Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

447 results about "Natural aging" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Natural aging is the spontaneous aging of a supersaturated solid solution at room temperature. This process is important for strengthening heat treatment of alloys containing aluminum, copper, magnesium and nickel. Natural aging is contrasted with artificial aging, which is done at elevated temperatures.

Keratin Treatment Formulations and Methods

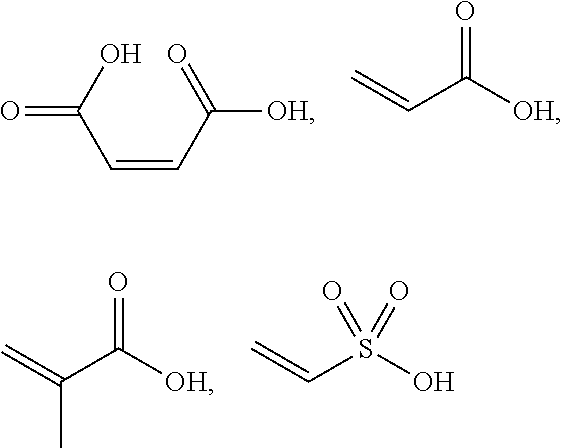

ActiveUS20150328102A1Simple methodReducing treatmentCosmetic preparationsHair removalReduction treatmentActive agent

Formulations, kits, and methods for rebuilding the disulfide bonds in keratin found in hair, skin, or nails. Hair that is damaged due to a hair coloring treatment and / or other reducing treatment, such as during a permanent wave, can be treated with the formulations containing one or more active agents. The formulations may be applied subsequent to a hair coloring treatment or simultaneously with a hair coloring treatment. Use of the active agent formulations during a permanent wave treatment prevents the reversion of the hair to its previous state, for at least one week, preferably at least three months, more preferably at least one year, most preferably greater than one year, after one or more than one application of the formulation. Application of the active agent formulation to skin or nails can help repair damaged disulfide bonds due to natural wear and tear or natural aging.

Owner:LIQWD

Manufacturing process for high-curvature full-profile thin-wall part

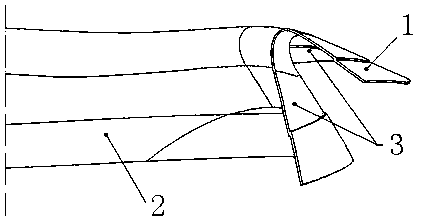

ActiveCN103639655ASolve Vibration ProblemsGuaranteed sizeAircraft componentsWorkpiecesMaterial removalNatural aging

The invention provides a manufacturing process for a high-curvature full-profile thin-wall part so as to solve the problem of processing deformation and vibration of an ultra-complex spatial thin-wall curved surface. By reasonable process layout, a segmented layer-by-layer processing mode is adopted, an appropriate cutter and a cutter handle are selected, working allowance of every process is set, natural aging time is set, cutting process parameters and feeding strategies are optimized, the uniform material removal amount of the part is guaranteed, an adding cushion block location and gypsum filling method is adopted simultaneously, the problem of clamping difficulty and vibration in part processing is solved, processing rigidity and clamping stability of the part are improved, deformation in the part processing process is controlled, and the part size and precision are guaranteed.

Owner:江西洪都航空工业股份有限公司

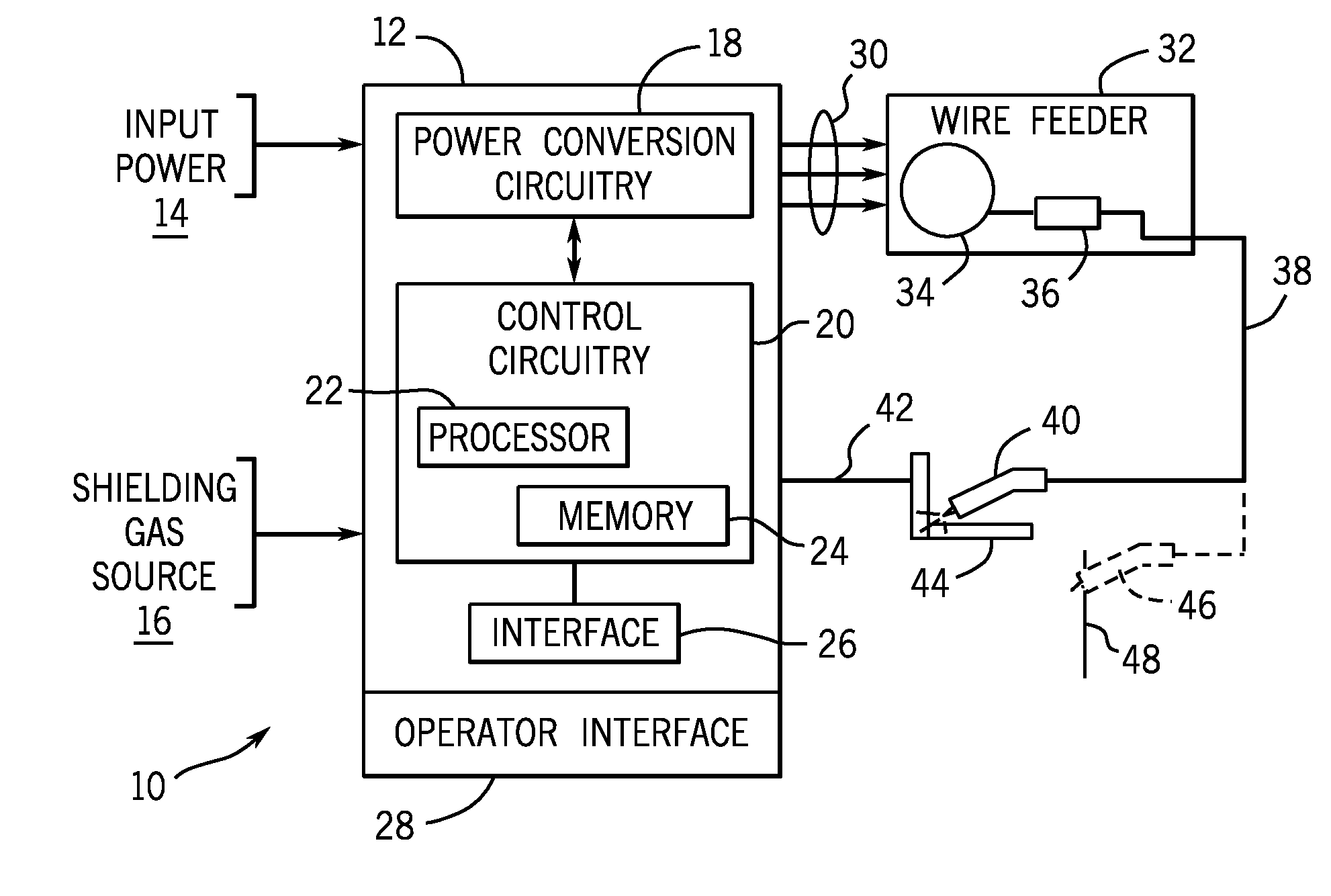

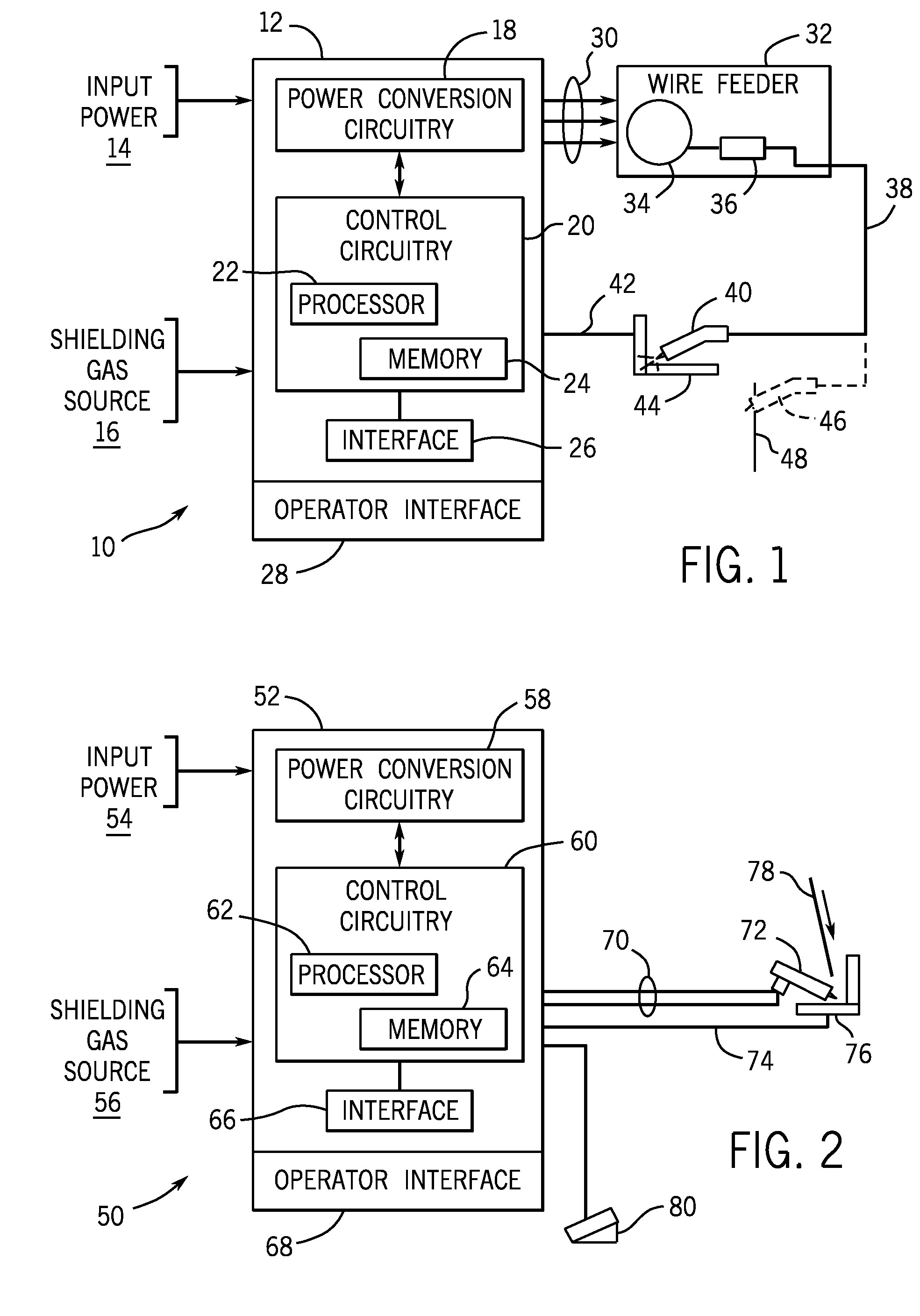

Aluminum alloy welding wire

InactiveUS20110194973A1Improve performanceHigh strengthCooking-vessel materialsElectron beam welding apparatusStress concentrationUltimate tensile strength

A composition for welding or brazing aluminum comprises silicon (Si) and magnesium (Mg) along with aluminum in an alloy suitable for use in welding and brazing. The Si content may vary between approximately 4.7 and 10.9 wt %, and the Mg content may vary between approximately 0.15 wt % and 0.50 wt %. The alloy is well suited for operations in which little or no dilution from the base metal affects the Si and / or Mg content of the filler metal. The Si content promotes fluidity and avoids stress concentrations and cracking. The Mg content provides enhanced strength. Resulting joints may have a strength at least equal to that of the base metal with little or no dilution (e.g., draw of Mg). The joints may be both heat treated and artificially aged or naturally aged.

Owner:HOBART BROS

Method for preparing fermentation wine by super-high pressure technology

ActiveCN101182444AGuaranteed nutritional valueMaintain colorAlcoholic beverage preparationFruit juiceHigh pressure

The invention relates to a preparation method of fermenting fruit wine with no addition of sulphur dioxide; the method uses a super high pressure technology. The raw materials of fruit and vegetable are pulped, decomposed by enzyme and filtered to prepare fruit and vegetable juice; according to a conversion relationship of preparing alcohol of 1 degree with 1.7g of sugar, white sugar or honey or condensed fruit and vegetable juice of high sugar content is used for adjusting the sugar concentration of the fruit and vegetable juice; citric acid or malic acid is used for adjusting the pH value to be below 4. After being treated by super high pressure of 100MPa to 1000MPa and for 1 minute to 60 minutes, 0.2g / L to 0.5g / L of excellent dried yeast of fruit wine is added; the main fermentation is done at a temperature between 20 DEG C and 25 DEG C for about 7 days; then the secondary fermentation is done at a temperature between 10 DEG C and 20 DEG C; the alcohol content can achieve the set requirement; residual sugar is less than 1g / L; raw fruit wine can be prepared after fermentation. After being treated under the pressure of 200MPa to 500MPa and for 20 minutes to 60 minutes, the raw fruit wine can achieve the effects of sterilizing and speeding up the natural aging. Compared with the traditional process, the invention shortens the time, improves the efficiency, and reduces the production cost. The production process is simple; the production cost is low; and the produced fruit wine has high safety and nutrition for eating.

