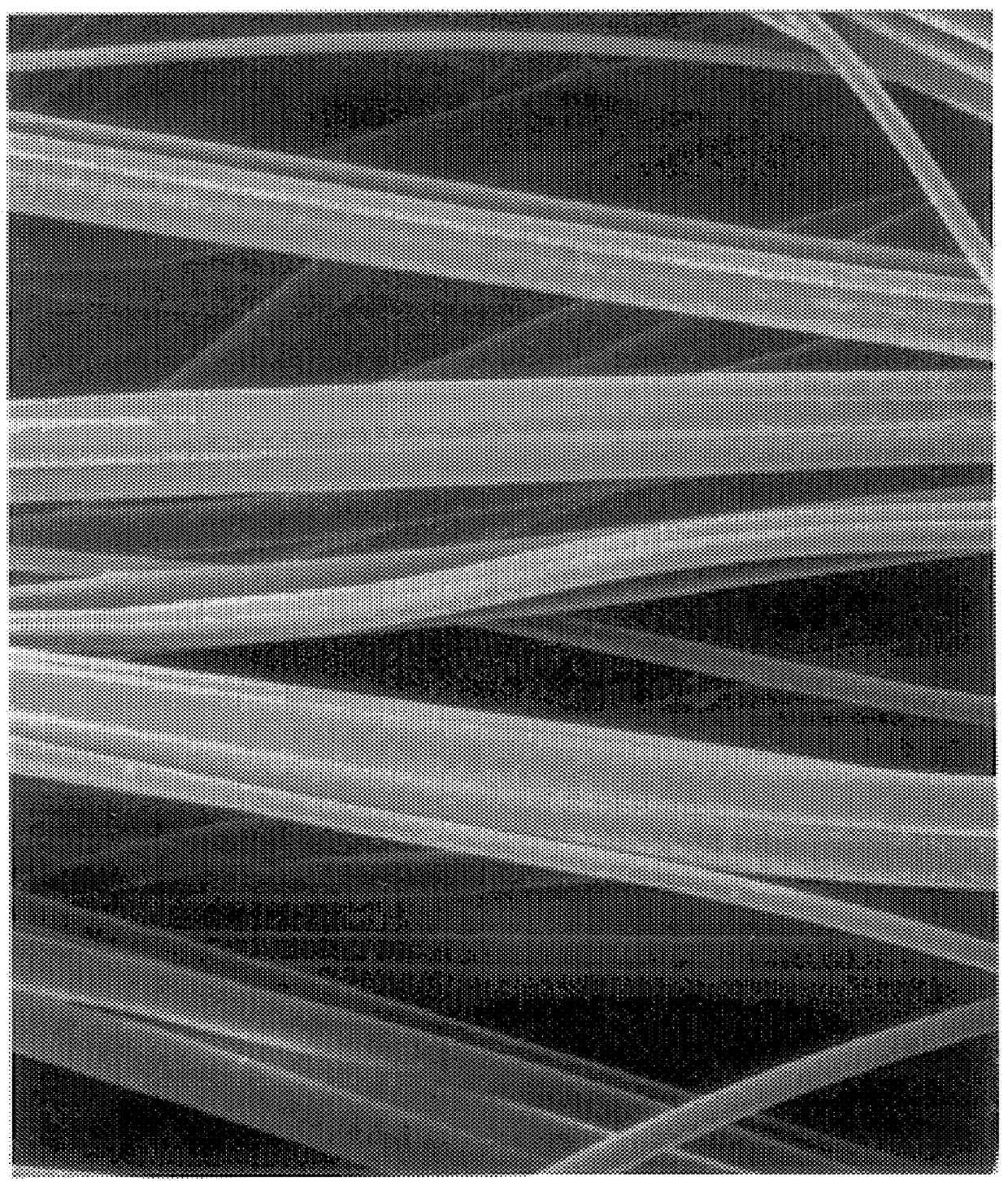

Nonwoven fabric, filter medium and process for producing the same

InactiveUS6136409AImprove foldabilityIncrease stiffnessLayered productsMembrane filtersPolymer scienceFiber bundle

A nonwoven fabric comprising thermoplastic resin fiber bundles, wherein numerically at least about 50% of all the fibers present are bonded to each other in the form of fiber bundles. The fiber bundles are arranged along substantially one direction.

Owner:TORAY IND INC

Display device

ActiveCN109032412ADeformation can not be recoveredImprove foldabilityStatic indicating devicesSolid-state devicesAdhesiveDisplay device

A display device is disclosed. An elastic support column is made in a folded area on the surface of a touch-sensitive layer, and an adhesive is filled around the elastic support column. The height ofthe elastic support column varies according to the change of the extrusion stress. And the thickness of the adhesive can be controlled by adjusting the height and density of the elastic support columnto ensure optimum folding effect. The invention can keep the appearance of the product without obvious change before and after folding, and avoid the adhesive deformation caused by thick adhesive andrepeated folding from being irrecoverable, thereby realizing flexible foldable touch display.

Owner:WUHAN CHINA STAR OPTOELECTRONICS SEMICON DISPLAY TECH CO LTD

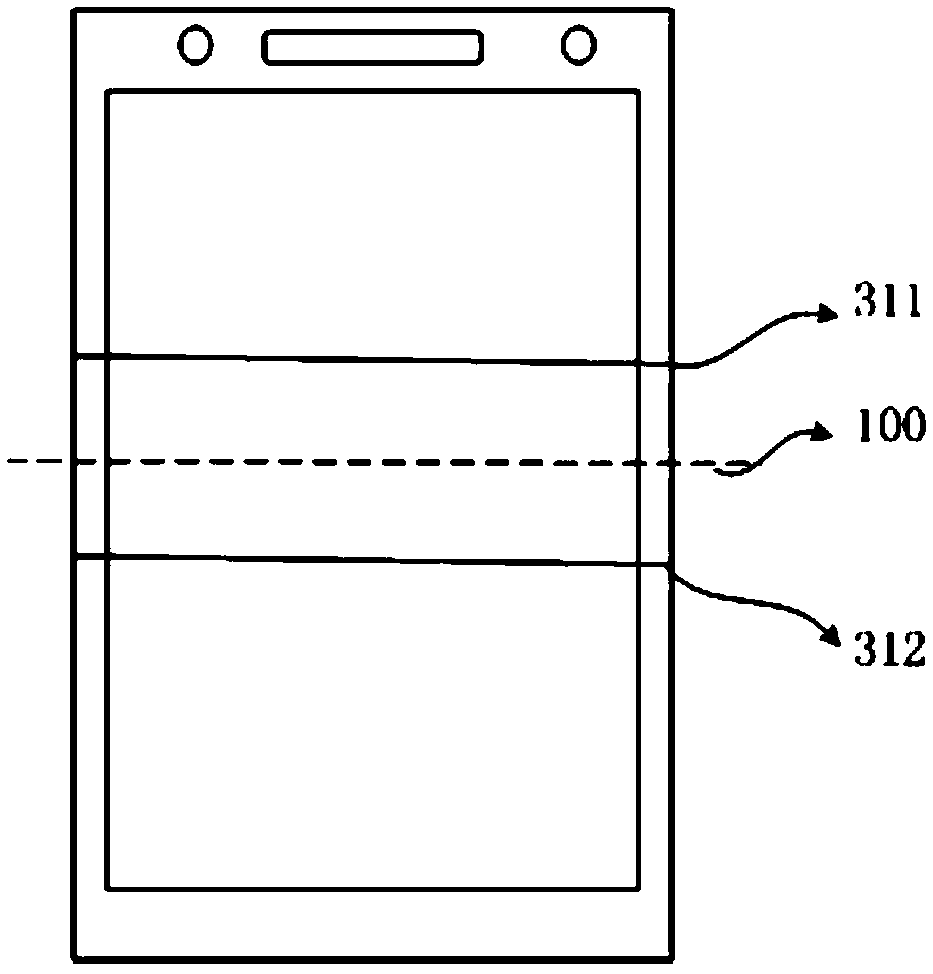

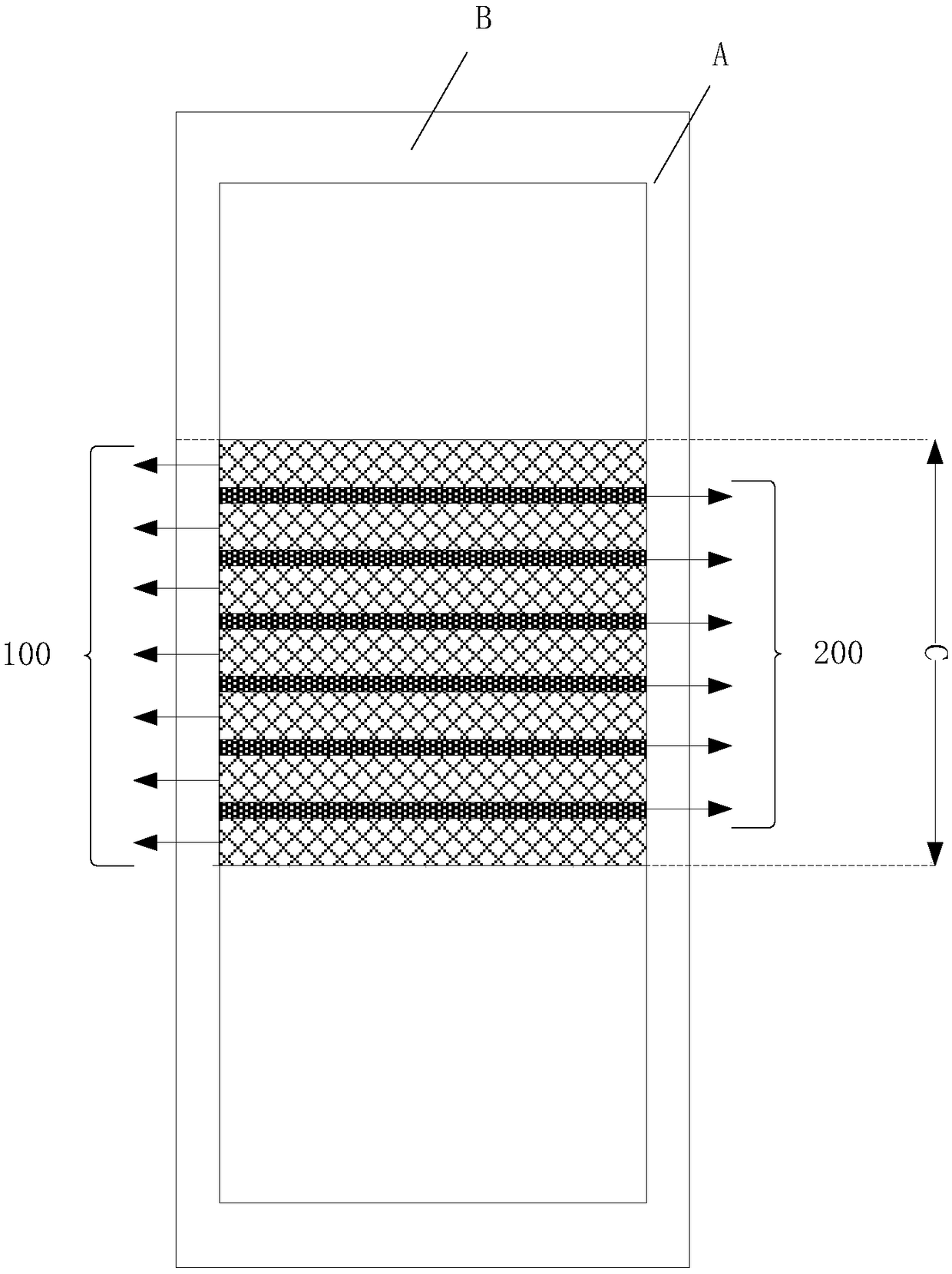

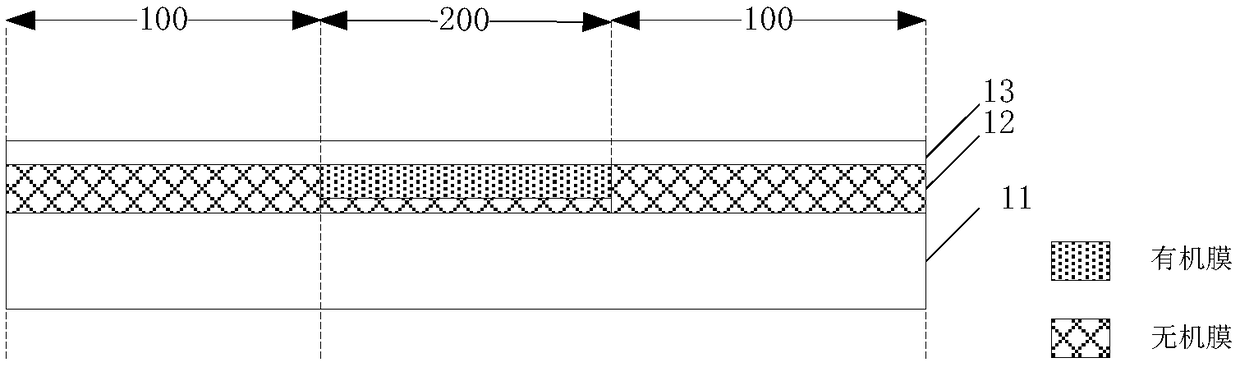

Folding screen and display device

ActiveCN108986671AImprove foldabilityExtended service lifeIdentification meansDisplay deviceEngineering

The invention provides a folding screen and a display device. Bending areas of the folding screen comprise difficultly-bending areas and easily-bending areas; the total thickness of inorganic membranes of the easily-bending areas is smaller than the total thickness of inorganic membranes of the difficultly-bending areas; and the total thickness of organic membranes of the easily-bending areas is greater than the total thickness of organic membranes of the difficultly-bending areas, so that the easily-bending areas can be easily bent relative to the difficultly-bending areas, therefore, the foldability of a display panel is realized, meanwhile, the folding areas have specificity, namely, the folding movements are completed by the easily-bending areas, the difficultly-bending areas do not realize folding, therefore, during the design of the display screen, damageable parts can be arranged in the difficultly-bending areas with pertinence, then when the display screen is folded, the difficultly-bending areas are non-movement areas, at the time, no damage is caused to the damageable parts, and thus the serve lives of the devices are prolonged. Therefore, with the folding screen disclosed by the embodiment of the invention, a powerful basis is provided for prolonging the service life of the folding display panel.

Owner:SHANGHAI TIANMA MICRO ELECTRONICS CO LTD

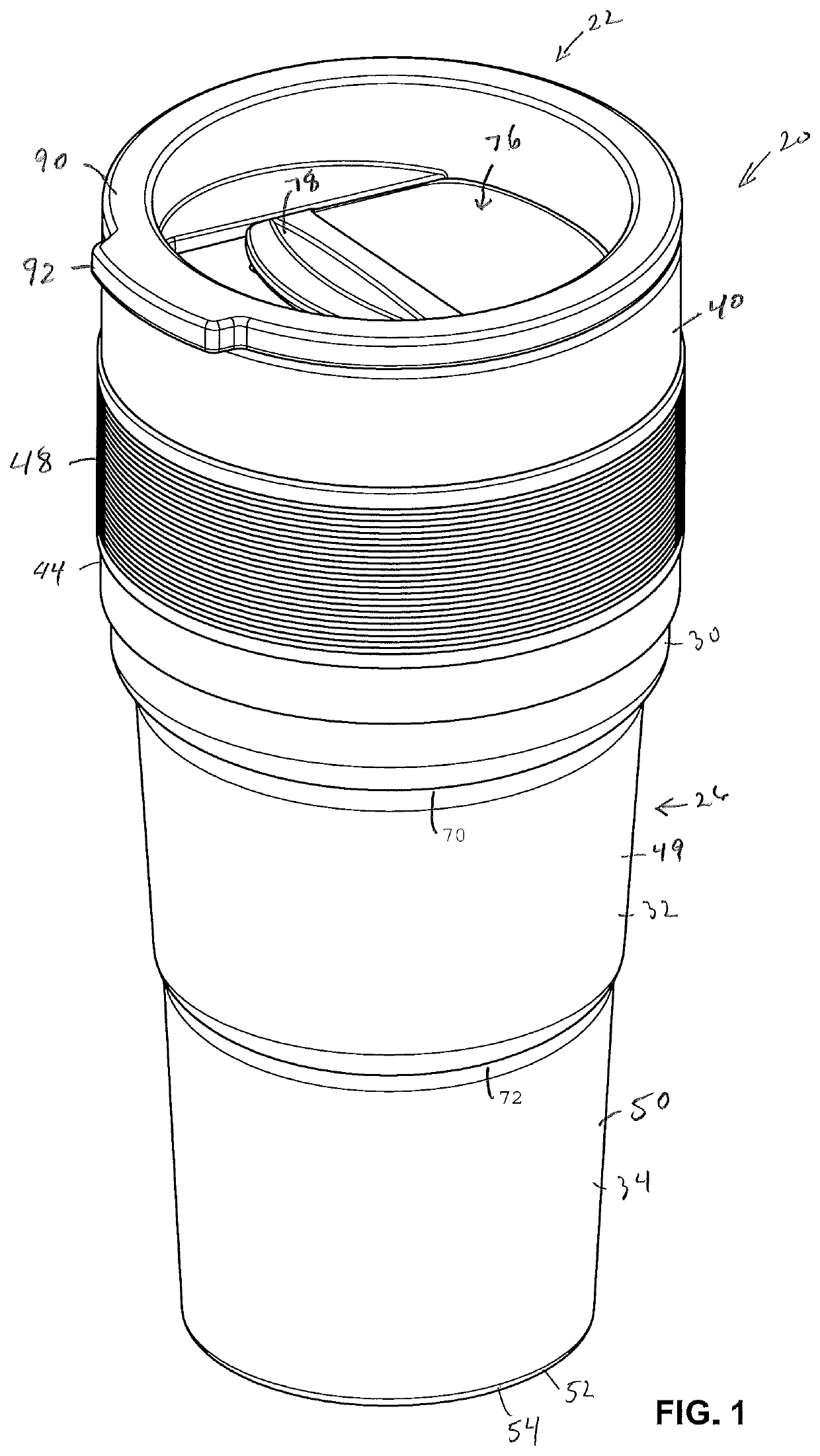

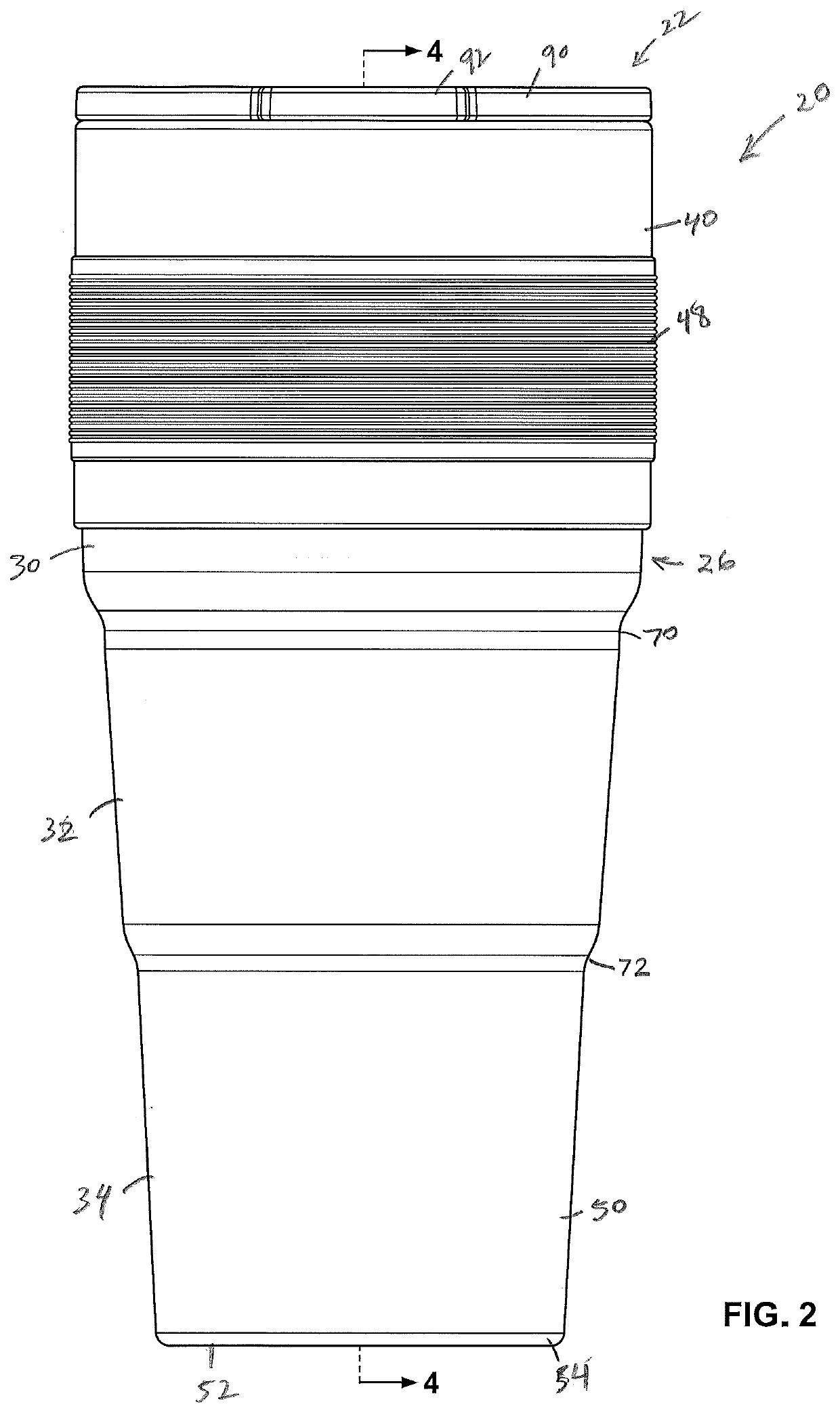

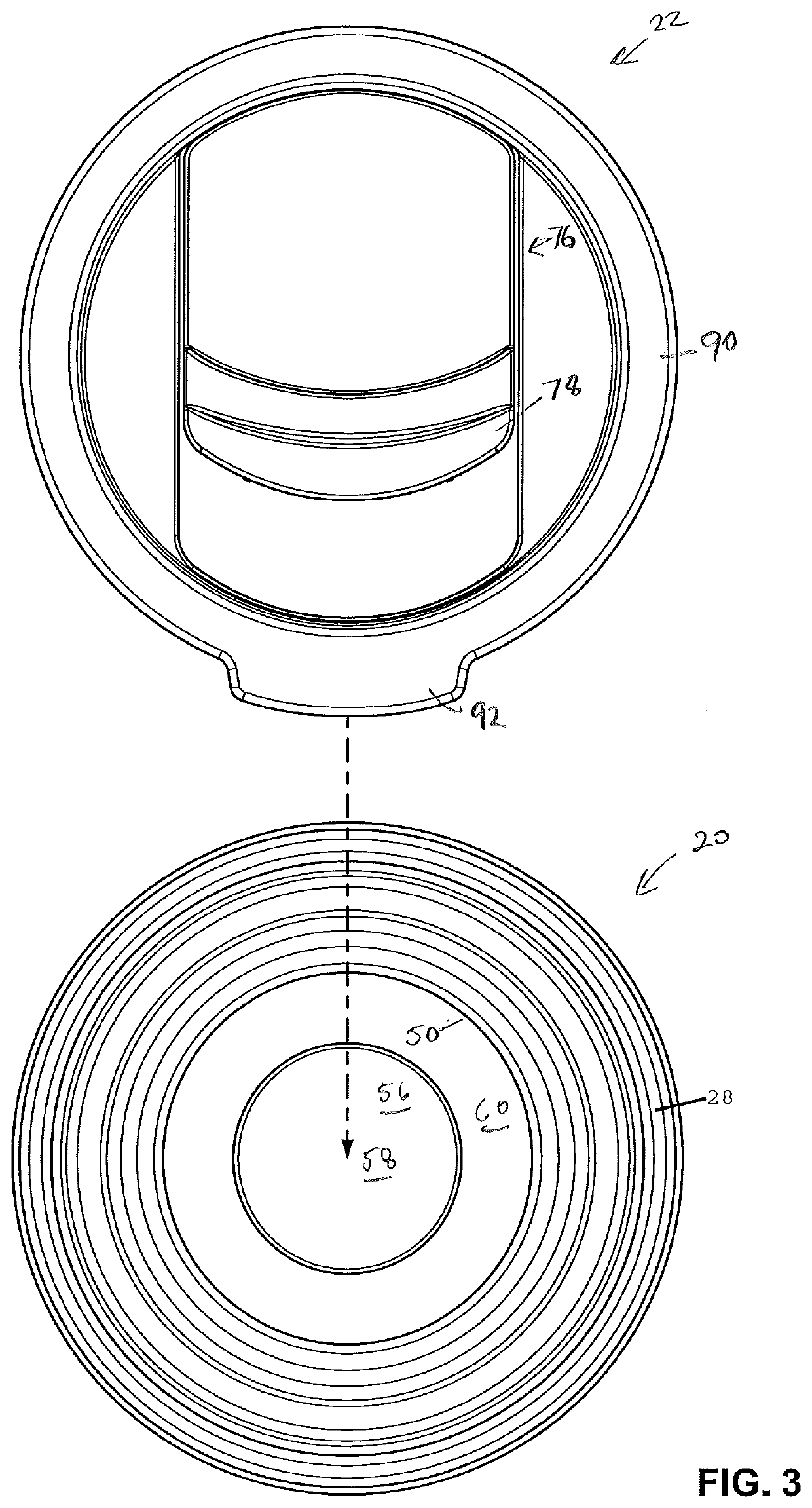

Collapsible cup

ActiveUS20200305619A1Easy to holdImprove foldabilityTravelling sacksBottlesEngineeringMechanical engineering

A collapsible container, particularly a cup or mug having a flexible body having a top tier, middle tier and a bottom tier is disclosed. The bottom tier has a base. The container has a first living hinge between the top and middle tiers and a second living hinge between the middle and bottom tiers. A rigid, preferably metal, plate is at least partially embedded in the bottom tier that makes the otherwise flexible base rigid. The container can have a rigid metal cladding around the top tier and a handle made of flexible material. The collapsible container may be made by injection molding.