Owner:山东康来农业科技发展有限公司

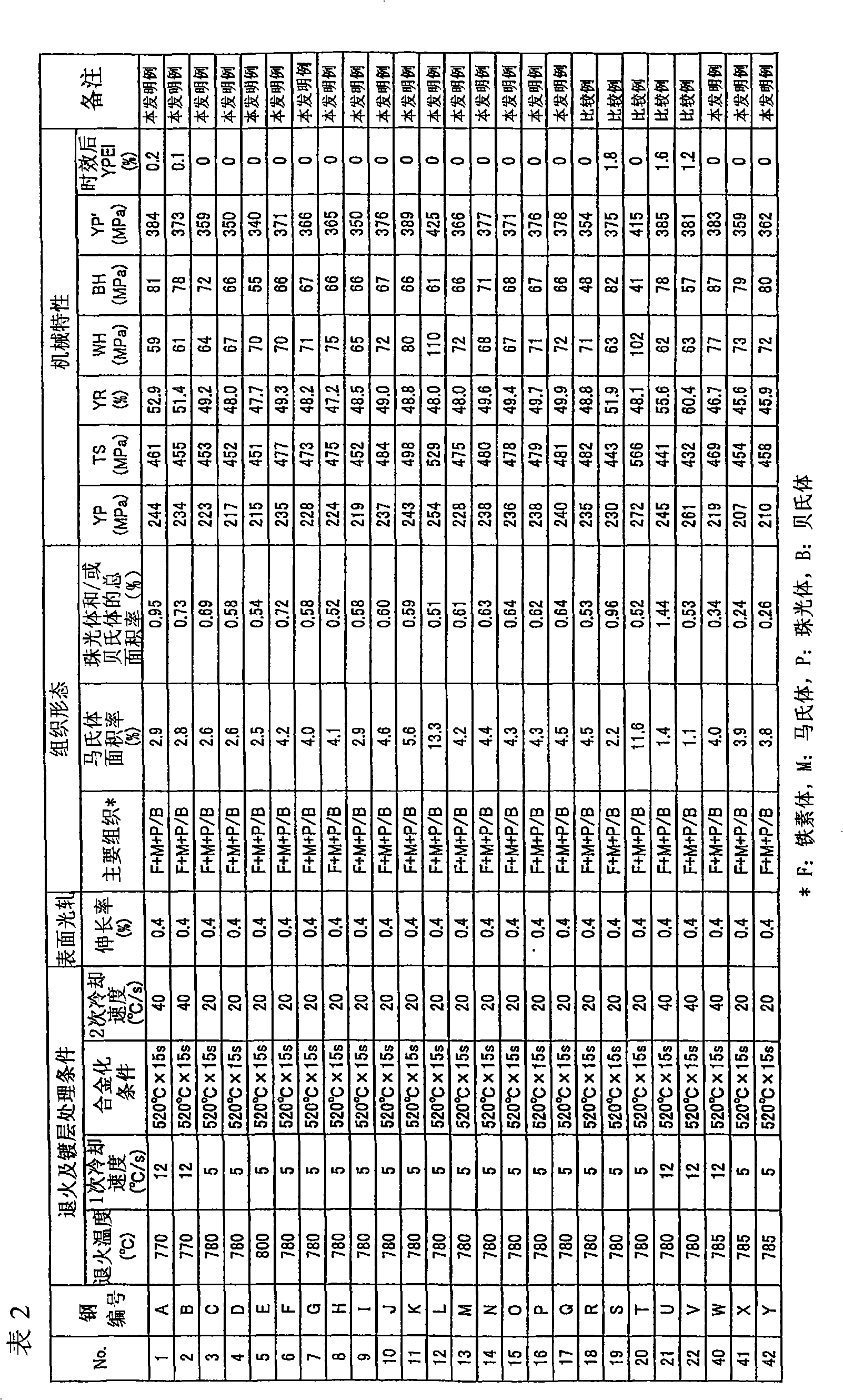

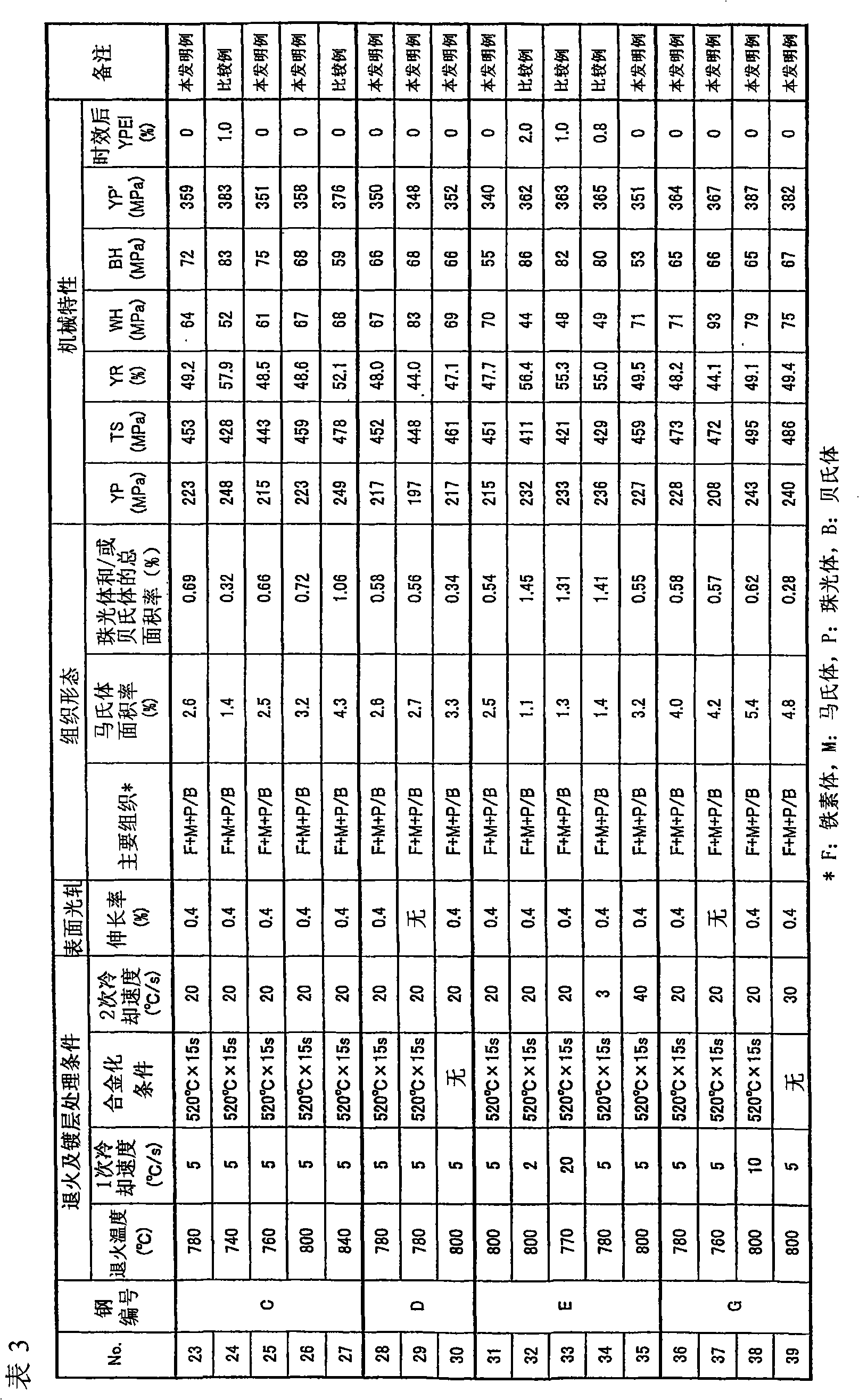

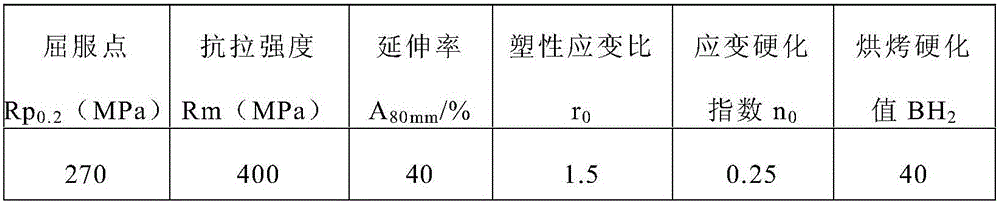

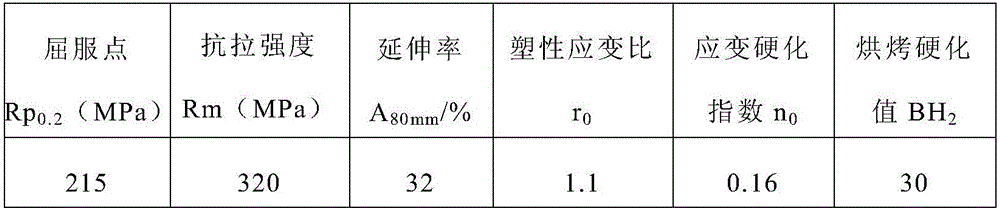

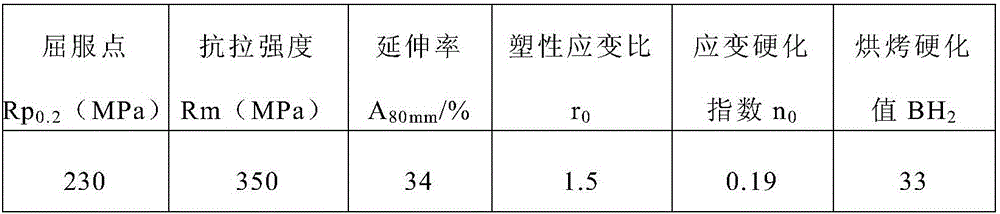

Dual phase steel sheet with good bake-hardening properties

ActiveUS20090242085A1Well-balanced strengthWell-balanced workabilityFurnace typesHeat treatment furnacesPre strainCooking & baking

A dual phase steel sheet with good bake-hardening properties is provided. The steel sheet is characterized in containing (in terms of percent by mass) C: no less than 0.06% and less than 0.25%; Si+Al: 0.5 to 3%; Mn: 0.5 to 3%; P: no more than 0.15%; and S: no more than 0.02%; and also meeting the following condition (in terms of space factor) that retained austenite is at least 3%, bainite is at least 30%, and ferrite is no more than 50%, and further characterized in differing in stress larger than 50 MPa before and after application of 2% pre-strain and ensuing heat treatment for paint baking at 170° C. for 20 minutes. The steel sheet has well-balanced strength and workability, exhibits good bake-hardening properties at the time of paint baking, and offers good resistance to natural aging.