Owner:TSUI SAM TUNG

Aluminum alloy sectional material used for automotive body and manufacturing method

The invention discloses an aluminum alloy sectional material used for an automotive body and a manufacturing method. The aluminum alloy sectional material is composed of the raw materials of, by mass, 0.13-0.17% of Si, 0.13-0.17% of Fe, 0.09-0.12% of Cu, 0.04-0.06% of Mn, 0.6-0.8% of Mg, 0.018-0.022% of Cr, 5.5%-5.8% of Zn, 0.15-0.195% of Zr, 0.027-0.033% of Ti and the balance Al, wherein the content of other single element is less than or equal to 0.05%, and the total content of other elements is less than or equal to 0.15%. The manufacturing method comprises the steps of smelting, purification treatment, rod forming through casting, homogenizing annealing, extruding, drawing, natural aging treatment, artificial aging treatment and other procedures, so that the material achieves good static collision effect, is quite suitable for manufacturing aluminum alloy crash boxes and longitudinal beams of automobile bumper systems, has the good mechanical performance and good abrasion resistance, fatigue resistance and anti-crash performance (static and dynamic collision impact performance), and can be put into mas production.

Owner:CYMA PRECISION ALUMINUM

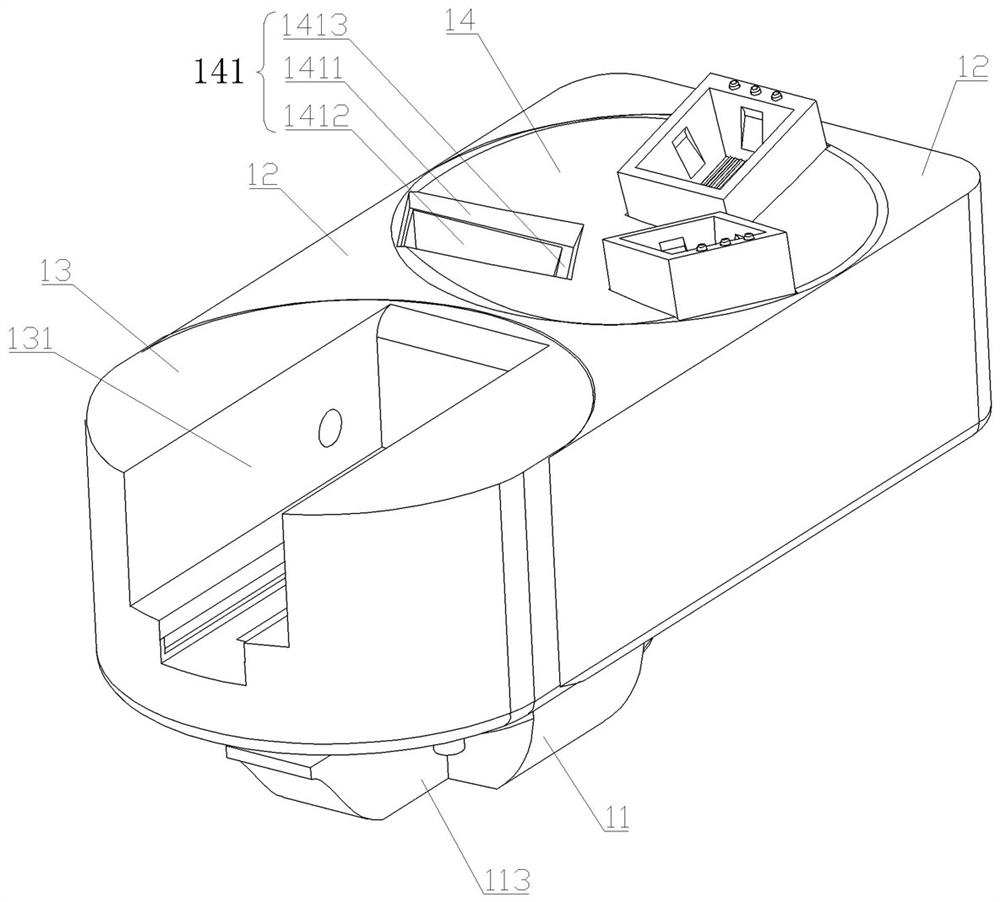

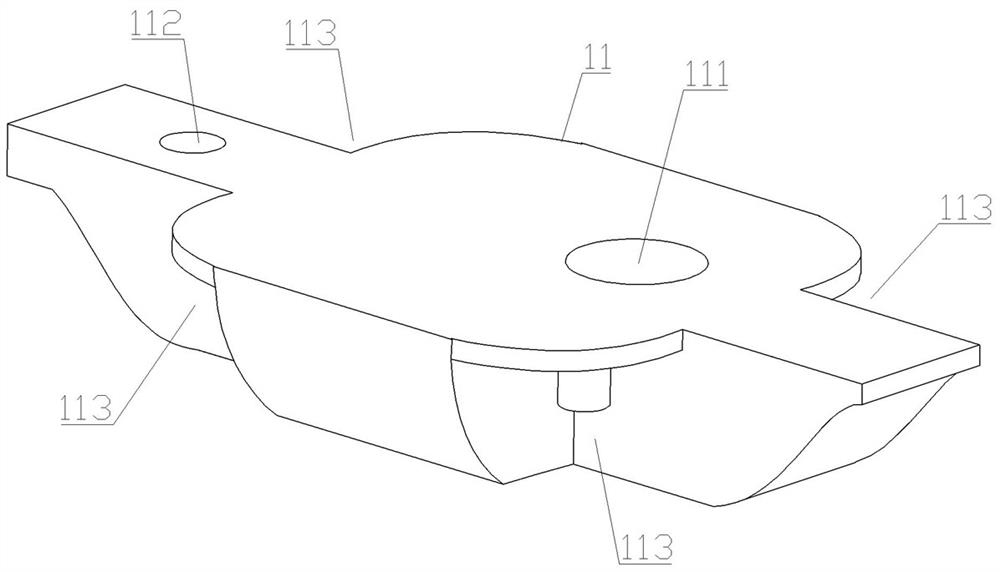

Nuclear emergency multi-functional operation robot

ActiveCN112091926AEasy maintenanceFor quick maintenanceProgramme-controlled manipulatorGripping headsPhysical medicine and rehabilitationPhysical therapy

A nuclear emergency multi-functional operation robot comprises a base, a mechanical arm, a tool replacing and connecting device and motion supporting devices, wherein the base comprises a base, a mounting seat A, a mounting seat B, a mounting seat C, a rotary driving mechanism A and a rotary driving mechanism B; the front end of the mechanical arm is connected to the mounting seat B; the tool replacing and connecting device comprises a male connector and a female connector which can be in butt joint or separated from each other; and the motion supporting devices are used for driving the motionof the nuclear emergency multi-functional operation robot. The operation robot has the advantages that various tail end tools can be integrated on the base, so that the operation robot can conveniently switch the tools to perform all kinds of operation according to operation requirements; the mechanical arm has excellent folding performance, so that the operation robot can conveniently pass through a narrow section in an operation environment; and the male connector and the female connector of the tool replacing and connecting device can realize quick butt-joint or separation, so that the operation robot can quickly switch the tools to perform all kinds of operation.

Owner:NANHUA UNIV

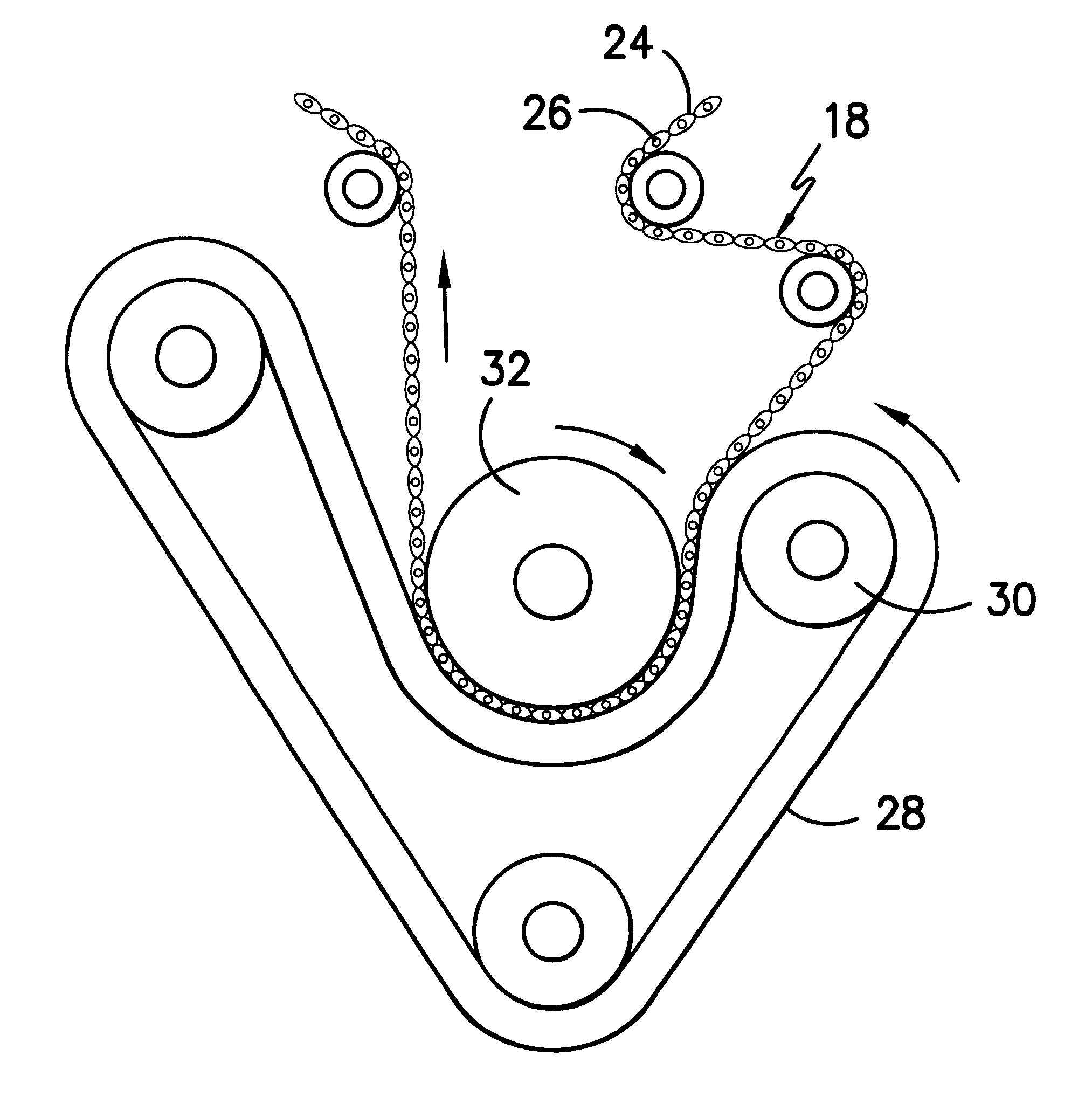

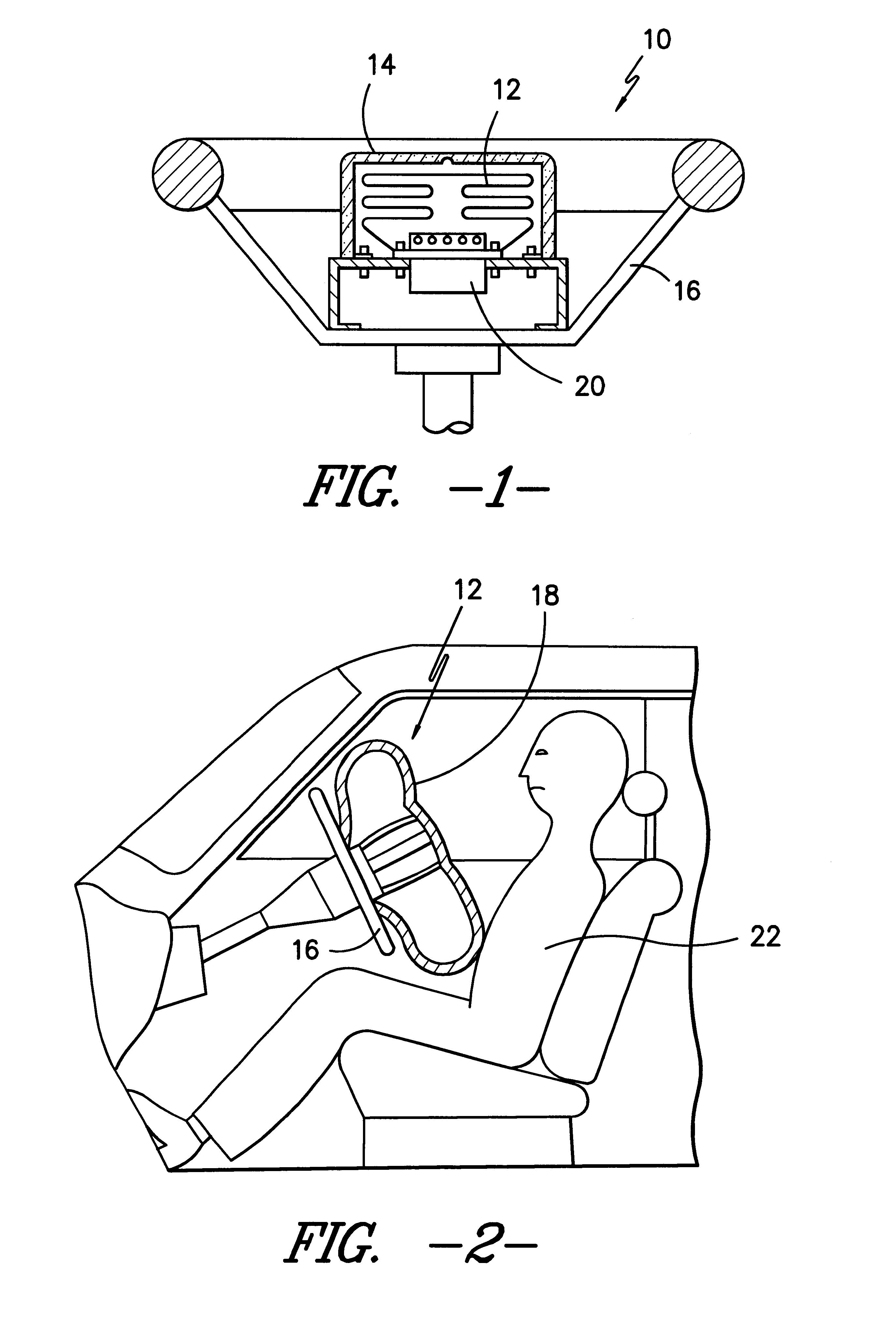

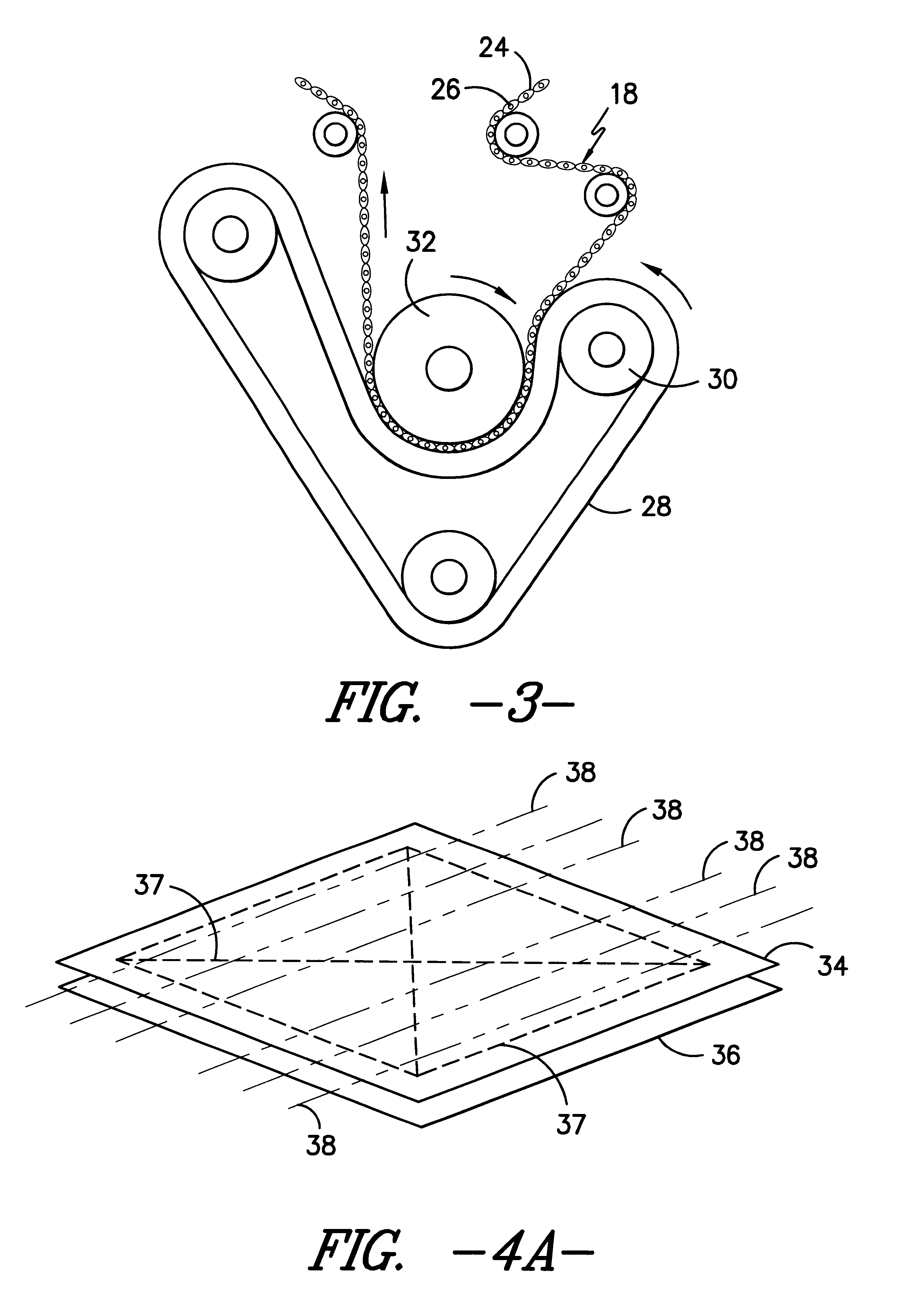

Air bag fabric possessing improved packed volume and stable air permeability

InactiveUSRE38769E1Improve foldabilityIncreasing air permeability characteristicShrinkingPedestrian/occupant safety arrangementYarnEngineering

A fabric for use in an air bag is provided. The fabric of the invention is produced by mechanically compressing a preliminary fabric constructed substantially of synthetic yarn such that the packed volume per unit area of the compressed fabric is less than the packed volume per unit area of the preliminary fabric. Air permeability is not adversely affected.