Owner:KOBE STEEL LTD

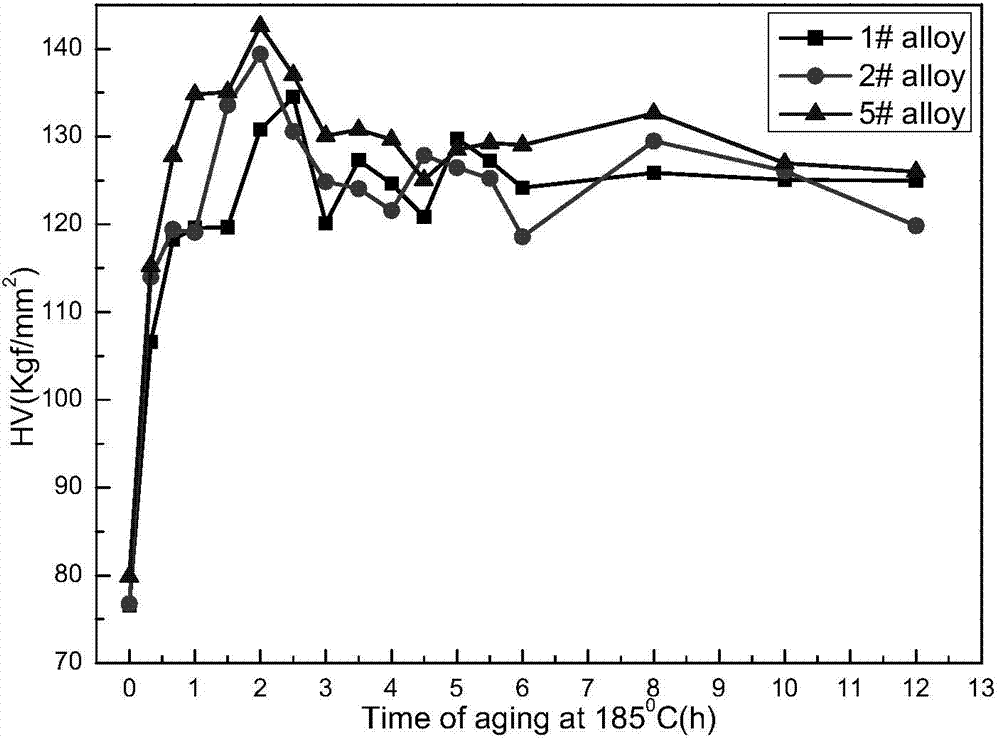

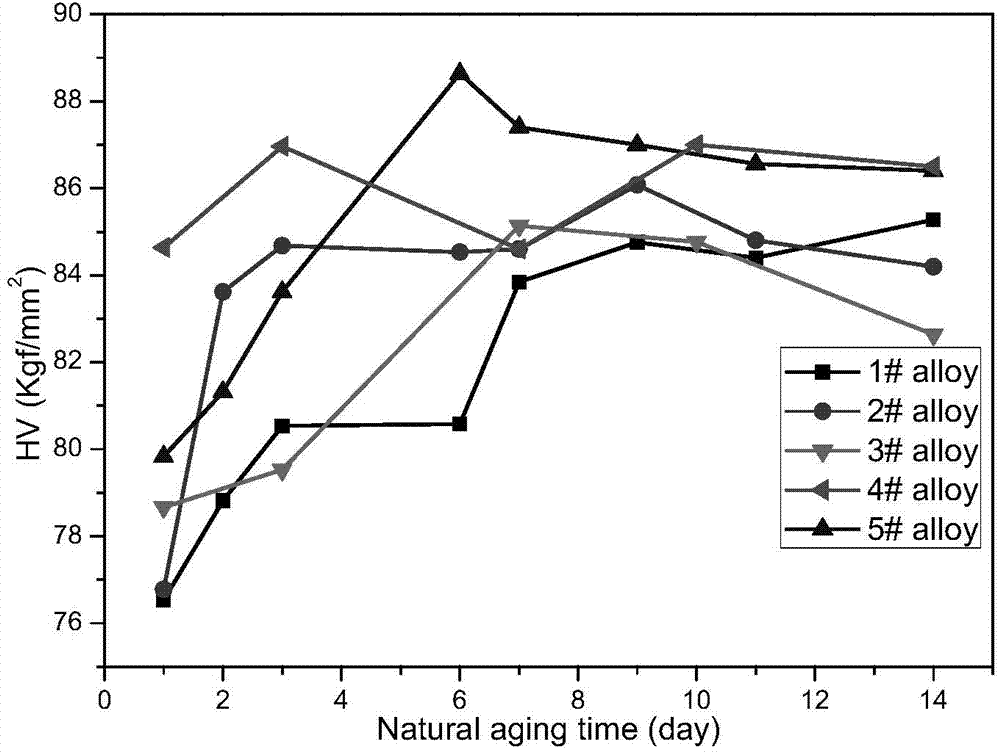

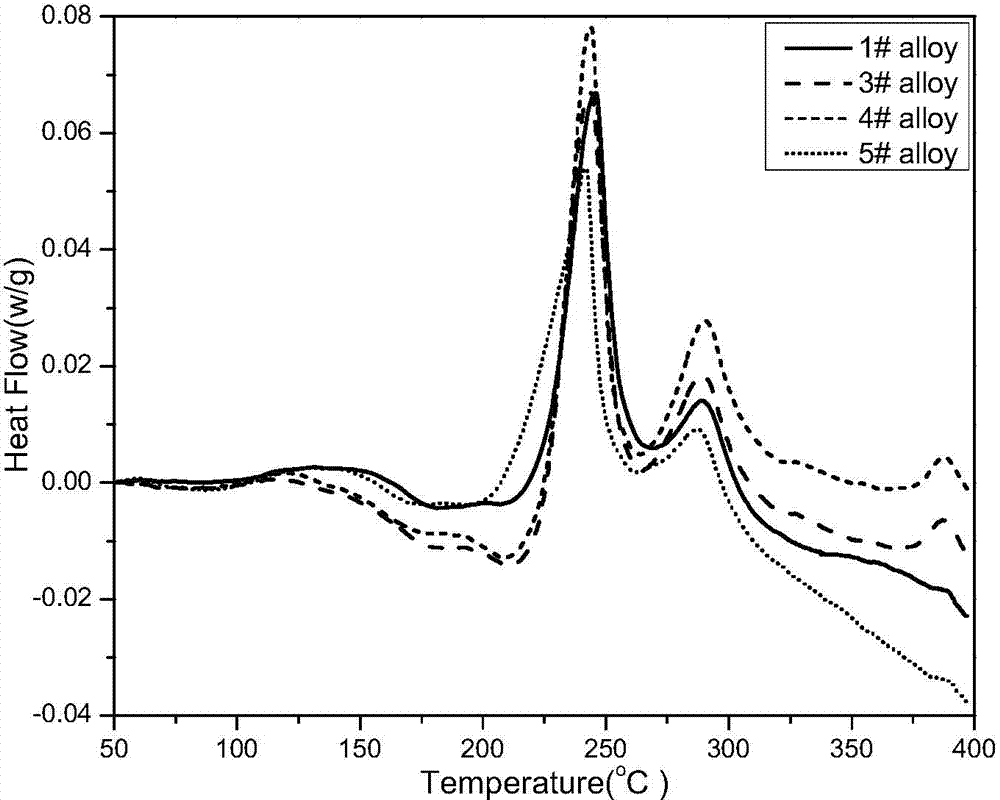

Fast aging response type Al-Mg-Si-Cu-Zn series alloy and preparation method thereof

InactiveCN103789583AHigh strengthFast time-sensitive response characteristicsRoom temperatureResponse type

The invention provides a novel Al-Mg-Si-Cu-Zn series alloy with fast aging response and a preparation method thereof. According to the invention, the novel Al-Mg-Si-Cu-Zn series alloy shows excellent fast aging response characteristic in an aging process by sufficiently utilizing the synergetic precipitation effect and synergetic strengthening effect of the main strengthening phases Mg2Si, MgZn2 and transitional phase of an Al-Mg-Si series alloy and an Al-Zn-Mg-Cu series alloy; the natural aging deterioration effect of a common Al-Mg-Si-Cu series alloy is certainly inhibited due to the simultaneous addition of Mg, Si, Cu and Zn elements and the addition of element Zn especially, the novel Al-Mg-Si-Cu-Zn series alloy has low strength and high room temperature stability after being subjected to preaging treatment at a certain temperature, which is favorable to the subsequent stamping forming of an alloy plate; a preaging-state alloy is greatly enhanced in strength after being subjected to high-temperature aging treatment and achieves the highest strength increment approaching to 150 MPa far higher than that of the traditional AA6016 and AA6111 alloys through short-term artificial aging at 185 DEG C for 20 minutes; the fast aging response characteristic is not only suitable for the preparation of an automobile outside plate, but also suitable for the related field with a special requirement on the aging precipitation speed of the alloy plate.

Owner:UNIV OF SCI & TECH BEIJING

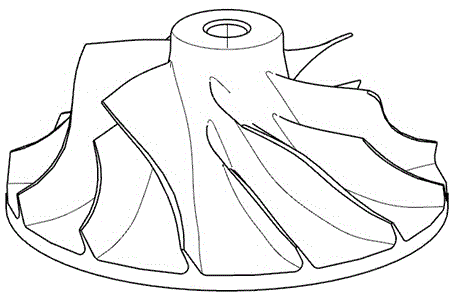

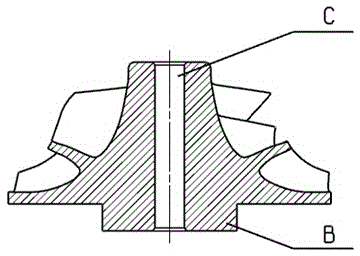

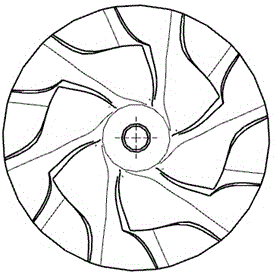

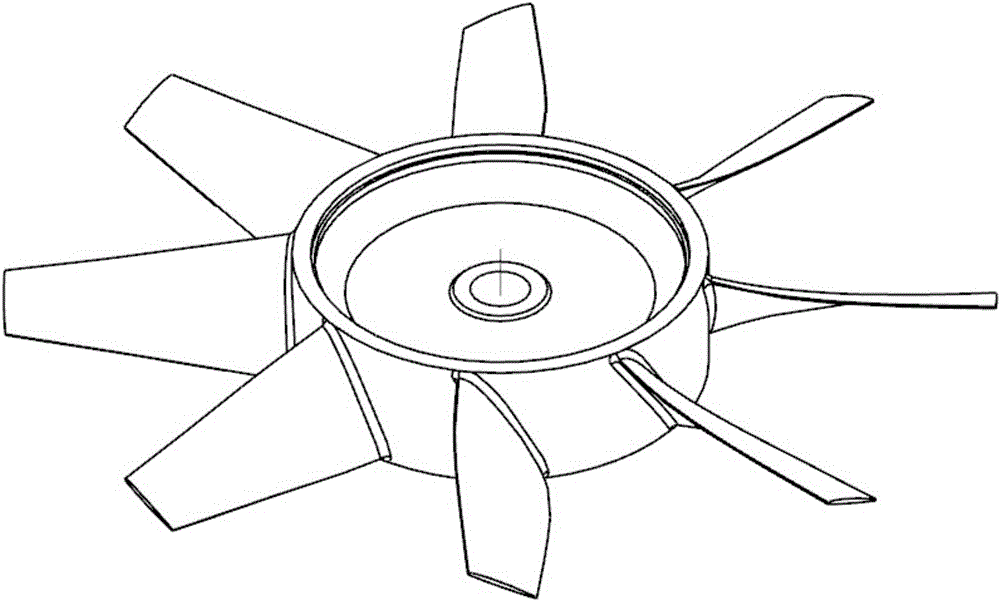

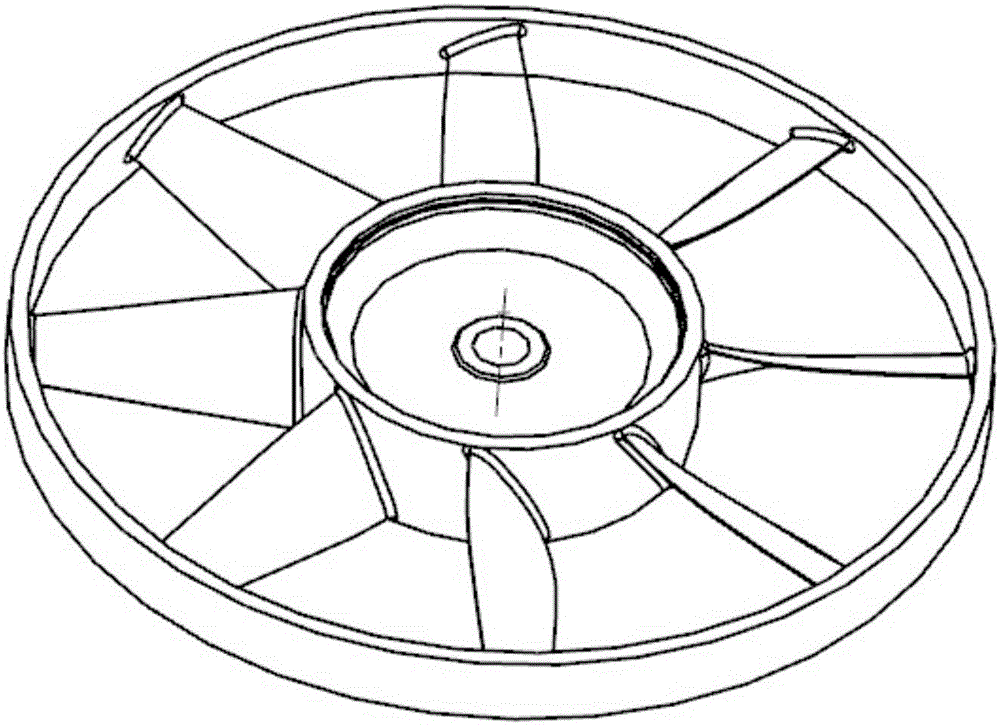

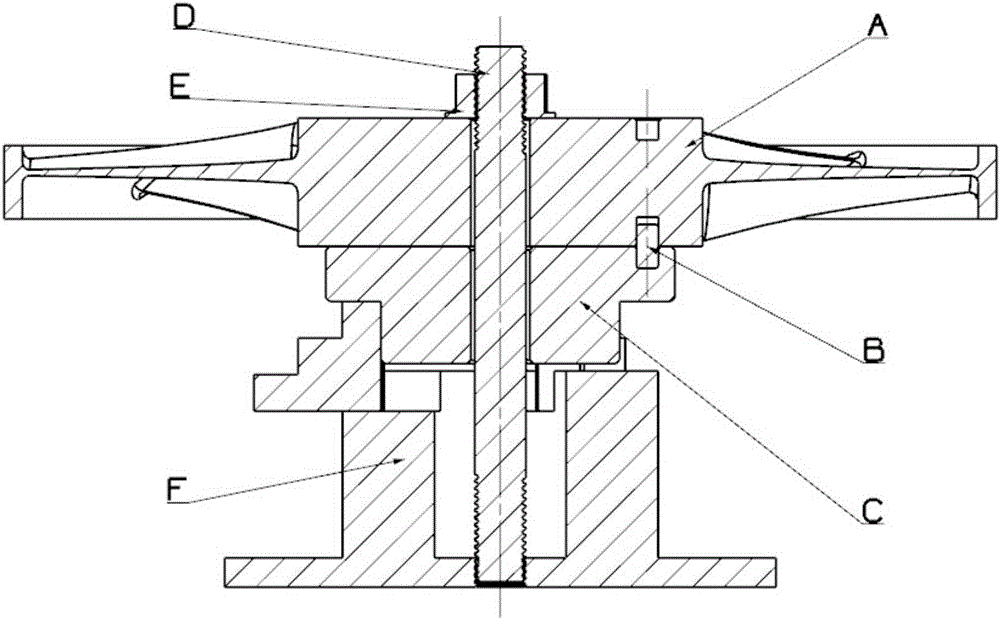

Process method for improving manufacturing accuracy of aluminum-alloy open-type integral impeller

The invention relates to a process method for improving the manufacturing accuracy of an aluminum-alloy open-type integral impeller. The method comprises the concrete steps of preparing materials, carrying out rough-turning on impeller blank shape, carrying out rough-turning on a process gripping head, carrying out heat treatment, carrying out artificial aging, carrying out semi-fine-turning on the process gripping head, carrying out semi-fine-turning on impeller shape, carrying out low-temperature treatment, carrying out five-axis-linkage-machining rough-milling, carrying out natural aging, carrying out five-axis-linkage-machining fine-milling, gripping, carrying out fine-turning on an axle hole, carrying out fine-turning on an impeller, gripping and carrying out dynamic balance. The impeller manufactured by adopting the process method provided by the invention has the characteristics that the shape is complete, the curved face is smooth and unhindered, blade curved faces and flow passage curved faces are low in deformation, and shown by the results of a fluorescent flaw detection, blade surfaces and front edges of the blades are flawless; during the dynamic balance of the integral impeller, mass reduction is relatively low, the qualified rate is high, and the qualified rate of excess-revolution tests of the integral impeller is greatly increased; the improvement of process for the series of integral impeller parts is realized, and good product quality, performance and design requirements are guaranteed; meanwhile, the stability of production quality is improved, and the reliability of products is improved.