Owner:MILLIKEN & CO

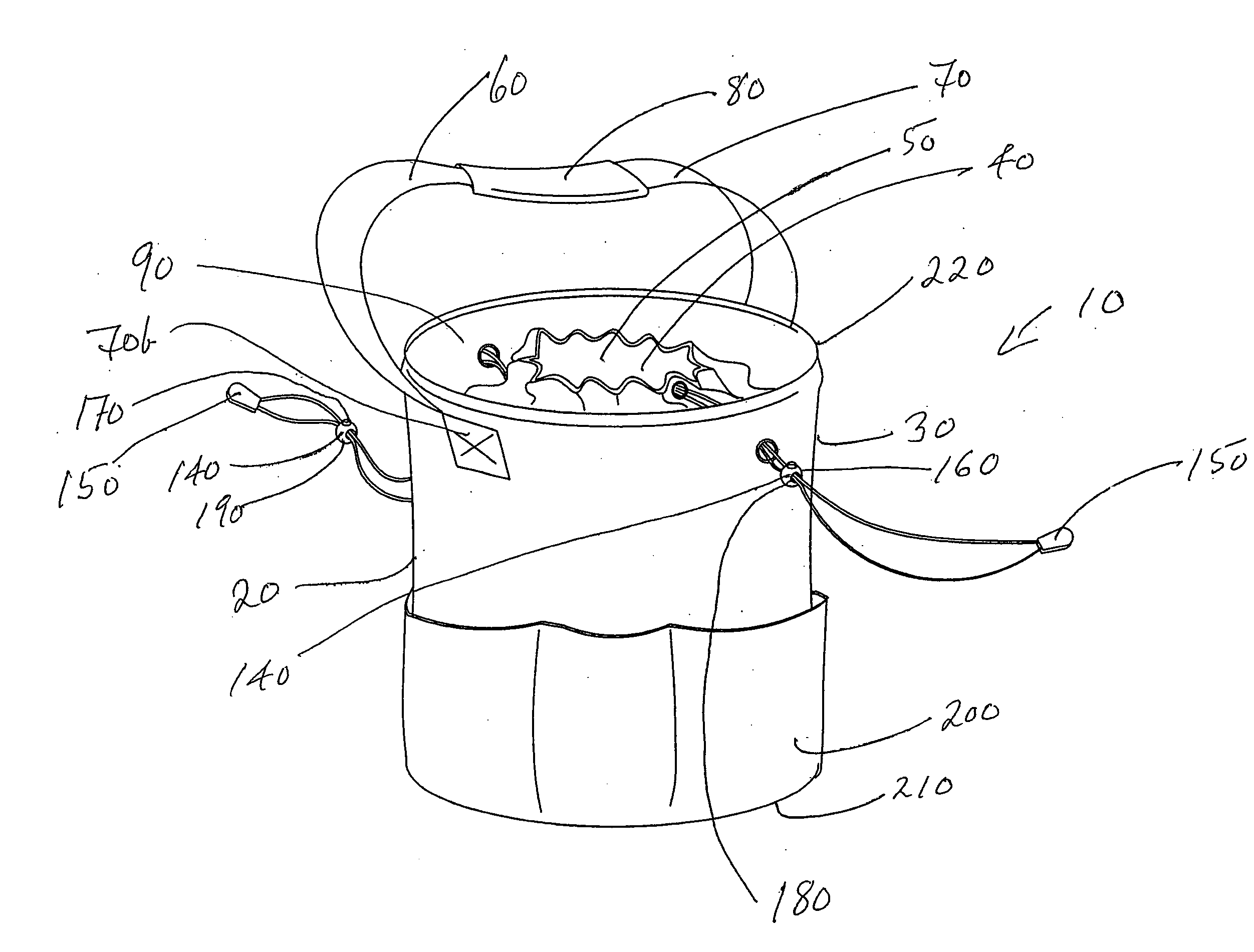

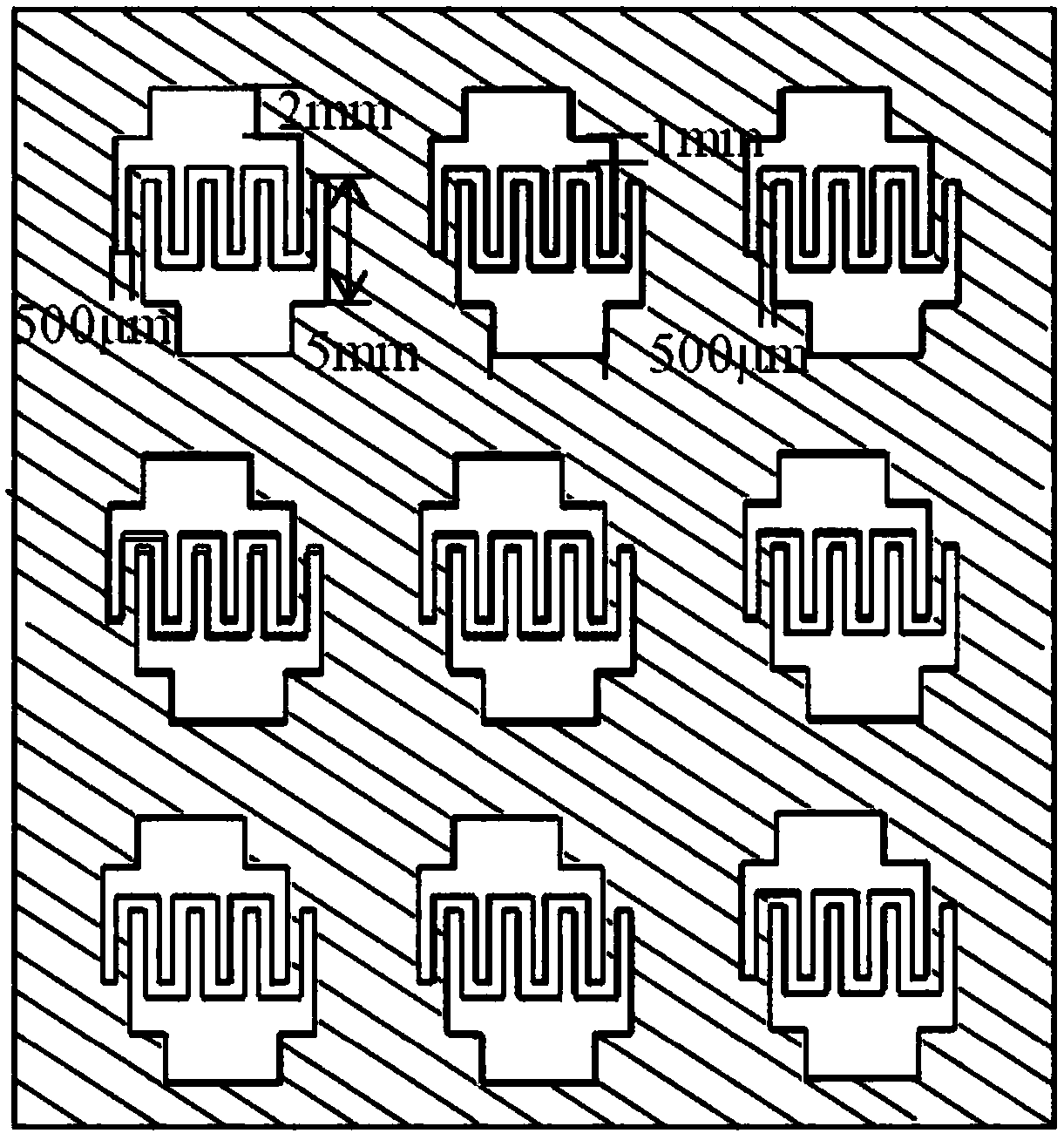

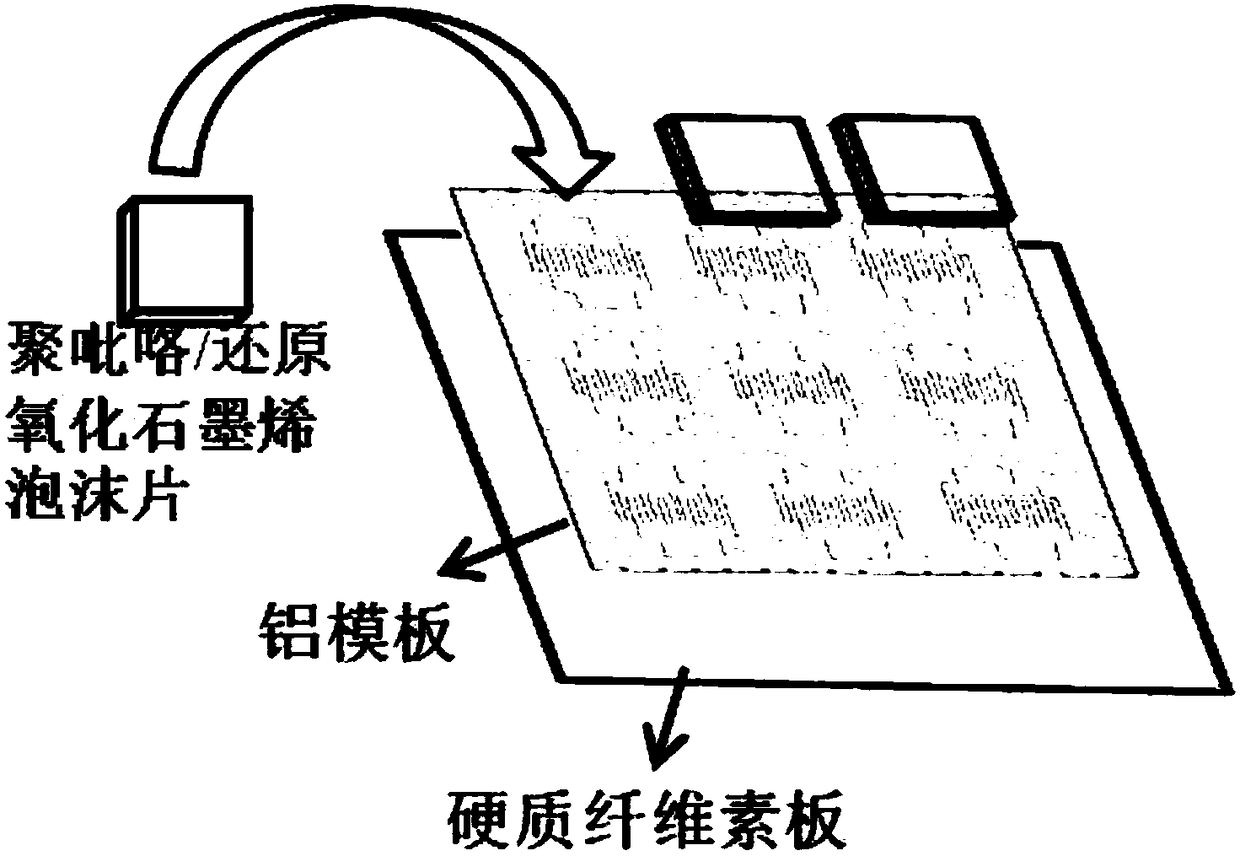

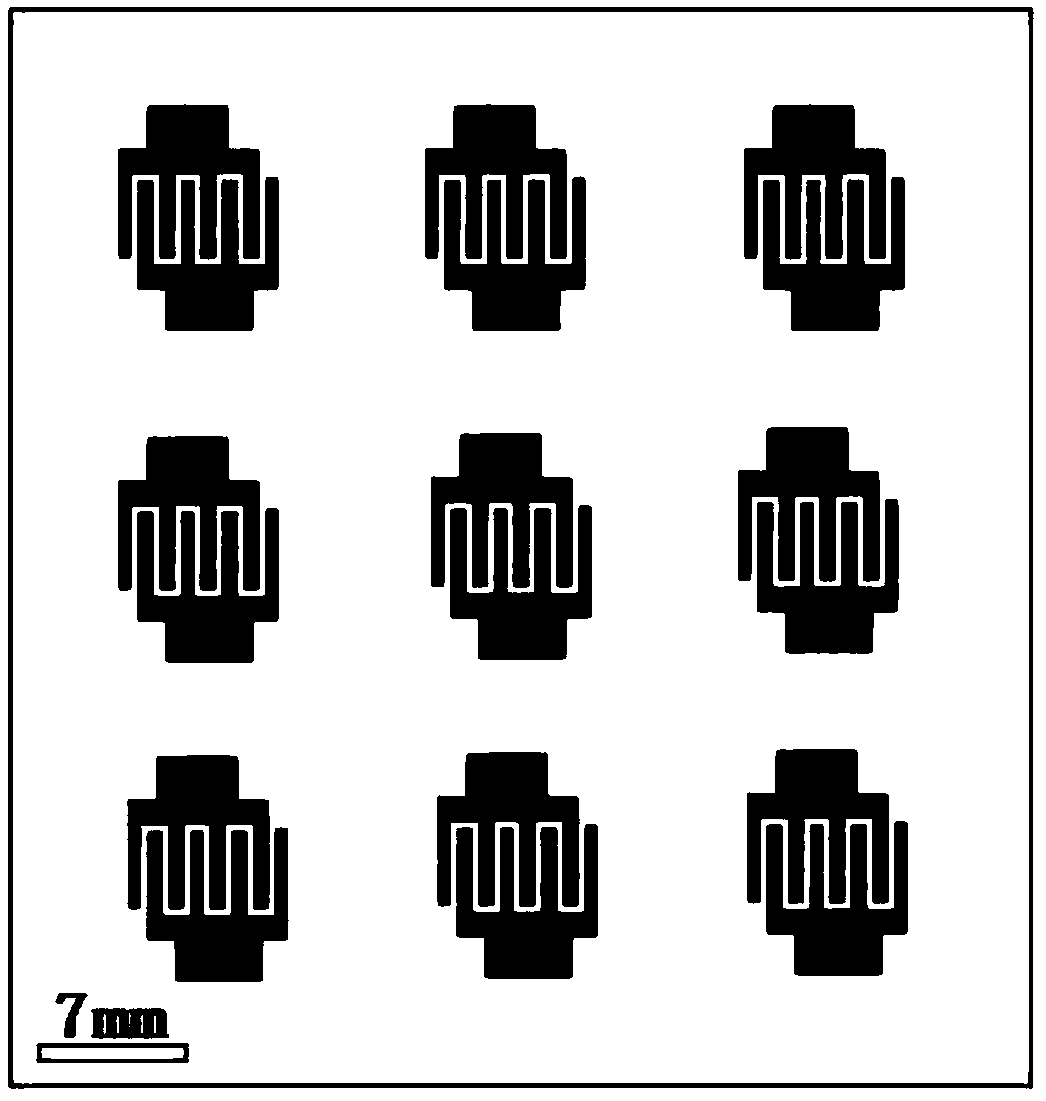

Manufacturing method of foldable paper-based micro supercapacitor

ActiveCN108447695AImprove Capacitive PerformanceIncrease migration rateHybrid capacitor electrodesHybrid/EDL manufactureSolid state electrolytePorosity

The invention relates to a manufacturing method of a foldable paper-based micro supercapacitor and belongs to the technical field of a micro energy storage device. The method comprises steps that a graphene or graphene composite electrode is imprinted onto a paper substrate through utilizing the template imprinting technology, the solid electrolyte is coated to the electrode, and the micro supercapacitor is manufactured on the paper substrate. The sheet-like graphene or graphene composite is imprinted through the template on the paper substrate to make the outline of the electrode clear and connectivity good, porosity and the water absorption property of the paper are utilized to ensure stability of the graphene or graphene composite electrode on the paper, foldability and flexibility of the paper are utilized to make the manufactured micro supercapacitor have good flexibility and foldability, wind energy collection and utilization and output of different voltages and currents can be realized, moreover, the manufacturing process is simple, operability is high, cost is low, and large scale manufacturing is realized.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

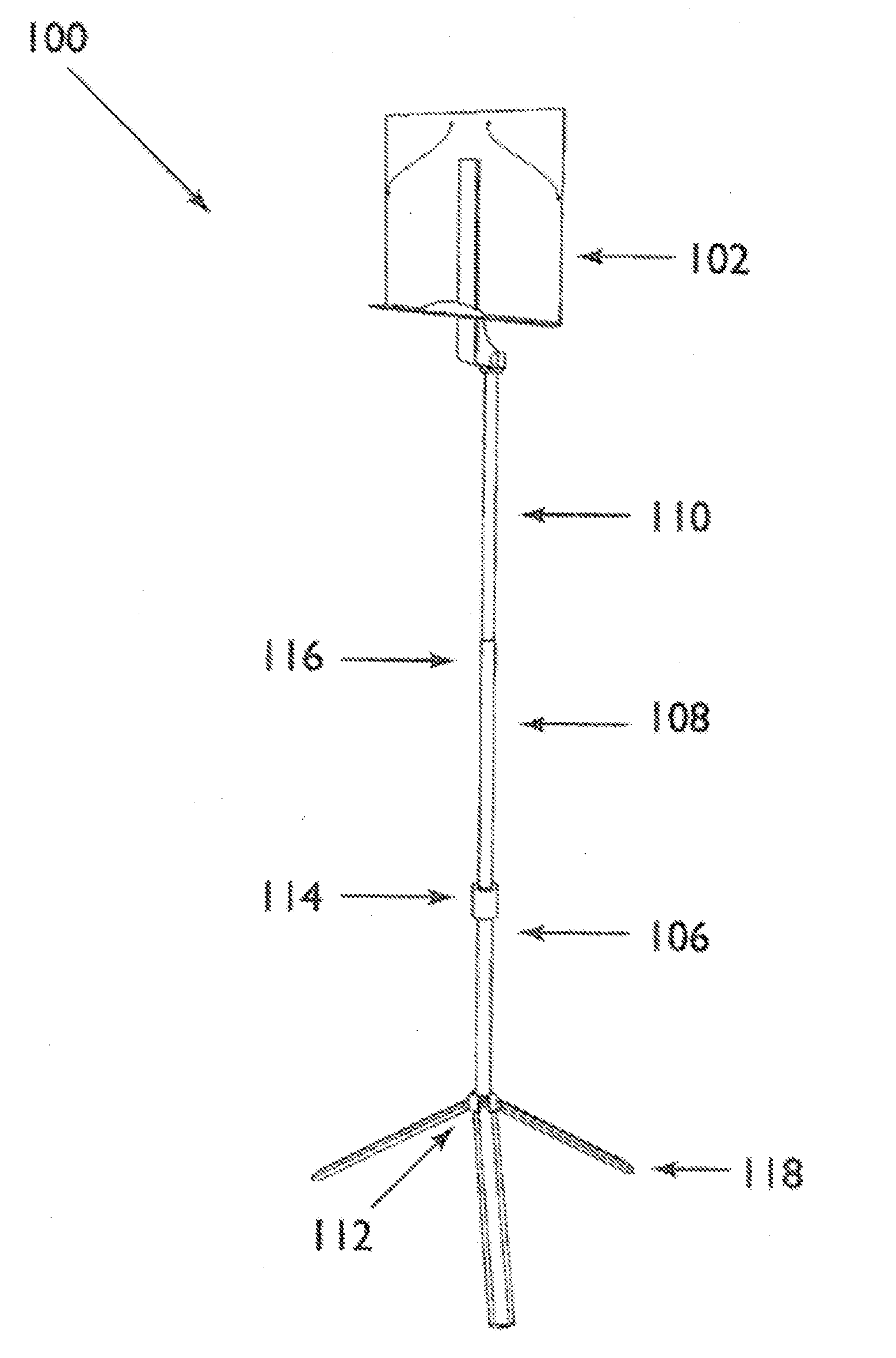

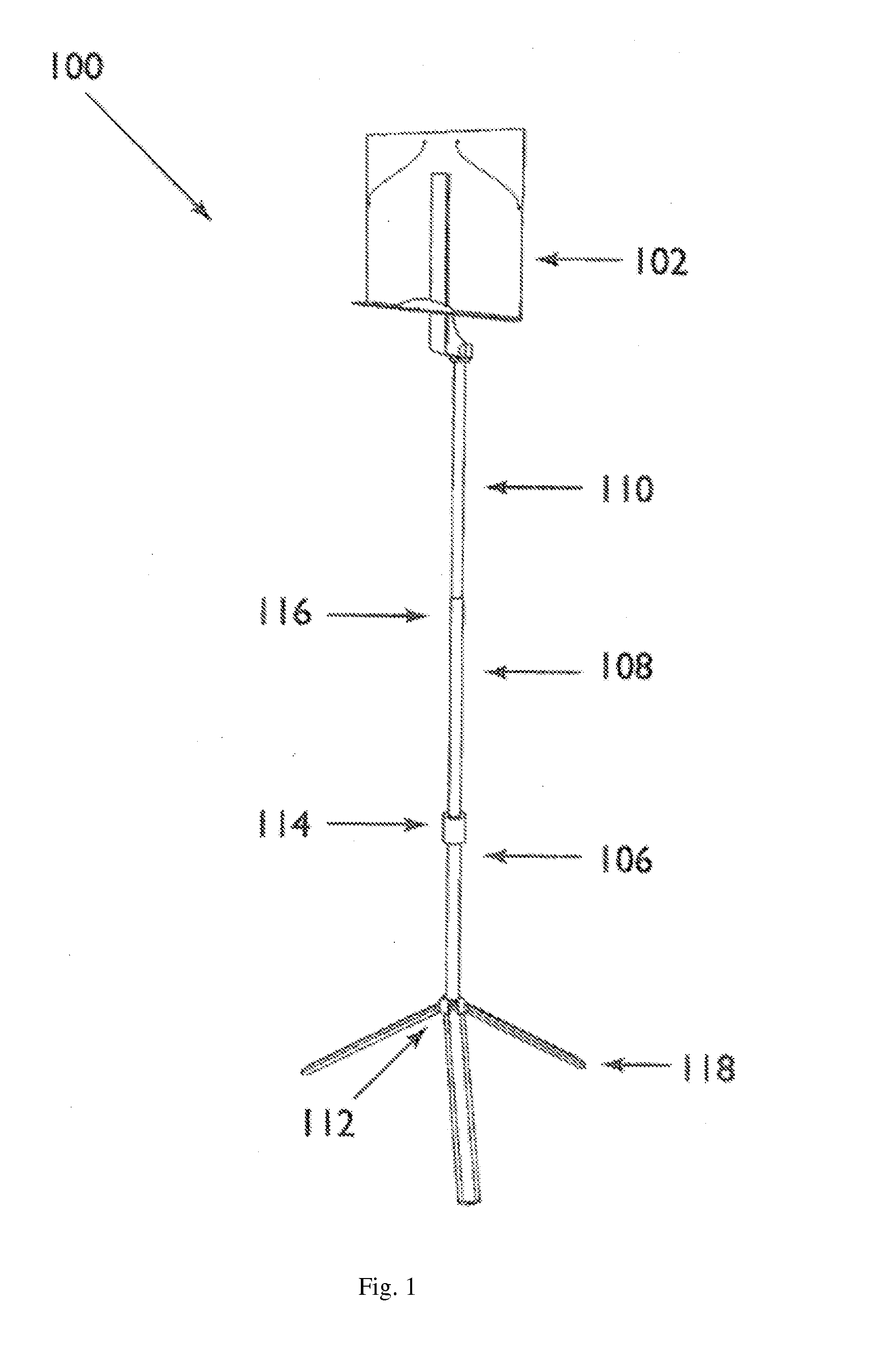

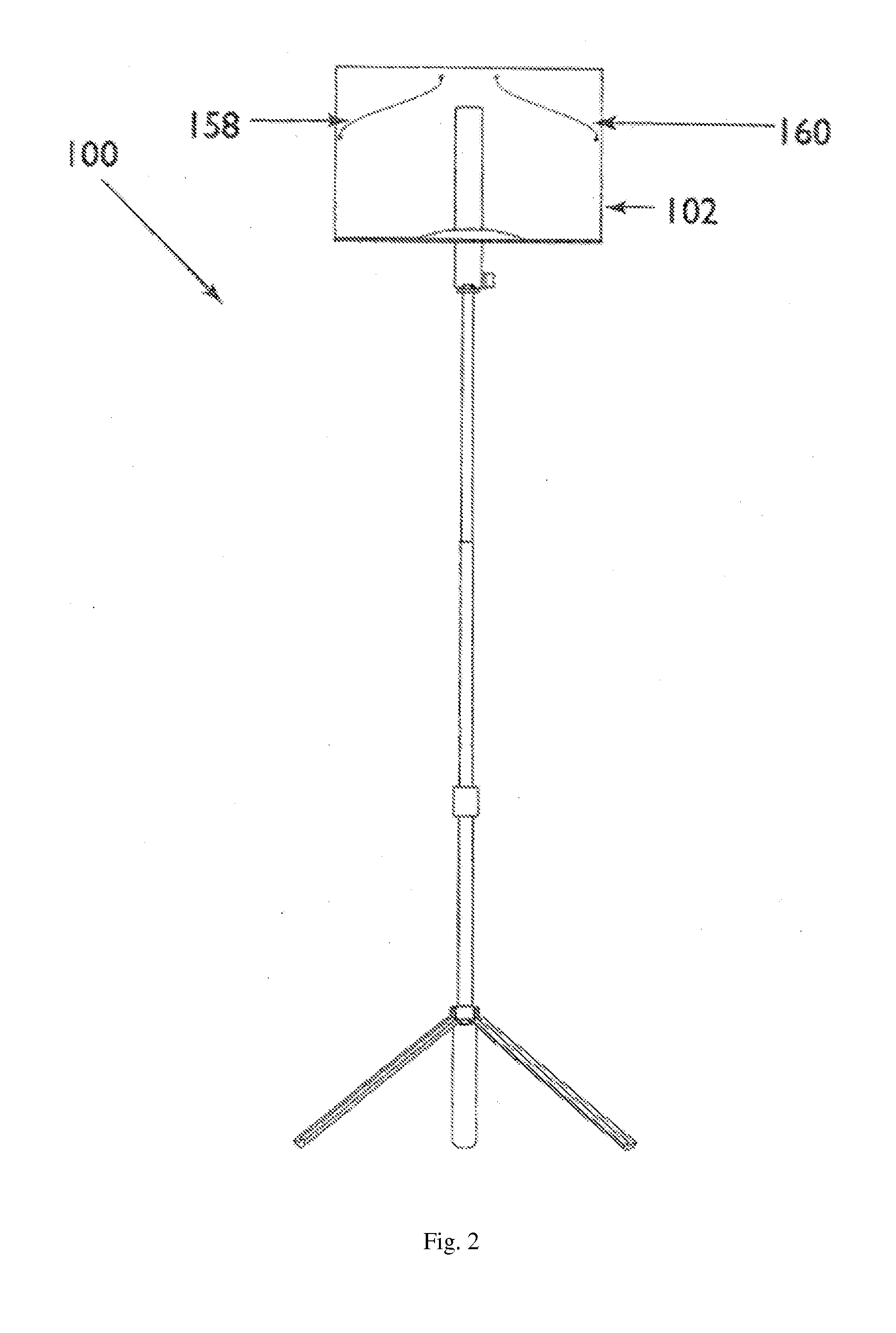

Foldable and portable music stand

A foldable and portable music stand (100) comprising: a music platform (102) for placing a music score and a music book; a pole comprising a main pole (106), a second pole (108), and a third pole (110); a foldable arm; and a support stand. The second pole (108) is sleeved in the main pole (106) in a sliding vertical adjustment manner; the third pole (110) is sleeved in the second pole (108) in a sliding vertical adjustment manner; the foldable arm is pivotally disposed at the top of the third pole (110); a locking ring (114) is disposed at the top of the main pole (106), so as to selectively lock the position of the second pole (108); a locking ring (116) is disposed at the top of the second pole (108), so as to selectively lock the position of the third pole (110); the music platform (102) is detachably connected to the foldable arm; a hollow groove is disposed on the surface of the foldable arm opposing the main pole (106); the hollow groove is slightly larger than the main pole (106), so that the main pole (106) can be nested in the hollow groove when the foldable portable music stand (100) is folded; the support stand is a foldable supporting base (118), is connected to a ferrule set (112) disposed at the bottom of the main pole (106) via a hinge, and can pivot between an unfolded position and a position adjacent to the main pole (106).