Owner:SHANGHAI INST OF TECH

Manufacturing process of ultra-long blade complex curved surface integral impeller made of aluminum alloy material

InactiveCN105904169AManufacturing process improvements and enhancementsComplete shapeOther manufacturing equipments/toolsNumerical controlCold treatment

The invention relates to a manufacturing process of an ultra-long blade complex curved surface integral impeller made of an aluminum alloy material. The manufacturing process includes the specific steps of preparing materials, conducting rough machining on the profile of an impeller workblank, conducting heat treatment, conducting artificial aging, conducting semifinishing on the profile of the impeller, conducting ice-cold treatment, drilling a positioning hole, conducting five-axis linkage rough machining, conducting natural aging, conducting five-axis linkage finish machining, conducting clamp treatment, conducting numerical control turning, conducting linear cutting, conducting clamp treatment and conducting dynamic balancing. By the adoption of the process technology method, the ultra-long blade complex curved surface integral impeller made of the aluminum alloy material is manufactured, the blade shape of the ultra-long blade complex curved surface integral impeller made of the aluminum alloy material is complete, deformation is small, the blade lines of the blade faces of blades are smooth, mass reduction in dynamic balancing is small, and the yield is high; and process improvement in the integral impeller part of the structure is achieved, product quality is guaranteed effectively, the design requirement is met effectively, the stability of production quality is improved, and the reliability of products is guaranteed.

Owner:SHANGHAI INST OF TECH

Aluminum alloy sheet

Disclosed is an aluminum alloy sheet resistant to deterioration through natural aging. The aluminum alloy sheet is an Al—Mg—Si aluminum alloy sheet containing 0.35 to 1.0 percent by mass of magnesium; 0.5 to 1.5 percent by mass of silicon; 0.01 to 1.0 percent by mass of manganese; and 0.001 to 1.0 percent by mass of copper, with the remainder being aluminum and inevitable impurities, in which the amount of dissolved silicon is 0.55 to 0.80 percent by mass, the amount of dissolved magnesium is 0.35 to 0.60 percent by mass, and the ratio of the former to the latter is 1.1 to 2. The aluminum alloy sheet may further contain 0.005 to 0.2 percent by mass of titanium with or without 0.0001 to 0.05 percent by mass of boron.

Owner:KOBE STEEL LTD

Cave soil storage natural aging method of wine

InactiveCN101812398AGood for natural agingThe sauce is outstandingAlcoholic beverage preparationSoil scienceAdditive ingredient

The invention discloses a cave soil storage natural aging method of wine, which comprises (1) the soil storage stage: injecting the well brewed wine into a wine jar with the periphery covered with a special soil layer of 30-40cm, and burying the wine jar in the underground soil with the depth of 1.2-1.5m for placing for 2-3 years, thereby volatilizing miscellaneous gases in the wine, penetrating impurities into the soil and achieving the coming down effect; simultaneously leading the wine to fully absorb essence qi of the ground and nutritional ingredients in the special soil outside the wine jar during the natural aging; and (2) the cave storage stage: injecting the wine which is stored through the soil storage stage into the wine jar with the periphery which is tightly coated with a plant rope, placing in a cave for continuing the natural aging for 3-120 years, leading the wine to continuously volatilize a variety of impurities and the miscellaneous gases therein, and simultaneously micro-absorbing the nutritional ingredients in the rope on the periphery of the wine jar. As the environment with basically constant temperature in four seasons in the cave is conductive to the natural aging of a wine body, compared with the wine which is stored ordinarily, the method has the advantages of more delicate and mellow wine body, more prominent Maotai flavor, long aftertaste, more lasting aroma and more nutrients.

Owner:程恩进 +3

1070 aluminum alloy explosion-proof foil and processing technology thereof

ActiveCN102912190ARaise room temperatureHigh temperature strengthLarge containersRheniumDehydrogenation

The present invention discloses a 1070 aluminum alloy explosion-proof foil and a processing technology thereof. The explosion-proof foil contains rhenium, iron, rare earth metals and aluminum. The processing technology includes preparing raw materials according to ratios, preparing the alloy, smelting, smelting in a holding furnace, grain refinement, online degassing and deslagging, filteration deslagging, continuous casting and rolling, cold rolling, finish rolling, cutting and packing. Due to the configuration of the material composition, deoxidation, desulfurization, dehydrogenation, denitrification and grain refinement abilities of the aluminum melt in the smelting process are improved, and the explosion-proof foil has characteristics of good corrosion resistance, high strength at a room temperature and a high temperature, good wear resistance, etc. By employing processing methods such as smelting, continuous casting and rolling, cold rolling, foil rolling, small feeding amount and multi-pass horizontal rolling, and natural aging, the strength and flexibility of the aluminum alloy foil are improved, with a short entire process and a low production cost. The aluminum foil mesh formed by slitting and expanding the explosion-proof foil has the advantages of good toughness, and being not easy to crack and shedding metal debris, so that the safety performance requirements of the aluminum alloy explosion-proof aluminum foil used in aerospace oil tank and fuel tank are satisfied in use.

Owner:新疆天展新材料科技有限公司

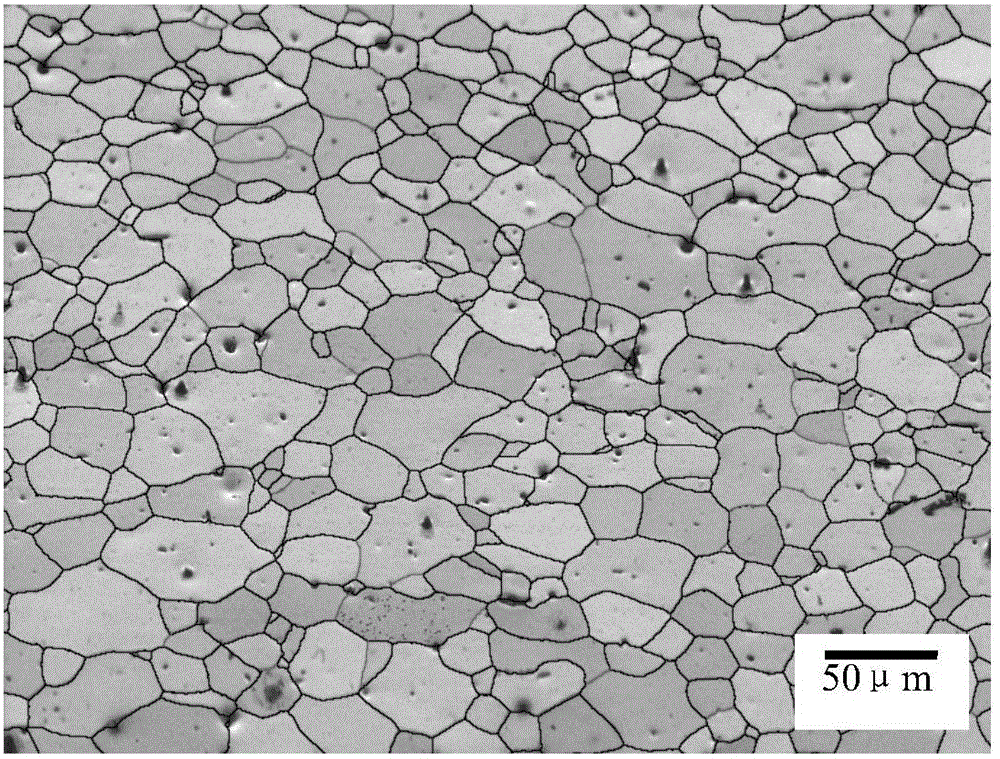

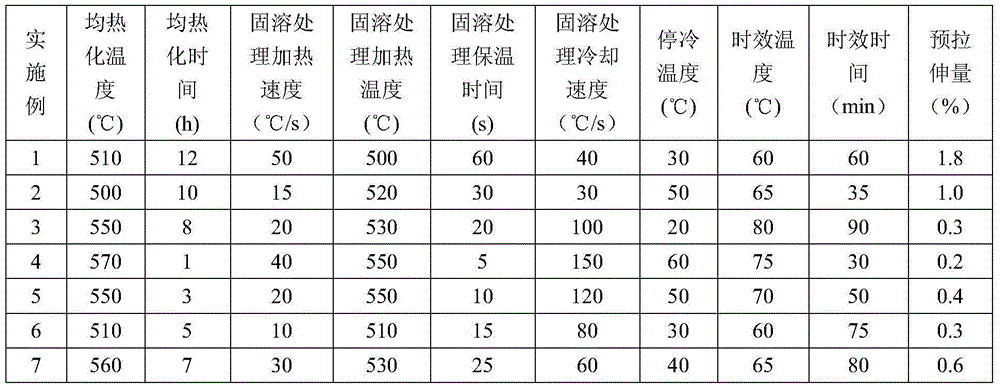

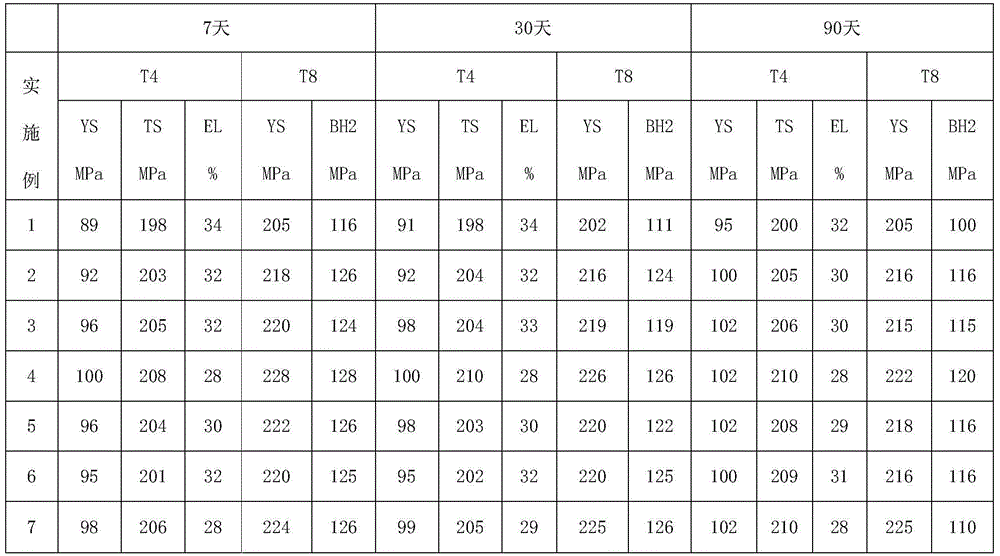

6000 series aluminum alloy material with high natural aging stability, aluminum alloy plate and preparing method of aluminum alloy plate

The invention discloses a 6000 series aluminum alloy material with high natural aging stability. The chemical elements of the material comprise, by mass, larger than or equal to 0.2% but smaller than or equal to 0.8% of Mg, larger than or equal to 0.8% but smaller than or equal to 1.5% of Si, larger than or equal to 0.07% but smaller than or equal to 0.25% of Sn, larger than 0 but smaller than or equal to 0.05% of Cu, larger than or equal to 0.02% but smaller than or equal to 0.2% of Mn, larger than 0 but smaller than or equal to 0.5% of Fe, larger than or equal to 0.05% but smaller than or equal to 0.15% of Ti, smaller than or equal to 0.2% of Zn, smaller than or equal to 0.1% of Cr and the balance Al and other inevitable impurities. Correspondingly, the invention further includes an aluminum alloy plate prepared through the 6000 series aluminum alloy material with high natural aging stability and a preparing method of the aluminum alloy plate. The aluminum alloy material and the aluminum alloy plate have good natural aging stability on the basis that the forming performance and the bake hardening performance are not reduced.

Owner:BAOSHAN IRON & STEEL CO LTD

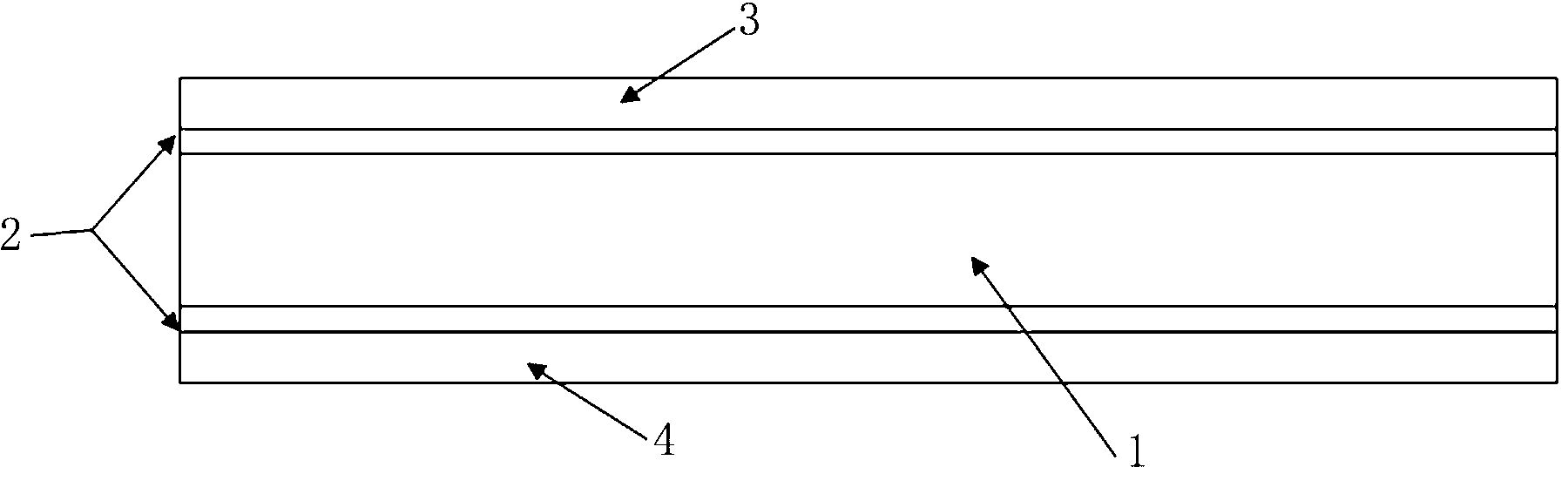

Composite plastic floor and manufacturing method thereof

InactiveCN103074990AImprove structural strengthImprove toughnessSynthetic resin layered productsLaminationTextile printerPolyvinyl chloride

The invention discloses a composite plastic floor, which comprises a wearing layer, a printing layer, a middle layer and a bottom layer, wherein the printing layer is a textile printing film; and the middle layer and the bottom layer are polrvinyl chloride sheets. The improvement made by the invention comprises: the middle layer is of a multi-layer polrvinyl chloride sheet combination structure, and glass fabrics are respectively arranged between each two polrvinyl chloride sheets of the middle layer; and the wearing layer is a transparent film with an outer surface being coated with a colourless UV (Ultraviolet) coating layer. The invention also discloses a manufacturing method of the composite plastic floor. The manufacturing method comprises the following process steps of: hot pressing, preserving, film spraying, tempering, natural aging, punching and slotting. The composite plastic floor manufactured by the invention has good wear resistance, long service life, simplicity in manufacturing, lower production cost, small deformation due to expansion and contraction, and high strength and toughness.

Owner:TAIZHOU HUALI PLASTIC

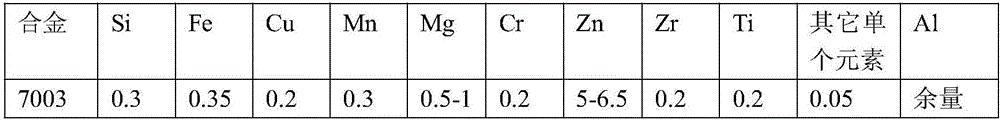

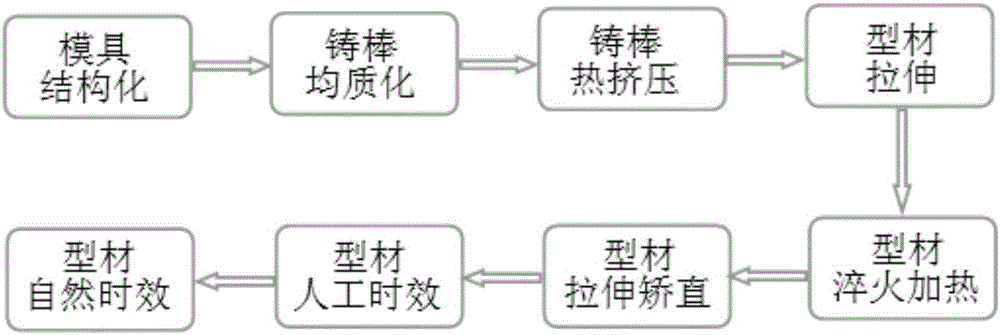

Manufacturing method of 7000-series aluminum alloy section for vehicular bodies

The invention discloses a manufacturing method of a 7000-series aluminum alloy section for vehicular bodies. The 7000-series aluminum alloy section comprises alloy elements including, by mass, 0.145%-0.155% of Si, 0.145%-0.155% of Fe, 0.09%-0.11% of Cu, 0.045%-0.055% of Mn, 0.58%-0.8% of Mg, 0.019%-0.021% of Cr, 5.5%-5.8% of Zn, 0.15%-0.19% of Zr, 0.028%-0.031% of Ti and the balance aluminum, wherein other single element content is smaller than or equal to 0.045%, other element total content is smaller than or equal to 0.15%, and a Zn / Mg ratio is controlled to be 7-10. The manufacturing method includes procedures of smelting, purification, casting for rod forming, homogeneous annealing, extruding, stretching, natural aging, manual aging treatment and the like, great static collision effects of materials can be achieved, the 7000-series aluminum alloy section is especially suitable for manufacturing of aluminum alloy energy absorption boxes and longitudinal beams for vehicular bumper systems, and comprehensive requirements of light weight of the vehicular bodies and energy absorption in low-speed and high-speed collision can be met.

Owner:CYMA PRECISION ALUMINUM

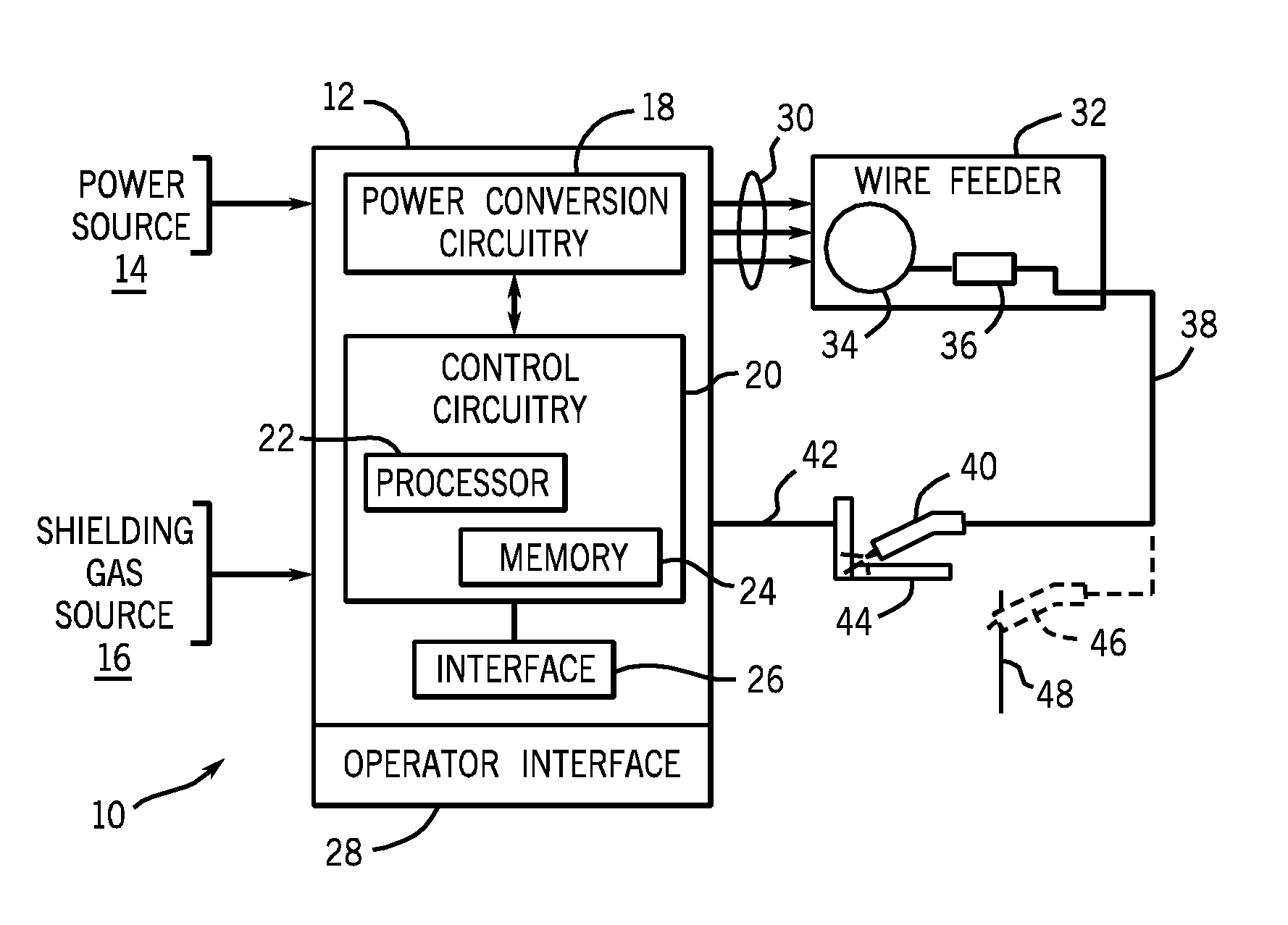

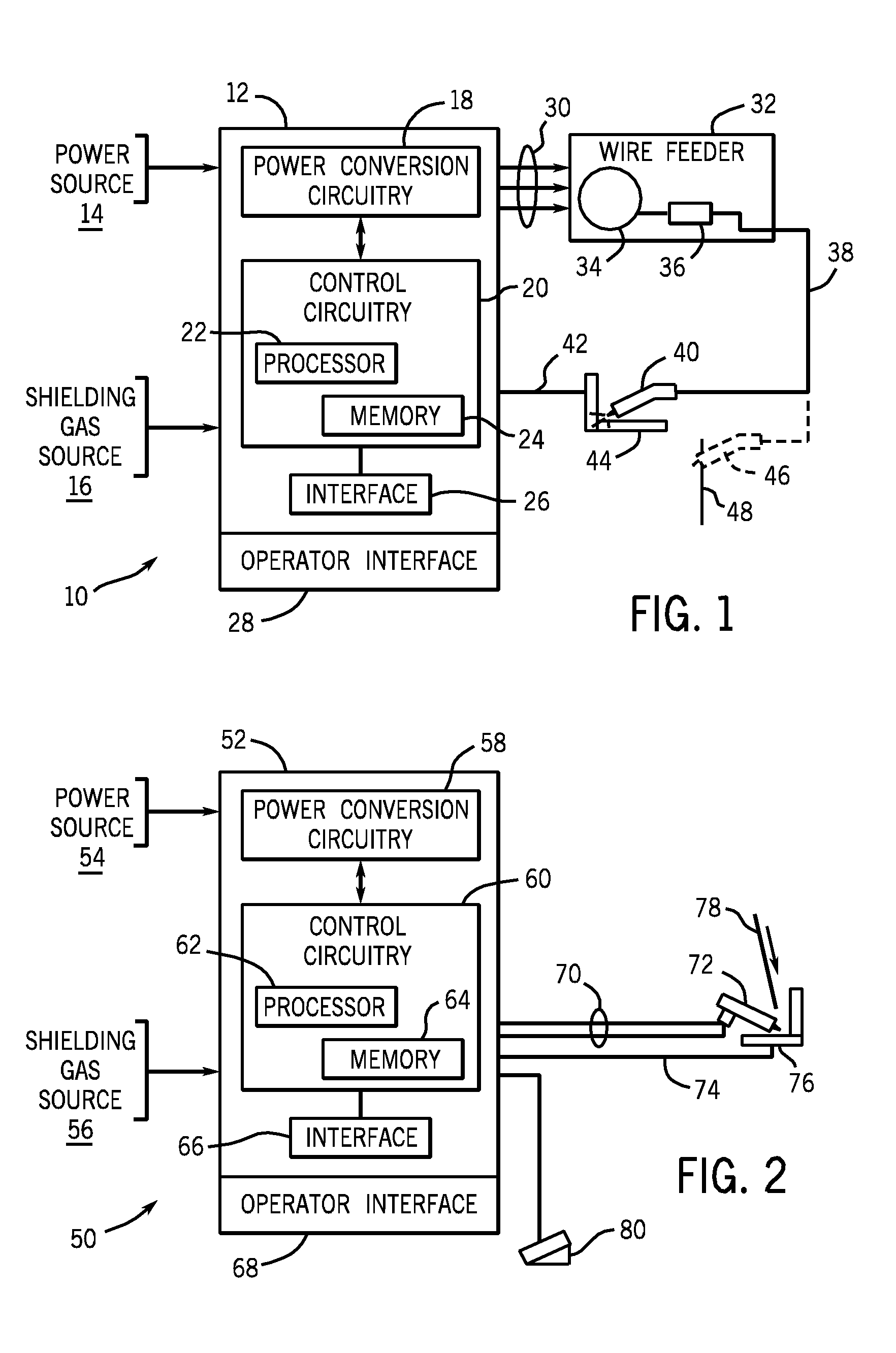

Aluminum alloy welding wire

ActiveUS20140190952A1Improve performanceHigh strengthArc welding apparatusWelding/cutting media/materialsStress concentrationUltimate tensile strength

A composition for welding or brazing aluminum comprises silicon (Si) and magnesium (Mg) along with aluminum in an alloy suitable for use in welding and brazing. The Si content may vary between approximately 4.7 and 10.9 wt %, and the Mg content may vary between approximately 0.20 wt % and 0.50 wt %. The alloy is well suited for operations in which little or no dilution from the base metal affects the Si and / or Mg content of the filler metal. The Si content promotes fluidity and avoids stress concentrations and cracking The Mg content provides enhanced strength. Resulting joints may have a strength at least equal to that of the base metal with little or no dilution (e.g., draw of Mg). The joints may be both heat treated and artificially aged or naturally aged.