Owner:NG WAI HO

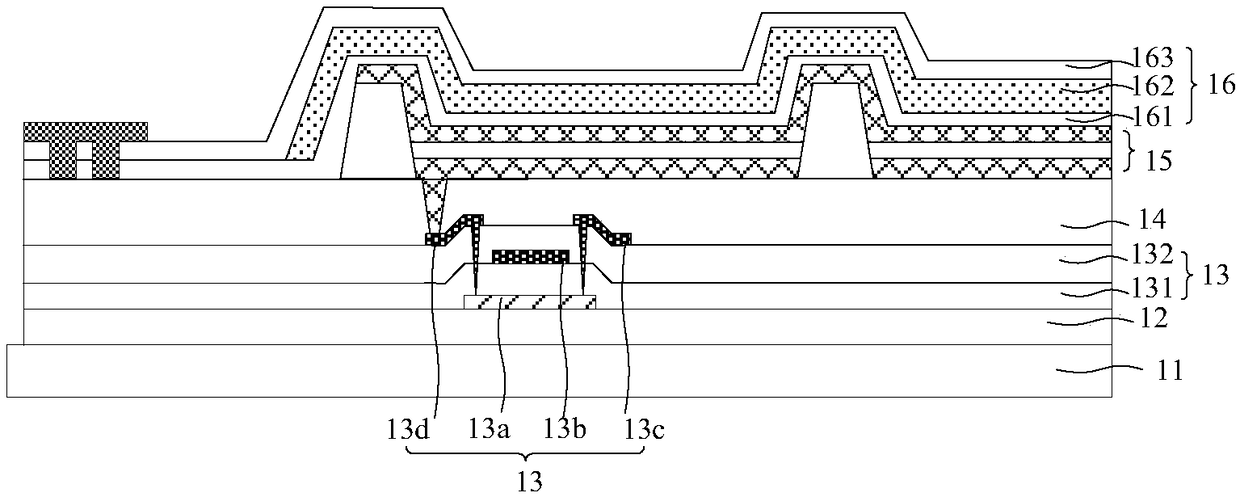

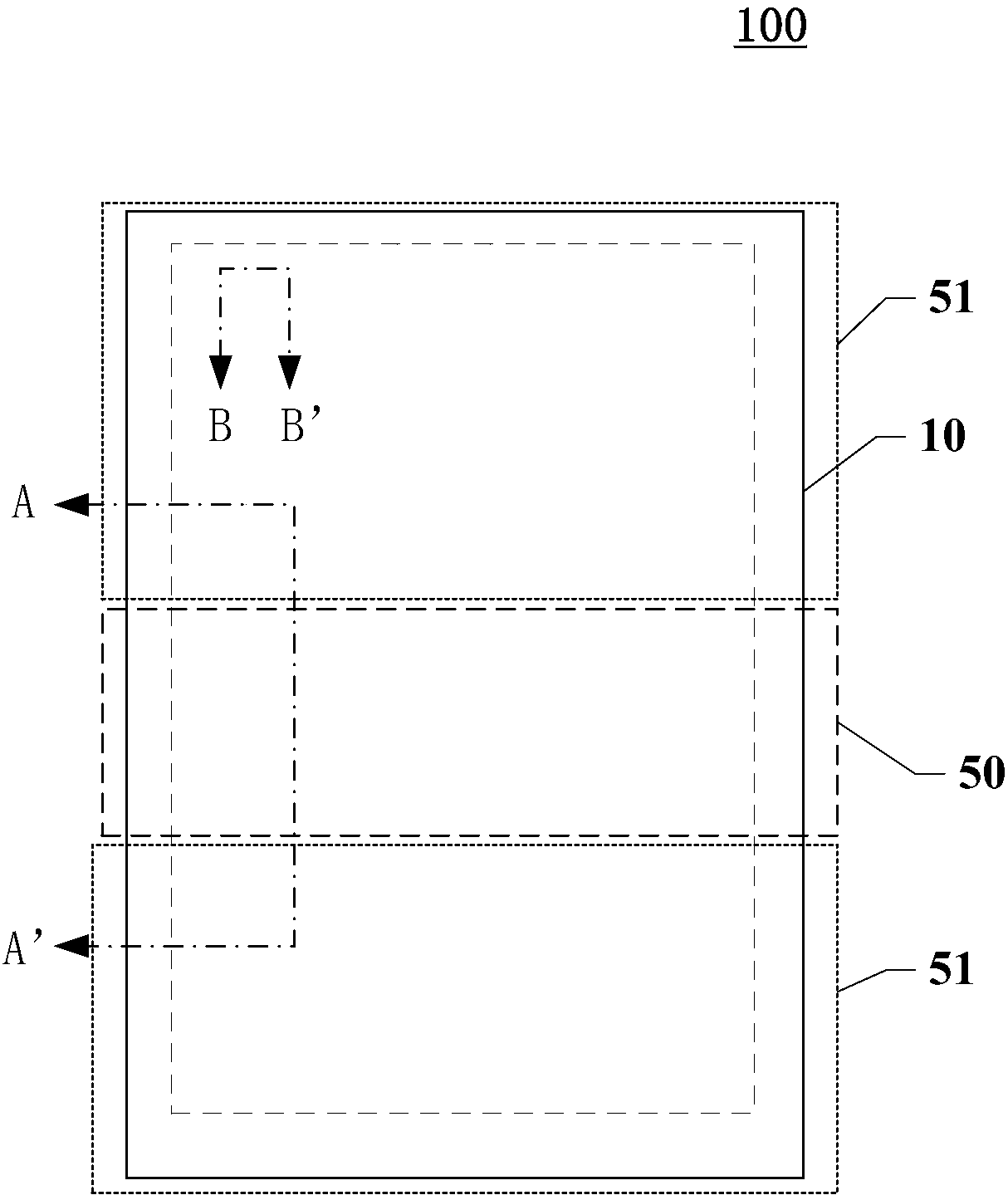

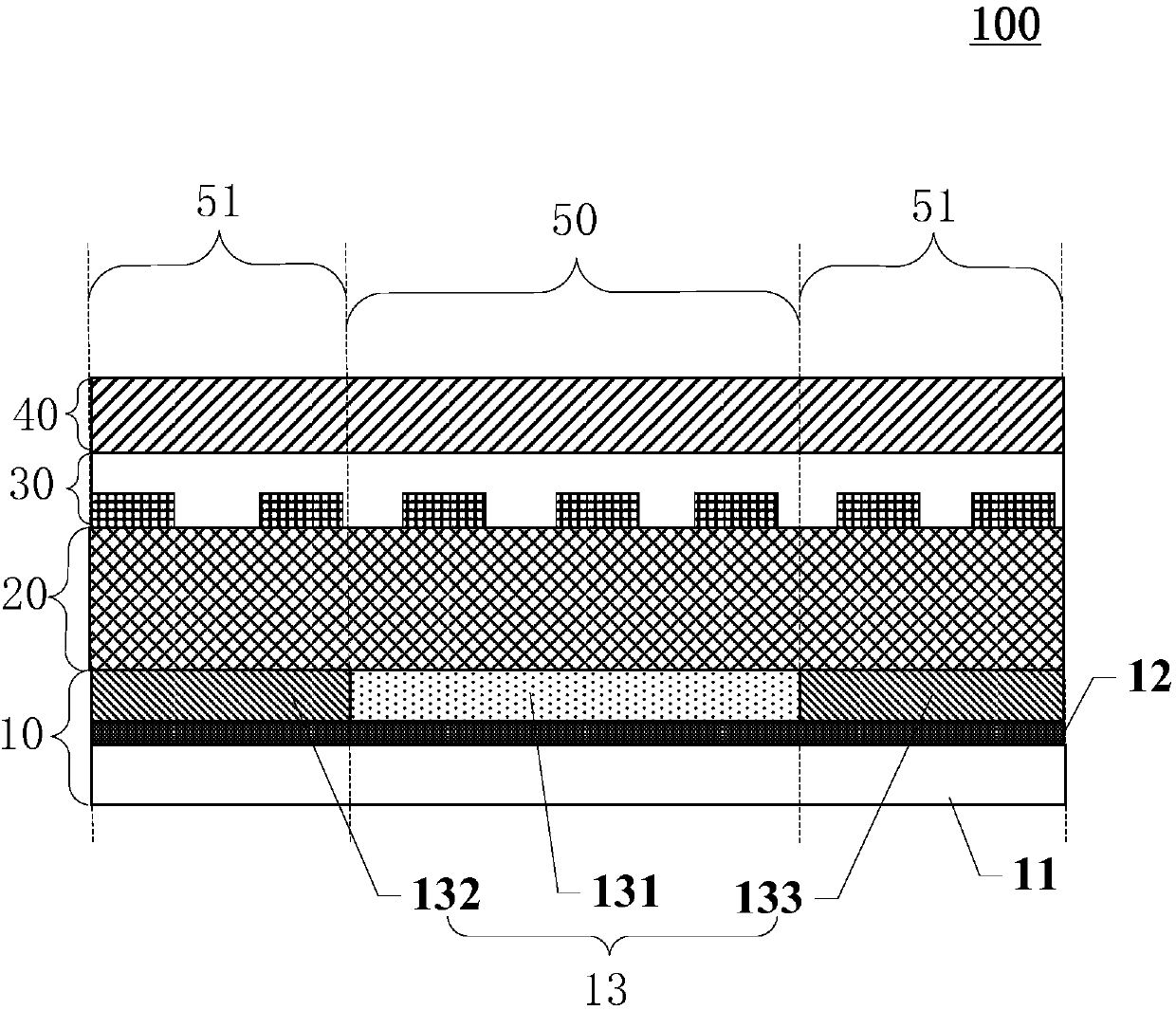

Display panel and preparation method thereof, and display device

ActiveCN108598138AIntegrity guaranteedAvoid crackingSolid-state devicesSemiconductor/solid-state device manufacturingDisplay deviceComputer science

The application discloses a display panel and a preparation method thereof, and a display device, and relates to the technical field of the display. A bending area and a non-bending area a provided, the display panel comprises at least one substrate, and a driving function layer, a light-emitting function layer and a package layer which are orderly arranged on the substrate along a direction far away from the substrate; the substrate comprises a first flexible base plate, and a first nano-film and a buffer layer orderly arranged on the first flexible base plate along a direction vertically faraway from the first flexible base plate, wherein the buffer layer is located at one side, close to the driving function layer, of the first nano-film, and comprises a first buffer layer located at the bending area and a second buffer layer located at the non-bending area, the first buffer layer and the second buffer layer are arranged at the same layer and have the same thickness, and the first buffer layer comprises organic materials. Therefore, the completeness of the first flexible base plate can be guaranteed, and the bending resistance of the display panel can be improved.

Owner:WUHAN TIANMA MICRO ELECTRONICS CO LTD

Manufacturing method for 7000-series aluminum alloy profile for automobile body

The invention provides a manufacturing method for a 7000-series aluminum alloy profile for an automobile body. Raw materials comprises the following alloy elements in percentage by mass: 0.119 to 0.138 percent of Si, 0.148 to 0.17 percent of Fe, 0.05 to 0.19 percent of Cu, 004 to 0.10 percent of Mn, 0.72 to 0.99 percent of Mg, 0.05 to 0.10 percent of Cr, 5.55 to 6.0 percent of Zn, 0.15 to 0.22 percent of Zr and 0.02 to 0.04 percent of Ti, wherein the content of a single element is less than or equal to 0.05 percent; the total amount of other elements is less than or equal to 0.15 percent; thebalance is aluminum; the ratio of Zn to Mg is controlled to be 6 to 8; and the processing process comprises the following treatments of smelting, performing purifying treatment, casting into a bar, performing homogenizing annealing, extruding, cooling, drawing, performing natural aging and performing artificial aging. The profile obtained by the manufacturing method provided by the invention has super-high strength mechanical properties and good corrosion resistance, fatigue resistance and crushing resistance, and is very suitable for batch production of parts, such as an aluminum alloy energyabsorption box, a front longitudinal beam, a rear longitudinal beam, a threshold and an automobile door anti-collision beam, used by an automobile bumper system.