Owner:HOBART BROS

Aluminum alloy section and machining method for suppressing a coarse grain ring of aluminum alloy section

ActiveCN109136506AImprove performance indicatorsSuppress coarse crystal ringFurnace typesHeat treatment furnacesAviation2024 aluminium alloy

The invention provides an aluminum alloy section and a machining method for suppressing a coarse grain ring of the aluminum alloy section, and relates to the field of aluminum alloy machining. The machining method for suppressing the coarse grain ring of the aluminum alloy section comprises the following steps: preparing raw materials according to alloy elementary compositions of 2024 aluminum alloy, and smelting and casting into a cast stick; carrying out first-time homogenization treatment on the cast stick by a two-stage homogenization system to obtain a primary homogenized cast stick; carrying out second-time homogenization treatment on the primary homogenized cast stick to obtain secondary homogenized cast stick; carrying out peeling treatment and extrusion treatment on the secondaryhomogenized cast stick to obtain an extruded section; and carrying out pre-stretching, solid solution heat treatment, stretch flattening and natural aging on the extruded section to obtain a 2024 aluminum alloy section. By the processing method, the coarse grain ring of the coarse grain ring of the 2024 aluminum alloy extruded section can be suppressed effectively, and various performance indexesof a final product are higher than standard requirements. The strength and toughness of the prepared aluminum alloy section are greatly improved, and the requirement of aluminum alloy for aviation ismet.

Owner:SHANDONG NANSHAN ALUMINUM +1

High-strength aluminum-alloy material, aluminum-alloy plate and manufacturing method thereof

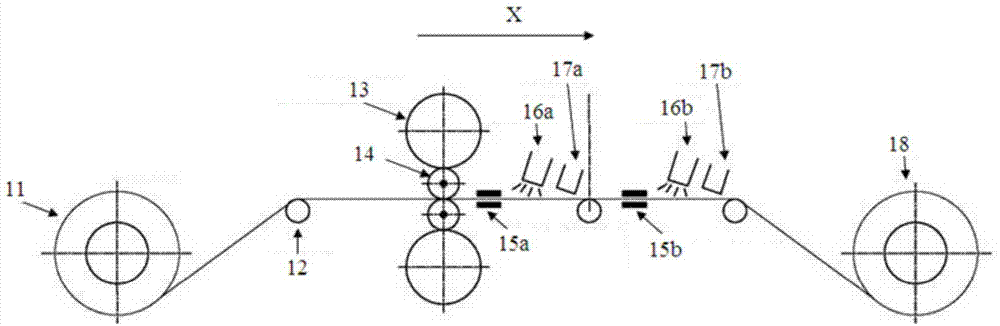

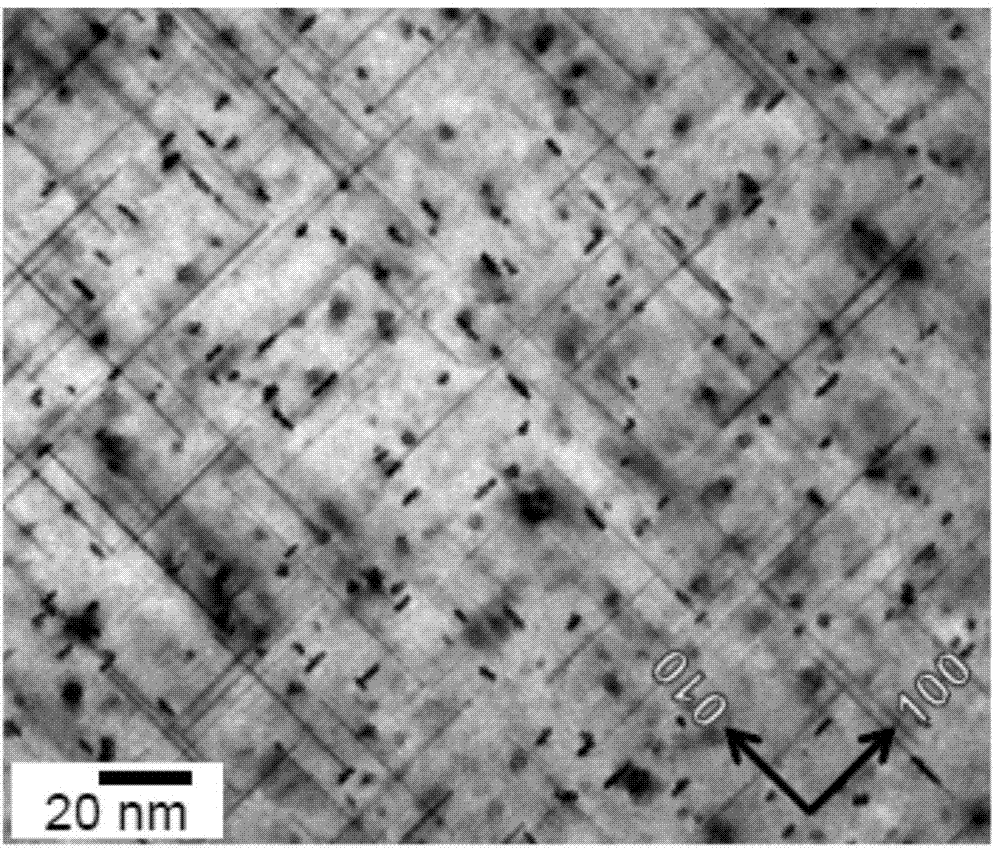

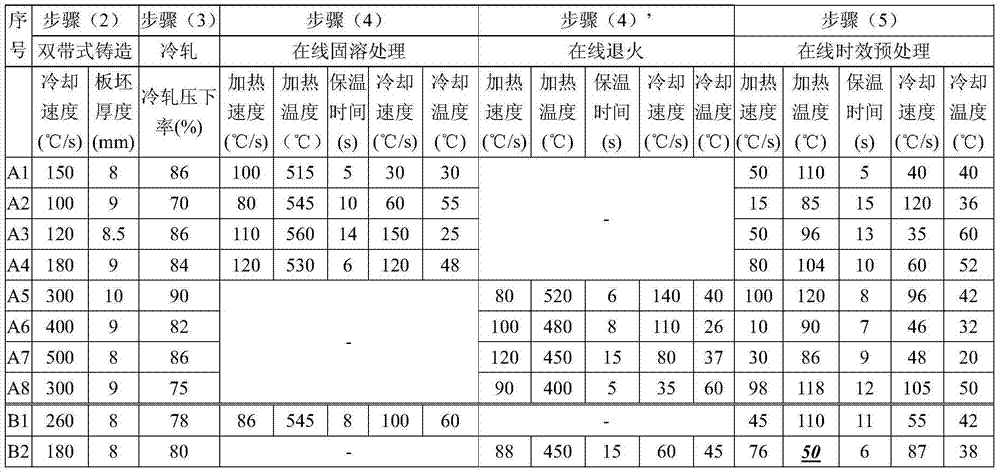

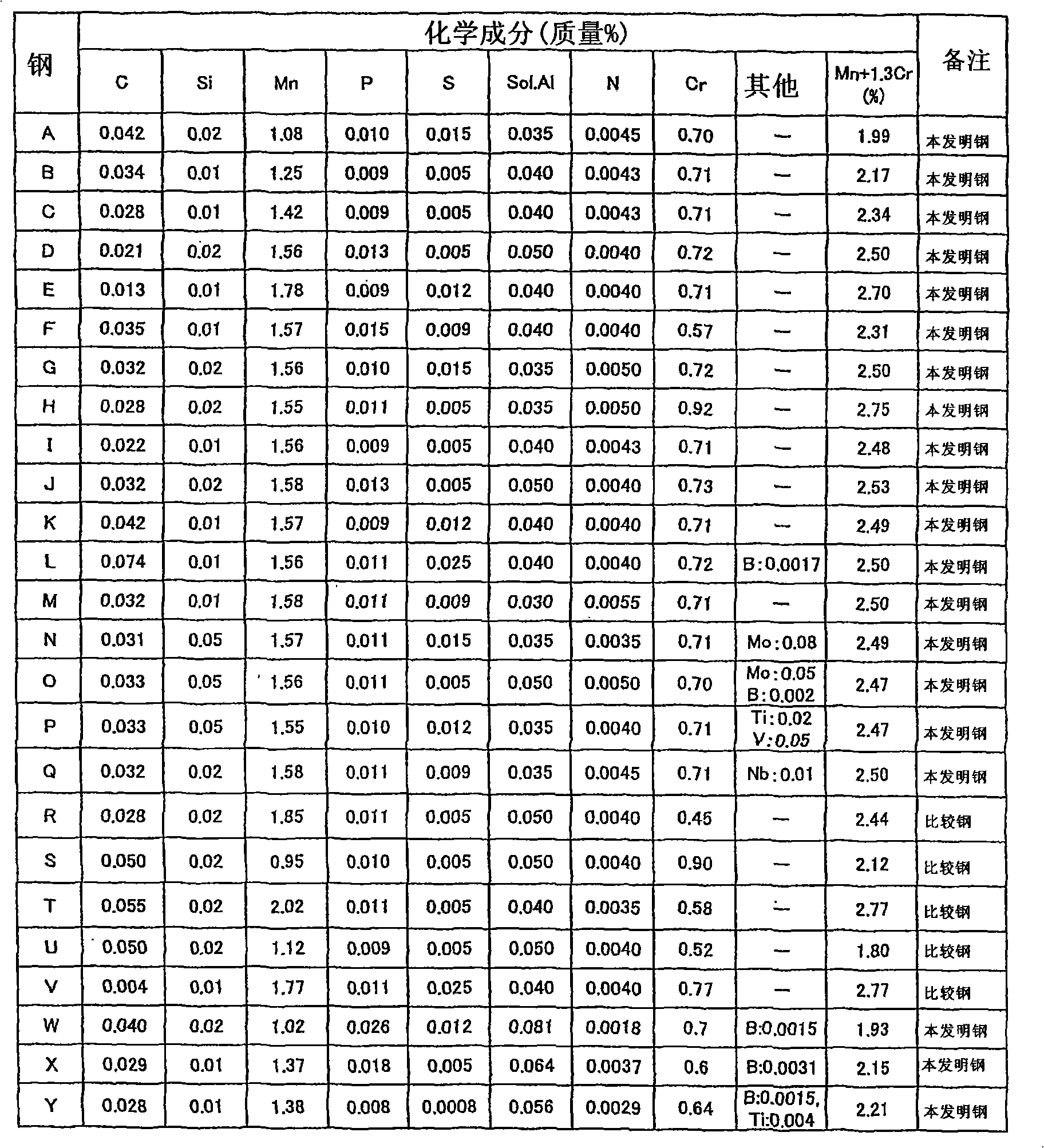

The invention discloses a high-strength aluminum-alloy material. The high-strength aluminum-alloy material contains the chemical elements in percentage by mass: not lower than 1.5% and not higher than 3.0% of Mg, not lower than 0.05% and not higher than 0.2% of Si, not lower than 0.1% and not higher than 0.2% of Mn, not lower than 0.2% and not higher than 0.4% of Fe, higher than 0 and not higher than 0.03% of Cu, higher than 0 and not higher than 0.05% of Ti, either not lower than 0.05% and not higher than 0.15% of Ca or not lower than 0.05% and not higher than 0.15% of Sr and the balance of Al and other unavoidable impurities. The invention further discloses an aluminum-alloy plate manufactured from the aluminum-alloy material. The invention further discloses a manufacturing method of the aluminum-alloy plate, wherein the method comprises the steps of carrying out double-strip casting, carrying out cold rolling, carrying out online solid solution treatment and carrying out online aging pretreatment. The high-strength aluminum-alloy material and the aluminum-alloy plate, disclosed by the invention, have relatively high strength and good natural aging stability. After painting and baking, the yield strength of the high-strength aluminum-alloy material and the aluminum-alloy plate is higher than 300Mpa.

Owner:BAOSHAN IRON & STEEL CO LTD

Broken stone water permeability pavement mixture with epoxy resin as adhesive agent

The invention relates to a gravel permeable pavement mixture taking epoxy resin as adhesive, in particular to a permeable pavement adhered by gravels, which solves the problem that the price of the cellulose and wood-cellulose derivatives in high-intensity permeable pavement mixture is high. The mixture comprises gravels, epoxy resin, additive, and materials of strengthening agent; according to weight, 100 parts of epoxy resin is correspondingly added into 1 to 20 parts of silica or sepiolite or silica and silica sepiolite to be the additive used for increasing viscosity of epoxy resin, and 1 to 10 parts of ceramic fiber to be the strengthening agent used for improving the hardness of epoxy resin and the intensity of permeable pavement, and 1 to 10 parts of glass fiber to be the strengthening agent used for improving the anti natural ageing of the permeable pavement; according to weight, 100 parts of gravels are added with 4 to 8 parts of epoxy resin with fiber added with additive and strengthening agent. The permeable pavement paved by the compound of the invention has the advantages of good environmental protection, easy construction, low cost and long service life.

Owner:厦门开亦成科技有限公司

High-strength hot-dip galvanized steel sheet and process for producing the same

ActiveCN101688277ALower yield stressAchieve lightweightHot-dipping/immersion processesFurnace typesSheet steelHigh intensity

A high-strength hot-dip galvanized steel sheet that even on the premise of ordinary CGL heat cycle, has a low yield stress and excels in resistance to natural aging and baking hardenability without reliance on the use of expensive Mo; and a process for producing the same. The constituent composition thereof comprises 0.01 to less than 0.08% C, 0.2% or less Si, more than 1.0 to 1.8% Mn, 0.10% or less P, 0.03% or less S, 0.1% or less Al, 0.008% or less N and more than 0.5% Cr so that the relationship 1.9=Mn(mass%)+1.3Cr(mass%)=2.8 is satisfied and comprising the balance iron and unavoidable impurities. The structure thereof has a ferrite phase and a martensite phase of 2 to 15% area ratio, and the cumulative area ratio of pearlite phase and / or bainite phase is 1.0% or less. In the productionof this hot-dip galvanized steel sheet, the temperature and cooling rate are controlled during the annealing / plating operation subsequent to cold rolling.

Owner:JFE STEEL CORP

Energy-saving powder metallurgy process

The invention discloses an energy-saving powder metallurgy process. The energy-saving powder metallurgy process includes steps of preparing, mixing, compacting, sintering, aging treatment, shaping and warehousing. According to the arrangement, powder materials are directly adopted without primary mashing and fed to a compacting die through a standard dosage barrel, thus high accuracy is achieved, compactness of part blanks is good, and pass percentage is high. Particularly, natural aging treatment is adopted to lead to low internal stress and remarkable energy saving after crystals are formed.

Owner:佛山市常捷粉末冶金科技有限公司

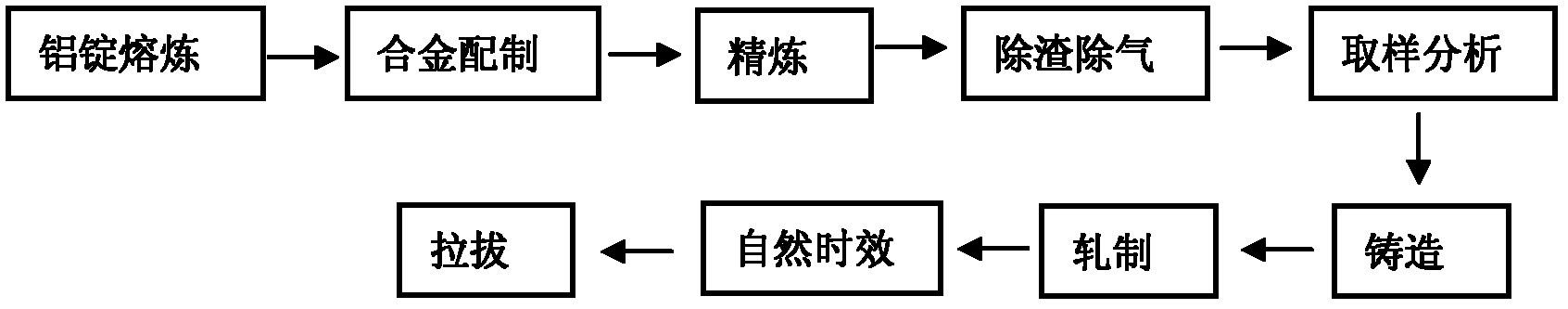

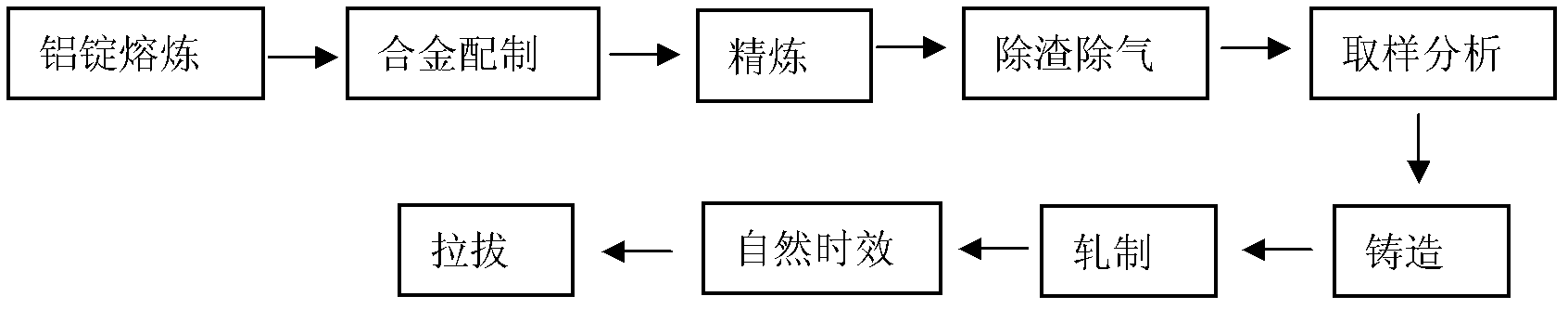

Method for preparing aluminium magnesium silicon alloy rod base and preparing high-strength aluminium magnesium silicon alloy conductor

The invention belongs to the field of electrotechnics, and provides a method for preparing an aluminium magnesium silicon alloy rod base and preparing a high-strength aluminium magnesium silicon alloy conductor. Through a smelting technique and refining especially the control of a rolling technique, an aluminium magnesium silicon alloy rod base with a specific state is prepared, and can be directly pulled, after the natural aging, to obtain an aluminium magnesium silicon alloy wire that accords with LHA1 and LHA2 requirements. As compared with a conventional technique, the aluminium magnesiumsilicon alloy rod base prepared by the method provided by the invention is stable in performance, and the aluminium magnesium silicon alloy wire prepared by the aluminium magnesium silicon alloy rod is stable in linearity without any artificial aging treating, thereby substantially reducing the cost for producing the aluminium magnesium silicon alloy wire and fully meeting the requirement of an aluminium alloy wire used for an overhead twisted wire.

Owner:SHANGHAI ELECTRIC CABLE RES INST

Production method for zinc electroplated baked hardened steel plate for automobile outer plate

ActiveCN105970094ANiobium is lowReduce carbon contentFurnace typesHeat treatment furnacesNatural agingCasting

The invention discloses a production method for a zinc electroplated baked hardened steel plate for an automobile outer plate and belongs to the field of cold-rolled deep-drawn zinc electroplating automobile steel. The production method comprises the following preparation steps that (1) constituent selection of the zinc electroplated baked hardened steel plate is conducted; (2) a plate blank is obtained through smelting and casting; (3) hot rolling is conducted after conventional heating; (4) conventional water cooling is conducted to the coiling temperature, and coiling is conducted; (5) cold rolling is conducted; (6) continuous annealing is conducted; (7) flattening is conducted; (8) conventional alkali washing, brushing, electrolytic degreasing and rinsing are conducted; and (9) zinc electroplating is conducted through a gravity method. According to the production method, the steel plate prepared through a conventional production technique is good in forming performance and baking and hardening performance, natural aging is avoided even if the steel plate is placed at the room temperature for months, and the performance is stable.

Owner:武汉钢铁有限公司

Aluminum alloy sheet with excellent baking paint hardenability

The aluminum alloy sheet of the present invention is a specific 6000-series aluminum alloy sheet in which the total sum (total amount) of Mg and Si existing in specific aggregates of atoms (clusters) is regulated and the total sum of Mg and Si existing in the aggregates of atoms is ensured so as to be balanced with the total amount of Mg and Si solid-solutionized in the matrix, and thus BH response (bake hardenability) after natural aging at room temperature and proof strength after BH treatment (bake hardening treatment) are further improved.

Owner:KOBE STEEL LTD

Method for accelerating aging of vinegar with ultrasonic wave

InactiveCN104232460AAccelerated agingFacilitate chemical reactionsVinegar preparationAlcohol ethylAccelerated aging

The invention discloses a method for accelerating aging of vinegar with ultrasonic wave, and belongs to the technical field of vinegar aging acceleration. The method comprises the following steps: storing newly brewed vinegar and ethanol which accounts for 0.55-0.85% of the volume of the vinegar in a container, sealing the mount of the container, keeping the temperature inside the container to be 30-40 DEG C, and applying low-frequency high-intensity ultrasonic wave with the frequency of 18-29 KHz and the ultrasonic density of 40-60 W / 100mL (the volume ratio of the ultrasonic power to the aging accelerated vinegar) to the vinegar in the container for 60-80 minutes. By adoption of the method, the aging effect of 3-5 years of natural aging can be achieved within 60-80 minutes, the aging time is greatly shortened, and the aging acceleration effect is remarkable.

Owner:JIANGSU UNIV

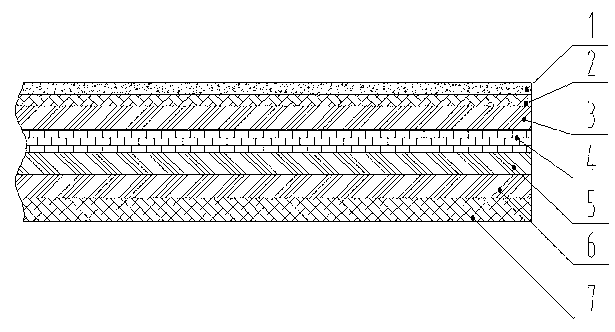

Aluminum alloy sheet for lateral plate of automobile radiator and manufacturing method for aluminum alloy sheet

ActiveCN103072330AIncrease the strength of the side panelsReduce manufacturing costCoatingsHeat exchange apparatusStrength of materialsUltimate tensile strength

The invention discloses an aluminum alloy sheet for a lateral plate of an automobile radiator and a manufacturing method for the aluminum alloy sheet. The aluminum alloy sheet for the lateral plate of the automobile radiator is characterized by comprising a natural aging layer, heat transfer layers, a brazing layer and an anticorrosive coating, wherein the brazing layer and the anticorrosive coating are respectively arranged on two sides of the natural aging layer; one heat transfer layer is arranged between the brazing layer and the natural aging layer; and the other heat transfer layer is arranged between the anticorrosive coating and the natural aging layer. The manufacturing method for the lateral plate of the automobile radiator comprises the steps of a smelting step, a saw cutting step, a face milling step, a hot rolling step, a welding step, a heating step, a hot rolling step, a cold rolling step, an annealing step of a finished product and a crosscut shearing step. The manufacturing method is characterized in that the smelting step comprises steps of smelting the natural aging layer, smelting the heat transfer layers, smelting the brazing layer and smelting the anticorrosive coating. The aluminum alloy sheet and the manufacturing method disclosed by the invention have the advantages that the strength of materials is gradually enhanced in air after the materials are processed, so that the strength of the lateral plate of the finished product of the radiator is improved, the thickness of the lateral plate is reduced, and the aims of reducing production cost of the automobile, saving energy and reducing emission are achieved.