Owner:TAISHAN CITY KAM KIU ALUMINUM EXTRUSION

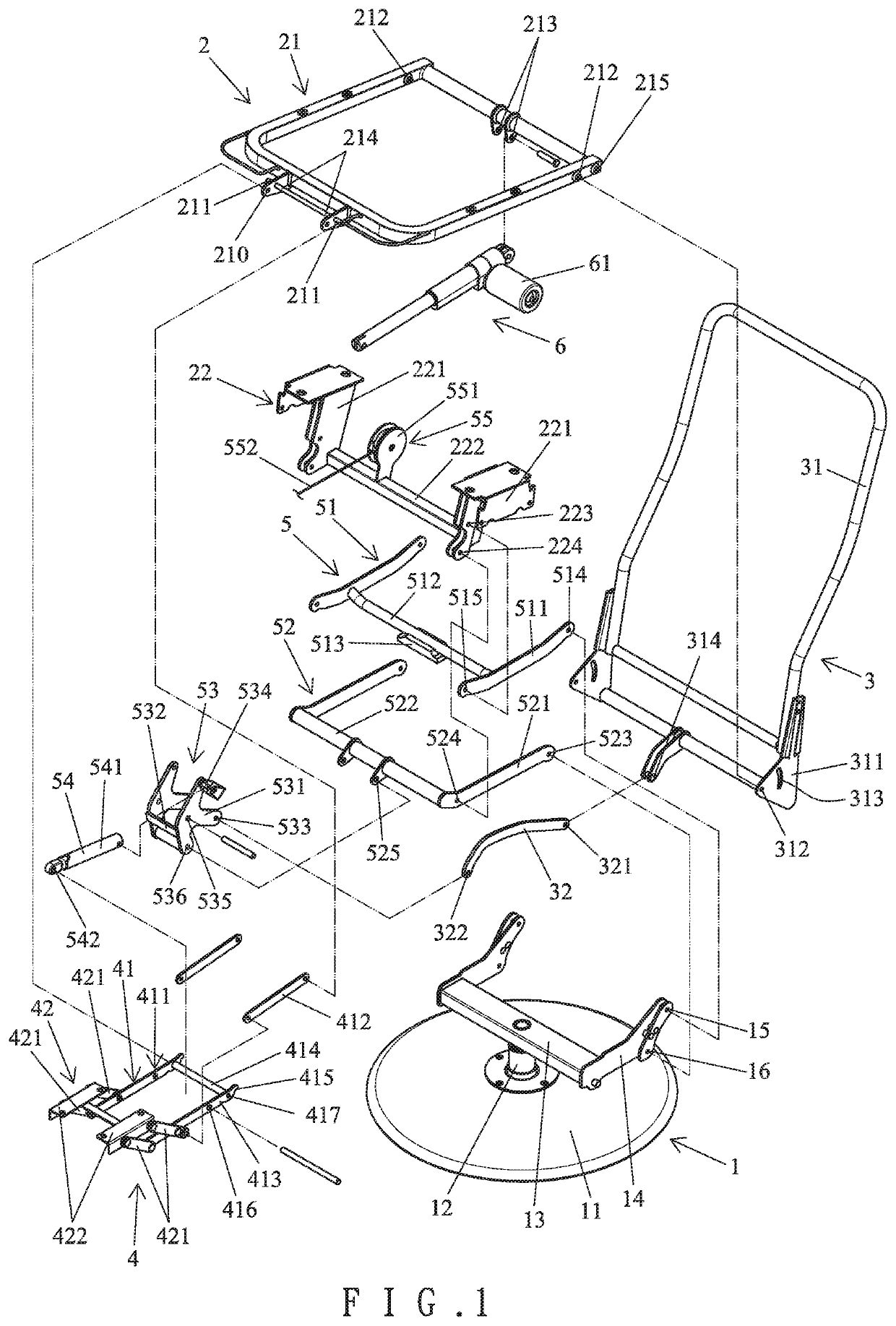

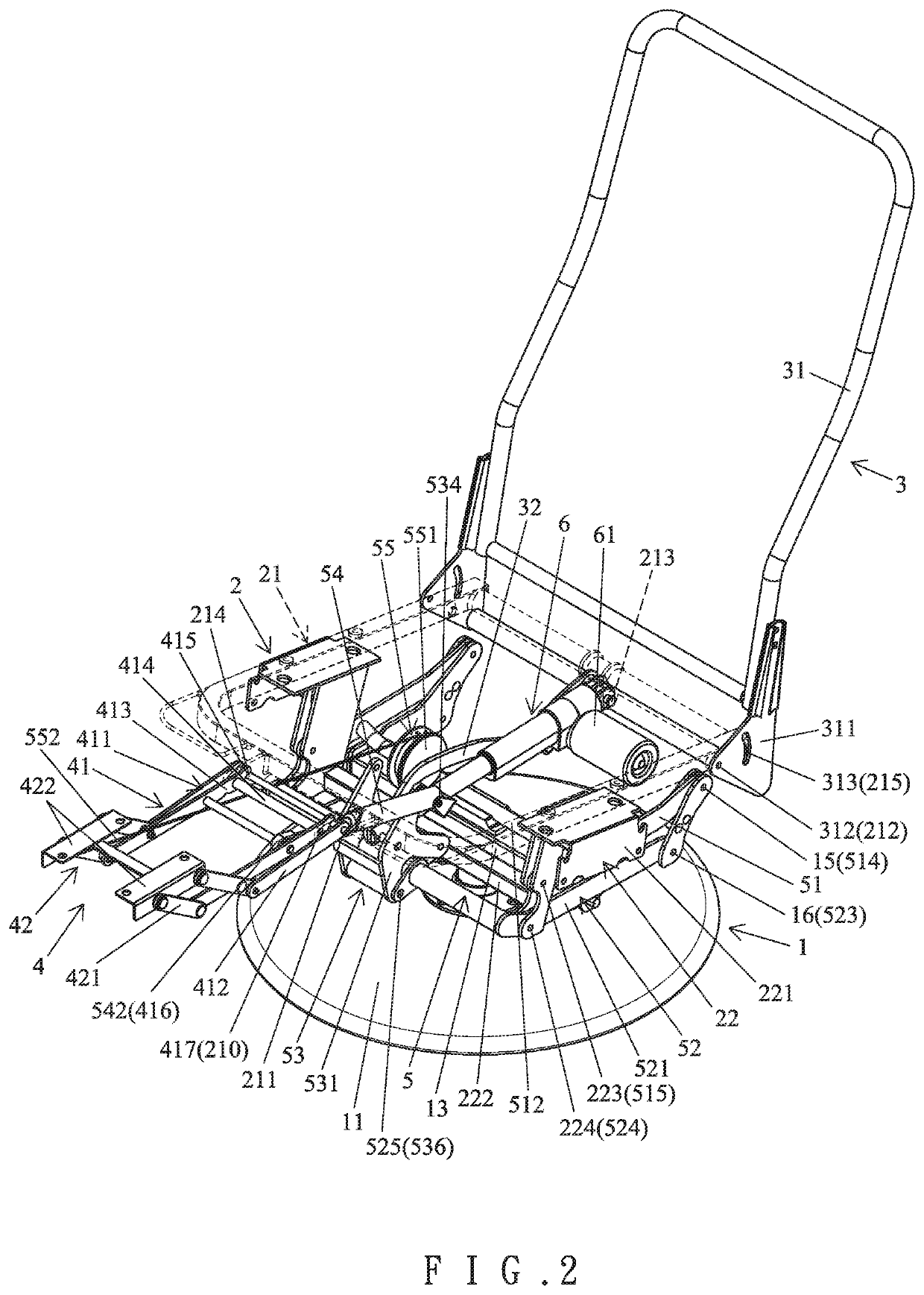

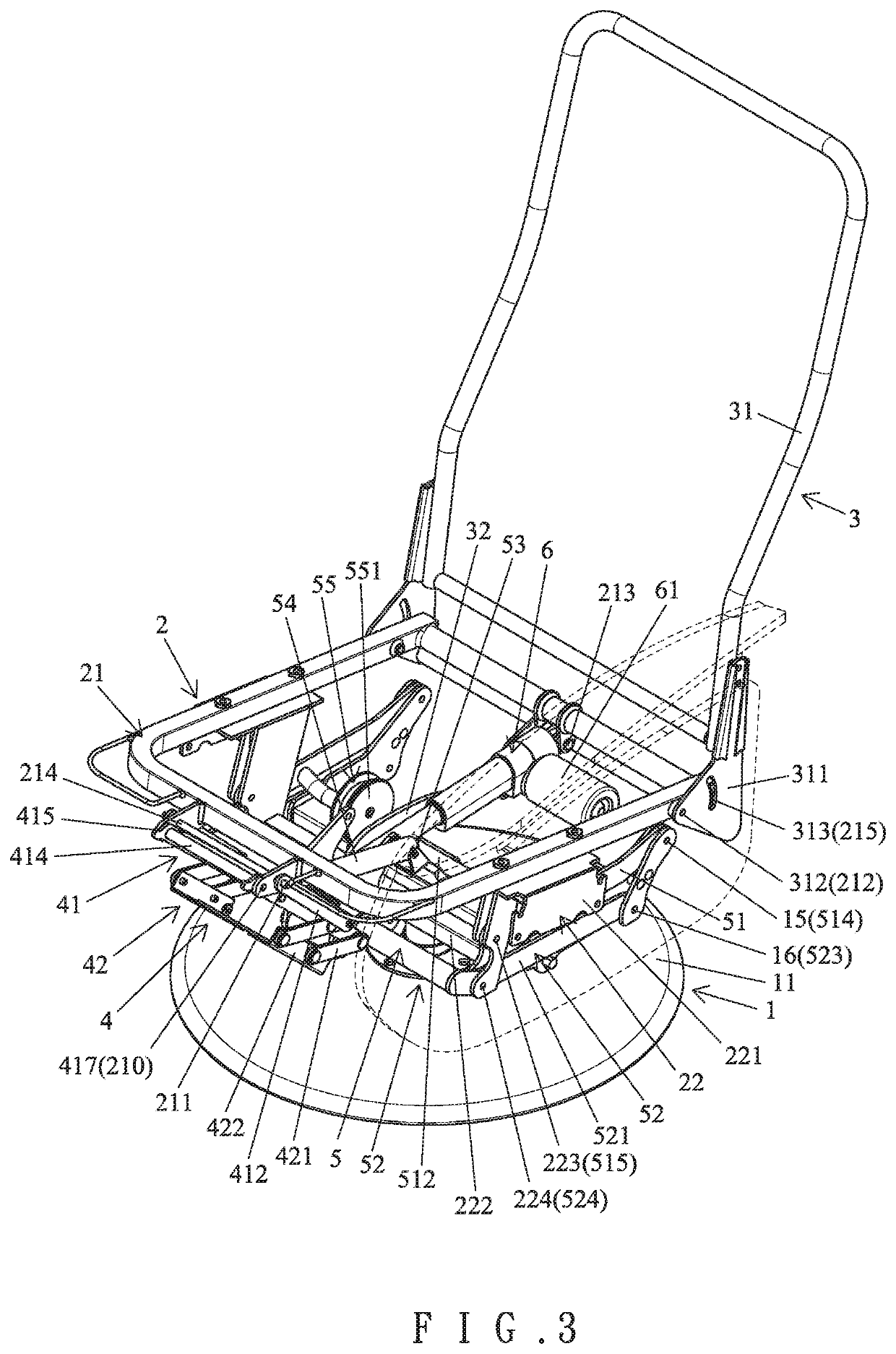

Electric-assisted leisure lifting recliner

ActiveUS10682271B2Improve convenienceImprove stabilityVehicle seatsWheelchairs/patient conveyanceControl theoryMechanical engineering

An electric-assisted leisure lifting recliner includes a back frame pivotably mounted to a seat frame unit. A footrest unit includes a connecting portion pivotably connected to a front end of the seat frame unit. First and second frames are pivotably connected to a base unit and the seat frame unit and are operable to move the seat frame unit vertically. A telescopic rod is pivotably connected to an actuating block and the connecting portion. An actuator pivotably connected to the actuating block can move the footrest unit to an extended state and to recline the back frame. When the connecting portion abuts against the seat frame unit, the telescopic rod can be shortened to independently recline the back frame. When a length of the actuator is shortened, the first and second frames and the seat frame unit are lifted, and a rear end of the seat frame rises.

Owner:LIN CHANG CHEN

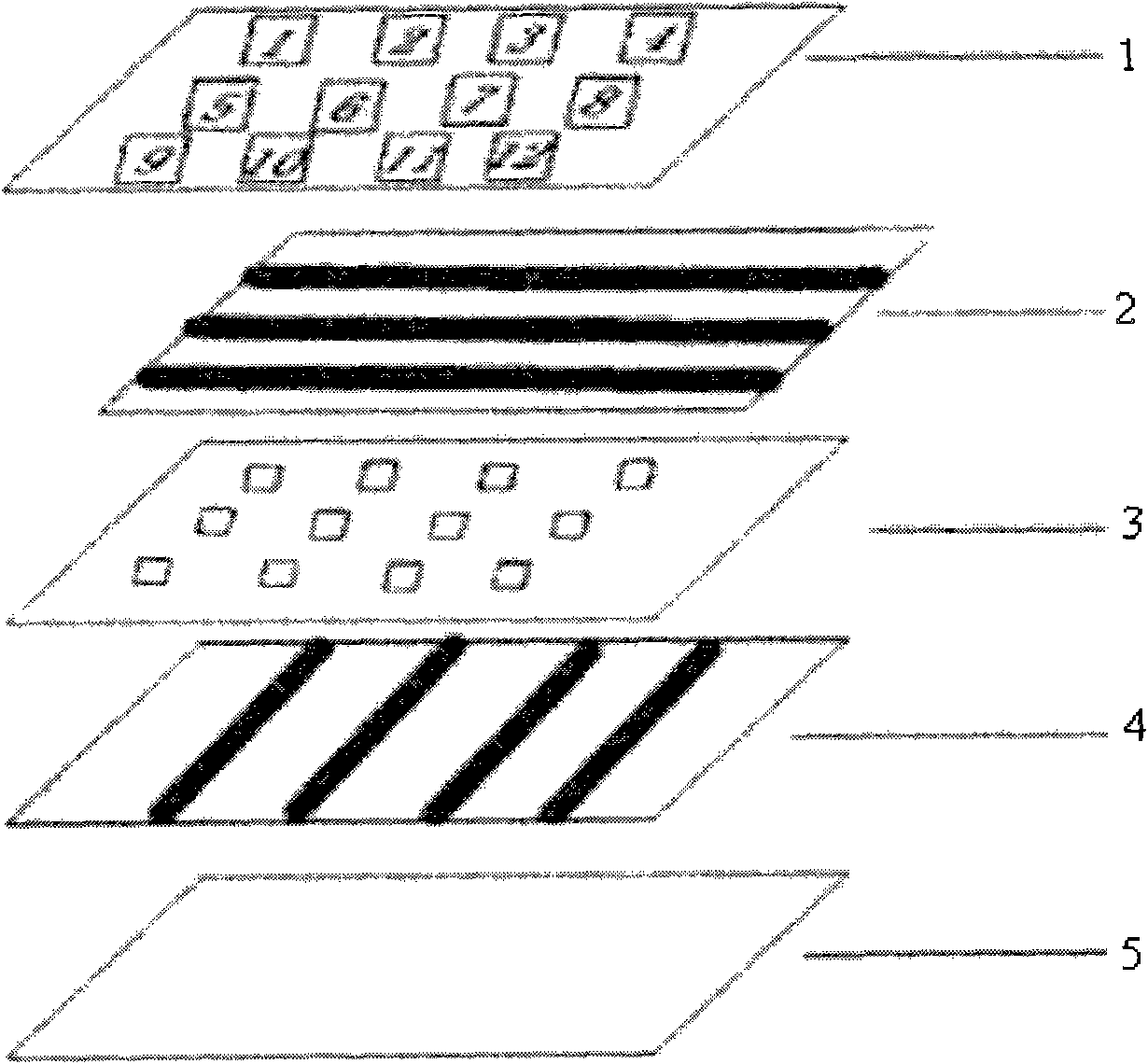

Embroidery type full fabric keyboard

InactiveCN101819467APracticalHigh sensitivity and accuracyInput/output for user-computer interactionEngineeringHuman body

The invention relates to an embroidery type full fabric keyboard. The keyboard comprises an upper covering layer, an upper conducting fabric layer, an insulating fabric layer, a lower conducting fabric layer and a lower covering layer which are arranged from top to bottom and all made of nonconductive fabric, wherein key symbols of the keyboard are marked on the upper surface of a key layer; the insulating fabric layer is provided with holes in one-to-one correspondence with the key symbols; a circuit in a line and a circuit in a row are defined by broidering conductive fiber on the upper and lower conductive fabric layers respectively; the insulating fabric layer is provided with corresponding electrodes formed by broidering at the positions corresponding to the holes; and two circuits are connected to a signal interface. Owing to the softness of the fabric, the keyboard can be coiled or folded and washed and realizes portability, foldability and full fabric while ensuring high flexibility and accuracy of the keyboard so as to open the way for the development of the computer worn on a human body.

Owner:DONGHUA UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com