Owner:NANTONG HENGJIN COMPOSITE MATERIALS

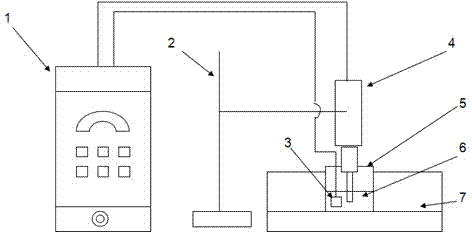

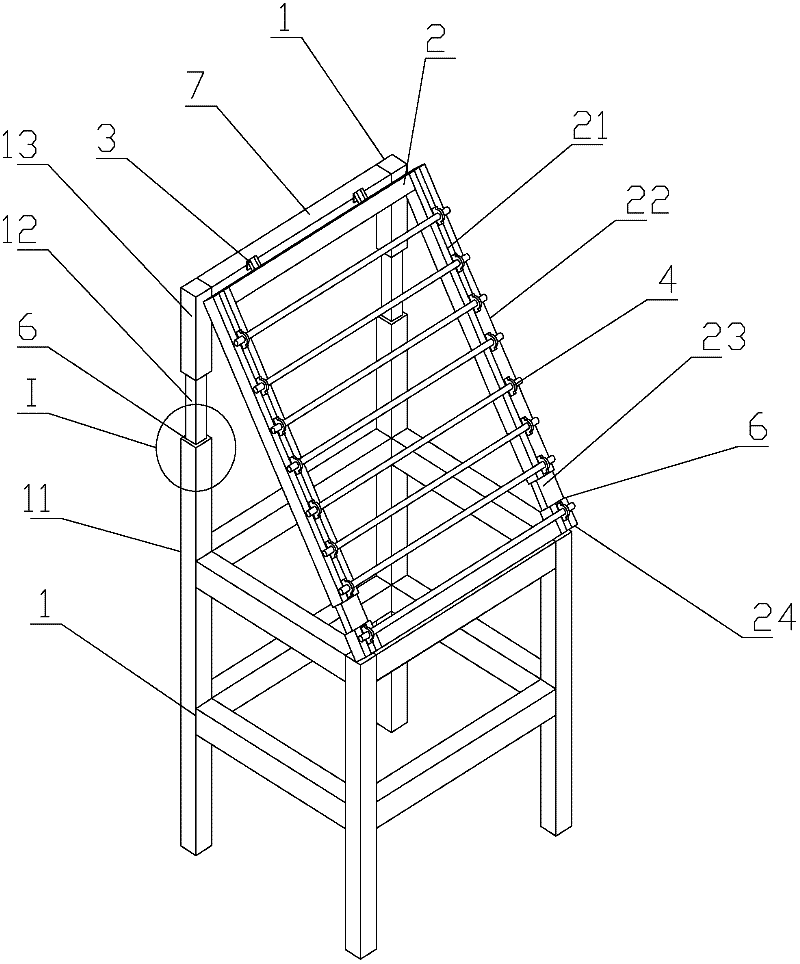

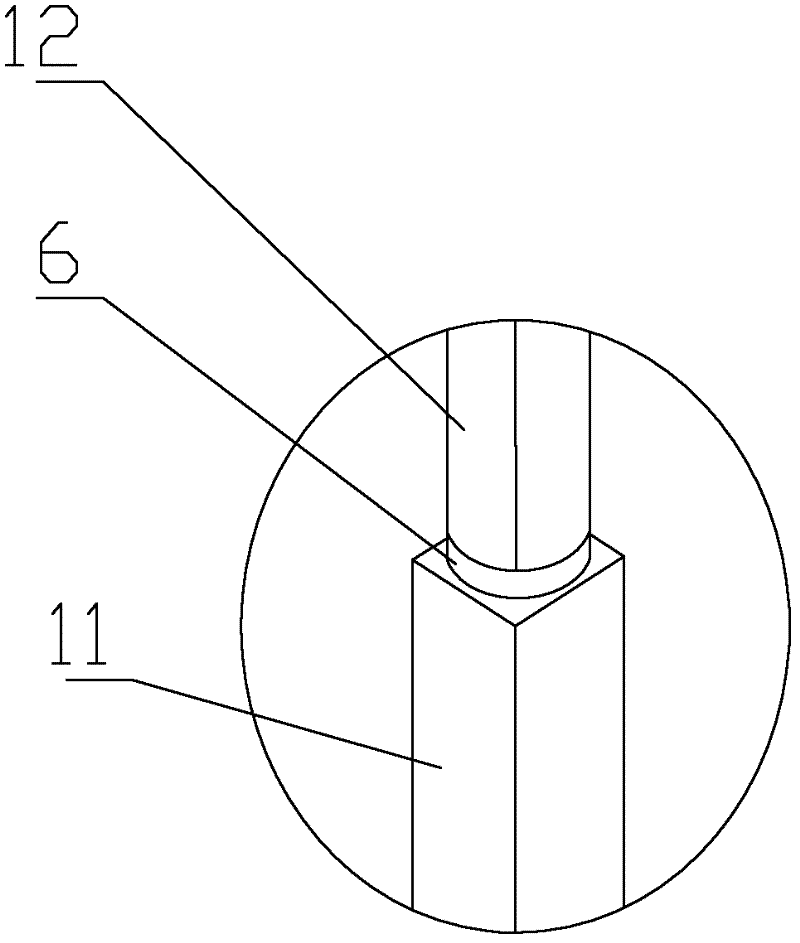

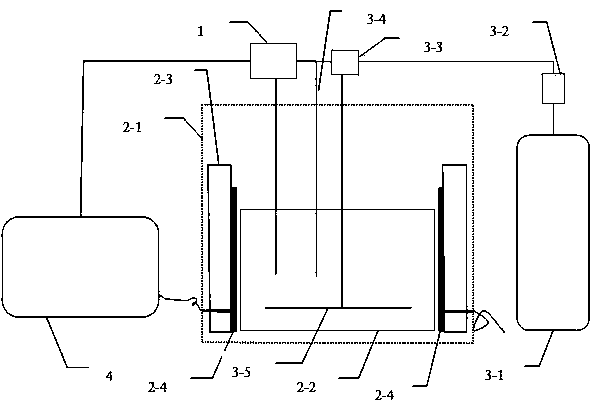

Natural corrosion and solarization test rack

ActiveCN102650585ASimple structureEasy to installWeather/light/corrosion resistanceEngineeringNatural aging

The invention relates to a natural corrosion and solarization test rack, which comprises a height-adjustable solarization rack bracket, and a length-adjustable test rack which is slantly arranged on the solarization rack bracket, wherein the test rack is hinged with the top end of the solarization rack bracket, and a plurality of groups of fixing fixtures used for fixing samples to be tested are arranged on the test rack. The natural corrosion and solarization test rack disclosed by the invention has the advantages that the length-adjustable test rack is hinged with the height-adjustable solarization rack bracket so as to make the angle between the test rack and the solarization rack bracket convertible, and the natural ageing and corrosion test rack can adapt to the tests on natural aging and corrosion of the samples to be tested, has a simple structure and a good use effect, and is convenient to assemble and use.

Owner:ZHEJIANG HUADIAN EQUIP TESTING INST +1

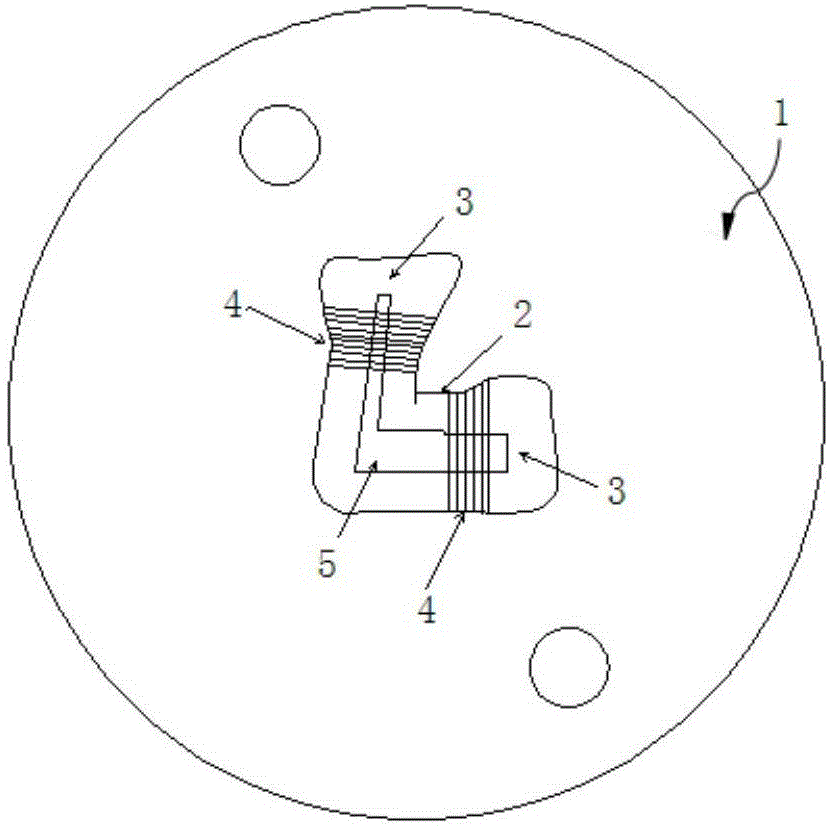

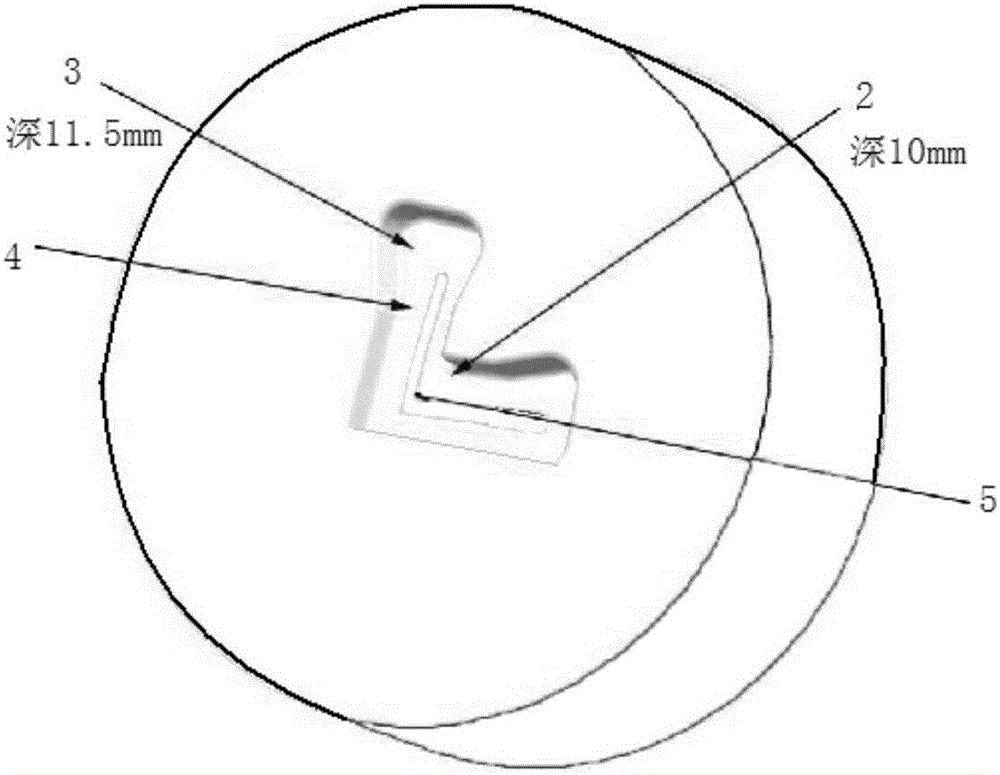

High-strength 2024 aluminum alloy thin-wall angle profile production process

ActiveCN106513456ASmall sizeHigh dimensional accuracyExtrusion dies2024 aluminium alloyNatural aging

Owner:CHINA ZHONGWANG

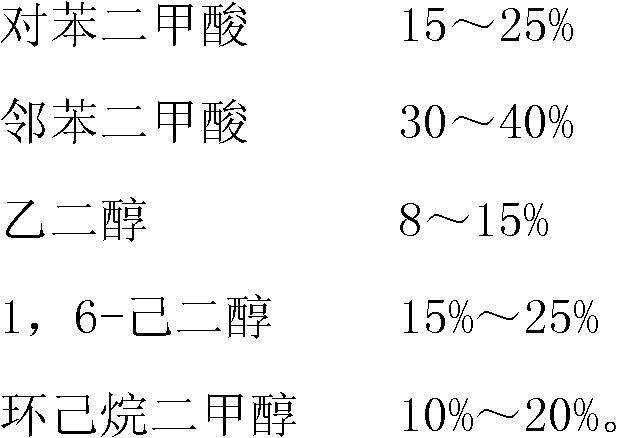

Preparation method of composite adhesive used for solar energy backboard

ActiveCN102250577AHigh crystallinityImprove temperature resistancePolyureas/polyurethane adhesivesPhotovoltaic energy generationAdhesiveEthyl acetate

The invention discloses a preparation method of a composite adhesive used for solar energy backboards. The invention belongs to the field of adhesive preparation. According to the invention, terephthalic acid, o-phthalic acid, ethylene glycol, 1,6-hexanediol, and cyclohexane dimethanol are adopted as raw materials. The raw materials are esterified and polycondensed. Ethyl acetate is added to the materials, and a proper amount of a nano-material is added to the mixture, such that a main agent is obtained. The main agent and a curing agent are mixed, such that the solar energy backboard composite adhesive is obtained. The adhesive has good bonding strength, ultraviolet aging resistance and natural aging resistance when used on solar energy backboards containing PVDF. When the adhesive is composed, laminated and tested by a double-eight-five aging test for 2000 hours, the peeling strength of the adhesive satisfies requirements of relative aspects of the industry.

Owner:NANTONG GAOMENG NEW MATERIAL

Method for evaluating running aging of thermal shrinkage insulating material

ActiveCN103852411AEvaluation is real and effectiveWeather/light/corrosion resistanceElectric power systemElectrical devices

The invention relates to a method for evaluating the running aging of a thermal shrinkage insulating material. The method comprises the steps of by combining the power failure overhauling plans of all power supply units, performing on-site sampling to the running aged thermal shrinkage insulating material on electrical equipment; classifying the thermal shrinkage insulating materials naturally aged under running mode; performing mechanical characteristic test to the running aged thermal shrinkage insulating material; performing aging electrical performance test to the running aged thermal shrinkage insulating material; microanalyzing the high-polymer crosslinked net structure of thermal shrinkage plastic; comparing the detection data of the running aged thermal shrinkage insulating material with the related data of a new insulating material, to obtain the final evaluation of the running aged thermal shrinkage insulating material. All samples for evaluation and testing are naturally aged after running in a power system for many years. Therefore, the research achievements can truly and effectively evaluate the aging situation of the thermal shrinkage insulating material, and have a positive effect on guiding the practical power production.

Owner:STATE GRID TIANJIN ELECTRIC POWER +1

Method for accelerating aging of brandy by oxidation-reduction potential combined high-pressure and micro-aerobic condition

ActiveCN103525674AAccelerated agingShorten aging timeAlcoholic beverage preparationAccelerated agingAerobic digestion

The invention relates to the technology of accelerating aging of brandy, and in particular relates to a method for quickly aging brandy by controlling irregular oak by oxidation-reduction potential combined high-pressure and micro-aerobic. The method comprises the following steps: putting brandy raw wine into a container; adding irregular oak; introducing oxygen into the brandy raw wine in the container, and applying a certain electric field intensity to control the oxidation reduction potential of the brandy raw wine to be 20mV-200mV. Therefore, extraction on the irregular oak by the brandy raw wine can be accelerated, and the aging time can be shortened. According to the method, the effect of aging the brandy raw wine for 10-30 minutes can be close to that of natural aging for 6-12 months, the aging time can be greatly shortened, and the aging efficiency can be remarkably improved.

Owner:HUIZHOU UNIV +2

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com